Patents

Literature

102results about How to "Improve the crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

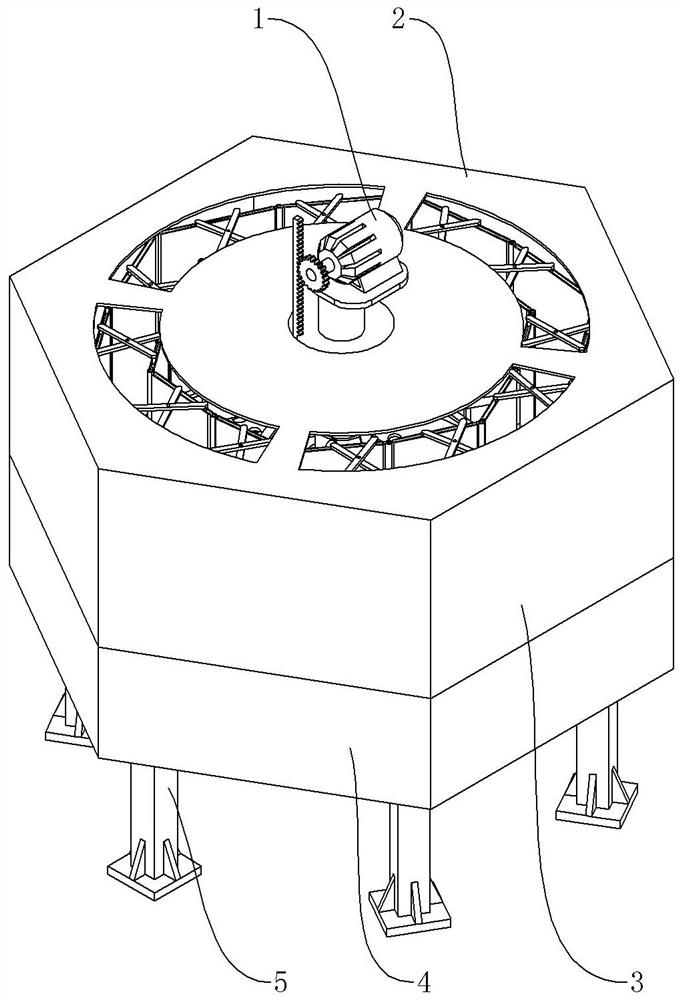

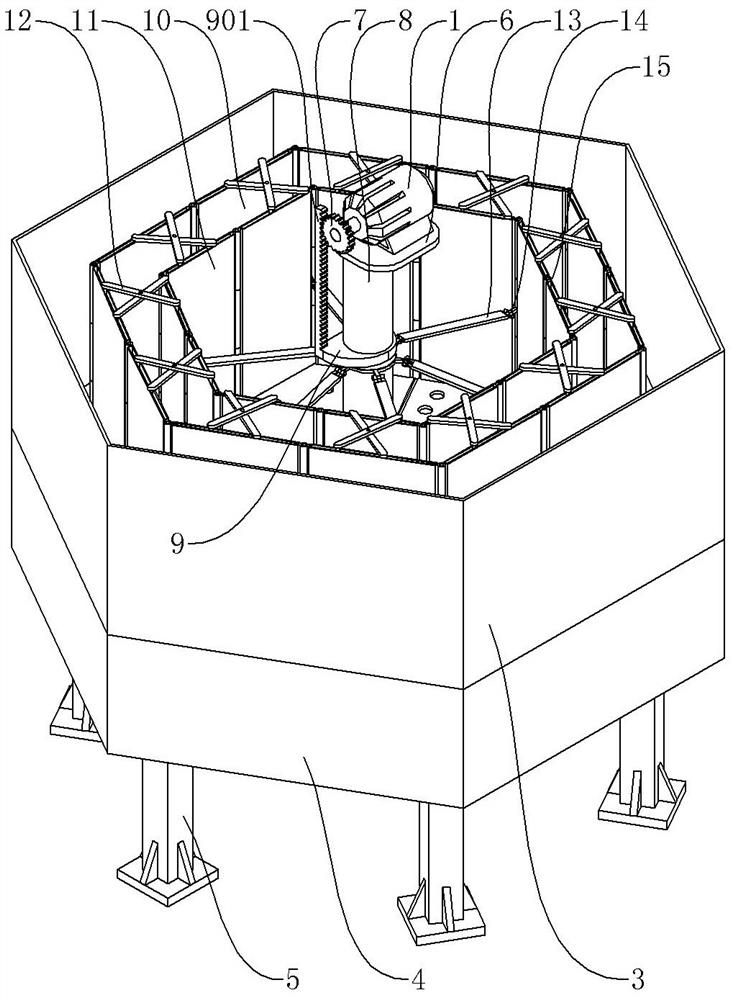

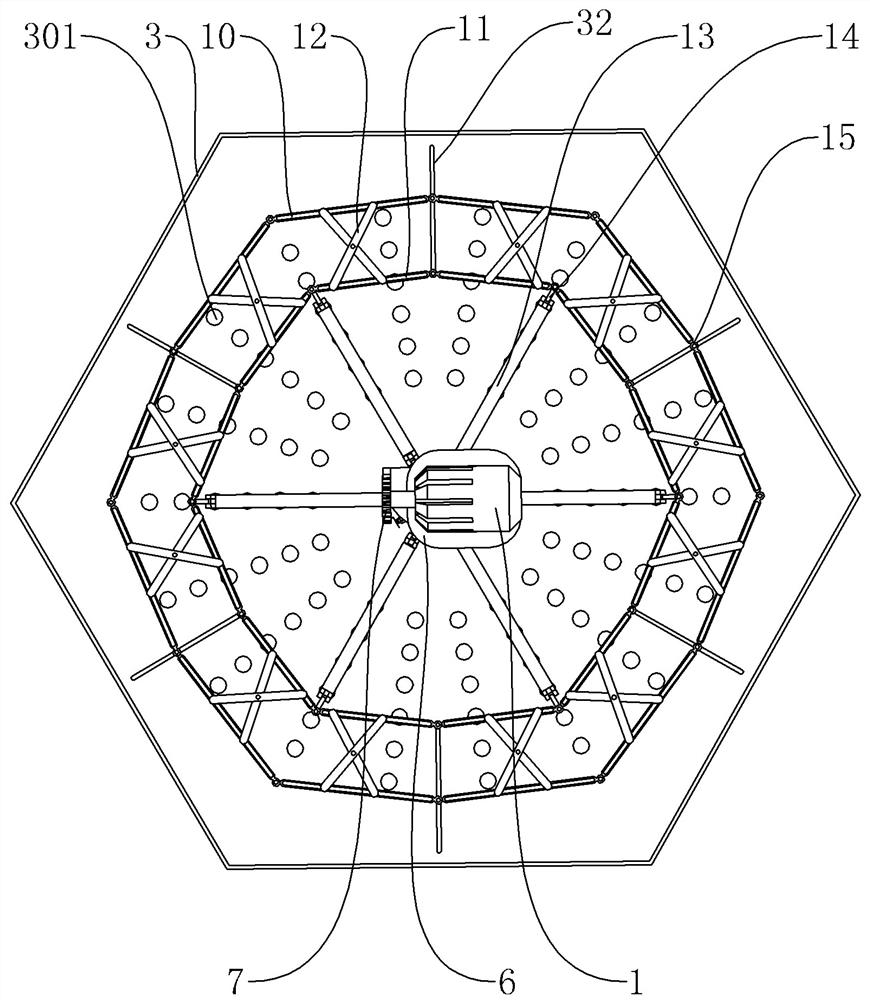

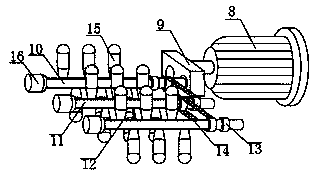

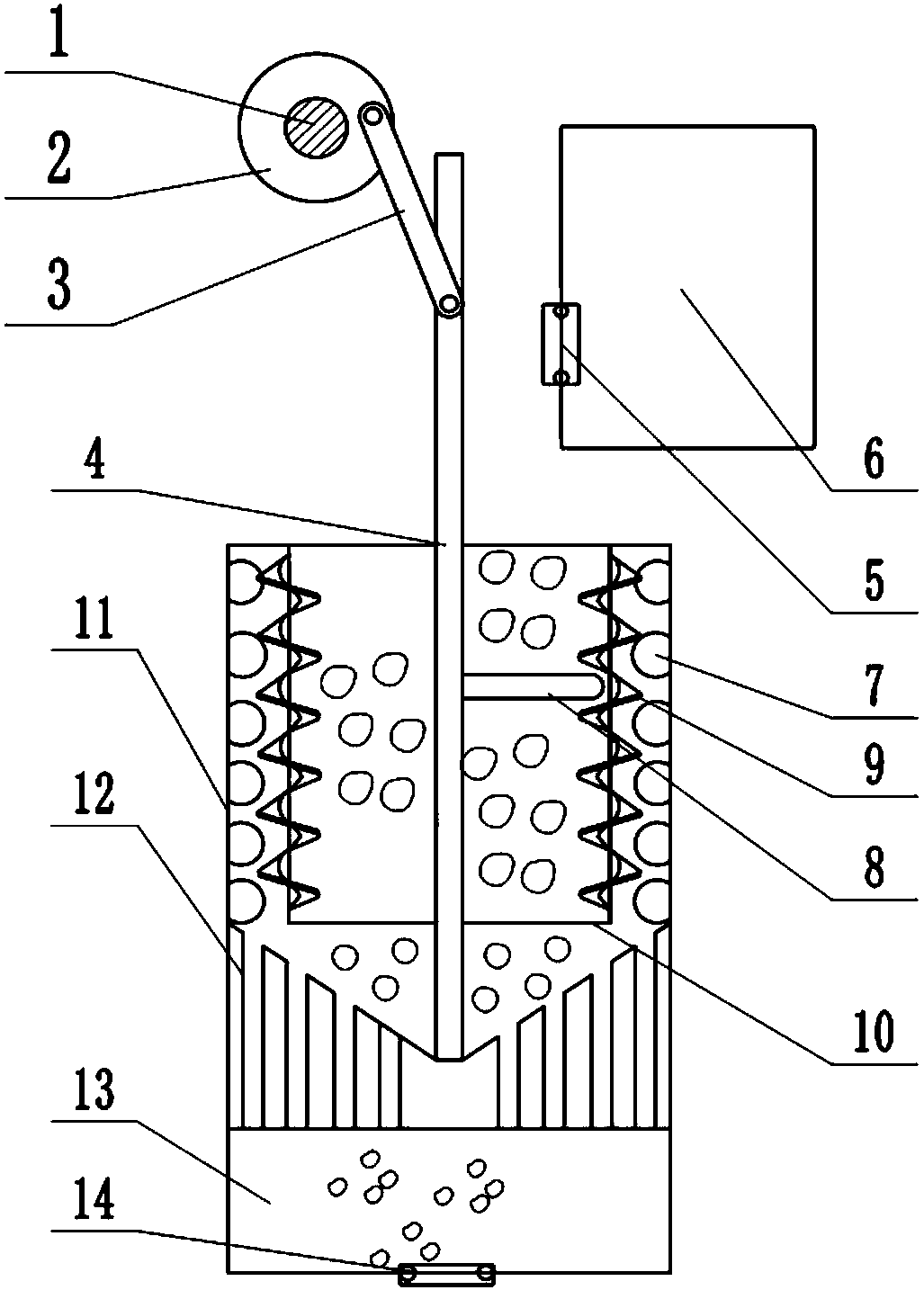

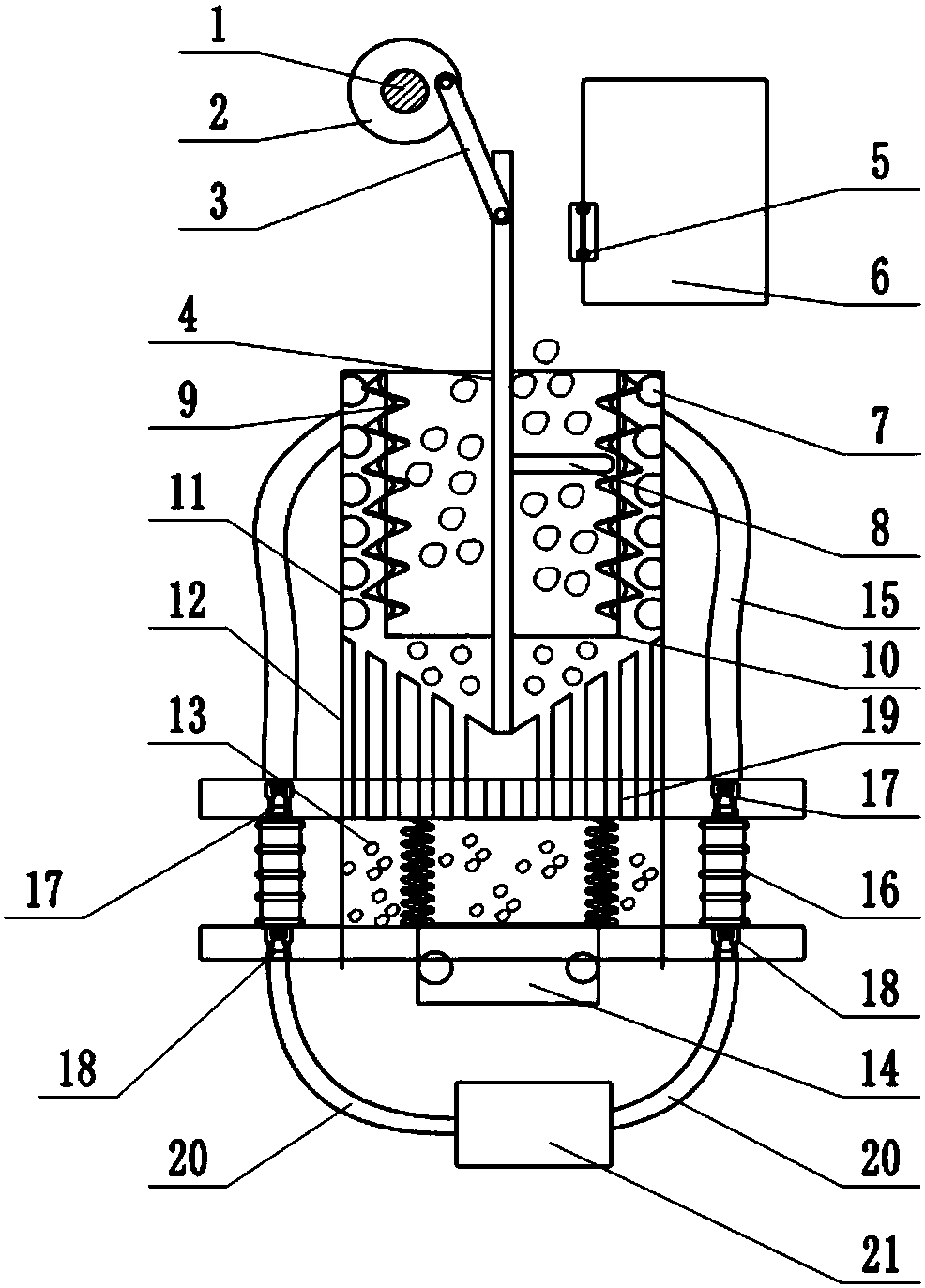

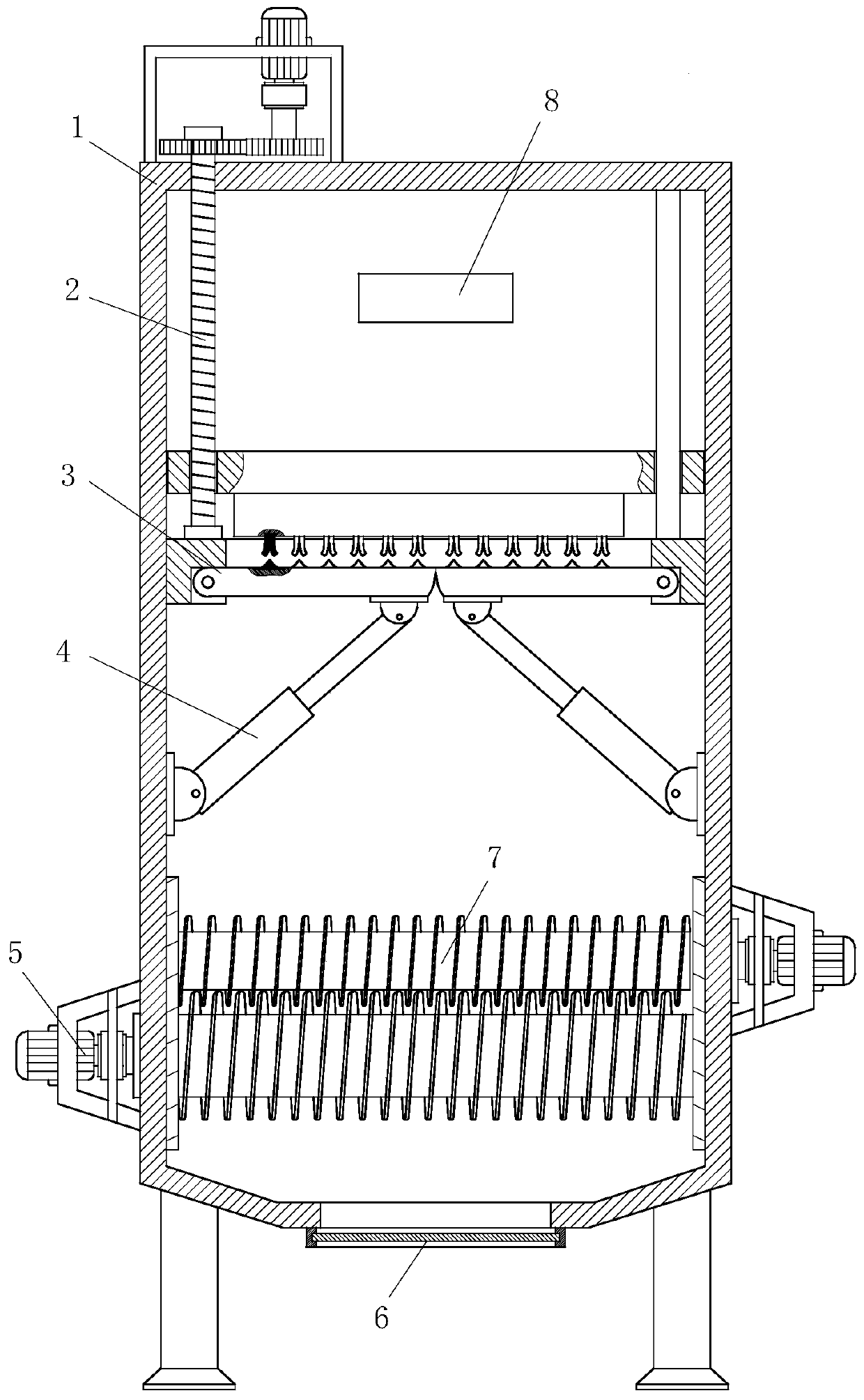

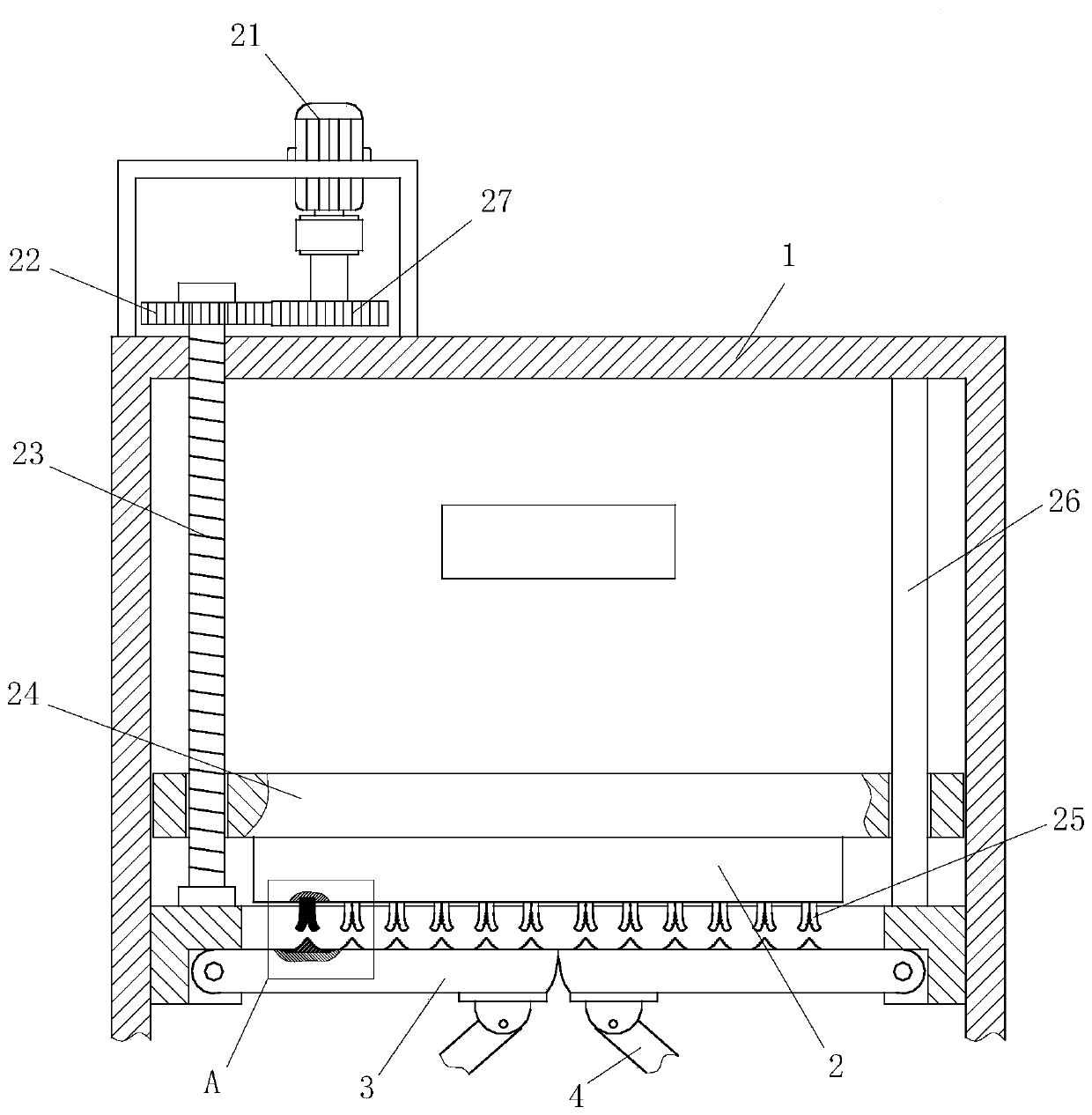

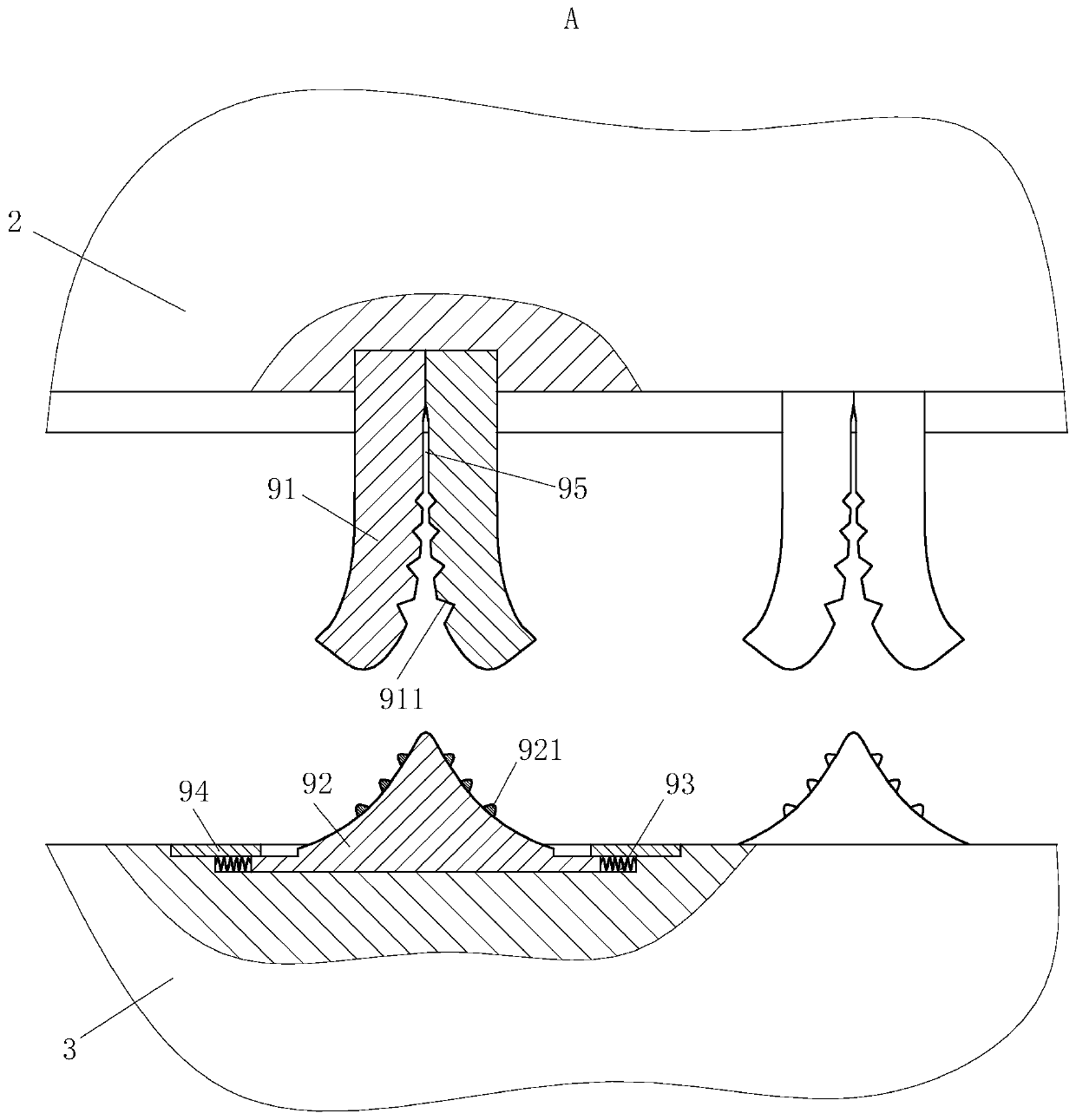

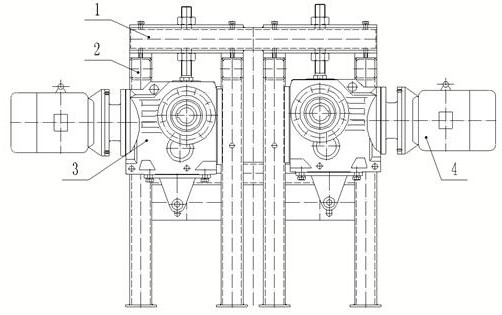

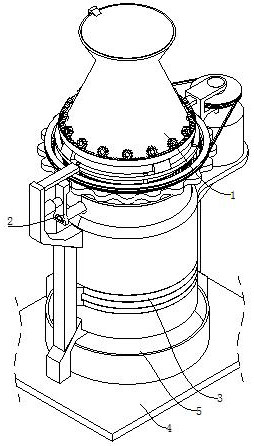

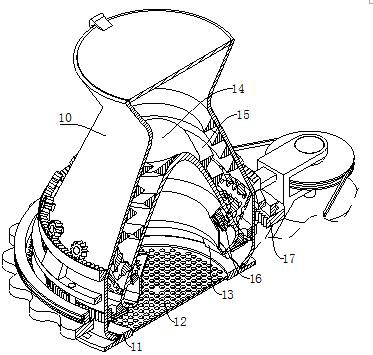

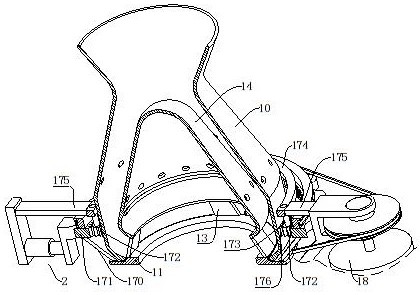

Polygonal hydraulic crushing device

InactiveCN113499840AImprove the crushing effectEvenly brokenGrain treatmentsGrindingStructural engineering

The invention relates to the technical field of grinding and crushing, in particular to a polygonal hydraulic crushing device. The polygonal hydraulic crushing device comprises a shell, a fixed shaft, a double-layer crushing ring, a mounting shaft, a movable shaft, a movable ring, a plurality of pull rods and a driving mechanism. A containing cavity with an upward opening is formed in the shell. According to the polygonal hydraulic crushing device, the polygonal inner crushing ring and the polygonal outer crushing ring are used for crushing materials in a crushing cavity, the shapes of the inner crushing ring and the outer crushing ring slide relatively in the changing process, so that the materials in the crushing cavity are rubbed, the crushing effect on the materials is enhanced, meanwhile, the materials move along with sliding of a crushing plate, thus the materials are crushed more uniformly, the crushing time is saved, and the crushing efficiency is improved.

