Patents

Literature

94results about How to "Expansive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

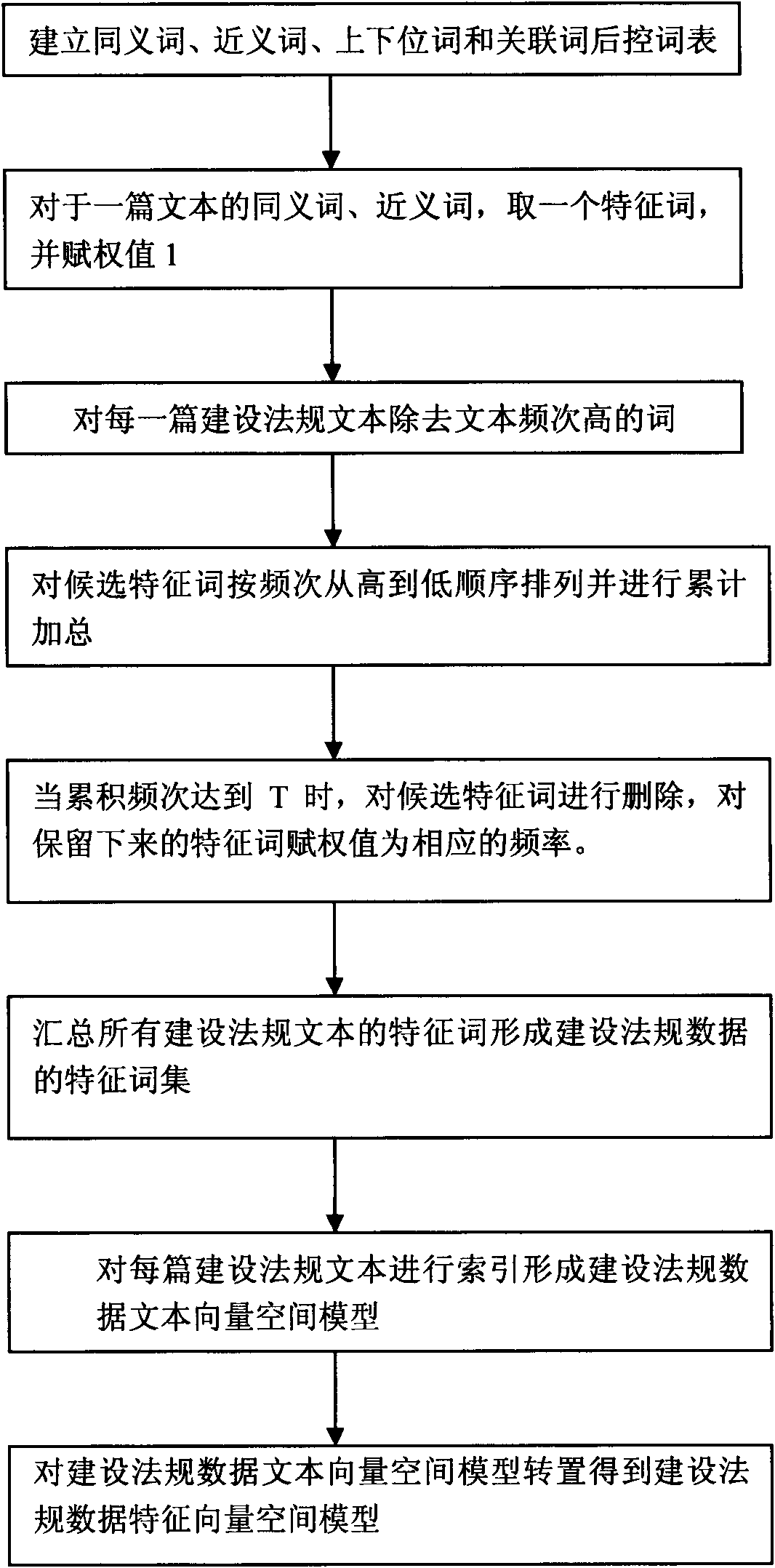

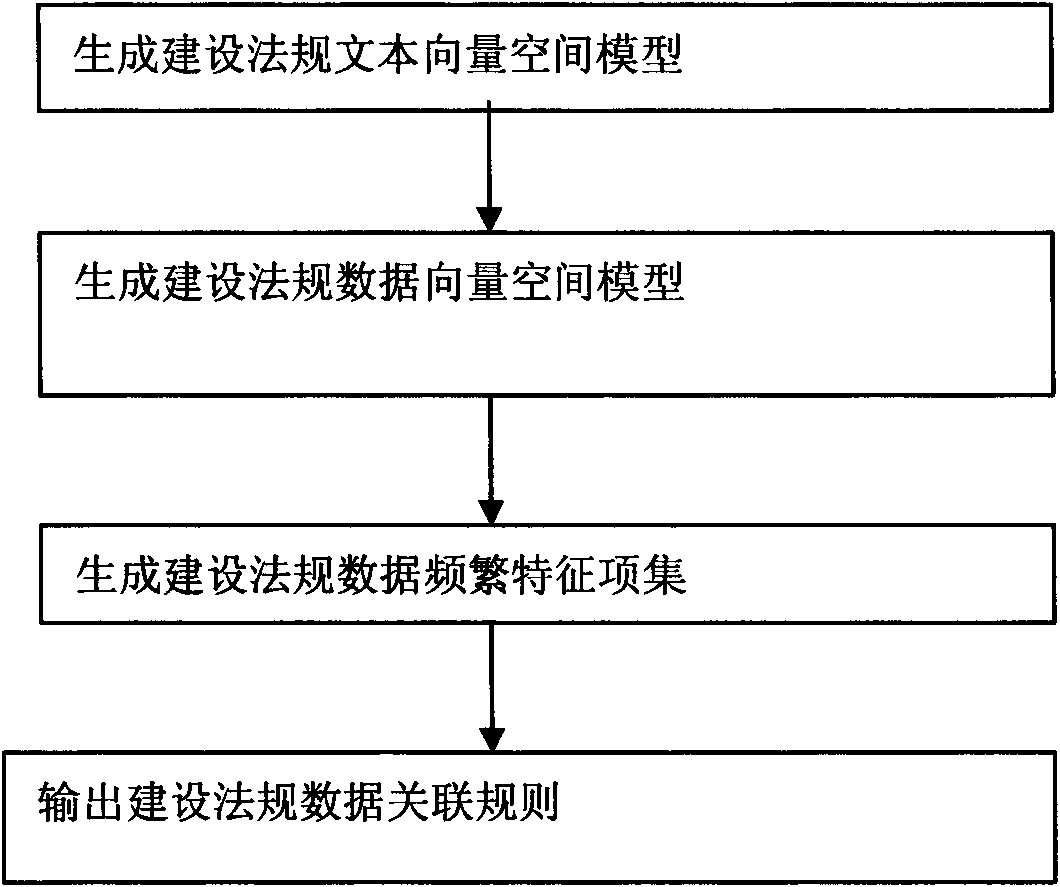

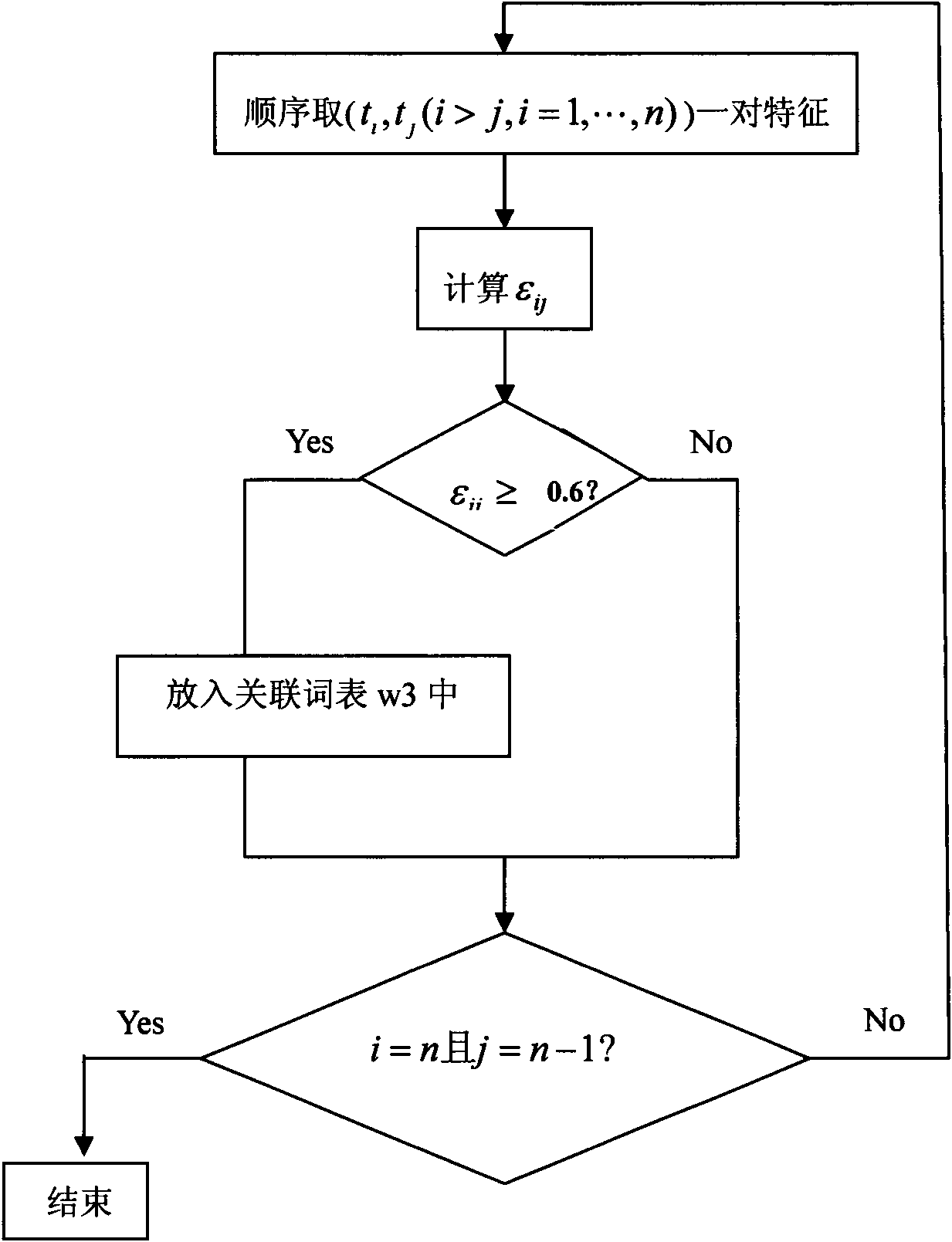

Method for mining data in construction regulation field based on associative regulation mining technology

InactiveCN101655857AImprove query performanceReduce dimensionalitySpecial data processing applicationsFeature vectorFeature set

The invention discloses a method for mining data in construction regulation field based on associative regulation mining technology; 1. a construction regulation text vector space model is generated, 2. a construction regulation data vector space model is generated, 3. the construction regulation data vector space model is subject transposition to generate a construction regulation data feature vector space model, namely, a frequent feature set is generated, and 4. construction regulation data association degree is calculated and an association rule is output. The method can mine the data in construction regulation field, provides higher recall ratio for a user inquiring data, recommends associative query contents, and solves the technical problem that the existing association analysis technologies can not carry out association analysis on outlier data.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

