Patents

Literature

278results about How to "Guaranteed cutting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

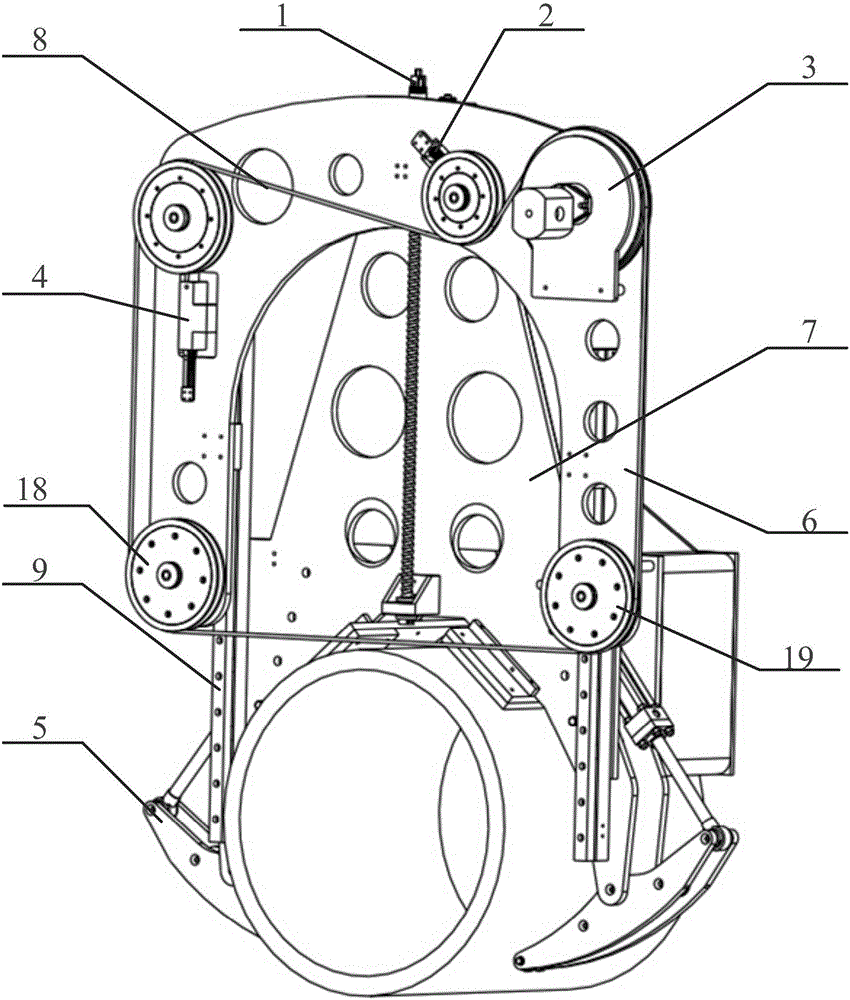

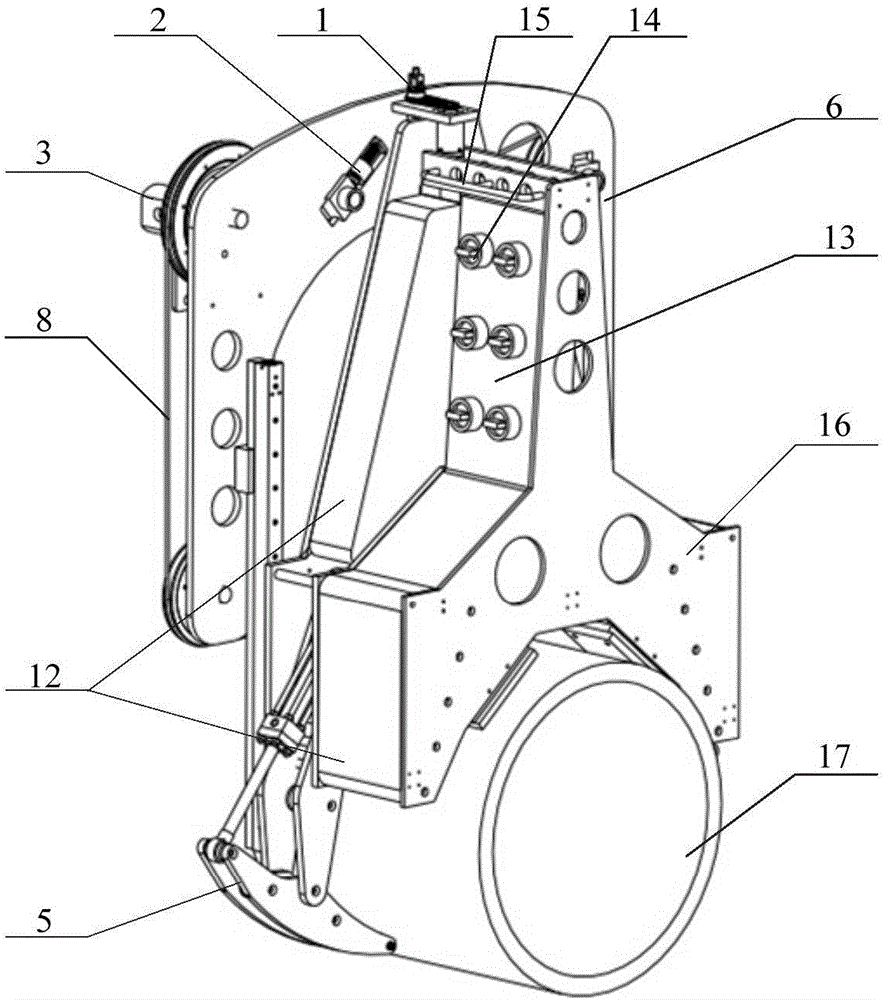

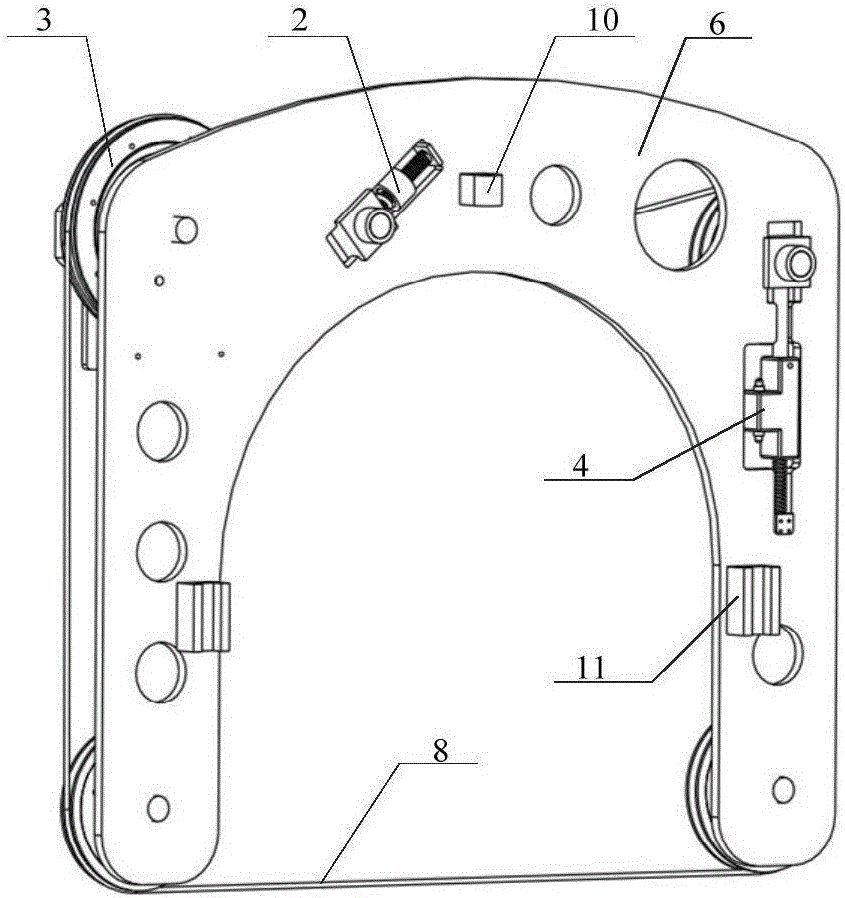

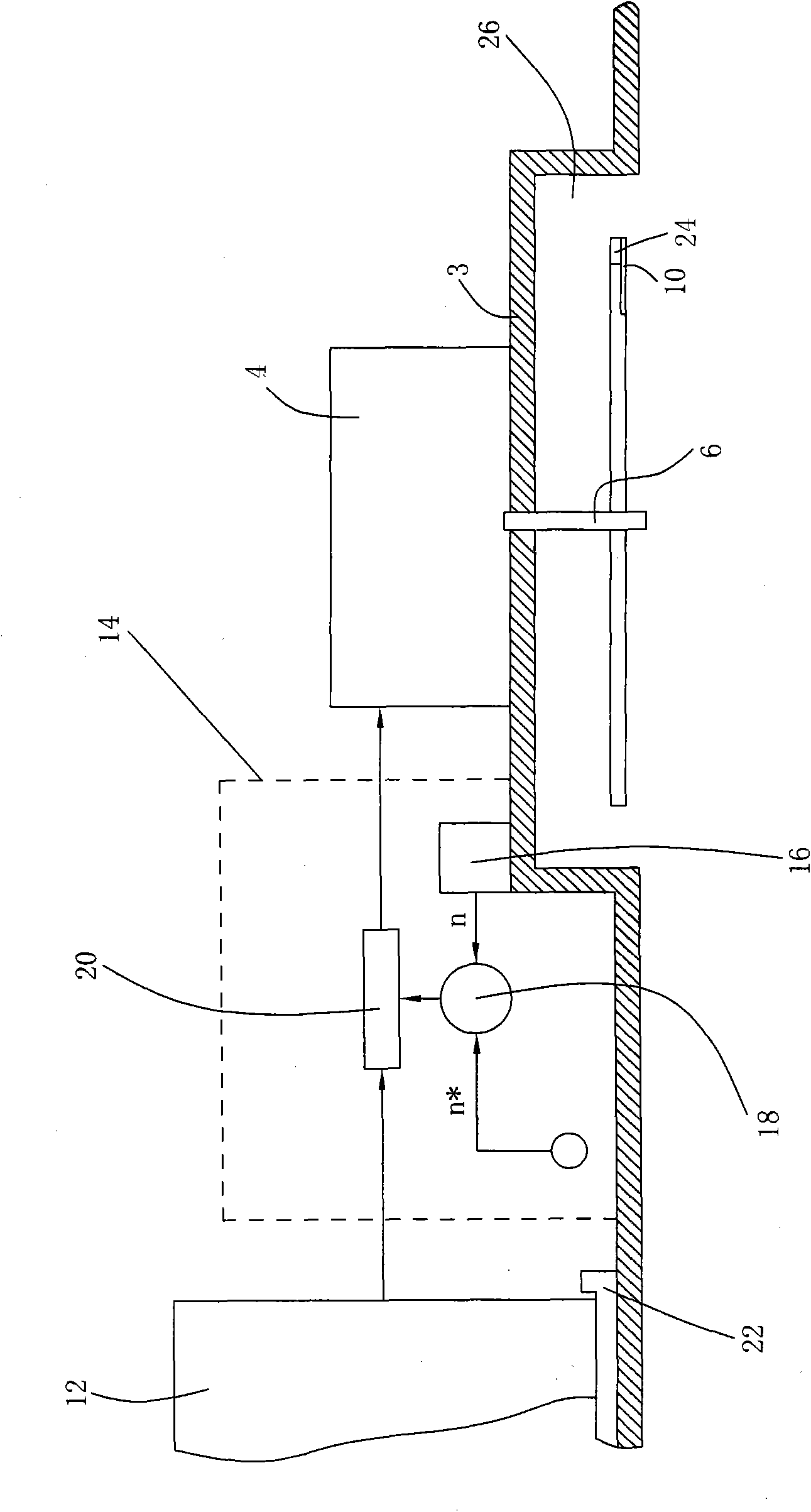

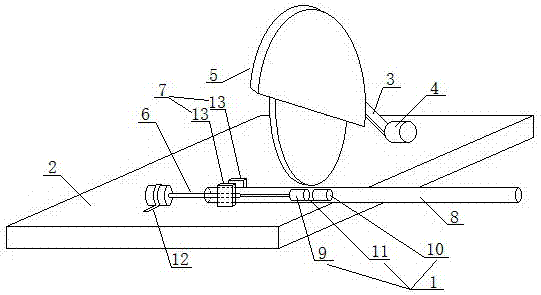

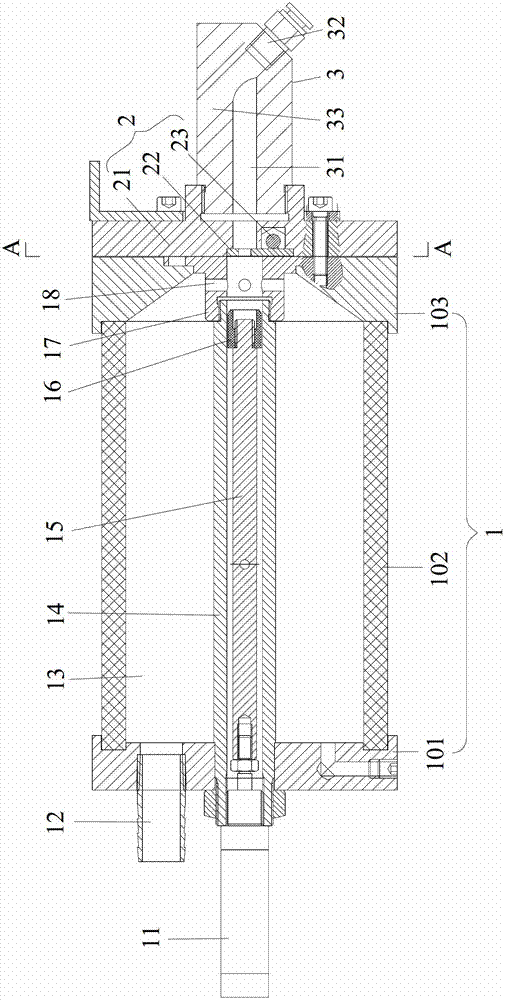

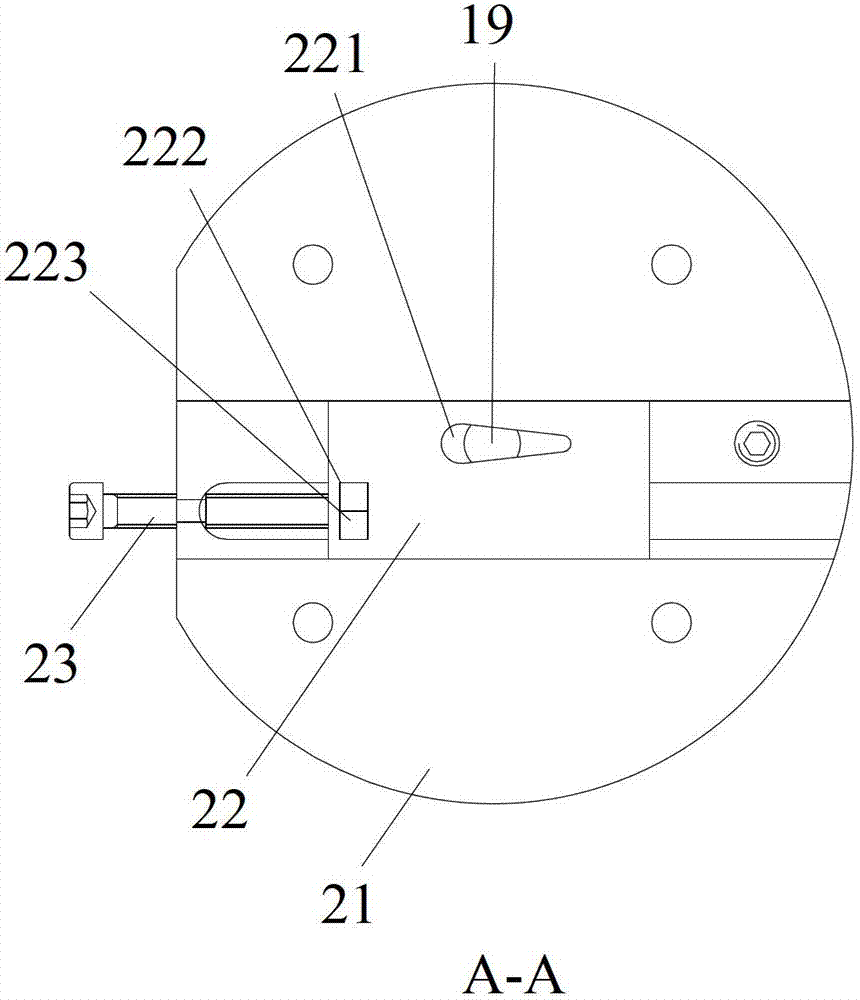

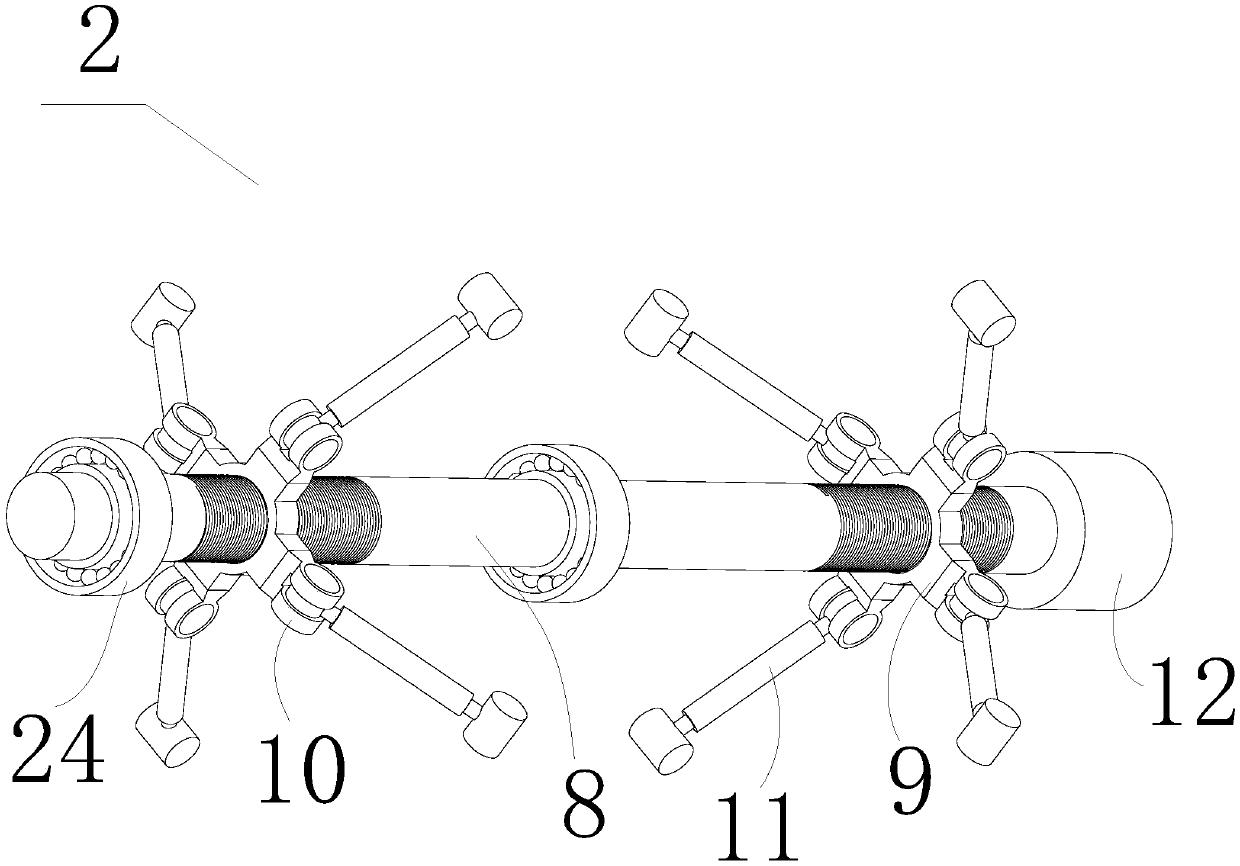

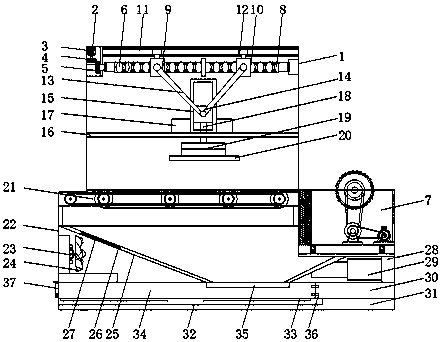

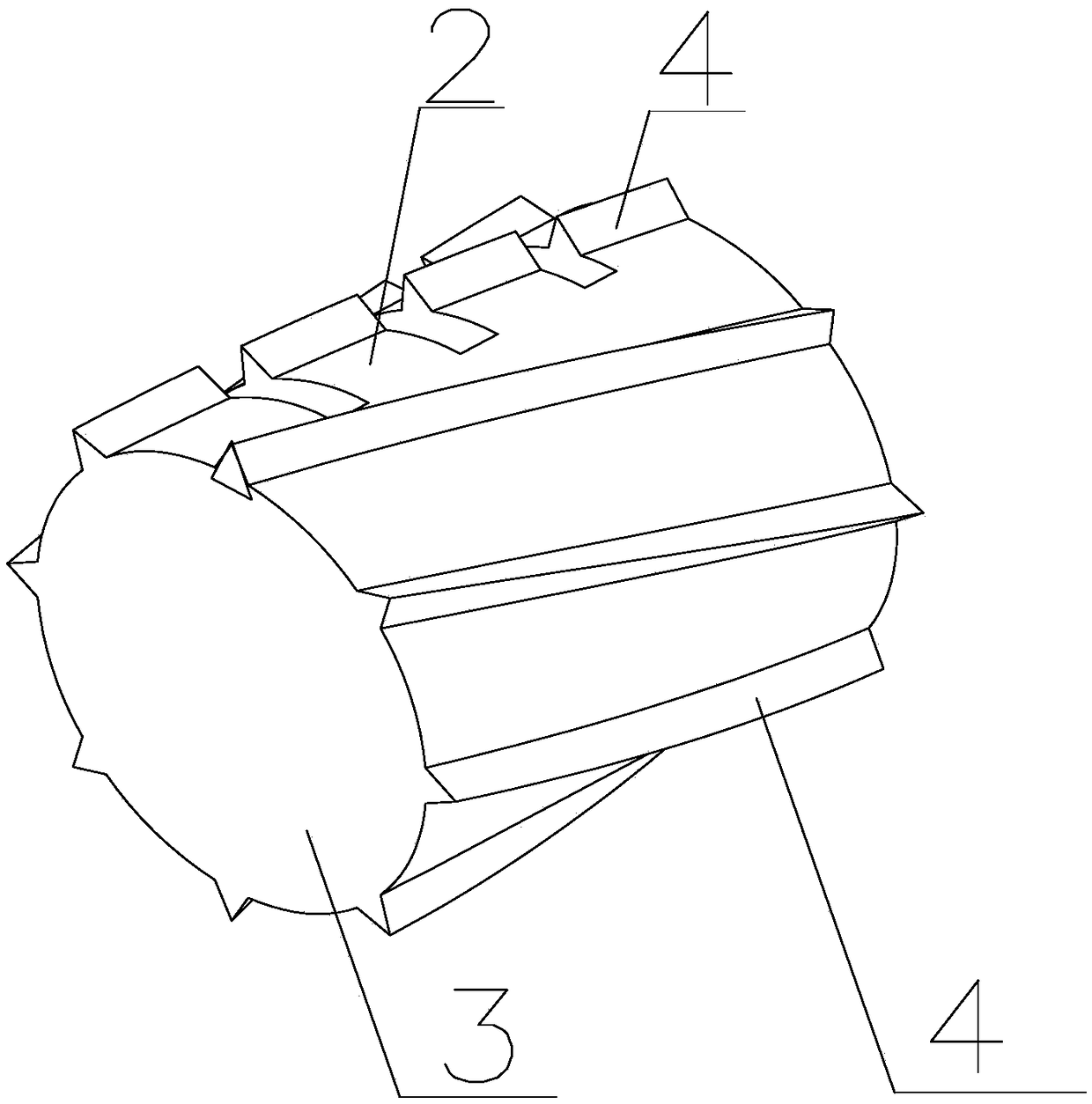

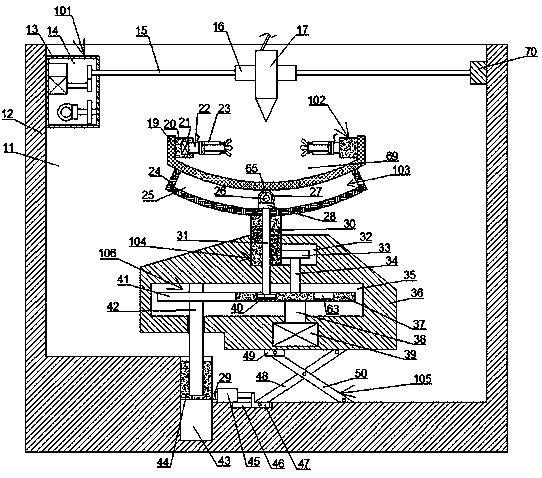

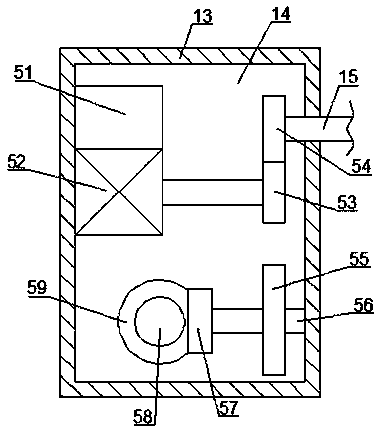

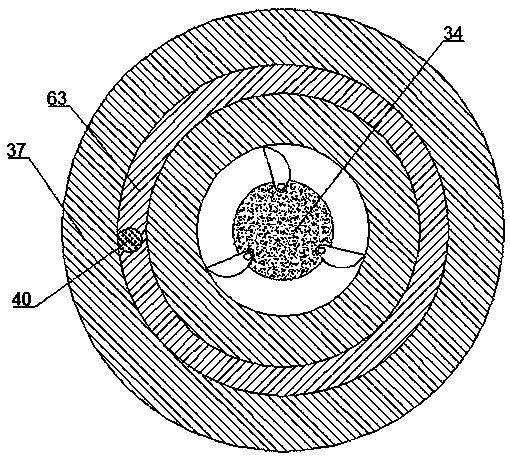

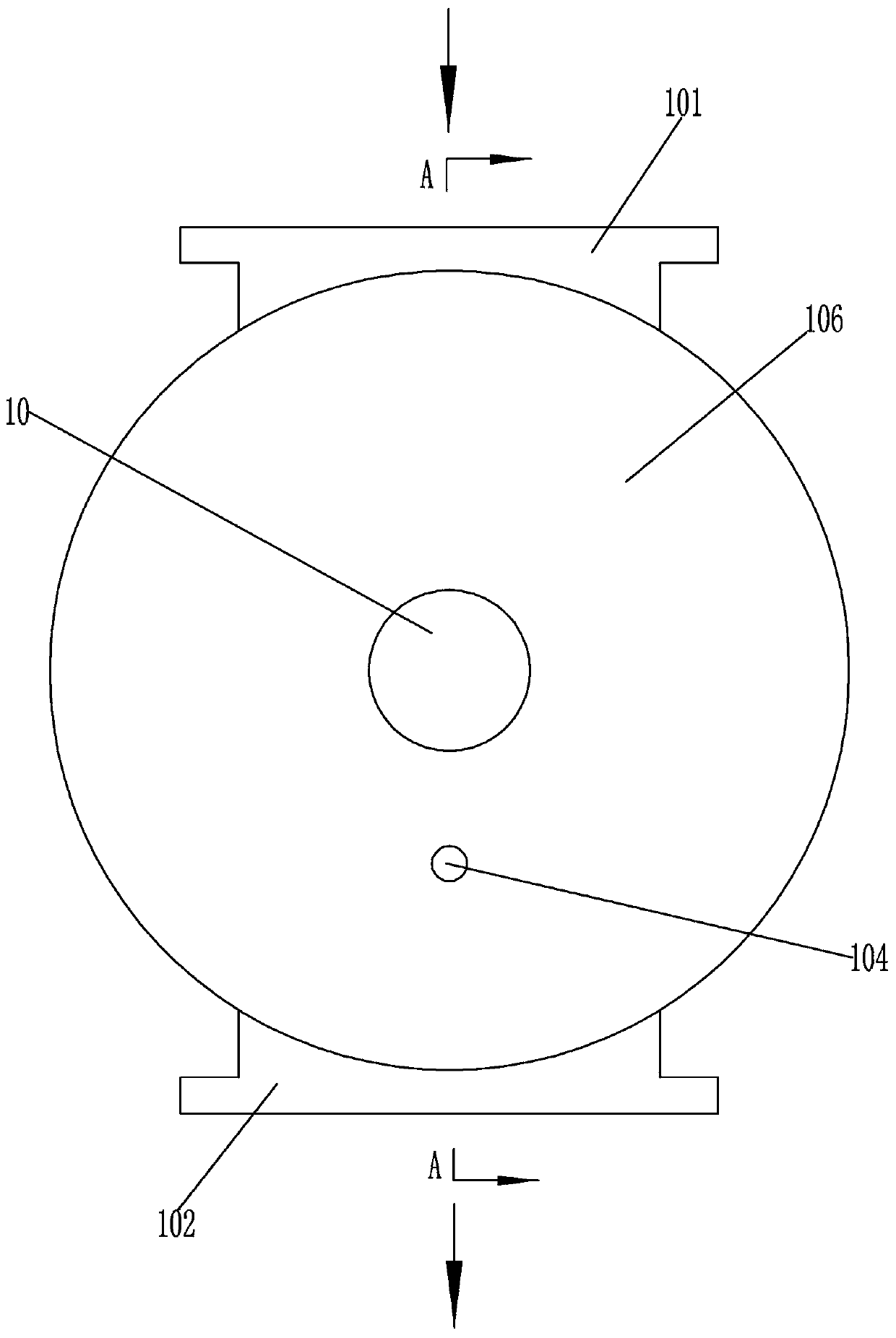

Deepwater diamond wire sawing machine

ActiveCN106141304AConvenient for underwater workGuaranteed lifeMetal sawing devicesMetal sawing accessoriesDiamond wire sawEngineering

