Patents

Literature

622results about How to "Short setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Polymer impression materials

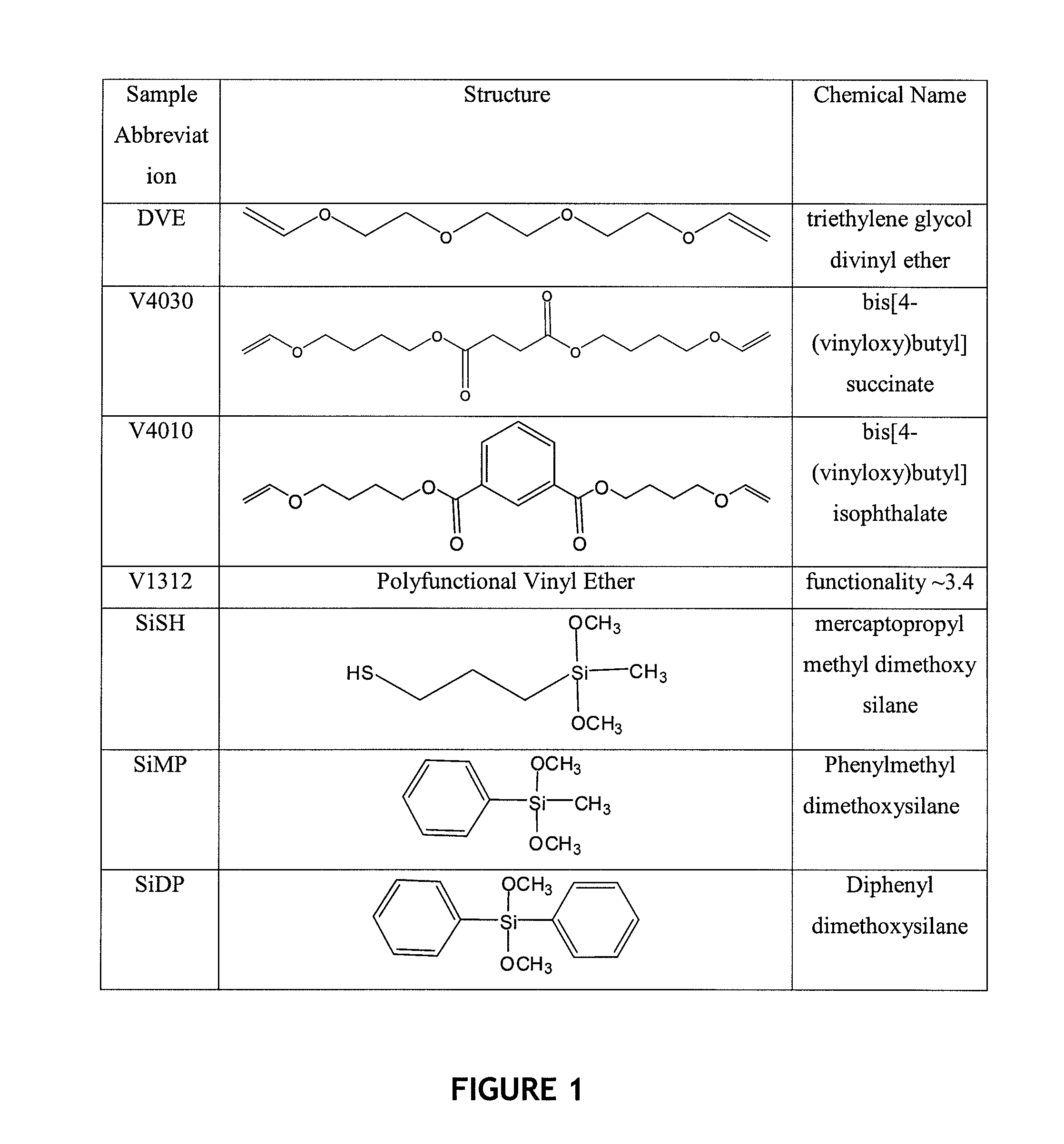

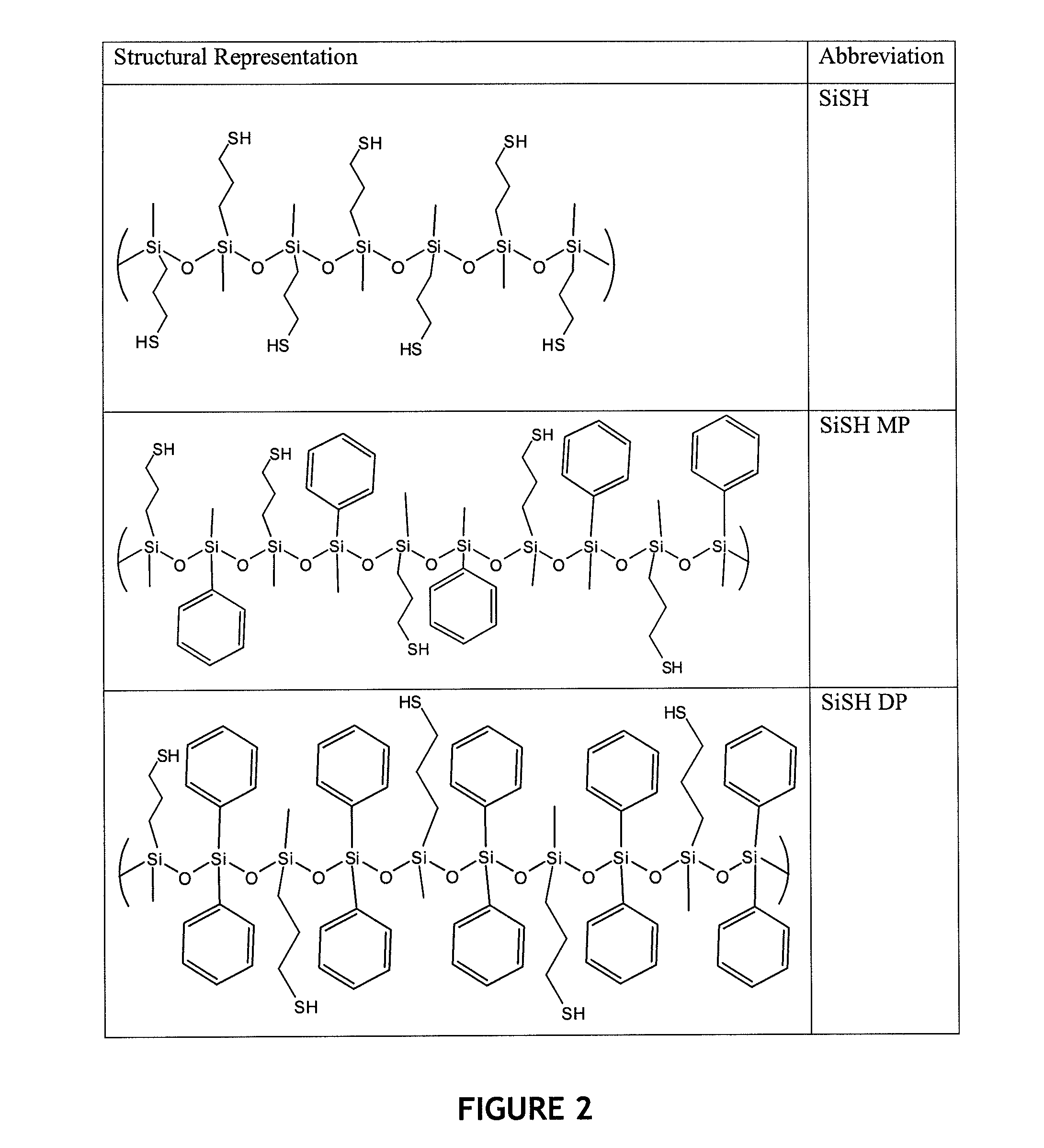

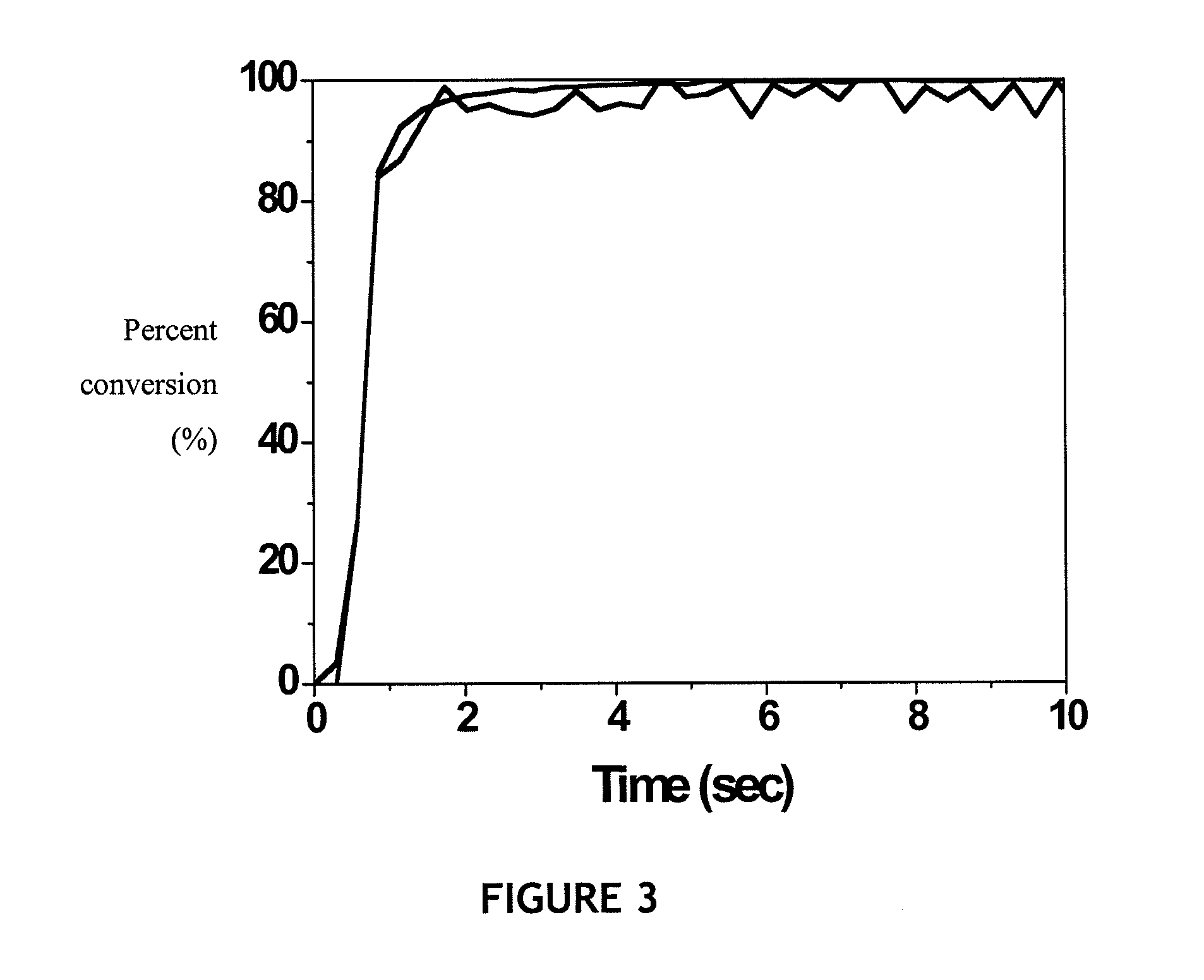

InactiveUS20100304338A1Long working timeShort setting timeImpression capsDental articulatorsVoid ratioDental impression material

This invention relates to methods and compositions for single component photoinitiated dental impression materials. The impression material is workable in its pre-cured state, cures rapidly upon exposure to light, and exhibits desirable processing conditions such as short setting time, long working time, no void formation, good wettability, mechanical properties, and detail reproduction.

Owner:UNIV OF COLORADO THE REGENTS OF

Hydraulic composition

ActiveUS20080196629A1Excellent self leveling capabilityShort setting timeCoatingsCellulose adhesivesWater solubleEther

Hydraulic compositions comprising a setting accelerator, a water-soluble cellulose ether having a degree of alkyl substitution of 1.6 to 2.5 which is a water-soluble alkyl cellulose or a water-soluble hydroxyalkyl alkyl cellulose, and water are useful as self-leveling compositions having an excellent self-leveling capability, a minimal change with time of fluidity, and a short setting time, or as cement mortar compositions having a long open time and a short setting time.

Owner:SHIN ETSU CHEM IND CO LTD

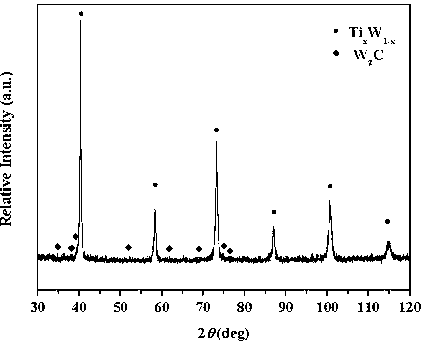

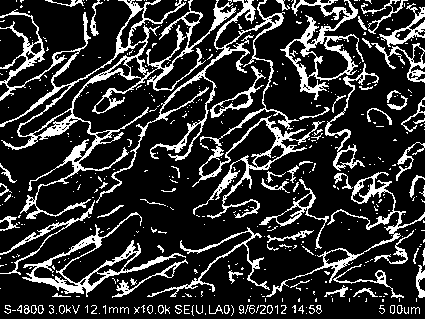

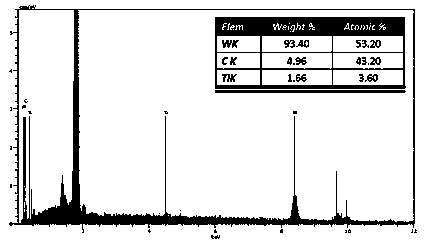

Method for preparing solid solution toughened wolfram-base composite material through laser rapid forming

InactiveCN103074532AImprove microstructureImprove performanceIncreasing energy efficiencySelective laser meltingHigh energy

The invention belongs to the technical field of laser rapid forming, and particularly relates to preparation of a solid solution toughened wolfram-base composite material. A preparation method of the solid solution toughened wolfram-base composite material is as follows: original mixed powder comprises W (wolfram) powder and TiC powder, wherein the TiC powder is 1-1.5wt percent of the total content; and the mixed powder is ball-milled in a high-energy mechanical ball mill for 30-45 h, and then the TiC / W composite material is formed by using a selective laser melting process. The parameters of the adopted laser process are as follows: the powder-bed depth is 50-60 Mum, the laser spot diameter is 200-210 Mum, the laser power is 120-140 W, the laser scanning rate is 100-300 mm / s, and the laser scanning interval is 120-140 Mum. According to the invention, the solid solution toughened wolfram-base composite material is successfully prepared through the method that combines high-energy mechanical ball milling and the selective laser melting process, and the fragility of W material is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flame-retarding polymer foam material and preparation method thereof

ActiveCN102127269AIncrease the amount addedAddition changeLaminationLamination apparatusPolymer sciencePolystyrene

The invention discloses a flame-retarding polymer foam material which is characterized by comprising polymer foam plastic, wherein the surface of the polymer foam plastic is provided with an organic flame retardant layer; and the organic flame retardant layer is formed by attaching a molten organic flame retardant to the surface of the polymer foam plastic through a spraying, coating or soaking way. The invention also discloses a preparation method of the flame-retarding polymer foam material. In the invention, a flame-retarding variety which is effective to the polymer foam plastic, in particular to extrusion foamed polystyrene foam plastic, is selected from numerous flame retardants, and the polymer foam product with excellent flame-retarding property is prepared by adopting a simple and feasible method. Through the invention, an effective method for increasing the addition amount of the flame retardant is obtained on the premise of not influencing the foaming property of the foam products and not reducing the strength and the insulation and thermal preservation property of foams, and different flame-retarding requirements can be met by flexibly changing the attaching amount of the flame retardant.

