Patents

Literature

1526results about How to "Guaranteed processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precision numerical control milling method for thin-wall parts

InactiveCN101602122AReduce stiffnessGuaranteed machining accuracyMilling equipment detailsNumerical controlEngineering

The invention discloses a precision numerical control milling method for thin-wall parts, and provides a processing method for reducing the milling deformation of the thin-wall parts and improving processing precision and surface quality. When a thin-wall part is finished by fine processing through end milling, the machining allowances of the side wall and a web plate are larger than those of the prior process, and are between 2 and 5mm respectively; when the side wall is processed, the axial depth ap is between 0.2 and 0.8mm, and the radial cutting width is 60 to 80 percent of the diameter of a cutting tool; and when the web plate is processed, the axial depth ap is between 2 and 5mm, and the radial cutting width ae is 10 to 20 percent of the diameter of the cutting tool. The processing method effectively slows down the reduction of the self-rigidity of workpieces and control the cutting force in the thin-wall direction when the processing efficiency is ensured, thereby effectively reducing and controlling the processing deformation of the thin-wall parts, and ensuring the processing precision and surface quality of the parts.

Owner:TIANJIN UNIV OF COMMERCE

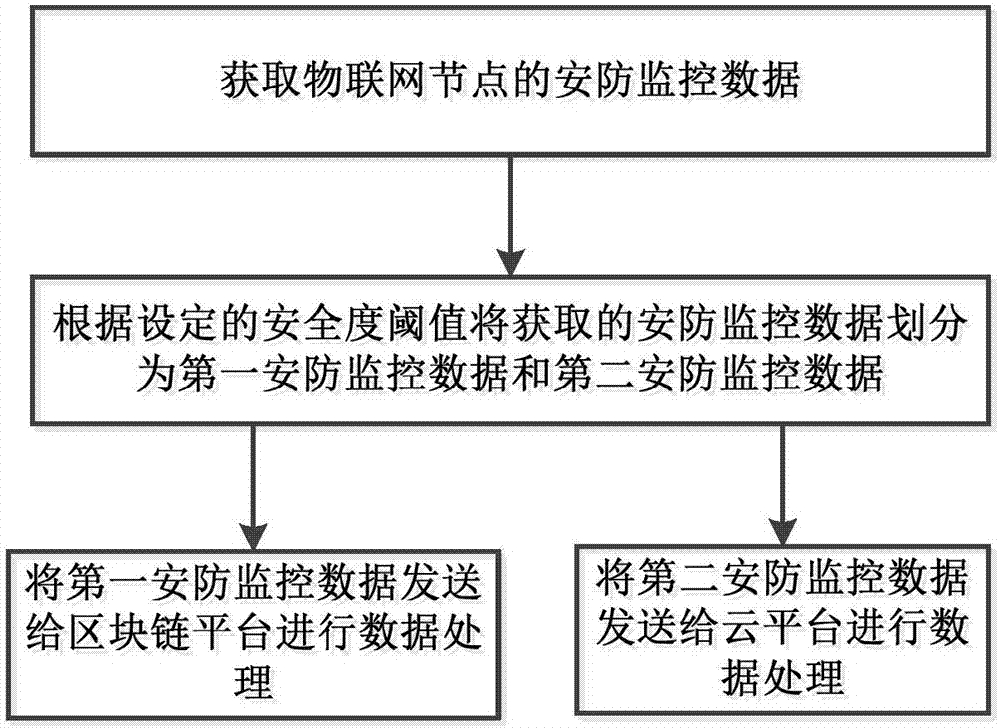

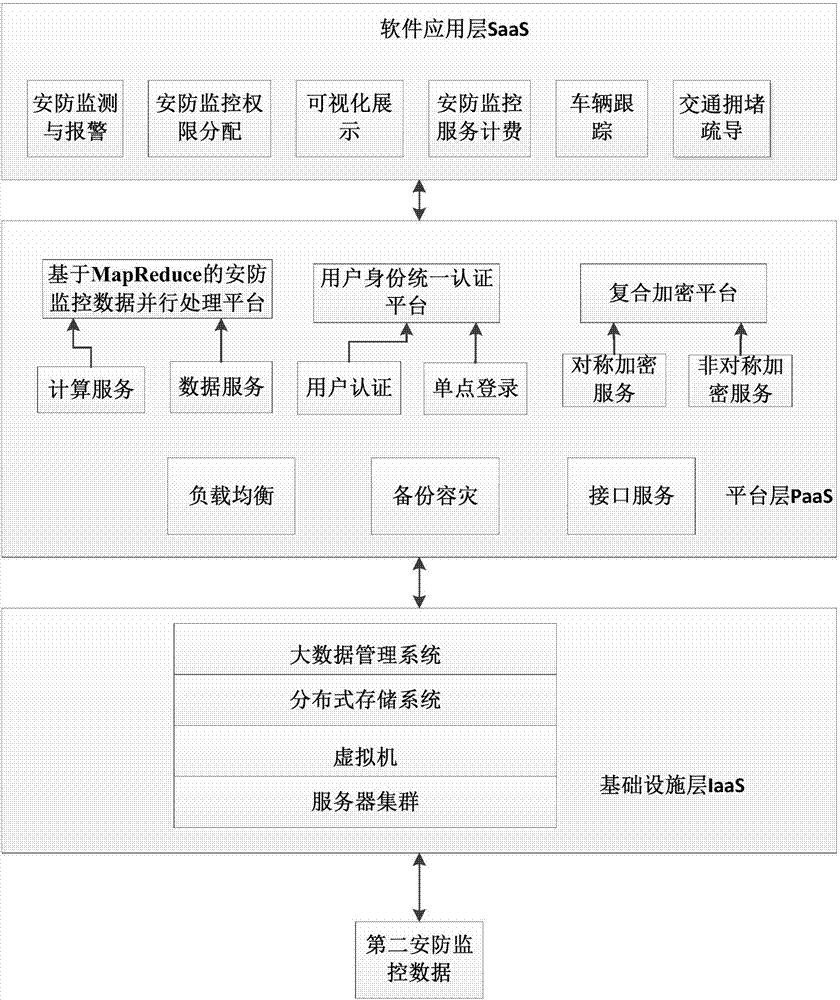

Security and protection monitoring big data processing method and system based on cloud computing

ActiveCN107465656AGuaranteed processing efficiencyEliminate potential safety hazardsClosed circuit television systemsData switching networksMonitoring dataBig data processing

The invention discloses a security and protection monitoring big data processing method and system based on cloud computing. The method comprises the following steps: obtaining security and protection monitoring data of an Internet of Things node; dividing the obtained security and protection monitoring data into first security and protection monitoring data and second security and protection monitoring data according to a set security threshold; sending the first security and protection monitoring data to a block chain platform for data processing; and sending the second security and protection monitoring data to a cloud platform for data processing. According to the security and protection monitoring big data processing method and system, the second security and protection monitoring data with relatively low security requirements are sent to the cloud platform for data processing, thereby ensuring the security and protection monitoring big data processing efficiency; meanwhile the first security and protection monitoring data with relatively high security requirements are sent to the block chain platform for data processing, and DDOS attack is defended by the features of openness, transparency and non-tempering of the block chain technology, thereby eliminating the potential safety hazards caused by the DDOS attack to the cloud platform and the distributed Internet of Things nodes, and being securer. The security and protection monitoring big data processing method and system can be widely used in the field of security and protection.

Owner:广州宏和网络科技有限公司

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

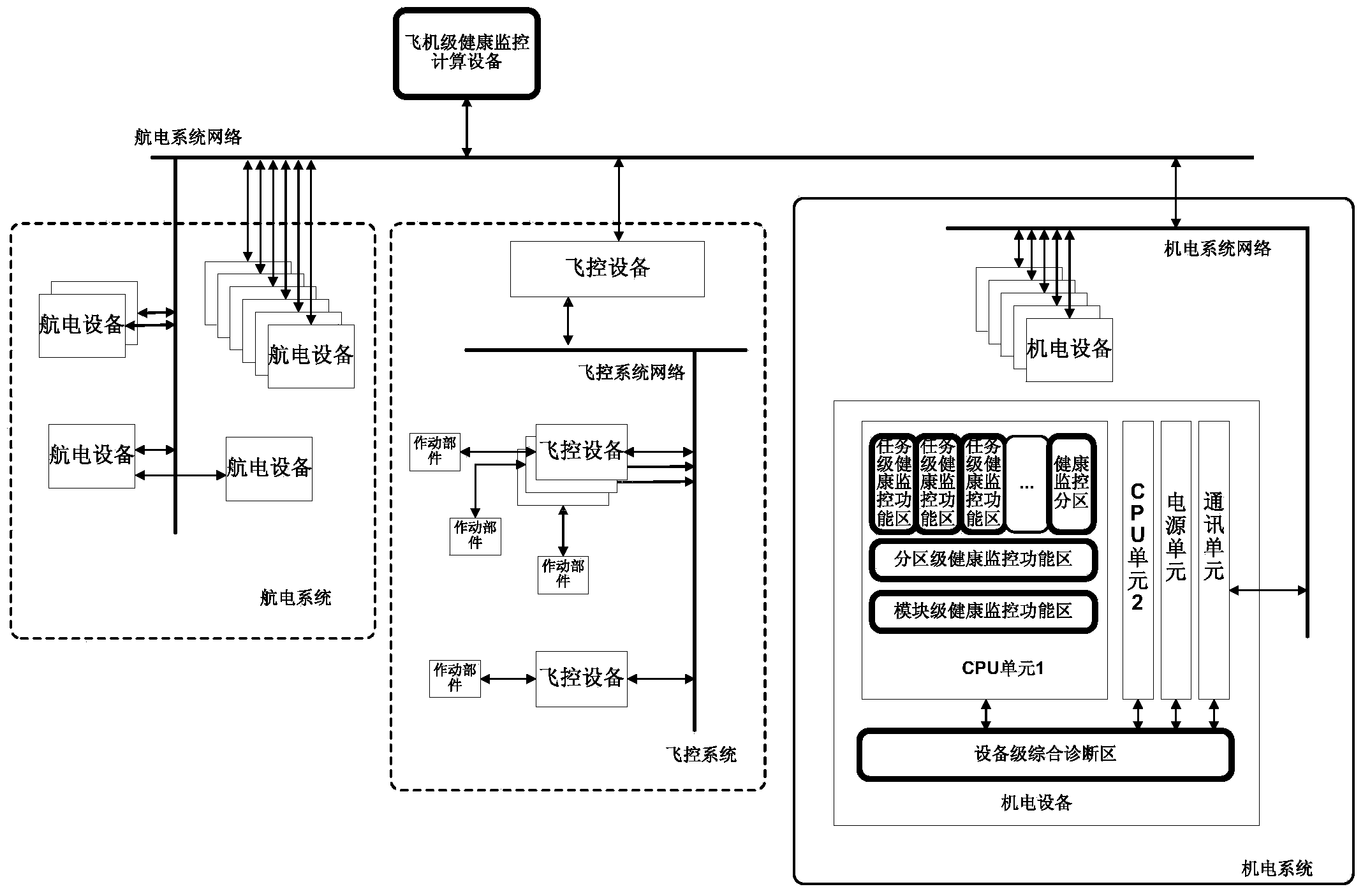

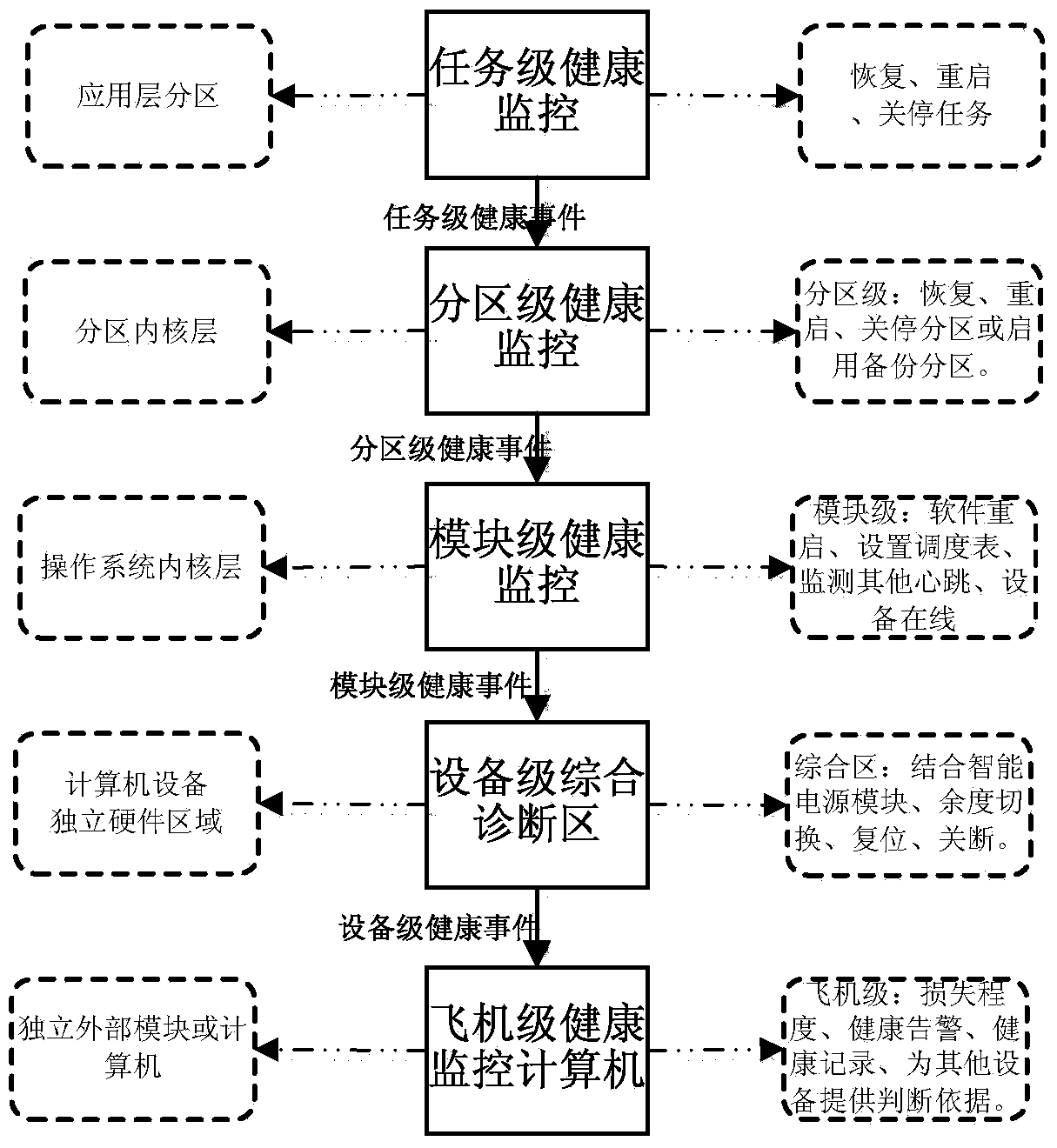

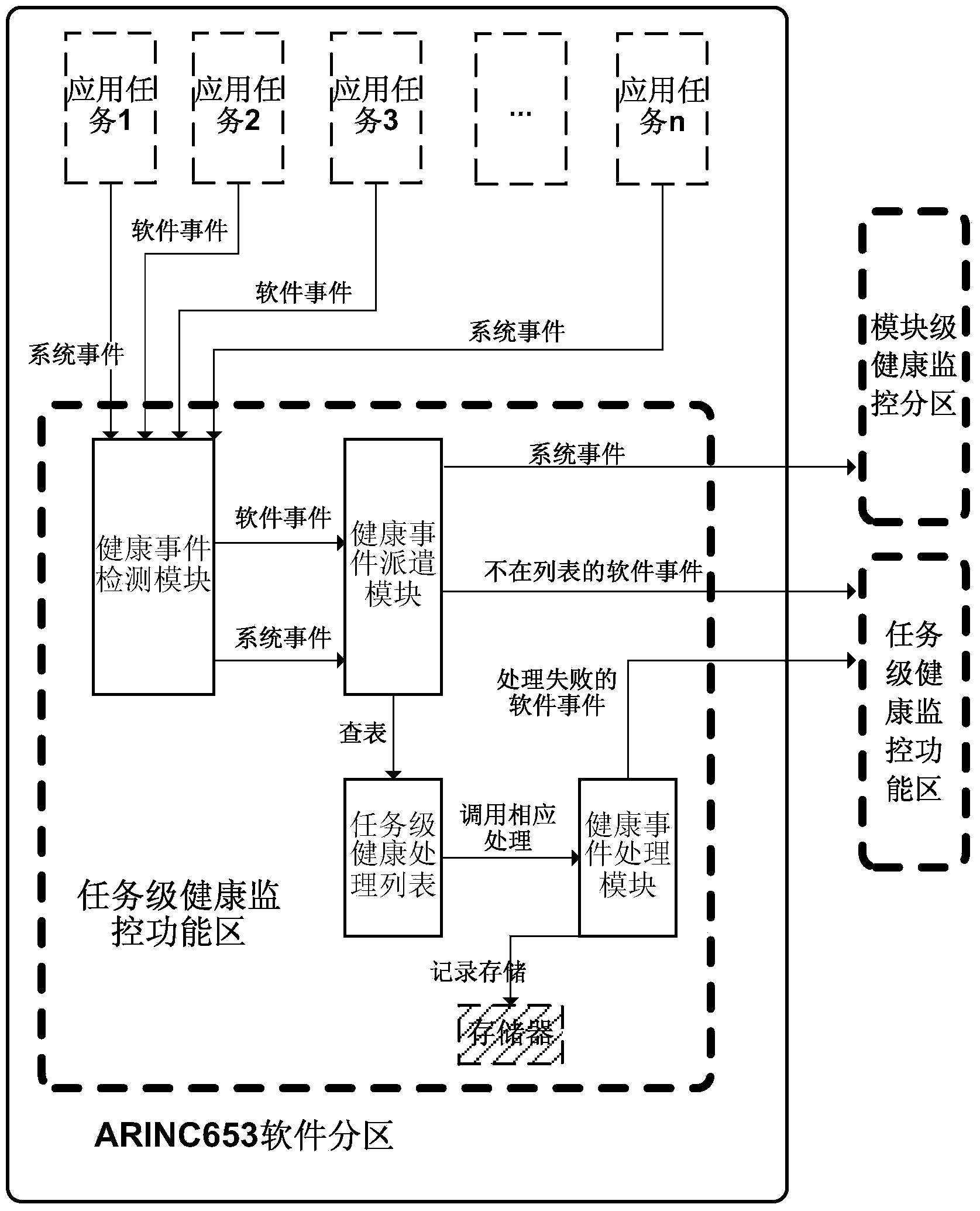

Health monitoring system of avionic electronic equipment based on ARINC653 standard

ActiveCN103544092AEnable on-board health managementEnsure safetyHardware monitoringOperational systemMonitoring system

The invention belongs to the aircraft avionics system technology and relates to a health monitoring system of avionic electronic equipment based on an ARINC653 standard. The health monitoring system adopts a mode of input step by step, diagnostic decision and stage treatment to process anomalous events, performs comprehensive diagnosis from a software task stage to an operation system and from an avionic electronic equipment layer to a full-aircraft system, and adopts a classification layered mode to assign fault events to processing steps of different stages according to a health monitoring stage, and processing permissions are enlarged step by step according to the health monitoring stage. By means of the mode of the stage treatment and report stage by stage, airborne health management of an aircraft is effectively achieved. Safety of fault processing is ensured through the processing permissions of different stages, and processing efficiency on the system fault events and sensing of the aircraft on the health states are improved by reporting the events stage by stage. Therefore, fault diagnosis recovery capability of the aircraft is effectively improved, and testability and safety of the aircraft are strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

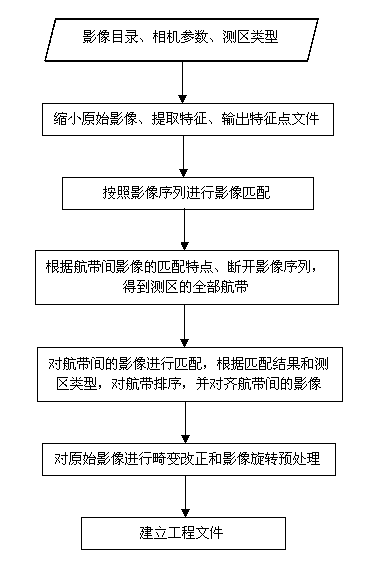

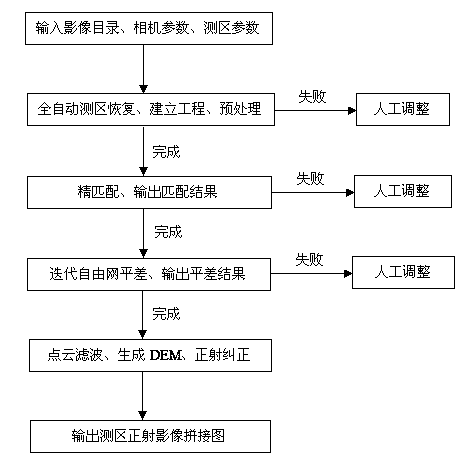

Low-altitude remote sensing image rapid and automatic splicing method without POS assisting

ActiveCN103927731AQuick stitchingAutomate processingImage enhancementImage analysisEngineeringRemote sensing

The invention discloses a low-altitude remote sensing image rapid and automatic splicing method without POS assisting. The method comprises the first step of full-automatic restoration of a low-altitude remote sensing image test area, the second step of conducting fine matching on a preprocessed image according to fine matching seed points to obtain a fine matching result, the third step of conducting free network adjustment iteration on the fine matching result to obtain an adjustment result, and the fourth step of conducting interpolation to generate a digital ground model of the image according to the adjustment result, obtaining a relative outer orientation element of the image under the free network coordinate system according to the adjustment result, conducting orthographic rectification on the image based on the digital ground model and the relative outer orientation element, and meanwhile generating an orthographic image splicing image of the test area. The method is free of POS data assisting, the orthographic image splicing image can be rapidly produced in a full-automatic mode, the remote sensing image quasi real-time processing requirement can be met, and the method is suitable for the fields of disaster emergency response, military security and the like.

Owner:WUHAN UNIV

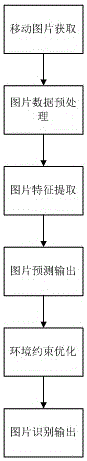

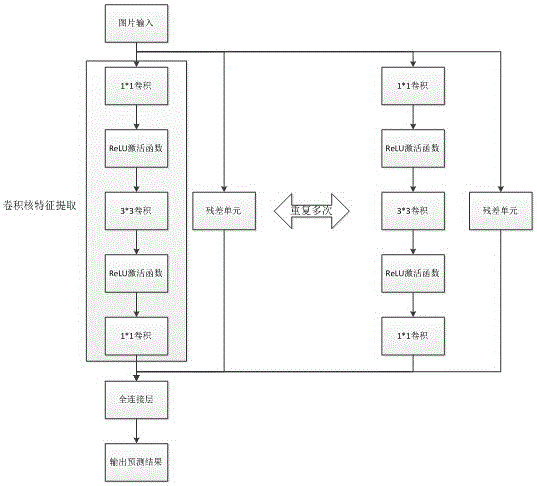

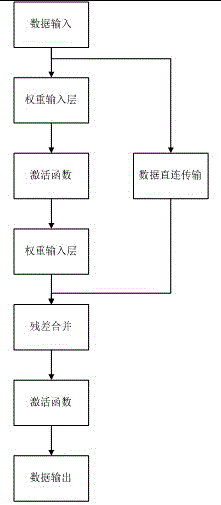

Rapid object recognition method for mobile robot based on deep learning

ActiveCN106228162AOvercoming complexityOvercome instabilityCharacter and pattern recognitionFeature extractionInstability

The invention discloses a rapid object recognition method for a mobile robot based on deep learning, and the method comprises the following steps: 1), the obtaining of a mobile image; 2), the preprocessing of image data; 3), the extracting of the features of the image; 4), image prediction output; 5), environment constrained optimization; 6), image recognition output. Through the unified integration of detection and recognition results, the method overcomes the shortcomings of the complexity and instability of a conventional object recognition system which needs to employ an object. Through a multilayer residual error network design and the generation of environment gravity constraint conditions, the method irons out the defect that an integrated object recognition system is poor in accuracy. The integration of detection and recognition tasks can guarantee the processing efficiency of a system, and improves the sensing capability of the robot in a moving process.

