Patents

Literature

365 results about "Induction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

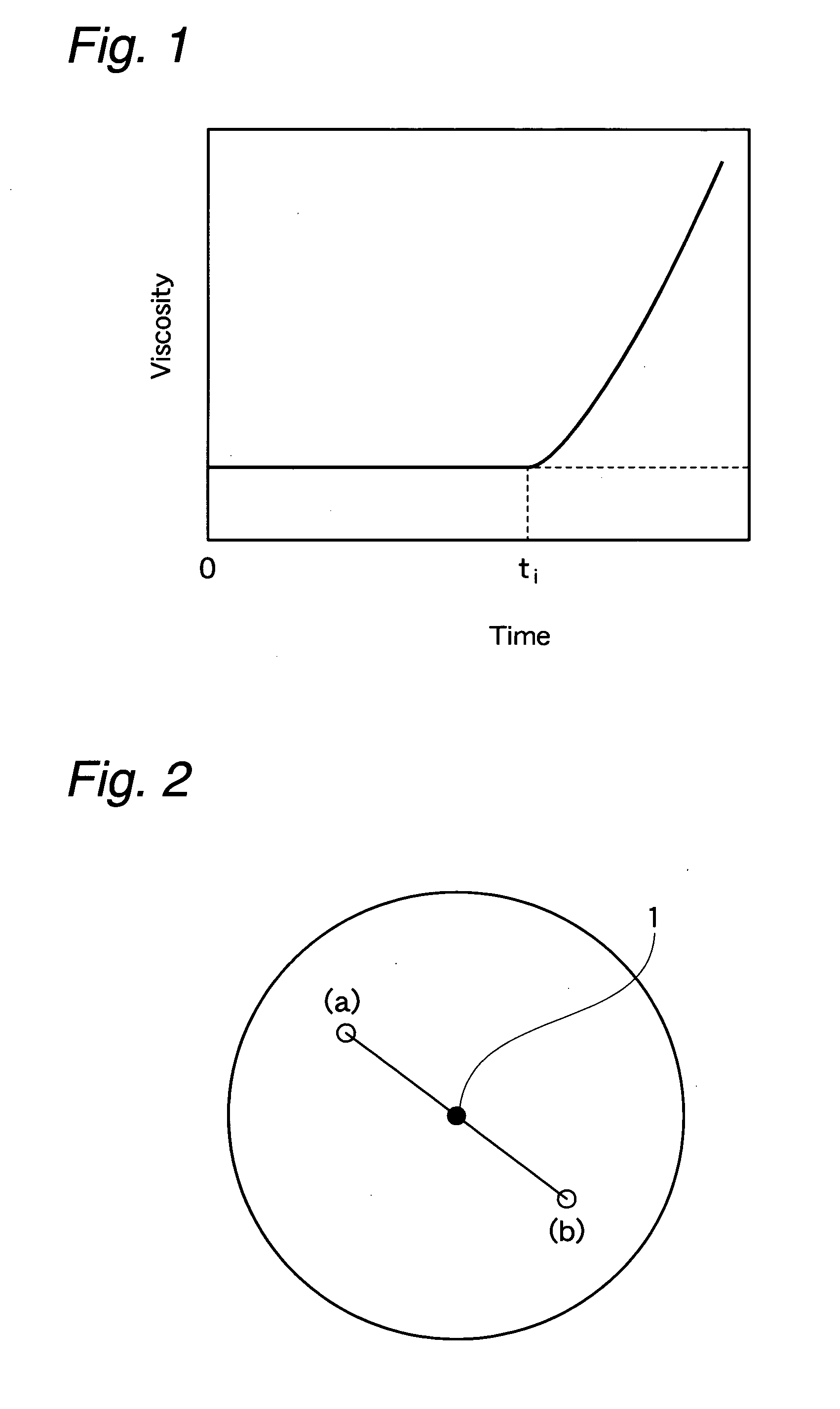

An induction period in chemical kinetics is an initial slow stage of a chemical reaction; after the induction period, the reaction accelerates. Ignoring induction periods can lead to runaway reactions.

Biofouling self-compensating biosensor

InactiveUS20070299617A1Reduce the burden onPatient compliance is goodImmobilised enzymesBioreactor/fermenter combinationsEngineeringBiofouling

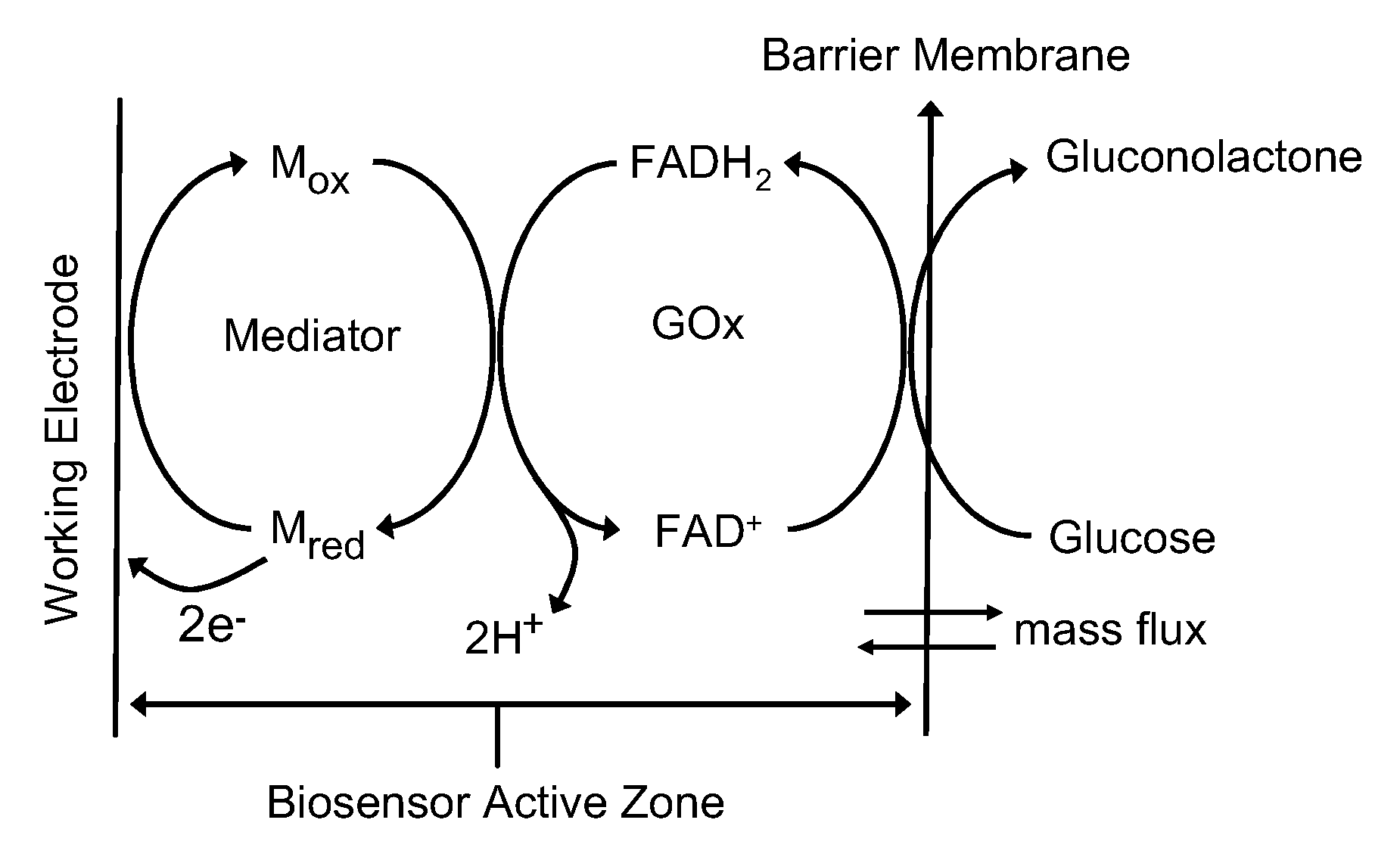

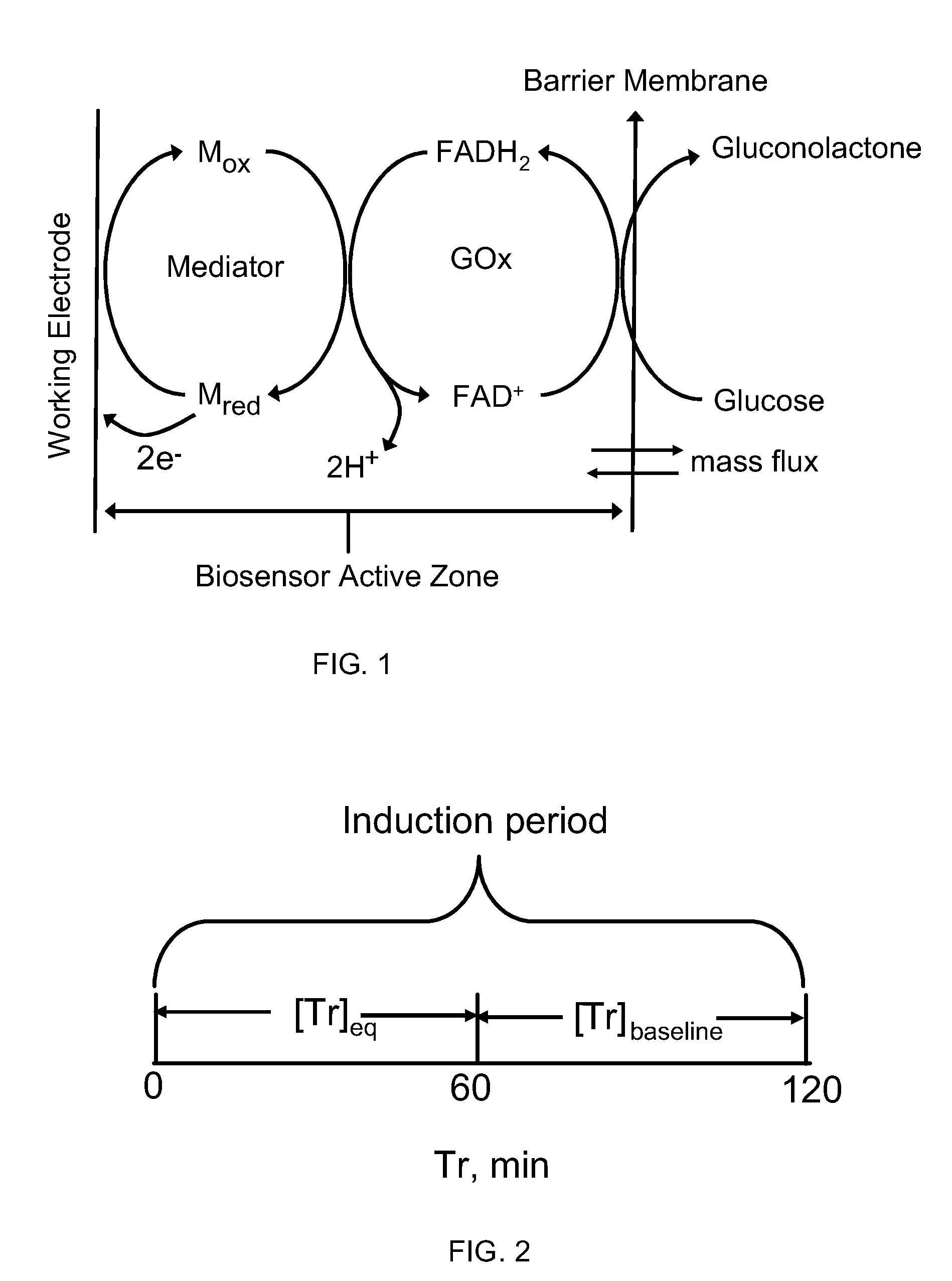

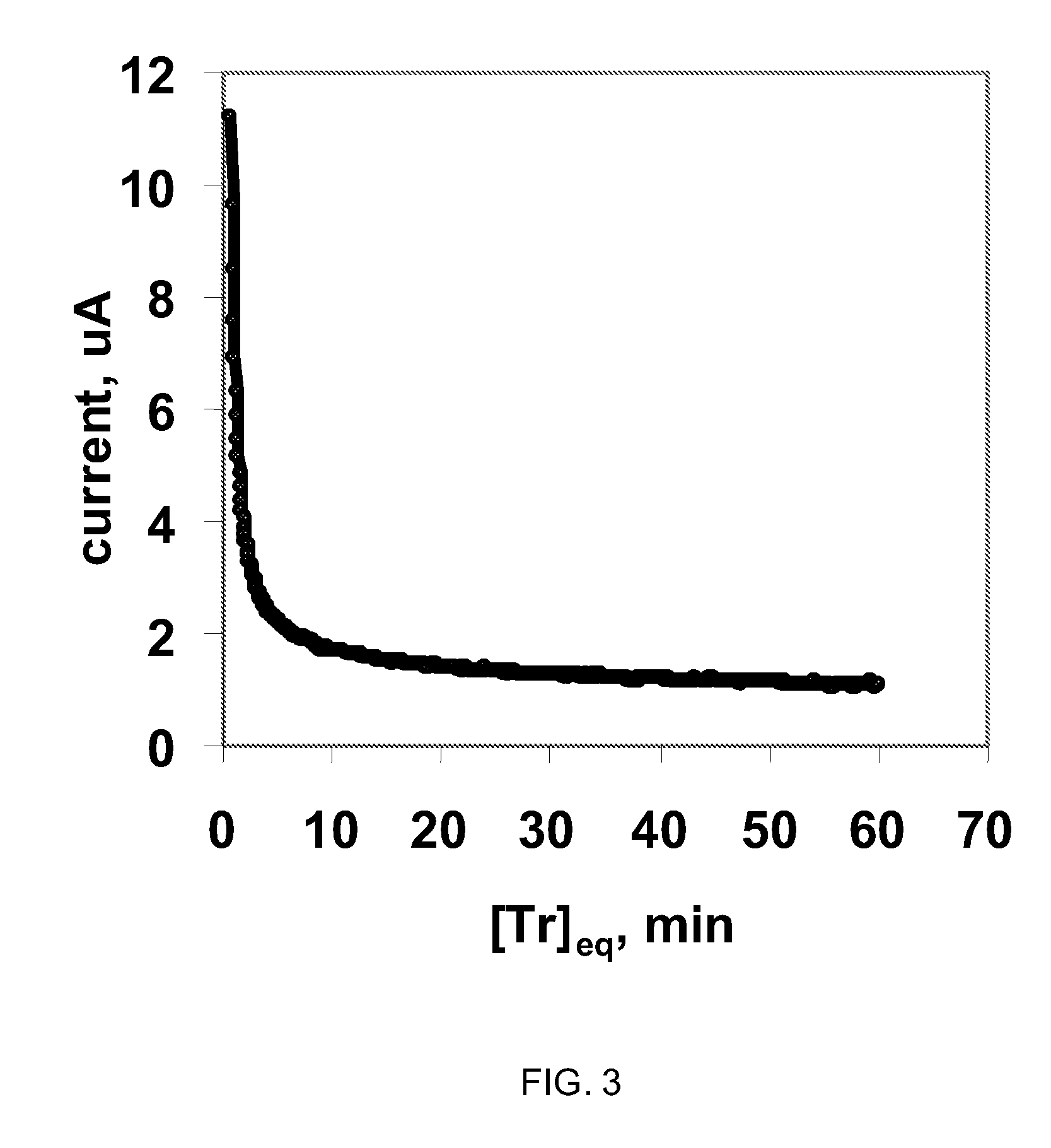

An in vivo biosensor disposed upon a subject comprising an electrochemical cell having a plurality of electrodes and a computer-controlled voltage source incorporating a potentiostat that is generative of a poise potential regime, which computer-controlled voltage source is operationally coupled to a computing device that: computes an output current whose magnitude is proportional to an amount of an analyte in a bodily fluid of the subject; and, adjusts the output current for drift due to biofouling at points in time greater than or equal to an induction period; and, outputs the amount of the analyte by transducing the adjusted output current. Methods and algorithms for adjusting the output current for drift due to biofouling are provided.

