Patents

Literature

157results about How to "Uniform melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

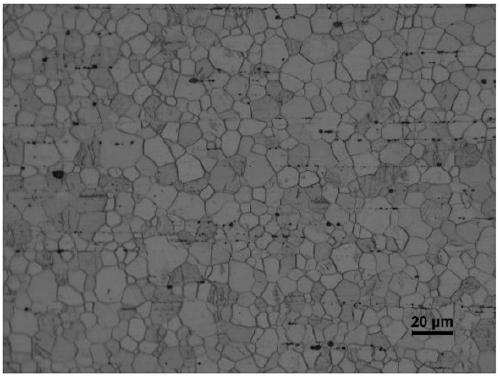

Low-cost non-rare-earth type high-strength magnesium alloy and preparing method thereof

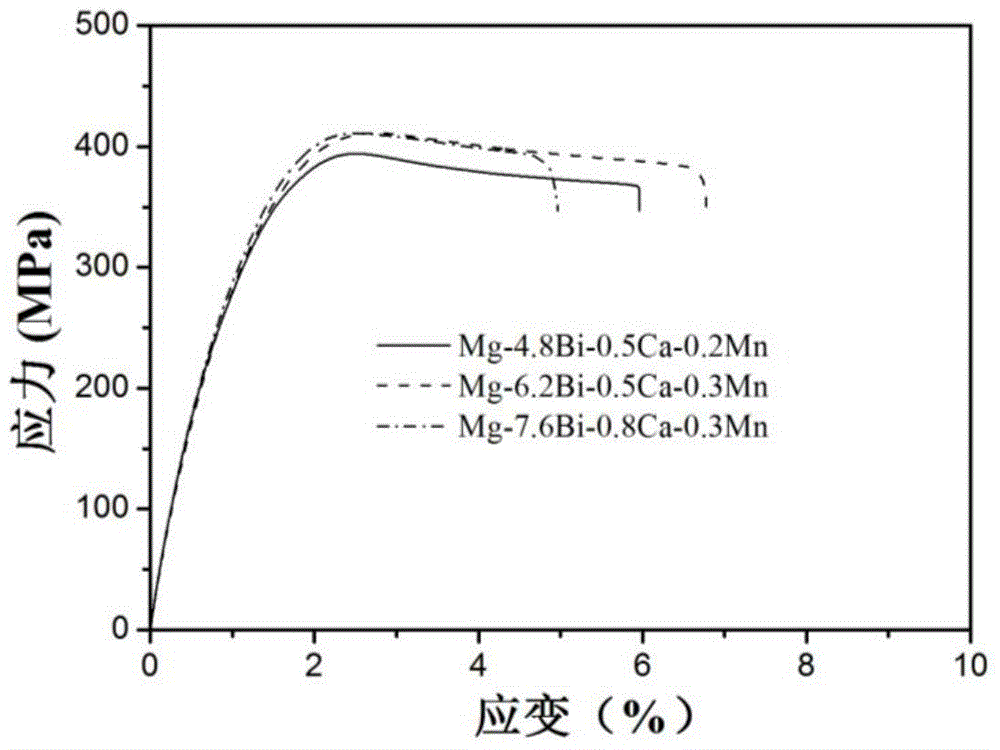

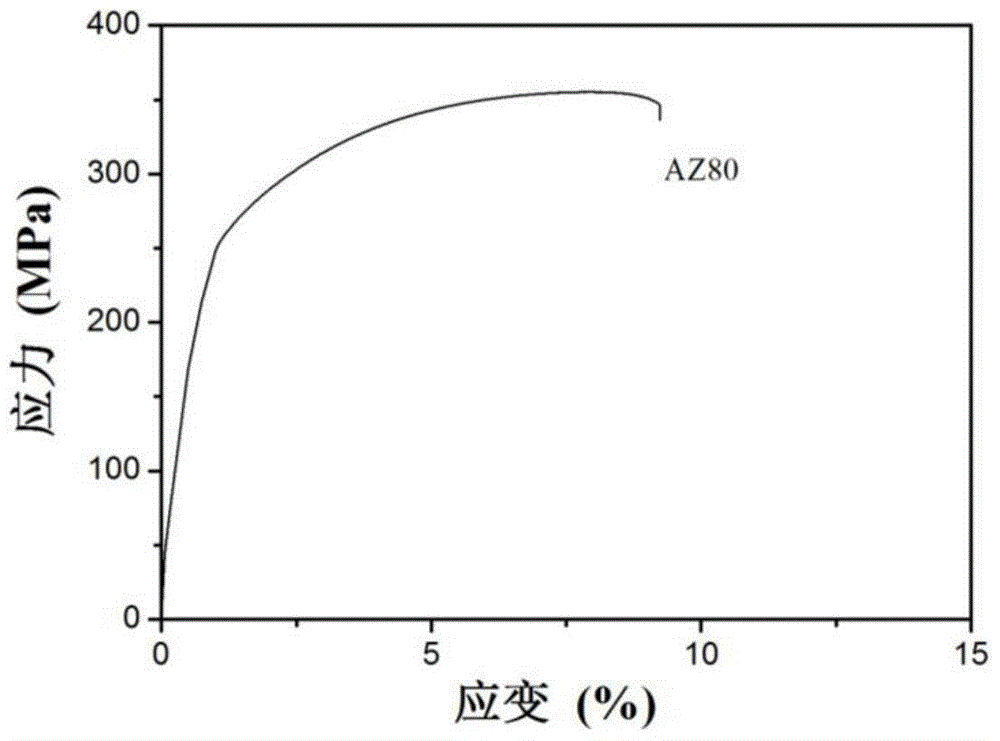

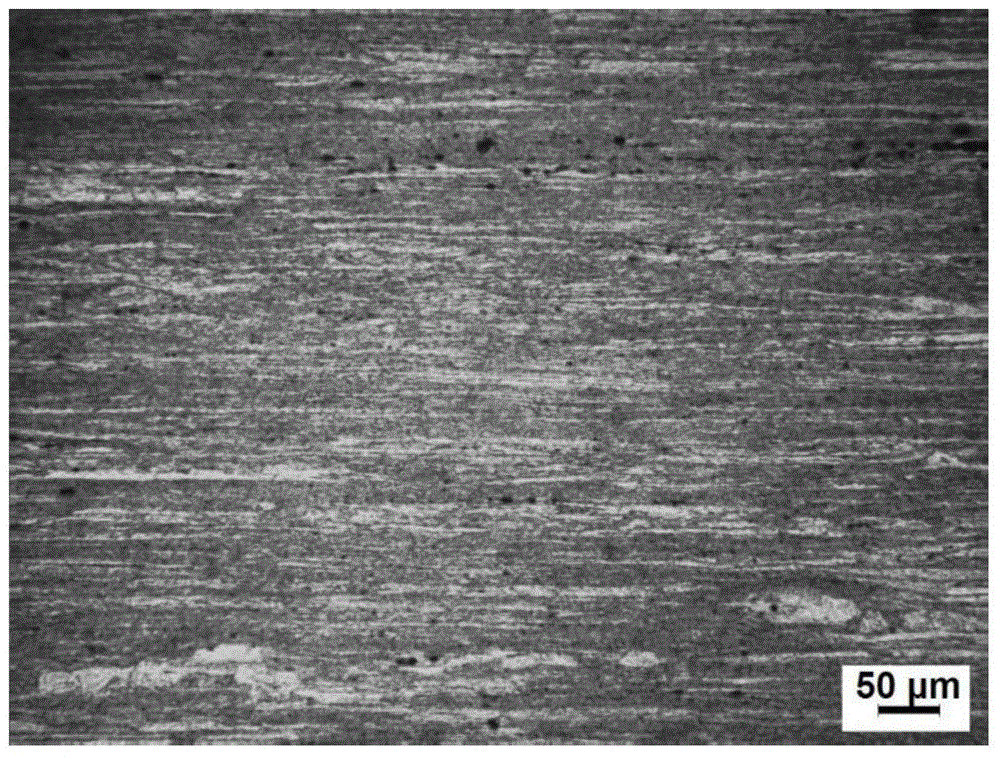

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

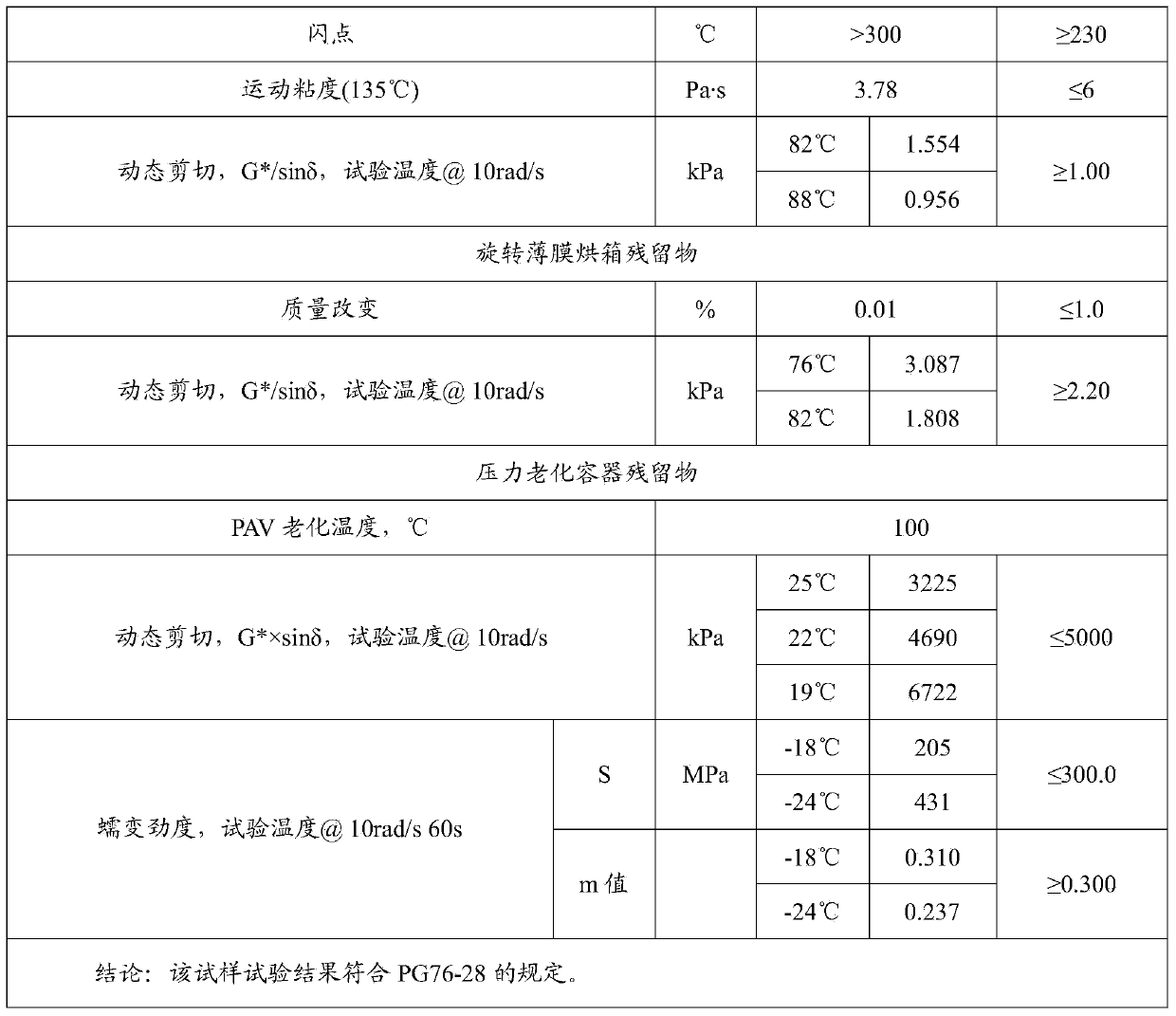

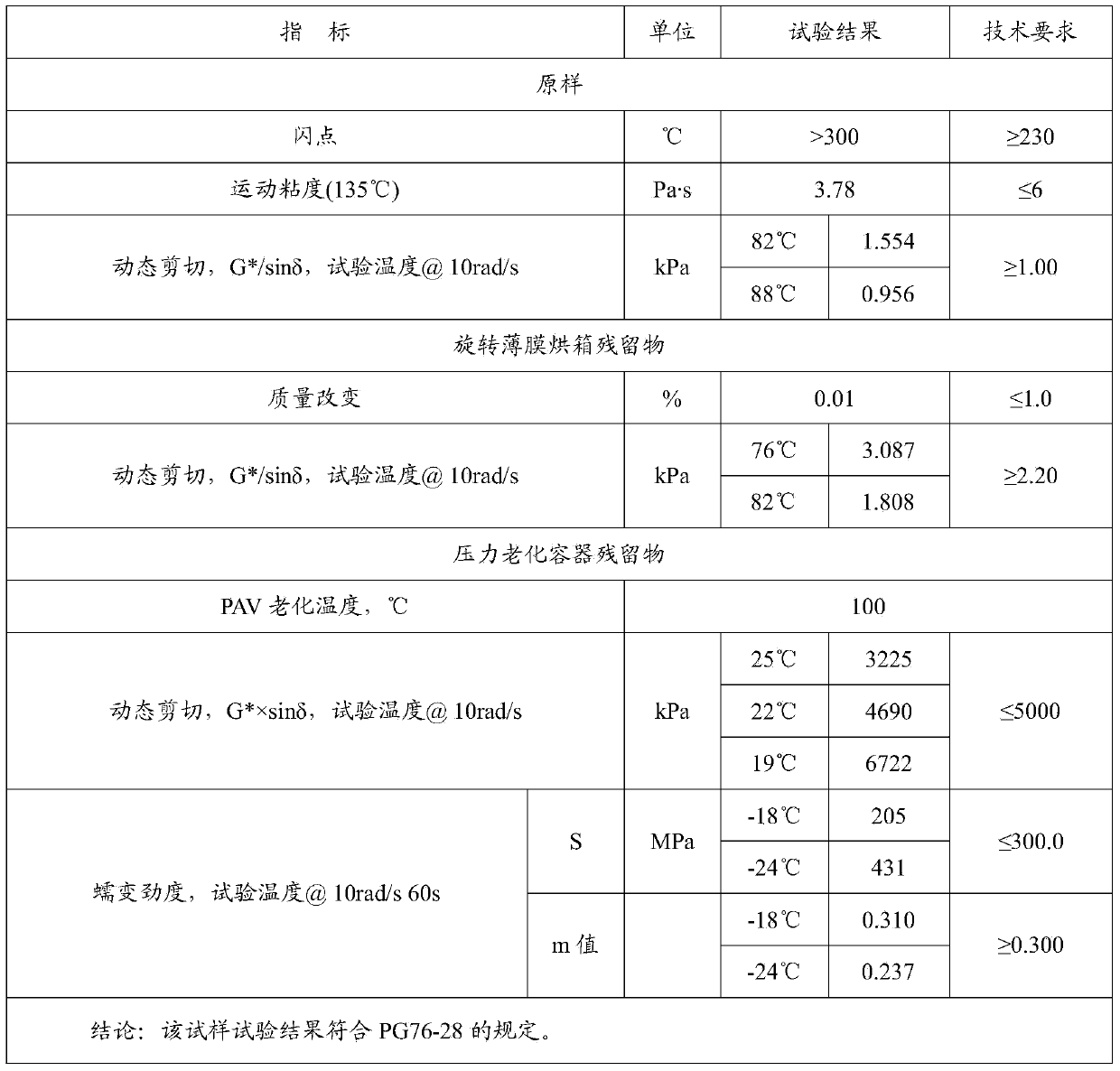

Rubber and plastic alloy modified asphalt and asphalt mixture

InactiveCN103436039AHigh temperature strengthGood modification effectPlastic recyclingBuilding insulationsPolymer scienceAlloy

The invention relates to the field of asphalt. A rubber alloy modifier is obtained with untreated waste plastics and waste tire rubber powder as main raw materials. Modified asphalt which does not affect the rubber / plastic independent modification effects and has good asphalt storage stability and simple production process is finally obtained by utilizing the modifier to modify asphalt. The modified asphalt can be applied to continuous dense gradation of an asphalt mixture. On the premise that the high-and-low temperature performance of the mixture meets the requirement, the water stability is obviously improved, thus achieving effective treatment of two types of polymer waste pollutants such as waste tire rubber powder and waste plastics and change of asphalt properties.