Owner:连云港传奇阻燃科技有限公司

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

Surface modifier for regenerated coarse aggregate

The invention relates to a surface active agent for surface reinforcement of reclaimed coarse aggregate, which is prepared mainly from the raw materials of (by weight percent) slag fines 80-90%, modified sodium silicate 2-8%, agglomerating agent 0.1-1% and solid packing material 1.0-17.9%.

Owner:WUHAN UNIV OF TECH

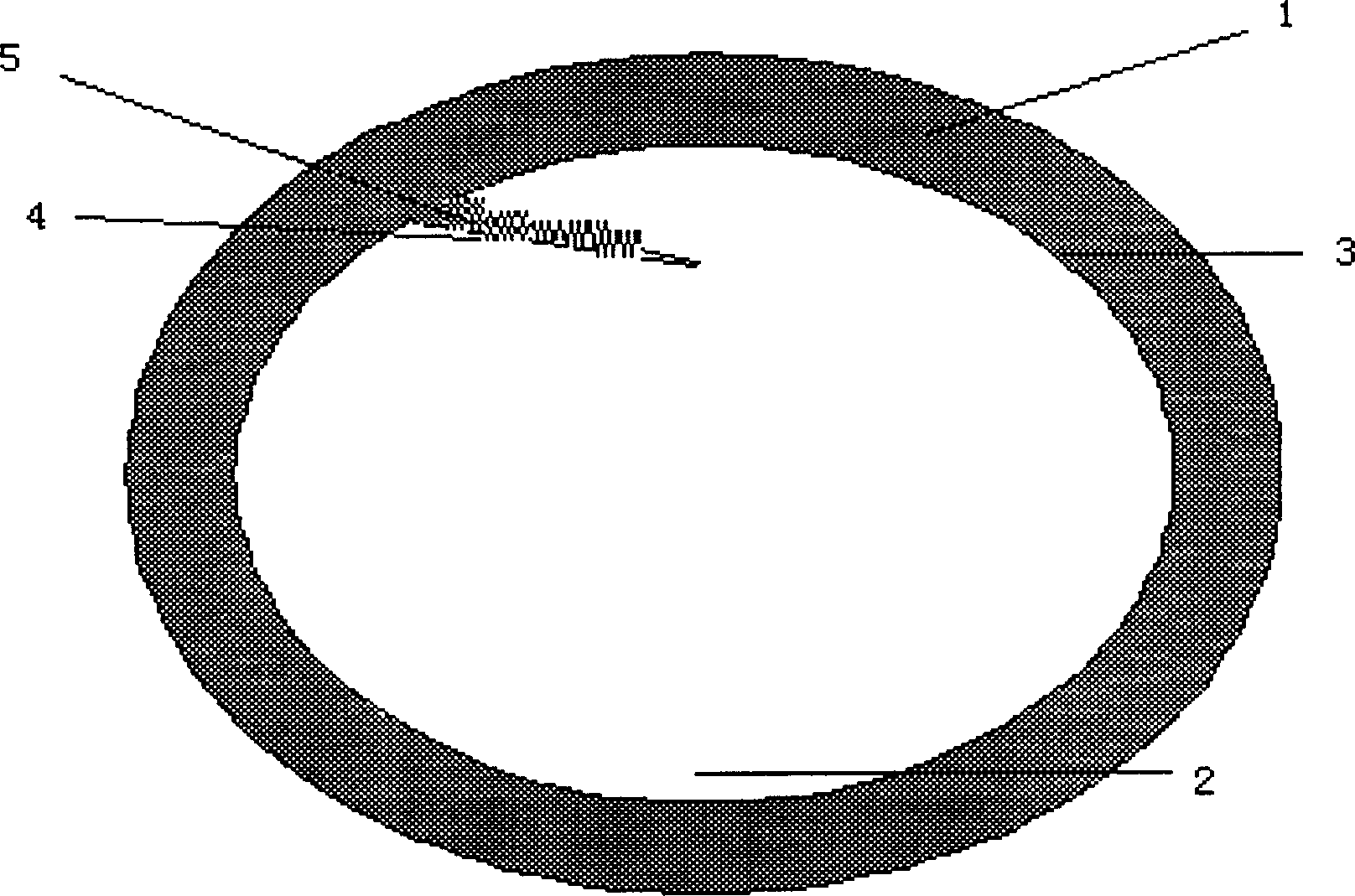

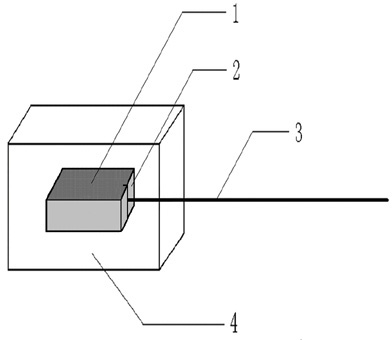

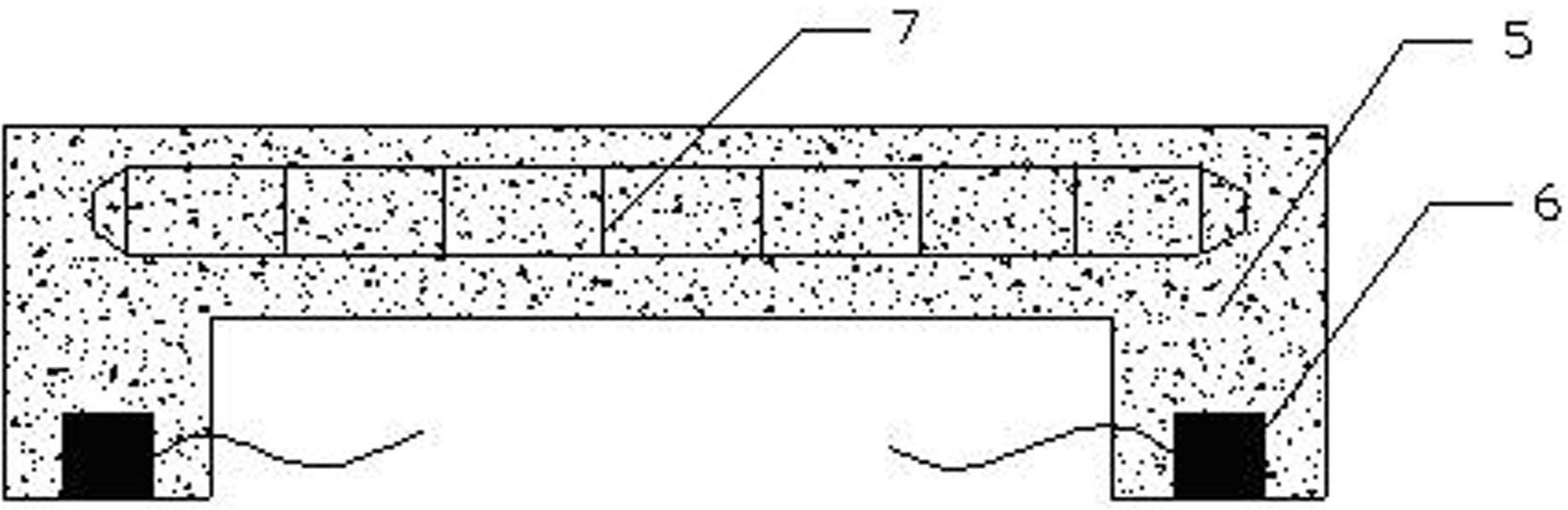

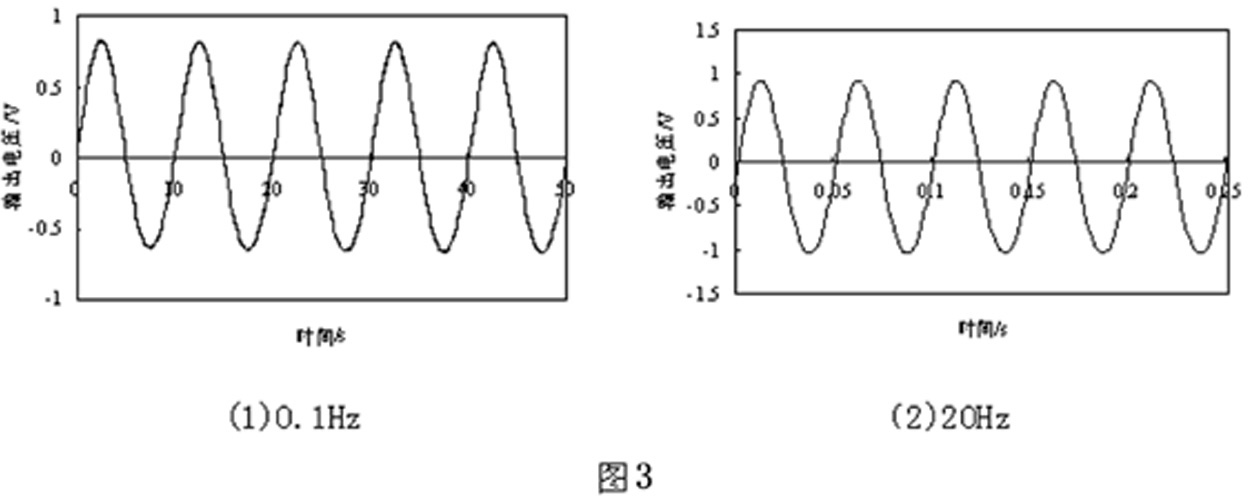

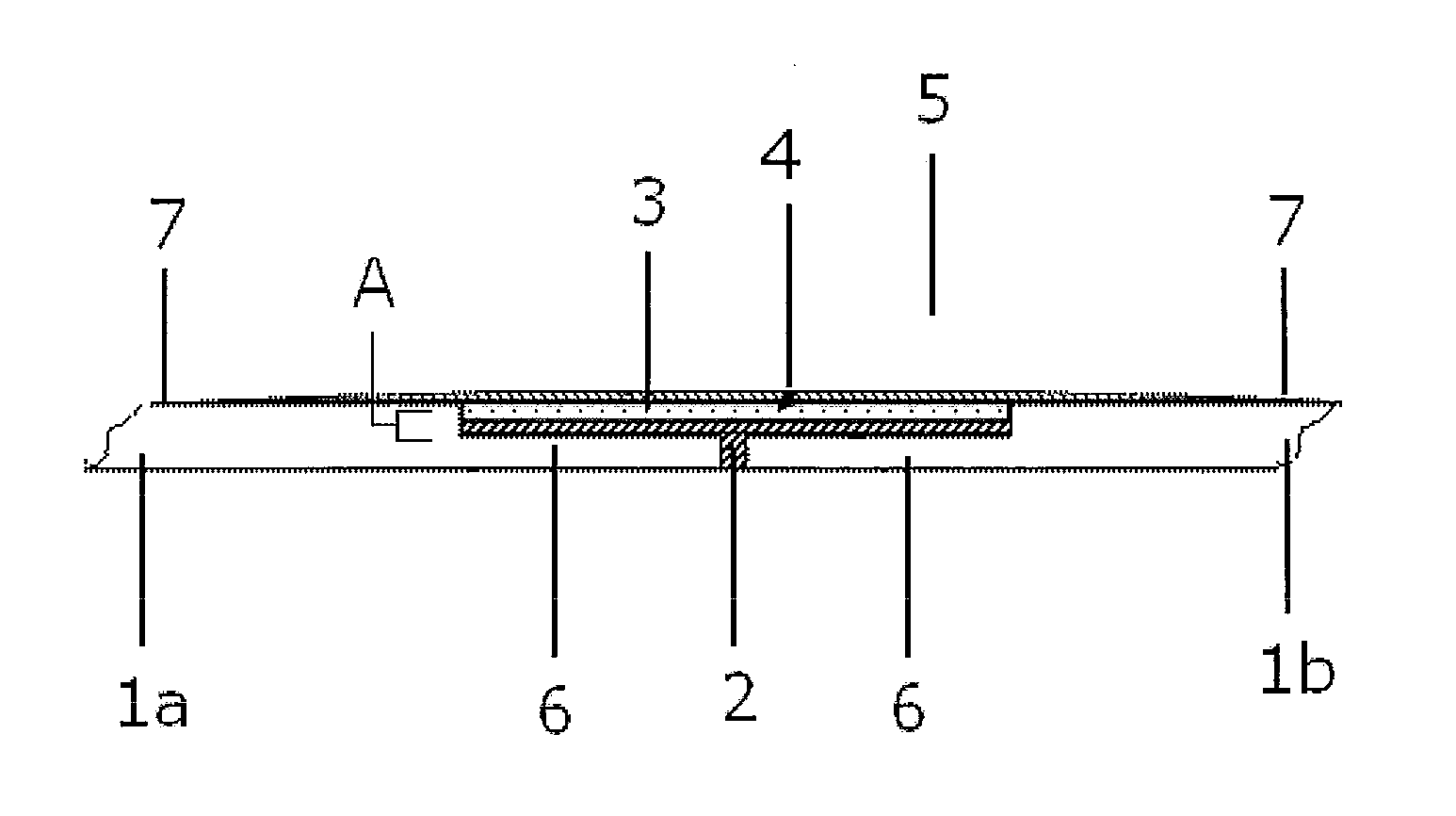

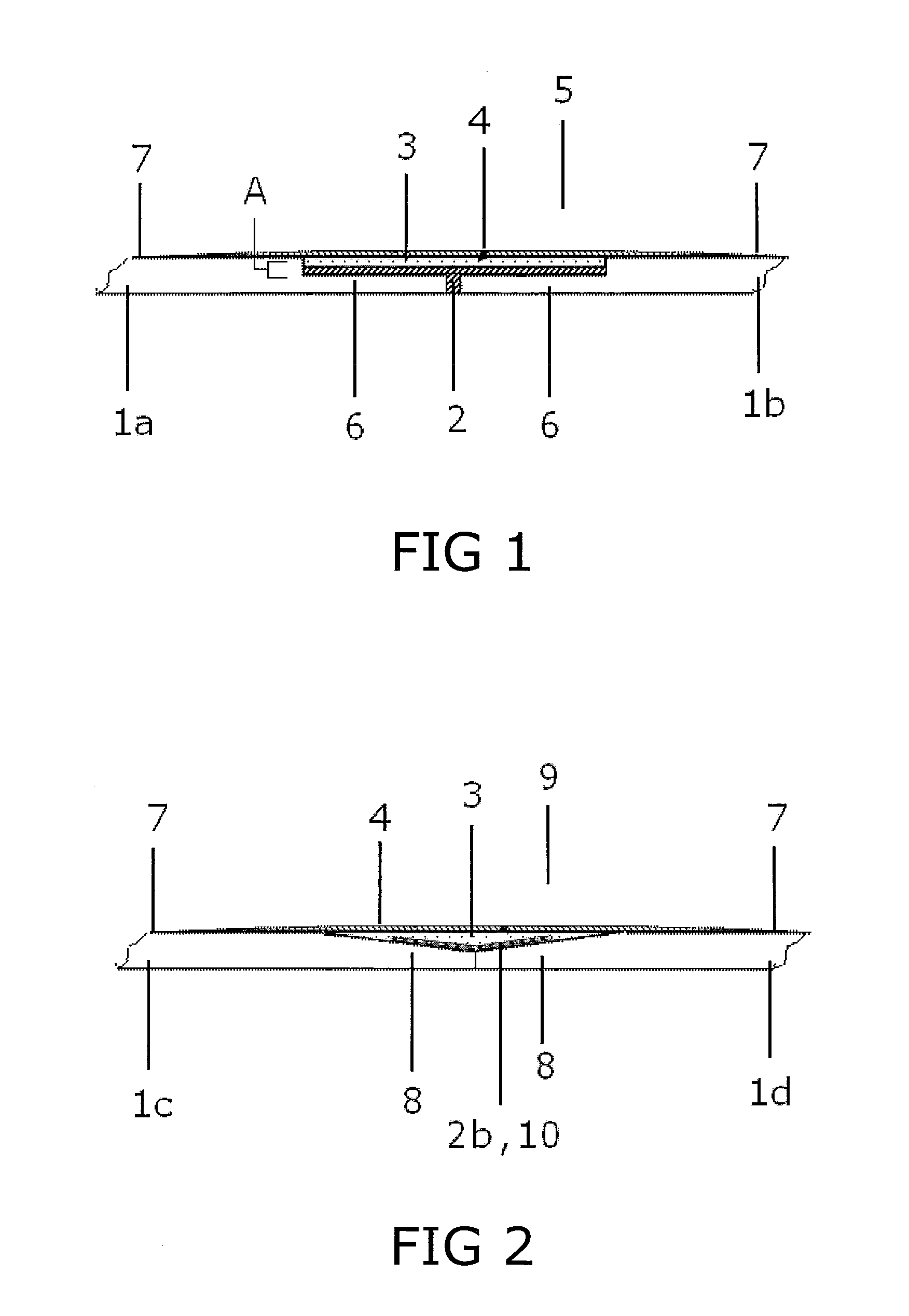

Piezoelectric sensor, beam type concrete sensor, and preparation methods and application thereof

InactiveCN102024900AImprove dynamic characteristicsStable signalPiezoelectric/electrostrictive device manufacture/assemblyDevices using time traversedFirming agentRoad surface

The invention discloses a piezoelectric sensor. The piezoelectric sensor comprises an induction component, wherein the induction component comprises a piezoelectric material and a pair of electrodes positioned on the upper surface and the lower surface of the piezoelectric material; an encapsulated shell is wrapped outside the induction component; the pair of electrodes on the piezoelectric material are connected with each other through a screened lead running through the encapsulated shell; and the encapsulated shell is prepared by mixing epoxy resin, a curing agent and cement according to the mass ratio of the epoxy resin to the curing agent to the cement of 1:0.4:1. The invention also discloses