Patents

Literature

104results about How to "High degree of alloying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

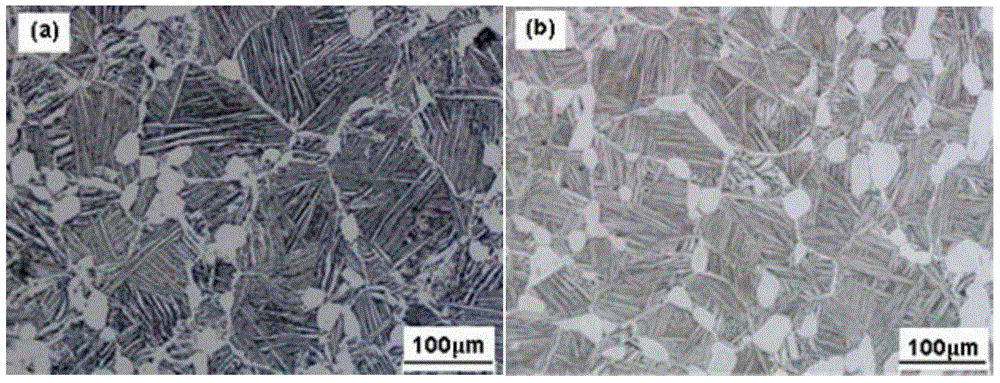

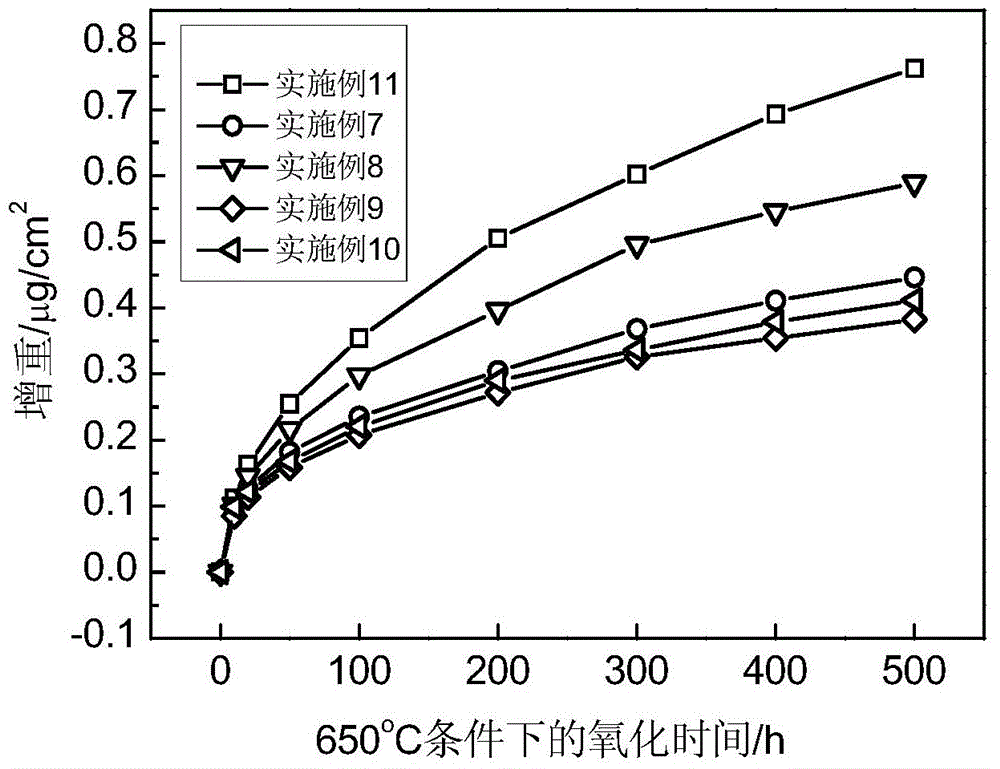

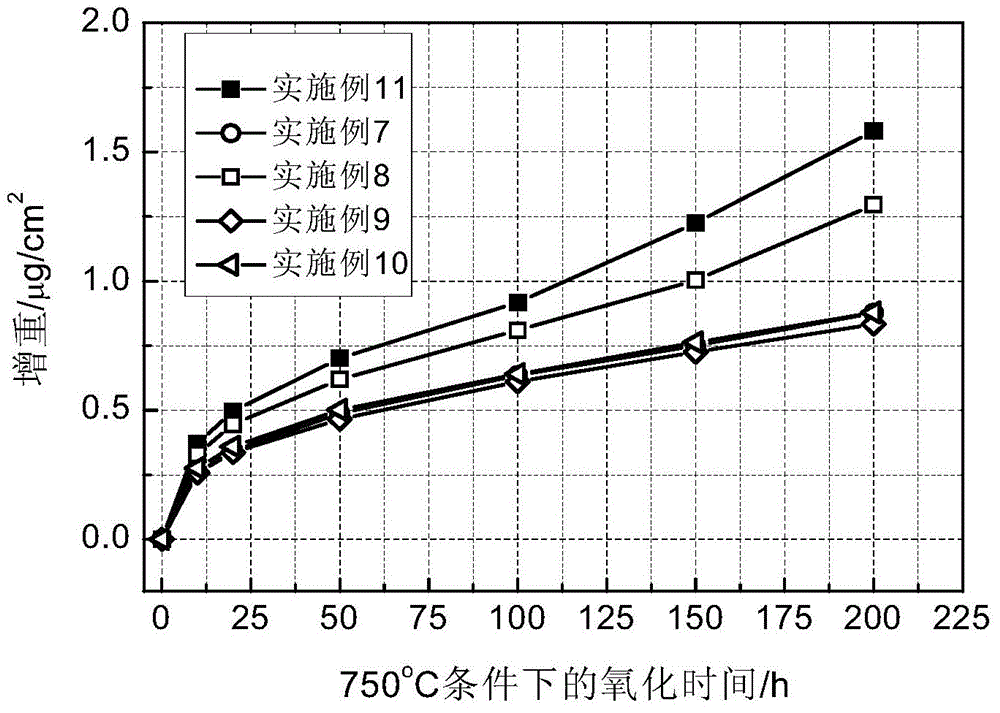

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

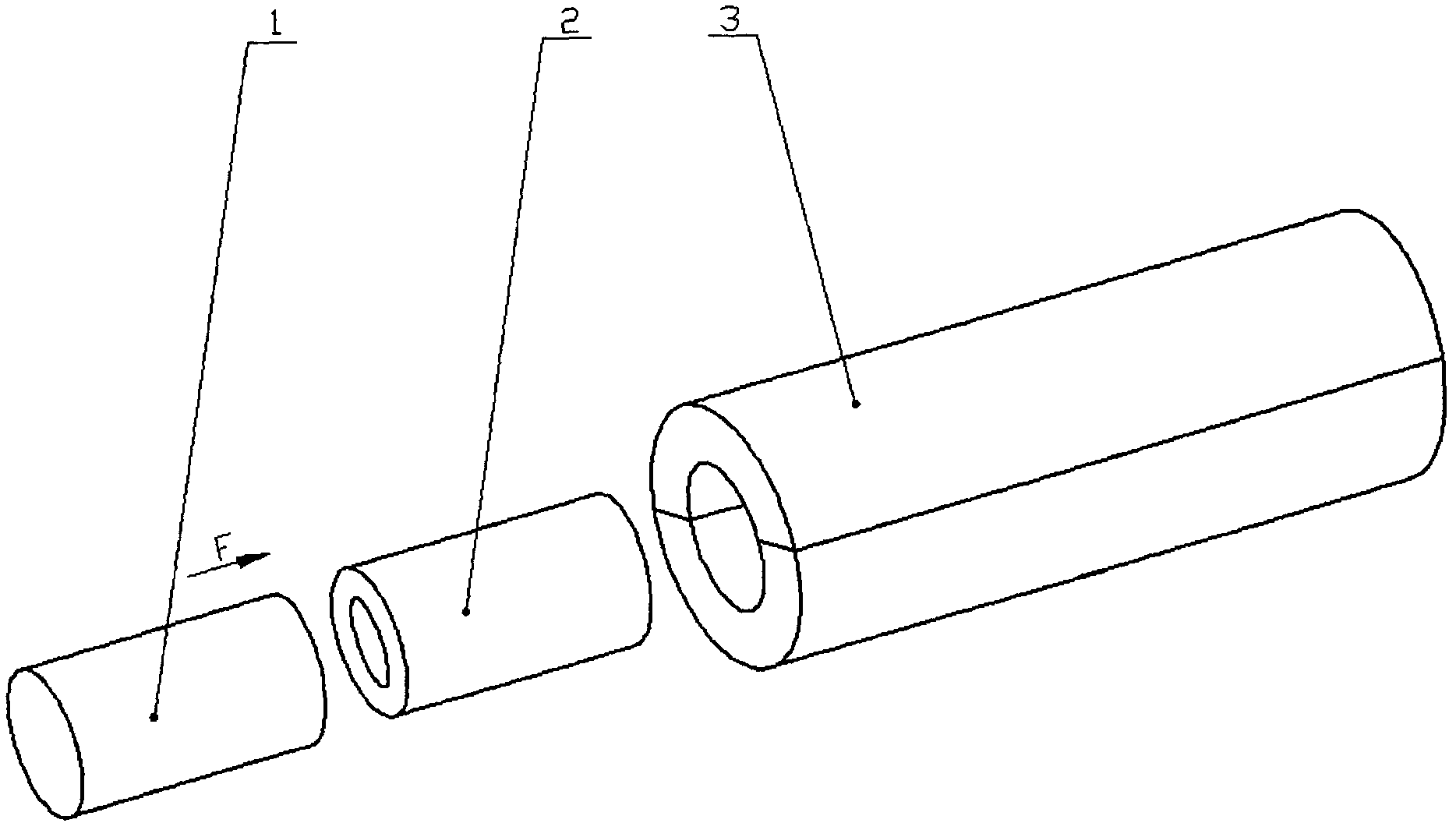

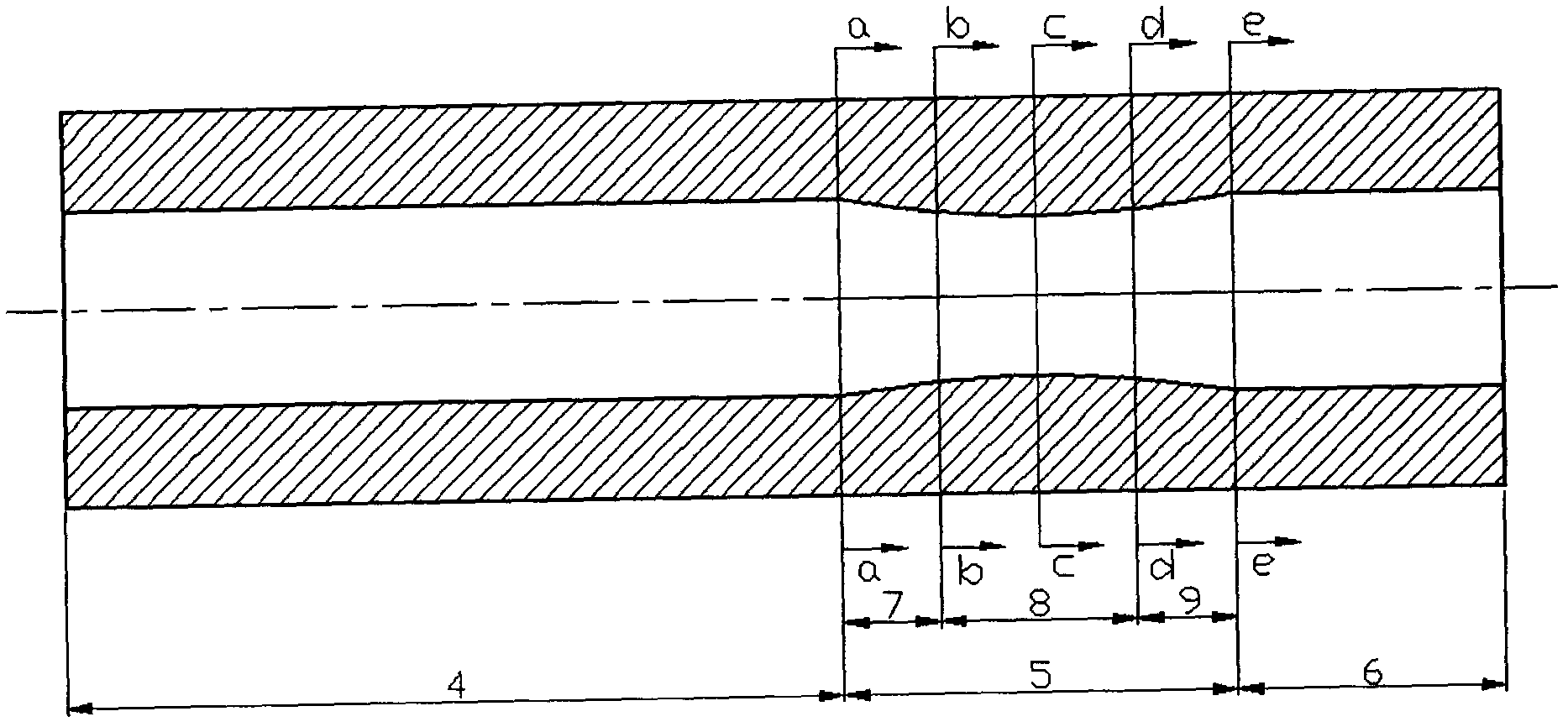

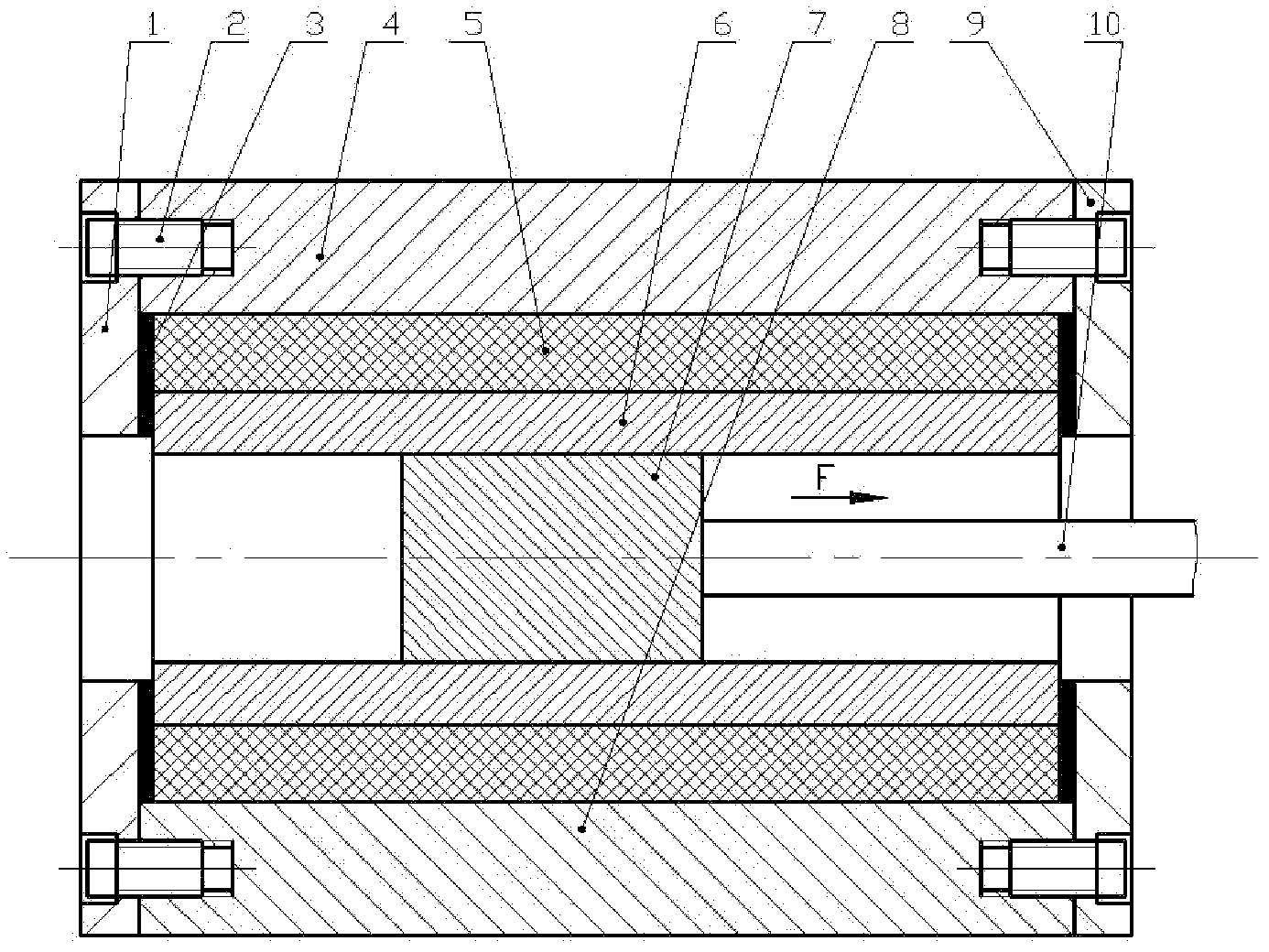

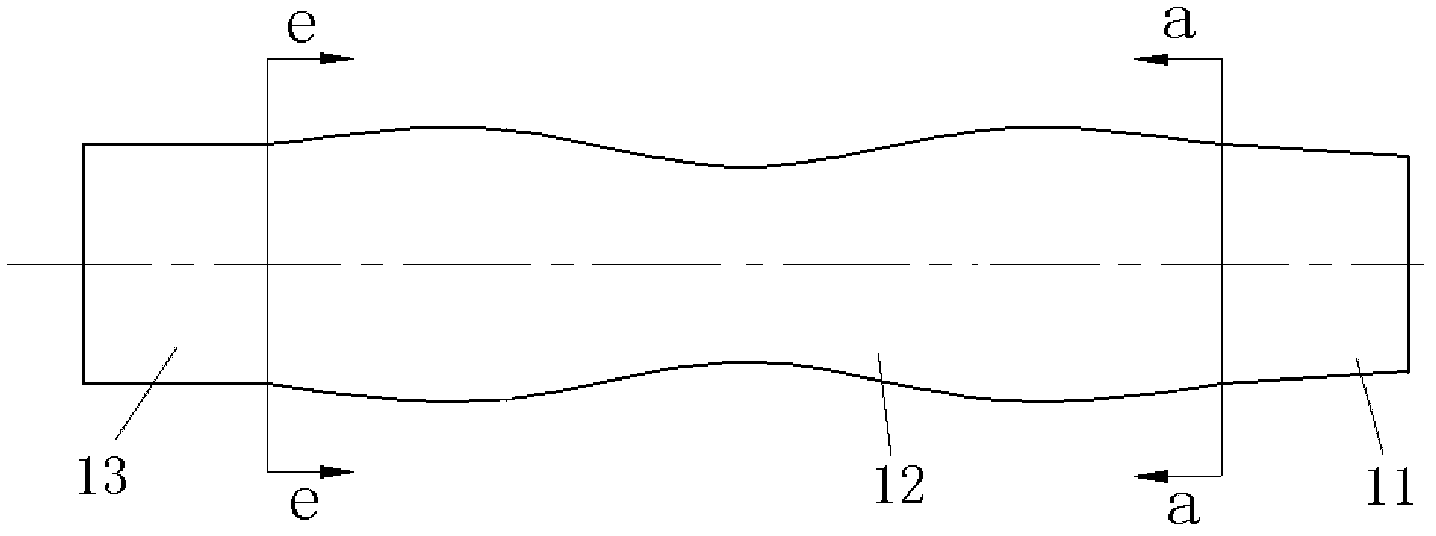

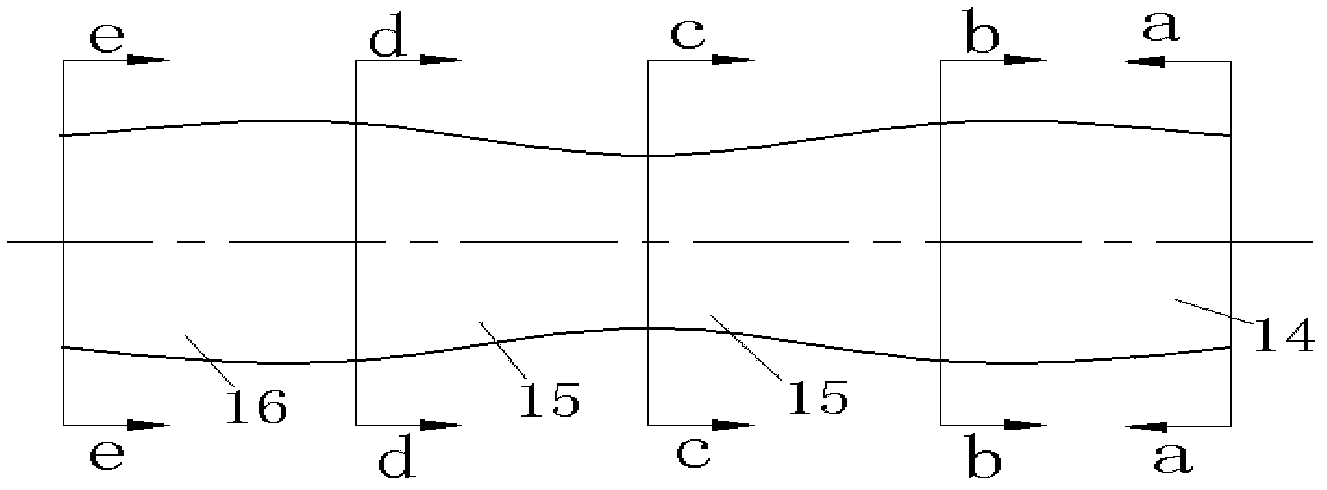

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

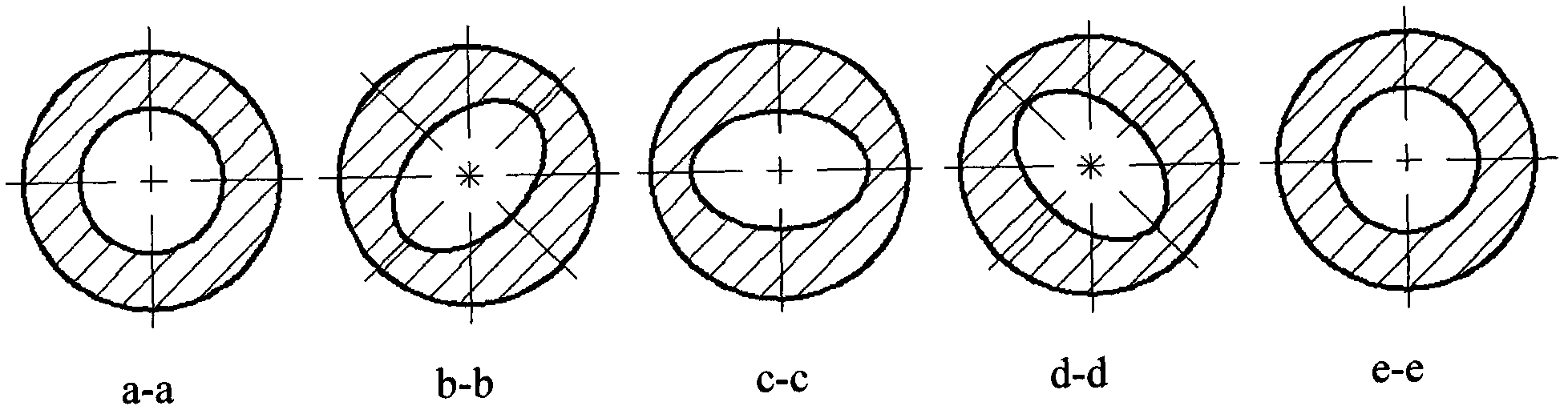

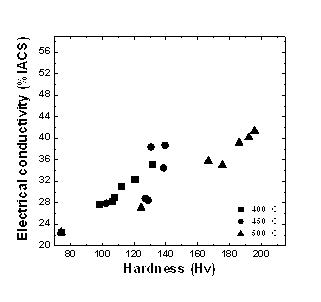

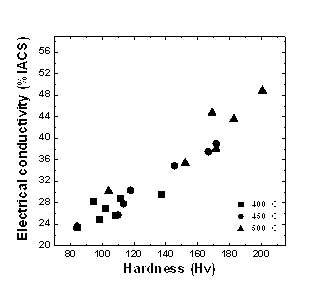

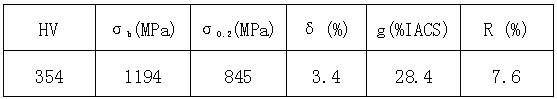

Cu-Ni-Si-based alloy and preparation method thereof

The invention belongs to the technical field of copper alloy material, and discloses Cu-Ni-Si-based alloy with high strength and high conductivity, and a preparation method thereof. The Cu-Ni-Si-based alloy is characterized in that the Cu-Ni-Si-V alloy comprises the following components in weight percent: 95.5-97.5% of Cu, 2.0-3.0% of Ni, 0.5-1.2% of Si, and 0-0.3% of V; and the method comprises specific steps as follows: smelting pure copper, pure silicon, pure nickel and pure vanadium in an induction furnace according to the proportion, casting in a metal die to obtain a blank, and performing ageing and solution treatment for the blank after hot rolling and cold rolling deformation treatment. As shown by experimental results, the added alloy V has the remarkable grain refinement function on the CU-Ni-Si alloy; and appropriately-added V (0.086 weight percent) can significantly improve the conductivity of the alloy, at the same time, the combination properties of the alloy are improved to the conductivity of 60% IACS and the hardness number of 205 Hv from the conductivity of 41.4% IACS and the hardness number of 195.7 Hv only with slight reduction in hardness; and the alloy with 0.086 weight percent V can separate out second phase with a volume fraction twice of that of the alloy before adding V.