Owner:山东高速交通建设集团有限公司

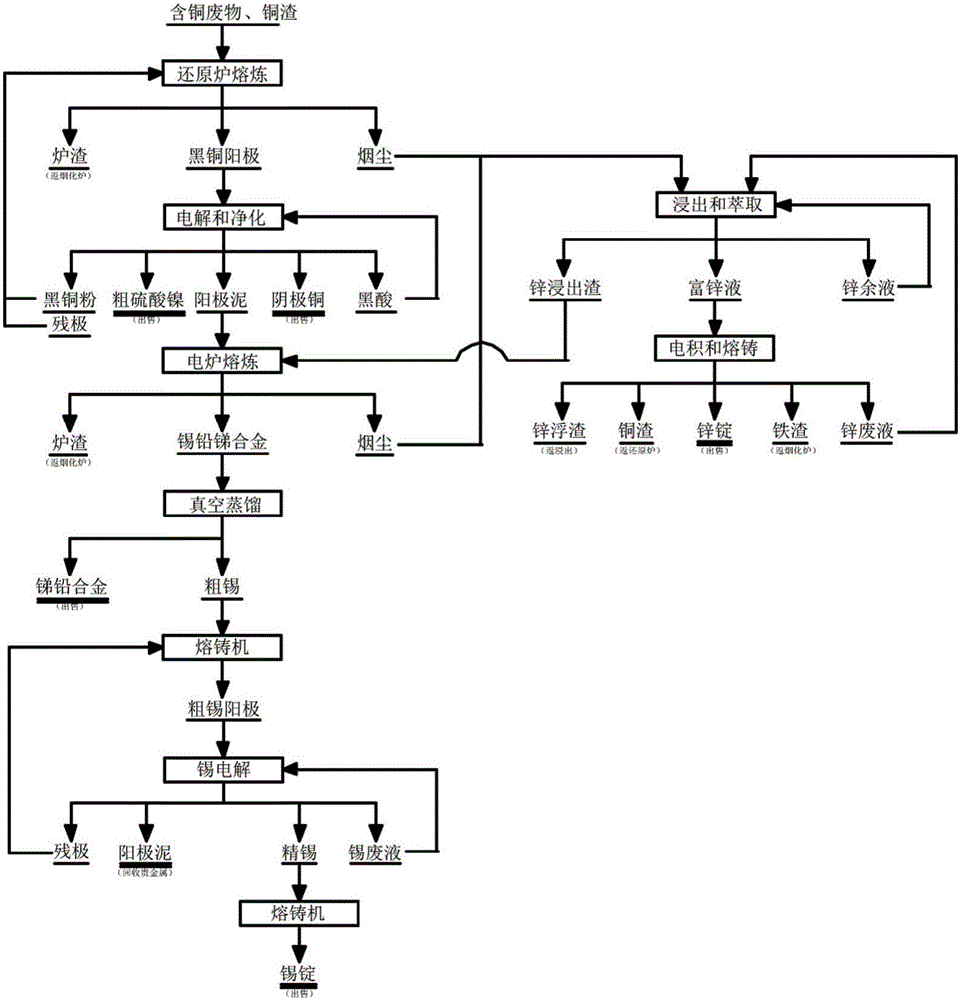

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Rubber and plastic alloy asphalt modifier

ActiveCN103421222AShort cutting timeGood high temperature performance and low temperature performancePlastic recyclingBuilding insulationsWaste tiresAsphalt

The invention relates to the field of asphalt additives and provides a rubber and plastic alloy asphalt modifier. The rubber and plastic alloy asphalt modifier is mainly made of untreated wasted plastic particles and wasted tire rubber powder and does not damage the individual modification effect of rubber and plastic. The rubber and plastic alloy asphalt modifier is good in asphalt storage stability performance and simple in the production technology. Rubber and plastic alloy modified asphalt manufactured with the rubber and plastic alloy asphalt modifier is applicable to continuously densely prepared asphalt blended materials. Under the condition that the high-temperature and the low-temperature performance of the blended materials can meet the requirements, water stability is obviously improved and two kinds of macromolecule wasted pollutants including wasted tire rubber powder and wasted plastic are effectively processed.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

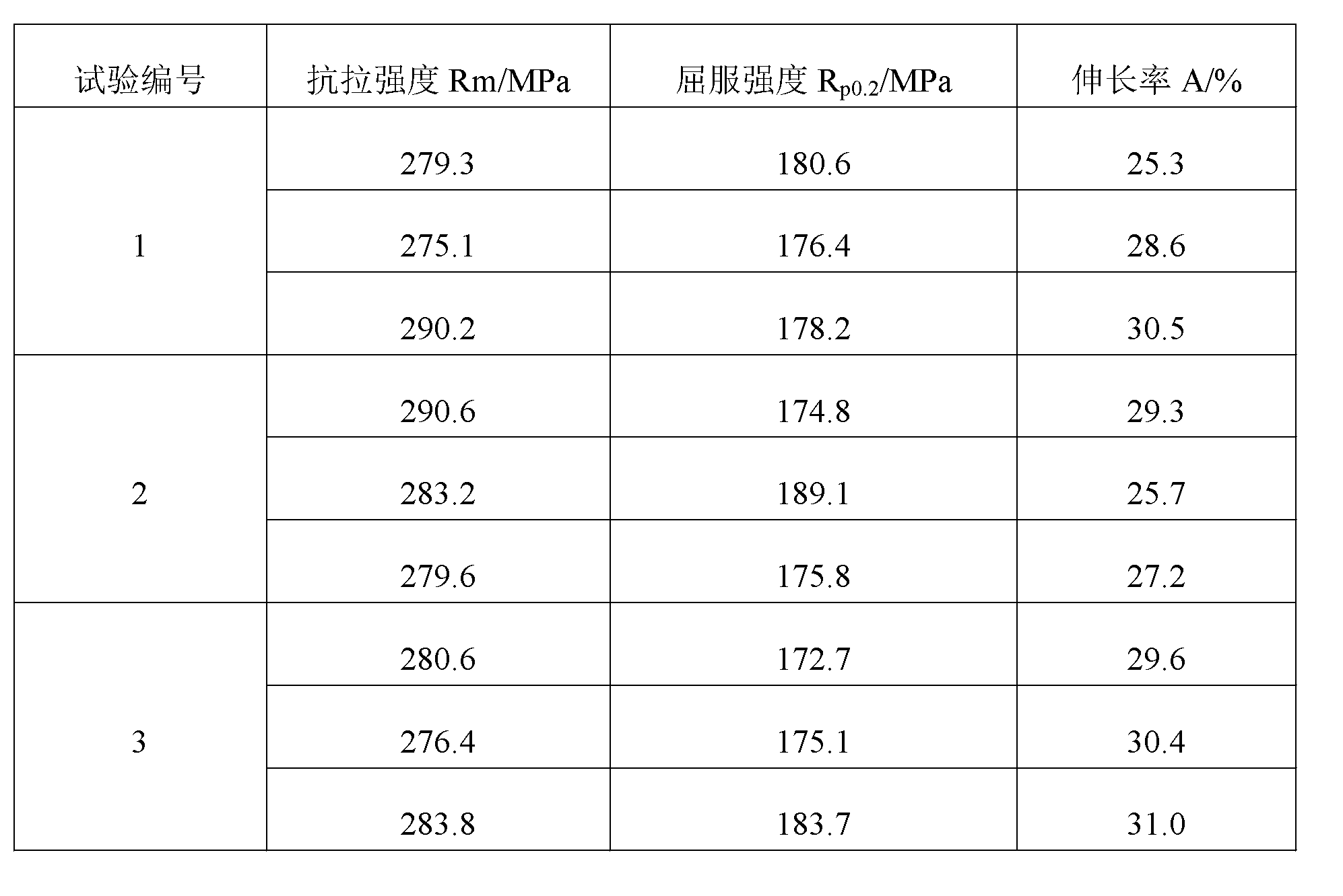

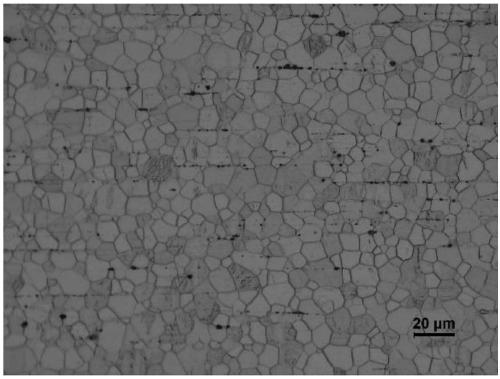

Rare earth magnesium-lithium alloy sheet and preparation method thereof

The invention discloses a rare earth magnesium-lithium alloy sheet and a preparation method thereof, belonging to the field of metal processing. The rare earth magnesium-lithium alloy sheet is characterized by comprising the following components in percentage by weight: 11-15% of Li, 0.5-2% of Y, 0.5-2% of Gd, 0.1-1% of Sc, 7-9% of Al and the balance of magnesium. The preparation method comprises the following steps of: melting magnesium and intermediate alloy by using an industrial medium-frequency or line-frequency induction melting furnace, adjusting the furnace temperature for heat preservation treatment, sampling from the furnace and carrying out rapid on-the-spot sample analysis after the heat preservation time is reached, and detecting whether the components are qualified; and hot rolling and cold rolling a pouring and rolling sheet, carrying out T6 treatment, then, making a mechanical sample, and measuring the mechanical property. By using the rare earth magnesium-lithium alloy sheet and the preparation method thereof, the strength of magnesium-lithium alloy is ensured, the plastic deformation capability of the magnesium-lithium alloy is also greatly enhanced, the production difficulty of the deformed magnesium-lithium alloy sheet is lowered, and the production efficiency is increased. The alloy smelting process is simple, convenient and reliable, convenient to operate and free of special processing process and alloy adding methods. A cast ingot is fine and uniform in tissue, free of meshy and thick sheet-like Mg17Al12 phase and uniform in precipitated phase. The rolling process is simple, convenient, reliable and feasible, and the sheet has favorable comprehensive mechanical property.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

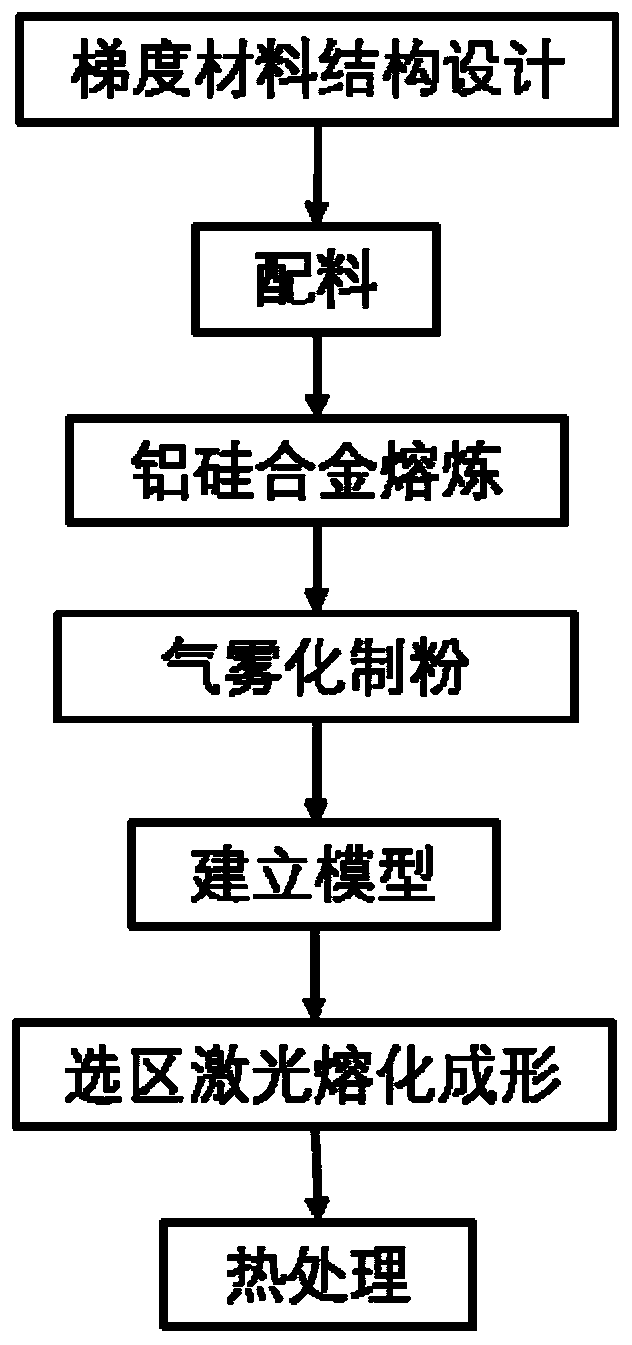

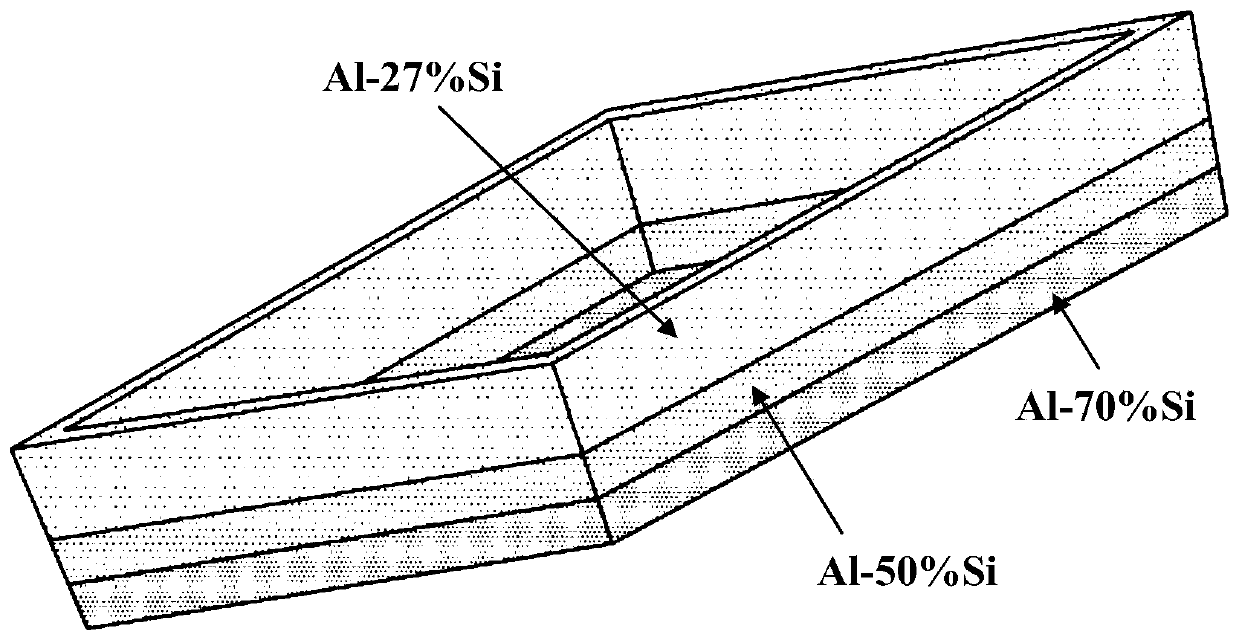

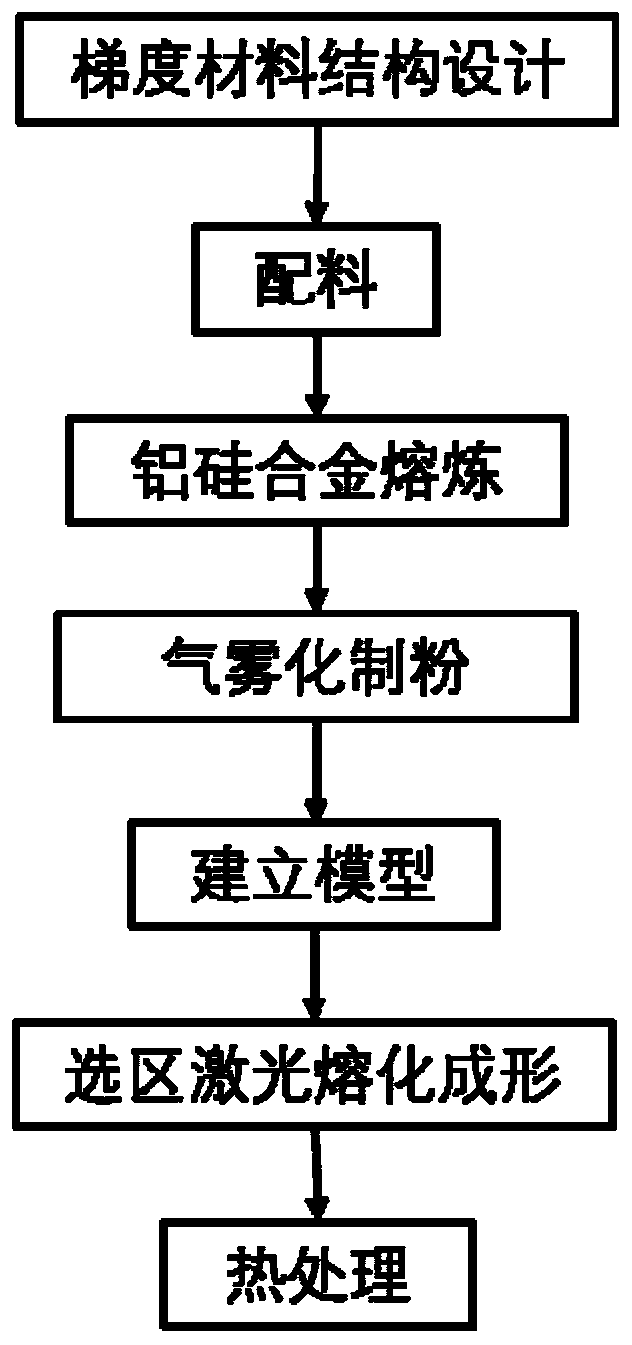

Aluminum-silicon gradient material and selective laser melting forming method thereof

ActiveCN109706353ALow densityImprove controllabilityAdditive manufacturing apparatusSelective laser meltingSilicon alloy

