Patents

Literature

154 results about "Pu element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plutonium is a radioactive chemical element with symbol Pu and atomic number 94. It is an actinide metal of silvery-gray appearance that tarnishes when exposed to air, and forms a dull coating when oxidized.

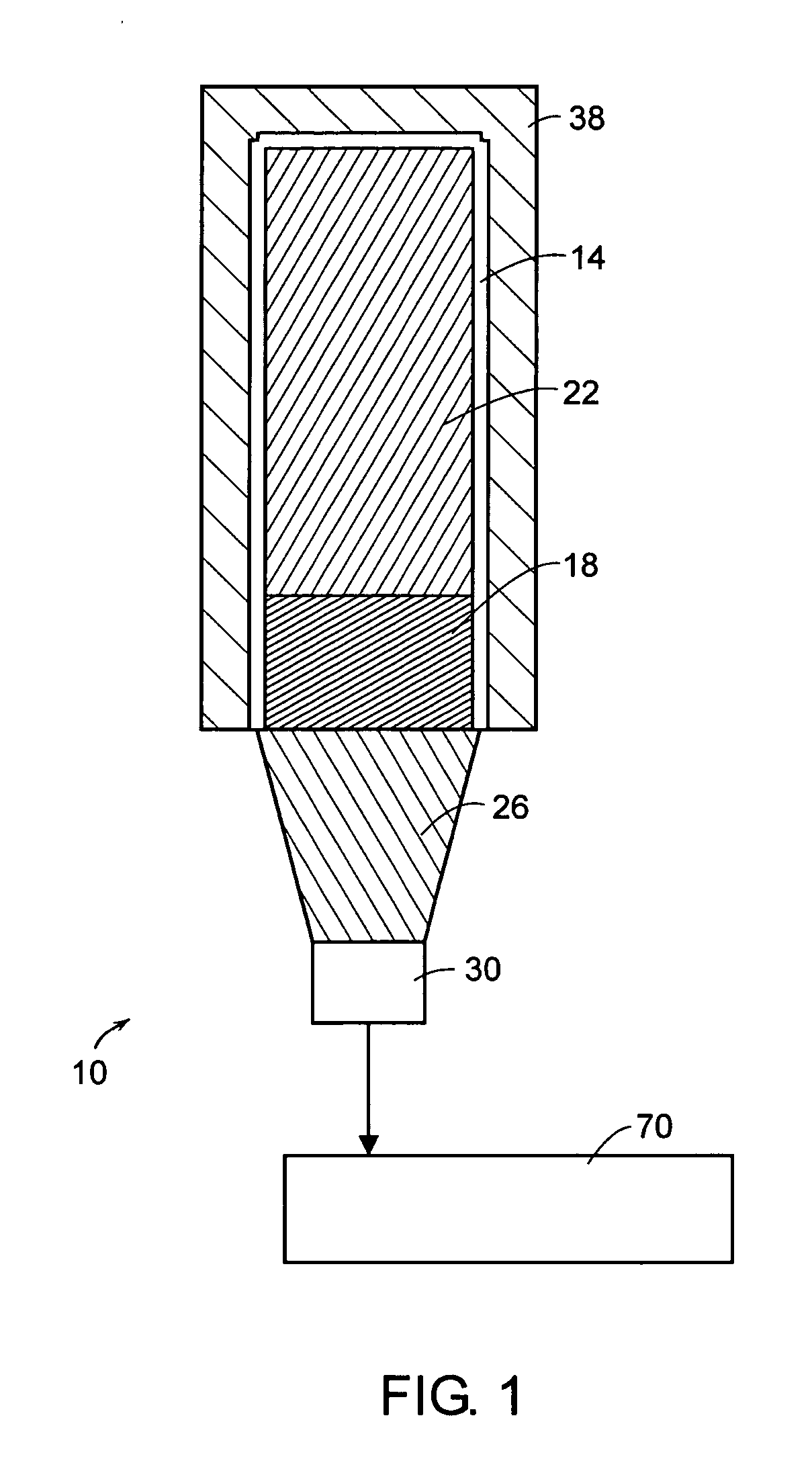

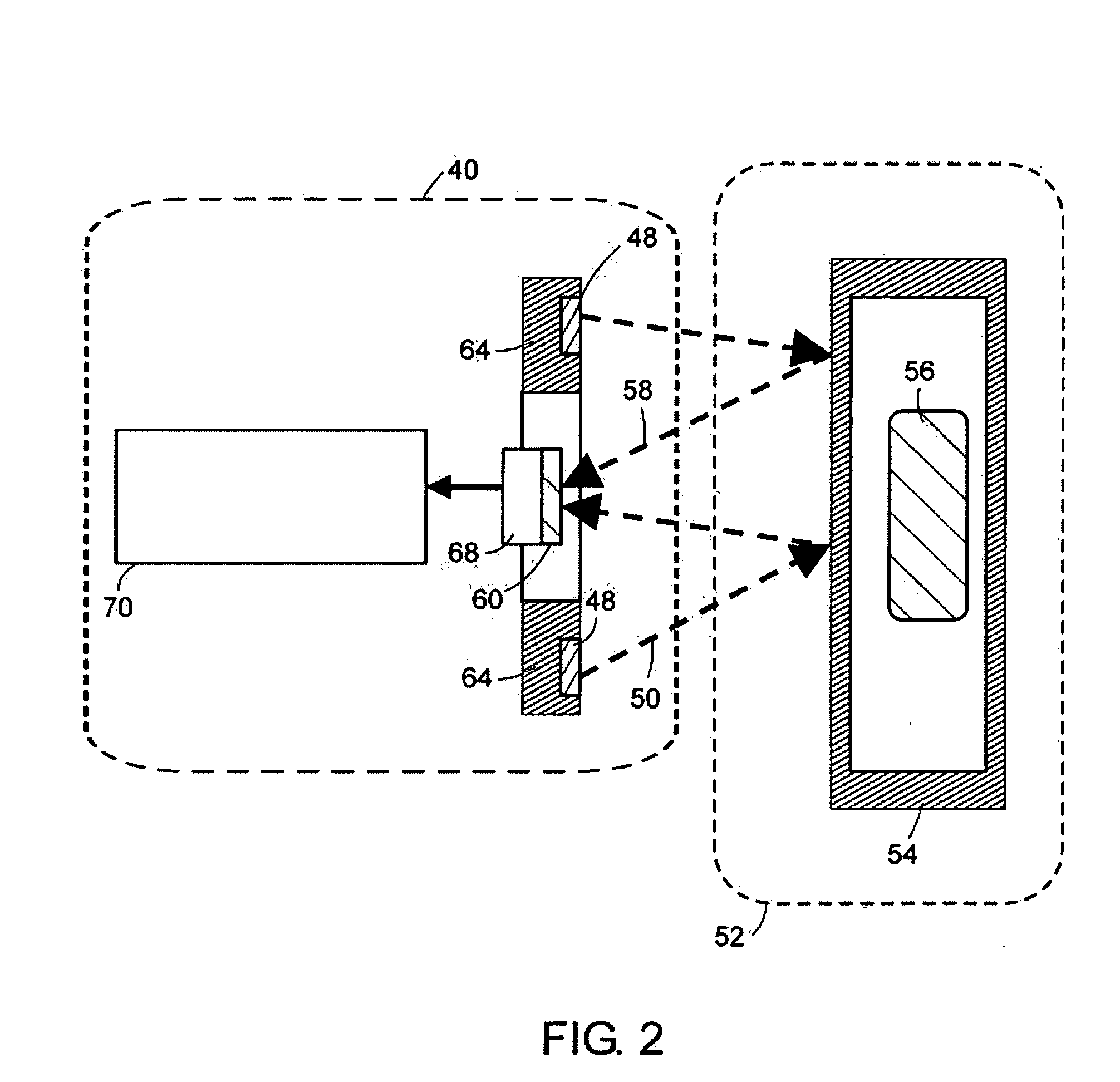

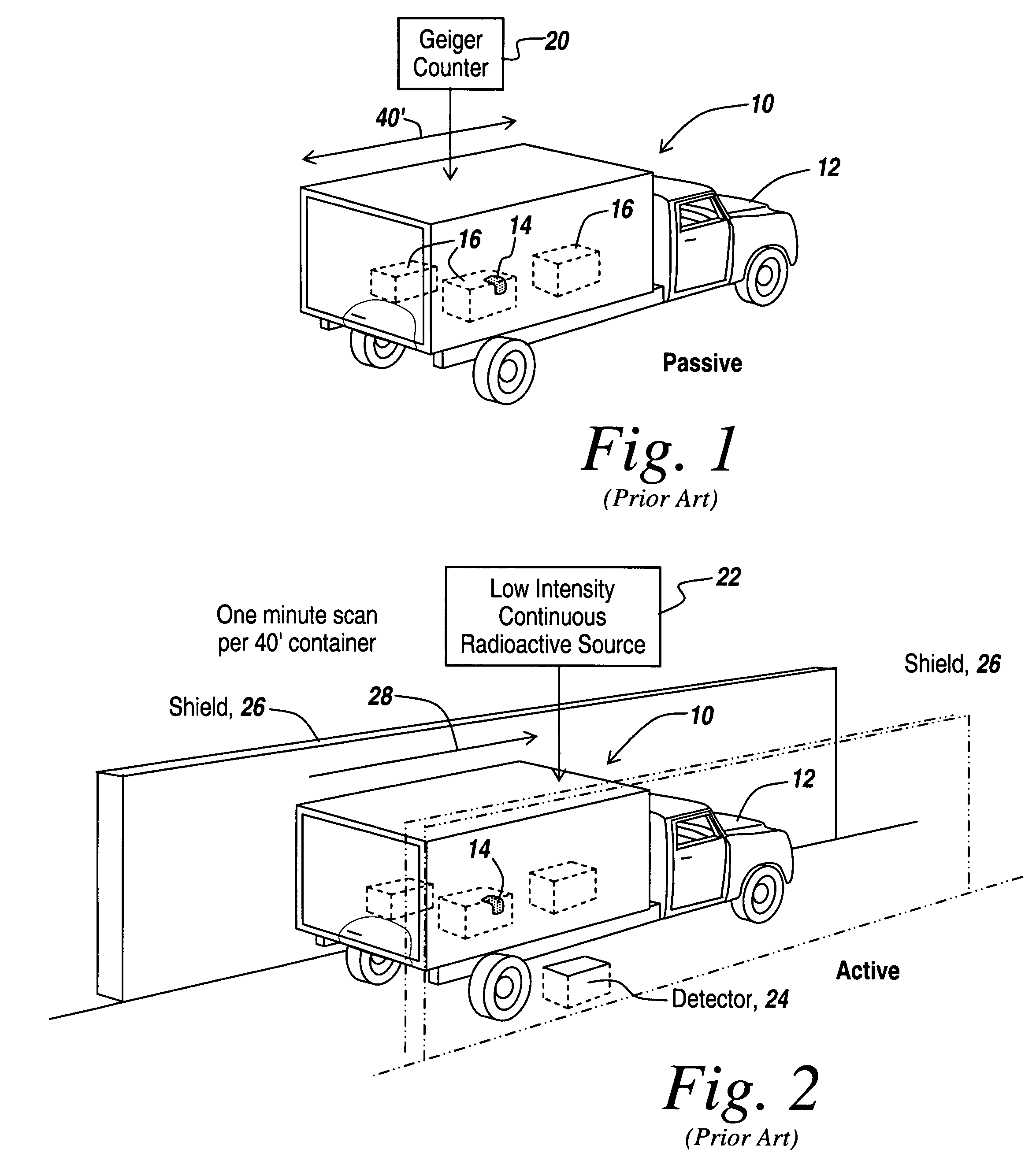

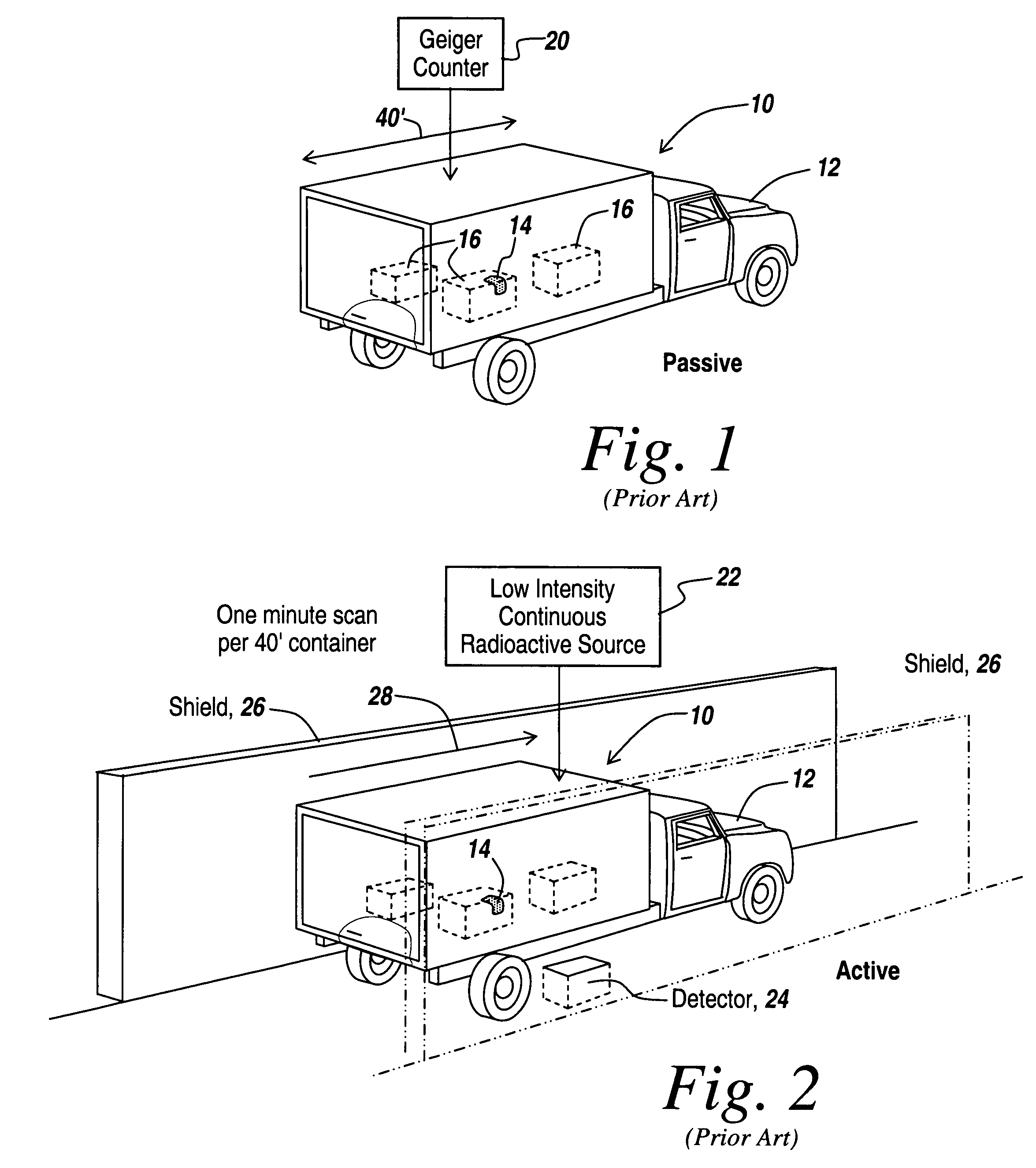

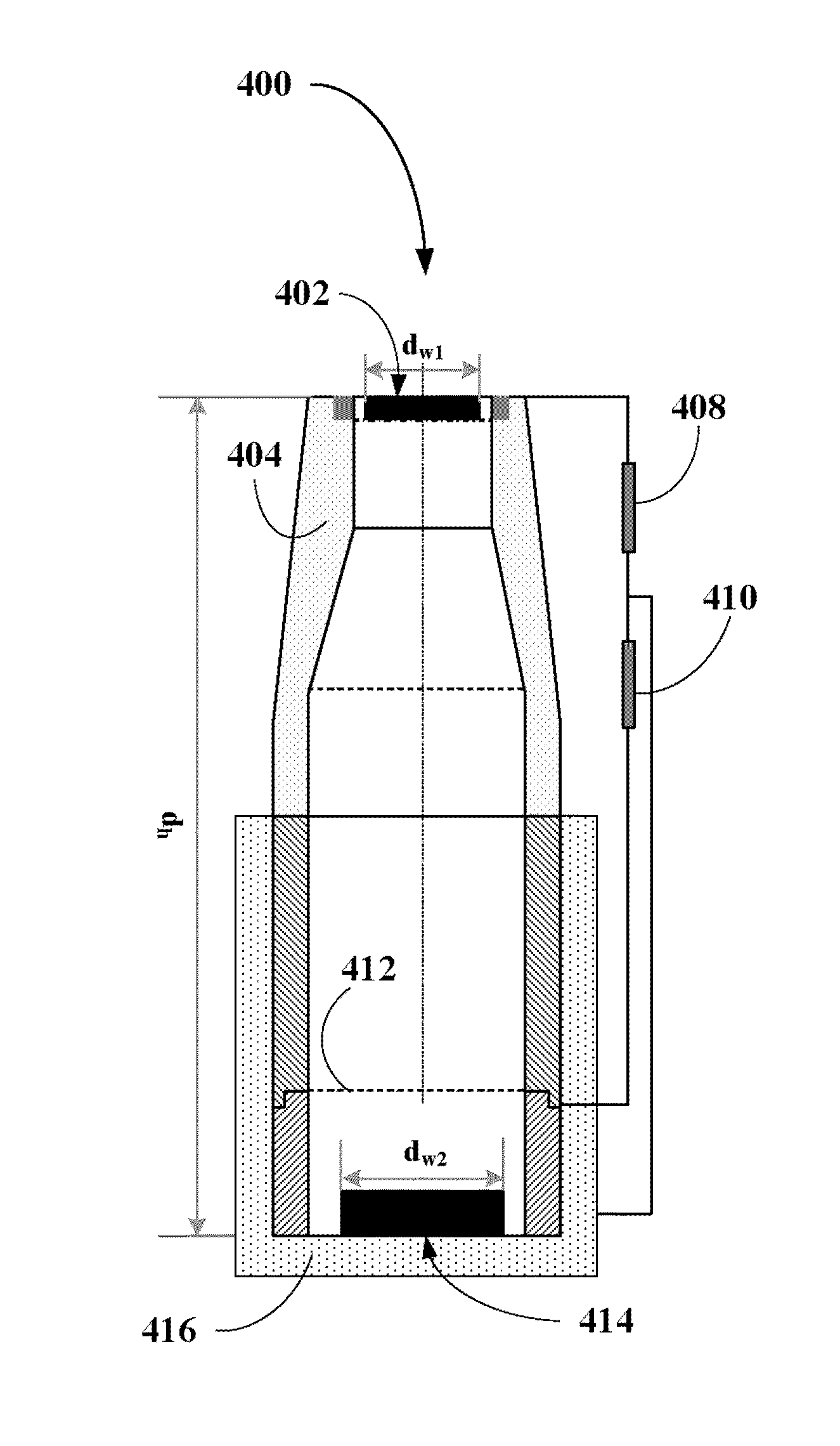

Neutron and gamma ray monitor

InactiveUS20050023479A1Light weightMore selectiveX-ray spectral distribution measurementMeasurement with scintillation detectorsNeutron emissionX-ray

An apparatus for selective radiation detection includes a neutron detector that facilitates detection of neutron emitters, e.g. plutonium, and the like; a gamma ray detector that facilitates detection of gamma ray sources, e.g., uranium, and the like; and / or an X-ray analyzer that facilitates detection of materials that can shield radioactive sources, e.g., lead, and the like.

Owner:THERMO NITON ANALYZERS

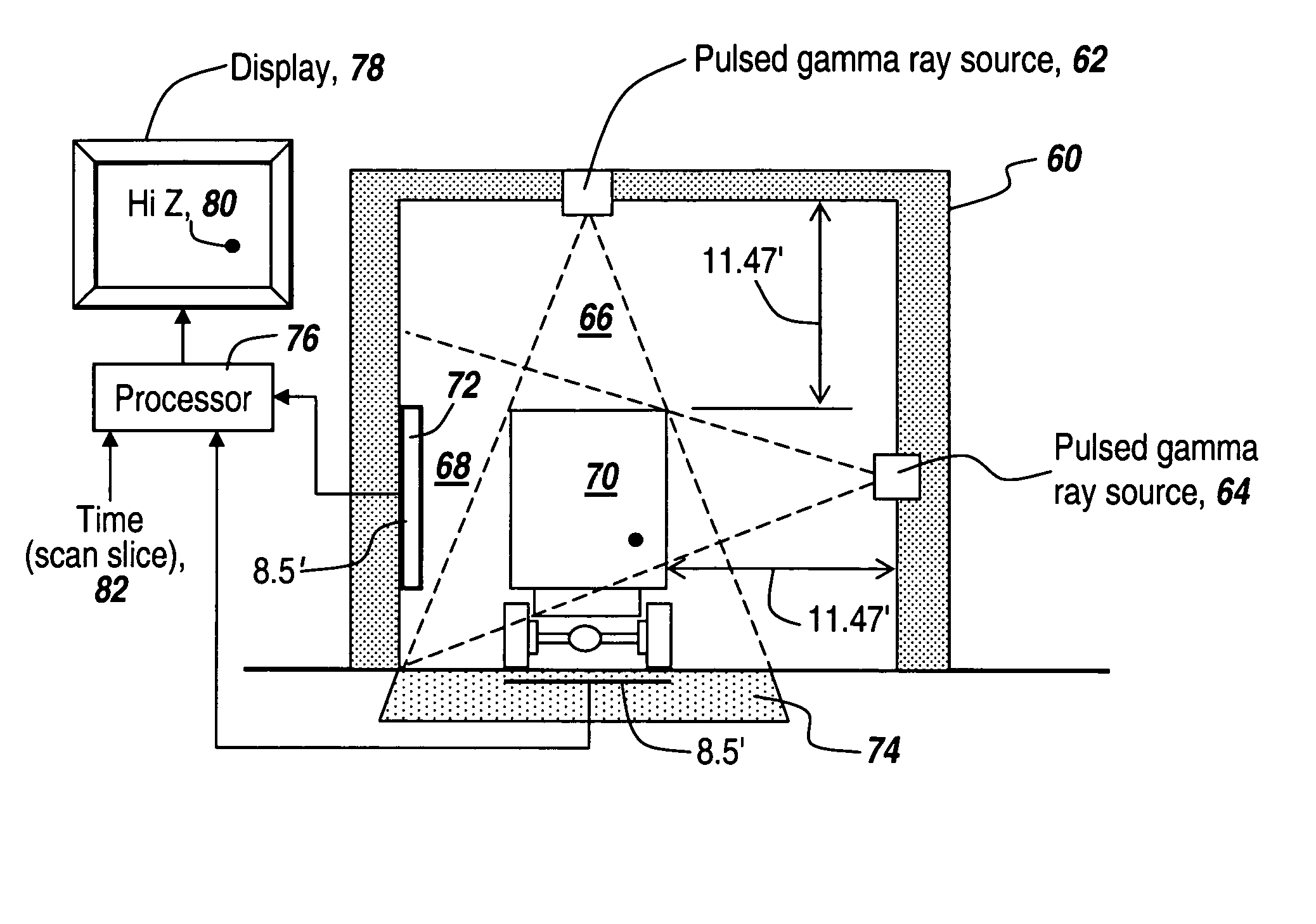

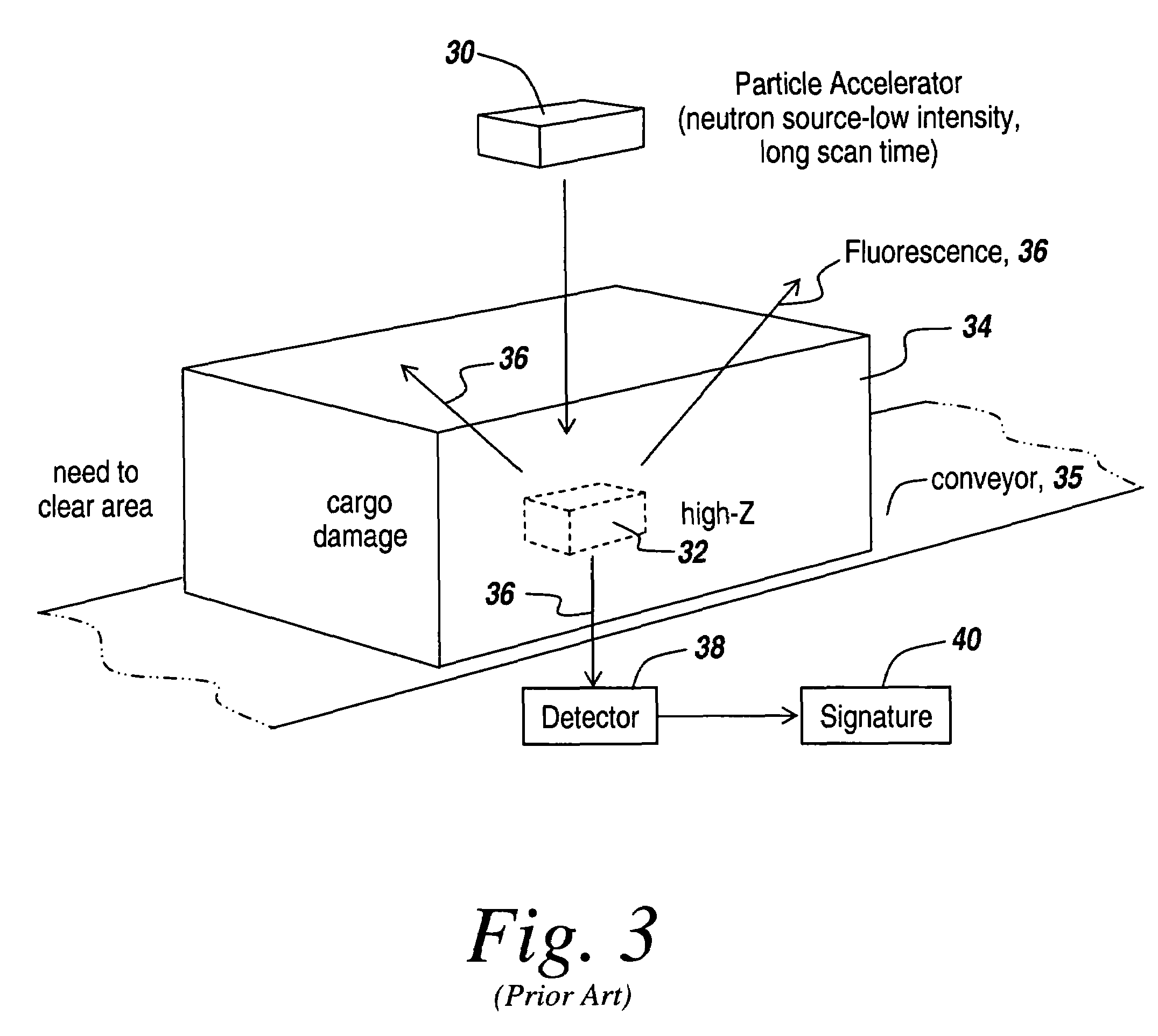

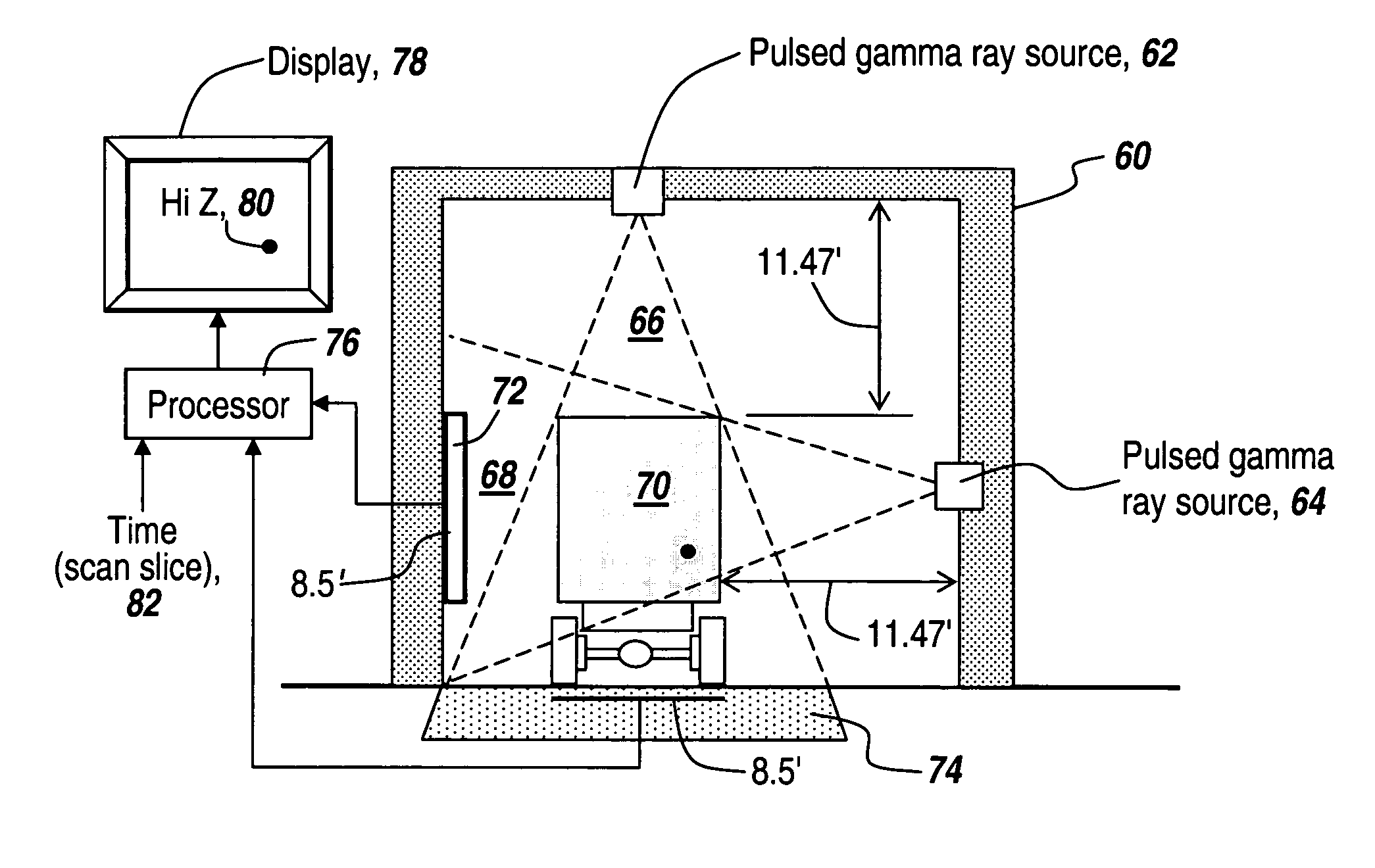

Method and apparatus for the safe and rapid detection of nuclear devices within containers

ActiveUS7379530B2Faster scan timeAccurate detectionX-ray apparatusMaterial analysis by transmitting radiationDisplay deviceHigh intensity

