Patents

Literature

489results about How to "Guarantee quality and efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

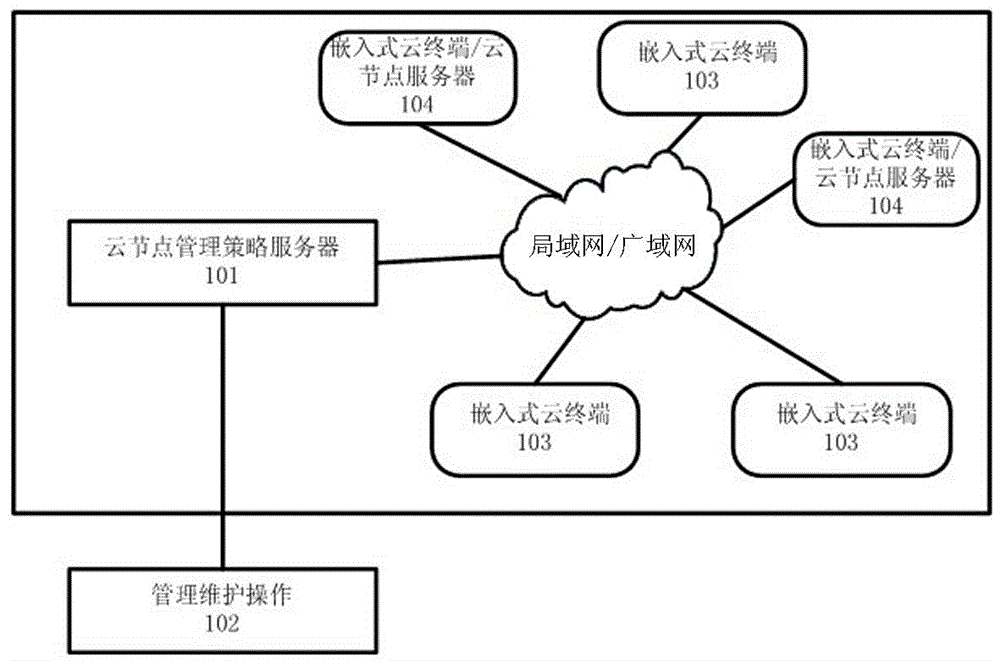

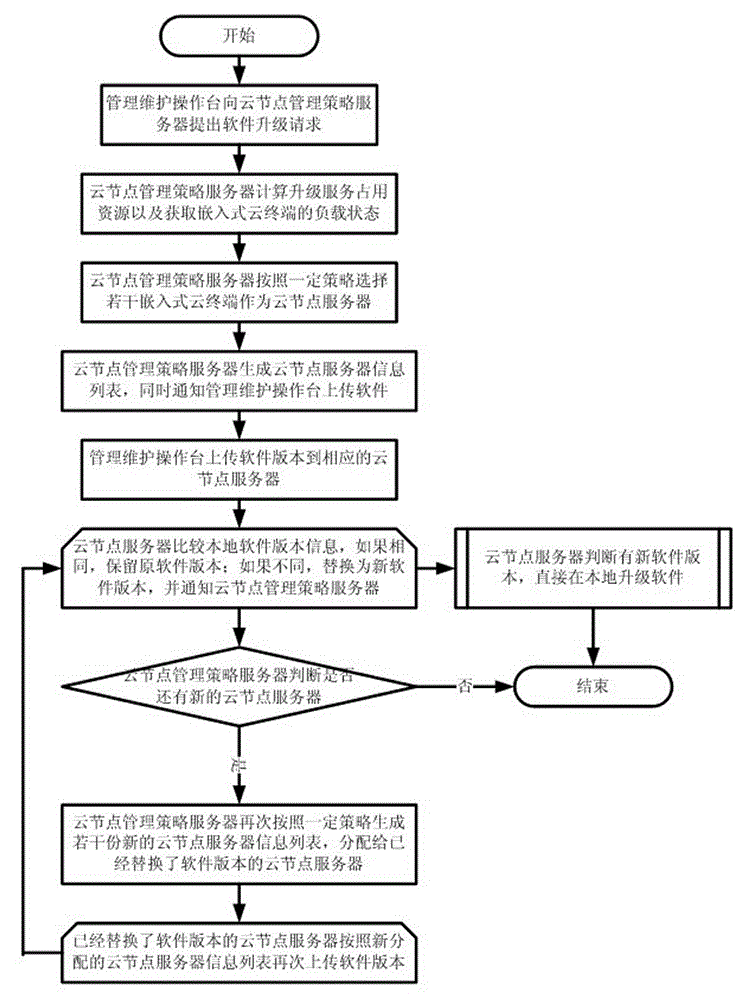

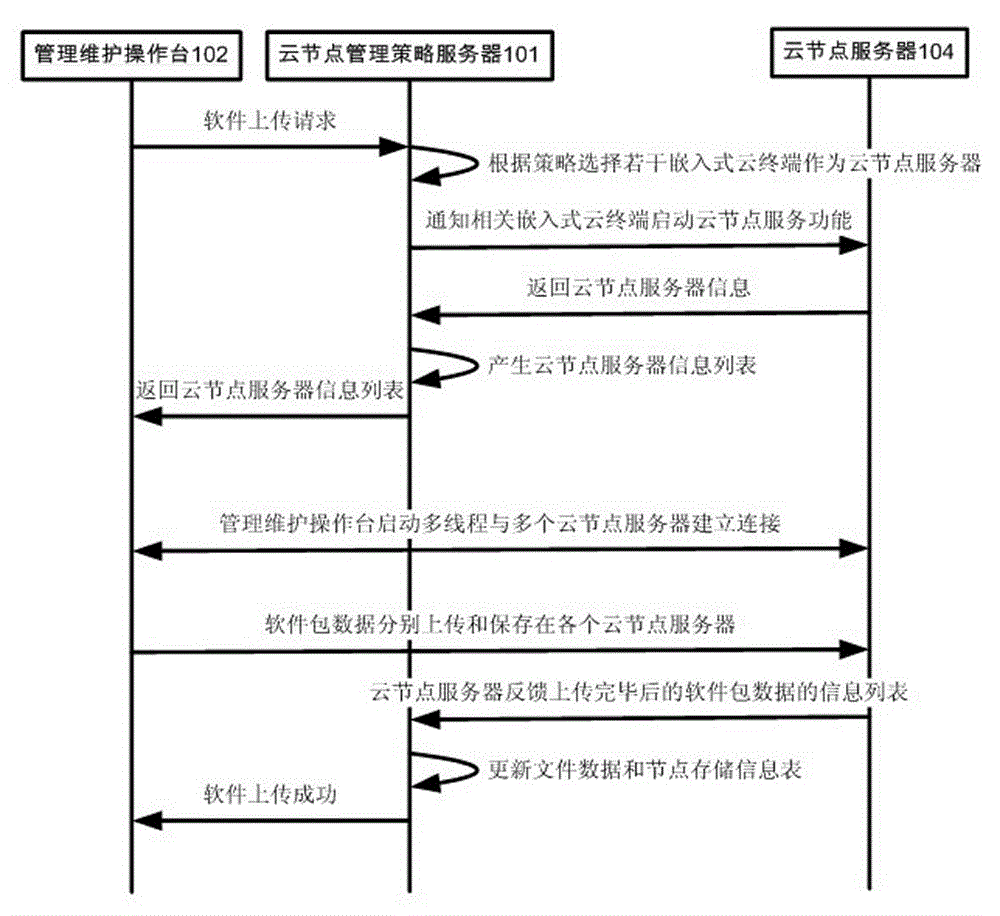

Terminal software online upgrading system and method based on cloud computing environment

InactiveCN102945175AEasy to upgrade and maintainSave resourcesProgram loading/initiatingTransmissionComputer terminalSoftware upgrade

The invention discloses a terminal software online upgrading system and a terminal software online upgrading method based on a cloud computing environment. The method specifically comprises the following steps that a management and maintenance operating platform makes a software upgrading request to a cloud node management strategy server; the cloud node management strategy server selects a plurality of embedded cloud terminals as cloud node servers according to certain strategies; the cloud node management strategy server issues a cloud node server information list to the management and maintenance operating platform; the management and maintenance operating platform uploads a software packet to corresponding cloud node servers; the cloud node management strategy server informs embedded cloud terminals and downloads the cloud node server information list to the embedded cloud terminals; and the embedded cloud terminals download software packet data from the designated cloud node servers and upgrade software. By adopting a cloud computing technique and a cloud computing method, the software upgrading of the embedded terminals on a large scale can be supported without adding special software upgrading servers, the stability is high and the upgrading effect is better if the embedded terminals are more.

Owner:HANGZHOU COMMNET +2

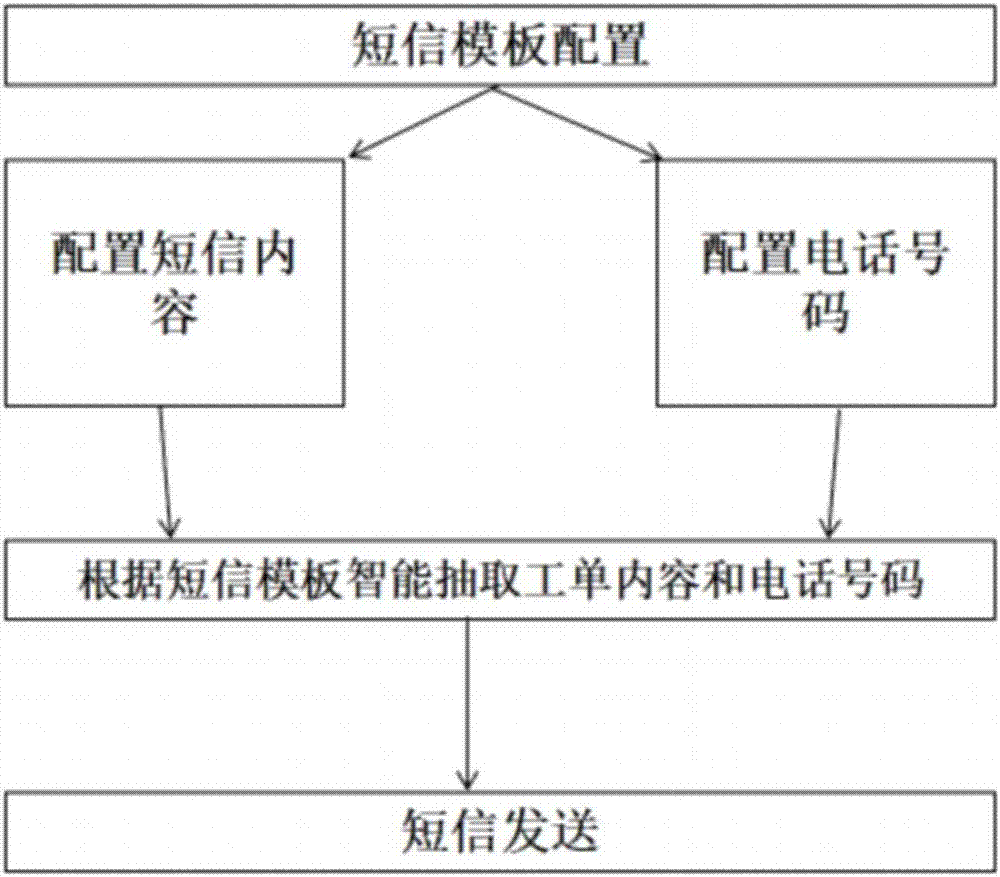

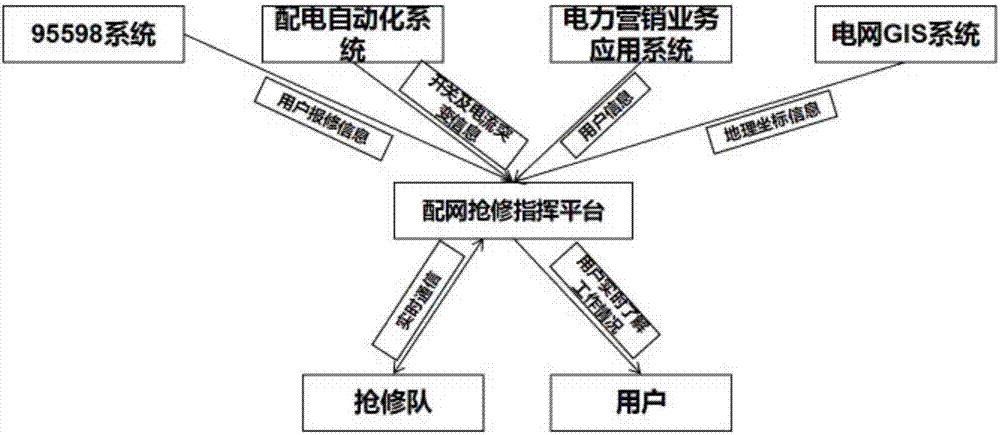

Short message platform optimization system and method of distribution network first-aid repair command platform

InactiveCN106875114AReduce the number of fault repairsImprove satisfactionMessaging/mailboxes/announcementsResourcesCollection systemFuzzy query

The invention discloses a short message platform optimization system and method of a distribution network first-aid repair command platform. The short message platform optimization system comprises a distribution network first-aid repair command platform. The distribution network first-aid repair command platform obtains user information from an electric power marketing service application system, obtains data from a power utilization information collection system, obtains distribution network fault information from a distribution automation system, collects user repair reporting information from a 95598 system, and obtains geographical coordinate information from a power grid GIS system. All the obtained information is stored in a fault information list. Fields are extracted from the fault information list to generate a short message template database. When a real fault work sheet is received, an address fuzzy query means is adopted in the short message template database to extract corresponding contents, and a first-aid repair work sheet short message is generated. The distribution network first-aid repair command platform sends the first-aid repair work sheet short message to a mobile terminal of a first-aid repair team, and provides a first-aid repair result of the first-aid repair team to a mobile terminal of a user as feedback in real time.