Owner:JIANGSU OSCEN HYDRAULIC TECH

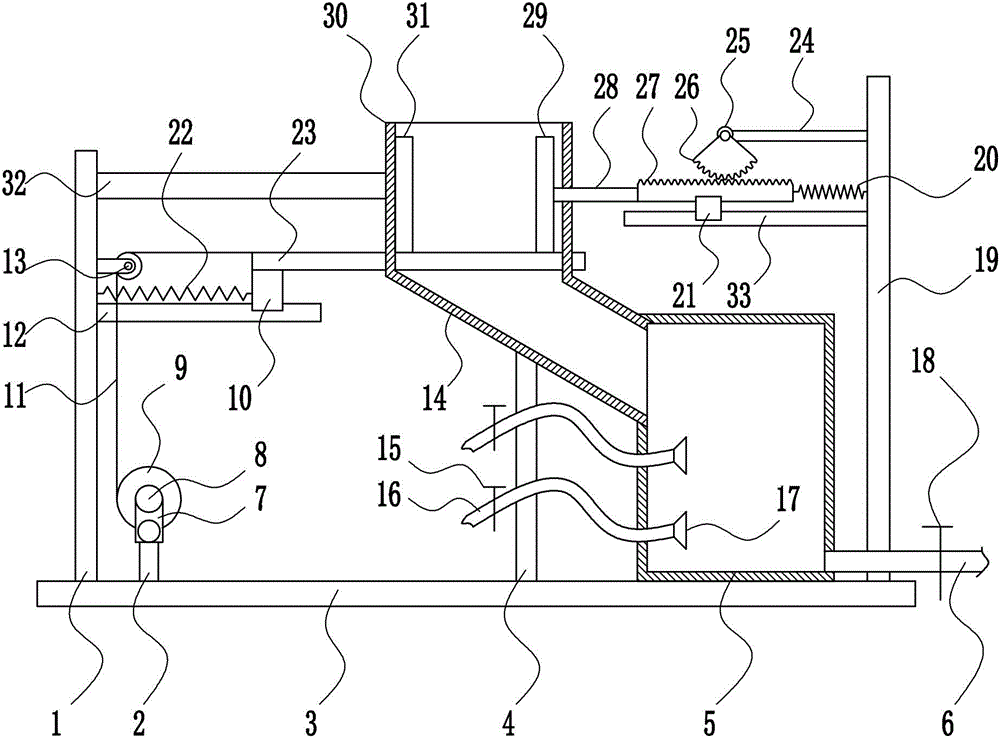

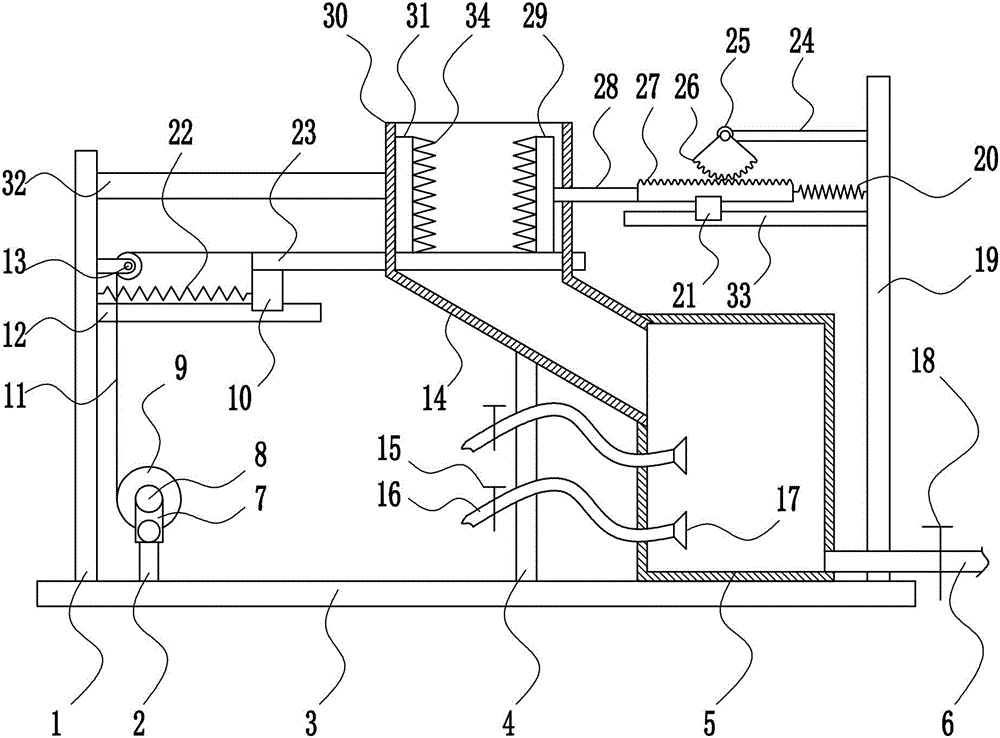

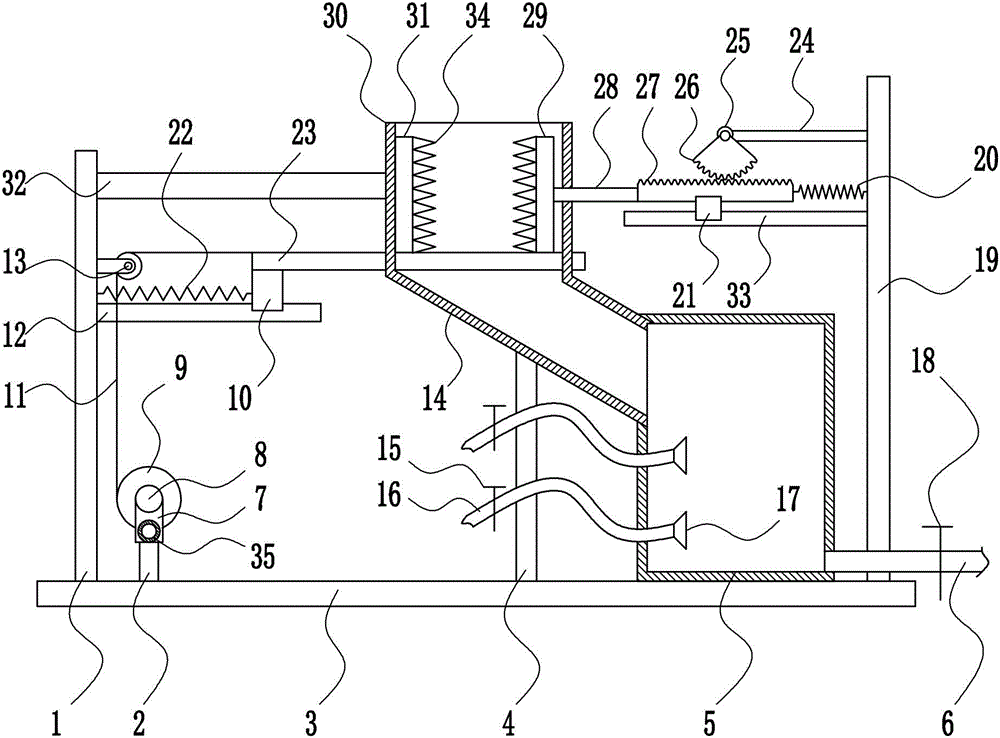

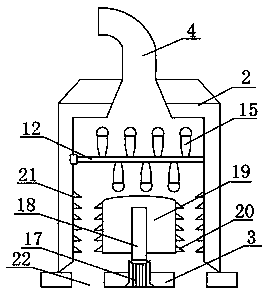

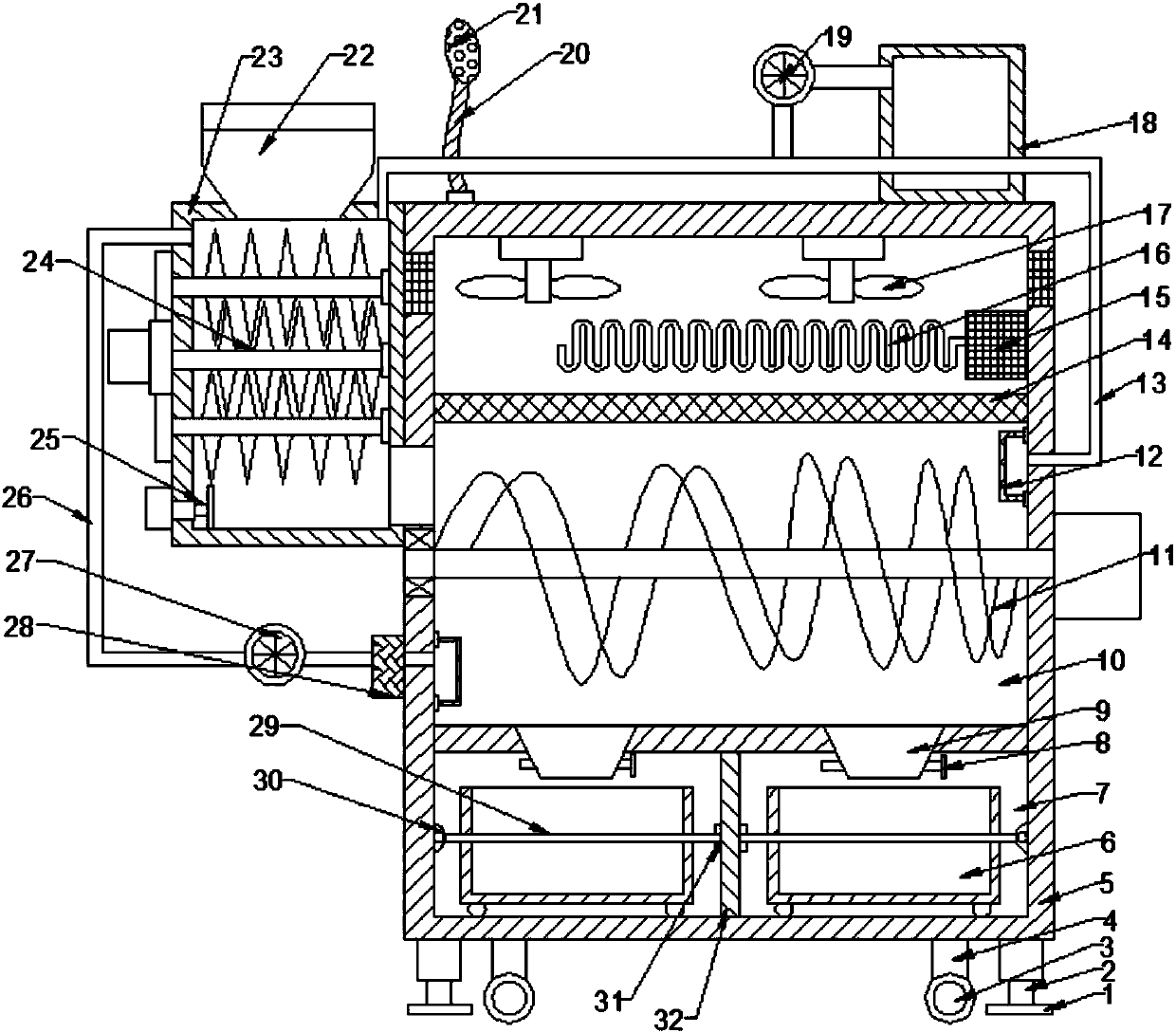

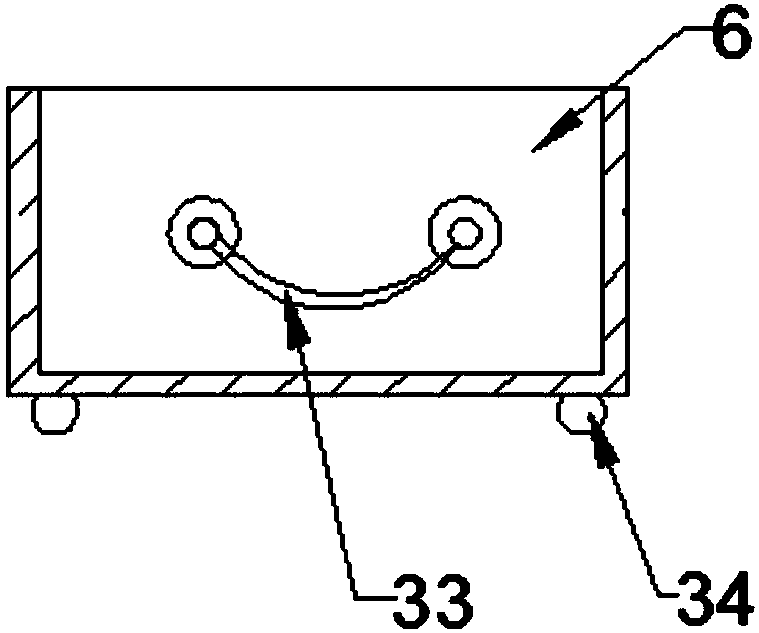

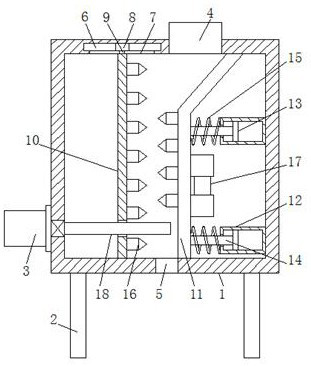

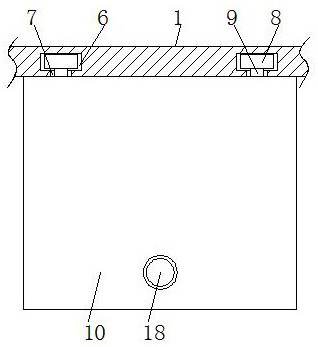

High-temperature melting equipment for preparing nano glass powder

InactiveCN106348571AImprove the crushing effectSpeed up the fallCharging furnaceGlass furnace apparatusConductor CoilNanotechnology

The invention relates to high-temperature melting equipment and in particular relates to high-temperature melting equipment for preparing nano glass powder. Aiming at solving the technical problems, the invention provides the high-temperature melting equipment for preparing the nano glass powder, which is simple to operate, rapid in melting speed and uniform in melting. In order to solve the technical problems, the high-temperature melting equipment for preparing the nano glass powder, provided by the invention, comprises a left frame, a first bearing seat, a bottom plate, a bracket, a melting box, a discharging pipe, a rocking handle, a first rotary shaft, a winding wheel, a first slide block, a pull wire, a first slide rail and the like; the left frame is welded at the left end of the top of the bottom plate; a left side of the top of the bottom plate is connected with the first bearing seat through a connection manner of a bolt. The high-temperature melting equipment for preparing the nano glass powder has the effects of simplicity in operation, short melting time and uniform melting; a worker can realize rapid melting of glass raw materials through utilizing the equipment; the high-temperature melting equipment is simple and convenient to operate and time and labor are saved.

Owner:徐州启迪双创科技企业孵化器有限公司

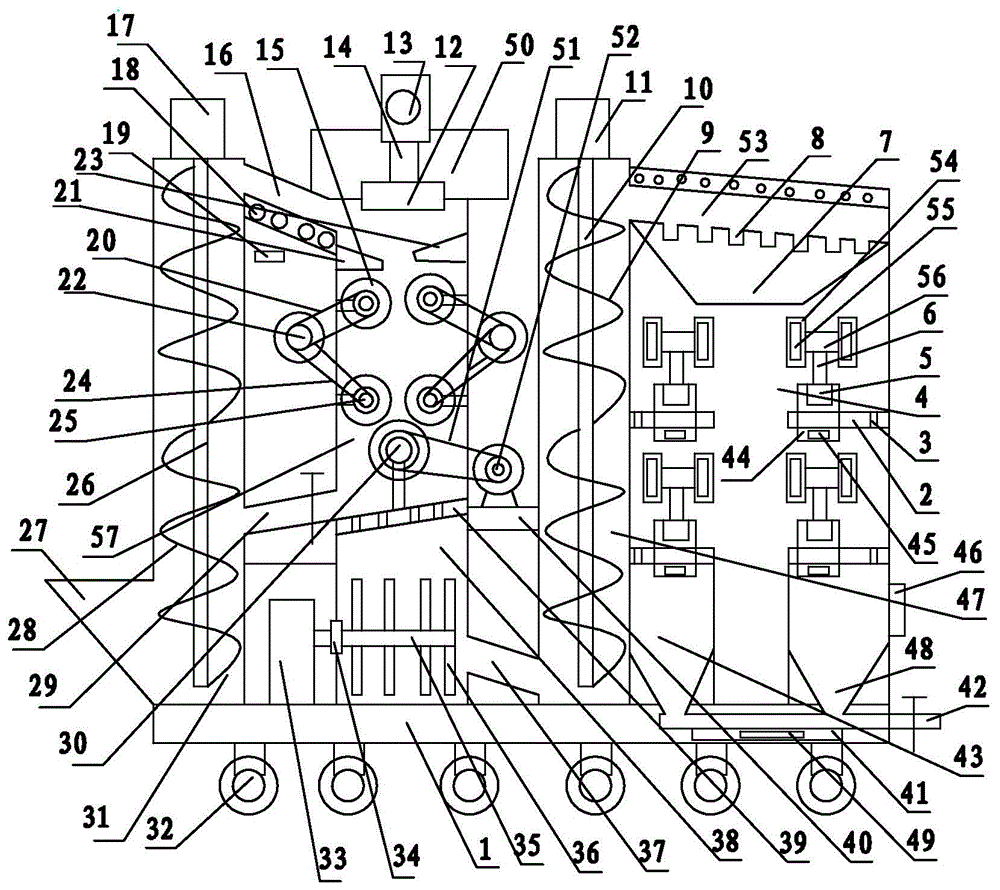

Livestock feed crushing device with iron removal function

InactiveCN107626400AEasy to remove ironQuality improvementFeeding-stuffDispersed particle filtrationIron removalTherapeutic effect

The invention provides a livestock feed crushing device with an iron removal function, and belongs to the technical field of livestock feed processing. A cover plate is welded to and fixedly arrangedat the lower ends of telescopic rods. An electromotor is fixedly arranged on the upper portion of the cover plate. A first crushing device is fixedly arranged on the lower portion of the electromotor.A screening vessel is arranged on the upper side of an inner cavity of a crushing box through a supporting frame. An iron taking bin door is arranged on the outer side of an iron removal device. A second crushing device is arranged on the lower side of the iron removal device. An electric telescopic plate is arranged on the lower side of the inner cavity of the crushing box. A spiral crushing device is arranged at the left end of a first motor. According to the livestock feed crushing device, through holes are formed in the bottom of an inner cavity of the screening vessel, and the function of screening feed with the dimension diameters meeting the standard is achieved; a moisture exhaust fan is arranged on the right side of the crushing box through an exhaust pipe, and the function of removing moisture in the feed is achieved; and the device has the beneficial effects of being simple in structure, high in practicality and good in crushing treatment effect.

