Patents

Literature

167 results about "Photon beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A photon beam consists of numerous photons which pass from the target, through beam modifying devices, and into the patient or phantom.

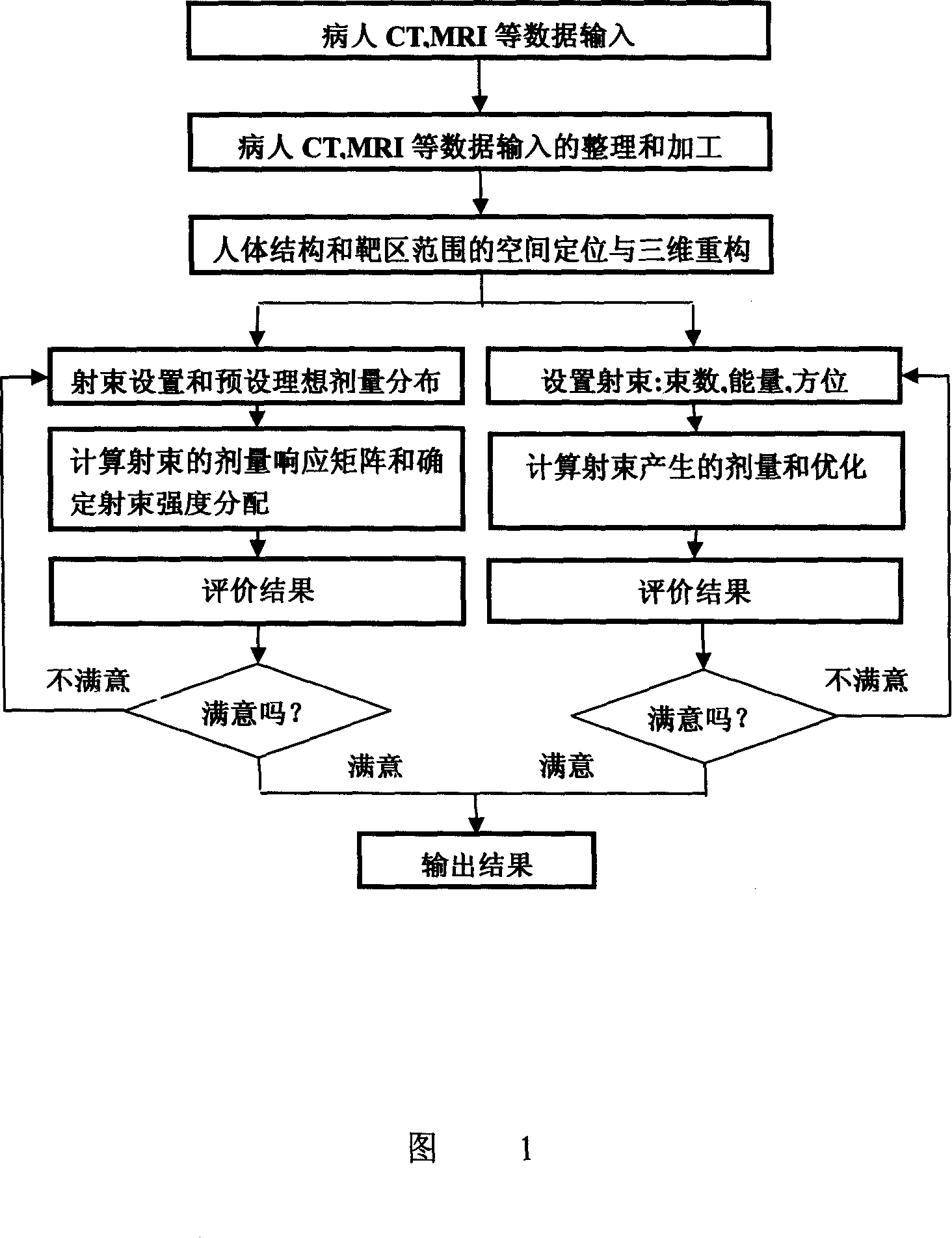

Precise radiotherapy planning system

InactiveCN101120871AImprove accuracyImprove the quality of lifeData processing applicationsSurgeryTumor targetLife quality

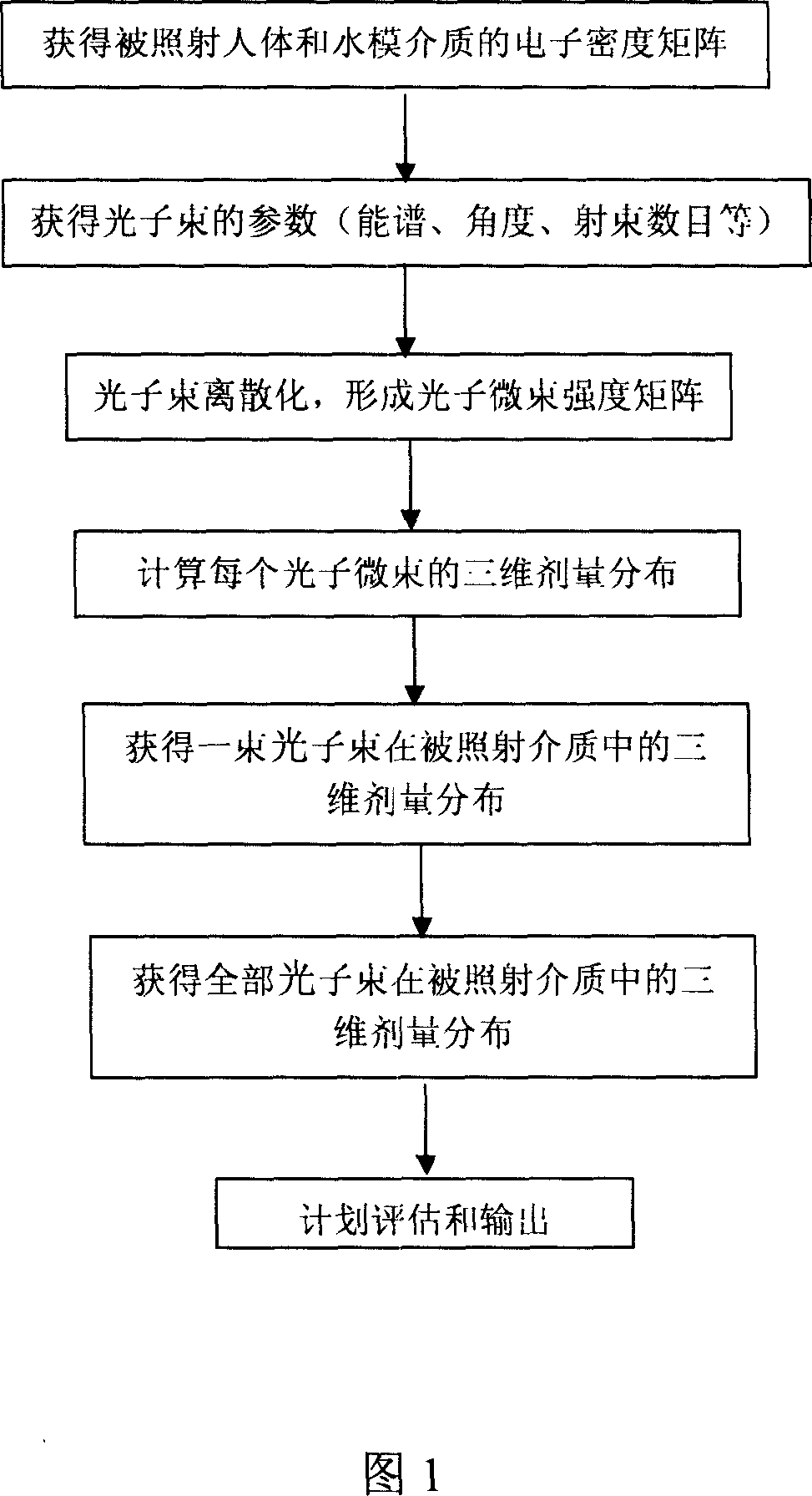

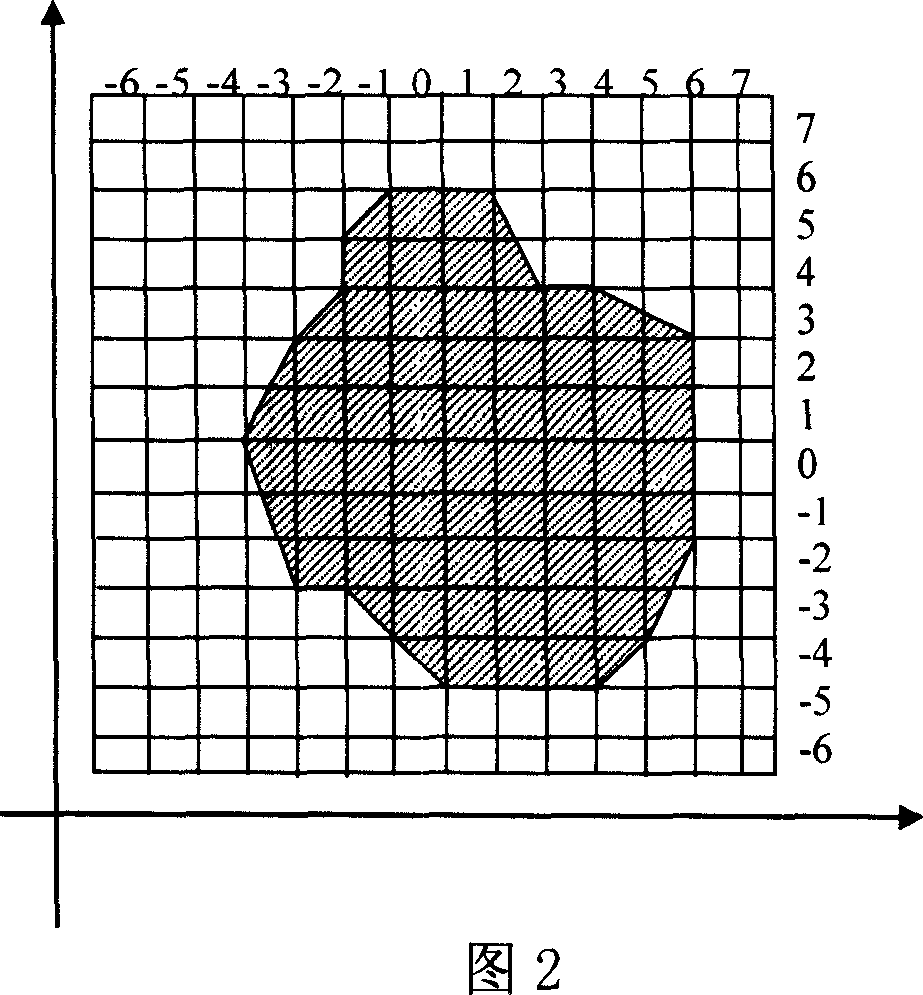

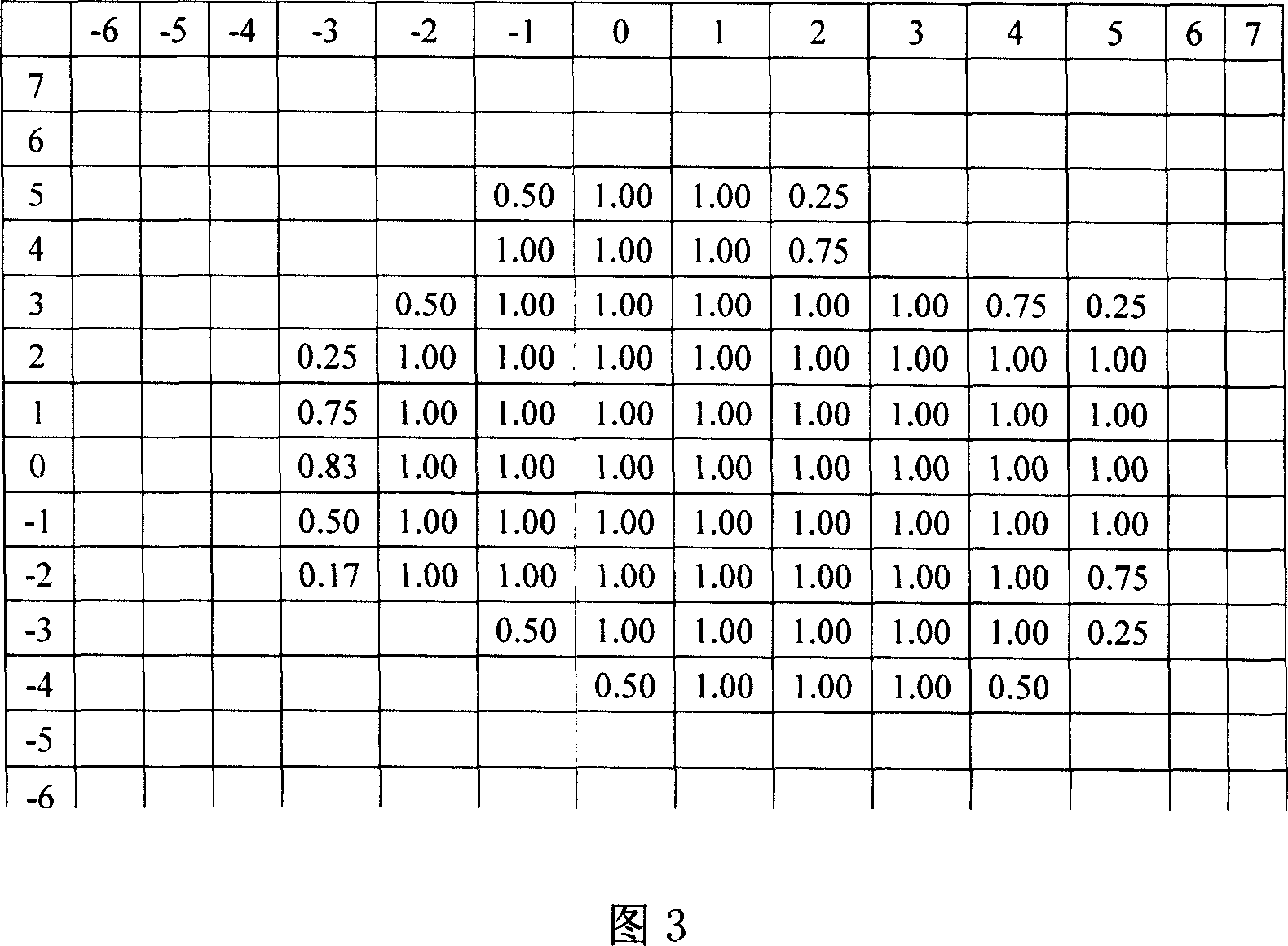

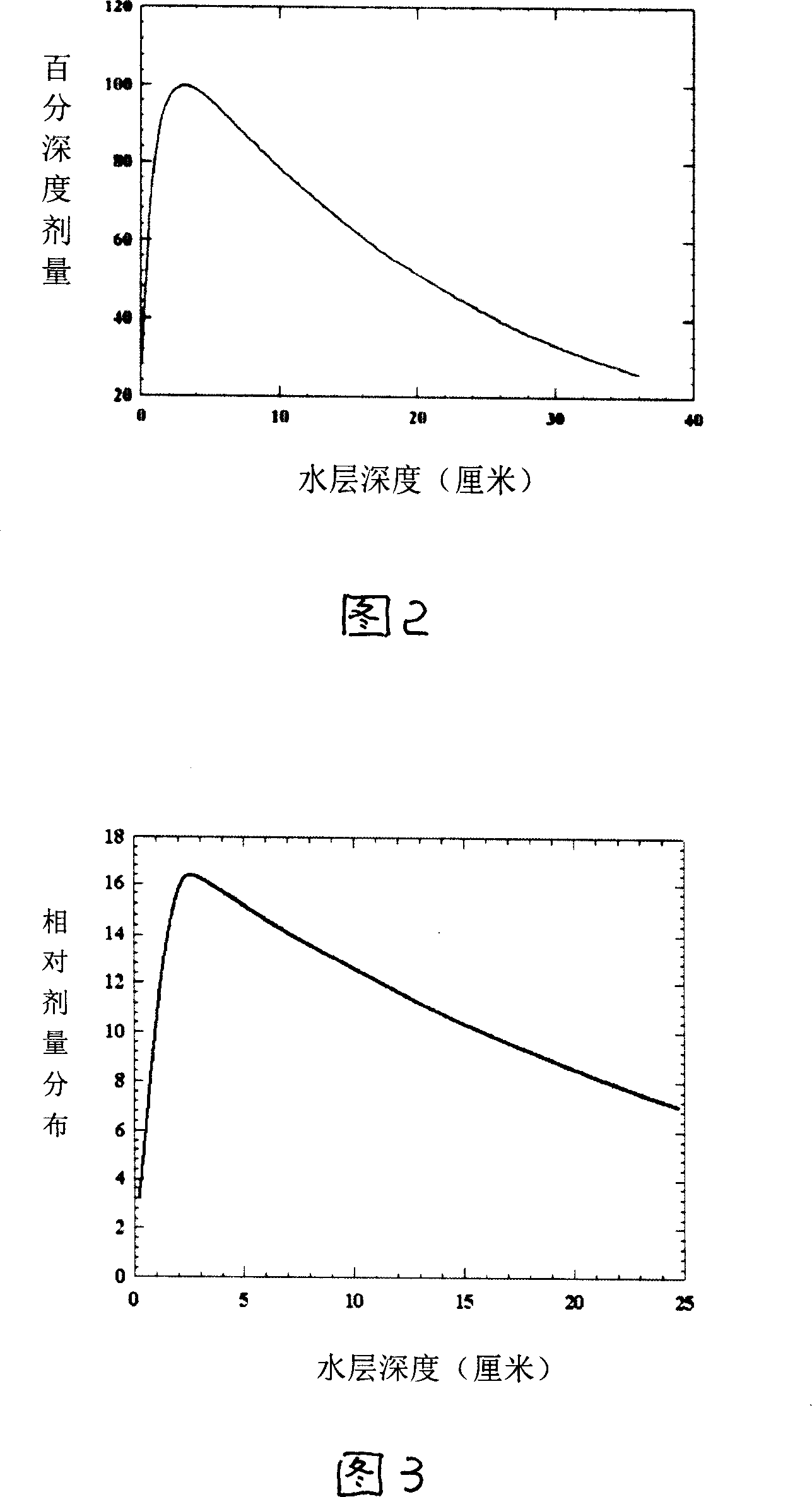

The present invention discloses an accurate radiation treatment planning system, which mainly comprises a three-dimensional medical image reconstruction module for reconstruction of human organs and the tumor target area, a three-dimensional dose calculation module of high accuracy photon beam, a three-dimensional dose calculation module of high accuracy electron beam, a conventional radiation plan designing module of the photon beam and the electron beam, a conformal radiation designing module of the photon beam and the electron beam, a reverse plan scheme designing module focused on the photon beam treatment. The present invention independently resolves the main and key technology of the radiation treatment planning system. The present invention develops a highly accurate algorithm and a fast precise optimal method of the three-dimensional dose distribution in photon beam and the electron beam, which distributes in non-uniform human medium. The present invention greatly improves accuracy of the embarking dose in tumor target area in patient body. Because the dose calculation speed has been improved dramatically, the advanced conformal radiation treatment planning system and the treatment planning system focused on radiation are feasible for clinical application. The present invention brings important benefits for improving the radiation treatment effect and improving life quality of the patient.

Owner:成都奇林科技有限责任公司

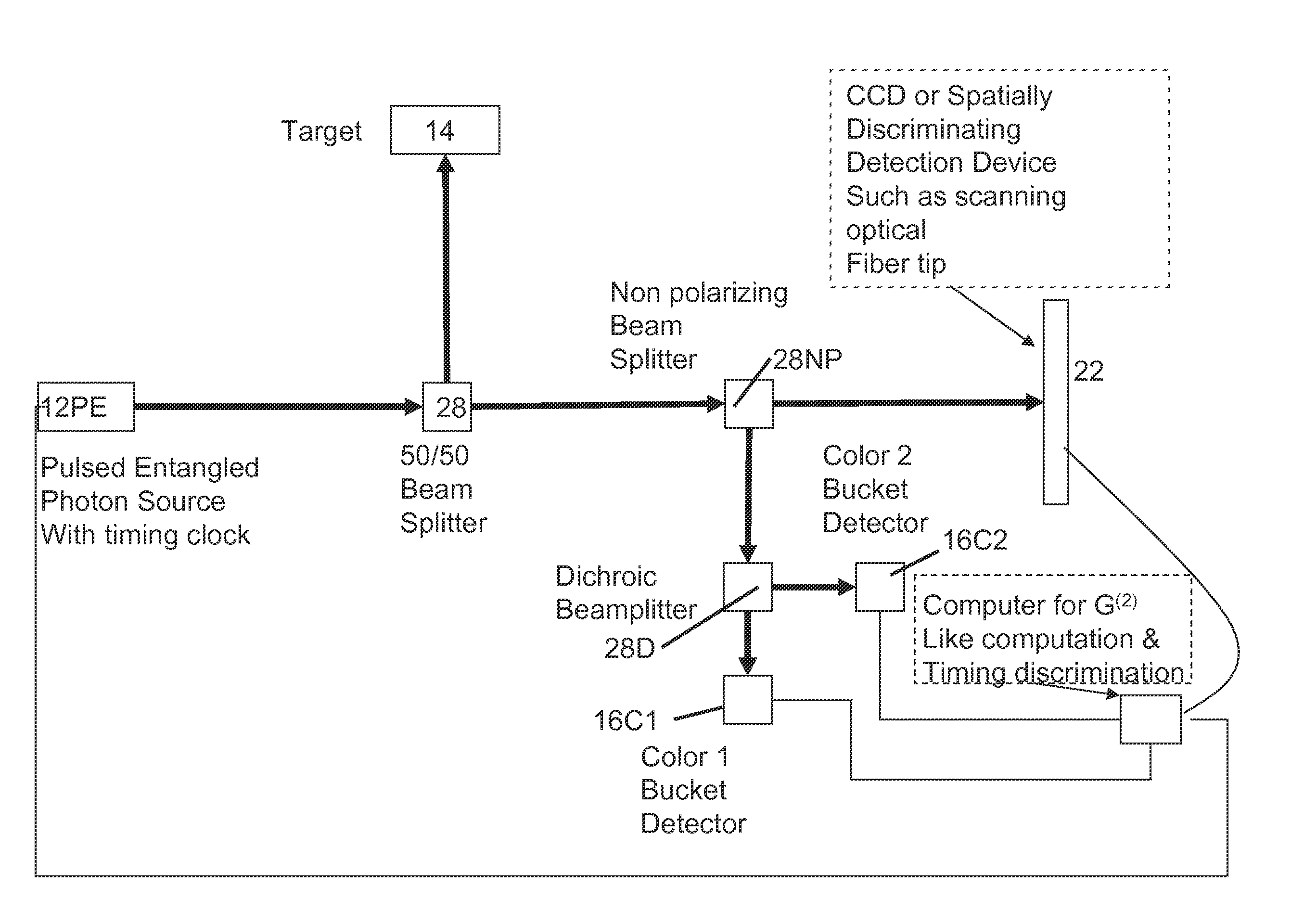

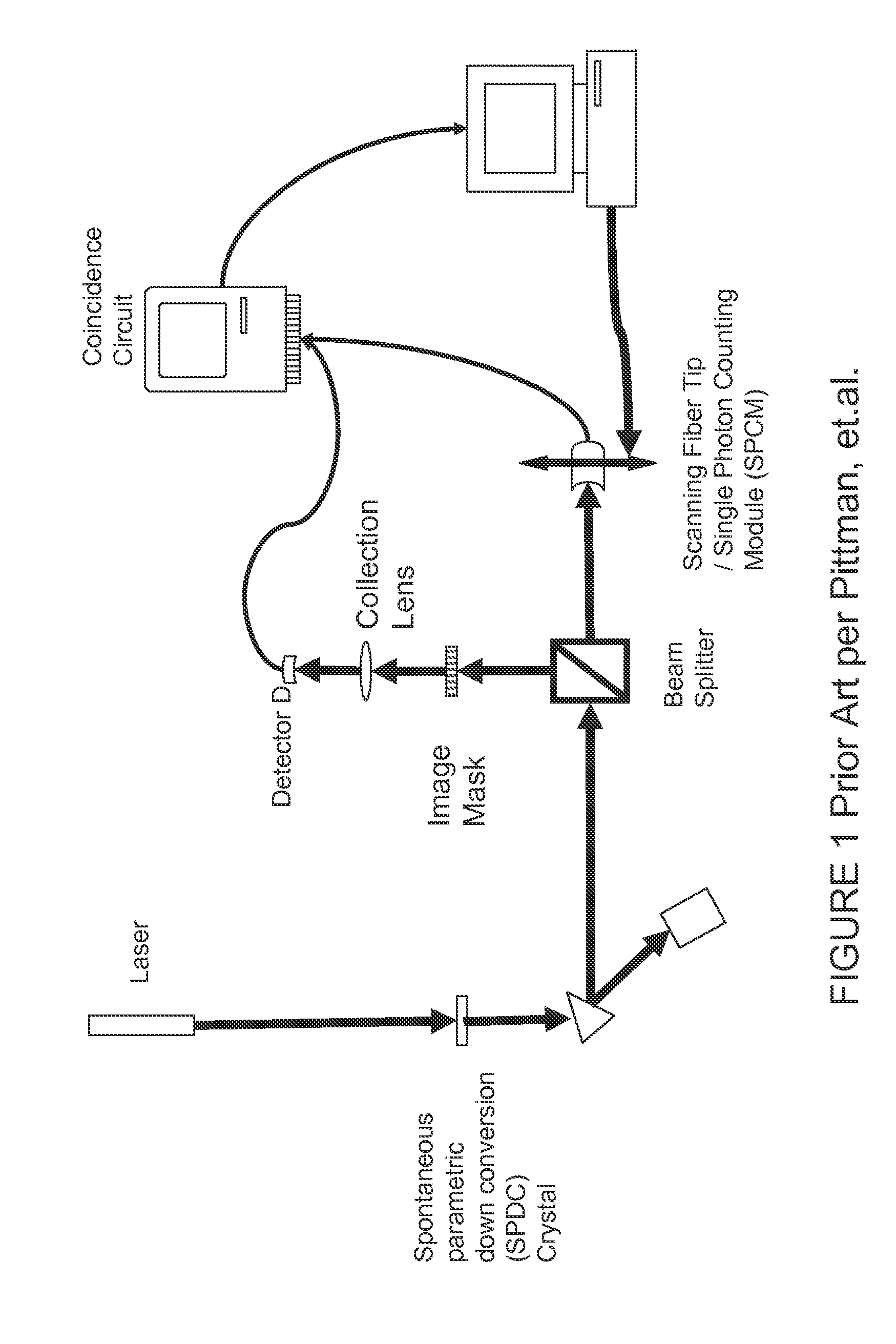

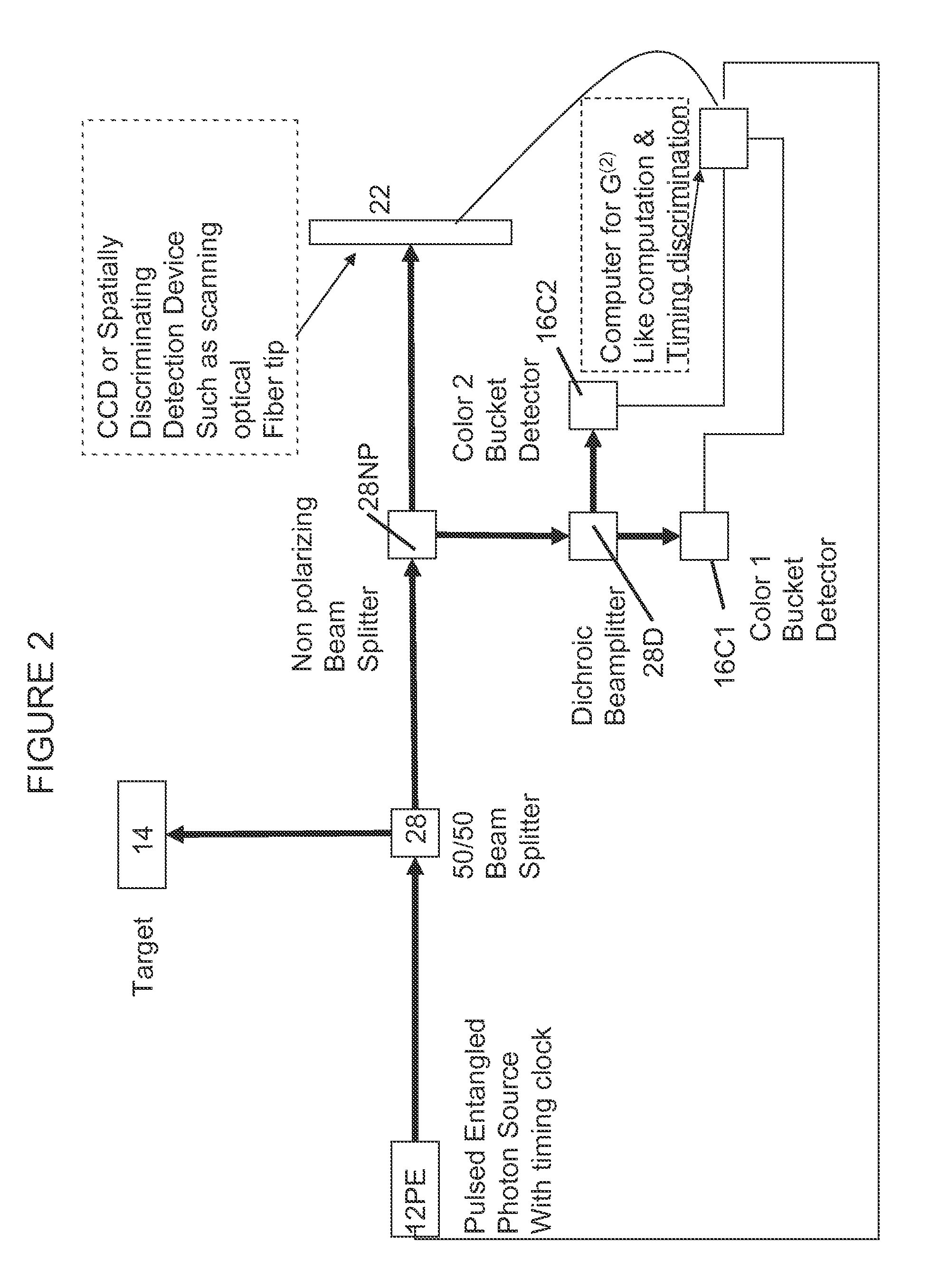

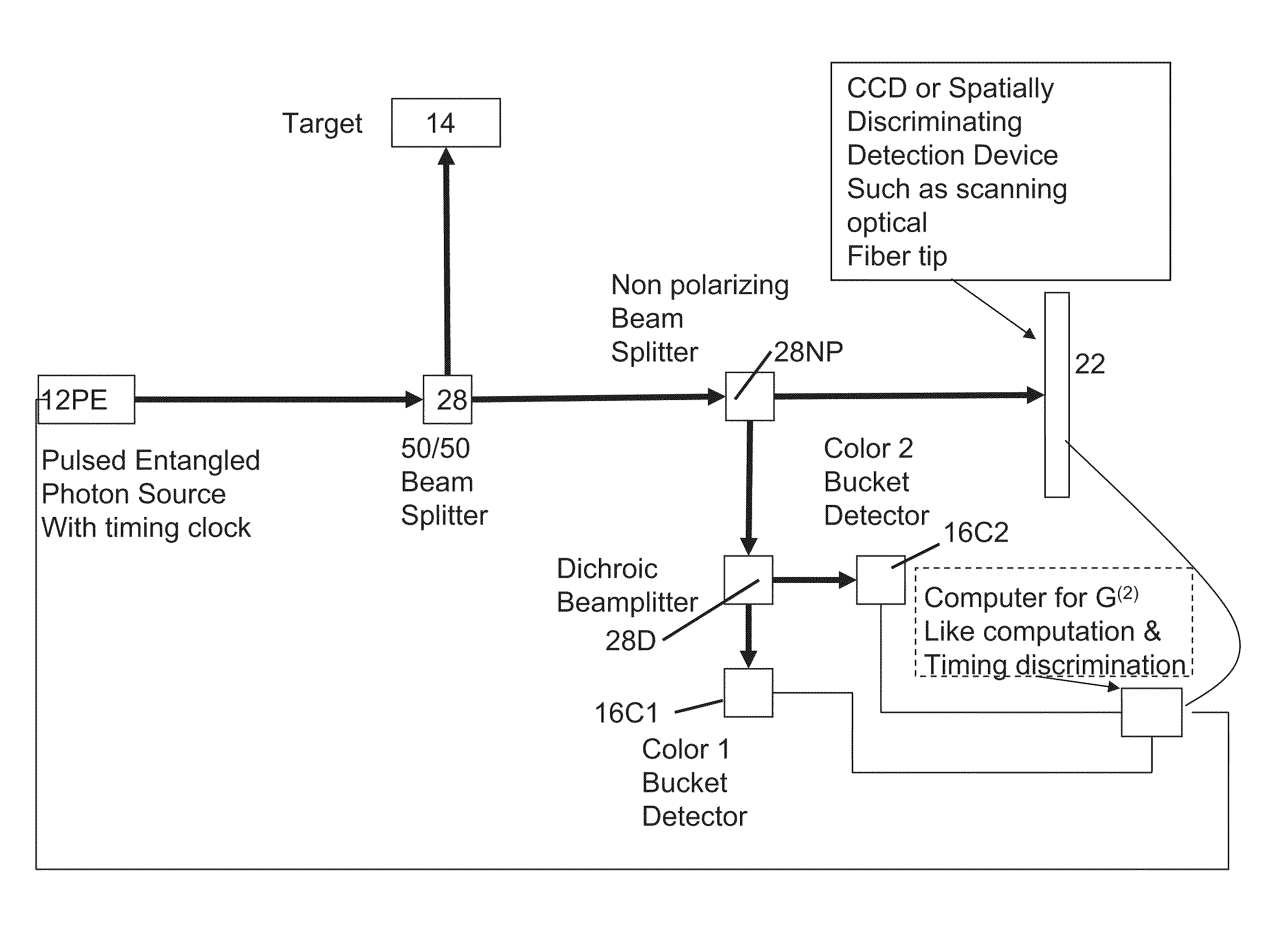

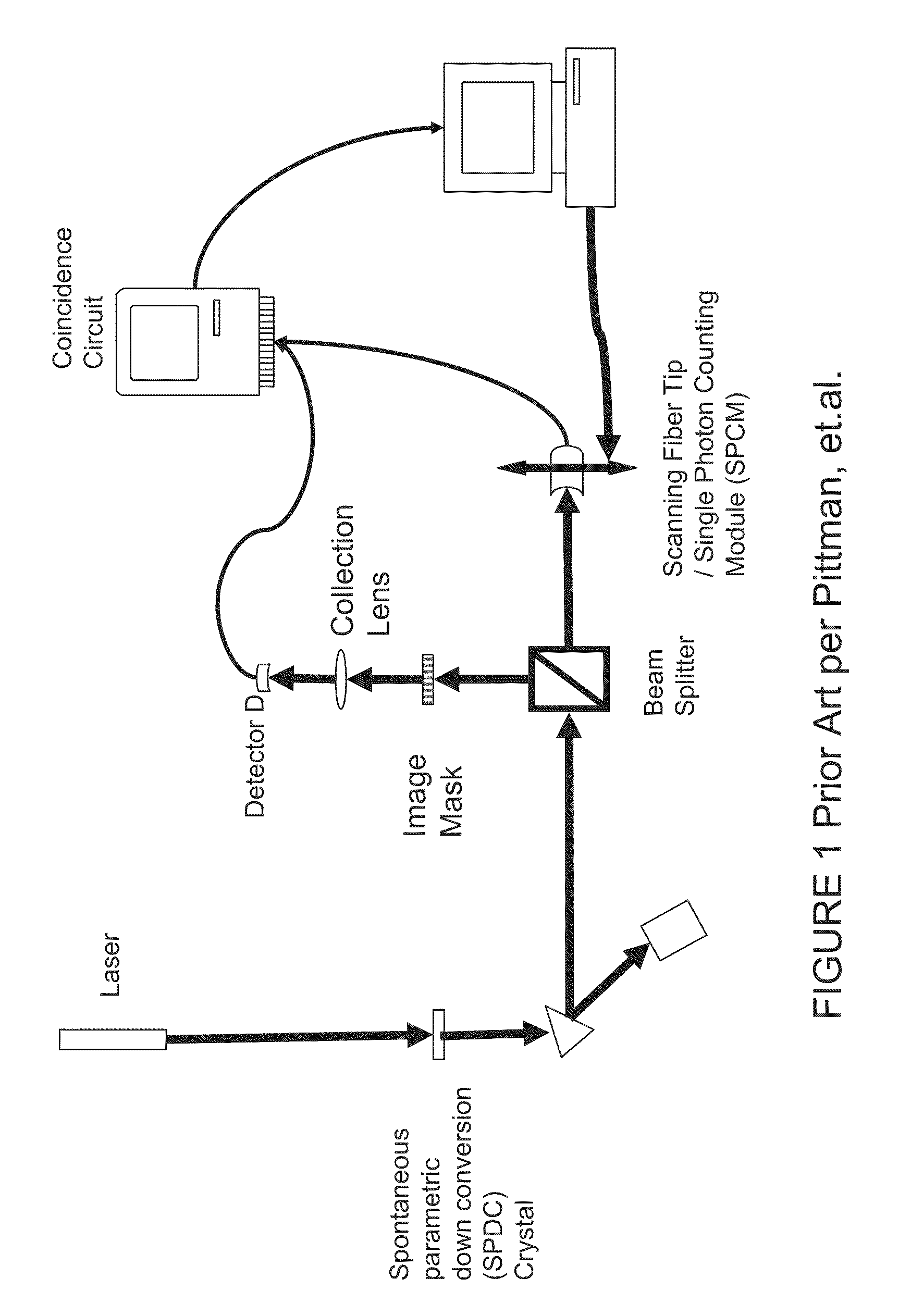

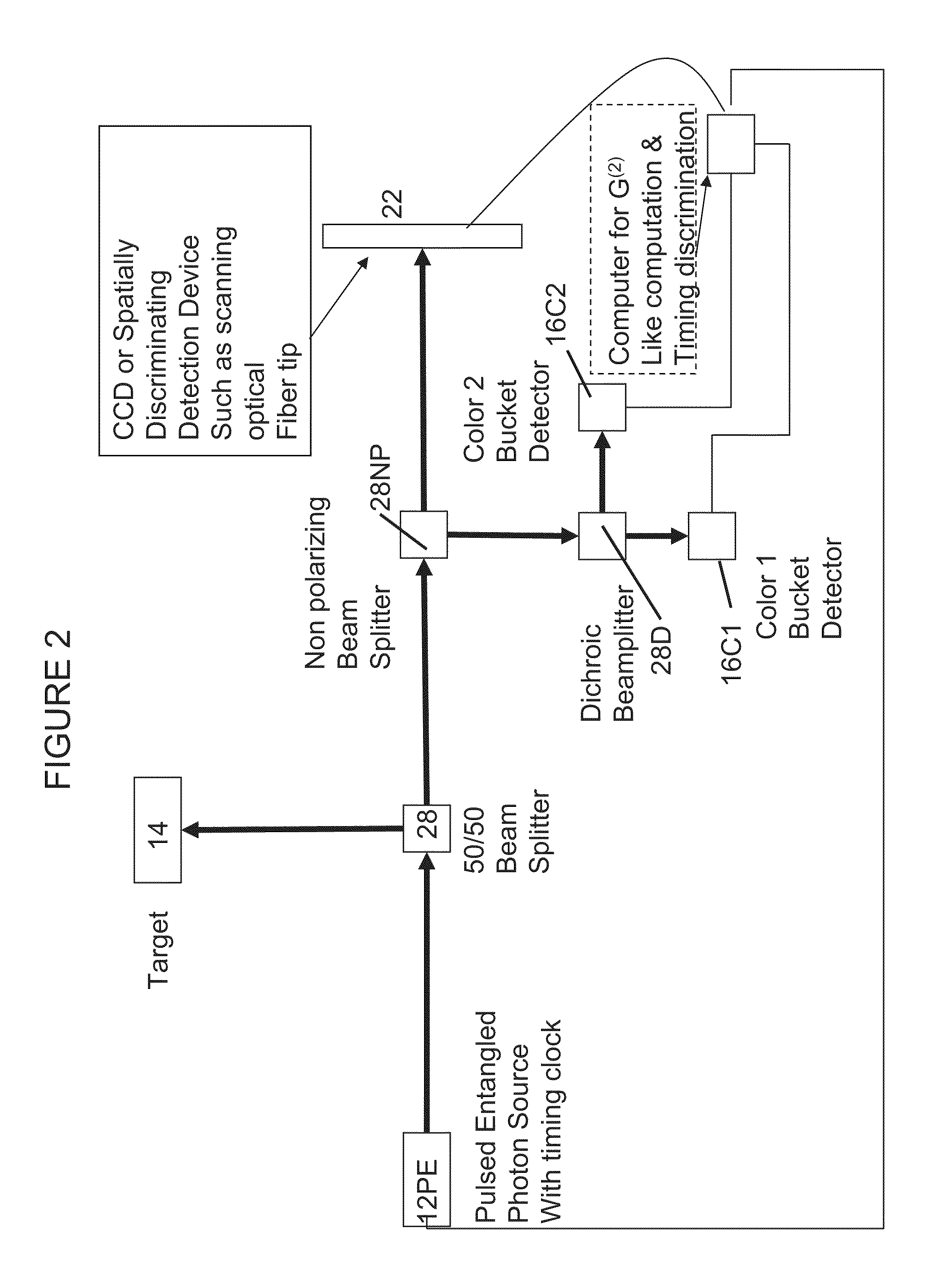

Method and system for quantum and quantum inspired ghost imaging

InactiveUS20090194702A1Scattering properties measurementsCounting objects on conveyorsGhost imagingLight beam

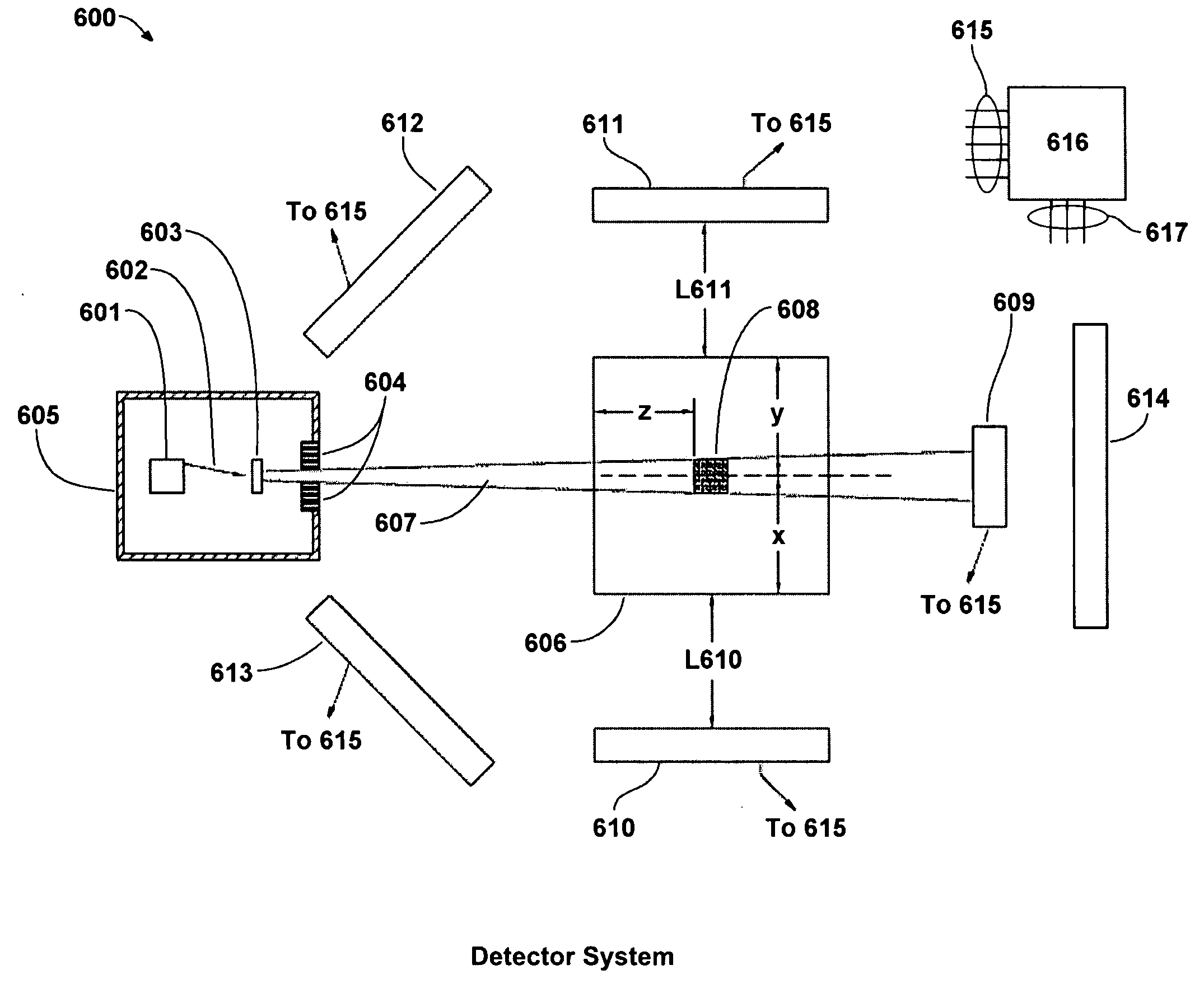

A preferred embodiment comprises a method and system for (a) detecting objects or targets which may or may not be nonreflective to electromagnetic radiation, and / or (b) generating an image of a subject or area, comprising generating an entangled photon pair beam; splitting the entangled photon pair beam into first and second parts; the first parts being directed in a first direction towards a first location, and the second parts being received into a measuring device; measuring the physical characteristics of the conjugate second parts to determine whether or not the first parts have encountered the presence or absence of an object at the first location in combination with the time that the first part takes to enter the first location. The method and system incorporate a photon beam in a reference path that never directly interacts with the object yet is determinative of presence or absence of an object at the first location. The splitting of the entangled photon pair beam occurs prior to the first parts being absorbed by said object, and the measuring of the characteristics of the conjugates occurs subsequent to the splitting of the entangled photon beam.