Owner:STATE GRID CORP OF CHINA +2

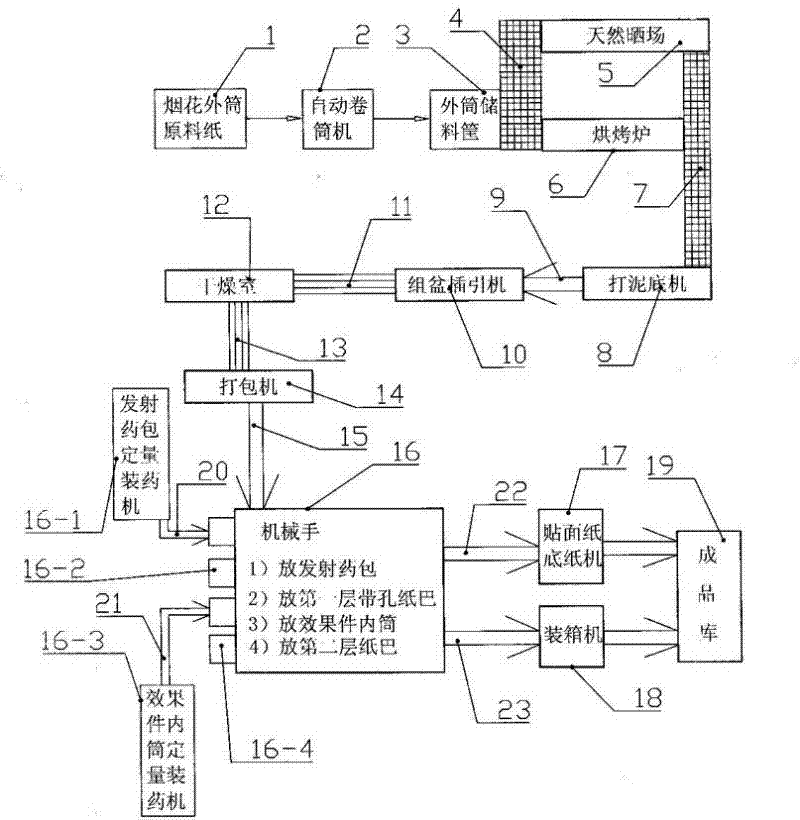

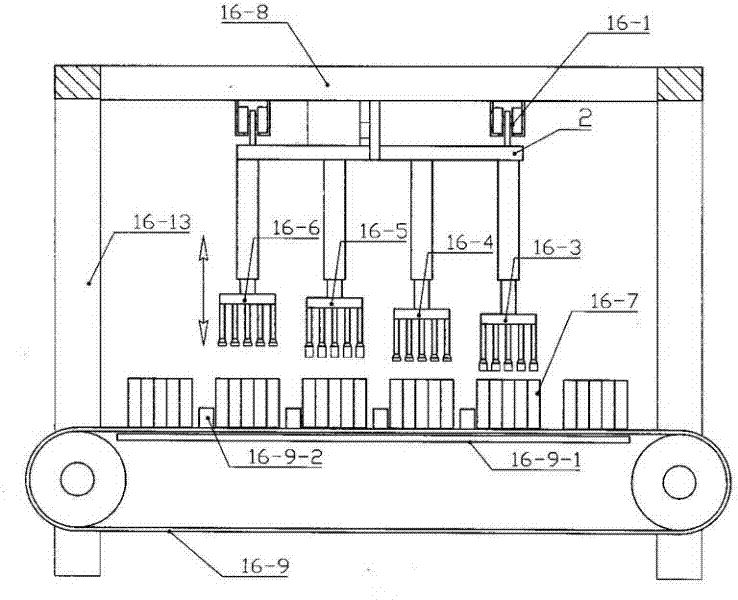

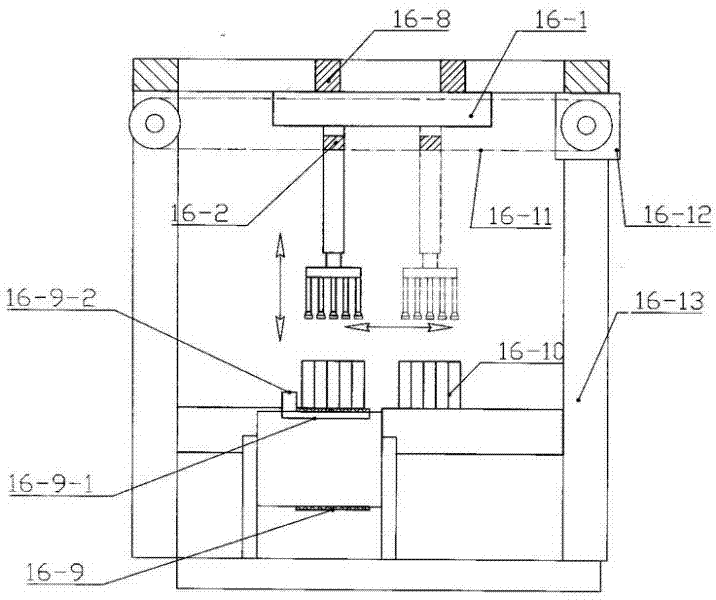

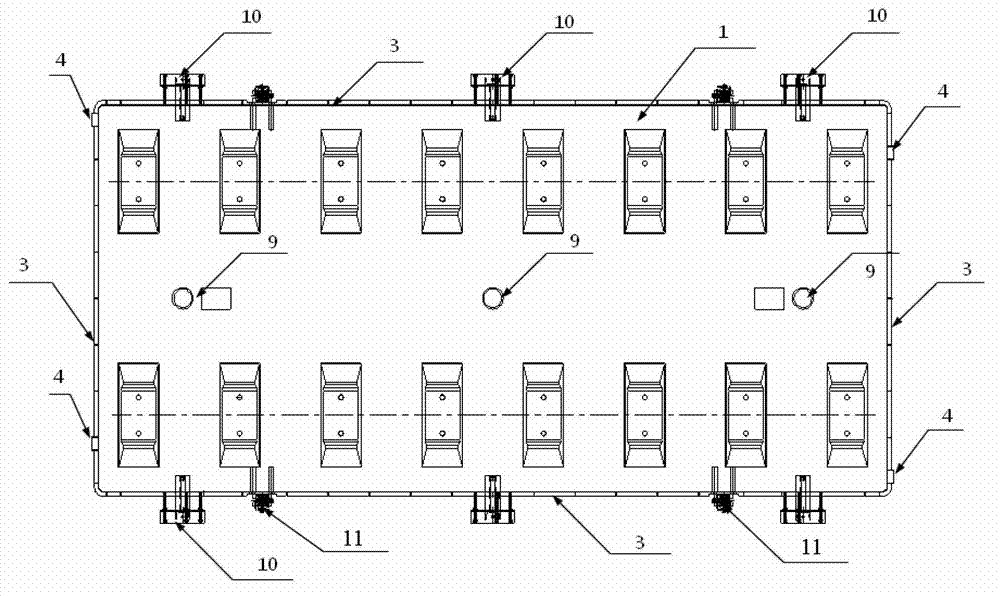

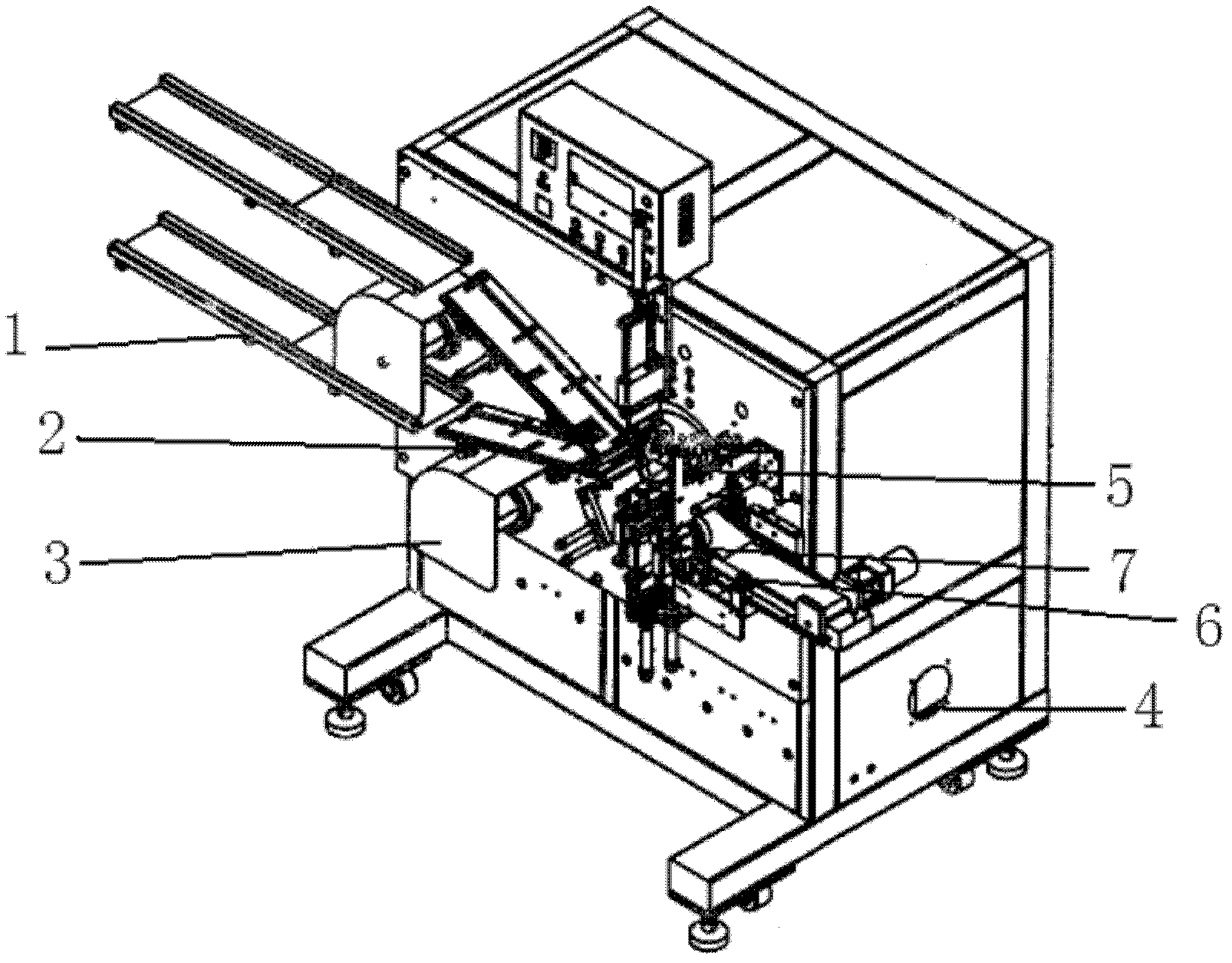

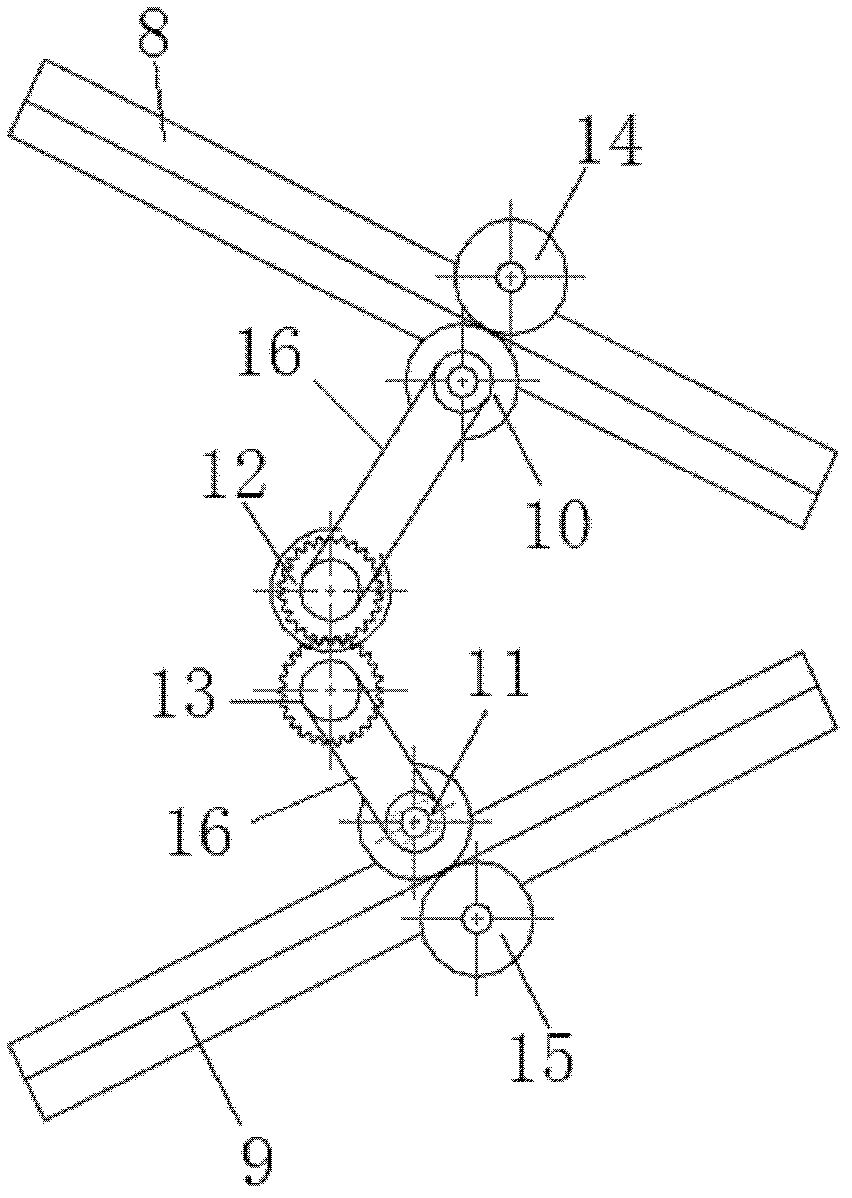

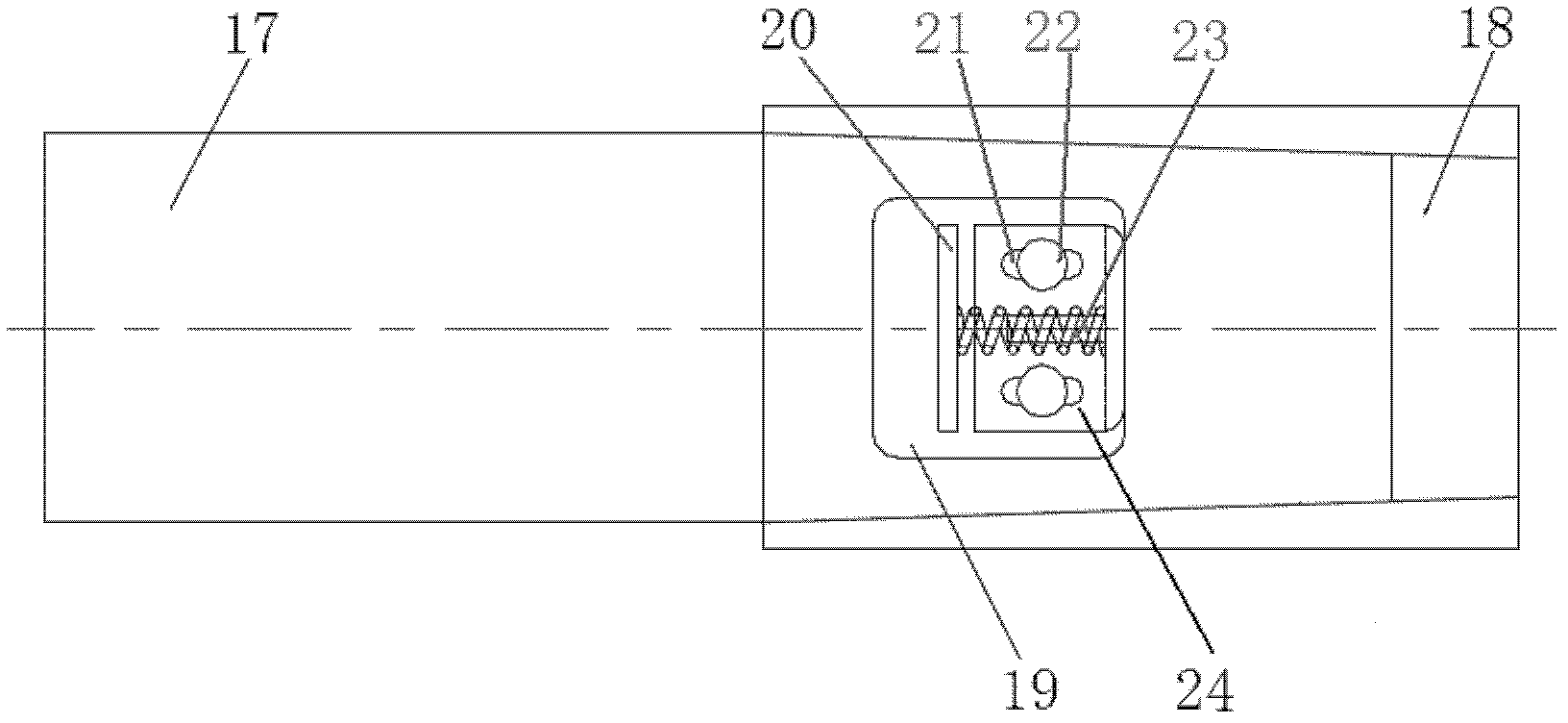

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

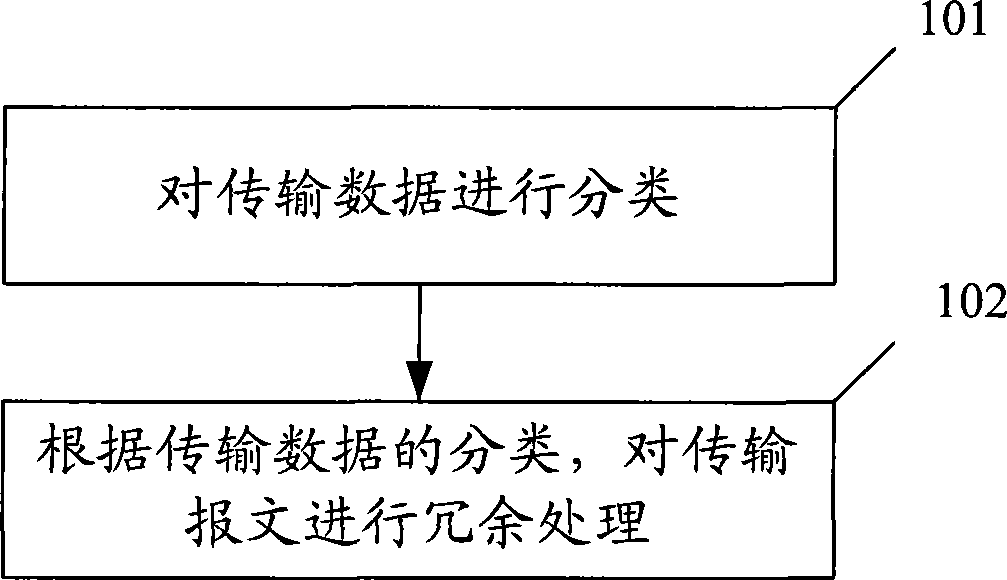

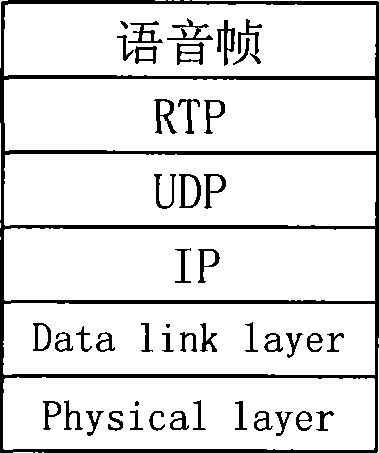

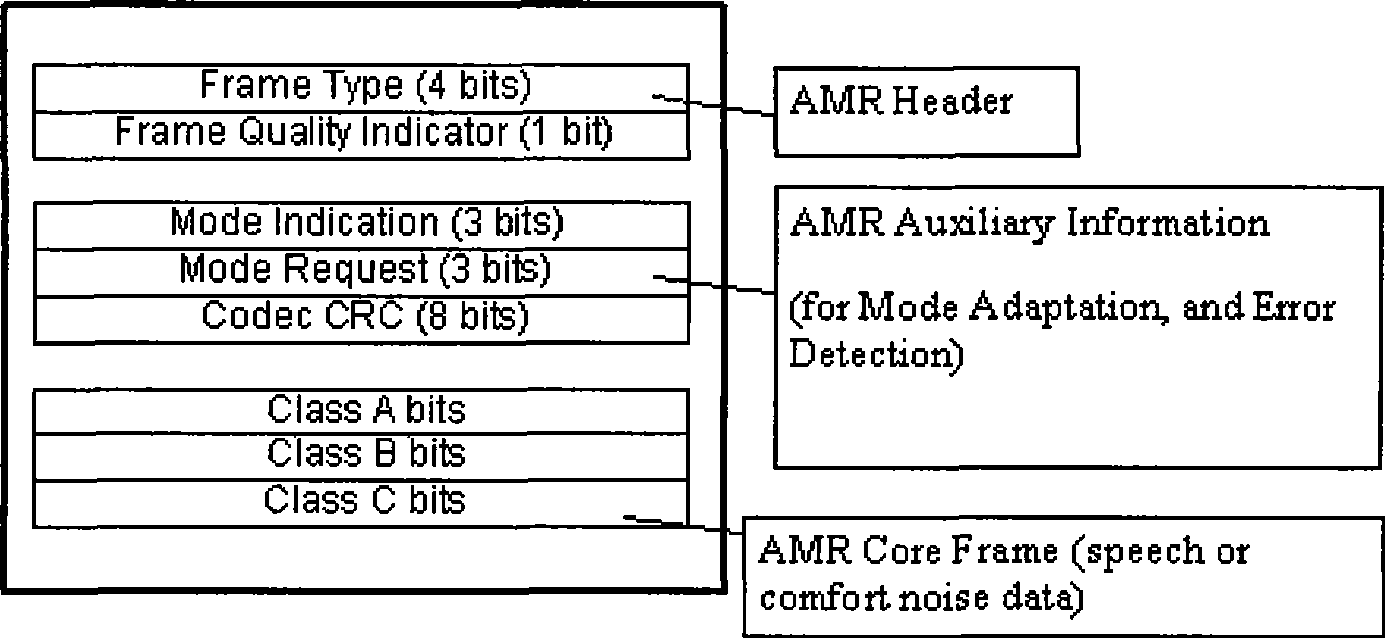

Method, device and system for improving data transmission quality

ActiveCN101547144AGuarantee quality and efficiencyGuaranteed transmission efficiencySource coding adaptationData switching networksEmbedded systemData transmission

The invention provides a method, a device and a system for improving data transmission quality. The method comprises the following steps: the redundancy processing for a transmission message is carried out according to the classification of transmission data. The redundancy processing for the transmission message is concretely carried out in such a way that the transmission message carries the content of another transmission message before the transmission message. In the invention, the redundancy processing for the transmission message is carried out by classifying transmission data according to the classification state of the transmission data, thus, under the condition that data packets are lost, the lost data packets can be recombined and recovered; and under the condition that the data packet losing rate is determined, the transmission quality and the transmission efficiency of the data can be further ensured.

Owner:HUAWEI TECH CO LTD

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

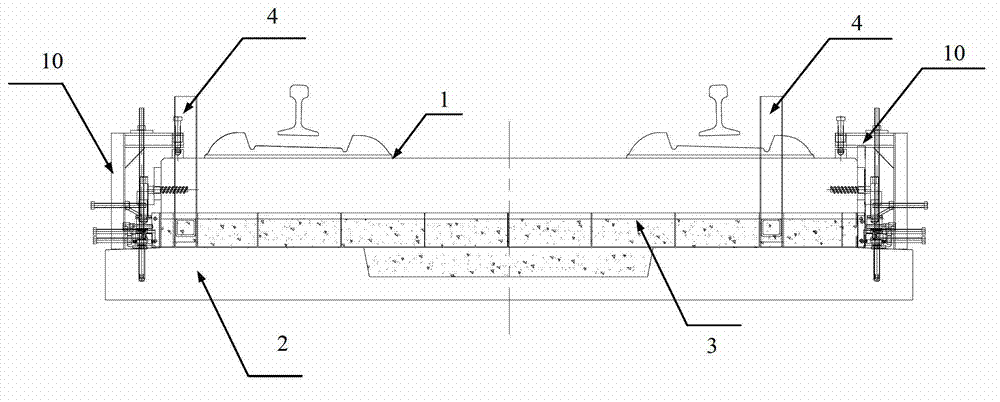

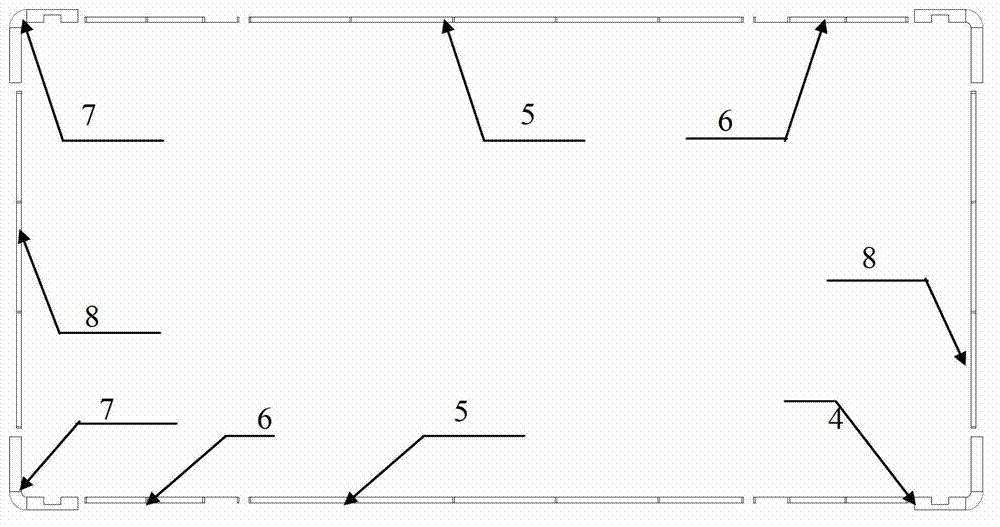

Slab ballastless track self-compacting concrete pouring construction method

InactiveCN103046441AGuarantee quality and efficiencyGuaranteed perfusion efficiencyRailway track constructionBuilding constructionSelf-consolidating concrete

Owner:CHINA CONSTR SIXTH ENG DIV CORP

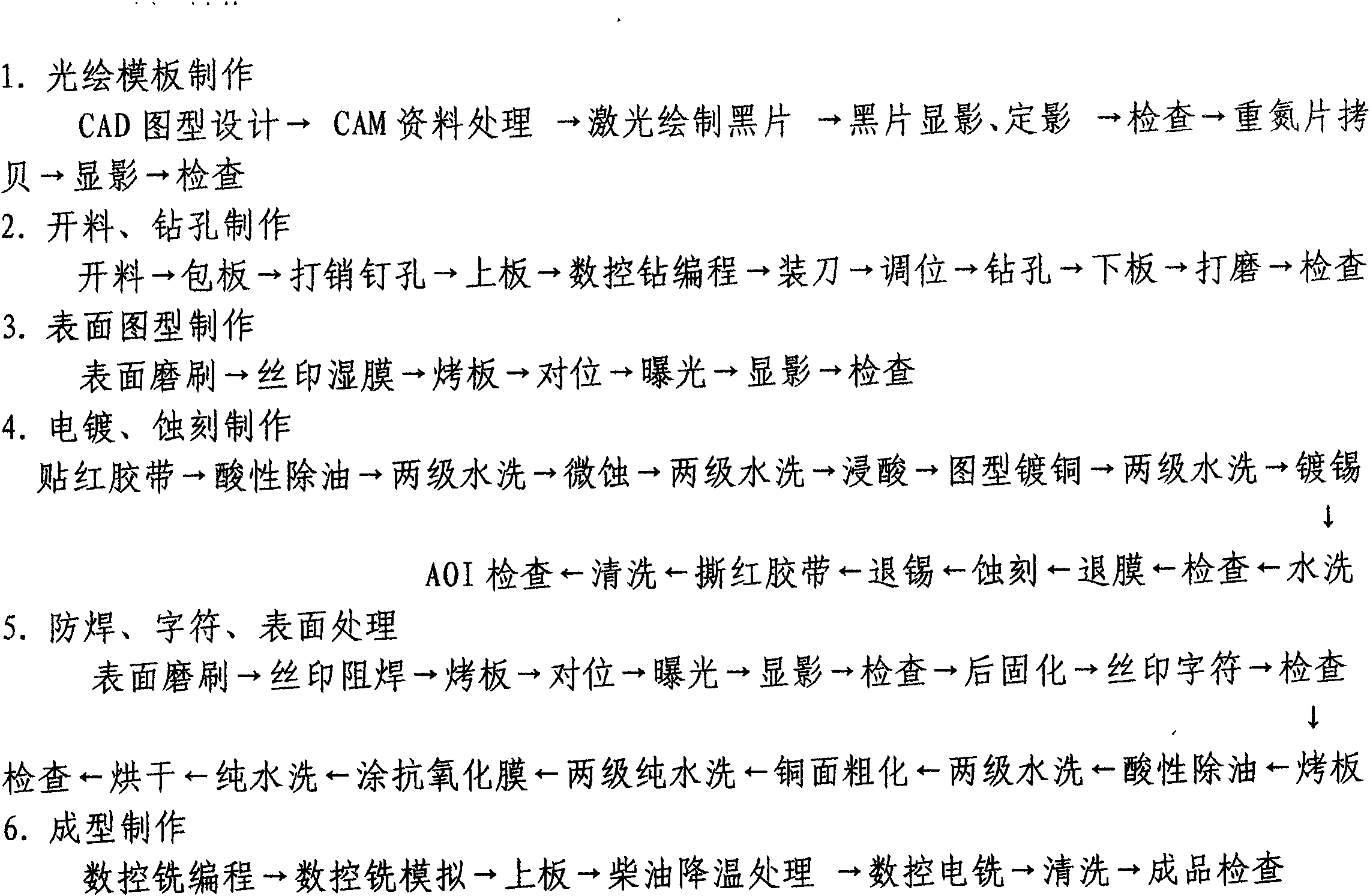

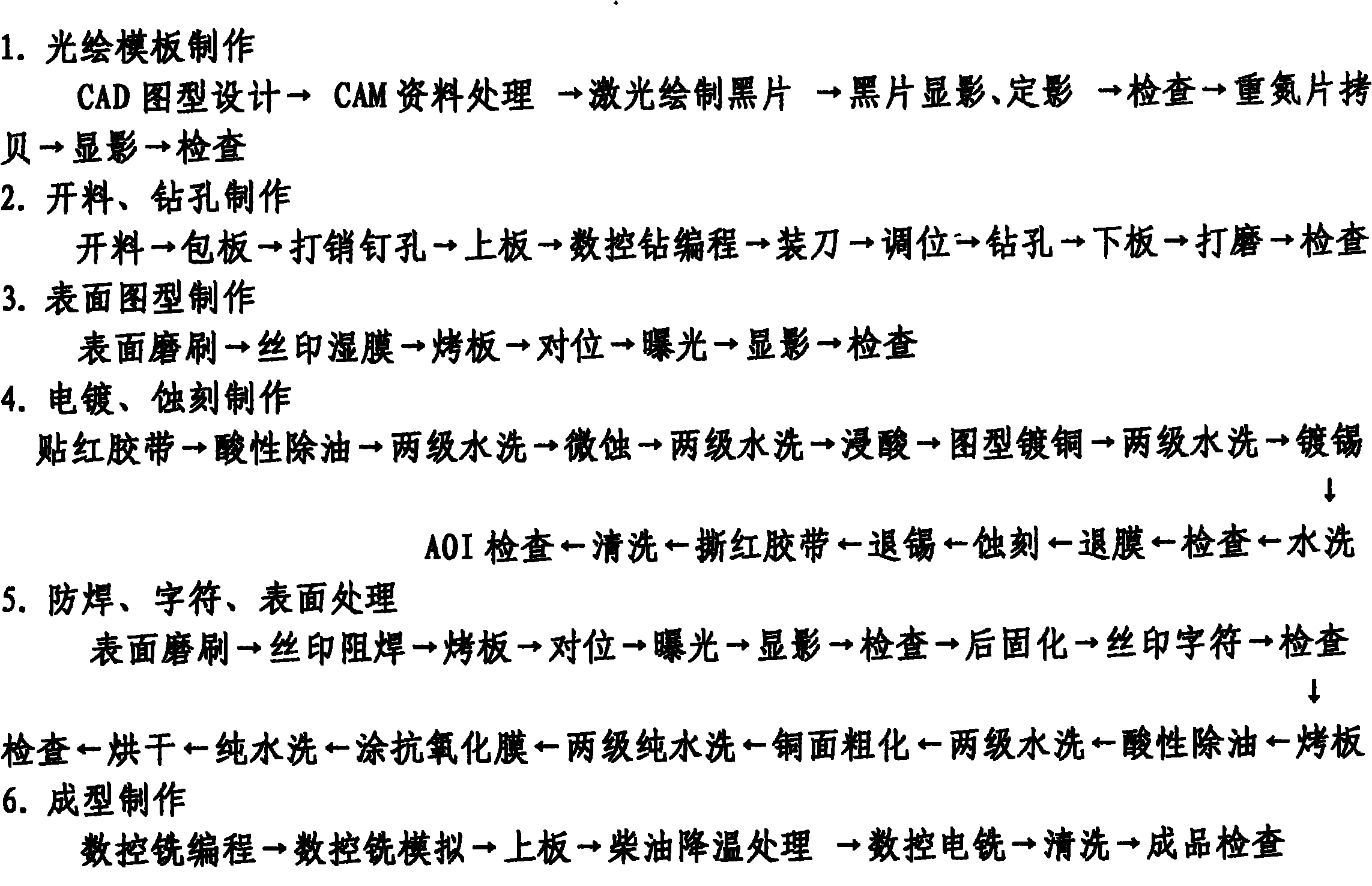

Method for making high-frequency aluminium-based circuit board

ActiveCN102159029AAvoid glitchesImprove performancePrinted circuit manufactureCircuit susbtrate materialsSurface patternElectrical and Electronics engineering

The invention discloses a method for making a high-frequency aluminium-based circuit board. The method comprises the following steps of: 1, making a photo-plotted template; 2, cutting and drilling holes; 3, making surface patterns; 4, electroplating and etching; 5, carrying out welding preventing and character and surface weldable processing; and 6, molding to make the high-frequency aluminium-based circuit board. The making accuracy of the method is high, the product quality and the work efficiency are effectively improved, and the performance of the made high-frequency aluminium-based circuit board is stable.

Owner:TAIZHOU JINDING ELECTRONICS

Three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and power generation system thereof

ActiveCN107317544ASolve the problem of non-standard water installationSolve the problem of irregular installationPhotovoltaic supportsWaterborne vesselsMulti functionalityPhotovoltaic power generation

Disclosed are a three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and a power generation system thereof. The photovoltaic power generation unit comprises a passage floating body and a connecting floating body arranged on a side wall of the passage floating body, wherein a power generation element is arranged on the connecting floating body. The system is formed by assembling three-in-one coupling insertion-pull type water surface photovoltaic power generation units vertically and horizontally. Horizontally, the passage floating body is assembled with a passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Vertically, the connecting floating body is assembled with the passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Finally, connecting floating bodies of a horizontal row of three-in-one coupling insertion-pull type water surface photovoltaic power generation units are independently fixed with passage floating bodies, so as to complete mounting of the whole power generation system. The unit has the characteristics of simple structure, convenient mounting and multi-functionality. The system assembly has the characteristics of simple structure and convenient mounting.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

