Patents

Literature

60results about How to "Adjust rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of synthetic base drilling fluid

The invention discloses a preparation method of a synthetic base drilling fluid. The preparation method comprises the steps of a. adding 2.0%-4.0% of organic soil, 3.0%-5.0% of main emulsifier, 2.0%-4.0% of auxiliary emulsifier, 0.1%-0.2% of wetting agent, 0.5%-2.0% of flow pattern conditioning agent and 2.0%-3.0% of CaO to 60-70% of synthetic base in percent by weight under a stirring condition, and stirring for 30min; b. preparing a CaCl2 solution with the mass concentration of 20%, and enabling CaCl2 to completely dissolve; c. slowly adding 10%-15% of CaCl2 aqueous solution in percent by weight to the synthetic base under a stirring condition; and d. adding 4.0%-6.0% of filtrate-loss reducer and 2.0%-3.0% of anti-sloughing blocking agent in percent by weight to the synthetic base under a stirring condition to form the synthetic base drilling fluid. The preparation method is simple in processing steps and easy in operation. The synthetic base drilling fluid prepared by the method has the characteristics of strong anti-sloughing inhibition capability, good salt and calcium erosion resistance performance and obvious lubrication performance.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

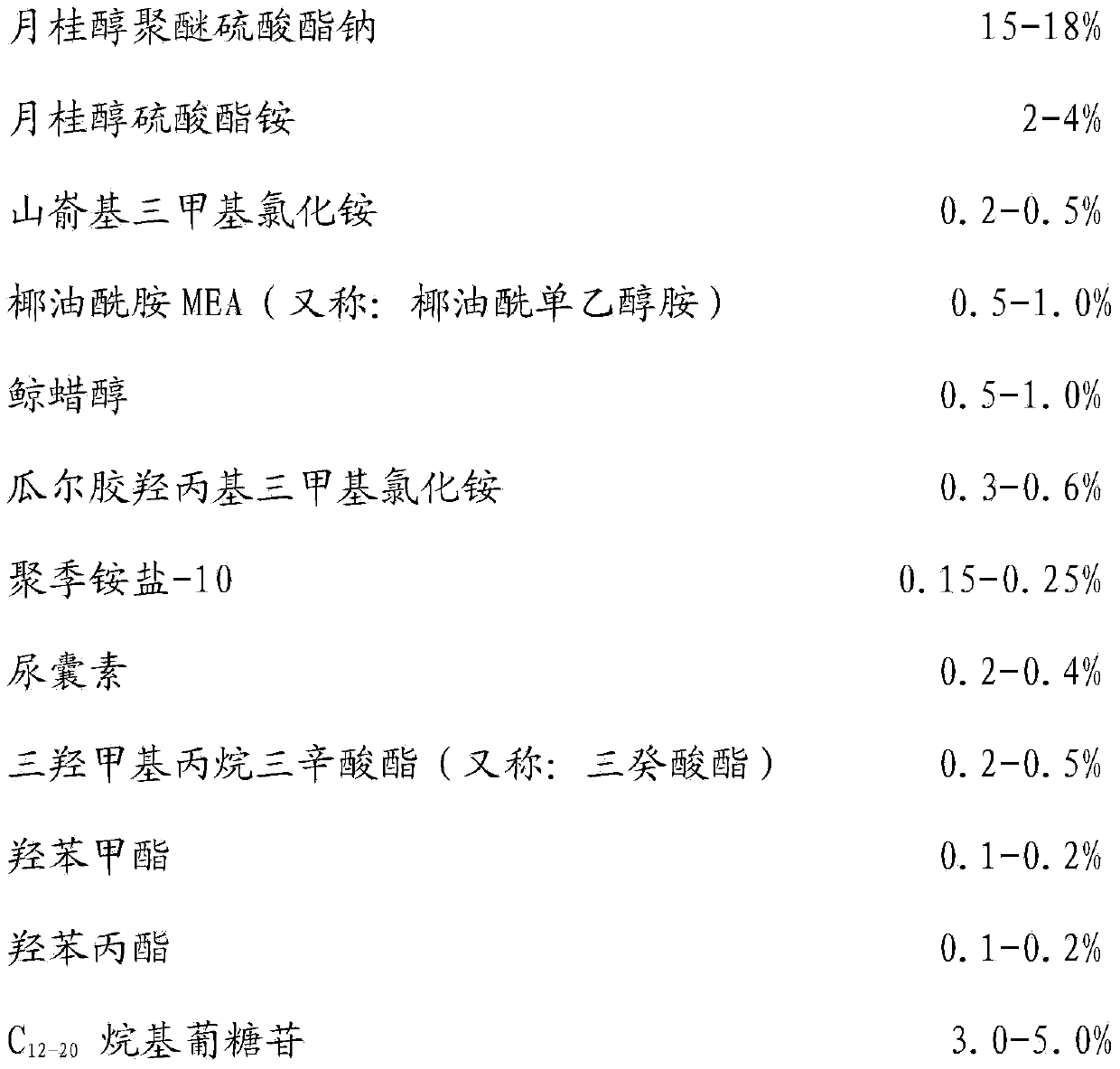

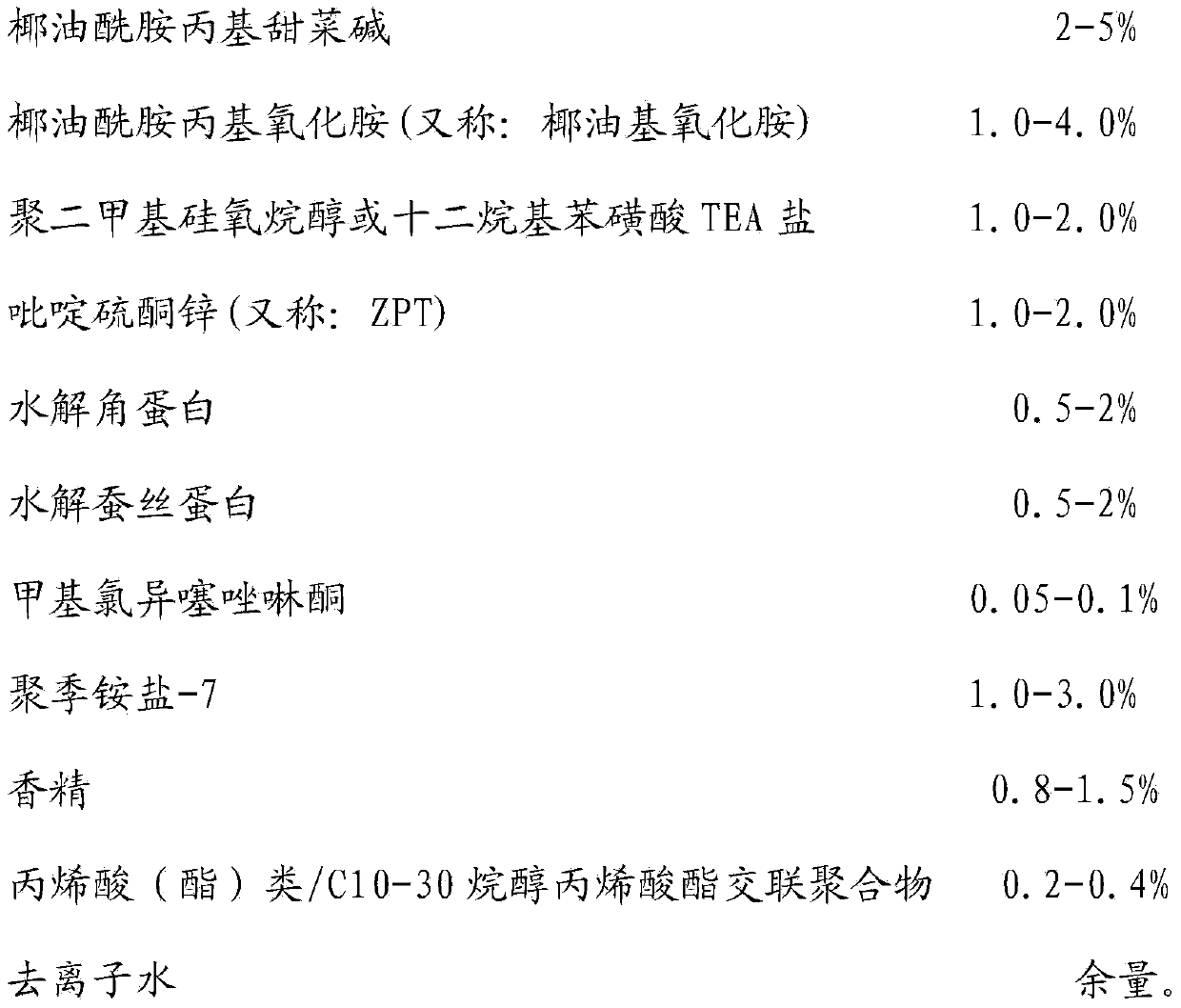

Three-in-one liquid shampoo and preparation method thereof

ActiveCN103735430AReduce stimulationImprove foaming speedCosmetic preparationsHair cosmeticsGuar hydroxypropyltrimonium chlorideCross-link

The invention discloses a three-in-one liquid shampoo and a preparation method thereof. The three-in-one liquid shampoo is prepared from the following raw materials: sodium laureth sulfate, ammonium lauryl sulfate, behentrimonium chloride, cocamidopropyl MEA, cetanol, guar hydroxypropyltrimonium chloride, polyquaternium-10, allantoin, trimethylol propane octanoate ester, methylparaben, propyl hydroxybenzoate, C12-20 alkyl polyglycoside, cocamidopropyl betaine, cocamidopropyl dimethylamine oxide, dimethiconol or dodecylbenzene sulfonic acid TEA salt, zinc pyrithione, hydrolyzed keratin, hydrolyzed silk protein, methyl-isothiazol-ketamine, polyquaternium-7, essence, crylic acid (ester) / C10-30 alkanol acrylic ester cross-linked polymer and deionized water. By adopting the three-in-one liquid shampoo, the stability of the product and the use effects of the raw materials can be improved, the three-in-one liquid shampoo achieves good cleaning and nursing effects, does not generate aggregation and stimulation problems after being used for a long period of time, and achieves the three-in-one effect of cleaning, nursing and conditioning.

Owner:广州市白云区大荣精细化工有限公司

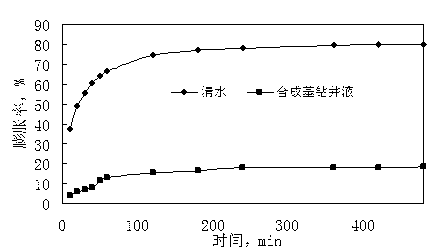

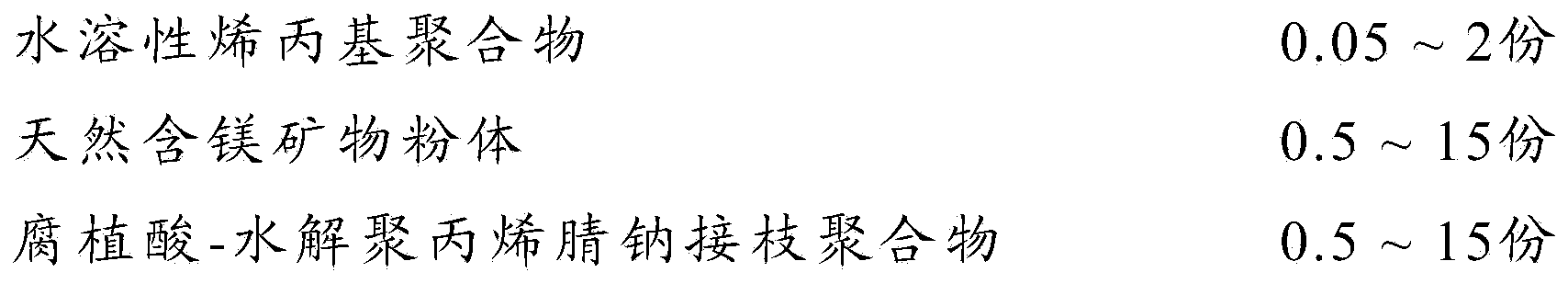

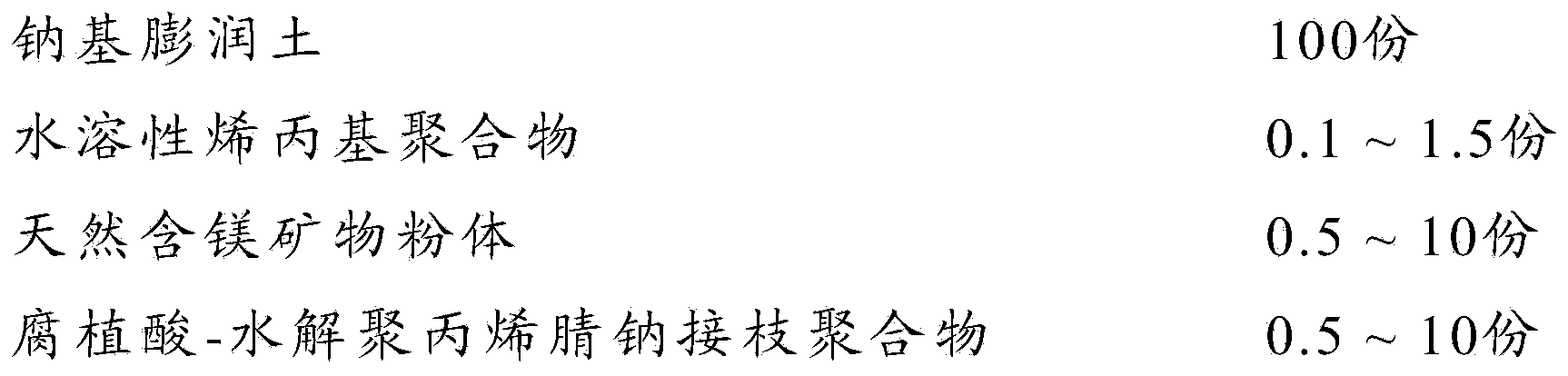

Thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and preparation method thereof