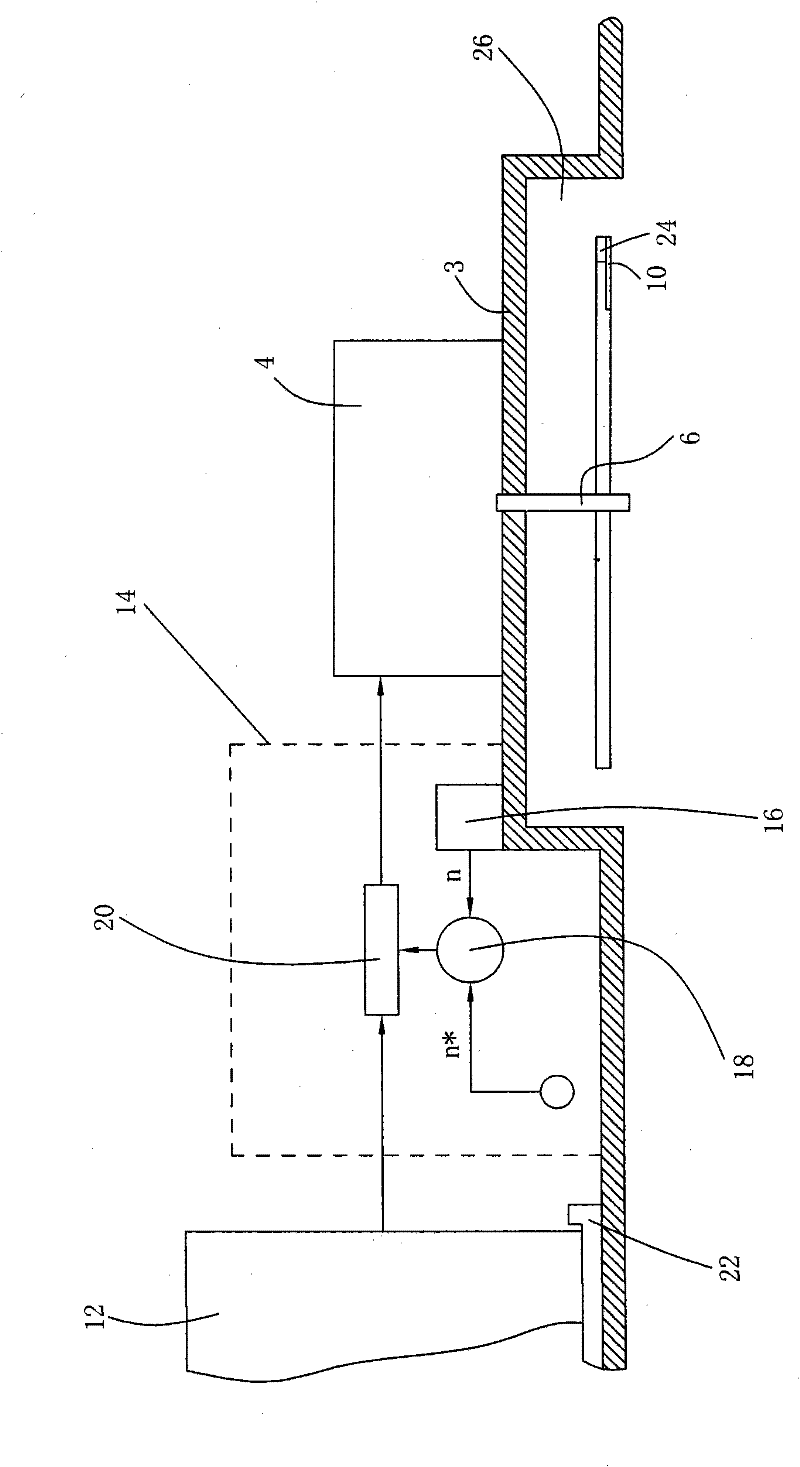

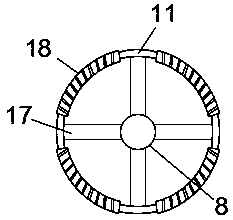

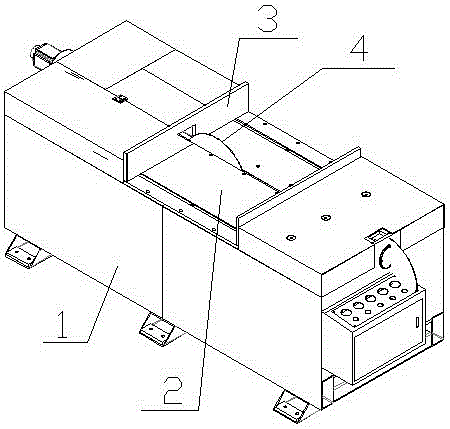

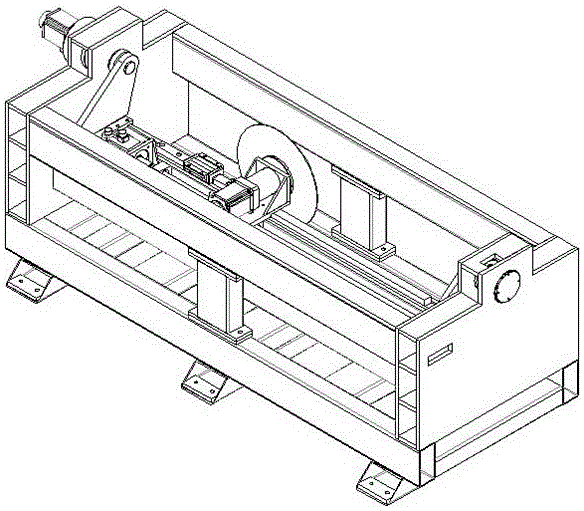

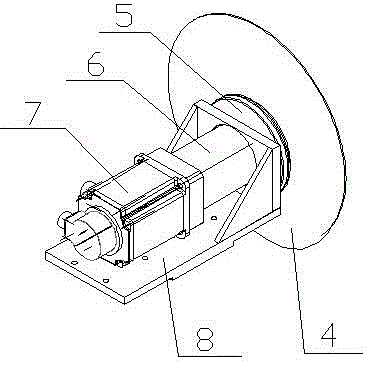

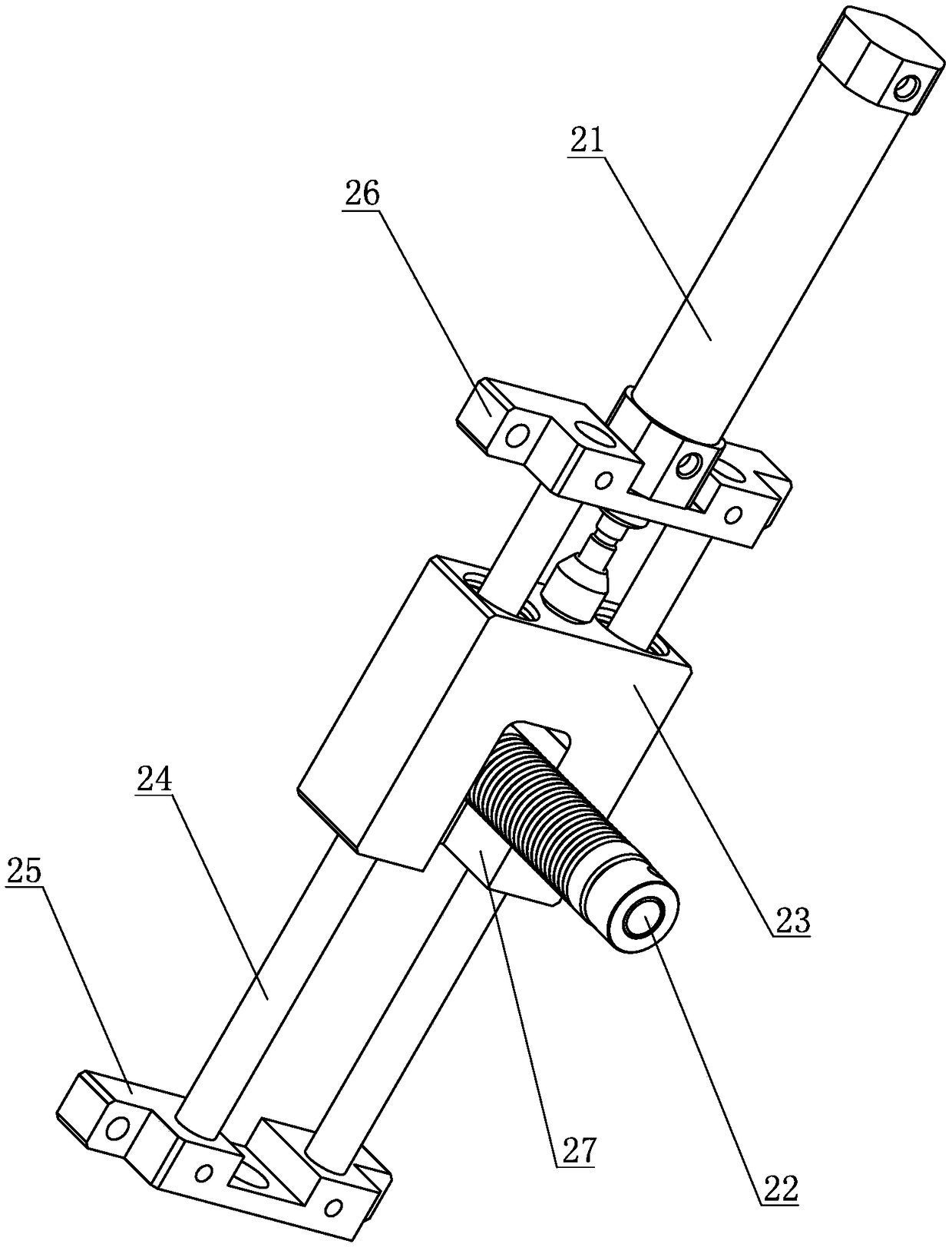

The invention provides a deepwater diamond wire sawing machine which is majorly composed of a cutting drive mechanism, a feeding drive mechanism, a feeding speed regulating mechanism, a string bead wire tensioning mechanism and clamping mechanisms, and used for completing cutting repair of underwater structures. The feeding speed regulating mechanism is adopted for the deepwater diamond wire sawing machine, the feeding speed can be regulated along with the change of tension of a string bead wire in the operating process, and the service life of the string bead wire, the cutting efficiency of the machine and the reliability of cutting operation are effectively guaranteed. The feeding drive mechanism can promote transmission separation of a feeding motor and a lead screw, so that overload protection for the feeding drive mechanism is achieved; and meanwhile, under the condition that the machine does not have power, a handle can be rotated for feeding, and integrally automatic and manual drive feeding is achieved. A strong spring, a nut and a screw are adopted for tensioning of the string bead wire tensioning mechanism, and vibration of the string bead wire in the cutting process can be effectively reduced accordingly. The deepwater diamond wire sawing machine is provided with buoyancy materials and a deepwater valve box and suitable for deepwater environment operation.

