Oil well cement chlorine-free coagulation accelerating early strength agent

A technology for early-strength and oil-well cement, applied in the field of early-strength accelerators, can solve the problems of long induction period, unfavorable cement stone cementation, slow cement hydration speed, etc., achieve short transition time, prevent annular interface channeling flow, preventing micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh various samples according to the following proportions:

[0035] Magnesium sulfate: triethanolamine: formamide: calcium formate: urea: naphthalenesulfonate = 1:0.1:0.1:2:1:0.5

[0036] Add the above-mentioned materials in turn in the mortar, pound into powder with a mortar stick, and mix evenly to make a coagulation accelerator and early strength agent. Use A01 as the coagulation accelerator and early strength agent code.

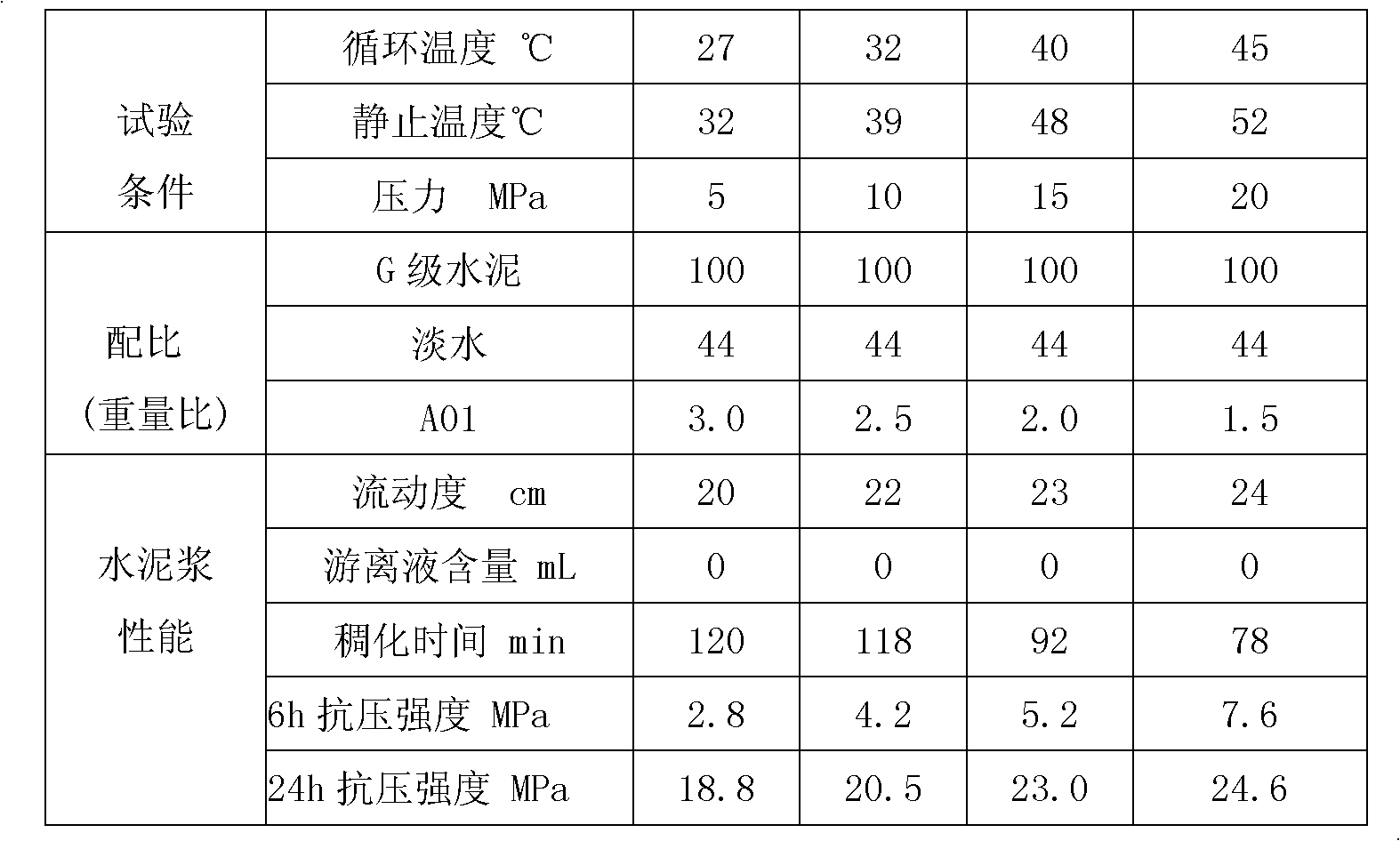

[0037] Table 1 Properties of cement slurry mixed with the accelerator and early strength agent under different test conditions

[0038]

Embodiment 2

[0040] Weigh various samples according to the following proportions:

[0041] Magnesium sulfate: triethanolamine: formamide: calcium formate: urea: naphthalenesulfonate = 2: 0.1: 0.1: 1: 1: 0.5

[0042] Add the above-mentioned materials in turn in the mortar, pound into powder with a mortar stick, and mix evenly to make a coagulation accelerator and early strength agent. Use A02 as the coagulation accelerator and early strengthening agent code.