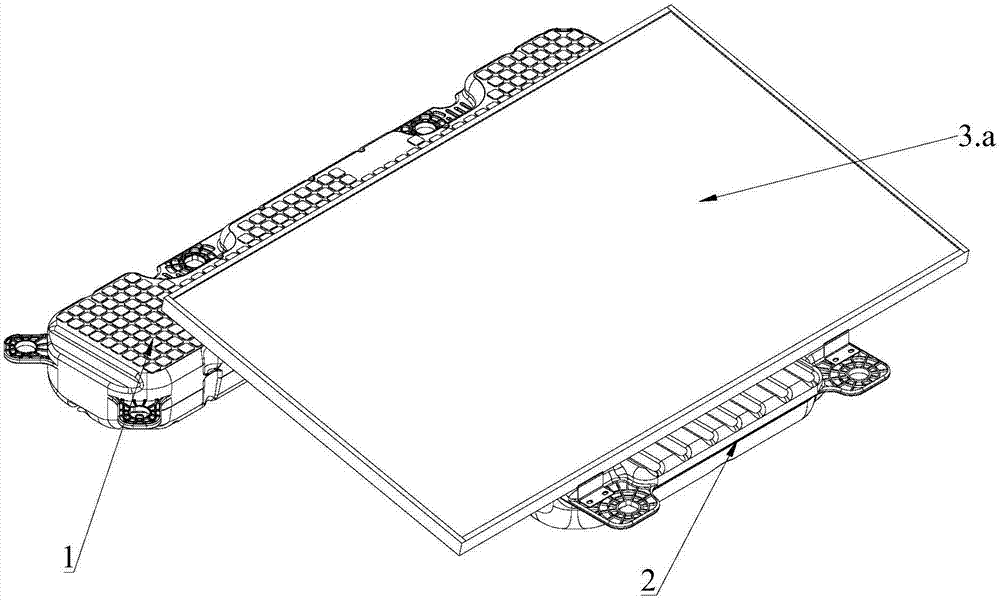

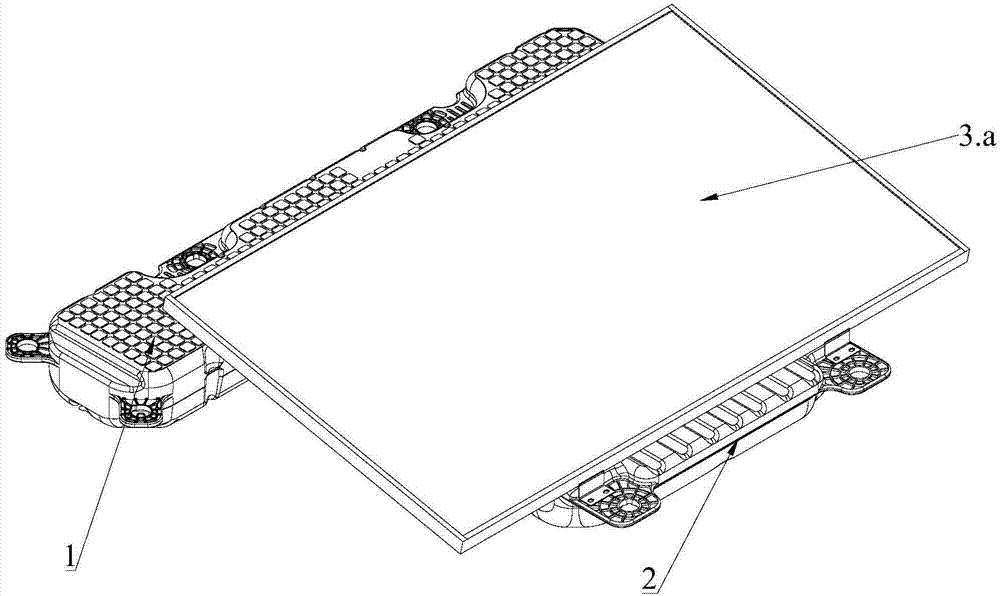

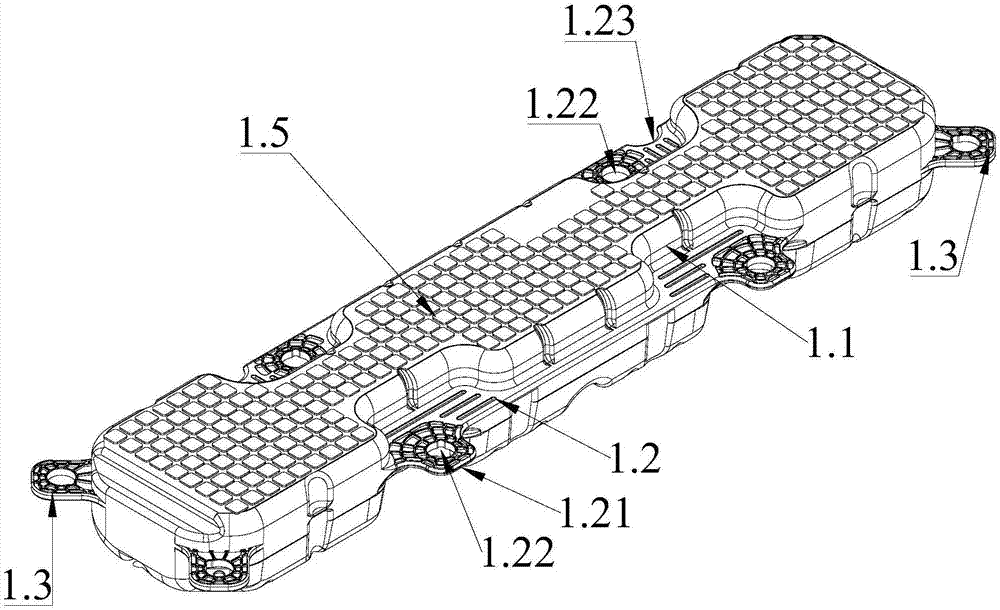

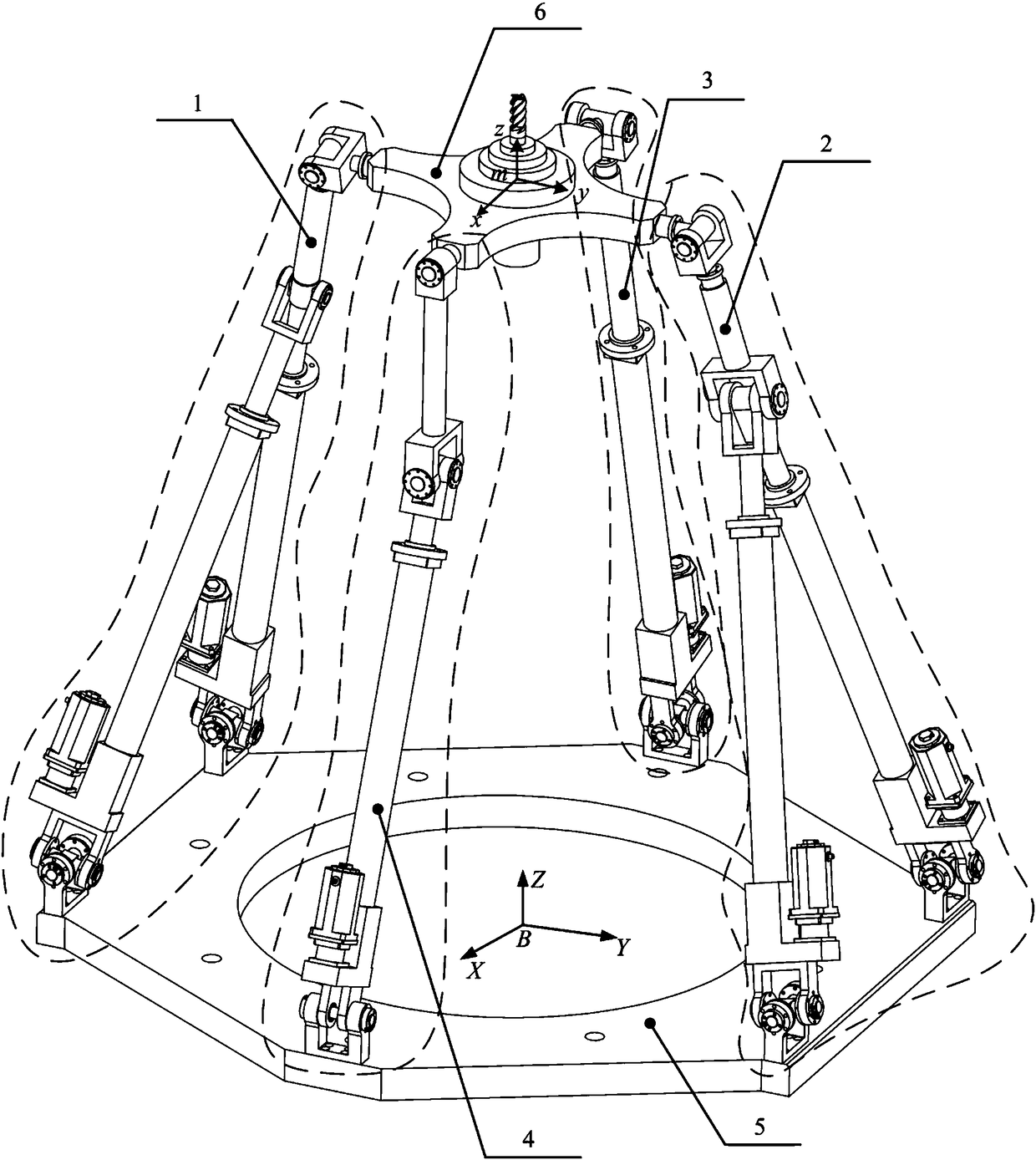

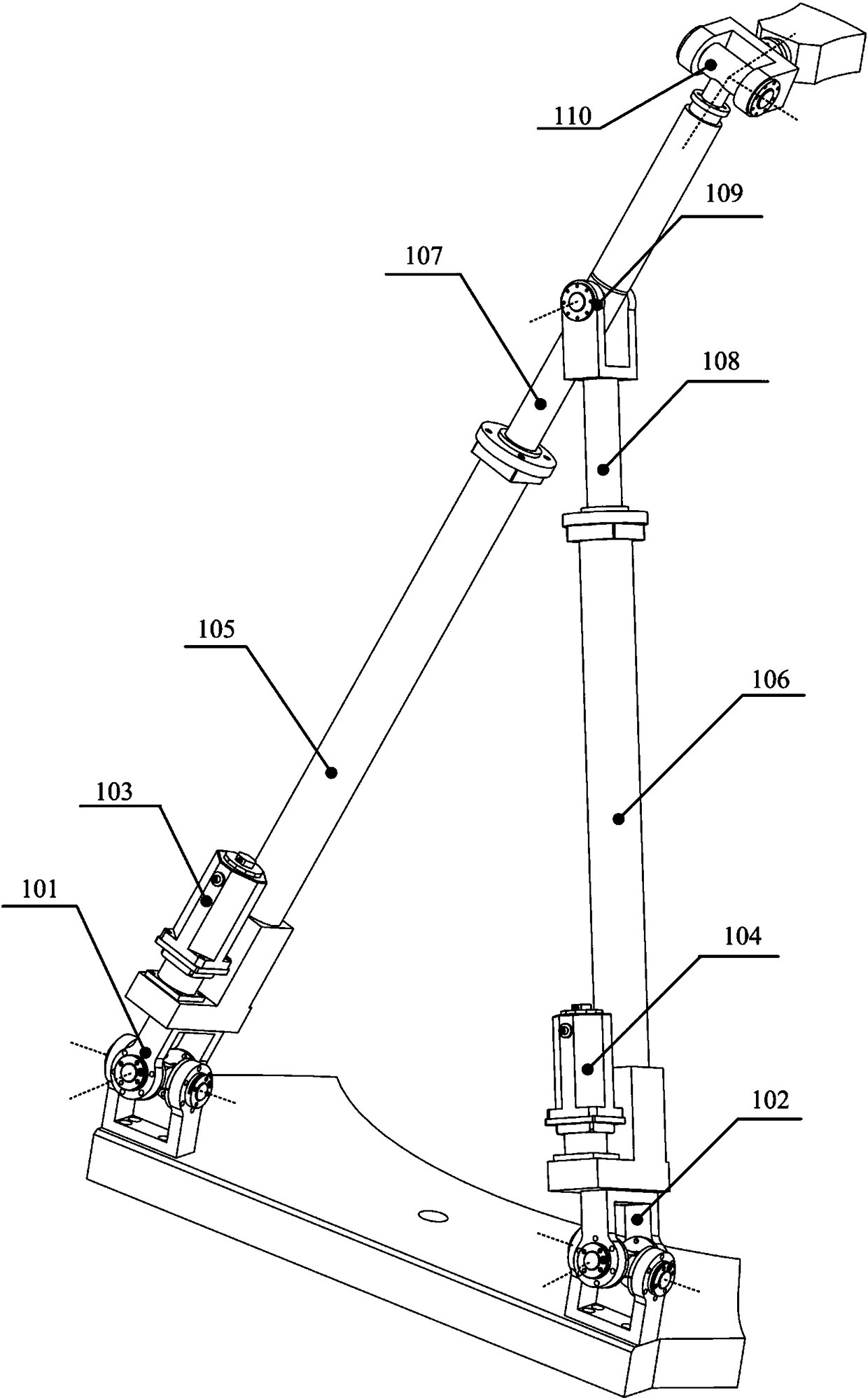

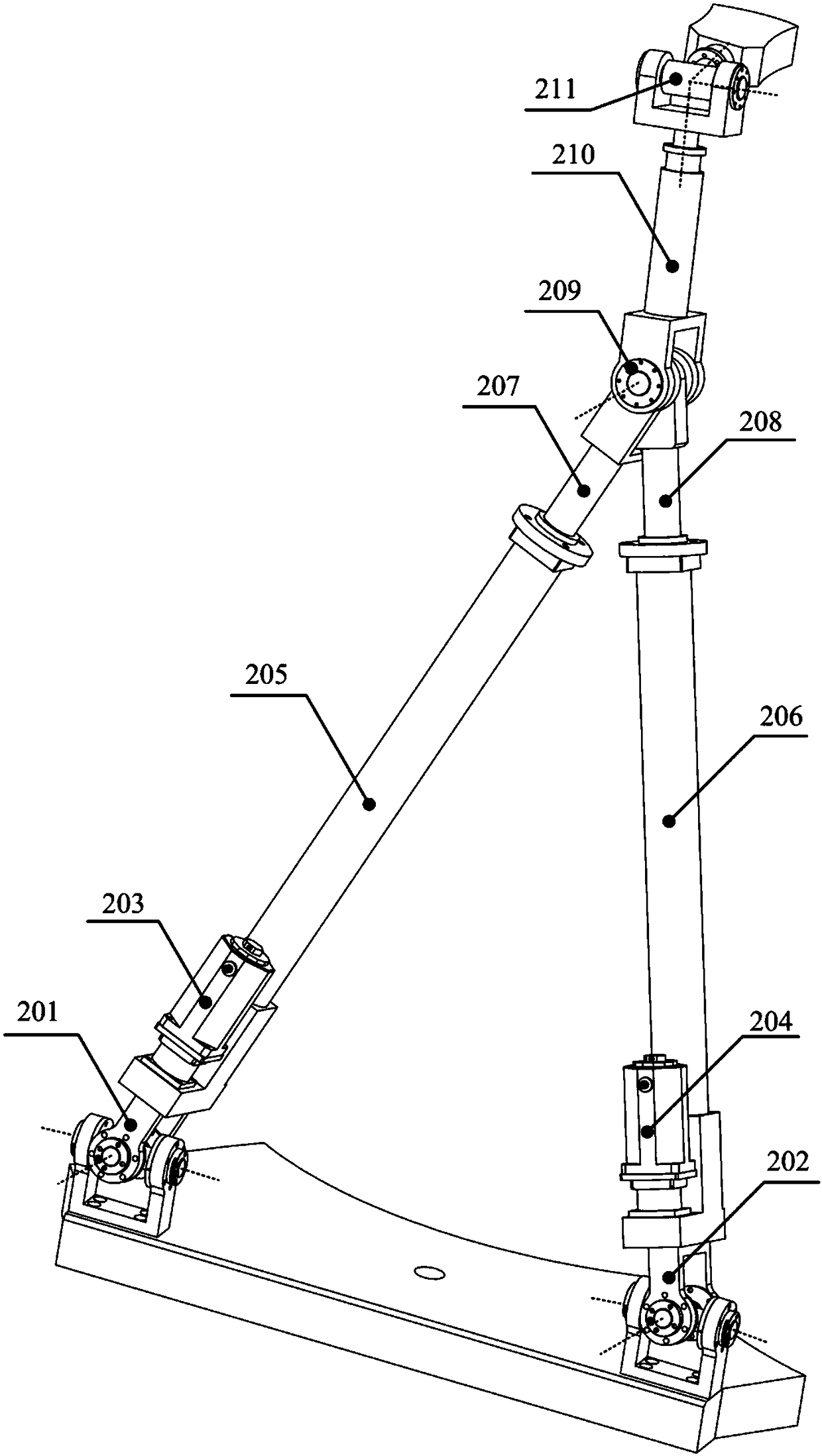

Redundant drive five degrees of freedom parallel machine tool with large rotation angle

InactiveCN108161490AHigh positioning accuracySolve processing problemsProgramme-controlled manipulatorLarge fixed membersTurn angleFree form

The invention relates to a redundant drive five degrees of freedom parallel machine tool with a large rotation angle. The redundant drive five degrees of freedom parallel machine tool with the large rotation angle includes a fixed platform, a movable platform for installing a main shaft head and a first driving branch, a second driving branch, a third driving branch and a fourth driving branch forconnecting the fixed platform and the movable platform, the structures of the first driving branch and the second driving branch are similar, and the first driving branch includes a hooke hinge, a servo driving unit, a revolute pair and a compound sphere hinge; the third driving branch includes a hooke hinge, a servo driving unit and a compound sphere hinge, the fourth driving branch includes a revolute pair, a servo driving unit, a hooke hinge and a revolute pair, and the movable platform of a machine tool and the four driving branches are hinged to form a space closed-cycle parallel mechanism; and the three-dimensional translation and the two-dimensional rotation of the space can be achieved by controlling six servo motors to drive the four branches. The redundant drive five degrees offreedom parallel machine tool with the large rotation angle has the advantages that the branch structures are simple and compact, the orientation workspace is large, the flexibility is high, the rigidity is large, and the singular configuration can be prevented, and can be used for high-speed, high-precision and efficiency machining for free-form surface in complex space.

Owner:BEIJING JIAOTONG UNIV

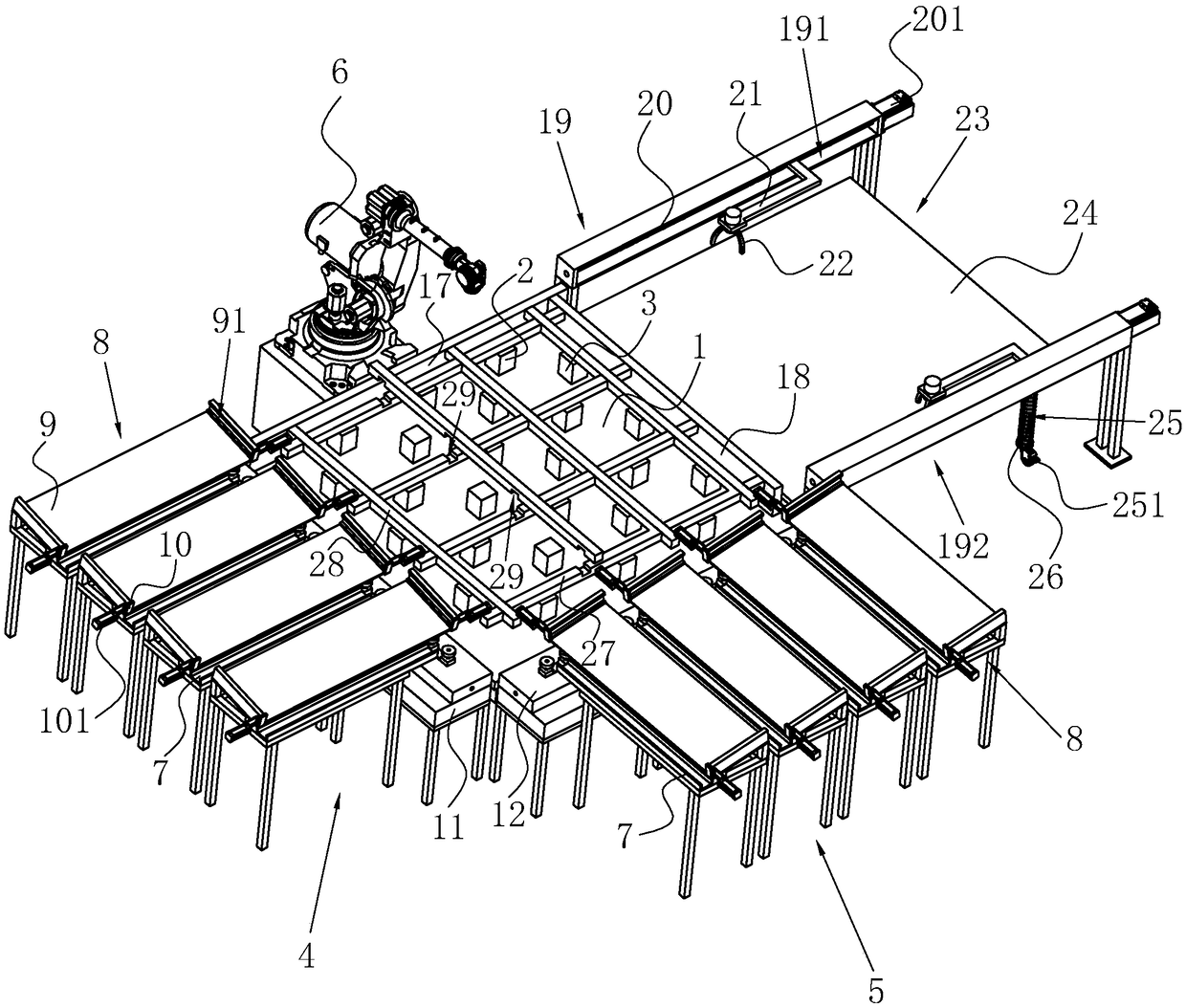

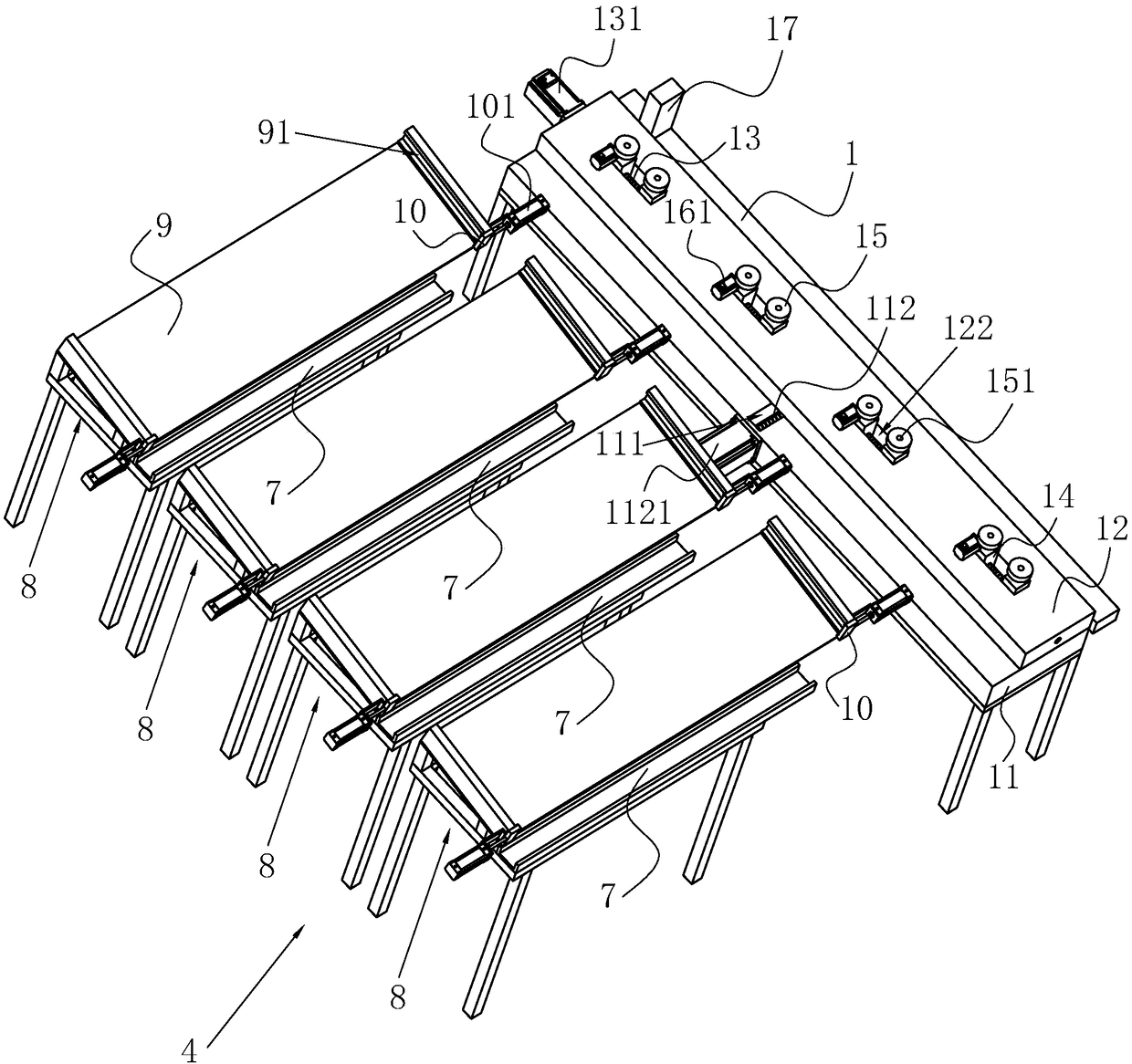

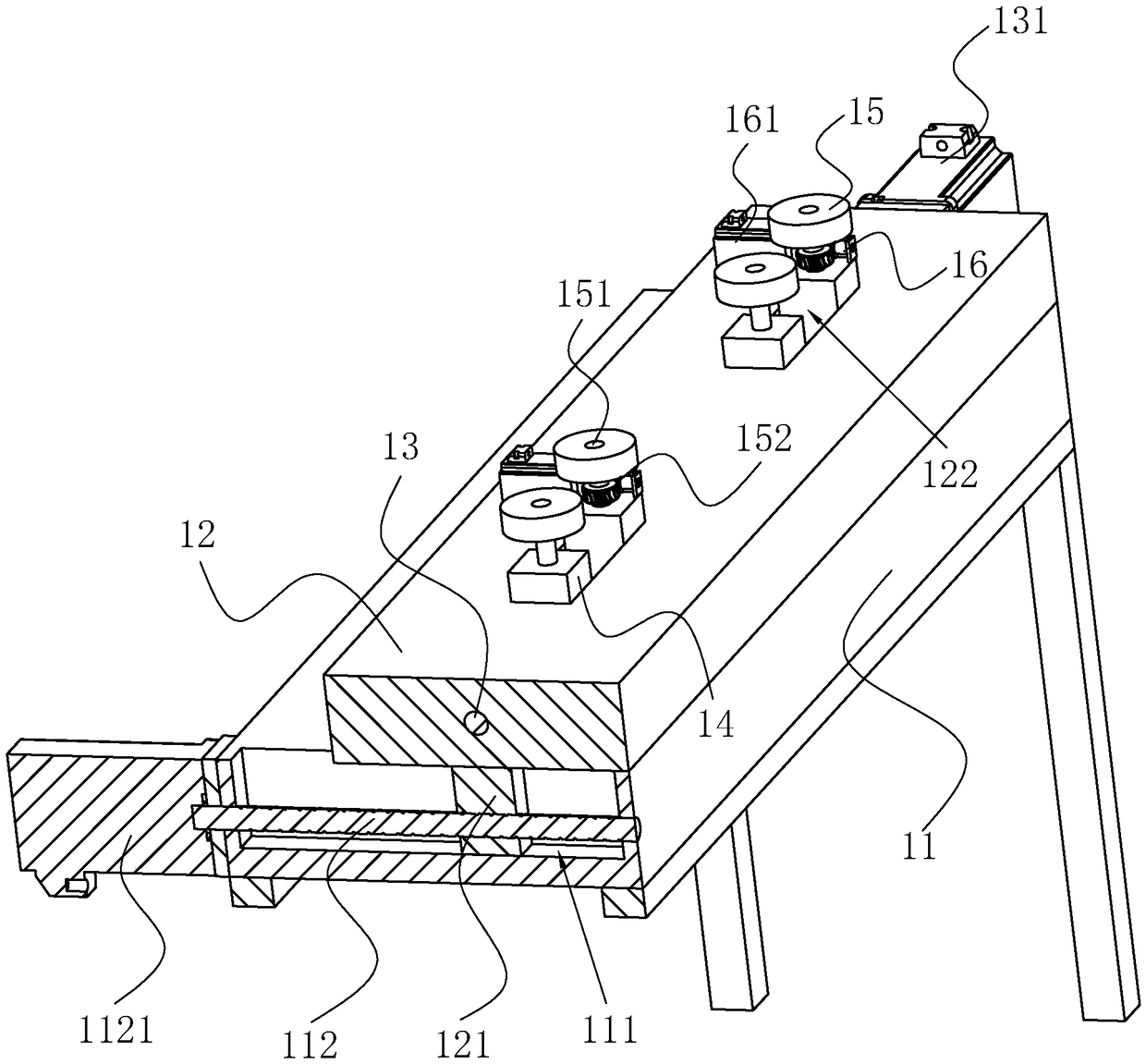

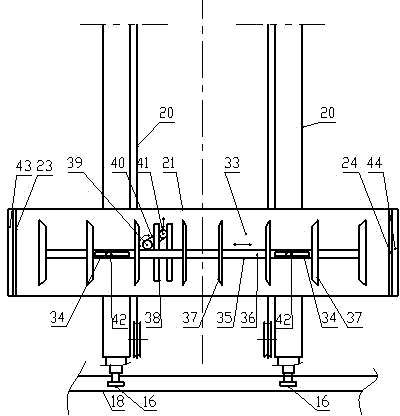

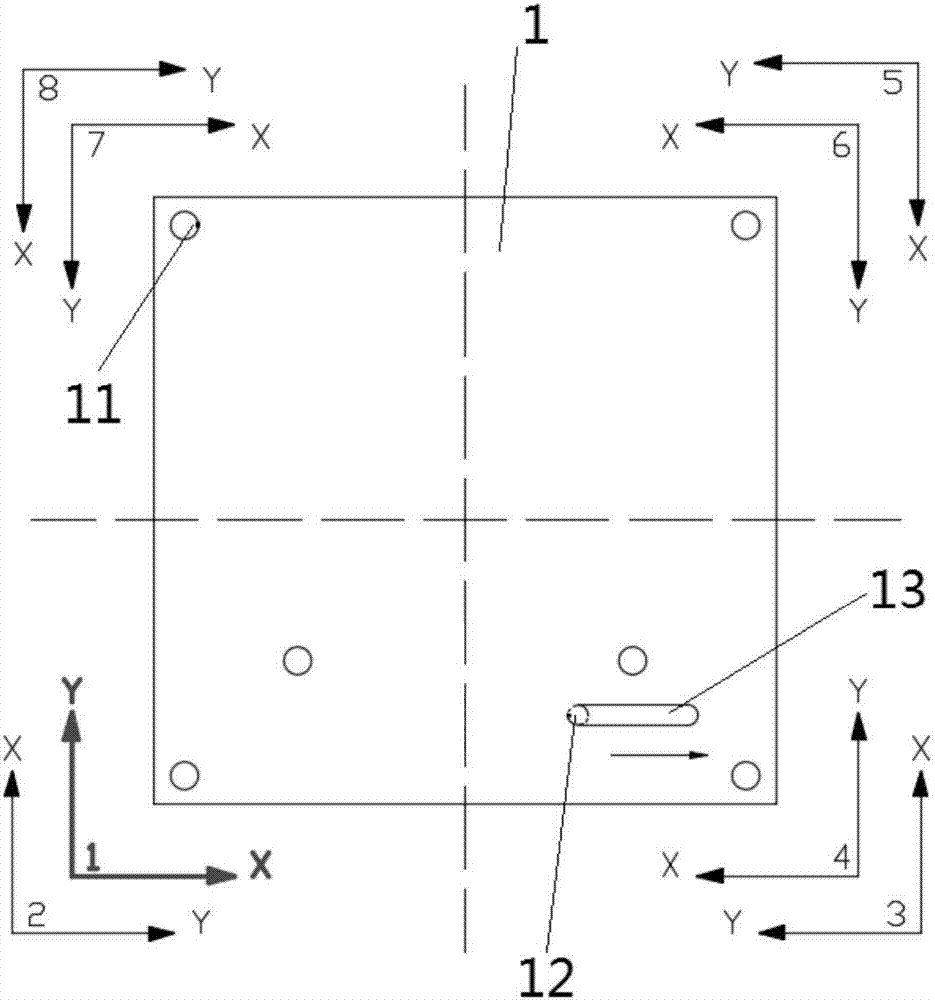

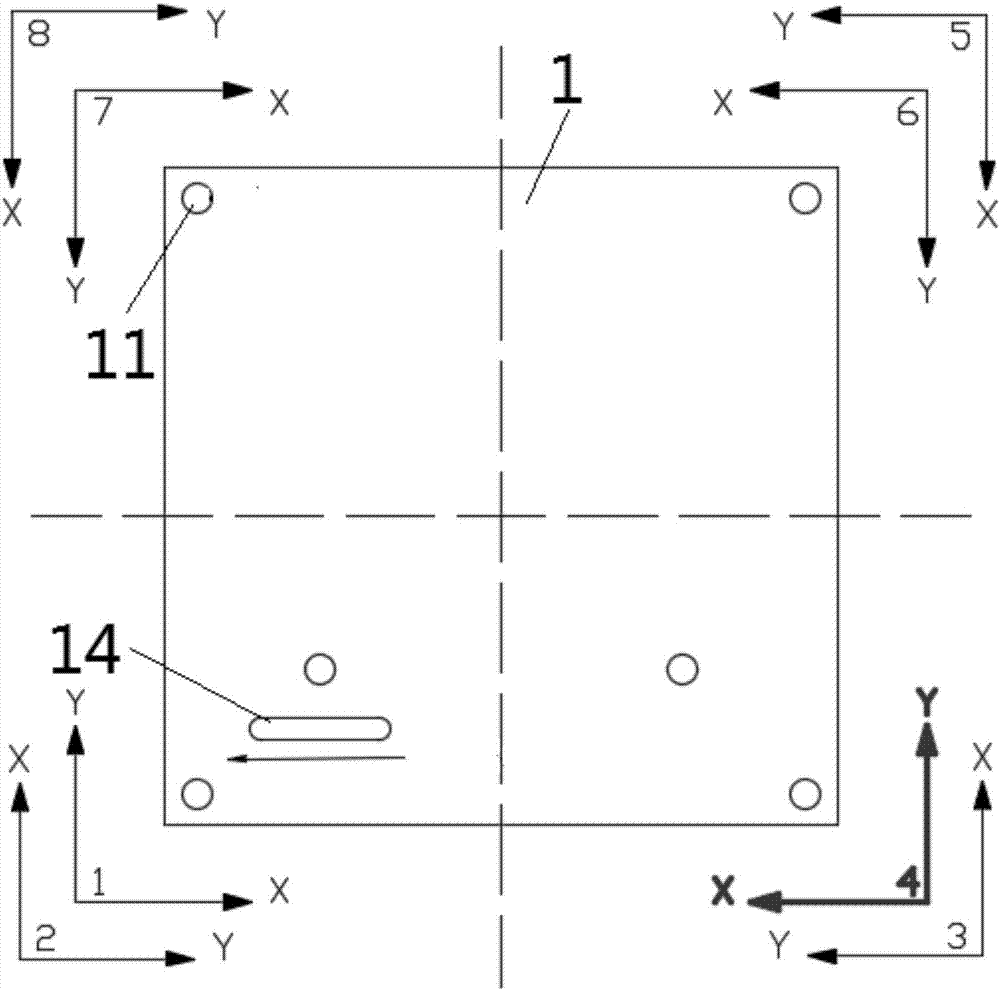

Automatic welding equipment applied to curtain wall framework,

ActiveCN109079370AGuarantee quality and efficiencyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSlide plateEngineering

The invention relates to automatic welding equipment applied to a curtain wall framework. The automatic welding equipment applied to the curtain wall framework comprises welding tables. A transverse feeding mechanism and a longitudinal feeding mechanism are separately arranged on the adjacent two sides of one group of the welding tables. A positioning mechanism is arranged on the welding tables, and a six-axis welding robot is arranged on the sides, opposite to the transverse feeding mechanism or the longitudinal feeding mechanism, of the welding tables. A discharging mechanism is arranged onthe other sides, adjacent to the six-axis welding robot, of the welding tables. The transverse feeding mechanism comprises transversely arranged guide rails, at least two guide rails are arranged at intervals in the longitudinal direction, and discharging frames are arranged on one sides of the guide rails in the length direction of the guide rails. Longitudinally arranged placing tables are arranged between the guide rails and the welding tables, sliding plates sliding in the length direction of the guide rails are arranged on the placing tables, and a plurality of groups of material conveying mechanisms corresponding to the guide rails one by one are arranged on the sliding plates. Each group of the material conveying mechanisms comprises at least one group of conveying wheels which aresymmetrically arranged, and the guide rails are positioned on the symmetric lines of the conveying wheels. The automatic welding equipment applied to the curtain wall framework effectively ensures thewelding quality and welding efficiency and reduces the labor intensity when working.