Owner:HARBIN ENG UNIV

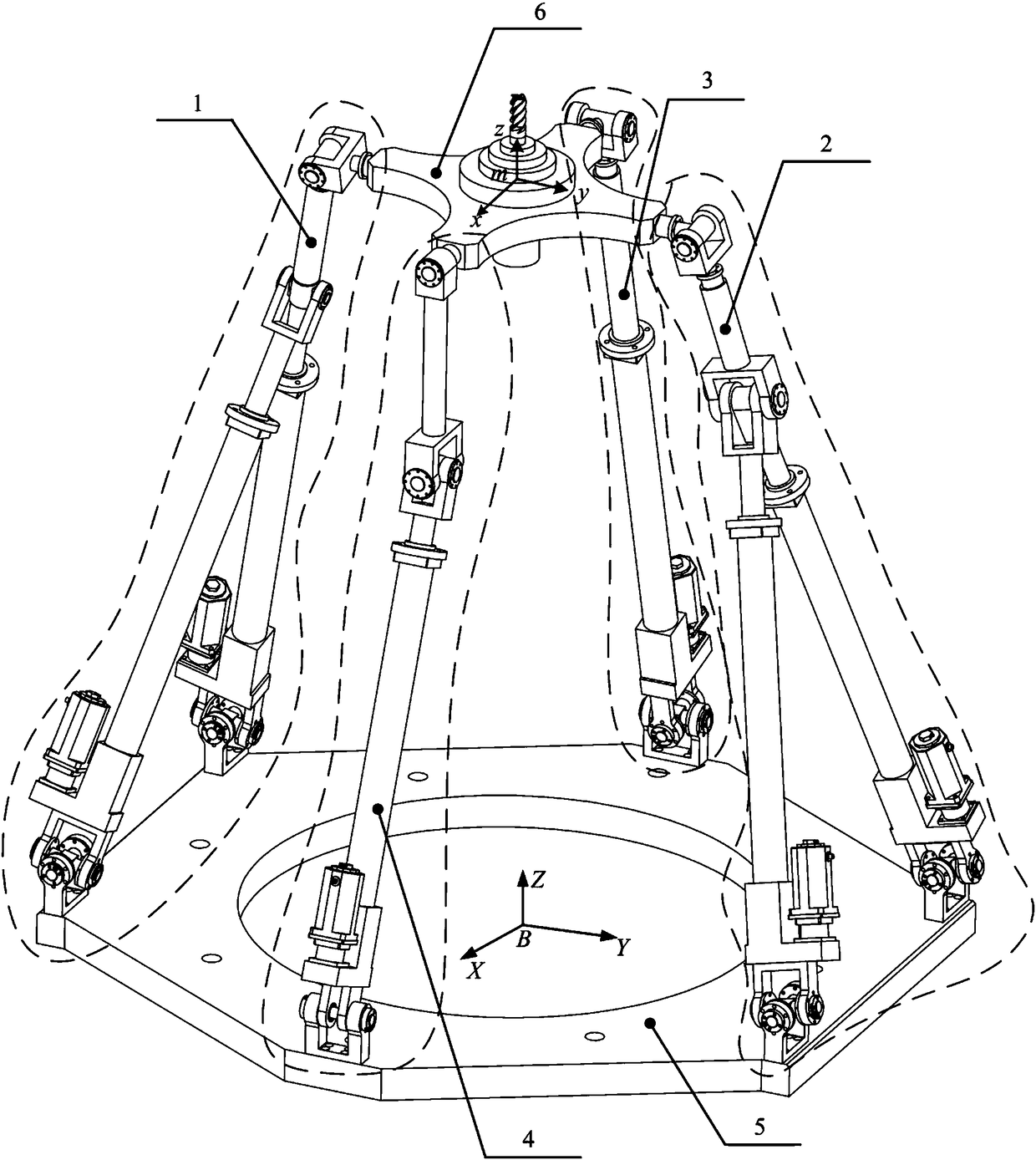

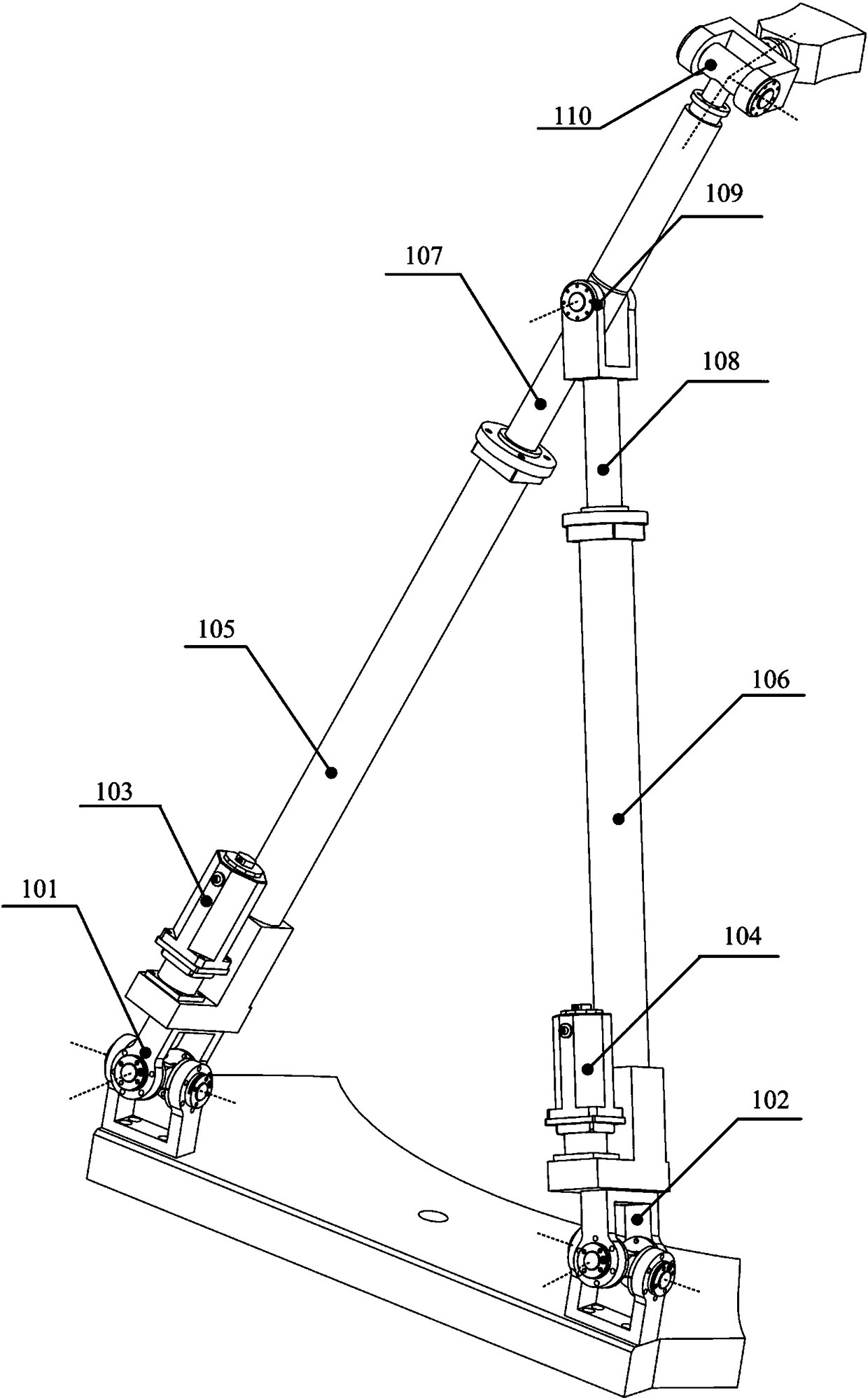

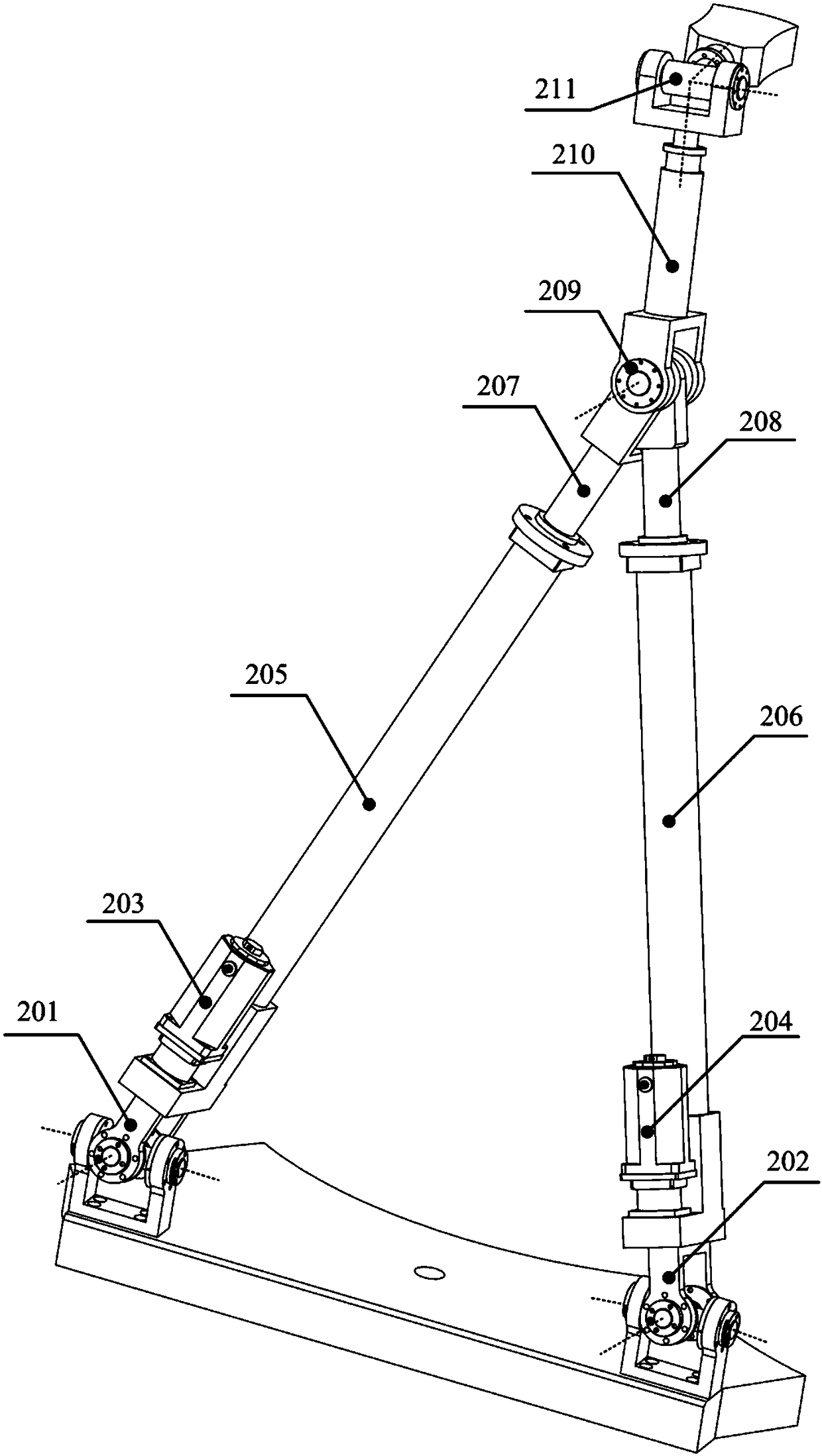

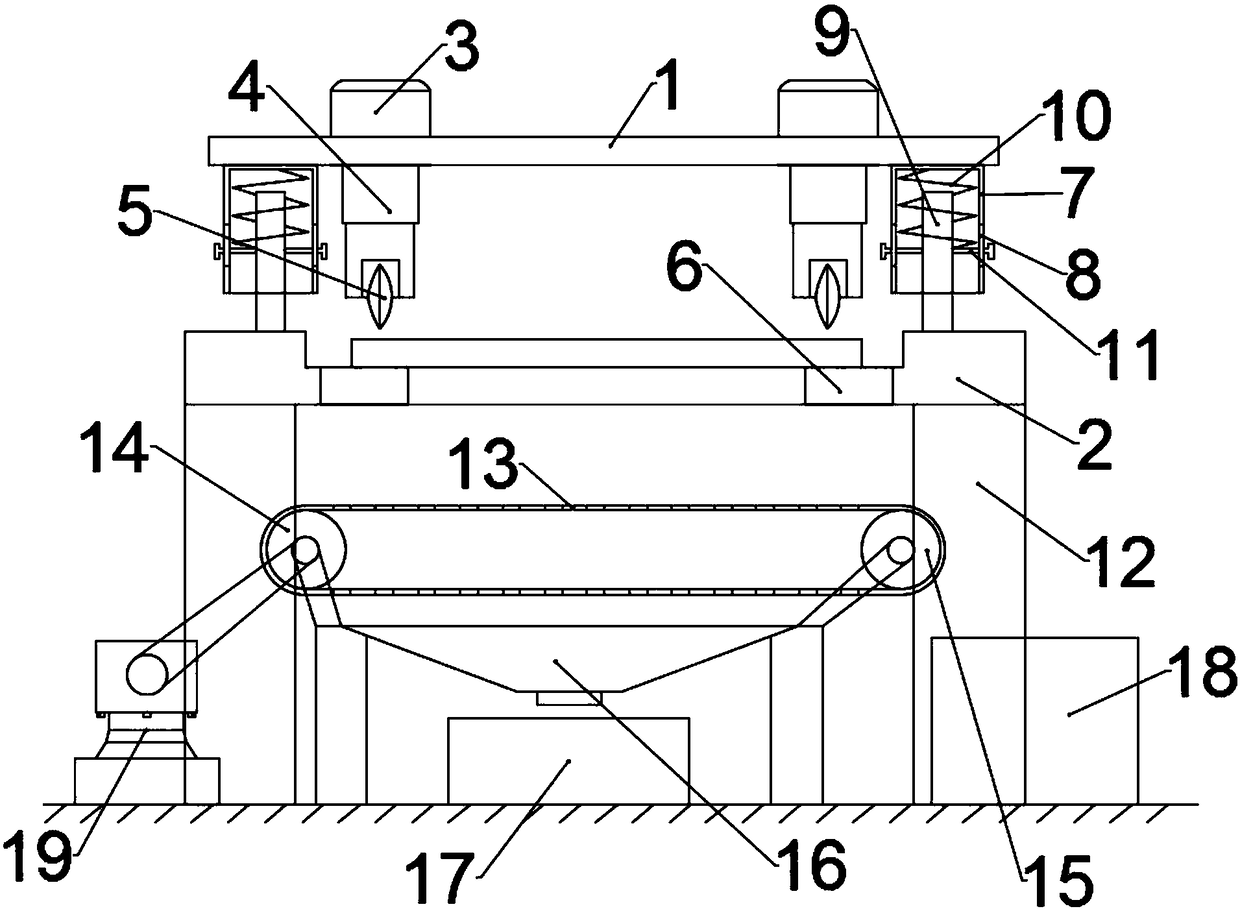

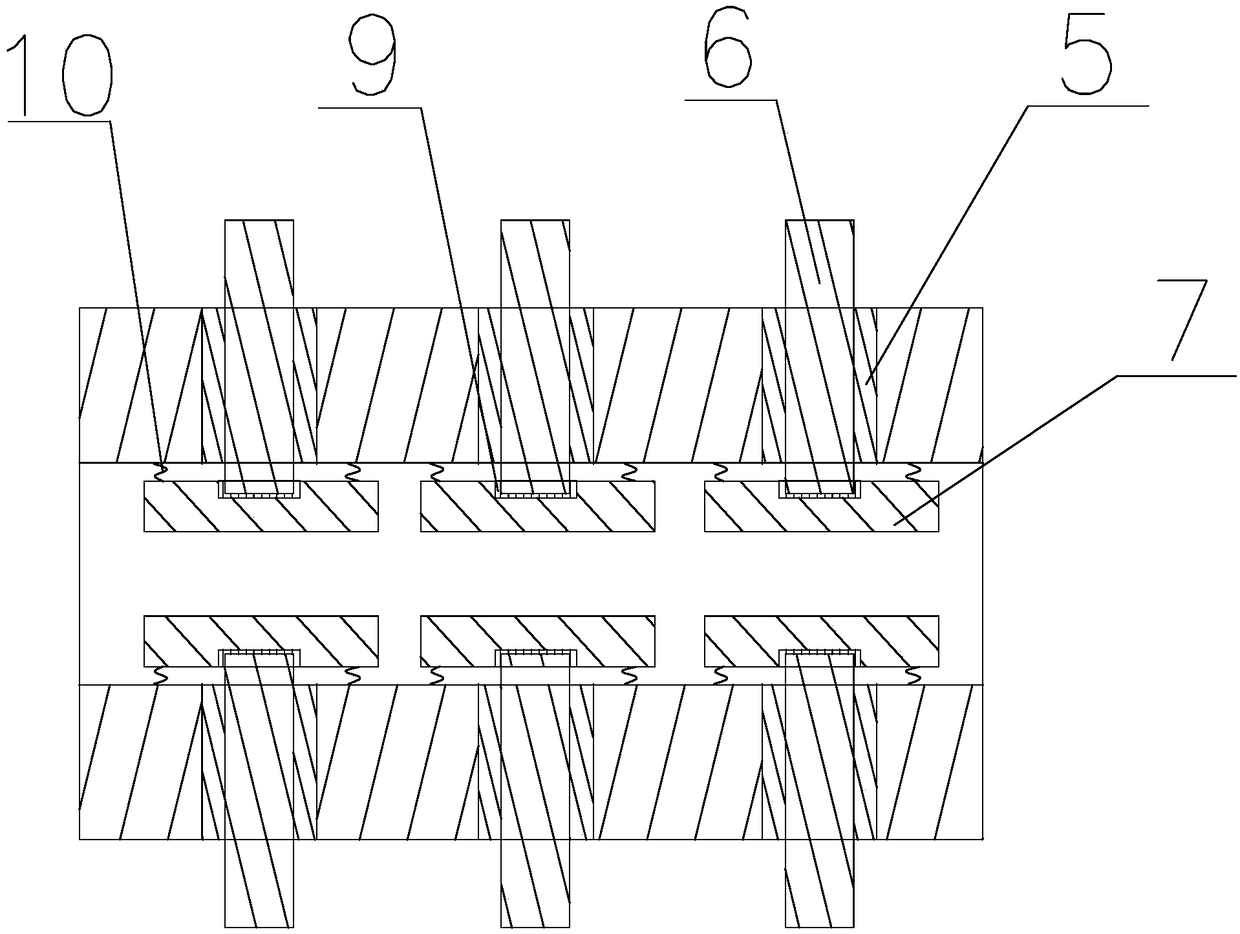

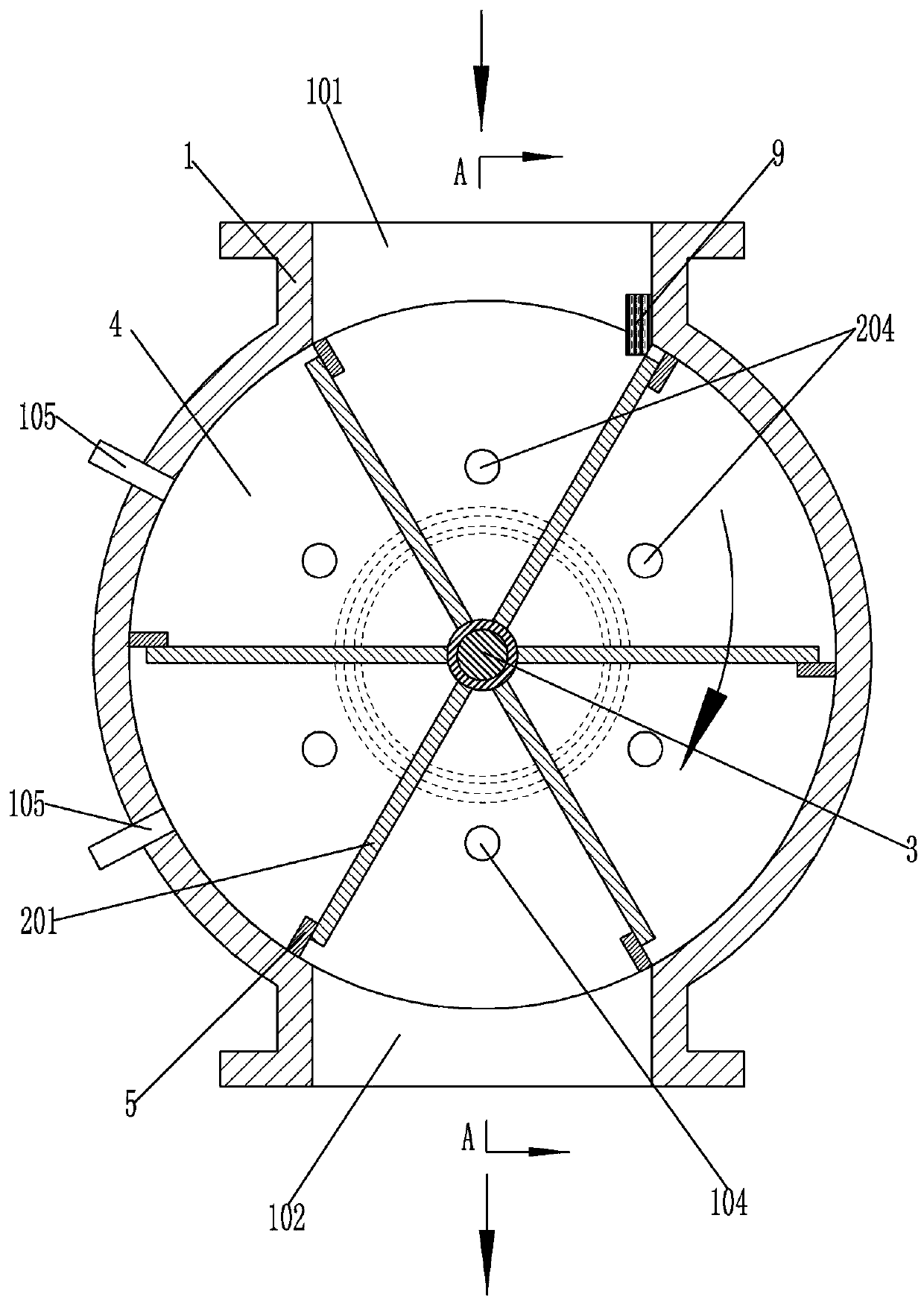

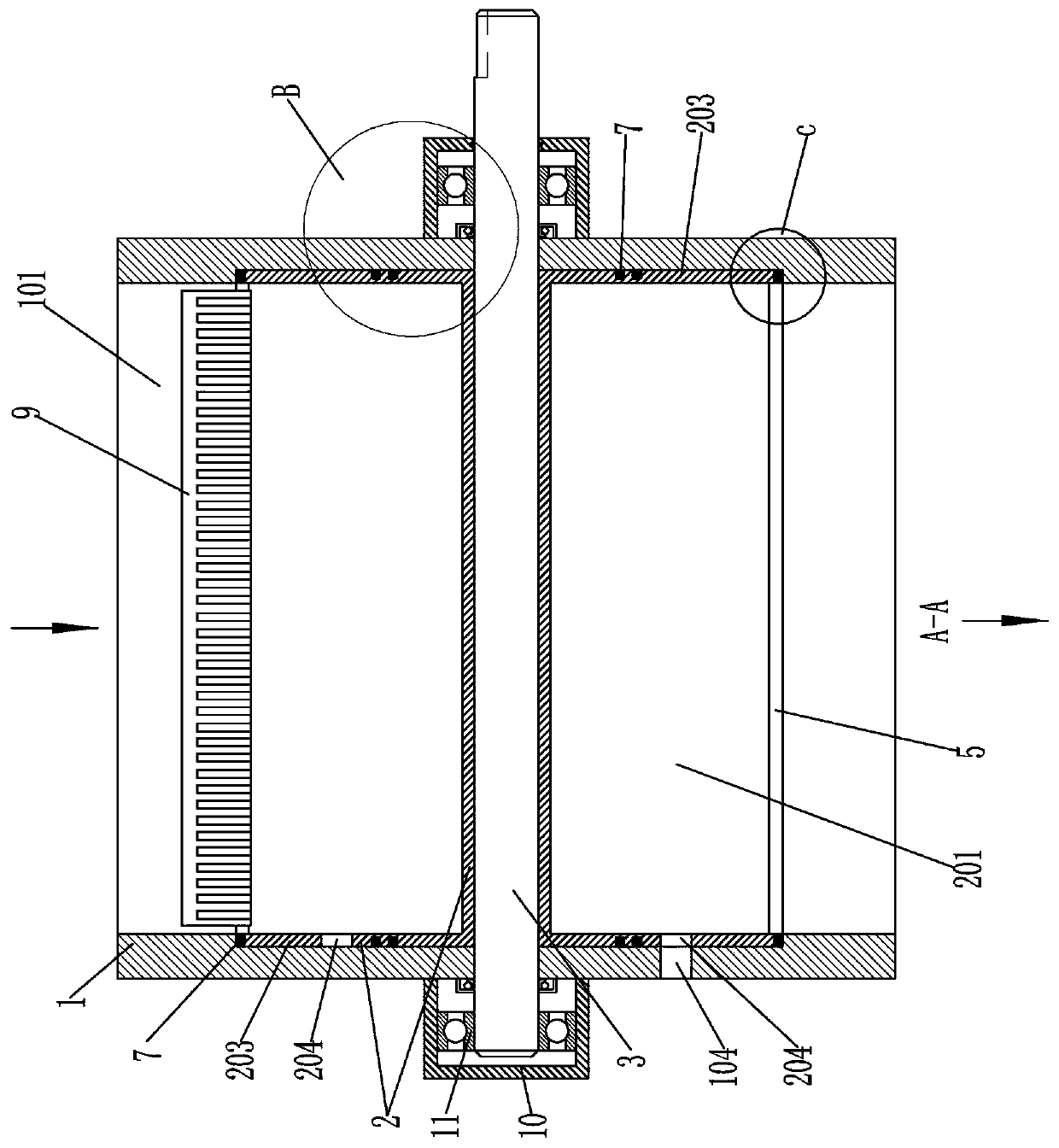

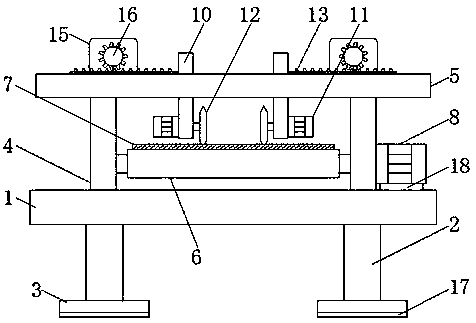

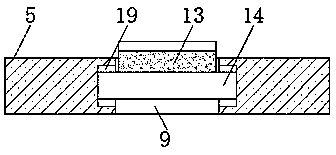

Redundant drive five degrees of freedom parallel machine tool with large rotation angle

InactiveCN108161490AHigh positioning accuracySolve processing problemsProgramme-controlled manipulatorLarge fixed membersTurn angleFree form

The invention relates to a redundant drive five degrees of freedom parallel machine tool with a large rotation angle. The redundant drive five degrees of freedom parallel machine tool with the large rotation angle includes a fixed platform, a movable platform for installing a main shaft head and a first driving branch, a second driving branch, a third driving branch and a fourth driving branch forconnecting the fixed platform and the movable platform, the structures of the first driving branch and the second driving branch are similar, and the first driving branch includes a hooke hinge, a servo driving unit, a revolute pair and a compound sphere hinge; the third driving branch includes a hooke hinge, a servo driving unit and a compound sphere hinge, the fourth driving branch includes a revolute pair, a servo driving unit, a hooke hinge and a revolute pair, and the movable platform of a machine tool and the four driving branches are hinged to form a space closed-cycle parallel mechanism; and the three-dimensional translation and the two-dimensional rotation of the space can be achieved by controlling six servo motors to drive the four branches. The redundant drive five degrees offreedom parallel machine tool with the large rotation angle has the advantages that the branch structures are simple and compact, the orientation workspace is large, the flexibility is high, the rigidity is large, and the singular configuration can be prevented, and can be used for high-speed, high-precision and efficiency machining for free-form surface in complex space.

Owner:BEIJING JIAOTONG UNIV

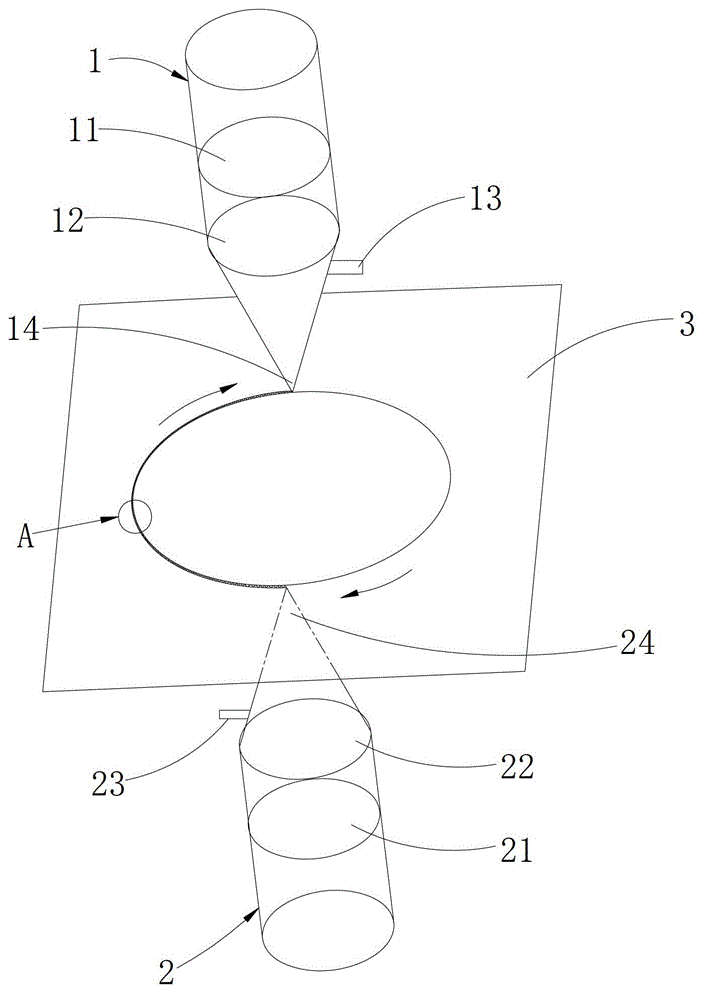

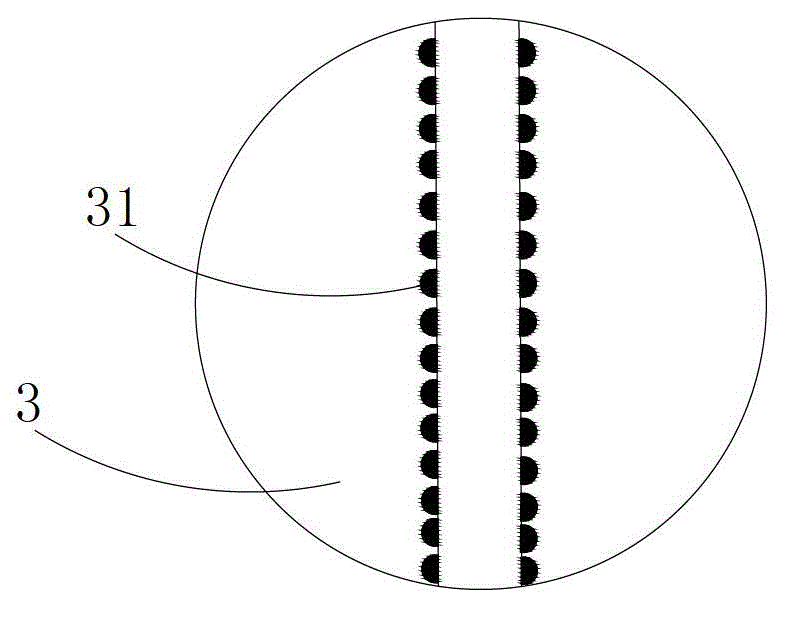

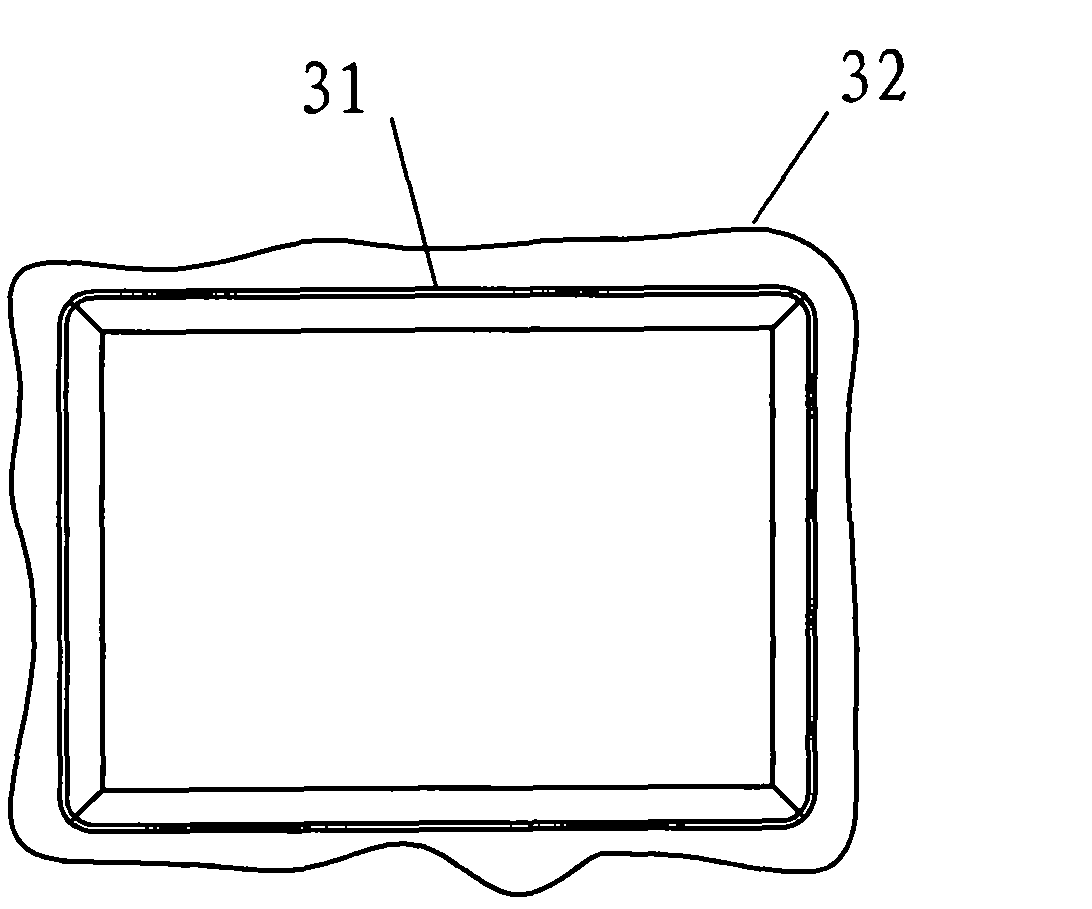

Laser processing method and laser cutting systems of high molecular workpieces

ActiveCN104014936AEfficient removalGuaranteed cutting efficiencyLaser beam welding apparatusLaser processingBeam splitter

The invention belongs to the technical field of laser processing, and discloses a laser processing method of high molecular workpieces. Two laser cutting heads irradiate the workpieces with two laser beams with different power values, the high-power laser beam moves along a processing track of the workpieces to cut the workpieces by a certain distance, and then the low-power laser beam moves along the processing track of the high-power laser beam for cutting. The invention further discloses two laser cutting systems for realizing the laser processing method, one laser cutting system comprises two laser oscillators, two laser drivers, two industrial personal computers and the two laser cutting heads, and the high-power laser beam and the low-power laser beam can independently controlled to be transmitted; the other laser cutting system comprises a laser oscillator, a laser driver, an industrial personal computer, the two laser cutting heads and a beam splitter used for splitting a laser beam transmitted by the laser oscillator to a high-power laser beam and a low-power laser beam.

Owner:HANS LASER TECH IND GRP CO LTD

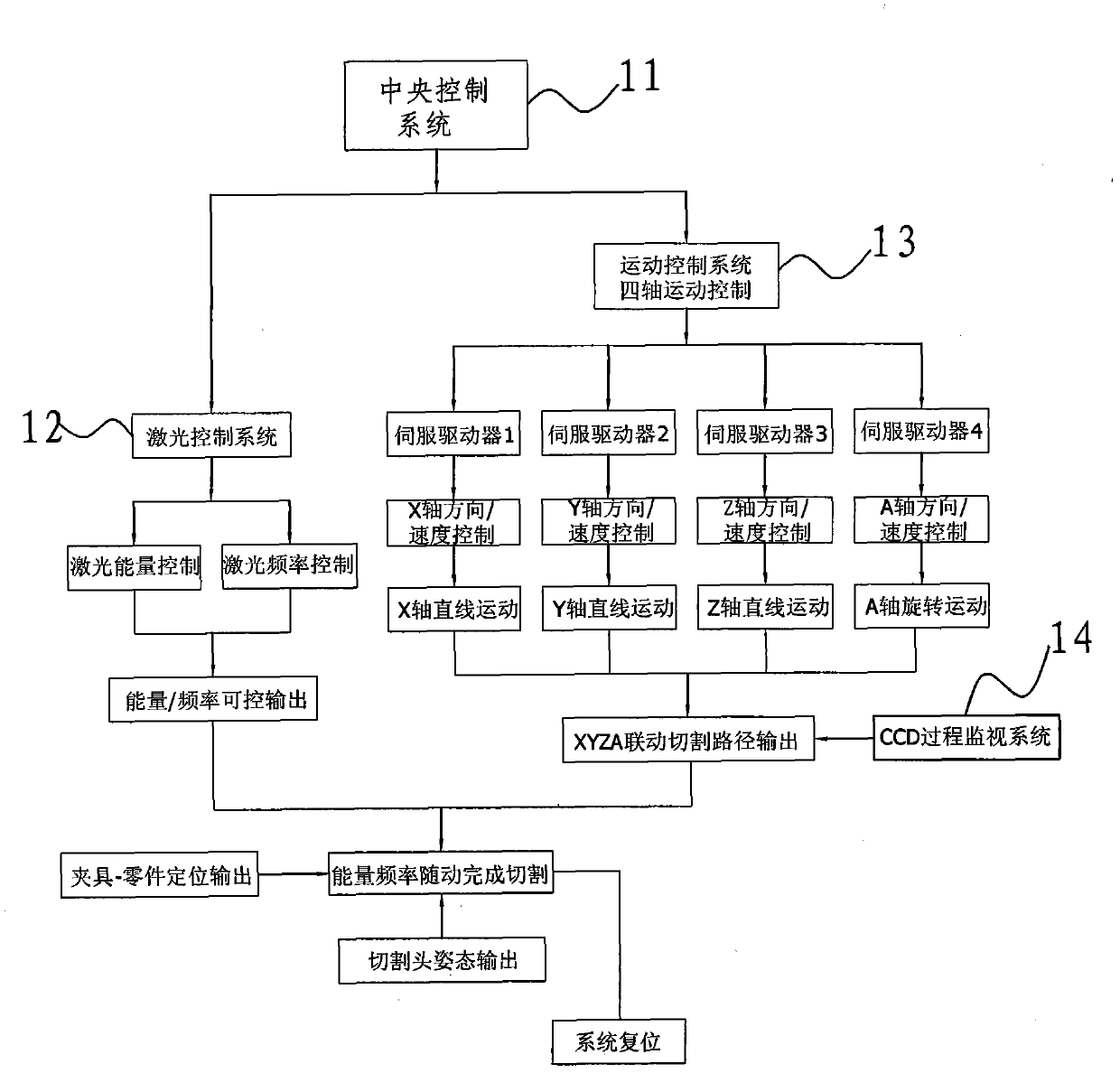

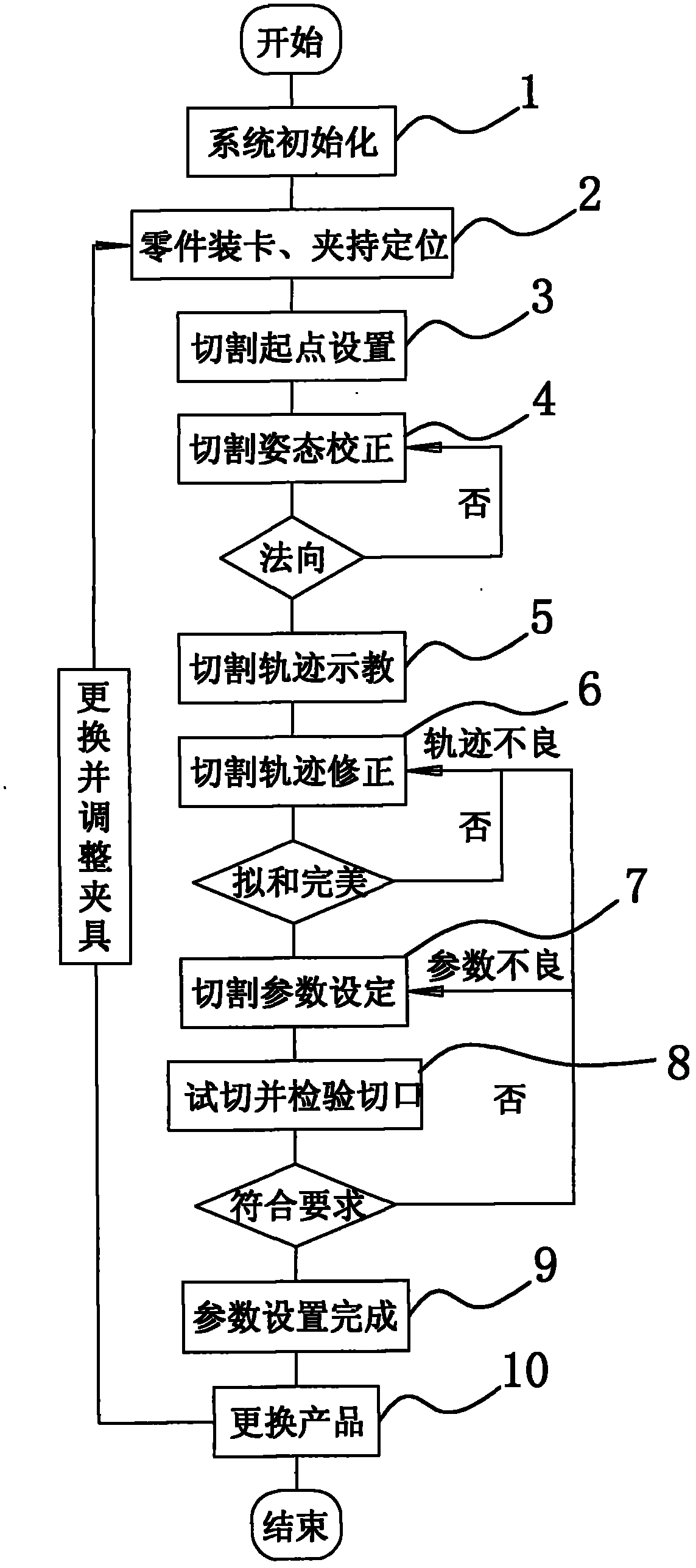

Laser cutting method

InactiveCN102000916ALower requirementGuaranteed continuityLaser beam welding apparatusNumerical controlEngineering

The invention provides a laser cutting method, in particular to a method for removing a water gap of an injection molding and a water gap of a film-covering piece by adopting a cutting path employing teaching programming and related program recording method. The teaching programming method comprises the following steps of: gradually recording the postures and the instant speeds of cutting heads on a curve one by one; associating the data to form continuous cutting motion; and teaching and storing a whole cutting path as a CNC (Computerized Numerical Control) program, wherein regular curves are used for teaching according to the characteristics, and irregular curves are used for teaching by adopting a short line segment fitting method. In the invention, by adopting a mode of controlling the motion of a worktable and the frequency and the energy of laser through program and a working mode of normal cutting, the requirement for operators can be lowered, meanwhile, the processing constancy and the joining continuity between a notch and an arc are ensured, the cutting quality is improved and the application range of laser cutting is further enlarged.

