Patents

Literature

12600results about How to "Inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

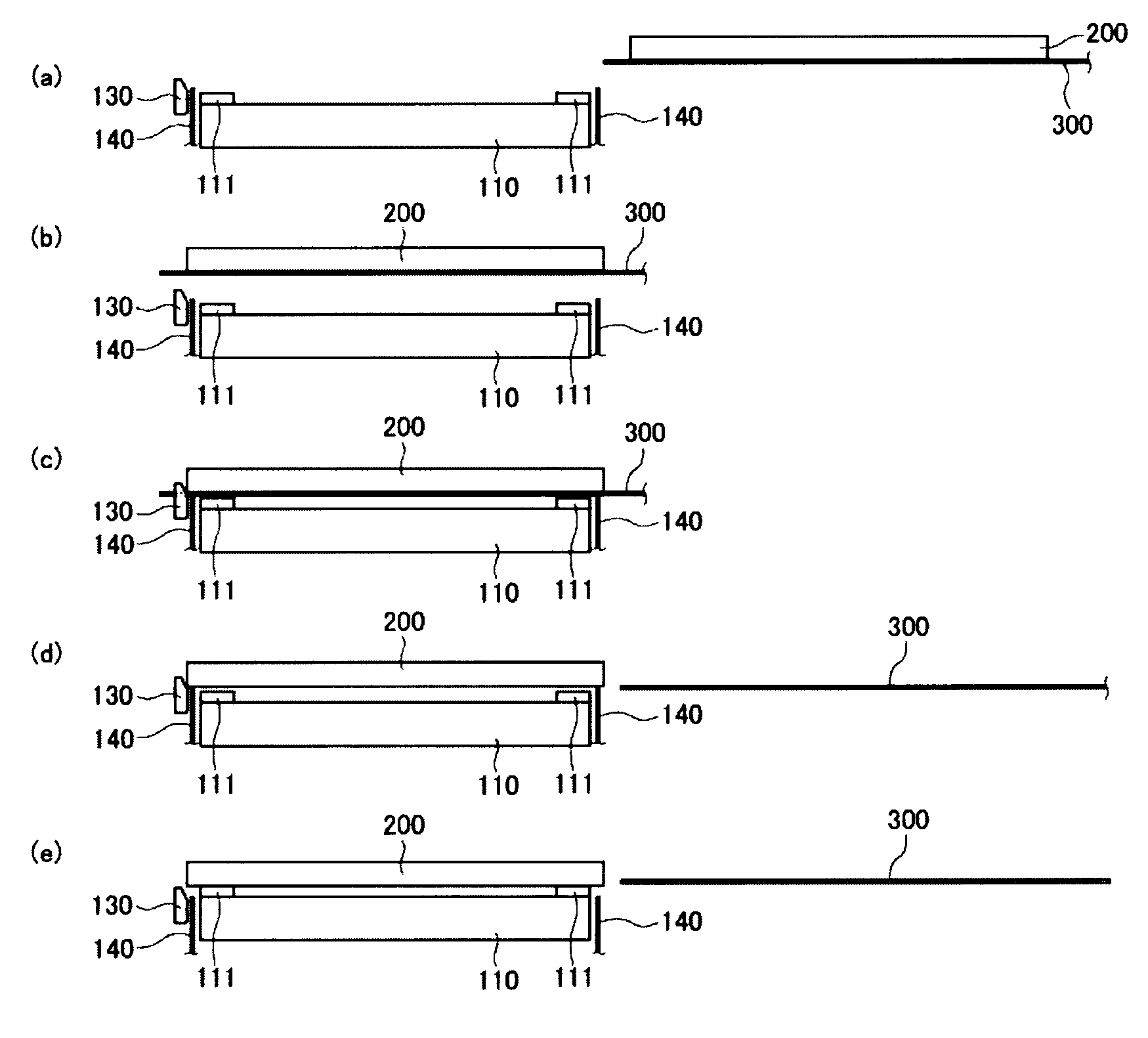

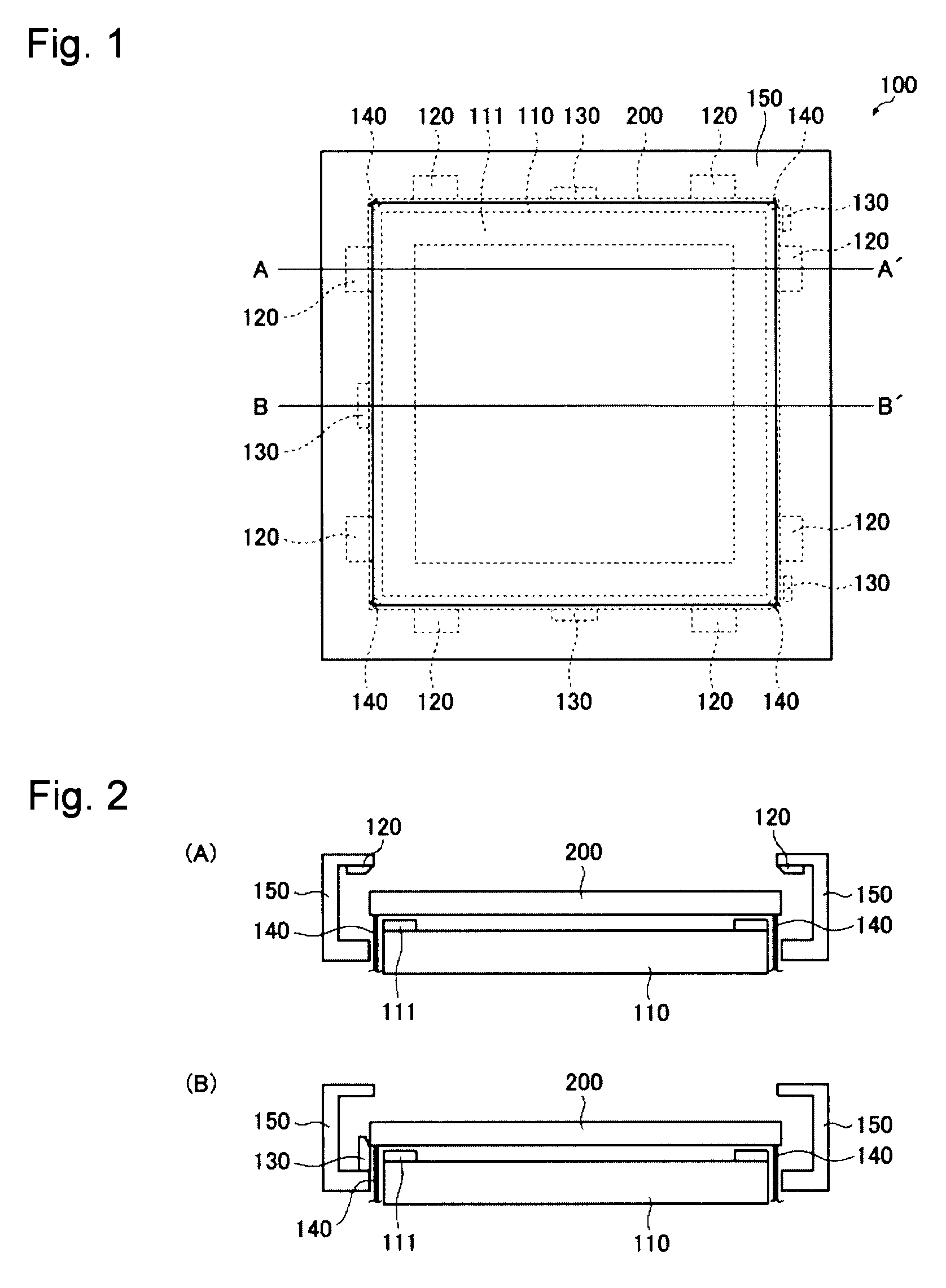

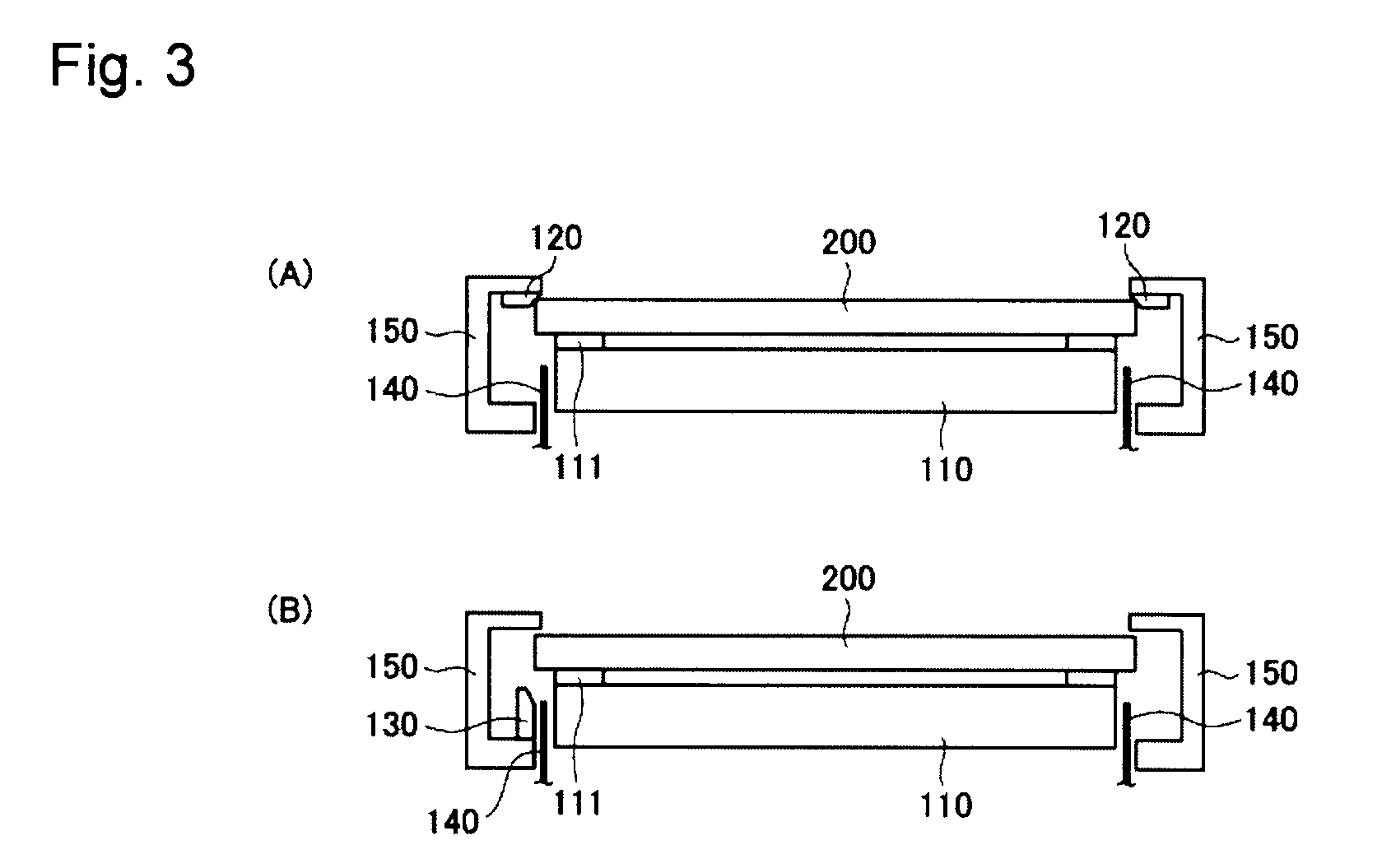

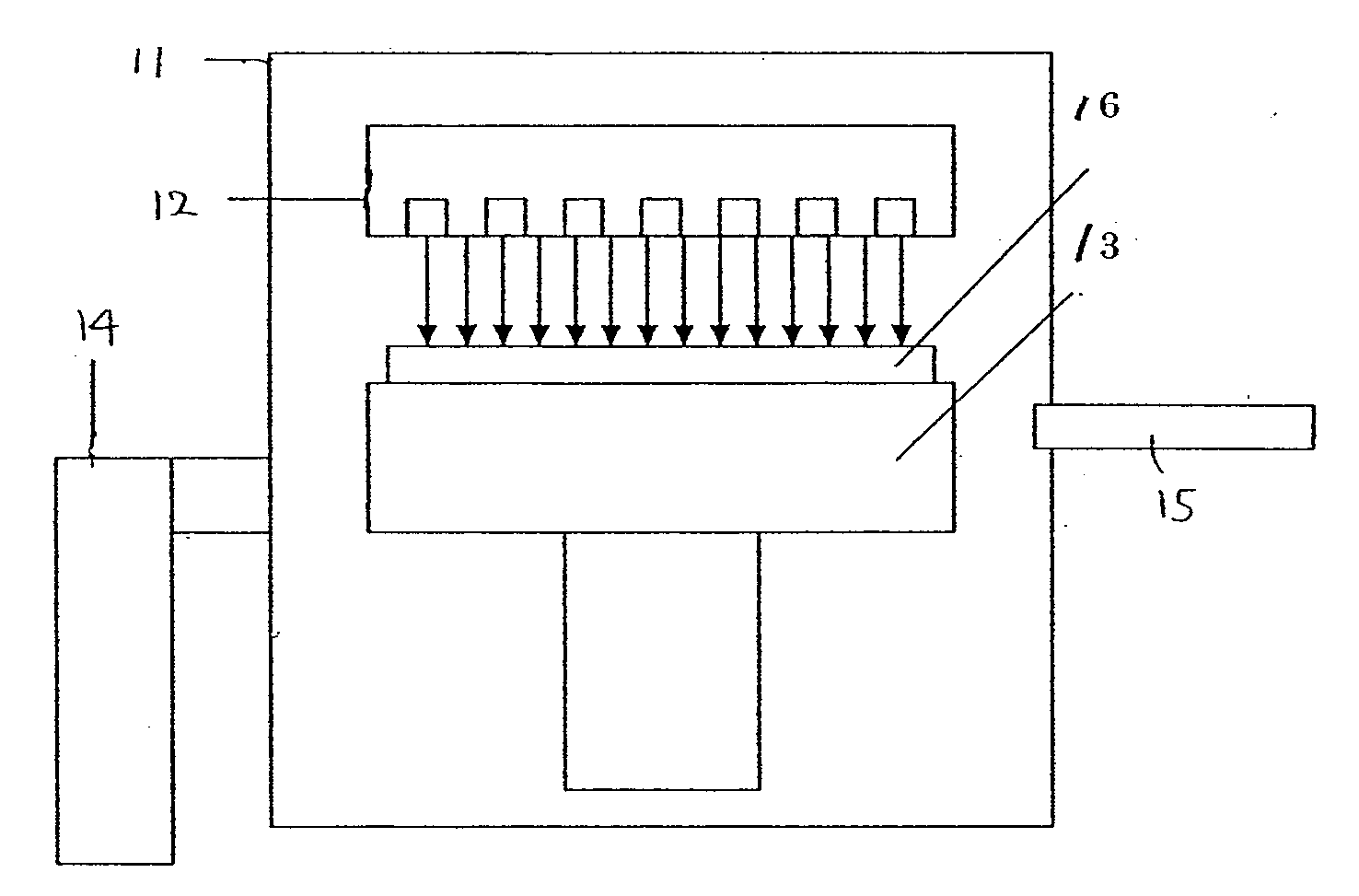

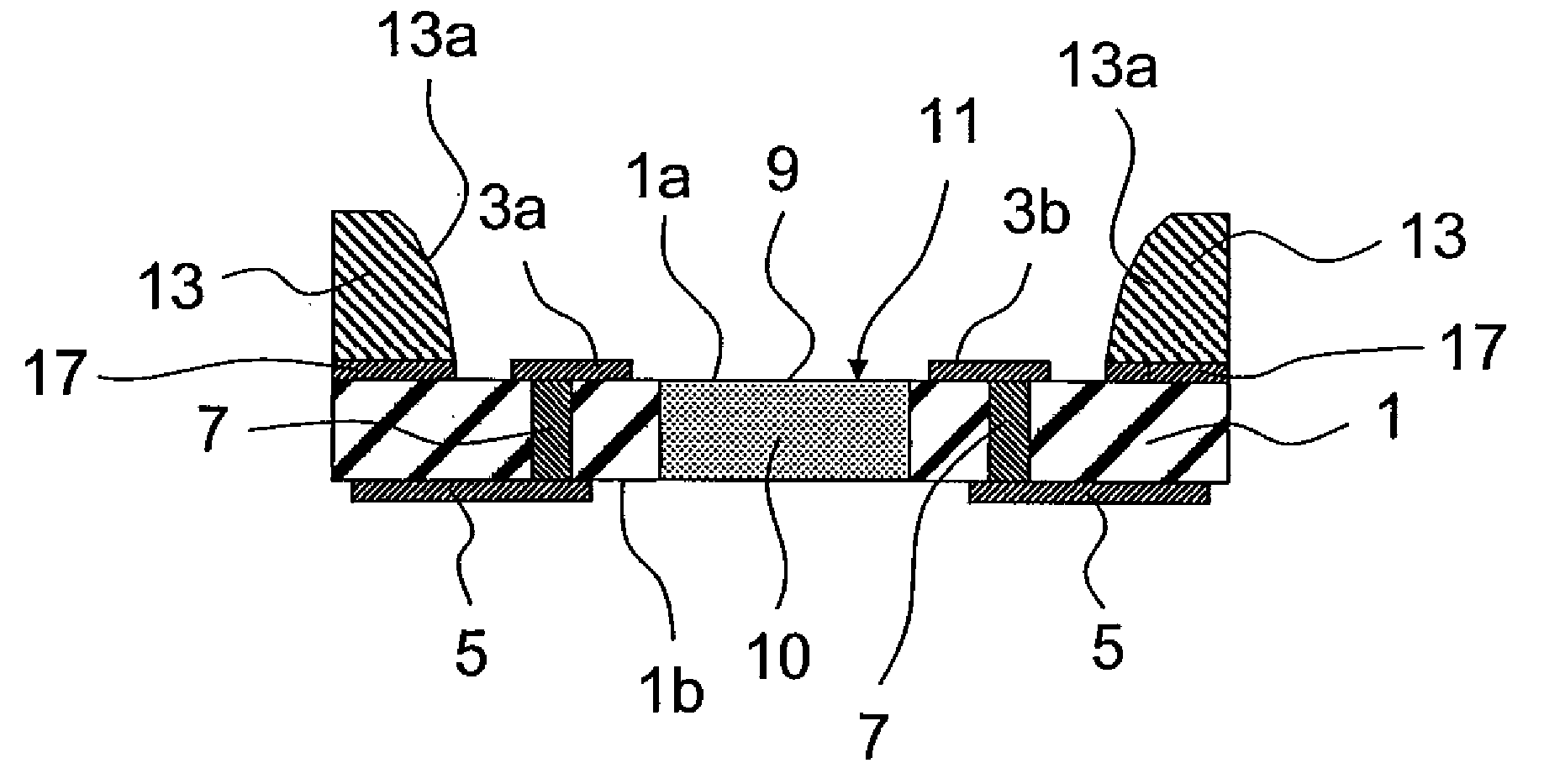

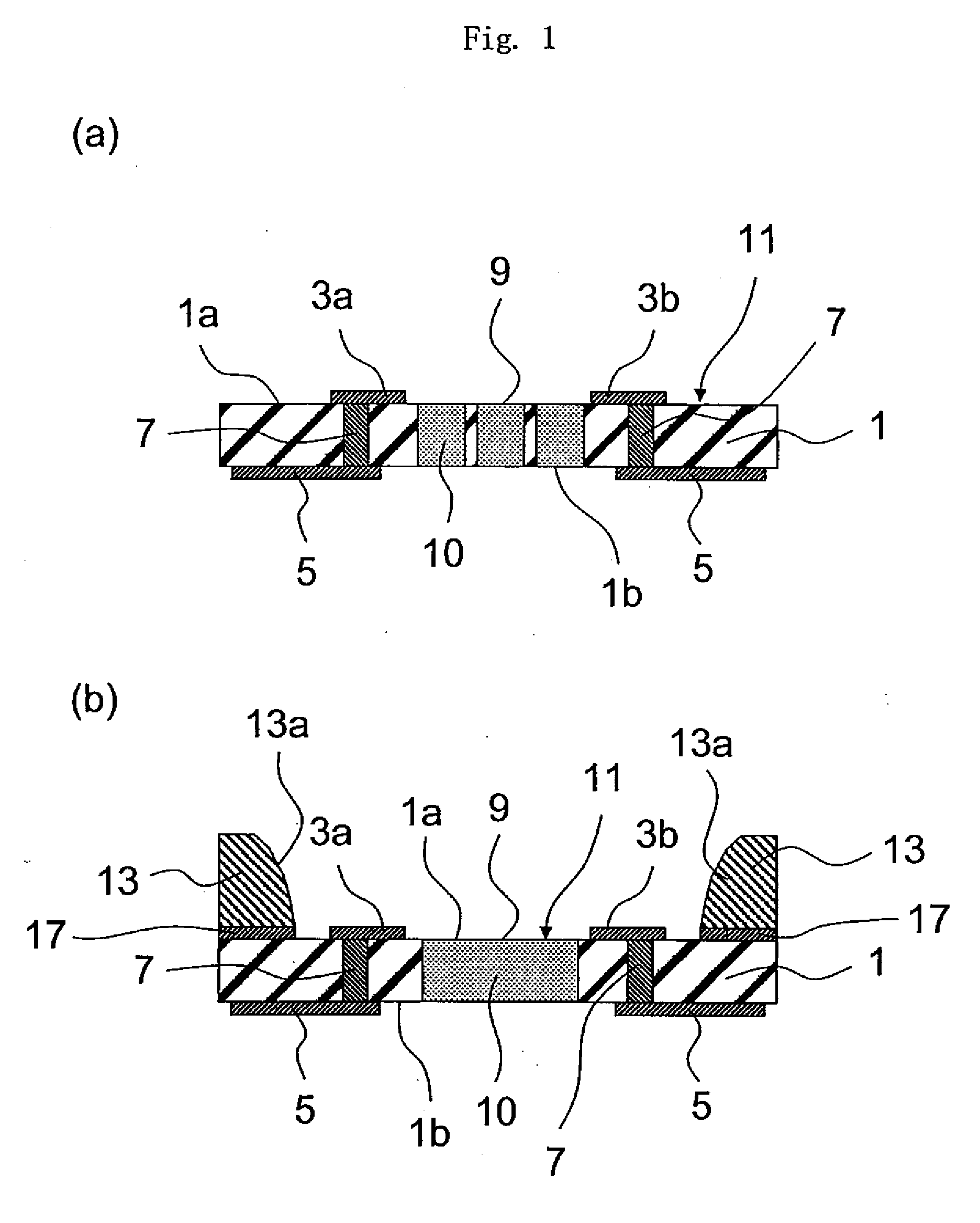

Glass substrate-holding tool and method for producing an EUV mask blank by employing the same

InactiveUS8967608B2InhibitionAccurate placementWorkpiece holdersVacuum evaporation coatingLithographic artistMaterials science

A glass substrate-holding tool employed during the production of a reflective mask blank for EUV lithography includes an electrostatic chuck and a mechanical chuck. A caught and held portion of a glass substrate caught and held by the electrostatic chuck, and pressed portions of the glass substrate pressed by the mechanical chuck are located outside a quality-guaranteed region on each of a film deposition surface and a rear surface of the glass substrate. The sum of a catching and holding force applied to the glass substrate by the electrostatic chuck and a holding force applied to the glass substrate by the mechanical chuck is at least 200 kgf. A pressing force per unit area applied to the glass substrate by the mechanical chuck is at most 25 kgf / mm2.