Owner:王威

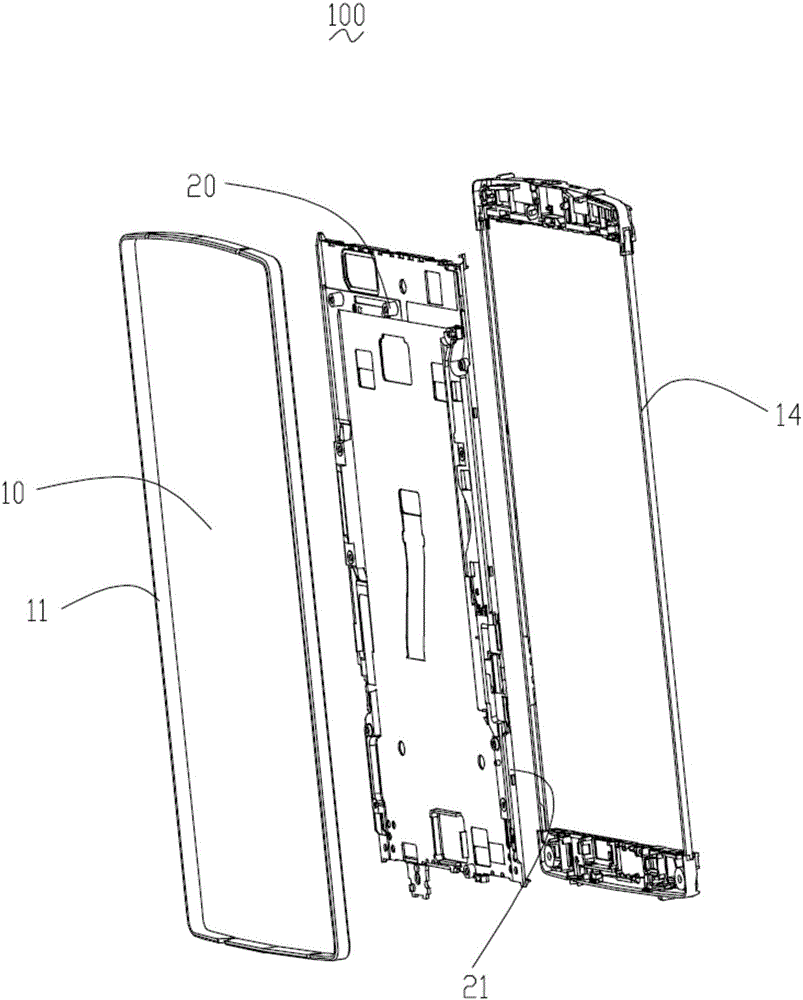

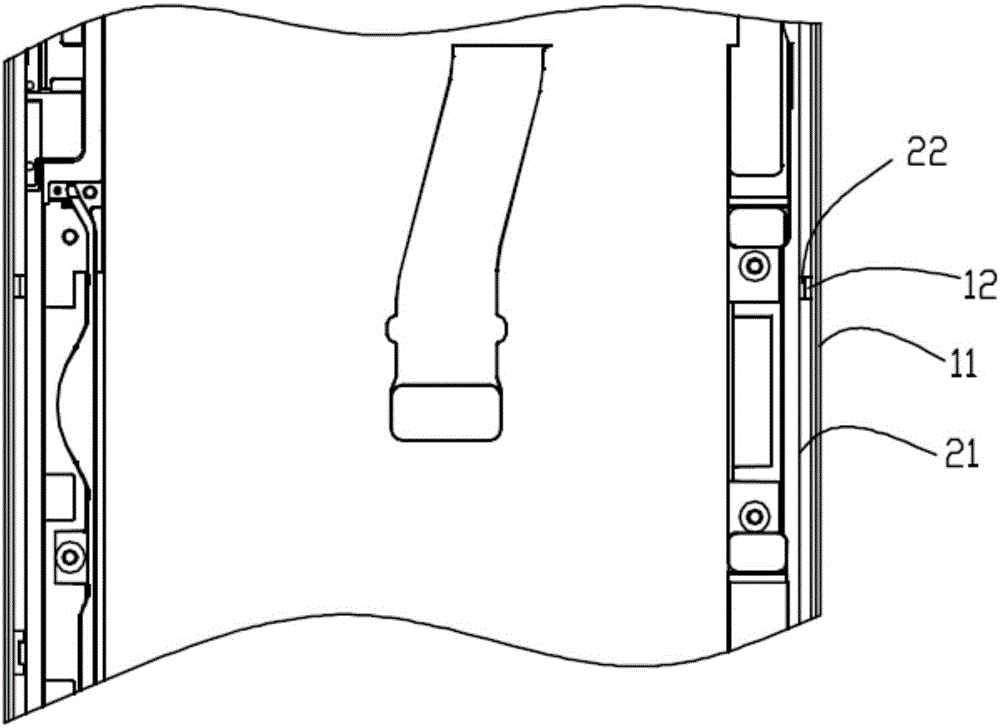

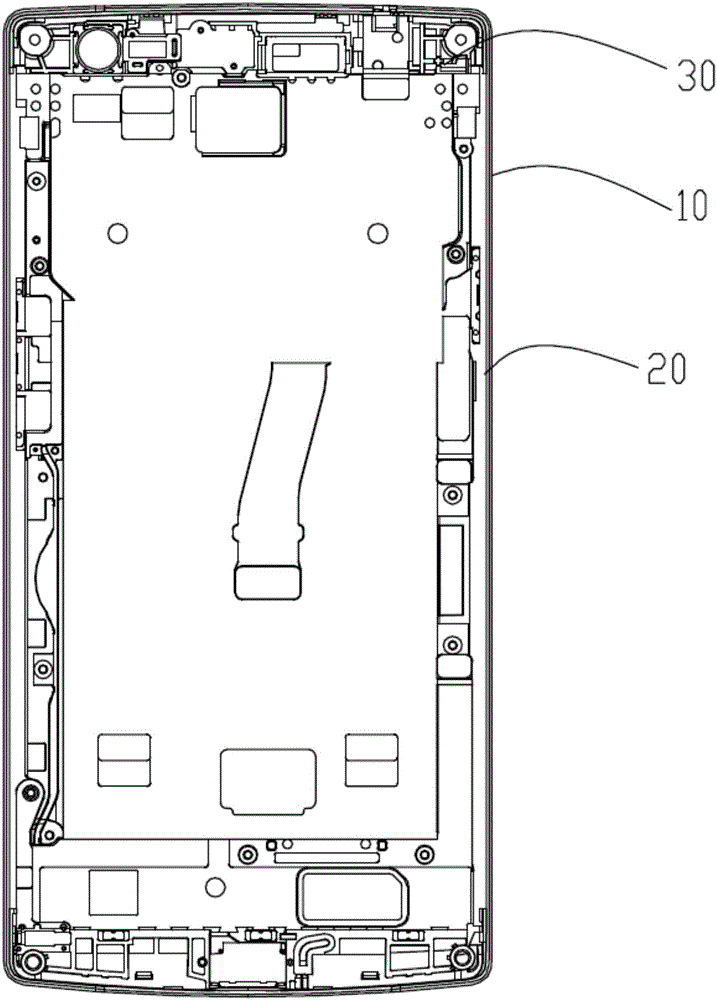

Casing manufacturing method, casing and electronic device

ActiveCN105108966AAvoid Process LimitationsImprove the quality effectCasings/cabinets/drawers detailsMetal sheetMachining

The invention provides a casing manufacturing method. The method comprises steps as follows: metal sheets are provided and machined to form an outer frame, wherein the outer frame comprises a peripheral side wall and an accommodating tank defined by the peripheral side wall; a middle frame is formed through mould forming and comprises an outer side wall; the middle frame is mounted in the accommodating tank, and the outer side wall and part of the inner surface of the peripheral side wall are fixedly connected through welding; a gap is formed in the part between the middle frame and the peripheral side wall; plastic filling is performed, and a filling area comprises the gap between the middle frame and the peripheral side wall; secondary machining is performed on size and appearance of the outer frame; the outer surface of the outer frame is subjected to surface treatment. The invention further provides an electronic device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

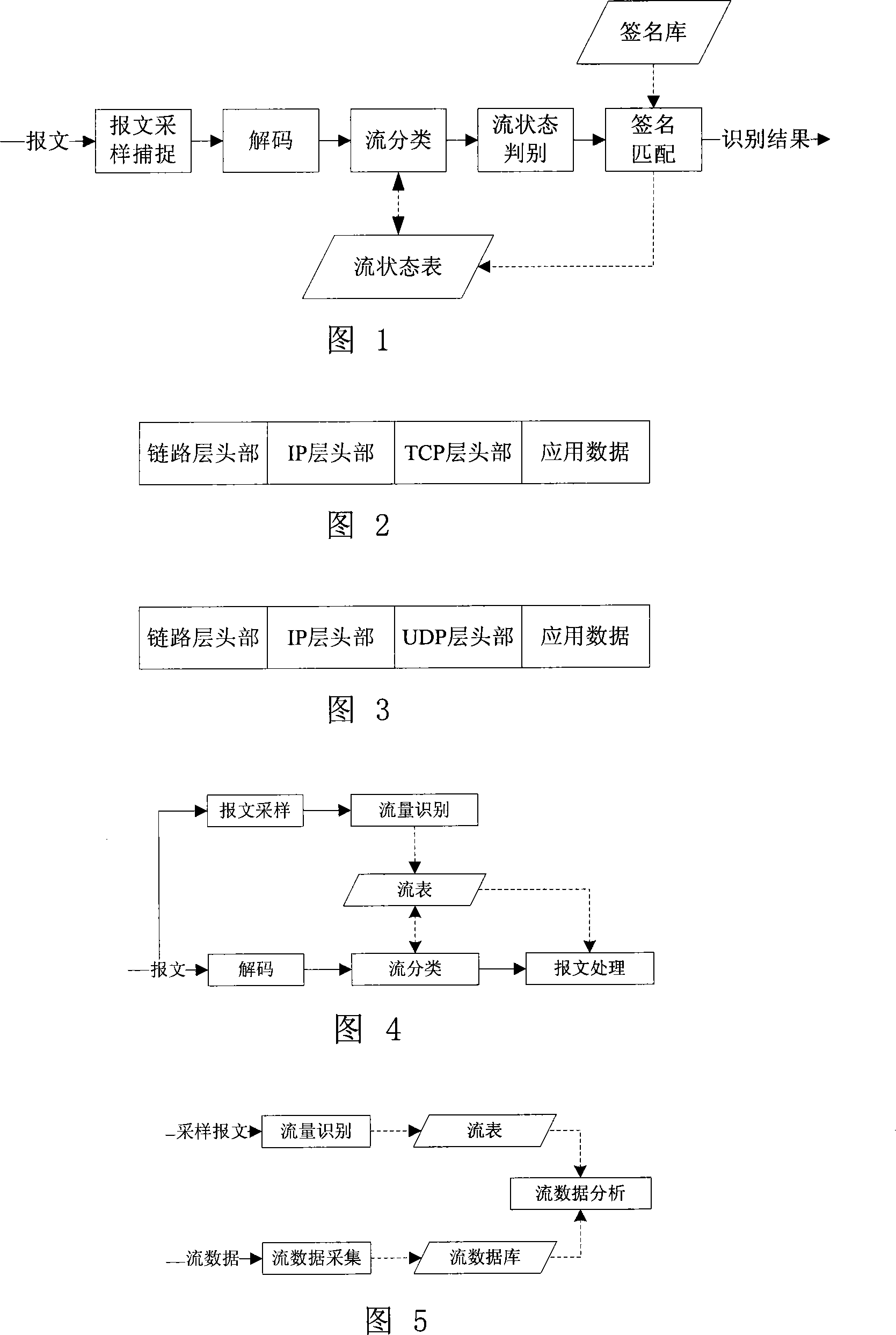

Packet sampling and application signature based internet application flux identifying method

InactiveCN101184000AImprove recognition accuracyImprove processing efficiencyUser identity/authority verificationData switching networksTraffic volumePacket sampling

The invention relates to an internet application flow rate identification method based on message sampling and application signing, comprising the following steps: firstly, message sampling capture: in accordance with sampling strategy and sampling rate the message is captured and decoded; secondly, decoding: the flow information and application data of the message is analyzed by decoding the message; thirdly, flow classification: according to the flow information of the message, a flow state table is found and maintained; fourthly, flow state distinguishing: the signature is matched if the application type of the flow state found through the flow classification is unknown; finally, signature matching: according to the application signature bank, the application data of the message is matched, if matched successfully, the application type of the flow state is updated, and the flow information and application type of that data stream is output. The method is of high accuracy in identification, high efficiency in processing, good expandability, high possibility in realization, and is applicable not only for message processing, but also for flow data analysis. The invention can be achieved in not only the network equipment, but also the network analysis system.

Owner:BEIJING JIAOTONG UNIV

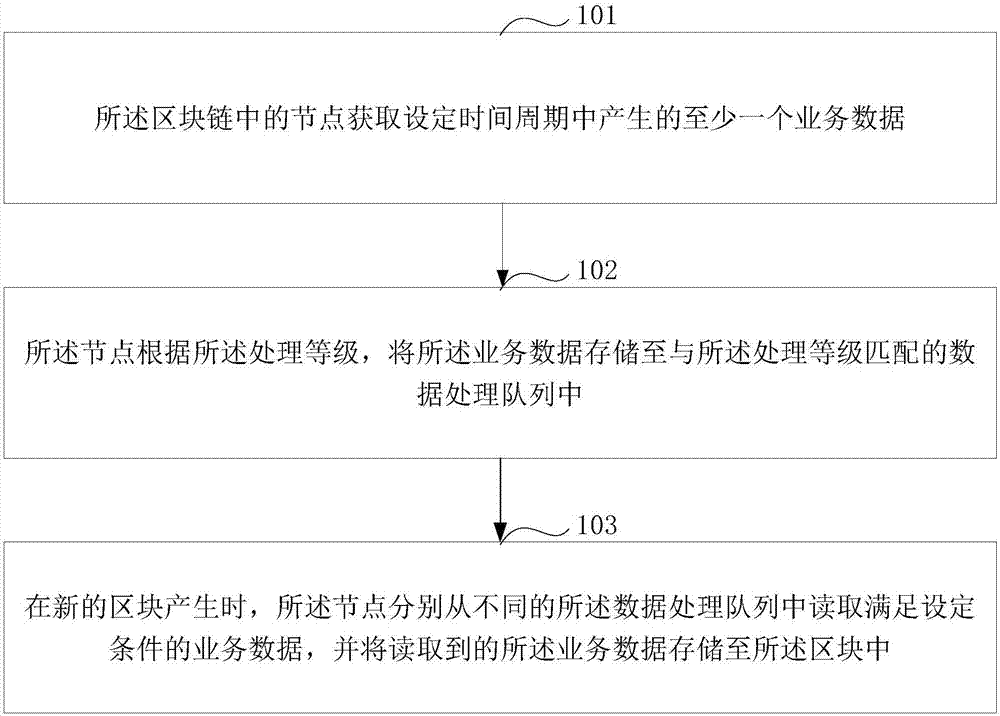

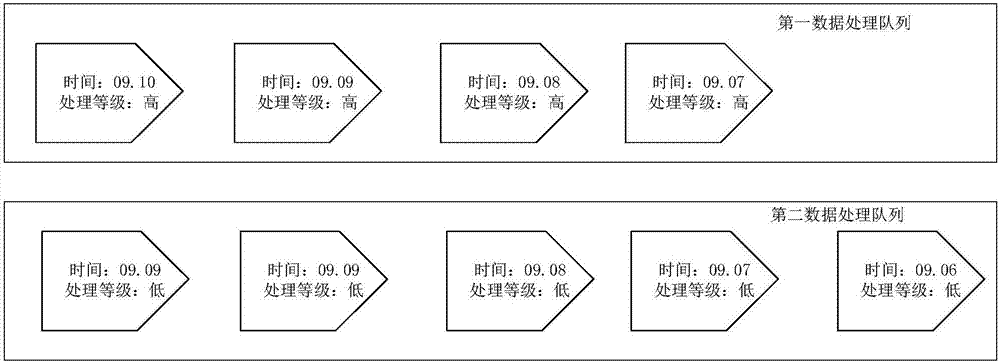

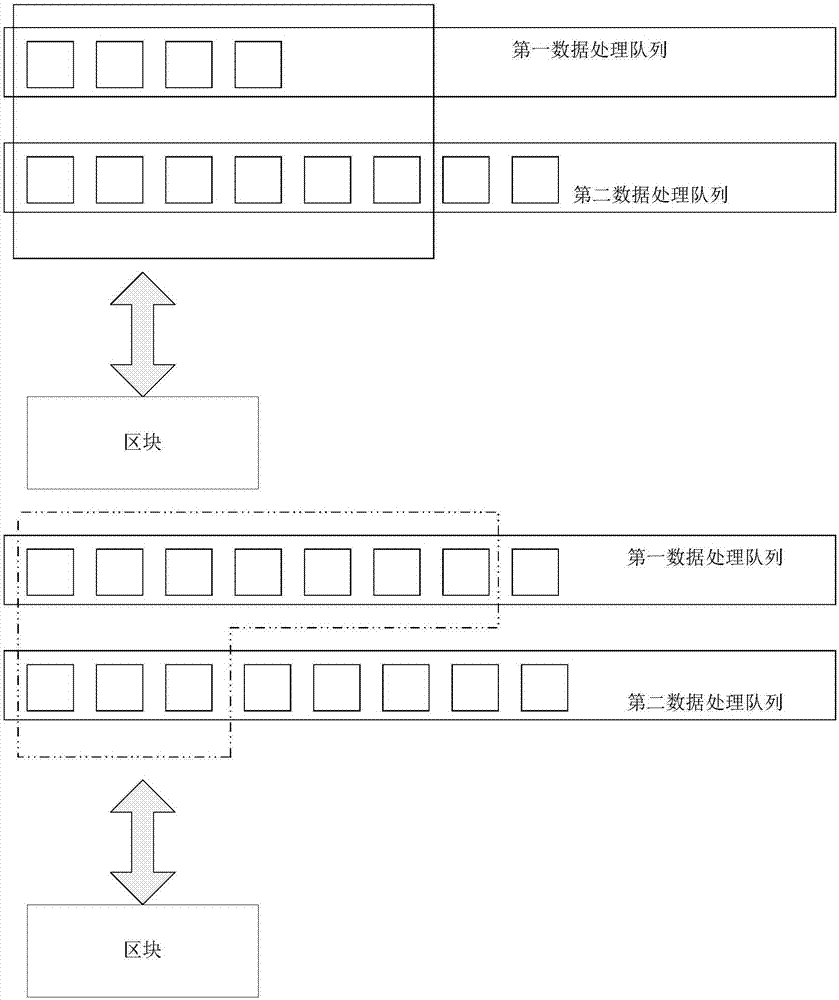

Data processing method and equipment based on blockchain

ActiveCN107391526AIncrease flexibilityImprove use valueDatabase distribution/replicationPayment architectureBusiness dataBlockchain

The invention discloses a data processing method and equipment based on a blockchain. The method comprises the following steps that: according to processing levels, storing different business data into different data processing queues; and when the data is stored into a block, according to a set condition, reading a certain quantity of business data from different data processing queues to realize a purpose that the business data of different processing levels can be processed. Therefore, a stipulation in the prior art that the business data is processed singly according to a time factor is broken through, and the problem in the prior art that the processing efficiency of business with a high business priority is low can be avoided. By use of the scheme provided by the embodiment of the invention, the processing efficiency of the business data of the business with the high business priority can be guaranteed, and the processing efficiency of the business data of business with the low business priority can be guaranteed. While the business processing priority is met, business data processing flexibility in the blockchain is increased, and the use value of the blockchain in a business application field is improved.

Owner:ADVANCED NEW TECH CO LTD

Sapphire substrate ultraprecision machining method based on fixed abrasive pad

ActiveCN103252708AFast processingEfficient processingLapping machinesLapping toolsMachining timeUltra precision

The invention discloses a sapphire substrate ultra-precision machining method based on a fixed abrasive pad. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad mainly relates to three steps of rough grinding, accurate grinding and polishing, namely, rough grinding is conducted on a cut sapphire substrate semi-finished product through a W75 nickel plated diamond FAP; then accurate grinding is conducted on a workpiece after rough grinding through a W28 nickel plated diamond FAP; last, polishing is conducted on the workpiece after accurate grind through a W5 diamond FAP, and grinding and polishing processes are finished. According to the sapphire substrate ultra-precision machining method based on the fixed abrasive pad, a sapphire substrate is machined, the time cost in the whole process is shortened within two hours, machining time of sapphire is greatly shortened, the sapphire substrate with the workpiece surface roughness (Ra) is smaller than 3nm can be finally obtained, surface defects such as pitting corrosion and scratches can be effectively removed, the damage of a subsurface is reduced and the quality of the surface is good. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad improves machining efficiency of the substrate and the quality of the surface of the substrate, and is low in cost and pollution-free.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

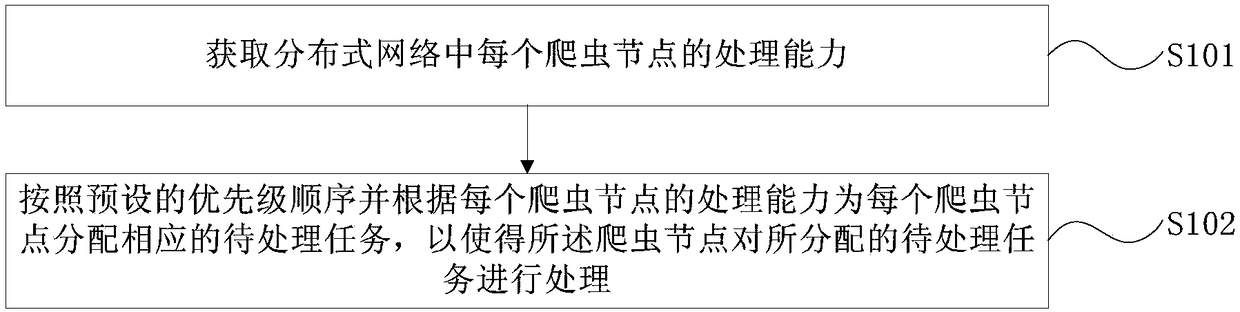

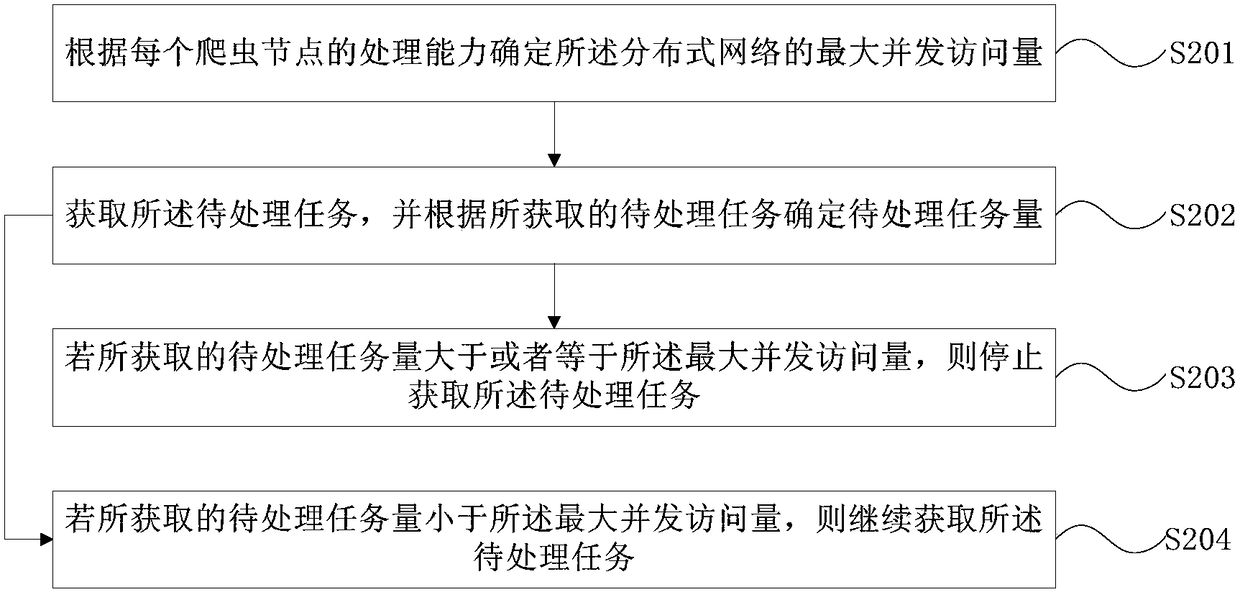

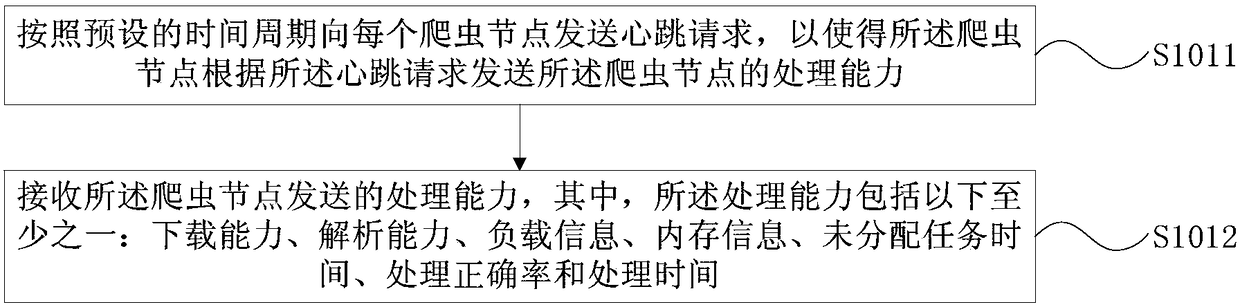

Distributed network crawler task scheduling method and apparatus

ActiveCN108205541AImprove practicalityEfficient managementWeb data indexingSpecial data processing applicationsWeb crawlerEffective management

The invention provides a distributed network crawler task scheduling method and apparatus. The method comprises the steps of obtaining processing capacity of each crawler node in a distributed network; and according to a preset priority sequence and the processing capacity of each crawler node, allocating corresponding to-be-processed tasks to each crawler node, thereby enabling the crawler node to process the allocated to-be-processed tasks. According to the distributed network crawler task scheduling method and apparatus provided by the invention, the corresponding quantity of the to-be-processed tasks are allocated to the crawler node according to the preset priority sequence and the processing capacity of each crawler node, so that the effective management of the crawler nodes is realized and the efficiency of processing the allocated to-be-processed tasks according to the processing capacity by each crawler node is ensured; and therefore, the practicality of the scheduling methodis improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