Owner:江苏中南建设装饰集团有限公司

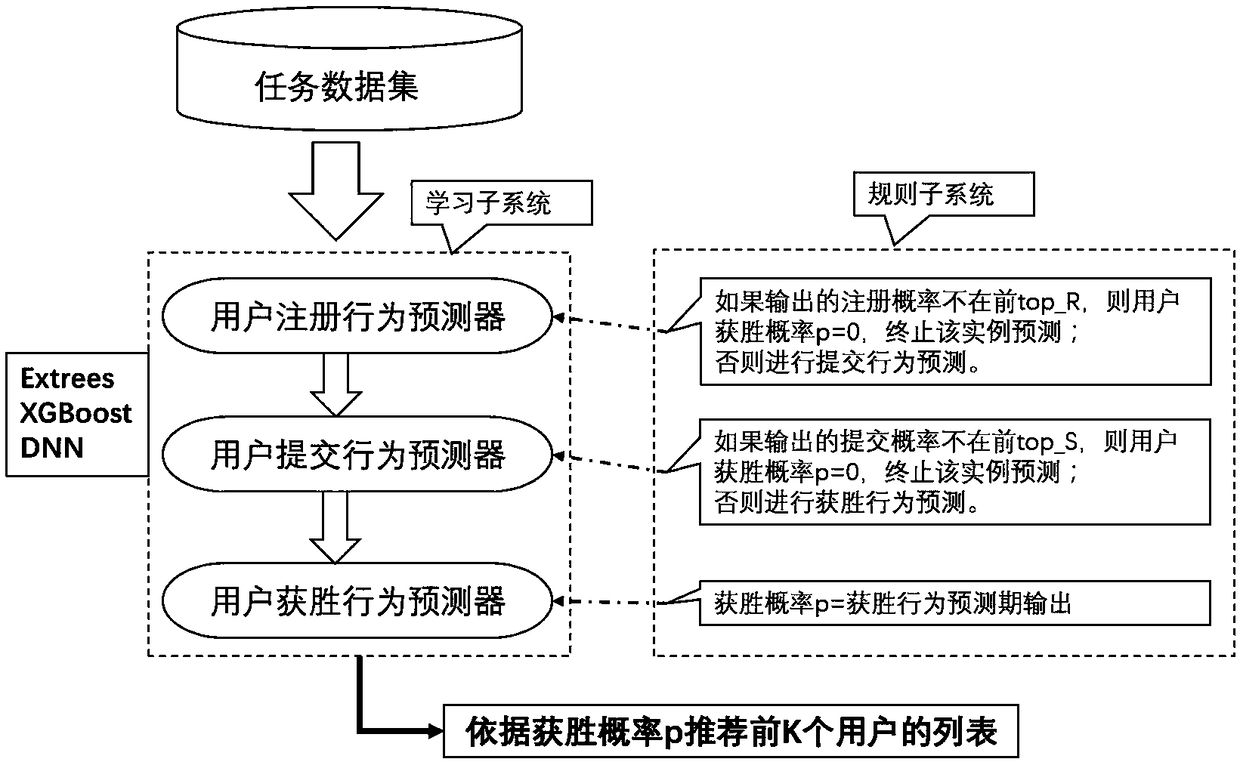

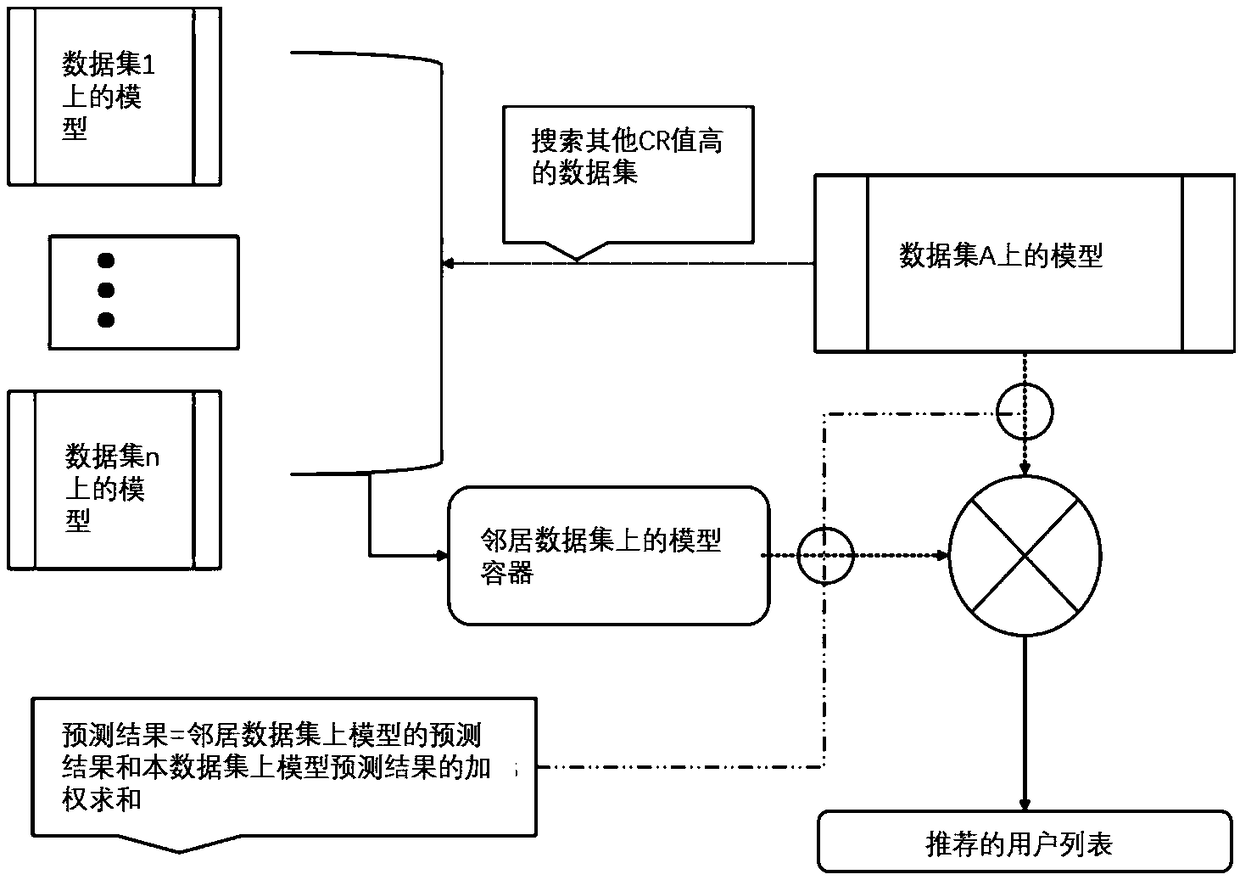

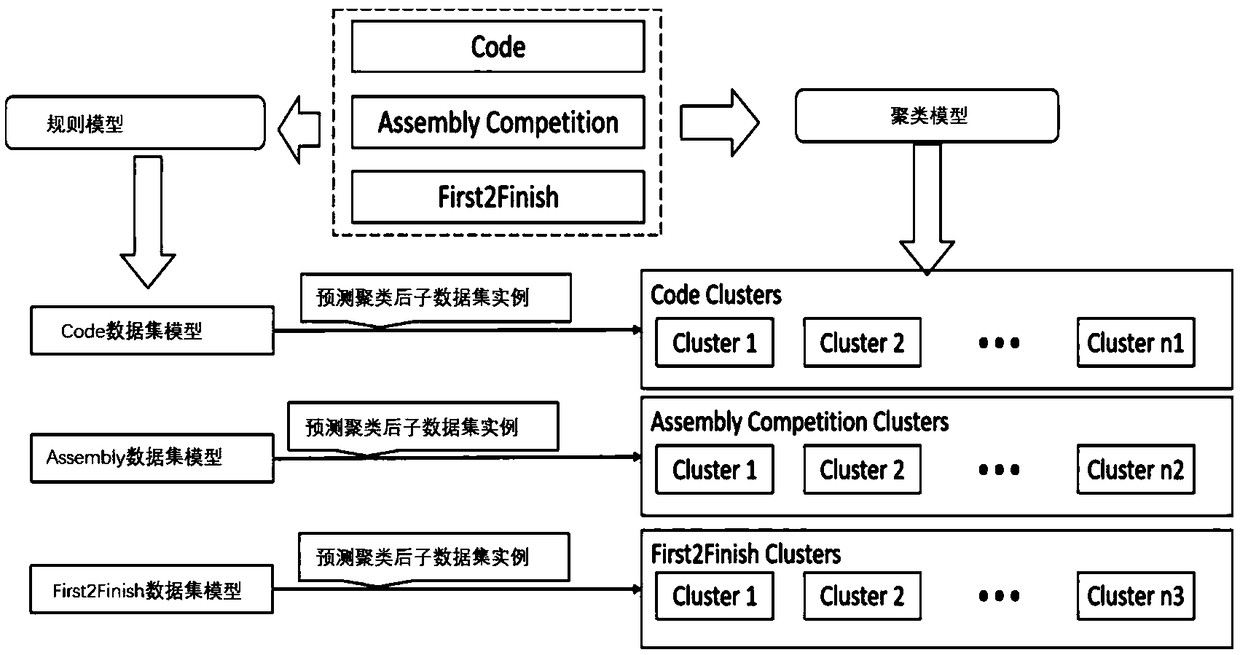

A neural network-based recommendation method for crowdsourced software developers

ActiveCN109032591AGuarantee quality and efficiencyEnsure development efficiencyModel driven codeNeural architecturesData setData mining

A neural network-based recommendation method for crowdsourced software developers is provided. The model in the method generally consists of three main components, a registration behavior predictor, asubmission behavior predictor and a winning behavior predictor, the submission behavior predictor performs prediction based on the situation after the user has registered, the winning behavior predictor predicts based on the situation that the user has submitted, the registrant predictor predicts that there is no prerequisite. In the learning of the task data set by the registration behavior predictor, if the output registration probability is not before top R, the user wins by 0, and the instance prediction is terminated; otherwise, the output detection is continued by using the submission behavior predictor. In the commit behavior predictor, if the output commit probability is not before top S, the user's winning probability is 0, and the instance prediction is terminated; otherwise, the user enters the winning behavior predictor; Finally, the winning probability is obtained by the user winning behavior predictor, and the list of the first K users is recommended according to the winning probability.

Owner:BEIHANG UNIV

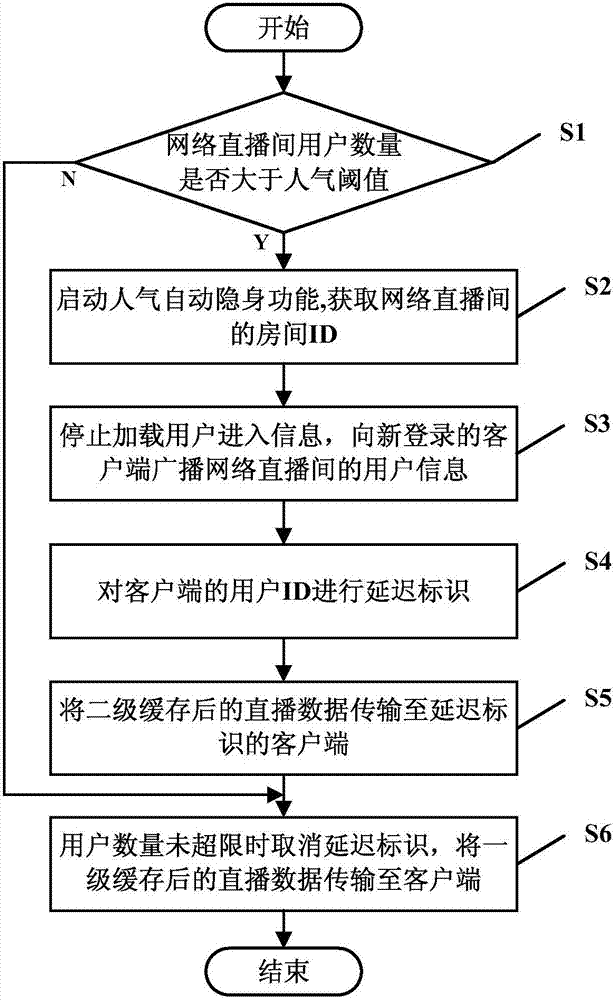

Data delay method and system based on network live broadcast room statistic information

ActiveCN106937136ARelieve pressureImprove work efficiency and work qualityTransmissionSelective content distributionData transmissionClient-side

The invention discloses a data delay method and system based on network live broadcast room statistic information and relates to the field of network data control. The method comprises the steps that a server side obtains the number of users of a network live broadcast room and obtains a room ID of the network live broadcast room when the number of the users of the network live broadcast room is greater than a popularity threshold; when it is monitored that a client side logs in, the server side stops loading user entering information to the network live broadcast room corresponding to the room ID; the server side carries out delay identification on a user ID of the client side; and when the client side attached with the delay identification makes a request for obtaining live broadcast data of the network live broadcast room, the server side transmits second-level cached live broadcast data to the client side. According to the method and the system, loads of the server side are clearly reduced, and the working quality and working efficiency of the server side are greatly improved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

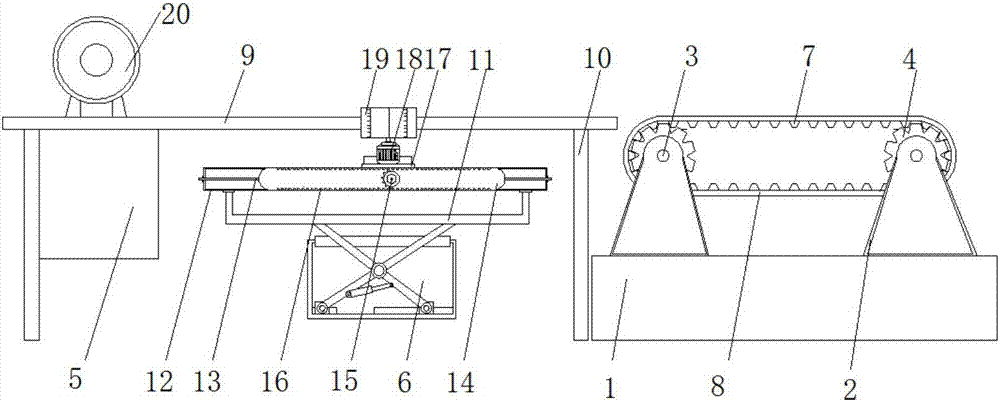

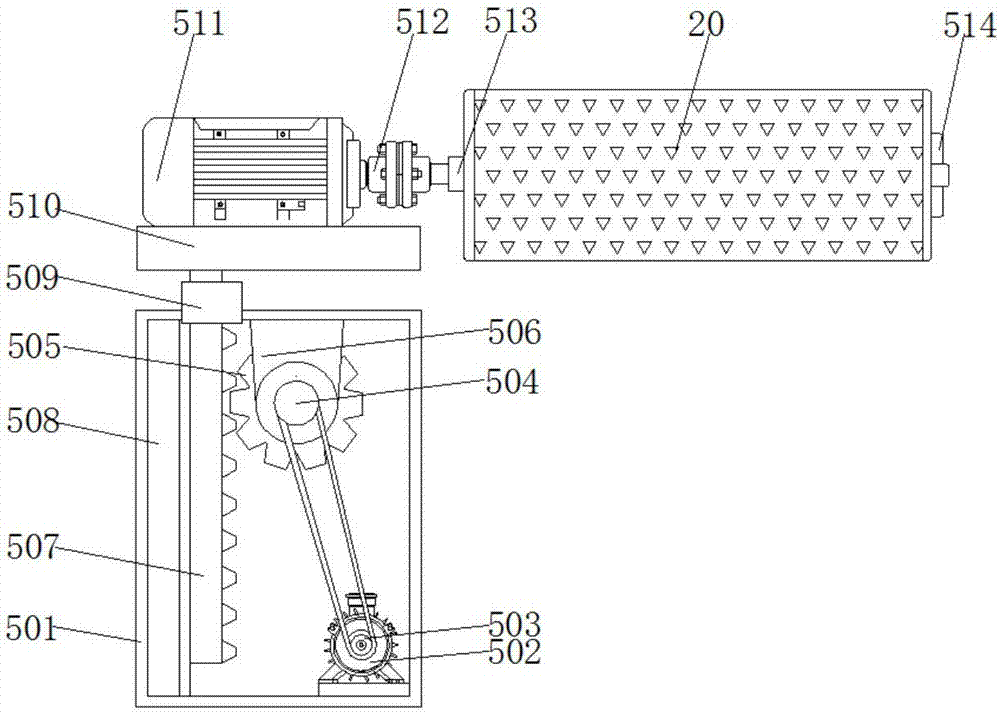

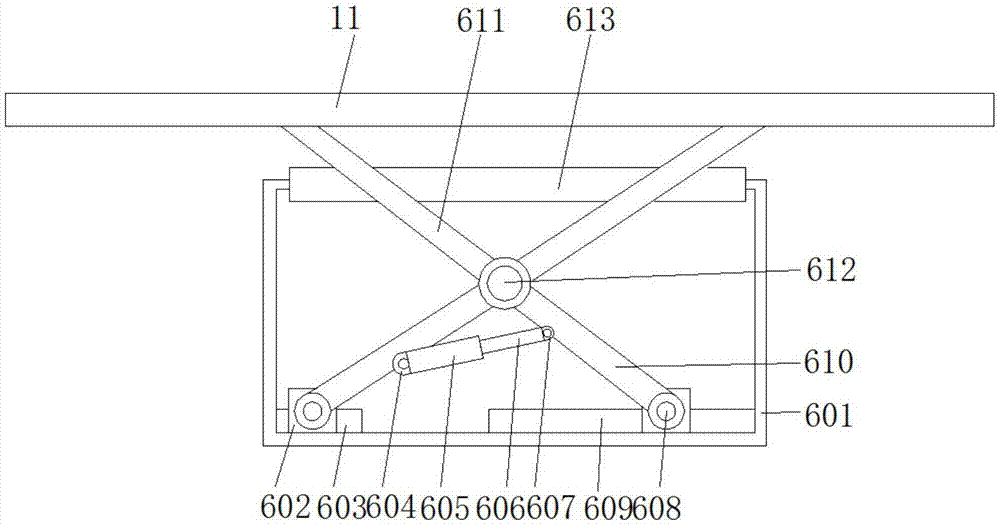

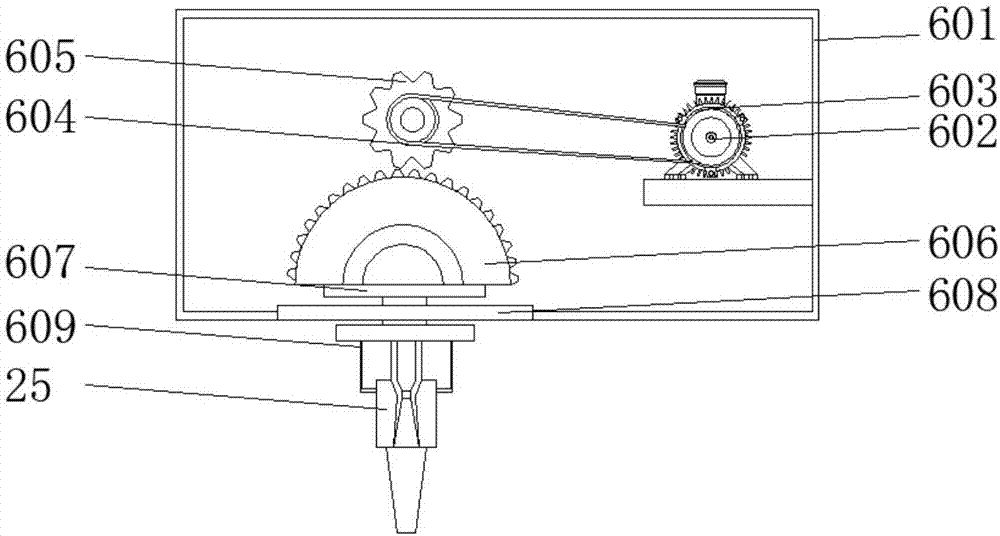

Automatic grinding machine for wood board processing

InactiveCN107263238AAchieve the purpose of moving up and downRealize moving up and downPlane surface grinding machinesEngineeringPulp and paper industry

The invention discloses an automatic grinding machine for wood board processing. The automatic grinding machine comprises a fixed installation base platform, wherein conveyor belt installation racks are fixedly connected to the top of the fixed installation base platform; a rotating shaft is rotatably connected to the top end of each of the conveyor belt installation racks; each of the rotating shafts is fixedly connected with a gear through a flat key; the gears are meshed and connected with a conveyor belt through a transmission toothed rack; a working platform is arranged on the left side of the fixed installation base platform; a grinding machine lifting device is arranged on one side of the inner wall of the working platform; and an up-down moving device is arranged at the position corresponding to the part below the middle of the working platform. The automatic grinding machine for wood board processing relates to the technical field of processing machinery. According to the automatic grinding machine for wood board processing, the following problems are solved: wood boards with different thicknesses can be ground by the grinding machine, the grinding quality and grinding efficiency are ensured, the production efficiency is improved, the production cost is reduced, the grinding efficiency and grinding quality are ensured through a reciprocating device, wood boards are prevented from improper grinding, and the life and property safety of workers is further ensured.

Owner:安吉县瑞旺竹木制品厂

Production process for weaving all-cotton cutting motif fabric by air-jet loom

The present invention discloses a production process for weaving all-cotton cutting motif fabric by an air-jet loom. The production process comprises the following steps of winding process, warping process, sizing process, drawing-in process, weft preparation, and weaving process. The cutting motif fabric is usually weaved by a rapier loom and is not suitably weaved by a high-speed air-jet loom. According to production process, the cutting motif fabric is weaved by the air-jet loom, product quality and production efficiency are ensured, and enterprises gain considerable benefits. Ground warp threads are drawn in front zones of heald frames, and droppers are drawn in back zones, thereby facilitating reduction of tension force of the ground warp threads. Colored warp threads are drawn in the back zones of the heald frames, droppers are drawn in the front zones, and tension force of the colored warp threads is relatively small, thereby facilitating increase of the tension force of the colored warp threads and reduction of knees defects. When the former processes are performed for production, the winding and warping processes are performed at a low speed, air splicing is configured to the winding process so as to reduce yarn hairiness, coating is important in the sizing process, the weaving process is assisted by early opening, large tension force and late weft insertion and the like, and the problem of weft stop is solved.

Owner:NANTONG HONGJINBEI ELECTRONICS TECH CO LTD

Building tubular product cutting clamp

InactiveCN107891297AIncrease clamping forceEasy to cutMeasurement/indication equipmentsPositioning apparatusBiochemical engineeringHydraulic pump

The invention discloses a building tubular product cutting clamp in the technical field of buildings. A clamp inner barrel is arranged in an inner cavity of a clamp outer barrel, a first clamping sheet and a second clamping sheet are arranged on the two sides of the inner cavity of the clamp outer barrel, pressure sensors are arranged inside the first clamping sheet and the second clamping sheet,a first piston barrel device and a second piston barrel device are connected to a first hydraulic oil pump and a second hydraulic oil pump through soft oil pipes correspondingly, a stepping motor is arranged on the side, far away from a clamp inner barrel, of the second hydraulic oil pump, and a controller is arranged on the side, far away from the second hydraulic oil pump, of the stepping motor.The building tubular product cutting clamp is high in reliability, the clamping force on a building tubular product is large, and looseness can be avoided in the cutting process; and in addition, themachining quality and the machining efficiency can be effectively guaranteed, length measurement on the building tubular product can be carried out through length scales on the clamp inner barrel soas to facilitate fixed-length tubular product cutting, and the cutting convenience is greatly improved.

