Cu-Ni-Si-based alloy and preparation method thereof

A cu-ni-si, based alloy technology, applied in the field of Cu-Ni-Si based alloy and its preparation, can solve the problems of not being obtained, and achieve the effects of reasonable alloy composition, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

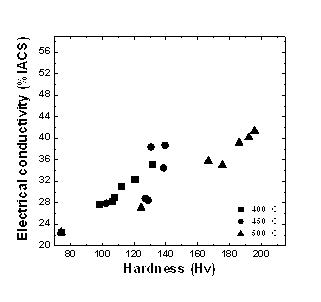

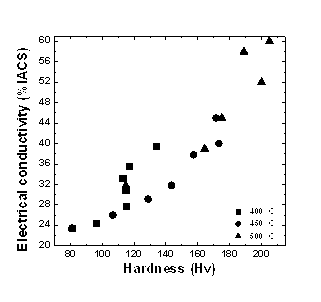

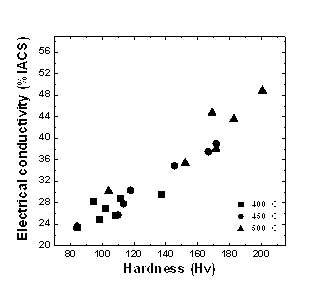

Image

Examples

Embodiment approach 1

[0020] High-strength and high-conductivity Cu-Ni-Si-based alloy, including Cu, Ni, Si, V, its proportion (mass percentage) is: Ni: 2.8%, Si: 0.7%, V: 0.1%, and the rest is Cu.

[0021] Step 1, blank preparation: Pure copper, pure silicon, pure nickel, and pure vanadium with a purity greater than 99.9% are prepared according to the following mass percentages: Cu 95.5~97.5%, Ni 2.0~3.0%, Si 0.5~1.2%, V 0~ 0.3% is smelted in a vacuum induction furnace. After all the raw materials are smelted, they are kept at 1250 ℃ for 20 minutes to ensure that all alloy elements are dissolved and fully diffused, and cast in a metal mold to obtain a length of 190mm, a width of 55mm, and a height of 30mm rectangular blank;

[0022] Step 2, deformation treatment: the billet is first subjected to homogenization annealing treatment at 980oC for 2 hours. The billets were then hot rolled at 980oC with a total deformation of 70%. After the hot-rolled alloy is descaled, it is cold-rolled at room tempe...

Embodiment approach 2

[0025] The difference from Embodiment 1 is that the percentage of V in the alloy composition ratio is increased to 0.2%. Others are the same as process 1. The specific composition ratio and mechanical properties of the alloy are shown in Table 1. After testing, the alloy has the best overall performance: the electrical conductivity is 50%IACS, and the hardness is 200Hv. The average grain size is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com