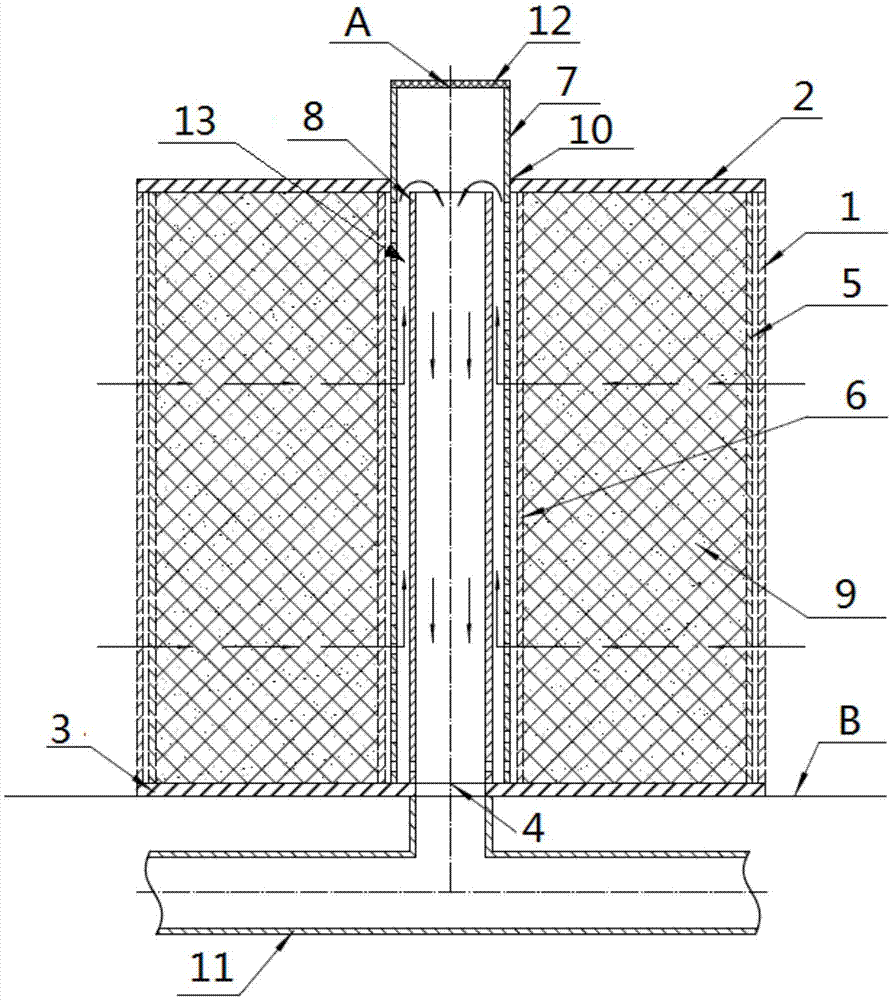

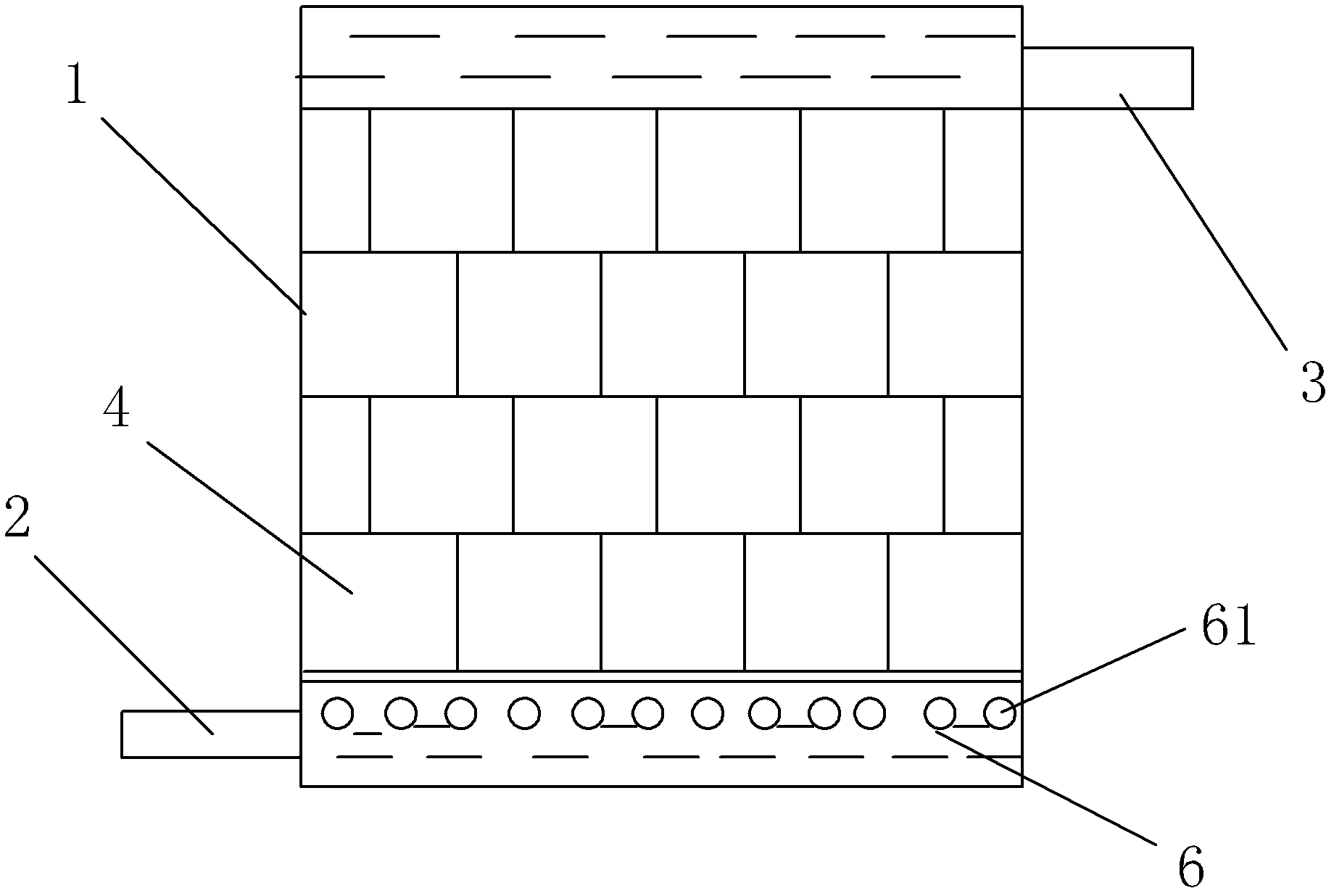

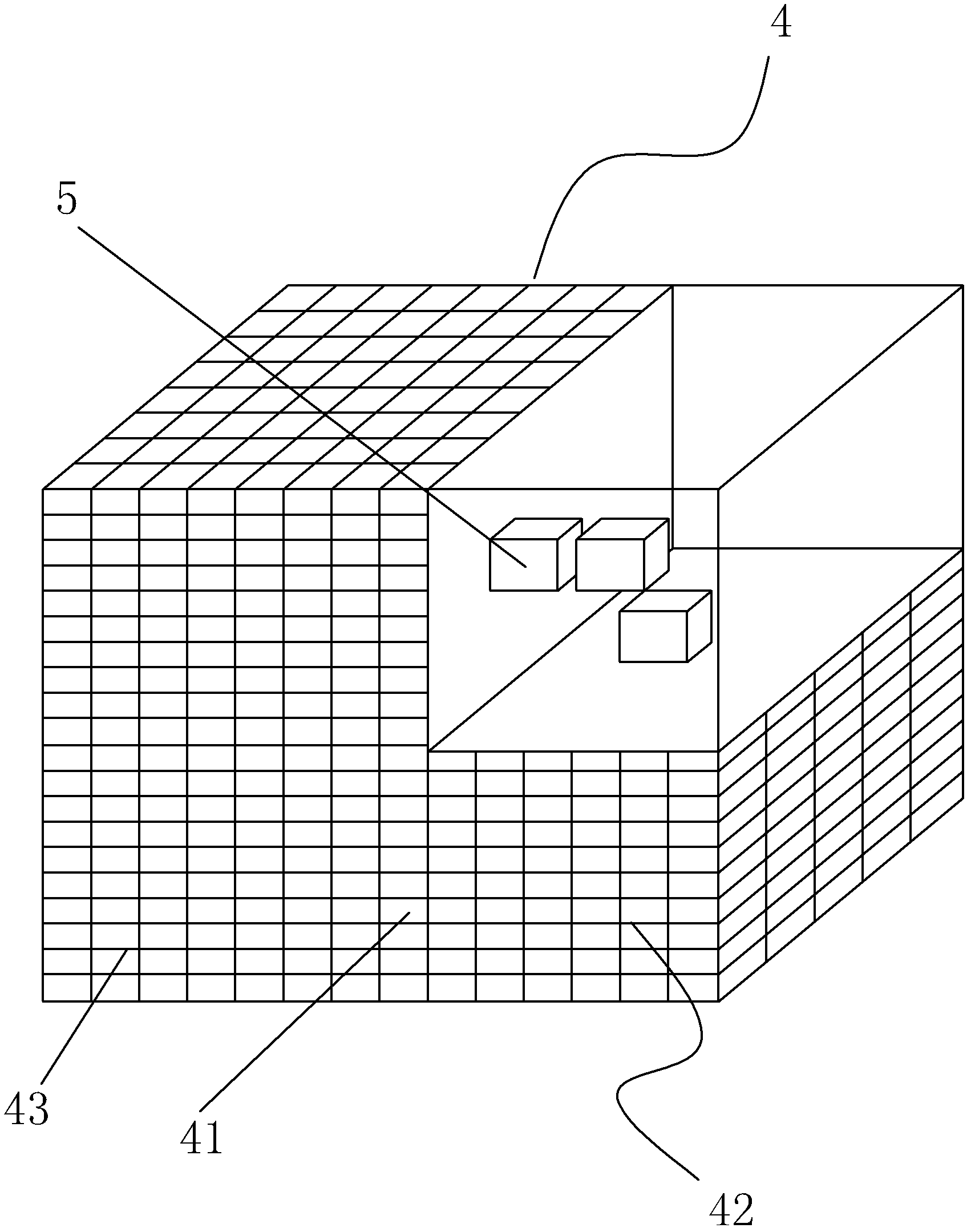

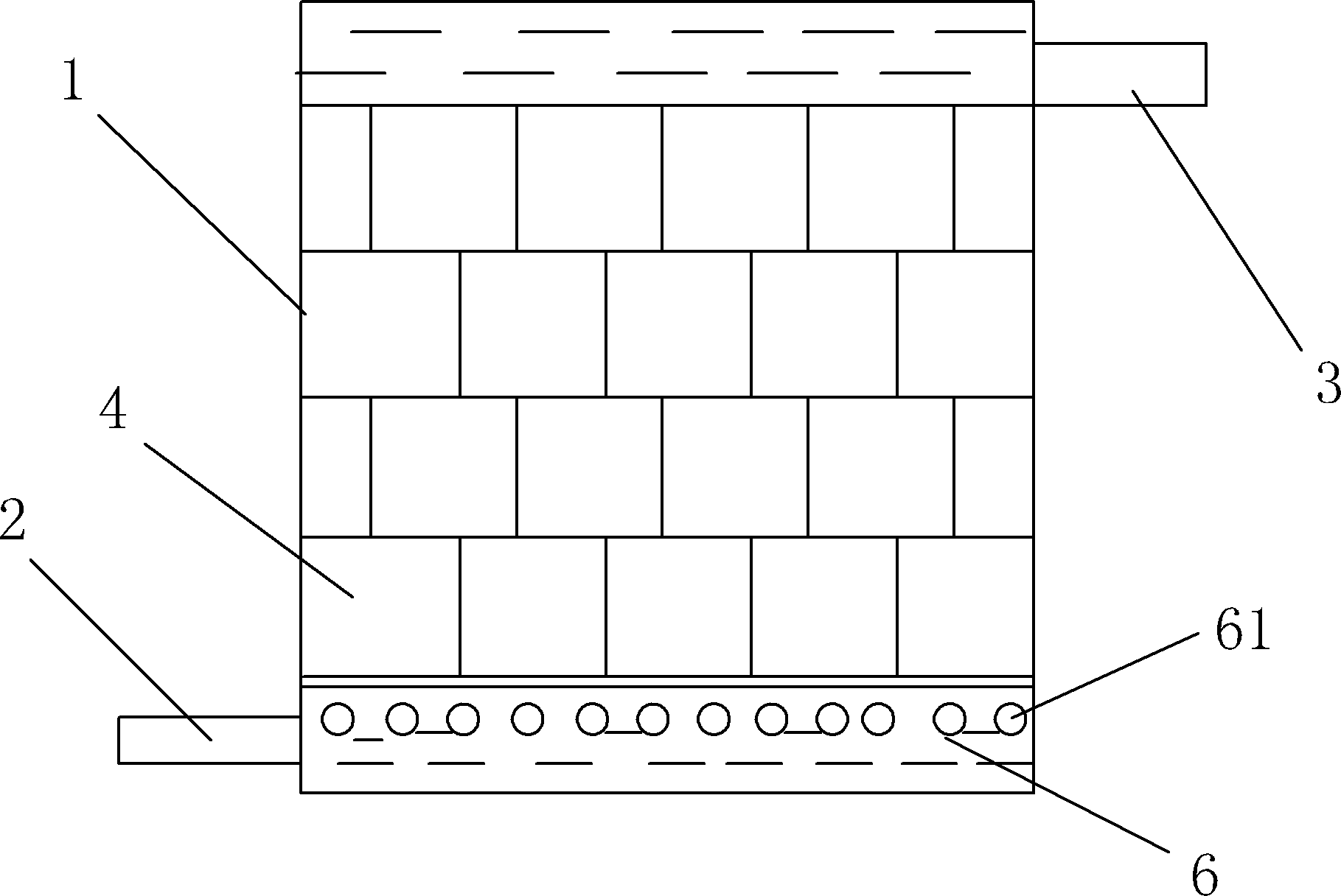

Efficient rainwater filter

ActiveCN105435495AGuaranteed utilizationGuaranteed processing efficiencyMembrane filtersLoose filtering material filtersFilter mediaEngineering

The invention discloses an efficient rainwater filter and belongs to the technical field of rainwater treatment devices. The efficient rainwater filter comprises a filter communicated with a drain pipe, a collecting pipe with a water hole is coaxially arranged in the filter, and a central cylinder is coaxially arranged in the collecting pipe. The central cylinder is provided with an overflow hole, the bottom end of the central cylinder is communicated with the drain pipe, and a rainwater retention channel is formed between the collecting pipe and the central cylinder. Rainwater accumulated in the rainwater retention channel is discharged through the overflow hole in the central cylinder. The efficient rainwater filter is simple in structure and convenient to manufacture and use; in the whole filtering process, not only is full contact between the rainwater and a filtering medium guaranteed, but also pollutants in the rainwater can be effectively removed, and the filtering medium utilization rate and the treatment efficiency of the filter are also guaranteed.

Owner:WUHAN MEIHUA YUSHUI ENVIRONMENT CO LTD

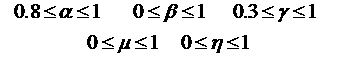

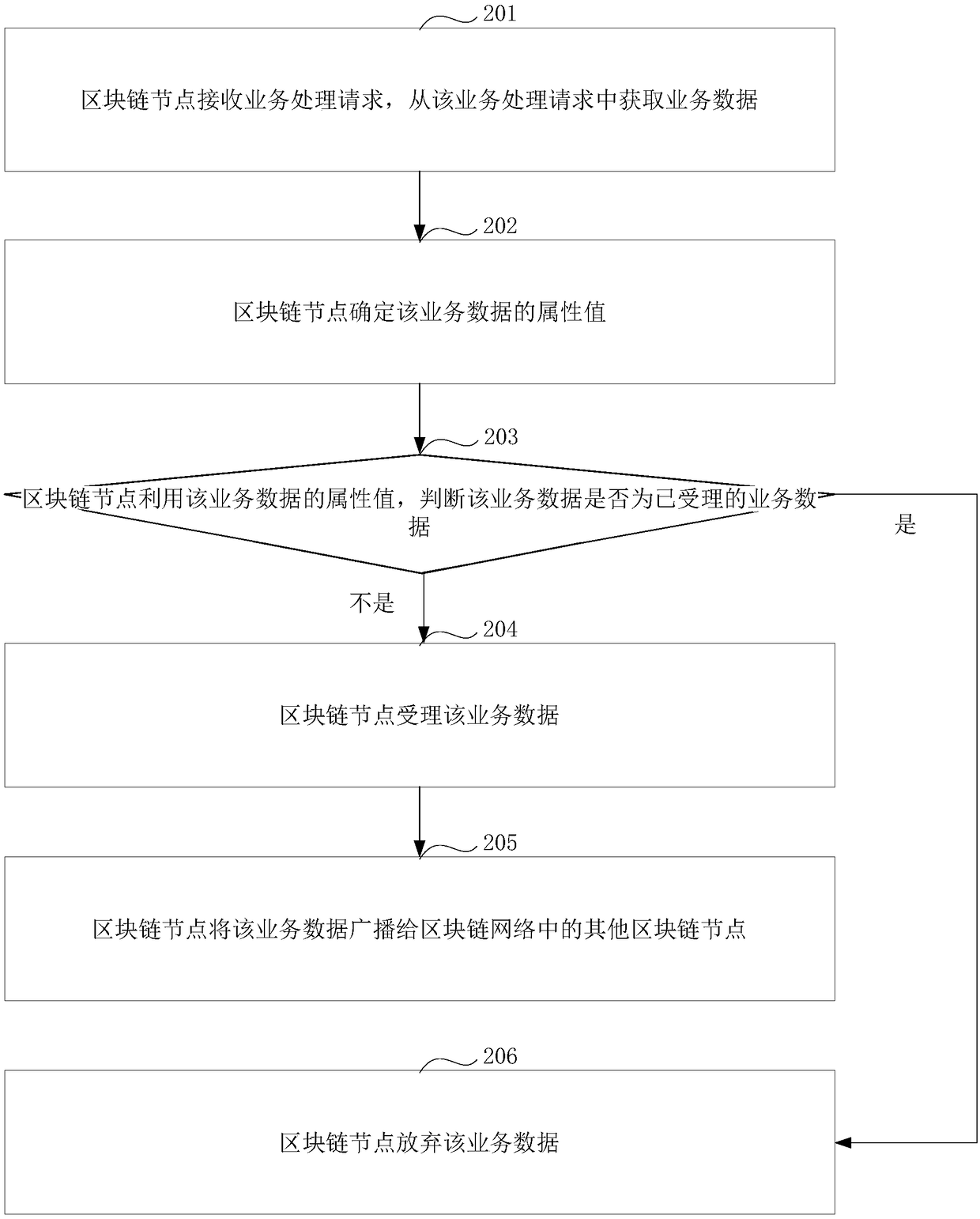

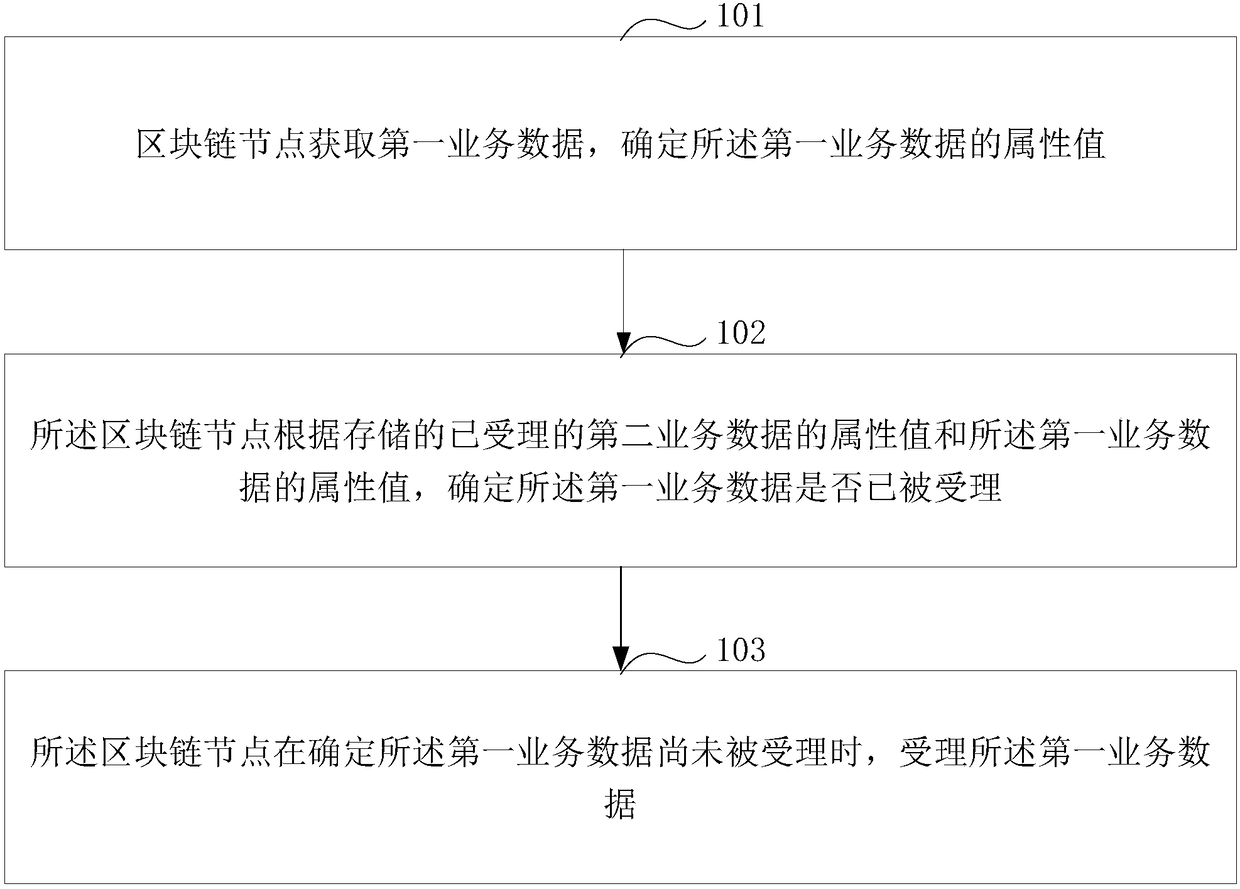

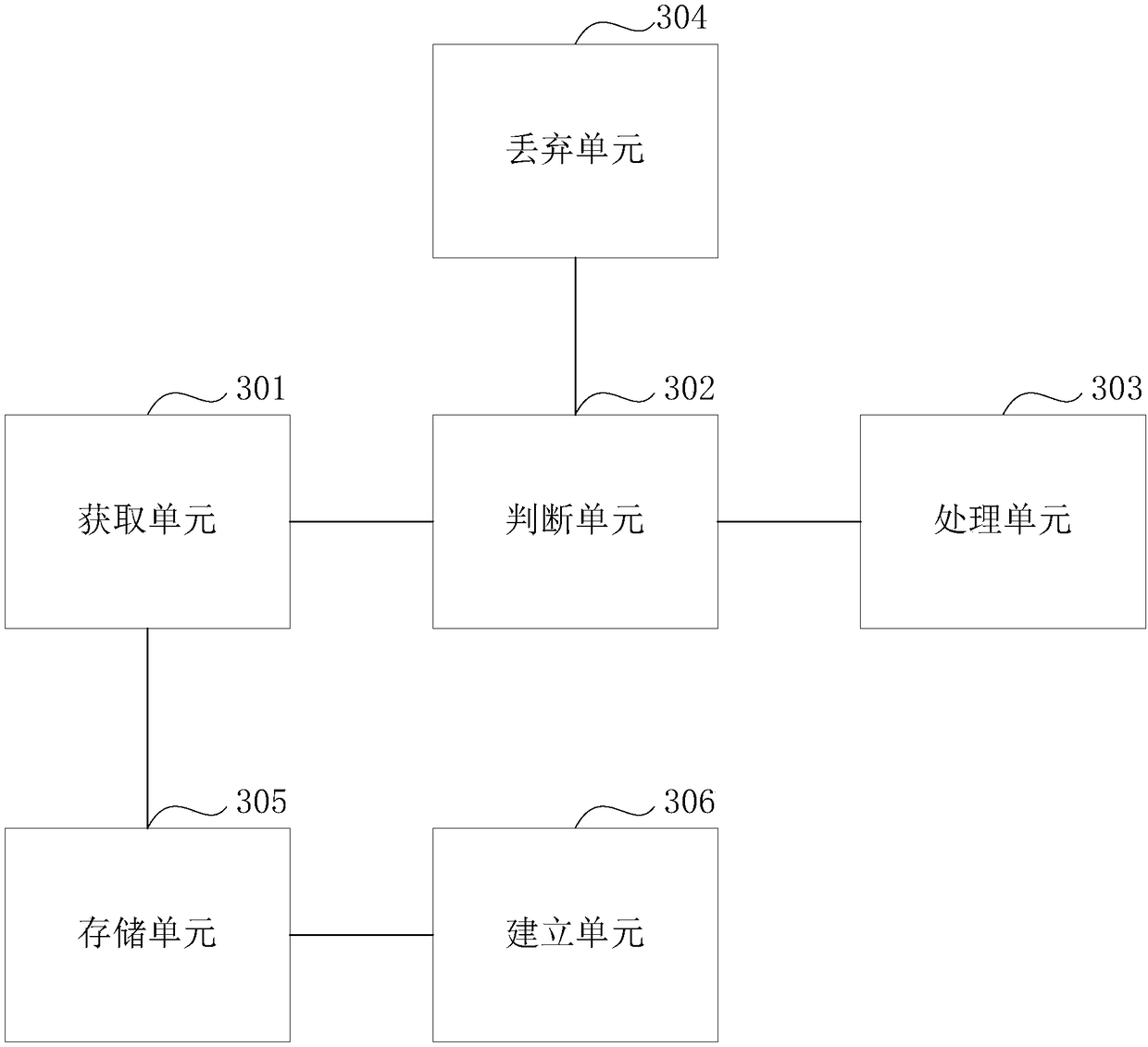

Data processing method and data processing equipment based on blockchain

ActiveCN108881120AGuaranteed processing efficiencyImprove throughputDatabase queryingCryptography processingBusiness dataData storing

The application discloses a data processing method and data processing equipment based on blockchain. The method comprises the following steps: determining whether the business data to be processed isaccepted by comparing the attribute value capable of representing the uniqueness of the business data to be processed with that of the accepted business data stored in a blockchain node, and startingto process the business data to be processed only when the business data to be processed is determined to be not accepted, which is capable of effectively preventing replay attack, thereby, since theattribute values of different business data are different at the same time, avoiding the problem that other business data cannot be processed caused by locking when a piece of business data is beingprocessed, effectively ensuring the efficiency of processing the business data of the blockchain network, and improving the throughput of the business data of the blockchain network.

