Patents

Literature

1922results about How to "Guaranteed production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

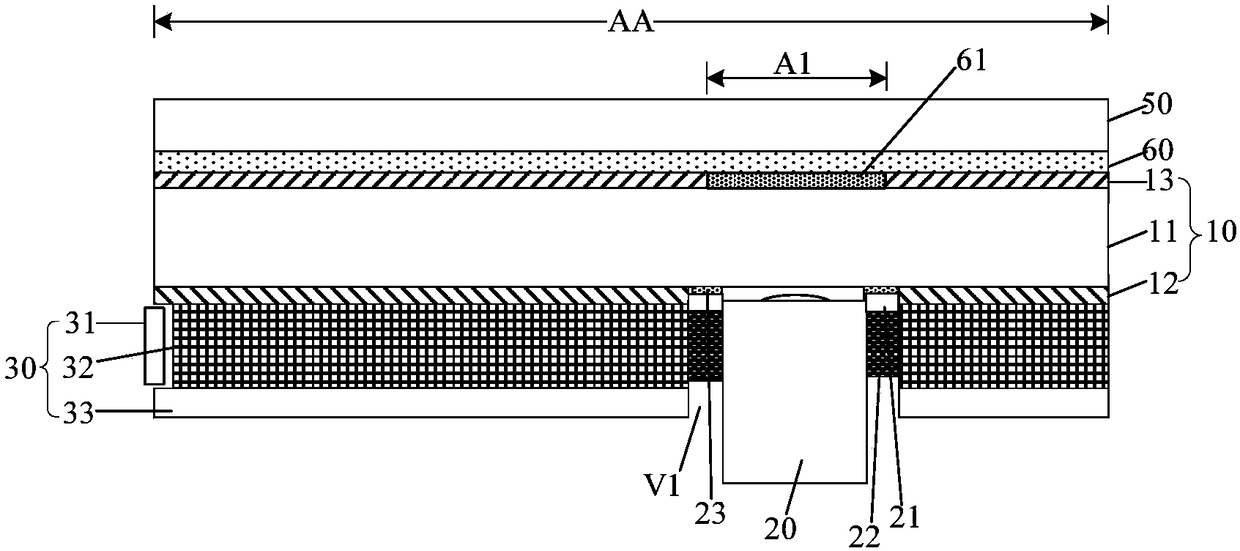

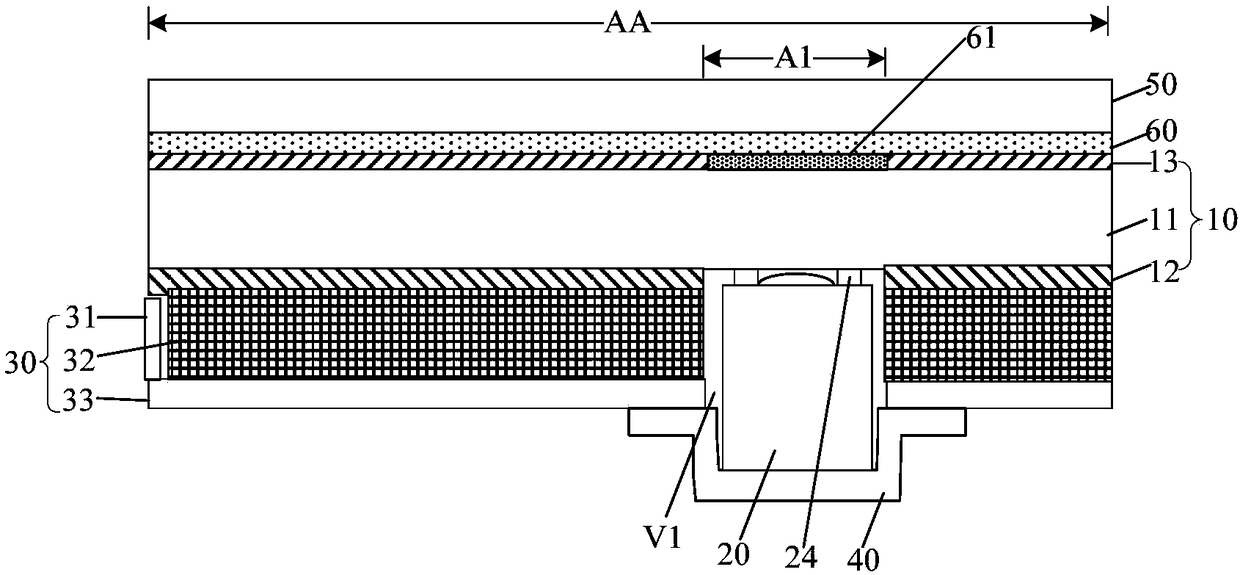

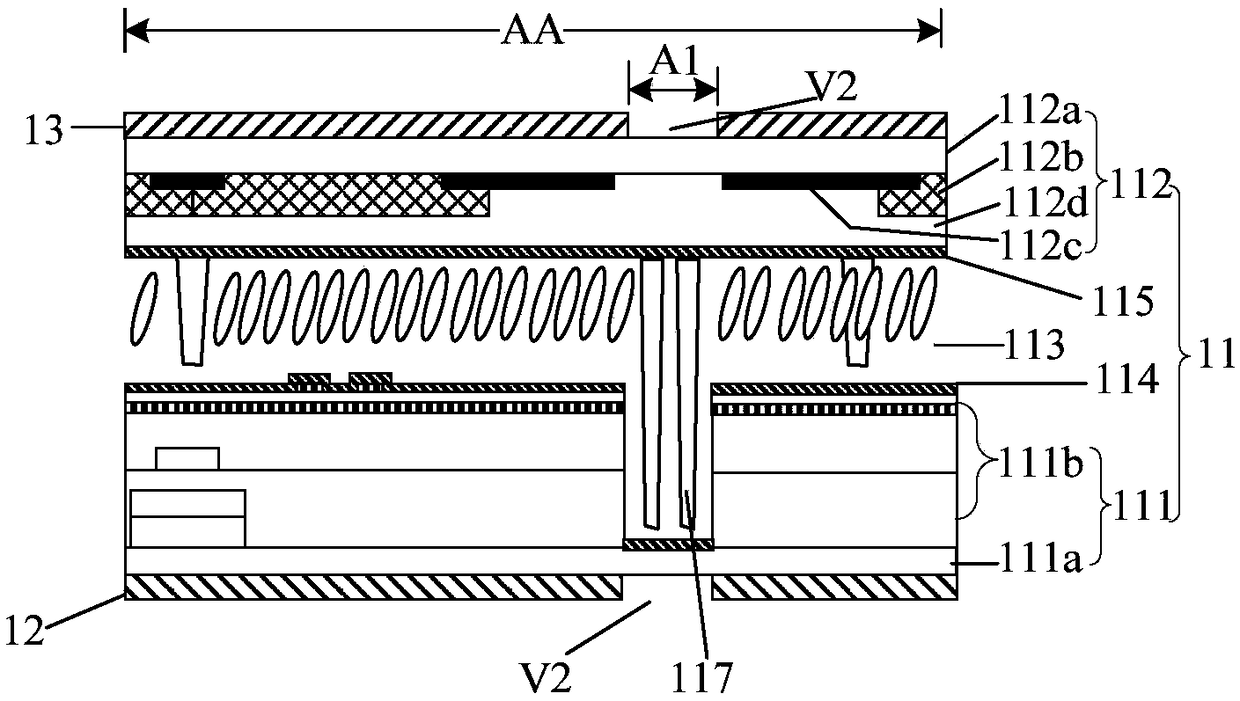

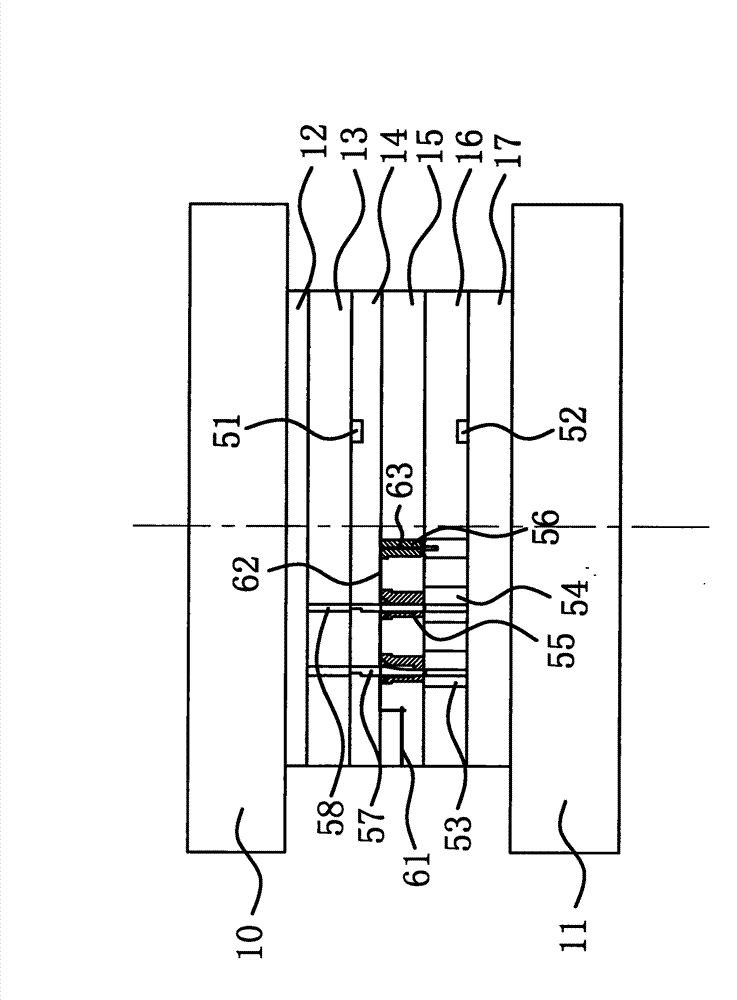

Display device

ActiveCN108594524AIncrease the screen ratioGuaranteed production efficiencyNon-linear opticsCamera lensDisplay device

The invention provides a display device. The display device comprises a display module and a camera located in a display area of the display module and located on one side, backing to the light emergent direction, of the display module; the display area of the display module comprises a light incidence area corresponding to a lens of the camera, and the light incidence area allows outside light topenetrate through, so that the penetrating outside light is irradiated to the lens of the camera. The screen-to-body ratio of the display device can be increased under the condition that the production efficiency and the product yield are guaranteed.

Owner:BOE TECH GRP CO LTD +1

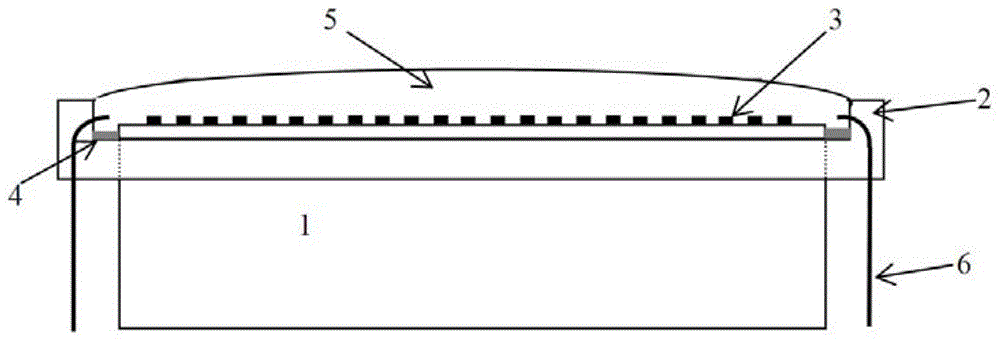

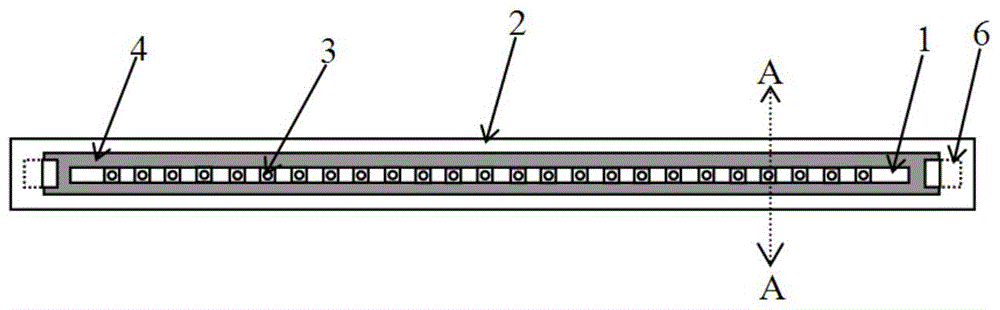

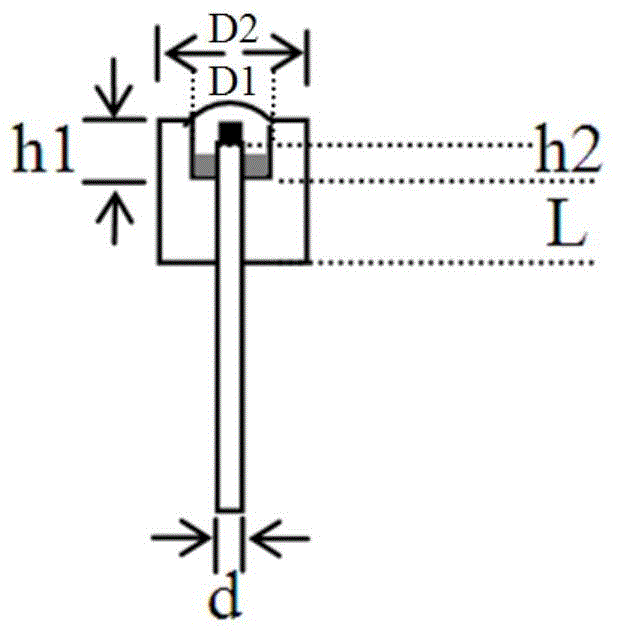

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

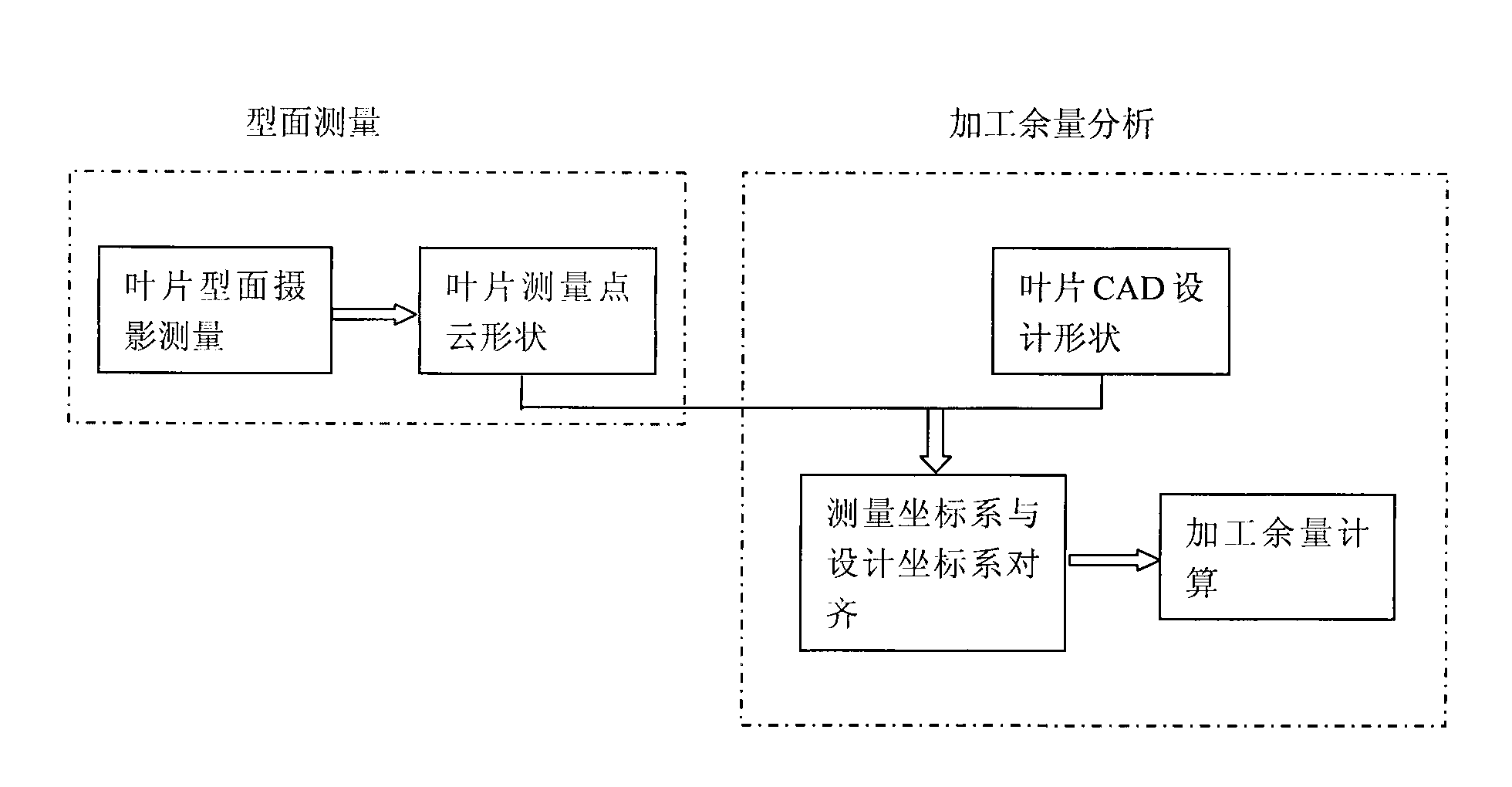

Water turbine blade blank profile measuring and machining allowance analyzing method

InactiveCN101634544AHigh speedImprove machining accuracyUsing optical meansCavitationMeasurement point

The invention relates to a water turbine blade blank profile measuring and machining allowance analyzing method capable of effectively solving the problem of water turbine blade blank profile measurement and machining allowance analysis to ensure the manufacturing quality and precision of the water turbine blades, comprising the following technical solutions: measuring the blade blanks by using a digital close range photogrammetry to obtain the measuring point cloud data shapes of the blank profiles consequently, aligning a measuring coordinate system where the measuring point clouds are located to a design coordinate system where a CAD design model is located, establishing a differential relation of free-form surface parameters with respect to rigid rotation parameters by using an analytic method derived by the multivariate of Newton iteration method to obtain a Jacobian matrix and Hessian matrix which are available for a target equation; then performing the numerical optimization calculation based on the LM method and Newton iteration method, and performing report or graphical output and print on the result. The inventive method is scientific, advanced, stable and reliable, and has high accuracy, thereby ensuring the hydraulic stability, production efficiency and cavitation property, and bringing enormous economic and social benefits.