Owner:US SEC THE ARMY THE

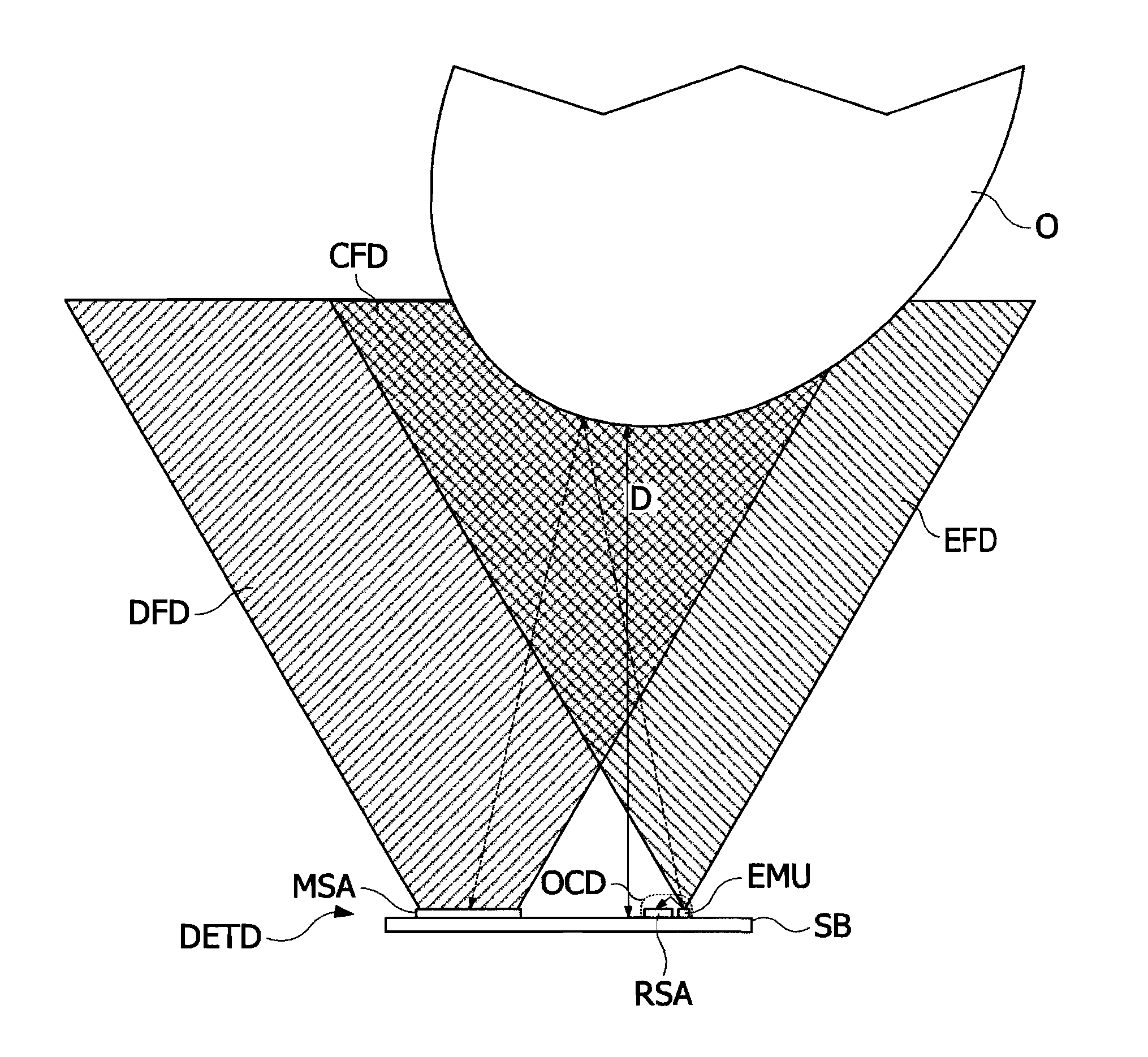

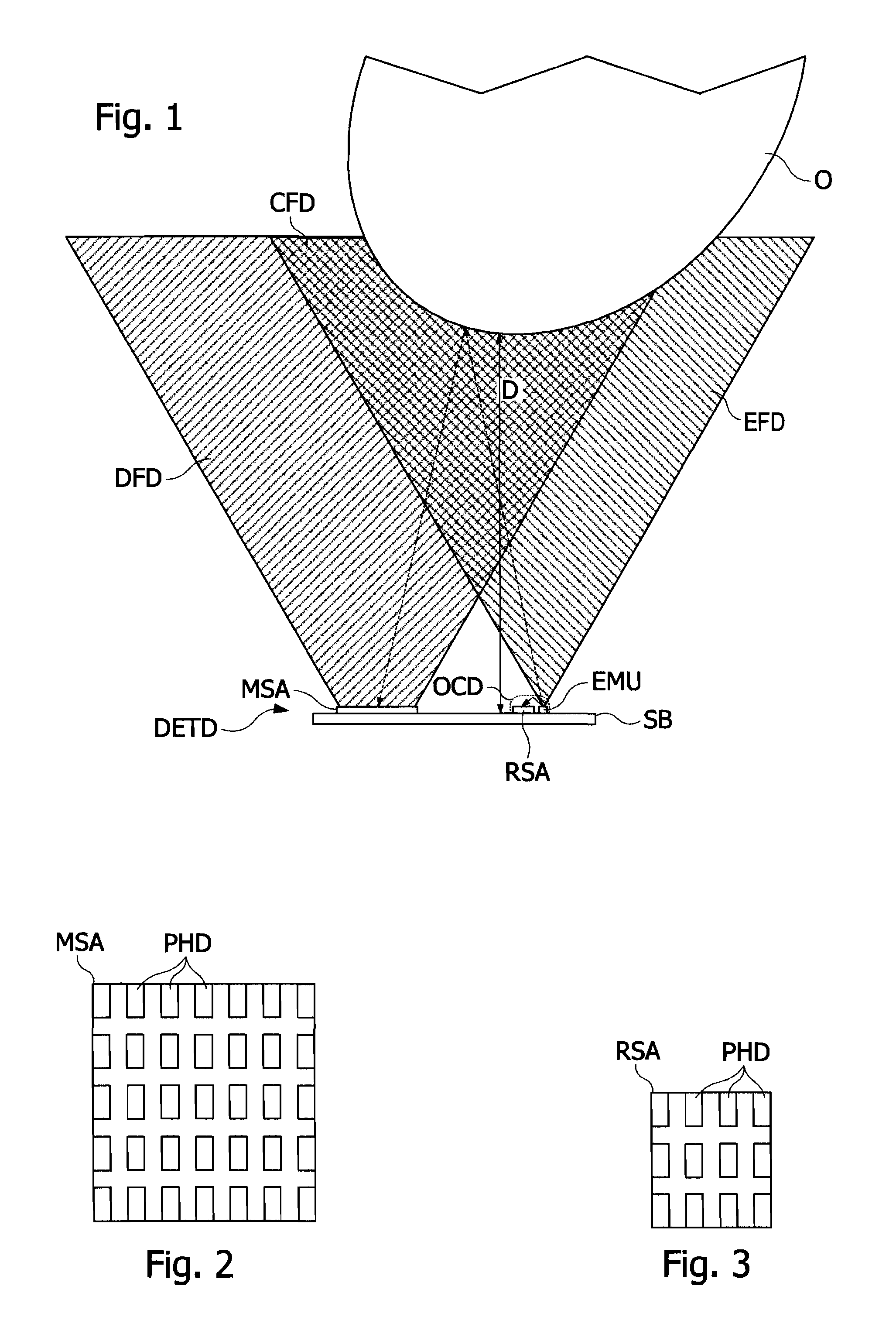

Device for detecting an object using spad photodiodes

ActiveUS20130175435A1Prevent distance measurementAvoid measuringOptical rangefindersMaterial analysis by optical meansLight beamPhotodiode

The disclosure relates to a method for detecting the presence of an object near a detection device, comprising: emitting pulses of an incident photon beam, detecting photodiodes which trigger avalanche after the reception by the photodiode of at least one photon of a reflected photon beam produced by a reflection of the incident beam on an object near the detection device, determining a distance between the photodiodes and an object in a detection area, as a function of the time between a transmit time of the incident beam and avalanche triggering times of the photodiodes, and correcting the distance determined as a function of a calibration measurement obtained in the absence of object in the detection area, to compensate for photon reflections on a transparent plate arranged between the photodiodes and the detection area.

Owner:STMICROELECTRONICS (GRENOBLE 2) SAS

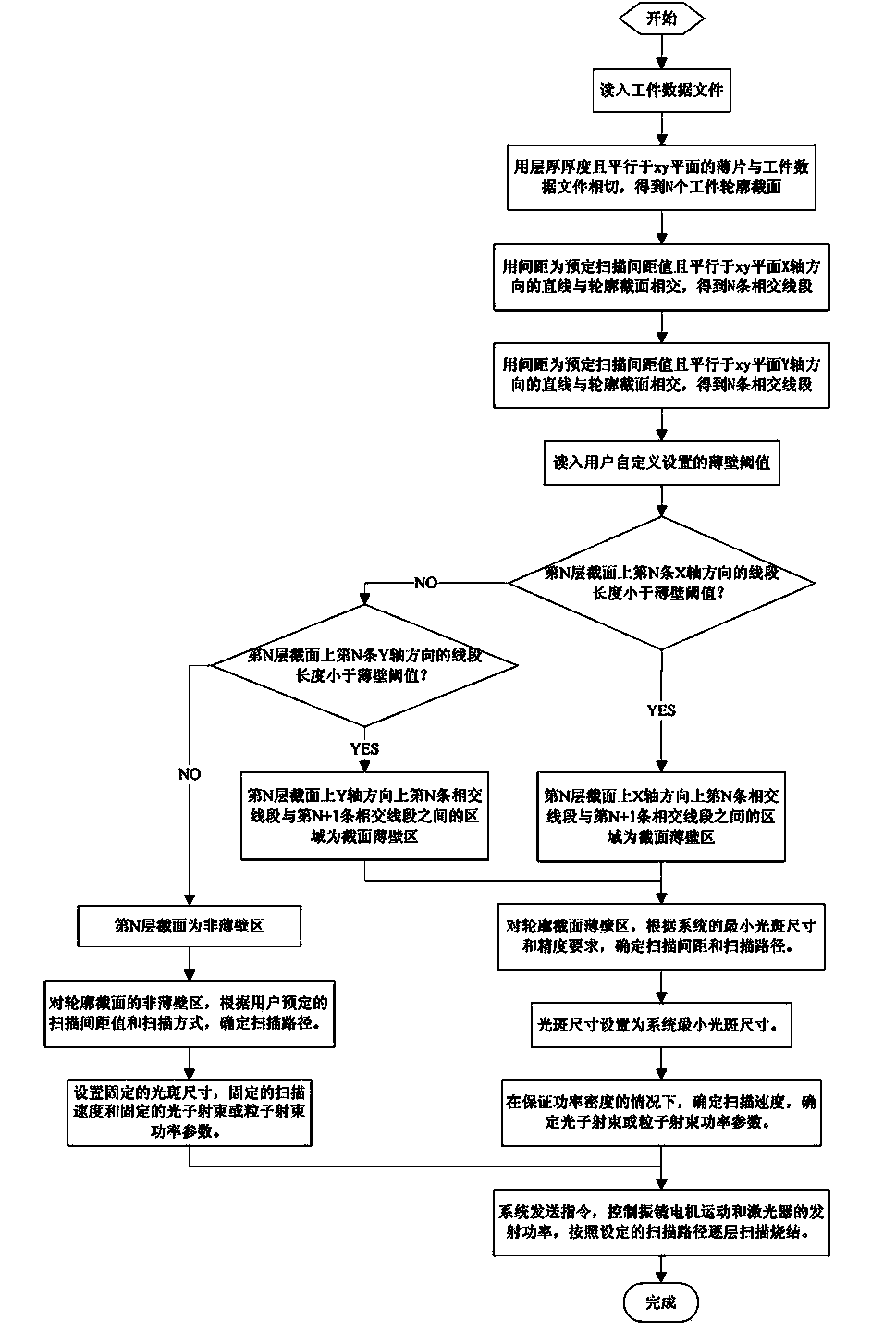

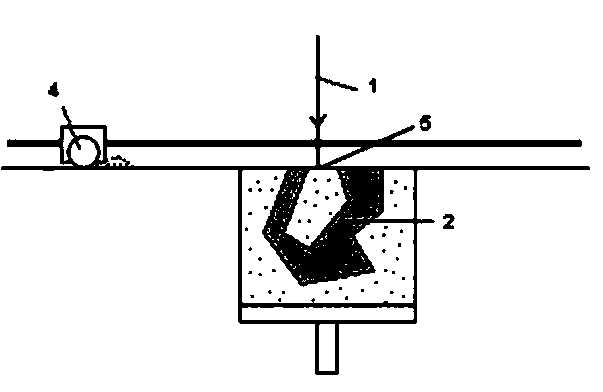

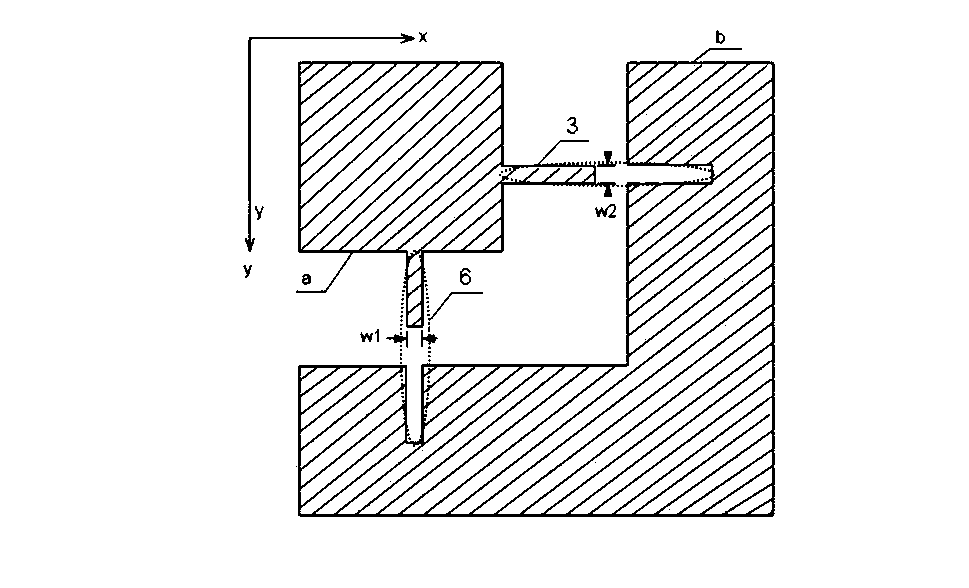

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

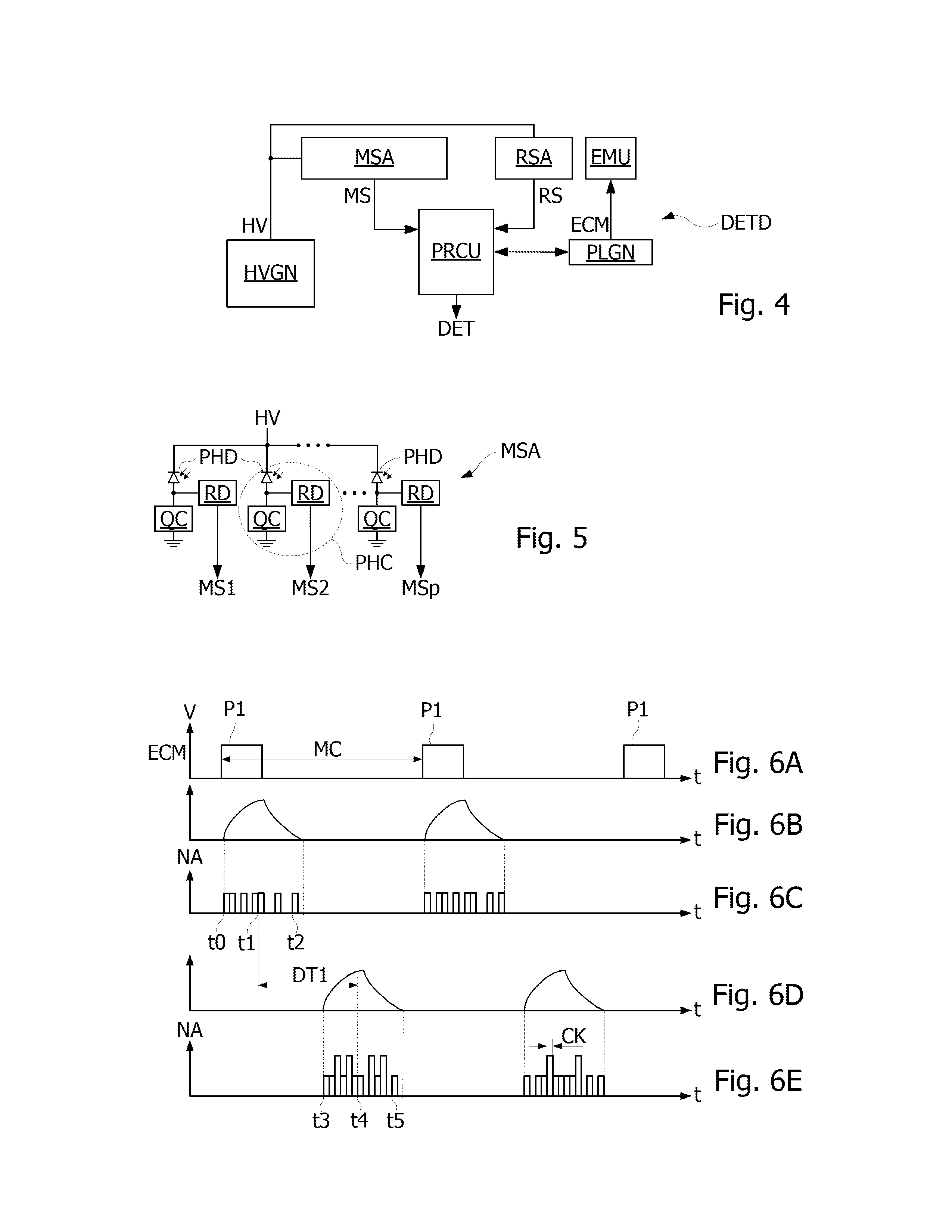

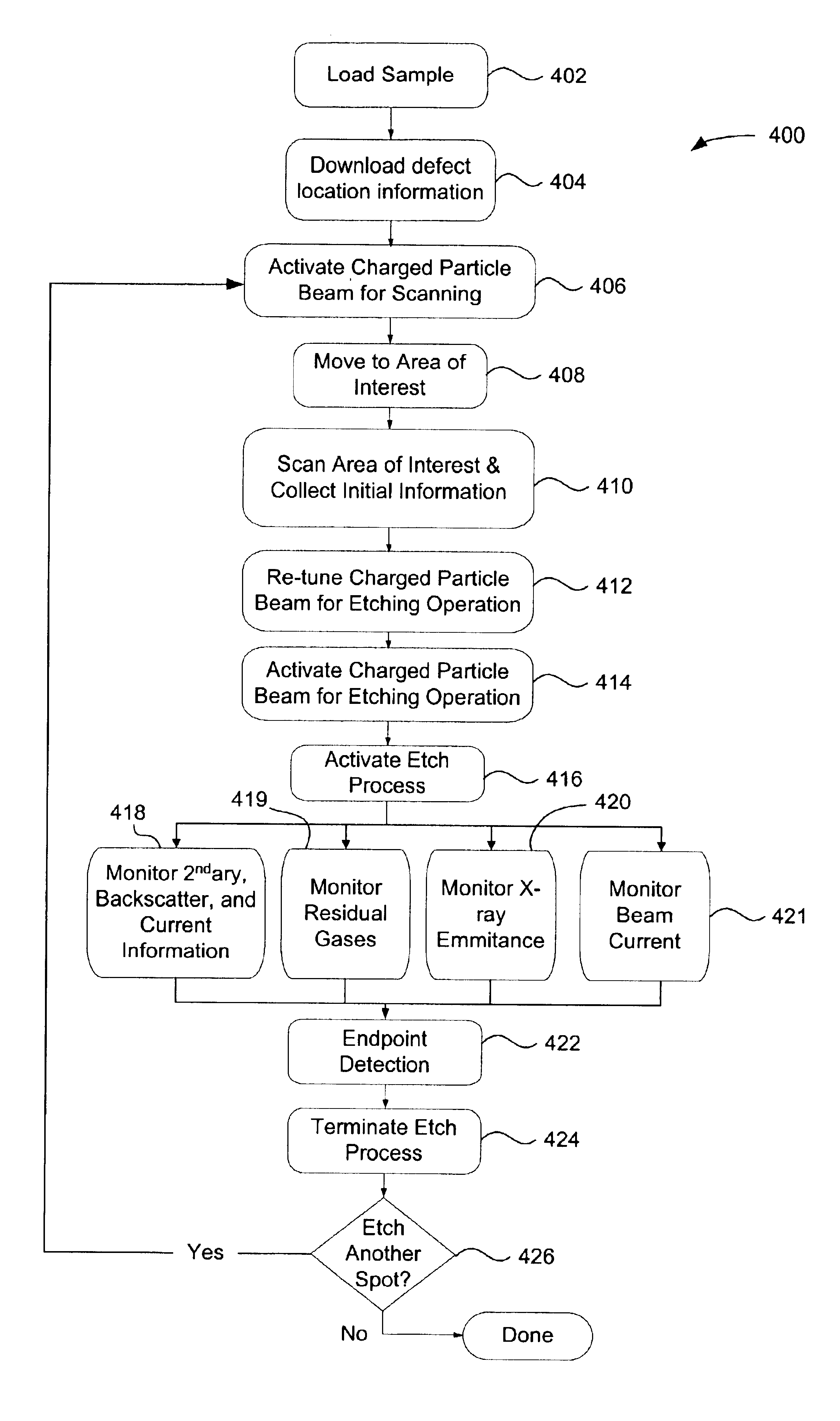

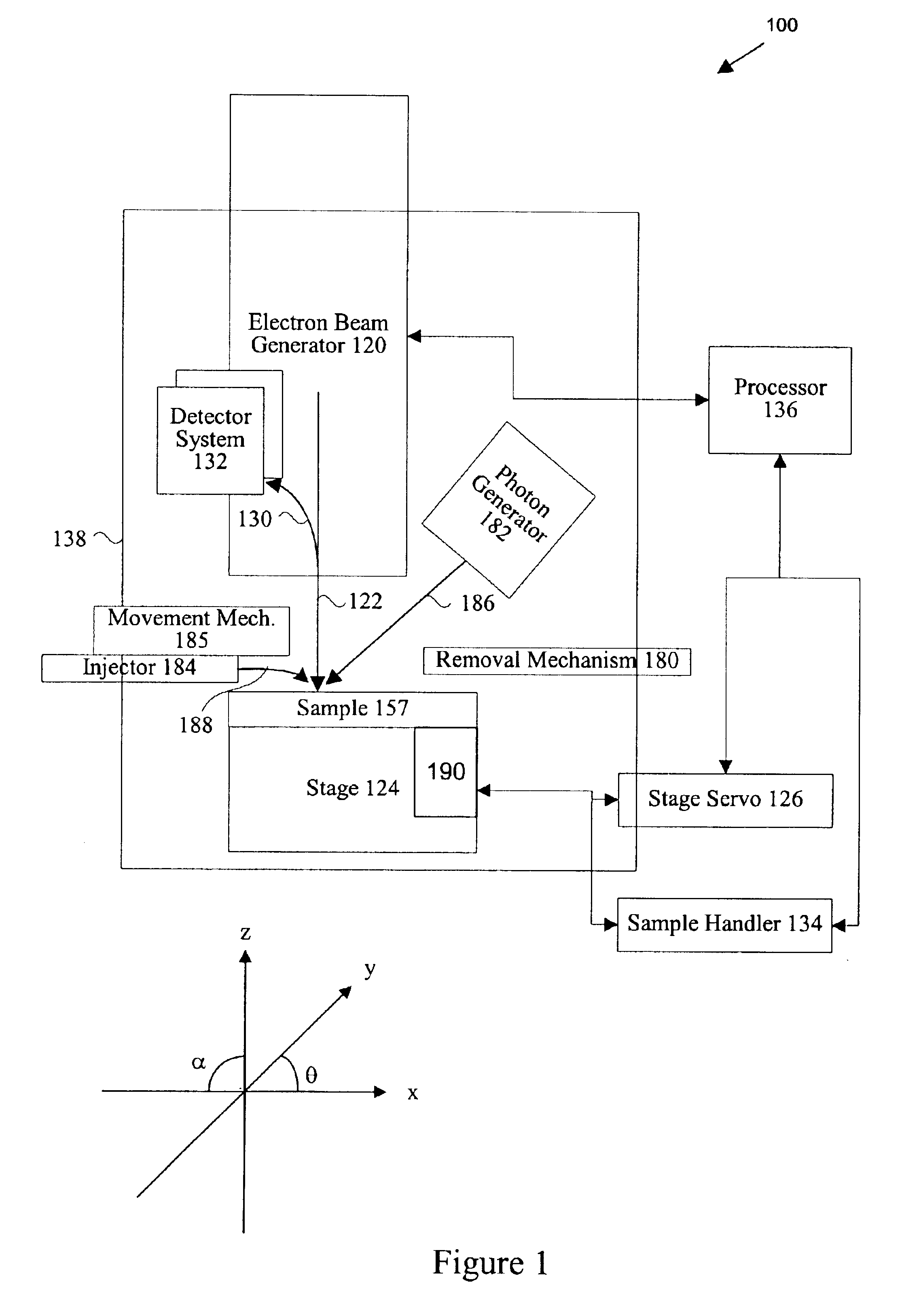

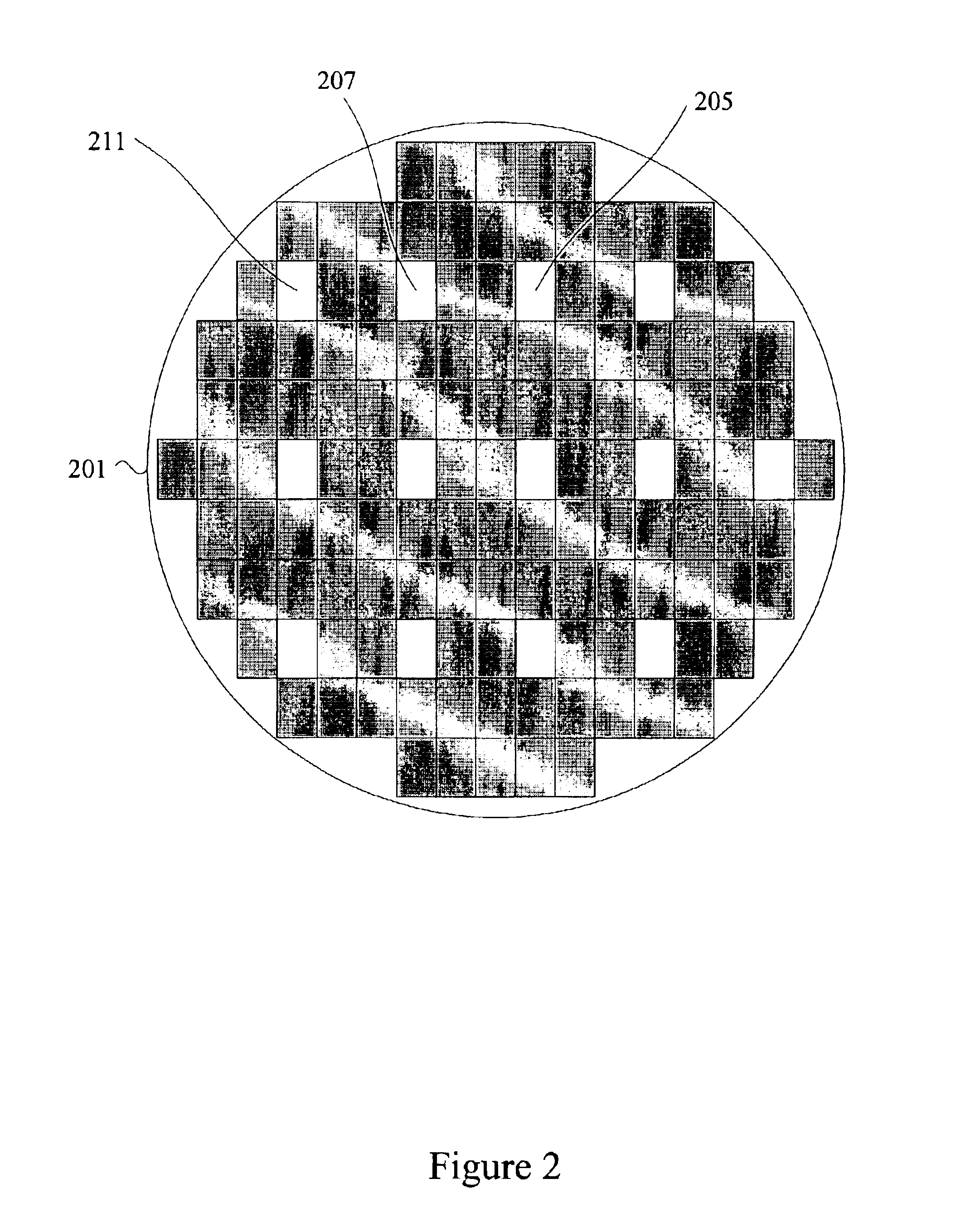

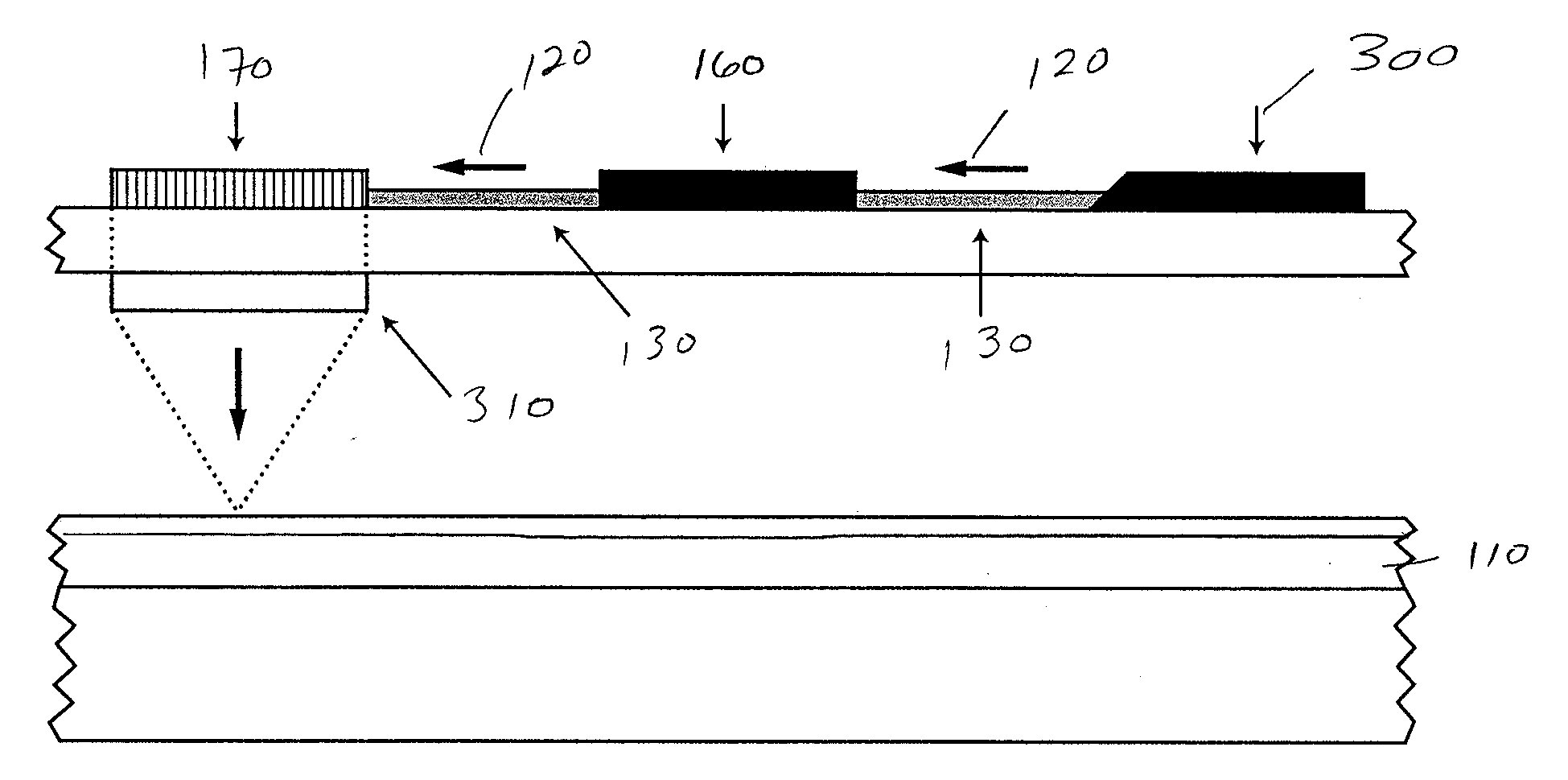

Method and apparatus for endpoint detection in electron beam assisted etching

InactiveUS6843927B2Semiconductor/solid-state device testing/measurementElectric discharge tubesSecondary electronsPhoton beam

Techniques for detecting endpoints during semiconductor dry-etching processes are described. The dry-etching process of the present invention involves using a combination of a reactive material and a charged particle beam, such as an electron beam. In another embodiment, a photon beam is used to facilitate the etching process. The endpoint detection techniques involve monitoring the emission levels of secondary electrons and backscatter electrons together with the current within the sample. Depending upon the weight given to each of these parameters, an endpoint is identified when the values of these parameters change more than a certain percentage, relative to an initial value for these values.

Owner:KLA TENCOR TECH CORP

Microphotonic maskless lithography

ActiveUS20080014534A1Improve scalabilityIncrease the number ofSemiconductor/solid-state device manufacturingDiffraction gratingsWaveguidePhoton beam

A maskless lithography system and method to expose a pattern on a wafer by propagating a photon beam through a waveguide on a substrate in a plane parallel to a top surface of the wafer.

