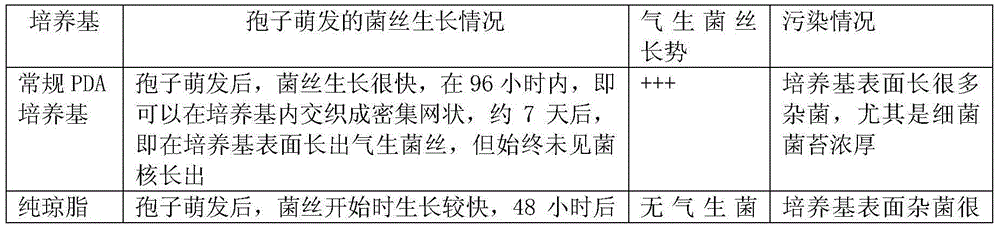

Patents

Literature

720results about How to "Inhibit expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display panel, display apparatus and preparation method for display panel

ActiveCN106653818AIncrease stressImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesOrganic light emitting deviceOptoelectronics

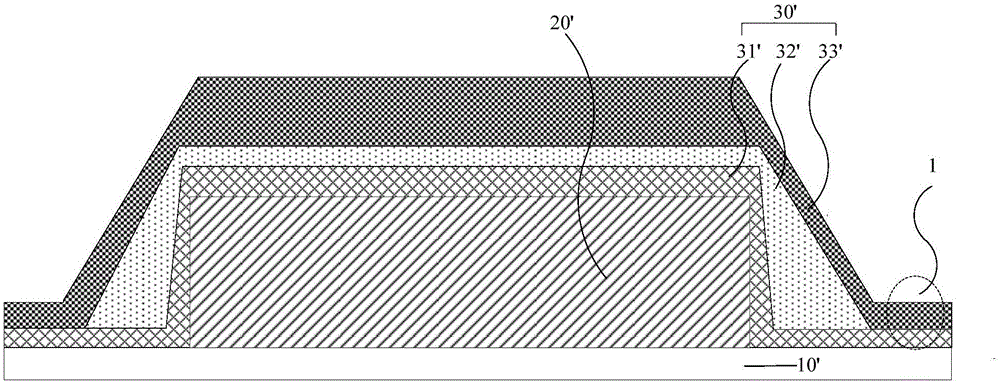

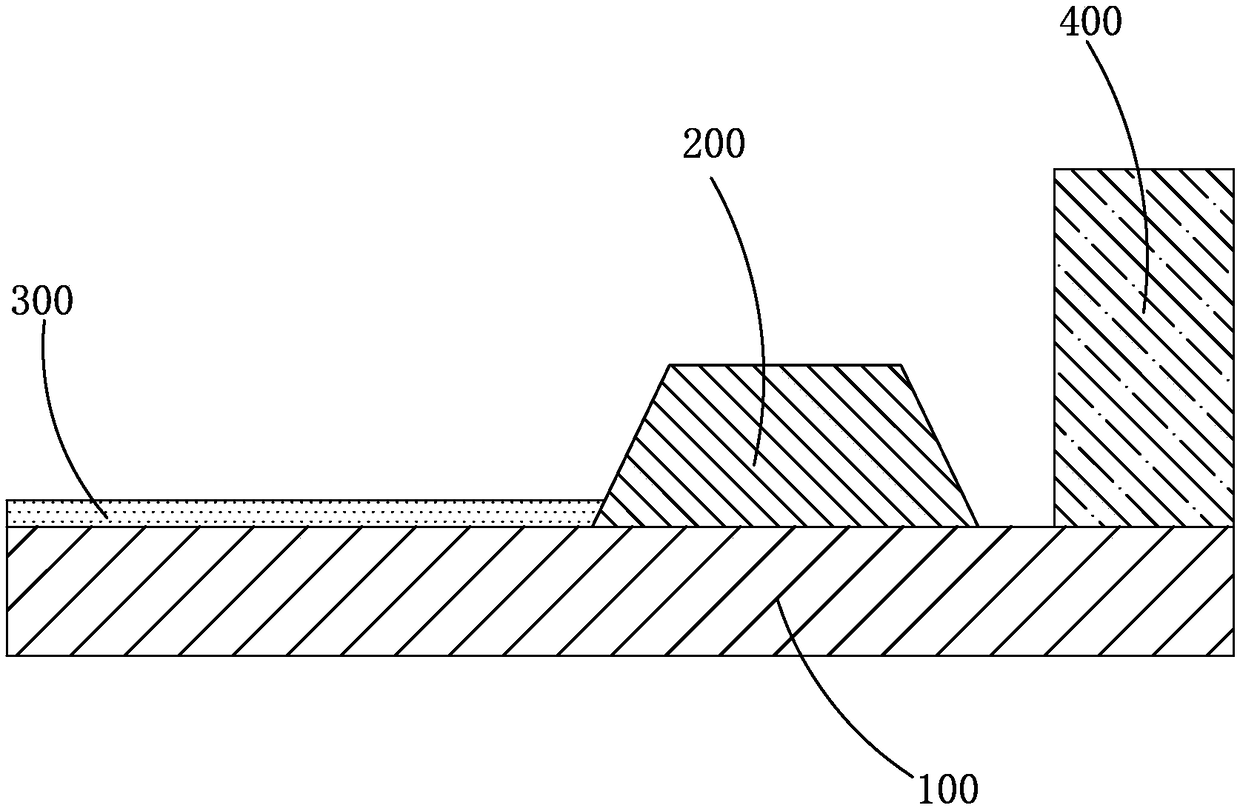

The invention discloses a display panel, a display apparatus and a preparation method for the display panel. The display panel comprises a substrate, an organic light emitting device, a thin film packaging layer, and a metal layer, wherein the substrate comprises a display region and a non-display region; the organic light emitting device is arranged in the display region of the substrate; the thin film packaging layer covers the organic light emitting device; the metal layer is positioned in the non-display region of the substrate; grooves are formed in the metal layer; and the grooves are filled with an organic layer. By virtue of setting the metal layer in the non-display region of the substrate, forming the grooves in the metal layer and filling the grooves with the organic layer, bending stress resistance and cutting stress resistance of an edge region are improved, so that risk of cracks on the edge is relieved, and crack expansion can be effectively prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

