Patents

Literature

289results about How to "Promote biodegradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel strain of bacillus amyloliquefaciens and its use

InactiveUS20100143316A1Inhibits pathogenic growthPromote biodegradationAntibacterial agentsBiocideBiotechnologyAmylase

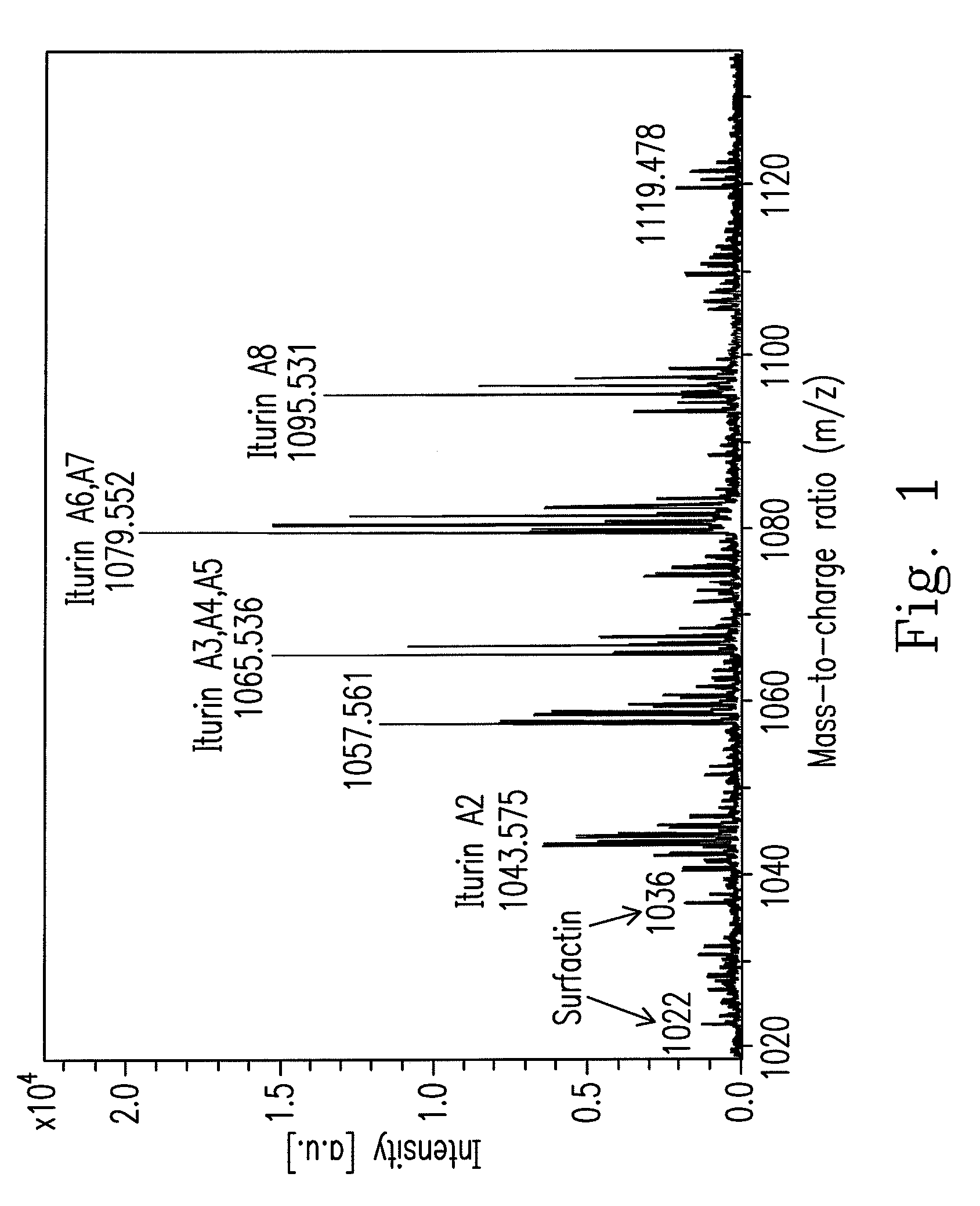

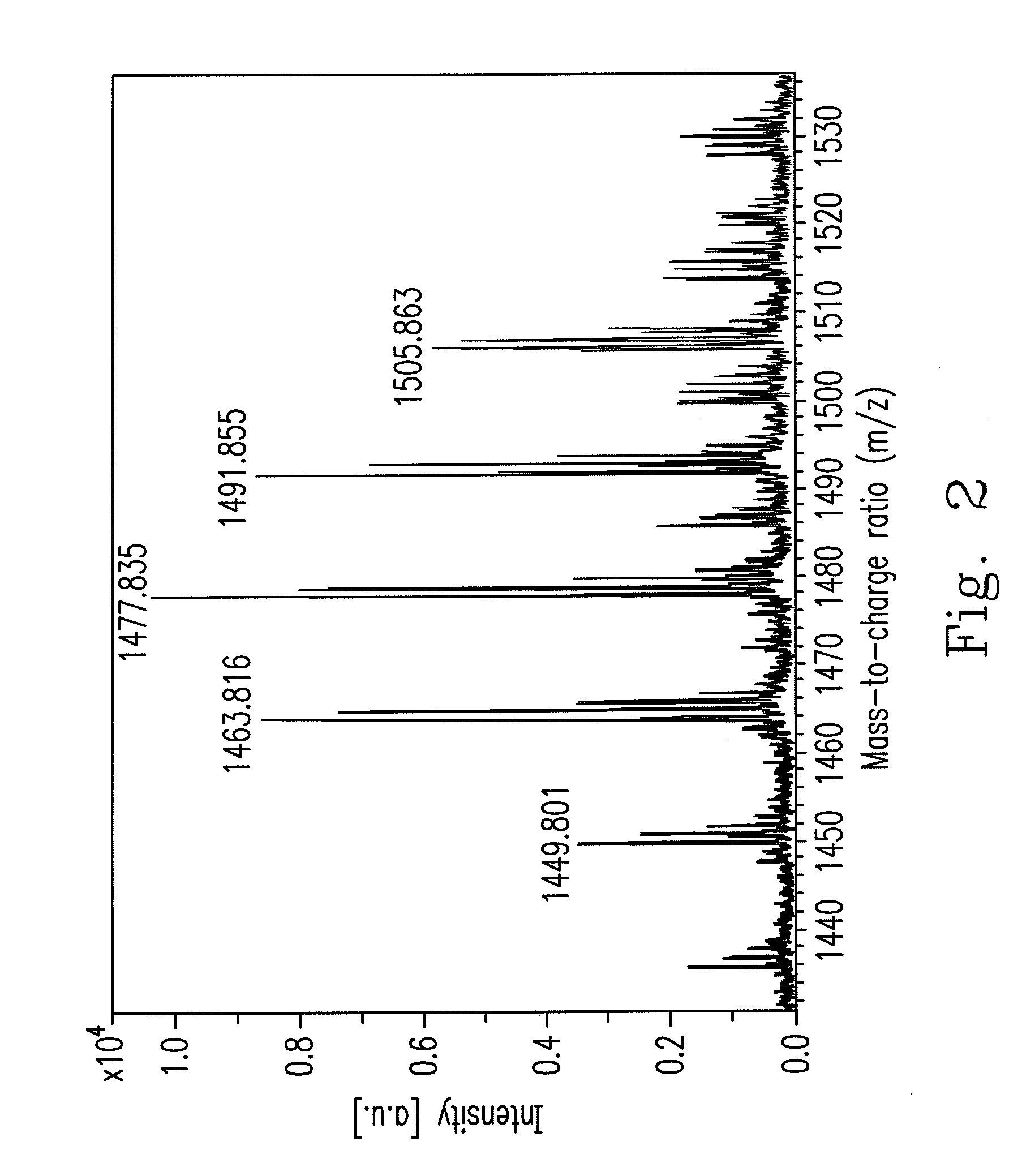

An isolated Bacillus amyloliquefaciens Ba-BPD1 having an Accession No. of DSM 21836 is provided. This novel strain has unique 16S ribosomal RNA sequenced as SEQ ID NO:1 and produces amylase, protease, cellulase and lipase, fibrinolytic enzyme to show their biodegradation capacities. Further, B. amyloliquefaciens Ba-BPD1 produces the antibiotic substances, such as iturin, fengycin and surfactin, and has antimicrobial capacity for inhibiting the fungal or bacterial growth. In conclusion, the novel strain of Bacillus amyloliquefaciens Ba-BPD1 and its products can be applied in agriculture, wastewater treatment, food industry and chemical industry.

Owner:AGRI CHEM & TOXIC SUBSTANCES RES INST COUNCIL AGRI EXECUTIVE YUAN

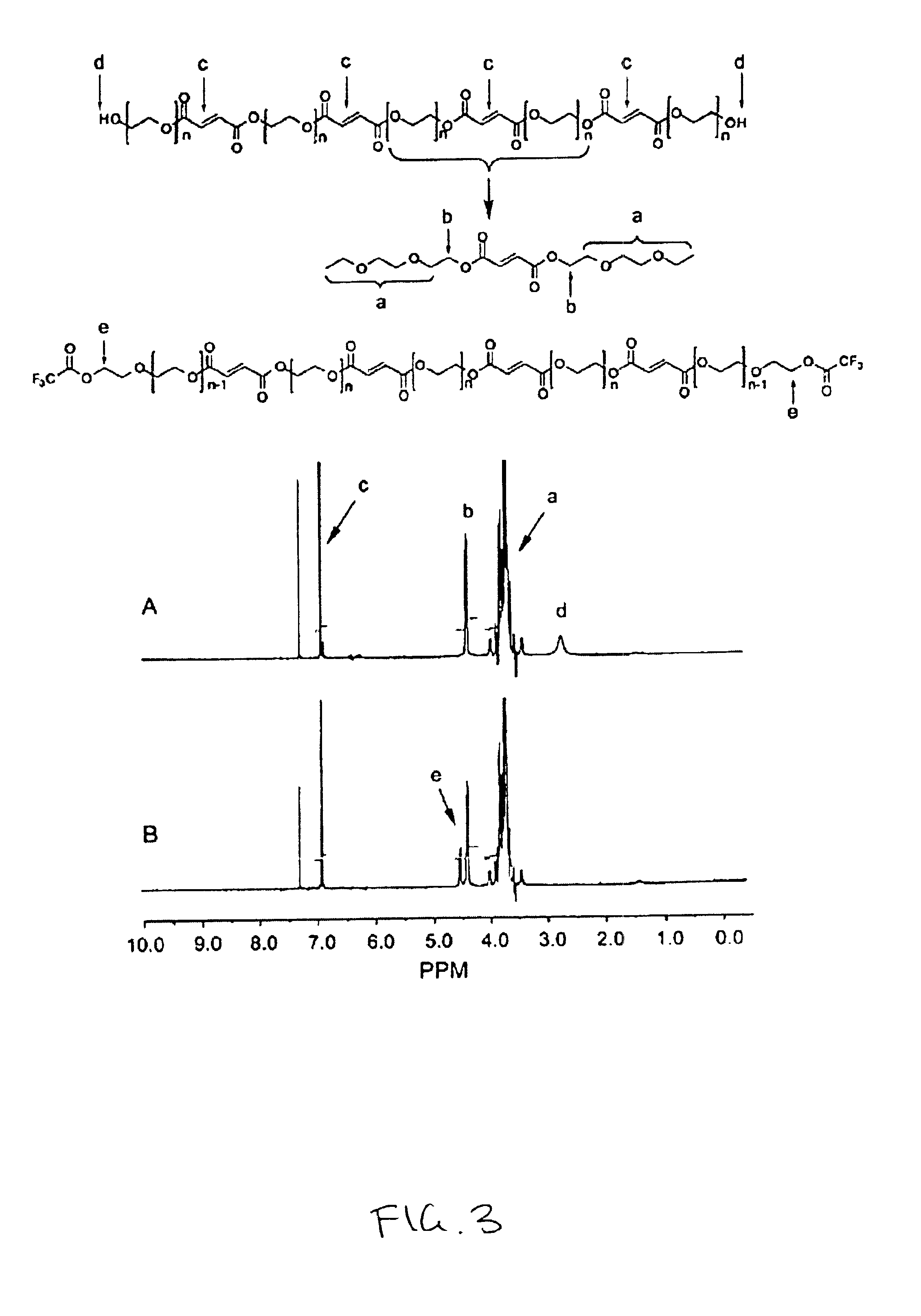

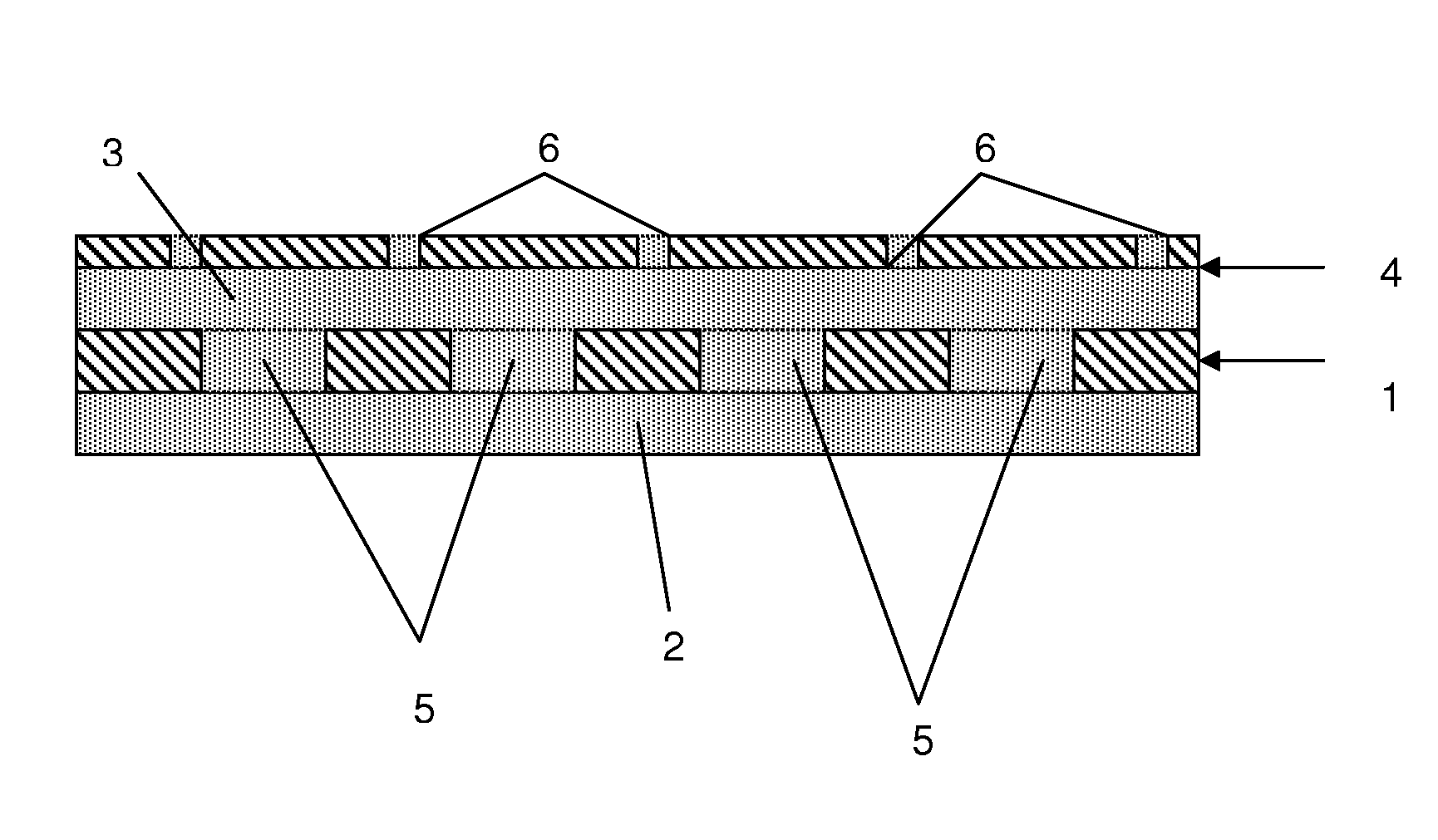

Biocompatible macromers

InactiveUS6884778B2Control mechanical propertyPromote biodegradationPowder deliveryPeptide/protein ingredientsPhotoinitiatorDouble bond

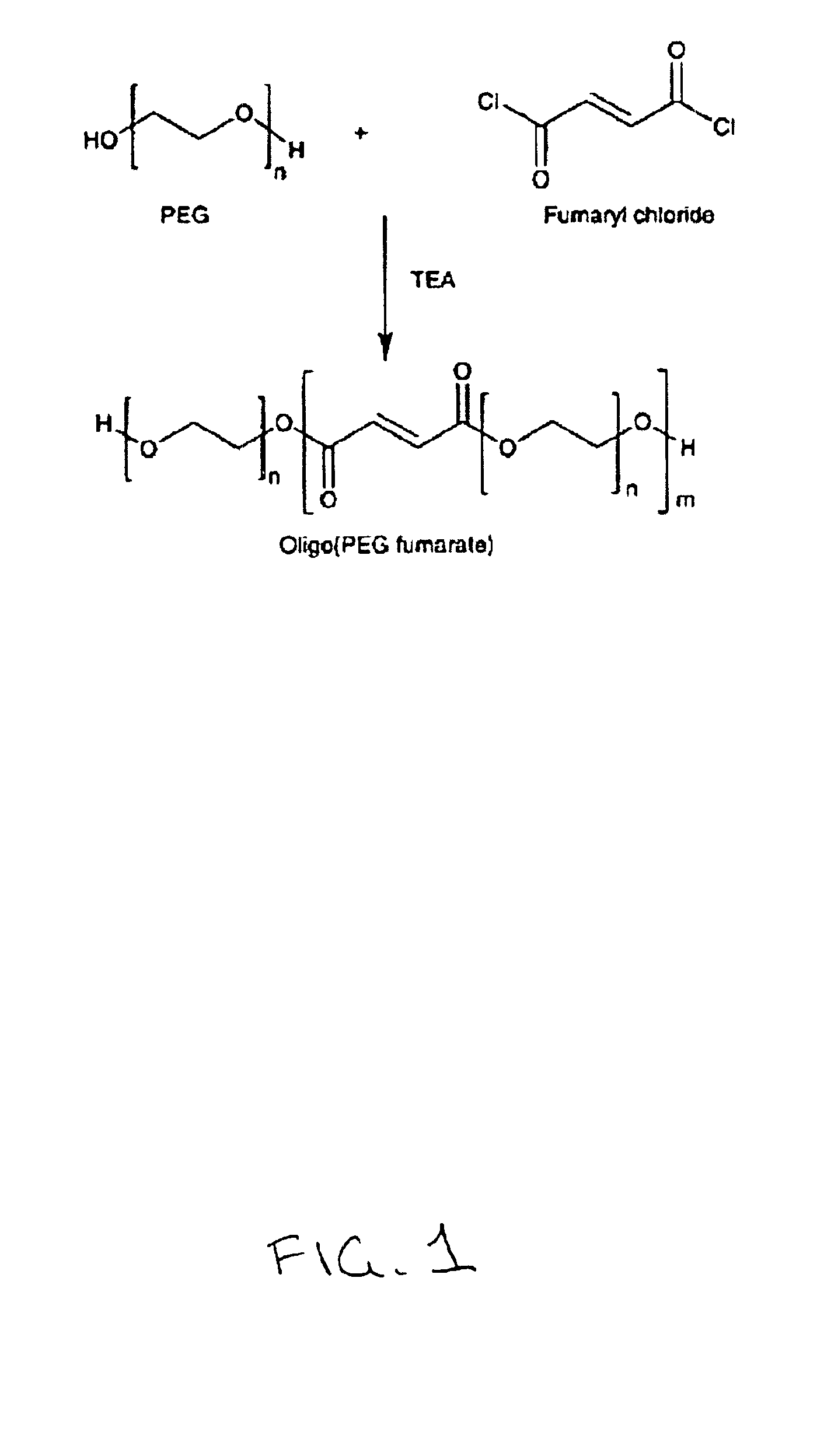

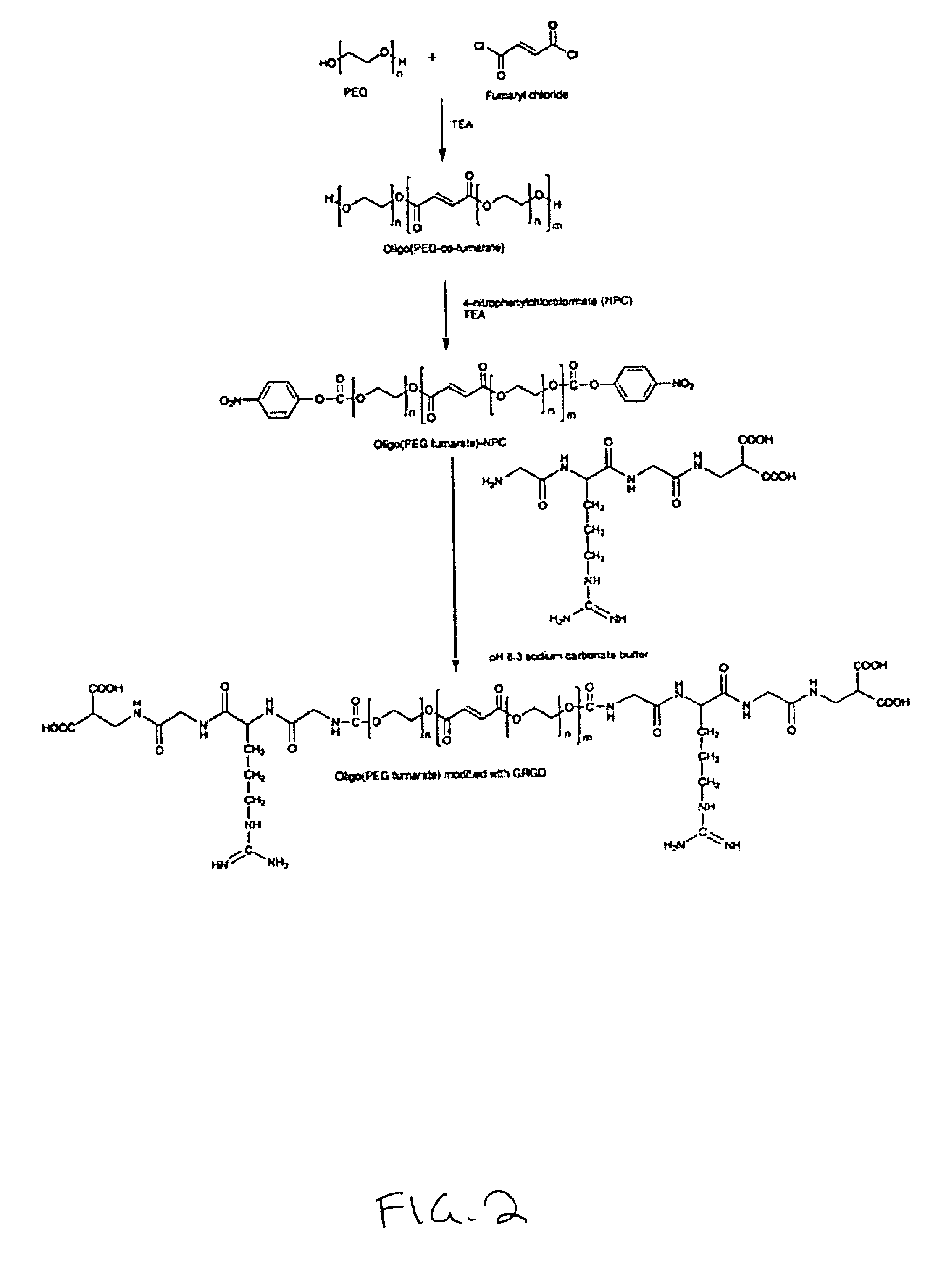

A new oligomer based on alternating fumaric acid and poly(ethylene glycol) (PEG) units is provided. The oligo(PEG fumarate) (OPF) may be functionalized by modification with a biocompatible organic group. Further, the OPF may be cross-linked using radical polymerization in the presence of either a chemical or photo initiator. A cross-linked OPF gel has a swelling behavior that is tunable dependent on the molecular weight of PEG. A cross-linkable PEG macromer, as exemplified by oligo(PEG fumarate), has unsaturated double bonds, for example in the fumaryl groups, along its macromolecular chain that allows for the preparation of hydrogels with tailored structure and properties.