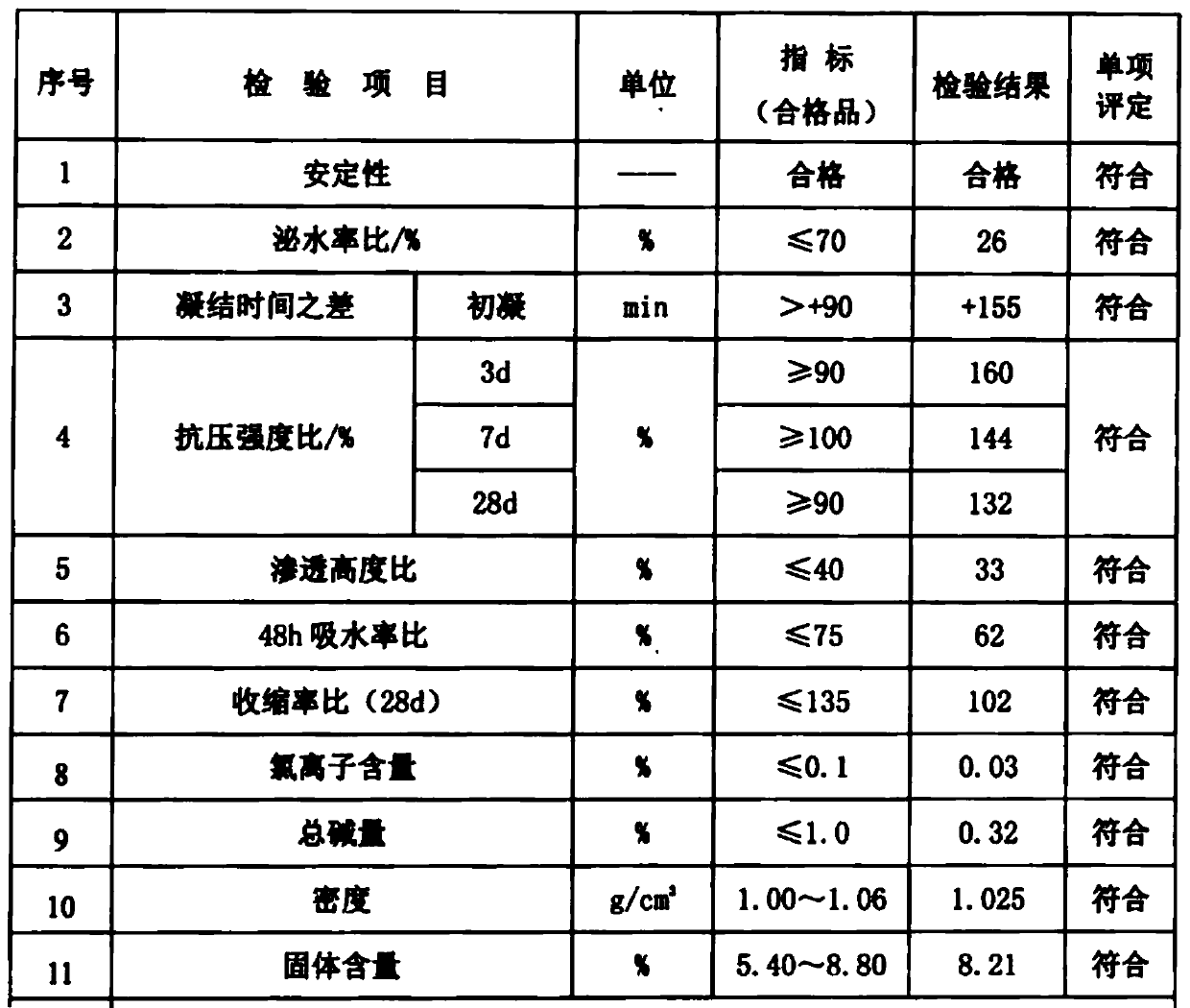

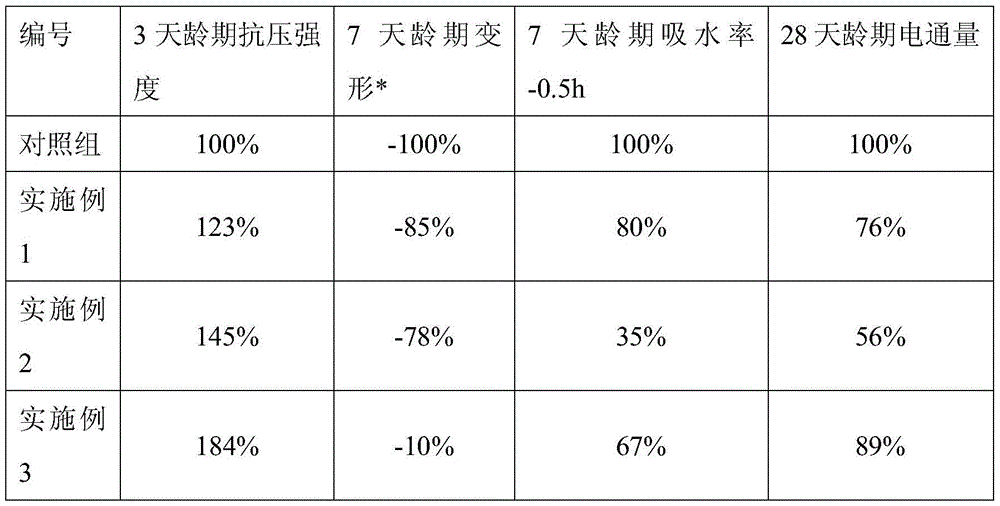

Grouting material for connecting steel bars in low temperature environment, and preparation method and application thereof

The invention discloses a grouting material for connecting steel bars in a low temperature environment, and an application thereof. The grouting material for connecting steel bars in the low temperature environment comprises, by weight, 35-55 parts of cement, 5-20 parts of a mineral admixture, 0-30 parts of an early strength component, 30-50 parts of aggregates, 0.1-0.5 part of a water reducer, 0-0.03 part of a plastic expansion agent, 0-0.1 part of an antifoaming agent, 0-0.05 part of a stabilizer, 0-0.05 part of an air entraining agent, 0-1 part of a setting retarder and 0-0.05 part of a setting accelerator. The fluidity of a grouting material mixture prepared after adding 0 DEG C water to the grouting material in a -5 DEG C environment and mixing the grouting material and the water is more than 260 mm 30 min later, so sufficient grouting time at a low temperature is ensured; the grouting material has the characteristics of low water-to-feed ratio and high fluidity, and the groutingmaterial still has an expansion performance and a good low-temperature hydration characteristic in a subzero temperature environment, is suitable for steel bar grouting connection construction in a -10-10 DEG C environment, and solves the problem of grouting construction in the low temperature environment, especially the below 0 DEG C environment; and the grouting material contains no chlorine salt and other early-strength components corroding the steel bars.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

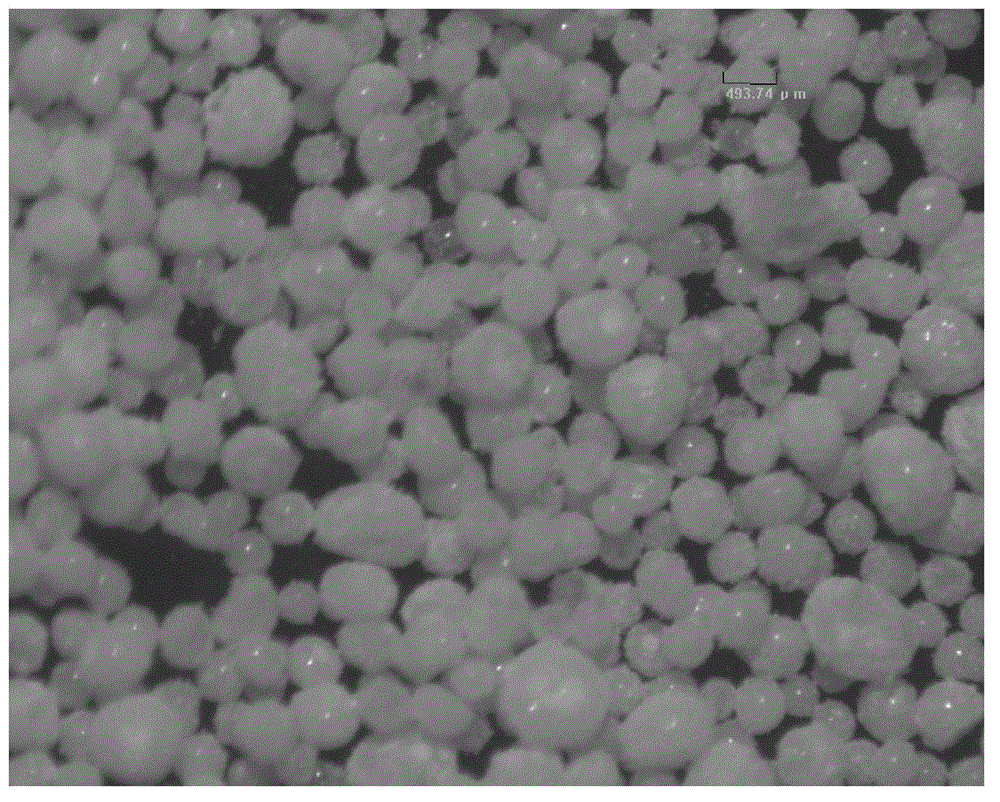

Process for preparing cross-linked sodium hyaluronate microspheres capable of being adopted as emboliaztion agent by adopting sodium hyaluronate as raw material

The present invention provides a process for preparing cross-linked sodium hyaluronate microspheres capable of being adopted as an emboliaztion agent by adopting sodium hyaluronate as a raw material. The process comprises the following steps: preparing a sodium hyaluronate alkaline solution gel with a concentration of 10-30% g / ml; adding the sodium hyaluronate alkaline solution gel to an emulsifier-containing oil phase, and carrying out high speed emulsification through a shearing machine, wherein an emulsification speed is 500-2000 rpm, and a time is 10-20 min; adding a certain amount of a cross-linking agent, stirring for 4-6 h at a room temperature, carrying out a cross-linking reaction, and standing overnight after completing the reaction, wherein a mass percentage of the cross-linking agent in the oil phase is 0.2-2%; and adopting a water-soluble organic solvent to wash to remove the oil phase remained on the surface of the microspheres, and finally drying to obtain the cross-linked sodium hyaluronate microspheres. According to the present invention, the preparation process is simple; and the size of the obtained microspheres is suitable for routine blood vessel emboliaztion, and the obtained microspheres have characteristics of controllable particle size, good microsphere shape, easy screening, elasticity, expandibility, no toxic-side effect on human body, good biocompatibility, good biodegradability, and ensured clinical safety.