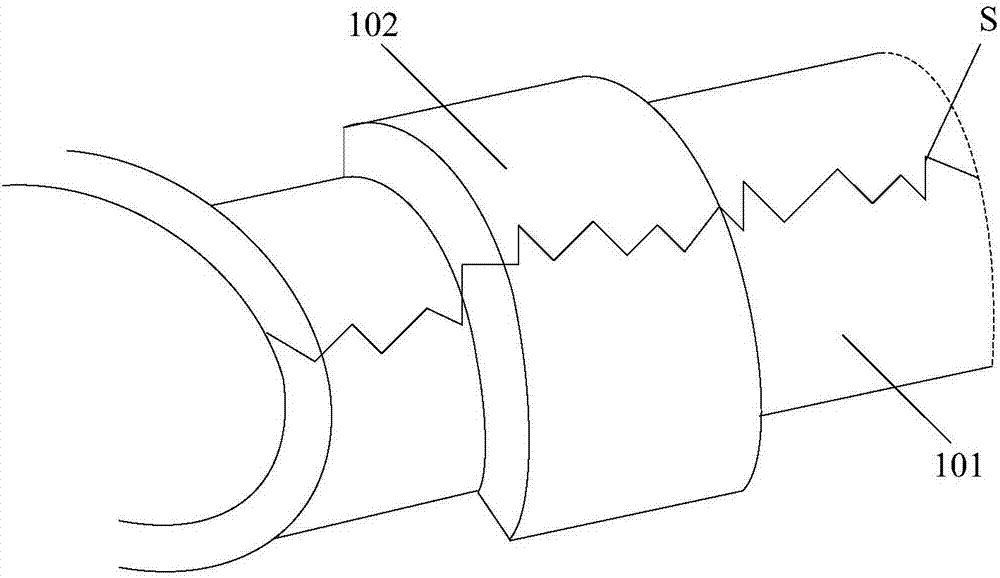

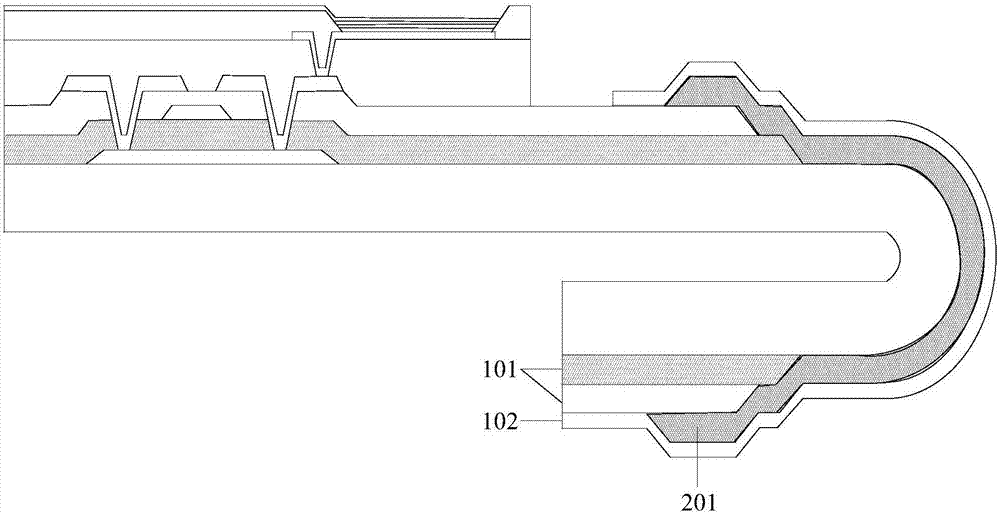

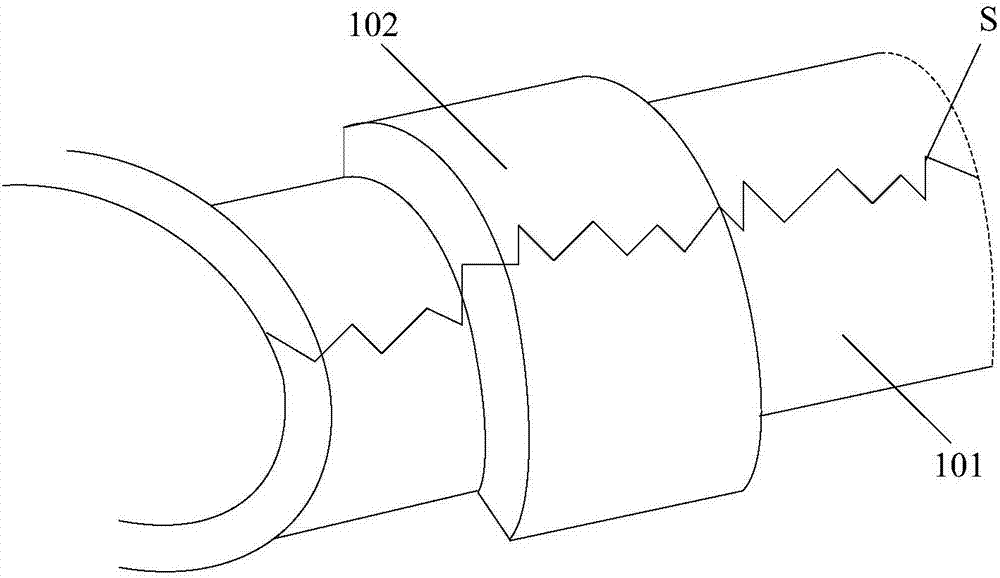

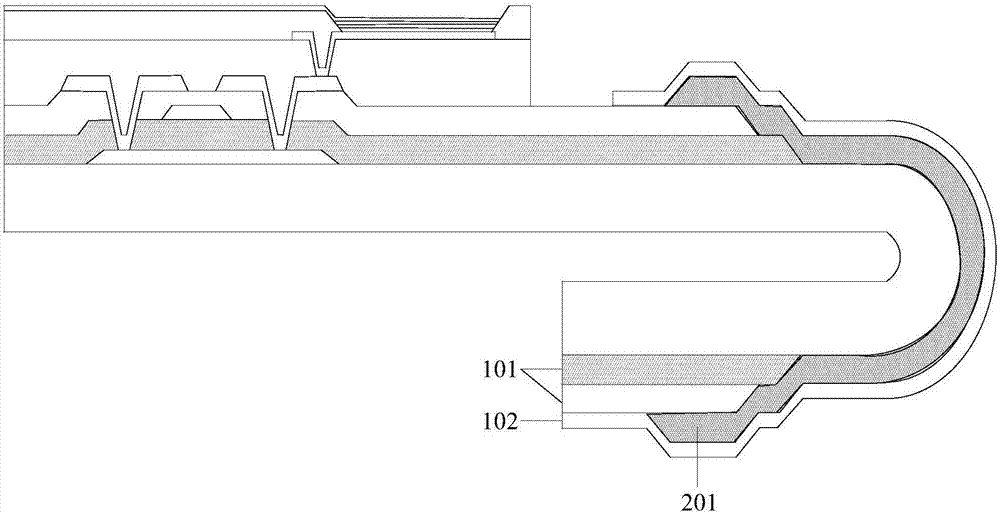

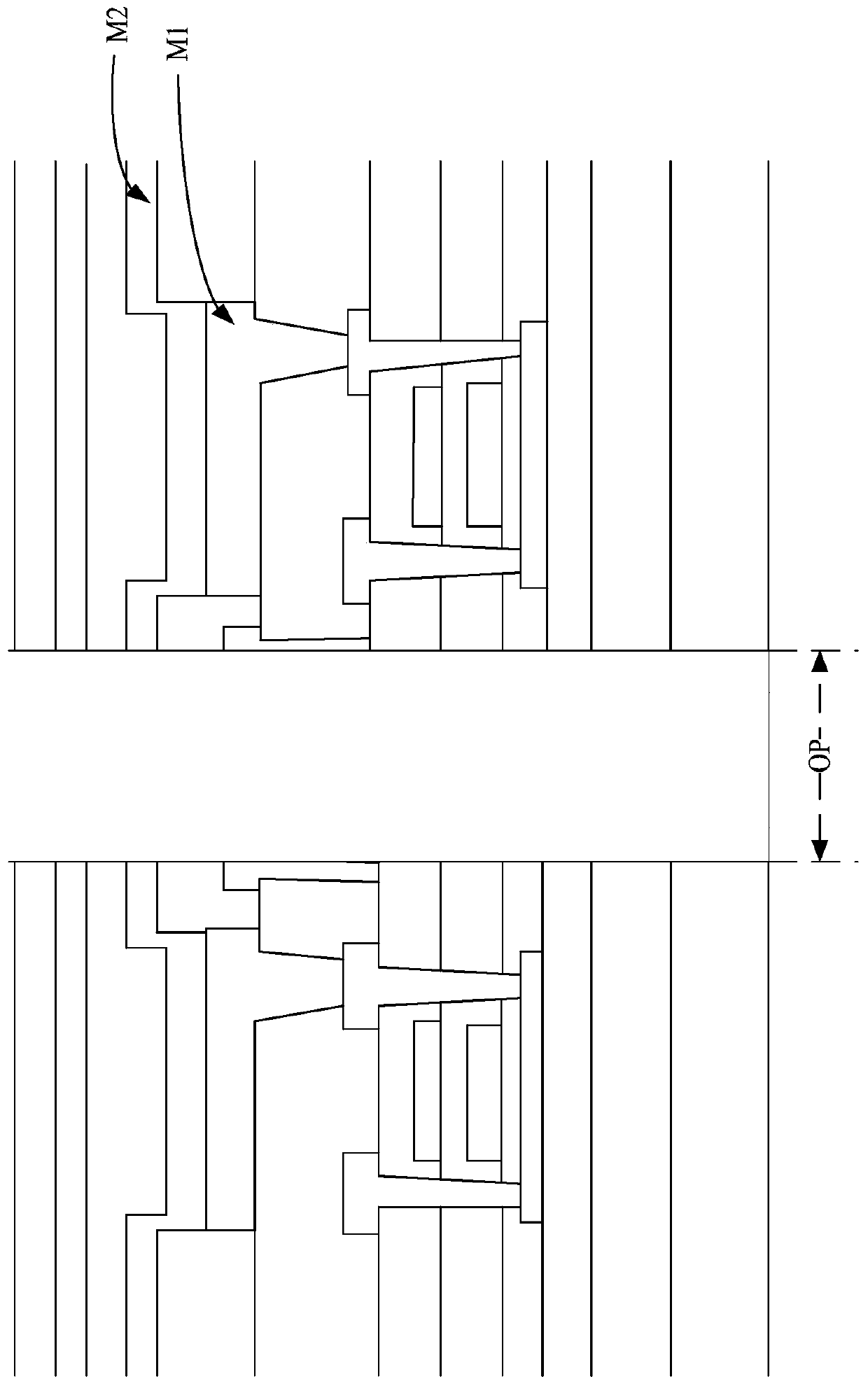

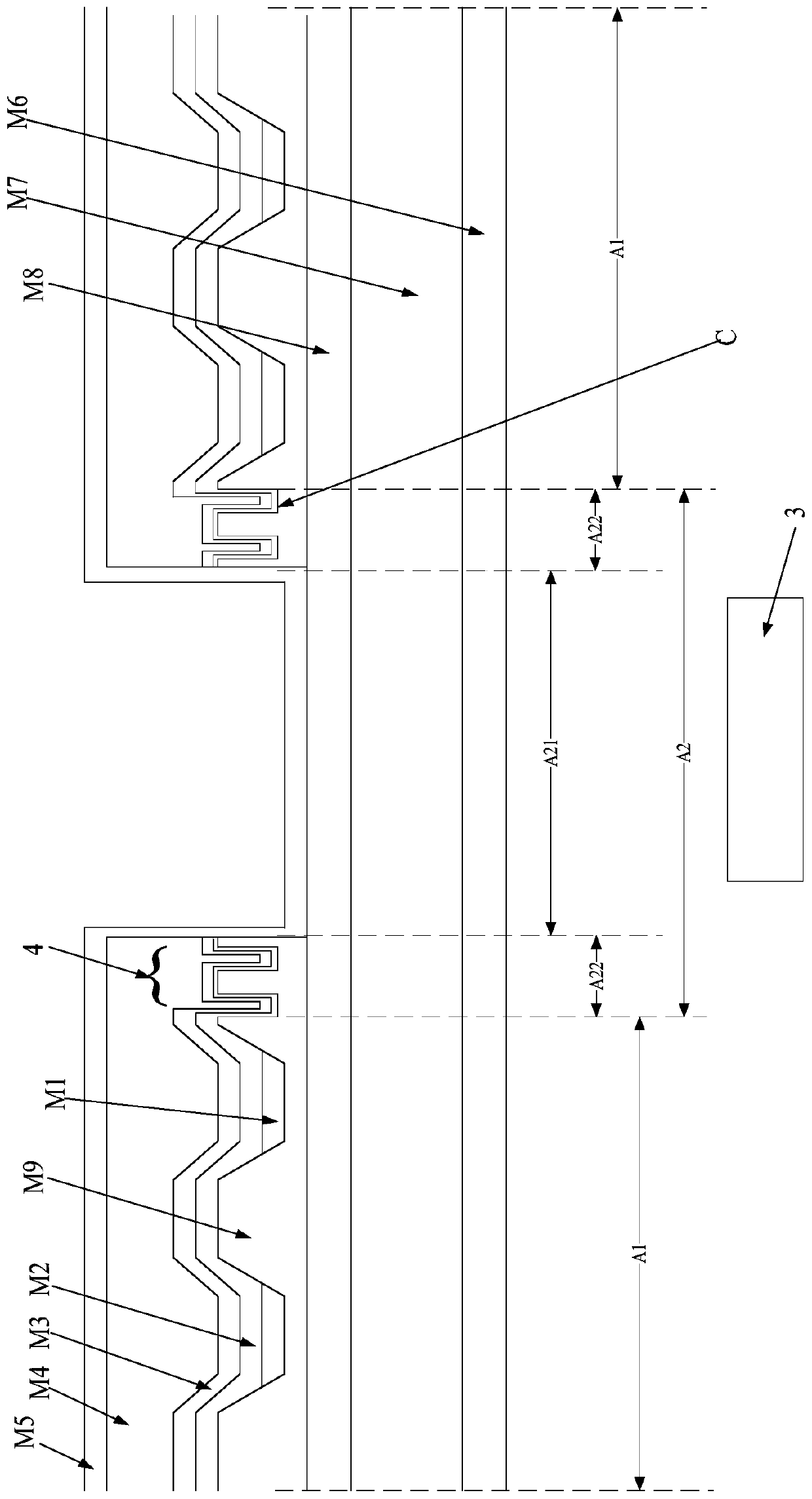

Flexible display panel, display device and flexible display panel manufacturing method

ActiveCN106972030APlay a shielding roleInhibit expansionFinal product manufactureSolid-state devicesDisplay deviceEngineering

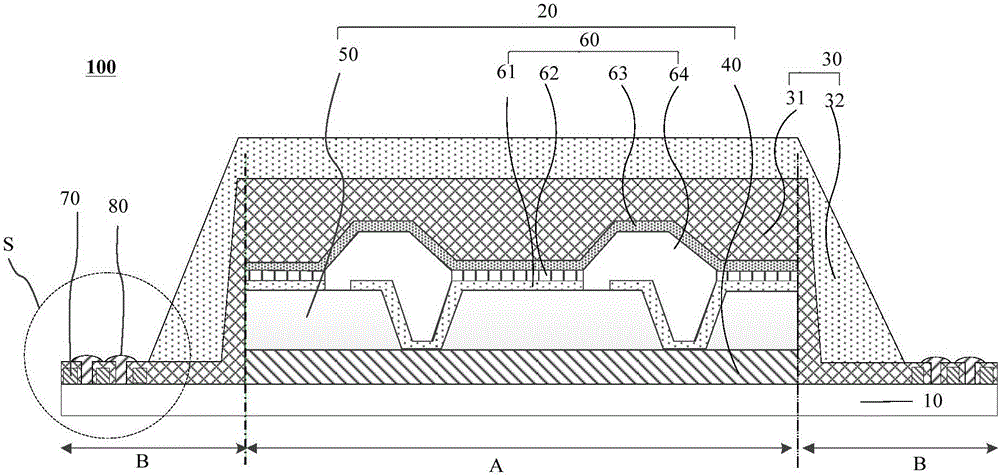

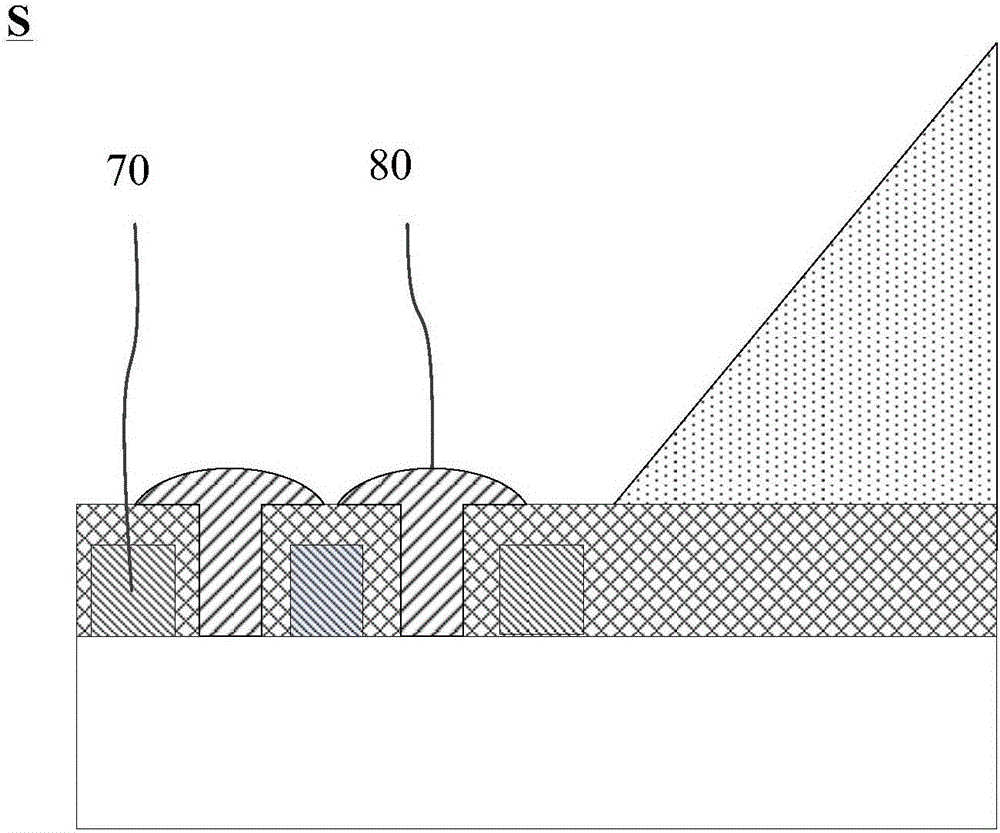

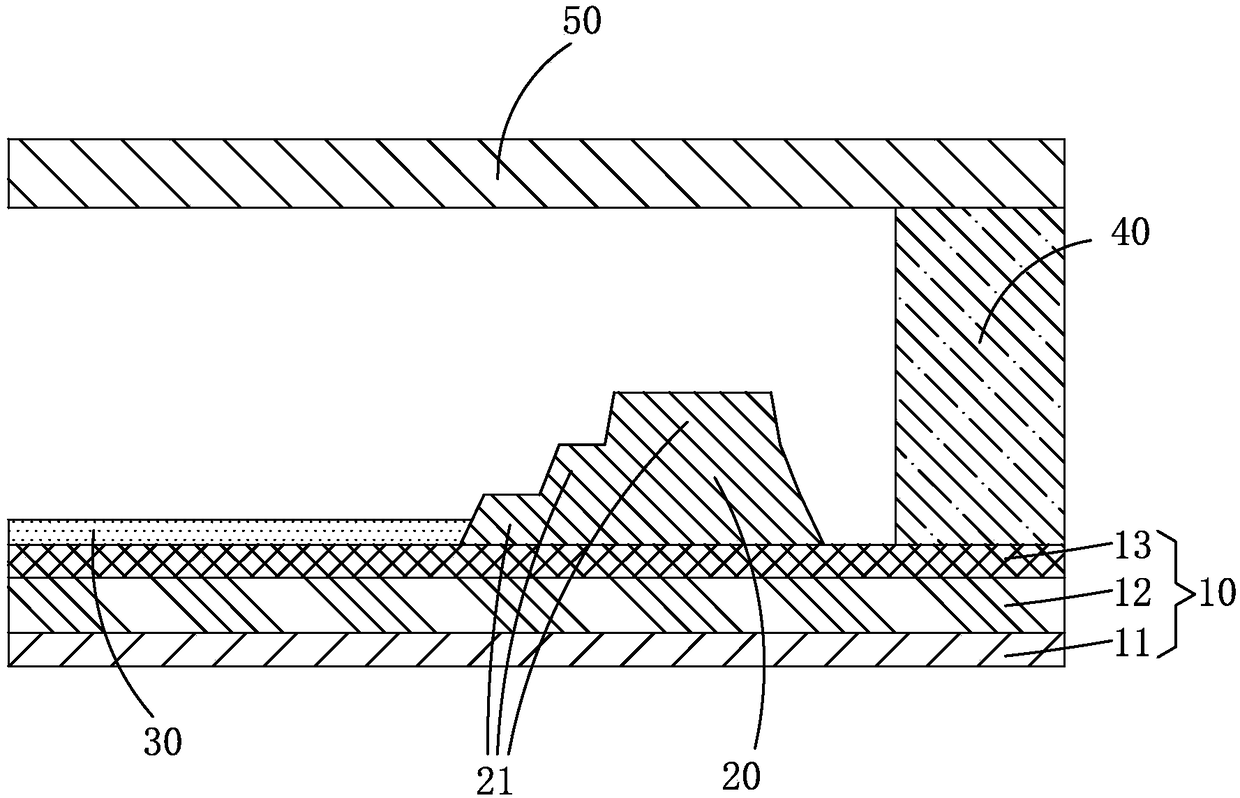

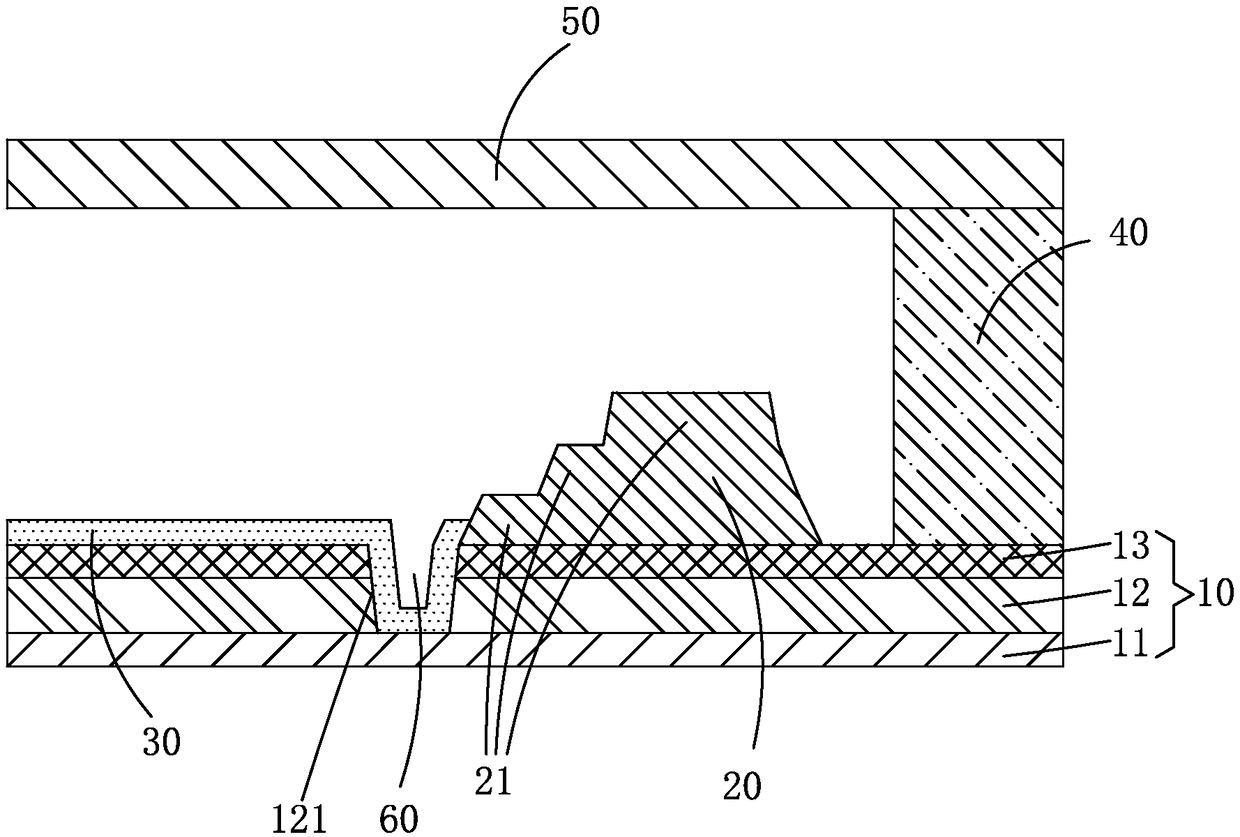

The invention discloses a flexible display panel, a display device and a flexible display panel manufacturing method. The flexible display panel comprises a flexible substrate, a conductive layer in a display area of the flexible substrate, multiple lines in an edge bending area of the flexible substrate, and an organic insulating layer between the conductive layer and the multiple lines on one hand and the flexible substrate on the other hand. The flexible display panel further comprises a first organic insulating layer at least arranged between the multiple lines in the edge bending area of the flexible substrate and the organic insulating layer. The first organic insulating layer is made of cured photoresist. As the first organic insulating layer made of cured photoresist can prevent cracks produced by the inorganic insulating layer from spreading to the multiple lines, the phenomenon of display failure is avoided. In specific implementation, the photoresist can be photoresist applied in the making process of the inorganic insulating layer. Therefore, two Mask processes are omitted, the production cost is saved, and the production efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

Flexible display panel, display apparatus and manufacturing method for flexible display panel

InactiveCN106920829APlay a shielding roleInhibit expansionFinal product manufactureSolid-state devicesElectricityEngineering

The invention discloses a flexible display panel, a display apparatus and a manufacturing method for the flexible display panel. The flexible display panel comprises a flexible substrate, a conductive layer which is arranged on a display region of the flexible substrate, a plurality of routing lines which are arranged on an edge bending region of the flexible substrate, and an inorganic insulating layer which is arranged among the conductive layer, the multiple routing lines and the flexible substrate; the conductive layer is electrically connected with the multiple routing lines; the flexible display panel also comprises a first organic insulating layer which is at least arranged in the edge bending region of the flexible substrate; and the first organic insulating layer is positioned between the multiple routing lines and the inorganic insulating layer. By virtue of the first organic insulating layer, expansion of cracks generated by the inorganic insulating layer to the multiple routing lines can be prevented, so that a phenomenon of display failure can be avoided; and in addition, compared with a technical scheme of adding two Mask processes in the prior art, the flexible display panel disclosed by the invention only needs to add one Mask process of manufacturing the first organic insulating layer, so that production cost is lowered while production efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