Owner:沈美珍

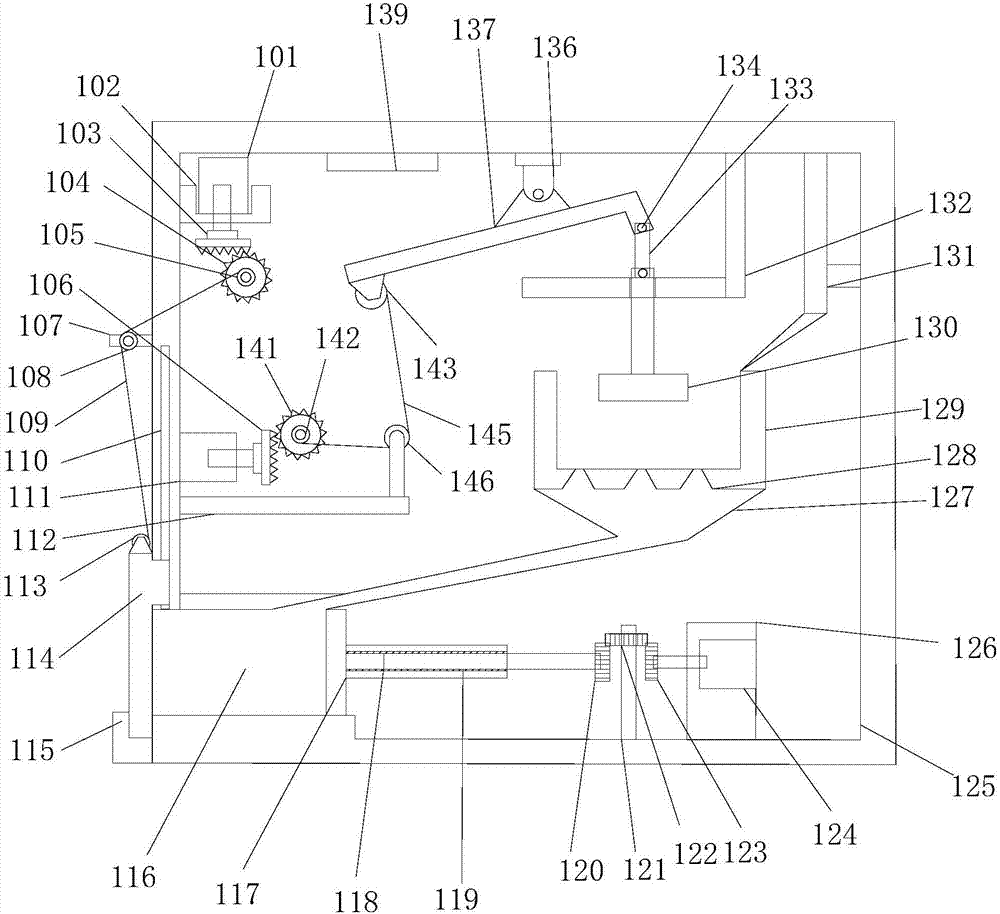

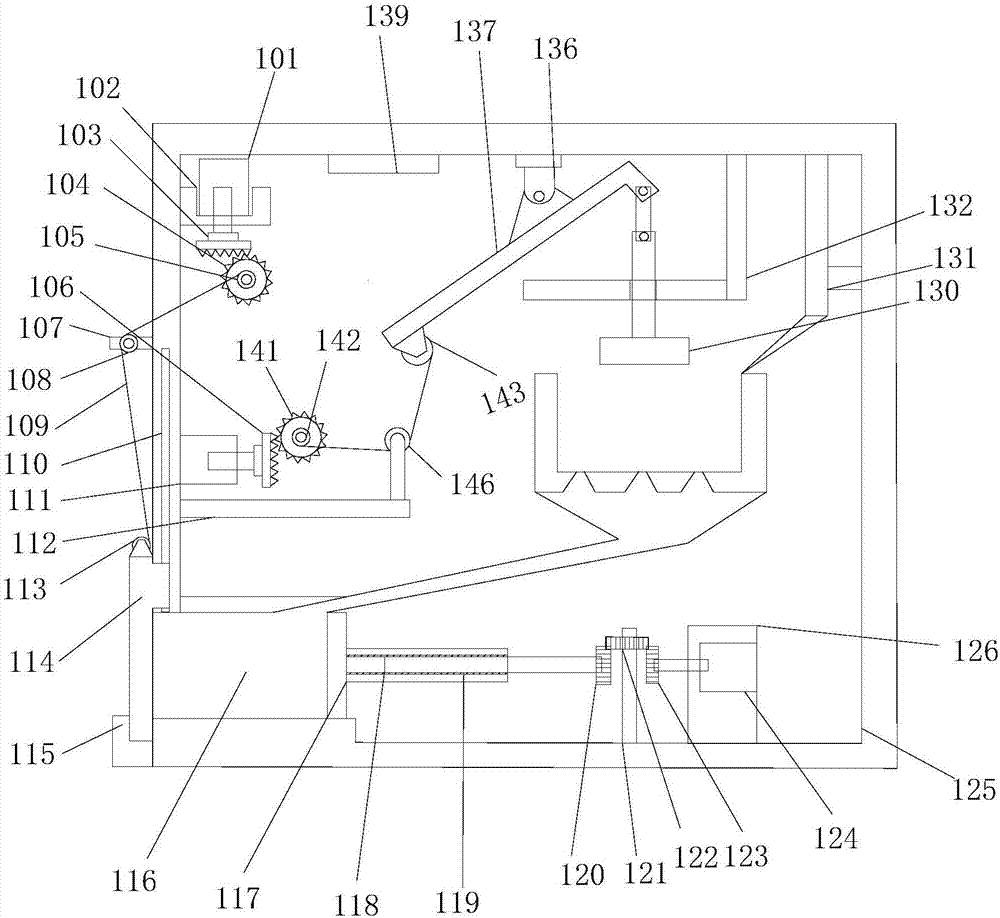

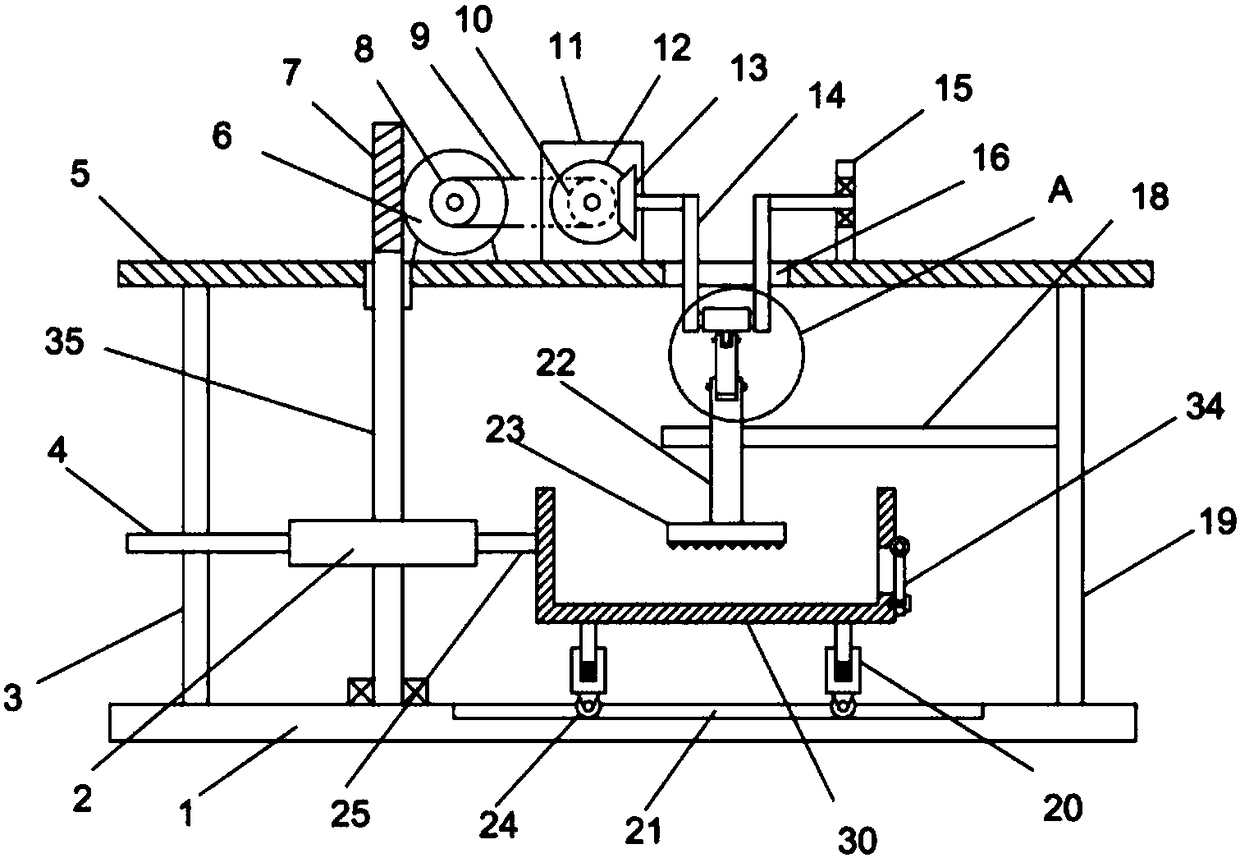

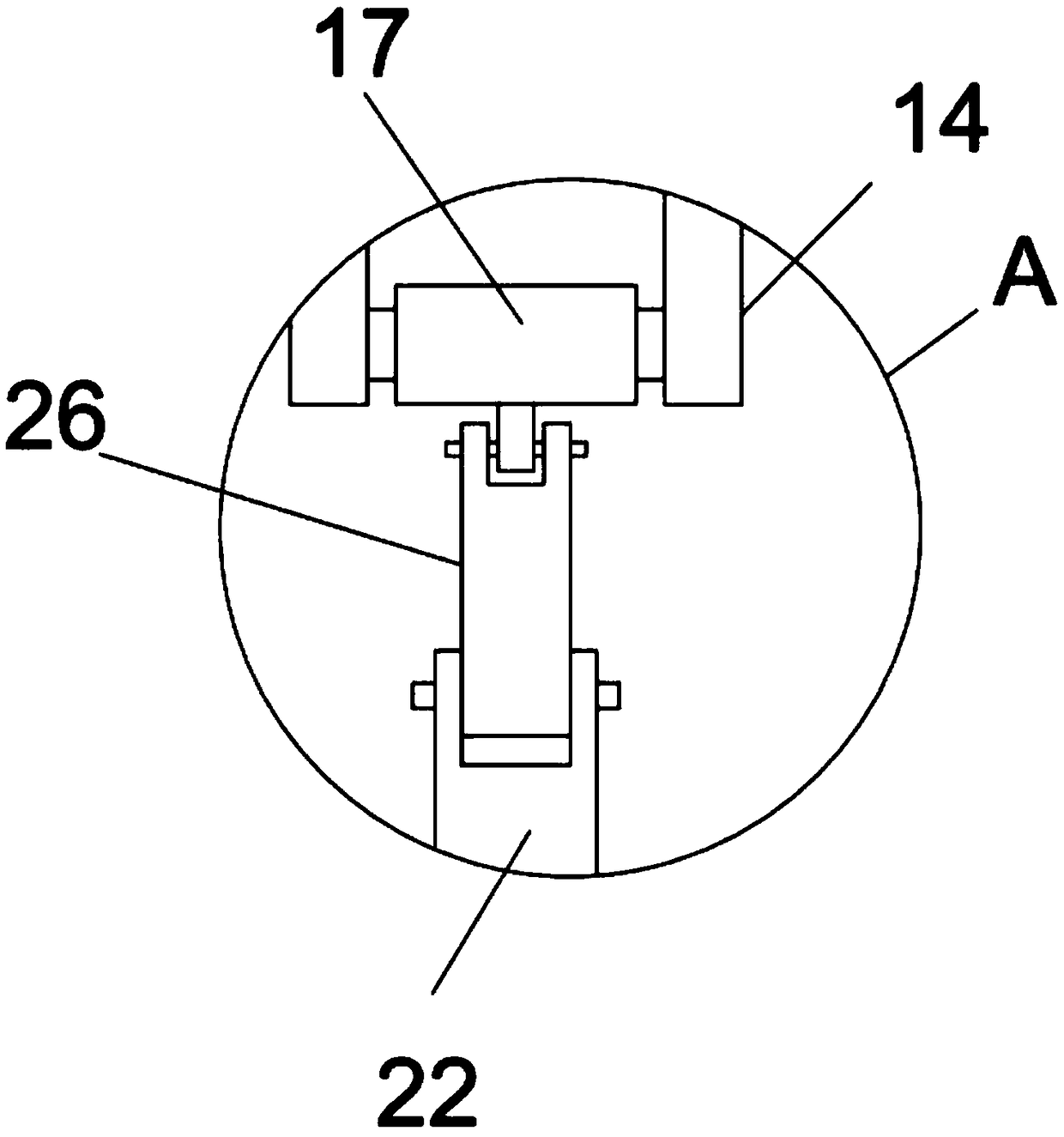

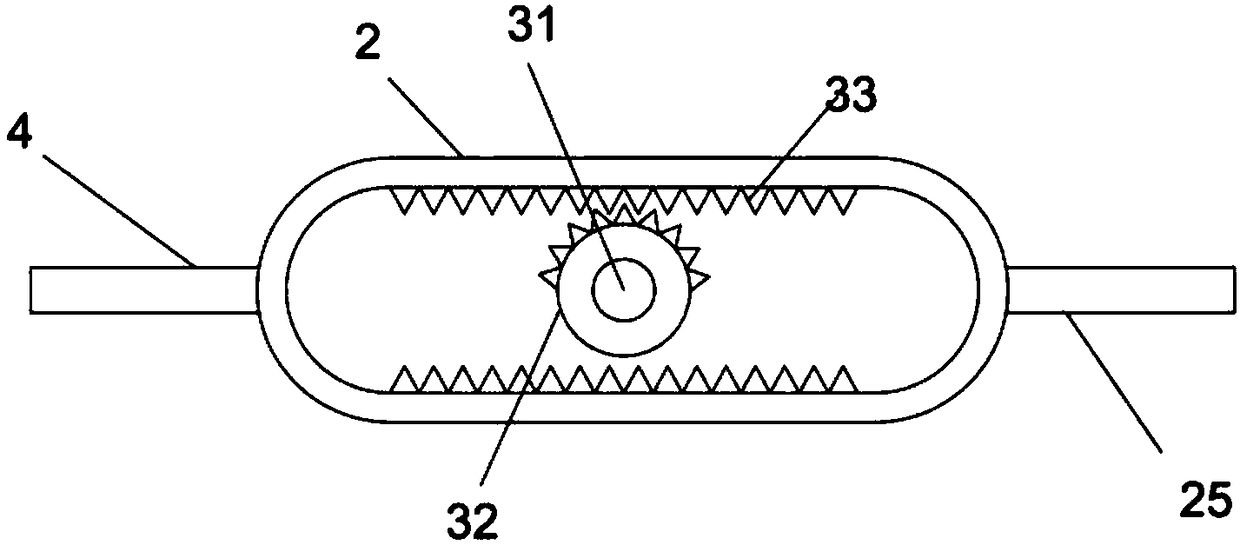

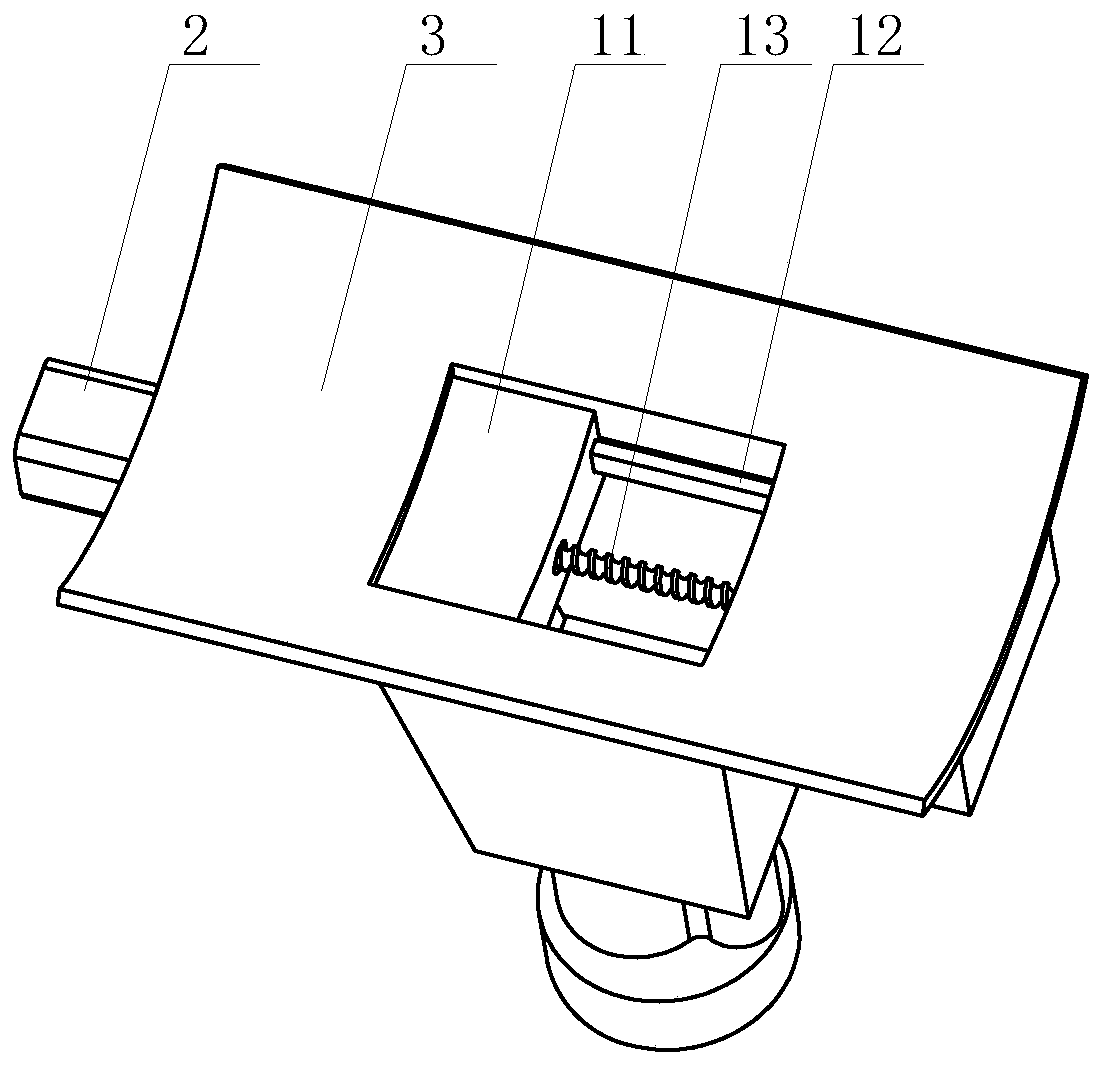

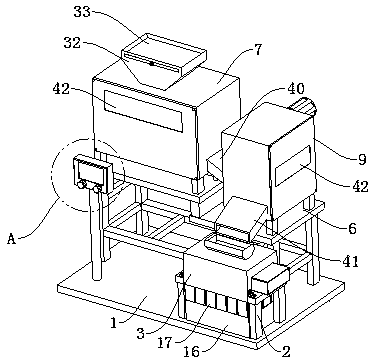

Scrap steel processing device and method

ActiveCN110841766AReduce volumeImprove the crushing effectGrain treatmentsPressesScrapStructural engineering

The invention discloses a scrap steel processing device. The scrap steel processing device comprises an extrusion box, a breakage box and a conveying platform. The breakage box is located above the extrusion box, and a separating plate is transversely riveted between the breakage box and the extrusion box. A material guide chute is fixedly arranged on the upper end face of the breakage box, a conveying belt structure is installed on the downward inclined portion of the material guide chute, and the bottom of the conveying belt structure is fixedly connected with a feeding platform. By the adoption of the scrap steel processing device and a scrap steel processing method, an existing breakage structure is improved, breaking hammers and a breaking channel are added and combined, scrap iron isbroken and then is damaged, the size is further reduced, and the breakage effect is improved; a lifting base which can actively lift scraps is designed, after the scraps are lifted, the lifting basecooperates with two press plates on the side face and a metal pressure wall on the top, the accumulative scraps are pressed from the four sides to form blocks, the size is greatly reduced, the scrapsare more conveniently conveyed after the blocks are formed, and the scrap steel processing device and method are suitable for different working conditions and bring the better application prospect.

Owner:马鞍山市龙腾机电科技有限公司

Coal briquette rapid crushing device

The invention discloses a coal briquette rapid crushing device. The device comprises a body; the left side wall and the right side wall of the body are symmetrically provided with two feeding pipes communicating with the interior of the body; connecting plates are vertically and fixedly installed on the lower surface of a transverse plate; an upper pressing plate is horizontally and fixedly arranged at the lower ends of the connecting plates; a lower pressing plate is horizontally arranged in the body; and a connecting block is fixedly provided with a first pull rope and a second pull rope which are symmetrically arranged. According to the coal briquette rapid crushing device, a cam drives the transverse plate to move up and down in a reciprocating mode so that the upper pressing plate andthe lower pressing plate can move towards or away from each other, and then the repeated crushing effect on coal briquettes is achieved; the upper pressing plate and the lower pressing plate are used for carrying out repeated extrusion on the coal briquettes at the same time, the crushing effect can be effectively improved, the rapid crushing effect can be realized, so that the coal briquettes can be more thoroughly crushed; and meanwhile, the crushed fine coal briquettes can penetrate through material falling through holes in the lower pressing plate to fall into the bottom of the body, sothat the amount of the coal briquettes on the lower bottom plate is reduced, and the coal briquettes can be spread on the lower bottom plate, and the full crushing effect on other coal briquettes is promoted.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

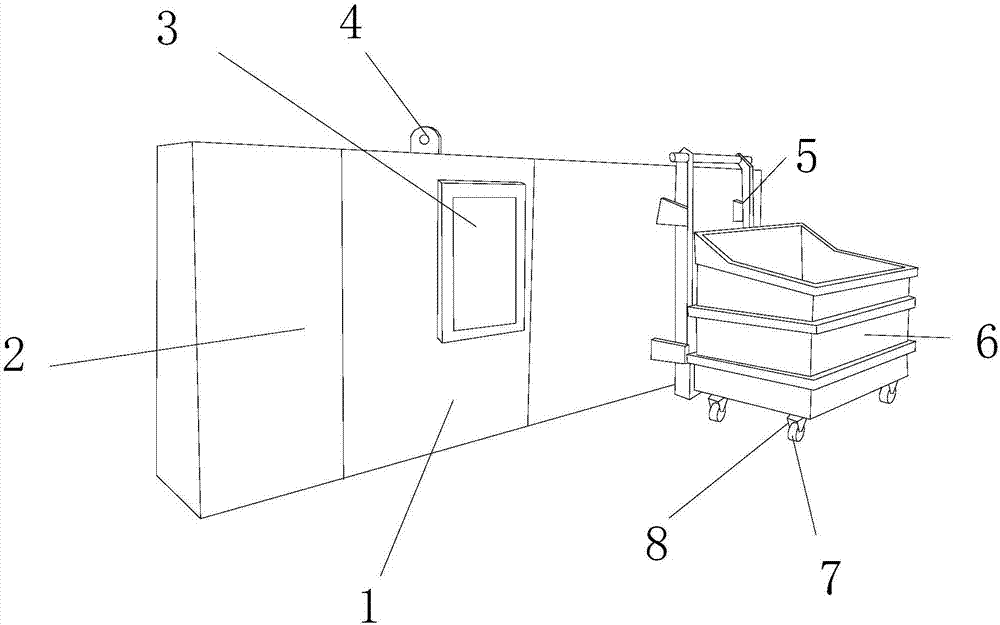

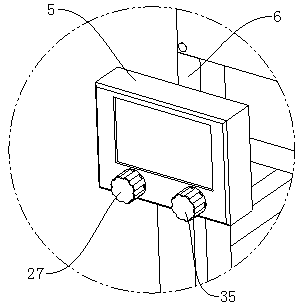

Waste garbage recycling processing equipment for production of solar panel components

InactiveCN107876129AGood crushing effectLow placementWaste accumulators reclaimingGrain treatmentsWaste management

The invention discloses waste garbage recycling processing equipment for production of solar panel components. The waste garbage recycling processing equipment structurally comprises a garbage recycling device, a machine body, a viewing window, a lifting lug, a fixing bracket, a containing frame, connecting blocks and movable wheels. The garbage recycling device is mounted in the machine body. Theside face of the viewing window is embedded into the front surface of the machine body. The top of the machine body is vertically connected with the bottom of the lifting lug. The back of the fixingbracket is fixedly connected with the front side of the right end of the machine body. The connecting blocks are sequentially connected into a rectangular structure and arranged at the bottom of the containing frame. The side faces of the movable wheels are movably connected with the interiors of the corresponding connecting blocks. By the adoption of the garbage recycling device of the waste garbage recycling processing equipment for production of the solar panel components, the garbage smashing processing effect is remarkable, the working efficiency is high, the operation is easy and fast, besides processed garbage can be compacted, the occupied position of the garbage is reduced, placing and transportation are more facilitated, and the practical value of the equipment is increased.