Owner:叶潇

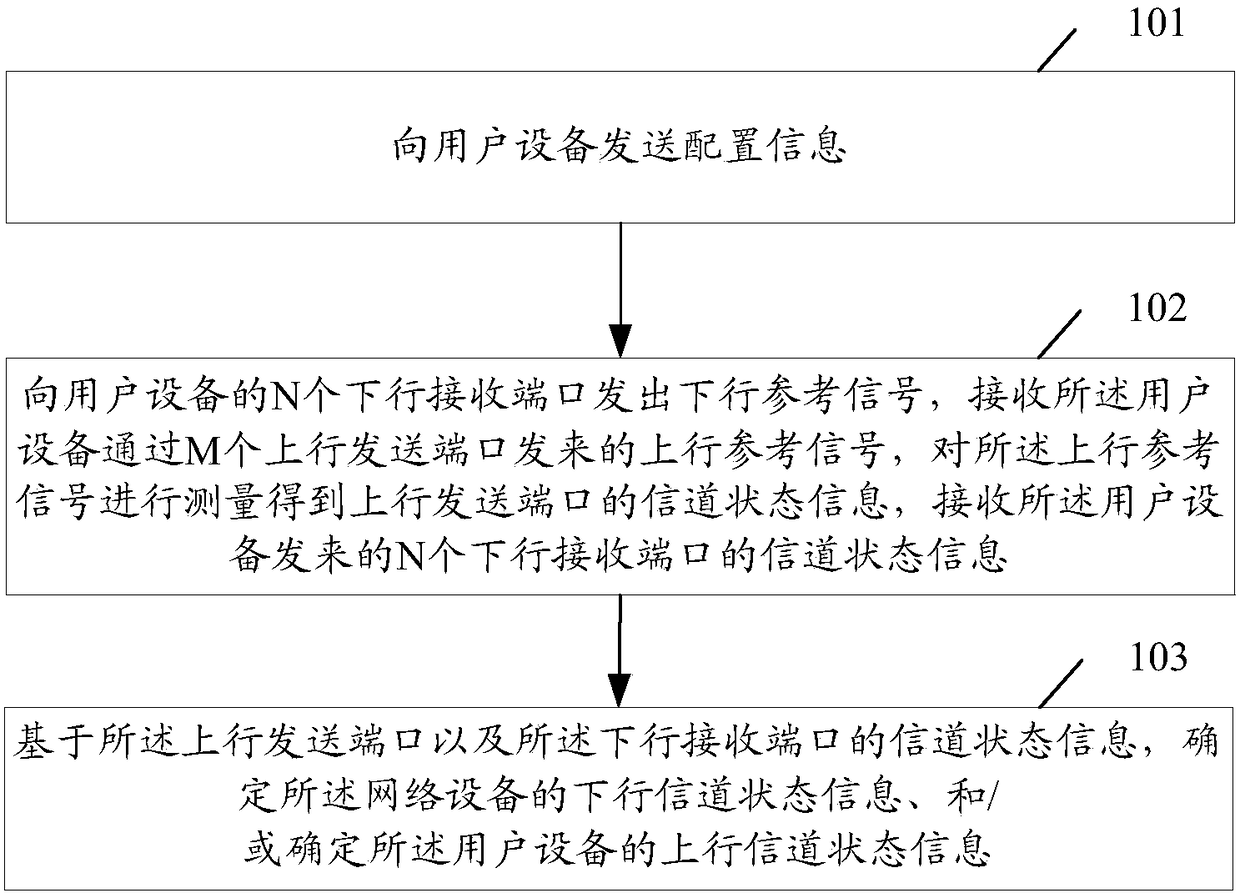

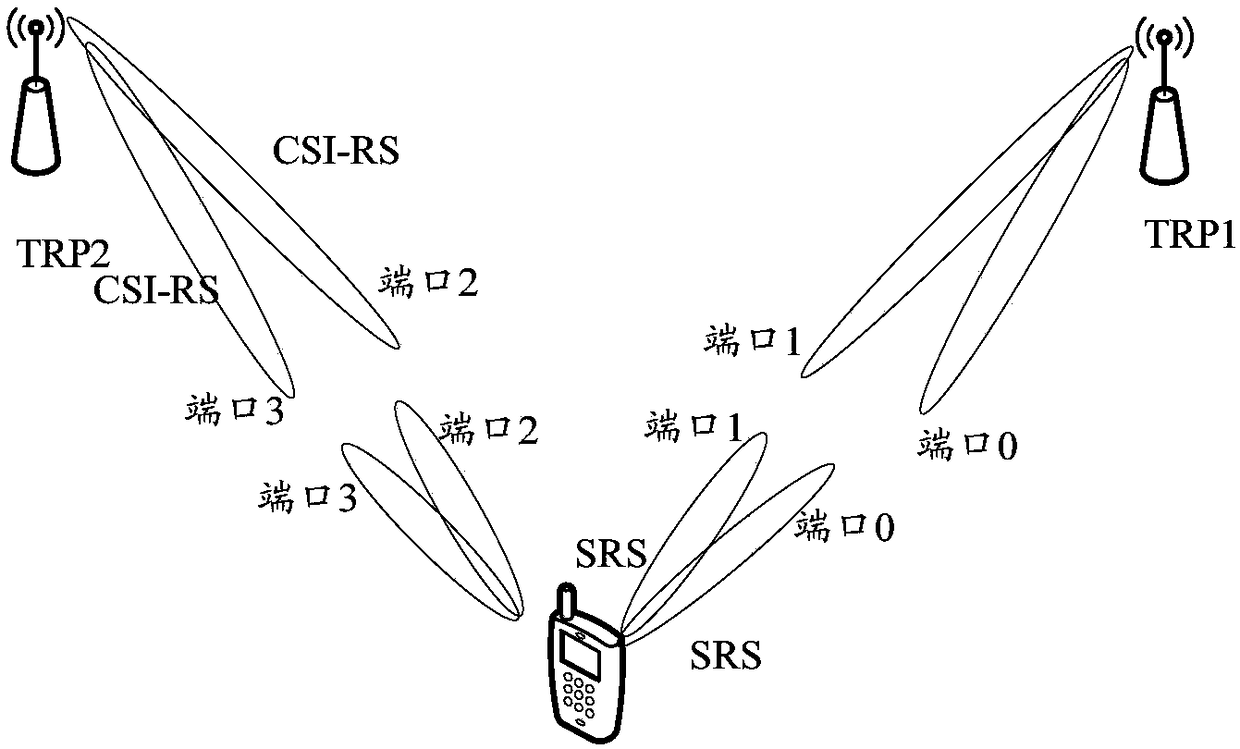

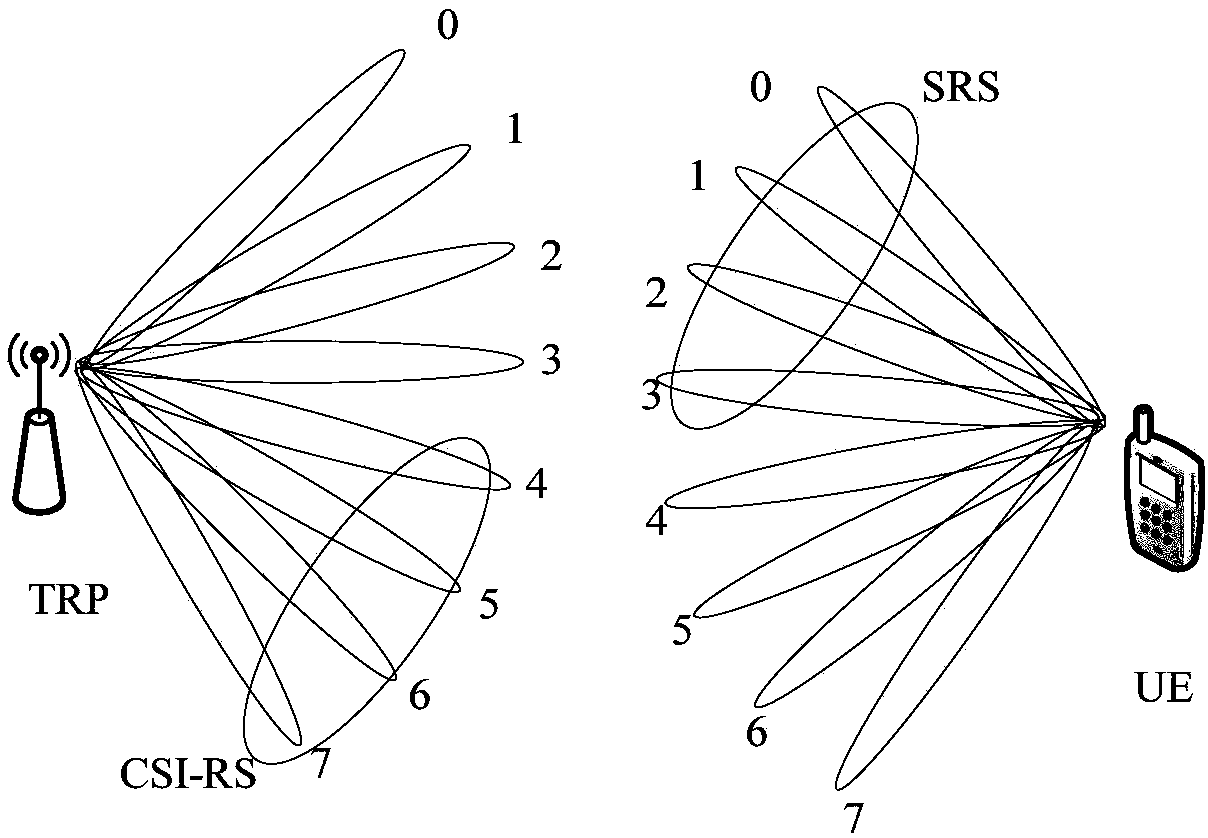

Channel condition detection method, network equipment and user equipment

ActiveCN108540995AEasy accessFull accessWireless communicationChannel state informationTelecommunications

The invention discloses a channel condition detection method, network equipment and user equipment. The method comprises the steps of sending configuration information to the user equipment; sending downlink reference signals to N downlink receiving ports of the user equipment, receiving uplink reference signals sent by the user equipment through M uplink sending ports, measuring the uplink reference signals to obtain channel state information of the uplink sending ports, and receiving the channel state information of the N downlink receiving ports sent by the user equipment; and determining downlink channel state information of the network equipment and / or determining uplink channel state information of the user equipment based on the channel state information of the uplink sending portsand the downlink receiving ports.

Owner:维沃软件技术有限公司

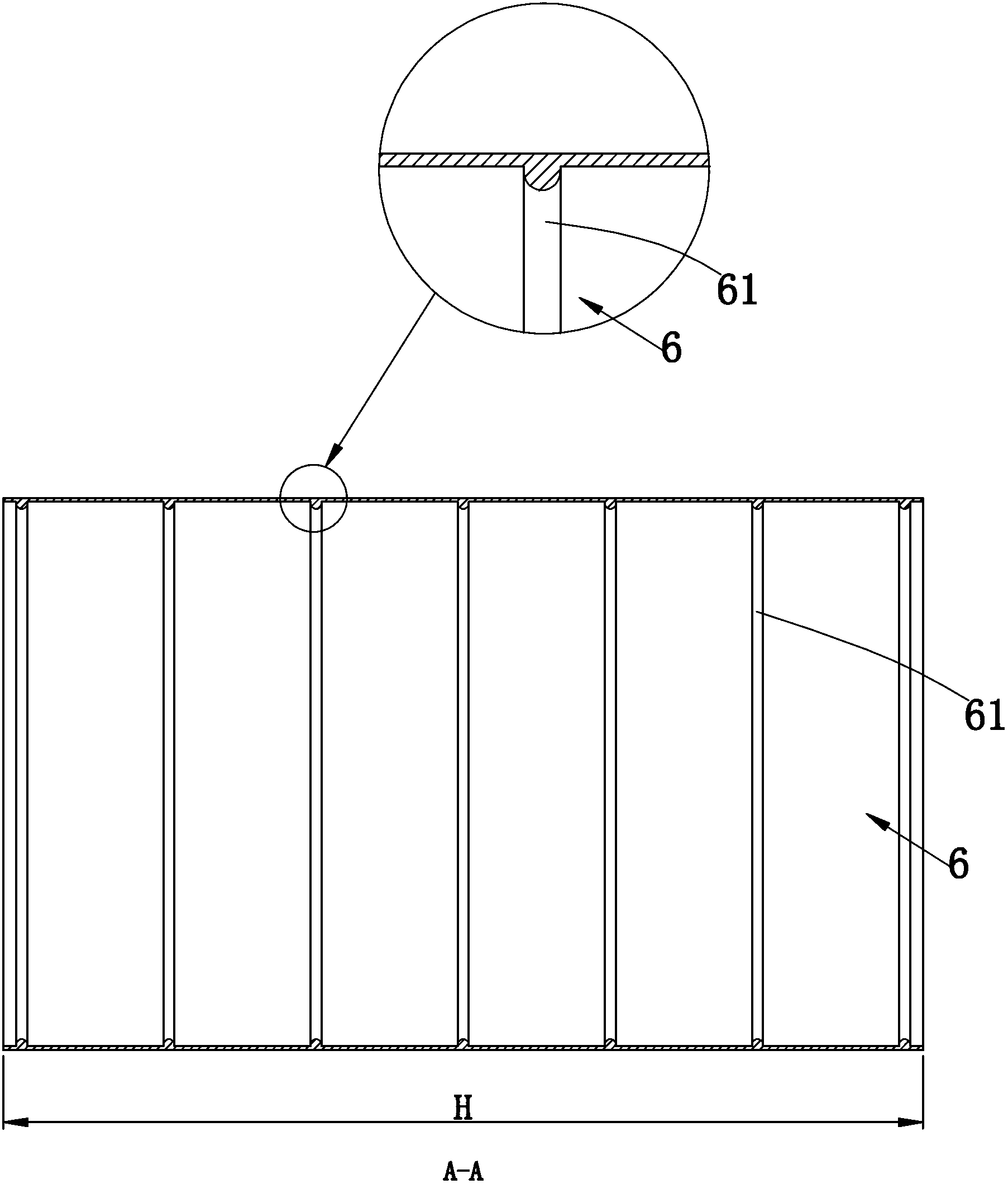

Large-sized glass fiber reinforced plastic shaping mold, as well as manufacturing equipment and manufacturing method thereof

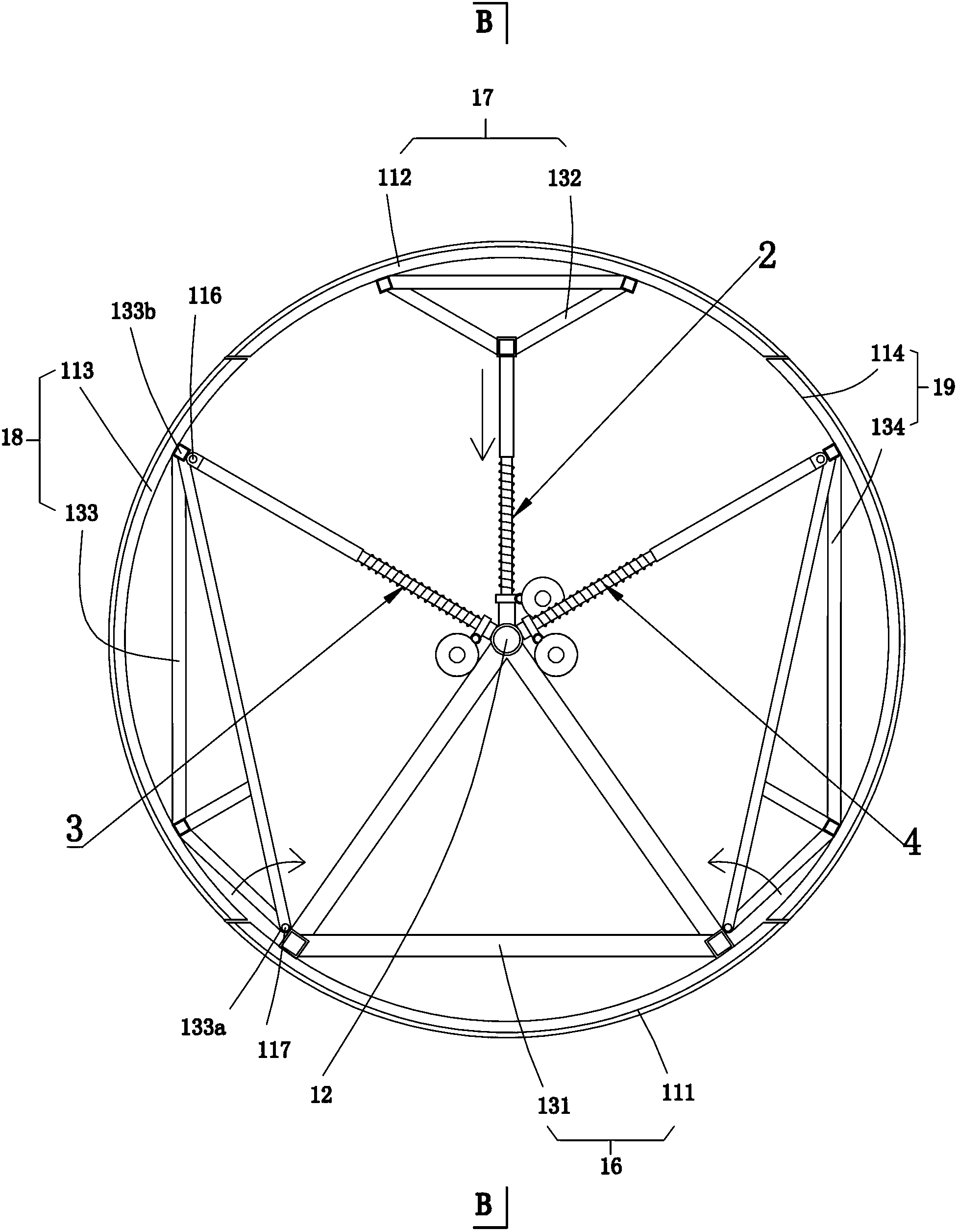

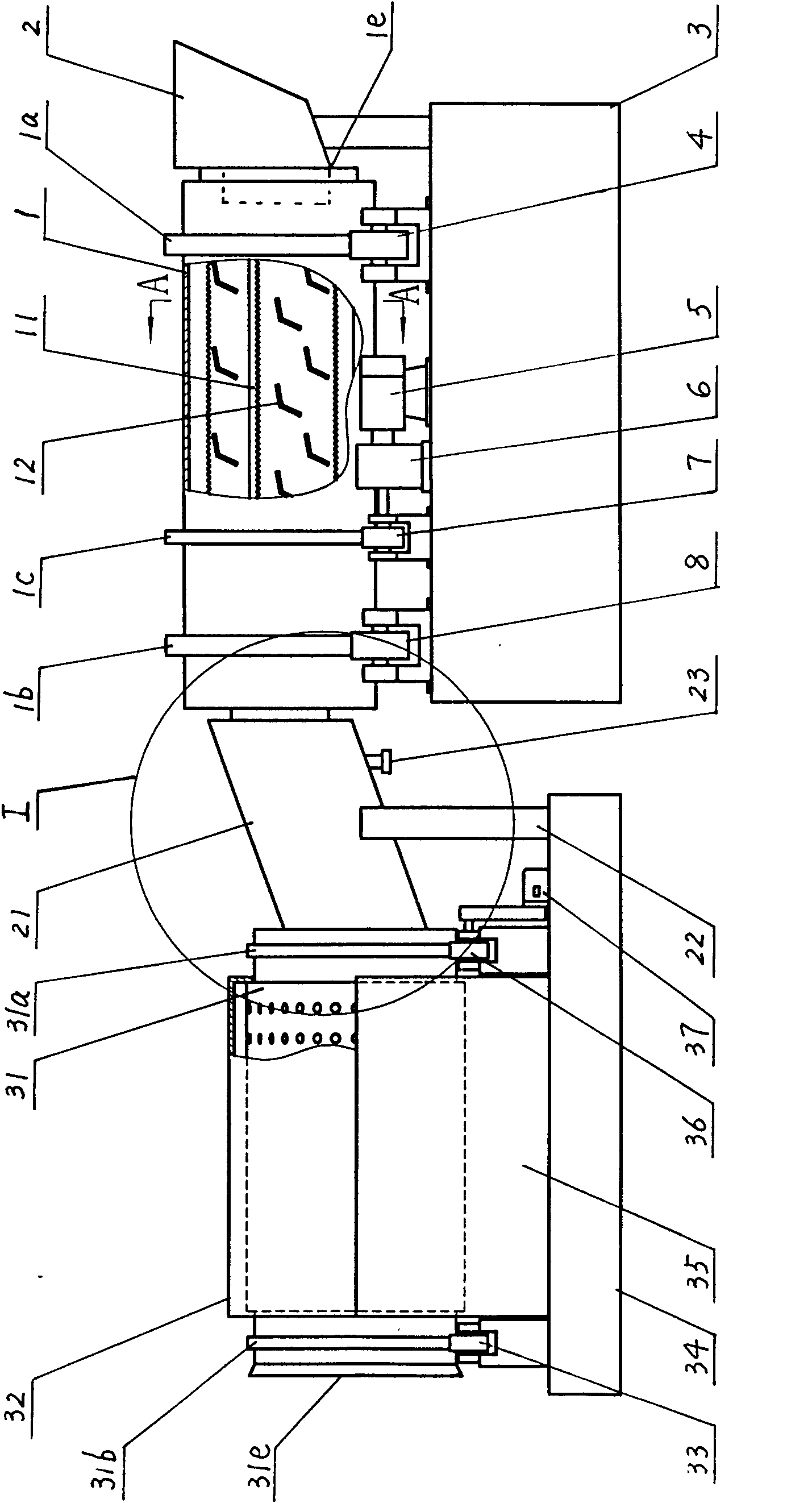

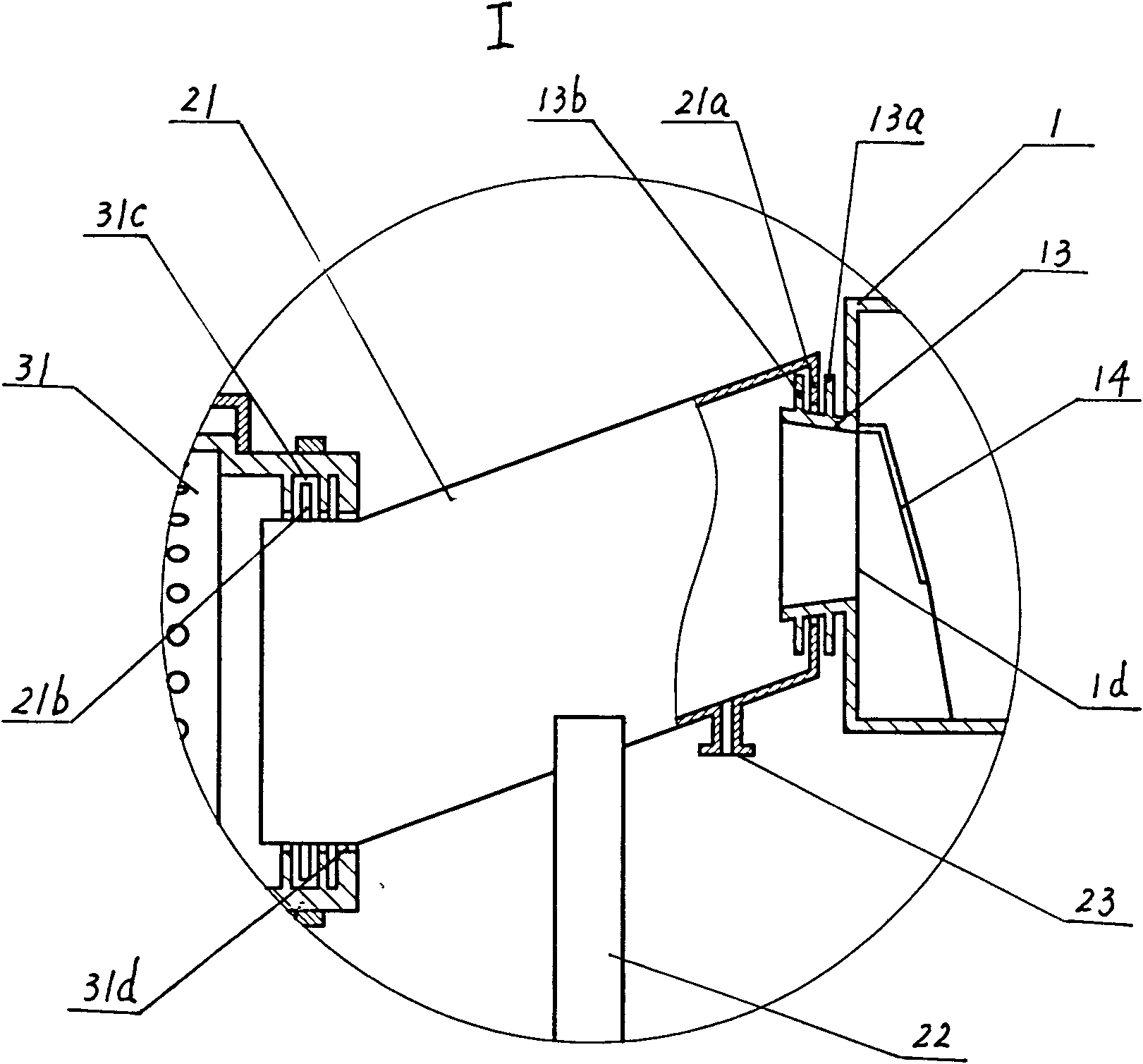

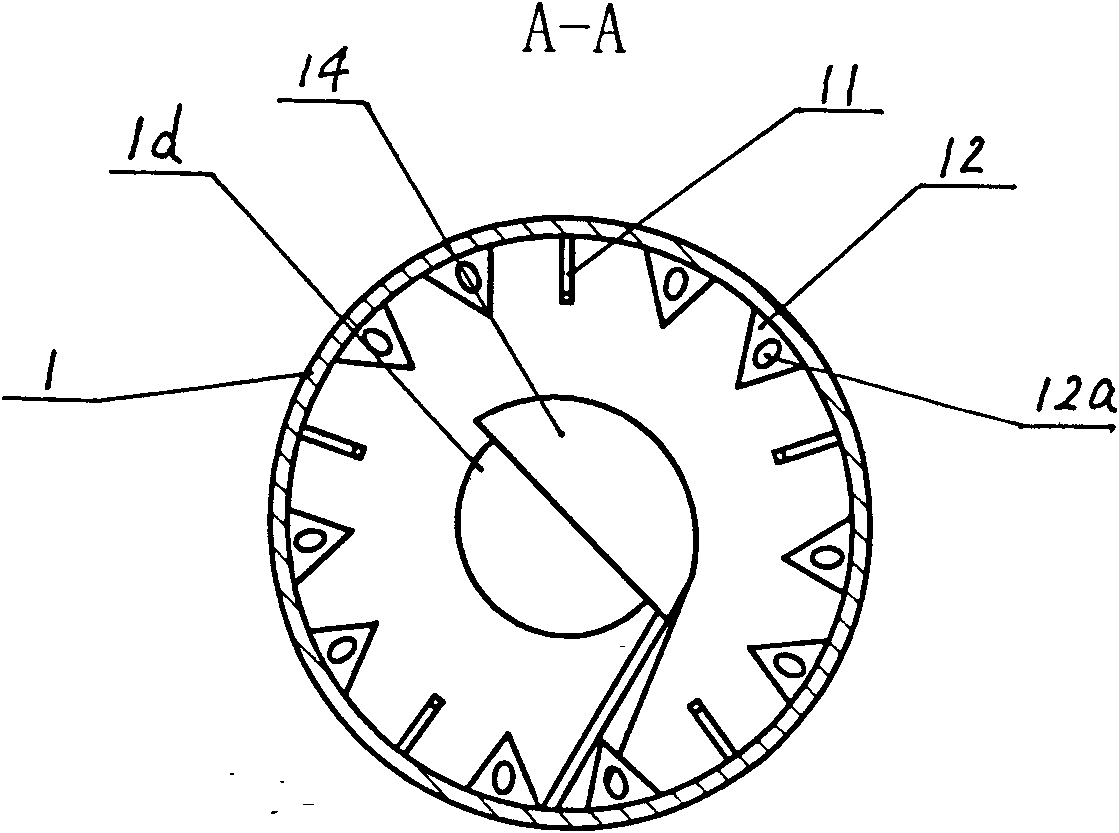

The invention discloses a large-sized glass fiber reinforced plastic shaping mold and a manufacturing method of the mold. The mold comprises an inner support body, at least one fixed mold plate, at least three moving mold plates and a traction mechanism, wherein the fixed mold plate and the moving mold plates are arranged on the inner support body around the inner support body; the traction mechanism is used for driving the moving mold plates to move forwards and backwards relative to the inner support body; the fixed mold plate is relatively fixed with the inner support body; the fixed mold plate and the moving mold plates surround together to form a straight cylindrical mold core; and a plurality of reinforcing rib grooves are arranged in an outer side wall of the mold core. By utilizing the die, a glass fiber reinforced plastic tank can be conveniently formed by integrally molding reinforcing ribs and a tank body, with convenience in demolding; the manufacturing method comprises the following steps: adhering sealing adhesive, feeding a demolding agent, winding and shaping, curing and fixing the shape, putting into a support trolley, shrinking the mold, putting into a demolding device, dissociating the tank body and taking out the tank body. By utilizing the manufacturing method, the glass fiber reinforced plastic tank body can be conveniently formed by integrally shaping the reinforcing ribs and the tank body, and the demolding is convenient.