Owner:郑州辰维科技股份有限公司

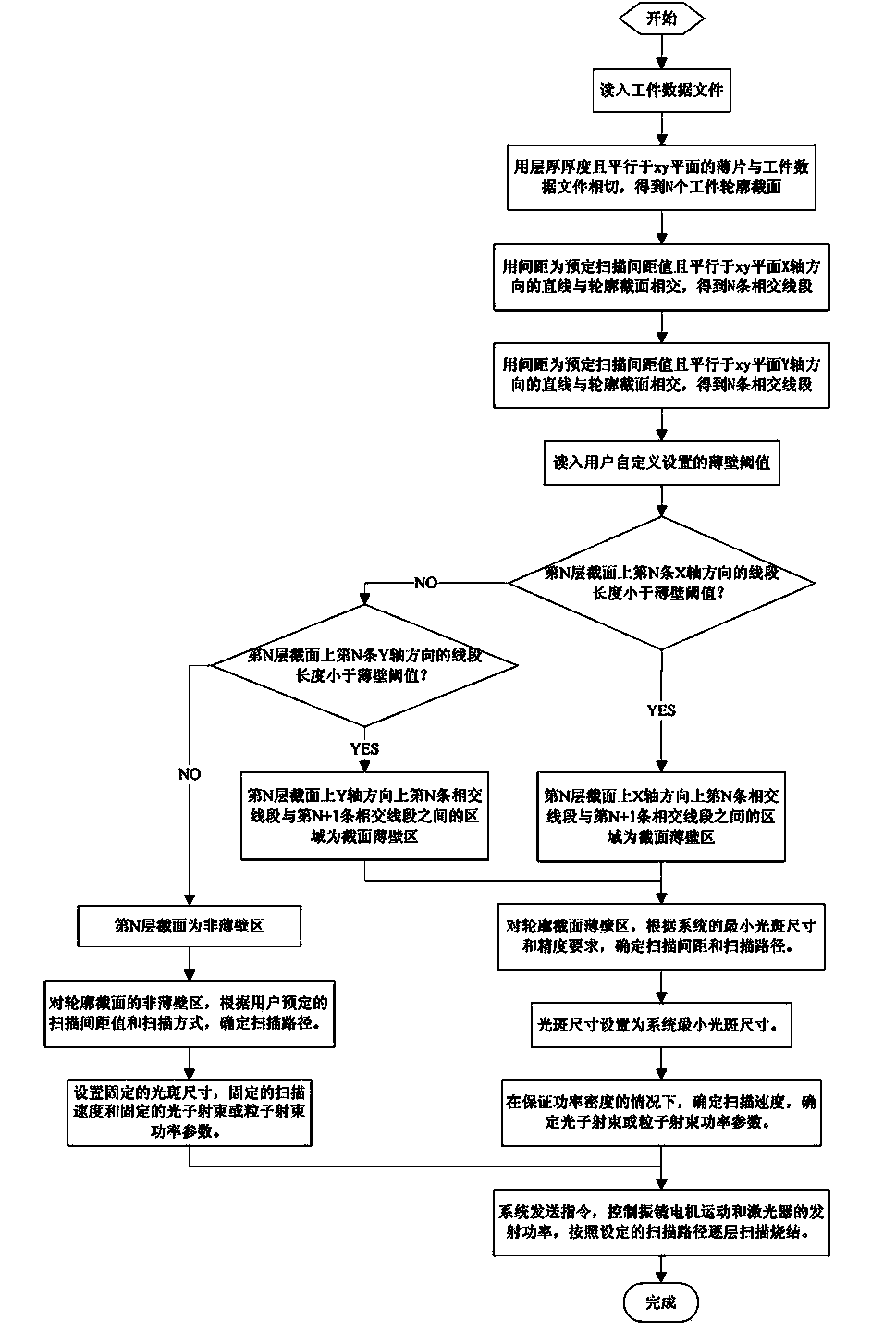

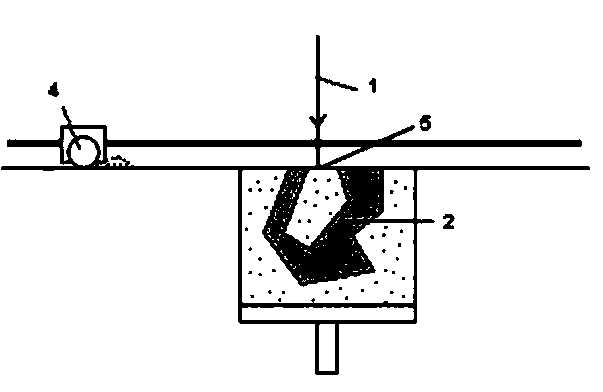

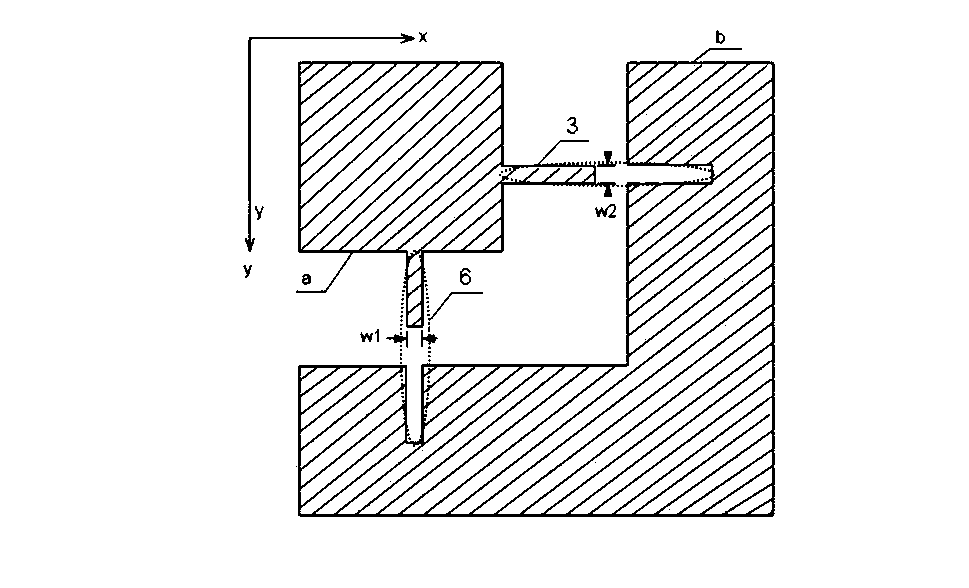

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

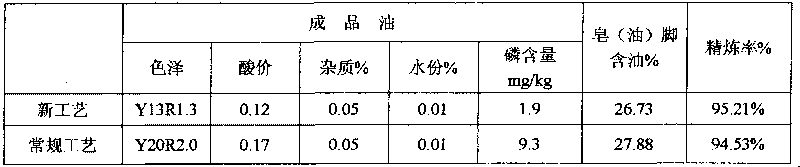

Novel process for refining oil-tea camellia seed crude oil

ActiveCN101735886AReduce side effectsLow reaction temperatureFatty-oils/fats refiningOil and greaseVegetable oil

The invention discloses a novel process for refining oil-tea camellia seed crude oil, which belongs to the technical field of grease refining in the fine and further processing of farm and sideline products. A process flow comprises the following steps: filtering the oil-tea camellia seed crude oil to eliminate impurities; performing a first low temperature acid reaction; performing low temperature alkali refining; removing soap; performing water washing after first acid adding; performing second water washing; and de-coloring and deodorizing the obtained product to obtain first-level oil-tea camellia seed oil. The novel process is characterized by improving the oil obtaining rate of refining, lowering production cost, improving product quality and stability and the like, and is used for refining the oil-tea camellia seed crude oil and refining rap oil, peanut oil and other vegetable oil.