Owner:RICE UNIV

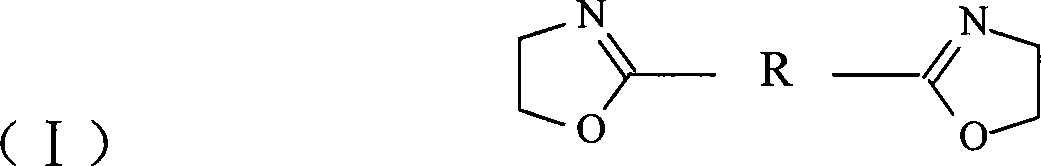

Prepn process of biodegradable polyamidoester

The present invention is preparation process of biodegradable polyamidoester. Dibasic alcohol and dibasic acid are first melt polycondensated to prepare low molecular weight polyester pre-polymer with number average molecular weight of 2000-9700 or inherent viscosity below 0.5; and the low molecular weight polyester pre-polymer is then melt and chain expanded with binary fatty oxazoline or binary aromatic oxazoline in the presence of chain expander to prepare biodegradable polyamidoester with number average molecular weight up to 39 KD and inherent viscosity up to 1.25 dL / g.

Owner:BEIJING UNIV OF CHEM TECH

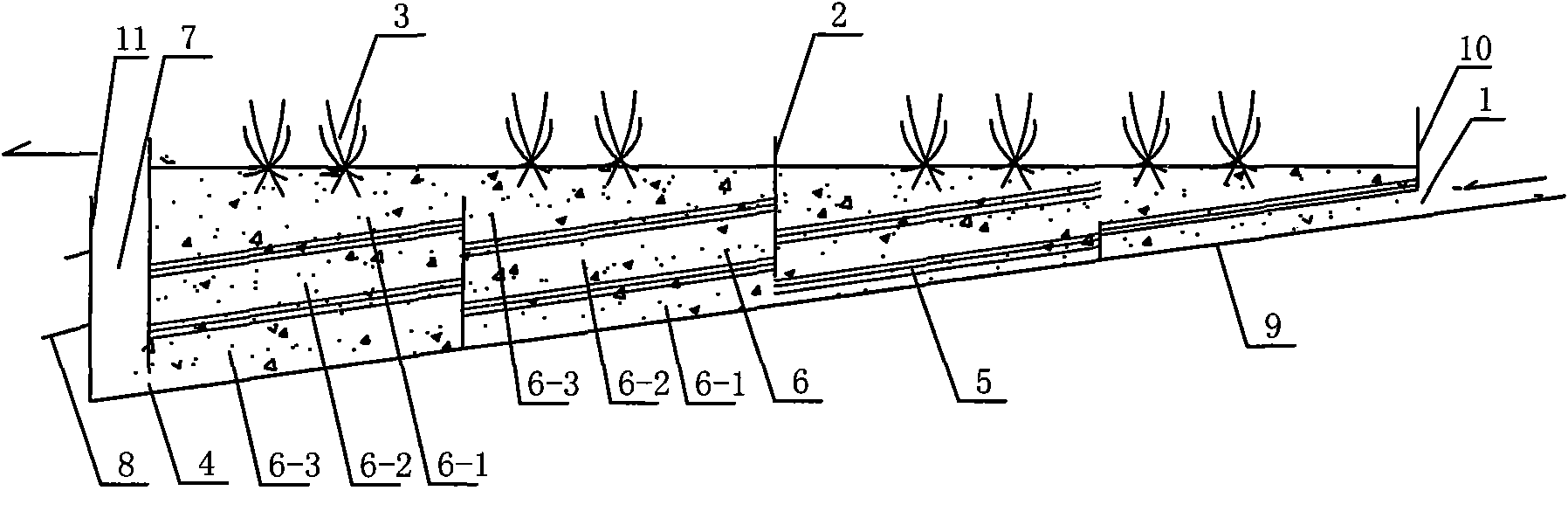

Subsurface flow constructed wetland sewage treatment system by drop water aeration oxygenation

InactiveCN101643278AExtended stayPromote biodegradationSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention relates to a subsurface flow constructed wetland sewage treatment system by drop water aeration oxygenation, composed of drop water aeration subsurface flow constructed wetlands in one stage or multistage series. Each stage of drop water aeration subsurface flow constructed wetland comprises a bed body, an inflow barricade, an outlet barricade and a drop water baffle; wherein a plurality of deflectors, gravel fillers and emergent aquatic plants are arranged in the bed body between the inflow barricade and the outlet barricade. The invention is even in water distribution, small inwake space and uniform in water impact, residence time of sewage in the bed body is extended, blocking is difficult, thus being beneficial to improving effluent quality and biodegradation of microorganism on nutrient such as nitrogen, phosphor and the like in the sewage, and construction and running cost is low. The invention, under the joint action of the effects, can effectively degrade pollutant of urban and town domestic sewage, a small amount of industry waste water and farm drainage and is applicable to mountain land and hilly country with certain gradient.

Owner:CHONGQING UNIV

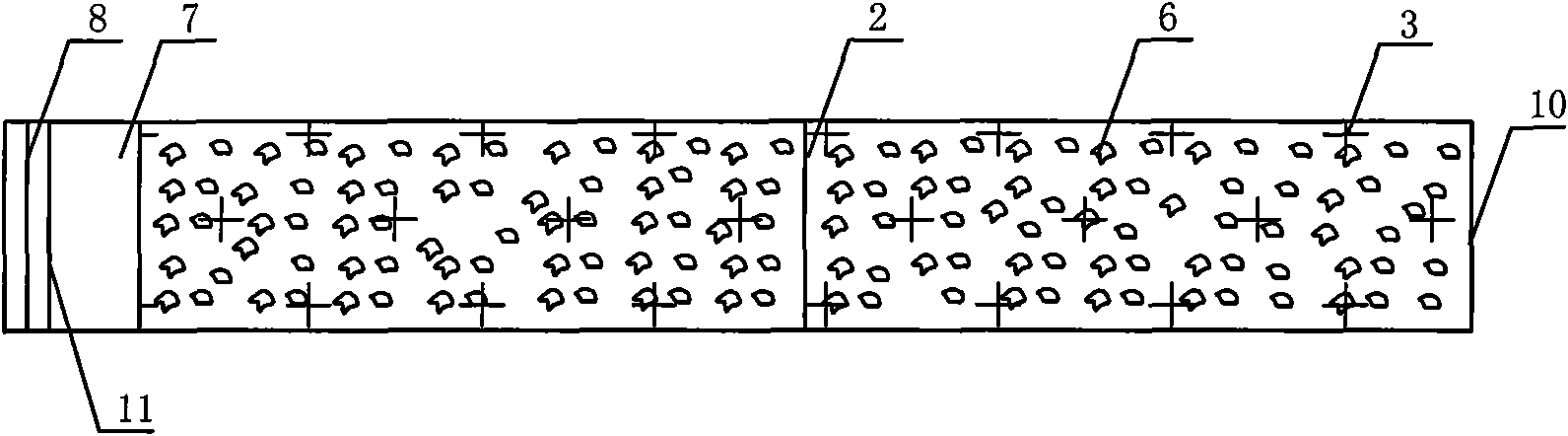

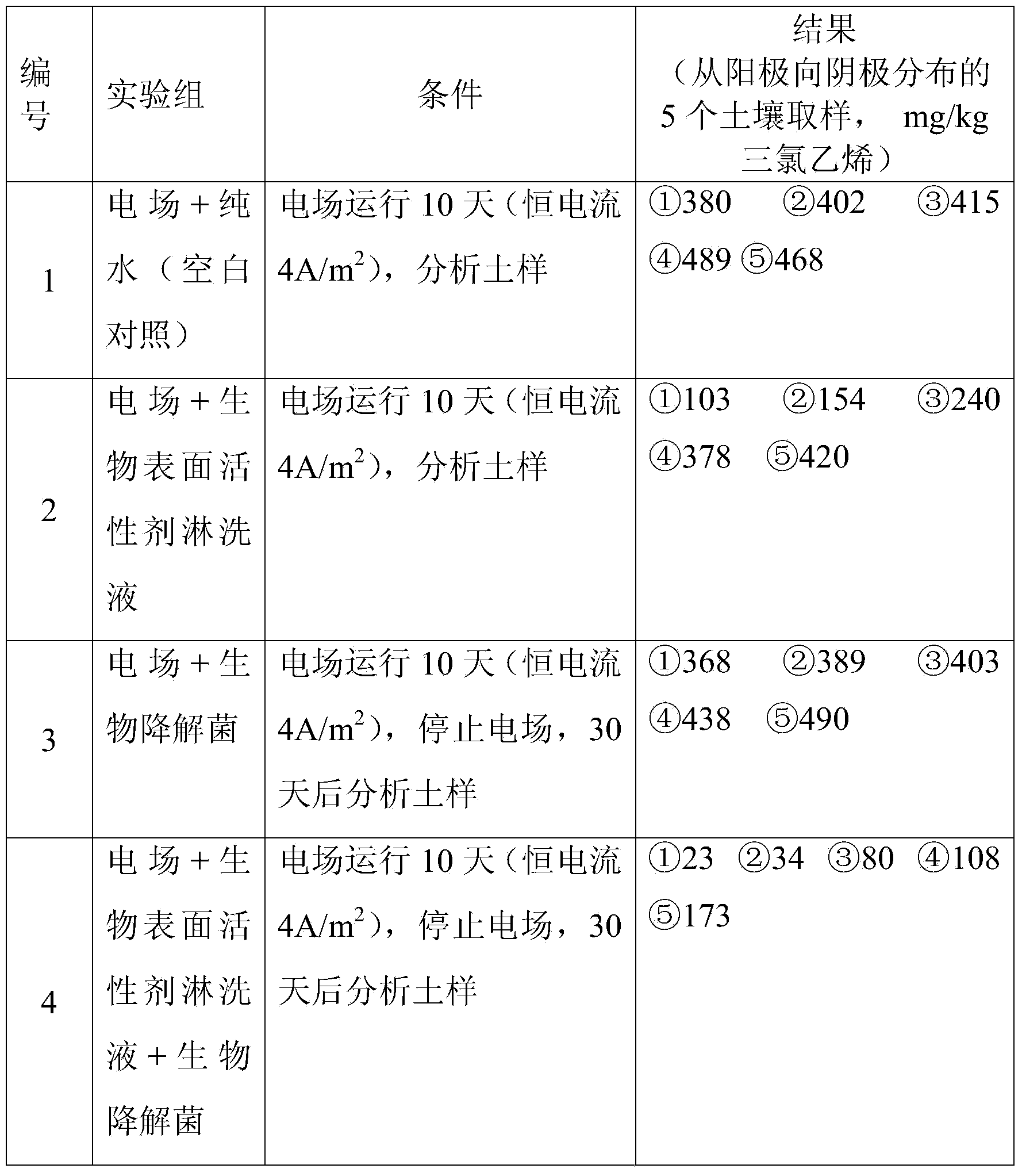

Progressive repair method for soil polluted by chlorinated organic compounds

InactiveCN104307860ATroubleshooting repairsSolving activityContaminated soil reclamationHigh concentrationMicroorganism

The invention provides a progressive repair method for soil polluted by chlorinated organic compounds. The repair method comprises the following steps: leaching the organic polluted soil by a water solution containing a bio-surfactant, and distributing most of persistent organic pollutants in the soil into a leaching solution; after finishing leaching, adding microbial degrading bacteria, and realizing the sustainable degradation of low-concentration organic compounds. The residual bio-surfactant cannot perform a negative function on the subsequent biodegradation of the organic pollutants, and can be used as a carbon source and be utilized by microorganisms. The bio-surfactant is used as a leaching agent, the organic pollutants are progressively degraded by a microorganism process, and the problems that the soil polluted by high-concentration chlorinated organic compounds is difficult to repair, traditional bio-surfactant produces residual toxicity, and the like are solved.

Owner:WUHAN UNIV

Enhancing the Disintegration and/or Degradation of a Smoking Article

InactiveUS20130047999A1Enhance disintegration and degradationEasily disintegrated and dispersedTobacco treatmentCigar manufactureEngineering

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

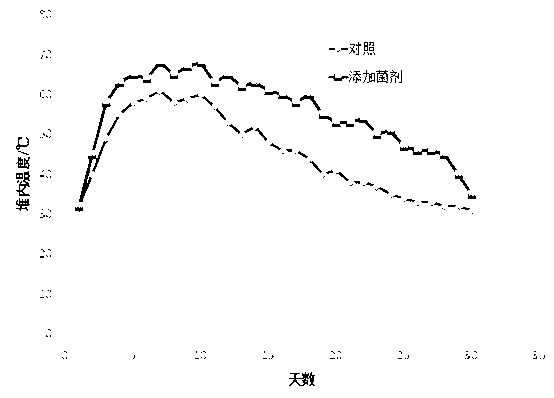

Microorganism bacterium agent for straw and excrement mixed composting

ActiveCN103232944AWell mixedPromote the process of mixed aerobic compostingFungiBio-organic fraction processingFecesPseudomonas putida

The invention discloses a microorganism bacterium agent for straw and excrement mixed composting. The microorganism bacterium agent is composed of the following strains: (2-6)*10<10>cfu of hair mould per gram, (2-6)*10<10>cfu of trichoderma virens per gram, (2-6)*10<10>cfu of geotrichum candidum per gram, (2-8)*10<9>cfu of saccharomyces cerevisiae per gram, (3-5)*10<11>cfu of bacillus thermophilus per gram, (2-6)*10<11>cfu of lactobacillus thermophilus per gram, (2-8)*10<10>cfu of white rot fungi per gram, (2-8)*10<10>cfu of monilinia fructicola per gram, (3-7)*10<8>cfu of pseudomonas putida per gram, (2-6)*10<11>cfu of nitrosococcus per gram, (1-4)*10<6>cfu of green algae per gram and (2-5)*10<7>cfu of blue-green algae per gram. The microorganism bacterium agent can promote a straw and excrement mixed aerobatic composting progress, shorten a composting period, improve a composting rotten degree, accelerate biodegradation of organic matters, alleviate ozone generation and diffusion during composting and reduce loss of nutrient substances such as nitrogen, can be applied to composting of different straw and excrement raw materials for composting enterprises and is used for producing bio-organic fertilizers.

Owner:山东土木启生物科技有限公司

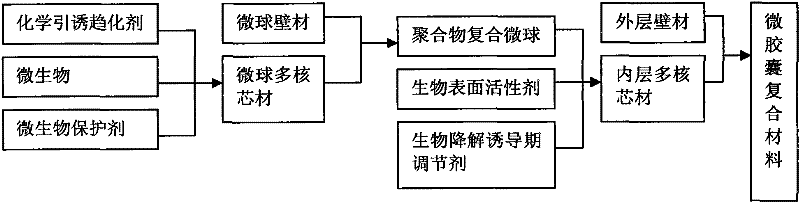

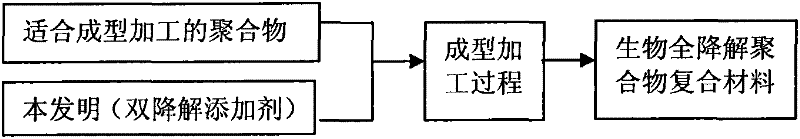

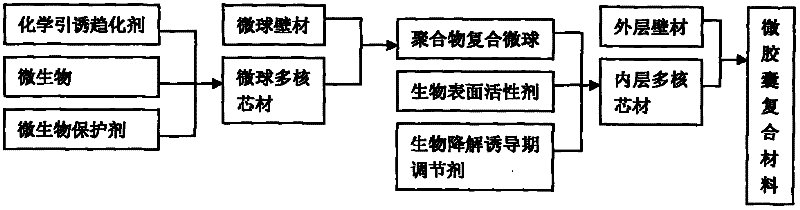

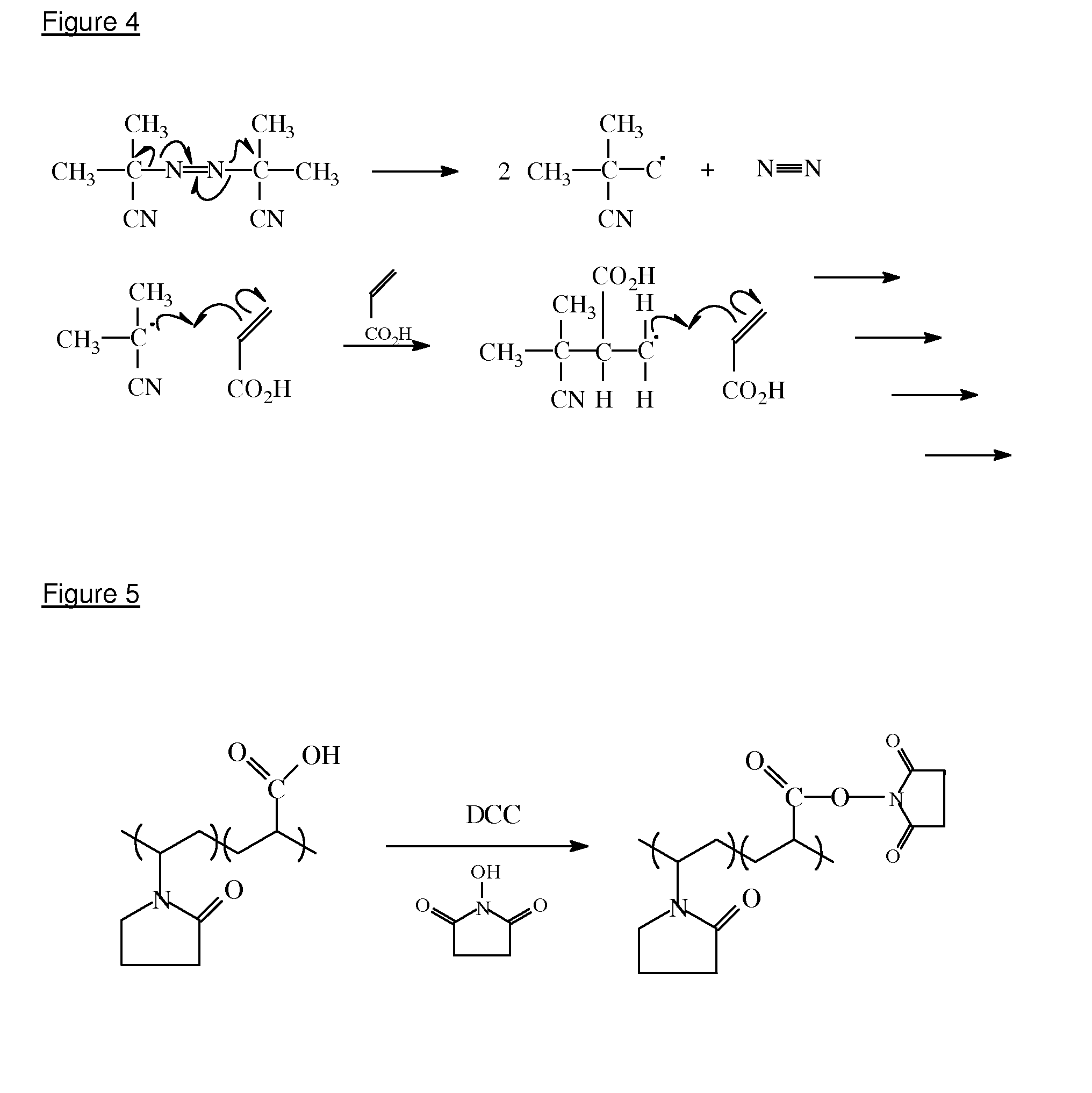

Dual-degradant additive for promoting photo oxidative degradation and biodegradation of polymer

InactiveCN102352064APromotes photooxidative degradationPromote biodegradationPhotooxidative degradationCarboxylic acid

The invention relates to a dual-degradant additive for promoting photo oxidative degradation and biodegradation of a polymer, comprising the following ingredients: 30-50 wt% of resin used as a carrier, 26-40 wt% of composite photo oxidative degradation accelerating agent, 1-5 wt% of photo oxidative degradation induction period regulator, 1-5 wt% of carboxylic acid or its derivative, and 15-25 wt%of microcapsule composite material. The dual-degradant additive disclosed herein can be applied on various polymers. By using the dual-degradant additive to mix with the polymer according to a certain proportion to prepare a composite material, the composite material can be degraded through photo oxidative degradation and biodegradation, has effects of repairing soil and compost, and has effects of oxygen barrier and flame resistance in many applications.