Owner:ASAHI GLASS CO LTD

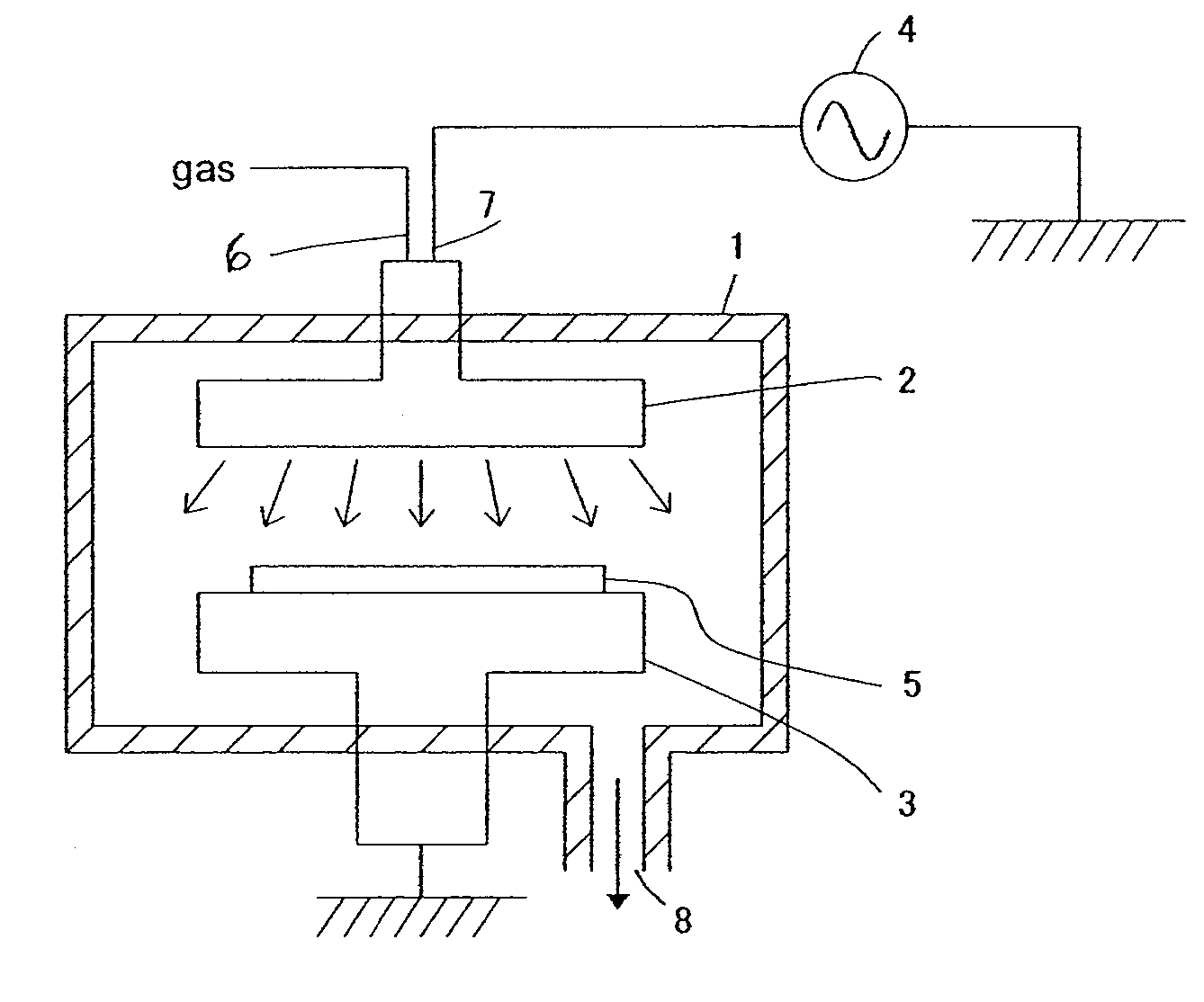

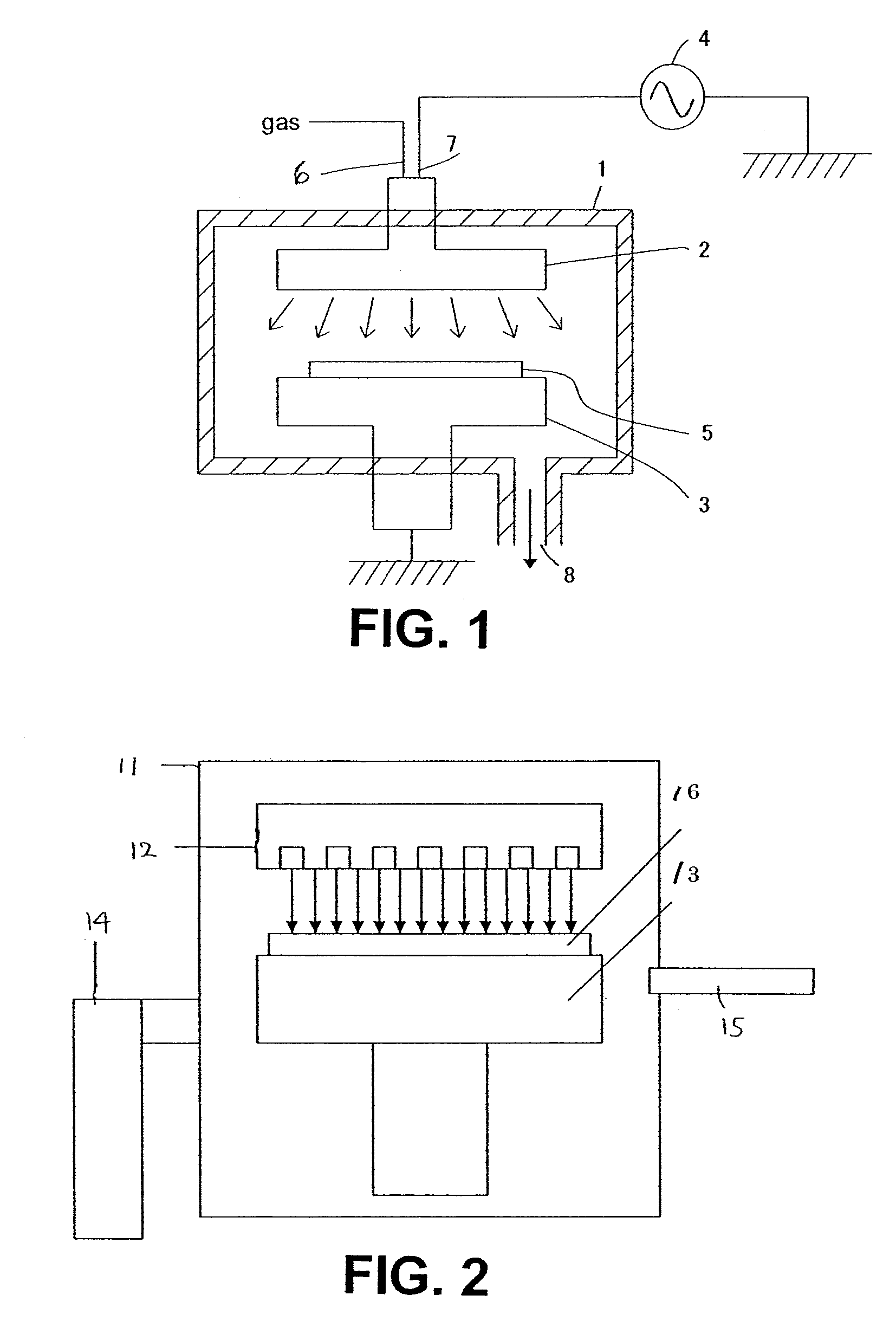

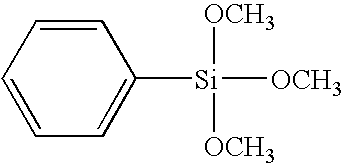

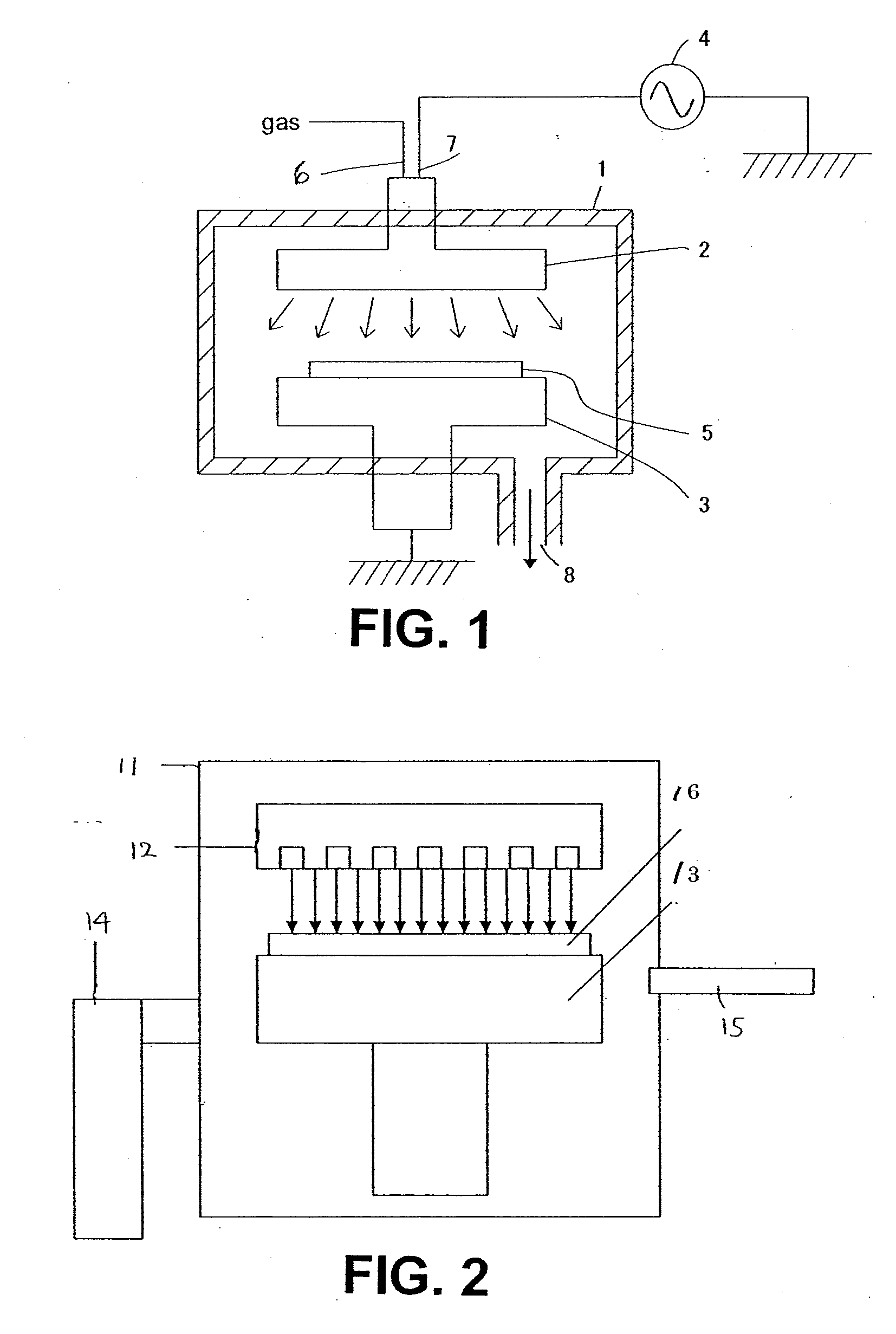

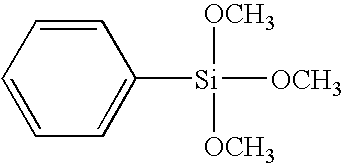

Method for forming insulation film

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

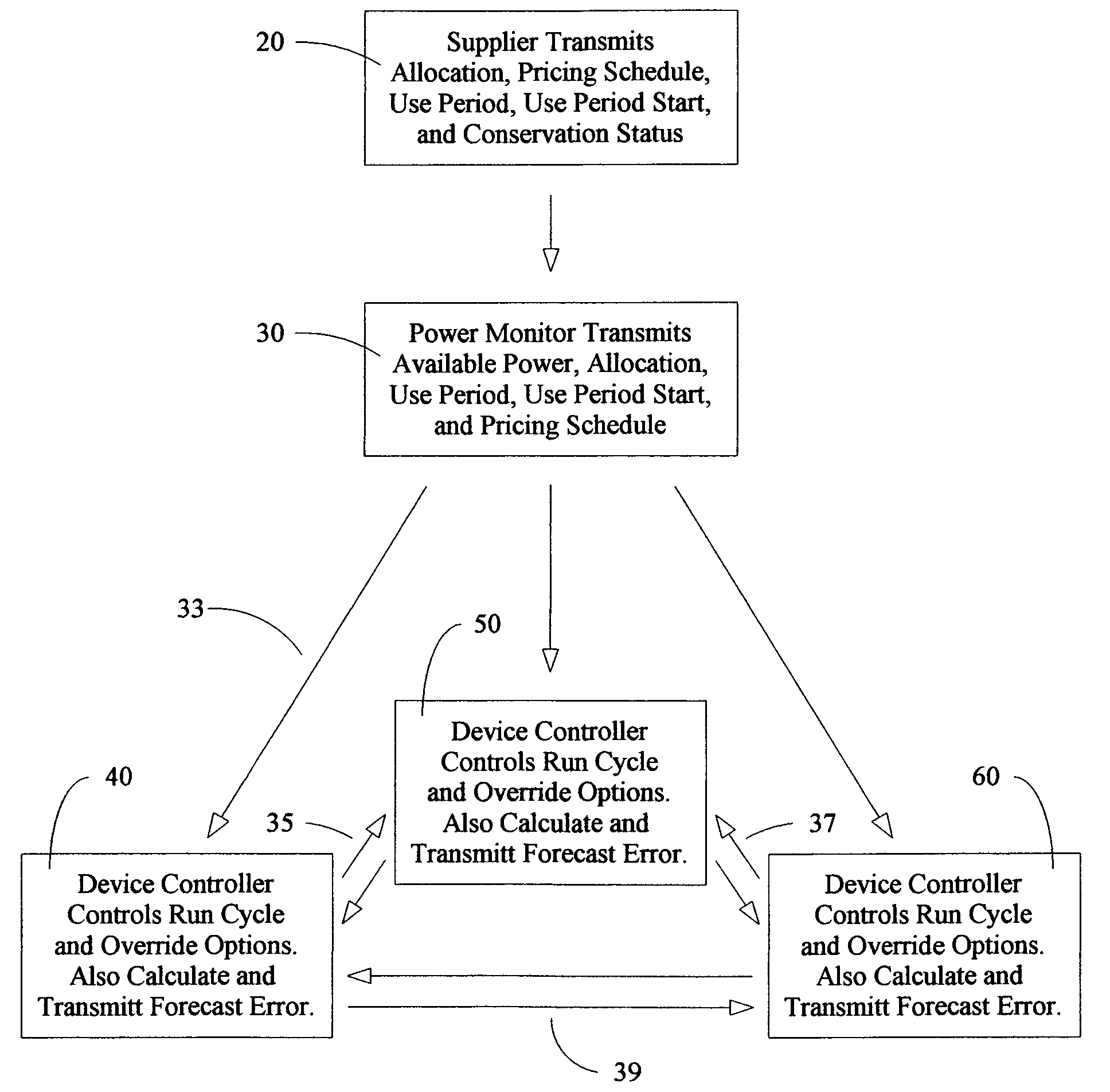

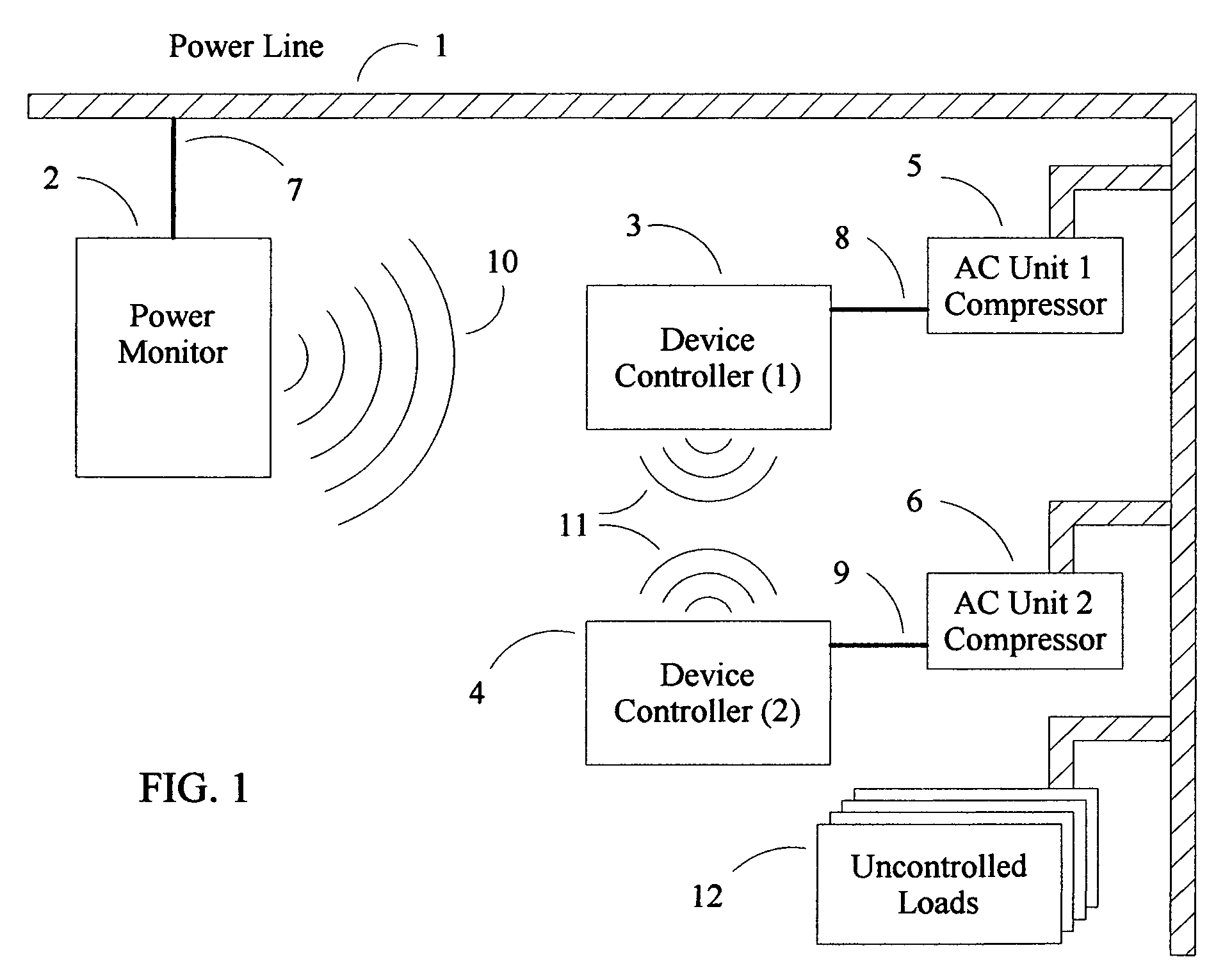

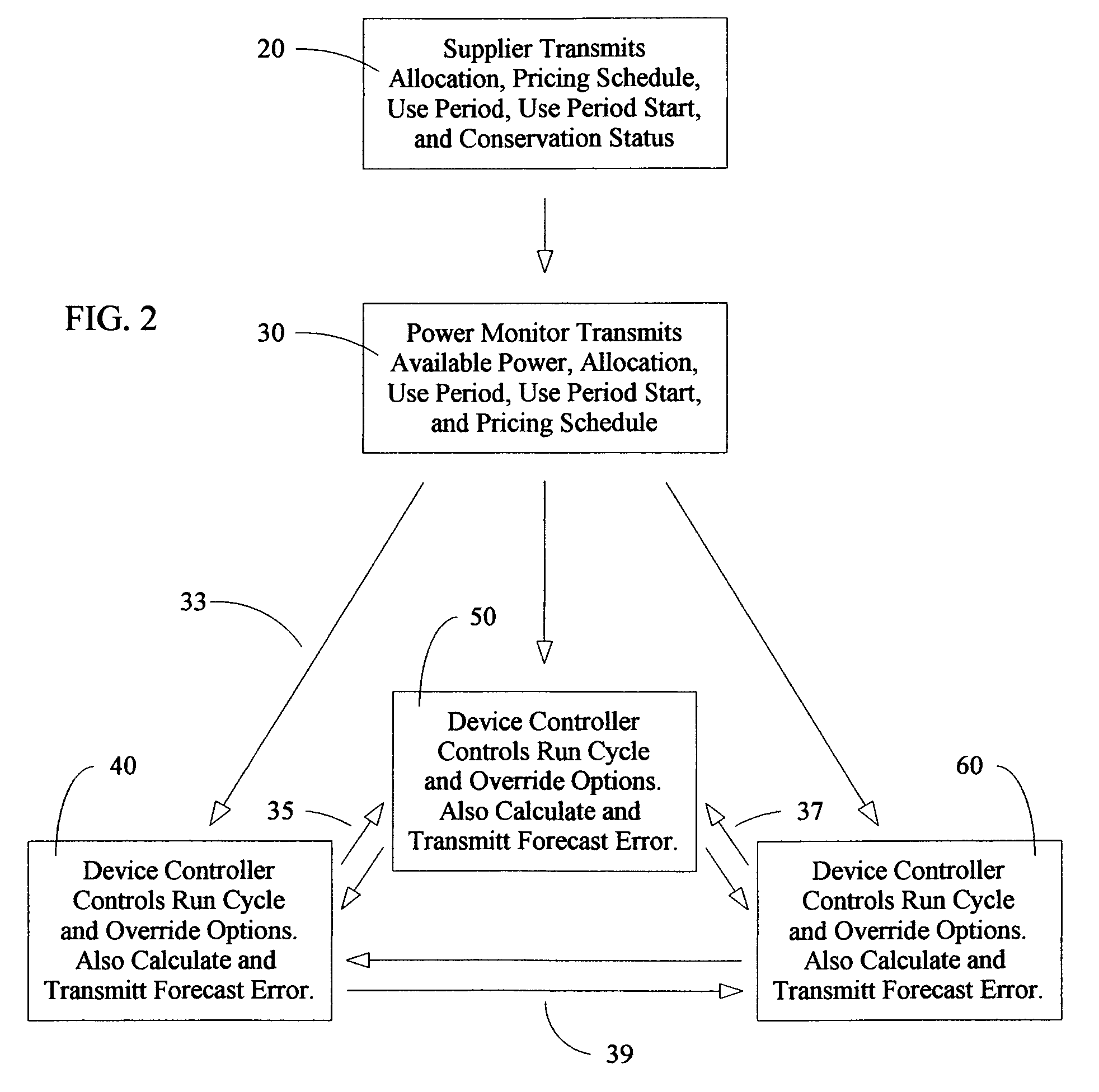

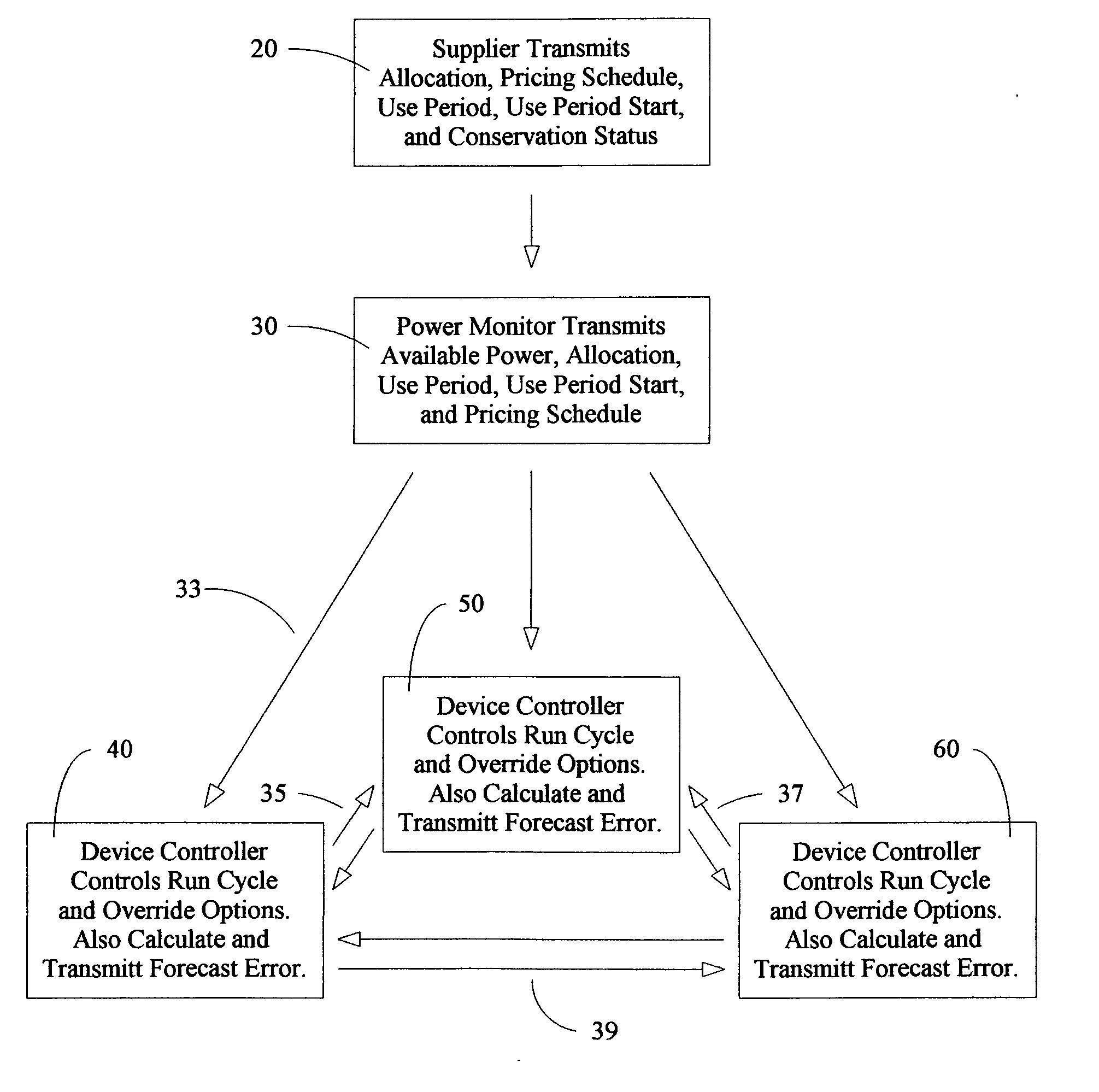

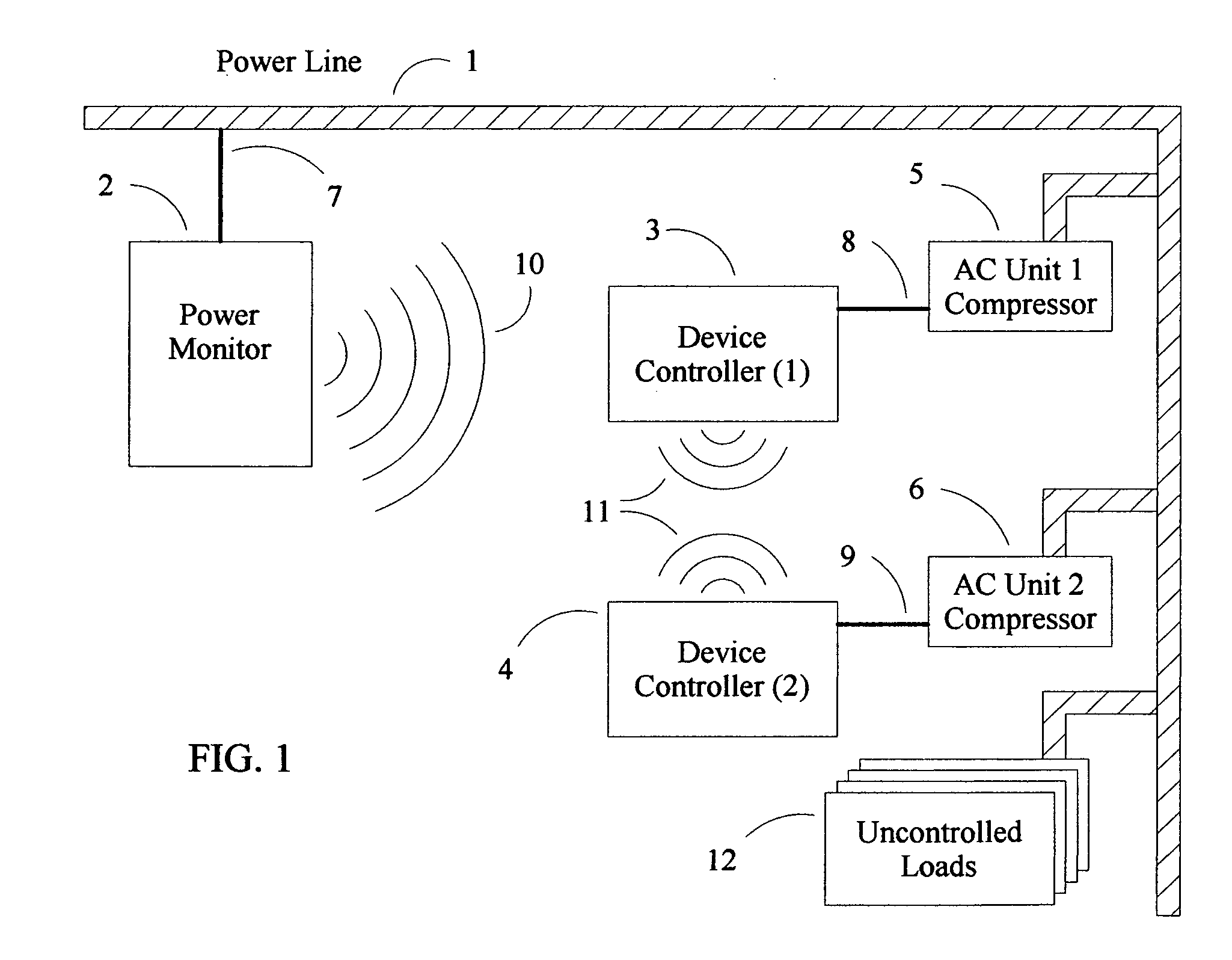

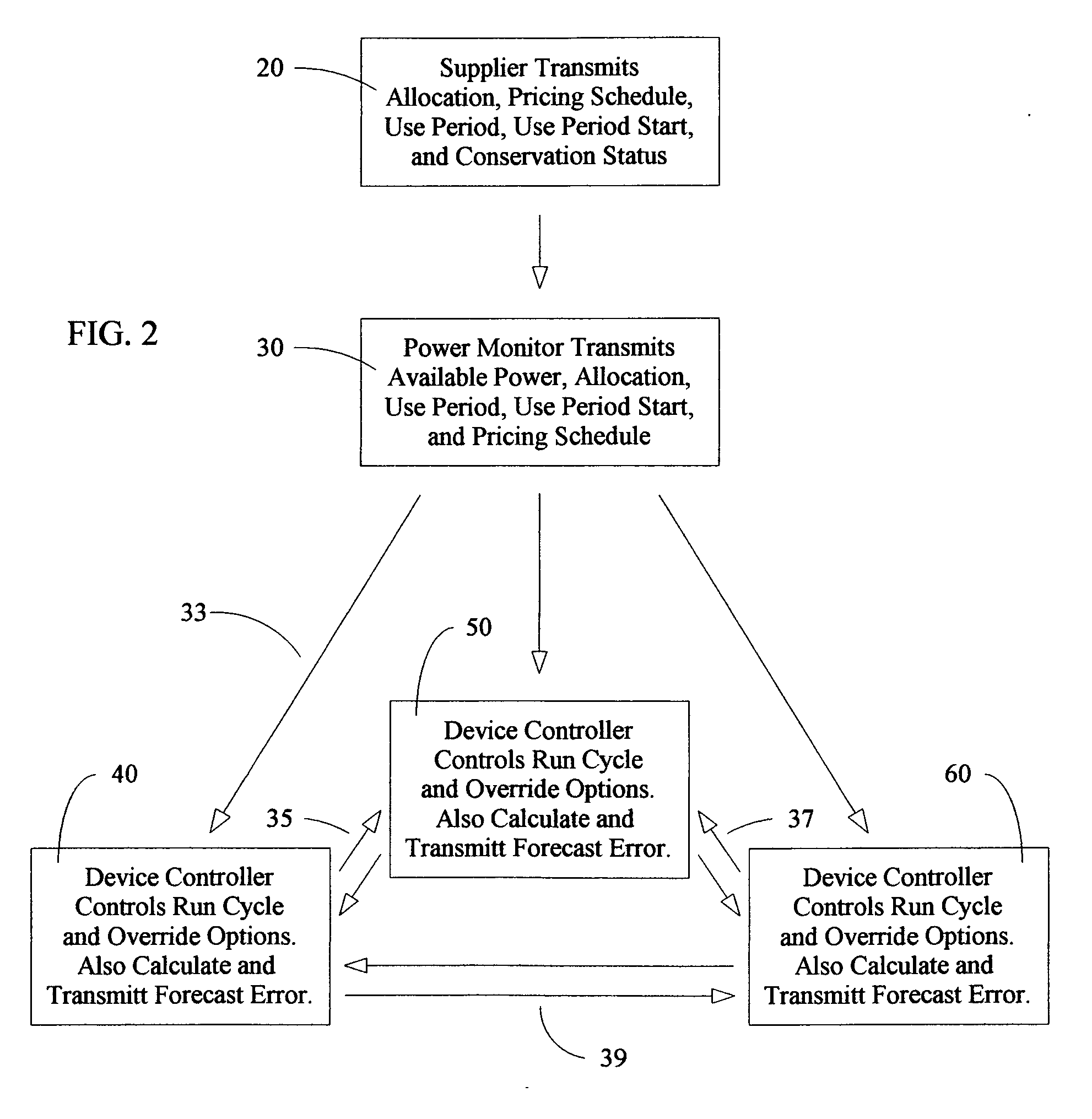

System and methods for maintaining power usage within a set allocation

InactiveUS7177728B2InhibitionReduce energy useMechanical power/torque controlLevel controlElectricityPower capability

An electric power management system includes a monitor for the total power usage of a facility that monitors a history of power consumption during a set time interval of a distribution system having at least one electric load. Predictions of available power are generated through out the time interval by comparing the history of power consumption to a set allocation. Available power predictions are transmitted to the at least one electric load. The at least one load control receives the power capability predictions and controls the energy usage of the at least one electric load such that the total energy usage of the facility does not exceed the set allocation.

Owner:JAY WARREN GARDNER

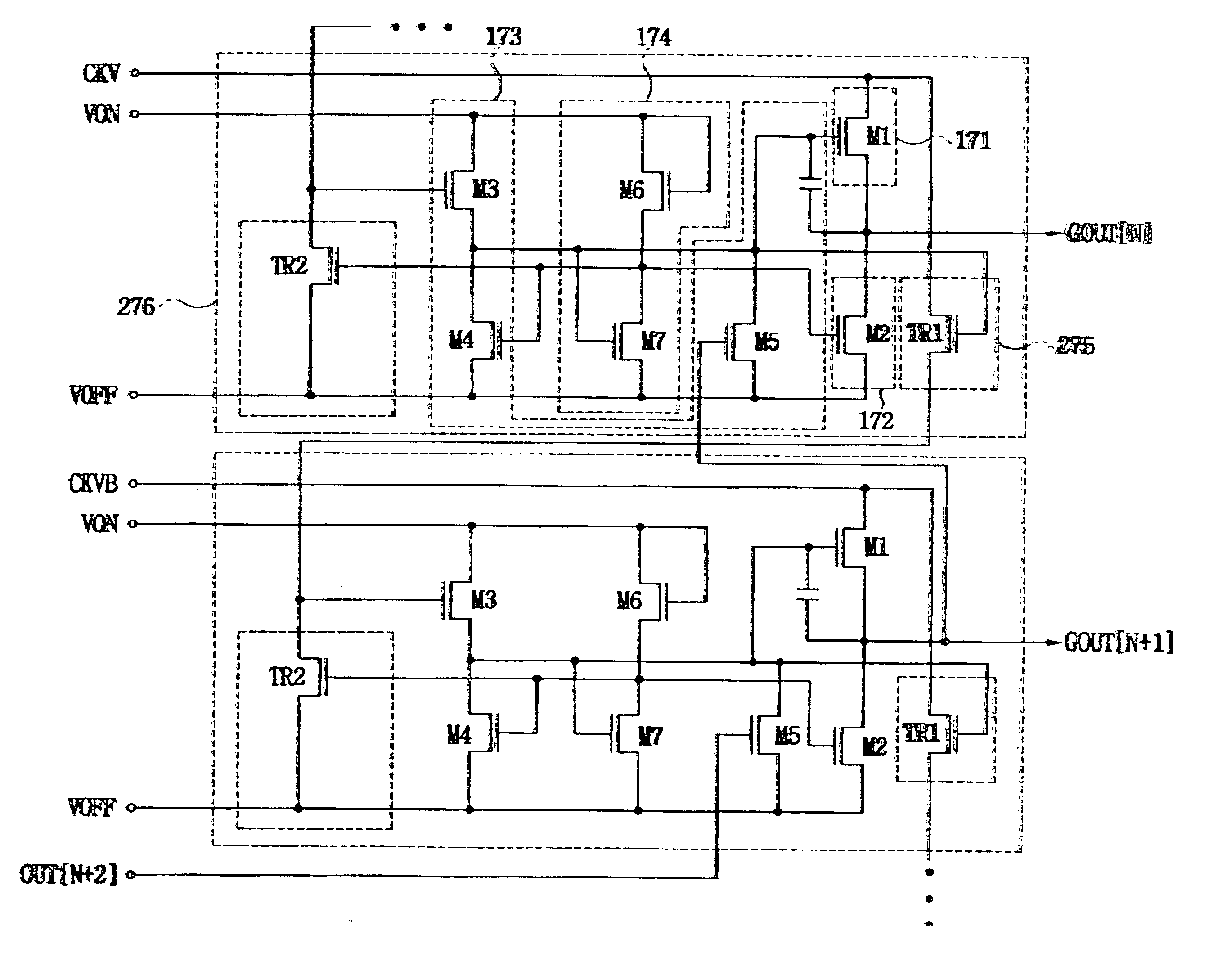

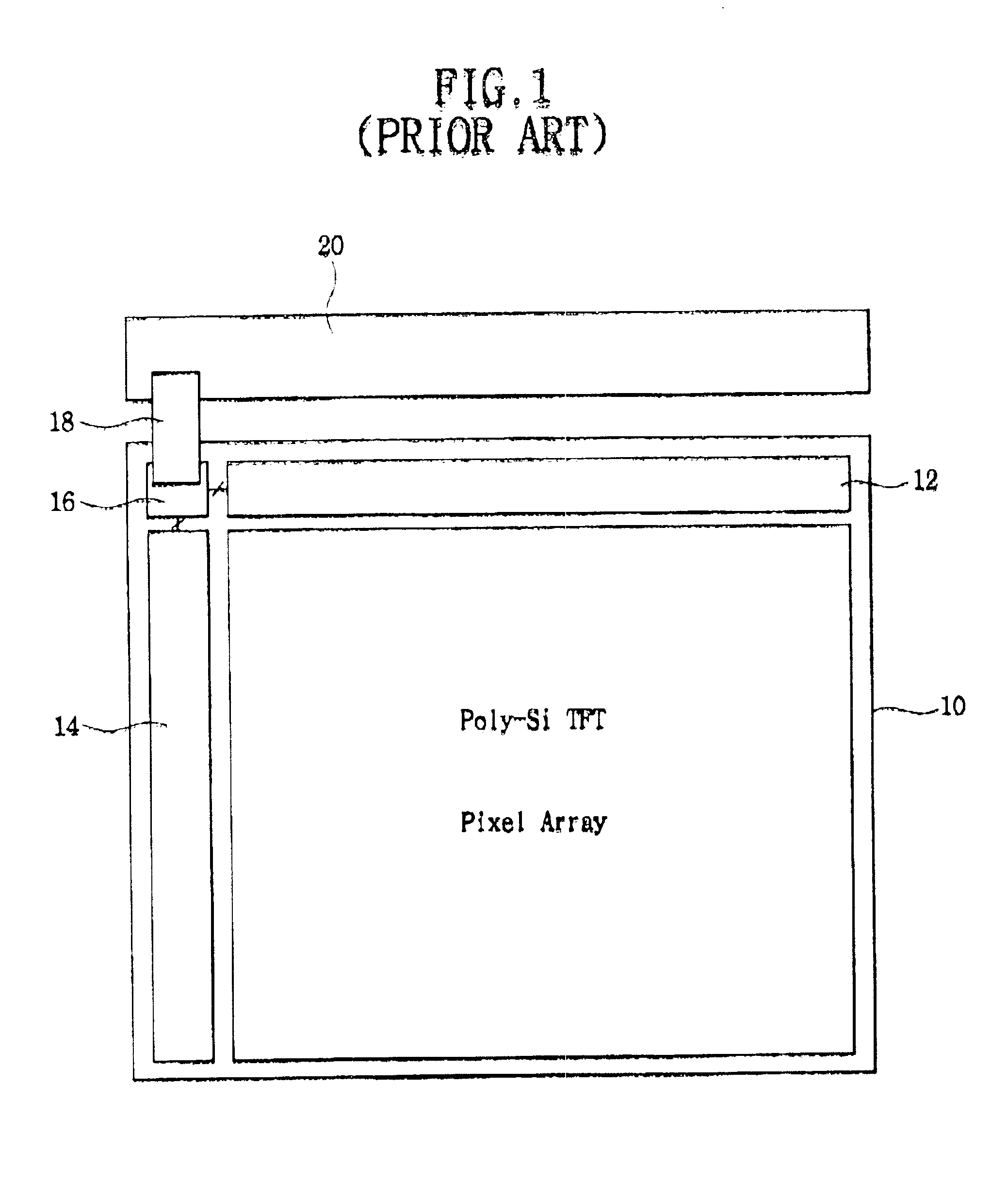

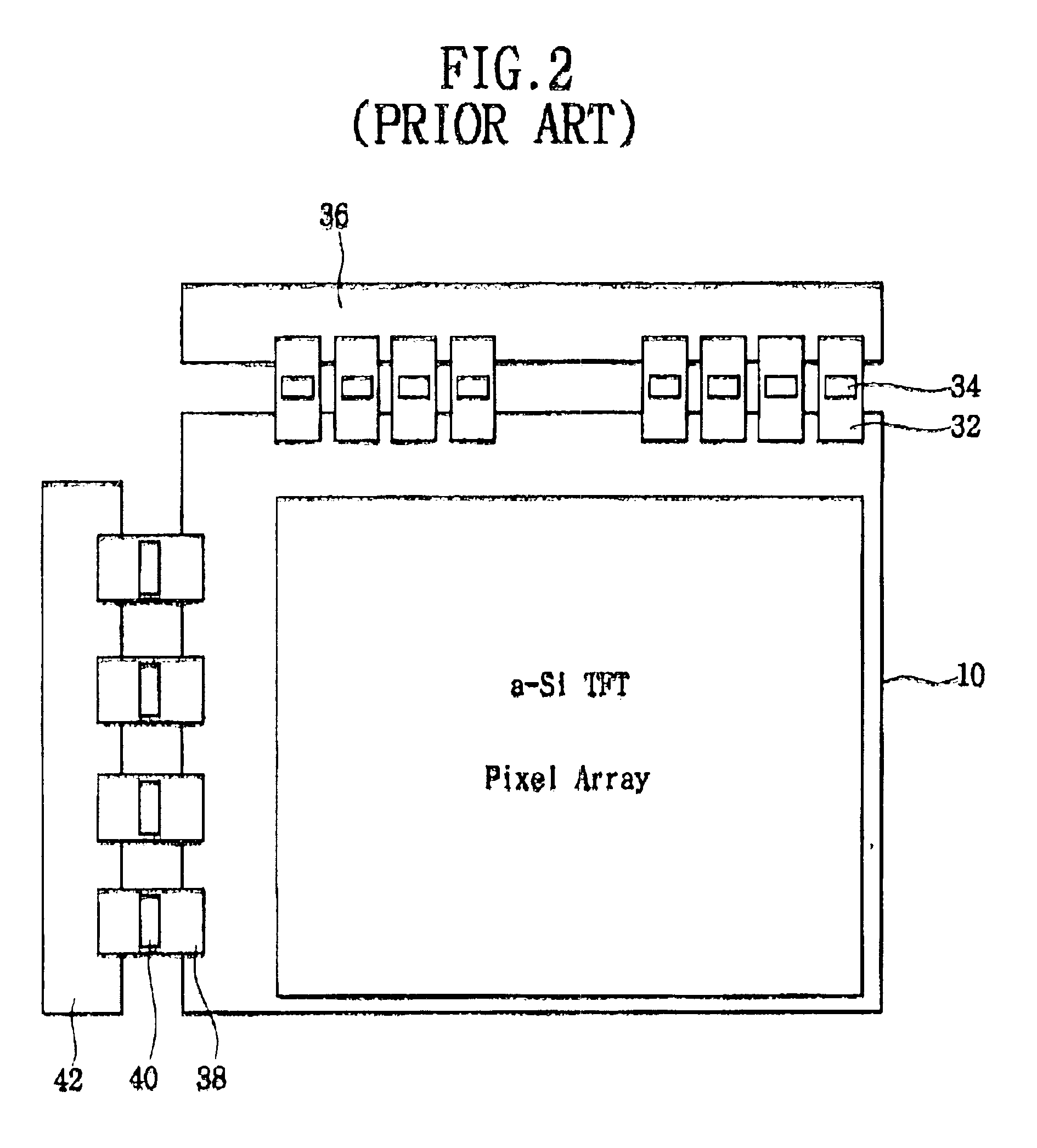

Method of driving a shift register, a shift register, a liquid crystal display device having the shift register

InactiveUS6845140B2InhibitionQuality improvementStatic indicating devicesDigital storageShift registerLiquid-crystal display

In a shift register and LCD device having the shift register that may be employed in the liquid crystal display device having a large screen size and a large resolution, the shift register includes stages cascade-connected with each other and each of the stages have a carry buffer for generating a carry signal. The pull-down transistor of each of the stages of the shift register is divided into a first pull-down transistor and a second pull-down transistor. A power voltage Vona larger than the power voltage Von applied to a clock generator is applied to the shift register. A signal delay due to the RC delay of the gate lines may be minimized, the shift register is independent of the variation of the threshold voltage of the TFTs, and image display quality may not be deteriorated.