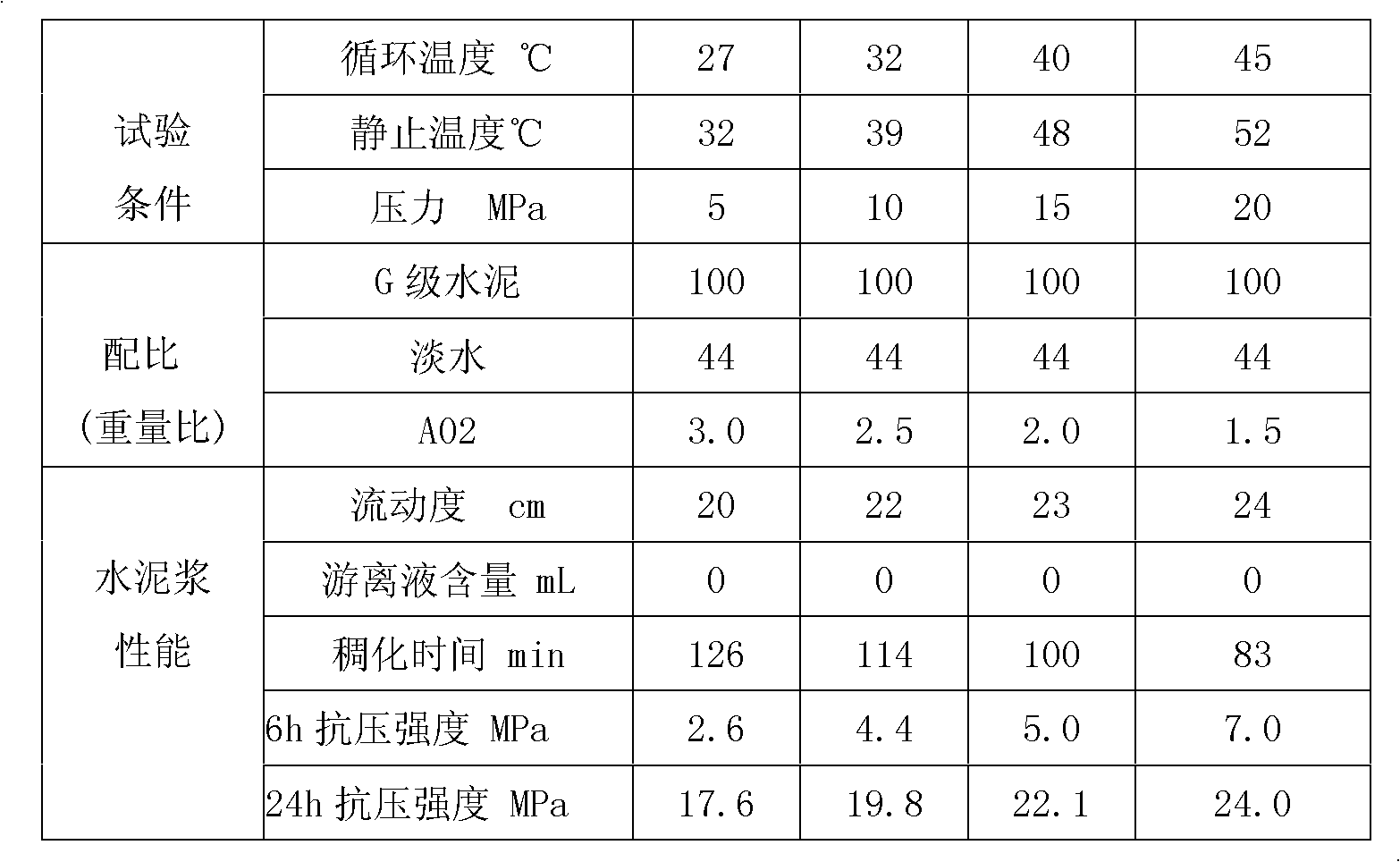

[0043] Table 2 Properties of cement slurry mixed with the accelerator and early strength agent under different test conditions

[0044]

Embodiment 3

[0046] Weigh various samples according to the following proportions:

[0047] Magnesium sulfate: triethanolamine: formamide: calcium formate: urea: naphthalenesulfonate = 1.5: 0.1: 0.1: 2: 0.5: 0.5

[0048] Add the above-mentioned materials in turn in the mortar, pound into powder with a mortar stick, and mix evenly to make a coagulation accelerator and early strength agent. Use A03 as the coagulation accelerator and early strengthening agent code.

