Soil curing agent

A technology of soil stabilizer and activator, which is applied in the field of building materials and can solve problems such as long curing time, collapse, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

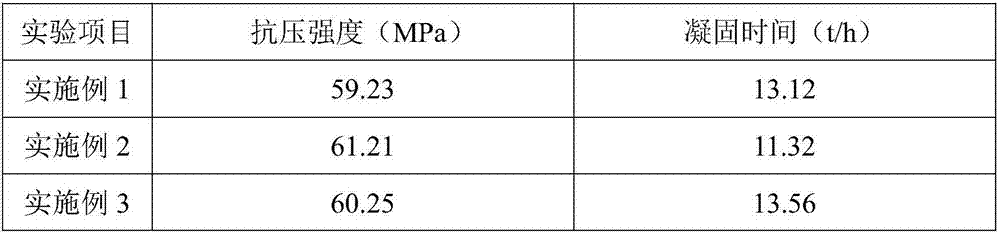

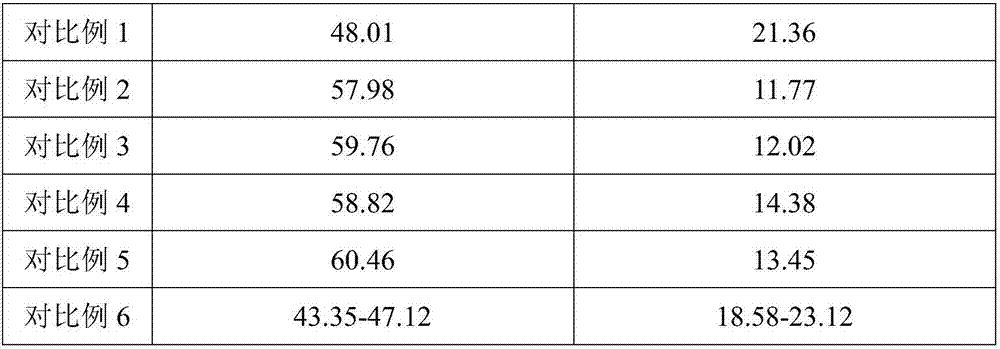

Examples

preparation example Construction

[0025] The preparation method of described soil solidifying agent, comprises the following steps:

[0026] S1. Modified material: polyvinyl butyral, calcium lignosulfonate, 3-aminopropyltrialkoxysilane, polyvinylpyrrolidone, and water are mixed by weight at a temperature of 30-50°C and sealed. The modified material is prepared by mixing and stirring for 3-4 hours, and the water content of the modified material is 70-90%;

[0027] S2. Mixing: Mix the modified material prepared in step S1 with ordinary Portland cement, sulfur-fixing ash, activator, early strength agent, silica fume, quicklime, and polyacrylamide in a weight ratio, and first mix the sulfur-fixing ash, Stir the activator, early strength agent, polyacrylamide and the modified material for 20-30 minutes, then add ordinary Portland cement, silica fume and quicklime, stir at a temperature of 25-40°C for 1-2 hours to obtain a mixed material ;

[0028] S3. Vacuum preparation: the mixed material prepared in step S2 is ...

Embodiment 1

[0031] A soil curing agent, in parts by weight, comprising the following raw materials: 27 parts of ordinary Portland cement, 607 parts of sulfur-fixed ash, 15 parts of activator, 11 parts of early strength agent, 12 parts of silica fume, 22 parts of quicklime, 13 parts of polyacrylamide, 112 parts of water, 35 parts of polyvinyl butyral, 27 parts of calcium lignosulfonate, 30 parts of 3-aminopropyltrialkoxysilane, 6 parts of polyvinylpyrrolidone;

[0032] The activator is modified water glass;

[0033] The early strengthening agent is diethanolamine;

[0034] The preparation method of described soil solidifying agent, comprises the following steps:

[0035] S1. Modified material: mix polyvinyl butyral, calcium lignosulfonate, 3-aminopropyltrialkoxysilane, polyvinylpyrrolidone, and water in a weight ratio at a temperature of 33°C under sealed conditions Stirring for 3 hours to prepare a modified material, the water content of the modified material is 73%;

[0036] S2. Mixin...

Embodiment 2

[0039]A soil curing agent, in parts by weight, comprising the following raw materials: 31 parts of ordinary Portland cement, 85 parts of sulfur-fixed ash, 17 parts of activator, 18 parts of early strength agent, 16 parts of silica fume, 27 parts of quicklime, 19 parts of polyacrylamide, 134 parts of water, 44 parts of polyvinyl butyral, 35 parts of calcium lignosulfonate, 36 parts of 3-aminopropyltrialkoxysilane, 28 parts of polyvinylpyrrolidone;

[0040] The activator is 7 parts of sodium aluminate, 10 parts of polyaluminum iron silicate;

[0041] The early strength agent is 12 parts of diethanolamine, 6 parts of potassium bicarbonate;

[0042] The preparation method of described soil solidifying agent, comprises the following steps:

[0043] S1. Modified material: mix polyvinyl butyral, calcium lignosulfonate, 3-aminopropyltrialkoxysilane, polyvinylpyrrolidone, and water in a weight ratio at a temperature of 46°C under sealed conditions Stirring for 3.6 hours to prepare a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com