Sand supply device for waterjet

A sand supply and water jet technology, applied in abrasive feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of easy water return, difficult adjustment, small sand volume, etc. Efficiency and smooth sand supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

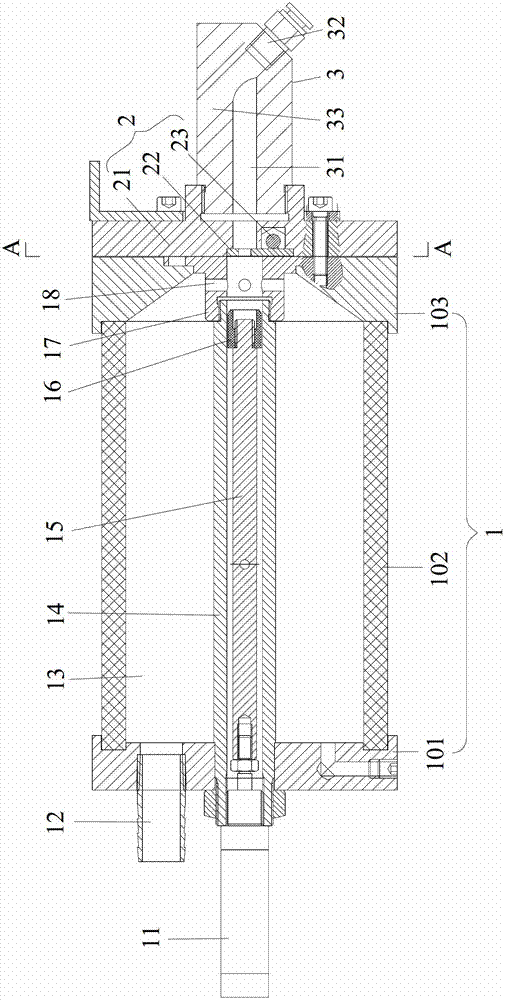

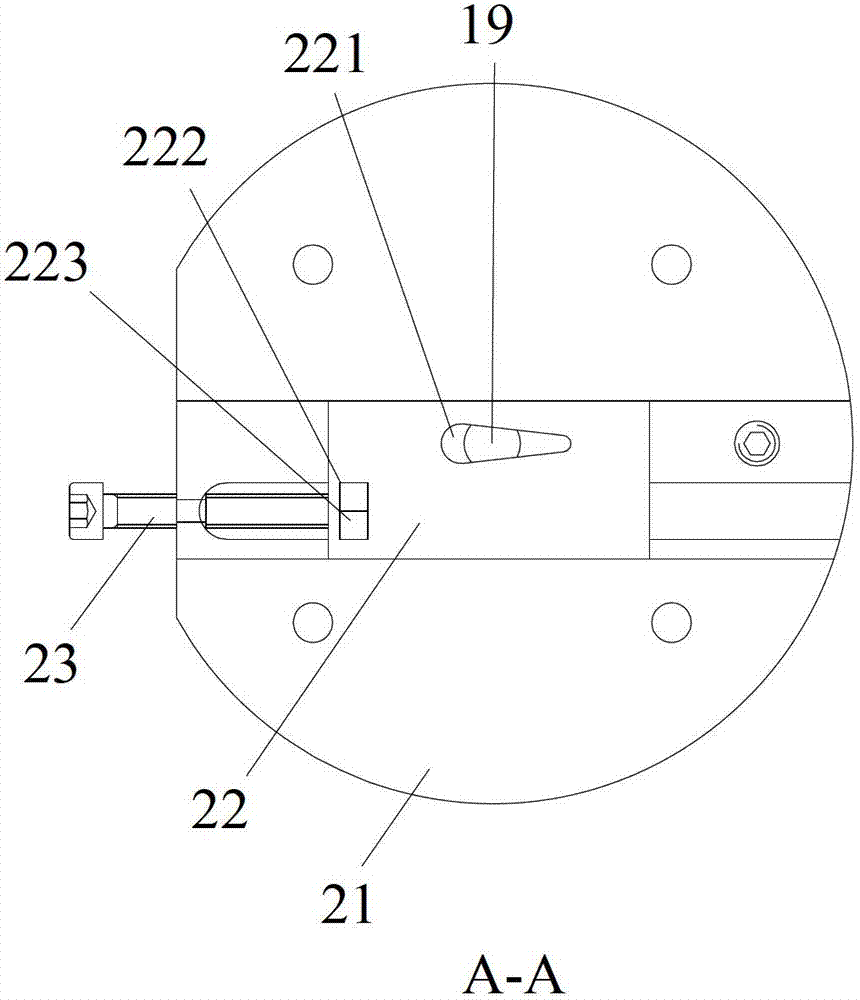

[0019] Please refer to Figure 1-2 , the water jet sand supply device includes a sand supply body 1, a cylinder 11 is installed on the outside of the upper end of the sand supply body 1, and a sand inlet 12 is provided on the outside of the upper end of the sand supply body 1, and the sand inlet A port 12 is located on one side of the cylinder 11, which is connected to a source of compressed air. A sand storage bin 13 is provided inside the sand supply body 1 , and the sand inlet 12 is connected to the sand storage bin 13 . The sand storage bin 13 is provided with a protection tube 14, a push rod 15 and a plug 16. The upper end of the protection tube 14 protrudes from the outside of the sand supply body 1, and the cylinder 11 is inserted into the protection tube 14. Inside the upper end, the protection tube 14 covers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com