Grinding type stone crushing device for municipal engineering construction

A technology of engineering construction and crushing device, applied in the field of stone crushing, can solve problems such as accumulation in the upper part of the mesh plate, and achieve the effects of improving the degree of crushing, improving the crushing effect, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

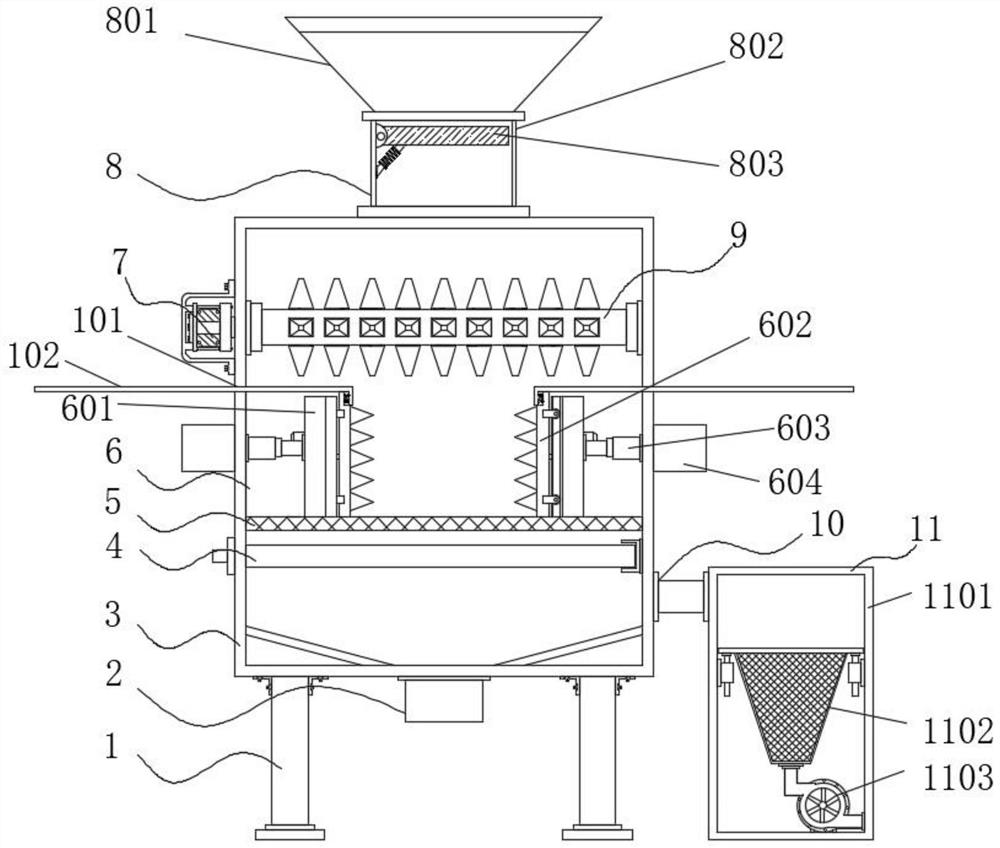

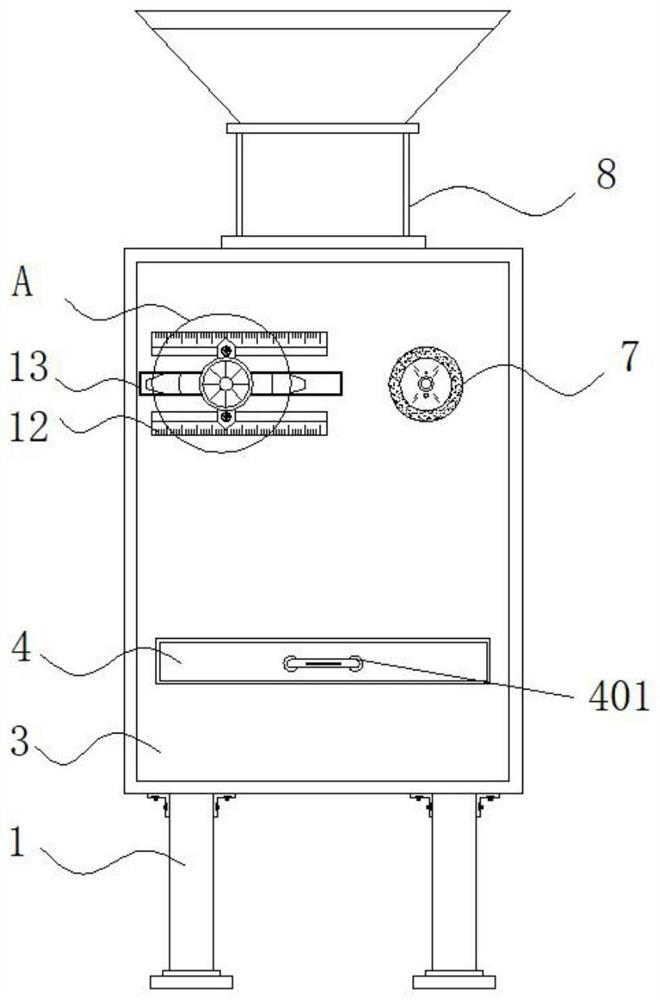

[0040] Example 1: See Figure 1-6 , a grinding-type stone crushing device for municipal engineering construction, comprising legs 1 and a body 3, four sets of legs 1 are fixedly connected to the four corners of the bottom of the body 3, and the bottom of the body 3 is fixedly connected to a discharge Port 2, the bottom end inside the body 3 is provided with a cleaning structure 4, the inside of the body 3 is fixedly connected with a mesh plate 5, the two sides inside the body 3 are provided with a crushing mechanism 6, and the top of one side of the body 3 is fixedly connected with a first drive Motor 7, the model of the first driving motor 7 is Y80S-2, the output end of the first driving motor 7 is fixedly connected with the first crushing roller 9 through a coupling, the top of the body 3 is fixedly connected with a protective structure 8, the body 3 The bottom end of the other side is fixedly connected with a dust outlet pipe 10, one side of the dust outlet pipe 10 is fixed...

Embodiment 2

[0045] Embodiment 2: The cleaning structure 4 is made up of a handle 401, a first magnet 402, a second magnet 403 and a cleaning frame 404. The cleaning frame 404 is arranged inside the body 3, and the two ends of the cleaning frame 404 are fixedly connected with four sets of second magnets. A magnet 403, two sets of first magnets 402 are arranged inside the cleaning frame 404, and a handle 401 is fixedly connected to one side of the cleaning frame 404;