Owner:MASSACHUSETTS INST OF TECH

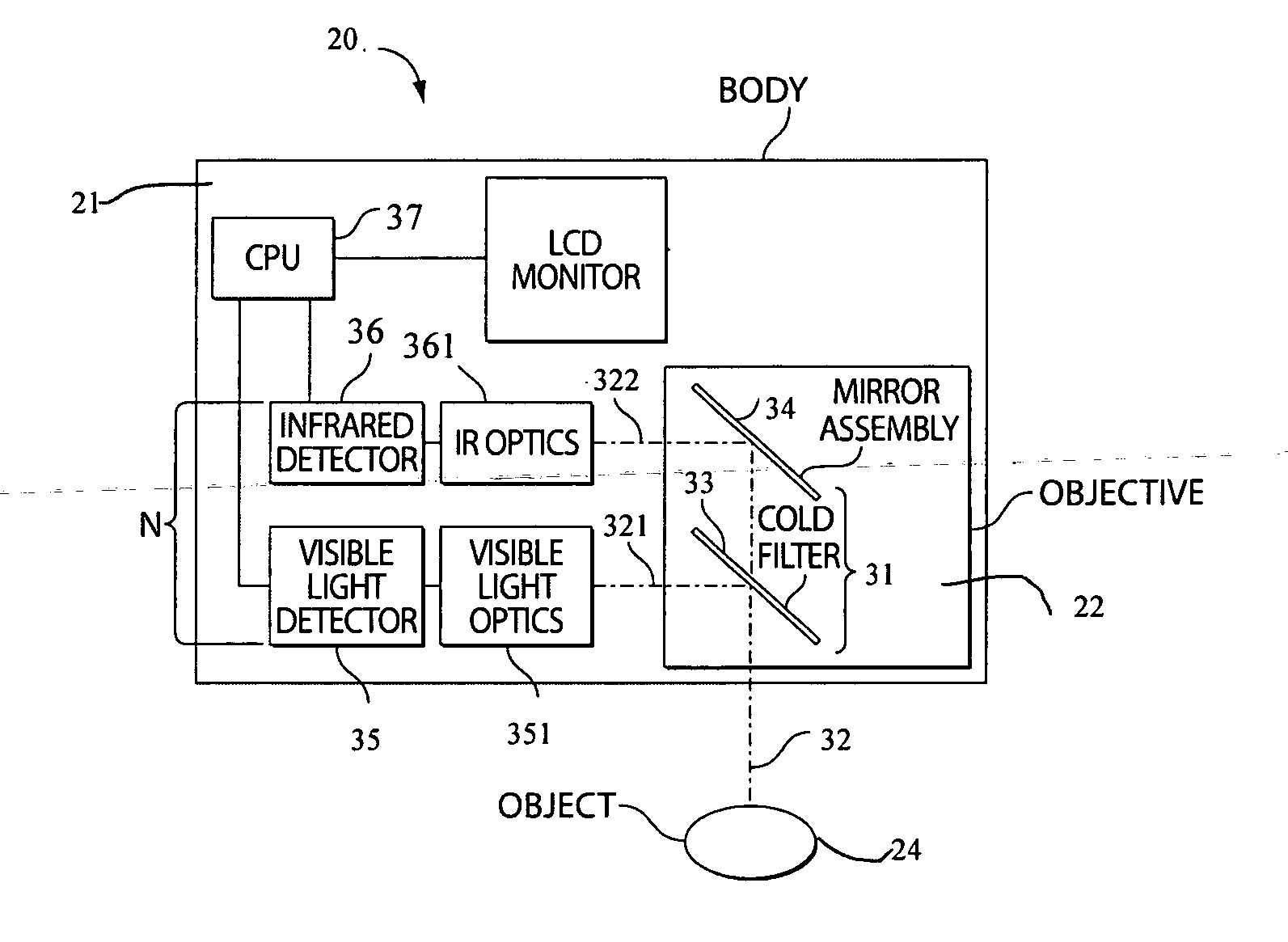

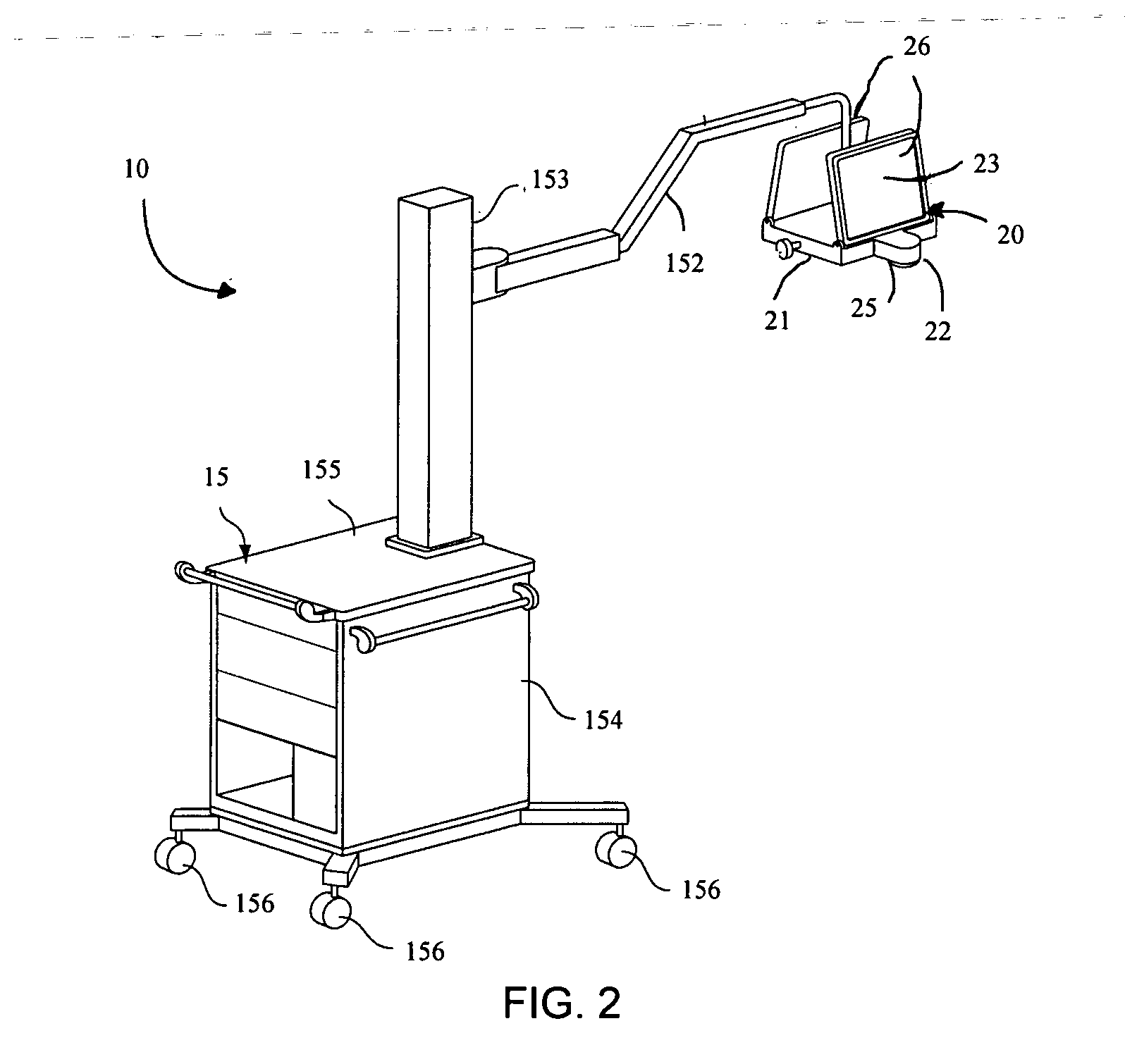

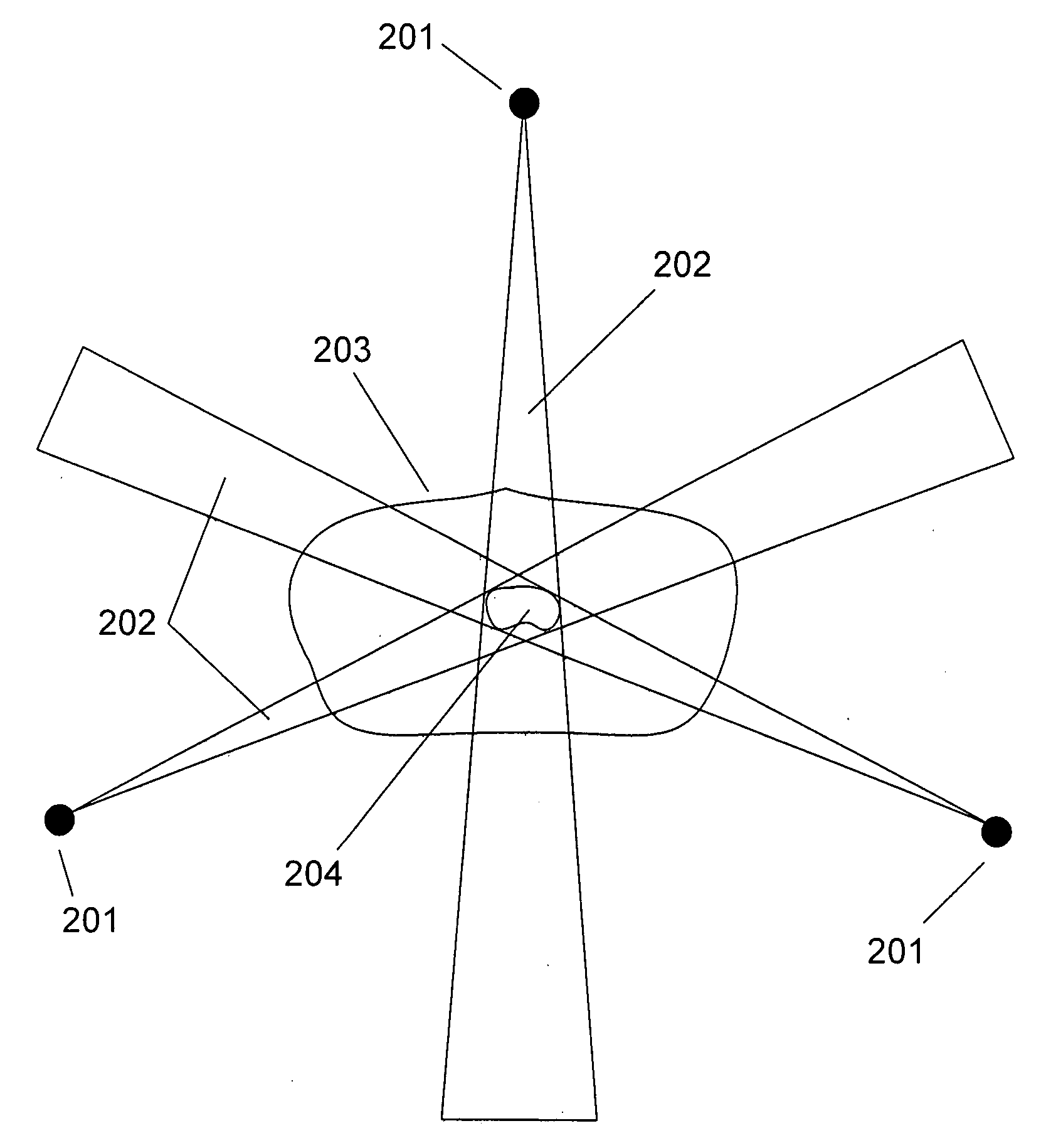

Visualizing Radiation Therapy Beam in Real-Time in the context of Patient's Anatomy

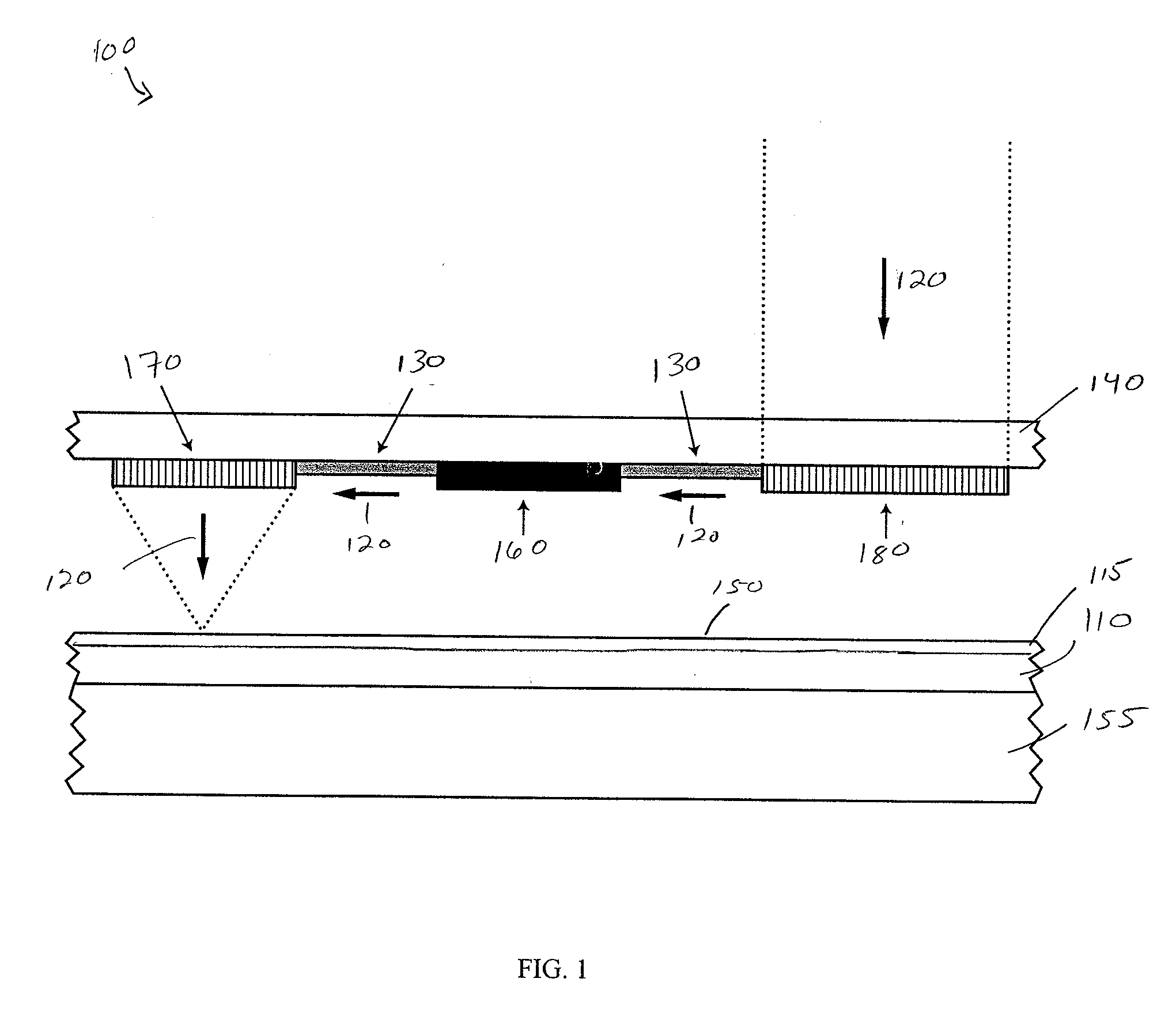

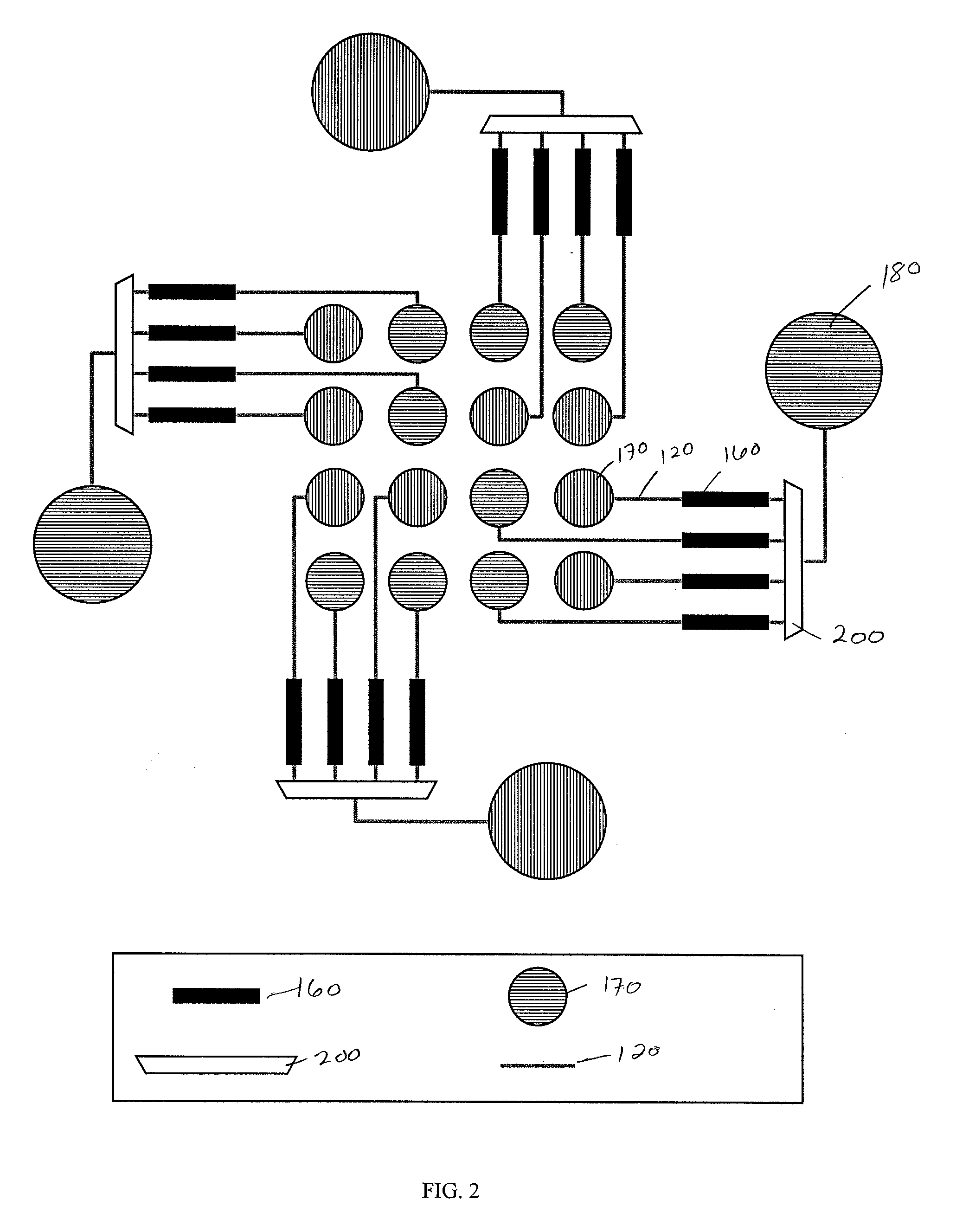

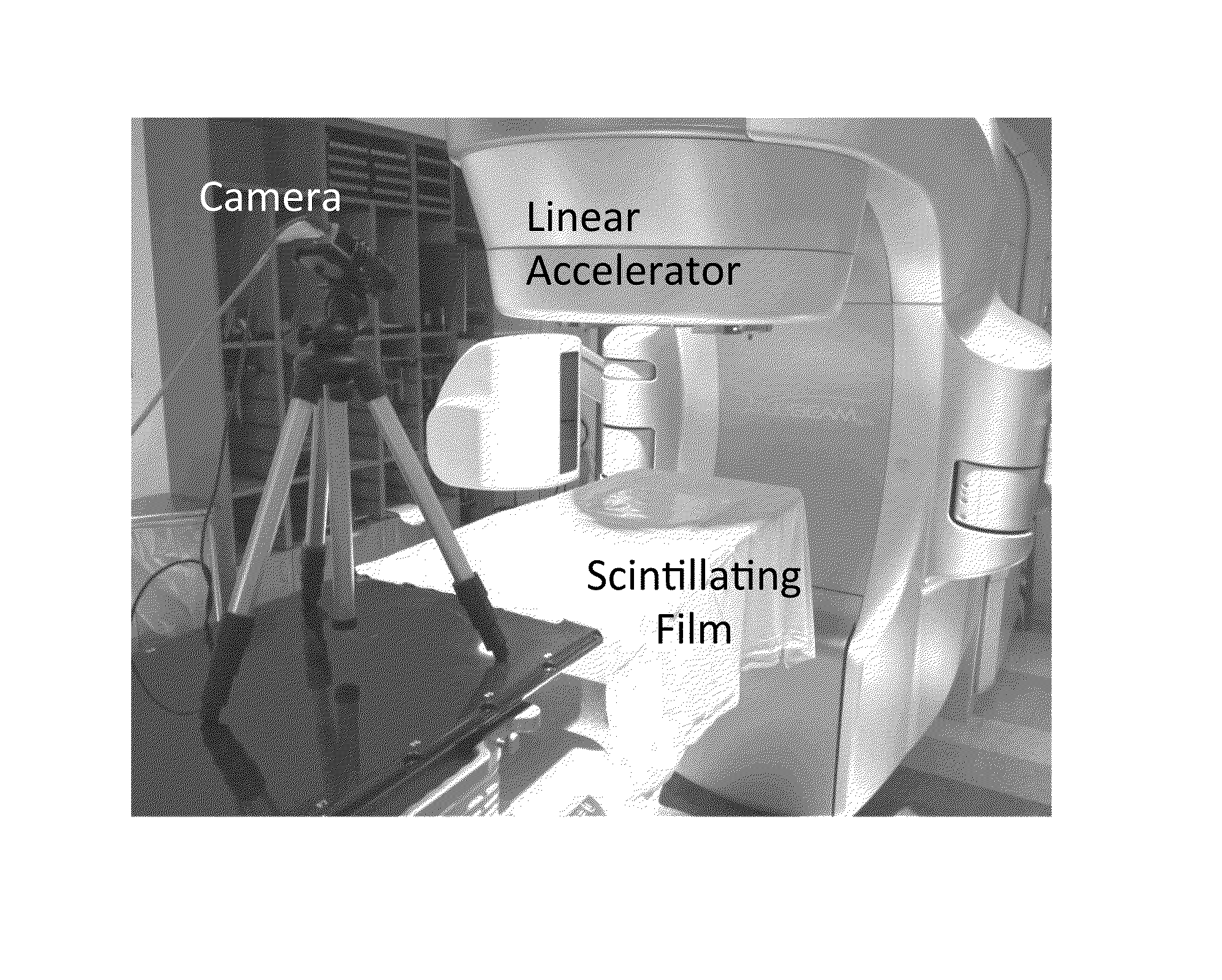

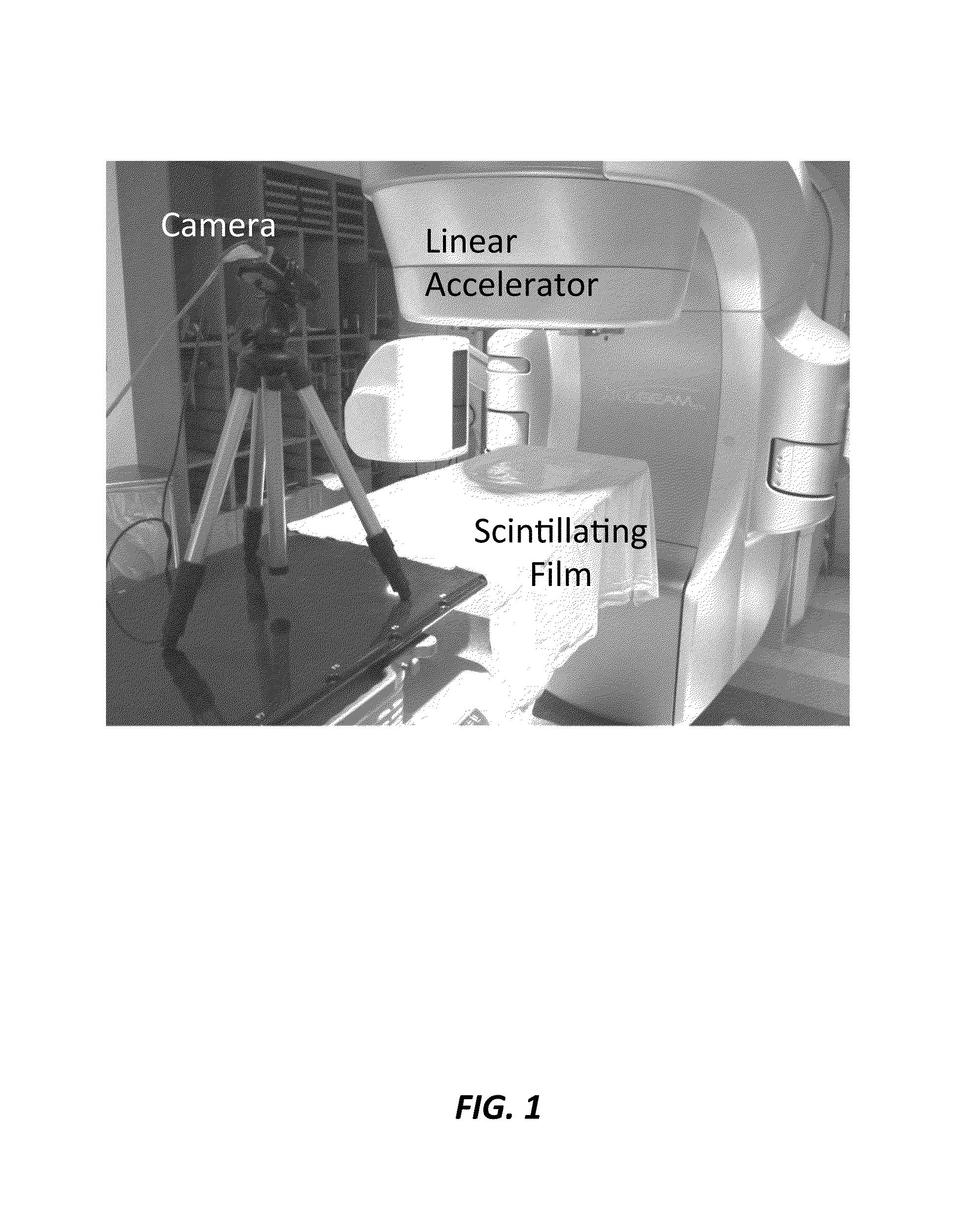

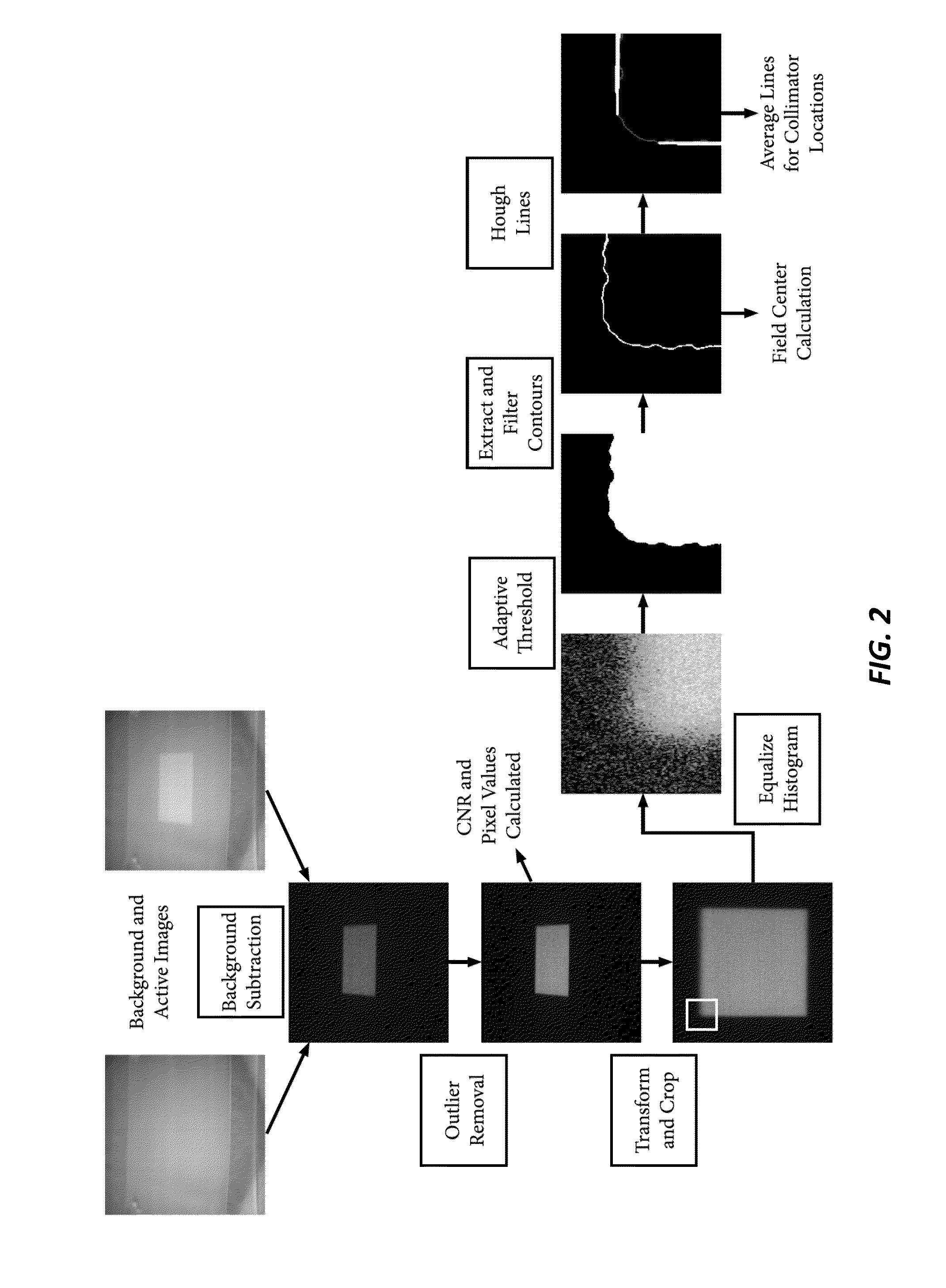

ActiveUS20150360056A1Material analysis by optical meansX-ray/gamma-ray/particle-irradiation therapyReal time validationTreatment delivery

A method of real-time radiotherapy beam visualization is provided that includes disposing a free-form flexible scintillating sheet on a subject of interest, irradiating the subject of interest with a source of ionizing radiation, where the free-forming flexible scintillating sheet emits light when irradiated by the therapeutic photon beam, collecting the emitted light and collecting ambient light reflected from the subject of interest and surrounding objects using a camera, where the collected light is converted to image data by the camera, where the image data is communicated to an appropriately programmed computer, and processing the image data to determine beam characteristics and the characteristics of the subject of interest, using the appropriately programmed computer, where the beam characteristics and the characteristics of the subject of interest are displayed in real-time to a machine operator enabling real-time verification of treatment delivery.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

