Tibetan incense and preparation method thereof

A Tibetan incense and agarwood technology, which is applied in the fields of botanical equipment and methods, pharmaceutical formulations, and chemicals used for biological control, etc., can solve the problems of complex preparation methods, numerous Tibetan incense components, and great fetal impact, and achieve strong aroma and conditioning. Skin, prevent the effect of grinding too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

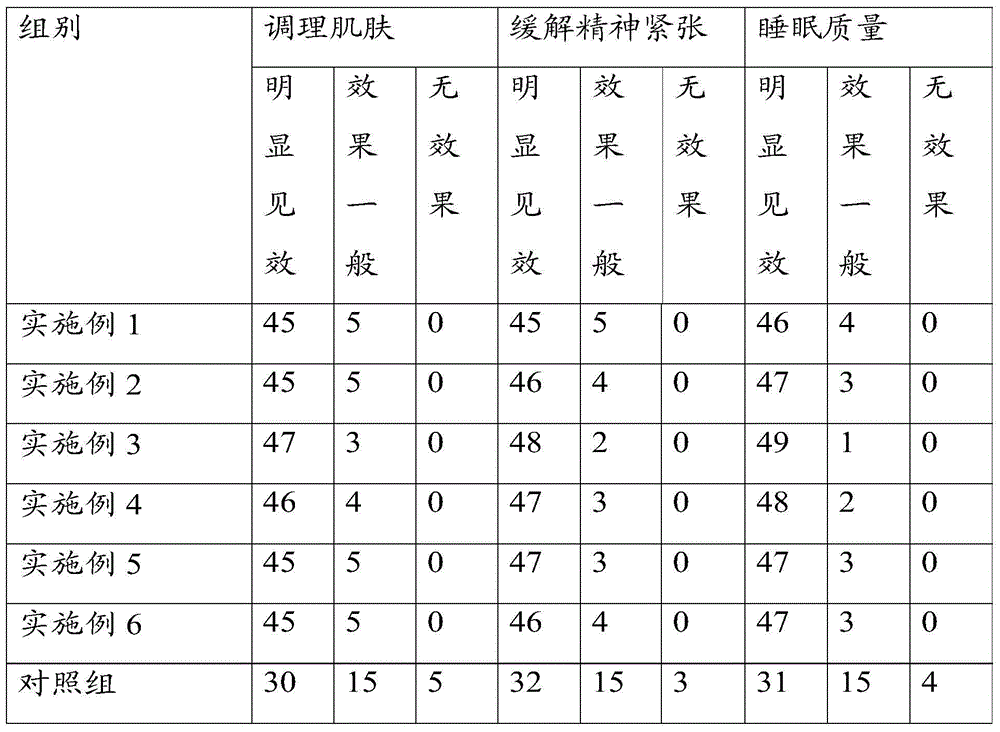

Examples

Embodiment 1

[0052] Get the following raw materials by weight, 30 parts of Tibetan cypress, 10 parts of white sandalwood, 20 parts of lichen, 10 parts of Chuanxiang, 12 parts of Tibetan woody, 5 parts of agarwood, 2 parts of brown sugar, 5 parts of benzoin, 2 parts of borneol, 2 parts of pangolin, 40 parts of red sandalwood, 30 parts of grass safflower, 3 parts of elm bark;

[0053] Prepared as follows:

[0054] (1) First, use a wooden trough and a mallet to continuously smash Tibetan cypress into a paste (generally 5 kg of Tibetan cypress coarse material needs one day to grind), and then fill it with a size of 10 x 15 x 30 cm. In a wooden film, pour it out and dry it to get incense bricks for use. When in use, smash the fragrant bricks and grind them into fine powder with a roller, put them into other raw materials according to the proportion of the recipe and stir them evenly.

[0055] (2) Grind white sandalwood, lichen, sichuan wood, Tibetan wood, agarwood, benzoin, borneol, pangolin,...

Embodiment 2

[0061] Get the following raw materials by weight, 33 parts of Tibetan cypress, 11 parts of white sandalwood, 21 parts of lichen, 13 parts of Chuanxiang, 15 parts of Tibetan woody, 8 parts of agarwood, 3 parts of brown sugar, 6 parts of benzoin, 3 parts of borneol, 3 parts of pangolin, 45 parts of red sandalwood, 32 parts of grass safflower, 4 parts of elm bark;

[0062] Prepared as follows:

[0063] (1) First, use a wooden trough and a mallet to continuously smash Tibetan cypress into a paste (generally 5 kg of Tibetan cypress coarse material needs one day to grind), and then fill it with a size of 10 x 15 x 30 cm. In a wooden film, pour it out and dry it to get incense bricks for use. When in use, smash the fragrant bricks and grind them into fine powder with a roller, put them into other raw materials according to the proportion of the recipe and stir them evenly.

[0064] (2) Grind white sandalwood, lichen, sichuan wood, Tibetan wood, agarwood, benzoin, borneol, pangolin,...

Embodiment 3

[0070] Get the following raw materials by weight, 35 parts of Tibetan cypress, 12 parts of white sandalwood, 22 parts of lichen, 15 parts of Chuanxiang, 16 parts of Tibetan woody, 10 parts of agarwood, 4 parts of brown sugar, 6 parts of benzoin, 4 parts of borneol, 4 parts of pangolin, 50 parts of red sandalwood, 35 parts of grass safflower, 5 parts of elm bark;

[0071] Prepared as follows:

[0072] (1) First, use a wooden trough and a mallet to continuously smash Tibetan cypress into a paste (generally 5 kg of Tibetan cypress coarse material needs one day to grind), and then fill it with a size of 10 x 15 x 30 cm. In a wooden film, pour it out and dry it to get incense bricks for use. When in use, smash the fragrant bricks and grind them into fine powder with a roller, put them into other raw materials according to the proportion of the recipe and stir them evenly.

[0073] (2) Grind white sandalwood, lichen, sichuan wood, Tibetan wood, agarwood, benzoin, borneol, pangolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com