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

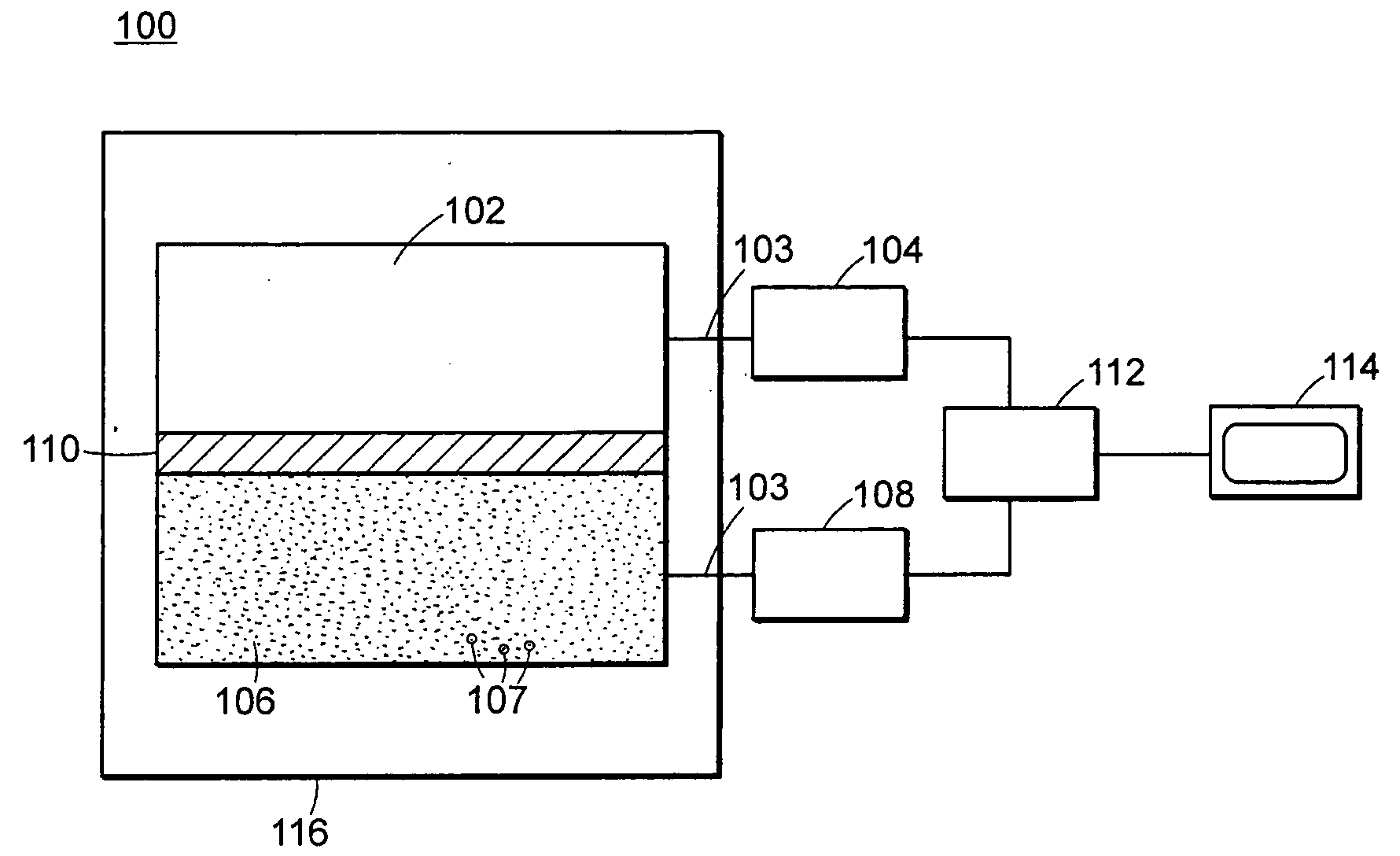

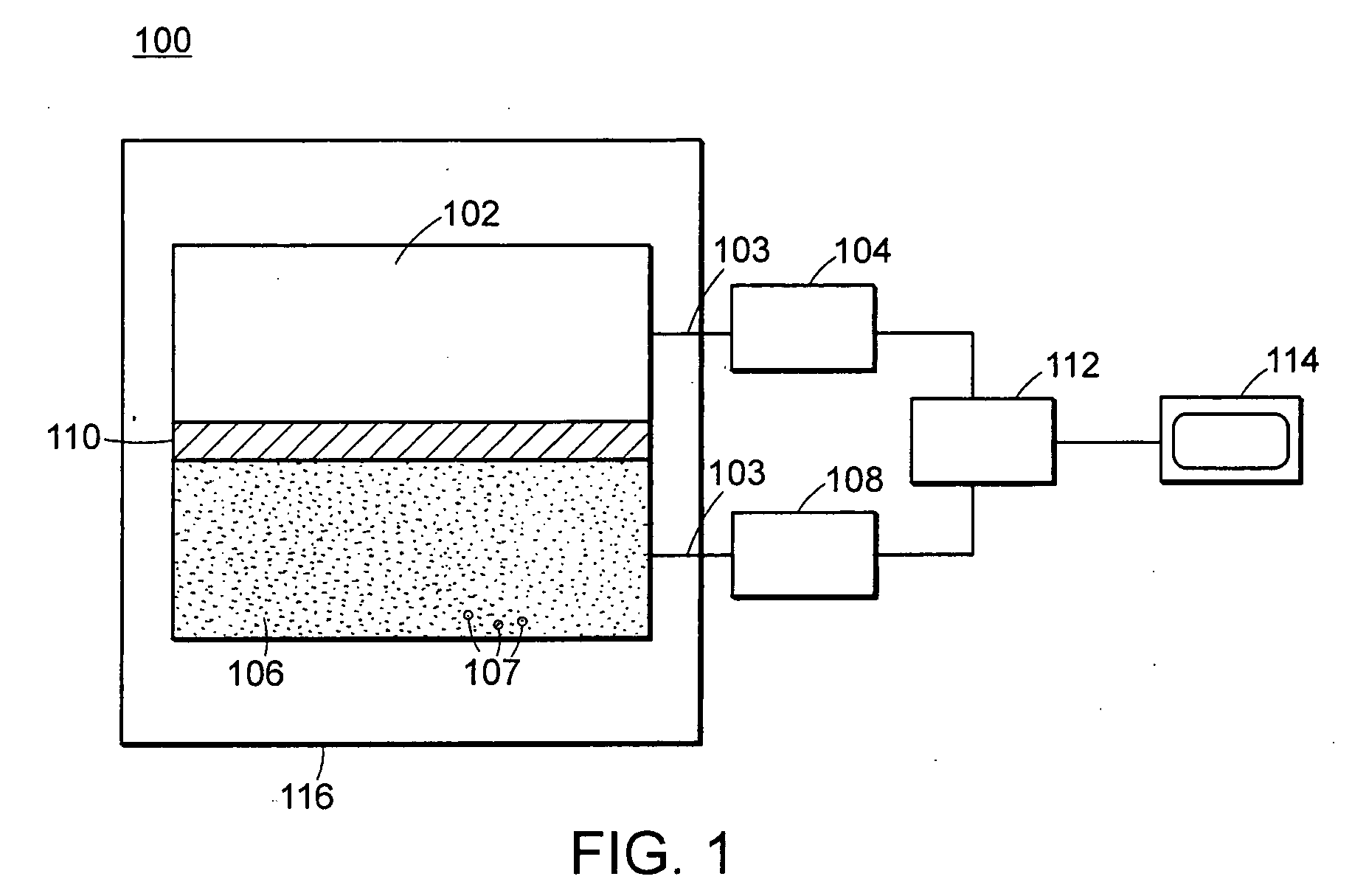

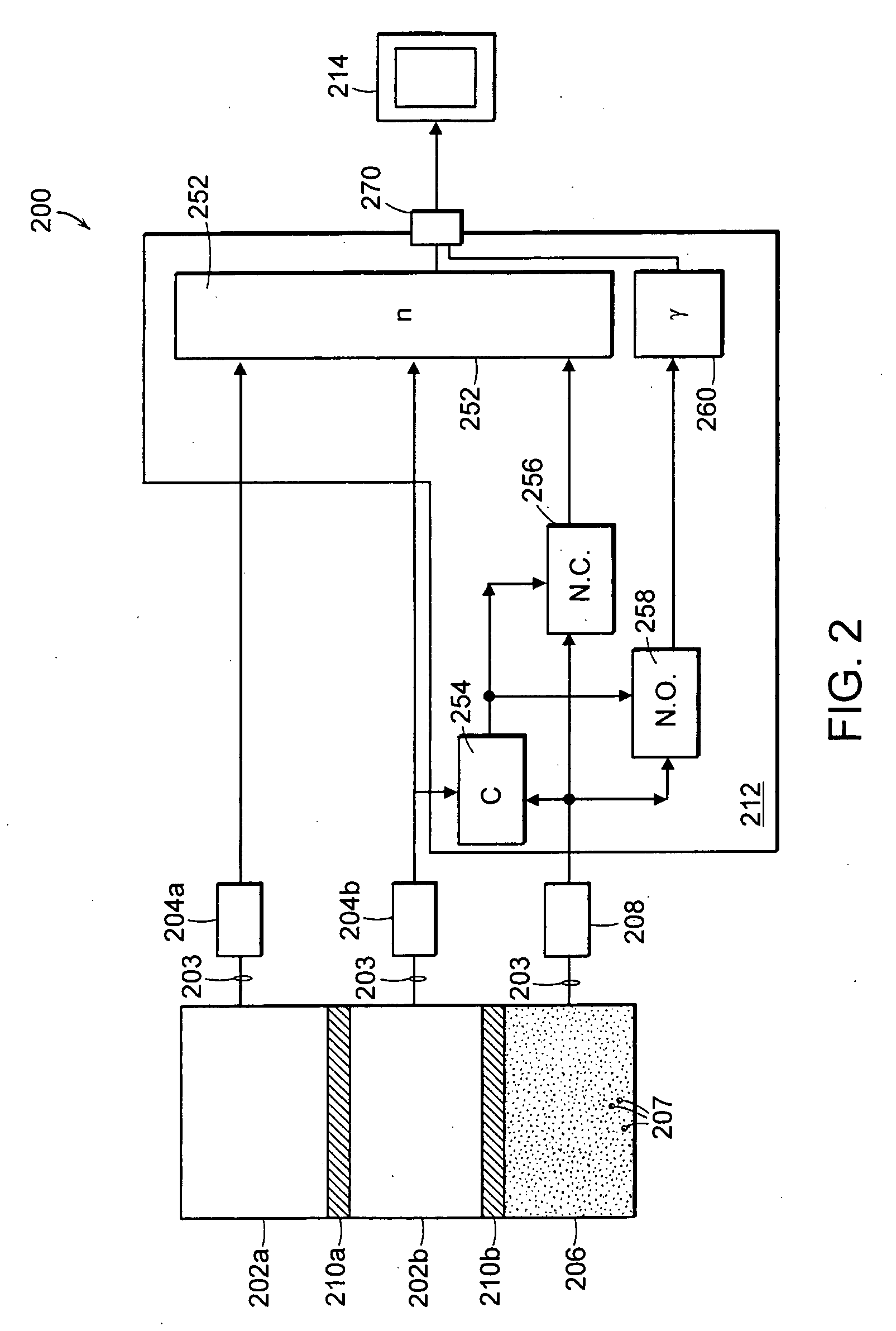

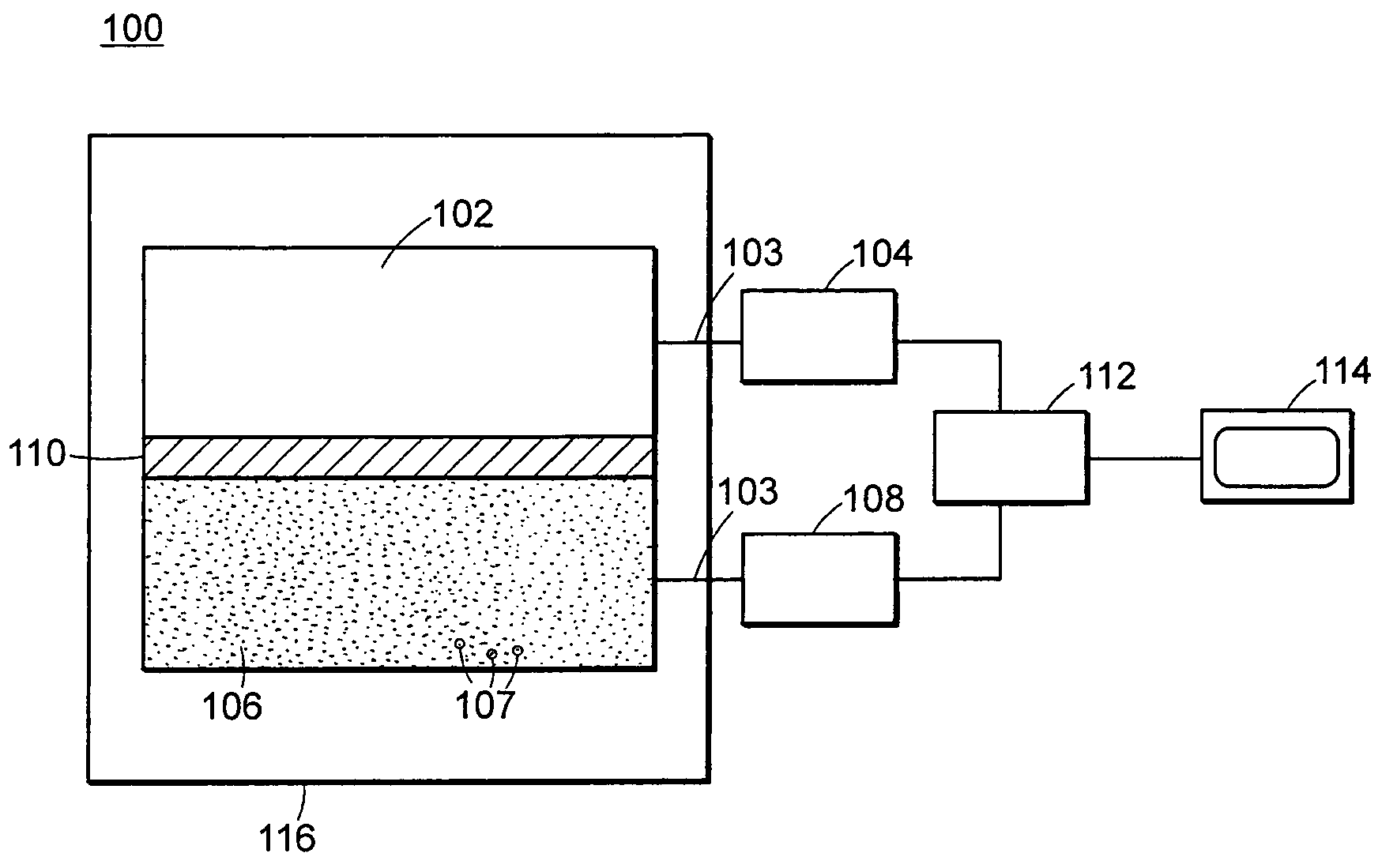

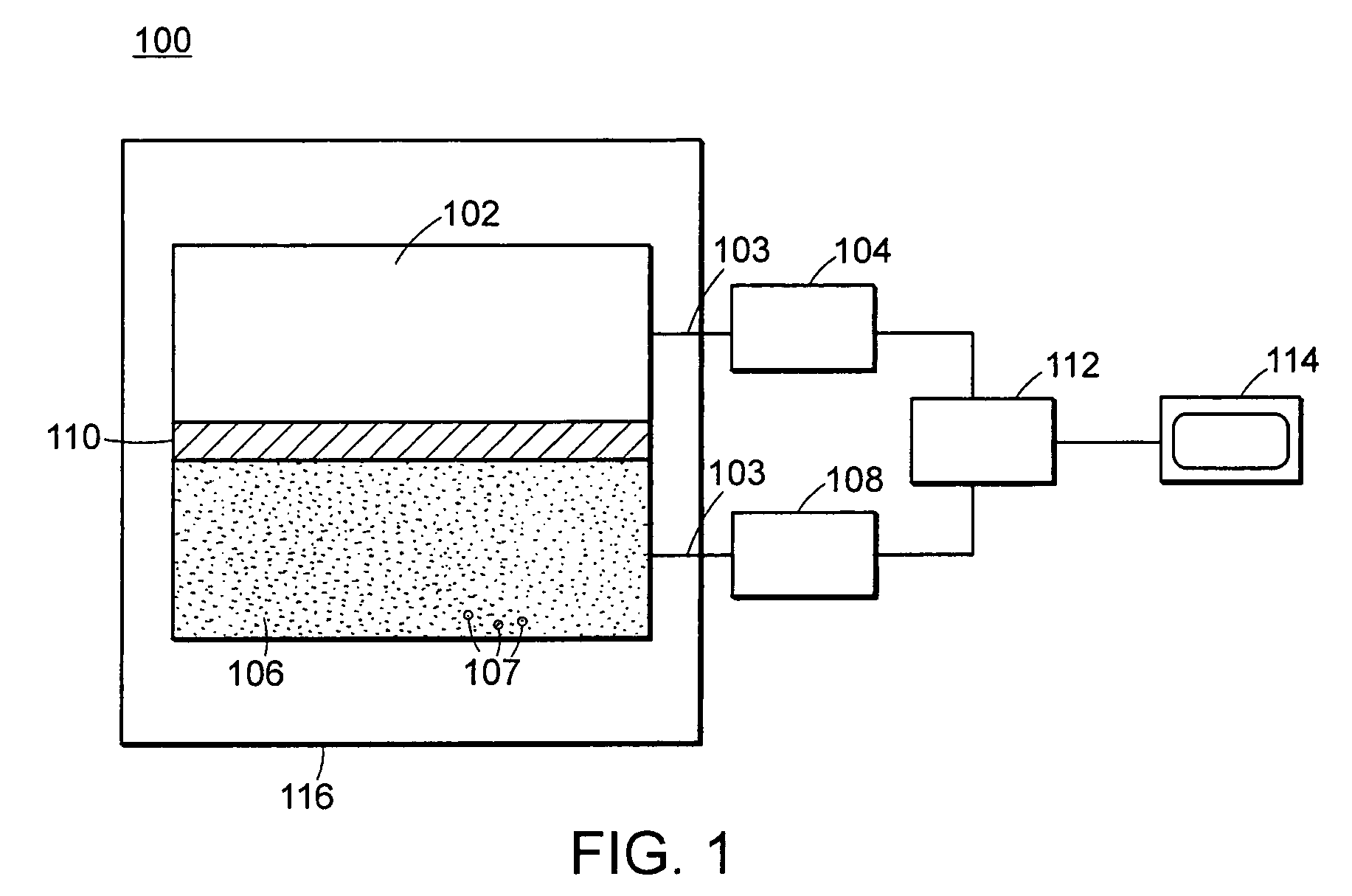

Neutron and gamma ray monitor

ActiveUS20070272874A1Easy to detectMeasurement with scintillation detectorsMaterial analysis by optical meansNeutron emissionLight guide

An apparatus for selective radiation detection includes a neutron detector that facilitates detection of neutron emitters, e.g. plutonium, and the like; a gamma ray detector that facilitates detection of gamma ray sources, e.g., uranium, and the like. The apparatus comprises a first light guide, optically coupled to a first optical detector; a second light guide, optically coupled to a second optical detector a sheet of neutron scintillator, opaque for incoming optical photons, said sheet of neutron scintillator sandwiched between the first and the second light guides. The second light guide comprises a gamma ray scintillator material.

Owner:THERMO NITON ANALYZERS

Neutron and gamma ray monitor

ActiveUS7525101B2Easy to detectMeasurement with scintillation detectorsMaterial analysis by optical meansNeutron emissionLight guide

Owner:THERMO NITON ANALYZERS

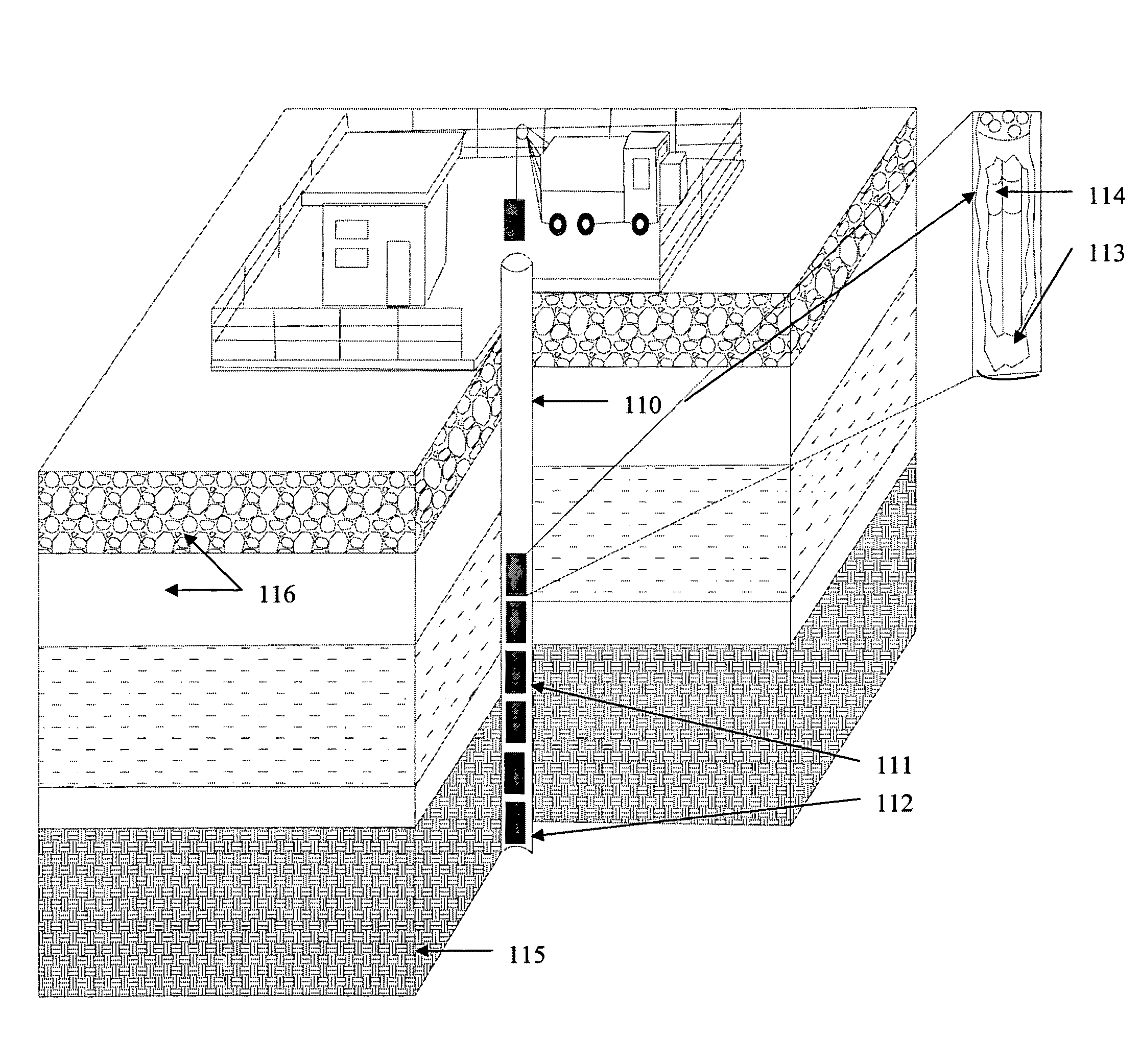

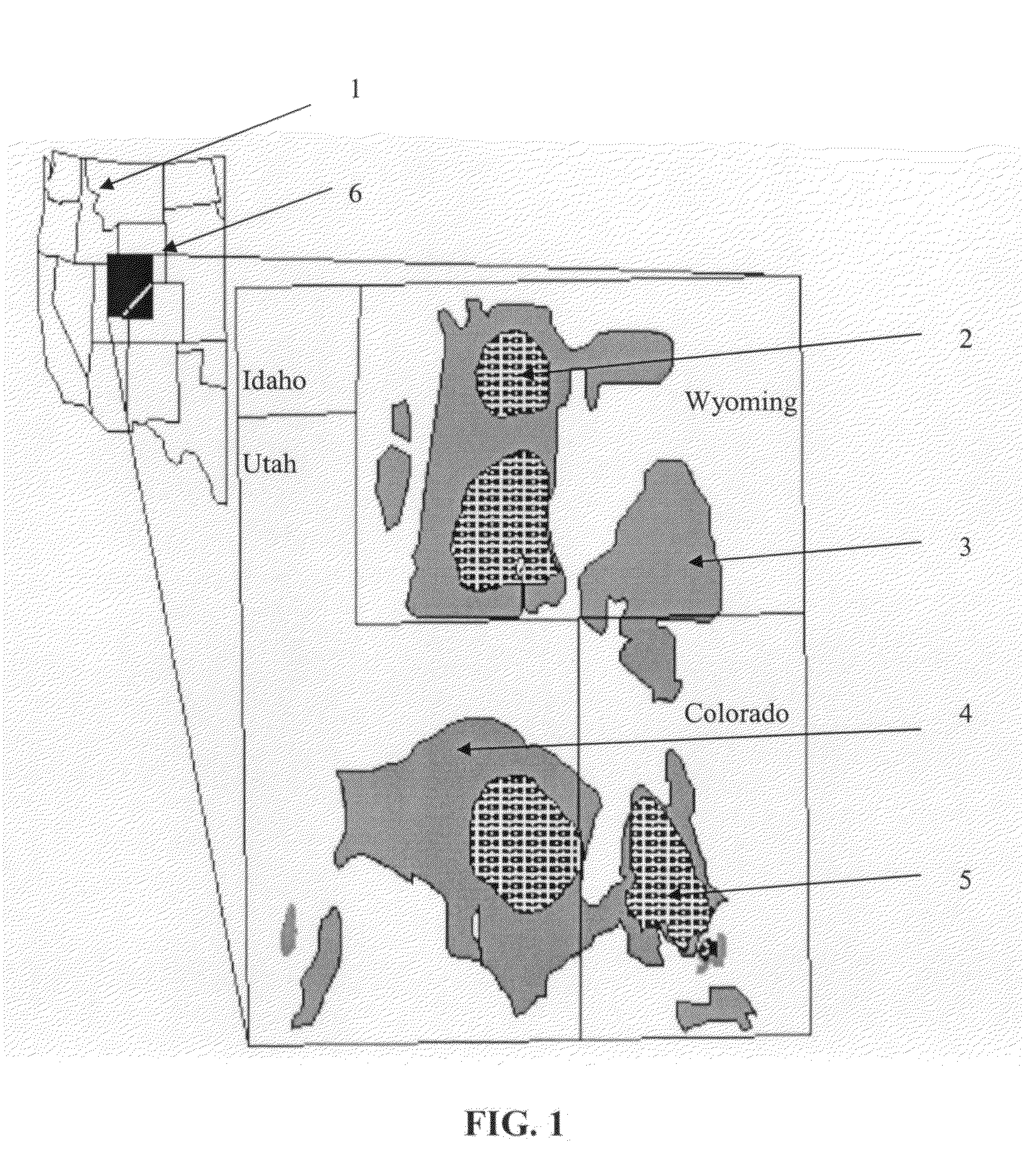

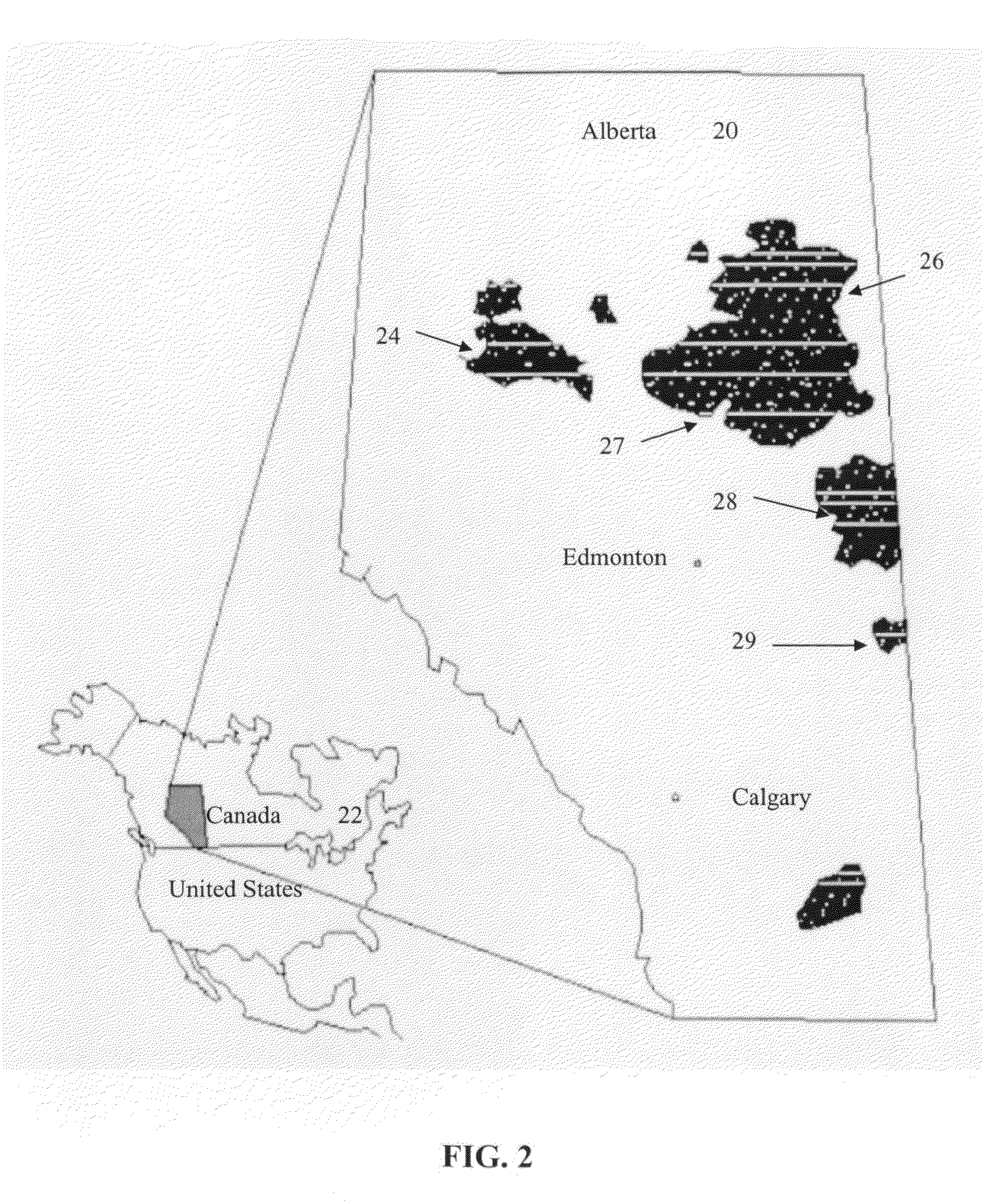

Nuclear Assisted Hydrocarbon Production Method

InactiveUS20100105975A1Reduced availabilityMinimized in sizeFluid removalShieldingHydrogenFormation fluid

A method is disclosed for the temporary or permanent storage of nuclear waste materials comprising the placing of waste materials into one or more repositories or boreholes constructed into an unconventional oil formation. The thermal flux of the waste materials fracture the formation, alters the chemical and / or physical properties of hydrocarbon material within the subterranean formation to allow removal of the altered material. A mixture of hydrocarbons, hydrogen, and / or other formation fluids are produced from the formation. The radioactivity of high-level radioactive waste affords proliferation resistance to plutonium placed in the periphery of the repository or the deepest portion of a borehole.