Owner:SAMSUNG DISPLAY CO LTD

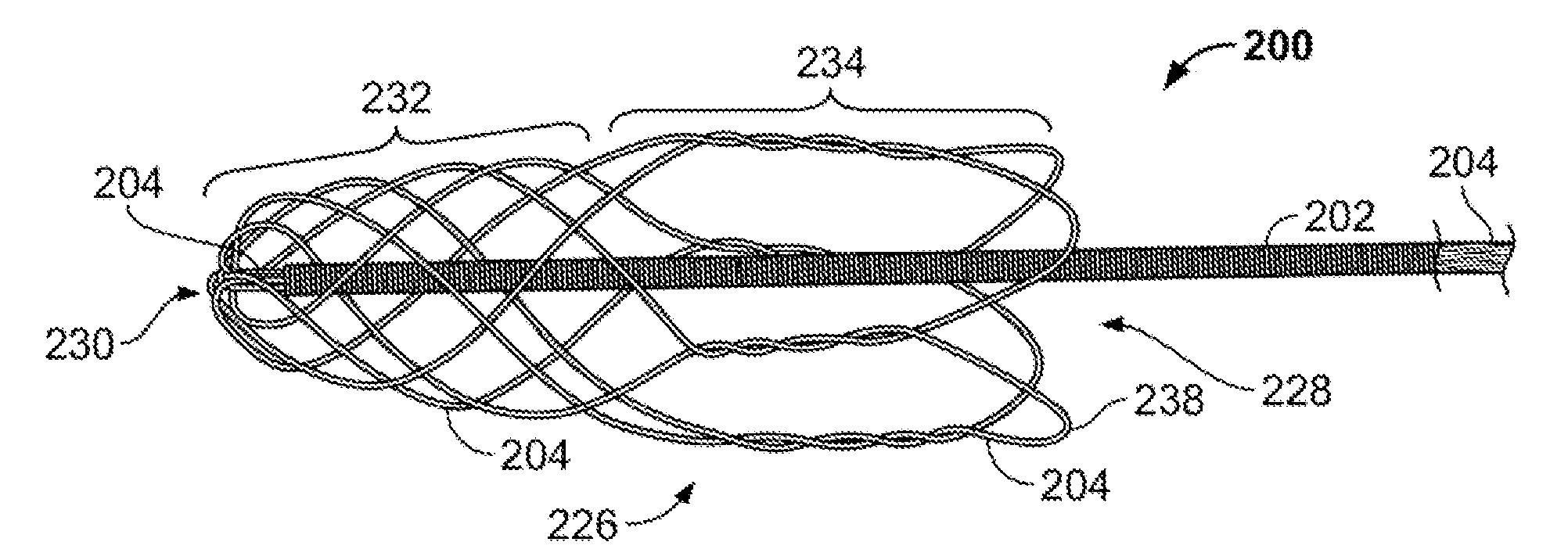

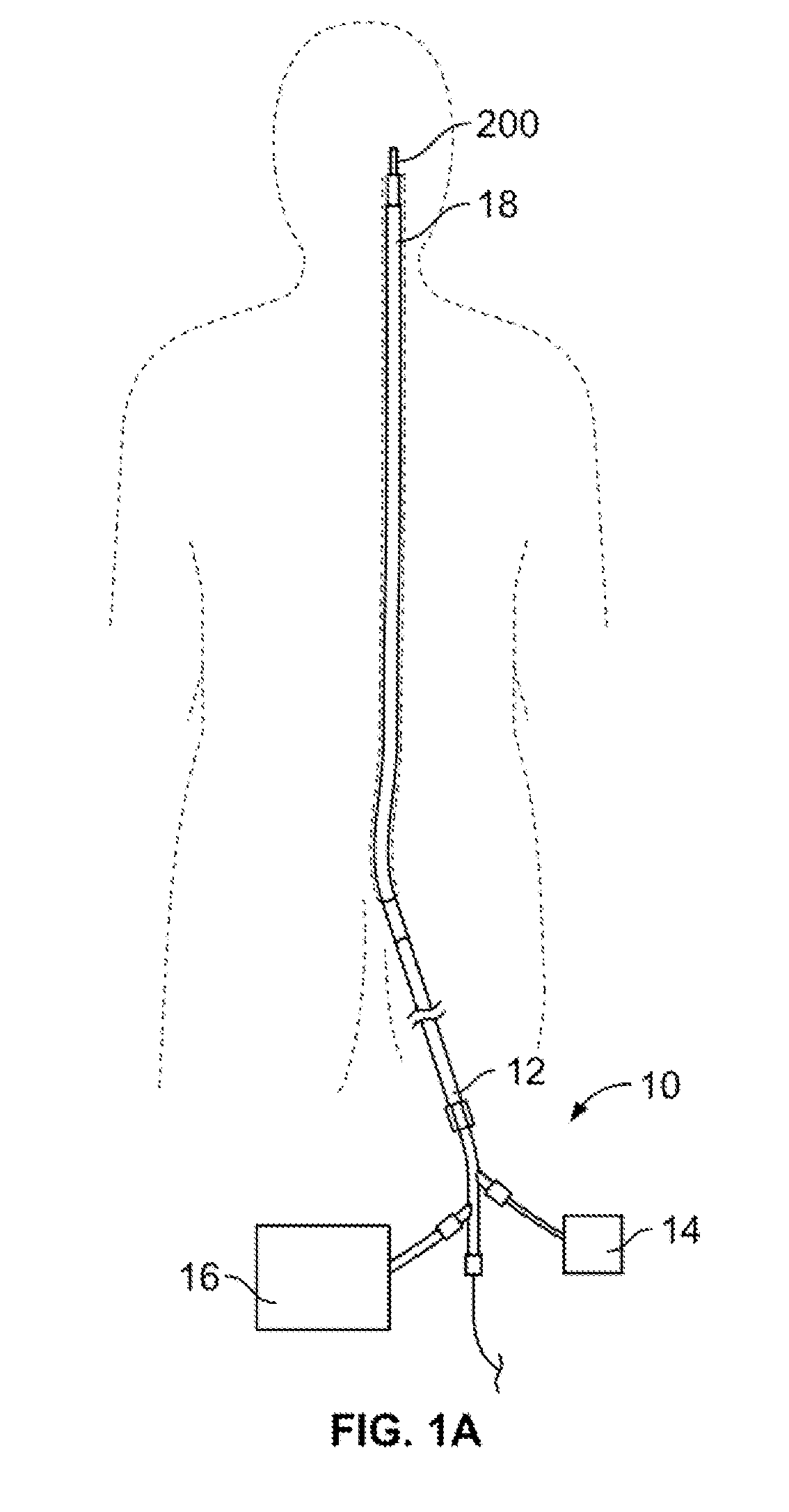

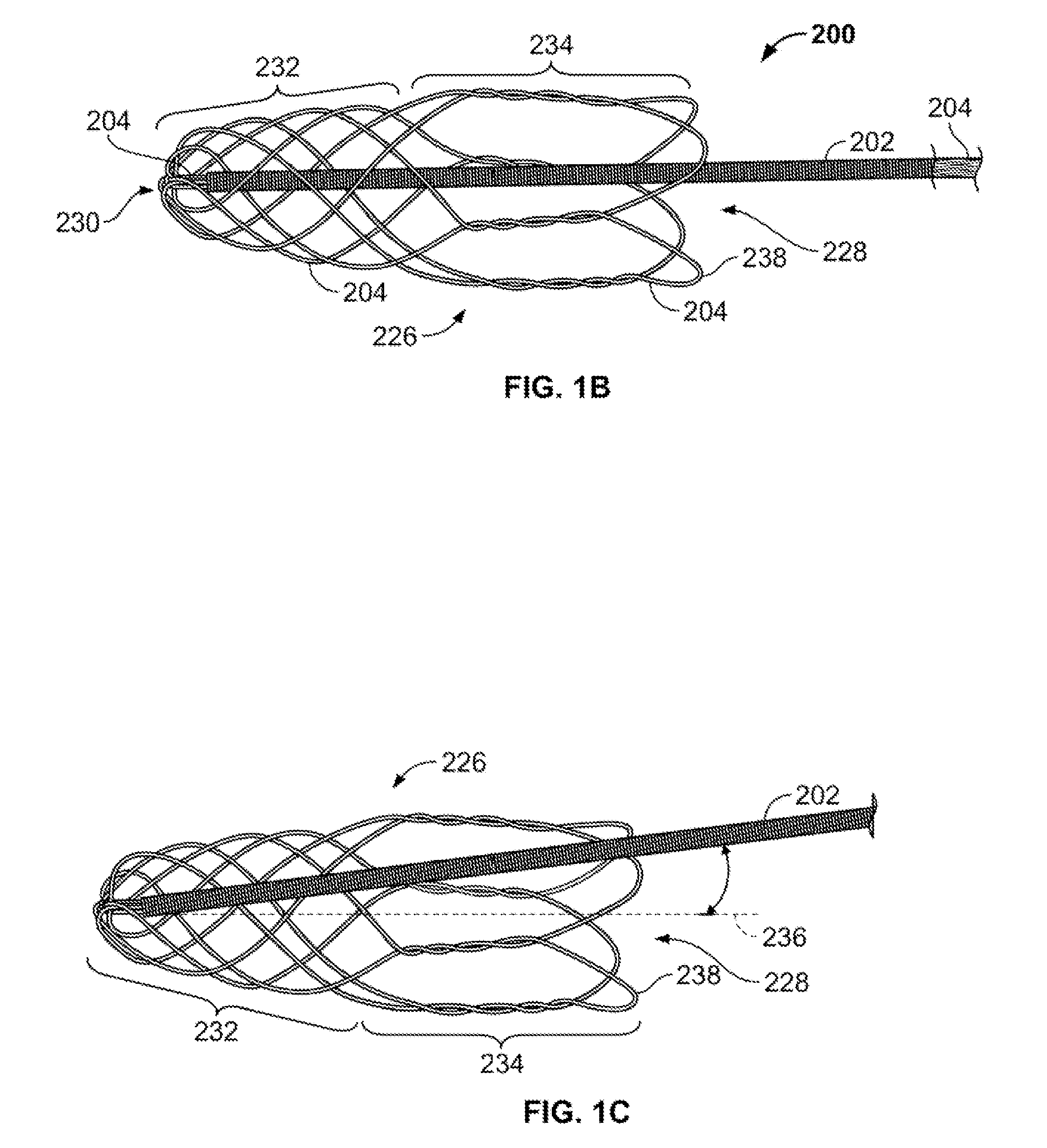

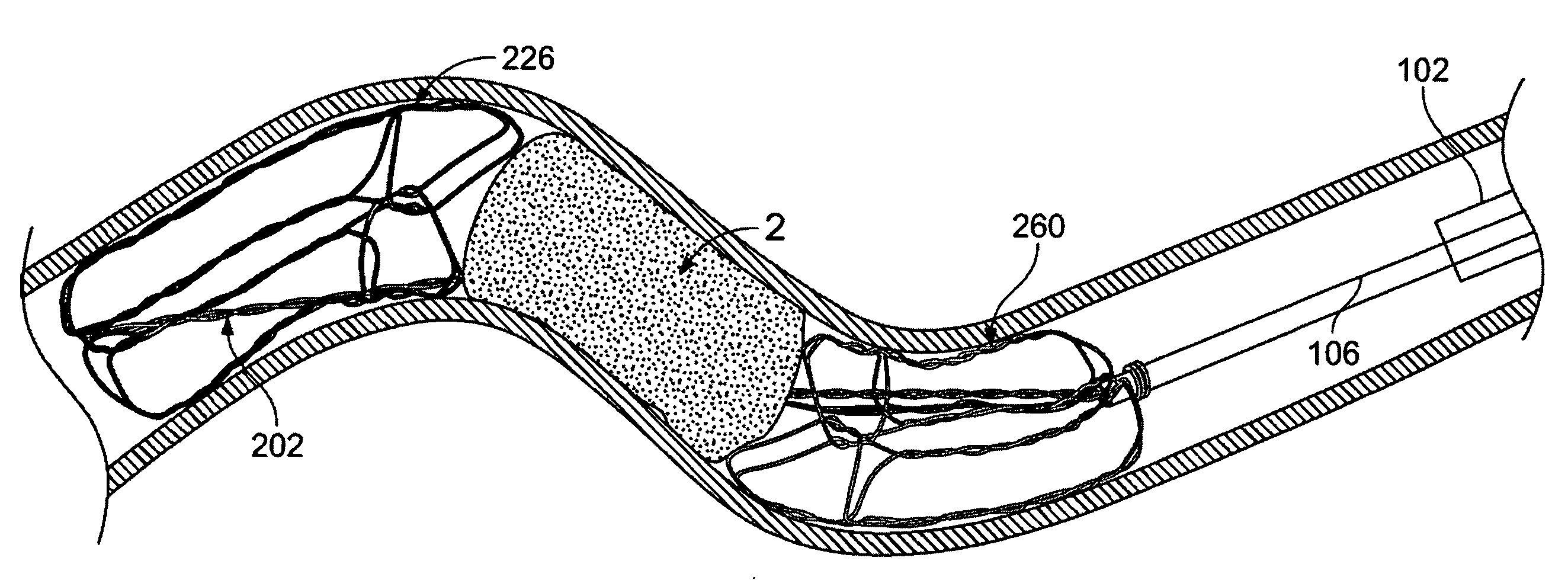

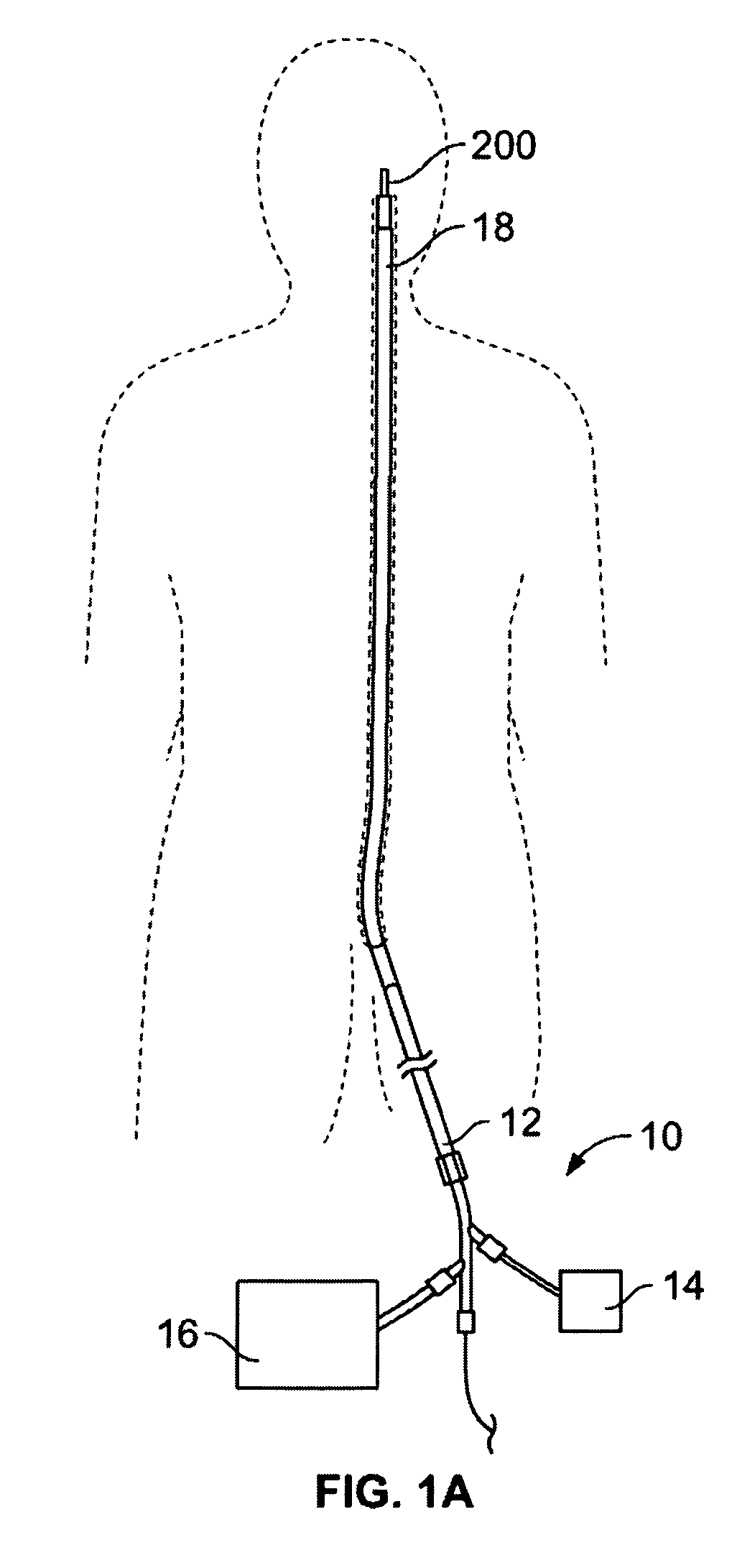

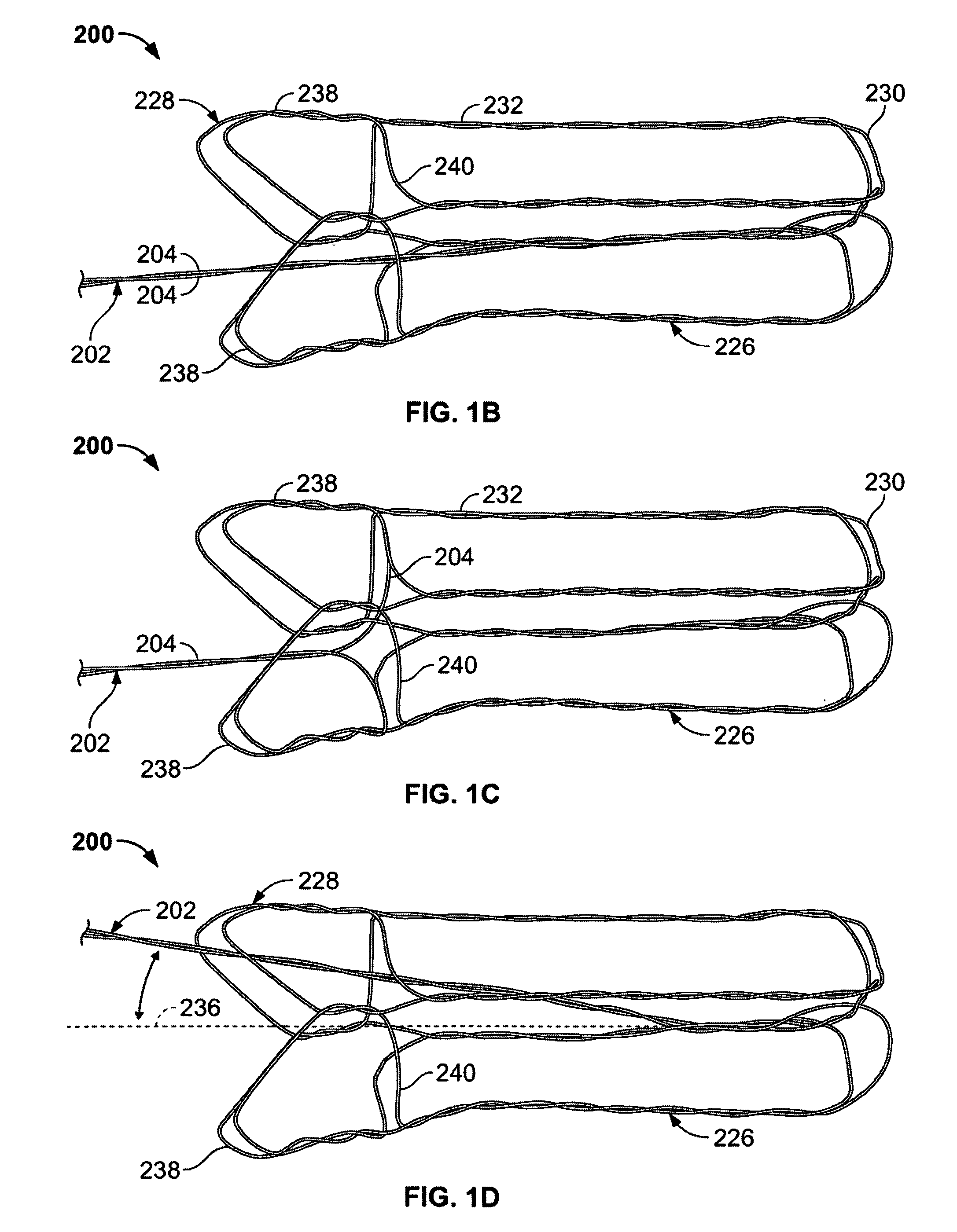

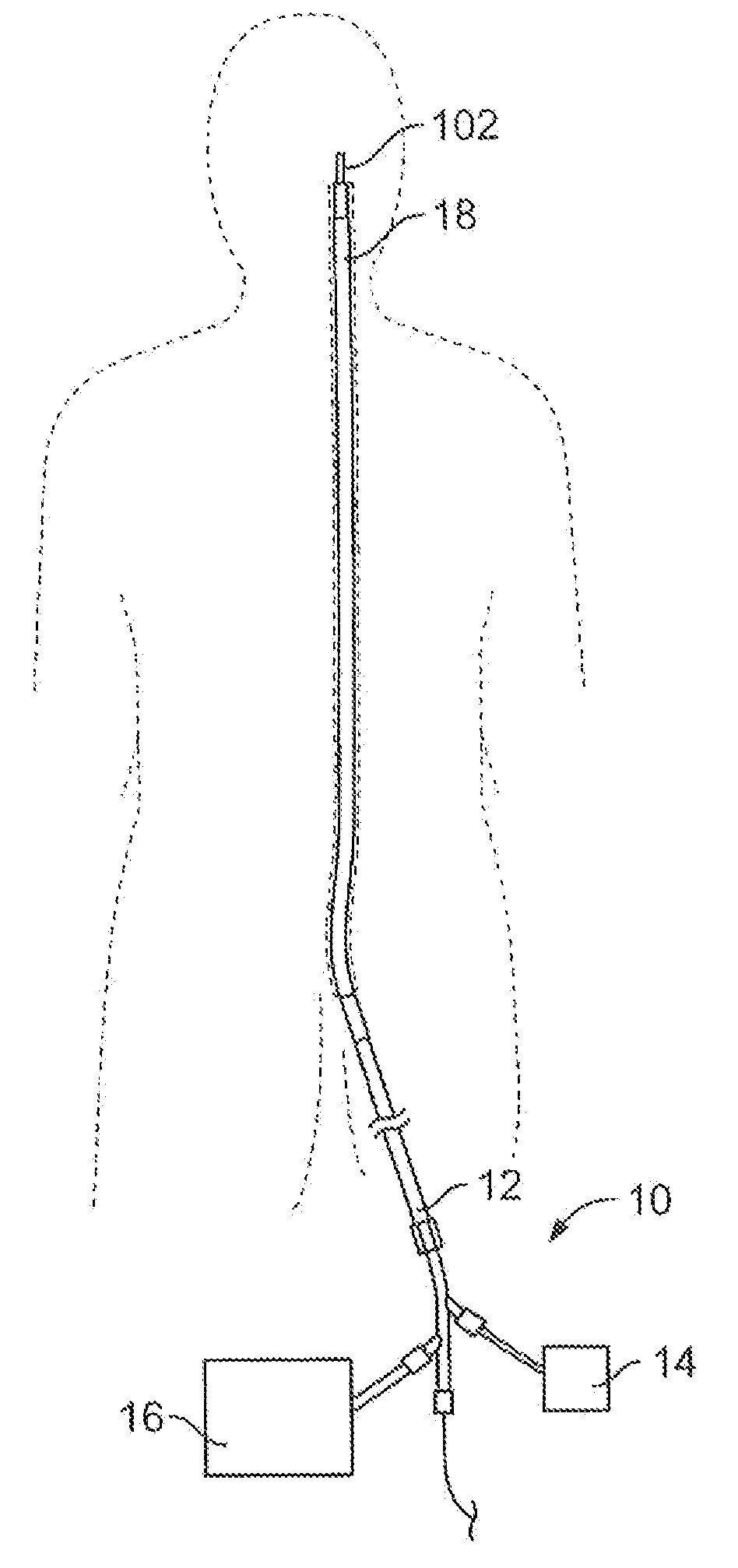

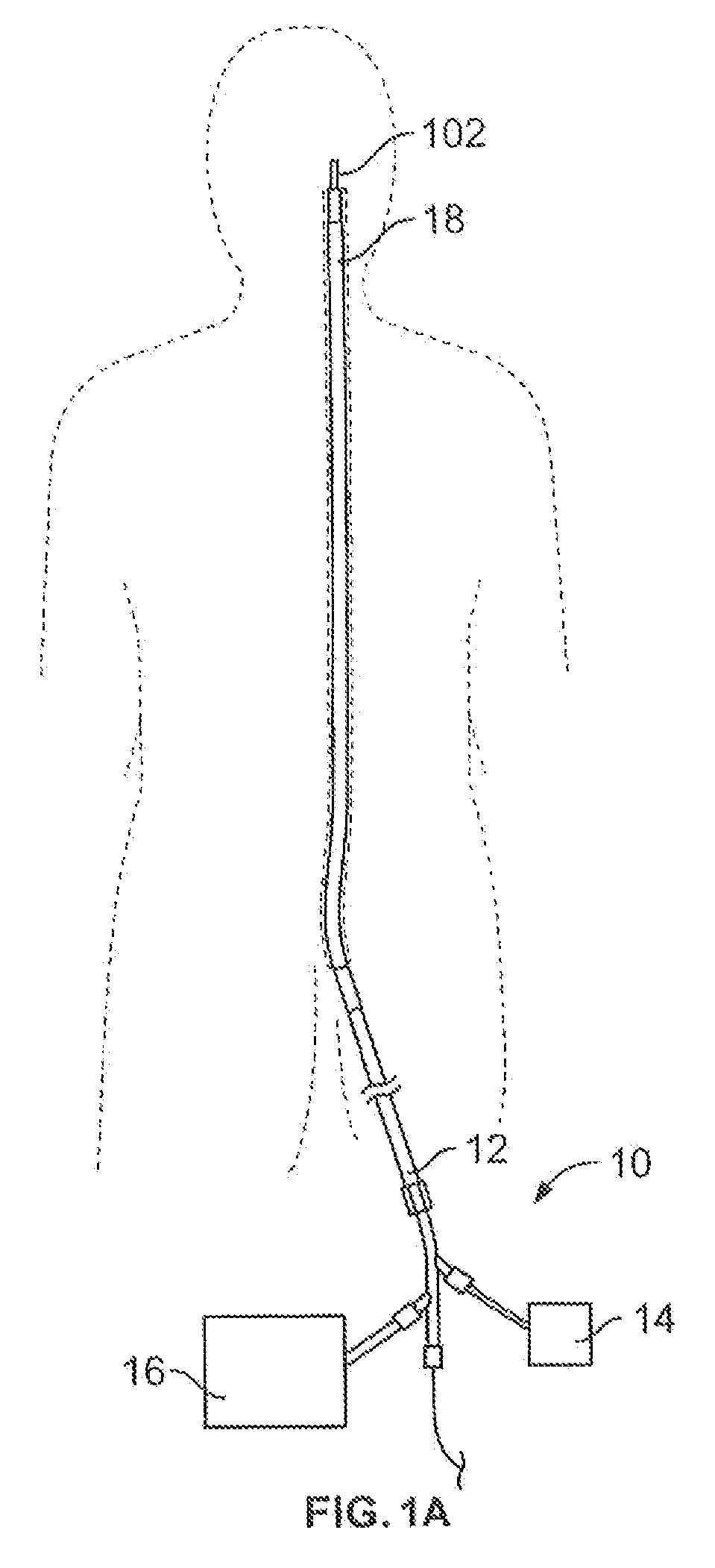

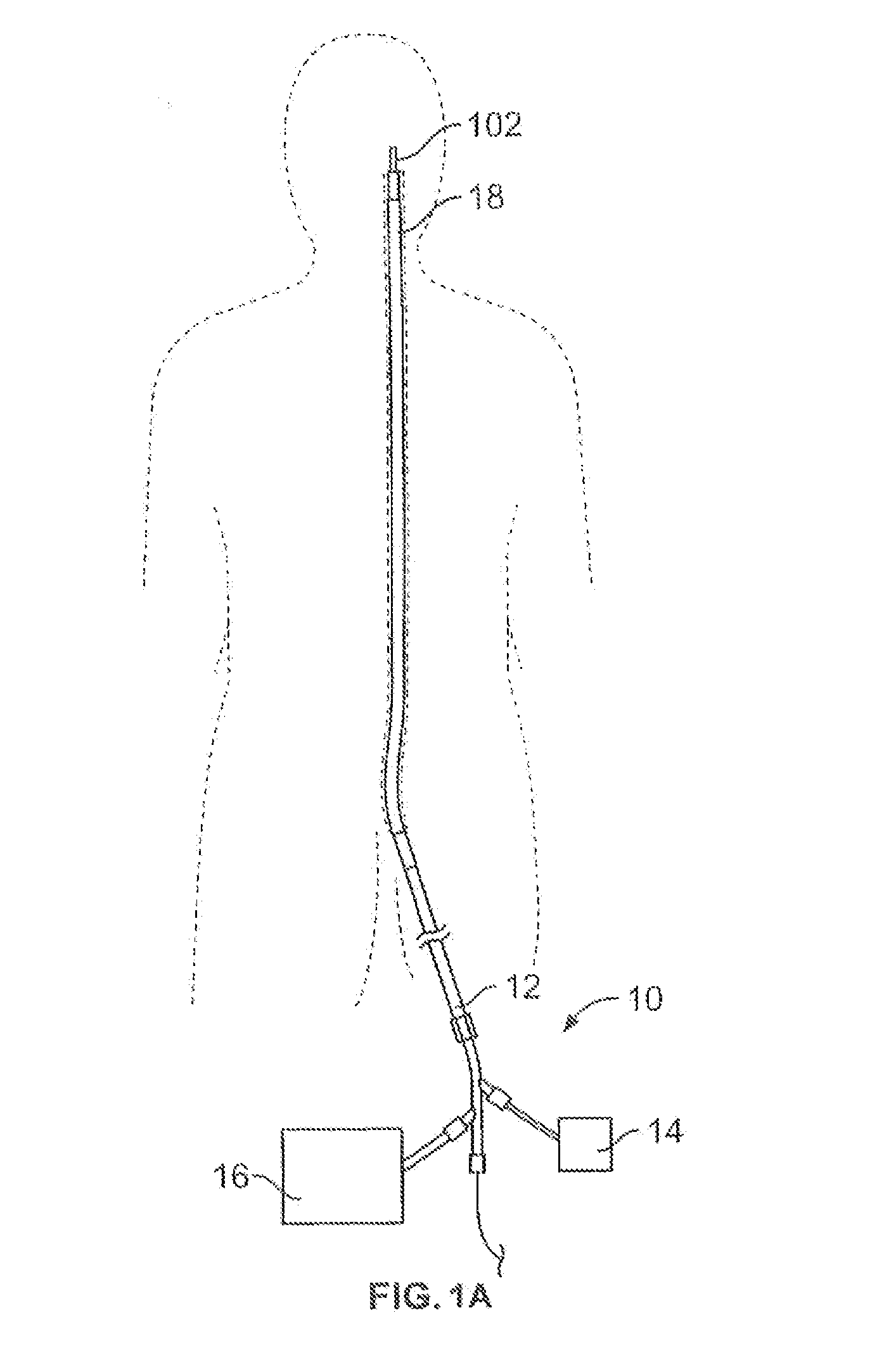

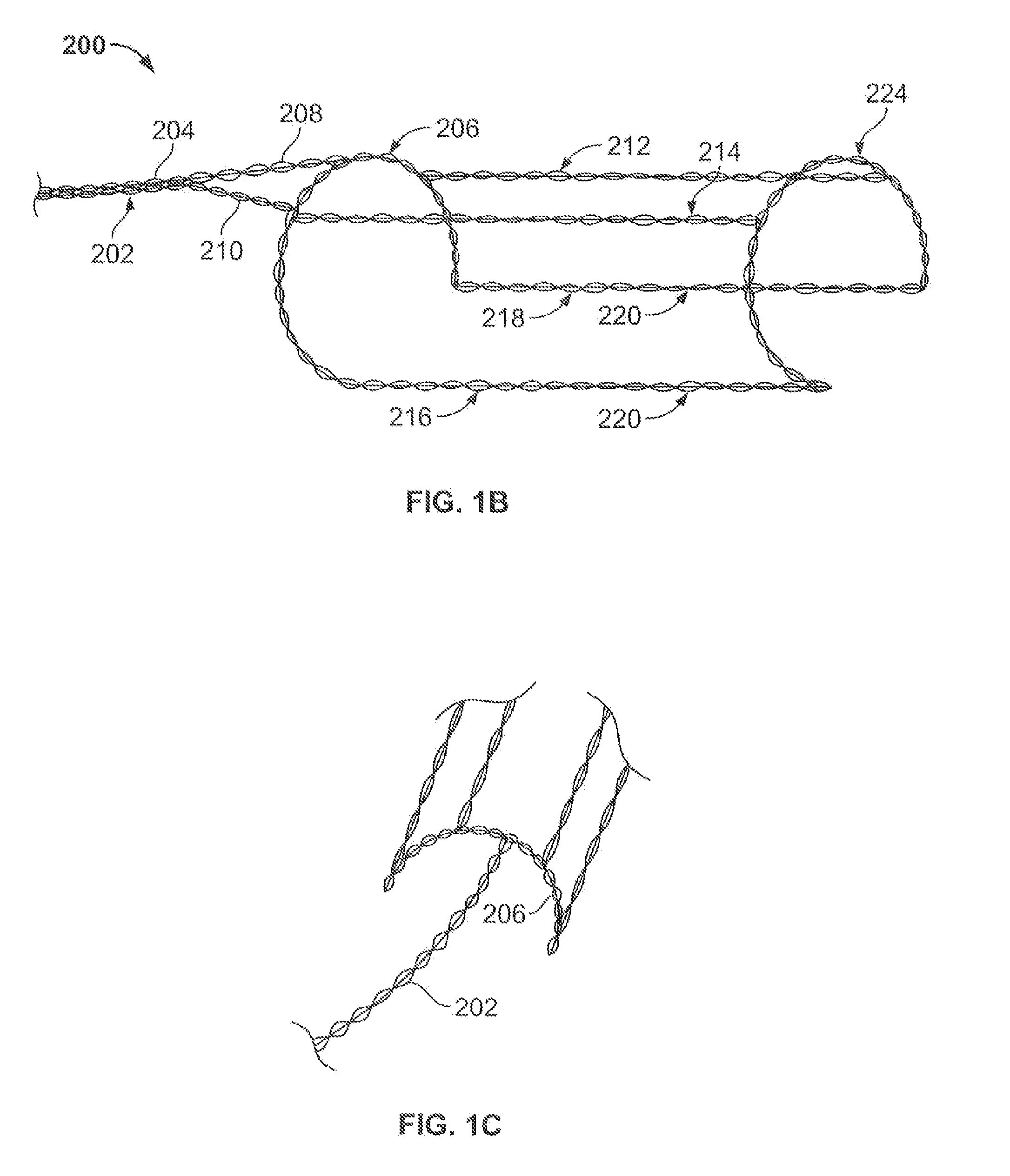

Retrieval systems and methods for use thereof

InactiveUS20090299393A1Increase abilityImproves strength and flexibilityCannulasDilatorsBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