Owner:TAIYUAN UNIV OF TECH

Copper base particle reinforced friction material

InactiveCN1995436AHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

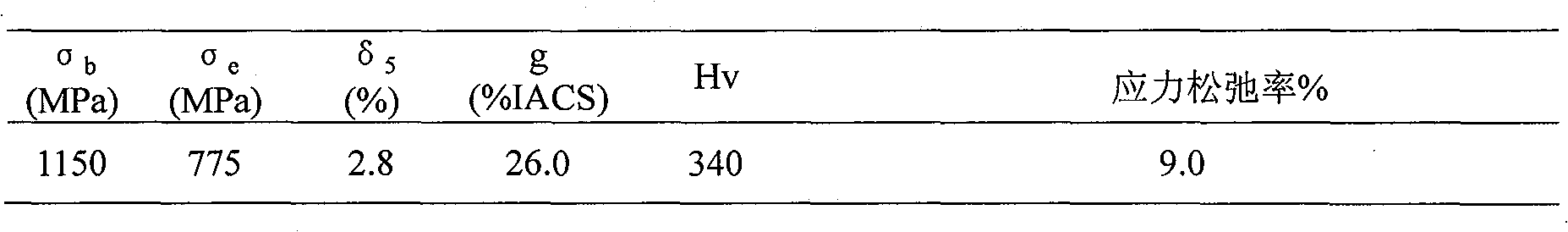

Method for preparing CuNiSiAl elastic copper alloy

InactiveCN101984107AReasonable compositionHigh degree of alloyingSolution treatmentStress relaxation

The invention relates to a method for preparing a CuNiSiAl elastic copper alloy, comprising the steps of fusion casting, homogenizing treatment, hot rolling, solid solution treatment, cold rolling, ageing treatment, secondary cold rolling, etc. The alloy has reasonable components, high alloying degree, simple production process and low production cost and is convenient to operate. Compared with beryllium bronze, the alloy produced by the invention has the advantages of high strength, good conductivity, high stress relaxation resistance and no toxic elements such as beryllium. The CuNiSiAl elastic copper alloy prepared by the invention has ultrahigh strength and high stress relaxation resistance and can be suitable for the high performance conductive elastic devices in the aerospace and microelectronics industries, such as high power hermetically sealed electromagnetic relays, etc.

Owner:CENT SOUTH UNIV +1

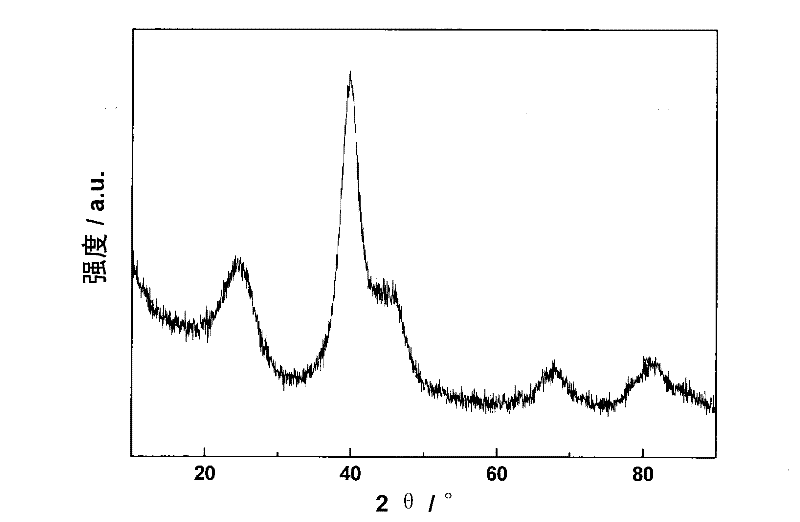

Superfine iron-copper alloy powder and preparation method thereof

The invention relates to superfine iron-copper alloy powder and a preparation method thereof. The superfine iron-copper alloy powder is prepared by using ferric oxalate powder at an industrial raw material stage and cupric oxide powder at an industrial raw material stage as raw materials through high-energy ball milling and hydrogen reduction and has a fisher particle size smaller than 1.0 microns and a oxygen content smaller than or equal to 0.5 percent by weight. The invention has the advantages that grains of the superfine iron-copper alloy powder are thinner, the physical and chemical properties are superior, and the manufacture cost is low.

