Scanning method for manufacturing three-dimensional object layer by layer

A technology of three-dimensional objects and scanning methods, which is applied in the direction of manufacturing tools, additive manufacturing, manufacturing auxiliary devices, etc., can solve the problems of insufficient processing accuracy, low production efficiency, and high production efficiency, so as to ensure processing accuracy, ensure production efficiency, and meet processing requirements. The effect of efficiency and the requirements of workpiece machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

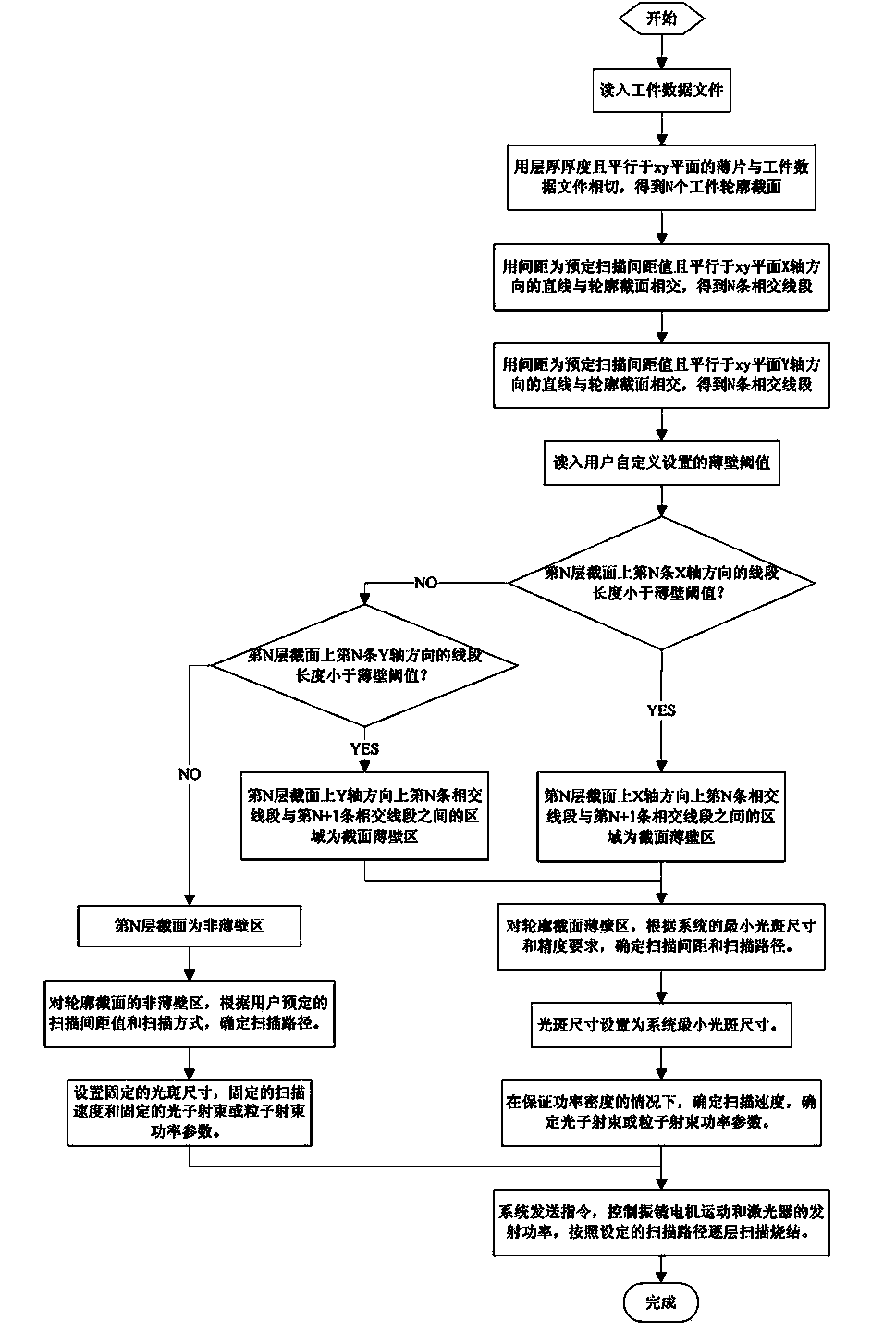

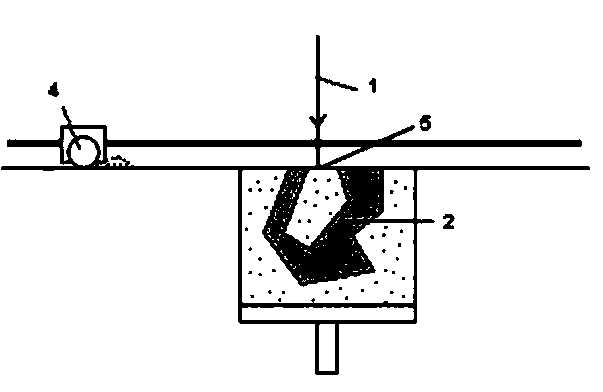

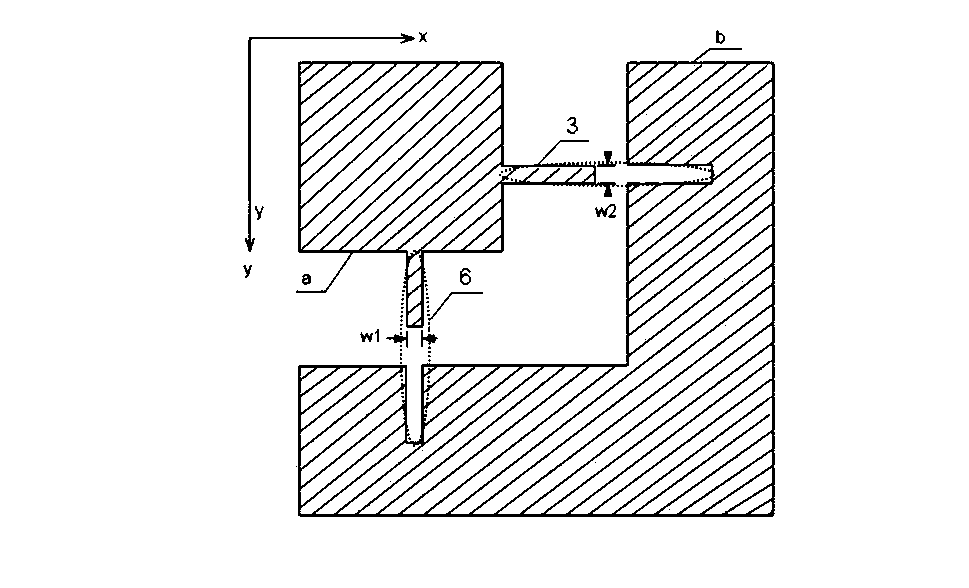

[0030] Such as figure 1 and figure 2 As shown, a scanning method of the present invention for manufacturing a three-dimensional object layer by layer is used in a layer manufacturing device. The present invention is based on the method of using photon beam or particle beam 1 to scan the three-dimensional object layer by layer, that is, the photon beam or particle beam 1 is used to shoot on the work table 5, and the cross-section of the three-dimensional object 2 to be processed passes through the laying mechanism 4 Tiled powders are subjected to fill-sweep sintering. The present invention adopts the method for area scanning of each layer to be processed, specifically comprises the following steps:

[0031] (1) Read in the workpiece data file;

[0032] (2) Use slices parallel to the xy plane to be tangent to the workpiece data fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com