Owner:SHENZHEN OASIS RAINBOW ELECTROMECHANICAL TECH

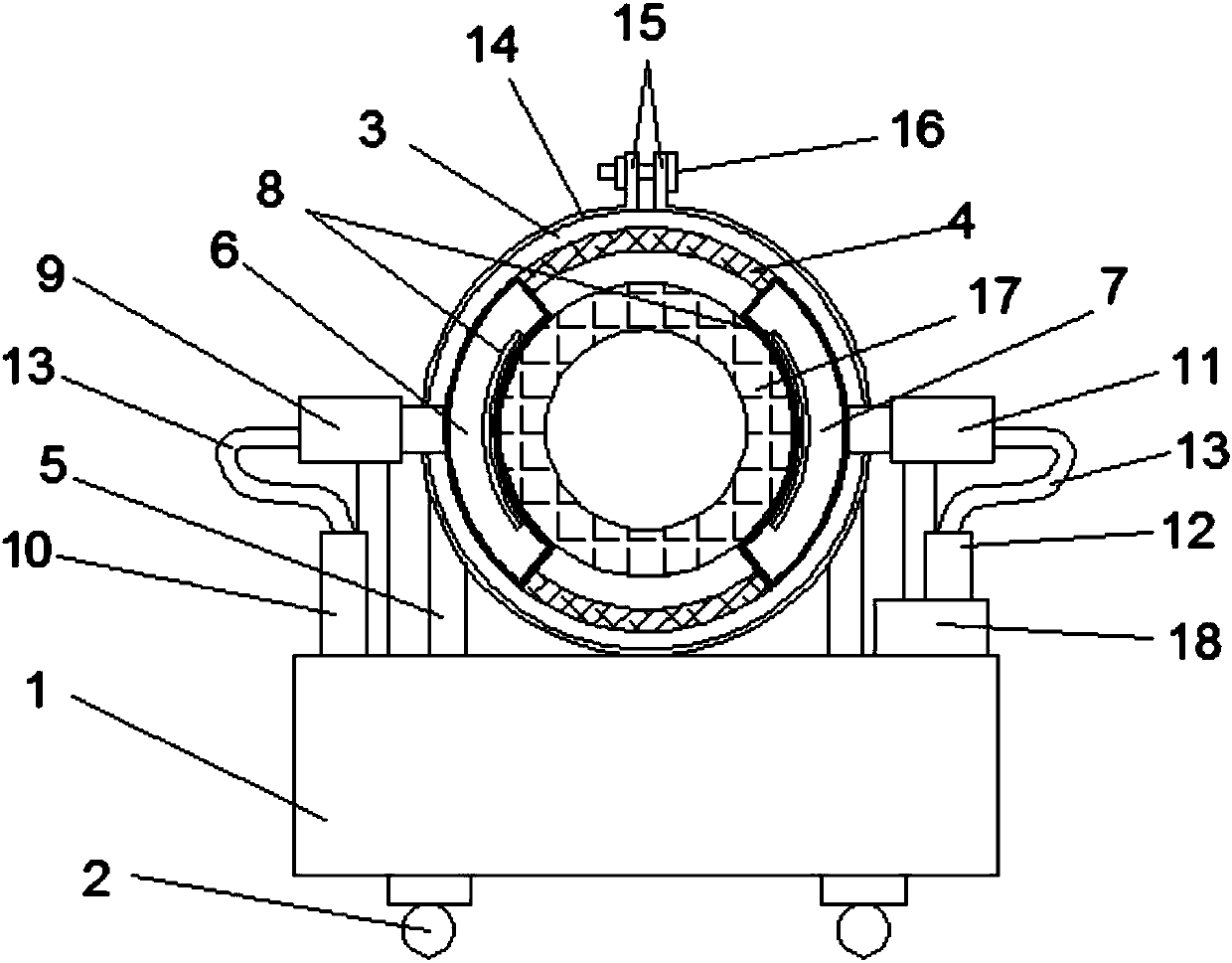

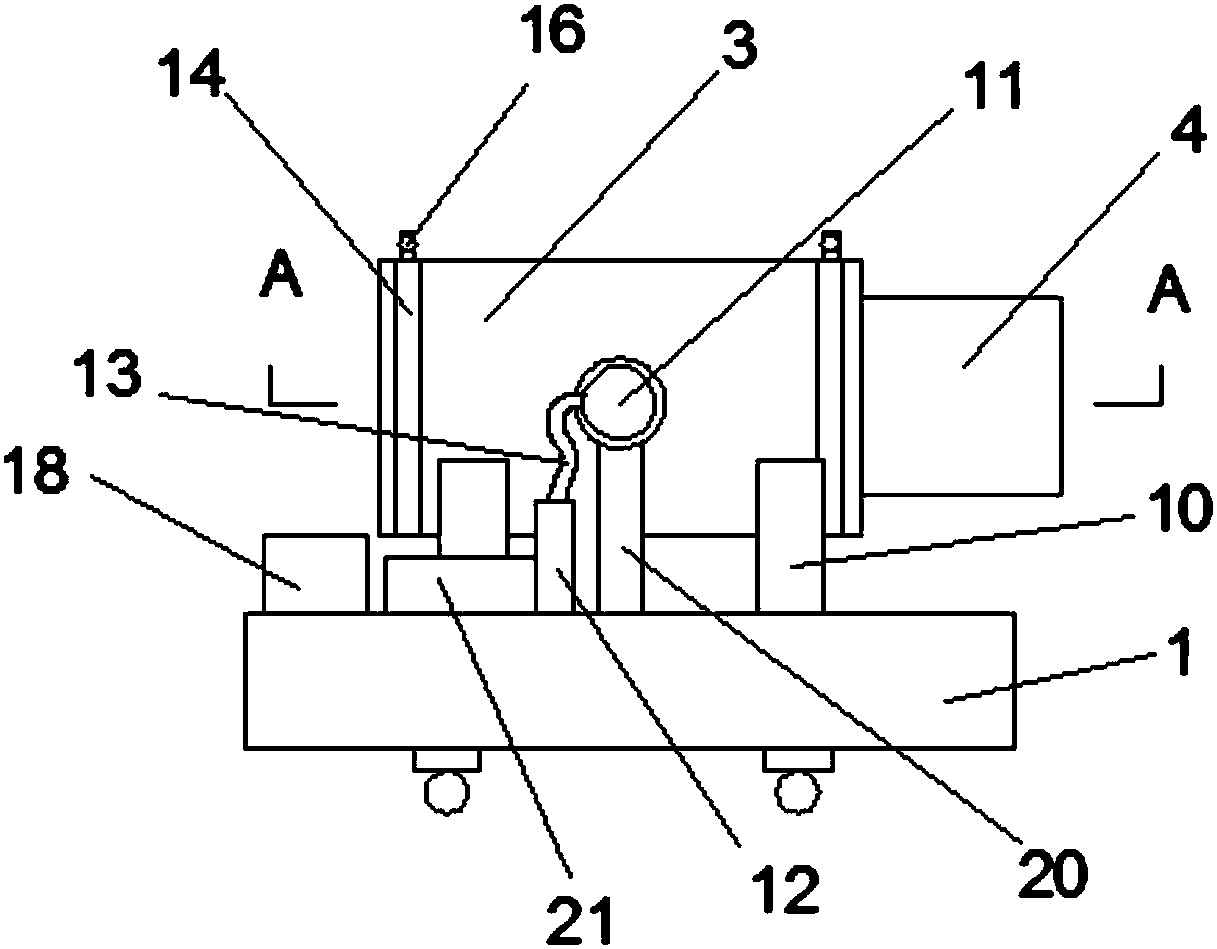

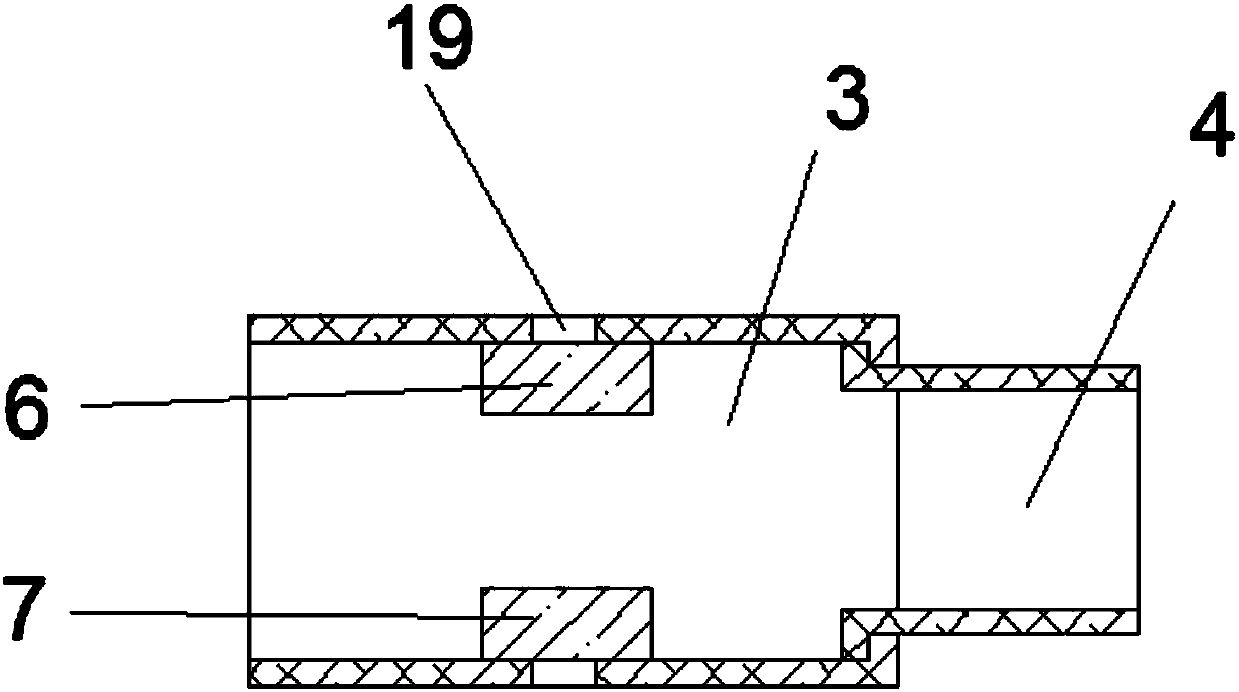

Split type rotary drum pulping device

InactiveCN101671970AGuarantee quality and efficiencyGuaranteed screening efficiencyRaw material divisionPulp and paper industry

The invention discloses a split type rotary drum pulping device comprising a pulping machine and a screening machine. The pulping machine is internally provided with a rotary drum; the inner wall of the rotary drum is connected with a plurality of scratch plates; the screening machine is internally provided with a screen drum; the wall of the screening drum is provided with a plurality of screen holes; a bottom plane of the pulping machine is higher than a bottom plane of the screening machine; a pulp passing drum is arranged between the pulping machine and the screening machine in an inclineway and is fixedly arranged on a base; a left port of the pulp passing drum is arranged on a pulp outlet of the rotary drum and communicated corresponding to the pulp outlet port; a right port of thepulp passing drum is arranged in a pulp inlet of the screen drum and communicated corresponding to the pulp inlet; and the rotary drum is internally connected with a pulp feeding hopper in a shape ofa spoon and the pulp feeding hopper corresponds to the pulp outlet port. The invention can solve the problems that the prior art cannot simultaneously meet the requirements of a pulping process and ascreening process, is easy to cause low pulping quality and screening efficiency and brings great difficulty to processing and manufacturing, hoisting transportation, installation and debugging of theequipment.

Owner:王秉华

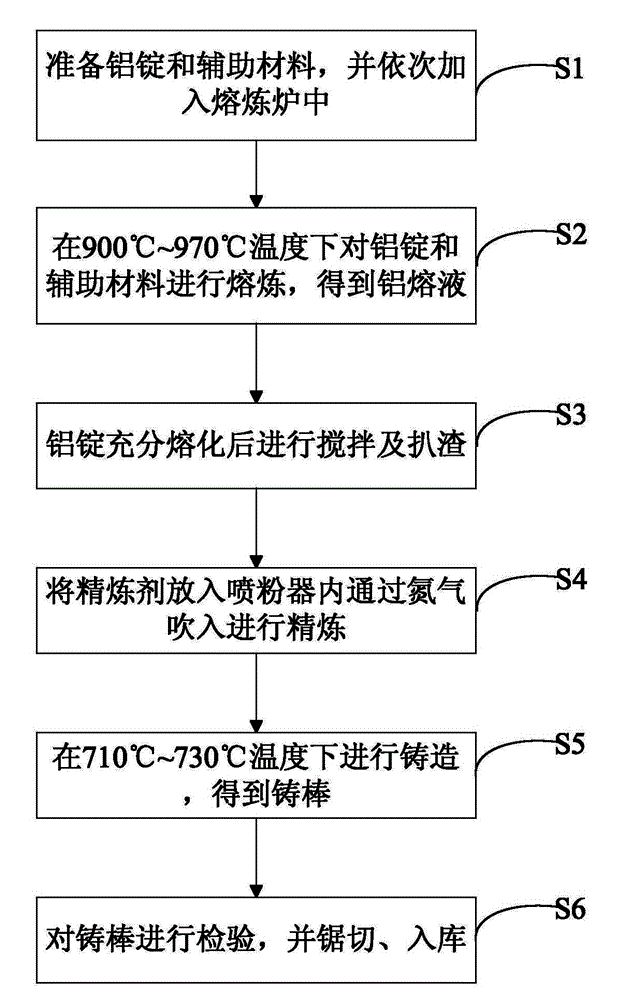

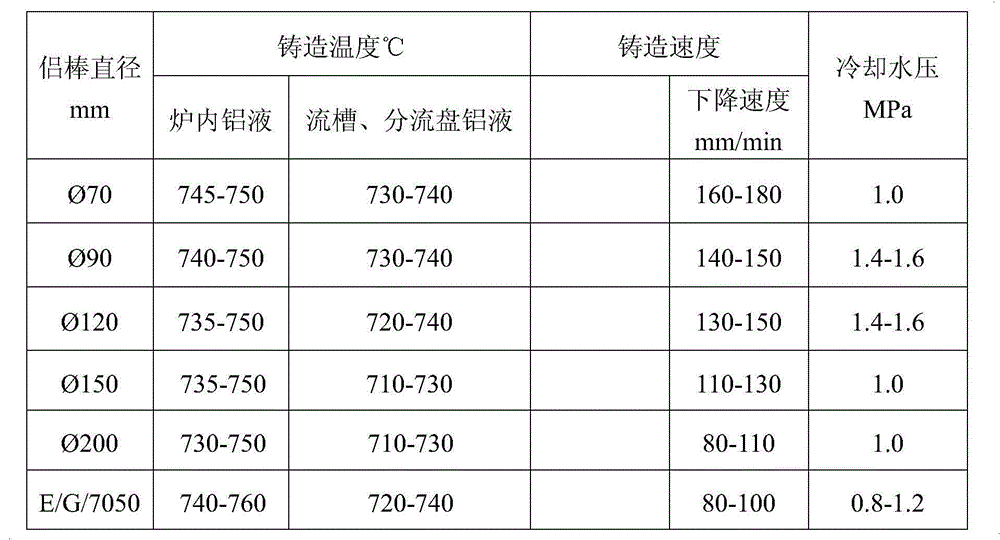

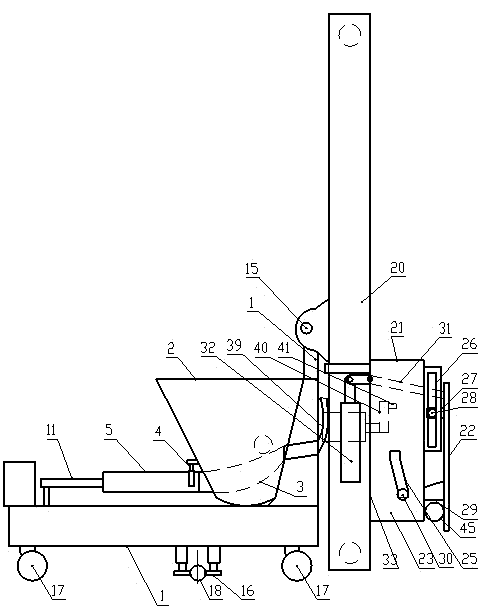

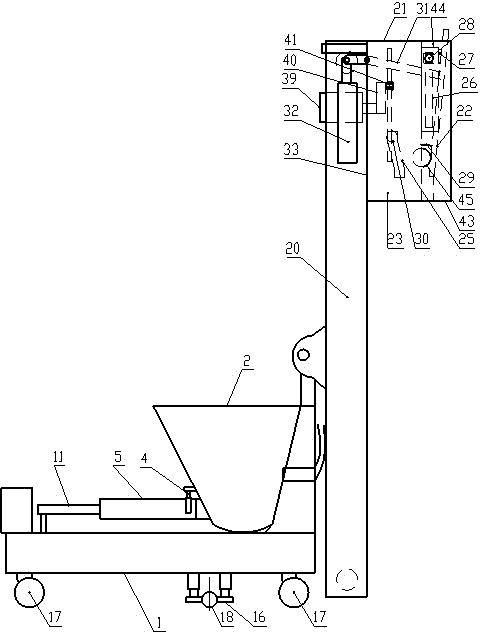

Aluminum bar smelting and casting process

The invention discloses an aluminum bar smelting and casting process which comprises the following steps: S1, preparing aluminum ingots and auxiliary materials, and sequentially adding into a smelting furnace; S2, smelting the aluminum ingots and the auxiliary materials at 900-970 DEG C to obtain an aluminum solution, wherein the temperature of the aluminum solution is 700-760 DEG C; S3, after the aluminum ingots are sufficiently molten, stirring, and removing slag; S4, putting a refining agent into a blow gun, and refining while blowing in the refining agent with nitrogen gas, wherein the temperature of the aluminum solution after refining is 730-760 DEG C; S5, casting at 710-730 DEG C to obtain cast bars; and S6, inspecting the cast bars, sawing, and warehousing. According to the invention, the aluminum bar smelting and casting process improves the aluminum alloy smelting and casting quality, and ensures the product quality and production efficiency.

Owner:张家港市昊天金属科技有限公司

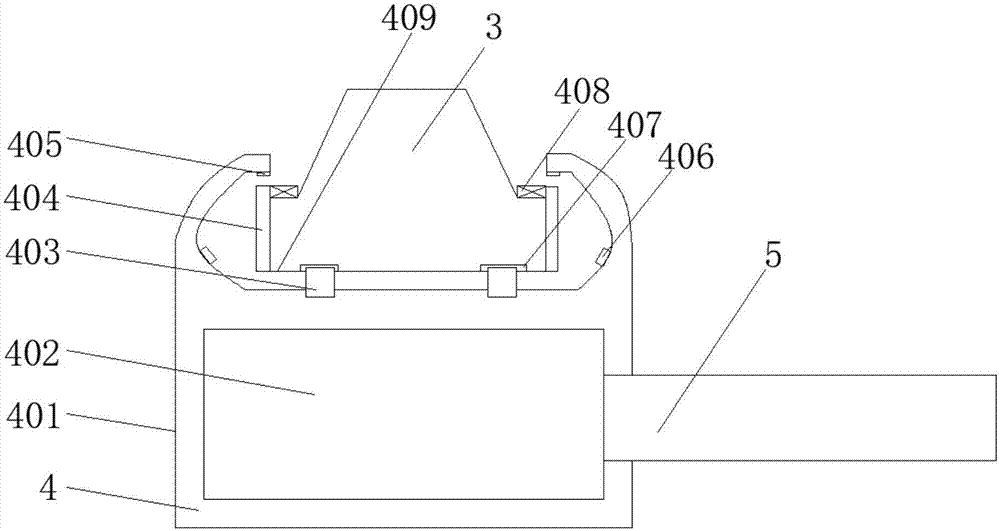

Automatic wall plastering machine

InactiveCN103924774AGuarantee the continuity of supplyGuarantee quality and efficiencyBuilding constructionsEngineeringMechanical engineering

An automatic wall plastering machine comprises a feeding system and a plastering head. The feeding system comprises a frame, a sliding frame and a hopper. The sliding frame is connected to the front side of the frame, and the hopper is connected to the frame. The plastering head of the wall plastering machine comprises a plastering head shell which is of a rectangular shell provided with an opening in the front side, and a left-side plate and a right-side plate are respectively arranged on the left side and the right side of the plastering head shell which is mounted on the sliding frame. The plastering head comprises a tongue plate vertically connected to the front side of the plastering head shell and a vertical moving mechanism driving the tongue plate to move vertically, the front side face of the tongue plate is provided with a plane, and dust leakage outlets are formed in the tongue plate. A swaying cylinder swing back and forth can be communicated with two feeding cylinders respectively, and the feeding cylinders not communicated with the swaying cylinder absorb mortar, so that continuous and sufficient amount of fed materials is realized, feeding continuity at the position of the plastering head can be guaranteed, and quality of wall plastering and operation efficiency are ensured.

Owner:ZHENGZHOU HUAZHONG CONSTR MACHINERY CO LTD

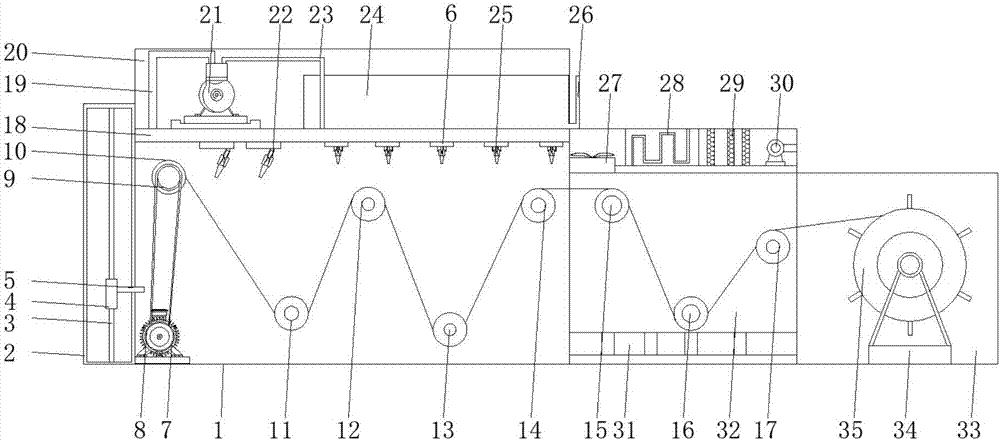

Automatic cleaning, drying and collecting integrated machine

ActiveCN107503052AAchieve the purpose of cleaningGuaranteed cleaning efficiencyLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to the technical field of textile machinery and discloses an automatic cleaning, drying and collecting integrated machine which comprises a chamber. A first motor is fixedly connected to one side of the inner wall bottom of the chamber through a motor mounting platform and is rotationally connected with a first belt pulley through an output shaft, the first belt pulley is in rotational connection with a second belt pulley through a belt, and the second belt pulley is in rotational connection with a first movable pulley through a rotating shaft. A water supply tank is fixedly connected to the upper portion of the inner wall of the chamber, and a water pump is fixedly connected to the inner wall bottom of the water supply tank through a water pump mounting platform. The automatic cleaning, drying and collecting integrated machine has advantages that automatic cleaning, drying and collecting of textile cloth are realized, cleaning quality and cleaning efficiency are guaranteed, operation efficiency is improved, labor amount of workers is decreased, production cost is reduced, suitableness for large-scale popularization is realized, all parts of the textile cloth can be cleaned, and operation efficiency can be guaranteed by cooperation with a drying device.

Owner:嘉兴市华阳纺织染整有限公司

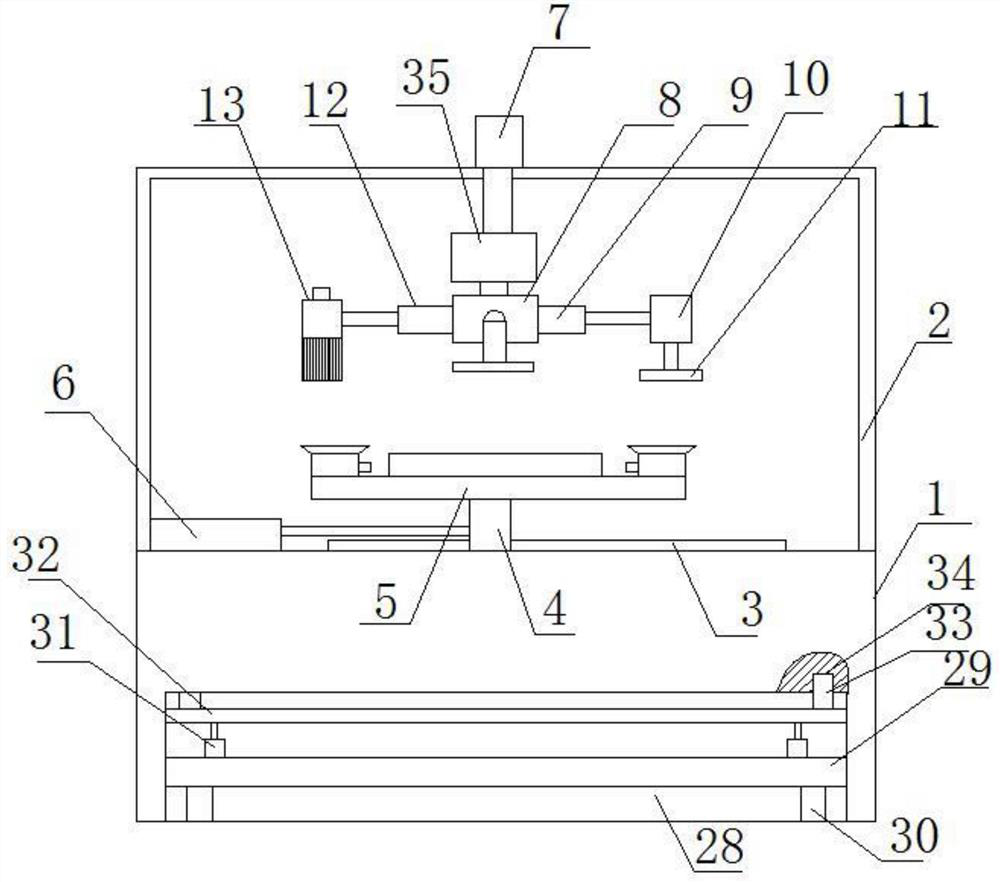

Semi-automatic winding machine and winding method for battery roll core

InactiveCN102368566AGuaranteed synchronicityQuality improvementFinal product manufactureElectrolyte accumulators manufactureWinding machineSemi automatic

The invention discloses a semi-automatic winding machine and a winding method for a battery roll core. The winding machine comprises a frame assembly, a pole piece feeding assembly and a winding pin assembly. The pole piece feeding assembly comprises two guide plates which are respectively used for placing passive and negative pole pieces. The winding pin assembly comprises a winding pin and a winding pin base. The frame assembly is provided with a synchronous conveying device for automatically conveying the passive and negative pole pieces on the guide plates to the winding pin. Due to the adoption of the technical scheme, the synchronous conveying device for automatically conveying the passive and negative pole pieces is additionally arranged, so that in the working process of the winding machine, the pole pieces which need to be wound only need to be fed into the guide plates and the passive and negative pole pieces are automatically and synchronously conveyed to the winding pin tobe wound under the mutual action of a driving roll and a guide roll, and thus, the synchronism of the passive and negative pole pieces in the conveying process is ensured, the cross infection betweenthe passive and negative pole pieces, which is generated in the operating process of an operator, can also be effectively prevented, the quality of the battery roll core is improved and the rejectionrate is reduced. Moreover, the production time can also be greatly saved and the labor intensity of the operator is also reduced.

Owner:铜陵市三圆机械制造有限公司

Polishing device for high-quality sheet metal processing

InactiveCN111633490AAchieve rotary grindingAchieve cleanupGrinding drivesPlane surface grinding machinesPolishingEngineering

The invention relates to the field of sheet metal processing, in particular to a polishing device for high-quality sheet metal processing. A cleaning mechanism comprises a box body, the upper end of the box body is provided with a first fan, the lower end of the box body is provided with a plurality of air outlets, the lower end of the box body is also provided with a cleaning brush, the inside ofa mounting seat is provided with a dust suction chamber, the rear side of the mounting seat is provided with a second fan communicating with the dust suction chamber, the inside of the dust chamber is provided with a filter screen, the front side of the mounting seat is provided with a dust suction pipe communicating with the dust suction chamber, and the lower end of the dust suction pipe is provided with a dust suction cover. The structure arrangement of the device realizes the cleaning of a sheet metal, so that debris do not remain on the sheet metal to affect the polishing, thereby ensuring the polishing quality and polishing efficiency of the sheet metal, and therefore, the polishing device has strong practicability.

Owner:陈二凤

Method for machining deep hole of long-cylinder part

InactiveCN104625152ASimplification-oriented approachGuarantee quality and efficiencyBoring/drilling machinesLongest DiameterMachining process

The invention relates to the field of machining, in particular to a method for machining a deep hole of a long-cylinder part. The method comprises the following steps that the locating datum of the part is machined, wherein two coaxial outer circles are machined at the positions, close to the two ends, of the part, and are adopted as a locating datum plane; a lead hole is machined, wherein the lead hole must be machined before hole boring of the part to guarantee the rigidity of the part and prevent cutter back-off and cutter vibration of a cutter bit in the machining process; the size of the lead hole is equal to that of the bored aperture, and the boring cutter bit is located in the lead hole through a wood guide block. According to the method, the deep hole of the long diameter in the barrel part is effectively machined, the machining quality and machining efficiency of the inner hole are guaranteed well, the wood guide block is adopted in the machining process, and the complex guide method of adopting an abrasion-resisting filter strip is simplified, so that machining is more convenient and economical, and the machining efficiency can be improved.