Owner:惠州市新宏泰科技有限公司

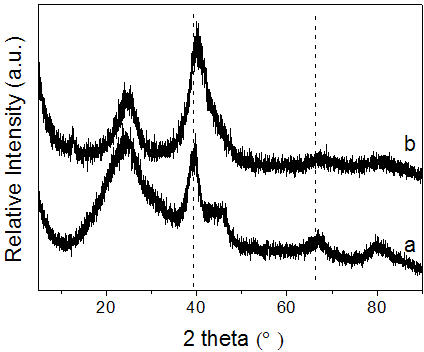

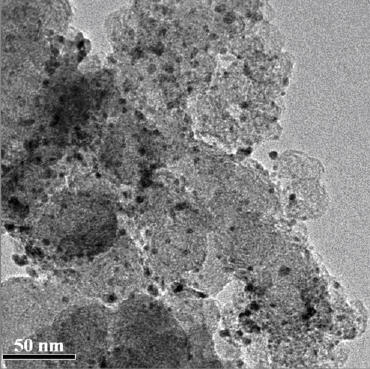

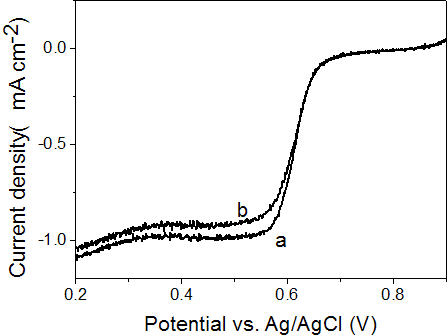

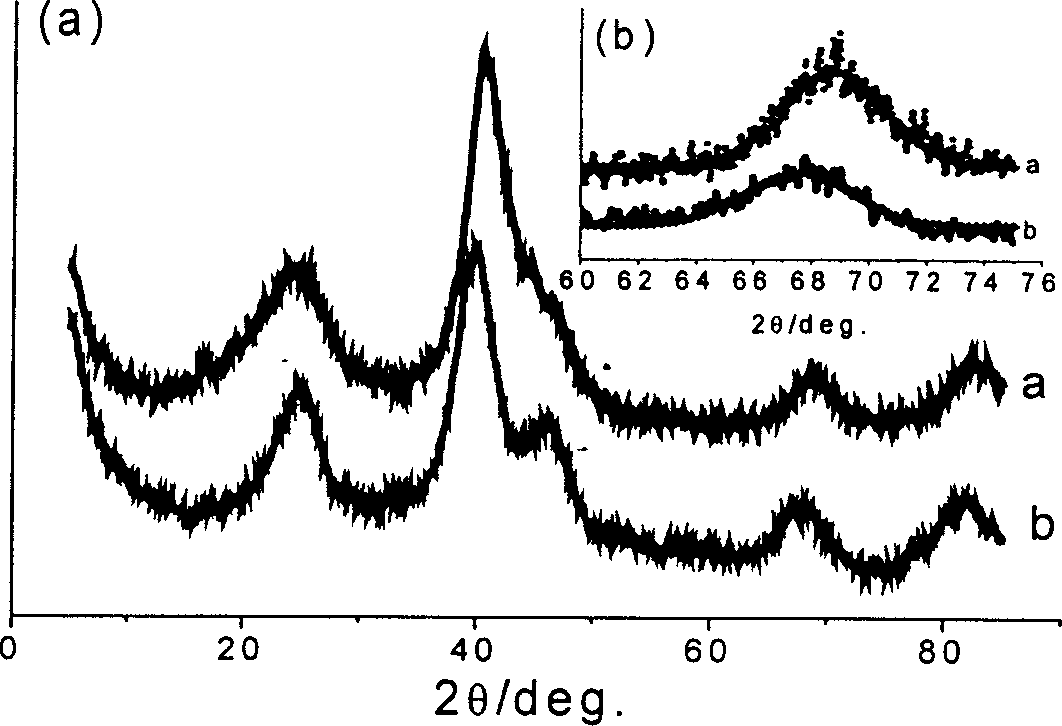

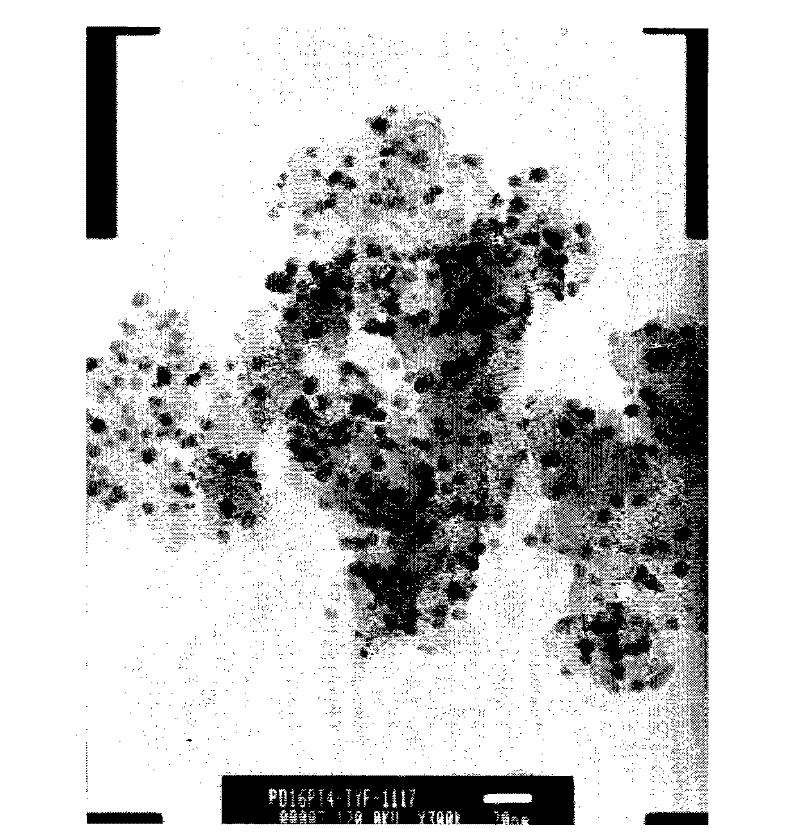

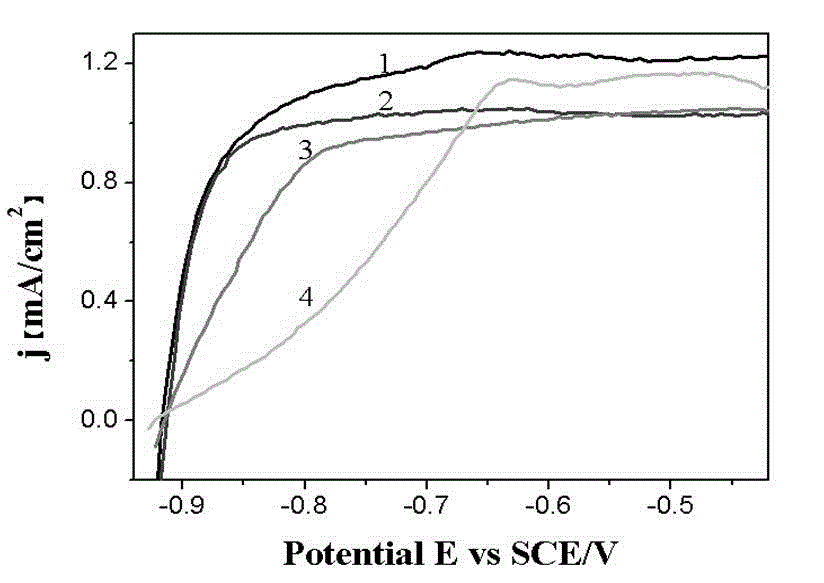

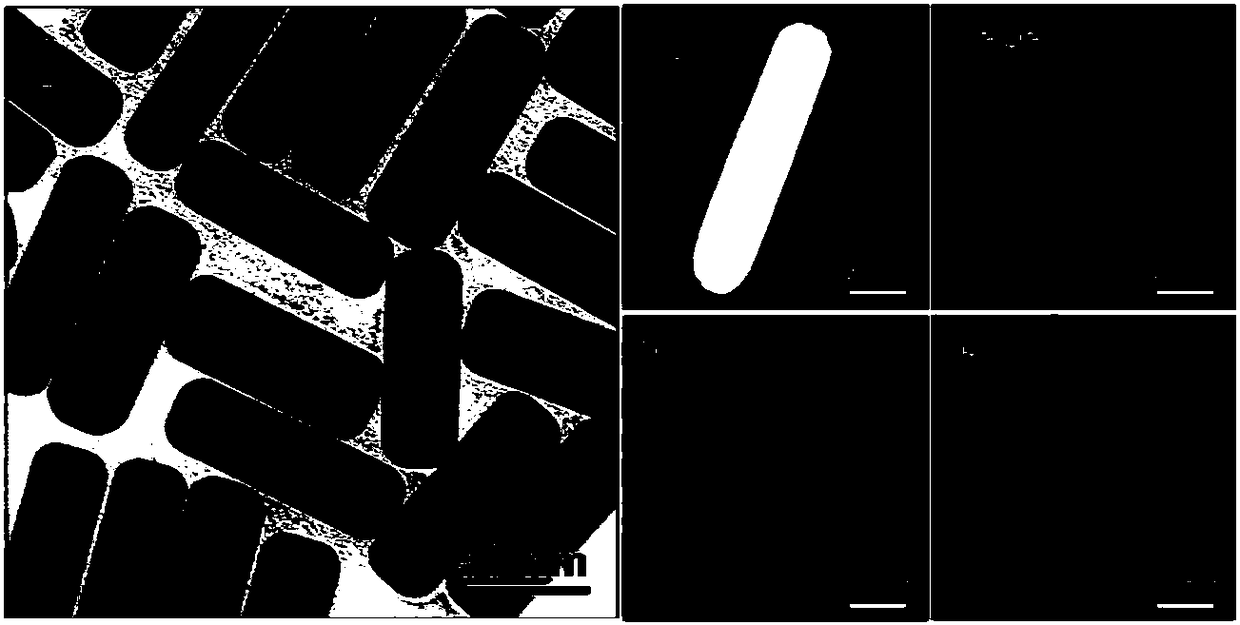

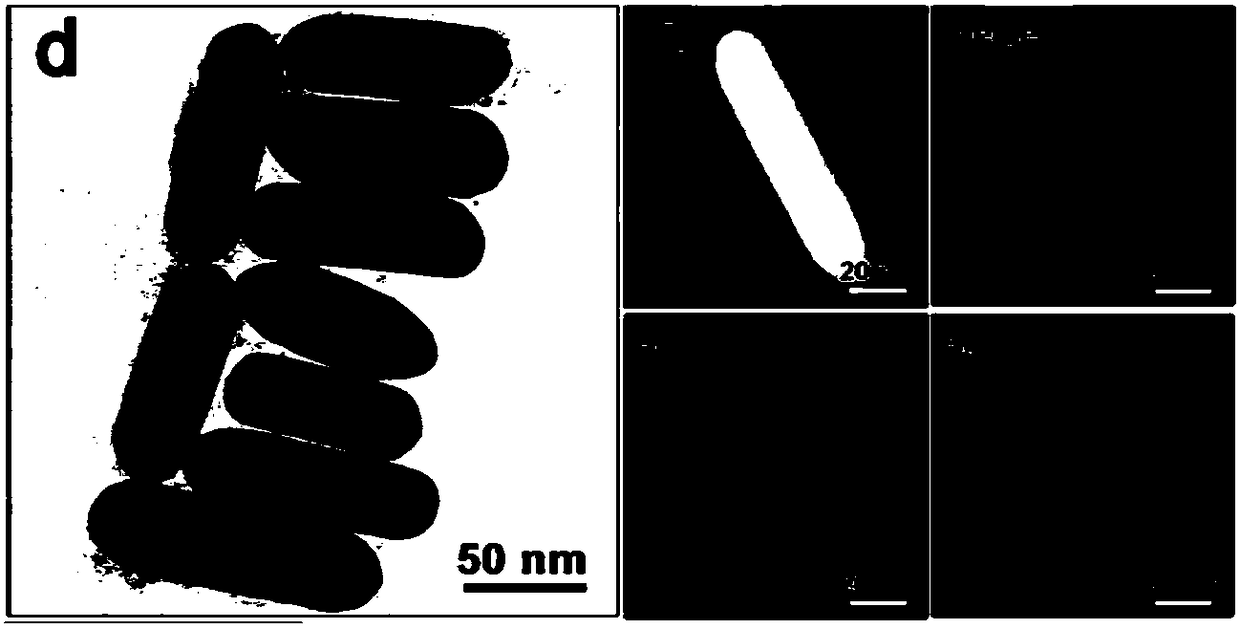

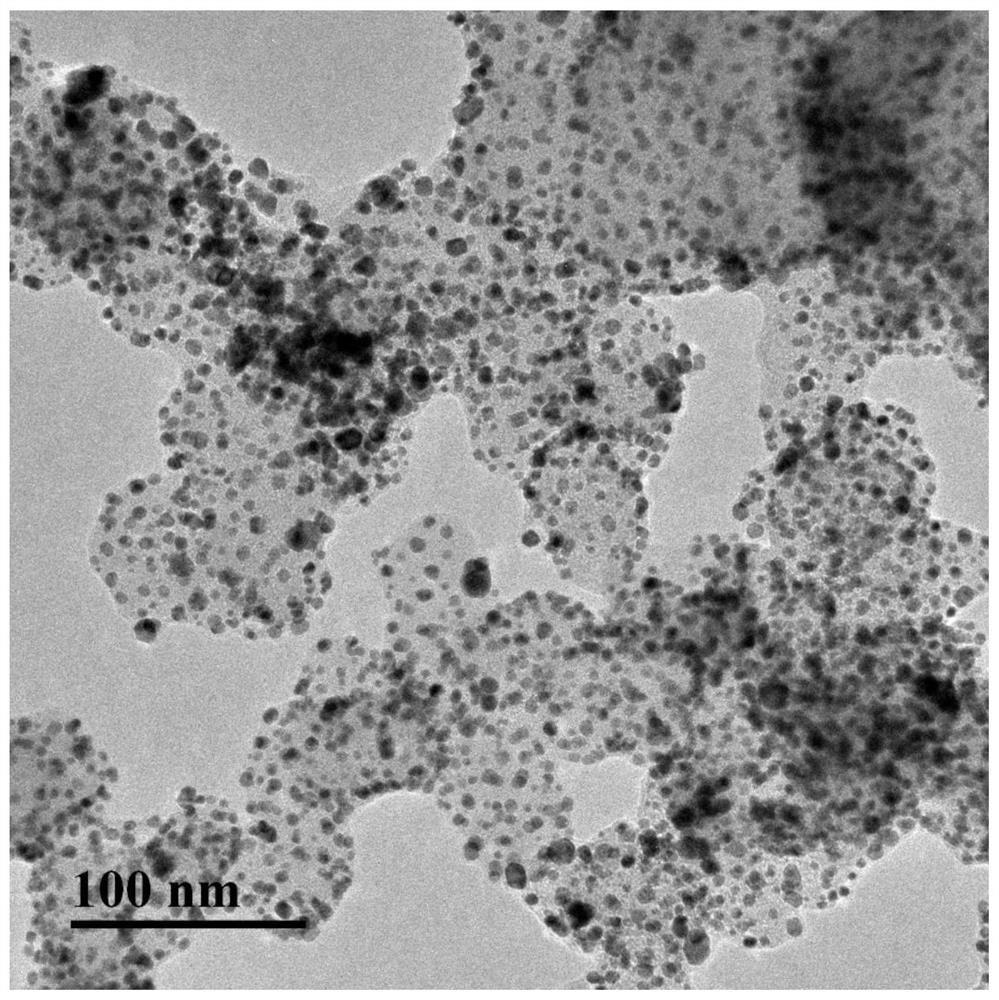

Method for preparing high-alloying carbon-supported PdFe nanocatalyst by in-situ reduction method

ActiveCN102166524AHigh degree of alloyingHigh activityCell electrodesNanotechnologyNanoparticleOxygen

The invention relates to a method for preparing a high-alloying carbon-supported PdFe nanocatalyst by an in-situ reduction method. The method comprises the following steps of: adding a soluble Pd<II> salt to a carbon support suspension, adding an Fe(CN)6<3-> or Fe(CN)6<4-> solution at 30-100 DEG C, controlling the mol ratio of the Pd<II> salt to the Fe(CN)6<3-> to be 1.5:1 or the mol ratio of the Pd<II> salt to the Fe(CN)6<4-> to be 2:1; fully stirring the mixture solution to obtain a component A, namely carbon-supported iron palladium prussiate or ferrous iron palladium prussiate nanoparticles; adding a reducing agent to the component A, fully stirring, reducing the nanoparticles in situ to obtain a component B; and washing with water and drying the component B to obtain the high-alloying carbon-supported PdFe nanocatalyst. The catalyst provided by the invention has obviously improved electrocatalytic performance on oxygen reduction and presents excellent electrocatalytic activity and stability. The preparation method provided by the invention is simple, economical and suitable for industrial large-scale production.