ActiveCN103525384AHigh pulping rateViscosity increase efficiencyDrilling compositionFiltrationWell drilling

The invention discloses thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and a preparation method of the thixotropy bentonite slurry. The thixotropy bentonite slurry is modified by a modifying agent comprising a water-soluble allyl polymer, natural magnesium containing mineral powder and a humid acid-hydrolysis sodium polyacrylonitrile graft polymer. The preparation method of the thixotropy bentonite slurry comprises the following steps: preparing sodium bentonite, preparing bentonite-based slurry, preparing the modifying agent and finally preparing the modified bentonite. The mud-making rate, the viscosity increasing efficiency and the de-filtration effect of the bentonite prepared by the method provided by the invention are greatly improved, and the modifying effect of the bentonite is far superior to that of bentonite modified by using a single modifying agent.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of spherical catalyst carrier

ActiveCN103041868AHigh yieldHigh strengthCatalyst carriersHydrocarbon oils refiningPtru catalystActive agent

The invention discloses a preparation method of a spherical catalyst carrier. According to the method, a spherical size stabilization method is adopted for preparation, and an anion surfactant and a cation surfactant are added into an aluminum oxide precursor, so that the physical properties of the surface of an aluminum oxide carrier are improved, the adhesion and rheology of materials during the carrier forming process are regulated, the plastic deformation of the carrier after forming is reduced, the yield of the spherical carrier is greatly improved, the strength of the spherical carrier is improved, and the proportion of complete particles in the spherical carrier is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of spherical catalyst carrier

The invention discloses a preparation method of a spherical catalyst carrier. According to the method, a spherical size stabilization method is adopted for preparation, and a gemini surfactant is added into an aluminum oxide precursor, so that the physical properties of the surface of an aluminum oxide carrier are improved, the adhesion and rheology of materials during the carrier forming process are regulated, the plastic deformation of the carrier after forming is reduced, the yield of the spherical carrier is greatly improved, the strength of the spherical carrier is improved, and the proportion of complete particles in the spherical carrier is improved. In addition, the gemini surfactant is adopted, so that Na<+>, Ca<2+>, K<+>, Cl<->, Br<->, F<->, I<-> and other negative and positive hetero ions can not be introduced; and furthermore, the gemini surfactant is larger in molecular weight and good in reaming effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Raw lacquer refining method

InactiveCN101747837AWith wear resistanceHigh transparencyNatural resin coatingsLacquerActive protein

The invention discloses a raw lacquer refining method. By weight percent, the refined raw lacquer consists of the following materials: 60 percent to 95 percent of raw lacquer, 1 percent to 5 percent of active protein, 1 percent to 5 percent of pH regulator, 0 percent to 5 percent of biomass and 0 percent to 20 percent of diluent, and the percentages of the materials are added up to 100 percent. The method adopts the biochemical catalytic reaction principle for the first time, and is integrated with the biochemical reaction and control technique to refine the raw lacquer; the surface chemistry technique and the bio-enzyme catalysis microenvironment regulation technique are adopted for the first time; other renewable biomass is used; the surface activity function of the bioprotein is utilized for the first time to regulate the rheological behaviour of the raw lacquer; and the lacquer film has high transparency, adhesive force and rigidity, and can be toned. The product has the excellent acid resistance, corrosion resistance, water resistance, oil resistance and wear resistance of the raw lacquer, and can be directly coated on furniture or indoor decorations. The product is applicable to modern furniture and indoor decoration as well as the surface coating of instruments and equipment.

Owner:中华全国供销合作总社西安生漆涂料研究所

Application of cellulose nanofiber as flow pattern regulator for drilling fluids

Owner:CHINA PETROCHEMICAL CORP +3

Micro-bubble elastic polyurethane waterproof coating

InactiveCN102329555ABroaden applicationGood film formingPolyurea/polyurethane coatingsParaffin waxStearic acid

The invention relates to a micro-bubble elastic polyurethane waterproof coating. The micro-bubble elastic polyurethane waterproof coating is characterized by comprising the following ingredients in parts by weight: 60-100 parts of polyurethane, 10-20 parts of isocyanate, 10-20 parts of water, 10-20 parts of zinc oxide, 0.1-1.0 part of talcum powder, 0.1-1.0 part of surfactant, 0.1-1.0 part of catalyst, 1-10 parts of hydroxypropyl methylcellulose, 80-100 parts of packing and 10-20 parts of plasticizer; the packing is any one of calcium carbonate, talcum powder and silicon dioxide; the plasticizer is any one of paraffin wax, castor oil, bisphthalate and stearic acid; the catalyst is methyldiethanolamine; and the surfactant is an anionic surfactant. The micro-bubble elastic polyurethane waterproof coating provided by the invention is safe and environment friendly because the organic solvent is adopted; and the coating has the advantages of easiness for coating and drying, good film forming property and smoothness.

Owner:WUJIANG RUIFENG WEAVING

Flux used for lead-free solder paste

ActiveCN106271221AEliminate negative effectsHigh activityWelding/cutting media/materialsSoldering mediaActive agentPolyamide

The invention discloses flux used for lead-free solder paste. The flux comprises the following components including, by mass percent, 25%-30% of dimerization rosin, 5%-8% of octadecanoic acid, 3%-5% of polyethylene glycol, 9%-12% of an active agent, 2%-5% of a surface active agent, 4%-5.5% of a thixotropic agent, 3%-5% of a catalyst, 1%-1.5% of corrosion inhibitor and the balance solvent. The active agent is formed by compounding adipic acid and sebacic acid. The surface active agent is formed by compounding cetyl trimethyl ammonium bromide and an OP-10 non-ionic surface active agent. The solvent is tetrahydrofurfuryl alcohol. The thixotropic agent is polyamide modified hydrogenated castor oil. The corrosion inhibitor is benzotriazole. According to the flux used for the lead-free solder paste, on the condition that the use amount of the rosin is reduced, the performance of the lead-free solder paste is greatly improved, weld spot forming quality and strength after welding are obviously improved, durability is improved, and defects of existing flux are effectively overcome.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