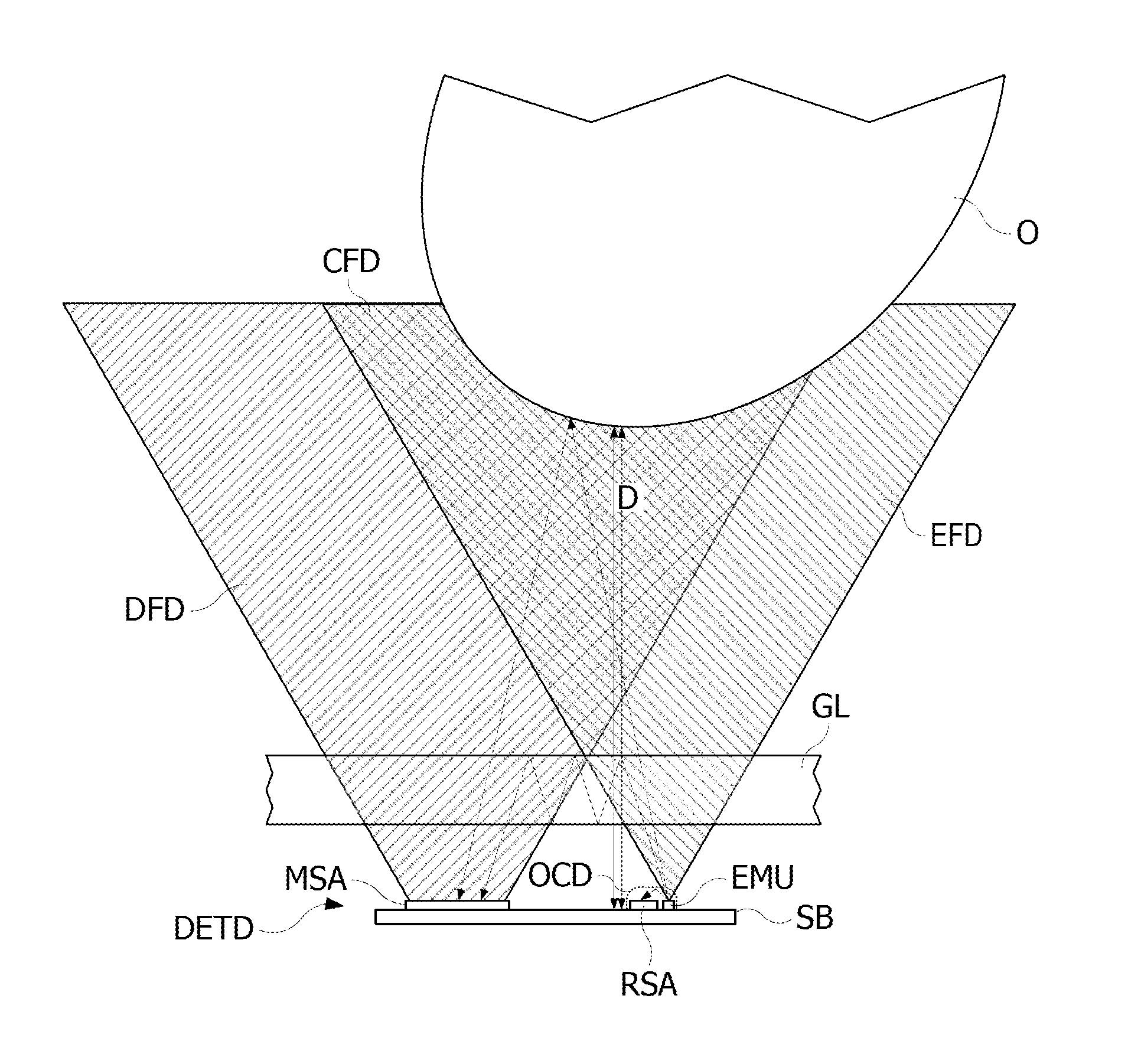

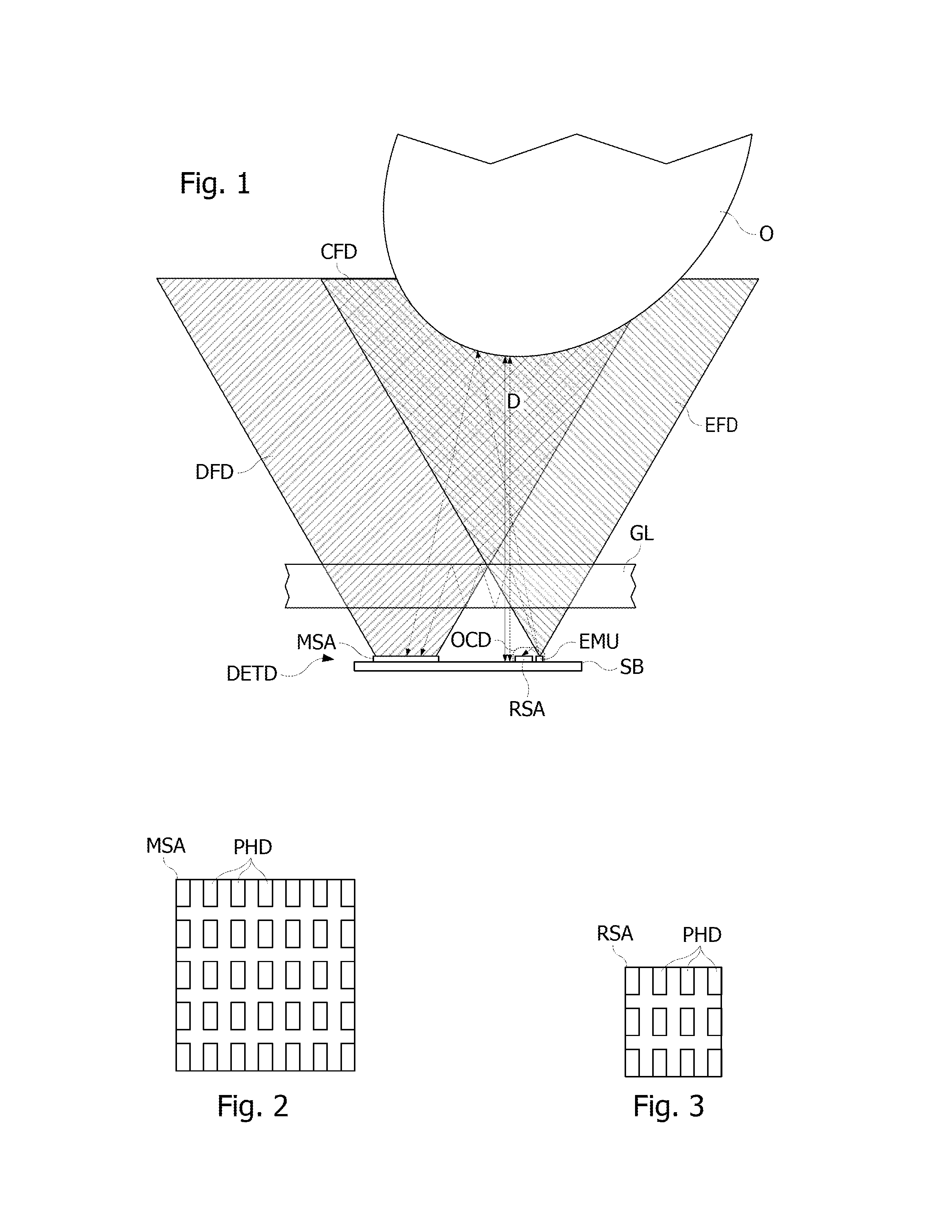

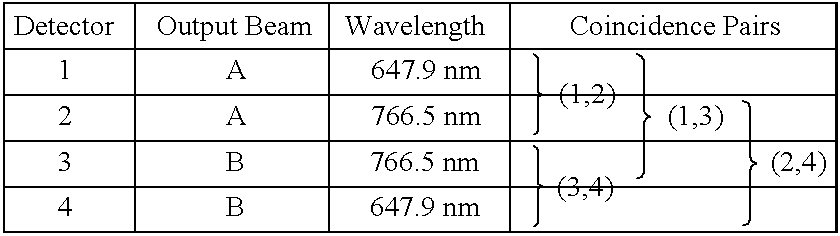

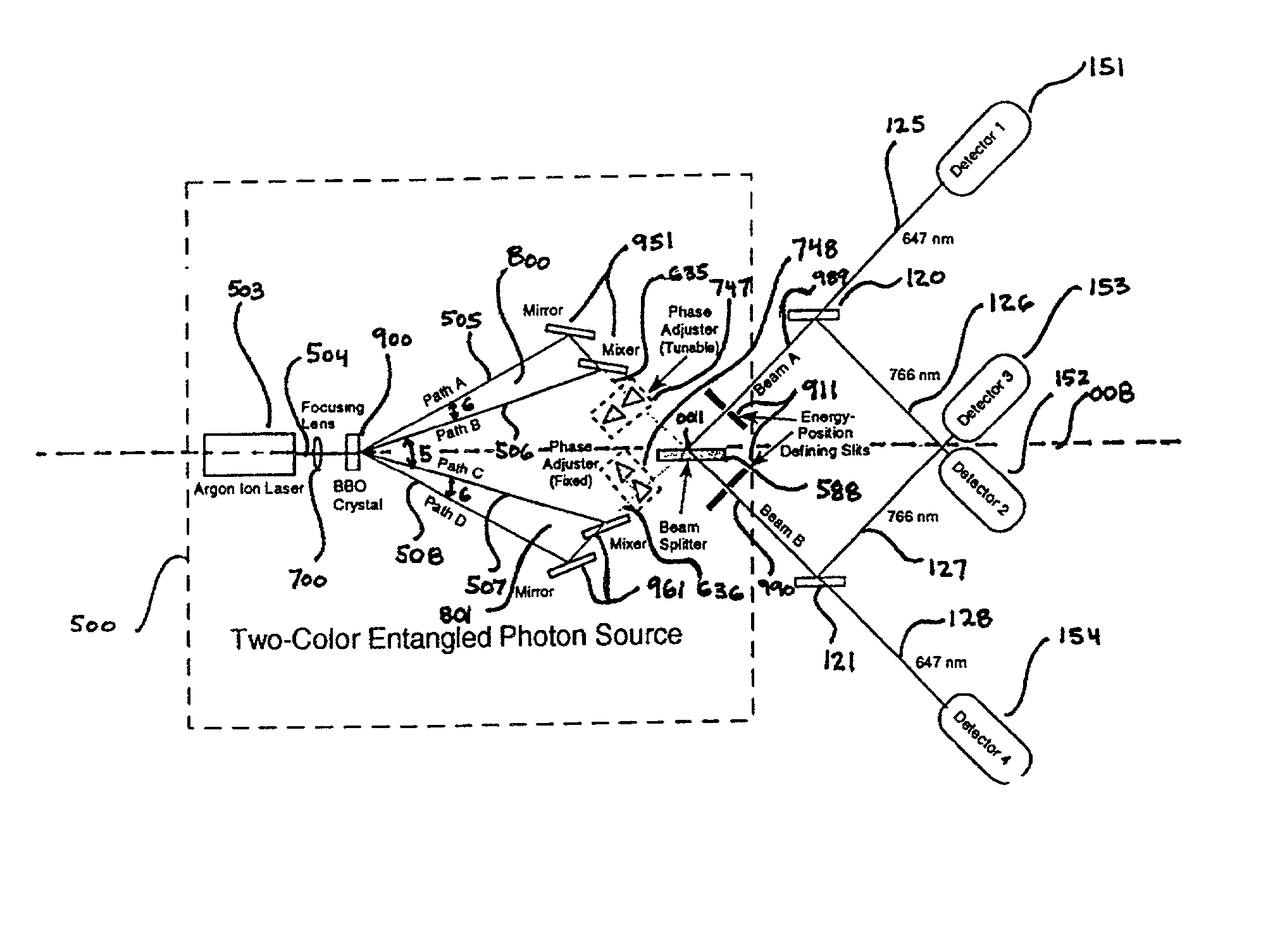

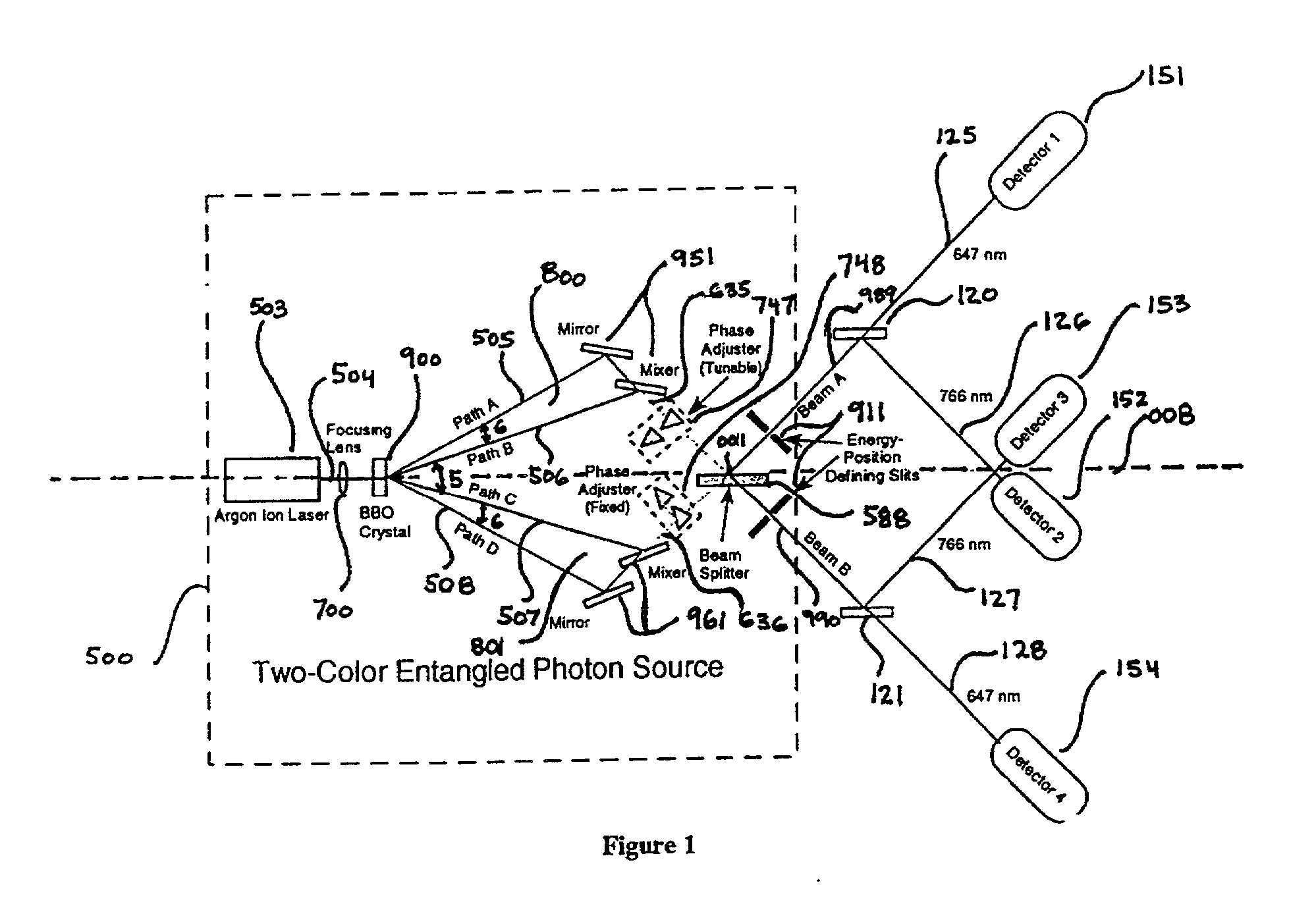

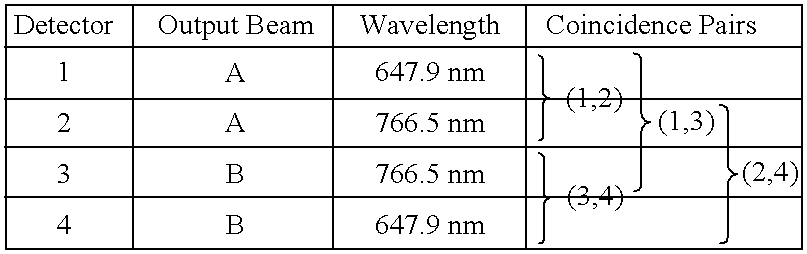

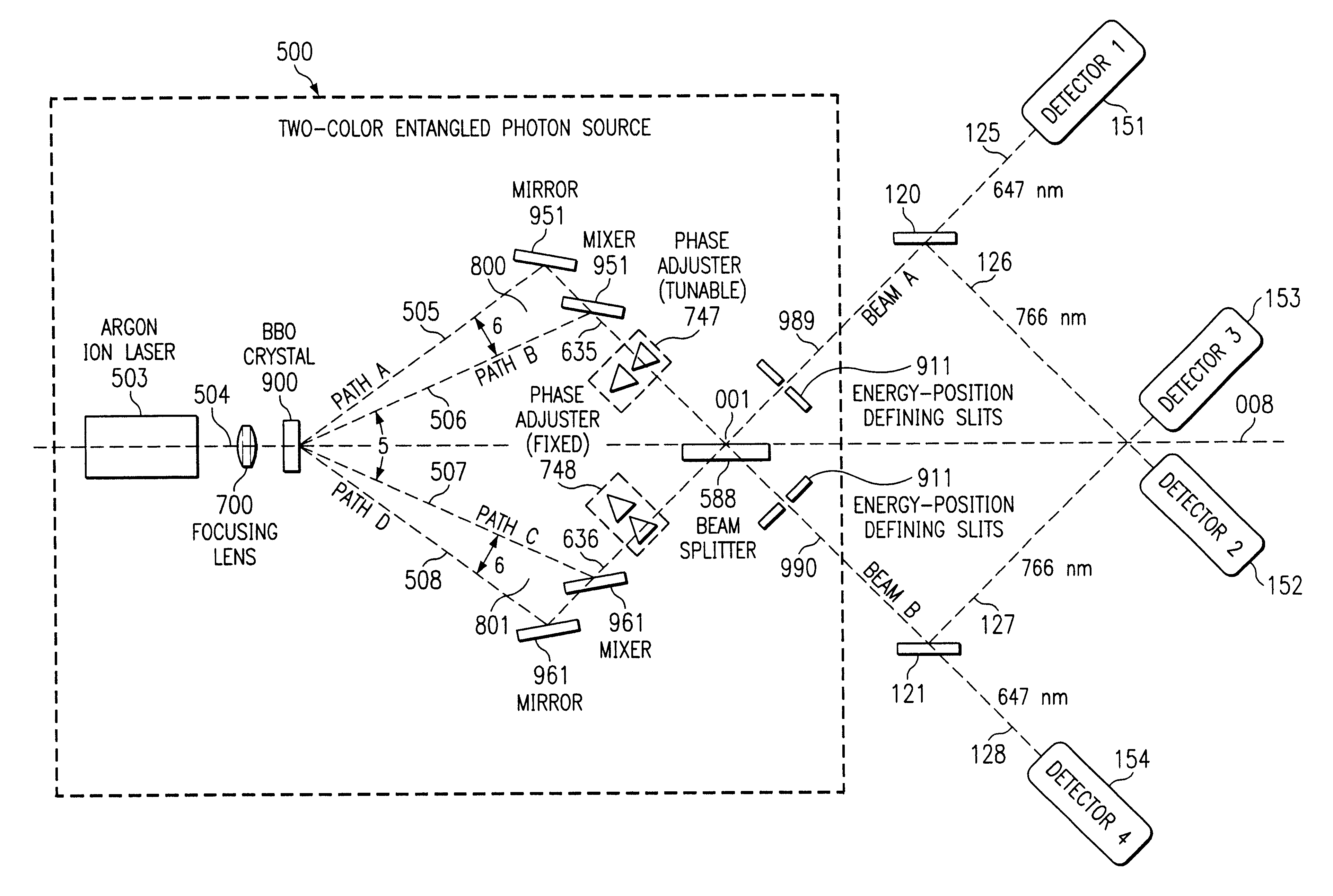

Optical microscope using an interferometric source of two-color, two-beam entangled photons

Systems and methods are described for an optical microscope using an interferometric source of multi-color, multi-beam entangled photons. A method includes: downconverting a beam of coherent energy to provide a beam of multi-color entangled photons; converging two spatially resolved portions of the beam of multi-color entangled photons into a converged multi-color entangled photon beam; transforming at least a portion of the converged multi-color entangled photon beam by interaction with a sample to generate an entangle photon specimen beam; and combining the entangled photon specimen beam with an entangled photon reference beam within a single beamsplitter. An apparatus includes: a multi-refringent device providing a beam of multi-color entangled photons; a condenser device optically coupled to the multi-refringent device, the condenser device converging two spatially resolved portions of the beam of multi-color entangled photons into a converged multi-color entangled photon beam; a beam probe director and specimen assembly optically coupled to the condenser device; and a beam splitter optically coupled to the beam probe director and specimen assembly, the beam splitter combining an entangled photon specimen beam from the beam probe director and specimen assembly with an entangled photon reference beam.

Owner:UT BATTELLE LLC

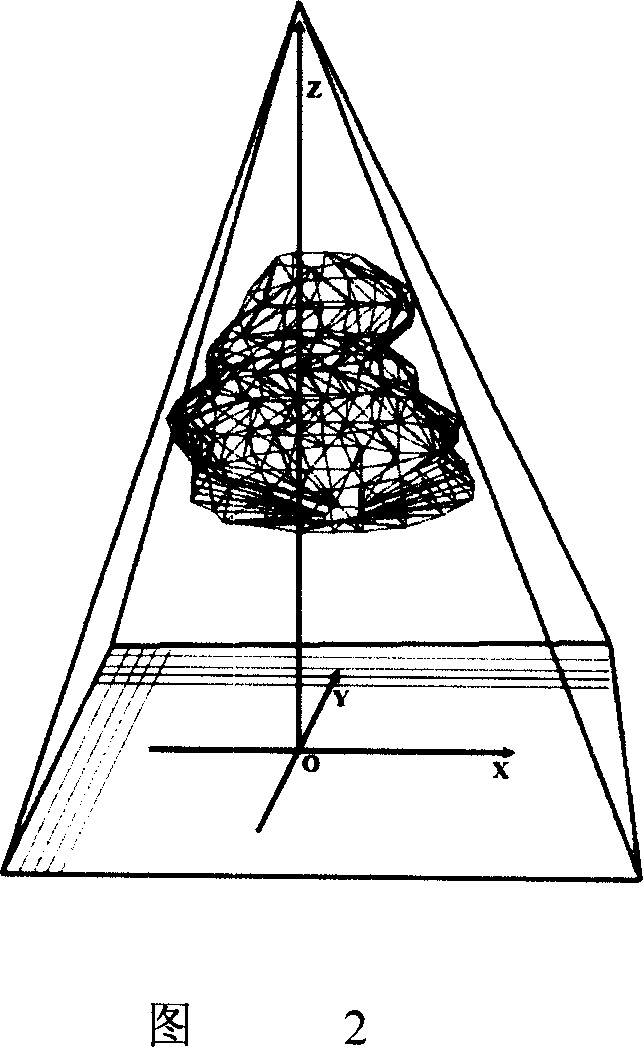

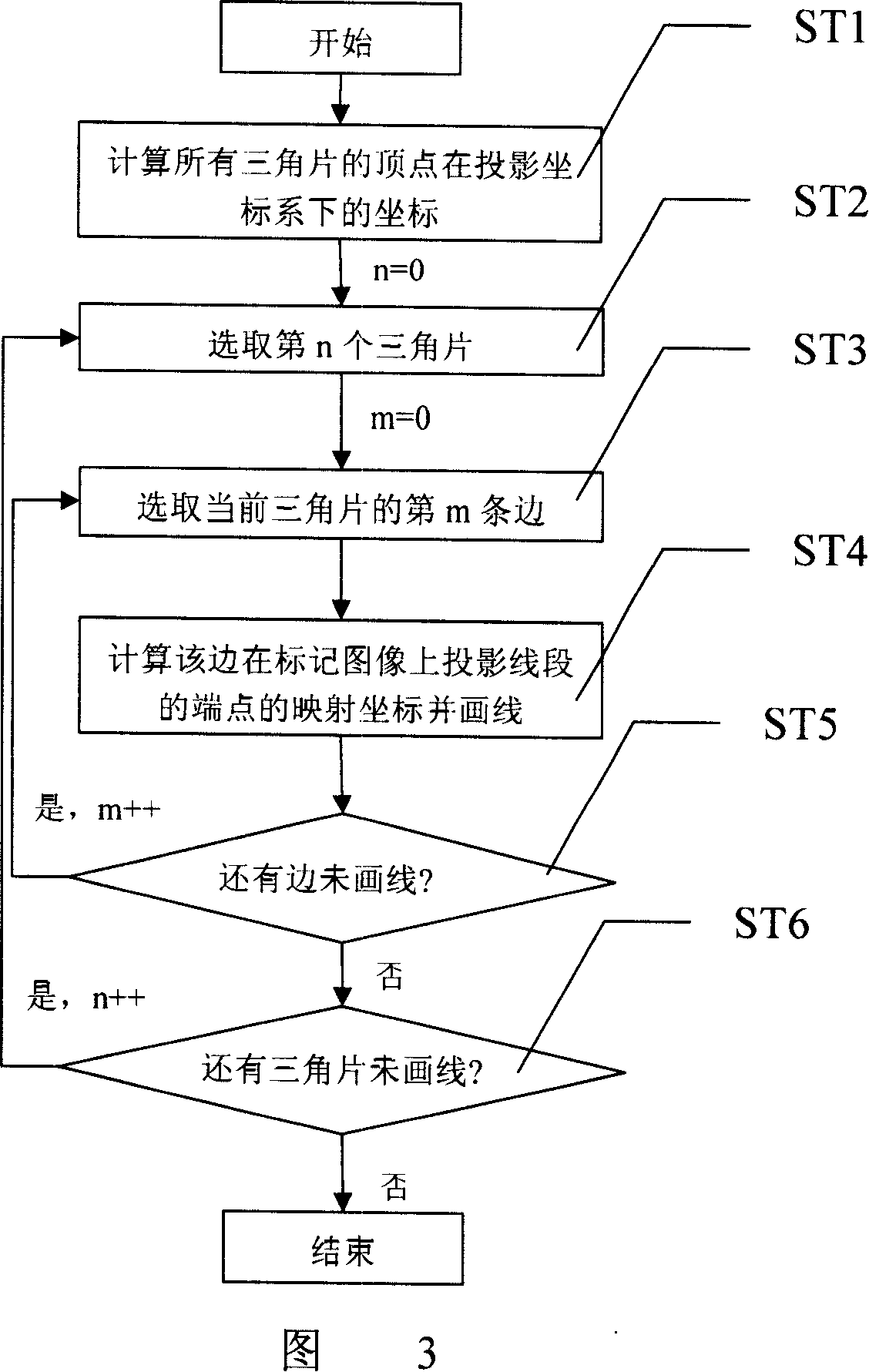

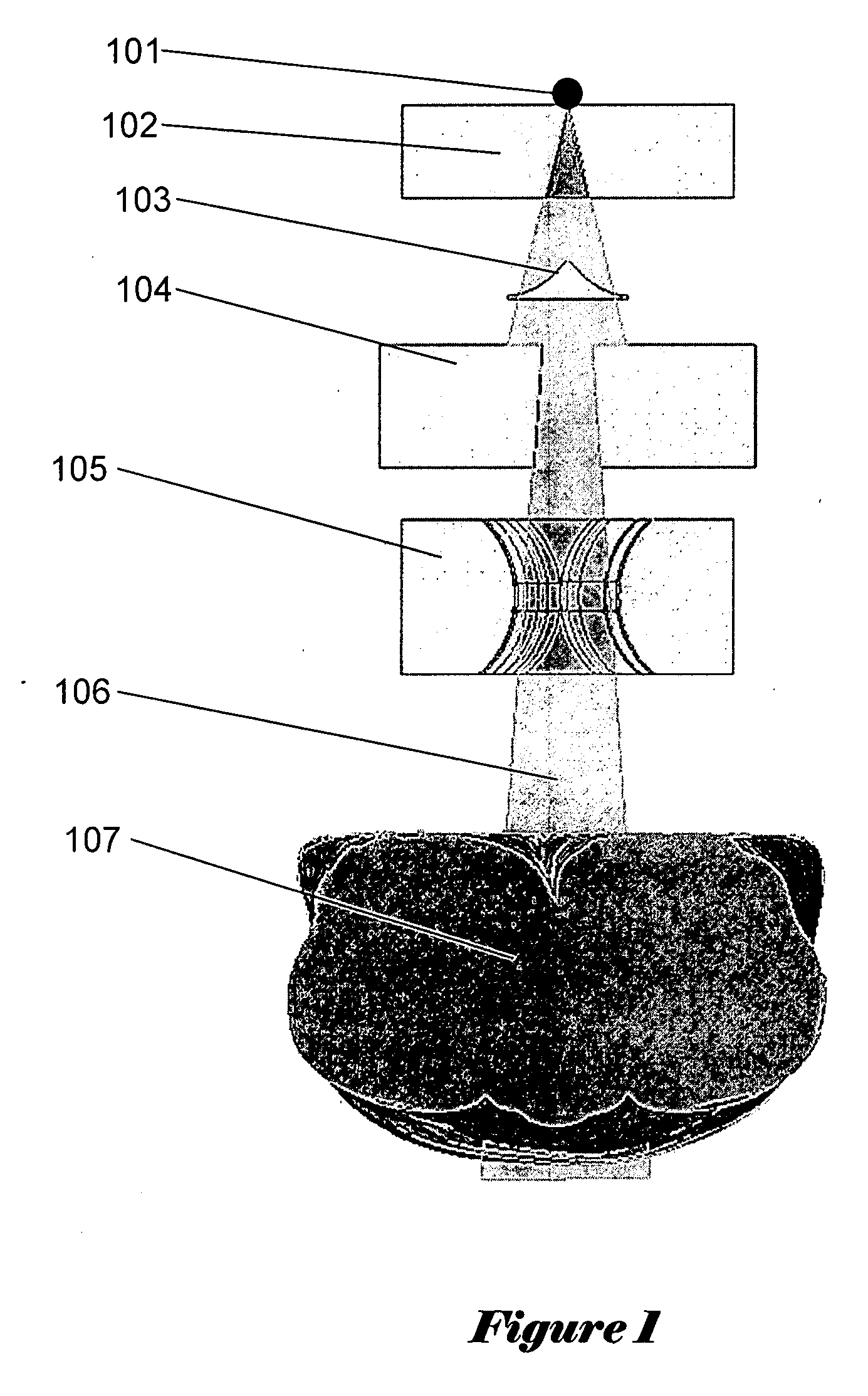

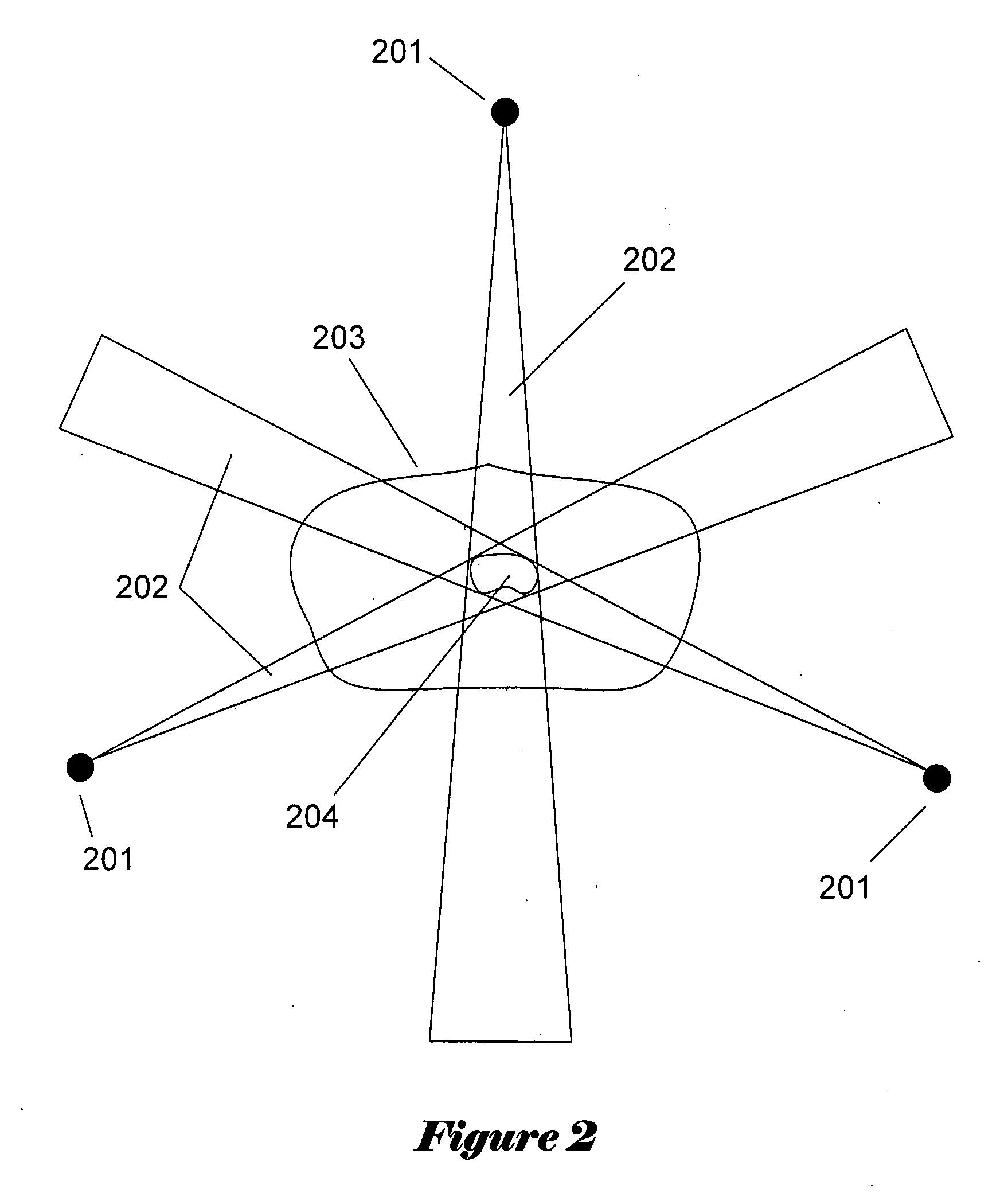

Comformable illumination of photon-beam radiant treatment

PendingCN101028192AClear two-dimensional imageClear three-dimensional imageSurgical instrument detailsLight therapyAnatomical structuresGraphics

A shape-adapting irradiation method for the photon beam radiotherapy of tumor includes such steps as using CT technique to obtain the density information of patient, reproducing the tumor position and the anatomical structure of adjacent organ and tissue, displaying 2D image and 3D image of target region by computer imaging technique, projecting the tumor and its infiltrative region onto the cross-section of photon beam at the outlet of accelerator, arranging a matched multi-blade collimator or shielding lead part to said outlet, inputting the information about the energy spectrum and angle distribution of photon beam, calculating and evaluating the dosage of photon beam, and regulating said collimator.

Owner:成都奇林科技有限责任公司

Quantum channel for the transmission of information

Systems and methods are described for a quantum channel for the transmission of information. A method includes: down converting a beam of coherent energy to provide a beam of multi-color entangled photons; converging two spatially resolved portions of the beam of multi-color entangled photons into a converged multi-color entangled photon beam; changing a phase of at least a portion of the converged multi-color entangled photon beam to generate a first interferometric multi-color entangled photon beam; combining the first interferometric multi-color entangled photon beam with a second interferometric multi-color entangled photon beam within a single beam splitter; wherein combining includes erasing energy and momentum characteristics from both the first interferometric multi-color entangled photon beam and the second interferometric multi-color entangled photon beam; splitting the first interferometric multi-color entangled photon beam and the second interferometric multi-color entangled photon beam within the single beam splitter, wherein splitting yields a first output beam of multi-color entangled photons and a second output beam of multi-color entangled photons; and modulating the first output beam of multi-color entangled photons.

Owner:UT BATTELLE LLC

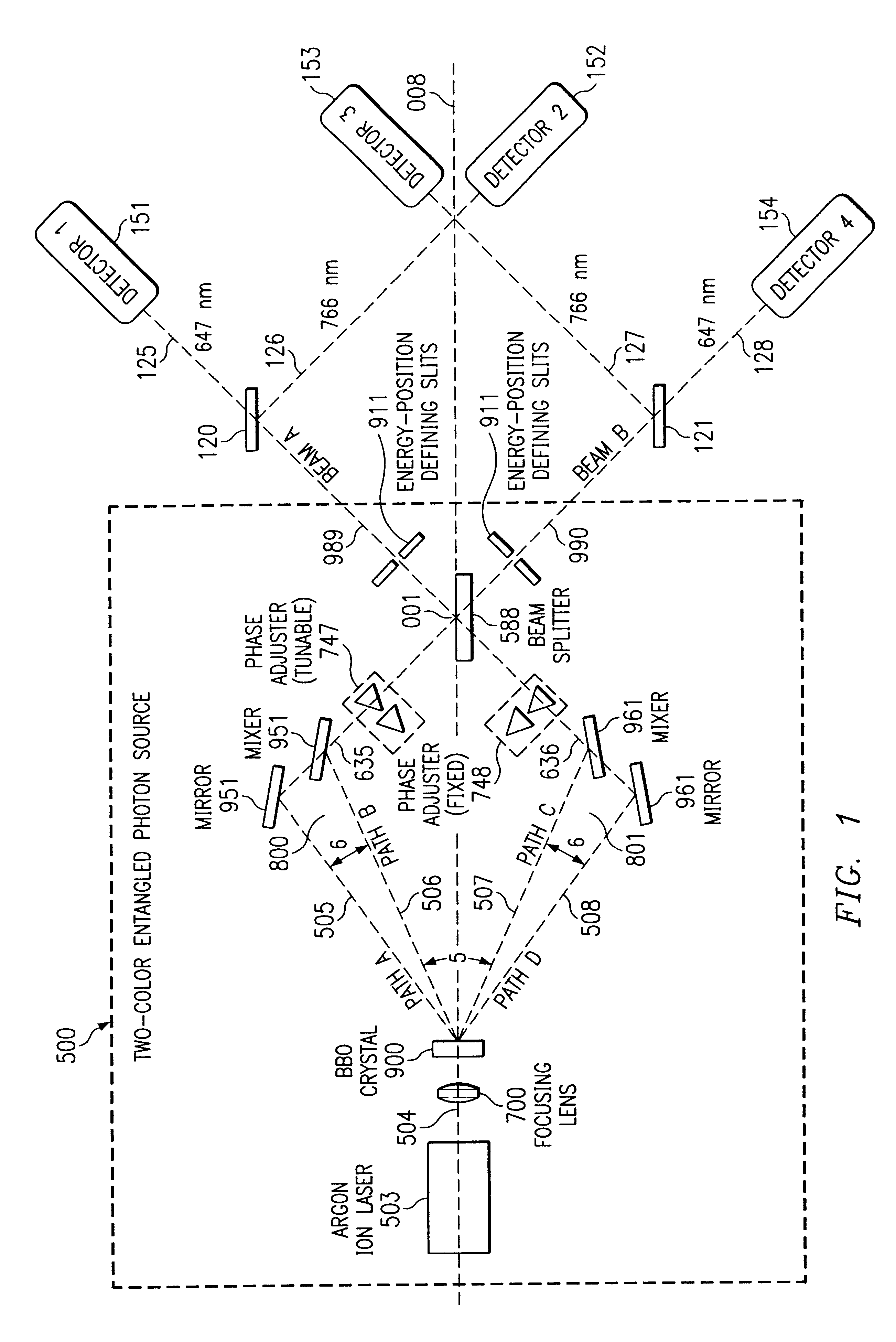

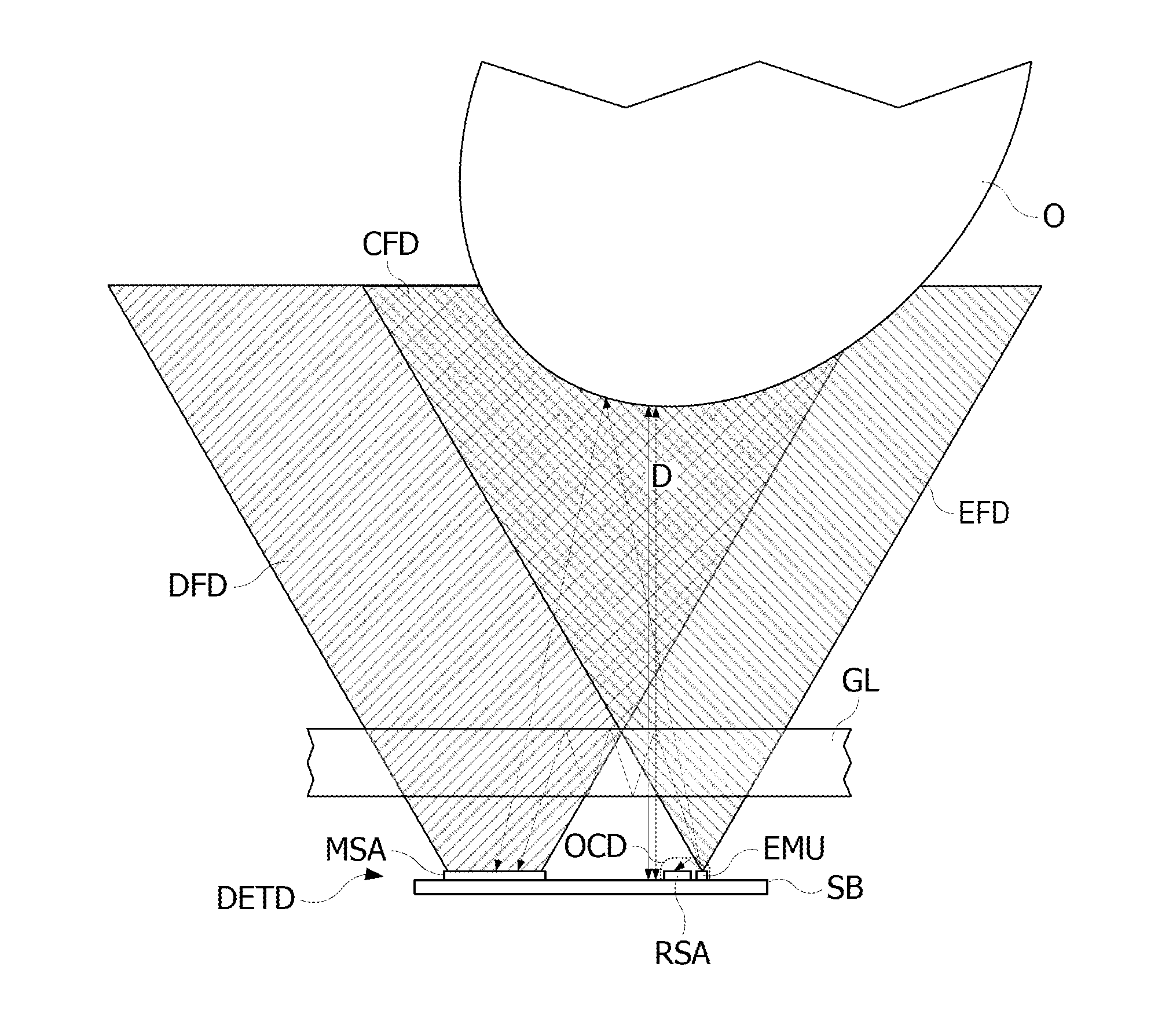

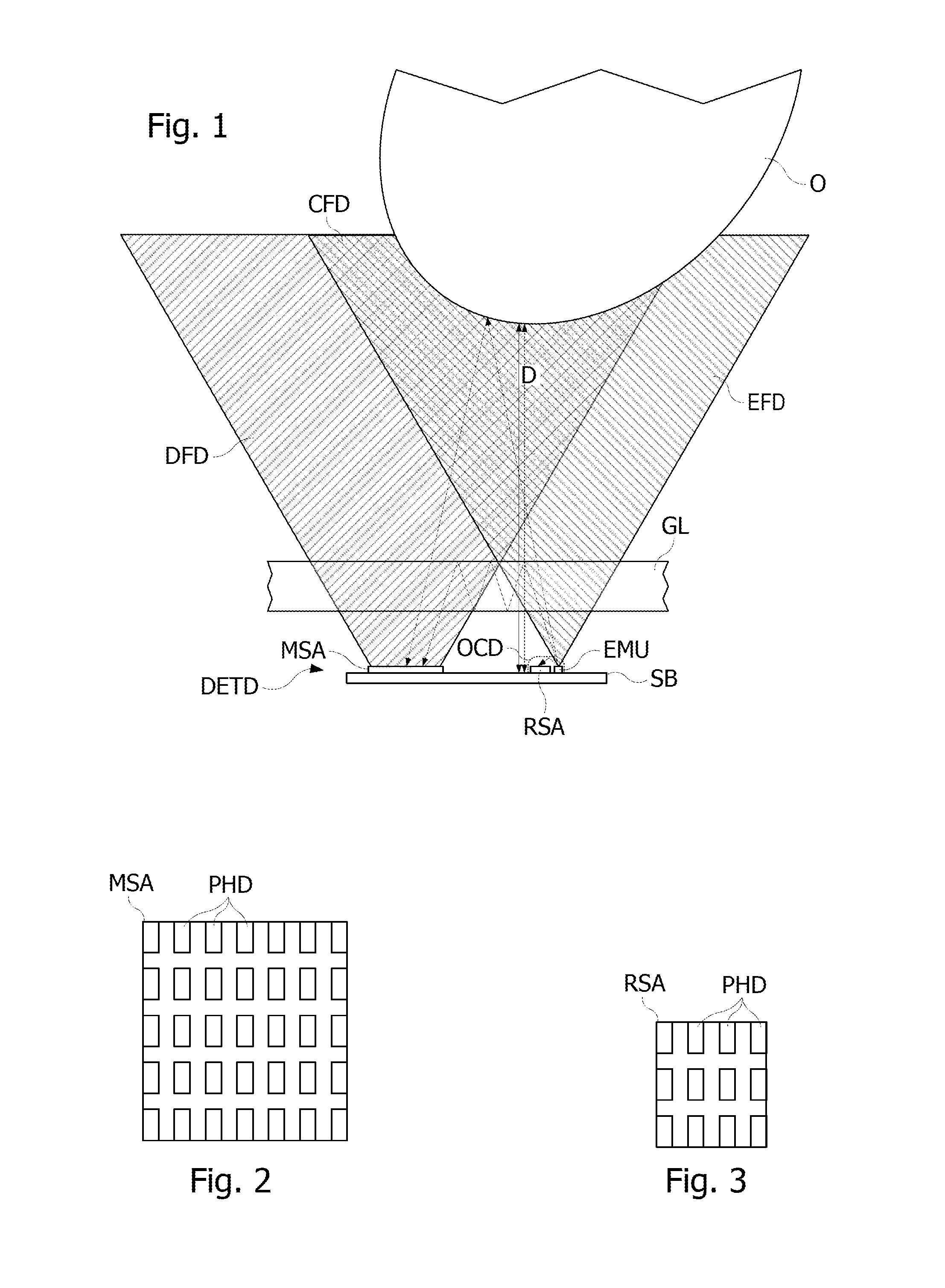

Systems and methods for localizing vascular architecture, and evaluation and monitoring of functional behavior of same

InactiveUS20060079750A1ContrastIncrease contrastDiagnostics using lightSensorsPost operativeDisplay device

A system is provided utilizing dynamic imaging protocol to localize vascular architecture, and to evaluate and monitor functional behavior of the vascular architecture for pre-operative, post-operative and diagnostic purposes. The system includes, among other things, a scanner having within its objective portion an assembly for capturing a photon beam emitted from an object being monitored. The system is also provided with a detection network designed to convert, into electronic signals, data correlated from the beam. A processor can be provided for generating discrete image data from the electronic signals for subsequent display as an image. The system can also include a display for viewing the image data. The system can further include a ruler for positioning on the object being monitored to permit subsequent translation of the image viewed in the display onto the object. Methods for evaluating, monitoring, and localizing the vascular architecture are also provided.

Owner:ADVANCED BIOPHOTONICS

Method and system for observing a subject at a first location based upon quantum properties measured at a second location

InactiveUS7847234B2Scattering properties measurementsCounting objects on conveyorsMeasurement deviceQuantum property

A preferred embodiment comprises a method and system for (a) detecting objects or targets which may or may not be nonreflective to electromagnetic radiation, and / or (b) generating an image of a subject or area, comprising generating an entangled photon pair beam; splitting the entangled photon pair beam into first and second parts; the first parts being directed in a first direction towards a first location, and the second parts being received into a measuring device; measuring the physical characteristics of the conjugate second parts to determine whether or not the first parts have encountered the presence or absence of an object at the first location in combination with the time that the first part takes to enter the first location. The method and system incorporate a photon beam in a reference path that never directly interacts with the object yet is determinative of presence or absence of an object at the first location. The splitting of the entangled photon pair beam occurs prior to the first parts being absorbed by said object, and the measuring of the characteristics of the conjugates occurs subsequent to the splitting of the entangled photon beam.

Owner:US SEC THE ARMY THE

Device having SPAD photodiodes for detecting an object with a selection of a number of photodiodes to be reversed biased

ActiveUS8963069B2High voltageIncrease the number ofPhotometryMaterial analysis by optical meansLight beamReverse bias

The disclosure relates to a method for detecting the presence of an object near a detection device, comprising: reverse biasing single photon avalanche photodiodes, at a bias voltage greater than a breakdown voltage of a PN junction of each photodiode, emitting pulses of an incident photon beam, detecting photodiodes which avalanche trigger after the reception by the photodiode of at least one photon of a reflected photon beam produced by a reflection of the incident beam on an object near the detection device, determining the object presence as a function of the existence of at least one avalanche triggering in one of the photodiodes, and selecting a number of photodiodes to be reverse biased in relation to the detection device, as a function of a load of a circuit for generating the bias voltage.