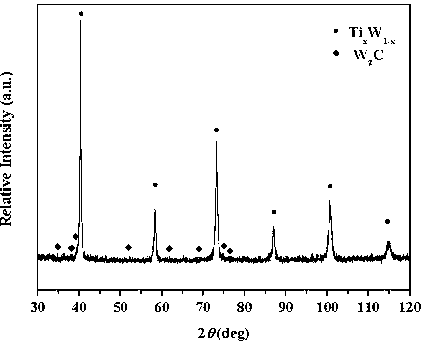

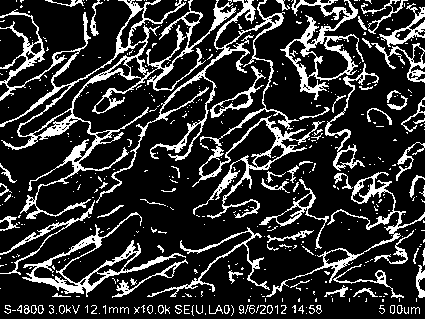

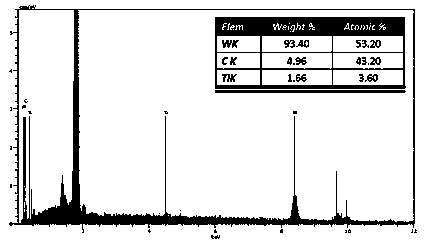

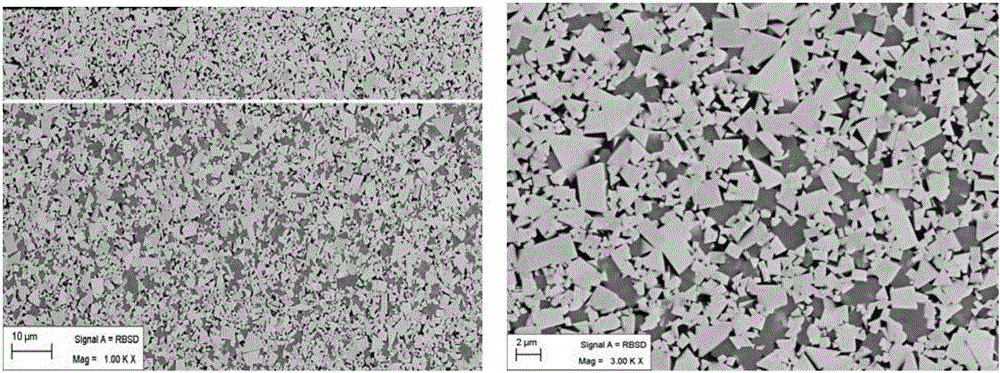

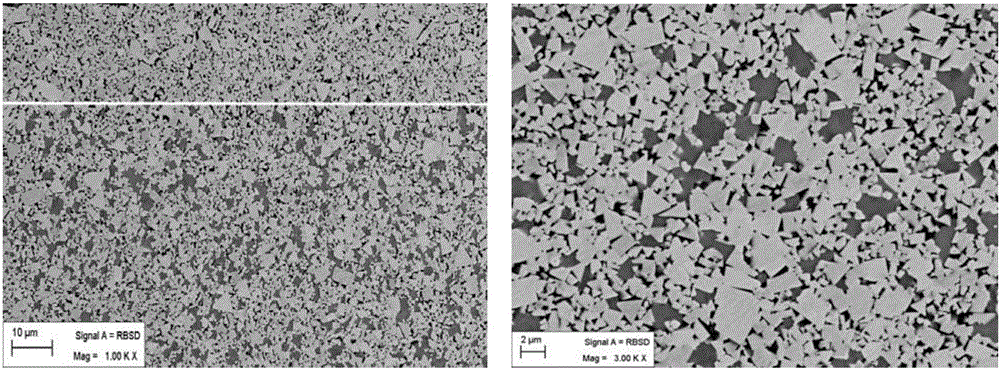

Method for preparing solid solution toughened wolfram-base composite material through laser rapid forming

InactiveCN103074532AImprove microstructureImprove performanceIncreasing energy efficiencySelective laser meltingHigh energy

The invention belongs to the technical field of laser rapid forming, and particularly relates to preparation of a solid solution toughened wolfram-base composite material. A preparation method of the solid solution toughened wolfram-base composite material is as follows: original mixed powder comprises W (wolfram) powder and TiC powder, wherein the TiC powder is 1-1.5wt percent of the total content; and the mixed powder is ball-milled in a high-energy mechanical ball mill for 30-45 h, and then the TiC / W composite material is formed by using a selective laser melting process. The parameters of the adopted laser process are as follows: the powder-bed depth is 50-60 Mum, the laser spot diameter is 200-210 Mum, the laser power is 120-140 W, the laser scanning rate is 100-300 mm / s, and the laser scanning interval is 120-140 Mum. According to the invention, the solid solution toughened wolfram-base composite material is successfully prepared through the method that combines high-energy mechanical ball milling and the selective laser melting process, and the fragility of W material is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

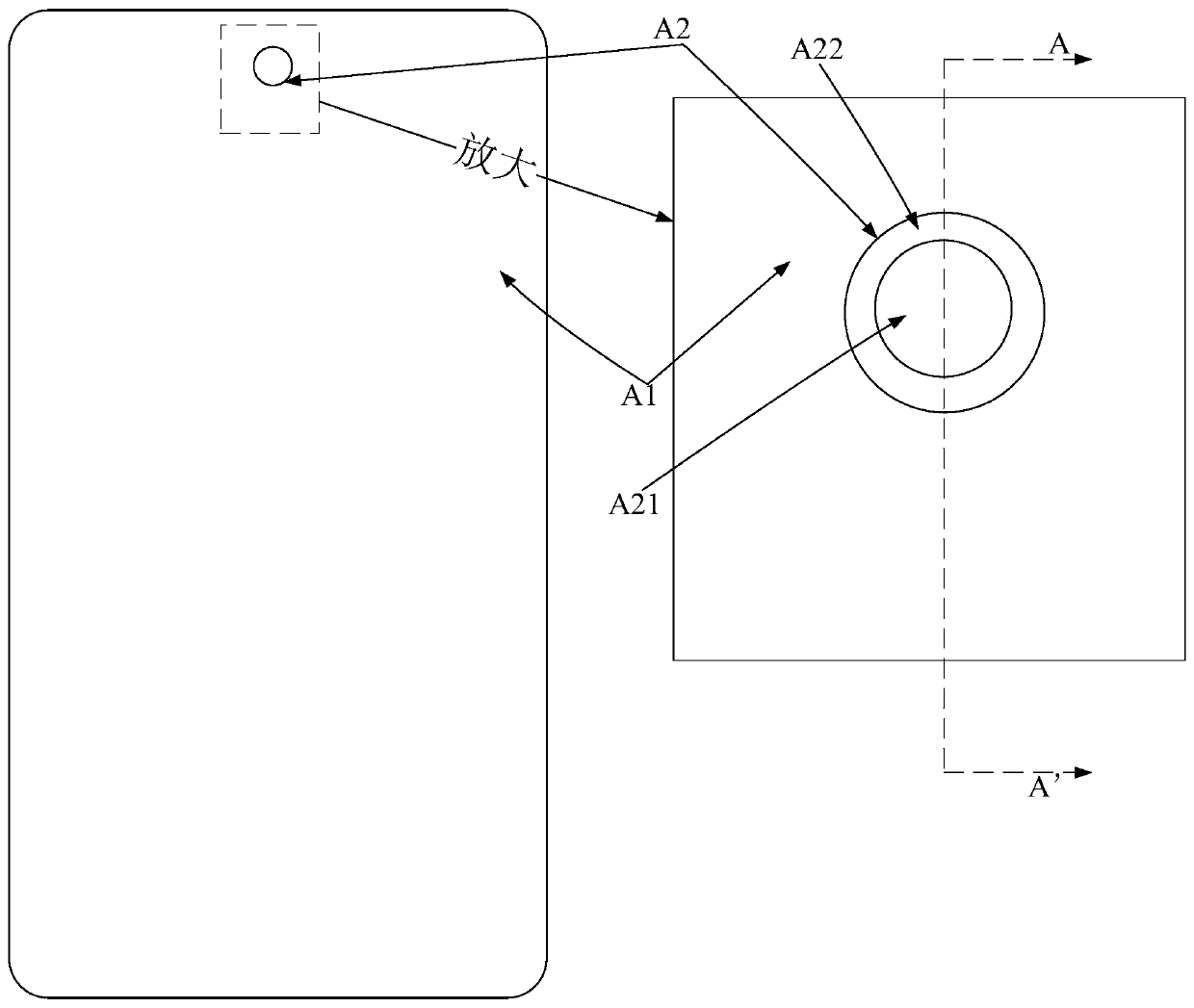

OLED display panel

InactiveCN110010665AImprove transmittanceDelay water and oxygen intrusionSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoLaser cutting

The invention provides an OLED display panel. The OLED display panel comprises an electronic element setting area corresponding to an electronic element setting position, wherein the electronic element setting area comprises a light transmission area and a buffer area, and a micro-nano structure is formed in the buffer area; according to the invention, the micro-nano structure is arranged in the buffer area between the light transmission area and the display area, and can prevent cracks generated by a common electrode layer such as a cathode from expanding to the display area when holes are dug by laser cutting or other processes, so that the technical problem is solved that the cracks generated by the cathode when the holes are dug expand to the display area in the conventional comprehensive screen technology, and the micro-nano structure can delay water and oxygen invasion of the side surface of the hole digging area in the hole digging process, so that the service life of the deviceis prolonged finally.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

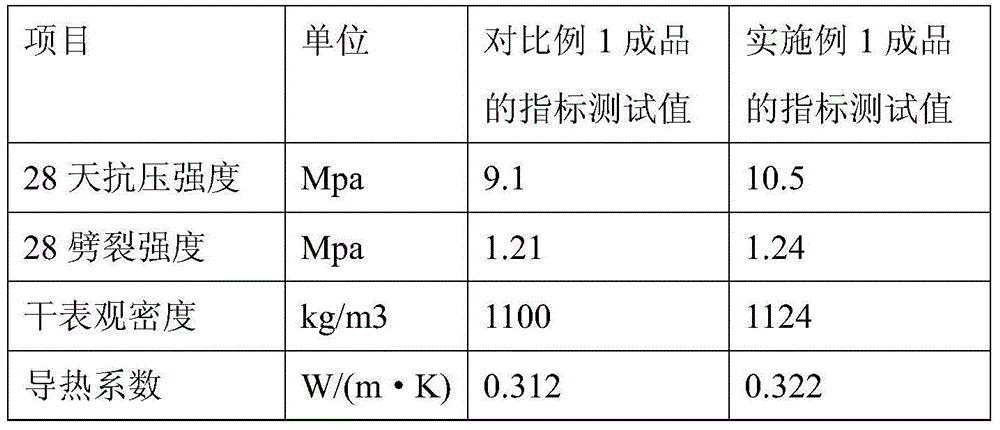

Lightweight aggregate concrete for heat preservation of structures

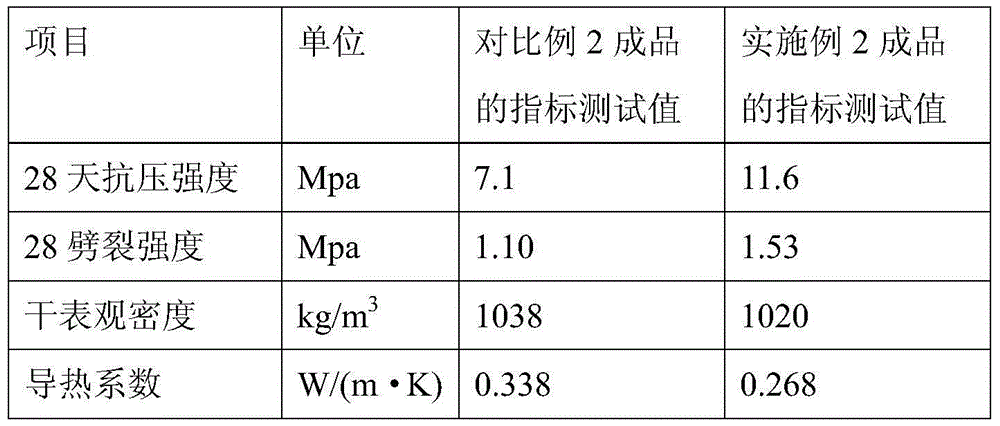

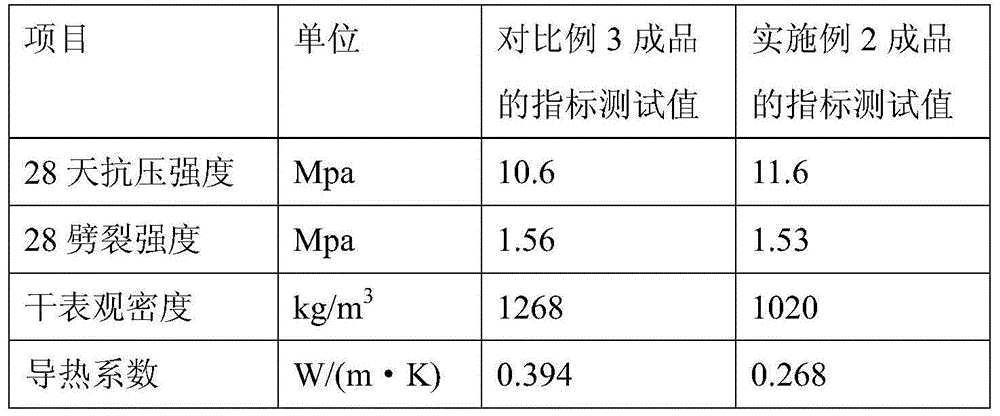

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

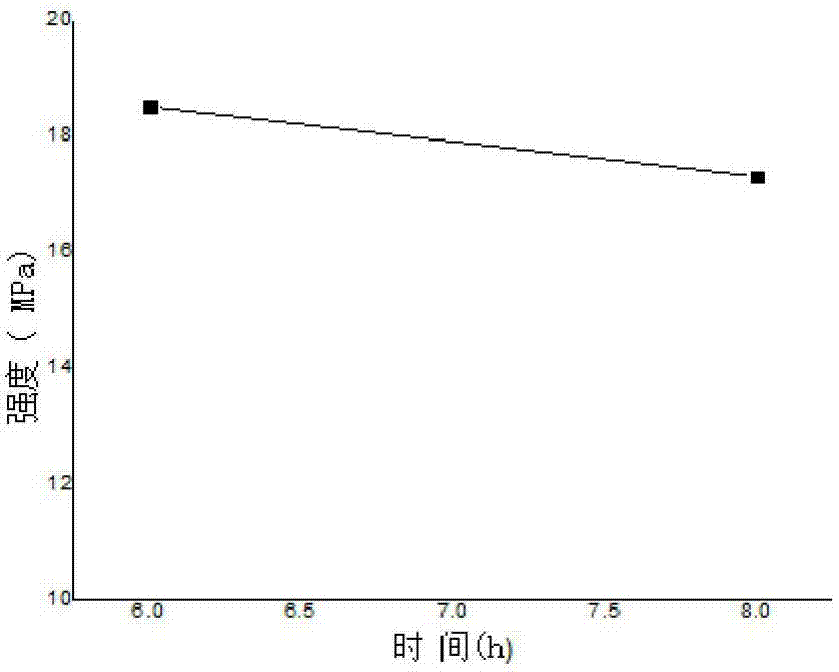

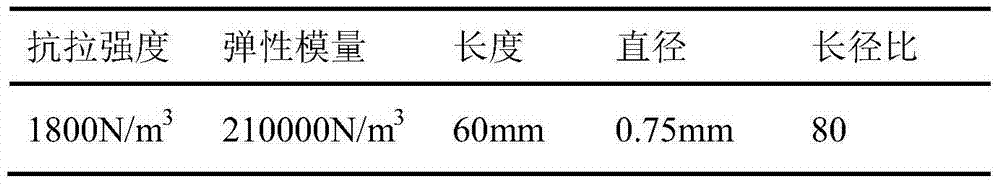

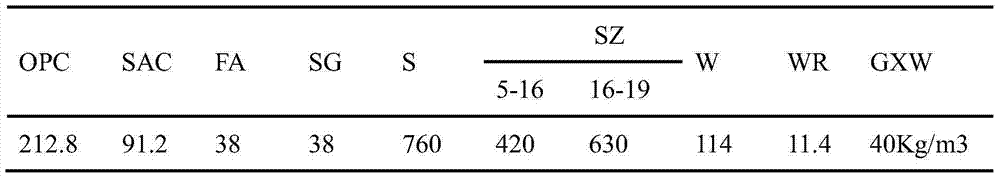

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

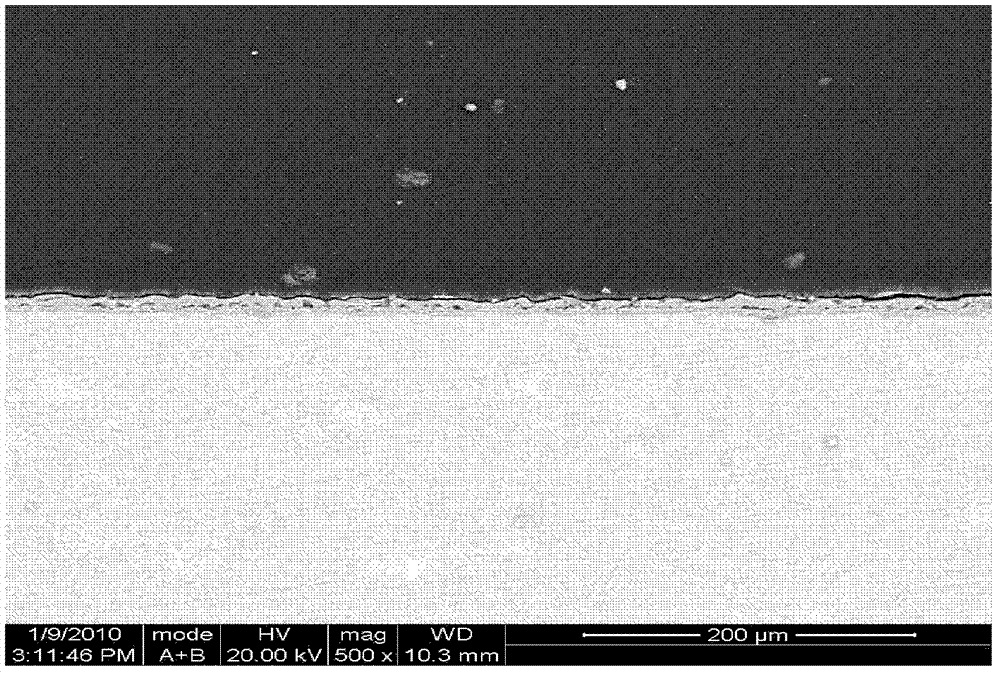

Magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and preparation method thereof