Owner:BAIRD JAMES RUSSELL

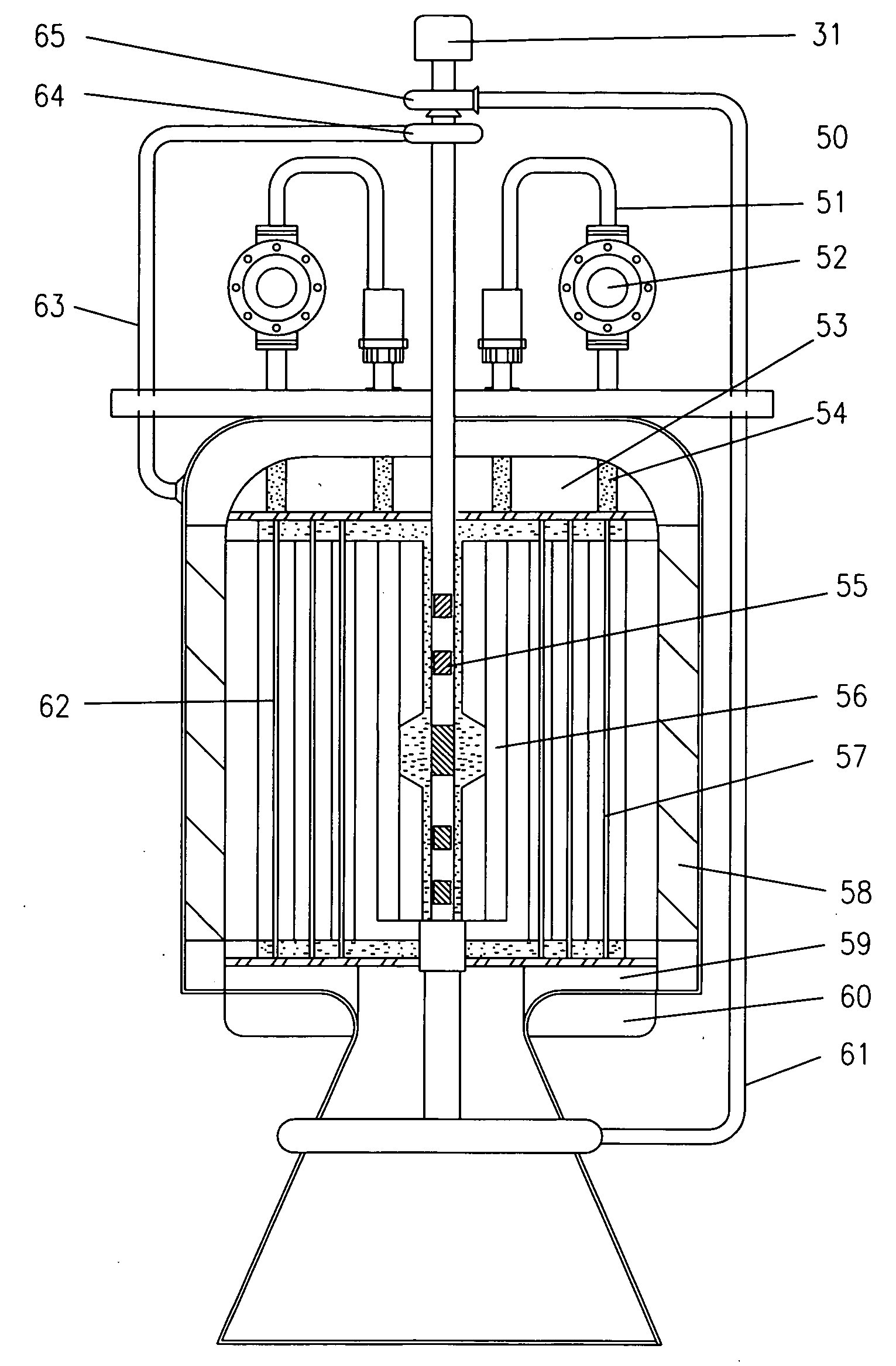

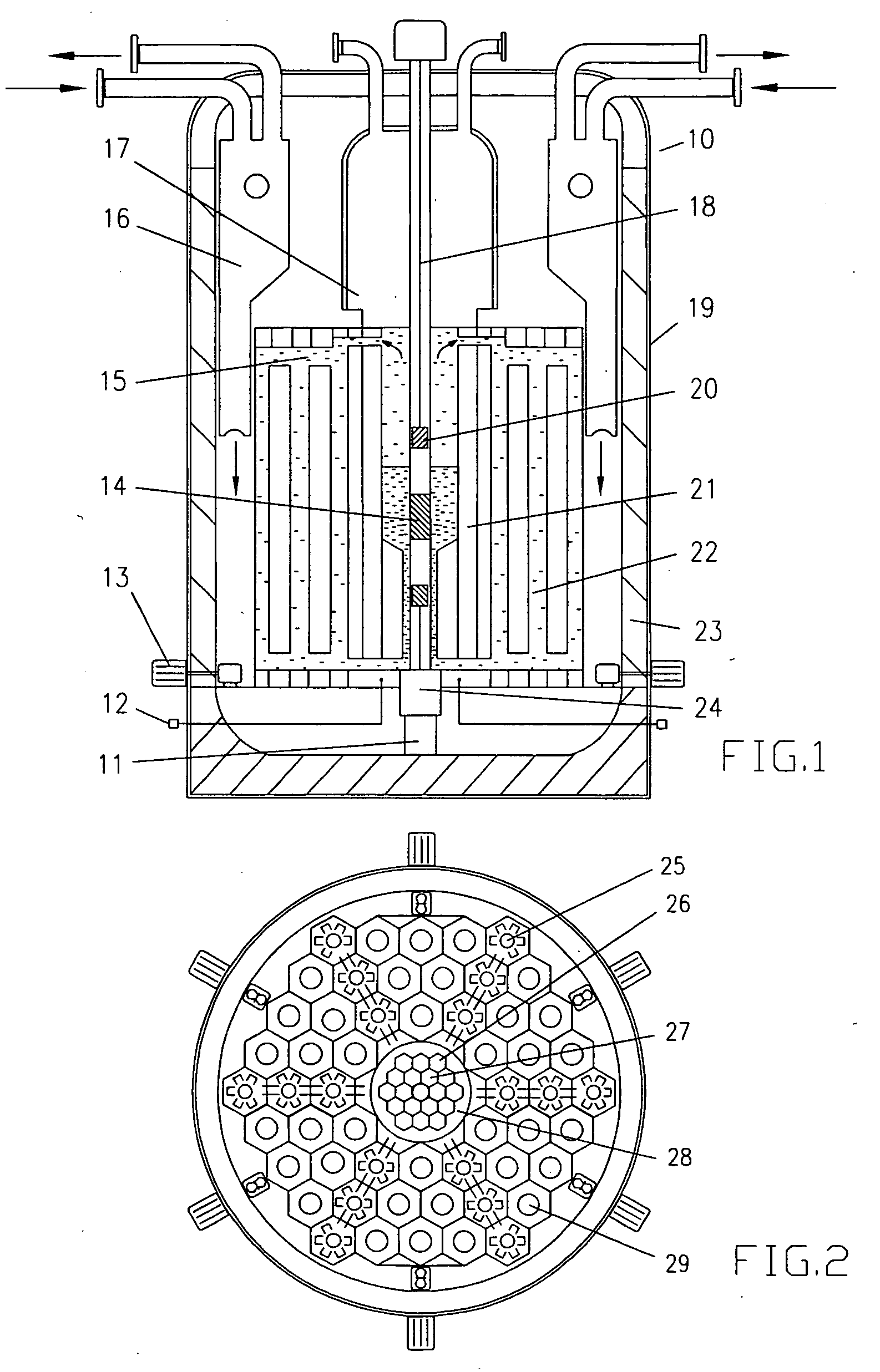

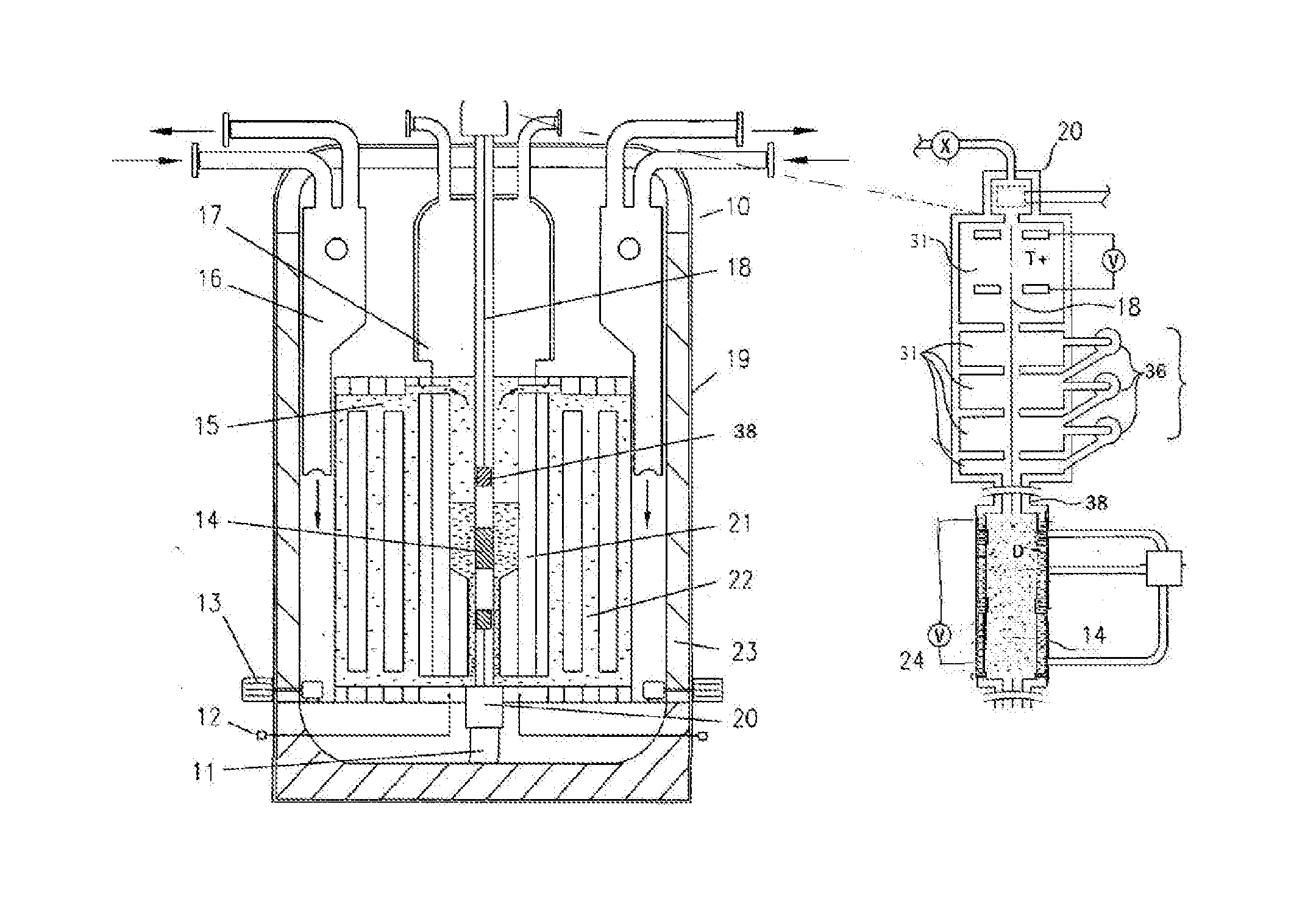

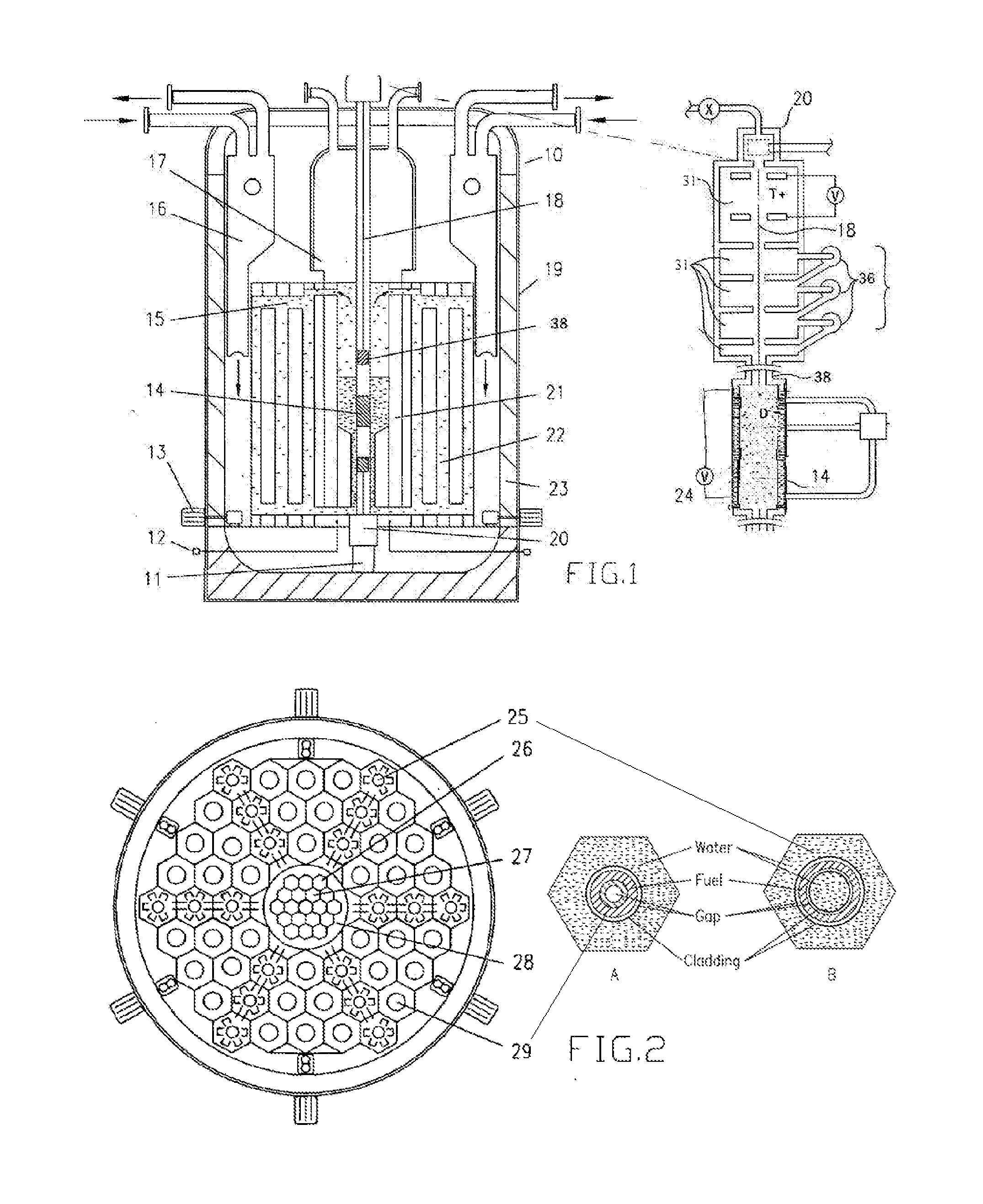

High flux sub-critical reactor for nuclear waste transmulation

InactiveUS20080232533A1Improve distributionImprove economyConversion outside reactor/acceleratorsNuclear energy generationHigh fluxPu element

A process to safely convert about 95% of the nuclear waste into a usable fuel source is disclosed. The process, involving a sub-critical power reactor and a proliferation-resistant fuel cycle, consumes depleted uranium or thorium fuel with fissionable fuel, including reactor or weapons-grade plutonium. The reactor is comprised of coaxial neutron and energy-amplifying regions separated by moderating and thermal neutron absorbing layers. Control of the water or gas-cooled reactor is provided by plutonium-helium loops with a variable volume flow rate and an external source of neutrons that quickly reacts to any fluctuations of the reactor parameters. A second embodiment of the invention is a compact sub-critical propulsion reactor utilizing fission electric cell and thermo-acoustic technology for electrical power generation.

Owner:BLANOVSKY ANATOLY

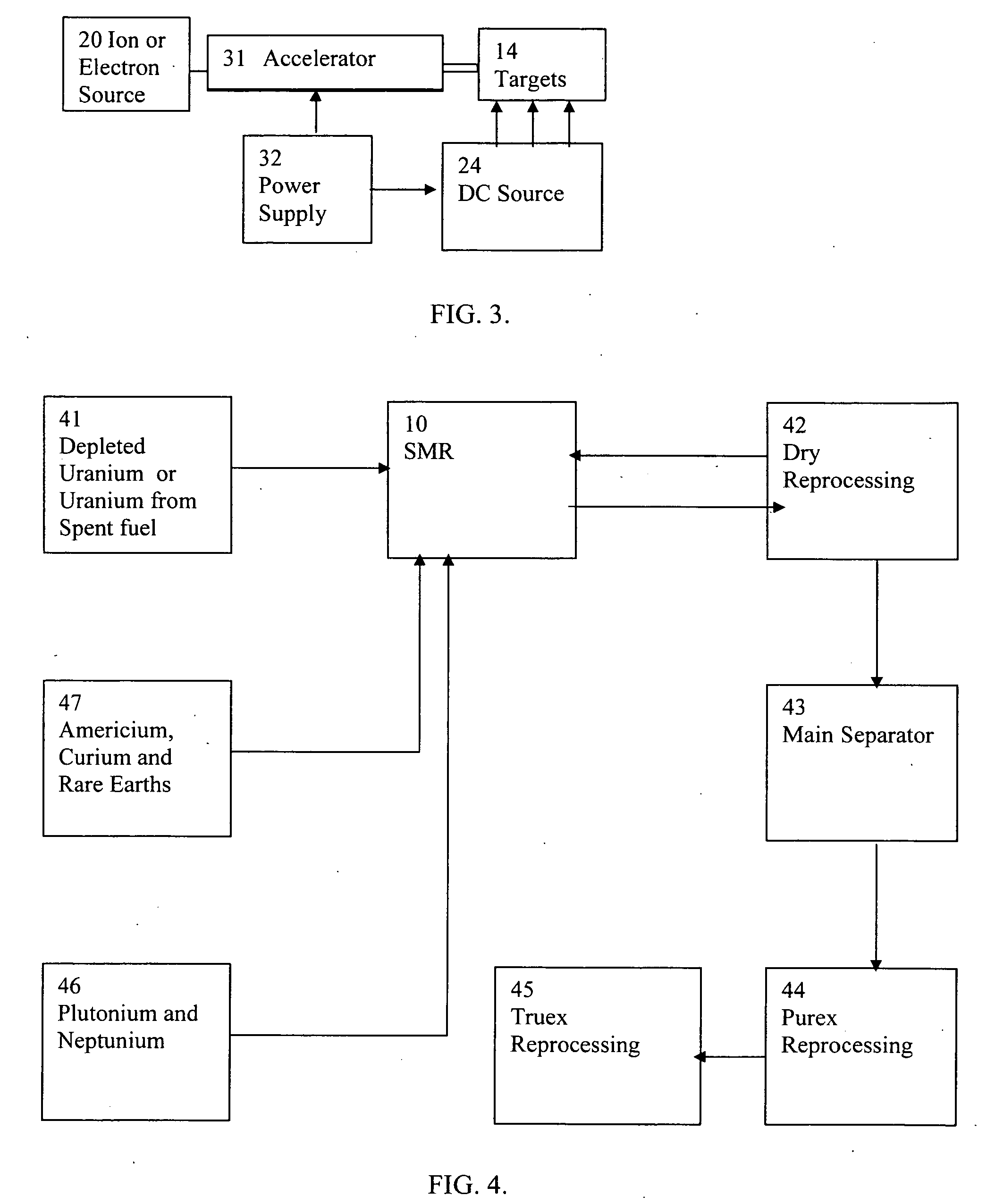

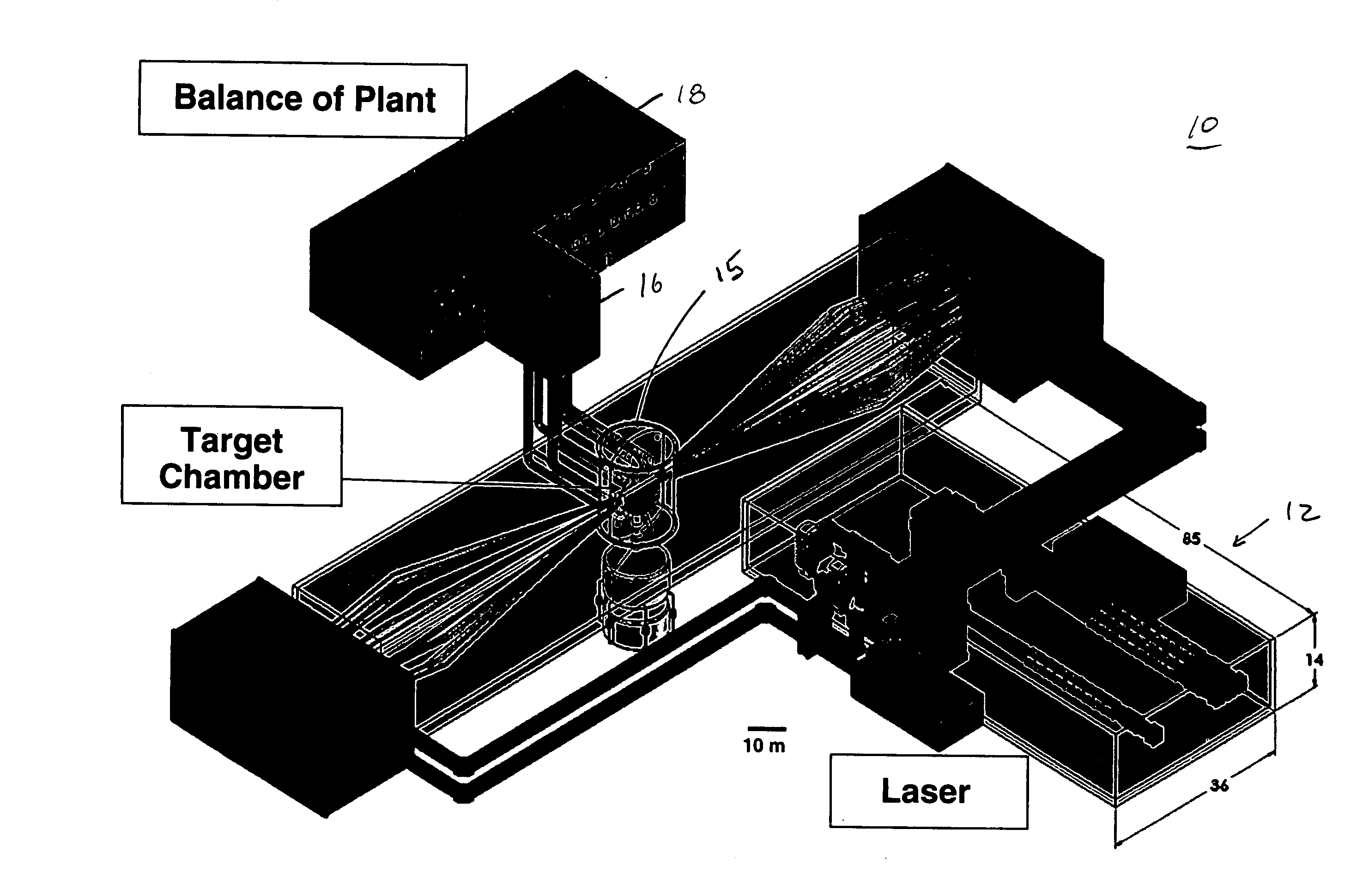

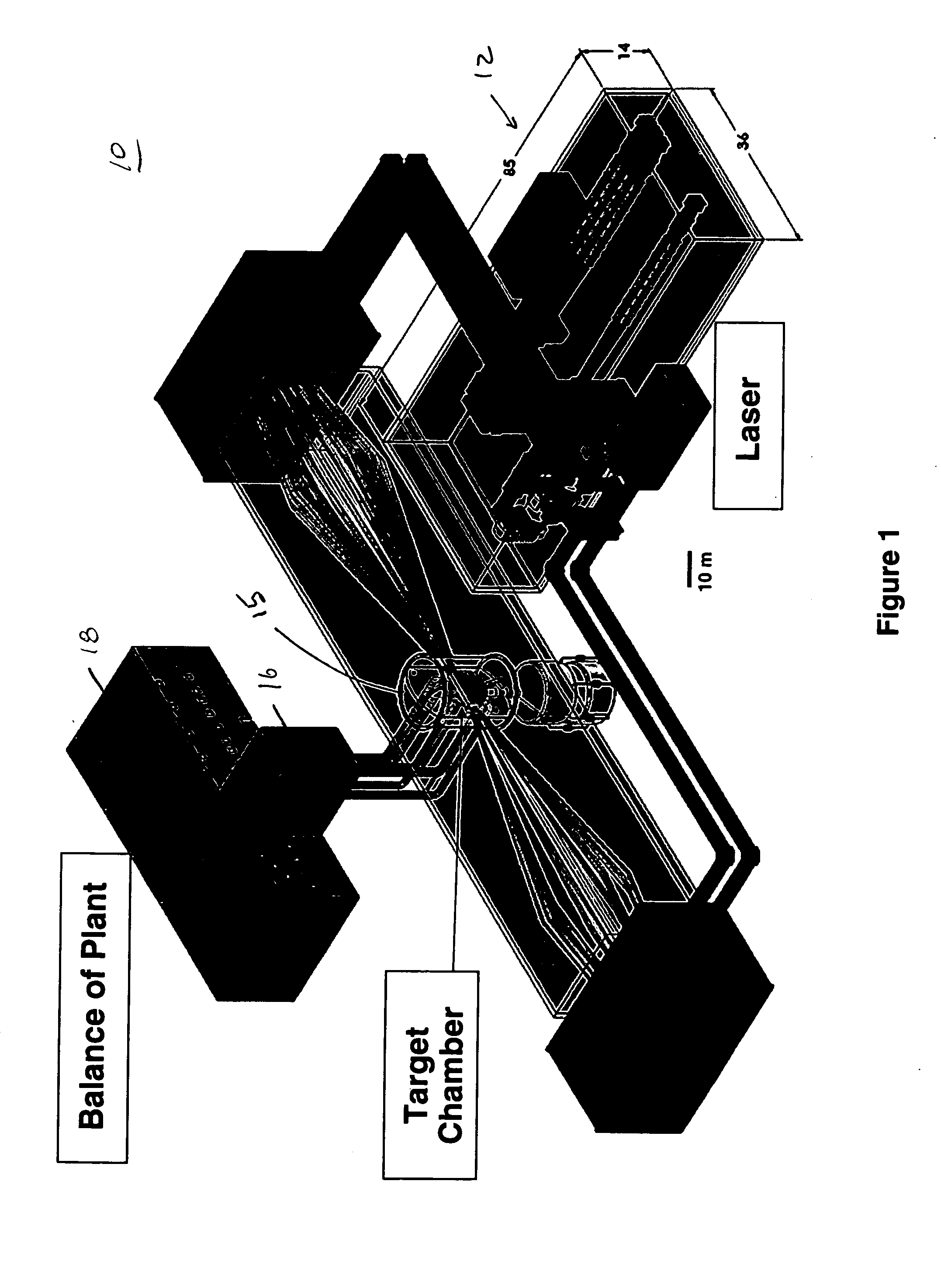

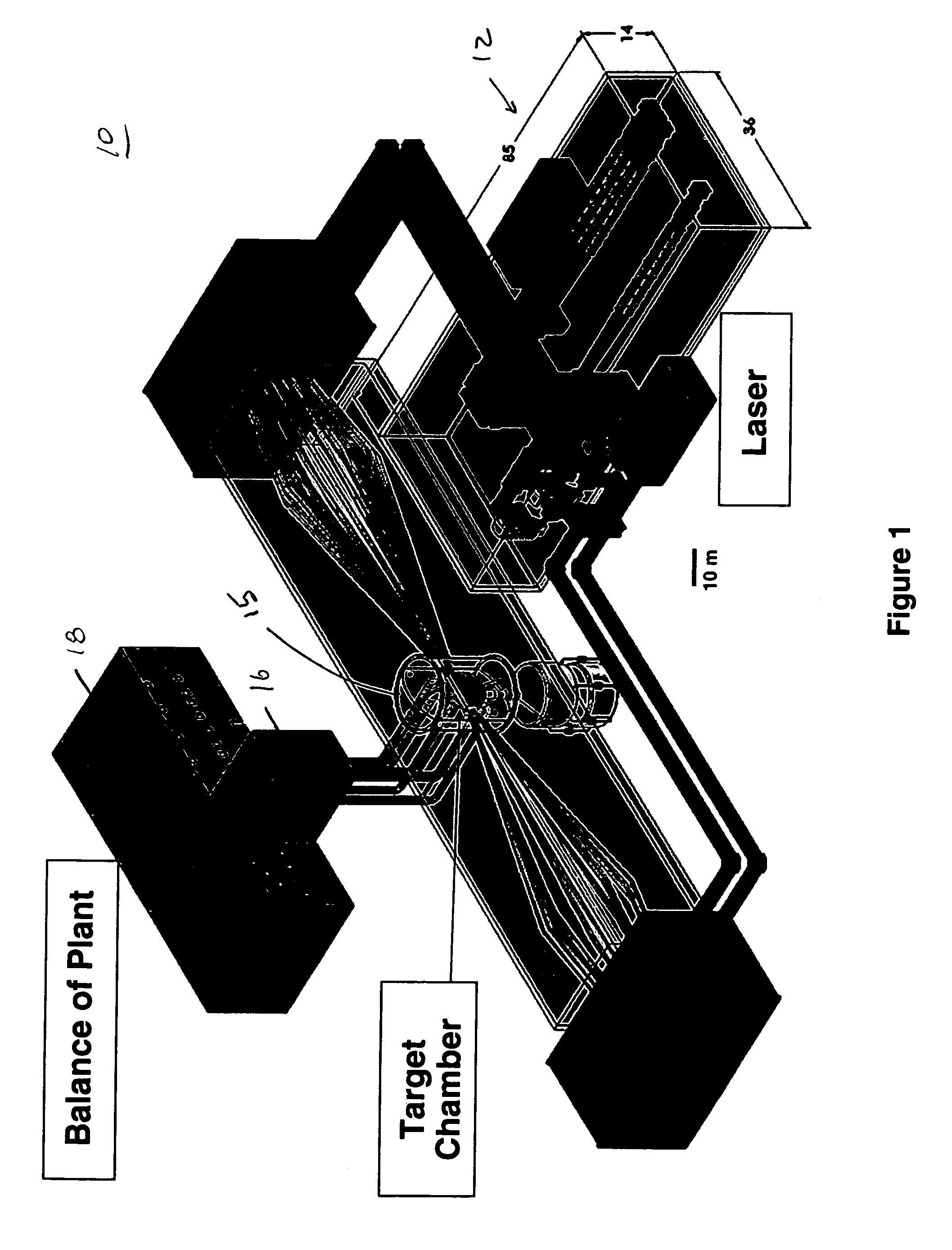

Control of a Laser Inertial Confinement Fusion-Fission Power Plant

ActiveUS20110286563A1Extended service lifeReduce spreadNuclear energy generationWaste based fuelFusion fissionEngineering

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

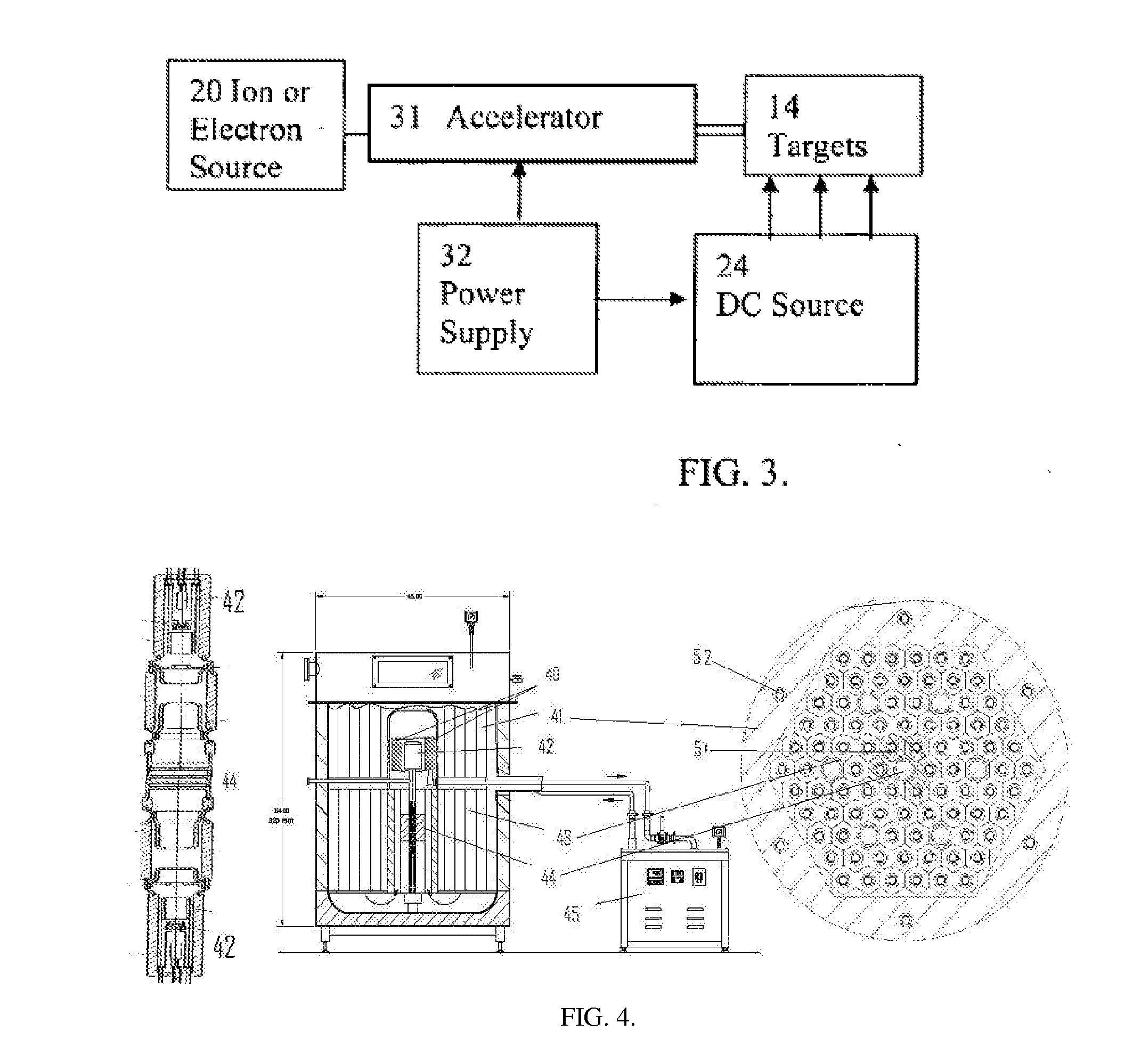

Sustainable Modular Transmutation Reactor

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

Method and apparatus for the safe and rapid detection of nuclear devices within containers

ActiveUS20070237294A1Faster scan timeAccurate detectionX-ray apparatusMaterial analysis by transmitting radiationHigh intensityGamma ray

A safe, reliable and rapid system for the detection of nuclear materials within containers includes the use of pulsed high-intensity gamma rays that can penetrate a container and its contents and can be detected outside the container to provide a display in which high-Z material, including lead, uranium, plutonium and other nuclear substances that absorb gamma rays are detected as black regions on the display. In one embodiment, orthogonal pulsed gamma ray beams illuminate the container from two different directions to provide three-dimensional slices from which the existence and location of nuclear threat materials can be ascertained in as little as four seconds for a 40-foot container.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