[0046] The second magnet 403 is provided with four groups and is symmetrically distributed about the vertical centerline of the removal frame 404;

[0047] Specifically, such as figure 1 As shown, because some of the broken stones are the ruins of buildings, the interior of the stones may contain steel bars or other iron materials. After the stones and steel bars enter the crushing device together, the broken stones that come out also contain steel bars inside. For the fragments of the iron block, a group of magnets that can...

Embodiment 3

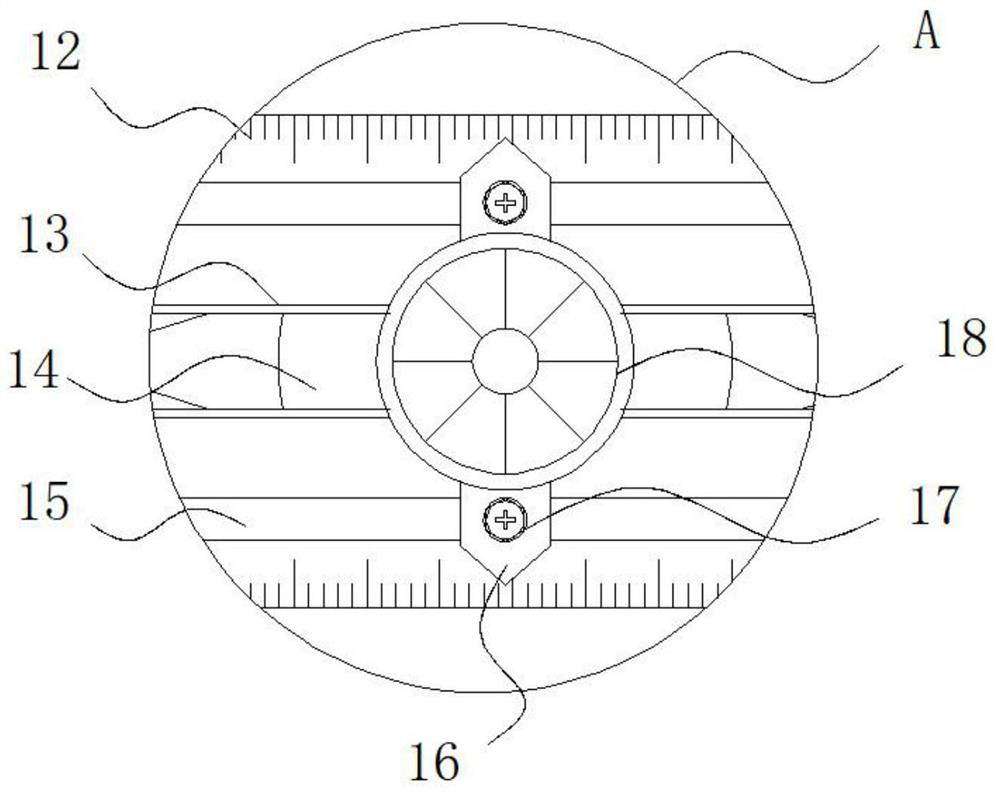

[0048] Example 3: See Figure 1-6 , a grinding type stone crushing device for municipal engineering construction also includes an adjustment mechanism, the adjustment mechanism includes a second crushing roller 14, the second crushing roller 14 is arranged at one end inside the body 3, and the top ends of the second crushing roller 14 both sides There are two groups of sliders 16 fixedly connected to the bottom, one side of the slider 16 is fixedly connected with an adjusting bolt 17, two groups of chute 13 are arranged on both sides of the body 3, and two groups of chute 13 are arranged at the top and bottom of the chute 13 A slideway 15, a scale plate 12 is arranged on the top of the slideway 15, and a second drive motor 18 is fixedly connected to one side of the body 3, and the model of the second drive motor 18 is Y90S-2;

[0049] The slider 16 is in the shape of "I", the slideway 15 is in the shape of "concave", and the slider 16 and the slideway 15 are in a sliding conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com