a preparation method of the piezoelectric sensor, a beam type concrete sensor comprising the piezoelectric sensor and application thereof. The piezoelectric sensor is stable in signal, high in signal to noise ratio, small in road surface damage degree, high in durability, simple in preparation process and low in cost. The beam type concrete sensor is simple in preparation, adjustable in volume, high in sensitivity, high in response speed, insusceptible to damage during construction; and the calculated running speed of a vehicle is basically consistent with the actual running speed of the vehicle, the measuring result is accurate and the error is small.

Owner:UNIV OF JINAN

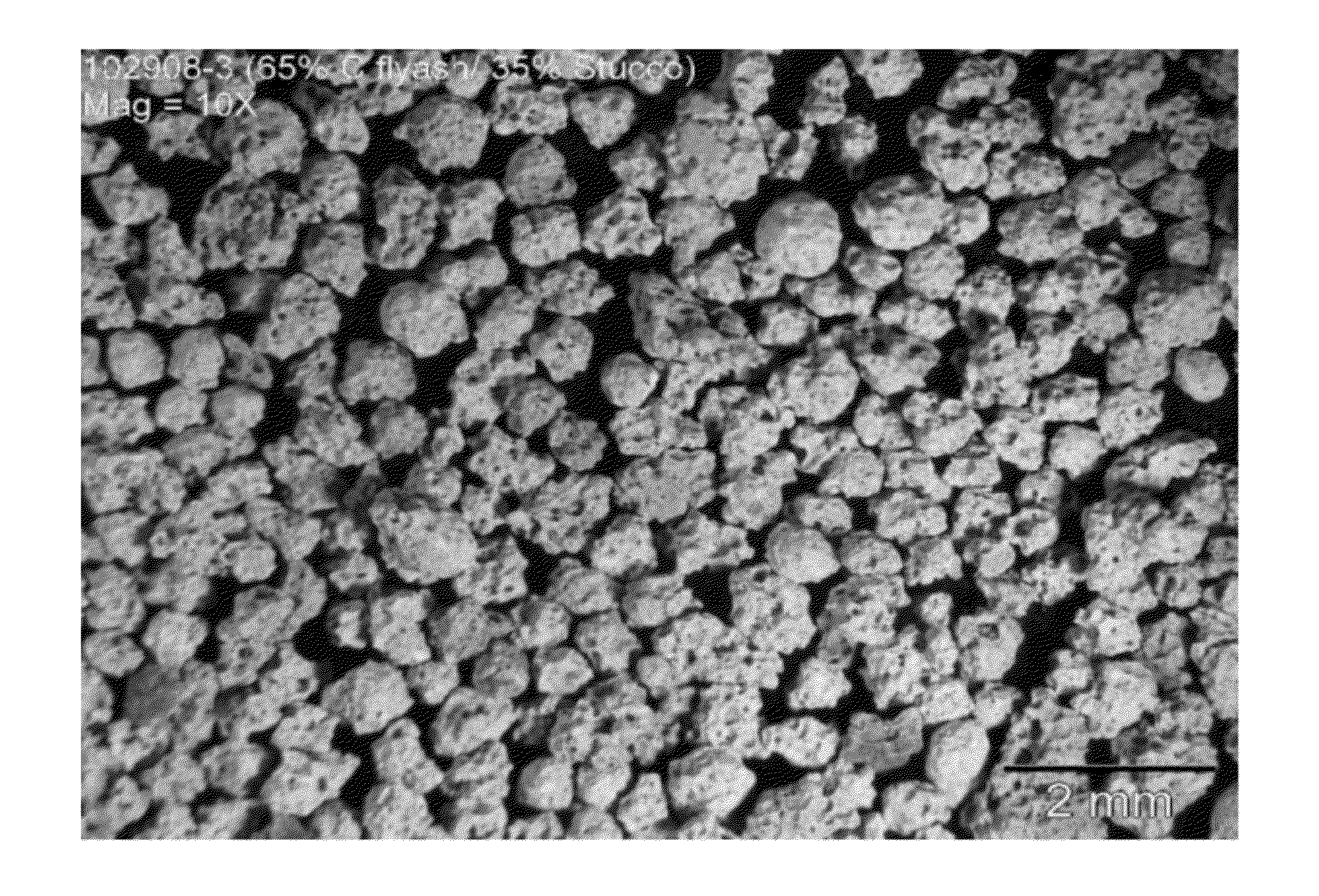

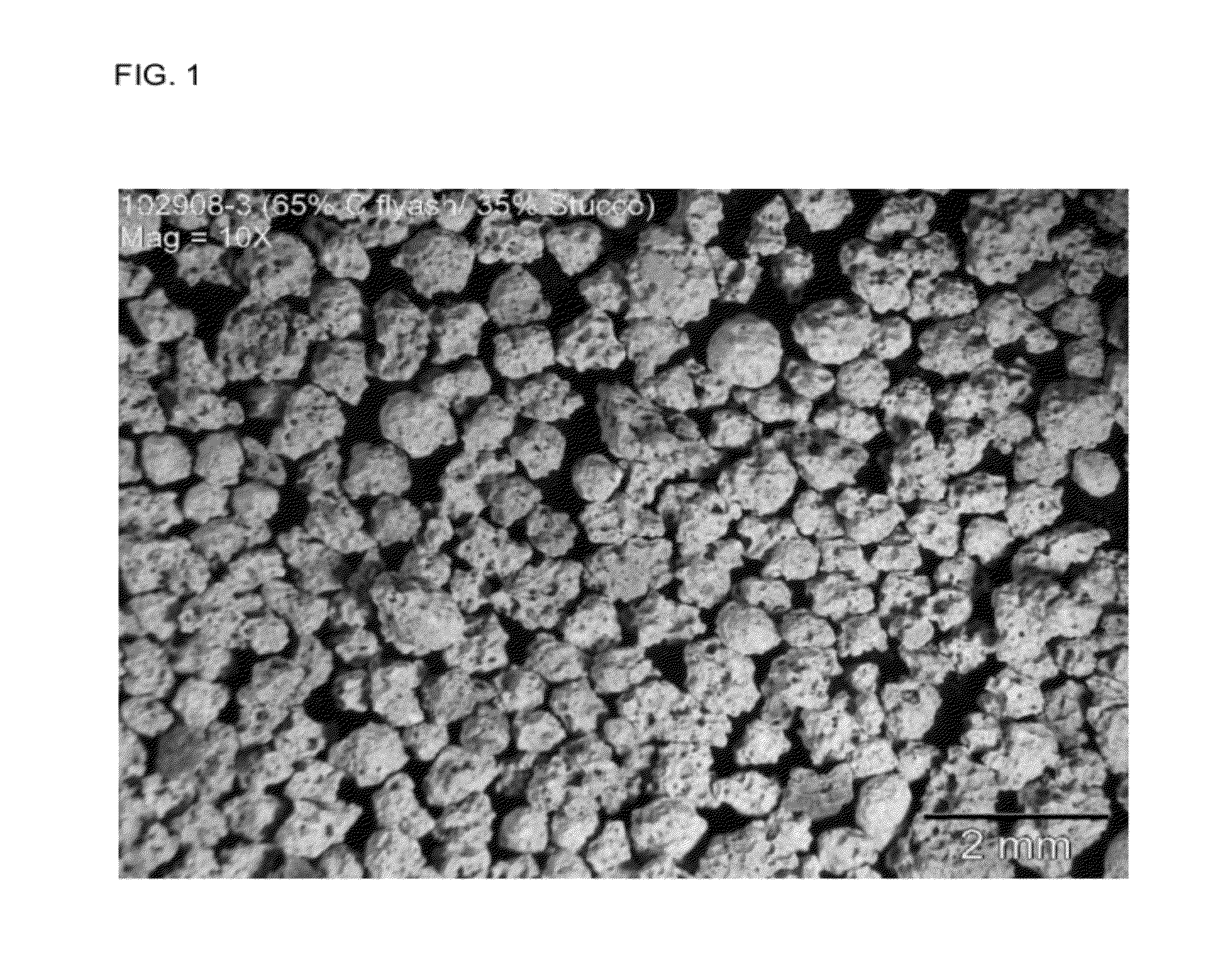

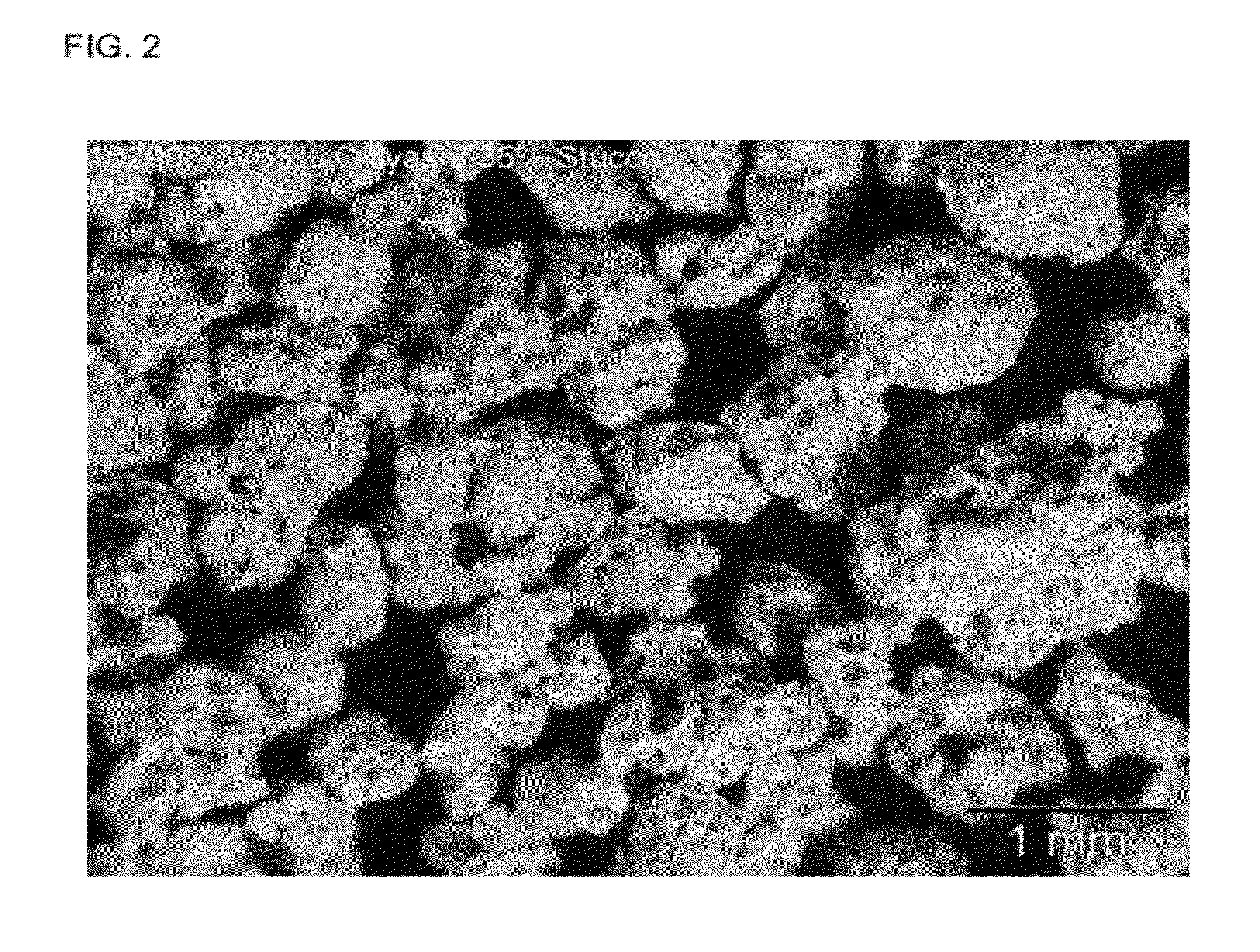

Method for In-Situ Manufacture of a Lightweight Fly Ash Based Aggregate

InactiveUS20120167804A1Short setting timeHigh compressive strengthSolid waste managementCeramicwarePolymer scienceAir entrainment

A method of making a rapid setting lightweight homogeneous foamed fly ash based cementitious aggregate composition with improved compressive strength for products such as panels is disclosed. The method mixes fly ash, alkali metal salt of citric acid, foaming agent for entraining air, optional foam stabilizing agent, a calcium sulfate such as stucco or gypsum, and water. Compositions are also disclosed which include mixtures of fly ash, particularly Class C fly ash alone or in mixtures with Class F fly ash, alkali metal salts of citric acid, foaming agents, a calcium sulfate such as calcium sulfate dihydrate or hemihydrate and an optional portland cement.