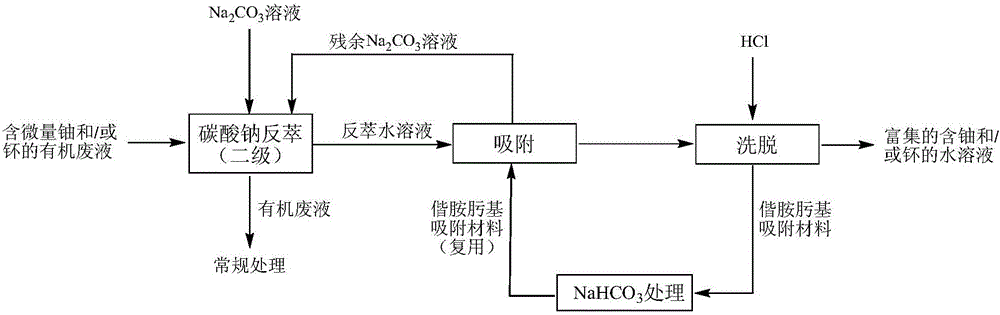

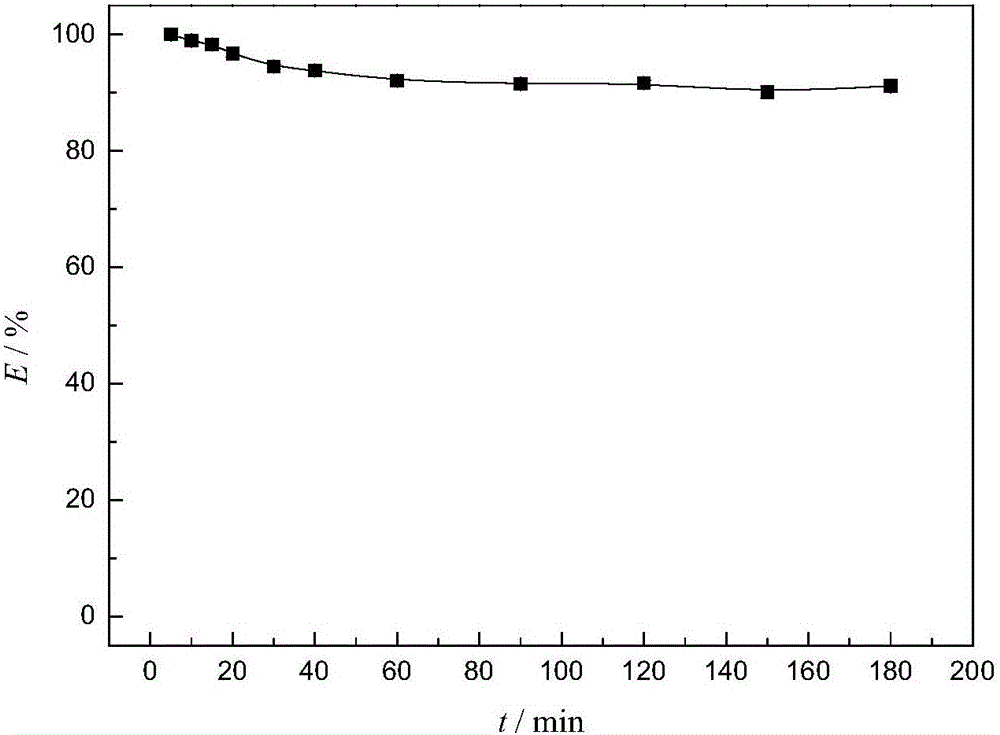

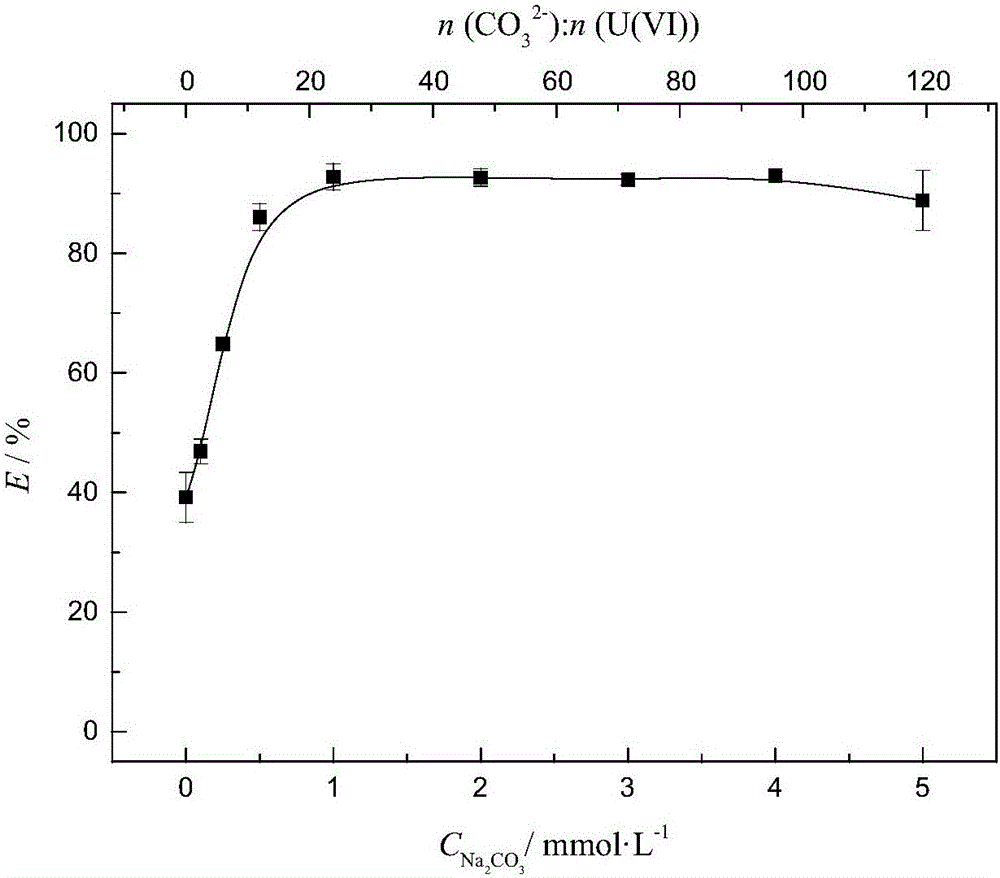

Recovery method for trace of uranium and/or plutonium in radioactive organic liquid waste

The prevent invention discloses a method for recovering a trace of uranium and / or plutonium from radioactive organic liquid waste. The method comprises: firstly, performing stripping on radioactive organic liquid waste with a carbonate solution; then performing oscillation adsorption, column chromatography or membrane filtration on a stripped aqueous phase by using a solid functional adsorption material; recycling a treated liquid again as a stripping solution; using acid to perform elution on the solid functional adsorption material that adsorbs the uranium and / or plutonium, to obtain a rich aqueous solution containing the uranium and / or plutonium; recycling the adsorption material after the elution by using an aqueous bicarbonate solution for soaking or washing. The method combines stripping of carbonate and recycling of a low concentration of uranium and / or plutonium from a (weak) alkaline aqueous solution, and achieves recycling of the functional adsorption material and the stripping solution, thereby reducing the amount of waste as much as possible.

Owner:PEKING UNIV

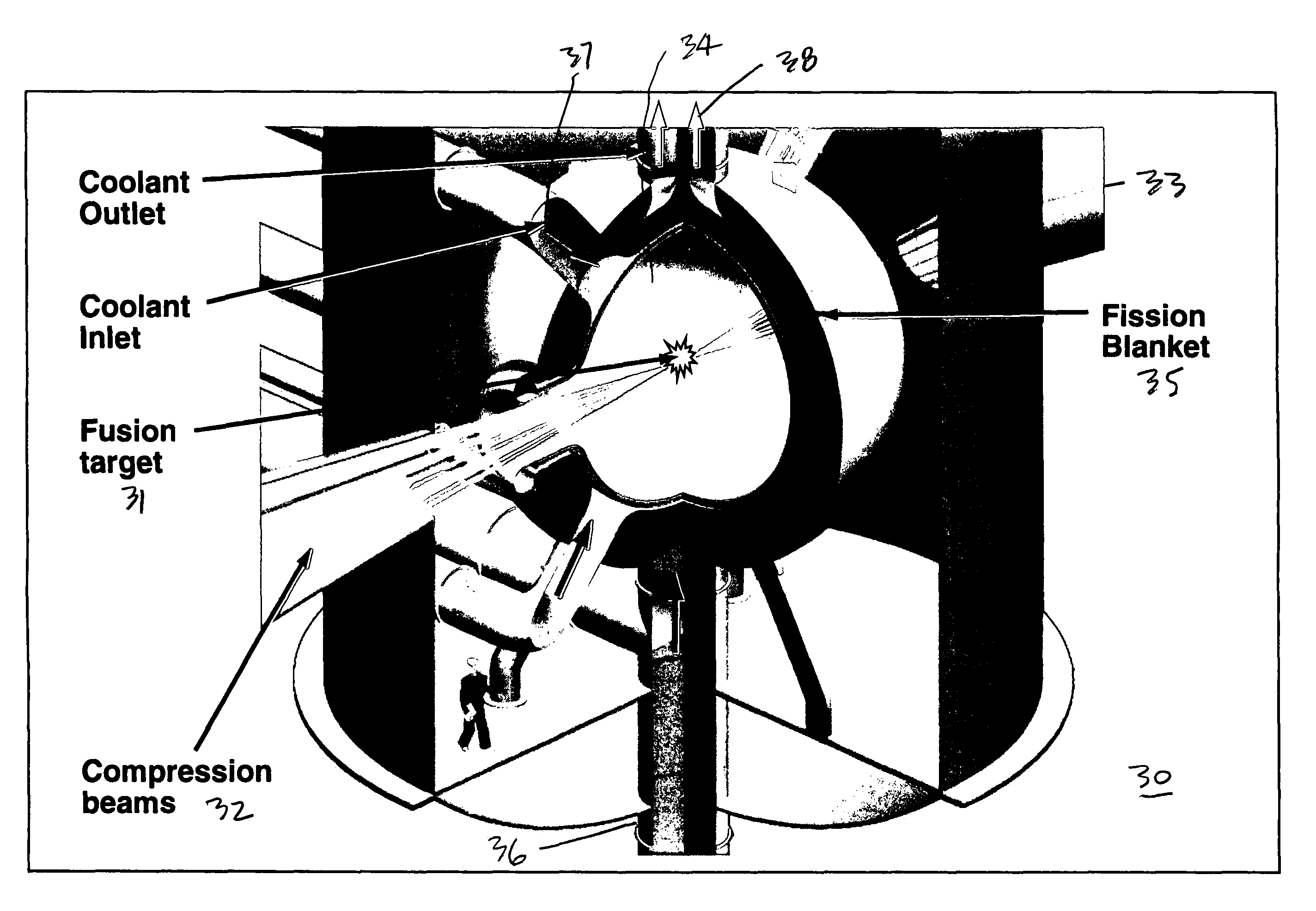

Control of a laser inertial confinement fusion-fission power plant

ActiveUS9171646B2Extended service lifeNuclear energy generationWaste based fuelFusion fissionEngineering

A laser inertial-confinement fusion-fission energy power plant is described. The fusion-fission hybrid system uses inertial confinement fusion to produce neutrons from a fusion reaction of deuterium and tritium. The fusion neutrons drive a sub-critical blanket of fissile or fertile fuel. A coolant circulated through the fuel extracts heat from the fuel that is used to generate electricity. The inertial confinement fusion reaction can be implemented using central hot spot or fast ignition fusion, and direct or indirect drive. The fusion neutrons result in ultra-deep burn-up of the fuel in the fission blanket, thus enabling the burning of nuclear waste. Fuels include depleted uranium, natural uranium, enriched uranium, spent nuclear fuel, thorium, and weapons grade plutonium. LIFE engines can meet worldwide electricity needs in a safe and sustainable manner, while drastically shrinking the highly undesirable stockpiles of depleted uranium, spent nuclear fuel and excess weapons materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

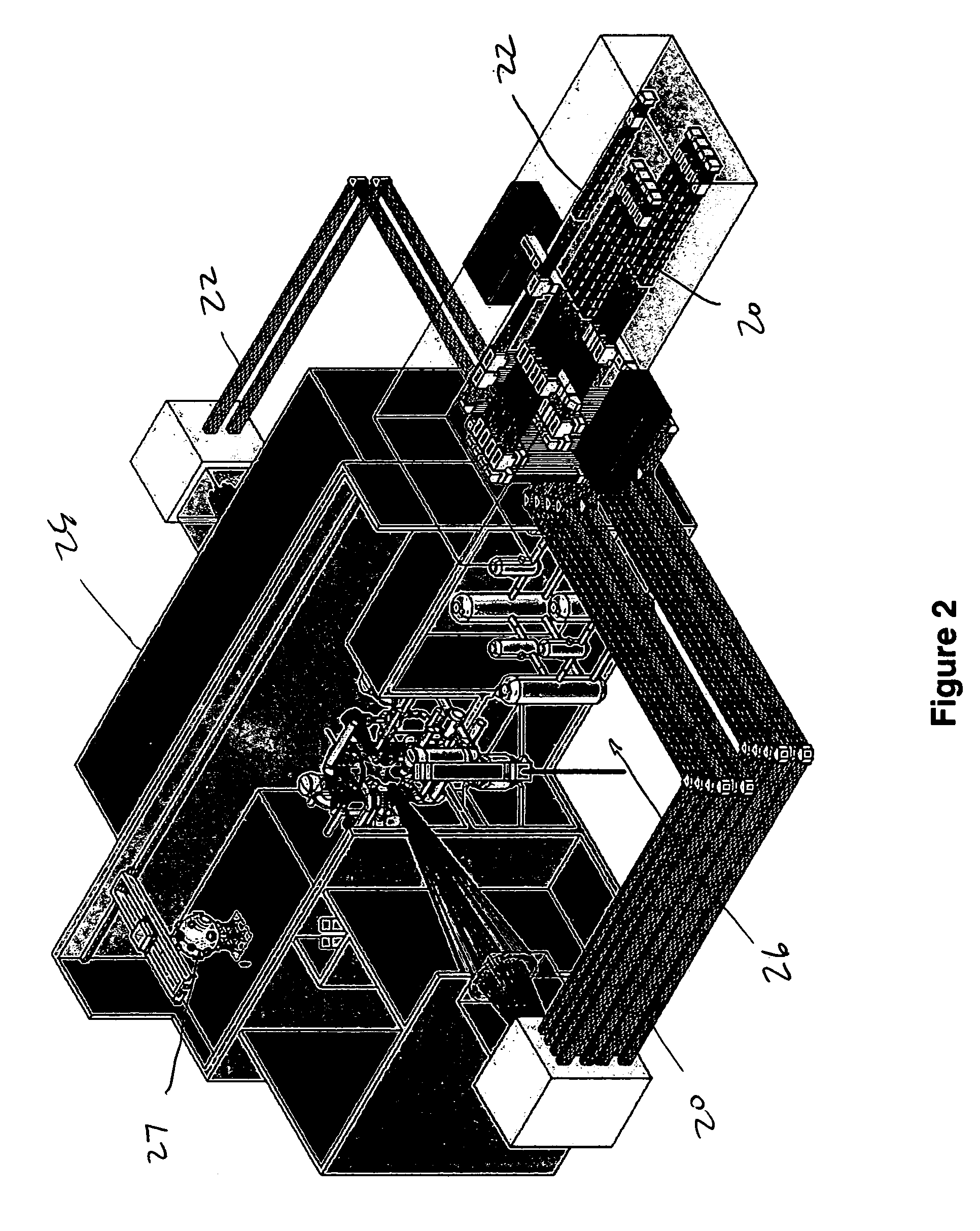

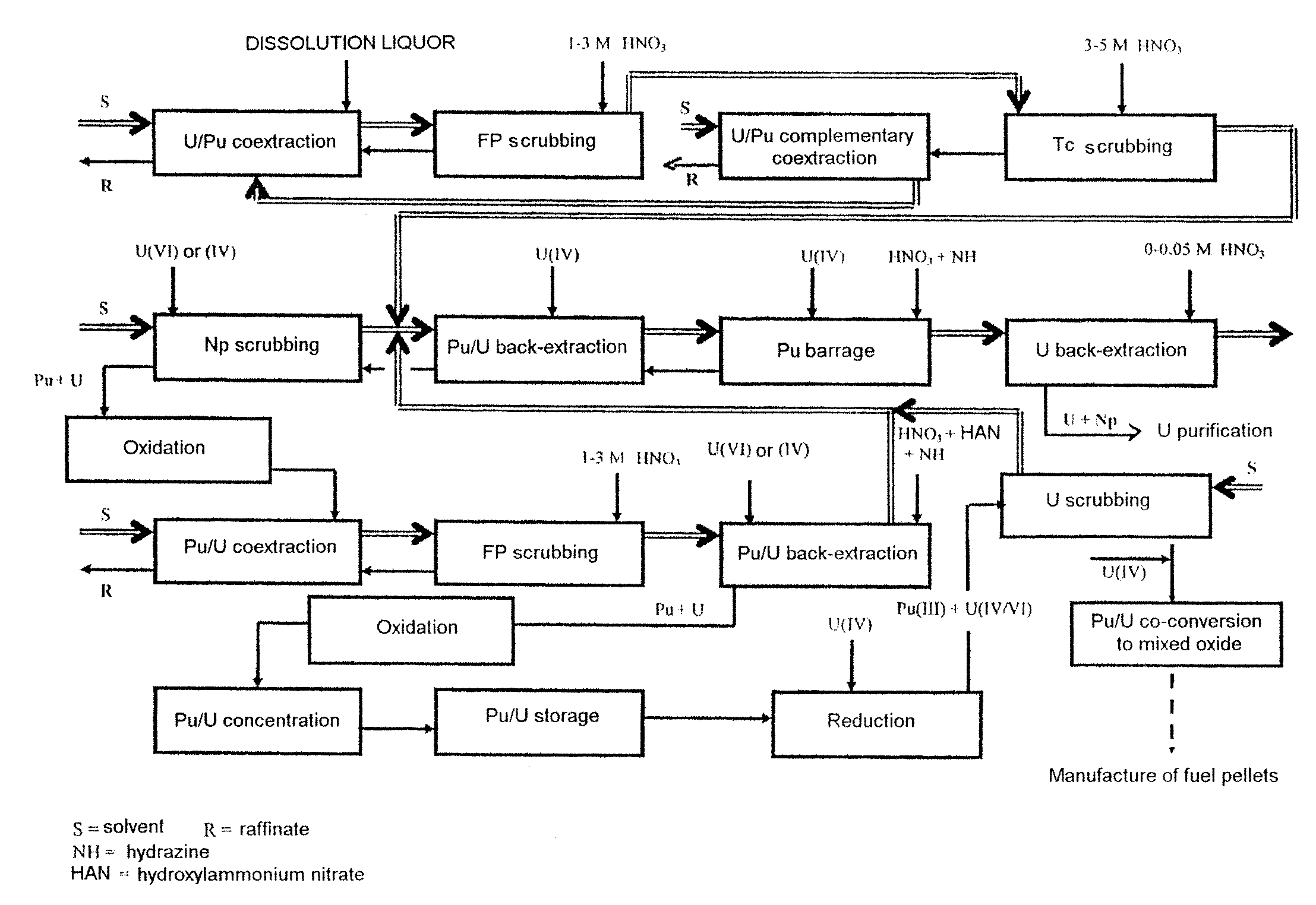

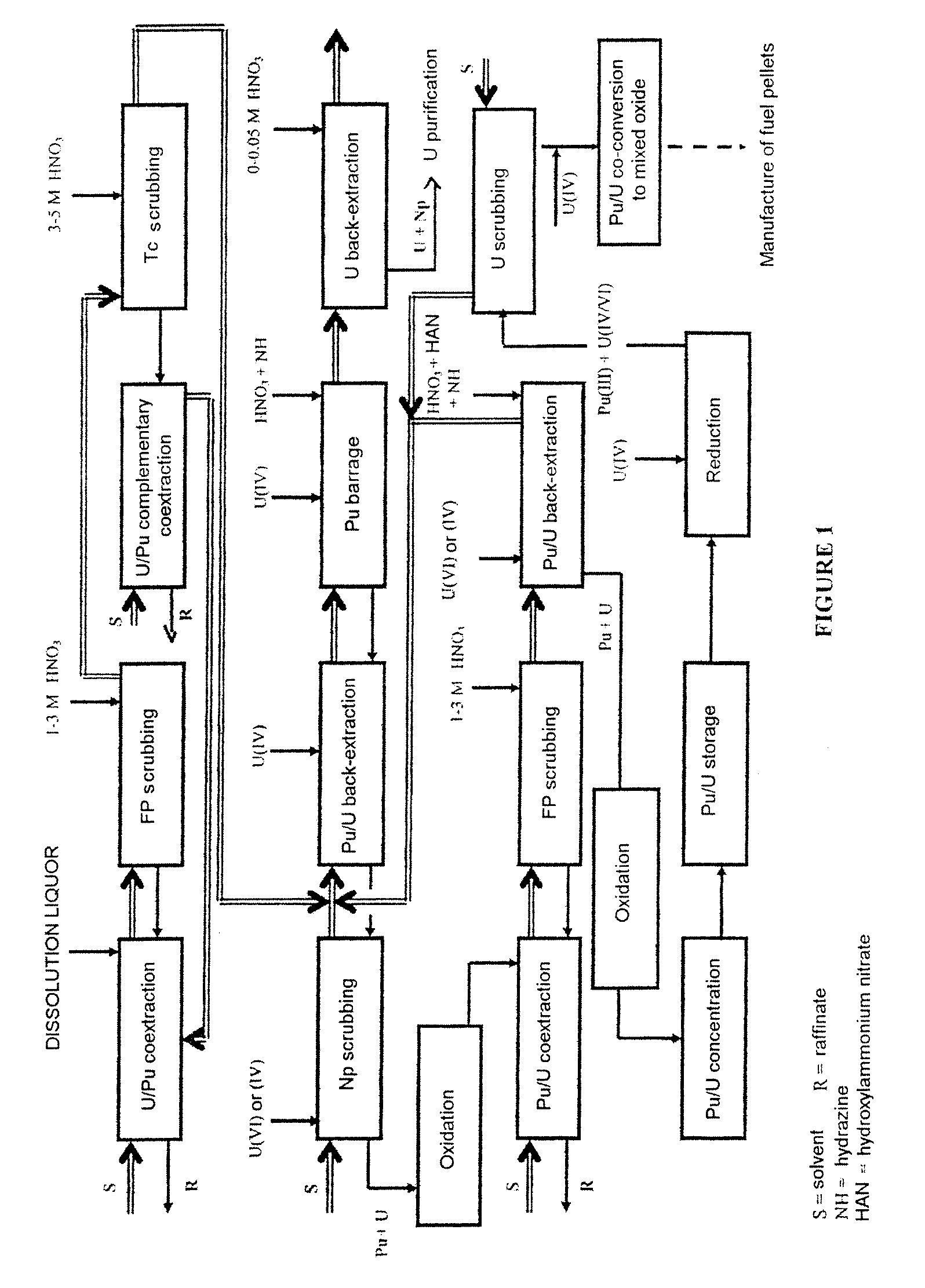

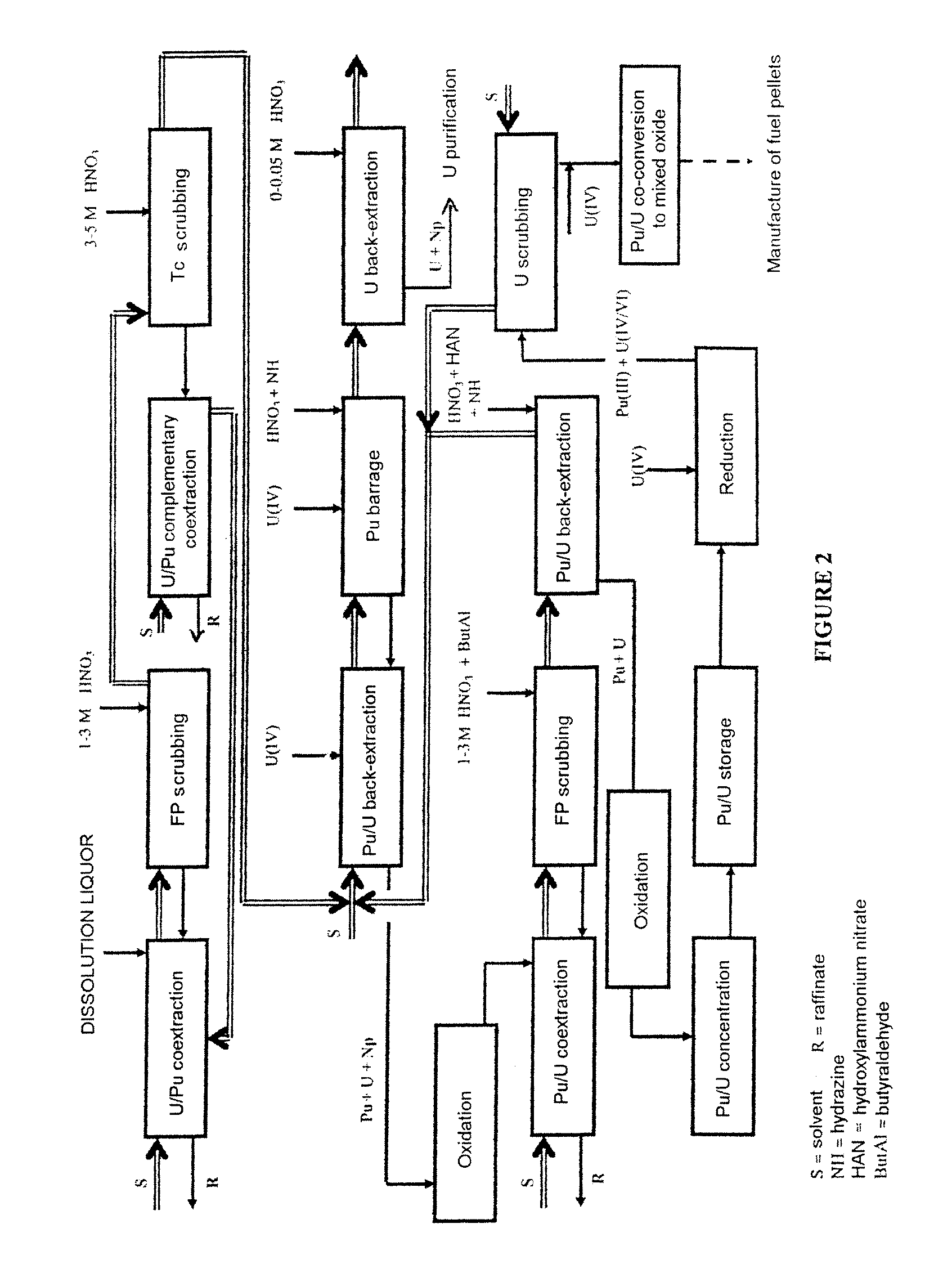

Process for reprocessing a spent nuclear fuel and of preparing a mixed uranium-plutonium oxide

ActiveUS20070290178A1Risk minimizationUranium compounds preparationSolvent extractionUranium oxideDissolution

The invention relates to a process for reprocessing a spent nuclear fuel and for preparing a mixed uranium-plutonium oxide, which process comprises: a) the separation of the uranium and plutonium from the fission products, the americium and the curium that are present in an aqueous nitric solution resulting from the dissolution of the fuel in nitric acid, this step including at least one operation of coextracting the uranium and plutonium from said solution by a solvent phase; b) the partition of the coextracted uranium and plutonium to a first aqueous phase containing plutonium and uranium, and a second aqueous phase containing uranium but no plutonium; c) the purification of the plutonium and uranium that are present in the first aqueous phase; and d) a step of coconverting the plutonium and uranium to a mixed uranium / plutonium oxide. Applications: reprocessing of nuclear fuels based on uranium oxide or on mixed uranium-plutonium oxide.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

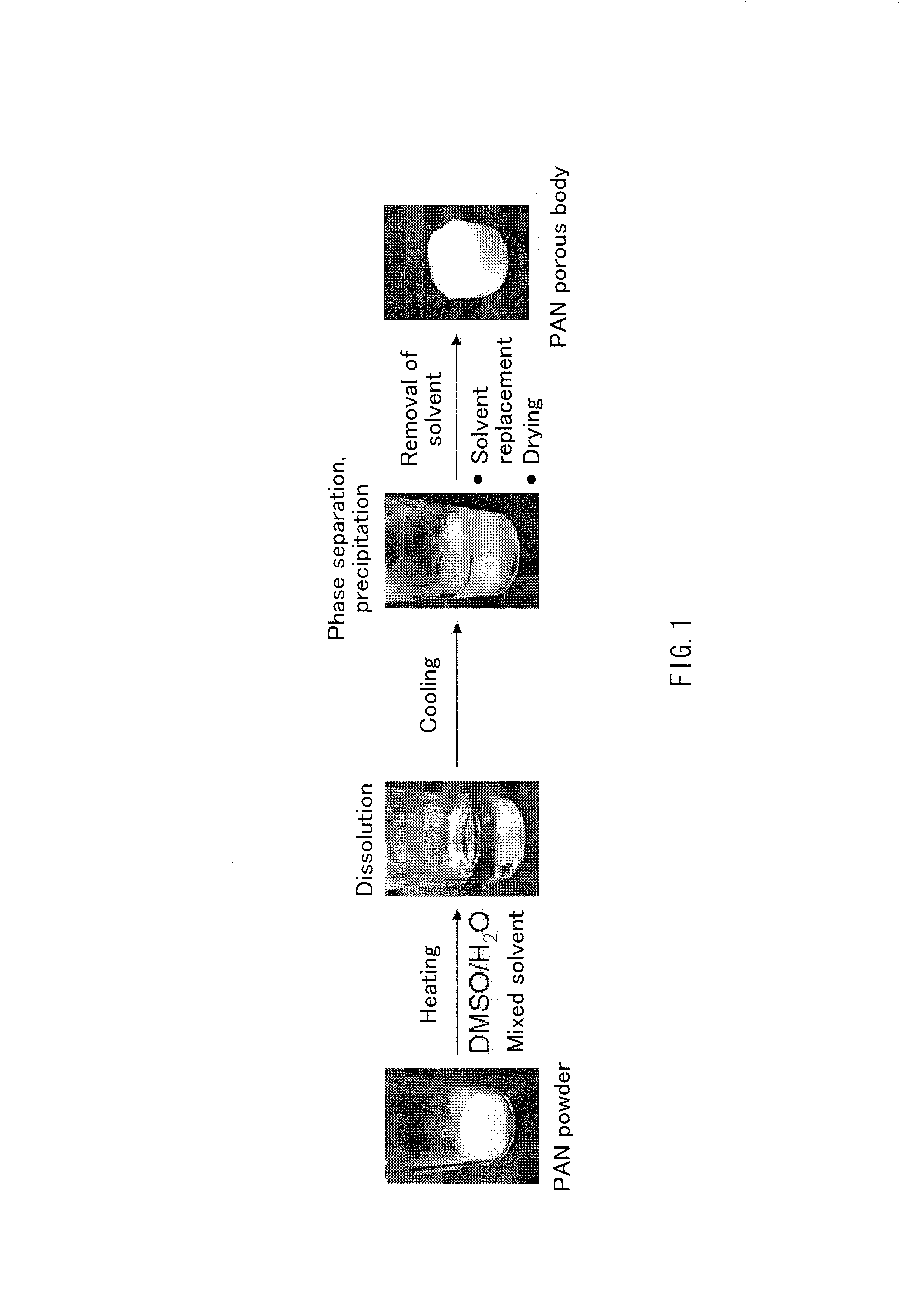

Amidoxime-modified polyacrylonitrile porous body

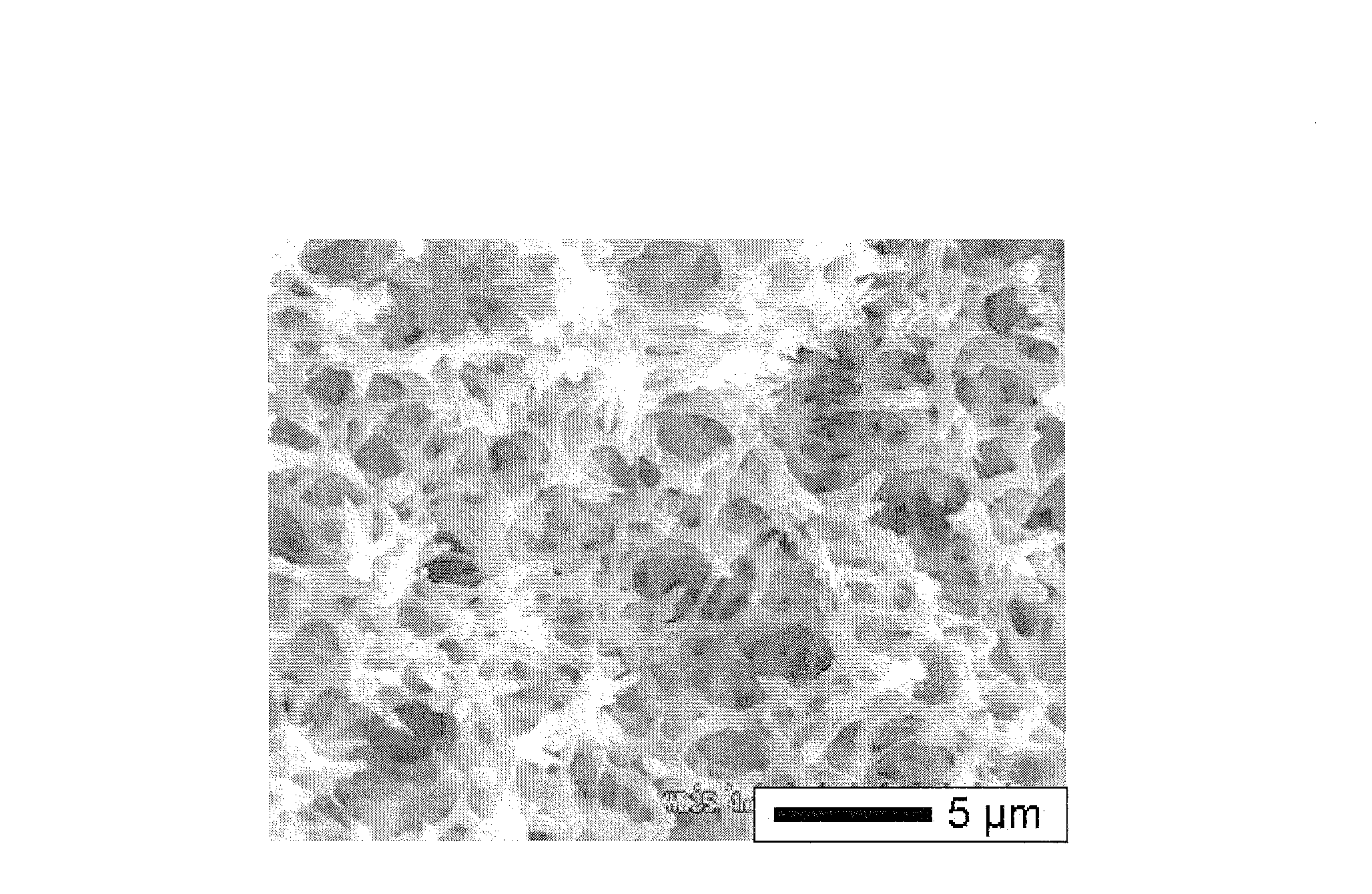

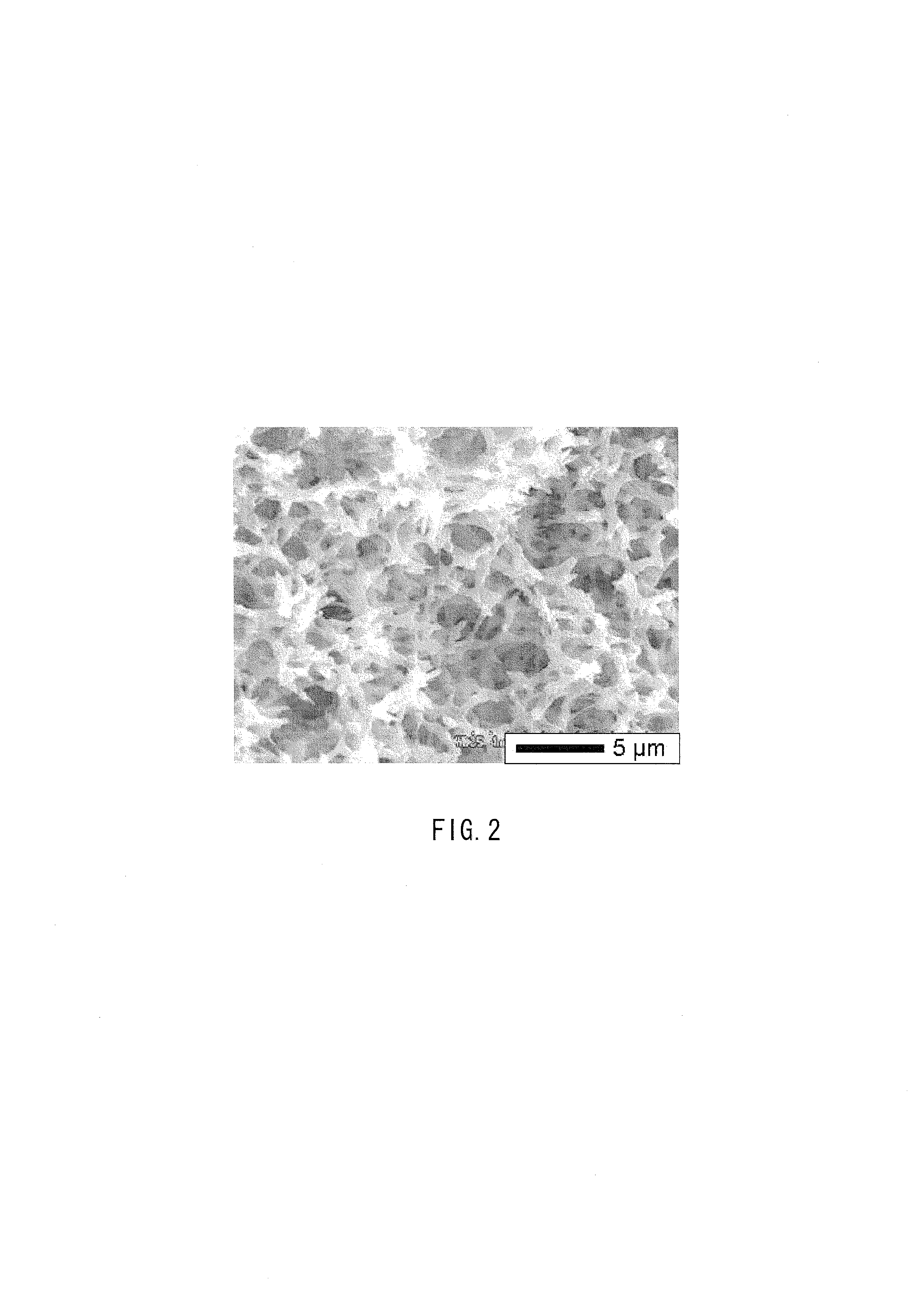

InactiveUS20130168322A1High metal adsorption capabilityCertain thicknessComponent separationOther chemical processesHydroxylamineIndium