Owner:乐志堡

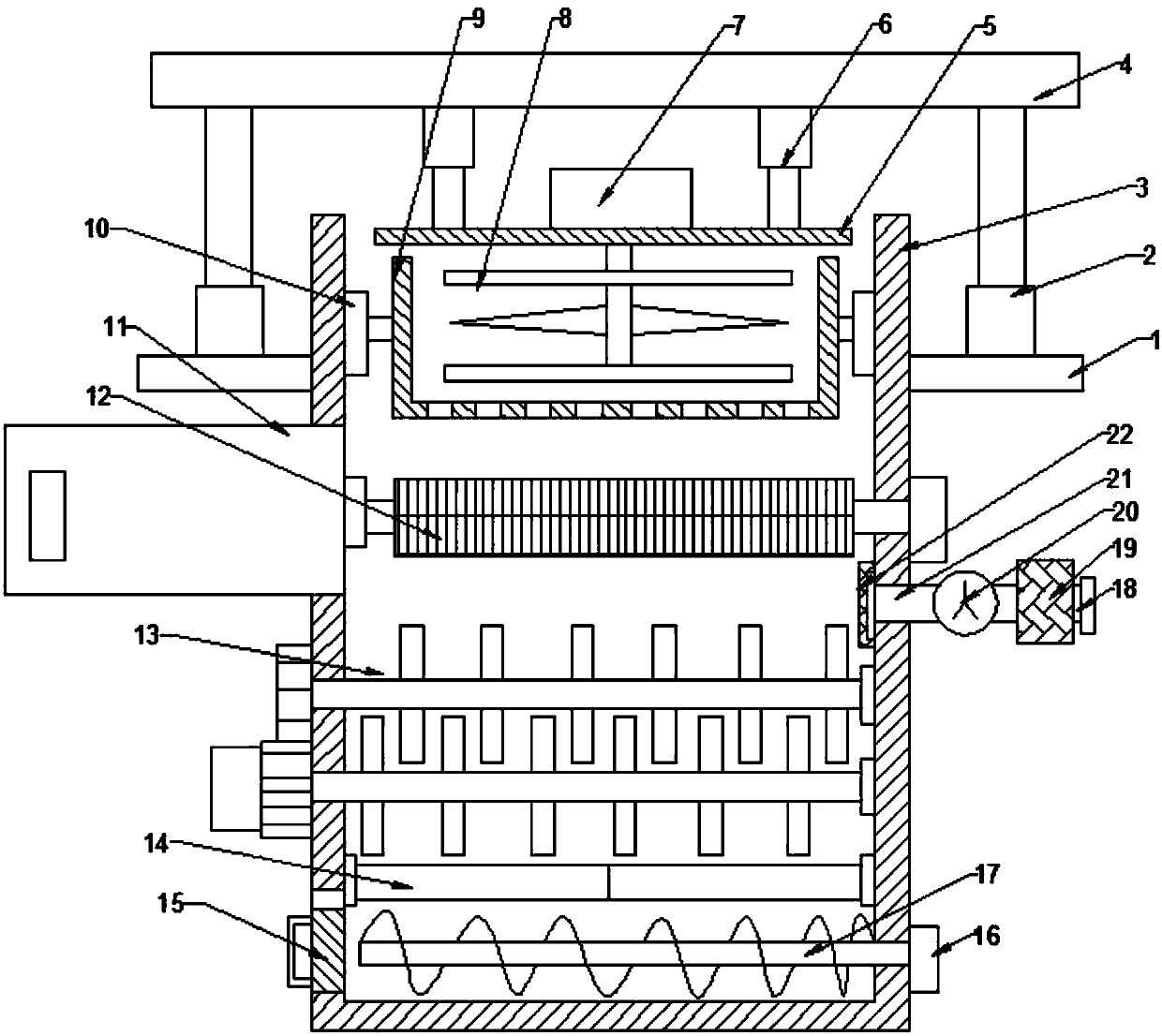

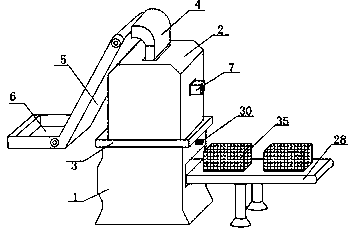

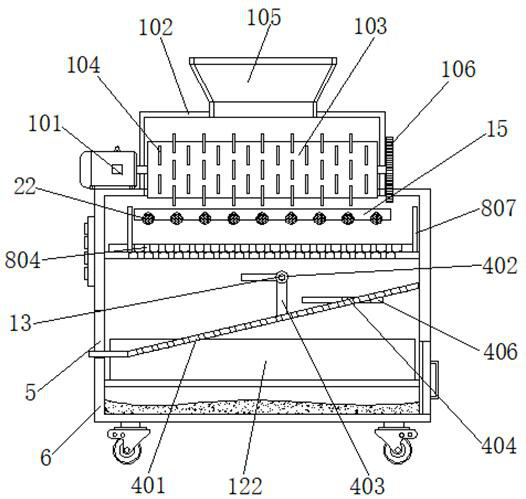

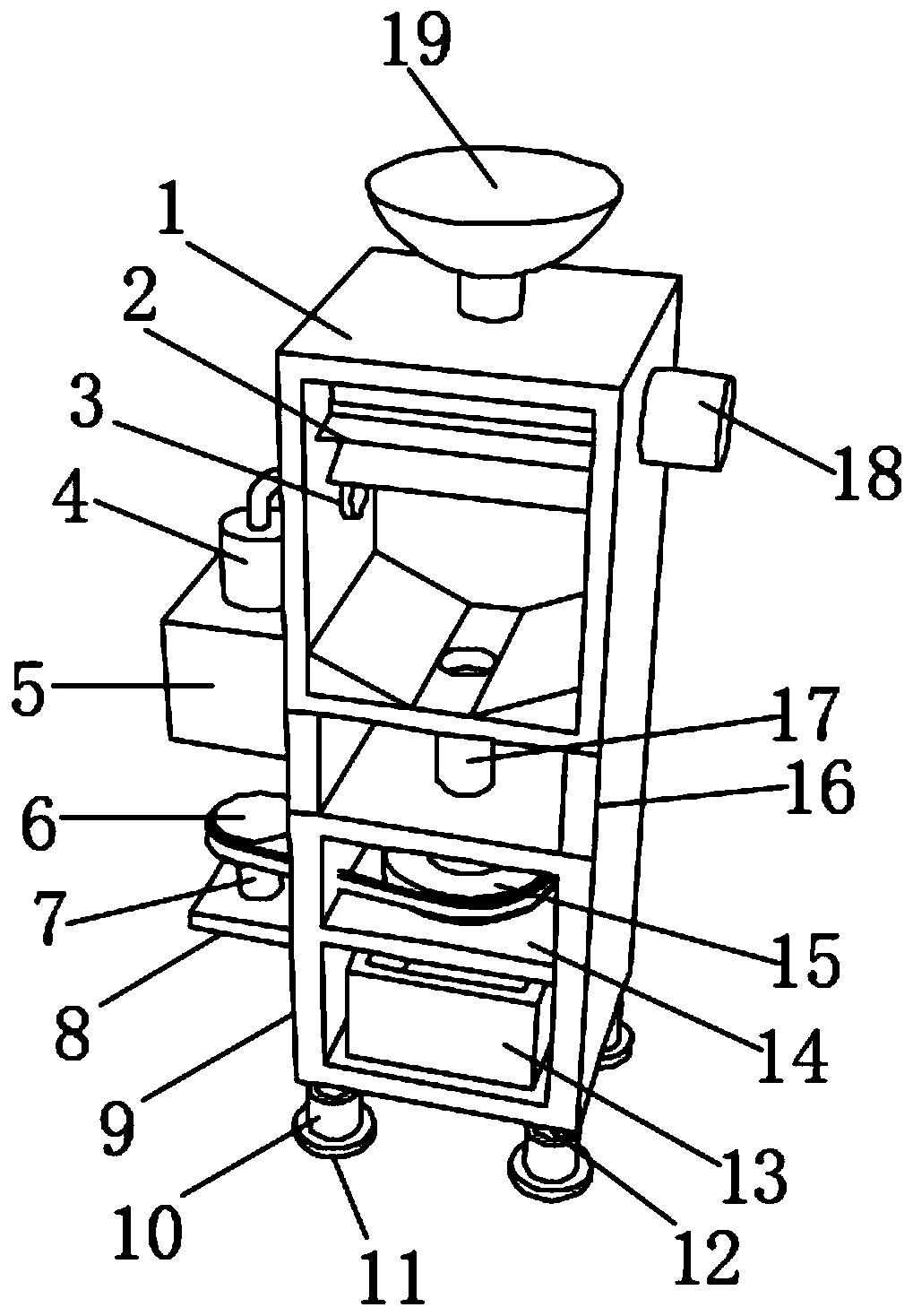

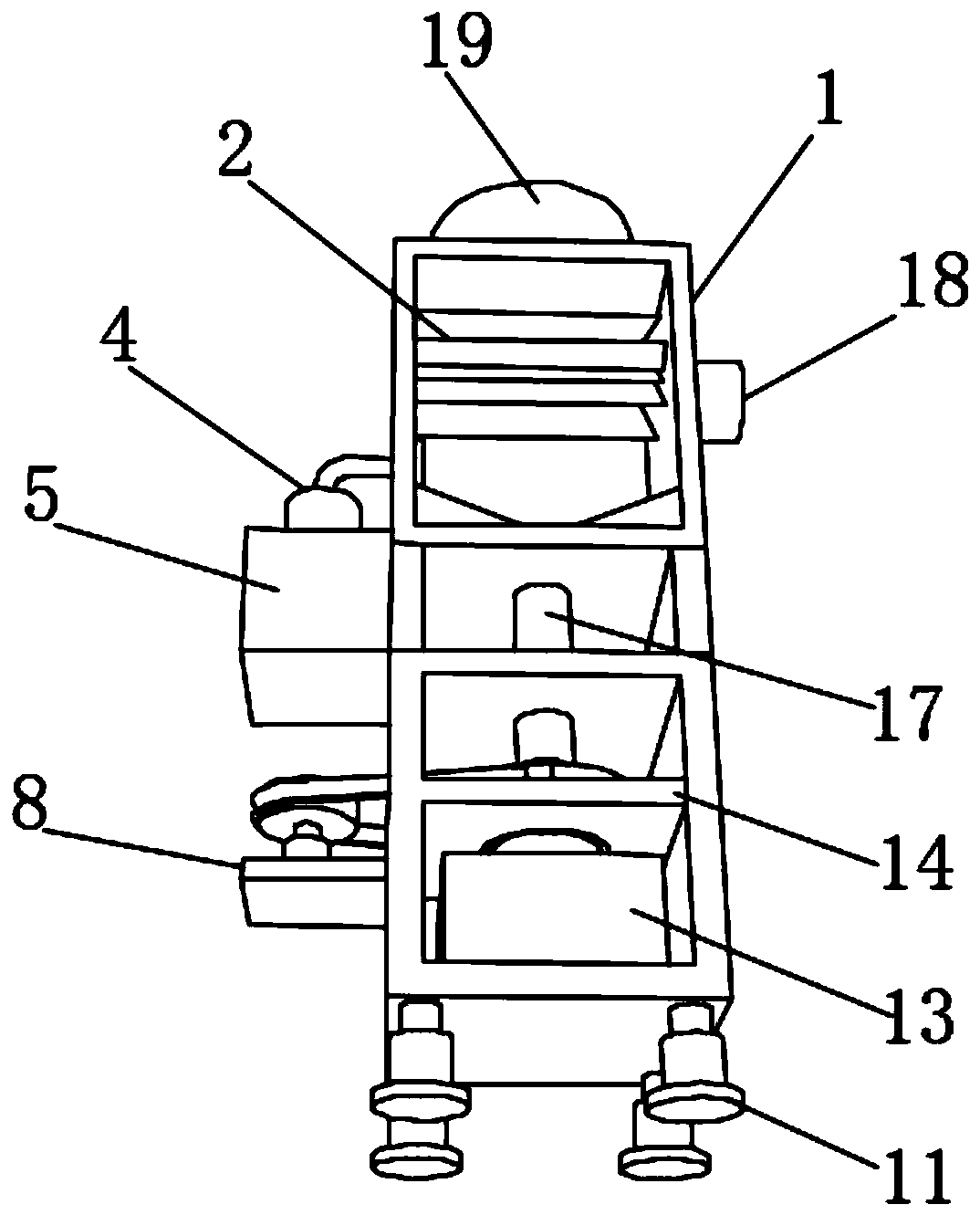

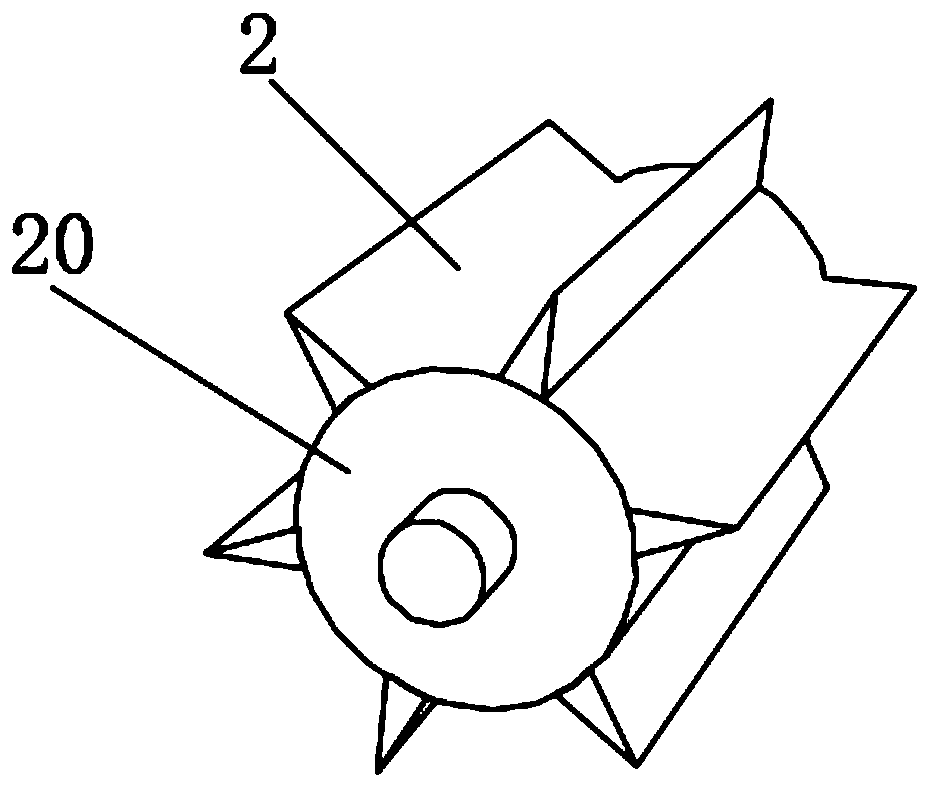

Crushing treatment device used for conveniently collecting and transferring livestock feed

ActiveCN107716033AEasy to transportImprove the crushing effectFeeding-stuffDrying gas arrangementsTherapeutic effectFodder

The invention provides a crushing treatment device used for conveniently collecting and transferring livestock feed, and belongs to the technical field of livestock feed treatment. The crushing treatment device comprises a supporting device and a crushing treatment device body. The crushing treatment device body is arranged in a crushing box. A material pushing device is arranged at the bottom inthe crushing box. An illumination lamp is arranged at the left end of the upper part of a treatment box through a universal hose. A helical stirring device is arranged in a stirring cavity. A dust-proof mesh plate is arranged below a helical heating pipe. A filtering grille is arranged on the inner right side of the stirring cavity. The upper surfaces of discharging hoppers are provided with discharging valves. According to the crushing treatment device, the helical heating pipe is arranged below a fan, so that the function of drying the feed in a hot air blowing-in mode is achieved; rollers are arranged at the lower end of a collecting box, and the outer side of the collecting box is provided with a pulling ring, so that the function of conveniently transferring the feed is achieved; andthe crushing treatment device has the characteristics of being simple in manufacturing process, high in practicability and good in feed crushing treatment effect.

Owner:正大康地农牧集团有限公司

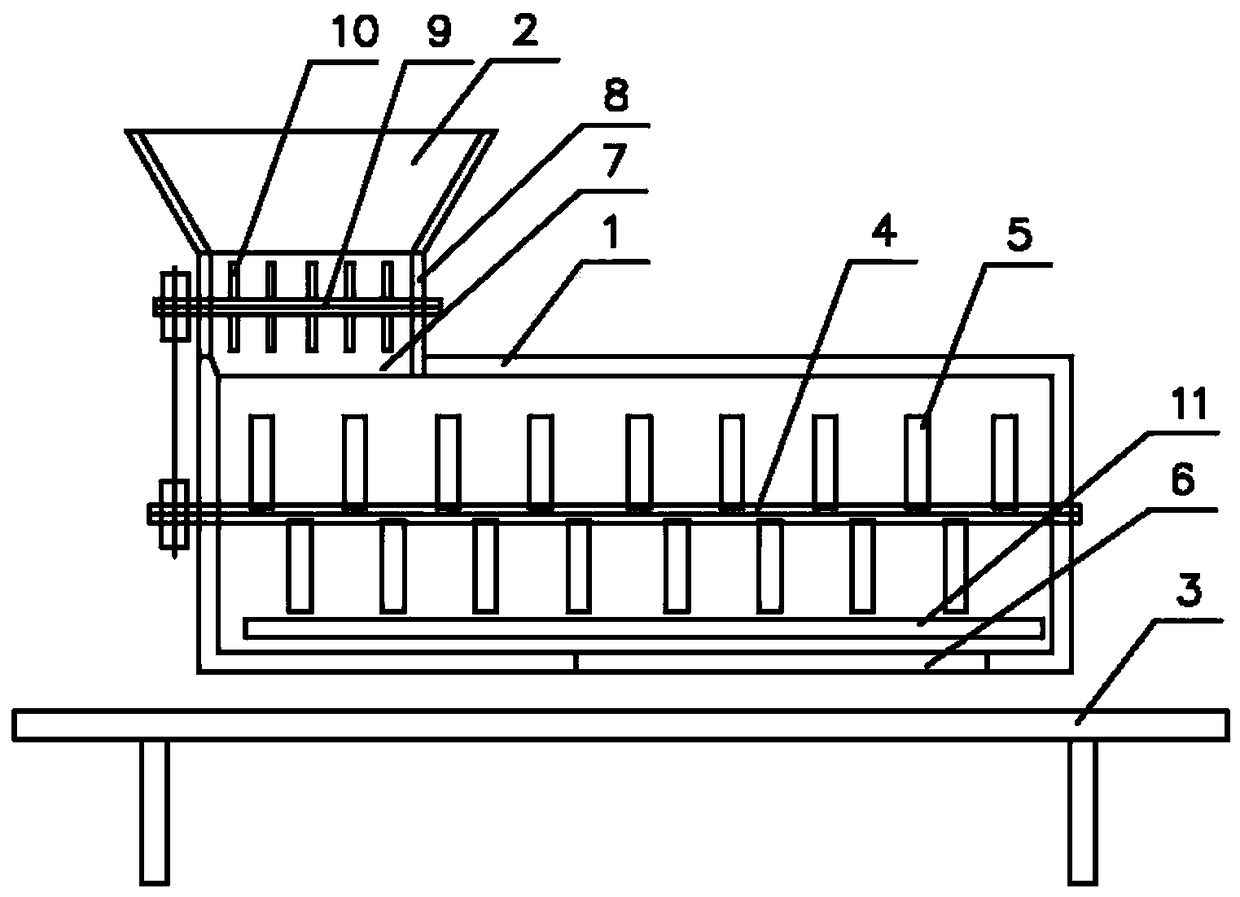

Material crushing magnetic separator

InactiveCN104907126AImprove the crushing effectEasy to separateSievingScreeningMagnetic separatorTherapeutic effect

The invention relates to a material crushing magnetic separator. The material crushing magnetic separator comprises a bottom seat, wherein a feeding cavity is formed in the left side of the upper portion of the bottom seat, a left lifting cavity is connected with the right side of the feeding cavity, a feeding pipe is connected with the upper portion of the right side of the left lifting cavity, a crushing cavity is connected with the right side of the feeding cavity, a return pipe is connected with the lower portion of the left side of the crushing cavity, a filter plate is arranged on the lower portion of the crushing cavity, a stirring cavity is formed in the lower portion of the filter plate, a blanking pipe is connected with the right side of the stirring cavity, a right lifting cavity is connected with the right side of the blanking pipe, a discharging cavity is connected with the upper portion of the right side of the right lifting cavity, a plurality of discharging holes are formed in the lower portion of the discharging cavity, a feeding cavity is located on the lower portion of each discharging hole, and separation cavities are arranged on the lower portions of the feeding cavities. The material crushing magnetic separator can effectively perform crushing treatment on materials, facilities lifting treatment after the materials are crushed, improves crushing treatment effects of the materials, facilitates drying treatment, performs magnetic separation after the materials are crushed more than once, conveniently separates out impurities, facilitates counting of the quantity of the impurities, improves separation treatment effects of the impurities, and is convenient to use.

Owner:陈守树

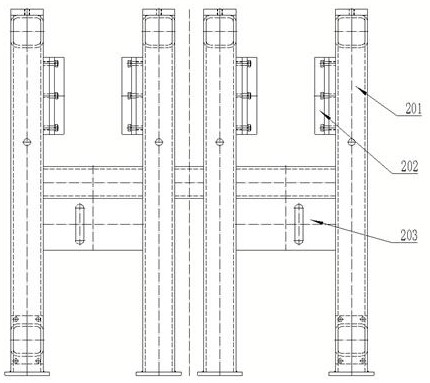

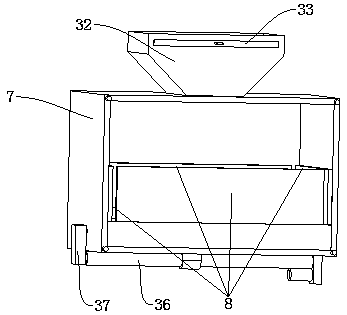

High-speed leftover fabric crushing device

InactiveCN109759197AImprove the crushing effectSimple structureGrain treatmentsEngineeringAutomation

The invention discloses a high-speed leftover fabric crushing device. The high-speed leftover fabric crushing device comprises supporting rods, a pair of first transverse rods are fixedly connected between the supporting rods at the left side and the right side, a pair of second transverse rods are fixedly connected between the supporting rods at the front side and the rear side, a transmission mechanism is arranged on the first transverse rod on the rear side and the second transverse rod on the left side and is connected with a cutter, a conveyor belt is arranged below the cutter, baffles are fixedly arranged on the front end surface and the rear end surface of the conveyor belt, a plurality of chopping boards are fixedly connected between the baffles on the front side and the rear side,the cutting boards are located right under the cutter, and a crushing box is arranged on the left side of the conveyor belt. The high-speed leftover fabric crushing device is simple in structure, reasonable in technique, high in automation degree, and good in the crushing effect, and can effectively prevent a blade from being clamped.

Owner:HUBEI TIANYUN NOISE REDUCTION & ANTIVIBRATION NEW MATERIAL

Crushing machine

The invention belongs to the technical field of mechanical equipment and particularly discloses a crushing machine. The crushing machine comprises a driving unit. A slide bar is hinged to the drivingunit. The slide bar is connected with a threaded rod. A feed box is arranged on one side of the driving unit. One side of the feed box is provided with a one-way feed door. A crushing unit is arrangedbelow the feed box. The crushing unit comprises a first-stage crushing part, a second-stage crushing part and a third-stage crushing part. The first-stage crushing part comprises a crushing box. Thecrushing box comprises an outer wall and an inner wall. The inner wall is of a hollow structure. The lower end of the inner wall is provided with a port. A cavity is formed between the outer wall andthe inner wall. The outer wall is provided with a plurality of protrusions distributed in a staggered mode. The inner wall is provided with feed ports. The inner wall is further provided with a spiral. The second-stage crushing part comprises a leakage net. The third-stage crushing part is arranged under the leakage net. The upper end of the third-stage crushing part is provided with a notch. Oneside of the third-stage crushing part is provided with a one-way discharge door. By adopting the crushing machine, the problems of the poor crushing effect, high cost and inconvenient operation are solved.

Owner:涌纬集团股份有限公司

Chinese herbal medicine crushing device for medical treatment

The invention discloses a Chinese herbal medicine crushing device for medical treatment. The Chinese herbal medicine crushing device for the medical treatment comprises a bearing bottom plate, and a left support plate and a right support plate which are vertically and fixedly installed on the bearing bottom plate. An upper top plate is horizontally and fixedly installed at the upper ends of the left support plate and the right support plate, a driving motor is fixedly installed on the upper top plate, and an output shaft of the driving motor is coaxially and fixedly provided with a first bevelgear. A driving belt gear and a driven wheel gear are sleeved and connected with the driving belts, and a connecting rod is hinged to a casing pipe. A horizontal extension plate is horizontally and fixedly installed on the left side wall of the right support plate. The Chinese herbal medicine crushing device for the medical treatment drives the longitudinal reciprocating motion of a sliding rod through the rotation of an arch shaft, the up-and-down reciprocating movement of a crushing pressing plate is realized and repeated impact crushing of Chinese herbal medicine in a crushing slot is carried out, crushing effect is greatly improved; the left-right reciprocating motion of a concentric-square-shaped frame realizes the left-right reciprocating motion of a crushing slot, the impact crushing of the crushing pressing plate to the Chinese herbal medicine in different positions in the crushing slot is realized, the crushing range is wide, and the Chinese herbal medicine is crushed fully.

Owner:齐芳

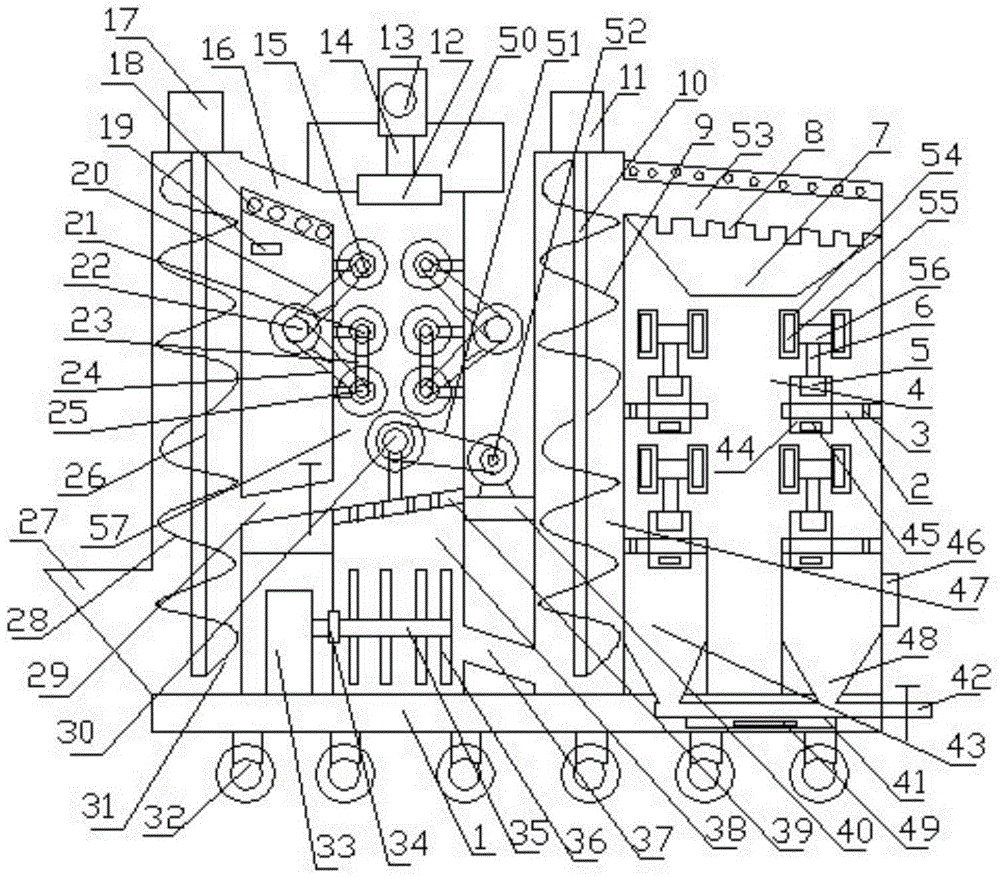

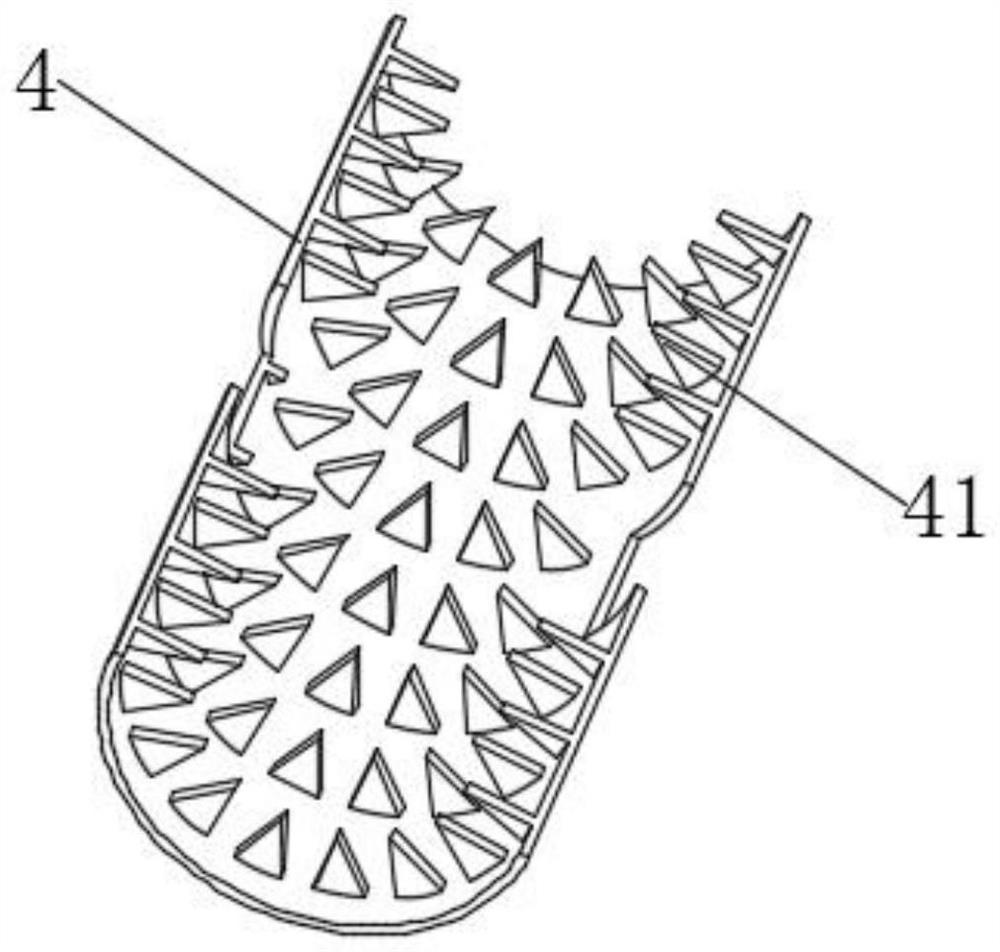

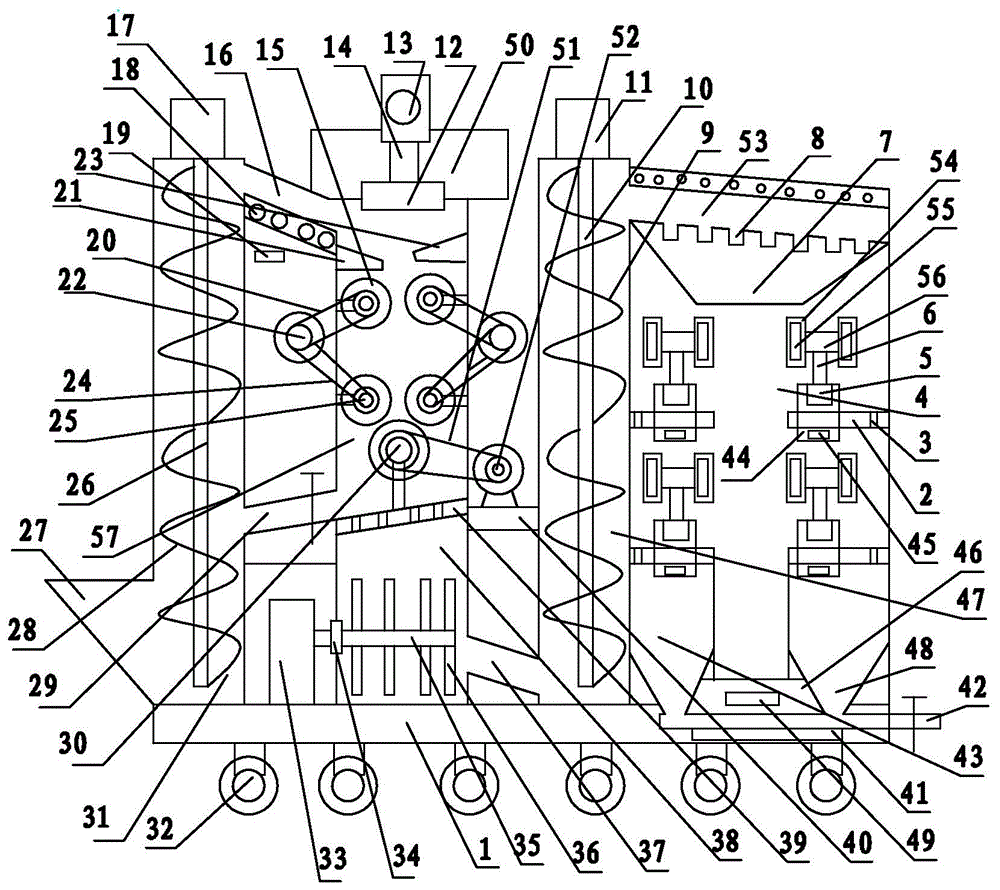

Solid waste treatment system with pre-treatment step

ActiveCN110237908AImprove stabilityImprove the crushing effectGrain treatmentsElectric machineryPre treatment

The invention belongs to the technical field of solid waste treatment, and in particular relates to a solid waste treatment system with a pre-treatment step. The system comprises a treatment box body, a primary crushing assembly and a crushing roller. A rotary sealing plate is arranged in the middle of the lower part in the treatment box body, the primary crushing assembly is arranged above the rotary sealing plate, and an electric hydraulic telescopic rod is connected between the lower end of the rotary sealing plate and the treatment box body. By arranging crushing knives in a combined manner, solid waste between an arc-shaped surface of an elastic arc plate and two side faces on a triangular slide block are ground, so that the crushing effect of the solid waste is improved. By mounting the triangular slide block on a chute in the sealing plate, on the one hand, a problem of transitional wear due to an excessive impact force as the single elastic arc plate is stressed is solved. On the other hand, the solid waste is paved on two crushing rollers uniformly, so that the probability that a crushing motor is burned is reduced, and the service life of the crushing motor is further prolonged.