Owner:UNITED STATES GYPSUM CO

Silicate-based light-weight foam concrete and preparation method thereof

ActiveCN106966670AImproved carbonation resistanceImprove the stability of mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses silicate-based light-weight foam concrete and a preparation method thereof. The silicate-based light-weight foam concrete is prepared from silicate cement, an inorganic admixture, water, a foaming agent and an additive, wherein the mass ratio of the inorganic admixture to the silicate cement is 0.3 to 1.3; the water accounts for 35 to 65 percent by mass; and the foaming agent accounts for 3 to 10 percent by mass. The silicate-based light-weight foam concrete has the beneficial effects that the silicate cement is used as a cementing material; and compared with a sulfoaluminate-based material, the silicate-based light-weight foam concrete has the advantages that the carbonation resistance, the mechanical performance stability, the temperature tolerance and other properties are improved. By adjustment of the contents of all functional components (a thickening time control agent, a foam stabilizer, a water reducing agent, an anti-cracking component, an expanding agent and the like), the silicate-based light-weight foam concrete can conform to various preparation conditions of the silicate cement used as a base material.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

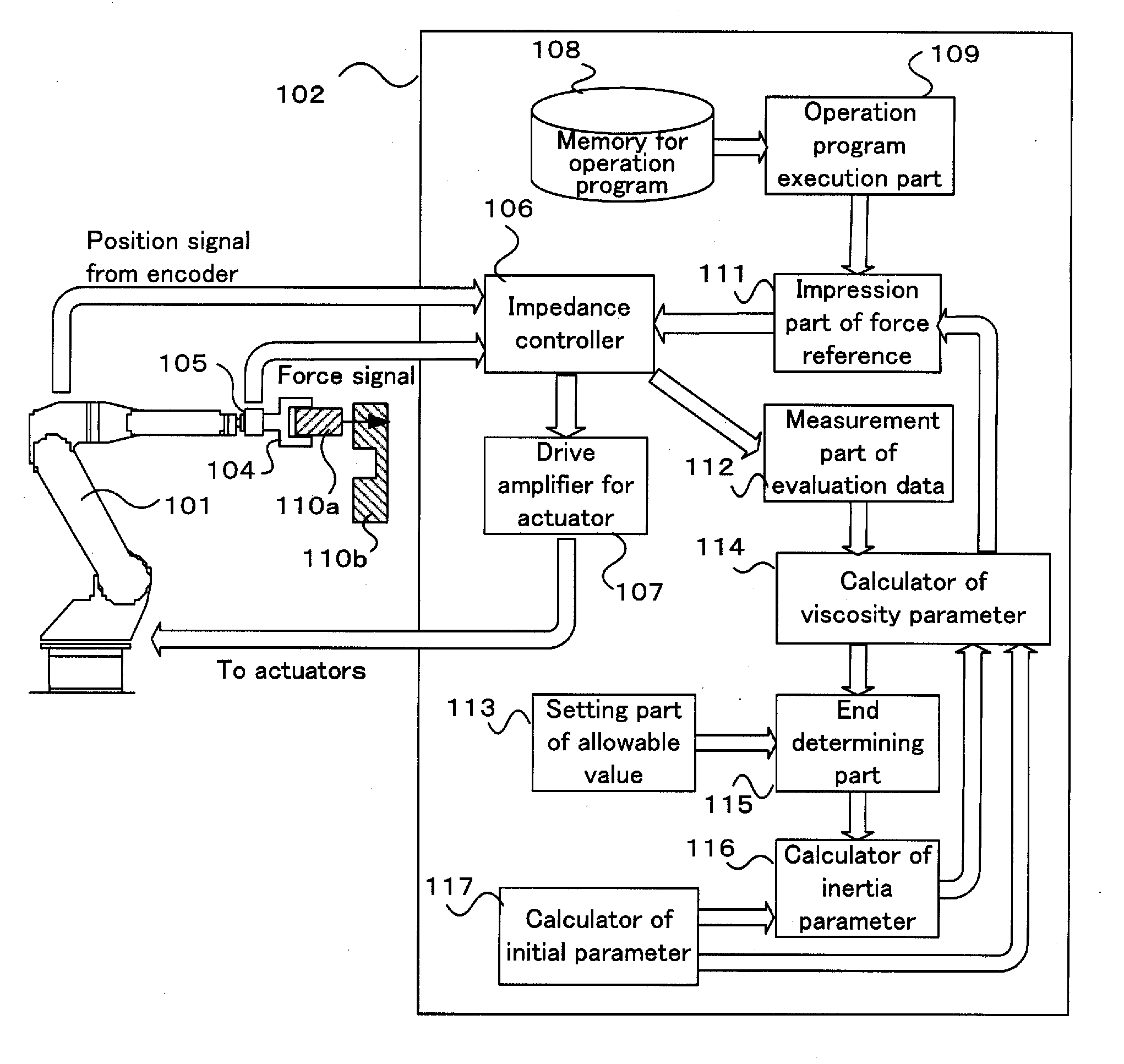

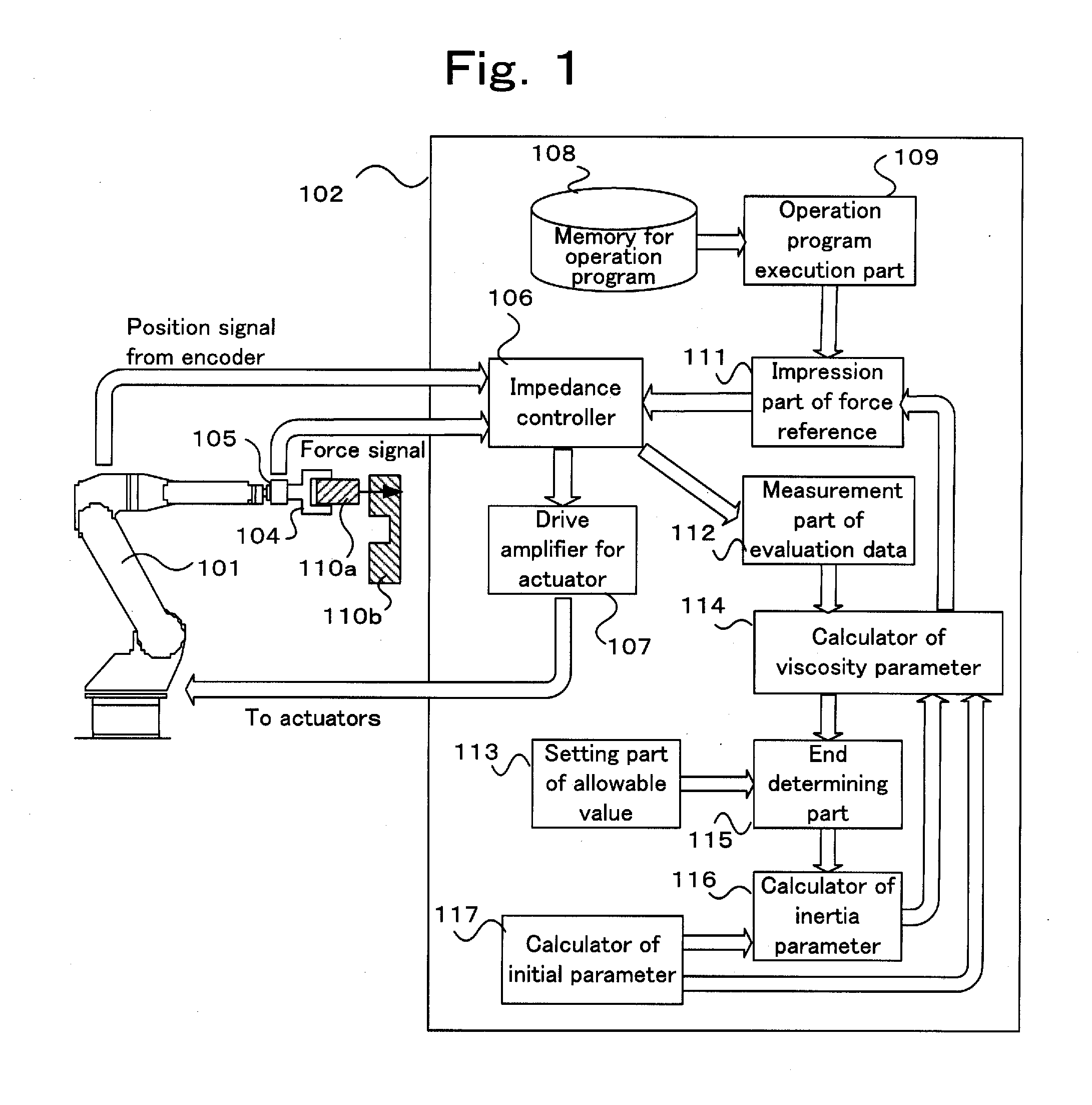

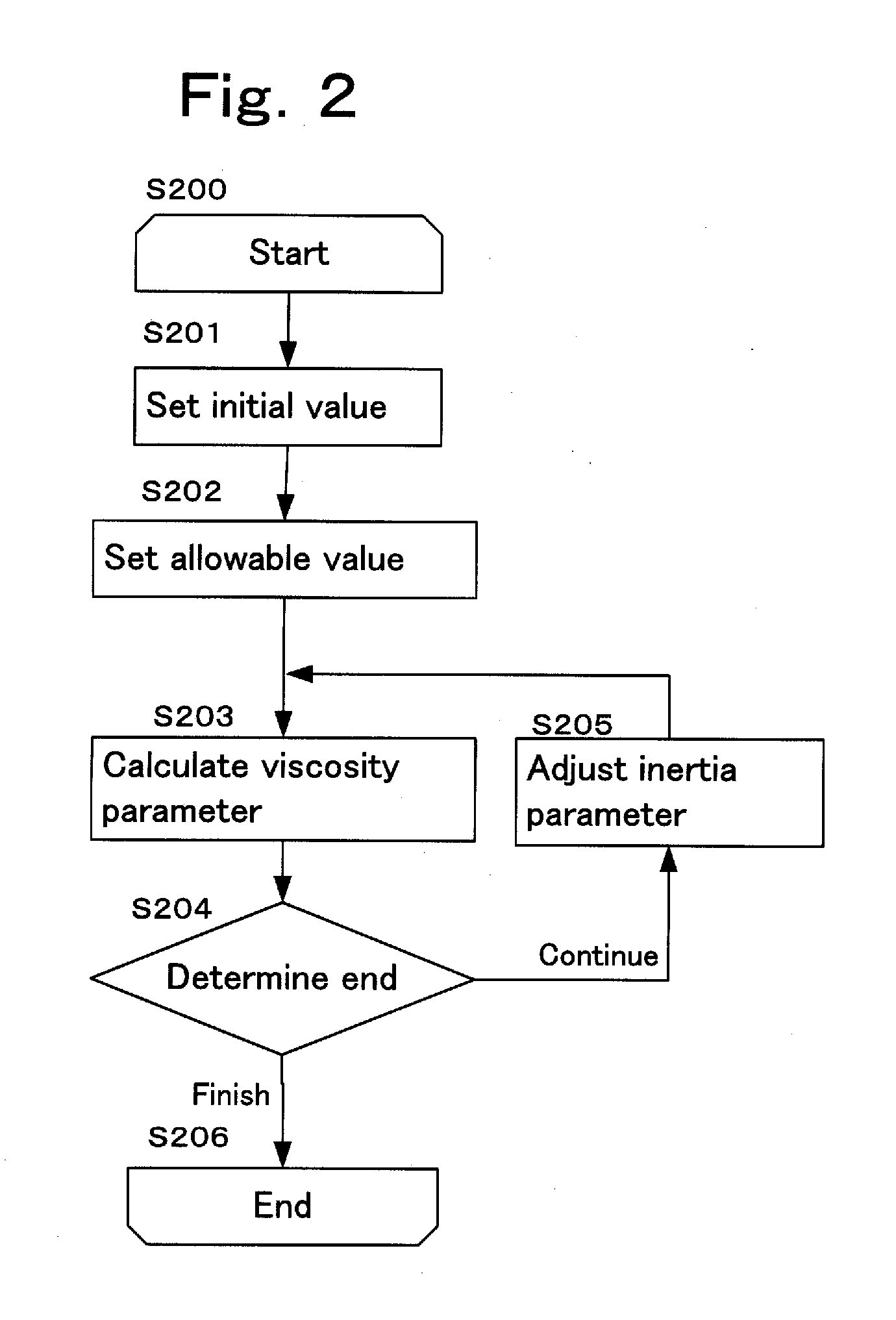

Apparatus and method for adjusting parameter of impedance control

InactiveUS20110093120A1Short setting timeProgramme controlProgramme-controlled manipulatorTime responseValue set

An apparatus has a parameter initial value calculator, a force reference impression part, an evaluation data measurement part, an allowable value setting part, a viscosity parameter calculator, an end determining part, and an inertia parameter adjusting part. The force reference impression part intermittently supplies a force reference to an impedance controller. The evaluation data measurement part measures setting time of time response, an overshoot amount, and the number of vibration times. The allowable value setting part sets allowable values of the overshoot amount and the setting time. The viscosity parameter calculator calculates a viscosity parameter with which the setting time becomes shortest. The end determining part determines the end or continuation of the process by comparing the adjustment values with the allowable values. The inertia parameter calculator adjusts the inertia parameter according to the adjustment values of the overshoot amount and the setting time.