Owner:丁邦瑞

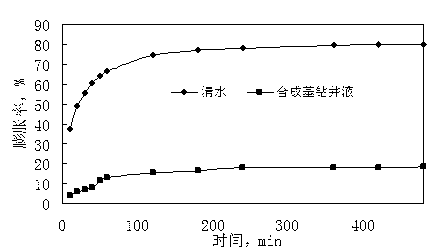

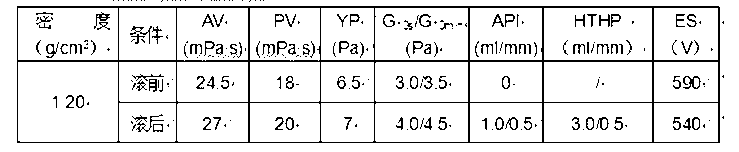

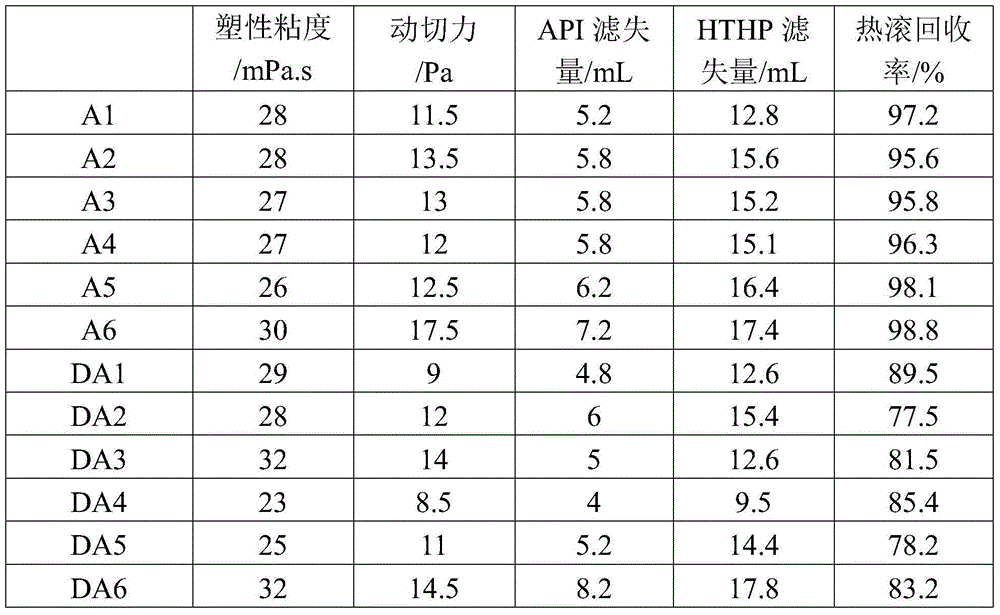

Preparation method of synthetic base drilling fluid

The invention discloses a preparation method of a synthetic base drilling fluid. The preparation method comprises the steps of a. adding 2.0%-4.0% of organic soil, 3.0%-5.0% of main emulsifier, 2.0%-4.0% of auxiliary emulsifier, 0.1%-0.2% of wetting agent, 0.5%-2.0% of flow pattern conditioning agent and 2.0%-3.0% of CaO to 60-70% of synthetic base in percent by weight under a stirring condition, and stirring for 30min; b. preparing a CaCl2 solution with the mass concentration of 20%, and enabling CaCl2 to completely dissolve; c. slowly adding 10%-15% of CaCl2 aqueous solution in percent by weight to the synthetic base under a stirring condition; and d. adding 4.0%-6.0% of filtrate-loss reducer and 2.0%-3.0% of anti-sloughing blocking agent in percent by weight to the synthetic base under a stirring condition to form the synthetic base drilling fluid. The preparation method is simple in processing steps and easy in operation. The synthetic base drilling fluid prepared by the method has the characteristics of strong anti-sloughing inhibition capability, good salt and calcium erosion resistance performance and obvious lubrication performance.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

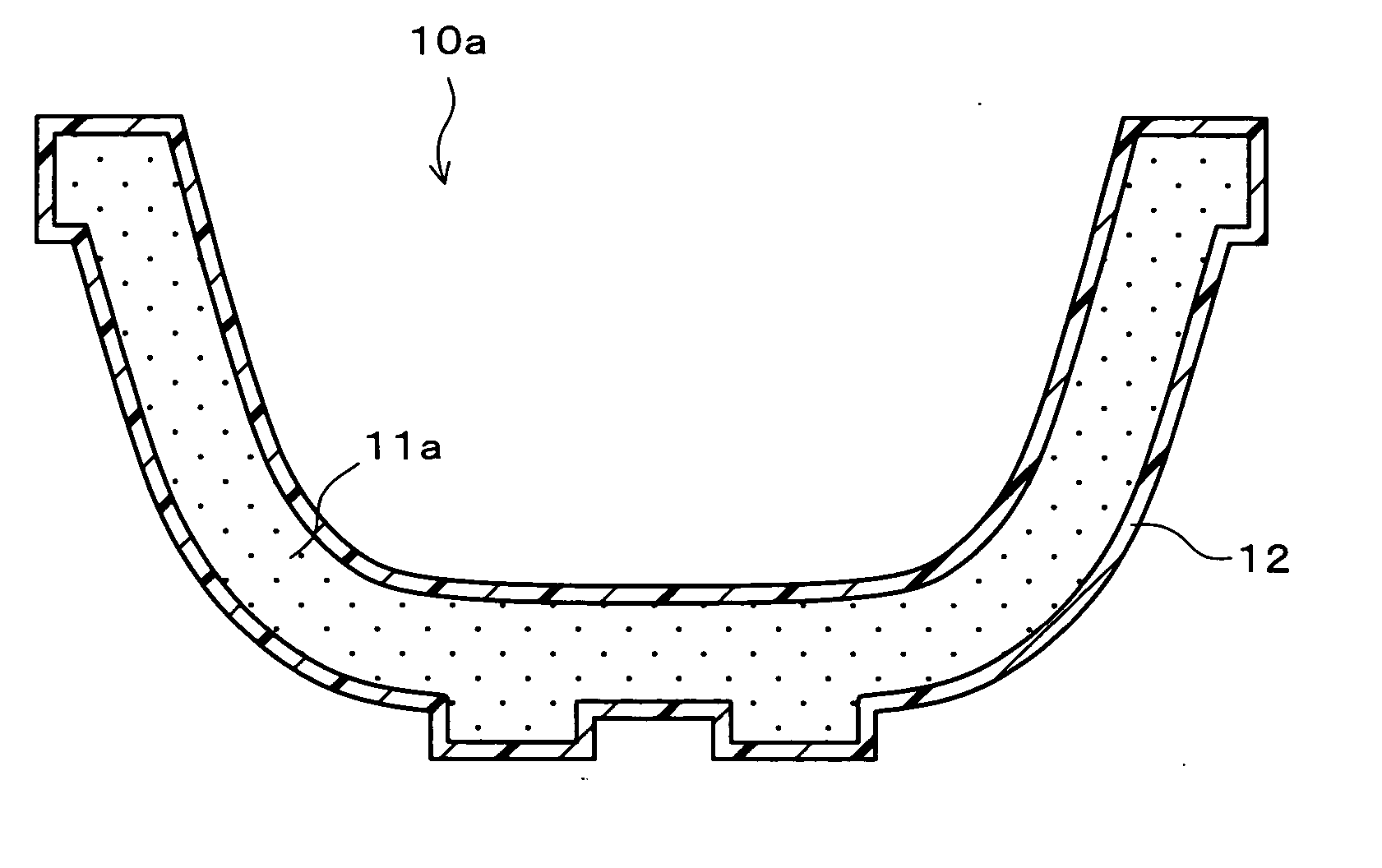

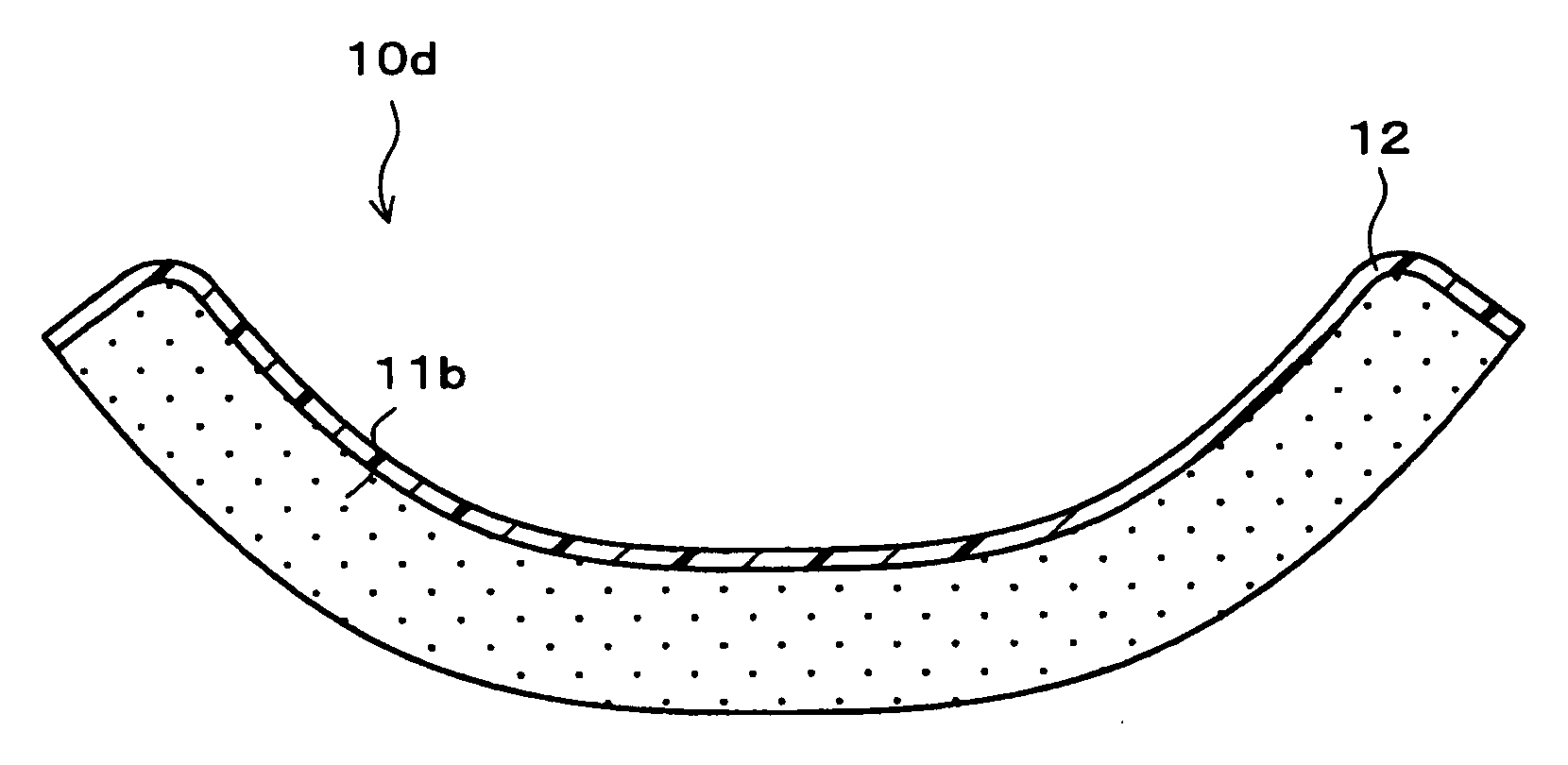

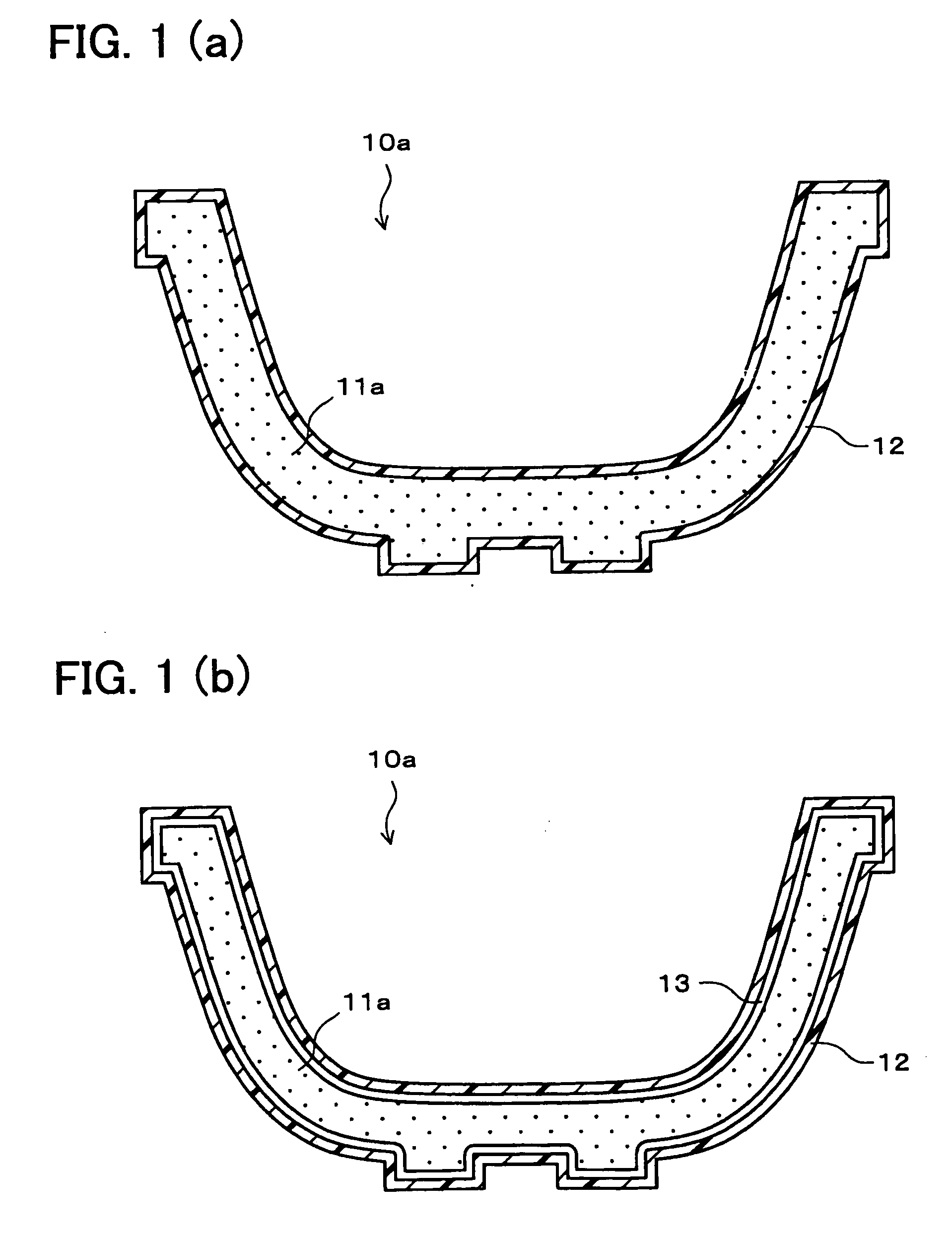

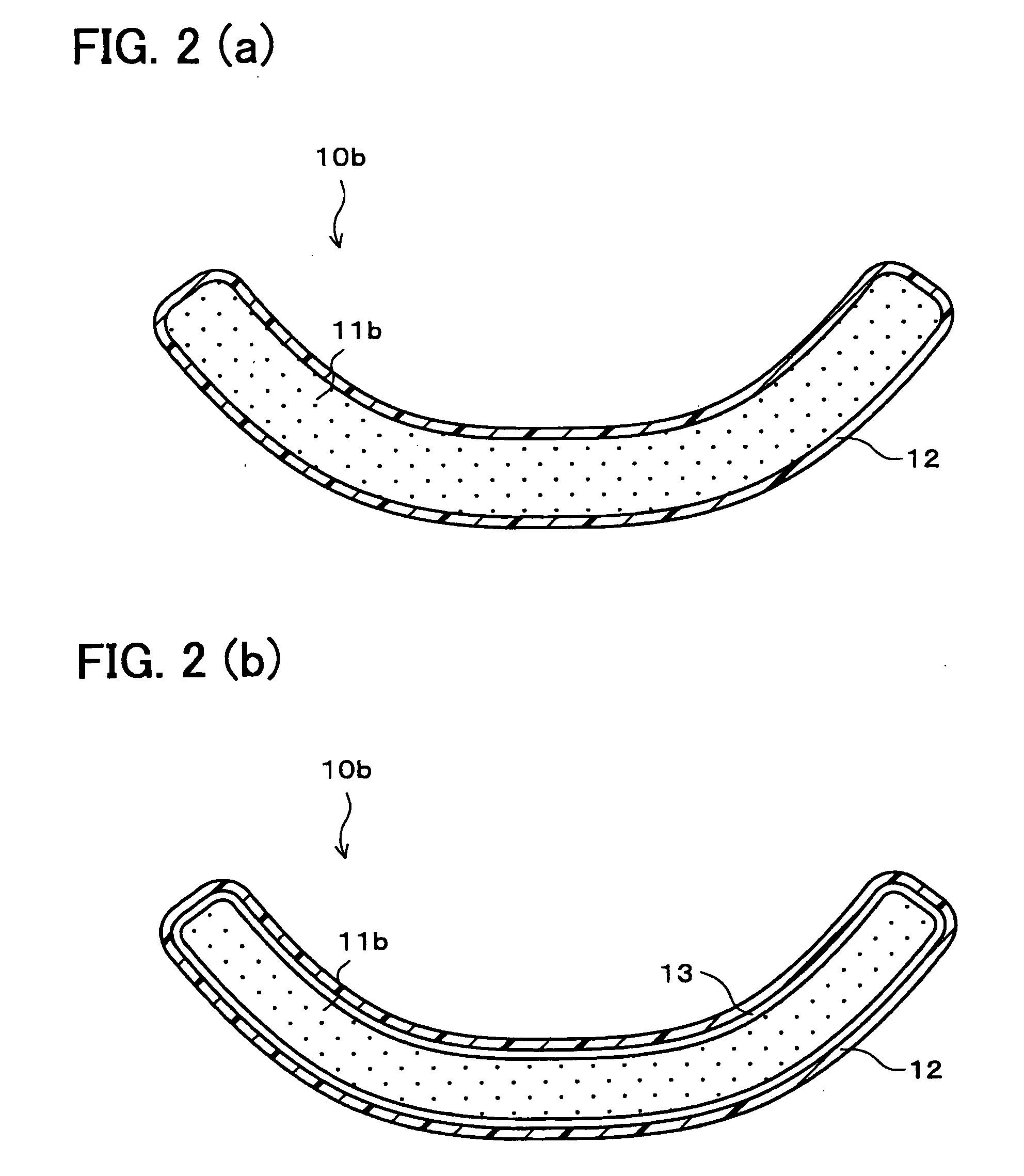

Biodegradable molding

InactiveUS20050202229A1Increased intensityIncrease physical strengthFlexible coversWrappersPolymer sciencePolyvinyl alcohol