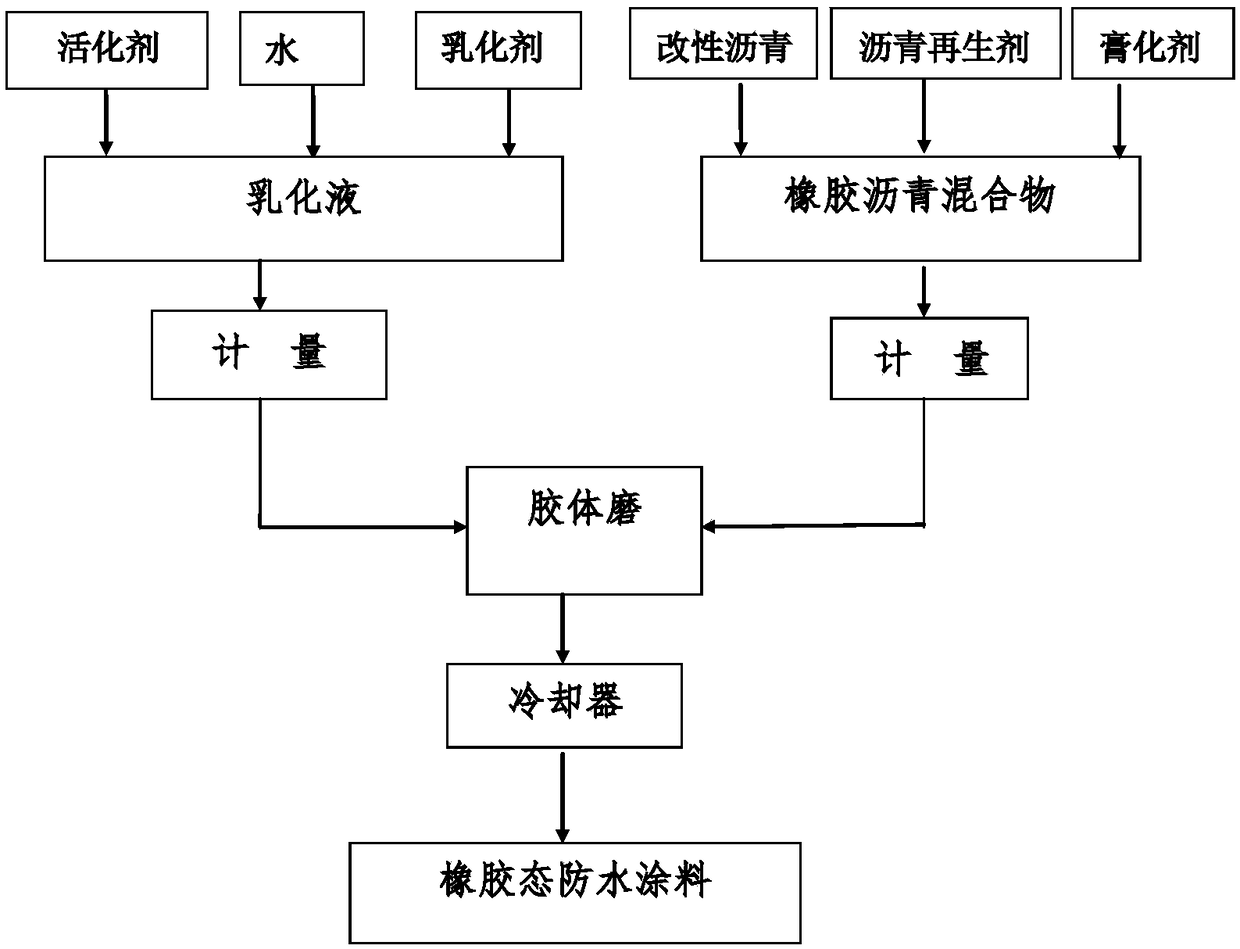

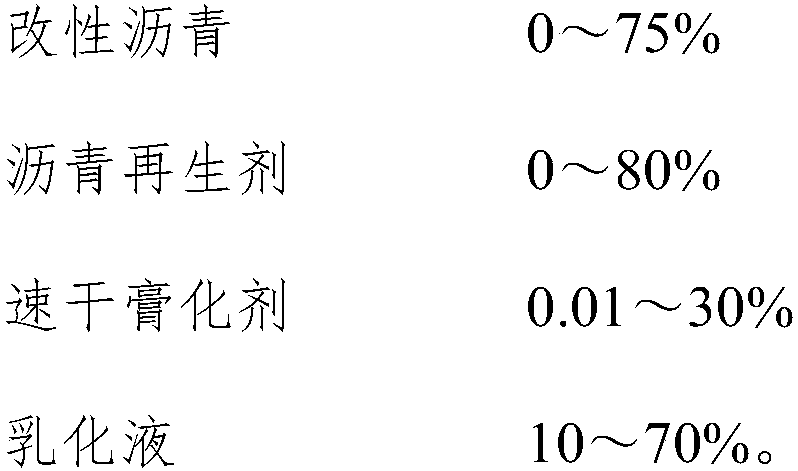

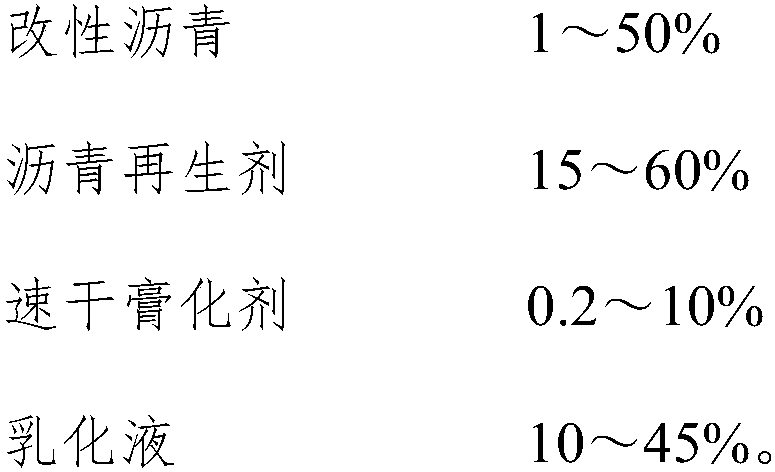

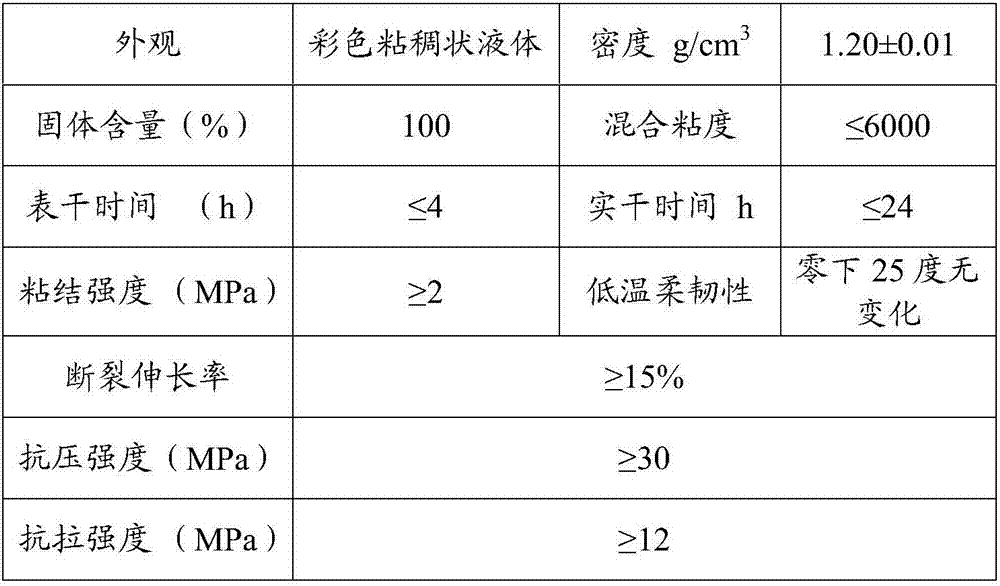

Multi-path thick coating and one-step molded rubber-state waterproof coating and preparation method thereof

InactiveCN108395844AReduce wax contentImprove performanceRoof covering using flexible materialsProtective foundationColloidAsphalt

The invention relates to multi-path thick coating and one-step molded rubber-state waterproof coating and a preparation method thereof and belongs to the technical field of sealing water prevention. The rubber-state waterproof coating provided by the invention is mainly prepared from the following raw materials in percentage by mass: 0 to 75 percent of modified asphalt, 0 to 80 percent of asphaltregeneration agent, 0.01 to 30 percent of quick-drying creaming agent and 10 to 70 percent of emulsified liquid; the rubber-state waterproof coating is prepared through steps of preparing a rubber asphalt mixture, preparing the emulsified liquid, emulsifying and creaming and de-foaming. According to the rubber-state waterproof coating, an inorganic creaming agent is used as the quick-drying creaming agent and the emulsified liquid is used for emulsifying and creaming the rubber asphalt mixture through a colloid mill by adopting a one-pot method and the prepared rubber-state waterproof coatingis uniform, fine and smooth and has high quality; the rubber-state waterproof coating has very good thixotropic performance, rapid dehydration and drying properties and excellent construction and application performance; the production efficiency is improved by applying the one-pot method and quality stability of a product and environment protection are facilitated.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

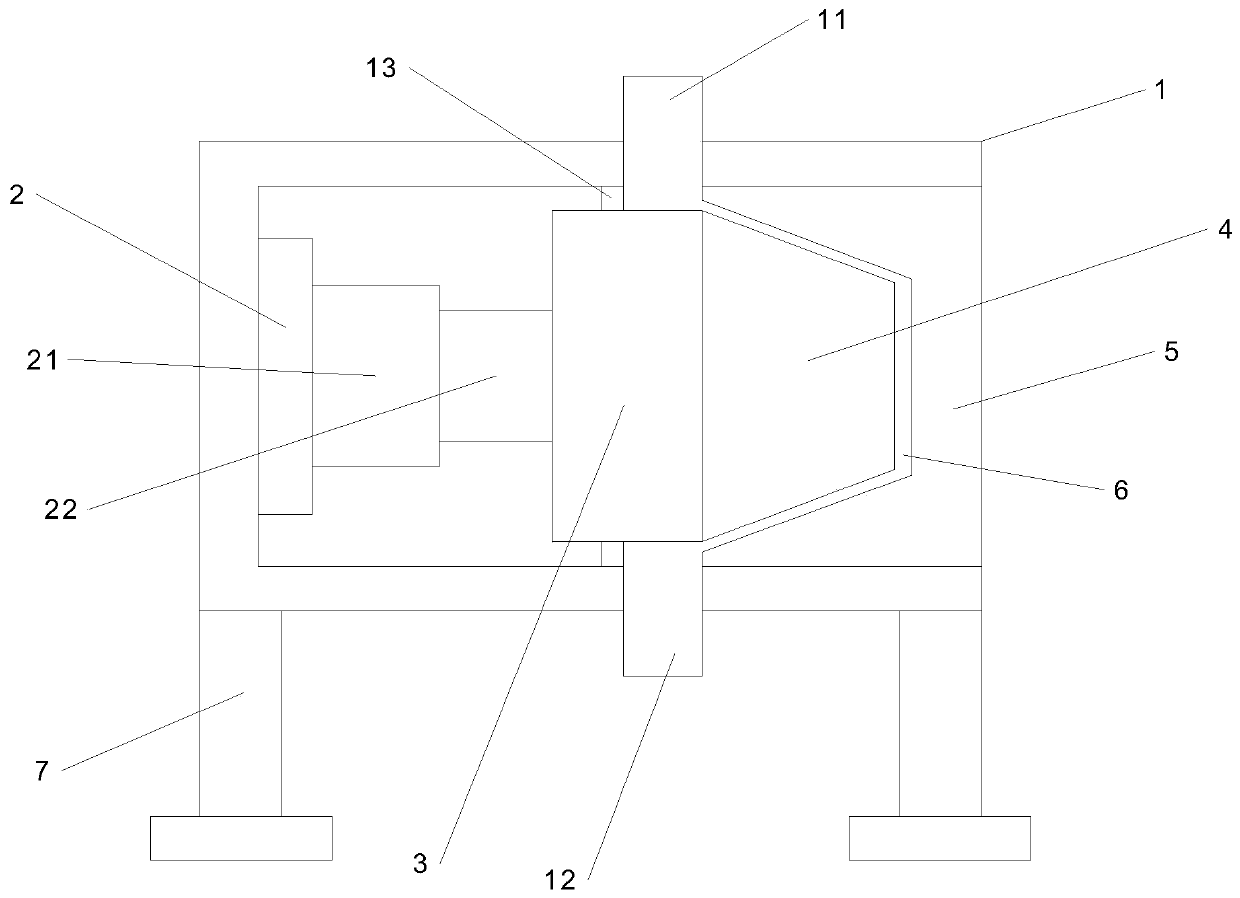

Preparation method of nano self-cleaning environment-friendly coating

InactiveCN111087835APrevent leakageReduce investmentAntifouling/underwater paintsPaints with biocidesOrganosolvPyrrolidinones