Owner:ADVANCED NEW TECH CO LTD

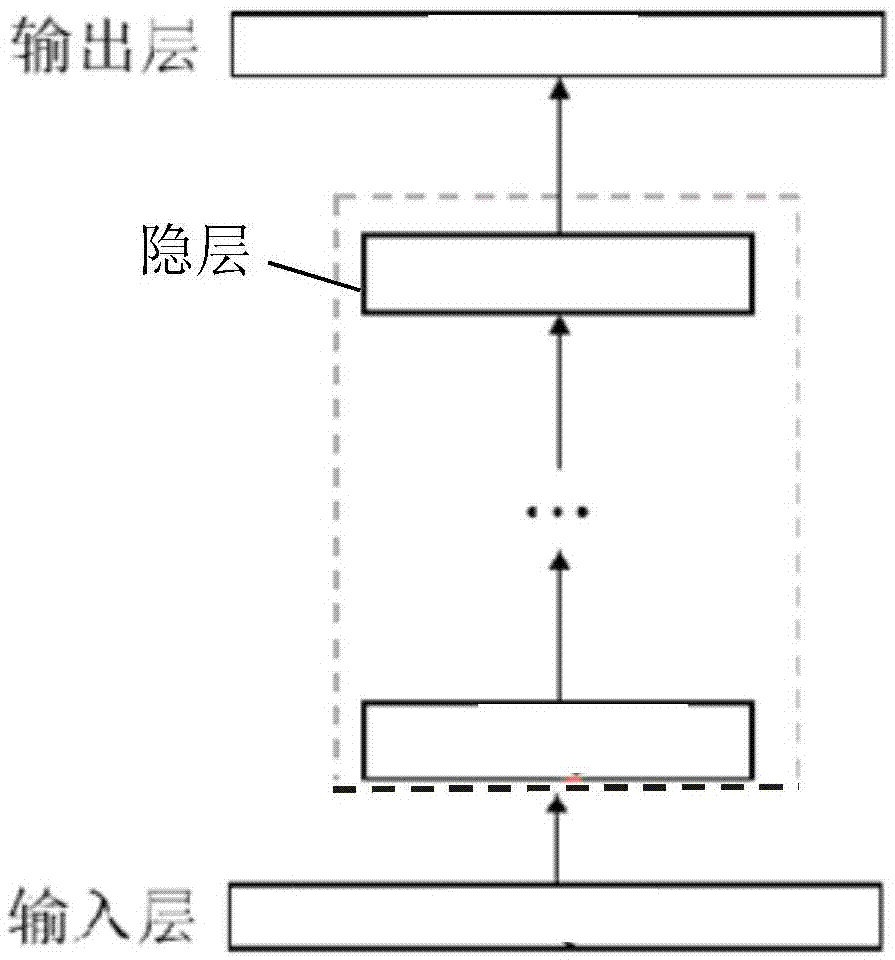

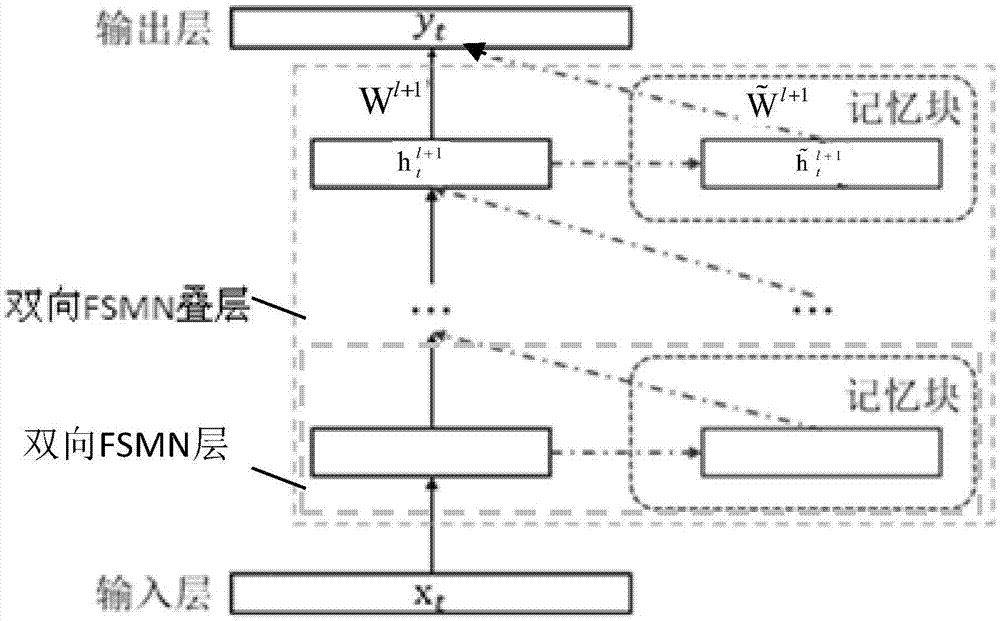

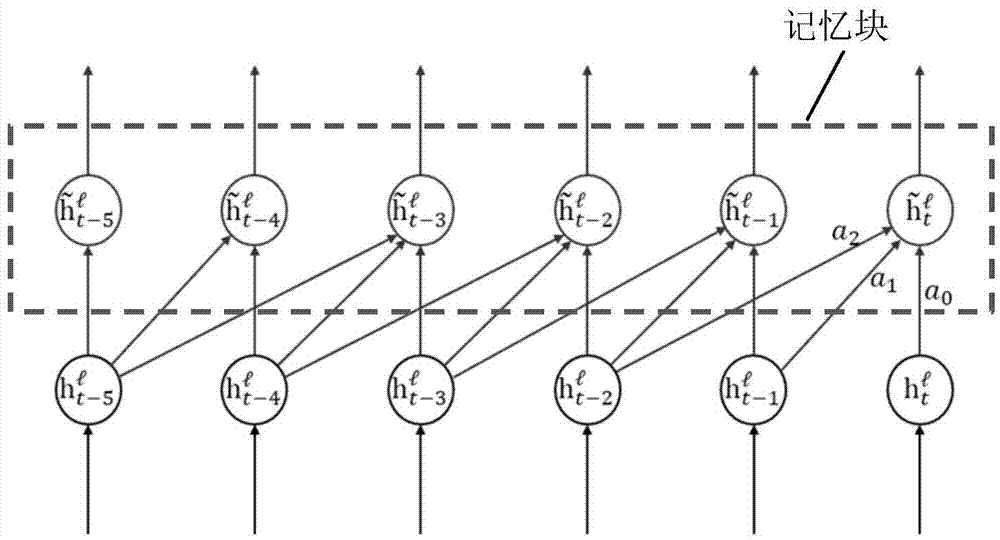

Feedforward sequence memory neuron network and construction method and system thereof

ActiveCN106919977AImprove the ability to process information and dataGuaranteed processing efficiencyNeural architecturesAlgorithmTime information

The invention discloses a feedforward sequence memory neuron network and a construction method and system thereof. The feedforward sequence memory neuron network comprises at least three layers of multiple nodes, wherein the first layer is an input layer, the last layer is an output layer, and other multiple nodes positioned between the input layer and the output layer form at least one hidden layer; each hidden layer comprises a memory block; the hidden layer and the memory block jointly form a bidirectional FSMN (Feedforward Sequence Memory Neuron Network) layer; and the memory block is used for storing the historical information and the future information of each frame of input information. Since the bidirectional FSMN layer comprises the memory block, the historical information and the future information of each frame of input information are stored, the long-time information of training data can be utilized, the process does not need to carry out bidirectional circulation feedforward, and information processing efficiency can be guaranteed.

Owner:IFLYTEK CO LTD

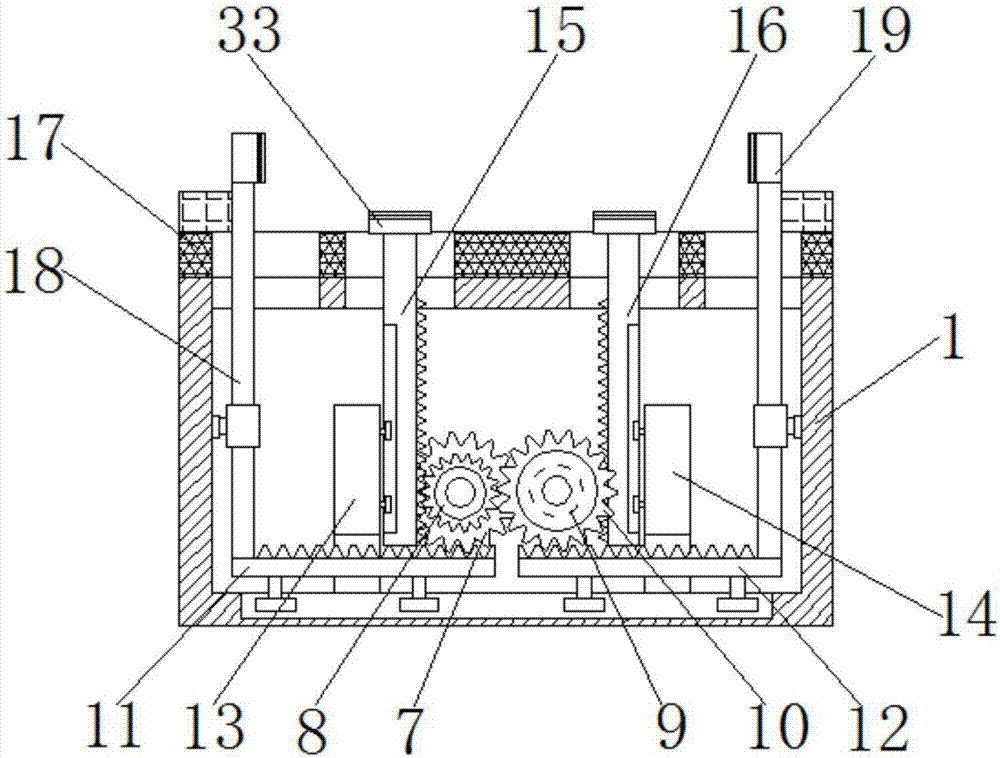

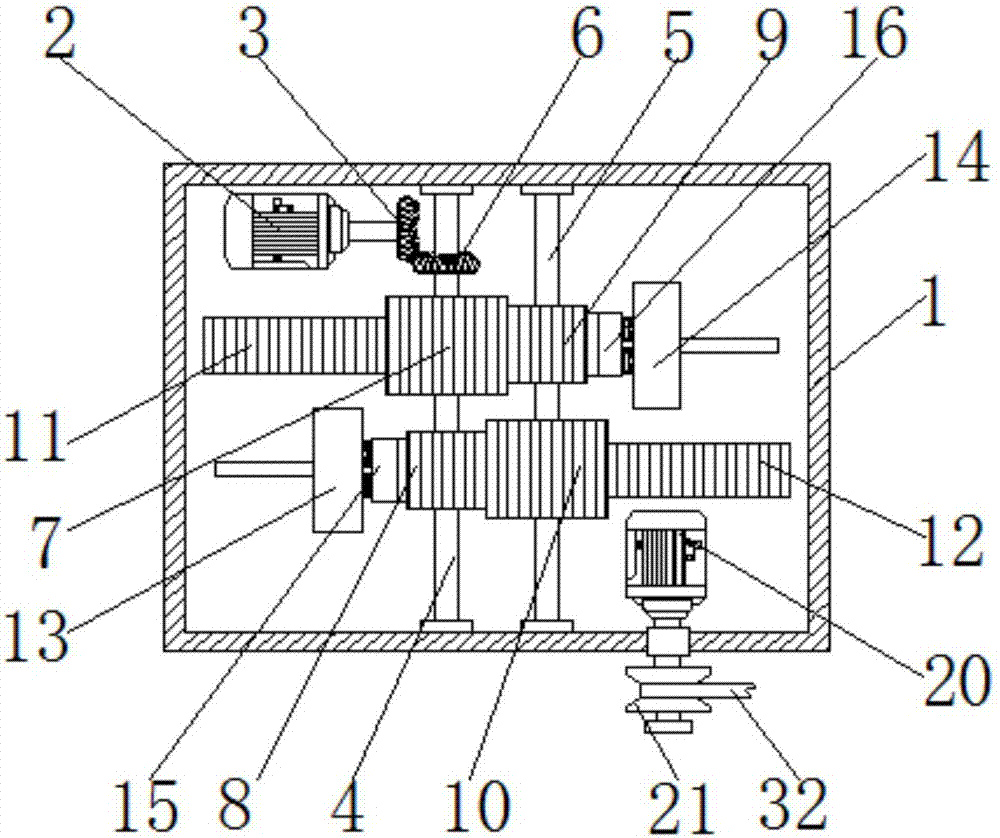

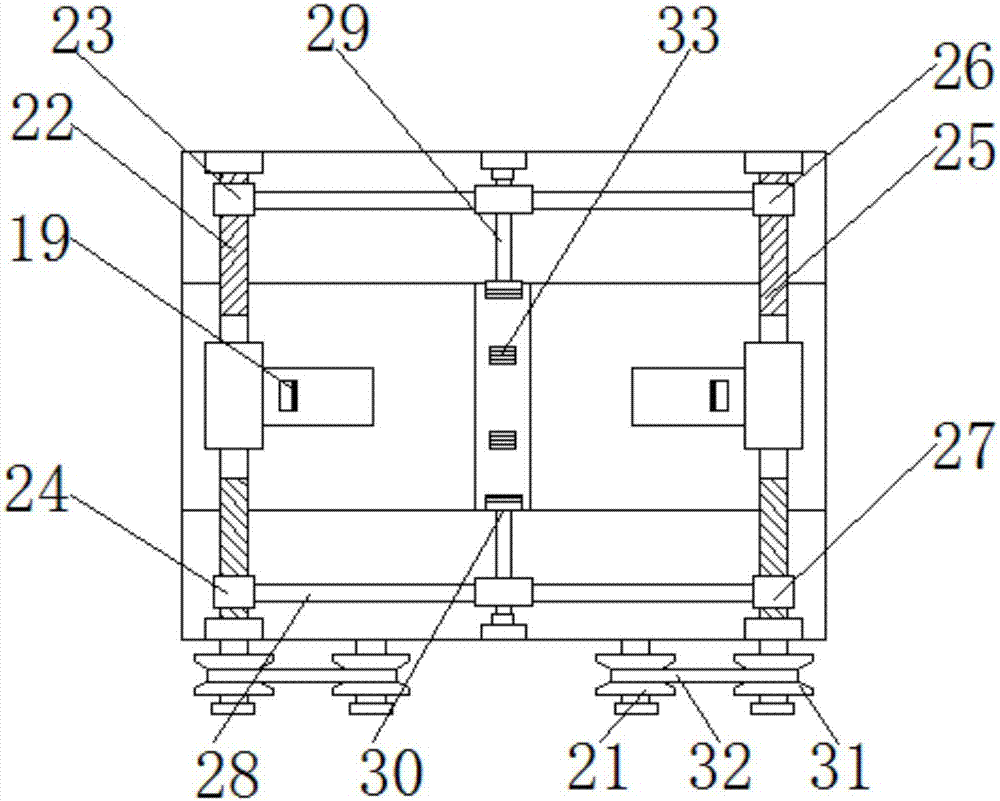

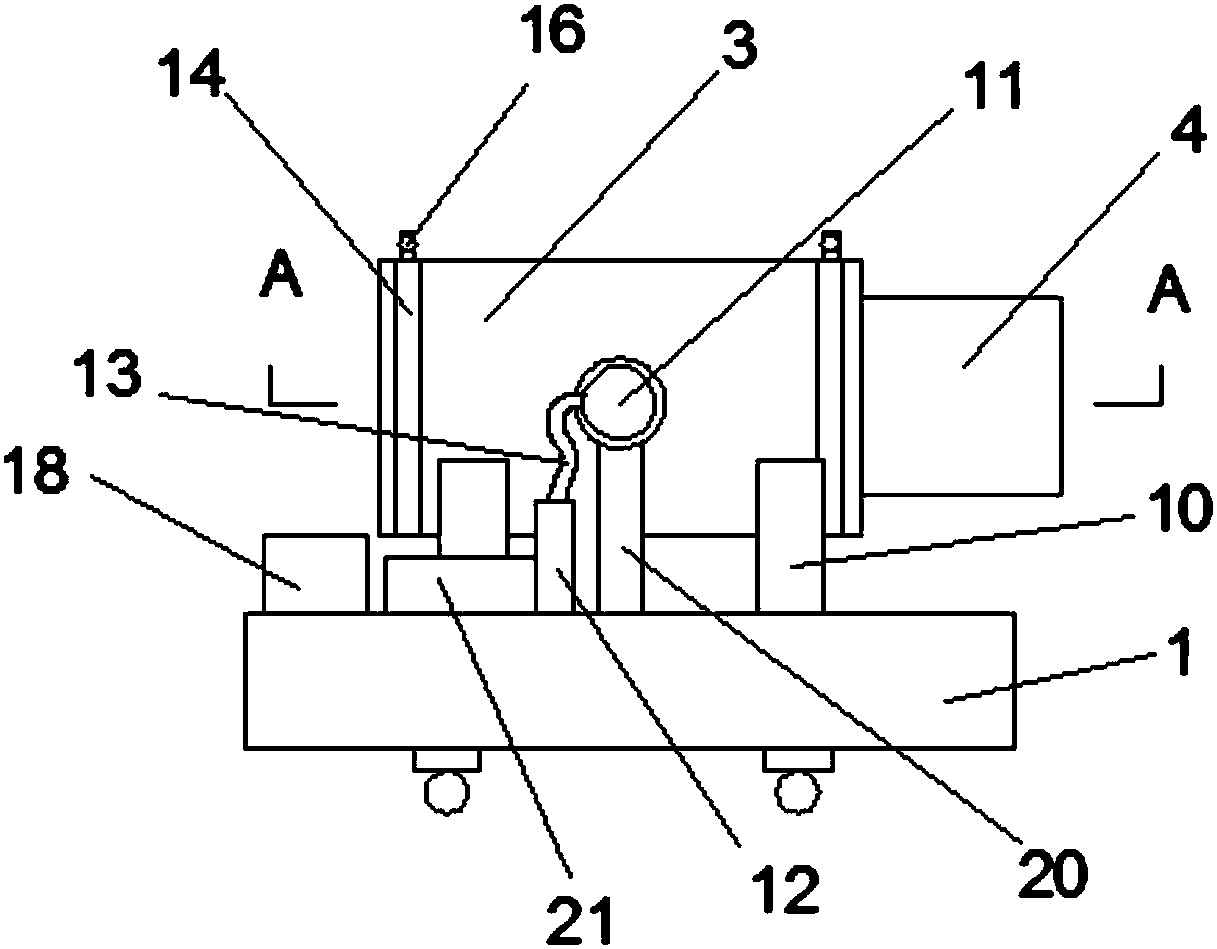

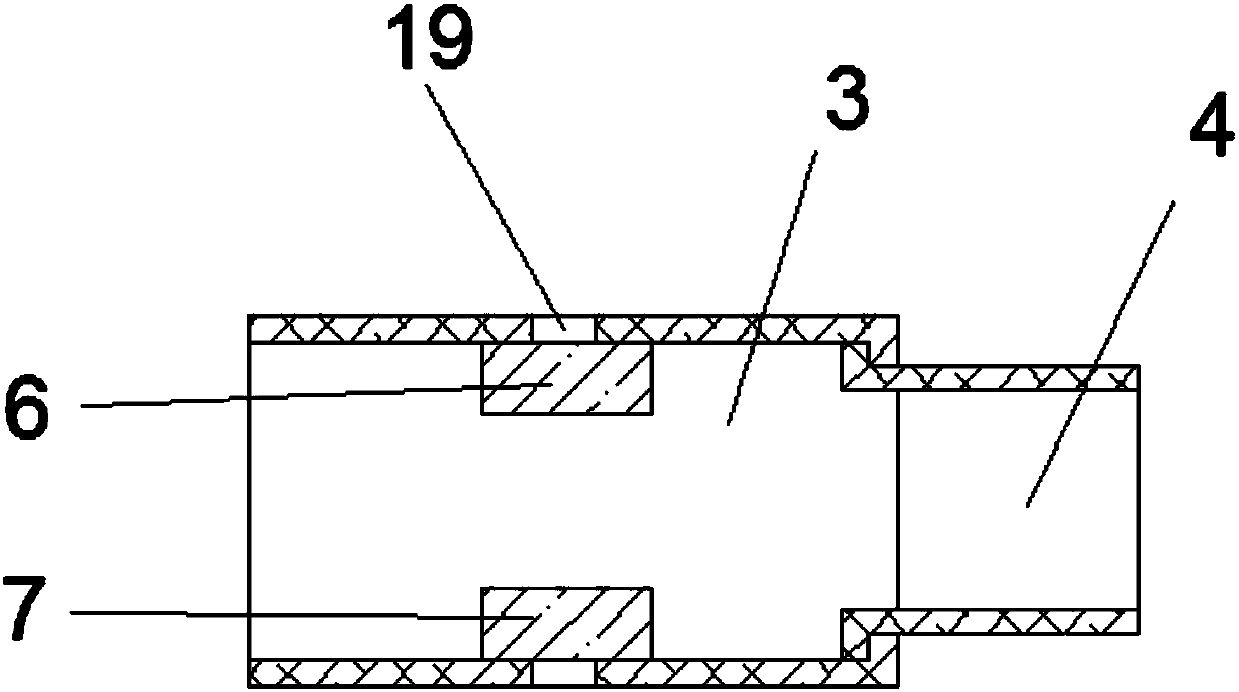

Clamping device for mold production

InactiveCN107214540ATo achieve the purpose of automatic removalEasy to processPositioning apparatusMetal-working holdersBiochemical engineering

The invention discloses a clamping device for mold production, which includes a box body, and is characterized in that: a first motor is fixedly connected to the bottom of the inner wall of the box, and a first bevel gear is sheathed on the surface of the output shaft of the first motor , the bottom of the inner wall of the box is rotatably connected to a first rotating rod and a second rotating rod through a support rod, and both ends of the first rotating rod are respectively rotatably connected to the front and back of the inner wall of the box through bearings, and the second Both ends of the rotating rod are respectively connected to the front and back of the inner wall of the box through bearings. The surface of the first rotating rod is sequentially sleeved with a second bevel gear, a first gear and a second gear from back to front. The invention relates to the field of mold technology. The clamping device for mold production achieves the purpose of automatically taking out the workpiece raised by the workbench, avoids the problem that it is difficult to take out the mold after reprocessing, ensures the processing efficiency, and facilitates the processing of the workpiece by the operator.