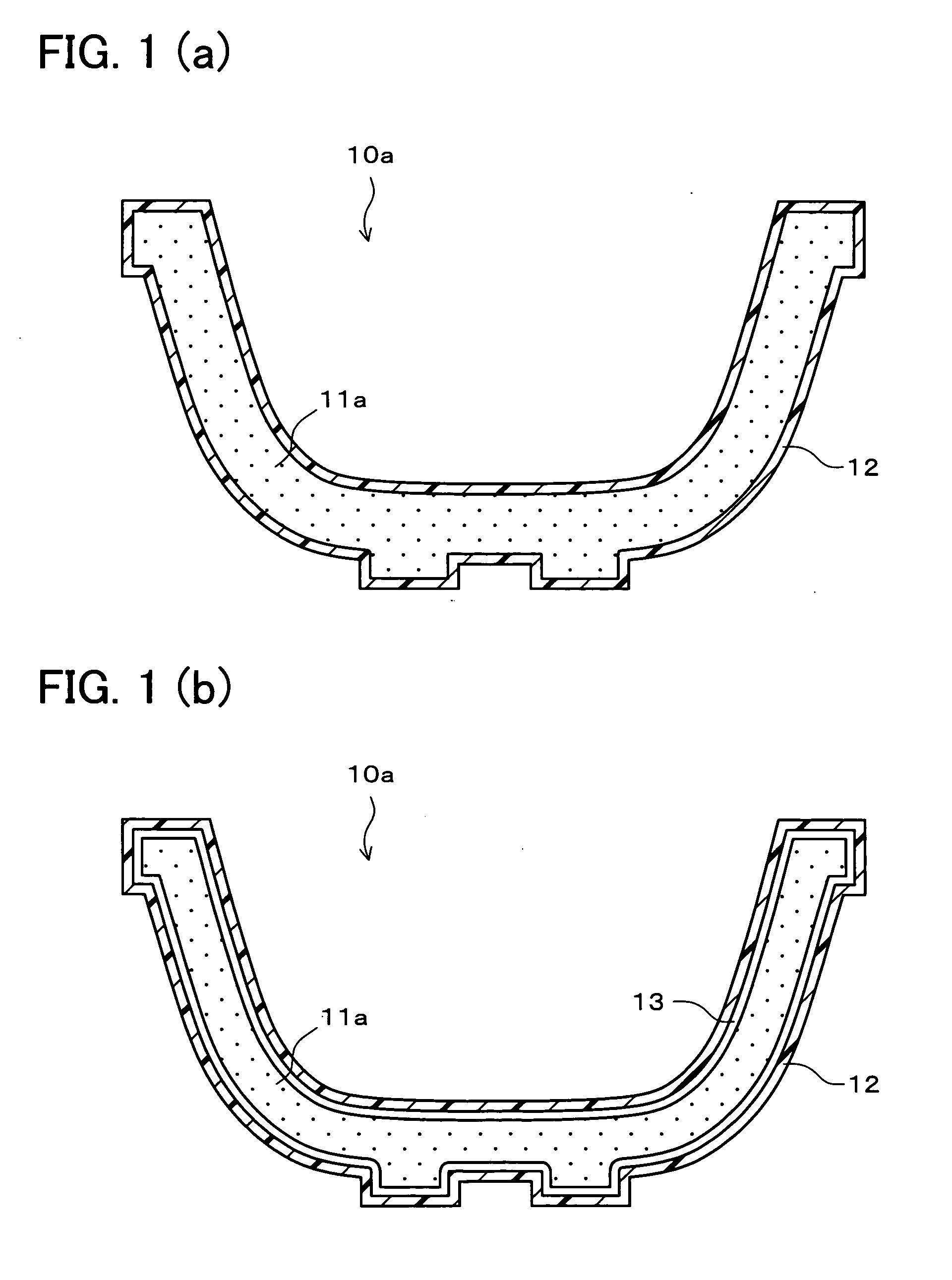

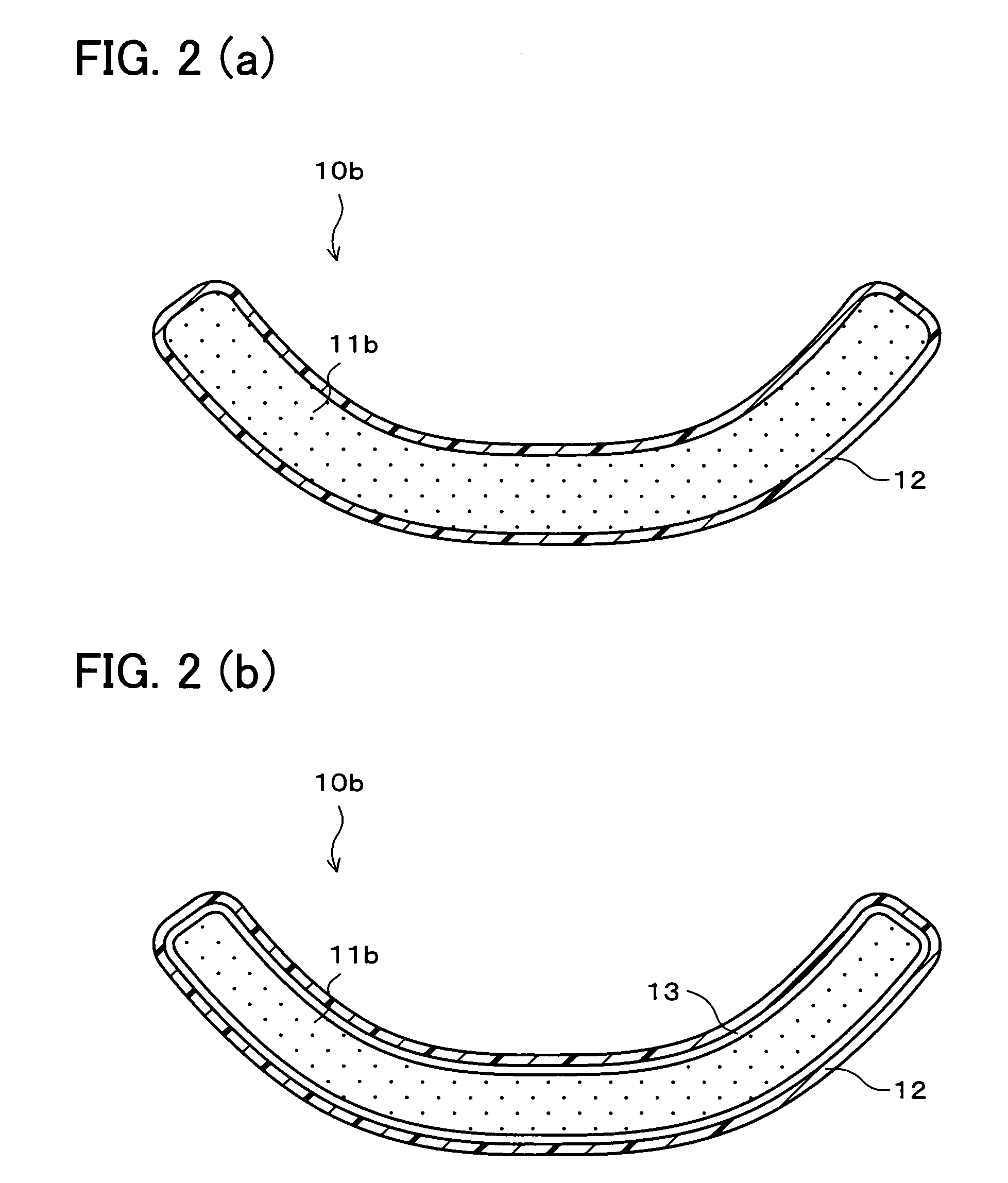

A bowl-shaped container (10a) which is as a biodegradable molded article adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing high-amylose starch and water, or a slurry or dough molding material containing starch, polyvinyl alcohol and water. For these reasons, it is possible to accomplish sufficient strength and at least sufficient water resistance, to exert a very excellent biodegradability and further to provide a biodegradable molded article having excellent moisture absorption strength mainly made of starch even if the biodegradable molded article has a complicated shape.

Owner:NISSEI CO LTD

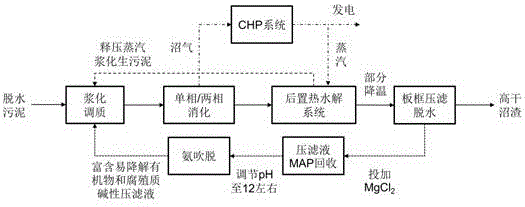

Sludge resource recovery method based on hydrothermal treatment of digested sludge

InactiveCN106746467AEfficient recyclingHigh yieldSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisRecovery methodFiltration

The invention discloses a sludge resource recovery method based on hydrothermal treatment of digested sludge. The method comprises the following steps: performing dehydration treatment on sludge so as to obtain dehydrated sludge with the solid content of 15-20%; mixing the dehydrated sludge and a press filtrate in which nitrogen and phosphorus are removed in a slurrying and tempering reactor, preheating, slurrying and tempering; pumping the sludge subjected to slurrying and tempering into an anaerobic digestion system so as to produce biogas; introducing the sludge subjected to anaerobic digestion into a pyrohydrolysis reactor for performing hydrothermal treatment, relieving pressure and cooling after pyrohydrolysis so as to obtain a mixed solution, and performing plate-frame pressure filtration dehydration so as to form high-dryness biogas residues; regulating the pH value of the press filtrate to 9-11, adding a magnesium salt to produce struvite so as to realize phosphorus recovery; regulating the pH value to 11-13, and performing ammonia stripping, thereby realizing nitrogen recovery; and refluxing the press filtrate in which nitrogen and phosphorus are removed back to the slurrying and tempering reactor, mixing with the dehydrated sludge, and performing cycle treatment. The method disclosed by the invention has the advantages that the sludge degradation rate and methane yield are effectively improved, and nitrogen and phosphorus resources are recovered.

Owner:TONGJI UNIV

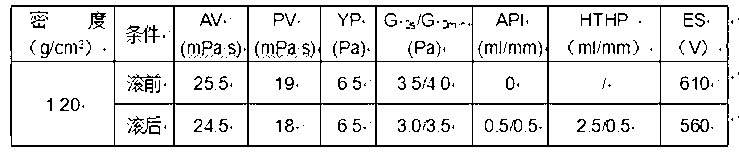

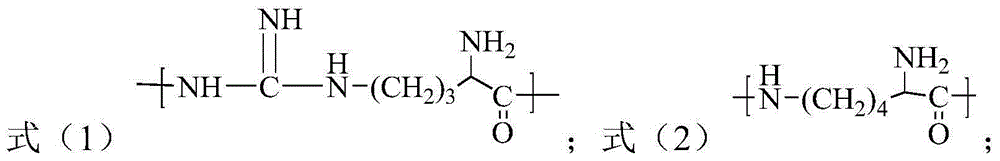

Bionic shale inhibitor and preparation method thereof and drilling fluid and application thereof

ActiveCN104789195AEasy accessHigh positive charge densityDrilling compositionEnvironmental resistanceStructural unit

The invention discloses a bionic shale inhibitor, comprising a structure unit shown in formula (1) and a structure unit shown in formula (2), the molar ratio of the structure unit shown in the formula (1) to the structure unit shown in the formula (2) is 0.26:1; and the shale inhibitor weight-average molecular weight is 800-4000g / mol. The invention also provides a preparation method of the bionic shale inhibitor, and the bionic shale inhibitor prepared by the method. The invention also provides a drilling fluid containing the bionic shale inhibitor and application thereof. The bionic shale inhibitor has high shale inhibition performance, environmental friendliness and no pollution.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

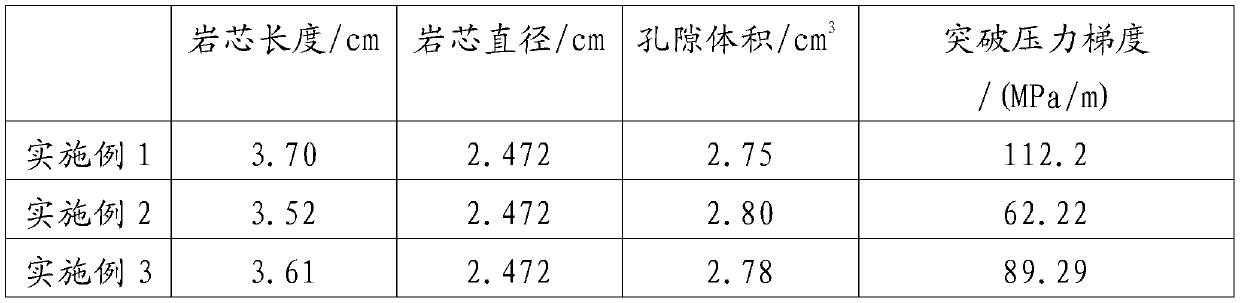

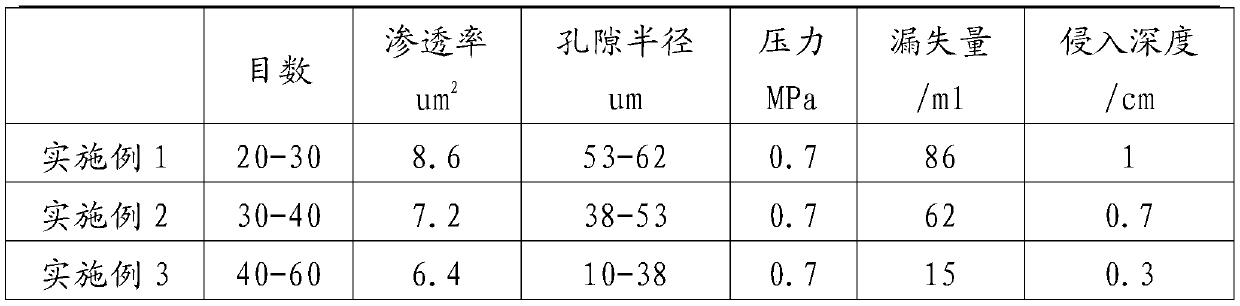

Degradable temporary plugging agent for workover and preparation method thereof

The invention belongs to the field of workover operations, and particularly relates to a degradable temporary plugging agent for workover and a preparation method thereof. The degradable temporary plugging agent comprises the following components in parts by mass: 5-7% of acrylic acid, 15-21% of acrylamide, 5-15% of inorganic mineral soil, 0.002-0.005% of a polymerization inhibitor, 6-12% of a degradation promoter, 0.02-0.1% of a crosslinking agent, 0.6-1.0% of an initiator, 7-10% of corn flour and the balance of water. The degradable temporary plugging agent for workover disclosed by the invention has good degradation performance and does not need to add an additional degradation process; for high-water cut oil wells, water wells and the like, the degradable temporary plugging agent can be degraded by itself and resume operation and production only under the condition of a reservoir (under the condition of 90 DEG C, the 48-hour degradation rate can reach more than 90%).

Owner:DAGANG OIL FIELD GRP +1

Total biodegraded thermoplastic starch resin

The composition of total-biodegraded thermoplastic starch resin includes (by weight portion) starch 50.0-75.0, blend A 5.0-20.0, blend B 10.0-20.0 graft modifier 1.0-5.0, chemical initiator 0.1-1.0, plasticizer 2.0-10.0, covering agent 0.3-3.0 and antioxidant 0.1-2.0, in which the blend A is one kind of more than one kind of thermoplastic resin, and the blend B is one kind of more than one kind of cellulose, polyvinyl alcohol, polyglycolic acid and polyester, and its graft modifier is one or more than one kind of long-chain unsaturated carboxylic acid and its ester. It can be directly used for making various tableware, cup, disk, film and package products, etc.

Owner:重庆远智能锁安全门有限公司

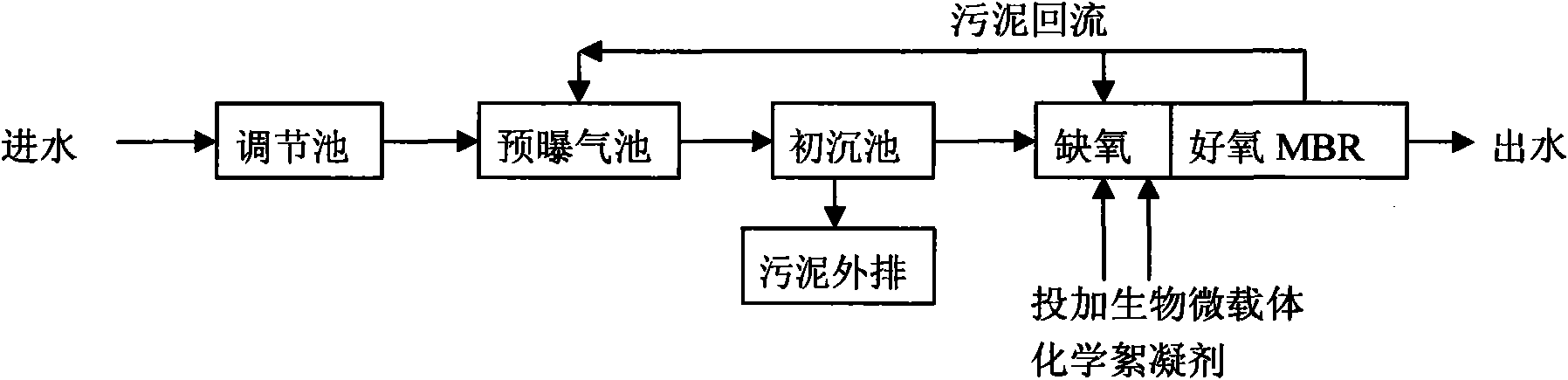

Efficient treatment process for printing and dyeing waste water

ActiveCN101624252ASimple processEasy to operate and manageTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationFlocculation

The invention discloses an efficient treatment process for printing and dyeing waste water. In the invention, after printing and dyeing waste water is homogenated by a regulating tank and preaerated by a preaeration tank, the printing and dyeing waste water enters a primary precipitating tank to be precipitated; the precipitated waste water enters an oxygen deficiency or an aerobic membrane bioreactor to be treated, and chemical flocculants and biological microcarrier with an absorption function are thrown into an oxygen deficiency zone of the membrane bioreactor; waste water mixture liquid enters an aerobic zone from the oxygen deficiency zone, and is separated by a membrane assembly in the aerobic zone; clean water realizes standard discharge after being filtered by the membrane assembly, and biochemical or materialized mud with high concentration in the aerobic zone respectively returns to the oxygen deficiency zone and the preaeration tank; the biochemical or materialized mud returning to the oxygen deficiency zone is continuously recycled in the membrane bioreactor; and after the biochemical or materialized mud returning to the preaeration tank mixes with the homogenated printing and dyeing waste water for biochemical or materialized absorption and flocculation, the biochemical or materialized mud returning to the preaeration tank enters the primary precipitating tank to be precipitated, and the precipitated mud is discharged out of the system. The invention is not only applicable for the treatment of printing and dyeing waste water, and is also suitable for the treatment of other difficultly degraded waste water.

Owner:江苏省环境工程技术有限公司

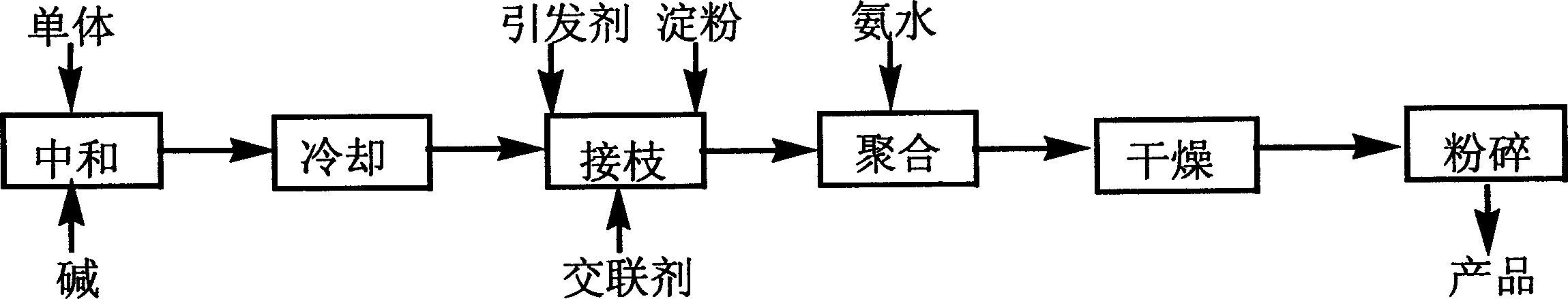

One-step synthesis process of producing biodegradable high-hydroscopicity resin directly with corn powder

The present invention belongs to chemical synthesis process of polymer and relates to the production of synthetic resin. By combining artificial polymerization and polymer grafting into one step, the present invention produces high-hydroscopicity resin with corn powder in one step. Turf is added into the material to improve performance and exothermic reaction for heat crosslinking is adopted for easy temperature control. The technological process is simple and produces no side product and waste, and the product has hydroscopicity of 800-1000 times and is biodegradable. The product may be used as water saving material in solving crop water deficiency problem.

