Carton cutting method based on time division method cutting knife tangent following control

A follow-up control and time division technology, applied in digital control, program control, electrical program control, etc., can solve the problems of poor stability and low control precision, and achieve good stability, guaranteed cutting efficiency, guaranteed quality and processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

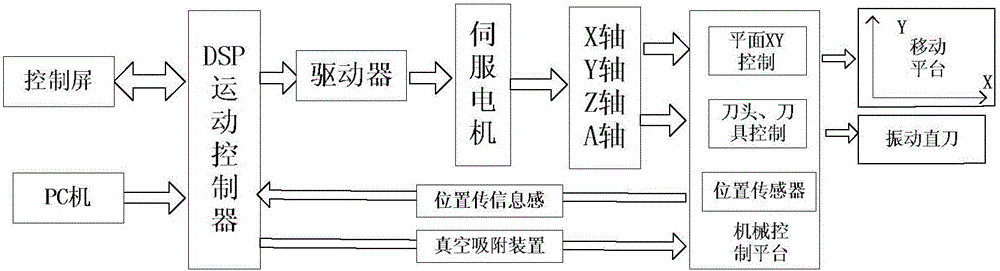

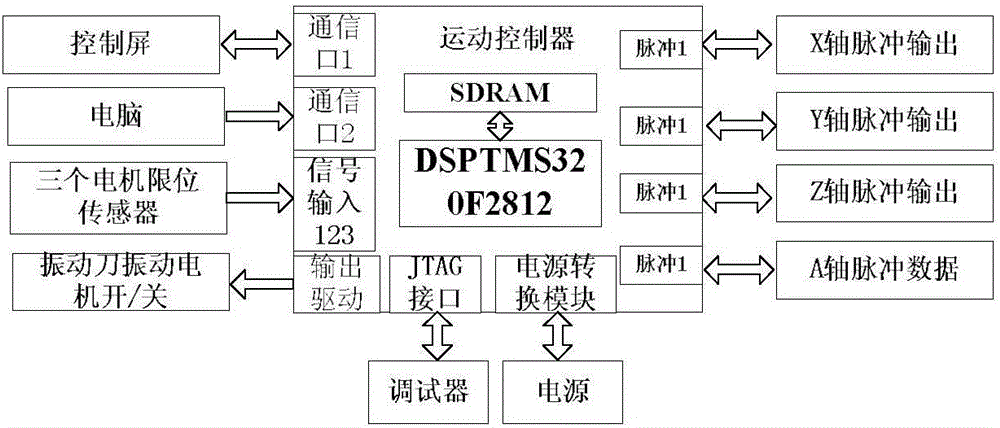

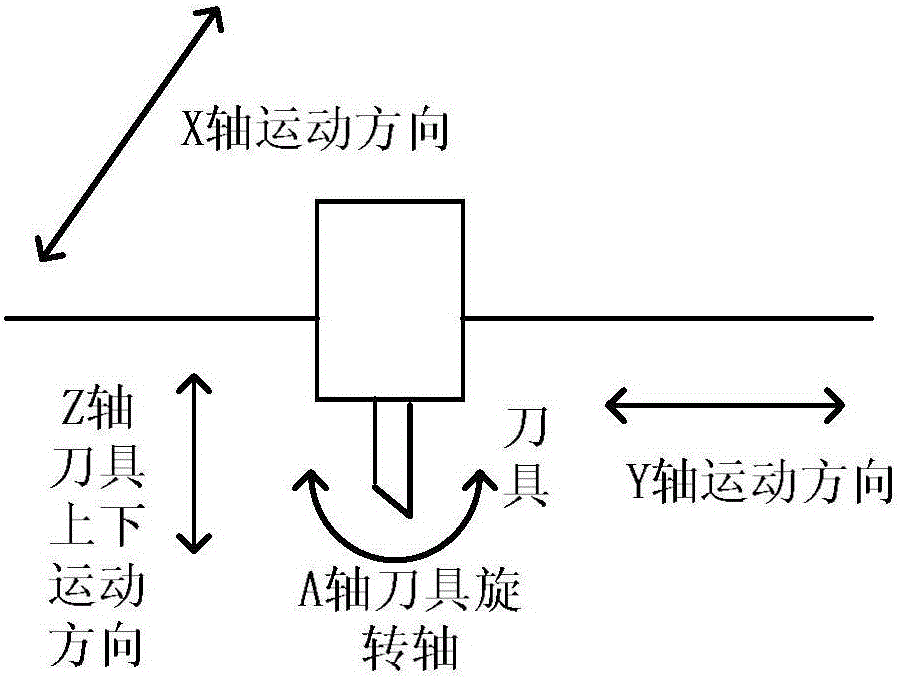

[0050] refer to Figure 1 to Figure 8, a carton cutting method based on the time division method cutter tangentially following control, the equipment for realizing the method includes a mechanical control platform for carrying cardboard, a controller and a human-computer interaction unit for controlling the cutting of cardboard and executing cutting commands , the upper computer for issuing graphics, the driving device for driving the motor, the mechanical control platform includes the control motor of each axis, the cutter for cutting cardboard, and the position sensor for position feedback, the upper computer The human-computer interaction unit is connected with the controller, and the driving device is respectively connected with the motors of the mechanical control platform of the controller, and the motors of the control platform control the movement of each axis. Hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com