Method for preparing solid solution toughened wolfram-base composite material through laser rapid forming

A technology of laser rapid prototyping and composite materials, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of low temperature performance and grain growth of W and its alloys, and achieve the improvement of microstructure and comprehensive properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

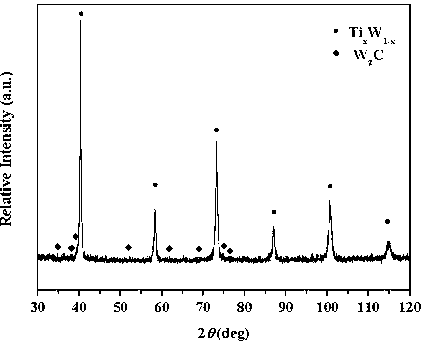

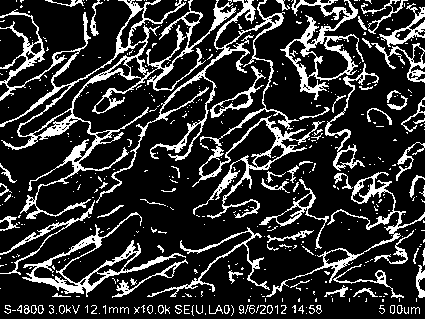

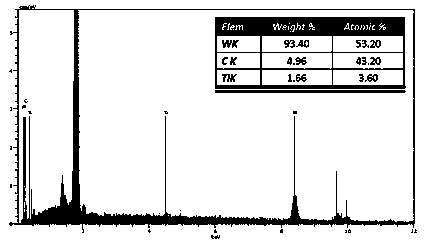

[0035] Step 1: The mixed powder is composed of TiC powder with a purity of more than 99.8% and an average particle size of 50-70 nm and W powder with a purity of more than 99.9% and an average particle size of 4.5-5.5 μm, of which the TiC powder component accounts for the total content of 1wt.%, and put it in the German Fristsch company Pulverisette 6 single-pot planetary high-energy ball mill for ball milling; use argon for protection, stainless steel balls as the ball milling medium, add stainless steel balls with a diameter of Ф6~Ф10 mm as the ball milling medium , the mass ratio of balls to powder is 8:1, the milling speed is 250 rpm, and the ball milling time is set to 30 h; Open the ball mill tank in the operation box, and put the powder sample into the sample bag.

[0036] Step 2: The SLM forming system used mainly includes: high-power Nd:YAG (λ=1.064 μm) laser, computer system for forming control, automatic powder spreading device and protective atmosphere device. Fir...

Embodiment 2

[0041] Step 1: The mixed powder is composed of TiC powder with a purity of more than 99.8% and an average particle size of 50-70 nm and W powder with a purity of more than 99.9% and an average particle size of 4.5-5.5 μm, of which the TiC powder component accounts for the total content of 1.3wt.%, and put it in Pulverisette 6 single-pot planetary high-energy ball mill of German Fristsch company for ball milling; use argon gas for protection, stainless steel balls as ball milling medium, add stainless steel balls with a diameter of Ф6~Ф10 mm as ball milling The medium, the mass ratio of balls to powder is 8:1, the ball milling speed is 300 rpm, and the ball milling time is set to 35 h; Open the ball mill tank in the vacuum operation box, and put the powder sample into the sample bag.

[0042] Step 2: The SLM forming system used mainly includes: high-power Nd:YAG (λ=1.064 μm) laser, computer system for forming control, automatic powder spreading device and protective atmosphere ...

Embodiment 3

[0047] Step 1: The mixed powder is composed of TiC powder with a purity of more than 99.8% and an average particle size of 50-70 nm and W powder with a purity of more than 99.9% and an average particle size of 4.5-5.5 μm, of which the TiC powder component accounts for the total content of 1.5 wt.%, and put it in Pulverisette 6 single-pot planetary high-energy ball mill of German Fristsch Company for ball milling; use argon gas for protection, stainless steel balls as ball milling medium, add stainless steel balls with a diameter of Ф6~Ф10 mm as ball milling The medium, the mass ratio of balls to powder is 10:1, the ball milling speed is 300 rpm, and the ball milling time is set to 45 h; Open the ball mill tank in the vacuum operation box, and put the powder sample into the sample bag.

[0048] Step 2: The SLM forming system used mainly includes: high-power Nd:YAG (λ=1.064 μm) laser, computer system for forming control, automatic powder spreading device and protective atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com