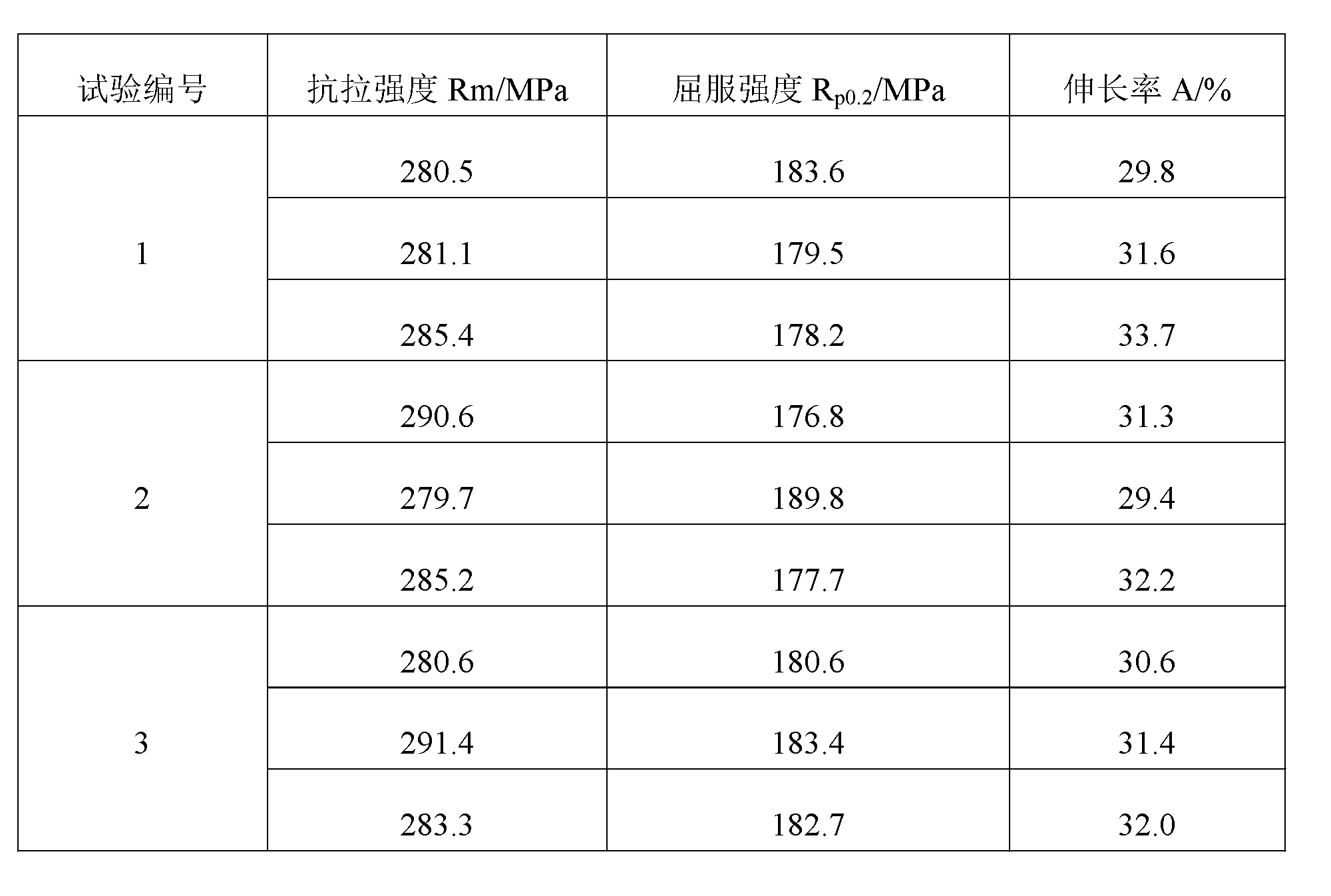

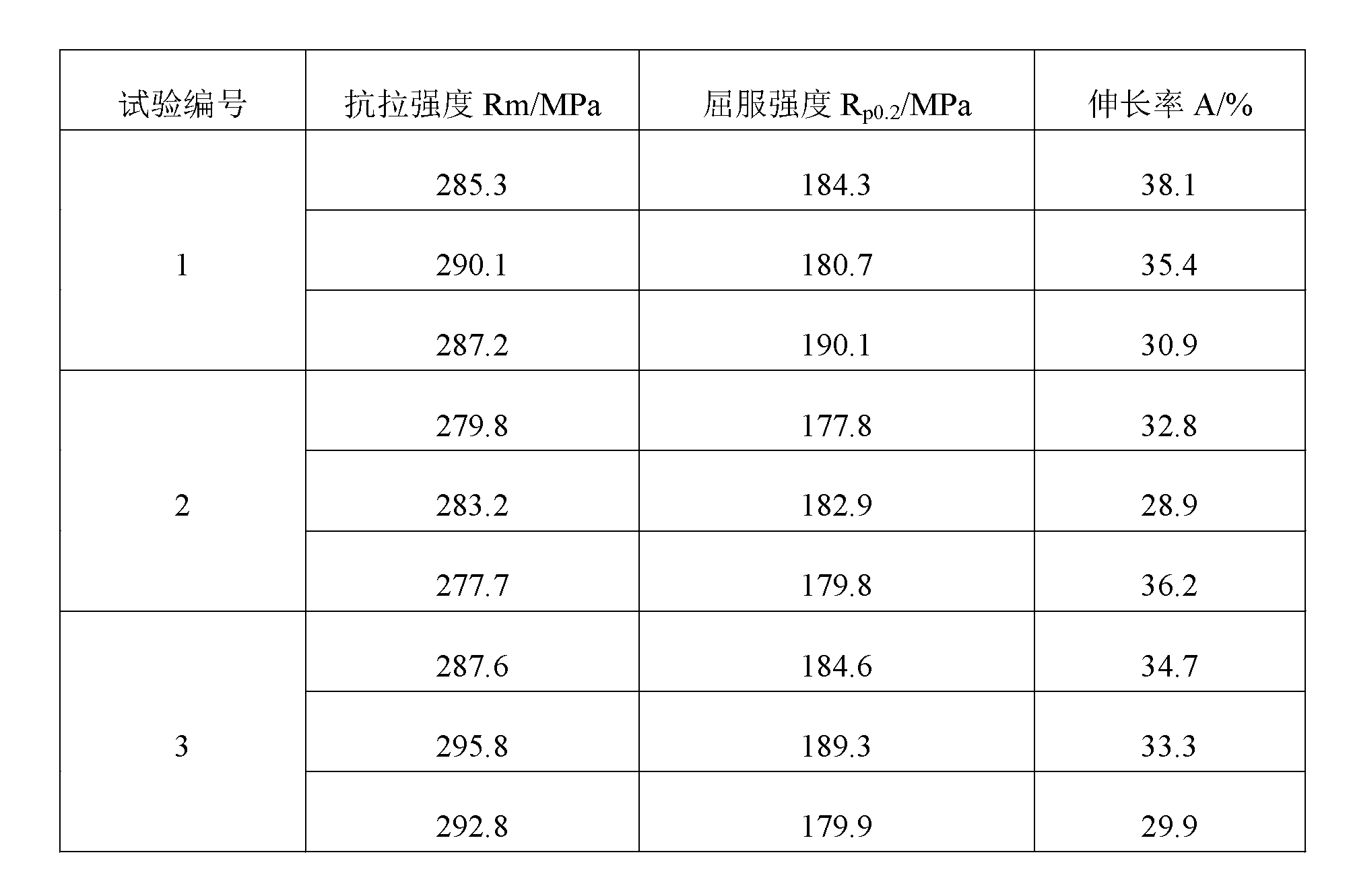

The invention relates to a selective laser melting forming method of an aluminum-silicon gradient material. The selective laser melting forming method comprises the following steps of S1, designing the components and shape of the aluminum-silicon gradient material, and preparing raw materials with different silicon contents according to the weight percentage, wherein the raw materials comprise 22%-70% of silicon and the balance aluminum by weight; S2, smelting the raw materials to obtain aluminum-silicon alloy melts with different silicon contents; S3, preparing aluminum-silicon alloy powder with different silicon contents with the aluminum-silicon alloy melts obtained in the S2 through gas atomization separately; S4, preparing the aluminum-silicon gradient material in the design shape with the aluminum-silicon alloy powder with different silicon contents obtained in the S3 through a selective laser melting technology; and S5, performing heat treatment to the aluminum-silicon gradientmaterial obtained in the S4. The invention further relates to the aluminum-silicon gradient material prepared with the method. The method stated in the invention has the advantages of high designability, simplification of working procedures, high utilization rate of the material, high processing accuracy and the like; and the gradient material stated in the invention is high in designability, andapplicable for electronic packaging shells.

Owner:CENT SOUTH UNIV

Efficient polymorphous fertilizer special for vegetables and preparation method thereof

The invention discloses an efficient polymorphous fertilizer special for vegetables, and relates to the technical field of agricultural fertilizers. The efficient polymorphous fertilizer special for the vegetables comprises the following raw materials of: 350-550 parts of urea, 40-150 parts of ammonium nitrate-phosphorus, 0-150 parts of ammonium sulfate, 150-280 parts of potassium sulfate, 100-220 parts of monoammonium phosphate and 0-10 parts of microelement fertilizer; and the raw materials are mixed, pelletized and cooled so as to obtain the polymorphous controlled-release fertilizer. The efficient polymorphous fertilizer special for the vegetables has the advantages of comprehensive and balanced nutrition, and being capable of inhibiting the occurrence of diseases and pests in soil, enhancing the disease resistance of crops, improving the fertilizer utilization rate and effectively enhancing the nutrition quality of the crops.

Owner:STANLEY AGRI GRP CO LTD

High-elongation special-shaped polyamide fiber 66 and production method thereof

ActiveCN106811818AProcess stabilityUniform viscosityNew-spun product collectionMonocomponent copolyamides artificial filamentChemistryFormic acid

The invention discloses high-elongation special-shaped polyamide fiber 66 and a production method thereof. The production method includes steps of nylon 66 saline solution, high-temperature concentration, high-pressure reaction, flash depressurization, fusion continuous polymerization, spinning, cooling, oiling, second-time drafting, loosening thermoforming and winding. Formic acid relative viscosity of the polyamide fiber 66 is 72-80, breaking strength is 3.0-4.0g / D, elongation at break is 40-50%, hot air shrinkage percentage of 177 DEG Cx2min is 3.0-5.0%, and monofilament linear density is 6-20dtex. The h igh-elongation special-shaped polyamide fiber 66 has the advantages of moderate strength, light weight, fatigue resistance, impact resistance, wear resistance, softness and easiness in processing, thereby being widely applied in the field of high-grade sports goods; a gap in the high-elongation special-shaped polyamide fiber 66 is filled in, and quality of the polyamide fiber 66 is up to international advanced level, so that the polyamide fiber 66 has high social and economic benefit.

Owner:SHEN MA INDUSTRY CO LTD

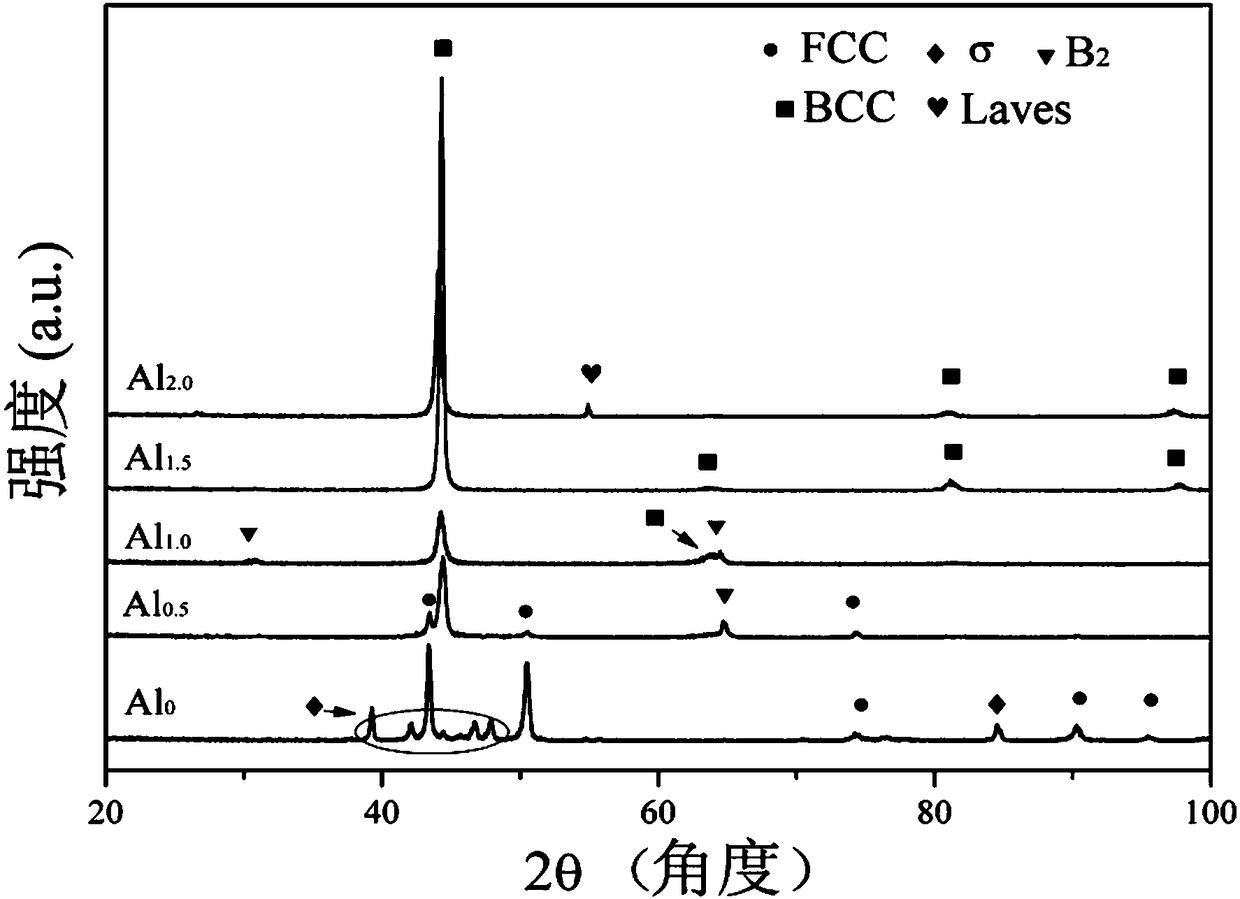

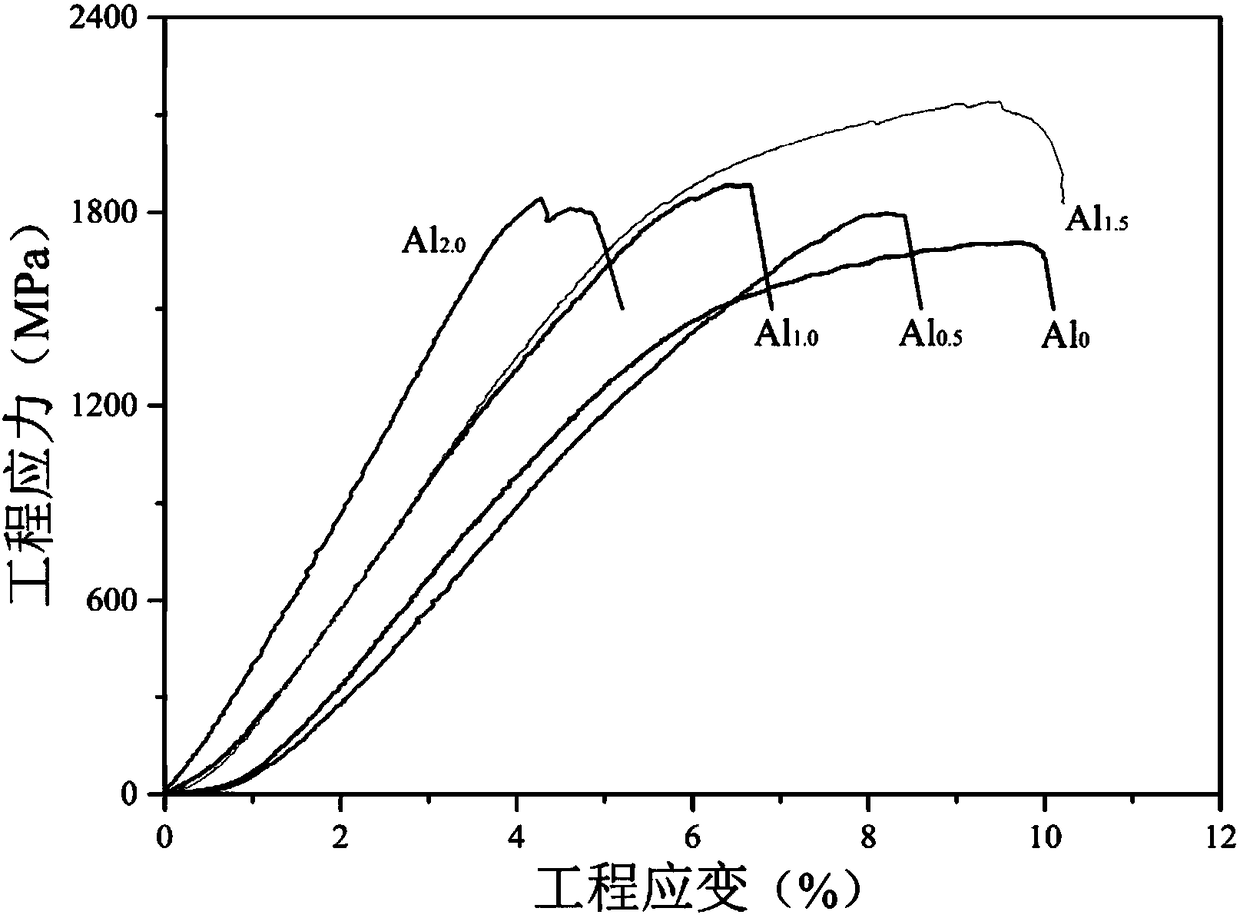

High-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and preparation method thereof

The invention discloses a high-strength refractory six-element high-entropy alloy CoCrFeNiVAlx and a preparation method thereof. The high-strength refractory six-element high-entropy alloy is composedof cobalt, chromium, iron, nickel, vanadium and aluminum which all have the purity of at least 99.9%; and all the elements are calculated according to the atomic percent, specifically, Co is 14-20 at%, Cr is 14-20 at%, Fe is 14-20 at%, Ni is 14-20 at%, V is 14-20 at%, and Al is 0-30 at%. The alloy is prepared through an intermediate alloying method, and the preparation steps include that Co, Ni,Fe and Al which are low in melting point are mixed and molten, Cr and V which are high in melting point are mixed and molten, smelting is performed repeatedly for several times, then two intermediatealloys are smelted, and smelting is performed repeatedly for several times so as to guarantee the uniformity. By means of the high-entropy alloy CoCrFeNiVAlx obtained through the method, the problemsthat Al is prone to being damaged by burning and multi-element alloy smelting is non-uniform can be solved excellently, the strength, hardness and plasticity are high, and the high-strength refractorysix-element high-entropy alloy CoCrFeNiVAlx and the preparation method thereof can be applied to the fields of aerospace, mechanical heavy industries and the like.

