Patents

Literature

1414results about How to "Guaranteed concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

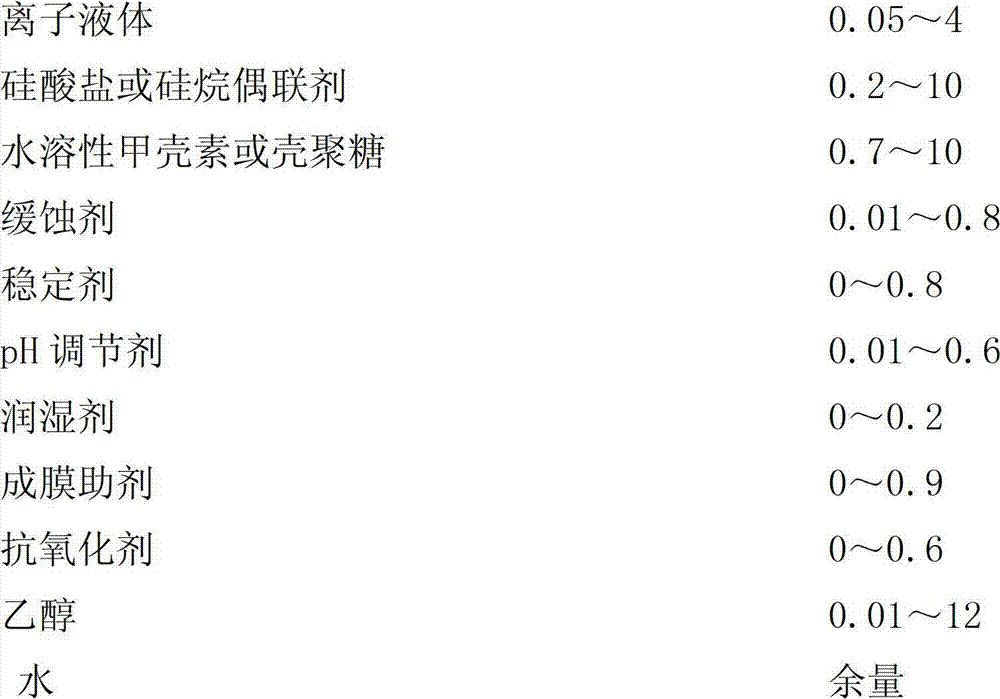

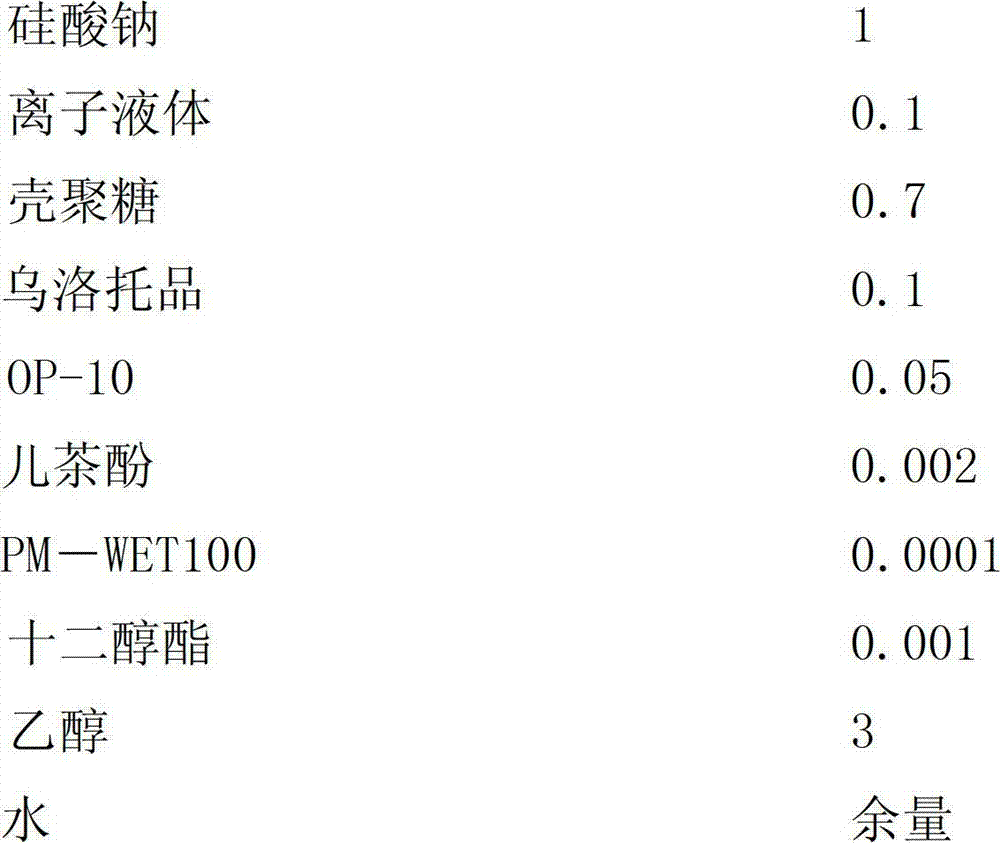

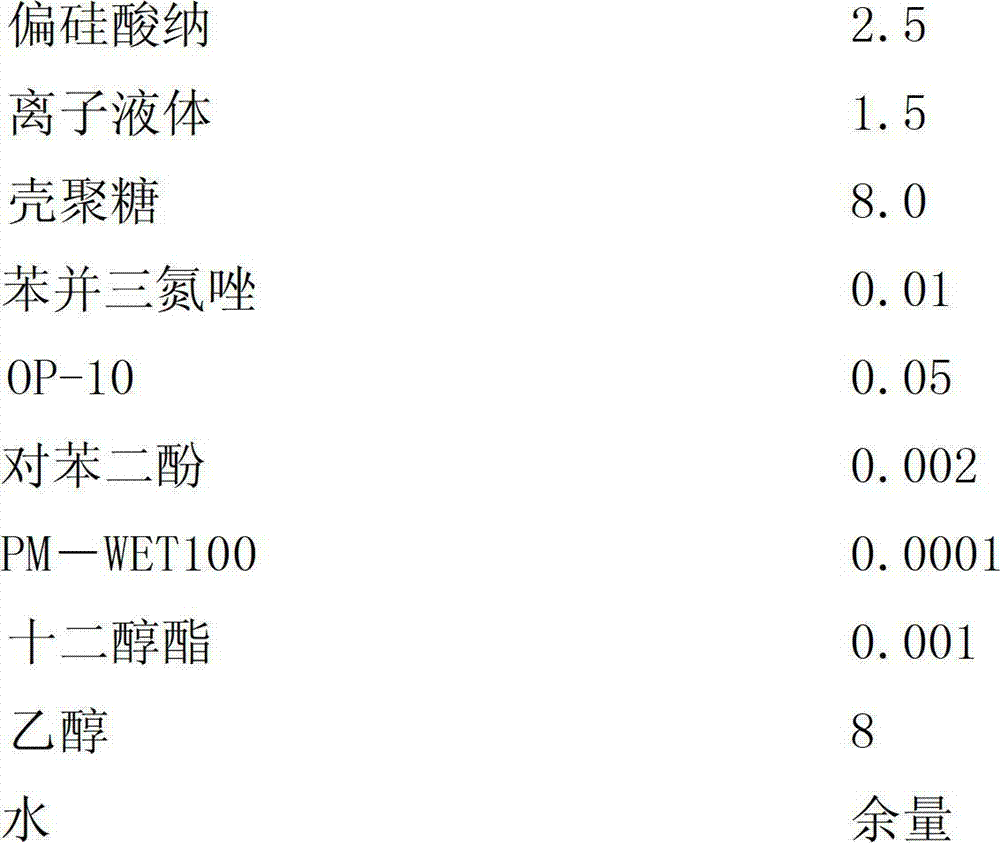

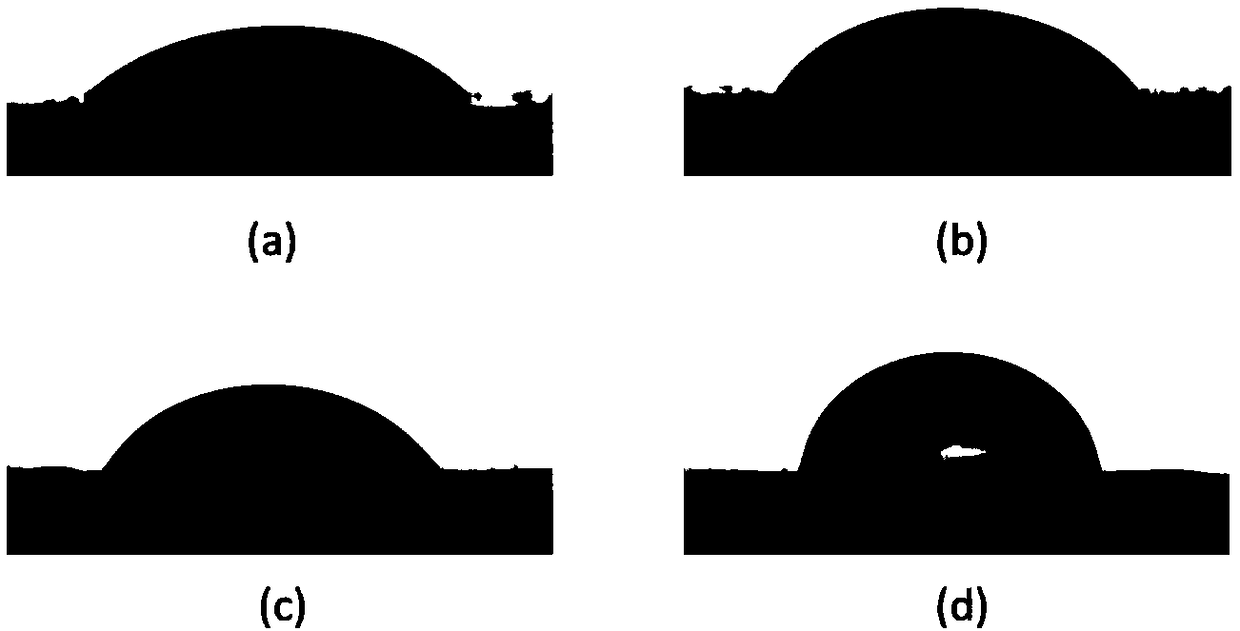

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

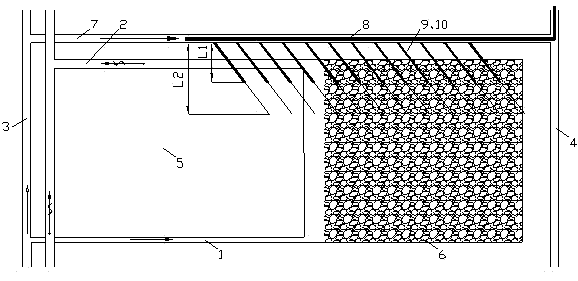

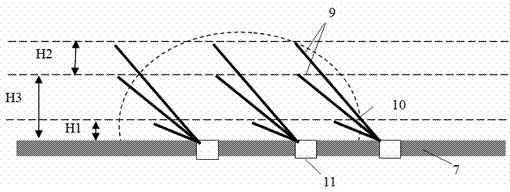

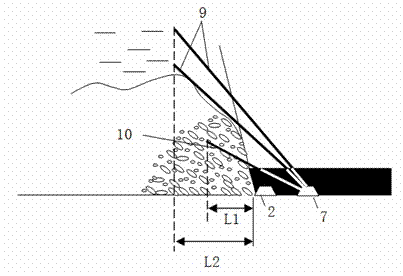

Gas extraction method of cross hole drilling area of gas discharge laneway

ActiveCN102226413AEffective interceptionEffective gush controlDirectional drillingGas removalDrill siteOblique angle

The invention discloses a gas extraction method of a cross hole drilling area of a gas discharge laneway, comprising the following steps: tunnelling an mining area return airway parallel to a mining area track roadway at the tail part of the gas discharge laneway; arranging drill sites on the gas discharge laneway along the roof of a coal seam at intervals; respectively constructing multiple high-level drilling holes with different oblique angles and different lengths and a low-level hole in a worked out area direction in the middle and upper part of each drill site; arranging an extraction pipe after hole drilling construction in each drill site is finished; sealing the holes; and connecting the drilling holes in each drill site into the extraction pipe of the gas discharge laneway through an upper confluence pipe and a lower confluence pipe for extraction, thus realizing the safe production of a gas coal seam group. The method is safe and reliable, can effectively intercept pressure relief gas at an upper neighbor layer, effectively controls the gas from flowing out from a stope face, lowers the gas concentration of an upper corner, and ensures the safe production of the stope face.

Owner:CHINA UNIV OF MINING & TECH

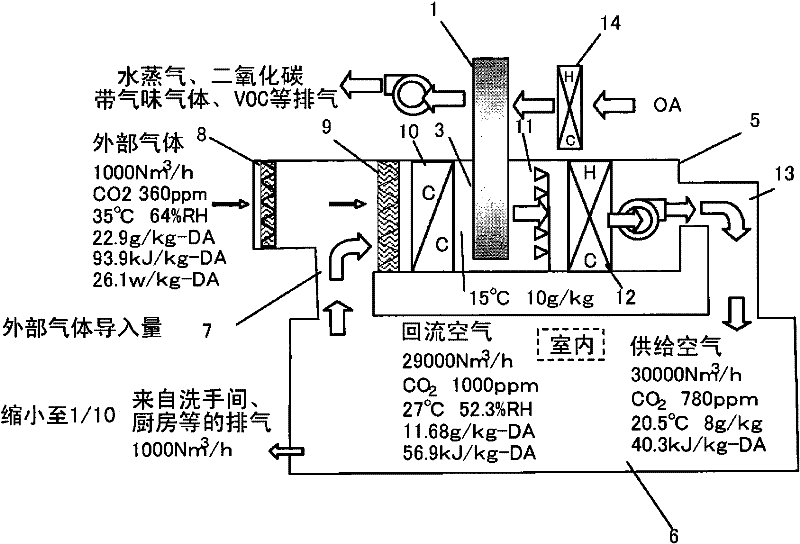

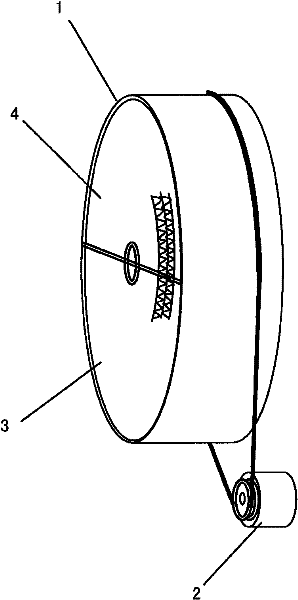

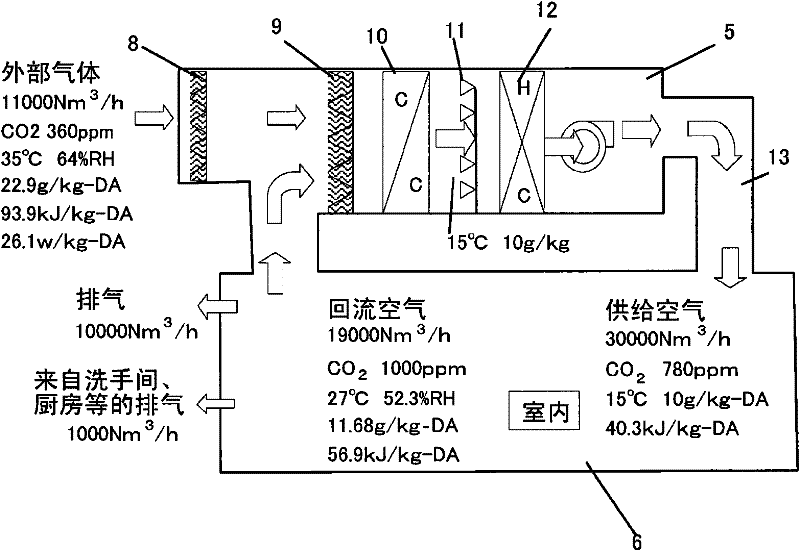

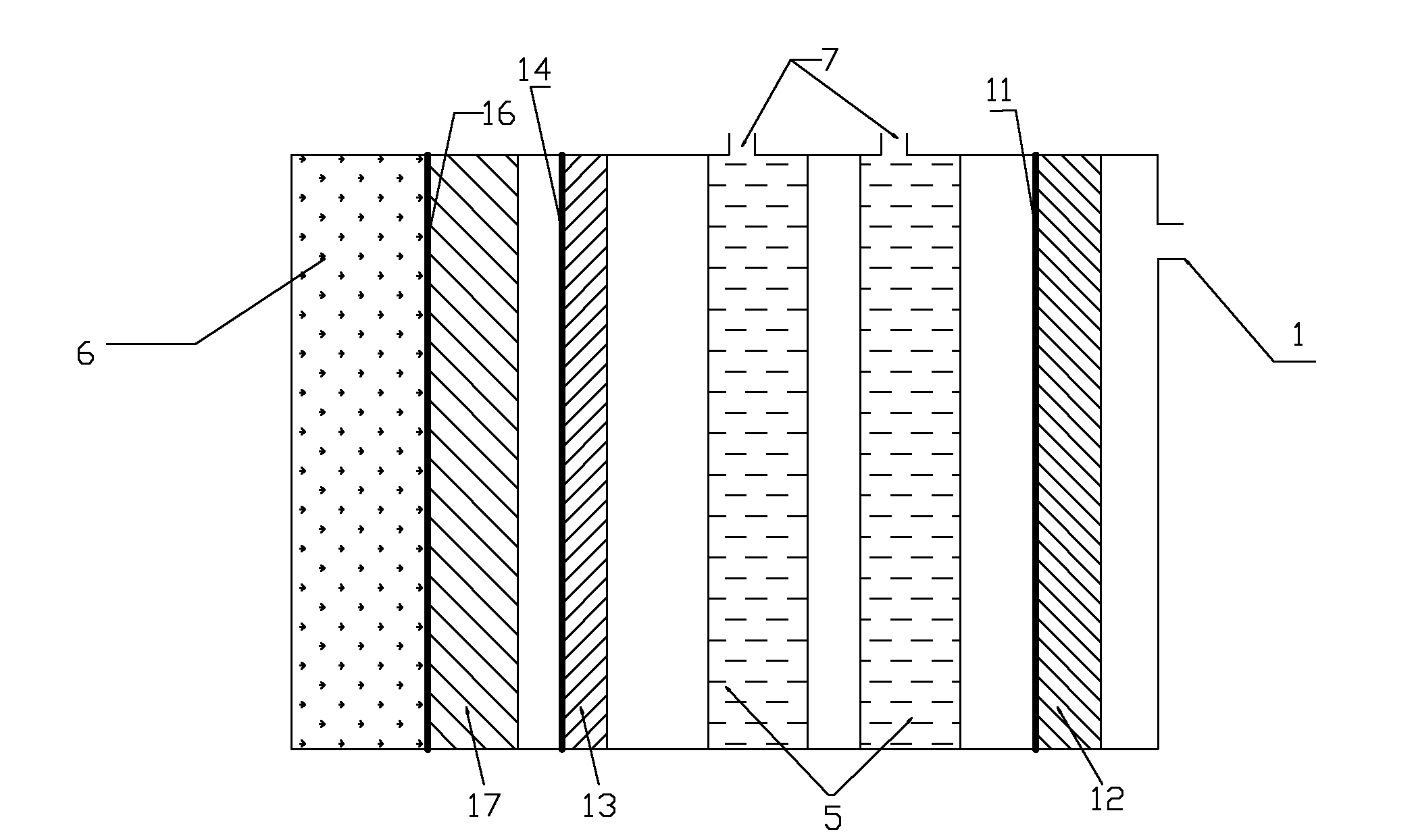

Air conditioning device

ActiveCN102052713AReduce humidityConcentration does not riseLighting and heating apparatusDispersed particle separationDesorptionHoneycomb

The invention provides an air conditioning device which can maintain indoor air environment and save energy with good effect even when the air-exchange amount is small. The air conditioning device is used for discharging carbon dioxide from the indoor. The air conditioning device is set in that the return air from a room (6) is cooled through an evaporator (10) of a heat pump cycle system; the cooled air passes through the adsorption zone (3) of a honeycomb type rotor (1) having the function of carbon dioxide absorption; outer air (OA) whose temperature increases by passing through a condenser (14) of the heat pump cycle system passes through a desorption zone (4) of the honeycomb type rotor (1). In this case, carbon dioxide contained in the air in the room (6) can be adsorbed to the honeycomb type rotor (1) and be discharged to the outside, thereby the internal environment of the room (6) can be maintained even the air exchange is in small amount.