Owner:YASKAWA DENKI KK

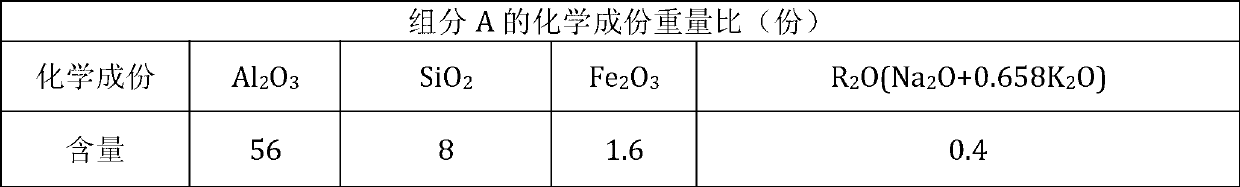

High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

ActiveCN102994058AAdjustable density and thickening timeGood liquidityDrilling compositionSilicate CementHeat regulation

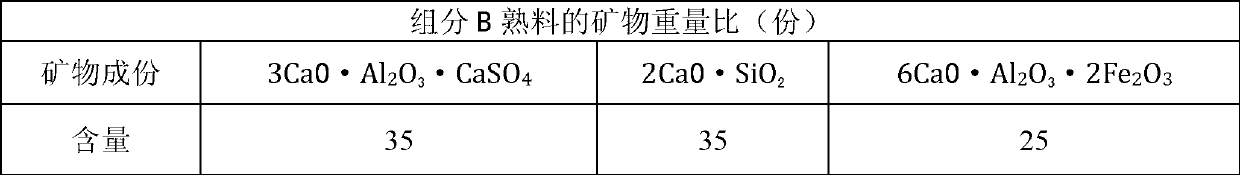

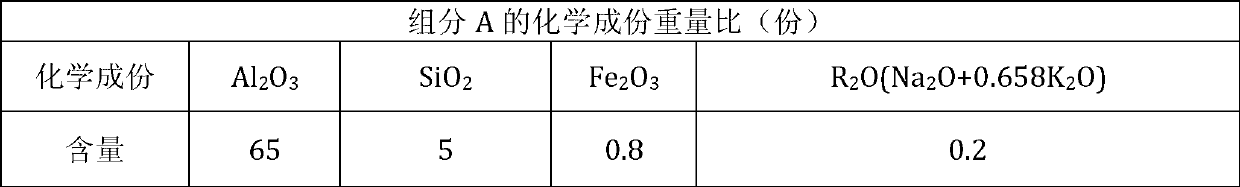

The invention relates to a high-temperature-resistant non-silicate cement paste system for cementing a thermal production well for thickened oil. The high-temperature-resistant non-silicate cement paste system is composed of the following components in parts by weight: 100 parts of high-temperature-resistant cement, 1.0-4.0 part(s) of fluid loss agent, 1.0-4.0 part(s) of dispersant, 0.5-3.0 part(s) of thickening time control agent, 60-120 parts of water and 15-80 parts of heat regulators, wherein the high-temperature-resistant cement is formed by mixing components A and B, the component A comprises 50-77 parts of Al2O3, 0.5-8.0 part(s) of SiO2, 0.5-2.5 part(s) of Fe2O3 and 0-0.4 part of R2O(Na2O+0.658K2O), and the component B comprises 33-63 parts of 3CaO.Al2O3.CaSO4, 14-37 parts of 2CaO.SiO2 and 15-35 parts of 6CaO.Al2O3.2Fe2O3. The high-temperature-resistant non-silicate cement paste system disclosed by the invention has great significance to enhancement of safe and efficient development of the thickened oil and has broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

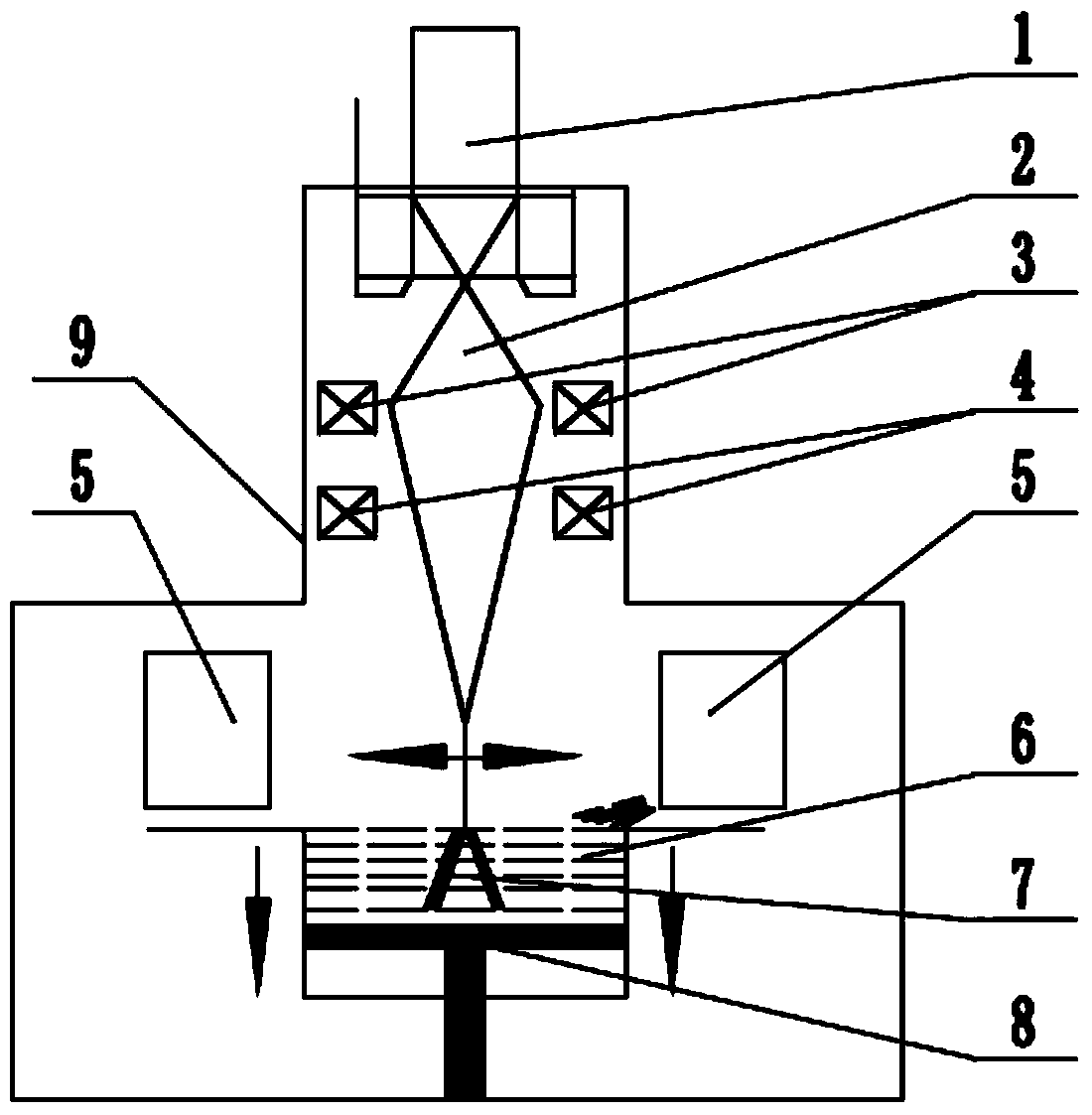

Preparation method for Nb-Si base ultra-temperature alloy turbine vane

InactiveCN103949646AFast preparationFast EBM methodTurbinesIncreasing energy efficiencyComputer Aided DesignTurbine blade

The invention belongs to the technical field of the turbine blade manufacturing, and particularly relates to a method for preparing an Nb-Si base ultra-temperature alloy turbine vane by the electron beam melting (EBM). Electron beam selection area high-speed forming equipment is utilized, and the preparation of the complex Nb-Si alloy turbine vane is directly finished in one step by a CAD (computer-aided design) model by setting a reasonable technological parameter; the obtained turbine vane has the advantages of high consistency, good forming precision and few defects; the alloy vane mainly consists of Nbss sosoloid and Nb5Si3 phase, so that the alloy vane has a small phase size and even distribution, and the combination property of the turbine vane can be improved. According to the method, no dies are required in the turbine vane forming process, alloy pollution and oxidation can be reduced, inclusion content is lowered, the alloy material use ratio is high, and the combination property of the vane can be improved.

Owner:BEIHANG UNIV

Multifunctional quick repair material for cement concrete pavements and preparation method thereof

The invention relates to pavement repair, particularly a multifunctional quick repair material for cement concrete pavements, which is prepared by mixing the following raw materials in percentage by weight: 20-30% of magnesium oxide, 14-26% of ammonium monoacid phosphate, 9-14% of boric acid, 5-20% of aluminate cement, 2-10% of fly ash, 2-10% of rubber powder, 0.5-1.5% of polypropylene fiber, 0.5-1.5% of redispersible latex powder, silica sol and water; the silica sol accounts for 20-60% of the water. The preparation method of the multifunctional quick repair material for cement concrete pavements is implemented by proportionally mixing the raw materials. The material is convenient for construction, has enduring effect after curing, and has quick and enduring repair capacities for most damage forms of cement concrete pavements.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Special cement-base patching material and cement concrete pavement quick repairing method

ActiveCN105294049AShort setting timeImprove early strengthRoads maintainenceMagnesium orthophosphateEmulsion

The invention discloses a special cement-base patching material and a corresponding cement concrete pavement quick repairing method built according to the special cement-base patching material. The patching material is prepared from the following ingredients in specific weight parts: magnesium phosphate cement, sulphate aluminum cement, early strength agents, water reducing agents, redispersible emulsion powder, pulverized fuel ash, silicon carbide, fine sand powder, detritus, carbon fiber and water-solubility polyurethane. The special cement-base patching material has the advantages that the mechanical performance, the anti-abrasion performance, the waterproof anti-permeability performance, the durability performance and the like meet application requirements; required construction equipment is simple; the construction process is simple and convenient; the influence of weather on construction is little; the construction can be performed at normal temperature and in rainy and snowy weather; the maintenance time is short; the traffics can be fast opened; the influence on the traffics is little; good social benefits and social benefits are realized; the engineering application prospects are wide.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

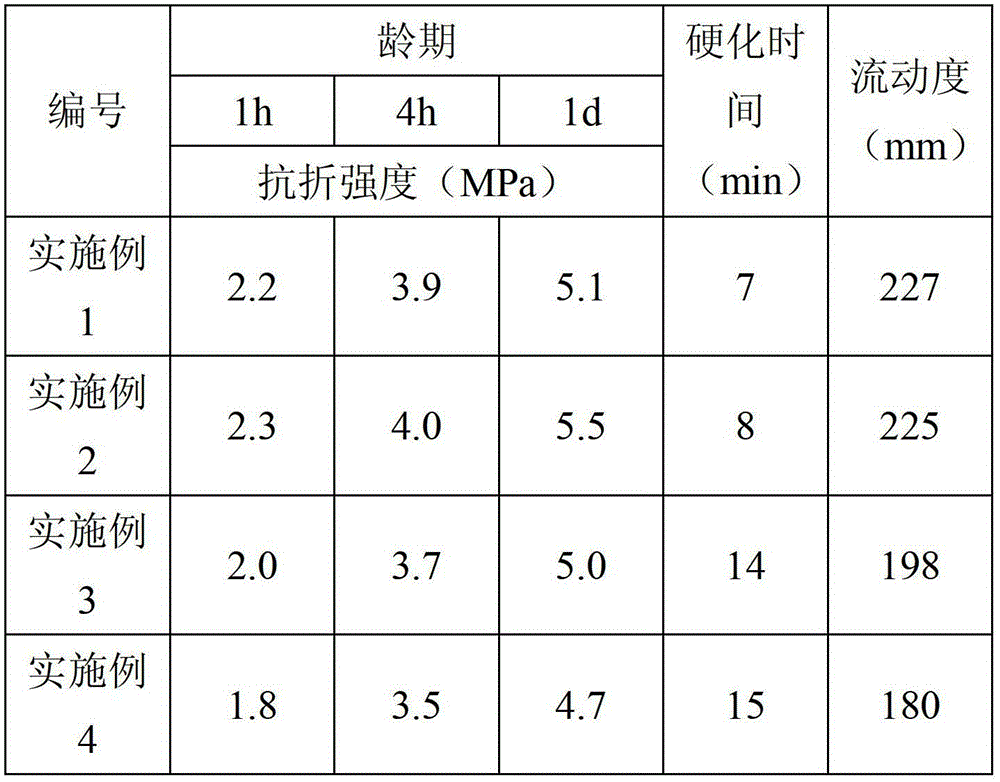

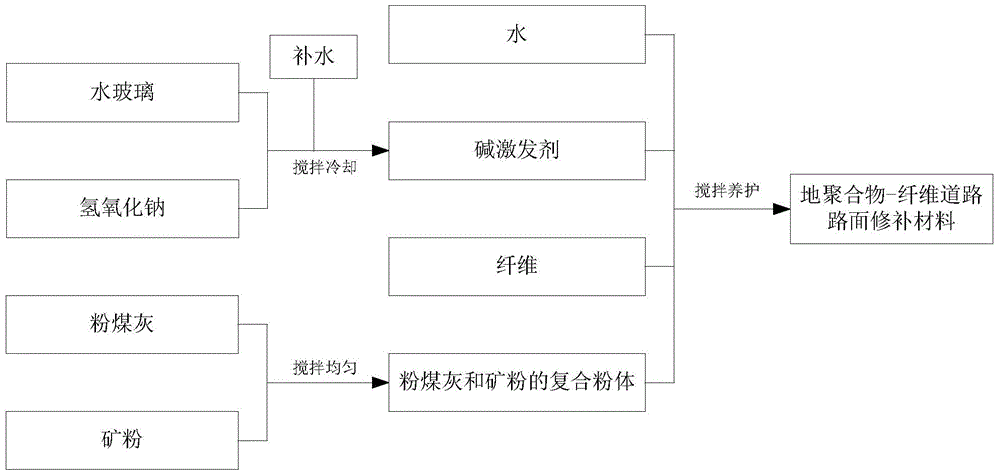

Geopolymer-fiber road pavement mending material and preparation method thereof

The invention discloses a geopolymer-fiber road pavement mending material and a preparation method thereof. The mending material comprises the following components according to parts by weight: 38-52 parts of pulverized coal ash, 12-27 parts of mineral powder, 25-34 parts of an alkali activator, 0.27-0.55 part of fiber, and 1.6-6 parts of water. The alkali activator is made by mixing water glass and analytical pure according to a modulus of 1.2-1.8. The preparation method comprises the steps: weighing the pulverized coal ash and the mineral powder proportionally, and mixing well preliminarily to obtain pulverized coal ash and mineral powder composite powder; weighing the water glass and analytical pure according to the ratio, adding the analytical pure quickly into water, and stirring and cooling to obtain alkali activator solution of required modulus; weighing water and fiber according to the ratio, mixing well the water and the alkali activator solution, adding into the fiber, preliminarily stirring, adding the composite powder, and stirring well to obtain the mending material. The geopolymer-fiber road pavement mending material is good in mobility, high in compressive strength and breaking strength tensile strength, has high hardening speed and early strength, is high in toughness and is applicable to road emergency mending and reinforcing.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