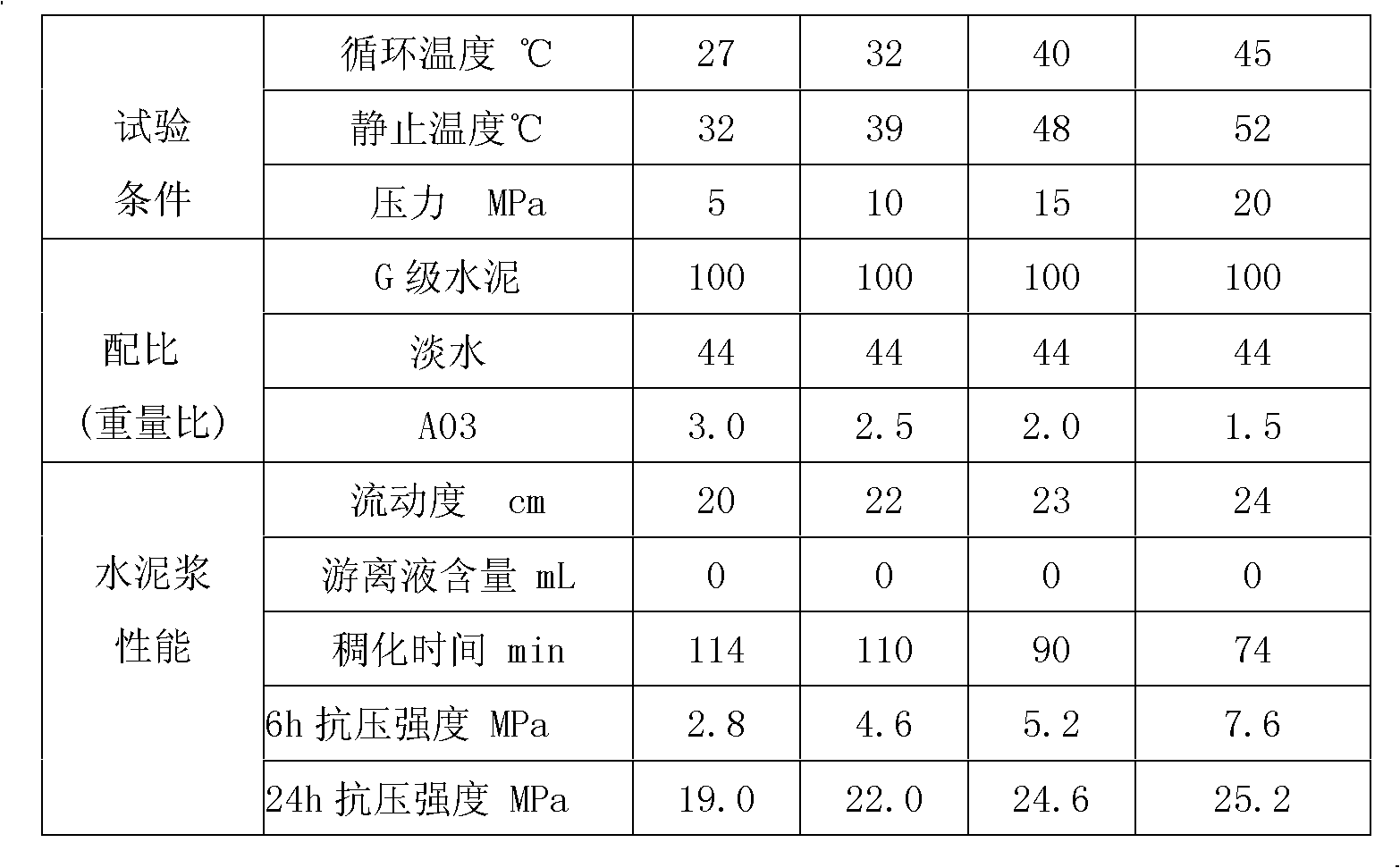

[0049] Table 3 Properties of cement slurry mixed with the accelerator and early strength agent under different test conditions

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com