Owner:HUNAN XINJINHAO TEA OIL

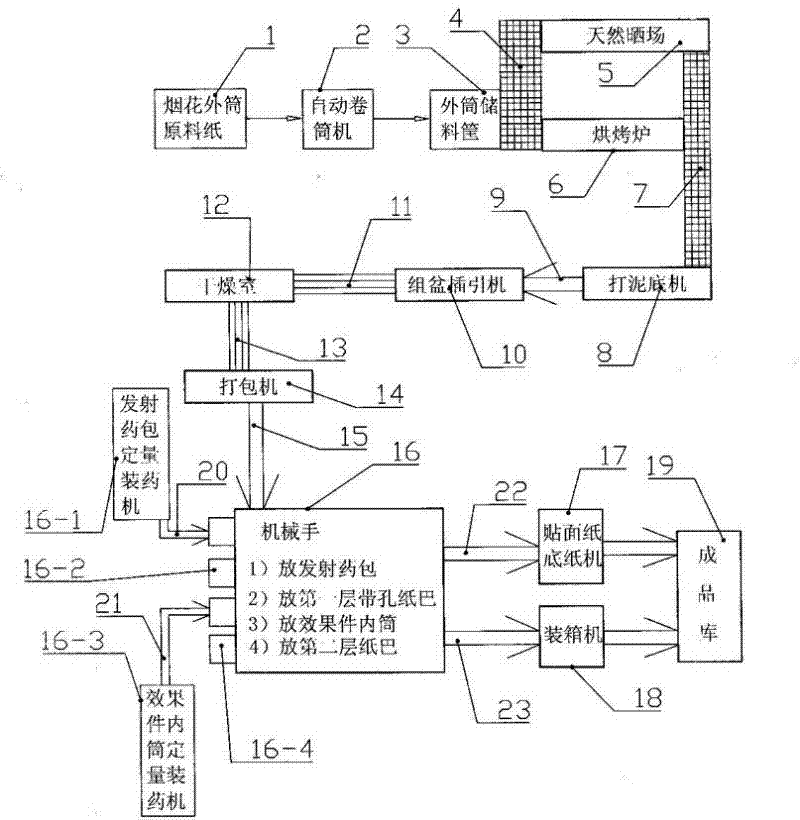

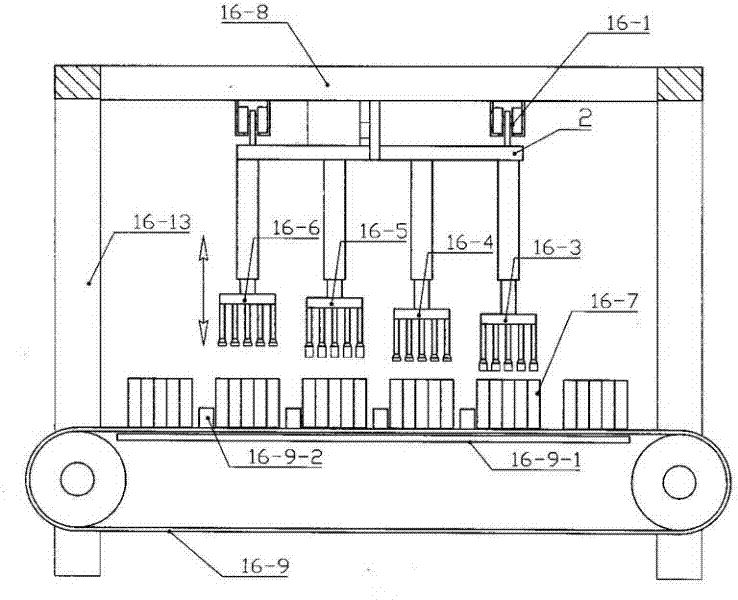

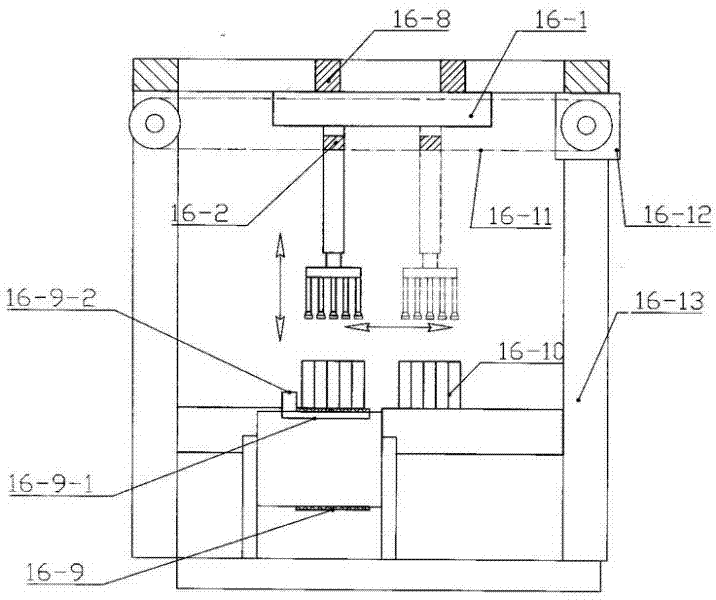

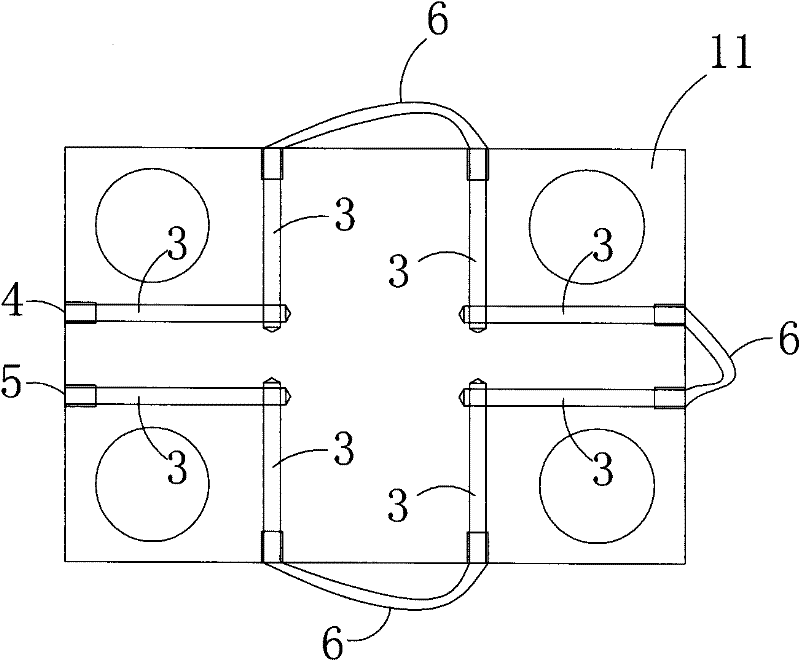

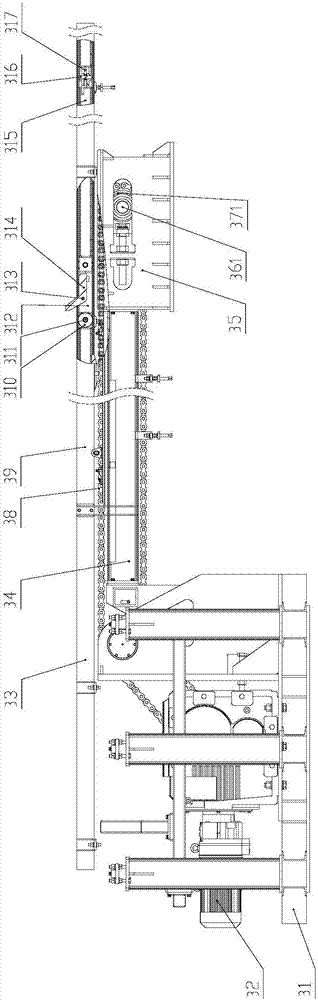

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

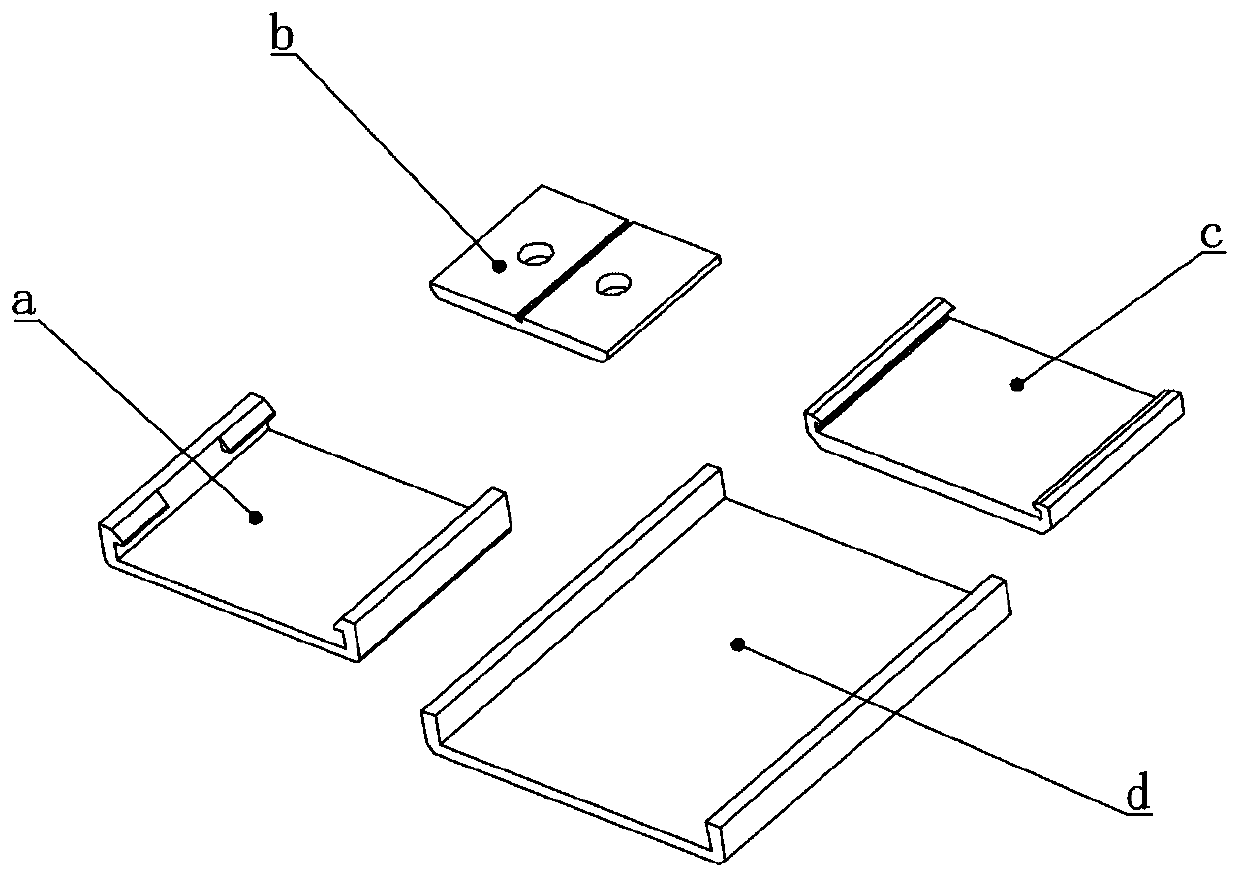

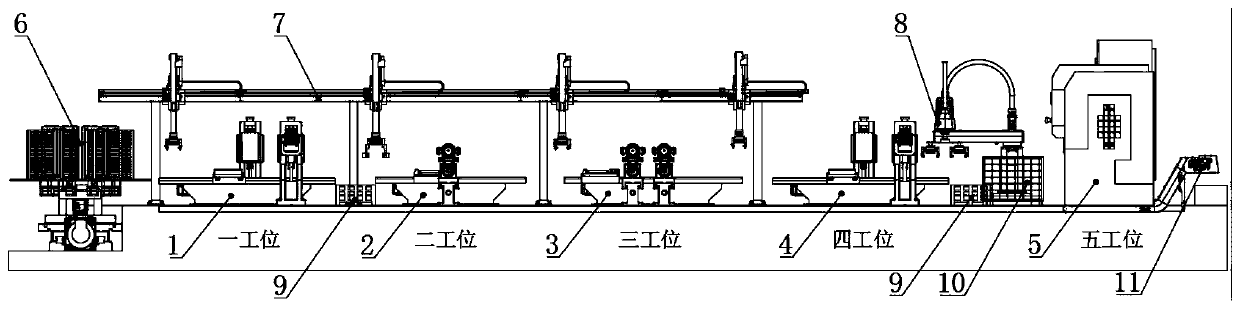

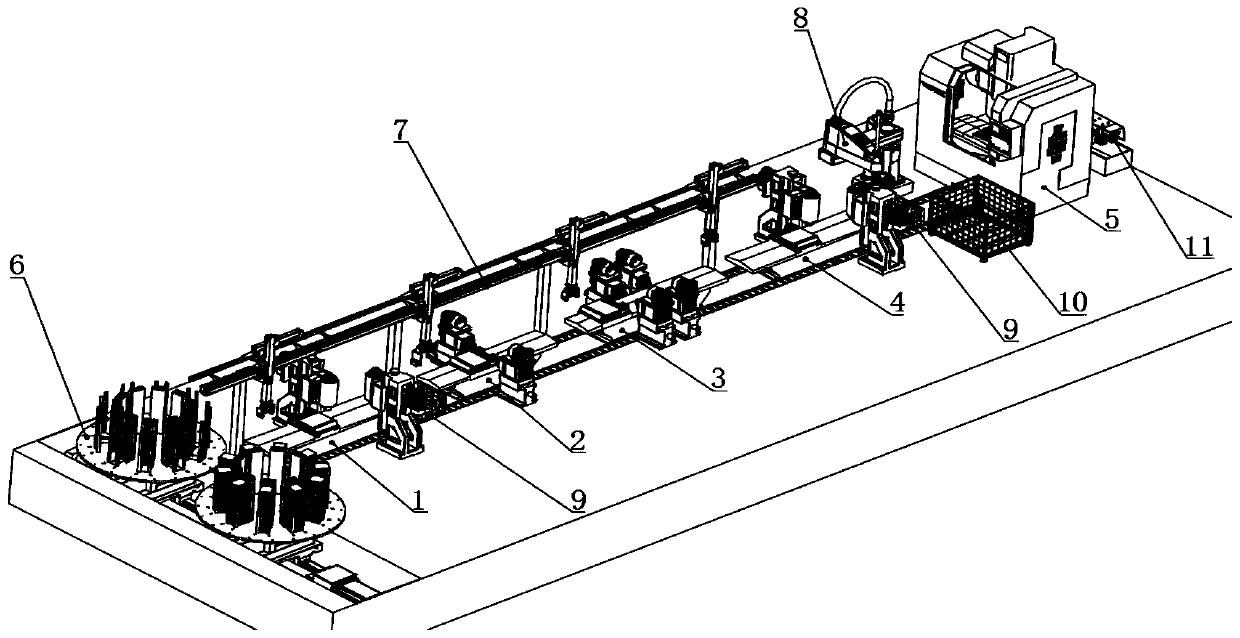

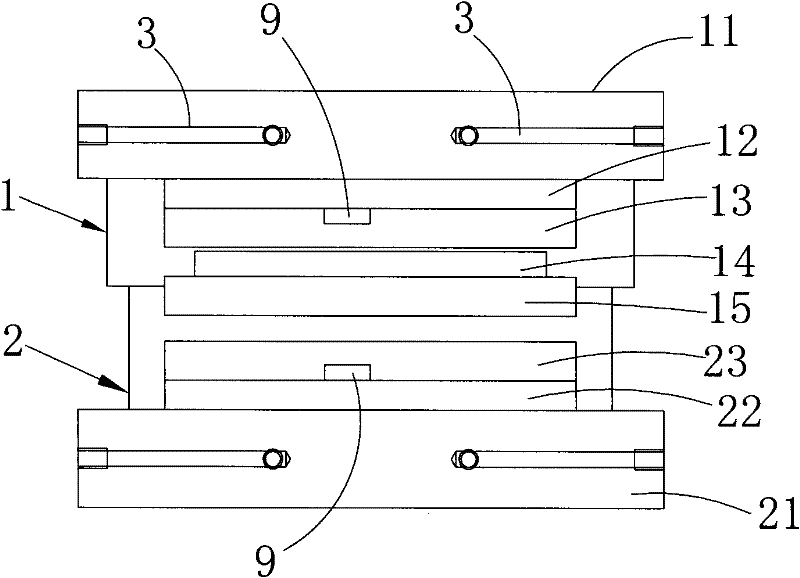

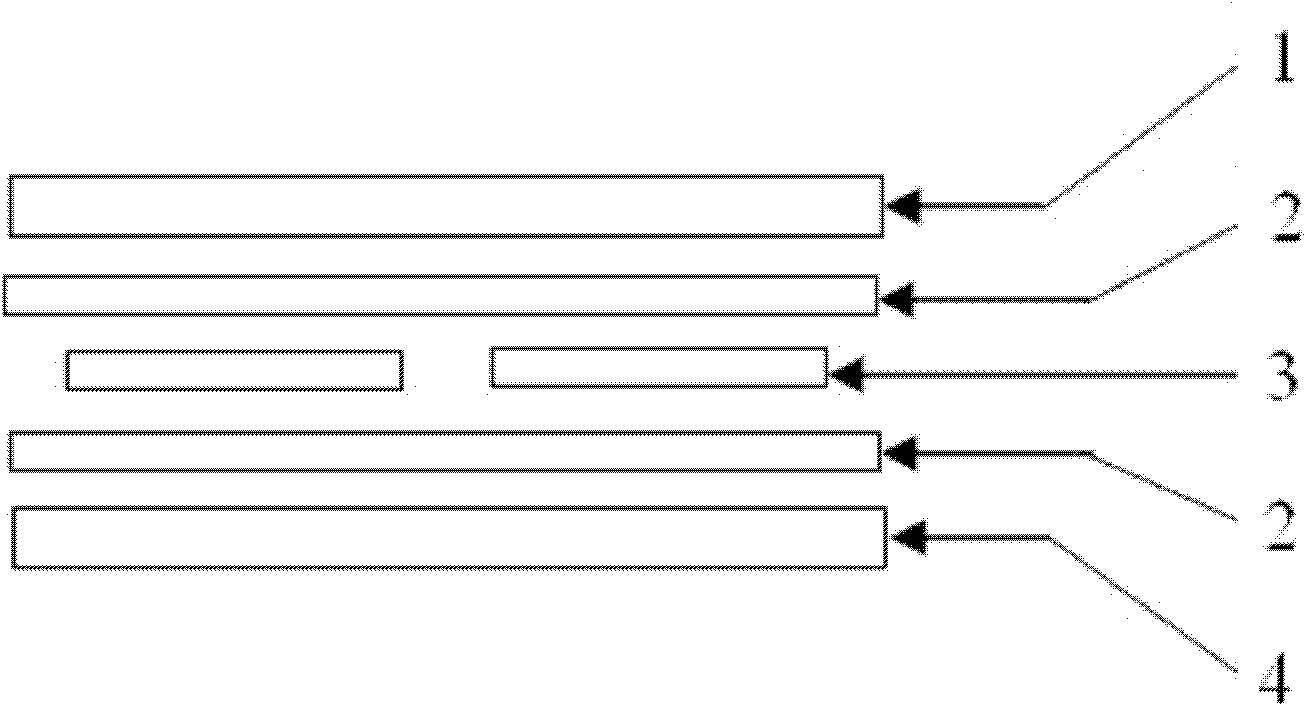

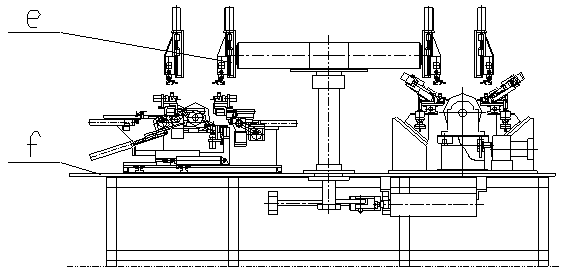

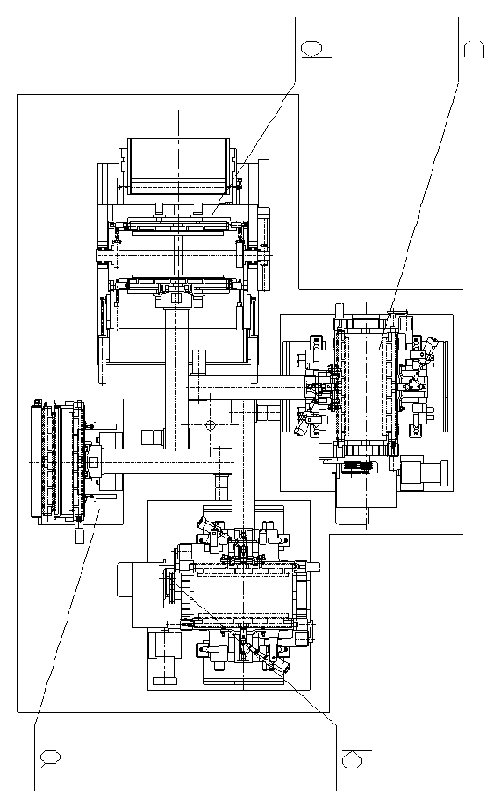

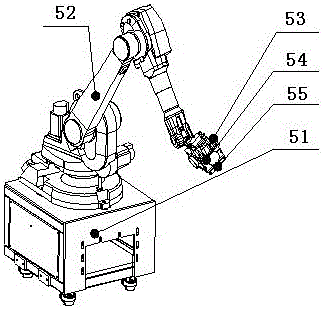

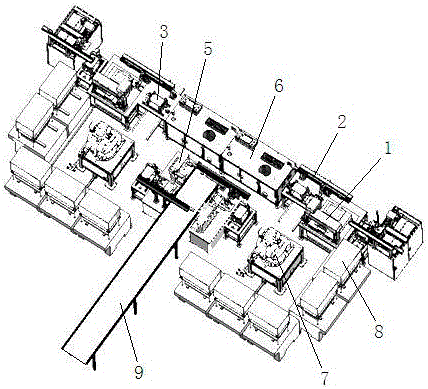

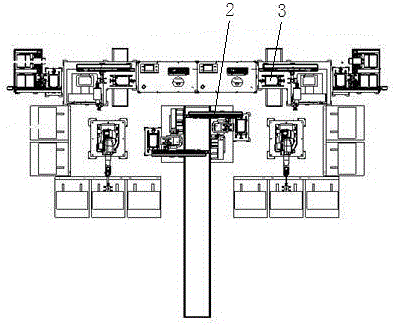

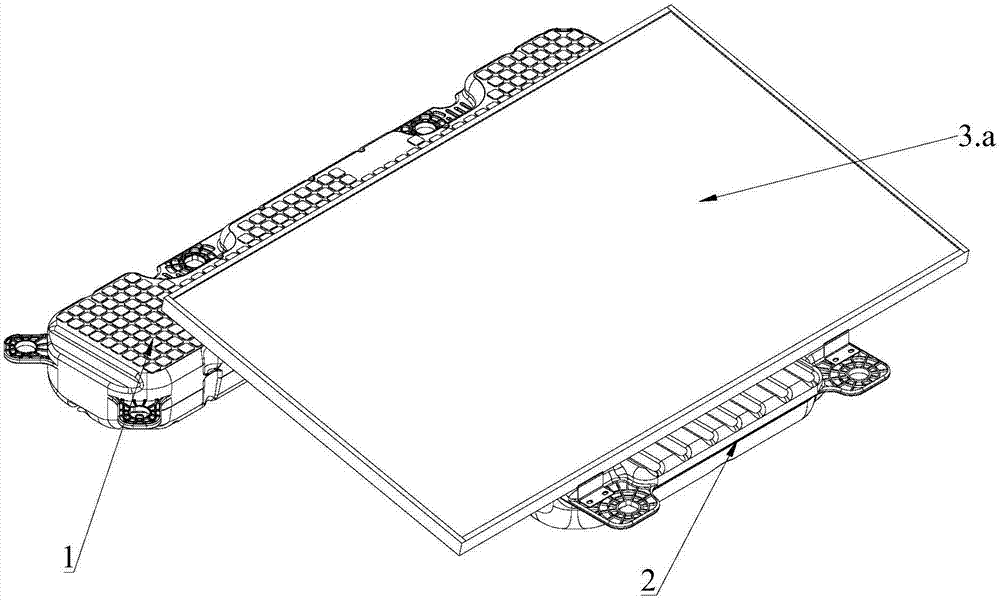

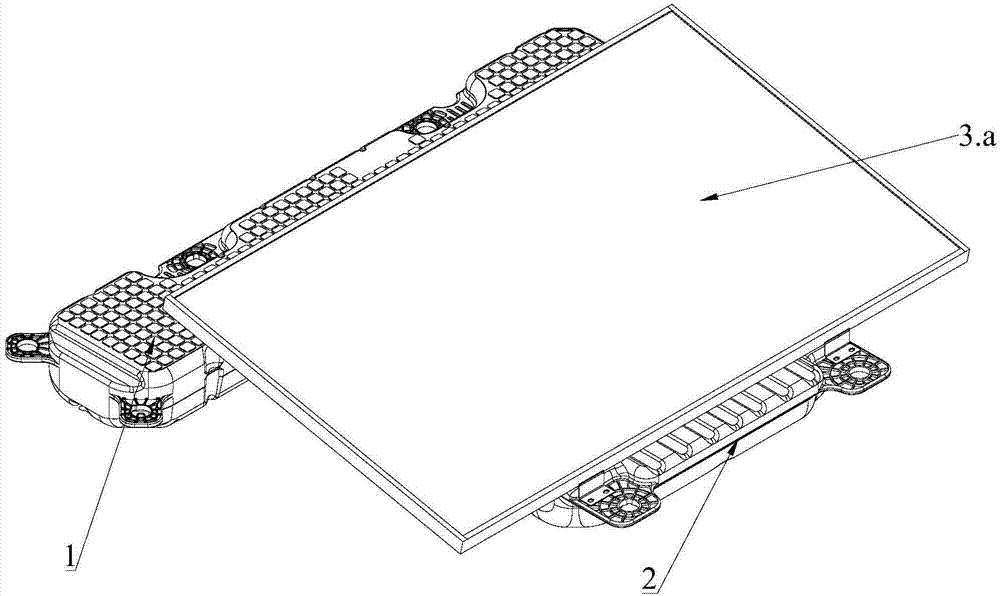

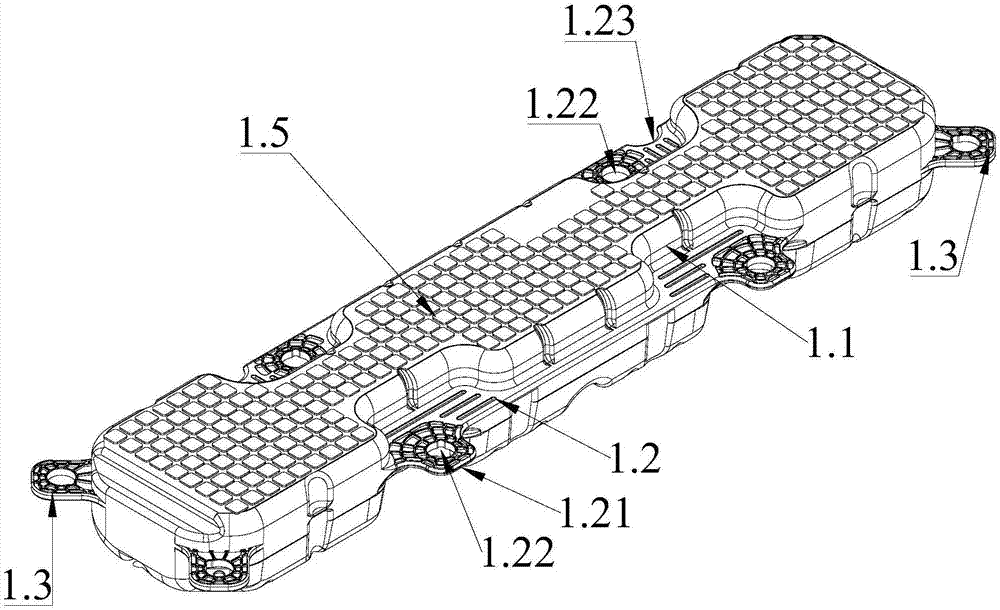

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

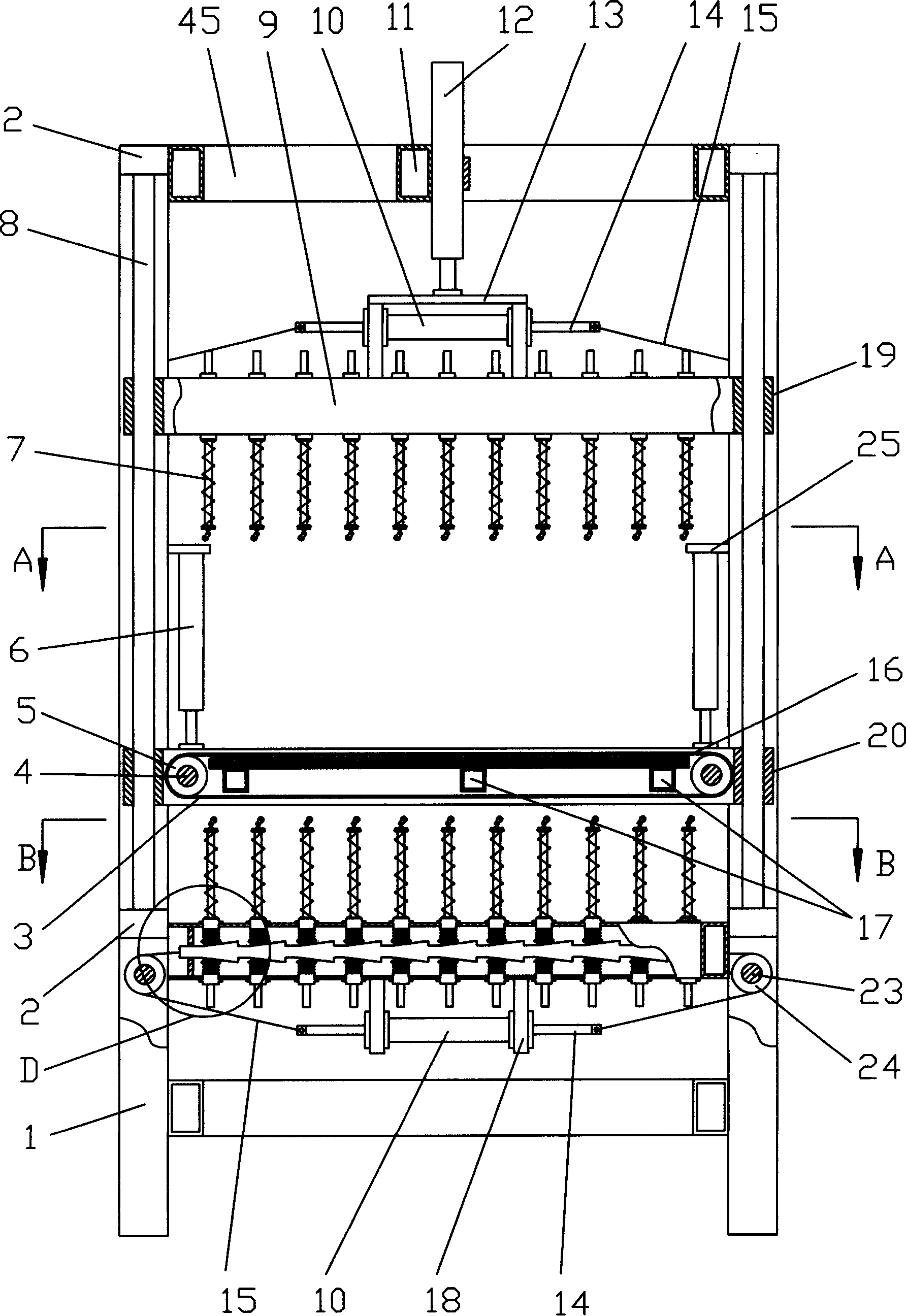

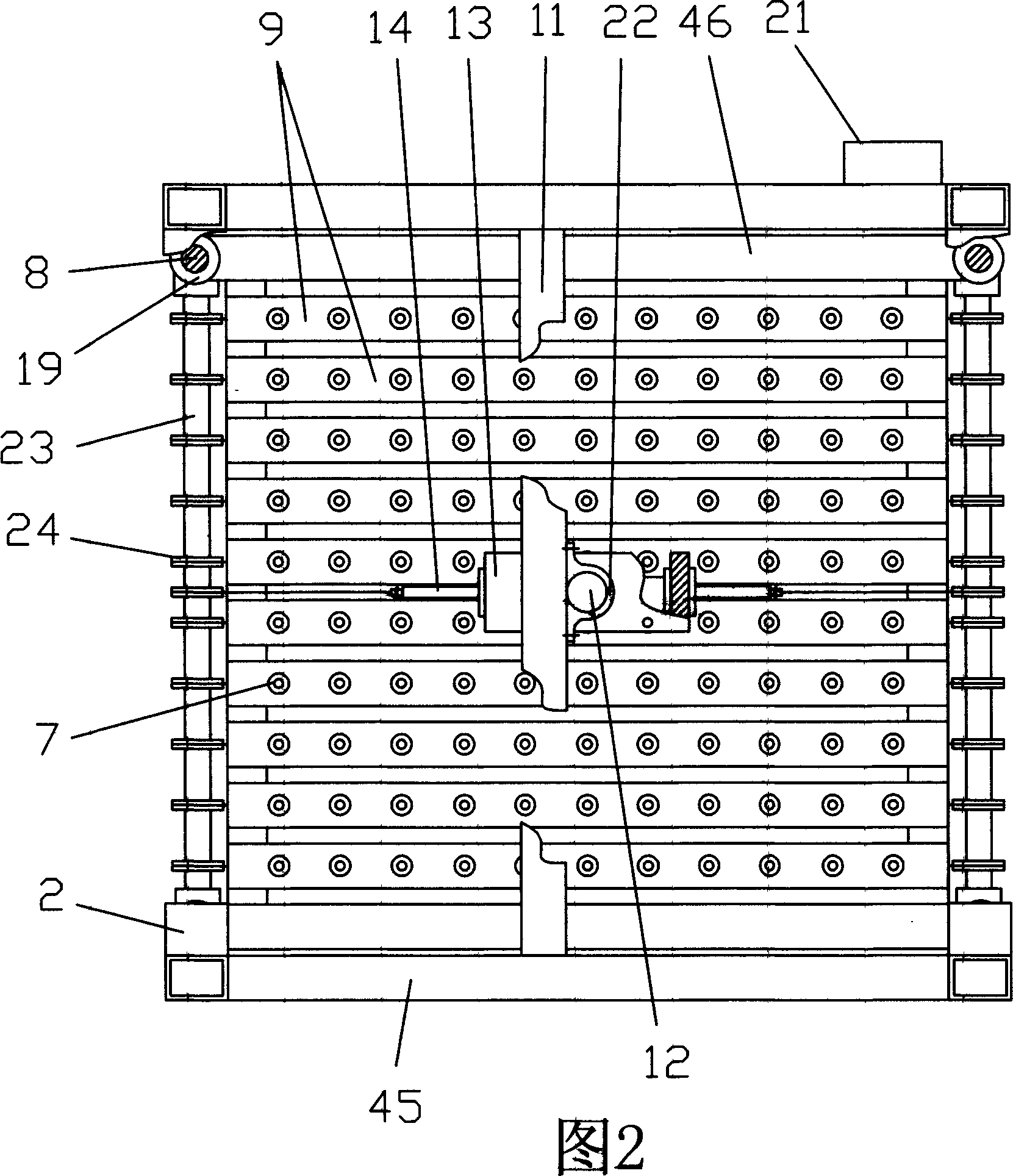

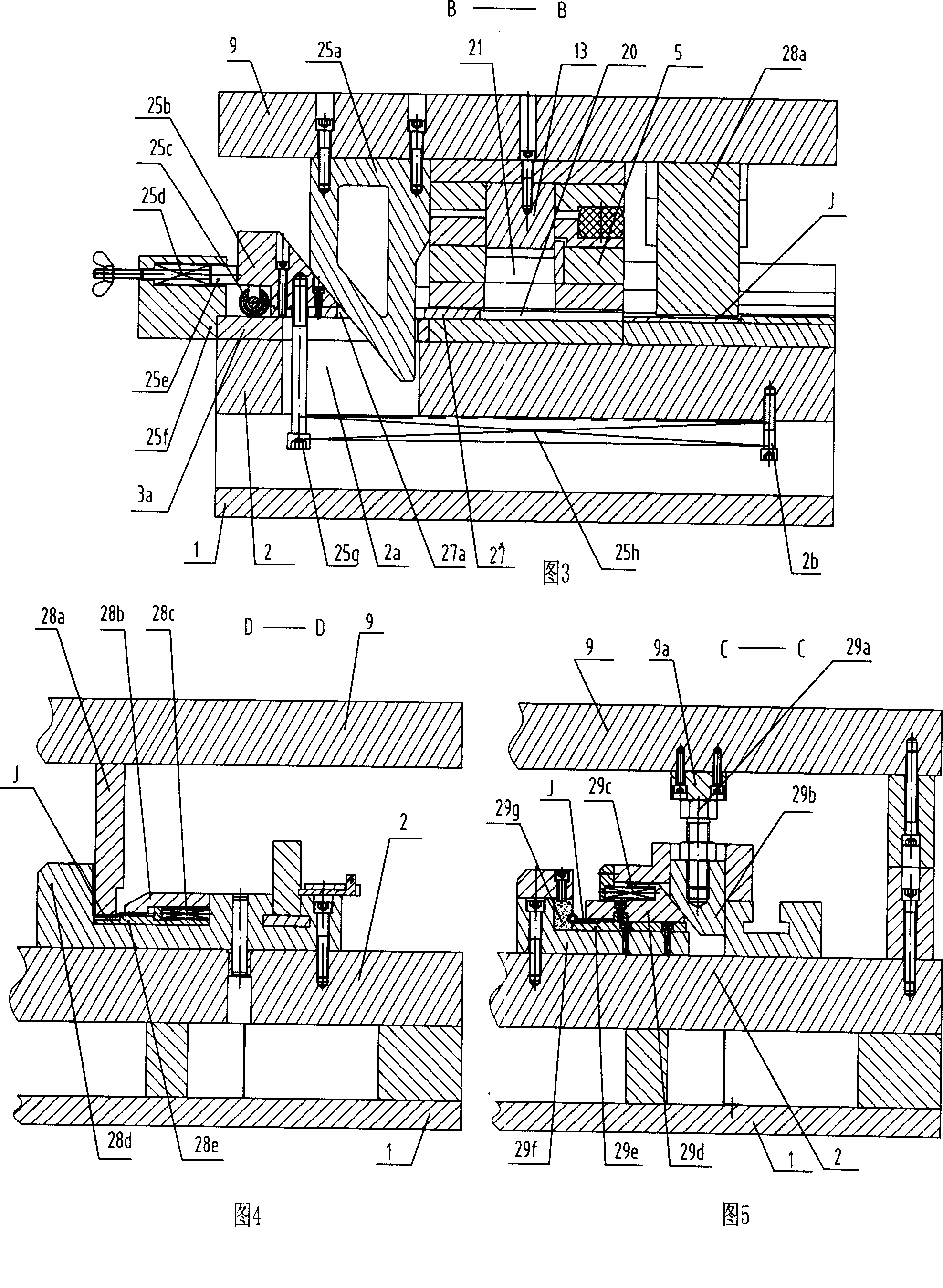

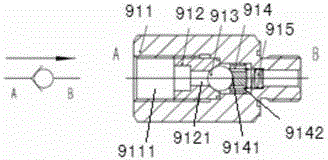

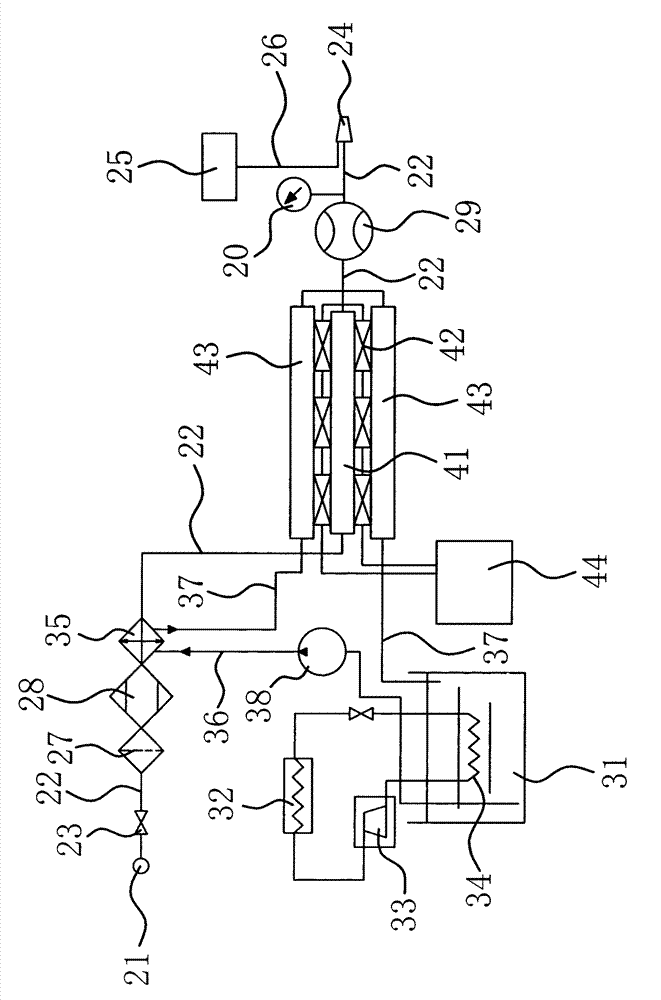

High speed stamping die with cooling structure

InactiveCN102233385AReduce the temperatureGuaranteed stamping accuracyShaping toolsEngineeringStamping process

The invention discloses a high speed stamping die with a cooling structure. The high speed stamping die is internally equipped with a cooling pipeline; a cooling liquid circulates in the cooling pipeline, the initial end of the cooling pipeline is a cooling liquid inlet, and the terminal end of the cooling pipeline is a cooling liquid outlet; and the high speed stamping die is also internally equipped with a temperature sensor for monitoring the temperature in the high speed stamping die. In the invention, the cooling liquid in the cooling pipeline can immediately conduct heat generated during the stamping process out of the high speed stamping die by utilizing a heat exchange mode so as to lower the temperature in the high speed stamping die; and a control device controls an infusion pump to adjust flow of the cooling liquid according to temperature information monitored by the temperature sensor so as to keep the temperature in the high speed stamping die within a certain range. Therefore, the high speed stamping die has the beneficial effects that the deformation and damage of the high speed stamping die are reduced and the service life of the high speed stamping die is prolonged while the stamping precision and production efficiency are ensured.