Owner:GUANGXI UNIV

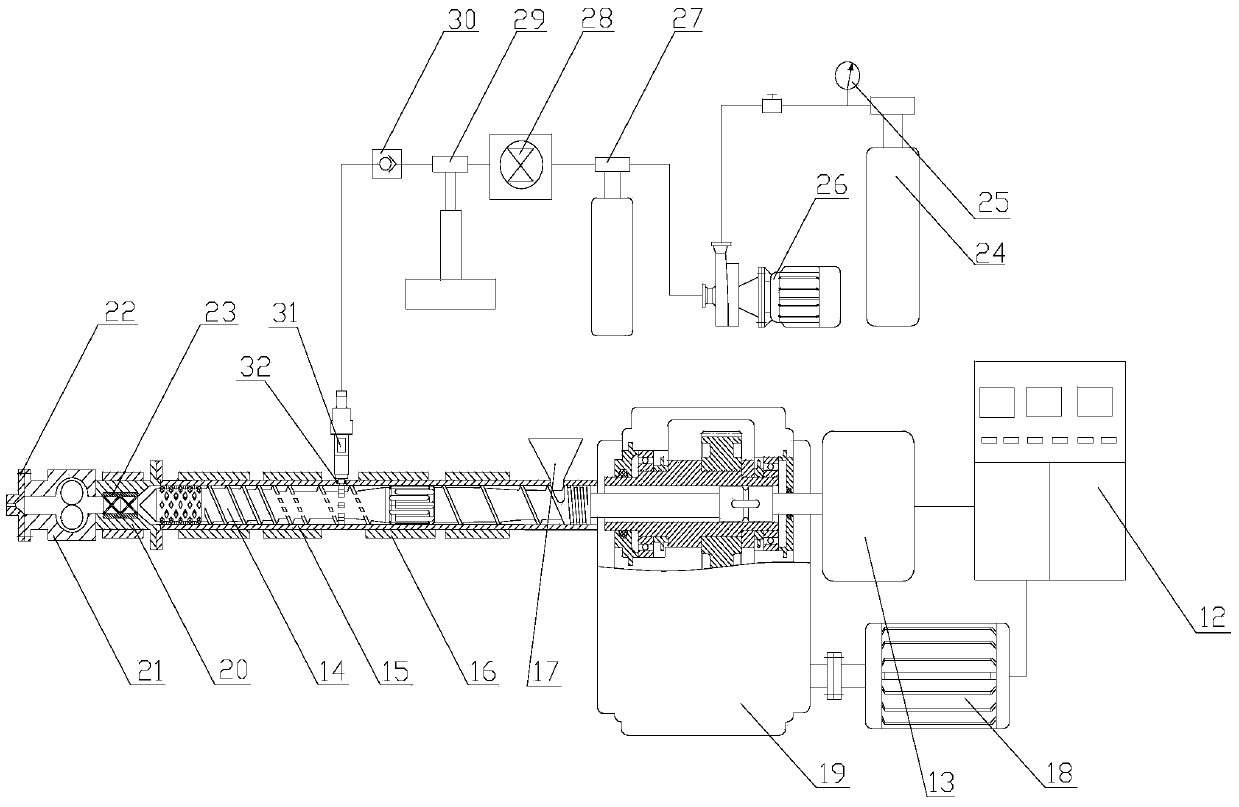

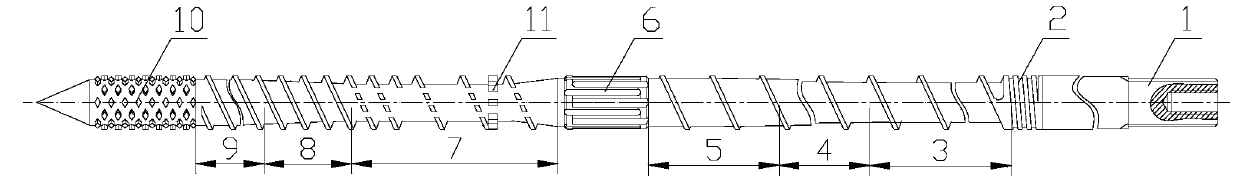

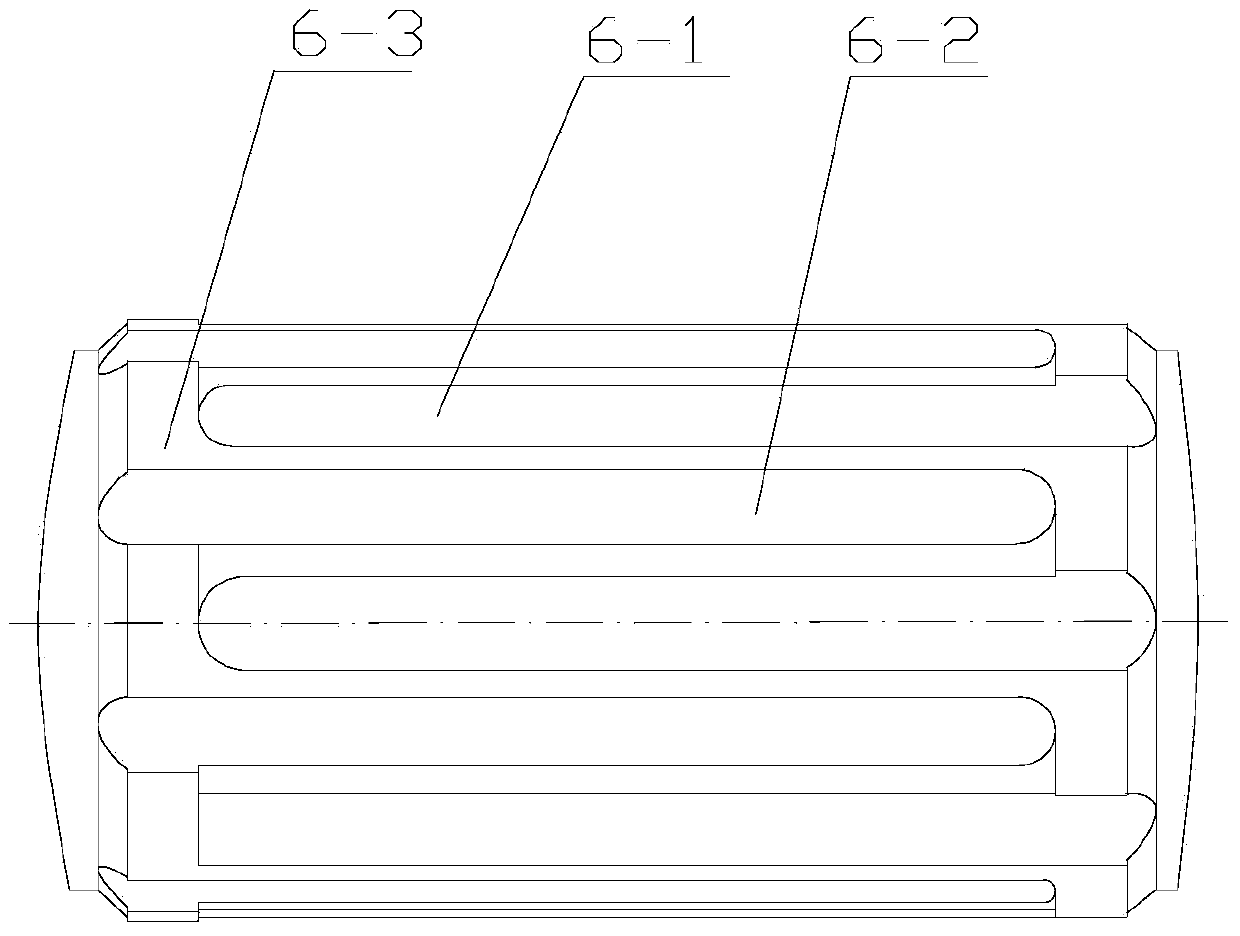

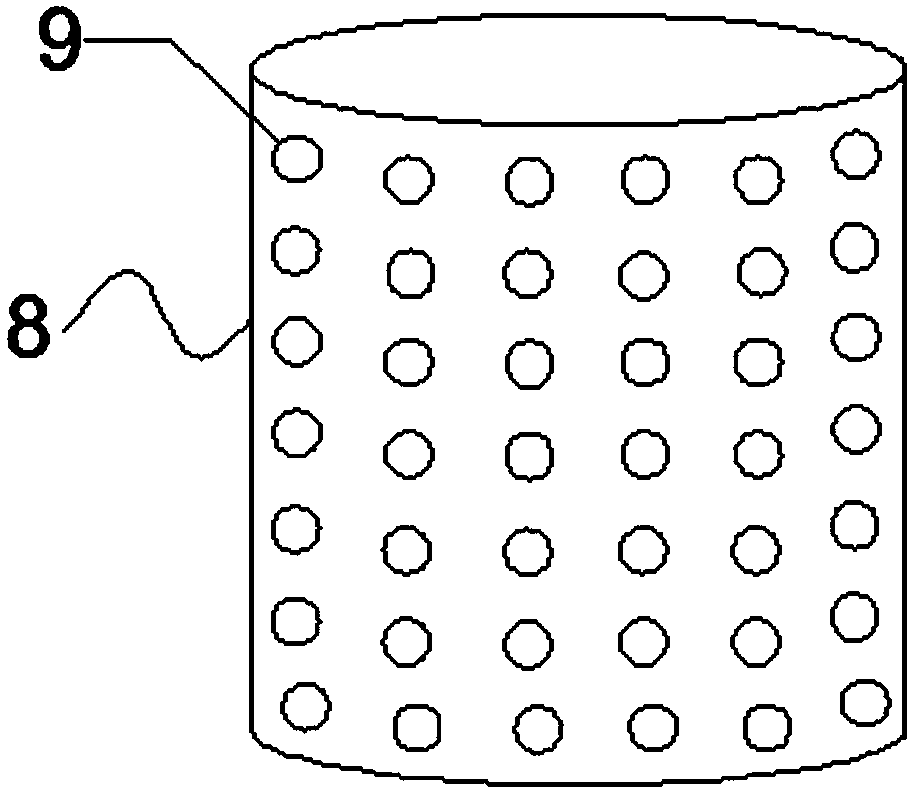

Apparatus and method for extrusion moulding of supercutical-fluid micropore plastic

The invention discloses an apparatus and a method for extrusion moulding of supercritical-fluid micropore plastic. The apparatus comprises an electric cabinet, a vibration exciter, a power unit, a plasticizing mixing unit, a supercritical fluid conveying unit and a moulding unit; the vibration exciter, the power unit, the plasticizing mixing unit and the moulding unit are in successive connection; the supercritical fluid conveying unit is arranged on the plasticizing mixing unit; and the vibration exciter, the power unit and the plasticizing mixing unit are all independently connected with the electric cabinet. The method comprises that the power unit drives a screw to rotate, the vibration exciter drives the screw to make periodic vibration at the axial direction; a material is plasticized and fused under the dual effects of shear force field and vibration force field of the screw; at the same time, the supercritical fluid conveying unit injects a supercritical fluid into a material barrel, and thus the supercritical fluid and the fused material rapidly form a single system of the supercritical fluid and a polymer melt under the dual force fields; and the single system finally enters the moulding unit for foaming fixing. The plasticizing mixing speed is fast, and the mixing effect of the supercritical fluid and the polymer melt is good.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing technology for preparing purified water containing water-soluble silicon

ActiveCN104098169APure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentDiseaseHigh concentration

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

Inner coating for improving glazing property of turned carbon-containing fireproof material and coating method thereof

The invention provides an inner coating for improving glazing property of turned carbon-containing fireproof material. The coating is prepared by uniformly mixing the following components in percentage by weight: 10-40% of bonder, 1-15% of dispersant, 10-80% of filler made of fireproof material and 10-30% of water. The components of the filler made of fireproof material are consistent to the components of the fireproof material to be turned. The coating provided by the invention mainly has the beneficial effects that the filler made of fireproof material in the using process has the effect of repairing surface pits of the carbon-containing fireproof material so as to further improve the coating of the outer antioxidant coating, so that the glazing and glaze burning condition as well as later burning effect are improved.

Owner:维苏威高级陶瓷(鞍山)有限公司

A production process for preparing purified water containing water-soluble silicon

ActiveCN104098169BPure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentHigh concentrationDisease

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

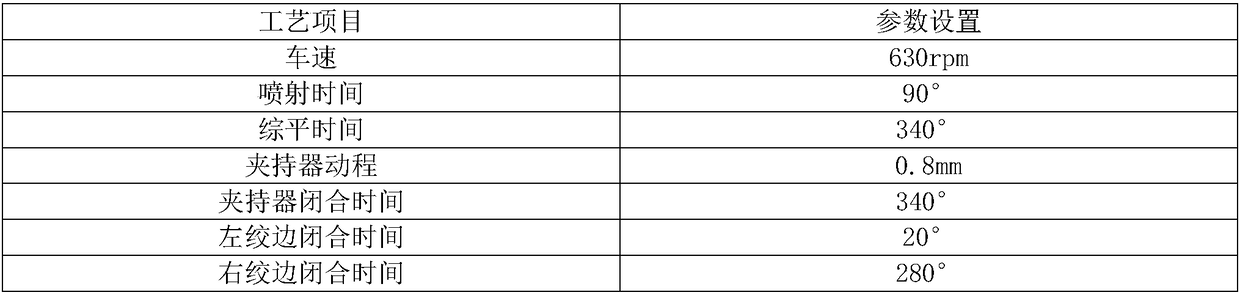

Anti-wrinkle soft uniform fabric and production process thereof

ActiveCN108950811AImprove uniformityImprove stabilityArtificial thread manufacturing machinesGrip property fibresFiberPolyester resin

The invention relates to a production process of anti-wrinkle soft uniform fabric. Firstly, polyester resin and an auxiliary agent thereof are fused, then extruded and pelletized into polyester chips;secondly, the polyester chips are subjected to a spinning process to form fine-denier polyester staple fibers; thirdly, with blended yarn of conventional polyester staple fibers and carded cotton aswarp yarn and blended yarn of fine-denier polyester staple fibers and combed cotton as weft yarn, the fabric is prepared through a siro spinning and weaving process. The production process has the advantages that according to the anti-wrinkle soft uniform fabric, the fitting surface is soft, comfortable and capable of absorbing moisture and discharging sweat, and the problem of poor comfort of traditional uniform fabric is well solved; the front surface of the fabric is clean, flat, full in granular weave, bright, smooth and soft in luster and smooth and cool in hand feel and has good anti-wrinkle performance, so that daily use and finishing of uniforms are more convenient and simpler; the fabric surface has clear weaves, good stiffness, little hairiness and high strength.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

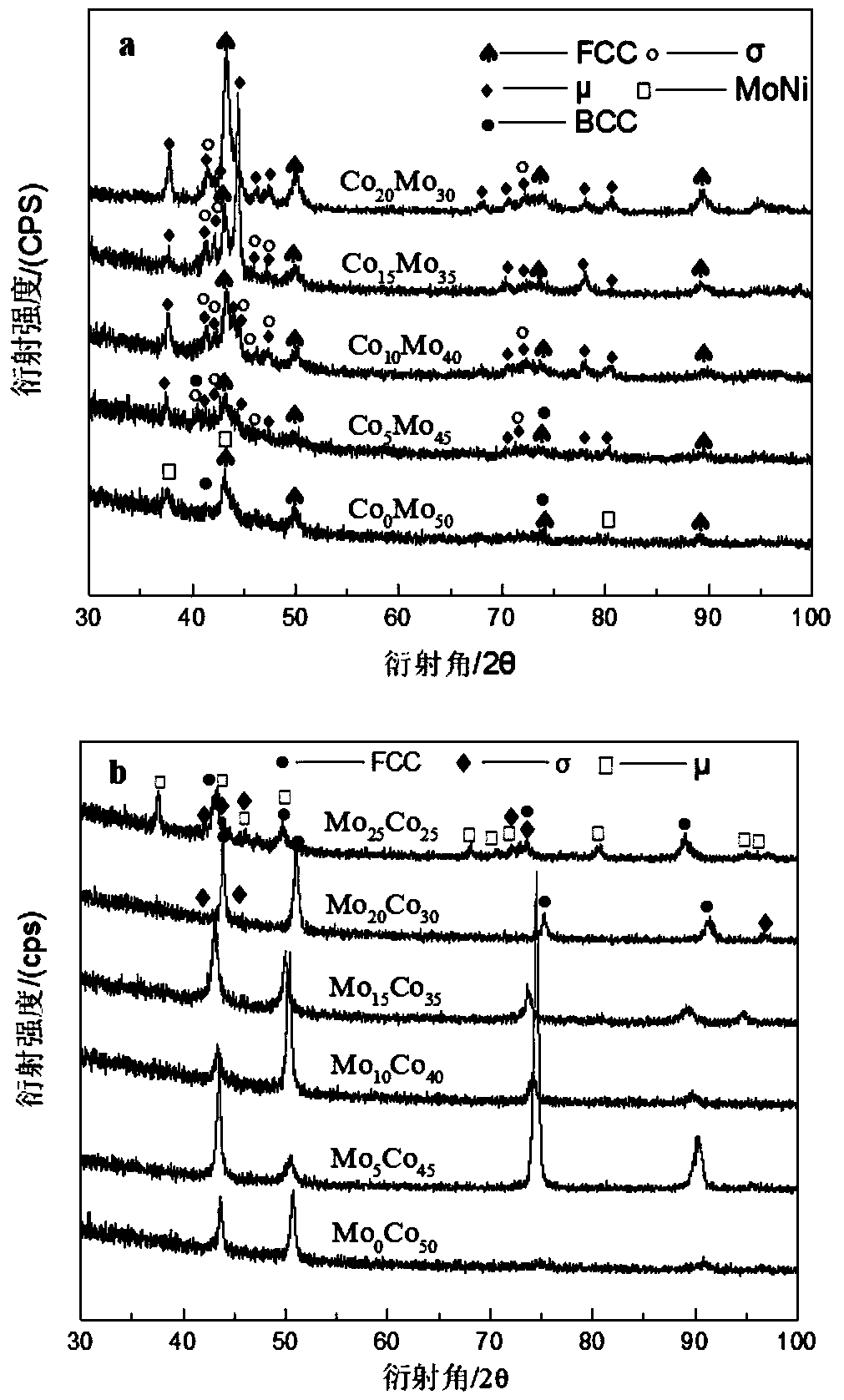

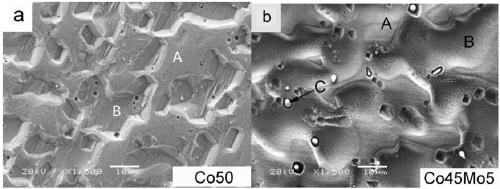

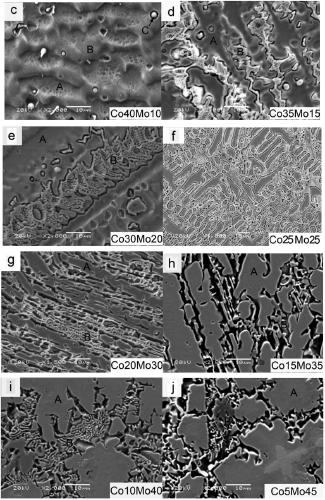

Multi-principal-component medium-entropy alloy and preparation method thereof

The invention relates to a multi-principal-component medium-entropy alloy and a preparation method thereof. The components of the multi-principal-component medium-entropy alloy are Fe25Ni25Co(50-x)Mox(x being greater than or equal to 0 and smaller than or equal to 50) in atomic percentage. The medium-entropy alloy with the components of Fe25Ni25Co25Mo25 has optical comprehensive mechanical properties: hardness being 411HV, yield strength being 1520 MPa, compressive strength being 2056MPa, and plasticity being 31%. The medium-entropy alloy disclosed by the invention is prepared by an electric-arc smelting method. The preparation method is simplified in process, is relatively low in difficulty and is relatively low in cost.