Method for forming insulation film

InactiveUS20070004204A1Reduce trafficDecrease in flow volumeSolid-state devicesSemiconductor/solid-state device manufacturingProduct gasPlasma reaction

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

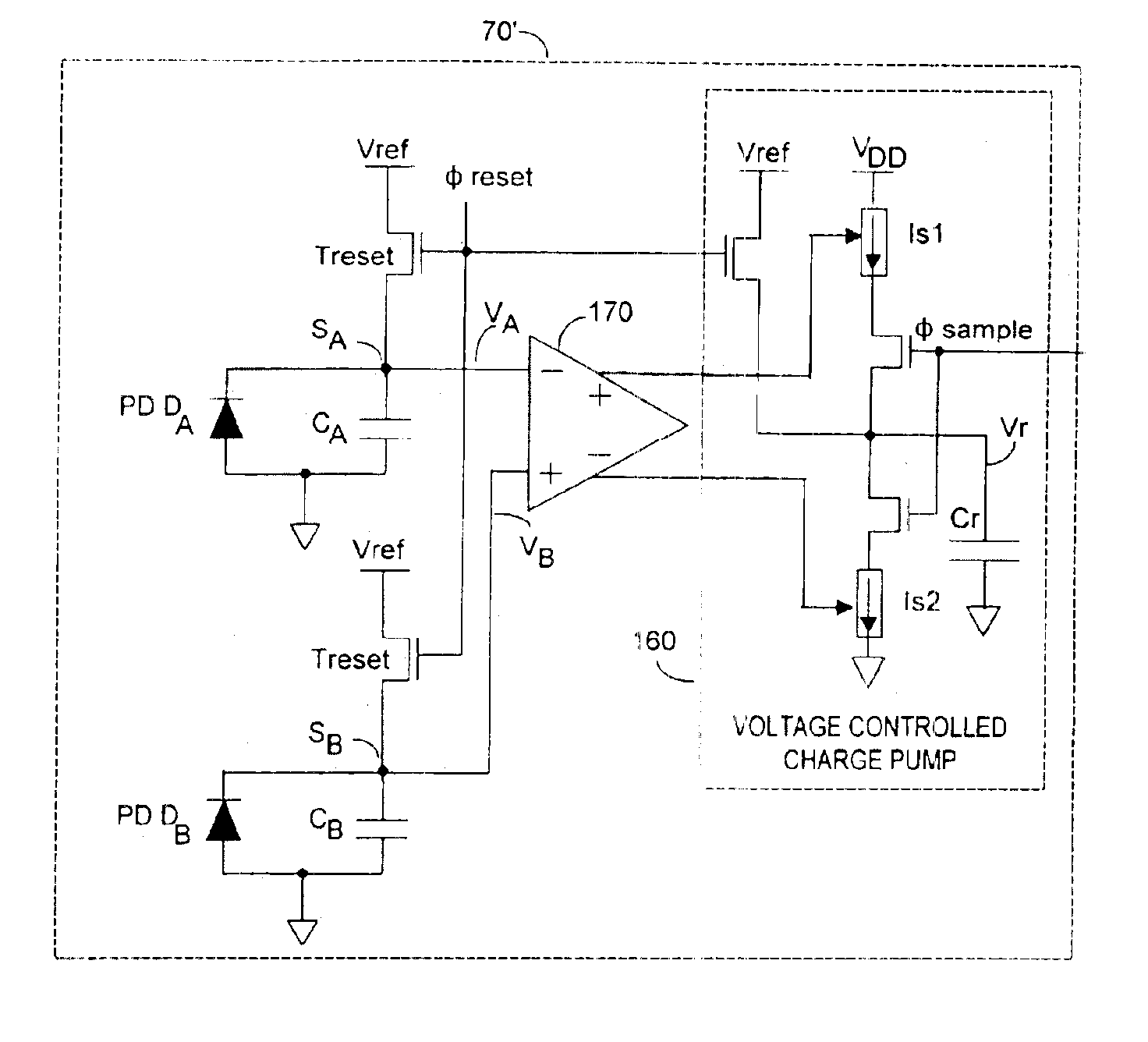

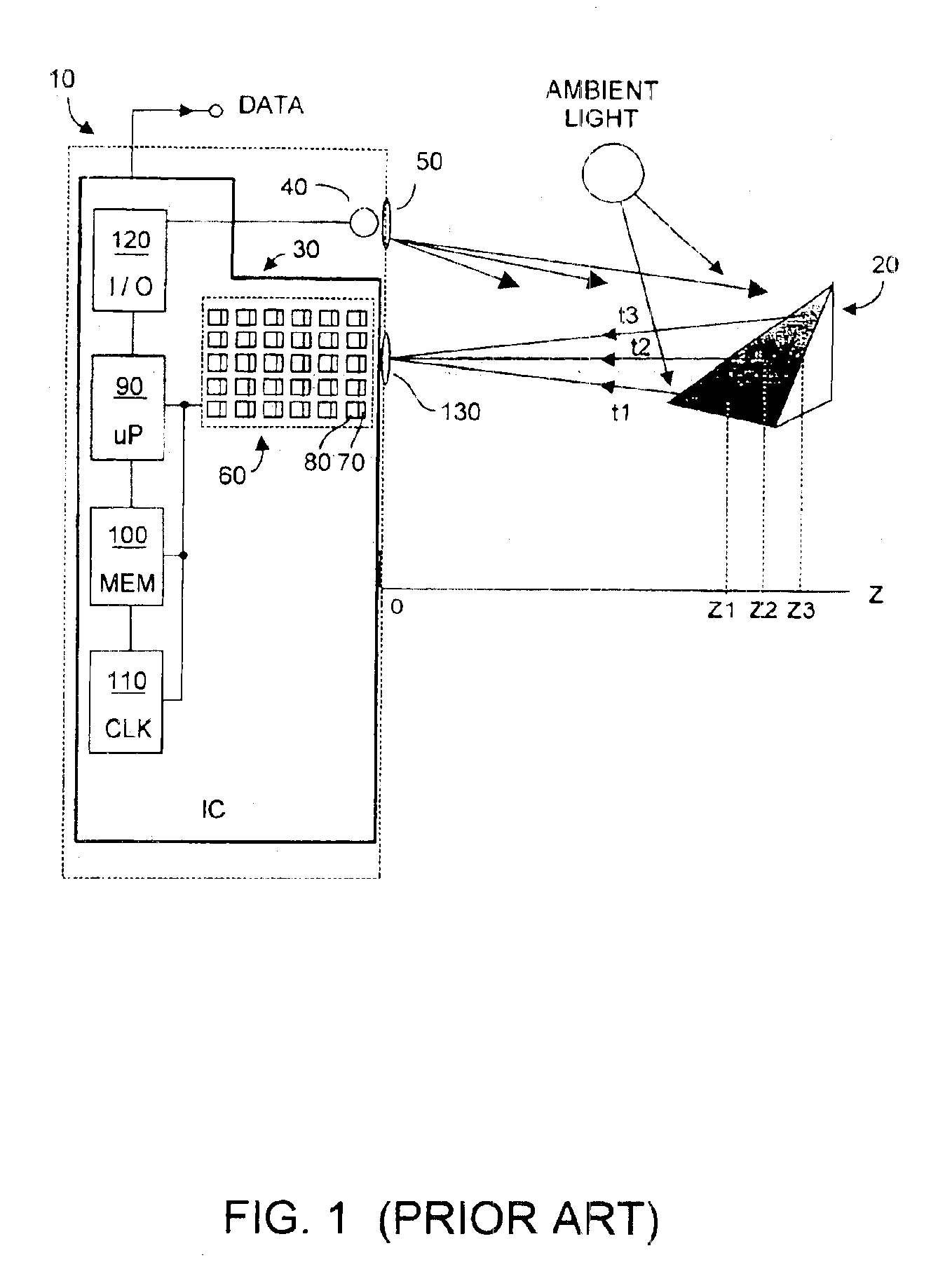

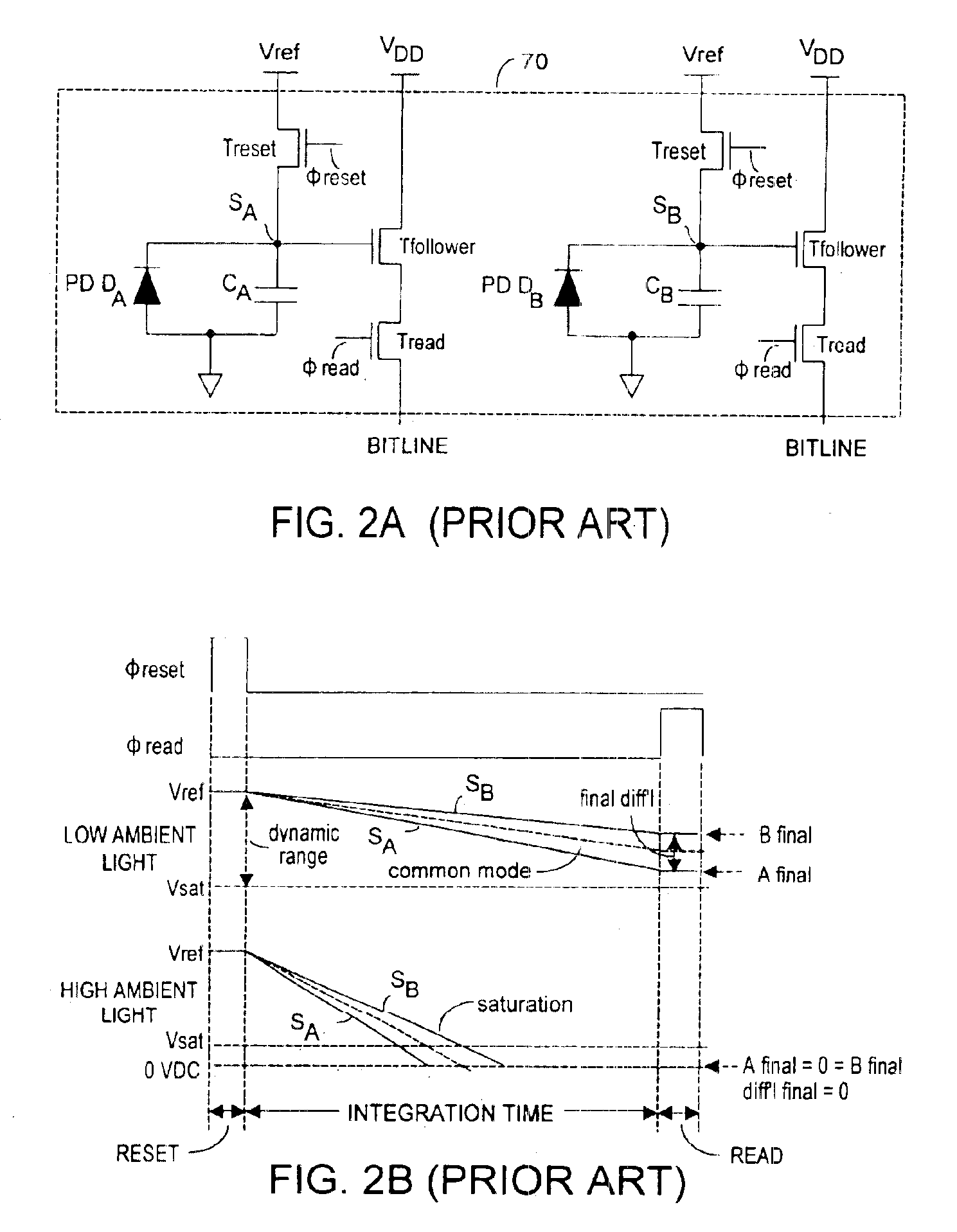

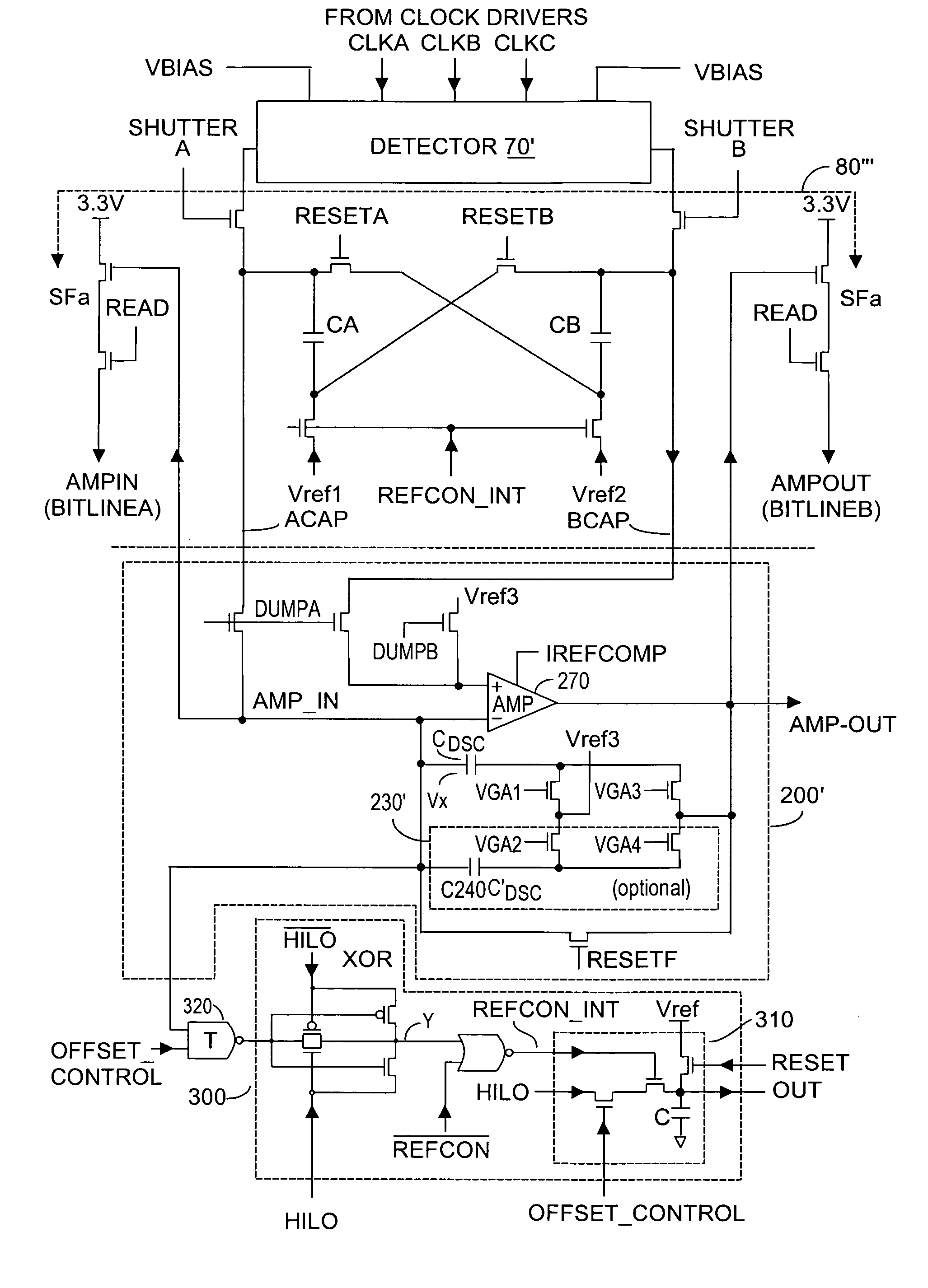

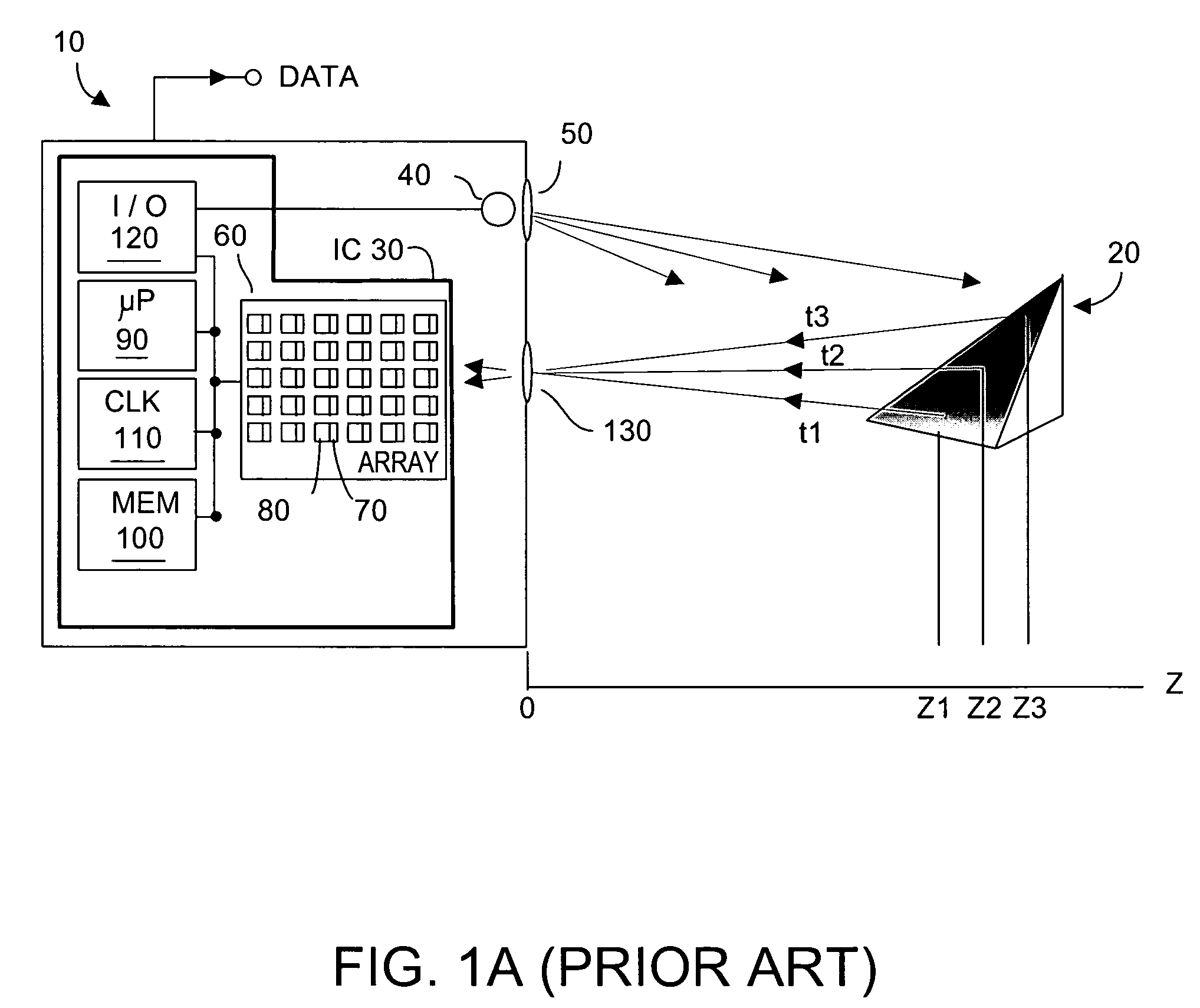

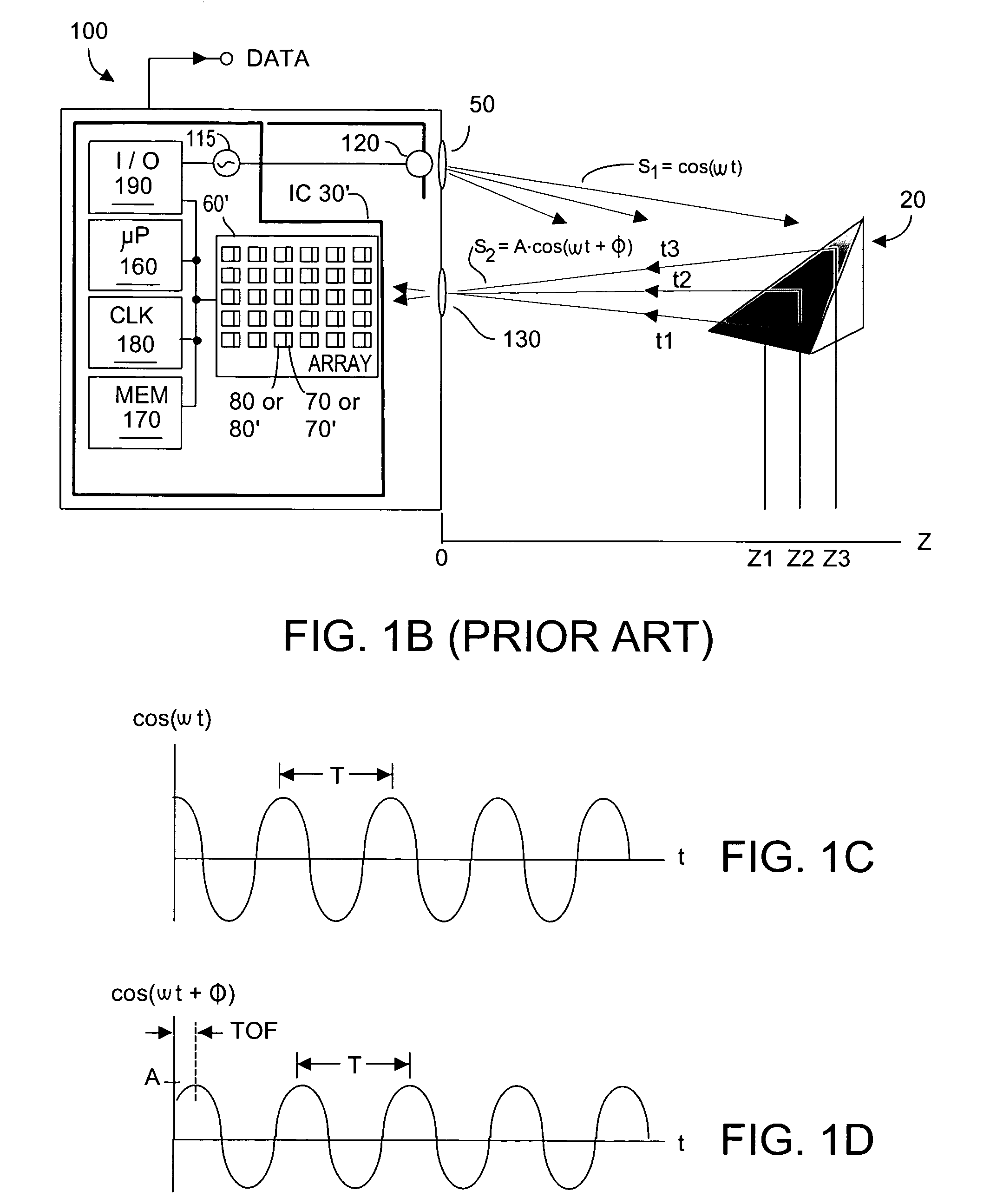

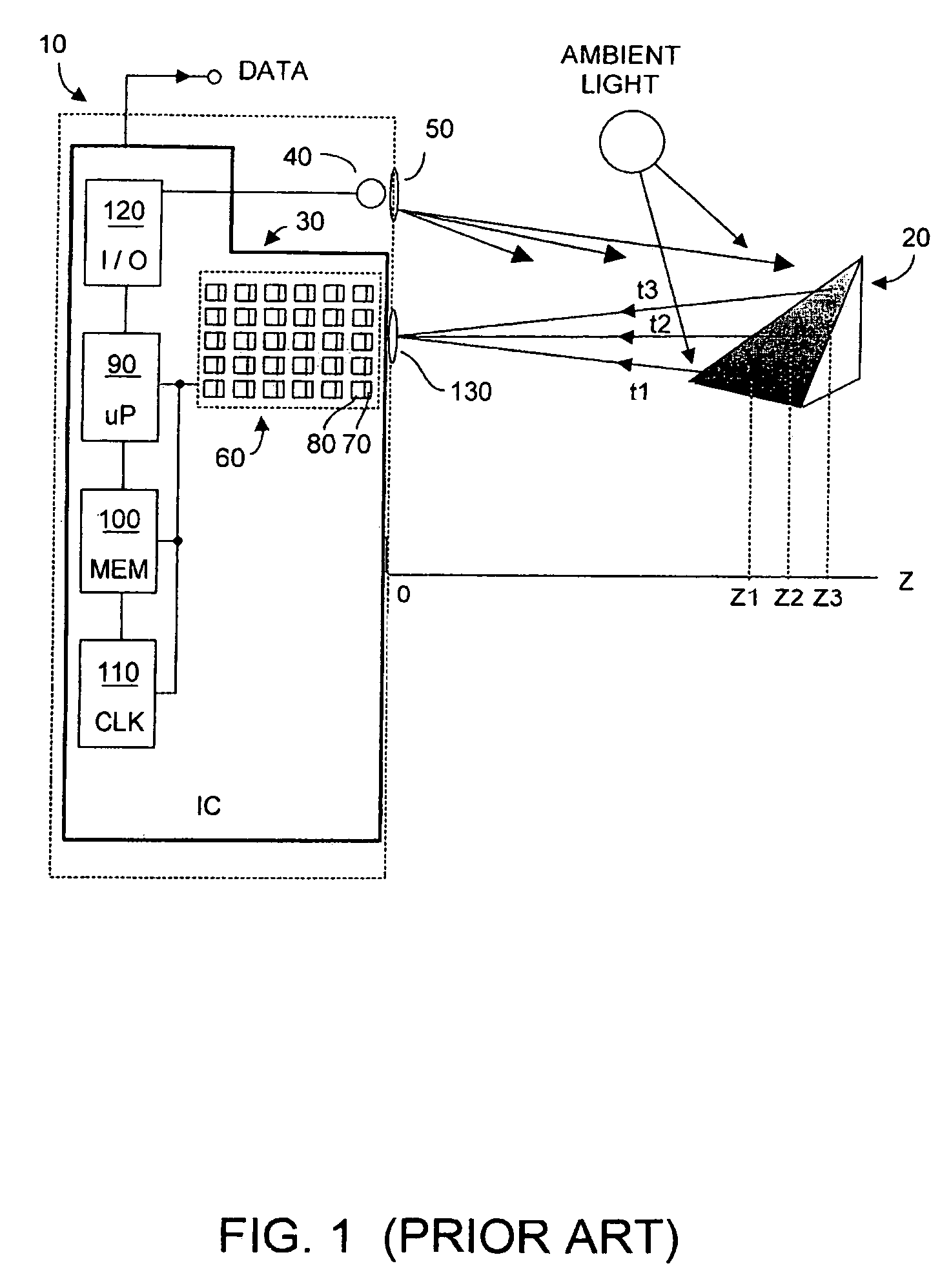

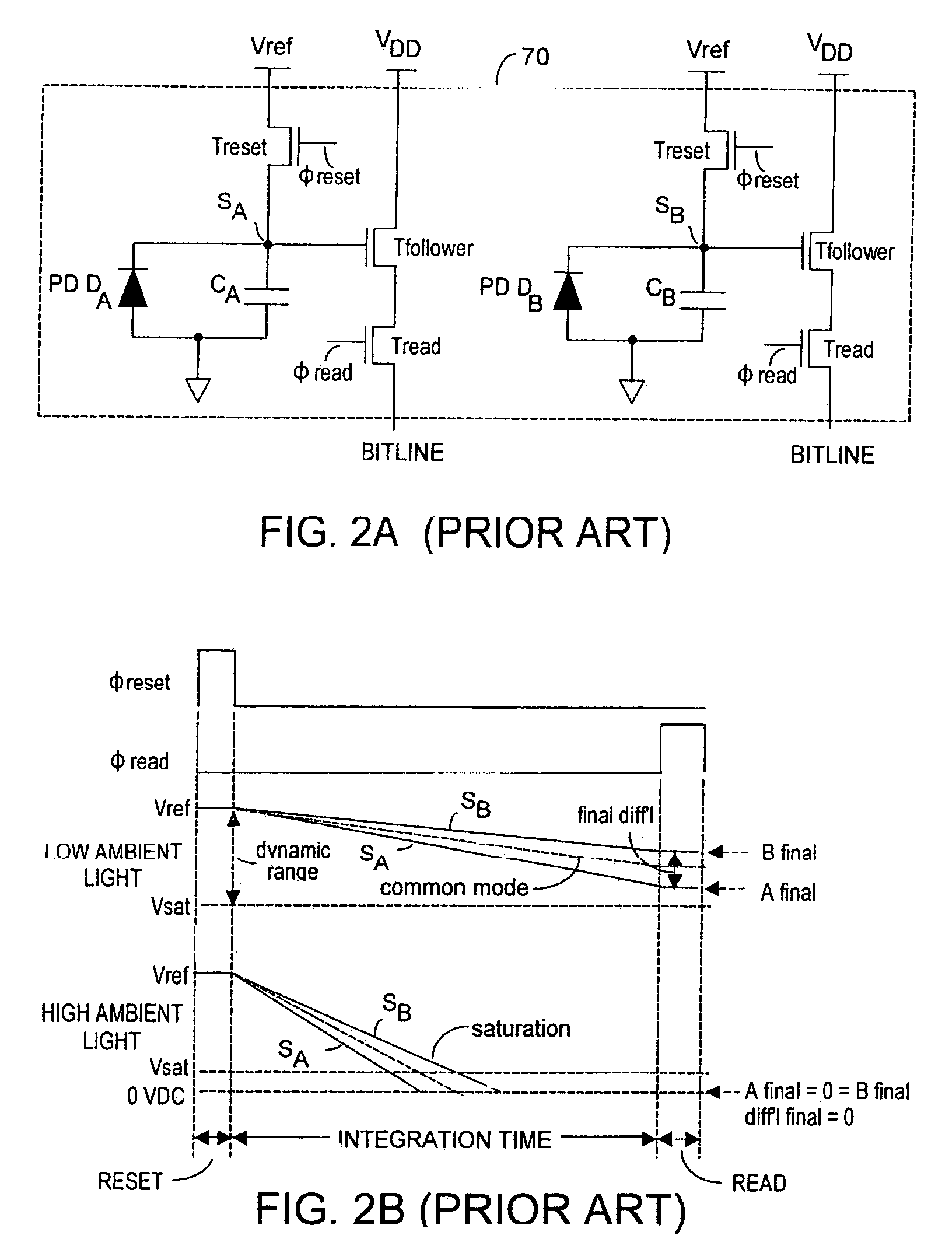

Method and system to differentially enhance sensor dynamic range

InactiveUS6919549B2Effective dynamic rangeInhibition effectTelevision system detailsOptical rangefindersPhotovoltaic detectorsPhotodetector

Effective differential dynamic range in a differential pixel detector is increased by avoiding saturation effects due to common mode contribution in optical energy to be detected. Photocurrent generated by each photodetector pair is directly integrated by an associated capacitor over an integration time T. Within time T, before either integrated capacitor voltage reaches Vsat for the photodetector, at least one of the capacitors is reset to a voltage such that the desired differential detector signal is still determinable. Reset may be generated externally or internally to the differential pixel detector.

Owner:MICROSOFT TECH LICENSING LLC

Articulating retrieval devices

ActiveUS20090069828A1Inhibit migrationImprove efficiencyCannulasSurgical veterinaryBiomedical engineeringFrictional resistance

The devices and methods described herein relate to improved structures for removing obstructions from body lumens. Such devices have applicability in through-out the body, including clearing of blockages within the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

System and methods for maintaining power usage within a set allocation

InactiveUS20050143865A1Reduce energy useHigh energyMechanical power/torque controlDc network circuit arrangementsDistribution power systemElectricity

An electric power management system includes a monitor for the total power usage of a facility that monitors a history of power consumption during a set time interval of a distribution system having at least one electric load. Predictions of available power are generated through out the time interval by comparing the history of power consumption to a set allocation. Available power predictions are transmitted to the at least one electric load. The at least one load control receives the power capability predictions and controls the energy usage of the at least one electric load such that the total energy usage of the facility does not exceed the set allocation.