Owner:LIANYUNGANG CCA CHEM CO LTD

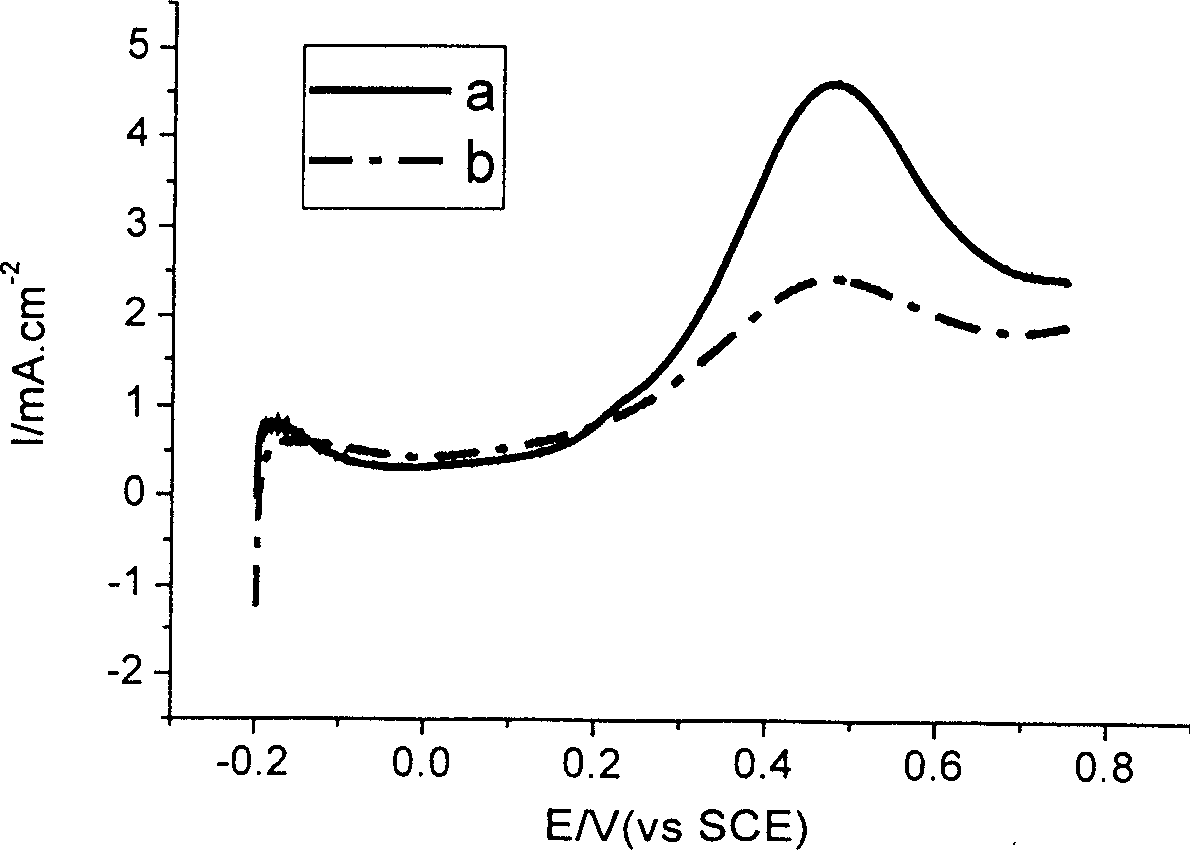

Complex reduction method for preparing highly alloyed Pt-based compound metal nato catalyst

InactiveCN1721062AHigh degree of alloyingExcellent electrocatalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSolventNano catalyst

Complex reduction preparation method for high alloying Pt-based composition nano metal catalyst comprises: inject in precursor: add solution of Pt compound and other metal compound in carbon-carrier; mix and obtain constituent A; the other metals mean Ru, Os, Pd, Rh, Ir or Cr; take liquid-phase reduction at low temperature: add excessive reducer solution and mix, the reduced metal salt particles absorb on carbon carrier, and obtain constituent B; post process: bake and de-solvent to the constituent B, take bath in water and alcohol; dry at 40-150Deg, and obtain carbon carried PtM / C catalyst (M= Ru, Os, Pd, Rh, Ir or Cr). This invention changes electrode potential and reduces Pt and other metal at the same time to achieve the ordered sedimentation of multiple metals and improve alloying degree.

Owner:NANJING NORMAL UNIVERSITY

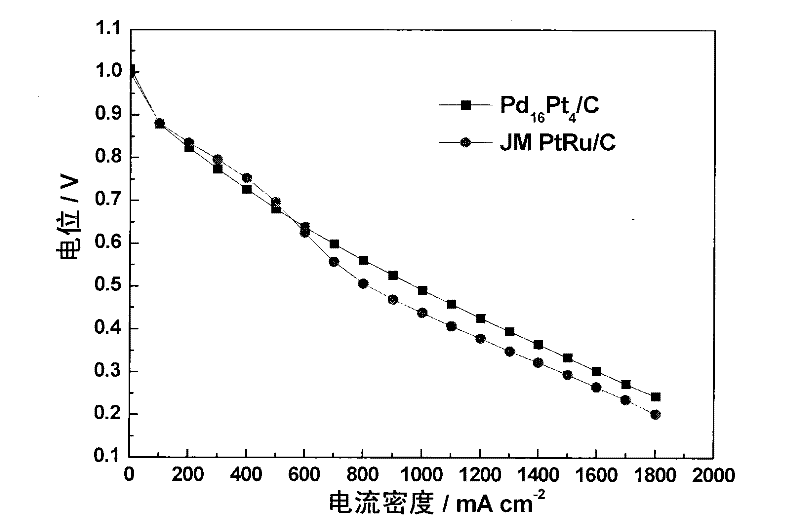

Application of an electrocatalyst in the anode of proton exchange membrane fuel cell

ActiveCN102299346AHigh degree of alloyingRestore fastCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrical conductorAlloy

The application of an electro-catalyst in an anode of a proton exchange membrane fuel cell is the application of the electro-catalyst in the anode of the proton exchange membrane fuel cell. The catalyst has the following characteristics: taking PdxPty alloy and the added one or more types of IIIB, IVB, VB, VIB, VIIB, VIII and IB group as active ingredient, wherein the content of the active ingredients accounts for 5%-70% of the weight of the catalyst, the rest is conductive carrier, the content of the Pd metal accounts for 50%-95% of the total weight of the metal. In the preparation method, a liquid phase reduction method is adopted, the main active ingredient Pd metal precursor is dissolved in a mixture solution of water and alcohol, ammonia water to be used as a complexing agent is added, and then other active ingredient precursors and conductive carriers are added; and the active ingredients can be reduced by a strong reducing agent and then the electro-catalyst is loaded on the conductive conductor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Copper base particle reinforced friction material

InactiveCN100467659CHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

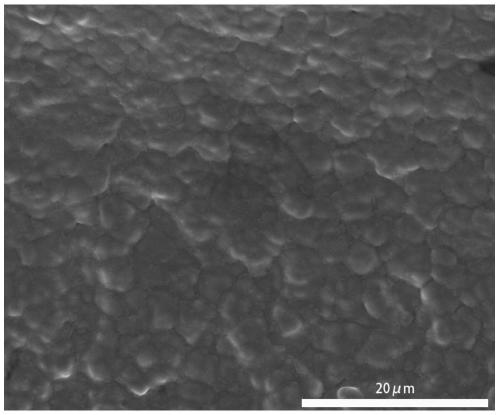

Cr-free dacromet coating prepared through mechanical alloying and preparation method thereof

InactiveCN105802285AHigh degree of alloyingGood flaky degree of powderAnti-corrosive paintsCorrosionZinc

The invention belongs to the field of coatings and particularly relates to a Cr-free dacromet coating prepared through mechanical alloying and a preparation method thereof.The Cr-free dacromet coating is prepared from, by mass, 50-55% of metal alloy slurry, 40-45% of a Cr-free passivation solution and 3-6% of a related auxiliary agent.The metal alloy slurry is prepared from metal alloyed powder and a wetting agent through a ball milling technology.The metal alloyed powder is prepared from sheet zinc powder and sheet aluminum powder through ball milling mechanical alloying.The mass ratio of the zinc powder to the aluminum powder is (5:1)-(9:1).The total mass of the zinc powder and the aluminum powder is the same as the mass of the wetting agent.The obtained Cr-free dacromet coating is more stable in performance and low in porosity, few microscopic cracks and holes of the coating exist, the compactness of the coating is high, the corrosion resistance of the coating is good, and the environmental requirement is met on the premise that the performance requirement is met.

Owner:WUHAN UNIV OF TECH

Iron-copper alloy powder and preparation method thereof

The invention discloses iron-copper alloy powder and a preparation method thereof. The iron-copper alloy powder is prepared from the following raw materials in percentage by mass: 10-30 percent of copper oxide powder and 70-90 percent of iron-copper pre-alloyed powder. The preparation method comprises the following steps: selecting the copper oxide powder prepared through roasting and crushing, uniformly mixing the copper oxide powder and the iron-copper pre-alloyed powder according to a ratio, carrying out active diffusion sintering on the mixture in a reducing atmosphere, crushing and sieving the mixture subjected to sintering, and finally preparing the iron-copper alloy powder. The iron-copper alloy powder is lower in apparent density and good in formability, has the apparent density being 2.5-3.0g / cm<3> and the green strength being 12-15MPa, makes up for the deficiencies in the prior art and broadens the application market.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

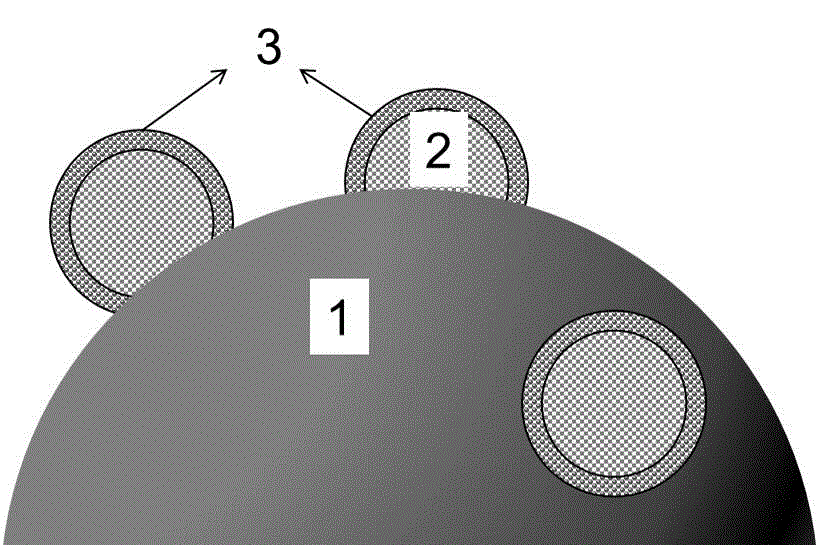

Carbon-loaded core-shell catalyst with nano copper nickel alloy core-precious metal shell and preparation method of catalyst

InactiveCN104549364AFacilitates selective depositionPrevent corrosion and peeling offCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrolysisNickel salt

The invention provides a carbon-loaded core-shell catalyst with nano copper nickel alloy core-precious metal shell and a preparation method of the catalyst, belonging to the field of fuel cells and energy-saving electrolysis. A conductive carbon material serves as a carrier, a base metal CuNi alloy with corrosion resistance and high alloying degree serves as a core, a precious metal (namely an alloy of one or two in M, Pt, Pd, Ru, Ir and Rh) serves as a shell layer, so that the carbon-loaded core-shell metal catalyst is prepared. The method comprises the following preparation steps: performing heat treatment on carbon dipped with copper and nickel salt at the temperature of 300-1000 DEG C under a reducing atmosphere, thereby obtaining CuNi / C; performing reflux reduction on CuNi / C in ethylene glycol containing the precious metal salt and PVP, thereby obtaining the CuNi@M / C core-shell catalyst. The alloying degree and corrosion resistance of the core CuNi are improved, the CuNi alloy surface is beneficial to precious metal selective deposition, and the precious metals in finite quantity are deposited on the CuNi core in a small layer number. According to the catalyst prepared by the method, the loading capacity of precious metals is reduced from 20 percent of the traditional catalyst to 5-10 percent, the electrocatalytic activity is not lowered, and the stability is high.