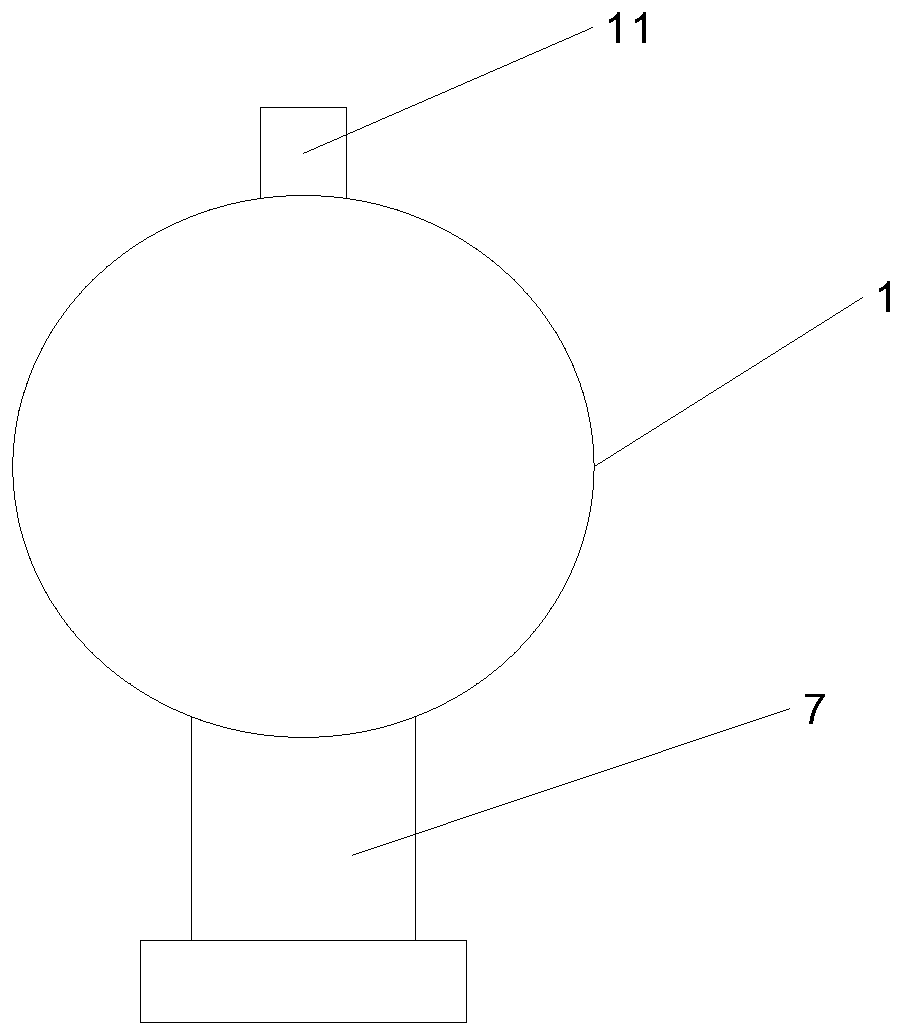

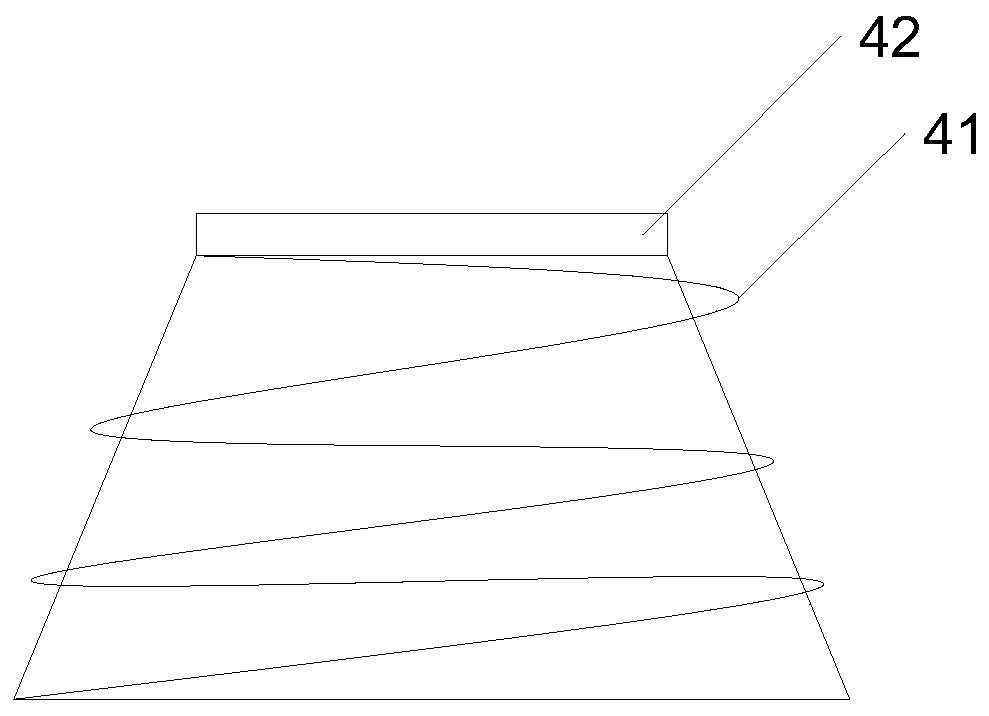

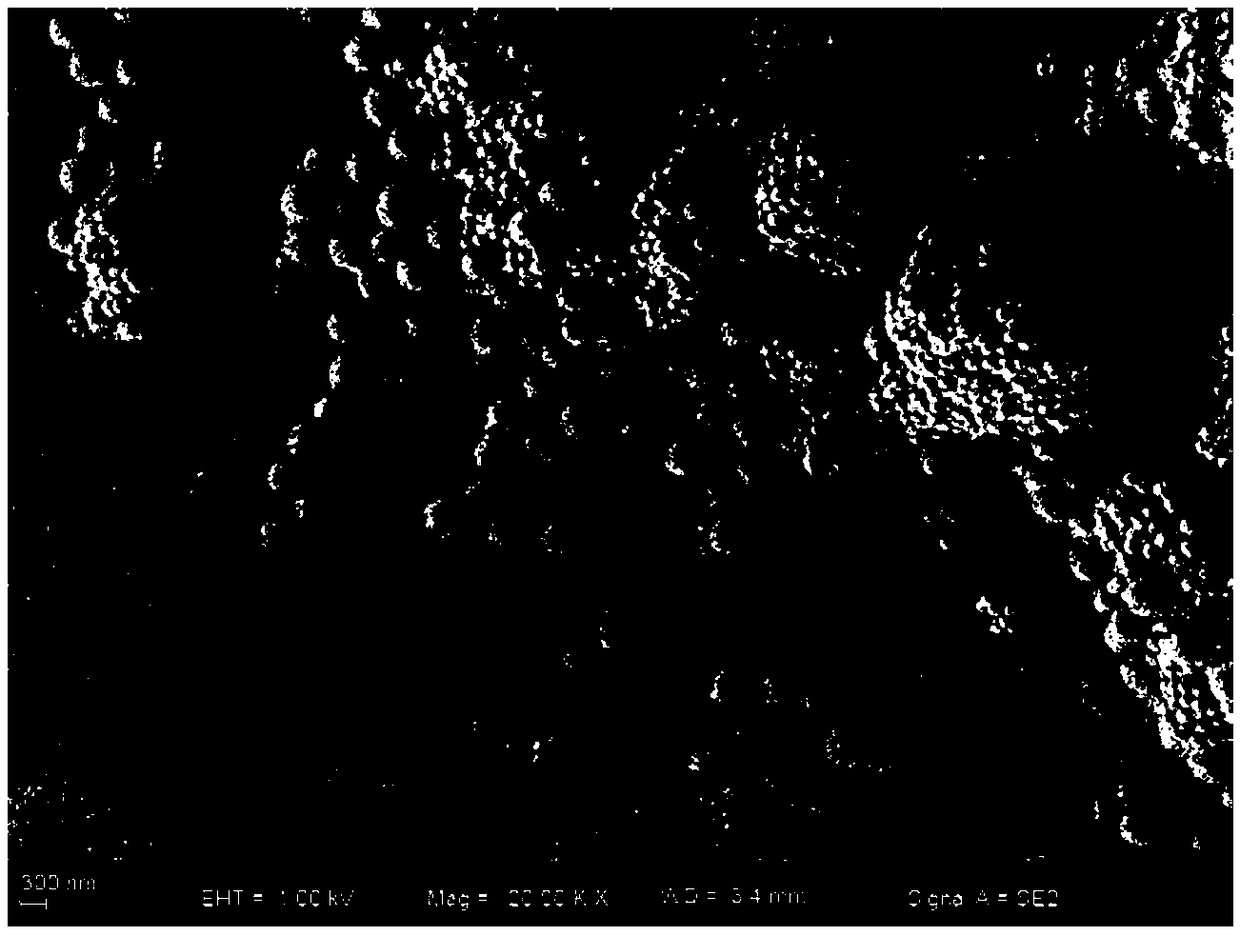

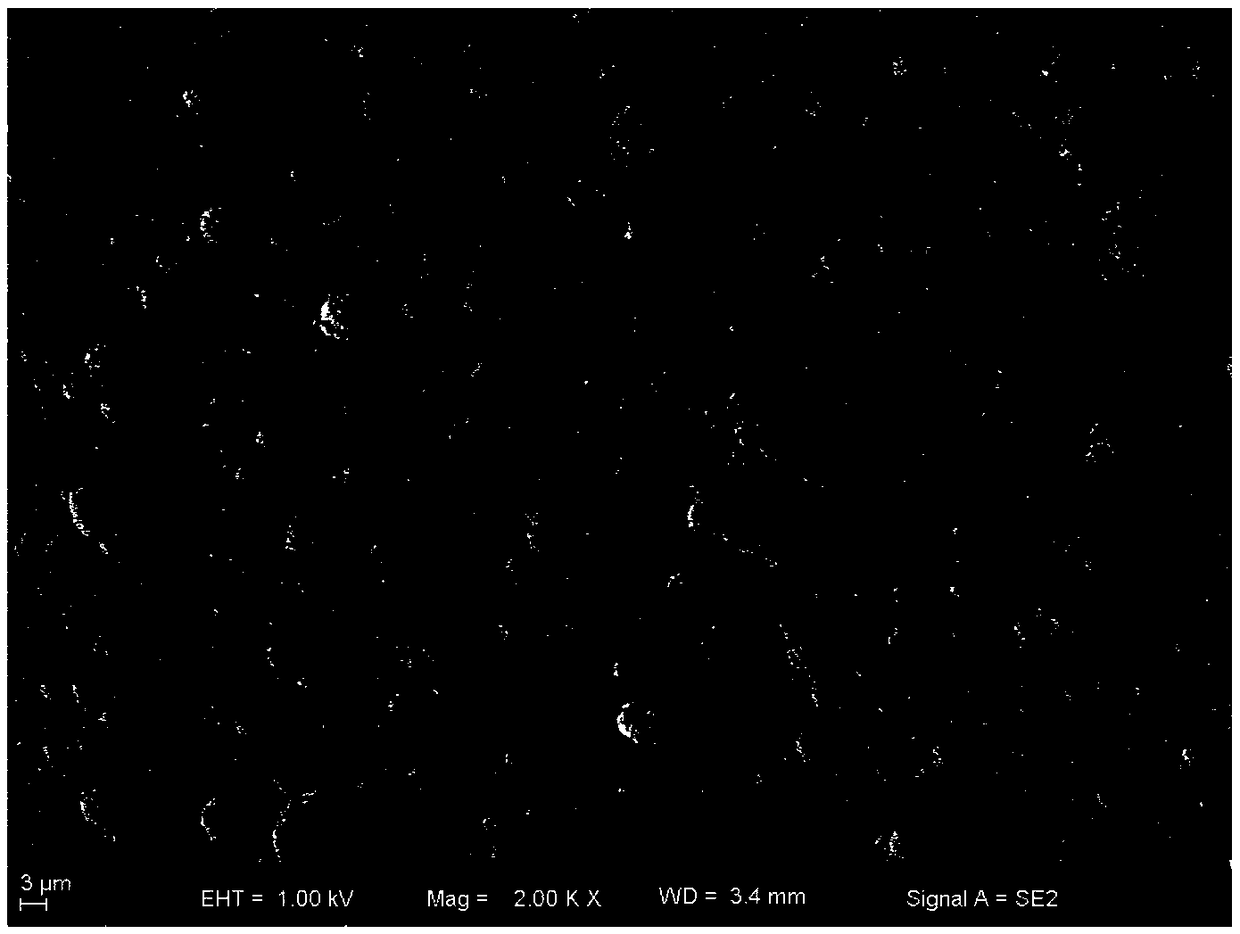

The invention discloses a preparation method of a nano self-cleaning environment-friendly coating. The preparation method comprises the following steps: firstly, putting a nano titanium dioxide colloid into a stirring reaction kettle; adding deionized water, ethanol and an organic solvent for reaction to prepare a nano titanium dioxide colloidal solution; adding the nano titanium dioxide colloidalsolution into a heating stirrer, meanwhile, adding zeolite, inorganic environment-friendly filler, polyvinylpyrrolidone and sodium benzoate at the same time, then performing a stirring reaction to prepare a nano titanium dioxide emulsion, adding the nano titanium dioxide emulsion into a stirring kettle, adding a thickening agent and a defoaming agent, thereby preparing the nano self-cleaning environment-friendly coating. The environment-friendly coating has super-hydrophobic and oleophobic performance and excellent self-cleaning performance. The invention further provides a ball milling device, the ball milling device is used for grinding and refining titanium dioxide particles, mixed materials roll in the wheel sand cutting groove formed in the ball milling device, grinding and refiningare achieved, and the ball milling effect is good.

Owner:骆瑜

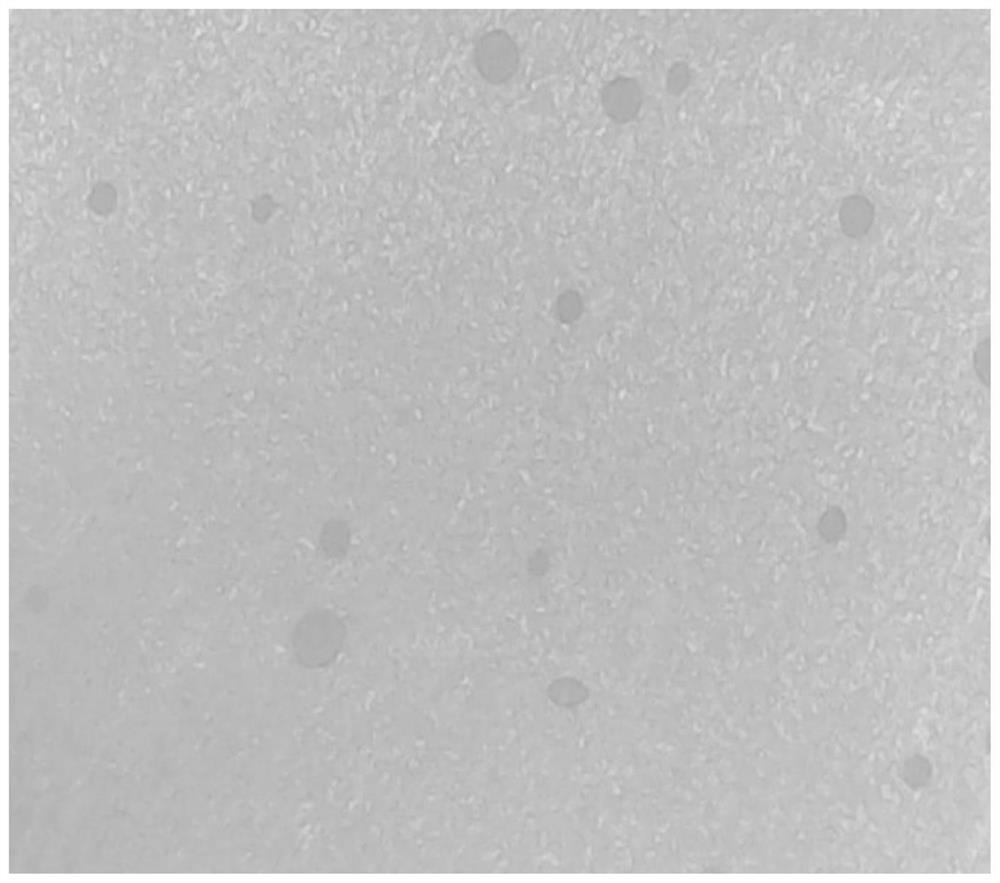

Coating slurry, coating diaphragm and preparation method thereof

The invention provides coating slurry, a coating diaphragm and a preparation method thereof, and relates to the technical field of a battery diaphragm. The coating slurry is formed on a base membraneto obtain the coating diaphragm. The coating diaphragm comprises the following components in parts by weight: 2.5 to 3.2 parts of polyvinylidene fluoride, 11 to 13 parts of polymethyl methacrylate, 0.7 to 1.2 parts of dispersing agent, 0.8 to 1.2 parts of thickening agent, 0.3 to 0.6 part of defoaming agent, 1.8 to 2.3 parts of adhesive and 17 to 20 parts of water. The coating diaphragm has good adhesion effect.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Filtrate reducer for drilling fluid as well as preparation method and application thereof

InactiveCN108774505AStrong filtration wallStrong anti-salt and anti-calcium performanceDrilling compositionBetaineTetrahydrofuran

The invention discloses a filtrate reducer for drilling fluid as well as a preparation method and application thereof. The filtrate reducer disclosed by the invention comprises the following raw material components in parts by weight: 25-30 parts of starch, 3-5 parts of tetrahydrofuran, 0.25-0.5 part of maleic anhydride, 20-30 parts of acrylamide propyl trimethoxysilane, 5-15 parts of 2-acrylamido-2-methylpropane sulfonic acid, 0.3-0.5 part of dimethyl sulfoxide, 5-10 parts of N-benzyl-3-pyrrolidone, 5-10 parts of ammonium persulfate, 5-10 parts of sodium hydrogen sulfite, 10-20 parts of alkyldimethyl betaine and 100 parts of water. The filtrate reducer disclosed by the invention achieves an excellent effect of reducing the filter loss in a clay free phase high-density drilling fluid system, and has excellent salt and calcium resistance and high pollution resistance; the filtrate reducer has an obvious effect of reducing the filter loss, is excellent in temperature and salt resistanteffect and has an excellent suspension effect on the solid phase; and the tackifying amplitude is moderate in the drilling fluid system, and field application requirements are well met.