Owner:KUNSHAN JIAHUA ELECTRONICS

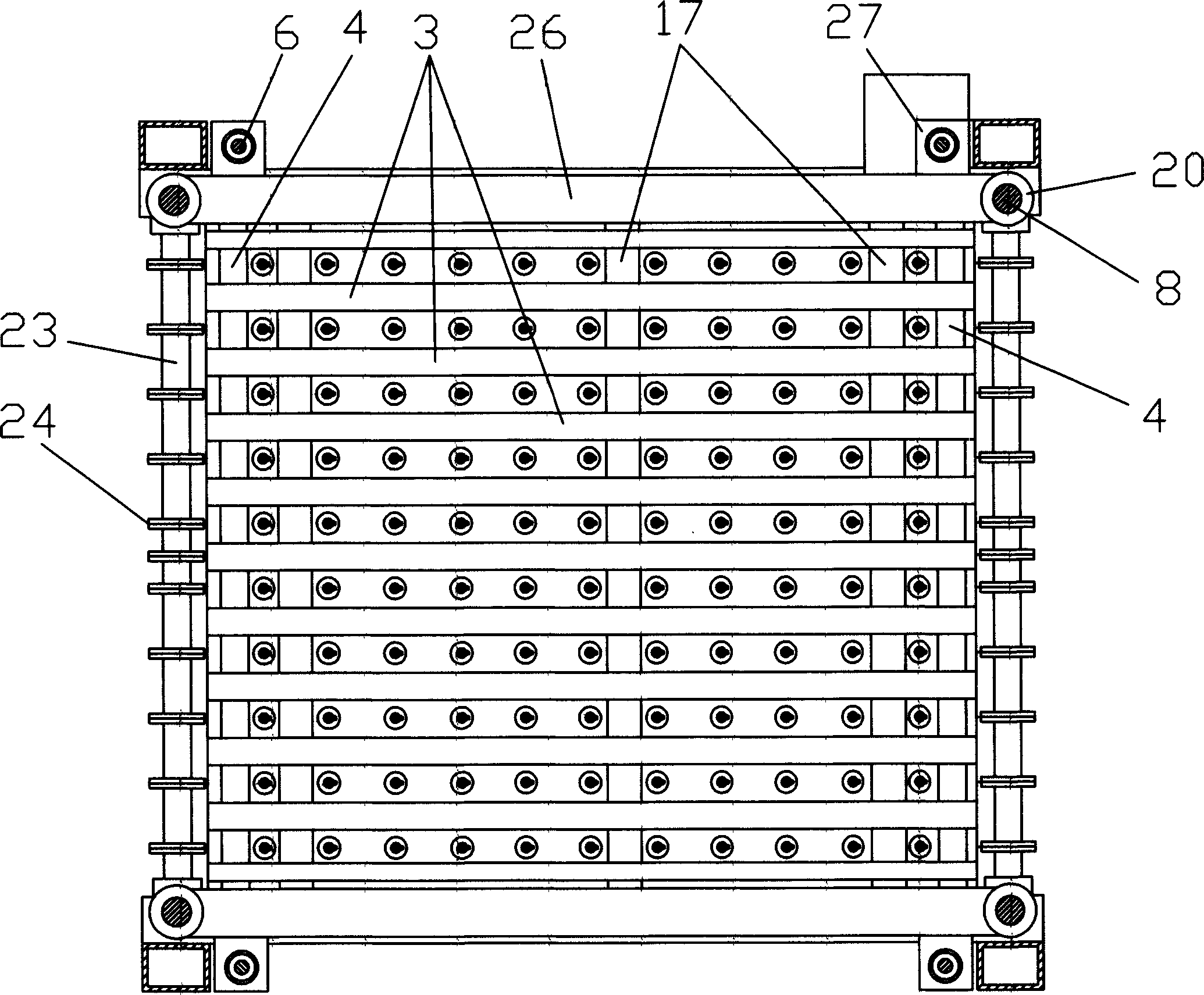

Double curved toughened glass cooling forming device

InactiveCN1587132AChange defectsMeet production requirementsGlass tempering apparatusDrive shaftEngineering

The double curved toughened glass cooling formation apparatus includes frame, upper forming unit, lower forming unit and conveying mechanism. The upper forming unit capable of moving up and down and the lower forming unit have glass forming curved surface comprising supporting points with adjustable height. The conveying mechanism capable of moving up and down is set on vertical guide tracks on the frame and includes support frame, conveying belts wound on two driving shafts and driving mechanism. The present invention can form various double curved surfaces in different forms, and this results in reduced investment in apparatus and raised apparatus utilization.

Owner:LUOYANG LANDGLASS TECH CO LTD

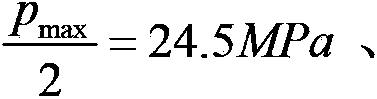

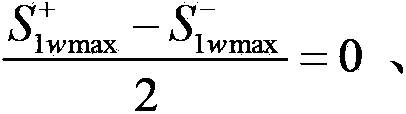

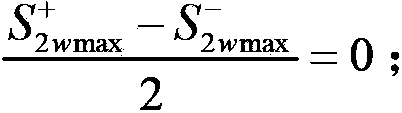

Comprehensive setting method for tension and rolling pressure in VC (Variable Crown) roll temper mill wet leveling process

ActiveCN103962390ATaking into account rolling stabilityGuaranteed mechanical propertiesRoll force/gap control deviceTension/compression control deviceSurface roughnessModel parameters

The invention provides a comprehensive setting method for tension and rolling pressure in a VC (Variable Crown) roll temper mill wet leveling process and belongs to the field of controlling. The comprehensive setting method comprises the following steps: related parameters are set by a temper mill control computer; related data or operational plans are acquired by the control computer through an input device or a superior computer; all operational parameters of the temper mill are controlled according to a pre-setting control mode, a method or setting parameters; all original values and optimizing step lengths are set according to equipment, technologies and quality parameters; under the premise of making ' taking rolling stability as optimized objective function and the finished product shapes, mechanical properties and surface roughness are qualified' as a constraint condition, three parts of metal model parameters such as rolling pressure, forwards and backwards tension and the like are taken as a whole to be set harmoniously; the rolling force and the forwards and backwards tension are set optimally; under the premise of guaranteeing product mechanical properties, the product mechanical properties, comprehensive control capability of the shapes and surface quality are improved, the production efficiency is guaranteed and the product quality is improved simultaneously.