Owner:BEIJING UNIV OF CHEM TECH

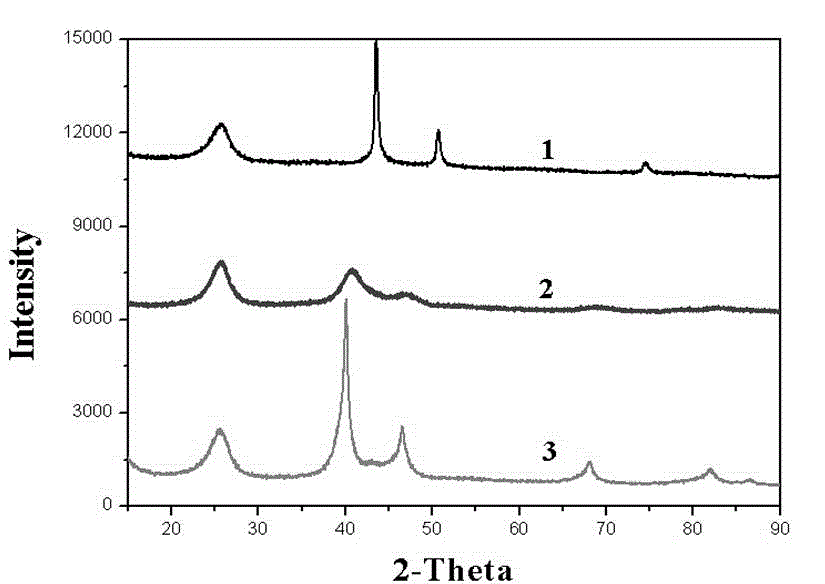

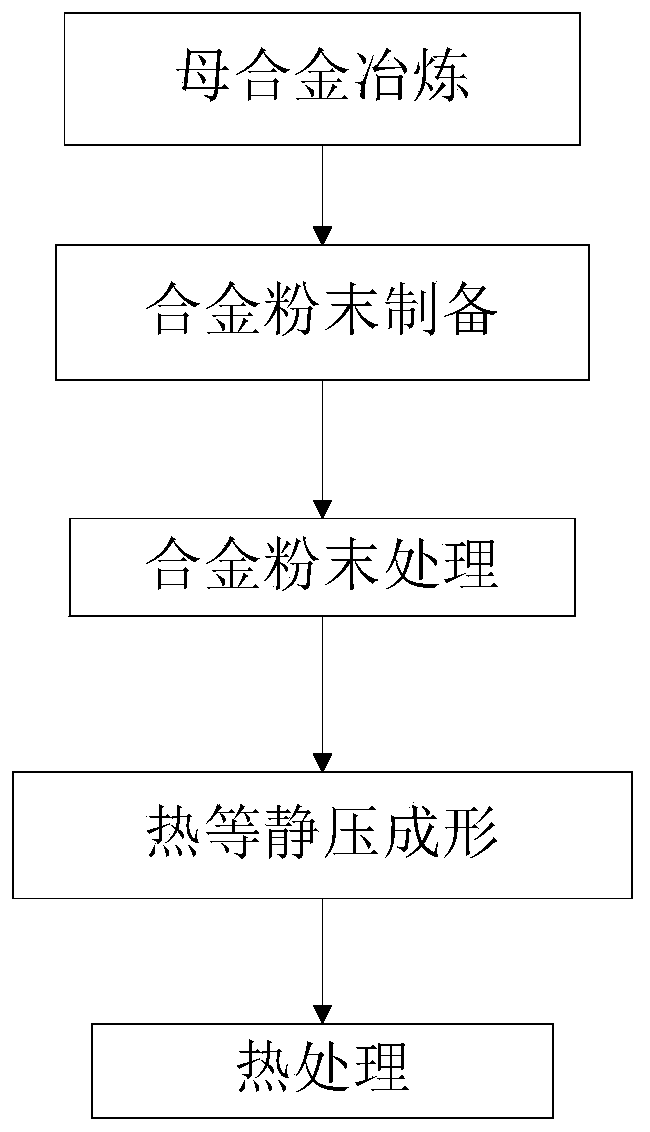

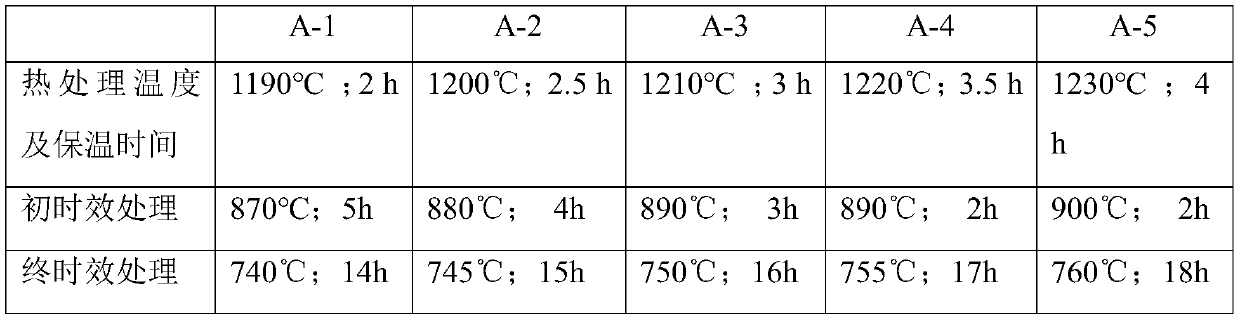

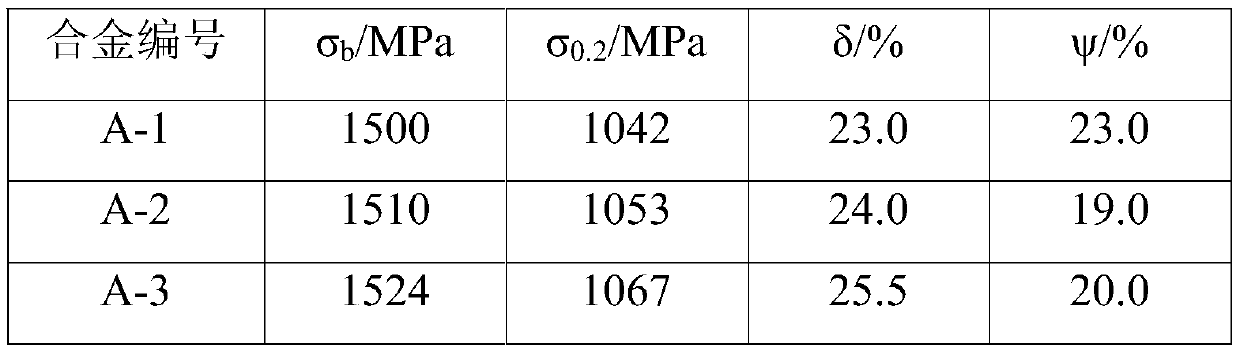

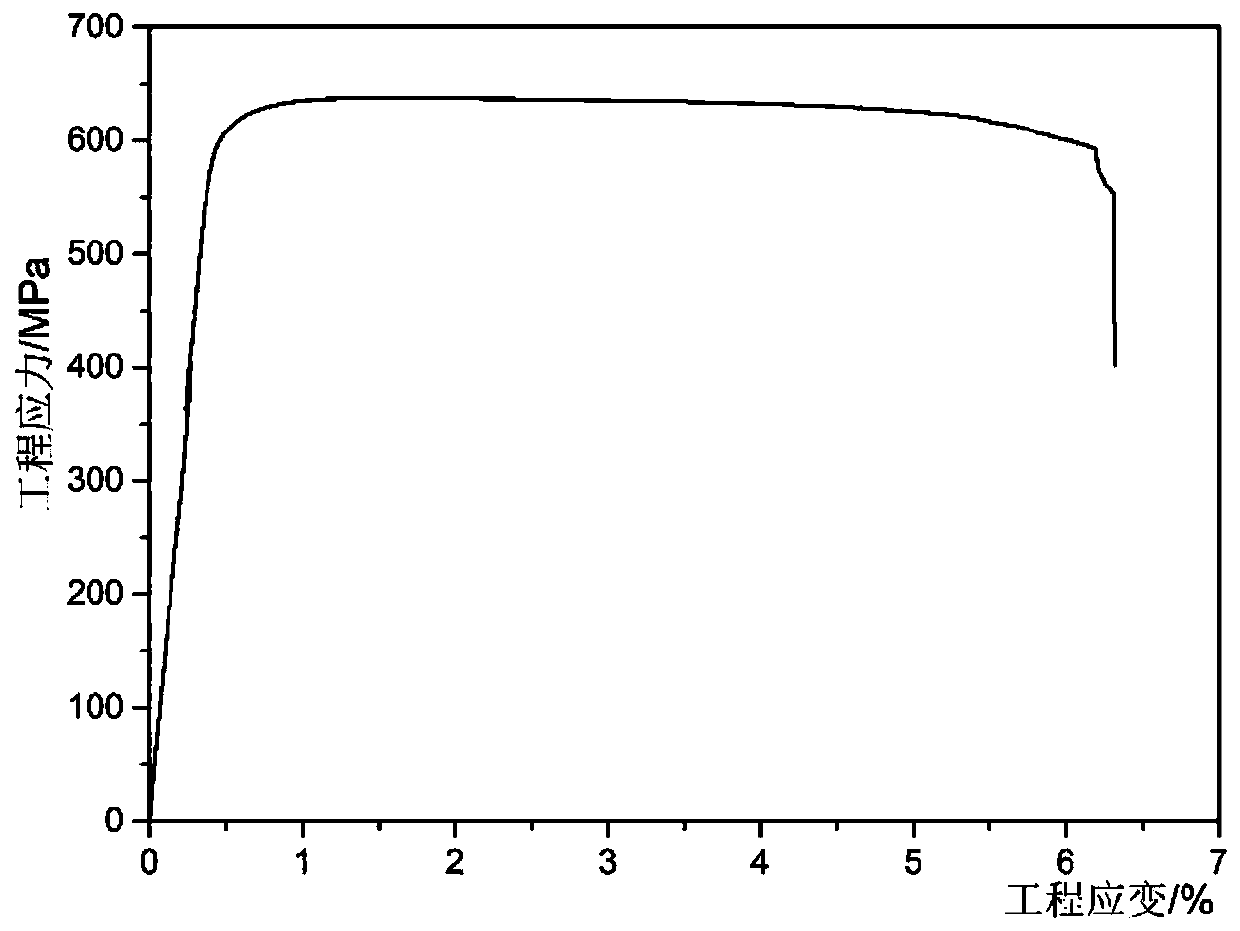

Nickel base powder high-temperature alloy with high tensile strength and preparation method thereof

ActiveCN110205523AImprove high temperature durabilityImprove acceleration performanceUltimate tensile strengthTurbine

The invention relates to a nickel base powder high-temperature alloy with high tensile strength and a preparation method thereof, belongs to the technical field of high-temperature alloys, and solvesthe technical problems of strict requirements on high-temperature alloy materials by such hot end parts as turbine discs in traditional engines and incapability of meeting the performance requirementsby traditional high-temperature alloy materials. The powder high-temperature alloy comprises the following chemical components in percentage by mass: 0.04-0.08 of C, 17.0-19.0 of Co, 11.0-13.0 of Cr,6.0-6.7 of W, 4.3-5.0 of Mo, 4.9-5.4 of Al, 1.5-1.9 of Ti, 2.5-2.9 of Nb, 0.2-0.5 of Hf, B less than 0.03, Zr less than 0.03, Mg less than 0.005, Ce less than 0.002, and the balance of Ni and other inevitable impurities. The powder high-temperature alloy achieves high tensile strength and excellent high-temperature creep resistance and high-temperature endurance, and is mainly used for preparingsuch hot end parts as aeroengine turbine discs.

Owner:BEIJING CISRI GAONA TECH

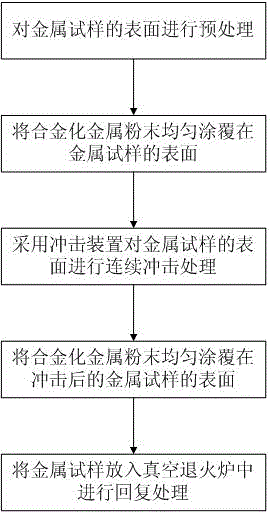

Metal surface acute deformation alloying method

InactiveCN105803449AIncreasing the thicknessHigh degree of alloyingPressure inorganic powder coatingPunchingPre treatment

The invention discloses a metal surface acute deformation alloying method. The metal surface acute deformation alloying method is characterized by comprising the following steps: (1) the surface of a metal sample is pretreated; (2) alloying metal powder is uniformly applied on the surface of the metal sample; (3) an impact device is adopted to continuously impact the surface of the metal sample; (4) the alloying metal powder is uniformly applied on the impacted surface of the metal sample; and (5) the metal sample is put in a vacuum annealing furnace for return treatment. The metal surface acute deformation alloying method is simple in process, is controllable in impact force in the punching process, can form higher residual compressive stress on the surface, facilitates prevention of cracks, and prolongs the service life.