Owner:ULTRADIAN DIAGNOSTICS

Cement Retarder Systems, and Retarded Cement Compositions

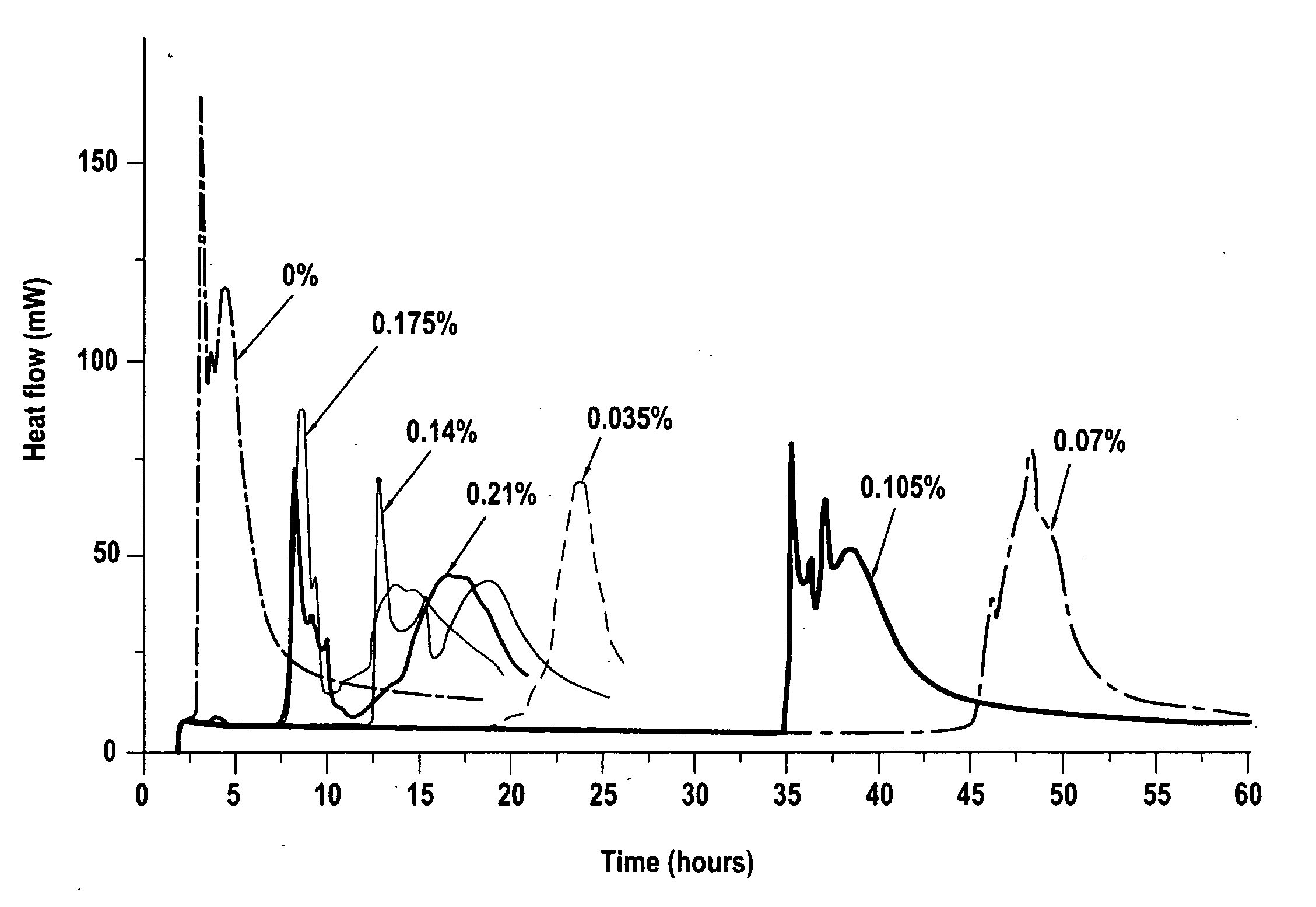

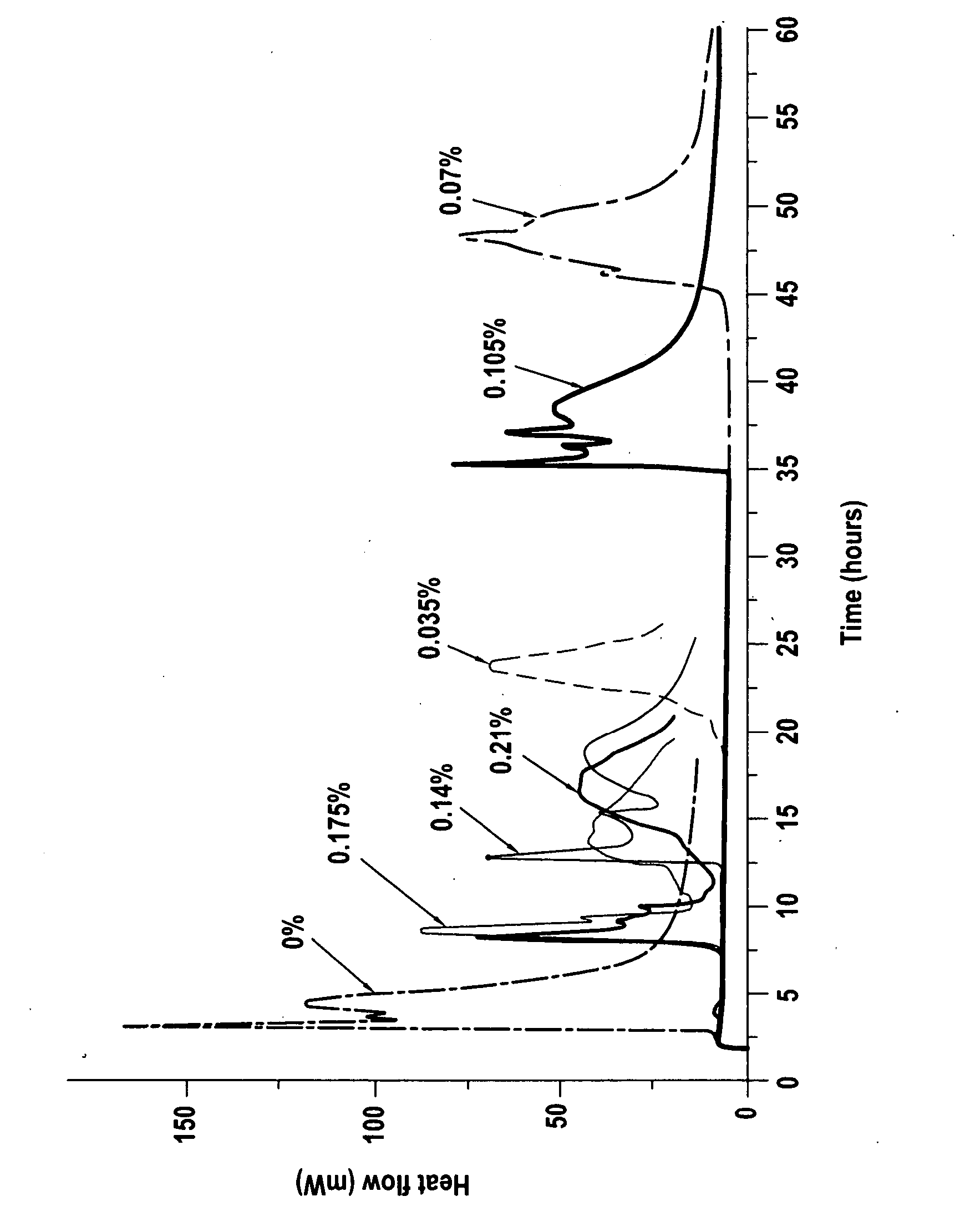

A cement retarder system for use in underground wells included a borate compound, an organophosphonate salt, and a copolymer formed from AMPS and a monomer selected from the group consisting of acrylic acid, acrylamide and mixtures thereof. A method of using the retarder system in an underground well having a borehole drilled therein with a borehole wall, and further including a casing disposed in said borehole, such that an annulus exists between said casing and said borehole wall, comprising the steps of providing a cement composition and a liquid carrier, providing a retarder system for said cement composition comprising a borate compound, an organophosphonate salt, and a copolymer formed from AMPS and a monomer selected from the group consisting of acrylic acid, acrylamide, and mixtures thereof, mixing a sufficient amount of said retarder system to create a desired induction period with said cement composition and said liquid carrier to form a cement slurry, pumping the cement slurry from the surface down the casing, and causing said slurry to return to the surface in the annulus between the casing and the borehole wall.

Owner:SCHLUMBERGER TECH CORP

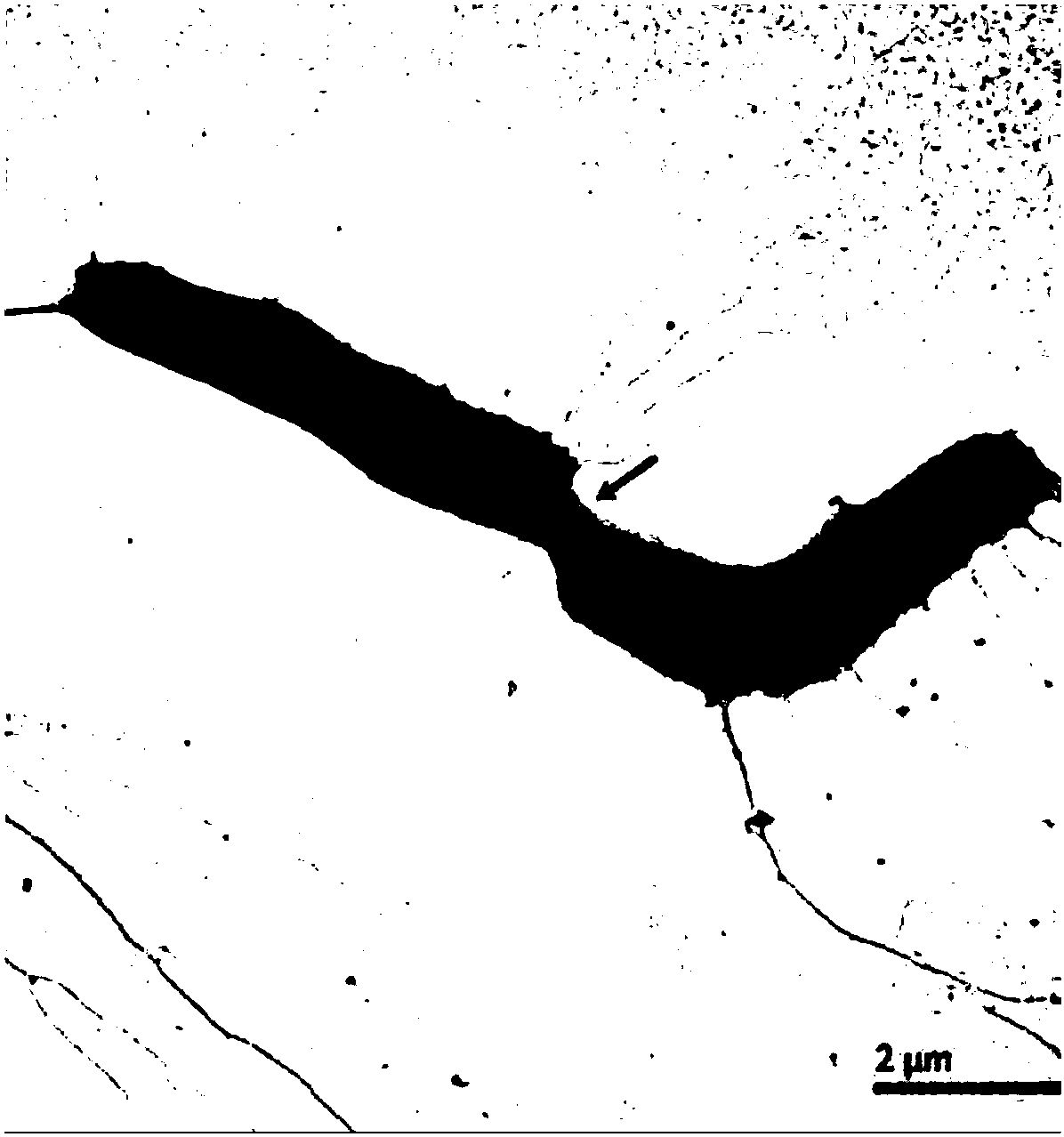

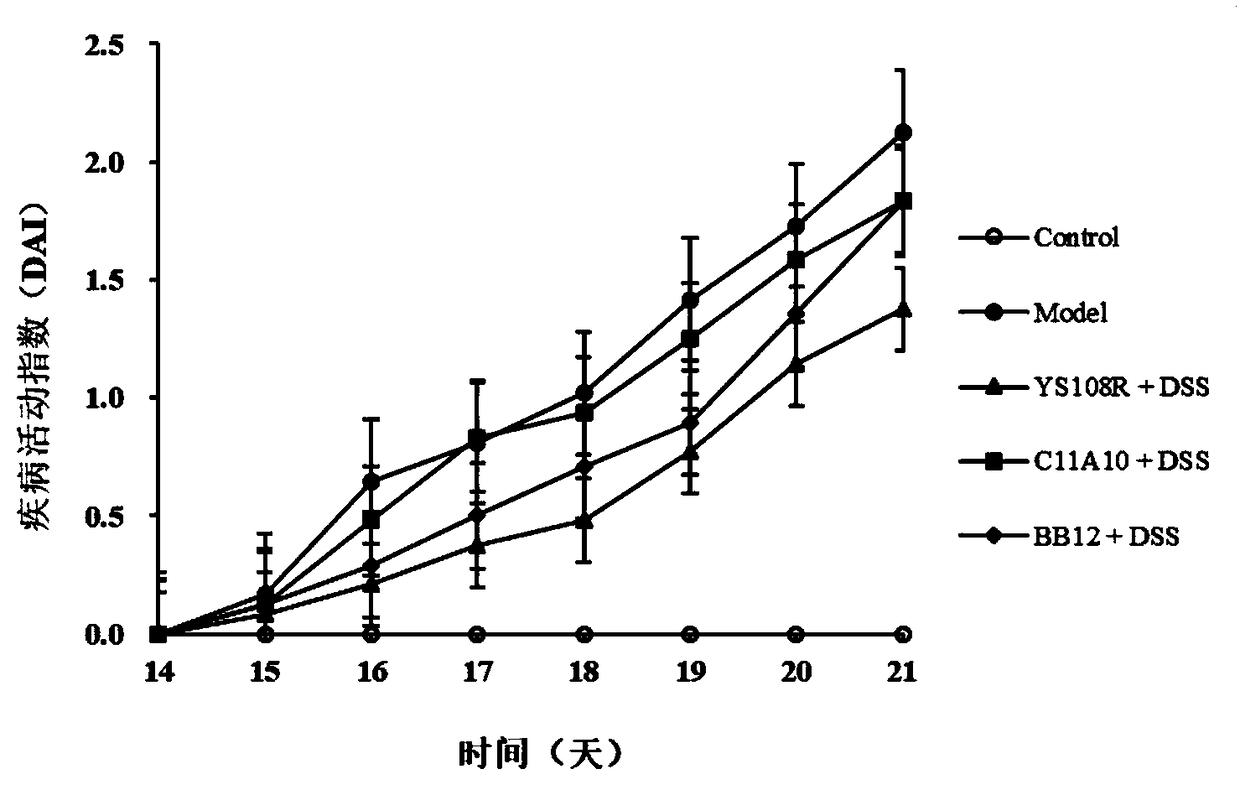

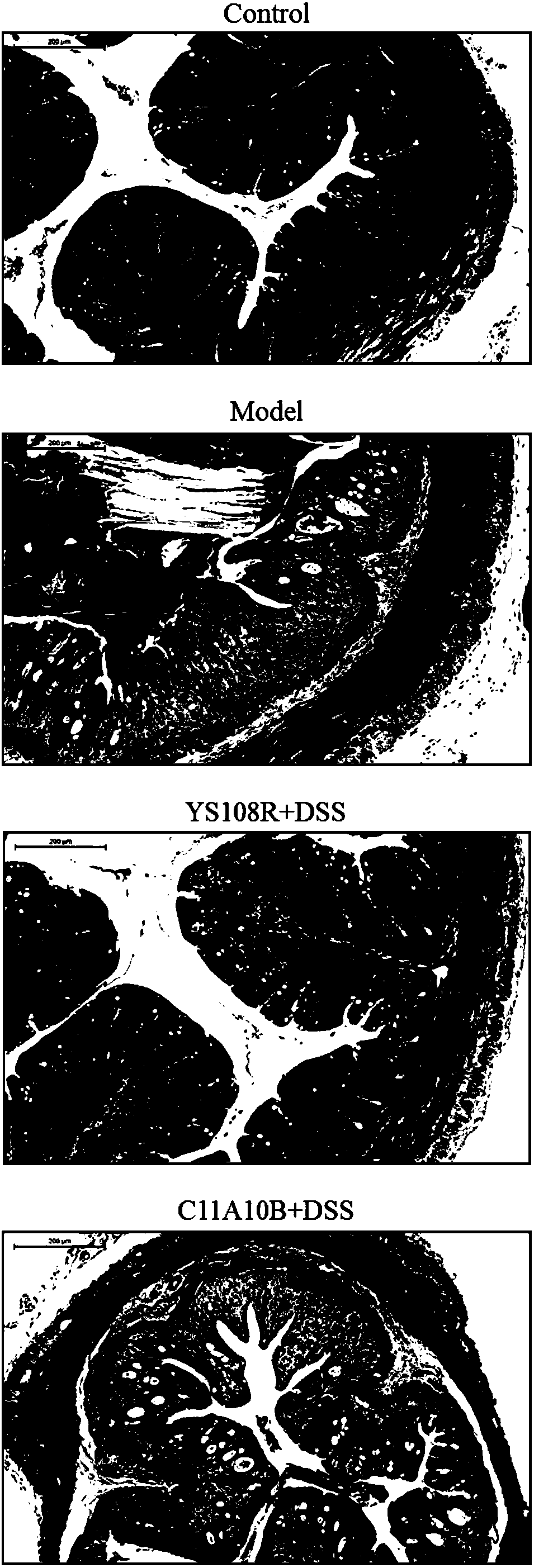

Bifidobacterium longum and application thereof

ActiveCN108220206AGood ability to tolerate simulated gastrointestinal fluidNo side effectsMilk preparationBacteriaHuman bodyBiotechnology

The invention discloses bifidobacterium longum and the application thereof and belongs to the technical field of biologics. The invention provides a bifidobacterium longum YS108R strain which has thecharacteristic of generating viscous exopolysaccharide, and has a remarkable improvement function on DSS (Dextran Sulfate Sodium) induced mouse colitis models. The strain has a relatively good capability of enduring simulated gastrointestinal fluids, is capable of remarkably reducing disease activity indexes of mice in the DSS induction period, and has an effective protection function on colon tissue. In addition, the bifidobacterium longum YS108R disclosed by the invention is separated from intestinal florae of healthy people, is free of toxic and / or side effects on human bodies, and has certain advantages when being compared with conventional medicine treatment. The strain can be used for preparing probiotic powder, fermented milk, and the like, and has wide market prospects.

Owner:无锡特殊食品与营养健康研究院有限公司

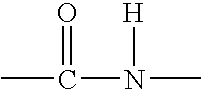

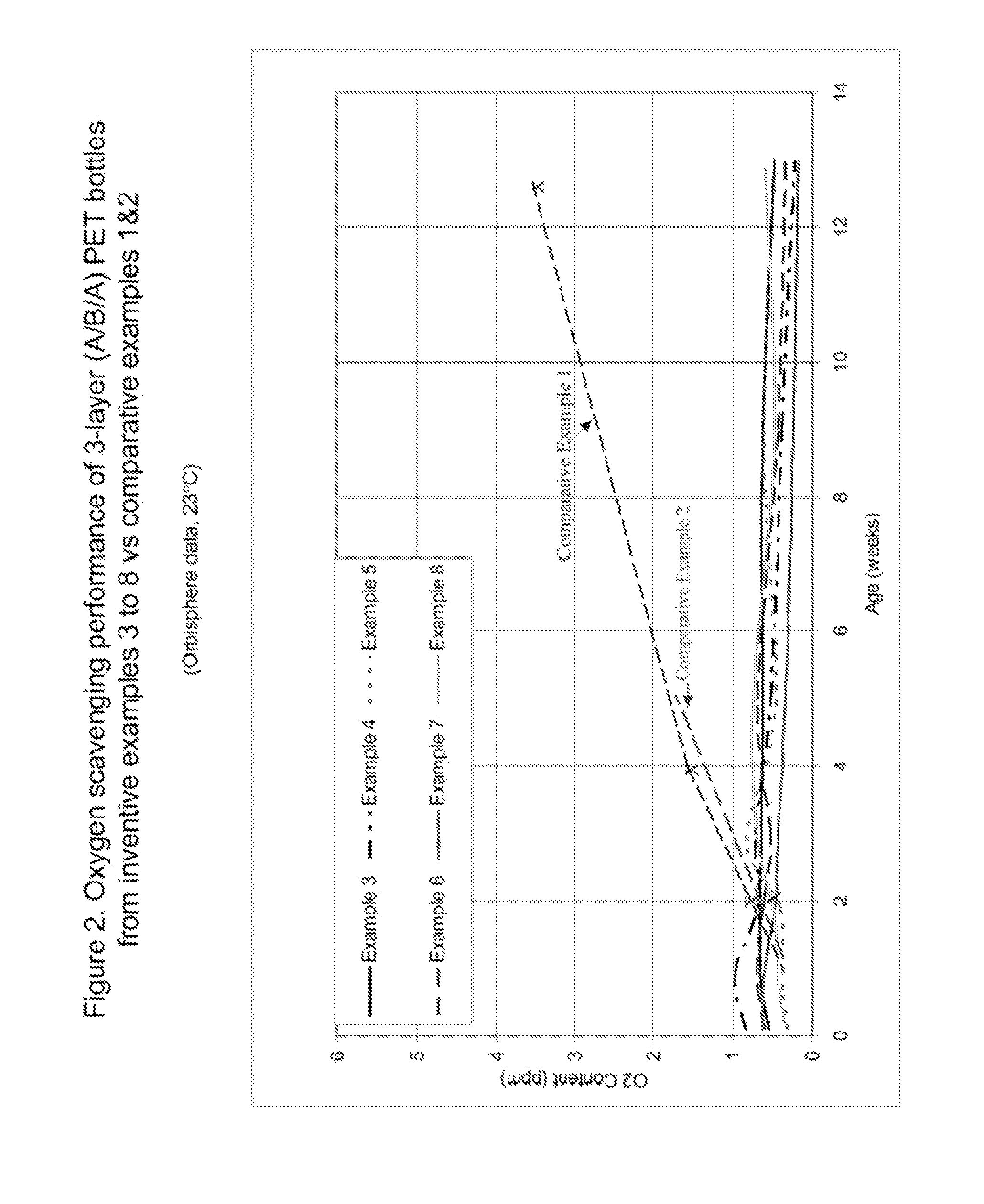

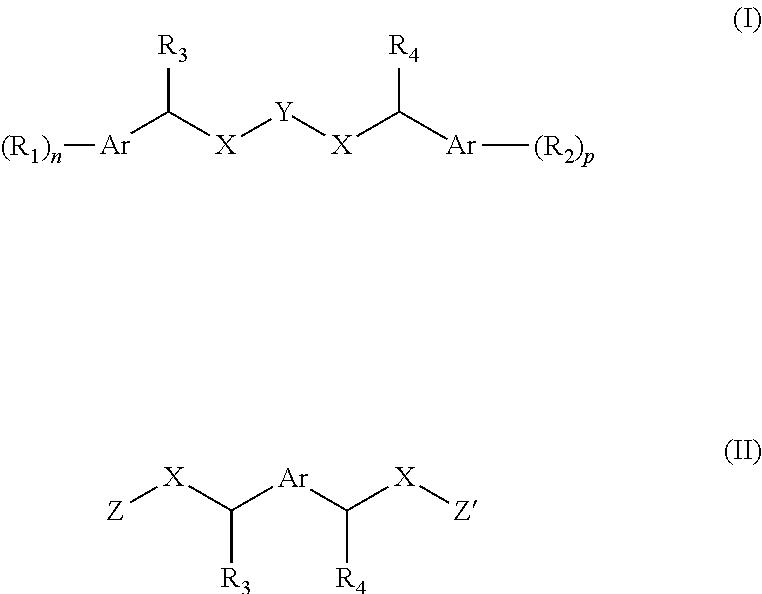

Polyester/polyamide blend having improved flavor retaining property and clarity

InactiveUS20060122306A1High oxygen barrierImprove performanceConductive materialSpecial tyresPolyesterPolyethylene terephthalate glycol

This invention relates to a polyester / polyamide blend having an excellent gas barrier property. More particularly, the present invention relates to combinations of a polyethylene terephthalate polymer and a polyamide polymer having an excellent gas barrier property and short oxygen scavenging induction periods, where the polyamide polymer has a C:A terminal group concentration ratio of 2:1 or more and a C+A terminal group concentration of at least 0.17 meq / g of polyamide polymer, wherein C represents a cumulative total of a terminal carboxyl group concentration and a terminal hydrocarbyl group concentration expressed in meq / g of polyamide, and A represents a terminal amine group concentration expressed in meq / g of polyamide.