Owner:HANGZHOU SINGCLEAN MEDICAL PROD

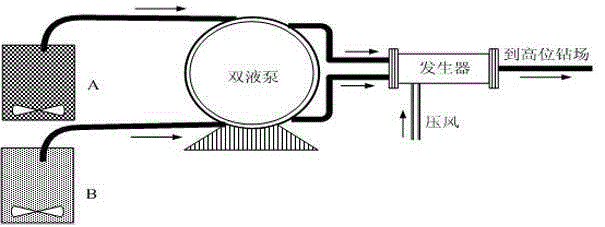

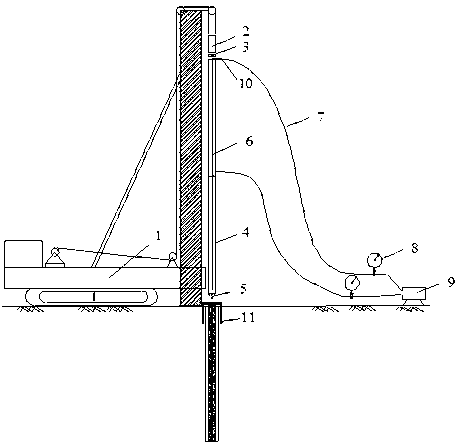

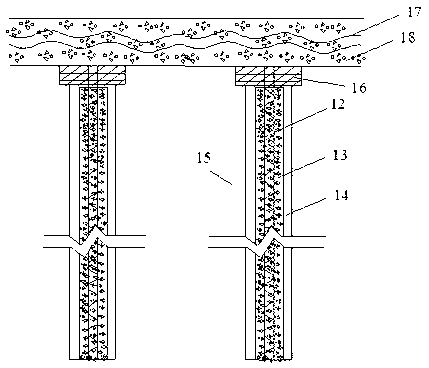

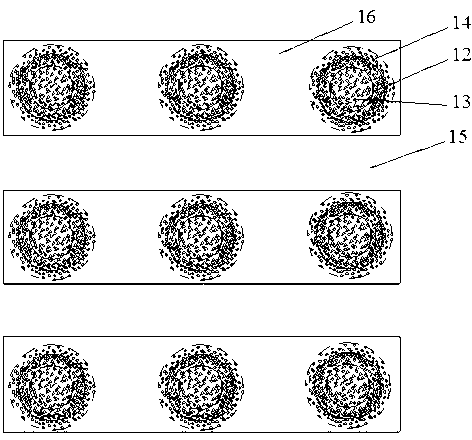

High polymer material slurry filled discrete material pile composite foundation and construction method thereof

The invention discloses a high polymer material slurry filled discrete material pile composite foundation and a construction method thereof. A discrete material pile is filled in a soft soil foundation through a vibrating immersed pipe, a rigid injection pipe is embedded in advance in the middle of the discrete material pile, a barrel-shaped cover plate is embedded on the top of the discrete material pile, and high polymer material slurry is sprayed to the discrete material pile at high pressure through a slurry injection system. The high polymer material slurry is filled in the clearance of the discrete material pile and splits to permeate into pile soil, so that the discrete material pile body is engaged and contacted with the soil around the discrete material pile, and the friction coefficient of the pile-soil contact surface is effectively increased. Bar pile caps are poured on the top which is formed by a high polymer material slurry filled discrete material pile body, a high polymer material slurry filled soil body and the pile soil. A high polymer material is insoluble and has certain expansibility. In the process of spraying at high pressure, water in a part of the soil body is discharged through a passage of the discrete material pile. The high polymer material slurry filled discrete material pile composite foundation has the advantages of simple construction process, strong operability, convenience in quality control, good engagement effect of the pile-soil contact surface, obvious economic benefit and significant effect for reinforcing the soft soil foundation.

Owner:HOHAI UNIV

High-water expansion filling material

InactiveCN101792291ANo disturbanceExpansiveSolid waste managementMaterial fill-upLiquid ratioResource recovery

The invention relates to a high-water expansion filling material belonging to the technical field of buildings, water bodies and subway mining. The high-water expansion filling material is characterized by being slurry containing fly ash, an expansive agent, a retardant, an accelerating agent, a curing agent and water. The solid-liquid ratio is 1:1.2 to 1.5, the proportion is 1.35, and the expansion rate is 10-30 percent. The invention solves the problems of active pressing top-filling and long-distance gravity feeding in medium and thick coal beds and has very important meaning to the improvement of the domestic mining biological environment and the increase of the resource recovery rate.

Owner:ZIBO WANGZHUANG COAL MINE

Cement concrete inner-doping waterproof agent and preparing method thereof

The invention provides a cement concrete inner-doping waterproof agent and a preparing method thereof. The cement concrete inner-doping waterproof agent is prepared from, by weight, 0.2-20% of nano aluminum oxide, 0.1-20% of a filer component, 0.1-20% of a hydrophobic component, 0.2-5% of emulsifier and the balance water. The cement concrete inner-doping waterproof agent has the advantages of early high strength, expansibility, hydrophobicity, permeability reduction, electric flux and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

Building rubbish pavement base material and preparation method thereof

The invention relates to a building rubbish pavement base material and a preparation method thereof. The pavement base material is prepared from the components in parts by mass: 95 to 96 parts of building rubbish recycled aggregate, 4 to 5 parts of binding material, 9.4 to 12.2 parts of water relative to the sum of the components i.e. the building rubbish recycled aggregate and the binding material, and 3.5 to 5.5 parts of alkali-activator relative to the mass of water. The pavement base material provided by the invention adopts building rubbish and industrial waste residues as main raw materials, and the material has the advantages of high strength, dry shrinkage, long construction working time and the like. By applying the building rubbish pavement base material provided by the inventionin a large scale, not only can considerable economic benefit be produced, but also a huge environmental protection benefit can be produced.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

Ecological soil conditioner capable of improving acid soil and preparation method

InactiveCN105950166AReduce acidityRaise the pHAgriculture tools and machinesOther chemical processesChemical structureEcological environment

The invention belongs to the technical field of soil improvement and particularly relates to an ecological soil conditioner capable of improving acid soil and a preparation method. The ecological soil conditioner comprises raw materials in parts by weight as follows: 30-60 parts of carbonized distillers' grains, 10-20 parts of industrial and agricultural waste, 10-15 parts of sargassum, 10-15 parts of water hyacinth, 5-10 parts of plant ash, 5-15 parts of nano-modified clay, 5-10 parts of sodium alginate, 1-10 parts of tamarind polysaccharide gum, 1-5 parts of chelated secondary elements and trace elements and 0.1-3 parts of graphene oxide. The ecological soil conditioner can regulate the pH value of the soil, promote granular structure formation of the soil, improve the physical and chemical structures of the acid soil, increase organic matter content of the soil, improve the moisture and fertilizer retention capacity, improve physical characteristics of the soil, creates a good ecological environment for plant growth, is excellent, meets the organic and pollution-free agricultural development trend and has larger popularization and application value.