Owner:张建华

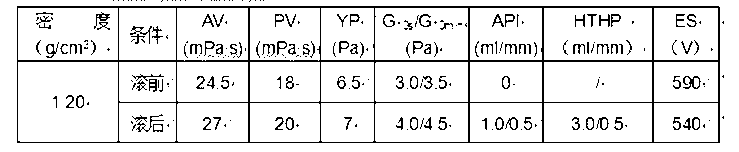

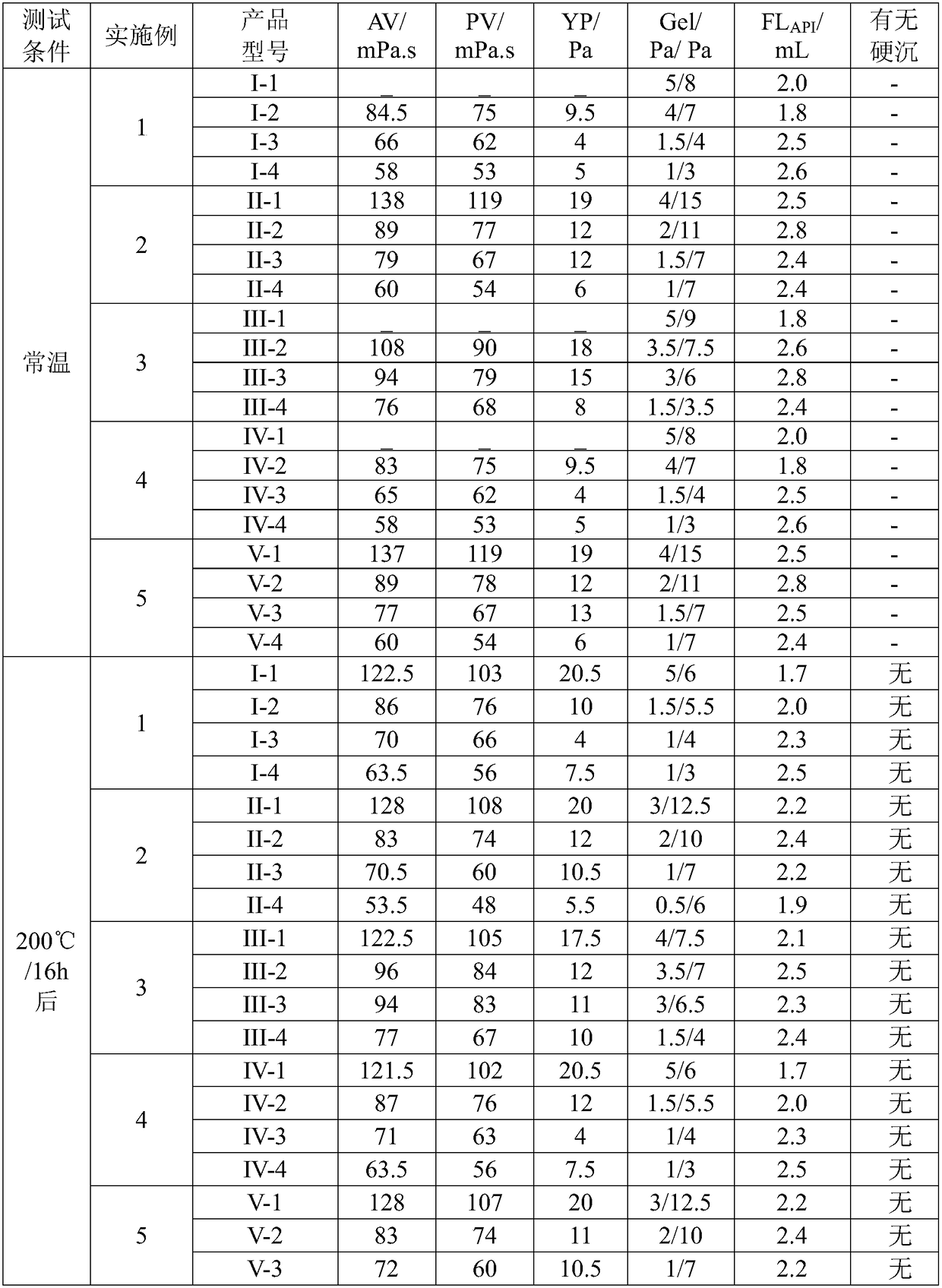

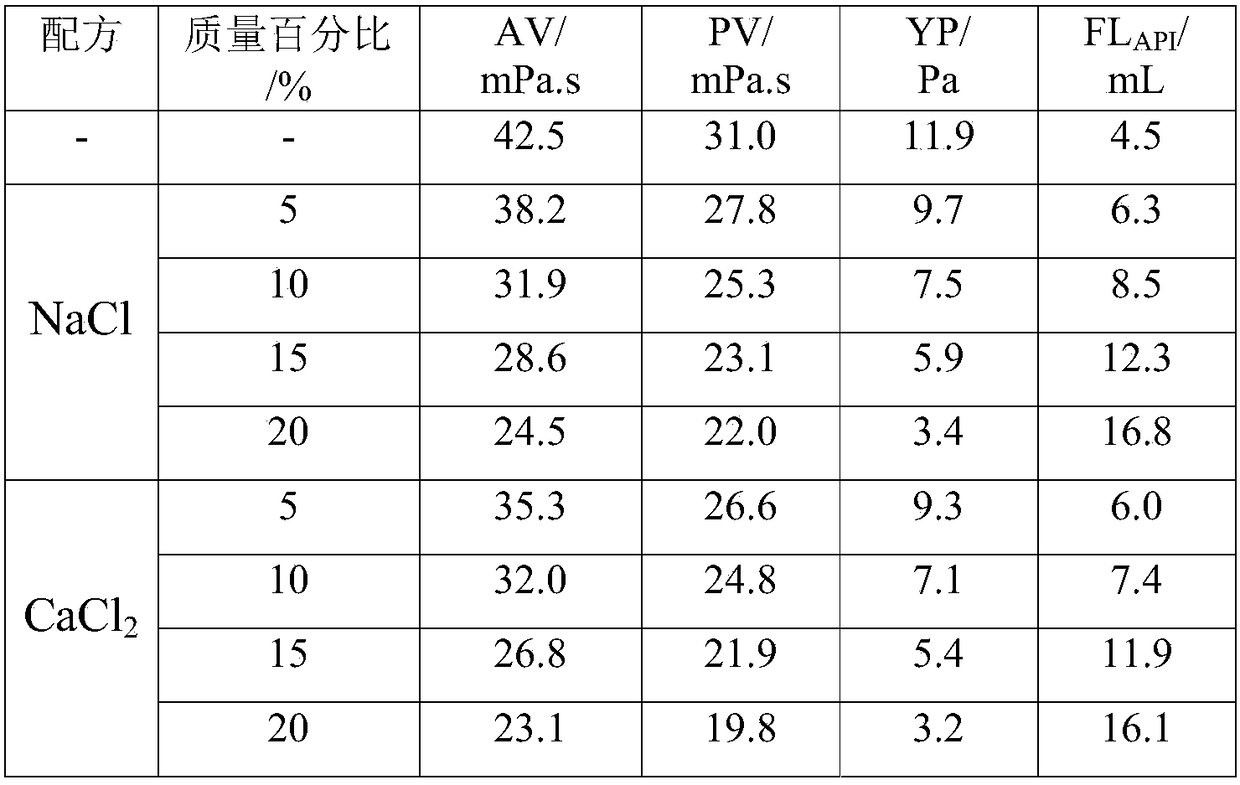

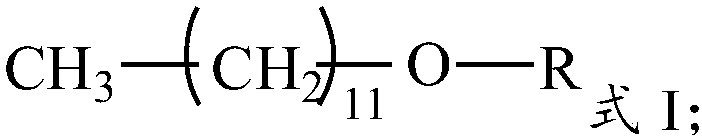

Biomass synthetic base drilling fluid and preparation method thereof

InactiveCN109517587AImprove the lubrication effectGood compatibilityDrilling compositionBiomassChemistry

The invention provides biomass synthetic base drilling fluid and a preparation method thereof and belongs to the technical field of expansion of petroleum natural gas environment-friendly type synthetic base drilling fluid. The biomass synthetic base drilling fluid provided by the invention comprises biomass base fluid, a CaCl2 water solution, organic soil, an emulsifier, a wetting agent, a fluidloss agent, CaO and barite. The biomass base fluid, the emulsifier and the wetting agent have a cooperative agent; under the cooperative effect of all components in the drilling fluid, the biomass synthetic base drilling fluid provided by the invention has relatively good performance; and all the raw materials are green and environmentally friendly and have a relatively low price and good biodegradability, and the biomass synthetic base drilling fluid is novel green synthetic base drilling fluid.

Owner:SINOPEC SSC +1

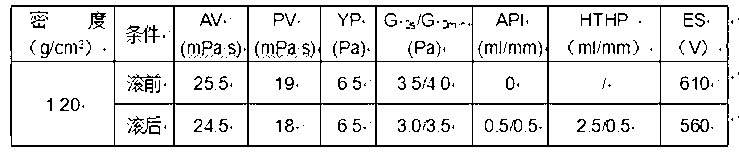

Drilling fluid for resisting heavy oil pollution

The invention relates to the technical field of drilling fluids used in petroleum drilling engineering, and particularly discloses a drilling fluid for resisting heavy oil pollution. The drilling fluid is prepared by mixing water, sodium bentonite, sodium carbonate, sodium carboxymethyl cellulose, low viscosity polyanionic cellulose, a filtrate loss reducer A, sulfonated phenolic resin, sulfonated lignite, industrial salt, an emulsifier B, an emulsifier C and barite, adjusting the pH value to 10 to 11 and aging at high temperature. The drilling fluid is prepared by reasonably compounding and synergistic effect of the above raw materials, can maintain good rheological properties, also increases significantly the capacity limitation of heavy oil, after the drilling fluid is polluted by 25% heavy oil, the drilling fluid still has good rheology and filtration loss property, the viscosity of the drilling fluid is effectively reduced, and the phenomenon of pasting a vibration sieve can be eliminated.

Owner:中石化石油工程技术服务有限公司 +1

Preparation method of cationic silicon-fluorine thinning agent for drilling fluid

ActiveCN105349119AEnvironmentally friendlyNo pollution in the processDrilling compositionMethacrylateWater baths

The invention discloses a preparation method of a cationic silicon-fluorine thinning agent for drilling fluid. The preparation method comprises the following steps: 1), sequentially adding 50 ml of methyl methacrylate and 100 ml of butyl acrylate into 500 ml of distilled water, stirring uniformly, further adding 7.5 ml of Span-80, stirring for 1 h to form a monomer pre-emulsion; 2), taking out the pre-emulsion, sequentially adding 35 ml of hexafluorobutyl methacrylate, 25 ml of dodecafluoroheptyl methacrylate, 25 ml of gamma-methacryloxypropyltrimethoxysilane and 40 ml of vinyl trimethoxy silane, and performing ultrasonic oscillation dispersion for 10 min; 3), taking 1 / 5 of emulsion which is subjected to ultrasonic oscillation, adding 3 g of ammonium persulfate into the emulsion, and adding the emulsion into a flask for heating in water bath, and further adding 3 g of ammonium persulfate and distilled water into the emulsion after the heated emulsion reaches the reaction temperature; 4), after the emulsion gives out blue light, dropwise adding the residual 4 / 5 of emulsion within 15 min, and adding 3 g of ammonium persulfate for heat preservation for 1 h, and finally taking out. With the adoption of the thinning agent prepared by adopting the preparation method provided by the invention, the interaction between clays is reduced, and the viscosity of drilling fluid is further decreased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Epoxy colored pavement finish paint and preparation and construction process thereof

InactiveCN107083157AExcellent physical and chemical propertiesGood weather resistanceIn situ pavingsAnti-corrosive paintsEnvironmental resistanceWeather resistance

The invention discloses an epoxy colored pavement finish paint and a preparation and construction process thereof. The epoxy colored pavement finish paint contains components A and B, wherein the component A is a curing agent, and the component B is prepared from, by mass, 30-50% of epoxy resin, 5-10% of reactive diluent, 0.5-2% of anti-settling agent, 1-5% of pigment, 20-40% of quartz powder and 20-40% of coarse whiting. The epoxy colored pavement finish paint is green and environmentally friendly, is free of irritant smell, has reliable and permanent adhesion power with different basal planes, also has good weather resistance and chemical corrosion resistance, is not saponified on alkaline concrete, and has excellent waterproof and dampproof properties, good flexibility, impact resisting property and excellent anti-slip protection property. In addition, the preparation process of the finish paint is simple, the conditions are mild, the construction time is longer than conventional time, construction operation is easy, the requirements for the environment is not strict during construction, and the finish paint is low in cost, economical, practical and suitable for large-area popularization.