Owner:山东同其数字技术有限公司

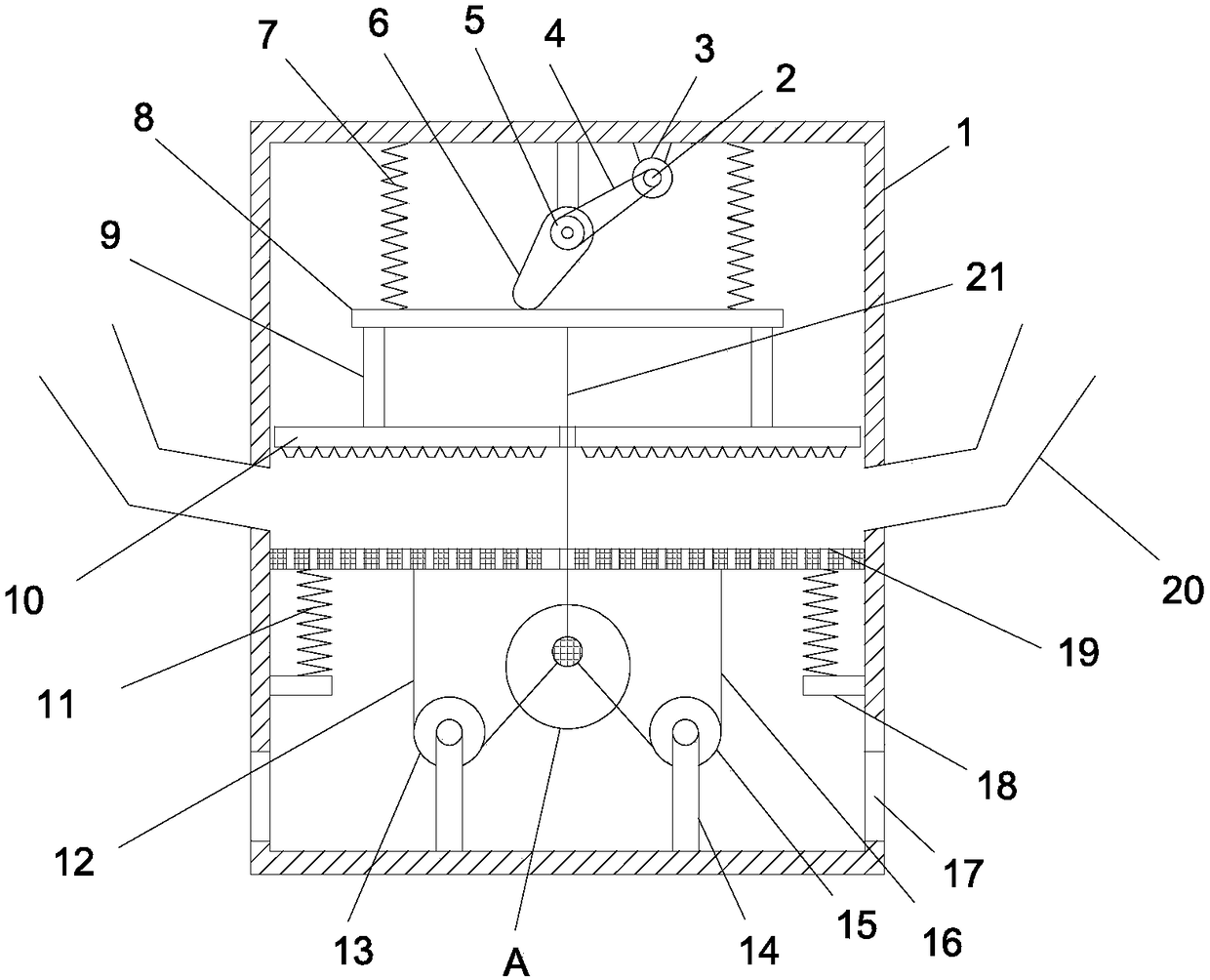

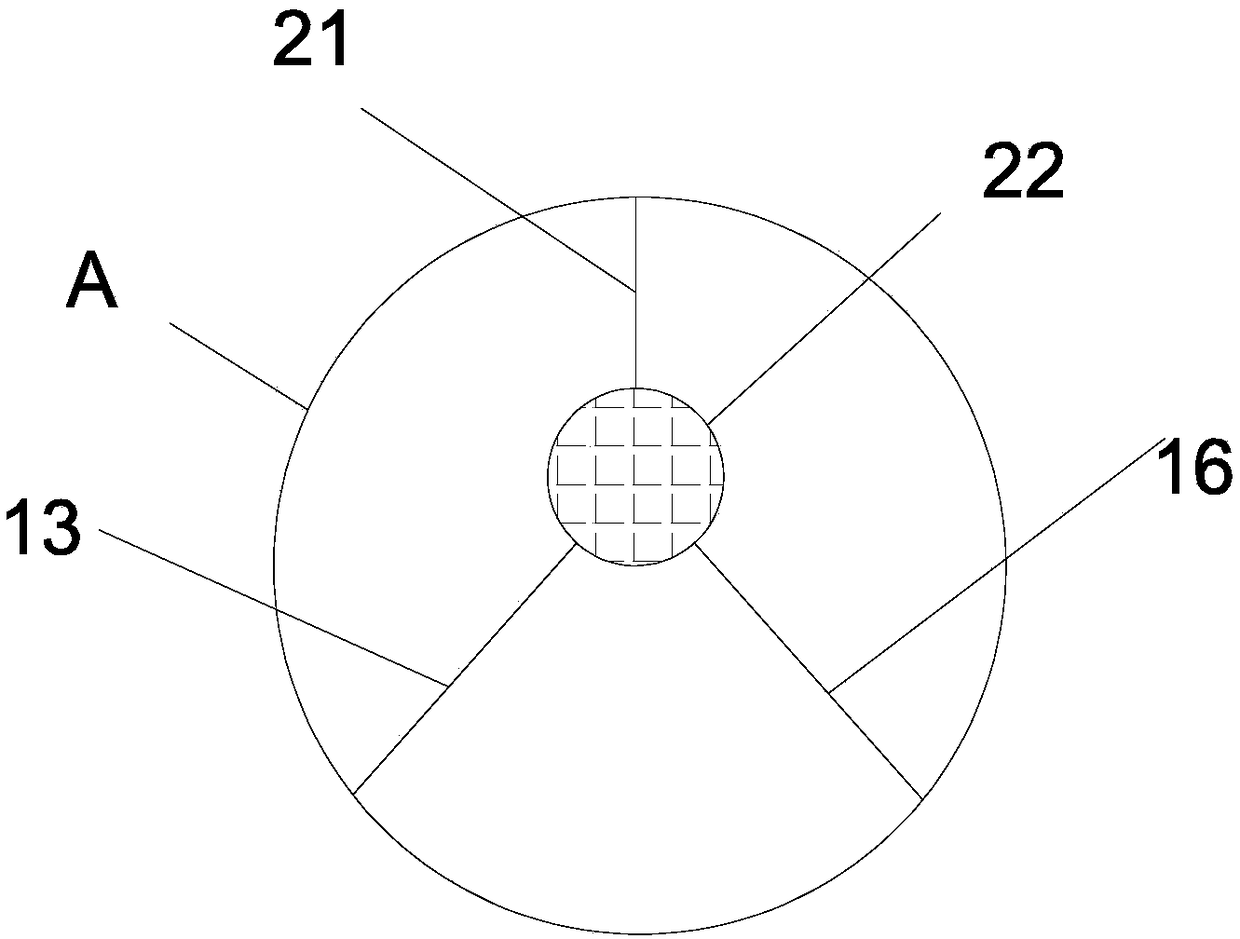

Vibration crushing device for construction waste resource recovering

PendingCN111701694AImprove the crushing effectSo as not to damageConstruction waste recoverySolid waste disposalElectric machineryCrusher

The invention provides a vibration crushing device for construction waste resource recovering and belongs to the technical field of construction waste treatment. The vibration crushing device comprises a bottom plate, a motor and a vibration crusher, wherein the motor is located on the left side of the upper end of the bottom plate, and the motor is fixedly connected with the bottom plate. The improved vibration crushing device for construction waste resource recovering has a good crushing treatment effect on construction waste, there is no damage to structures inside the device when the construction waste is vibrated and broken, the working efficiency is improved, and actual use is facilitated. The improved vibration crushing device for construction waste resource recovering can remove the crushed construction waste from the crusher in time, and the construction waste does not need to be vibrated and broken again after the crushed construction waste in the crusher is manually removed,so that the problem that the labor consumption is relatively high is solved, the operation is simple and convenient, and the practicability is high in the actual use process.

Owner:CHINA THIRD METALLURGICAL GRP

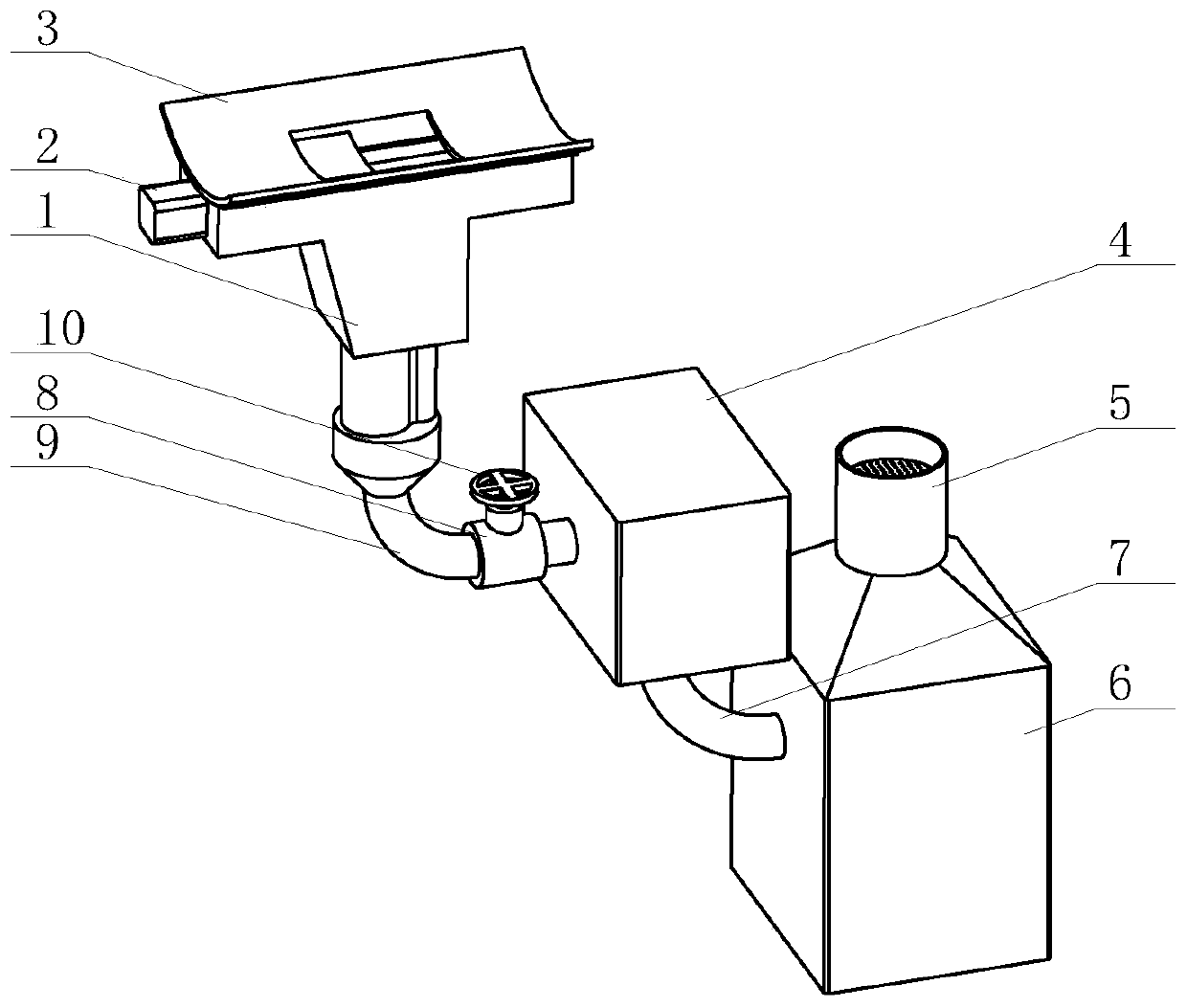

Sludge discharging device for sewage treatment

InactiveCN111569524AImprove the crushing effectEliminate sludgeSludge treatment by de-watering/drying/thickeningDispersed particle filtrationSewage treatmentSettling chamber

The invention discloses a sludge discharging device for sewage treatment. The sludge discharging device comprises a settling chamber, and a filter chamber, a coarse channel and a fine channel which are arranged below the settling chamber. The filter chamber is provided with a sludge discharge port communicated with the settling chamber, the sludge discharge port is provided with a flow isolation mechanism, and the flow isolation mechanism is provided with a sliding flow isolation block for closing or opening the sludge discharge port; the coarse channel and the thin channel are arranged belowthe filter chamber, the upper ends of the coarse channel and the thin channel are both communicated with the filter chamber, and the lower ends of the thin channel and the coarse channel are both communicated with the converging chamber; a filtering plate is arranged in the filter chamber, a plurality of filtering holes are formed in the filtering plate, the filtering plate is located above the communicating opening of the thin channel and the converging chamber, a crushing mechanism is arranged in the coarse channel, the crushing mechanism comprises a support and a crushing blade assembly, the crushing blade assembly is installed on the support, and the support is fixed to the inner wall of the coarse channel. Sludge can be screened and crushed, the problem of blockage of a pipeline or equipment is avoided, and the sludge treatment efficiency is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Automatic material smashing and magnetic separation separator

InactiveCN104923338AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsEngineeringMaterial supply

The invention relates to an automatic material smashing and magnetic separation separator comprising a base. A feeding cavity is formed in the left side of the upper portion of the base. The right side of the feeding cavity is connected with a left lifting cavity. The upper portion of the right side of the left lifting cavity is connected with a feeding pipe. The right side of the feeding pipe is connected with a smashing cavity. The lower portion of the left side of the smashing cavity is connected with a material return pipe. The lower portion of the smashing cavity is provided with a filtering plate. The lower portion of the filtering plate is provided with a stirring cavity. The right side of the stirring cavity is connected with a discharging pipe. The right side of the discharging pipe is connected with a right lifting cavity. The upper portion of the right side of the right lifting cavity is connected with a discharging cavity. The lower portion of the discharging cavity is provided with multiple discharging holes. A material supplying cavity is formed below the discharging holes. A separation cavity is arranged below the material supplying cavity. The automatic material smashing and magnetic separation separator can effectively smash materials, conveniently lift smashed materials, improves the material smashing effect and facilitates drying, magnetic separation is conducted after repeated smashing, impurities can be conveniently separated from the materials, statistics of the weight of the impurities can be conveniently conducted, the impurity separation effect is improved, and the automatic material smashing and magnetic separation separator is convenient to use.

Owner:郑小燕

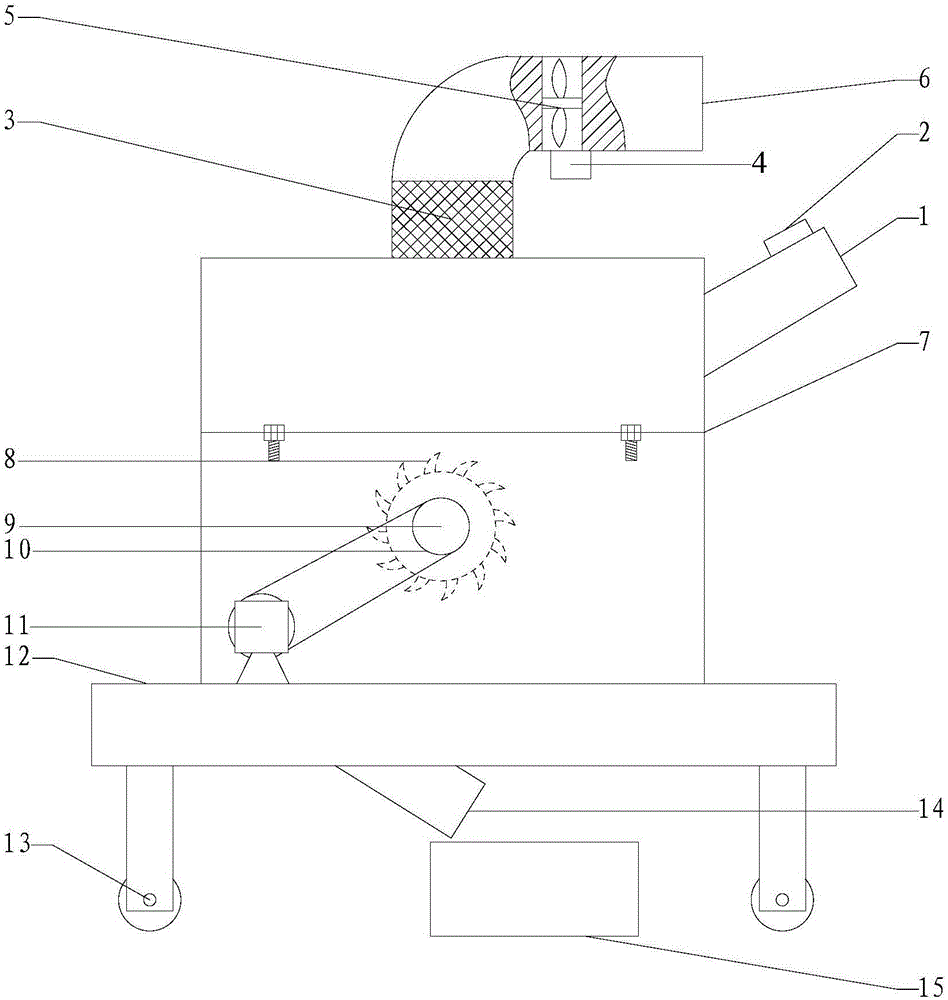

Plastic crusher

PendingCN107433699AEasy to moveEasy to fixPlastic recyclingDirt cleaningDrive shaftWorking environment

The invention relates to the field of plastic machinery, and in particular relates to a plastic crusher which comprises a box body mechanism, a crushing mechanism and a supporting mechanism; the box body mechanism comprises a feed inlet, a dust collecting device and a main box body; the crushing mechanism comprises a driving motor, a hob, a belt pulley and a driving shaft; and the supporting mechanism comprises a platform, casters, a screening filter screen, a discharge port and a storage hopper. The plastic crusher has the advantages that: the existing crusher structure is simplified; the box body mechanism is layered; the crushing mechanism in the box body can be conveniently repaired when the crusher fails; the dust collecting device is added to reduce dust generated by the crusher, improve working environment and improve safety of production; a muffler layer covering the box body can reduce working noise, and improve the working environment; and the casters are increased to make movement and fixation of the crusher more convenient.

Owner:三明华盈塑胶有限公司

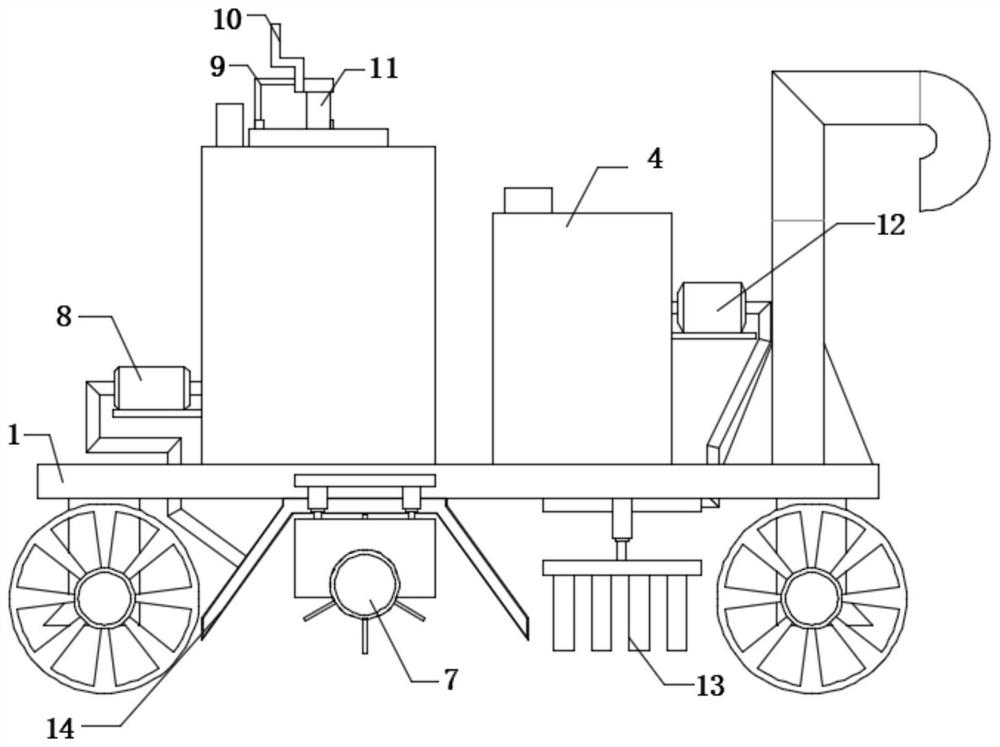

Desertified land remediation device for municipal landscaping

InactiveCN113263045AAvoid lossImprove the crushing effectSoil lifting machinesSpadesHydraulic cylinderSoil science

The invention belongs to the technical field of desertification land remediation, and particularly relates to a desertified land remediation device for municipal landscaping, and provides the following scheme that the desertified land remediation device comprises a cart, a soil remediation agent storage box is fixedly connected to the outer wall of the top of the cart, and a spraying assembly is arranged on the outer wall of the soil remediation agent storage box. According to the device, an injection assembly is arranged; after a soil turning assembly turns soil, the soil is loose, a second hydraulic cylinder is adjusted to drive down-pressing barrels on an adjusting plate to be pressed into the soil, and all dislocation plates in the down-pressing barrelscut the soil, so that the pressing resistance is reduced; after the soil is subjected to barrel-shaped forming through the down-pressing barrels, a second hydraulic cylinder is adjusted to take the down-pressing barrels out of the soil, and a water pump conveys water in a water tank into a water spraying plate; and the water is sprayed into all the down-pressing barrels on the adjusting plate through water holes and then enters the cylindrical soil below, and in the process that the water falls down in the soil, irrigation of all layers in the soil is achieved, and the water remediation effect is improved.

Owner:时雨欢

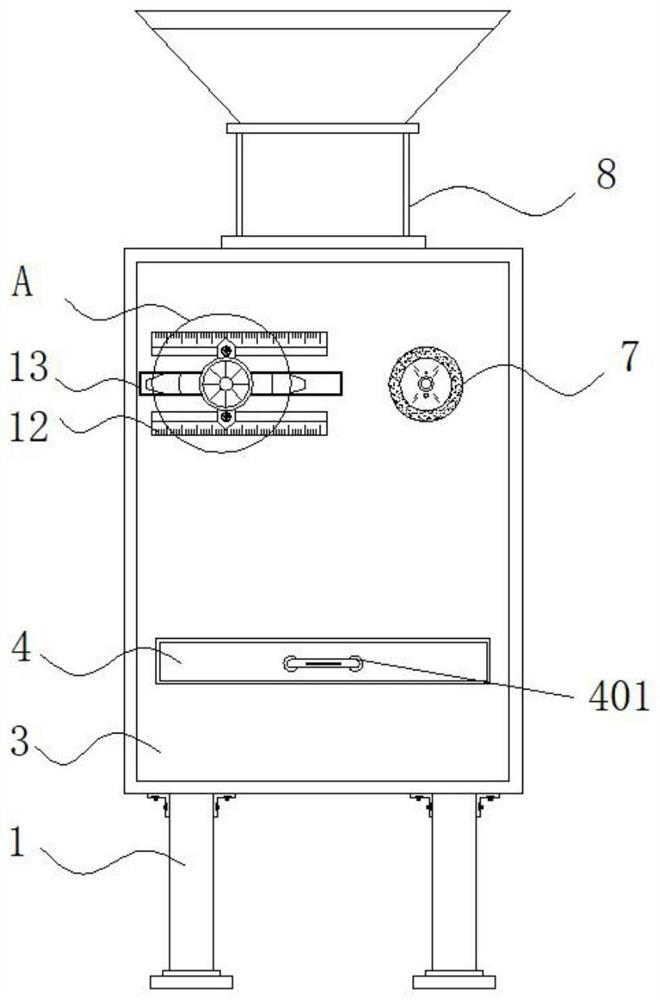

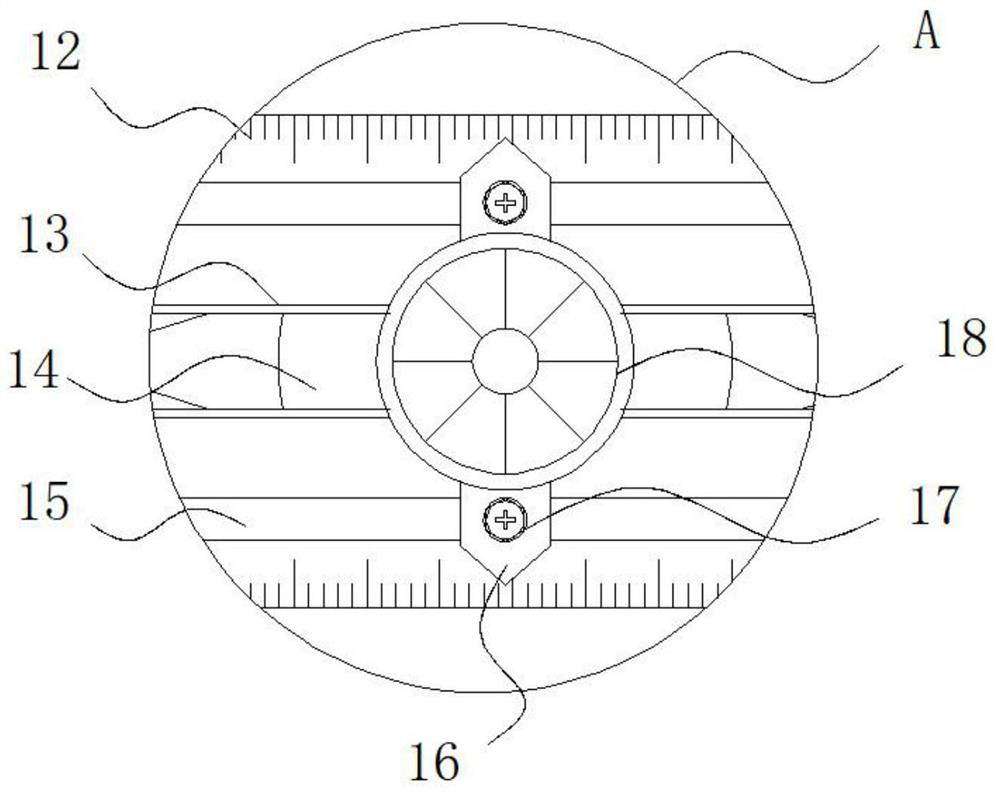

Pig feed crushing and drying integrated processing equipment

ActiveCN111905911AImprove the crushing effectImprove practicalityFeeding-stuffGrain treatmentsElectric machineryDrive motor

The invention discloses pig feed crushing and drying integrated processing equipment. The pig feed crushing and drying integrated processing equipment comprises a main body bin, wherein a crushing assembly is arranged at the middle position of the top of the main body bin; mounting bins are symmetrically arranged at two sides of the main body bin; a connecting bin is arranged at the top end of theinner part of each mounting bin; bearings B are symmetrically arranged at the middle positions of the top and the bottom of each connecting bin; a crankshaft is arranged at the inner sides of the bearings B; an eccentric wheel is arranged at the top of the outer side of the crankshaft; and a bearing A is arranged at the bottom of the outer side of the crankshaft in a sleeving manner. According tothe pig feed crushing and drying integrated processing equipment disclosed by the invention, the crushing assembly, a driving motor, the mounting bins, the main body bin, a chopping assembly, a connecting rod, the crankshaft, the connecting bins, the bearings B and the eccentric wheel are matched for use, and arc-shaped blades at the inner sides of blanking holes are continuously staggered with each other, so that pig feed falling from the blanking holes is chopped for the second time, the crushing and processing effect of the whole processing equipment on the pig feed is greatly improved, and the practicality of the processing equipment is also improved.