Owner:SICHUAN SHILIWANG AGRI SCI & TECH DEV CO LTD

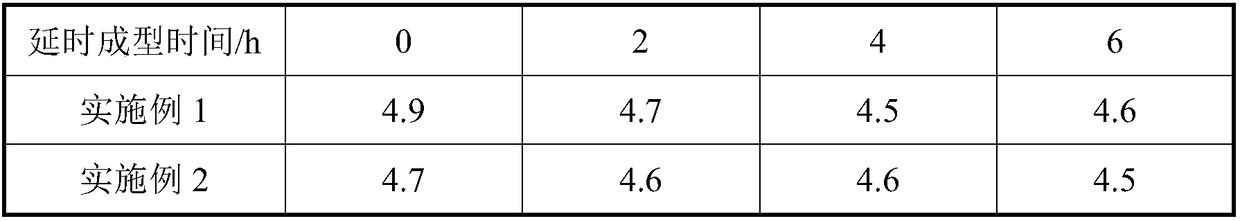

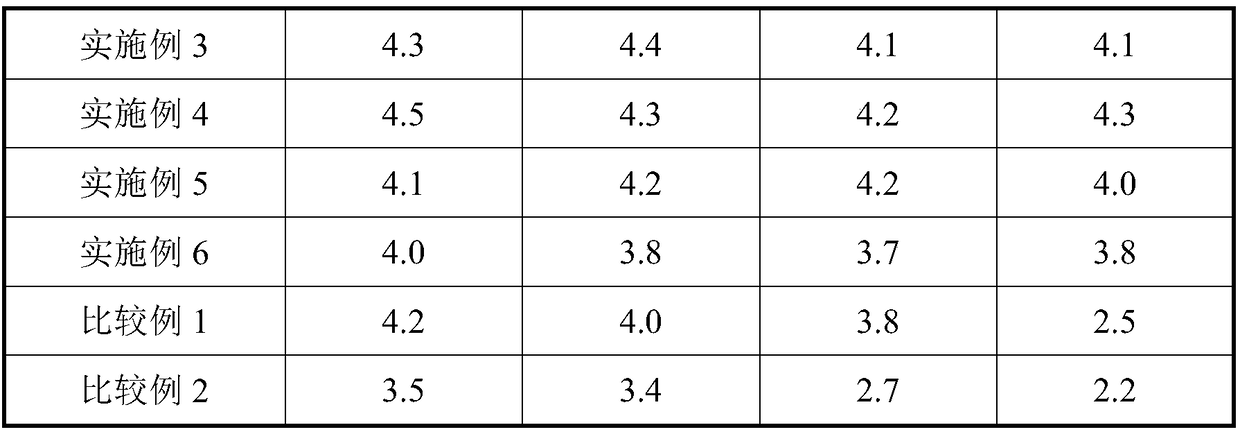

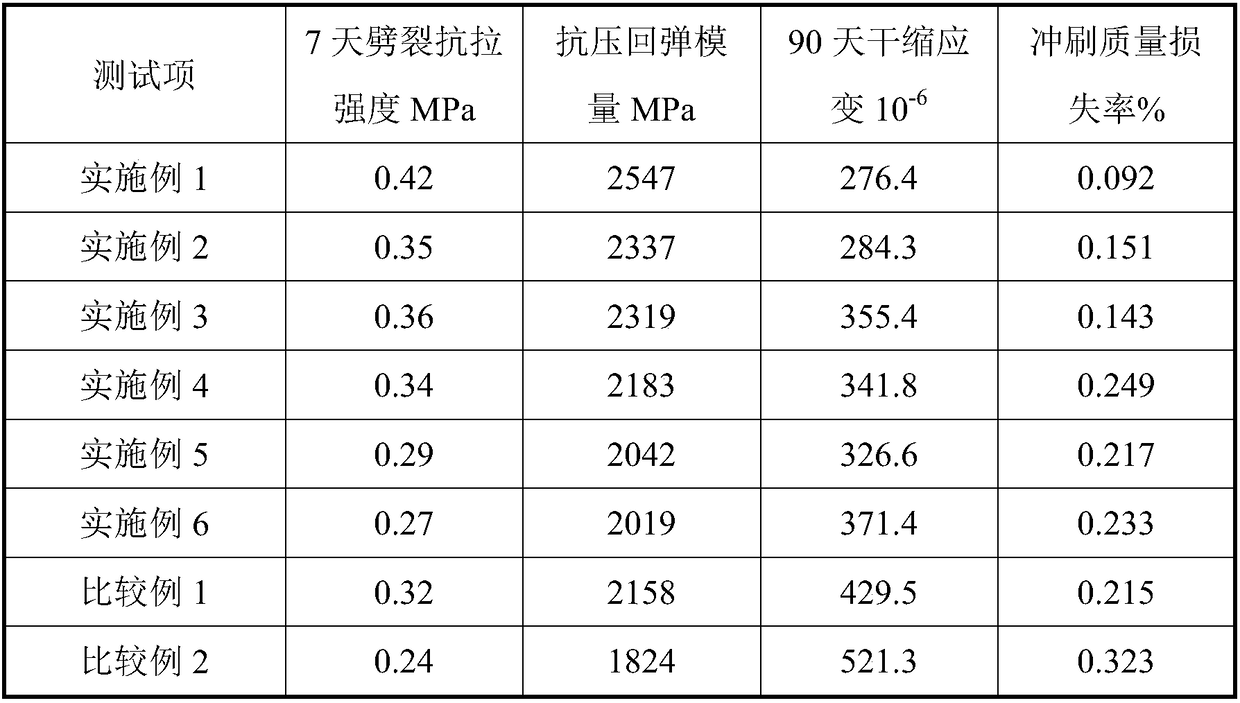

Solid sulfur ash masonry mortar

The invention discloses solid sulfur ash masonry mortar. The solid sulfur ash masonry mortar is characterized by comprising the following components in parts by weight: 200 to 490 parts of solid sulfur ash, 30 to 100 parts of lime, 410 to 770 parts of sand, and 0.1 to 0.5 part of water holding thickener. The solid sulfur ash is used as a main raw material for preparing the masonry mortar, so that solid sulfur ash slag discharged by a circulating fluidized bed can be fully utilized, waste of land resources and pollution to the natural environment when the solid sulfur ash is stacked in open air are reduced, meanwhile, the contractility of the masonry mortar is reduced, the water holding property of the masonry mortar is improved, the cost of the masonry mortar is reduced, and the practicability is strong.

Owner:SOUTHWEAT UNIV OF SCI & TECH

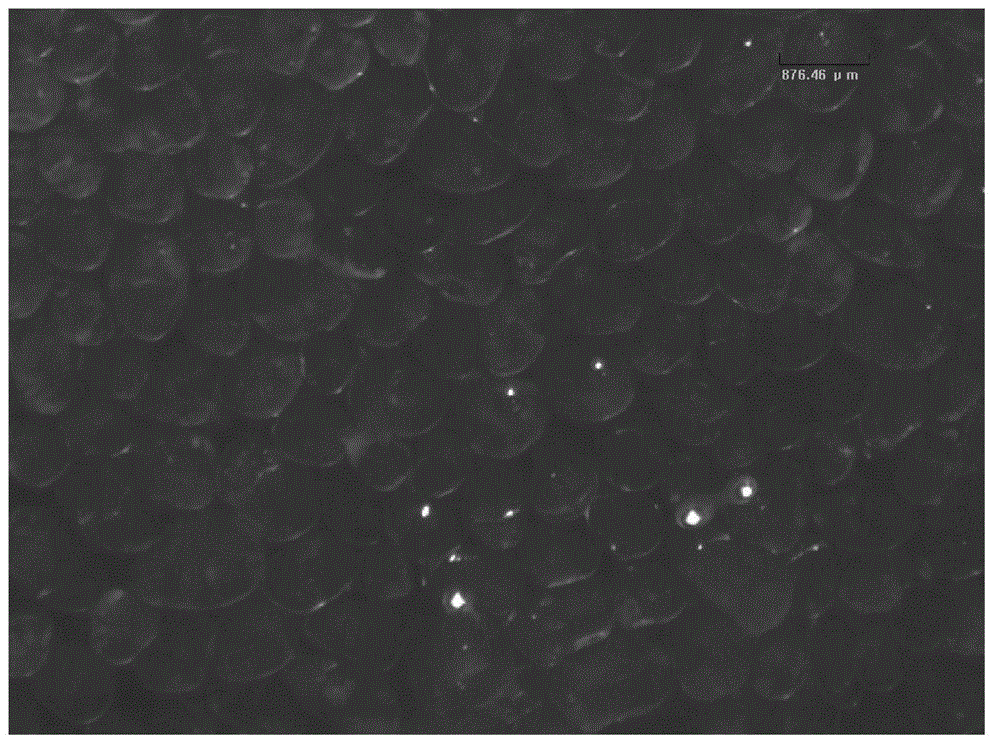

Method for preparing gelatin microballoon embolization agent

InactiveCN103006573AGood biocompatibilityPromote degradationGranular deliveryMacromolecular non-active ingredientsCross-linkSide effect

The invention relates to a method for preparing a gelatin microballoon embolization agent, which comprises the following steps of dissolving gelatin or mixture of gelatin and medicine at 30-70 DEG C, filtering to obtain gelatin solution with 15%-60% of solid content, adding gelatin solution into oil phase liquid paraffin with mass ratio of 1%-2% of stabilizer Span 80, wherein the volume ratio of water and oil is 1 / 1-1 / 10, stirring for 15 minutes by 200-800r / min, adding cross-linking agent aldehyde compound with mass percent of 2%-50% at low temperature of 0-10 DEG C, solidifying for 1-2 hours, washing or drying the cross-linking agent to obtain the microballoon embolization agent after freeze drying or dehydration. The method has the beneficial effects that the gelatin microballoon embolization agent has certain elasticity and expansibility, the surface is smooth, the sphere is obvious, the size and the shape of the sphere is uniform, the grain size is controllable, clinical embolization effect can be improved, and side effect can be lowered, the clinical controllability is strong, antitumor drug can be added into the microballoon in manufacture process, so that double therapeutical effect of medicine treatment and embolization can be realized. The gelatin has good biocompatibility and biodegradablity, and clinical safety can be guaranteed.

Owner:杭州艾力康医药科技有限公司

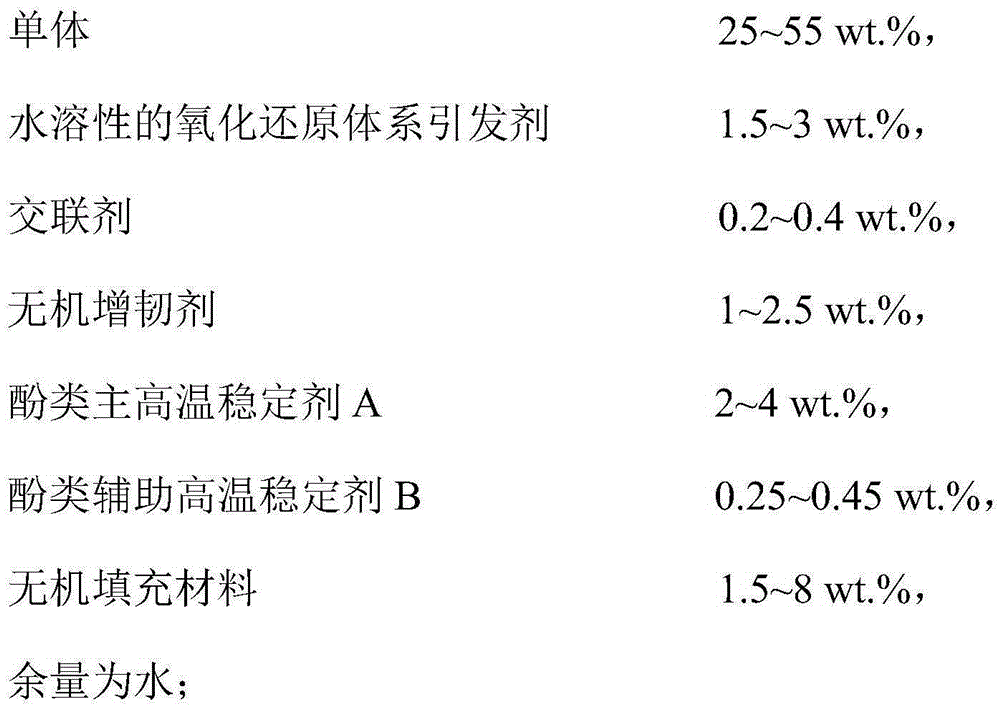

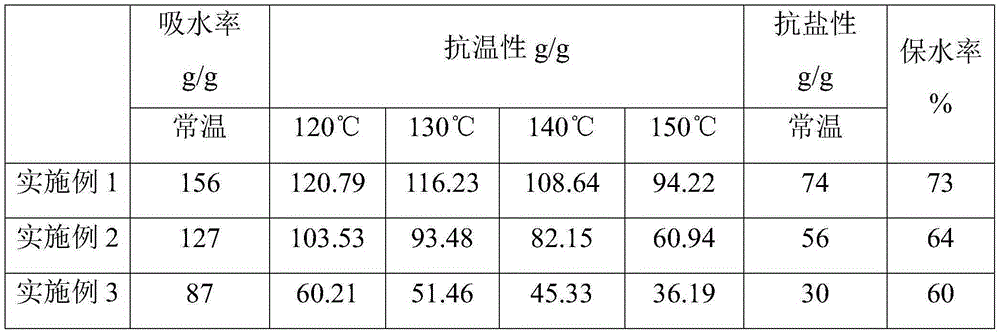

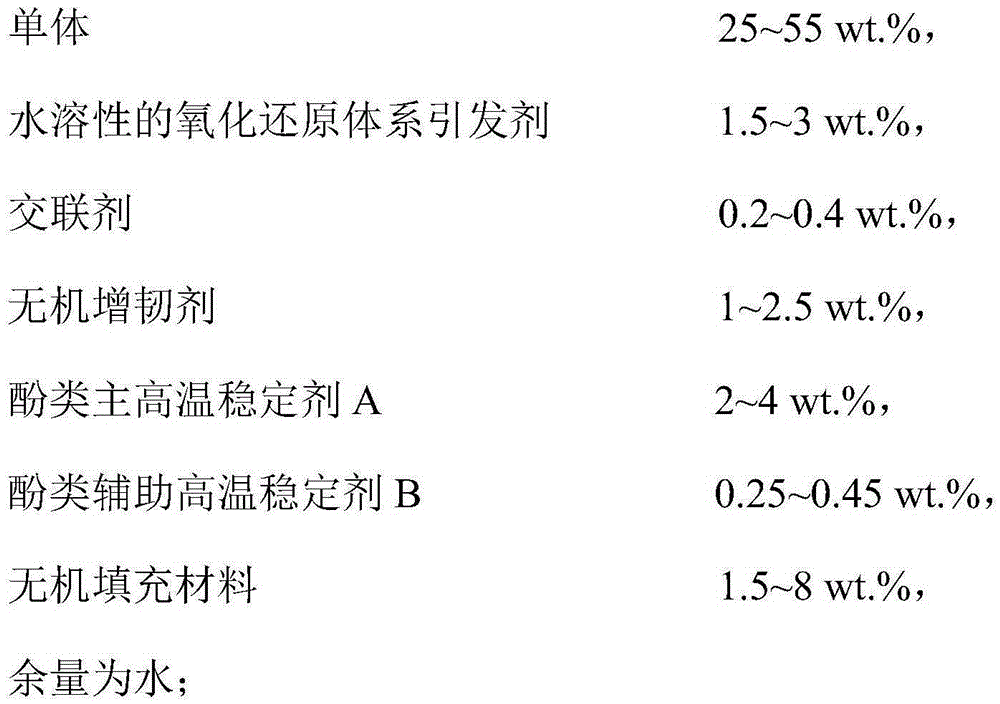

Plugging agent and preparation method of same

The invention discloses a plugging agent and a preparation method of the same, wherein the plugging agent is prepared from following substances, by mass, 25-55% of a monomer, 1.5-3% of a water-soluble redox system initiator, 0.2-0.4% of a crosslinking agent, 1-2.5% of an inorganic toughening agent, 2-4% of an anti-oxidizing agent A, 0.25-0.45% of an anti-oxidizing agent B, 1.5-8% of an inorganic filling material and the balanced being water, wherein the monomer is a mixture of acrylamide and acrylic acid. The preparation method includes the steps of neutralizing the acrylic acid with an alkali, mixing the acrylic acid with an acrylamide water solution, adding the inorganic toughening agent, a phenol main high-temperature stabilizer A and a phenol main high-temperature stabilizer B, stirring the mixture, adding the pre-hydrated inorganic filling material and mixing the mixture uniformly, adding the crosslinking agent and the initiator, performing a reaction until the mixture forms a viscoelastic colloidal substance; and drying and crushing the colloidal substance to obtain the plugging agent. The plugging agent is expansible, is excellent in temperature and salt resistance, is simple in preparation method and is easy to operate.