Owner:深圳市威尔地坪材料有限公司

Waterborne acrylic acid modified alkyd pre-coating primer for railway vehicle and preparation method of pre-coating primer

InactiveCN109554061ABig performance impactInconvenient to paintAnti-corrosive paintsWater basedSoftened water

The invention belongs to the technical fields of pre-coating primers and preparation methods thereof. The invention discloses a waterborne acrylic acid modified alkyd pre-coating primer for a railwayvehicle and a preparation method of the pre-coating primer. The main technical characteristics of the pre-coating primer are that the waterborne acrylic acid modified alkyd pre-coating primer for therailway vehicle comprises water-based resin, wherein the water-based resin is prepared from the following components in parts by weight: 2-4 parts of plant oil, 1.29-1.47 parts of a polyhydric alcohol, 20-40 parts of saturated binary acid, 20-40 parts of unsaturated binary acid, 10-20 parts of acrylic acid, 10-20 parts of methacrylic acid, 1.5-2.0 parts of butyl acrylate, 20-40 parts of styrene, 20-40 parts of a cosolvent, 15-30 parts of a neutralizer, 10-20 parts of xylene, 0.01-0.03 part of an initiator, and 29-32.5 parts of softened water with conductivity of less than or equal to 10 [mu]S / cm. The resin is used for preparing the pre-coating primer which is a polymer taking lipophilic alkyd as a core and taking a hydrophilic acrylate copolymer as a shell. The particle size is small, compactness of the obtained paint film is high, the adhesive force is strong, and corrosion resistance is good.

Owner:ANPING JINLONG VEHICLE EQUIP

Preparation method of hydroxyl acrylate emulsion for waterborne wood paint

The invention discloses a preparation method of a hydroxyl acrylate emulsion for waterborne wood paint. The method comprises the following steps: using a core-shell synthesis technique, firstly generating a soft core with very small particle size by adopting microemulsion polymerization, and then polymerizing a layer of hard shell with a room-temperature self-crosslinking function; wherein the hydroxyl-containing function can be uniformly or emphatically distributed in the core and the shell layer as required, and the monomer composition of the shell layer contains a proper amount of functional monomer diacetone acrylamide capable of carrying out room-temperature self-crosslinking and is matched with adipic dihydrazide to carry out room-temperature self-crosslinking; the obtained product has the characteristics of small particle size, high transparency, good polishability, good hardness and good tolerance, and is suitable for being used as single-component or double-component wood paint, especially varnish primer.

Owner:CHANGSHU BATF TECH CO LTD

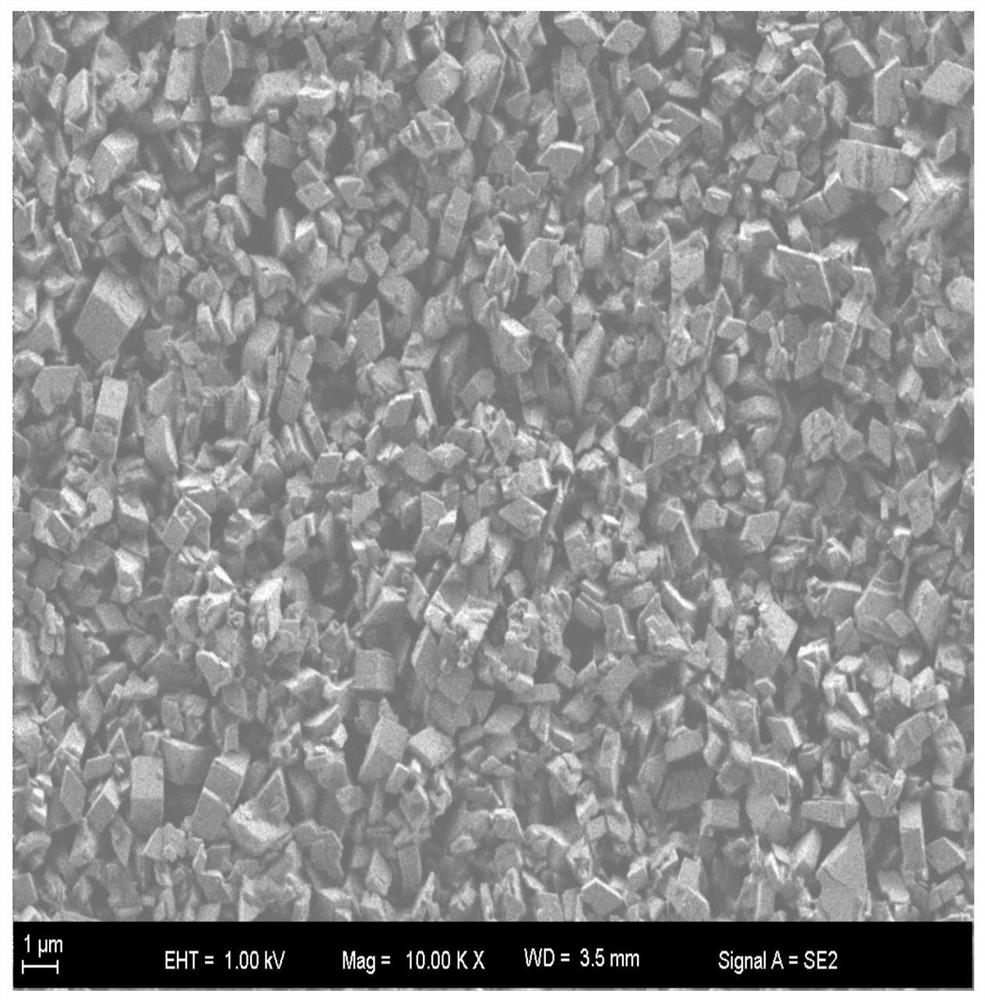

PMMA coating slurry, PMMA compound coating diaphragm and preparation method thereof

The invention relates to PMMA coating slurry, a PMMA compound coating diaphragm and a preparation method thereof and belongs to the technical field of battery diaphragms. The PMMA coating slurry is prepared from the following raw materials in parts by weight: 1-4 parts of polymethyl methacrylate, 1.0-2.0 parts of a thickener, 0.00001-0.0001 part of a wetting agent and 5-20 parts of water. According to the PMMA coating slurry, taking water as a solvent and polymethyl methacrylate as a film forming component, water is evaporated at a certain temperature, so that the coating slurry forms a film on the surface of a base film. As the interface bonding action of polymethyl methacrylate is relatively good, so that the adhesive strength of the coating diaphragm is improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

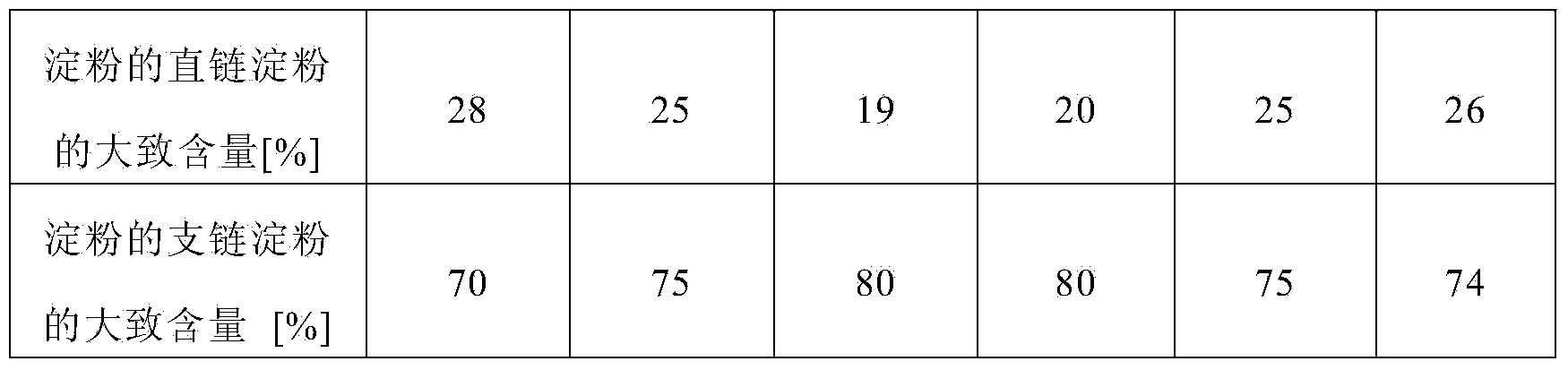

Borax-free starch adhesive compositions

InactiveCN104364335AAdjust rheologyGood solubility in cold waterNon-macromolecular adhesive additivesWater-repelling agents additionCardboardSolubility

#CMT# # / CMT# Use of solid sodium aluminate with sodium oxide / alumina ratio of 1-1.5, alumina content of 53-55% and a particle size distribution of 0.1-1 mm, where the amount of solid sodium aluminate is 1-35, preferably 2-10 wt.% with respect to starch portion, or an aqueous sodium aluminate solution with a solid content of 10-45 wt.% based on starch portion, sodium oxide / alumina ratio of 1.5-1.5 and alumina content of 5-25 wt.%, as component in borax-free starch glue for paper and corrugated cardboard production, is claimed. #CMT#USE : # / CMT# The solid sodium aluminate or aqueous sodium aluminate solution is useful as component in borax-free starch glue for paper and corrugated cardboard production (claimed). #CMT#ADVANTAGE : # / CMT# Sodium aluminate exhibits good solubility in water. #CMT#EXAMPLE : # / CMT# No suitable example given.

Owner:KURITA WATER INDUSTRIES LTD

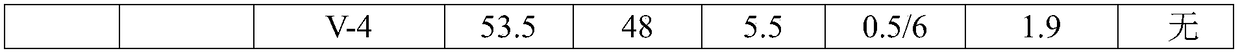

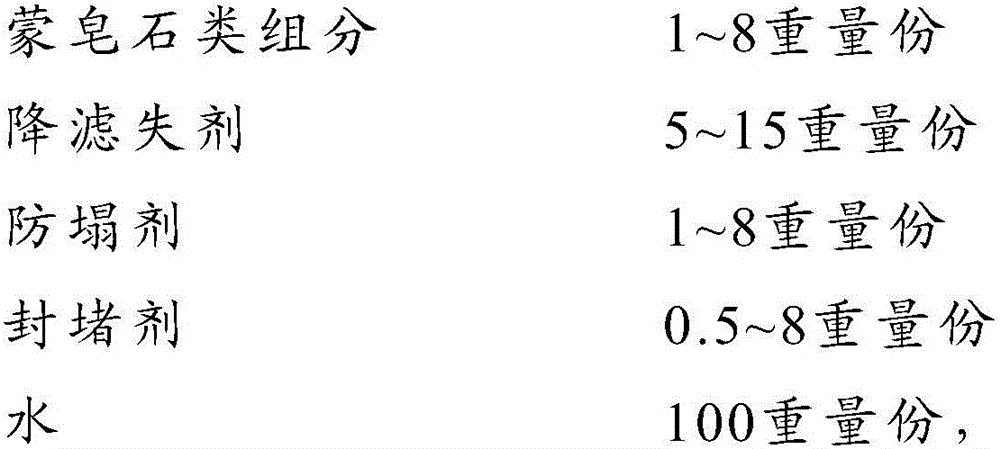

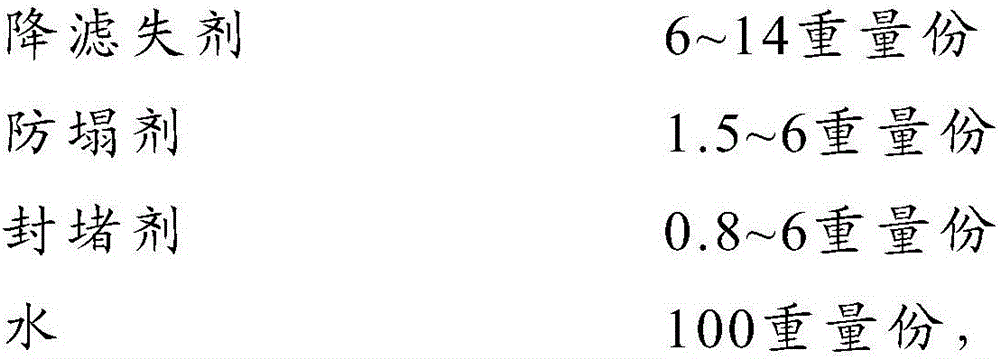

Water-based drilling fluid and preparing method thereof

ActiveCN105907384AReduce fluid lossImprove rheologyDrilling compositionSurface-active agentsDrilling fluid

The invention provides water-based drilling fluid and a preparing method thereof. The water-based drilling fluid avoids extra-added high temperature resistant thickening agent, high temperature resistant diluent and high temperature stabilizing agent or surface active agent and also has good filtration controlling performance, rheological property and high temperature stability at a high temperature of 220 DEG C. The method for preparing the water-based drilling fluid is convenient and easy to implement and suitable for drilling field use.