Owner:陈杨平

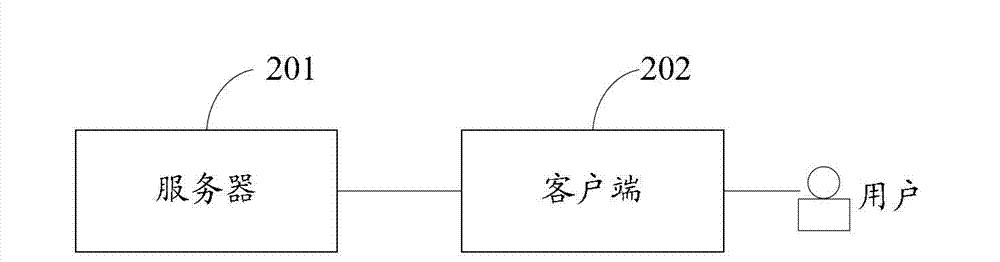

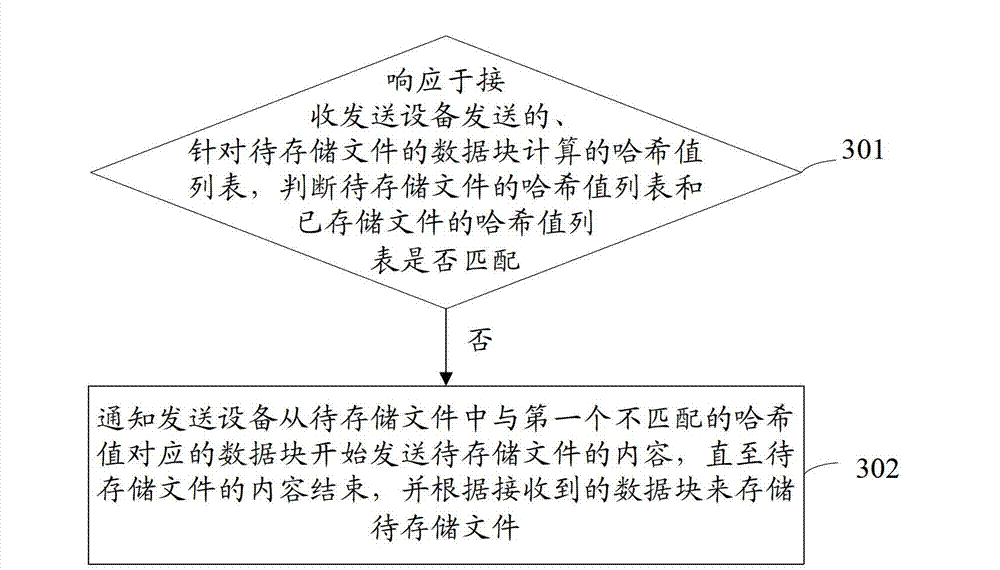

File storage method and device and file sensing method and device

ActiveCN103246730AImprove interactive experienceReduce network trafficSpecial data processing applicationsFile storage

The invention provides a file storage method. The method comprises the steps of responding to a hash value list which is sent by a sending device and calculates data blocks of a file to be stored, and determining whether the hash value list of the file to be stored is matched with a hash value list of a stored file; and if the hash value list of the file to be stored is not matched with the hash value list of the stored file, informing the sending device to send content of the file to be stored starting from the data block corresponding to the first unmatched hash value in the file to be stored until content of the file to be stored is ended, and storing the file to be stored according to received data blocks. According to the file storage method, through the file level storage method, the file index can be maintained at a low cost, so that processing resources and performance expenses of a receiving device are reduced. Besides, the invention provides a file storage device, such as a server. Additionally, the invention further provides a file sending method and device, such as a client.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

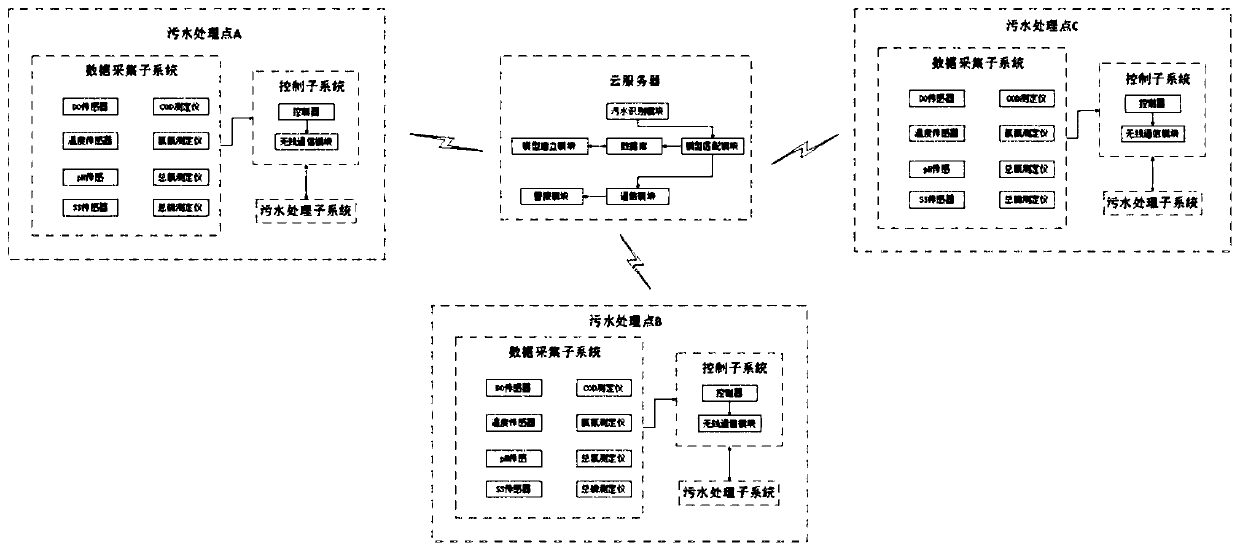

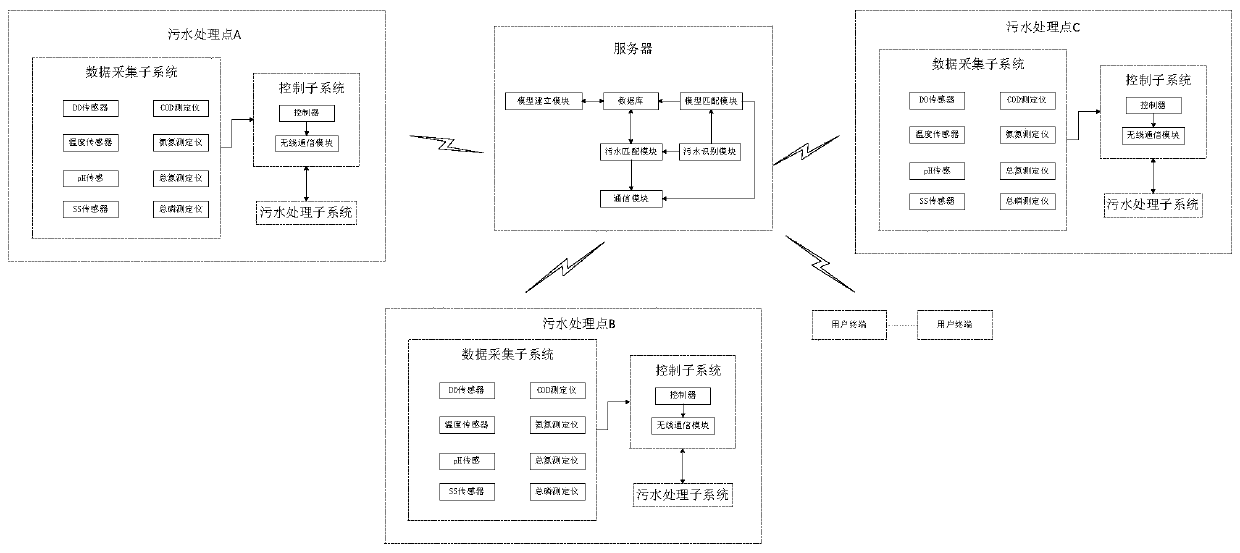

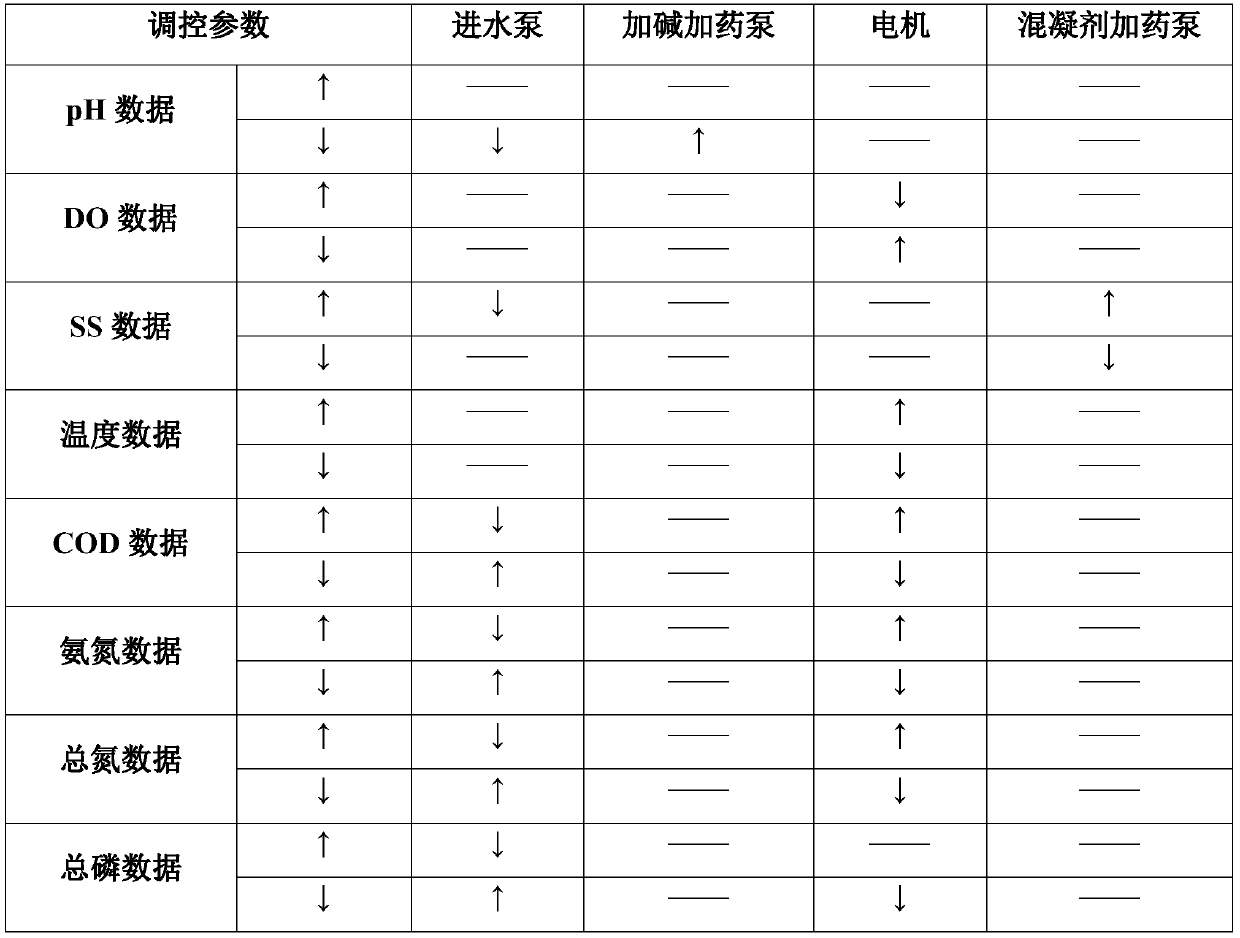

Dynamic regulating type sewage working condition treatment system

ActiveCN109879474AEnsuring the quality and efficiency of wastewater treatmentRealize intelligent controlSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentControl modelsSewage

The invention discloses a dynamic regulating sewage working condition treatment system, and relates to the technical field of sewage treatment. The system comprises: a data collecting subsystem for collecting the water quality information of sewage treatment points; a sewage identification module for identifying sewage types and sewage treatment points corresponding to the water quality information; a database for storing the total water quality information and control models of the sewage treatment points with different types; a model building module for establishing control models for optimizing various sewage treatment devices according to the total water quality information of one of the sewage treatment points with one type; and a model matching module for selecting the control modelcorresponding to the one sewage treatment point with the sewage type according to the currently received water quality information, and transmitting the control information of the control model to a control subsystem in order to make the control subsystem control the running parameters of each sewage treatment device according to the regulation information.

Owner:CHONGQING TECH & BUSINESS UNIV

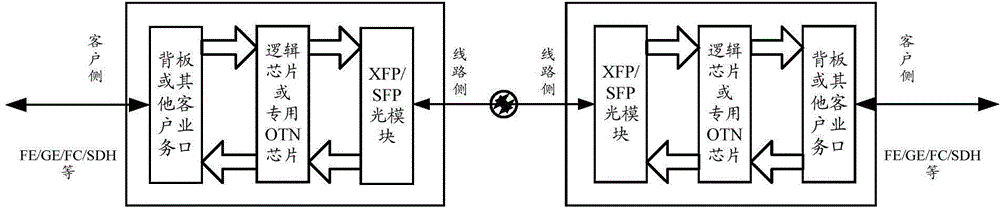

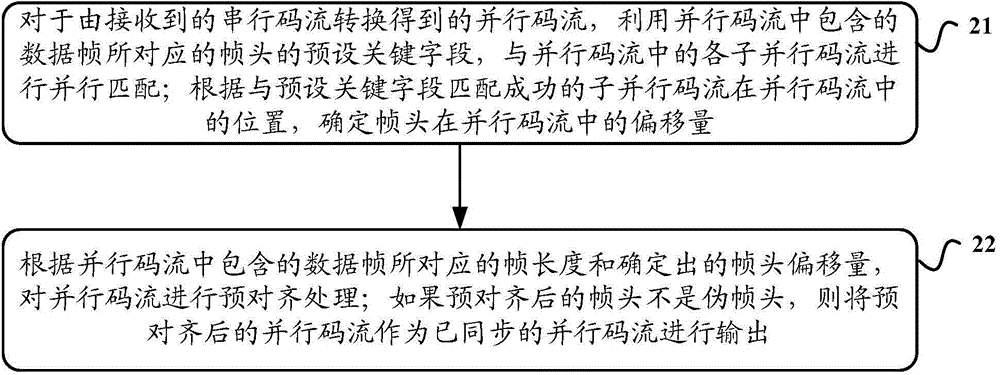

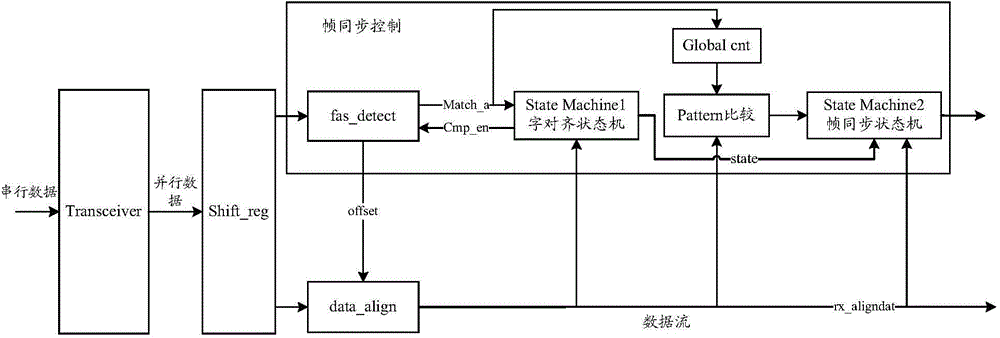

Frame synchronization method and device

ActiveCN104935393AImprove processing efficiencyReduce processing delayMultiplex system selection arrangementsTime-division multiplexSerial codeFrame synchronization

The embodiment of the invention discloses a frame synchronization method and device, and relates to the field of communication, wherein the method and device are used for improving the processing efficiency of frame synchronization. In the embodiment of the invention, the method comprises the steps: converting a received serial code stream and obtaining a parallel cod stream; employing a preset key field of a frame head corresponding to a data frame contained in the parallel code stream to match with each sub parallel code stream in the parallel code stream in a parallel manner; determining the offset of the frame head in a parallel code stream according to the position of the sub parallel code stream, which is successfully matched with the preset key field, in the parallel code stream; carrying out the pre-aligning processing of the parallel code stream according to the frame length corresponding to the data frame contained in the parallel code stream and the determined offset of the frame head; judging whether the pre-aligned frame head is a pseudo frame head or not, enabling the parallel code stream after pre-aligning to serve as a synchronized parallel code stream if the pre-aligned frame head is not the pseudo frame head, and outputting the parallel code stream, thereby solving the above problems.

Owner:RAISECOM TECH

Domestic sewage treatment device with waste residue collecting function

InactiveCN109847426AAvoid cloggingGuaranteed unobstructedStationary filtering element filtersSewageDrive motor

The invention relates to the technical field of sewage treatment, and particularly discloses a domestic sewage treatment device with a waste residue collecting function. The device comprises a box body, a water tank, a driving motor, a hollow rotating shaft, a rotating joint, a cleaning rod, a brush, a filter screen, a supporting seat and a nozzle. A supporting seat is fixedly mounted in the middle of the top end of the filter screen. The bottom end of the hollow rotating shaft rotationally communicates with a second water conveying pipe through a rotating joint. A residue collecting groove isformed in the upper surface of the filter screen. The water inlet end of the nozzle is connected with the second water conveying pipe. A supporting rod is fixedly mounted on the hollow rotating shaft. A cleaning rod being parallel to the filter screen is fixedly arranged on the support rod. Under the cooperation of the driving motor, the cleaning rod, the first water conveying pipe, the hollow rotating shaft, the rotating joint, the water pump, the second water conveying pipe and the nozzle, waste residues formed after sewage is filtered are easy to clean, smoothness of meshes in a filter screen is guaranteed, and therefore the sewage treatment efficiency is effectively guaranteed, and the device is suitable for application and popularization.

Owner:安徽世绿环保科技有限公司

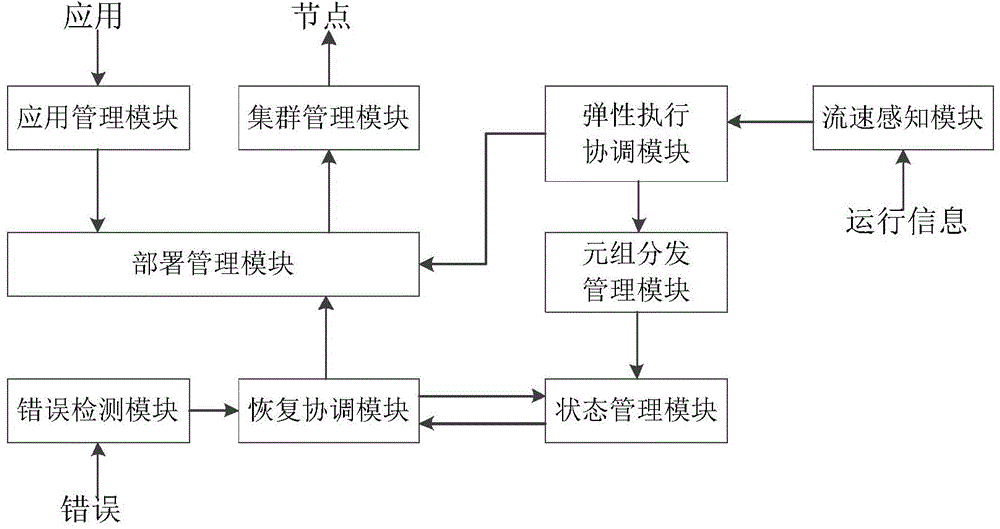

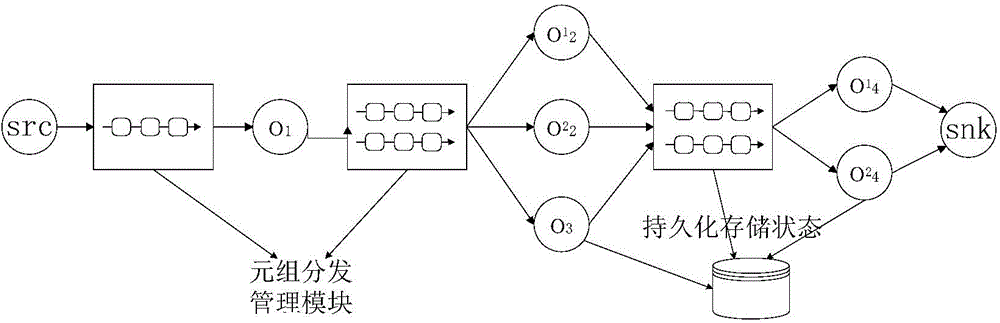

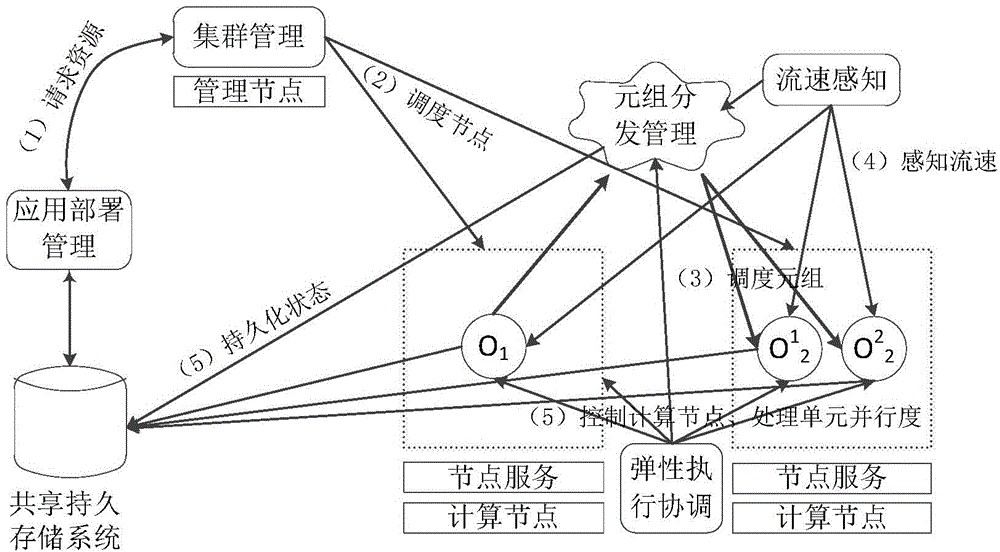

Real-time streaming computing flow speed perceiving elastic execution tolerant system

ActiveCN104794015AReduce recovery calculationsLong-term stable application operating environmentFault responseResource consumptionModularity

The invention discloses a real-time streaming computing flow speed perceiving elastic execution tolerant system. According to the system, a tight coupling relation of tuple transmitting, computing, state maintaining and processing units in a traditional streaming computing frame is changed into a modular and specialized loose coupling relation, in combination with a flow speed perceiving module, an elastic execution module, a state management module and the like, the system can control the processing time of all stages precisely, and thus display of a whole application is guaranteed. The system can conduct quick response to input steam changes or available resource changes quickly through flow speed perceiving. A distribution module can change the distribution relation flexibly and send tuples in batches timely, and resource consumption and sending delay are further reduced. The system can adjust the parallel numbers of processing units and nodes transparently through elastic execution so as to keep the application stable and guarantee delay. The system is made to have the unbelievable tolerant capacity through state management and persistent storage. The proper numbers of tuples are stored, the application recovery is accelerated, and the failure recovery speed is further increased in combination with parallel recovery of elastic execution.

Owner:HUAZHONG UNIV OF SCI & TECH

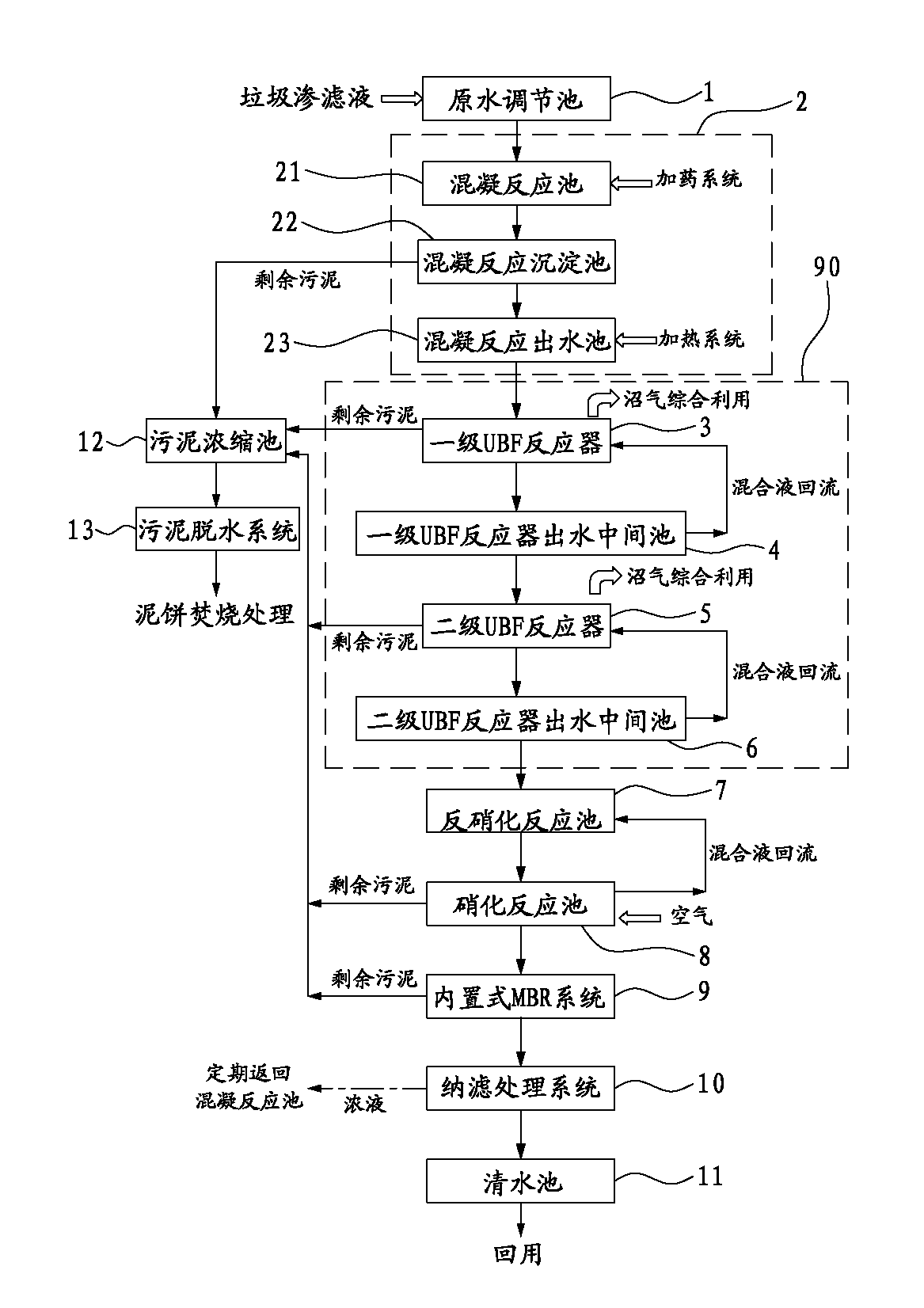

Treatment method for waste incineration power plant leachate and device thereof

ActiveCN102795746AGuaranteed concentrationGuaranteed processing efficiencyTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSludgeFiltration

The invention discloses a treatment method for waste incineration power plant leachate and a device thereof. The waste leachate is put into a raw water regulation pool, a coagulation reaction system, a first-stage UBF reactor, a first-stage UBF reactor effluent middle pool, a second-stage UBF reactor, a second-stage UBF reactor effluent middle pool, a denitrification pool, a nitration pool, a built-in MBR system, and a nanofiltration system for processing. According to the invention, the UBF reactor effluent middle pools are arranged behind the UBF reactors for mud-water separation and backflow after the UBF reactor effluent, guaranteeing the mud concentration in the UBF reactors and treatment effeciency. Using a built-in MBR membrane module placed in a biochemical pool helps to reduce floor space and lower energy consumption. The use of physical and chemical, biochemical, and membrane filtration technology association for the direct treatment of waste leachate can reach recycling with zero emission.

