Lignin organic slow-release liquid fertilizer for wheat and preparation method thereof

A lignin and organic technology, which is applied to the field of lignin organic slow-release liquid fertilizer for wheat and its preparation, can solve the problems of insignificant growth promotion effect of wheat, ineffective balance of effective nutrients, damage to soil aggregate structure, and the like. The effect of fertilizer utilization, increasing salt-base exchange capacity, and improving soil condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

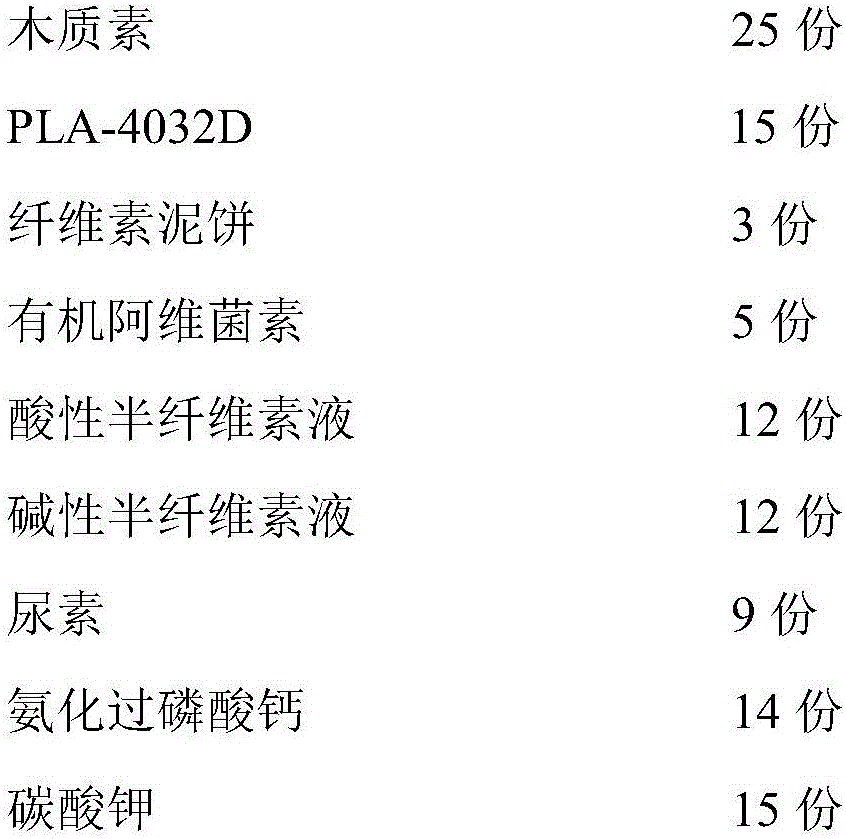

Embodiment 1

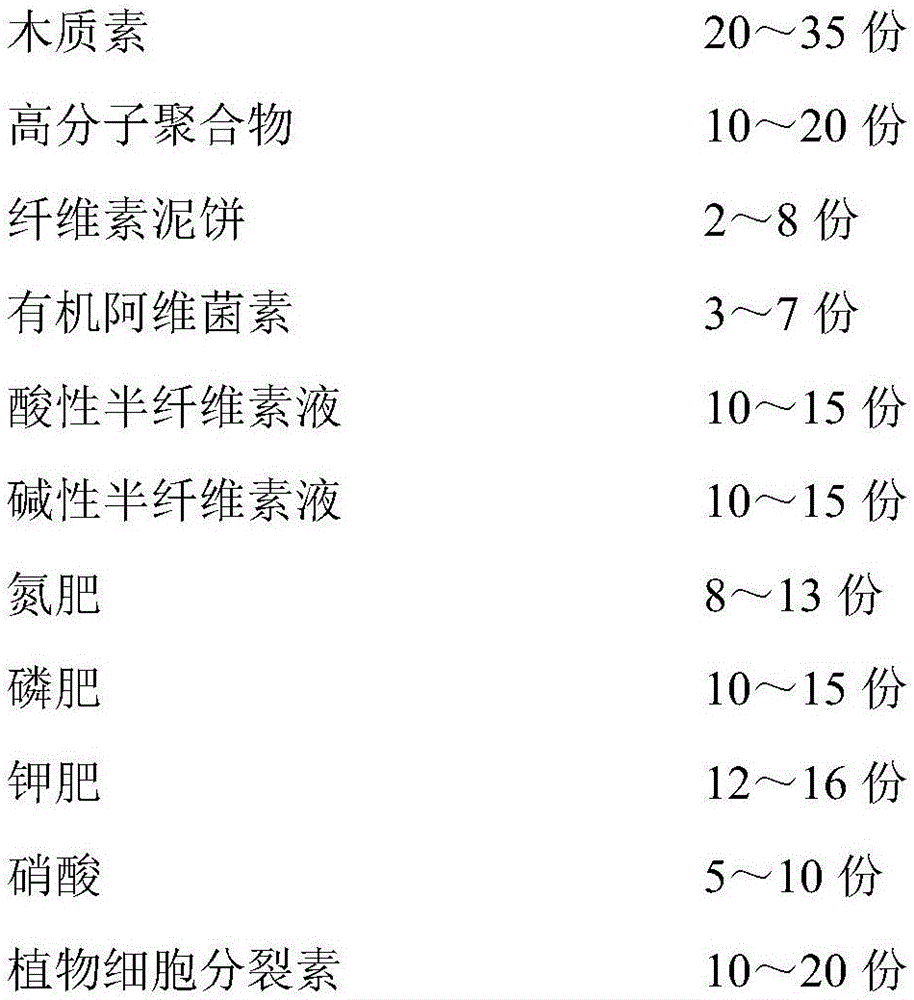

[0033] The lignin organic slow-release liquid fertilizer for wheat is characterized in that it is made of the following raw materials in parts by weight:

[0034]

[0035]

[0036] Wherein, the preparation method of lignin is as follows:

[0037] (1) Using corn stalks as raw materials, first cut and remove dust through a pulverizer, and then steam-explode at 3.0 MPa for 5 minutes, after solid-liquid separation, add lye to the obtained solid, and cook and separate at 90°C for 1 hour to obtain lignin black liquor;

[0038] (2) Add 40ppm of Ca(OH) to lignin black liquor 2 Carry out flocculation and sedimentation, and filter through a filter with a filtration accuracy of 20 μm to obtain lignin clear liquid;

[0039] (3) Send the lignin clear liquid into the tubular ultrafiltration membrane, control the pressure of the ultrafiltration membrane stack to 8.0MPa, the temperature to 30°C, and the flux to 50m 3 , to obtain the ultrafiltration concentrate and ultrafiltration liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com