Owner:NORTHEAST NORMAL UNIVERSITY

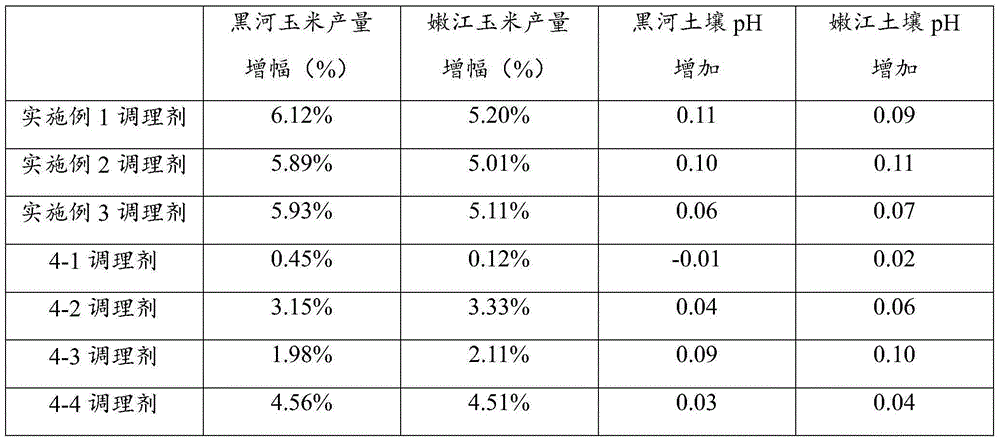

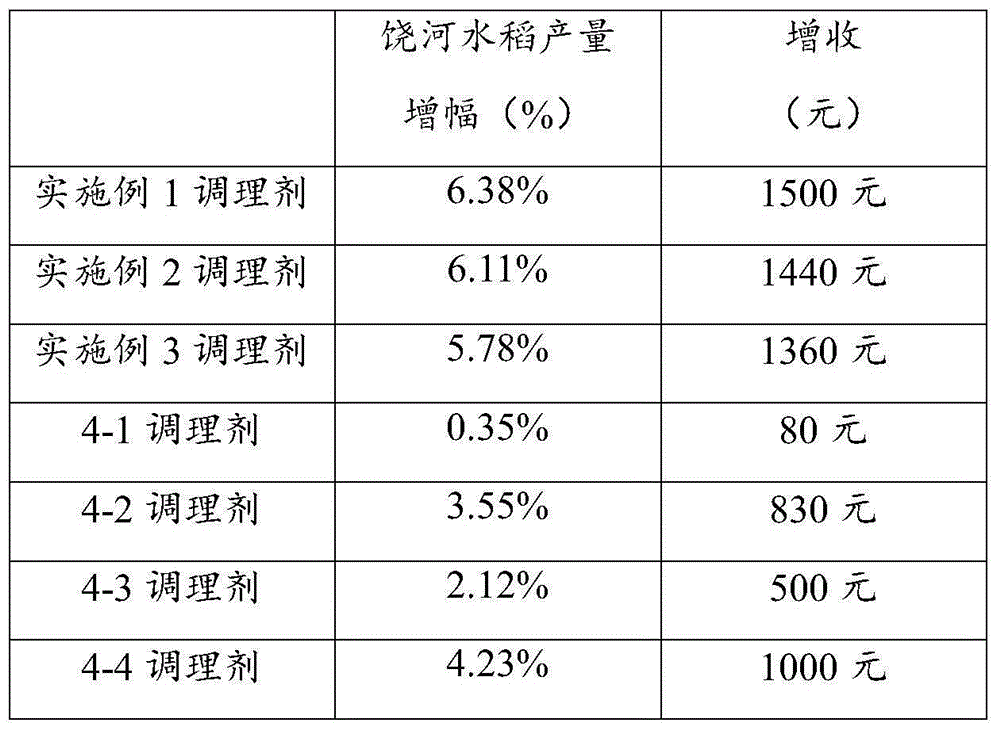

Soil conditioning agent, and preparation method and applications thereof

ActiveCN105131963AImprove physical and chemical propertiesIncrease profitAgriculture tools and machinesOther chemical processesMicrobial agentBiology

The invention discloses a soil conditioning agent, and a preparation method and applications thereof, and belongs to the technical field of soil pollution remediation and modification. The soil conditioning agent comprises, by mass, 45 to 70% of crop straw low temperature anaerobic carbide, 20 to 35% of an organic fertilizer, 5 to 20% of humic acid, 5 to 10% of clay, and 5 to 10% of EM microbial agent. The invention also provides a preparation method and applications of the soil conditioning agent. The soil conditioning agent is capable of eliminating residual toxin of herbicide polluted soil, and repairing polluted soil, is capable of improving soil physical and chemical properties of paddy field soil and acidified soil, increasing fertilizer utilization rate, reducing fertilizer loss, promoting crop growth, and increasing grain yield.

Owner:INST OF SOIL FERTILIZER & ENVIRONMENT RESOURCE HEILONGJIANG ACADEMY OF AGRI SCI

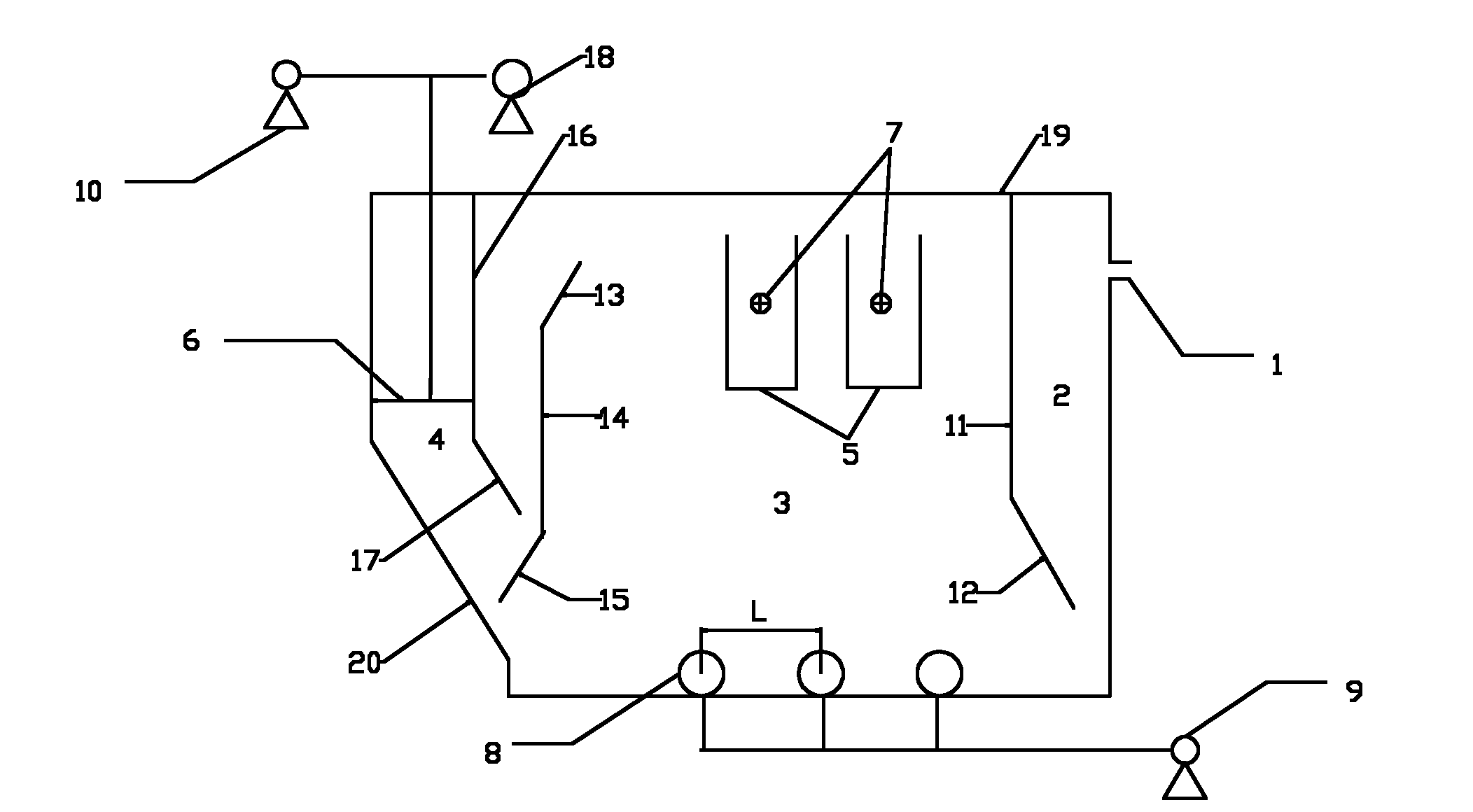

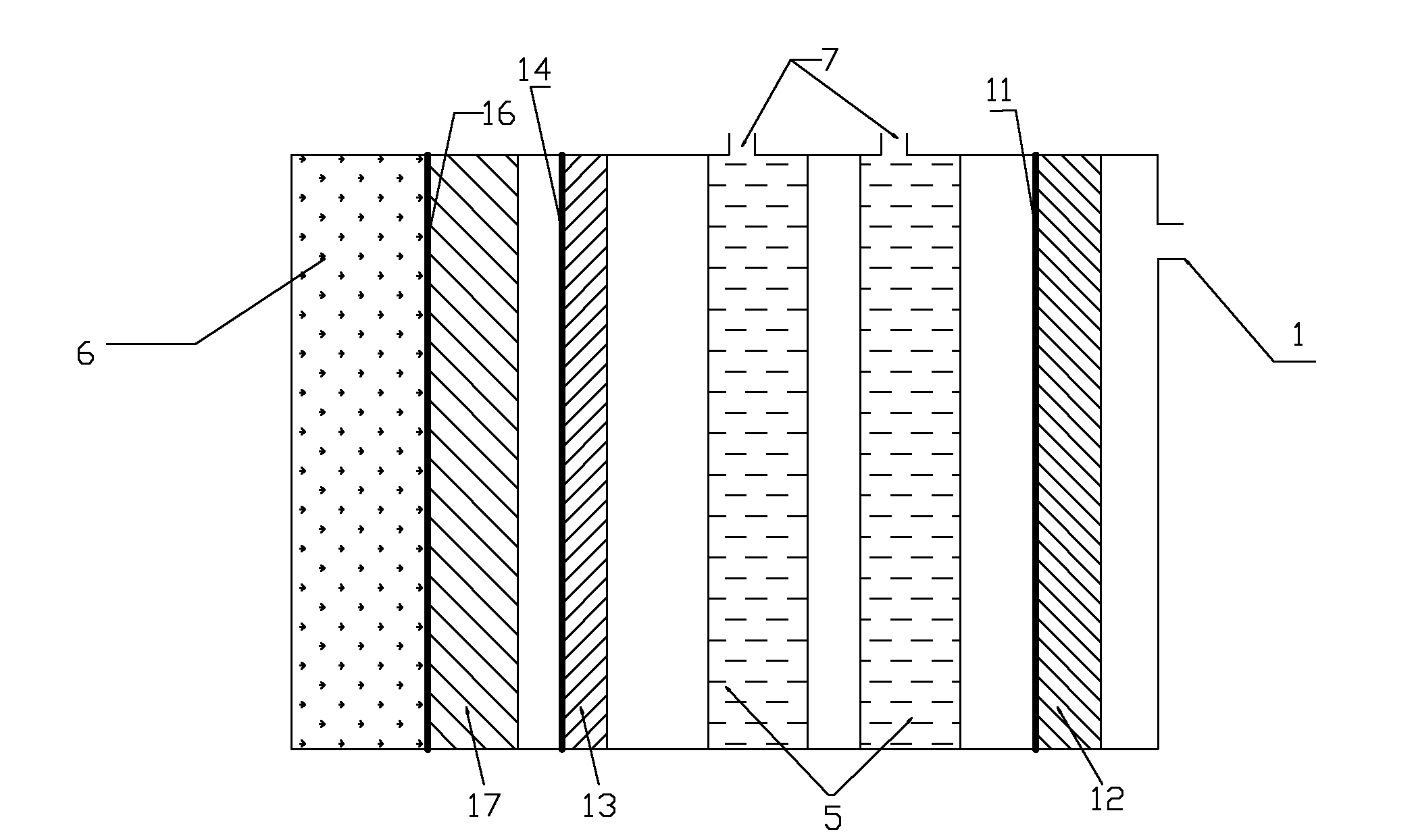

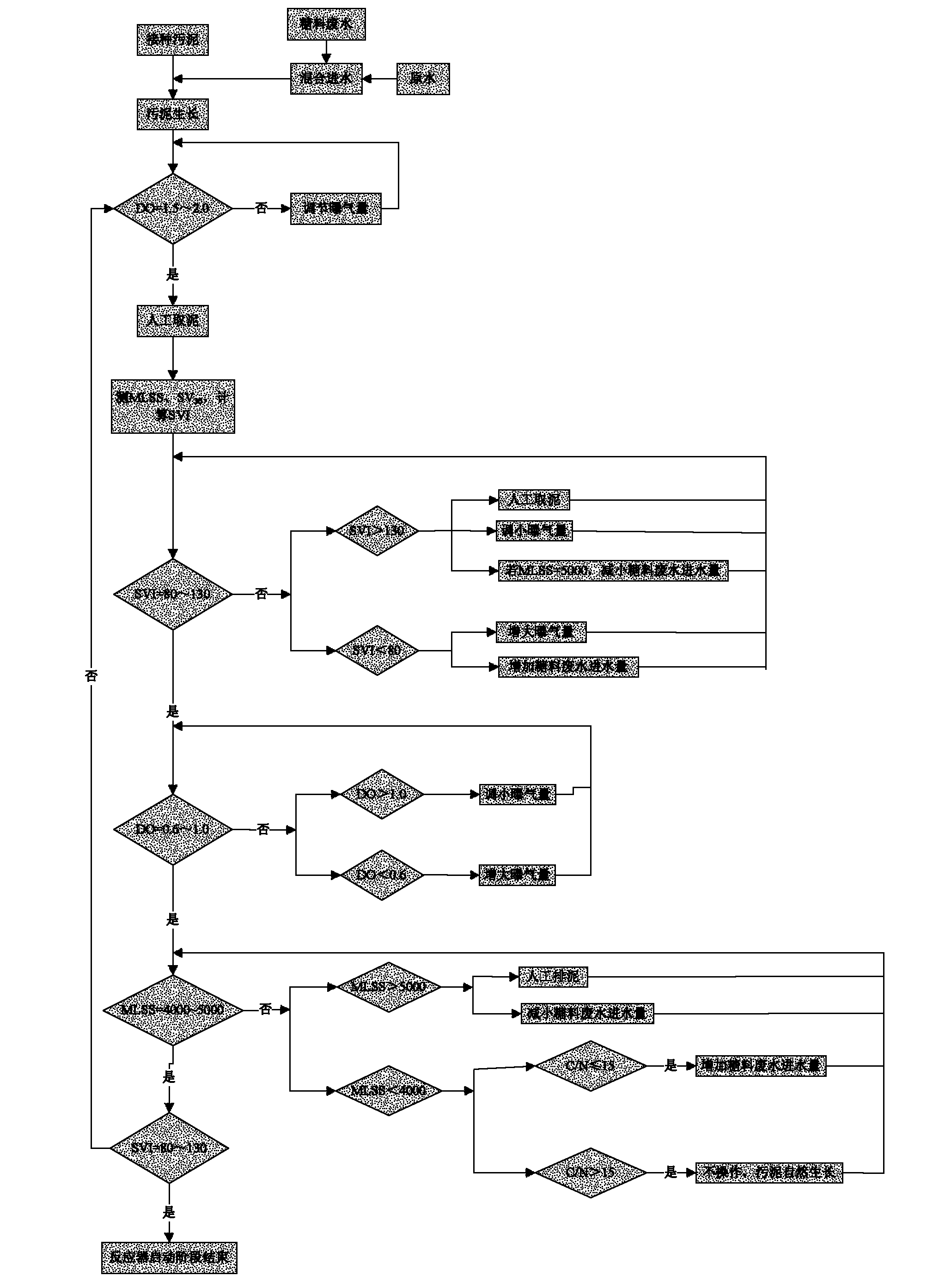

Sludge reflow-free device with simultaneous nitrification and denitrification (SND) function and operation control method thereof

ActiveCN102173510ASolve the problem that it is difficult to control the microbial metabolic environmentEasy to operate and controlControlling ratio of multiple fluid flowsTreatment with aerobic and anaerobic processesSludgeCombined use

The invention discloses a sludge reflow-free device with a simultaneous nitrification and denitrification (SND) function. The device comprises a pool body; the sidewall of the pool body is provided with a main water inlet; the interior of the pool body is divided by a clapboard into a diversion area, an aeration area and a sludge precipitation area in sequence; the aeration area is internally provided with an overflow groove; the bottom of the aeration area is provided with microporous aeration devices distributed uniformly; and the sludge precipitation area is internally provided with a membrane element. The invention also discloses an operation control method of the device. By skillful arrangement of aeration pipes and combined use with a biological membrane, the power cost and the operating cost of sludge reflow are saved, and the purpose of reducing energy consumption is achieved. The biological environment to be achieved by the simultaneous nitrification and denitrification is adjusted indirectly through adjusting parameters such as active sludge concentration, sludge age, unit sludge load and the like; the operation is strong in human controllability, and the problem that the microbial metabolic environment in the SND technology is not easy to control is solved.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

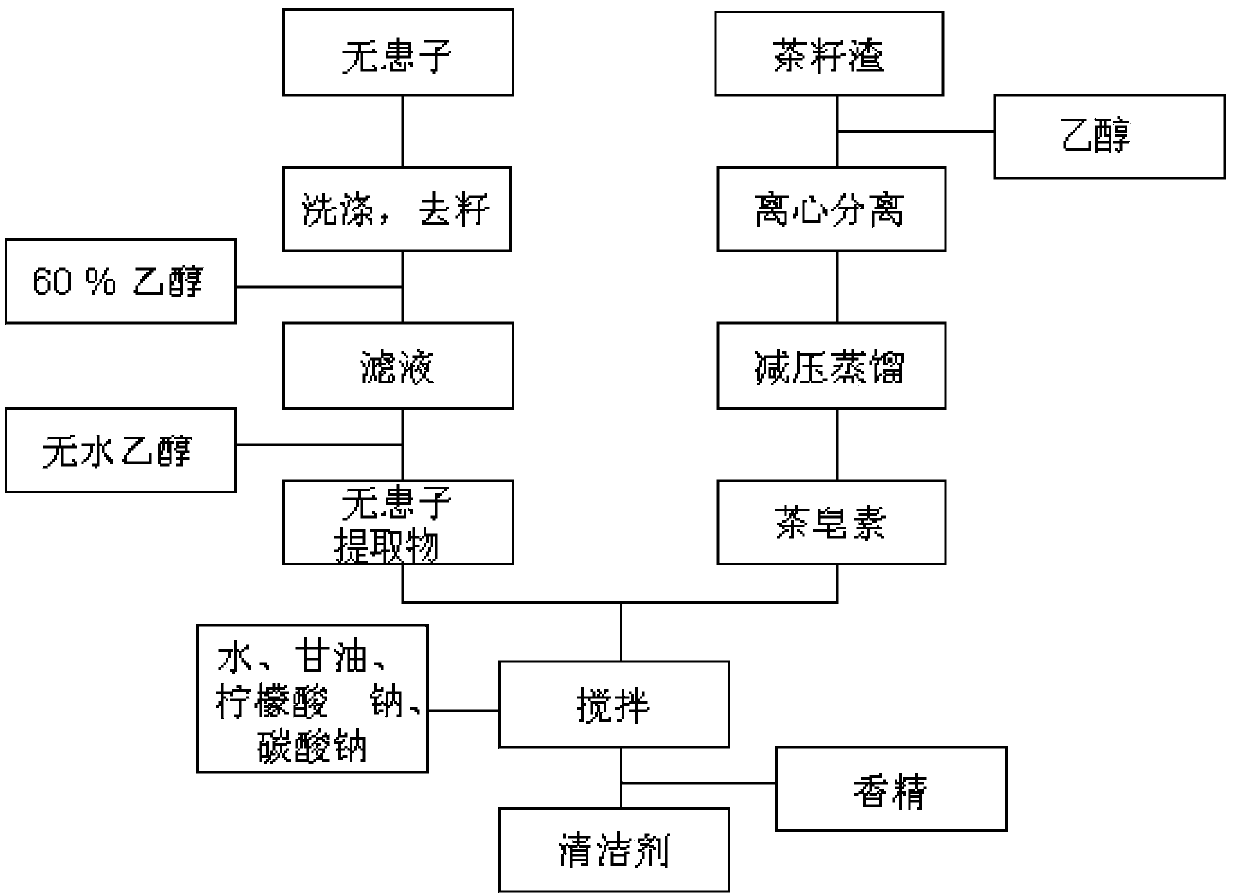

Natural detergent and preparation method and application thereof

InactiveCN103952245APromote biodegradationProtect environmentInorganic/elemental detergent compounding agentsSurface-active detergent compositionsChemistryGlycerol

The invention discloses a natural detergent and a preparation method and application thereof. The soapberry natural detergent comprises the following components in percentage by weight: 4%-8% soapberry extractives, 2%-5.5% of tea saponin, 1%-2.8% of glycerol, 2%-7.8% of sodium citrate, 1.2%-3.6% of sodium carbonate, 1.5%-3.6% of carboxymethyl cellulose and the balance of water. The soapberry natural detergent disclosed by the invention has the advantages of no stimulation, no toxicity, rapidness and thoroughness in biodegradation, environment protection, sustainable development and the like by adopting the soapberry and the tea saponin as main components; raw materials, namely the soapberry and the tea saponin are convenient and easy to obtain; the soapberry natural detergent is rich and exquisite in foam, has the effects of bacteria growth inhibition, disinfection and the like, achieves a submissive effect by being matched with the glycerol, is regulated in pH value by being matched with the sodium carbonate, further exerts the detersive synergistic effect of the soapberry extractives and the tea saponin, is outstandingly enhanced in detersive capacity and can be widely applied to oil stain washing or fabric washing.