Owner:JAY WARREN GARDNER

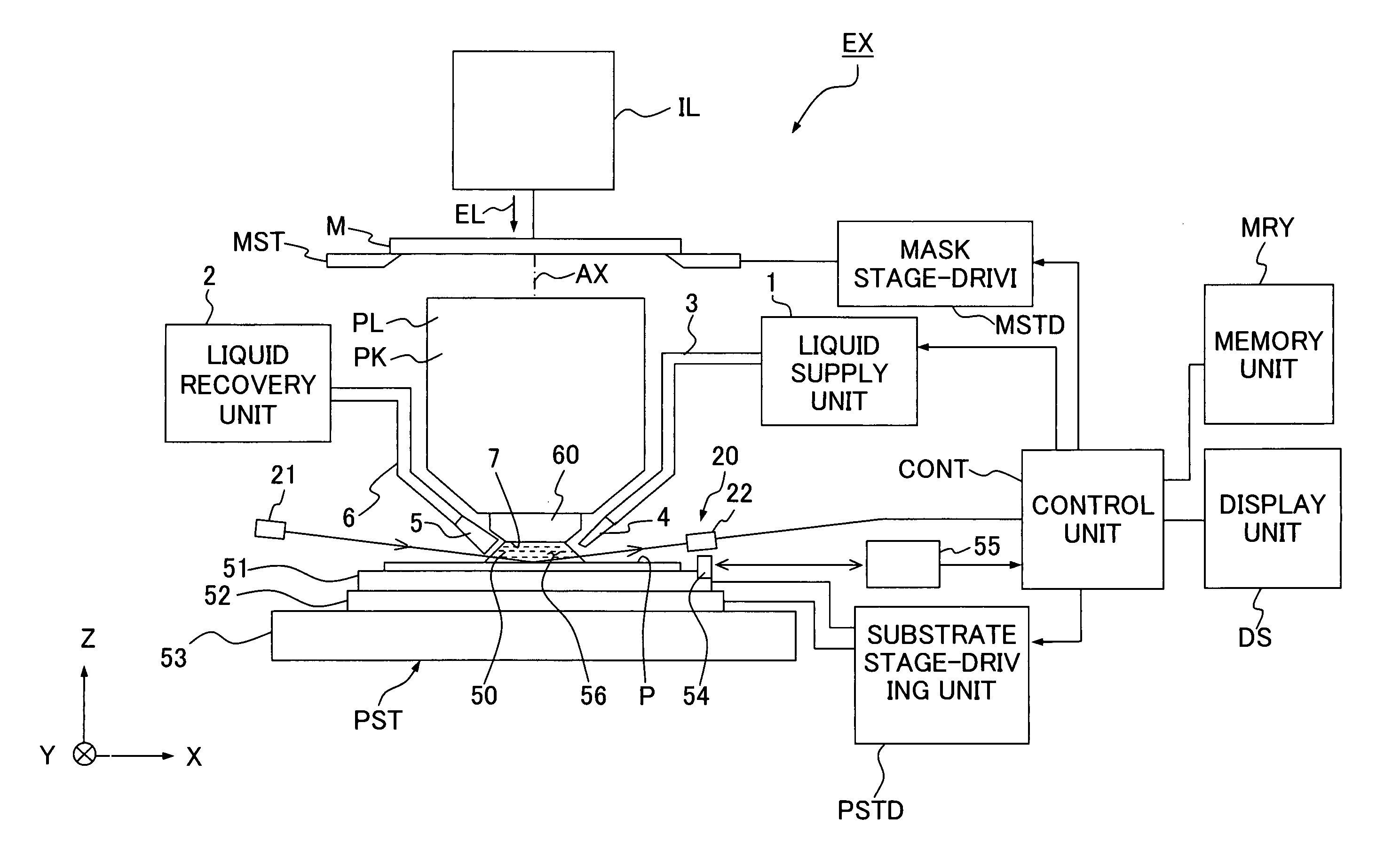

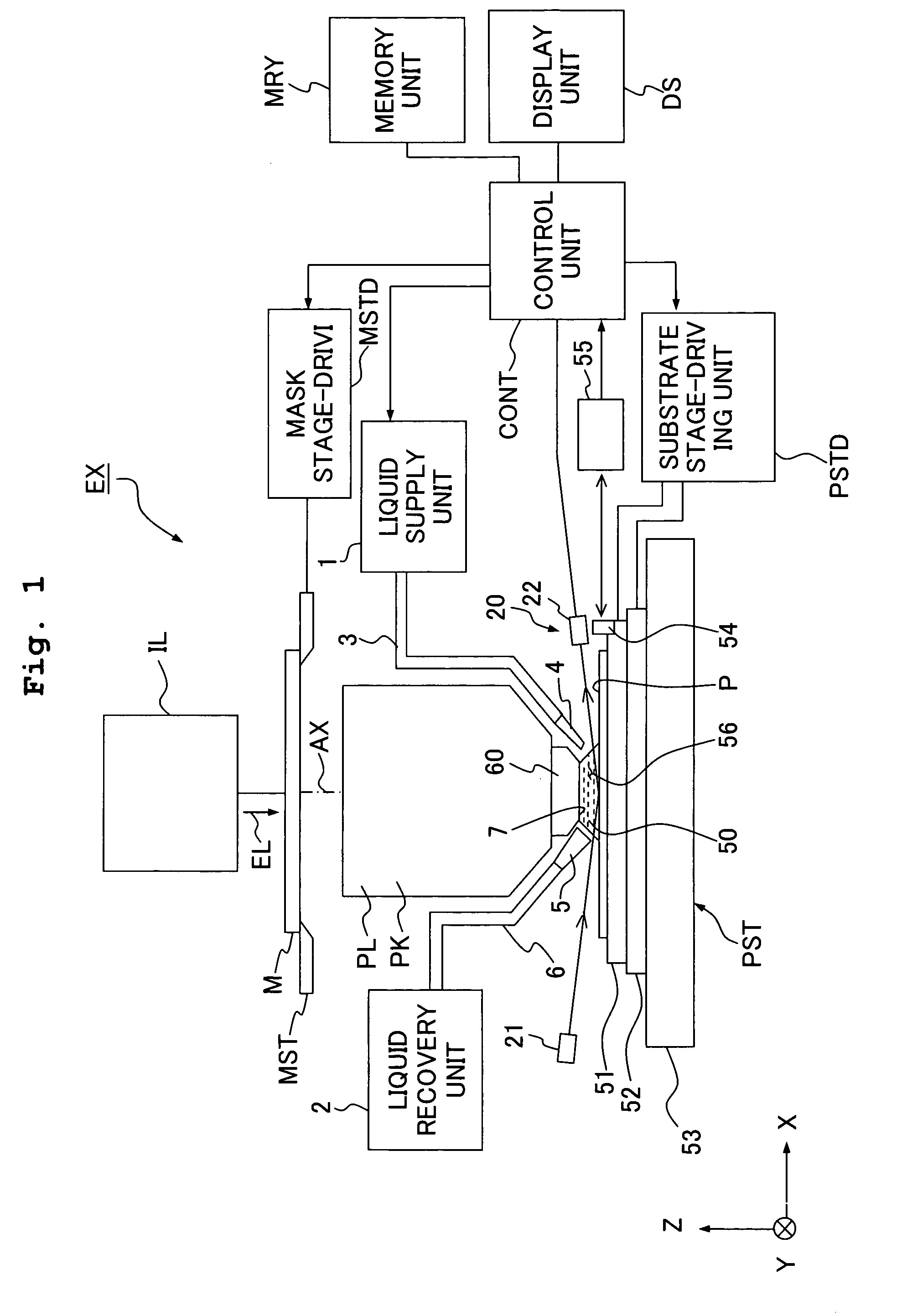

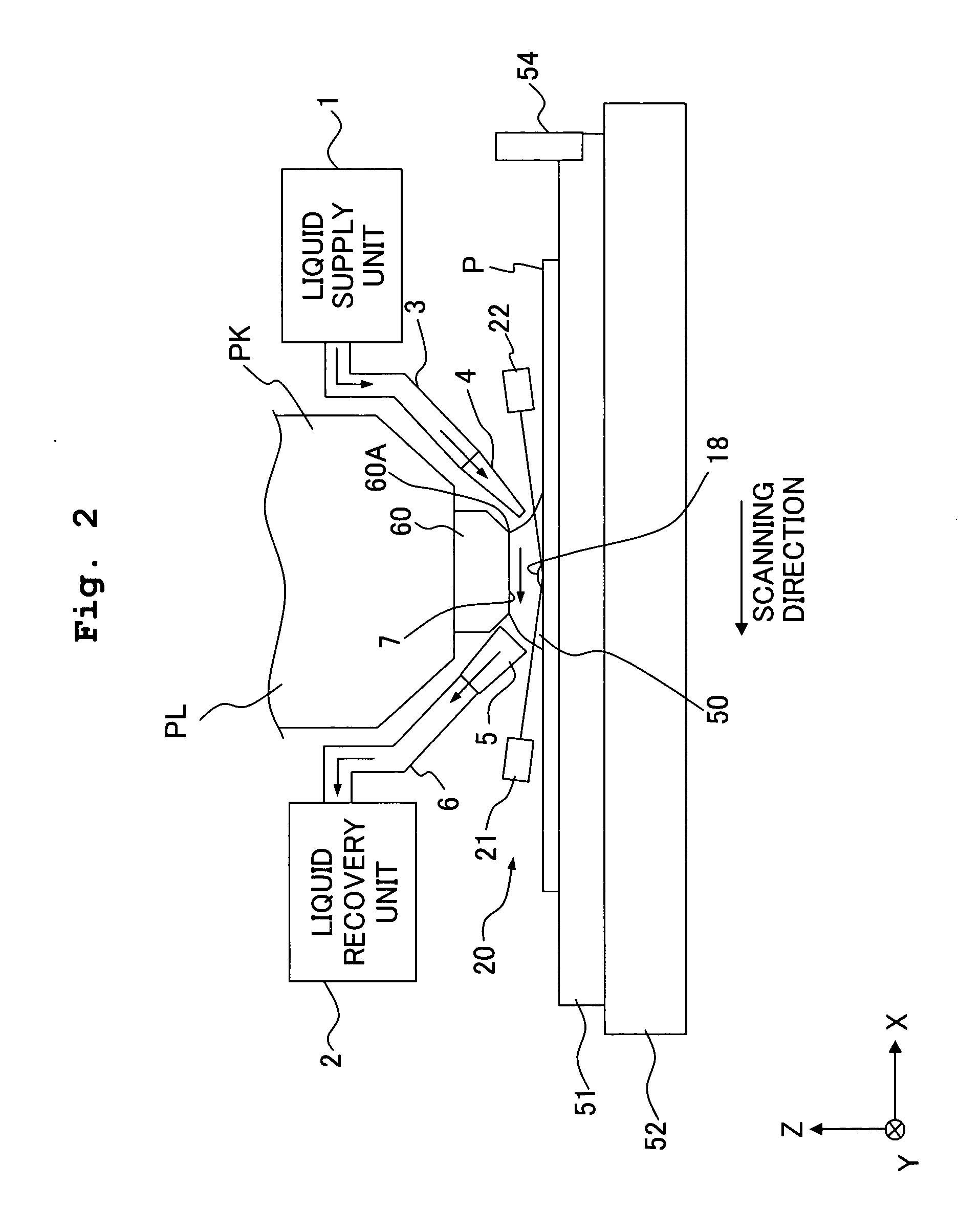

Exposure apparatus and method for producing device

InactiveUS20050264774A1Increase productivityCurb productivity declineInvestigating moving fluids/granular solidsScattering properties measurementsBubble DetectorAir bubble

An exposure apparatus, wherein an exposure of a substrate (P) is carried out by filling at least a portion of the space between a projection optical system and the substrate (P) with a liquid and projecting an image of a pattern onto the substrate (P) via the projection optical system and the liquid, includes a bubble detector (20) which detects air bubble or bubbles in the liquid between the projection optical system and the substrate (P). Consequently, the exposure apparatus is capable of suppressing deterioration of a pattern image caused by bubbles in the liquid when an exposure is carried out while filling the space between the projection optical system and the substrate with the liquid.

Owner:NIKON CORP

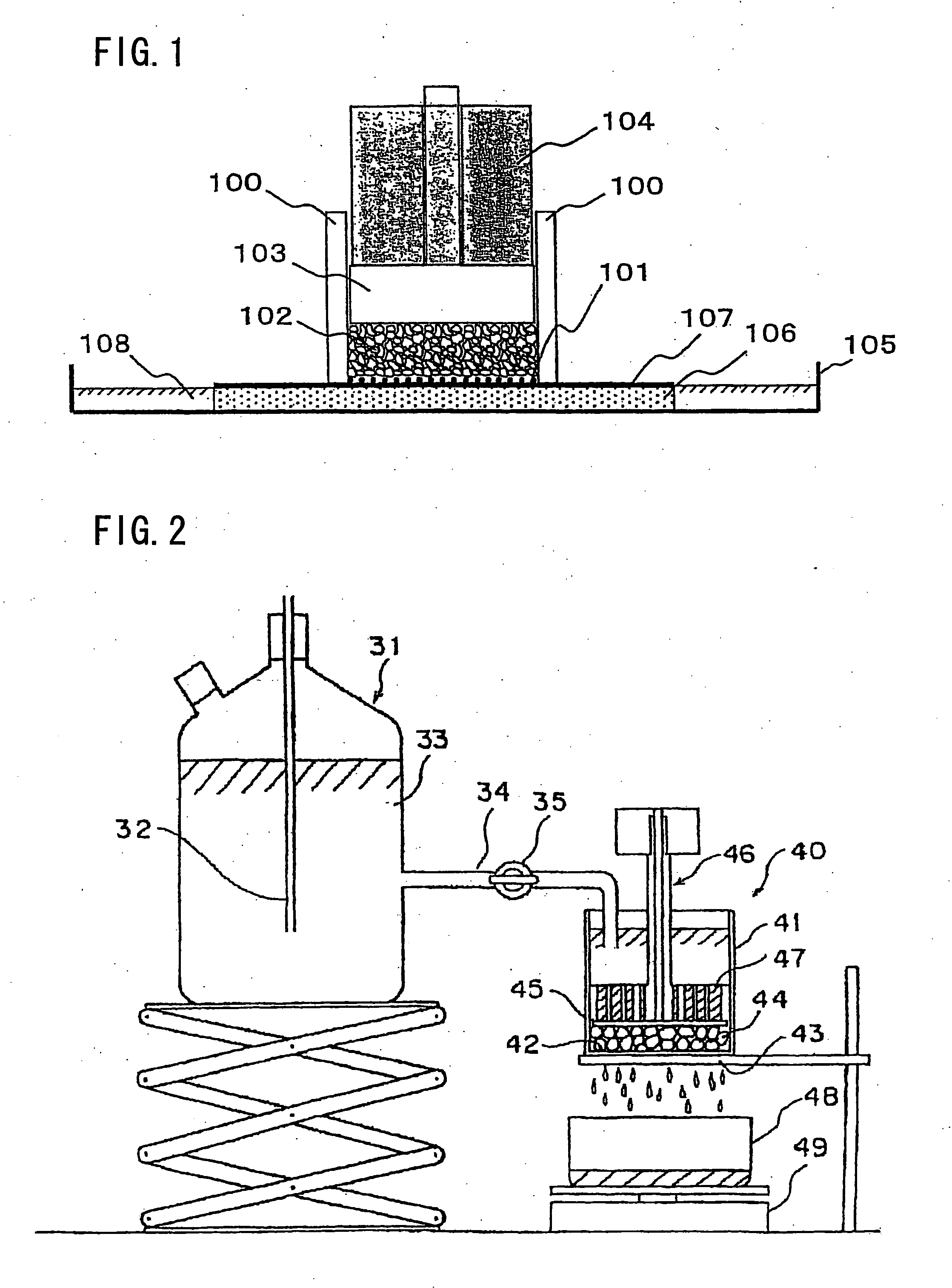

Water absorbent resin composition and production method thereof

InactiveUS20050288182A1Promote absorptionInhibitionOther chemical processesBaby linensCross-linkAbsorption capacity

The water absorbent resin composition and the production method thereof according to the present invention are characterized by including: water absorbent resin particles having an internal cross-linked structure obtained by polymerizing a water-soluble unsaturated monomer; a nitrogenous ketone compound (A) (containing no carboxyl group) having a structure represented by formula (1); and a bivalent and / or trivalent and / or tetravalent water-soluble metal salt, wherein a total amount of the nitrogenous ketone compound (A) and the bivalent and / or trivalent and / or tetravalent water-soluble metal salt ranges from 0.01 to 100 parts by mass with respect to 100 parts by mass of the water absorbent resin particles, thereby providing a water absorbent resin composition, having an excellent absorption capacity represented by a centrifuge retention capacity (CRC), an absorbency against pressure of 4.83 kPa (AAP) etc., having excellent liquid permeability and liquid diffusion properties, having excellent fluidity at the time of moisture absorption, having an excellent damage resistance property, effectively suppressing occurrence of dusts, hardly bringing about permeation of added metal compounds into water absorbent resin particles, hardly bringing about segregation of added metal compounds.

Owner:NIPPON SHOKUBAI CO LTD

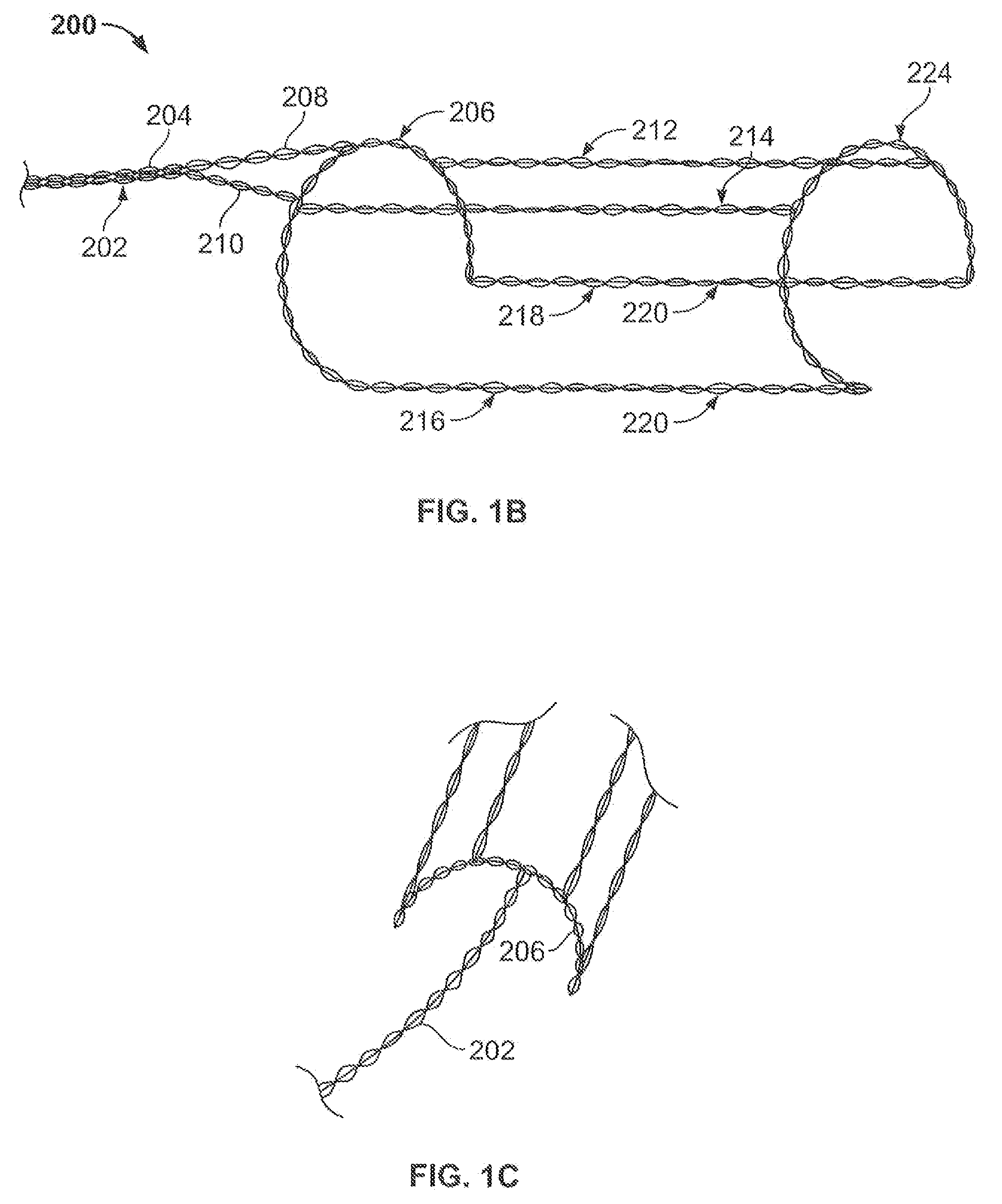

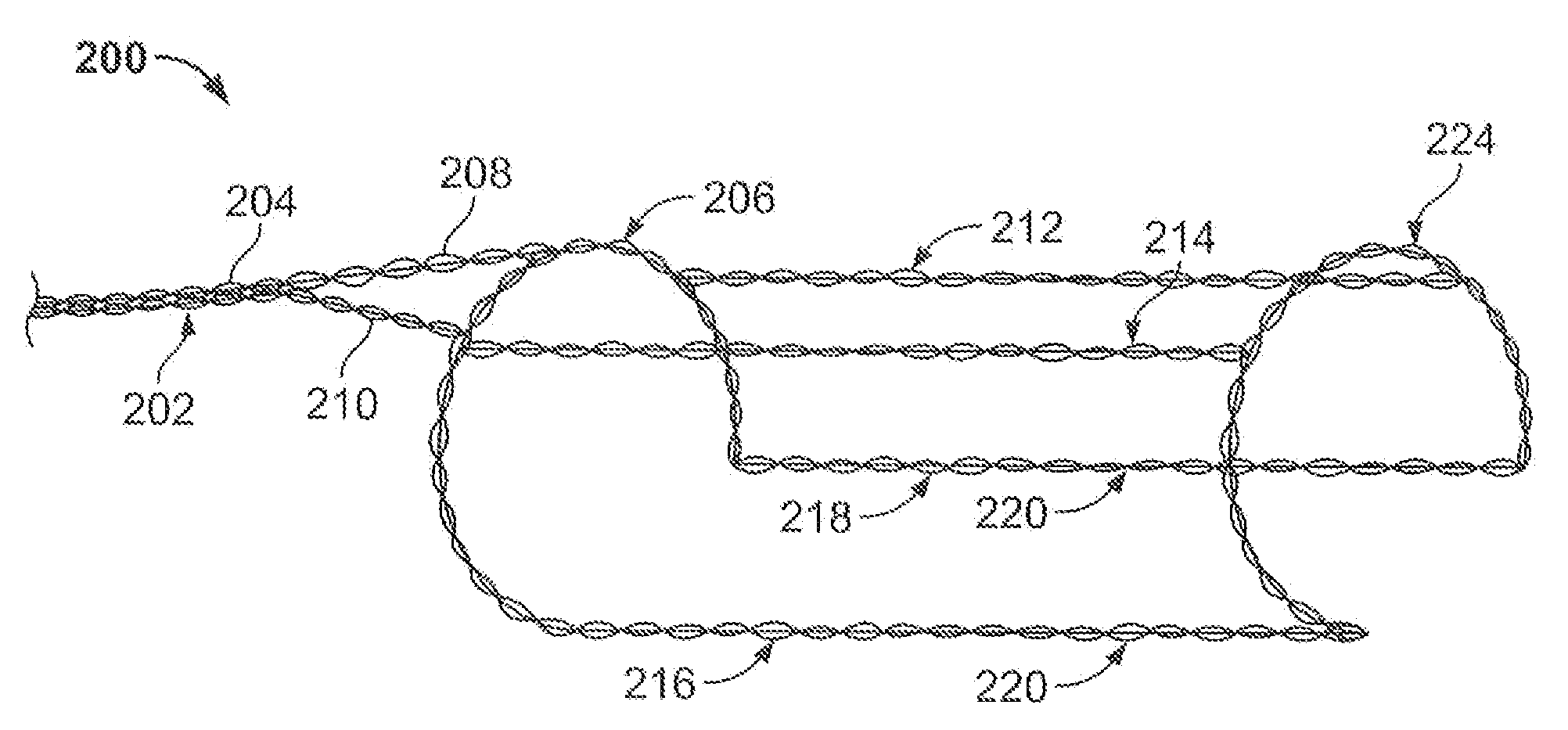

Complex wire formed devices

InactiveUS20080262528A1Shorten the lengthAvoid insufficient lengthDilatorsExcision instrumentsMedicineFrictional resistance

The devices and methods described herein relate to jointless construction of complex structures. Such devices have applicability in through-out the body, including clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

Complex wire formed devices

InactiveUS20080262532A1Shorten the lengthAvoid insufficient lengthDilatorsExcision instrumentsFrictional resistanceMedicine

The devices and methods described herein relate to jointless construction of complex structures. Such devices have applicability in through-out the body, including clearing of blockages within body lumens, such as the vasculature, by addressing the frictional resistance on the obstruction prior to attempting to translate and / or mobilize the obstruction within the body lumen