InactiveCN103085379AAchieving densification and sealingReduce defectsAnodisationCeramic layered productsCross-linkMicro arc oxidation

The present invention discloses a magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and a preparation method thereof. The coating comprises a micro-arc oxidation ceramic layer, a self-assembly nanometer film and an inorganic metal ceramic coating, wherein the micro-arc oxidation ceramic layer, the self-assembly nanometer film and the inorganic metal ceramic coating are sequentially attached on the magnesium alloy surface. The preparation method comprises: carrying out plasma electrolysis oxidation on the surface of a magnesium alloy substrate to form a micro-arc oxidation ceramic coating, then carrying out dipping or high pressure spraying of a self-assembly nanometer film as a connection layer on the surface of the ceramic layer, and adopting a low temperature sintering method to prepare an inorganic metal ceramic coating on the surface of the self-assembly nanometer film. According to the present invention, the head group of the self-assembly nanometer film and the micro-arc oxidation bottom layer ceramic layer form chemical bonding, and a sealing treatment is performed on micro-pores of the micro-arc oxidation film; a high density cross-linking effect on active function groups in the inorganic metal ceramic coating by the self-assembly nanometer film is achieved through the end group; and the magnesium alloy surface composite protection coating prepared by using the method has characteristics of good bonding strength, corrosion resistance, scratching resistance and high hardness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Non-homogeneous gradient hard alloy and preparation method thereof

ActiveCN105803288AImprove toughnessHigh strengthTransportation and packagingMetal-working apparatusMetallic materialsMaterials science

The invention discloses non-homogeneous gradient hard alloy and a preparation method thereof. According to the non-homogeneous gradient hard alloy, Co serves as a binding phase, a tungsten carbide and titanium-containing cubic phase compound serves as a hard phase, the titanium-containing cubic phase compound accounts for 2-8 wt.% of the mass fraction of the non-homogeneous gradient hard alloy, tungsten carbide grain distribution has a double-peak structure, the original particle size is rough and fine, and the non-homogeneous gradient hard alloy is of a surface structure without a titanium-containing cubic phase compound with the average binding phase content 1-2 times of a nominal binding phase content. The preparation method includes the steps of material preparation, mixing, milling, compression molding and sintering. The non-homogeneous gradient hard alloy has higher hardness, toughness and bending strength and can meet the machining requirement of cast iron, alloy steel, stainless steel and other metal materials, the preparation method is simple in process, and cost is low.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

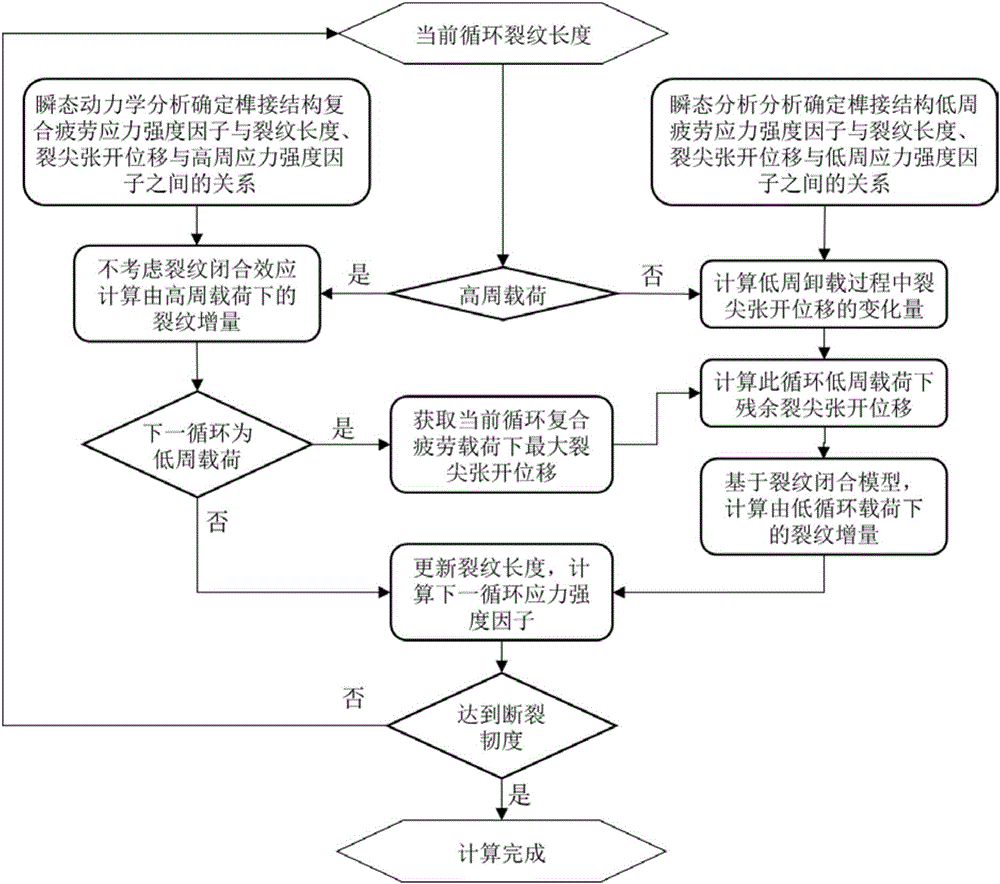

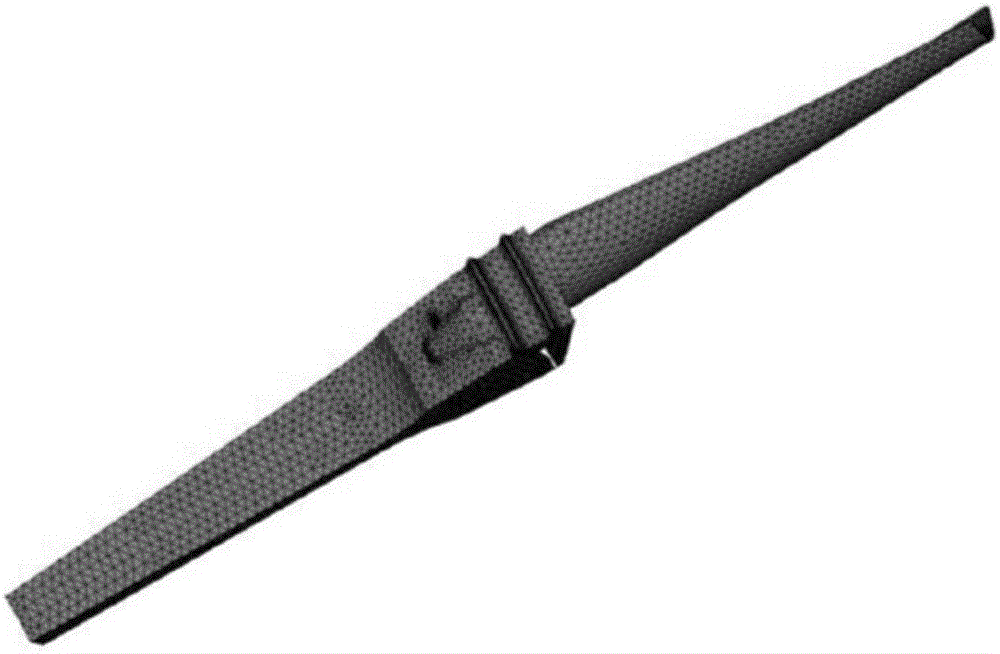

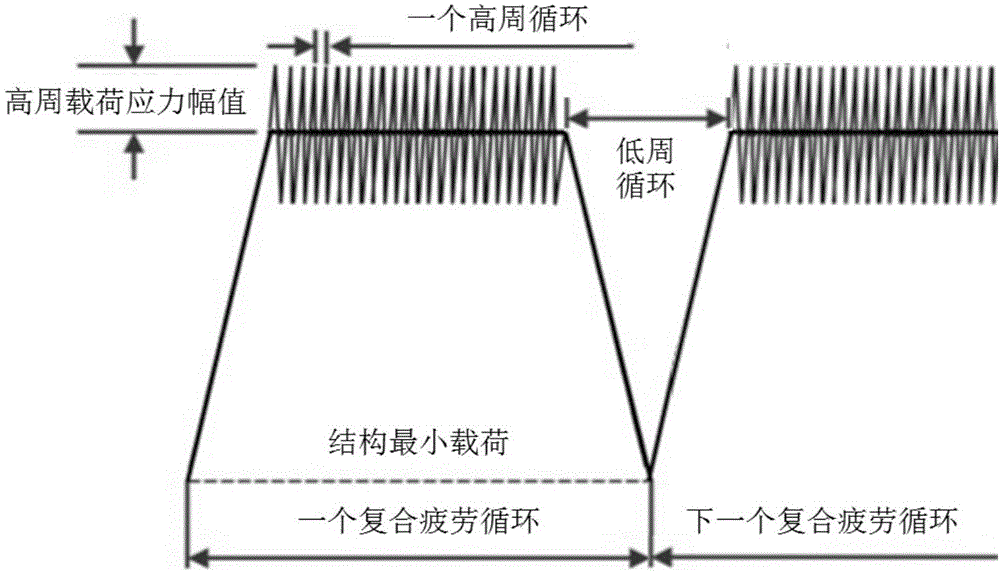

Method for predicting high-low-cycle composite fatigue crack growth life of turbine joggle structure

ActiveCN106644490AImprove scalabilityInhibit expansionEngine testingCrack tip opening displacementEngineering

The invention relates to a method for predicting the high-low-cycle composite fatigue crack growth life of a turbine joggle structure, and the method comprises the steps: (1), building a crack growth model giving consideration to a crack closure effect; (2), determining a high-cycle load stress intensity factor model; (3), determining a low-cycle load stress intensity factor model; (4), judging whether a current cycle is a high-cycle load or not: executing step (5) if the current cycle is the high-cycle load, or else executing step (6); (5), calculating a composite fatigue lower crack increment, judging whether a next cycle is a low-cycle fatigue load or not: obtaining the maximum crack tip opening displacement of the current cycle if the next cycle is the low-cycle fatigue load, and executing step (7), or else executing step (8); (6), calculating the variance of the low-cycle load lower crack tip opening displacement; (7), calculating the residual crack tip opening displacement and crack increment according to the results inputted at steps (5) and (6); (8), updating the crack length, repeatedly carrying out the steps (4)-(7) if the maximum stress intensity factor is less than the fracture toughness, or else completing the calculation, and obtaining the crack growth life.

Owner:BEIHANG UNIV

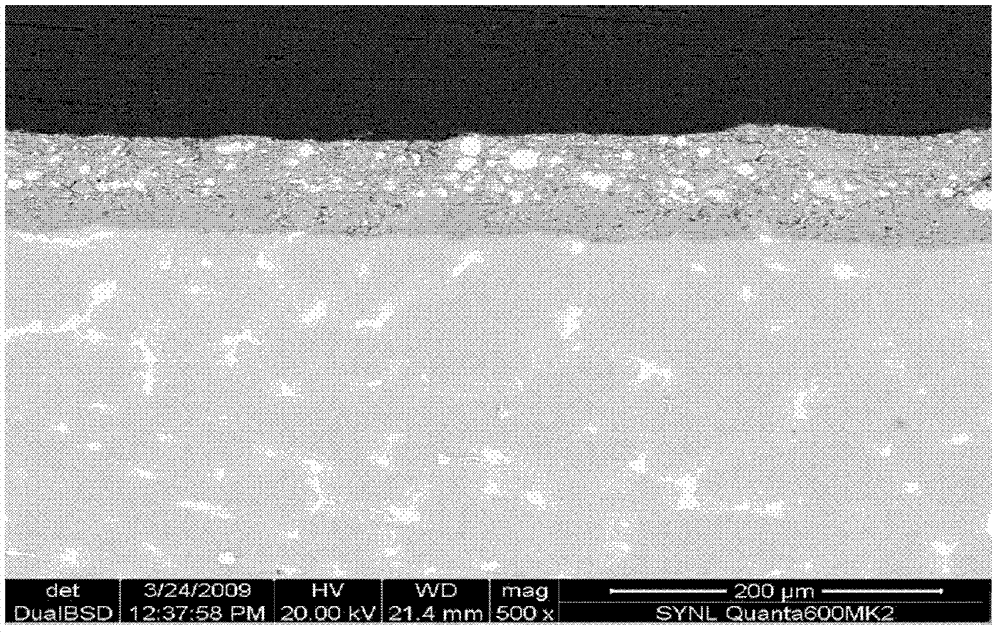

Method for preparing WC hard alloy wear resistance area on petroleum drill rod surface

ActiveCN102453901AExtended service lifeImprove toughnessMetallic material coating processesLaser beam welding apparatusHigh power lasersAlloy coating

The invention relates to a method for preparing a WC hard alloy wear resistance area on a petroleum drill rod surface. The method is characterized in that: the method comprises the following steps: (1) carrying out a pretreatment for the petroleum drill rod surface; (2) selecting alloy powder and adjusting an automatic powder feeding device; (3) cladding a bottoming alloy coating by a high power laser; (4) cladding spherical WC and Ni-Cr-B-Si mixed alloy powder by the high-power laser; (5) carrying out defectoscopy inspection after cladding. According to the present invention, the gradient coating method is adopted to prepare the WC hard alloy wear resistance area on the petroleum drill rod surface, the nickel-base alloy powder is adopted as the bottoming layer, the high wear resistance WC hard alloy powder is adopted as the working layer, such that the good binding strength of the working layer and the substrate is ensured in the case of meeting of the working layer characteristics, and the cracks can be prevented from expanding to the substrate during the using process, wherein the nickel-base alloy powder has good toughness and high strength, and has good metallurgy compatibility with the substrate.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

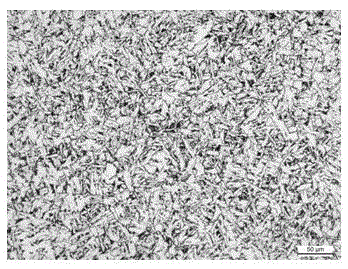

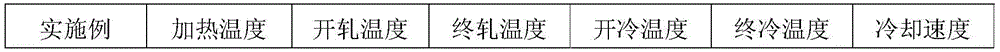

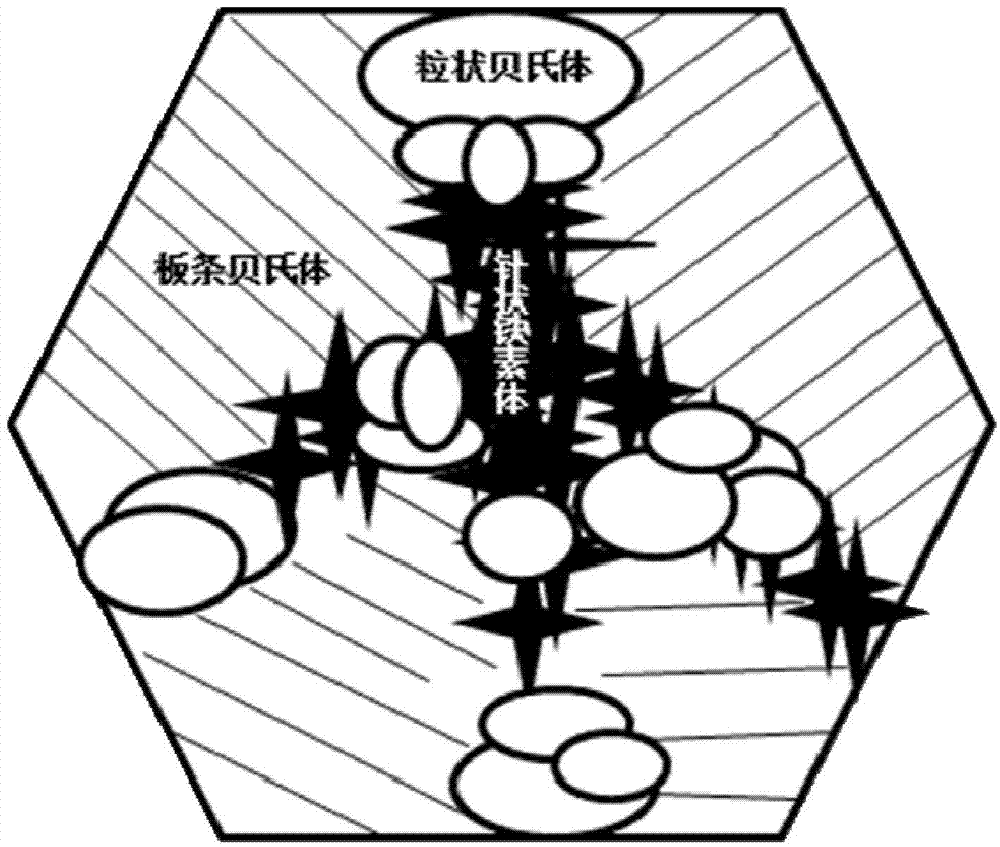

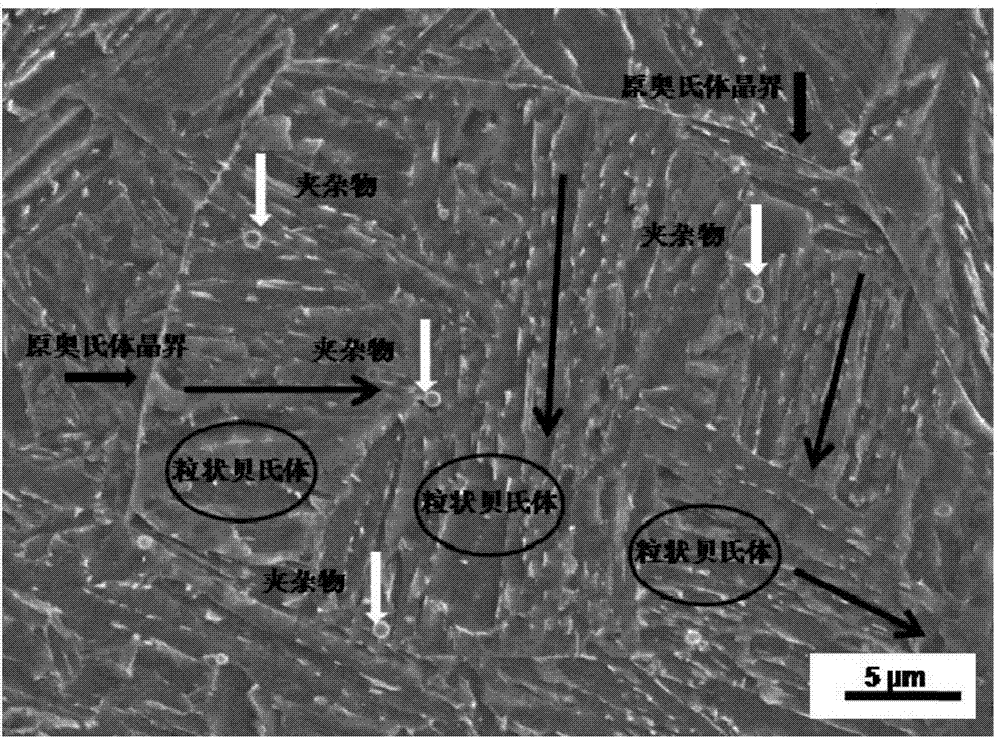

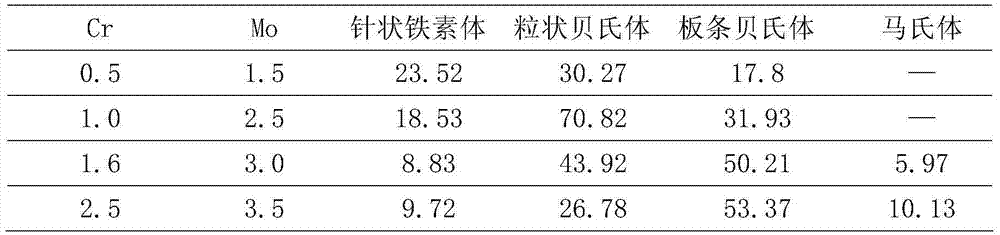

High-strength-toughness and high-temperature hot rolled steel plate and preparation method thereof