Owner:SEIBU GIKEN CO LTD

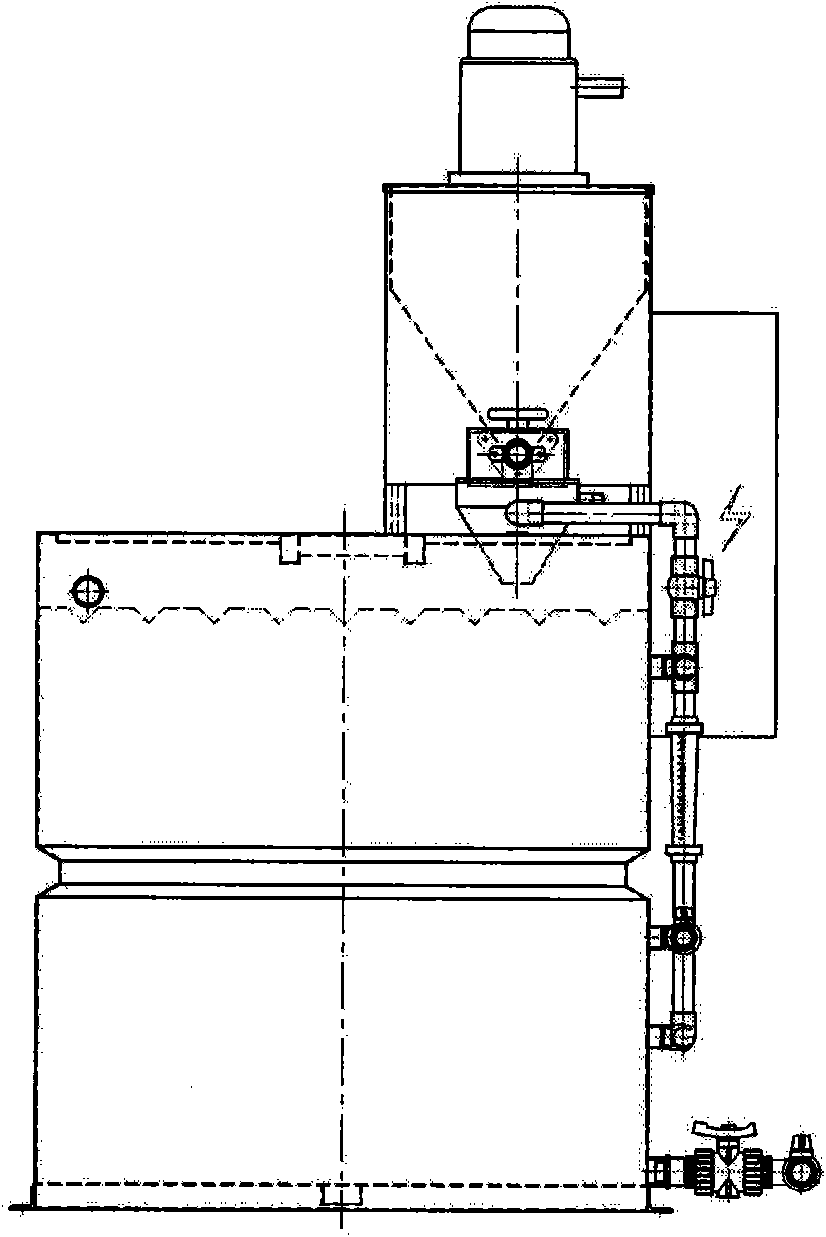

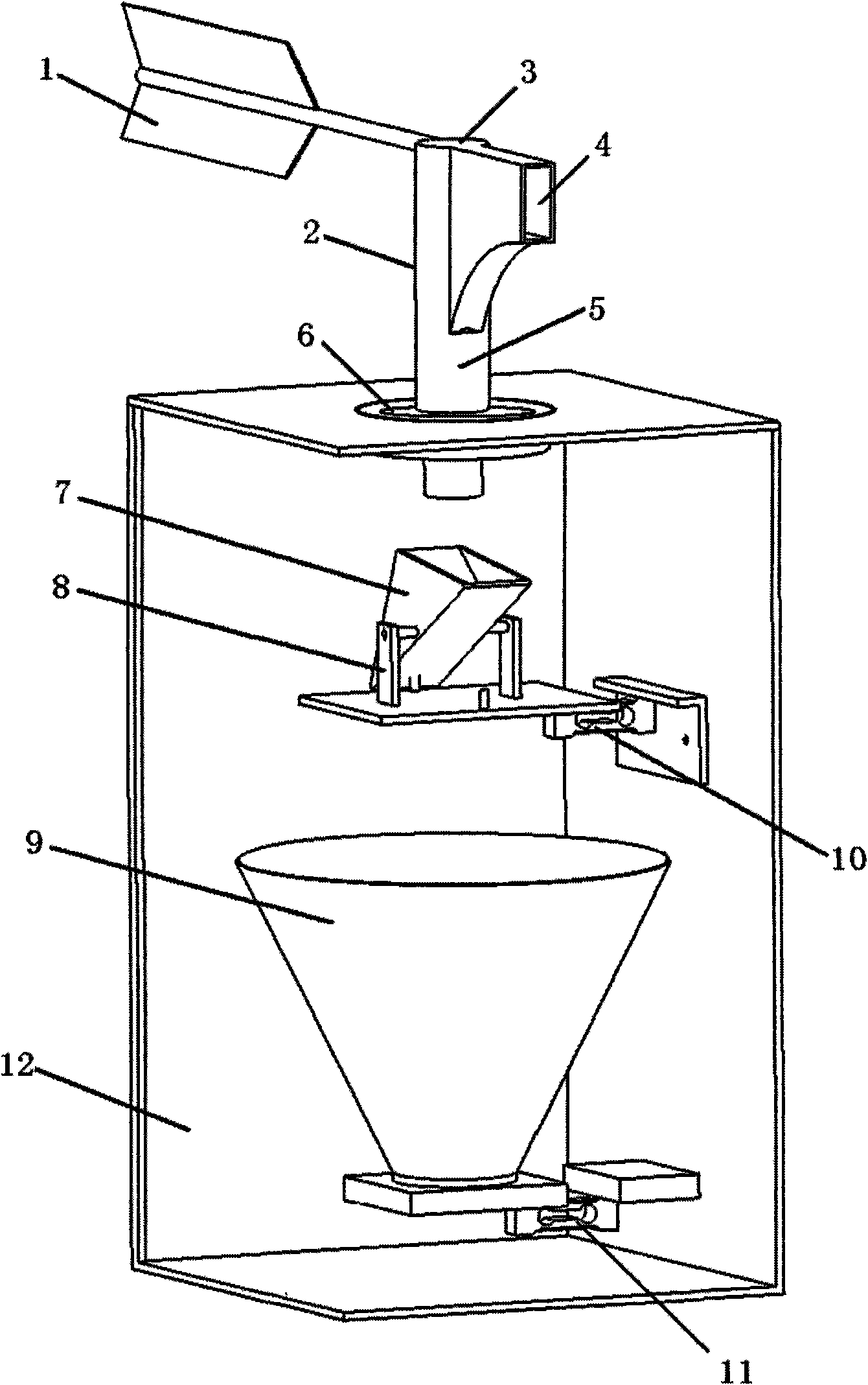

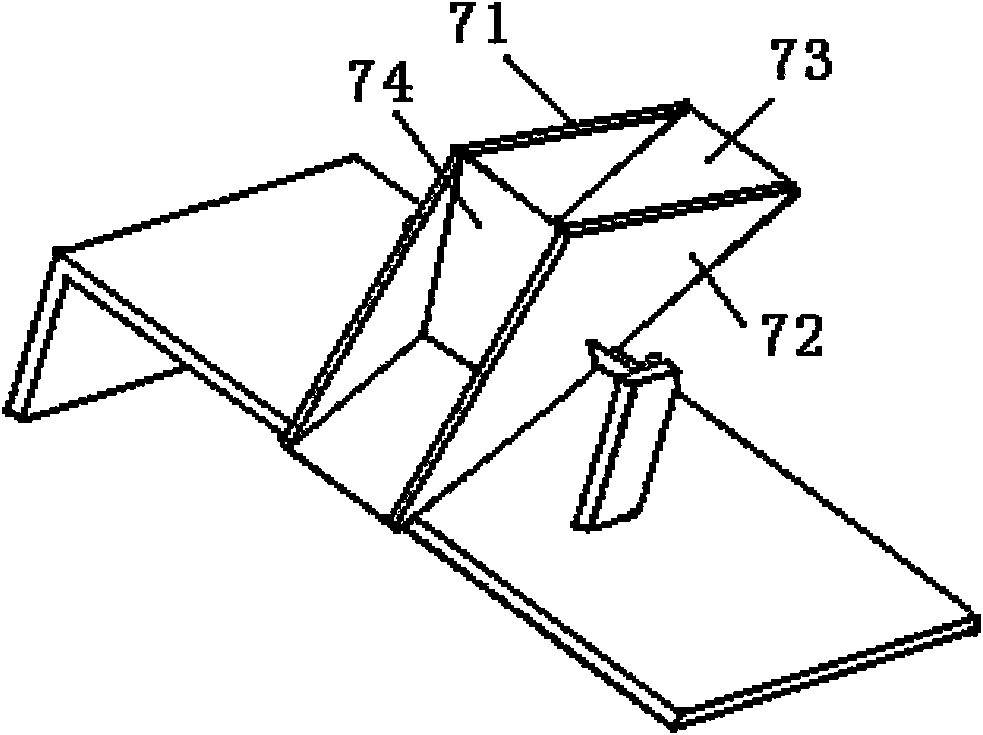

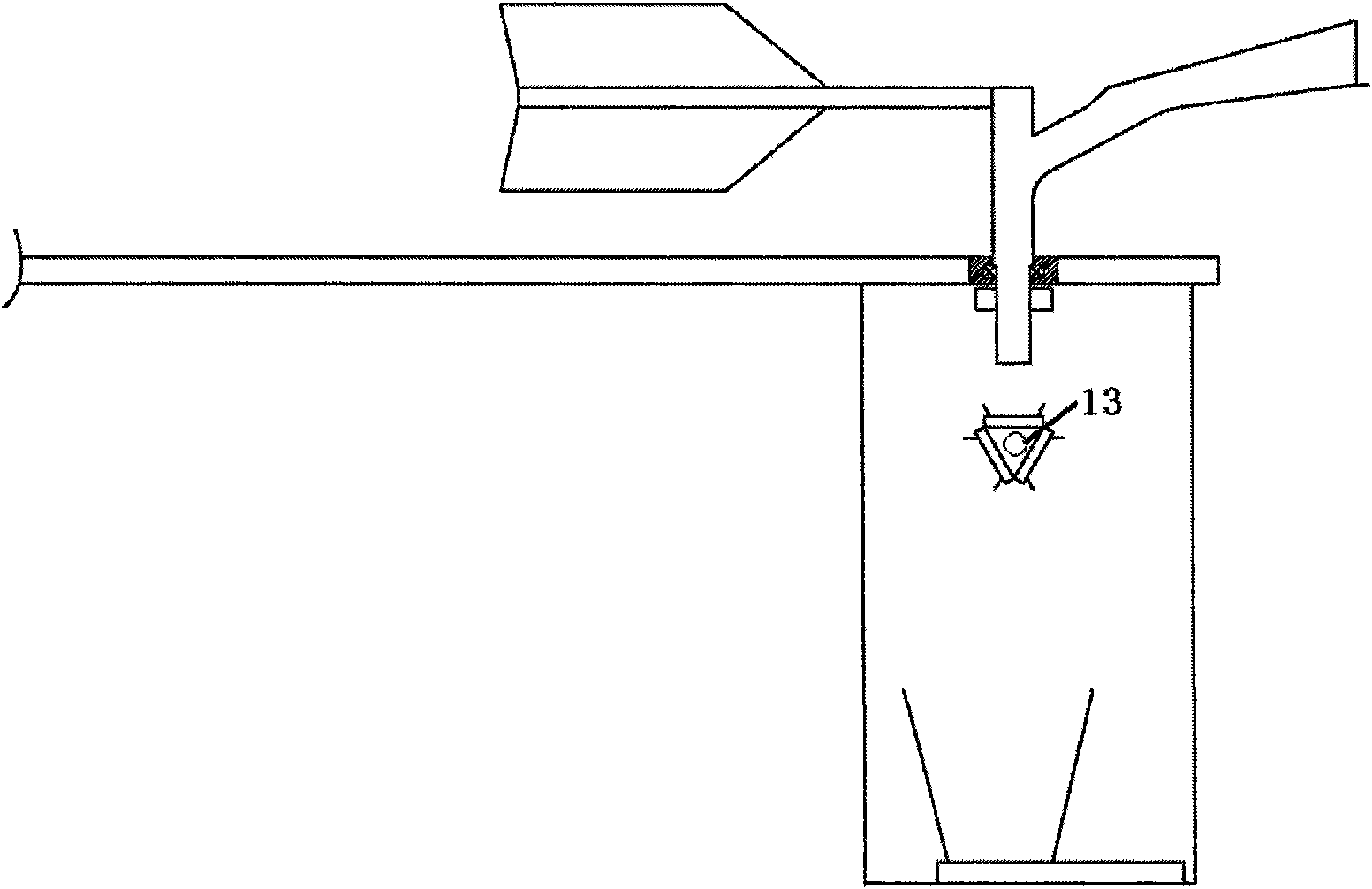

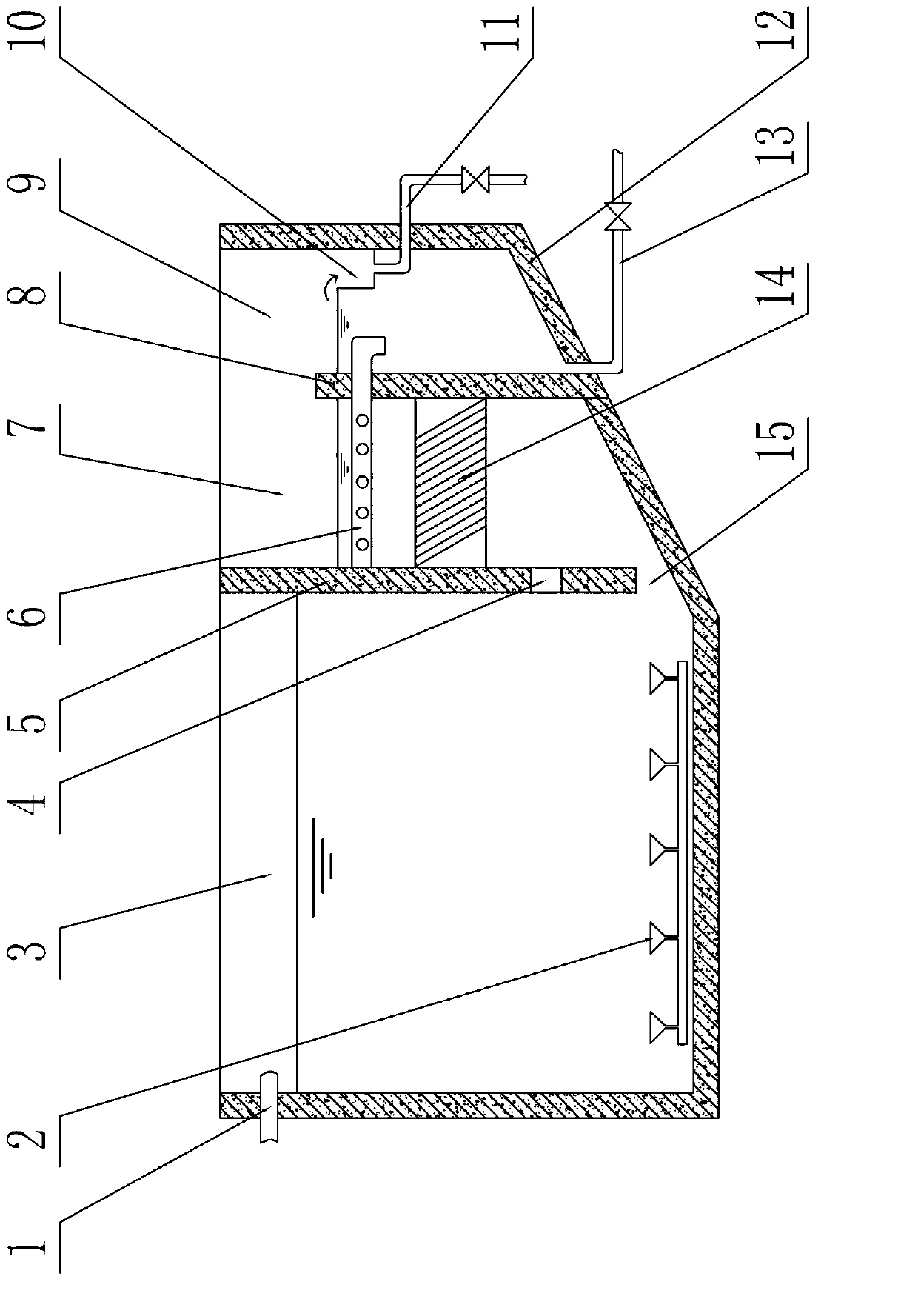

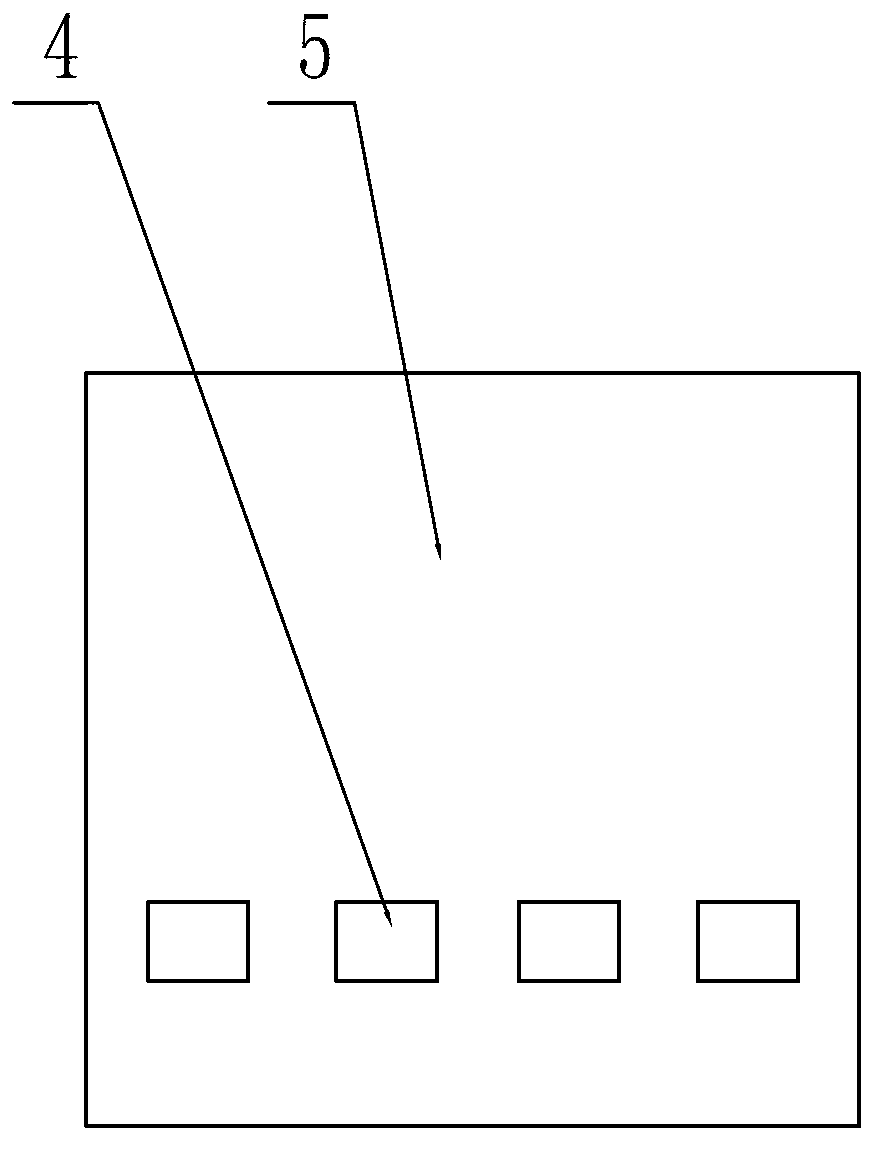

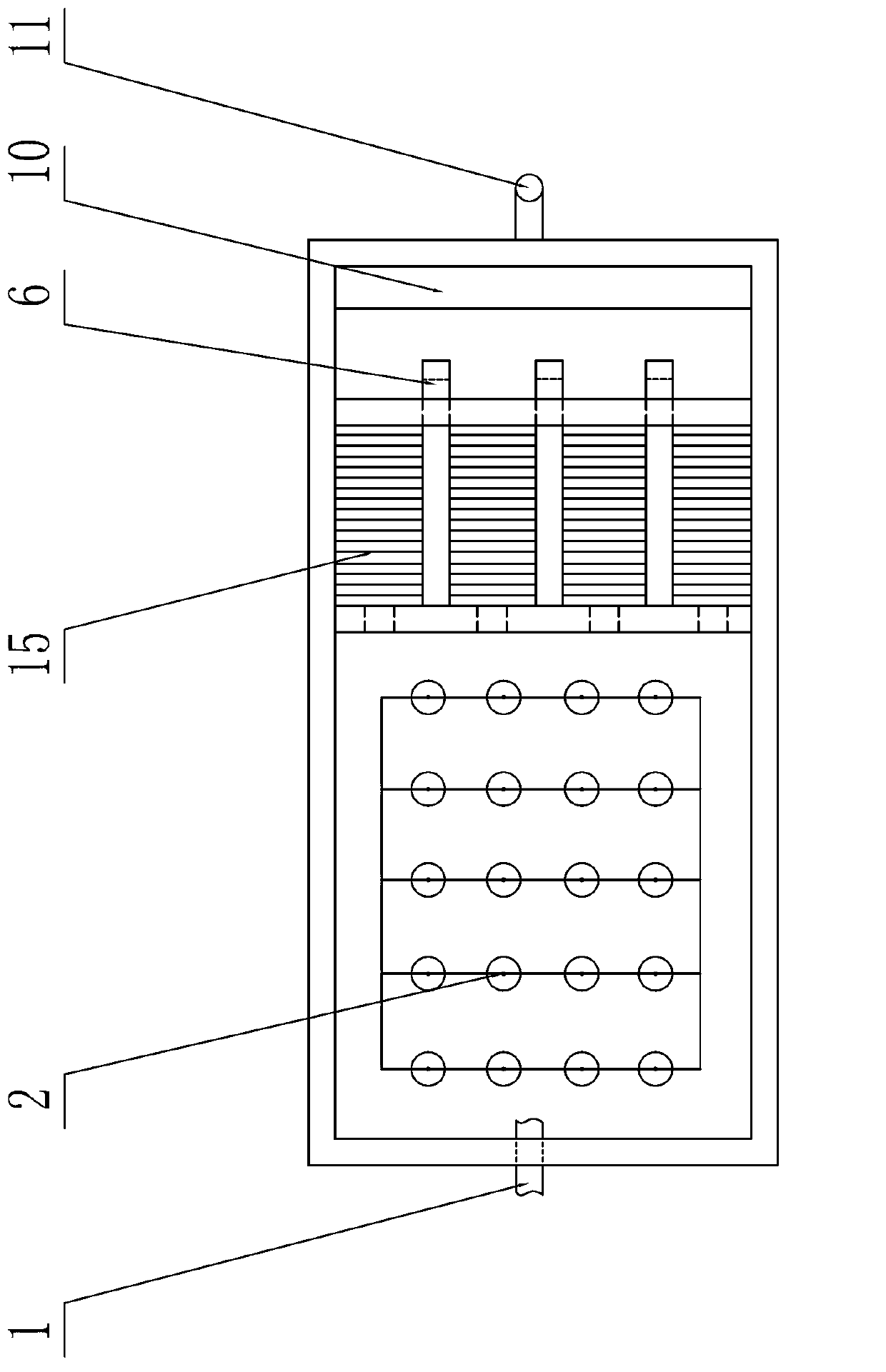

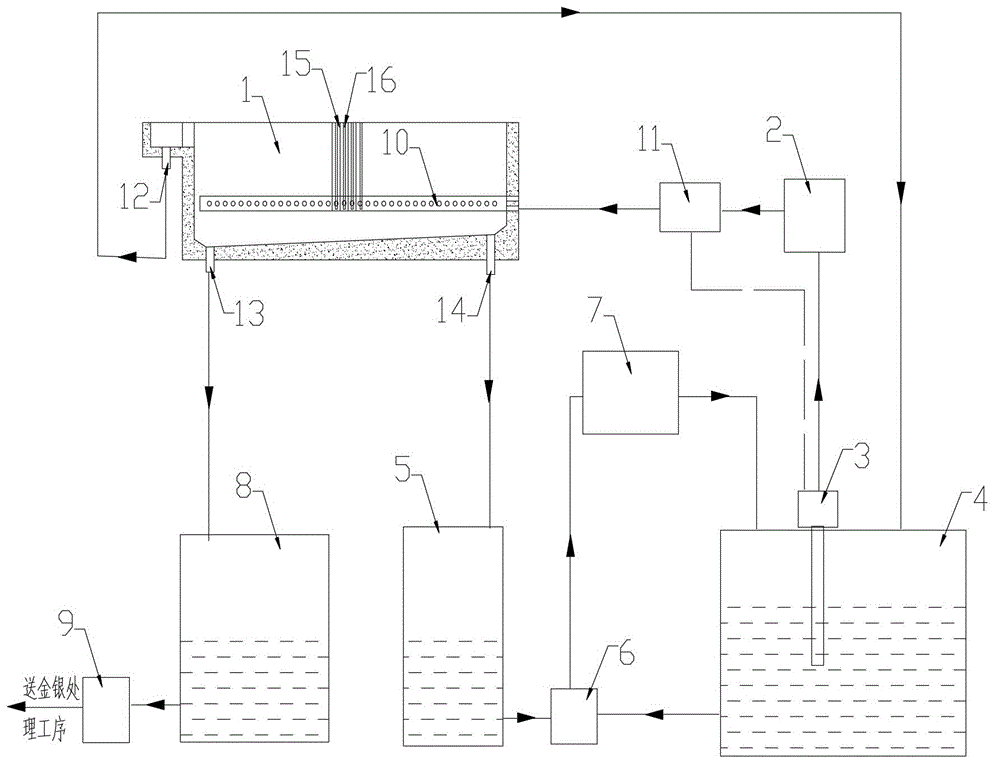

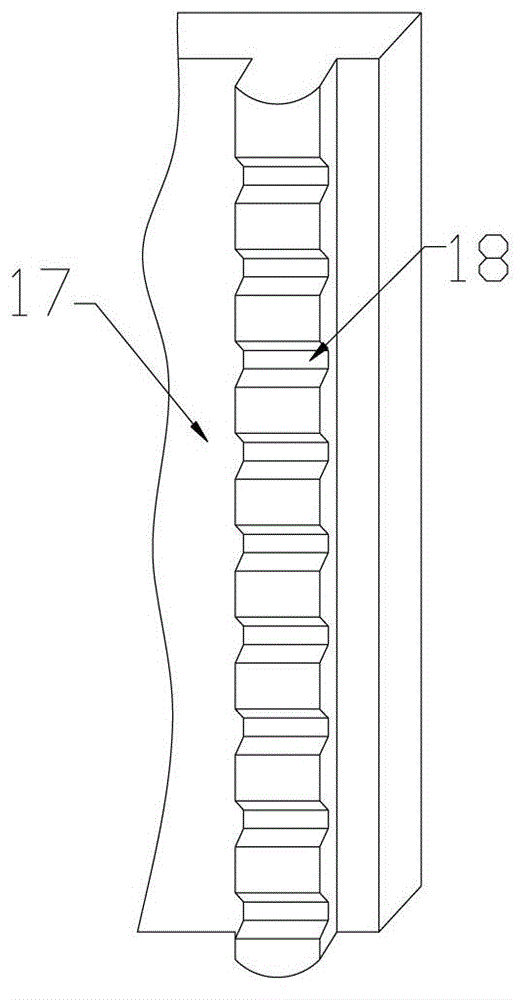

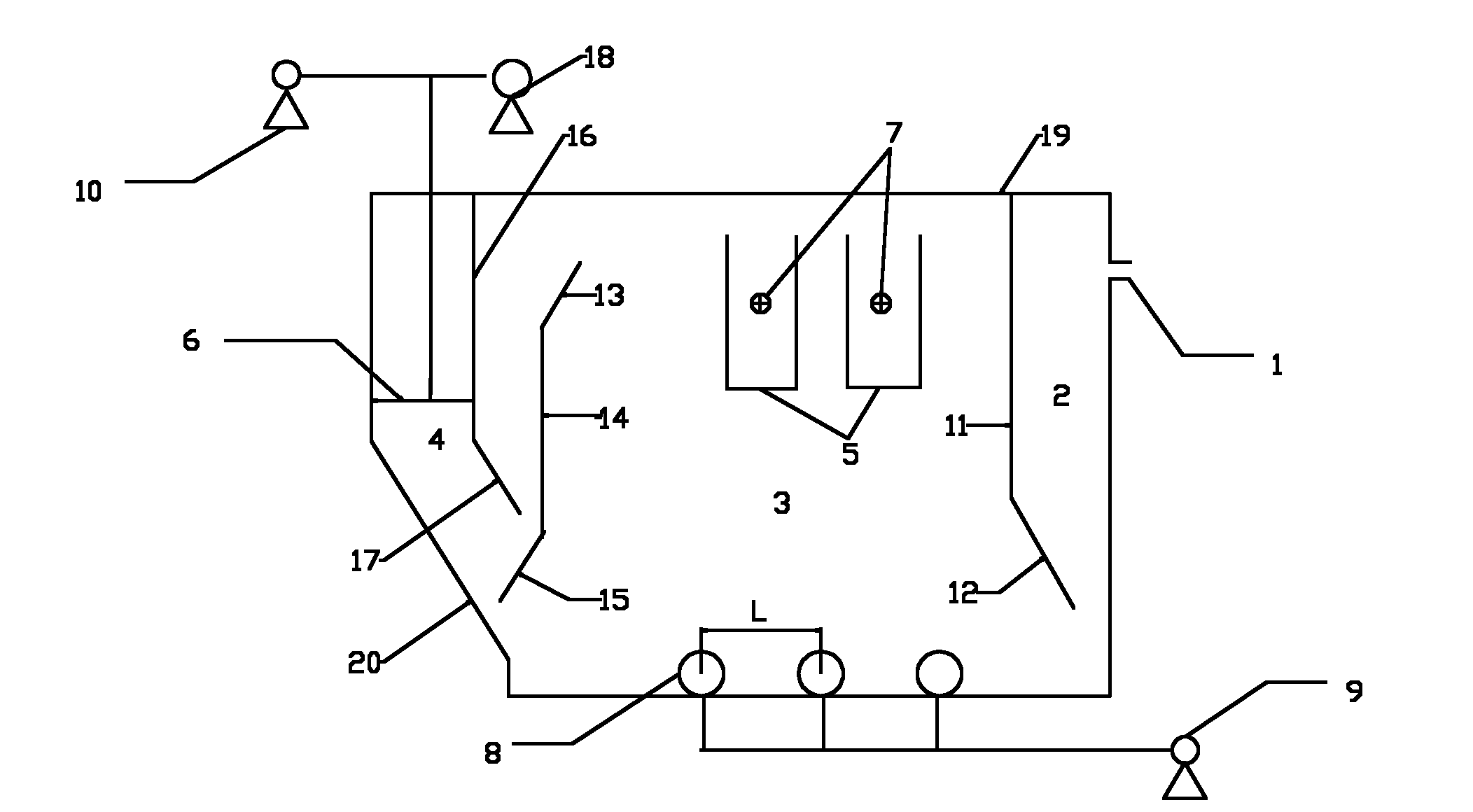

Automatic dosing device for sewage treatment

InactiveCN102020406AStir wellStable concentrationSludge treatment by de-watering/drying/thickeningLow speedMedicine

The invention discloses an automatic dosing device for sewage treatment, which consists of a medicine dissolving box, a medicinal powder dosing device, a medicine dissolving mixer, a mixer driving motor, a water inlet pipe, a medicine outlet pipe and a dosing pump. A pre-infiltrating device is arranged between the medicinal powder dosing device and the medicine dissolving box; the medicine dissolving box are separated by two overflow weirs to form a dissolving tank, a curing tank and a storing tank which are adjacent in turn; and a homogenizing stirrer is arranged in the curing tank. The pre-infiltrating device is arranged in the automatic dosing device for sewage treatment and is used for soaking dry flocculant powder, medicine solution flows into the dissolving tank by means of gravity and is stirred and mixed, the curing tank and the storing tank are arranged, low-speed stirring is carried out in the curing tank, and medicine solution meets the requirements of homogenization, curing and activity; the medicine solution passes through the overflow weirs to flow into the solution storing tank, so that the dissolving and stirring of the dry powder, the homogenization and curing of the solution and the dosing of the liquid medicine are synchronously carried out, and the efficiency and the liquid medicine utilization rate are improved; and the dry powder is accurately weighed, the caking of the dry powder is avoided, the concentration of the liquid medicine is ensured, and the medicine solution can be diluted on line according to requirement of actual application concentration.