Owner:BAOSHAN IRON & STEEL CO LTD +1

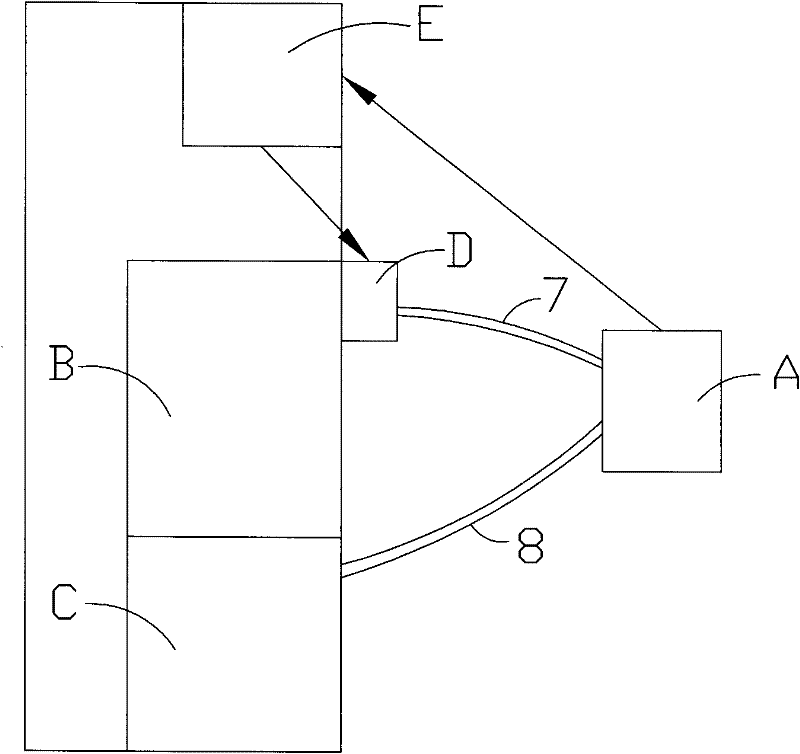

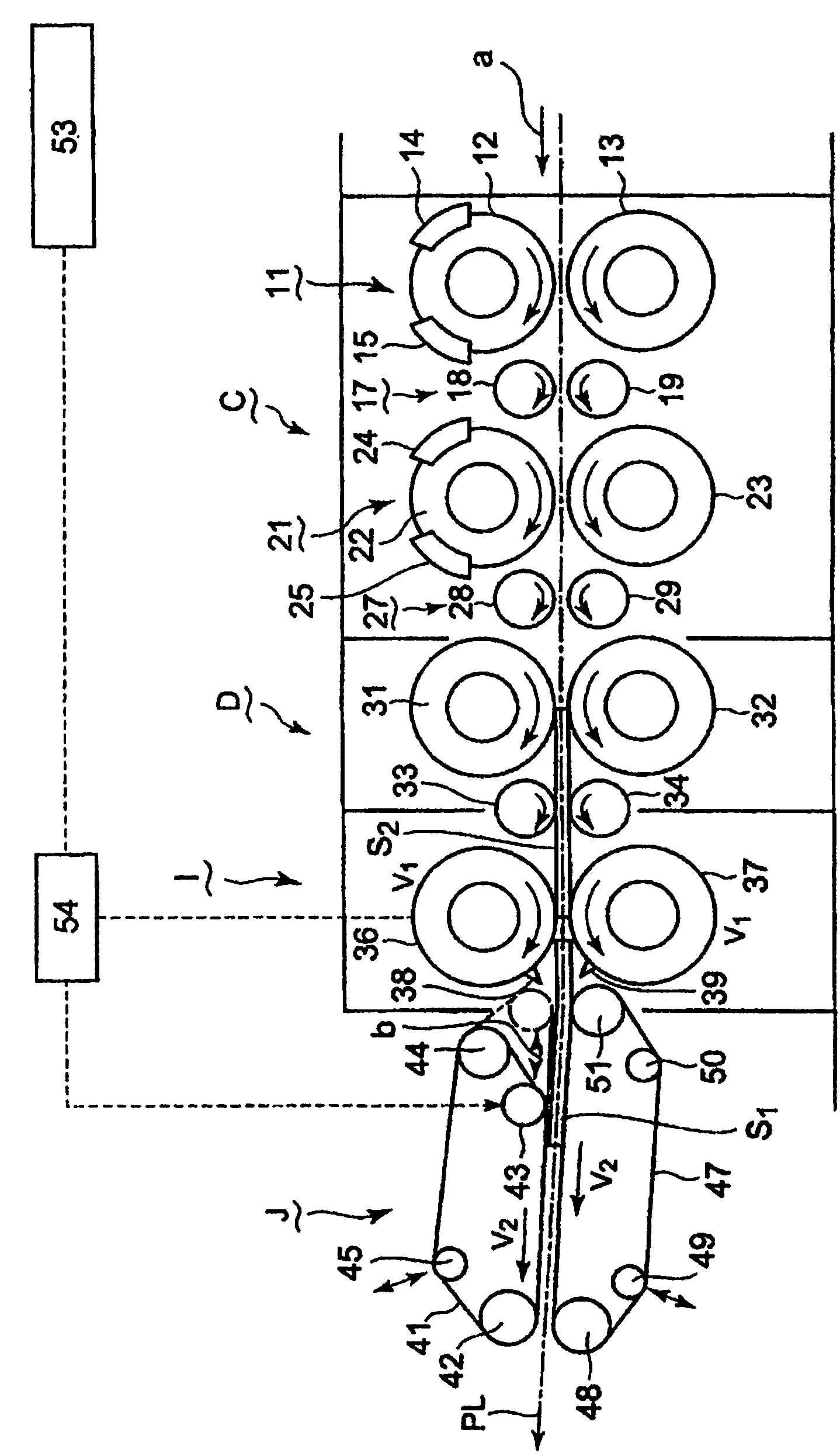

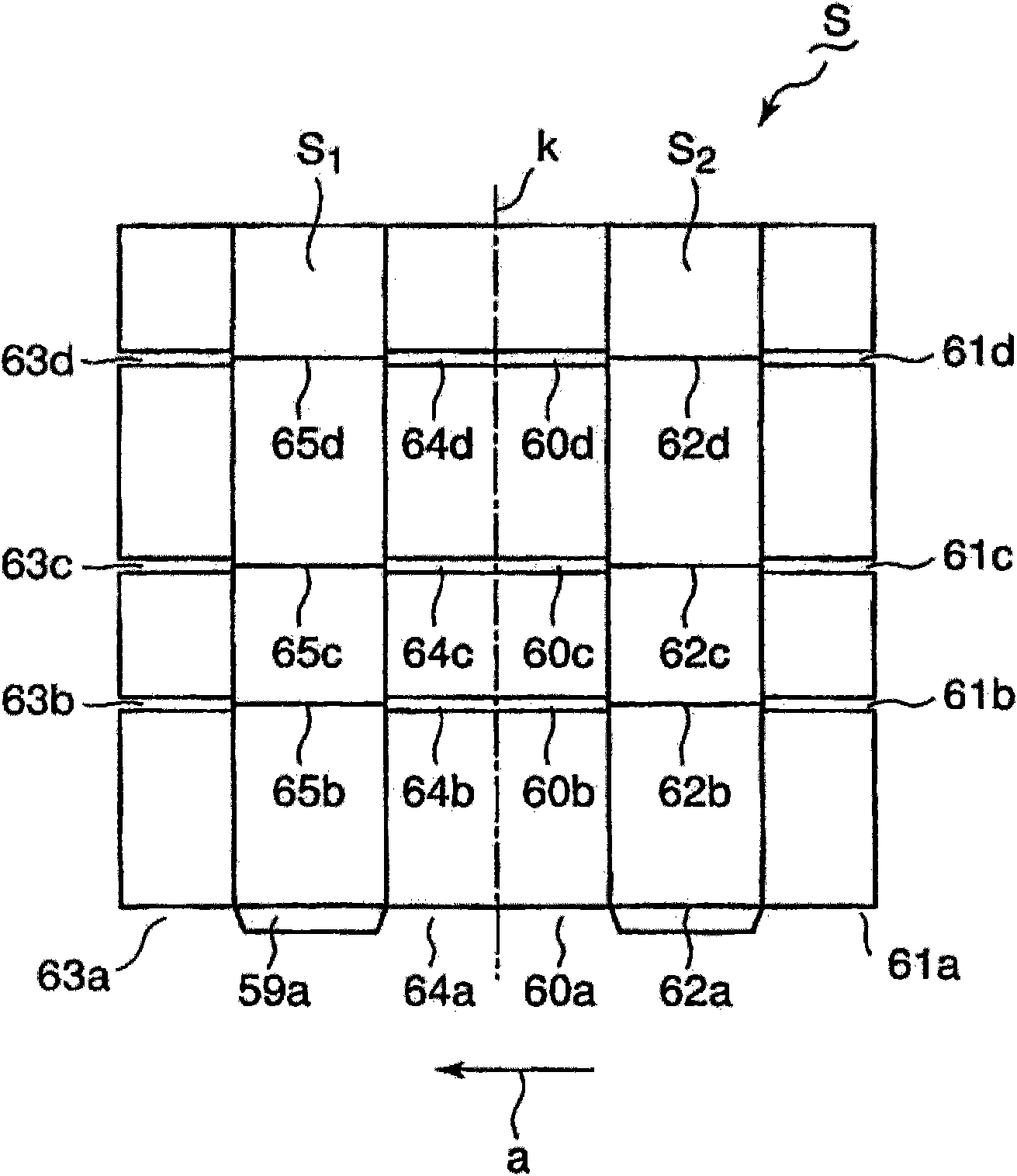

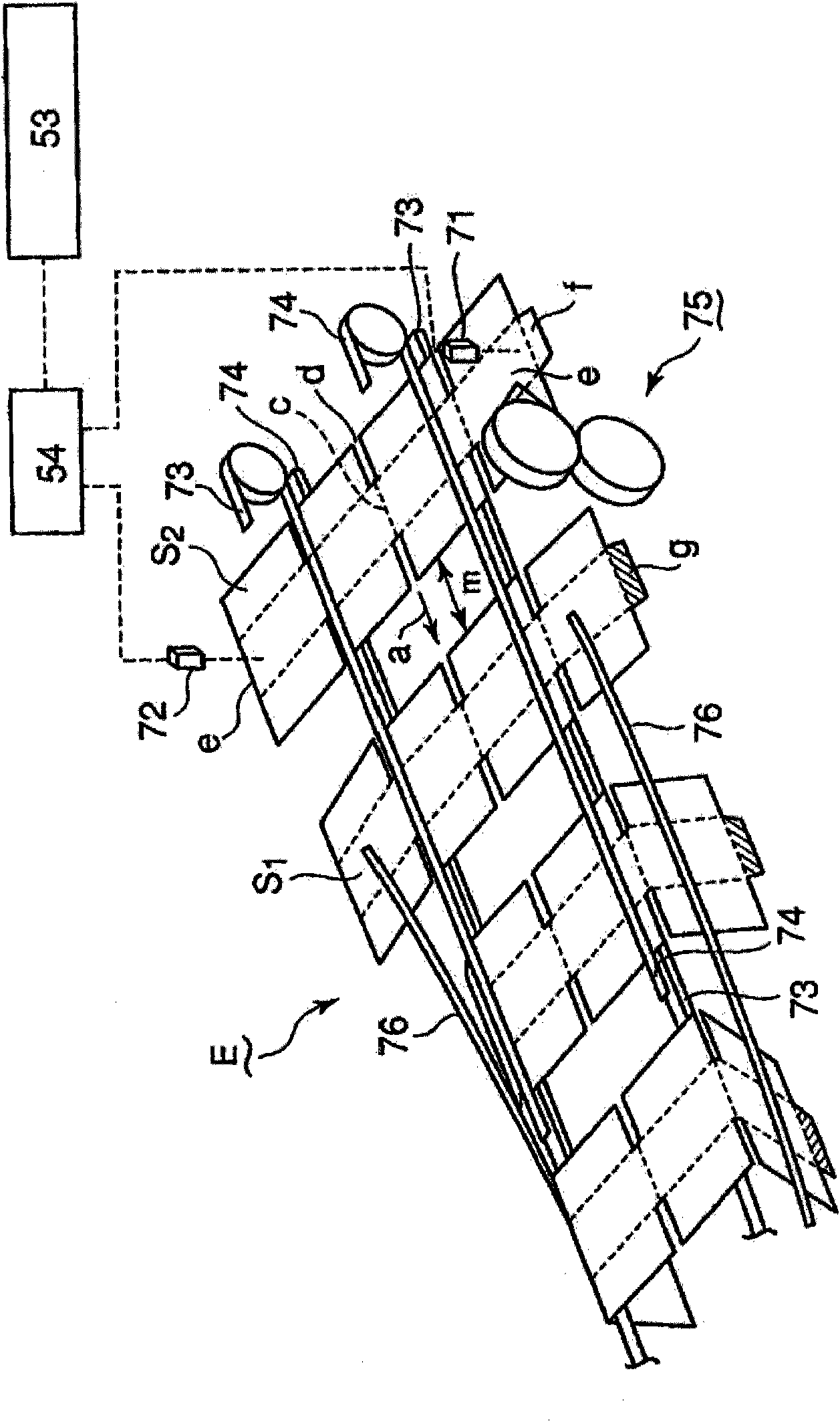

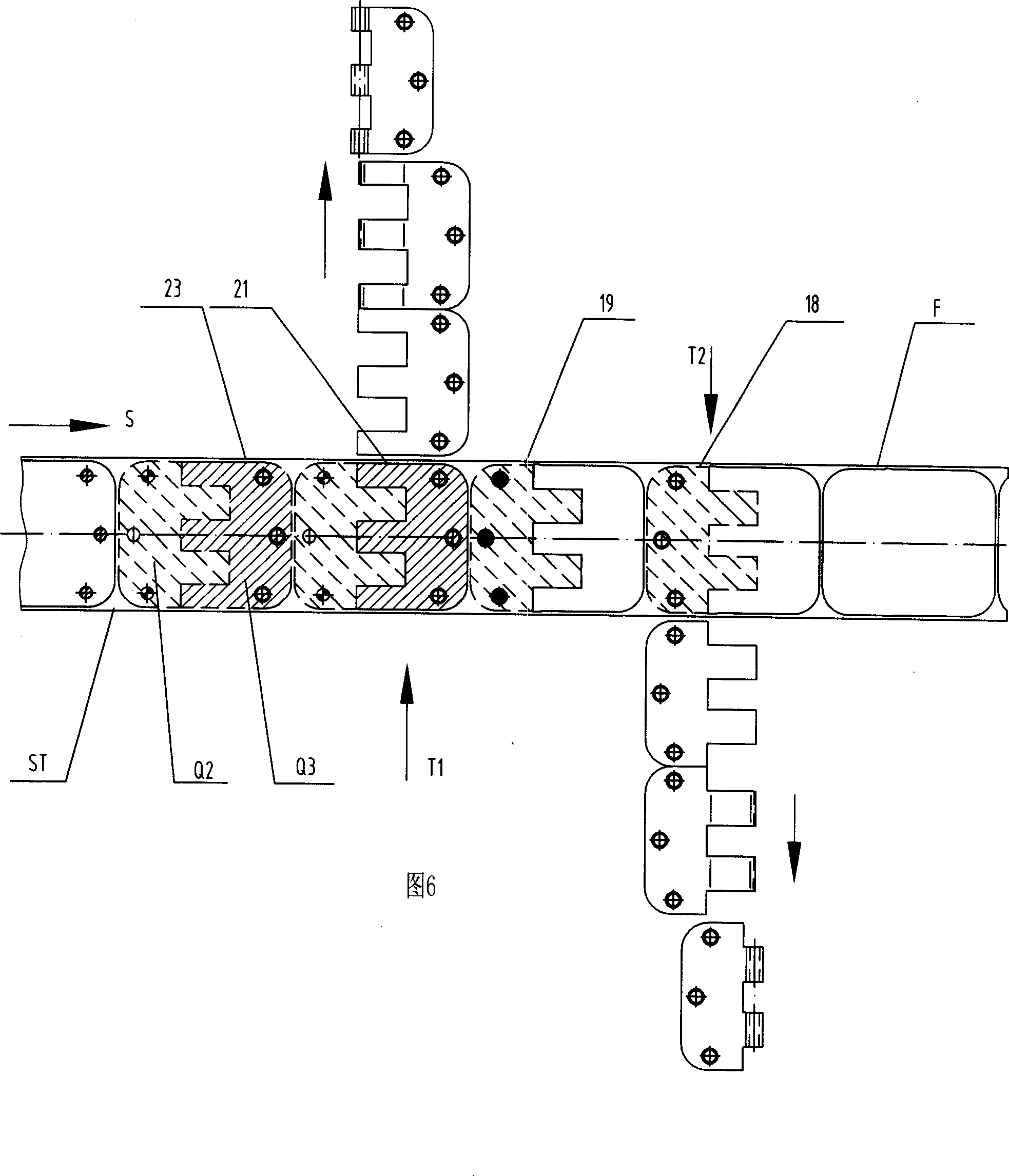

Method and device for making box of corrugated cardboard sheet

ActiveCN101873926ASmall spanEasy to handleBoxes/cartons making machineryPaper-makingCountermeasureCardboard box

Disclosed is a method for producing a cardboard box by performing a box-making process of a corrugated cardboard sheet which is formed to have dimensions of a plurality of cardboard boxes wherein the yield of the cardboard sheet and the production efficiency are enhanced and a countermeasure can be taken against paper powder. A method for making a box of a corrugated cardboard sheet by performinga box-making process of a cardboard sheet (S) which is formed to have dimensions of a plurality of cardboard boxes and then cutting the cardboard sheet (S) into dimensions of one cardboard box comprises a step (I) for cutting the cardboard sheet (S) into dimensions of one cardboard box by a cut line (k) in the direction intersecting the conveyance direction (a) along a box making line (PL) after a ruling and grooving step (C) and before a pasting and folding step (E), and a speed increase step (J) for spacing the cardboard sheets (S1) and (S2) thus cut by a set dimension following to the cutting step (I) by increasing the speed of the cardboard sheets (S1) and (S2) while conveying toward a subsequent step.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

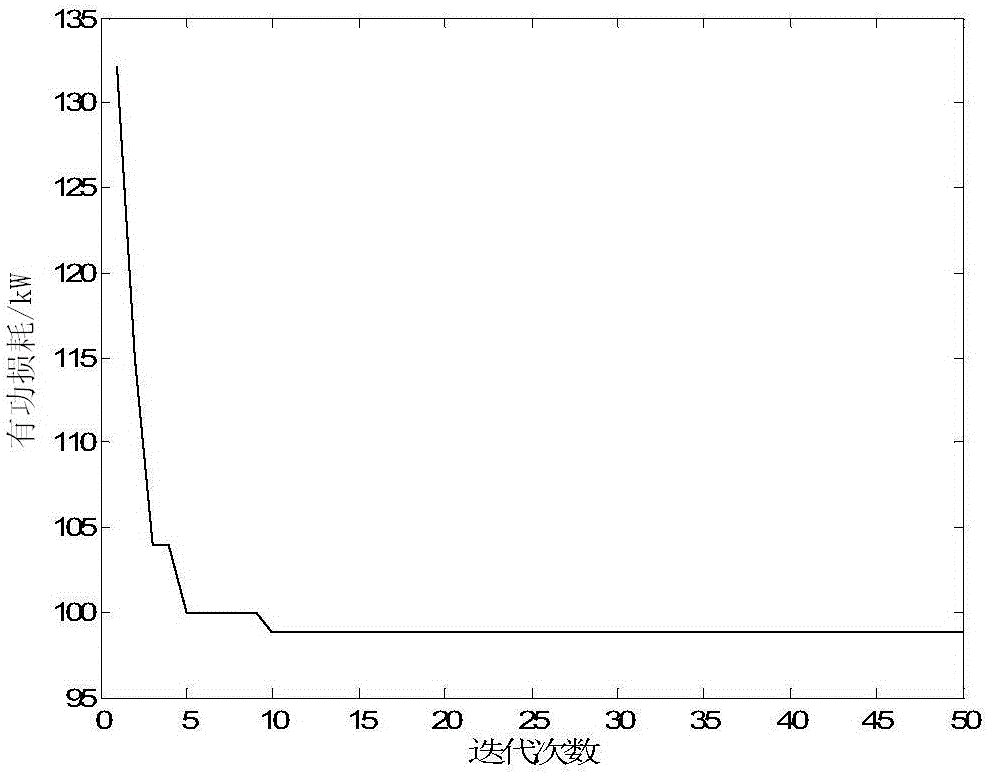

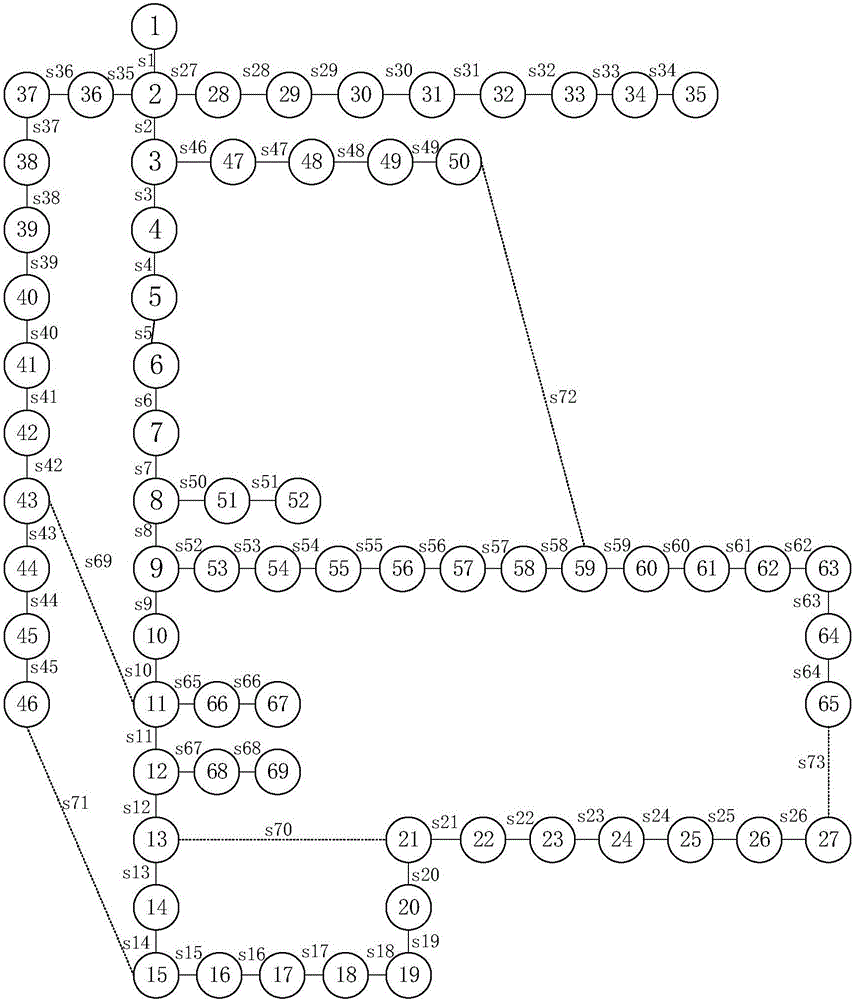

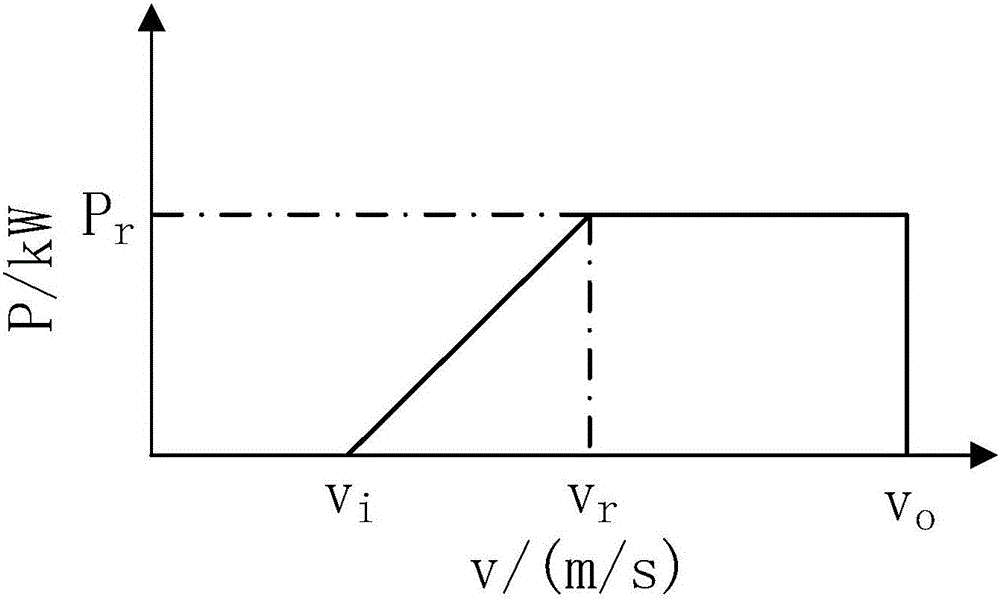

Multi-target distribution network reconstruction method considering distributed generation and load uncertainty

ActiveCN105741193AExcellent indicatorsGuaranteed production efficiencyData processing applicationsAc network circuit arrangementsBiogeographySimulation

The invention discloses a multi-target distribution network reconstruction method considering distributed generation and load uncertainty. Wind power output force, photovoltaic power generation and load uncertainty are taken into consideration in the method. The three most important evaluation indexes, of optimized operation of a distribution network, including active loss, minimal voltage value of nodes and load balancing degree, namely three optimizing reconstruction targets, are given. Wind power output force, photovoltaic power output force and load uncertainty factors are processed through a scene analytical method. The final reconstruction scheme is obtained through multi-target disturbance biogeographic algorithm and fuzzy set theory. A multi-target reconstruction decision solution can be rapidly found, and high searching efficiency is ensured. Under an absorbing distributed power supply condition, various indexes of a network can be improved substantially through network reconstruction, so that the reconstruction is more adaptable to a real decision-making process.

Owner:HOHAI UNIV

Polyurethane resin and preparation method and application thereof

ActiveCN104004159APrevents self-crosslinking reactionsAvoid gel phenomenonFibre treatmentPolyesterPolymer science

The invention provides polyurethane resin. The polyurethane resin is mainly prepared from, by weight, 150 parts to 200 parts of polyols, 10 parts to 45 parts of chain extender, 100 parts to 150 parts of isocyanate, 0.1 part to 10 parts of antioxidant, 0.1 part to 1 part of reaction terminator, 500 parts to 800 parts of solvent and reaction activity regulator. The polyols contain 40 percent to 70 percent of PTMG, 0 to 45 percent of polyester polyol, 0 to 15 percent of polycarbonate diol, 0 to 25 percent of polycaprolactone diol and 5 percent to 10 percent of modified polydimethylsiloxane diol. The invention further provides a preparation method and application of the polyurethane resin. Tiny and even cells can be formed when the prepared polyurethane resin is used for processing superfine fiber synthetic leather, and thus the produced superfine fiber product can have fine fold lines and plump fleshy feeling.

Owner:XUCHUAN CHEM SUZHOU

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Powder metallurgy component and production method of powder metallurgy component with through hole

The invention discloses a powder metallurgy component which is compressed by powder materials. The powder materials includes, by weight, 100 parts of iron powder, 1.8-2.2 parts of copper powder, 0.-1.0 part of graphite powder, 2.0-3.0 parts of nickel powder, 0.4-0.8 part of molybdenum powder, 0.5-1.0 part of micro powder wax, and 0.5-1.0 part of calcium fluoride. The invention further disposed a production method of the powder metallurgy component with a through hole. The method includes: well mixing the powder materials, placing the mixed alloy iron-based powder in a die for compressing forming, sintering, mechanically drilling, thermally processing, and surface vibration grinding to obtain the powder metallurgy component. The produced powder metallurgy component is high in precision, strength and hardness, good in wear resistance, widely applicable to manufacturing of various bevel gears, and the like.

Owner:江苏宏创精密制造有限公司

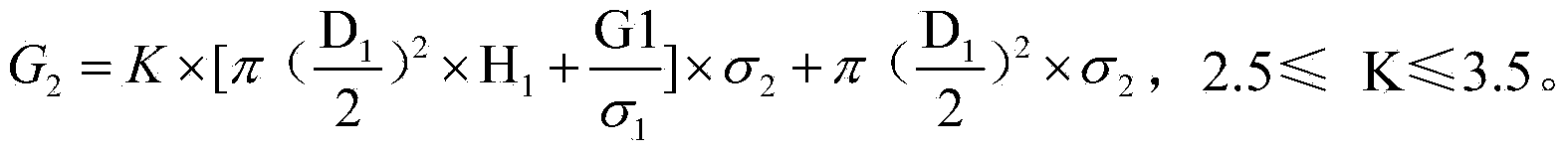

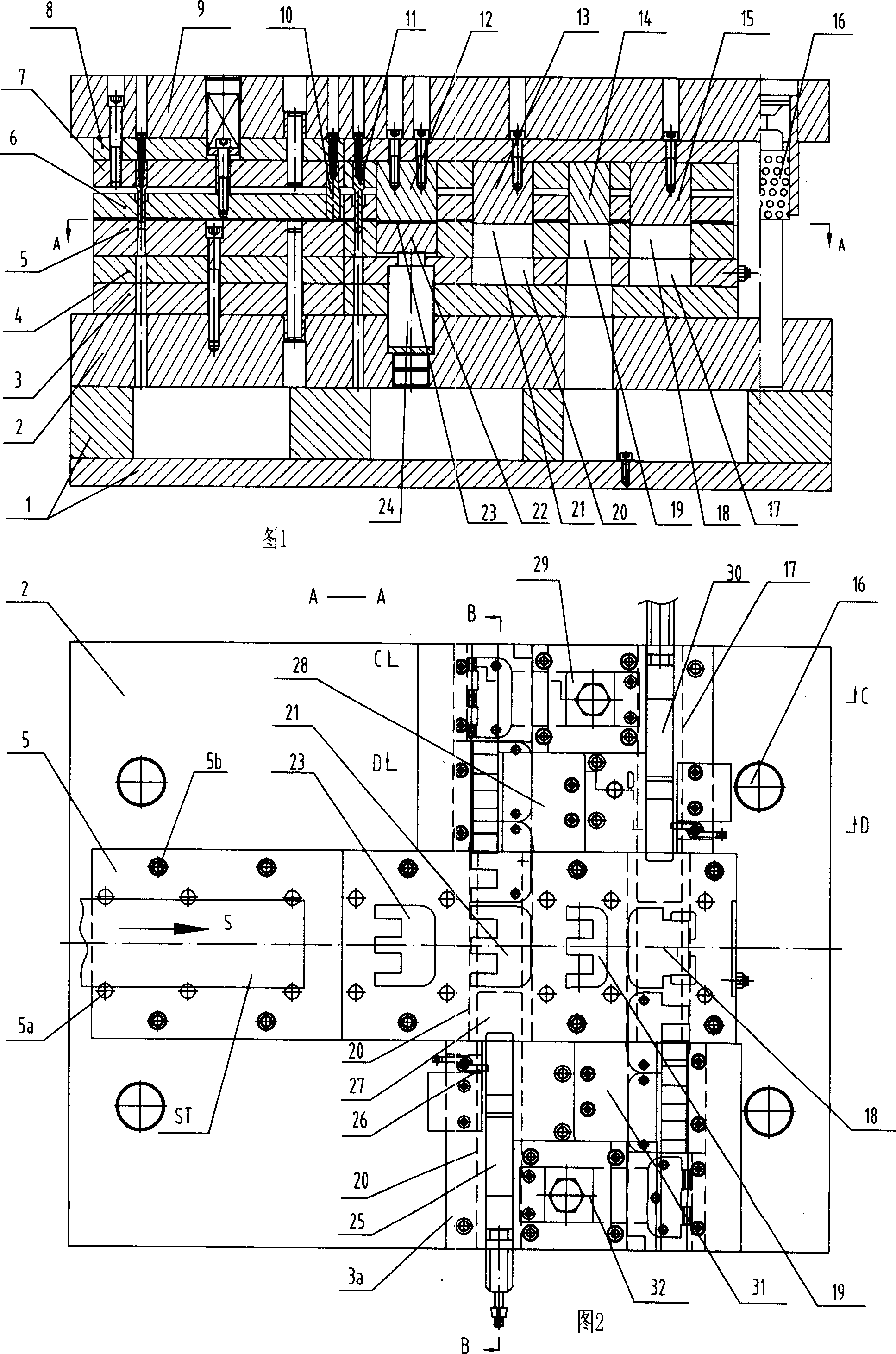

Complete cutting type belt coil pipe stepped mould for hinger

InactiveCN101011716AGuaranteed utilizationRealize one-time moldingShaping toolsMetal-working feeding devicesPunch pressStirrup

A hinge blade nest cutting winding progressive die comprises up die and bottom die and the connecting guide post, with the up die having stirrup punch head, three claw punch head and two claw punch head, with the bottom die having stirrup, three claw die and two claw die, with the later tow having a horizontal slide path, one side of which having a discharge device linked with the up die, bending die linked with the up die on the other side, and the winding die. It realizes the one time forming with the stirrup, shear cutting, bending and winding, with precision and improved production efficiency and reduced cost. One set of die, a punch machine and an operator will get everything done.