Owner:JINAN BEST ANIMAL HUSBANDRY TECH

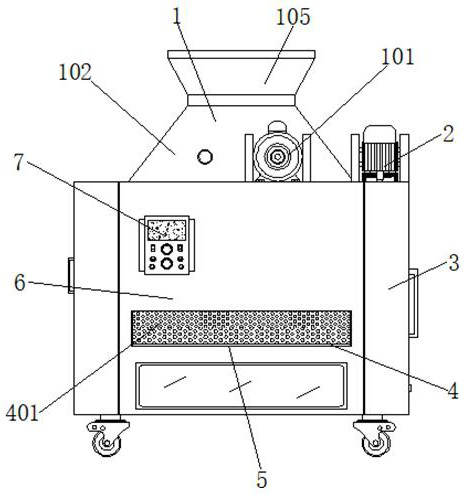

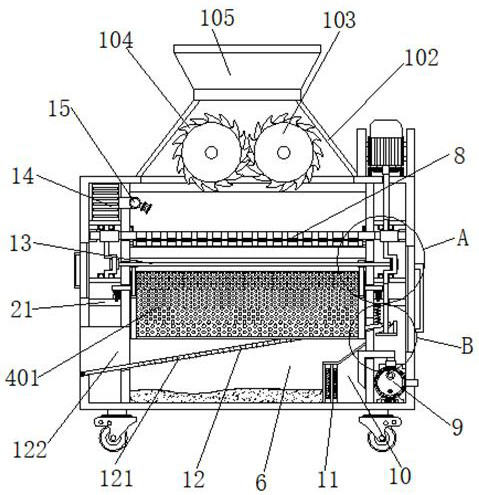

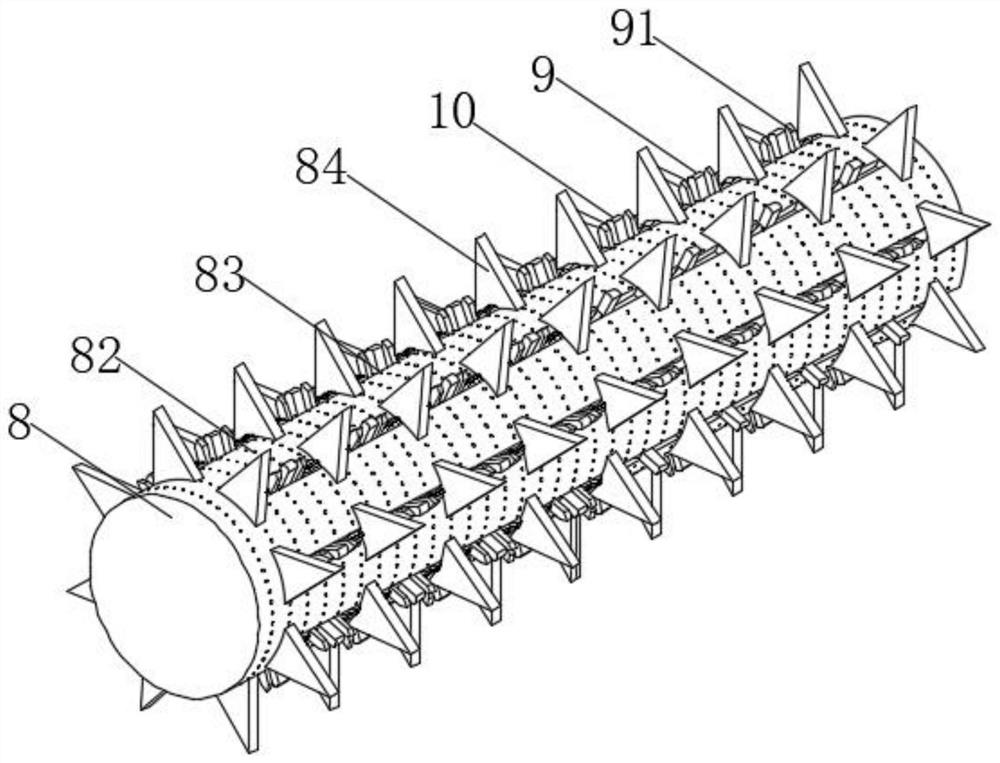

Waste plastic bag recycling device

InactiveCN113232200AImprove the crushing effectImprove crushing effectPlastic recyclingGrain treatmentsPlastic bagPull force

The invention relates to the technical field of plastic processing equipment, and discloses a waste plastic bag recycling device which comprises a base, supporting legs are fixedly installed at the four corners of the bottom of the base correspondingly, supporting plates are fixedly installed on the left side and the right side of the end, away from the supporting legs, of the base correspondingly, and recycling barrels are arranged at the ends, away from the base, of the supporting plates. The interior of the recycling barrel is hollowed out, a feeding hopper is arranged at the center axis of the top of the recycling barrel, and the feeding hopper communicates with the top of the recycling barrel. According to the waste plastic bag recycling device, when a crushing roller rotates, a fixed crushing thorn exerts extrusion force on an extrusion rod, and the extrusion rod pushes an extrusion moving mechanism to move under the action of the extrusion force, so that auxiliary crushing cutters on the two sides can be pushed to move, and the auxiliary crushing cutters on the two sides move to exert transverse pulling force on a plastic bag; and under the action of transverse pulling force, the crushing effect of the device on the plastic bags can be enhanced.

Owner:刘红甫

Multifunctional medicinal material processing device

PendingCN110711632AImprove processing qualityGuarantee product qualityNon-rotating vibration suppressionDirt cleaningMedicinal herbsStructural engineering

The invention discloses a multifunctional medicinal material processing device. The multifunctional medicinal material processing device comprises a second smashing box. Horizontally-arranged grindingplates are fixed to the inner walls of the two sides of the second smashing box through screws, discharge holes of annular structures are formed in the outer walls of the tops of the grinding plates,sliding grooves are formed in the portions, located on the peripheries of the discharge holes, of the grinding plates, balls slide on the inner walls of the sliding grooves, and the outer walls of the tops of the balls are connected with a grinding disc in a sliding manner. A first smashing box is fixed to the outer wall of the top of the second smashing box through a screw, a servo motor is fixed to the outer wall of one side of the first smashing box through a screw, an output shaft of the servo motor is connected with a smashing barrel through a coupler, and annularly-distributed smashingblades are fixed to the outer wall of the smashing barrel through screws. A good smashing processing effect is achieved, the processing quality of medicinal materials is improved, during preliminary smashing, dust on the surfaces of the medicinal materials can fly, the dust can be sucked into a dust collecting box through a dust suction pump to be collected, and the production quality of the medicinal materials is guaranteed.