Owner:李连江

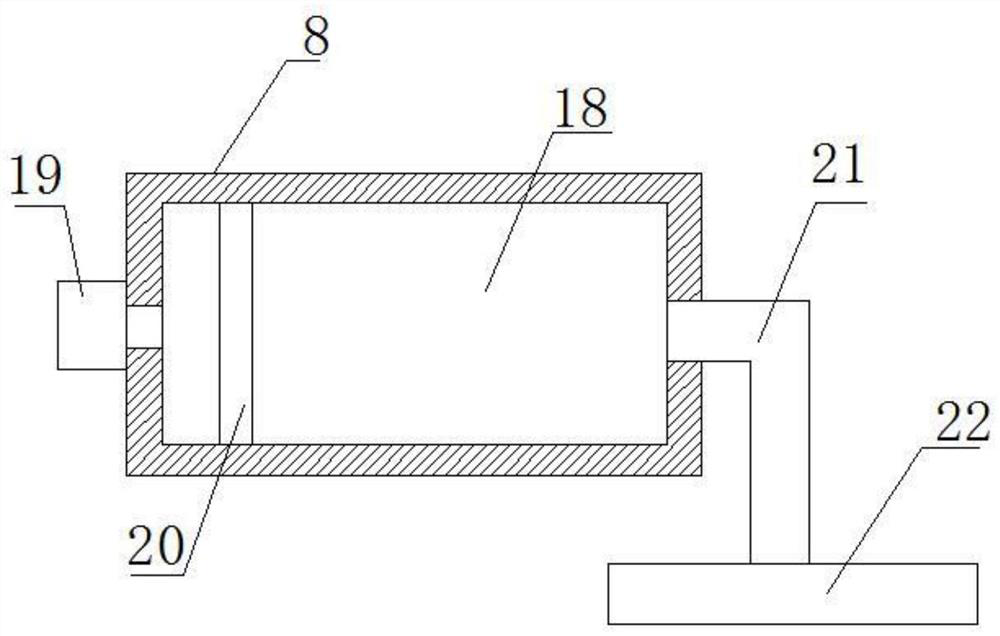

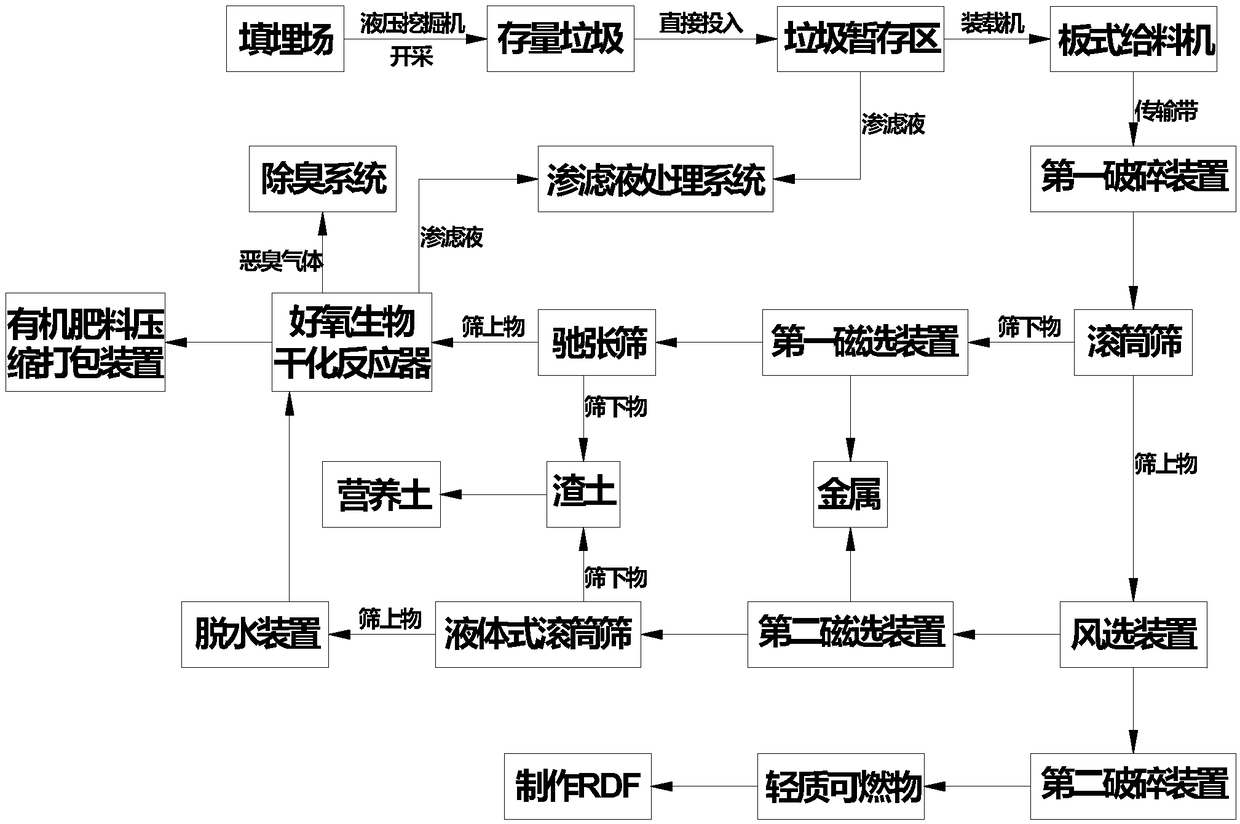

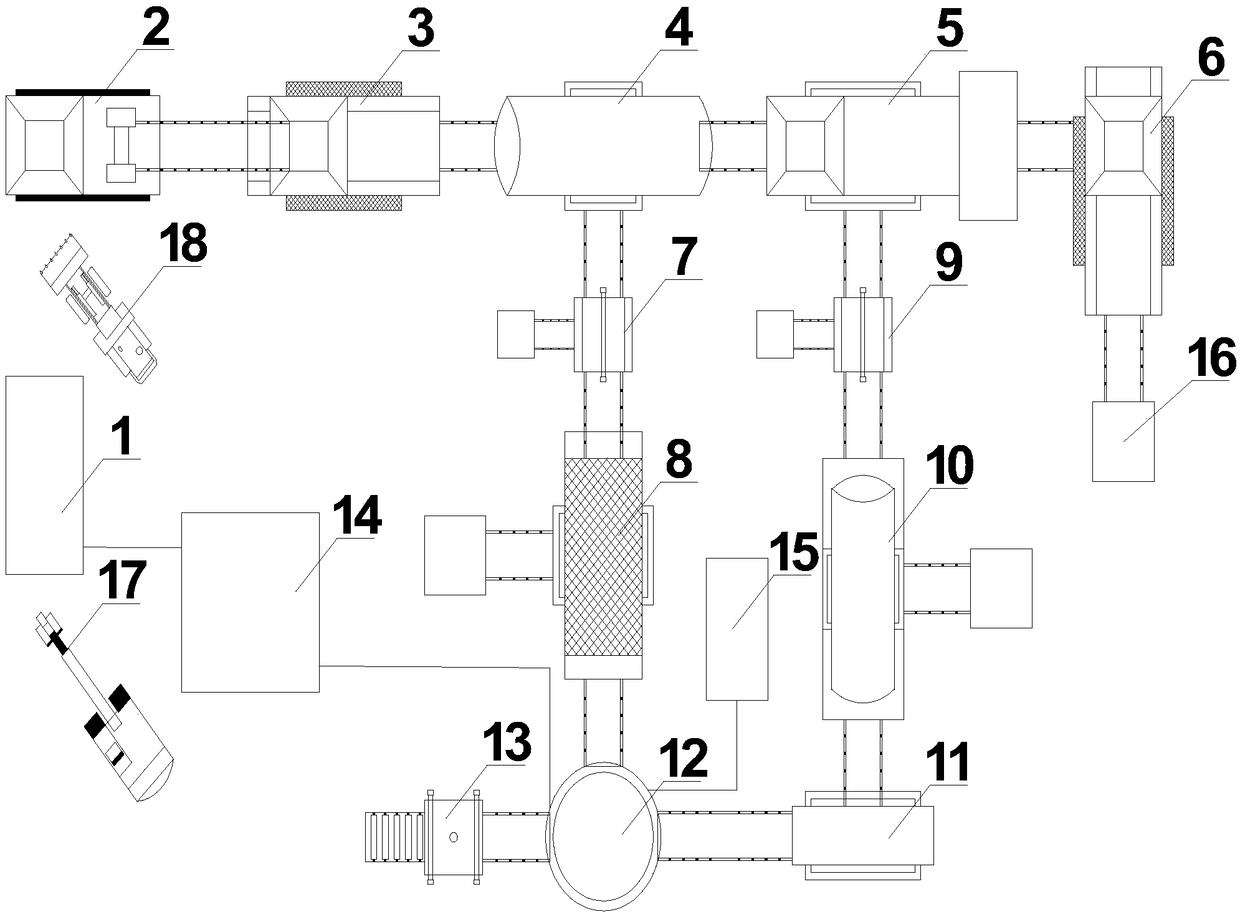

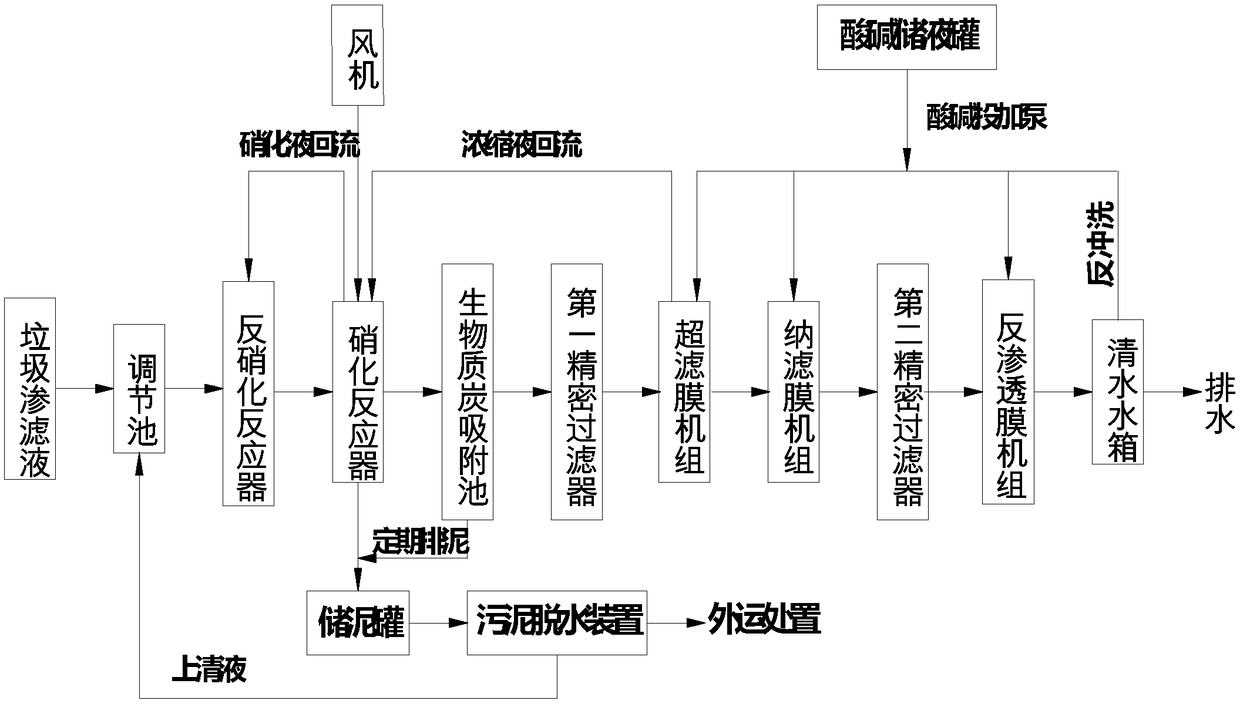

Stock garbage in-situ resourceful treatment method and stock garbage in-situ resourceful treatment system

ActiveCN108787699ARealize high resource utilizationReduce landfill volumeSolid waste disposalDispersed particle separationAir separationOrganic fertilizer

The invention discloses a stock garbage in-situ resourceful treatment method and a stock garbage in-situ resourceful treatment system. The system comprises a garbage temporary storage area, a plate feeder, a first breaking device, a drum screen, an air separation device, a second breaking device, a first magnetic separation device, a tension and relaxation screen, an aerobic biological drying reactor, an organic fertilizer compressing and packing device, a second magnetic separation device, a liquid type drum screen, a dewatering device, a percolating liquid treatment system and a deodorization system; garbage in the garbage temporary storage area is transported to the plate feeder; the plate feeder is sequentially connected with the first breaking device and the drum screen; a first outlet of the drum screen is connected with the air separation device; a first outlet of the air separation device is connected with the second breaking device; a second outlet of the air separation deviceis sequentially connected with the second magnetic separation device, the liquid type drum screen and the dewatering device; an outlet of the dewatering device is connected with a first inlet of theaerobic biological drying reactor; a second outlet of the drum screen is connected with the first magnetic separation device and the tension and relaxation screen; an outlet of the tension and relaxation screen is connected with a second inlet of the aerobic biological drying reactor; an outlet of the aerobic biological drying reactor is connected with the organic fertilizer compressing and packing device; the aerobic biological drying reactor is further connected with the percolating liquid treatment system and the deodorization system; and the garbage temporary storage area is further connected with the percolating liquid treatment system. Production of secondary pollution can be completely prevented, and highly-resourceful utilization of the stock garbage can be achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

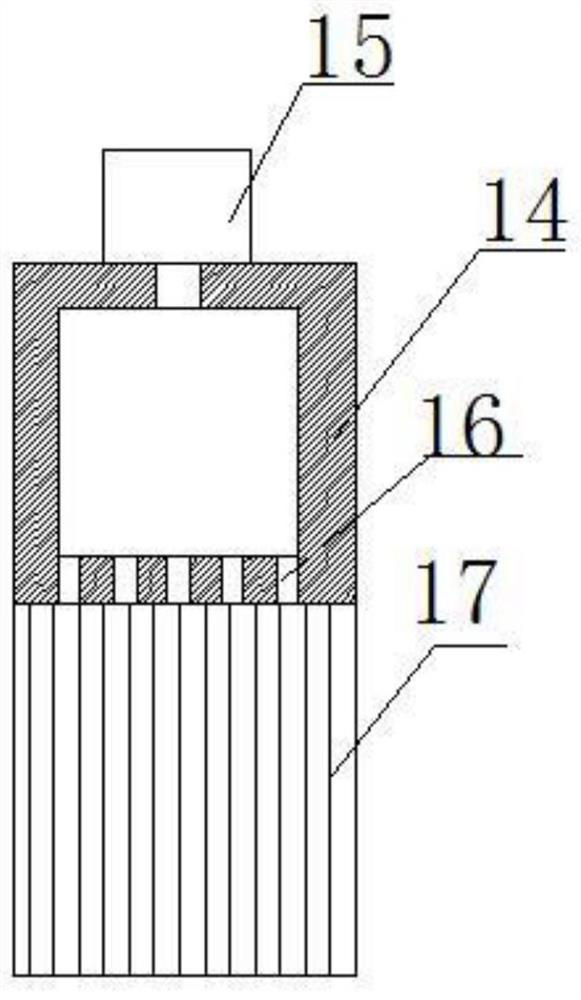

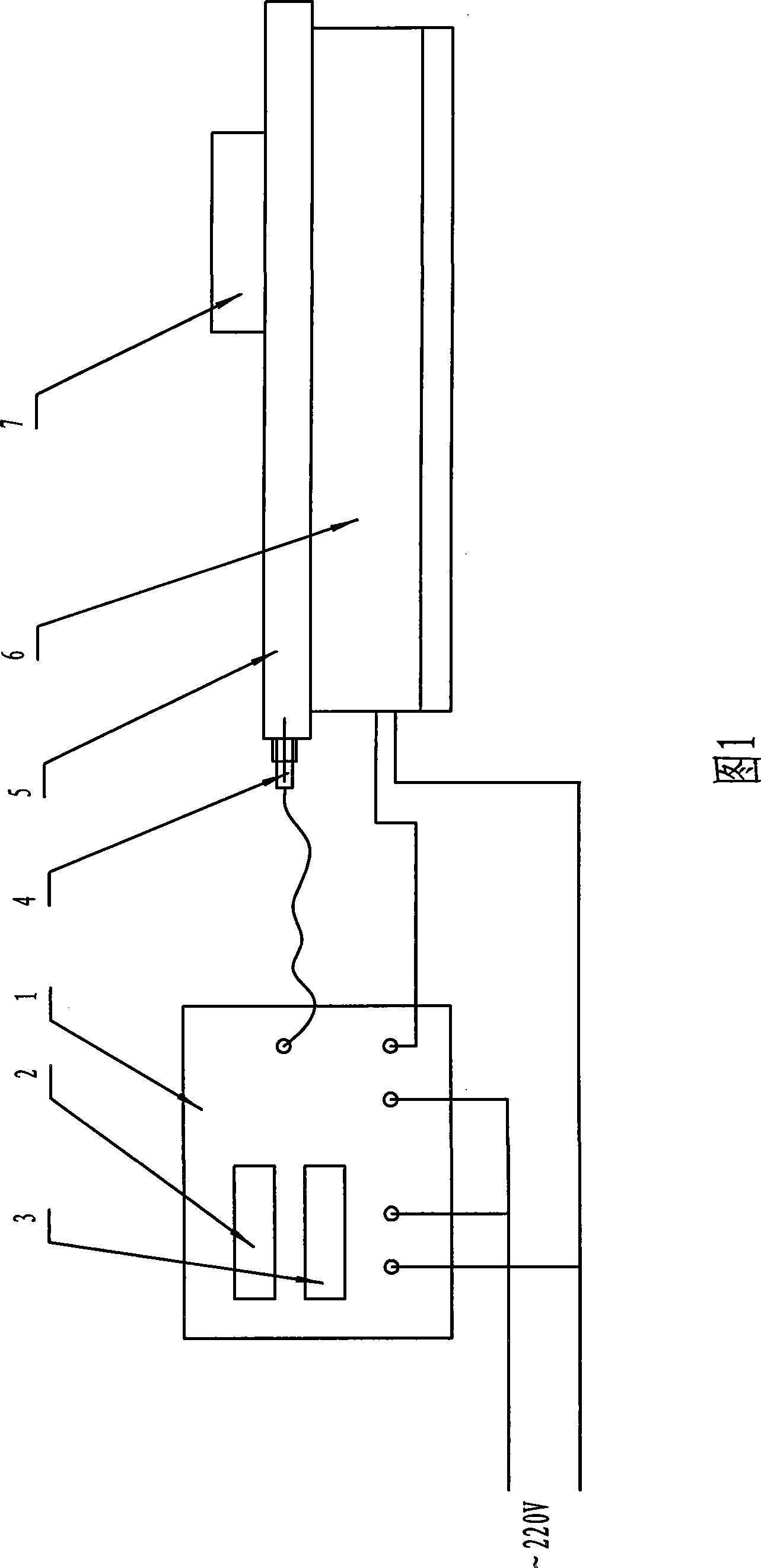

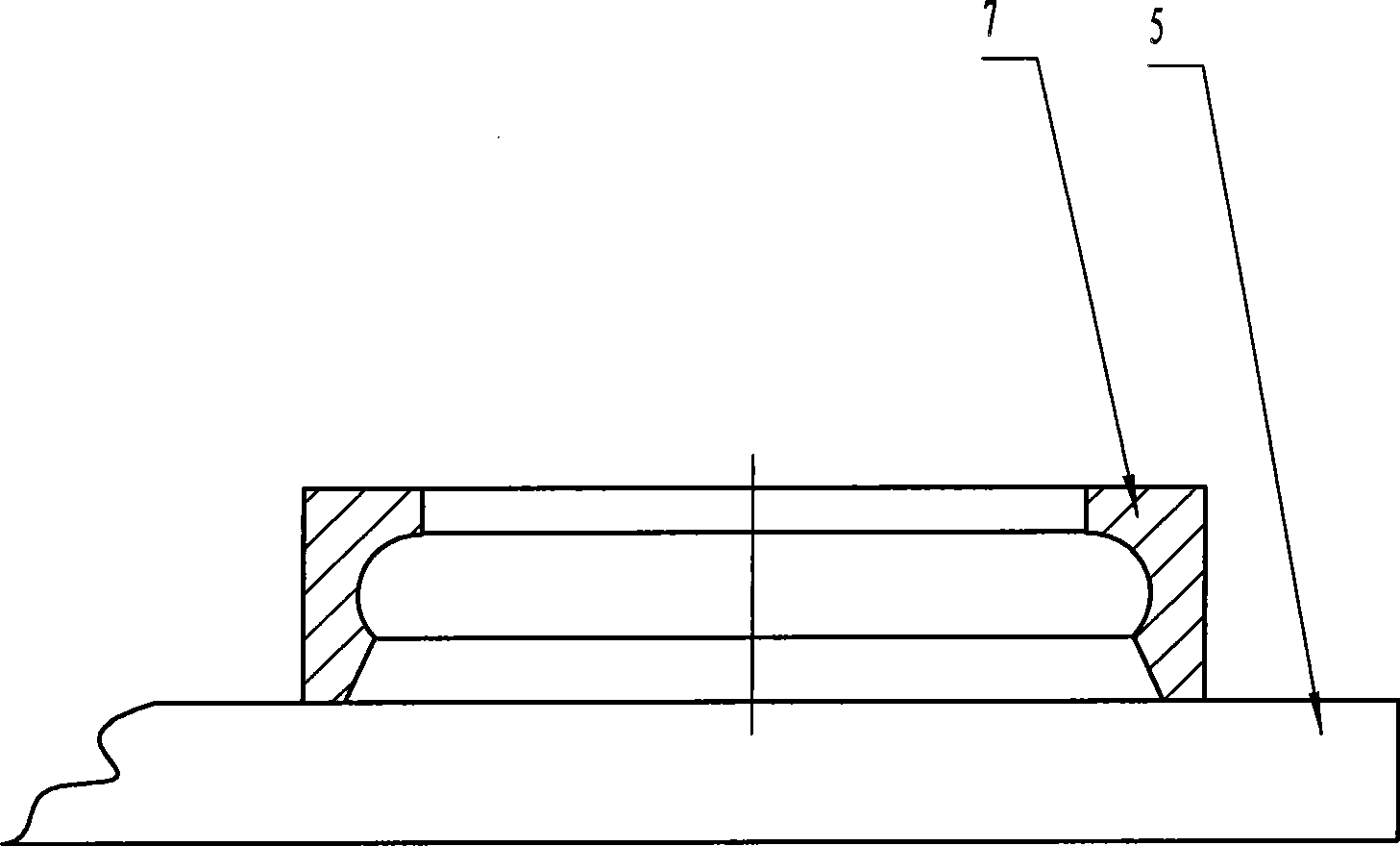

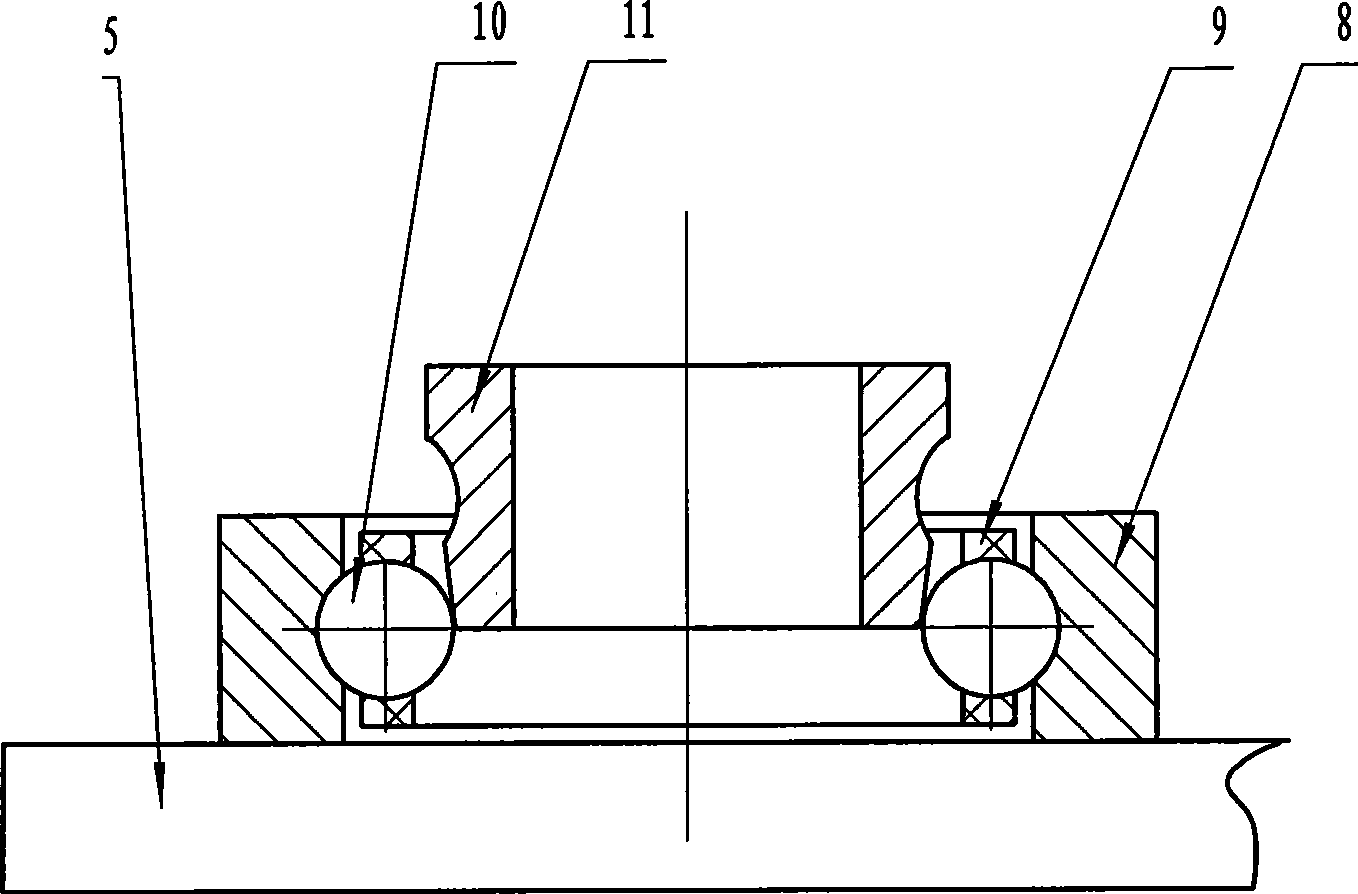

Thermal assembling method for angular contact ball bearing and heating apparatus

InactiveCN101457795AGuarantee quality and efficiencyGuaranteed assembly efficiencyTemperatue controlBearing componentsTemperature controlElectricity

The invention discloses a method for thermally assembling an angular contact ball bearing and a heating device. The heating device comprises a temperature controller and an electric heating device; the temperature controller is connected with the heating element of the electric heating device by a power supply circuit; the top part of the electric heating device is provided with an electric hot plate table-board used for holding and heating the outer sleeve ring of the bearing; a thermoelectric couple capable of feeding back the actual temperature signal of the electric hot plate table-board inserted into the electric hot plate table-board is connected with the outside of the temperature controller; during the thermal assembling, the outer sleeve ring of the bearing or the outer sleeve ring of the bearing internally provided with a retainer is arranged on the electric hot plate table-board; then the temperature controller controls the electric heating device to be electrified for heating and controls the heating temperature of the electric hot plate table-board until the outer sleeve ring of the bearing, or the outer sleeve ring of the bearing internally provided with a retainer is heated and thermally expanded to a required caliber; then the outer sleeve ring of the bearing, or the outer sleeve ring of the bearing internally provided with a retainer is combined and sheathed with the other parts of the bearing. The invention overcomes the defects of oil boiling heating of the thermal assembling of the bearing, can reduce oil smoke pollution and can improve the production safety.