Owner:TYCO HEALTHCARE GRP LP

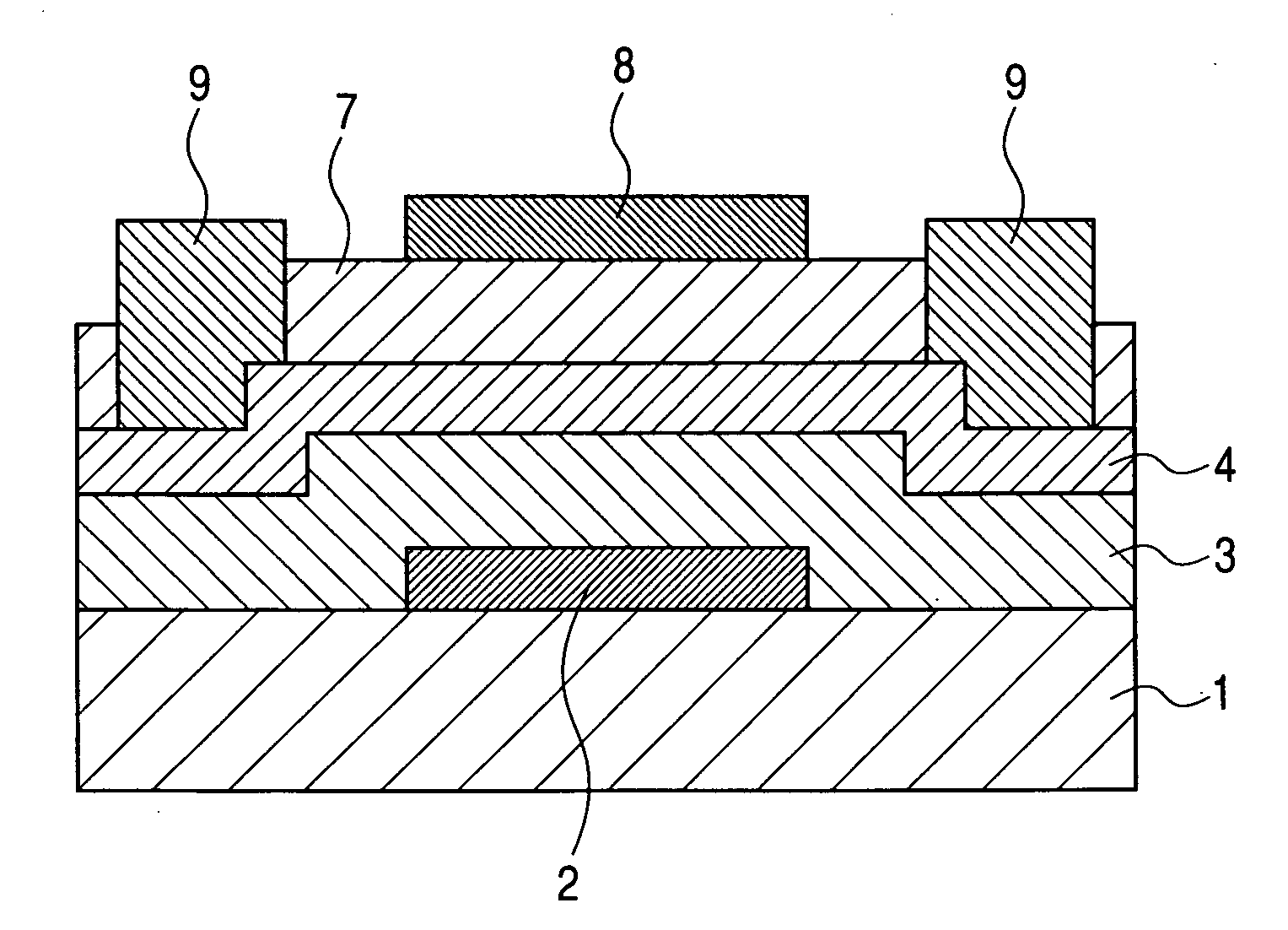

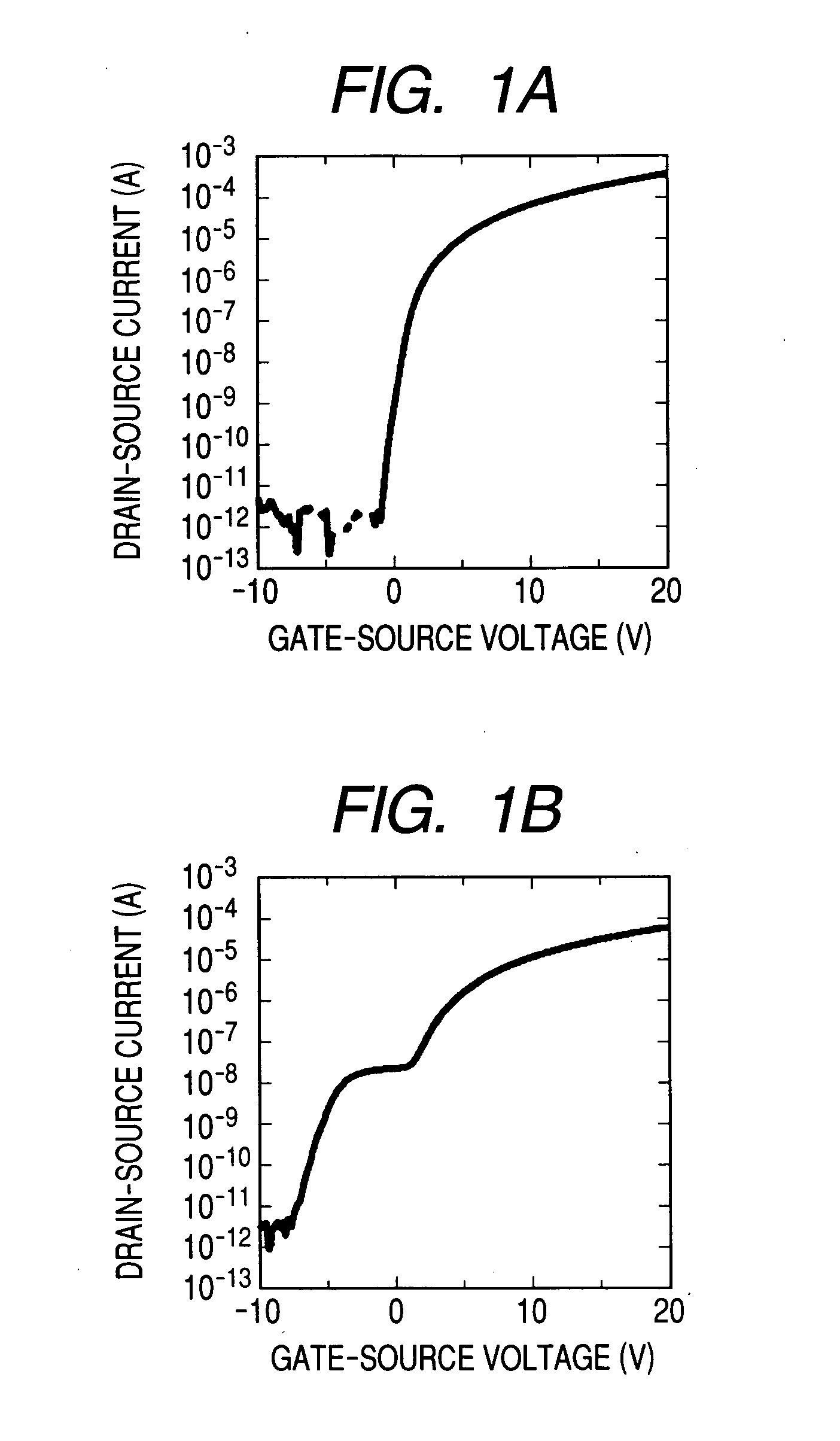

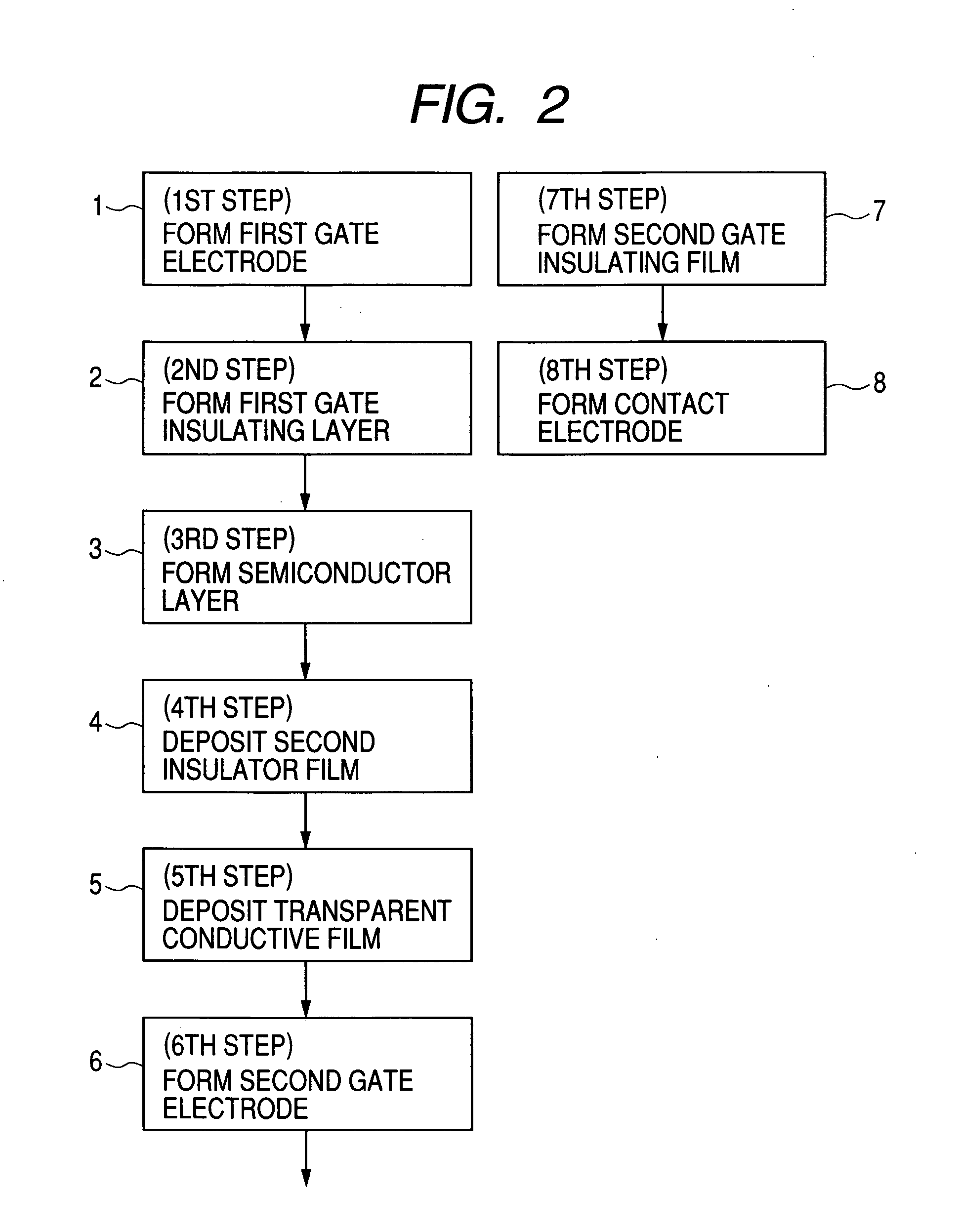

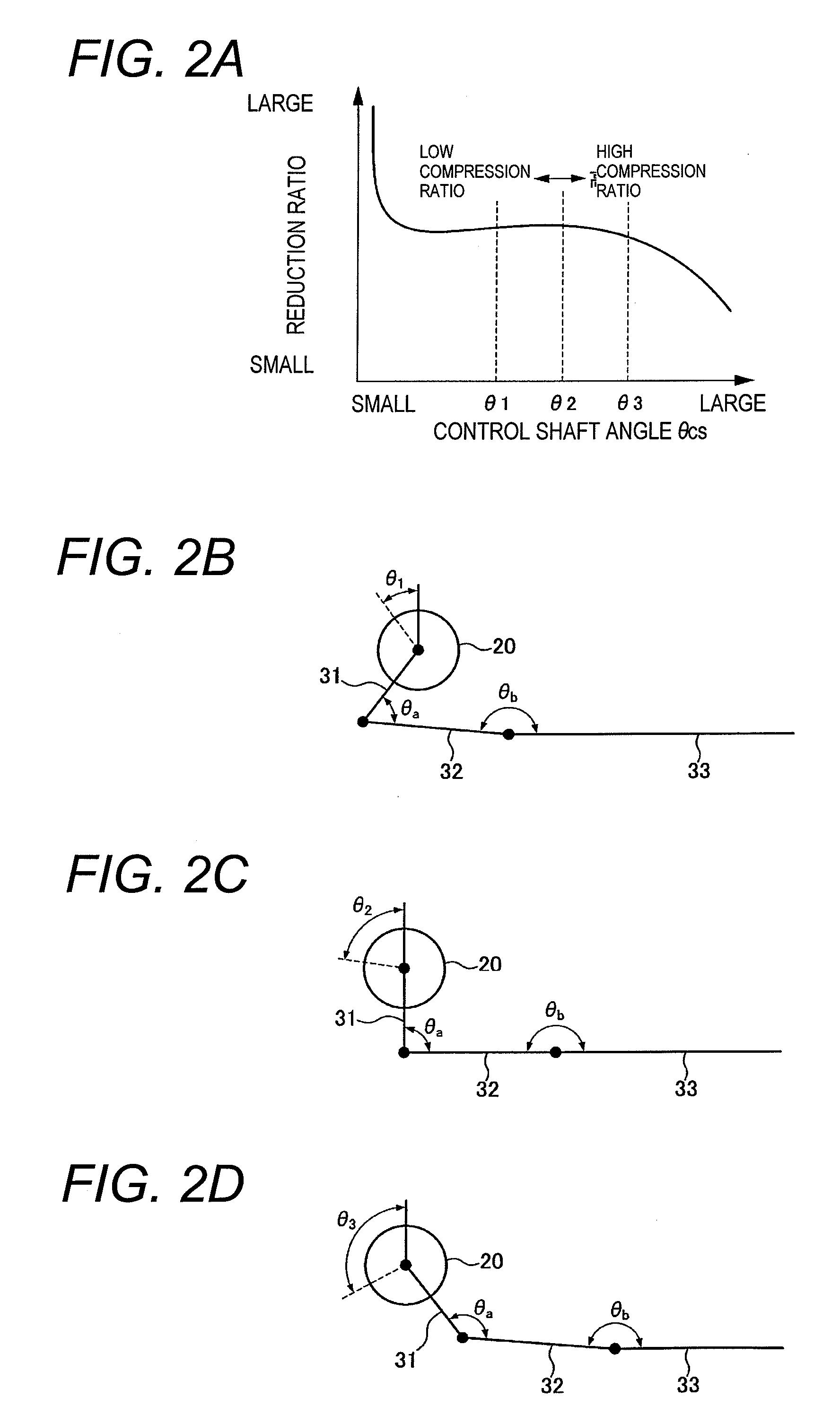

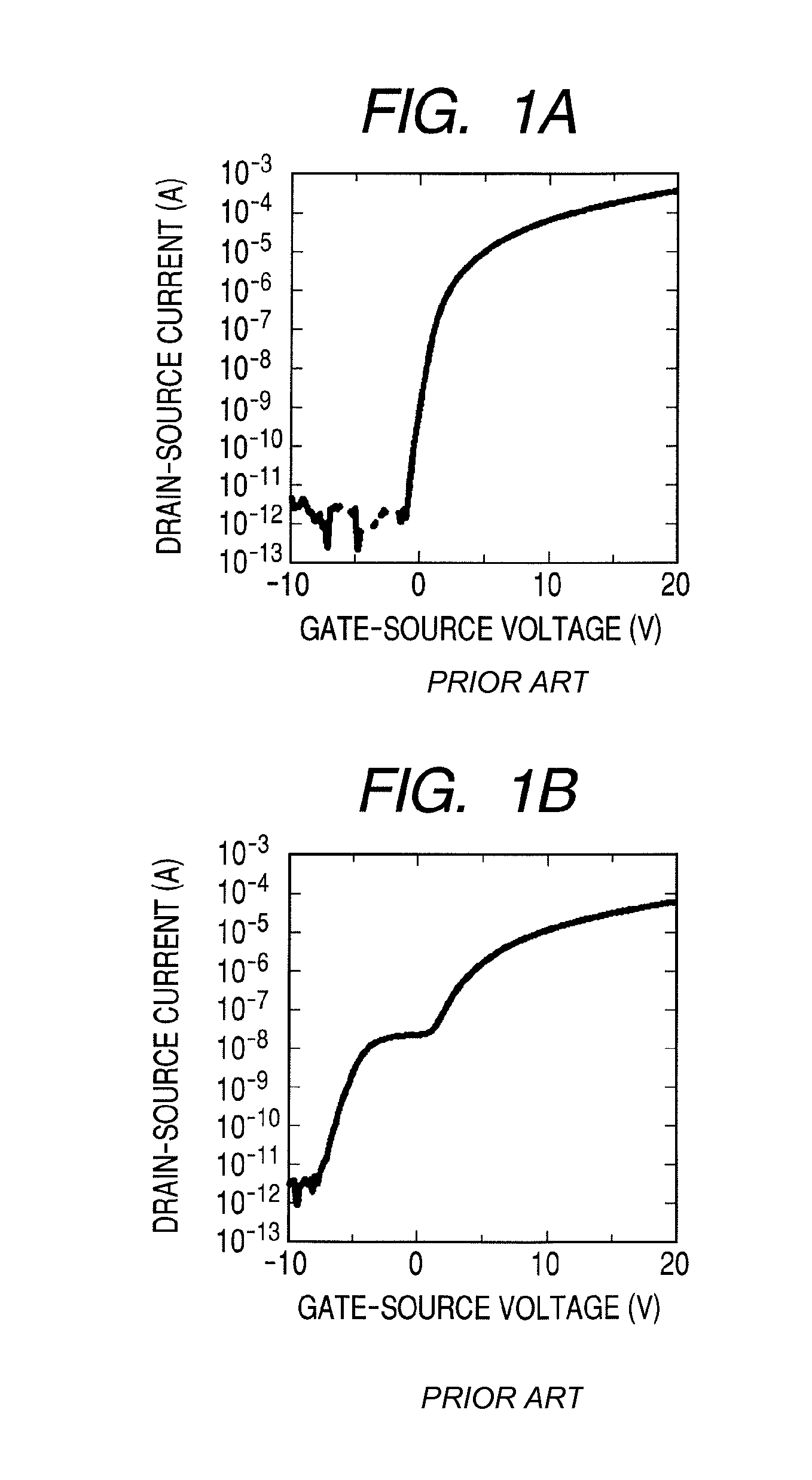

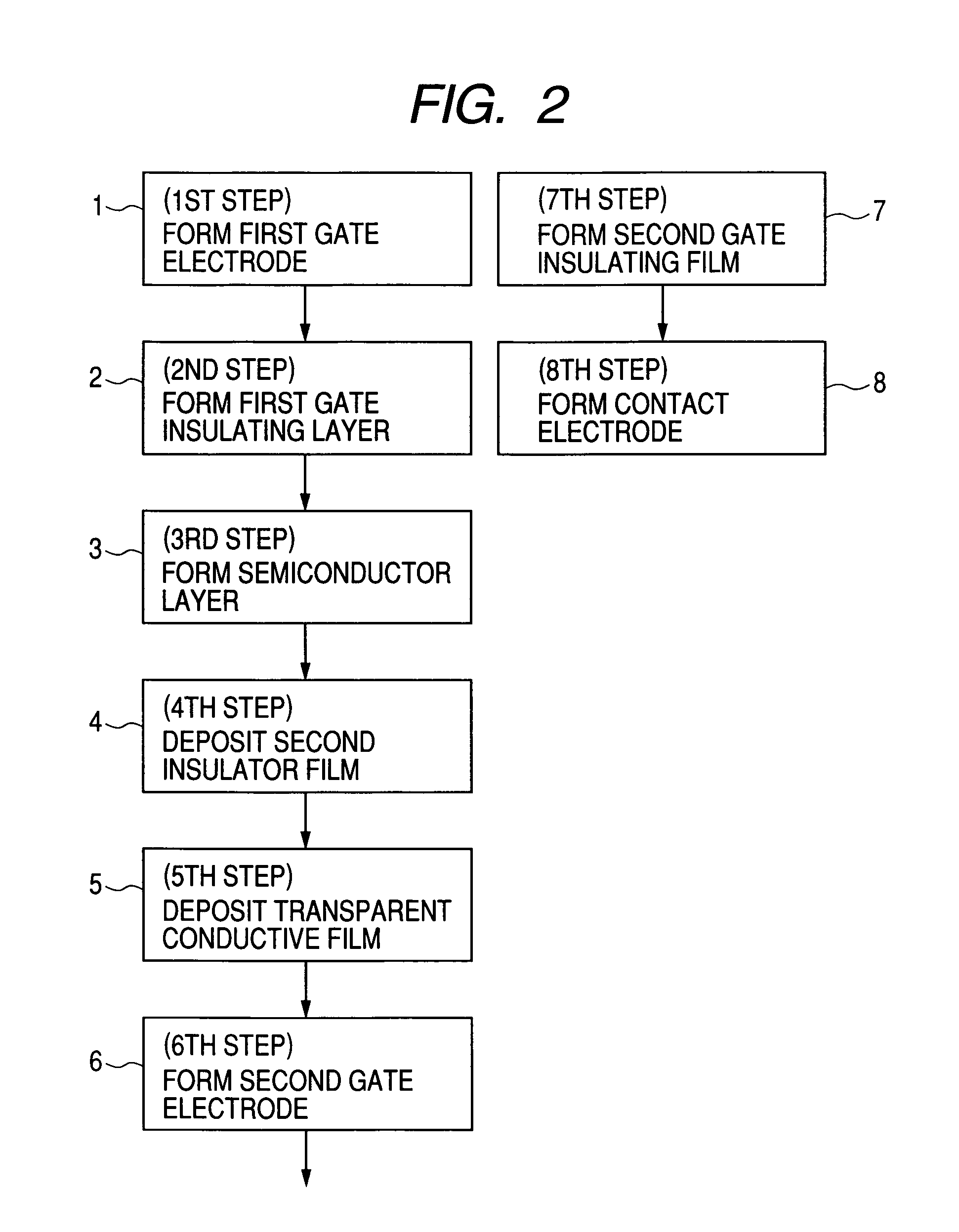

Thin film transistor and method of producing same

InactiveUS20100244022A1InhibitionTransistorSemiconductor/solid-state device manufacturingOxide semiconductorOxide

A first gate electrode (2) is formed on a substrate (1); a first gate insulating layer (3) is formed so as to cover the first gate electrode (2); a semiconductor layer (4) including an oxide semiconductor is formed on the first gate insulating layer (3); a second gate insulating layer (7) is formed on the semiconductor layer (4); a second gate electrode (8) having a thickness equal to or larger than a thickness of the first gate electrode (2) is formed on the second gate insulating layer (7); and a drain electrode (6) and a source electrode (5) are formed so as to be connected to the semiconductor layer (4).

Owner:CANON KK

Abuse-resistant controlled-release opioid dosage form

InactiveUS20030065002A1High oral : parenteral potency ratioEliminate the effects ofBiocideNervous disorderControlled releaseOpioid antagonist

Abuse-resistant, controlled release opioid tablets are a combination containing an opioid antagonist such as naloxone at a level that needed to suppress the euphoric effect of the opioid, if the combination were crushed to break the controlled release properties causing the opioid and opioid antagonist to be released as a immediate release product as a single dose. The controlled release nature of the table prevents the accumulation of orally effective amounts of opioid antagonist when taken normally. The opioid antagonist is contained in a controlled-release matrix and released, over time, with the opioid.

Owner:PURDUE PHARMA LP

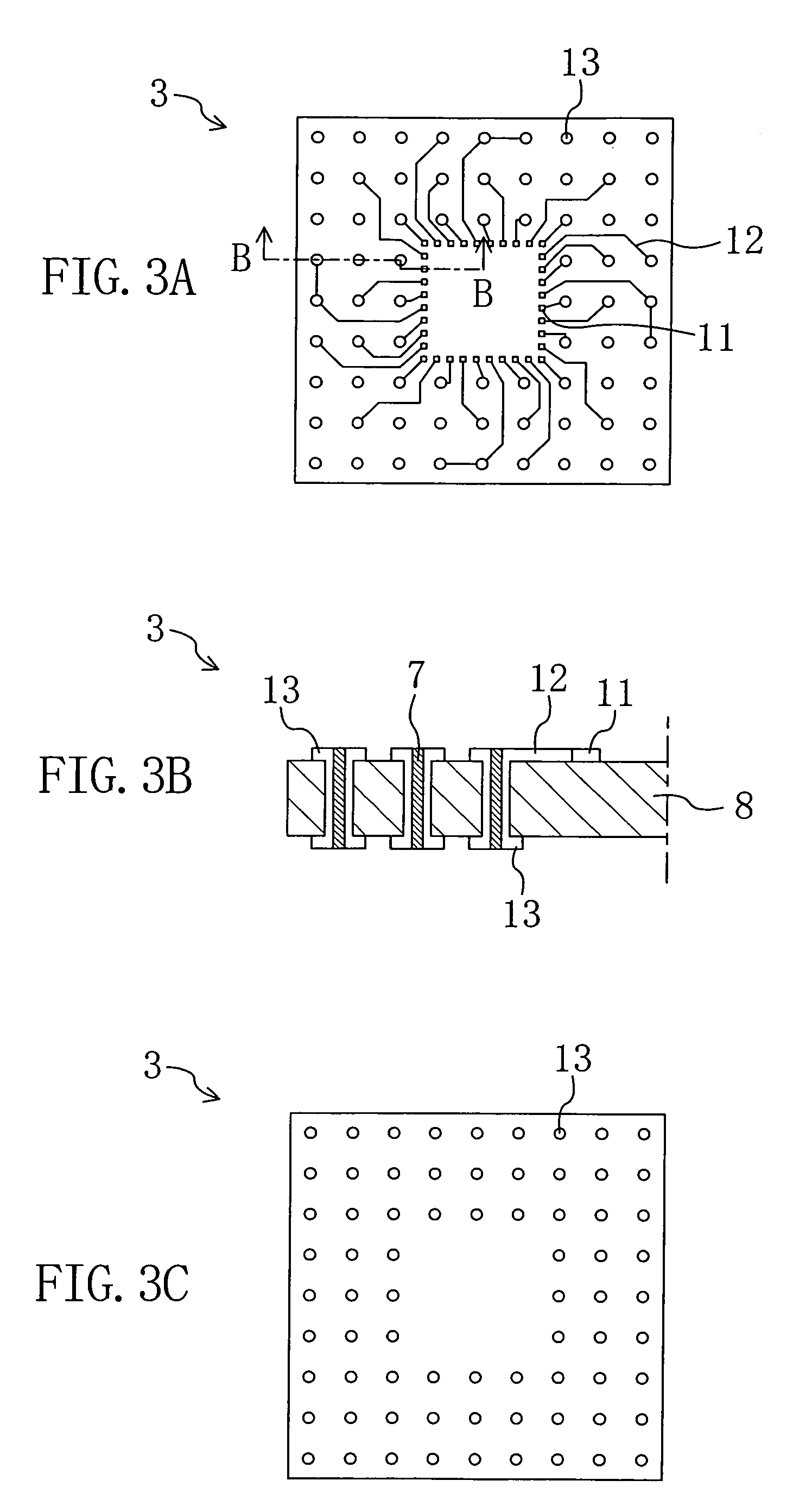

Wiring Board for Light-Emitting Element

InactiveUS20080043444A1InhibitionHigh bonding strengthPrinted circuit aspectsSolid-state devicesElectrical conductorHeat conducting

A wiring board for light-emitting element, comprising a ceramic insulating substrate, and a conductor layer formed on the surface or in the inside of the insulating substrate, and having a mounting region mounting a light-emitting element on one surface of the insulating substrate; wherein the insulating substrate is provided with a heat-conducting pole-like conductor having a thermal conductivity higher than that of said insulating substrate; and the heat-conducting pole-like conductor is extending through the insulating substrate in the direction of thickness thereof from the light-emitting element mounting region of the insulating substrate, and is formed by the co-firing with the insulating substrate. The wiring board is produced inexpensively by co-firing, features excellent heat-radiating performance, is capable of quickly radiating the heat from the light-emitting element when the light-emitting element is mounted, and effectively prevents a decrease in the brightness of the light-emitting element caused by the heat.

Owner:KYOCERA CORP

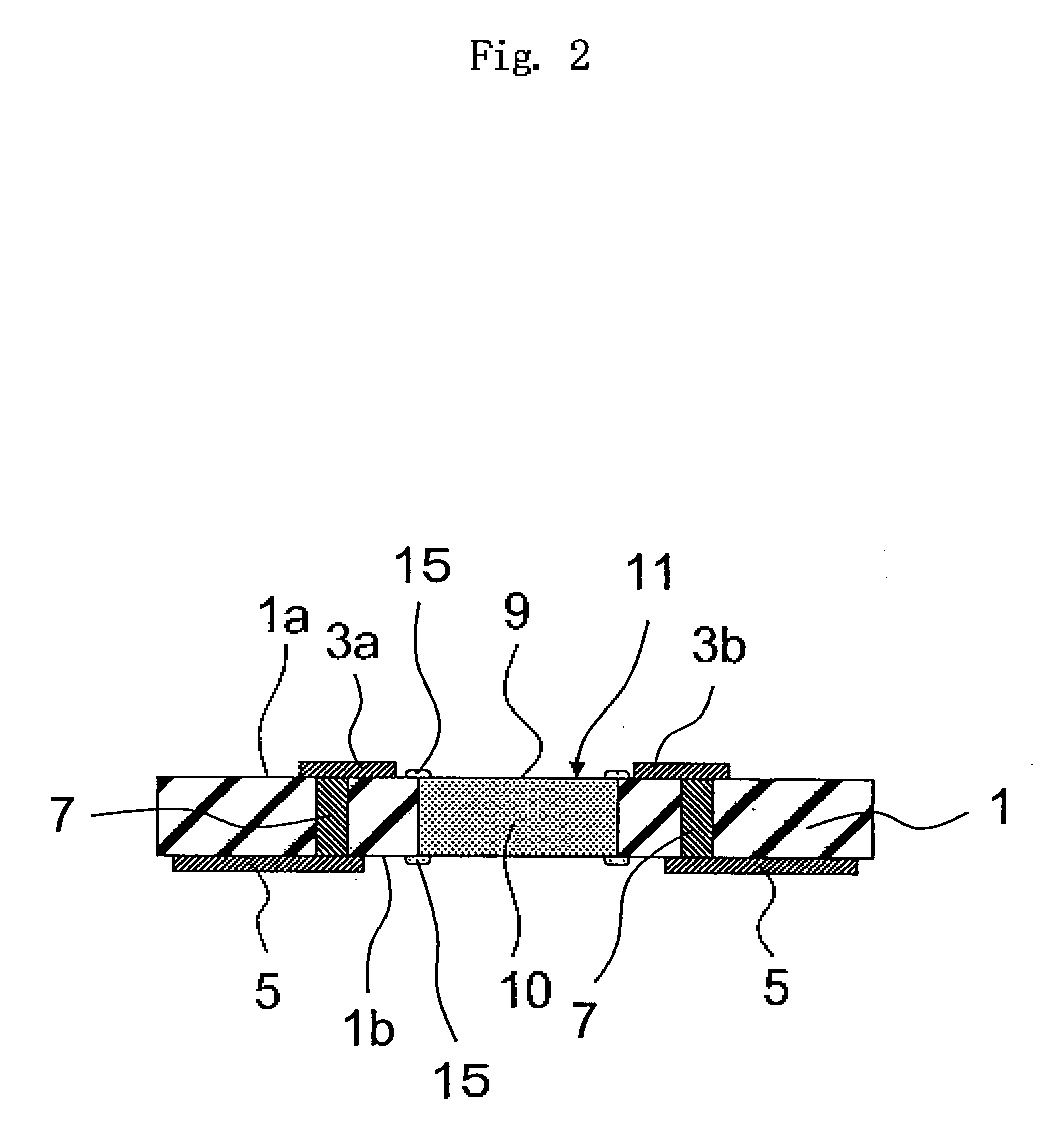

Method for preparing humic acid and salt thereof by oxidation and degradation of brown coal

The invention discloses a method for producing humic acid and salt thereof through the oxidative degradation of young lignite. The method comprises the following steps: carrying out the oxidation reaction of the lignite containing the humic acid and aqueous hydrogen peroxide solution; after the reaction, obtaining water soluble fulvic acid through centrifugal separation, supernatant filtration, concentration and drying; adding alkali into the fulvic acid to prepare a fulvic acid salt product; carrying out the alkaline extraction and centrifugal separation of the residue deposit of the production of the fulvic acid, adding acid into the supernatant till the pH value is 1 to 2, carrying out a reaction at an increased temperature or room temperature, carrying out centrifugal separation after the reaction is finished, and obtaining purified ulmic acid after precipitation and drying; and directly concentrating and drying the supernatant in the previous step to obtain the humate. The method can improve the yield of the fulvic acid and total humic acid in the young lignite, and simultaneously increase the active group in the humic acid. The method can be used for producing fulvic acid, fulvic acid salt, ulmic acid and ulmic acid salt products. In particular, the method puts an end to the environmental pollution caused by the nitric acid which is taken as an oxidation degradation agent. In addition, the method has a short technological line, low cost, simple requirements on equipment, and moderate conditions. The method which can be applied to the industrialized production has good application prospect.

Owner:KUNMING UNIV OF SCI & TECH +4

Pyrazole compound and medicinal composition containing the same

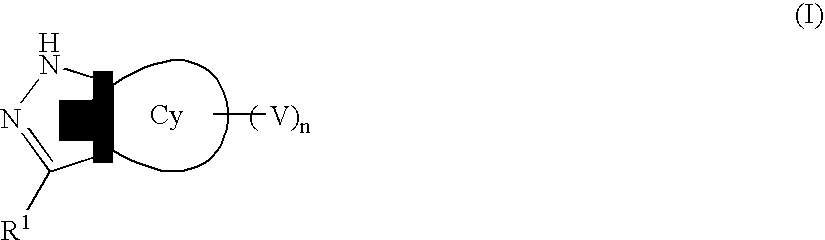

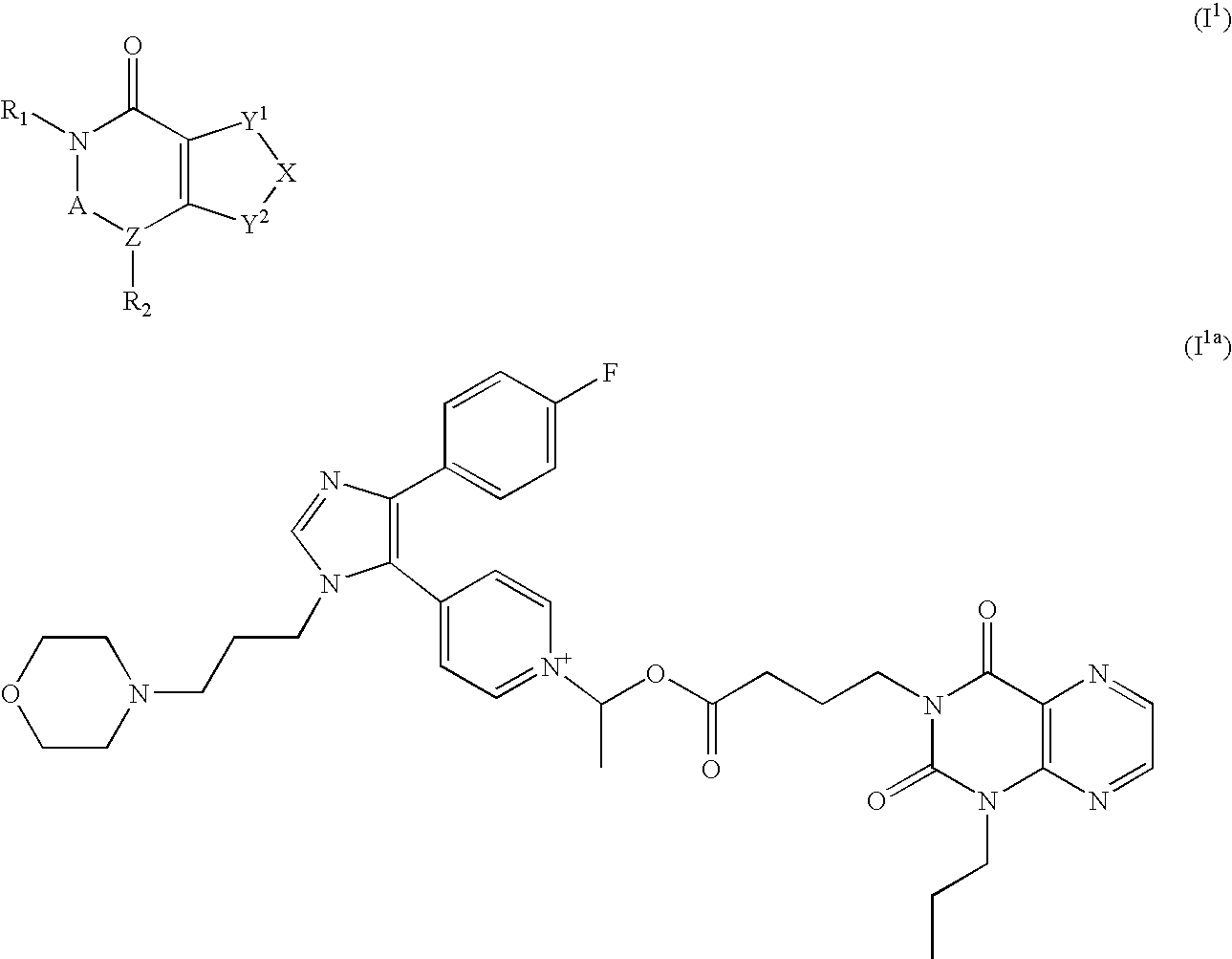

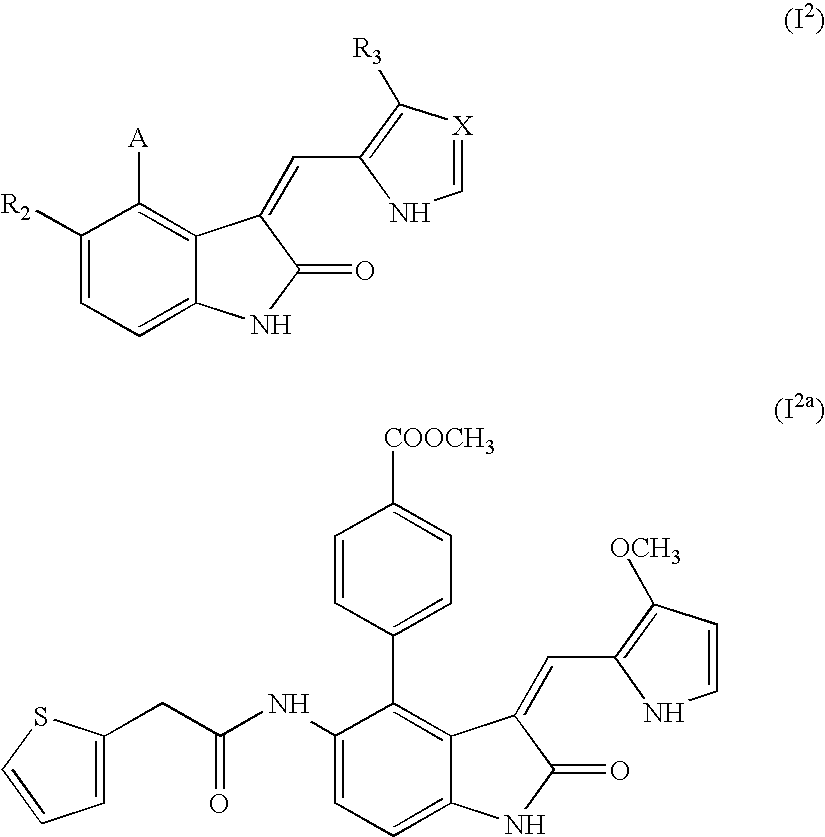

The present invention provides a novel compound having an excellent JNK inhibitory effect. That is, it provides a compound represented by the following formula, a salt thereof or a hydrate of them.Wherein R1 designates —(CO)h—(NRa)j—(CRb═CRc)k—Ar (wherein Ra, Rb and Rc each independently designate a hydrogen atom, a halogen atom, hydroxyl group, an optionally substituted C1-6 alkyl group or the like;Cy designates a 5- or 6-membered heteroaryl; andV each independently designate the formula -L-X—Y (wherein L designates a single bond, an optionally substituted C1-6 alkylene group or the like; X designates a single bond or the formula -A- (wherein A designates NR2, O, CO, S, SO or SO2) and so on; and Y designates a hydrogen atom, a halogen atom, nitro group or the like).

Owner:EISIA R&D MANAGEMENT CO LTD

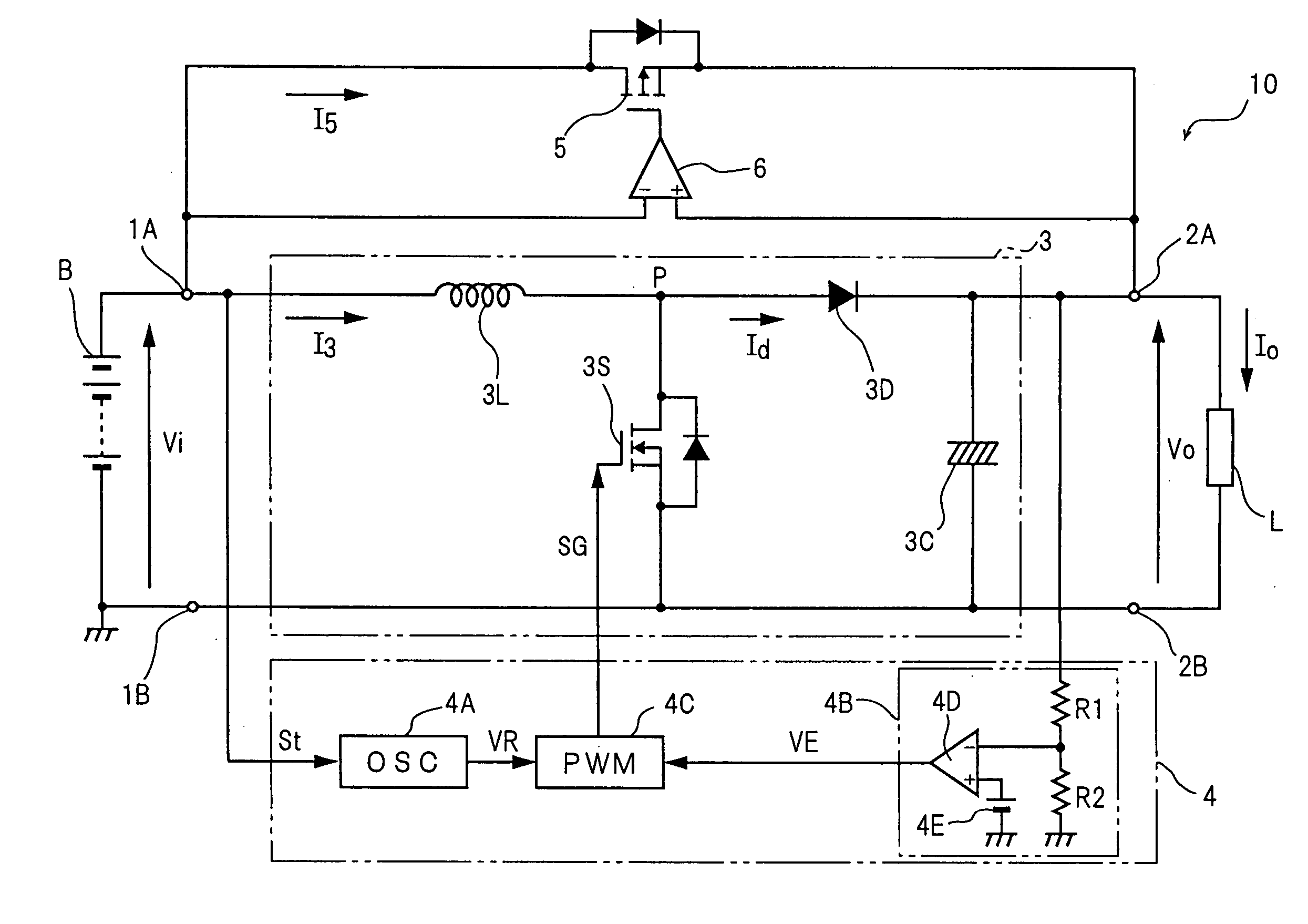

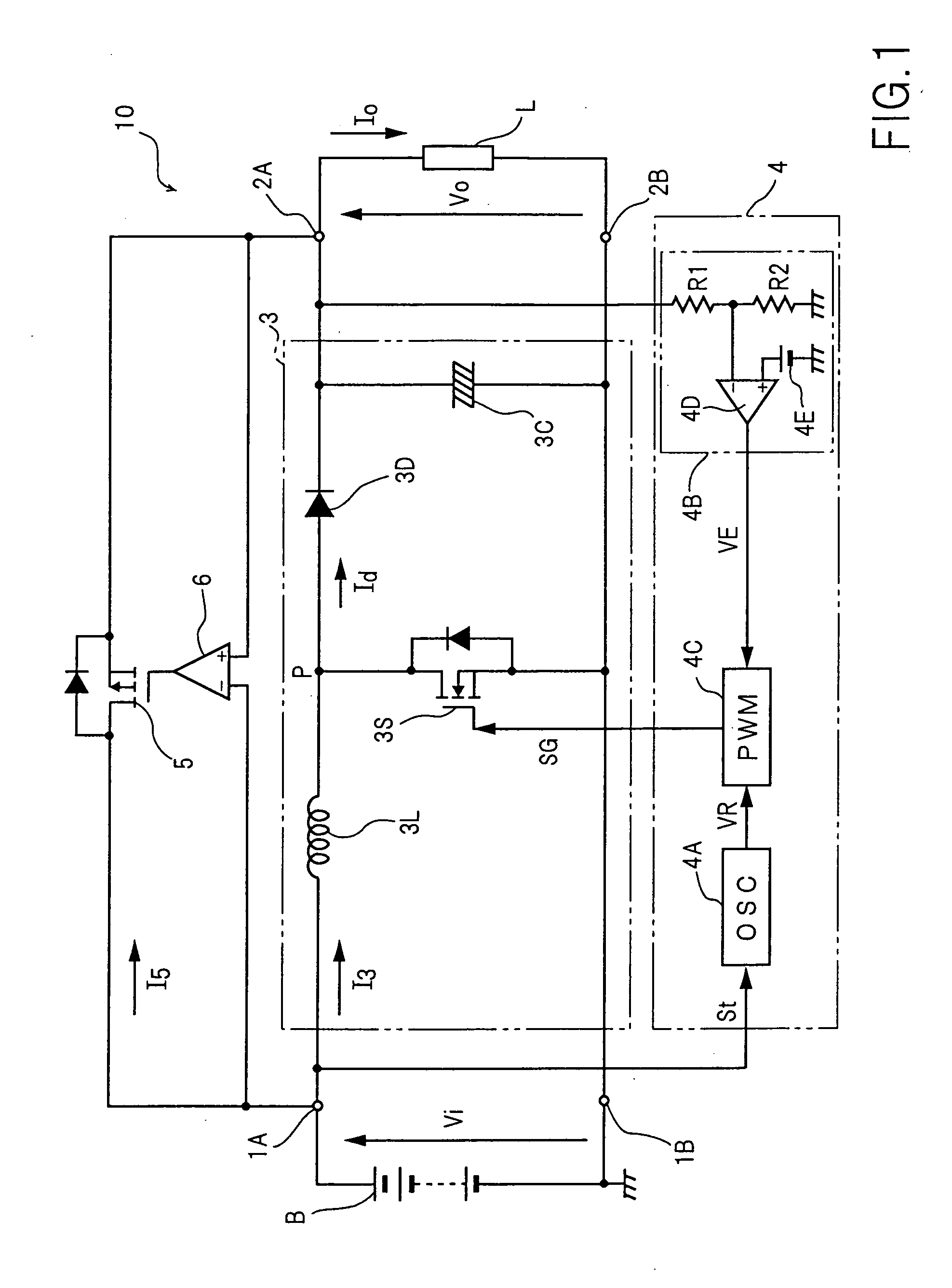

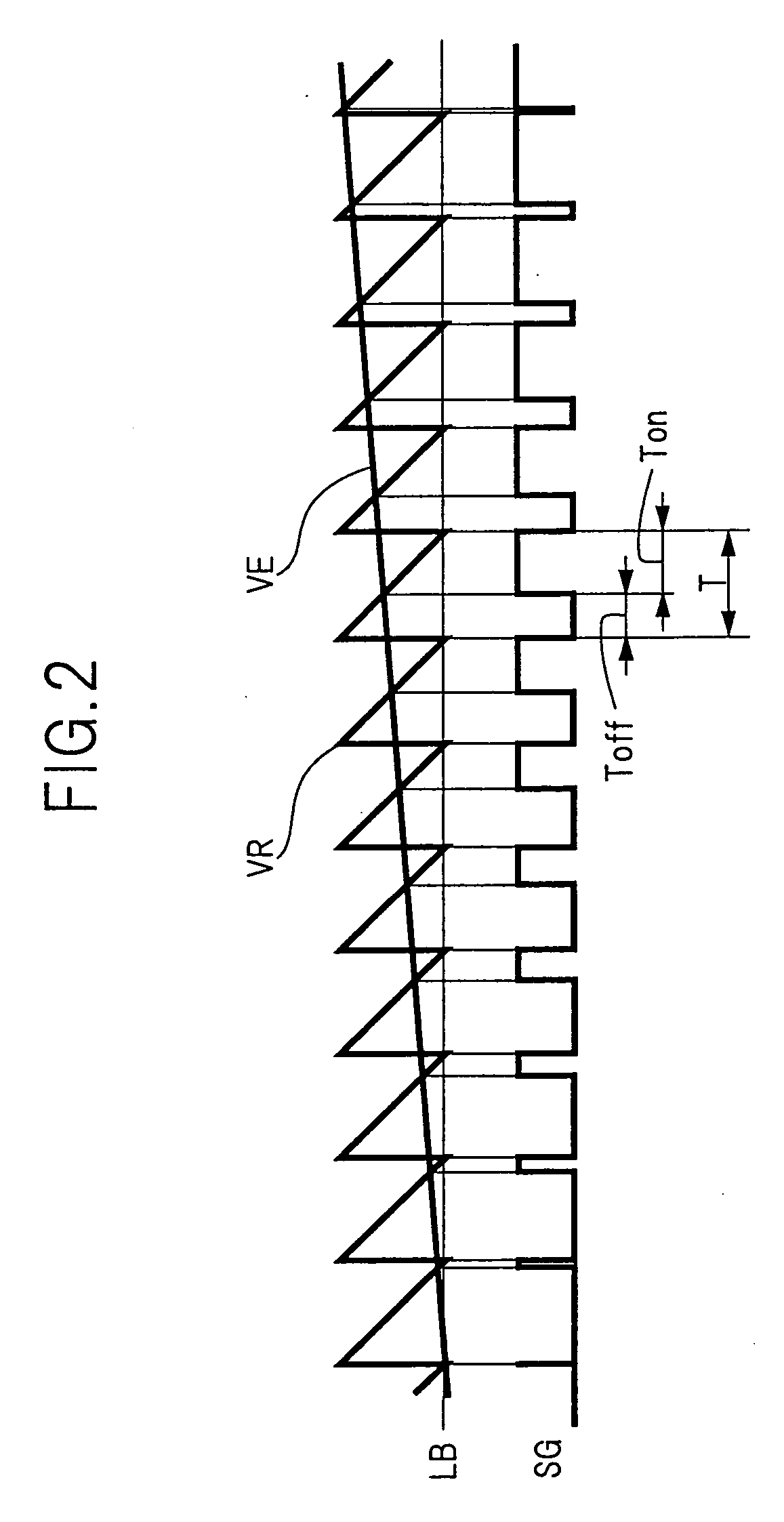

Direct-current power supply and battery-powered electronic apparatus and equipped with the power supply

InactiveUS20060006850A1InhibitionSmall circuit sizeDc-dc conversionProtective switchesBoost chopperElectrical battery

A bypass control section (6) maintains a bypass switch (5) in the ON state during the period when a battery voltage (Vi) is higher than the output voltage (Vo) to an external load (L). Upon falling of the output voltage (Vo) at a desired voltage (ET), a converter control section (4) starts switching control at once, and a step-up chopper (3) promptly starts boost operation. The bypass control section (6) maintains the bypass switch (5) in the ON state from the start of the boost operation of the step-up chopper (3) until the match between the battery voltage (Vi) and the output voltage (Vo).