Owner:HANS LASER TECH IND GRP CO LTD

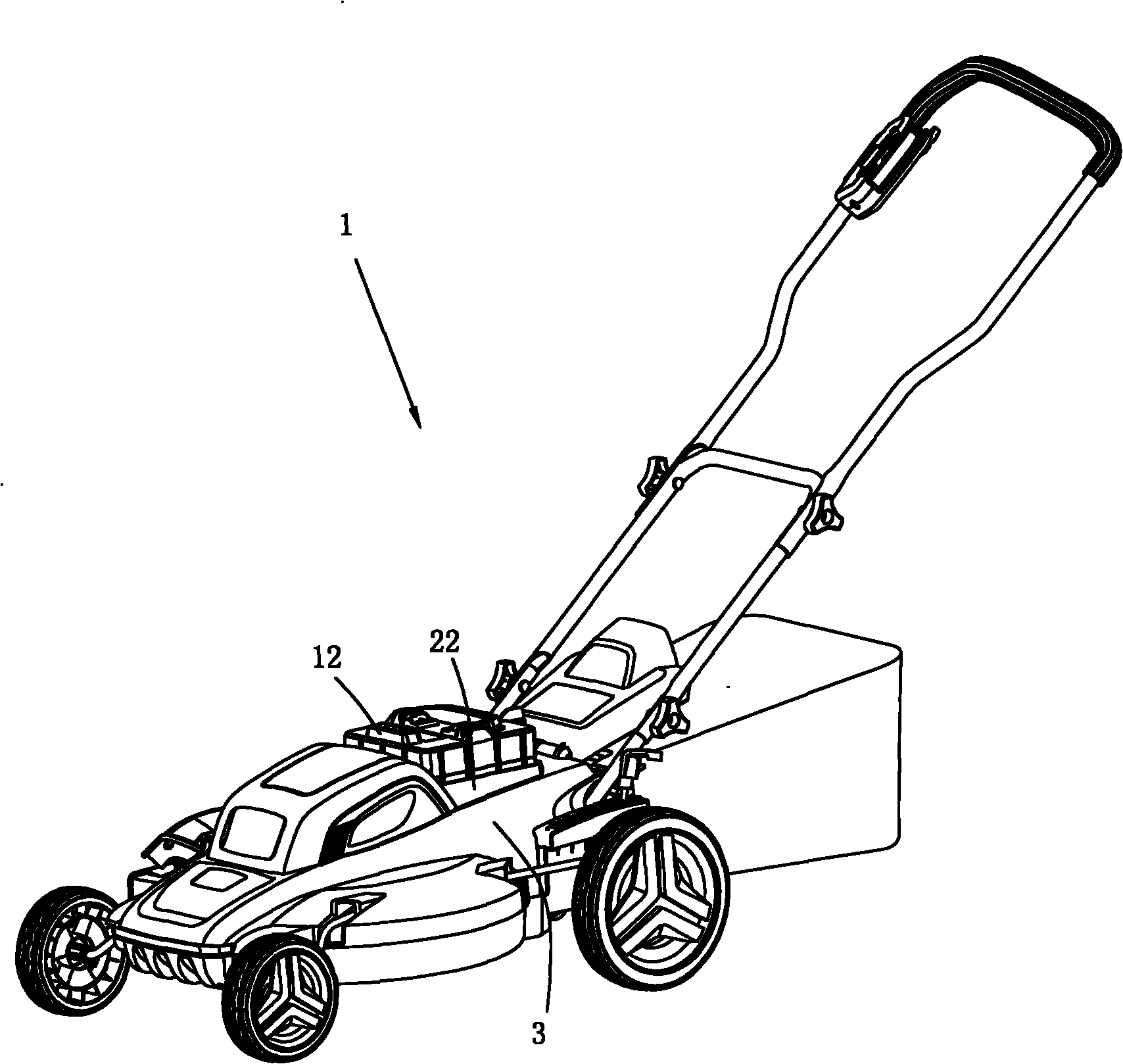

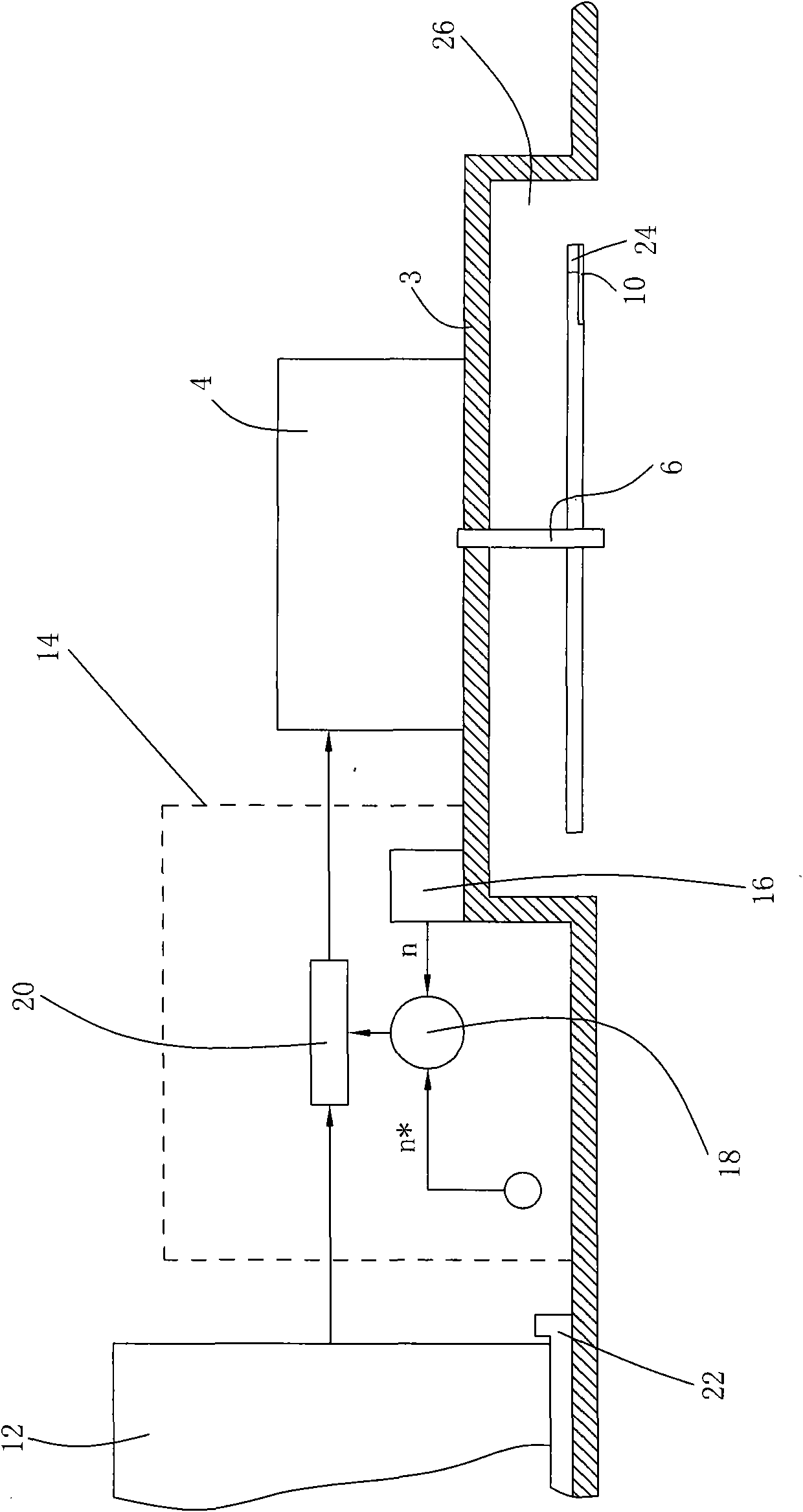

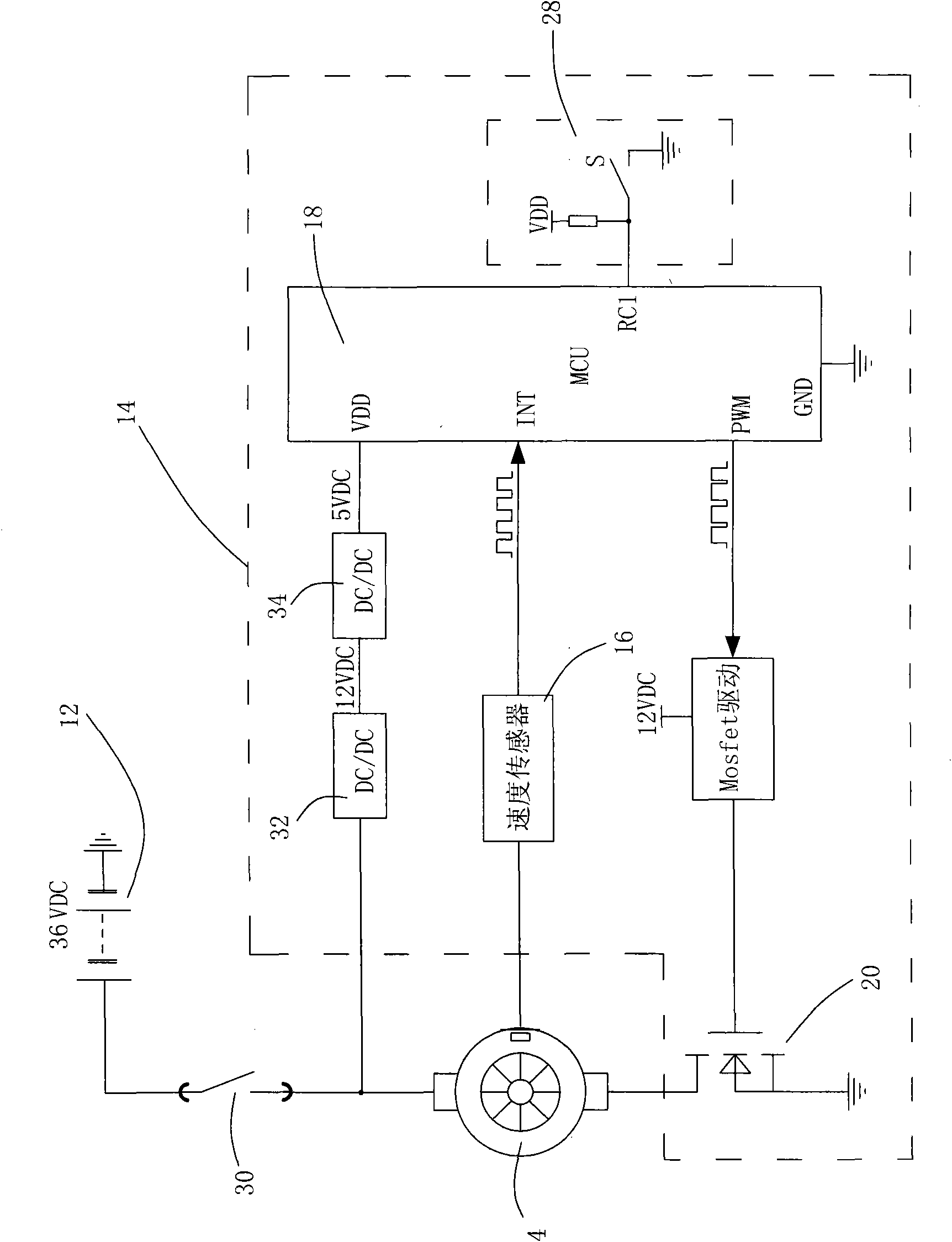

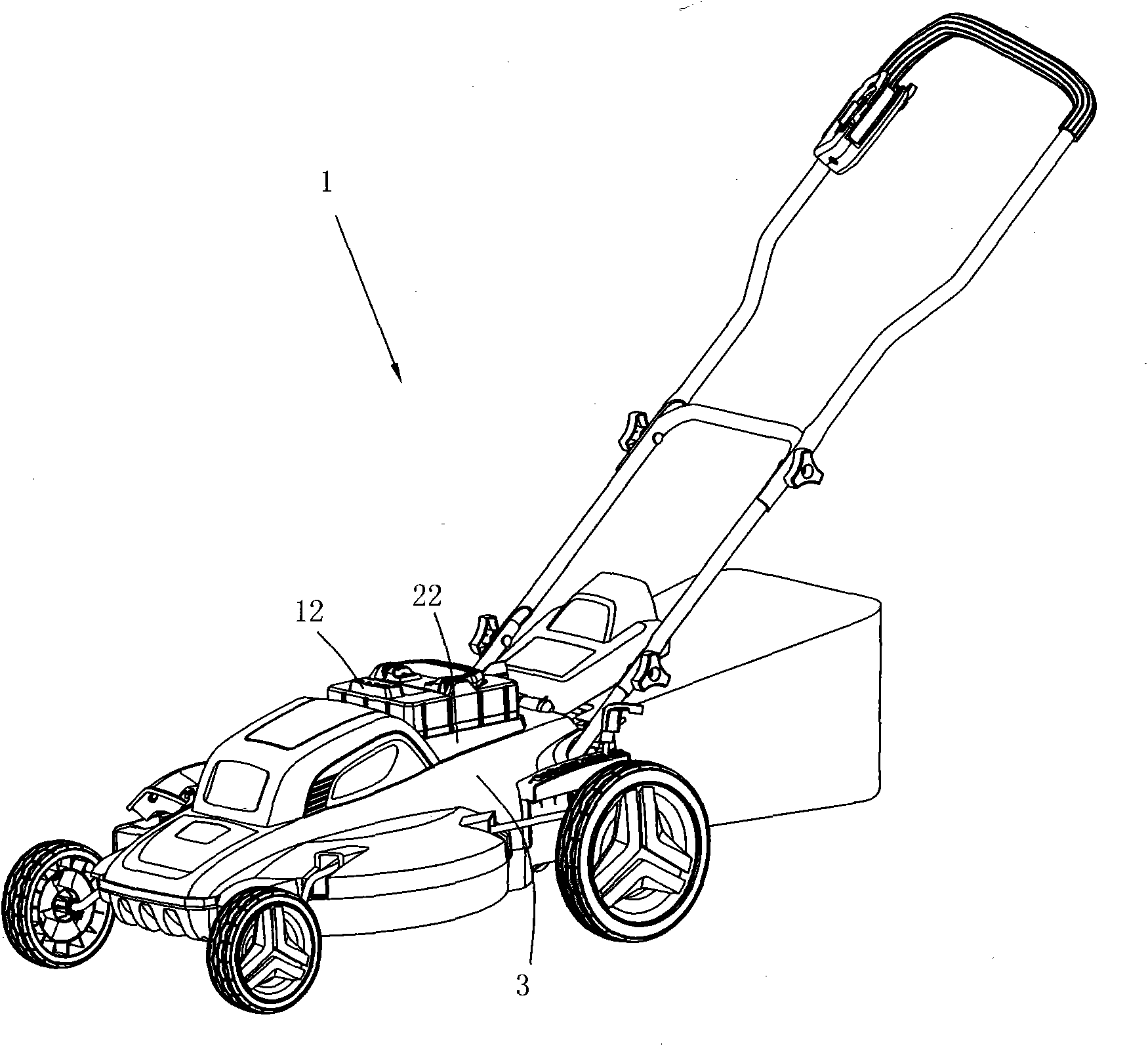

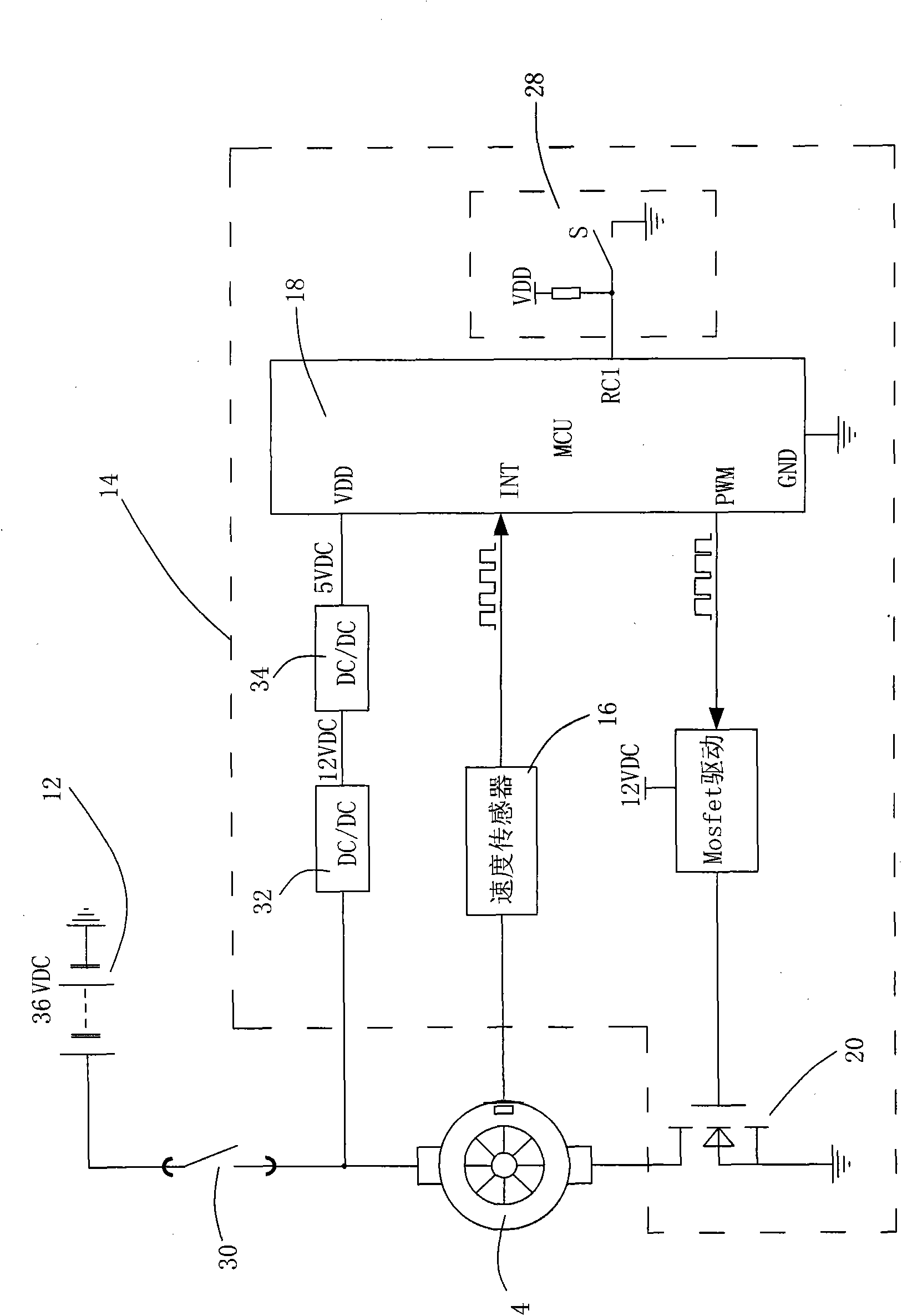

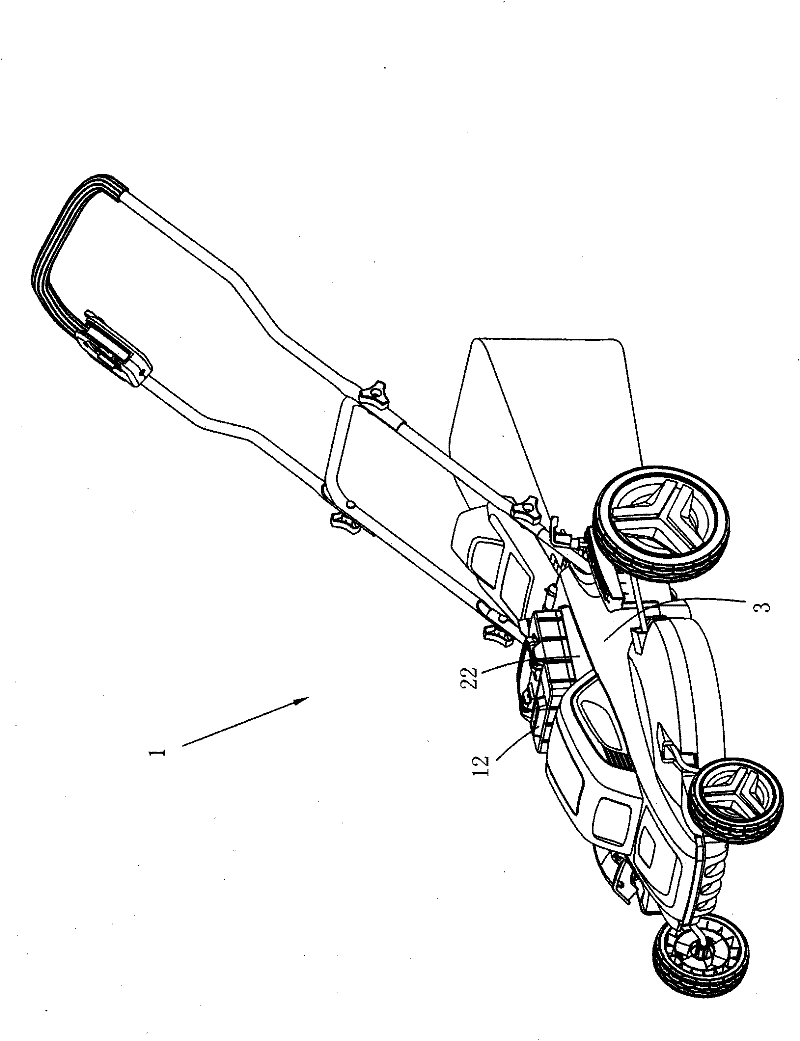

Mower

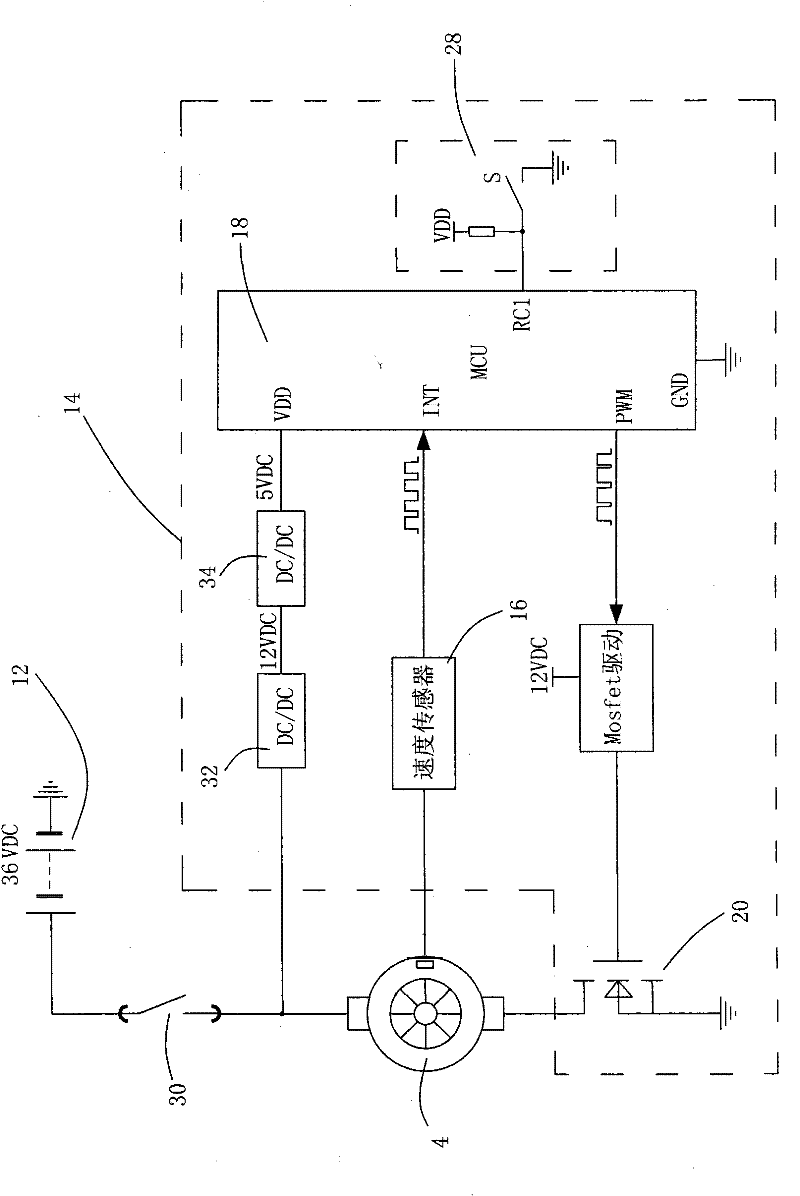

InactiveCN102057800AGuaranteed cutting efficiencyReduce noiseDC motor speed/torque controlMowersElectrical batteryMotor shaft

The invention discloses a mower which comprises a shell, a direct current motor, a blade, a battery and a speed control device, wherein the direct current motor is connected on the shell; the direct current motor is provided with a motor shaft; the blade is used for mowing, is connected on the motor shaft, and is provided with at least one cutting edge; the battery is installed in the shell, provides energy for the direct current motor when the mower works, thus driving the blade to rotate at a cutting speed; and the speed control device is used for optionally fixing the cutting speed to at least one presupposed permanent speed.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Mowing machine

InactiveCN102084754AGuaranteed cutting efficiencyReduce noiseDC motor speed/torque controlElectric motor controlControl theoryMotor shaft

The invention discloses a mowing machine which comprises a shell, a motor, a blade, a power providing device and a speed controlling device, wherein the motor is connected to the shell and is provided with a motor shaft; the blade is used for mowing grass and is connected to the motor shaft and provided with at least one cutting edge; the power providing device provides energy for the motor when the mowing machine works so as to drive the blade to rotate at a cutting speed; and the speed controlling device can be used for selectively fixing the cutting speed on at least one preset constant speed.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