Owner:NEWSKY CHINA ENVIRONMENT & TECH

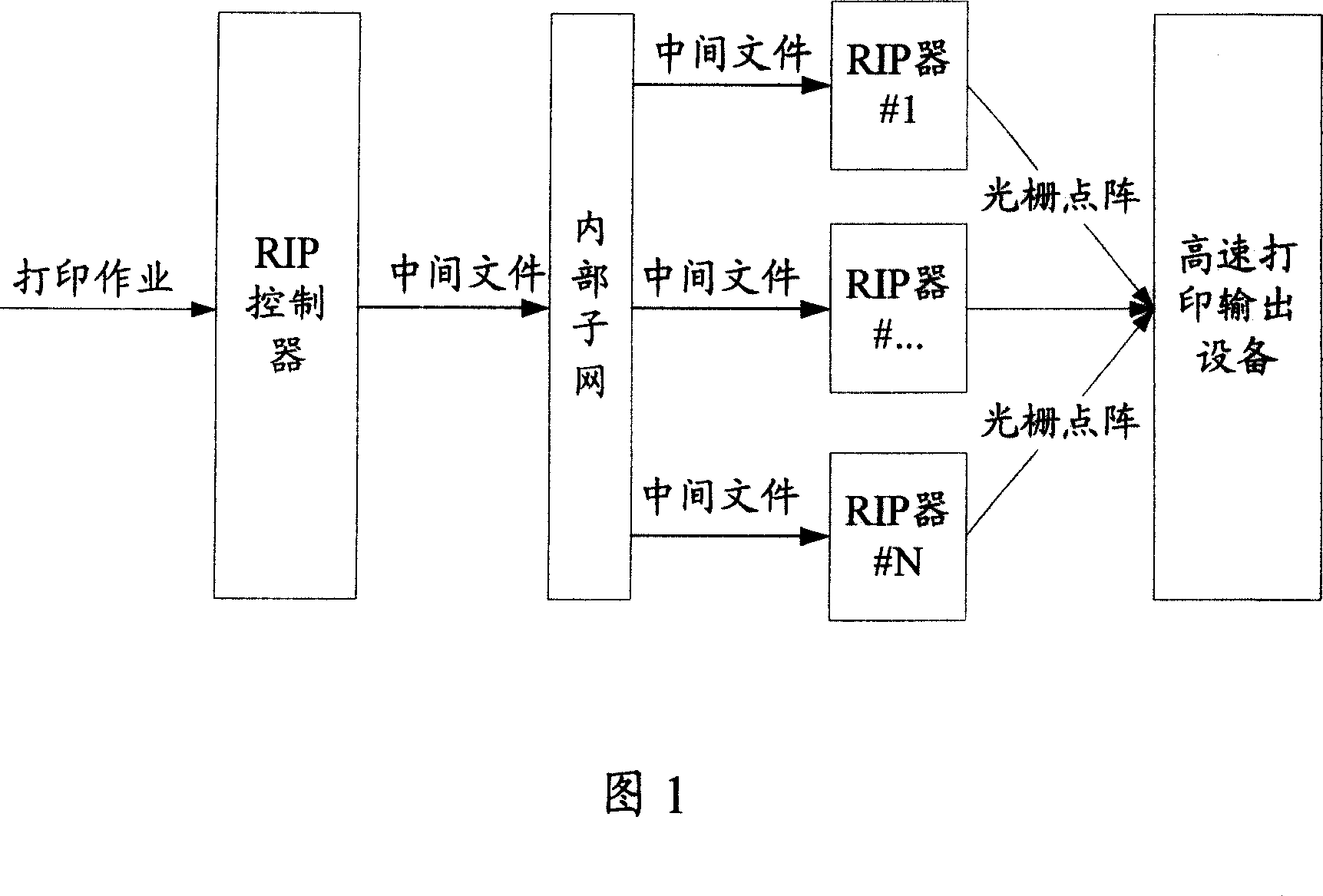

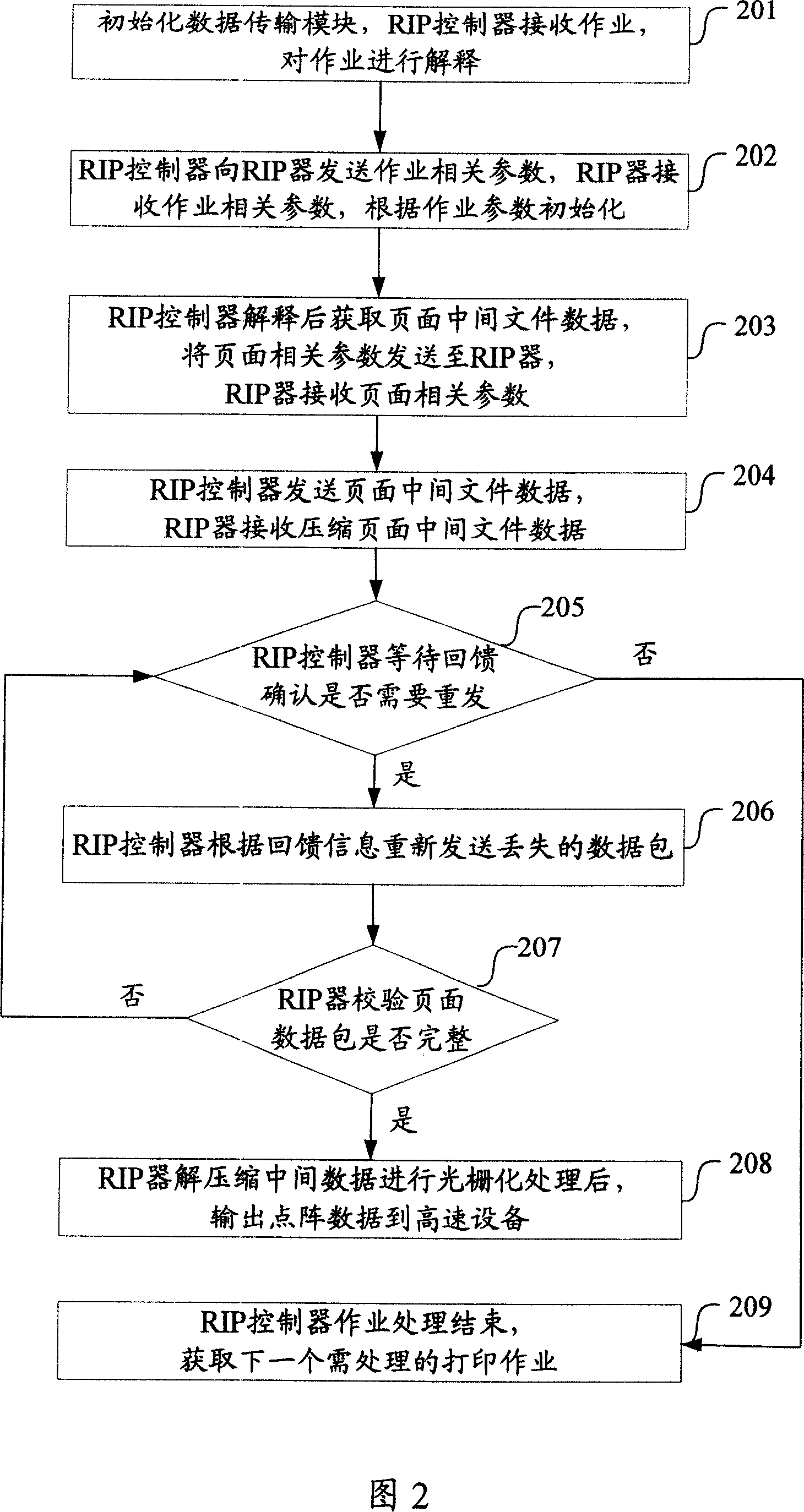

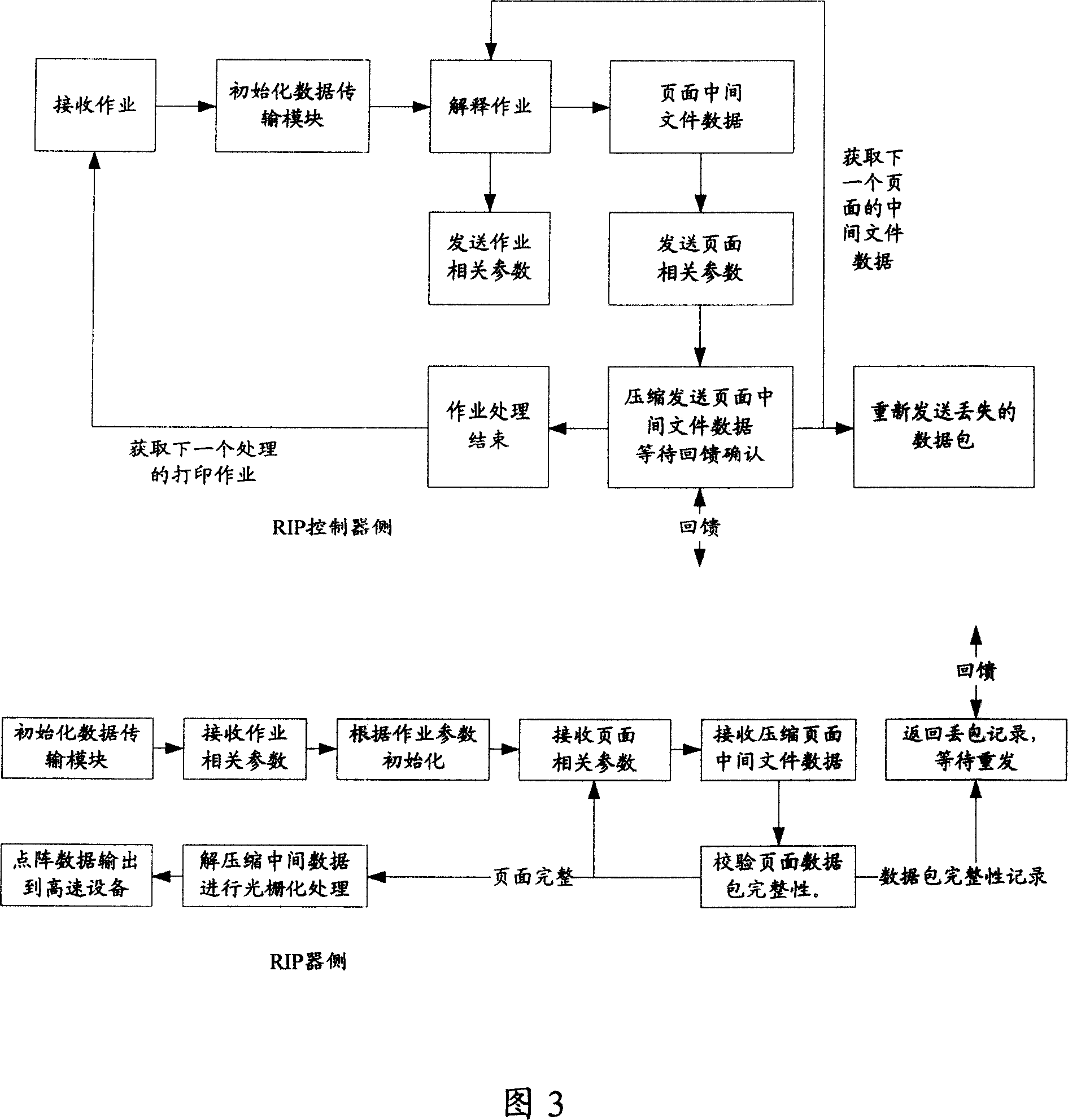

Data transmission system and method for distributed optical grating picture processing

InactiveCN101131626AReduce occupancyAcquisition speed is fastTransmissionDigital output to print unitsGratingOutput device

This invention discloses a kind of distributed grating image processing data transfer system of the figure and image printing treatment. In this invention method after the grating image processing controller interprets the printing describing language to the document data use the user data paper agreement to distribute it to the grating processor for grated process. In this invention system the grating image processing controller connects with the multiple grating image processor through the first data transfer module and the first transfer module is distributed to the grating image processor for grated process through the user data paper agreement after the first transfer module interprets the printing describing language to the document data in the grating image processing controller. By using this invention the transfer velocity is quicker and the occupation for the network resource is less and it improves the getting velocity of the grating image processing system for the processing work resource at the same time improves the processing velocity of the distributed grating processing system and it is satisfied for the requirement of high speed printing output device.

Owner:PEKING UNIV +1

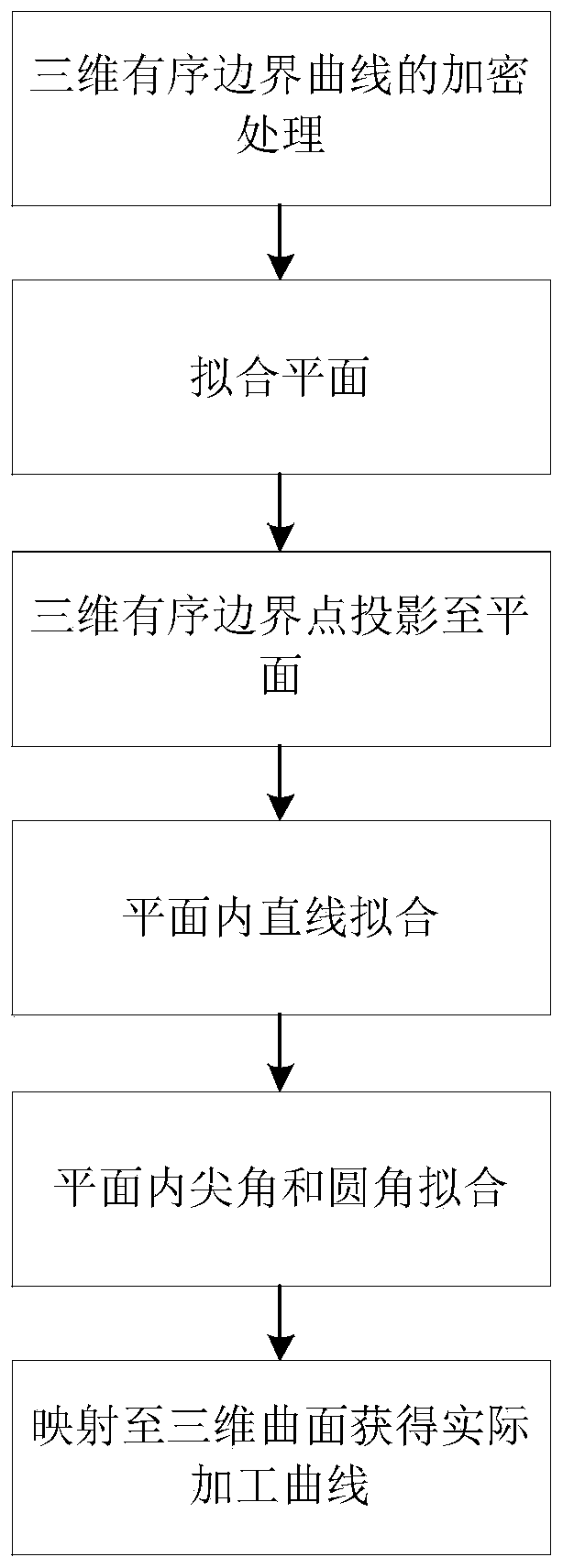

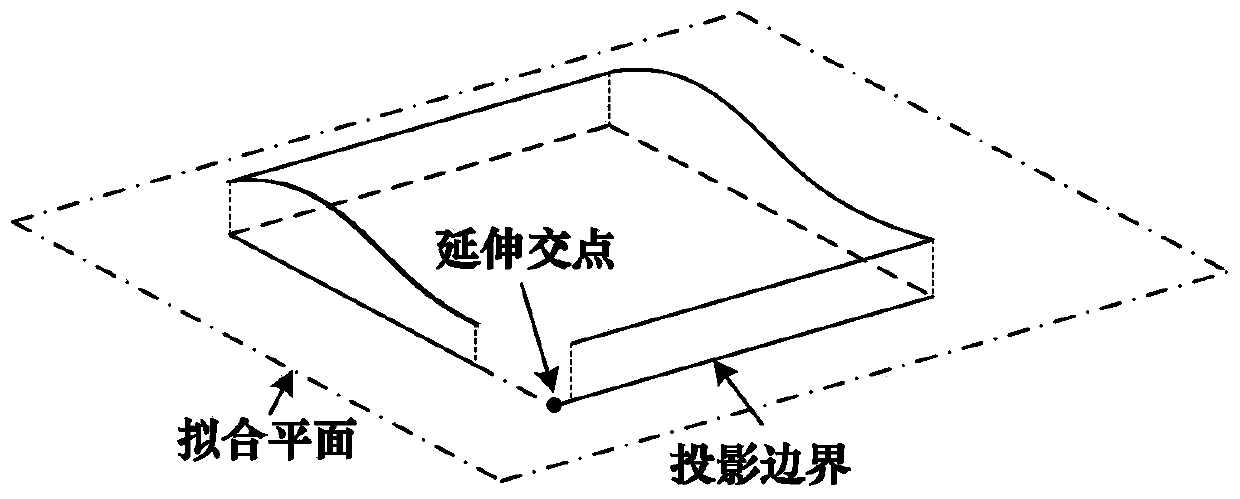

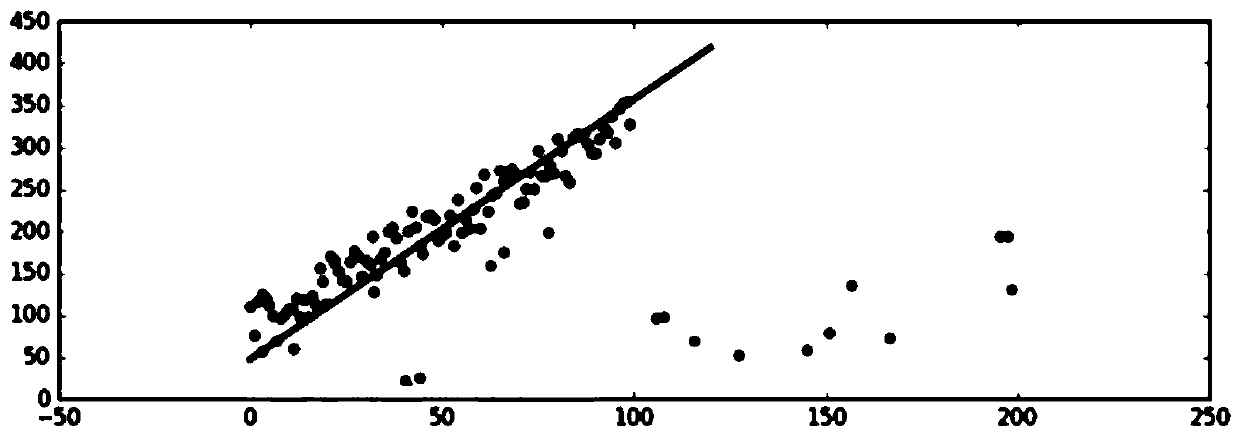

Method for constructing actual machining curve of small-curvature part based on point cloud boundaries

ActiveCN110349252AGuaranteed processing efficiencyEnsure consistencyGeometric CADCharacter and pattern recognitionMachine partsPoint cloud

The invention belongs to the field of robot vision detection, and discloses a curve discretization method based on point cloud boundary geometrical characteristics. The curve discretization method comprises the following steps: (a) encrypting a three-dimensional ordered boundary curve of a part to be processed; (b) fitting the encrypted boundary points into a plane, and projecting each boundary point into the plane to obtain a projection point; (c) carrying out straight line Euclidean clustering and line point sets in a plane, and fitting the obtained point sets into a straight line; (d) carrying out Euclidean clustering on the projection points which are not fitted into the straight line to obtain a corner point set, and carrying out sharp corner or round corner fitting on the corner point set to obtain a fitted boundary curve in a plane; and (e) mapping the fitted boundary curve to the curved surface of the three-dimensional ordered boundary curve to obtain the actual machining curveof the to-be-processed part. By means of the curve discretization method, the actual machining curve is obtained through the point cloud data of the to-be-machined part, and sharp corner and round corner characteristics are reserved, and the machining precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