Owner:EASTMAN CHEM CO

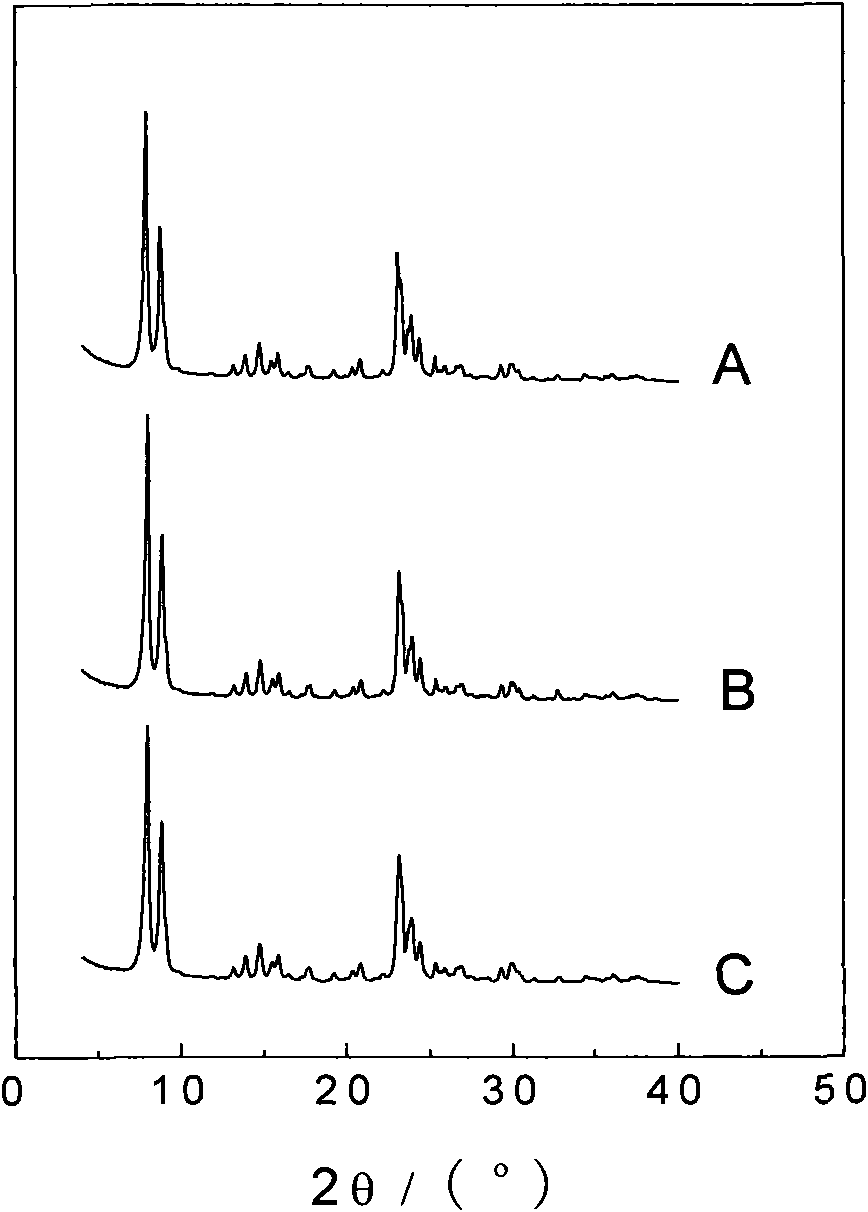

Method for modifying titanium-silicon zeolite material

ActiveCN101850985AHigh catalytic oxidation activityGood catalytic activity and stabilityCrystalline aluminosilicate zeolitesTitaniumAqueous solution

The invention discloses a method for modifying a titanium-silicon zeolite material. The method comprises the following steps of: adding titanium-silicon zeolite into aqueous solution of pore-forming agent and alkali source, then treating the obtained mixture in a closed reaction kettle under a hydrothermal treatment condition, and reclaiming a product to obtain the modified titanium-silicon zeolite material. According to the modifying method, the titanium-silicon zeolite material is favorable for adsorption and diffusion of the reactants and the product, and the active center thereof is easily contacted. Compared with the prior art, in oxidation reaction, the titanium-silicon zeolite material obtained by adopting the modifying method has the advantages of shortened reaction induction period, high oxidation activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Accelerant for generating gas hydrate

ActiveCN103962078AImprove production efficiencyReduced nucleation timePressurized chemical processGaseous fuelsMass ratioSolid particle

The invention relates to a natural gas hydrate, and particularly to an accelerant for strengthening the generation of a gas hydrate. The accelerant for generating the gas hydrate, provided by the invention, is prepared by compounding of a novel anion gemini surfactant and solid activated carbon particles with a strong heat transmission effect at a certain mass ratio; a liquid mixture is formed after the high-speed mechanical agitation and the ultrasonic dispersion are conducted on the reagent, and the essence is that solid particles with a high heat-conducting property are wrapped in the gemini surfactant, so that nanometer solid particles cannot be agglomerated easily, and the mixing solution with uniformly dispersed solutes is formed, and the mixing solution is free of sediment; the application temperature ranges from 0 DEG C to 10 DEG C, the pressure ranges from 0 MPa to 12 MPa, and the time of hydrate generation induction period ranges from 1 min to 3 min; compared with the pure water system, the generation speed rate of the hydrate is increased by 140%-200%.

Owner:南通东湖国际商务服务有限公司

Combination circulation steam turbine lubricating oil composition

ActiveCN101240212AExcellent high temperature oxidation resistanceMeet lubrication needsAdditivesAntioxidantRust

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Owner:PETROCHINA CO LTD

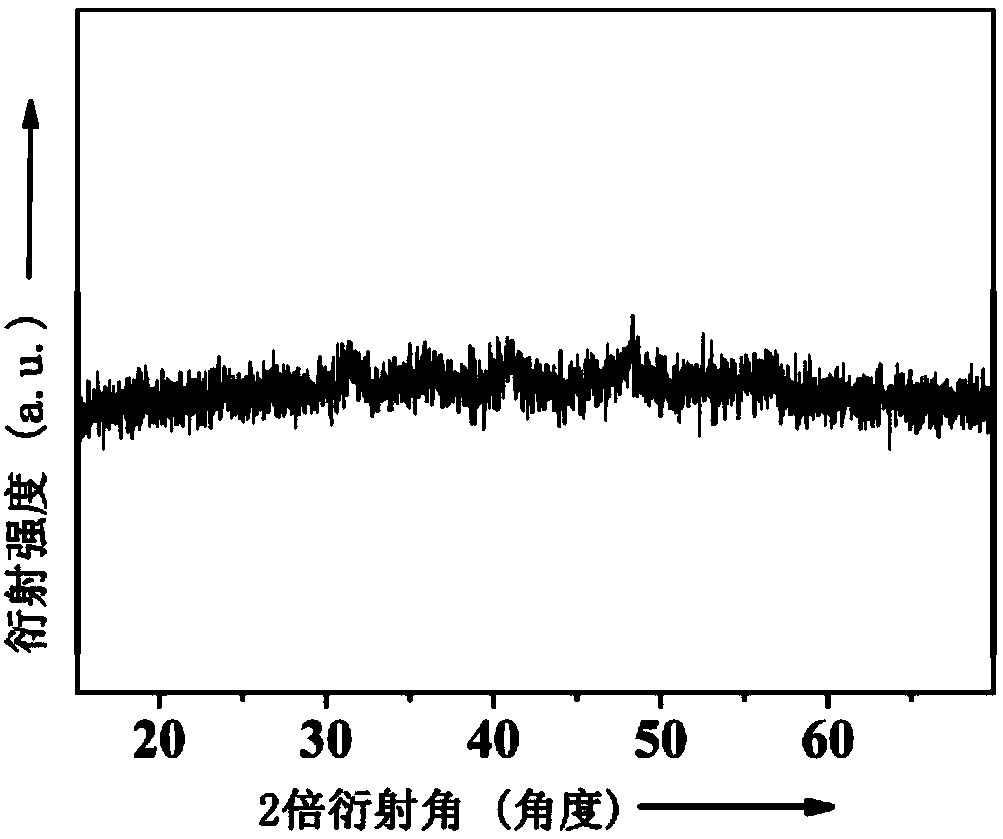

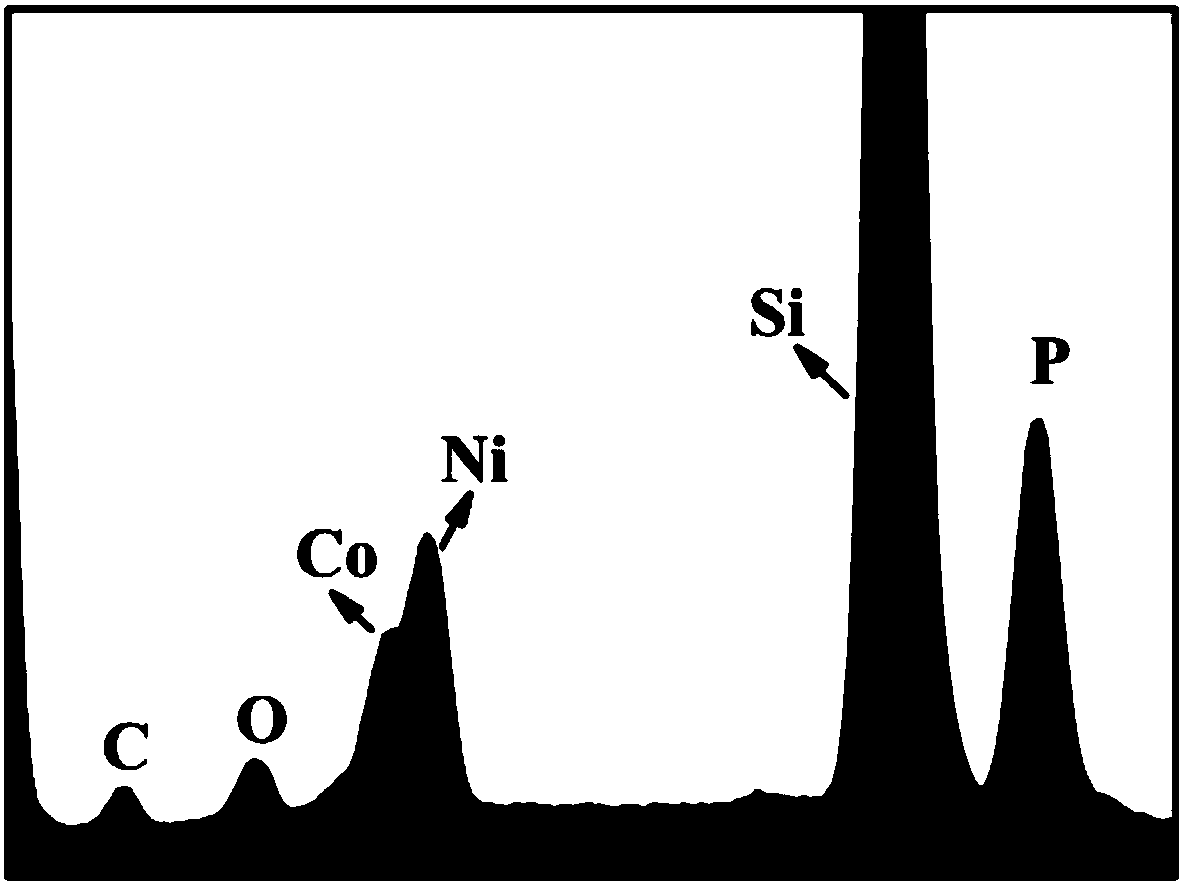

Hydrogen storage material hydrolysis and hydrogen releasing system taking monodispersed or supported phosphorus-containing metal compound as catalyst

ActiveCN108525685ASave raw materialsHigh catalytic efficiencyPhysical/chemical process catalystsHydrogen productionHydrolysisAqueous solution

The invention discloses a hydrogen storage material hydrolysis and hydrogen releasing system taking a monodispersed or supported phosphorus-containing metal compound as a catalyst. The system comprises a hydrogen storage material and water, and further comprises a catalyst, wherein the catalyst is one or multiple of a monodispersed multi-metal phosphide, a supported multi-metal phosphide, a monodispersed single-metal and multi-non-metal phosphorus-containing compound, a supported single-metal and multi-non-metal phosphorus-containing compound, a monodispersed multi-metal multi-non-metal phosphorus-containing compound and a supported multi-metal multi-non-metal phosphorus-containing compound. Alkali is added into an aqueous solution of the monodispersed or supported phosphorus-containing metal to improve the catalytic rate of the catalyst and shorten the induction period. The catalysis efficiency of the supported catalyst is higher than that of the monodispersed catalyst. The system provides a batch of efficient novel catalysts for hydrolysis and hydrogen releasing of the hydrogen storage material, and provides a method for increasing the hydrolysis rate of the hydrogen storage material under the catalysis of the phosphorus-containing metal compound.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

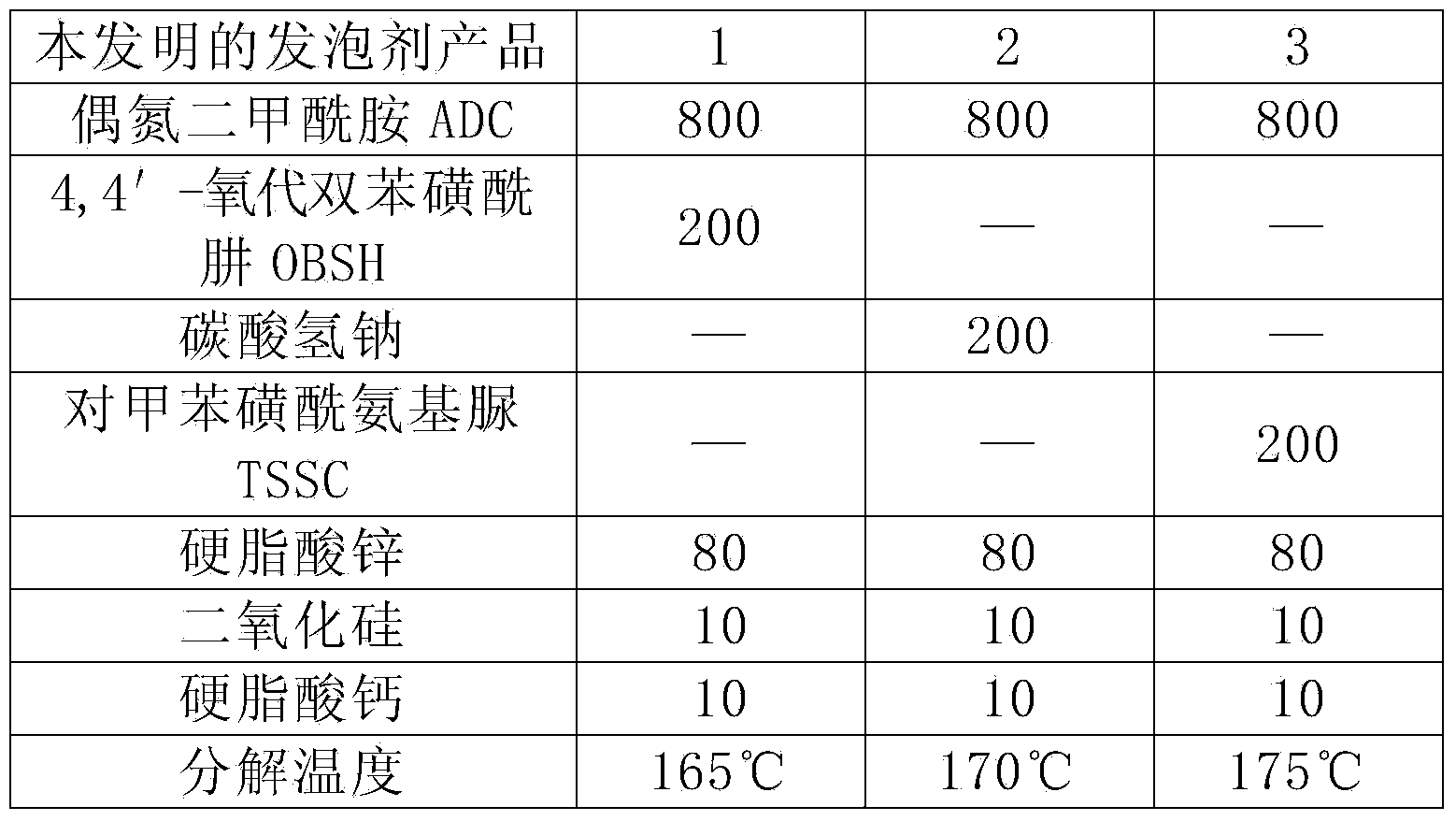

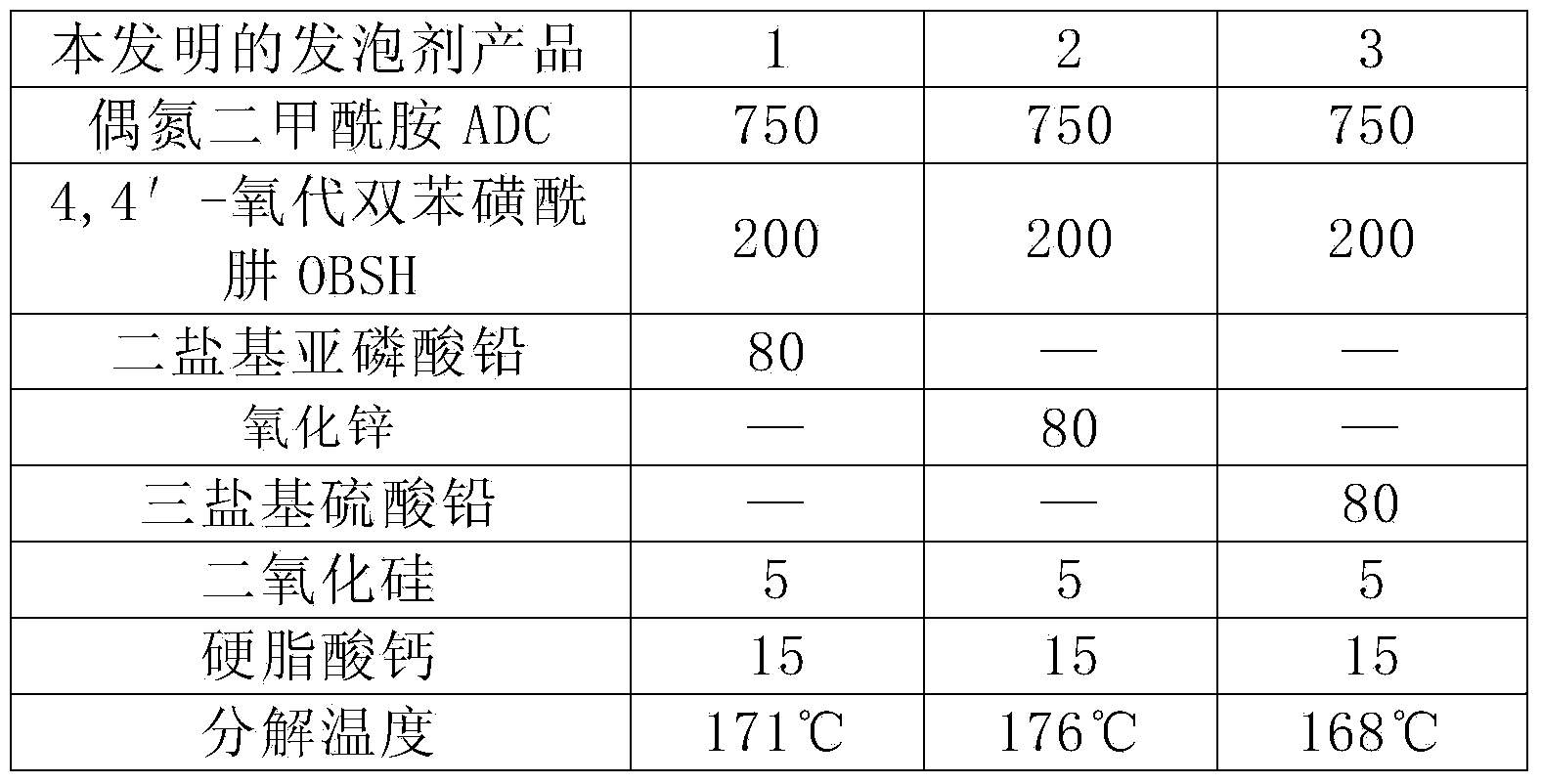

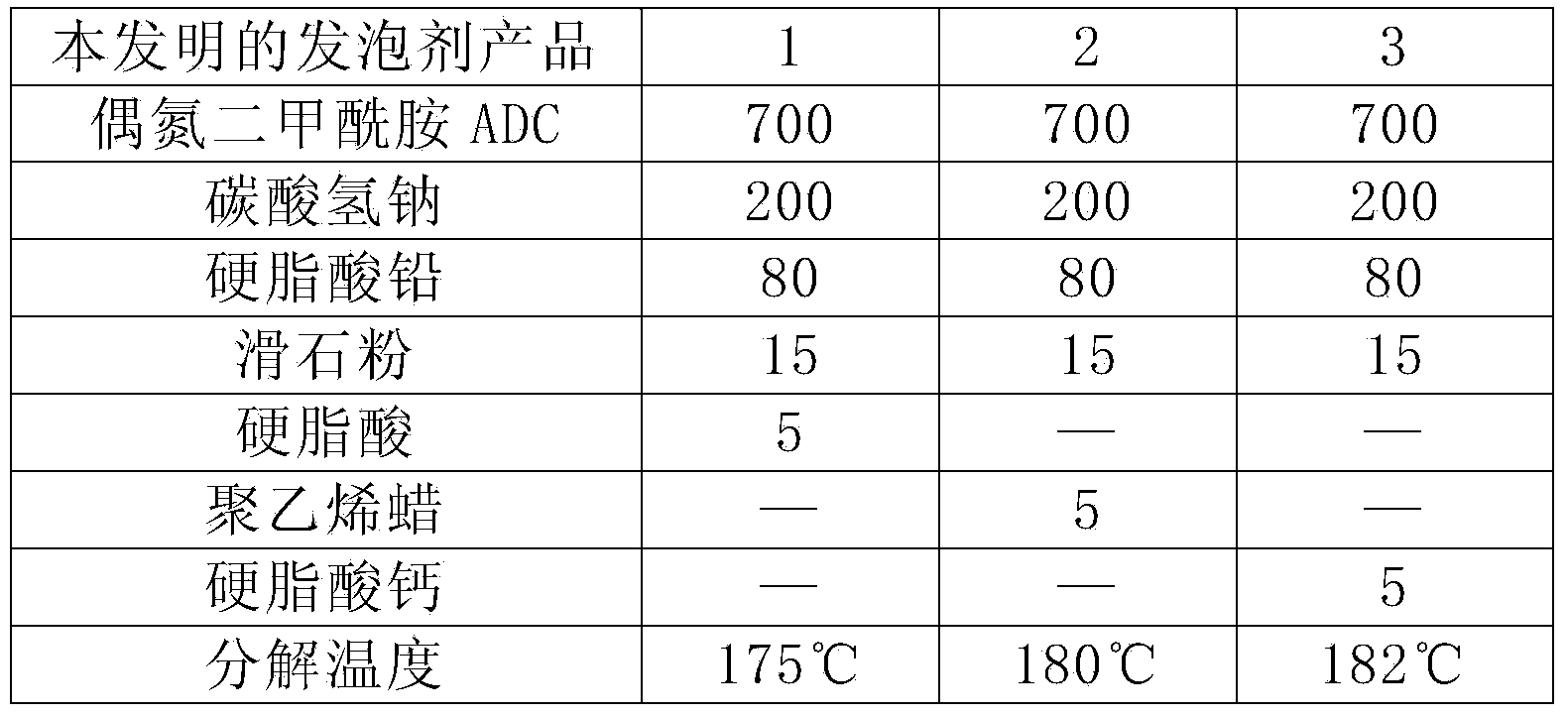

Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

The invention discloses a special foaming agent for a hard PVC (polyvinyl chloride) low-foaming material and a preparation method thereof. The special foaming agent comprises the following materials in parts by weight: 20-80 parts of azodicarbonamide (ADC), 20-80 parts of auxiliary foaming agent, 1-20 parts of activating agent, 0.2-10 parts of dispersing agent and 0.2-5 parts of processing agent. The preparation method comprises the steps: adding the dispersing agent and the processing agent in a mixer, mixing for 3-7 minutes, and sequentially uniformly mixing the ADC, the auxiliary foaming agent and the activating agent in the mixer to prepare the special foaming agent. The special foaming agent is suitable for hard PVC low-foam materials such as PVC crushing and low-foaming sectional bars, tubular products and sheets, a wood-plastics low-foaming material and the like. The special foaming agent has the positive effects that 1, the decomposition temperature is 160-190 DEG C, and is within a processing temperature range of the hard PVC low-foaming material; 2, the foaming process is short in induction period, the decomposition is performed without mutation, and the foaming process is easily controlled; 3, the hard PVC low-foaming material is used on a hard PVC low-foaming product, and has a smooth surface and has no discoloring and ageing phenomena; and 4, the special foaming agent is low in cost and good in comprehensive performance, and accords with the use requirement.

