Construction method of lattice light-gauge steel house

A construction method and light steel technology, which is applied to the processing of building components, building structures, and building materials, can solve problems such as hollows and cracks in post-applied mortar, achieve short setting time, tight combination, and save construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

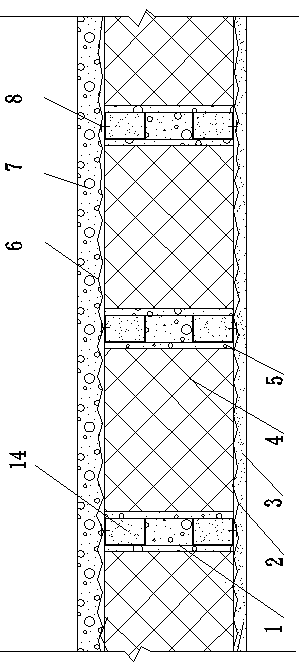

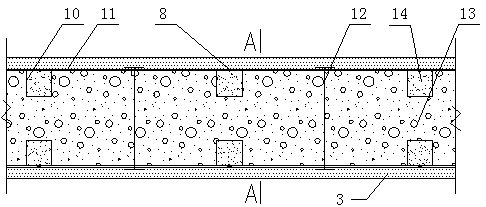

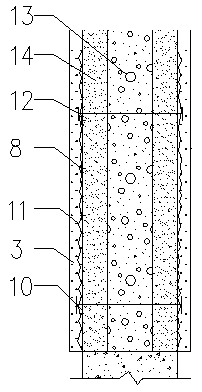

[0054] Embodiment 1: as Figure 1-4 As shown, a construction method of a lattice light steel house comprises the following steps:

[0055] A. Basic treatment:

[0056]a1. Construction foundation according to design requirements;

[0057] a2. Fix the light steel rectangular pipe with the standard connector and install it on the foundation;

[0058] a3. Install hydropower equipment pipelines according to the design requirements;

[0059] B. Wall construction:

[0060] b1. Install light steel keel frame;

[0061] b2. Fix and connect the non-detachable metal mesh on both sides of the light steel keel frame;

[0062] b3. Spread cement mortar on the outside of the non-demolition metal mesh to form a non-demolition formwork;

[0063] b4. Fill lightweight concrete between the demolition-free formwork;

[0064] C. Building and roof panel construction:

[0065] c1. Support the load-bearing steel skeleton on the load-bearing components, and arrange the spacing according to the de...

Embodiment 2

[0073] Embodiment 2: as figure 1 , 2 As shown, a construction method of a lattice light steel house comprises the following steps:

[0074] A. Basic treatment:

[0075] a1. Construction foundation according to design requirements;

[0076] a2. Fix the light steel rectangular pipe with the standard connector and install it on the foundation;

[0077] a3. Install hydropower equipment pipelines according to the design requirements;

[0078] B. Wall construction:

[0079] b1. Install light steel keel frame;

[0080] b2. Fix and connect the non-detachable metal mesh on both sides of the light steel keel frame;

[0081] b3. Spread cement mortar on the outside of the non-demolition metal mesh to form a non-demolition formwork;

[0082] b4. Fill lightweight concrete between the demolition-free formwork;

[0083] b5. Pour filler into the light steel rectangular tube to form a light steel rectangular tube-concrete composite component.

[0084] C. Building and roof panel constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com