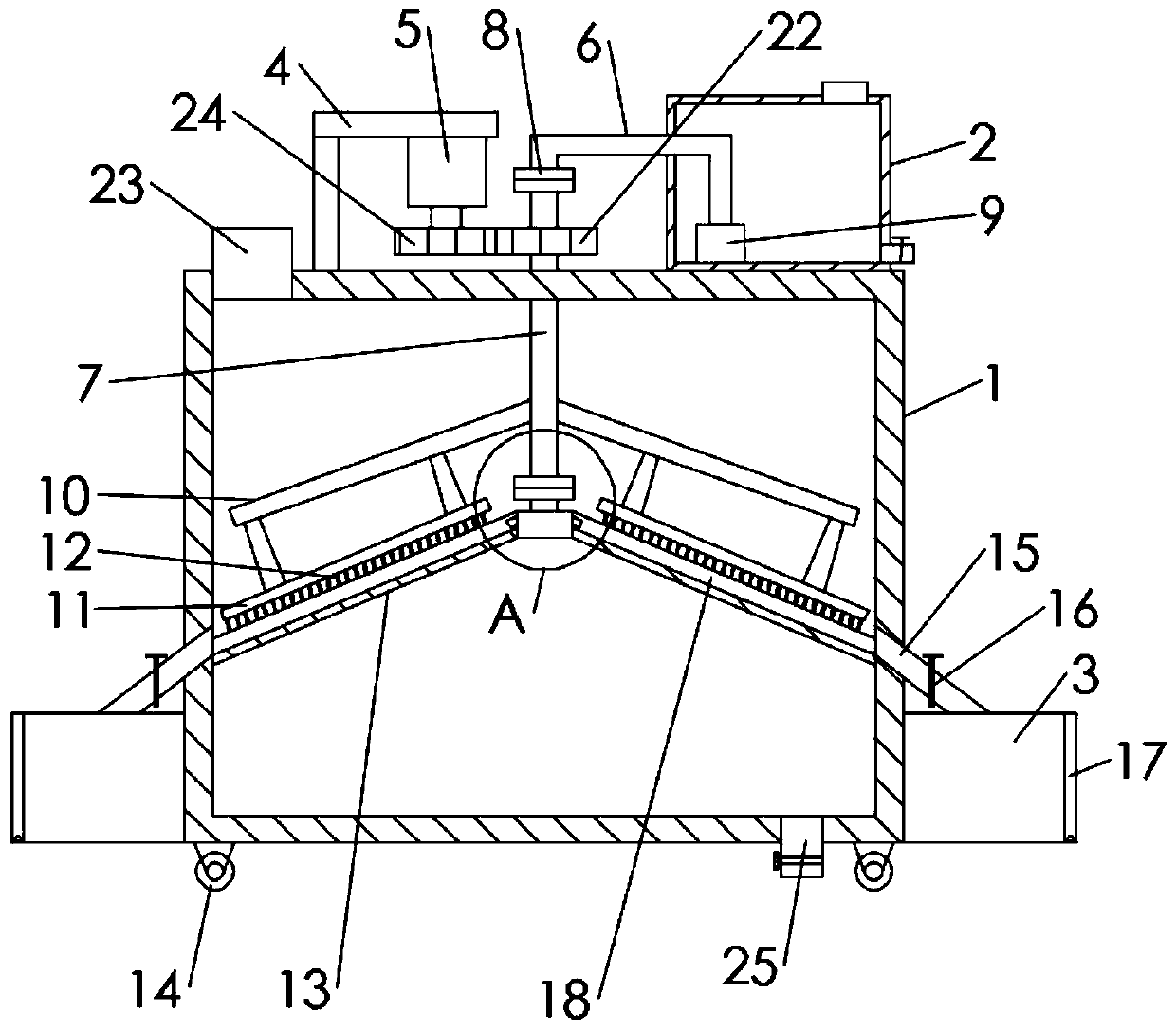

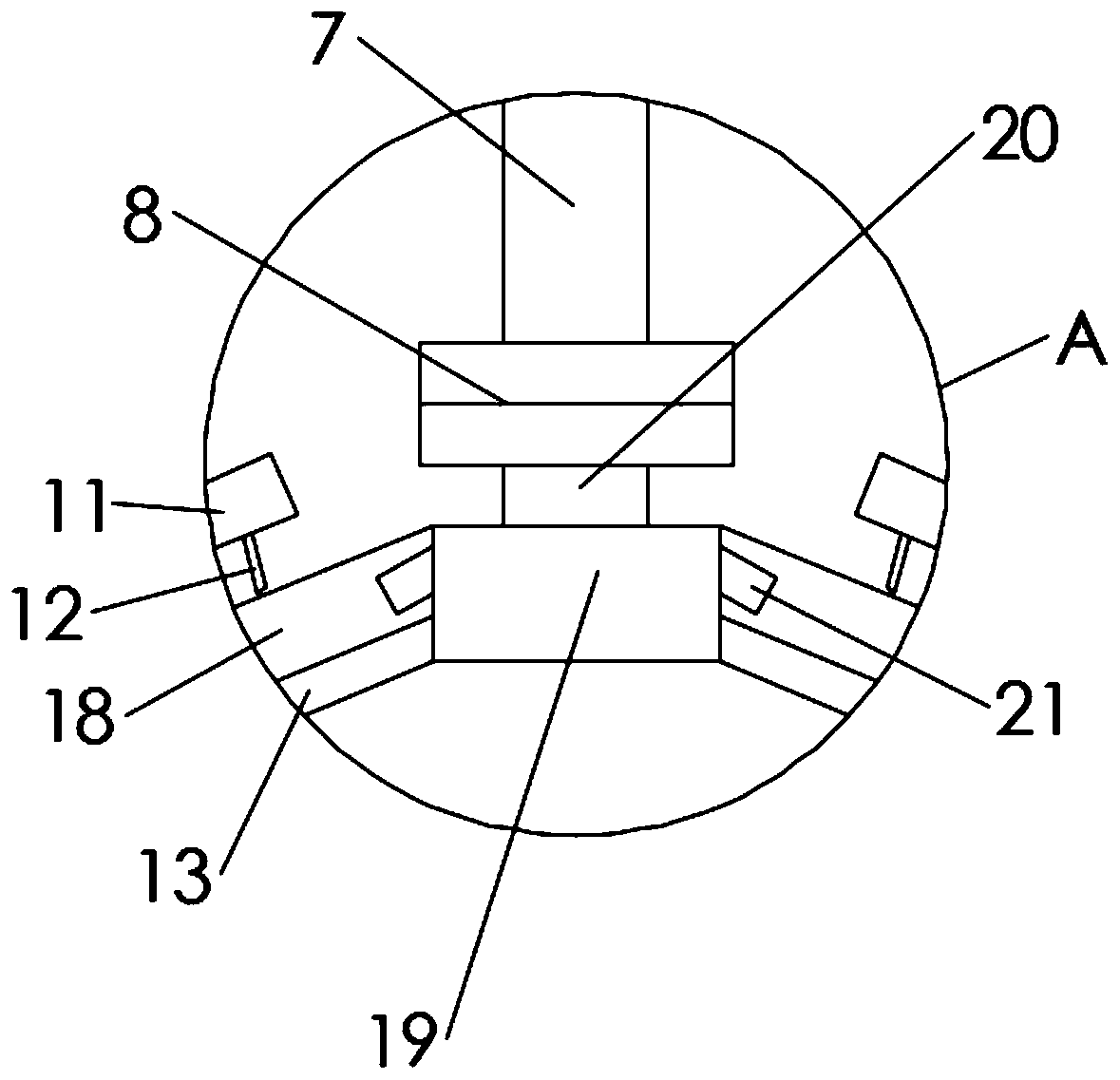

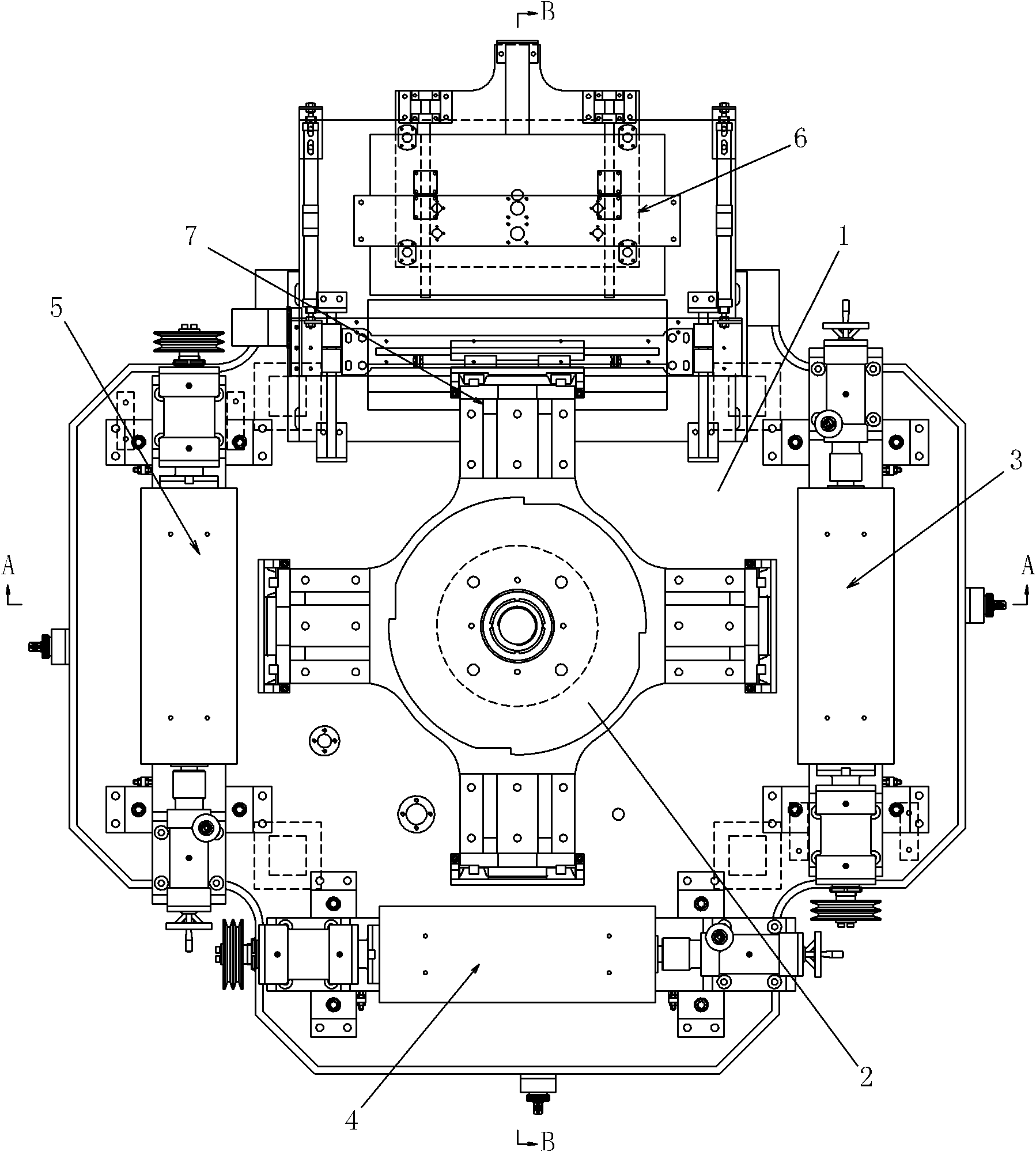

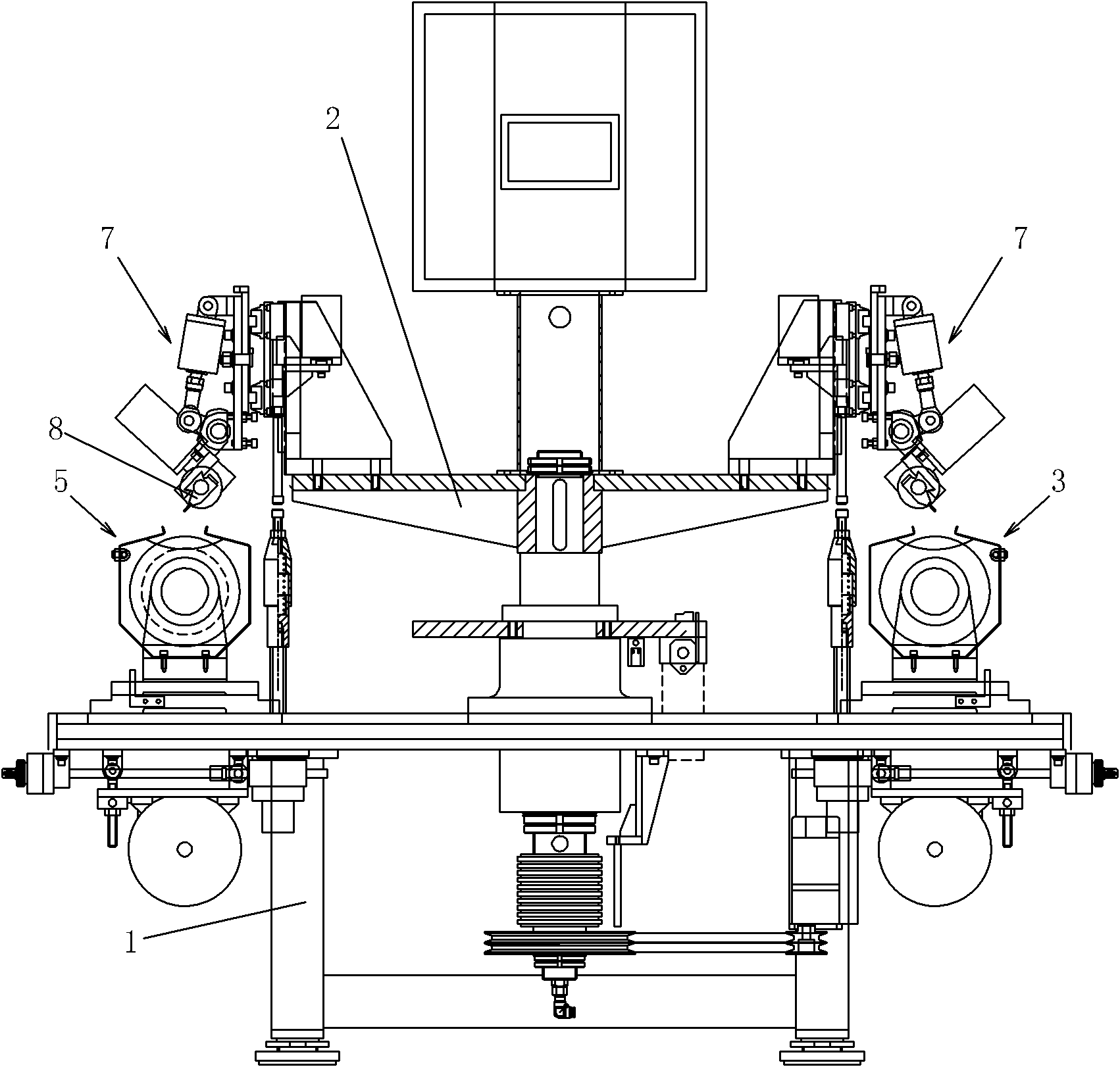

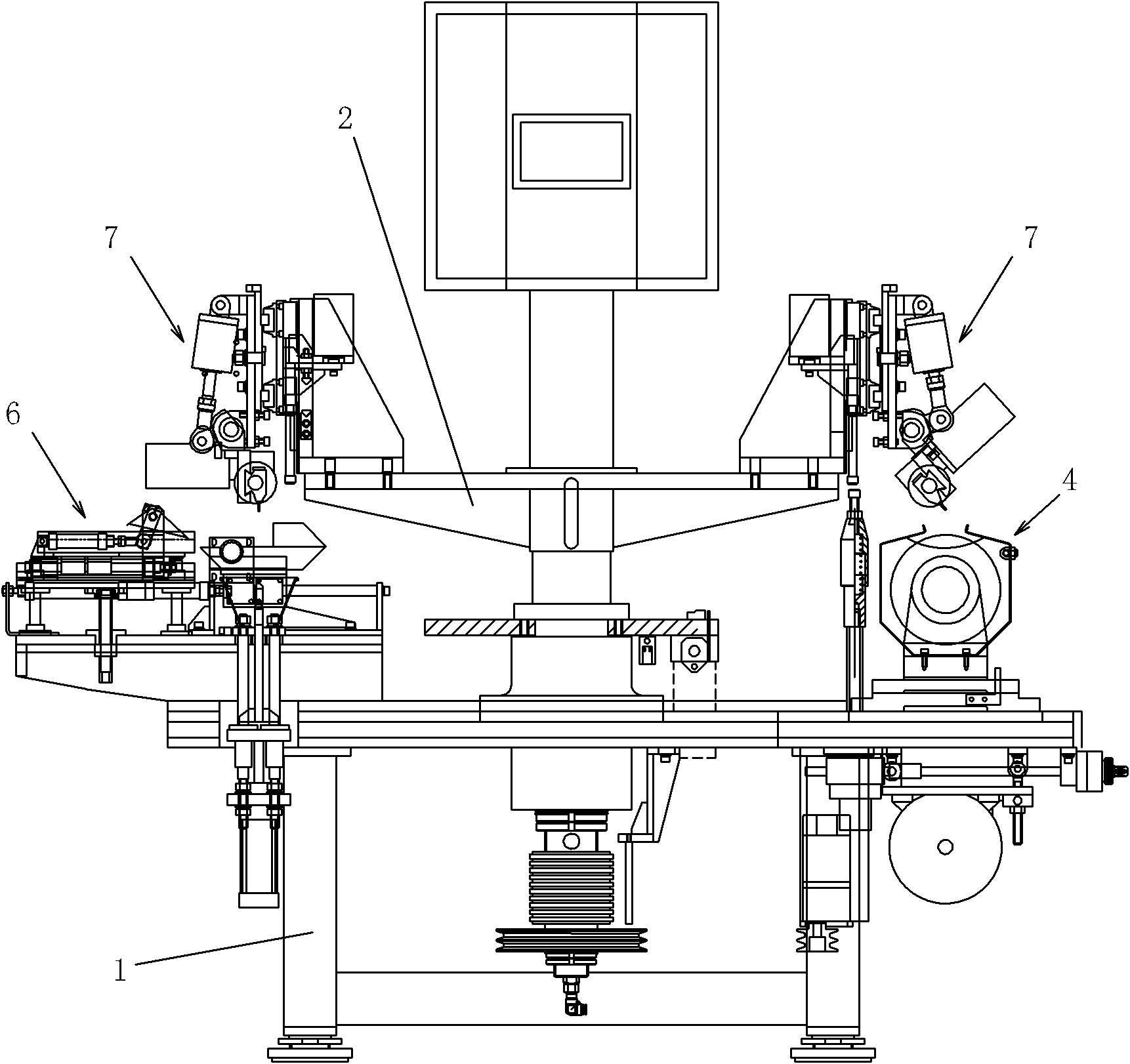

Multi-station rhinestone slant grinding and polishing machine

InactiveCN102211305AReduce extra spaceReduce waiting timeEdge grinding machinesEngineeringMechanical engineering

The invention relates to a multi-station rhinestone slant grinding and polishing machine comprising a frame. A rotating rack is arranged on the frame. A plurality of noses are arranged on the rotating rack. A rhinestone clamp is arranged on each nose. A loading / unloading station, a grinding station and a polishing station corresponding to the plurality of noses are formed on the frame. An automatic loading / unloading mechanism is arranged on the loading / unloading station, while a grinding mechanism is arranged on the grinding station and a polishing mechanism is arranged on the polishing station. The present technical scheme employs the automatic loading / unloading mechanism to realize automatic loading and unloading operations, thereby greatly reducing the operating time of the local station and the waiting time of other stations and also guaranteeing the utilization rate of equipment and the processing efficiency; furthermore, the two stations are combined into one loading / unloading station, so that the volume and the take-up space of the machine are greatly reduced; therefore, the machine is convenient for transportation and use.

Owner:虞雅仙

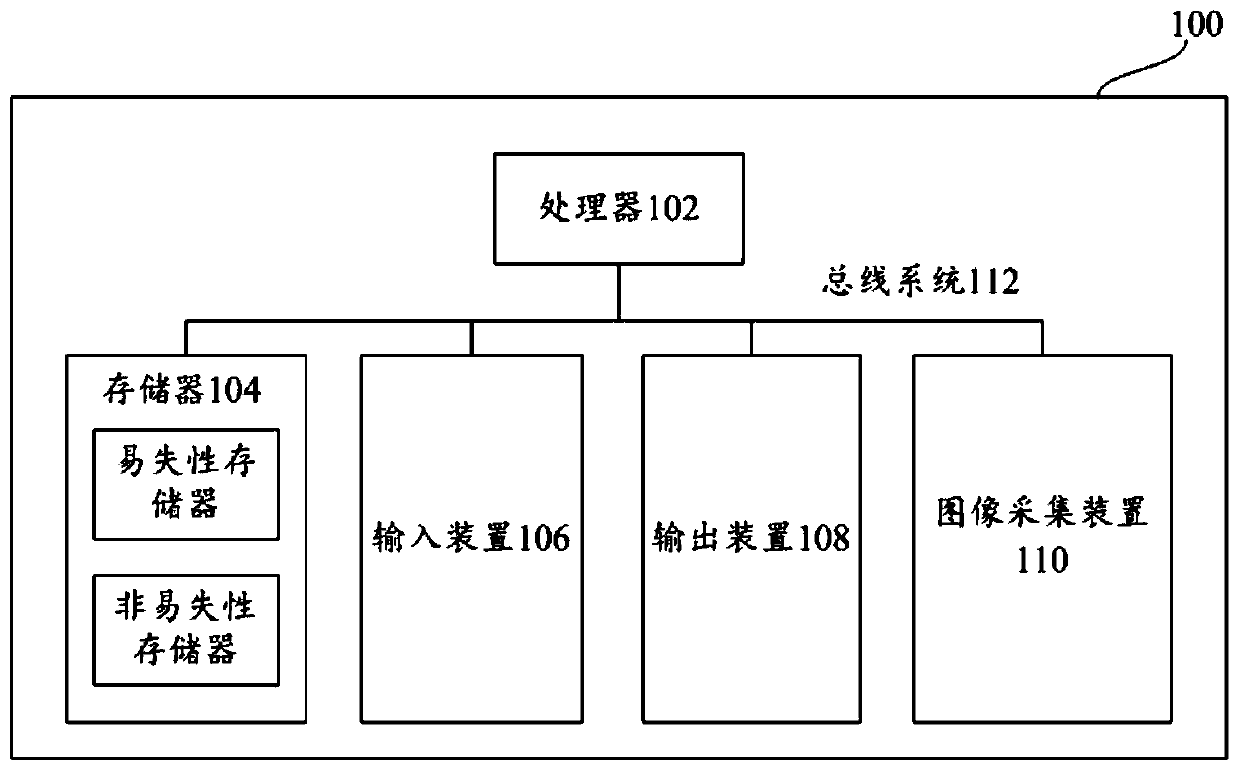

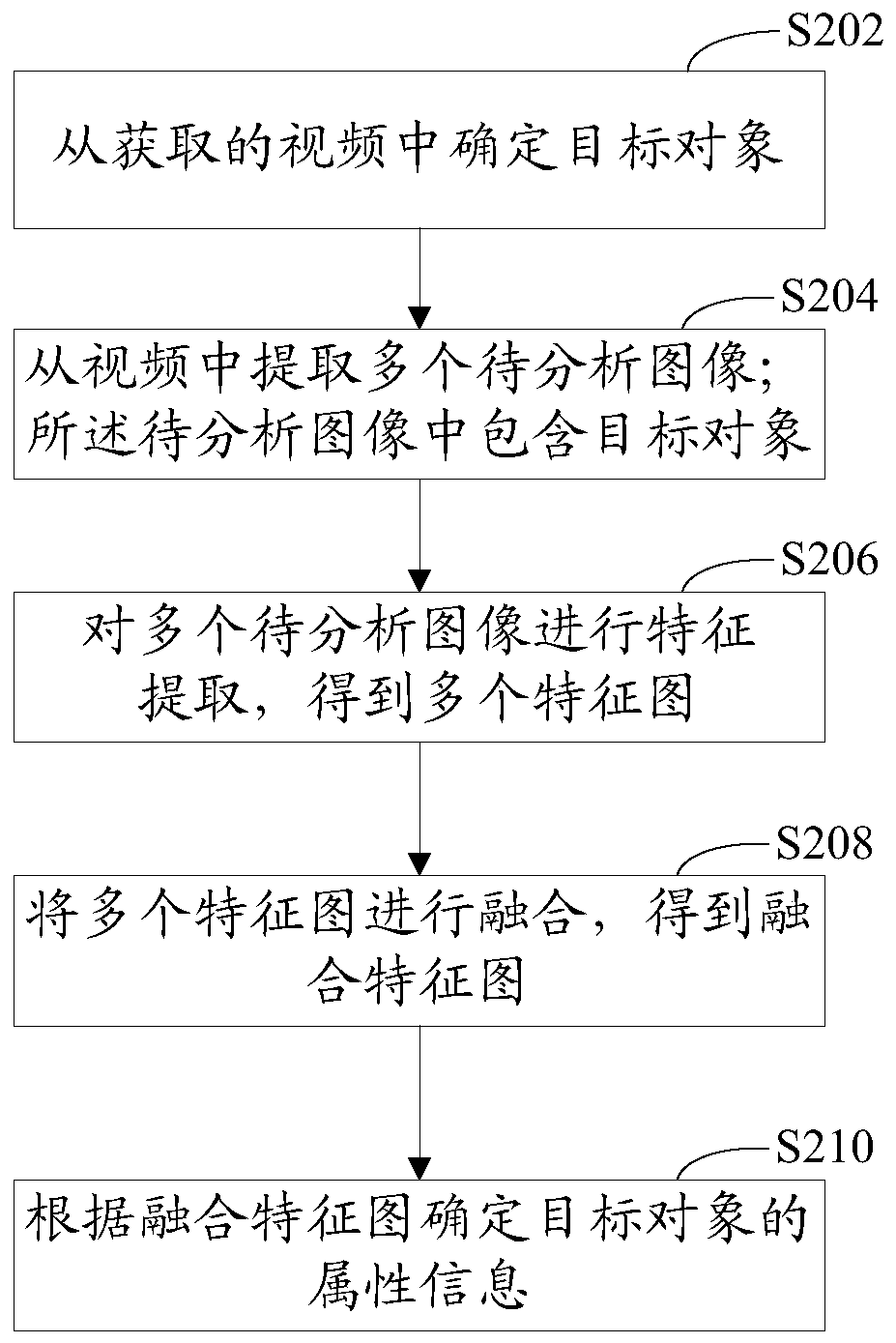

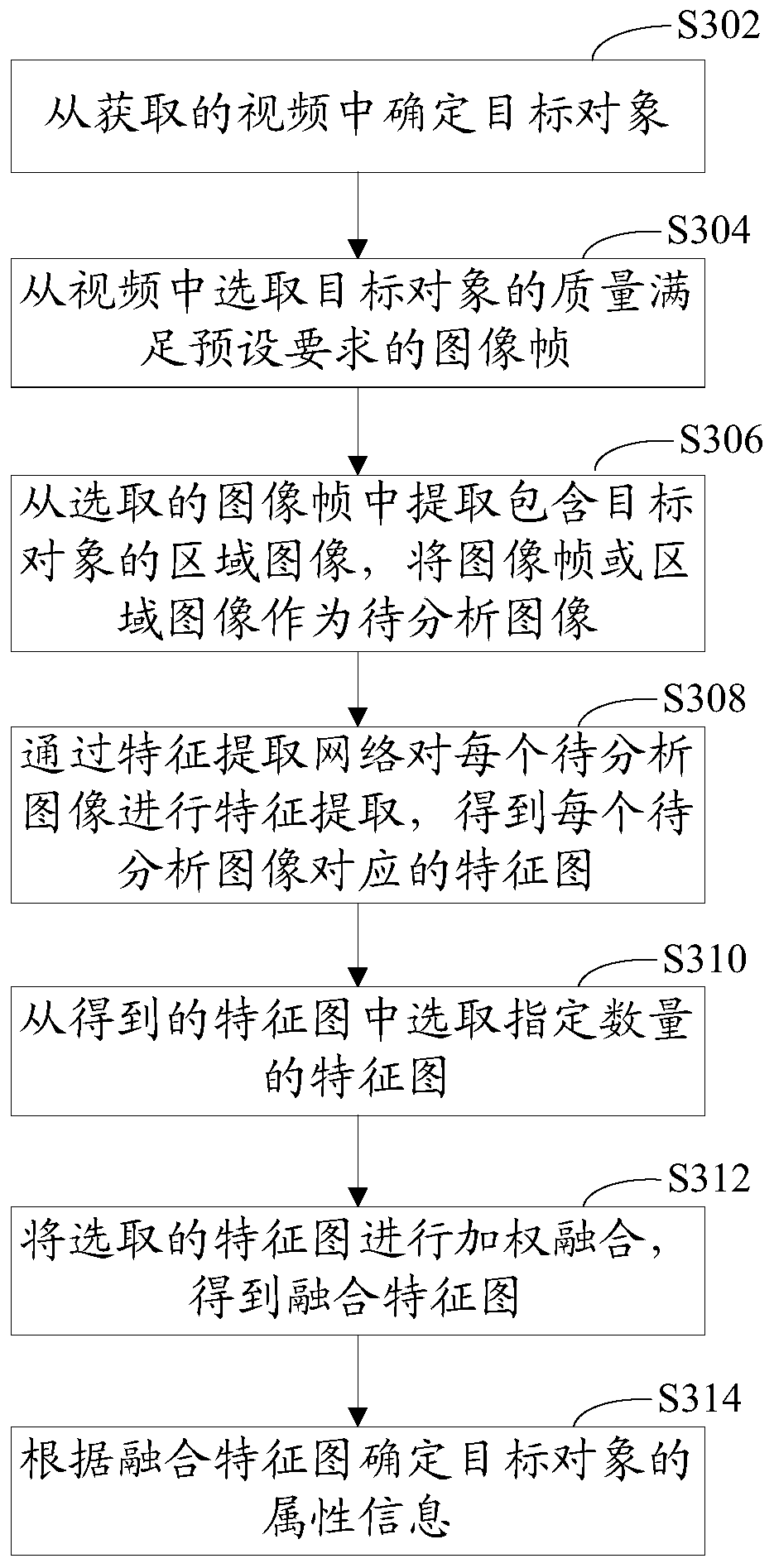

Video processing method and device and electronic equipment

InactiveCN109886951AImprove accuracyHeavy computationImage analysisCharacter and pattern recognitionFeature extractionImaging processing

The invention provides a video processing method and device and electronic equipment, belongs to the technical field of image processing, and is used for carrying out attribute analysis on a target object in a video. The method comprises the steps of firstly determining a target object in an acquired video, extracting a plurality of to-be-analyzed images containing the target object from the video, performing feature extraction on the plurality of to-be-analyzed images to obtain a plurality of feature maps, fusing the plurality of feature maps to obtain a fused feature map, and determining attribute information of the target object according to the fused feature map. The method can improve the accuracy of the attribute analysis result while guaranteeing the processing efficiency.