Owner:伟业重工(安徽)有限公司

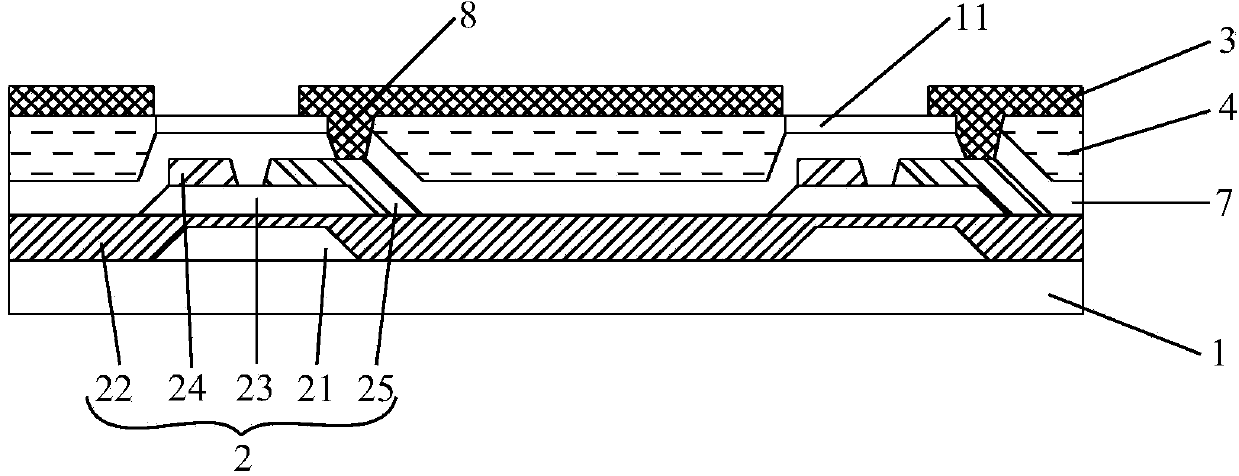

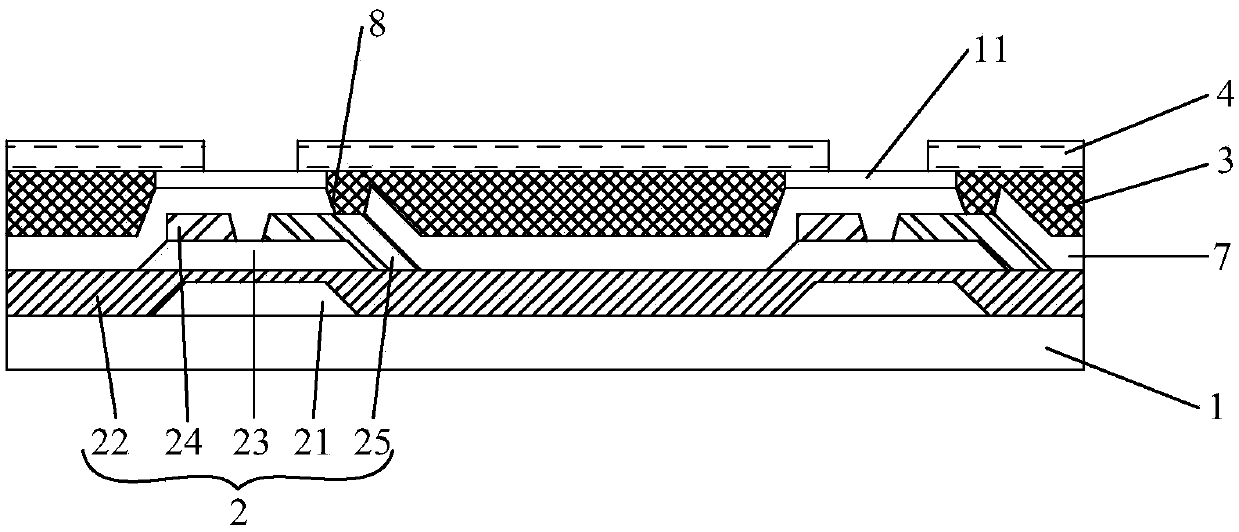

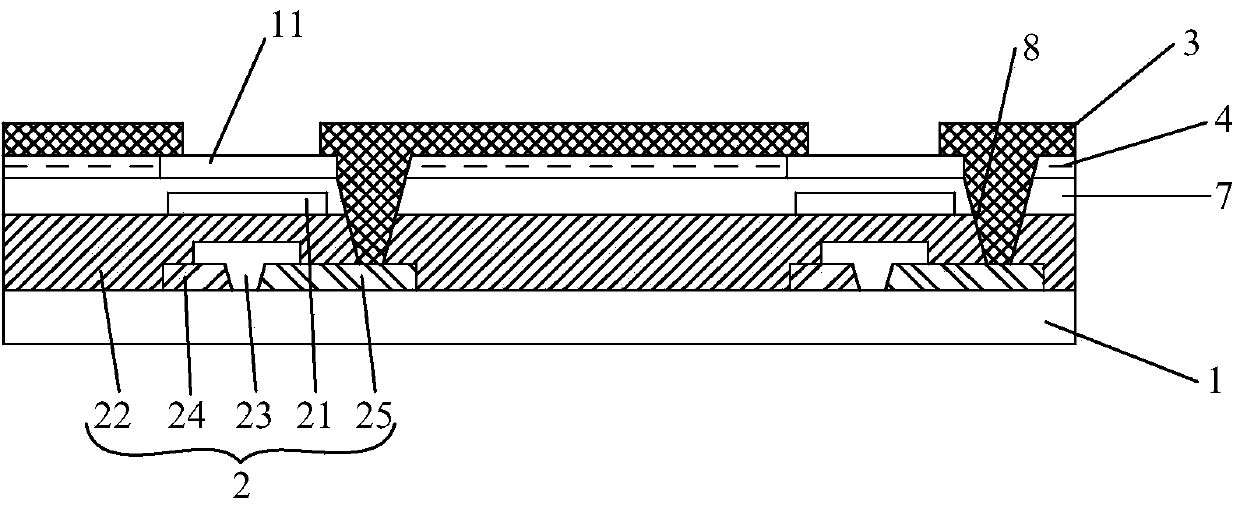

Array substrate, preparation method thereof and display device

ActiveCN103700674AEnsure production safetyGuaranteed production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceProtection layer

The embodiment of the invention discloses an array substrate, a preparation method thereof and a display device, and relates to the technical field of display. According to the array substrate, the preparation method and the display device, disclosed by the invention, the layer structure of the array substrate can be simplified, the preparation difficulty of the array substrate can be reduced, and thus the production yield of the array substrate can be increased. The array substrate comprises a liner substrate, a TFT (Thin Film Transistor) unit, a colorful film and a flat protection layer, wherein the TFT unit is positioned above the liner substrate, the flat protection layer is electrically connected with a drain electrode of the TFT unit, and the flat protection layer is conductive.

Owner:BOE TECH GRP CO LTD

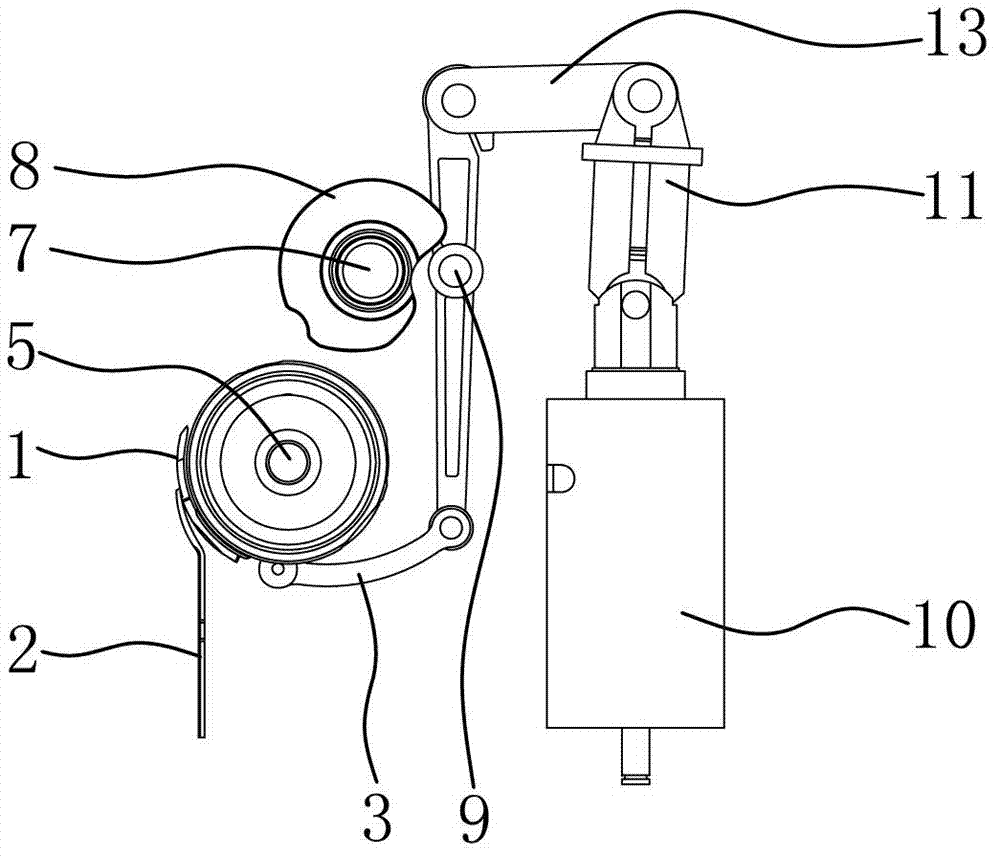

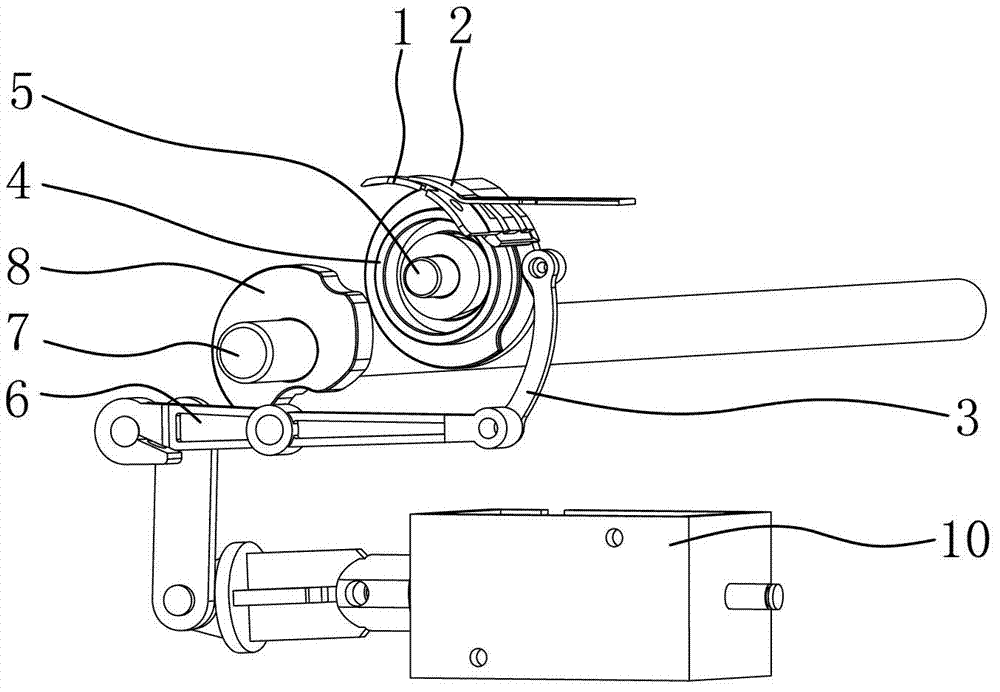

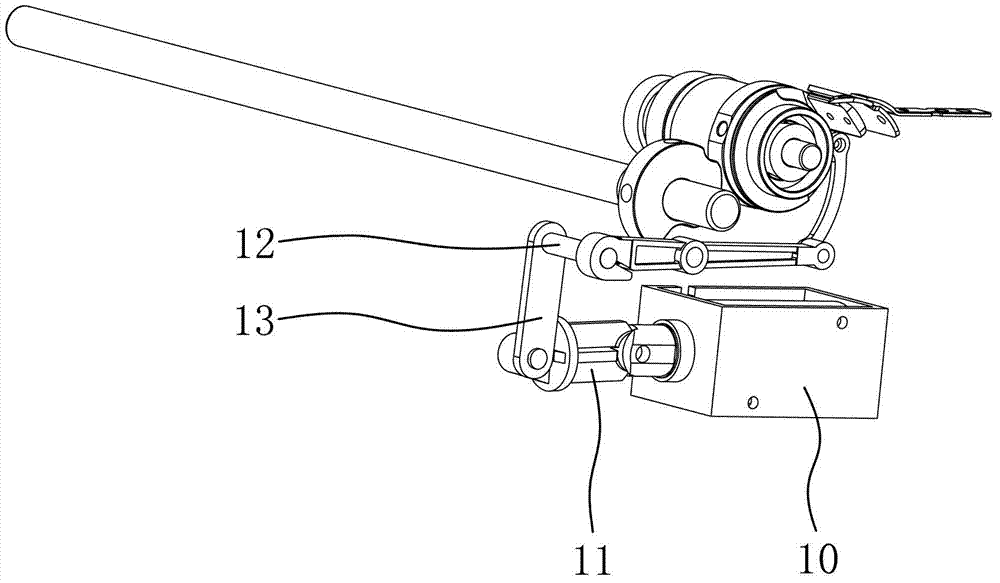

Automatic cutting device of sewing machine

InactiveCN102877230AAvoid hitting pinsGuaranteed stable workNeedle severing devicesEngineeringKnife holder

The invention provides an automatic cutting device of a sewing machine and belongs to the technical field of sewing machines. The device can solve the problems of discontinuous operation, affected production efficiency and the like caused by the needle-bumping phenomenon in the prior art. The device comprises a moving knife, a fixing knife, a connecting rod and a cutting electromagnet, which cooperate with each other to cut threads, wherein the fixing knife is fixed on a base of the sewing machine, the moving knife and one end of the connecting rod are fixed on a cutting knife holder, the cutting knife holder is sleeved on a lower shaft, the other end of the connecting rod is hinged with one end of a transmission rod, and the other end of the transmission rod is connected with a moving iron of the cutting electromagnet; and a feed lifting rock shaft is provided with a cutting cam, the cutting cam is positioned on the side of the transmission rod, and the transmission rod is fixedly provided with a cylindrical pin which is matched with the cutting cam to drive the transmission rod to move. The device provided by the invention has the advantages of high cutting accuracy, convenience in operation, simple structure and the like.

Owner:JACK SEWING MASCH CO LTD

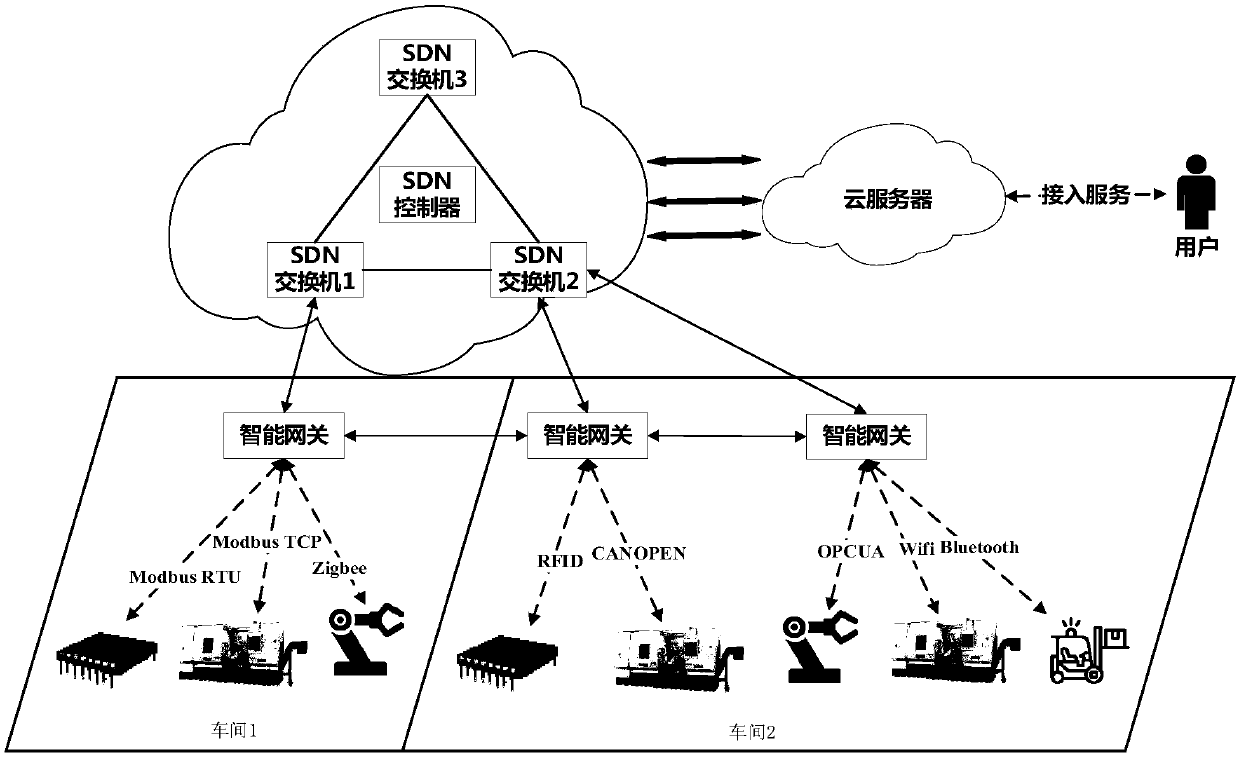

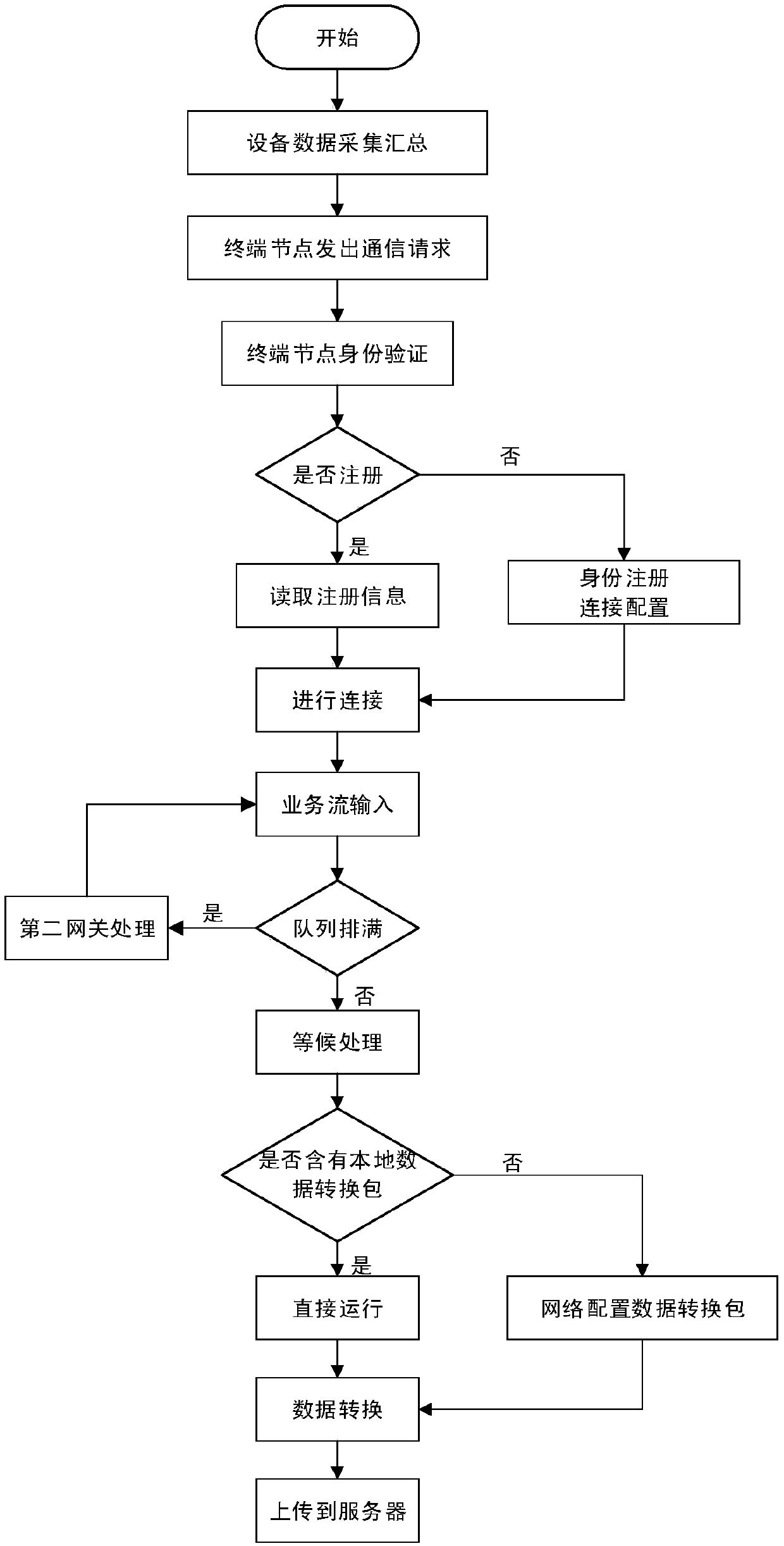

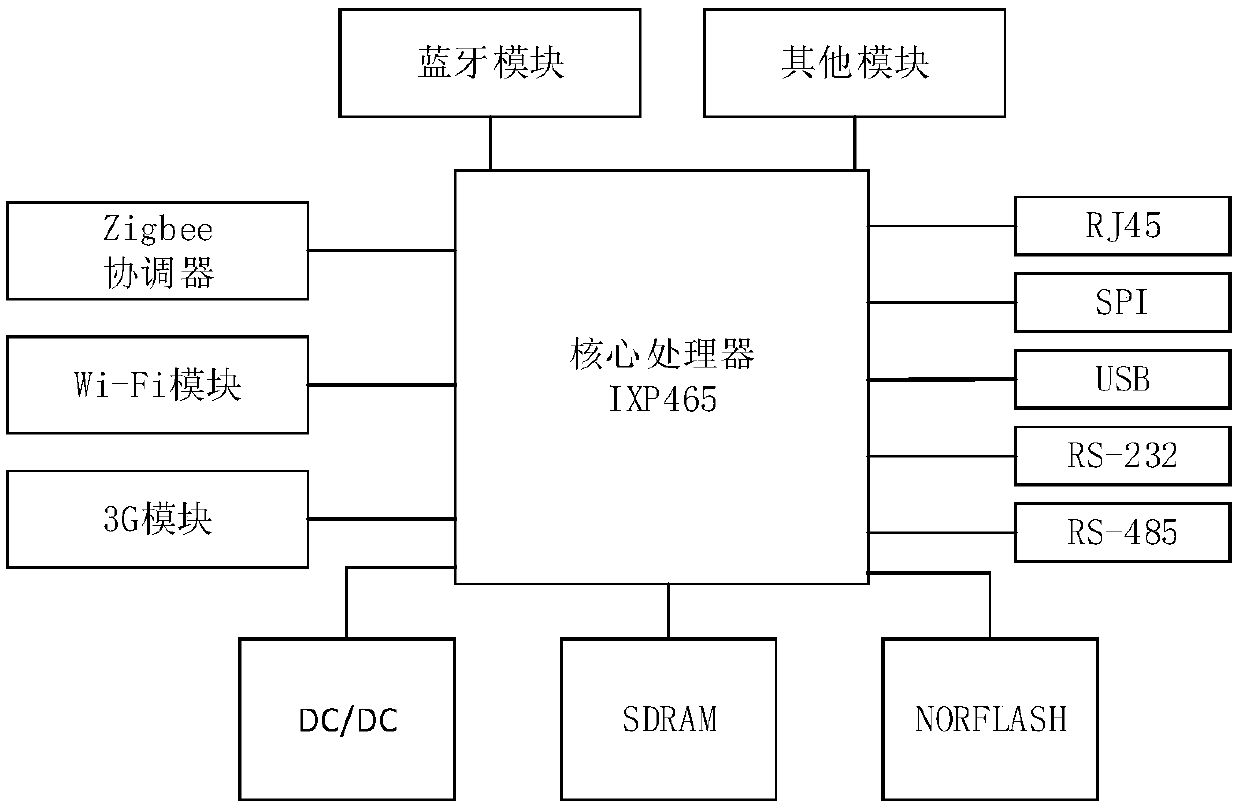

Software-defined network (SDN) based multi-mode data interaction system and method for intelligent production line

ActiveCN109639467AFlexible and convenient collectionSimple hardware structureData switching networksInteraction systemsDistributed intelligence

The invention discloses a software-defined network (SDN) based multi-mode data interaction system and method for an intelligent production line. The system comprises an equipment layer, a conversion layer, a network layer, and a server layer, wherein the equipment layer comprises underlying equipment, sensors and data acquisition nodes, and is used to acquire equipment operation information and carry out data summarization; the conversion layer comprises distributed intelligent gateways, and is used for data format conversion and interaction with the network layer; the network layer is erectedthrough an SDN, and is used for dynamic configuration of a conversion protocol of the conversion layer and data transmission path optimization; and the server layer stores different protocol conversion installation packages through establishment of a database, and is used for storage of acquired data and access of user services. The system disclosed by the invention has the advantages that an equipment control plane and a data plane are decoupled based on the SDN, so that network traffics can be flexibly controlled; and a wired network is mixed with a wireless network, so that a data acquisition network system is more flexible and convenient, and is more applicable to the current production line situation.

