Gas extraction method of cross hole drilling area of gas discharge laneway

A gas discharge roadway and gas drainage technology, which is applied in the direction of gas discharge, earthwork drilling, directional drilling, etc., can solve the problems of gas gushing, heavy construction workload of high drainage roadways, and long preparation time for recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

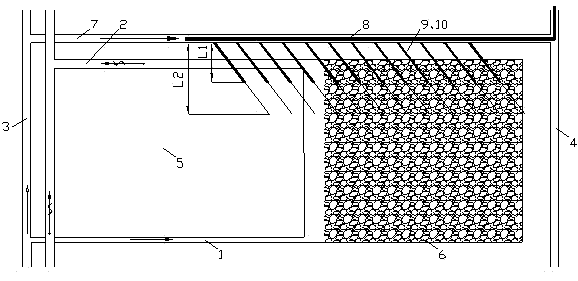

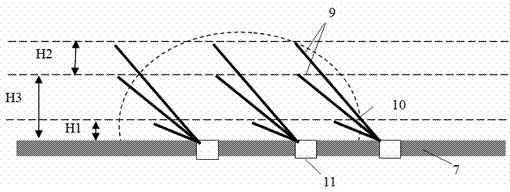

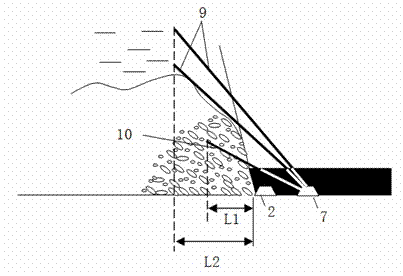

[0020] Such as figure 1 As shown, the method for gas drainage in the gas discharge lane of the present invention is based on the geological exploration information of the coal seam. A gas discharge roadway 7 parallel to the return airway 2 of the working face is excavated in the main roadway 3. The gas discharge roadway 7 can be used as the air inlet roadway adjacent to the mining face. The cross-sectional area of the gas discharge roadway 7 is 5-8m 2 ; The distance between the gas discharge lane 7 and the return air lane 2 of the working face is 15-30m. Then excavate a mining area return air lane 4 parallel to the mining area track lane 3 at the tail of the gas discharge lane 7 and in the protection coal pillar of the working face, so that the air intake of the mining area track lane 3 enters the gas discharge lane 7 along the The return air lane 4 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com