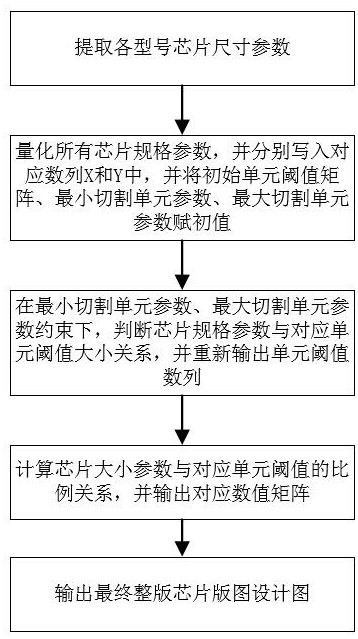

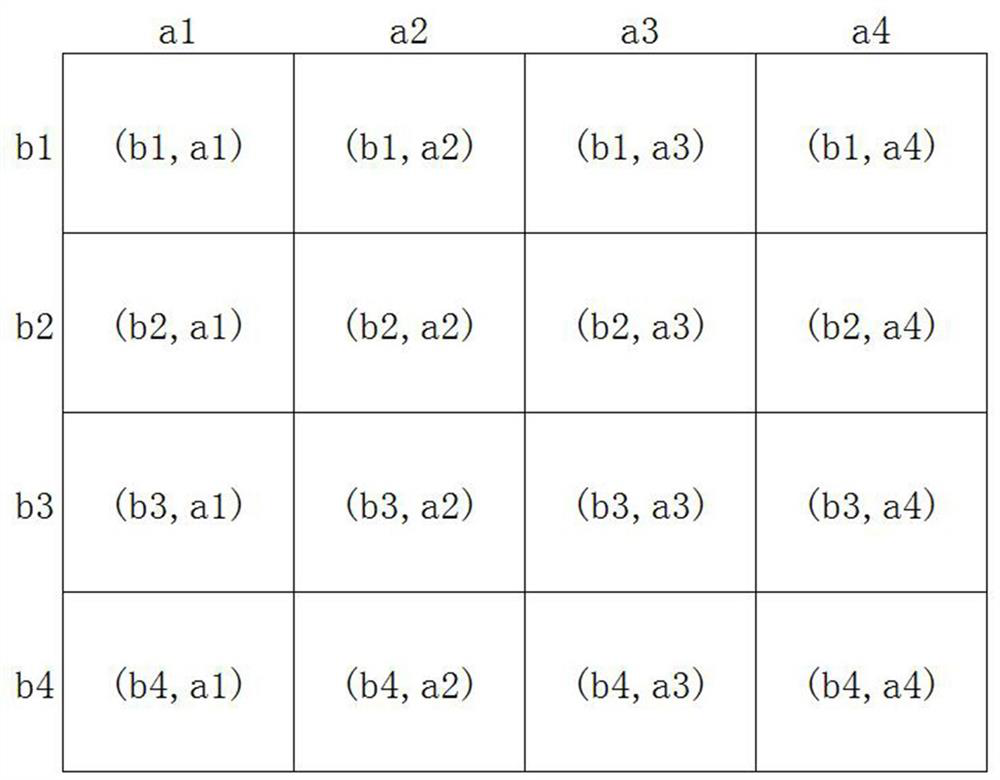

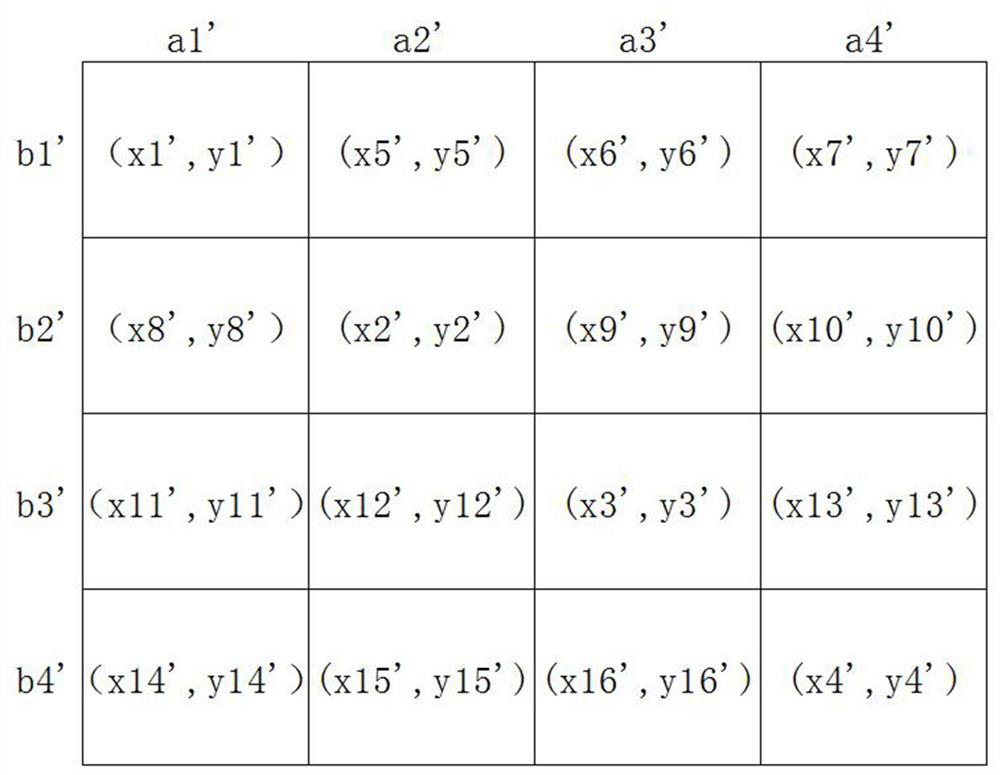

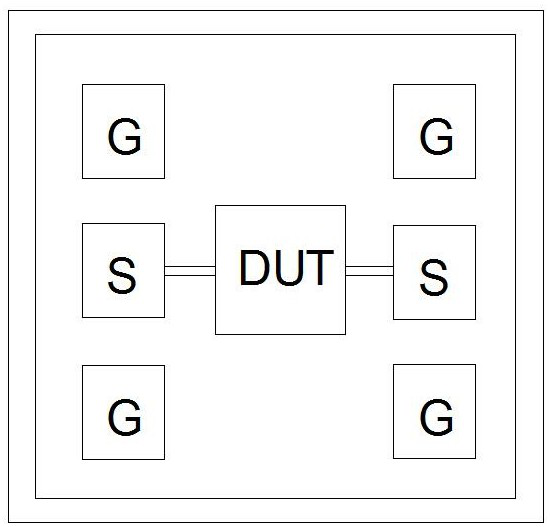

Layout design method of multi-model chip, chip prepared by layout design method and terminal

ActiveCN114548020ADesign flexible adjustmentEfficient outputSolid-state devicesComputer aided designChip sizeLayout

The invention discloses a layout design method of a multi-model chip and a chip and a terminal prepared by the layout design method, and belongs to the technical field of semiconductors, and the layout design method comprises the following steps: obtaining size parameters of each model of chip and initial values of each parameter quantity; under the constraint of the maximum cutting unit parameter and the minimum cutting unit parameter, the size relation between the chip size parameter and the corresponding initial unit threshold value is judged, and the chip unit threshold value is adjusted; and calculating a proportional relation between the threshold value of the corresponding chip unit and the chip size parameter, and outputting a layout design drawing. According to the method, the threshold values of the chip units are adjusted according to the sizes of the chips of different models, the whole layout can be quickly divided into a plurality of independent operation areas, then the proportional relation between the chips and the chip units is further calculated, the chips of the corresponding number are quickly arranged in the corresponding chip units, and in a certain threshold value range, the number of the chips is greatly reduced. The layout design can be simply, quickly and flexibly adjusted according to own chip design parameters of customers, and the layout design drawing is efficiently output.

Owner:成都复锦功率半导体技术发展有限公司

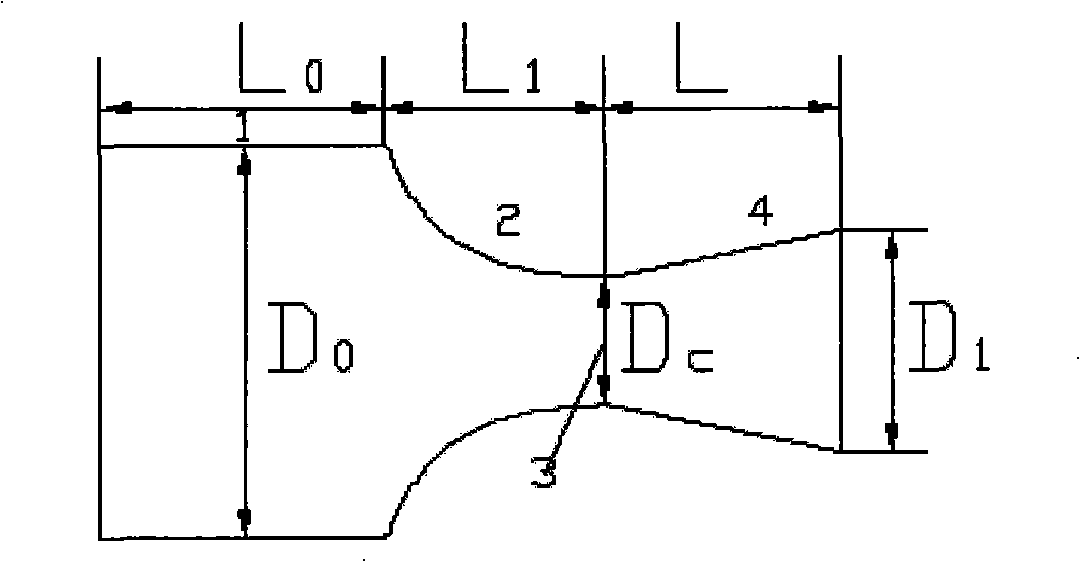

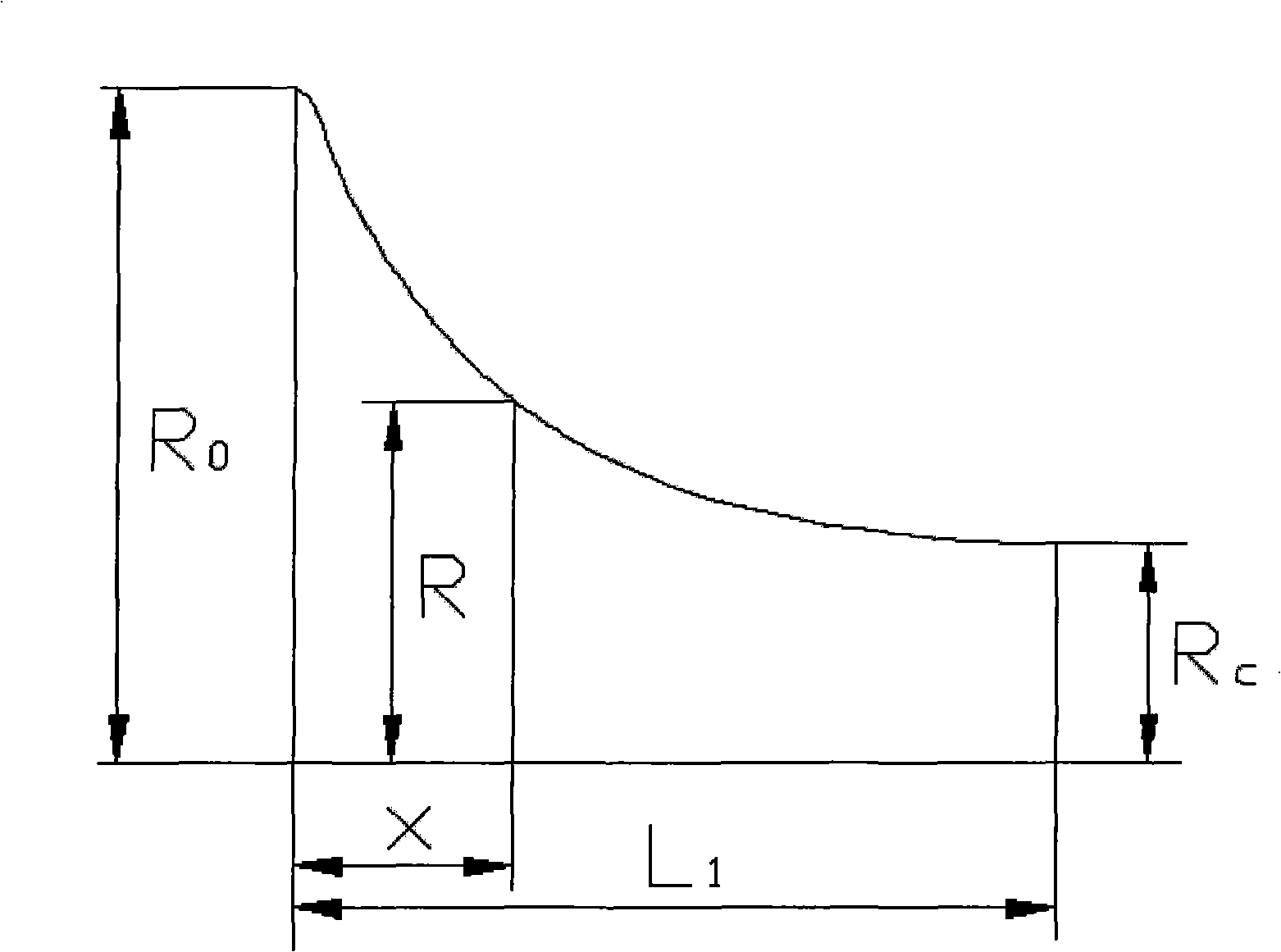

Simple fold line scaling supersonic nozzle for numerical control laser cutting

InactiveCN101284333AIncrease air velocityGuaranteed accuracyLaser beam welding apparatusNumerical controlMomentum

The invention relates to a simple broken-line scaling supersonic nozzle used for digital controlled laser cutting, which comprises a parallel segment, a shrinkage segment, a throat part and an extension segment. The extension part is a straight line segment; the ratio between the entry radius R0 of the shrinkage segment and the radius Rc of the throat part is determined by the entry mach number M0 of the shrinkage segment, the mach number Mc of the throat part and an aerothermodynamic factor K; the ratio between the exit radius R1 of the extension segment and the radius Rc of the throat part is determined by the exit mach number M1 of the extension segment, the mach number Mc of the throat part and the aerothermodynamic factor K; when R0 / Rc is equal to a constant, and R1 / Rc is equal to a constant, the exit mach number of the supersonic nozzle is kept as a fixed value under the action of gas pressure. When the supersonic nozzle conducts digital controlled laser cutting, the air stream sprayed from the nozzle is uniform, and the mass flow rate and the momentum are large, thereby effectively blowing off molten metal and other slag. Furthermore, the cut is narrow and tidy, without adhering slag staying on the edge of cutting seam, and the cutting quality and efficiency are obviously improved.

Owner:SHANGHAI JIAO TONG UNIV

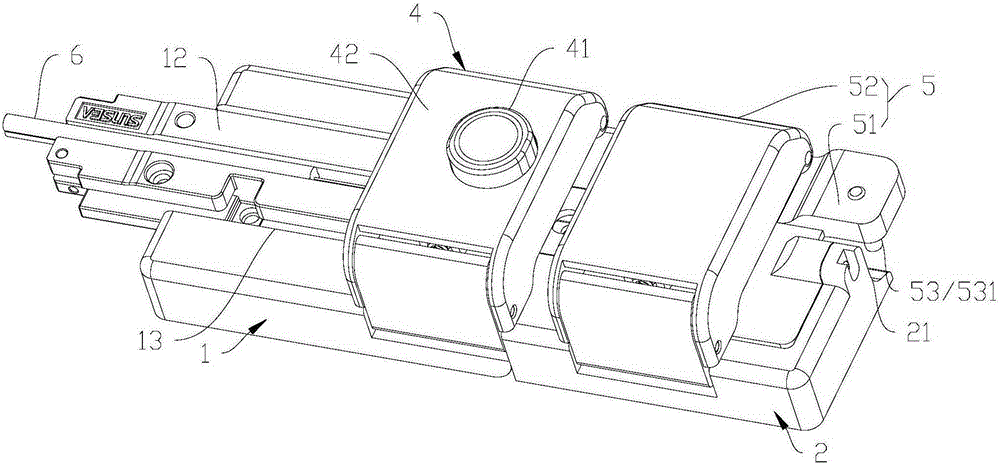

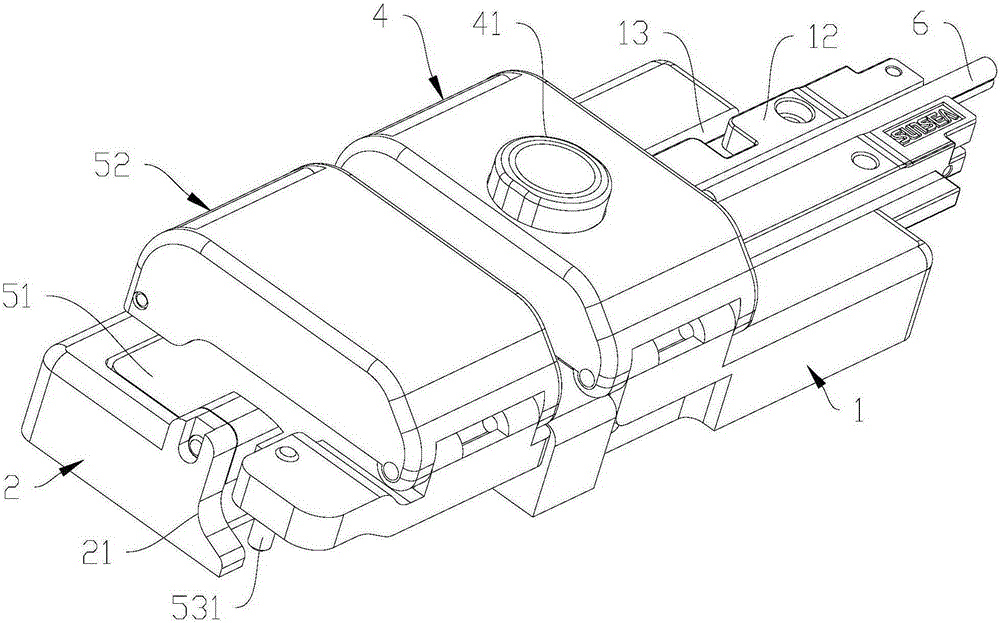

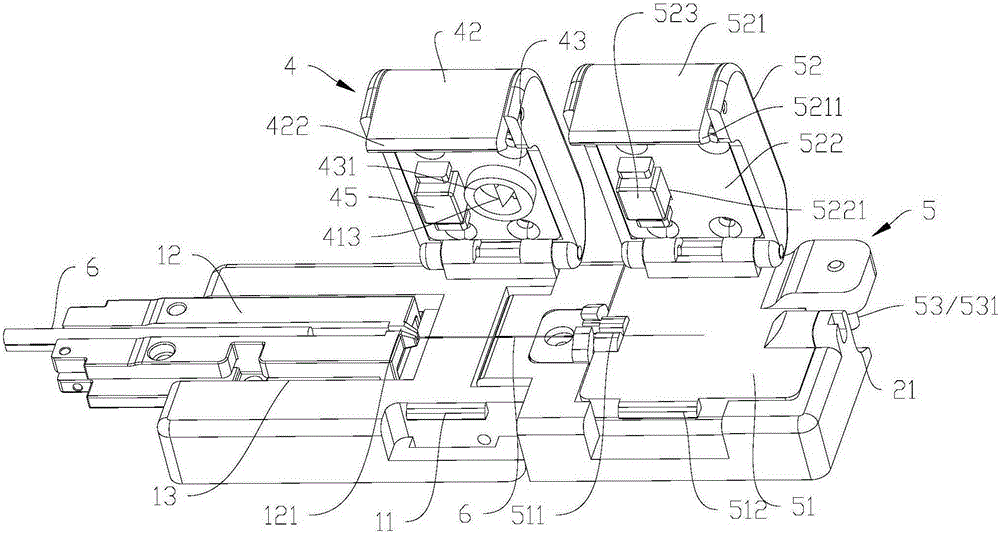

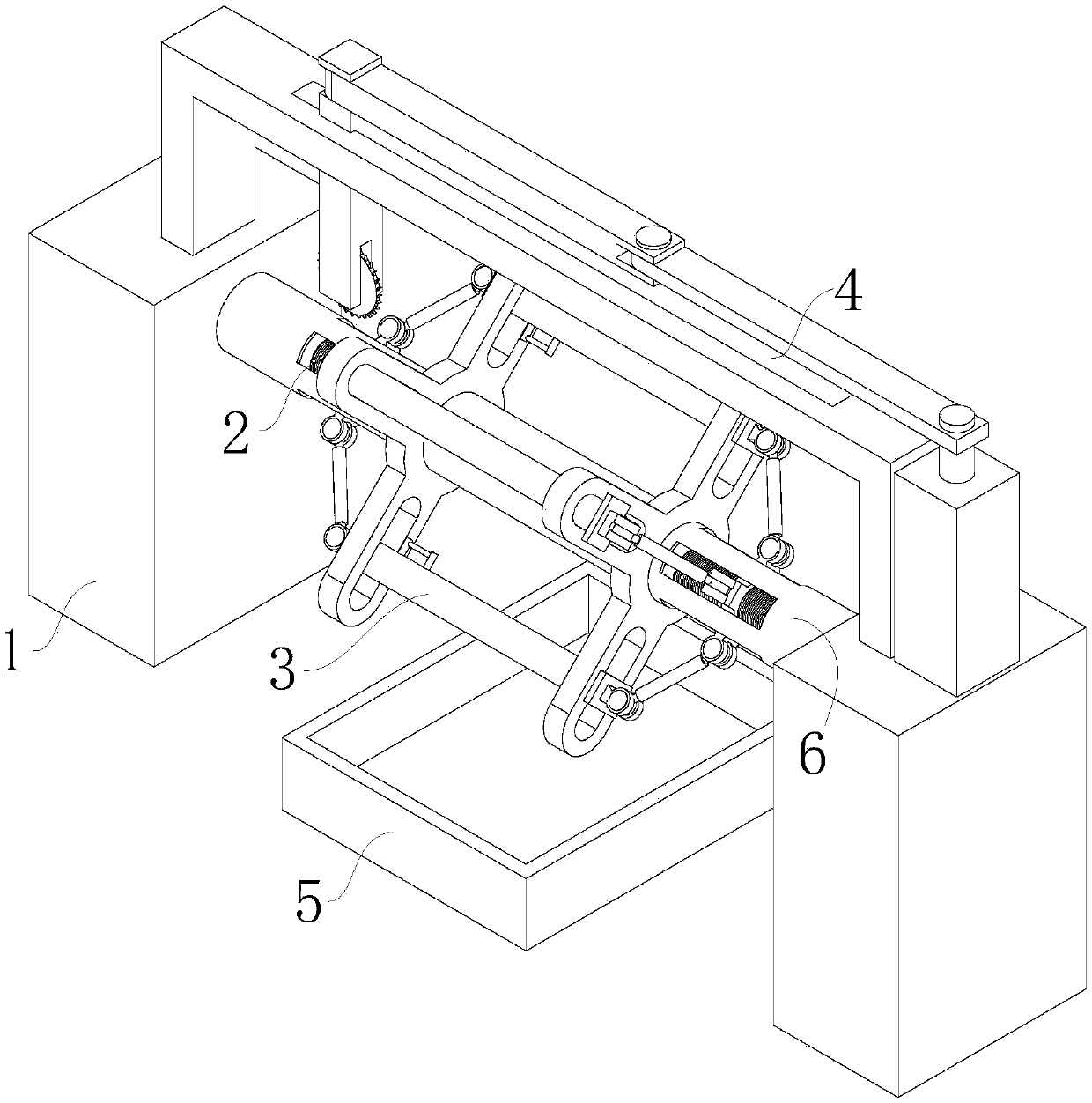

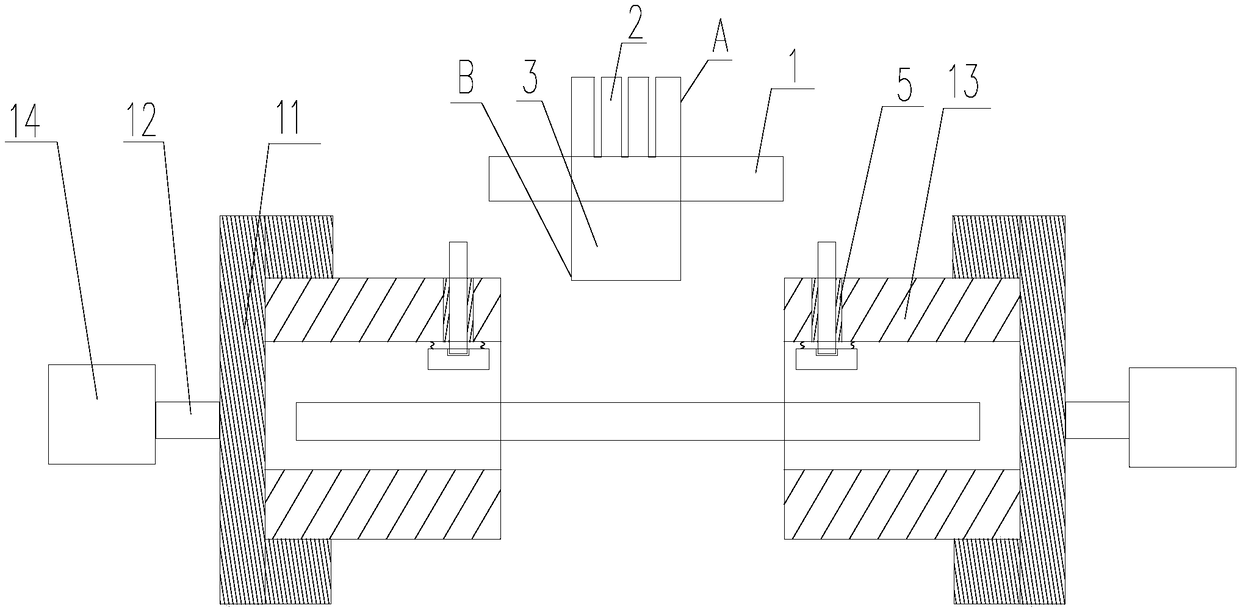

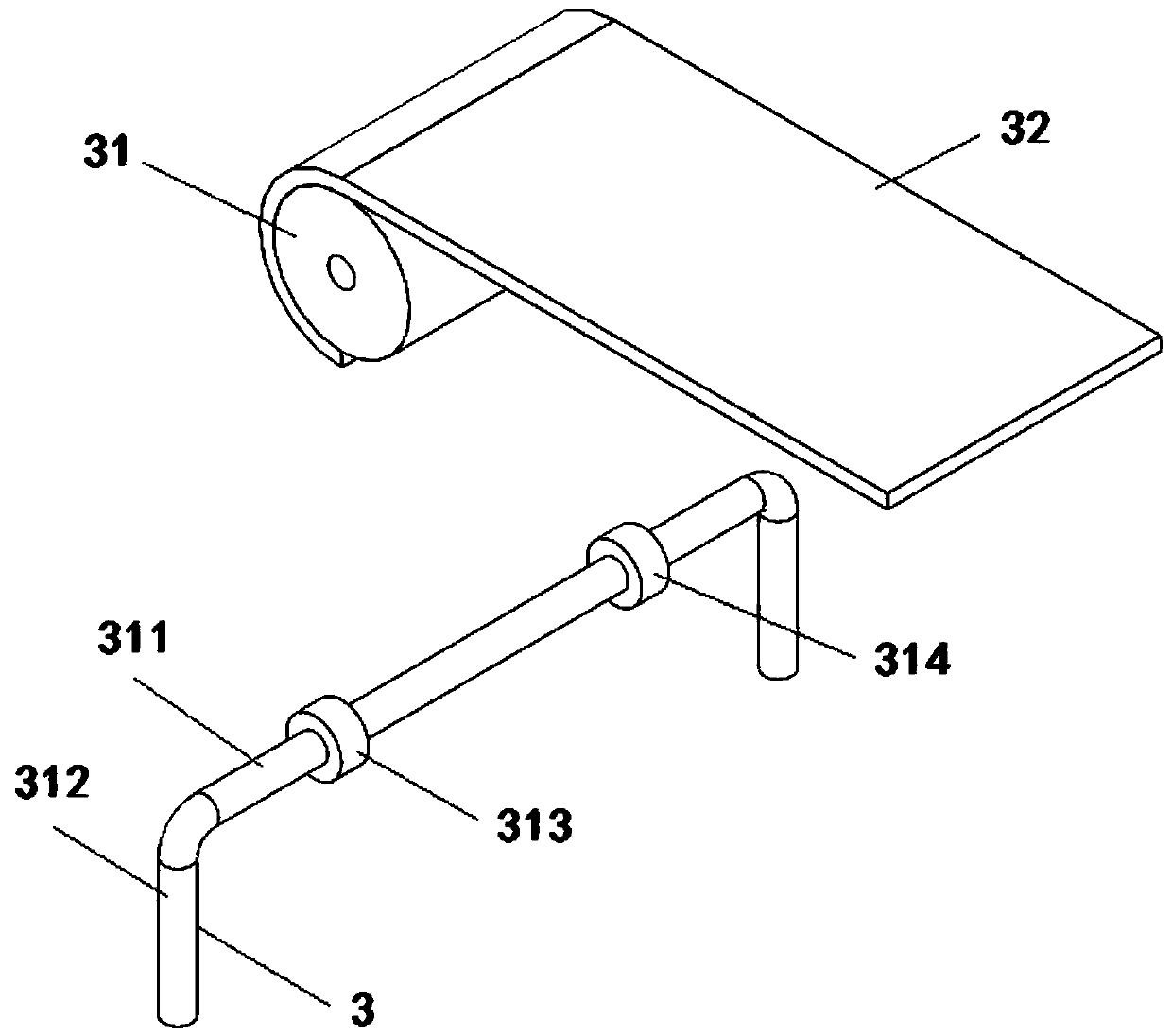

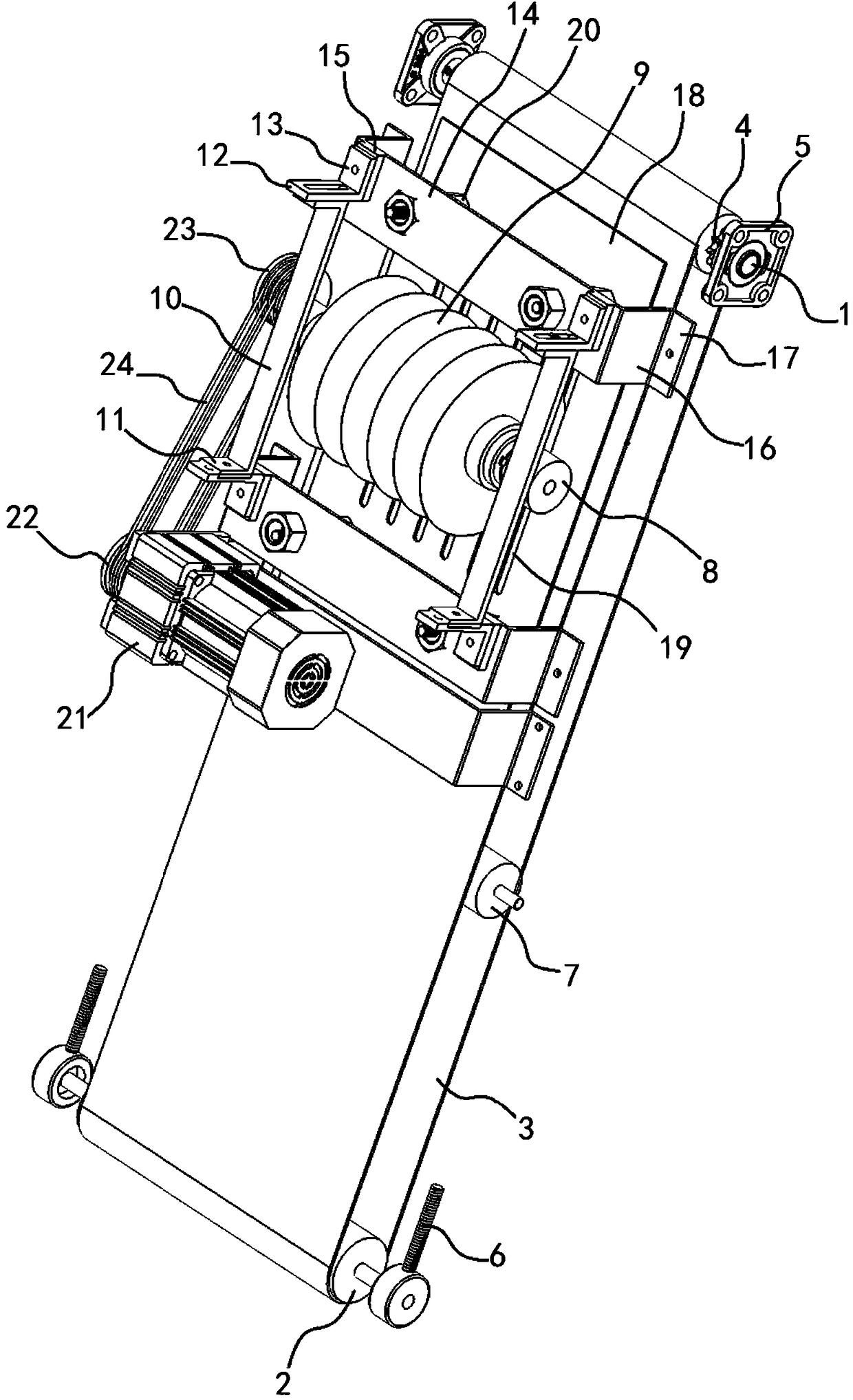

Optical fiber cutting device

ActiveCN105182472APrecise positioningGuaranteed cutting efficiencyCoupling light guidesEngineeringMechanical engineering