The invention discloses a high-strength-toughness and high-temperature hot rolled steel plate and a preparation method thereof. The high-strength-toughness and high-temperature hot rolled steel plate is prepared from the following chemical components in percentage by weight: 0.04-0.15 percent of C, 0.05-0.35 percent of Si, 0.5-2.5 percent of Mn, 0.005-0.025 percent of Ti, smaller than or equal to 1.0 percent of Cr, smaller than or equal to 0.5 percent of Mo, smaller than or equal to 1.0 percent of Ni, smaller than or equal to 0.5 percent of Cu, smaller than or equal to 0.003 percent of B, smaller than or equal to 0.02 percent of P, smaller than or equal to 0.01 percent of S, smaller than or equal to 0.007 percent of N, 0.001-0.006 percent of O, smaller than or equal to 0.03 percent of the total content of elements including Al, Zr, Mg, Ca and rare earth and the balance of Fe and inevitable impurity elements. The preparation method of the steel plate comprises the following steps: smelting and casting according to the components, carrying out high-temperature continuous rolling by adopting an austenite, carrying out accelerated cooling by watering the steel plate after being rolled, and then air cooling to room temperature, wherein the heating temperature of a steel billet is 1150-1260 DEG, the cooling temperature is larger than or equal to 5 DEG C / s. and the finish cooling temperature is 550-650 DEG C . As a microscopic structure of the steel plate is a fined acicular ferrite type structure, the steel plate is good in strength and toughness properties. The preparation method of the steel plate is flexible in process and simple in operation, saves the cost and improves the production efficiency.

Owner:NORTHEASTERN UNIV

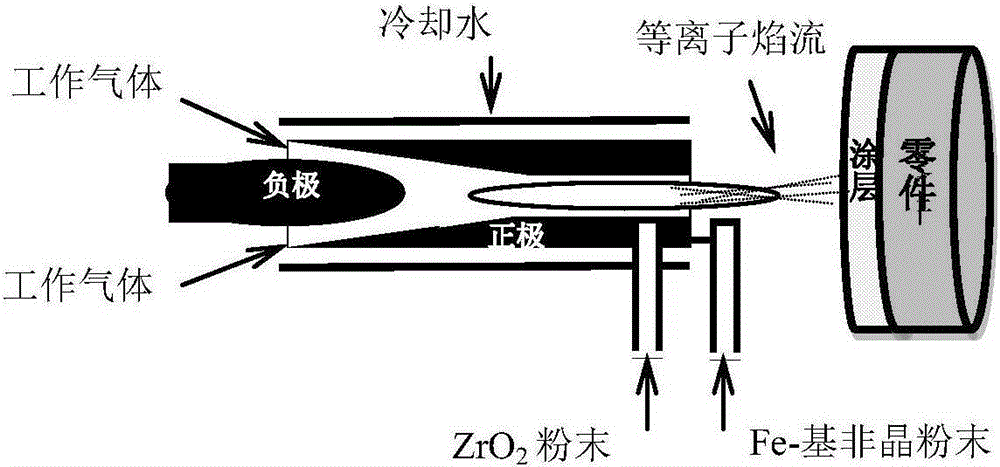

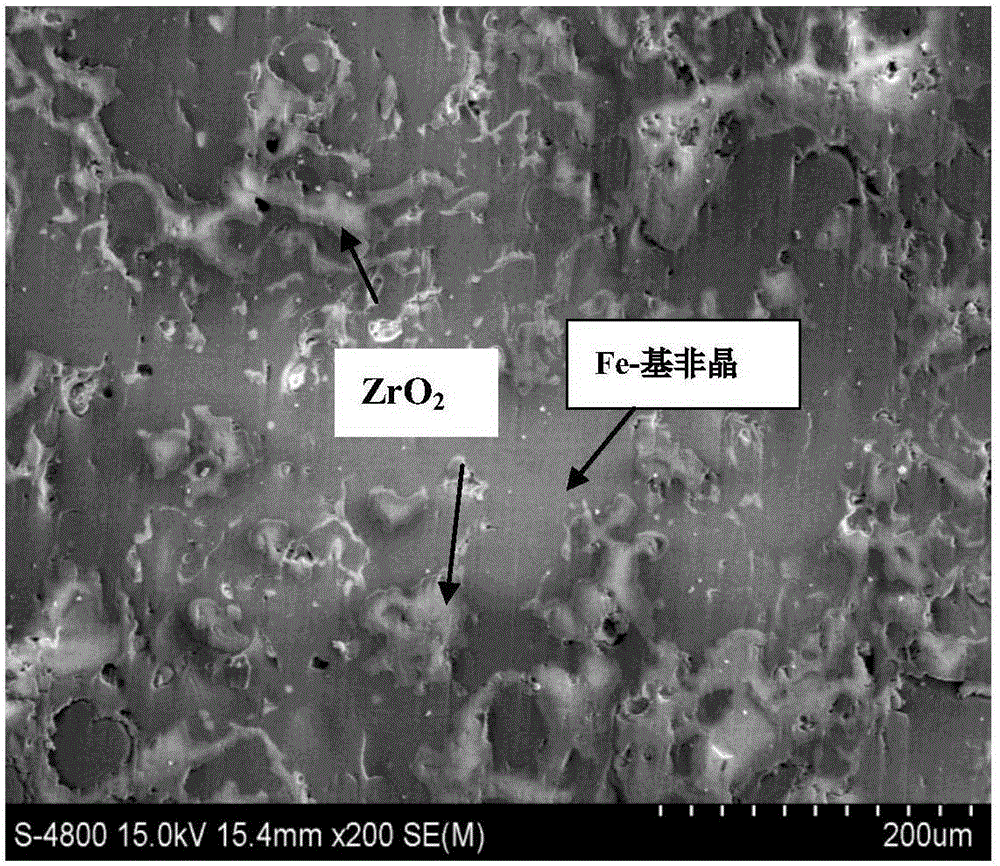

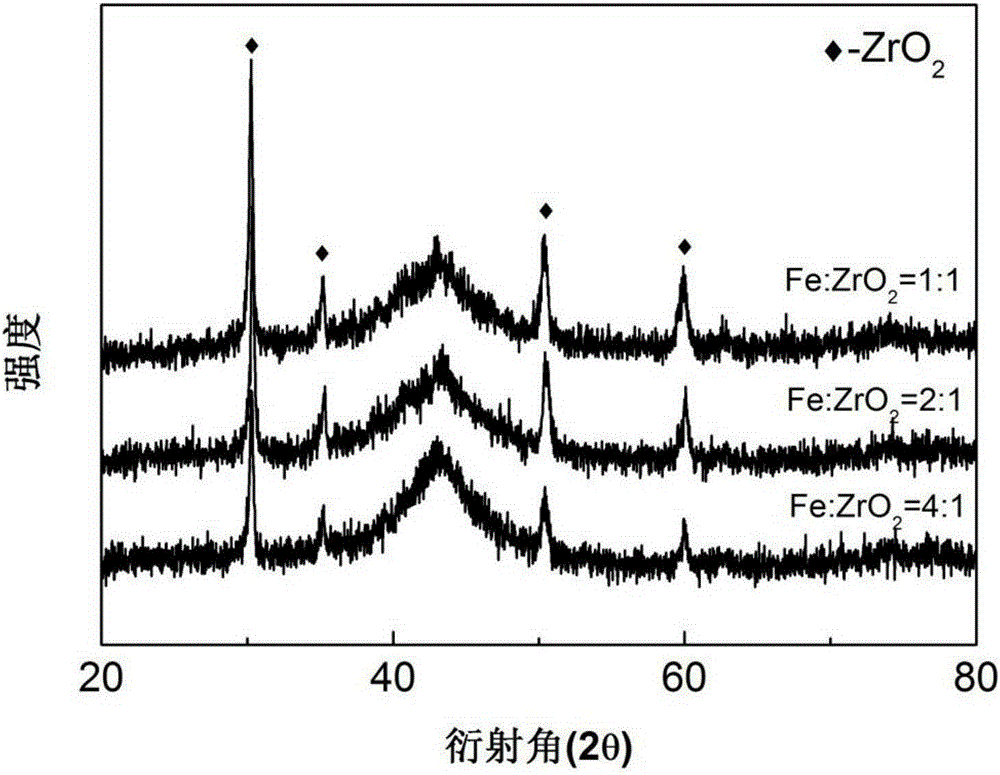

Method for preparing ceramic/iron-based amorphous composite coating

ActiveCN105200363AThe proportion of ingredients can be adjustedWide range of ingredientsMolten spray coatingAbrasive blastingMicrometer

The invention discloses a method for preparing a ceramic / iron-based amorphous composite coating. The method includes the following steps that 1, cleaning pretreatment is carried out on the surface of an alloy workpiece before spraying is carried out; 2, abrasive blasting coarsening activating treatment is carried out; 3, spraying is carried out on the surface of the alloy workpiece with a plasma spraying technology, and a binding bottom layer with the thickness ranging from 80 micrometers to 100 micrometers is obtained; 4, spraying is carried out on the surface of an alloy workpiece base body obtained in the step 3 with a multi-path and different-position plasma spraying powder feeding technology, wherein the powder feeding gas flow for ceramic powder ranges from 18 L / min to 23 L / min, and the powder feeding gas flow for iron-based amorphous powder ranges from 10 L / min to 200 L / min; finally the ceramic / iron-based amorphous composite coating is obtained. According to the method, as the plasma multi-path and different-position powder feeding technology is adopted, amorphous materials and ceramic can be co-deposited on the base body, and the proportion of ingredients of the composite coating can be adjustable and controllable. The obtained ceramic-amorphous composite coating has higher rigidity and higher abrasion resistance compared with a single amorphous coating.

Owner:HEBEI UNIV OF TECH

Hot rolling roller for rolling nonferrous metal, and manufacturing method thereof

The present invention discloses a hot rolling roller for rolling a nonferrous metal, and a manufacturing method thereof. Chemical components of the roller comprise, by weight, 0.50-0.80% of C, 0.30-1.20% of Si, 0.20-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 4.50-6.00% of Cr, 0.20-0.80% of Ni, 0.20-1.00% of Mo, 0.10-0.50% of V, and the balance of Fe and unavoidable impurities. The manufacturing method of the roller comprises the following process steps: a, refining a steel ingot; b, forging a roller blank; c, carrying out quenching and tempering, and carrying out mechanical processing; d, carrying out a quenching heat treatment; and e, carrying out a tempering treatment. The hot rolling roller has characteristics of high wear resistance, good thermal cracking resistance and good electrochemical corrosion resistance, and a service life of the hot rolling roller can be increased by more than 50% compared with the ordinary Cr3 roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

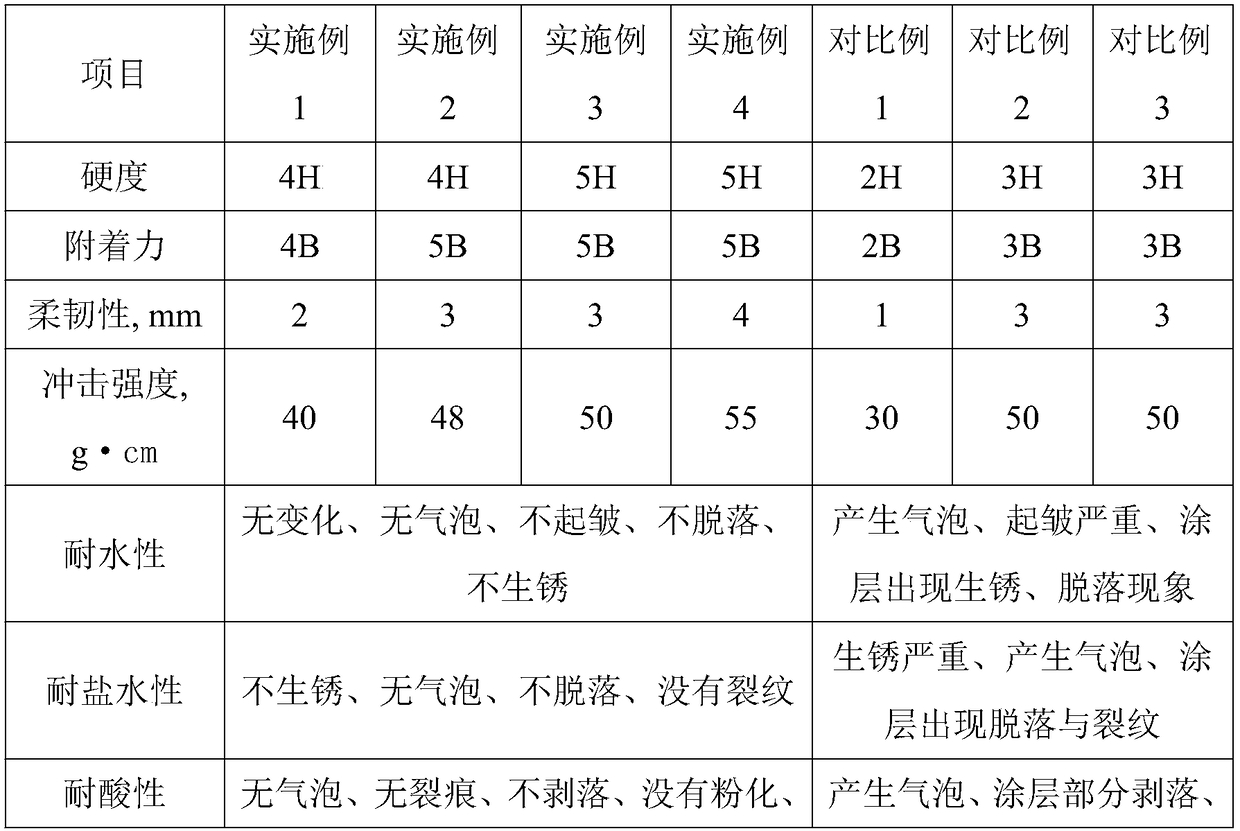

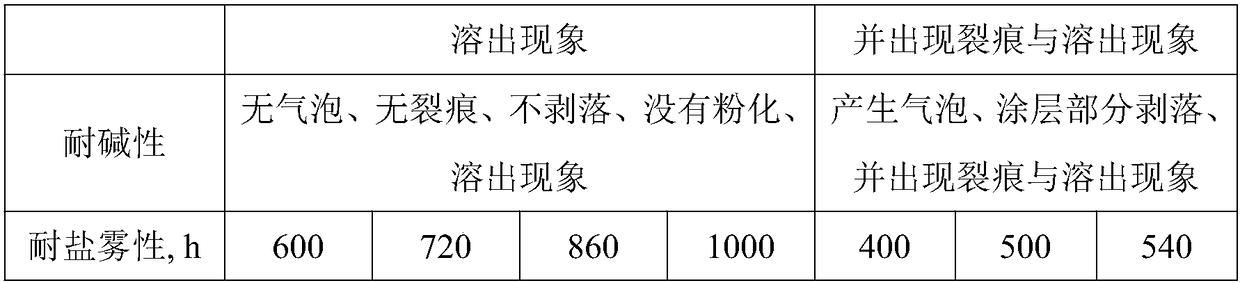

Process for preparing rust-bearing rust-proof heavy-duty coating

ActiveCN102690558AHigh solid contentLittle effect of viscosityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceHeavy duty

The invention relates to a process for preparing a rust-bearing rust-proof heavy-duty coating and belongs to the technical field of rust-bearing rust-proof heavy-duty coating preparation. The process comprises the following steps: 1) stirring; 2) grinding; 3) dispersing; 4) preparing a resin; 5) preparing the coating; and 6) stirring. The production process is simple and quick, and the produced coating has high permeability, high solid content and low viscosity and can passivate active and harmful iron compounds in a rust layer into harmless fillers.