Owner:JIANGSU UNIV OF SCI & TECH

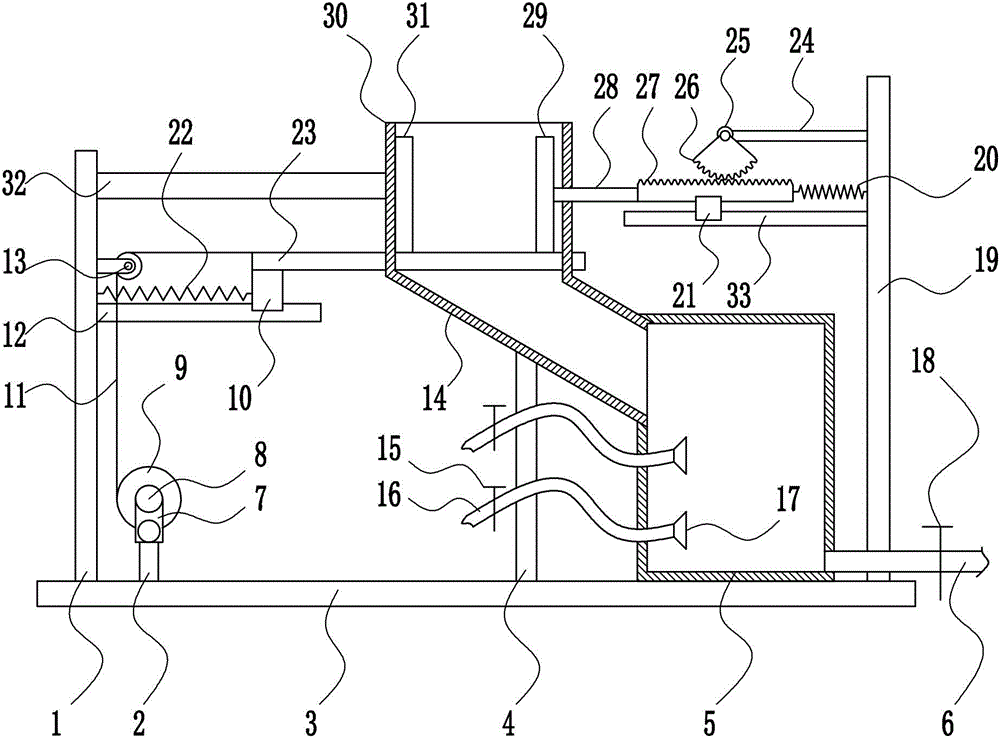

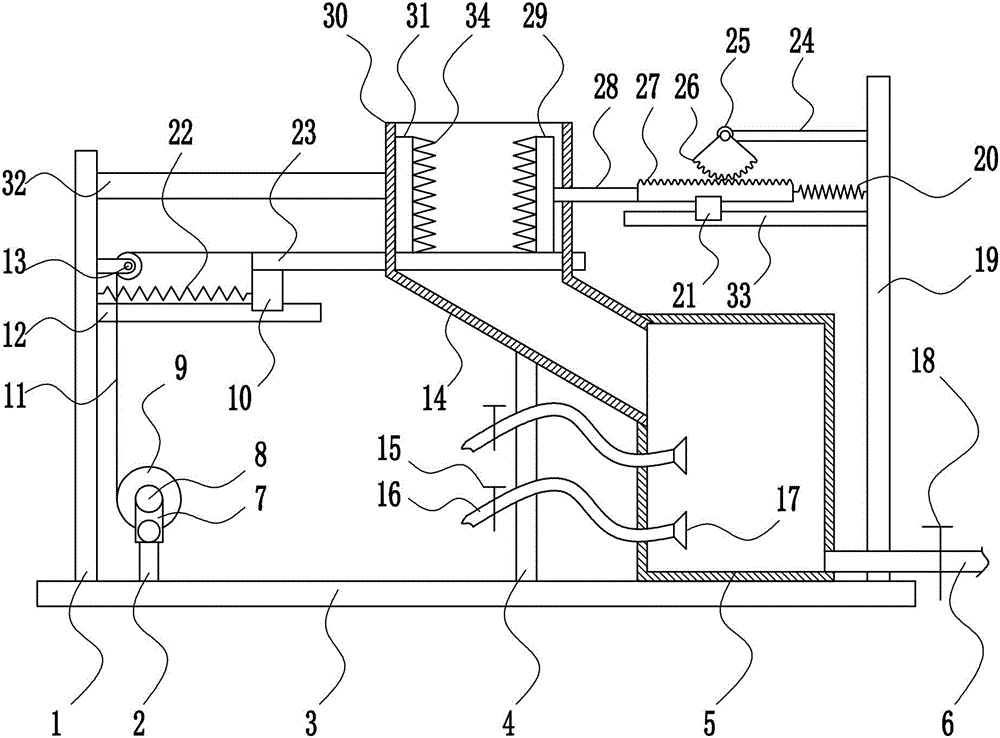

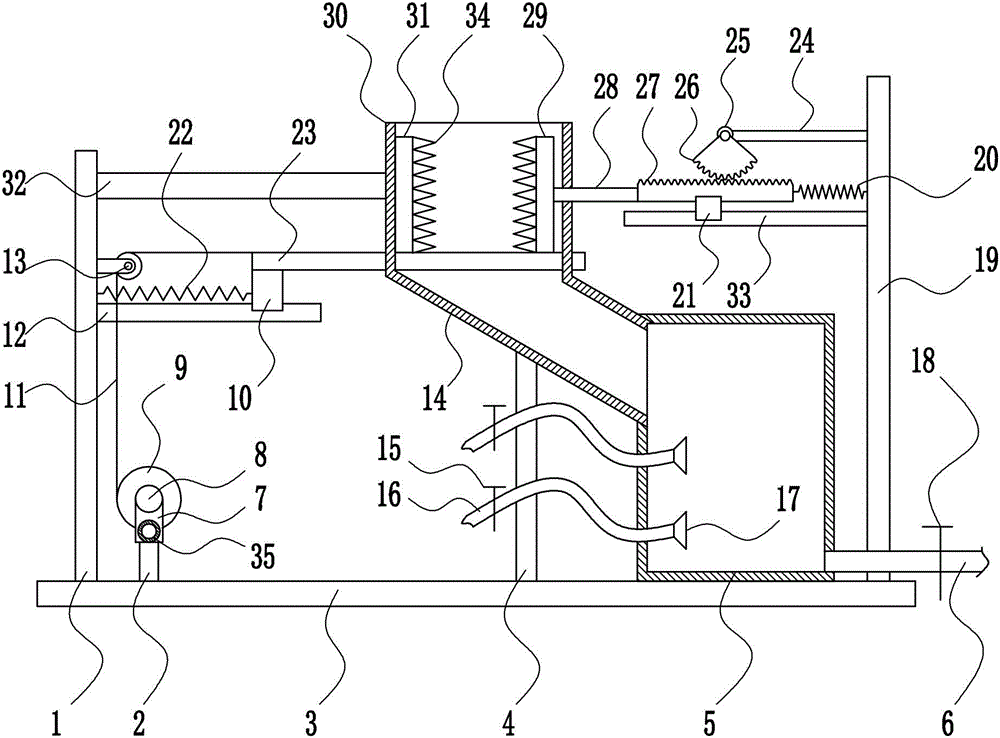

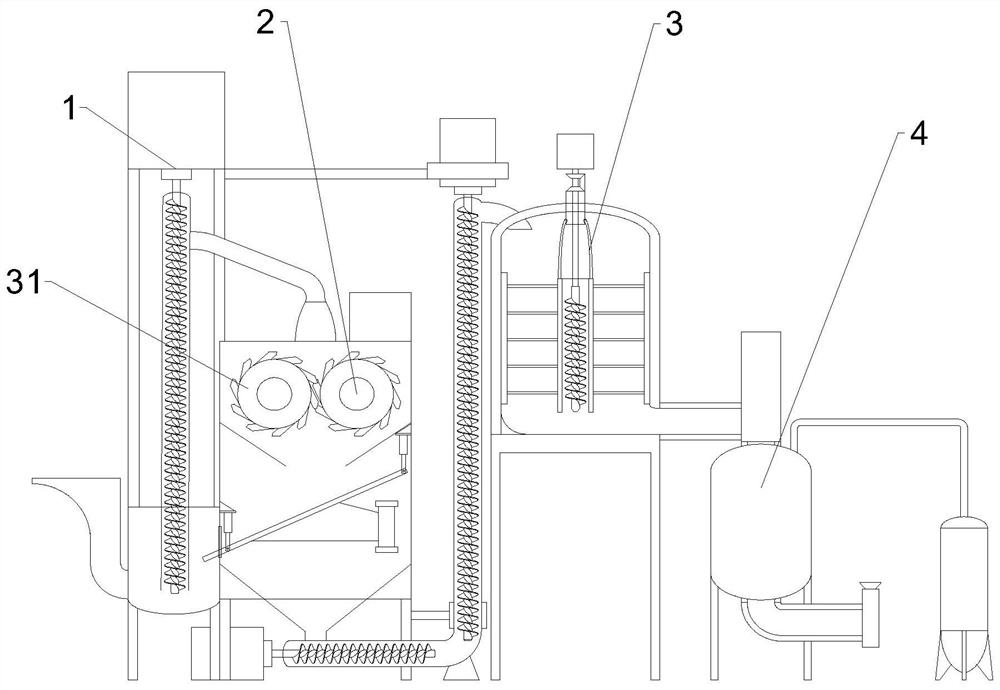

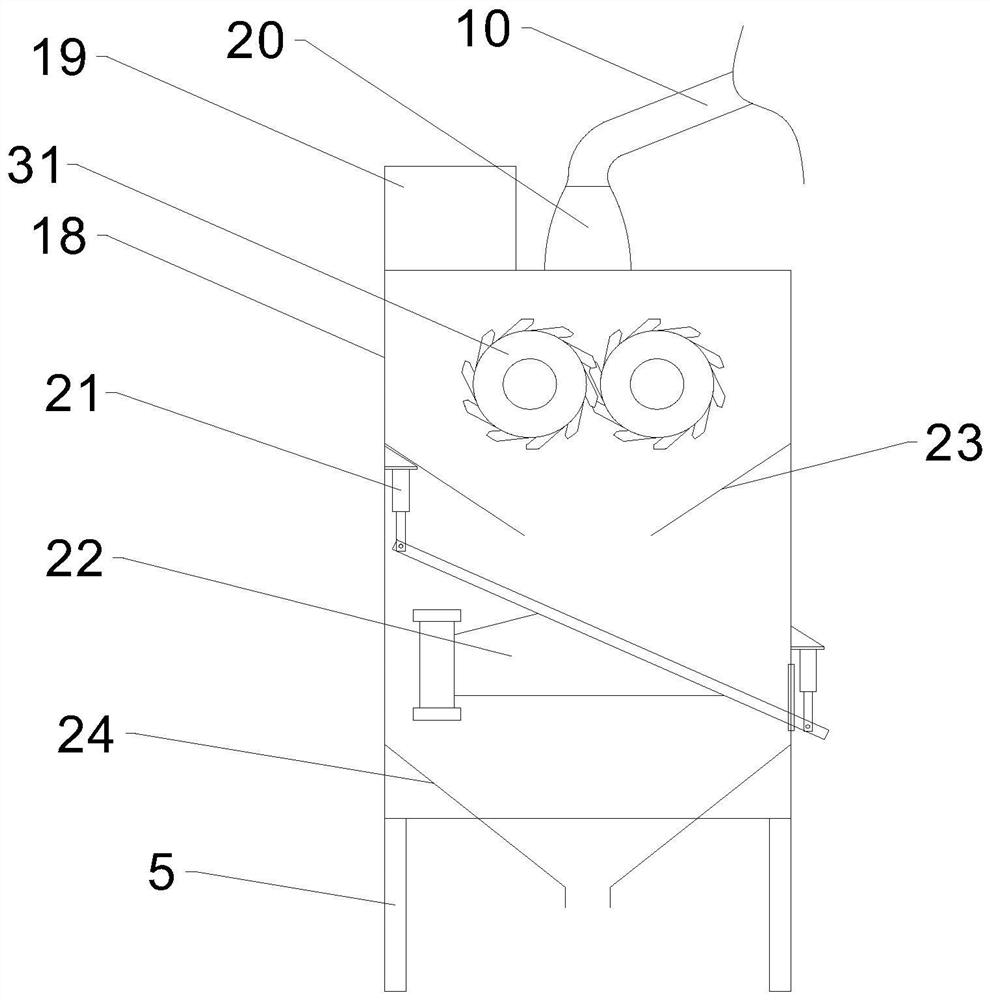

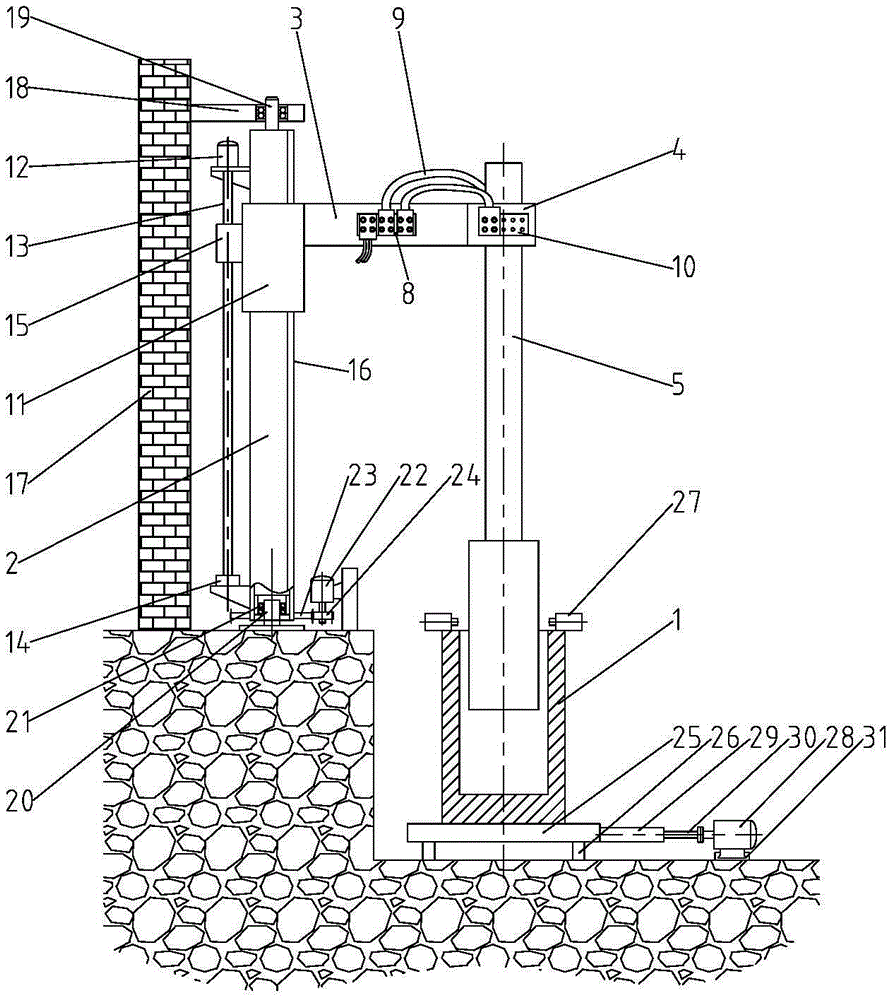

High-temperature melting equipment for preparing nano glass powder

InactiveCN106348571AImprove the crushing effectSpeed up the fallCharging furnaceGlass furnace apparatusConductor CoilNanotechnology

The invention relates to high-temperature melting equipment and in particular relates to high-temperature melting equipment for preparing nano glass powder. Aiming at solving the technical problems, the invention provides the high-temperature melting equipment for preparing the nano glass powder, which is simple to operate, rapid in melting speed and uniform in melting. In order to solve the technical problems, the high-temperature melting equipment for preparing the nano glass powder, provided by the invention, comprises a left frame, a first bearing seat, a bottom plate, a bracket, a melting box, a discharging pipe, a rocking handle, a first rotary shaft, a winding wheel, a first slide block, a pull wire, a first slide rail and the like; the left frame is welded at the left end of the top of the bottom plate; a left side of the top of the bottom plate is connected with the first bearing seat through a connection manner of a bolt. The high-temperature melting equipment for preparing the nano glass powder has the effects of simplicity in operation, short melting time and uniform melting; a worker can realize rapid melting of glass raw materials through utilizing the equipment; the high-temperature melting equipment is simple and convenient to operate and time and labor are saved.

Owner:徐州启迪双创科技企业孵化器有限公司

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

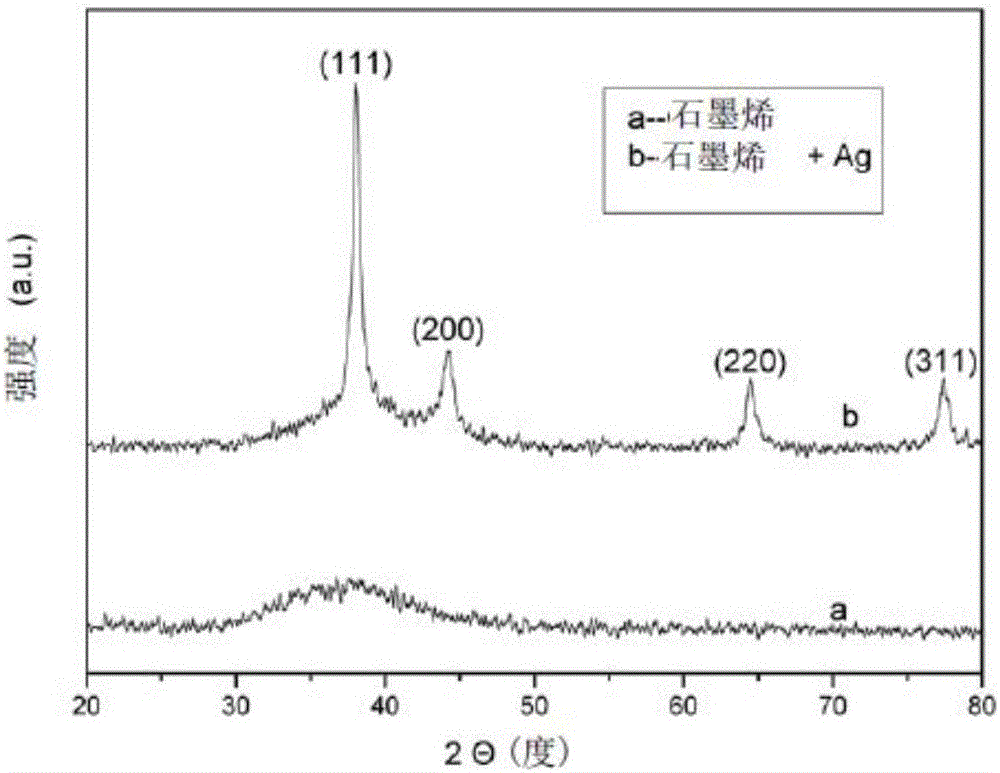

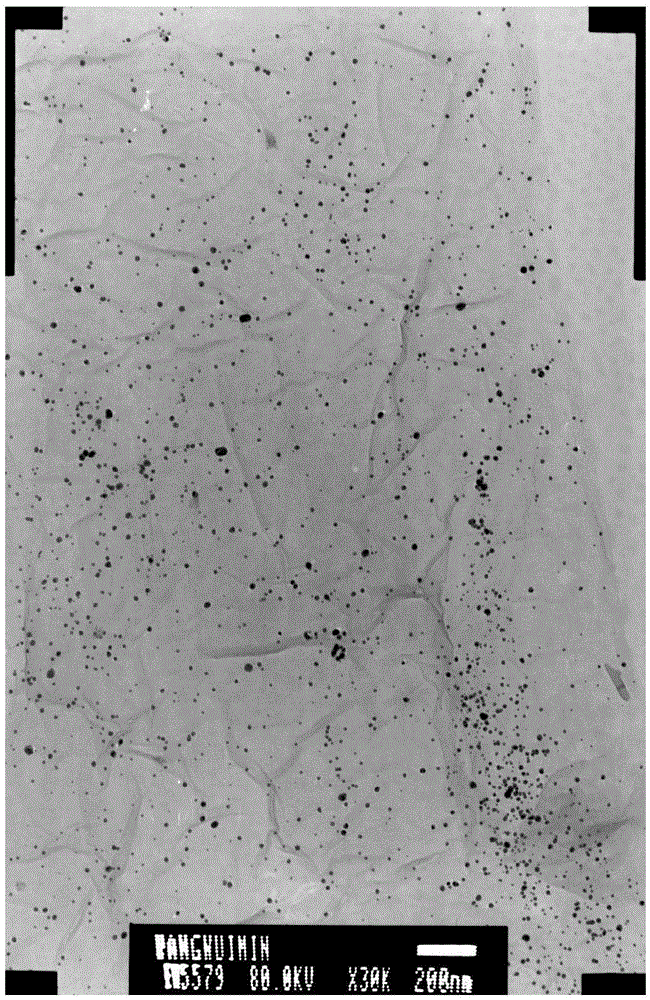

Improved magnesium-nickel-lanthanide series hydrogen storage electrode alloy graphene modification method

The invention relates to a surface modification method for Mg-Ni-La series hydrogen storage electrode alloy, and belongs to the technical field of metallic functional materials. The method mainly comprises the following steps that a magnesium-nickel-lanthanide series, that is, Mg-Ni-La series amorphous alloy, a silver / graphene nano-composite film, tetrahydrofuran and cyclohexane are mixed so that surface modification treatment can be conducted on Mg-Ni-La series hydrogen storage electrode alloy, wherein the Mg-Ni-La series amorphous alloy is 0.8-1.5 grams, and 1 gram is preferred; the silver / graphene nano-composite film is 0.3-0.7 gram, and 0.5 gram is preferred; the tetrahydrofuran is 1-1.5 ml; and the cyclohexane is 1-2 ml. The Mg-Ni-La series hydrogen storage electrode alloy treated through the surface modification method has the characteristics of being high in electrochemical capacity, good in discharging stability and the like.