An amidoxime-modified PAN porous body obtained by reacting with hydroxylamine a polyacrylonitrile porous body that is monolithic, has a thickness of 1 mm or more and contains polyacrylonitrile (PAN) as the main component to convert a nitrile group of the polyacrylonitrile porous body into an amidoxime group. This porous body is a porous body for adsorbing a metal ion, for example, an ion of metal such as copper, iron, nickel, vanadium, indium, gallium, silver, mercury, lead, uranium, plutonium, cesium, barium, lanthanum, thallium and strontium.

Owner:OSAKA UNIV +1

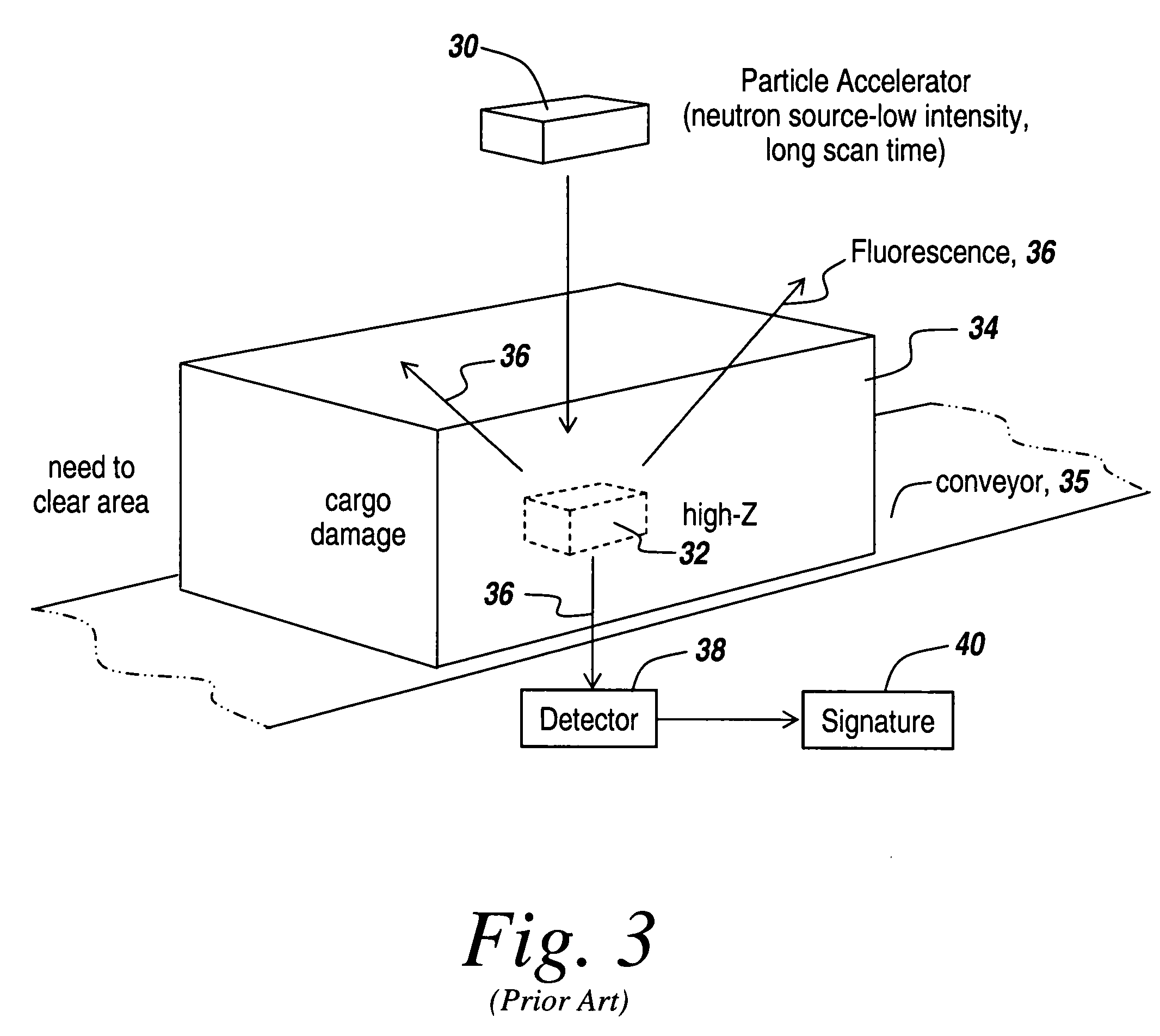

Apparatus and method for detection of fissionable materials

An apparatus and method for the detection of fissionable materials (e.g. uranium and plutonium) in cargo, vehicles, soil, waste, etc. utilizing a penetrating photon beam causing emission of neutrons from such materials. The neutrons are detected by selected detectors able to function throughout an appropriate test and emission period. Suitable detectors are of the super-heated droplet type. The photon energy, beam intensity and direction, number of beams, emission period and detector arrangement are chosen to give the desired sensitivity for the fissionable elements of concern.

Owner:BUBBLE TECH INDS

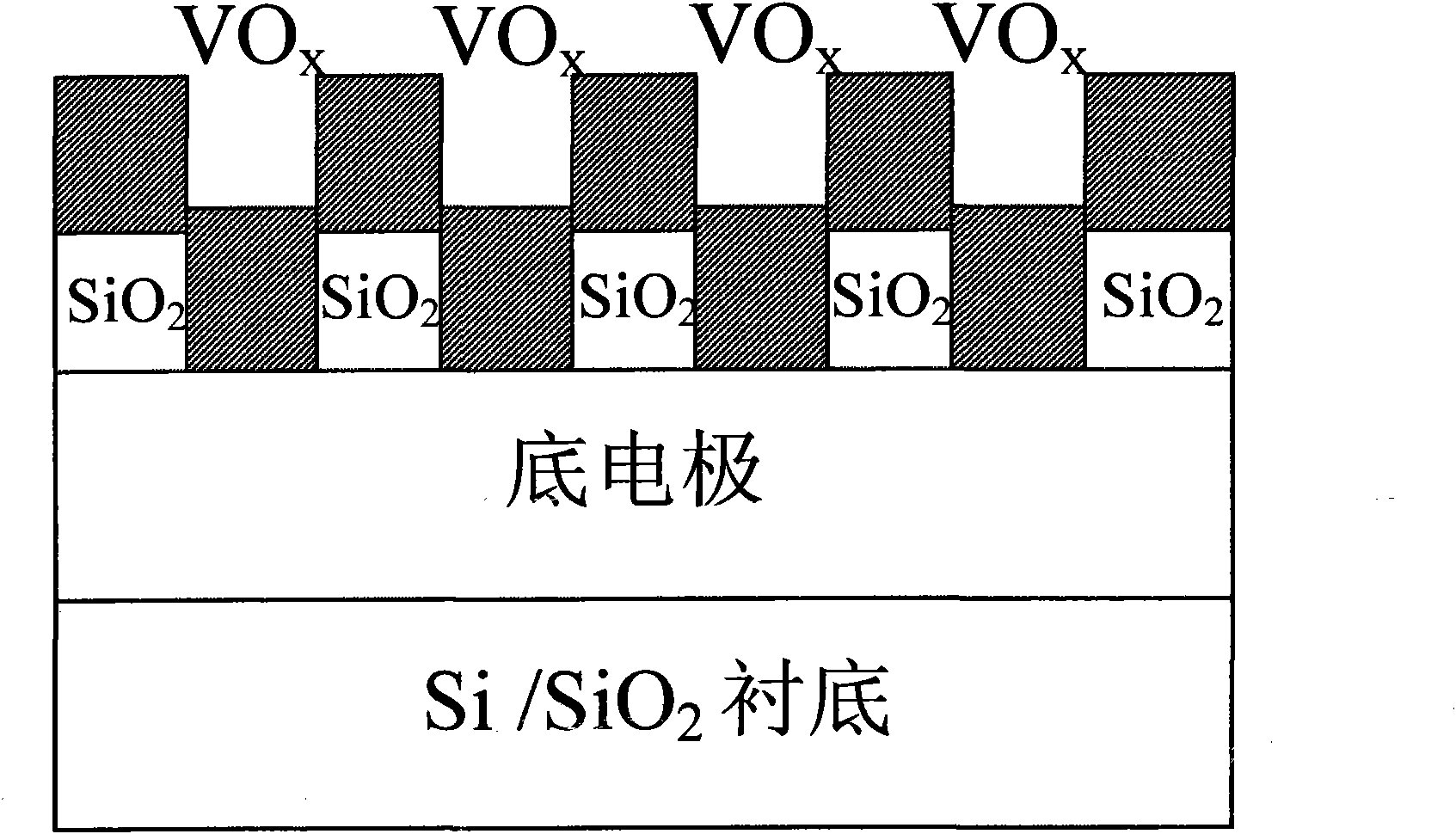

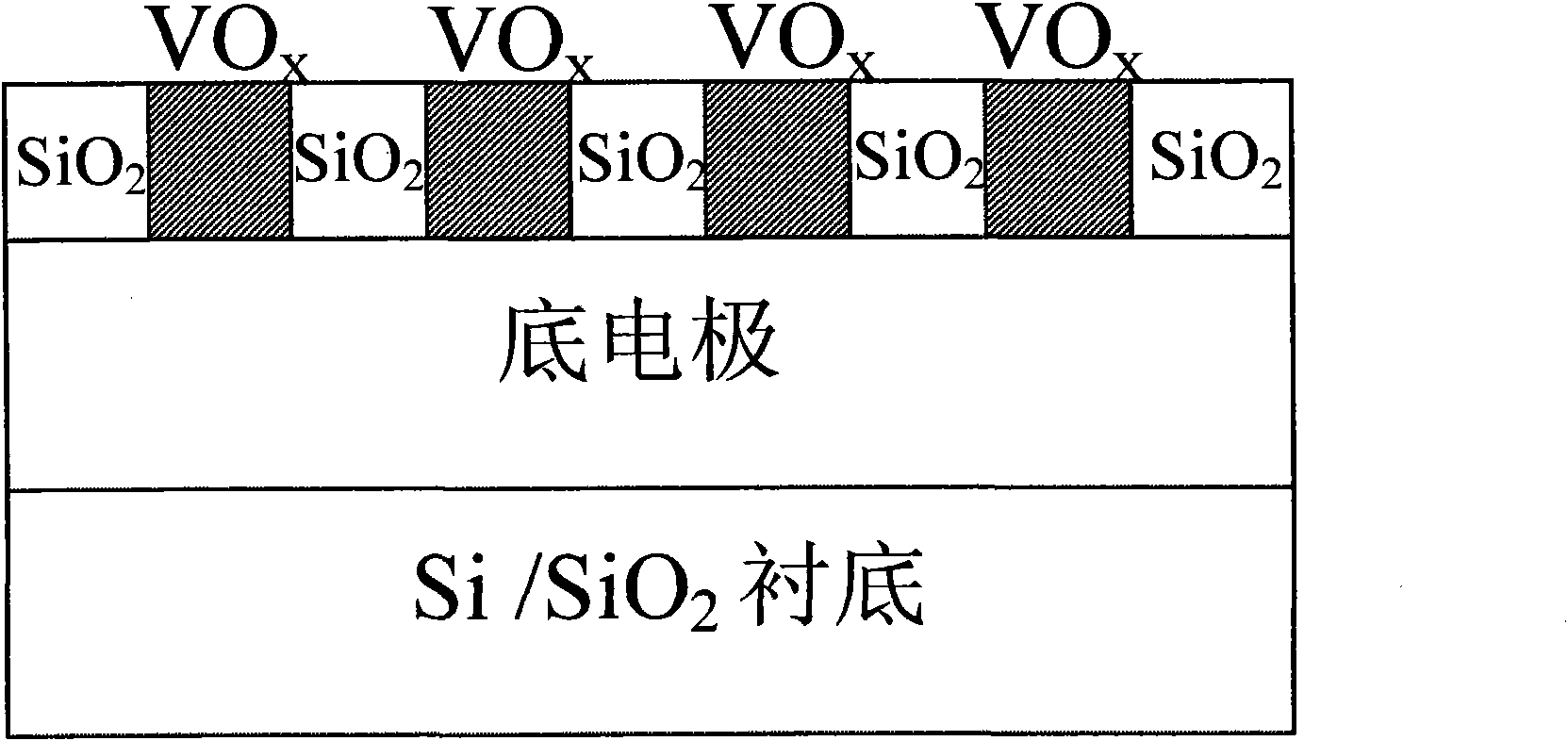

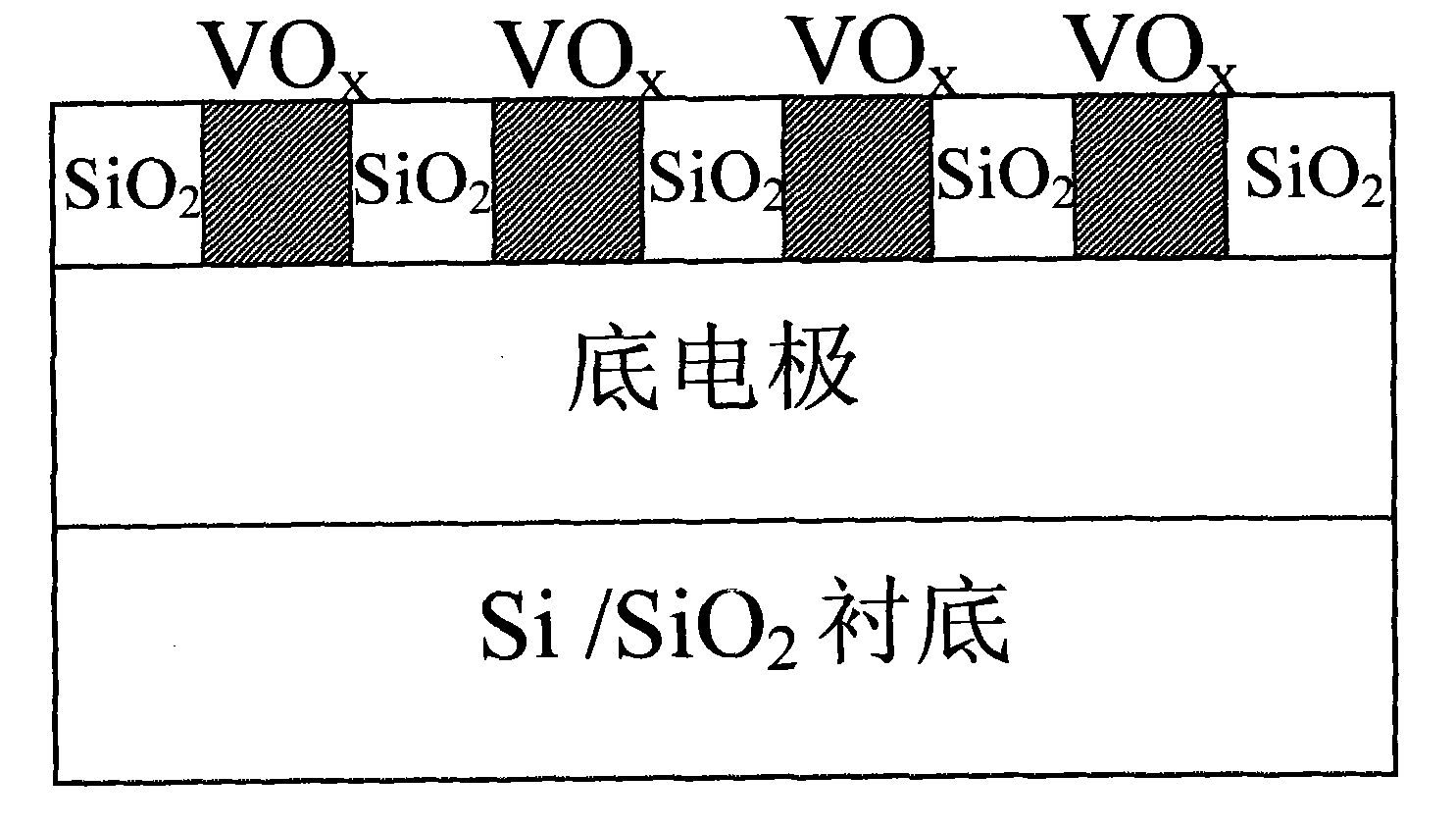

Nano polishing solution for chemically mechanical polishing of vanadium oxide and application thereof

ActiveCN102127372AEasy to corrodeEasy to polluteBiocideOther chemical processesOrganic basePolyethylene glycol

The invention relates to nano polishing solution for chemically mechanical polishing of vanadium oxide, which consists of a nano-abrasive, a pH regulator, a surfactant, a defoaming agent, a bactericide, a cleaning aid and a solvent, wherein the nano-abrasive is zirconium oxide, titanium oxide, plutonium oxide or silica; the pH regulator comprises inorganic base of KOH and organic base of tetramethylammonium, tetraethyl ammonium hydroxide or hydroxy amine; the surfactant is silicane polyethylene glycol ether, polyethylene glycol ether or 2-(2-dodecyloxyethoxy)ethanol; the defoaming agent is poly(dimethylsilane); the bactericide is isomerous thiazolidinone; the cleaning aid is isopropanol; and the solvent is deionized water. The invention has the advantages that: the polishing rate is stably controllable, the damage is low, the cleaning is simple, equipment is not corroded, the environment is not polluted, and the storage time is long; and a vanadium oxide film material is subjected to the chemically mechanical polishing by the nano polishing solution for preparing a resistive random access memory, and the method is simple and practicable, and is completely compatible with an integrated circuit process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