Owner:开源环保(集团)有限公司

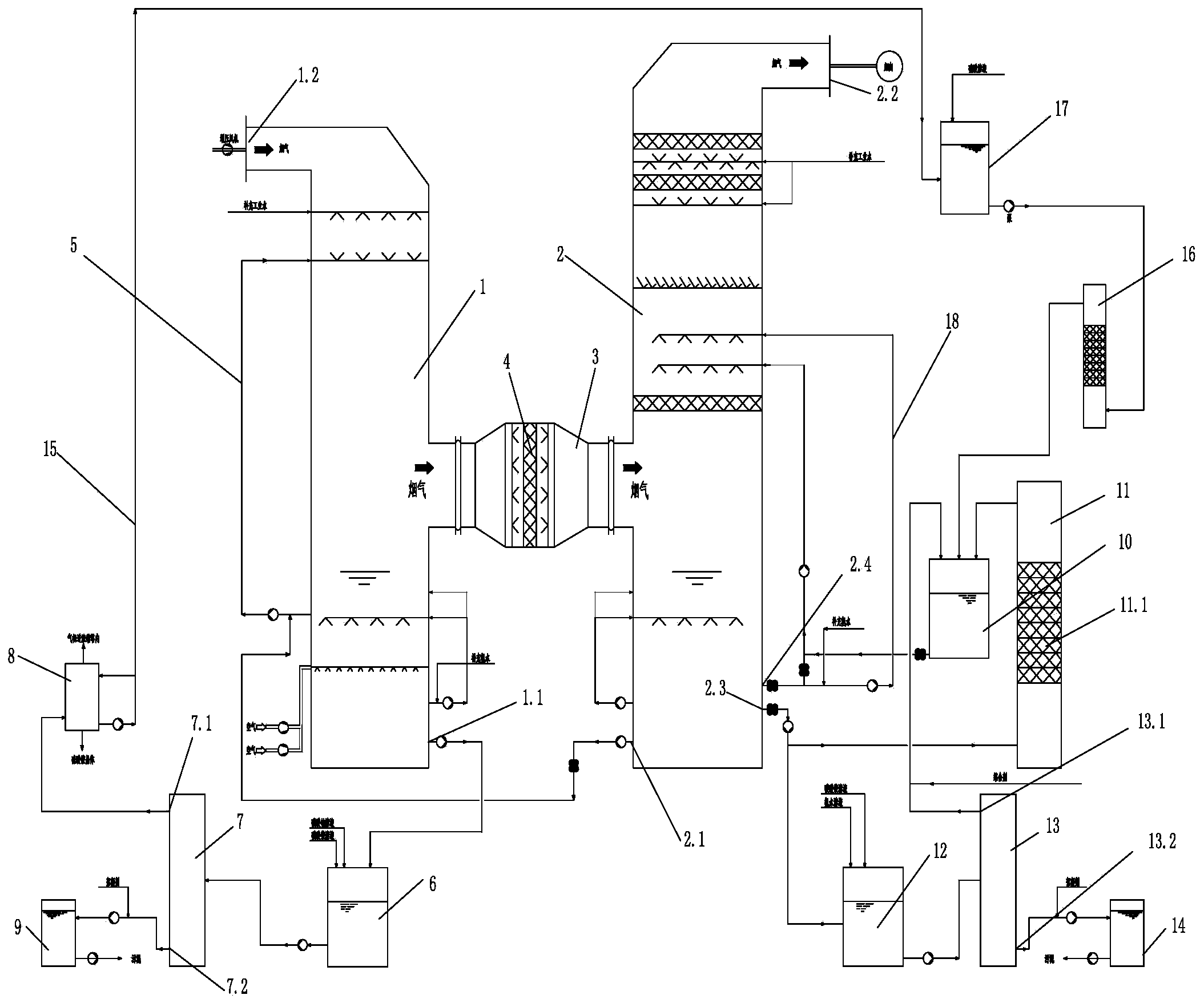

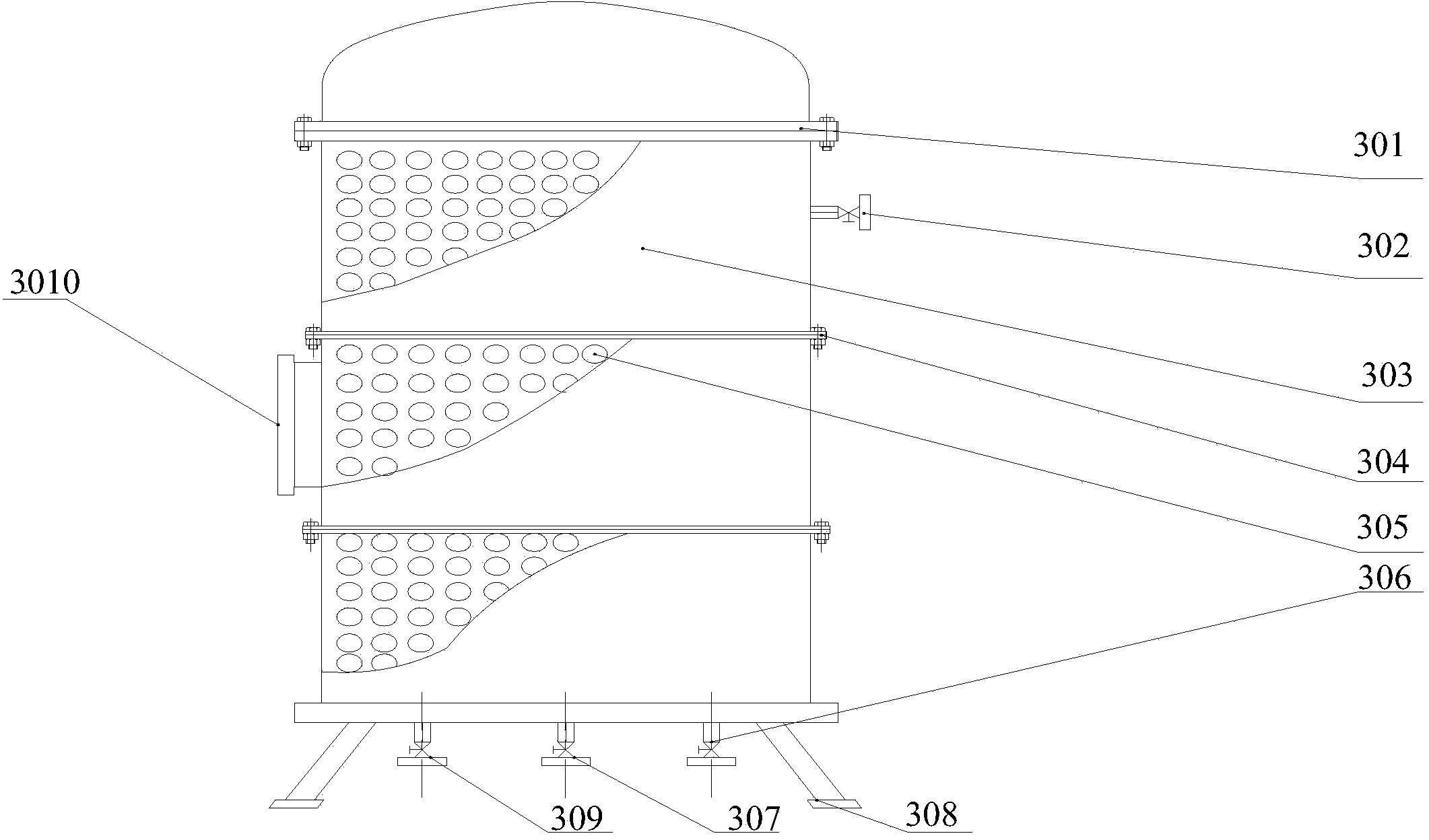

Synchronous denitration process based on wet ammonia process flue gas desulfurization

InactiveCN104226095ALow investment costLow running costDispersed particle separationAmmonium sulfatesSulfateFlue gas

The invention discloses a synchronous denitration process based on wet ammonia process flue gas desulfurization. The problems such as high operating cost and equipment investment cost, complex process and high energy consumption existing in an existing process are solved. According to the technical scheme, the process comprises the following steps: pressurizing flue gas, feeding the flue gas into a concentrating tower, allowing the flue gas to contact and react with a concentrated solution in the tower, feeding the flue gas out of the concentrating tower into an absorption tower to contact and react with absorption liquid in the tower, feeding a small amount of reacted concentrated solution at the bottom of the concentrating tower into an ammonium sulfate crystallization system, and adding a complexing agent EDTA-Fe (II) or adding EDTA-Na salt and ferrous sulfate according to a molar ratio of 1:1 into the absorption liquid in the absorption tower, so that the concentration of the EDTA-Fe (II &III) in the absorption liquid is 0.015-0.05mol / L; and feeding a small amount of absorption liquid in the absorption tower into the concentrating tower to be mixed with the concentrated solution. The synchronous denitration process disclosed by the invention has the advantages of simplicity, low operating cost and equipment investment, capacity of performing high-efficiency synchronous desulfurization and denitration and low energy consumption.

Owner:WUHAN WUTUO TECH +2

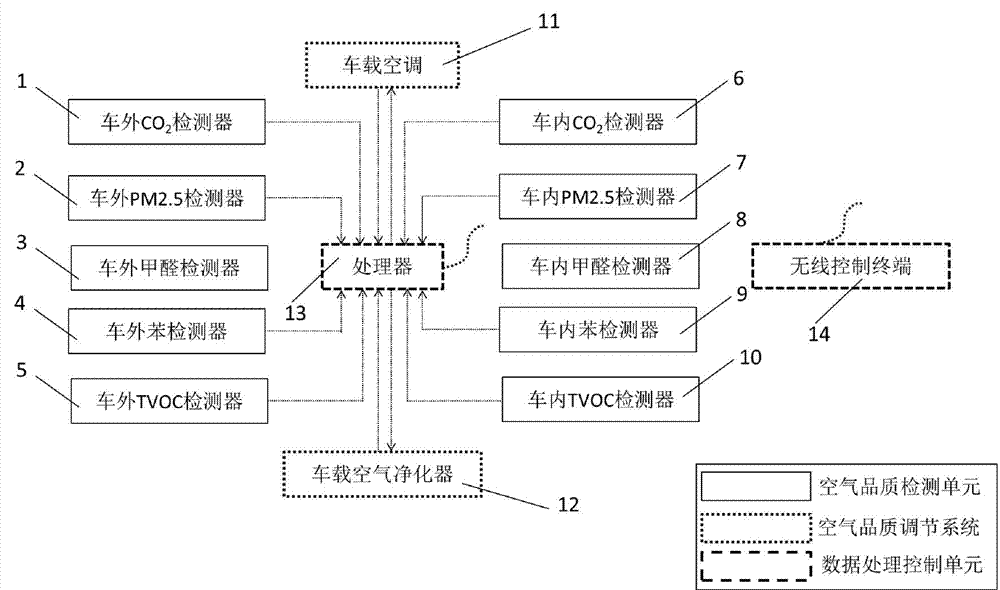

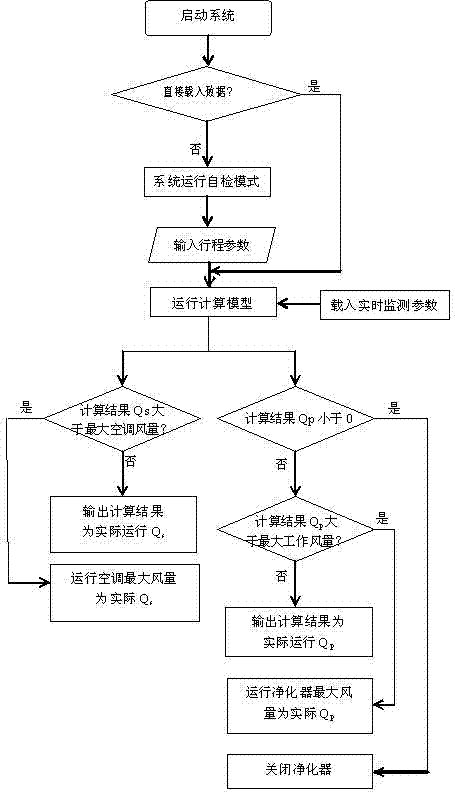

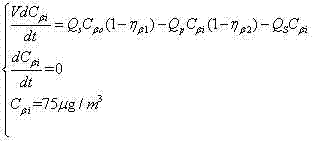

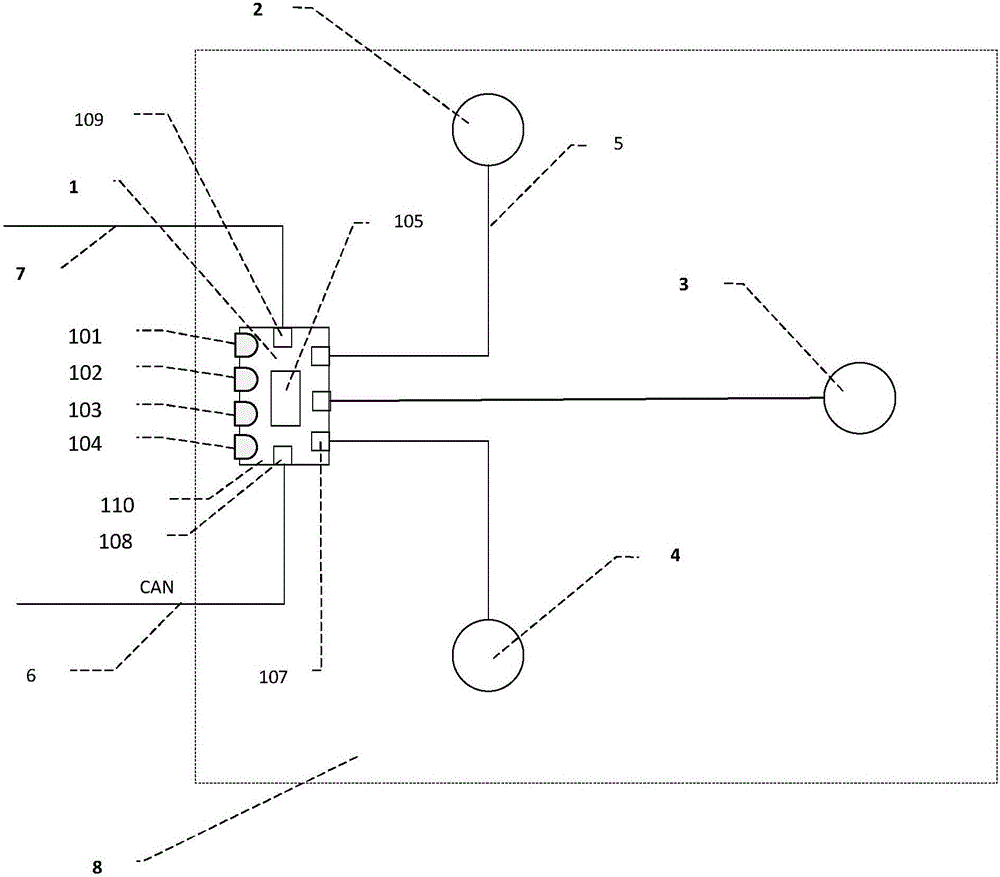

Intelligent adjusting system of in-vehicle air quality and application method thereof

ActiveCN104760490ARealize intelligent adjustmentGuaranteed concentrationAir-treating devicesWireless controlAutomatic control

The invention relates to an intelligent adjusting system of in-vehicle air quality and an application method thereof. The system comprises an air quality detecting unit, an air quality adjusting unit and a data processing control unit. The air quality detecting unit comprises a concentration detector of pollutants inside and outside a vehicle; the air quality adjusting unit comprises a vehicle-mounted air conditioner and a vehicle-mounted air purifier; the data processing control unit comprises a processor and a wireless control terminal; and the processor and the wireless control terminal are connected through an internet of things technology. Controllers input travel parameters through the wireless control terminal; the parameters are transmitted into the processor through networking; the processor calculates optimal operation parameters of the air quality adjusting unit through a pre-built calculation model and data input by the air quality detecting unit and the air quality adjusting unit, and returns and performs an instruction to realize intelligent adjustment of the in-vehicle air quality. The system can detect the pollution level of the pollutants inside and outside the vehicle in real time, optimally adjusts the operation parameters of the vehicle-mounted air conditioner and a vehicle-mounted air filter, and improves the in-vehicle air quality. The adjusting system has such characteristics as advanced and reasonable settings, realization of automatic control, complete functions and simple and fast operation.

Owner:XIAMEN MAXMAC AIR TECH

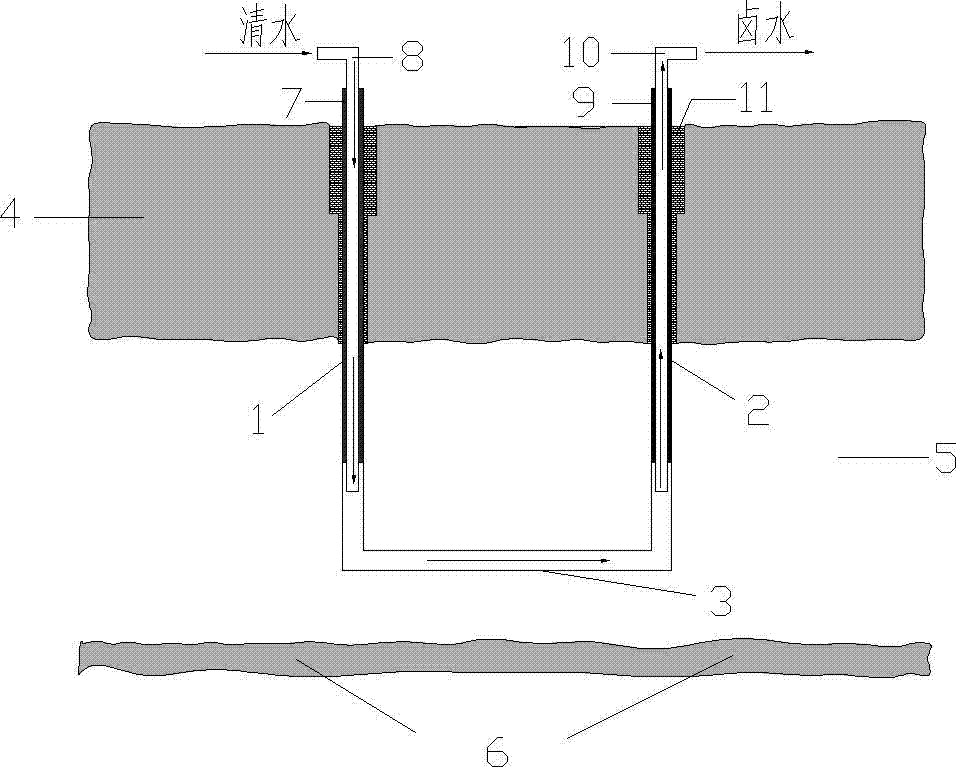

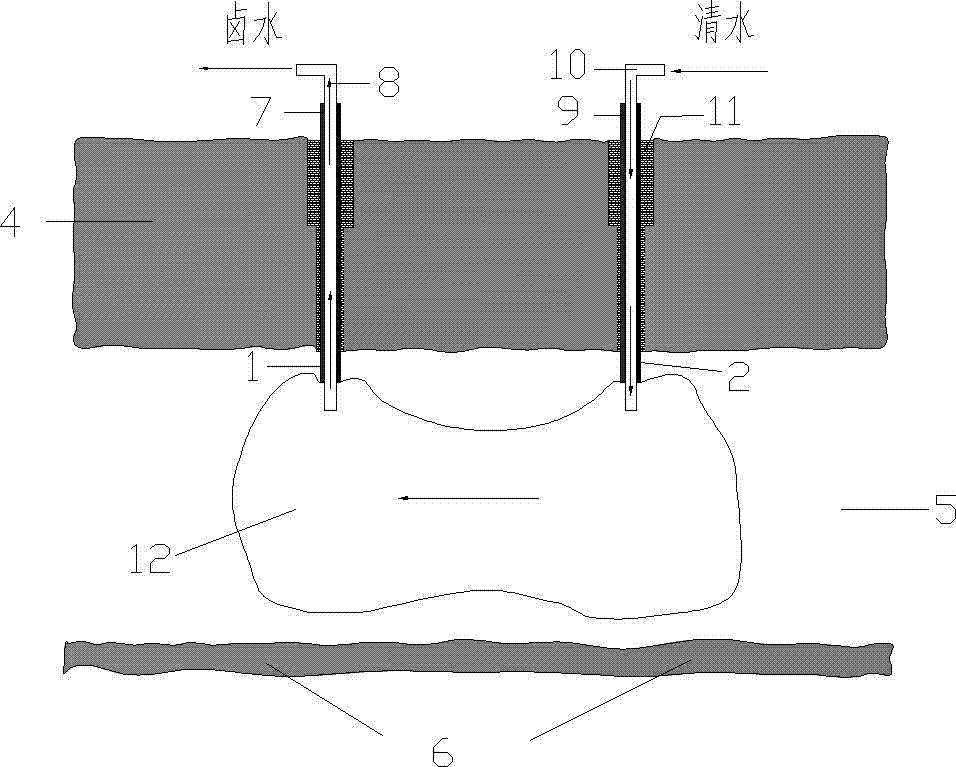

Double-vertical shaft horizontal butt joint salt cavern deposit construction method

The invention discloses a double-vertical shaft horizontal butt joint salt cavern deposit construction method. The method comprises the following steps of: (1) respectively constructing two vertical shafts on a salt rock ore layer; (2) constructing a horizontal well between the two vertical shafts; (3) respectively arranging a technical sleeve and an inner pipe in each vertical shaft; and (4) injecting clear water into one vertical shaft, discharging brine water from the other vertical shaft, exchanging the positions for water inflow and brine discharge after a period of time, and circulating in such a way till the shape of a cavity is similar to a horizontal calabash, thereby completing cavity construction. By utilizing the method, the construction speed of the salt rock cavern can be increased, a single-well casing arrangement process can be simplified, and the cavity construction cost can be reduced; and the concentration of the extracted brine water can be ensured on the premise of meeting the shape control of the cavity construction, and the brine water can be directly conveyed to a brine water treatment enterprise.