Owner:STMICROELECTRONICS (GRENOBLE 2) SAS

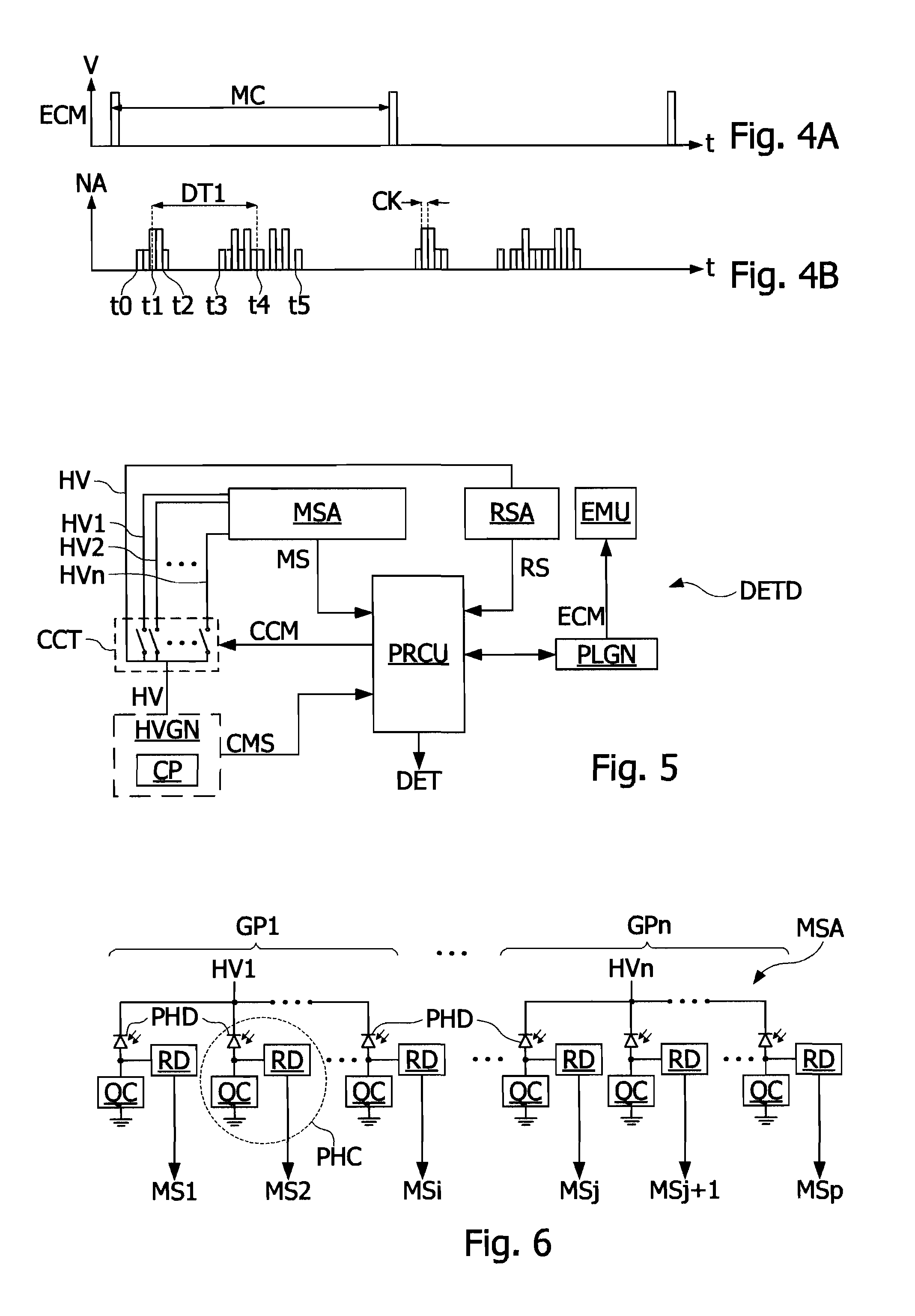

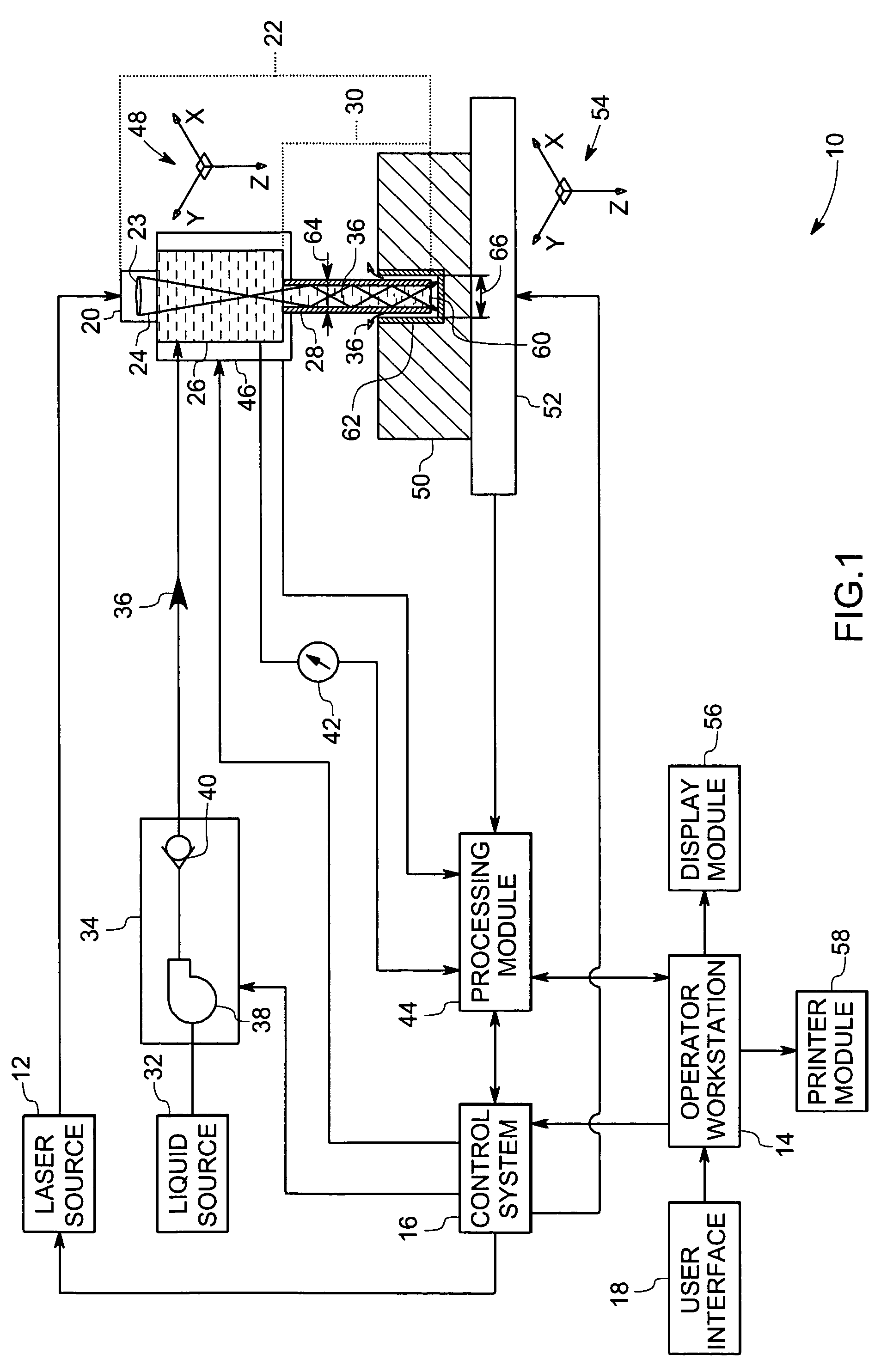

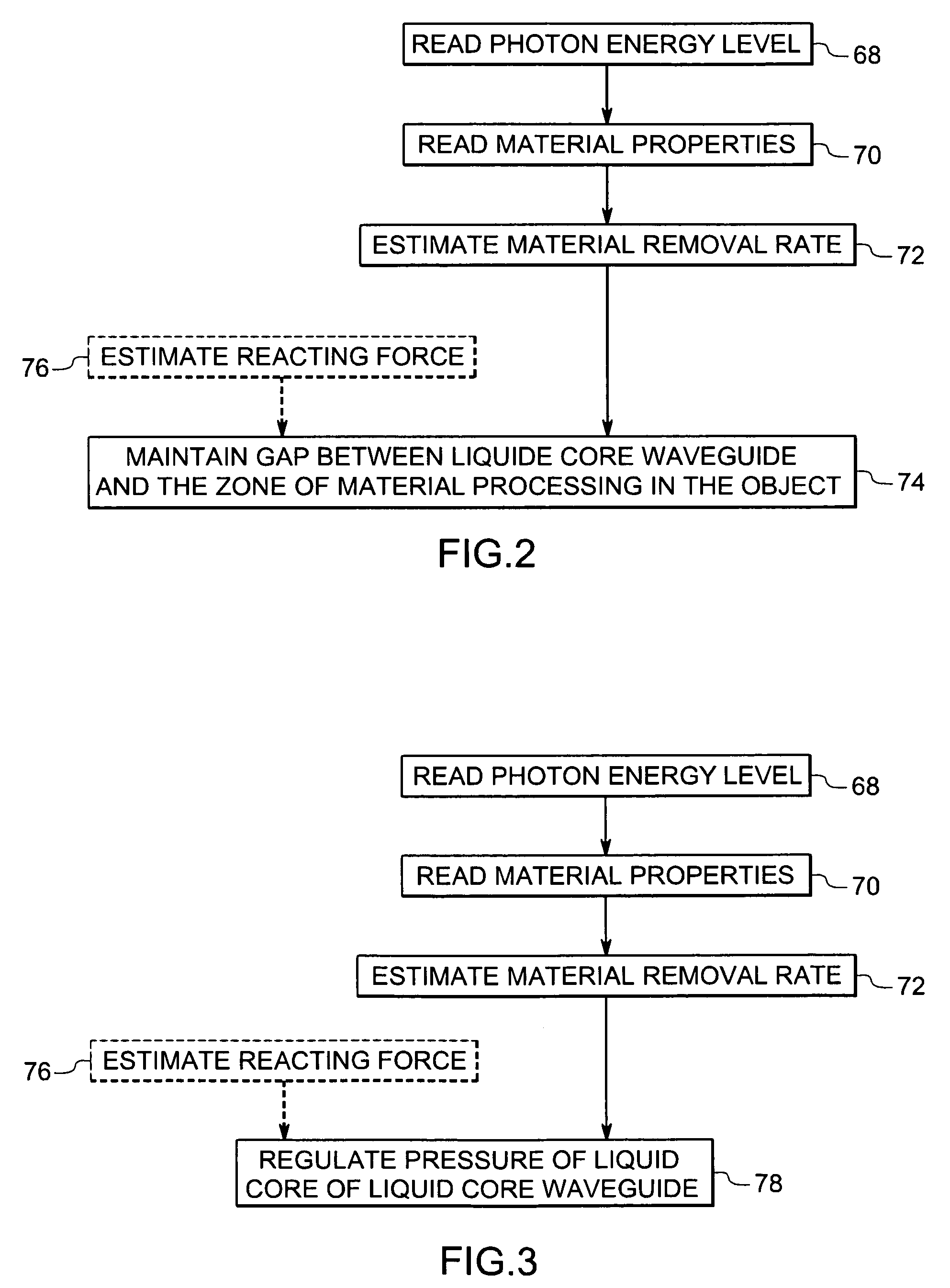

Photon energy material processing using liquid core waveguide and a computer program for controlling the same

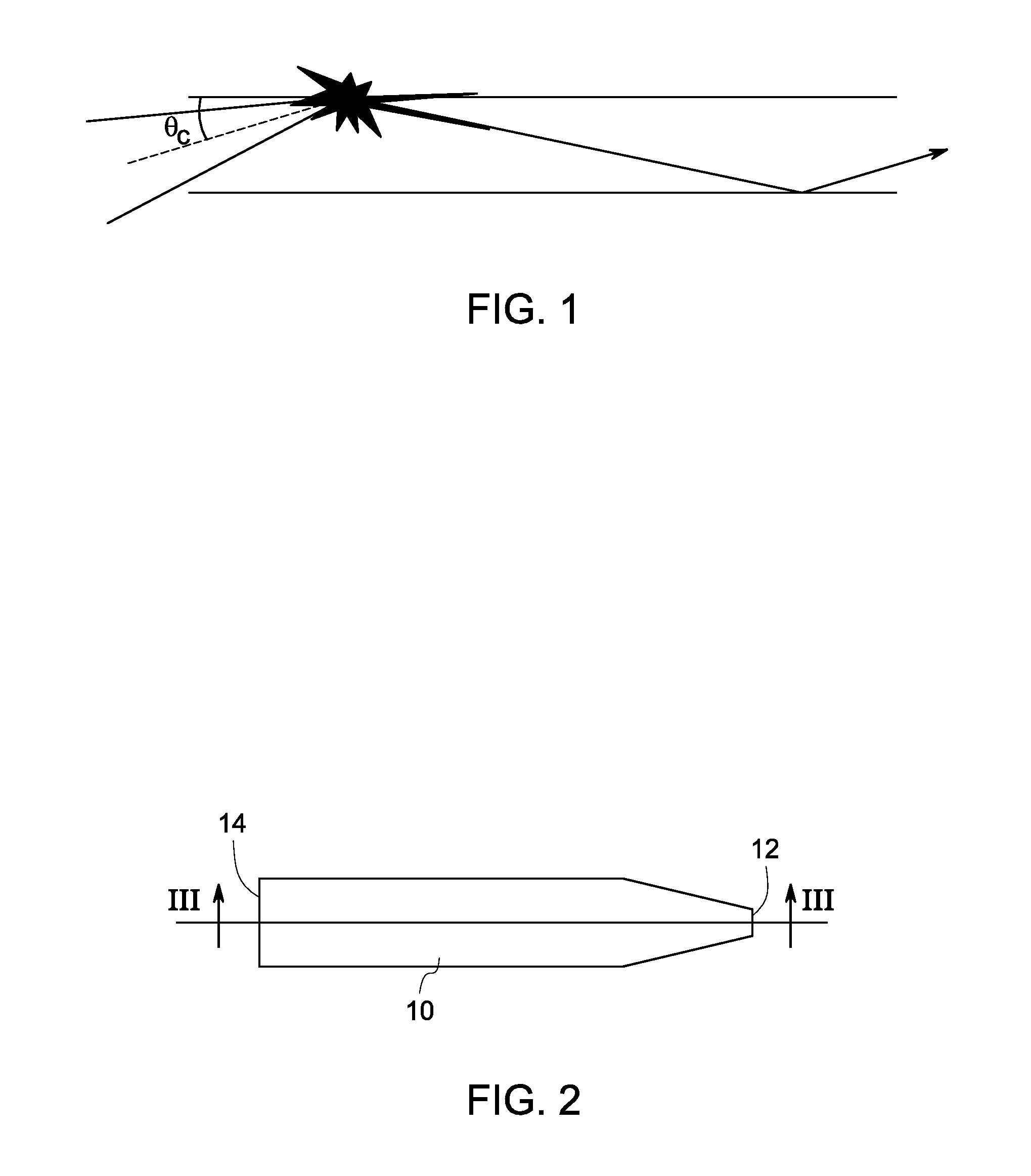

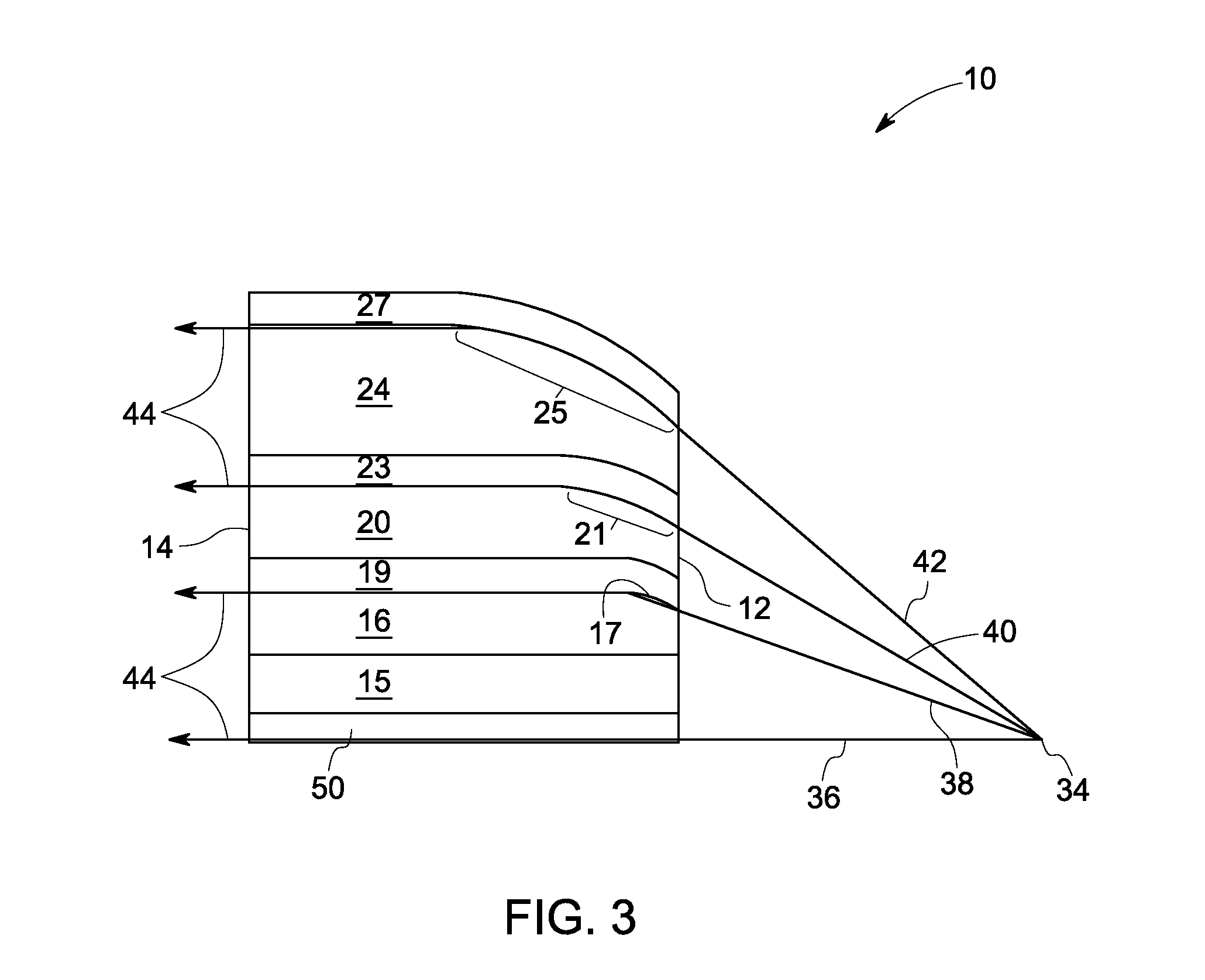

A liquid core waveguide photon energy material processing system is provided. The system includes a photon energy source configured to generate a high intensity photon beam for material processing. The system also includes a liquid core waveguide configured to transmit the high intensity photon beam towards at least one object for material processing. The liquid core waveguide in-turn includes a liquid core having a first refractive index and a cladding element having a second refractive index and configured to guide the liquid core, wherein the first refractive index is higher than the second refractive index. The system further includes a liquid source configured to generate the liquid core. The liquid core includes a liquid solution.

Owner:GENERAL ELECTRIC CO

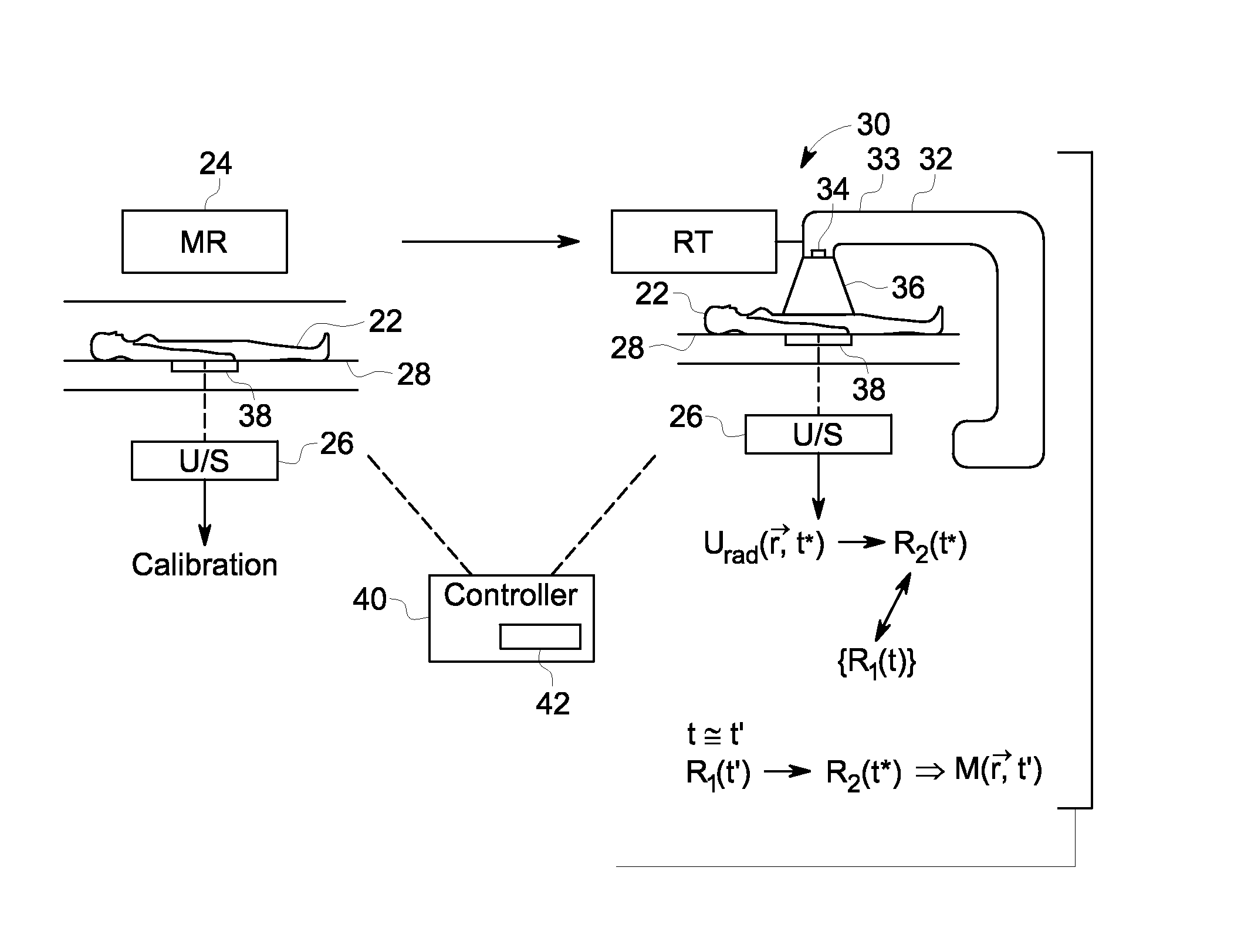

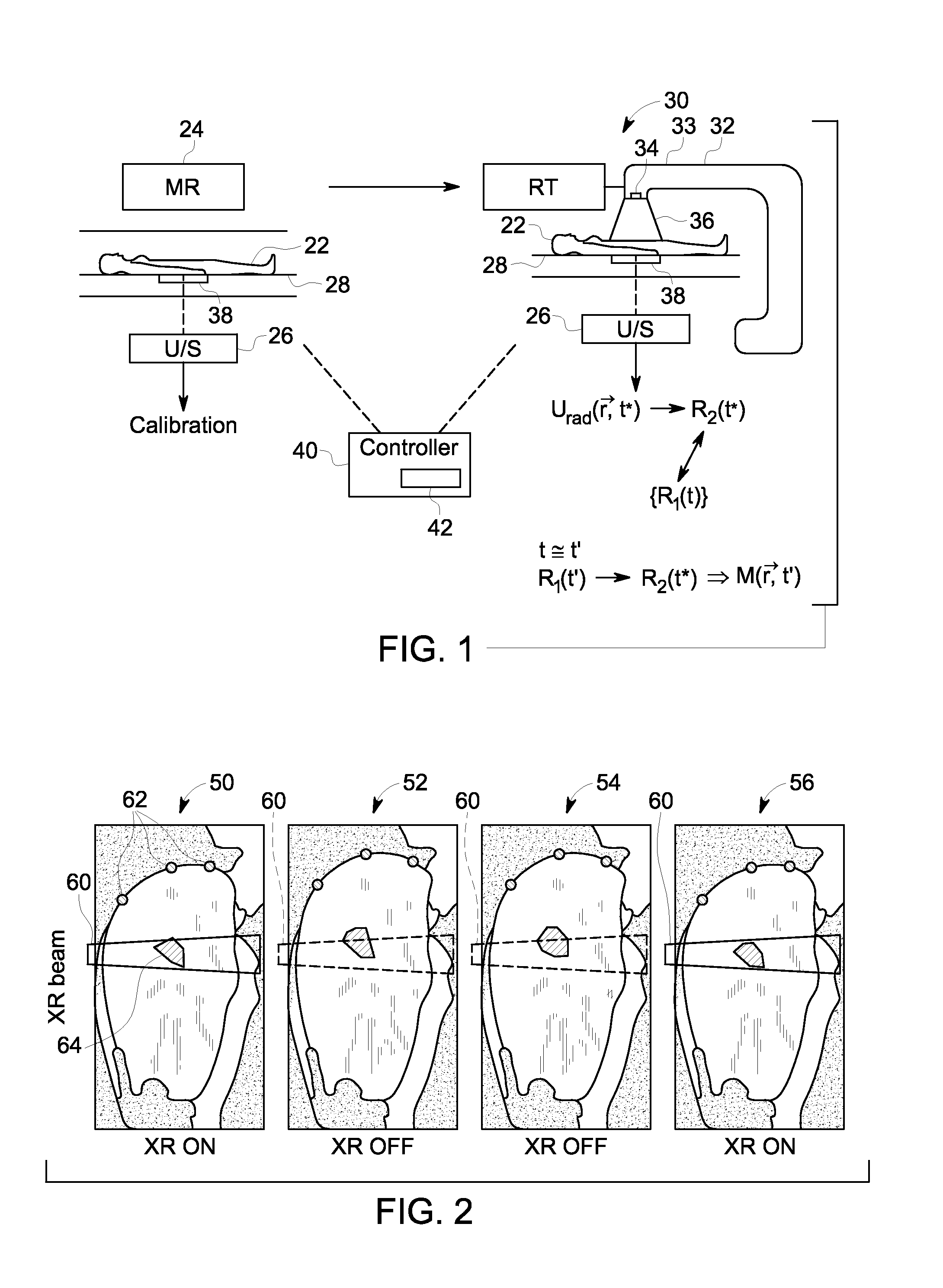

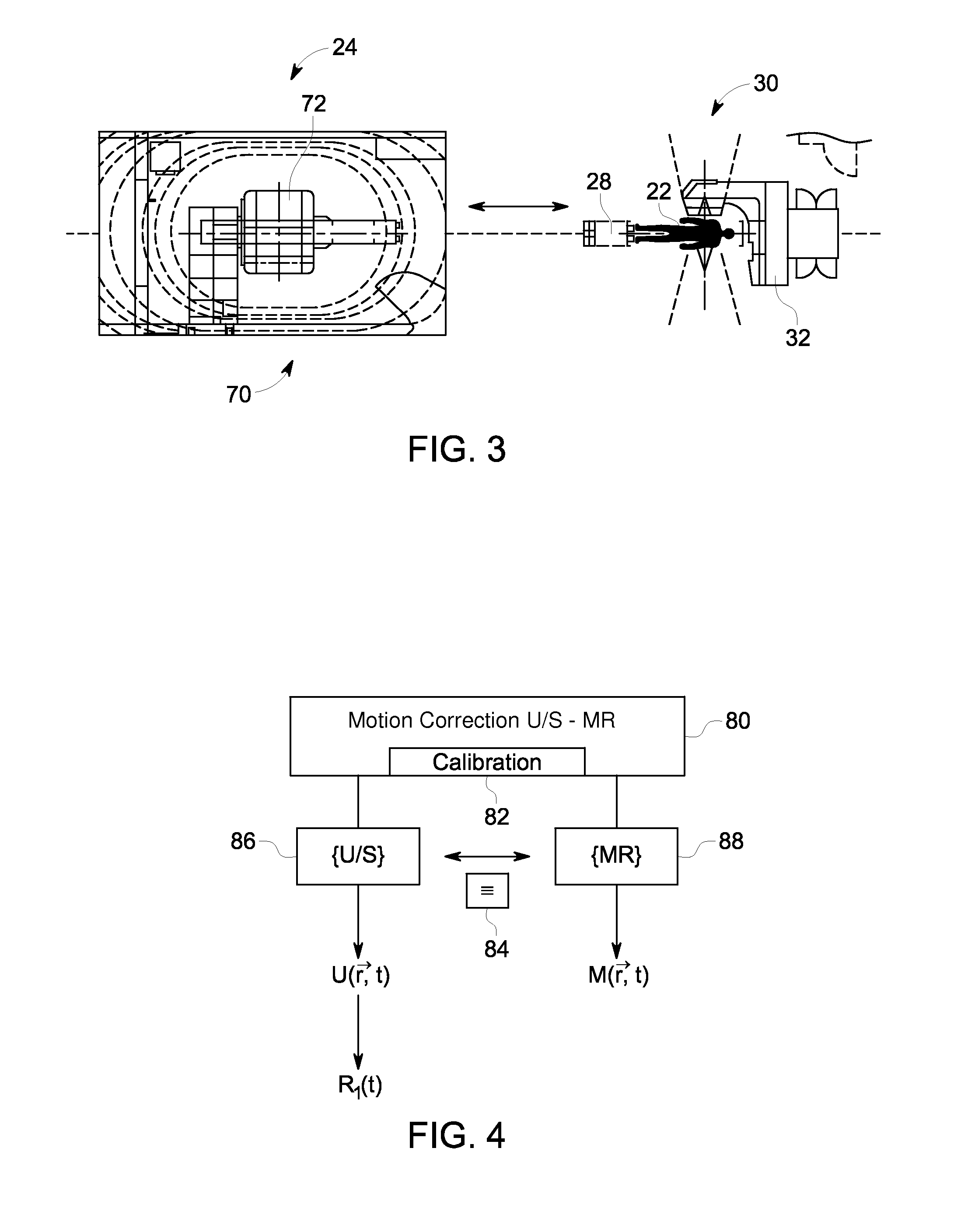

Methods and systems using magnetic resonance and ultrasound for tracking anatomical targets for radiation therapy guidance

Methods and systems using magnetic resonance and ultrasound for tracking anatomical targets for radiation therapy guidance are provided. One system includes a patient transport configured to move a patient between and into a magnetic resonance (MR) system and a radiation therapy (RT) system and an ultrasound transducer coupled to the patient transport, wherein the ultrasound transducer is configured to acquire four-dimensional (4D) ultrasound images concurrently with one of an MR acquisition or an RT radiation therapy session. The system also includes a controller having a processor configured to use the 4D ultrasound images and MR images from the MR system to control at least one of a photon beam spatial distribution or intensity modulation generated by the RT system.

Owner:GENERAL ELECTRIC CO

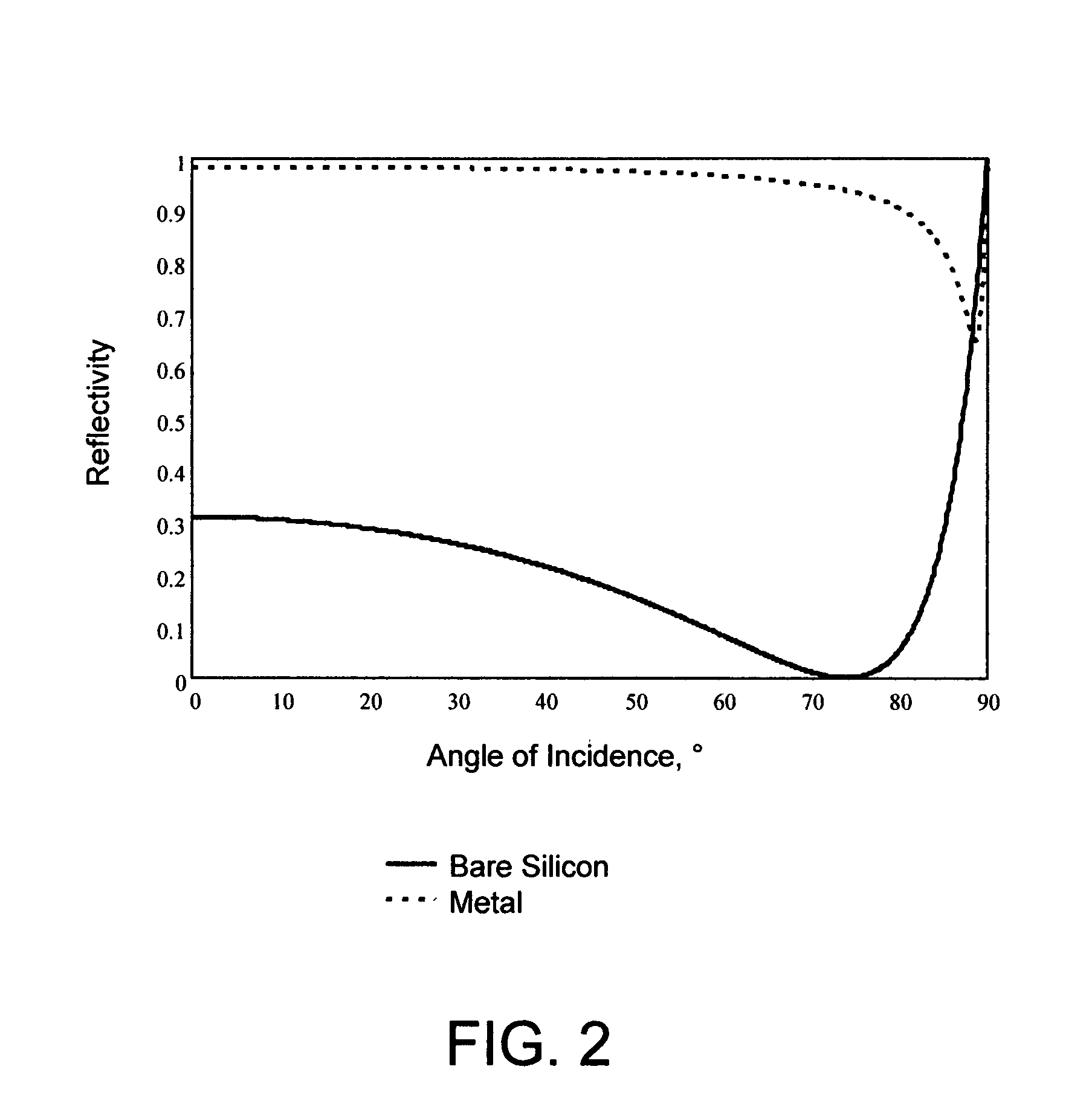

Minimization of surface reflectivity variations

InactiveUS20090114630A1Minimize changesMinimize the maximum substrate surface reflectivitySemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesSurface patternLength wave

Apparatuses and methods are provided for processing a surface of a substrate. The substrate may have a surface pattern that exhibits directionally and / or orientationally different reflectivities relative to radiation of a selected wavelength and polarization. The apparatus may include a radiation source that emits a photonic beam of the selected wavelength and polarization directed toward the surface at orientation angle and incidence angle selected to substantially minimize substrate surface reflectivity variations and / or minimize the maximum substrate surface reflectivity during scanning. Also provided are methods and apparatuses for selecting an optimal orientation and / or incidence angle for processing a surface of a substrate.