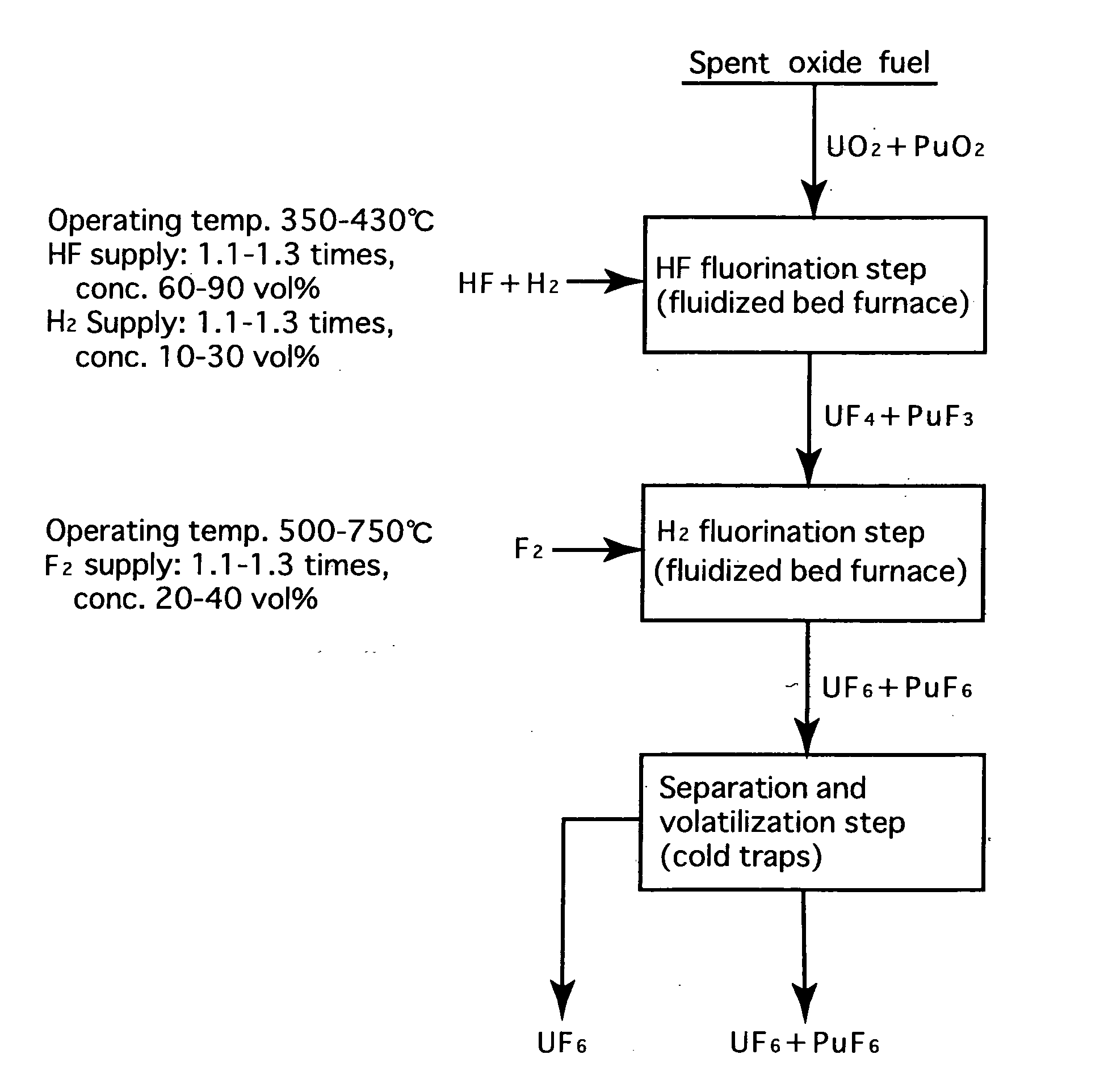

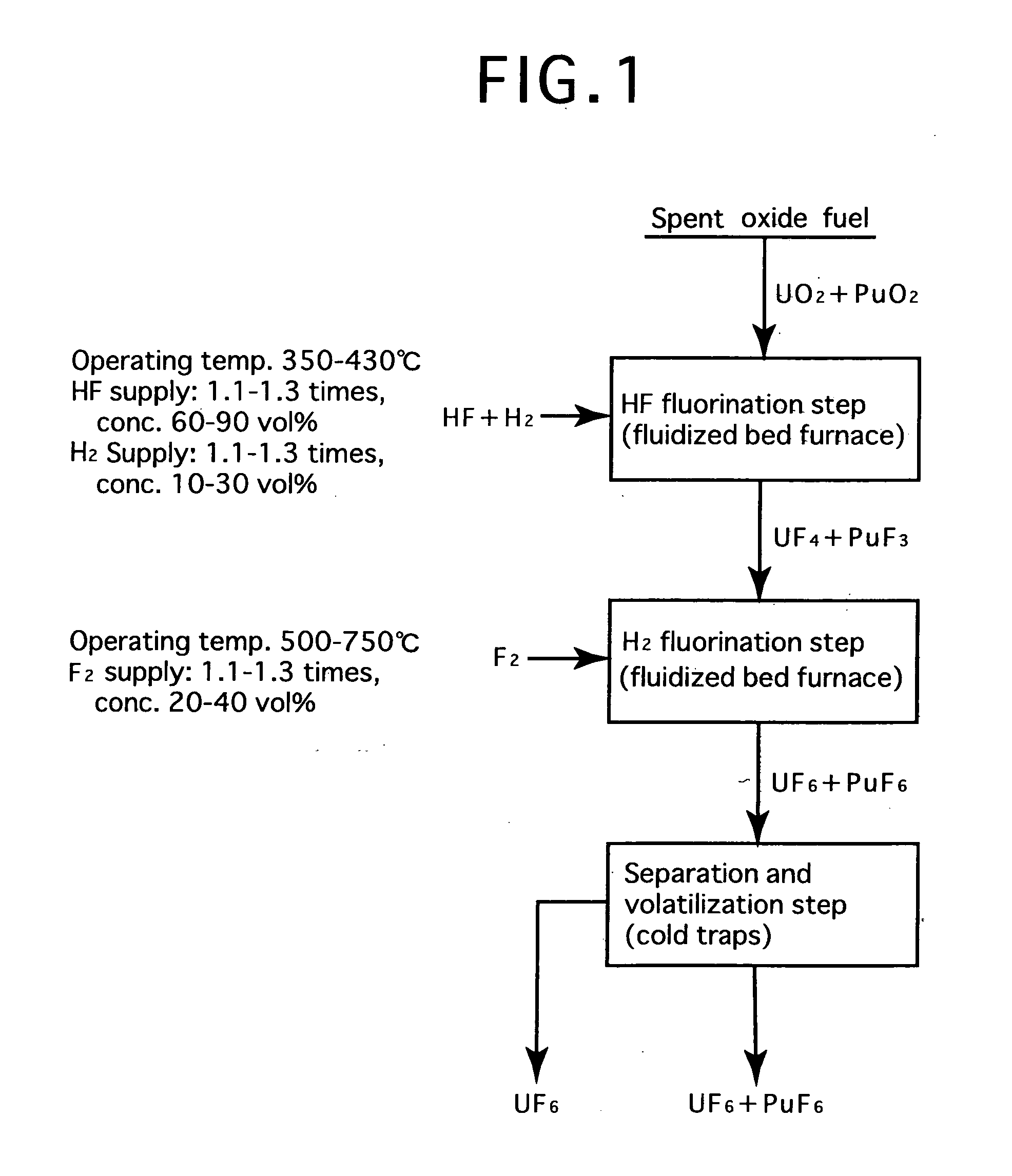

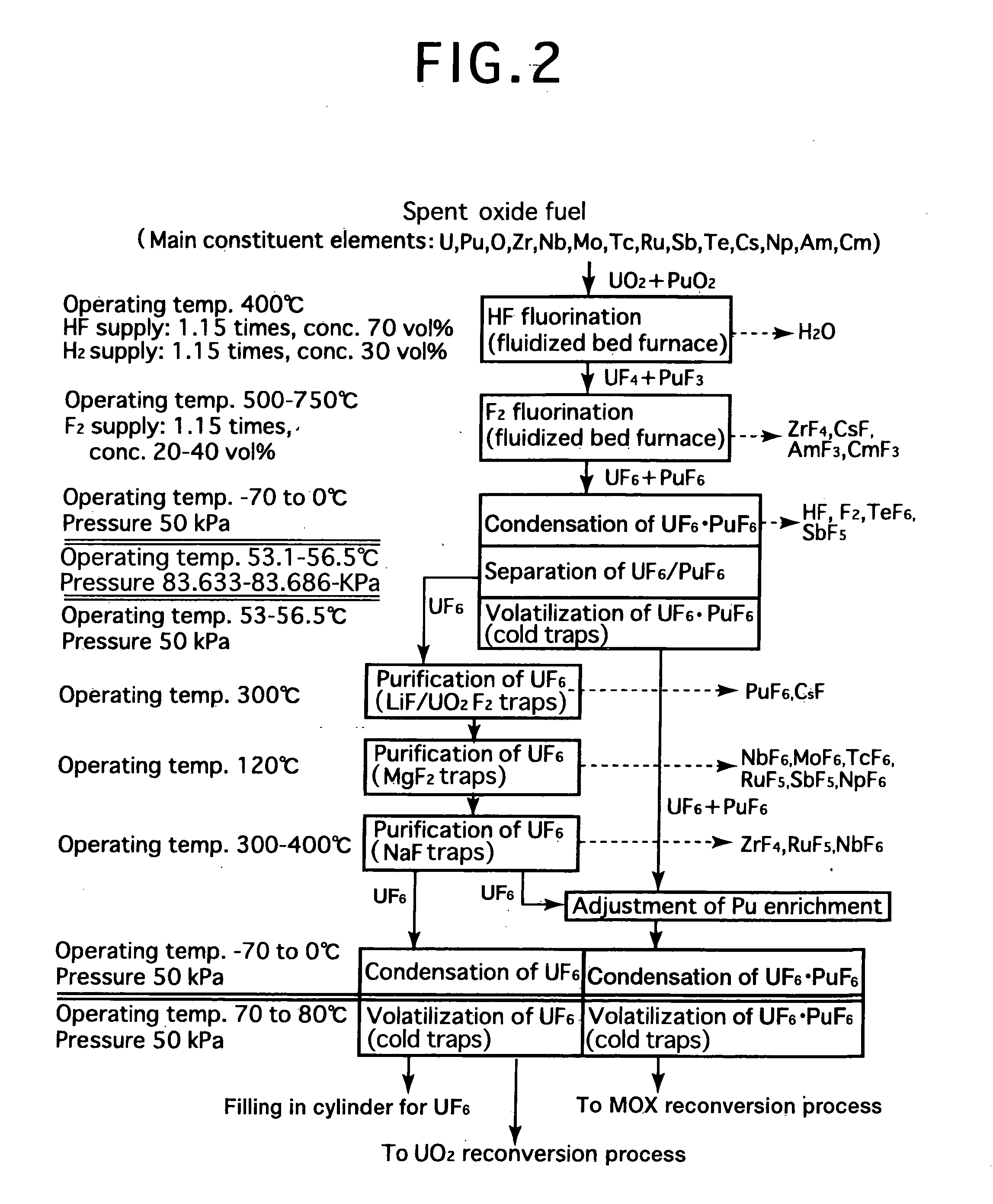

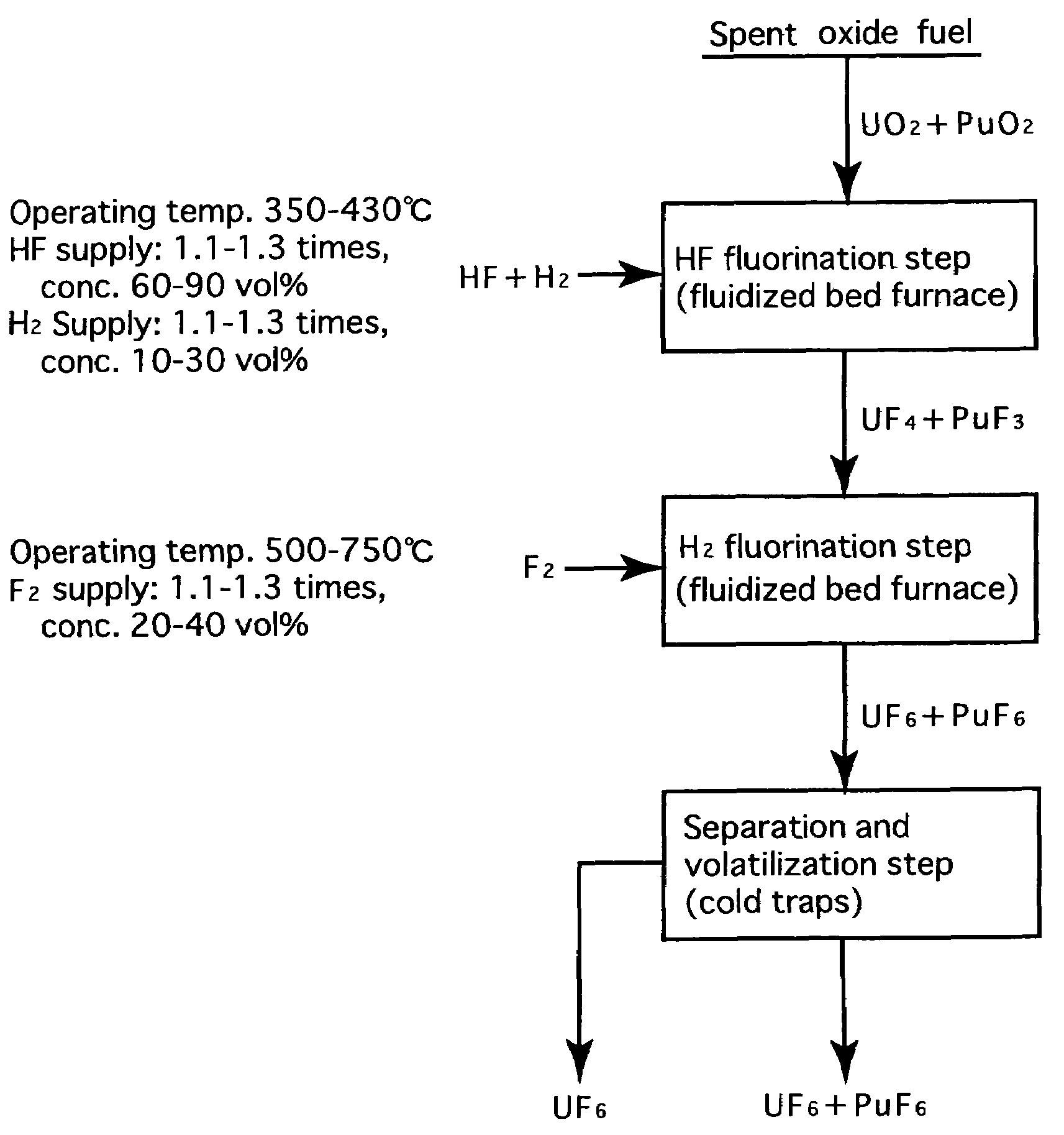

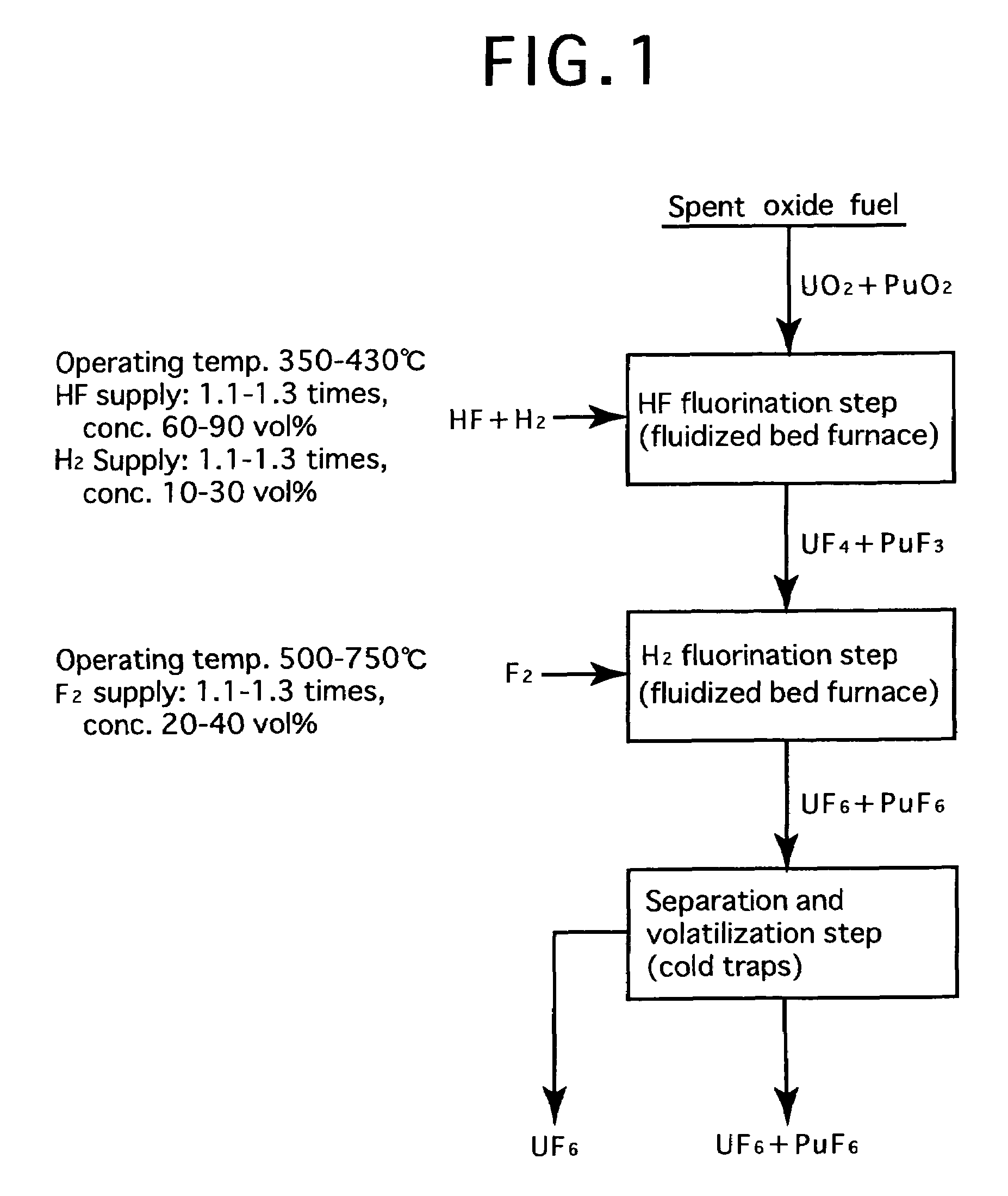

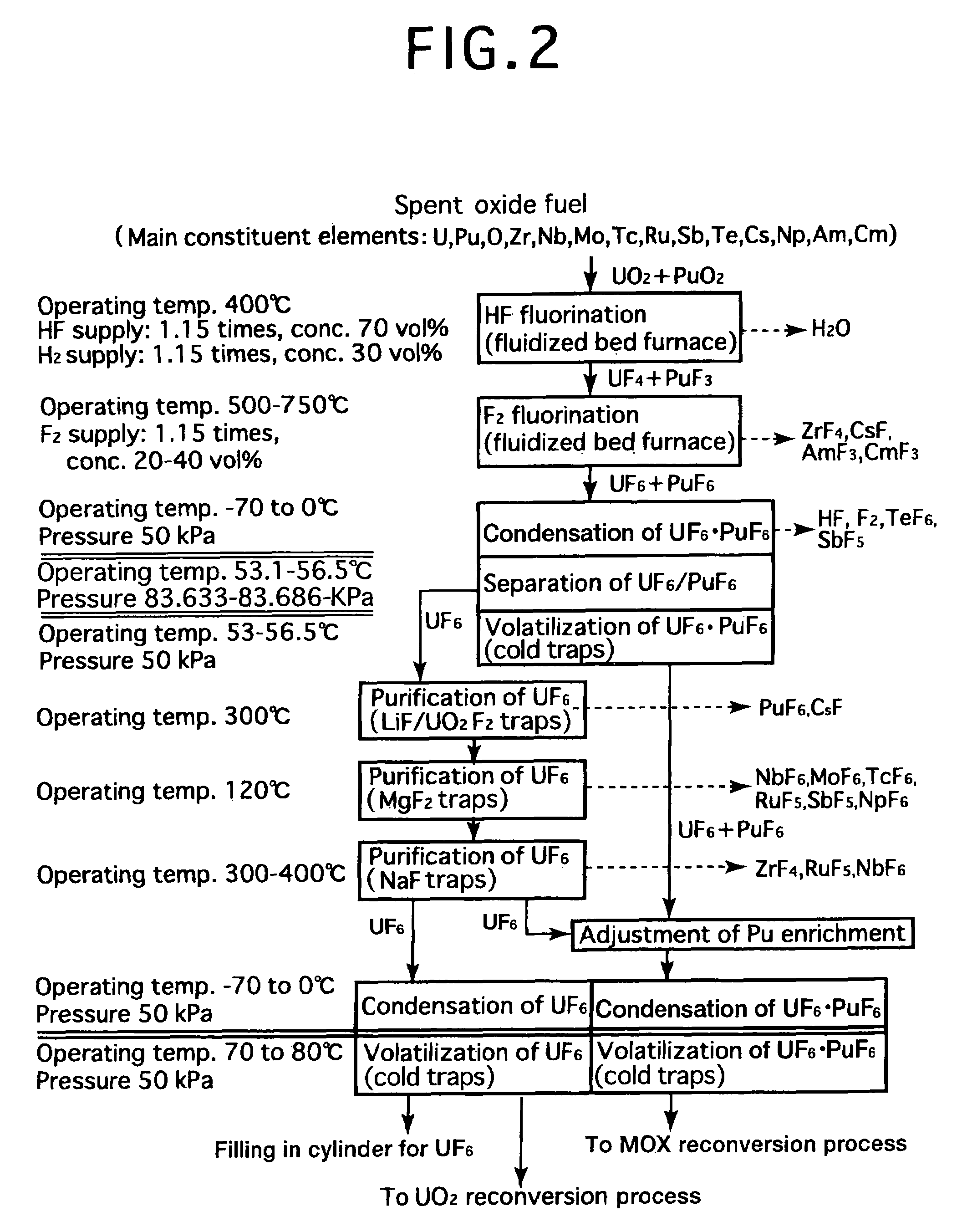

Reprocessing method by fluoride volatility process using fractional distillation

InactiveUS20060057042A1Increase ratingsRaise the ratioPlutonium compoundsUranium fluoridesHydrogen fluorideHydrogen

Fluorine or a fluorine compound is subjected to a reaction with a spent oxide fuel to produce fluorides of uranium and plutonium, and recovering the fluorides using a difference in volatility behavior. The method includes steps of: subjecting a mixture of UO2 and PuO2 with hydrogen fluoride mixed with hydrogen to HF-fluorinate uranium and plutonium into UF4 and PuF3; subjecting UF4 and PuF3 with a fluorine gas to F2-fluorinate uranium and plutonium into UF6 and PuF6; and fractionating UF6 and PuF6 using a difference in phase change of obtained UF6and PuF6, removing a part of UF6, and volatilizing the remaining UF6 and PuF6 at the same time. By such a reprocessing method, PuF4 hard to undergo a reaction is prevented from being formed as an intermediate fluoride, the material of a reactor is hard to be corroded, and a consumption of expensive fluorine gas is reduced.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

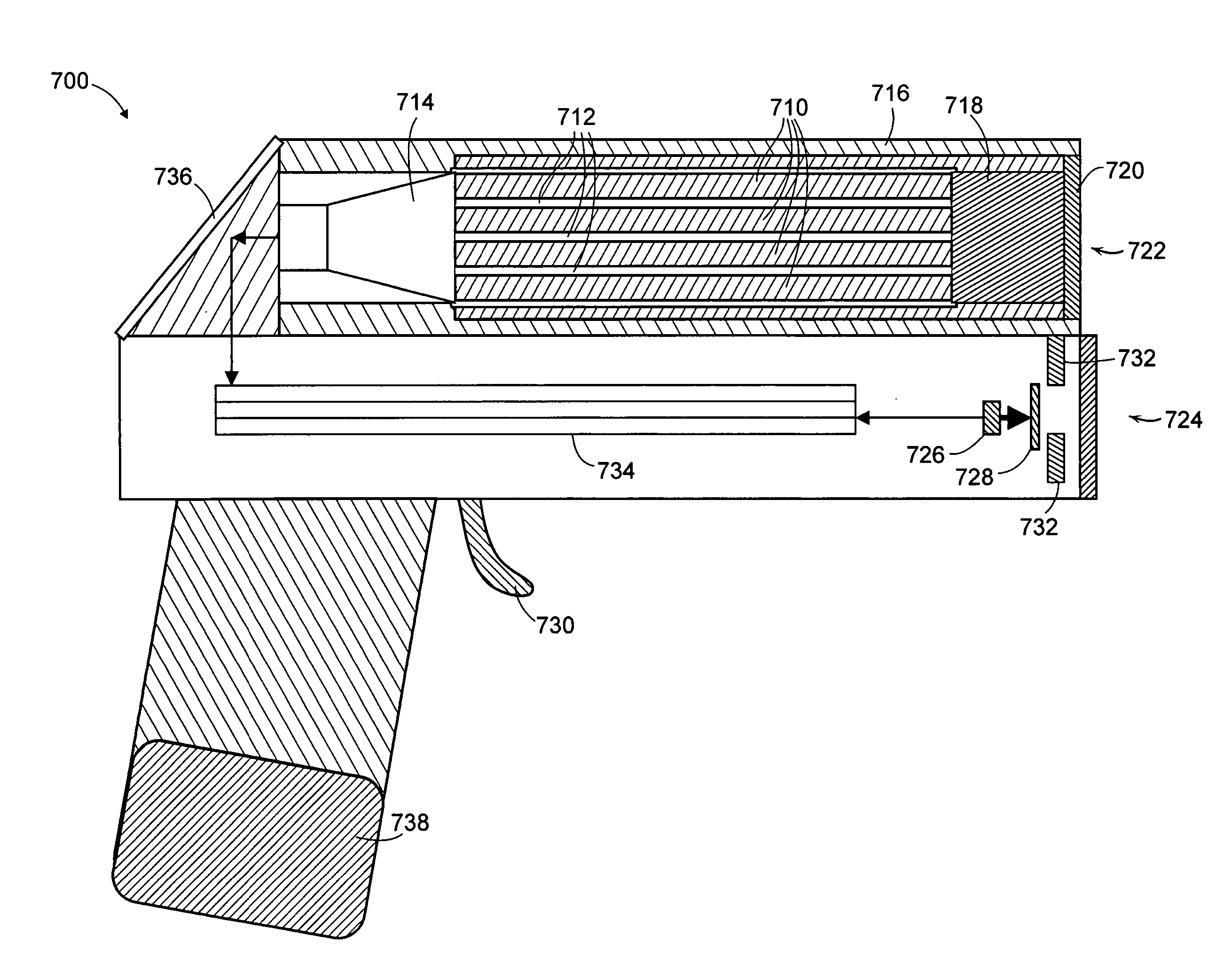

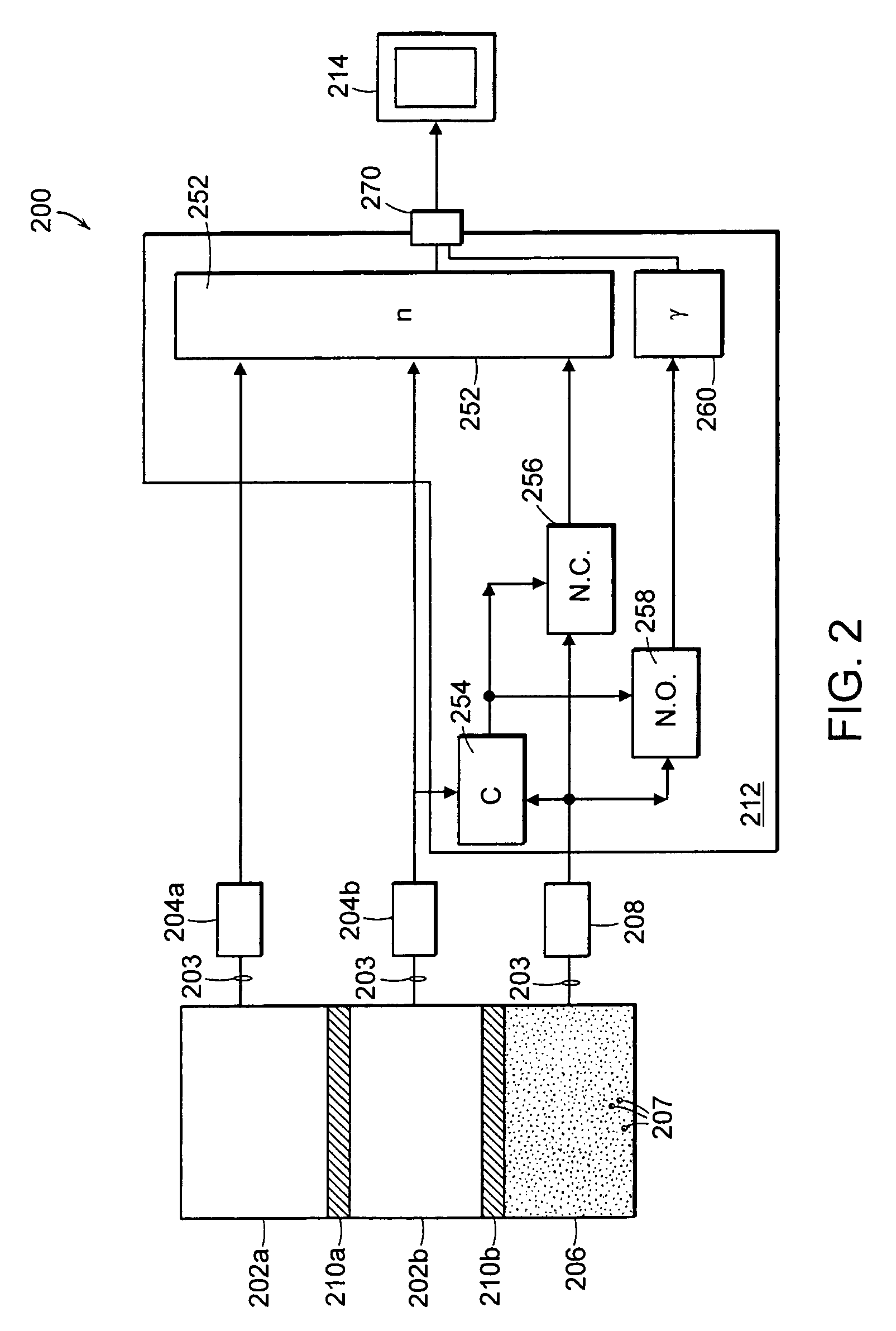

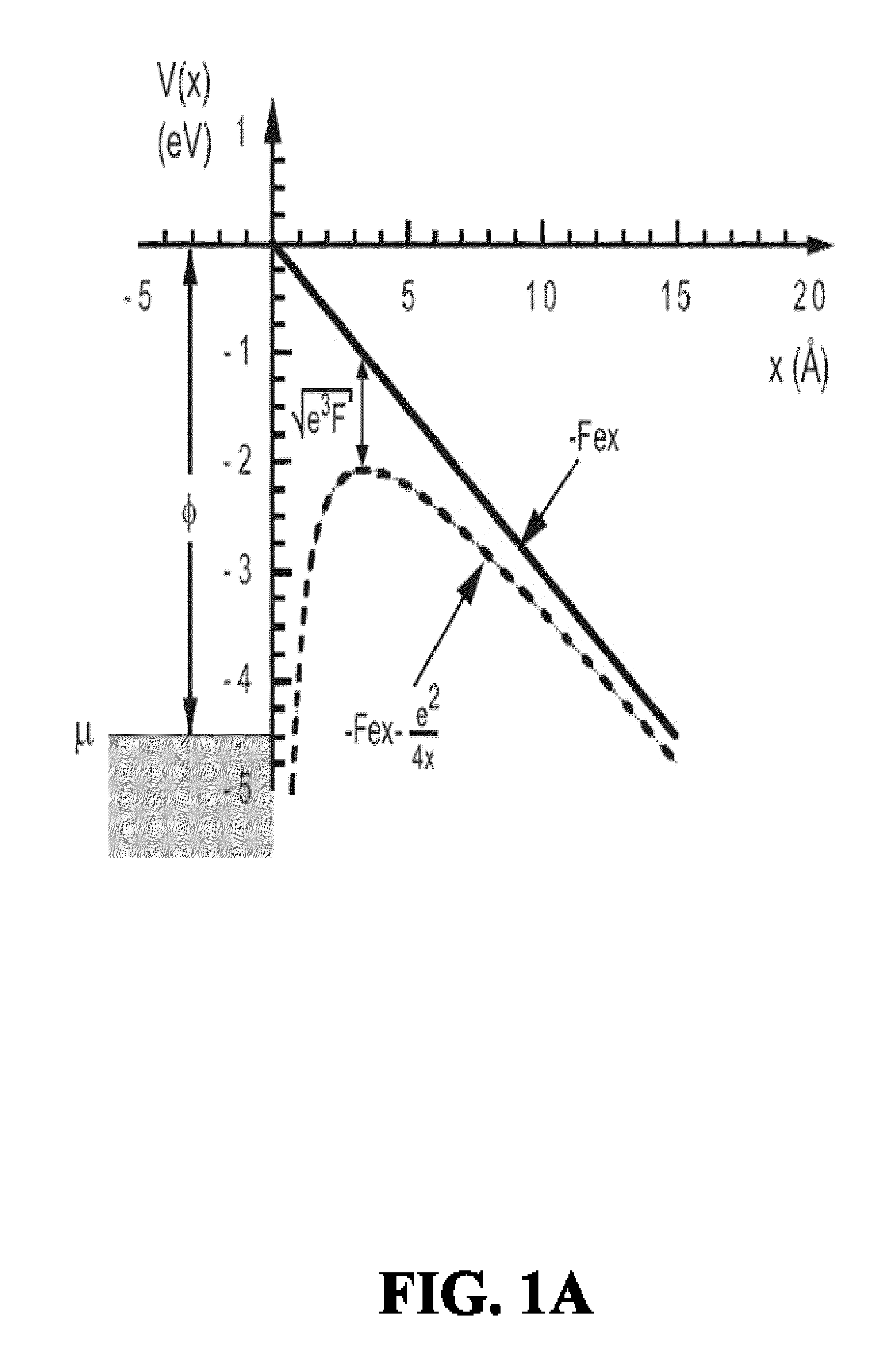

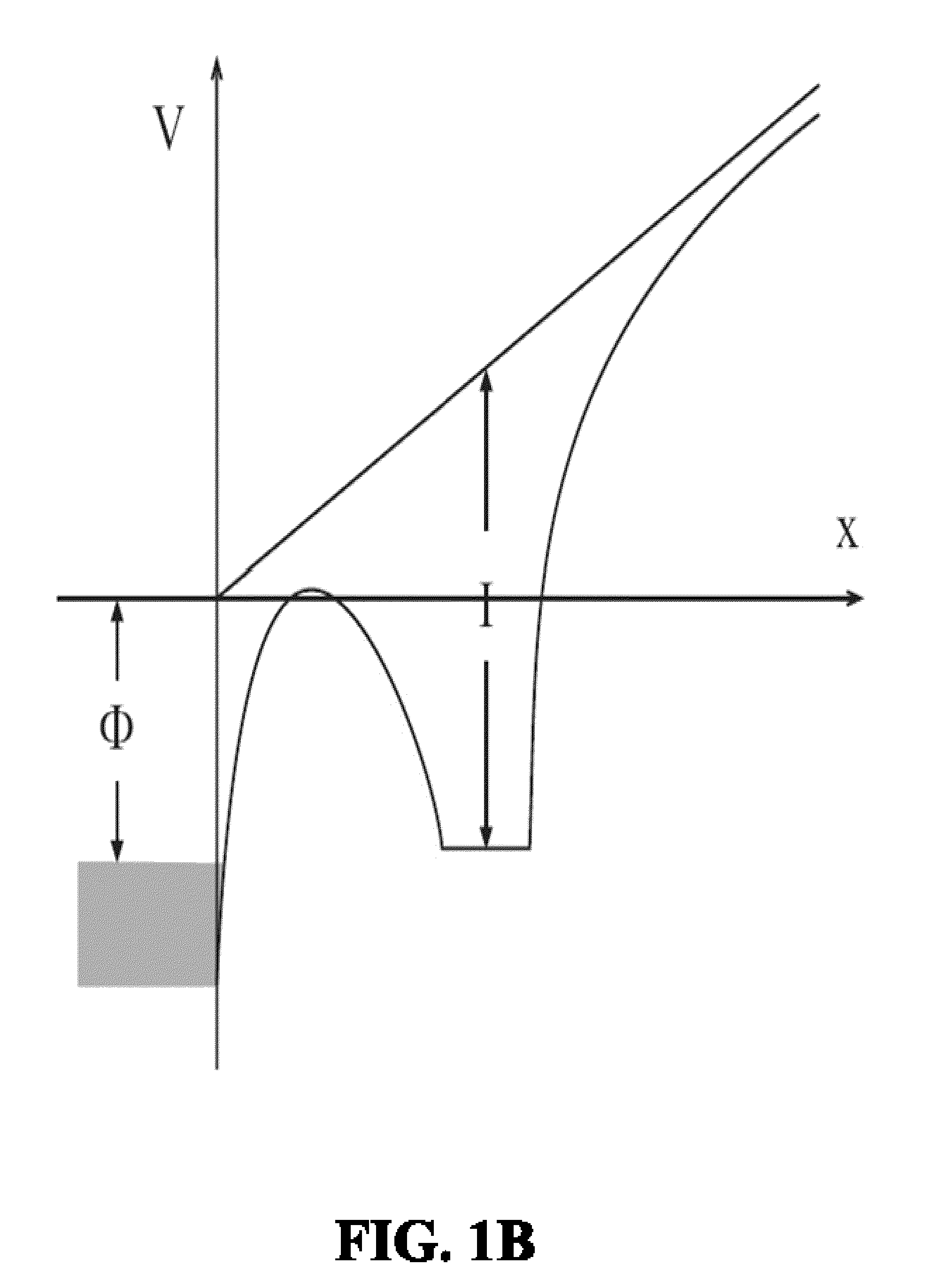

Portable/mobile fissible material detector and methods for making and using same

InactiveUS20100301196A1Reduce total powerSmall sizeLaser detailsMaterial analysis using wave/particle radiationDelayed neutronPu element

A portable and / or mobile detector for highly enriched uranium (HEU) and weapon grade plutonium (WGPu) is disclosed the detects HEU and / or WGPu based on neutron induced fission of a portion of the HEU and / or WGPu and detecting delayed neutron and / or γ-rays emission from delayed neutron emitters formed from the induced fission reactions.

Owner:CHU WEI KAN +1

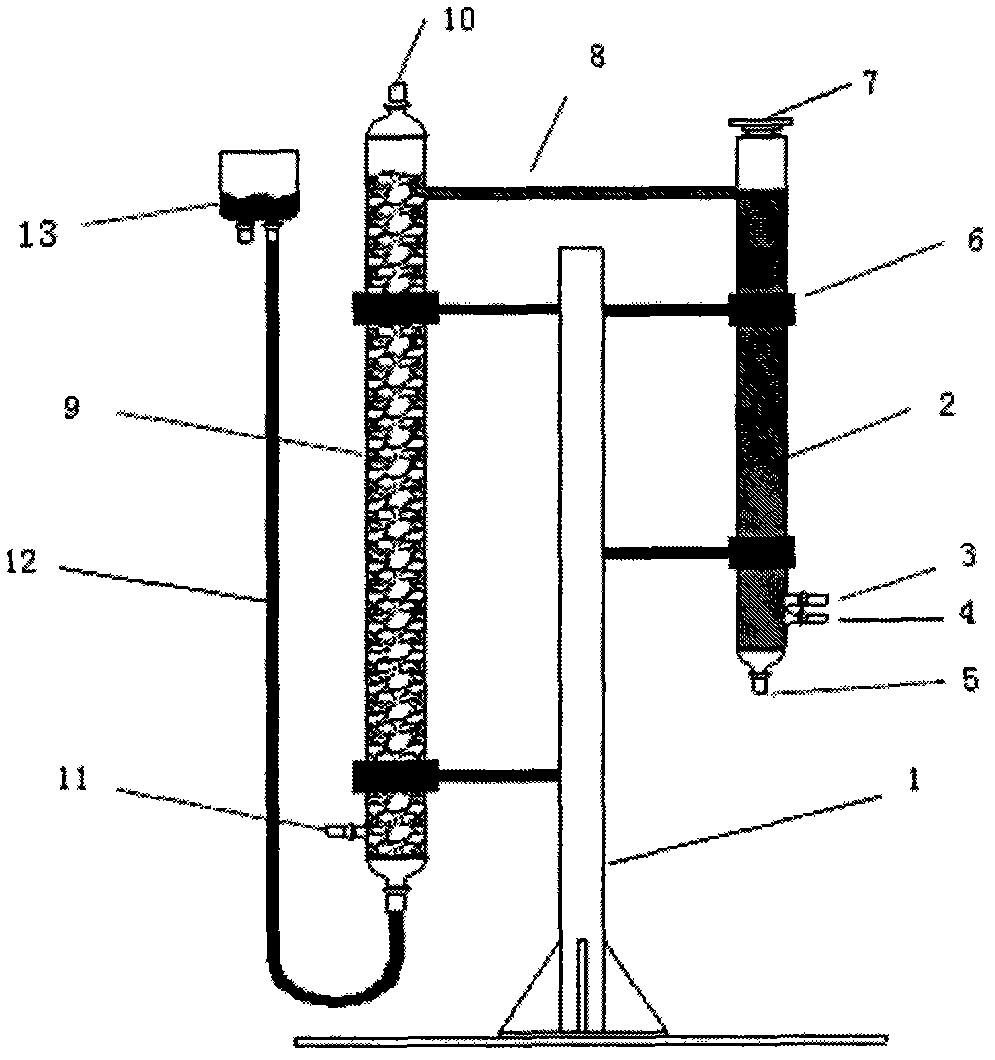

Device for oxidized adjusting plutonium valence by N2O4

ActiveCN102412002AImprove contact effectNuclear energy generationReactor fuel elementsNitric oxideNitrogen oxide

The invention discloses a device for oxidized adjusting plutonium valence by N2O4, comprising a Pu (III) oxidized column and a nitrous acid eliminating column, wherein the Pu (III) oxidized column and the nitrous acid eliminating column are connected via a material fluid transporting pipe. The device provided by the invention increases the utilization rate of the N2O4, reduces the escaped nitric oxide and realizes the continuous operation of the plutonium valence adjusting process and the remaining nitrous acid eliminating process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Reprocessing method by fluoride volatility process using fractional distillation

InactiveUS7323153B2Reduce consumptionNot easy to corrodePlutonium compoundsUranium fluoridesHydrogen fluorideFluoride volatility

Fluorine or a fluorine compound is subjected to a reaction with a spent oxide fuel to produce fluorides of uranium and plutonium, and recovering the fluorides using a difference in volatility behavior. The method includes steps of: subjecting a mixture of UO2 and PuO2 with hydrogen fluoride mixed with hydrogen to HF-fluorinate uranium and plutonium into UF4 and PuF3; subjecting UF4 and PuF3 with a fluorine gas to F2-fluorinate uranium and plutonium into UF6 and PuF6; and fractionating UF6 and PuF6 using a difference in phase change of obtained UF6 and PuF6, removing a part of UF6, and volatilizing the remaining UF6 and PuF6 at the same time. By such a reprocessing method, PuF4 hard to undergo a reaction is prevented from being formed as an intermediate fluoride, the material of a reactor is hard to be corroded, and a consumption of expensive fluorine gas is reduced.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