Owner:BEIJING KUANGSHI TECH

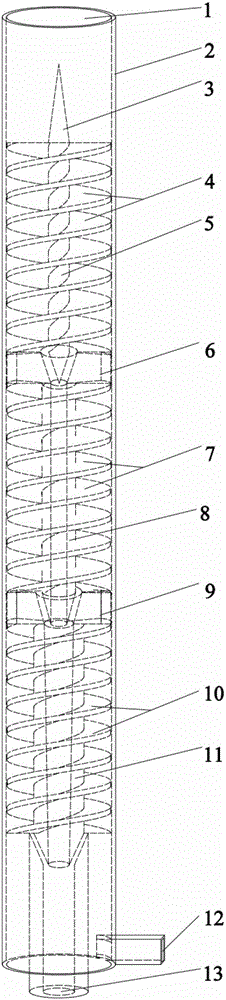

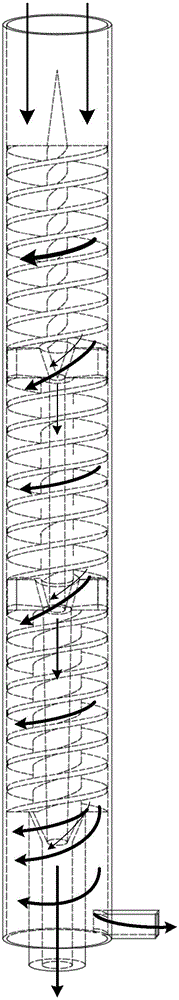

Multi-stage varied-diameter screw oil-water separator

ActiveCN105664538AReduce the flow cross-sectional areaIncrease rotation speedLiquid separationOil waterEngineering

The invention discloses a multi-stage varied-diameter screw oil-water separator capable of realizing efficient separation aiming at separating mediums under high-viscosity and small-particle states. The multi-stage varied-diameter screw oil-water separator is characterized in that a wall barrel at least comprises two stages of separating units; each separating unit consists of a spiral sheet, an inner pipe and a flow division body which are connected; a spiral runner consists of the wall barrel, the spiral sheet and the inner pipe; each stage of spiral sheet is independent; a flow stabilizing cone is fixed at the upper end of one inner pipe; an inverted frustum-shaped circular pipe channel is fixed in the center of the flow division body through two fan-shaped connection bodies, and the diameters are gradually reduced along the axial direction; the tail ends of the inner pipes are inversely frustum-shaped and are matched with the inner circular pipe channels in the flow division bodies, with an annular overflow space; the outer diameter of each inner pipe is gradually increased, and the circular pipe channels of the corresponding stages are enlarged according to the same ratio; the tail end of the inner pipe of the last stage is connected to the top end of an overflow pipe; and the overflow pipe is matched with the tail end of the inner pipe of the last stage, so that an annular overflow space with a gradually reduced diameter is formed.

Owner:NORTHEAST GASOLINEEUM UNIV

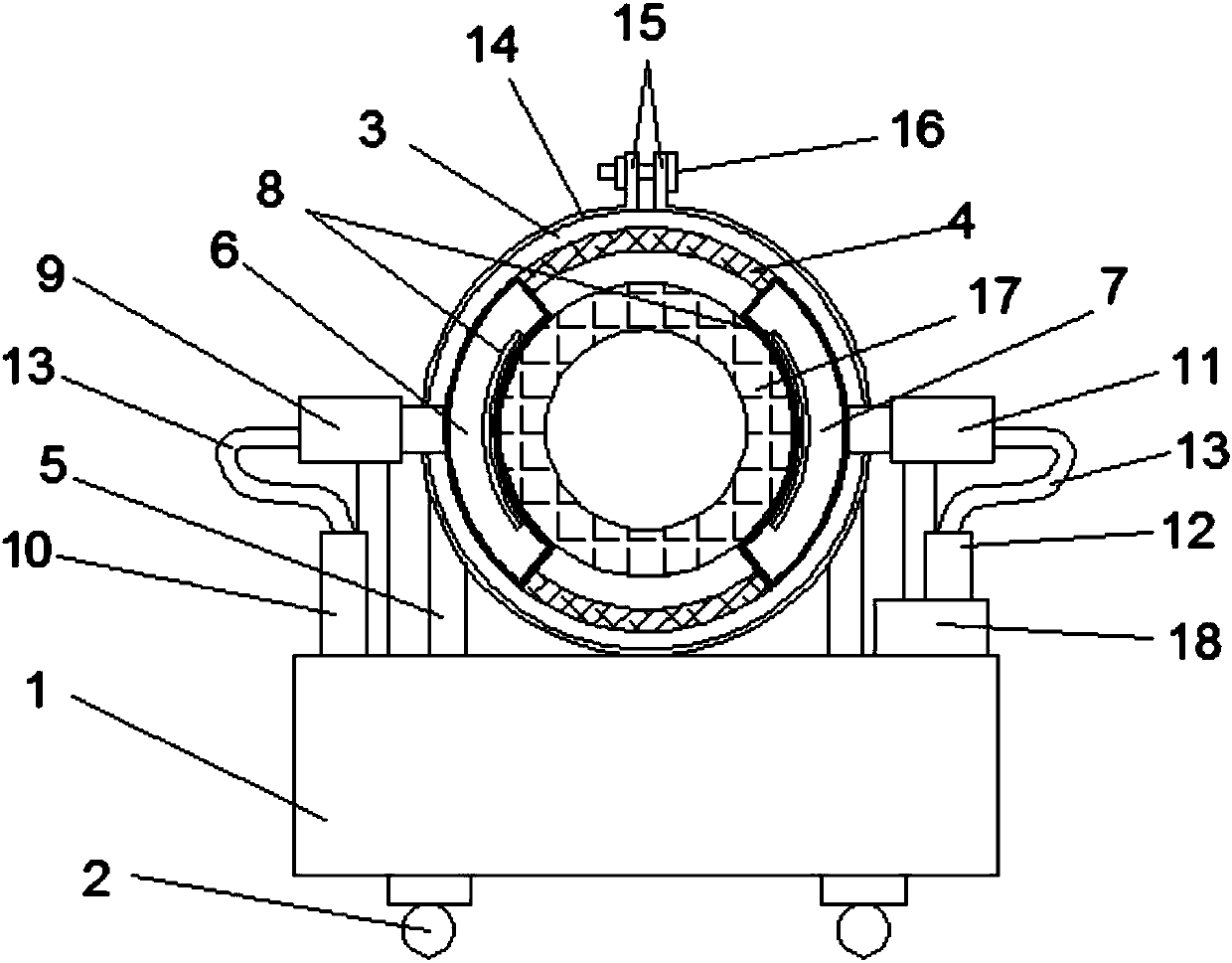

Synchronous denitrification and dephosphorization sewage treatment device for immobilized microorganism CASS (cyclic activated sludge system)

InactiveCN102659282AImprove impact resistanceShort reaction timeMultistage water/sewage treatmentActivated sludge systemWater pipe

The invention discloses a synchronous denitrification and dephosphorization sewage treatment device for an immobilized microorganism CASS (cyclic activated sludge system). The synchronous denitrification and dephosphorization sewage treatment device comprises a pond. A water inlet tube is arranged at one end of the pond, a water outlet tube is arranged at the other end of the pond, a hollow gridding reaction box is disposed in the pond, immobilized microorganism carriers are arranged in the hollow gridding reaction box, and an aeration device is arranged at the bottom of the pond. The synchronous denitrification and dephosphorization sewage treatment device aims to overcome shortcomings in the prior art, is simple in structure, and is efficient and stable.

Owner:中山市子源生物环境科技有限公司

Building tubular product cutting clamp

InactiveCN107891297AIncrease clamping forceEasy to cutMeasurement/indication equipmentsPositioning apparatusBiochemical engineeringHydraulic pump

The invention discloses a building tubular product cutting clamp in the technical field of buildings. A clamp inner barrel is arranged in an inner cavity of a clamp outer barrel, a first clamping sheet and a second clamping sheet are arranged on the two sides of the inner cavity of the clamp outer barrel, pressure sensors are arranged inside the first clamping sheet and the second clamping sheet,a first piston barrel device and a second piston barrel device are connected to a first hydraulic oil pump and a second hydraulic oil pump through soft oil pipes correspondingly, a stepping motor is arranged on the side, far away from a clamp inner barrel, of the second hydraulic oil pump, and a controller is arranged on the side, far away from the second hydraulic oil pump, of the stepping motor.The building tubular product cutting clamp is high in reliability, the clamping force on a building tubular product is large, and looseness can be avoided in the cutting process; and in addition, themachining quality and the machining efficiency can be effectively guaranteed, length measurement on the building tubular product can be carried out through length scales on the clamp inner barrel soas to facilitate fixed-length tubular product cutting, and the cutting convenience is greatly improved.

Owner:叶潇

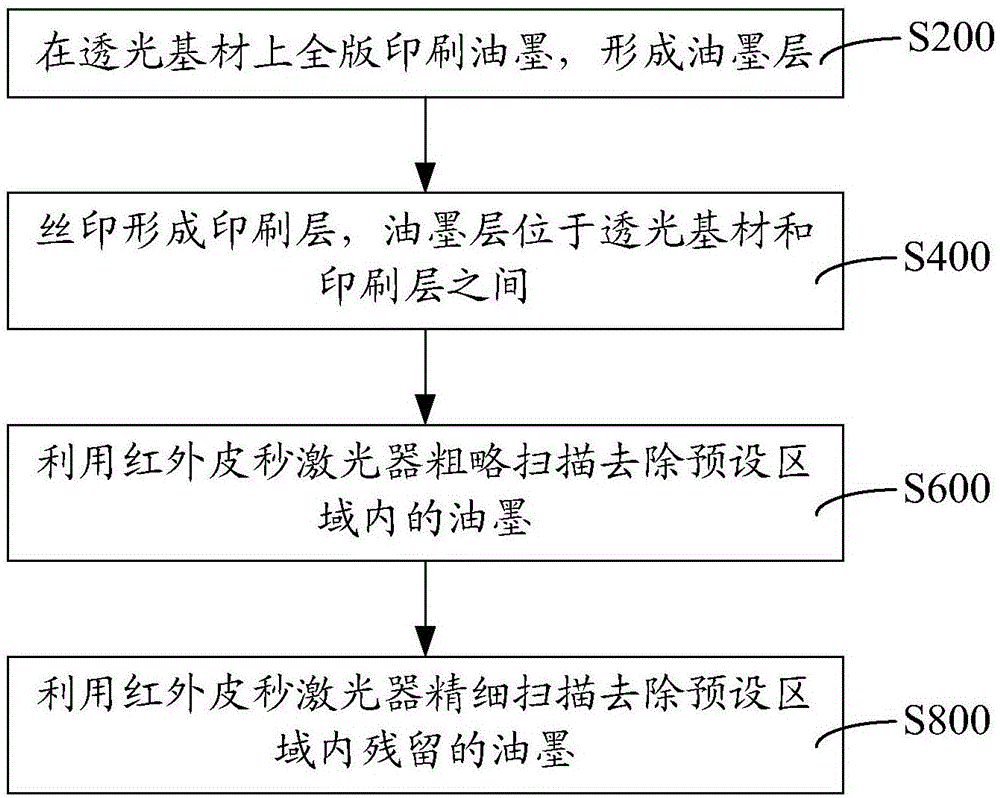

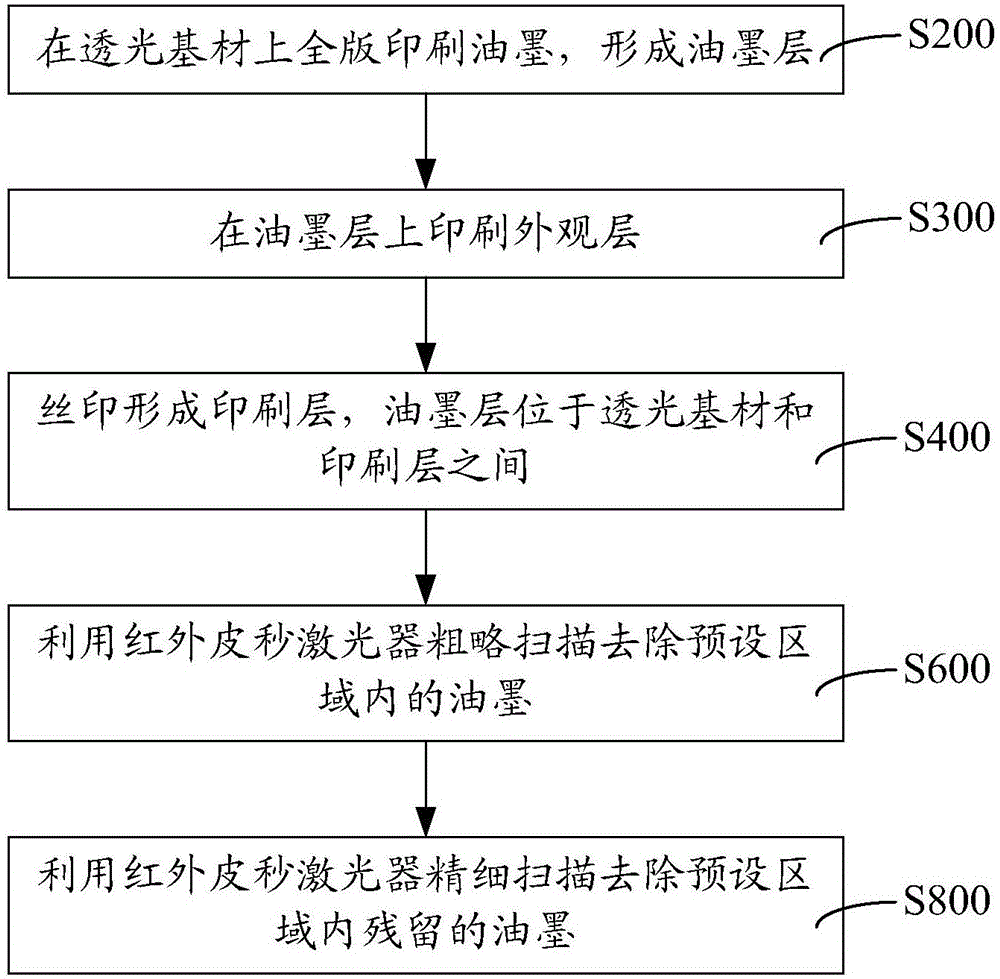

Printing processing method

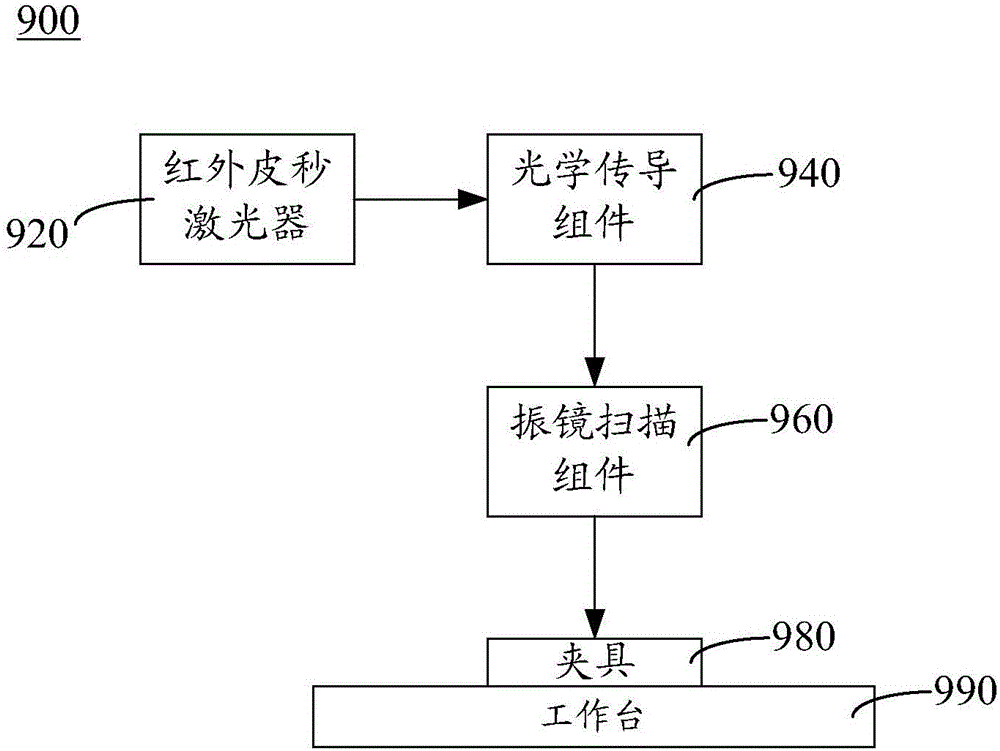

ActiveCN106739589AClean processingQuick removalOther printing apparatusPrinting after-treatmentPicosecond laserLaser processing

The invention relates to a printing processing method. The printing processing method comprises the following steps that ink is arranged on a light-transmitting base material in a full plate printing manner to form an ink layer; a printing layer is formed through silk printing, and the ink layer is located between the light-transmitting base material and the printing layer; an infrared picosecond laser device is utilized for rough scanning to remove ink in a preset area; and the infrared picosecond laser device is utilized for fine scanning to remove ink left in the preset area. The ink is removed through lasers in the preset area so as to be used for backlight transmission, the infrared picosecond laser device weak in energy is utilized for processing, and the light-transmitting base material is prevented from being destroyed by the too strong lasers. The ink removing step comprises rough scanning and fine scanning, most ink of the preset area can be fast removed through rough scanning, and the processing efficiency can be guaranteed easily. After rough scanning, further laser processing is quite close to the light-transmitting base material, and fine scanning is adopted to be beneficial to protecting the light-transmitting base material; and the ink is removed thoroughly, and the light-transmitting effect is good.

Owner:HANS LASER TECH IND GRP CO LTD

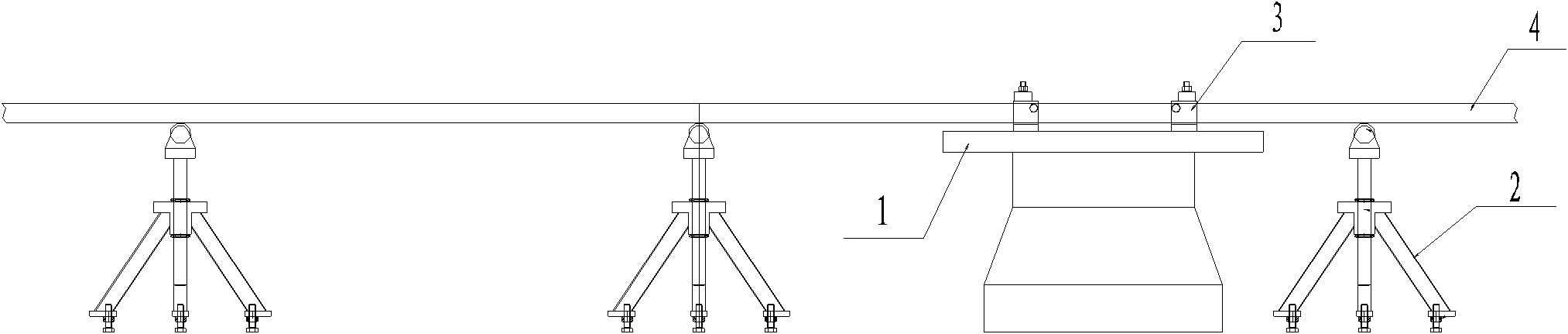

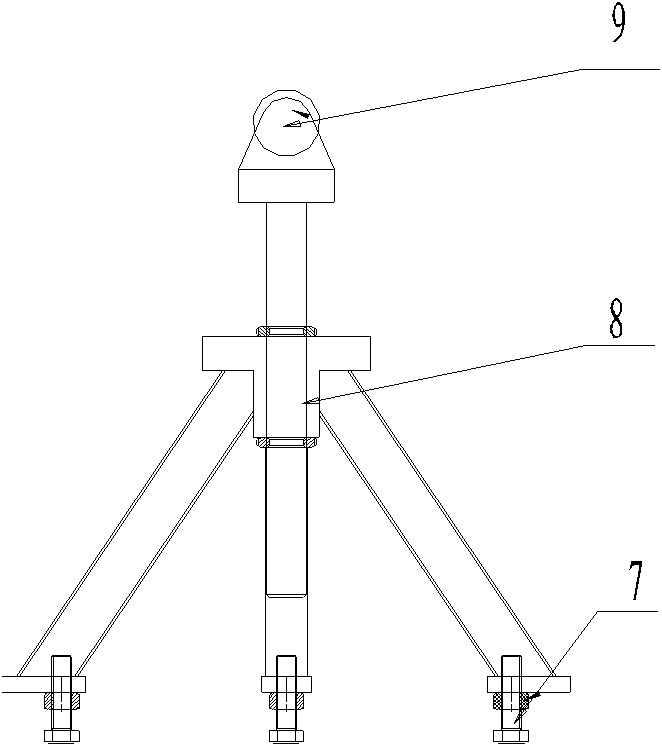

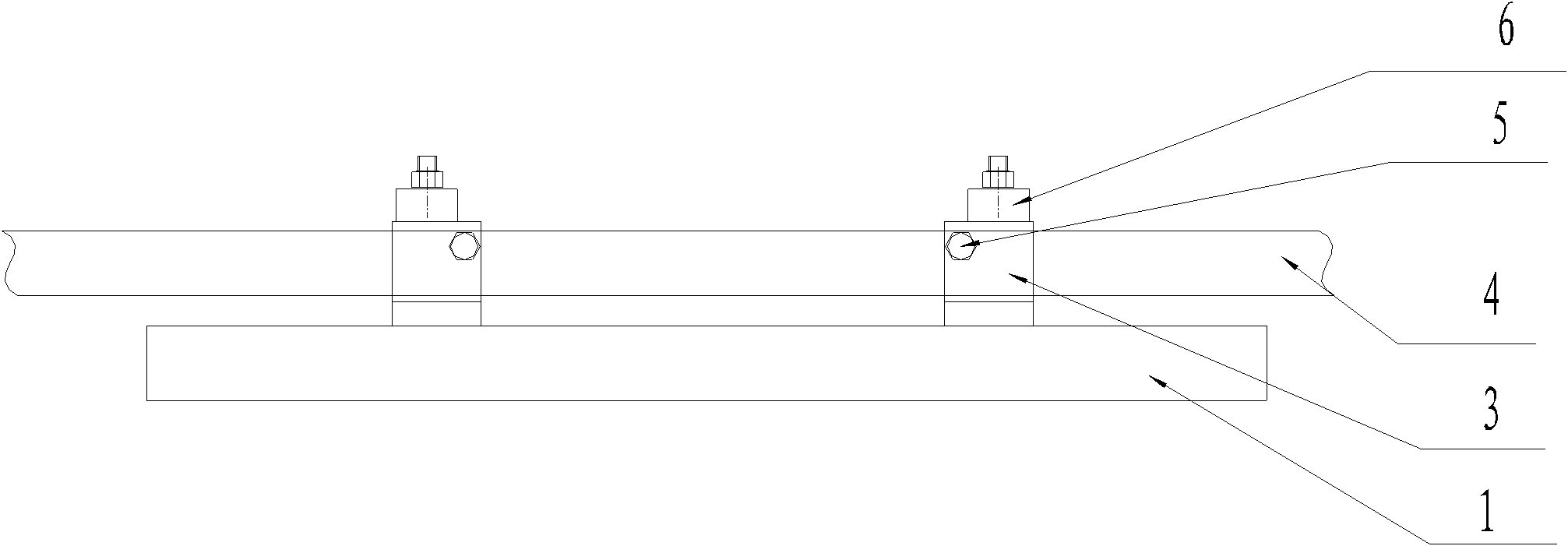

Overlong sectional material machining device and method

ActiveCN102303154ASimple and reasonable structureGuaranteed dimensional accuracyMilling equipment detailsPositioning apparatusEngineeringMachining

The invention discloses an overlong sectional material machining device and method. The overlong sectional material machining device comprises a milling machine and a bracket, wherein the height of a working platform of the milling machine is adjustable and the working platform can be fed along the length direction of a workpiece; a plurality of clamps used for positioning the workpiece are fixedon the working platform in parallel; a roller is arranged at the top end of the bracket; and the bracket is arranged on the two sides of the working platform, and the bracket and the clamps are arranged on the same straight line and used for supporting the workpiece which is machined. The overlong sectional material machining device has a simple and reasonable structure, overcomes the defects of the prior art, realizes the advantages of low cost, high machining efficiency and high machining precision, and can be widely applied to machining of various overlong sectional materials. The invention also provides an overlong sectional material subsection milling method.

Owner:CRRC TANGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com