Owner:ULTRATECH INT INC

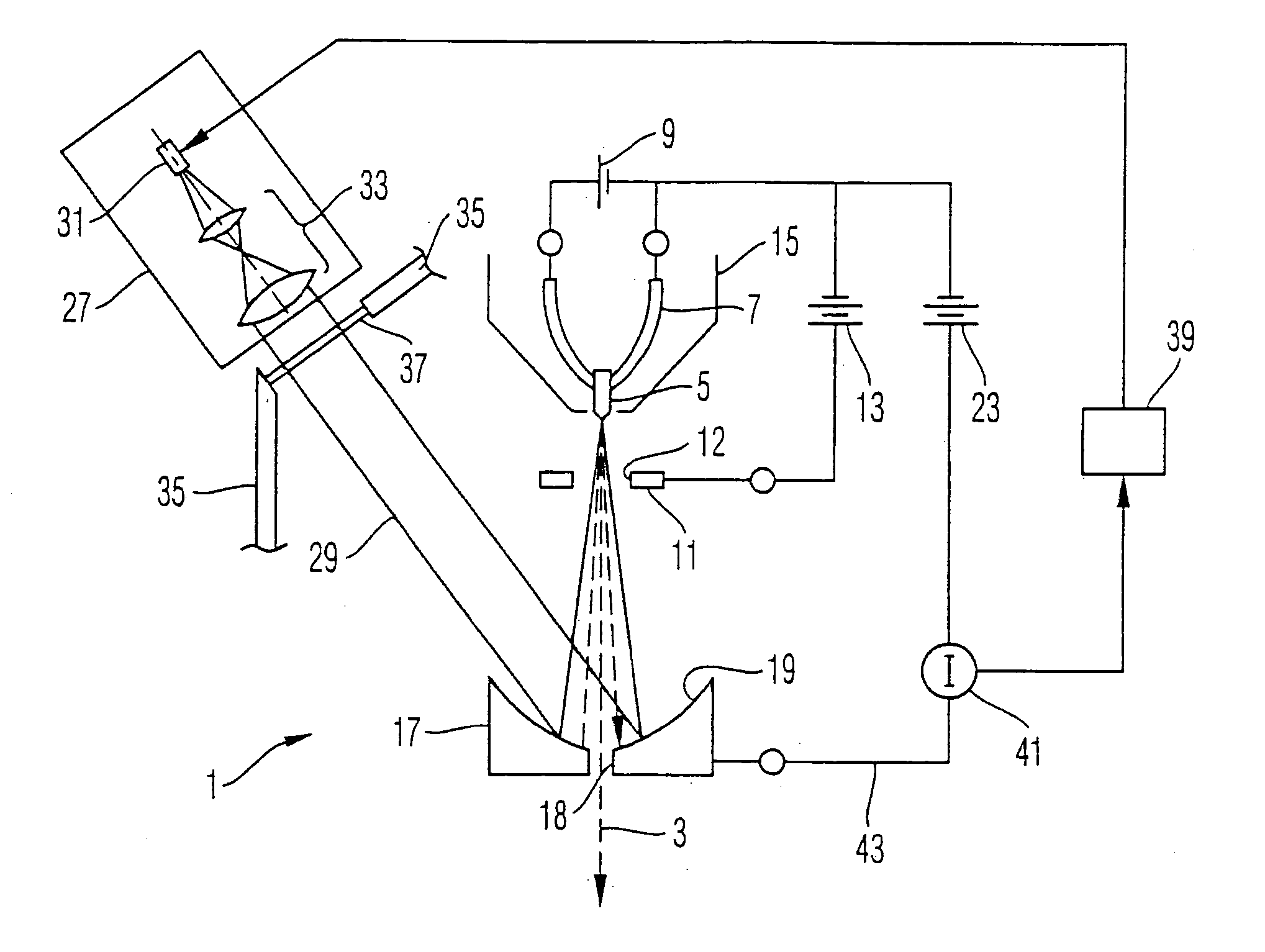

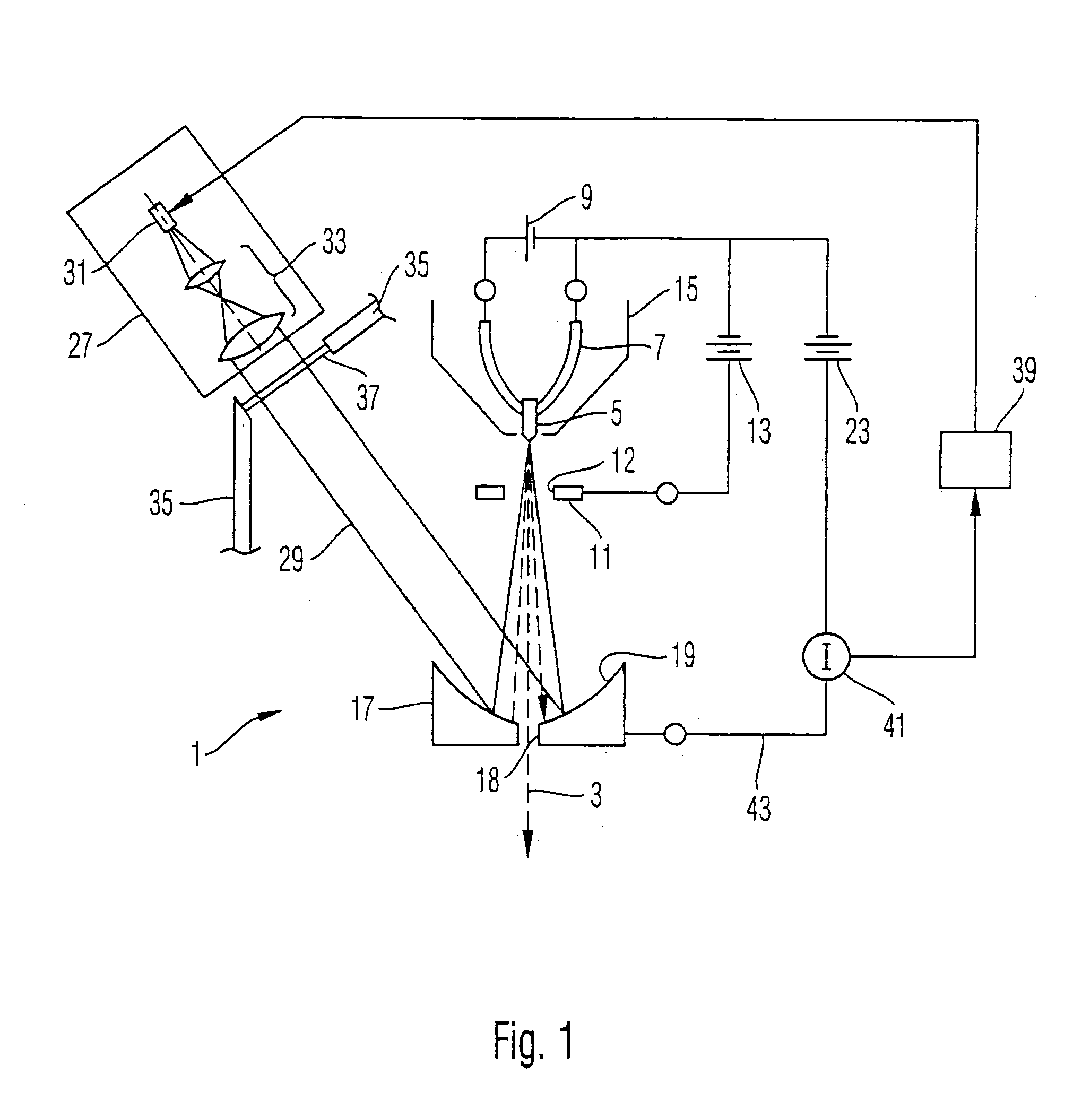

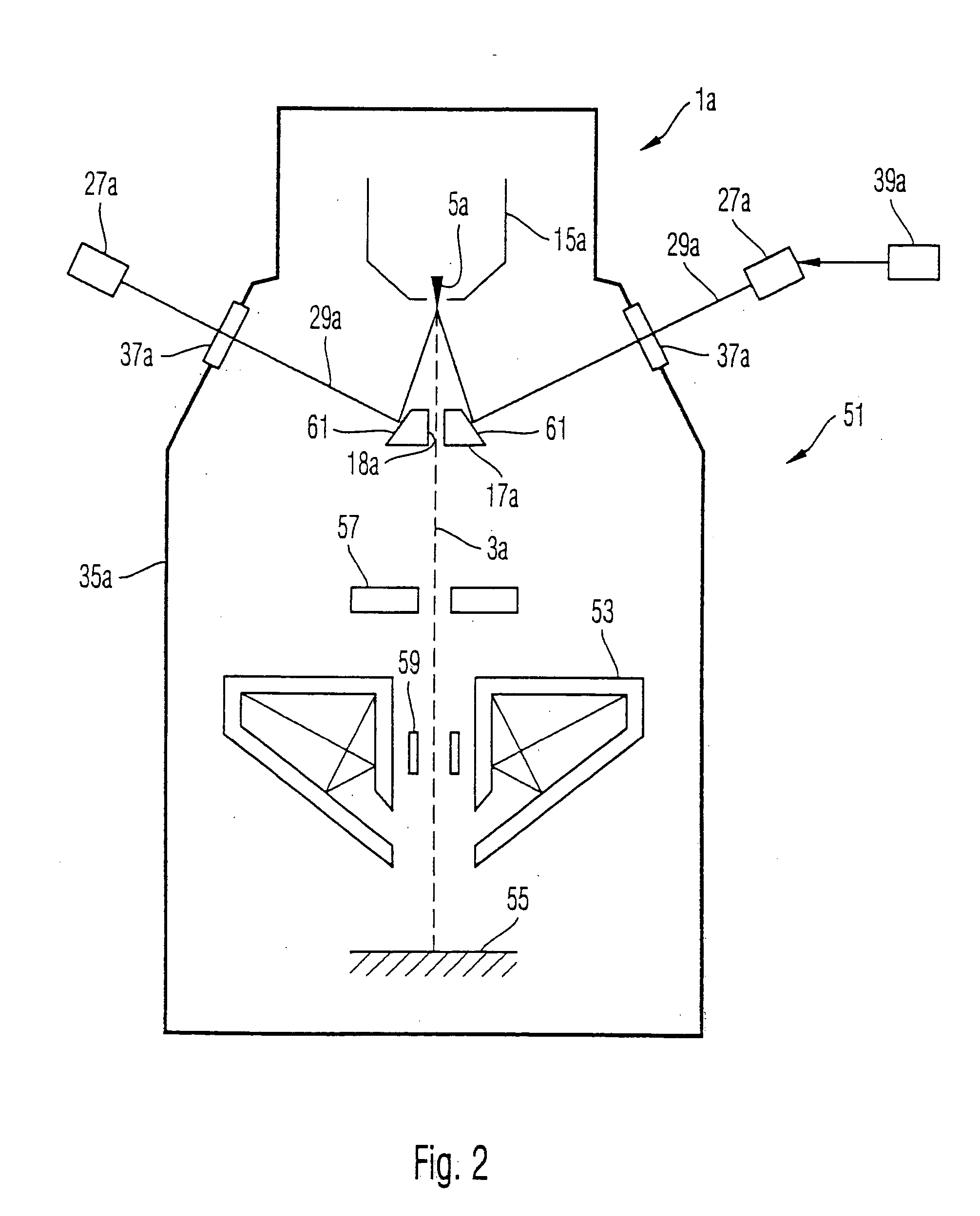

Electron beam source, electron optical apparatus using such beam source and method of operating an electron beam source

InactiveUS20040124365A1Reduce widthImprove adjustabilityMaterial analysis using wave/particle radiationSemiconductor/solid-state device manufacturingBeam sourcePhoton beam

An electron beam source comprises a source surface illuminated with a photon beam of adjustable intensity. The photon beam assists emission of electrons from the source surface due to a photo effect. An electric extraction field further assists in electron emission. Further, a heater is provided for further assisting in electron emission by a thermionic effect. An electron beam current is measured, and the intensity of the photon beam is adjusted based on the measured electron beam current.

Owner:CARL ZEISS SMT GMBH

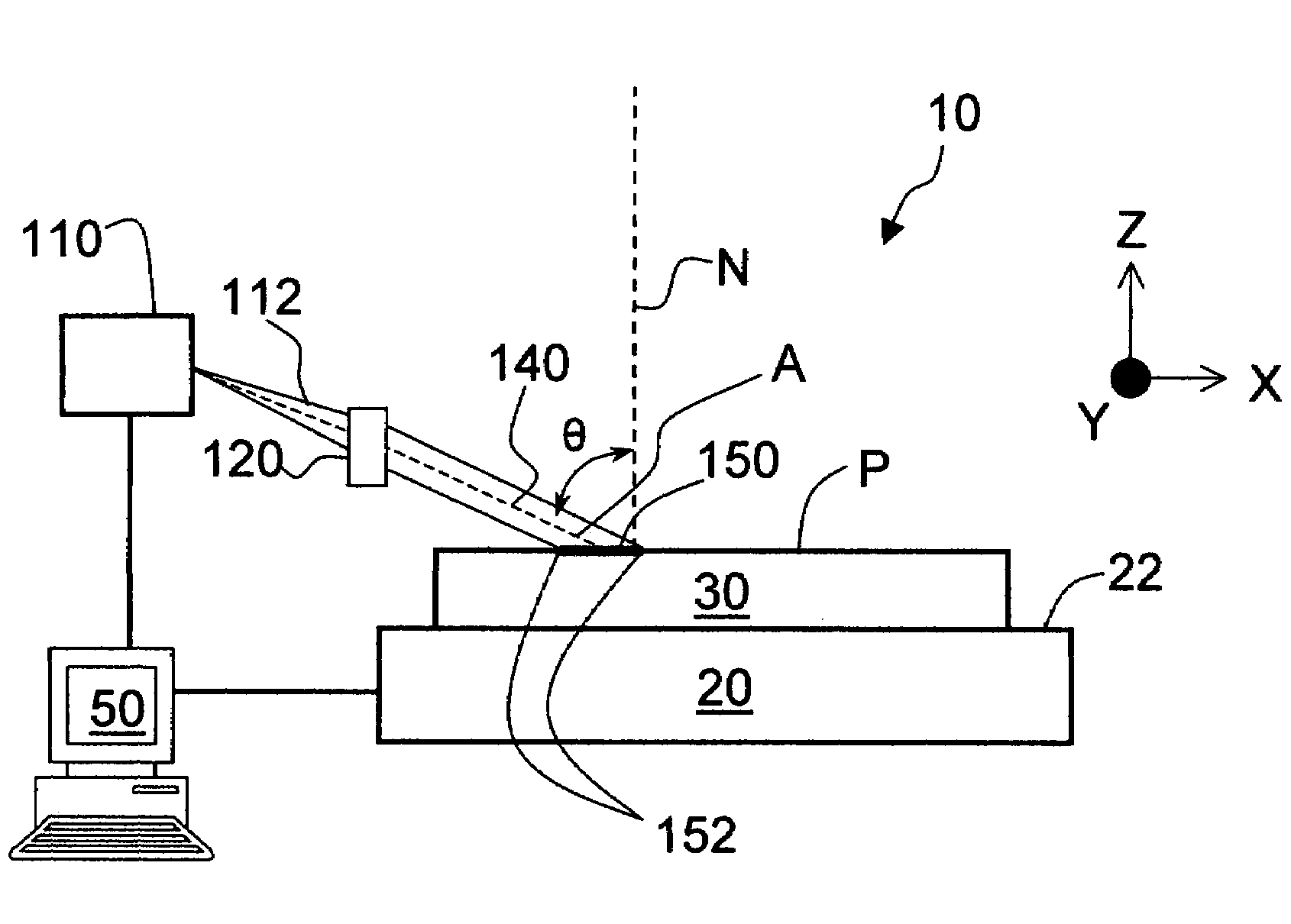

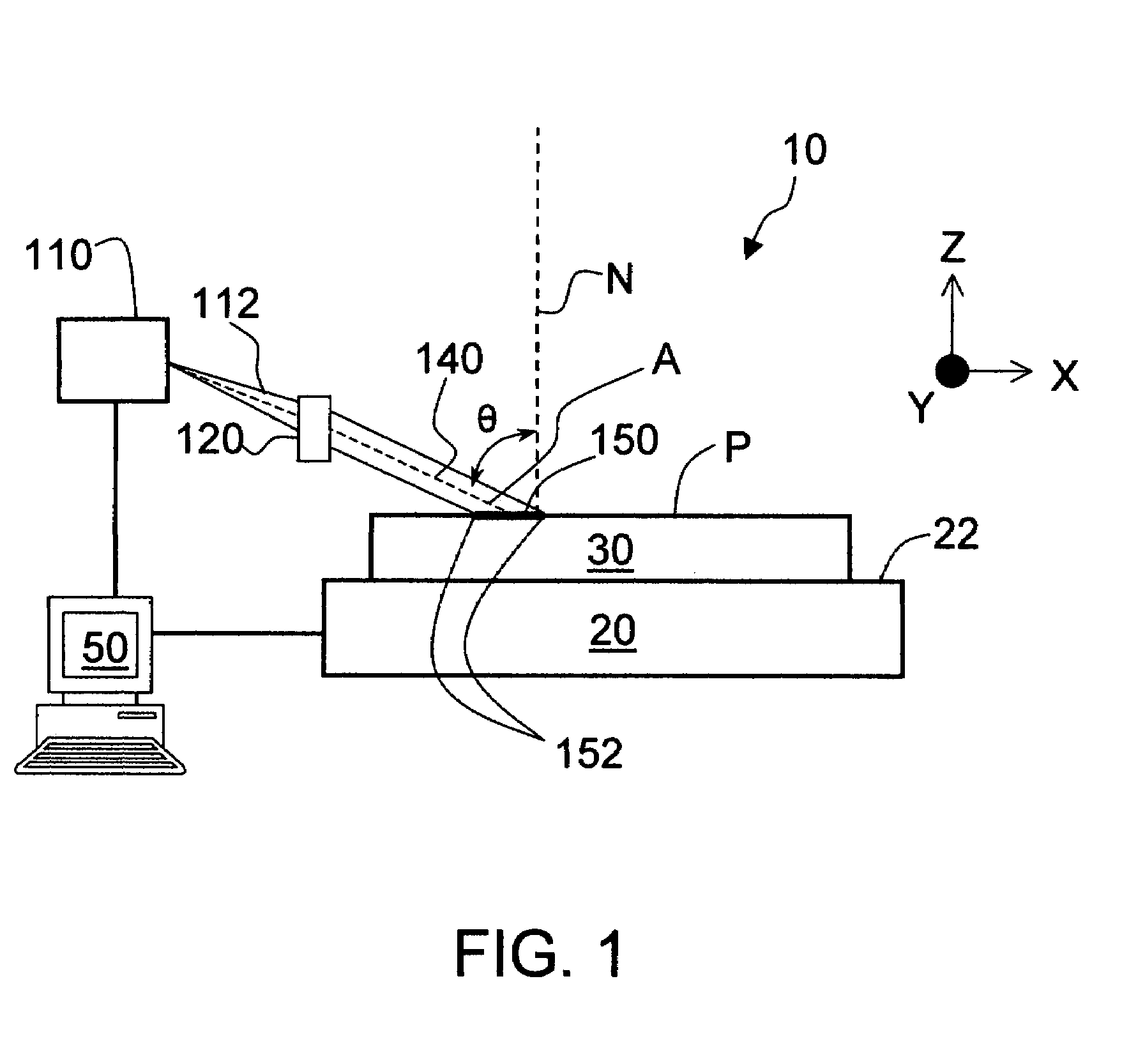

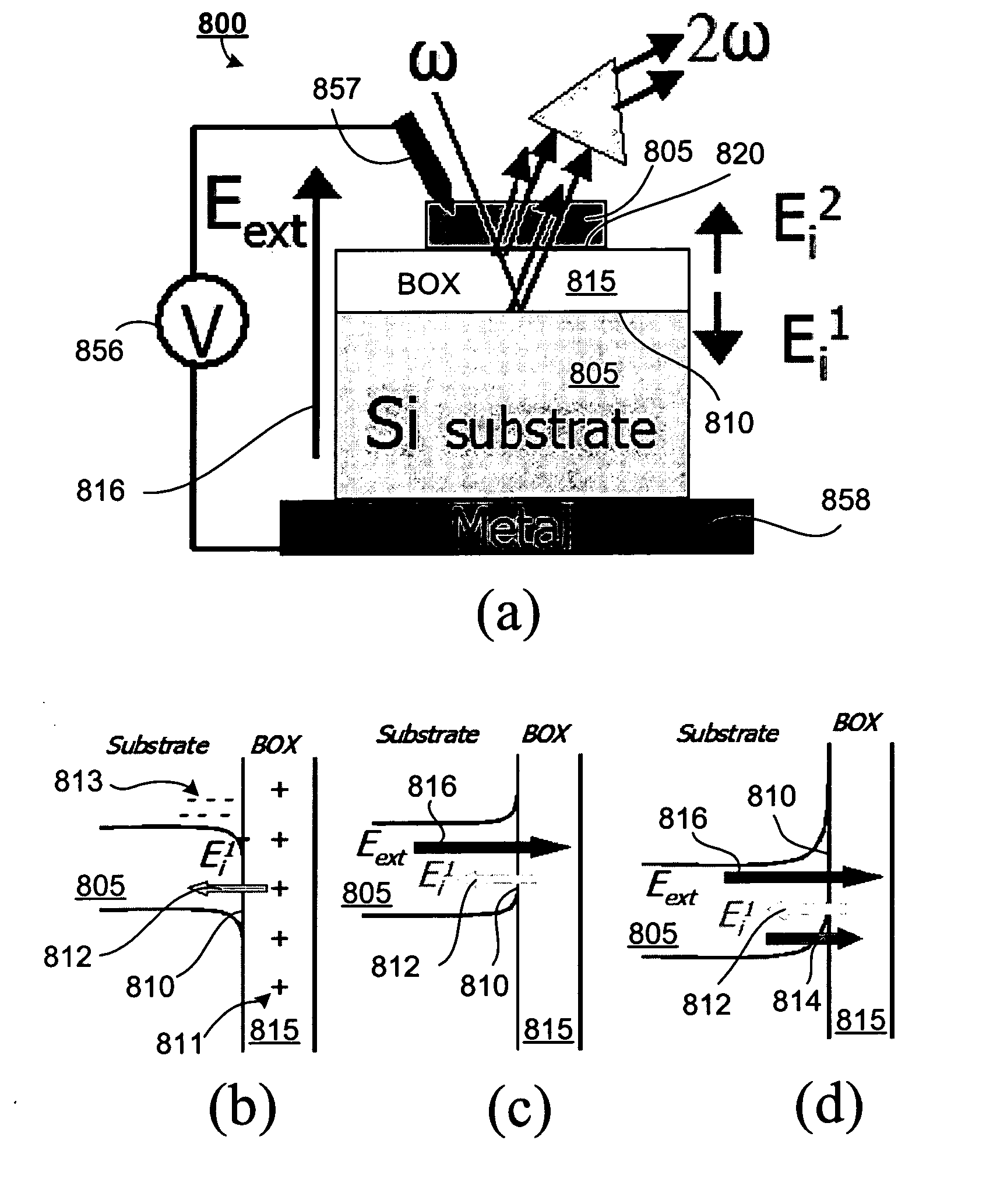

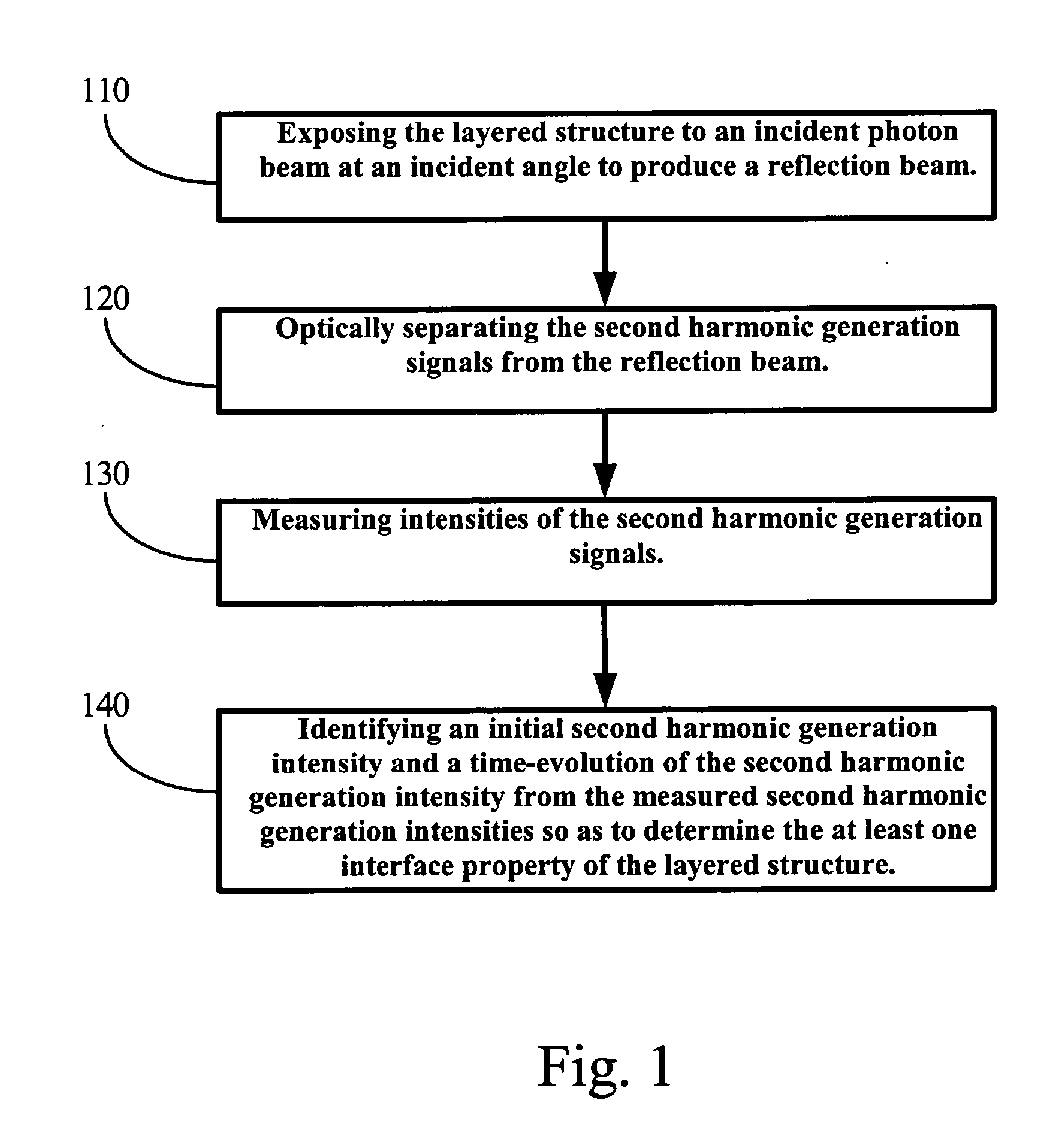

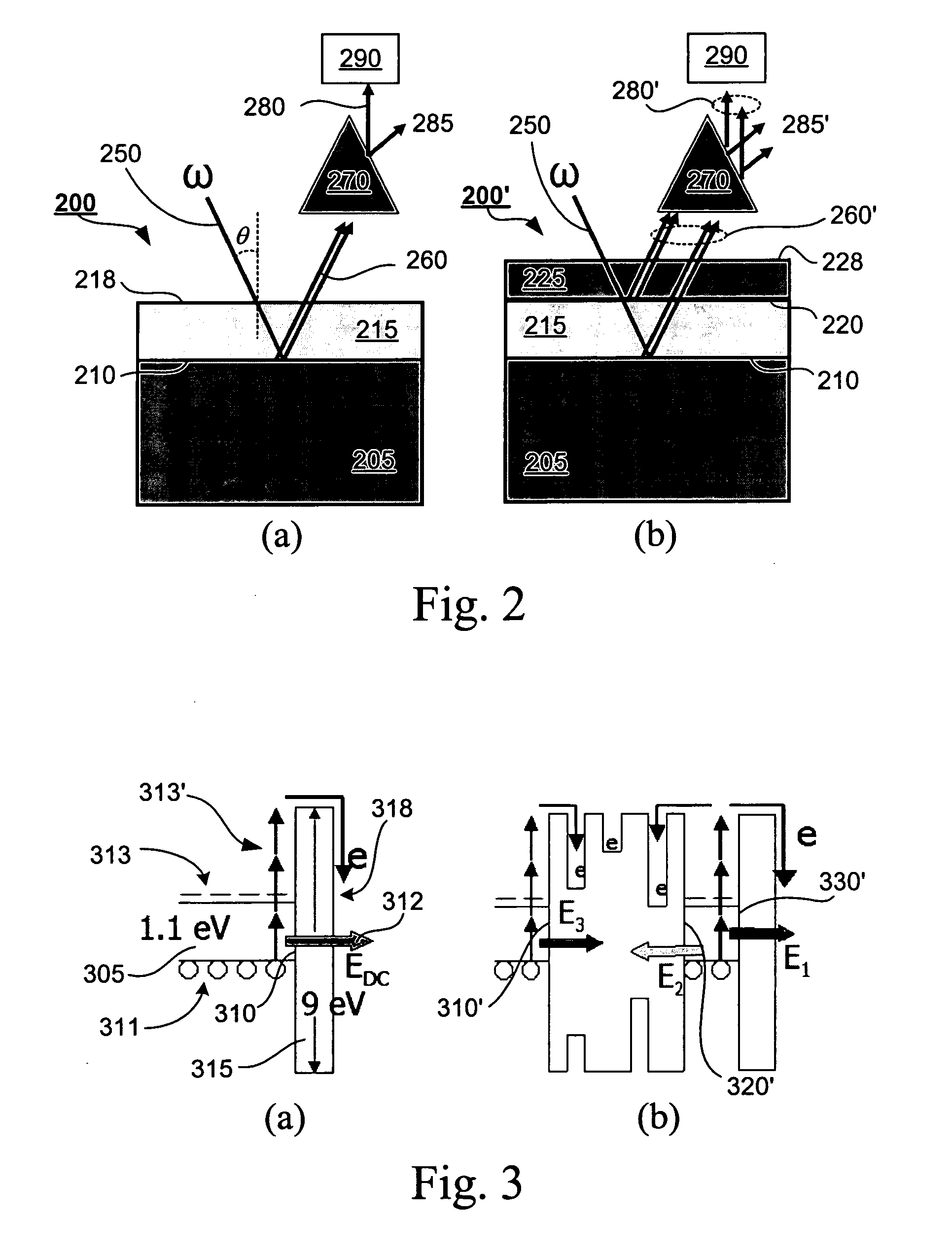

Apparatus and methods of using second harmonic generation as a non-invasive optical probe for interface properties in layered structures

InactiveUS20060044641A1Scattering properties measurementsAnalysis by material excitationHarmonicNon invasive

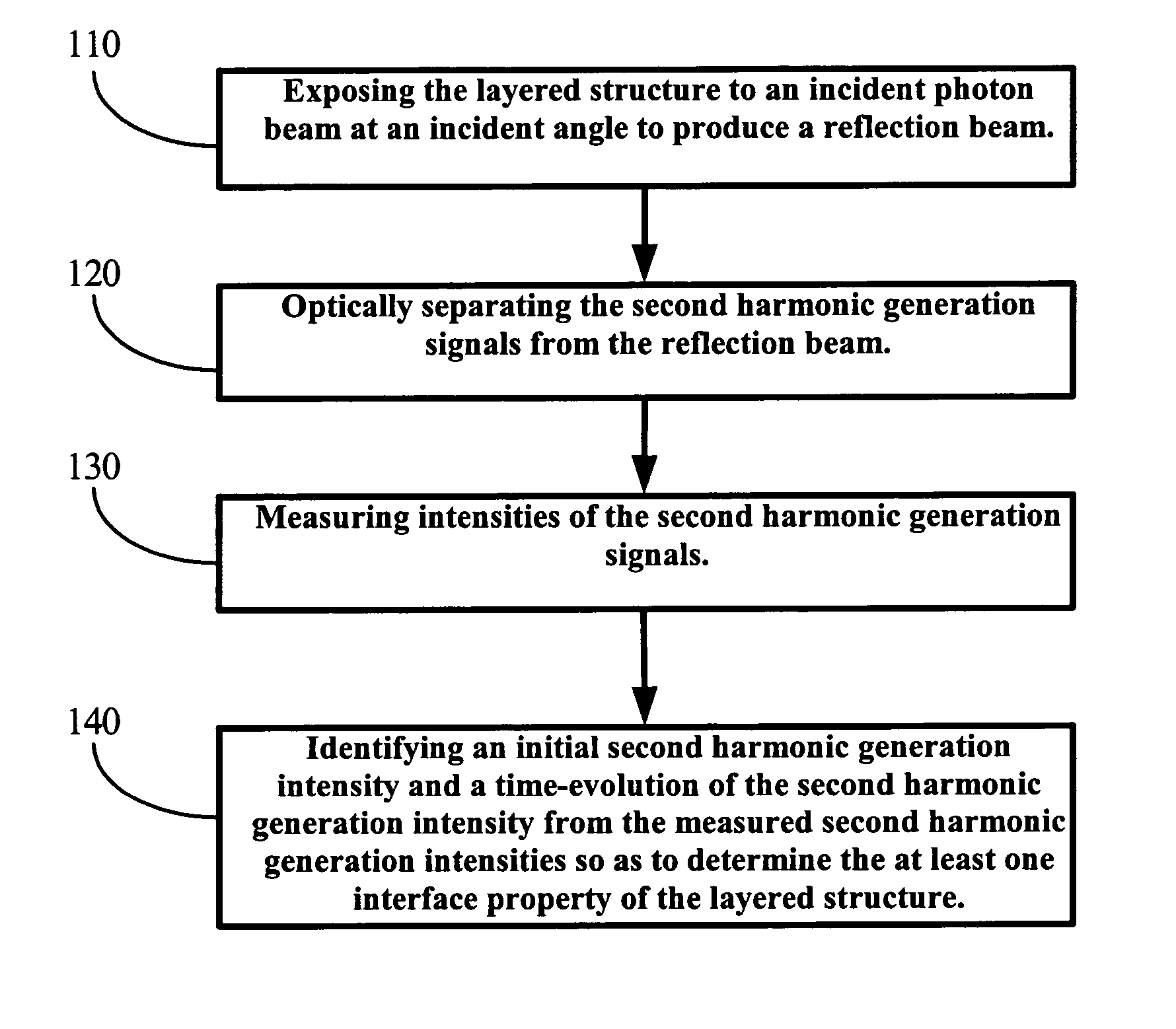

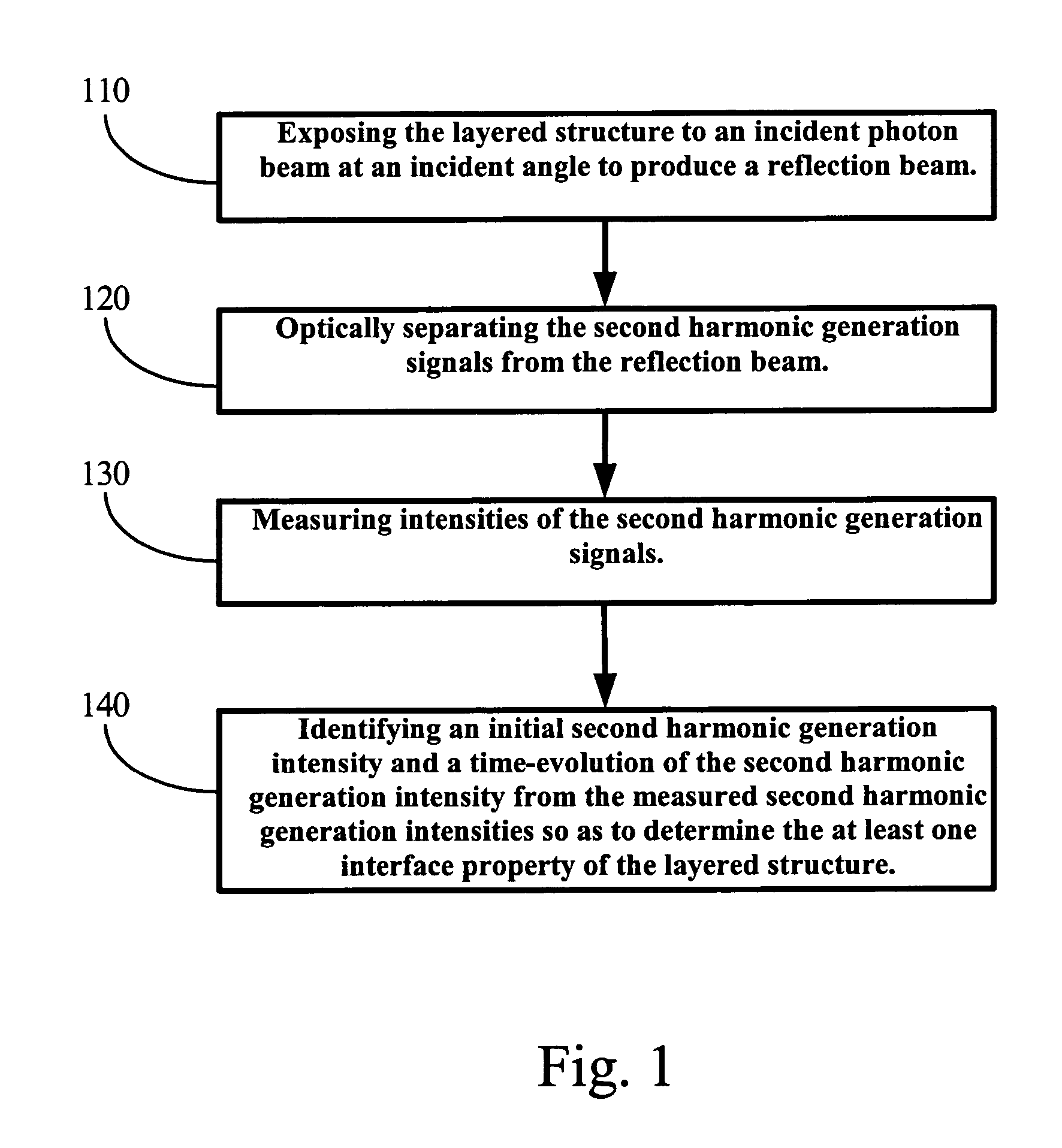

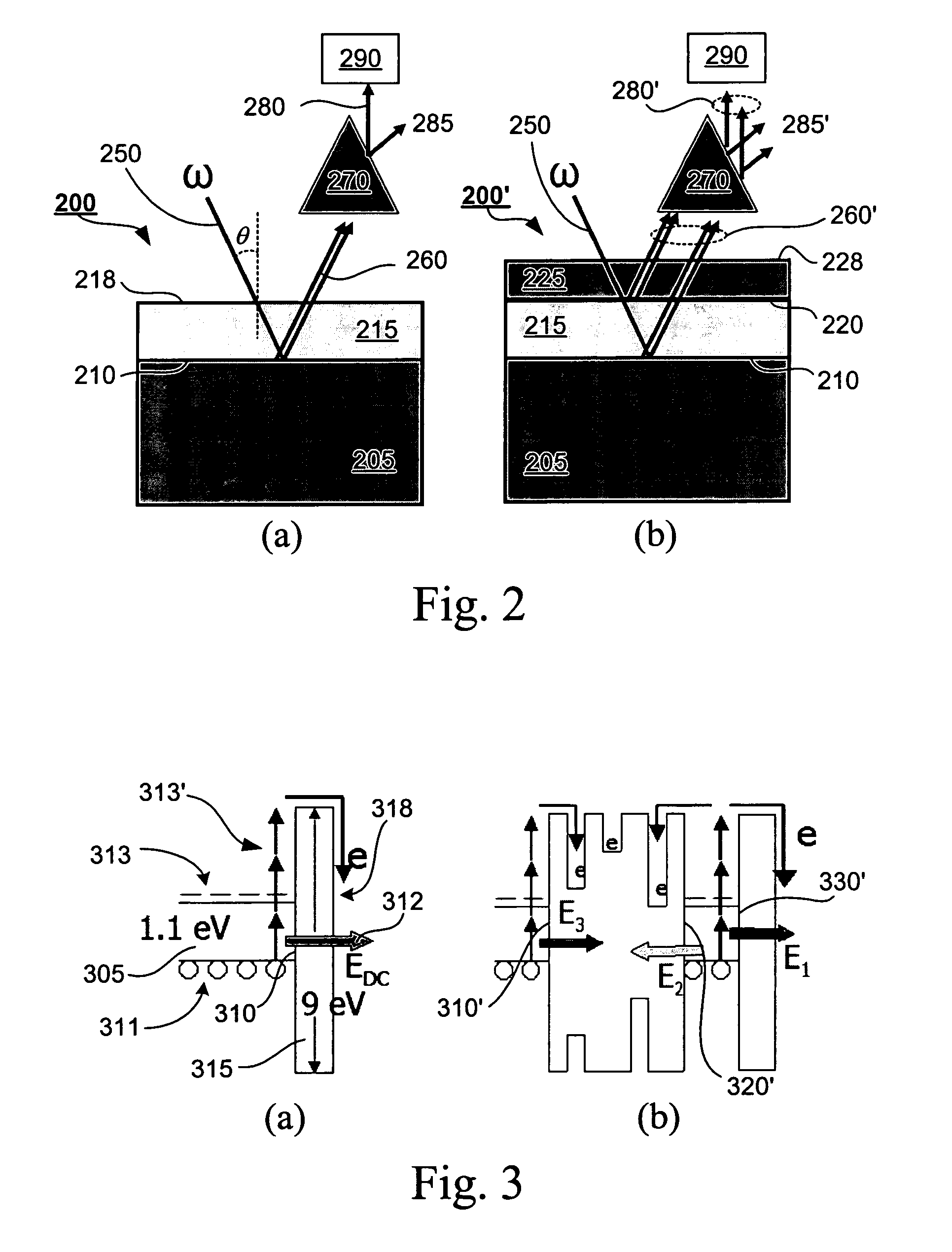

A method for non-invasively probing at least one interface property in a layered structure having at least one interface. In one embodiment, the method includes the steps of exposing the layered structure to an incident photon beam at an incident angle to produce a reflection beam, measuring intensities of the second harmonic generation signals from the reflection beam, and identifying an initial second harmonic generation intensity and a time evolution of second harmonic generation intensity from the measured second harmonic generation intensities so as to determine the at least one interface property of the layered structure.

Owner:VANDERBILT UNIV

Device for detecting an object using SPAD photodiodes

ActiveUS9006641B2Avoid measuringOptical rangefindersMaterial analysis by optical meansLight beamPhotodiode

The disclosure relates to a method for detecting the presence of an object near a detection device, comprising: emitting pulses of an incident photon beam, detecting photodiodes which trigger avalanche after the reception by the photodiode of at least one photon of a reflected photon beam produced by a reflection of the incident beam on an object near the detection device, determining a distance between the photodiodes and an object in a detection area, as a function of the time between a transmit time of the incident beam and avalanche triggering times of the photodiodes, and correcting the distance determined as a function of a calibration measurement obtained in the absence of object in the detection area, to compensate for photon reflections on a transparent plate arranged between the photodiodes and the detection area.