Owner:NINGDE NORMAL UNIV

Agricultural waste-composting treatment method

InactiveCN101851125AIncrease steam explosion pretreatment processHas a crushing effectBio-organic fraction processingClimate change adaptationCompostWater content

The invention relates to an agricultural waste-composting treatment method taking stream explosion method for pretreatment. The method comprises: proportioning materials in a C / N ratio of 20:1-30:1; determining the appropriate dosage of crops straw and livestock / poultry excrement; mixing the determined raw materials well; performing stream explosion pretreatment; adjusting water content to be between 50 and 60 percent; and performing composting treatment for 25 to 28 days to obtain organic fertilizer rich in organic substances and nutrients. By utilizing a stream explosion technique to treat agricultural waste, the method has the advantages of effectively improving the biological conversion rate of aerobic or anaerobic treatment and shortening treatment time, thereby achieving the aims of improving equipment utilization rate, reducing operation cost, solving the problem of environmental pollution and bringing social and economic benefits.

Owner:杨春和

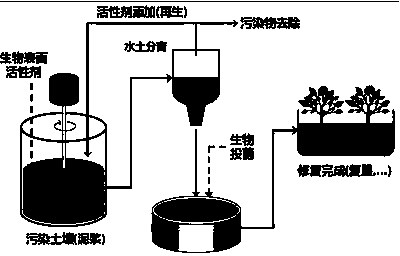

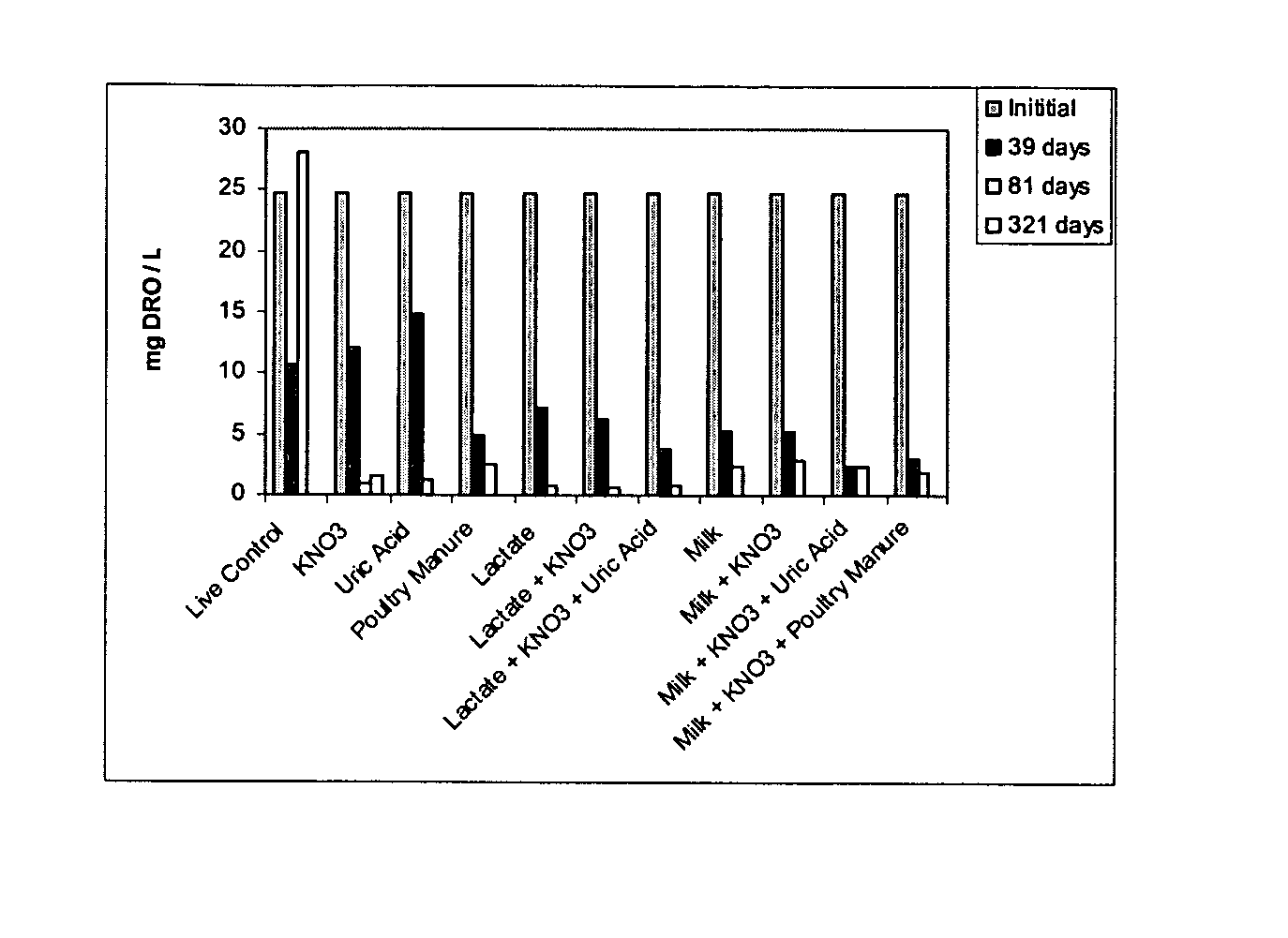

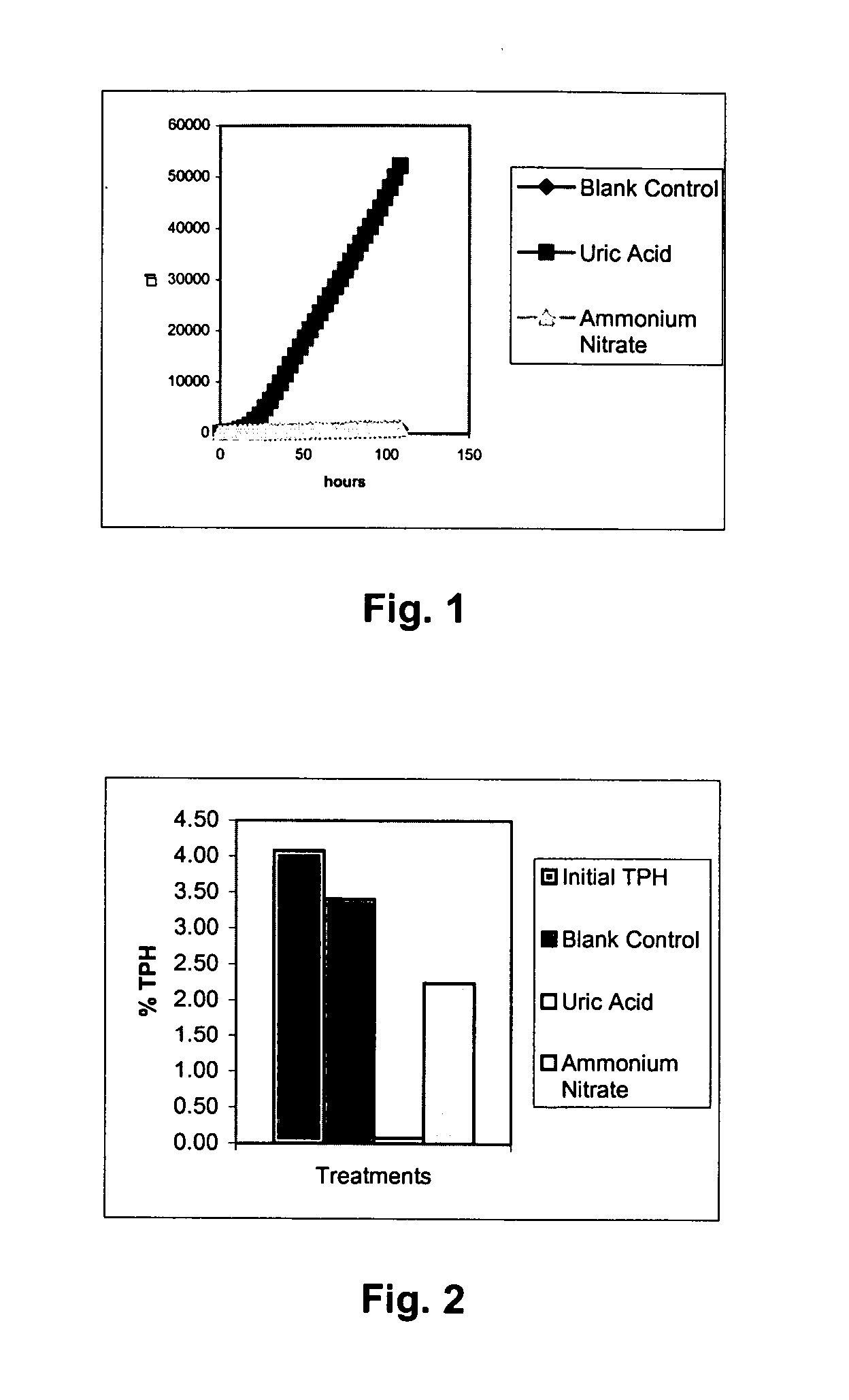

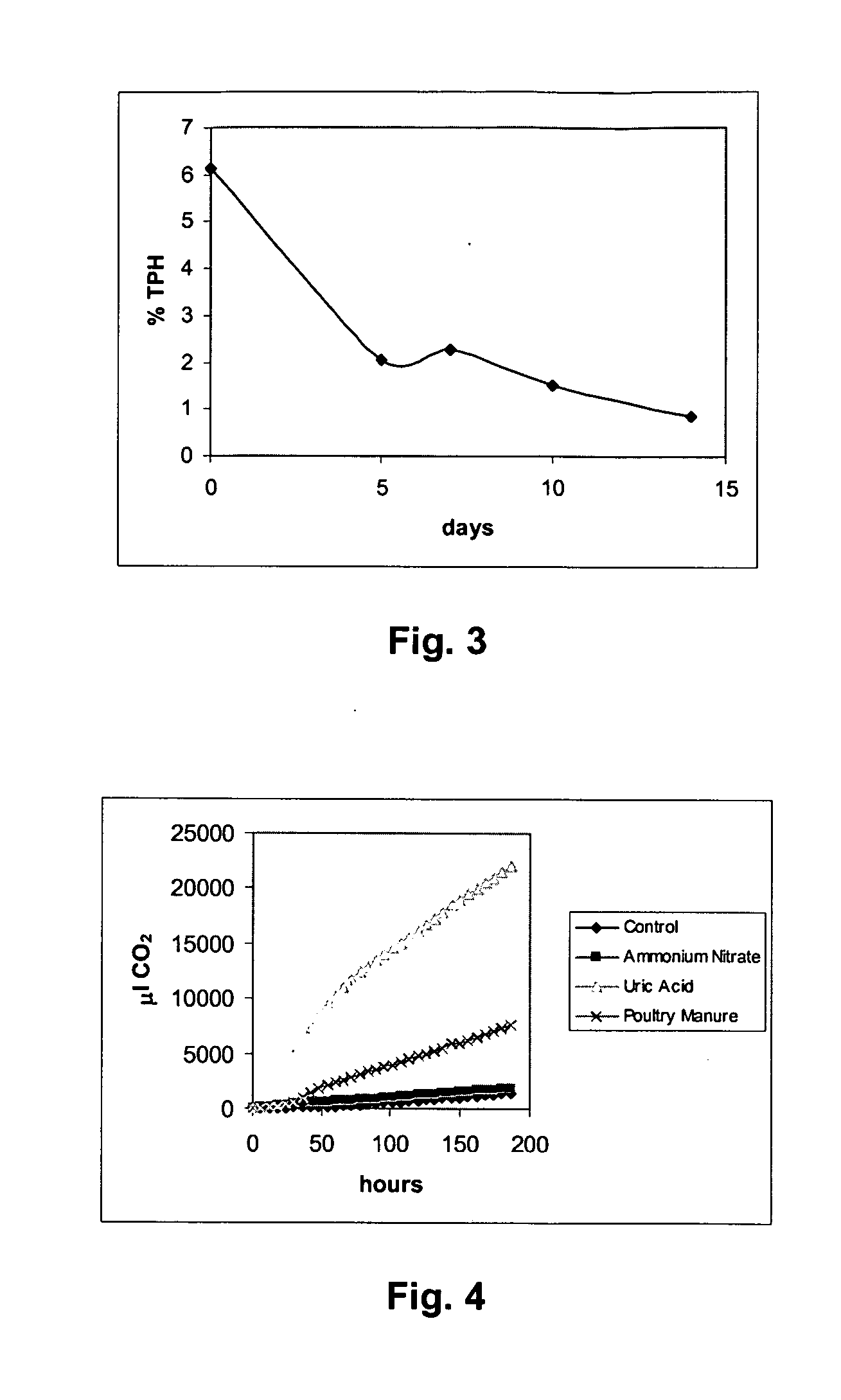

Methods of enhancing biodegradation of groundwater contaminants

ActiveUS20070017866A1Promote biodegradationAccelerates the biodegradation processContaminated soil reclamationWater/sewage treatmentNitrogenGroundwater

Systems and methods for co-enhancing contaminant degradation such as LNAPL and DNAPL degradation. Embodiments of the inventive technology may relate to assuring adequate amounts (e.g., concentrations) of certain substances (e.g., nitrogen, electron acceptor, bacteria, microbial substrate) so that degradation of LNAPL and DNAPL is enhanced as intended. Any of the inventive methods may involve the amendment of groundwater with one or more particular substance (uric acid, electron acceptors, microbial substrate, as but a few examples) in order to enhance DNAPL, and perhaps also, LNAPL degradation.

Owner:ADVANCED ENVIRONMENTAL TECH

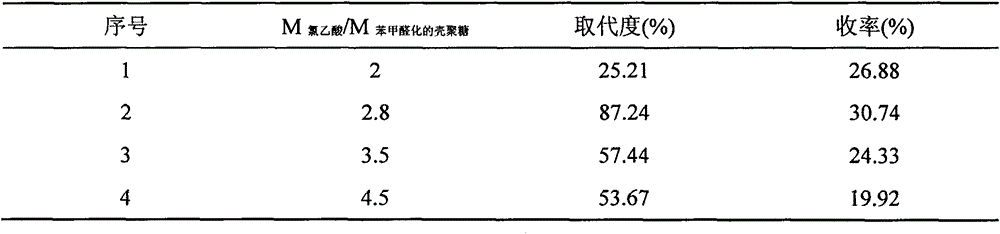

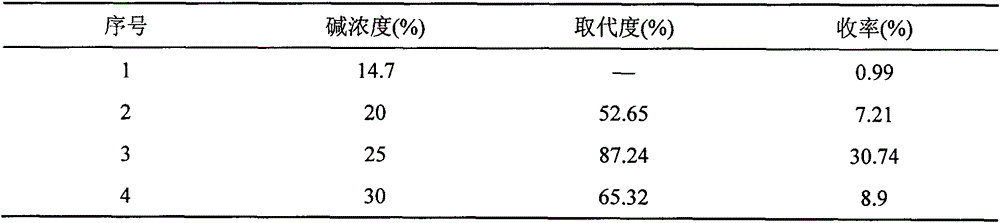

Preparation method of O-carboxymethyl chitosan

InactiveCN105085715AImprove adsorption capacityAvoid stickingO carboxymethyl chitosanChemical industry

The invention provides a preparation method of single-C6-site selectively-substituted O-carboxymethyl chitosan. The preparation method comprises the following steps: 1) reacting a raw material chitosan to generate benzaldehyde-modified carboxymethyl chitosan, wherein an imine structure generated by the reaction between benzaldehyde and amino Schiff base is utilized to protect the amino group on the chain; 2) carrying out carboxymethyl reaction on the reaction product and chloroacetic acid under alkaline conditions by using isopropanol as a medium to generate benzaldehyde-modified O-carboxymethyl chitosan; and 3) immersing the benzaldehyde-modified O-carboxymethyl chitosan under acidic conditions for 48 hours to remove benzaldehyde, thereby generating the single-C6-site selectively-substituted O-carboxymethyl chitosan. Compared with the N,O-carboxymethyl chitosan and N-carboxymethyl chitosan, the prepared O-carboxymethyl chitosan contains both amino and carboxy groups, and thus, has better procoagulant activity, biodegradability and bacteriostatic action. The O-carboxymethyl chitosan can accelerate injury healing and effectively prevent tissue adhesion and scar formation. The O-carboxymethyl chitosan has favorable adsorbing effects on acid ions and proteins, can be connected with multiple biological active substances, has high loading capacity for heavy metal ions, and is widely used in the fields of food, medicine, chemical industry and the like.