Owner:QINGDAO UNIV

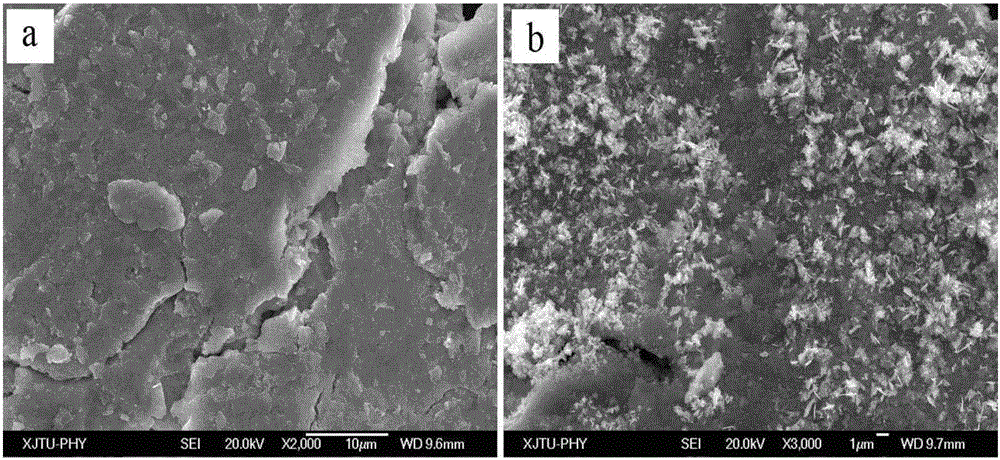

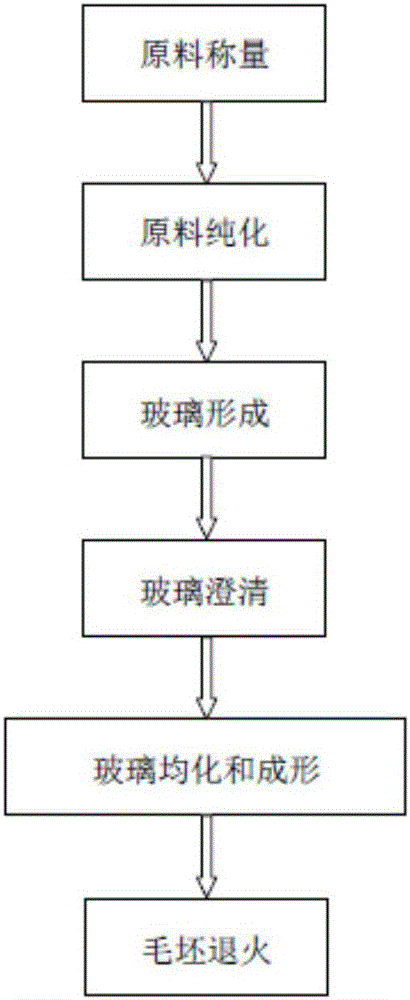

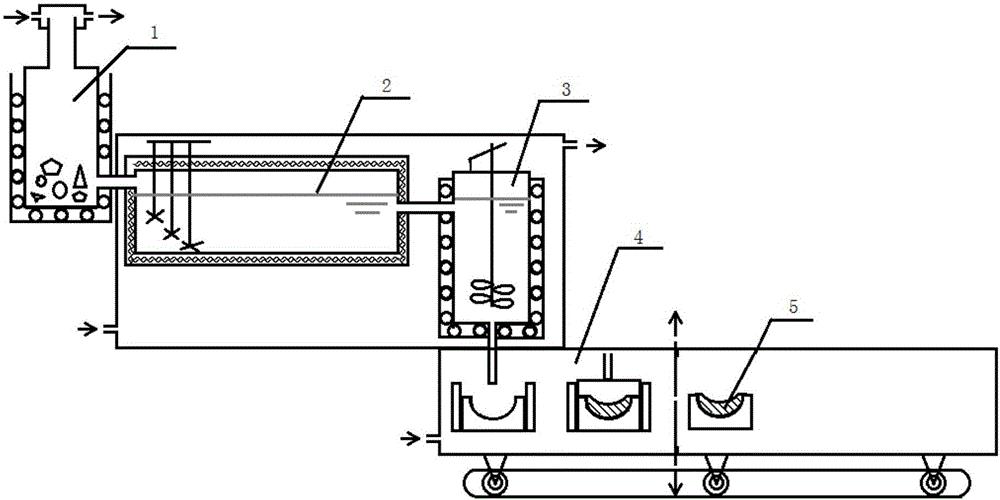

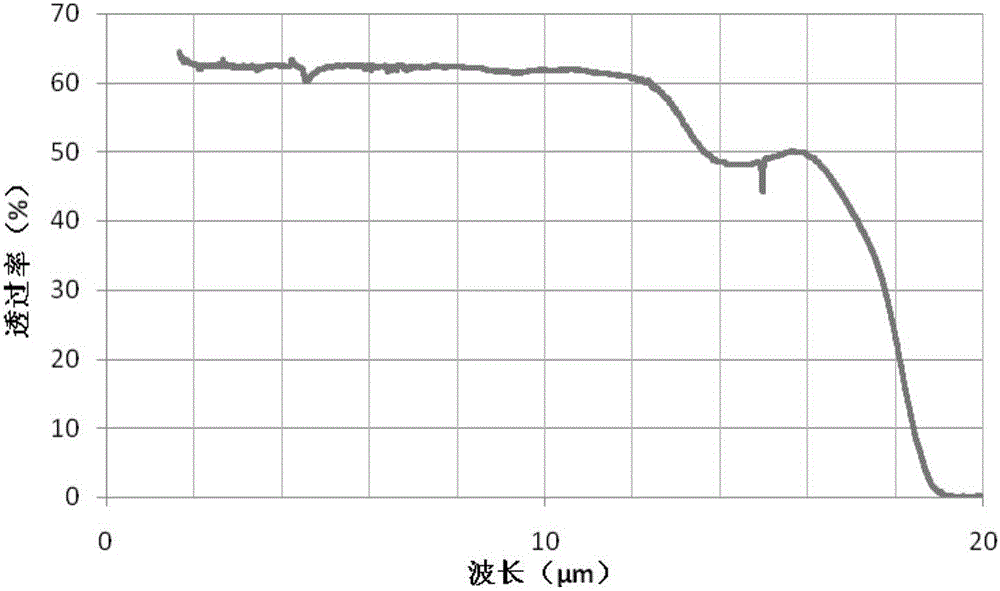

Preparation method of chalcogenide glass

ActiveCN106116110AIncrease production capacityReduce abnormal volatilityGlass furnace apparatusGlass productionChalcogenide glassShielding gas

The invention relates to a preparation method of chalcogenide glass. The method comprises the following steps: 1) under anhydrous and anoxic conditions, weighing and mixing raw materials for the chalcogenide glass, transferring the mixture of raw materials to a raw material purification-glass forming unit, and purifying; 2) heating to 800-900 DEG C, insulating, fully reacting the glass raw materials to form a glass melt, introducing a protective gas, flowing the glass melt to a glass clarification-homogenization unit through a feeding pipe, mixing, sending the mixture into a glass homogenization-formation unit; 3) cooling to 400-500 DEG C, flowing out the evenly stirred glass melt through a bottom leakage pipe, so as to obtain a formed product; and 4) annealing to obtain the chalcogenide glass. The continuous production of raw material feeding, purification, glass formation, clarification, homogenization and formation improves the optical homogeneity, batch stability, yield and production efficiency of the chalcogenide glass.

Owner:CHINA BUILDING MATERIALS ACAD

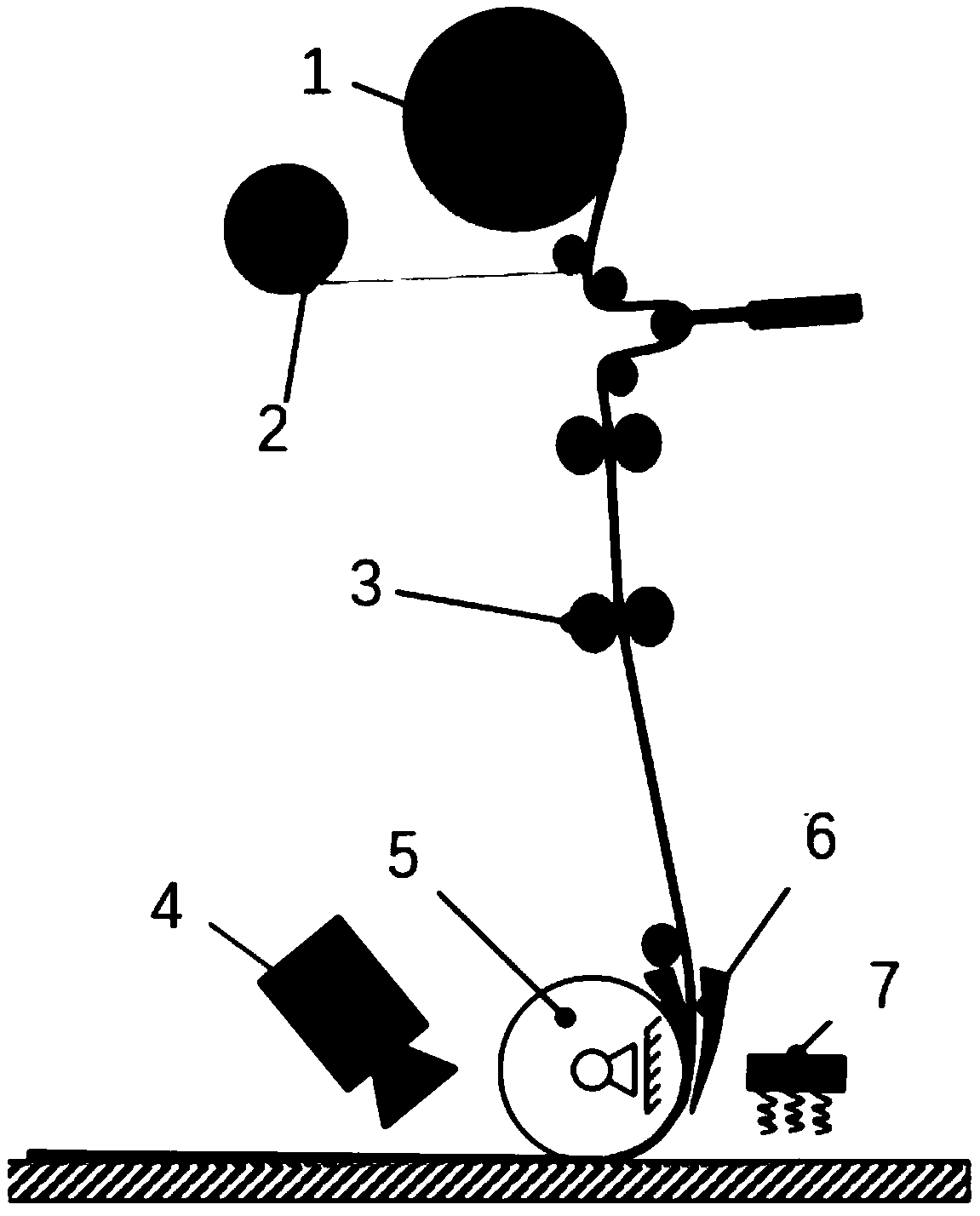

Device for preparing continuous fiber reinforced resin-based composite component

InactiveCN109571932AFast preparationHeating fastManufacturing heating elementsManufacturing material handlingAviationResin-Based Composite

The invention relates to a device for preparing a continuous fiber reinforced resin-based composite component. Adopted parts comprise a raw material storing disc, a tension stabilizing device, a feeding unit, a real-time monitor, a compaction roller, a cutting unit, an infrared heater and the like; and the device adopts far-infrared heating, by combining a fiber laying and in-situ solidifying technology, the high-property composite component is quickly manufactured, and the specific working processes are that raw materials are conveyed to the lower end under control of the feeding unit, the materials are molten through infrared heating, then the upper layer and the lower layer are bonded under the effect of the compaction roller, and the whole component is printed in circulating and reciprocating modes. The device can be applied to the basic fields such as aerospace and military national defense, the technological monopoly of foreign countries on China is broken through, and development in the aspects such as quick manufacturing and quick repairing of the composite component for national aerospace is promoted.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

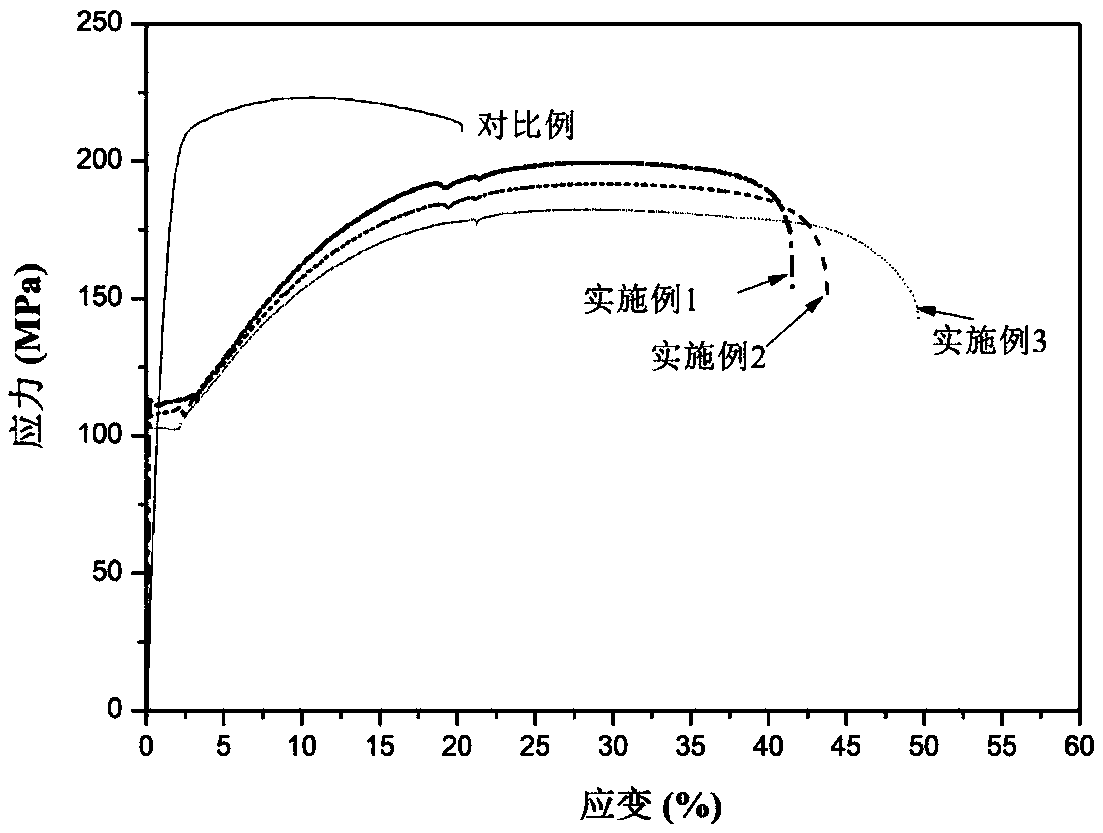

High-plasticity magnesium alloy and preparation method thereof

ActiveCN109402429AImprove flame retardant performanceGood plasticity at room temperatureChemical compositionRoom temperature

The invention relates to high-plasticity magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Nd-Mn magnesium alloy, and comprises the following chemical components in percentages by mass: 2-8 wt% of Bi, 1.5-4 wt% of Nd, 0.05-0.15 wt% of Mn, and the balance of Mg and inevitable impurities, and moreover, the mass ratio of Bi to Nd equals to 1.3-2: 1. The process is simple, the plasticity of deformed magnesium alloy at the room temperature is excellent, the ductility at the room temperature reaches 43% or above, and meanwhile, the flame retardant property is good.