Owner:STMICROELECTRONICS (GRENOBLE 2) SAS

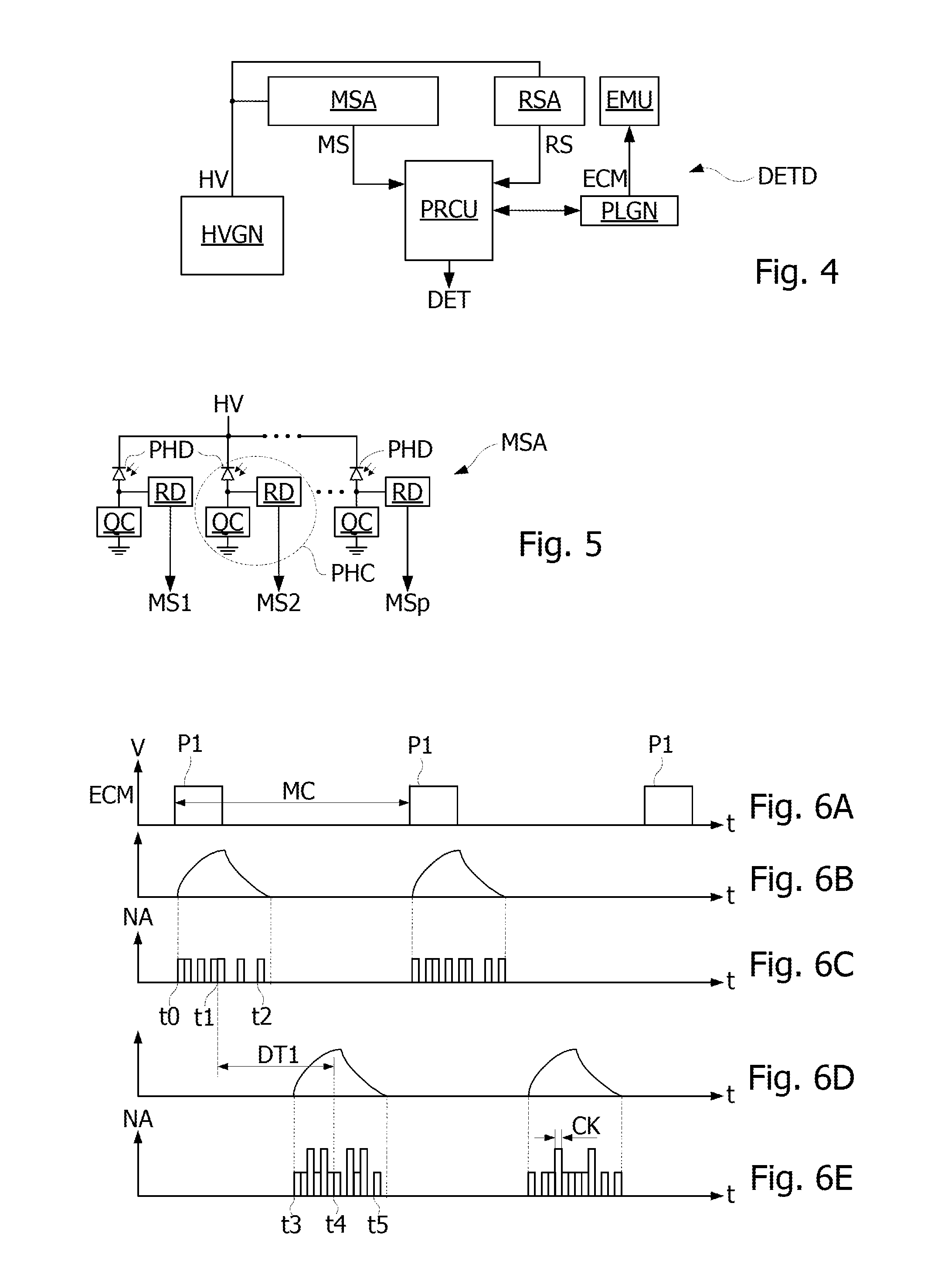

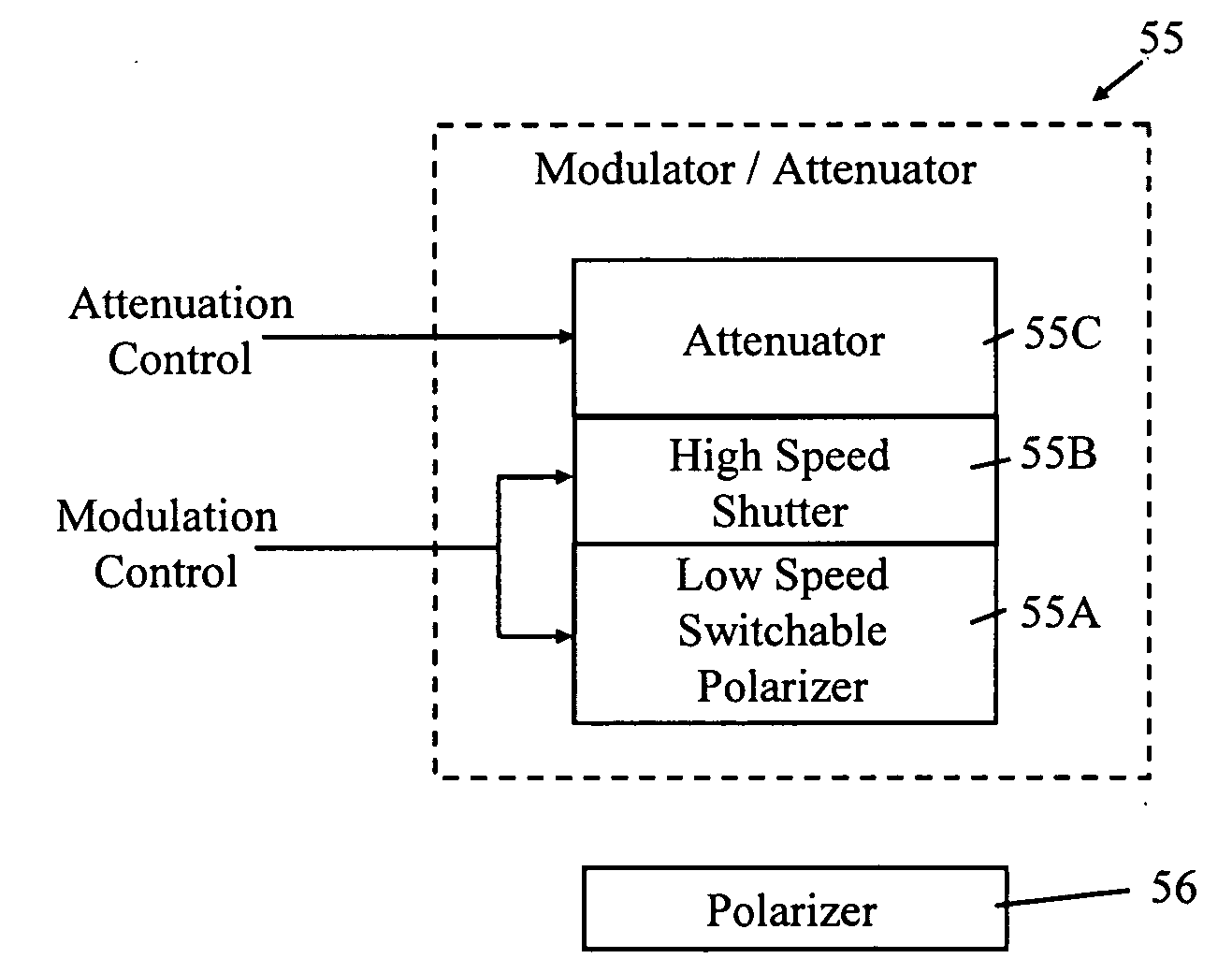

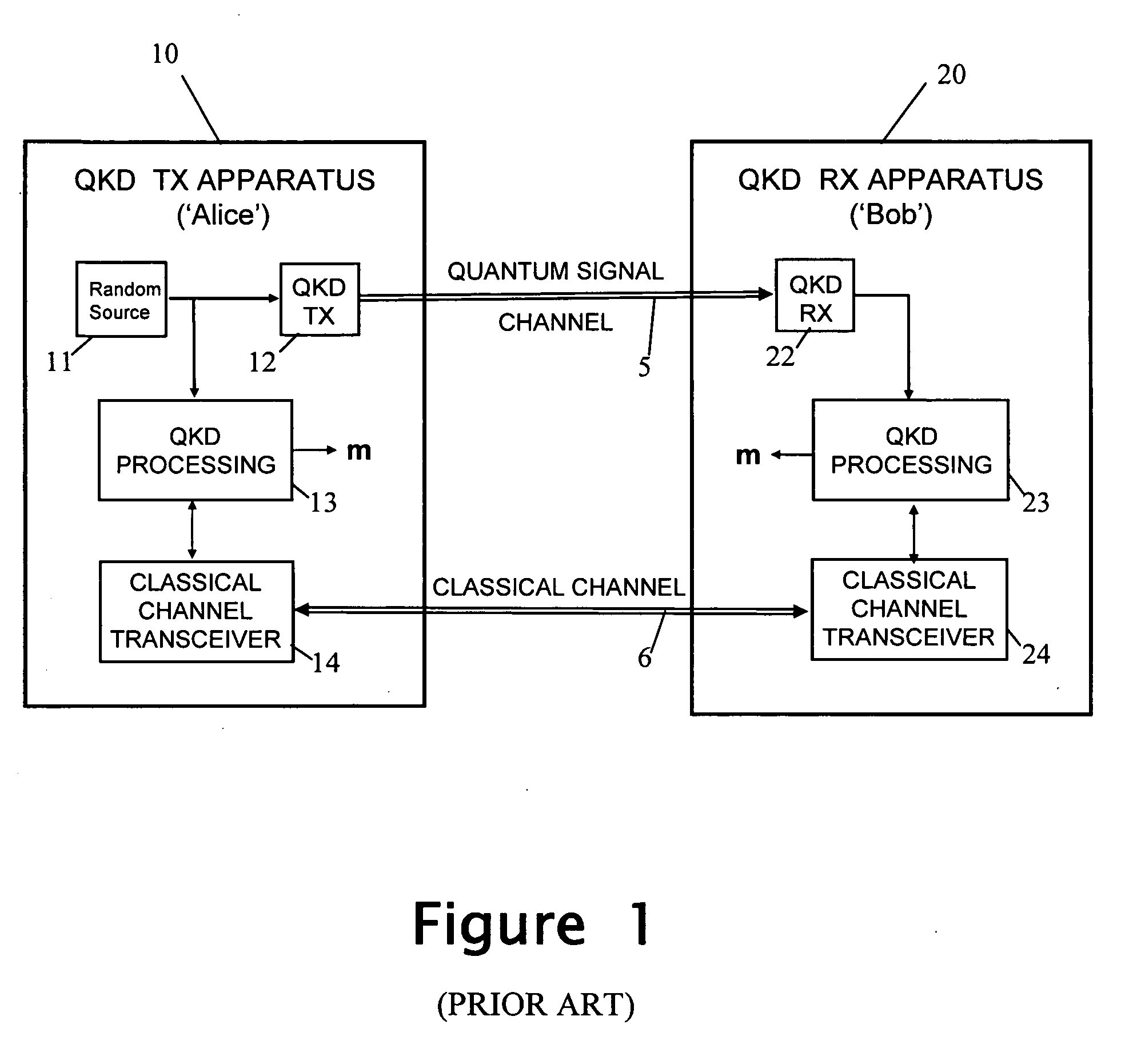

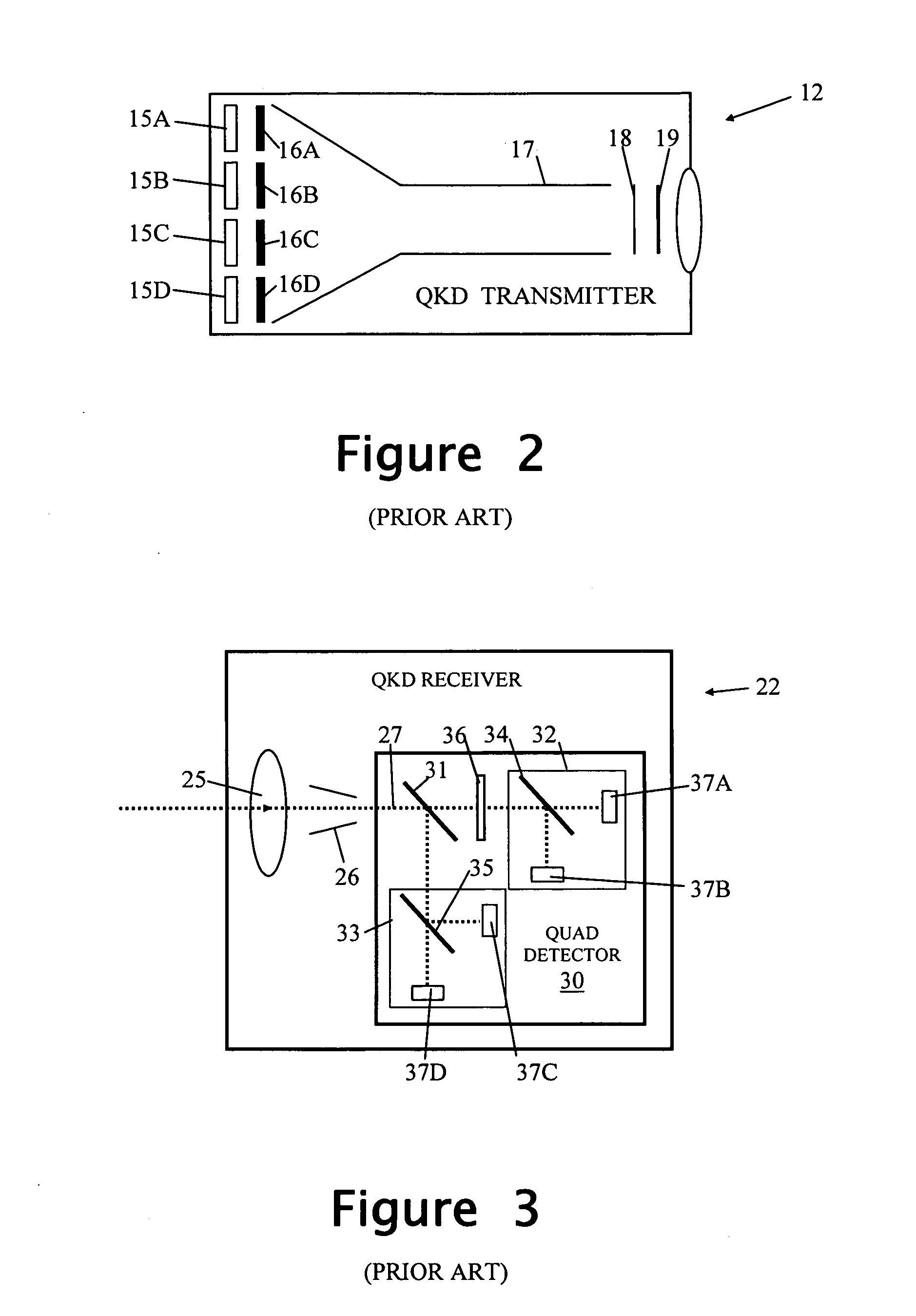

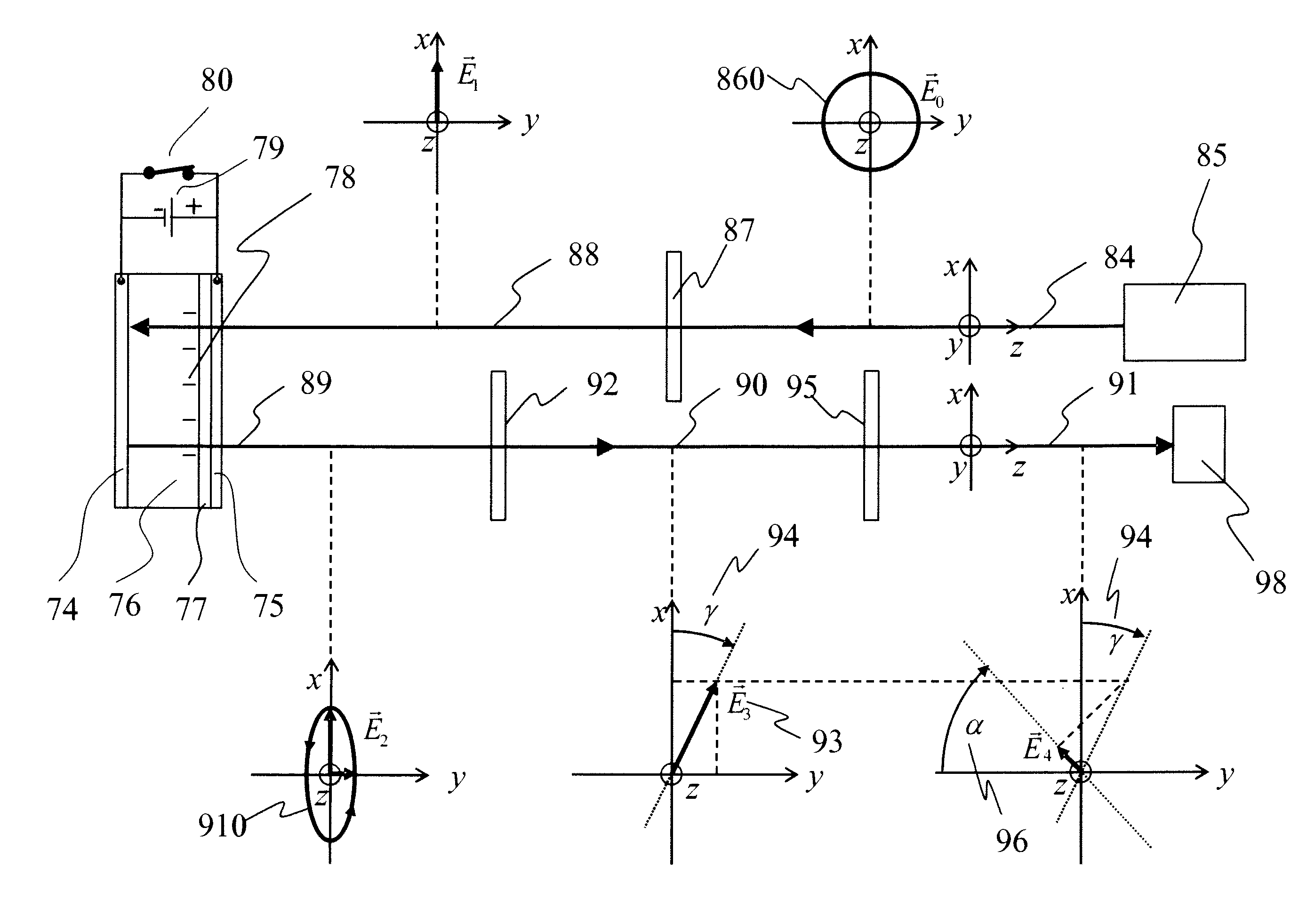

QKD transmitter and transmission method

ActiveUS20100080394A1Key distribution for secure communicationUser identity/authority verificationUltrasound attenuationLight beam

In order to facilitate alignment of a QKD transmitter and QKD receiver, the transmitter is provided with a retro-reflector for returning to the receiver a photon beam originating at the latter. The transmitter is arranged to polarization modulate the retro-reflected beam. The transmitter is provided both with an intensity detector for generating an indication of retro-reflected photon intensity, and an intensity-dependent controller for controlling the QKD transmitter in dependence on the detected photon intensity. In one embodiment, this control involves aborting operation of the QKD transmitter upon an unexpectedly high photon intensity being detected; in another embodiment, the intensity indication is used to control the attenuation of the retro-reflected beam so as stabilize the average retro-reflected photon count per unit time.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Apparatus and methods of using second harmonic generation as a non-invasive optical probe for interface properties in layered structures

InactiveUS7158284B2Scattering properties measurementsAnalysis by material excitationLight beamNon invasive

A method for non-invasively probing at least one interface property in a layered structure having at least one interface. In one embodiment, the method includes the steps of exposing the layered structure to an incident photon beam at an incident angle to produce a reflection beam, measuring intensities of the second harmonic generation signals from the reflection beam, and identifying an initial second harmonic generation intensity and a time evolution of second harmonic generation intensity from the measured second harmonic generation intensities so as to determine the at least one interface property of the layered structure.

Owner:VANDERBILT UNIV

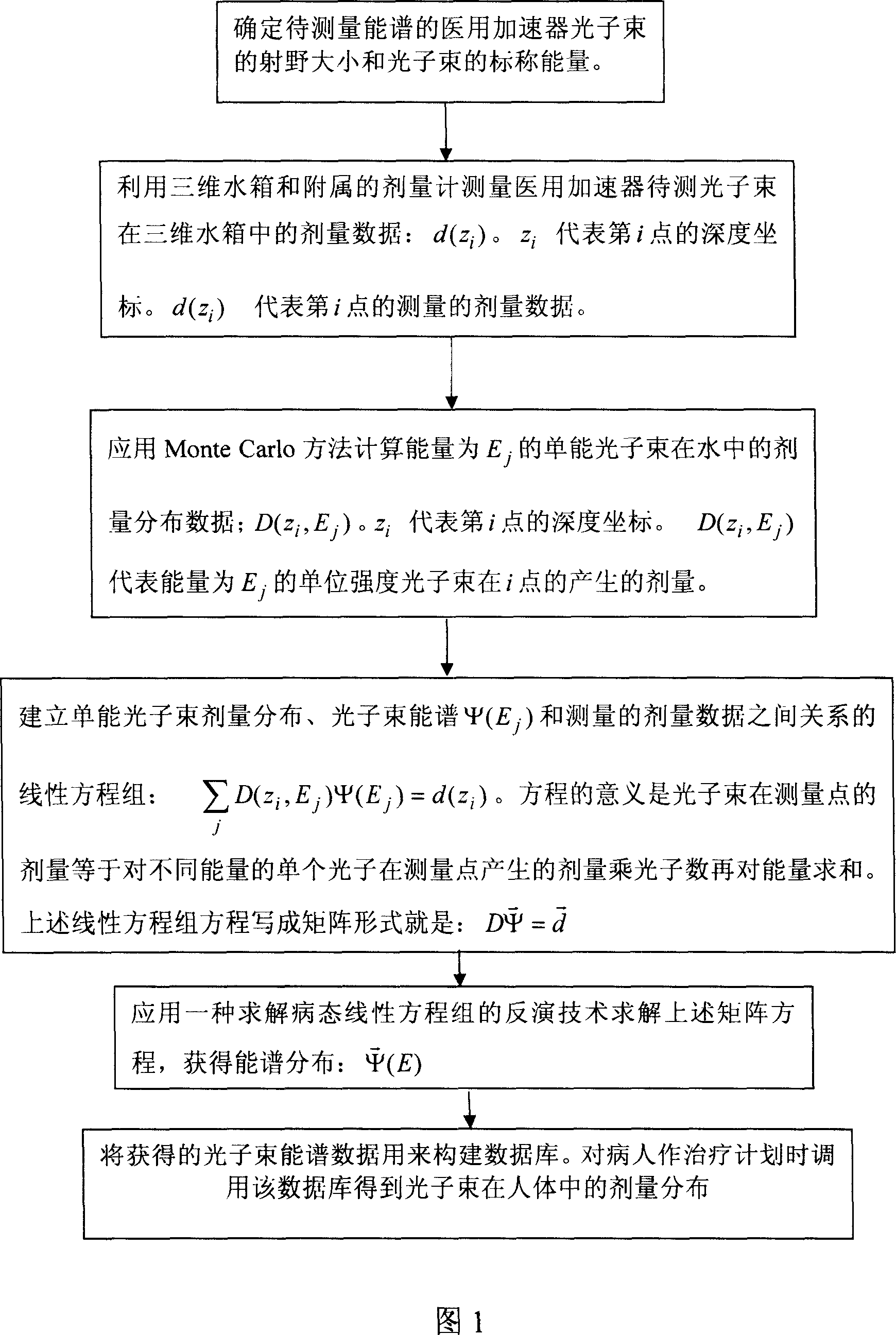

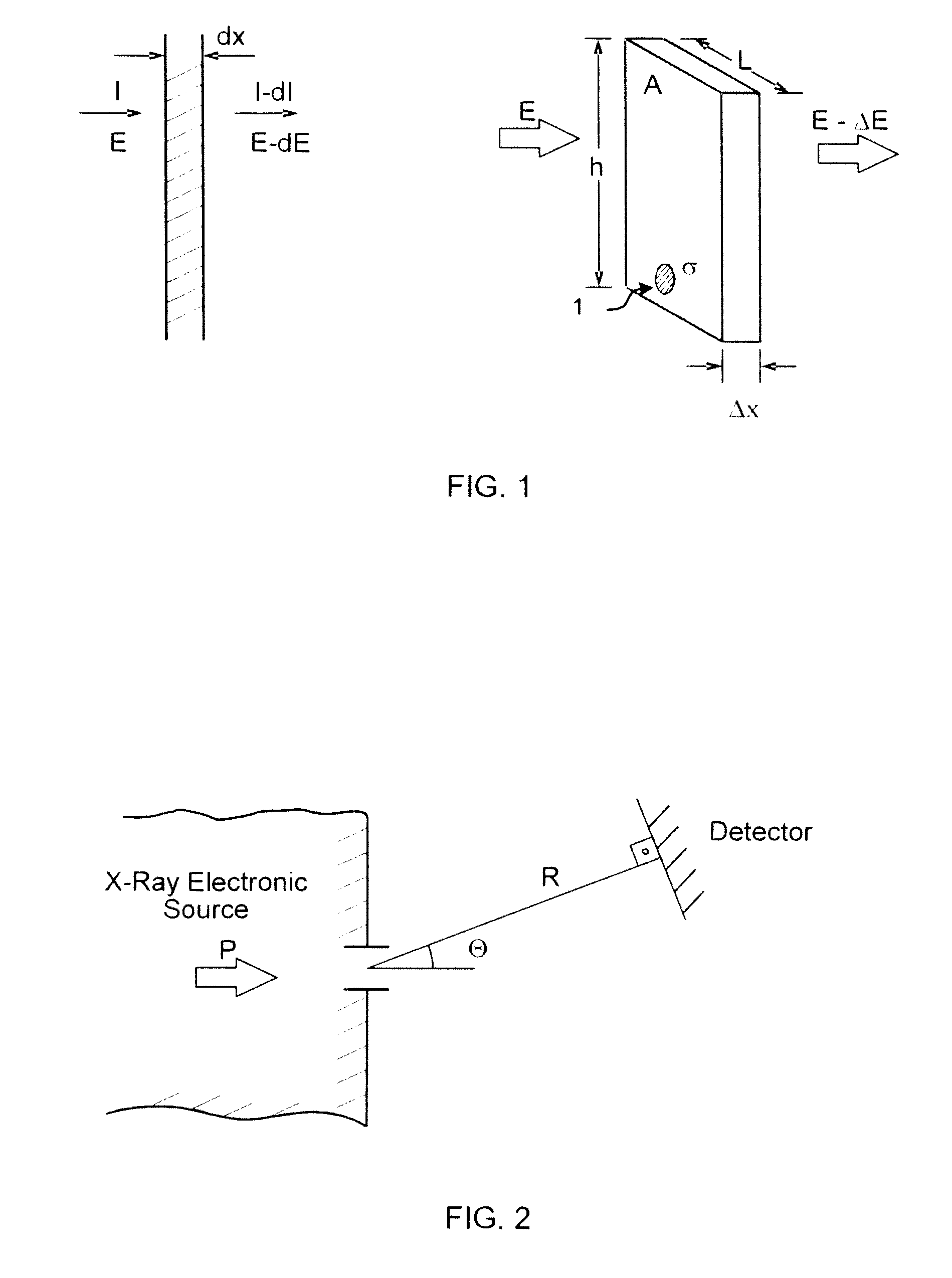

Method for measuring photon beam energy spectrum of medical accelerator

InactiveCN101071172ASimple processQuick measurementDosimetersX-ray/gamma-ray/particle-irradiation therapySpectroscopy methodsRadiotherapy unit

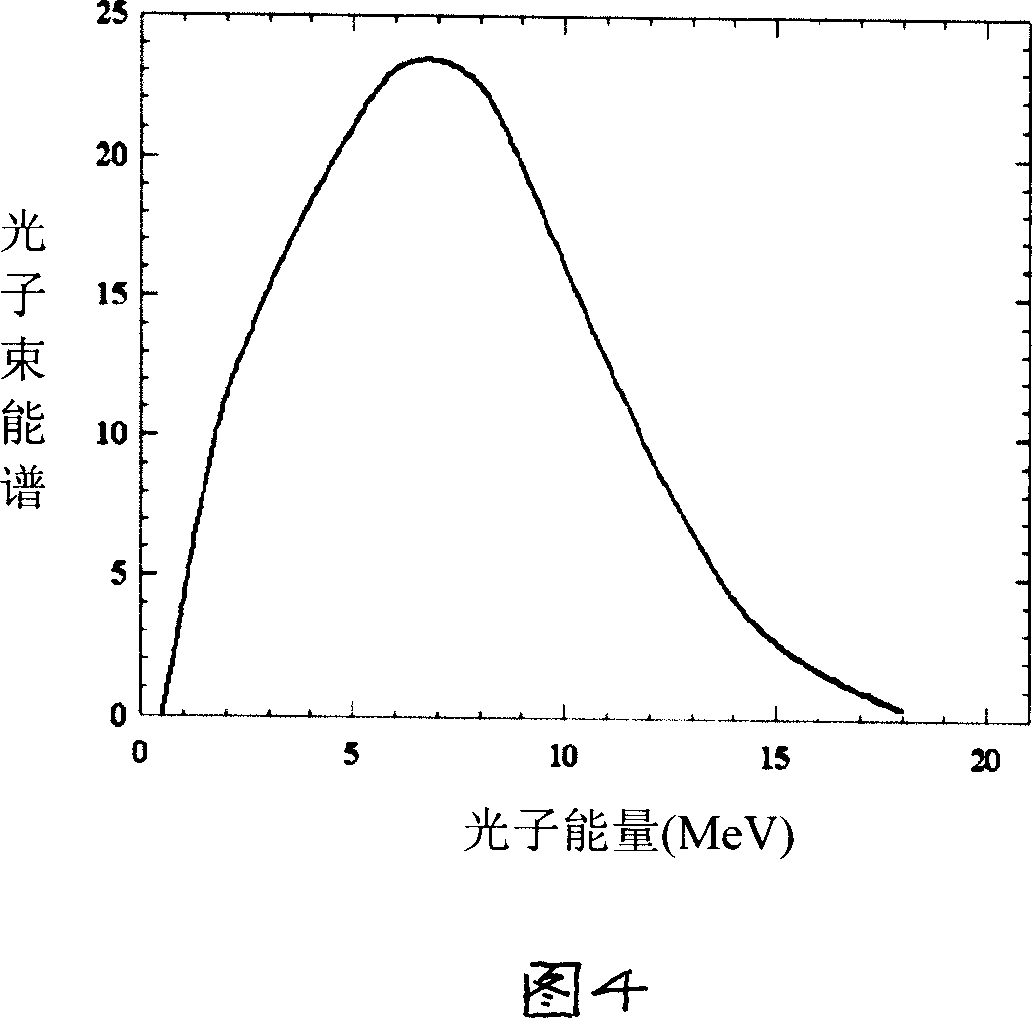

This invention discloses a medical accelerator measuring the photon beam spectroscopy method. steps are as follows: a. measuring medical accelerator exit collimator system in the three-dimensional photon beam dose distribution in water, access to data; b. Application different Monte Carlo method a number of group single-energy photon beam in the water to the dose distribution data; c. establishment of single-energy photon beam dose distribution in the water, the photon beam spectroscopy and measurement data between the dose of linear equations; by measuring the photon beam d. Die dose in the water data, the results of the application of energy photon beam weighted algorithm to solve linear equations available photon beam spectroscopy; advantage of this invention is: only in measuring photon beam dose distribution in water tanks, software reuse of this invention to be a photon beam spectroscopy data, the use of fast simpler; all radiotherapy units have radiotherapy water tanks, the invention will enable hospitals measured photon spectrum-free purchase equipment, reduce cost measurement; not photon spectrometer radiotherapy simplified the process and improve the efficiency of the treatment.

Owner:成都奇林科技有限责任公司

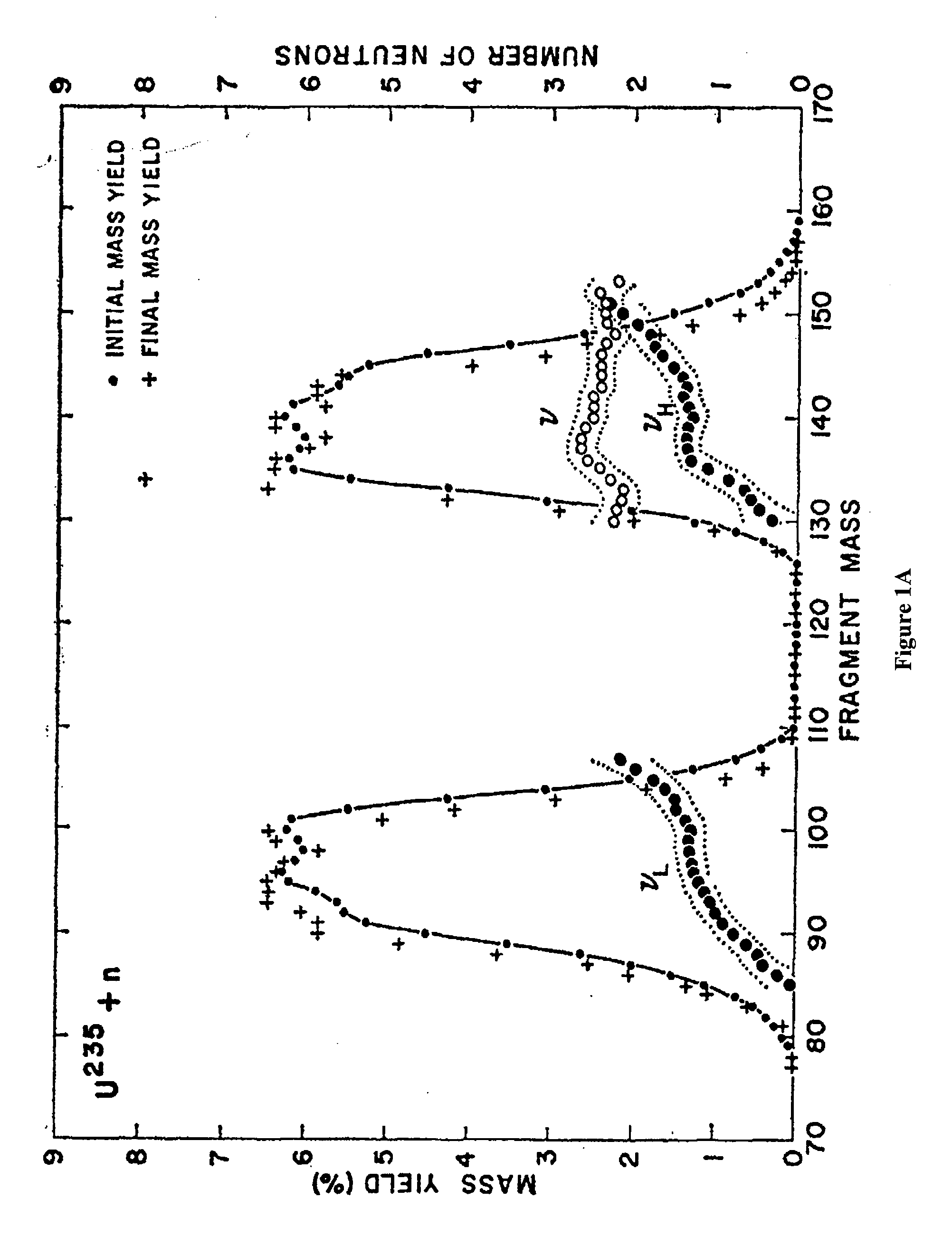

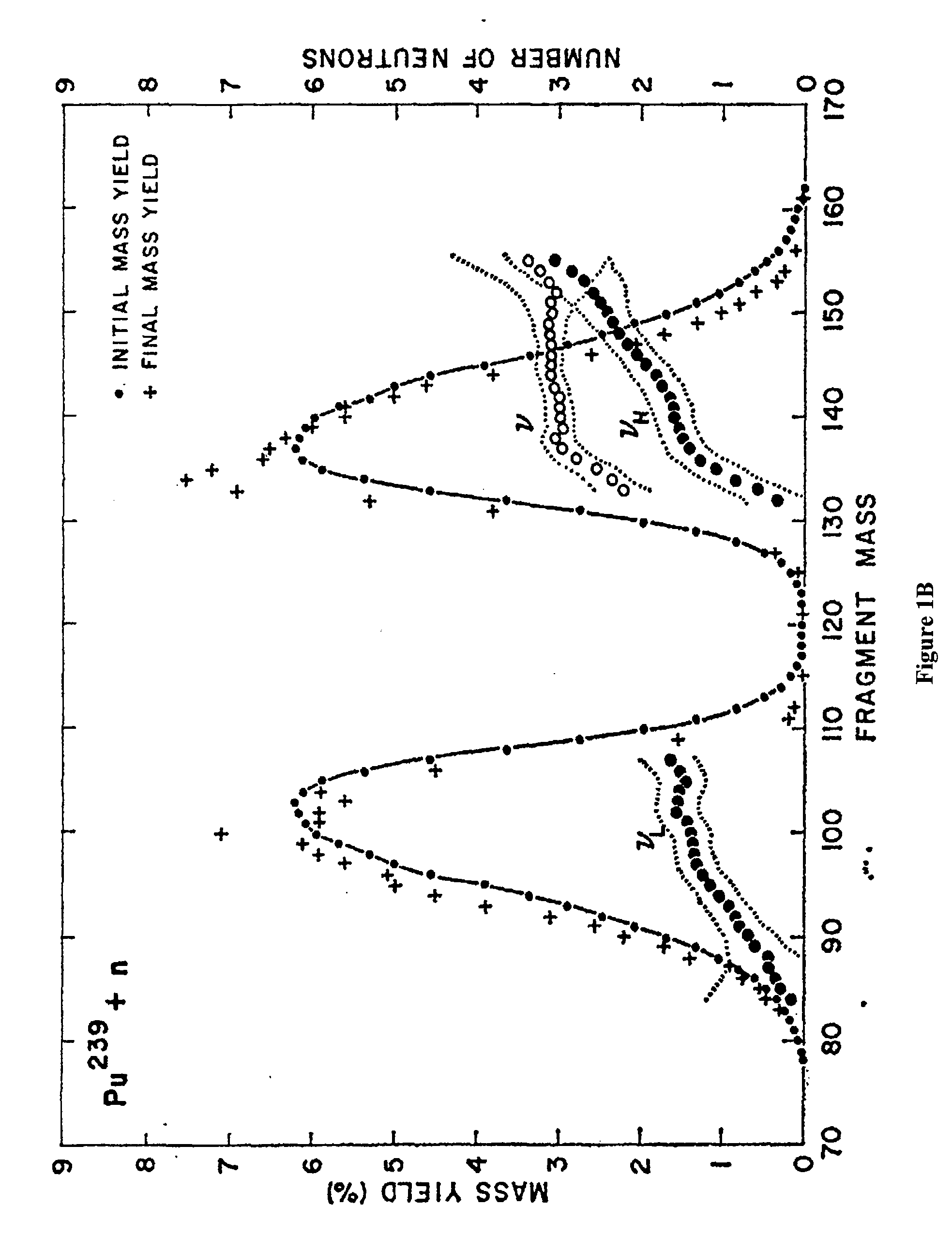

Non-intrusive method to identify presence of nuclear materials using energetic prompt neutrons from photon-induced fission

InactiveUS20090074128A1Improve detection rateSolve the high false positive rateConversion outside reactor/acceleratorsNeutron radiation measurementBeam energySmall fragment

Methods and systems for non-intrusively detecting the existence of fissile materials in a container via the measurement of energetic prompt neutrons are disclosed. The methods and systems use the unique nature of the prompt neutron energy spectrum from photo-fission arising from the emission of neutrons from almost fully accelerated fragments to unambiguously identify fissile material. The angular distribution of the prompt neutrons from photo-fission and the energy distribution correlated to neutron angle relative to the photon beam are used to distinguish odd-even from even-even nuclei undergoing photo-fission. The independence of the neutron yield curve (yield as a function of electron beam energy or photon energy) on neutron energy also is also used to distinguish photo-fission from other processes such as (γ, n). Different beam geometries are used to detect localized samples of fissile material and also fissile materials dispersed as small fragments or thin sheets over broad regions. These signals from photo-fission are unique and allow the detection of any material in the actinide region of the nuclear periodic table.