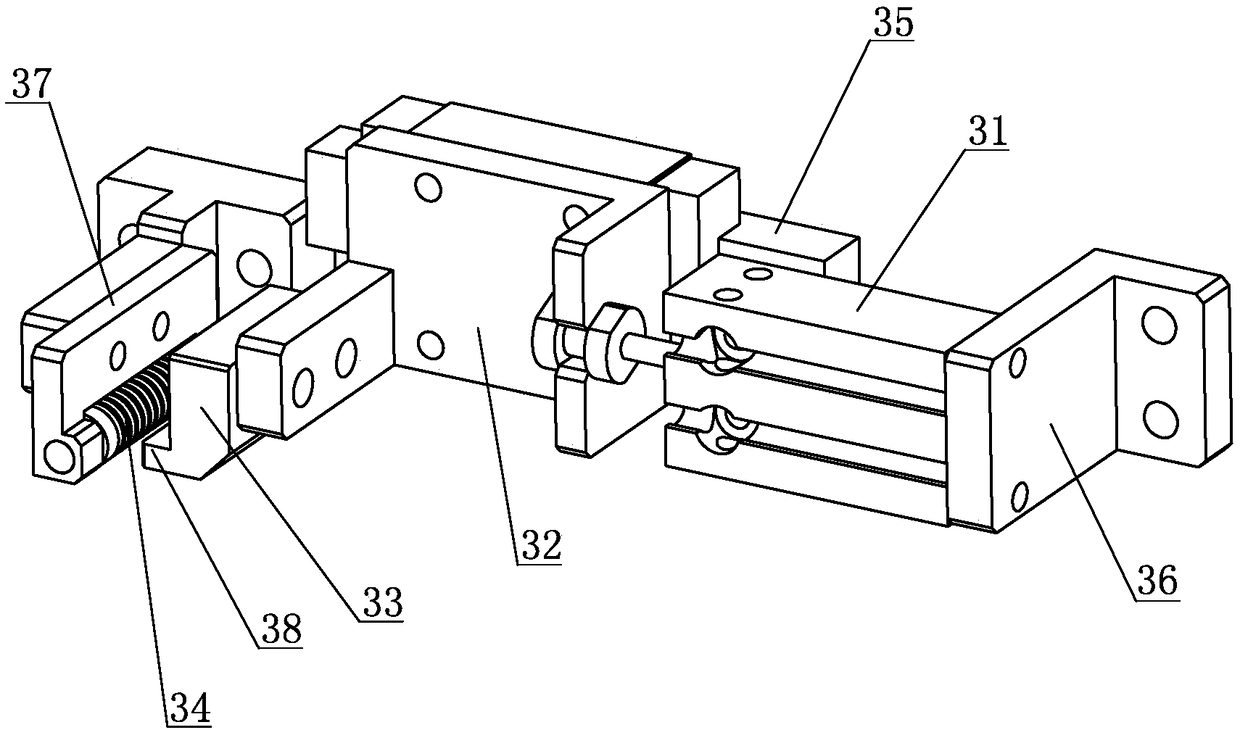

An optical fiber cutting device of the present invention comprises a substrate, a rotating base, a keeping mechanism, a first clamping unit, a cutter assembly and a second clamping unit. One end of the substrate is in hinge joint with one end of the rotating base mutually, and the keeping mechanism is arranged between the substrate and the rotating base to provide an action force for keeping the rotating base and the substrate parallel and level. The first clamping unit is arranged on the substrate and the second clamping unit is arranged on the rotating base to fix the to-be-cut optical fibers at the corresponding positions respectively, the cutter assembly is arranged on the first clamping unit to form shear marks on the to-be-cut optical fibers between the fixed positions of the first and second clamping units, and after the rotating base overturns and breaks the optical fibers, the keeping mechanism enables the rotating base to return automatically, thereby guaranteeing that the rotating base is positioned with the substrate accurately before and after rotation, and guaranteeing the cutting efficiency and the cutting precision.

Owner:SHENZHEN EPLU SCI TECH

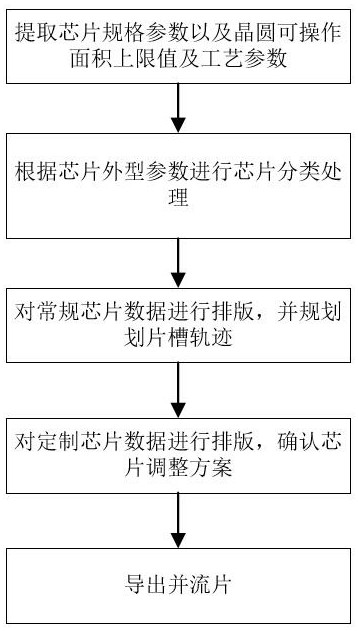

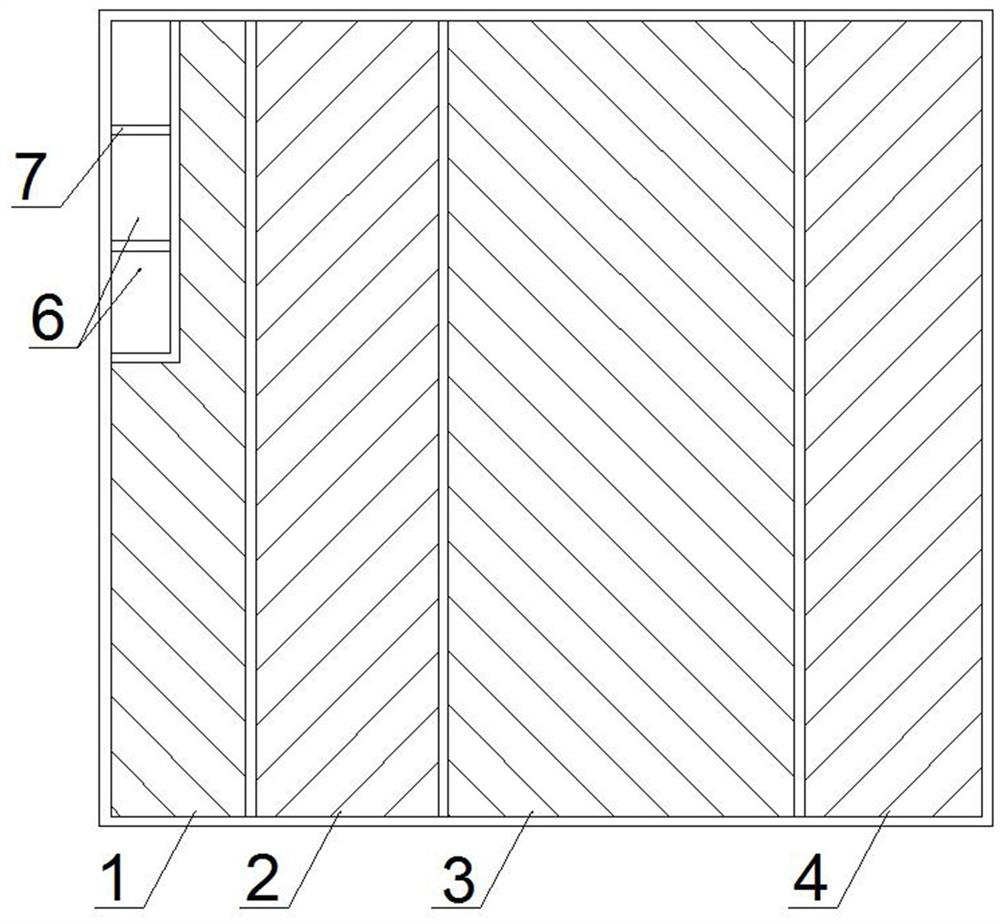

Cutting layout design method suitable for introducing customized chip and chip prepared by cutting layout design method

ActiveCN114548019AGuaranteed cutting efficiencyReduce the risk of secondary cuttingCAD customisation/personalisationSolid-state devicesProgramming languageLayout

The invention discloses a cutting layout design method suitable for introducing a customized chip and a chip prepared through the cutting layout design method, and belongs to the technical field of semiconductors. Chip classification processing is carried out according to chip appearance parameters, and conventional chip data and customized chip data are obtained; performing typesetting calculation according to the conventional chip data and the upper limit value of the operable area of the wafer, and outputting all layout design sketches with penetrating scribing grooves; and performing secondary design on the reserved position in the layout design sketch according to the customized chip data, and outputting a secondary layout design sketch. According to the method, a conventional chip is firstly subjected to typesetting design to obtain a layout design sketch penetrating through a scribing groove, so that the secondary cutting risk is greatly reduced; under the condition that the area is reserved, the scribing groove design of the customized chip is planned, the overall change of the layout design sketch is controlled within the minimum range, and the layout design sketch compatible with the customized chip is obtained on the basis that conventional chip layout is not affected, so that the layout cutting yield and efficiency are guaranteed.

Owner:成都复锦功率半导体技术发展有限公司

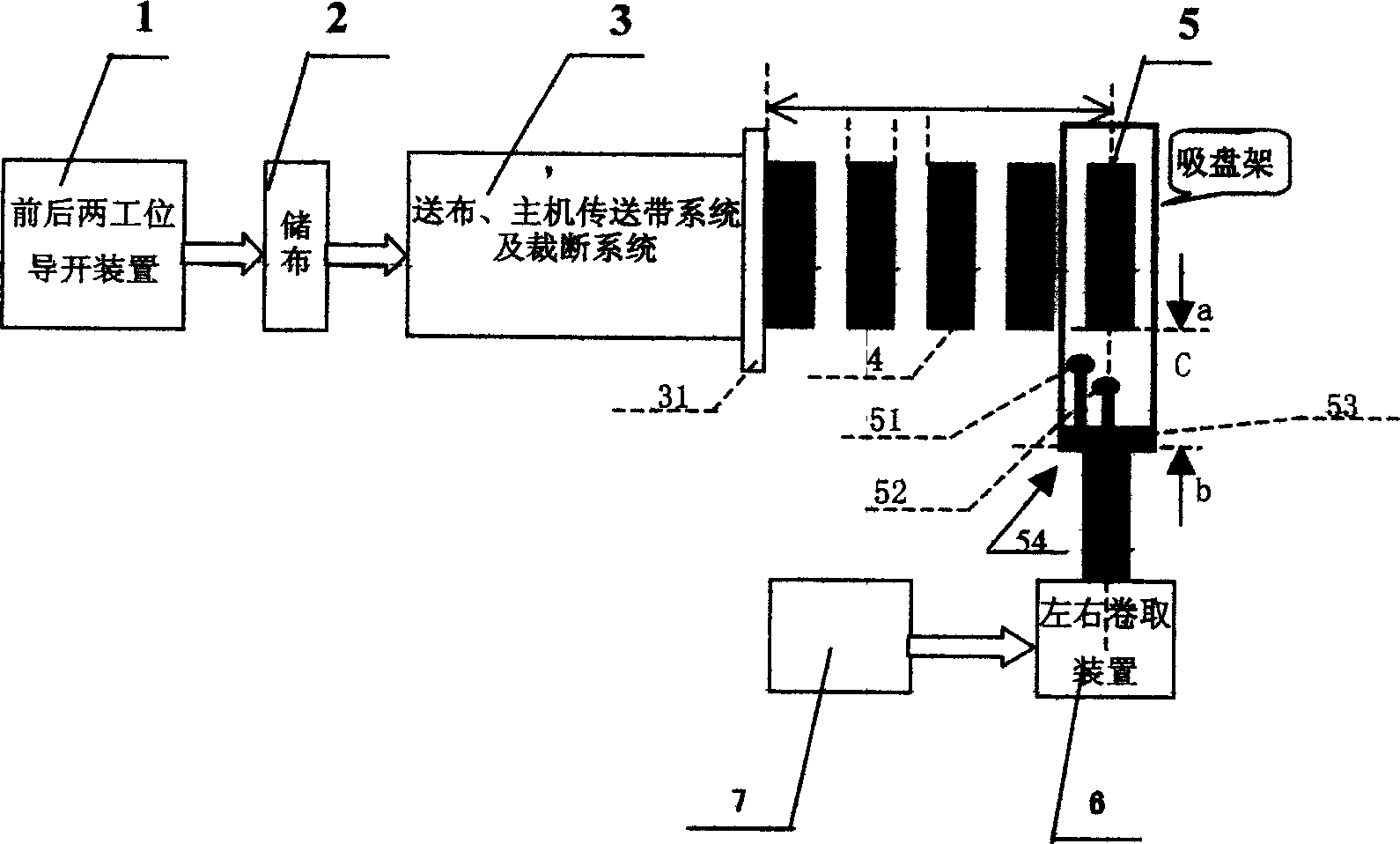

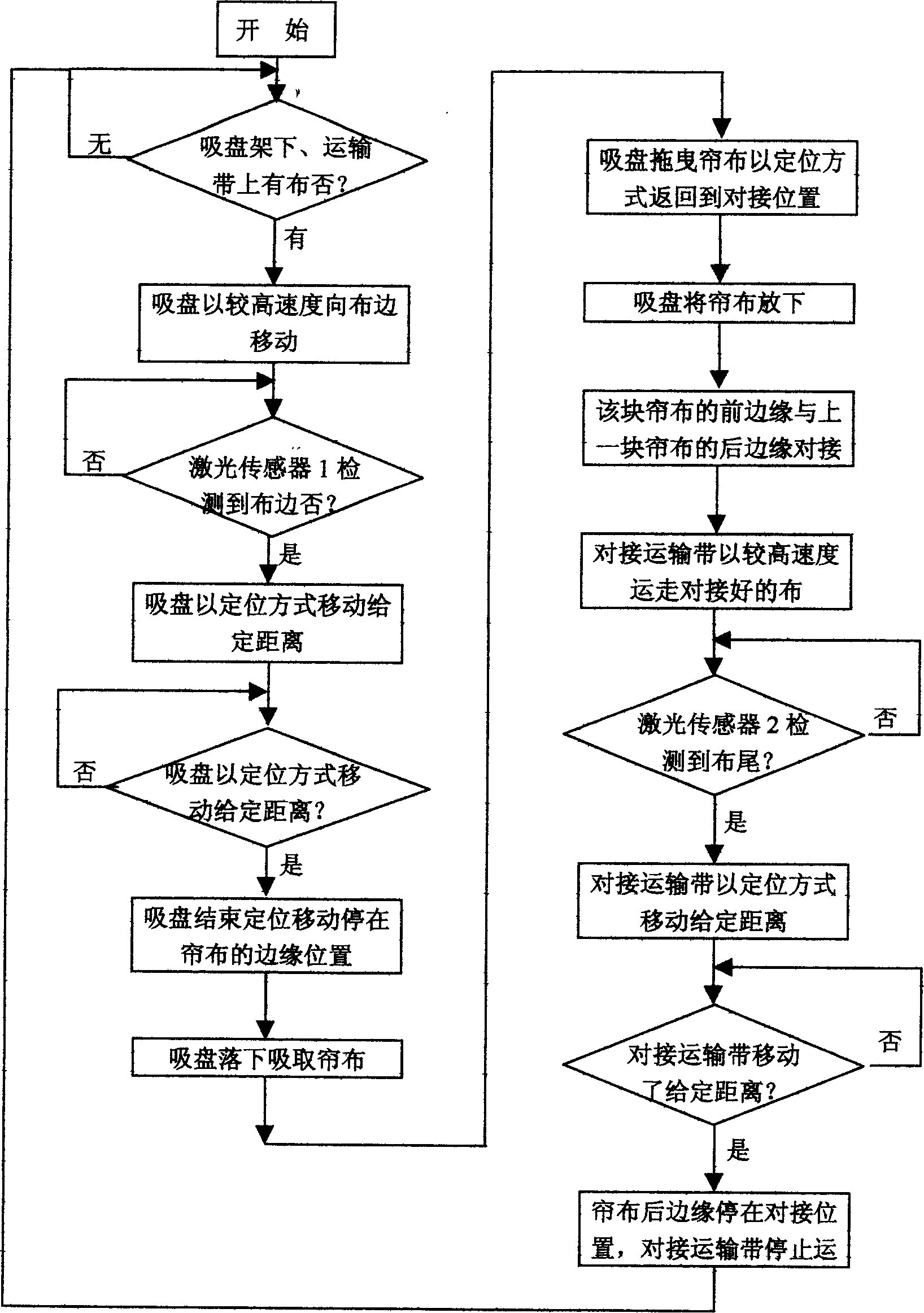

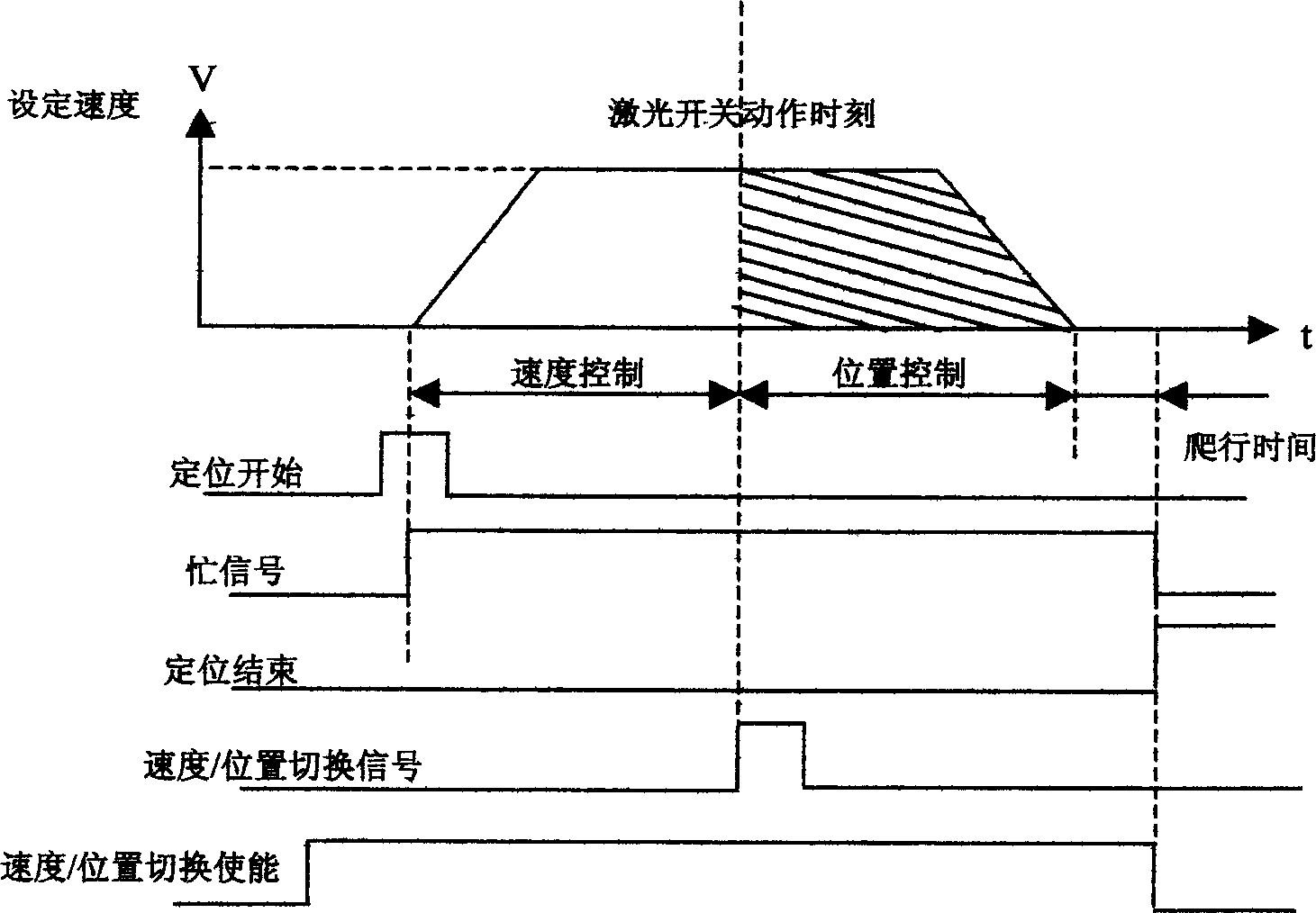

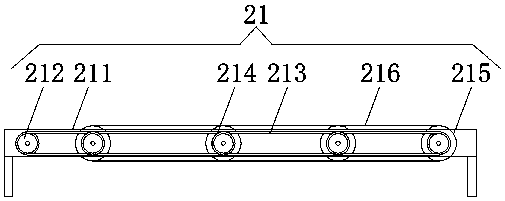

Method for controlling suction and abutment system for fully-automatic cutting machine of radial tyre fiber cord fabric

The invention discloses a kind fiber curtain cloth automation cut machine assimilate and meet system control method, the system including guide equipment, store cloth equipment, transmission and cut equipment, curtain, acetabula frame, assimilate and meet pull equipment, assimilate and meet control equipment, the control method is though the acetabula assimilate and test the curtain cloth by laser, the test signal drive the acetabula all data service mode change (speed mode and position mode)to achieve accumulate confirm length and pull slot, test edge automatism, to achieve accumulate assimilate and meet. This method is the integrate and comprehensive of the advanced technology. Its form is simple and run accumulatly and reliable, use and maintain easy.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

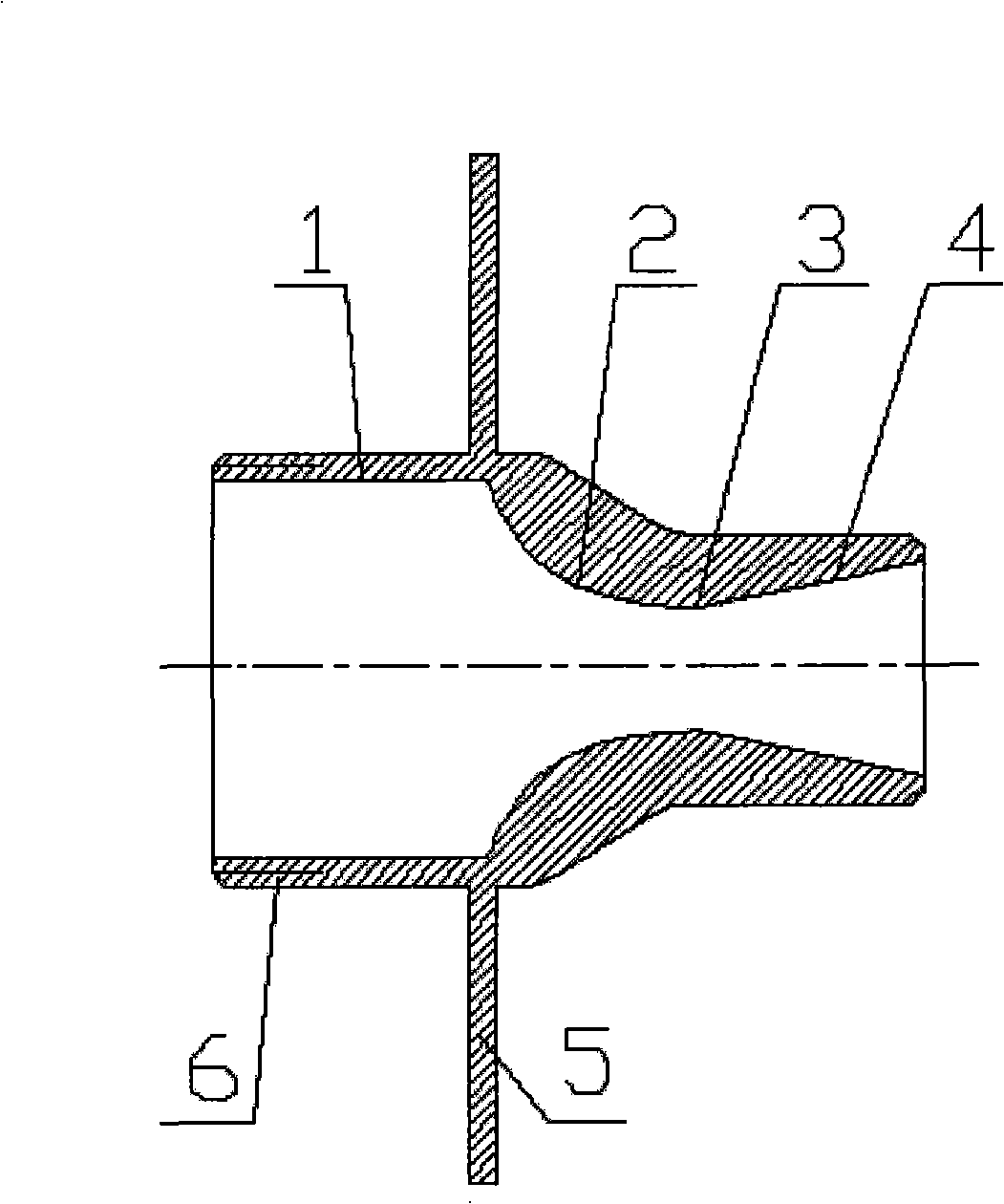

Anti-compression type metal hose cutting device

ActiveCN107378097AGuaranteed cutting efficiencyGuaranteed efficiencyTube shearing machinesShearing machine accessoriesEngineeringElectric control

The invention relates to an anti-compression type metal hose cutting device. New electrically controlled structure design is adopted, a lining support (1) corresponding to a metal hose (8) various in diameter one to one respectively is connected through an electrically controlled telescopic rod (6), through the arrangement of a motor fixedly arranged on the electrically controlled telescopic rod (6) and a clamping device (7) used for fixing the metal hose (8), the lining support (1) can thus move in the metal hose (8) with the corresponding diameter, based on the distance, matched with the thickness of an electrically controlled rotating cutter disk (5), between two cylinders in the lining support (1), a rotating motor controls the electrically controlled rotating cutter disk (5) through a rotating arm (3), and a cutter disk body of the electrically controlled rotating cutter disk (5) achieves cutting of the metal hose (8) through the distance between the two cylinders in the lining support (1); in this way, based on the lining support (1) and electrically controlled cutting, the cutting efficiency of the metal hose (8) is ensured, and at the same time, the deformation problem of a cutting end hole can be effectively avoided.