Owner:PENGLAI WEIYANG NEW MATERIALS

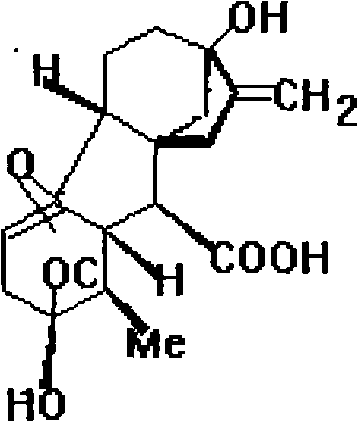

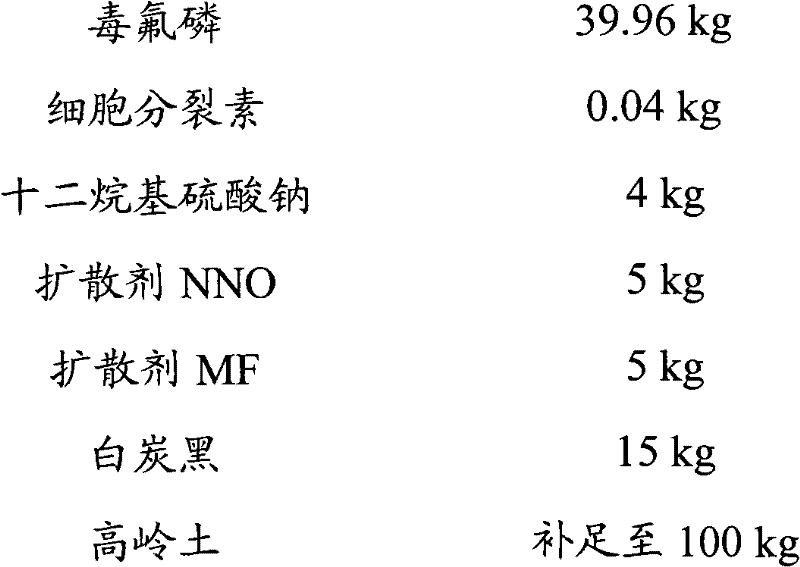

Composite of toxic fluoride phosphate and plant growth regulator

ActiveCN102388918AEfficient prevention and controlInhibit expansionPlant growth regulatorsBiocidePhosphateTobacco mosaic virus

The invention provides a formulation composite comprising toxic fluoride phosphate and at least one growth regulator. According to the weight part, the toxic fluoride phosphate accounts for 10%-80% of the formulation composite, the growth regulator accounts for 0.0001%-2% of the formulation composite, the formulation composite also comprises an assistant, an surface active agent, a solvent and a carrier accepted by agriculture, and the formulation composite can be prepared into wettable powder, suspending agent, missible oil, microemulsion, emulsion in water, water dispersible granule, dry suspending agent, seed coating agent and other agents. The formulation composite can be used for preventing and curing tobacco mosaic virus, cucumber mosaic virus, and various virus diseases caused by viruses on rice, such as tobacco mosaic, cucumber mosaic, tomato virus disease, pepper virus disease, rice virus disease and the like and achieves the effects of improving efficacy, treating in a compatible manner, delaying medicine resistance, reducing the using amount of toxic fluoride phosphate and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

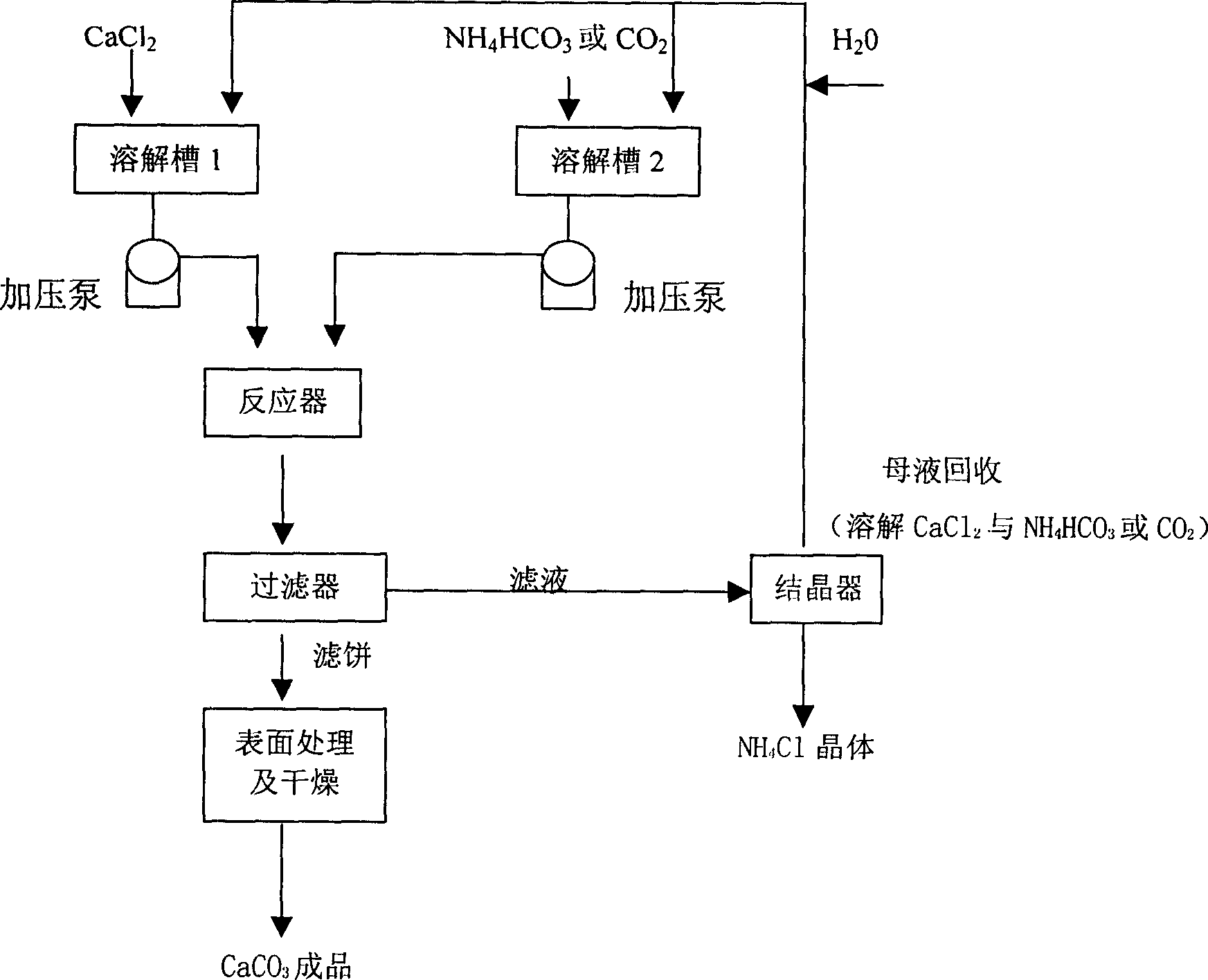

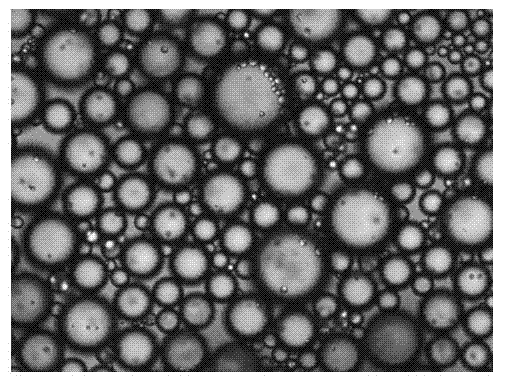

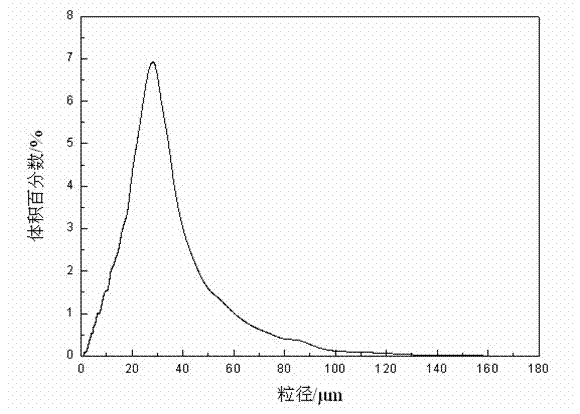

Method for preparing porous super fine calcium carbonate

InactiveCN1757597AInhibit expansionImprove heat transfer performanceCalcium/strontium/barium carbonatesCarbonate/bicarbonate preparationAqueous solutionFilter cake

A process for preparing the porous superfine calcium carbonate includes such steps as respectively preparing the aqueous solution of CaCl2 and the aqueous solution of NH4HCO3 and CO2, isometric colliding reaction while controlling flow and temp, filtering, recovering the mother liquid of ammonium chloride, drying filtered cake, grinding to obtain product, and preparing the ammonium chloride crystals from its mother liquid.

Owner:SHANGHAI INST OF TECH

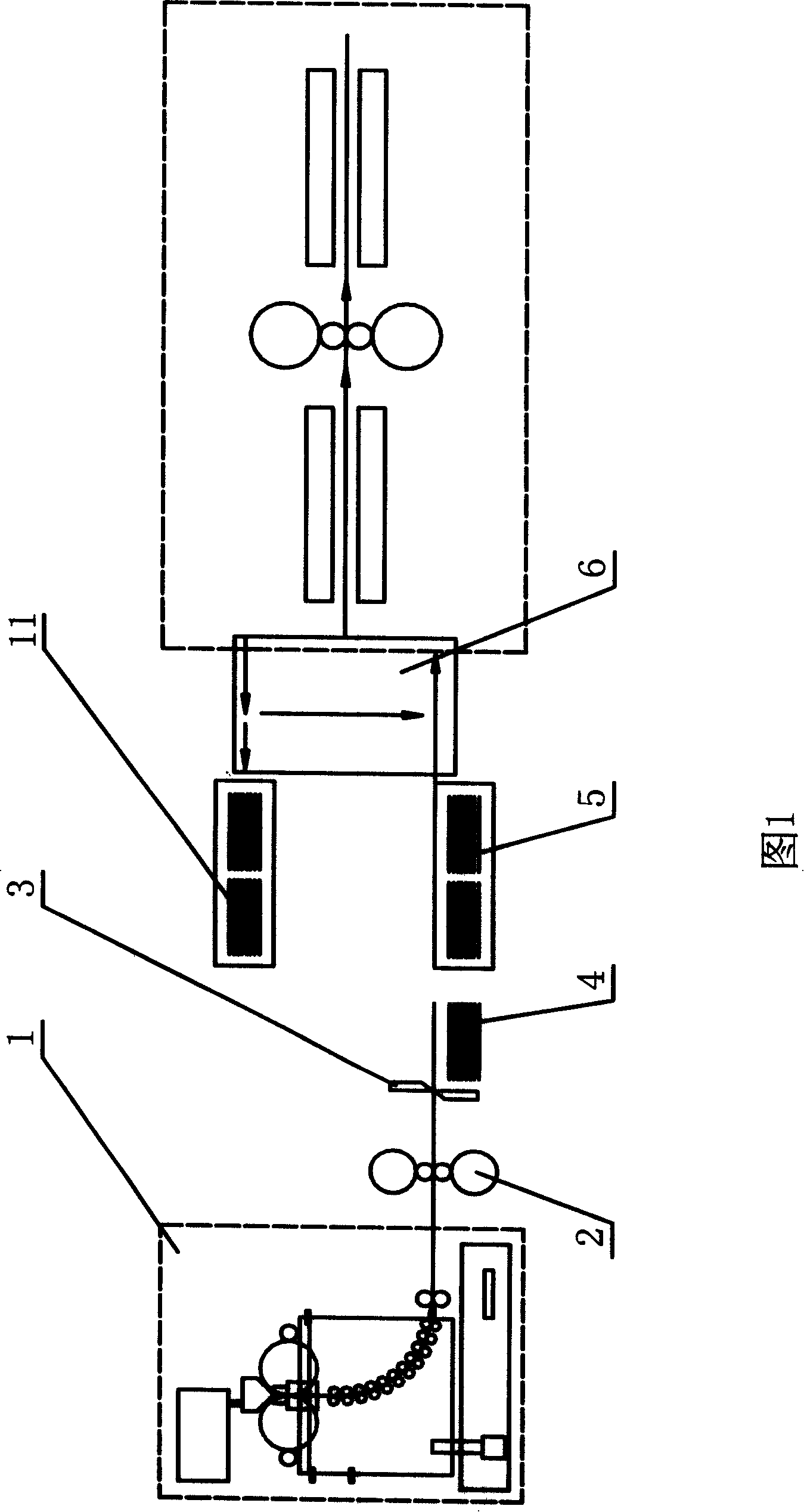

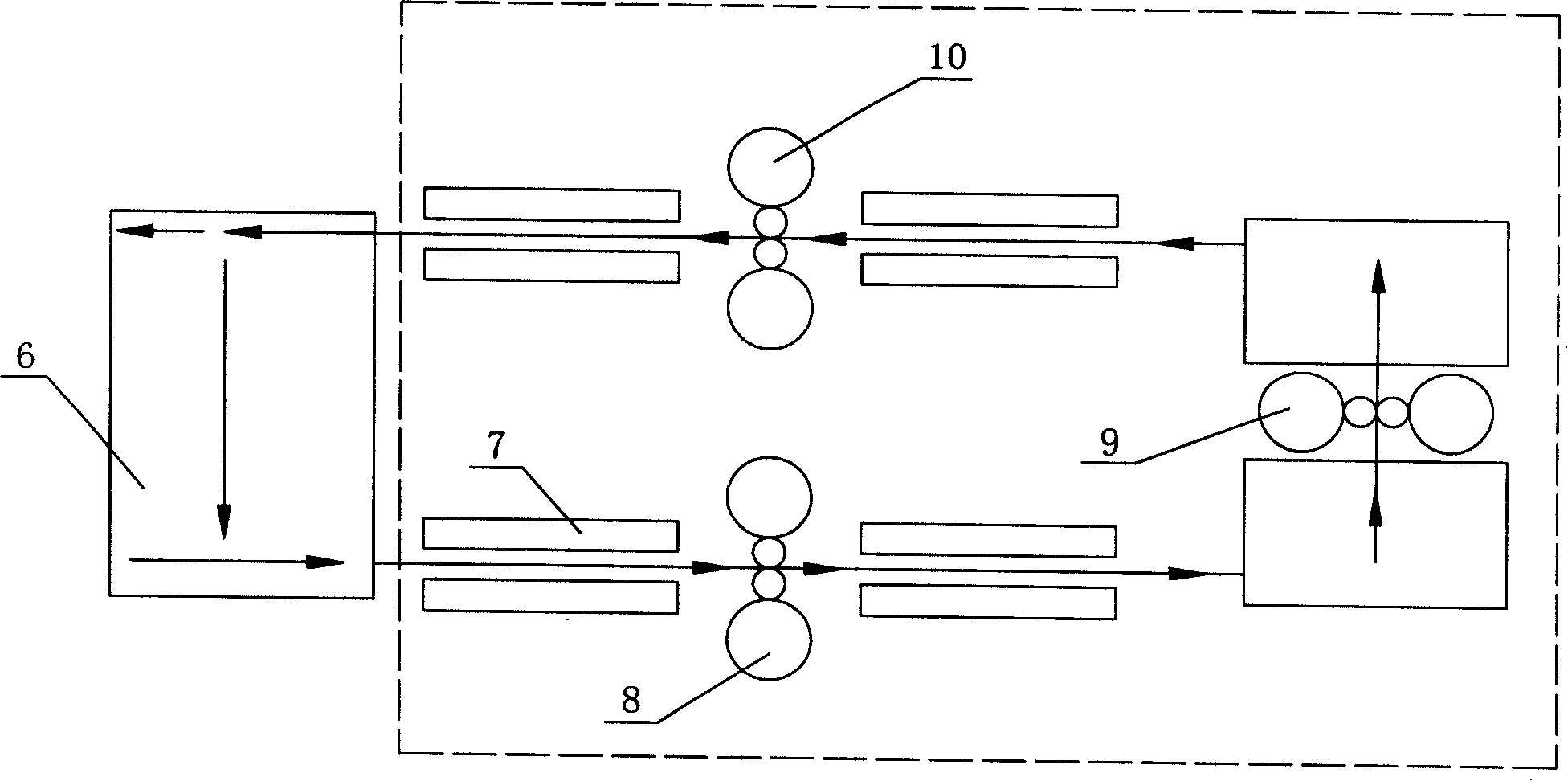

Rolling controlling method and device for double-roller continuous casting magnesium alloy sheet

InactiveCN101190491AImprove performanceGood molding effectRoll force/gap control deviceTemperature control deviceThin slabContinuous annealing

The invention discloses a dual-roll continuous casting magnesium alloy thin plate rolling control method and a device. The method comprises that magnesium alloy solution is formed in an integrated casting and rolling machine; the temperature of a casting plate out of a casting roll is 300 DEG C to 500 DEG C and casting and rolling speed is 10m / min to 90m / min; the casting and rolling plate is cooled in oil with control temperature of 200 DEG C to 400 DEG C and plate-out thickness is 1mm to 4mm; uniform annealing disposal is carried out before the hot rolling of the casting and rolling plate; the front and the rear of a rolling machine are provided with heat preservation rolls for heat supplementation; finished magnesium alloy plate of 0.2mm to 1mm can be rolled in an annealing period. The device comprises an integrated casting and rolling machine, a continuous annealing furnace behind the casting and rolling machine, three four-roll hot rolling machines arranged in 90 DEG and heat preservation rolls at the front and the rear, a flying shear and an edge-cutting shear. By adopting casting rolling and rolling methods to produce the magnesium alloy plate, the invention has the advantages of short flow, low production cost, uniform composition of products, good surface quality and uniform mechanical performance in all directions. The method and the device can be applied to the production of the magnesium alloy and aluminium alloy thin plates in all series.