Owner:PASSPORT SYSTEMS INC

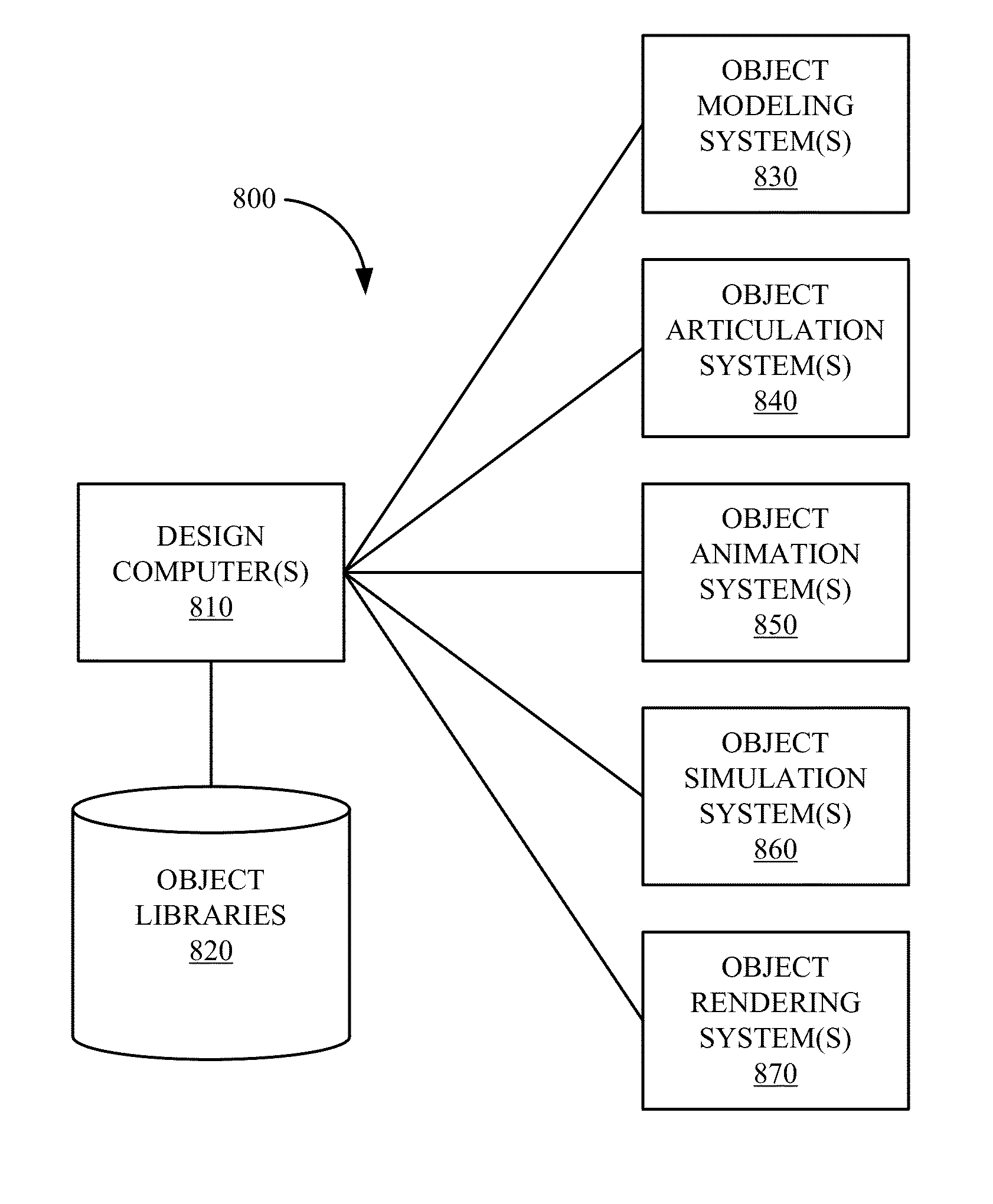

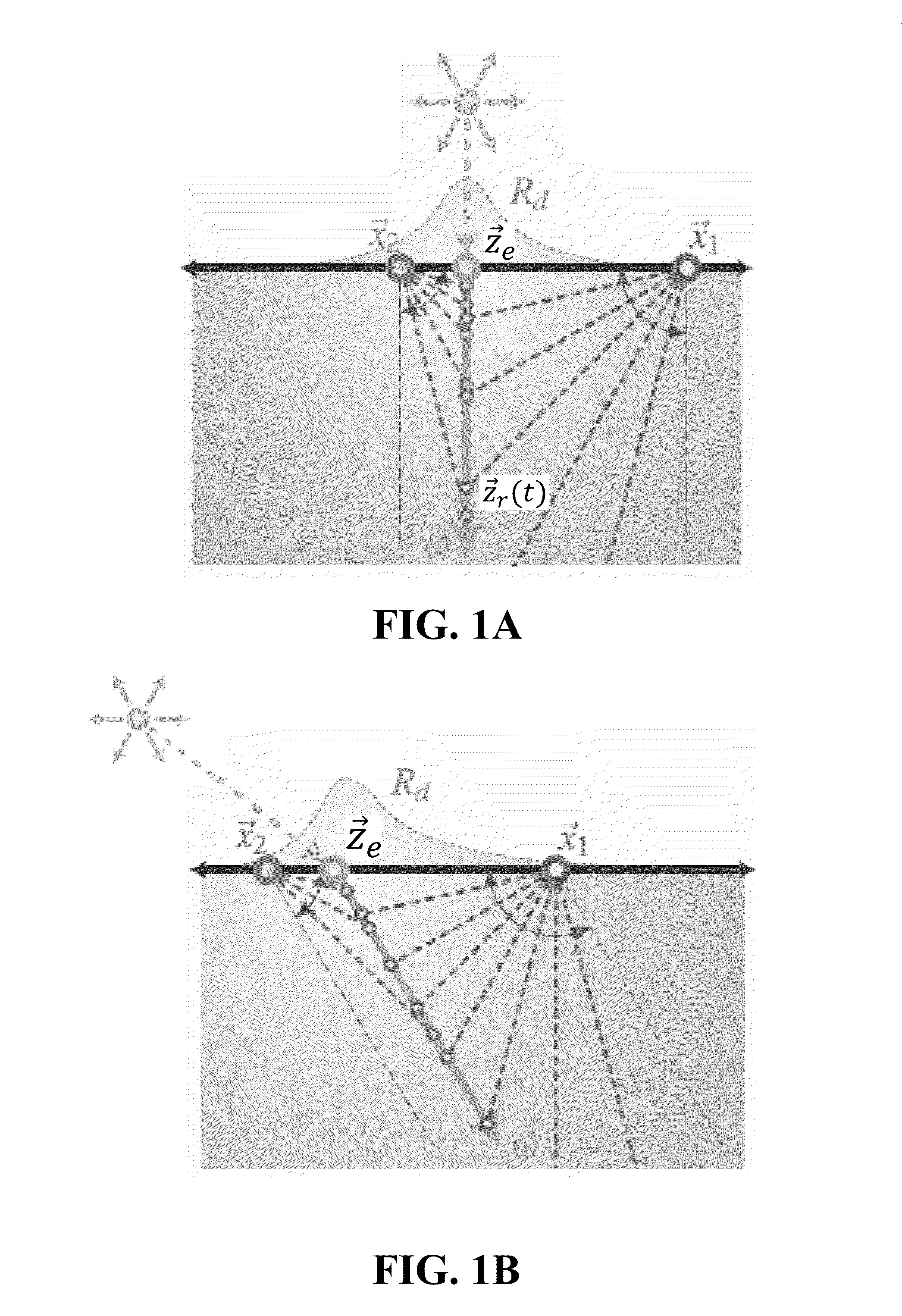

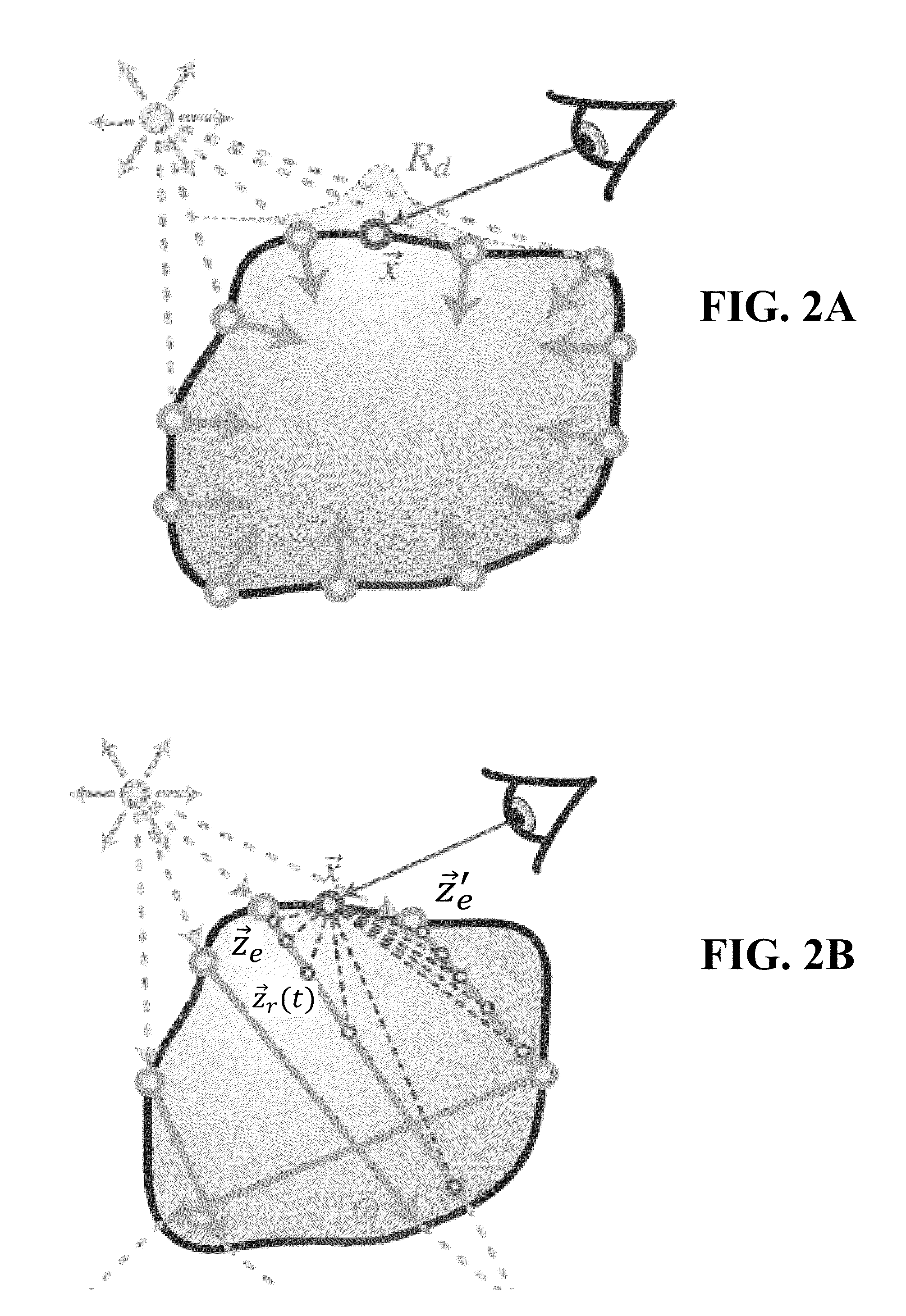

Photon beam diffusion

ActiveUS20140204087A1Reduce functionUniformity and functionAnimation3D-image renderingLight beamRadiant exitance

An efficient numerical method for accurately rendering translucent materials using photon beam diffusion is provided that can account for multilayer materials and directional incident and exitant effects at the surface. In an embodiment, refracted incident light is represented continuously as a photon beam instead of as discrete photons. An integration scheme for calculating a radiant exitance value at a point on the surface of the translucent material is disclosed that uses importance sampling and evaluates a radiant function at a limited number of points along the beam.

Owner:PIXAR ANIMATION

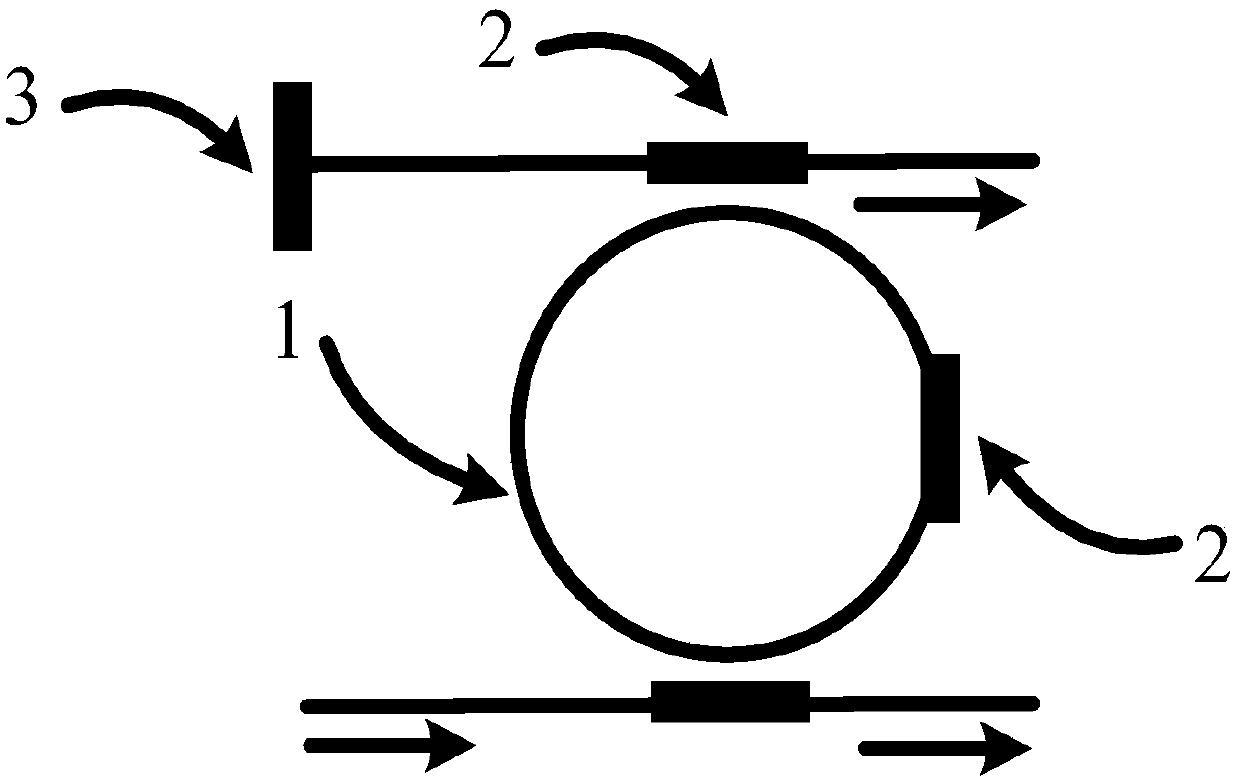

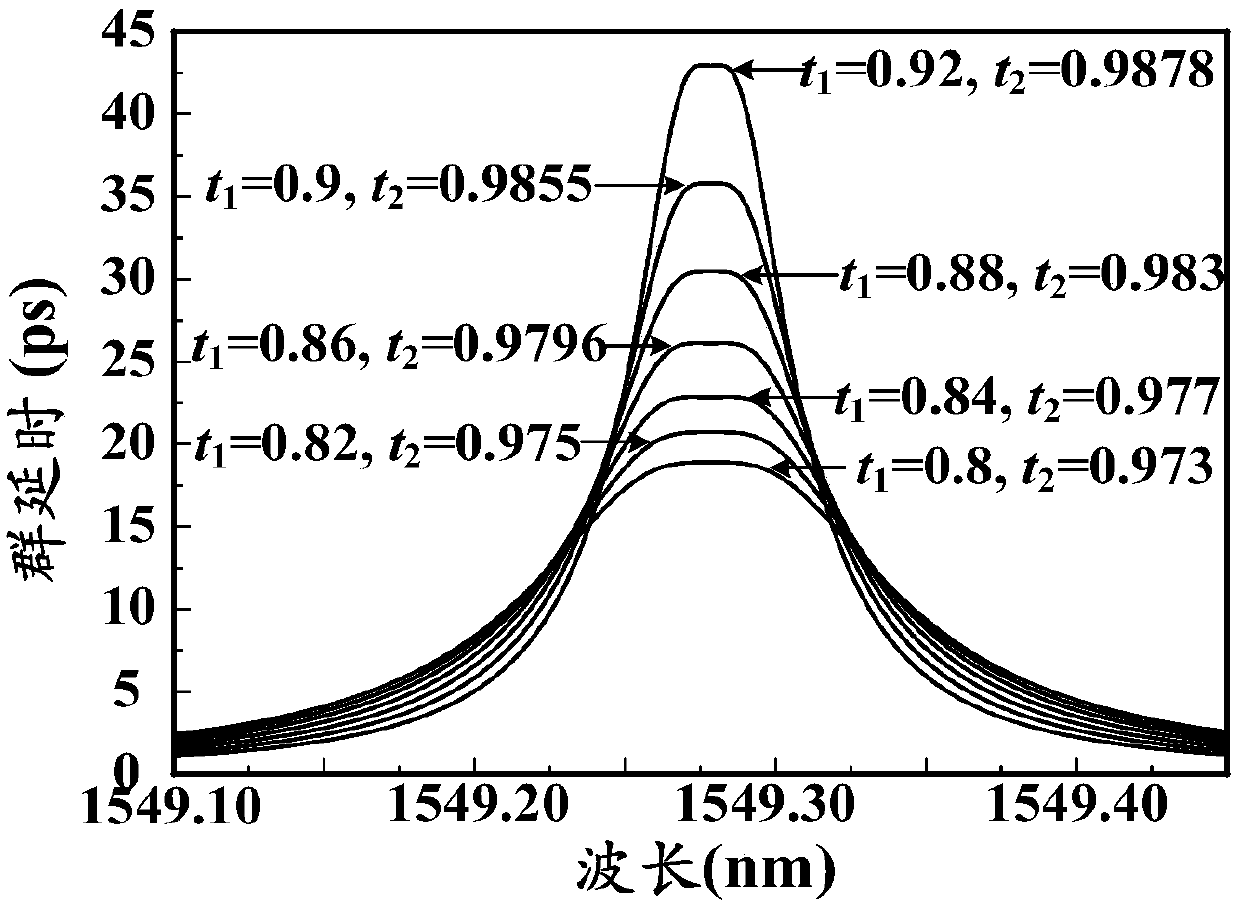

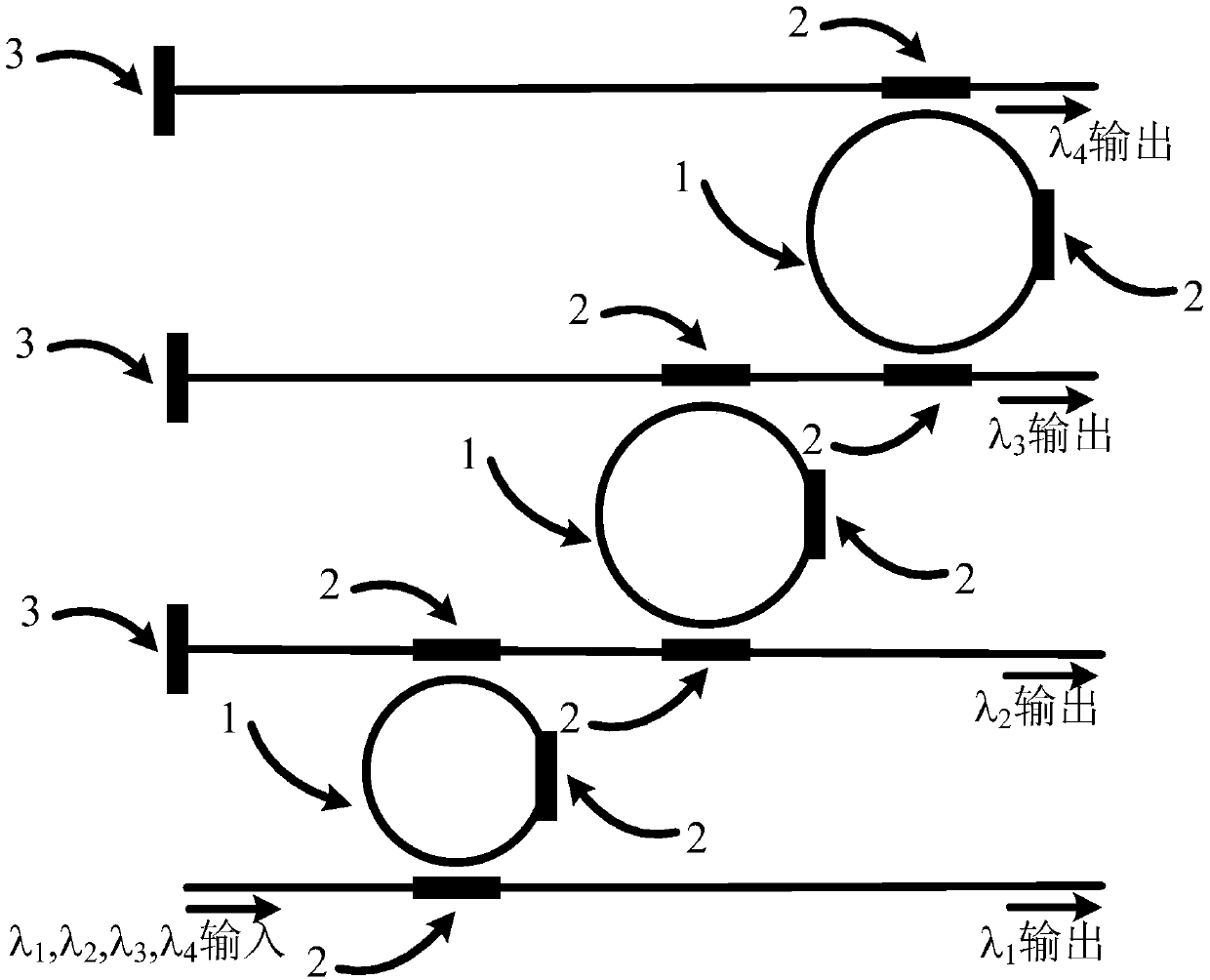

Reflective microring resonator, multi-wavelength light delayer and photon beam-forming chip

The invention discloses a reflective microring resonator. The reflective microring resonator comprises an upper download type microring resonator, wherein the upper download type microring resonator comprises a microring and a channel waveguide coupled with the microring, a download end of the upper download type microring resonator is provided with a light reflection structure, and the reflectivemicroring resonator further comprises a coupling control module used for controlling the coupling amount of the microring and the channel waveguide to make a group delay state of resonant light in two directions in the reflective microring resonator satisfy the fast and slow light cancellation condition. The invention further discloses a multi-wavelength light delayer, a photon beam-forming method and a photon beam-forming chip. The reflective microring resonator is advantaged in that true wideband light delay can be achieved, and the delay amount can be flexibly adjusted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Apparatus and method for detection of fissionable materials

An apparatus and method for the detection of fissionable materials (e.g. uranium and plutonium) in cargo, vehicles, soil, waste, etc. utilizing a penetrating photon beam causing emission of neutrons from such materials. The neutrons are detected by selected detectors able to function throughout an appropriate test and emission period. Suitable detectors are of the super-heated droplet type. The photon energy, beam intensity and direction, number of beams, emission period and detector arrangement are chosen to give the desired sensitivity for the fissionable elements of concern.

Owner:BUBBLE TECH INDS

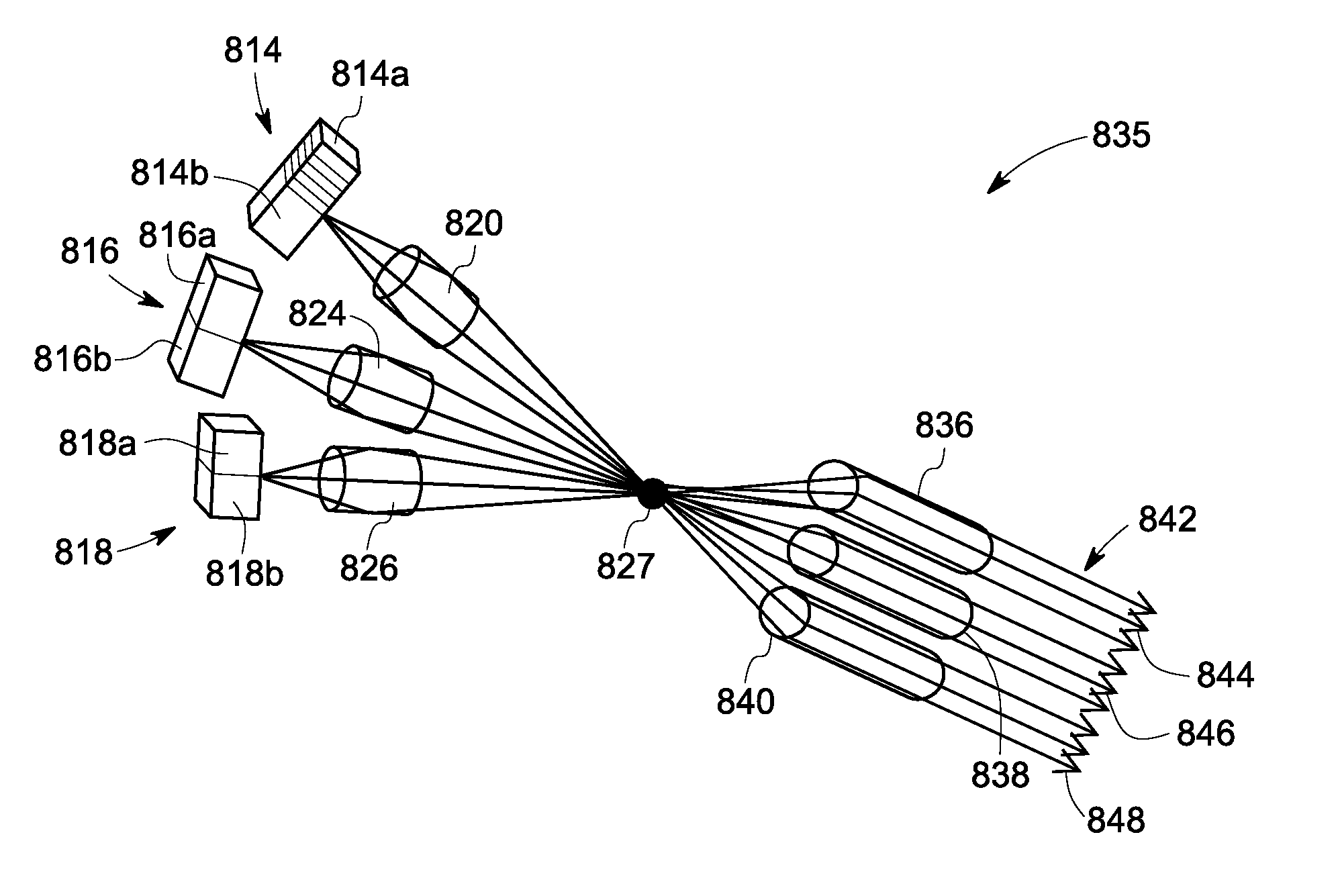

High flux photon beams using optic devices

A system for producing at least one high flux photon beam is provided. The system includes two or more photon sources configured to produce photon beams, and at least one first stage optic device coupled to at least one of the photon sources and providing at least one focused photon beam through total internal reflection, wherein at least one of the photon beams and the focused photon beams are combined at a virtual focal spot.

Owner:GENERAL ELECTRIC CO

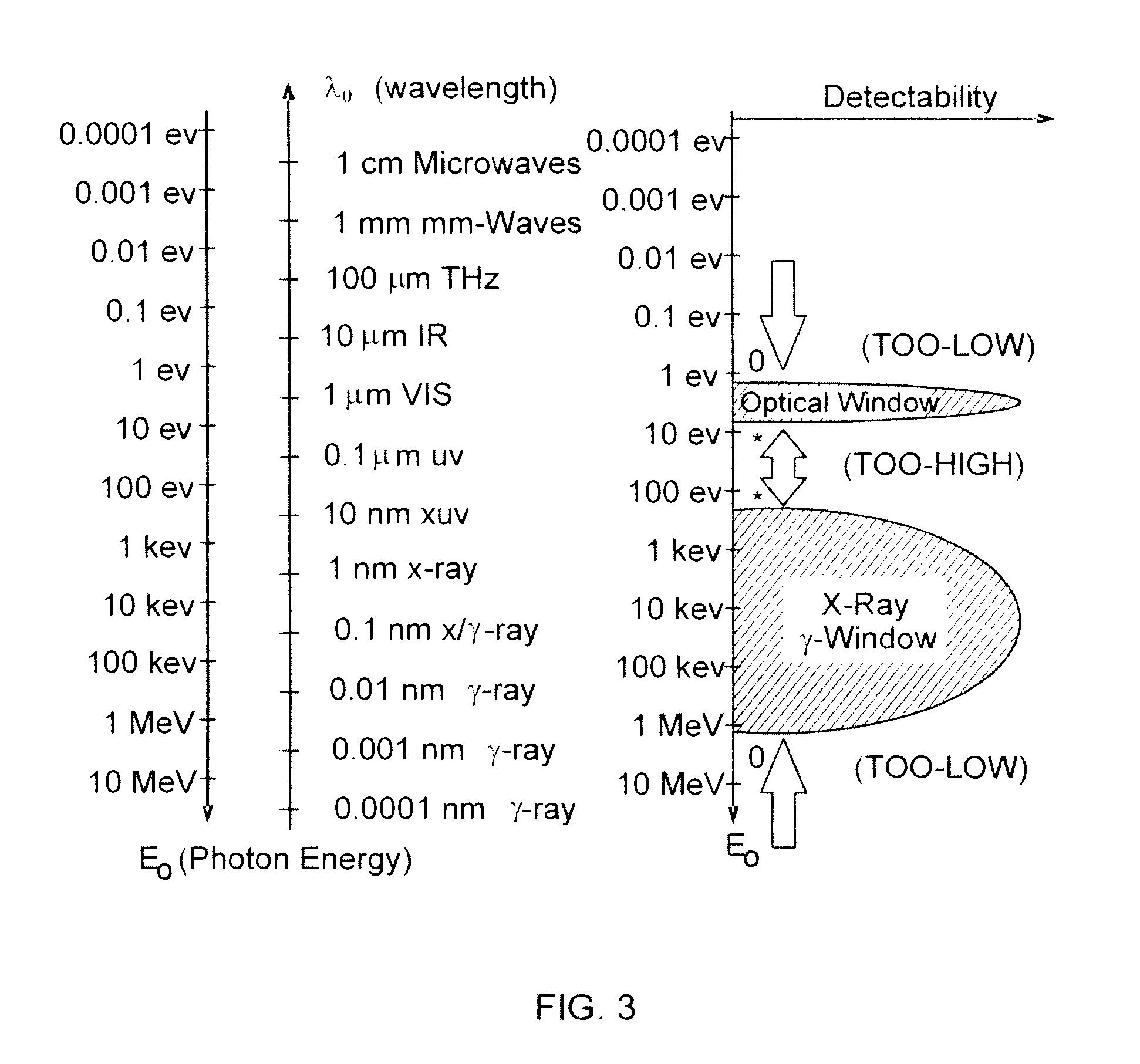

Quantum-imaging system and mode of operation and method of fabrication thereof

ActiveUS7781739B1Quality improvementIncrease catch rateElectric discharge tubesPhotometryOperation modeSpectrometer

A quantum-imaging system for detecting photons, including short-wavelength (<1 nm) photons, is provided. A quantum imaging system can include optical read-out and optical means, and can be configured to perform as both a photon counter and a photon spectrometer. A quantum-imaging system can function as a photon counter and be configured to measure photon beam fluences (e.g., in J / cm2) for both strong beams and weak beams, the latter ones, for example, in the intensity range of 1 pJ / cm2sec, or 0.1 μSv / h. The quantum-imaging system can also function as a photon spectrometer and can be configured to measure photon energies with high energy resolution such as, for example, 1% of photon energy.

Owner:MERCURY MISSION SYST LLC

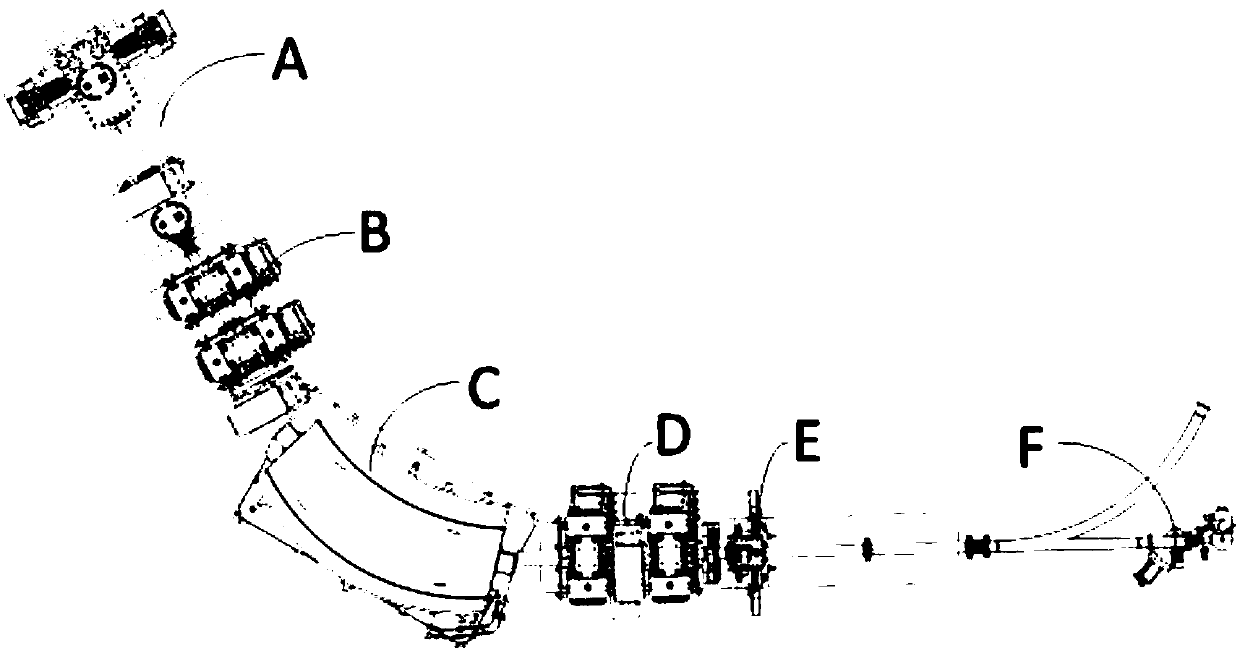

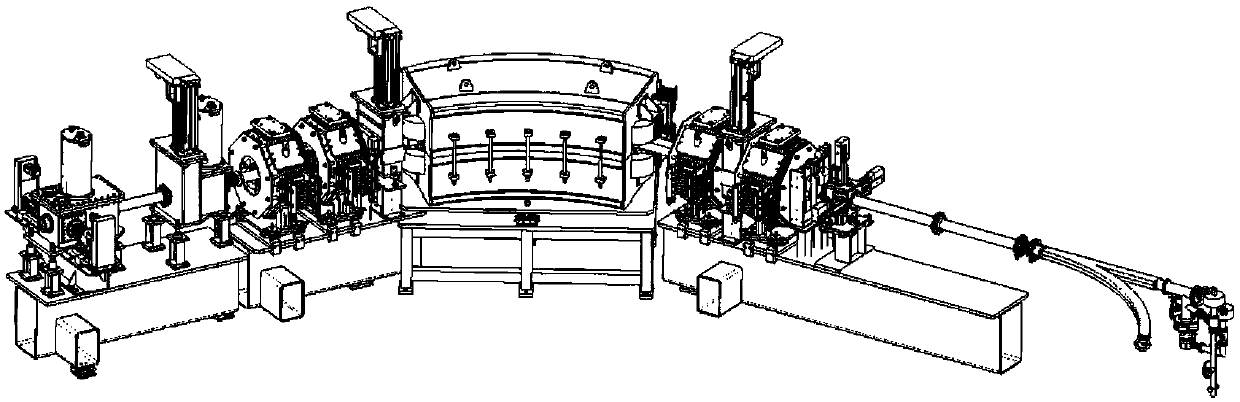

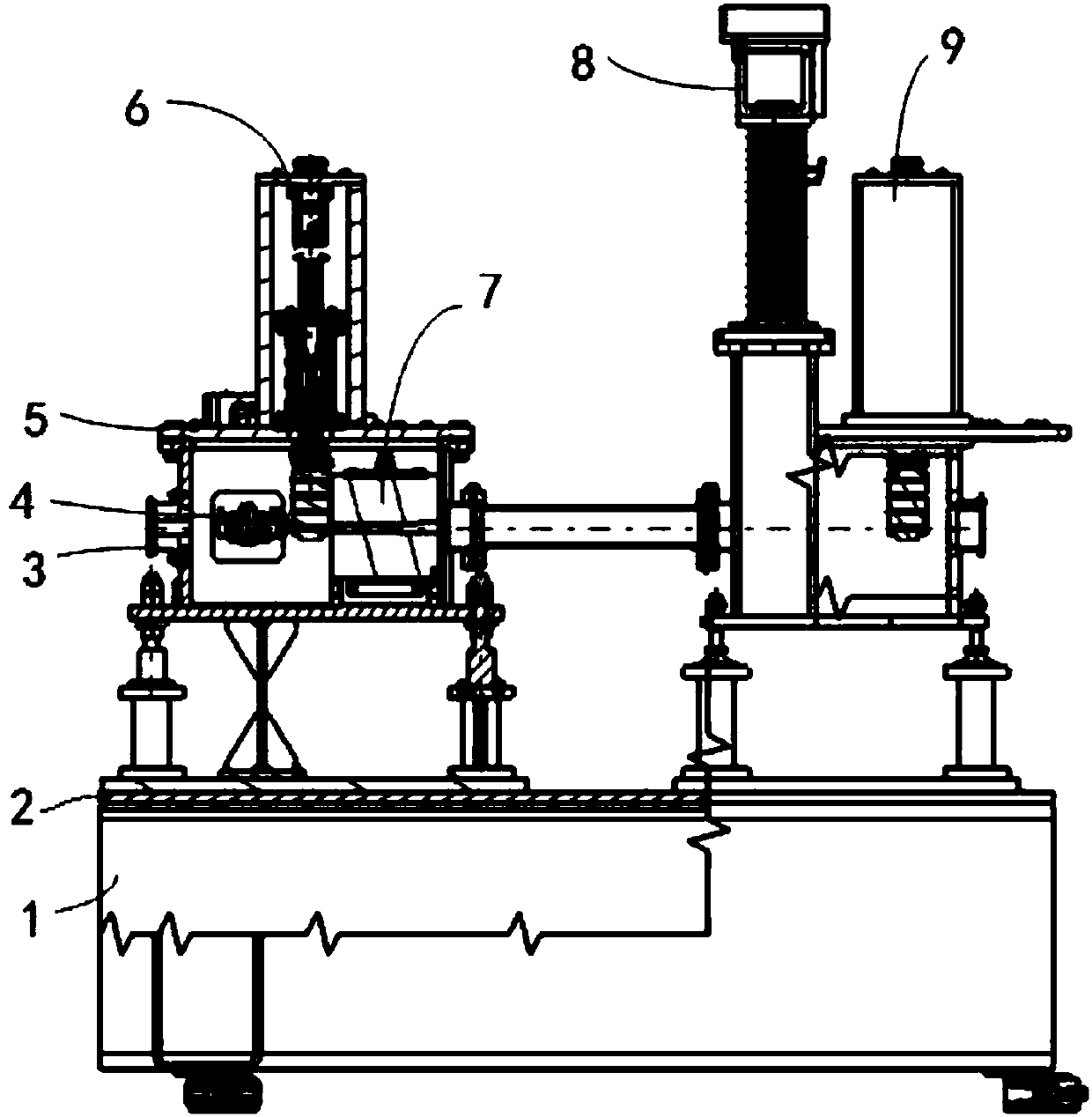

Superconducting proton device energy selecting system and realizing method thereof

The invention discloses a superconducting proton device energy selecting system and a realizing method thereof. The energy selecting system comprises the components of an energy reduction segment which performs energy reduction, energy spreading and divergency adjustment on an entering photon beam; a focusing and correcting segment B which detects divergency of the beam, performs signal feedback to a control system, wherein the control system adjusts magnitude of a magnetic field and corrects the movement track of the beam; a deflecting segment C which realizes higher amplitude of the protonswith higher energy spreading degree from the central track of the beam in a radial direction; a secondary focusing segment D which focuses the beam again; and an energy selecting segment E which realizes passing of the proton beam at the designed central position, thereby realizing preliminary screening of the beam. According to the superconducting proton device energy selecting system and the realizing method thereof, the energy and divergency of the proton beam, screening quality of the proton beam and making the making satisfy the requirement of a treatment end.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

Method and system for the calculation of dose responses for radiotherapy treatment planning

InactiveUS20080004845A1Rapid dose calculationQuick calculationDiagnostic recording/measuringComputation using non-denominational number representationPhoton Beam Radiation TherapyBeam direction

Method and system that allows patient dose response functions to be calculated, prior to treatment planning, for external photon beam radiotherapy. In one embodiment, for each location where a separate dose value is desired, referred to as a dose region, adjoint calculations are performed to calculate the adjoint solution fields associated with that dose region. Once potential beam directions are specified, a ray tracing process is performed to transport the adjoint solution fields out of the patient and to locations where treatment plan parameters may be specified. The output of this process is the dose response at each dose region resulting from a prescribed photon fluence, at a given location, direction, and energy.

Owner:TRANSPIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com