Owner:NANJING INST OF TECH +1

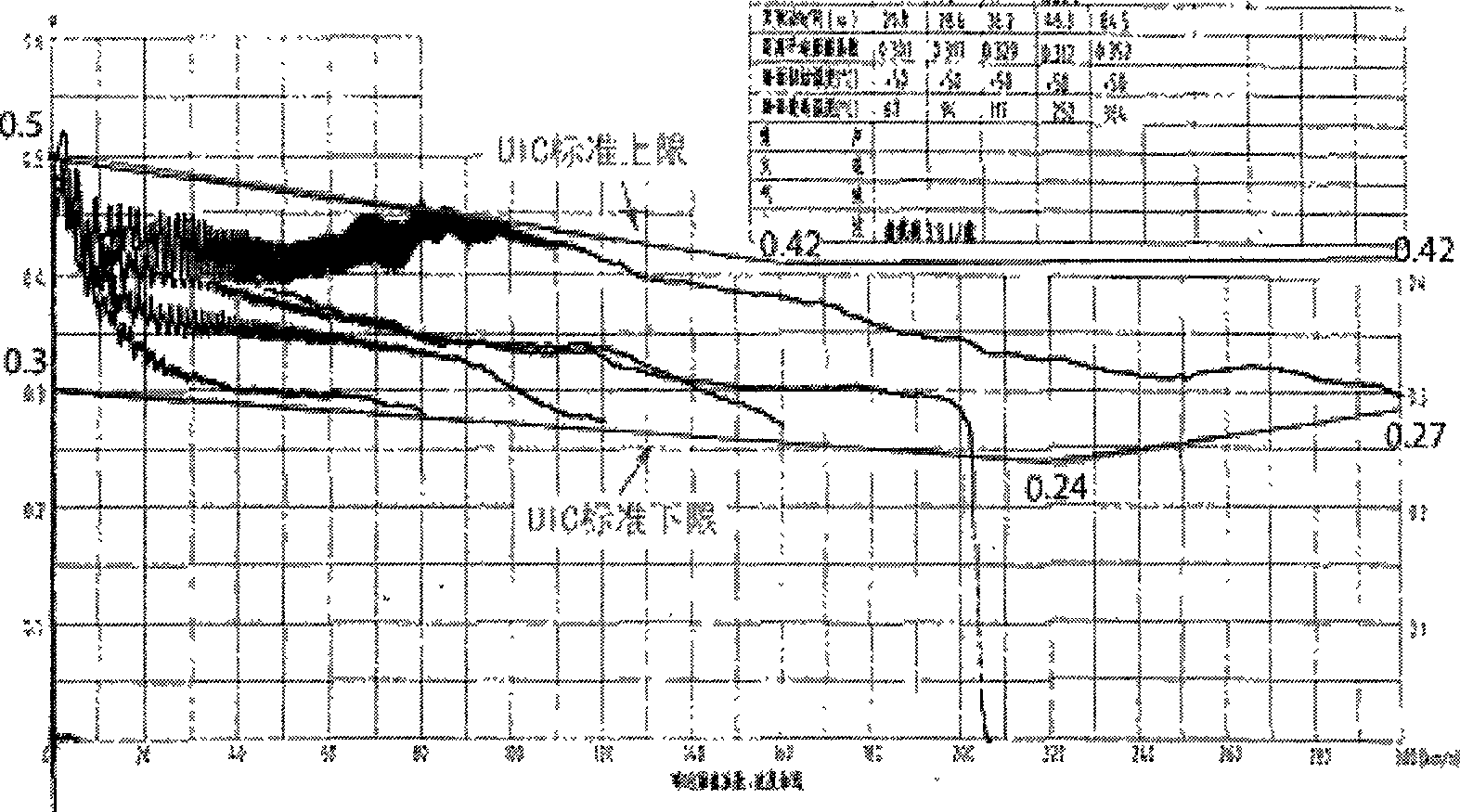

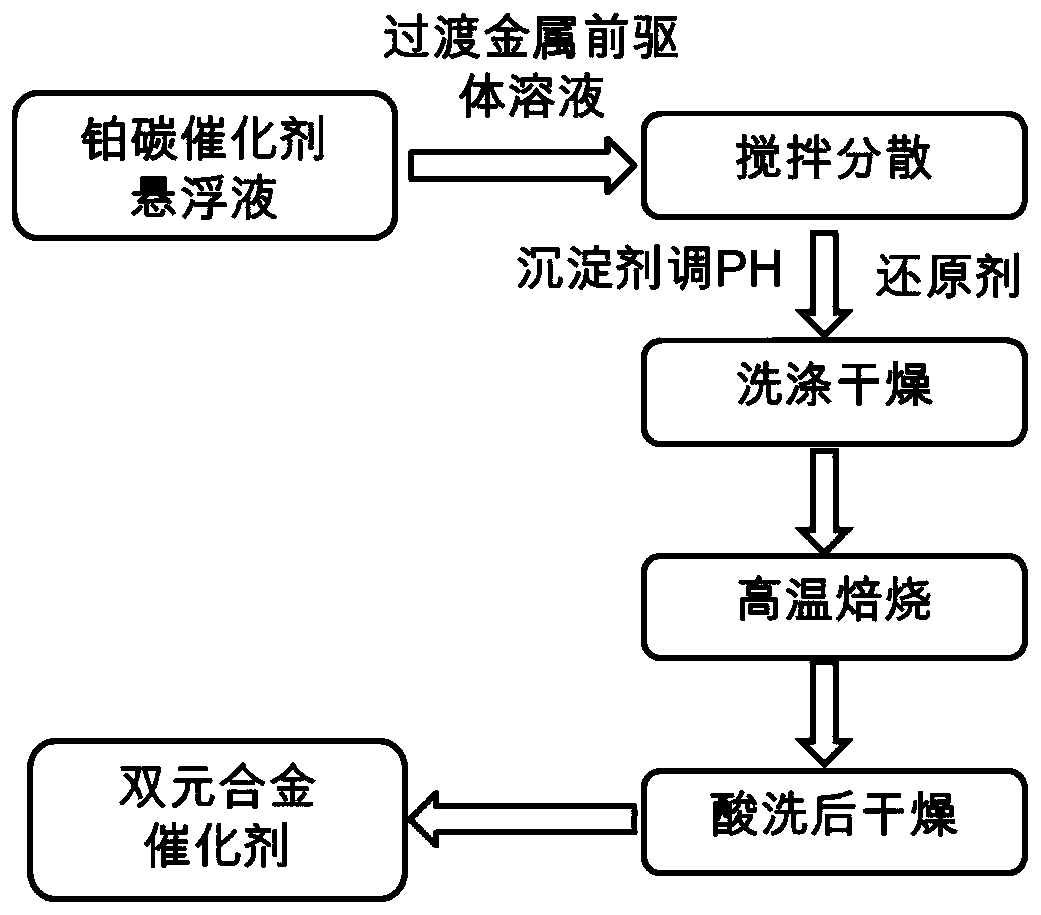

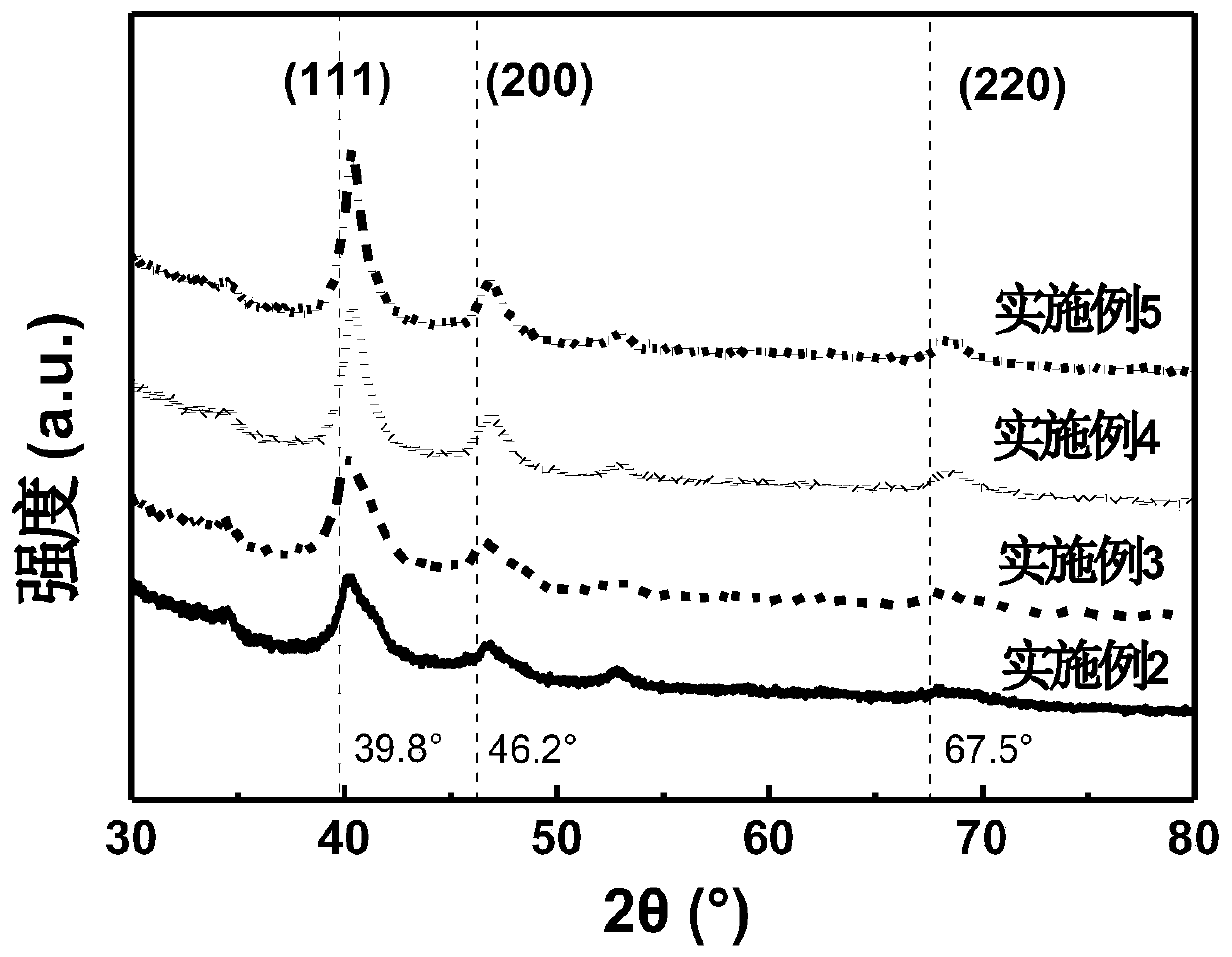

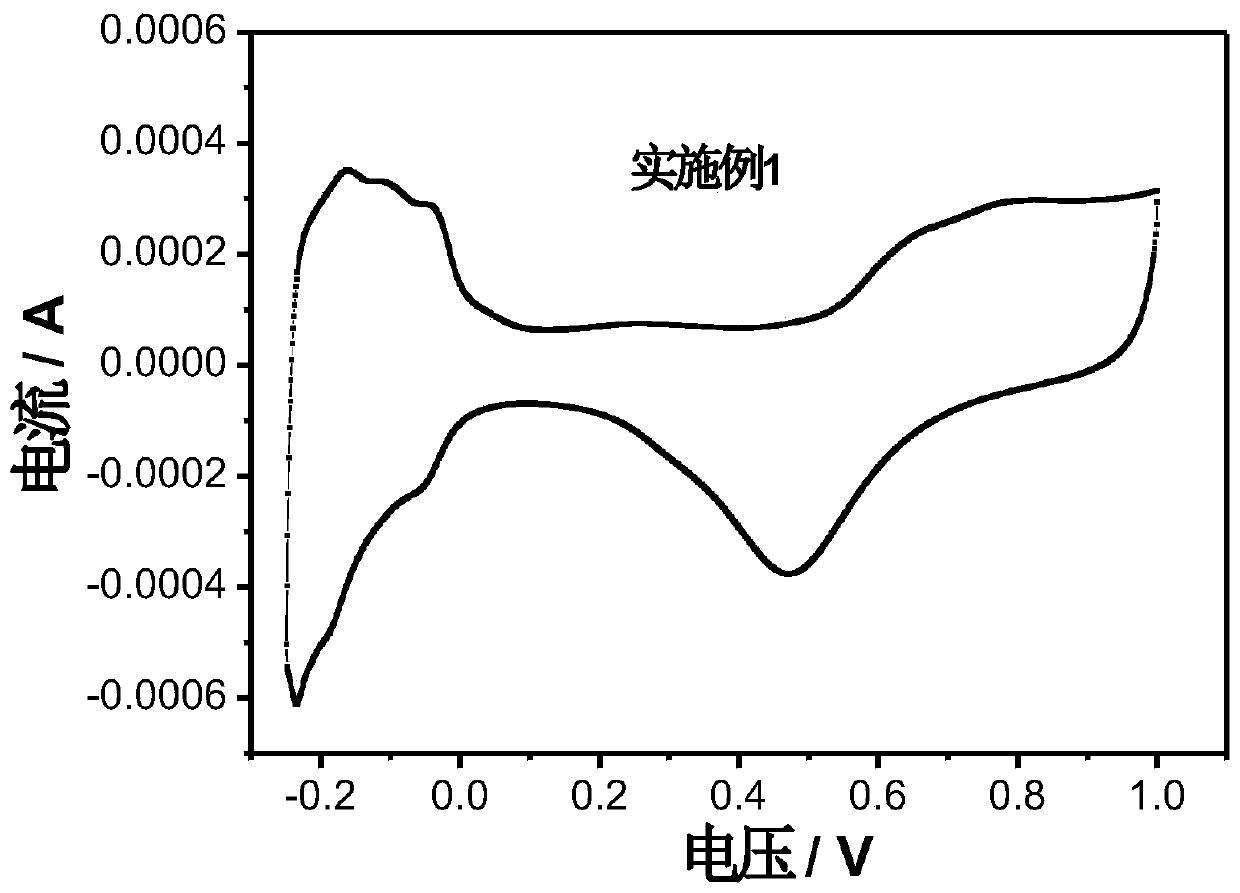

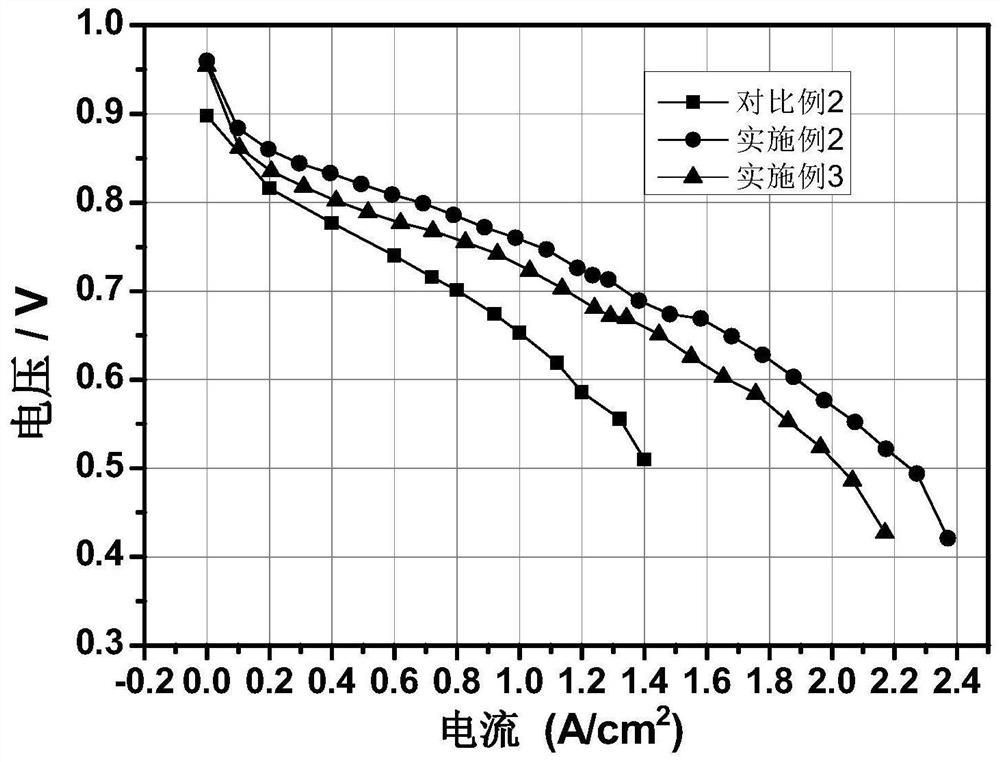

High-temperature preparation method of proton exchange membrane fuel cell binary alloy catalyst

PendingCN111589454ALow priceReduce dosageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention belongs to the technical field of new energy materials and application, and particularly relates to a high-temperature preparation method of a proton exchange membrane fuel cell binary alloy catalyst. The preparation method comprises the following steps: (1) mixing and stirring a transition metal precursor solution and a platinum-carbon catalyst suspension to fully disperse; (2) adding a precipitant solution and a reducing agent solution into a mixed solution dispersed in step (1), adjusting the pH value of the mixed solution to 9-13, centrifuging or filter-pressing and washing for multiple times after complete precipitation, and fully drying to obtain catalyst precursor powder; and (3) roasting the catalyst precursor powder at high temperature, cooling, pickling, and dryingto obtain catalyst powder. The transition metal element and the platinum catalyst are used for forming the binary alloy catalyst, the cost of the catalyst can be reduced, after the transition metal and platinum form an alloy, crystal lattices of platinum shrink, and the adsorption energy of the surface to oxygen is reduced, so the catalytic activity of the oxygen reduction reaction is improved.

Owner:WUXI WEIFU HIGH TECH CO LTD

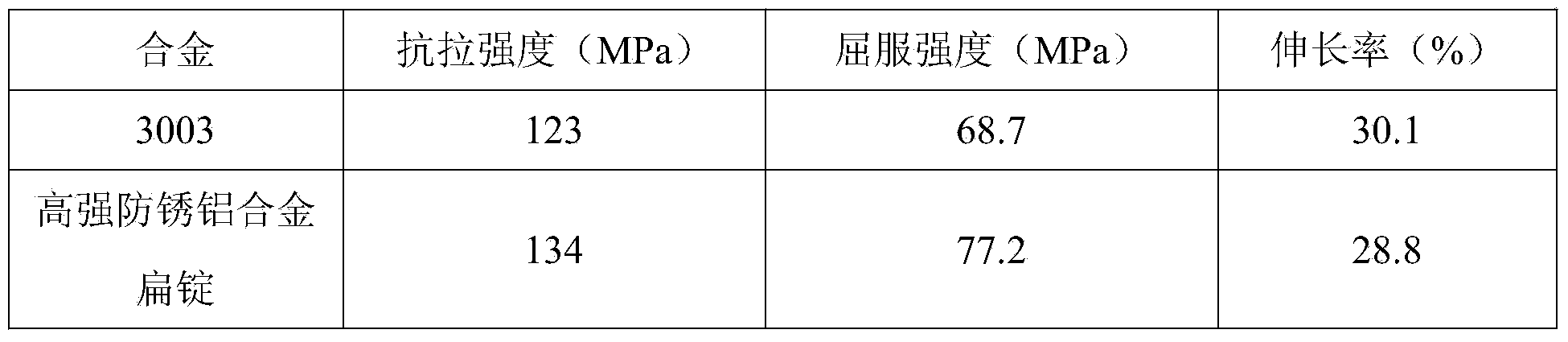

Manufacturing method of high-strength antirust aluminum alloy slab ingot

ActiveCN104264015AIncrease productivityIncrease the degree of diffusionIngotUltimate tensile strength

The invention discloses a manufacturing method of a high-strength antirust aluminum alloy slab ingot and relates to a manufacturing method of an aluminum alloy slab ingot. The manufacturing method solves the problems that a core of an existing composite material is mainly a 3003 alloy, but the 3003 alloy hardly meets the requirements of the current market on the high-performance composite material due to low alloying degree and low strength. The method comprises the following steps: 1, melting, and 2, forming, so that the high-strength antirust aluminum alloy slab ingot is obtained. The manufacturing method is used for manufacturing the high-strength antirust aluminum alloy slab ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

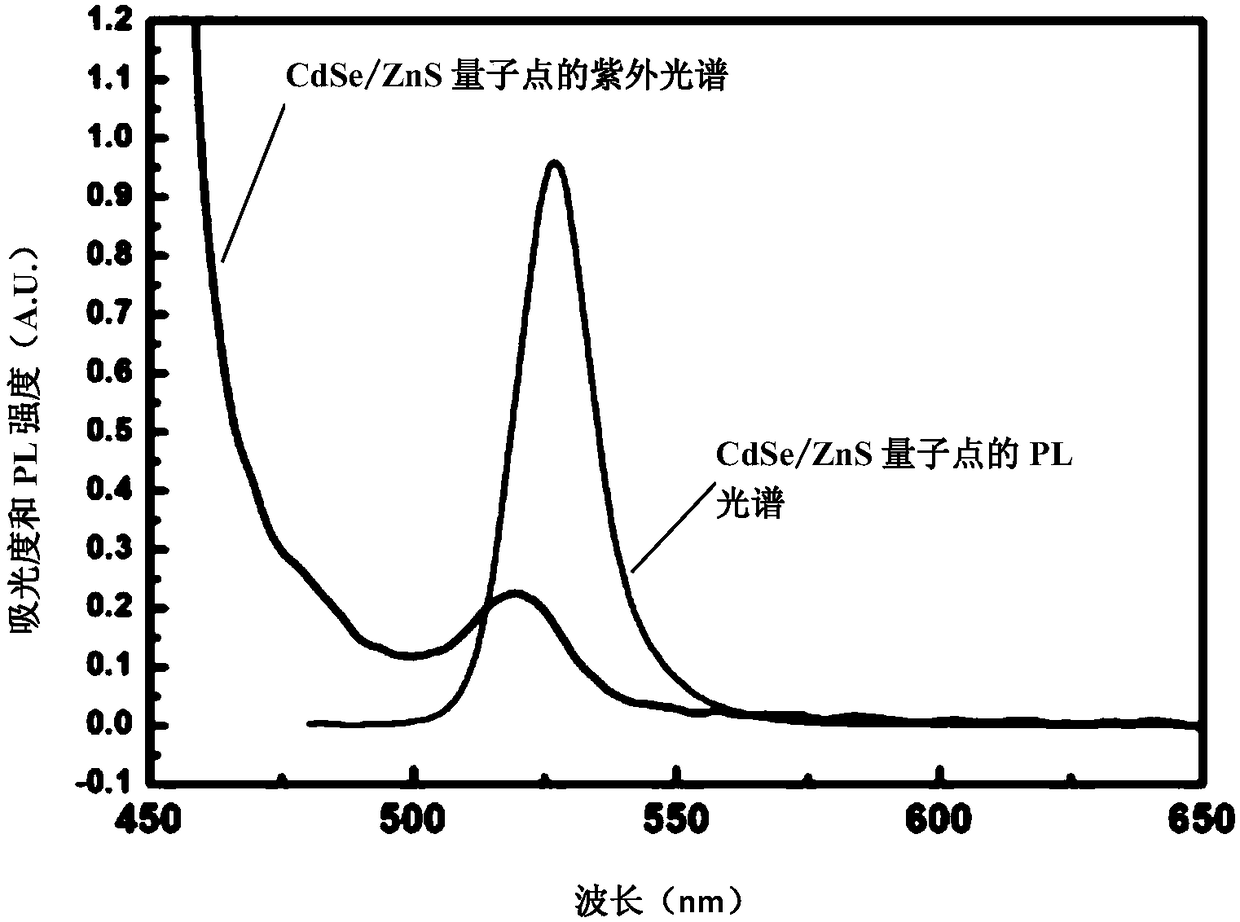

Quantum dot synthesis method

ActiveCN108587628AUniform growthHigh degree of alloyingMaterial nanotechnologyNanoopticsSynthesis methodsSulfur

The invention discloses a quantum dot synthesis method. The synthesis method comprises the steps that a CdZnSe quantum dot serving as a nucleus is provided; a mixed reaction system containing the CdZnSe quantum dot, a cadmium source, a zinc source and a sulfur source reacts, and a CdZnS transition layer is formed on the CdZnSe quantum dot, wherein the zinc source comprises a precursor obtained byshort chain zinc fatty acid and amine which react under activation of a phosphine source. Accordingly, by means of the zinc source high in activity, the phenomenon that CdS is generated simply, so that the quantum dot efficiency is low can be avoided, the activity difference among Cd, Zn and S can be reduced, the quantum dot internal defects brought by the lattice parameter difference are reduced,and the quantum dot efficiency is improved. The obtained quantum dots are high in absorbance, high in luminous efficiency, uniform in size, good in monodispersion and narrow in half peak width.