Owner:HEBEI UNIV OF TECH

Linear type efficient electrostatic spinning spray nozzle

InactiveCN102953129AEvenly distributedTake advantage ofSpinnerette packsFilament/thread formingTemperature controlElectrospinning

The invention discloses a linear type efficient electrostatic spinning spray nozzle, which is suitable for the electrostatic spinning of a polymer fusant. The linear type efficient electrostatic spinning spray nozzle comprises a main runner, a crescent runner, a linear nozzle, a diversion trench and a heating and temperature control devices, wherein the polymer fusant enters the crescent runner via the main runner; the fusant can flow to the linear nozzle on a cylindrical wall surface by a crescent flow diversion surface; the polymer flowing out of two sides of the cylindrical wall flows to the bottom end of a horizontal charging barrel via an outer wall surface; secondary shunting of the fusant can be realized by the diversion trench; and after an electrostatic field is added, multiple strands of evenly-injected flows are respectively formed on two sides of the bottom end. According to the linear type efficient electrostatic spinning spray nozzle disclosed by the invention, the problem that materials are left in the nozzle can be solved, and the linear type efficient electrostatic spinning spray nozzle has higher spinning efficiency and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

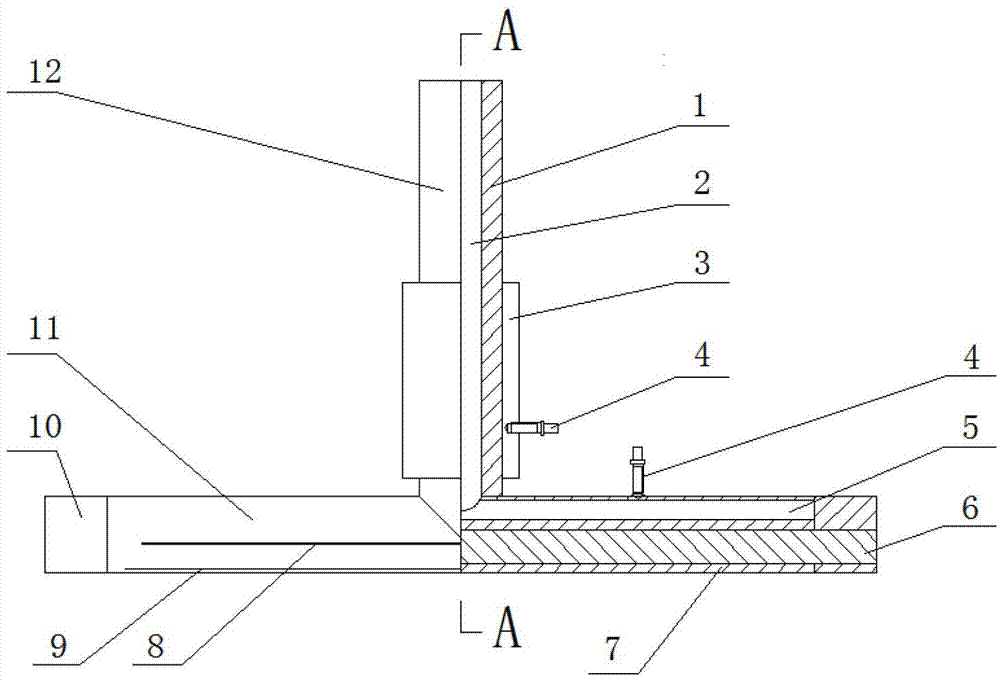

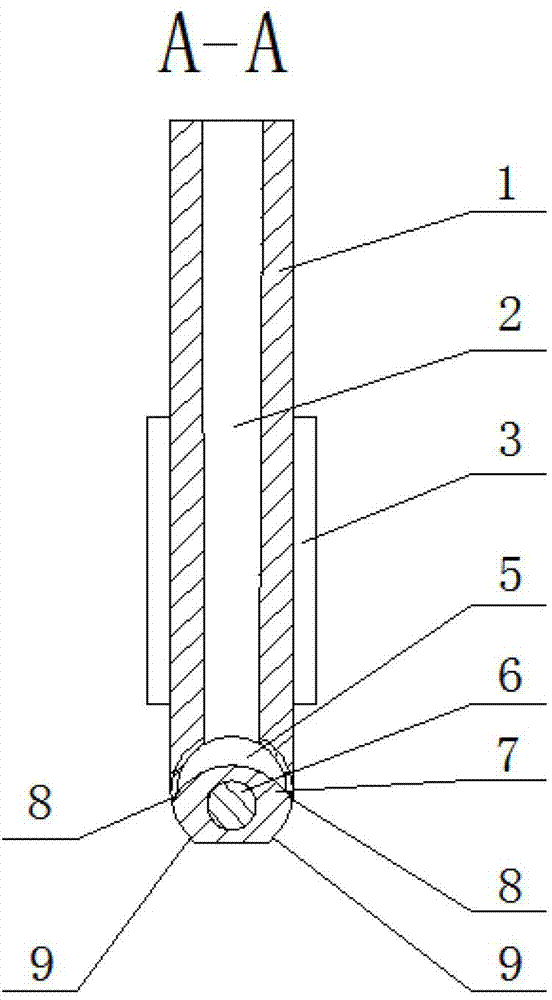

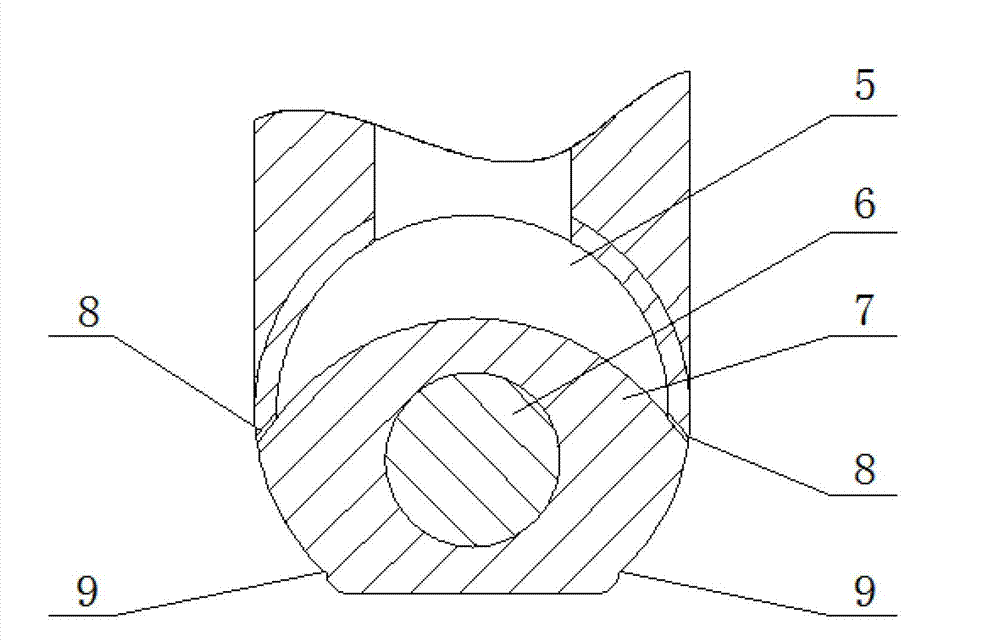

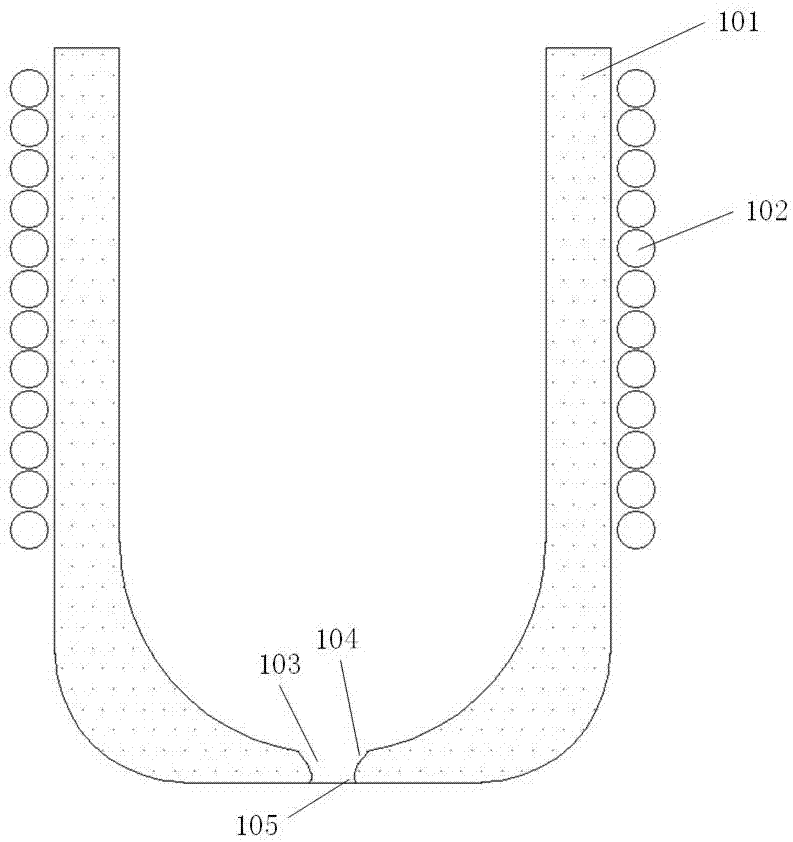

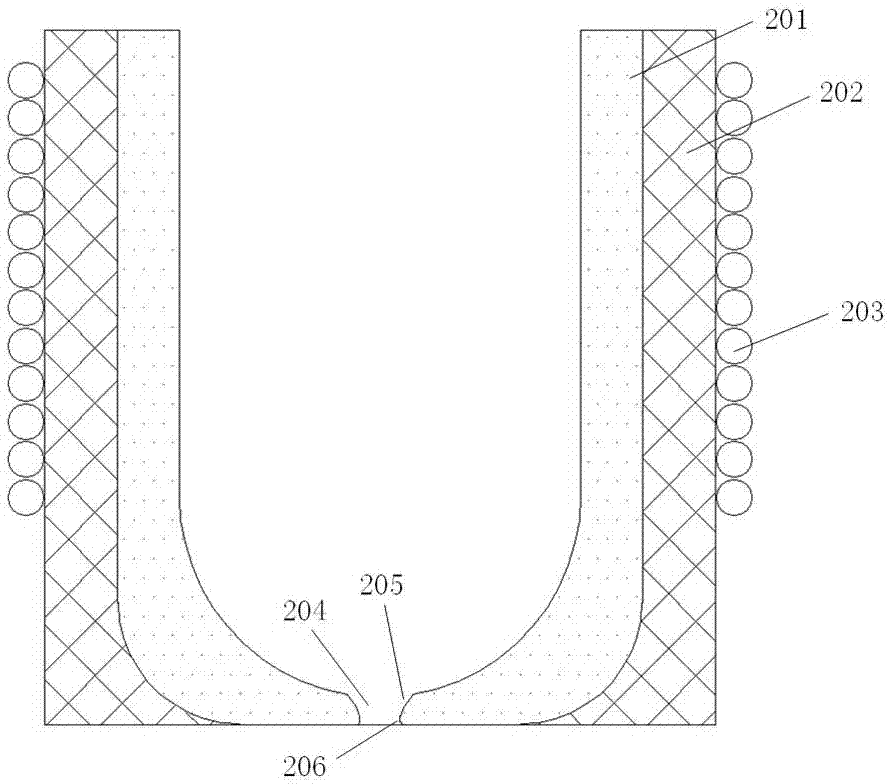

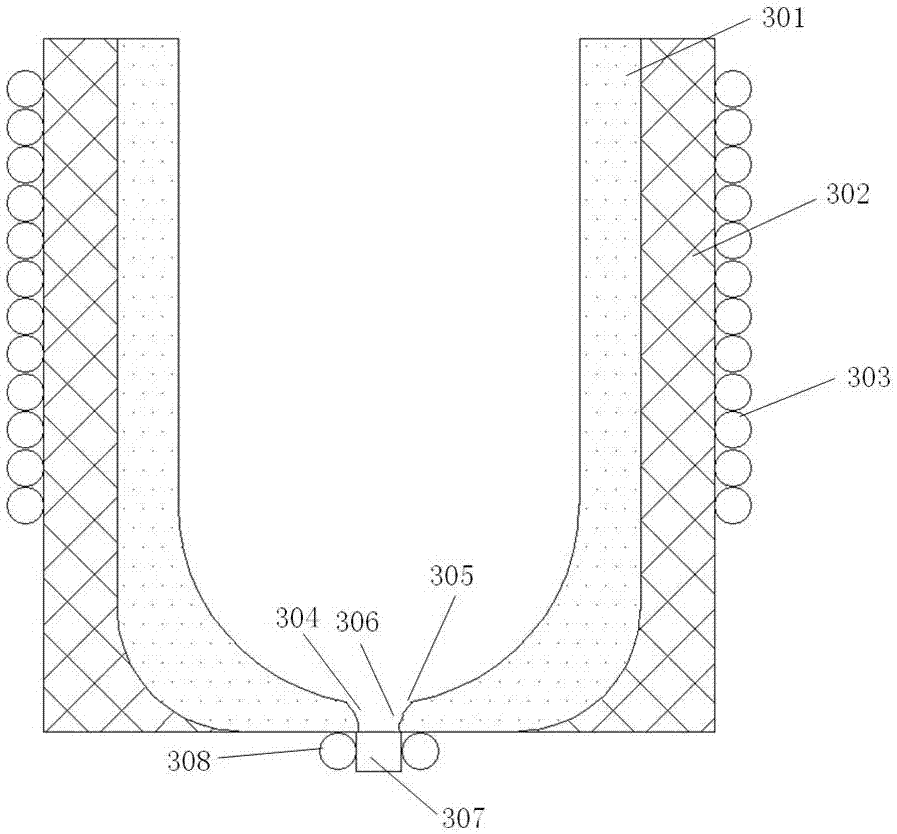

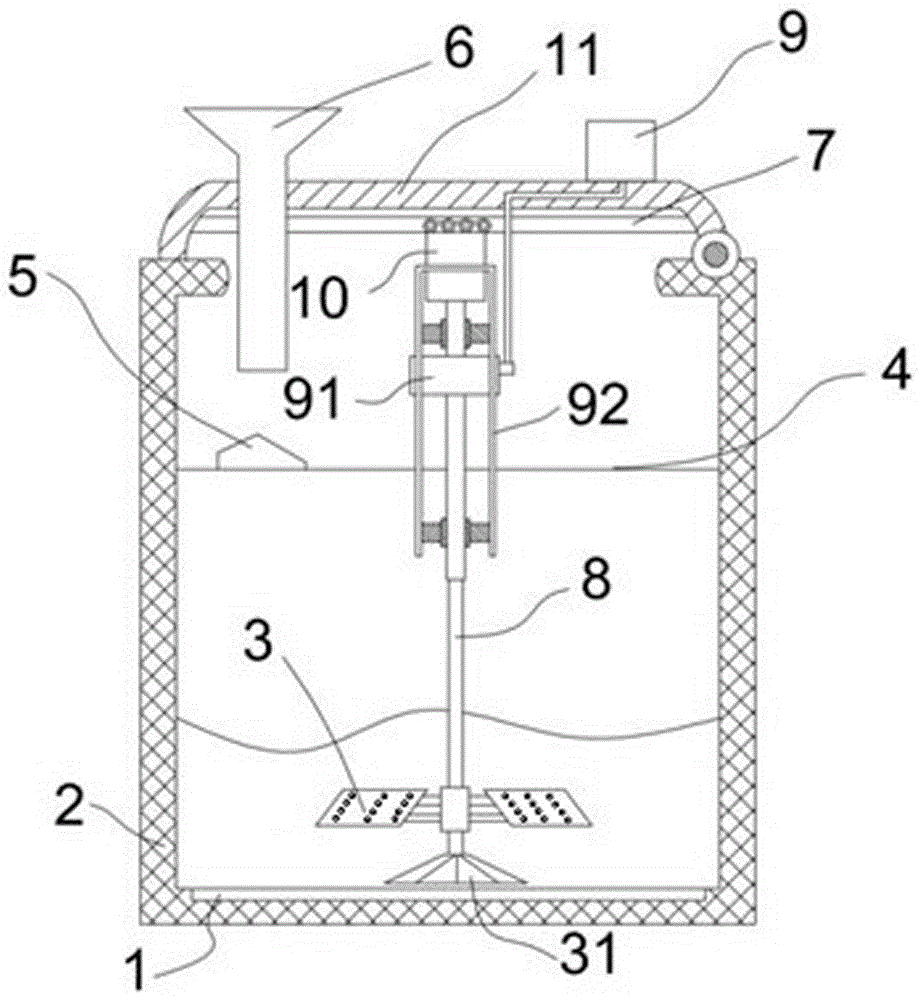

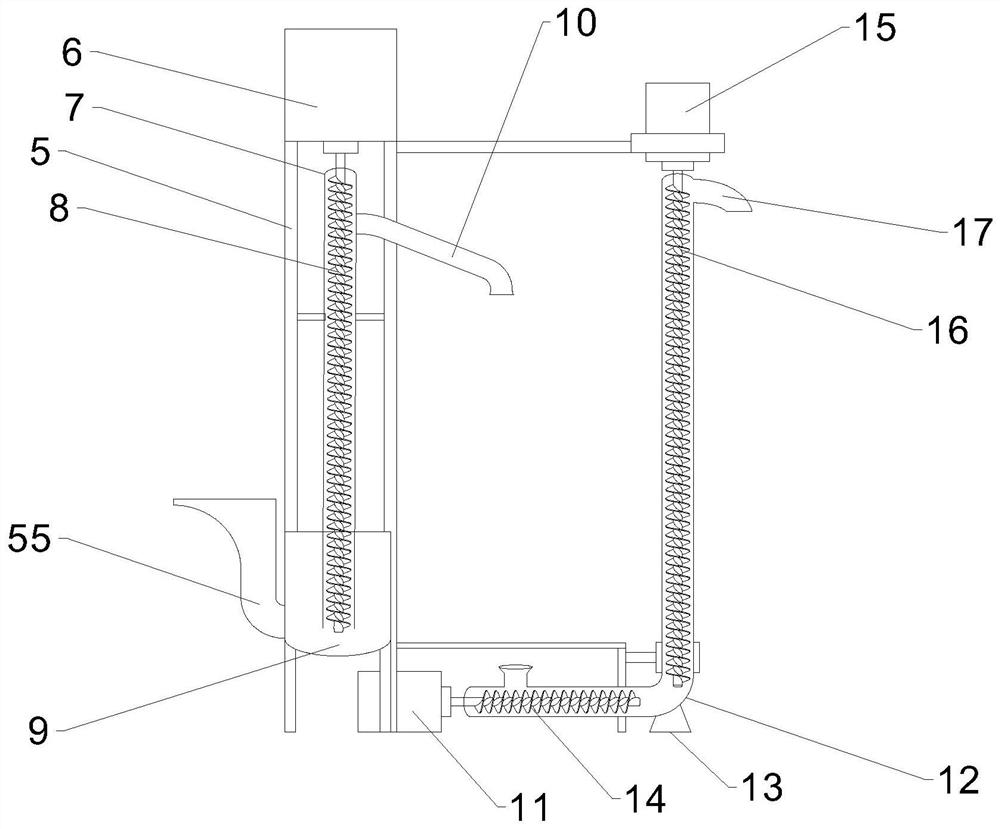

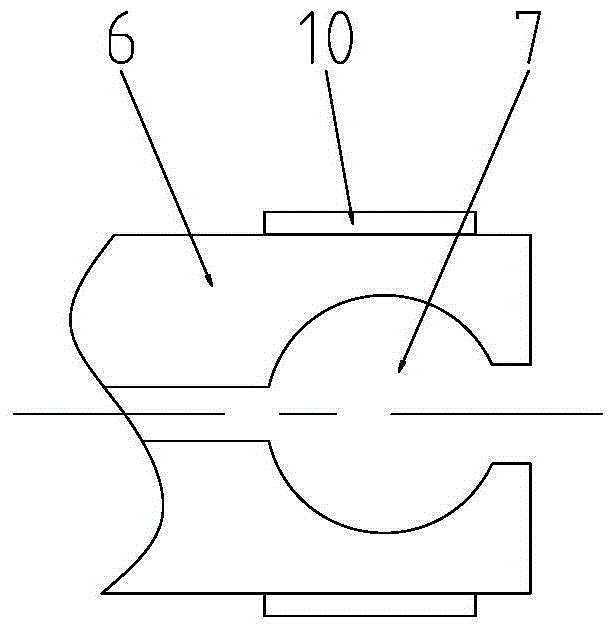

Smelting device and alloy smelting method

PendingCN107024115AUniform meltingAvoid the disadvantages caused by the blanking process of dumping the crucibleIncreasing energy efficiencyCrucible furnacesCrucibleAlloy

The invention discloses a smelting device. The smelting device comprises a crucible body. The smelting device is characterized in that a through hole used as a discharging hole is formed in the bottom part of a crucible, wherein a smelting sensing coil is arranged at the outside of the crucible, and the working length of the smelting sensing coil is not greater than the height of the crucible; the smelting sensing coiling is provided with a driving assembly in a connecting manner and is driven by the driving assembly to move opposite to the crucible in the axial direction of the crucible. With the adoption of the smelting device and the smelting device, the shortages caused by a discharging technology of toppling over the crucible in the prior art can be avoided; alloy raw material can be uniformly smelted; and moreover, the device and the method are convenient and reliable, applicable to various alloy smelting applies, and particularly applicable to a smelting alloy smelting technology with high requirement.