Owner:WEIFANG YAXING GRP CO LTD

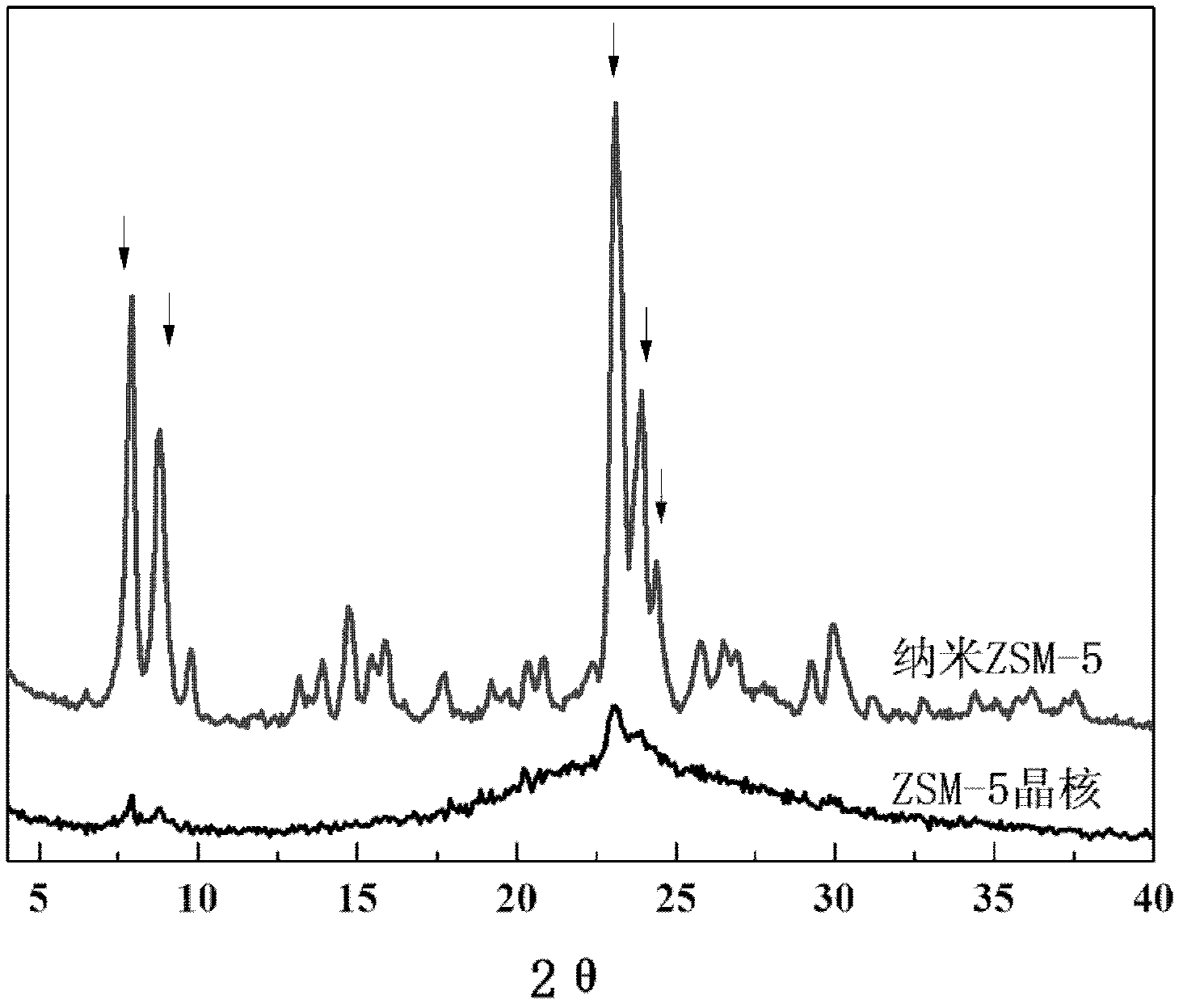

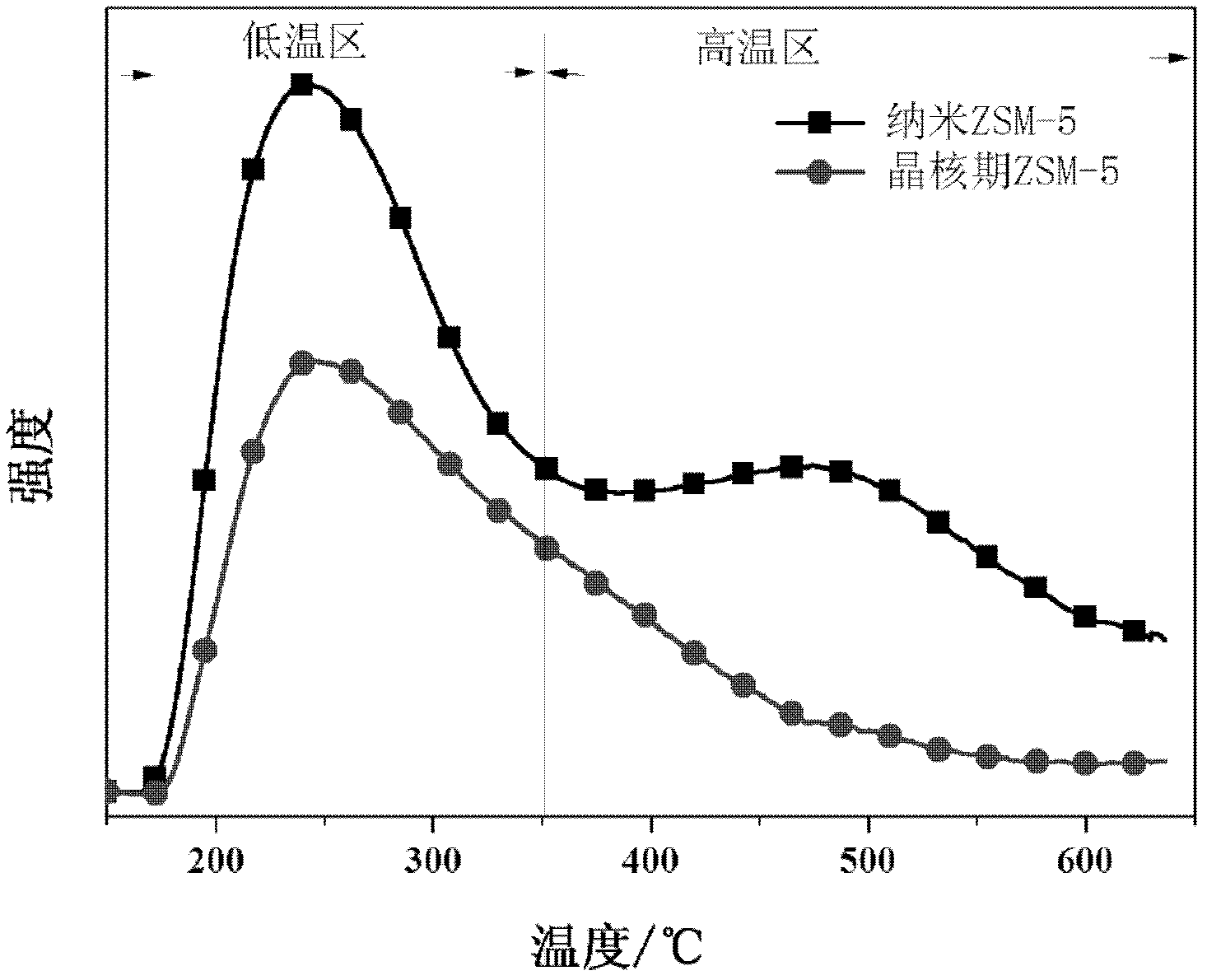

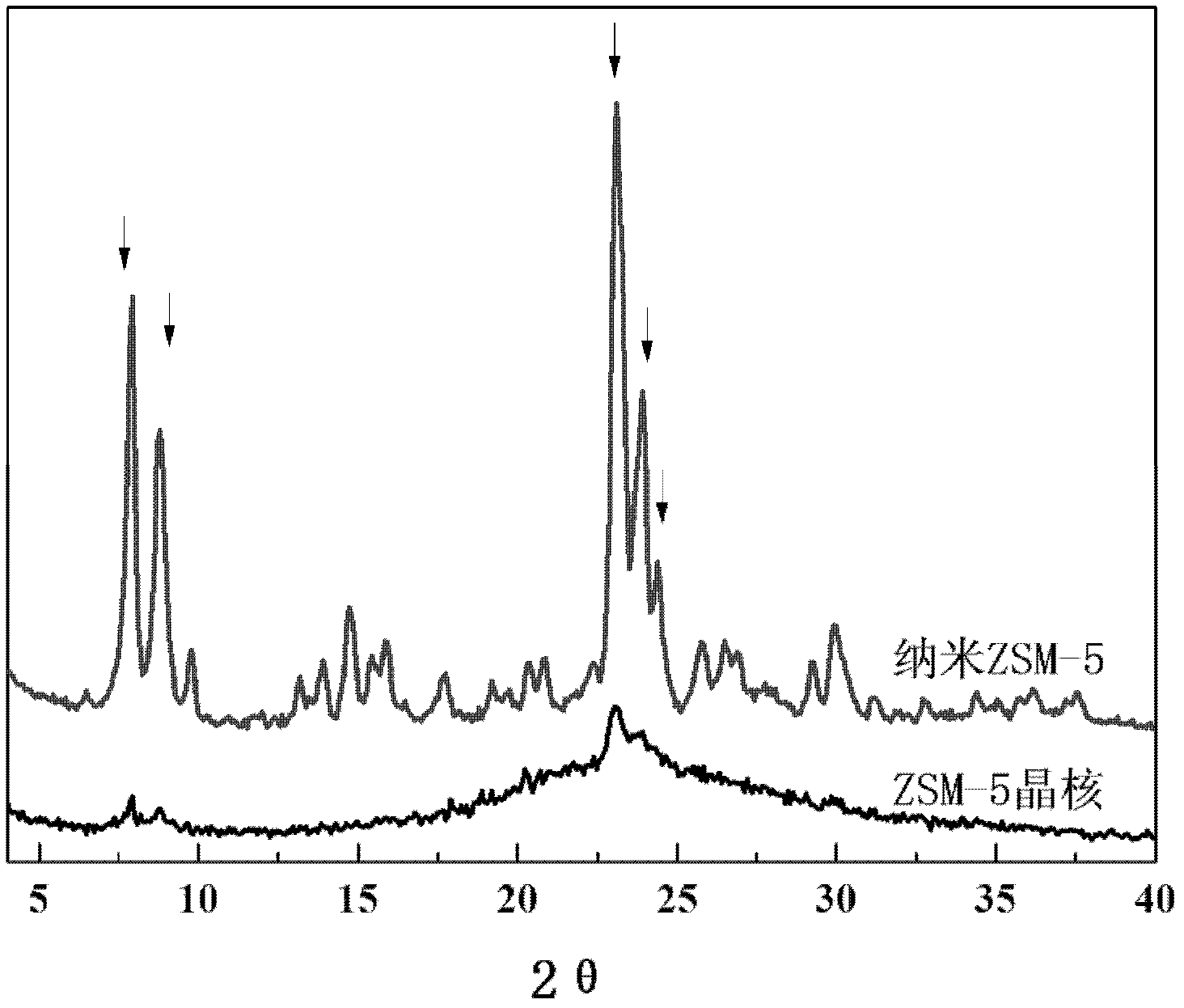

Method for preparing propene by catalytic cracking

InactiveCN102302945AInhibition of structuringHigh selectivityMolecular sieve catalystsBulk chemical productionPetrochemicalSide reaction

The invention belongs to the field of petrochemical industry, and relates to a method for preparing propene by catalytic cracking, which is characterized by comprising the following steps: firstly synthesizing molecular sieve ZSM-5 crystal nuclei, and preparing a silicon source, seed crystals, templating agent and deionized water into a colloidal liquid; preparing an aluminum source, inorganic acid or alkali and deionized water into a solution; while stirring, adding the solution into the colloidal liquid to prepare a uniform gel; carrying out hydrothermal crystallization on the gel, and stopping crystallization before the crystallization induction period finishes; and preparing the molecular sieve ZSM-5 crystal nuclei into a catalytic cracking catalyst which is used for preparing propylene and isobutylene by cracking olefins. The molecular sieve ZSM-5 crystal nuclei catalyst only has a weak acid center; the crystal grains are very tiny and do not need any modification treatment, and hydrogen transfer aromatization and other side reactions can be obviously inhibited without any negative pressure or diluent gas condition, thereby enhancing the selectivity of the target product, simplifying the catalytic cracking technique and lowering the catalyst cost.

Owner:DALIAN UNIV OF TECH

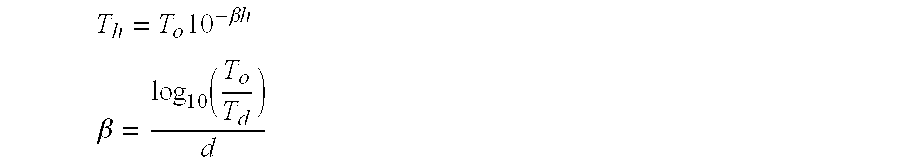

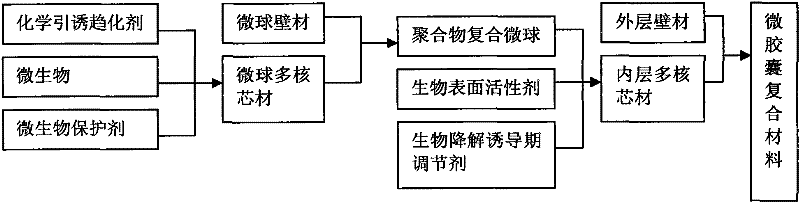

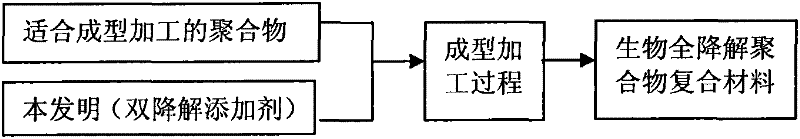

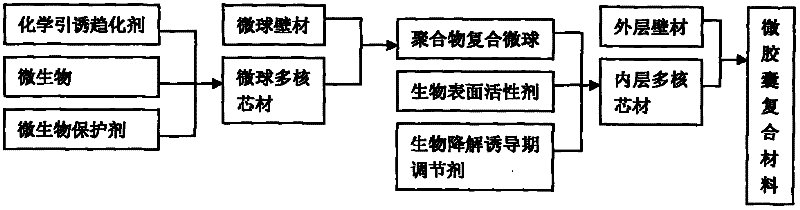

Dual-degradant additive for promoting photo oxidative degradation and biodegradation of polymer

InactiveCN102352064APromotes photooxidative degradationPromote biodegradationPhotooxidative degradationCarboxylic acid

The invention relates to a dual-degradant additive for promoting photo oxidative degradation and biodegradation of a polymer, comprising the following ingredients: 30-50 wt% of resin used as a carrier, 26-40 wt% of composite photo oxidative degradation accelerating agent, 1-5 wt% of photo oxidative degradation induction period regulator, 1-5 wt% of carboxylic acid or its derivative, and 15-25 wt%of microcapsule composite material. The dual-degradant additive disclosed herein can be applied on various polymers. By using the dual-degradant additive to mix with the polymer according to a certain proportion to prepare a composite material, the composite material can be degraded through photo oxidative degradation and biodegradation, has effects of repairing soil and compost, and has effects of oxygen barrier and flame resistance in many applications.

Owner:丁邦瑞

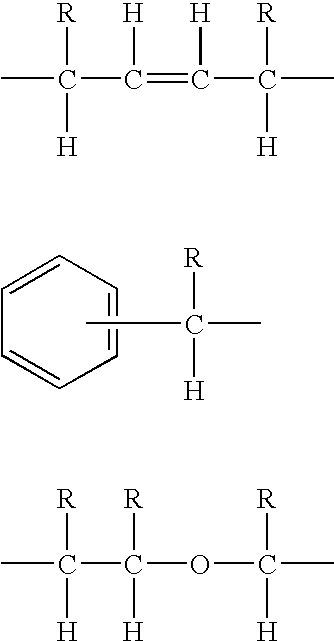

Nonwoven fabric capable of being elongated and composite nonwoven fabric comprising said nonwoven fabric laminated

An extensible nonwoven fabric comprises a fiber comprising at least two olefin-based polymers. These olefin-based polymers are of the same kind and have different induction periods of strain-induced crystallization as measured at the same temperature and shear strain rate. A composite nonwoven fabric of the invention comprises at least one layer comprising the extensible nonwoven fabric.