Owner:CNPC BOHAI DRILLING ENG

Anti-dispersion intensifier for underwater cast-in-place pile concrete and using method thereof

ActiveCN101830665AGood flocculation effectExcellent dispersion resistanceSolid waste managementFiberSlag

The invention discloses an anti-dispersion intensifier for underwater cast-in-place pile concrete, which comprises a polycarboxylic acid water reducer, hydroxyethyl methyl cellulose ether, starch ether, polyvinyl alcohol fiber, superfine ground slag, sodium tripolyphosphate, sulphoaluminate cement clinker and desulfurized gypsum. According to the technical scheme, when the product of the invention is added in underwater cast-in-place pile concrete during the preparation of the underwater cast-in-place pile concrete, the flocculability of the concrete is increased, the anti-dispersion performance is improved in a concrete casting process, the increase effect of the post strength of the concrete is obvious, the concrete has certain expansibility, the friction between the pile body and the soil is increased, and the bearing capacity of the pile body is improved.

Owner:珠海市振业混凝土有限公司 +1

Cementing material using construction waste as main component and preparation method of cementing material

The invention discloses a cementing material using construction waste as a main component and a preparation method of the cementing material. The material comprises brick-concrete micropowder, concrete micropowder, mineral slag micropowder, cement, and one of an additive combination of sodium hydroxide and water glass and an additive combination of calcium chloride and calcium hydroxide. The setting time and volume stability of the cementing material provided by the invention all meet the relevant cement standards, and the compressive strength and flexural strength for 3 days and 28 days reachPC32.5-grade strength; and compared with traditional cement, the cementing material provided by the invention has an obvious price advantage, is used in a large scale, can greatly alleviate pressureon the urban environment by the construction waste, and has social benefits far greater than economic benefits.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

