Functional nanofiber filtering material and preparation method and application thereof

A nanofiber and filter material technology, applied in the field of functionalized nanofiber filter material and its preparation, can solve the problems of no sterilization and adsorption of oily particles, heavy metal silver damage, cumbersome production process, etc., and achieves easy regulation and good structure and performance. The effect of adsorption and separation, the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of functionalized nanofiber filter material, the specific steps are:

[0058] (1) Dry polylactic acid (PLA) in a vacuum oven at 60°C for 2 hours. Accurately weigh 14.235g N-N dimethylformamide with an electronic balance and place it in a 25ml beaker, then weigh 0.015g C 3 N 4 Nanosheet (the atomic force microscope image and thickness analysis image of the nanosheet are shown in Figure 5a with 5b shown) placed in N-N dimethylformamide, ultrasonically oscillated for 6 hours, took out the beaker, accurately weighed 0.75g of dried polylactic acid powder with an electronic balance, placed it in the beaker, stirred magnetically at room temperature for 24 hours, and prepared a uniform and Stable with C 3 N 4 Polyacrylonitrile spinning solution for nanosheets.

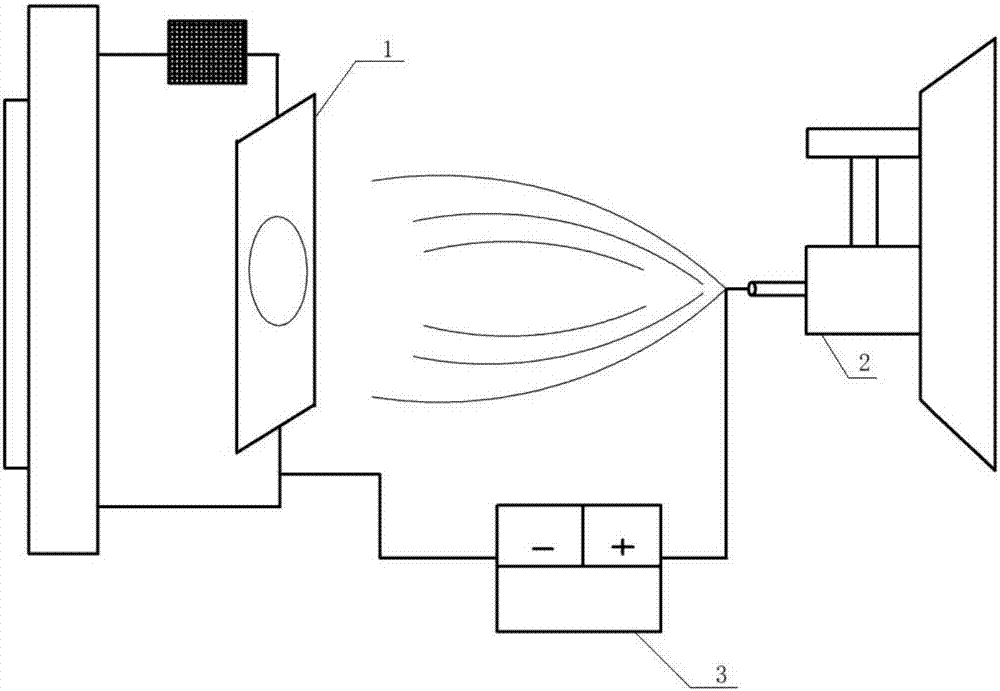

[0059] (2) Prepare the spinning solution obtained in step (1) on the substrate by electrospinning technology, specifically use figure 1 The electrospinning equipment shown is for electrospin...

Embodiment 2

[0062] A preparation method of functionalized nanofiber filter material, the specific steps are:

[0063] (1) Dry polyvinyl chloride (PVC) powder in a vacuum oven at 60° C. for 2 hours. Accurately weigh 5.625g N-N dimethylformamide and 5.625g tetrahydrofuran with an electronic balance and place them in a 50ml beaker, then weigh 1.5g C 3 N 4 Nanosheet (the atomic force microscope image and thickness analysis image of the nanosheet are shown in Figure 5a with 5b shown), placed in the above mixed solvent, vibrated with an ultrasonic oscillator for 6 hours, took out the beaker, accurately weighed 2.25g of dried polyvinyl chloride powder with an electronic balance, placed it in the beaker, stirred magnetically at room temperature for 24 hours, and prepared Uniform and stable C 3 N 4 Polyvinyl chloride spinning solution for nanosheets.

[0064] (2) Prepare the spinning solution obtained in step (1) on the substrate by electrospinning technology, specifically use figure 1 The...

Embodiment 3

[0067] A preparation method of functionalized nanofiber filter material, the specific steps are:

[0068] (1) Dry the polyvinylidene fluoride (PVDF) powder in a vacuum oven at 60° C. for 2 hours. Accurately weigh 8.25g N-N dimethylformamide with an electronic balance and place it in a 50ml beaker, then weigh 3gC 3 N 4 Nanosheet (the atomic force microscope image and thickness analysis image of the nanosheet are shown in Figure 5a with 5b shown) in the above solvent, vibrated with an ultrasonic oscillator for 5 hours, took out the beaker, accurately weighed 3.75 g of dried polyvinylidene fluoride powder with an electronic balance, placed it in the beaker, stirred magnetically at room temperature for 24 hours, and prepared a uniform and stable C 3 N 4 Polyvinylidene fluoride spinning solution for nanosheets.

[0069] (2) Prepare the spinning solution obtained in step (1) on the substrate by electrospinning technology, specifically use figure 1 The electrospinning equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com