Owner:邱铸权

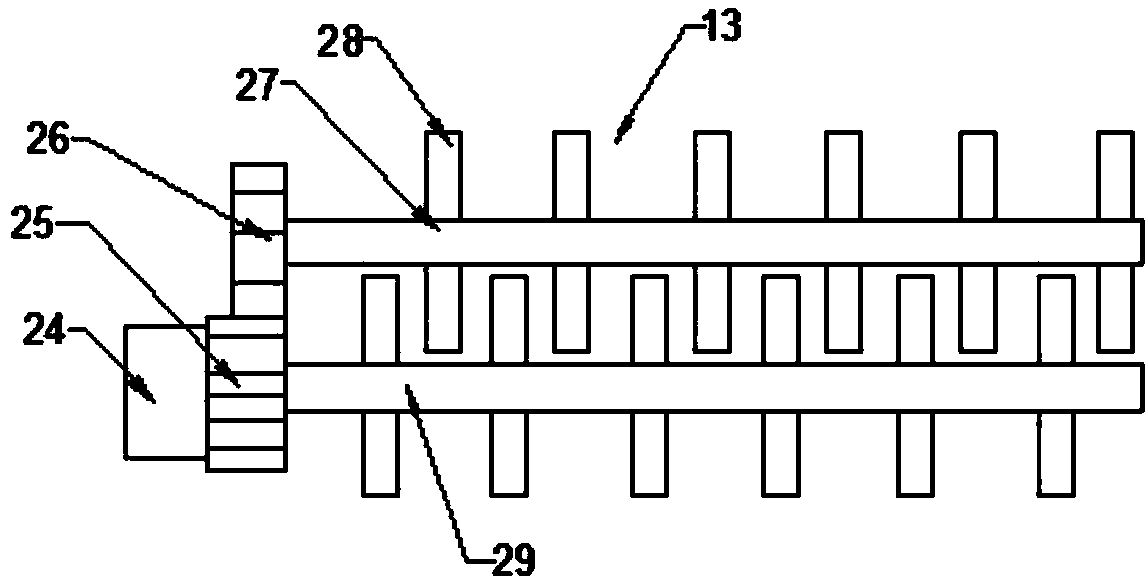

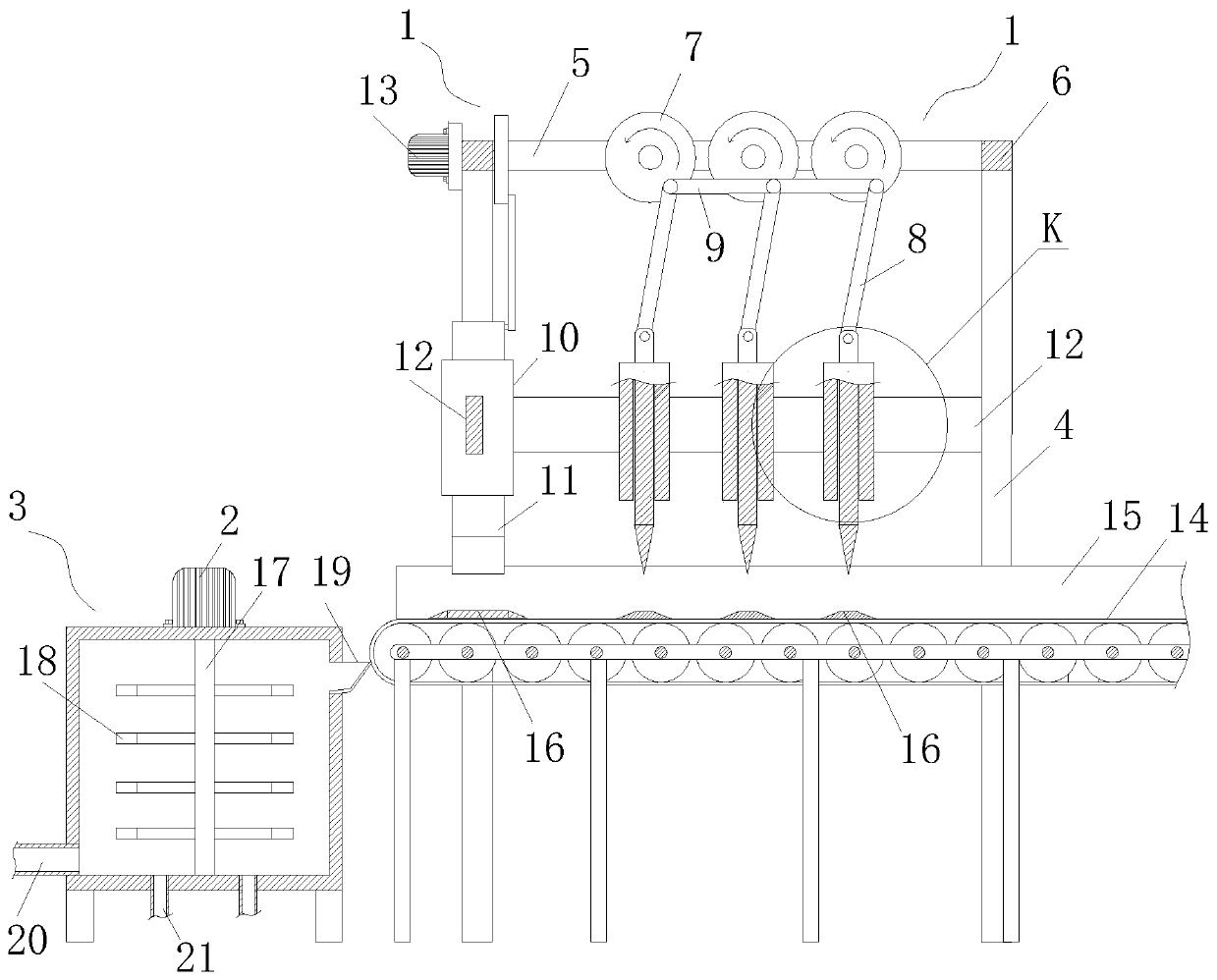

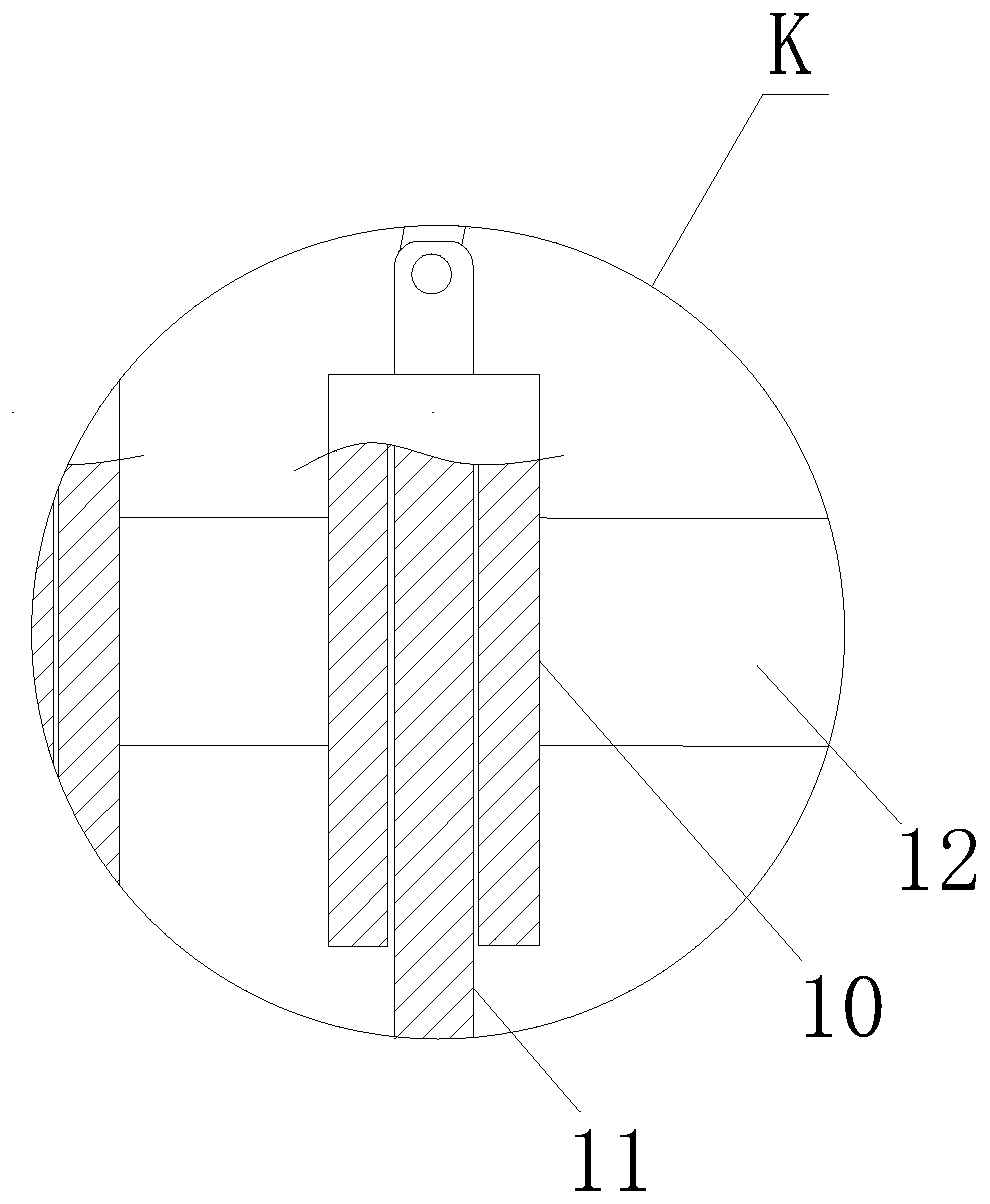

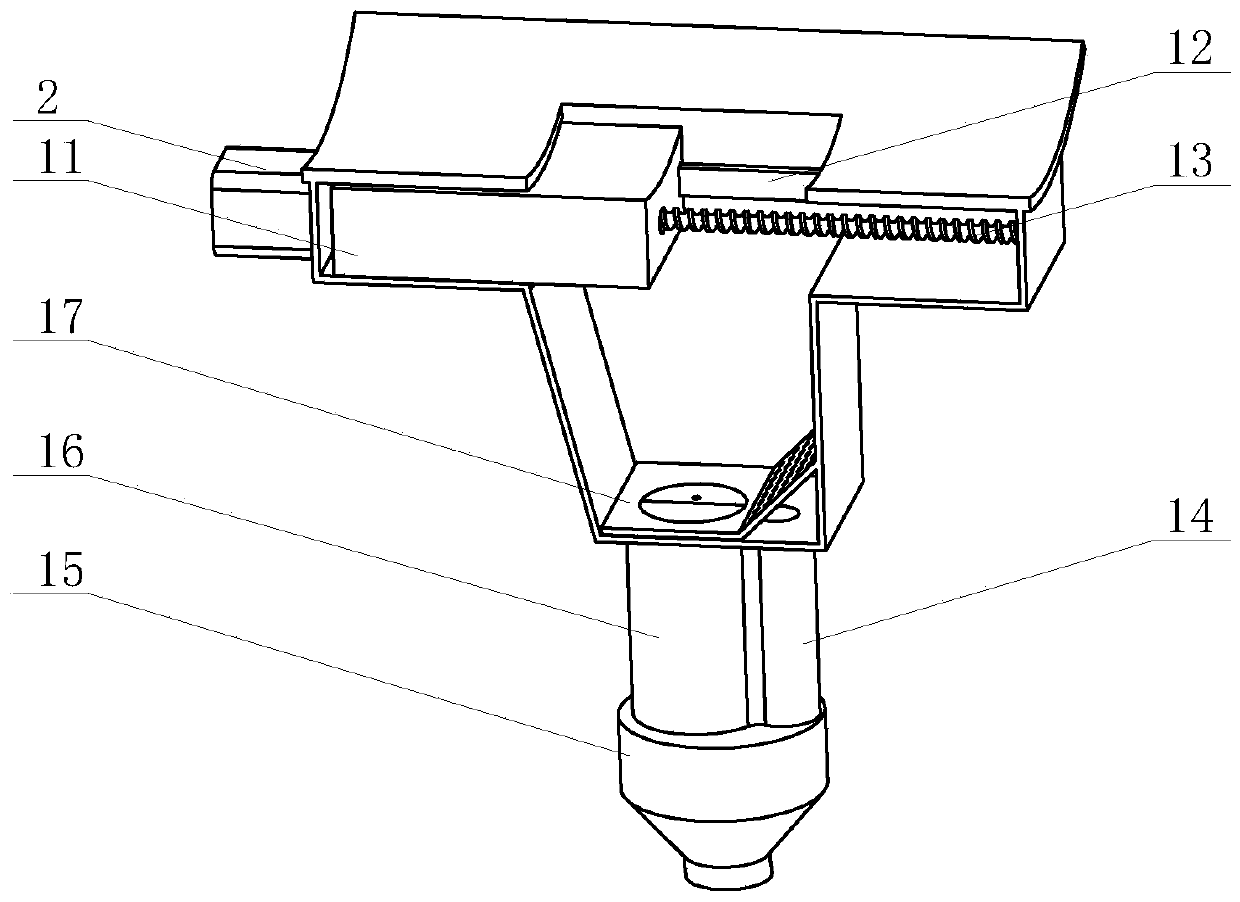

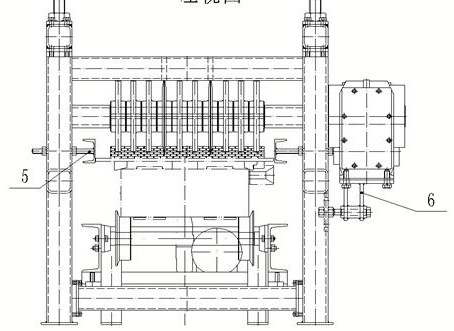

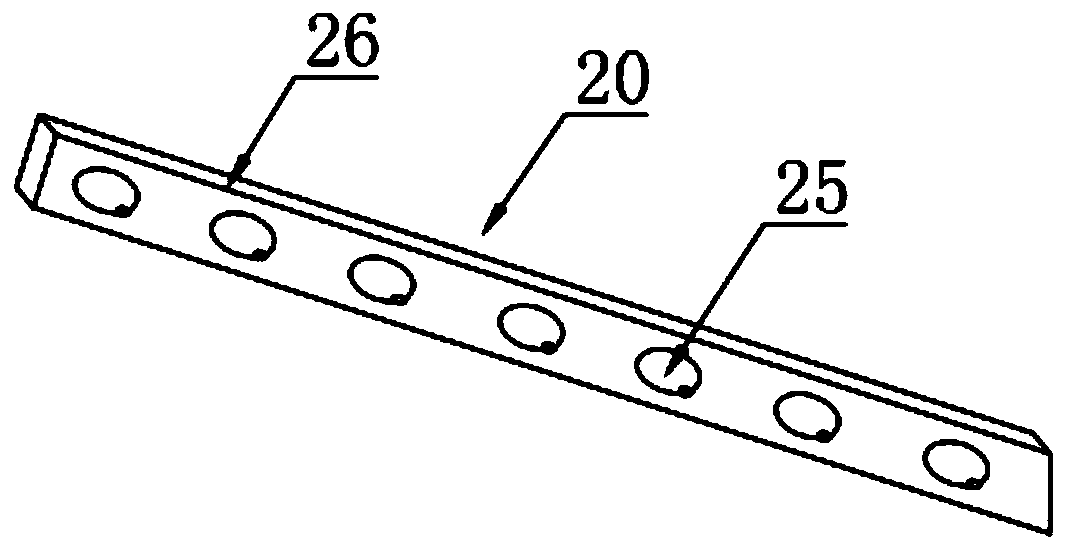

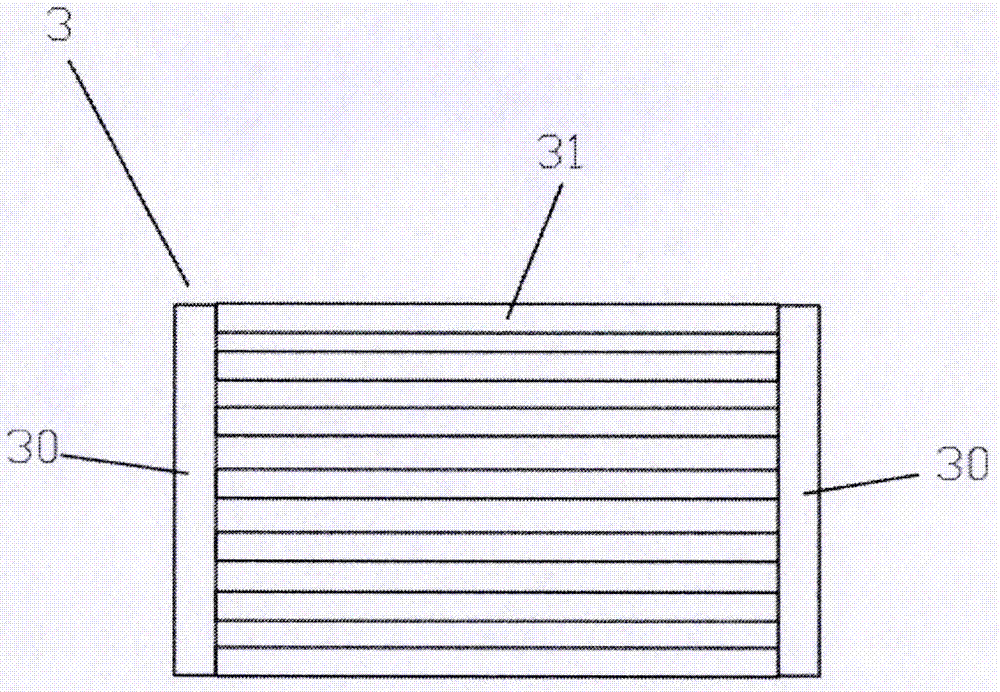

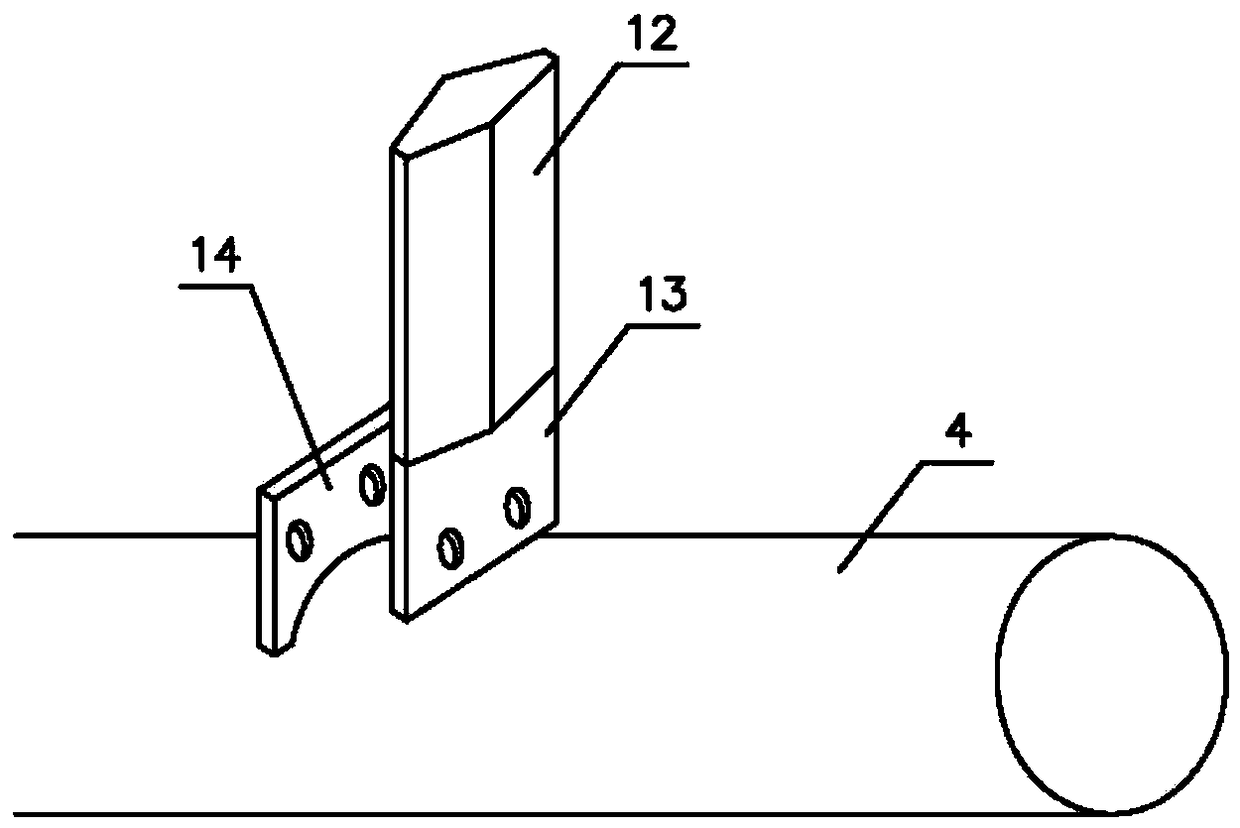

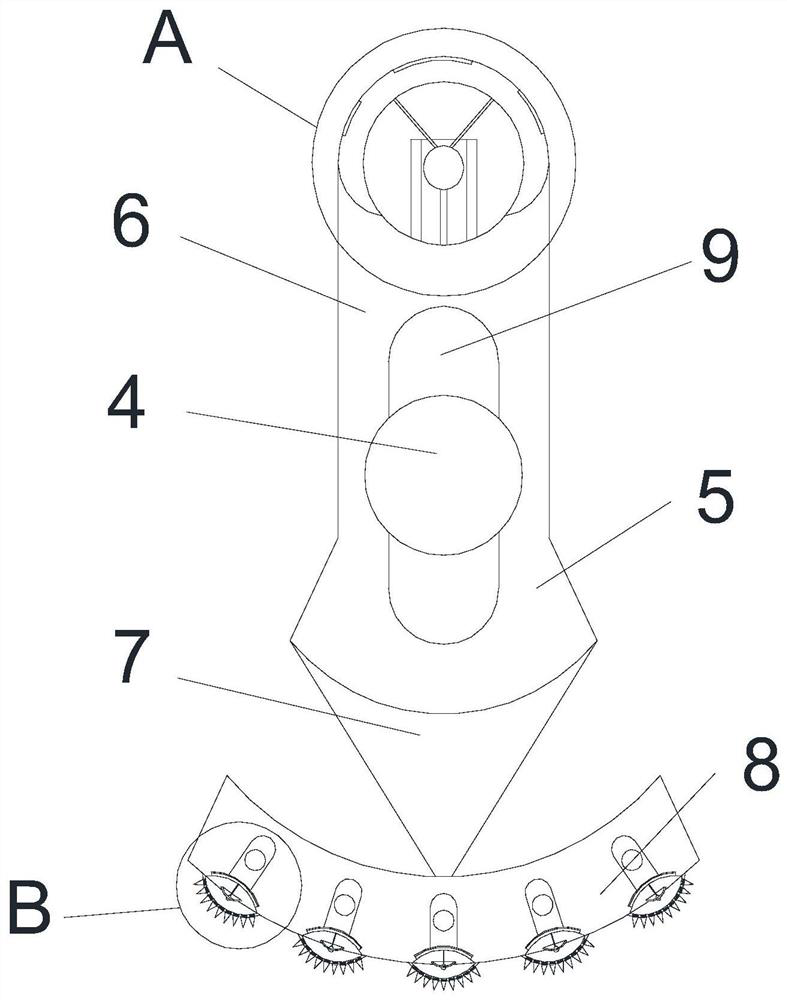

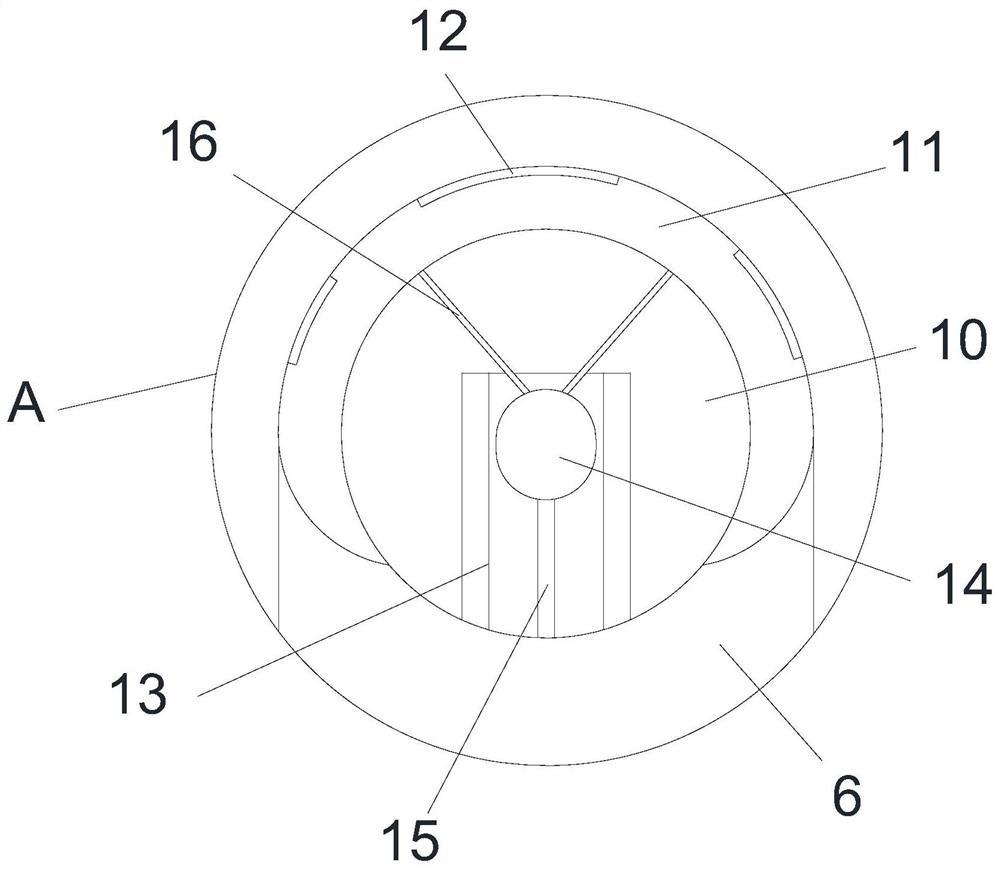

Bottom skin crushing mechanism for aerated concrete plate

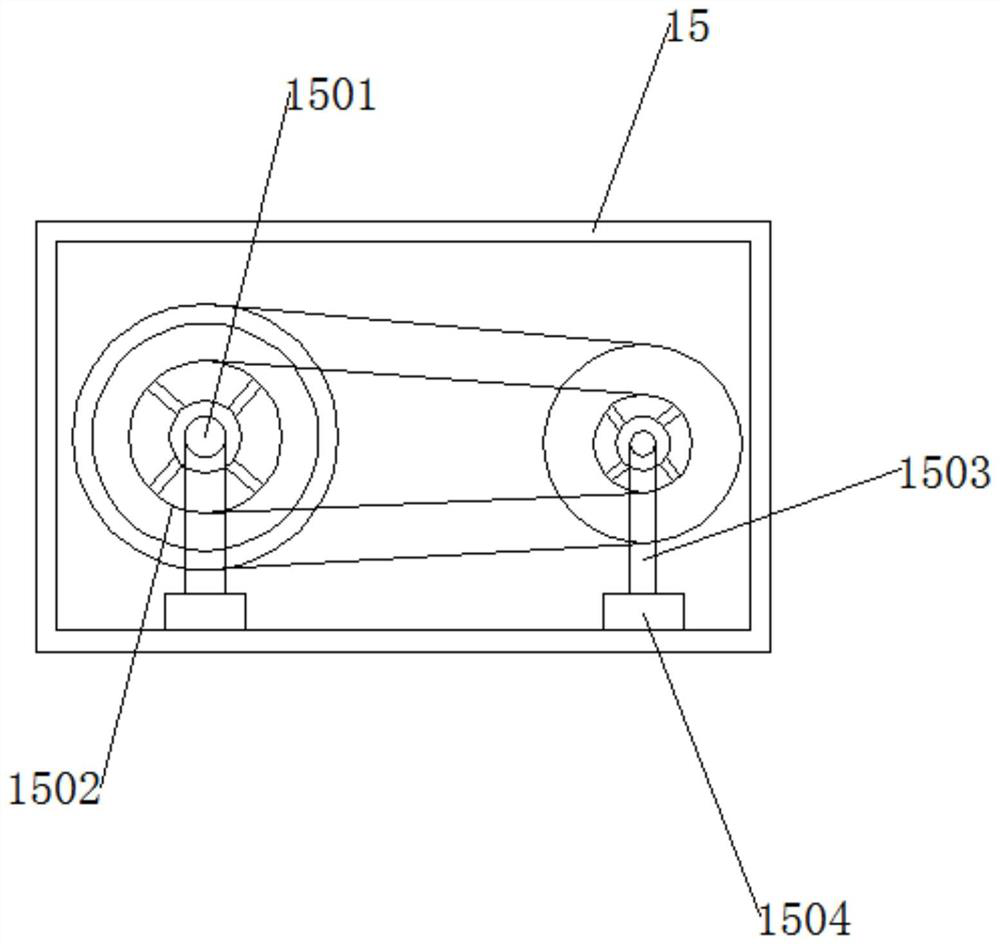

PendingCN111605082AImprove the crushing effectReduce debris splashWorking accessoriesGrain treatmentsElectric machineryLeather belt

The invention discloses a bottom skin crushing mechanism for an aerated concrete plate. The mechanism comprises a cross beam, a framework, a tunneling device, a crushing device, a waste limiting device and an anti-twisting arm. The cross beam and the framework are connected via bolts; the waste limiting device is connected with the framework via bolts; and the tunneling device and the crushing device are fixed with the cross beam via a large-size processing threaded shaft. The anti-twisting arm connects the tunneling device, the crushing device and the framework. According to the mechanism, guiding of waste to be crushed is realized via waste limiting, so the waste to be crushed is precisely loaded into the lower parts of the crushing device and the tunneling device. A motor in the tunneling device drives a tunneling cutter disc and a compacting wheel to realize primary crushing of the waste, and a motor in the crushing device drives a crushing cutter disc and a compacting wheel to realize thorough crushing of a bottom skin. The device solves the problem that the after-kettle bottom skin is easy to remove; through crushing by the device, an after-kettle waste overturning platform can easily overturn bottom skin waste into a waste transportation belt; and technical support is provided for a production process of aerated plates with after-kettle bottom skin removed.

Owner:DONGYUE MACHINERY GRP

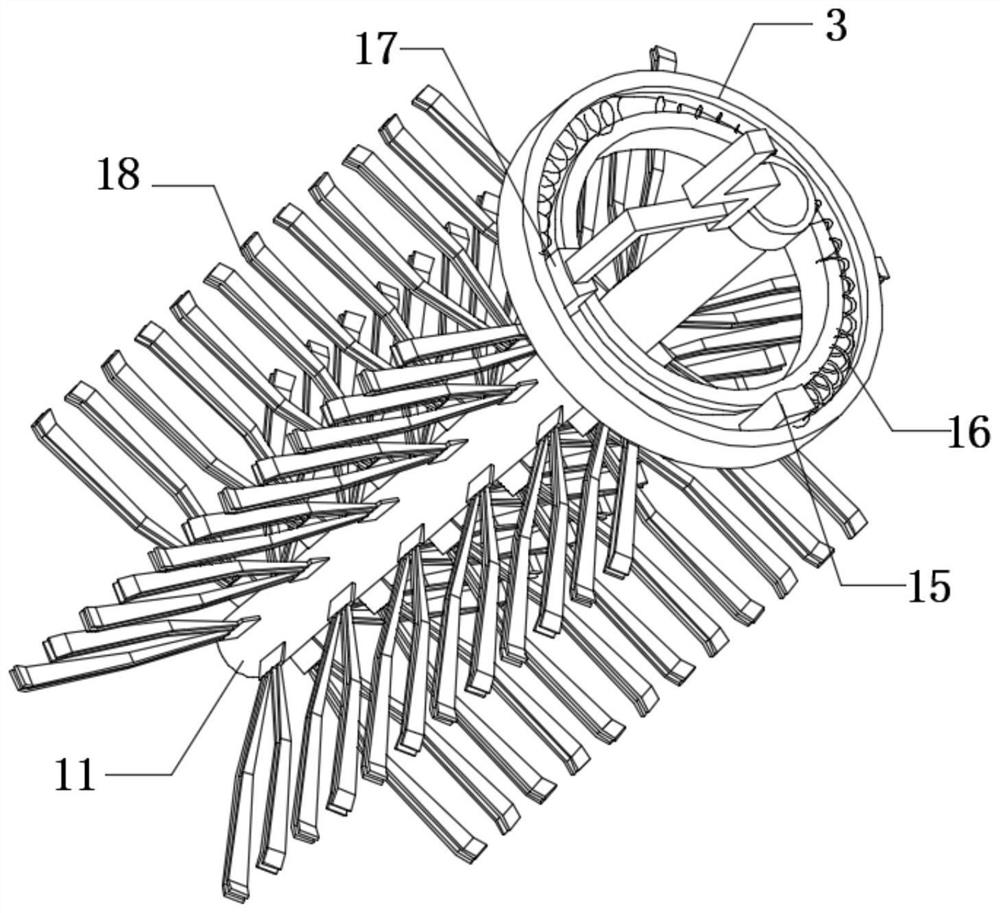

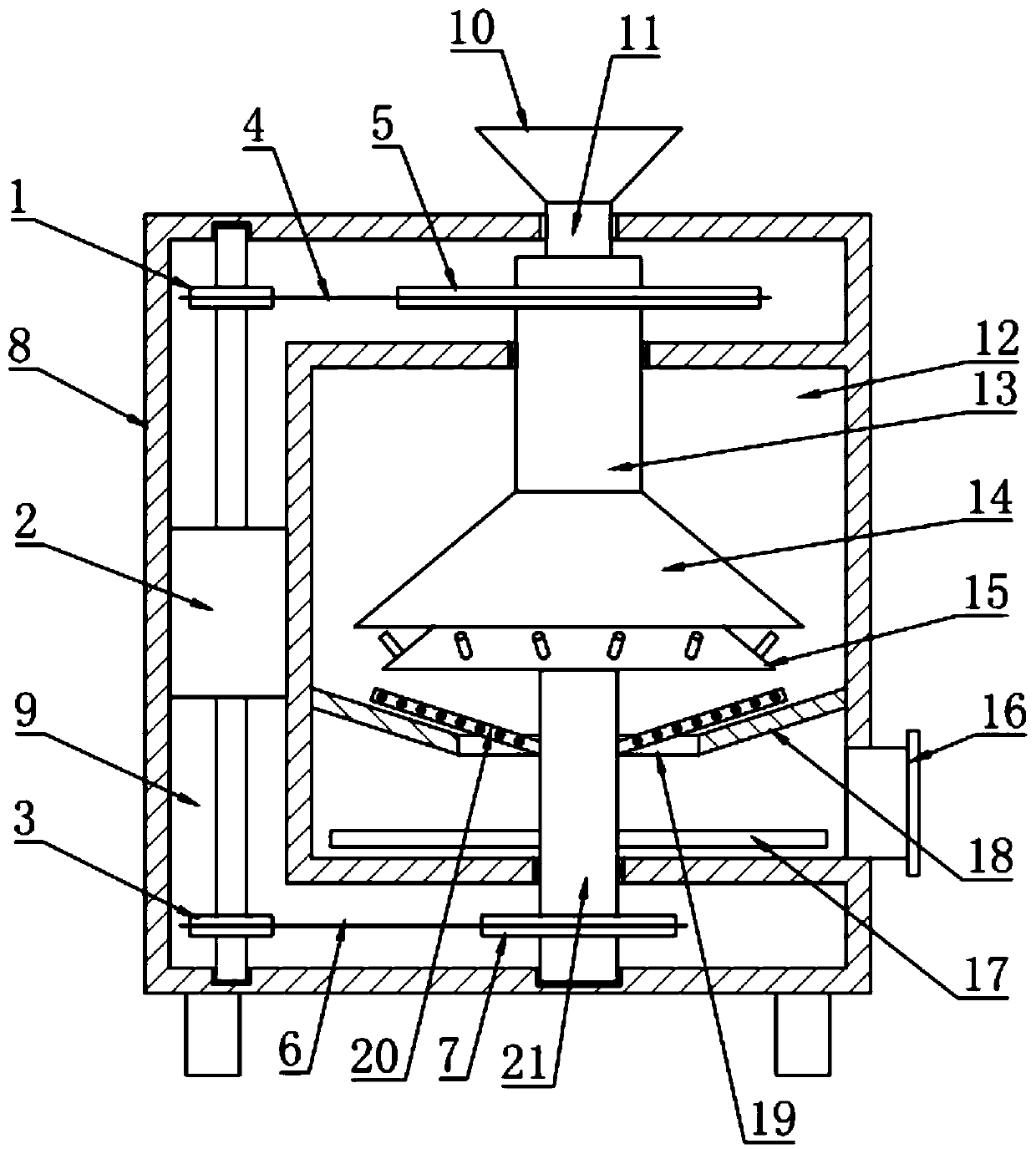

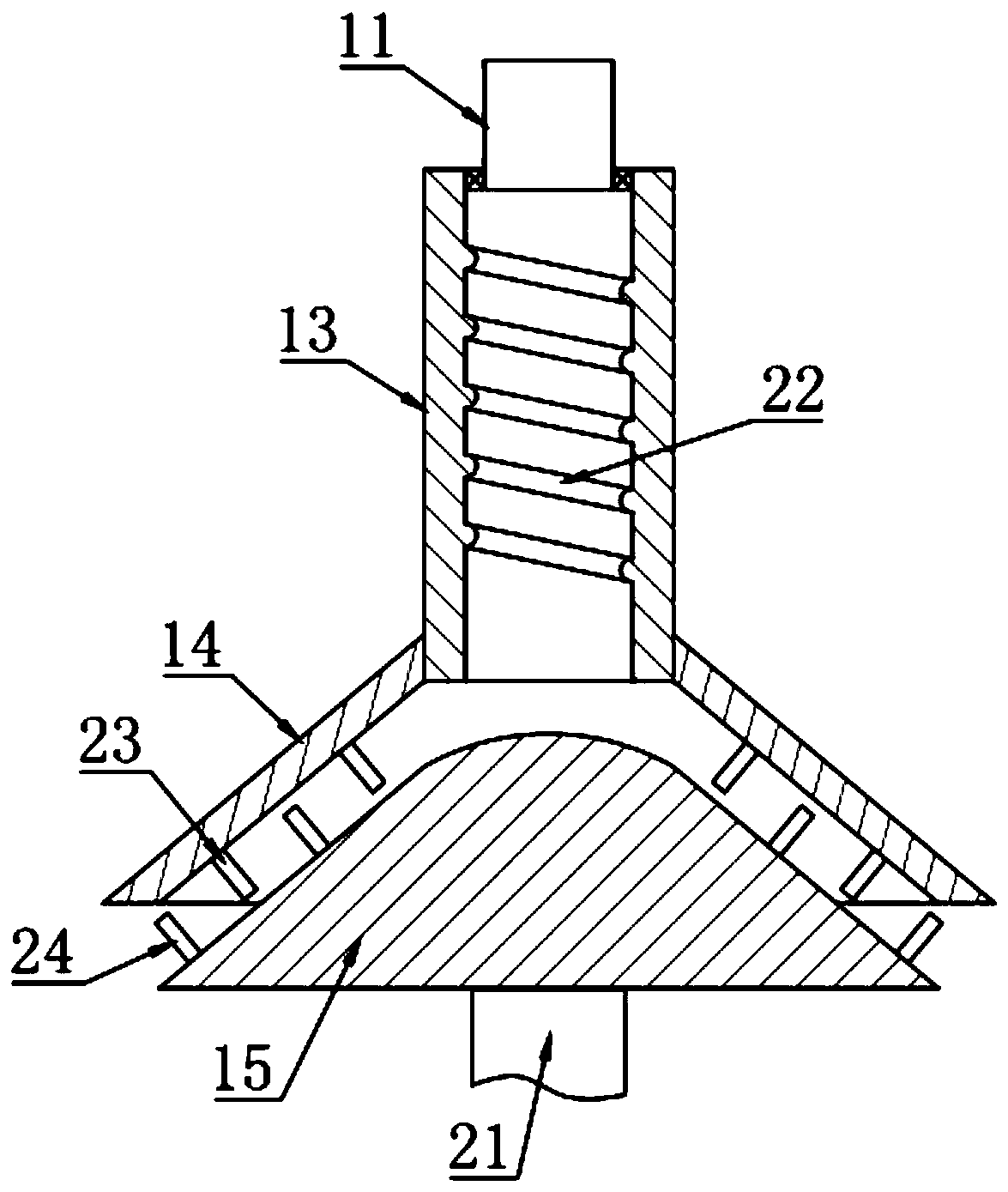

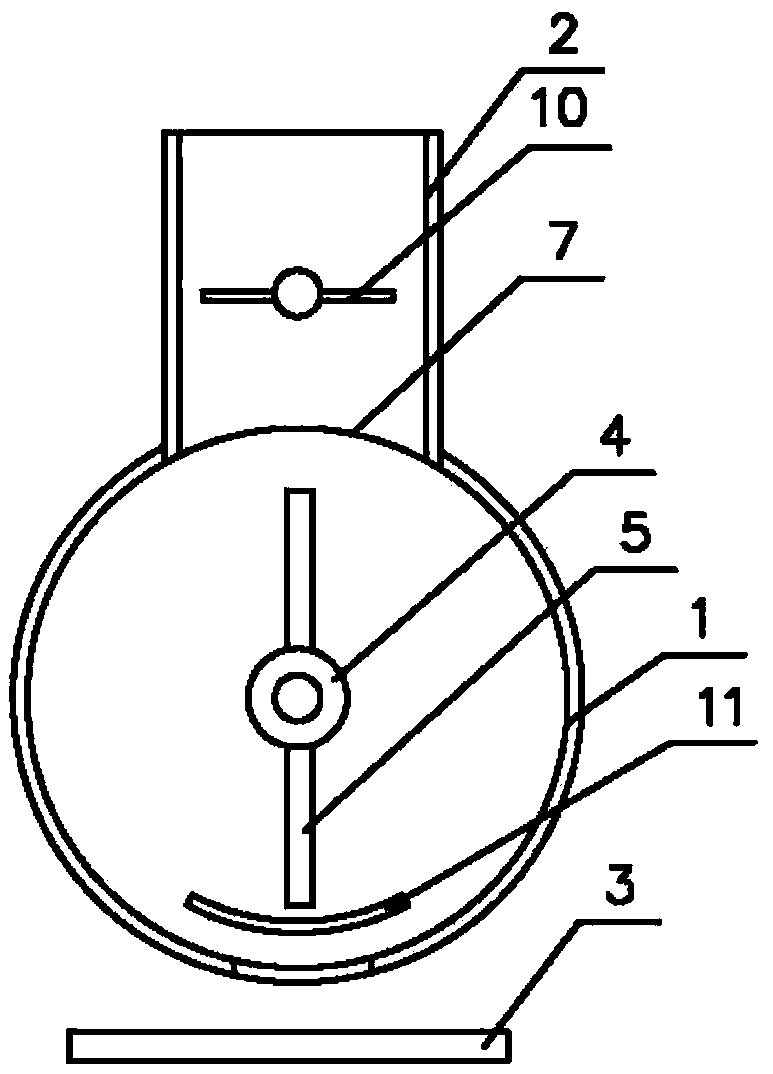

Vertical rubbing-breaking processing machine for traditional Chinese medicinal materials

InactiveCN110976048AKneading broken fastImprove the crushing effectGrain treatmentsEngineeringMechanical engineering

The invention relates to the field of processing for traditional Chinese medicinal materials, and specifically relates to a vertical rubbing-breaking processing machine for traditional Chinese medicinal materials. The vertical rubbing-breaking processing machine for the traditional Chinese medicinal materials comprises a machine body, wherein a processing cavity is formed in the machine body; a drive cavity is formed in the outer side of the processing cavity; an upper rotary barrel and a lower rotary shaft are rotationally installed at the top and the bottom of the processing cavity separately; the upper rotary barrel and the lower rotary shaft are driven to carry out differential rotation in the same direction by a drive mechanism arranged in the drive cavity; an upper breaking cover isinstalled and fixed to the lower end of the upper rotary barrel; a lower breaking table matched with the upper breaking cover is installed and fixed to the upper end of the lower rotary shaft; a plurality of first breaking teeth and a plurality of second breaking teeth are installed on the inner wall of the upper breaking cover and at the outer side of the lower breaking table separately; a material guide plate is installed and fixed to a part at the lower side of the lower breaking table, of the cavity wall of the processing cavity; a plurality of secondary breaking assemblies are circumferentially distributed and arranged at the upper side of the material guide plate; and the inner ends of the secondary breaking assemblies are fixed to the lower rotary shaft. Through differential controlin the same direction, and the arrangement for the breaking structures, the vertical rubbing-breaking processing machine for the traditional Chinese medicinal materials is capable of carrying out high-efficiency breaking processing on the traditional Chinese medicinal materials, and good in processing effect.

