High speed stamping die with cooling structure

A high-speed stamping and cooling structure technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy damage and scrapping of molds, influence of high-speed stamping accuracy, errors, etc., to reduce deformation and damage, and ensure stamping accuracy. and production efficiency, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

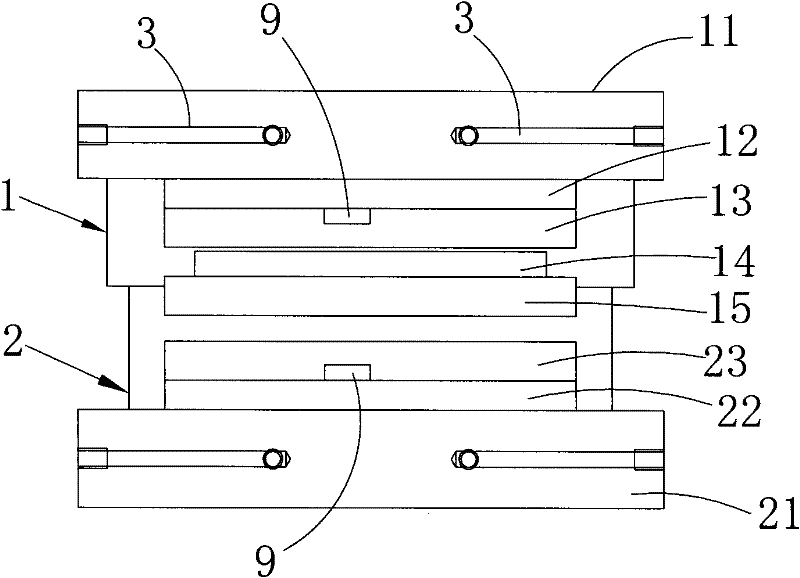

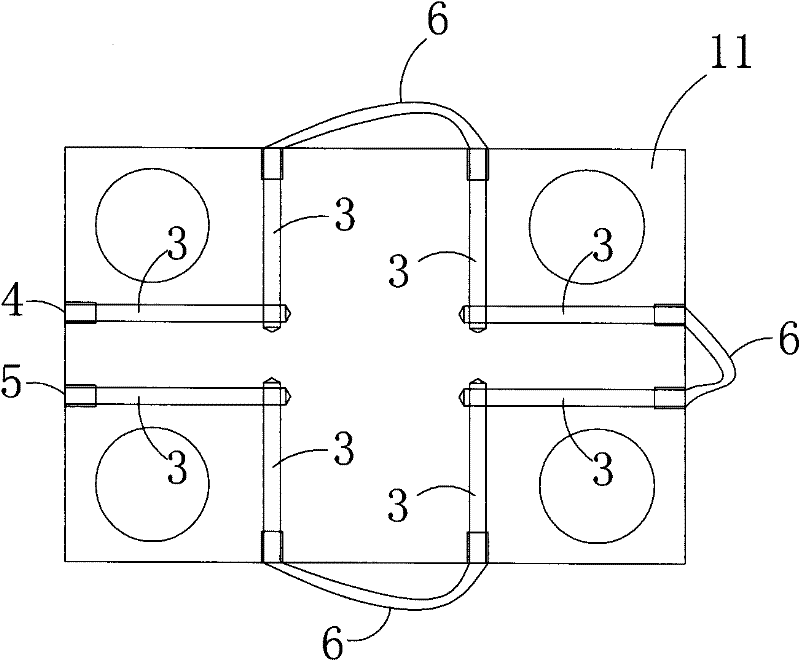

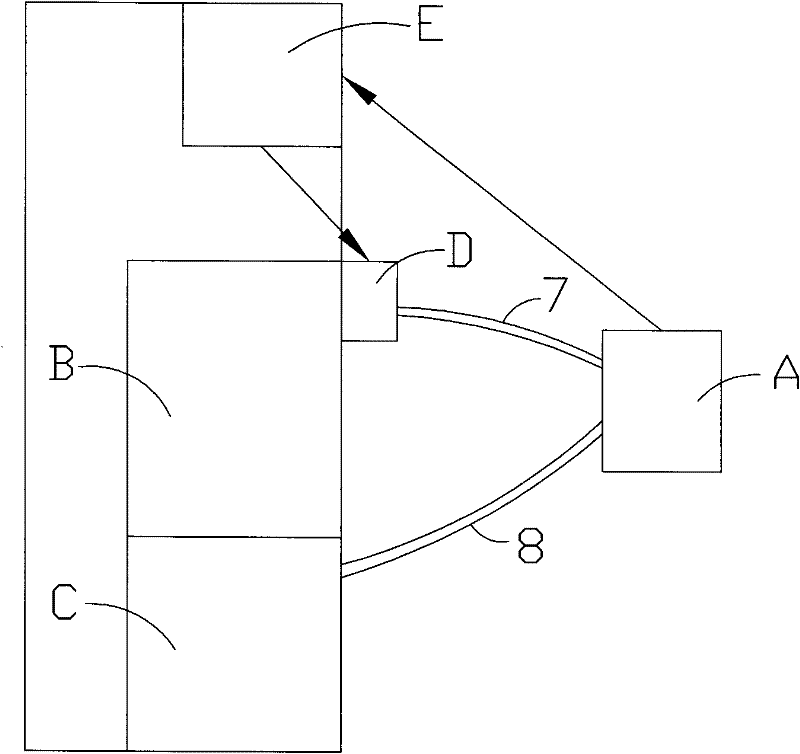

[0020] Embodiment: A kind of high-speed stamping die with cooling structure, such as figure 1 As shown, it includes an upper mold 1 and a lower mold 2, and the upper mold 1 includes an upper mold base 11 and an upper mold fixing backing plate 12, a punch fixing plate 13, a discharge plate fixedly connected with the upper mold base in turn from top to bottom. Backing plate 14 and stripping plate 15, the lower die 2 includes a lower die base 21, a lower die base plate 22 and a lower die plate 23 fixedly connected to the lower die base from bottom to top in sequence, and a cooling pipeline is provided inside the high-speed stamping die , there is cooling liquid circulating in the cooling pipeline, the starting end of the cooling pipeline is the cooling liquid inlet, the terminal of the cooling pipeline is the cooling liquid outlet, and there is a high-speed stamping die inside for monitoring the high-speed Temperature sensor 9 for the internal temperature of the stamping die.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com