Owner:WUXI YONGXING METAL HOSE

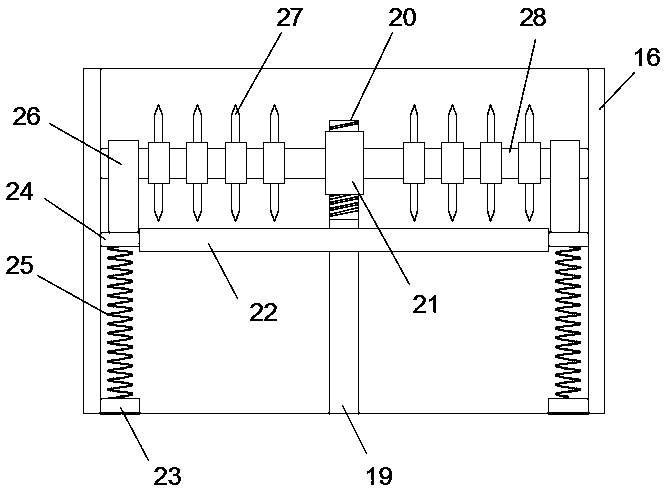

Efficient cutting device for rubber synchronous belt corner cutting

The invention discloses an efficient cutting device for rubber synchronous belt corner cutting. The efficient cutting device for rubber synchronous belt corner cutting comprises a cutting table; corner crushing through holes are formed in the two side table surfaces of the cutting table; a fine material collecting box is placed on the bottom end ground of a fine material charging hopper; a crude material collecting box is correspondingly placed on the ground rightly below the right side of a right side followup rotating wheel; guide sliding channels are respectively formed in the left side wall and the right side wall of a box body of a lifting buffer box; and a compression buffer spring sleeves a rod body of a support frame rod between the top side wall of an inner cavity of the lifting buffer box and the upper surface of a plate body of a movable slide plate. Cut leftovers can be smoothly classified and collected, so that the problem of untidy table surface caused by accumulation ofthe leftovers on the worktable is prevented, and meanwhile, the problem of unsuccessful cutting caused by deviation of a belt body is prevented; the rubber synchronous belt cutting effect is improved;and the cutting efficiency is guaranteed.

Owner:贵溪静星信息技术服务有限公司

Cropper

InactiveCN102204451AGuaranteed cutting efficiencyReduce noiseMowersEmergency protective circuit arrangementsCopperMotor shaft

The invention discloses a copper comprising a shell, a direct current motor, a blade, a battery and a control device, wherein the direct current motor is connected to the shell and is provided with a motor shaft; the blade for cropping is connected to the motor shaft and is provided with at least one cutting edge; the battery is installed in the shell and provides energy for the direct current motor when the cropper works so as to drive the blade to rotate at one cutting speed; and the control device fixes the cutting speed to at least one preset constant revolving speed.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Waste plastic grinder for producing PVC building template, and using method

InactiveCN110614735AGuaranteed cutting efficiencyGuaranteed grinding efficiencySievingScreeningArchitectural engineeringMixing chamber

The invention discloses a waste plastic grinder for producing a PVC building template. The waste plastic grinder for producing the PVC building template comprises a shell; support legs is symmetrically and fixedly connected to the bottom side of the shell; a mounting plate is fixedly connected to the support legs; a driving device is arranged on the mounting plate; a lower grinding roller is arranged in the shell; telescopic cylinders are symmetrically and fixedly connected to the inner wall of the shell; an upper grinding roller is fixedly connected to output ends of the telescopic cylinders,a mixing chamber is fixedly connected to the shell; a connecting shaft is fixedly connected to the lower grinding roller; a rotating shaft is rotatably connected to the inner wall of the mixing chamber; and a plurality of cutting blades are symmetrically and fixedly connected to the rotating shaft. According to the waste plastic grinder for producing the PVC building template, a worm rotates andthen drives a worm wheel to rotate, so that the rotating shaft rotates, the cutting blades shred plastic, the cutting efficiency is guaranteed through the high dense distribution of the cutting blades, the waste plastic is subjected to fragmentation treatment before grinding, and the later grinding efficiency is guaranteed.

Owner:欧阳春洲

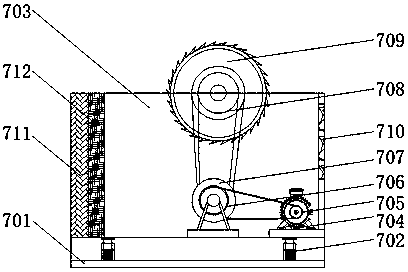

Multifunctional discharging sawing machine sawing device

InactiveCN106735541AHigh cutting precisionImprove consistencyMetal sawing devicesMechanical engineeringEngineering

The invention discloses a multifunctional discharging sawing machine sawing device which comprises a saw mechanism, a feeding mechanism and an angle adjustment mechanism; the sawing mechanism is installed on the feeding mechanism, the feeding mechanism is installed on the angle adjustment mechanism and comprises a feeding frame, the feeding frame is provided with a ballscrew, the ballscrew is provided with a nut seat, and the sawing mechanism is fixed to the nut seat. By means of the multifunctional discharging sawing machine sawing device, multiple steel profiles can be cut in multiple angles, straight-opening sawing and inclined-opening sawing can be performed on the same profile, in the cutting process, the angles are converted automatically and completed completely automatically, sawing precision is high, consistency is good, and product quality is improved.

Owner:JINAN HUAXIN AUTOMATION ENG

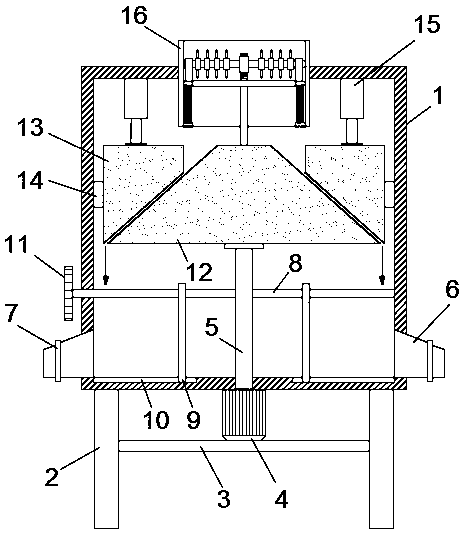

Sand supply device for waterjet

ActiveCN103072091AGuaranteed cutting efficiencyEffective size controlAbrasive feedersEngineeringWater jet cutter

The invention discloses a sand supply device for a waterjet. The sand supply device comprises a sand supply main body, wherein a sand storage bin is arranged in the sand supply main body; a sand inlet communicated with the sand storage bin is formed at the upper end of the sand supply main body; a sand discharge groove communicated with the sand storage bin is formed at the lower end of the sand storage main body; a sand supply port is formed at the lower end of the sand supply main body; two ends of the sand supply port are respectively communicated with the sand storage bin and the sand discharge groove; a pneumatic valve capable of opening and closing the sand supply port is arranged in the sand storage bin; and a sand supply flow regulating piece which can adjust the size of the sand discharge groove is mounted at the lower end of the sand supply main body. The sand discharge quantity of the sand supply device for the waterjet is adjustable, so that the cutting efficiency of the waterjet can be guaranteed.

Owner:广州华臻机械设备有限公司

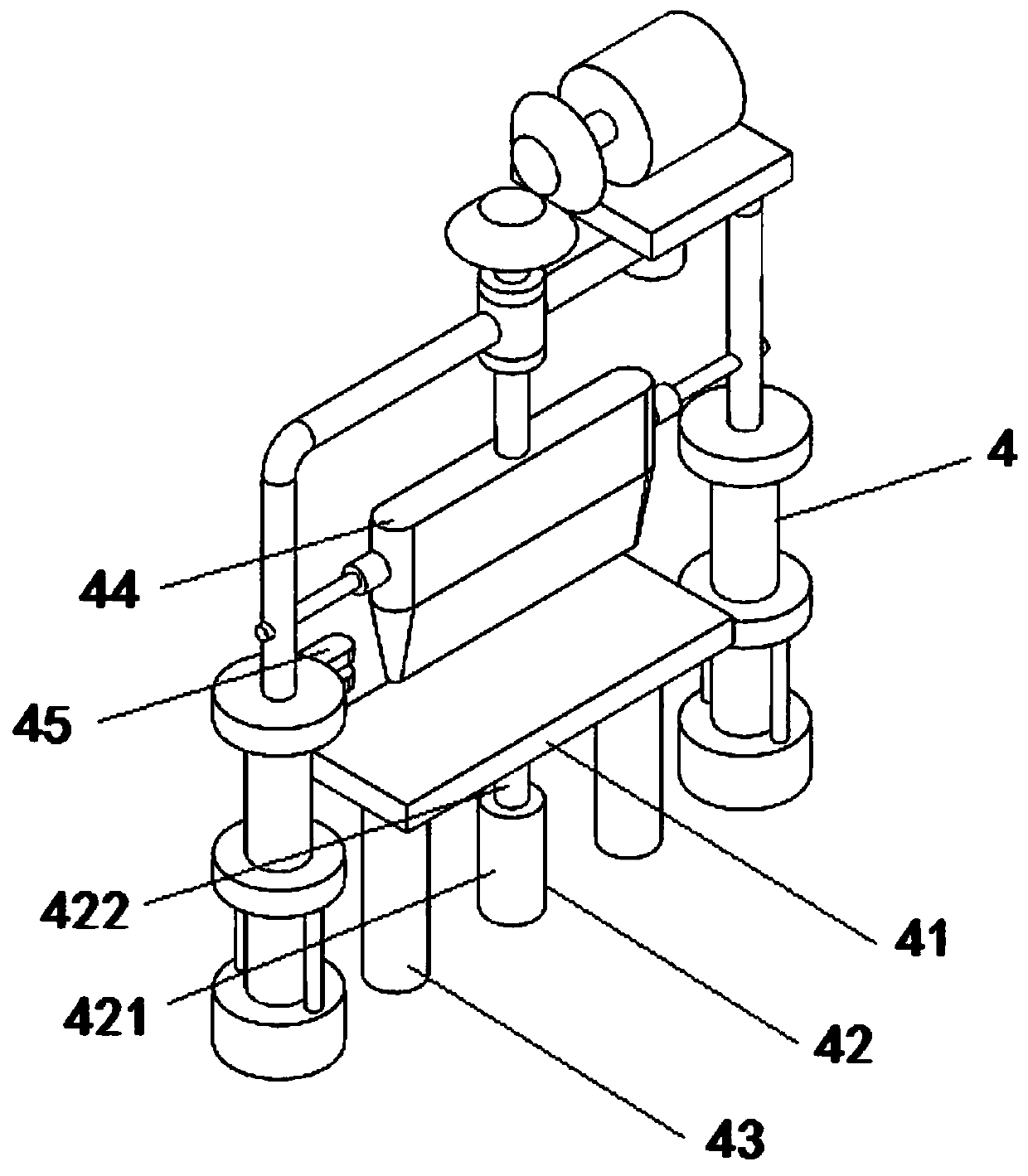

Novel automation rope fixed-length cutting-off device

InactiveCN109664352AGuaranteed cutting safetyGuaranteed cutting efficiencyMetal working apparatusElectric machineryEngineering

The invention relates to the technical field of packing ropes, in particular to a novel automation rope fixed-length cutting-off device. The novel automation rope fixed-length cutting-off device comprises a supporting mechanism, an adjusting mechanism, a rope winding mechanism, a cutting mechanism, a collecting box and a rotating column. According to the novel automation rope fixed-length cutting-off device, the rope is winded on connection rods through the rope winding mechanism, the perimeter of each circle on a column body formed by the connection rods is the same, the length of the rope isconverted into the perimeter of the column body formed by the rope and the connection rods through winding, so that the fact that the length of each section is the same after the rope is cut off is guaranteed, the length of the rope after cutting can be guaranteed to be the same no matter which position the cutting is performed on after the rope is winded on the connection rods, the rotating column is driven by a stepping motor, the fact that adjusting discs will not block a moving rack all the time is guaranteed, the cutting safety is guaranteed, in addition, a cutting piece rotates all thetime to guarantee the cutting efficiency, the moving rack is driven to perform reciprocating motions through a speed adjusting motor, the cutting is conveniently performed, the rope can fall into thecollecting box when the cutting is finished, rope scattering is avoided, the whole process is quite easily automated, and the rope fixed-length cutting-off efficiency is greatly improved.

Owner:徐志远

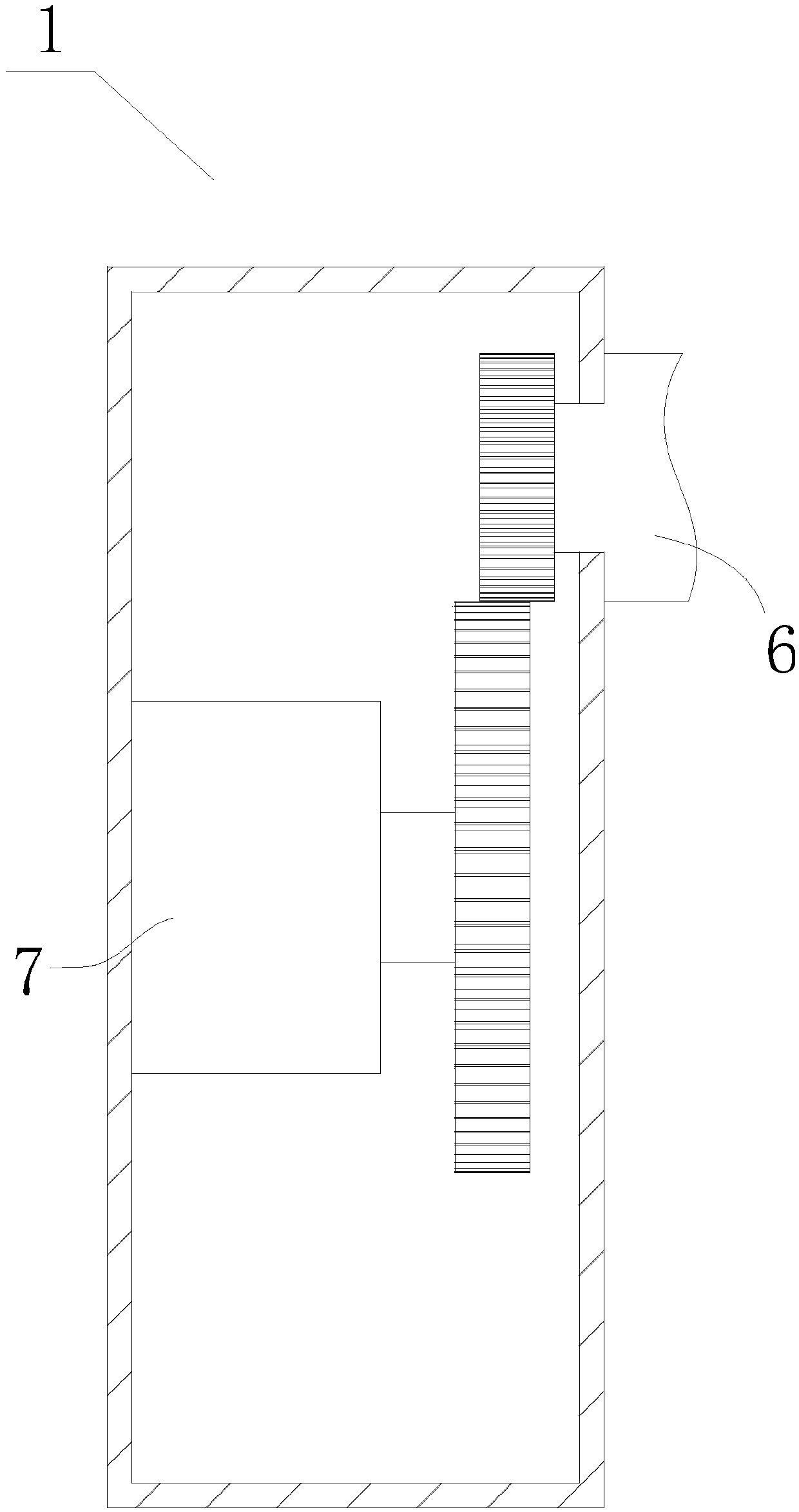

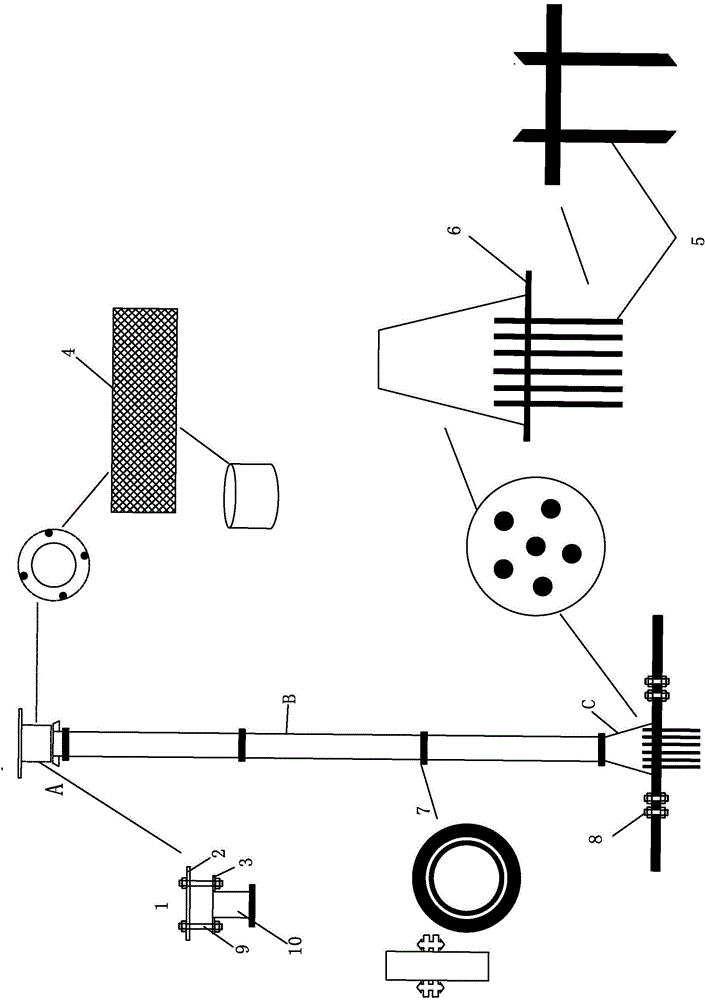

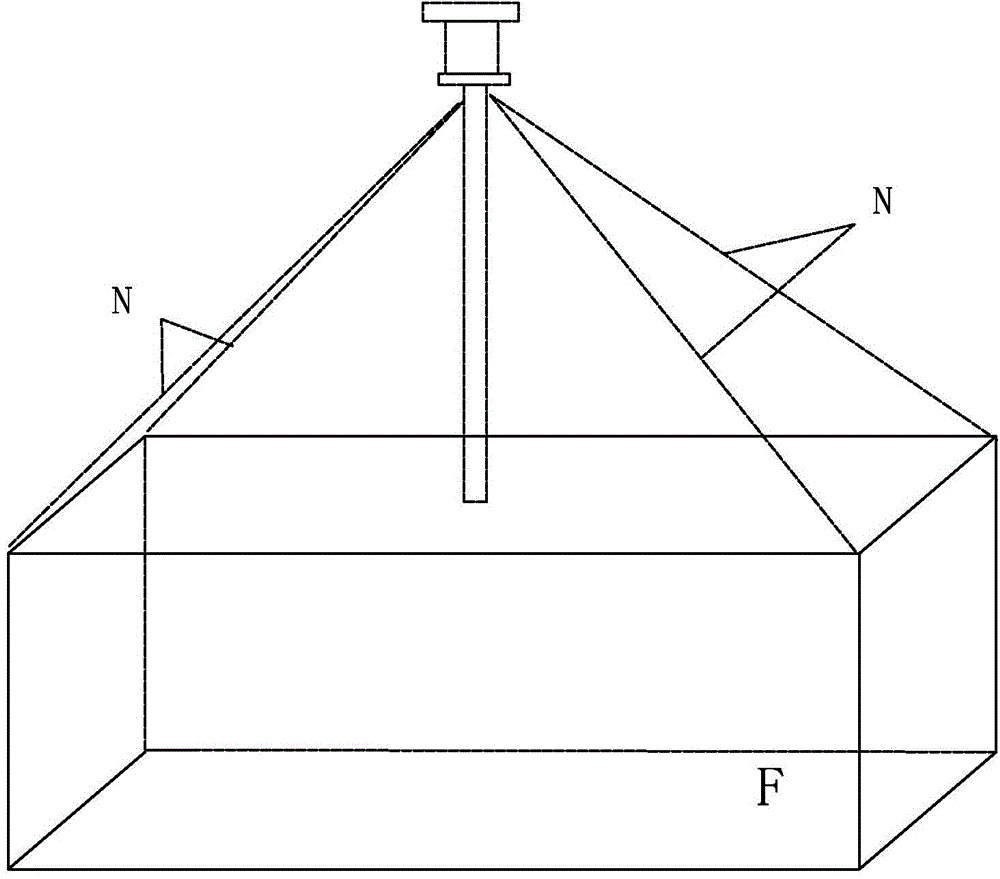

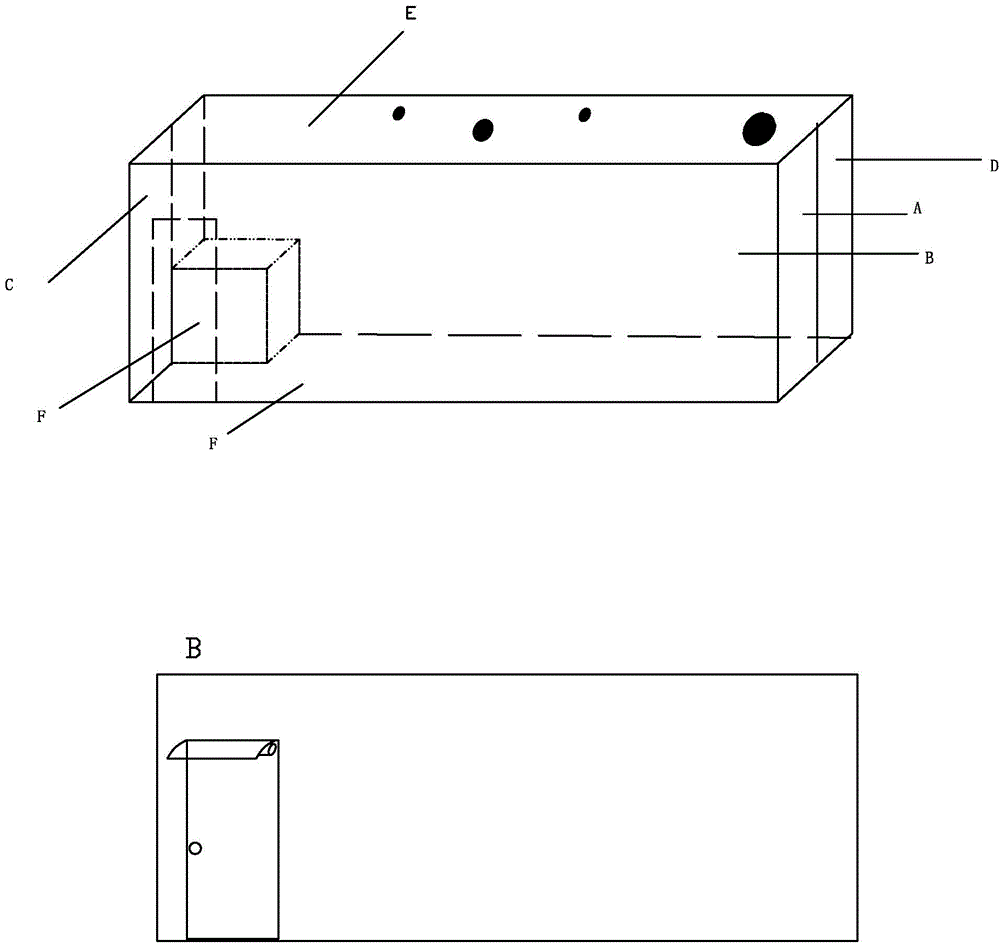

Ground aerosol movement integrated observation system

InactiveCN103604727ARealize integrated observationQuality improvementWithdrawing sample devicesLarge containersPunchingInsulation layer

The invention discloses a ground aerosol movement integrated observation system which comprises a sampling pipe, a container, an equipment frame, integrated observation equipment and the like, wherein the sampling pipe is fixed on a top cover of the observation container; the container comprises a container body, the wall of the container body comprises three layers of structures, and a heat preservation and insulation layer and an inner-wall surface layer are additionally provided; and the equipment frame is arranged inside the container, and comprises a fixed steel frame and an equipment cabinet, the equipment frame comprises an upright and cross beams, the upright is formed by indirectly or directly connecting a plurality of internal-hemming and punching C type galvanized steels and the container body, the equipment cabinet is fixed at the center of the container, and used for placing various instrument equipment. The integrated observation system is arranged on the equipment cabinet inside the container, the instrument equipment is serially or parallel connected, orderly integrated and reasonably combined, a plurality of cutting heads are used by a sampling pipeline in the container for separating aerosols with different particle sizes, and the comparison and mutual verification among instruments are enhanced. A circuit in the container adopts a circuit arrangement structure with higher safety coefficient.

Owner:LANZHOU UNIVERSITY

Plastic-wood plate automatic cutting and garbage treatment device

PendingCN107553549AGuarantee quality and efficiencyGuaranteed cutting efficiencyMetal working apparatusElectric machineGear wheel

The invention discloses a plastic-wood plate automatic cutting and garbage treatment device which comprises a working box. A power machine case is fixedly connected to the top of the inner wall of theworking box, a power motor is fixedly connected to the top of the inner wall of the power machine case, a first bevel gear is rotationally connected to the power motor through an output shaft, a second bevel gear is meshed to the position below the first bevel gear and is fixedly connected with a first threaded rod through a flat key, and the end, far away from the power machine case, of the first threaded rod is fixedly connected with a second threaded rod through a coupler. The plastic-wood plate automatic cutting and garbage treatment device relates to the technical field of plastic-wood plate machining machines. According to the plastic-wood plate automatic cutting and garbage treatment device, fixed conveying and cutting of a plastic-wood plate and reasonable treatment on garbage areachieved, stability of the plastic-wood plate during cutting can be guaranteed, the cutting quality, the cutting efficiency and the working speed can be guaranteed, garbage treatment and machine cleaning are facilitated, and the machine is maintained more conveniently.

Owner:浙江尚元塑木制品有限公司

Anti-deformation cutting device of metal hose

InactiveCN108856860AActive fixed connectionReduce distortionTube shearing machinesShearing machine accessoriesScrew threadMetal hose

The invention discloses an anti-deformation cutting device of a metal hose. The rotation speed of a cutter body is 0.5N times of the rotation speed of the metal hose, wherein N is a positive integer,and the cutter body only rotates one round; the two ends of the metal hose are placed into a cylindrical placing box with the middle part being hollow, the placing box is provided with four through holes, the through holes are in threaded connection with connection rods, the two ends of the connection rods are at outside of the through holes, the ends, in the placing box, of the connection rods are connected with connection plates, the connection plates on the four connection rods form a hollow cylinder, the connection rods rotate in the through holes to adjust the distance between the connection plates and the inner wall of the placing box, and the metal hose is fixed into the hollow cylinder composed of the four connection plates. The device can effectively relieve the stress when cutting the metal hose to prevent the metal hose from deforming in the cutting process, and thus the metal hose is more convenient to use for a long time.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Automobile engine hood stamping die waste removing device

InactiveCN108057807ASave energy useReduce manufacturing costMetal-working feeding devicesMetal working apparatusScrapDischarge efficiency

The invention provides an automobile engine hood stamping die waste removing device. The automobile engine hood stamping die waste removing device comprises a product placement seat; a stamping die isarranged above the product placement seat, and the upper end of the stamping die is provided with a stamping air cylinder; the product placement seat is provided with a waste blowing pipe, an air blower is arranged beside the product placement seat, and the waste blowing pipe is connected with the air blower through a pipeline; and the stamping air cylinder is provided with a position sensor, theair blower is controlled to work through the position sensor so that the waste blowing pipe can be driven to discharge waste. Stamping is conducted on a product placed on the product placement seat through the stamping die, in addition, the waste blowing pipe is driven by the air blower to discharge the waste, the position of the stamping die is judged through the position sensor, air blowing isstopped during stamping and started again after stamping is completed, on the premise that the waste discharging efficiency is ensured, the energy source using amount is decreased, and the productioncost is reduced.