Owner:UNIV OF SCI & TECH LIAONING +1

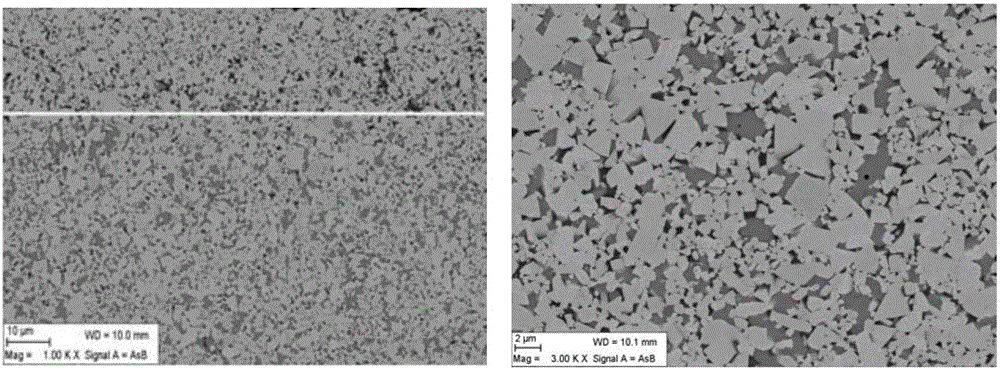

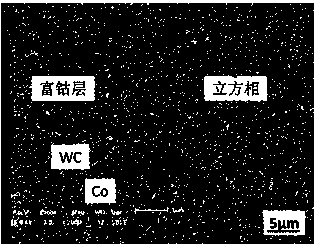

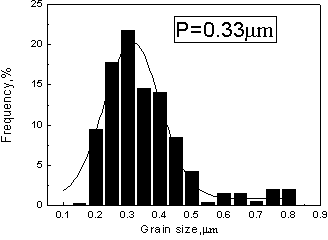

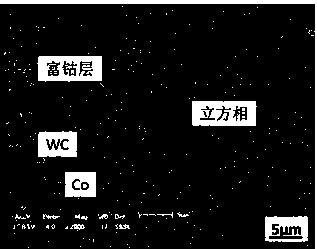

Ultra-fine crystal gradient alloy with rich-cobalt surface and preparation method thereof

The invention belongs to the field of hard alloy preparation, and in particular relates to an ultra-fine crystal gradient alloy with a rich-cobalt surface and a preparation method of the alloy. According to the ultra-fine crystal gradient alloy with the rich-cobalt surface, a gradient layer with the rich-cobalt surface, which is 10-40mu m thick, is formed by taking WC (Wolfram Carbide) and cubic phase carbonitride as a core part hard phase and cobalt as the binding phase, wherein the average size of the crystal particles of WC in the hard phase and the gradient layer is 0.2-0.4mu m, the content of cobalt in the gradient layer with the rich-cobalt surface is 1.2-2 times of the standard content of cobalt of hard alloys, and the gradient layer with the rich-cobalt surface is free of the cubic phase carbonitride. The preparation method comprises the following steps: firstly, preparing the materials, wet-grinding and pressing into a material blank, and supplying an inert gas with the pressure of 5-10MPa before reaching a liquid phase sintering temperature, wherein the liquid phase sintering temperature is 1,350-1,500 DEG C. By charging the gas with certain pressure in the liquid phase sintering period, the ultra-fine crystal gradient alloy with the rich-cobalt surface is prepared, the WC crystal grains are refined, a rich-cobalt surface layer of certain thickness is obtained, the sintering period is shortened, and the production cost is lowered.

Owner:NORTHEASTERN UNIV LIAONING

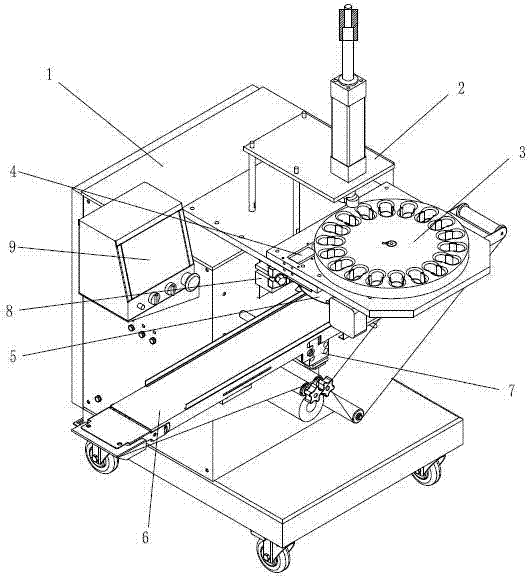

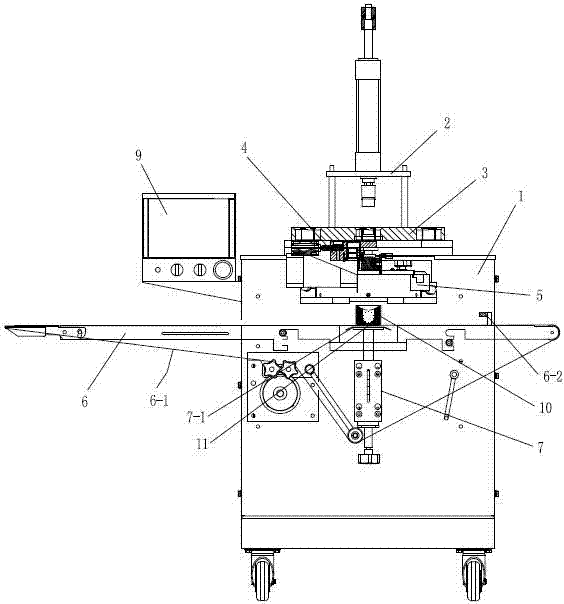

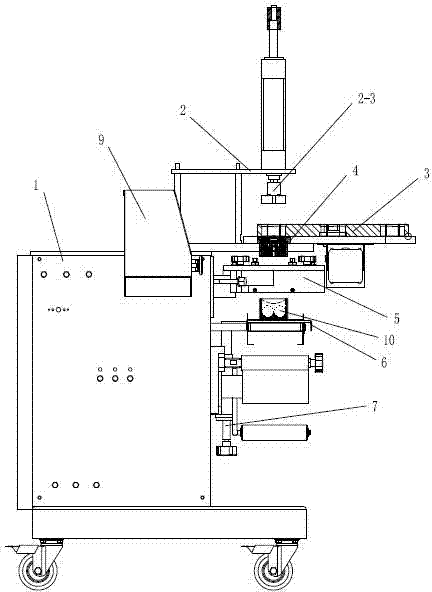

Device and method for filling stuffing into flour dough and sealing flour dough

The invention discloses a device for filling stuffing into flour dough and sealing the flour dough. The device comprises a rack, wherein the rack is longitudinally provided with a filling device, a material rotating disk, a material opening and closing switch, a sealing package pinching cutter device, a delivery device and a flour dough height regulating device in sequence; the material rotating disk, the material opening and closing switch and the sealing package pinching cutter device are provided with material channels; and a driving device controls lifting motion and synchronous on and off of the sealing package pinching cutter device, and lifting motion of the flour dough height regulating device. According to a method for filling the stuffing into the flour dough and sealing the flour dough, the driving device controls the connection and coordination of lifting of the sealing package pinching cutter device, opening and closing of each blade, rotary feeding of the material rotating disk and filling of an air cylinder accurately. With the adoption of the device and the method, stuffing filling and sealing of the flour dough can be integrally completed at a stage, the sealing is completed by synchronized actions of upper sealing of the flour dough and fixing of the outer diameter of the lower part, the forming quality of a product can be ensured, and the production cost is reduced.

Owner:YANG JENQ MACHINERY

Self-repairing microcapsule used for metal anticorrosion coating and preparation method thereof

InactiveCN102391710AImprove mechanical propertiesWide variety of sourcesAnti-corrosive paintsMicroballoon preparationAuto industryCrazing

The invention discloses a self-repairing microcapsule used for a metal anticorrosion coating and a preparation method thereof, which belong to the technical field of self-repairing materials. The wall material of the self-repairing microcapsule is urea resin, the core material of the self-repairing microcapsule is natural plant oil, and the self-repairing microcapsule is prepared with a one-step in-situ polymerization method. The natural plant oil has the advantages of wide source and low cost and is easy to obtain. The metal anticorrosion coating is coated on the surface of metal to form an anticorrosion coating. Microcracks appear in the long-term use process, the self-repairing microcapsule embedded in the coating is broken by external force, and released natural plant oil and oxygen in the air can directly generate crosslinking polymerization reaction without catalysts to repair the microcracks to prevent the surface of the metal from being further corroded. The self-repairing microcapsule synthetized by the core material substance has the advantages of good mechanical performance, simple preparation technology and low cost and can be widely applied to the self repairing of metal anticorrosion coatings, such as automobile industry, ship industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

