Redundant drive five degrees of freedom parallel machine tool with large rotation angle

A technology with a degree of freedom and a large rotation angle, which is applied in the direction of manipulators, manufacturing tools, and large fixed members, etc., can solve the problems of low processing efficiency of free-form surfaces, and achieve the effect of ensuring quality and cutting efficiency, large working space, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand a redundantly driven five-degree-of-freedom parallel machine tool with a large rotation angle provided by the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and detailed embodiments, and the content of the present invention is not limited to the embodiments.

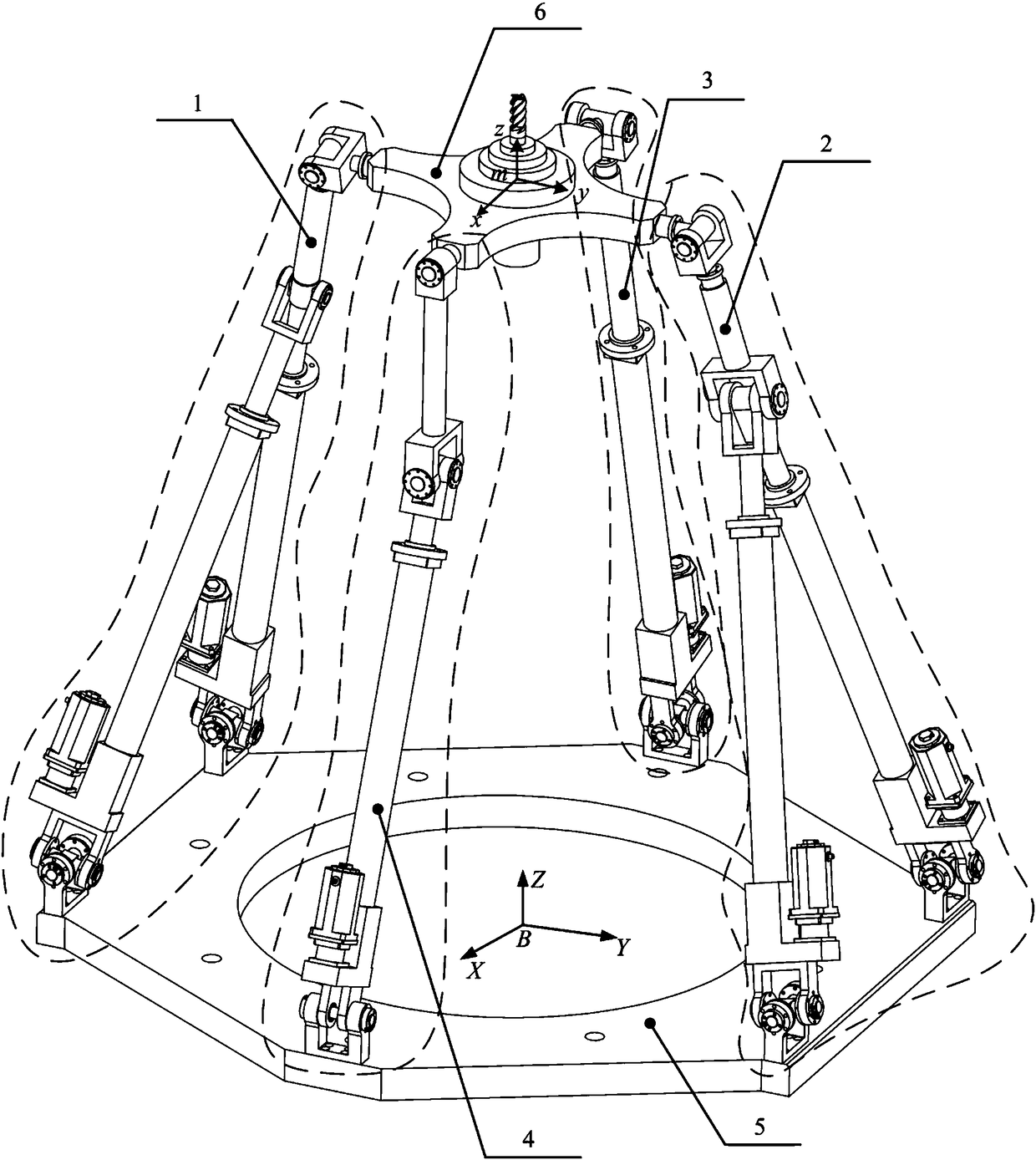

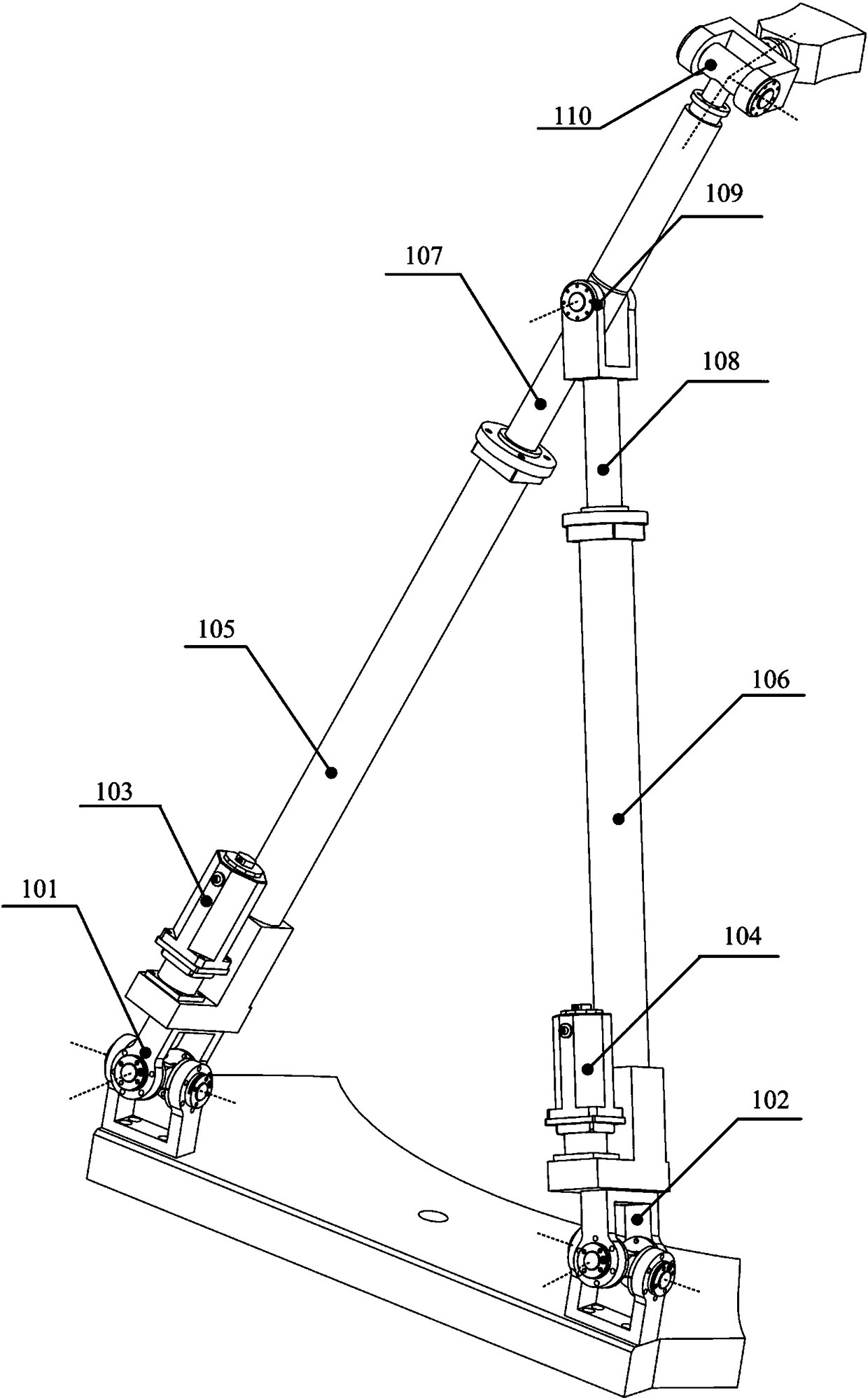

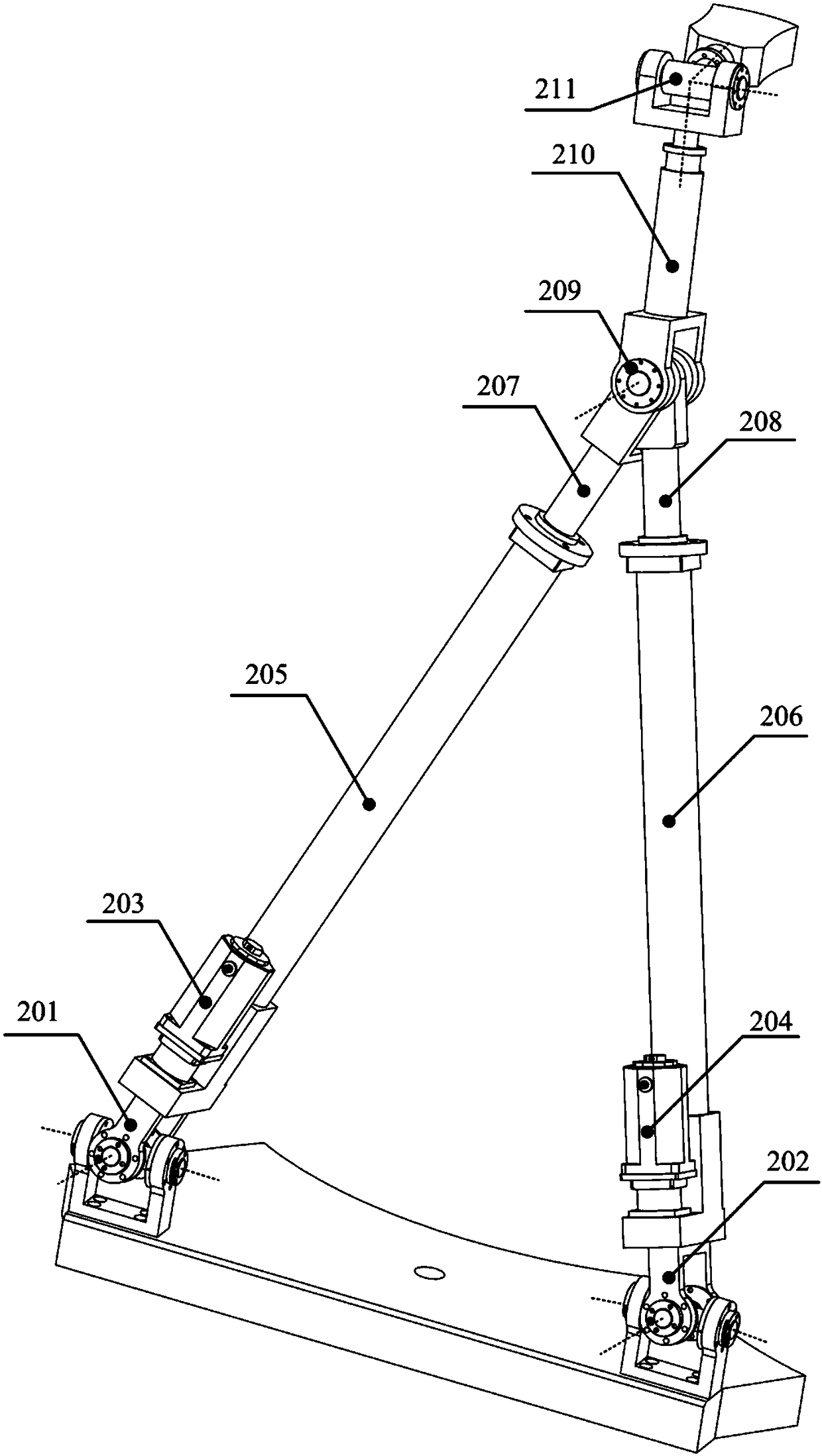

[0029] figure 1 A schematic diagram of the overall structure of a redundantly driven five-degree-of-freedom parallel machine tool with a large rotation angle provided by the present invention, which includes a fixed platform 5, a moving platform 6 on which the spindle head is installed, and a first drive branch 1 connecting the moving and fixed platforms. The second drive branch 2, the third drive branch 3, and the fourth drive branch 4, and the fixed platform 5 can realize the moving platform through the coordinated linkage of the first drive branch 1, the second drive branch 2, the third drive branch 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com