Owner:BEIJING INST OF EXPLORATION ENG

Drilling powder for geological prospecting and preparation method thereof

The invention belongs to the field of drilling of geological prospecting, and relates to drilling powder for geological prospecting and a preparation method thereof. The drilling powder is characterized by comprising the following raw materials in parts by weight: 700-750 parts of bentonite, 40-60 parts of emulsion polymer, 70-100 parts of sulfonated lignite, 40-70 parts of hydrolyzed polyacrylonitrile ammonium salt, 20-100 parts of lubricant, and 40-60 parts of barite. The drilling powder has multiple effects and strong applicability, is environment-friendly, has low preparation cost, and has the preparation method which is simple and easy to operate.

Owner:濮阳市诚信钻采助剂有限公司

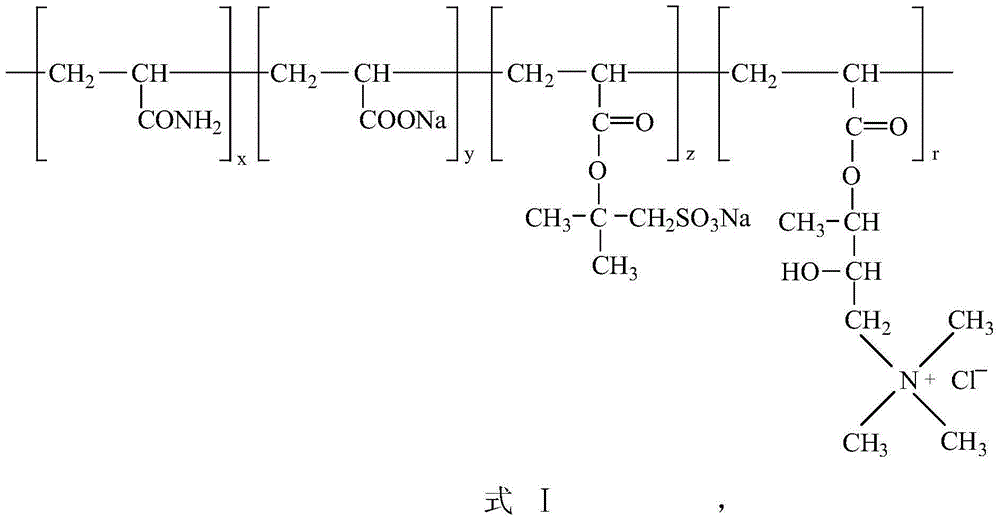

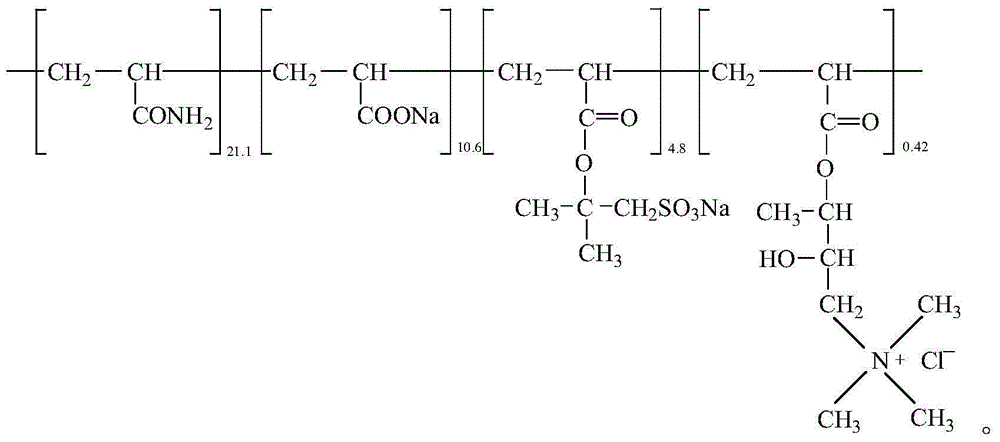

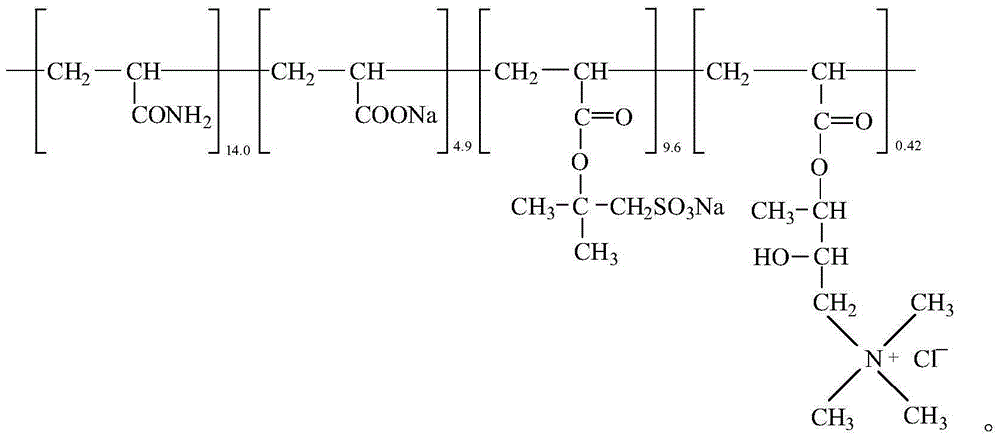

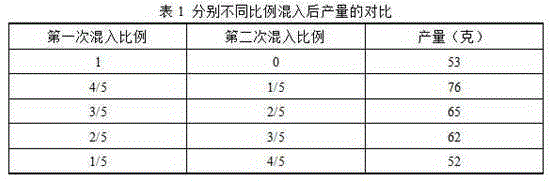

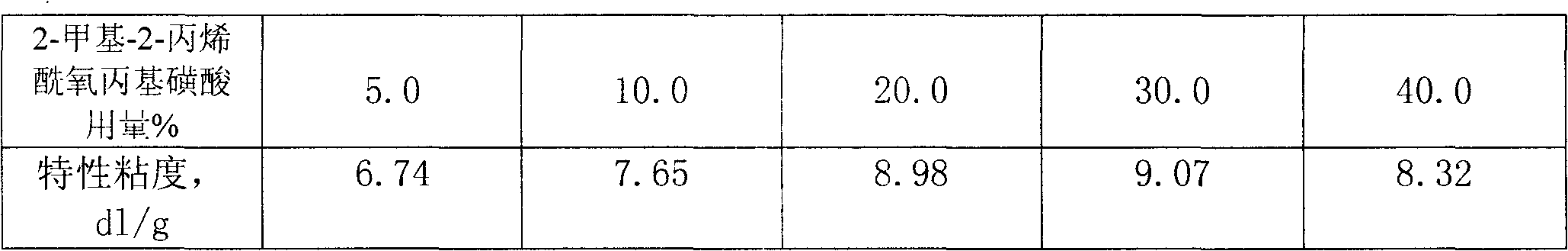

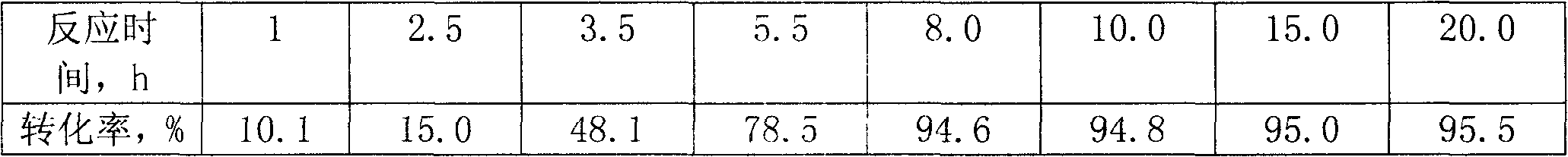

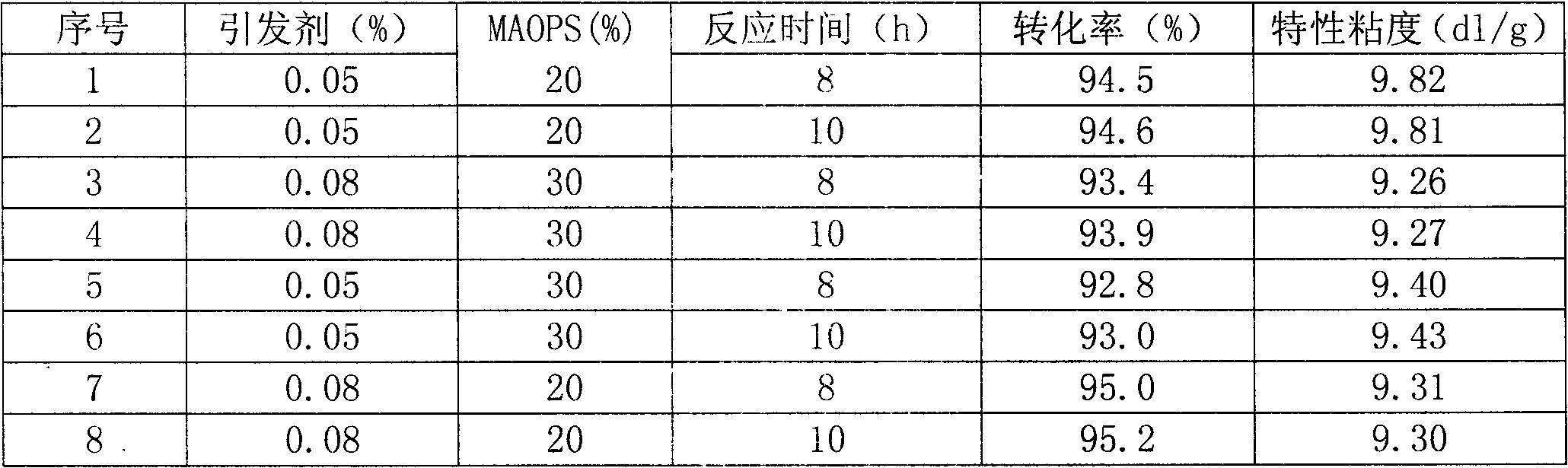

Production method of polymer for drilling fluid

The invention discloses a production method of a polymer for a drilling fluid, comprising the following steps: dissolving 2-methyl-2- acyloxy propyl sulfonate in water, then adding water in equimolar sodium hydroxide, stirring for dissolving and cooling, mixing the two mixtures and then adding a proper amount of acrylamide and acrylic acid, stirring for dissolving, heating up the mixed liquid to 35 DEG C with introducing nitrogen, then adding an initiating agent having an amount accounting for 0.05-0.08 % of the total weight of acrylamide and acrylic acid, uniformly stirring, then introducing nitrogen for a certain time, reacting for 8-10 h at a constant temperature of 35 DEG C to obtain a gel product, cutting and pelleting the gel product, and drying to obtain the polymer for the drilling fluid. The polymer produced by the invention has strong salt resistance and calcium pollution resistance, strong ability to inhibit clay hydrating and dispersing, and strong flocculation and coating capacities, can be applied in fresh water drilling fluid, salt-water drilling fluid, saturated salt-water drilling fluid, seawater drilling fluid and other drilling fluids, and has good compatibility with other treating agents to drilling fluid.

