Plastic crusher

A technology of plastic crusher and crushing mechanism, which is applied in the direction of plastic recycling, mechanical material recycling, smoke and dust removal, etc. It can solve the problems of threatening the life safety of operators, difficulty in maintaining the crushing mechanism, and reducing production safety, so as to improve the working environment. Improve the crushing capacity, move and fix the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

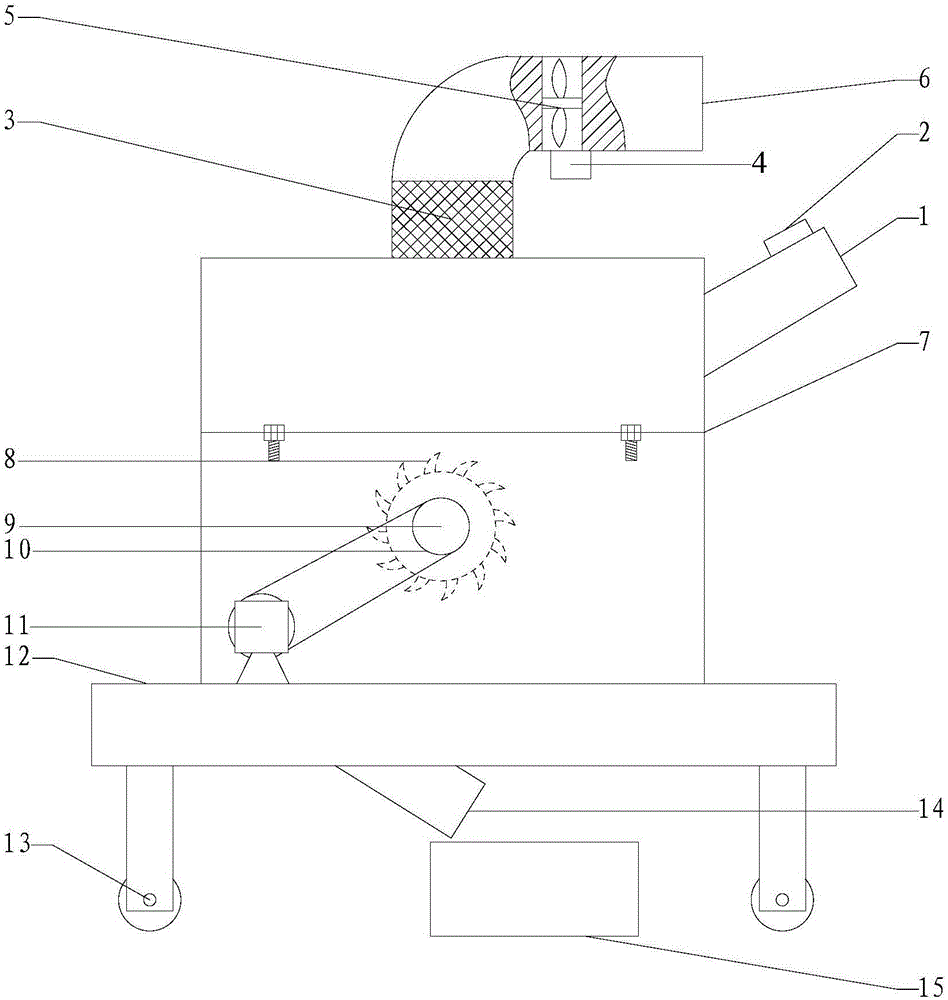

[0042] A plastic crusher, including a box body mechanism, a crushing mechanism, and a supporting mechanism;

[0043] The box body mechanism includes a feed port 1, a dust collection device, and a box body 7; the crushing mechanism includes a drive motor 11, a hob, a pulley 10, and a drive shaft 9; the support mechanism includes a platform 12, casters 13, The screening filter, the discharge port 14 and the storage hopper 15; the feed port 1 and the dust collection device are respectively arranged on the upper part of the box body 7; the crushing mechanism is placed in the box body 7 of the box mechanism; The drive motor 11 is placed on the platform 12 of the support mechanism; the hob of the crushing mechanism is fixed on the drive shaft 9; the pulley 10 of the crushing mechanism is fixed on the drive shaft 9; the drive motor 11 drives the pulley through a belt 10 drive the drive shaft 9 to rotate; the box body 7 is fixed on the platform 12 by bolt connection; the screening filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com