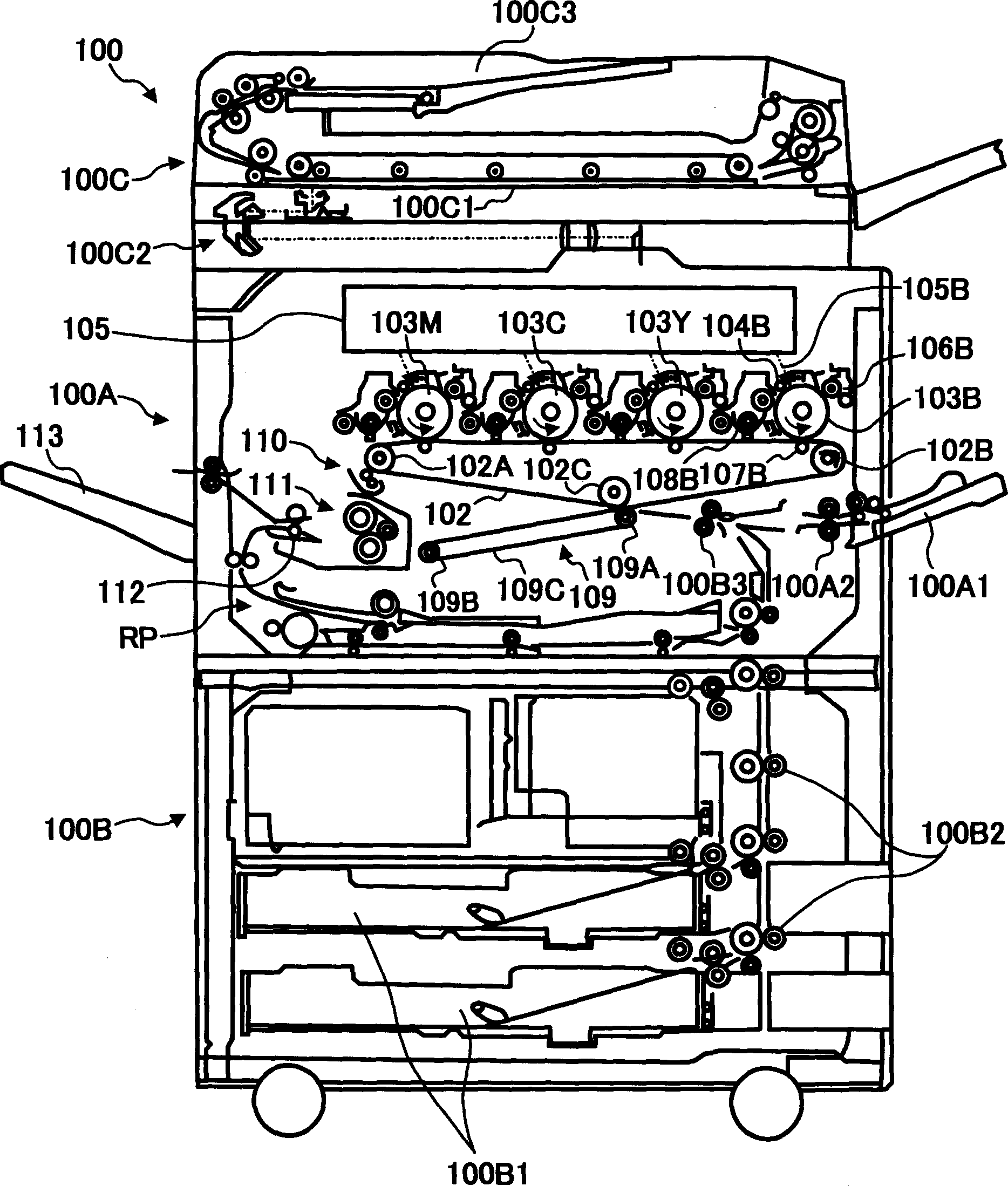

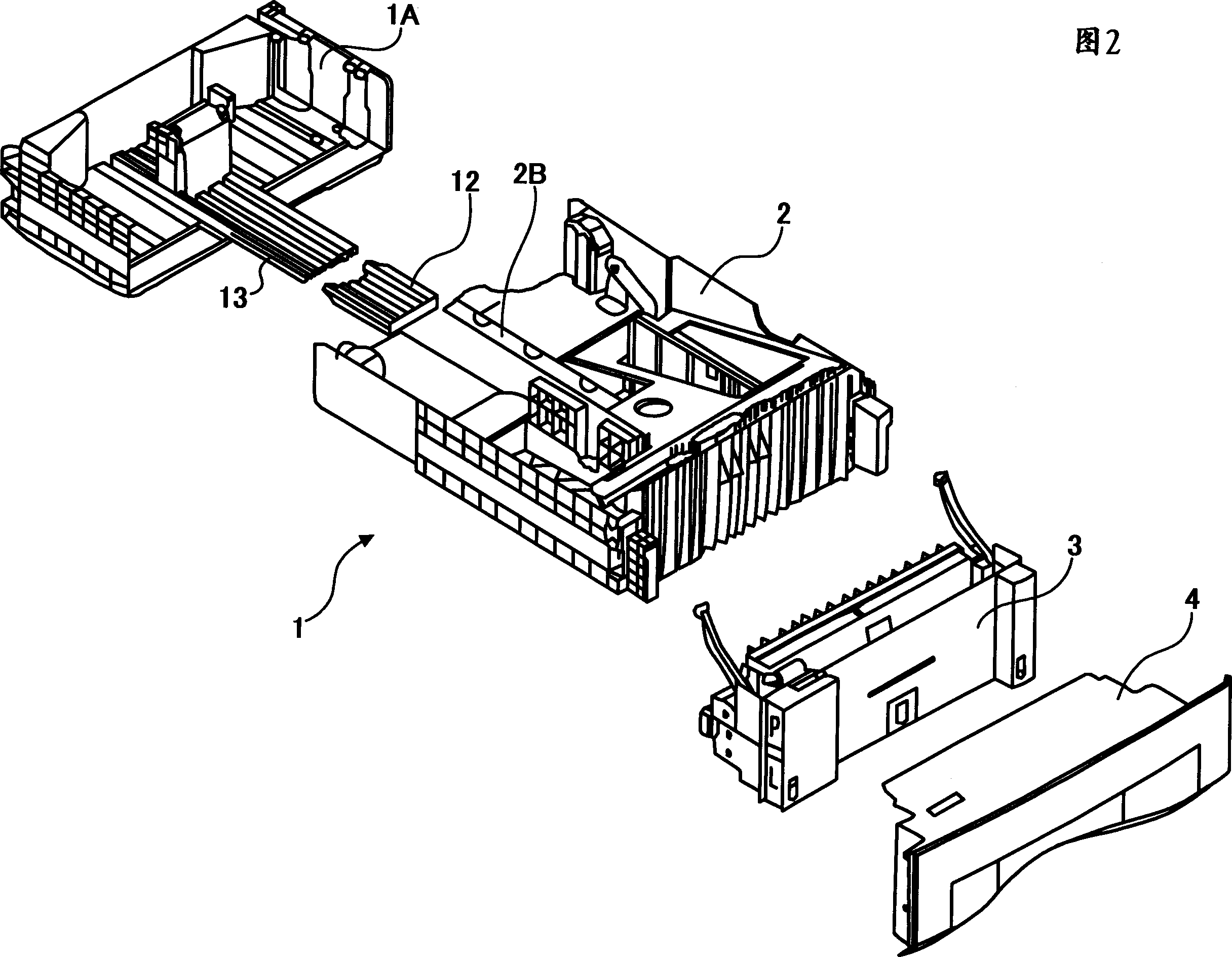

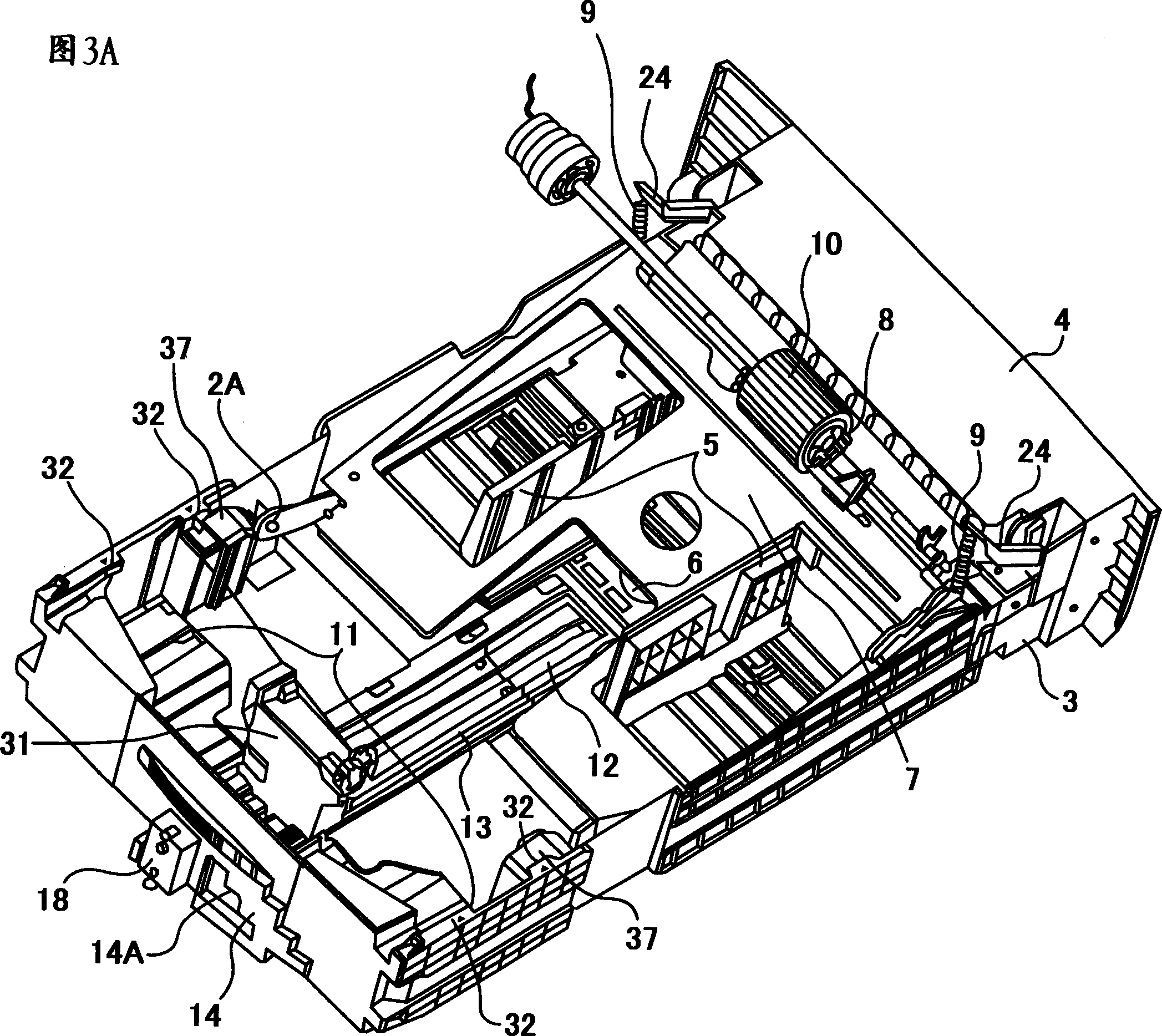

Paper feeding device and image forming apparatus

InactiveCN1534394AIncrease management costsExhaustion status correctly judgedFunction indicatorsShoe lace fasteningsImage formationEngineering

Owner:RICOH KK

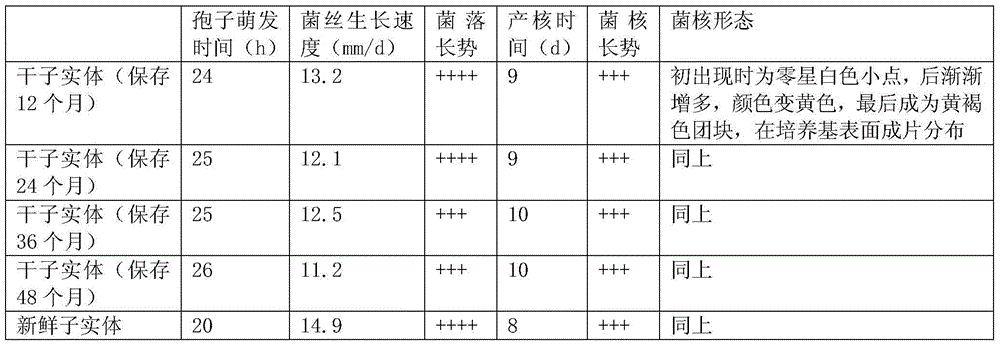

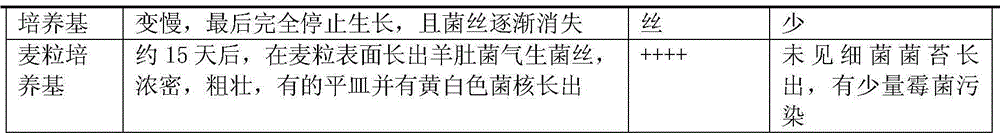

Method for preserving and separating toadstool strain through sporocarp dried in shade

ActiveCN104686196AFor long-term storageOvercome seasonal constraints on productionFungiMicroorganism preservationMicroorganismMicrobiological Techniques

The invention belongs to the technical field of microorganisms, relates to a method for preserving and separating a toadstool strain through sporocarp dried in the shade, and aims to solve the technical problems that a conventional toadstool strain preservation method is limited by season, complex to operate, easy in causing pollution and relatively high in cost. According to the technical scheme, the method for preserving and separating toadstool strain through sporocarp dried in the shade comprises the following steps: a, preserving the strain; b, separating the strain. The method provided by the invention is low in cost, simple to operate, unlimited by season, capable of effectively preserving activity of the strain, and convenient in transporting and preserving the strain.

Owner:重庆市潼南区中药研究院有限公司

High-strength toughness titanium carbonitride base metal ceramic material and preparing method thereof

The invention relates to a high-strength toughness titanium carbonitride base metal ceramic material and a preparing method thereof, and belongs to the technical field of metal ceramic material preparing. The raw materials used by the high-strength toughness titanium carbonitride base metal ceramic material comprise, by weight percent, 35 to 65% of titanium carbonitride powder, 0.5 to 8% of titanium carbonitride whiskers, 10 to 20% of M composed of cobalt and nickel, 10 to 30% of an addition agent A and the balance tantalum carbide, wherein the addition agent A is composed of tungsten carbideand molybdenum carbide. The sum of weight percents of all components if 100%; the granularity of the titanium carbonitride powder ranges from 2 to 4 micrometers, the diameter of the titanium carbonitride whiskers ranges from 1 to 2 micrometers, and the length ranges from 15 to 20 micrometers. The preparing method comprises the steps that after all raw materials are matched and got according to design components, uniform mixing and pressing molding are carried out, and sintering is carried out at the temperature of 1420 DEG to 1520 DEG C, and a finished product is obtained. The material is reasonable in design, the obtained product is excellent in performance, and the large-scale industrial application and production are facilitated.

Owner:HUNAN UNIV

Liquid crystal display panel and manufacturing method thereof

InactiveCN109143689AReduce the risk of strippingSolve weak adhesionNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises a first substrate, a baffle wall, an alignment film and frame glue,wherein the baffle wall, the alignment film and the frame glue are arranged on the first substrate, the baffle wall is in an annular shape, the alignment film is arranged at an inner side of the baffle wall, the frame glue is arranged at an outer side of the baffle film, the baffle film comprises at least two layers of sub baffle walls which are sequentially arranged from bottom to top, each subbaffle wall is in an annular shape, in two adjacent layers of baffle walls, the projection of an inner side wall of the sub baffle wall at an upper layer is arranged between an inner side wall and anouter side wall of the sub baffle wall at a lower layer, so that the inner side wall of the baffle wall is in a step shape, the climbing resistance of a solution for forming the alignment film at theinner side wall of the baffle wall is greatly improved during preparation of the alignment film at the inner side of the baffle wall by a solution film formation mode, the alignment film is preventedfrom being expanded out of the baffle plate and overlapped with the frame glue, and the stripping risk of the frame glue is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for treating and controlling desertificated land

InactiveCN1515648AControl desertificationGovernance of desertificationMicroorganismsCultivating equipmentsEcological environmentBio engineering

The present invention relates to a method for controlling desertified land, and starting with the restoring and reconstructing microecologic environment and including the following three steps: (A). making enrichment culture of microbial algae and fungi in the microecologic environment of land block to be controlled; (B) separating out dominant group from them, using modern bio-engineering technique to make large-scale culture, then inoculating the cultured organism into the land block to be controlled; and (C). directly adding nutrient elements necessary for microbial algae and fungi into the land block to be controlled, at the same time planting drought-resistant plants, and utilizing sunshading net to cover and fix then on the controlled land block surface.

Owner:SICHUAN UNIV

Silicon nitride based nano complex gradient function ceramic tool material and preparation thereof

The invention provides a silicon nitride-based nano composite functionally gradient ceramic cutter material and a preparation method thereof. The ceramic cutter material is provided with a five-layer symmetrical gradient level structure; the component contents of the symmetrical layers relative to a central layer are the same and the thickness of each layer is consistent; the components of each layer are all micron Si3N4, nano Si3N4, nano TiC, nano TiN, Al2O3 and Y2O3. The preparation method thereof is as follows: (1) preparing materials according to the content of each component in each layer; (2) dispersing the nano materials in each layer; (3) mixing the other materials in each layer with the dispersed nano materials to obtain the powder material of a composite ceramic material which disperses excellently; and (4) employing a powder layering paving method and a hot pressing sintering technique to carry out loading and sintering. The invention improves the anti-bending intensity and the fracture toughness property of the materials, and improves the fracture toughness property of the materials; while the gradients of the nano TiC and the nano TiN are arranged in layers, thus leading the mechanical property of the cutter material to be changed in stagewise gradient, and being capable of effectively easing the residual heat stress.

Owner:SHANDONG UNIV

Gas shield metal core welding wire used for high-strength steel welding based on ULCB structure

ActiveCN103586594AImproved arc stabilityHigh strengthArc welding apparatusWelding/cutting media/materialsSilicon alloyShielding gas

The invention discloses a gas shield metal core welding wire used for high-strength steel welding based on a ULCB structure. The gas shield metal core welding wire comprises an outer skin and a flux core. The outer skin is composed of a mild-carbon steel strip. By weight,, carbon accounts for 0.025-0.035% of the mild-carbon steel strip is. The width of the steel strip is 10-12mm, and the thickness of the steel strip is 0.6-0.8mm. The flux core comprises, by the weight, 7-12% of manganese, 3-16% of ferrosilicon, 0.5-2% of chromium, 8-14% of nickel, 2-4% of molybdenum, 0.5-3% of zirconium silicon alloy, 0.5-3.5% of fluoride and 0.5-3.5% of ferrotitanium, and the balance is iron power. The filling rate of the flux core is 15-21%. Mixed gas of argon and carbon dioxide is selected as shielding gas for welding, and the carbon dioxide content is 5-20%. The metal core welding wire has good welding technology performance, formed weld joints are beautiful, the strength of deposited metal can reach 800-950MPa, and impact toughness at the low temperature of 40 degrees below zero can reach above 60J.

Owner:江苏伯翰焊接材料有限公司

Graphene high temperature resistant corrosion-resistant coating for metallic material and preparation method of graphene high temperature resistant corrosion-resistant coating

InactiveCN108276866AReduce coagulationImprove anti-corrosion performanceAnti-corrosive paintsPolyvinyl butyralPolyvinyl alcohol

The invention relates to a graphene high temperature resistant corrosion-resistant coating for a metallic material and a preparation method of the graphene high temperature resistant corrosion-resistant coating. The graphene high temperature resistant corrosion-resistant coating consists of the following components in parts by weight: 6-12 parts of graphene oxide, 20-45 parts of a phenolic resin,2-6 parts of polyvinyl butyral, 1-4 parts of rare earth chloride, 12-30 parts of graphene quantum dots, 2-5 parts of a heat conduction metallic powder, 3-6 parts of carbon nanotubes, 12-30 parts of asolvent, 2-6 parts of an antioxidant, 5-9 parts of a curing agent and 12-18 parts of a defoaming agent, wherein the graphene quantum dots is 2-4nm in size; the solid content of the phenolic resin is 45-55%. According to the graphene high temperature resistant corrosion-resistant coating provided by the invention, by the virtue of the good dispersibility of the graphene quantum dots in solvents andrelatively good non-covalent functions of the graphene quantum dots with graphene sheets, two-dimensional sheet structures of the graphene can be overlapped layer by layer in the coating, a compact physical insulating layer can be formed, and the corrosion resistance of the coating can be improved.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

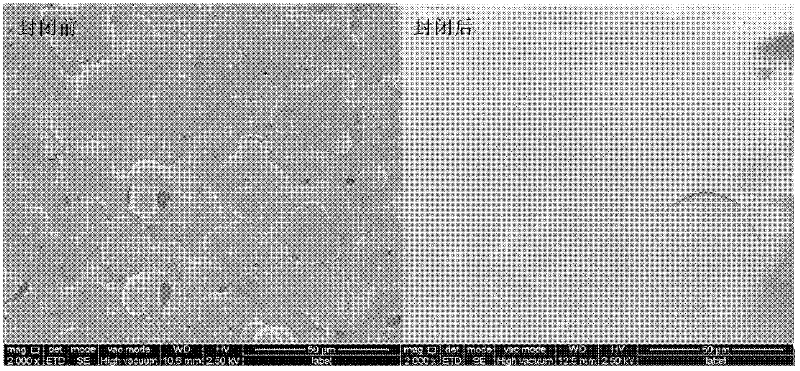

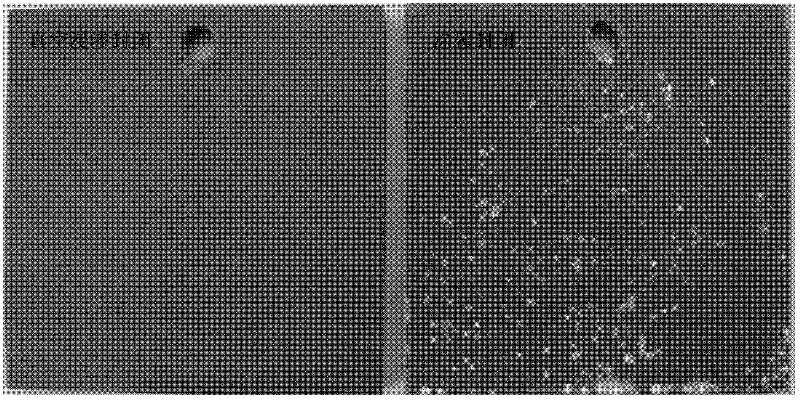

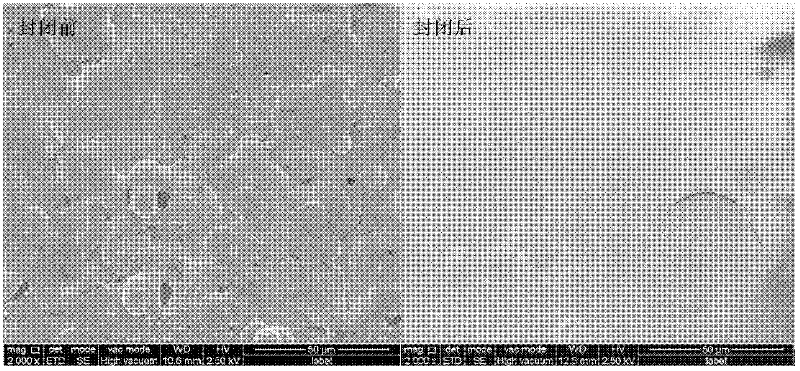

Sealing treatment method of micro arc oxidation ceramic membrane

InactiveCN102330139AReduce porosityImprove corrosion resistanceSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a sealing treatment method of a micro arc oxidation ceramic membrane. The sealing treatment method comprising the following steps: firstly, decontaminating and deoiling the surface of an aluminium alloy micro arc oxidation sample to be sealed with acetone; then carrying out ultrasonic vibration cleaning by adopting distilled water of 50-60 DEG C; subsequently, carrying out vacuum impregnation by adopting an organic silicon stock solution and more than 95% alcohol; and finally putting the aluminium alloy micro arc oxidation sample into a heat preserving furnace for heat preservation so as to complete sealing treatment. By applying the sealing treatment method of the micro arc oxidation ceramic membrane, the abrasion resistance and corrosion resistance performances of the micro arc oxidation membranous layer can be greatly improved, the contamination performance of the oxidation membranous layer can be effectively reduced, the electrical insulating property of the oxidation membranous layer is improved, and the toughness of the membrane layer is improved.

Owner:CSIC NO 12 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com