Owner:中国平煤神马集团联合盐化有限公司

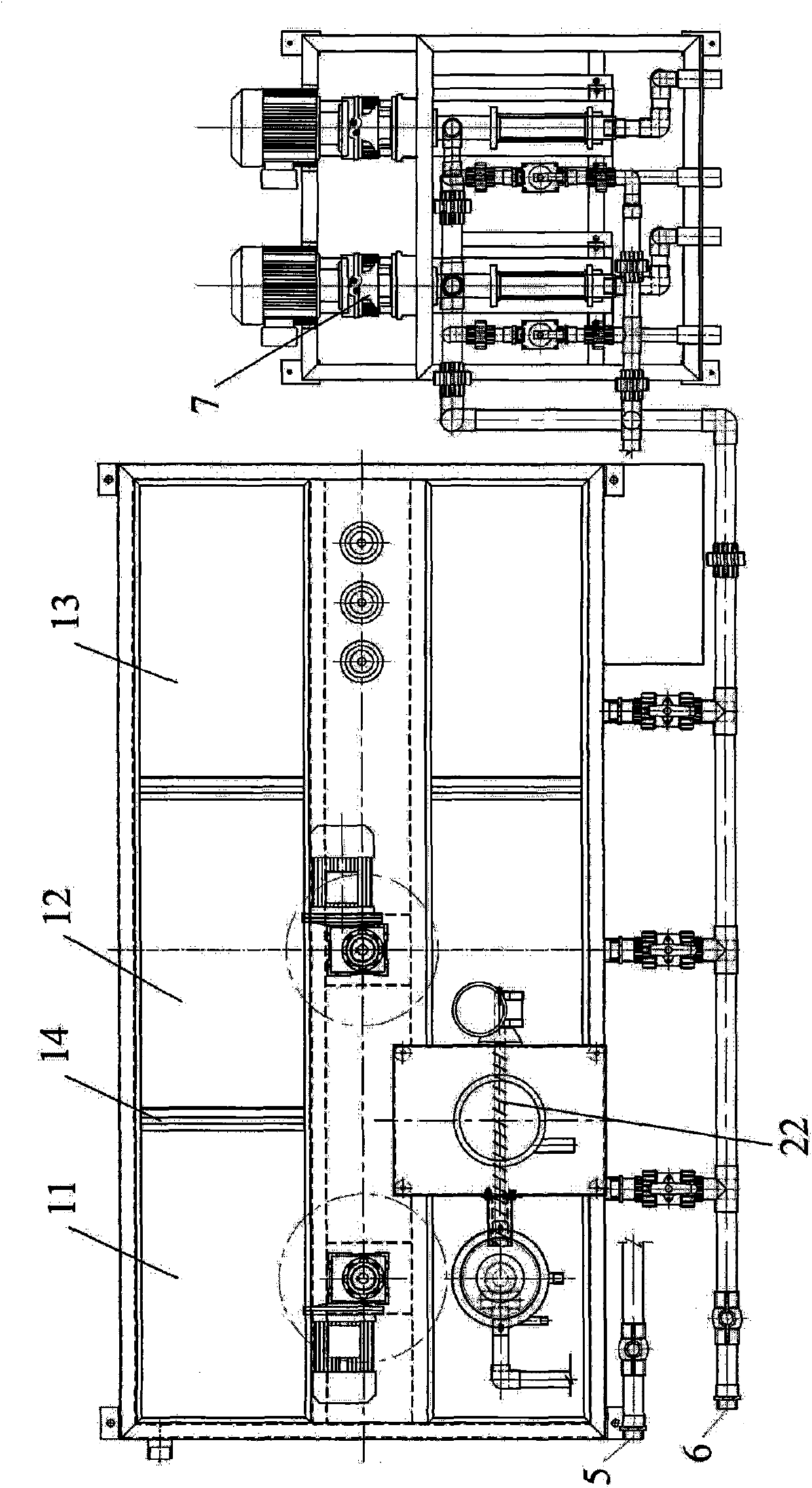

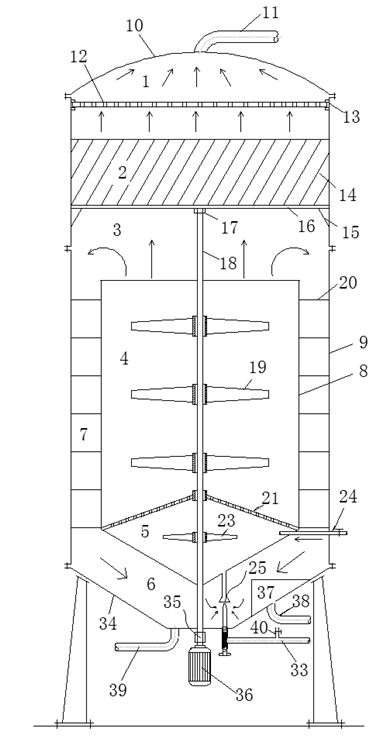

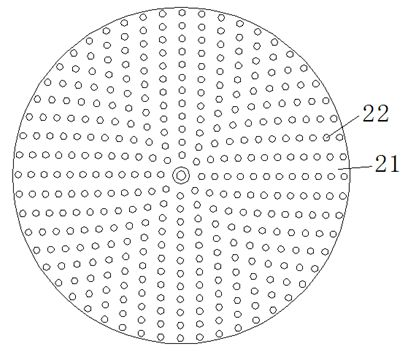

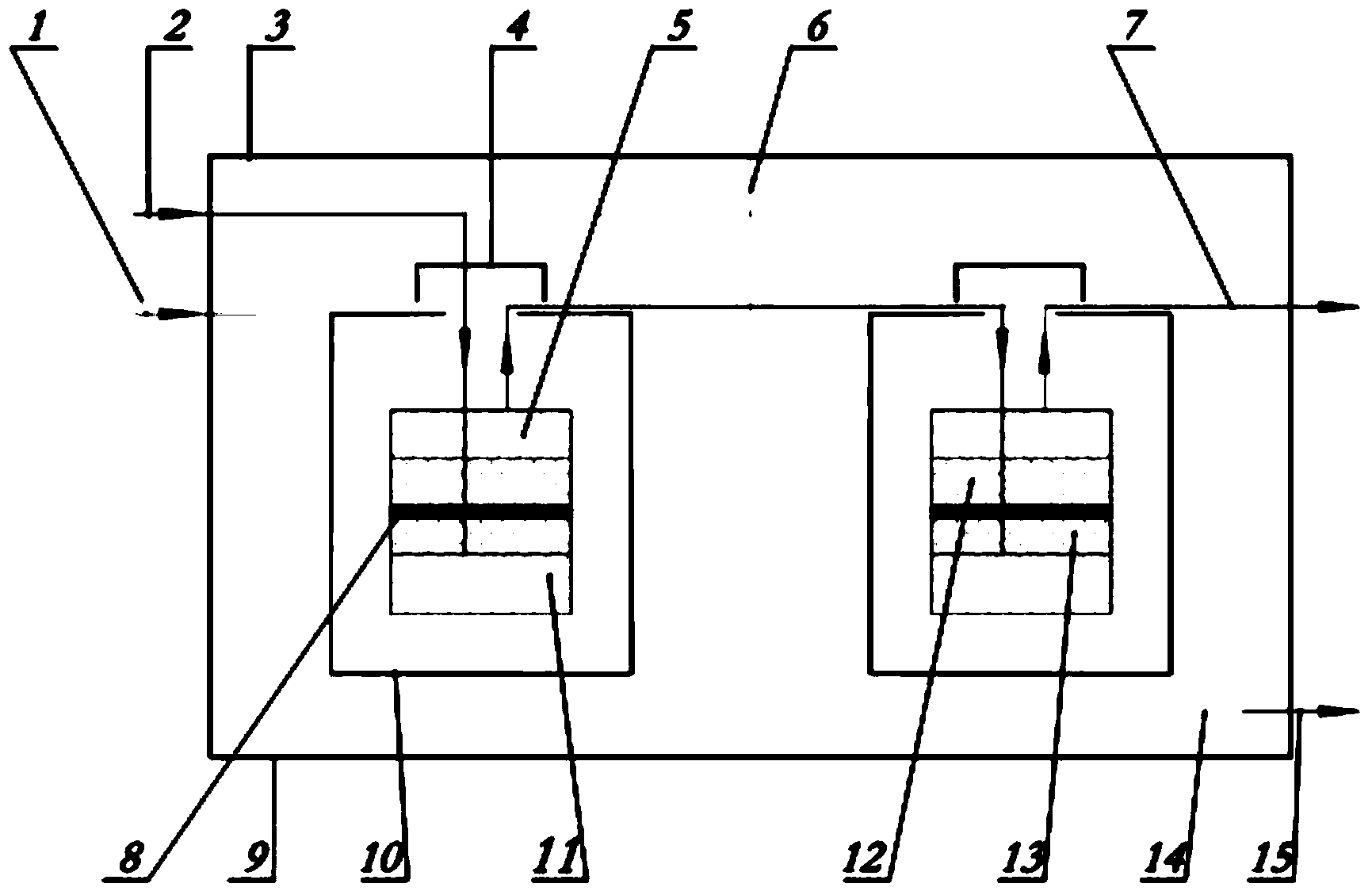

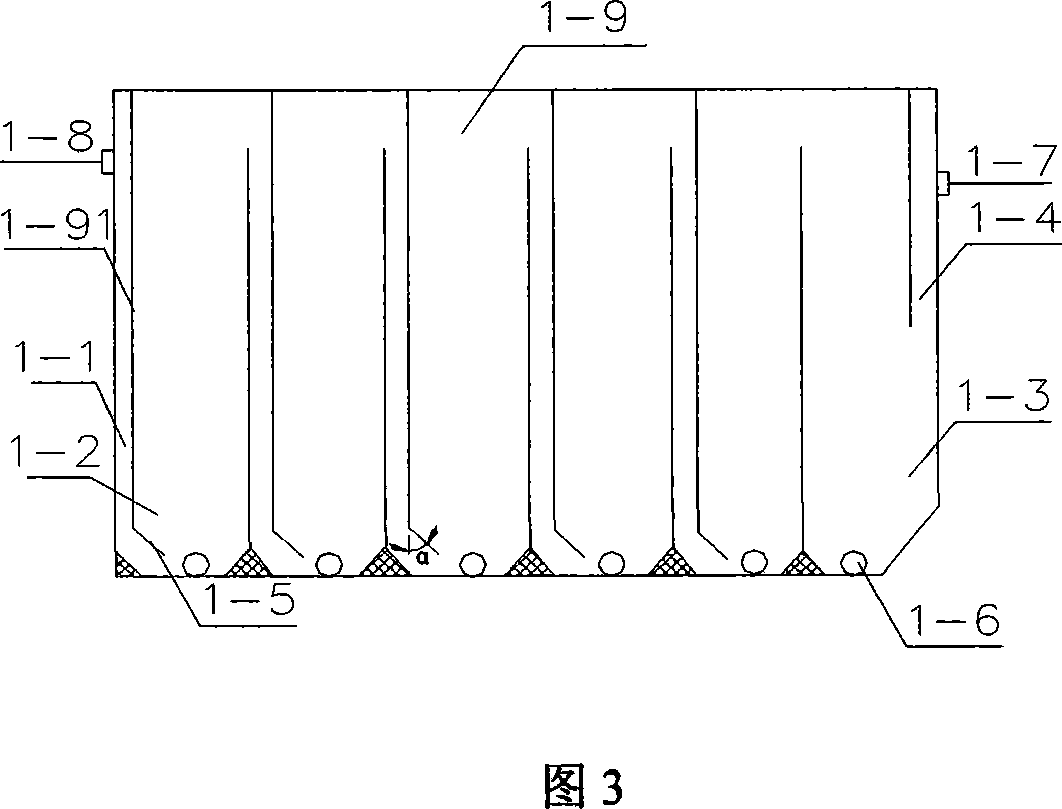

Integrated water purifying and processing equipment

ActiveCN102001769AGuaranteed concentrationReduce dosageMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSludge

The invention discloses integrated water purifying and processing equipment. The equipment comprises an external barrel and an internal barrel, wherein a convex head is arranged at the top of the external barrel; a water outlet is formed in the center of the convex head; a conical bottom plate is arranged at the bottom of the external barrel; a mixer motor and a speed reducer are arranged in the center of the bottom of the conical bottom plate; the speed reducer is provided with a stirring shaft; the side wall of the conical bottom plate is provided with a dredge pipe; an escape pipe is arranged at the bottom of the conical bottom plate; the inner side of the external barrel is divided into a clean water zone, an inclined tube settling zone, a mud and water separating zone, a secondary cluster flocculation zone, a primary flocculation reaction zone and a mud collection zone in turn from top down; a sludge concentrating zone is arranged between the internal barrel and the external barrel; the equipment is provided with a coagulant quick coagulation device and a sludge hydraulic automatic backflow device to keep the concentration of the sludge in the reaction zone stable; the sludge concentrating zone is provided with a spiral bevel plate to efficiently concentrate the sludge; and the clean water zone is provided with a water collecting plate to realize pressure effluent. The equipment has a simple structure, compact layout and high space utilization rate, is convenient to operate, and is suitable for clarifying tap water in middle-sized and small cities and purifying industrial water by primarily removing turbidity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

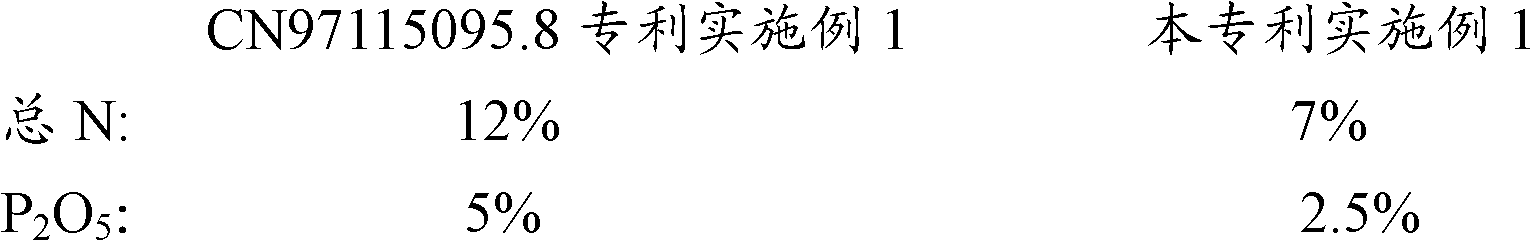

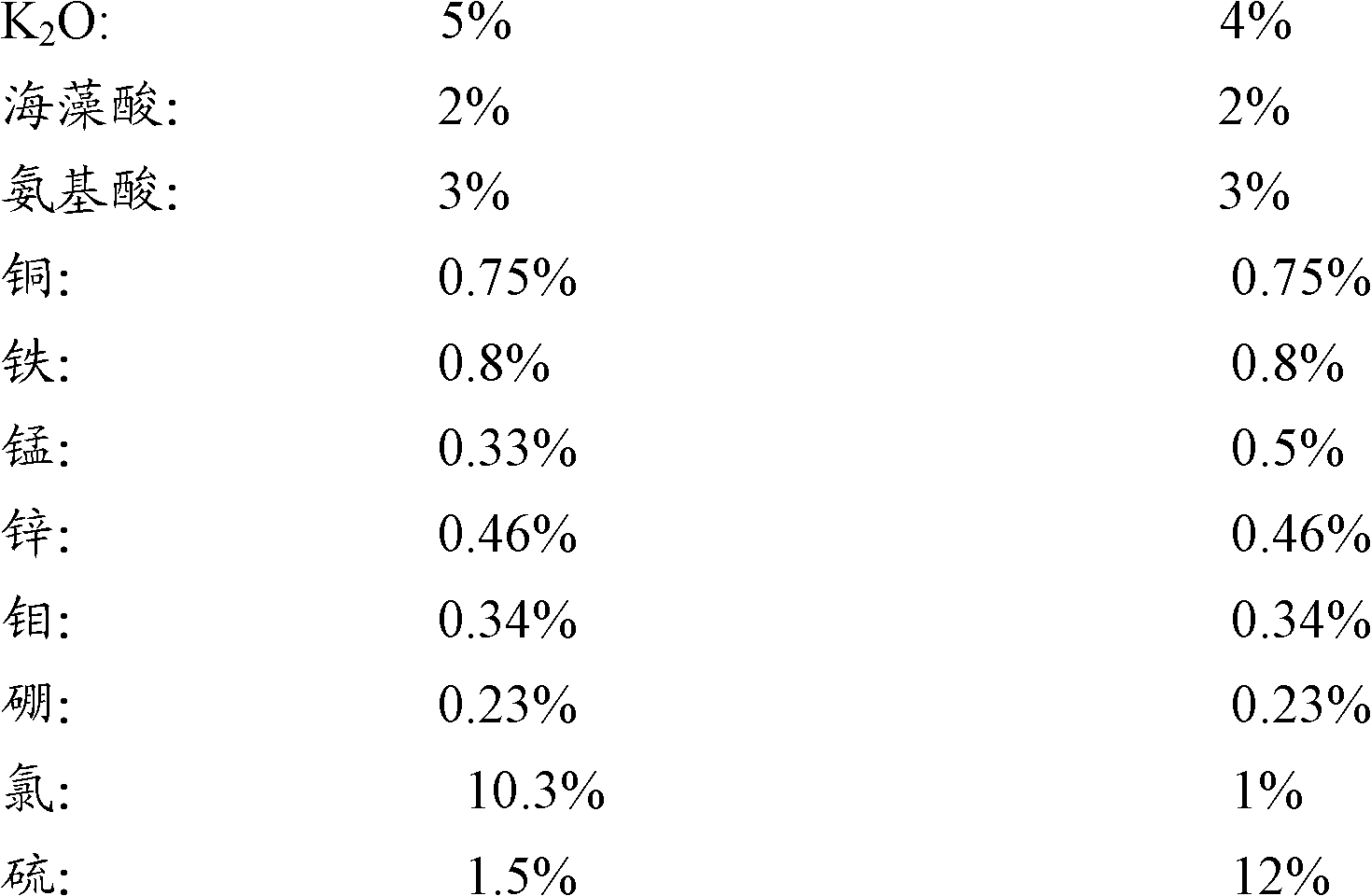

Functional composite liquid fertilizer and preparation method thereof

ActiveCN102584420AGood for chloride ion concentration rangeReduce concentrationFertilizer mixturesManganesePlant growth

The invention provides a functional composite liquid fertilizer prepared by marine organisms and a preparation method of the functional composite liquid fertilizer. The functional composite liquid fertilizer contains the following components in percentage by weight: 6-10% of total N6, 2-4% of phosphorus pentoxide, 4-6% of potassium oxide, 2-6% of alginic acid, 3-6% of amino acid, 0.5-1.0% of copper, 0.8-1.6% of iron, 0.66-1.32% of manganese, 0.5-1.0% of zinc, 0.6-1.8% of molybdenum, 0.2-0.6% of boron, 0.5-1.5% of chlorine and 6-15% of sulfur. According to the functional composite liquid fertilizer, proceeding from the requirements in plant growth, various nutrients and plant growth regulating substances are enhanced, and the functions of preventing diseases, expelling insects, increasing production and the like are highlighted on the basis of nutrients.

Owner:BEIJING LEILI MARINE BIOINDUSTRY INC

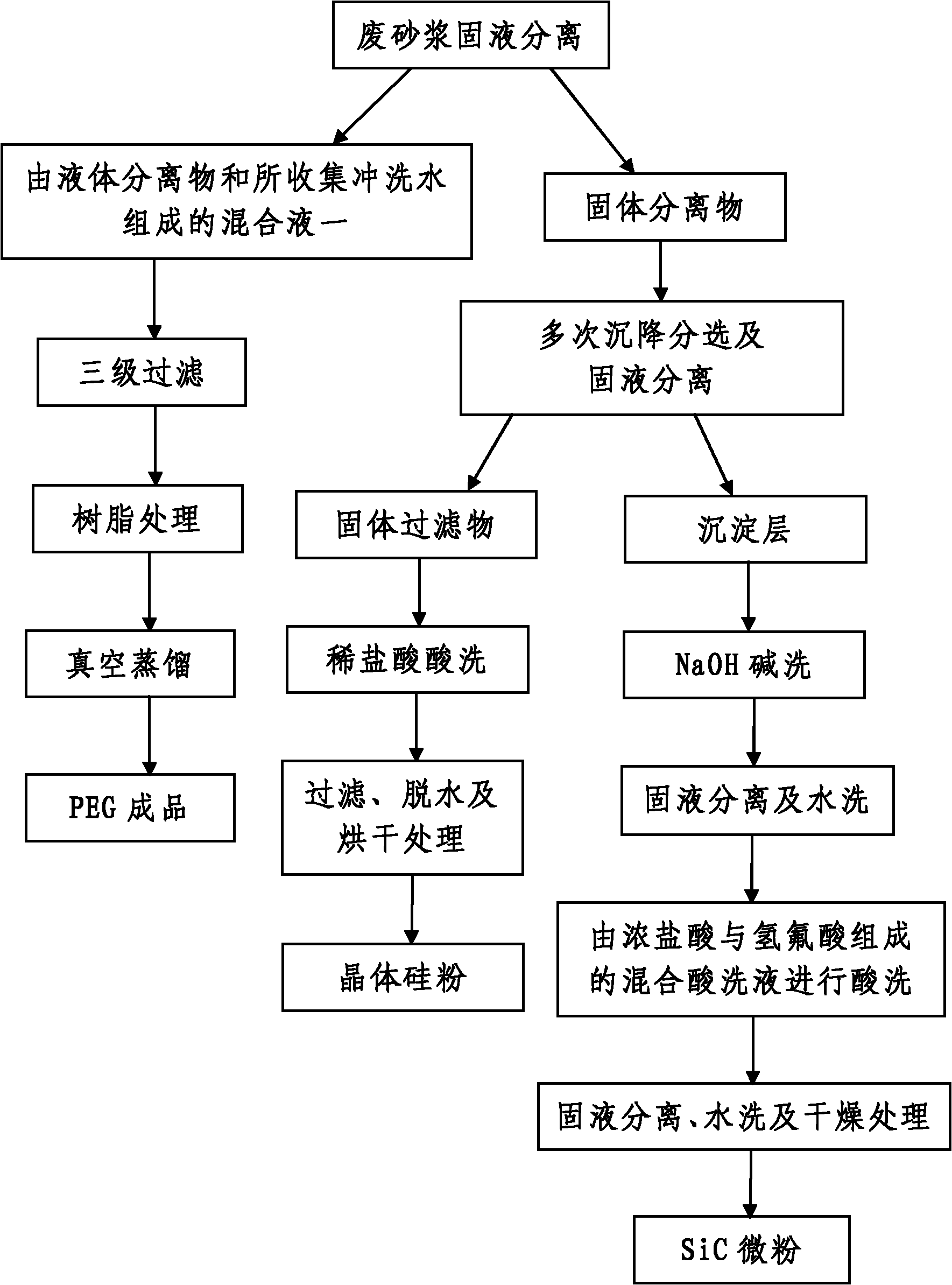

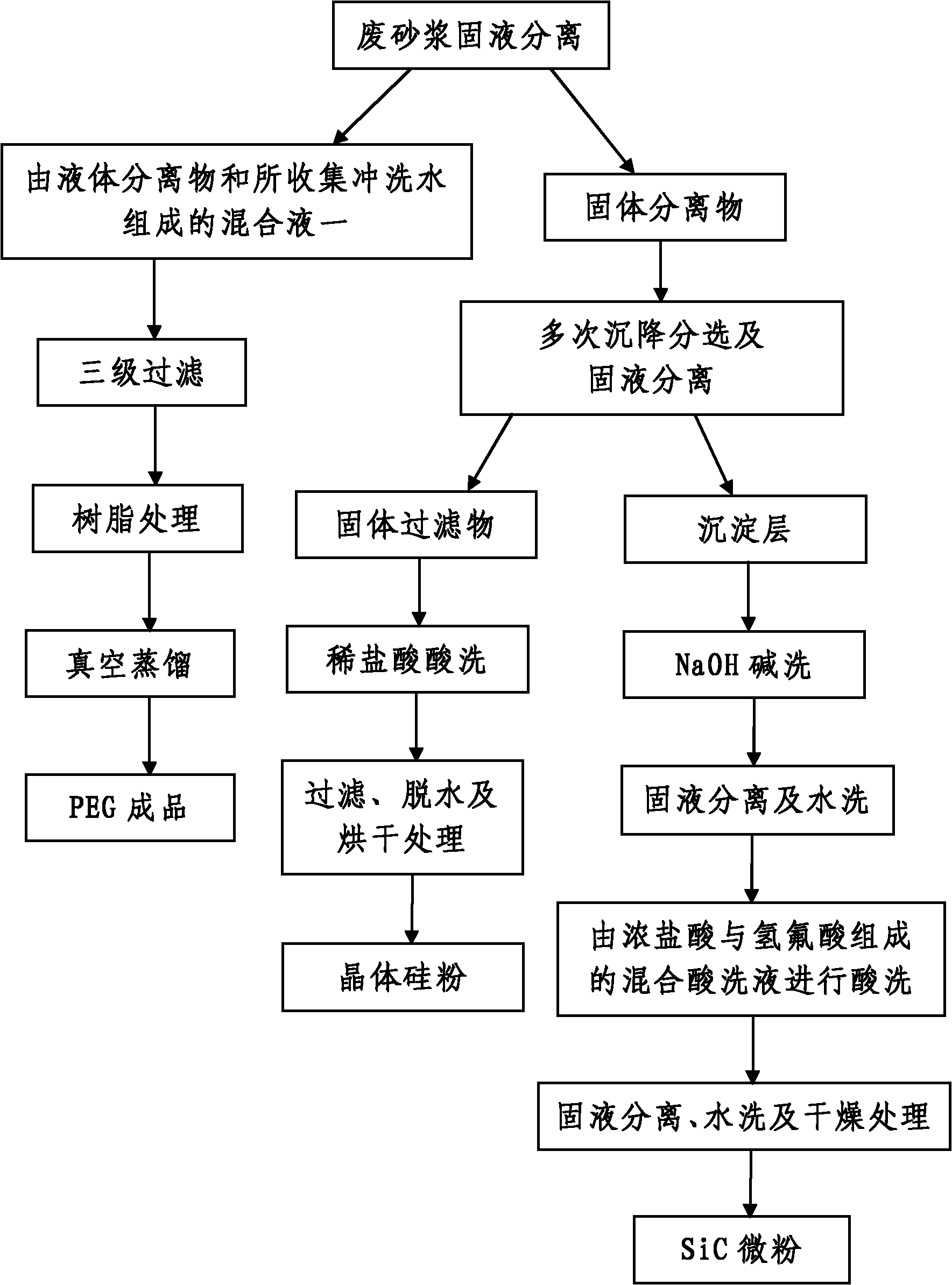

Separation and purification method of silicon wafer cutting waste mortar

InactiveCN102108317AReasonable designThe method steps are simpleSilicon compoundsLubricant compositionPurification methodsFiltration

The invention discloses a separation and purification method of silicon wafer cutting waste mortar. The method comprises the following steps: 1) performing solid-liquid separation to waste mortar to obtain solid separated substance and mixed solution 1; 2) separating and recycling polyethylene glycol (PEG), namely performing tertiary filtration to the mixed solution 1, performing resin treatment and performing vacuum distillation to obtain PEG finished product; 3) separating and recycling crystalline silicon powder, namely performing multiple settlement sortings and solid-liquid separations to the solid separated substance, pickling the obtained solid separated substance, filtering, dewatering and drying to obtain crystalline silicon powder; and 4) separating and recycling SiC fine powder, namely performing multiple settlement sortings and solid-liquid separations to obtain a precipitation layer, pickling, performing solid-liquid separation, rinsing and drying to obtain SiC fine powder. The method of the invention has reasonable design, simple steps, convenient operations, high efficiency and low investment and operation cost, the large-scale production is easy to realize and the separated and purified PEG, crystalline silicon powder and SiC fine powder have good qualities.