Owner:苏州一佳一生物科技有限公司

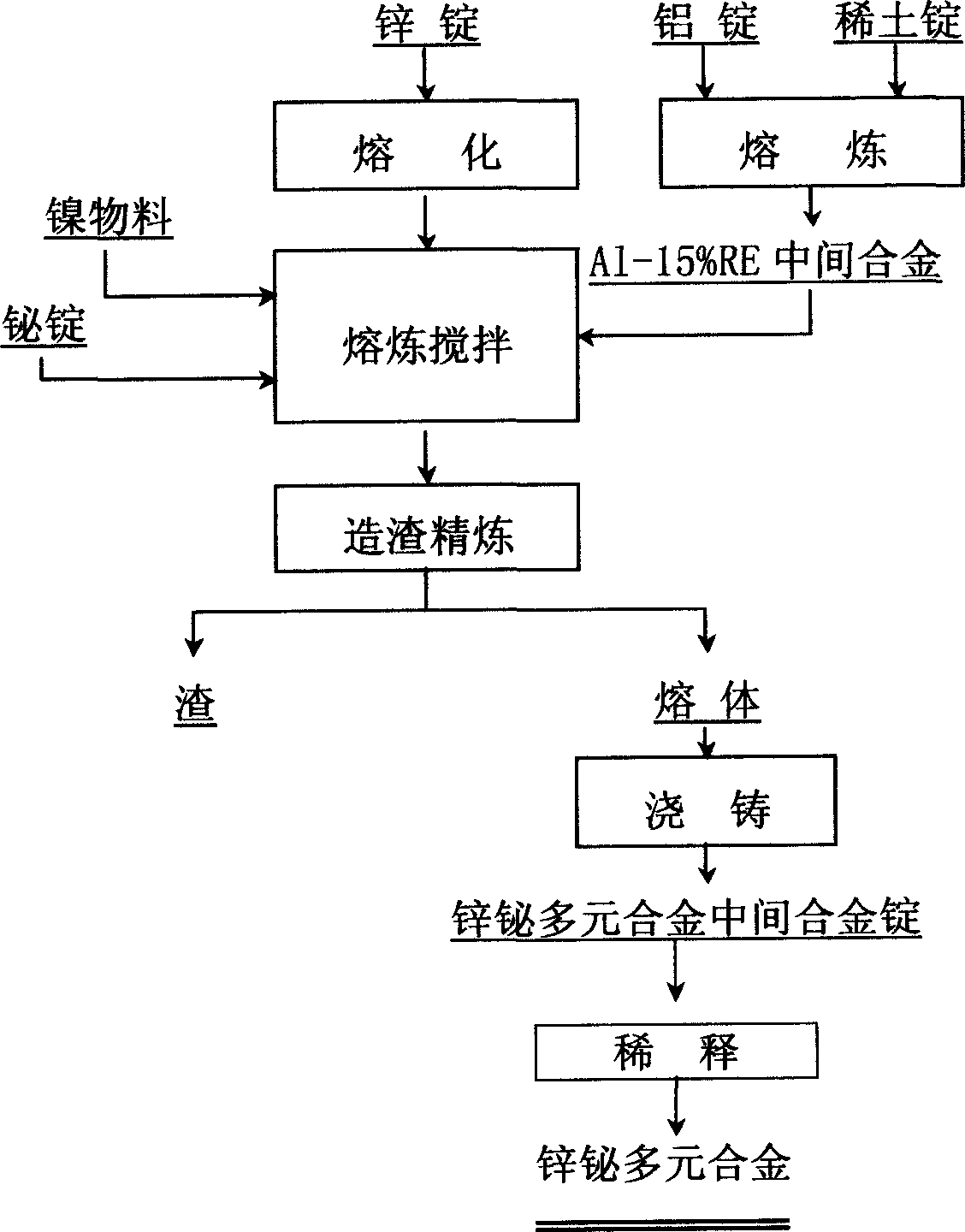

Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

The present invention relates to production of zinc alloy. The technological scheme of producing Zn-Bi alloy includes first compounding intermediate alloy with alloy ingot and RE ingot at the smelting temperature of 750-850 deg.c, subsequent smelting zinc ingot at 550-650 deg.c and adding nickel material and final adding bismuth ingot to form the polynary Zn-Bi alloy. The said process can avoid the burning loss of RE metal to avoid waste, may have certain amount of Al-RE intermediate alloy added to form different alloys, and has smelting and stirring time over 15 min to reach effect of homogeneous mixing. The present invention uses preferably inducing furnace as smelting apparatus and the product has stable and homogeneous alloy element components, high alloy element utilization and clean and environment friendly production process.

Owner:株洲冶炼集团有限责任公司

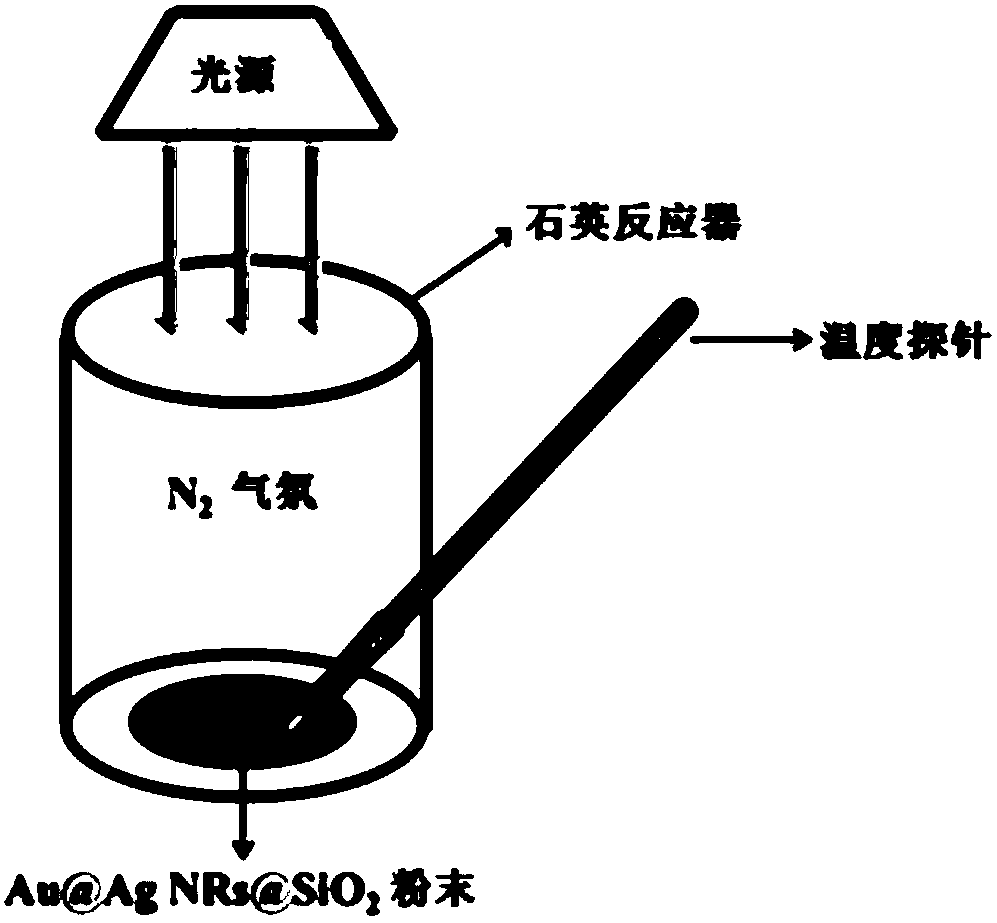

Method for preparing alloy nanoparticle

ActiveCN108568518AEasy to operateMild conditionsTransportation and packagingMetal-working apparatusMetal alloyCore shell

The invention provides a method for preparing an alloy nanoparticle. The method utilizes good SPR properties and local heating ability of precious metal materials and heat insulation and original shape maintaining functions of SiO2 nano layers, so that different metal atoms in a multi-metal structure of a core-shell structure migrate to form the multi-metal alloy nanoparticle with constant morphology. The method uses sunlight or simulated sunlight as a light source without the need for other energy sources, the method is green, environmentally friendly and simple and quick to operate, completely alloyed nanoparticles of various morphologies can be prepared, and the prepared alloy nanoparticle has good dispersion performance, uniform size and excellent stability.

Owner:SUZHOU UNIV

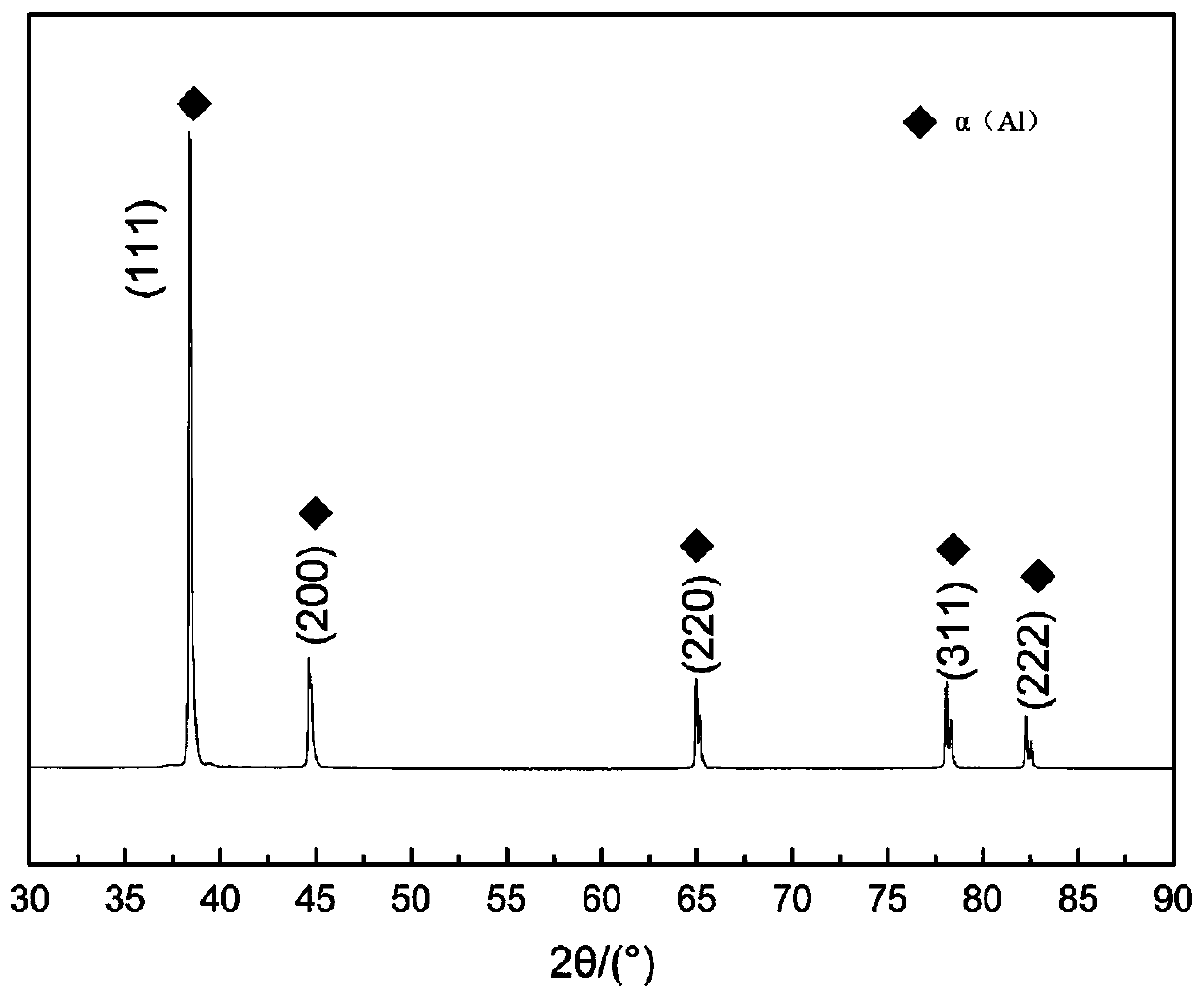

Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy and preparation method thereof

The invention relates to an Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy which is prepared from the following components in percentage by mass: 10-12 percent of Zn, 2-3 percent of Mg, 0.5-1.5 percent of Cu, smaller than 0.2 percent of a total amount of Fe and Si, smaller than 0.2 percent of impurity and the balance of Al. A preparation method for the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy comprises the following steps of step 1, adding industrial pure aluminum in a crucible resistance furnace for heating and complete melting according to the mass percentage, and then sequentially adding a Cu source, a Zn source and an Mg source until all the materials are thoroughly molten; step 2, performing stirring, refining with degassing and slag skimming; step 3, spraying a prepared metal liquid to a copper roller to prepare a strip; step 4, performing cold isostatic pressing on the strip obtained through rapid solidification to obtain a cold-pressed blank; step 5, performing hot extrusion on the cold-pressed blank to obtain an extruded rod; and step 6, finally, performing heat treatment on the extruded rod. By adopting the technical method provided by the invention, the process flow is simplified, the material utilization rate is high, and the Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy has high strength and shaping and has a good application prospect in the fields of aerospace, automobiles and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

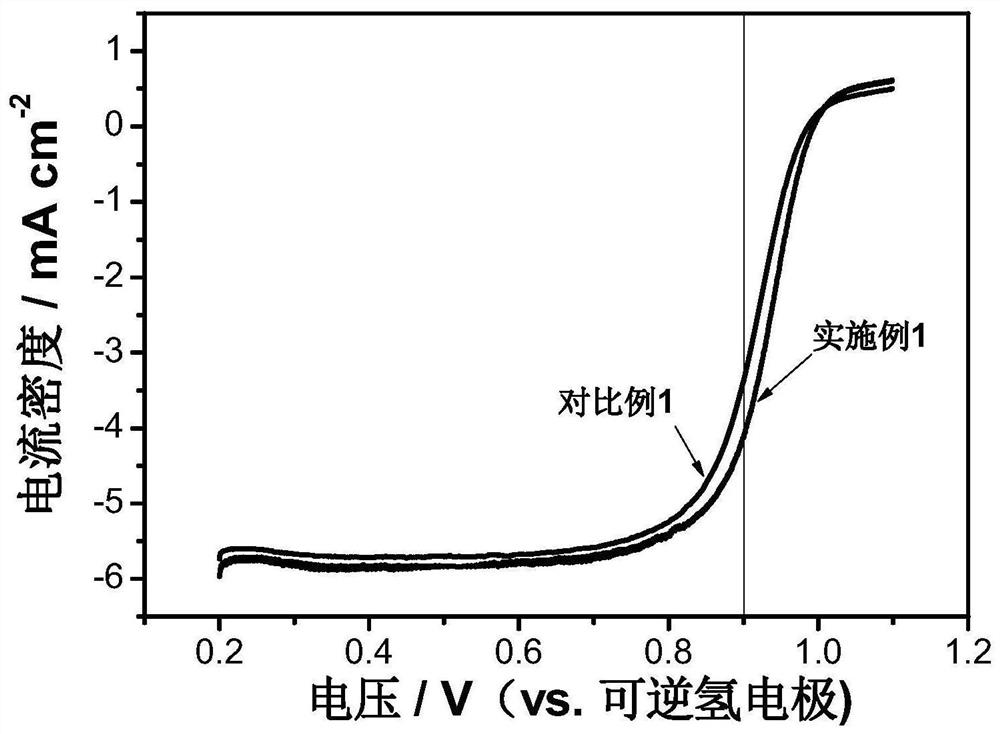

Platinum-cobalt alloy carbon catalyst for proton exchange membrane fuel cell and preparation method of platinum-cobalt alloy carbon catalyst

ActiveCN113540481AThe preparation process is highly operableEase of commercializationCell electrodesSolid electrolyte fuel cellsPtru catalystMetallurgy

The invention belongs to the technical field of fuel cells, and particularly relates to a platinum-cobalt alloy carbon catalyst for a proton exchange membrane fuel cell and a preparation method of the platinum-cobalt alloy carbon catalyst. The preparation method of the platinum-cobalt alloy carbon catalyst comprises a pretreatment process and a reaction process. The obtained crude platinum-cobalt alloy catalyst is subjected to post-treatment, a post-treatment solution A is added into the crude platinum-cobalt alloy catalyst during post-treatment, after treatment is conducted for 0.5-200 h at the temperature of 0-80 DEG C, part of a solvent is removed, then a post-treatment solution B is added, after continuous treatment is conducted for 0.5-200 h at the temperature of 0-80 DEG C, washing is conducted, and drying at 20-85 DEG C is conducted to obtain the platinum-cobalt alloy carbon catalyst. According to the prepared crude platinum-cobalt alloy catalyst, unalloyed elements and impurities on the surface of the catalyst can be removed through post-treatment, raw materials used in the preparation process are environmentally friendly, the preparation technology is high in operability, and commercialization is easy to achieve; and the prepared platinum-cobalt alloy catalyst is excellent in catalytic activity, good in oxygen reduction performance and high in power density when applied to a single battery.