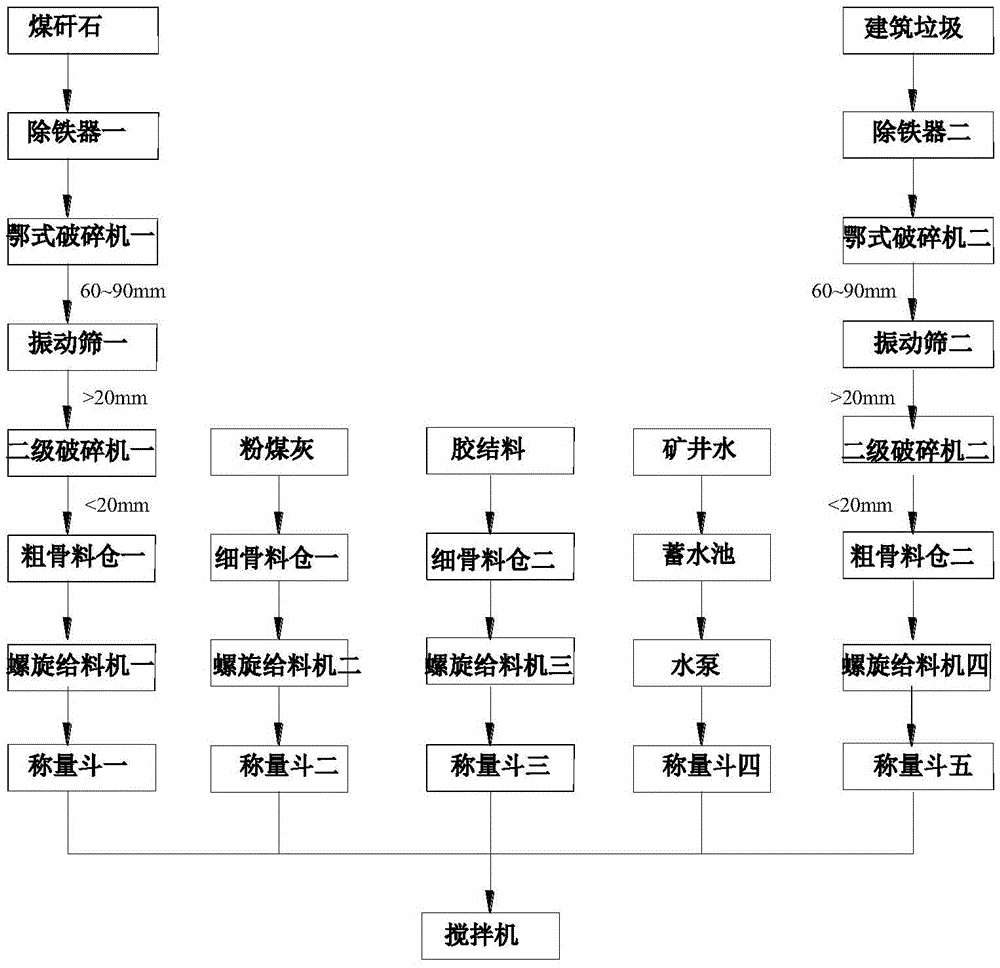

Plasterboard Jointing System

InactiveUS20120031555A1Reduce installation delayLow shrinkageRoof covering using tiles/slatesCovering/liningsEngineeringGypsum

The present invention provides a system of jointing and finishing plasterboard sheets. The system comprises adjacently abutted first and second plasterboard sheets and a connective material. The connective material is applied to a region at or near the side edge portions of the first and second plasterboard sheets and which securely joins the side edge portion of the first plasterboard sheet to the side edge portion of the second plasterboard sheet. There is also provided a joint filling compound and a finishing compound, which are optionally also applied to the region of the first and second plasterboard sheets.

Owner:CSR BUILDING PRODUCTS LTD

Rapid repair material based on building broken stones and preparation method thereof

The invention relates to building stone repairing. A rapid repair material based on building broken stones comprises a gelation mixture which quickly solidifies with water, wherein the gelation mixture comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. A preparation method of the materials comprises the following steps of: 1, preparing the magnesium phosphate cement; 2, mixing the magnesium phosphate cement, the sand and the silica sol so as to form the gelation mixture which comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. The gelation mixture can be quickly solidified with the water to repair the stones. In addition, the gelation mixture is gelatineous before being solidified and facilitates construction; after the solidification, the small solidification shrinkage rate and a durable effect are obtained; and the repair material has high hardness and good water resistance after the solidification.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

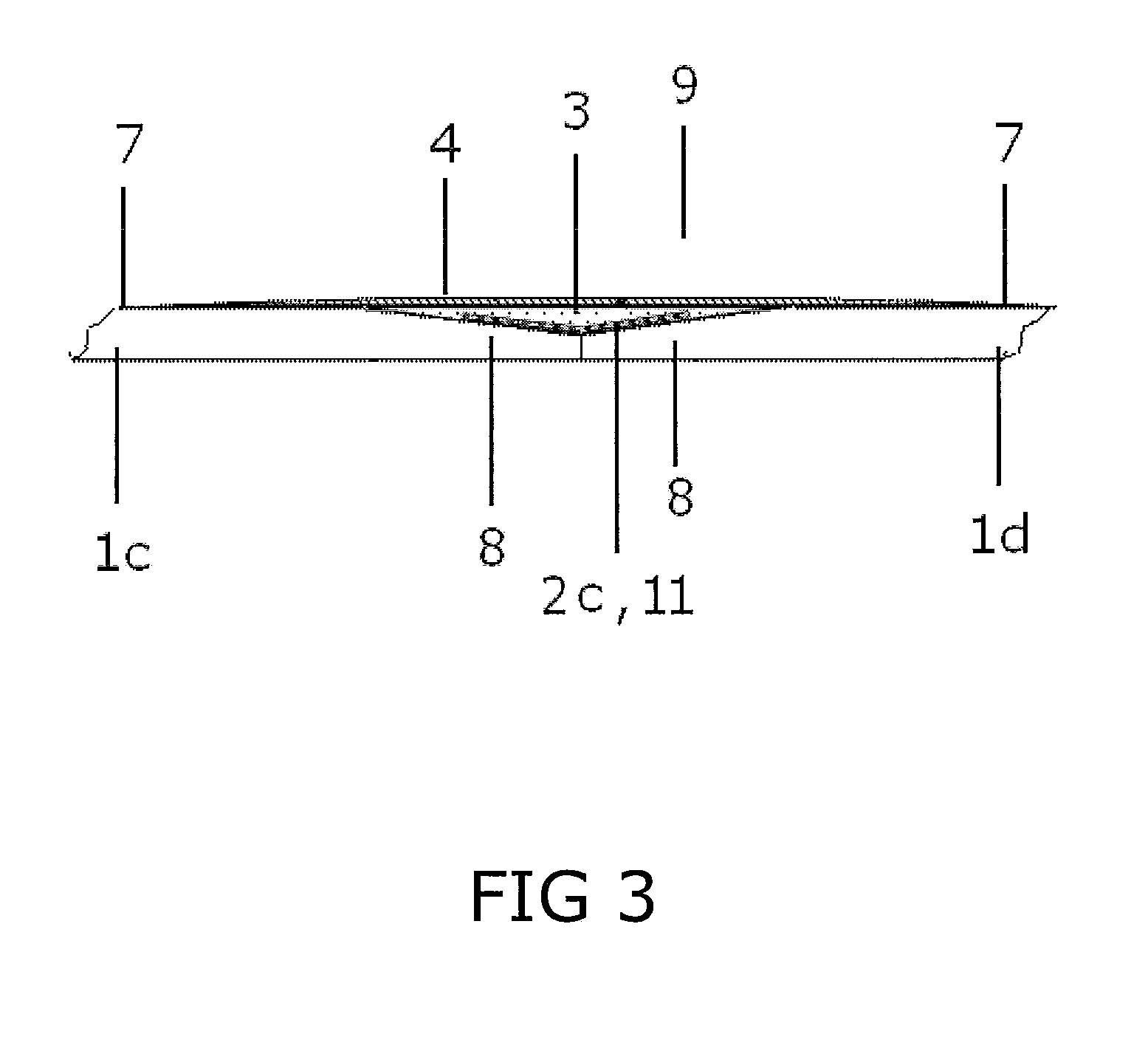

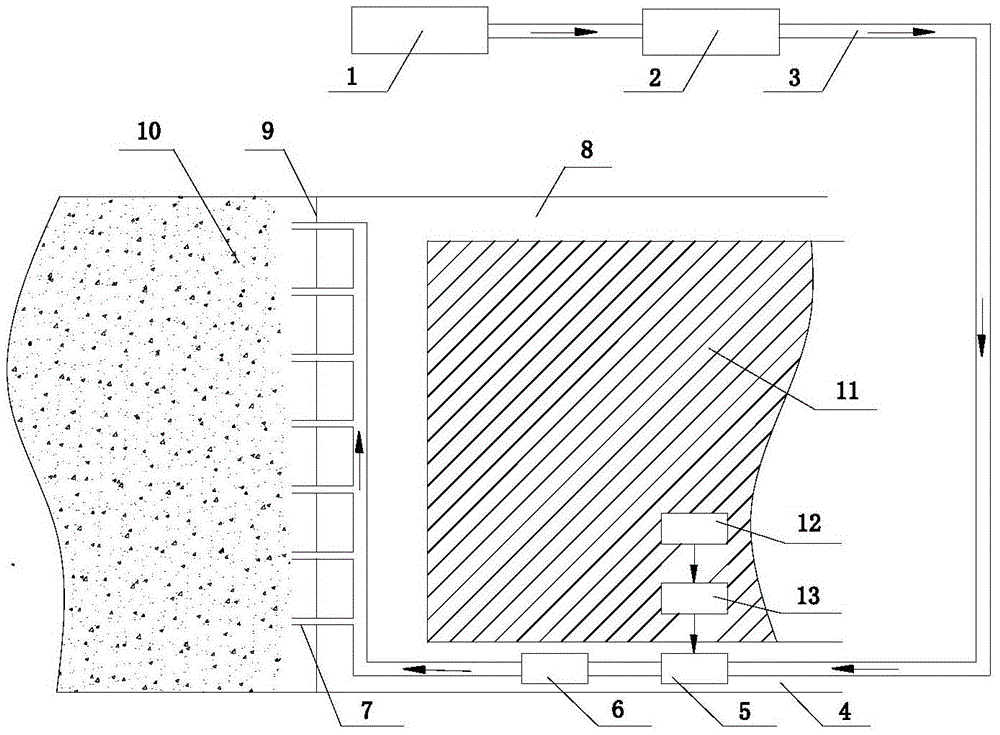

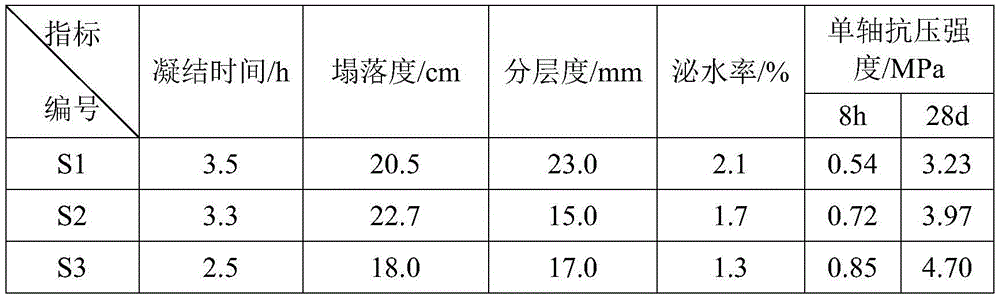

Coal mine paste-like filling material using construction waste, and preparation and filling method thereof

InactiveCN105481314AHigh strengthImprove stabilitySolid waste managementMaterial fill-upFilling materialsWater reducer

The invention provides a coal mine paste-like filling material using construction waste. The material comprises the following raw materials: a coarse aggregate containing 450-500Kg of construction waste and 400-450Kg of gangue; a fine aggregate containing 350-400Kg of fly ash and 200-250Kg of a binder; an admixture containing 6.0-12.5Kg of an accelerator and 2.0-7.5Kg of a water reducer; and 550-630Kg of mine water. According to the invention, construction waste, gangue and other wastes are used to prepare the paste-like filling material with good pumpability, low bleeding rate and degree of stratification, short setting time, high strength and stability, and low cost. The invention also provides a preparation and filling method of the coal mine paste-like filling material using construction waste.

Owner:ANHUI UNIV OF SCI & TECH

Multiphase nano ceramic particle reinforced Al-based composite material and laser 3D printing forming method thereof

The invention discloses a multiphase nano ceramic particle reinforced Al-based composite material and a laser 3D printing forming method thereof. AlSiMg powder with a purity of 99.9% and above and a particle size of 15-30 mu m is selected as a composite material base of the Al-based composite material; a powder composition with a purity of 99.9% or above and a particle size of 10-100 mu m is selected as a reinforced phase of the Al-based composite material, and the powder composition comprises Al2O3, SiO2, TiN and TiC, ZnO and Y2O3; after the two kinds of powder are mixed, the obtained mixture is sequentially subjected to high-temperature calcining synthesis, ball-milling and 3D printing forming, so that a required 3D block can be processed. The Al-based composite material obtained according to the invention has uniformly refined microscopic structures and excellent mechanical properties, and in comparison with the performance levels of traditional casting or powder metallurgy products of corresponding materials, the comprehensive mechanical properties of the Al-based composite material are increased by 25% or above.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

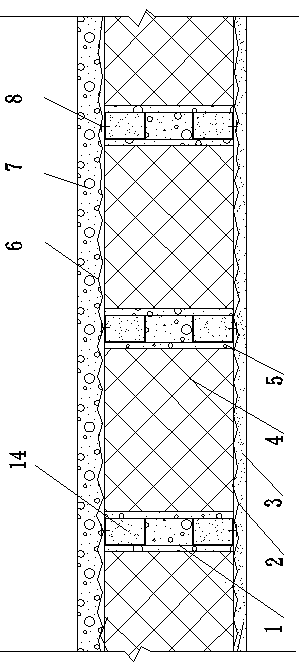

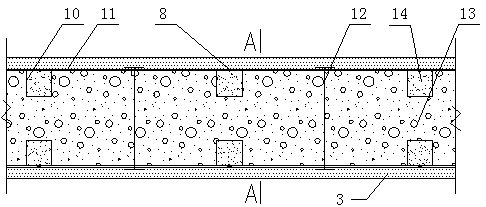

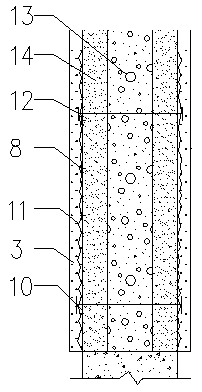

Construction method of lattice light-gauge steel house

InactiveCN103104094AShort setting timeShorten the construction periodWallsFloorsMetal meshThermal insulation

The invention discloses a construction method of a lattice light-gauge steel house. The construction method of the lattice light-gauge steel house comprises the following steps of foundation treatment, wall body construction, and storied building panel construction. The construction method of the lattice light-gauge steel house is ingenious in design and simple in process, the light-gauge steel house has better structure strength and earthquake resistant property, and construction material cost is reduced. The storied building panels and the wall body are formed by removal-free templates and plaster at a time, and plaster processing is not needed. Metal meshes and cement mortar are combined closely, the quality common faults of hollow bulge and the like caused by traditional secondary plastering are overcome, and additional heat-preservation and thermal-insulation materials and secondary construction procedures are not needed.

