Aluminosilicate tempered glass and preparation method thereof

A technology of aluminosilicate glass and tempered glass, applied in the field of glass manufacturing, can solve problems such as unusable use, mechanical properties of traditional cover glass need to be further improved, loss of display function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides the preparation method of the aluminosilicate strengthened glass, comprising the following steps:

[0074] Mixing raw materials according to the composition of the aluminosilicate glass, performing melting treatment, then annealing and forming to prepare the aluminosilicate glass;

[0075] Immersion of aluminosilicate glass in NaNO 3 and KNO 3 Ion exchange is carried out in mixed molten salts to prepare the aluminosilicate strengthened glass.

[0076] The specific preparation process of the aluminosilicate glass involved in the present invention can be obtained in the traditional flat glass manufacturing process, and its manufacturing process is not limited to the float forming process, overflow down-draw method, lead-up method, flat drawing method, and calendering method Wait.

[0077] In one example, the melting temperature ranges from 1500°C to 1700°C.

[0078] In one example, the annealing temperature is 550°C-750°C.

[0079]...

Embodiment 19

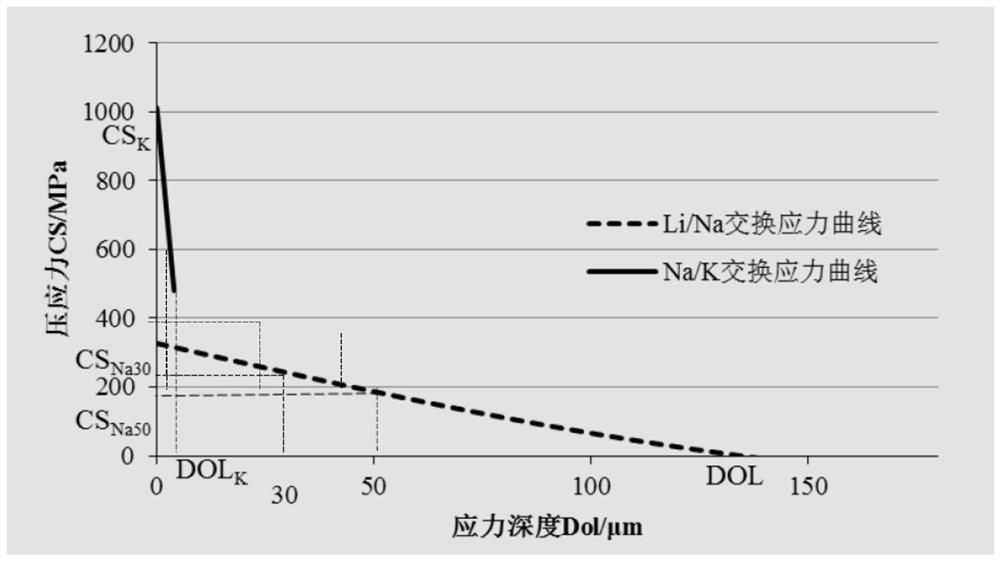

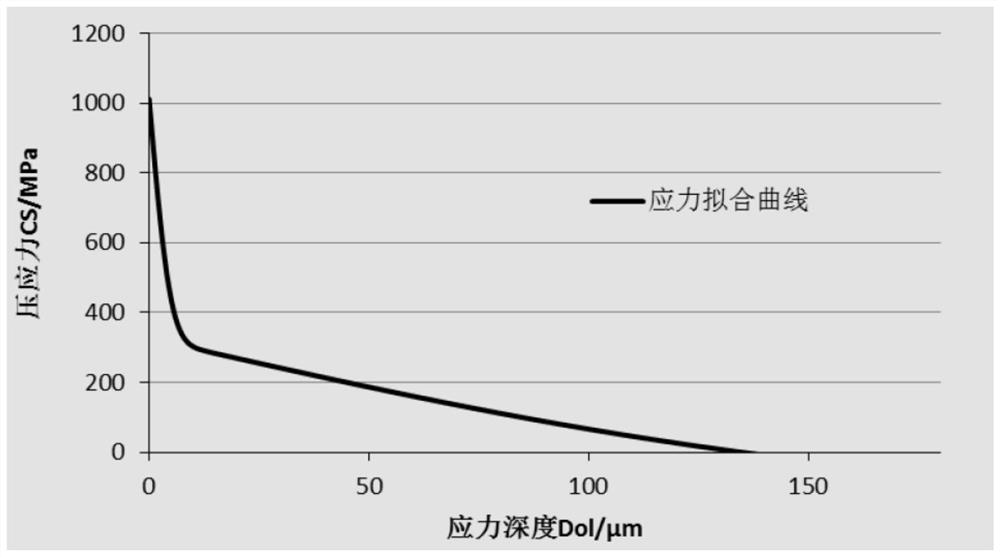

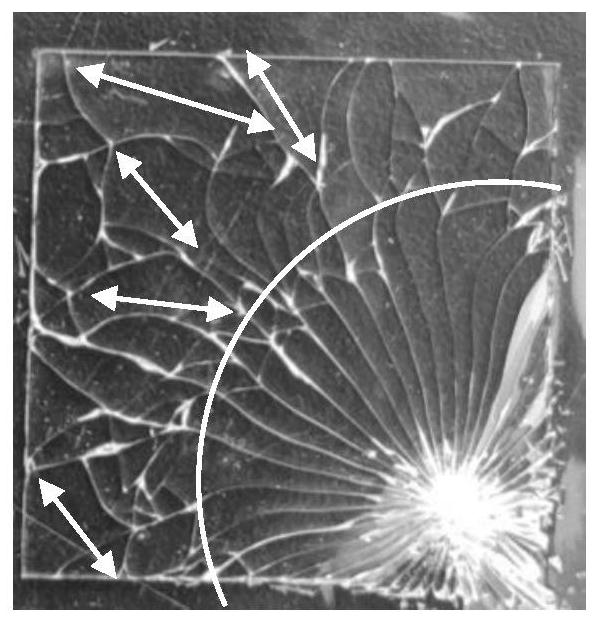

[0118] Embodiment 19 On the base component of embodiment 5, reduce Y 2 o 3 to 0.1%, the reduced part is added to SiO 2 Above, its glass sample was immersed in a mixed solution of 10wt% sodium nitrate and 90wt% potassium nitrate. After 2 hours at a temperature of 420°C, its CS Na30 208MPa, CS Na50 133MPa, CS K 906MPa, DOL is 124μm, CT is 79.84MPa, DOL K is 5.3 μm, and its surface potassium and sodium ion exchange is inhibited, CS K 、DOL K Slightly reduced, but its fragmentation gamma value has decreased to 16.9mm.

Embodiment 20

[0119] Embodiment 20 On the base component of embodiment 5, K 2 O increased to 2%, reduced SiO 2 Components, the glass sample of which is immersed in a mixed melt of 10wt% sodium nitrate and 90wt% potassium nitrate, at a temperature of 420°C, after 2 hours, is tested by a stress tester, and its CS Na30 176MPa, CS Na50 132MPa, CS K 933MPa, DOL is 122μm, CT is 88.46MPa, DOL K It is 6.8μm, and its fragmentation γ value has decreased to 19.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com