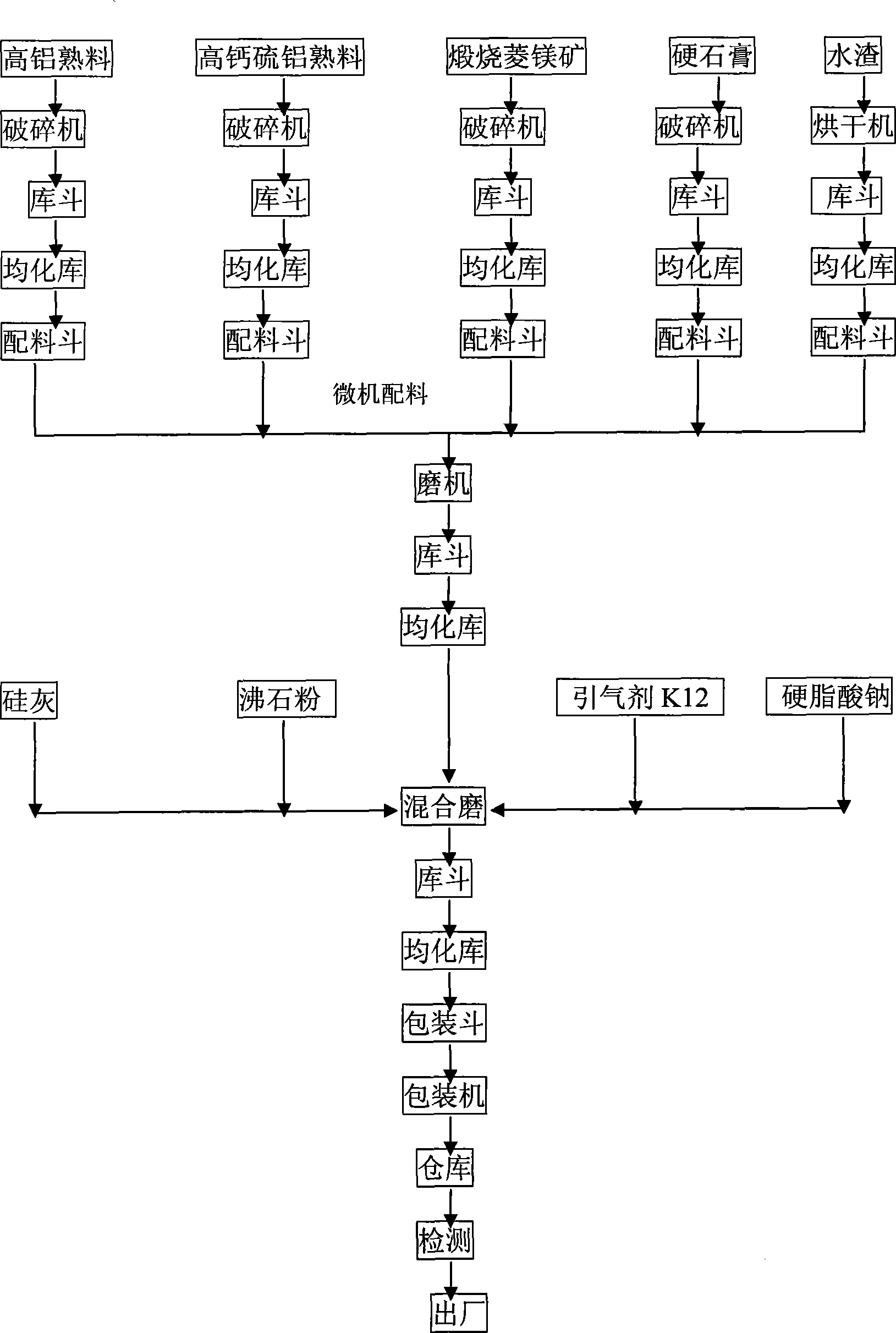

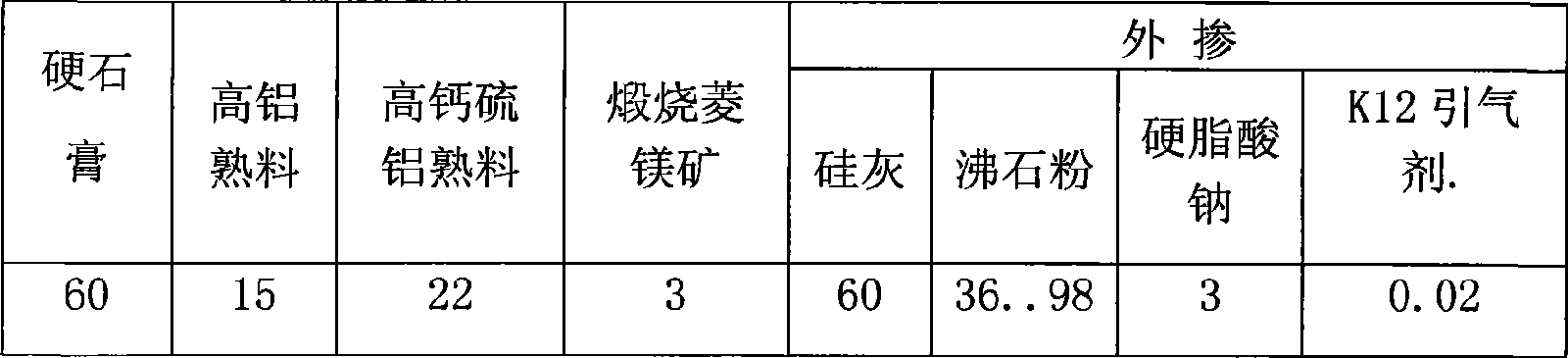

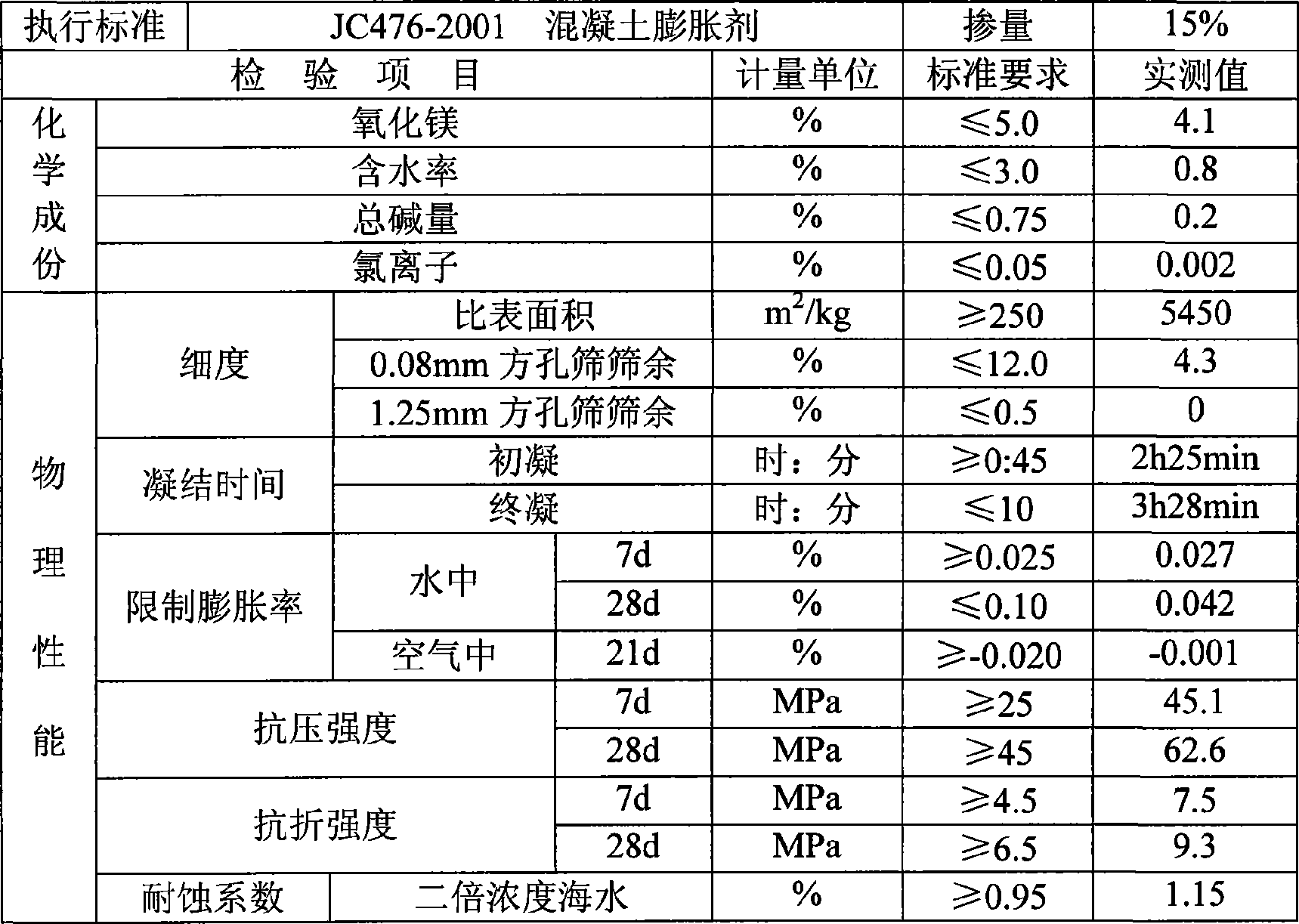

Durable type three-expansion source cement expansive material

InactiveCN101456694AImprove resistance to chloride ion penetrationImprove permeabilitySolid waste managementSodium stearateCrack resistance

The invention discloses durable three expansion source concrete expanding agent, which is characterized by comprising anhydrite, high-aluminum clinker, high calcium-sulfur-aluminum clinker, calcined magnesite and the like as the preparation raw materials according to a weight proportion, in addition, the raw materials are added with air entraining agent K12, siliceous dust, zeolite powder and water repellent sodium stearate. A preparation method comprises steps of crushing, common blending, blended powder grinding and external finished product blending. The expanding agent has low alkali content, has certain expansibility, and improves cracking resistance and impermeability of concrete. The expanding agent after being added into the concrete can remarkably improve compactness, impermeability, anti-scouring property and abrasion-resisting property of the concrete, reduces permeability and water absorption greatly so that the concrete has higher self-defending capability and environmental medium erosion resistance, improves sulphate erosion resistance and carbonizing resistance of the concrete greatly, is favorable for improving safety and durability of the reinforced concrete, and is suitable for various concretes.

Owner:广西云燕特种水泥建材有限公司

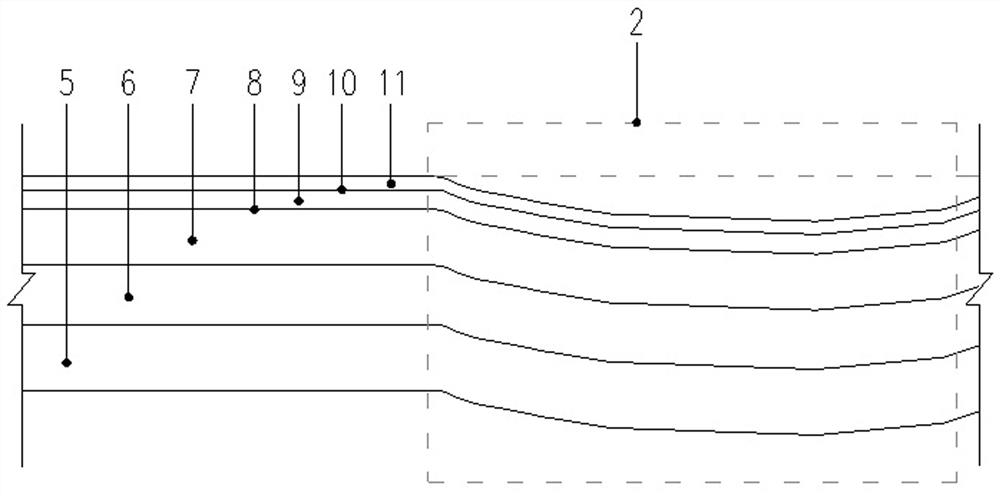

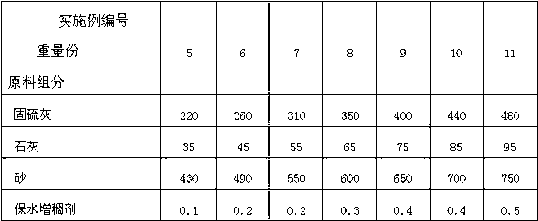

Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof

ActiveCN104017025ANovel structureImprove stabilityGroup 5/15 element organic compoundsPolyesterEpoxy

The invention relates to a flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and a preparation method thereof. The compound has a structural formula shown in the specification. The preparation method comprises the following steps of dropwise adding silicon tetrachloride into a solution of 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo-[2.2.2]-octane (PEPA) and an organic solvent at 20 DEG C, heating to 80-140 DEG C, performing stirring reaction for 4-10 hours, adding a fixed quantity of an acid-binding agent, stirring for 1 hours, and ending the reaction when detecting that the pH value of the solution is 5-6; cooling, performing suction filtration, washing by water, and drying to obtain tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate. The compound is the excellent halogen-free phosphorus-silicon synergistic flame retardant charring agent and can be applied to polyolefin, polyester, polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, the process is simple, the equipment investment is low, and the industrialized production is easy to realize.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

Oil well cement chlorine-free coagulation accelerating early strength agent

ActiveCN102321459AObvious procoagulant effectReduce contentDrilling compositionCalcium formateCritical time

The invention relates to an oil well cement chlorine-free coagulation accelerating early strength agent, which consists of the following components in parts by weight: 1.0-2.0 parts of sulfate, 0.05-0.10 part of triethanolamine, 0.05-0.10 part of formamide, 1.0-2.5 parts of calcium formate, 0.5-2.0 parts of urea and 0.5-1.0 part of naphthalene sulfonate, wherein the suitable temperature of the coagulation accelerating early strength agent is 20-45 DEG C; the coagulation accelerating early strength agent can be applied to cement slurry systems of various densities, has high compatibility with various additive systems and does not have influence on cement slurry performance; a product designed by the invention does not contain any chloride; the cement slurry thickening time can be shortened; the cement slurry stability is improved; the cement stone early strength is improved; the critical time is shortened; thus, water channeling after well cementation is effectively prevented; and the early strength agent can be matched with corresponding additive and admixture for use and can be widely applied to low-temperature shallow wells and adjustment well cementation construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Road engineering base course and soil road base polymer grouting material

The invention provides a road engineering base course and soil road base polymer grouting material. The material is characterized by comprising the following components in parts by weight: 100 parts of metallurgical slag, 30 parts of high-lime fly ash, 10 parts of metakaolin, 1-3 parts of thickening water-retaining agent, 30 parts of alkaline exciting agent and 2-4 parts of additive. The material has the advantages of quick setting, early strength, large fluidity and good permeability.

Owner:上海城西城建工程勘测设计院有限公司

Method for preparing plugging agents

InactiveCN107033864AImprove thermal stabilityHigh strengthDrilling compositionCross-linkPolymer science

The invention belongs to the technical field of a sealing-up and plugging materials, and particularly relates to a method for preparing plugging agents. The method includes smashing diatomaceous earth, bentonite, sepiolite and the like and mixing and stirring the diatomaceous earth, the bentonite, the sepiolite and water to obtain suspension; collecting emulsion from rubber trees, mixing and heating the emulsion, heavy calcium carbonate, carboxymethyl celluloses and polyamide fibers to obtain first mixtures; adding silane coupling agents into the first mixtures and carrying out ultrasonic treatment to obtain modified natural emulsion; mixing, heating and stirring the modified natural emulsion and lauroyl diethanolamine solution to obtain second mixtures, adding initiators, the suspension and cross-linking agents into the second mixtures, stirring the second mixtures, the initiators, the suspension and the cross-linking agents to obtain third mixtures and adding acrylamide solution into the third mixtures; carrying out reaction and then discharging and drying reaction products to obtain the plugging agents. The method has the advantages that the plugging agents prepared by the aid of the method are high in blocking speed and plugging success rate, formed plugging layers are high in loading capacity, good plug forming effects can be realized, repeated leakage can be prevented, and the plugging agents are little in environmental influence and free of pollution, are non-toxic and can be constructed safely and quickly.

Owner:石磊

Environment-friendly decoration cement

The invention discloses environment-friendly decoration cement and belongs to the technical field of building materials. The environment-friendly decoration cement is prepared from the following raw materials in parts by weight: 45-60 parts of Portland cement, 0-4 parts of an expanding agent, 4-10 parts of metakaolin, 2-6 parts of silicon powder, 1-3 parts of crystal whiskers, 5-10 parts of redispersible emulsion powder, 1-2 parts of a water reducer, 0.3-1.0 part of a defoaming agent, 0.1-0.15 part of cellulose ether, 5-10 parts of ground calcium carbonate and 10-15 parts of an environment-friendly material. The environment-friendly decoration cement disclosed by the invention has no problems such as alkali efflorescence and cracking and has good peaceability, corrosion resistance and environment-friendly performance.

Owner:JIAHUA SPECIAL CEMENT

Decorative cement

The invention discloses decorative cement and belongs to the technical field of building materials. The decorative cement comprises, by weight, 45 to 60 parts of Portland cement, 0 to 4 parts of an expander, 4 to 10 parts of metakaolin, 2 to 6 parts of silicon powder, 1 to 3 parts of whiskers, 5 to 10 parts of redispersible latex powder, 1 to 2 parts of a water reducing agent, 0.3 to 1.0 part of adefoaming agent, 0.1 to 0.15 parts of cellulose ether and 15 to 20 parts of ground calcium carbonate. The decorative cement prevents alkali crystallization and cracking and has good workability and corrosion resistance.