Owner:成都绿建科技有限公司

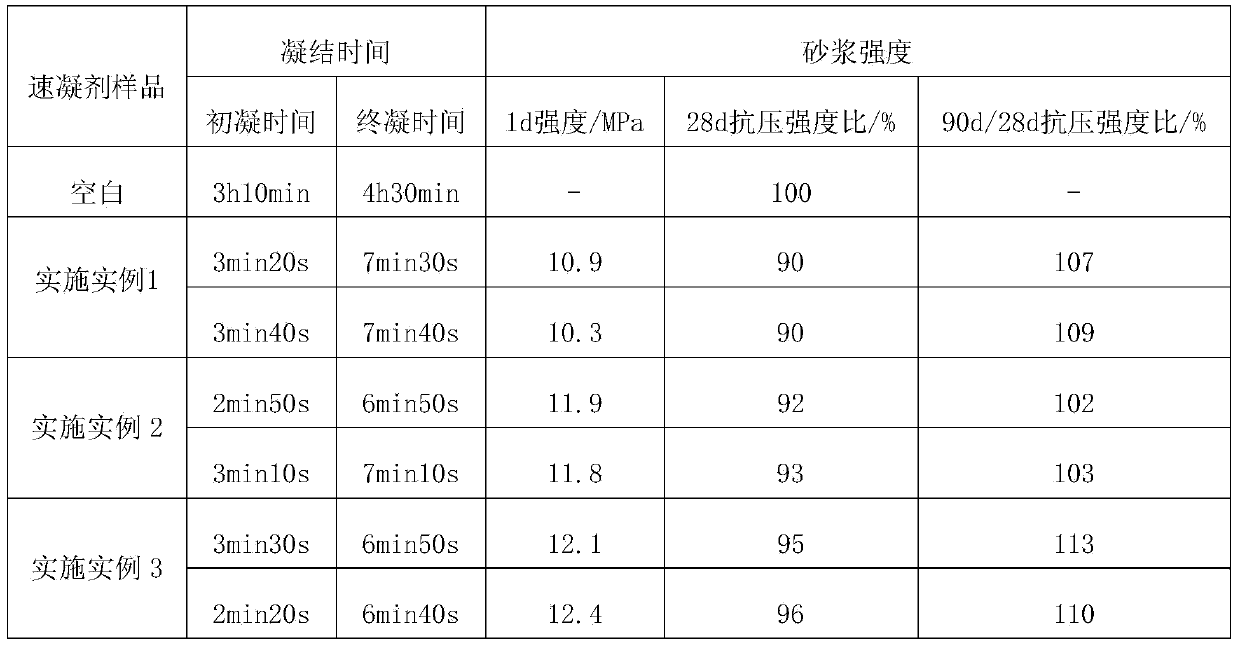

Low-resilience and low-alkaline liquid accelerator for sprayed concrete and preparation method thereof

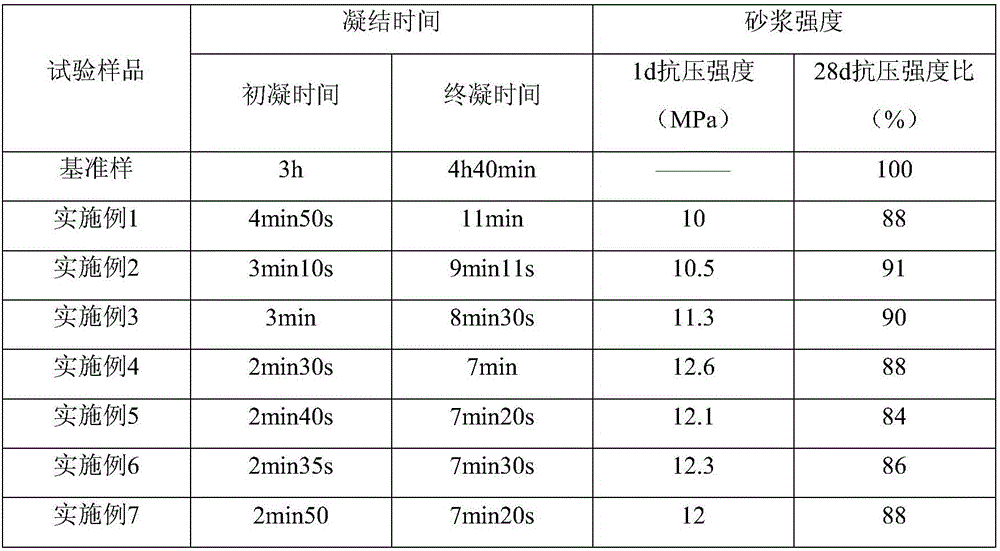

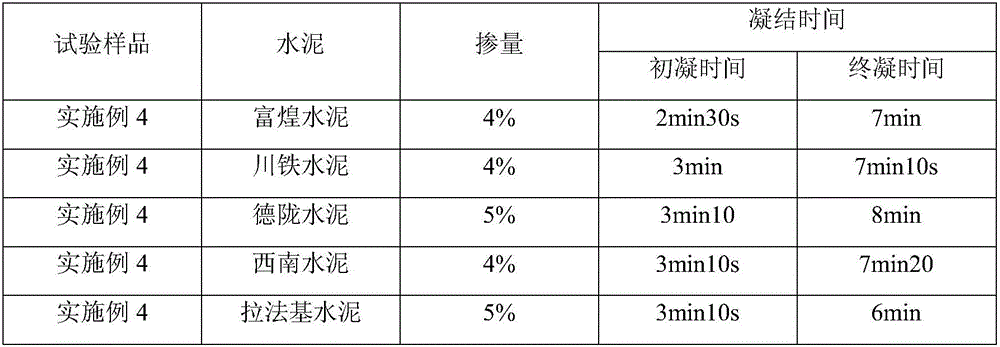

The invention relates to a low-resilience and low-alkaline liquid accelerator for sprayed concrete and a preparation method thereof. The accelerator is prepared from the following raw materials: an aluminate mother liquid, a modifier, hydramine and a stabilizer, wherein the mass ratio of the modifier and the aluminate mother liquid is 1: (1-5), the dosage of hydramine is 0.5-2.5% of the sum of the modifier and the aluminate mother liquid in mass, the dosage of the stabilizer is 0.3-2% of the sum of the modifier and the aluminate mother liquid in mass; the stabilizer is one of vinylon glue, EDTA (Ethylene Diamine Tetraacetic Acid) and xanthan gum. The preparation method comprises the following steps: preparing the aluminate mother liquid; preparing the modifier; and preparing the low-alkaline liquid accelerator. The adulterate amount of the accelerator provided by the invention is 3-6% mass of cement, the initial setting time is 3 minutes and the final setting time is 8 minutes, and the requirements of JC477-2005 accelerator for sprayed concrete are satisfied. The accelerator is uniform and stable and strong in adaptability with cement, can be used for effectively reducing resilience and dust amount in construction of prayed concrete, and is short in setting time and less in loss of long-term strength.

Owner:刘翠芬

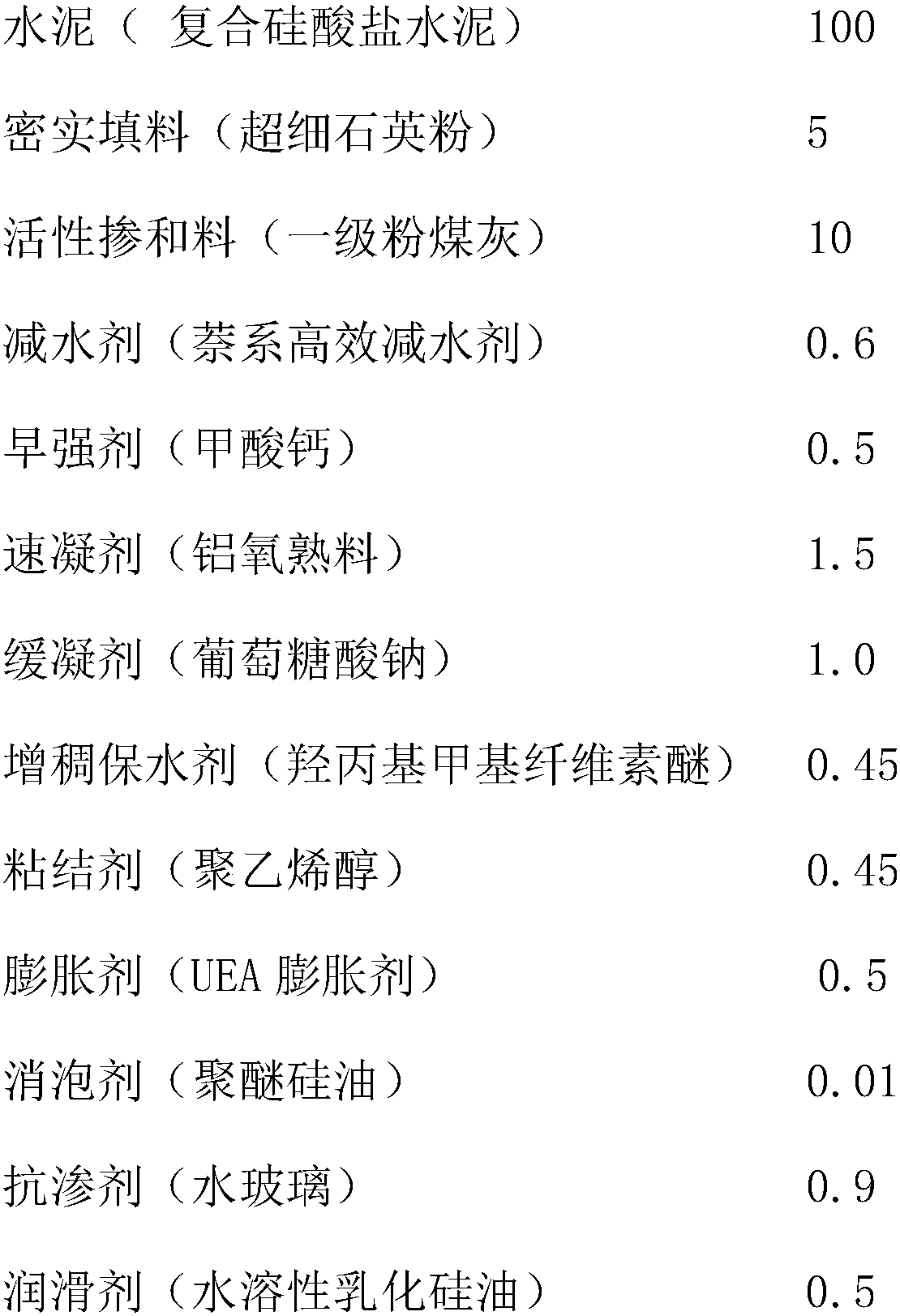

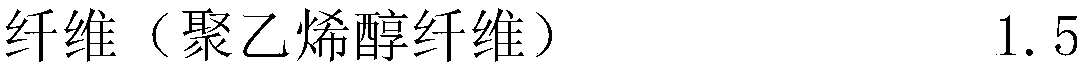

3D printing based cement based inorganic gelling material and preparation method thereof

InactiveCN108484041AWide variety of sourcesLow costAdditive manufacturing apparatusFiberFoaming agent

The invention provides a 3D printing based cement based inorganic gelling material and a preparation method thereof, and relates to a 3D printing material. In order to solve the problems of poorer printing precision and high-precision building component printing incapability of the existing gelling material for printing, the invention provides the 3D printing based cement based inorganic gelling material with the following technical scheme that the 3D printing based cement based inorganic gelling material is prepared from the following ingredients of cement, compaction filling materials, active mixing materials, water reducing agents, earth strength agents, accelerators, retarders, thickening water preservation agents, bonding agents, expansion agents, anti-foaming agents, anti-seepage agents, lubricating agents and fiber. The 3D printing based cement based inorganic gelling material has the beneficial effects that the preparation is simple and convenient; good continuous extrusion performance is realized; good overlapped layer building performance is realized; excellent waterproof, anti-seepage function and good anti-cracking performance are realized.

Owner:深圳市明远建筑科技有限公司

Phosphogypsum based high flow state grouting material

InactiveCN104628349ARealize resource utilizationImprove water resistanceSolid waste managementMass ratioResource utilization

The invention discloses a phosphogypsum based high flow state grouting material. The phosphogypsum based high flow state grouting material is composed of the following components in parts by weight: 50-70 parts of phosphorus based semi-hydrated gypsum, 20-40 parts of coal ash, 8-12 parts of compound activator, 6-10 parts of gypsum whisker, 0.05-0.15 part of retarder, 0.2-0.6 part of water reducing agent, 0.04-0.08 part of water retaining agent and 0.02-0.06 part of water repellent. Wherein, the phosphorus based semi-hydrated gypsum is phosphorus based high-strength gypsum or a mixture of the phosphorus based high-strength gypsum and phosphorus based building gypsum with a mass ratio of 4:1 to 5:1. The grouting material is prepared from the phosphogypsum in the invention to achieve the resource utilization of the phosphogypsum, and is green and environmentally friendly. The coal ash is used as a mineral admixture, and acetylene sludge and cement are used as an alkali activator to reduce the cost and well improve the water resistance and durability of the grouting material, and the gypsum whisker is used for modifying the grouting material to improve the breaking strength of the grouting material.

Owner:WUHAN UNIV OF TECH

Multi-source solid waste-based grouting cementing material as well as preparation method and application thereof

The invention relates to a multi-source solid waste-based grouting cementing material as well as a preparation method and application thereof. The grouting cementing material is prepared from the following raw materials in parts by weight: 60 to 80 parts of red mud, 60 to 80 parts of other solid wastes, 40 to 60 parts of an excitant and 10 to 20 parts of an additive, wherein the other solid wastescomprise the following raw materials in parts by weight: 15-25 parts of furnace slag, 15-25 parts of mineral slag, 10-20 parts of steel slag and 8-20 parts of desulfurized gypsum. The preparation method is simple; the prepared grouting cementing material is short in setting time, high in early strength, high in stone body mechanical strength, excellent in erosion resistance and suitable for coastal karst broken rock mass reinforcement and treatment engineering, engineering safety construction in coastal areas can be guaranteed, the solid waste stockpiling pressure is relieved, the problem ofenvironmental pollution caused by red mud is solved, high added value is achieved, and comprehensive utilization of the red mud is promoted.