Owner:FENGYE TIMS WUHU AUTO PARTS CO LTD

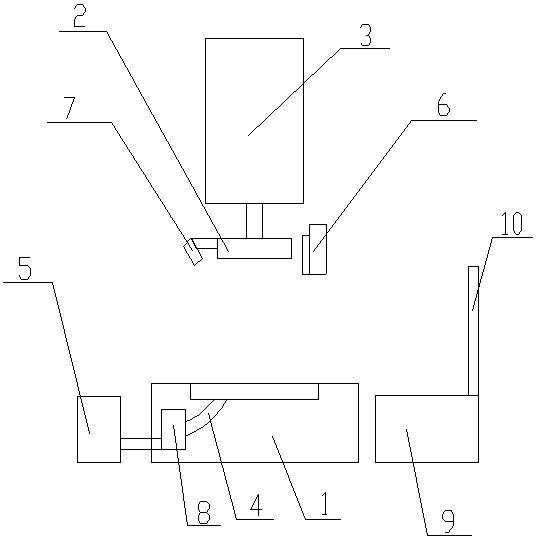

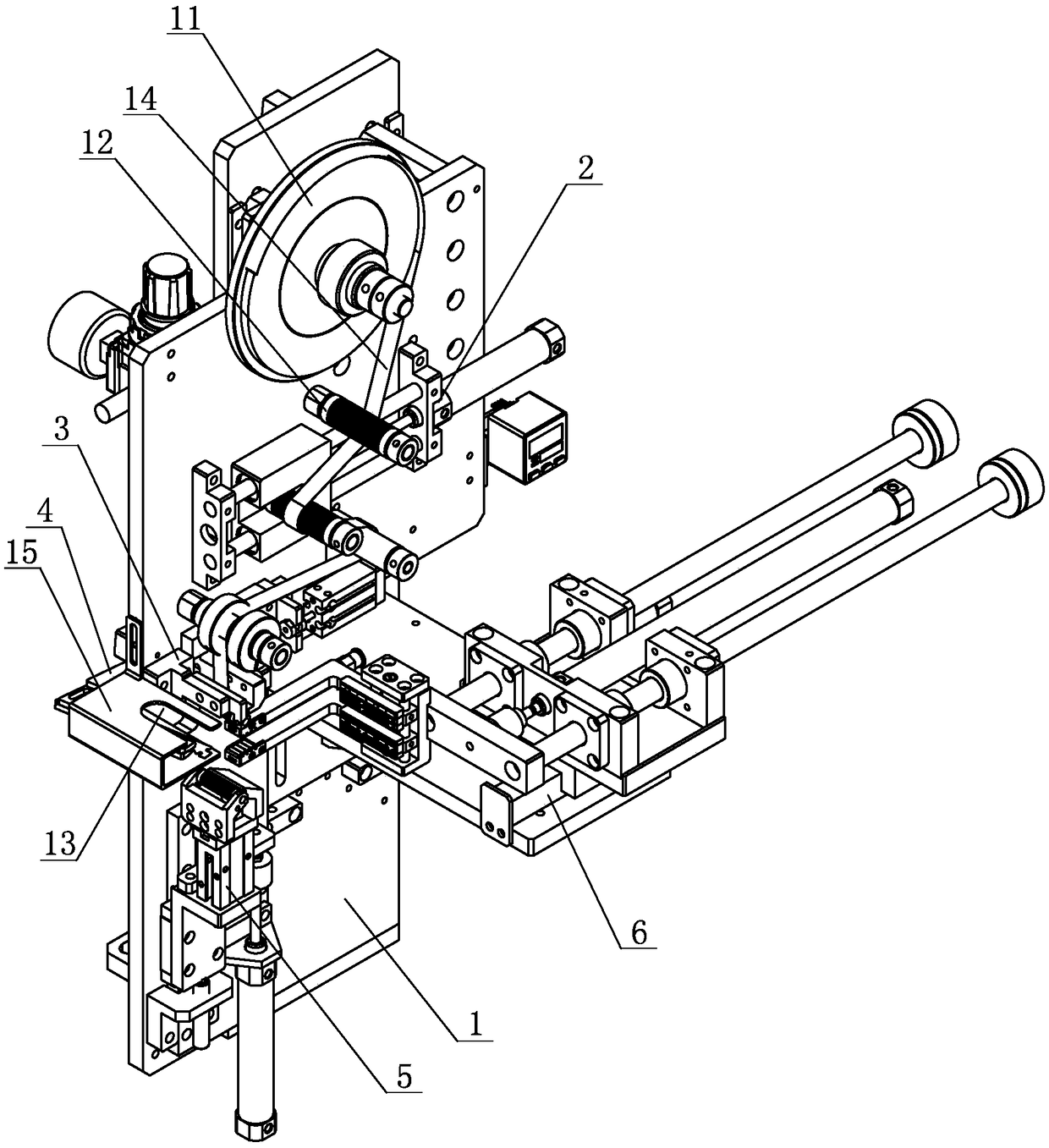

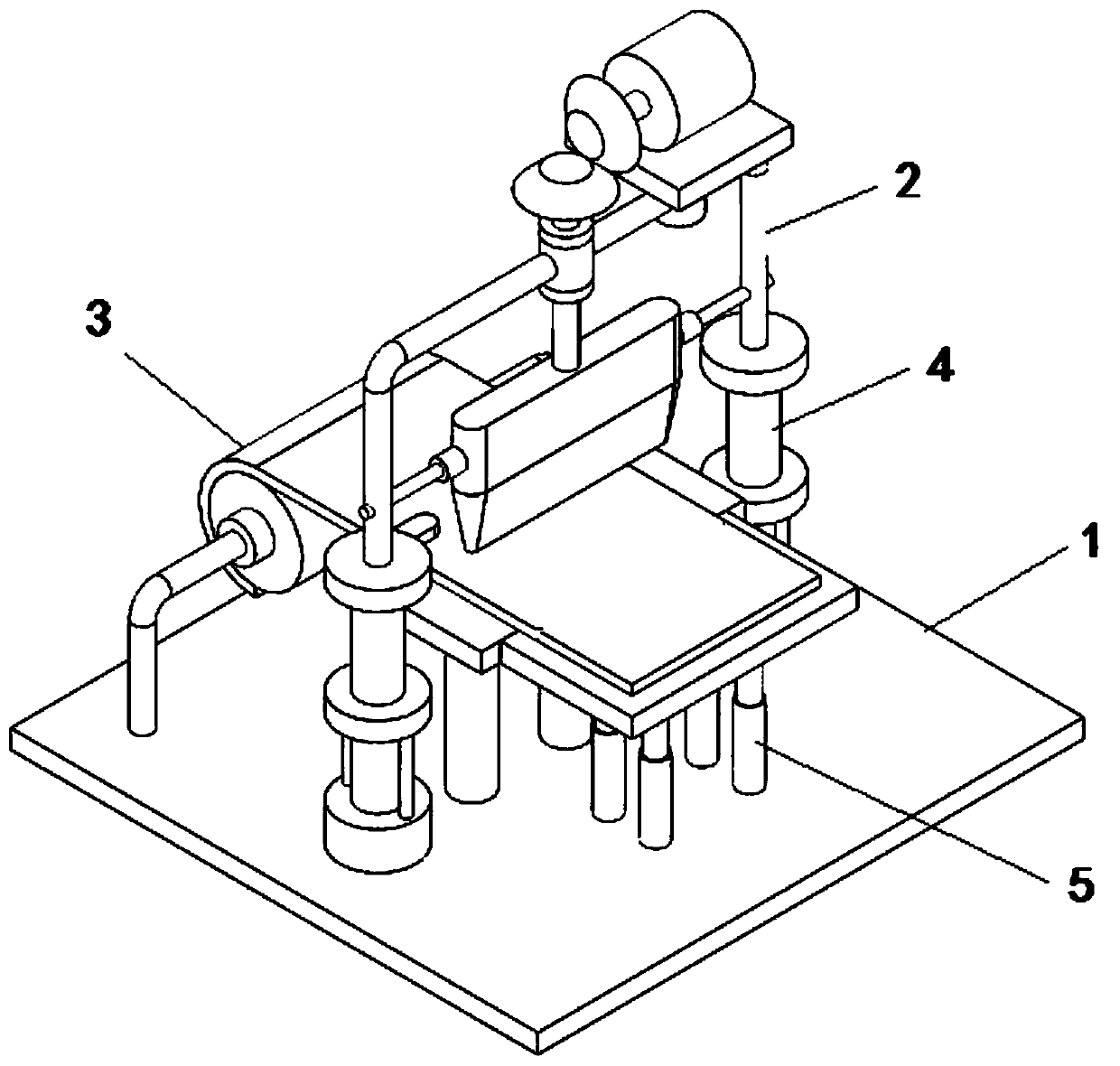

Tape applicator for battery cells

PendingCN109449498AImprove efficiencyQuality improvementFinal product manufactureElectrolyte accumulators manufactureEngineeringBattery cell

The present invention discloses a tape applicator for battery cells. The tape applicator comprises: a vertical plate, a tape tray, a tensioning mechanism, a tape clamping mechanism, a tape cutting mechanism, a tape stretching mechanism, a tape applying mechanism and a plurality of root drives. The tape disc is rotatably mounted on the top of the vertical plate; the tensioning mechanism is arrangedunder the tape tray; the tape clamping mechanism is arranged under the tensioning mechanism; the tape stretching mechanism is arranged directly under the left side of the tape clamping mechanism; theleft side of the vertical plate is provided with a cutting groove, and the cutting groove is arranged between the tape clamping mechanism and the tape stretching mechanism; the left side of the tapecutting mechanism is movably arranged in the cutting groove; the tape applying mechanism is installed under the tape clamping mechanism; and the left side of the tape applying mechanism is arranged between the tape clamping mechanism and the tape stretching mechanism. According to the technical scheme of the present invention, the efficiency and quality of applying the tape on the product can be improved.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

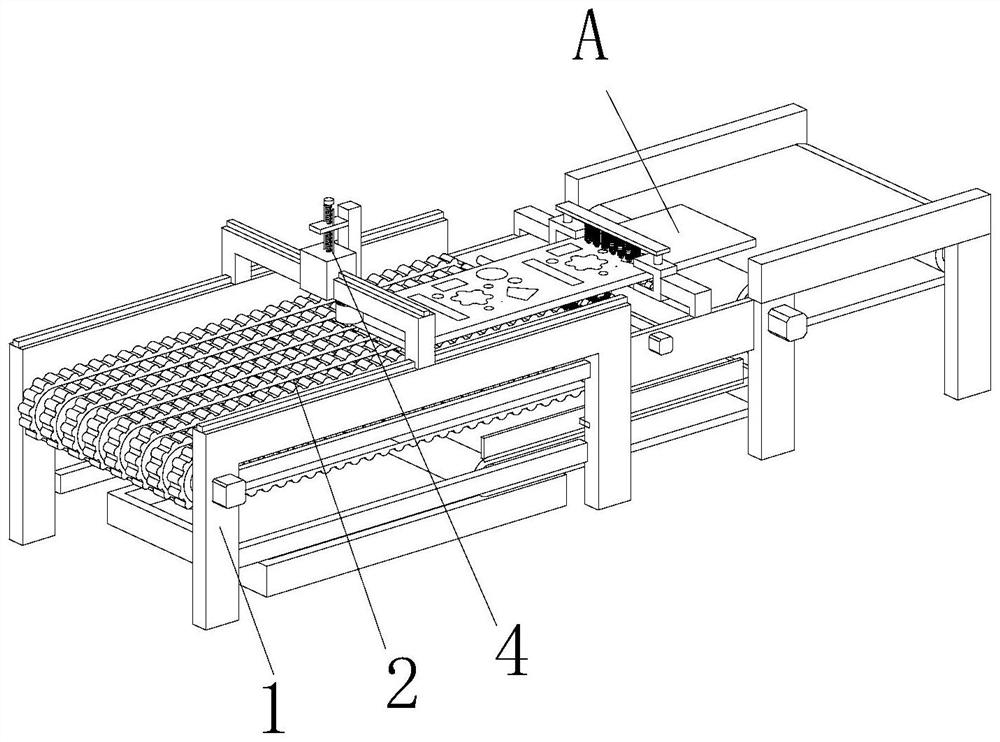

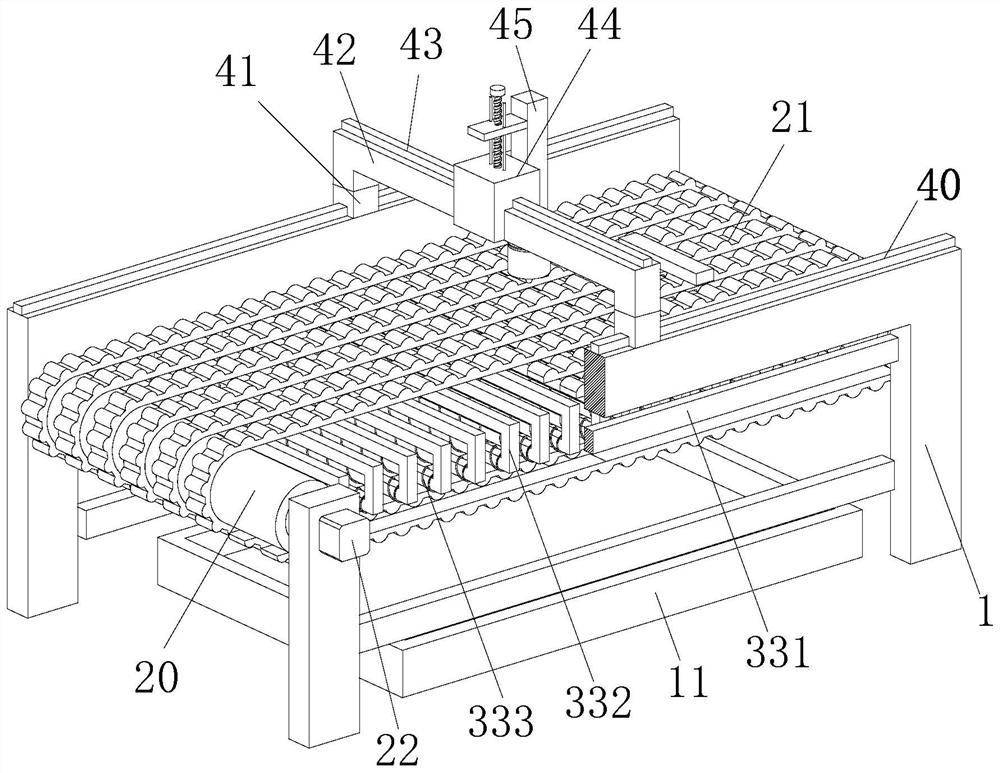

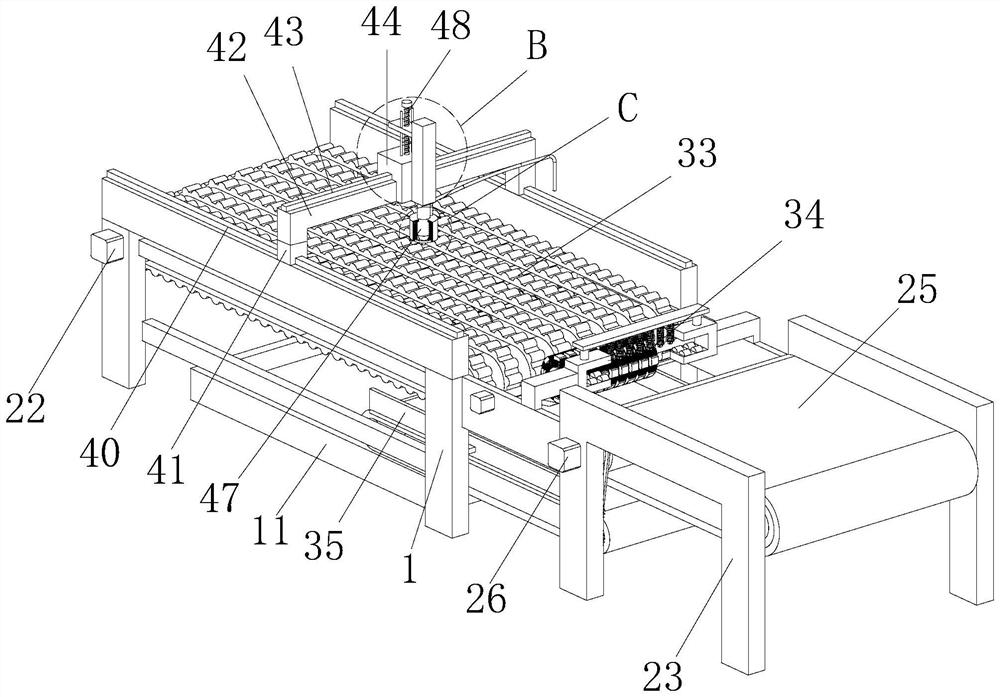

Cutting device for spinning

ActiveCN111230944AGuaranteed cutting efficiencyImprove work efficiencySevering textilesMetal working apparatusSpinningStructural engineering

The invention discloses a cutting device for spinning. The cutting device is characterized by comprising a mounting bottom plate and a cutting device body fixedly mounted on the top surface of the mounting bottom plate, wherein the cutting device body comprises a textile winding mechanism, a cutting mechanism and a cut product placing mechanism which are sequentially arranged from left to right. According to the cutting device, through arrangement of the cutting mechanism, lifting of a cutter head is controlled to lift through a second hydraulic rod, cutting of textile fabric is completed, theworking efficiency is improved, through arrangement of the textile winding mechanism, the cutting mechanism and the cut product placing mechanism which are sequentially set, the whole set of cuttingdevice is provided, and the cutting efficiency of the textile fabric is guaranteed.

Owner:临沂协润工贸有限公司

Numerical control laser cutting machine

InactiveCN114406491AGuaranteed magnetic forceGuaranteed cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlWorking environment

The invention provides a numerical control laser cutting machine, and relates to the technical field of laser cutting, the numerical control laser cutting machine comprises a fixing frame, a conveying device and a laser cutting device, the fixing frame is provided with the conveying device, and the conveying device is provided with the laser cutting device; in addition, the numerical control laser cutting machine can solve the following problems that a, after a plurality of products are cut on a plate through an existing numerical control laser cutting machine, the products can be clamped at notches of the plate and cannot be separated from the plate through the dead weight, so that the cut plate needs to be subjected to secondary treatment manually, and the cutting efficiency of the numerical control laser cutting machine is seriously affected. And b, a large amount of smoke can be generated in the process of cutting plates by the existing numerical control laser cutting machine, the whole working environment can be seriously polluted after long-time laser cutting, and meanwhile, miscellaneous slag and fire generated in the cutting process can be splashed everywhere.

Owner:陆丹丹

Laser cutting device capable of achieving three-dimensional cutting based on complex workpieces

InactiveCN110116278ALower the altitudeGuaranteed cutting efficiencyLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a laser cutting device capable of achieving three-dimensional cutting based on complex workpieces. The laser cutting device comprises a main machine body; a working cavity withan opening facing upwards is formed in the main machine body; a control mechanism is arranged between the inner walls of the two sides of the working cavity; the control mechanism comprises a laser head which can emit cutting laser and can be moved back and forth or left and right through the control mechanism; the working cavity is provided with a clamping mechanism; and the clamping mechanism is located on the lower side of the control mechanism. The laser cutting device can be used for laser cutting of the complex workpieces, a costly multi-dimensional laser cutting head does not need to be used, three-dimensional laser cutting can be achieved by adding some simple clamping members under the two-dimensional laser cutting condition, and the cost is effectively reduced while the cuttingefficiency and product quality are ensured.

Owner:FOSHAN XIANNA CRAFTS CO LTD

Backwind-preventing high-pressure-difference-resisting rotary feed valve

The invention relates to a backwind-preventing high-pressure-difference-resisting rotary feed valve. An empty side of a feed valve housing is provided with two symmetric exhaust vents; high-pressure air leaked from a high-temperature pipeline to the empty side can be exhausted via the two exhaust vents in time to prevent upward backwind of the high-pressure air so that a material inside a hopper is prevented from being lifted, failing of normal discharging is prevented, thus the problem about influences on the discharging efficiency is solved, and damages, caused by the high-pressure air accumulated inside the housing, of a sealing ring are prevented as well; the end part of a rotary impeller is connected with a soft wear-resisting bar; the wear-resisting bar makes close contact with the inner wall of the housing so as to realize sealing between rotary blades and the inner wall of the housing and prevent air leakage from affecting the discharging; a scraping brush arranged on the feedvalve housing can be used for scraping away residual materials between the wear-resisting bar and the inner wall of the housing so as to prevent the sealing between the rotary impeller and the inner wall of the housing, and therefore the feed valve provided by the invention solves the problems about backwind and leakage of the air inside the feed valve, improves the conveying efficiency of air transportation and achieves great popularization and application values.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

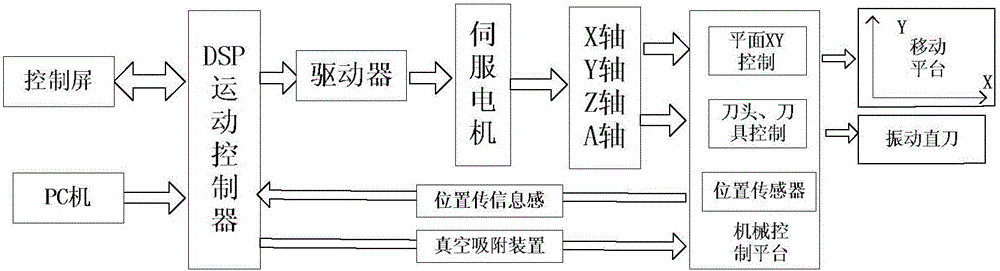

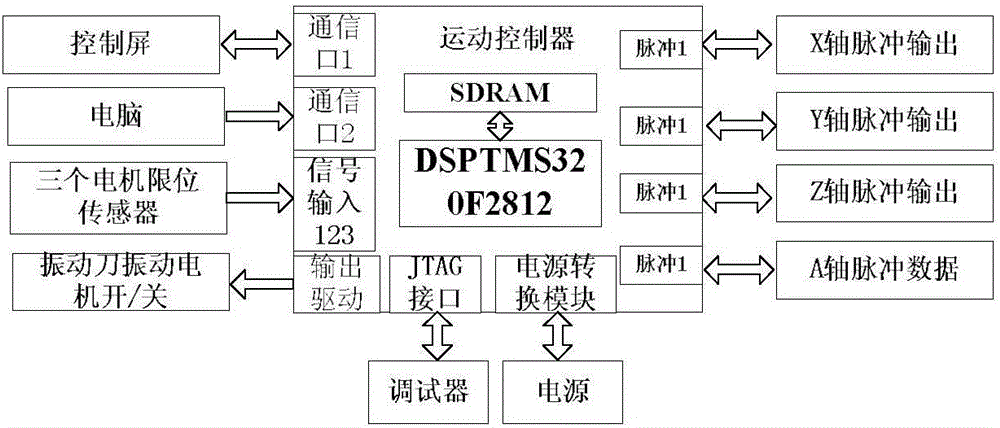

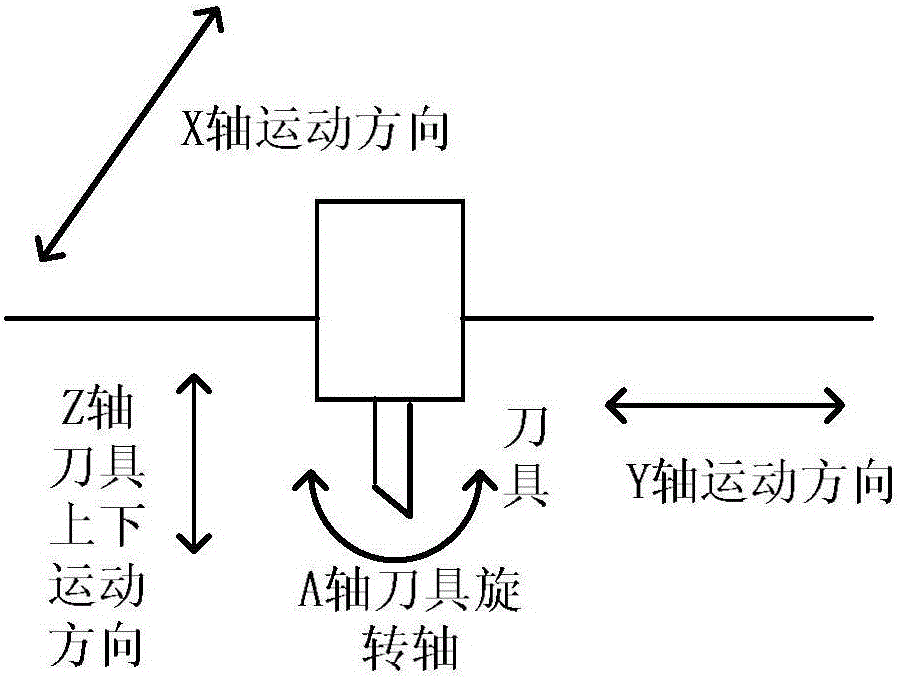

Carton cutting method based on time division method cutting knife tangent following control

InactiveCN105929795AGuaranteed cutting accuracyGuaranteed cutting efficiencyNumerical controlGraphicsCarton

The invention provides a carton cutting method based on time division method cutting knife tangent following control. The carton cutting method comprises the following steps that step one, an upper computer issues a PLT file to a controller; step two, the controller reads PLT file graphic information, wherein the PLT file graphic information is composed of multiple straight lines and circular curves; and step three, whether the current cutting line is a straight line or a circular curve is judged, 3.1) if the current cutting line is the straight line, cutting is performed according to the existing method; and 3.2) if the current cutting line is the circular curve, a cutting knife is rotated to a position tangent with a circular start point firstly, the start angle of the cutting knife is determined, a circular curve tangent following motion model is determined, and the feed amount of an X-axis and Y-axis knife rotation shaft of each interpolation cycle is determined by adopting a circular time division method so that tangent following of the cutting knife can be realized. According to the carton cutting method based on time division method cutting knife tangent following control, the carton cutting method can enhance control precision and has great stability.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

Decorative laminated board cutting device

InactiveCN108972657AAvoid sticking to each otherUninterrupted cutting workMetal working apparatusEngineeringConveyor belt

The invention provides a decorative laminated board cutting device. The decorative laminated board cutting device includes a conveying mechanism, a cutting mechanism, a limiting mechanism and a driving mechanism. The conveying mechanism is provided with a space for placing laminated boards, the cutting mechanism is positioned above the conveying mechanism, the driving mechanism is connected with the cutting mechanism and drives the cutting mechanism to run, and therefore the cutting mechanism can conduct cutting treatment on the laminated boards on the conveying mechanism; the limiting mechanism is positioned between the conveying mechanism and the cutting mechanism and makes the laminated boards stay at the same position on the conveying mechanism. A group of annular blades are installedon a cutting shaft of a cutting device and used for cutting the laminated boards placed on a stainless steel conveyor belt, wherein only one laminated board can be cut at a time, and therefore the laminated boards are prevented from being bonded to one another. Meanwhile, since the annular blades are arranged, each laminated board can be cut into a preset size at a time, and the conveyor belt cancontinuously transfer the laminated boards, the cutting work is not paused, the cutting efficiency is ensured, improvement of the working efficiency is facilitated, and the quality of products is improved.

Owner:嘉善缔嘉装饰材料有限公司

LED lamp strip cutting device

InactiveCN109421089AIncrease productivityEasy to operateMetal working apparatusAgricultural engineeringEconomic benefits

The invention discloses an LED lamp strip cutting device. The LED lamp strip cutting device comprises a workbench, and the two sides of the bottom of the workbench are fixedly connected with supporting legs. The bottoms of the supporting legs are fixedly connected with a bottom plate. The two sides of the top of the workbench are fixedly connected with supporting plates, and the tops of the supporting plates are fixedly connected with a cross plate. A conveying roller is movably connected between the two supporting plates through a rotary shaft, and the top of the conveying roller is movably connected with a lamp strip body. One side of each supporting plate is fixedly connected with a conveying motor. According to the LED lamp strip cutting device, by arranging the supporting plates, thecross plate, the conveying roller, a conveying motor, a movable hole, a movable plate, a cutting motor, cutting discs, a tooth plate, a sliding plate, a transmission motor and a gear, the distance between the two cutting discs can be correspondingly adjusted according to needs, and the adjusting process is easy to operate; and use is convenient, the production efficiency of LED lamps is improved,and then great economic benefits are brought to LED lamp processing enterprises.

Owner:李国女

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com