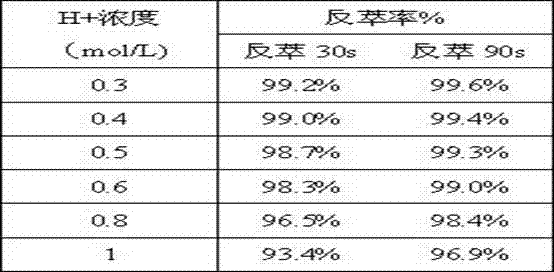

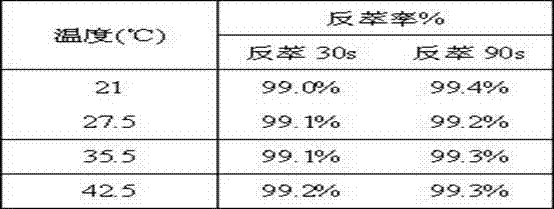

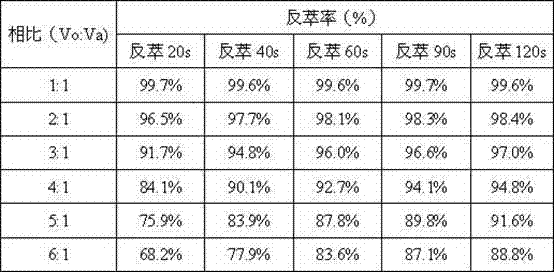

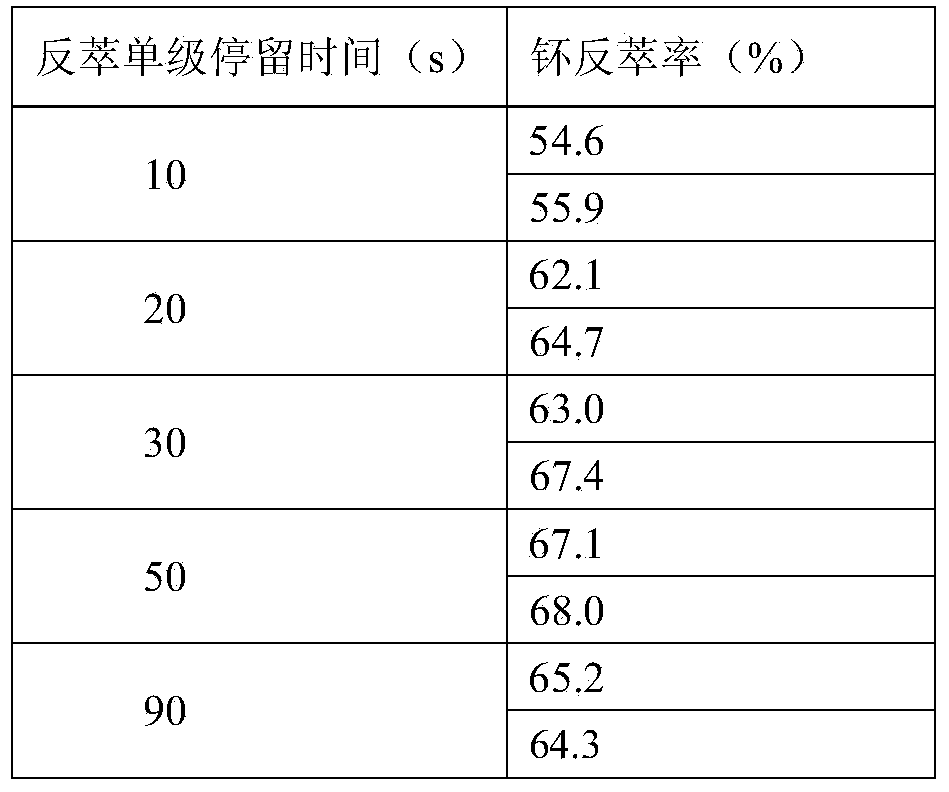

Method for separating U (uranium) from Pu (plutonium) in Purex process

The invention which belongs to the technical field of radioactive post-treatment concretely relates to a method for separating U from Pu in a Purex process. The method comprises the following steps: 1, removing nuclear reaction splinters except U and Pu; 2, coextracting codecontaminated U and Pu to a TBP (tributyl phosphate) / kerosene mixed liquor with a volume percentage of 30%; and 3, adding a reducing agent HSC (hydroxysemicarbazide) to the mixed liquor in step 2, and fully mixing to back-extract Pu (III) which is reduced from Pu (IV) in an organic phase to an aqueous solution of hydrogen nitrate, wherein the ratio of the molar concentration of the HSC in an aqueous phase solution to the molar concentration of Pu in an organic phase solution is 5-60, the volume ratio of the organic phase solution to the aqueous phase solution is 1:1-6:1, the temperature is 21-42.5DEG C, and the concentration of H<+> is 0.3-1mol / L. A technical scheme provided by the invention allows Pu (IV) in the organic phase to be rapidly reduced and back-extracted to the aqueous phase, the reaction time is two magnitudes shorter than the reaction time of the prior art, the technological process is simplified, and the separation efficiency is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Radioactive wastewater treatment technology and synthesis of treatment agent of radioactive wastewater

The invention discloses a radioactive wastewater treatment technology and the synthesis of a treatment agent of radioactive wastewater. A modified product Y3-8103 is used for chemically reacting with radioactive wastewater, all heavy metal elements and all radioactive elements, namely cesium137, uranium 235, thorium, plutonium, thallium, protium, deuterium, tritium, radon, Sr-90 and radium, listed in the periodic table of elements and wastewater generated by all artificial nuclides. Alpha radioactive rays, beta radioactive rays, gamma radioactive rays and neutron radioactive rays are attenuated in a nationally specified mode. The radioactive wastewater treatment technology and the synthesis of the treatment agent of the radioactive wastewater can also be used for treating radioactive seawater or waste residues generated by wastewater treatment and can be used for treating heavy metal wastewater discharged by a lead-acid battery enterprise and an electronic plant and mine nucleus waste residues. The treatment cost of the radioactive wastewater is different along with different radioactive element concentration contents or different waste residue radioactive element concentration contents and different atomic weights in the wastewater, and the treatment cost of the wastewater and the waste residues ranges from RMB 90 yuan / m<3> to RMB 680 yuan / m<3>, radioactive energy with the alpha, beta and gamma radioactive ray radiant quantity smaller than or equal to 0.01Bq / 1-1.10Bq / 1 can be discharged to the ambient environment by the wastewater and the waste residues, the emission limit standard allowed by the international is reached, and secondary pollution is avoided. The radioactive wastewater treatment technology and the synthesis of the treatment agent of the radioactive wastewater are suitable for treating wastewater and waste residues of a nuclear power plant and treating wastewater and waste residues in mining with the radioactive elements, and are also suitable for treating wastewater containing heavy metal, namely lead, cadmium, mercury, arsenic, chromium, nickel, copper and manganese.

Owner:叶绍朋

Plutonium purification and concentration method

ActiveCN104004928AHigh yieldIncrease the concentration factorProcess efficiency improvementFuel reprocessingAfter treatment

The invention belongs to the technical field of fuel-short after-treatment and discloses a plutonium purification and concentration method. The method comprises the following steps: extracting tetravalent plutonium in a nitric acid solution into a 30% TBP (tributyl phosphate)-kerosene solution with relatively small volume for purification and concentration in a centrifugal extractor, reducing tetravalent plutonium into trivalent plutonium by using a dimethylhydroxylamine-containing nitric acid solution with relatively small volume, performing back extraction on trivalent plutonium, and further purifying and concentrating plutonium in a water phase. In the whole concentration process, a plutonium replenishment and extraction link is removed. The method is simple in step, short in time and small in solvent radiation effect; the plutonium back-extraction yield reaches up to 99.98% while the plutonium concentration is increased by more than 10 times.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

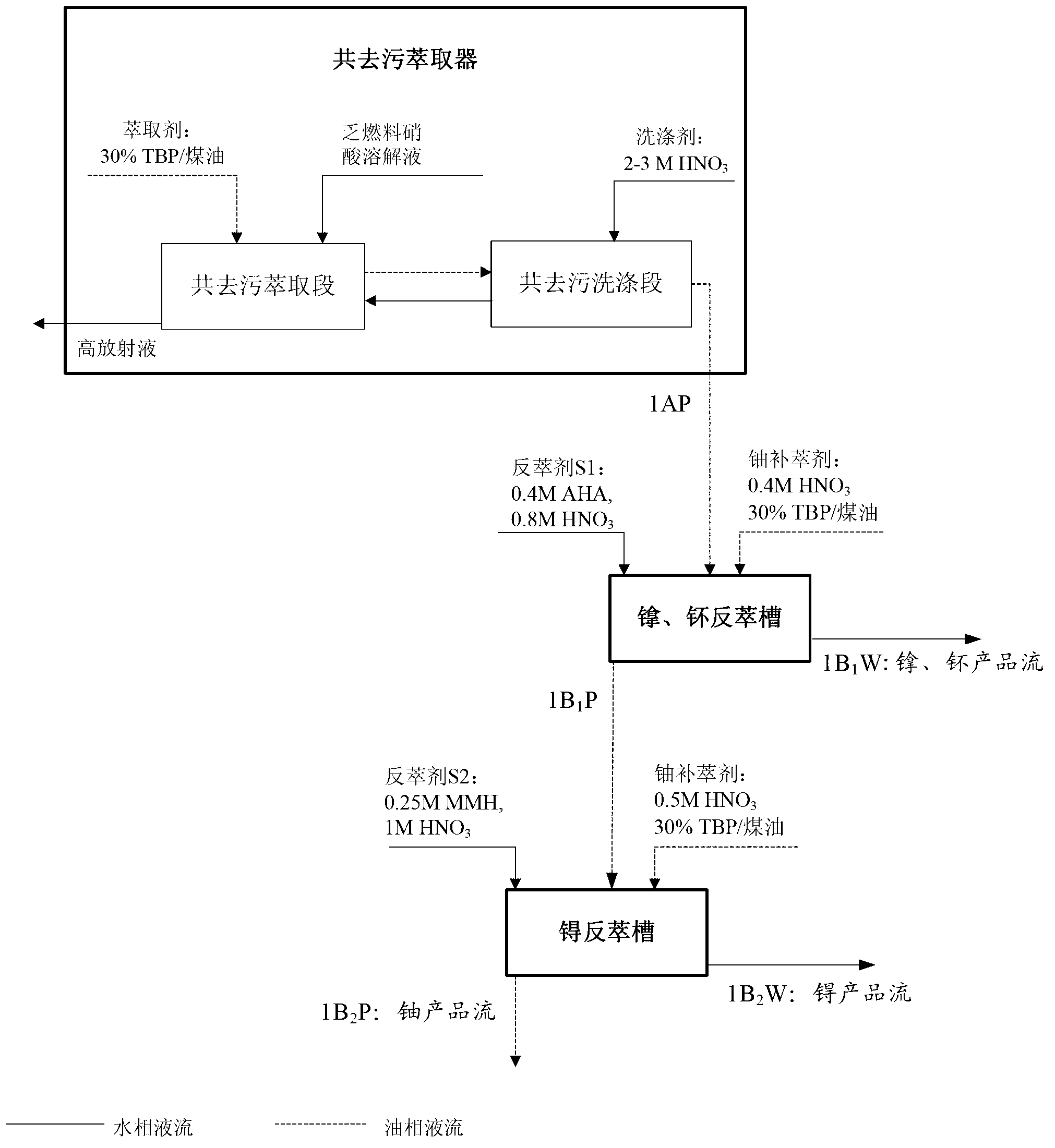

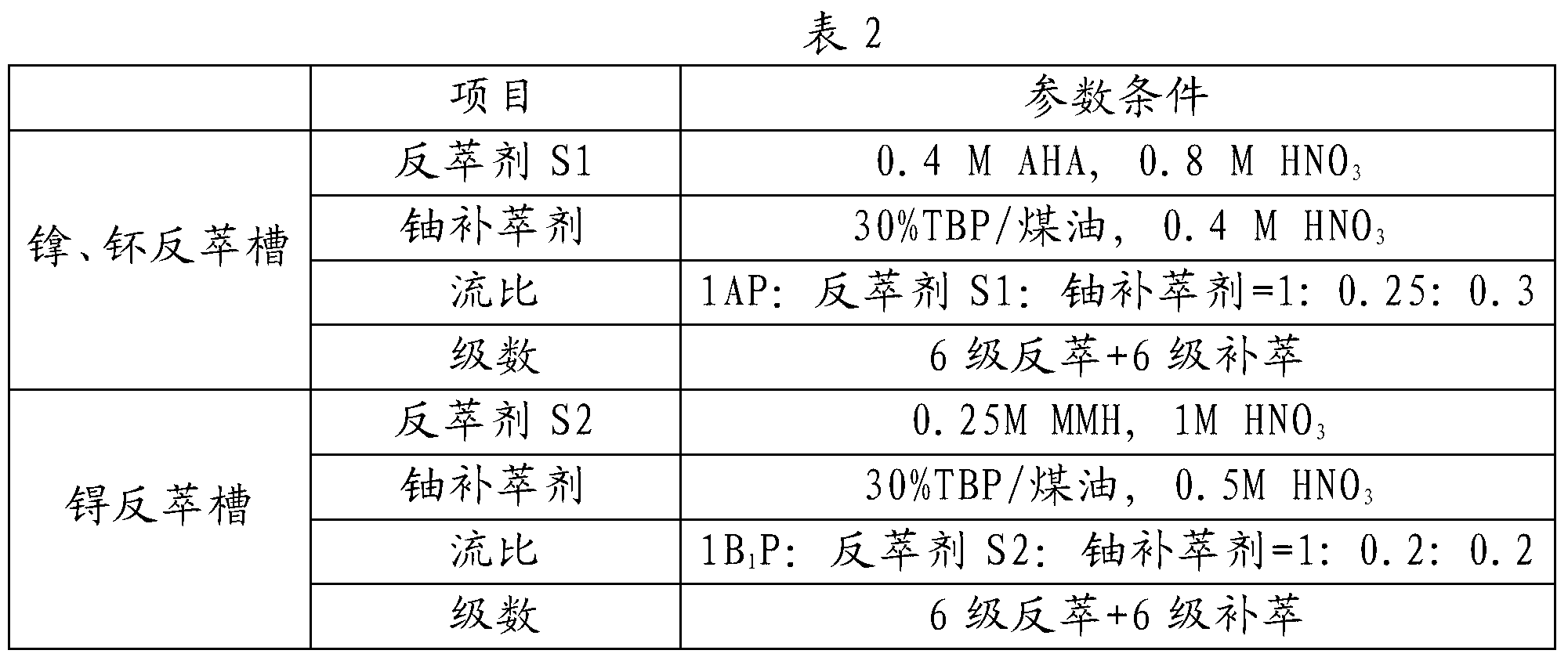

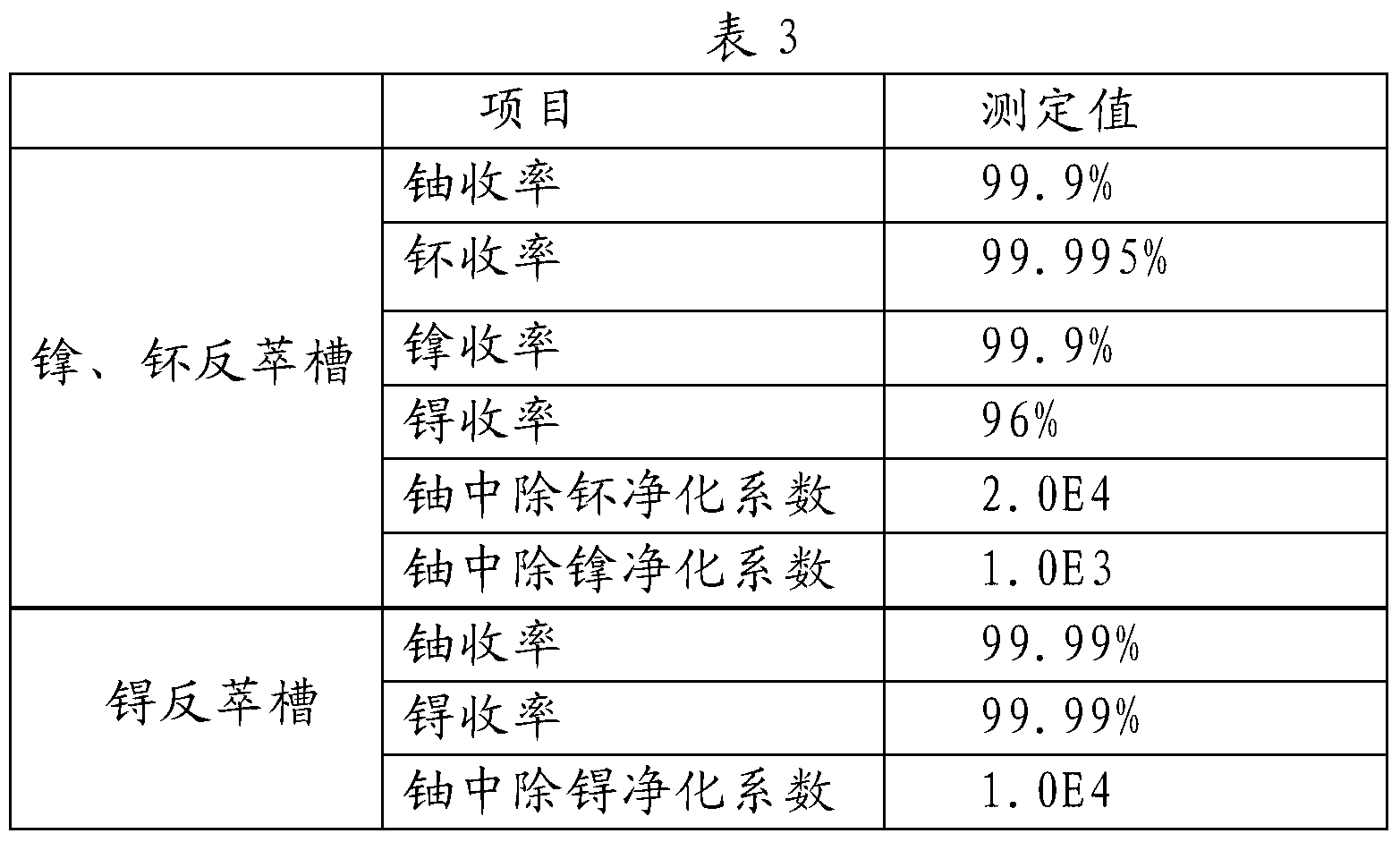

PUREX process for separating technetium

ActiveCN103325431AStep-by-step restore implementationGo simpleRadioactive decontaminationTechnetiumSalt free

The invention relates to a PUREX process for separating technetium. The PUREX process includes the steps: (1) co-decontamination and co-extraction: co-extracting uranium, plutonium, neptunium and the technetium in spent fuel nitric acid solution into an organic phase and washing co-extraction liquid; (2) plutonium and neptunium reverse extraction: reversely extracting the plutonium and the neptunium in the co-extraction liquid into a water phase by reverse extraction agents S1 containing AHA and then adding uranium supplement extraction agents for supplement extraction to obtain the water phase containing the plutonium and the neptunium and an oil phase containing the uranium and the technetium; (3) technetium reduction and reverse extraction: reducing and reversely extracting the technetium in the oil phase containing the uranium and the technetium into the water phase by reverse extraction agents S2 containing reducing agents and then adding uranium supplement extraction agents for supplement extraction to obtain a water phase containing the technetium and an oil phase containing the uranium, wherein the oil phase containing the uranium enters a subsequent uranium purification process. The neptunium, the plutonium and the technetium are reduced step by step through a step-by-step reduction method, the technetium can be separated out, the trend of elements is simpler and more uniform, all the reducing agents are salt-free reagents, remaining reagents are easily damaged, and the subsequent process is less affected.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Radiation attenuation elastomeric material, a multilayer glove for protection against ionizing radiations and their uses

ActiveUS20120217423A1Remarkable flexibilityRemarkable propertyOther chemical processesShieldingElastomerPlastic materials

The invention relates to a radiation attenuation elastomeric material of the type comprising an elastomer in which a powder of metal oxides is dispersed, and which is characterized in that the powder of metal oxides comprises from 70 to 90% by mass of bismuth trioxide, from 5 to 15% by mass of tungsten trioxide and from 5 to 15% of lanthanum trioxide.It also relates to the use of this elastomeric material for making individual protective articles against ionizing radiations.It further relates to a multilayer protective glove against ionizing radiations, at least one layer of which is formed by said elastomeric material, as well as to the use of this glove for protection against ionizing radiations emitted by powders of nuclear fuels, notably with plutonium.Fields of application: the nuclear industry for handling powders of nuclear fuels but also medical imaging, interventional radiology, nuclear medicine, processing of plastic materials, inspection and control of manufactured parts, etc.

Owner:PIERCAN +1

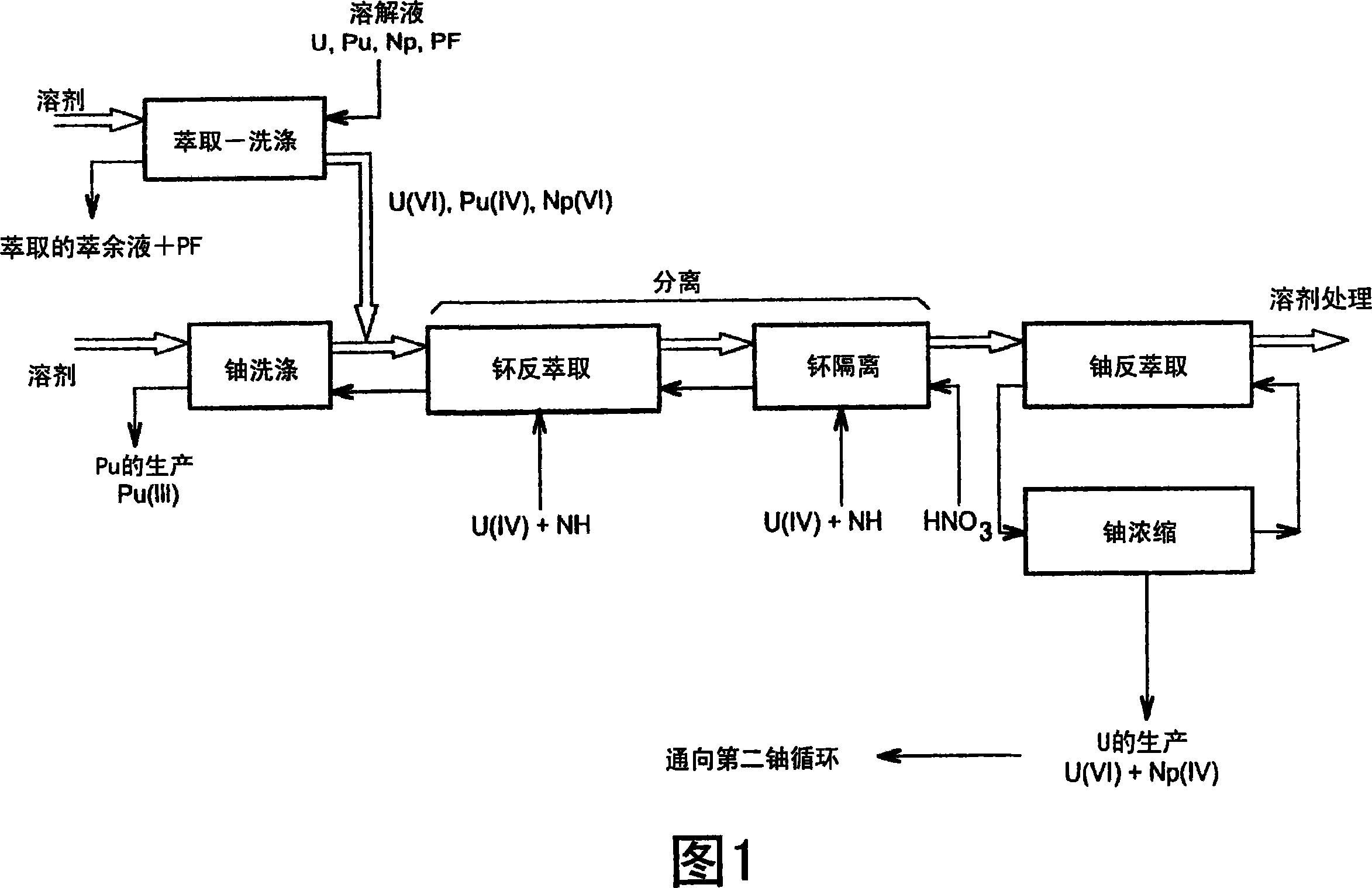

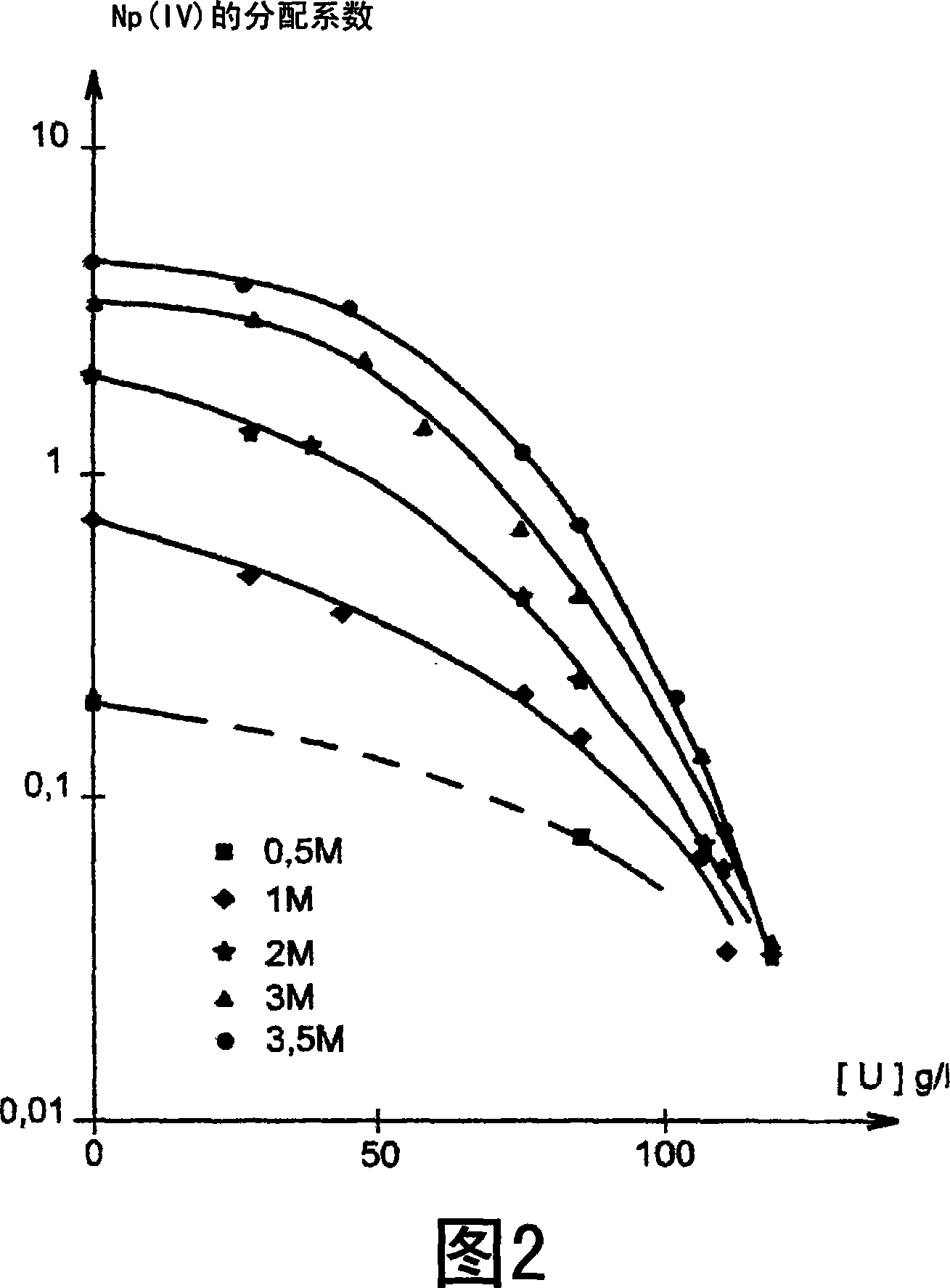

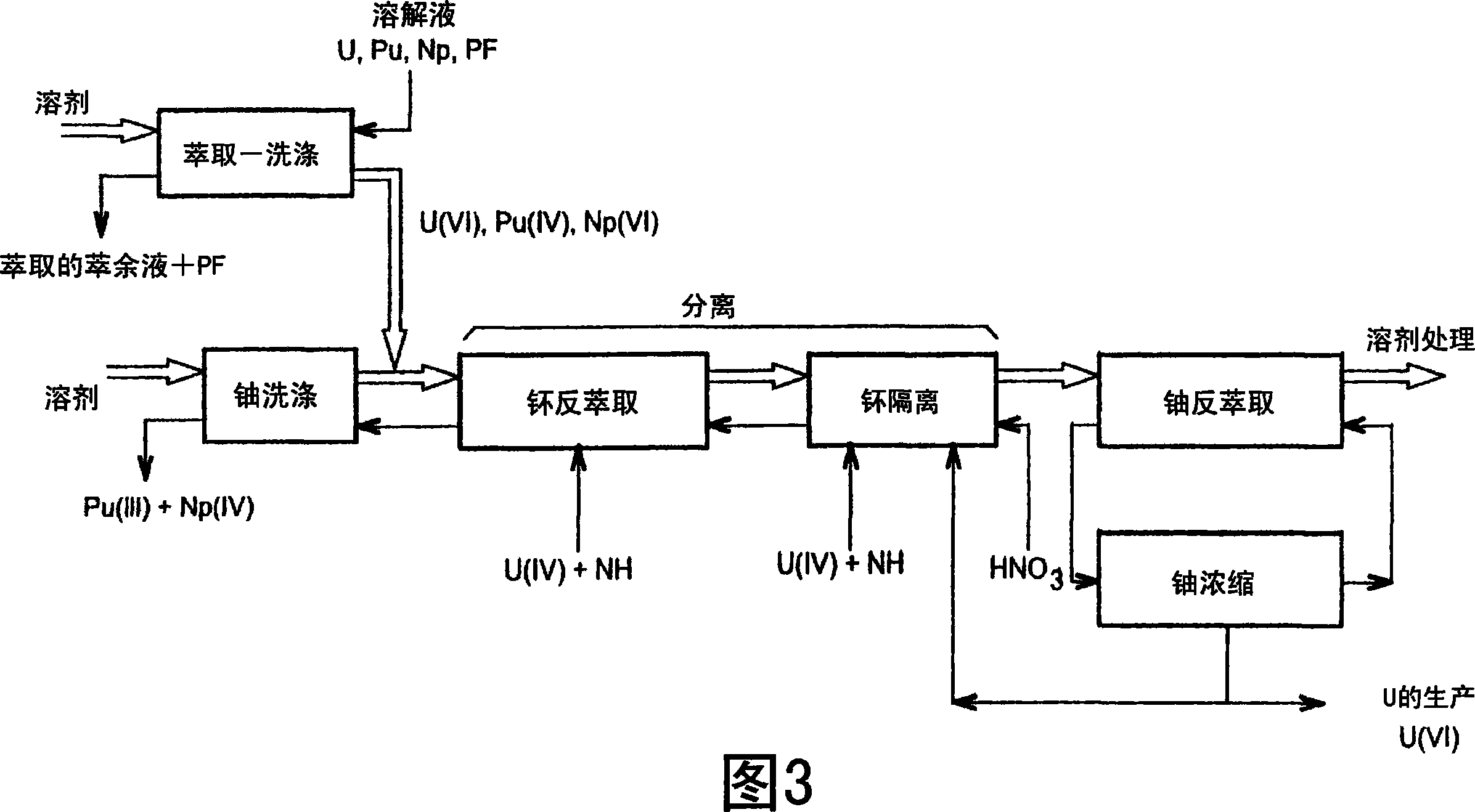

Improvement of the purex method and uses thereof

ActiveCN101088129AEfficient separationNuclear energy generationRecycling and recovery technologiesSolventPu element

The procedure consists of separating the uranium, plutonium, other actinides and fission products from the spent fuel in a nitric acid solution, separating the uranium from the plutonium in two separate flows by extracting the plutonium from the solvant phase in a nitric acid aqueous solution with a reducing agent, and then concentrating the solution containing the uranium (III). Part of the concentrated solution is used to extract the actinides (IV) present in the oxidated state, the actinides (IV) being neptunium (IV), thorium (IV) and / or plutonium (IV).