Owner:PANASONIC CORP

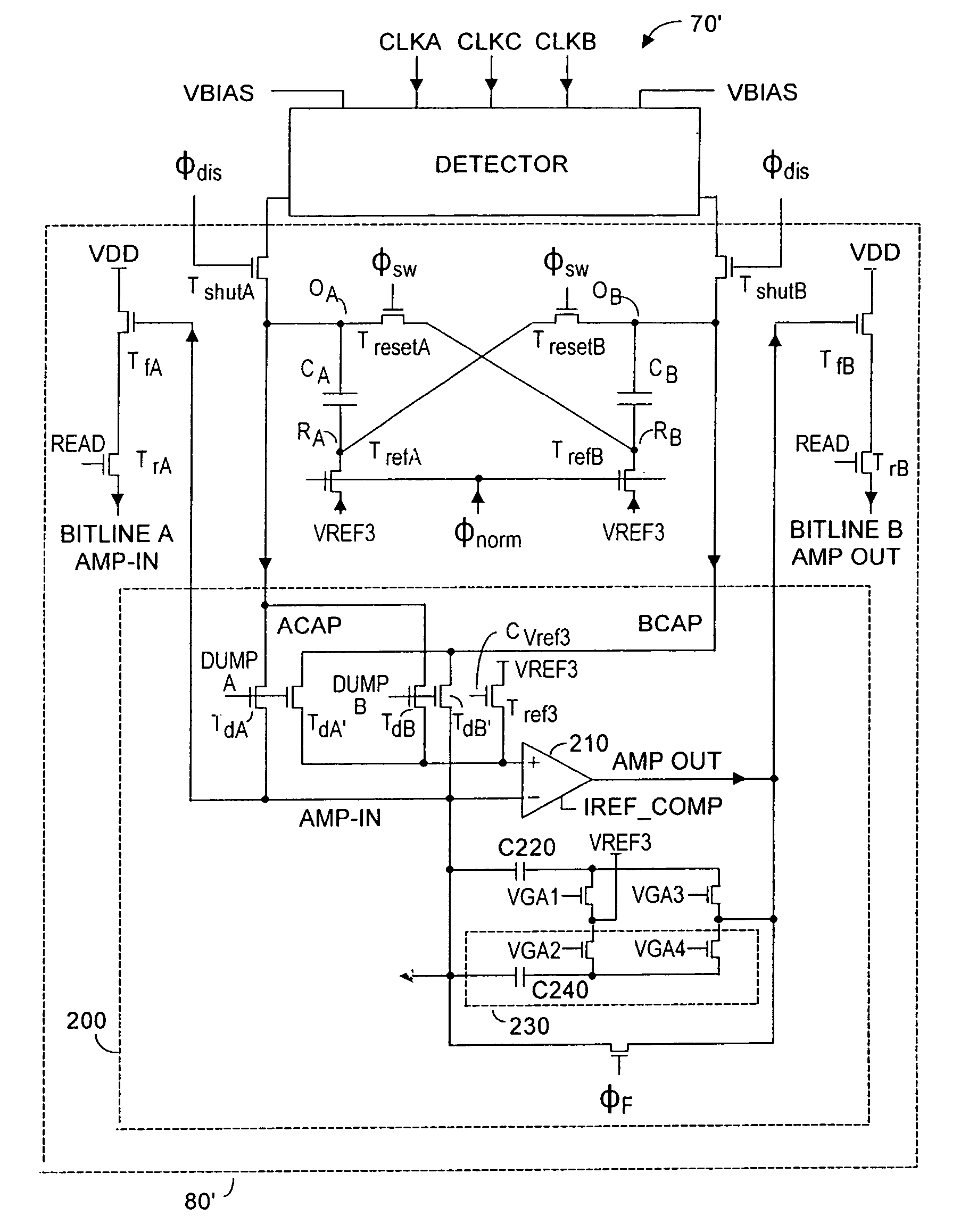

Method and system to enhance differential dynamic range and signal/noise in CMOS range finding systems using differential sensors

ActiveUS7157685B2Extend effective differential dynamic range of differentialInhibitionTelevision system detailsOptical rangefindersCMOSCapacitor voltage

Owner:MICROSOFT TECH LICENSING LLC

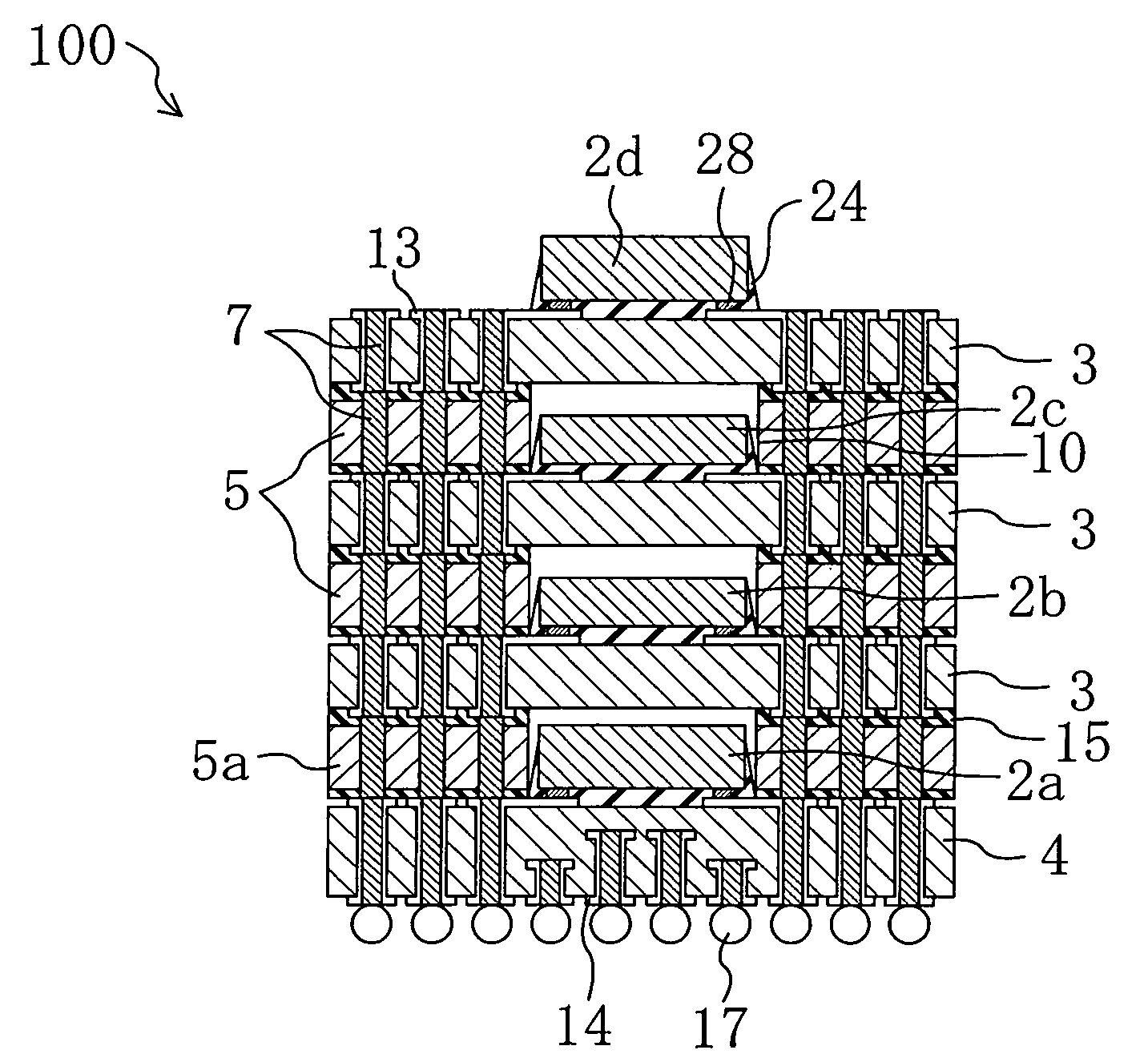

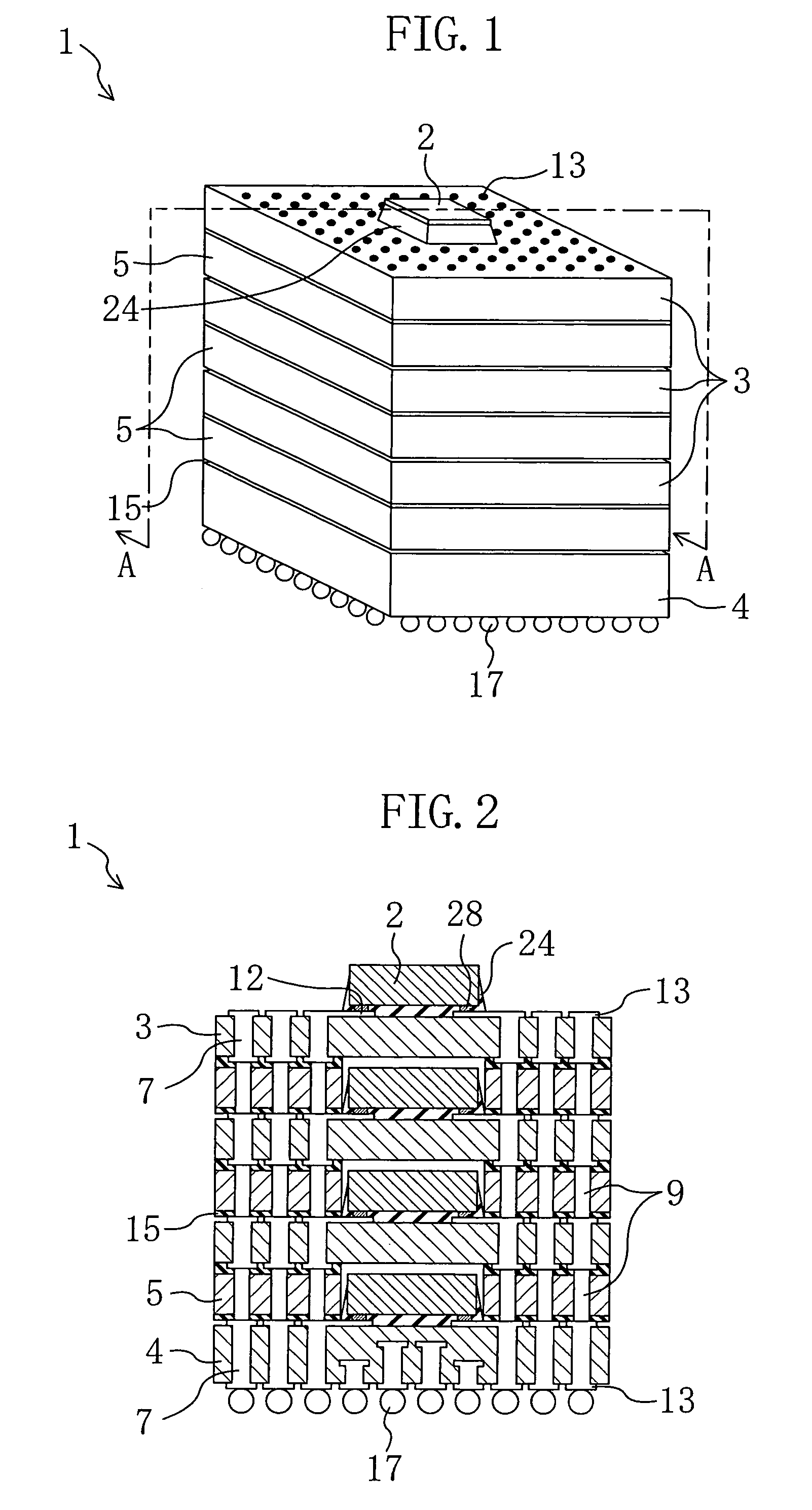

Multi-level semiconductor module and method for fabricating the same

ActiveUS7365416B2InhibitionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chip

A semiconductor module is formed by alternately stacking resin boards 3 on which semiconductor chips 2 are mounted and sheet members having openings larger than the semiconductor chips 2 and bonded to the resin boards 3. The resin board 4 located at the bottom out of the resin boards 3 is thicker than the other resin boards 3.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

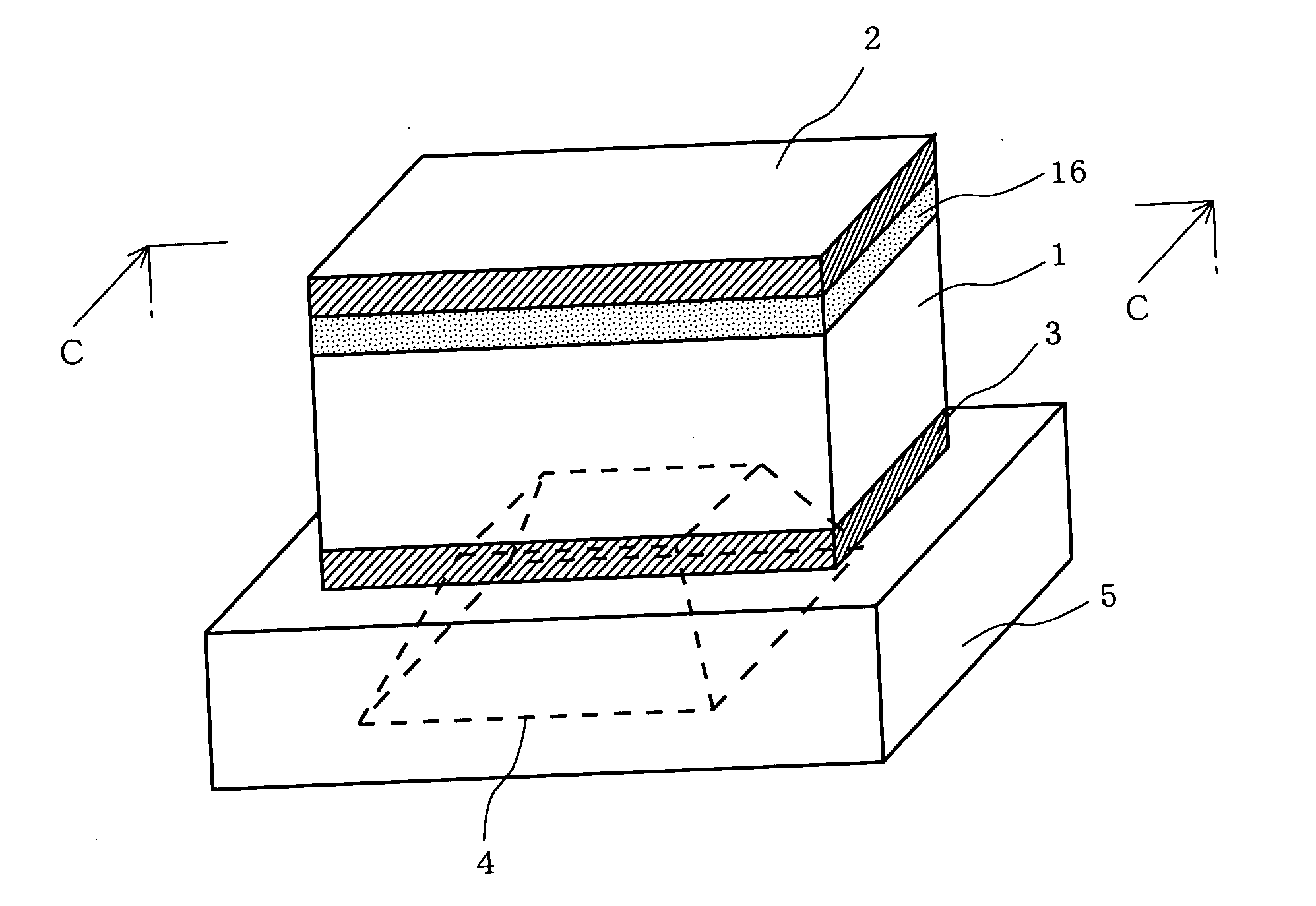

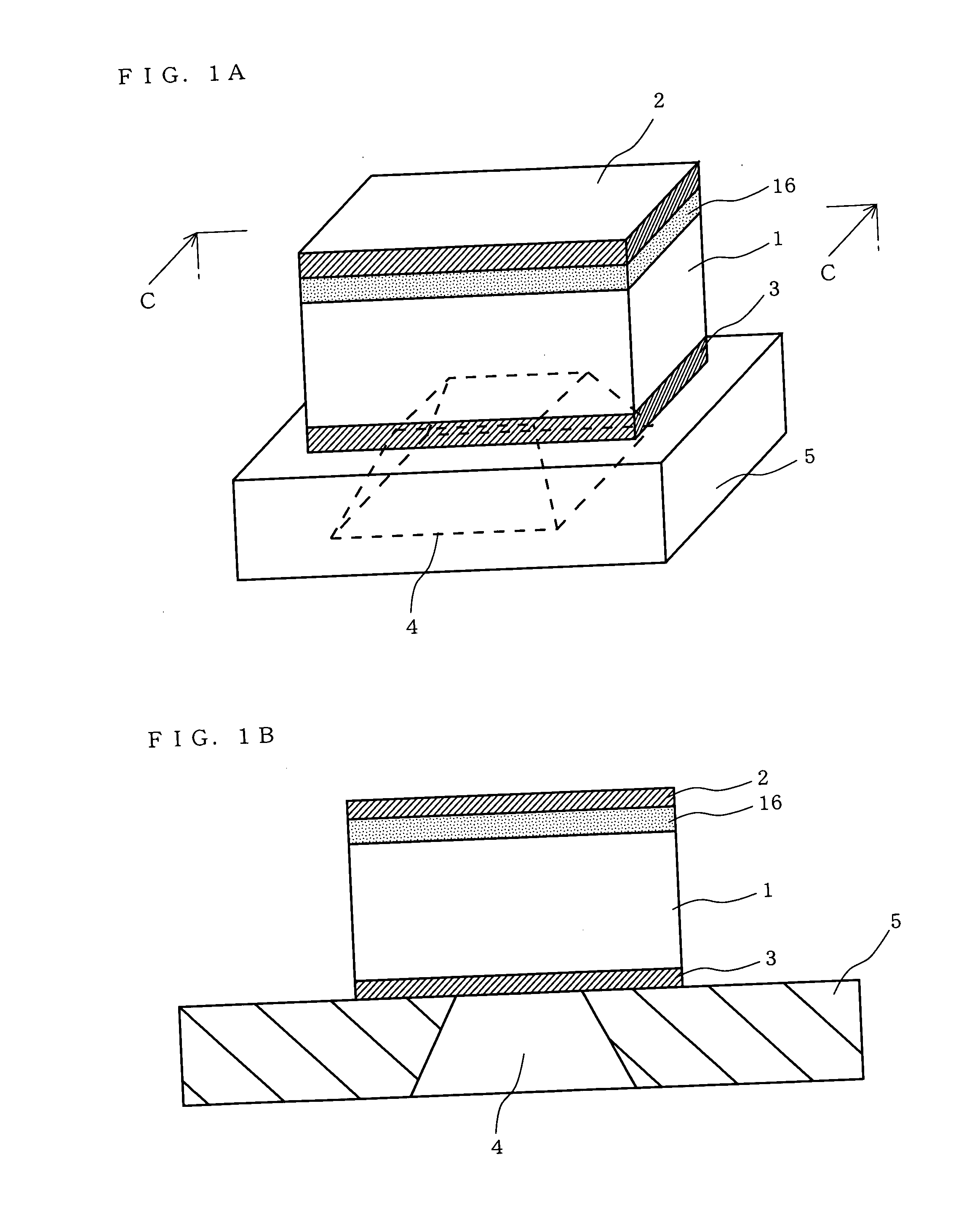

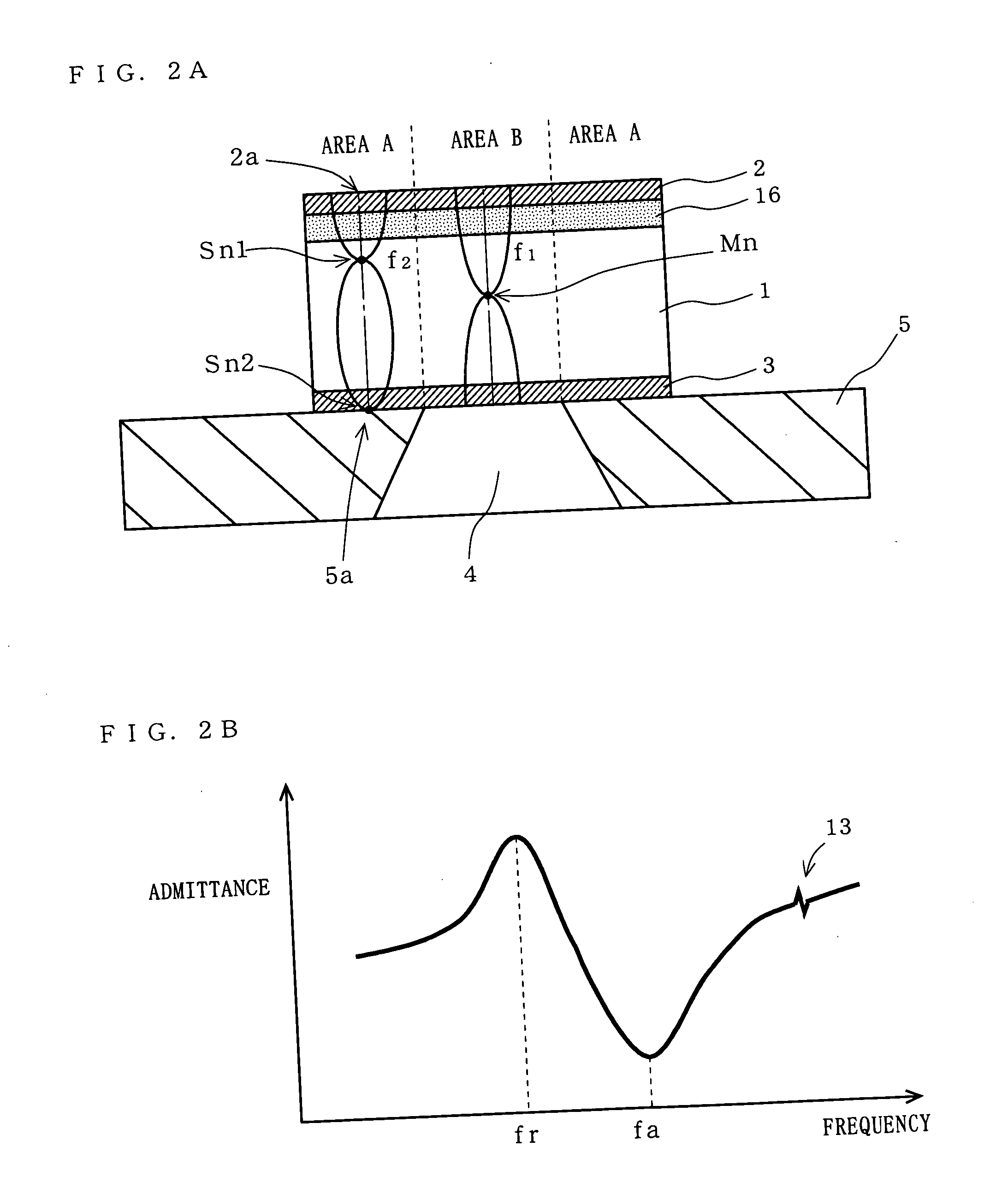

Piezoelectric resonator, filter, and duplexer

ActiveUS20050057117A1Avoid problemsInhibitionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksControl layerMetallic materials

A piezoelectric resonator of the present invention is structured such that on a substrate 5 having a cavity 4 formed therein, a lower electrode 3, a piezoelectric body 1, a spurious component control layer 16, and an upper electrode 2 are formed in this order from bottom up. The spurious component control layer 16 is a layer for controlling a spurious frequency, and composed of, for example, a metallic material, a dielectric material, or a piezo electric material. By additionally providing the spurious component control layer 16, it is made possible to cause variation of the spurious frequency due to unwanted variation to become greater than variation in resonance frequency of the main resonance of the piezoelectric resonator. Thus, it is possible to realize a piezoelectric resonator having an admittance frequency response where no spurious component occurs between resonance frequency fr and antiresonance frequency fa.

Owner:PANASONIC CORP

Method and system to differentially enhance sensor dynamic range using enhanced common mode reset

ActiveUS7176438B2Extend effective differential dynamic range of differentialInhibitionTelevision system detailsTelevision system scanning detailsAudio power amplifierPhotodetector

Owner:MICROSOFT TECH LICENSING LLC

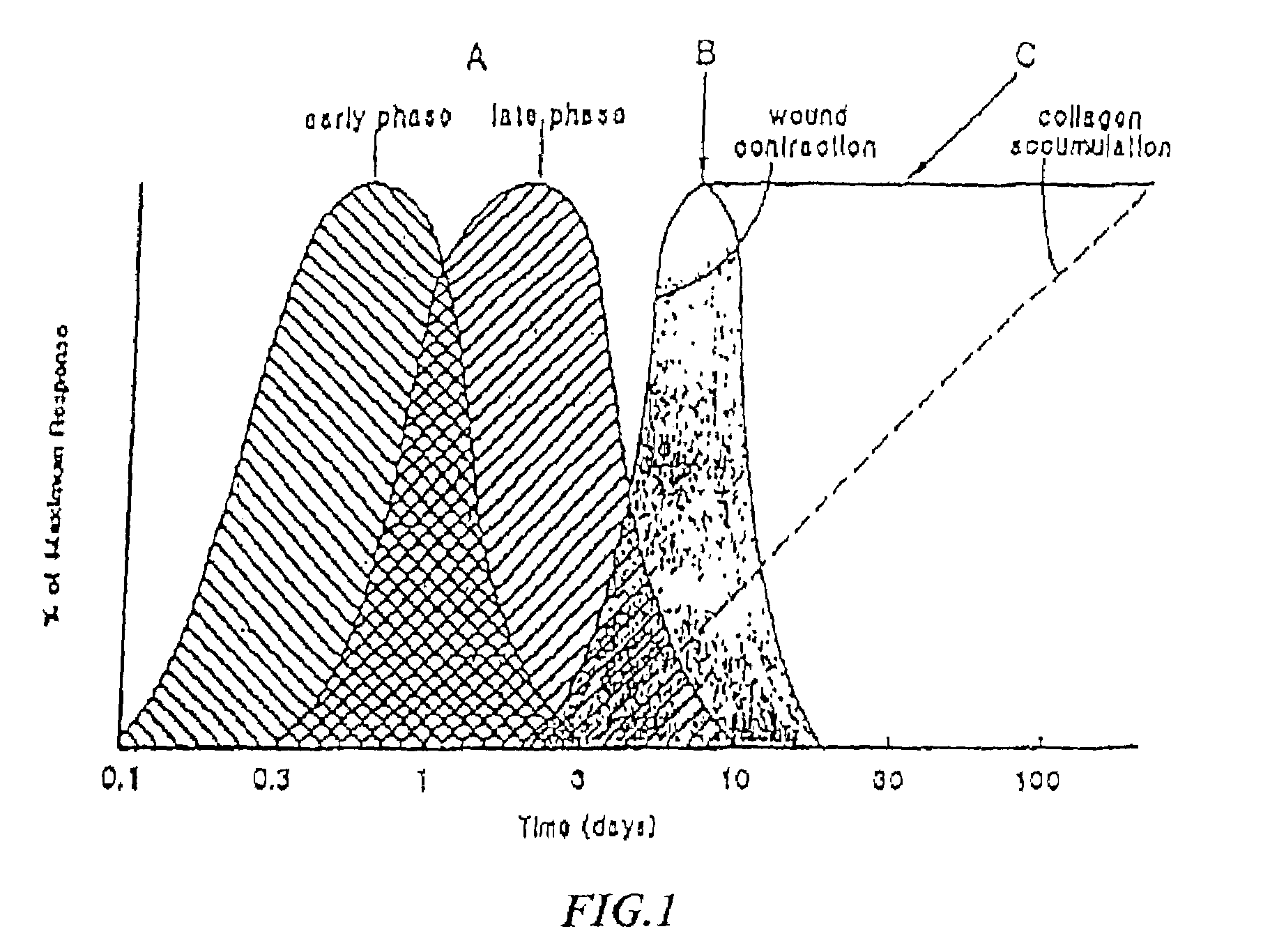

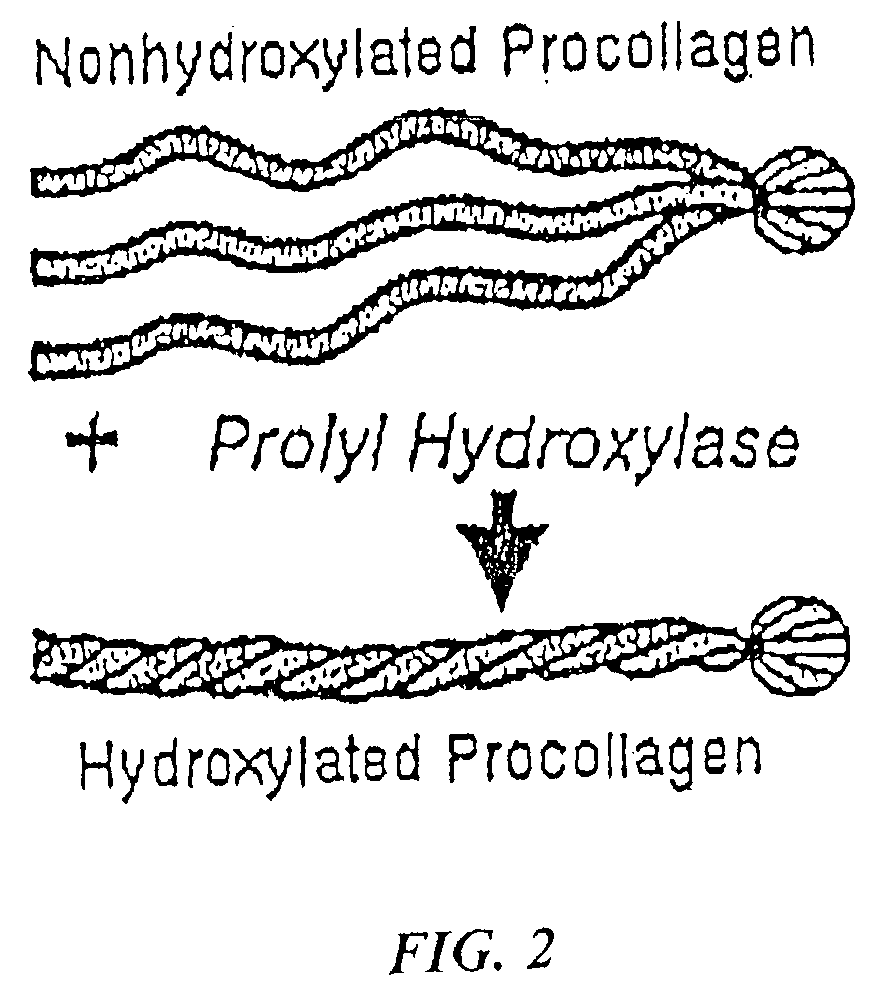

Prevention of regression in thermal ciliary muscle tendinoplasty

InactiveUS7044945B2Reduce the amplitudeReduce rangeLaser surgeryDiagnosticsCollagen shrinkageCross-link

Methods and apparatus are provided that prevent or inhibit functional regression caused by the stromal remodeling resulting from epithelial or fibroblastic apoptosis or necrosis in patients who will undergo or have undergone a thermal ciliary muscle tendinoplasty or scleral collagen shrinkage procedures. Methods and compositions are provided that prevent apoptosis in epithelial cells by stromal cooling during thermal tendinoplasty procedures; that create or restore stabilizing molecular cross-links between scleral stromal lamellar fibers; and that interrupt at least one step in the stromal remodeling response including inhibition of apoptosis, fibroblastic proliferation and migration, and inhibition of collagenesis.