Owner:MITSUI CHEM INC

Complex catalyst contg. two or more than two kinds of bimetal cyanide, prepn. method and application thereof

InactiveCN1459332AOrganic-compounds/hydrides/coordination-complexes catalystsCyanide compoundHigh resistance

A complexing catalyst contains two or more than two bimetallic cyanides (BMC), organic coordination agent, soluble metallic salt, polyether polyol, and organic siloxane. Its advantages are storage stability, high reaction activity, and high resistance to high reaction temp. up to 210 deg.C, and short inducing time.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

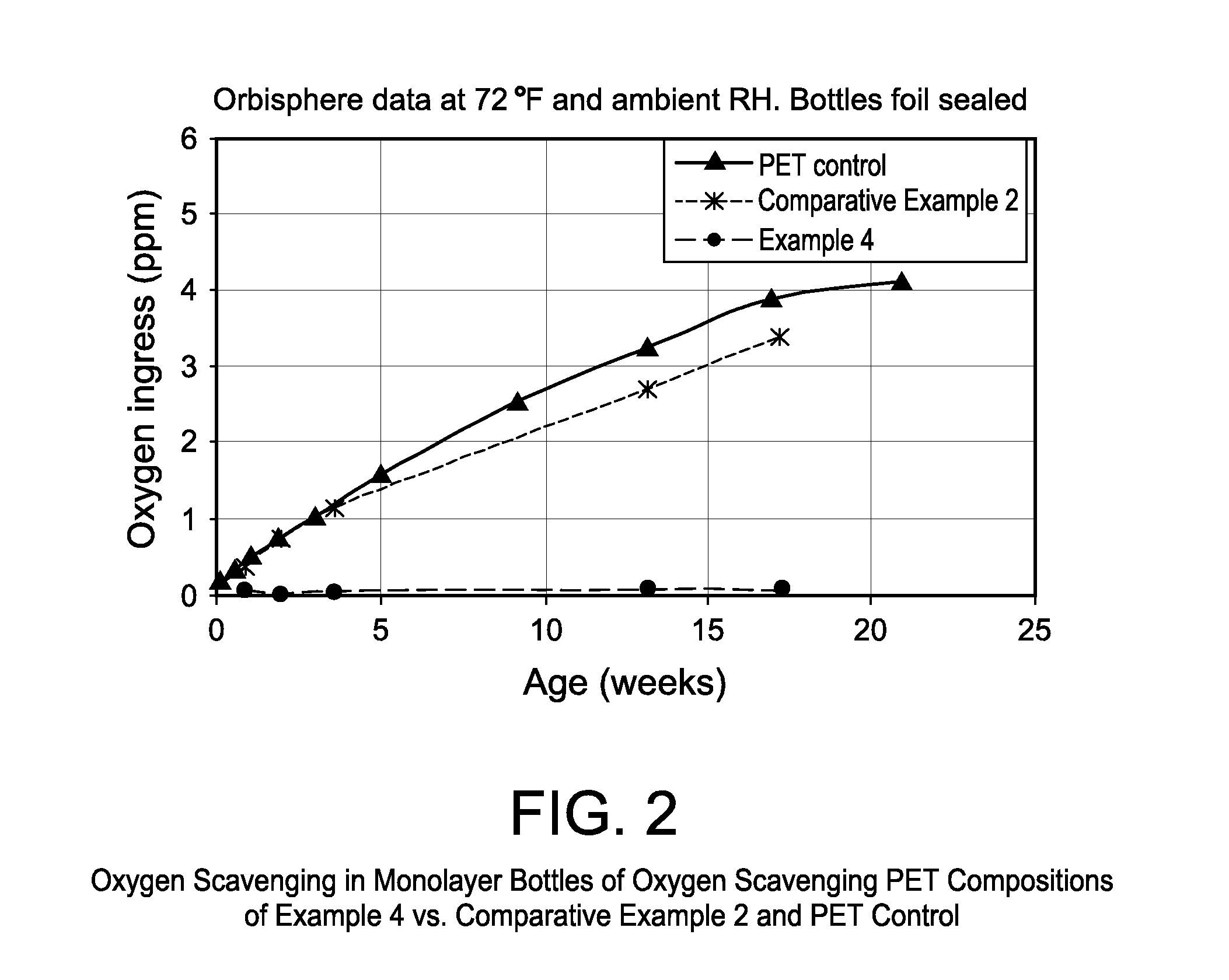

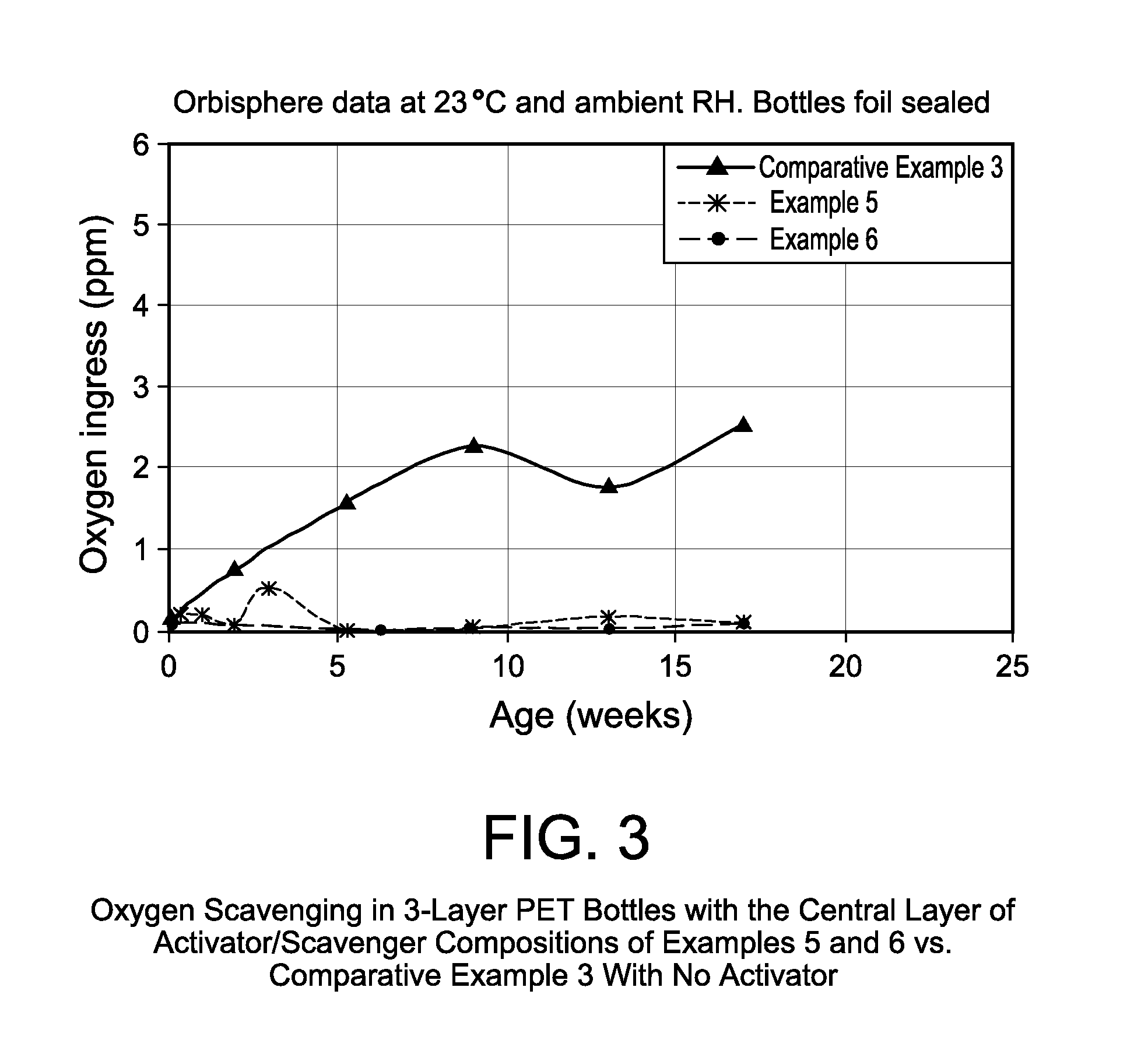

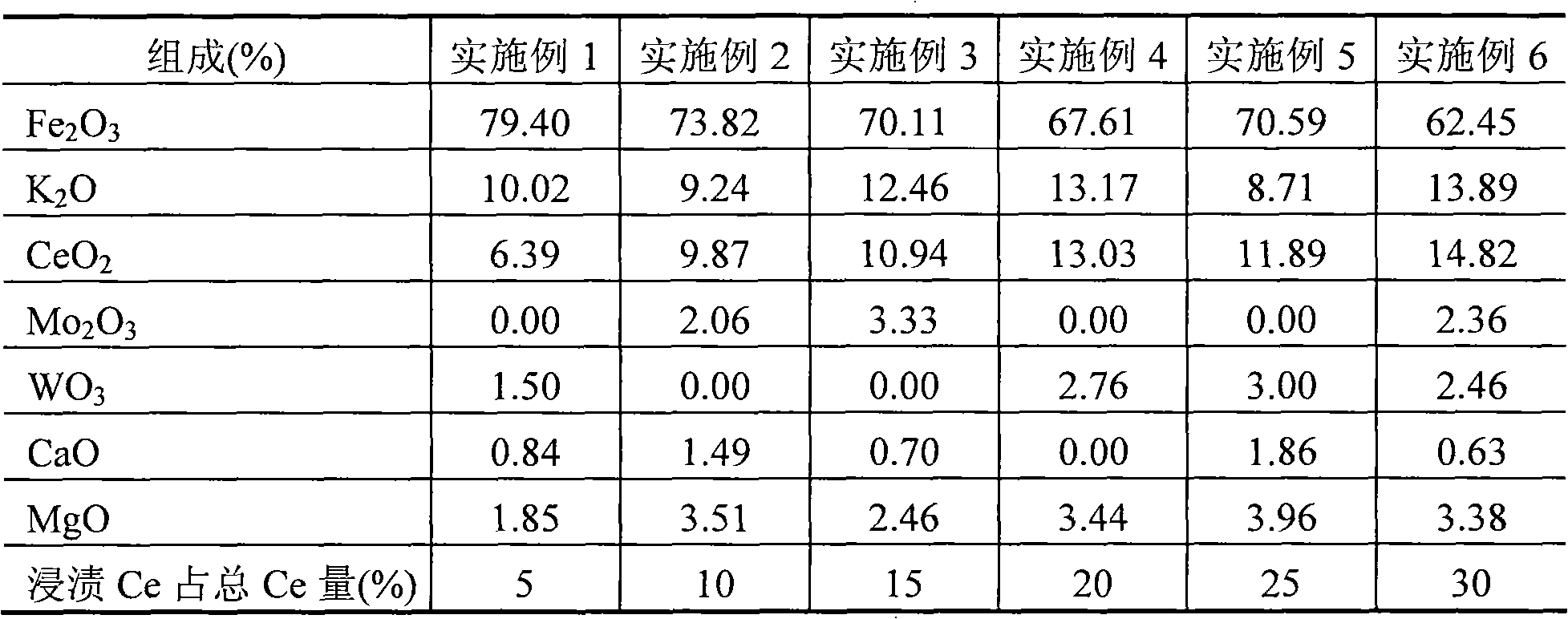

Activated oxygen scavenging compositions for plastic containers

The present invention provides a composition comprising: a polyester base polymer; at least one non-polymeric oxidizable organic compound; at least one transition metal in a positive oxidation state, said metal being present in the composition in an amount of from about 10 to about 400 ppm; and at least one activator compound selected from the group consisting of: (i) a polyester ionomer containing a sulfoisophthalate moiety, (ii) a polyol derivative and (iii) a N-hydroxyimide, wherein the at least one non-polymeric oxidizable organic compound is present in an amount of from about 0.10 to about 10 weight percent of the composition, and wherein the at least one activator compound is present in an amount of from about 0.01 to about 5 weight percent of the composition. The compositions of the present invention do not exhibit an induction period prior to the onset of oxygen scavenging upon formation into a container.

Owner:GRAHAM PACKAGING CO LP

Chemically cross-linked polyethylene composition and preparation method thereof

The invention provides a chemically cross-linked polyethylene composition and relates to the technical field of peroxide cross-linked polyethylene. The composition is prepared by adding 100 parts by weight of polyethylene and 0.01-5 parts by weight of auxiliary cross-linking agent in the formula of the peroxide cross-linked polyethylene, wherein the auxiliary cross-linking agent is an allyl organic compound. According to the method provided by the invention, the allyl organic compound is added to be used as the auxiliary cross-linking agent, thus the use amount of organic peroxide can be effectively reduced, simultaneously the cross-linking density of a tubular product can be maintained and the oxidation induction period of the tubular product can be effectively prolonged, thereby prolonging the service life of the tubular product. The preparation method can be widely applied to the preparation of a chemical cross-linked polyethylene tubular product and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Clean preparation process for hexafluropropylene oxide

ActiveCN1634902ARealize green productionSolve the destructive effectOrganic chemistryBulk chemical productionHexafluoropropyleneAtmospheric ozone

The invention discloses an environmental protection method for preparing hexafluropropylene oxide from hexafluoropropylene by dioxygen liquid phase oxidation method. The method employs at least one supercritical fluid as solvent for replacing the CFCs with destructive effect to atmospheric ozone layer. The supercritical fluid as solvent is used in the invention which can reduce induction period of reaction and prevent the temperature raise in short time at the beginning of reaction.

Owner:SINOCHEM LANTIAN +1

Full-biodegradation plastic starch master batch, preparation and uses thereof

The invention discloses a full biodegradable plastic starch master batch, a preparation method and application thereof. The plastic starch master batch comprises the following compositions in portion by weight: 60 to 75 portions of starch, 20 to 30 portions of vectors, 1 to 5 portions of compatilizer, 1 to 5 portions of lubricant, 1 to 5 portions of modifier and 1 to 5 portions of degradation accelerant. The plastic master batch takes the starch as a bioactive substance which is added with light, oxygen and the thermal degradation accelerant, and has the characteristic of multi-degradation under the action of the light, the oxygen, heat and microorganisms. The degradation process of the full biodegradable plastic starch master batch is as follows: after the induction period (controllable) is over, a product is degraded into chips and powder, assimilated with the environment finally, and is continuously degraded under certain environmental condition (aerobic), and CO2 and water are finally generated and can not cause secondary pollution when entering into soil, wherein the degradation period can be adjusted and controlled as required by change of the addition of a composite degradation regulator and the bioactive substance. The full biodegradable plastic starch master batch also has the advantages of simple preparation technology, low production cost and so on.

Owner:孙彦升

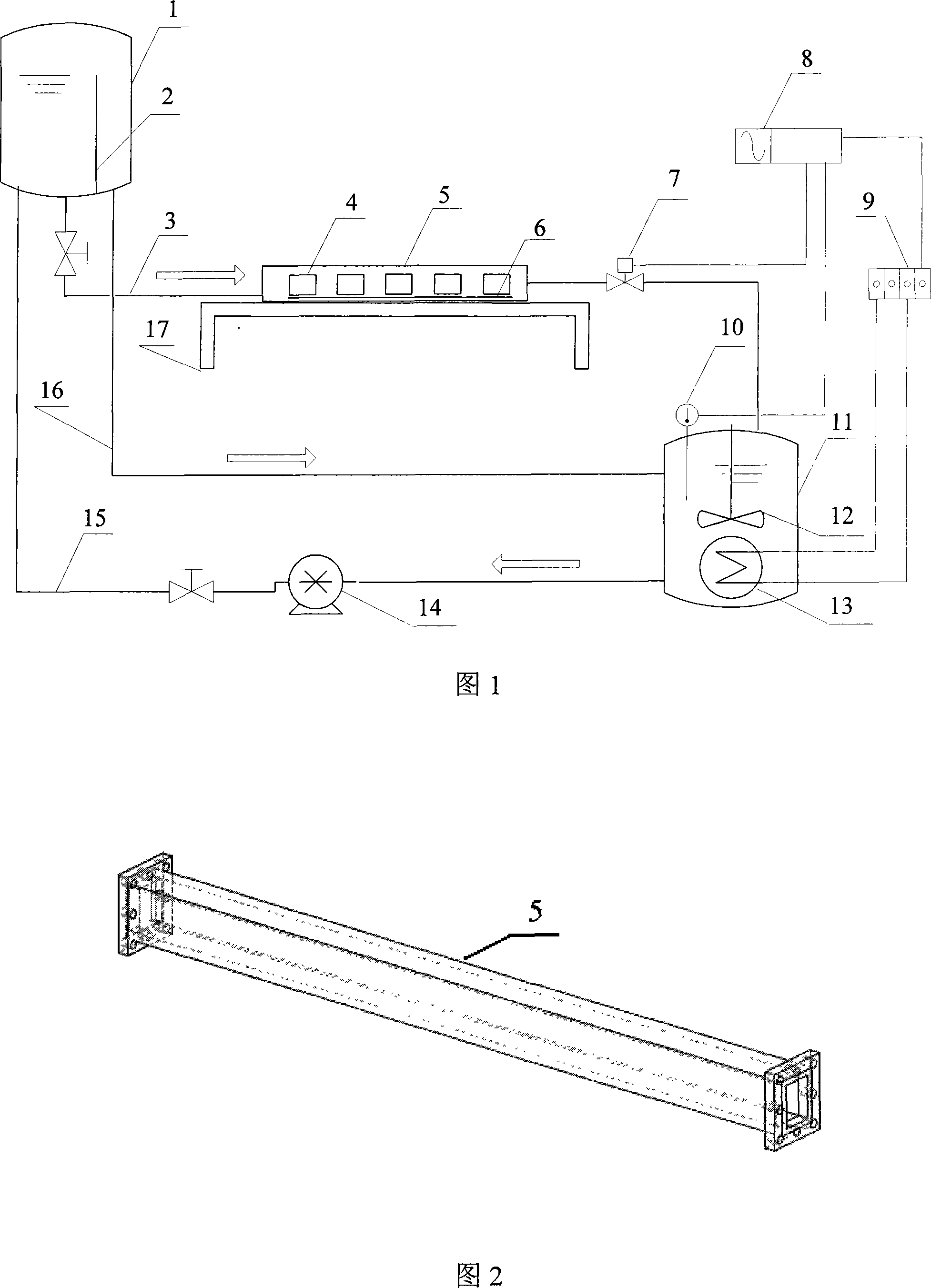

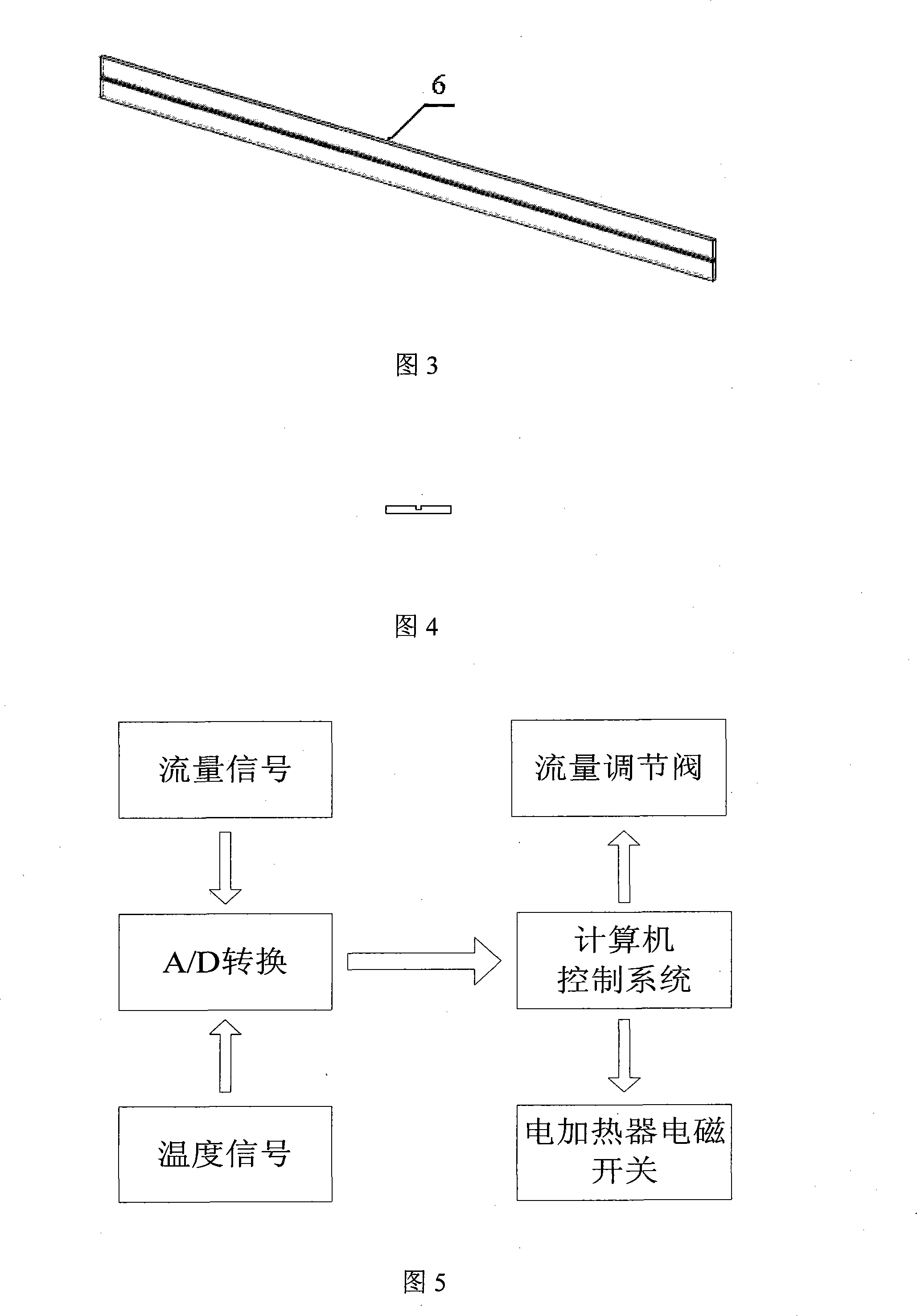

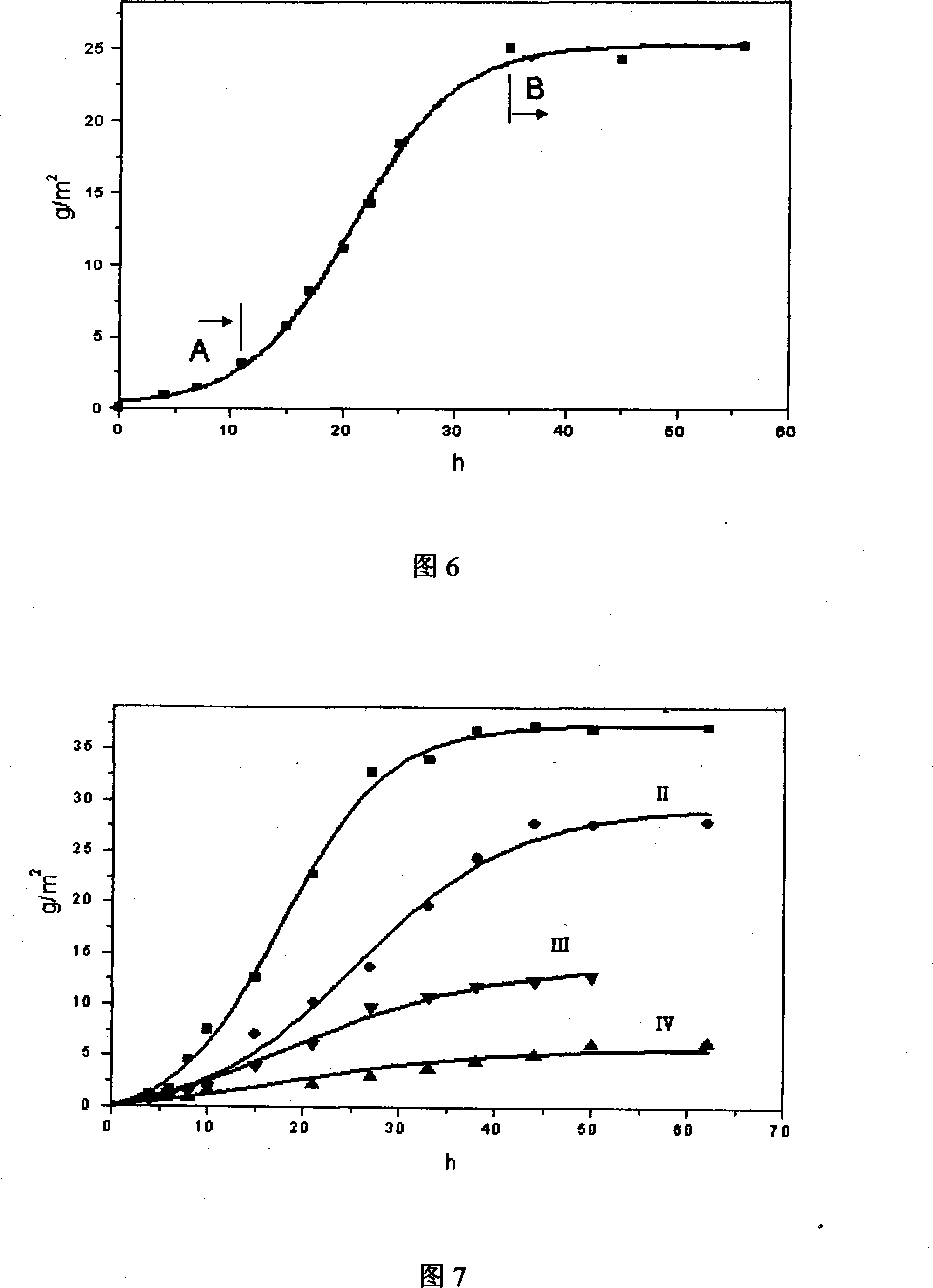

Method and device for measuring anti-dirty performance of material surface based on weight method