Owner:ORANO RECYCLAGE

Chemical separation procedure for burnup analysis of spent fuel element

ActiveCN103337265AChemical separation achievedReduce radiation doseNuclear energy generationNuclear monitoringIon exchangeChemical separation

The invention relates to a chemical separation procedure for burnup analysis of a spent fuel element. The chemical separation procedure comprises the following steps of: (I) dissolving a spent fuel element block, namely putting the spent fuel element block into concentrated nitric acid and concentrated hydrochloric acid mixed liquid with the volume ratio of 3:1 to make the spent fuel element block be completely dissolved, and cooling the dissolving liquid to room temperature; (II) diluting the dissolving liquid, namely mixing the dissolving liquid cooled in the step (I) and nitric acid, uniformly stirring the dissolving liquid and the nitric acid to obtain diluted dissolving liquid; and (III) separating uranium, plutonium, molybdenum and neodymium by a column chromatography method through the diluted dissolving liquid obtained in the step (II). The invention establishes a novel chemical separation procedure for measuring the burnup of the spent fuel element; according to the chemical separation procedure, some novel levextrel, ion exchange material and high performance liquid chromatography technologies are adopted, so that chemical separation of the uranium, the plutonium, the molybdenum and the neodymium is realized; the operation procedure is greatly simplified; the operation difficulty is reduced; and the radiation to researchers is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

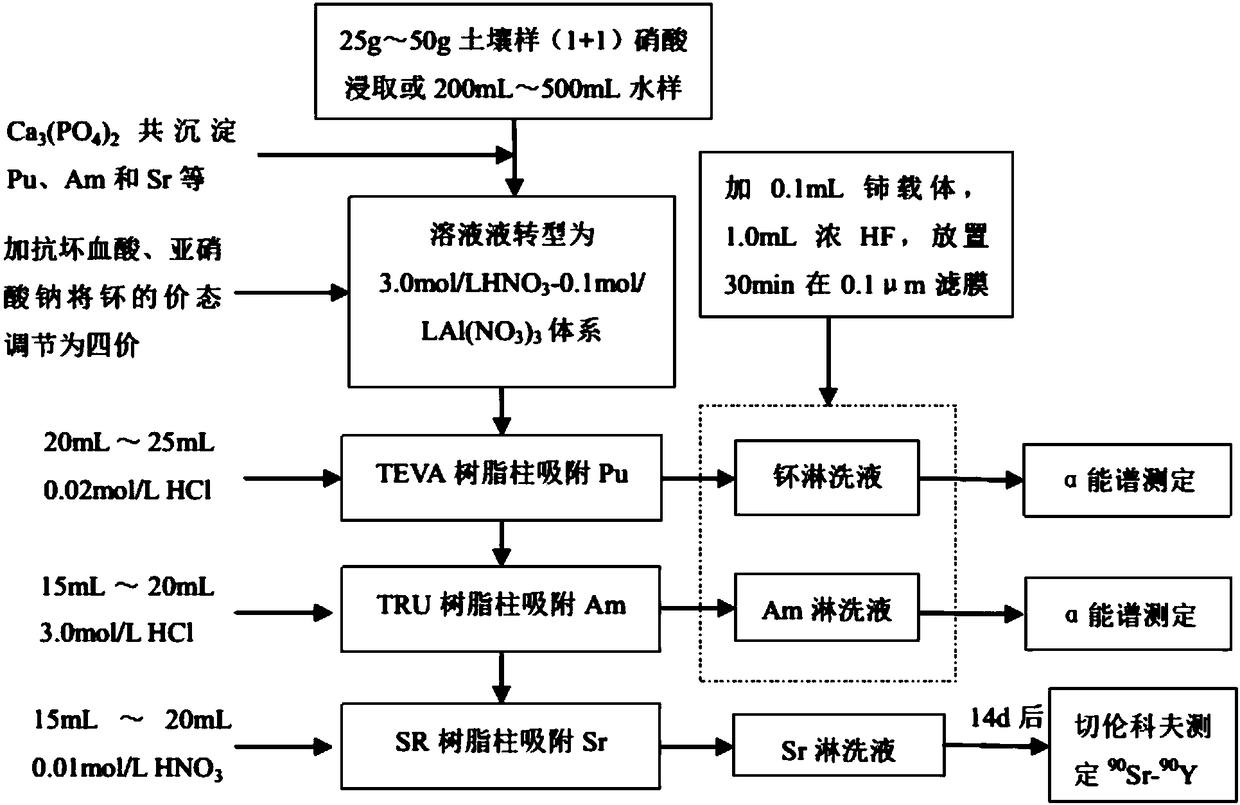

Method for separating and determining Pu, <241>Am and <90>Sr in low-radioactivity sample

InactiveCN108152112AShorten the analysis cycleLess staffX-ray spectral distribution measurementPreparing sample for investigationPu elementSodium nitrite

The invention relates to a method for separating and determining <238-240>Pu, <241>Am and <90>Sr in a low-radioactivity sample, which comprises the following steps: (1) sample pretreatment; (2) separation and enrichment of <238-240>Pu, <241>Am and <90>Sr: after ascorbic acid and sodium nitrite are added into a solution obtained in step (1) to regulate the valence state of plutonium into tetravalence, the solution passes through a TEVA, TRU and SR tandem extraction chromatography resin column, and the flow velocity is kept at 1mL / min to 1.2mL / min; at the moment, <238-240>Pu is adsorbed on the TEVA column, <241>Am is adsorbed on the TRU column, and <90>Sr is adsorbed on the SR column; 20mL to 25mL of hydrochloric acid solution which is 0.02mol / L is used for eluting <238-240>Pu on the TEVA column, 15mL to 20mL of hydrochloric acid solution which is 3.0mol / L is used for eluting <241>Am on the TRU column, and 15mL to 20mL of nitric acid solution which is 0.01mol / L is used for eluting <90>Sron the SR column; (3) determination of <238-240>Pu, <241>Am and <90>Sr: a cerium fluoride micro-deposition method is adopted to prepare an Alpha source, and the <238-240>Pu eluent and the <241>Am eluent are measured on the Alpha energy spectrum; the <90>Sr eluent is placed for 14 days, and after <90>Sr<-><90>Y is balanced, determination is carried out by the Cerenkov counting method. The analysismethod can be adopted to separate and enrich Pu, <241>Am and <90>Sr in a sample, and the period of analyzing Pu, <241>Am and <90>Sr is shortened.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

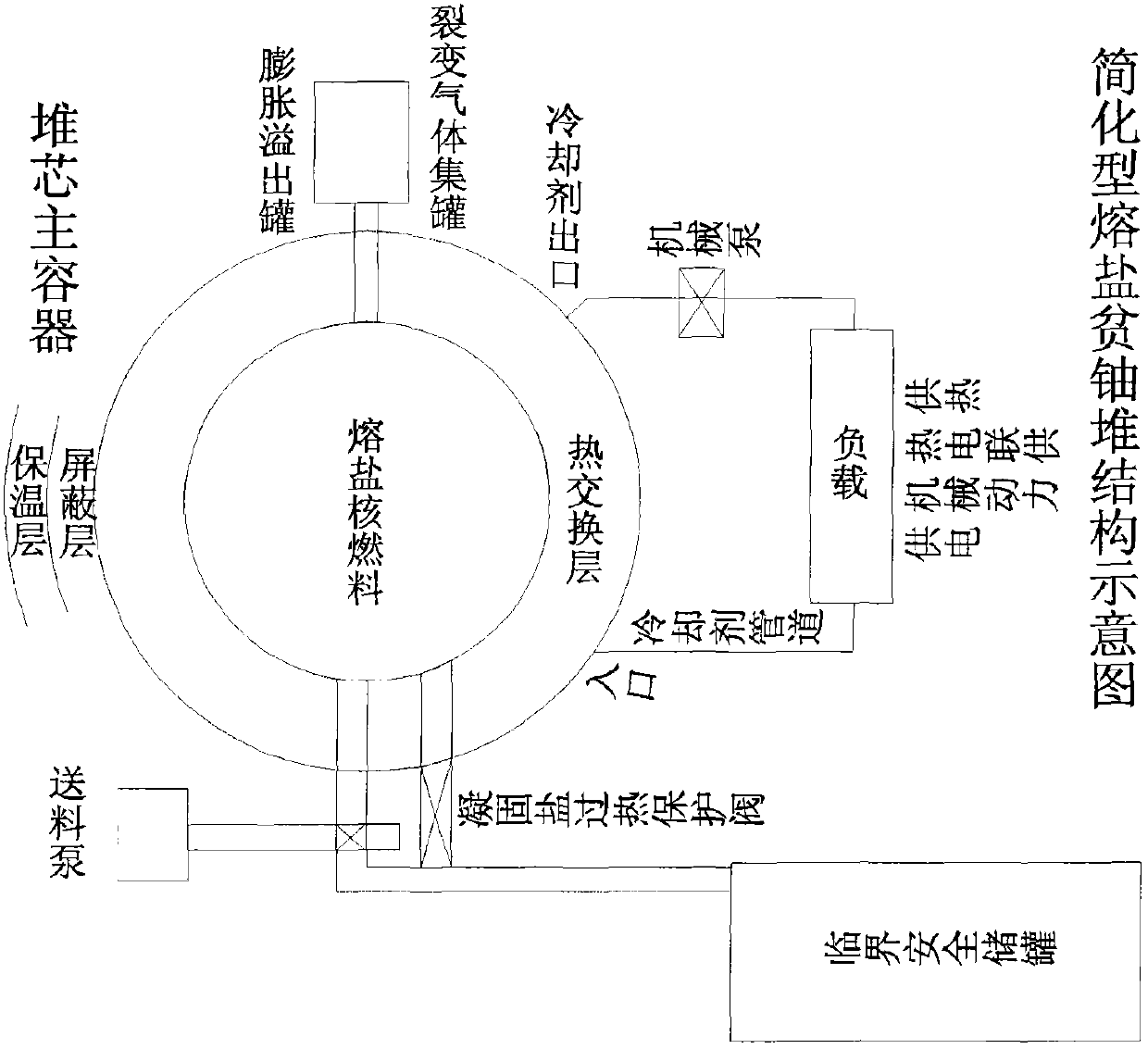

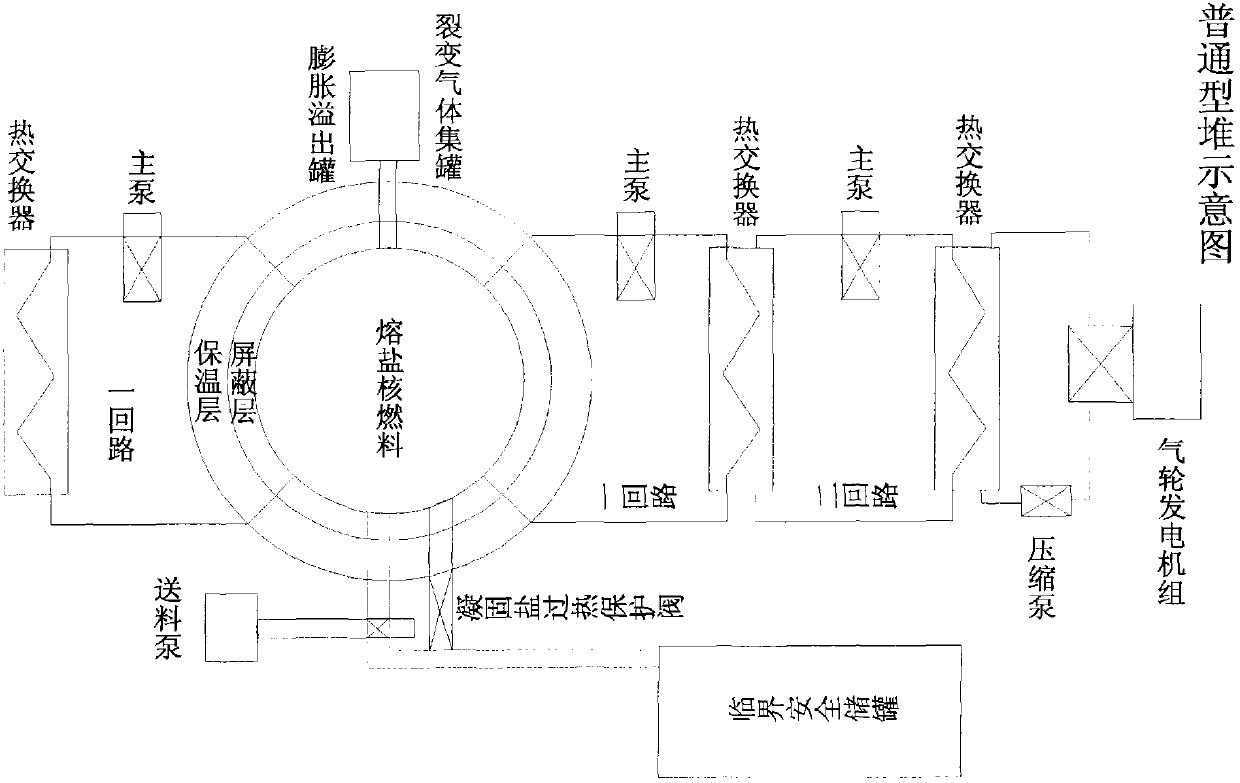

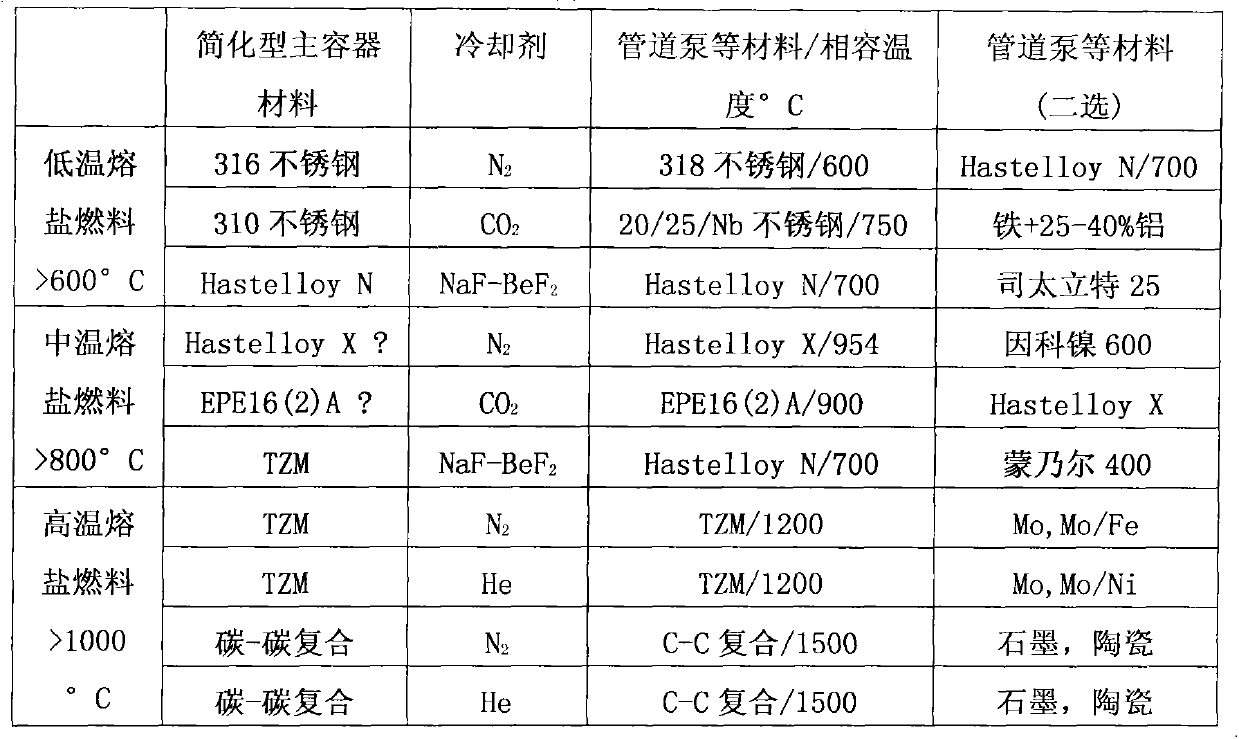

Molten salt depleted uranium reactor

PendingCN104183277AIncrease fuel consumptionSimple structureNuclear energy generationSubcritical reactorsNitrogen gasSteel pipeline

The invention discloses a molten salt depleted uranium reactor, belonging to the technical field of molten salt reactors; fast neutron spectrum, chloride molten salt, uranium plutonium cycle and depleted uranium are used; after start, only by use of a nuclear fuel of self proliferation, long-term stable and safe operation can be achieved, and a supercritical accident may not happen; negative feedback can keep in the critical state; the entire uranium plutonium cycle can be completed in the reactor; normal operation only requires the use of the depleted uranium, the reactor itself does not need uranium enrichment and purification; and high burnup of the depleted uranium can be realized. The reactor has the advantages of simple structure and easy operation, is very suitable for large-scale popularization and application. The reactor is applicable to various types of molten salt formulas and structure materials. The technology, complete set of system technology, engineering and industrialization are feasible. The preferred system is as follows: simplified low temperature IV type + 316 stainless steel main container + nitrogen coolant + 318 stainless steel pipeline pump heat exchanger and the like. Fission nuclear energy can be used to fully meet the national long-term energy needs, at the same time, the problems of the shortage of uranium resources, nuclear criticality safety and low carbon development can be solved, and the reactor is mainly used for heat, electricity or mechanical power supply.

Owner:董保国 +2

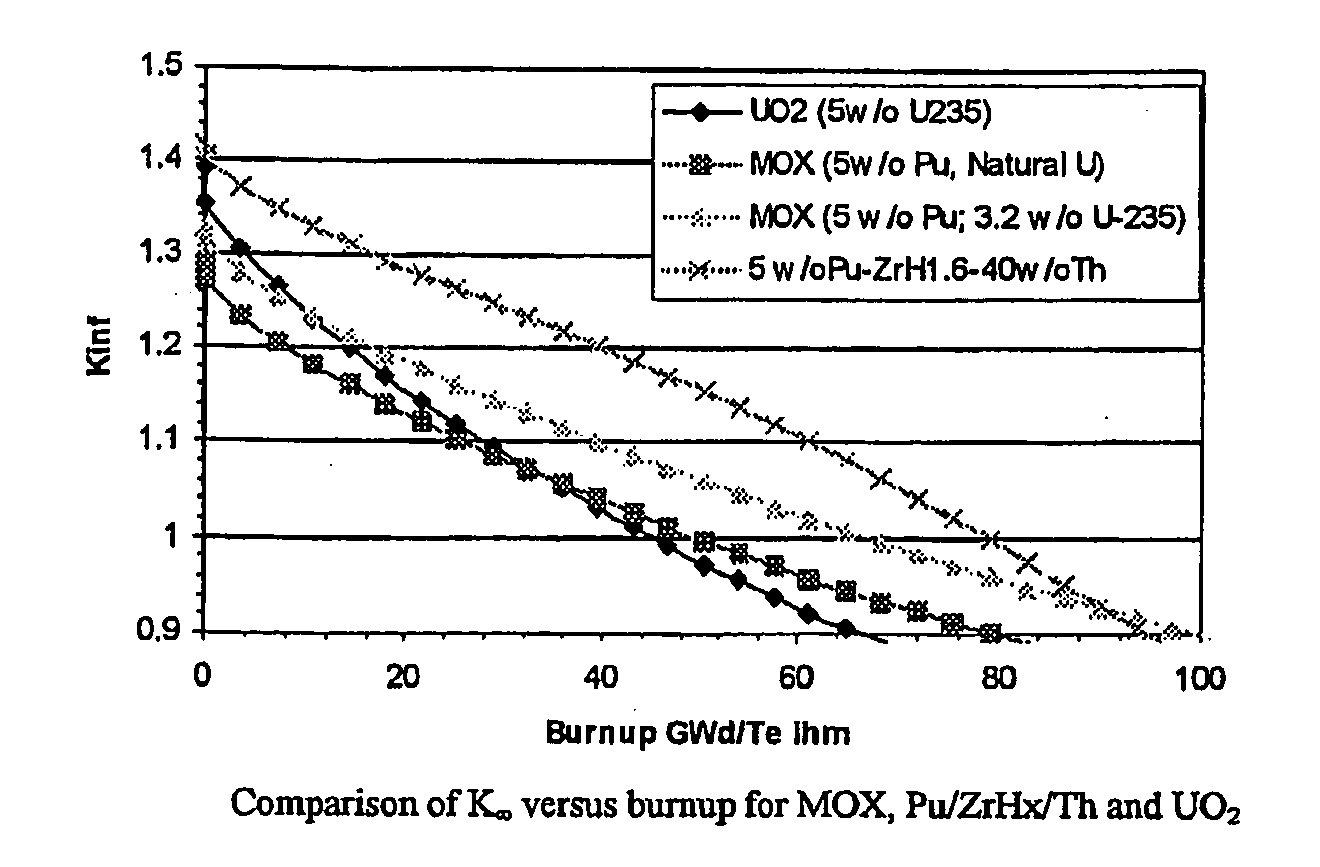

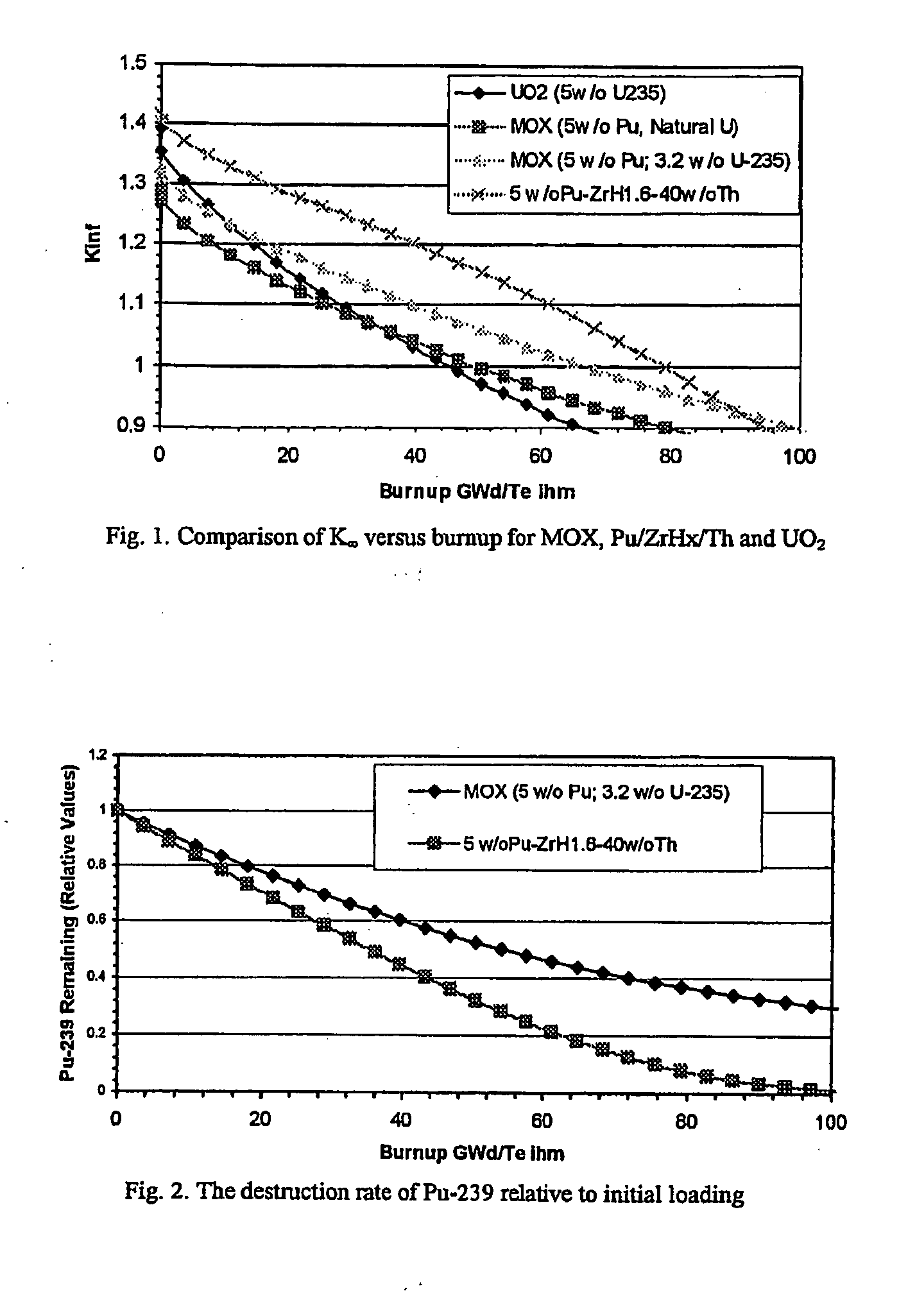

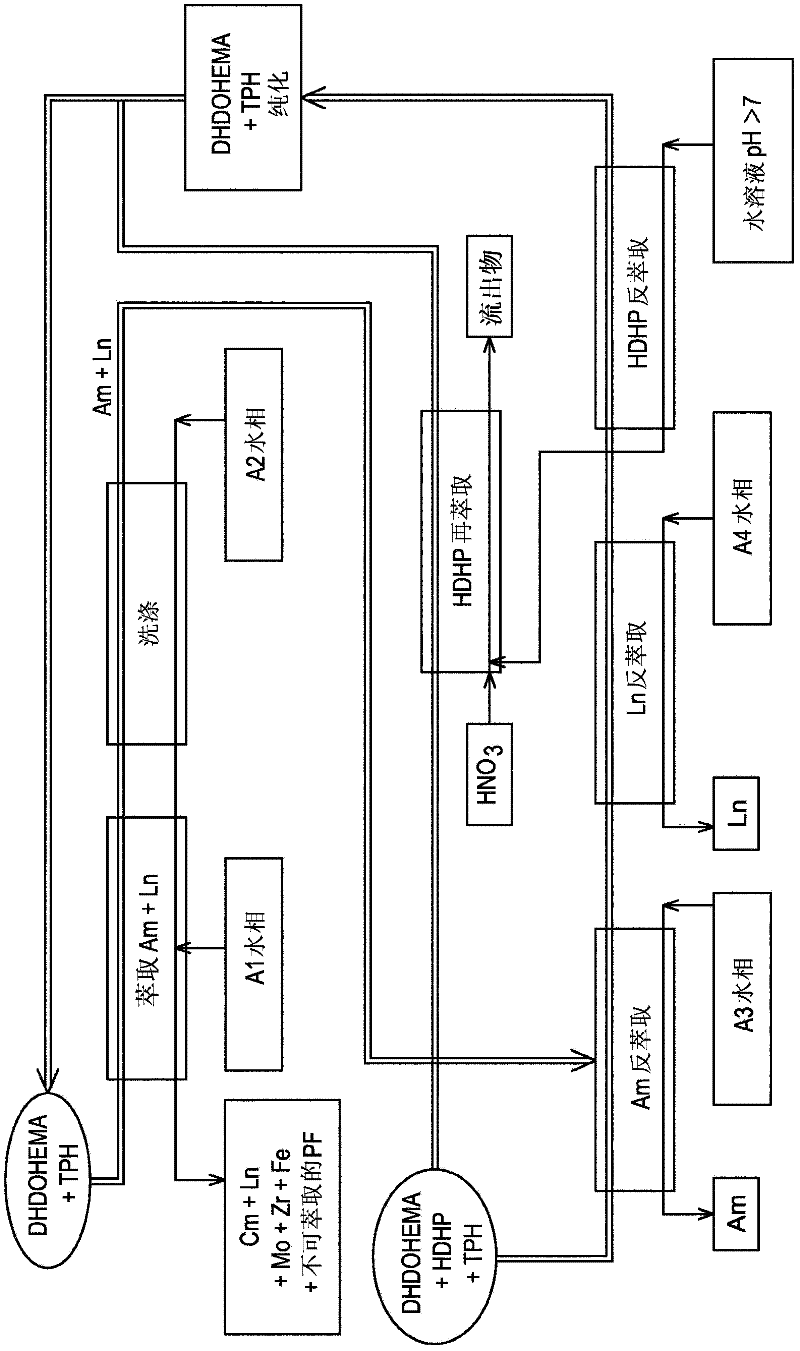

Plutonium/Zirconium Hydride/Thorium Fuel Matrix

The present invention is directed to a plutonium-based nuclear fuel that is suitable for burning weapon-grade and reactor-grade plutonium in a light water reactor, thereby reducing the amount of such material that could potentially be used to manufacture a weapon. In one embodiment, the fuel is comprised of plutonium, zirconium hydride, and thorium, with the zirconium hydride comprising more than about 20% by weight of the fuel.

Owner:UNIVERSITY OF DENVER

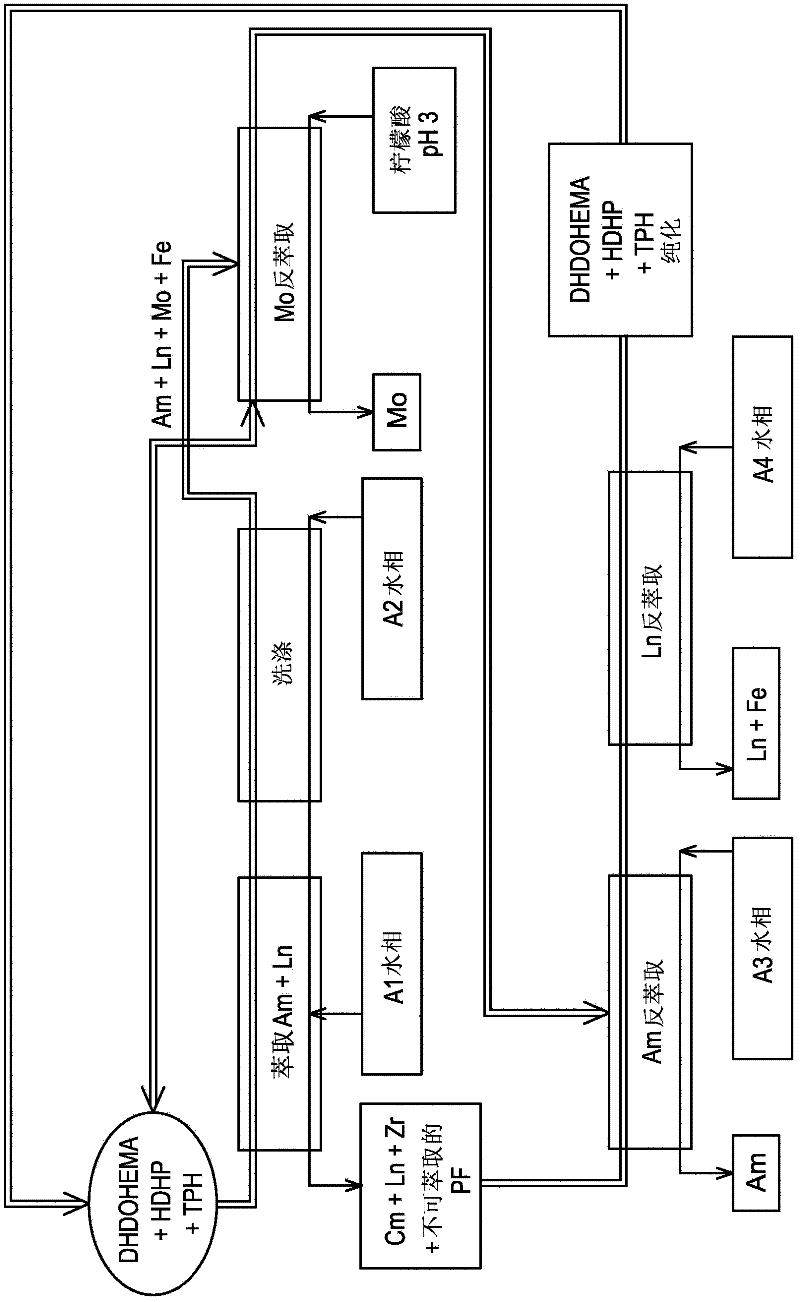

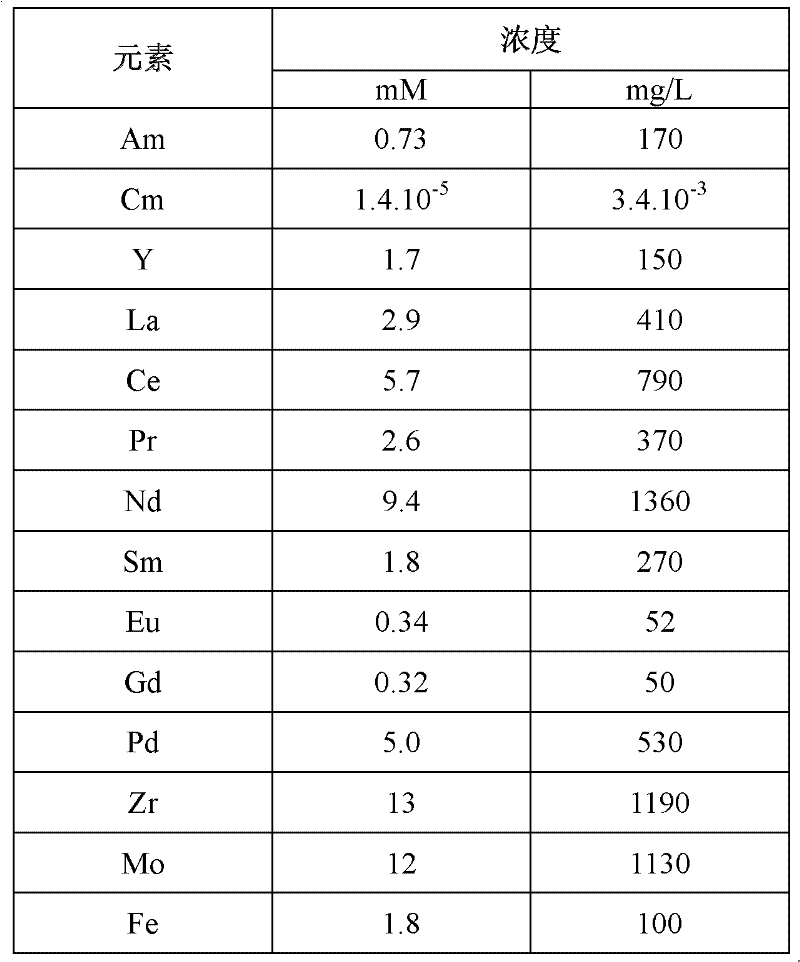

Method for selectively recovering americium from an aqueous nitric phase

ActiveCN102471824AReduce acidityFavorable removalNuclear energy generationTransuranic element compounds preparationLanthanidePu element

The invention relates to a method for selectively recovering americium from an aqueous nitric phase containing americium, curium, and fission products including lanthanides and yttrium, but free of uranium, plutonium and neptunium, or which contains only traces of the latter elements. The invention can be used for processing and recycling irradiated nuclear fuels, in particular to remove americium from raffinates from methods for extracting and purifying uranium and plutonium such as the PUREX and COEXTM methods.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com