Owner:宋佳

Smelting furnace for uniform full feeding

ActiveCN106766885AAvoid accumulationInvest evenlyFurnace componentsCrucible furnacesEngineeringIngot

The invention discloses a smelting furnace for uniform full feeding. A slide rail for passing through the center of a furnace cover is arranged on the inner surface of the furnace cover; a stirring paddle includes a hydraulic rod and a blade connected to one end of the hydraulic rod; a pulley is mounted at the other end of the hydraulic rod, and is slidingly matched with the slide rail; the pulley is connected with a slide motor; the hydraulic rod is an extension rod, and is connected with an extension motor; the inner wall of a furnace body is connected with a cache frame through a spring; the cache frame includes a leakage ring, and a cross bar connected with the inner wall of the leakage ring; and a discharge port of a material channel is positioned above the intersection of the cross bar. The extension motor shortens the stirring paddle, and slides the stirring paddle to one side, so that an aluminum ingot is fully fed in the smelting furnace; the inner wall of the furnace body is connected with the cache frame through the spring; the cache frame includes the leakage ring and the cross bar; and the discharge port of the material channel is positioned above the intersection of the cross bar, so that the fed aluminum ingot is stopped in the intersection of the cross bar, and is rebounded to fall in the smelting furnace by a hole formed by the cross bar so as to prevent nonuniform smelting.

Owner:湖南振升恒佳新材料科技有限公司

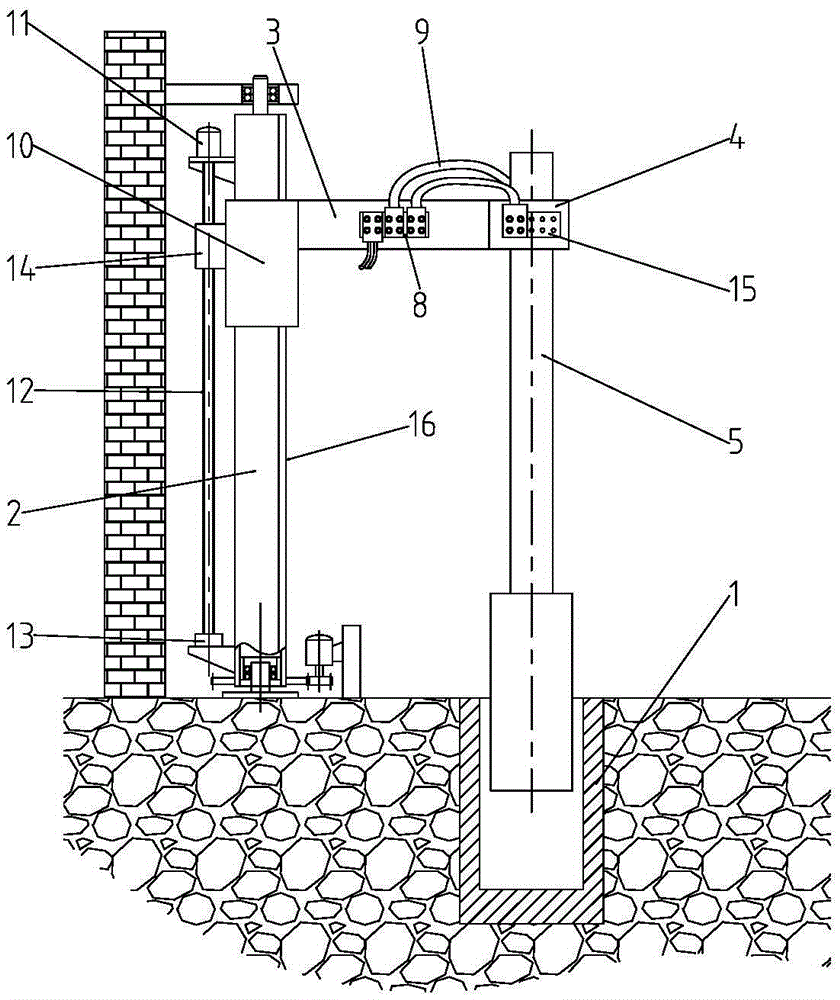

Electroslag remelting furnace stably rising and falling

InactiveCN106544524AUniform current distributionImprove product qualityDrive motorIndustrial engineering

The invention discloses an electroslag remelting furnace stably rising and falling. The electroslag remelting furnace comprises a crystallizer and a vertical supporting column which is provided with a cross arm slidably matched with the vertical supporting column. A clamping device is arranged on the end, being located above the crystallizer and being away from the vertical supporting column, of the cross arm. An electrode stretching into the crystallizer is fixed to the clamping device in a clamped mode. The clamping device comprises two oppositely arranged clamping pieces. A clamping cavity used for clamping the electrode is formed between the two clamping pieces. Distributor plates connected with a power supply device are arranged on the side wall of one side of the cross arm. Connecting cables are arranged between the distributor plates and the two clamping pieces. A lifting slide sleeve is arranged at the other end of the cross arm. The vertical supporting column is provided with a driving mechanism which comprises a driving motor fixedly mounted at the top end of the vertical supporting column. An output shaft of the driving motor is fixedly connected with a threaded screw rod. A limiting base is arranged at the lower end of the vertical supporting column and sleeves the lower end of the threaded screw rod in a rotary cooperation mode. The lifting slide sleeve is provided with an inner threaded sleeve matched with the threaded screw rod.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

High-toughness halogen-free low-smoke flame-retardant power tube and preparation method thereof

PendingCN113087995ACrushed fullyStir wellGrain treatmentsTubular articlesEthylene glycol monophenyl etherMelting tank

The invention discloses a high-toughness halogen-free low-smoke flame-retardant power tube and a preparation method thereof. Modified resin is prepared from the following raw materials in parts by weight: 75-90 parts of isotactic polyethylene resin, 8-11 parts of ethylene glycol monophenyl ether superfine powder, 4-6 parts of nitrile rubber, 4-6 parts of halogen-free flame retardant powder, 1-4 parts of a synergistic flame retardant and 6-18 parts of ultrahigh molecular weight polyethylene resin. Raw material particles with overlarge particle sizes are conveyed into a material storage box to be crushed again, the screened raw materials are conveyed into a mixing mechanism, the raw materials entering a material mixing tank are mixed uniformly through circular stirring, the raw material particles entering a melting tank are subjected to circular stirring from inside to outside, the melting tank is kept vacuum through a vacuum pump, the melting speed of the raw material particles is increased, and the high-toughness halogen-free low-smoke flame-retardant electric power tube is obtained through extrusion, so that the situation that the performance of the electric power tube is uneven due to uneven raw materials is avoided, and the yield of the electric power tube is greatly increased.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Preparing method for ablation-resistant high-ortho phenolic fibers

InactiveCN105332081AIncreased fracture energyImproves ablation resistanceMonocomponent synthetic polymer artificial filamentMelt spinning methodsRoom temperatureNitrogen

The invention discloses a preparing method for ablation-resistant high-ortho phenolic fibers. A phenolic compound and formaldehyde are mixed according to a certain proportion, then a certain amount of citric acid as a catalyst is added, and a boiling reaction is carried out for 0.5-4 h; diluted concentrated sulfuric acid is added, and the reaction continues for 30-50 min; decompression and dehydration are carried out for 0.5-2.9 h, boric acid accounting for 1-8% by mass is added for a modification reaction after the temperature reaches 90-97 DEG C, and boiling is carried out for 2 h at the constant temperature; decompression and dehydration are carried out, and dehydration is stopped when the temperature of resin reaches 110 DEG C; the resin is subjected to melt spinning at 120-160 DEG C; nascent fibers are put into a prepared curing solution, the temperature is increased to 95 DEG C gradually from the room temperature, and the nascent fibers are naturally cooled to the room temperature after constant temperature is achieved; the temperature is gradually increased for thermosetting under the nitrogen condition. The fiber strength of the high-ortho phenolic fibers ranges from 3 cN / dtex to 36 cN / dtex, the modulus ranges from 40 cN / dtex to 400 cN / dtex, and the cross-linking degree ranges from 32% to 38%.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of high-strength veneer board for packaging box

ActiveCN107297793AGood weather resistanceImprove wear resistanceOther plywood/veneer working apparatusWood veneer joiningWeather resistanceHigh intensity

The invention mainly relates to the technical field of machining of artificial boards and discloses a preparation method of a high-strength veneer board for a packaging box. The preparation method comprises the following steps: heating, immersing, freezing, gluing, carrying out hot pressing and trimming. The method is simple; the strength of the obtained high-strength veneer board for the packaging box is remarkably improved and the bearing capability reaches 5173kg; a wood core veneer is sufficiently heated and dried and the moisture content is lower than that of conventional wood, so that an adsorption capability of the core veneer on a subsequent treatment solution can be improved and the production efficiency is improved; a face veneer is heated and subjected to heat insulation, so that the weather resistance and wearing resistance of the face veneer can be improved and the service life of the veneer board is prolonged; the core veneer is a poplar board and has the advantages of wide raw material source, low price and strong buffering capability; the face veneer is an ecological resin board added with sodium carbonate and the face veneer is safe and has no toxin and has strong bearing capability and buffering capability, so that the durability of the veneer board is improved and the service life is prolonged; the veneer board can be recycled and repeatedly utilized so that the environment is protected and the cost is saved.

Owner:阜南盛原木业有限公司

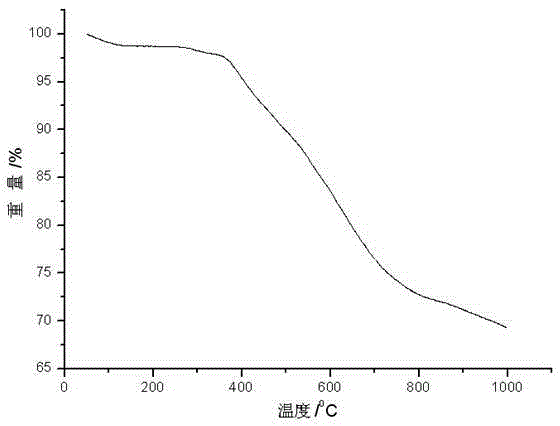

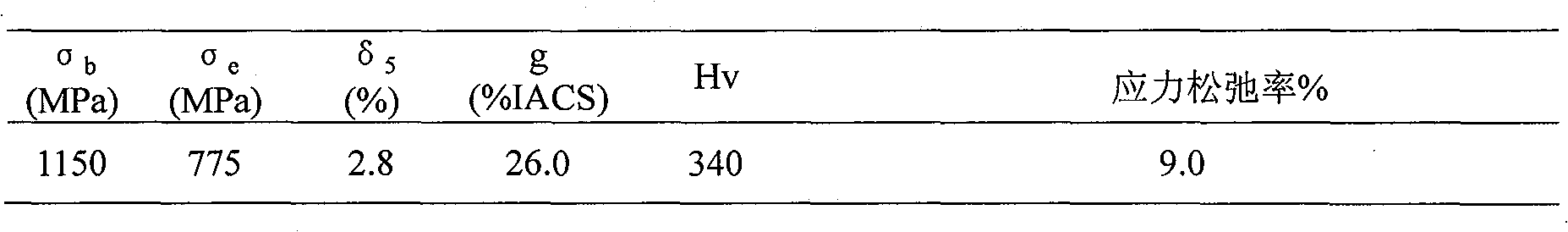

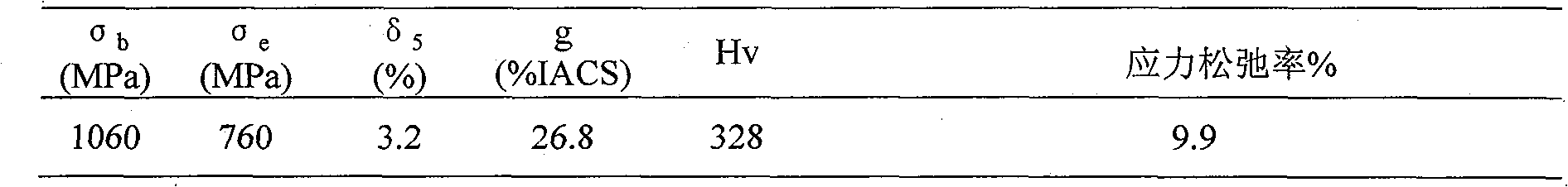

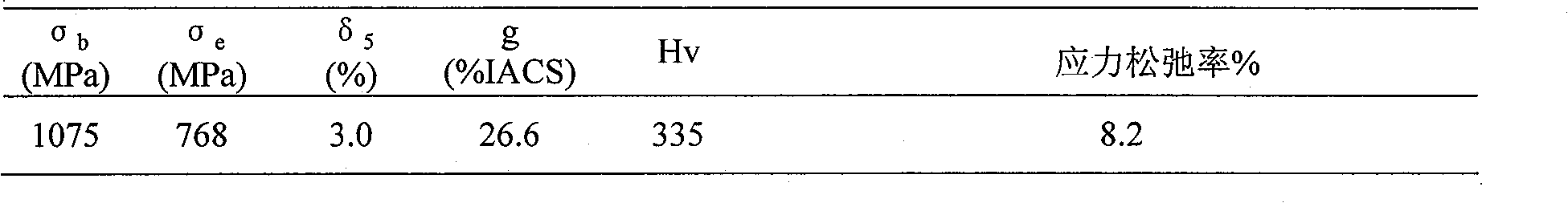

Ultra-high strengthen, high-conductivity CuNiSi series elastic copper alloy and method for preparing same

Disclosed is a CuNiSi system elastic copper alloy with ultra high strength and high conductivity as well as a method for the production thereof, having (in weight percent ): Ni: 6.4 to 8.2wt percent; Si: 1.2 to 1.8wt percent; Sn: 0.3 to 0.5wt percent; Mg: 0.1 to 0.2wt percent; Zr: 0.1 to 0.2wt percent; and balance Cu, and the method for the production thereof comprises five steps of: (1) CuNiSi non-vacuum secondary remelting and ingot casting; (2) homogenizing treatment and hot rolling; (3) twin-stage solution treatment; (4) cold rolling; and (5) time effect treatment. The elastic copper alloy and the method have advantages of reasonable alloy constituents, high alloying degree, simple production process, convenient operation, low production cost, high alloy strength, high conductivity and good stress relaxation resistance, and can realize the preparation of large specification billet, and Ni and Si content in the prepared target alloy system is high, and the process method of the invention is suitable for the industrialized production, and can replace the current aerospace high-power hermetically sealed electromagnetic relays, as well as raw materials and production processes of high performance conductive elastic devices in the electronic industry.

Owner:CENT SOUTH UNIV

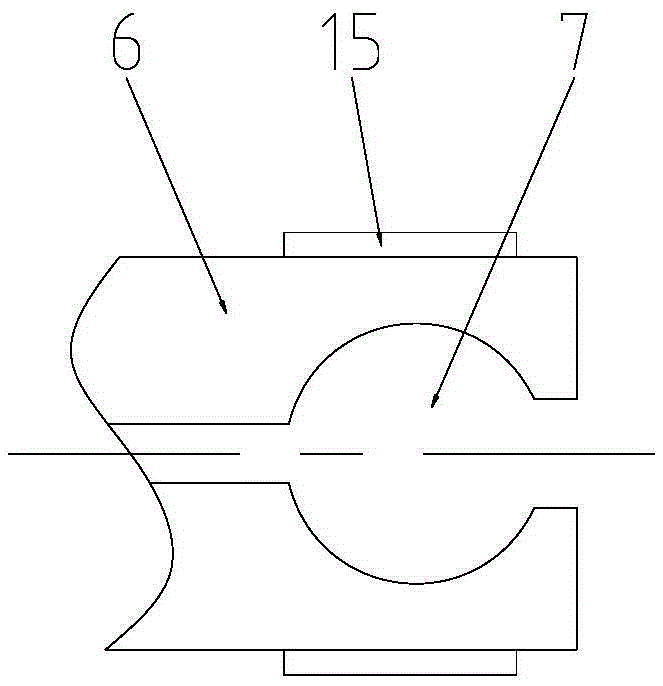

Electroslag remelting furnace with accurate positioning function

InactiveCN106544521APrecise control of lifting heightPrecise position adjustmentEngineeringElectro-slag remelting

The invention discloses an electroslag remelting furnace with the accurate positioning function. The electroslag remelting furnace with the accurate positioning function comprises a crystallizer and a vertical supporting column located on one side of the crystallizer; the vertical supporting column is provided with a transverse arm in sliding fit with the vertical supporting column; the end, away from the vertical supporting column, of the transverse arm is located above the crystallizer and provided with a holder; an electrode extending into the crystallizer is clamped and fixed to the holder; the electroslag remelting furnace with the accurate positioning function further comprises a transverse arm lifting mechanism used for controlling lifting of the transverse arm, a stand column rotation mechanism used for controlling the vertical supporting column to rotate, and an electrode centering mechanism used for centering and positioning of the crystallizer and the electrode; the electrode centering mechanism comprises a supporting seat fixedly arranged below the crystallizer and a position adjusting mechanism used for adjusting the position of the supporting seat; the crystallizer is fixedly installed on the supporting seat; universal idler wheels are arranged below the supporting seat; and photoelectric sensors used for detecting the position of the electrode are annularly and evenly arranged on the top face of the crystallizer.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com