InactiveCN101246105AShorten the research cycleRemove technical barriers to comparisonWeighing by absorbing componentMeasurement deviceSludge

The present invention provides a measuring device for assessing the antisludging capability of the surface of the material, the measuring device mainly comprises an upper water tank, a lower water tank, an experiment box, a test desk, an upper water pipe, a lower water pipe, an overflow pipe, an overflow plate, an electric power, a temperature adjusting device, a working medium flow regulating device through the experiment box, a cycling pump and the like; the upper water tank and the lower water tank through the upper water pipe, and the upper water tank and the lower water tank through the lower water pipe and the experiment box respectively form a circulating system. When the working medium flows through the experiment box the sludge matter will deposit on the surface of the measured material test piece. When the test piece is detached and is dried by the constant-temperature electro-heating ventilating drying cabinet, the added weight of the test piece is weighted and the curve chart of the relationship between the added weight of the test piece and the time is drafted, and the antisludging capability is assessed by comparing the induction period of the dirt and the asymptotic value. The device can do assessing to one material or working medium, also can execute contrastive analysis to a plurality of materials and different working mediums, and has the advantages of high accuracy, good repeatability, quick evaluating, simple operation and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

Method for inducing and culturing umbilical cord mesenchymal stem cells into nerve cells

InactiveCN104004713AHas the function of inducing dischargeShort induction periodNervous system cellsNeurulationElectric discharge

The invention provides a method for inducing and culturing umbilical cord mesenchymal stem cells into nerve cells. According to the invention, a combined method of two steps of pre-induction and induction is adopted, and an optimized pre-induction culture solution and an induction culture solution are prepared. The induction mode is short in induction period and high in cell differentiation homogeneity. Electrophysiological detection finds that the obtained nerve cells have the function of induced electric discharge, which indicates that the induced nerve cells are obtained successfully.

Owner:广州雅安生物科技有限公司

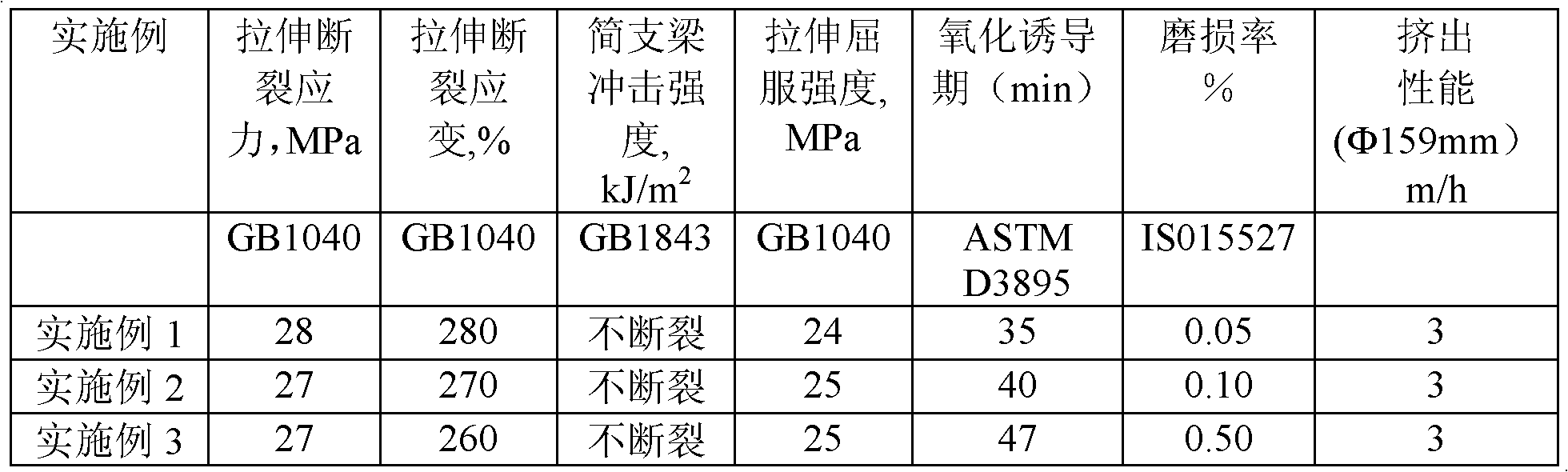

Composition for preparing polyethylene pipe with superhigh molecular weight and preparation method thereof

ActiveCN102382344AExcellent heat and oxygen aging resistanceImprove mechanical propertiesPolymer scienceProcedure Agents

A composition for preparing polyethylene pipe with superhigh molecular weight and a preparation method thereof are disclosed. The composition is prepared by the following raw materials by weight percentage: polyethylene with superhigh molecular weight: fluoropolymer processing agent: polyethylene wax: calcium stearate / zinc stearate compound: complex antioxidant: carbon black is equal to 100 parts: 0.01-0.1: 1-8:0.1-1.0:0.1-0.5:0.5-3. The preparation method comprises the steps of: putting the polyethylene resin with superhigh molecular weight, starting a mixer, putting the calcium stearate / zinc stearate compound into the mixer to mix for 1-2 hours, then adding the complex antioxidant, polyethylene wax, fluoropolymer processing agent and carbon black to mix for 2-3 hours; and detecting the bulk density according to GB / T1636 and sealing and packaging. The polyethylene pipe composition with superhigh molecular weight prepared by the method has excellent heat-resisting and anti-aging performance with oxidation induction time at 200 DEGC longer than 30 minutes. The polyethylene pipe composition with superhigh molecular weight further has excellent mechanical, wear-resisting, corrosion resisting, heat-resisting and anti-aging properties and extrusion process performance.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing submicron all-silicon DD3R molecular sieve

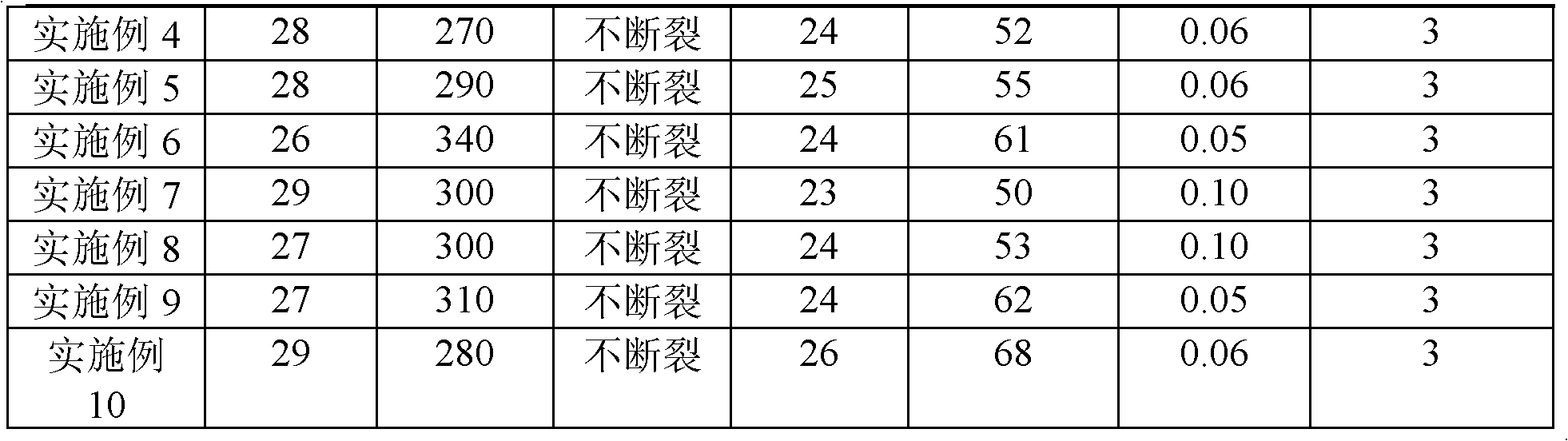

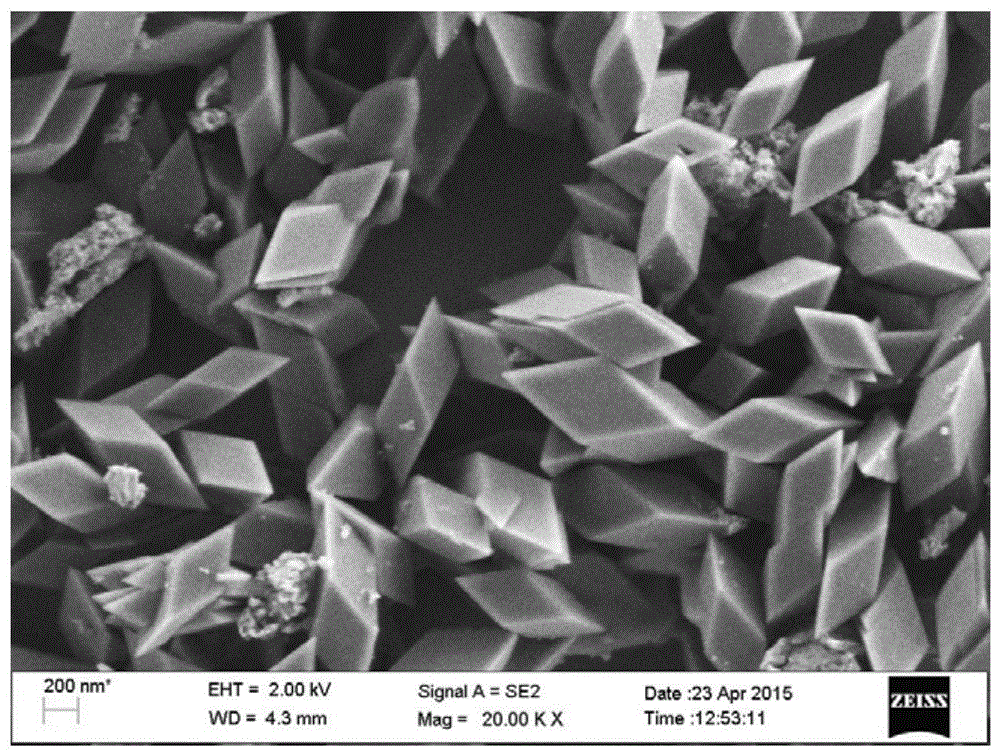

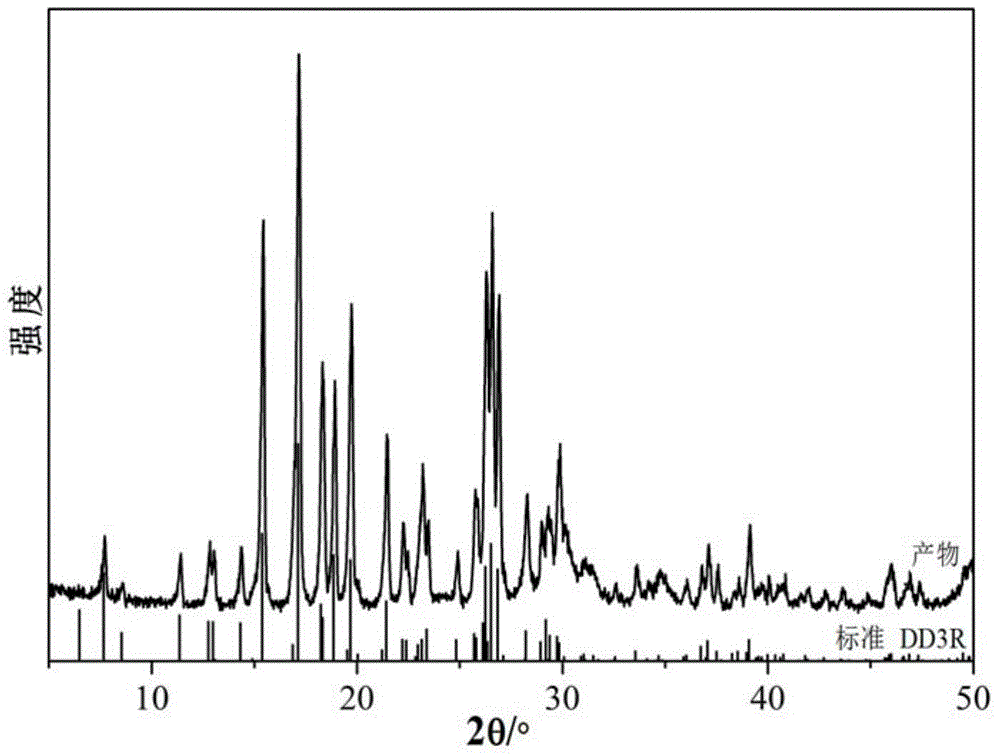

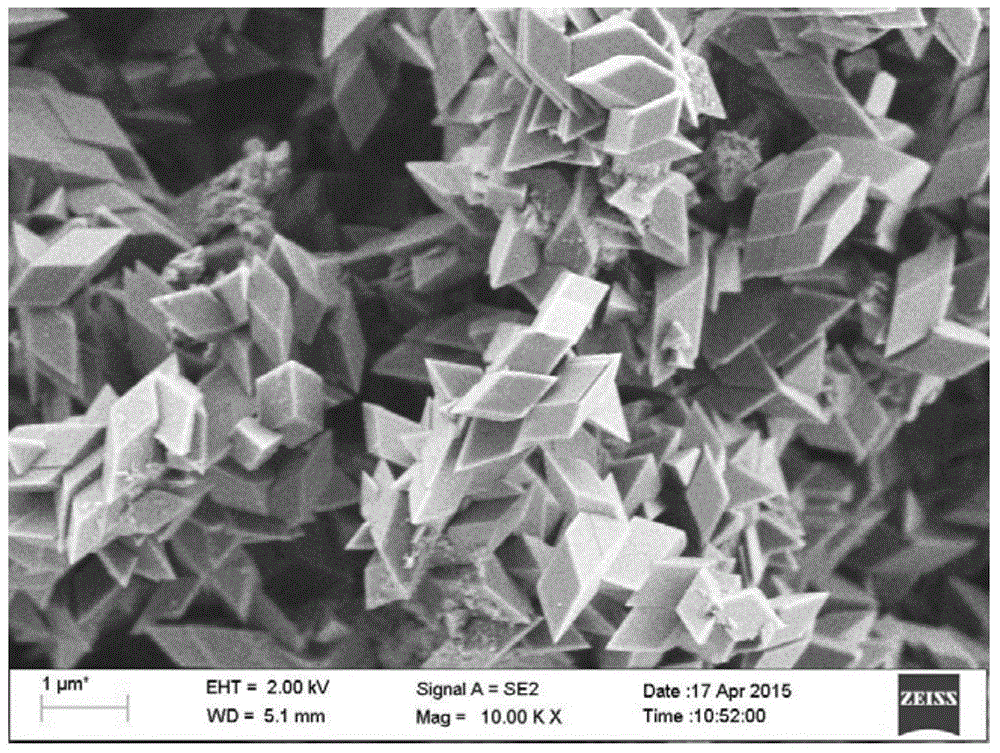

InactiveCN105016354AShort synthesis cycleUniform scaleSilicaMolecular-sieve silica-polymorphsTetramethylammonium hydroxideSeed crystal

The present invention provides a method for preparing a submicron all-silicon DD3R molecular sieve. The method comprises the following steps: 1) mixing a silicon source, amantadine, water and an auxiliary template agent to obtain crystal synthesis mother liquor and stirring and ageing the crystal synthesis mother liquor; and 2) adding 0.01-5% by mass of seed crystals into the crystal synthesis mother liquor and heating the crystal synthesis mother liquor with the seed crystals at 120-220 DEG C, wherein the auxiliary template agent is one or more selected from the group consisting of tetramethyl ammonium hydroxide, tetraethyl ammonium hydroxide, tetraethyl ammonium fluoride, tetraethyl ammonium bromide, tetrabutyl ammonium hydroxide and tetrabutyl ammonium bromide. According to the present invention, by adopting the method of mixing the template agent and adding the seed crystals, an induction period in a crystallization process is greatly shortened, a crystallization rate is increased and a synthesis period of the DD3R molecular sieve is shortened, so that the synthesis period of the submicron all-silicon DD3R molecular sieve is shortened from 25 days in the prior art to 3 hours; and the prepared DD3R molecular sieve is uniform in crystal size, has a particle size less than 1 micrometer, has a yield rate close to 100%, and has great application potential in adsorption and separation fields.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

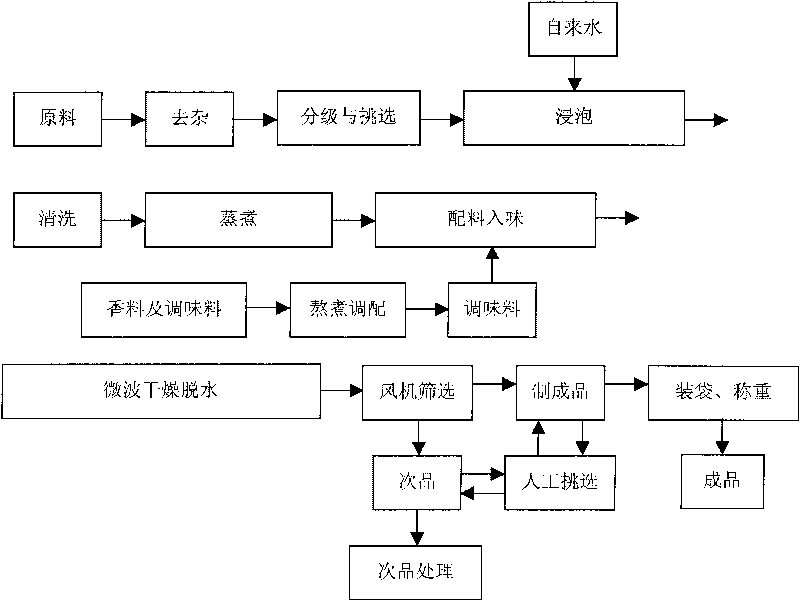

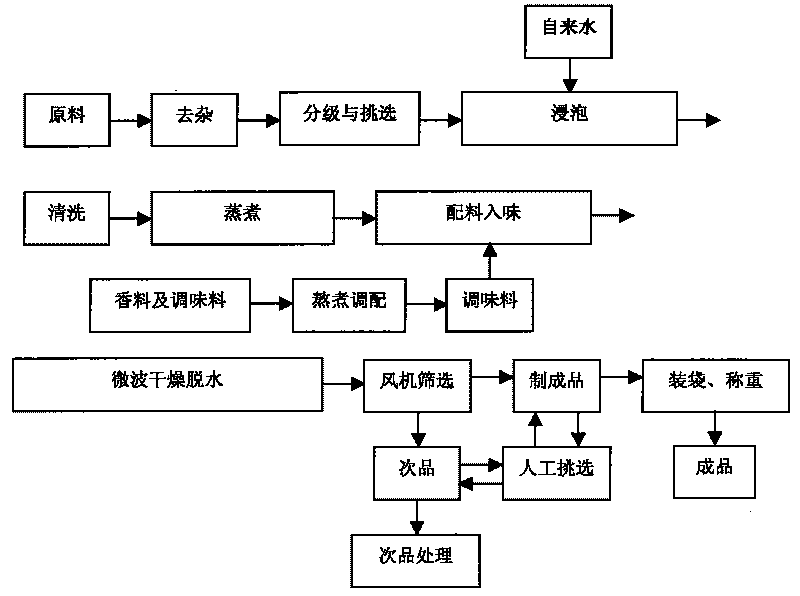

Method for producing dried salted peanuts

InactiveCN101703282AShorten drying timeShorten the production cycleFood preparationAir separationMicrowave power

The invention relates to a method for efficiently producing dried salted peanuts, which comprises the of selecting peanuts, cooking the peanuts, seasoning the peanuts, dehydrating the peanuts and performing air separation on the peanuts, wherein the peanuts are dehydrated in a microwave drying machine (furnace), the microwave power is between 1,000 and 6,000 W, and the microwave drying time is 4 to 10 minutes. The method can shorten the drying time from 50 to 70 hours of the conventional art to 4 to 10 minutes to significantly shorten the production period of products, improve the production efficiency, and simultaneously reduce the production energy consumption and production cost and reduce the pollutant discharges. The dried salted peanuts produced by the method are fragrant and crisp and have a good flavor mouthfeel, and particularly, the bad products generated in the drying process are reduced, the oxidation stability of the products is good, the oxidation induction period is prolonged to over 11 hours from 9 hours of the conventional art, and the shelf life is obviously prolonged. The method is convenient to produce various dried salted peanut products with different flavors.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Oxygen scavenging resin with short induction period

ActiveUS20120114887A1Improve clarityLow degreeSynthetic resin layered productsEmulsion paintsPolymer sciencePtru catalyst

The present invention relates to a composition comprising a polyester, a copolyester ether, and an oxidation catalyst, wherein the copolyester ether comprises a zinc compound and at least one polyether segment selected from the group consisting of poly(tetramethylene ether) and poly(tetramethylene-co-alkylene ether). The present invention further relates to articles made from the composition and methods to make the composition and the articles.