Owner:SHAANXI DESHENG NEW ENERGY

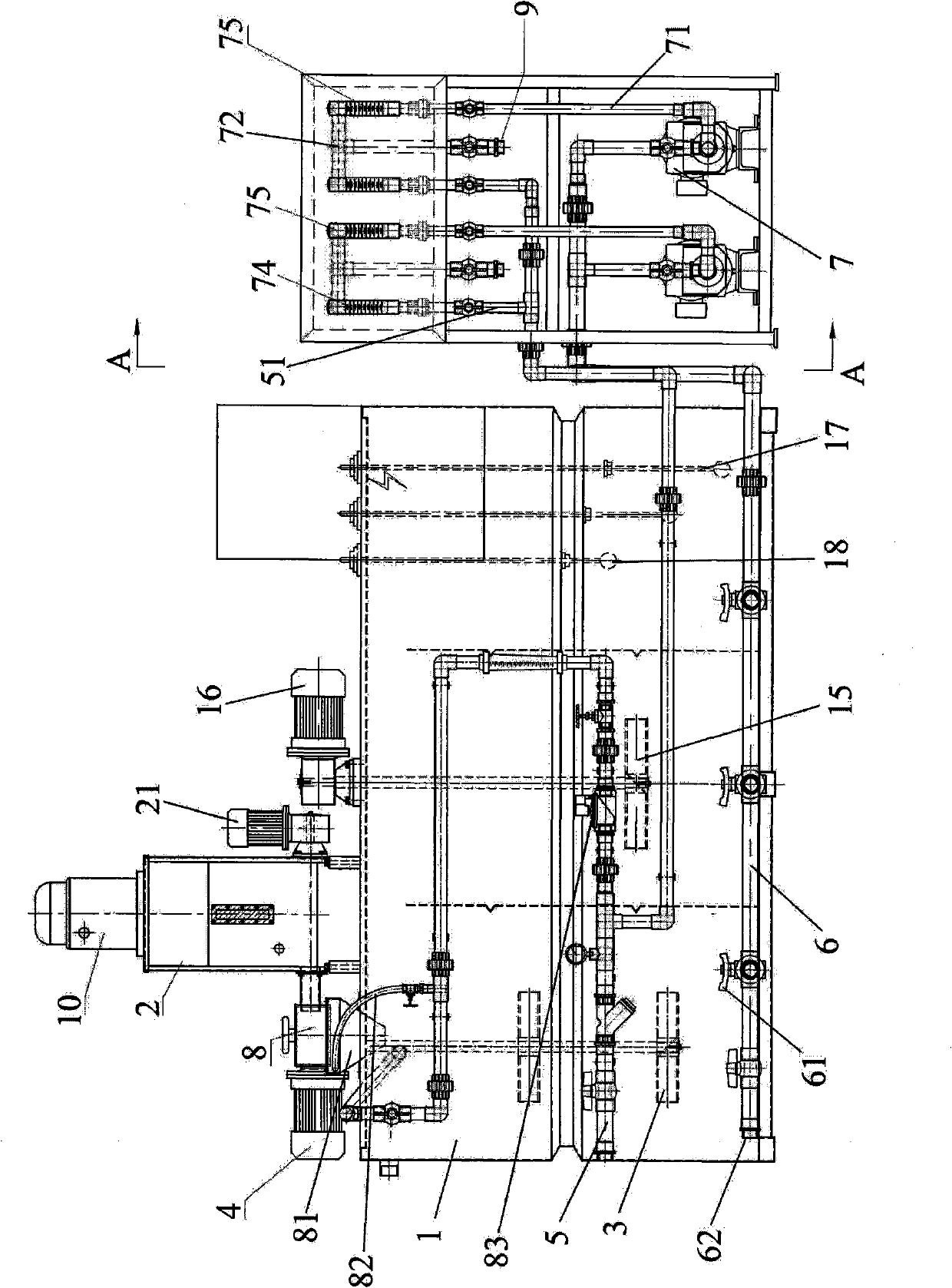

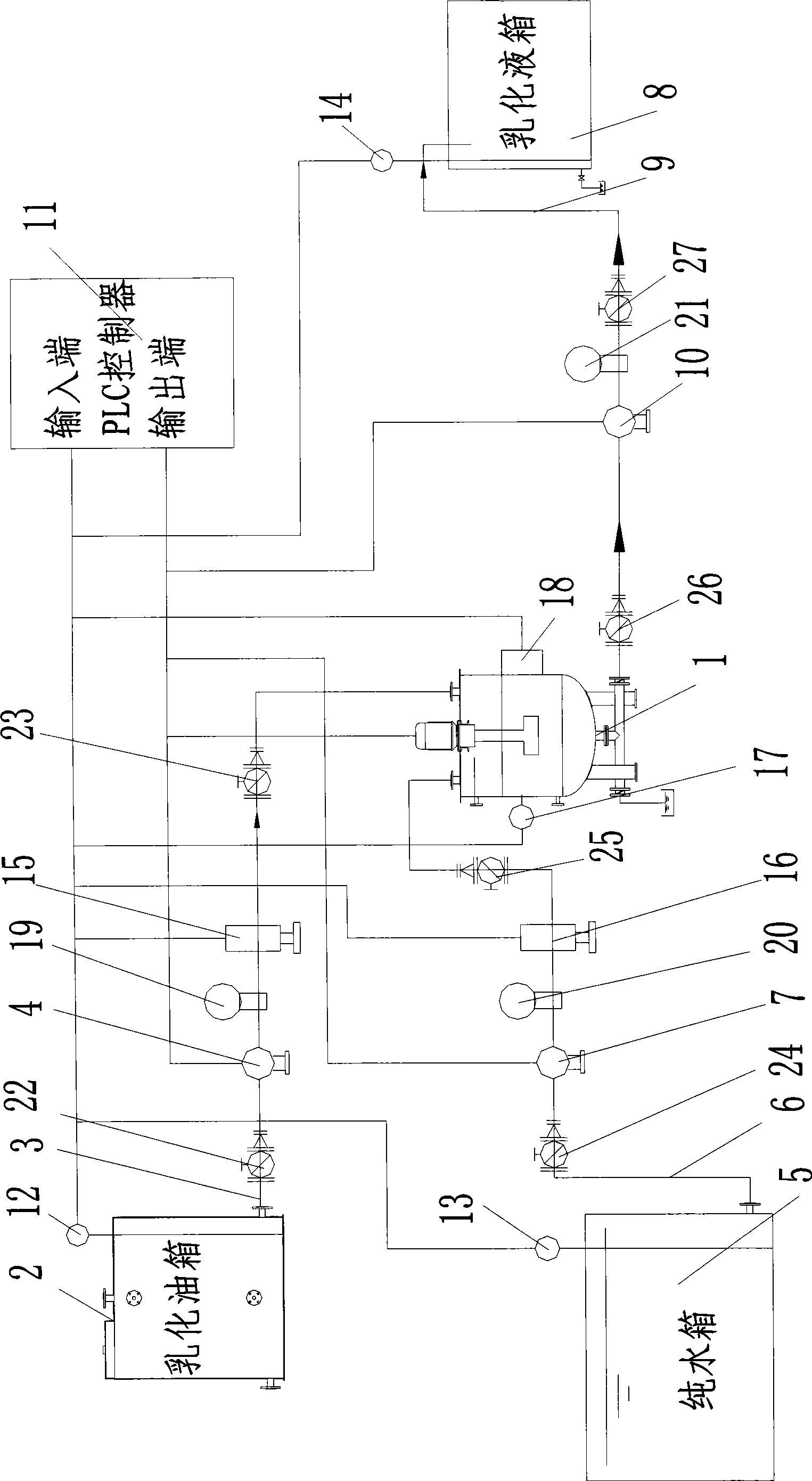

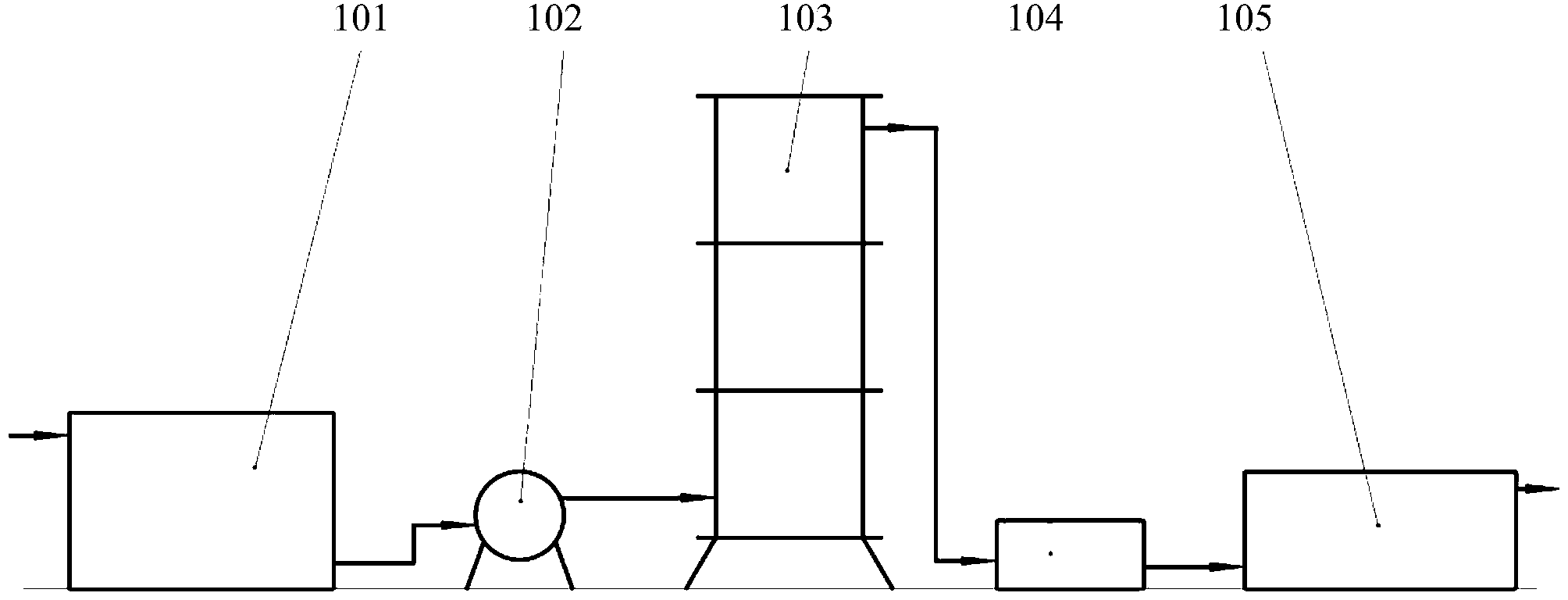

Emulsified liquid mixing device for coal mine

InactiveCN101530757AIncrease the level of automationGuaranteed concentrationMixing methodsMixer accessoriesCoalEmulsified oil

The invention discloses an emulsified liquid mixing device for a coal mine, which comprises the following parts: an emulsified oil distribution part, a pure water distribution part, an emulsifier, an emulsified liquid treatment part and a PLC control part, wherein the emulsified oil distribution part and the pure water distribution part are communicated with an input port of the emulsifier used for oil-water emulsification, and an output port of the emulsifier is communicated with the emulsified liquid treatment part. The device is mainly characterized by combining the automatic mixing of an emulsified liquid and the concentration detection of the emulsified liquid together, and monitoring the liquid level of an emulsified oil tank and an emulsified liquid tank at the same time, thereby improving the automation level of the production of the coal mine, also ensuring the concentration of the emulsified liquid, and protecting various operation elements of a hydraulic system.

Owner:江苏华彬给排水设备有限公司

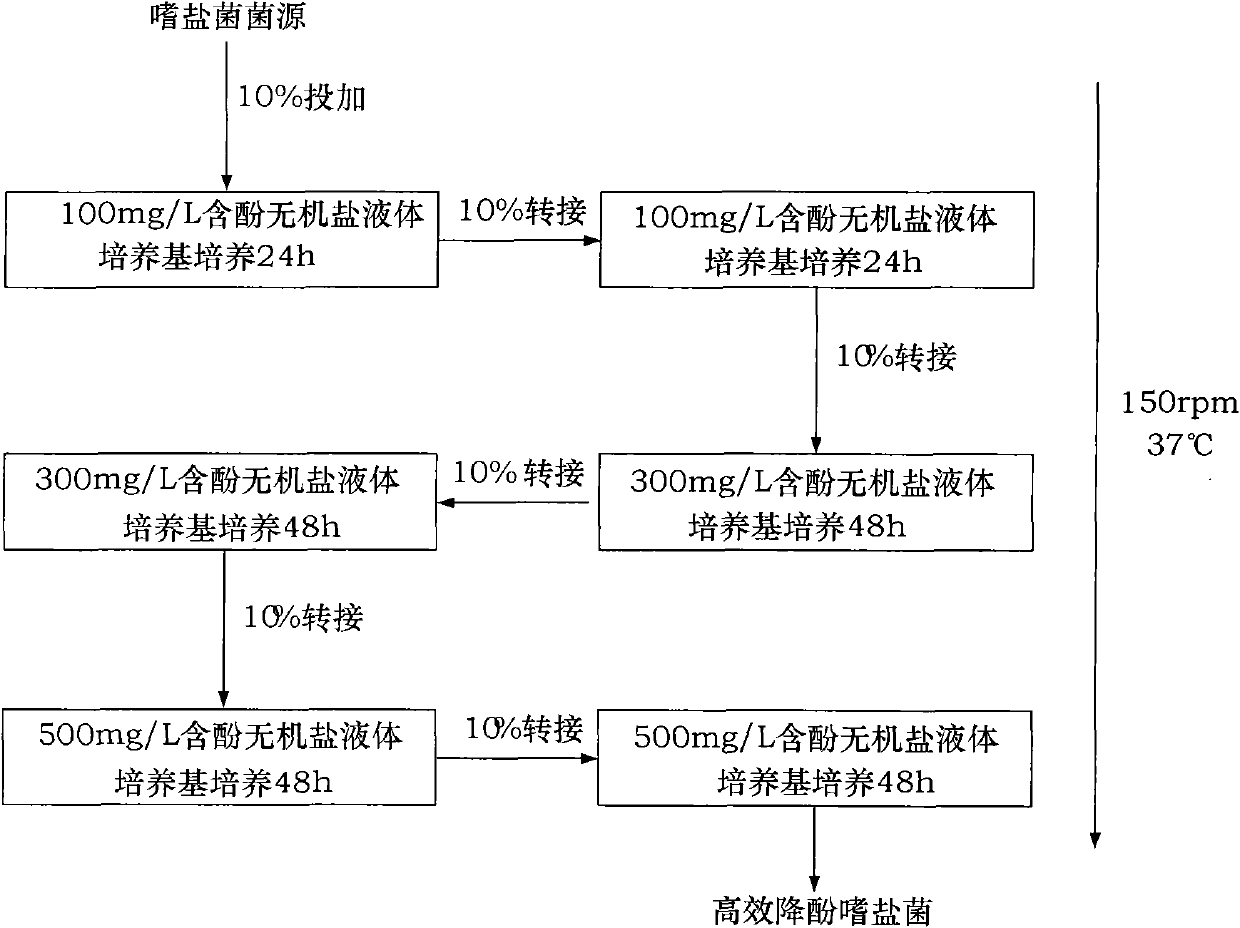

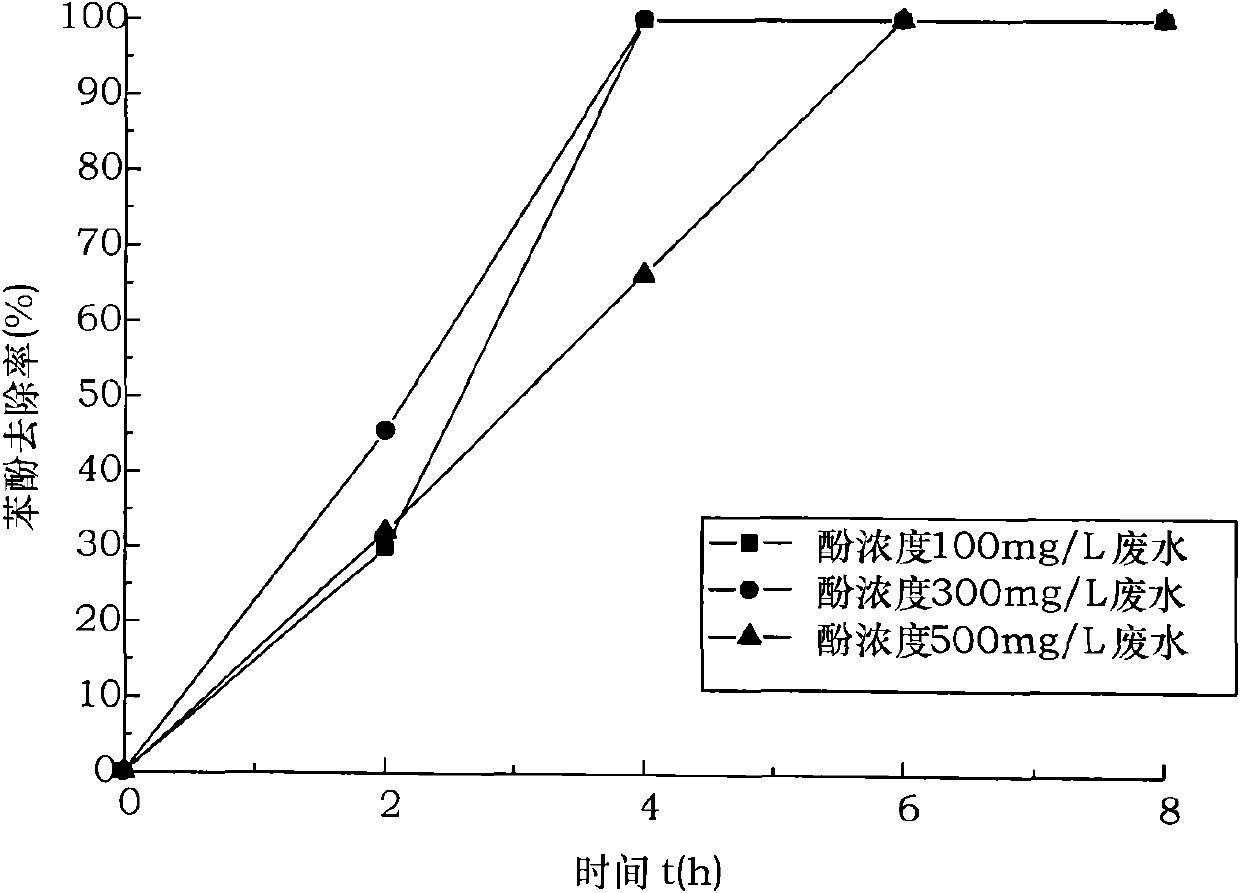

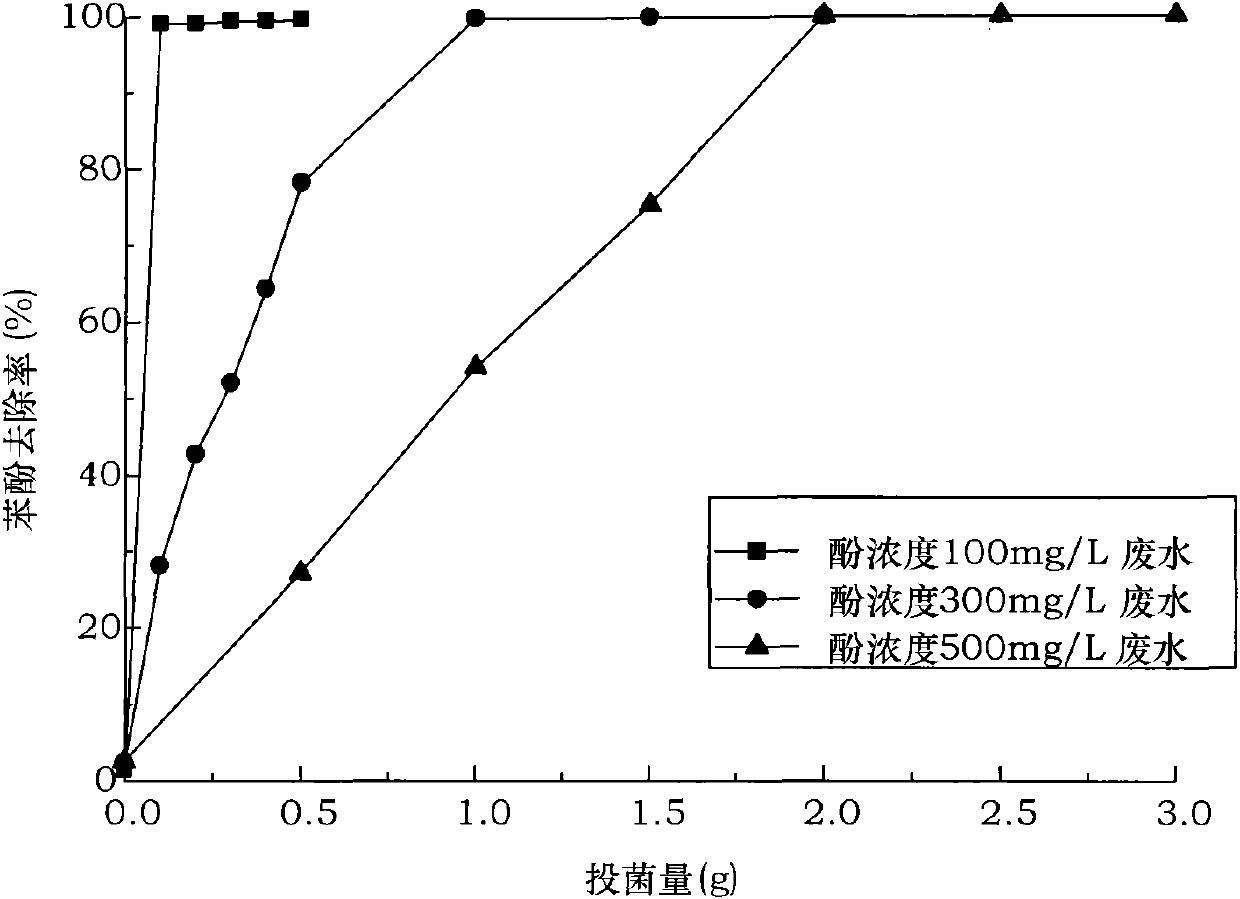

Preparation of efficient phenol-degrading halophilic bacteria and application thereof

InactiveCN101768564AOptimal hydraulic retention timeThe performance advantage of reducing phenol is obviousBacteriaTreatment using aerobic processesActivated sludgeBatch processing

The invention discloses a preparation of efficient phenol-degrading halophilic bacteria and an application thereof, belonging to the technical field of treatment of waste water and sewage. In the invention, halophilic bacteria in the sewage or sludge are taken as a bacteria source; a gradient domestication method is adopted to screen efficient phenol-degrading halophilic bacteria which have strong degradation capability, can adapt to higher salt concentration and can grow well by taking phenol as the sole carbon source in the phenol-containing waste water with the salt content of 5-6% and thephenol concentration of 100-500mg / L; under the environment of high salt and high phenol, the phenol-degrading performance of the mycelium has obvious advantages over that of the traditional activatedsludge method. The strain can be applied to phenol-degrading treatment of waste water to determine the optimal water power retention time and the optimal bacteria input amount and batch processing time, and the operational conditions can be optimized through orthogonal experiments. The screening of the efficient phenol-degrading halophilic bacteria has high application value, and can provide a reference for the removal of phenol in the oil extraction waste water and the industrial treatment of the phenol-containing wastewater with high content of salt in petrochemistry industry.

Owner:BEIHANG UNIV

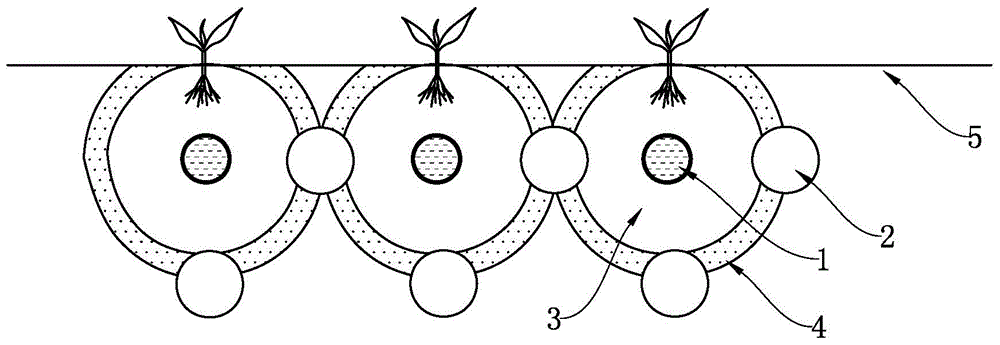

Method for comprehensively treating saline and alkaline land through combination of irrigation and planting

ActiveCN104904365AImprove the effect of salt removalImprove abilityClimate change adaptationWatering devicesPipeflowMoisture

The invention discloses a method for comprehensively treating saline and alkaline land through combination of irrigation and planting. The method comprises the following steps: (a) paving underground pipelines, including micro-moisture pipes for irrigation and salt discharge underground pipes for discharging salt; (b) leveling and furrowing the saline and alkaline land for irrigation salt discharge, wherein the irrigation salt discharge includes underground salt discharge and surface salt discharge and specifically comprises the following three steps in sequence: I, performing underground salt discharge; II, performing surface salt discharge, and performing rapid large-area surface salt discharge on the saline and alkaline land subjected to the underground salt discharge through a flood irrigation way; III, repeating the underground salt discharge; (c) planting suaeda salsa on a large area, continuously performing micro-moisture irrigation salt discharge before and after seedling emergence of the suaeda salsa, performing micro-moisture irrigation intermittently after branching of the suaeda salsa till the end of the peak-growth period of the suaeda salsa, pulling up the suaeda salsa by the roots, and planting crops or continually planting the suaeda salsa according to the soil salinity to further reduce salinity.

