Method for preparing high-alloying carbon-supported PdFe nanocatalyst by in-situ reduction method

A nano-catalyst, alloyed carbon technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Uniformity, uneven atomic distribution and other problems, to achieve the effect of high degree of alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] The method for preparing high-alloyed carbon-supported PdFe nano-catalysts by in-situ reduction method comprises the following steps:

[0031] 1. Weigh 60 mg of Vulcan XC-72R activated carbon powder from Cabot Company, add 3.0 ml of 0.05 mol / L K to adjust the pH value to 1.0 ~ 6.0 2 PdCl 4 Solution, mechanically stirred or ultrasonically oscillated, add 2.0 ml 0.05 mol / L K at a pH of 1.0 to 6.0 at 30 to 100°C 3 Fe(CN)6 Solution, mechanically stirred for 2 to 72 hours to make the mixture uniform.

[0032] 2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), and mechanically stirred for 1 hour to completely react the palladium ferricyanide precursor with the reducing agent.

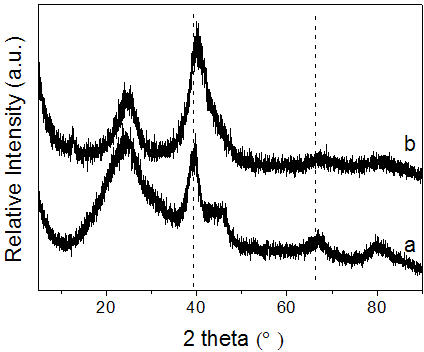

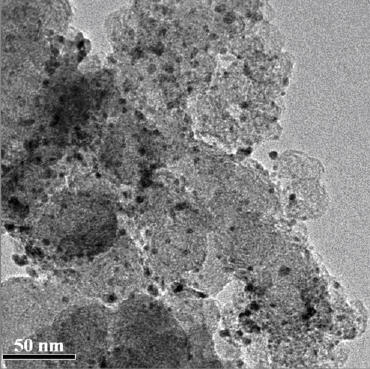

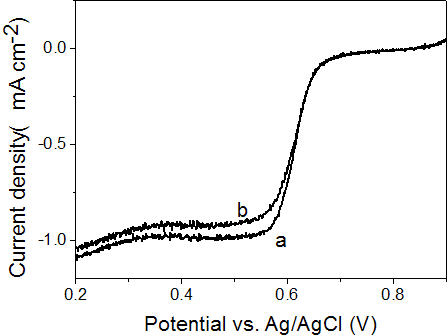

[0033] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 Drying at 50°C under the same conditions can produce Pd with a metal loading of 20% and a PdFe atomic ratio of 3:2. 3 Fe 2 / C...

example 2

[0035] The method for preparing high-alloyed carbon-supported PdFe nano-catalysts by in-situ reduction method comprises the following steps:

[0036] 1. Weigh 60 mg of carbon nanotubes (CNTs) with a diameter of 10-20 nm, and add 3.0 ml of 0.05 mol / L K to adjust the pH value to 1.0 ~ 6.0 2 PdCl 4 Solution, mechanically stirred or ultrasonically oscillated, add 2.0 ml 0.05 mol / L K at a pH of 1.0 to 6.0 at 30 to 100°C 3 Fe(CN) 6 Solution, mechanically stirred for 2 to 72 hours to make the mixture uniform.

[0037] 2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), and mechanically stirred for 1 hour to completely react the palladium ferricyanide precursor with the reducing agent.

[0038] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 Drying at 50°C under the same conditions can produce Pd with a metal loading of 20% and a PdFe atomic ratio of 3:2. 3 Fe 2 ...

example 3

[0040] The method for preparing high-alloyed carbon-supported PdFe nano-catalysts by in-situ reduction method comprises the following steps:

[0041] 1. Weigh 60 mg of carbon molecular sieve, add 3.0 ml of 0.05 mol / L K to adjust the pH value to 1.0 ~ 6.0 2 PdCl 4 Solution, mechanical stirring or ultrasonic vibration, at 30 ~ 100 ℃, add 1.5 mL 0.05 mol / L K 4 Fe(CN) 6 Solution, mechanically stirred for 2 to 72 hours to make the mixture uniform.

[0042] 2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), and mechanically stirred for 1 hour to completely react the palladium ferrocyanide precursor with the reducing agent.

[0043] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 Drying at 50°C under the same conditions can produce graphene-supported Pd with a metal loading of 20% and a PdFe atomic ratio of 2:1. 2 Fe 1 Nanoparticle catalysts, in which the cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com