Owner:SOUTH CHINA UNIV OF TECH

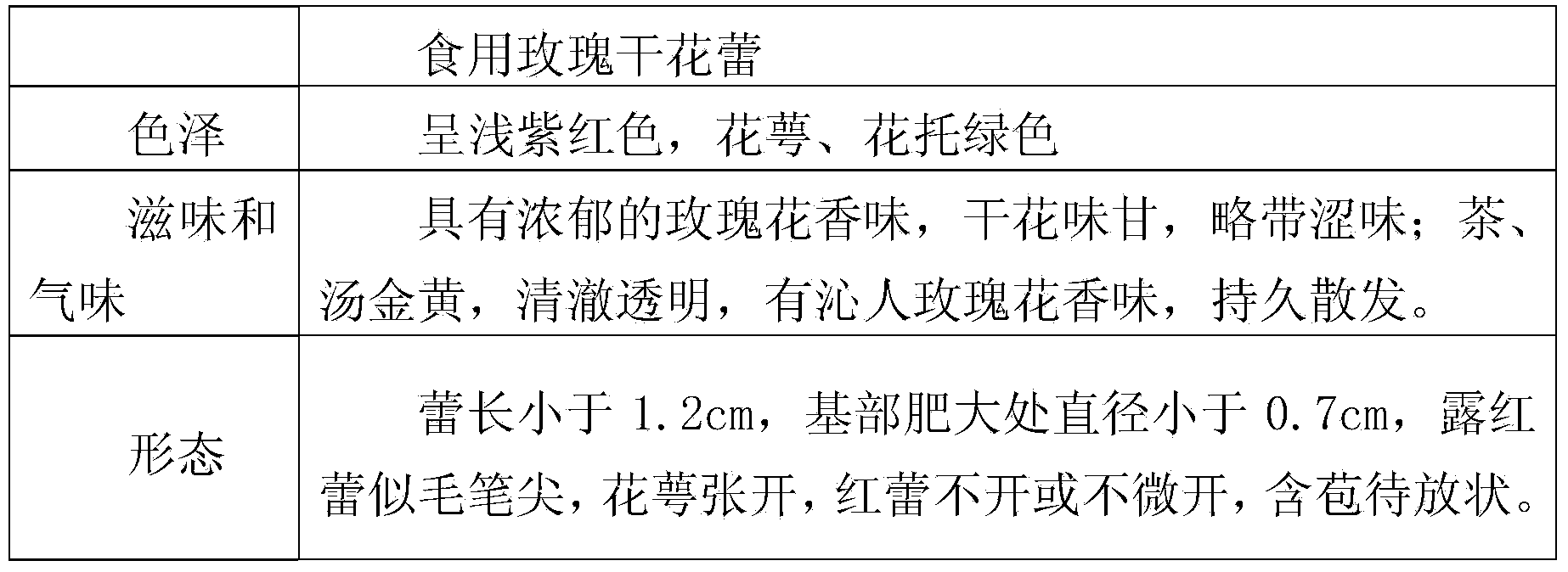

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

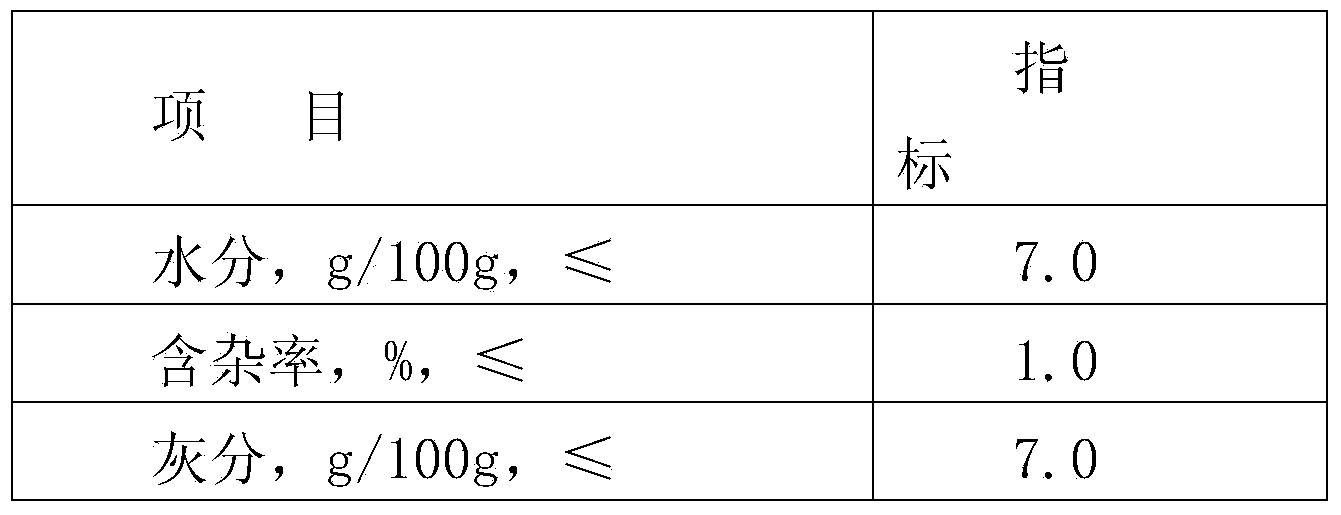

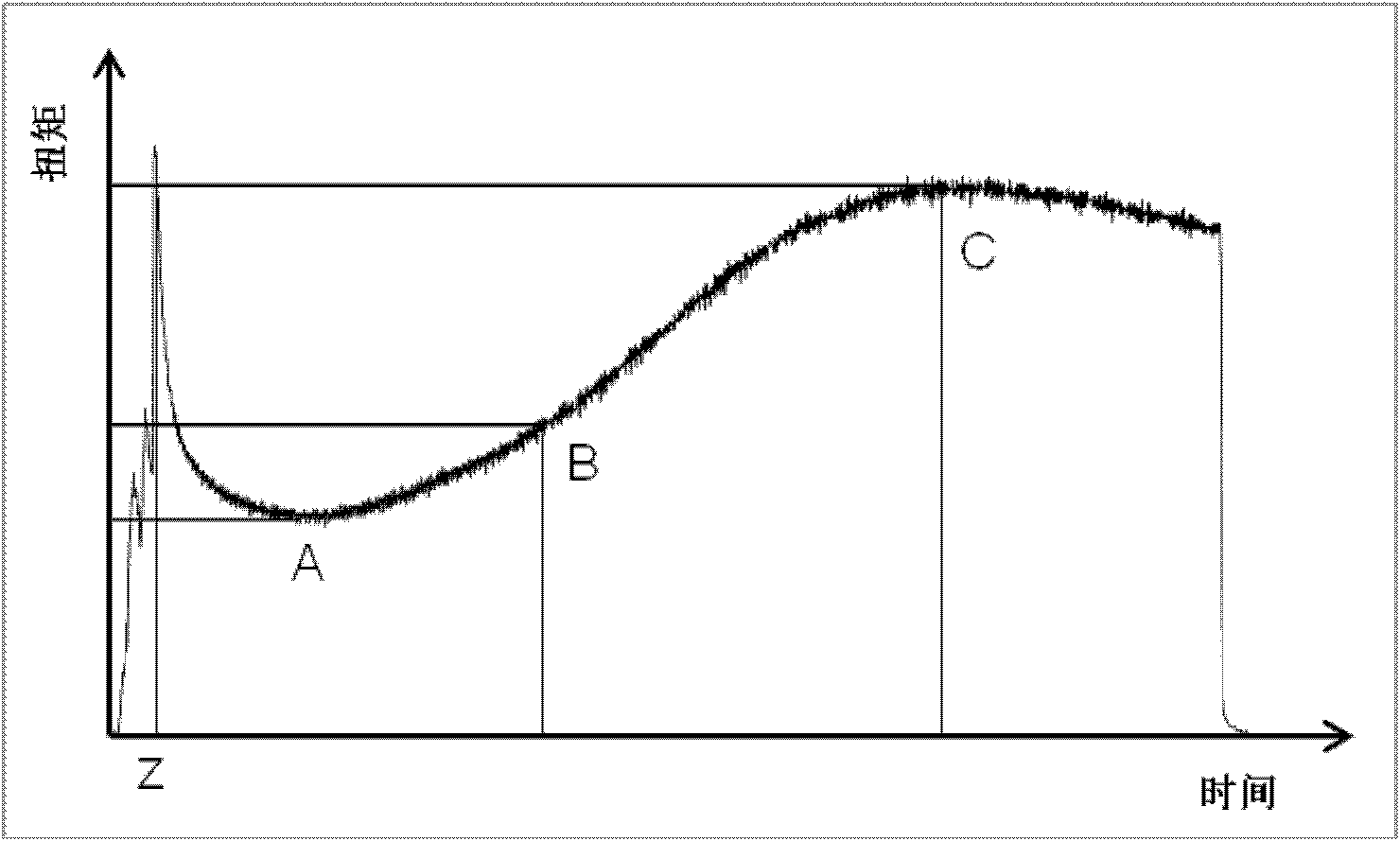

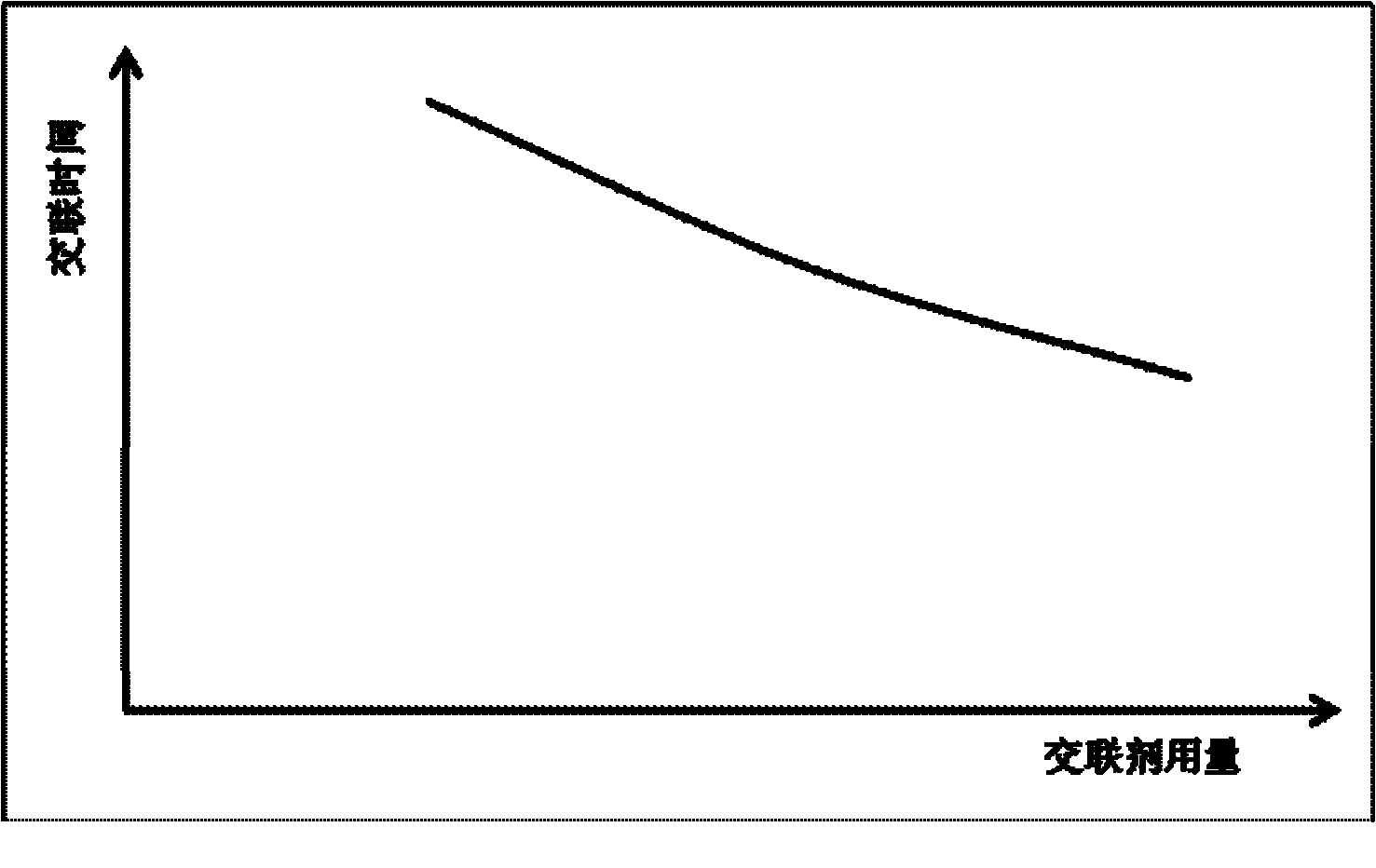

Packaging adhesive film for solar cell

InactiveCN101820001AGuaranteed production efficiencyEasy to processPhotovoltaic energy generationSemiconductor devicesCross-linkSolar cell

The invention relates to a packaging adhesive film for a solar cell, which can effectively prolong scorch time T2 and improve the processing and packaging properties of an EVA adhesive film on the basis of small change on total cross-linking time TC. The packaging adhesive film for the solar cell contains a copolymer of ethylene-vinyl acetate (EVA), a cross-linking agent, a cross-linking inhibitor and a radical trap, wherein, the masses of the cross-linking inhibitor and the radical trap are respectively 0.1-1.0% and 0-0.3% of the mass of the ethylene-vinyl acetate copolymer, and the cross-linking time of the packaging adhesive film for the solar cell is 10-30min. In the invention, the cross-linking inhibitor and the radical trap are added based on the formula of the existing packaging adhesive film for the solar cell to form a stable molecular structure with active radicals generated in the peroxide cross-linking agent, thus effectively preventing early-stage cross-linking and over cross-linking, and effectively prolonging the scorch time T2 on the basis of guaranteeing the total cross-linking time TC to meet the requirements.

Owner:南京红宝丽新材料有限公司

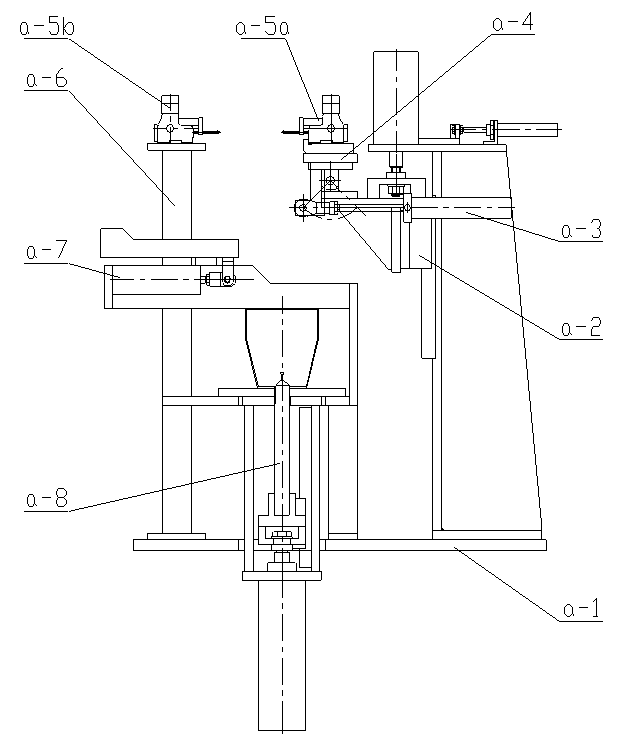

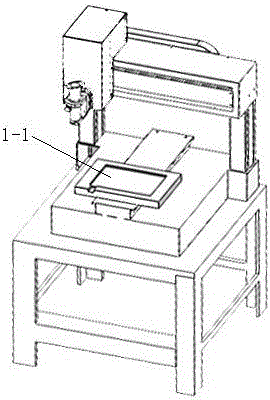

Double-station and full-automatic rhinestone grinding and polishing machine

InactiveCN103273396AGuaranteed production efficiencyLow costEdge grinding machinesButt jointEngineering

The invention relates to a double-station and full-automatic rhinestone grinding and polishing machine. A bead feeding station part, a grinding station part, a polishing station part and a butt joint and bead discharging station part are arranged in the four directions of a working table respectively. A transfer manipulator is arranged in the middle of the working table. Two sets of hackle locating devices are arranged on the two sides of a grinding wheel of a grinding station and a polishing wheel of a polishing station respectively, the working face of each hackle faces the grinding wheel or the polishing wheel, and other stations are respectively provided with two sets of hackle locating devices, so that the whole equipment forms inner circle circulation and outer circle circulation. The rotary transfer manipulator not only has the function of rotating and transferring, but also can transversely move, so that hackles working in the inner circle and the outer circle are grabbed respectively. The mode that the double hackles work on the grinding station and the polishing station is adopted, all procedures needed by grinding and polishing of rhinestones can be completed only through one grinding and polishing device and one rotary transfer manipulator, and cost of the equipment is greatly reduced on the premise of ensuring working efficiency.

Owner:义乌琳多饰品有限公司

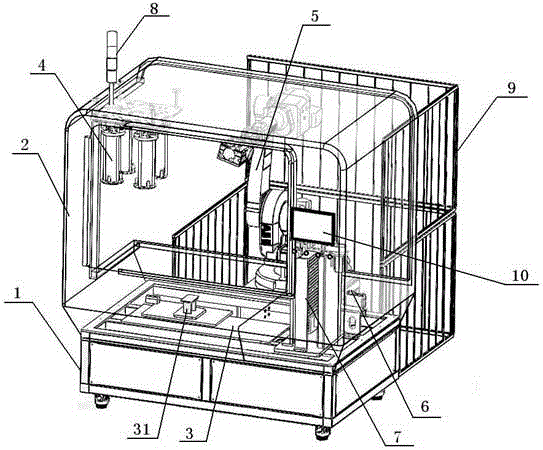

Mechanical arm grinding device

ActiveCN105666283AImprove grinding effectGrinding speed is fastGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a mechanical arm grinding device. The mechanical arm grinding device comprises a rack, a shell, a jig fixing table, an automatic abrasive paper feeding mechanism, a grinding mechanism, an automatic abrasive paper tearing mechanism and an automatic feeding mechanism. The shell is vertically arranged at the upper portion of the rack, and the jig fixing table is horizontally arranged at the upper portion of the rack. The automatic abrasive paper feeding mechanism is arranged on the top of the inner wall of the shell. The automatic abrasive paper tearing mechanism and the automatic feeding mechanism are both arranged on the jig fixing table. The automatic abrasive paper tearing mechanism is arranged on one side edge of the automatic feeding mechanism. The grinding mechanism is movably arranged on one side edge of the rack and extends to be close to the automatic abrasive paper feeding mechanism in the shell. By means of the manner, the whole back face of a mobile phone shell is ground, the side face of the mobile phone shell is subjected to profiling grinding, and the position accuracy and the production efficiency are guaranteed through the grinding mechanism. Meanwhile, the mechanical arm grinding device has the beneficial effects of being simple in appearance, compact in structure, small in occupied space, convenient to move and place, convenient to operate, capable of being controlled in a full-automatic manner, simple, fast and the like.