Owner:韩明智

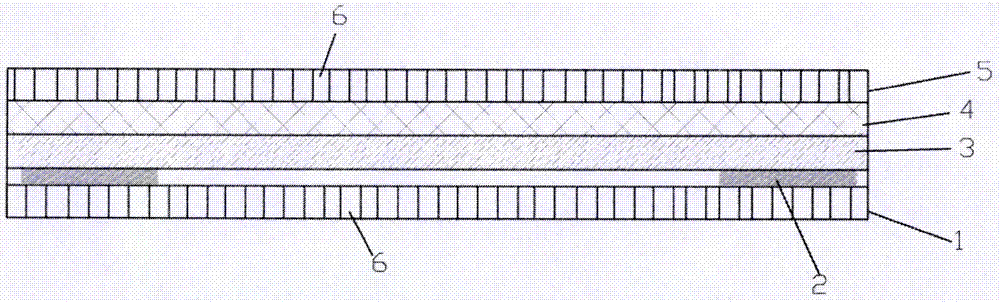

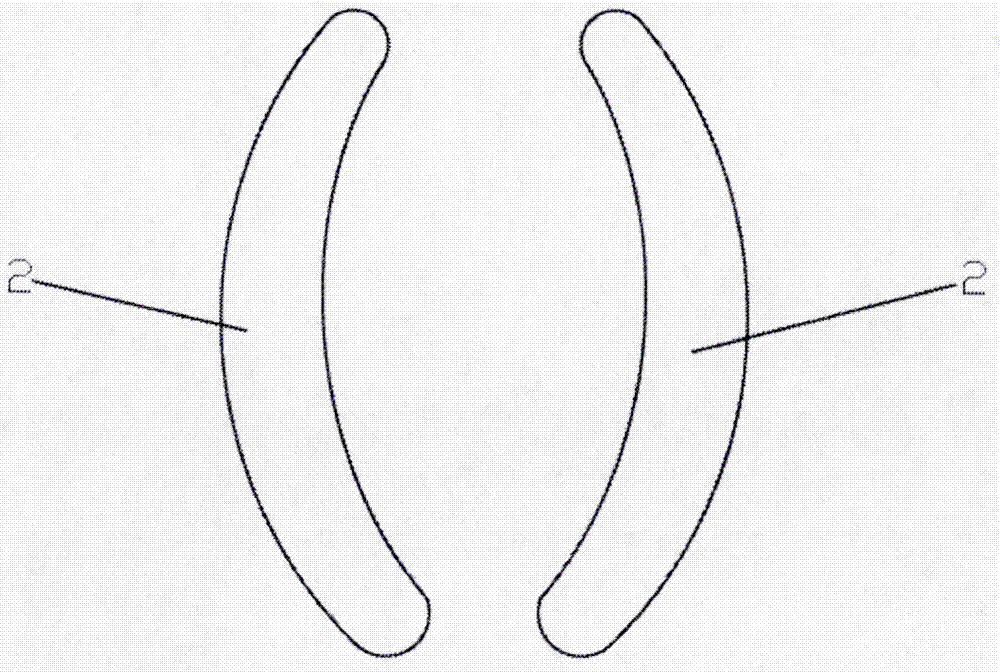

Antibacterial and hemostatic ointment, antibacterial and hemostatic medicine and preparation methods of antibacterial and hemostatic ointment and antibacterial and hemostatic medicine

InactiveCN107412520AInhibitionImprove loading effectAntibacterial agentsPharmaceutical non-active ingredientsAdditive ingredientTraditional medicine

The invention relates to antibacterial and hemostatic ointment, an antibacterial and hemostatic medicine and preparation methods of the antibacterial and hemostatic ointment and the antibacterial and hemostatic medicine. The traditional Chinese medicinal ingredients are reasonable in compatibility, particularly, the scheme of mixing traditional Chinese medicinal powder and extract is disclosed for the first time, the combination of nano-scale traditional Chinese medicinal powder and extract is taken as the basis, the advantages of the traditional Chinese medicinal materials are exerted, and the problem of mutual influences is also solved; the traditional Chinese medicinal powder and extracting solution are mixed at low temperature, thus the mutual reaction is avoided, the loss of the efficacies is avoided, the prepared ointment is kept at low temperature and is taken out when used, and in combination with the effects of through holes, graphene and body temperature, the temperature rise of the ointment is rapid, and then the efficacies are achieved. For the antibacterial and hemostatic ointment, the antibacterial and hemostatic medicine and the preparation methods of the antibacterial and hemostatic ointment and the antibacterial and hemostatic medicine, all the ingredients are reasonably mixed, an ointment plaster can be prepared by adopting the antibacterial and hemostatic ointment and supporting cloth, so that bacteria possibly generated due to the fact that the ointment is in contact with the human skin and exposed to the outside can be effectively inhibited.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Crusher suitable for quick-frozen food

InactiveCN110404623AUniform sizeImprove the crushing effectFood shapingGrain treatmentsEngineeringCrusher

The invention relates to the technical field of food processing, in particular to a crusher suitable for quick-frozen food. The crusher comprises a base and a crushing mechanism. The crushing mechanism comprises a crushing box and a crushing assembly. A controller, a heating mechanism and an even-pressing mechanism are further included. The heating mechanism comprises a heating box and a heating assembly. The even-pressing mechanism comprises a protection box and an extrusion assembly. The heating assembly and the extrusion assembly are both electrically connected with the controller. The crusher suitable for the quick-frozen food has an even pressing function, the quick-frozen food obtained after ice melting can be evenly pressed, crushing of the crusher is facilitated, meanwhile the crushed food is even in size, then the crushing effect is promoted, the selling quantity is further increased, eating experience of customers is further improved, observation windows are further designedin the outer walls of the heating box and the protection box, thus the heating process and even pressing process are visible, crushing time can be saved, and then work efficiency is promoted.

Owner:丽水市愿旺食品有限公司

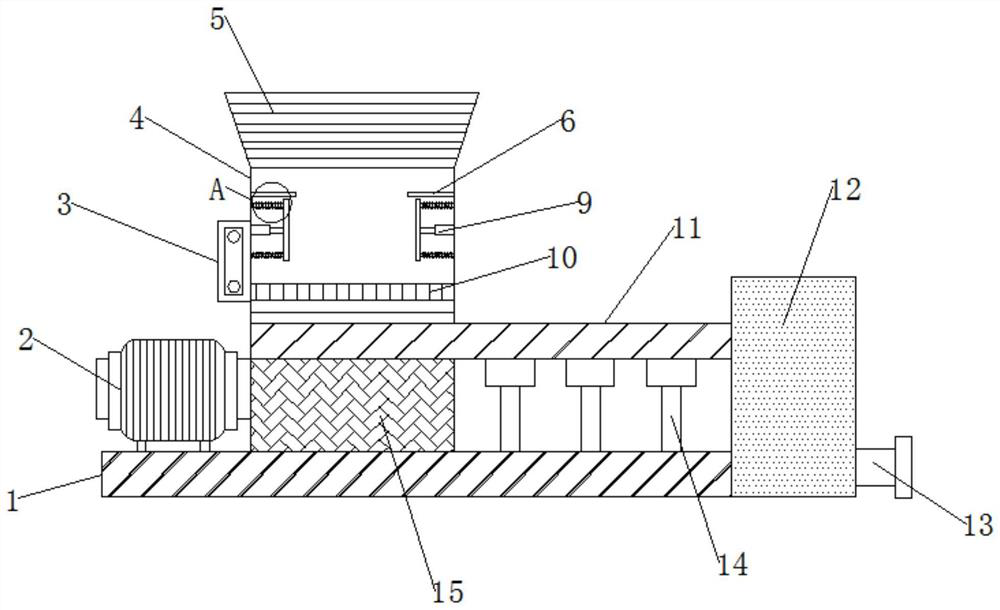

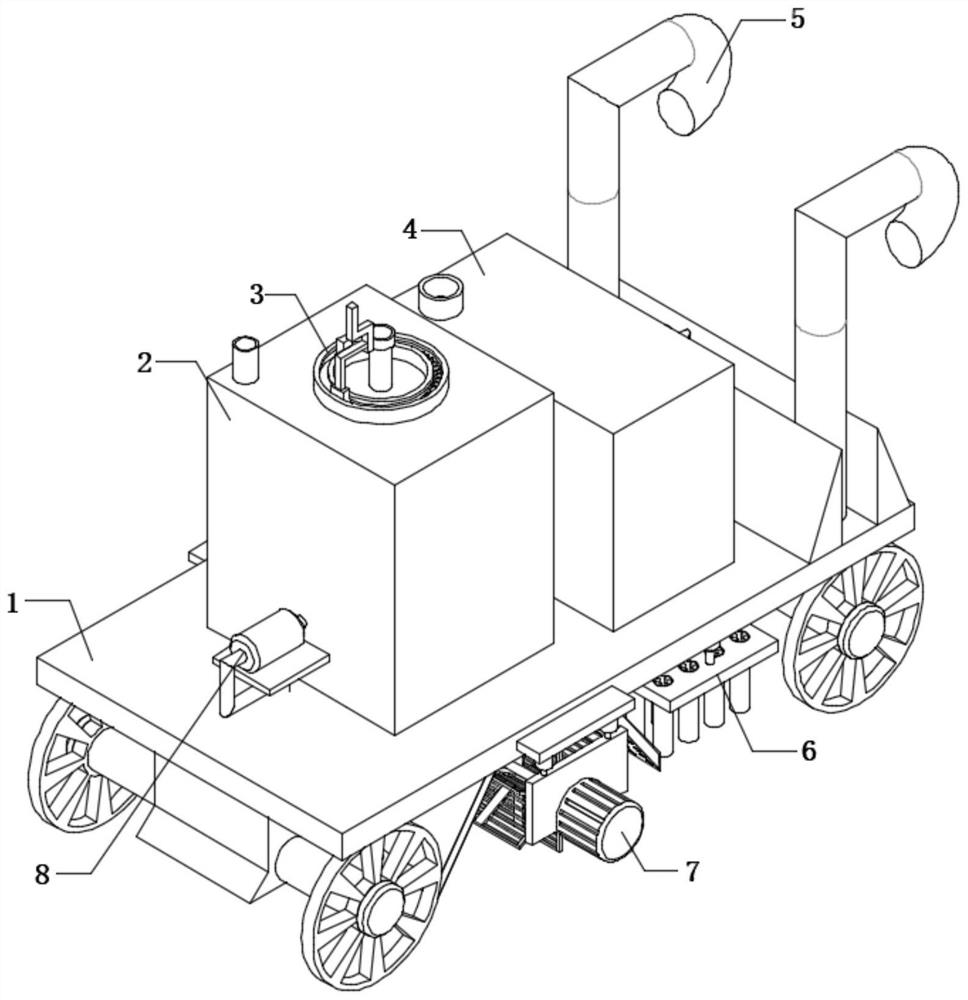

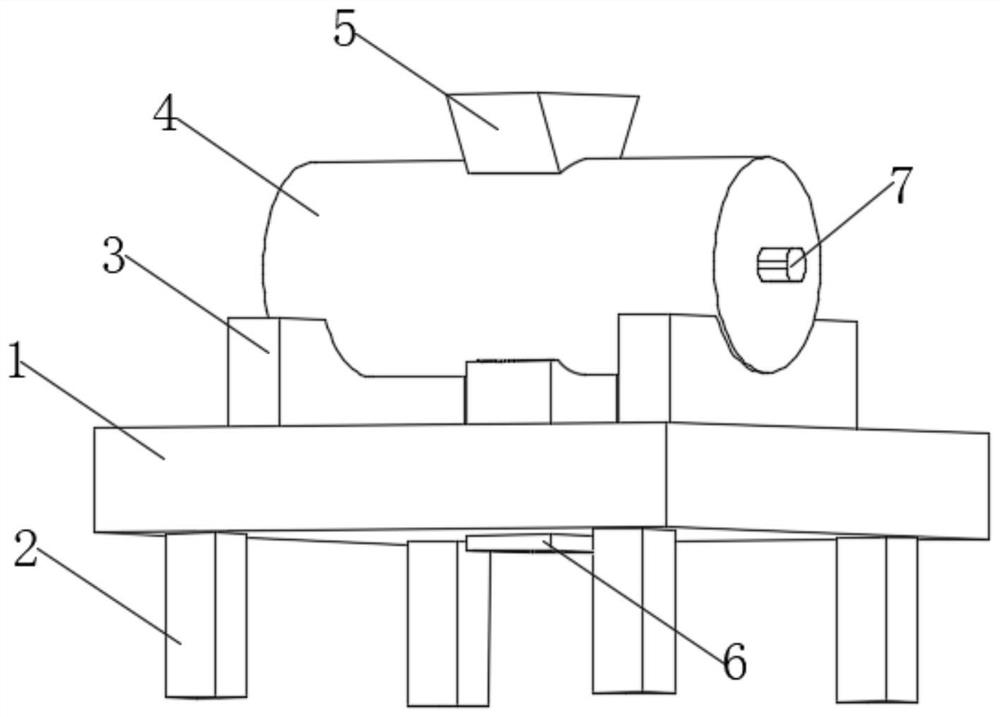

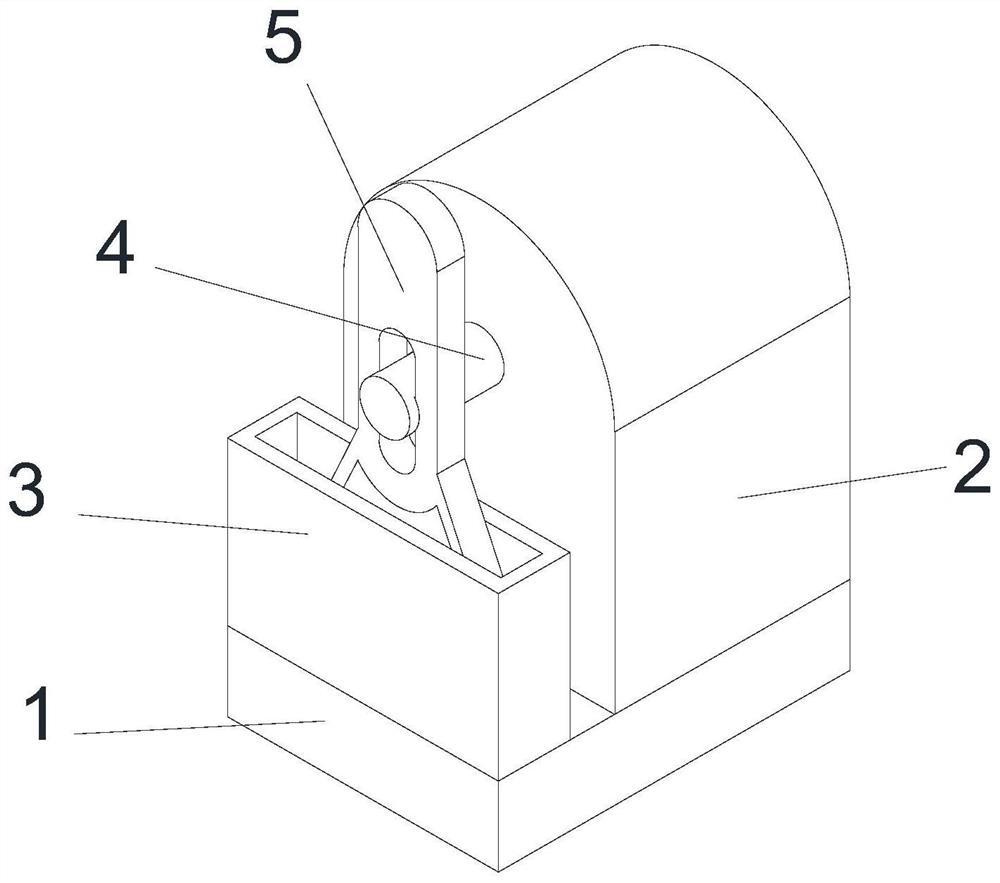

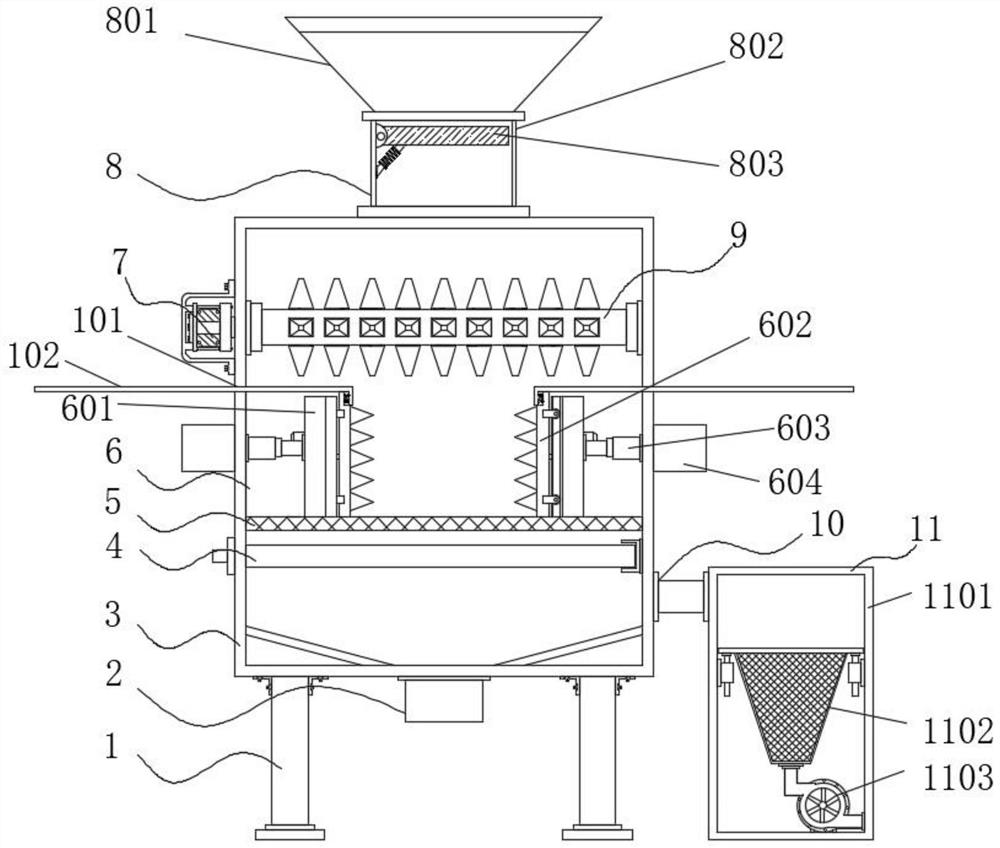

Biomass fuel forming and granulating device

PendingCN114653439AImprove the crushing effectImprove uniformityDrying gas arrangementsSolid fuelsProcess engineeringExtrusion Granulation

The invention relates to a biomass fuel forming granulation device which comprises a smashing mechanism used for smashing and stirring biomass raw materials, a drying mechanism used for stirring and drying the biomass raw materials is arranged on the lower side of the smashing mechanism, an extrusion granulation mechanism is installed at the lower end of the drying mechanism, and a base is installed at the lower end of the extrusion granulation mechanism. A material receiving box used for receiving materials is arranged at the upper end of the base and located on the lower side of a discharge port of the extrusion granulation mechanism; the biomass fuel particle production device can solve the following problems in the biomass fuel particle production process in the prior art: the biomass raw material crushing process is relatively simple, so that the biomass raw material crushing effect is relatively poor; no mechanism for stirring biomass raw materials is arranged in the whole process of manufacturing the biomass fuel; and only fixed-point air blowing can be performed, so that the biomass raw materials on the lower side easily block an air flue, the biomass raw materials on the upper side cannot be subjected to air blowing drying, and the drying effect on the biomass raw materials is reduced.

Owner:杨婷婷

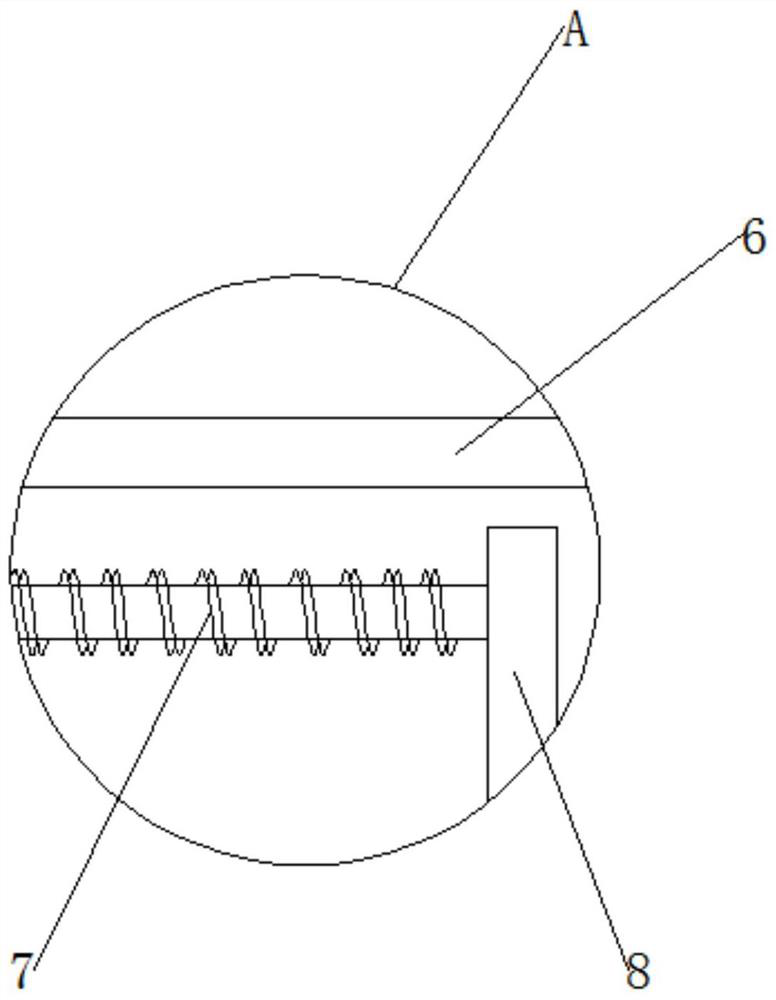

Caked fertilizer crushing device for agriculture

PendingCN111604107AImprove the crushing effectImprove work efficiencyGrain treatmentsFertilizerElectric machinery

The invention relates to the technical field of agricultural devices, and discloses a caked fertilizer crushing device for agriculture. The caked fertilizer crushing device for the agriculture comprises a box body, wherein supporting legs are fixedly connected to the bottom of the box body, a servo motor is fixedly connected to one side of the bottom of the box body, a feeding opening is fixedly connected to the top of the box body, a discharging opening is formed in the bottom of the box body, a sliding groove is formed in the inner wall of the top of the box body, a long-strip-shaped hole isformed in the top of the box body, the sliding groove communicates with the long-strip-shaped hole, a sliding block is movably connected into the sliding groove, and a connecting rod is fixedly connected to the bottom of the sliding block. According to the caked fertilizer crushing device for the agriculture, the servo motor drives a lead screw to rotate, so that a movable plate does transverse reciprocating motion, a vibration motor is used for driving a baffle to shake, crushing teeth on the movable plate and crushing teeth on the baffle crush caked fertilizers, the crushing teeth can makefull contact with the fertilizers through the elastic action of springs, the crushing effect is improved, and the labor intensity of people is reduced.

Owner:盘小青

Waste material treatment device

The invention relates to a waste material treatment device. The waste material treatment device comprises a shell, a feeding hopper and a conveyor belt, wherein the feeding hopper is arranged above the shell; the conveyor belt is arranged below the shell; a cutter shaft is arranged in an inner cavity of the shell; a cutter is fixedly mounted on the cutter shaft; a feeding opening communicated withthe feeding hopper is formed in the upper end of the shell; a discharging opening is formed in the lower end of the shell; a feeding and crushing cabin is arranged between the feeding hopper and thefeeding opening; a feeding cutter shaft is mounted in an inner cavity of the feeding and crushing cabin by means of a bearing; a feeding cutter is fixedly mounted on the feeding cutter shaft; an arc-shaped plate is fixedly arranged between the cutter shaft and the discharging opening; a gap is formed between the upper surface of the arc-shaped plate and the moving trajectory of the cutter; and a gap is formed between the lower surface of the arc-shaped plate and the inner wall of the shell. The waste material treatment device is simple in structure, low in using and maintaining cost, and goodin crushing treatment effect.

Owner:江苏卫航智昊通信科技有限公司

Material grinding device

ActiveCN112808361AImprove crushing and grinding efficiencyEasy to grindGrain treatmentsDrive shaftStructural engineering

The invention discloses a material grinding device, and relates to the field of material processing. The material grinding device comprises a base table, wherein a driving equipment box is fixedly installed on the right side of the top of the base table; driving equipment is arranged in the driving equipment box; a material box is fixedly installed on the left side of the top of the base table; and a driving shaft is fixedly installed at the output end of the driving equipment in the driving equipment box. According to the material grinding device provided by the invention, when the driving shaft begins to rotate, due to the relation between a groove in the driving shaft and an adjusting groove in a main plate, during rotating of the driving shaft, the two ends of the grinding device are limited by the driving shaft and gravity, so that materials in the material box can be strongly impacted; and meanwhile, a lower plate is arc-shaped rubber, the materials can be preliminarily impacted and crushed by the lower plate, and the materials can be better ground when being refined by the top end of the main plate, so that the material crushing and grinding efficiency is improved.

Owner:山东青牧牧业科技有限公司

Automatic magnetic separator for materials

InactiveCN104959206AImprove the crushing effectEasy to separateMagnetic separationGrain treatmentsMagnetic separatorTherapeutic effect

The invention relates to an automatic magnetic separator for materials. The automatic magnetic separator comprises a base, wherein a feeding cavity is formed in the left side of the upper part of the base; a left lifting cavity is connected to the right side of the feeding cavity; a material supplying pipe is connected to the upper part of the right side of the left lifting cavity; a crushing cavity is connected to the right side of the material supplying pipe; a material returning pipe is connected to the lower part of the left side of the crushing cavity; a filtering plate is arranged at the lower part of the crushing cavity; a stirring cavity is formed at the lower part of the filtering plate; a discharging pipe is connected to the right side of the stirring cavity; a right lifting cavity is connected to the right side of the discharging pipe; a discharging cavity is connected to the upper part of the right side of the right lifting cavity; a plurality of discharging holes are formed in the lower part of the discharging cavity; a material supplying cavity is formed below the discharging holes; a separating cavity is formed below the material supplying cavity. The automatic magnetic separator disclosed by the invention can be used for crushing materials and favorably lifting the crushed materials, so that the crushing treatment effect of the materials is improved; in addition, the drying treatment is facilitated, magnetic separation is carried out after crushing for multiple times, and impurities are conveniently separated; besides, the mass of the impurities is conveniently counted, the separating treatment effect of the impurities is improved, and the convenience in use is realized.

Owner:陈少军

Grinding type stone crushing device for municipal engineering construction

InactiveCN112973855AIncrease the degree of fragmentationImprove the crushing effectMagnetic separationGrain treatmentsElectric machinerySlag

The invention discloses a grinding type stone crushing device for municipal engineering construction. Waste left after crushing by a first crushing roller falls on a net plate, a crushing motor is used for driving a transmission plate to rotate, and then crushing plates are pushed to reciprocate up and down in a vertical guide groove; in the movement process, the lower ends of the crushing plates knock the net plate, so that falling of disintegrating slag on the upper portion of the net plate is accelerated; a telescopic rod is pushed out through an electric push rod, and then the two crushing plates are oppositely combined, so that incompletely-crushed materials on the upper portion of the net plate are crushed again; and in the crushing process, due to mutual friction motion between the two crushing plates, the crushed materials between the two crushing plates can be ground, and the crushing effect on the crushed materials is improved.

Owner:李煜新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com