Owner:WEIFANG YOURONG IND

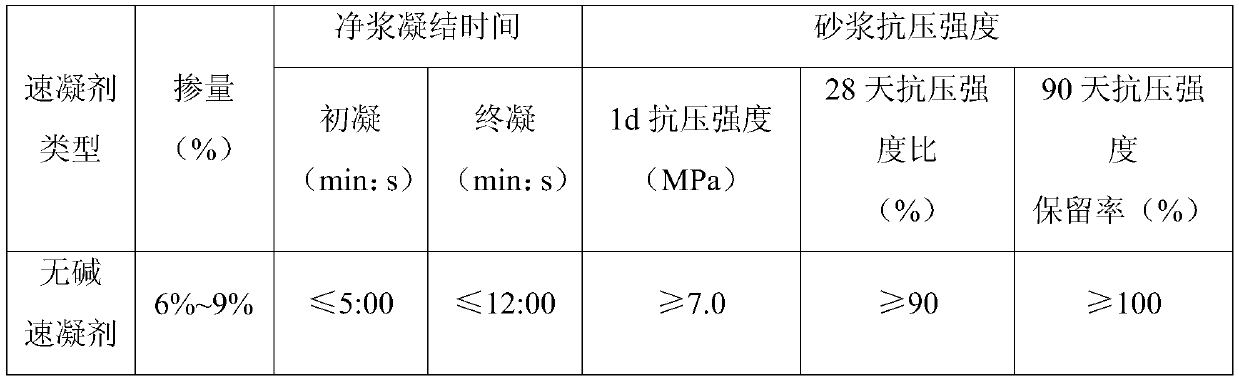

Low-dosage high-early-strength alkali-free liquid accelerator and preparation method thereof

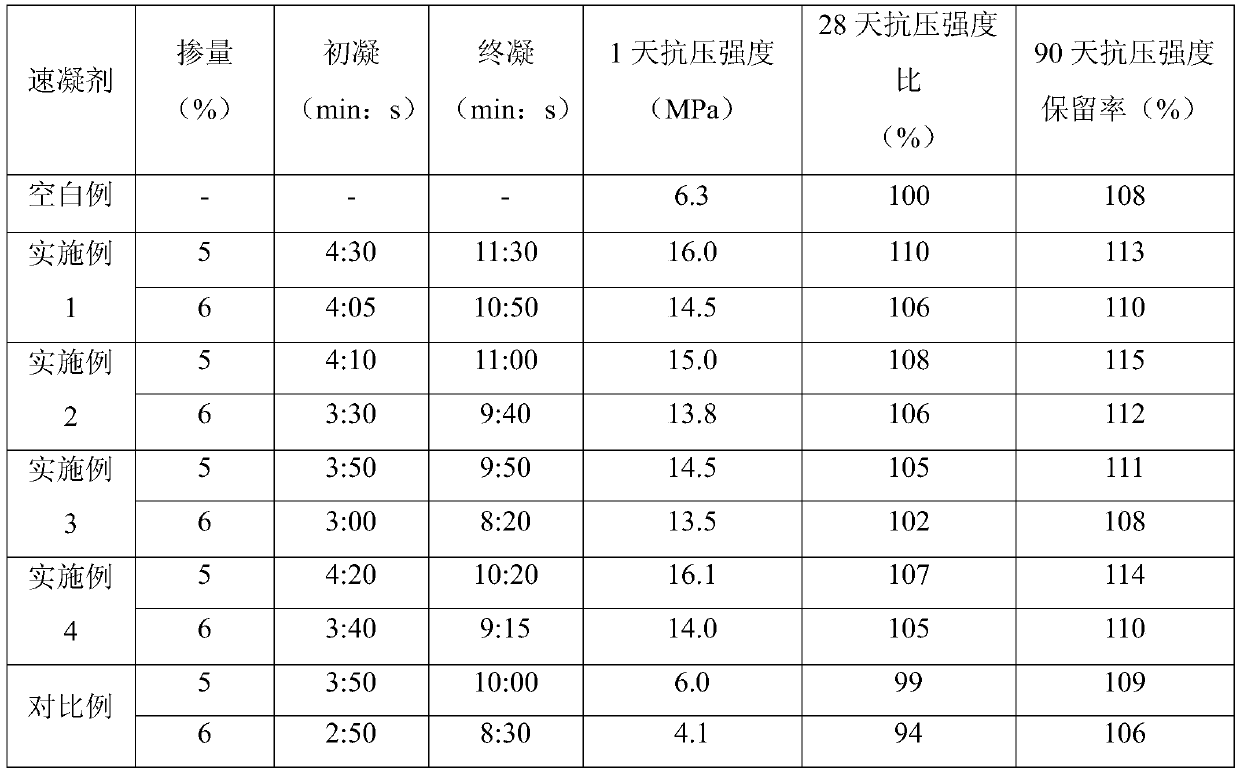

The invention discloses a low-dosage high-early-strength alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from the following raw materials: 1, an alkali-free liquid accelerator; 50%-60% of modified aluminum sulfate, 2%-4% of a fluorine-aluminum complex solution, 3%-6% of an organic cosolvent, 1%-2% of a pH regulator, 0.5%-1.5% of an inorganic stabilizer, 0.3%-0.5% of a viscosity regulator, 4%-6% of a composite early strength agent and the balance of water, wherein the sum of the mass percentages of the components is 100%. The invention also provides a preparation method of the alkali-free liquid accelerator. The preparation process of the alkali-free liquid accelerator is simple; hydrofluoric acid-free process, alkali-free, chlorine-free, rust-free steel bar, non-polluting environment. Meanwhile, when the mixing amount of the alkali-free liquid accelerator is 5%-6%, the technical requirements of GB / T35159-2017 on the alkali-free accelerator can be met, the one-day compressive strength is larger than or equal to 13.0 MPa, and the alkali-free liquid accelerator has the advantages of being low in mixing amount, good in stability, high in early strength and large in later strength retention rate.

Owner:刘翠芬

Zero-emission treatment system and method of epoxy ethane

InactiveCN103706233AFully dissolveImprove liquidityDispersed particle separationChemicalsEpoxyTreatment system

The invention discloses a zero-emission treatment system and method of epoxy ethane. The method comprises the following steps: firstly, a chemical combination treatment is carried out on an epoxy ethane waste gas in a chemical combination device; the epoxy ethane waste gas generates a sulfonation reaction with a sulfonation reaction agent in the chemical combination device; the epoxy ethane is oxidized to generate carbon dioxide and ethylene glycol; the generated carbon dioxide and the residual epoxy ethane waste gas are discharged into a turbulence ball tower; the residual epoxy ethane waste gas is output to the turbulence ball tower by a gas-liquid pump and is fully mixed and dissolved in hot water pumped by the gas-liquid pump in the turbulence ball tower; then, the epoxy ethane waste gas dissolved in the wastewater is treated on the basis of an aeration tank, a sedimentation tank and a filter tank, and meanwhile, organic matters in the wastewater can be treated as well, wherein micro-biological degradation is mainly used for carrying out oxygenation degradation on the epoxy ethane waste gas dissolved in the water through microbial communities forming flocculating constituents in the aeration tank; finally, CO2, H2O, NH3, SO42 and the like are generated and are discharged with the water, so that the epoxy ethane waste gas is treated.

Owner:杨亮月 +1

Fully automatic and high-precision dust and sand collector

InactiveCN102073071AAccurate response to changing situationsRealize fully automatic monitoringRainfall/precipitation gaugesICT adaptationTime dynamicsCollection system

Owner:INST OF DESERT METEOROLOGY CMA URUMQI +1

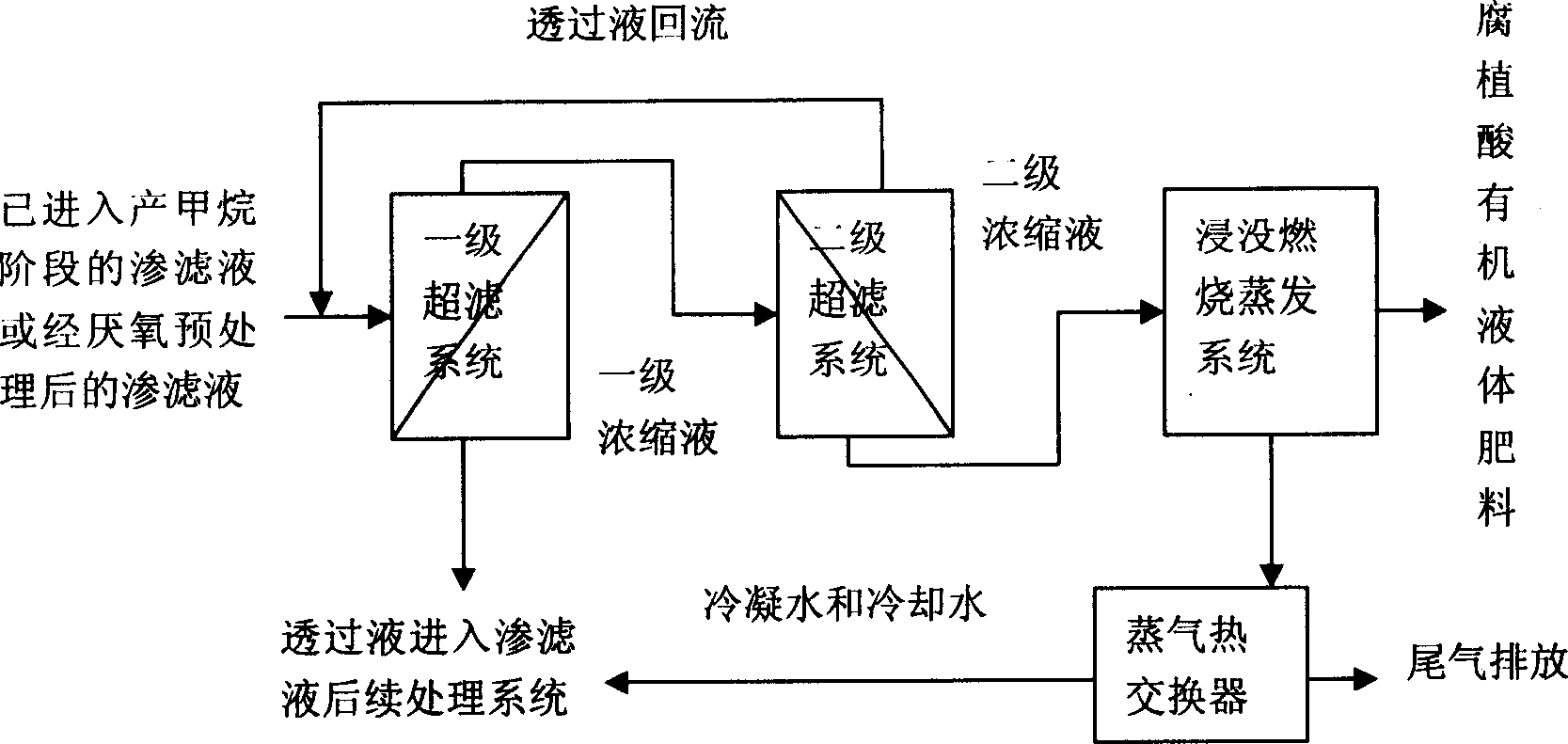

Resource process for percolation liquid of city life garbage landfill

InactiveCN1648075ASolve difficult problemsUnification of environmental benefitsBio-organic fraction processingClimate change adaptationCombustion chamberOrganic fluid

The technological process of utilizing percolation liquid from domestic garbage landfill belongs to the field of garbage treating technology. The present invention aims at raising the percolation liquid treating level to reach the exhaust standard. The technological process of utilizing percolation liquid from domestic garbage landfill includes the following steps: 1) pumping the percolation liquid to the first stage of ultrafiltering system and treating in pressure difference of 0.3-0.5 MPa, 5-10 times concentration and membrane separation to obtain the first stage of concentrated liquid; 2) pumping into the second stage of ultrafiltering system and treating in pressure difference of 1.0-1.5 MPa, 4-5 times concentration and membrane separation to obtain the second stage of concentrated liquid; and 3) treating in immersing, burning and evaporating system at burning temperature over 750 deg.c, immersing depth 0.3-0.6 m and 5-10 times concentration to obtain liquid organic fertilizer.

Owner:TSINGHUA UNIV

Method for improving forage nutritional value of cottonseed meal through microbial fermentation

InactiveCN104186957AImprove the nutritional value of feedHigh protein contentAnimal feeding stuffBiotechnologyCellulose

The invention utilizes a microbial fermentation technology to improve the forage nutritional value of the cottonseed meal, so as to improve the forage quality of the cottonseed meal, increase the addition proportion in the forage and realize the promotion of the protein nutritional value and the feeding value of the cottonseed meal, aiming at the disadvantages that cottonseed meal is rich in antinutritional factors of free gossypol, cellulose, oligosaccharide, phytic acid and the like, the protein quality is relatively poor and the content of essential amino acids of methionine and the like is low and unbalanced, so that the large-scale forage of cottonseed meal is restricted. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the technology of 'composite enzymatic hydrolysis and multi-strain three-step solid-state fermentation', so as to prepare the fermented cottonseed meal product that is high in the free gossypol, cellulose degradation degree and the protein content; the cottonseed meal product is rich in nutritional ingredients of probiotics, vitamins, enzyme, amino acid, short peptide, high-grade protein and the like; the method for improving the forage nutritional value of cottonseed meal through the microbial fermentation has the advantages of prompting growth and development, improving the utilization ratio of the forage, enhancing immunization, improving intestinal micro ecology, preventing diseases and the like. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the solid-state fermentation; the manufacturing technology is simple; the energy consumption is low; zero environmental pollution is generated; and the investment is small. Therefore, mass production is easy.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Improved aeration settling tank

ActiveCN102863079ASmall footprintLow investment costSustainable biological treatmentBiological water/sewage treatmentSludgeSewage treatment

The invention belongs to waste water treatment equipment, especially relating to an improved aeration settling tank. The improved aeration settling tank comprises a tank body, a water inlet pipe arranged in front of the side wall of the tank body, a slope tilting downwards from end to beginning and arranged on the bottom of the tank body, an aerator arranged on the bottom of the tank, a water tank arranged at the inner side of a tank wall on the tail end of the tank body and inclined plates distributed at interval and in parallel in front of the water tank; the front side and the back side of the inclined plate are respectively provided with a first partition wall and a second partition wall; the first partition wall and the second partition wall divide the tank body into an aerobic zone, a pre-settling zone and a clean water zone which are arranged from front to back at interval; the pre-settling zone is communicated with the aerobic zone through water inlet holes and sludge returning holes arranged on the first partition wall; a perforated water collector pipe is arranged in parallel on the upper portion of the second partition wall; the inlet of the perforated water collector pipe is arranged in the pre-settling zone above the inclined plate, and the outlet thereof is arranged in the clean water zone; a sludge pipe is arranged on the bottom of the tail end of the clean water zone; the bottom of the water tank is communicated with the exterior of a water pipe. The improved aeration settling tank overcomes the technical defect that the degradation rate of pollutants is low in the prior art and has the advantages of good sludge settling effect, high degradation rate of the pollutants and so on.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

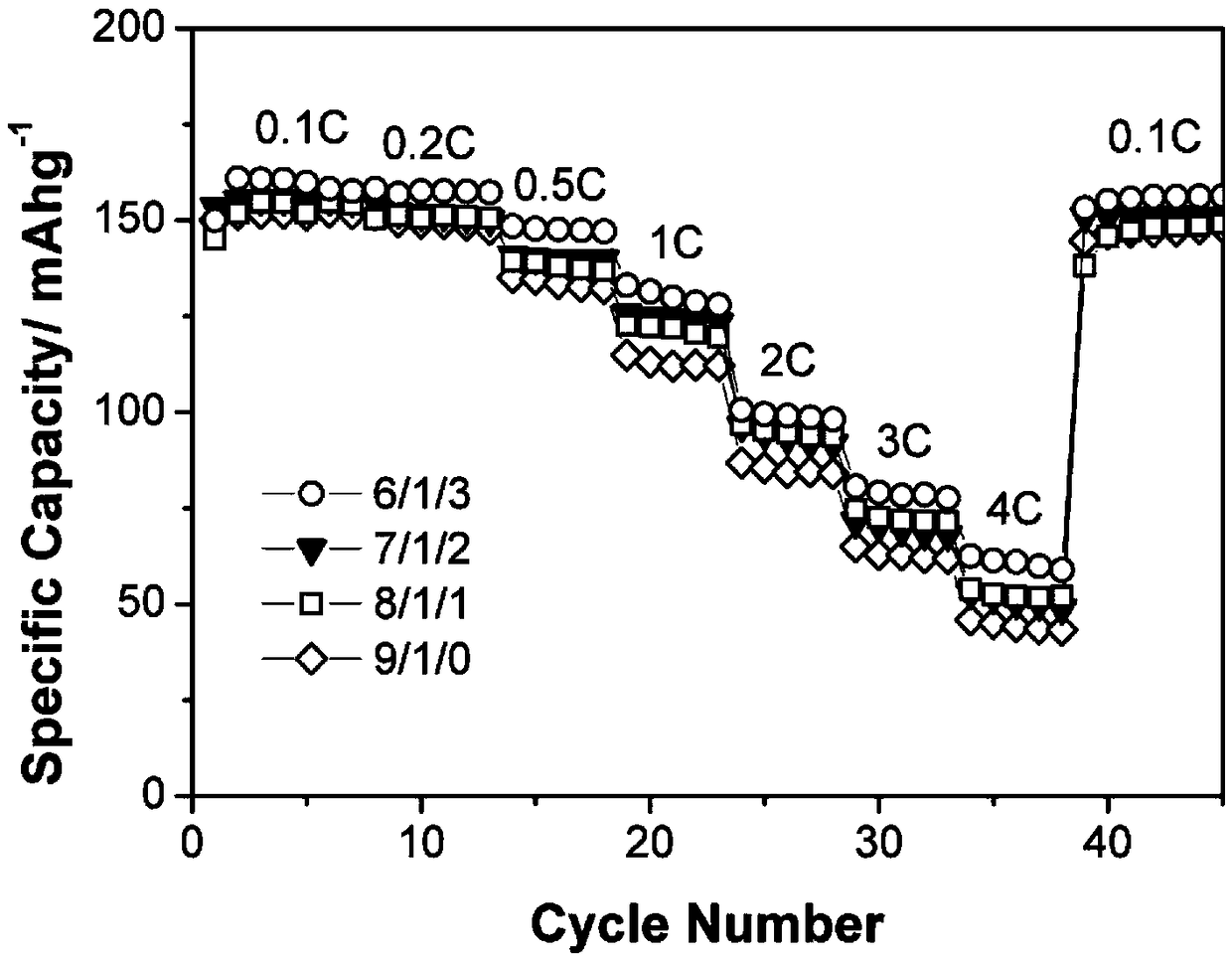

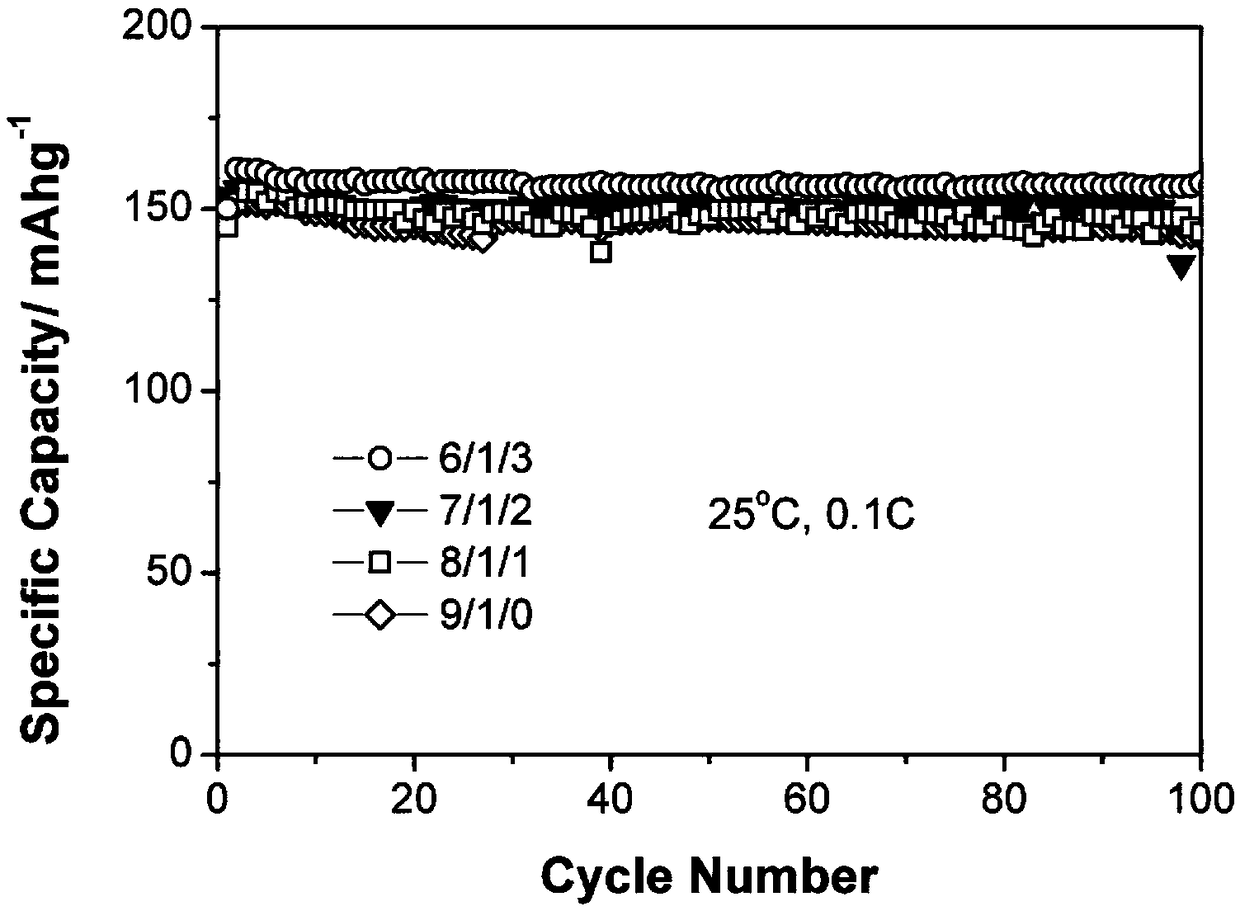

High-concentration electrolyte for lithium ion battery, preparation method thereof, and lithium ion battery

InactiveCN109449487AReduce viscosityImprove wettabilitySecondary cellsOrganic electrolytesSolventElectrochemical response

The invention provides a high-concentration electrolyte for a lithium ion battery. The electrolyte comprises lithium salt, a non-aqueous solvent and a wetting agent; the concentration of the lithium salt is higher than 2 mol / L; and the wetting agent is selected from fluoro-ether compounds. The wetting agent is added in the electrolyte, so that the viscosity of the electrolyte is reduced and the wettability is improved while the high concentration is ensured; the dynamic characteristic of the electrochemical reaction on the electrode / electrolyte interface is good, and the reaction polarizationis small. Therefore, the wetting agent is added in the electrolyte so that the safety of the electrolyte can be improved, the protection of an aluminum current collector is realized, the viscosity ofthe high-concentration electrolyte is reduced, and the problem of poor wettability of the electrolyte is solved; and the electrochemical stable voltage of the electrolyte exceeds 4.5V, so the electrolyte is suitable for a high-voltage positive electrode material; the capacity of the battery is fully played; and the energy density of the battery is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