Owner:江苏华航威泰机器人科技有限公司

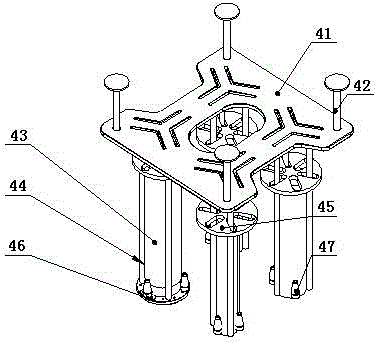

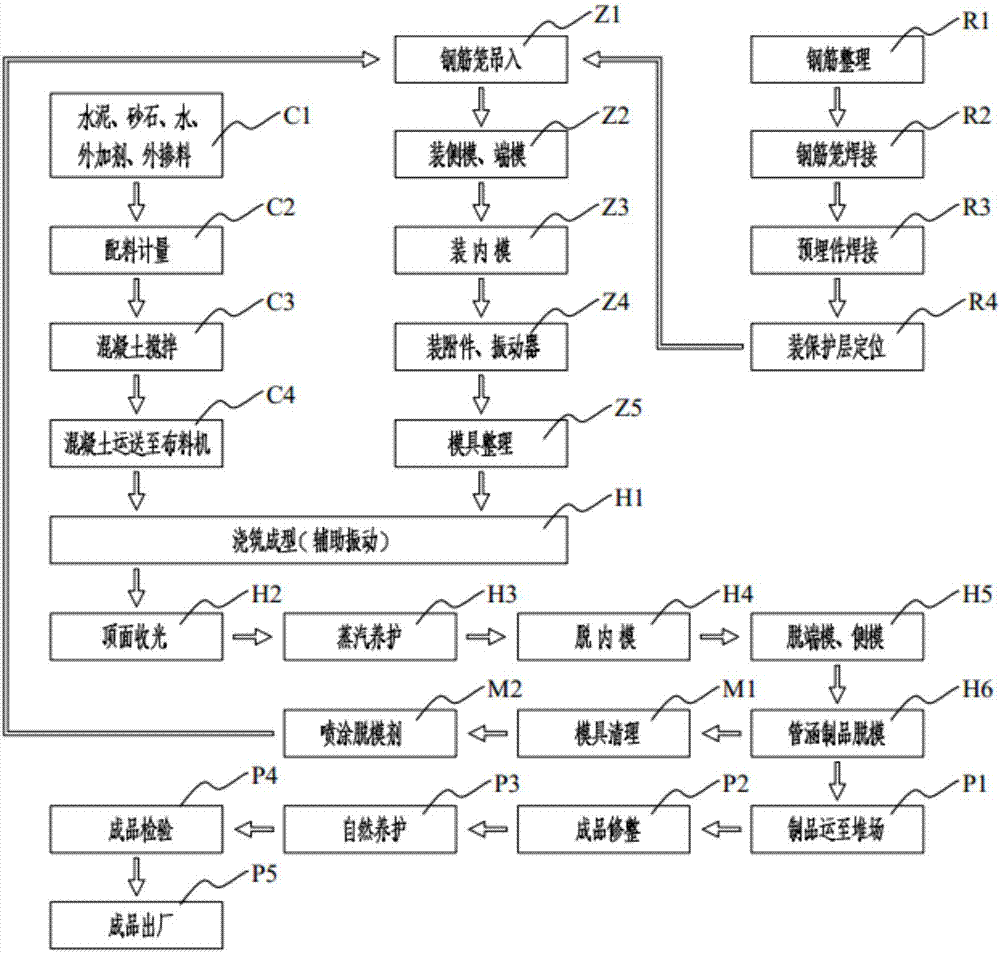

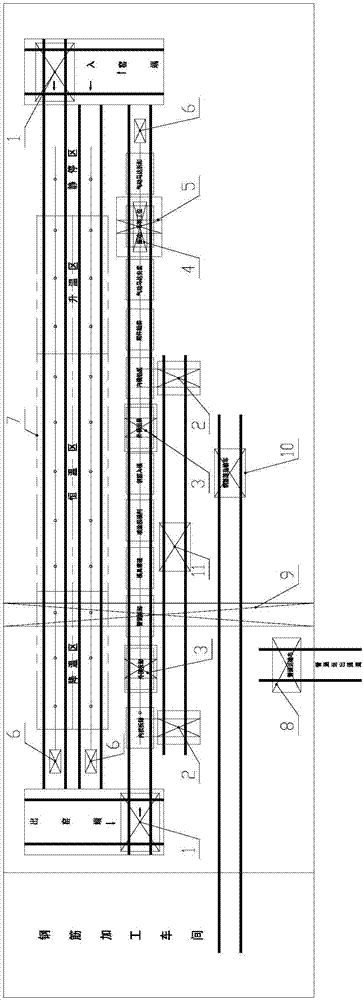

Prefabricated concrete pipe culvert production assembly line and production process

ActiveCN107042580AImprove precast production efficiencySave landVehicle dissasembly recoveryCeramic shaping plantsRebarAssembly line

The invention provides a prefabricated concrete pipe culvert production assembly line and a production process. The production assembly line comprises a reinforcement machining workshop, a reinforcement cage conveying line, a mold dismounting and mounting conveying line, a reinforcement mold assembling line, a material distribution zone, a maintaining line and a finished product conveying-out line. The reinforcement cage conveying line is arranged at an output port of the reinforcement machining workshop, and the mold dismounting and mounting conveying line is parallel to the reinforcement cage conveying line. The reinforcement mold assembling line is parallel to the mold dismounting and mounting conveying line. The material distribution zone is arranged on the reinforcement mold assembling line. The maintaining line is parallel to the reinforcement mold assembling line. Translation shuttle buses are arranged at the two ends of the maintaining line and the two ends of the reinforcement mold assembling line. A crown block is erected on the two outer sides of the reinforcement cage conveying line and the maintaining line. The layout occupies small spaces, workshop land is saved, the prefabrication production efficiency of pipe culverts is effectively improved, the worker labor intensity is lowered, the production cost is lowered, and the quality consistency and reliability of pipe culvert products can be ensured.

Owner:博奥重工装备制造(天津)有限责任公司

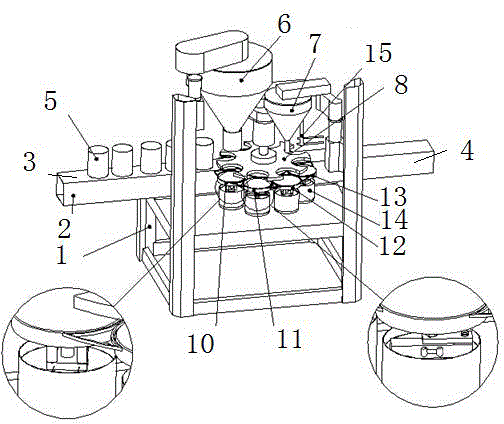

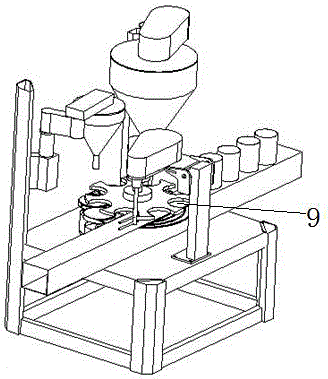

Filling machine and filling process thereof

The invention relates to a filling machine. The filling machine is characterized in that a conveying device is arranged on a frame, a star-shaped rotting disc, a weighing system and a stopping device are arranged at one side of the conveying device, wherein the weighing system and the stopping device are matched with the star-shaped rotting disc, and a filling device is arranged above the star-shaped rotting disc. The star-shaped rotting disc is composed of a rotating disc body and a center shaft connected with the rotating disc body, 6-18 can body clamping grooves are evenly distributed in the periphery of the rotating disc body, the weighing system is arranged at one side of the conveying device, and the star-shaped rotting disc is arranged above the conveying device and the weighing system. Empty cans are conveyed to the star-shaped rotating disc through the conveying device and enter a secondary weighing station after prefilling, primary weighing and supplement filling are finished, if the set weight requirement is met, can bodies are output along the output end, if the weight of the can bodies does not reach the standard, the can bodies are stopped by the stopping device, the unqualified can bodies can only rotate again along with the star-shaped rotating disc to enter the supplement filling station, the steps are circularly executed in this way until the weight of the can bodies reaches the standard, it is ensured that output canned products are measured accurately, and inferior-quality products are avoided.

Owner:昆山博正攀巨包装设备有限公司

Comprehensive assembly line for automatic adhesive-dispensing and hot-pressing

InactiveCN106081612AEasy to operateIncrease productivityLiquid surface applicatorsConveyorsAdhesiveEngineering

The invention discloses a comprehensive assembly line for automatic adhesive-dispensing and hot-pressing. The comprehensive assembly line for automatic adhesive-dispensing and hot-pressing comprises adhesive-dispensing machines, material transferring manipulators and transferring-loading platforms, wherein a pressure gauge used for detecting a gas pressure is installed at a gas inlet port of each adhesive-dispensing machine; each material transferring manipulator is used for transferring a workpiece subjected to adhesive dispensing into the next link, and is provided with a rotary cylinder, a suction disc frame installed on a main shaft of the rotary cylinder and capable of horizontally rotating, and four suction discs adjustably installed on the suction disc frame; each transferring-loading platform is used for receiving the workpiece subjected to adhesive dispensing, and is provided with a slide rail, a pair of slide tables slidably installed on the slide rail, a carrying table connected between the two slide tables, and a lead screw matched with the slide tables through a thread pair; and external threads with opposite spiral directions are machined at the two ends of the lead screw respectively, and each slide table is matched with a section of the corresponding external thread, thus a distance between the two slide tables is adjusted under rotation of the lead screw. The comprehensive assembly line for automatic adhesive-dispensing and hot-pressing, which is disclosed by the invention, has the beneficial effects of being convenient to operate, fully-automatic in control, and simple and fast; the position accuracy and production efficiency are ensured by the material transferring manipulator; and high production efficiency is achieved, and the labour cost is saved.

Owner:昆山优乐智机器人科技有限公司

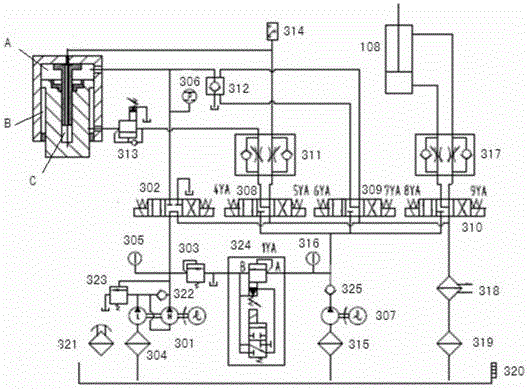

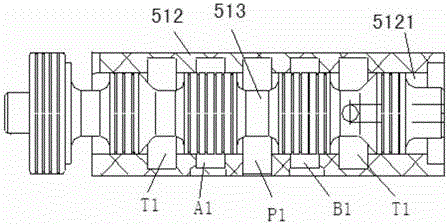

Double hydraulic system and hydraulic machine

The invention discloses a hydraulic machine and a double hydraulic system. The double hydraulic system comprises a first route of hydraulic system body and a second route of hydraulic system body. The double hydraulic system is of a logic linkage structure, and therefore the first route of hydraulic system body is used when the hydraulic machine is in the idle stroke (fast advancing) and the return stroke (fast retreating), and the large-flow rapid movement is achieved; high-pressure hydraulic oil is directly driven by the second route of hydraulic system body when the hydraulic machine is in the feeding stroke, and therefore the high-pressure system pressure can be directly obtained by the hydraulic machine, the higher working force can be obtained, and the overall weight of the hydraulic machine is reduced at a large proportion. By means of the double hydraulic system, the hydraulic machine can be applied under the power of 40 Mpa or higher, for instance, 40 Mpa, 55 Mpa, 70 Mpa, 100 Mpa, 120 Mpa, 150 Mpa and 200 Mpa, the overall weight of the hydraulic machine can be greatly reduced, all types of use efficiency, such as the running speed, of the hydraulic machine can be kept, and the production efficiency can be ensured.

Owner:GUANGDONG HUAYE POWER TECH

Three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and power generation system thereof

ActiveCN107317544ASolve the problem of non-standard water installationSolve the problem of irregular installationPhotovoltaic supportsWaterborne vesselsMulti functionalityPhotovoltaic power generation

Disclosed are a three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and a power generation system thereof. The photovoltaic power generation unit comprises a passage floating body and a connecting floating body arranged on a side wall of the passage floating body, wherein a power generation element is arranged on the connecting floating body. The system is formed by assembling three-in-one coupling insertion-pull type water surface photovoltaic power generation units vertically and horizontally. Horizontally, the passage floating body is assembled with a passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Vertically, the connecting floating body is assembled with the passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Finally, connecting floating bodies of a horizontal row of three-in-one coupling insertion-pull type water surface photovoltaic power generation units are independently fixed with passage floating bodies, so as to complete mounting of the whole power generation system. The unit has the characteristics of simple structure, convenient mounting and multi-functionality. The system assembly has the characteristics of simple structure and convenient mounting.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

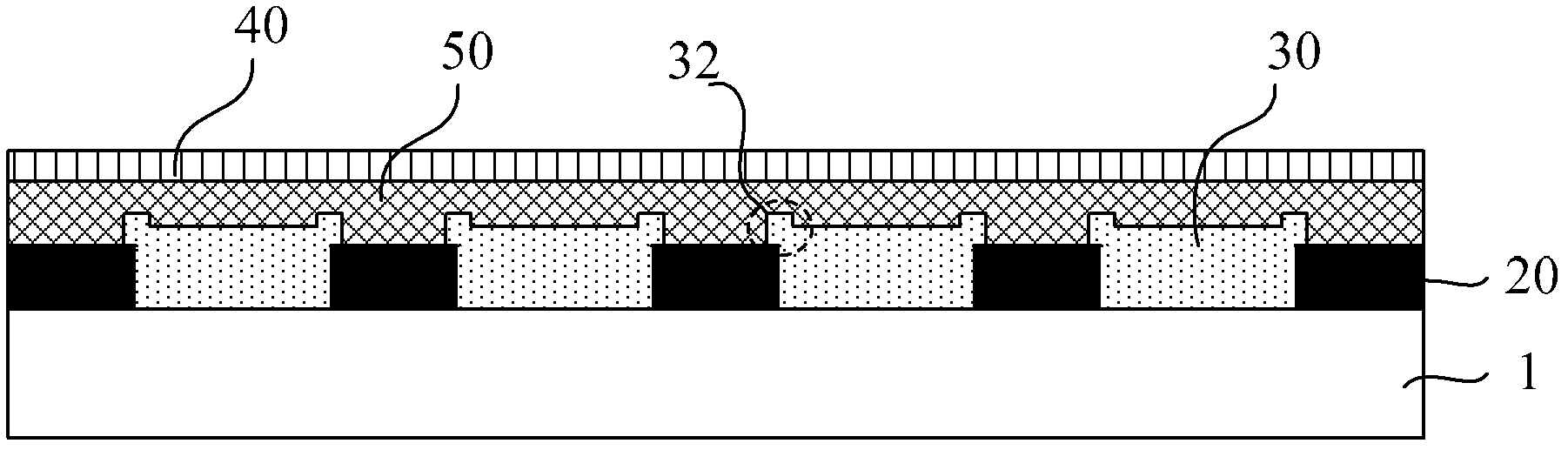

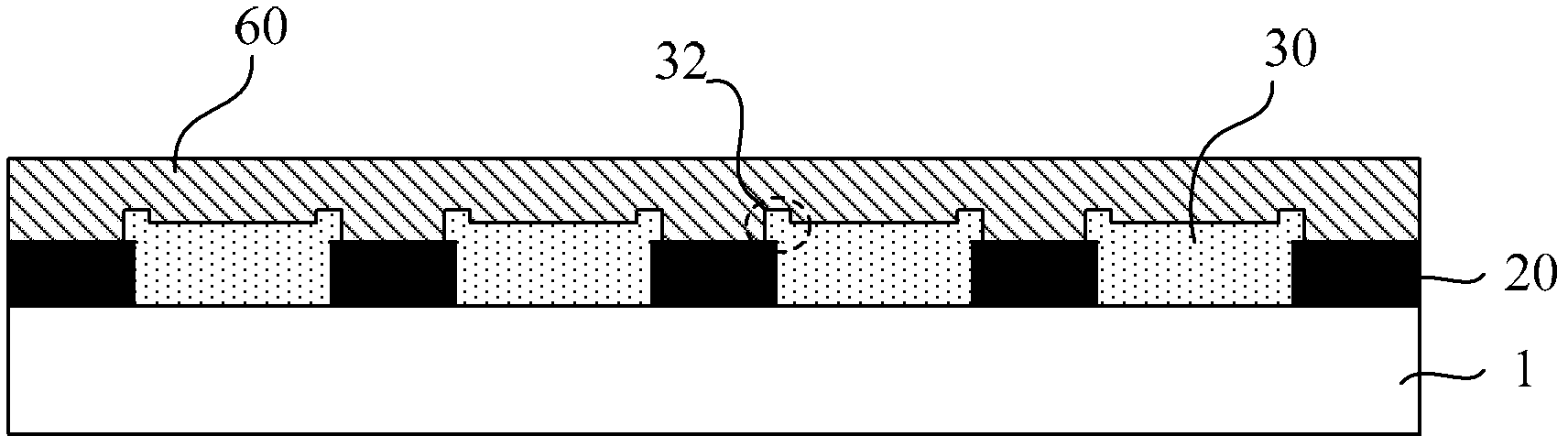

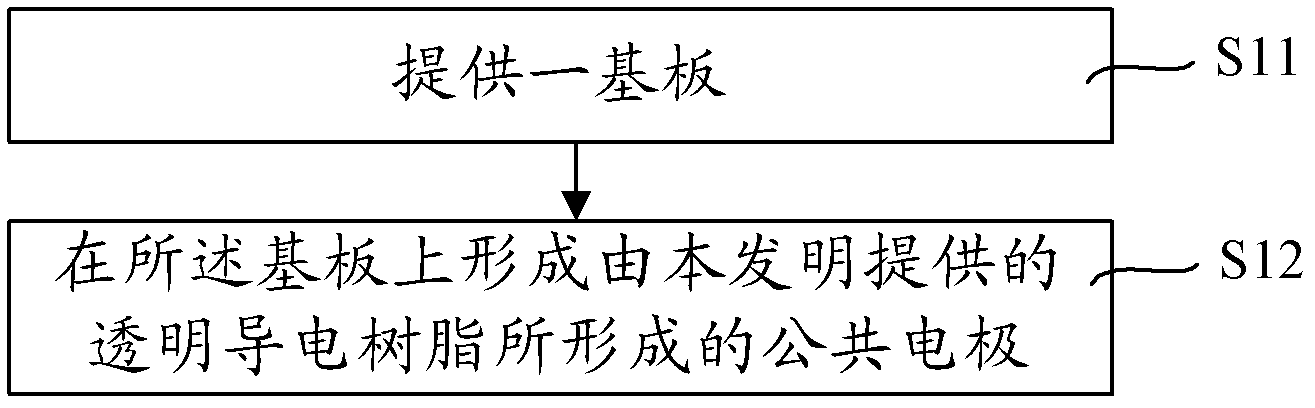

Transparent electroconductive resin, color film substrate and its manufacturing method, liquid crystal display device

ActiveCN102627823AGood light transmissionImprove conductivityNon-conductive material with dispersed conductive materialNon-linear opticsLiquid-crystal displayManufacturing technology

The invention discloses a transparent electroconductive resin, a color film substrate and its manufacturing method and a liquid crystal display device, relates to the technical field of liquid crystal display, and aims to raise properties of the liquid crystal display device and simultaneously simplify the manufacturing technology of the liquid crystal display device. The transparent electroconductive resin disclosed by the invention contains a transparent matrix resin, organic acid-doped polyaniline and toluene. The color film substrate disclosed by the invention contains a substrate, on which a common electrode formed by the transparent electroconductive resin is disposed. The invention can be applied to the manufacturing field of the liquid crystal display panel.

Owner:BOE TECH GRP CO LTD

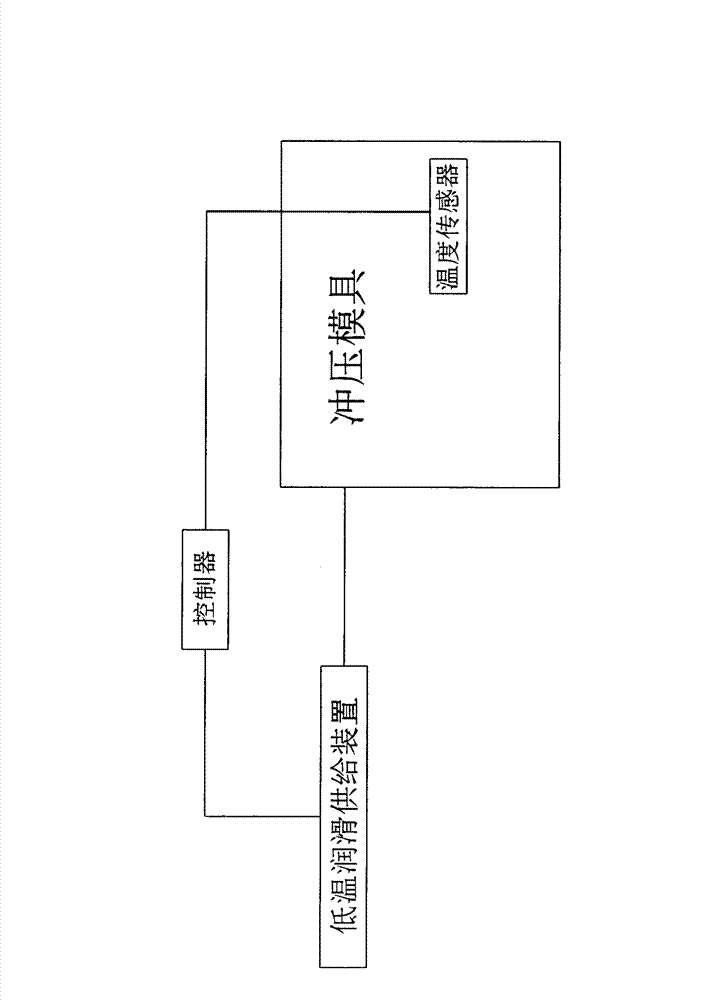

High speed stamping die with low temperature lubricating structure

InactiveCN102921818AReduce deformation or damageExtended service lifeShaping toolsStamping processLubrication

The invention provides a high speed stamping die with a low temperature lubricating structure and belongs to the technical field of dies. The invention solves the problems of bad cooling effect, bad lubricating effect and short service life of the current stamping die. The high speed stamping die with the low temperature lubricating structure comprises an upper die holder and a lower die holder, wherein a forming plate group composed of an upper die lining plate, a punch fixing plate, a discharge lining plate, a discharging plate, a lower template and a lower die lining plate is arranged between the upper die holder and the lower die holder, a forming assembly is arranged in the forming plate group, an oil gas path communicated with the forming assembly is arranged between the forming plate groups, and the inlet of the oil gas path is connected with a low temperature lubrication feeding device. The low temperature lubrication feeding device mixes and atomizes low temperature compressed air and micro-lubricating oil to form low temperature gas-liquid two-phase stream, and the low temperature gas-liquid two-phase stream is jetted to a stamping processing region through a gas channel so as to permeate the low temperature cold air to a stamping processing contact interface with oil particles atomized by the micro-lubricating oil to play a lubricating effect and effectively take away the heat generated during the stamping process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com