High-concentration electrolyte for lithium ion battery, preparation method thereof, and lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the field of high-concentration electrolyte for lithium-ion batteries and its preparation, to achieve the effects of improving battery energy density, small reaction polarization, and good kinetic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the above-mentioned electrolyte, which includes the following steps:

[0043] Under protective atmosphere conditions, mixing non-aqueous solvents and wetting agents to obtain a mixed solution;

[0044] Lithium salt is added to the mixed solution and mixed uniformly to obtain a high-concentration electrolyte for lithium ion batteries.

[0045] In the present invention, a non-aqueous solvent and a wetting agent are first mixed under a protective atmosphere to obtain a mixed solution. Wherein, the protective atmosphere conditions are selected from argon or nitrogen. The present invention has no special restrictions on the mixing method, as long as the mixing method is well known to those skilled in the art.

[0046] Then, lithium salt is added to the mixed solution, and after the lithium salt is completely dissolved and mixed uniformly, a high-concentration electrolyte for lithium ion batteries is obtained.

[0047] In the...

Embodiment 1

[0061] Electrolyte formula: lithium salt lithium hexafluorophosphate (LiPF 6 ), non-aqueous organic solvent dimethyl carbonate (DMC), fluoroethylene carbonate (FEC), wetting agent 1,1,1,3,3,3-hexafluoroisopropyl methyl ether (HFPM).

[0062] Electrolyte preparation method: In a glove box filled with argon, mix DMC, FEC, HFPM with 10mL solvent according to the volume ratio provided in Table 1, and slowly add lithium salt lithium hexafluorophosphate (LiPF 6 ), make the concentration of the lithium salt 3mol / L, and stir until the lithium salt is completely dissolved to obtain an electrolyte.

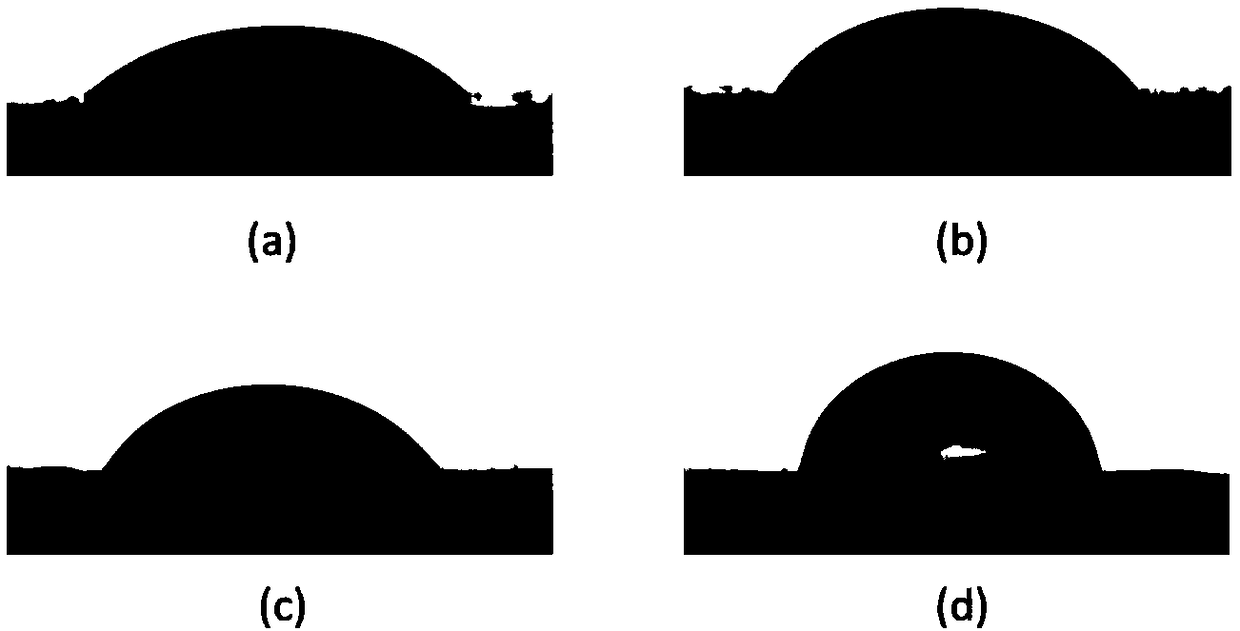

[0063] Performance test: Determine the viscosity and contact angle of the prepared electrolyte. The results are shown in Table 1 and figure 1 , figure 1 It is the test chart of the contact angle of electrolyte with different formula ratios. figure 1 (A), (b), (c) and (d) in Table 1 correspond to the contact of electrolytes obtained in different ratios of DMC / FEC / HFPM in (a), (b), (c) and (d) in Ta...

Embodiment 2

[0069] Electrolyte formula: lithium bis(trifluoromethylsulfonyl)imide (LiTFSI), non-aqueous organic solvent tetramethylurea, wetting agent 1,1,1,3,3,3-hexafluoroisopropyl Base methyl ether (HFPM):

[0070] Electrolyte preparation method: In a glove box filled with argon, mix tetramethylurea and HFPM with 10mL solvent at a volume ratio of 70:30, and slowly add lithium salt bis(trifluoromethylsulfonyl)imide lithium ( LiTFSI), the concentration of the lithium salt is shown in Table 2. Stir until the lithium salt is completely dissolved to obtain an electrolyte.

[0071] Performance test: Determine the conductivity of the prepared electrolyte, the viscosity of the electrolyte, and the contact angle.

[0072] Table 2 Test results of viscosity, contact angle and conductivity of different electrolytes

[0073]

[0074] Determine the corrosion of aluminum foil in the electrolyte, and see the results Figure 4 , Figure 4 Corrosion of aluminum foil in electrolyte with different formula ratios...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com