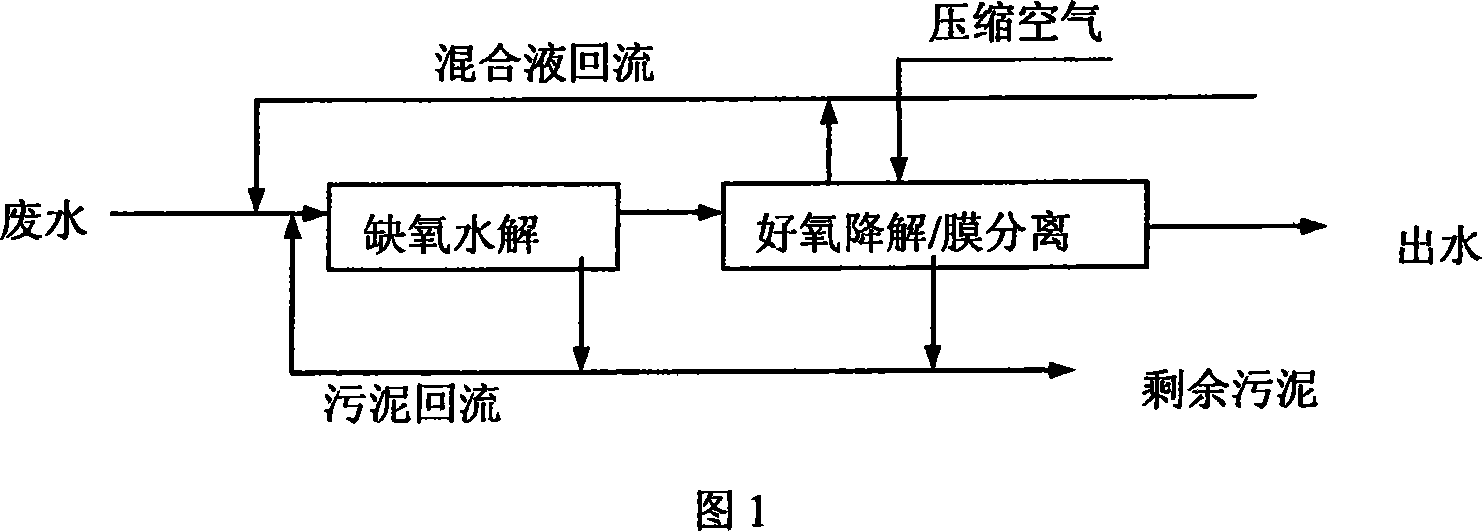

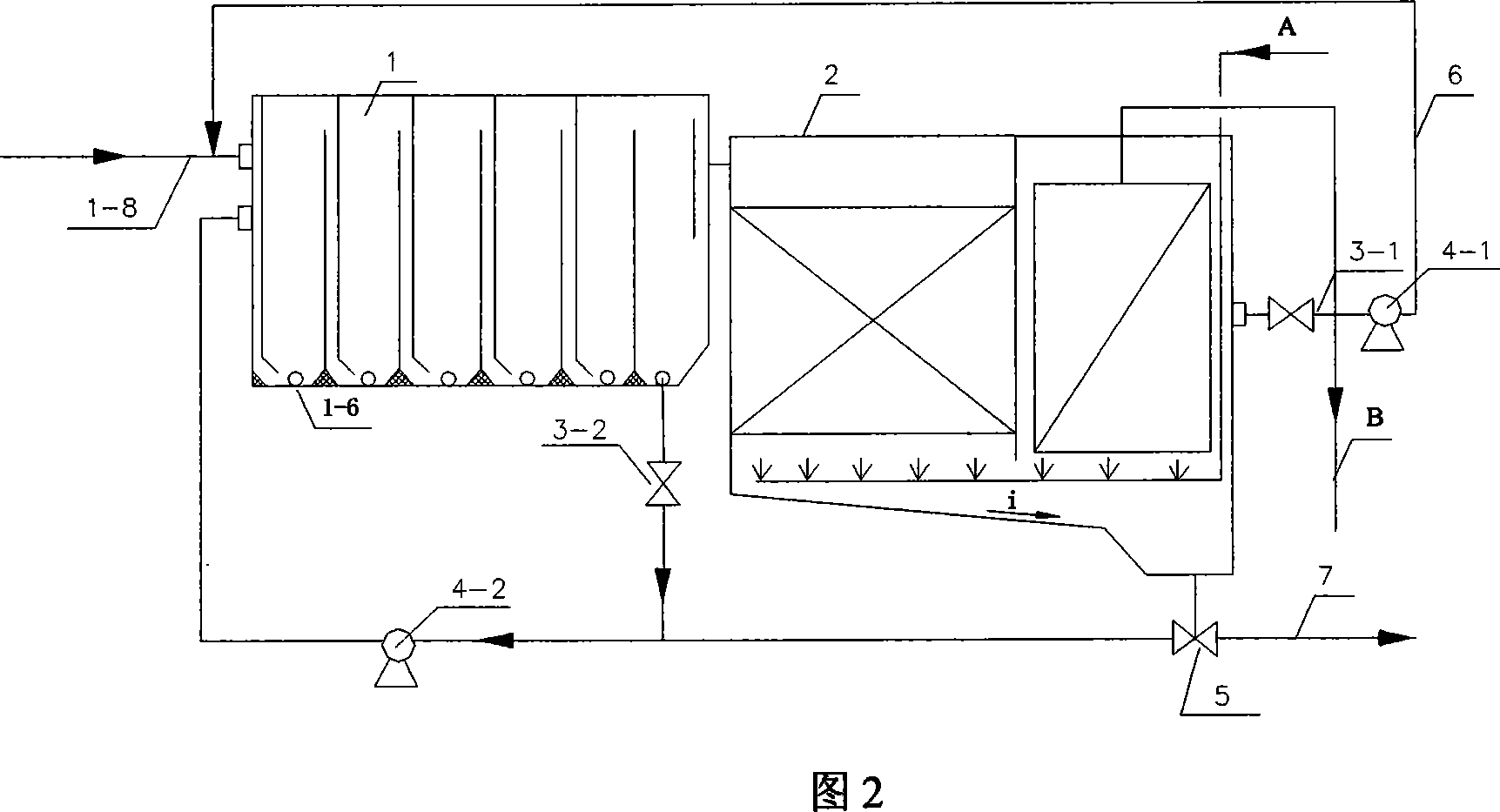

Equipment and method for treating wastewater difficult to be degraded by biology method of hydrolysis composite membrane

InactiveCN101050042AEnsure processing performanceClear functionWater contaminantsWater/sewage treatment bu osmosis/dialysisSludgeWastewater

This invention relates to apparatus and method for treating wastewater by hydrolysis-composite membrane biological method. The apparatus comprises: a multi-grid hydrolysis reactor and a composite membrane bioreactor. The method comprises: (1) introducing wastewater into the multi-grid hydrolysis reactor, and hydrolyzing in an anaerobic condition; (2) introducing the hydrolyzed wastewater into the contact oxidation region of the composite membrane reactor, and performing aerobic biological treatment; (3) introducing wastewater into the membrane separation region of the composite membrane bioreactor, and performing further aerobic biological treatment; (4) returning the sludge produced in the multi-grid hydrolysis reactor and the composite membrane bioreactor to the flow-guide region.

Owner:SOUTHEAST UNIV

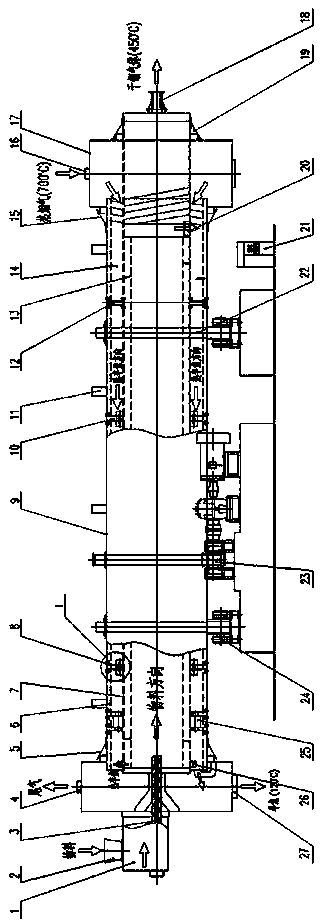

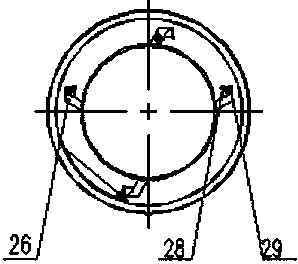

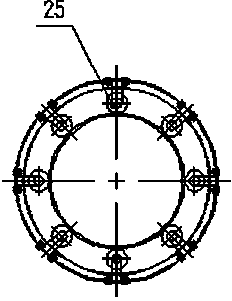

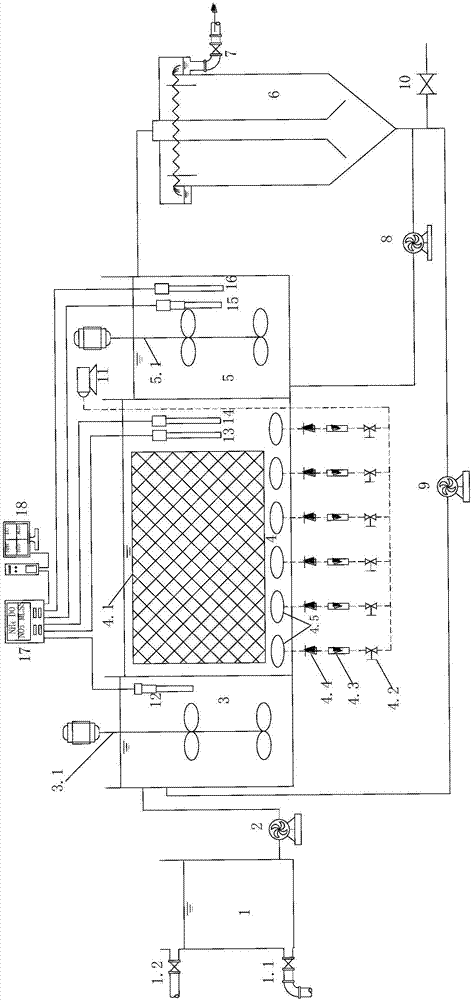

Multilayer rotary kiln based small granular material destructive distillation method

ActiveCN103952165ALow running costGuaranteed concentrationEnergy inputIndirect heating destructive distillationGranularityFlue gas

The invention relates to a multilayer rotary kiln based small granular material destructive distillation method. The method comprises the following steps: adding oil shale granules (with the granularity of 0-20mm) with the water content of below 5% to a bunker from a kiln head, sending to the inner cylinder of a rotary kiln by a spiral conveying device, heating the material in the inner cylinder to 500DEG C through the circulation of high temperature hot flue gas (with the temperature of 700DEG C) from a hot blast stove in an annular channel between an outer cylinder and the inner cylinder to pyrolyze the oil shale material in order to generate a destructive distillation gas and semicoke, and carrying out purifying recovery on the destructive distillation gas to obtain gas and shale oil; and adding the semicoke into the annular channel from the inner cylinder, allowing the semicoke to run along a direction opposite to the material running direction in order to carry out heat exchange of the material in the inner cylinder and absorb the waste heat of the semicoke, discharging parts of the semicoke from the stove, and adding a small amount of the semicoke to the inner cylinder for the mixing of the small amount of the semicoke with a normal temperature mixture in order to further utilize the waste heat of the semicoke. The method has the advantages of simple technology, low energy consumption, no pollution, high product quality, realization of the industrial large-scale production, and easy large-area popularization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

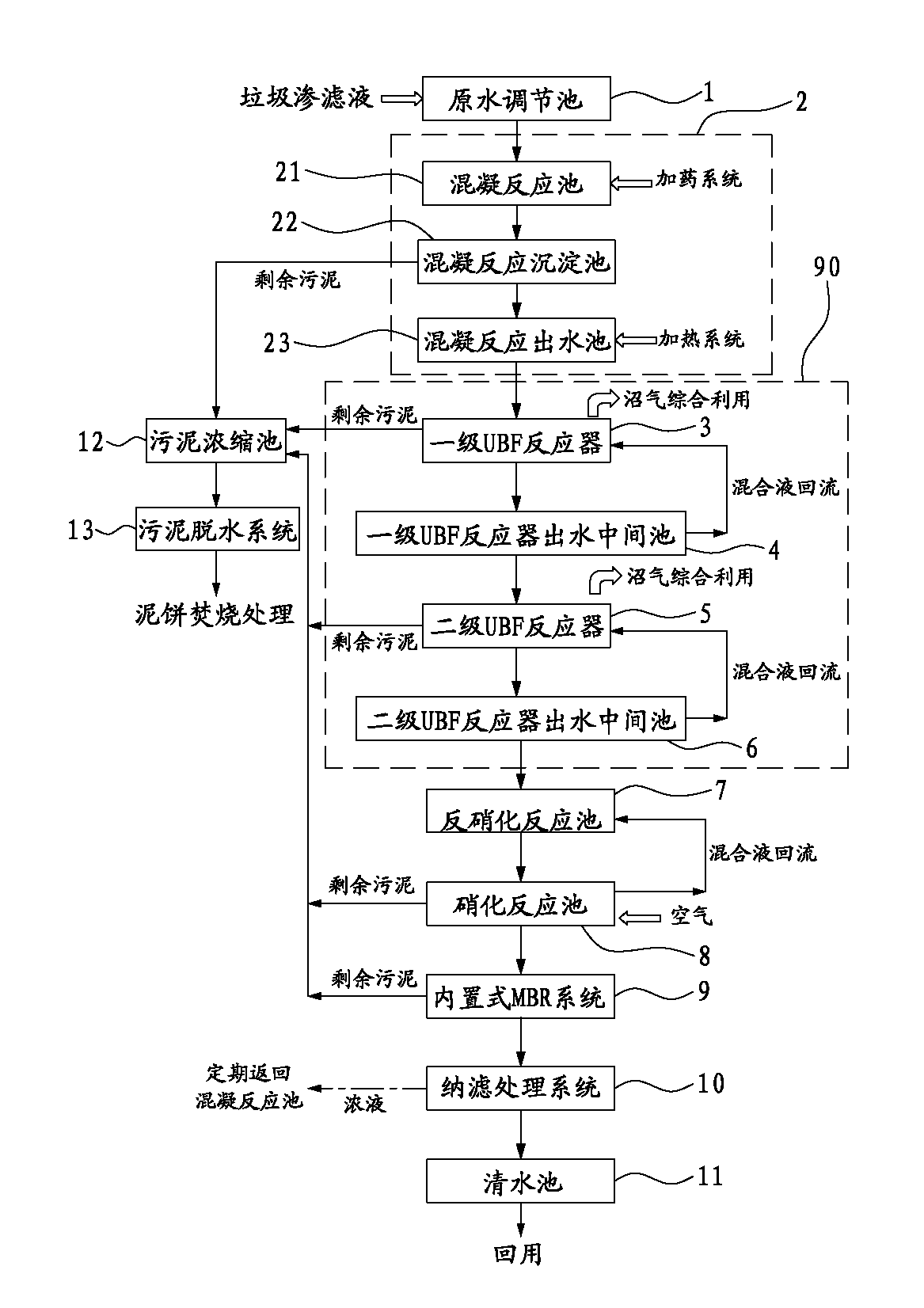

Treatment method for waste incineration power plant leachate and device thereof

ActiveCN102795746AGuaranteed concentrationGuaranteed processing efficiencyTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSludgeFiltration

The invention discloses a treatment method for waste incineration power plant leachate and a device thereof. The waste leachate is put into a raw water regulation pool, a coagulation reaction system, a first-stage UBF reactor, a first-stage UBF reactor effluent middle pool, a second-stage UBF reactor, a second-stage UBF reactor effluent middle pool, a denitrification pool, a nitration pool, a built-in MBR system, and a nanofiltration system for processing. According to the invention, the UBF reactor effluent middle pools are arranged behind the UBF reactors for mud-water separation and backflow after the UBF reactor effluent, guaranteeing the mud concentration in the UBF reactors and treatment effeciency. Using a built-in MBR membrane module placed in a biochemical pool helps to reduce floor space and lower energy consumption. The use of physical and chemical, biochemical, and membrane filtration technology association for the direct treatment of waste leachate can reach recycling with zero emission.

Owner:NEWSKY CHINA ENVIRONMENT & TECH

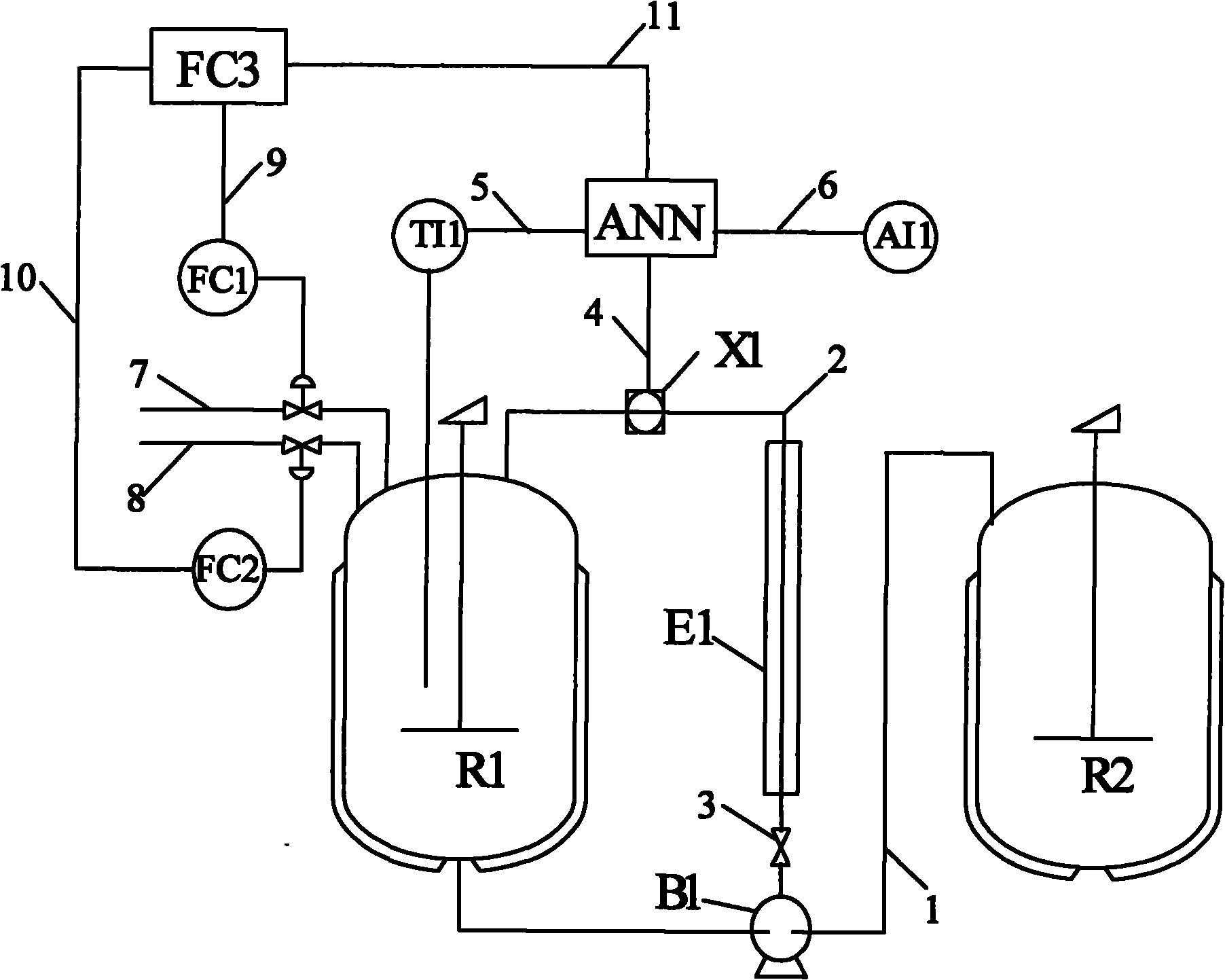

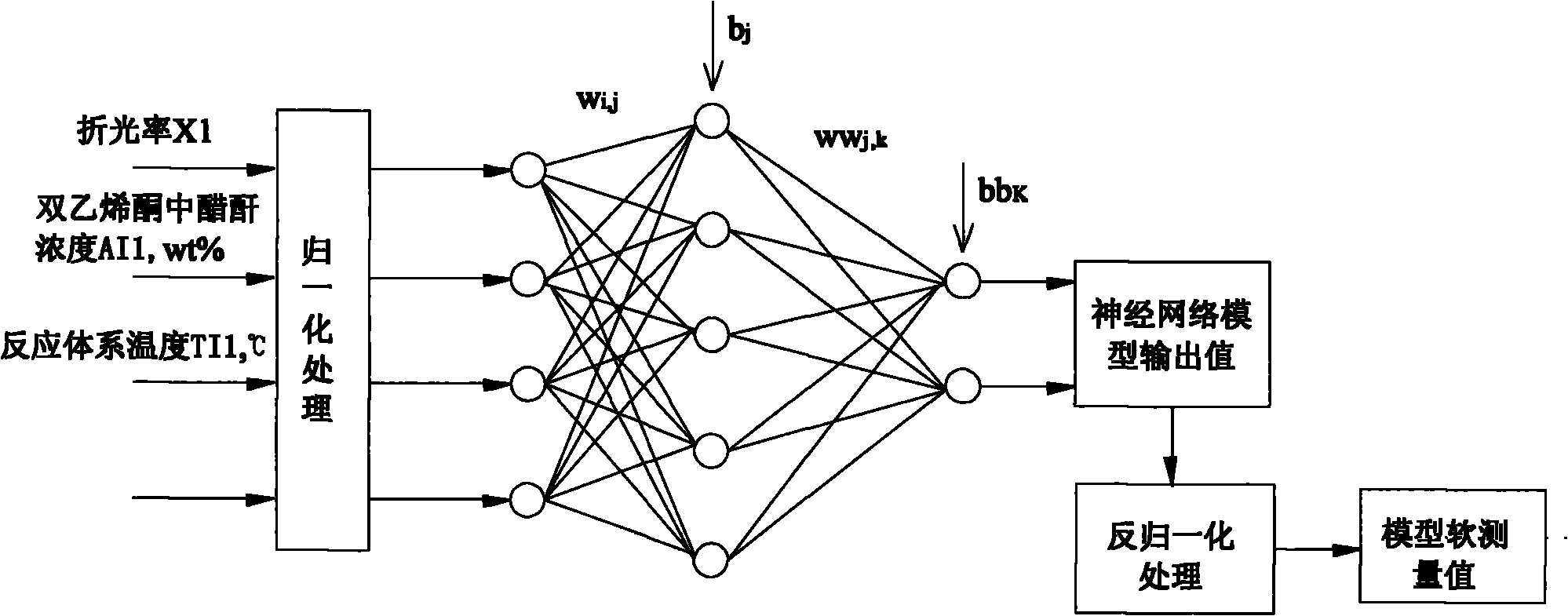

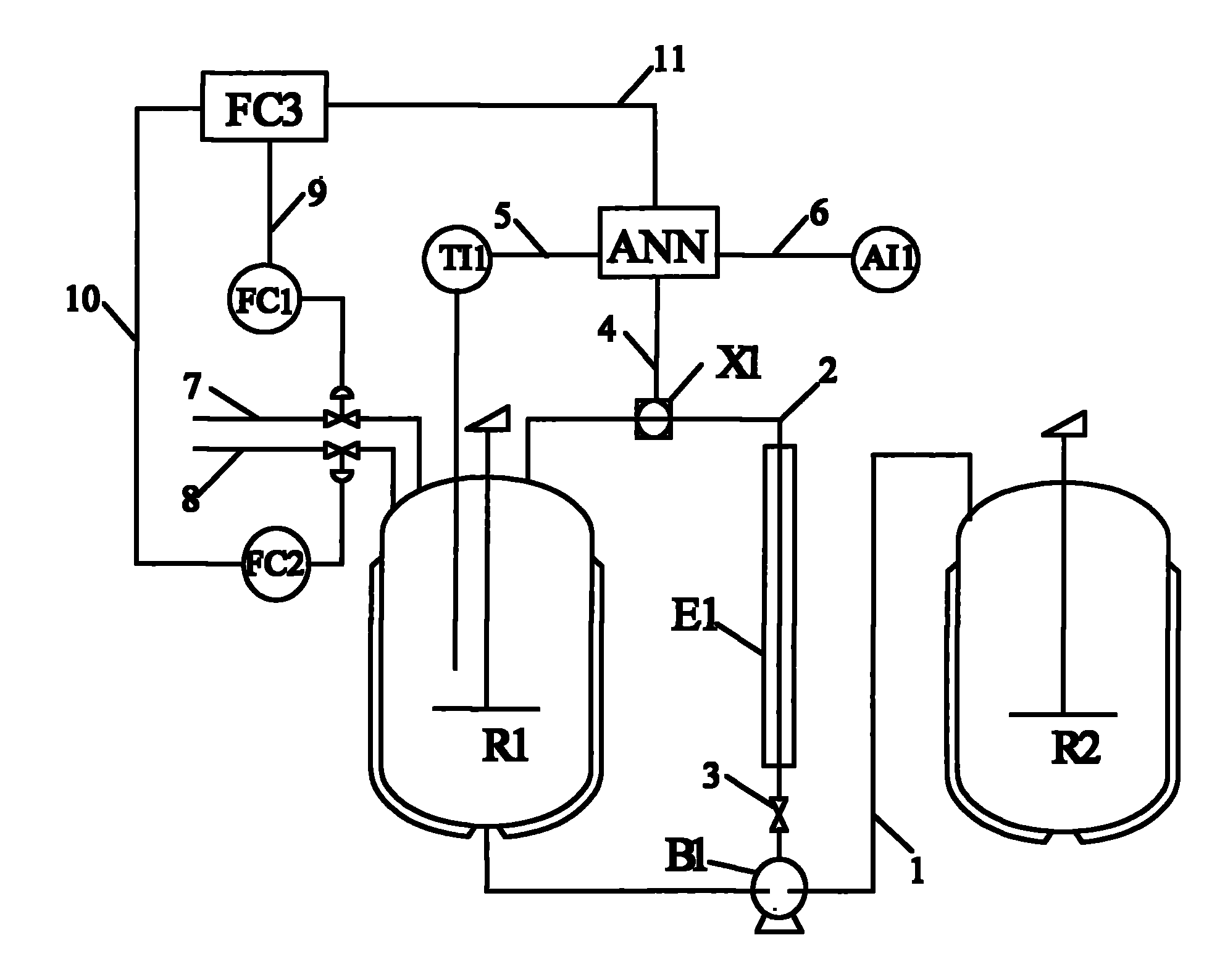

Method and device for detecting and controlling acetoacetic ester continuous reaction system on line

InactiveCN102103363AReal-time monitoring of component concentrationsComponent concentration ensuresComponent separationPhase-affecting property measurementsChemistryAcetic anhydride

The invention provides a method and device for detecting and controlling an acetoacetic ester continuous reaction system on line. The method comprises the following steps of: proportionally controlling the inventory ratings of diketene and fatty alcohol for undergoing an esterification reaction; testing the refractive index and the reaction temperature of the reaction system on line; establishinga neural network soft measurement model for indirectly measuring the concentration of a main component in a reaction kettle according to the refractive index, the content of acetic anhydride in fed diketene and the reaction temperature; and correcting and controlling a flow proportion controller based on the model so as to realize online detection and control of the acetoacetic ester continuous reaction system. By adopting the method and the device, the concentration of the main component in the reaction system can be monitored in real time in an acetoacetic ester continuous preparation process, an abnormal reaction condition is avoided, raw material input quantity proportion can be correspondingly controlled in time according to real-time detection data simultaneously, the concentration of the main component in the reaction system is kept in a normal process range, and the acetoacetic ester continuous preparation process is further optimized.