Owner:JIAHUA SPECIAL CEMENT

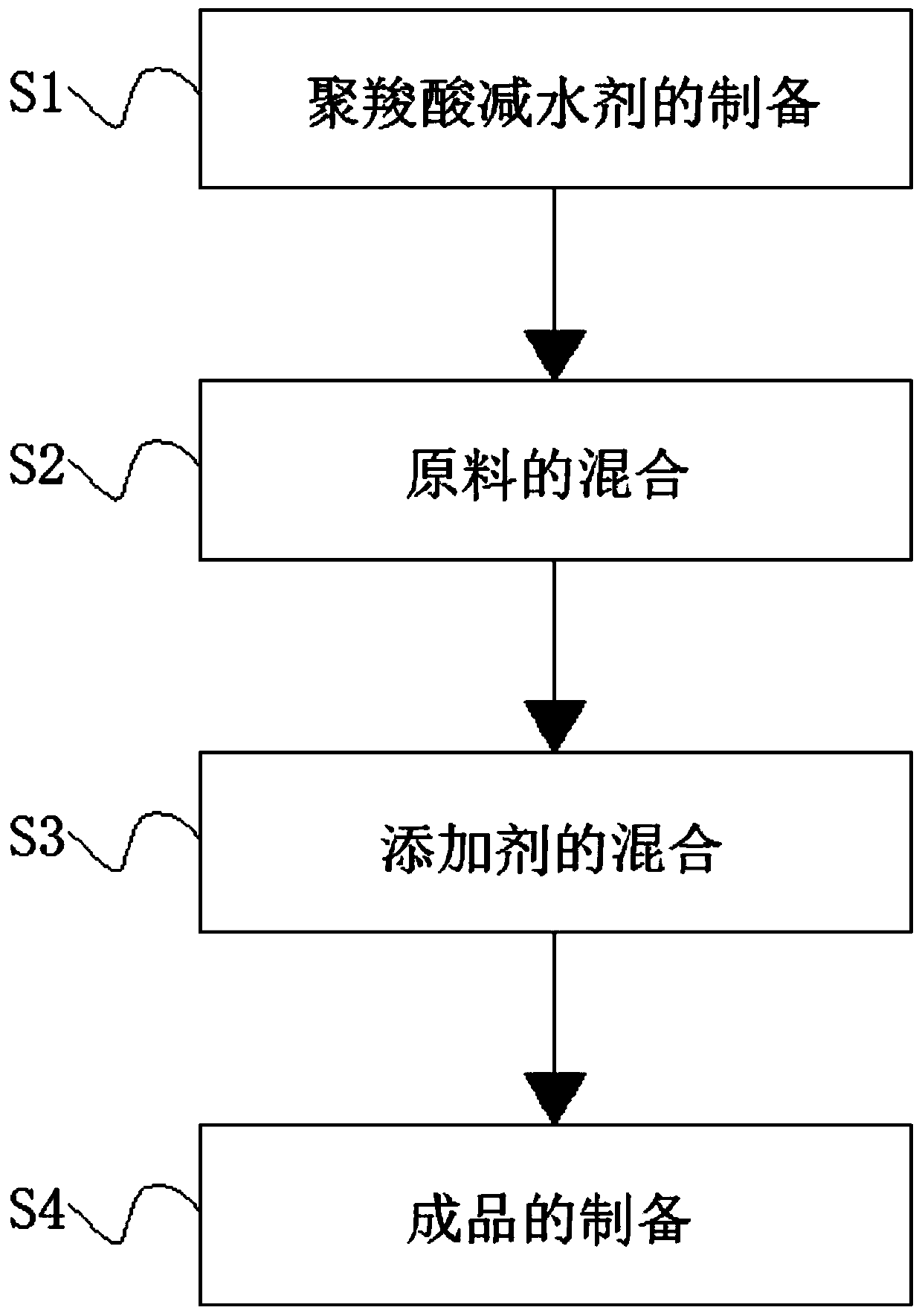

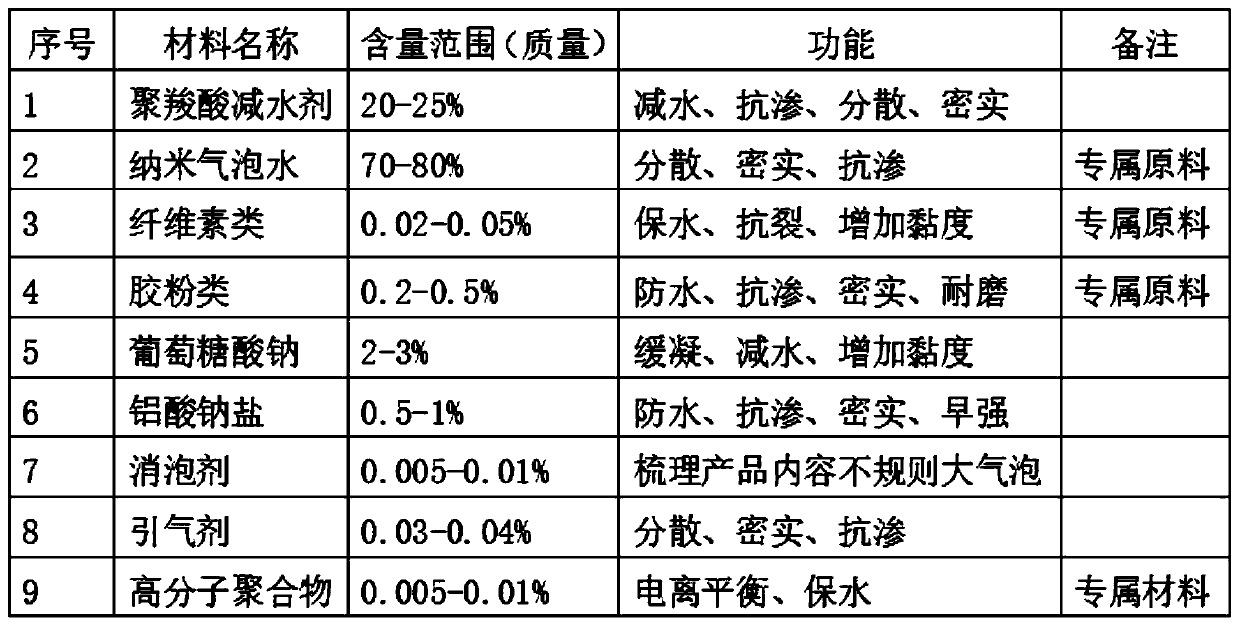

Preparation method of micro-nano porous impermeable crack-resistance concrete additive

The invention discloses a preparation method of a micro-nano porous impermeable crack-resistance concrete additive, and belongs to the technical field of building water resistance. The preparation method comprises following steps: 1, preparation of a polycarboxylic acid water reducer; 2, raw material mixing; 3, additive mixing; and 4, finished product preparation. According to the preparation method, combined water resistance is replaced by concrete structure type water resistance, water-proof material cost is reduced greatly, multi-layer water-proof construction process is avoided, so that construction time is shortened, construction working efficiency is increased greatly, artificial construction steps are reduced greatly, artificial cost is reduced, and artificial construction imbalancehidden trouble is avoided; a concrete self water-proof system is adopted, so that water resistance lasting period is as long as building service life, in the prior art, maintenance cost is extremelyhigh because of leakage caused by various factors in water proof construction, while almost no daily maintenance is needed in the invented technology.

Owner:广西北海市圣峰建材科技有限公司

Inorganic filling material

The invention discloses an inorganic filling material which comprises materials A and materials B, wherein the materials A comprise the following components in parts by mass: 70 to 80 parts of bauxite powder, 1 to 2 parts of calcium formate, 15 to 20 parts of aluminum oxide, 2 to 5 parts of gypsum, 15 to 20 parts of coal ash and 2 to 5 parts of calcium powder, and the materials B comprise the following components in parts by mass: 30 to 40 parts of gypsum, 20 to 25 parts of lime, 1 to 2 parts of compound accelerator, 0.1 to 1 part of water reducing agent, 1 to 5 parts of expanding agent, 0.1 to 1 part of lauryl sodium sulfate, 1 to 5 parts of polyolefin and 0.1 to 1 part of alkali lignin. The filling material makes close contact with the periphery of a roadway, so as to form a sealed body with good integrality, the integrality is strong, the compressive property is good, a filling body has expansibility, and downhole safe conditions are improved; no combustion or combustion supporting exists, obvious explosion-proof and anti-static properties are achieved, and the gas sealing and fire preventing and extinguishing effects are good; the filling rate is high, a top plate is easy to control, and the top plate in a gob can be effectively controlled, so as to limit depression of the ground.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

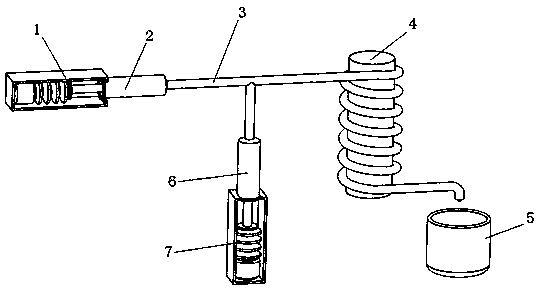

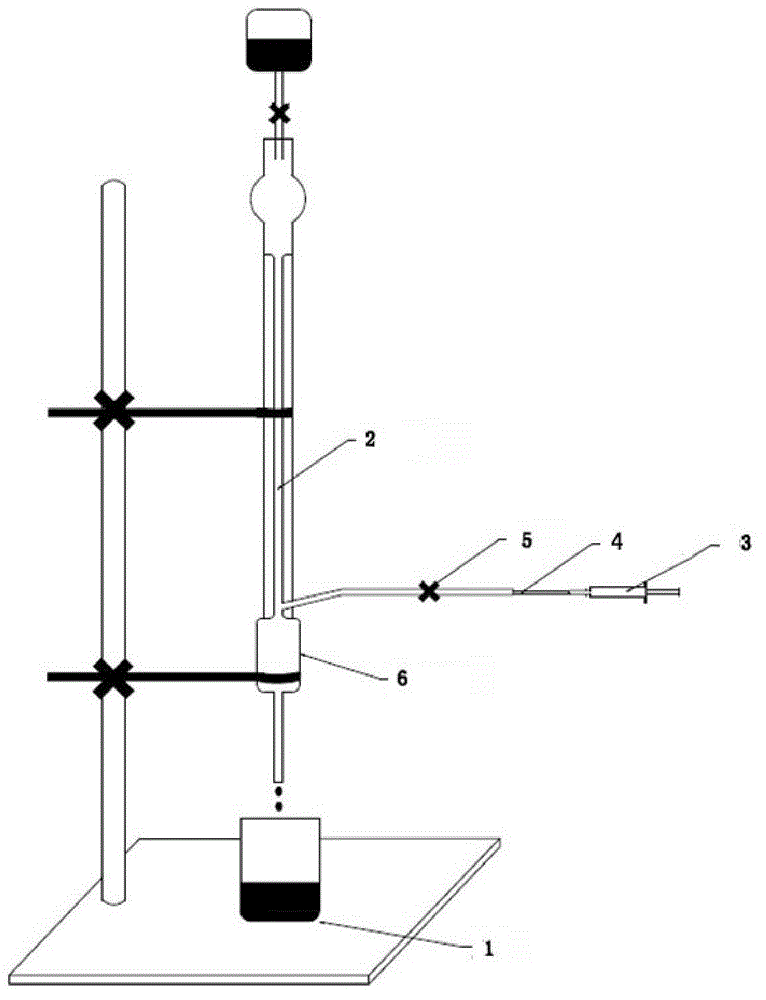

Gelatin microsphere embolic agent with uniform particle size and preparation method thereof

PendingCN109529096AImprove roundnessUniform particle sizeSurgical adhesivesPharmaceutical delivery mechanismNarrow rangeGelatin microspheres

The invention discloses a gelatin microsphere embolic agent with a uniform particle size and a preparation method thereof. The method comprises the following steps: dissolving gelatin or a mixture ofthe gelatin and medicines in water at 40-70 DEG C, adding a 0.1-1% photoinitiator, performing uniform stirring and filtration to obtain a 15-50% gelatin solution mixture, shearing the gelatin solutionmixture and oil phase liquid paraffin containing span80 with a mass ratio of 1-20% in a microchannel so as to form gelatin microspheres, wherein the water / oil volume ratio is 1 / 1 to 1 / 10, and the gelatin microspheres formed by shearing wind around a radiation source device at a certain rate in the microchannel, the distance between the radiation source and the gelatin microspheres is 3-30 cm, andthe radiation time is 1-30 min, collecting the microspheres into a container after the radiation, and then performing washing and dehydration to obtain the microsphere embolic agent. The gelatin microspheres prepared by the method of the invention have good roundness, uniform particle size and certain elasticity and expansibility, and the particle size of the microspheres is distributed in any narrow range of 50-1000 micrometers.