Owner:LUOYANG BEARING SCI & TECH CO LTD

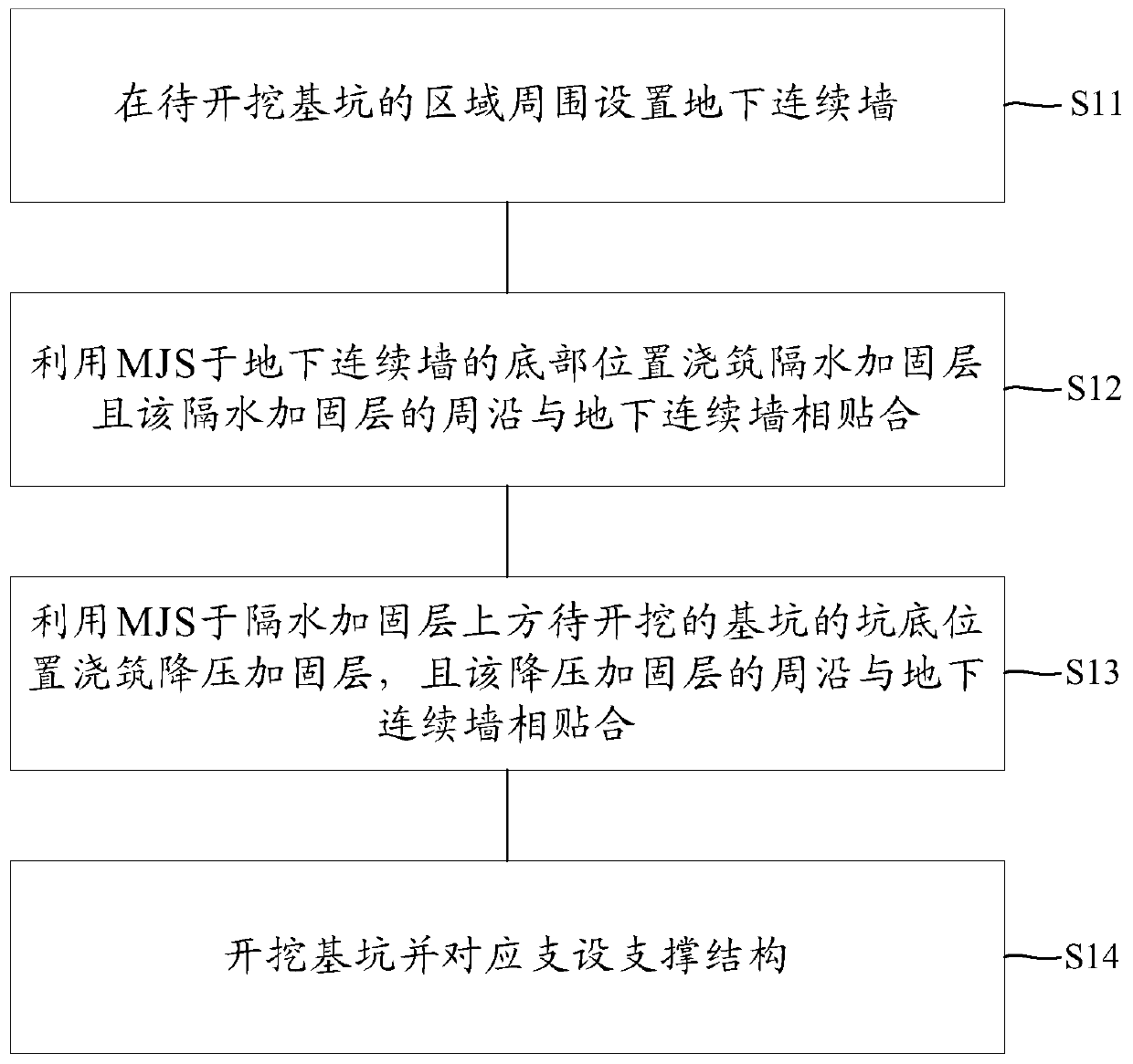

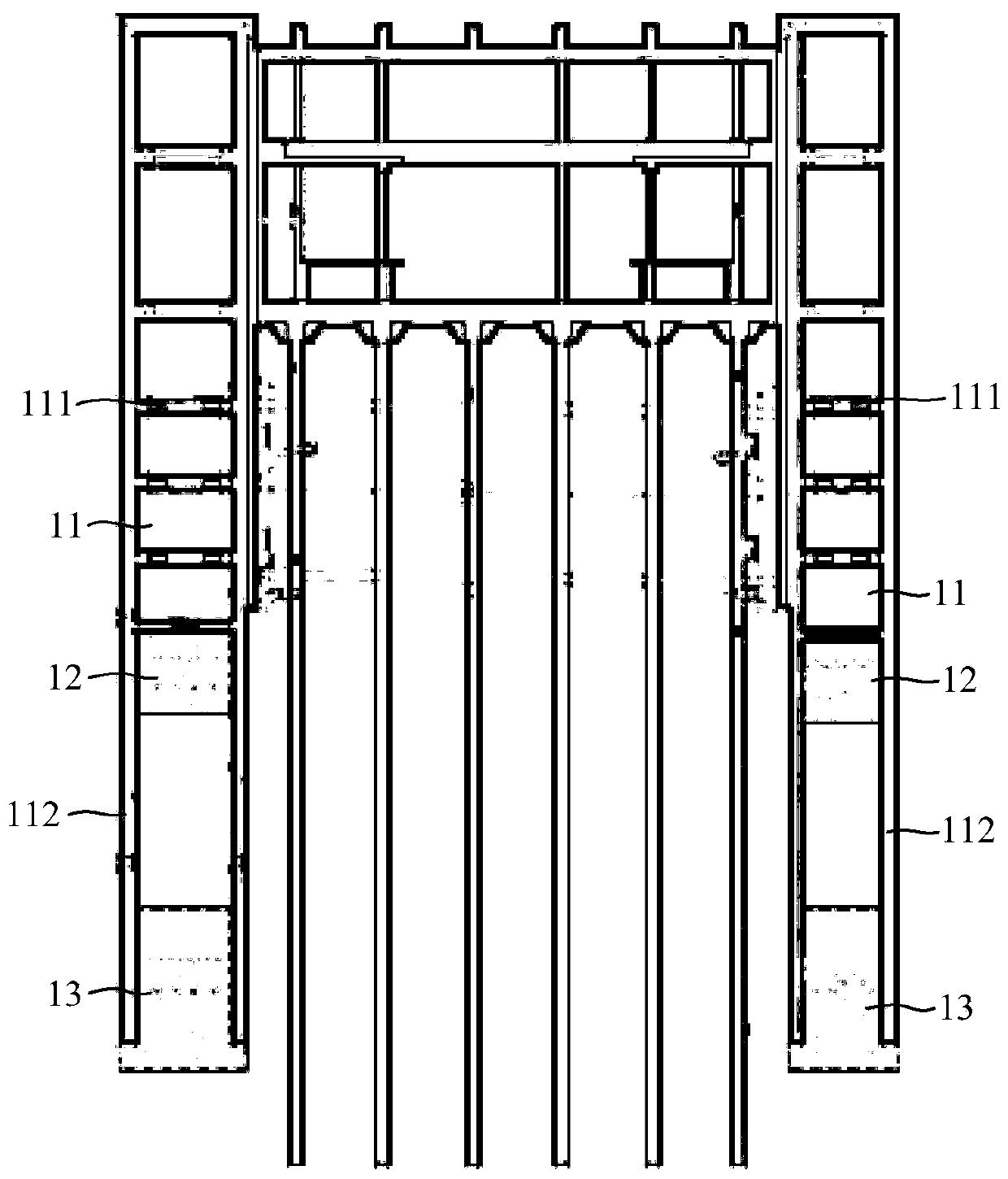

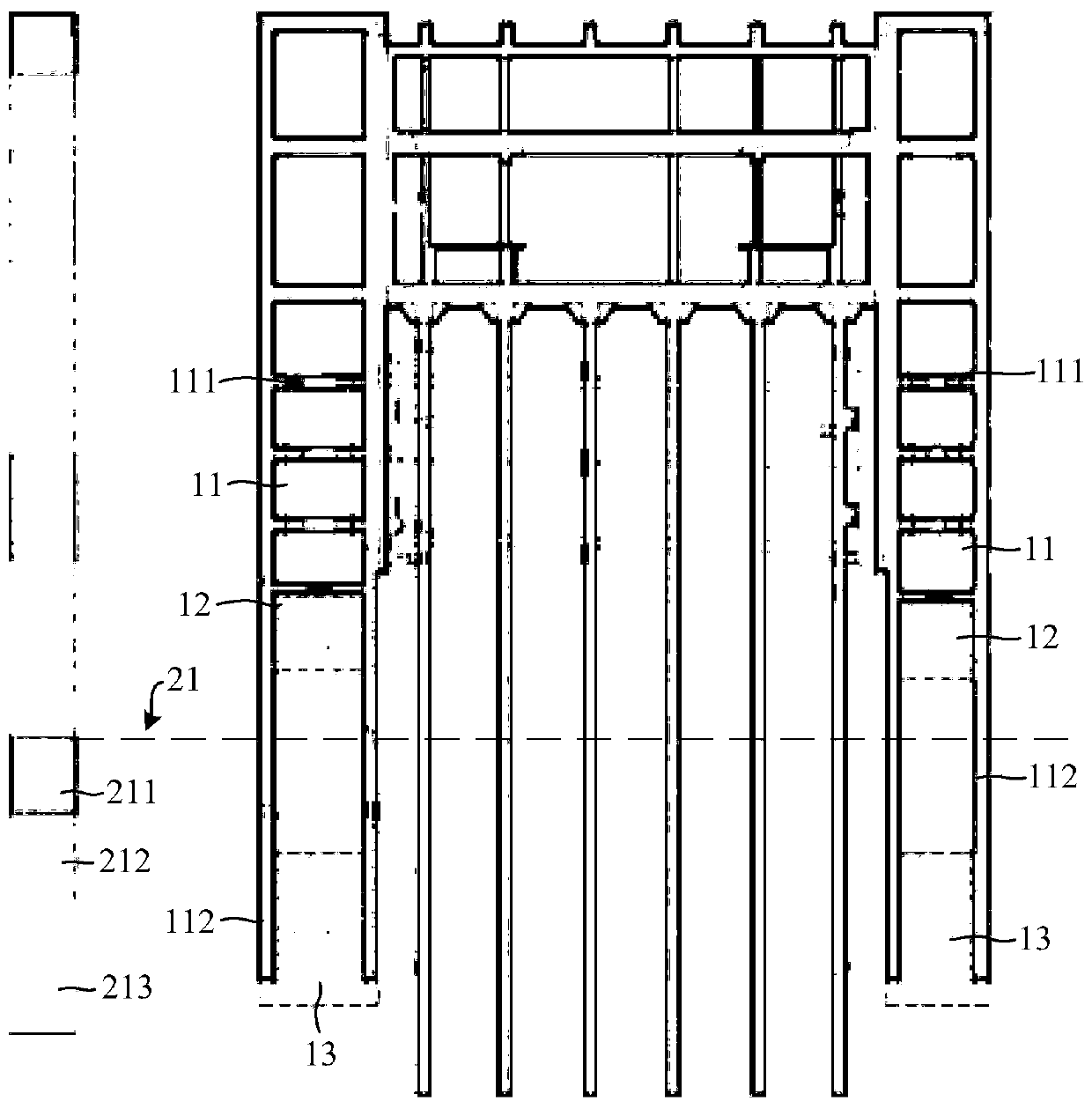

Construction method for anti-uprush of ultra-deep foundation pit

ActiveCN110387884ASolve the hidden danger of pressurized water inrushWill not cause subsidenceExcavationsSlurry wallEngineering

The invention relates to a construction method for anti-uprush of an ultra-deep foundation pit. The bottom of the foundation pit to be excavated is close to a confined aquifer, and the construction method comprises the steps of setting a underground diaphragm wall around the area of the foundation pit is to be excavated; pouring a water-retaining reinforcement layer at the bottom position of the underground diaphragm wall through using MJS, and the periphery of the water-retaining reinforcement layer is adhered to the underground diaphragm wall; pouring a depressurization reinforcement layer at the bottom position of the foundation pit to be excavated above the water-retaining reinforcement layer by using MJS, and the periphery of the depressurization reinforcement layer is adhered to theunderground diaphragm wall; and excavating the foundation pit and supporting a support structure correspondingly. The construction method provided by the invention effectively solves the problem of uprush hidden danger of the confined aquifer when excavating the ultra-deep foundation pit, and has little influence on the surrounding environment during construction, does not cause settlement of surrounding buildings, and can ensure construction quality and construction efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

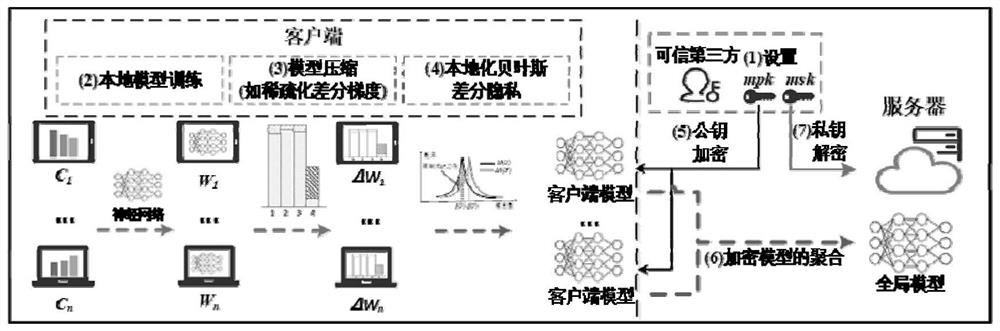

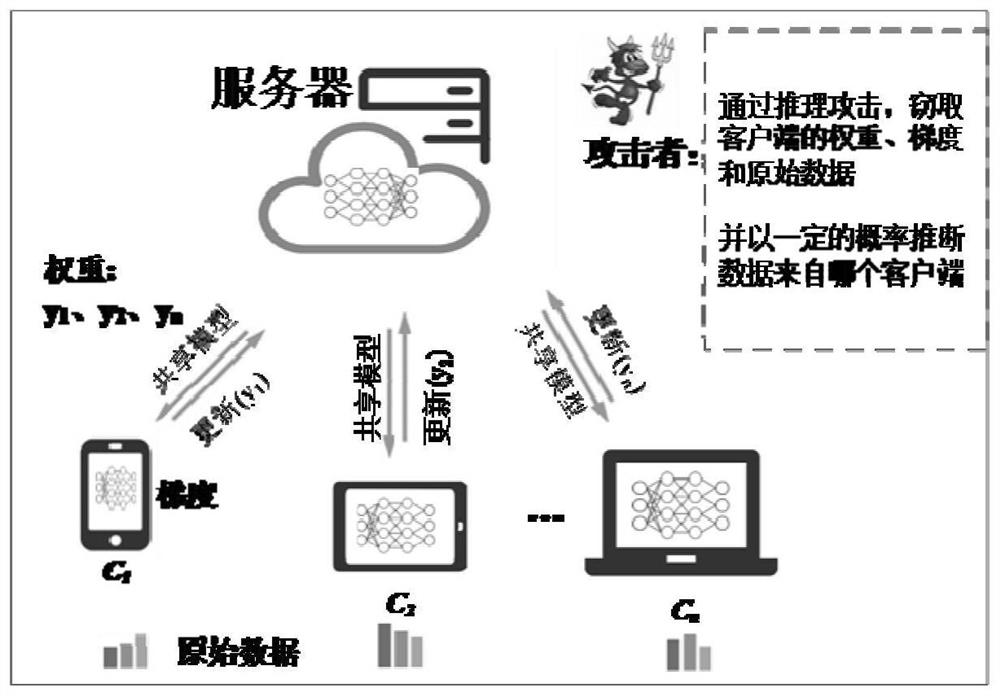

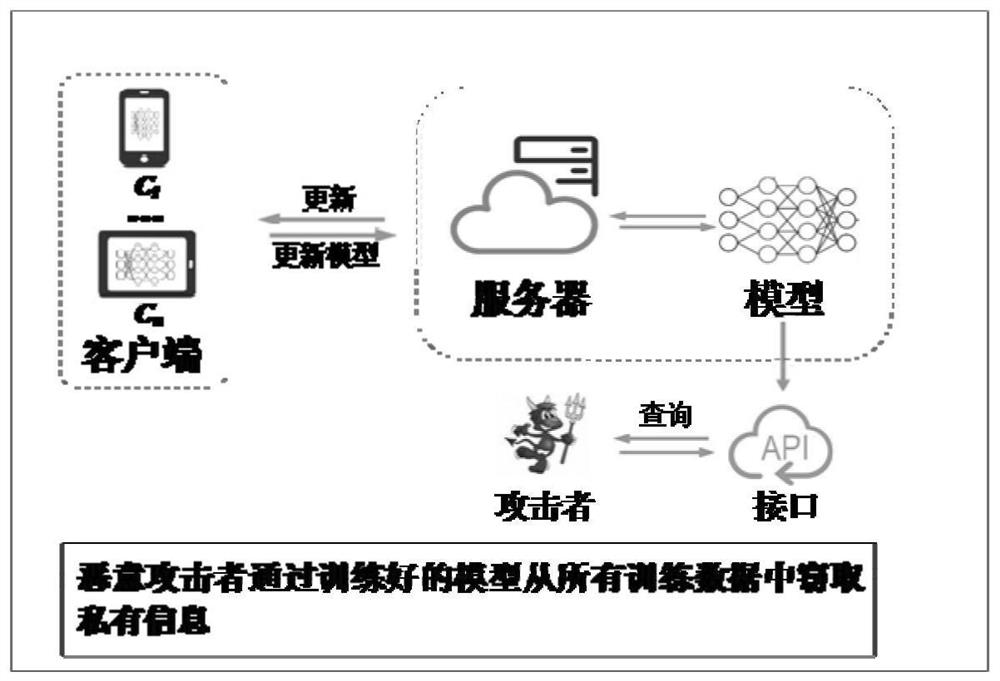

Composite privacy protection method and system, computer equipment and storage medium

ActiveCN112966298AProtect source privacyGuarantee quality and efficiencyDigital data protectionQuality of serviceThird party

The invention provides a composite privacy protection method and system, computer equipment and a storage medium; the method comprises the steps: generating an encryption public key of a client and a decryption private key of a server through a trusted third party in advance according to the weight of the client; sending, by the server, a first model and a first model parameter to the client; training the first model by the client according to local data, and updating the first model parameter to a second model parameter; performing a differential privacy algorithm to add the noise to the second model parameter by the client to obtain a third model parameter; according to the encryption public key, performing, by the client, function encryption on the third model parameter to obtain an encryption model and sends the encryption model to the server; and according to the decryption private key, decrpyting, by the server, the encryption model to obtain a global model. According to the method, privacy protection is enhanced, and model service quality and learning efficiency are improved.

Owner:GUANGZHOU UNIVERSITY

Milling method for PCB microgroove formation

InactiveCN108012420AImprove efficiencyExtend tool lifePrinted circuit manufactureMilling equipment detailsTerminal pointEngineering

The invention is suitable for the technical field of PCB machining, and discloses a milling method for PCB microgroove formation. The milling method comprises the following steps that the PCB is fixedon the machining position; the cutting hole penetrating through the circuit board is drilled on the PCB by using a drill; a first milling cutter is adopted to cut from the cutting hole and the firstmilling cutter drills to the depth of 0.5-0.7 time of the board thickness of the PCB and then the first milling cutter performs the first time of horizontal milling on the PCB along a first directionaccording to a first path; the PCB after completion of the first time of horizontal milling is overturned and fixed; and a second milling cutter cuts from the end point corresponding to the first pathand the second milling cutter drills to the depth of 0.5-0.7 time of the board thickness of the PCB and then the second milling cutter mills to the start point corresponding to the first path along asecond direction according to the direction opposite to the first path. According to the milling method for PCB microgroove formation, the service life of the cutter can be enhanced under the premiseof guaranteeing enhancement of the groove profile quality through the machining method of two-side milling.

Owner:SHENZHEN JINZHOU PRECISION TECH

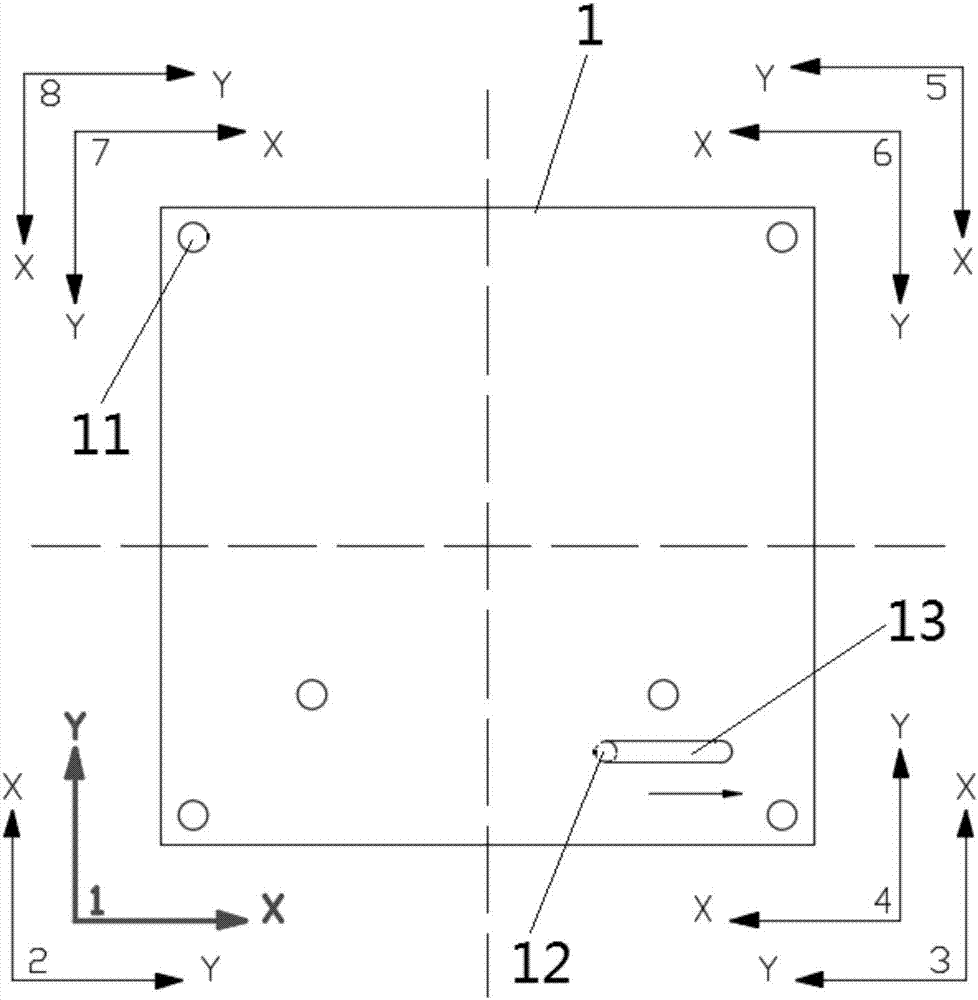

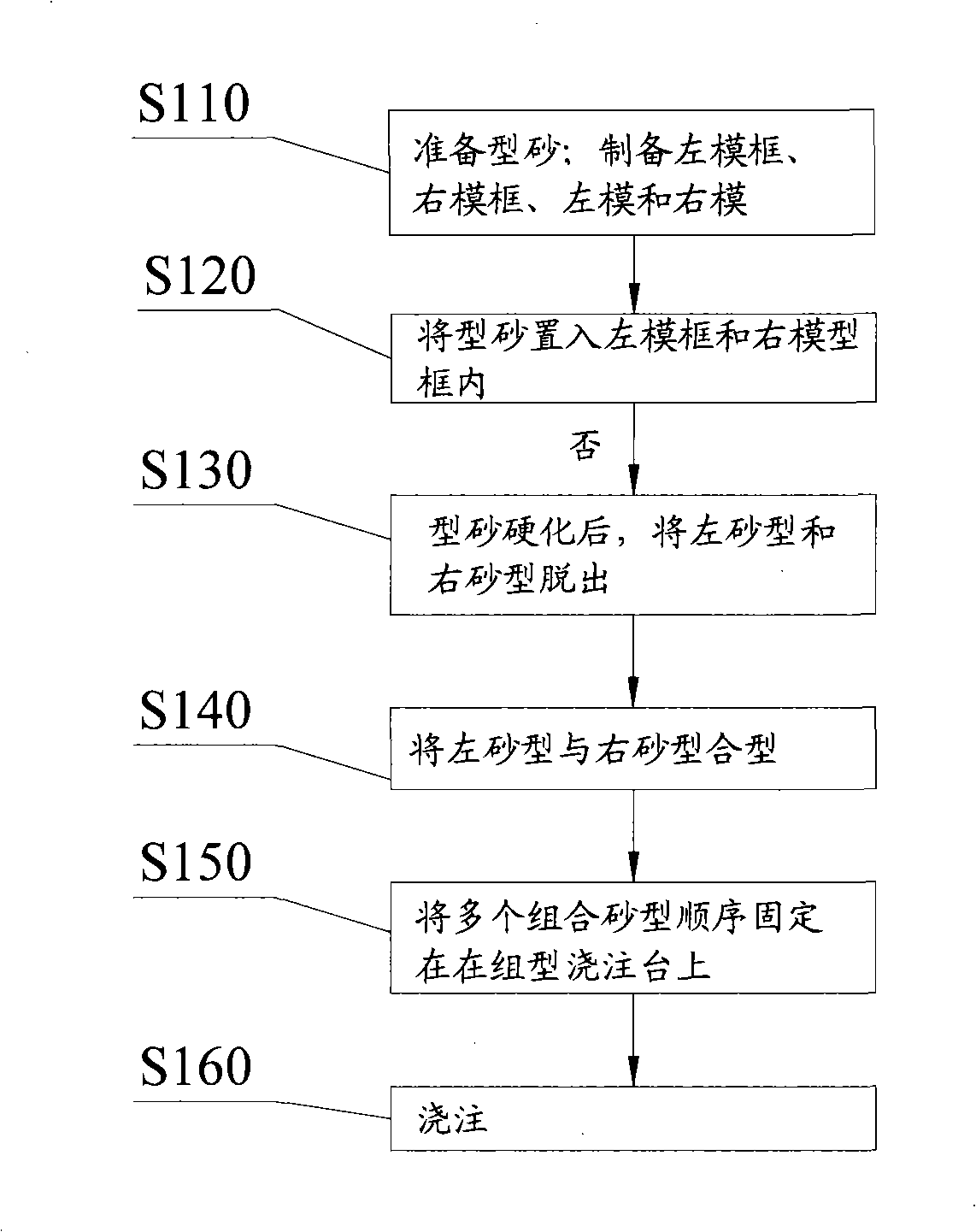

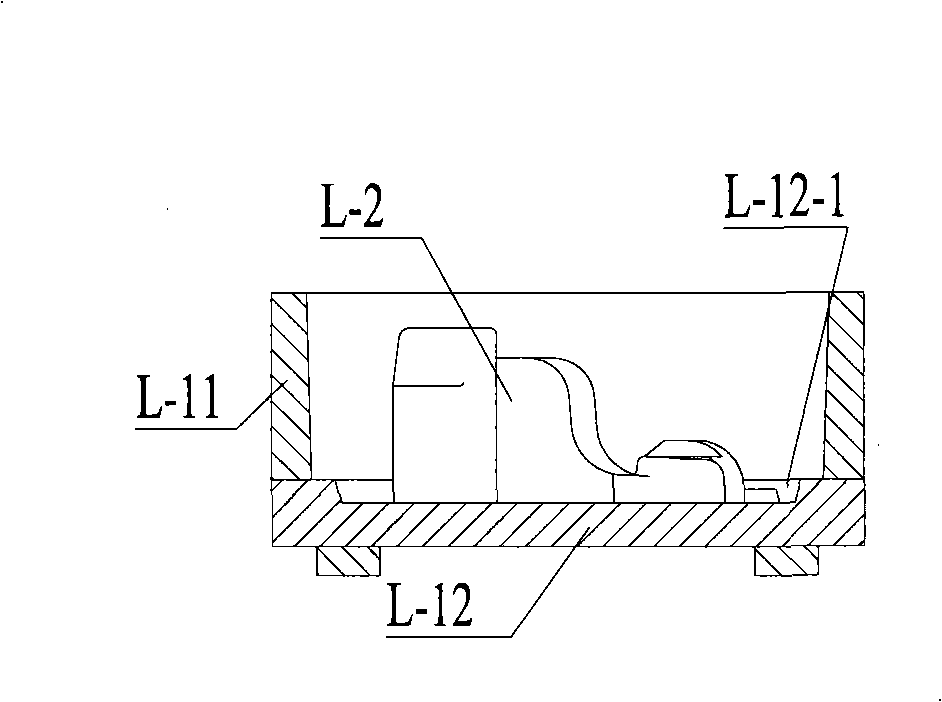

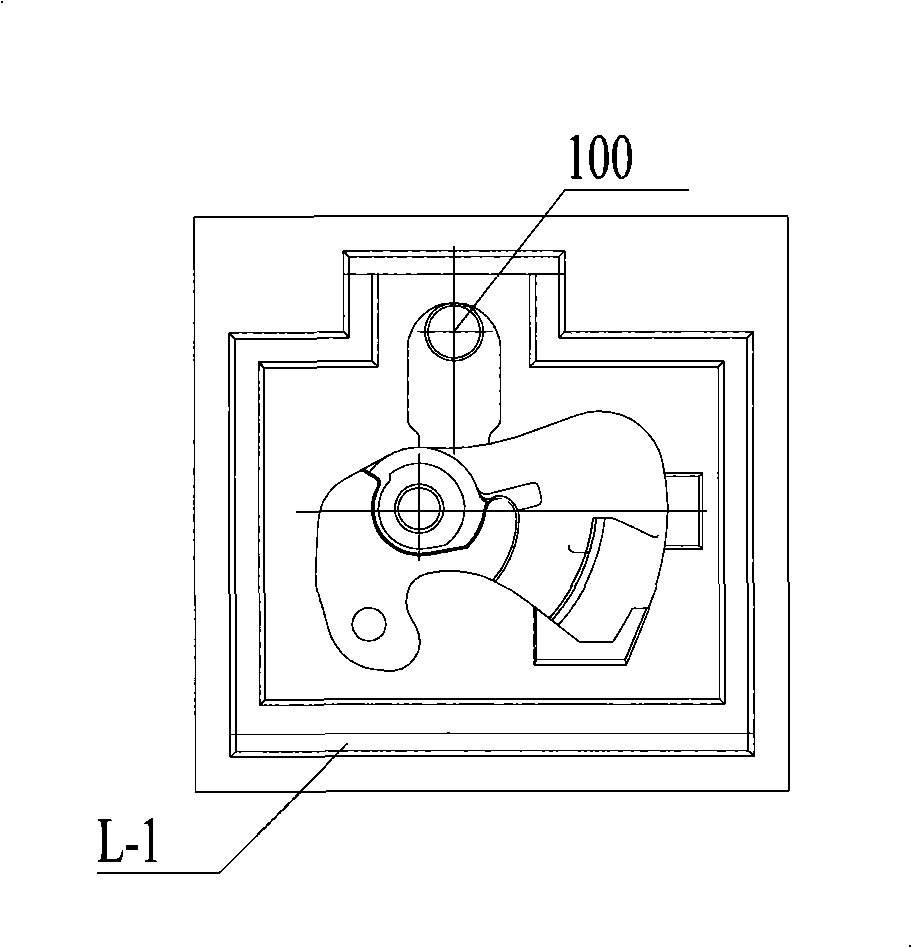

Coupler knuckle casting method

InactiveCN101402130AReduce manufacturing costEasy to produceFoundry mouldsFoundry coresHardnessKnuckle

The invention discloses a method for casting a coupler knuckle. The method is characterized by realizing boxless shaping by shaping hardened molding sand in a molding frame to obtain left molding sand and right molding sand. During shaping, a left molding frame, a right molding frame, a left mold and a right mold are processed with materials which have low hardness and are easy to process, thereby greatly reducing the difficulty in processing the mold for casting the coupler knuckle, reducing the manufacture cost of casting tools, shortening the preparation period of the casting tools of the coupler knuckle, accordingly reducing the production period for casting the coupler knuckle and making the casting of the coupler knuckle meet the requirements for small-batch production and the process test of new product as well as production requirements on short delivery time.

Owner:CRRC QIQIHAR ROLLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com