Owner:SHANGHAI WUJING CHEM

Copper electrolysis system and running method

ActiveCN103334123AReduce power consumptionReduce manufacturing costPhotography auxillary processesProcess efficiency improvementElectrolysisPower flow

The invention provides a copper electrolysis system which comprises an electrolysis tank, a cooling device, a driving device, an electrolyte storage tank and a conducting bar, wherein a liquid supply device is arranged on an inside wall of the electrolysis tank; an outlet of the driving device is connected with an inlet of the cooling device; the outlet of the cooling device is connected with a liquid supply pipeline of the liquid supply device; an electrolyte draining port of the electrolysis tank is connected with the inlet of the electrolyte storage tank; the outlet of the electrolyte storage tank is connected with the inlet of the driving device; the conducting bar is arranged at an upper edge of the electrolysis tank; and a conductive rod of a cathode and a hanging lug of an anode are respectively lapped with the conducting bar. Due to the cooperative use of the electrolysis tank, the cooling device, the driving device and the conducting bar, the copper electrolysis system provided by the invention causes the current density to be higher and the electrolysis tank voltage to be lower during a copper electrolysis, so that the yield of copper is higher and the energy consumption is lower.

Owner:YANGGU XIANGGUANG COPPER

Device and method for strengthening anaerobic ammonia oxidation and nitrogen removal process through segmented backflow of sludge

ActiveCN107381813AReduce the impactImproved shock load capabilityWater treatment parameter controlWater contaminantsActivated sludgeContinuous flow

The invention discloses a device for strengthening anaerobic ammonia oxidation and nitrogen removal process. The device comprises a raw-water storage tank, a feed pump, a biochemical reactor and a continuous flow reactor of a sediment tank; the continuous flow reactor is connected with a PLC (programmable logic controller); the biochemical reactor contains an anaerobic zone, an aerobic zone and an anoxic zone; the urban raw-material storage tank is communicated with a water inlet pipe of the biochemical reactor through the feed pump, and sewage is sequentially connected with the anaerobic zone, the aerobic zone, the anoxic zone and the sediment tank through the water inlet pipe; the sediment tank is subjected to sludge and water separation, and a supernatant is discharged as yielding water; in the anaerobic zone, activated sludge absorbs an organic matter synthesized internal carbon source degraded into the water; in the aerobic zone, coupling of short-cut nitrogen removal and anaerobic ammonium oxidation is realized by controlling dissolved oxygen, and nitrogen removal rate of the system is increased.

Owner:BEIJING DRAINAGE GRP CO LTD

Lithium battery box extinguishing method

The invention provides an early warning and automatic control method for thermal runaway of lithium batteries. The method is characterized in that once the batteries in a battery box cause a fire due to development of thermal runaway development, an extinguishing device is automatically started immediately to release an extinguishing agent for extinguishing, and the extinguishing agent is released several times. According to the method, the defect that in an existing traditional extinguishing mode, multiple fires which are caused by fire resurgence and thermal runaway extension in lithium battery box fire controlling cannot be controlled is overcome, extinguishing can be conducted multiple times by releasing the extinguishing agent multiple times in the method, continuous cooling can be conducted, fire resurgence is effectively inhibited, thermal runaway extension is prevented, property losses are reduced, and malignant fire accidents are avoided to the greatest extent.

Owner:南京能启能电子科技有限公司

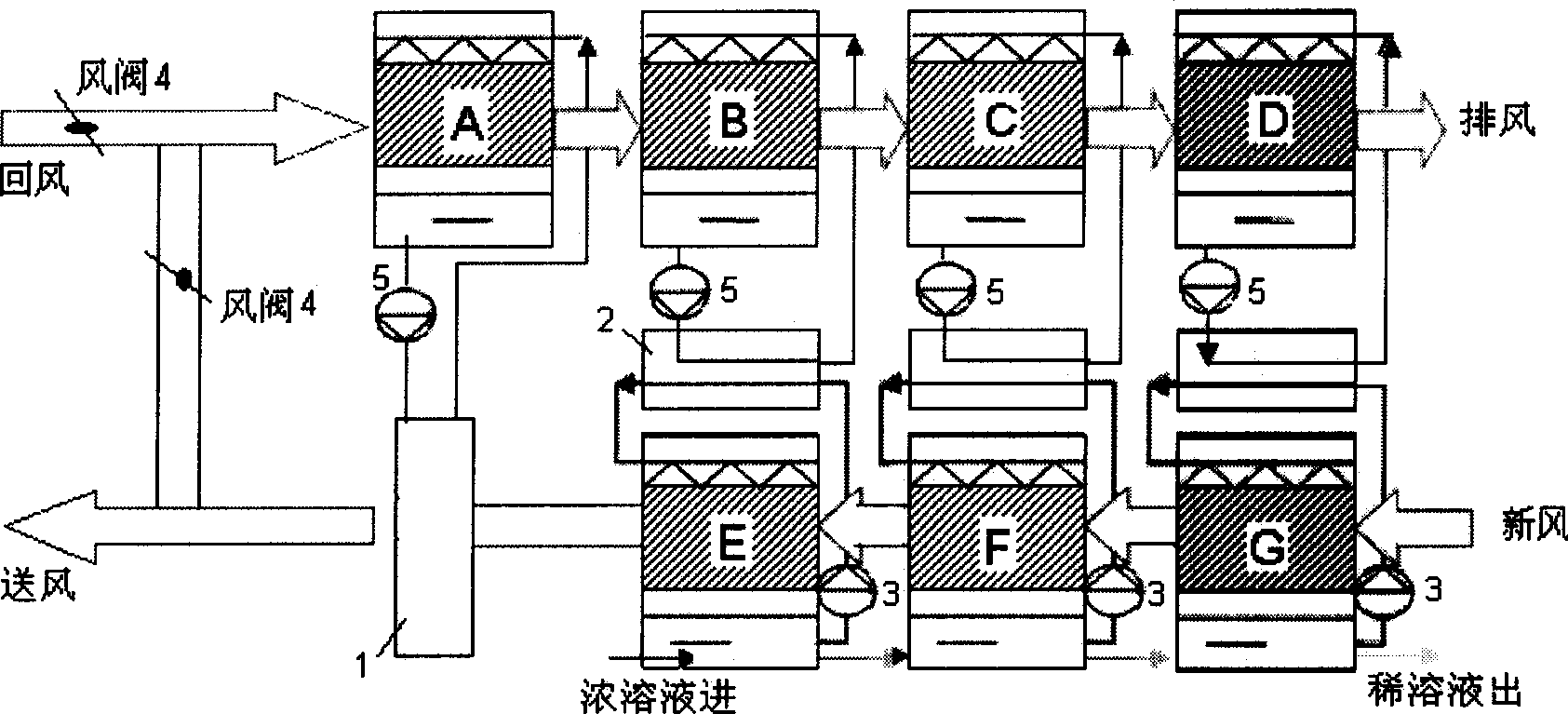

Whole-thermal reclaiming type thermal-drive solution ventilation processor set by using evaporative cooling of return air

ActiveCN1865789AGuaranteed concentrationEnergy recovery in ventilation and heatingLighting and heating apparatusEvaporative coolerEnergy technology

The invention relates to a recycle thermal-driving solution fan, which uses reflux air to vaporize and cool. Wherein, said invention comprises gas-liquid direct-contact modules (A-G), sheet heat exchanger, solution self-circulate pump, fan valve, and water pump; the upper channel is formed by the modules (A, B, C, D); the lower channel is formed the modules (E, F, G); the upper modules (B, C, D) is relative to the lower layer modules (E, F, G) to form three-stage heat recycles; each stage of upper and lower modules are connected by the sheet heat exchanger; the solution is cooled to be sprayed in the lower modules (E, F, G), to directly contact the air to dehumidify the air; and the dense solution enters into the lower modules (E, F, G); the upper module (A) contains the vaporizing cooling process between air and cold water, to generate cold water into the lower air cooler to reduce the temperature of air.

Owner:TSINGHUA UNIV +1

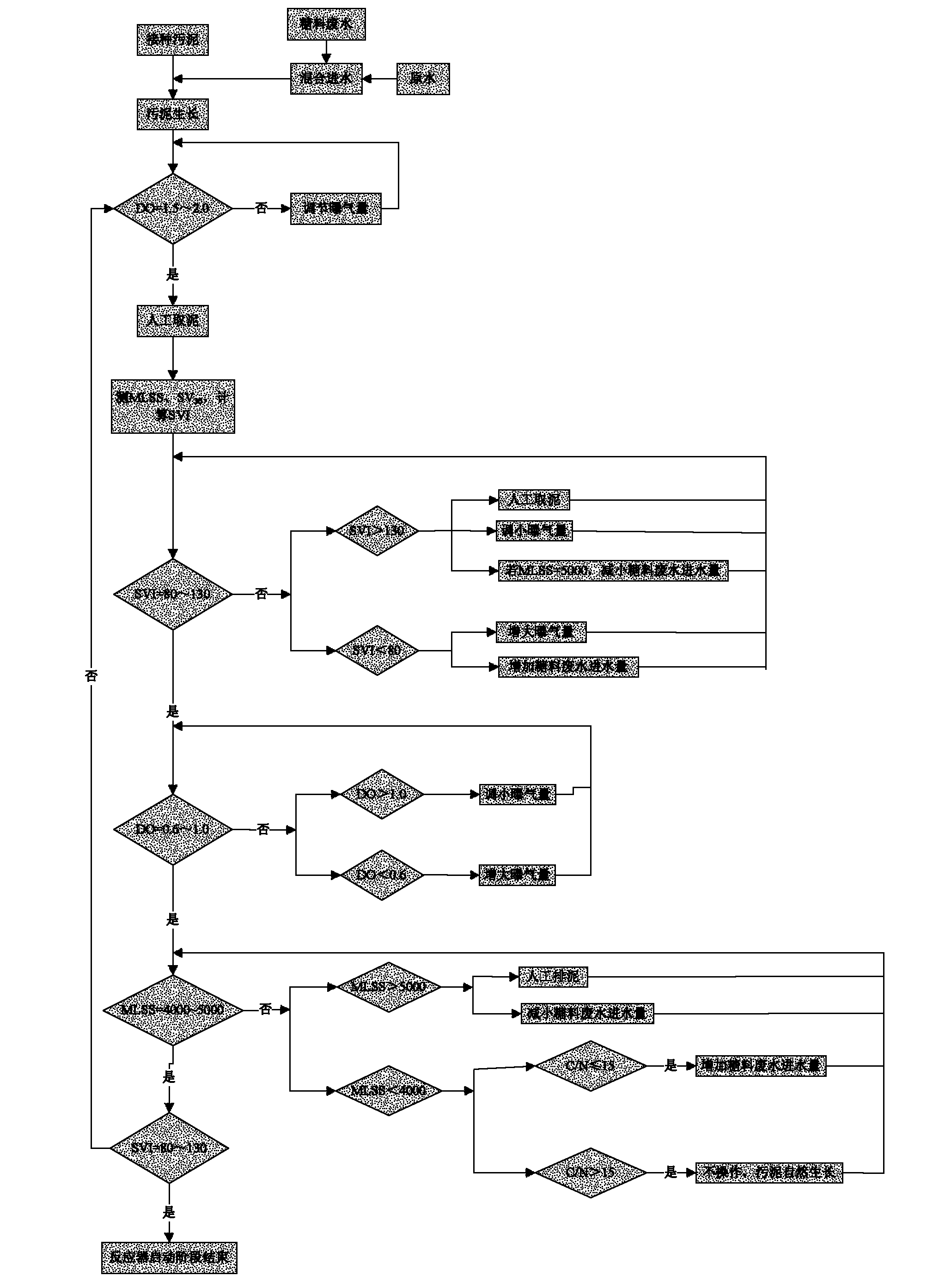

Sludge reflow-free device with simultaneous nitrification and denitrification (SND) function and operation control method thereof

ActiveCN102173510ASolve the problem that it is difficult to control the microbial metabolic environmentEasy to operate and controlControlling ratio of multiple fluid flowsTreatment with aerobic and anaerobic processesSludgeCombined use

The invention discloses a sludge reflow-free device with a simultaneous nitrification and denitrification (SND) function. The device comprises a pool body; the sidewall of the pool body is provided with a main water inlet; the interior of the pool body is divided by a clapboard into a diversion area, an aeration area and a sludge precipitation area in sequence; the aeration area is internally provided with an overflow groove; the bottom of the aeration area is provided with microporous aeration devices distributed uniformly; and the sludge precipitation area is internally provided with a membrane element. The invention also discloses an operation control method of the device. By skillful arrangement of aeration pipes and combined use with a biological membrane, the power cost and the operating cost of sludge reflow are saved, and the purpose of reducing energy consumption is achieved. The biological environment to be achieved by the simultaneous nitrification and denitrification is adjusted indirectly through adjusting parameters such as active sludge concentration, sludge age, unit sludge load and the like; the operation is strong in human controllability, and the problem that the microbial metabolic environment in the SND technology is not easy to control is solved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

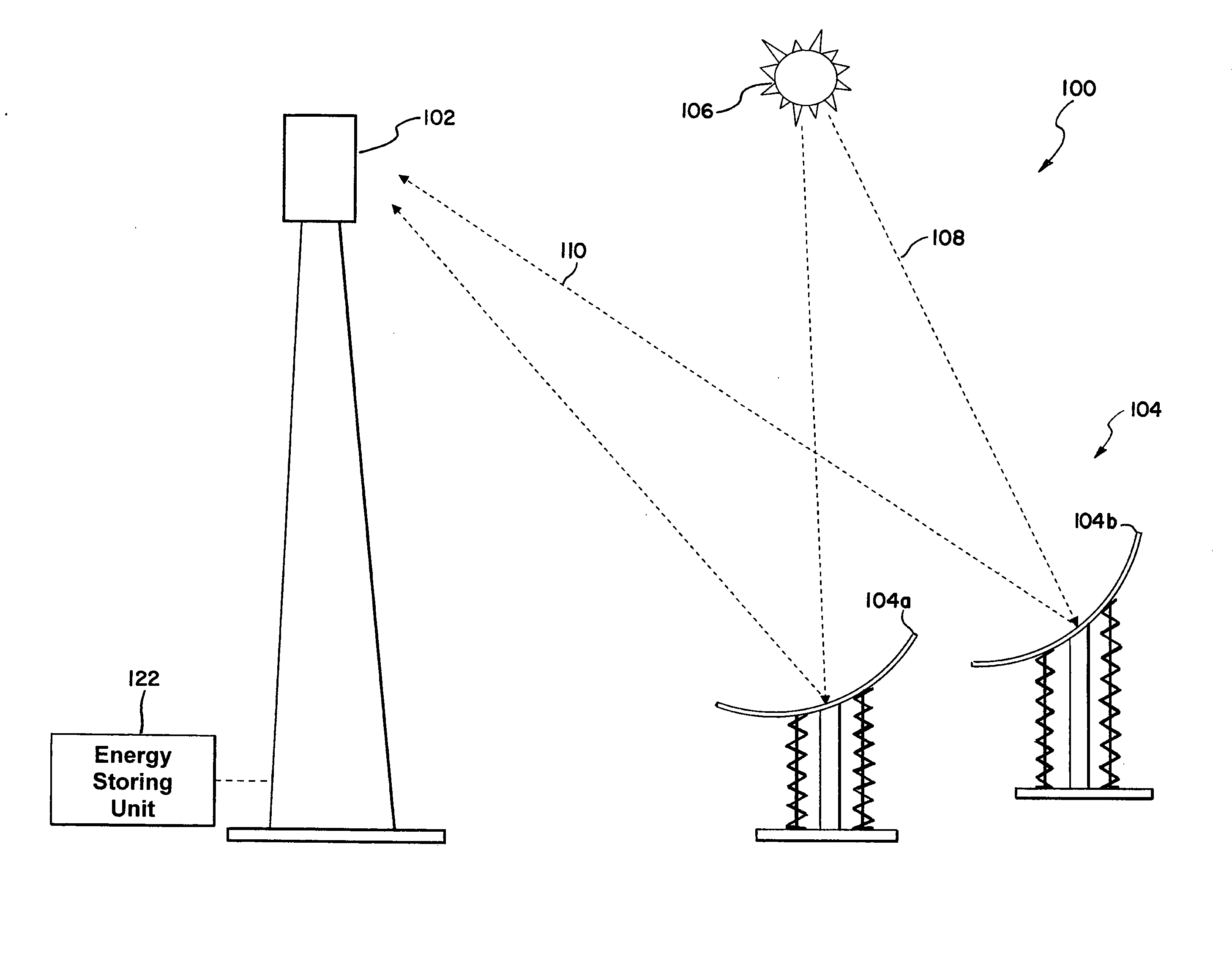

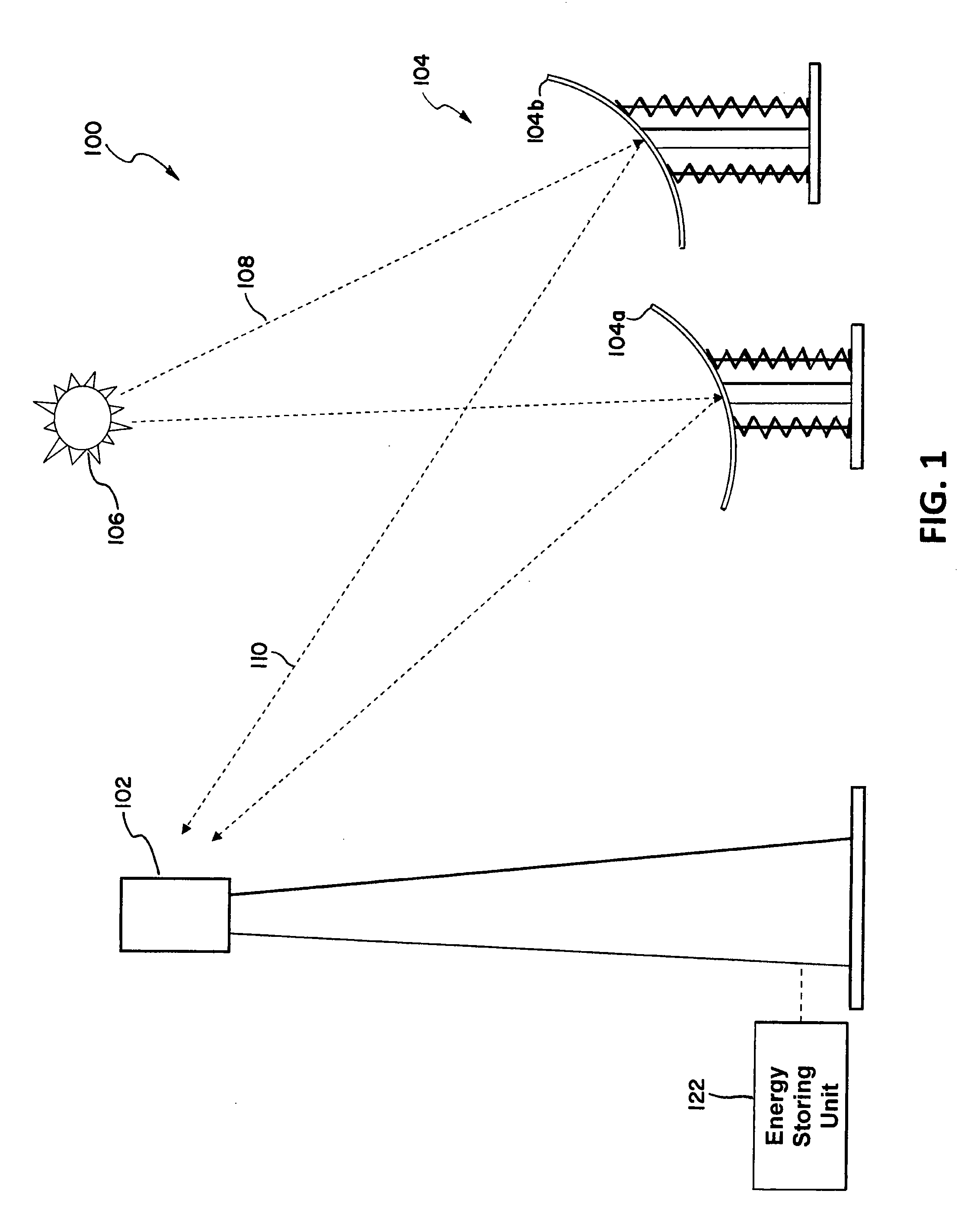

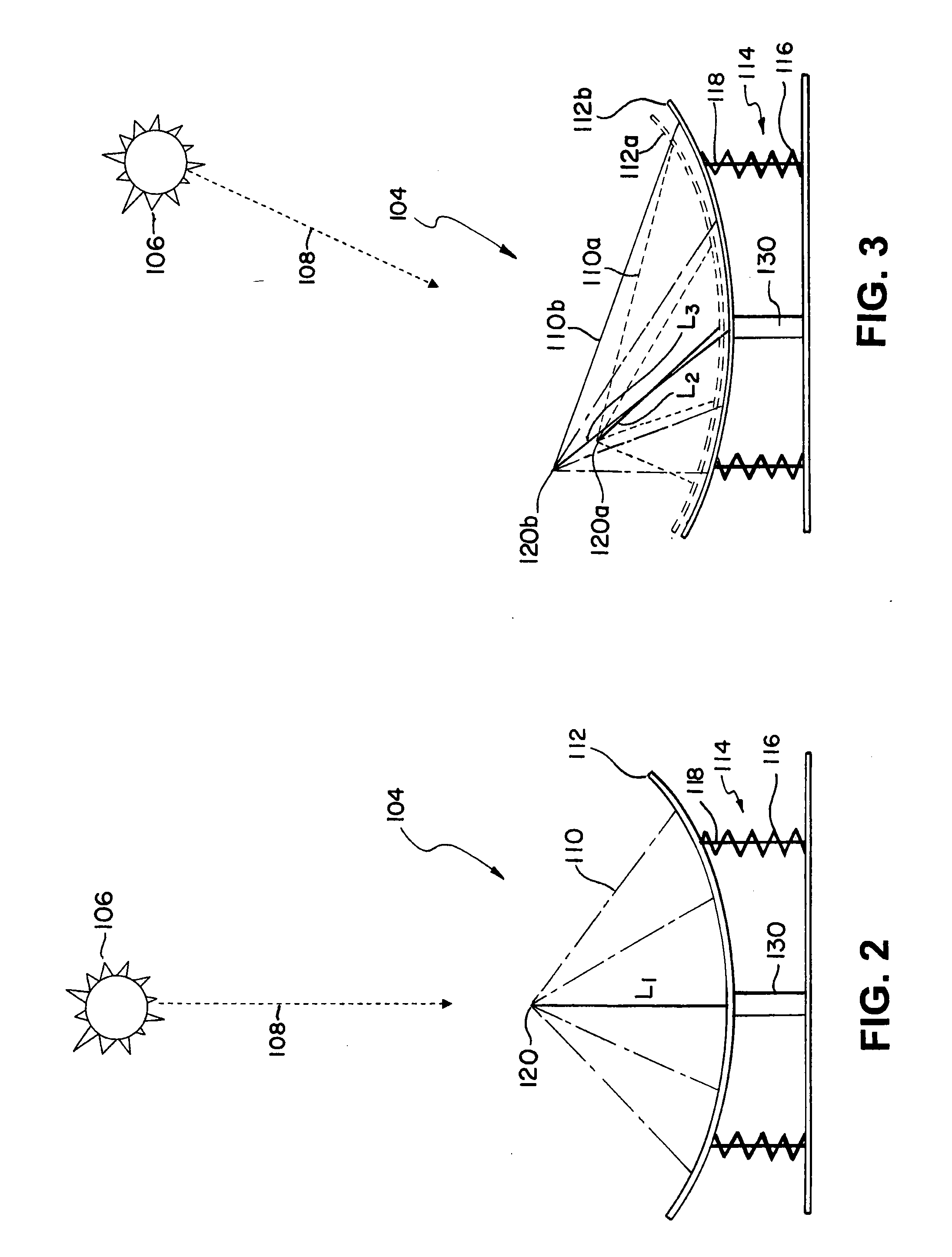

Method and apparatus to control a focal length of a curved reflector in real time

ActiveUS20120204859A1Produce energyGuaranteed concentrationSolar heating energyMirrorsEngineeringTower

The present invention relates to a method and apparatus to control a focal length of a curved reflector in real time. An energy generation system includes curved reflectors, a tower, and an energy storing unit connected to the tower. The curved reflectors reflect and concentrate light from a light source onto the tower. The tower converts the received light into usable energy which is stored in the energy storing unit. Each of the curved reflectors can include a curved body, a stand, and / or an actuation unit. The curved body reflects the light from the light source to concentrate it onto the tower. When the light source moves, the curved body pivots about the stand to track the light source. The actuation unit is activated to adjust a focal length of the focal point of the curved body to ensure that the reflected light is concentrated at the tower.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com