Double curved toughened glass cooling forming device

A technology of tempered glass and forming device, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large equipment investment, difficult equipment realization, low utilization rate, etc., to ensure production efficiency and improve equipment utilization rate. , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

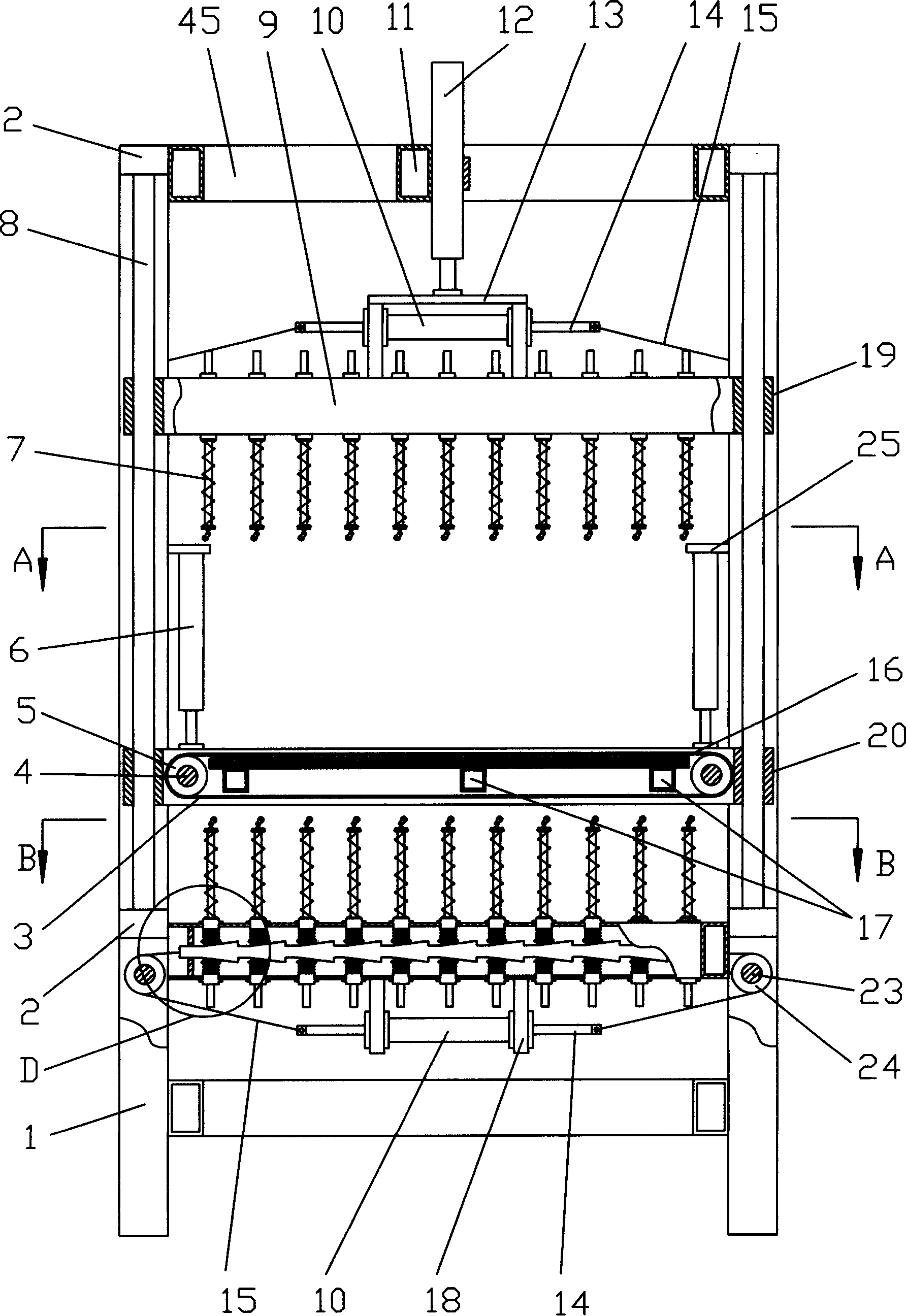

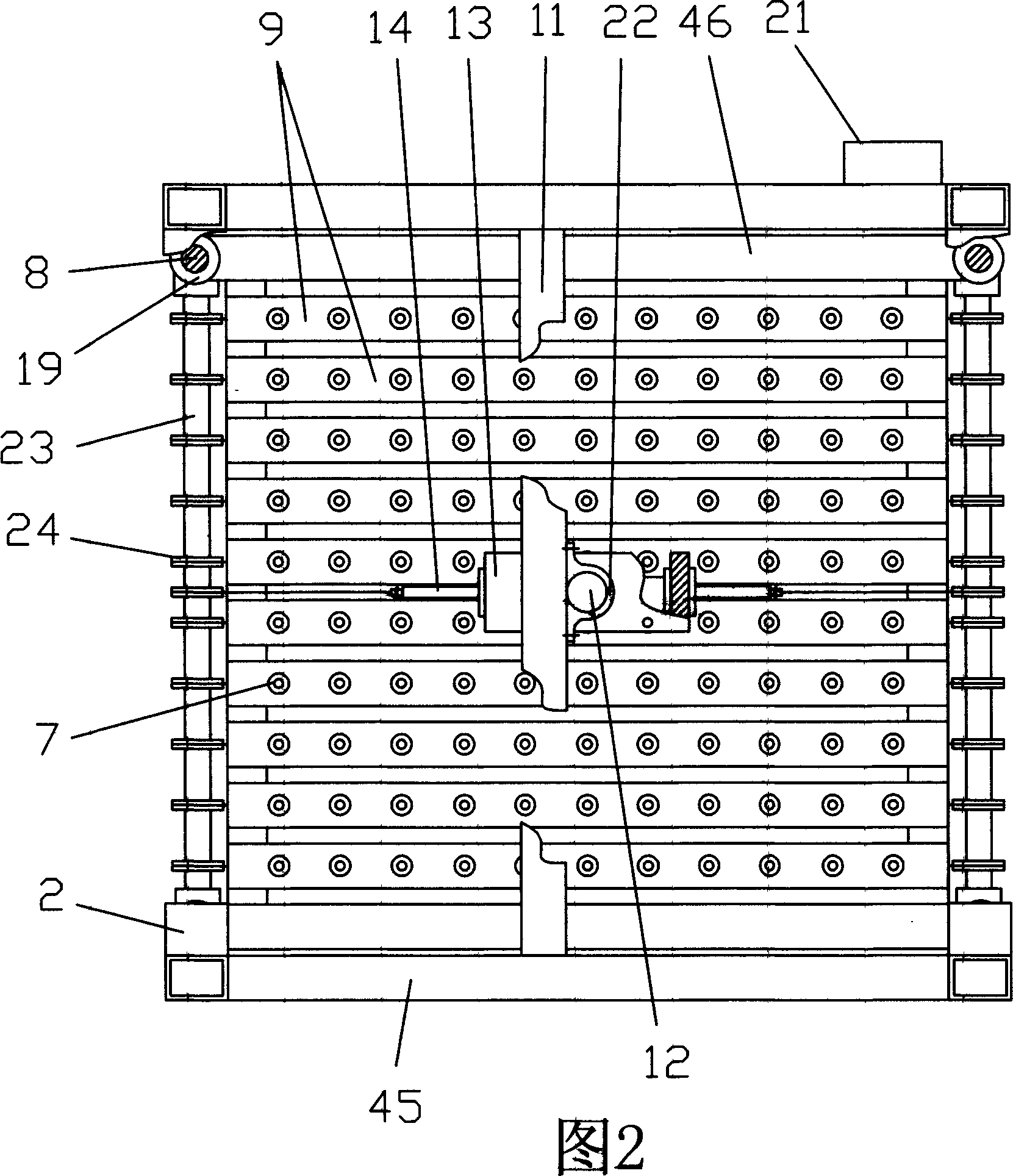

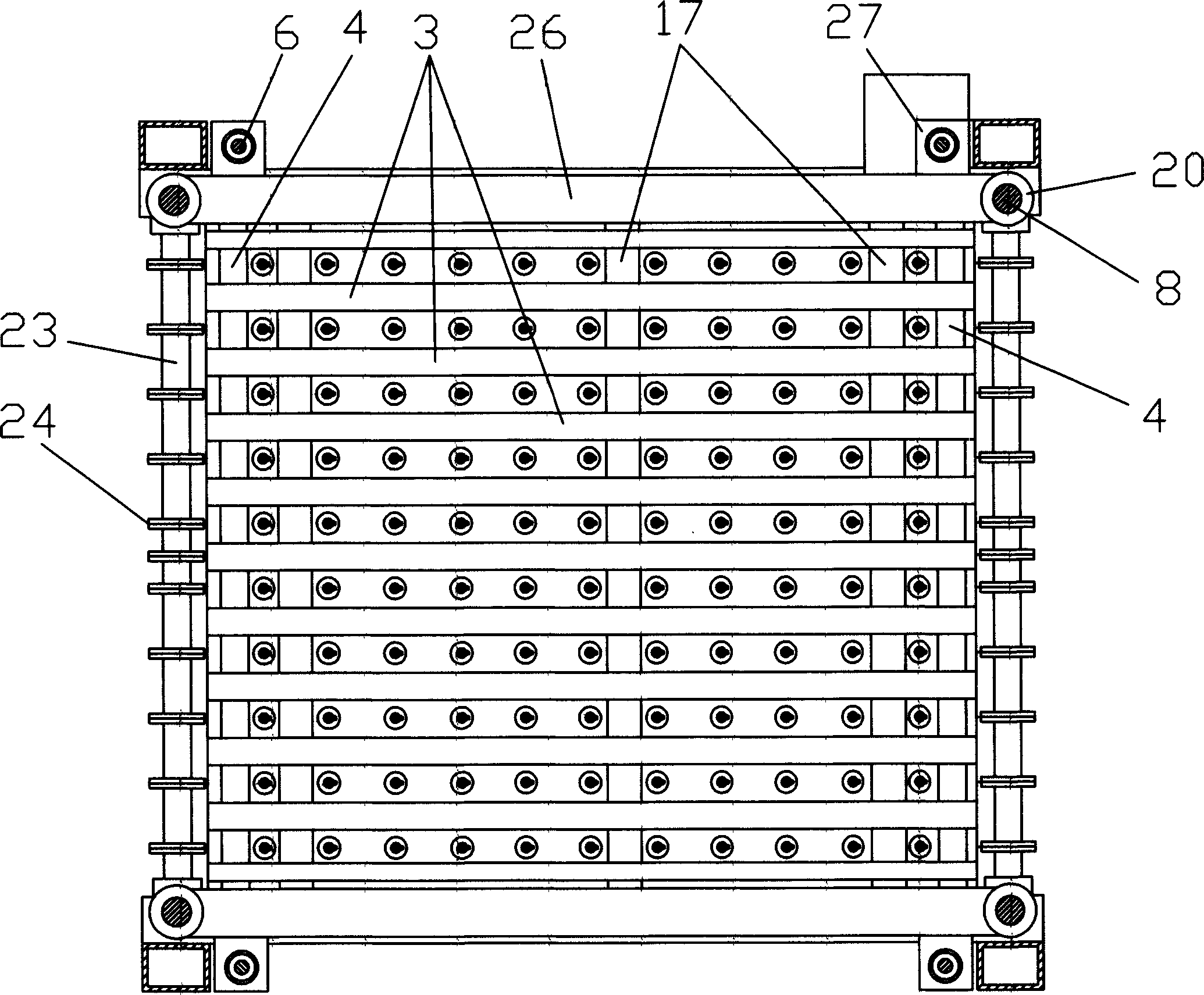

[0028] Such as Figure 1 ~ Figure 4 As shown, the hyperboloid tempered glass cooling forming device of the present invention includes a frame, an upper forming device, a lower forming device, and a conveying mechanism.

[0029] Frame 1 is made of four columns and several connecting beams 45, wherein a beam 11 is arranged in the middle part of the top of the frame, and a vertical guide column 8 is respectively arranged on each column through support 2 .

[0030] The upper forming device includes a crossbeam 9, a point support 7, and a point support locking mechanism; the crossbeam 9 is made of a square tube, and several crossbeams 9 are arranged in parallel at certain intervals, and the ends of two crossbeams 9 are respectively fixed to each other by connecting rods 47, And form a frame structure together with the beams 46 on both sides, each beam 46 two ends are respectively provided with a guide sleeve 19; All are installed with several point-shaped supports 7 at certain inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com