Owner:WUXI WEIFU HIGH TECH CO LTD

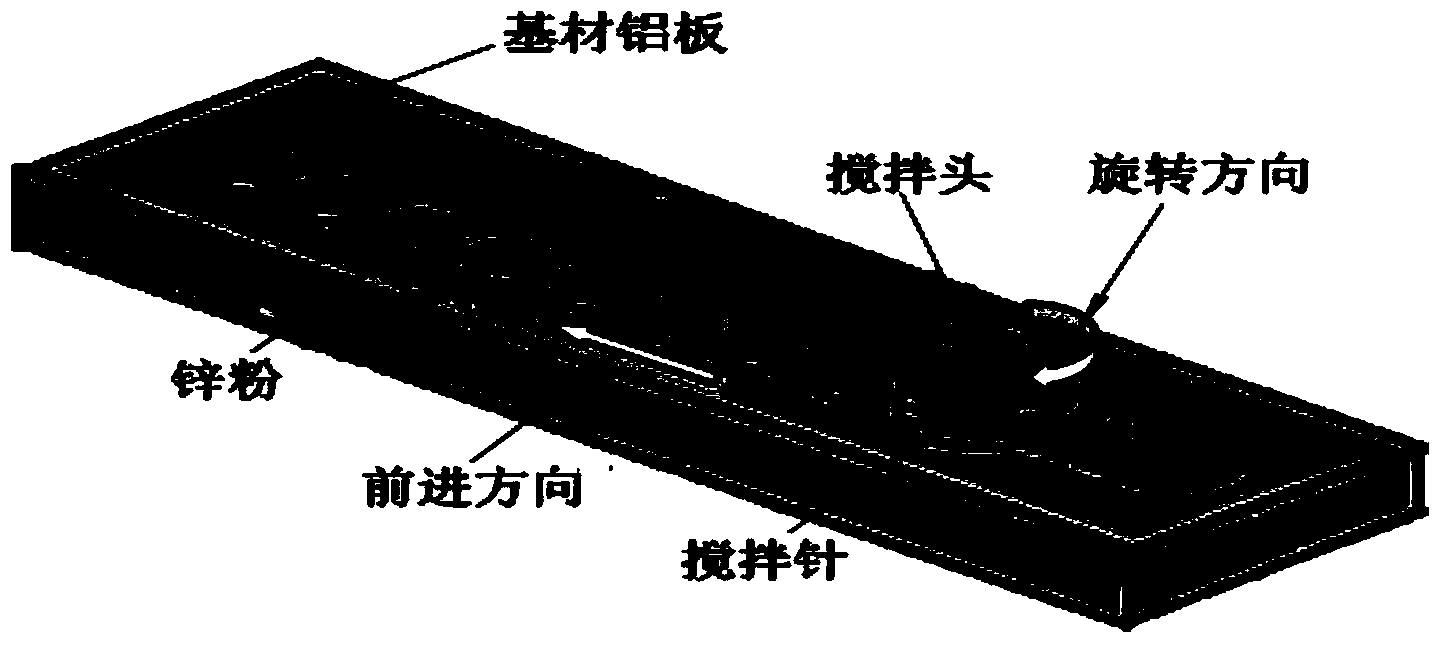

Al-Zn composite material and solid-state alloying manufacturing method thereof

The invention discloses an Al-Zn composite material which comprises an Al base body and Al-Zn alloy blocks distributed on the Al base body. The Al-Zn alloy blocks are distributed in the Al base body in an array. The embodiment of the invention further discloses an Al-Zn composite material solid-state alloying manufacturing method. Firstly, an aluminum sheet is selected, and rows of small holes are formed in the aluminum sheet, then the small holes are filled with zinc powder and compacted, and finally the small holes filled with the zinc powder and the peripheral area of the small holes are mechanically mixed and rubbed. The Al-Zn alloy blocks in the Al-Zn composite material is high in alloying degree, the Al-Zn alloy blocks and the Al base body are tightly combined, and the using requirement of special environments can be met. The mixing and rubbing method is used for processing the Al-Zn composite material, and the alloy blocks can be directly manufactured under the solid phase condition. The technology is simple, the requirement for equipment is low, and the obtained alloy organizational structure is compact and fine in crystalline grain.

Owner:CHONGQING UNIV

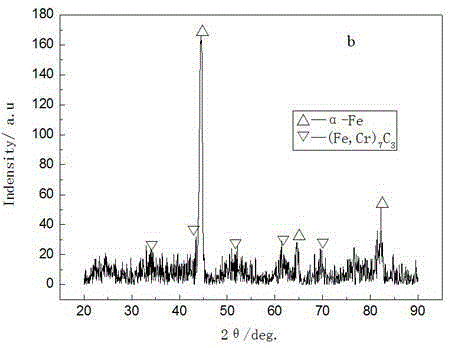

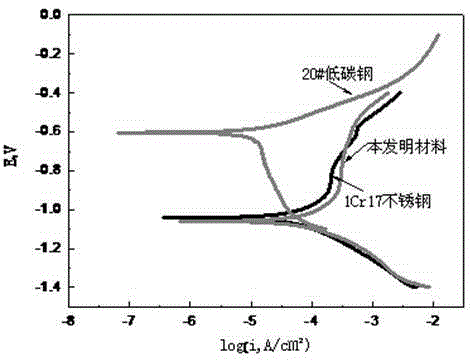

Low-cost and long-service-life surface layer gradient material with stainless steel performance and preparing method of low-cost and long-service-life surface layer gradient material

ActiveCN105386034AReduce manufacturing costLow costHeat inorganic powder coatingMicro nanoSurface layer

The invention discloses a low-cost and long-service-life surface layer gradient material with stainless steel performance. The surface layer gradient material comprises a surface layer gradient structure with stainless steel performance. The grain size of the surface layer gradient structure is gradually increased from the surface to the core part to be the same as the grain size of a base body. The solid solubility and the carbide content of the surface layer gradient structure are gradually reduced from the surface to the core part. The solid solubility and the carbide content of the surface layer gradient structure are gradually reduced from the surface to the core part. An ideal micro-nano gradient structure is formed through the surface pretreatment, preset metal powder, large stress-strain impact deformation treatment and returning treatment, the alloying degree and the alloying depth of the surface layer gradient material are obviously improved, no obvious interface exists between the gradient layer and the base body, and transition is continuous. The technology is simple, production is safe, and cost is low. 80-85% of material surface layer alloy elements are converted into a solid solution, 15-20% of material surface layer alloy elements are converted into carbide, and the alloying depth is larger than 300 microns. The corrosion resistance of the material is obviously improved, the service life of the material is obviously prolonged, and the corrosion resistance and the service life of the surface layer gradient material are equivalent to the stainless steel performance.

Owner:南京首勤特种材料有限公司

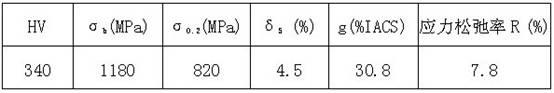

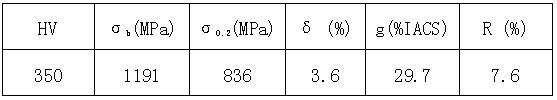

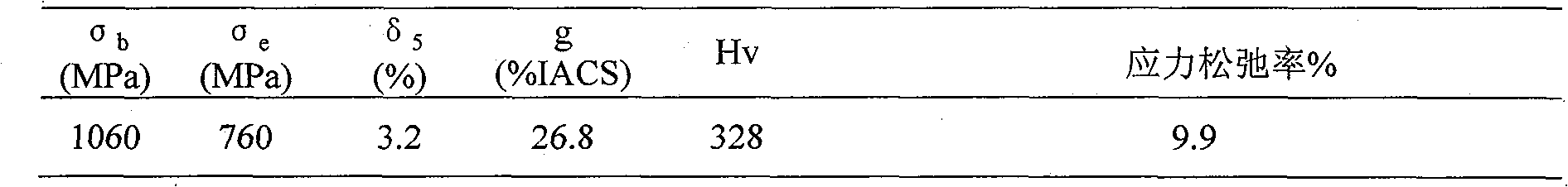

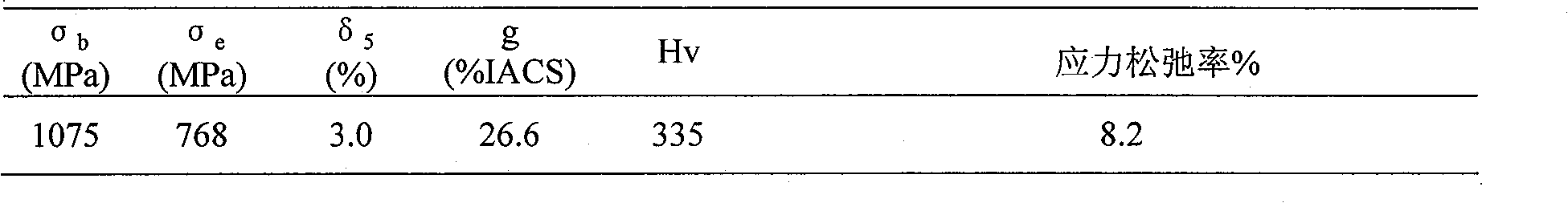

Ultra-high strengthen, high-conductivity CuNiSi series elastic copper alloy and method for preparing same

Disclosed is a CuNiSi system elastic copper alloy with ultra high strength and high conductivity as well as a method for the production thereof, having (in weight percent ): Ni: 6.4 to 8.2wt percent; Si: 1.2 to 1.8wt percent; Sn: 0.3 to 0.5wt percent; Mg: 0.1 to 0.2wt percent; Zr: 0.1 to 0.2wt percent; and balance Cu, and the method for the production thereof comprises five steps of: (1) CuNiSi non-vacuum secondary remelting and ingot casting; (2) homogenizing treatment and hot rolling; (3) twin-stage solution treatment; (4) cold rolling; and (5) time effect treatment. The elastic copper alloy and the method have advantages of reasonable alloy constituents, high alloying degree, simple production process, convenient operation, low production cost, high alloy strength, high conductivity and good stress relaxation resistance, and can realize the preparation of large specification billet, and Ni and Si content in the prepared target alloy system is high, and the process method of the invention is suitable for the industrialized production, and can replace the current aerospace high-power hermetically sealed electromagnetic relays, as well as raw materials and production processes of high performance conductive elastic devices in the electronic industry.

Owner:CENT SOUTH UNIV

A kind of high-strength and high-conductivity cucrzrmg series copper alloy wire material and preparation method thereof

ActiveCN108060323BHigh strengthIncrease the number ofConductive materialMetal/alloy conductorsPower flowIngot casting

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Die-casting aluminum alloy for 5G communication base station shell and preparation method thereof

The invention discloses a die-casting aluminum alloy for a 5G communication base station shell. The die-casting aluminum alloy is characterized in that the alloy is prepared from the following components in percentage by weight: 5-8% of Si, 0.05-0.09% of Tc, 0.01-0.04% of Cd, 0.07-0.1% of Nb, 0.01-0.03% of Ag, 0.02-0.05% of Ca, 0.06-0.08% of Sr, 0.5-1.2% of Cr, 2-4% of Zn, 0.01-0.03% of Ir, 0.001-0.003% of B, 0.04-0.07% of rare earth element, 0.003-0.005% of surface metallized graphene, and the balance of Al and inevitable impurities. The content of the inevitable impurities does not exceed 0.01%. The invention further provides the preparation method of the die-casting aluminum alloy for the 5G communication base station shell. The die-casting aluminum alloy for the 5G communication base station shell is better in mechanical property and corrosion resistance, better in heat conductivity and die-casting process stability, longer in service life and lighter in weight, and is the first choice of 5G communication base station shell materials.

Owner:HEFEI KUNQING MASCH TECH CO LTD

Porous chromium alloy material and preparation method thereof

InactiveCN101831674AGood high temperature oxidation resistanceHigh strengthMetallic materialsUltimate tensile strength

The invention relates to a porous chromium alloy material and a preparation method thereof, wherein the porous chromium alloy material is in a three-dimensional netted structure, a base material is porous metallic iron, nickel or an iron-nickel alloy, metallic chromium is plated on the surface of the base material, and the mass of the chromium accounts for 5-30 percent of the gross mass of a metal material. The preparation method thereof comprises the following steps of: plating the chromium on the surface of the porous metallic iron, the nickel or the iron-nickel alloy; and then, carrying out heat processing on the iron, the nickel or the iron-nickel alloy after chromium plating in a heat processing furnace. The porous chromium alloy material has high temperature resistance, higher strength, simple preparation process and low cost and is suitable for large-scale production.

Owner:CHANGSHA LYRUN NEW MATERIAL CO LTD

Manufacturing method for scale breaking tension leveler working roll

ActiveCN103589850AImprove toughnessIncreasing the thicknessFurnace typesHeat treatment furnacesStress distributionMedium frequency

The invention discloses a manufacturing method for a scale breaking tension leveler working roll. By adopting Cr12MoVCo die steel as the material, the manufacturing method includes the steps of: rough turning, hardening and tempering, semi-finish turning, shaping treatment, coarse grinding of roll surface, preheating, medium frequency spray quenching, isothermal treatment, tempering, and finish machining, thus obtaining a finished product. Specifically, the preheating temperature is 400-450DEG C, the medium frequency spray quenching temperature is 1100-1200DEG C, the isothermal temperature is 200-250DEG C, and the tempering temperature is 500-550DEG C. In the invention, by changing the thermal treatment process, under the circumstance of obtaining quenched martensite on the surface, a transition layer is mainly based on bainite, high hardness and high wear resistance of the surface are retained, toughness of the transition layer and the core is increased, the occurrence of microcracking is reduced, and the fracture risk in use is avoided. The thickness of the transition layer is increased, the overall strength of the roll is increased, the stress distribution is more reasonable, and the grinding performance of the roll is improved.

Owner:宜兴市鑫源辊业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com