Owner:TREVIRA HLDG GMBH

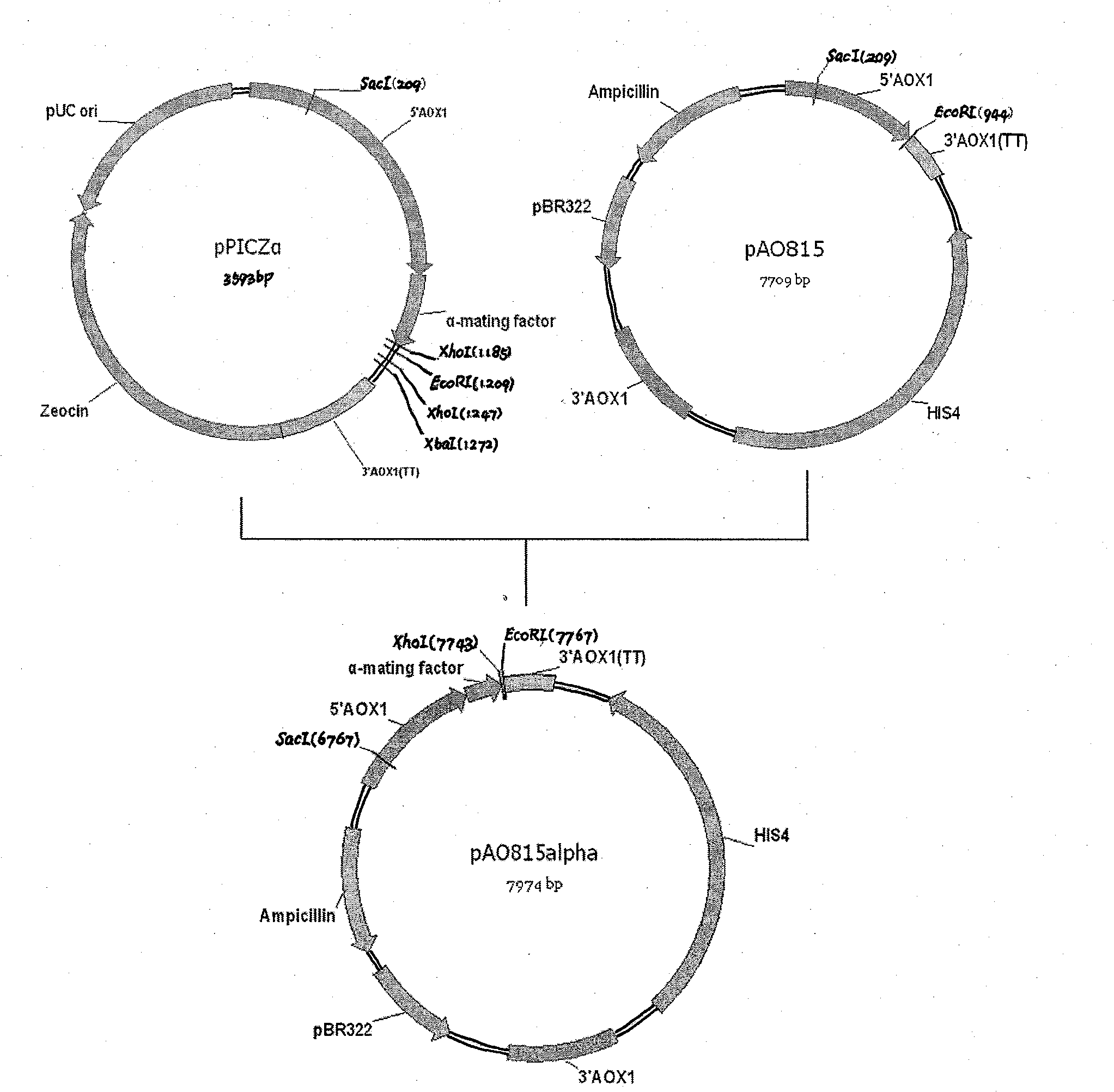

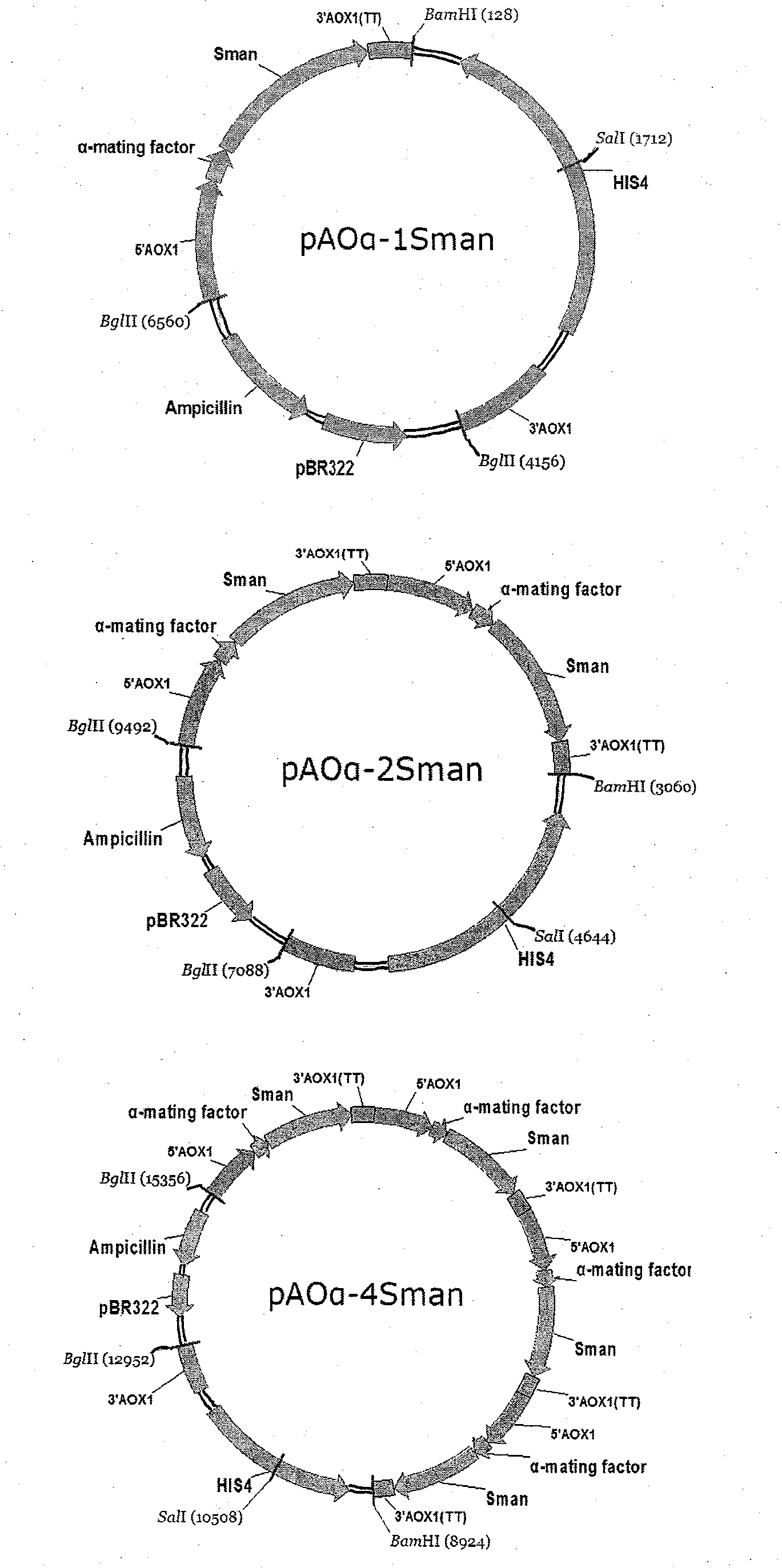

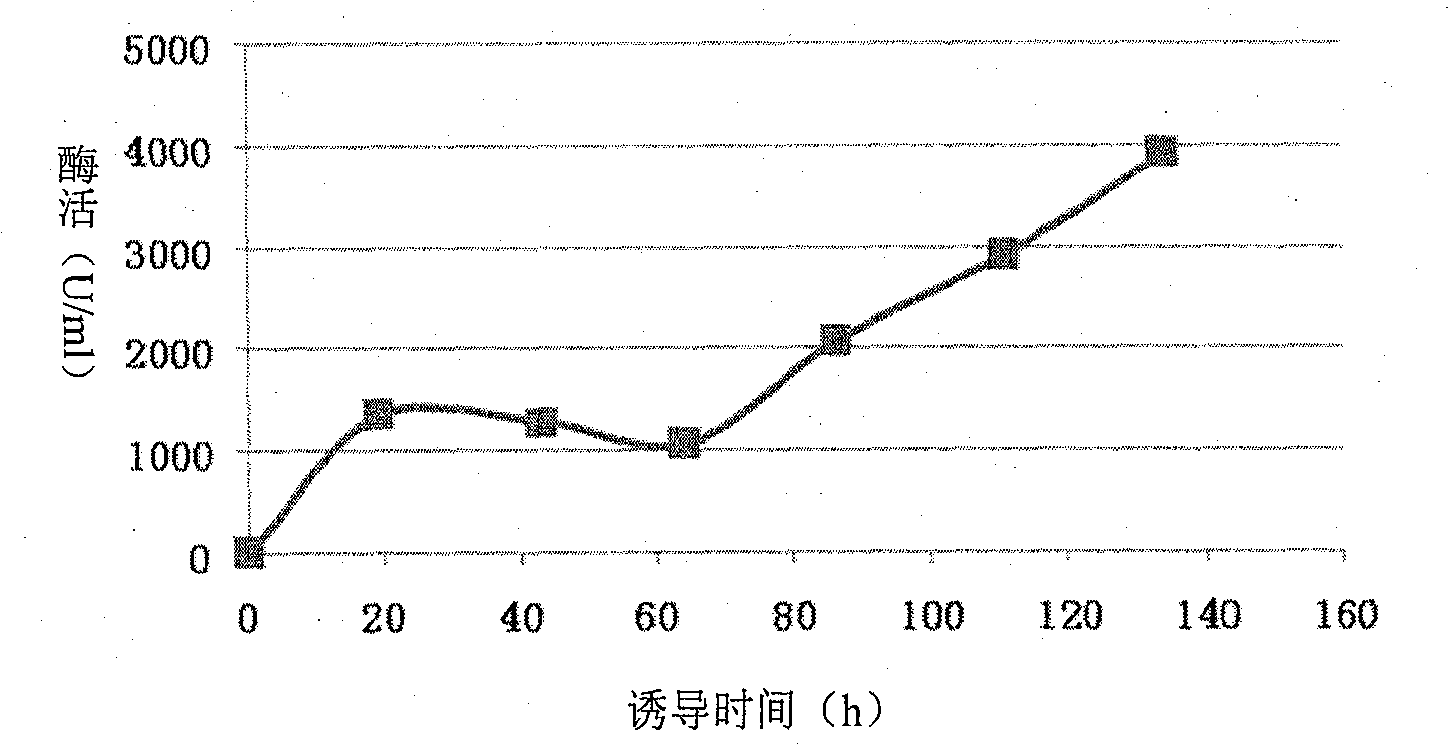

Method for preparing beta-mannase and special strain

The invention discloses a method for preparing beta-mannase and a special strain. The strain is Pichia pastoris GS4SMAN CGMCC NO.4095. The recombinant strain disclosed by the invention contains a plurality of copied mannase genes expressed under methanol induction. Experiments show that by means of a process, disclosed by the invention, for producing alkaline mannase through high-density fermentation by using the recombinant strain, the enzyme activity of the alkaline mannase can reach 6336u / ml finally in an induction period of 84 hours. The method disclosed by the invention has the advantages of low cost, simplicity for operation and high yield. Therefore, the method disclosed by the invention has a wide application prospect in the field of mannase preparation.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

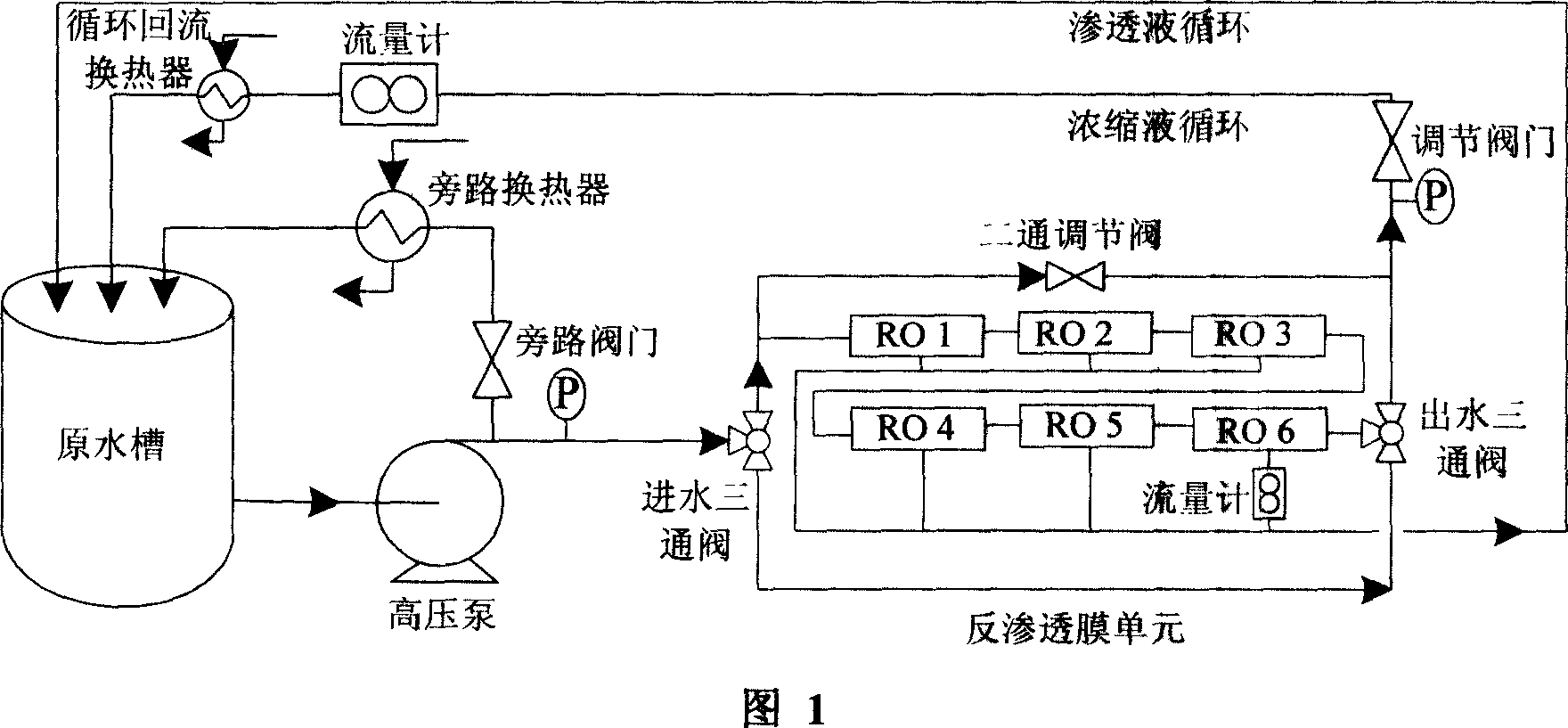

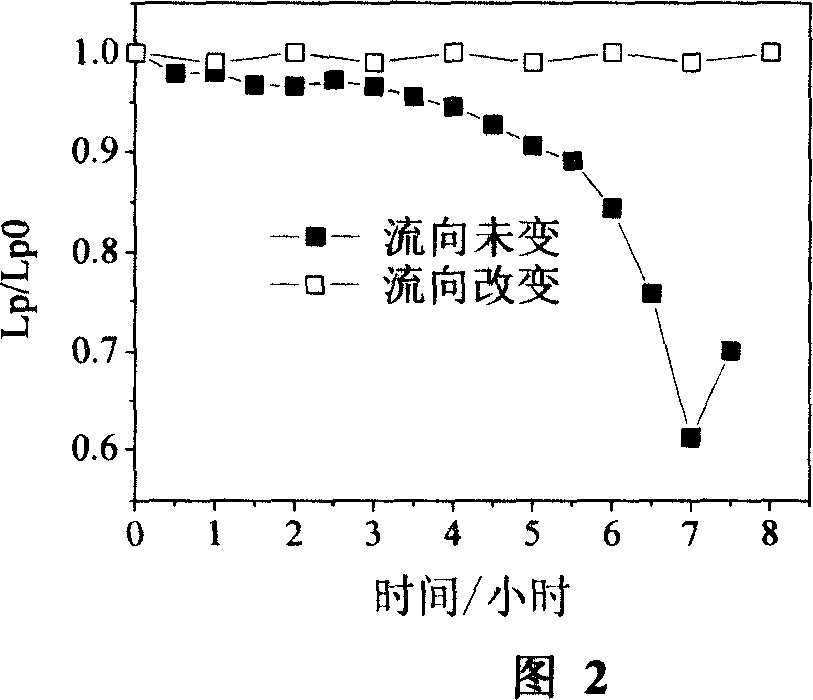

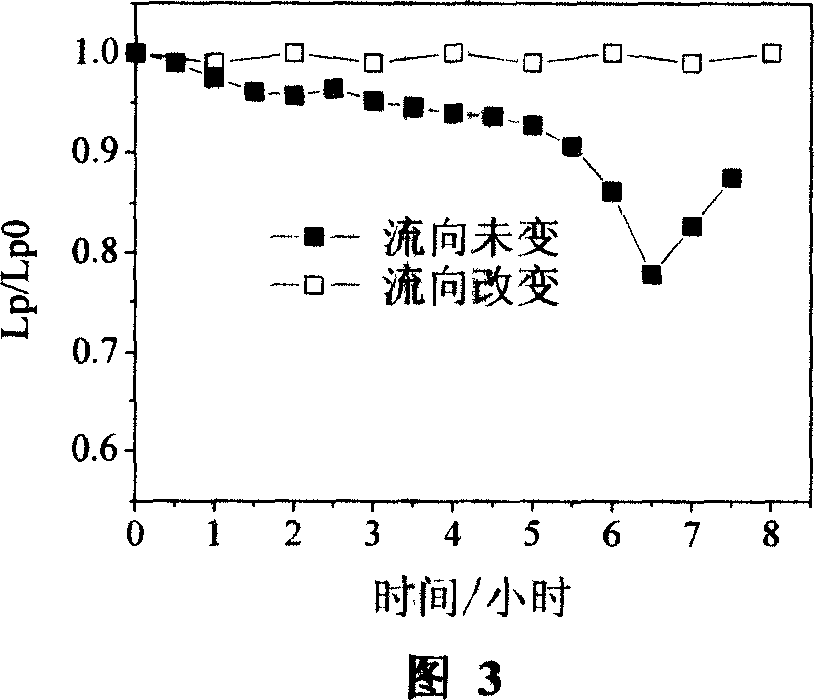

Changing flow direction method for blocking reverse osmosis membrane fouling under the scale inhibitor existing

InactiveCN101053776APrevent scalingExtend your lifeSemi-permeable membranesHigh concentrationMembrane fouling

The invention relates to a switching flow method for preventing the reverse osmosis membrane from fouling via a scale inhibitor, which connects in series plurality of branch putaminas to form a reverse osmosis membrane unit, the penetrating fluid tube of each branch putamina is connected and together flows into the penetrating fluid conduit, and in the process of operation of reverse osmosis system and in the interval smaller than membrane fouling induction period, the flow direction of water in the membrane unit is alternately changed to break the high concentration boundary layer built at the surface of the membrane to extend fouling induction period to prevent the reverse osmosis membrane from fouling. The permeability coefficient of the reverse osmosis membrane can be obtained, and then the retarding degree for the membrane fouling can be obtained by monitoring the penetrating fluid flow of the last breach putamina, based on the operation pressure and the osmotic pressure of the solution. The invention can prevent the membrane from fouling effectively, reduce the washing frequency for the commercial reverse osmosis system, prolong the using life of the membrane, and provide a simple method to reduce the run cost.

