Coating slurry, coating diaphragm and preparation method thereof

A technology of coating slurry and diaphragm, which is applied in the field of coating diaphragm and its preparation, and coating slurry, which can solve the problems of insufficient adhesion and PVDF coating adhesion difficult to meet customer requirements, so as to reduce surface tension , Increase adhesion, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a coated diaphragm as described above includes: coating the coating slurry on the surface of the base film to form an aqueous coating, and then drying at a temperature of 30-80°C. Among them, the coating method includes roll coating or dip coating.

[0027] Since the coated diaphragm of this embodiment is formed by the coating slurry on the surface of the base film, the preparation process is simple, the production efficiency is high, and it is suitable for large-scale industrial production.

Embodiment 1

[0030] (1) Add 3 kg of polyvinylidene fluoride and 1 kg of ethylene bis-stearamide to 18 kg of deionized water, mix and stir for 2 hours to make them uniformly dispersed, and then add 12 kg of polymethyl methacrylate solution and stir for 0.5 hours. Finally, add 1kg of polyvinyl alcohol, 0.5kg of mineral oil, 2kg of polyacrylate and stir evenly to obtain the water-based PMMA / PVDF coating slurry;

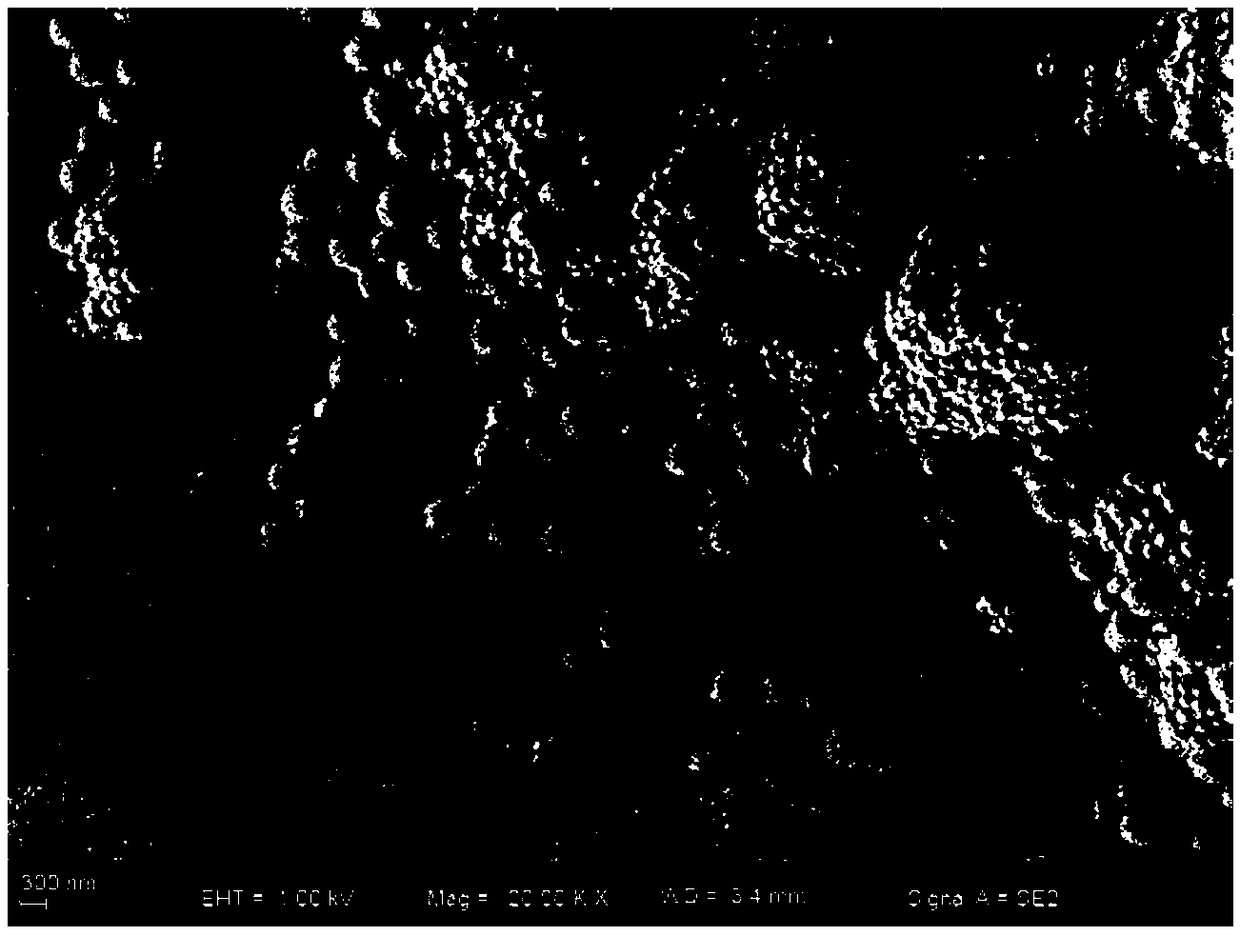

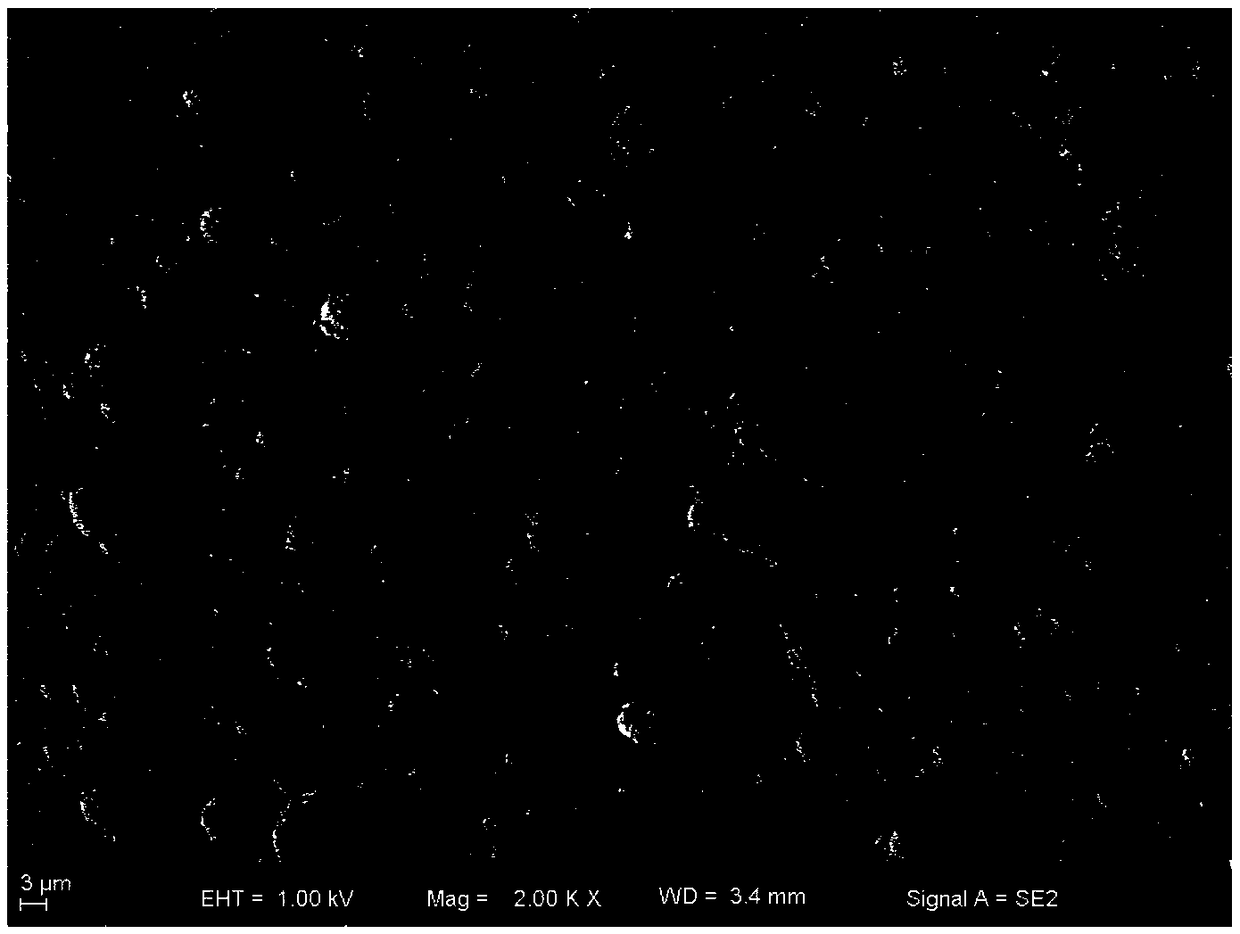

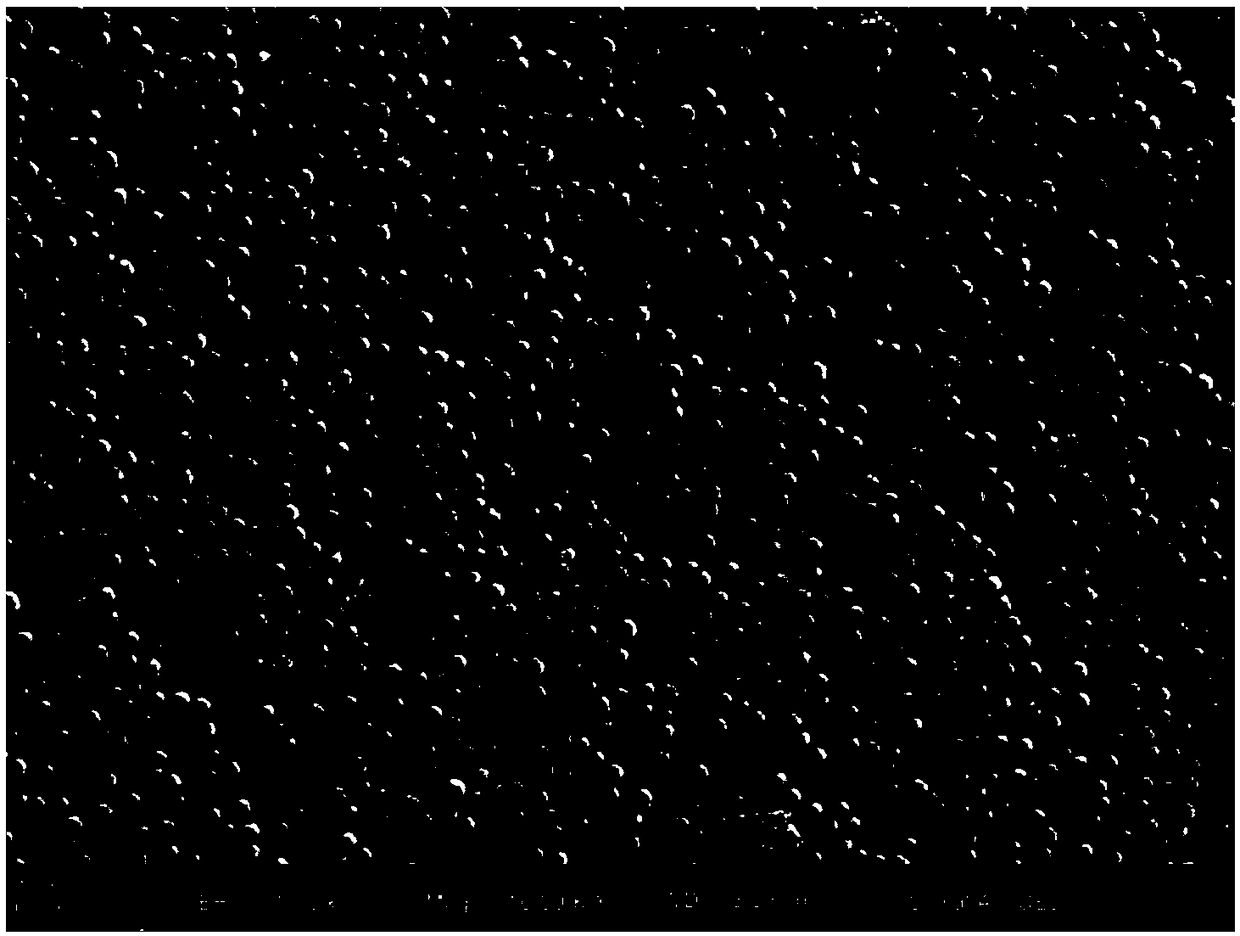

[0031] (2) Coating the above-mentioned aqueous PMMA / PVDF coating slurry on one surface of the polyolefin base film to form a 1-2um aqueous coating, and then baking and drying in an oven at 50° C. for 5 minutes to obtain a coated diaphragm.

Embodiment 2

[0033] (1) Add 3 kg of polyvinylidene fluoride and 1 kg of liquid paraffin to 18 kg of deionized water, mix and stir for 1 h to make them uniformly dispersed, and then add 12 kg of polymethyl methacrylate solution and stir for 0.5 h. Finally, add 1kg of polyvinylpyrrolidone, 0.5kg of natural oil and 2kg of epoxy resin and stir evenly to obtain the water-based PMMA / PVDF coating slurry;

[0034] (2) Coating the above aqueous PMMA / PVDF coating slurry on both sides of the polyolefin base film to form a 1-2um aqueous coating, and then baking and drying in an oven at 80° C. for 1 min to obtain a coated diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com