Owner:深圳麦普奇医疗科技有限公司

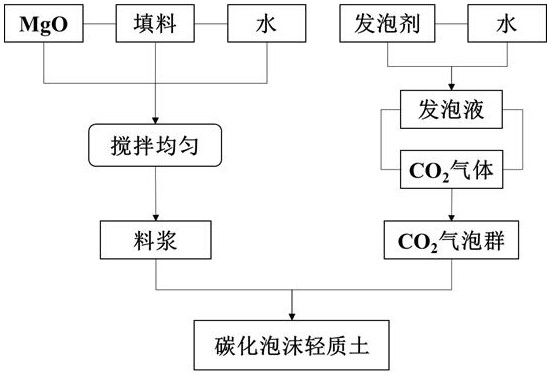

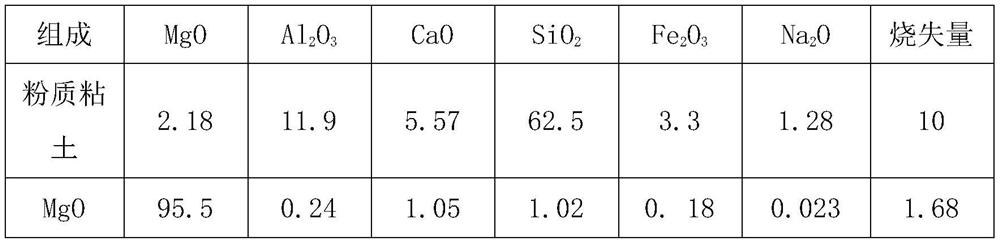

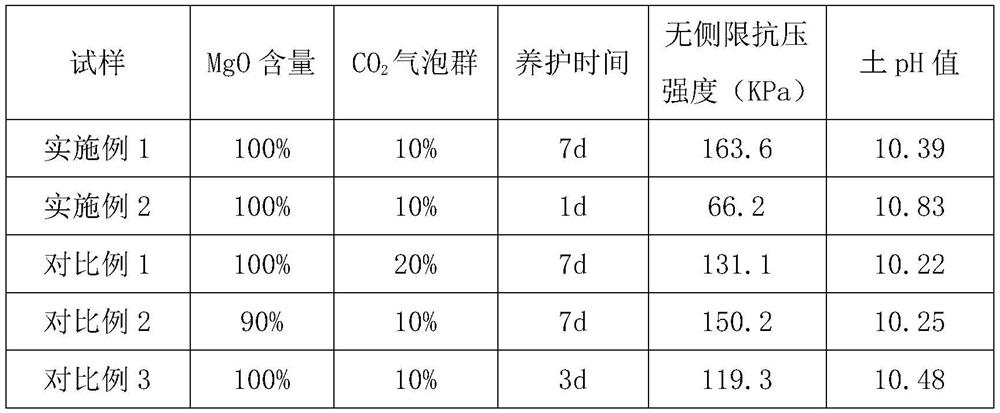

Carbonized foam light soil and preparation method thereof

The invention belongs to the technical field of civil construction engineering materials, and particularly relates to green and low-carbon foam light soil prepared by using carbon dioxide and magnesium oxide as raw materials. The carbonized foam light soil is prepared from the following raw materials in parts by weight: 10 to 200 parts of magnesium oxide, 10 to 100 parts of a filler, 2 to 45 parts of CO2 bubble group and 20 to 400 parts of water. According to the invention, based on the problems of large carbon emission and serious energy consumption caused by a cement curing agent used by traditional bubble mixed light soil, the invention aims to provide a novel bubble mixed light soil operation method, so that a foundation treatment technology is promoted to be converted from high pollution and high energy consumption to low carbon, environmental protection and sustainable conversion, and the light soil is prepared by taking magnesium oxide as a curing agent and carbon dioxide gas as a raw material of bubbles.

Owner:SOUTHEAST UNIV

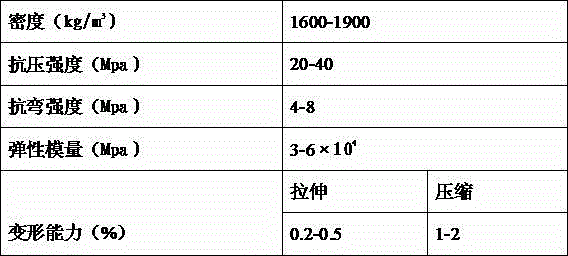

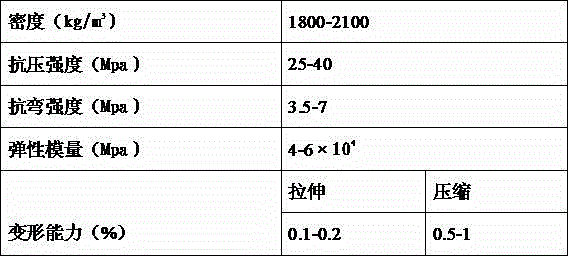

Non-blending macromolecule concrete and construction method thereof

InactiveCN102718433AImprove adhesionRaise the ratioRoads maintainenceRoad engineeringMaterials science

The invention belongs to the technical field of road engineering and particularly relates to a non-blending macromolecule concrete and a construction method thereof. The non-blending macromolecule concrete is prepared from the following components in percent by weight: 80-89% of aggregate, 8-15% of macromolecule material and 3-5% of additive. The construction method comprises the following steps of: selecting the aggregate with a material diameter of 0-0.5 mm, 0.5-3 mm or 3-30 mm according to a place to be used in a construction process; adding the selected aggregate and the additive to a die or a set place; and injecting the macromolecule material in the aggregate under pressure of 4-10 Mpa, and then curing for 15-25 minutes, so that the construction of the non-blending macromolecule concrete can be completed. According to the non-blending macromolecule concrete provided by the invention, the macromolecule material is used as an adhesion agent, so that the non-blending macromolecule concrete has the advantages of low production cost, simple preparation and construction process, wide construction condition, high firmness and durability, and simple last-stage maintenance. The non-blending macromolecule concrete can be used for buildings in a special environment, the road engineering, maintenance engineering, underground engineering and the like.

Owner:河南万里交通科技集团股份有限公司

Mineral inorganic hole-sealing material and preparing method and using method thereof

The invention provides a mineral inorganic hole-sealing material. The mineral inorganic hole-sealing material is prepared from, by mass, 10-87% of cement, 10-50% of pulverized fuel ash, 1-20% of alum,1-20% of accelerator and 1-20% of gypsum powder. The mineral inorganic hole-sealing material is small in density, low in mass, high in plasticity and permeability and high in quick solubility, is noteasily caked, is high in pressure resistance, high in pressure resistance and high in setting rate and has expansibility after solidification. The invention further provides a preparing method and using method of the mineral inorganic hole-sealing material, and the preparing method of the mineral inorganic hole-sealing material is easy to operate and implement.

Owner:淮南久辉工贸有限责任公司

High-humic-acid soil curing agent and preparation method thereof

The invention belongs to the technical field of curing agents, and particularly relates to a high-humic-acid soil curing agent and a preparation method thereof. The high-humic-acid soil curing agent comprises substances in percentage by mass: 25%-40% of steel slag, 15%-25% of fly ash, 10%-15% of quick lime, 10%-20% of ordinary Portland cement, 6%-10% of an exciting agent, 1%-5% of an ion replacing agent, 1%-3% of a water repellent, 4%-6% of a retarder, 1%-2% of an early strength agent, 1%-3% of a filling agent, 1%-3% of a stabilizer, 1%-2% of an air entraining agent, 0.5%-1% of a water reducing agent and 0.5%-2% of a humic acid modifier. The high-humic-acid soil curing agent has the effects and advantages that the influence of humic acid on soil can be effectively reduced, the shear strength, the compressibility and the water stability of the soil are improved, the pore size, the compressibility and the permeability of the soil are reduced, and good economic and environmental benefits are achieved.

Owner:吉林建筑科技学院

Method for repairing pavement by reinforcing roadbed through grouting

The invention discloses a method for repairing a pavement by reinforcing a roadbed through grouting. The method comprises the following steps that the grouting position is determined; drilling is carried out according to the designed vacancy; slurry pouring is carried out; hole finishing is carried out; transferring to a next hole site for construction is carried out, wherein an interlaced jump grouting method is adopted for construction in order to avoid influences on peripheral existing hole sites; after grouting construction is finished, curing is conducted for 5 days, and then qualification detection is conducted; after the roadbed reinforced through grouting is detected to be qualified, C20 plain concrete with the thickness of 30 cm is poured into a C20 road groove; after the C20 plain concrete is cured to reach the strength of 70% or above, an emulsified asphalt viscous oil layer is spread; asphalt concrete is paved; a rubber asphalt stress absorption layer is paved; and after aqualified treatment area and other areas which do not need to be treated are milled and planed, a fine-grained AC-13 and SBS asphalt concrete upper surface layer is finally paved together. By means ofthe scheme, the old and stubborn problem of long-term pavement subsidence at local positions of a road can be effectively solved.

Owner:HUALAN DESIGN GRP CO LTD

Insulation material having air purifying function and preparation method thereof

InactiveCN107098721AImprove buffering effectImprove heat resistanceCeramicwarePolyesterCalcium silicate

The invention provides an insulation material having air purifying function and a preparation method thereof, which relate to the field of the insulation material. The insulation material comprises the following raw materials in parts by weight: 14-20 parts of calcium silicate powder, 10-28 parts of granite powder, 15-17 parts of polyurethane, 17-23 parts of alumina silicate powder, 5-9 parts of magnesium oxide, 7-13 parts of mineral wool, 4-8 parts of polyester fiber, 21-35 parts of bamboo charcoal, 7-13 parts of bentonite, 9-13 parts of meerschaum powder, 15-19 parts of phenolic foam, 11-31 parts of vermiculite, 15-21 parts of waste polyethylene foamed plastic, 9-15 parts of boron fiber, 13-21 parts of polyacrylonitrile fiber, 27-35 parts of cement, 0.2-0.4 parts of an air-entrainer, 0.1-0.7 parts of a delayed coagulant, 0.1-0.3 parts of a heat stabilizer, 0.3-0.7 parts of a water reducer, 0.2-0.6 parts of a foaming agent, and 4-8 parts of water. The preparation method comprises the following steps: 1) raw material weighing; 2) roasting; 3) crushing; 4) stirring; 5) pressurization moulding; and 6) drying. The insulation material has the advantages of high intensity, good heat insulation performance, environmental protection and energy saving.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000011.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000012.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/BSA0000105126520000021.PNG)