Owner:JIANGSU SHUANGLIN MARINE BIOLOGICAL PHARM CO LTD

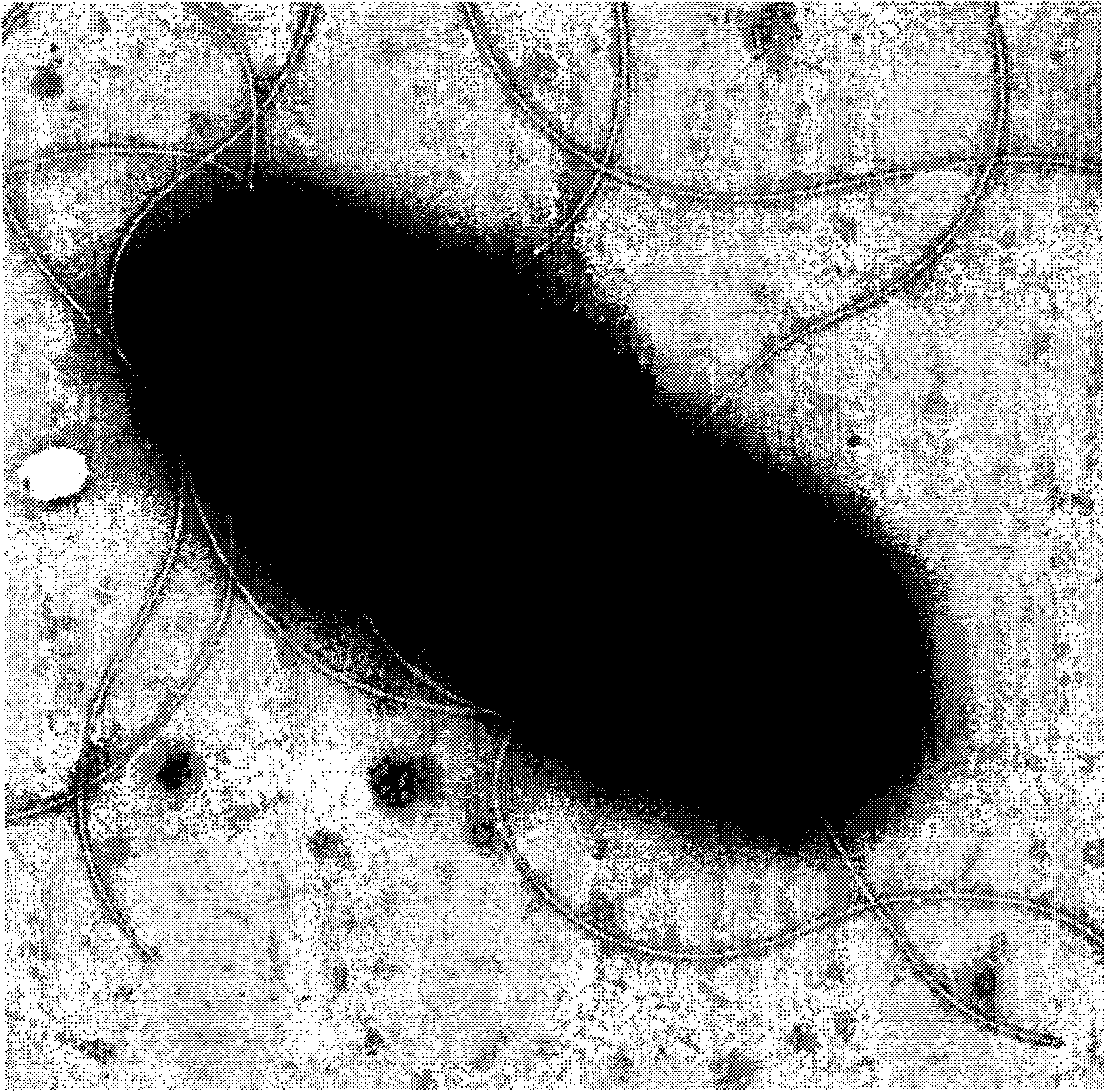

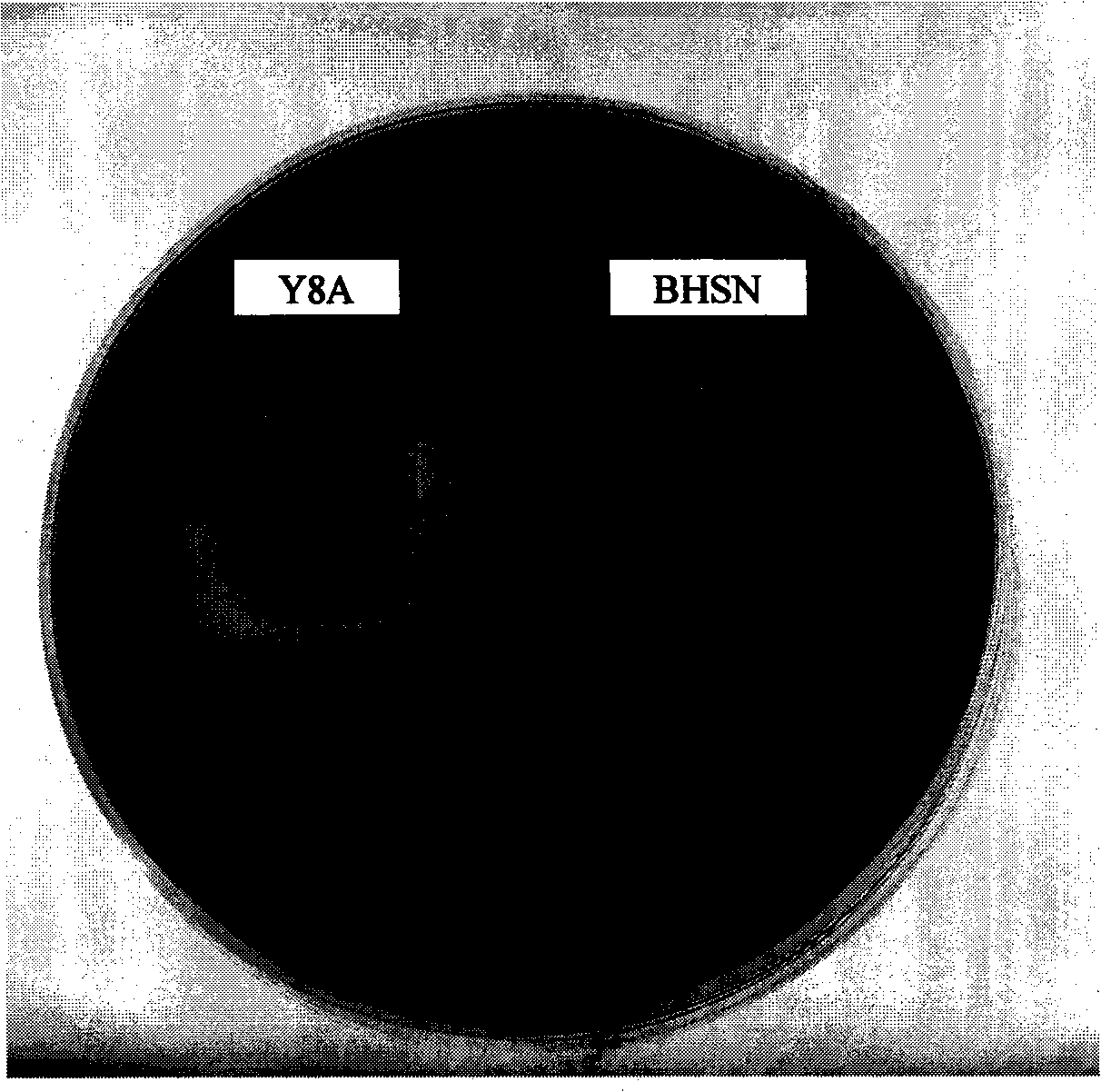

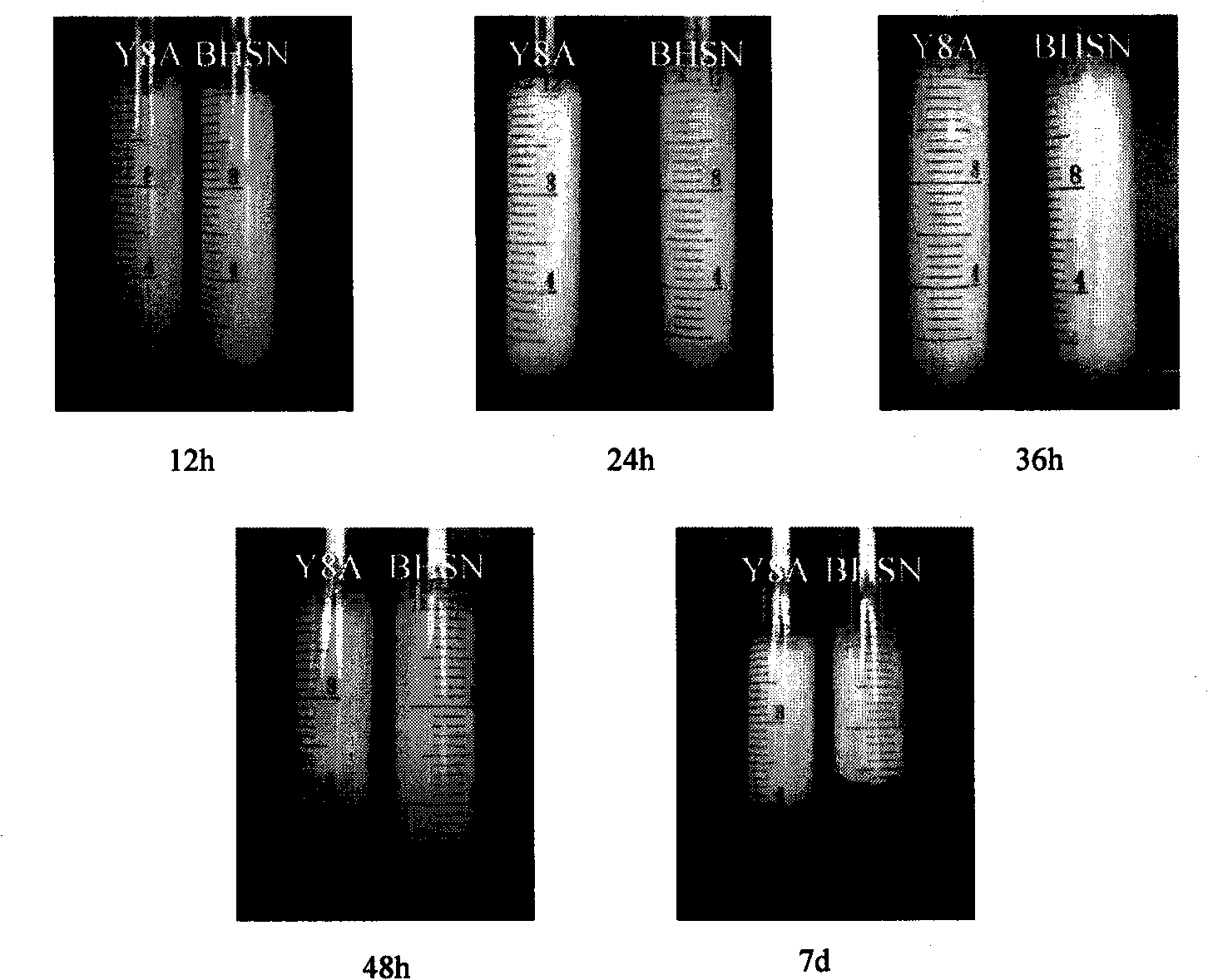

Lipopeptide-producing bacillus pumilus and application thereof

ActiveCN101560483AThe fermentation process is simpleEasy to operateBacteriaWater contaminantsAntibiotic YBacterial strain

The invention discloses a lipopeptide-producing bacillus pumilus, and classification thereof is named to be Bacillus pumilus Y8A which is preserved by China Center for Type Culture Collection (CCTCC) in Wuhan University with the preservation number of CCTCCM 209108. The invention also discloses an application of the lipopeptide-producing bacillus pumilus in promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide. Bacterial strain Y8A of the invention can produce lipopeptide biosurfactant with high efficiency and stability, thereby effectively promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide degrading bacteria. Bacterial strain Y8A with the function of efficiently producing lipopeptide is expected to work as a new-generation bacteria and cosolvent for antibiotic production and, is widely used in agriculture, medicine, cosmetic and food industries, and can be used for restoration of pollutant environment together with other organic pollution degrading microbes. The bacterial strain is resistant to a plurality of antibiotics with easy fermentation course and convenient operation.

Owner:NANJING AGRICULTURAL UNIVERSITY

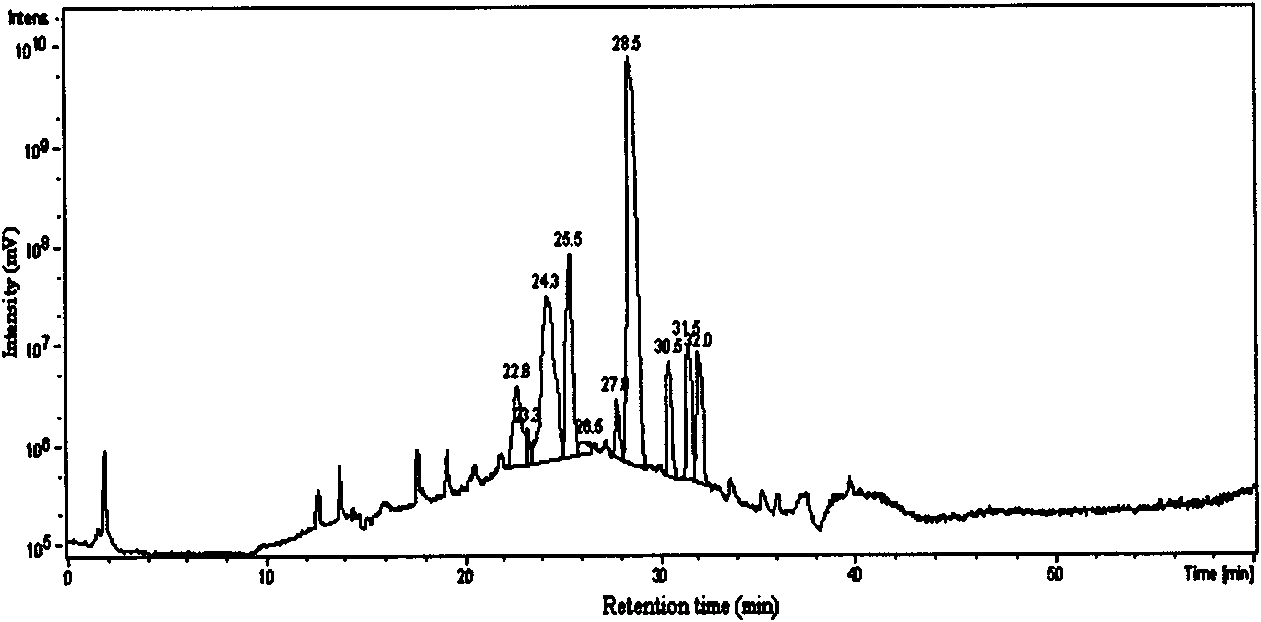

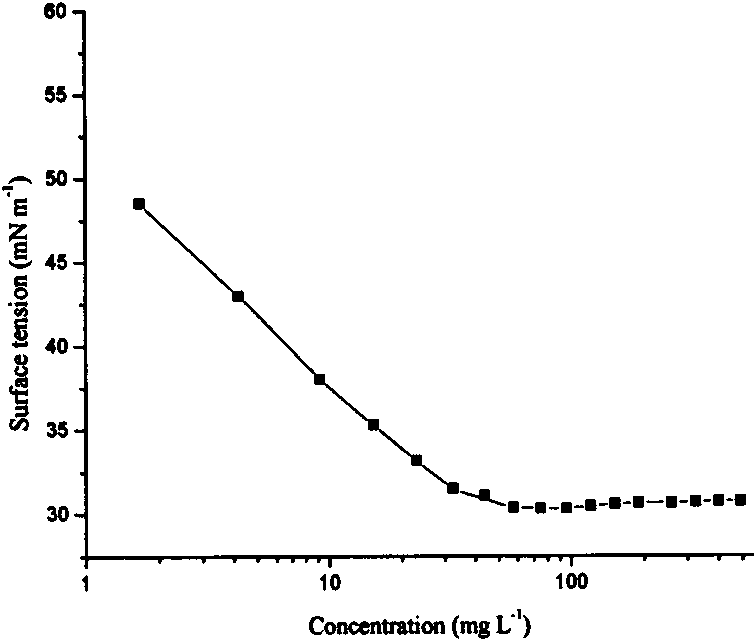

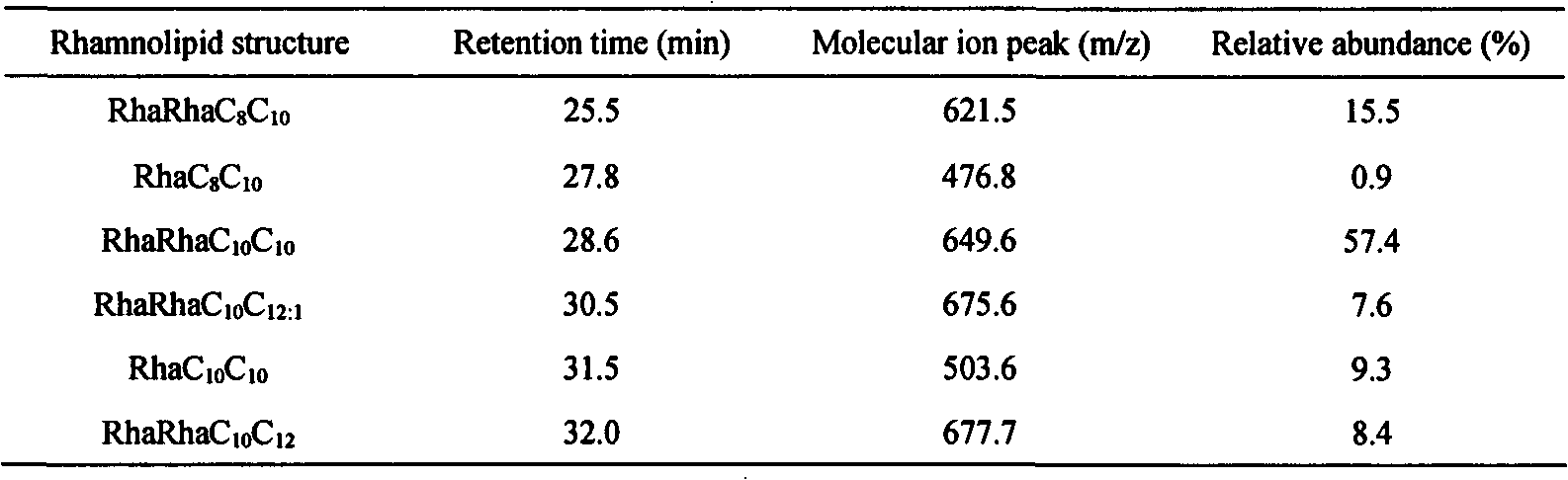

Application of high-content dirhamnolipid of pseudomonas aeruginosa in bio-remediation

InactiveCN102337226APromote biodegradationImprove surface activityBacteriaContaminated soil reclamationPolycyclic aromatic hydrocarbonCritical micelle concentration

The invention relates to an application of high-content dirhamnolipid of pseudomonas aeruginosa in the bio-remediation. The high-content dirhamnolipid produced by the fermentation of pseudomonas aeruginosa is mainly applied in the bio-remediation field of polluted soil or water body. The invention has the following advantages: the content of dirhamnolipid in the dirhamnolipid mixture is as high as 90%; by the use of the high-content dirhamnolipid, water surface tension can be reduced from 71.4 mN / m to 30.5 mN / m; the critical micelle concentration is 48mg / L; the high-content dirhamnolipid has high surface activity; under extreme conditions of high temperature, high salt and high pH and the like, the high-content dirhamnolipid can still maintain high surface activity and emulsifying capacity, can remarkably promote biodegradation of polycyclic aromatic hydrocarbons and has a latent application value in the bio-remediation.