Owner:HUIXIAN AEROSPACE CHEM NO 1 FACTORY

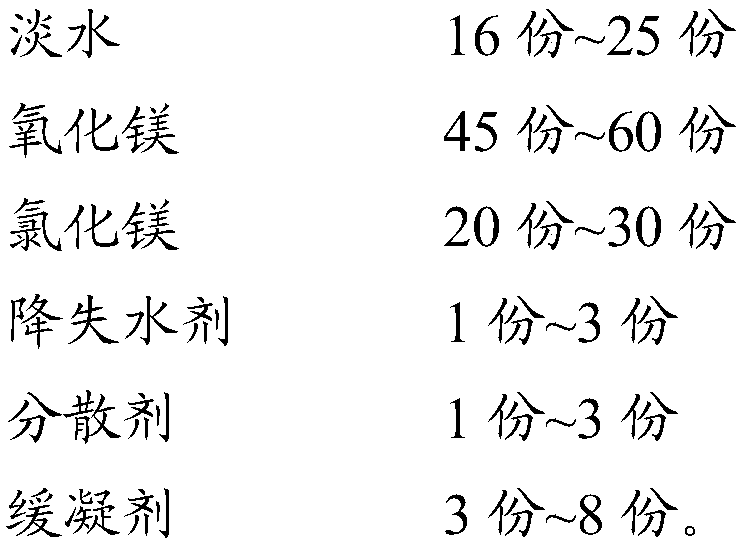

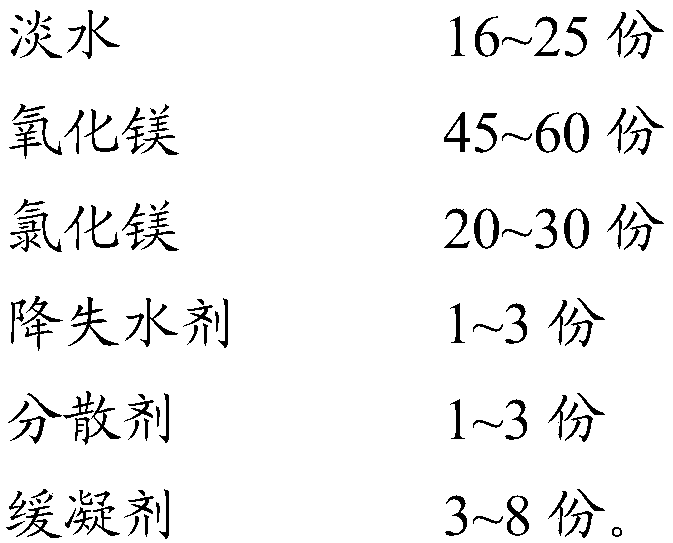

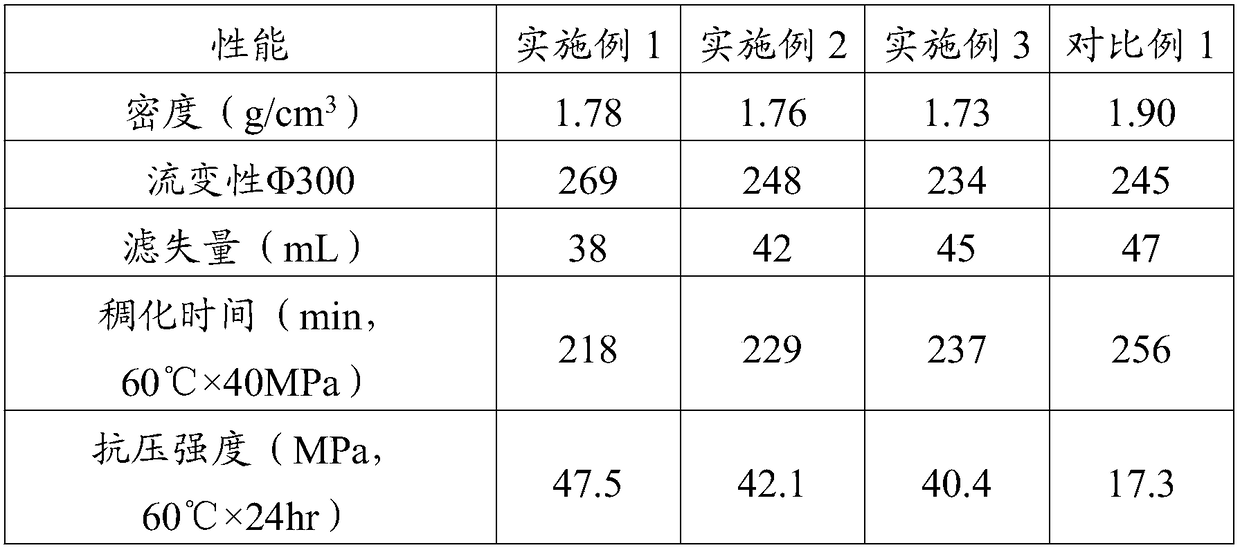

Magnesium oxychloride cement paste, preparation method and application thereof in prevention of oil base drilling fluid loss

PendingCN108751924AHigh compressive strengthSolve the problem of not being able to meet the plugging strength requirementsProductsReagentsMagnesiumOxide

The invention provides a magnesium oxychloride cement paste. The magnesium oxychloride cement paste is prepared from the following raw materials in parts by weight: 16 to 25 parts of fresh water, 45 to 60 parts of magnesium oxide, 20 to 30 parts of magnesium chloride, 1 to 3 parts of a fluid loss agent, 1 to 3 parts of a dispersing agent and 3 to 8 parts of a retarder. The magnesium oxychloride cement paste provided by the invention has preferable strength, and can be used for blocking large and medium sized drilling fluid loss. Moreover, the magnesium oxychloride cement paste provided by theinvention also has preferable compressive strength under the invaded pollution of oil base drilling fluids.

Owner:YANGTZE UNIVERSITY +1

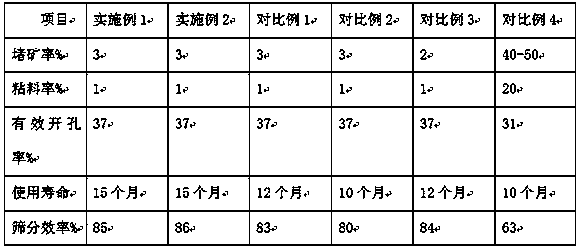

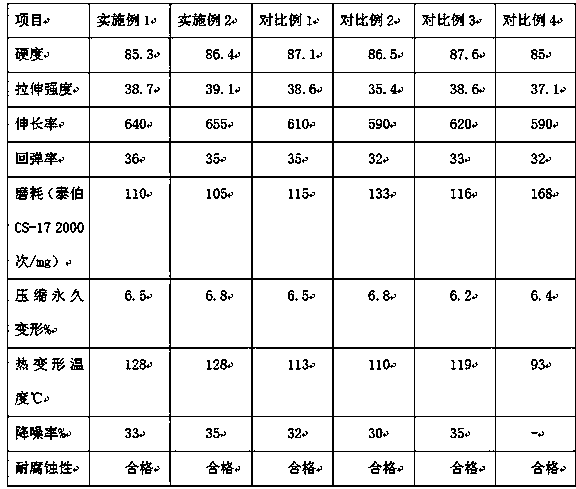

Polyurethane sieve mesh with advantages of noise reducing, high-temperature resistance and corrosion resistance

PendingCN109294211AImprove thermal performanceImproves electrical properties but improves arc resistance of plasticsMechanical propertyChemistry

The invention discloses a polyurethane sieve mesh with advantages of noise reducing, high-temperature resistance and corrosion resistance, wherein the polyurethane sieve mesh comprises thermoplastic polyurethane, a vinyl ester resin, melamine, carboxyl-terminated liquid nitrile butadiene rubber, chlorinated polyethylene, a titanate coupling agent, and a filler. According to the present invention,through the material blending modification, the sieve mesh has advantages of excellent mechanical property, high tensile strength, excellent tear resistance, good elasticity, good resilience, good uniformity and good stability, can maintain the stable performance after multiple use, cannot be clogged, further has advantages of good heat resistance, corrosion resistance, excellent aging resistance,good bearing capacity, good corrosion resistance, good impact resistance, good shock absorption performance, wear resistance and aging resistance, and can be used in ore screening, chemical industryfiltration, and other application fields.

Owner:含山县领创新材料科技有限公司

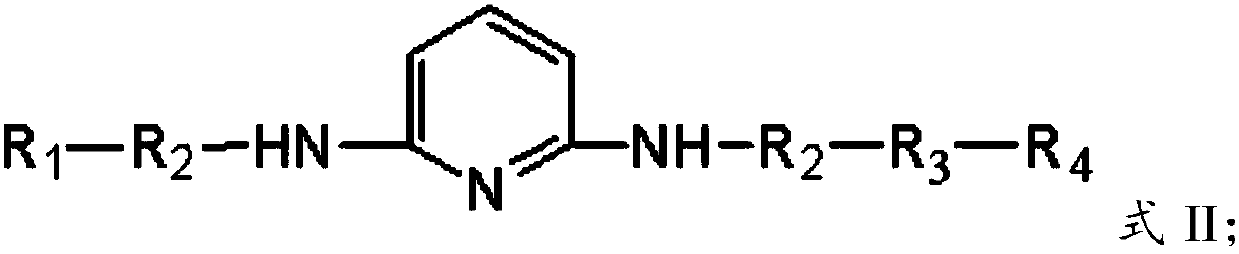

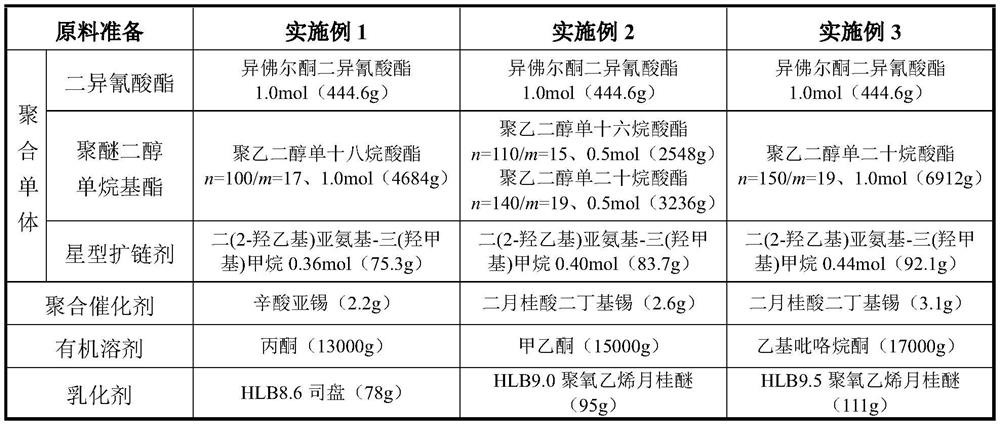

Asymmetric star polyurethane thickener with cationic core and preparation method thereof

ActiveCN112898529BInhibition of associationStrengthen associationDyeing processCoatingsTextile printerEndcapping

The invention relates to an associative polyurethane thickener used in the processing fields of water-based paint, textile printing, water-based resin coating, etc., in particular to an asymmetric star-shaped polyurethane thickener with a cationic core and a preparation method thereof. The method includes: raw material preparation; active capping; star chain extension; finished product. In the present invention, the polyurethane thickener molecule with a star structure has a cationic "core" and differentiated branched "arms", and the active groups on the chain extender have a large distance and different activities; The "core" of tertiary amine cations and the extended chain branches with large distances help to inhibit the association in the molecule and endow it with certain anti-electrolyte properties; the branched "arms" of different lengths in the thickener molecule make it The intermolecular association ability is stronger, the association structure is more complete, and the dosage is less; the asymmetric structure of the thickener molecule makes the structure of the product more abundant and the comprehensive performance is more excellent.

Owner:WUHAN TEXTILE UNIV +1

Preparation method of modified resin ink coating

InactiveCN106752320AEvenly dispersedImprove thermal stabilityInksPolyesterHexa(methoxymethyl)melamine

The invention discloses a preparation method of a modified resin ink coating. The preparation method comprises the following working procedures: 1) taking an appropriate amount of polyester modified methyl phenyl silicone resin and the like into a refining mill, and carrying out grinding dispersing to obtain a primary product; 2) adding a dispersing agent, a silane coupling agent and the like into the primary product, and carrying out grinding dispersing to obtain a secondary product; 3) adding hexakis(methoxymethyl)melamine into the secondary product, and carrying out grinding dispersing to filter and obtain an ink main agent; 4) adding dimethylbenzene and cyclohexanone into the ink main agent, and stirring to obtain the modified resin ink coating. Ink prepared by adopting the preparation method has good printability and paint film property while high temperature resistance is guaranteed.

Owner:重庆伟恒包装有限公司

PMMA coating slurry, PMMA composite coating diaphragm and preparation method thereof

A PMMA coating slurry, a PMMA composite coating diaphragm and a preparation method thereof, the invention belongs to the technical field of battery diaphragms, comprising: the raw materials thereof include, in parts by weight: 1-4 parts of polymethyl methacrylate, thickening 1.0-2.0 parts of agent, 0.00001-0.0001 parts of wetting agent and 5-20 parts of water. The PMMA coating slurry uses water as a solvent and polymethyl methacrylate as a film-forming component. Under a certain temperature, after water evaporates, the coating slurry forms a film on the surface of the base film. Methyl ester has a better interfacial bonding effect, which increases the adhesion of the coated separator.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Preparation method of high-temperature color retention printing ink

InactiveCN106752331AImprove thermal stabilityHigh physical and mechanical strengthInksPolyesterCyclohexanone

The invention discloses a preparation method of high-temperature color retention printing ink, which comprises the following procedures of: 1) adding an appropriate amount of polyester modification methoxyphenyl silicon resin, barium sulfate and the like into a refiner and performing grinding and dispersion to form a primary product, 2) adding octaphenyl polyoxyethyiene, polytetrafluoroethylene wax, polyether modified siloxane and an organosilicon defoaming agent into the primary product and performing grinding and dispersion to form a secondary product, 3) adding hexamethoxy methyl melamine resin into the secondary product and performing grinding, dispersion, filtration and discharging to form an ink main agent, and 4) adding an appropriate amount of dimethylbenzene and cyclohexanone into the ink main agent and performing stirring to form the high-temperature color retention printing ink. The ink prepared by the method has high temperature resistance and good printability and paint film performances. With the adoption of barium sulfate, silicon dioxide and low melting point glass powder as filling, the filming heat resistance of the ink is improved; the rheological and thixotropic properties of the ink are adjusted; and the physical mechanical strength of a film layer is improved.

Owner:重庆伟恒包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com