Owner:SHANDONG UNIV

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Soil curing agent

ActiveCN107973571AImprove setting timeGood comprehensive effect of compressive strengthFirming agentSoil texture

The invention discloses a soil curing agent, which belongs to the technical field of building materials. The soil curing agent comprises the following raw materials: common silicate cement, solid sulphur ash, an excitant, an early strength agent, silica fume, quick lime, polyacrylamide, water, polyvinyl butyral, calcium lignosulphonate, 3-amino propyl trialkoxysilane and polyvinylpyrrolidone. Theabove soil curing agent is prepared through the steps of carrying out material modification, mixing, vacuum preparation and the like. The soil curing agent has a simple preparation technology. When the soil curing agent is adopted, the solidification time of a roadbed can be obviously shortened, the compressive strength of the roadbed is improved, time limit for construction are shortened, and thesoil curing agent can be applied to the soil solidification of different soil textures.

Owner:江苏路业建设有限公司

Medical adhesive or hemostatic

InactiveCN102247617ALow priceSimple preparation processSurgical adhesivesAbsorbent padsChemistryHemostatics

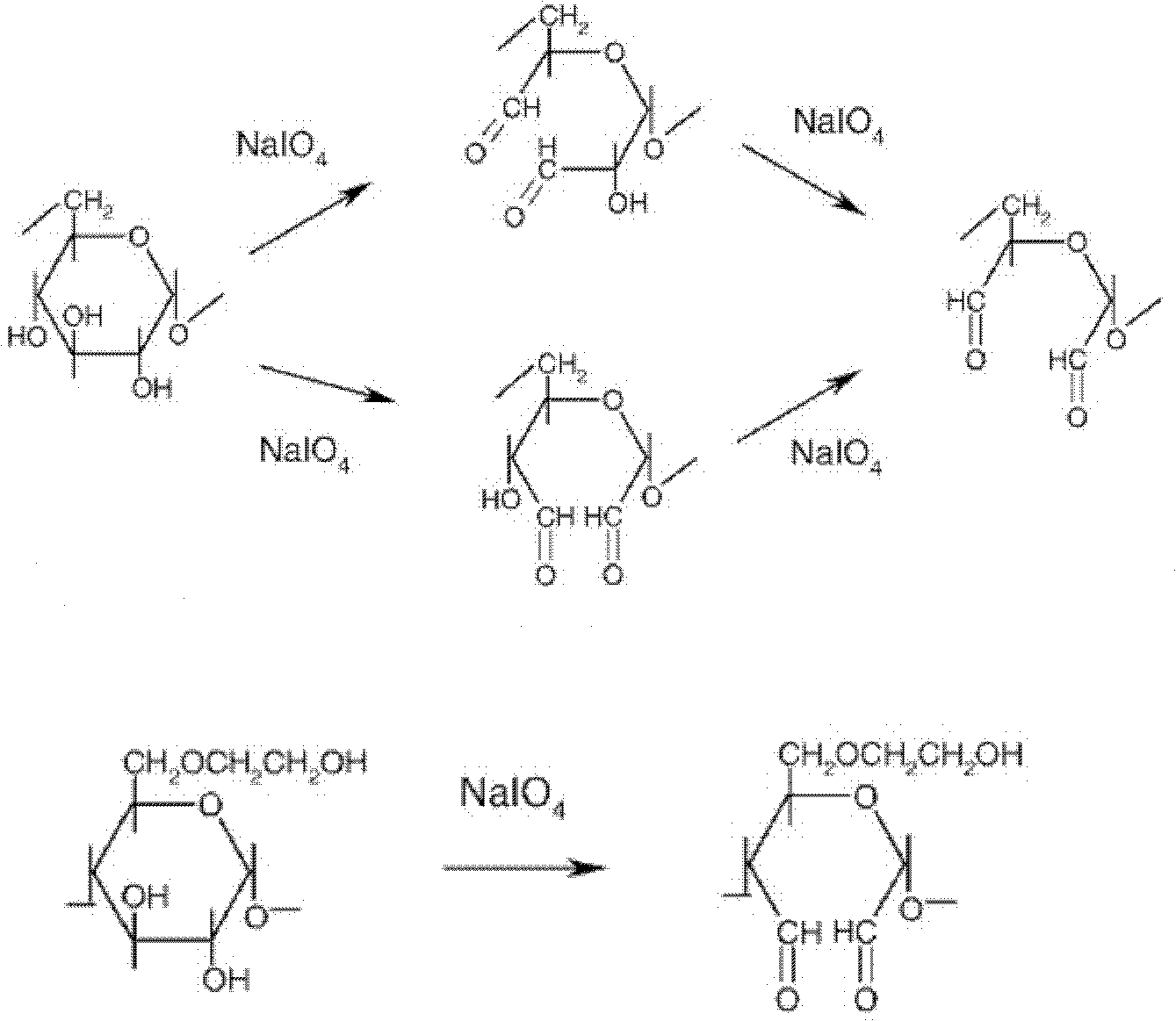

The invention relates to a medical adhesive or hemostatic, which comprises aminated gelatin aqueous solution and aldehydic polysaccharide aqueous solution, wherein a method for preparing the aminated gelatin aqueous solution comprises the following steps of: adding gelatin, ethylenediamine and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide in a mass ratio of (2-20):(1-10):(1-5) into water for reaction, dialyzing, freezing and drying to obtain the aminated gelatin aqueous solution; and a method for preparing the aldehydic polysaccharide aqueous solution comprises the following steps of: mixing polysaccharide or starch aqueous solution and NaIO4 aqueous solution in a volume ratio of (1-2):(1-2), reacting at room temperature, dialyzing, freezing and drying to obtain the aldehydic polysaccharide aqueous solution. In the medical adhesive or hemostatic, the coagulation time is shorter than that of fibrin glue, and the bonding strength is higher than that of the fibrin glue; the fibrin glue bonds incisions on backs of rats with the length of 2cm successfully, and is used for the hemostasis of incisions of livers of the rats; and a preparation process for aminated gelatin and aldehydic polysaccharide is simple and low in cost.

Owner:莫秀梅

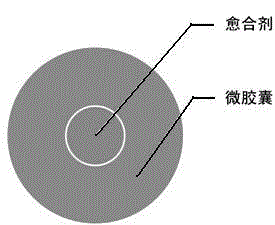

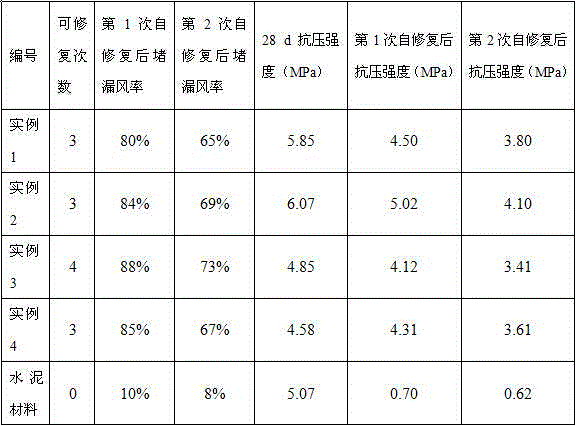

Bionic self-healing material for air leakage stoppage in coal mine

The invention relates to a bionic self-healing material for air leakage stoppage in a coal mine. The bionic self-healing material comprises a fast-setting expanding material, microcapsules containing a healing agent, and a catalyst, wherein the fast-setting expanding material comprises several of a cement clinker, coal ash, steel slag, mountain flour, salty mud, carbide slag, an expanding agent, a water reducing agent and sand, and each microcapsule is composed of a wall material (polymer resin) and a core material (the healing agent); the wall material of each microcapsule is at least one of urea resin, melamino-formaldehyde resin, melamine urea-formaldehyde resin and polyurethane, the healing agent is at least one of olefins containing double bonds, such as polyurethane prepolymer, isocyanate, phenolic resin, epoxy resin, styrene, acrylics and dicyclopentadiene (DCPD), and the catalyst is at least one of Grubbs catalyst, dibutyltin dilaurate and amines. The bionic self-healing material for air leakage stoppage in the coal mine disclosed by the invention has the advantages of being automatic in detection and healing, moderate in expansion, fast to set, good in conveying performance, strong in setting performance, green and environmentally friendly, and low in price.

Owner:胡相明

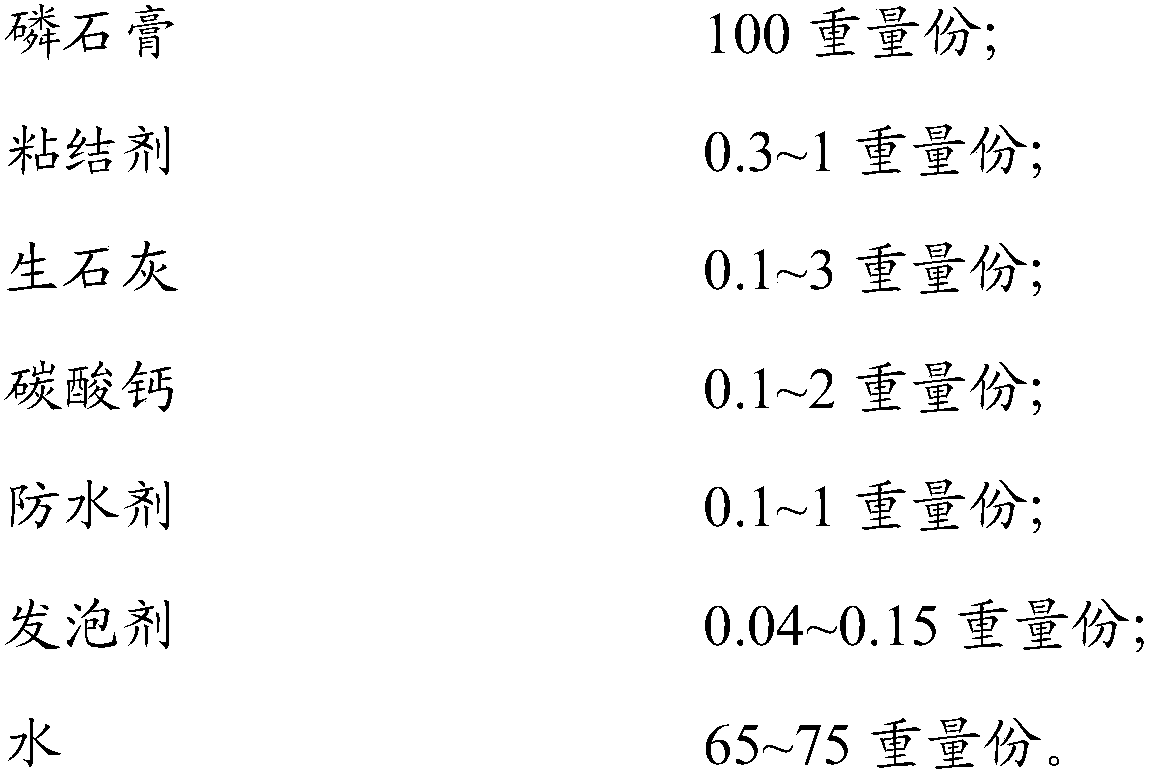

Pretreatment method of phosphogypsum and paper gypsum board and preparation method thereof

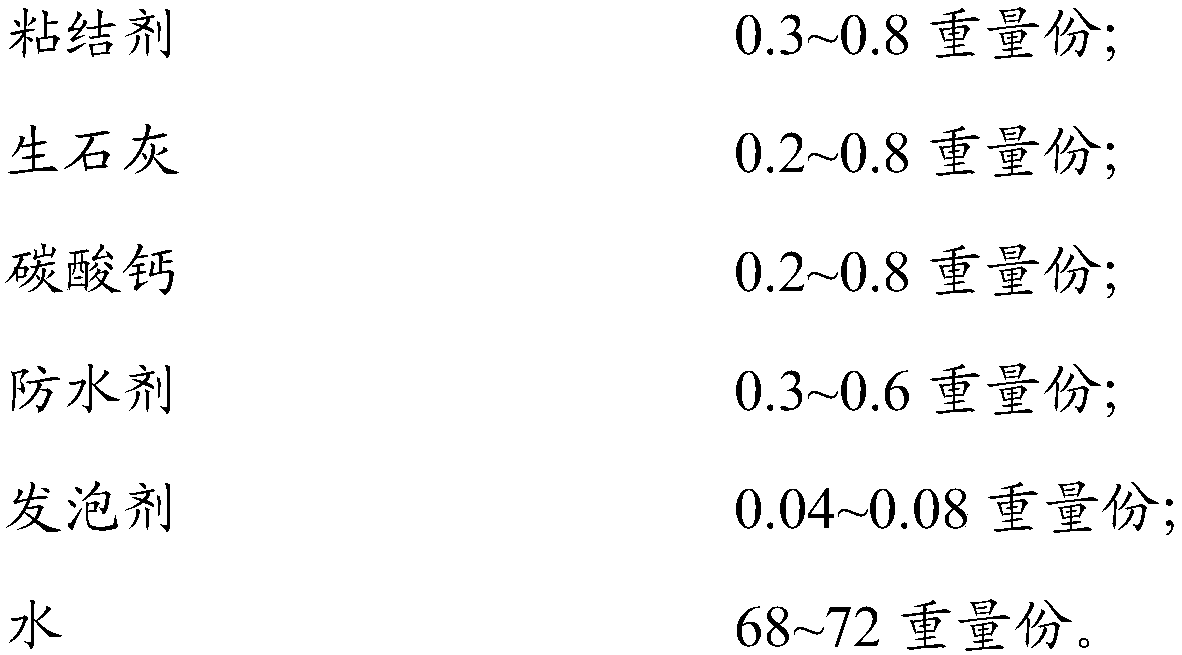

InactiveCN109133687AReduce water demandShort setting timeSurface layering apparatusCeramicwareGypsumPre treatment

Provided are a pretreatment method of phosphogypsum and a paper gypsum board prepared by using the treated phosphogypsum and a preparation method thereof. The pretreatment method of the phosphogypsumcomprises the steps of drying and mixing the phosphogypsum with quicklime by 100:0.1-3, by weight, grounding, calcining at 140-180 DEG C, and aging; the paper gypsum board comprises, by weight, 100 parts of phosphogypsum, 0.3-1 part of binder, 0.1-3 parts of raw lime, 0.1-2 parts of calcium carbonate, 0.1-1 part of water repellent, 0.04-0.15 part of foaming agent and 65-75 parts of water; the method comprises the steps of mixing the pretreated phosphogypsum with other raw materials, stirring to form a slurry, forming upper and lower protective papers, drying, and cutting according to sizes. The method achieves the comprehensive utilization of the phosphogypsum, and the performance of the prepared paper gypsum board meets the requirements of national standards.

Owner:BEIJING NEW BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com