Owner:浙江凯锐环保股份有限公司

Catalyst of preparing pyrocatechol and hydroquinone in phenol hydroxylation

The invention relates to a catalyst of preparing benzenediol in a phenol hydroxylation and a preparation technology thereof. The catalyst contains Fe2O3, ferro compound and zero valent ferri. The catalyst can transform phenol into the pyrocatechol and the hydroquinone in water containing oxyful in 0.5h (comprising about 25min of induction period) under the condition that the proportion of H2O2 to phenol is 1:1 and the temperature is 60 DEG C with the result that the transformation ratio of the phenol can reach 28 percent, the yield of the benzenediol reaches 25.5 percent, and the proportion of the pyrocatechol to the hydroquinone is about 1.3. When the proportion of H2O2 to phenol is 1.5:1, the transformation ratio of the phenol can reach 44 percent, and the yield of the benzenediol reaches 38.8 percent. The catalyst has low cost, simple preparation and stable performance. The catalyst is remarkably characterized by achieving the transformation ratio of the phenol from 0 to 28 percent within less than 2min of reaction, having higher activity and effectively reducing the side reaction.

Owner:ZHEJIANG NORMAL UNIVERSITY

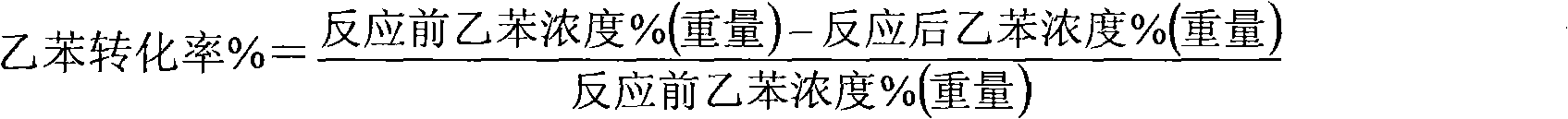

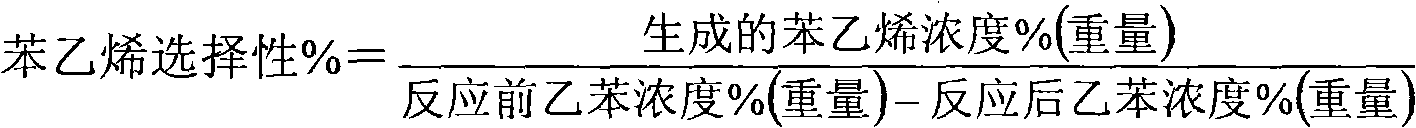

Method for preparing styrene catalyst by ethyl benzene dehydrogenation

ActiveCN102039204AHigh activityHigh initial activityCatalyst activation/preparationHydrocarbonsCeriumDehydrogenation

The invention relates to a method for preparing a styrene catalyst by ethyl benzene dehydrogenation, which mainly solves the problems of low initial activity and long induction period of the catalyst in the prior art. The method comprises the following steps of: mixing a required amount of cerium source, a required amount of iron source, potassium source, molybdenum source or tungsten source and mixture thereof, alkaline earth metal oxide and pore forming agent uniformly, and molding, drying and roasting to obtain a catalyst precursor I; and carrying the rest cerium source on the catalyst precursor I by adopting a dipping method, and drying and roasting to obtain the required catalyst. According to the technical scheme, the problems are well solved, and the method can be used for industrial production of preparing the styrene by ethyl benzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low phosphorous oxygen scavenging compositions requiring no induction period

The present invention provides a composition comprising: a polyester base polymer; at least one non-polymeric oxidizable organic compound; at least one transition metal in a positive oxidation state, said metal being present in the composition in an amount of from about 10 to about 400 ppm, wherein the polyester base polymer comprises less than about 40 ppm phosphorous. The compositions of the present invention do not exhibit an induction period prior to the onset of oxygen scavenging upon formation into a container.

Owner:GRAHAM PACKAGING CO LP

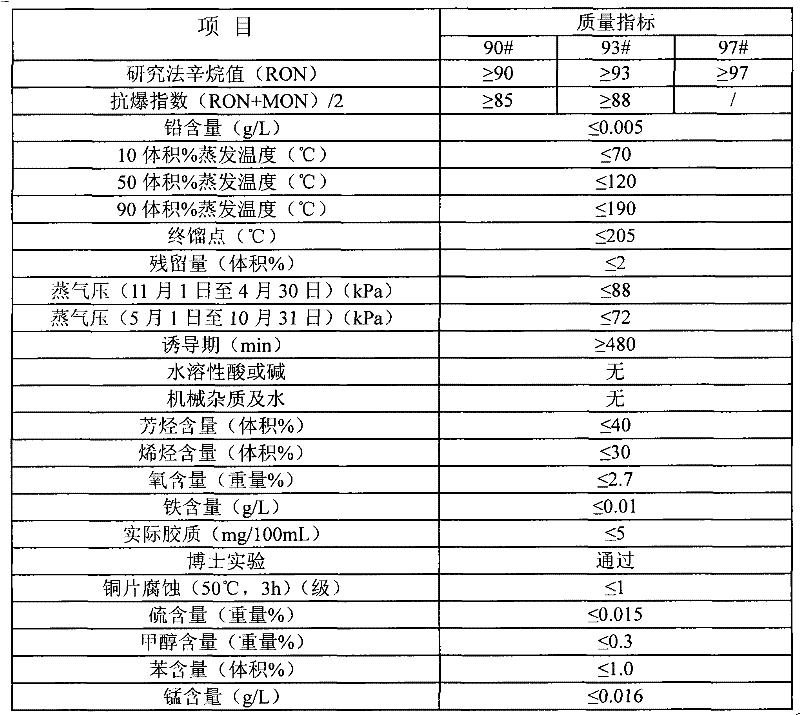

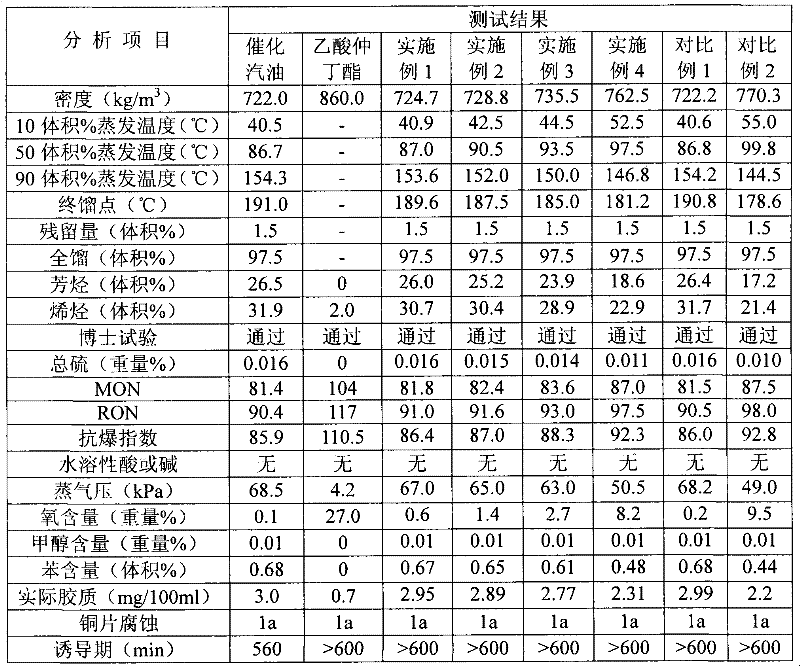

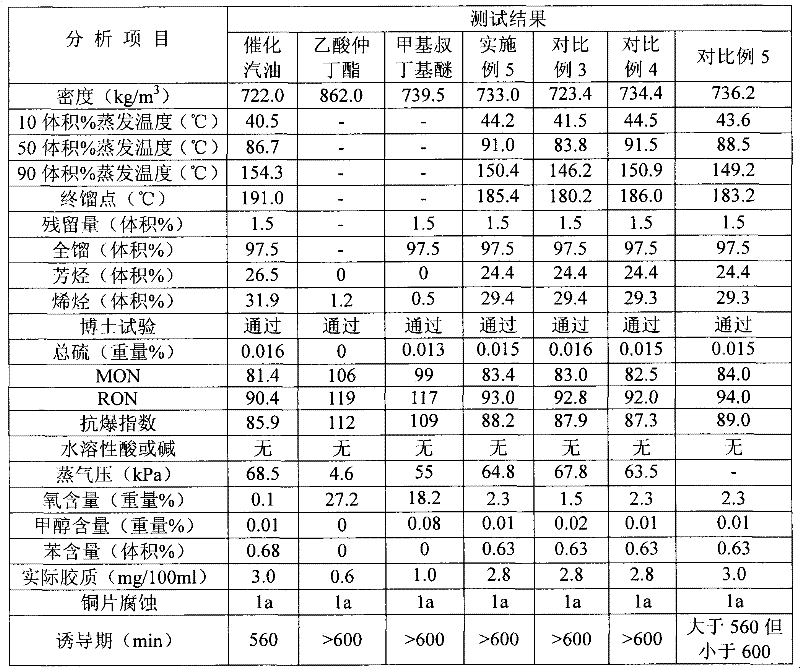

Gasoline composition and preparation method thereof

ActiveCN102234549ABoost octaneLow toxicityLiquid carbonaceous fuelsFuel additivesSec-Butyl acetateChemistry

The invention provides a gasoline composition and a preparation method thereof. The gasoline composition comprises 70-99wt% of raw gasoline and 1-30wt% of sec-butyl acetate measured as the total weight of the gasoline composition, with good anti-knock property, green and environmental protection and low cost. The raw materials used in the preparation method have strong adaptability and good broadspectrum activity, and are simple and easy to do. By comparing the gasoline composition obtained by adding 9.8wt% of sec-butyl acetate in catalytic gasoline with the catalytic gasoline used as raw gasoline, the research octane number (RON) increases to 93.0 from 90.4, the motor octane number (MON) increases to 83.6 from 81.4, the anti-knock index increases to 88.3 from 85.9, the induction period is longer than 600min, the content of the existent gum is only 2.77mg / 100ml, and other indexes all meet the prescribed standards of Stage III.

Owner:HUNAN ZHONGCHUANG CHEM

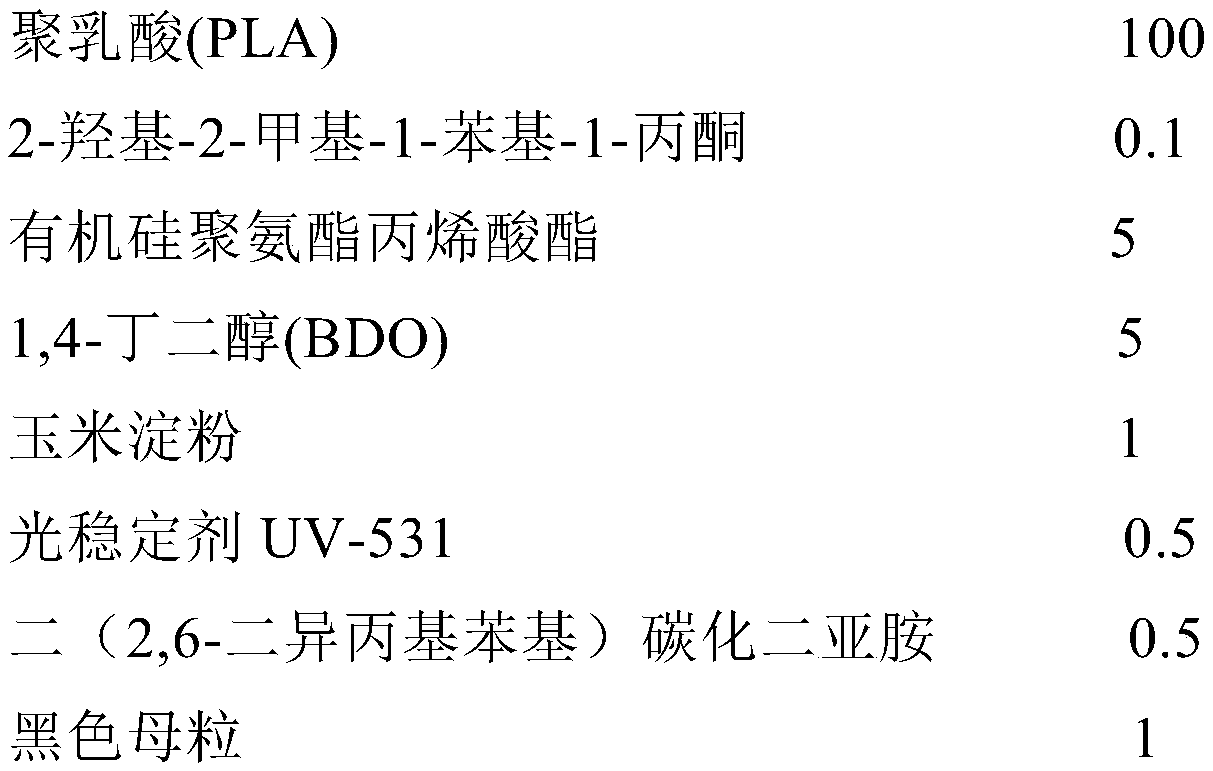

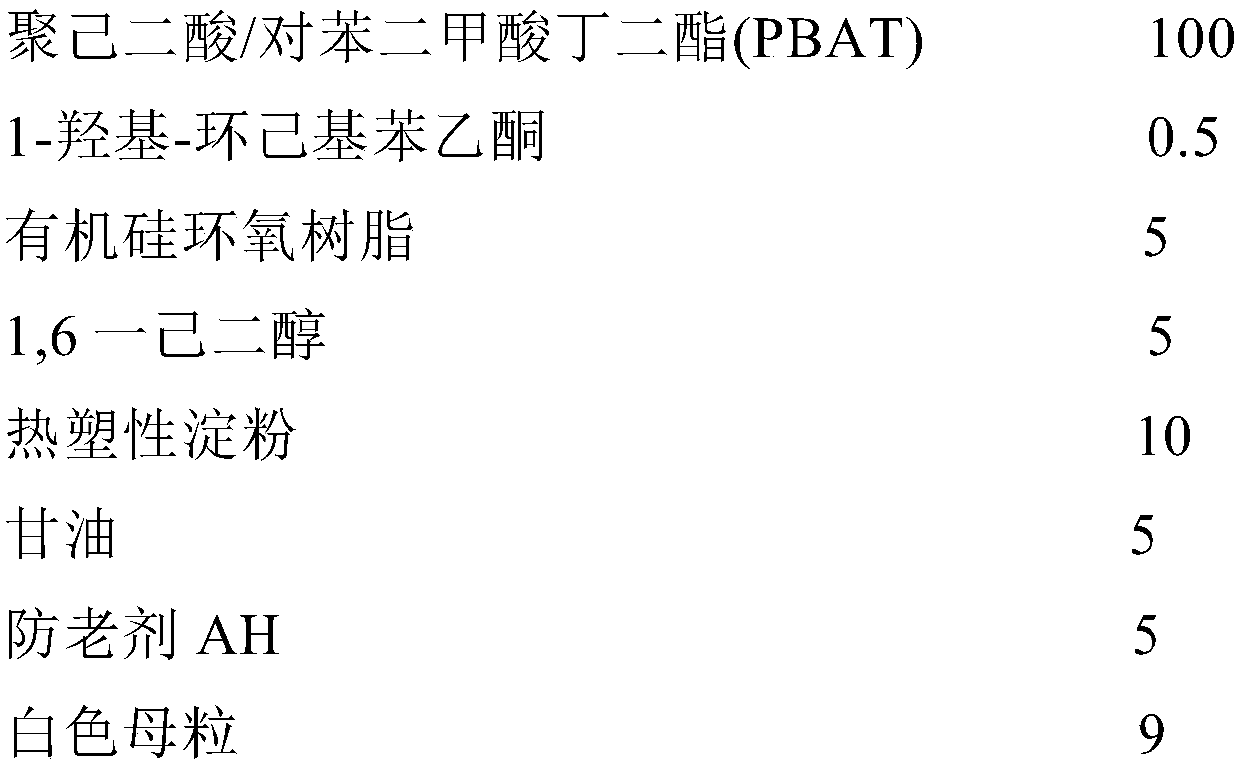

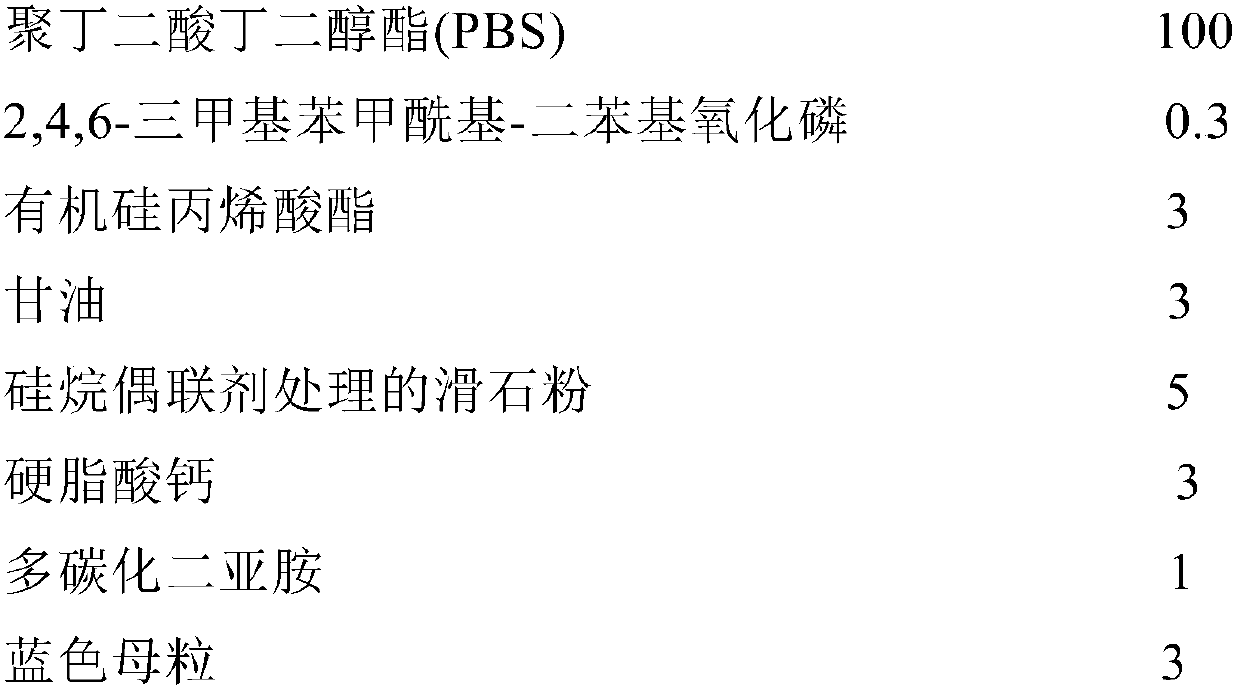

Hydrolysis-resistant ultraviolet (UV) photoaging resistant biodegradable plastic mulching film and preparation method thereof

ActiveCN109535675AImprove water resistanceImprove UV aging resistanceClimate change adaptationCultivating equipmentsOligomerAging resistance

The invention provides a hydrolysis-resistant ultraviolet (UV) photoaging resistant biodegradable plastic mulching film and a preparation method thereof. The hydrolysis-resistant UV photoaging resistant biodegradable plastic mulching film comprises the following raw materials in parts by mass: 100 parts of biodegradable polyester, 0.1-0.5 part of a photoinitiator, 1-5 parts of a light-cured polyester oligomer, 1-5 parts of a polyester chain extender, 1-10 parts of filler and 1-10 parts of an auxiliary agent. The mulching film provided by the invention has the characteristics of hydrolysis resistacne, UV aging resistance and high strength, and the degradation induction period can reach 60-120 days.

Owner:北京惠林苑生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com