Owner:EAST CHINA UNIV OF SCI & TECH

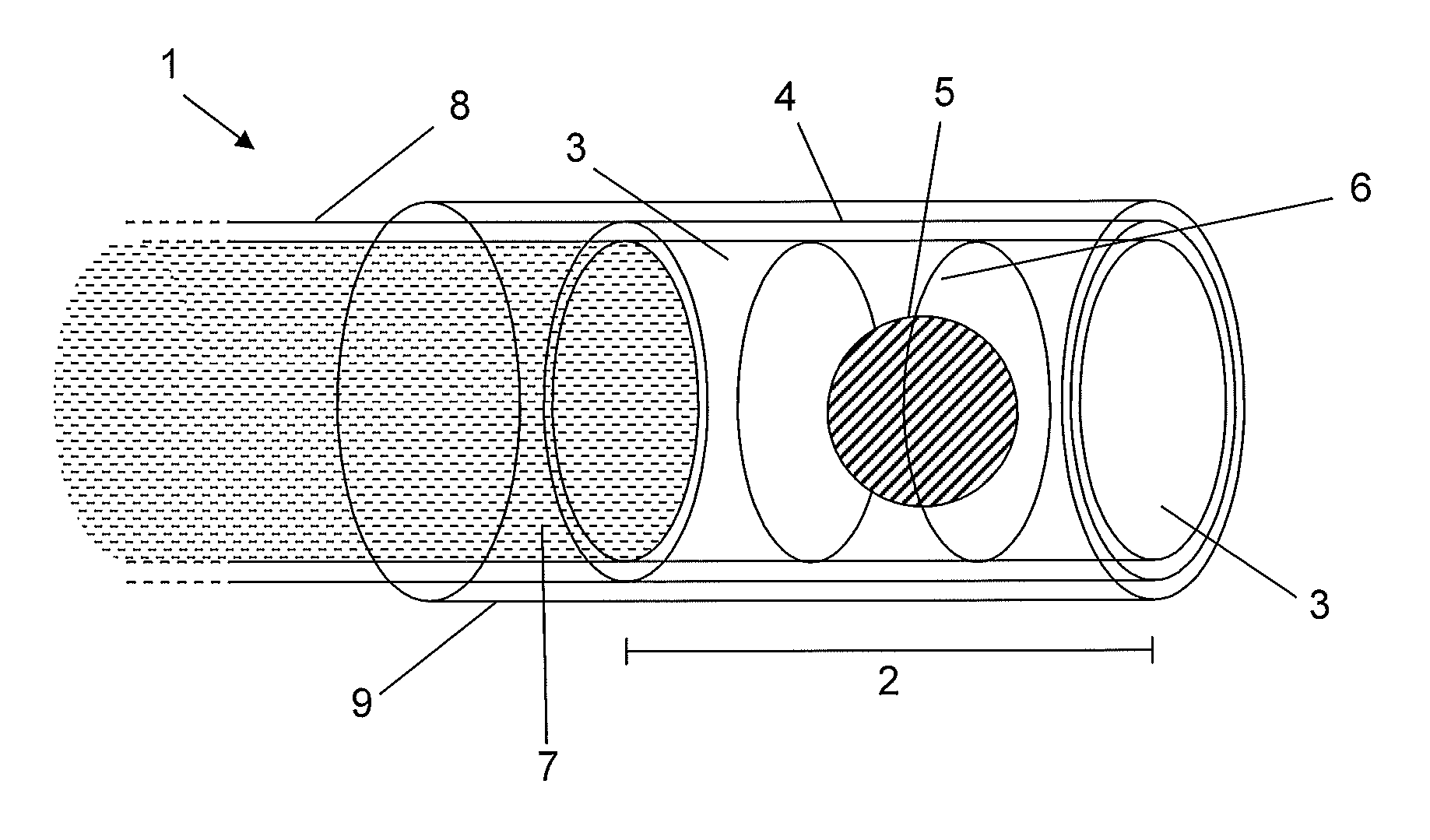

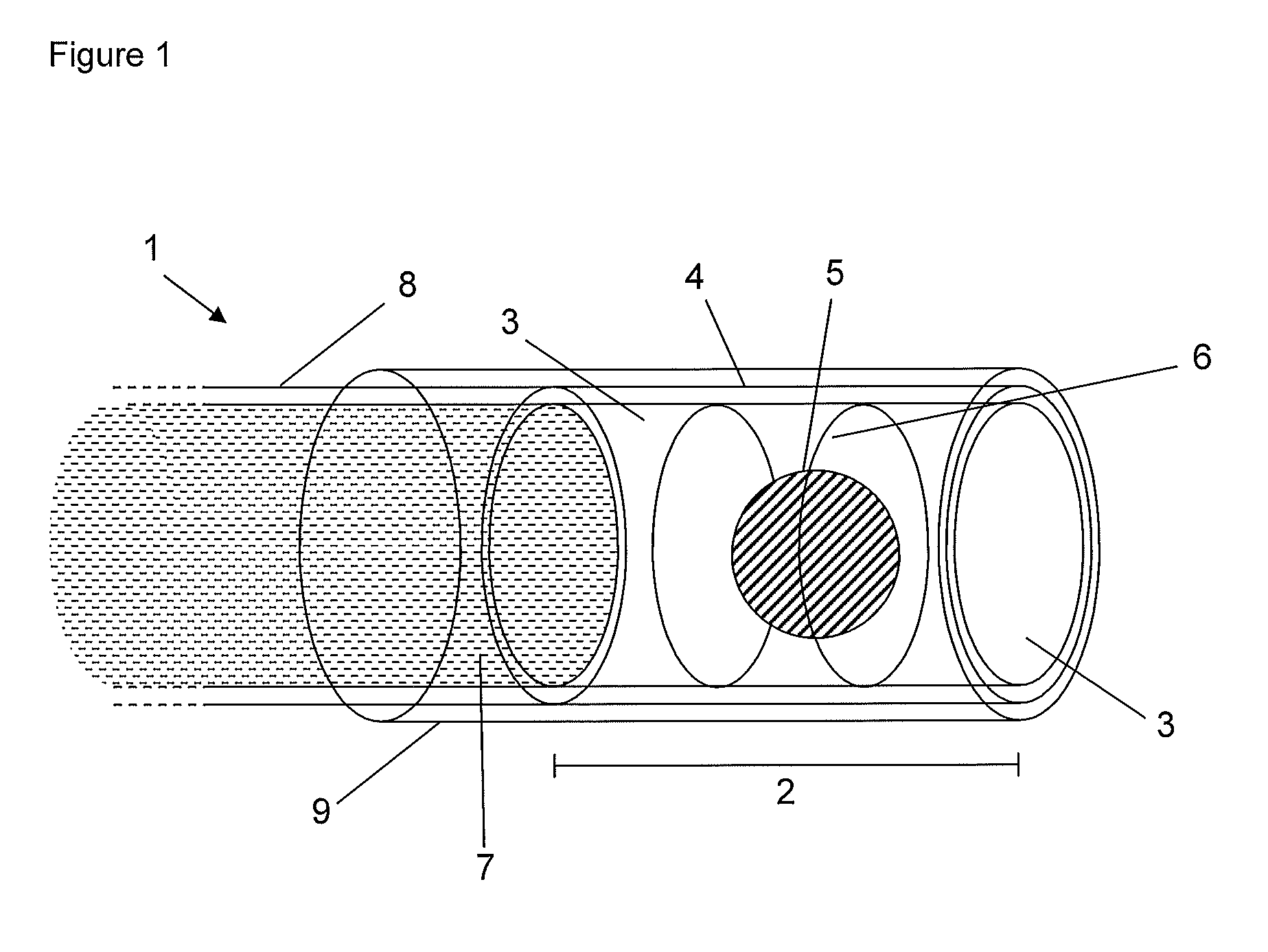

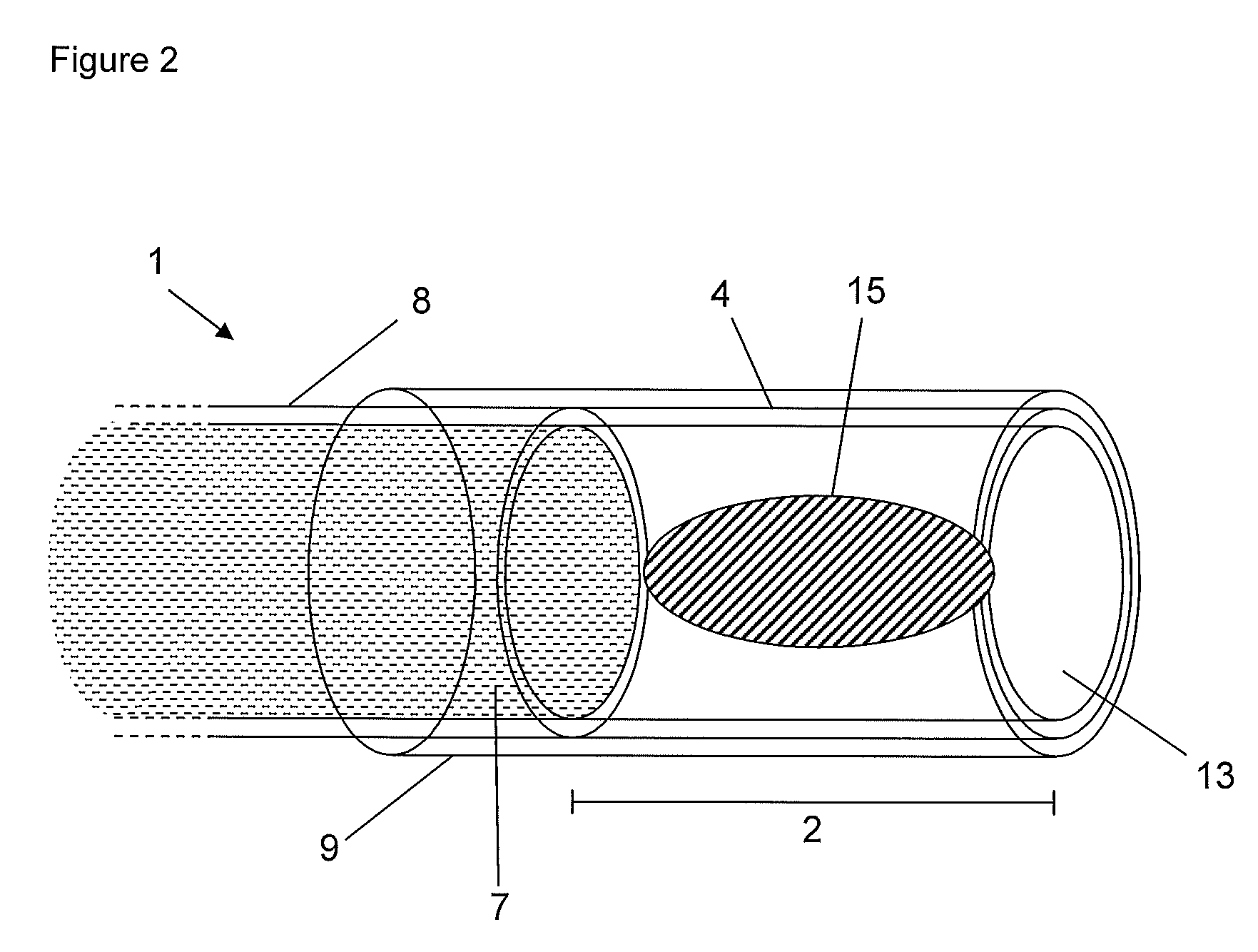

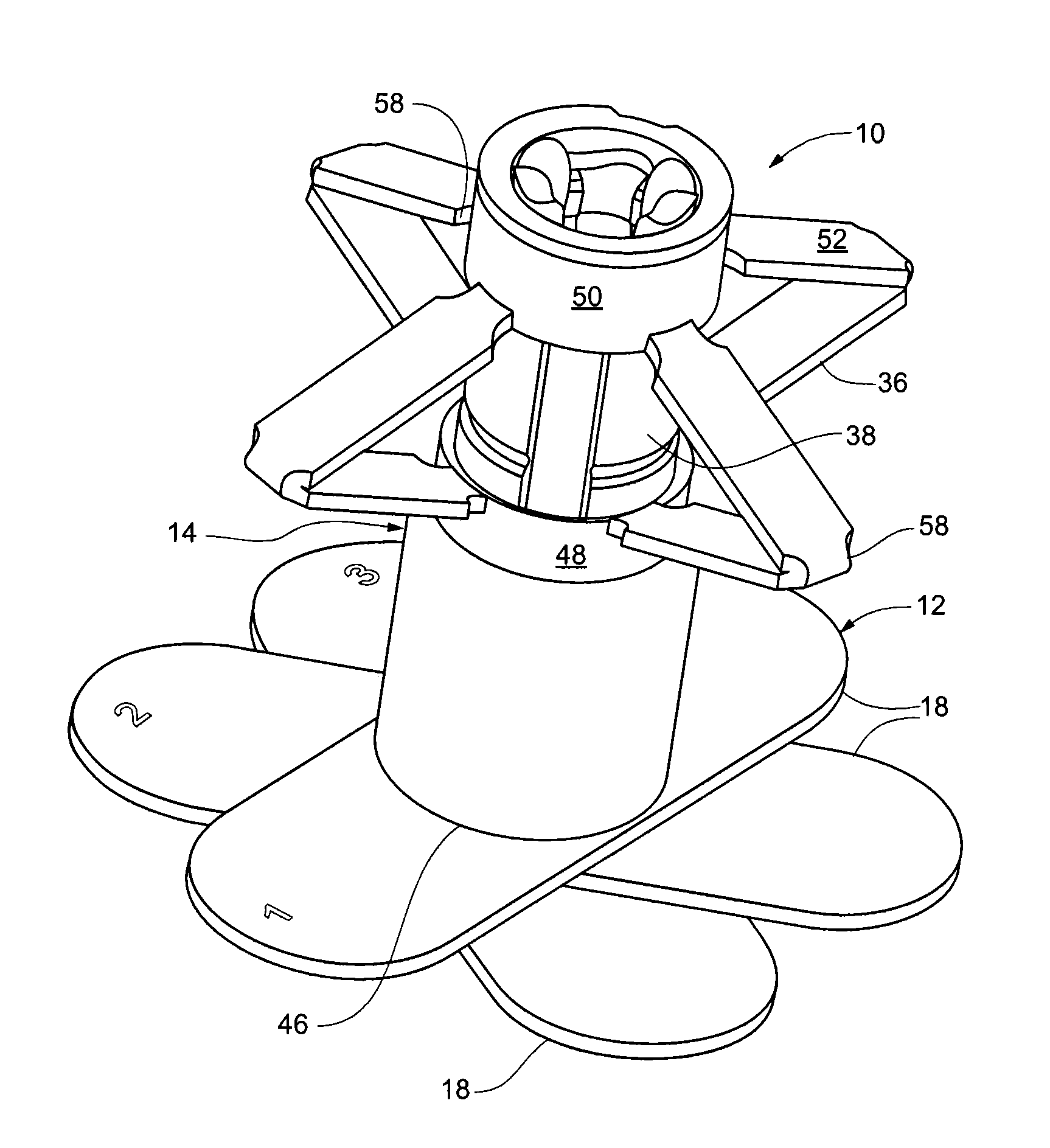

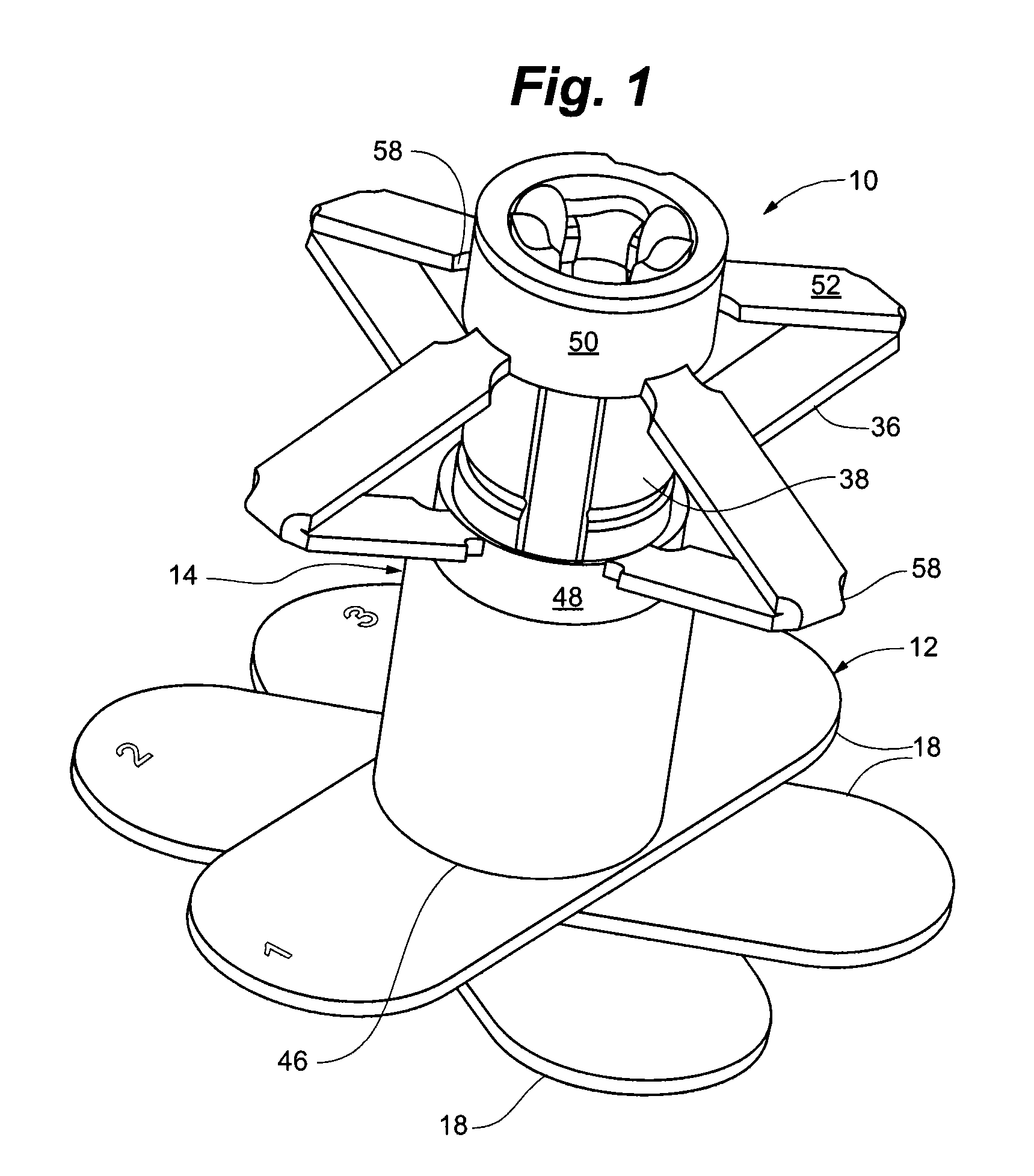

Metal vascular aperture closure device

InactiveUS8192456B2Easy to foldReduce the cross-sectional areaSuture equipmentsBlood vesselsBlood vesselBlood vessel walls

A closure device to be inserted at least partially through a blood vessel wall aperture in a blood vessel wall, having at least two metal petals that can be inserted through the blood vessel wall aperture and into the lumen of the blood vessel. The petals are structured to prevent withdrawal through the blood vessel wall aperture when the length of the petal is generally aligned with the blood vessel wall. The metal petals have alignment features that tend to urge them into alignment relative to each other. The closure device includes a metal expansion member that is alterable from an unexpanded state to an expanded state. A bioabsorbable tensioning member interconnects the petals and the metal expansion member and is securable to the metal expansion member.

Owner:TELEFLEX LIFE SCI LTD

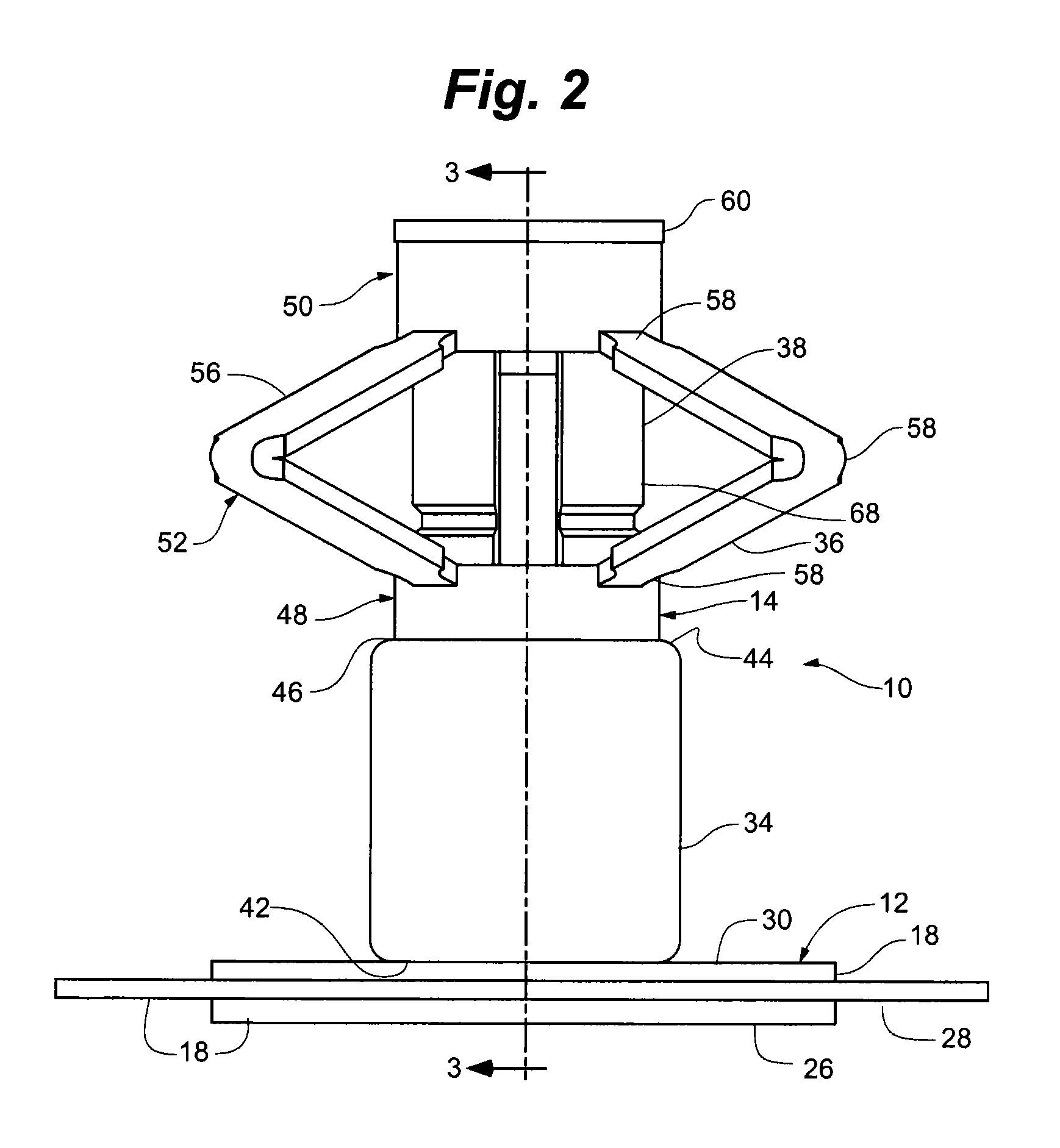

Tissue-adhesive formulations

InactiveUS20090018575A1Maintaining pliability and physical property of supportReduces and eliminates cracking and crumblingSurgical adhesivesAbsorbent padsTissue adhesivesBiomedical engineering

A tissue-adhesive formulation comprises a particulate material having tissue-reactive functional groups, in admixture with a particulate buffer material. The formulation is preferably free or substantially free of materials of human or animal origin. In preferred embodiments, the formulation consists, or consists essentially of, an anhydrous or partially hydrated blend of particulate material having tissue-reactive functional groups and particulate buffer material. Also disclosed is a multilayer sheet comprising a structural support coated on at least one side thereof with such a tissue-adhesive formulation.

Owner:TISSUEMED LTD

Biodegradable molded article

InactiveUS20090008819A1Satisfaction intensityPromote biodegradationFlexible coversWrappersPolymer sciencePolyvinyl alcohol

A bowl-shaped container (10a) which is as a biodegradable molded article adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing high-amylose starch and water, or a slurry or dough molding material containing starch, polyvinyl alcohol and water. For these reasons, it is possible to accomplish sufficient strength and at least sufficient water resistance, to exert a very excellent biodegradability and further to provide a biodegradable molded article having excellent moisture absorption strength mainly made of starch even if the biodegradable molded article has a complicated shape.

Owner:NISSEI CO LTD

Complex stephanoporate bracket of calcium sulphate and freeze drying bone as well as preparation method thereof

InactiveCN101176798APromote biodegradationEvenly distributedCoatingsProsthesisChemistryTemperature treatment

The invention relates to a compound porous support and a preparation method, in particular to a calcium sulfate and freeze-dried bone compound porous support and the preparation method, belonging to the medical instrument technical field. The compound sizing agent of the half water calcium sulfate powder and the mashed freezing person homogeneous allograft bone is made; after the calcium sulfate sizing agent is evenly painted on polyurethane foam, the calcium sulfate ceramic porous support is obtained through the drying and the high-temperature treatment; after immersed in the compound sizing agent to get coating, the calcium sulfate ceramic porous support is positioned in the inner door environment for being dried naturally; then after heating and drying, the invention is produced.

Owner:孙海钰 +1

Mite killing laundry detergent

InactiveCN103865672APowerful decontaminationPromote biodegradationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAcarusSURFACTANT BLEND

The invention discloses a mite killing laundry detergent. The mite killing laundry detergent comprises the following components in parts by weight: 0.5-6 parts of N,N-di(3-aminopropyl) dodecyl amine, 6-31 parts of anionic surfactant, 12-43 parts of nonionic surfactant, 0.1-0.5 part of thickening agent, 0.1-0.5 part of chelating agent and 40-60 parts of deionized water. The laundry detergent disclosed by the invention is prepared by compounding the surfactants which are excellent in performance, gentle, safe, nontoxic and rapid in biological degradation and a mite killing agent, and can be used for effectively removing and killing various mites as well as cleaning.

Owner:李克豪

Compound porous bracket and method of producing the same

The invention relates to a composite porous scaffold and a preparation method thereof, in particular to a composite porous scaffold combining calcium sulfate and apatite compound and a preparation method thereof, and pertains to the technical field of medical apparatus and instruments. Composite sizing material combining calcium sulfate hemihydrate powder and crushed apatite compound is first prepared; calcium sulfate sizing material is evenly brushed on polyurethane foam to obtain a porous calcium sulfate ceramic scaffold after the steps of drying and high-temperature treatment. The obtained porous calcium sulfate ceramic scaffold is then immersed in the composite sizing material and then placed indoors for natural drying after the treatment of sizing hanging and finally heated and dried to obtain the composite porous scaffold combining calcium sulfate and apatite compound of the invention.

Owner:孙海钰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com