Owner:SAND BRUCE J

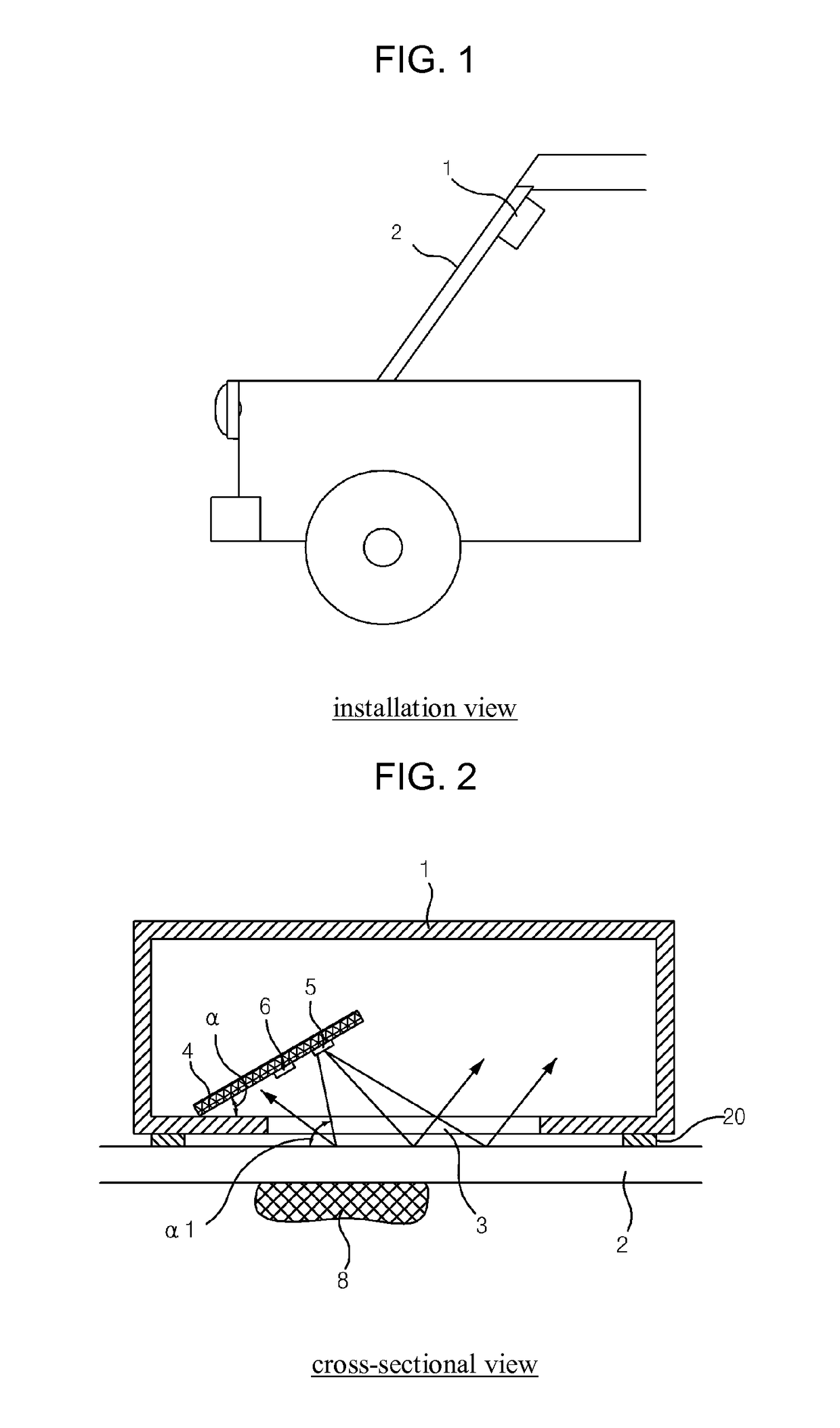

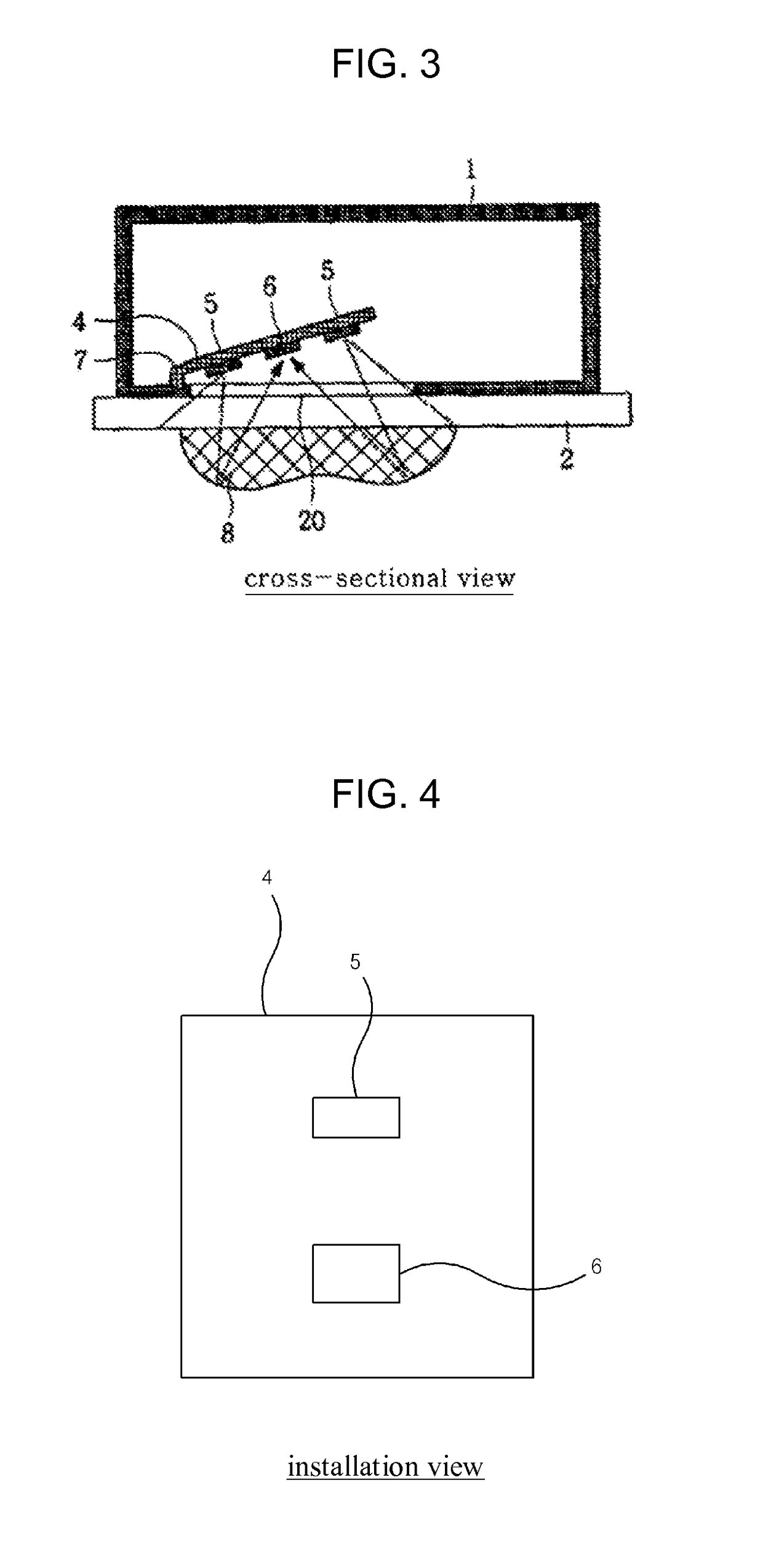

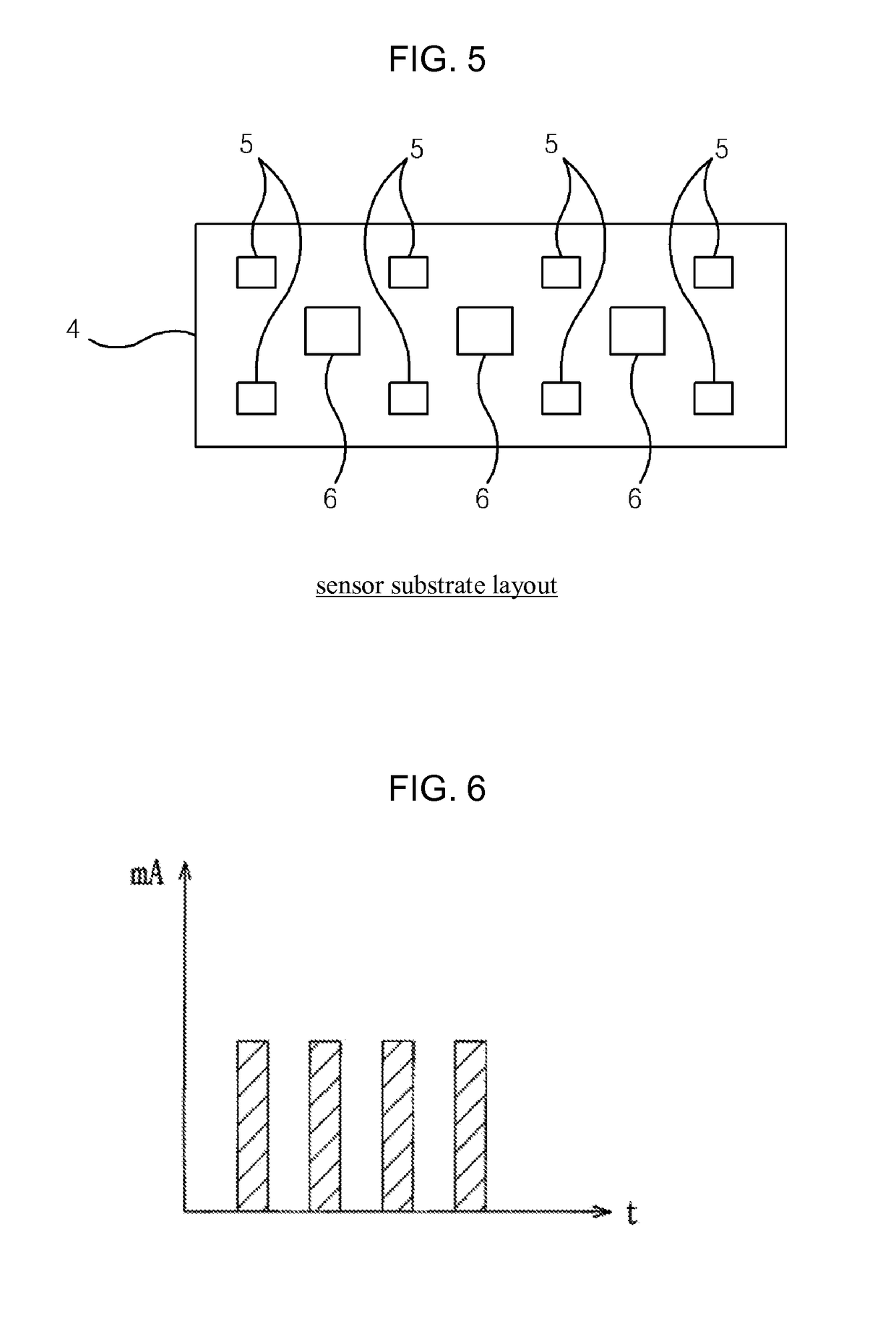

Rain sensor

ActiveUS8471513B2Low failure ratePrevent degradationOptical radiation measurementDC motor speed/torque controlOptoelectronicsRain sensor

During rain, including a light source (5) for radiating light such that the light is transmitted through a vehicle window (2), a light receiving element (6) for sensing an optical signal when the light radiated from the light source (5) is reflected from the raindrop fallen on the vehicle window (2) and performing a photoelectric transduction, and a receiver (9) for receiving the photoelectrically transduced signal from the light receiving element (6) and judging the level of rainfall. The light source (5) and the light receiving element (6) are inclined with respect to the surface of the vehicle window (2) such that the light of the light source (5) directly reflected from the vehicle window (2) exits to the outside of the light receiving element (6) and the light reflected from a raindrop (8) on the vehicle window (2) is received by the light receiving element (6) to operate a vehicle wiper.

Owner:HAN SEA YEOUN

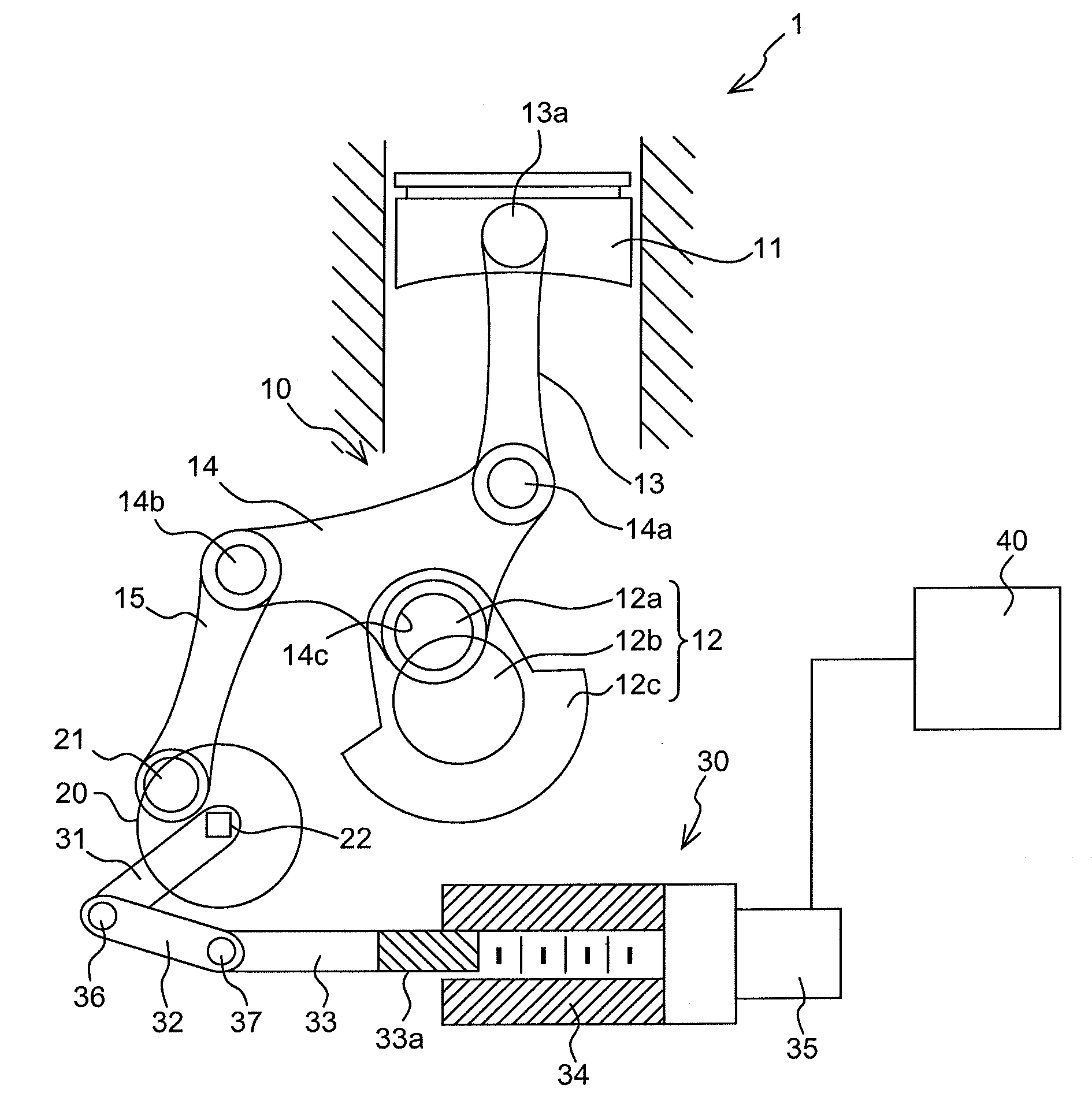

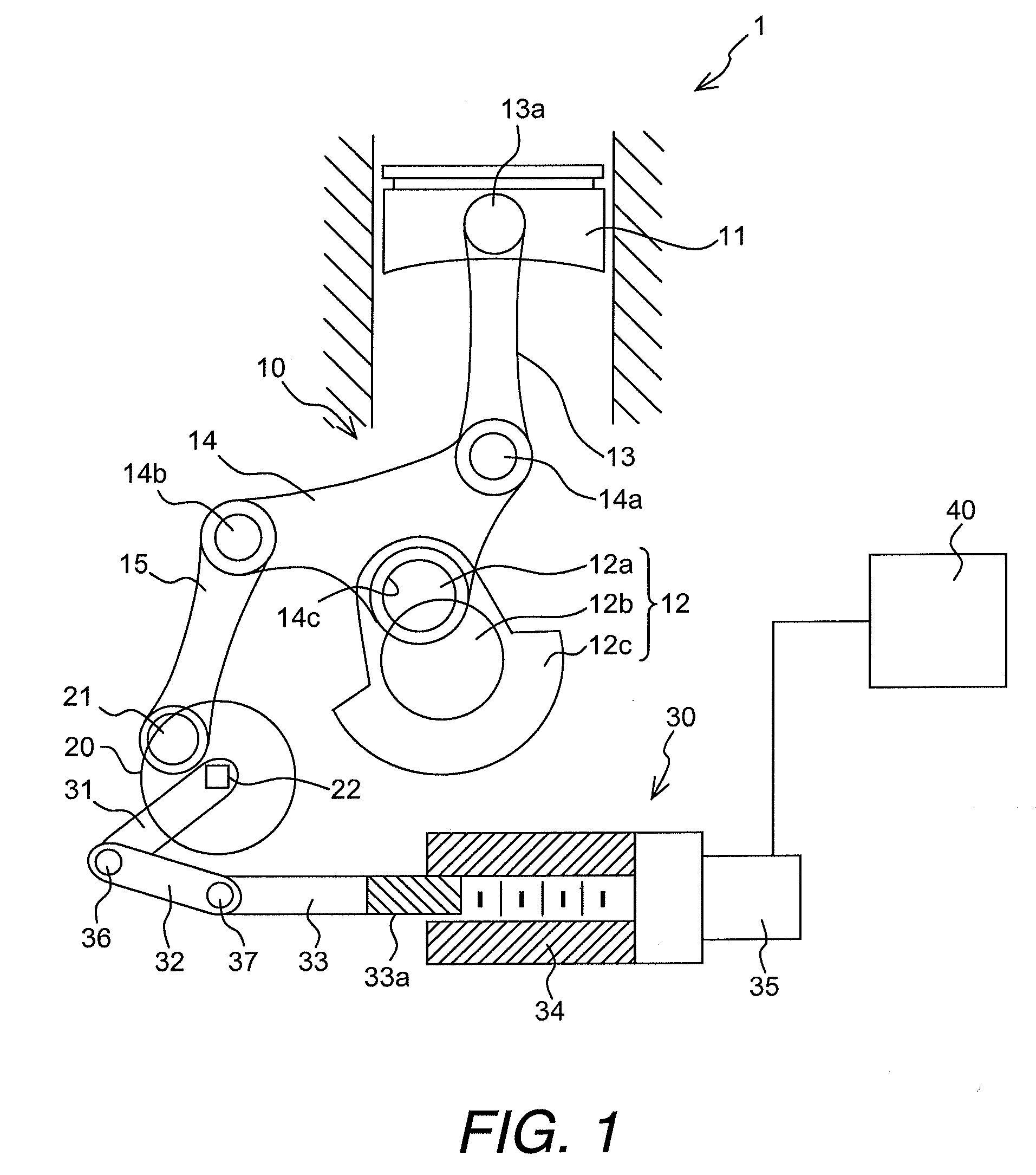

Multi-link variable compression ratio engine

ActiveUS20090107454A1Frequently knockedInhibitionConnecting rodsMachines/enginesTop dead centerReduction ratio

A multi-link variable compression ratio engine is provided with a crankshaft, a piston, a control shaft, a linkage, a motor and a reduction mechanism. The crankshaft moves the piston within an engine cylinder. The control shaft has an eccentric axle eccentric relative to its center-axis. The linkage operatively connects the piston to the crankshaft and the crankshaft to the eccentric axle of the control shaft. The motor rotates the control shaft so a top-dead-center position of the piston changes to vary compression ratios by changing the positions of the eccentric axle and the linkage. The reduction mechanism couples the motor to the control shaft to transmit a reduced rotation of the motor to the control shaft so a reduction ratio of a rotation angle of the motor to a rotation angle of the control shaft is less at high-compression ratios than at intermediate compression ratios.

Owner:NISSAN MOTOR CO LTD

System and method for automatically suggesting diverse and personalized message completions

ActiveUS20150058720A1Increase productivityImprove user experienceAlphabetical characters enteringNatural language data processingPersonalizationConfidence threshold

Disclosed is a system and method for suggesting messages that are automatically learned, personalized and diversified by leveraging messages sent by a large number of users in order to provide message completions that are as engaging as possible. The disclosed systems and methods learn from recurrent messages sent to a recipient, and suggest message completions based upon user behavior. The systems and methods compute a ranked list of suggested message completions after every key stroke or character input, and if the list satisfies a given confidence threshold, it is returned and displayed to the user.

Owner:R2 SOLUTIONS

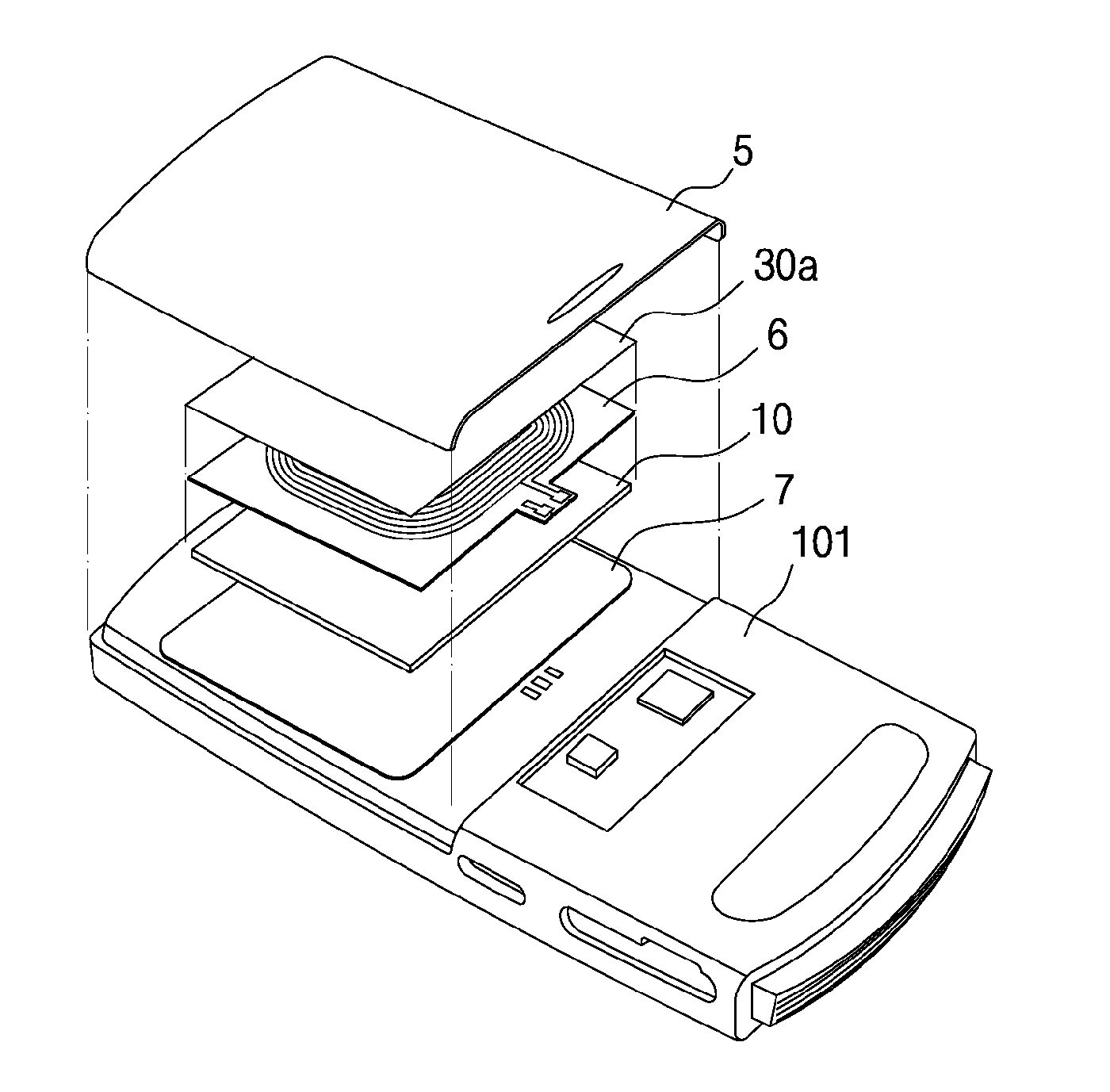

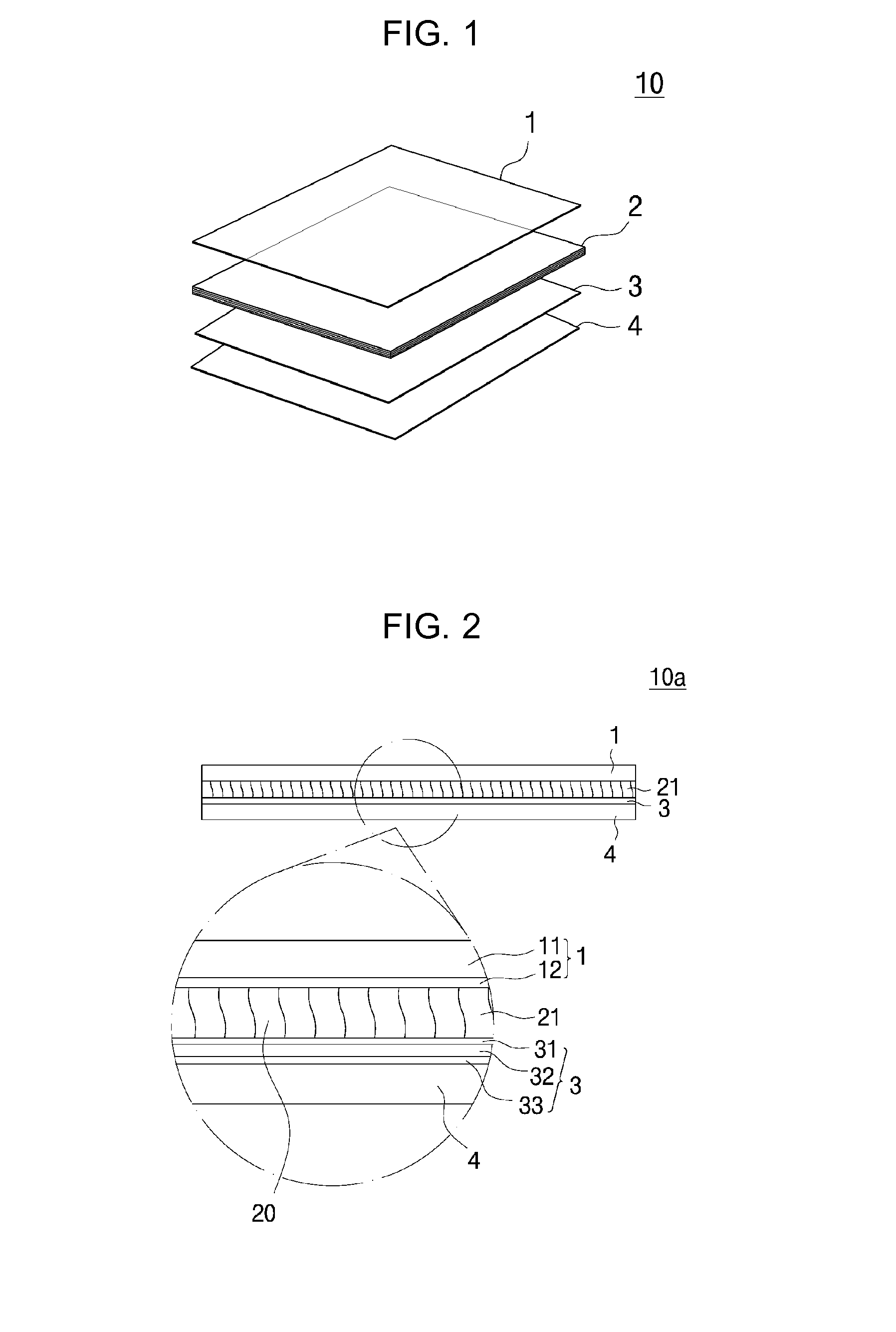

Magnetic field shielding sheet for a wireless charger, method for manufacturing same, and receiving apparatus for a wireless charger using the sheet

ActiveUS20150123604A1Reduce lossesHigh quality factorNear-field transmissionShielding materialsElectric power transmissionTerminal equipment

Provided are a magnetic field shield sheet for a wireless charger, which blocks an effect of an alternating-current magnetic field generated when a charger function for a portable mobile terminal device is implemented in a non-contact wireless manner on a main body of the portable mobile terminal device and exhibits excellent electric power transmission efficiency, a method of manufacturing the sheet, and a receiver for the wireless charger by using the sheet. The sheet includes: at least one layer thin magnetic sheet made of an amorphous ribbon separated into a plurality of fine pieces; a protective film that is adhered on one surface of the thin magnetic sheet via a first adhesive layer provided on one side of the protective film; and a double-sided tape that is adhered on the other surface of the thin magnetic sheet via a second adhesive layer provided on one side of the double-sided adhesive tape, wherein gaps among the plurality of fine pieces are filled by some parts of the first and second adhesive layers, to thereby isolate the plurality of fine pieces.

Owner:AMOSENSE

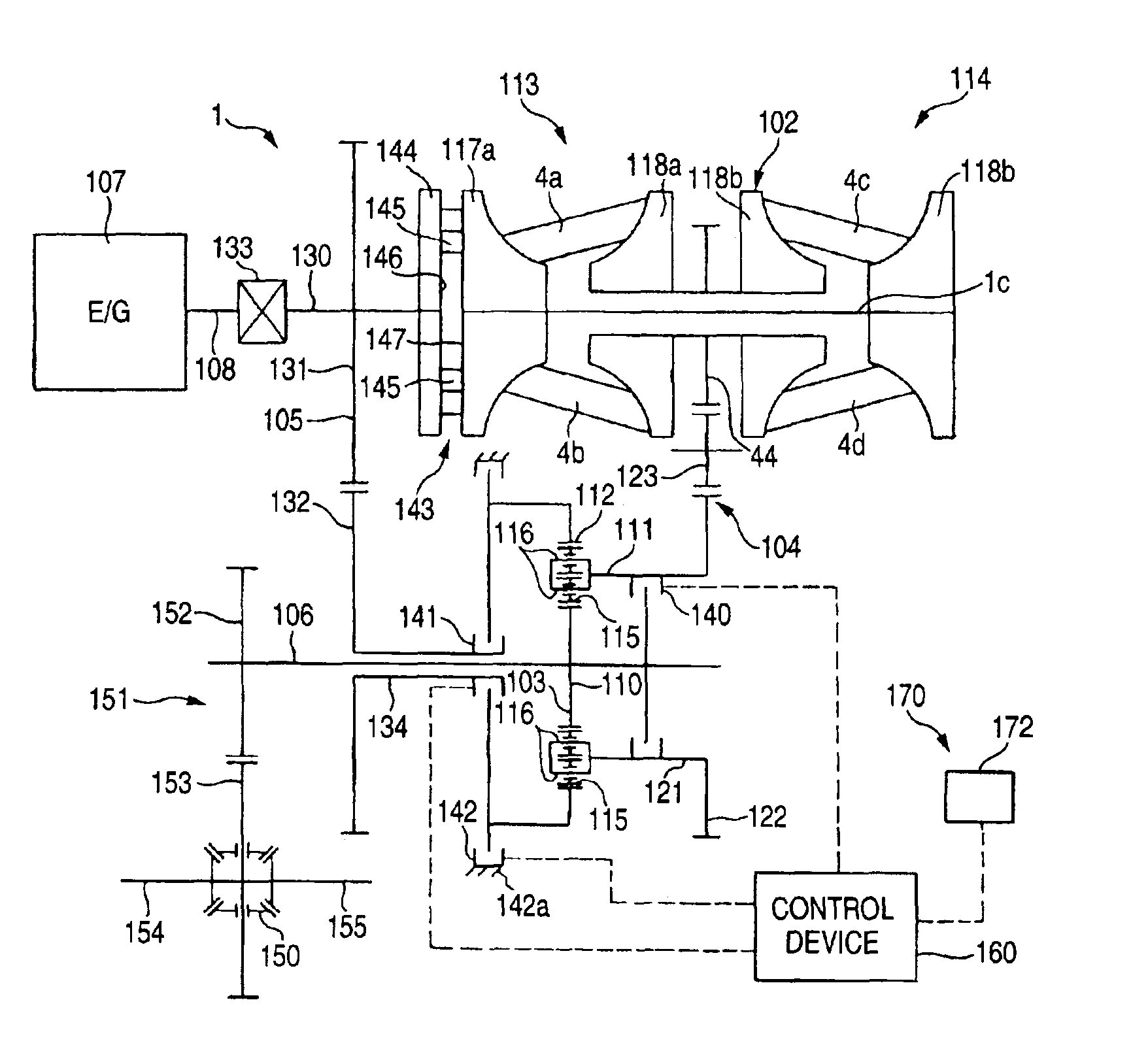

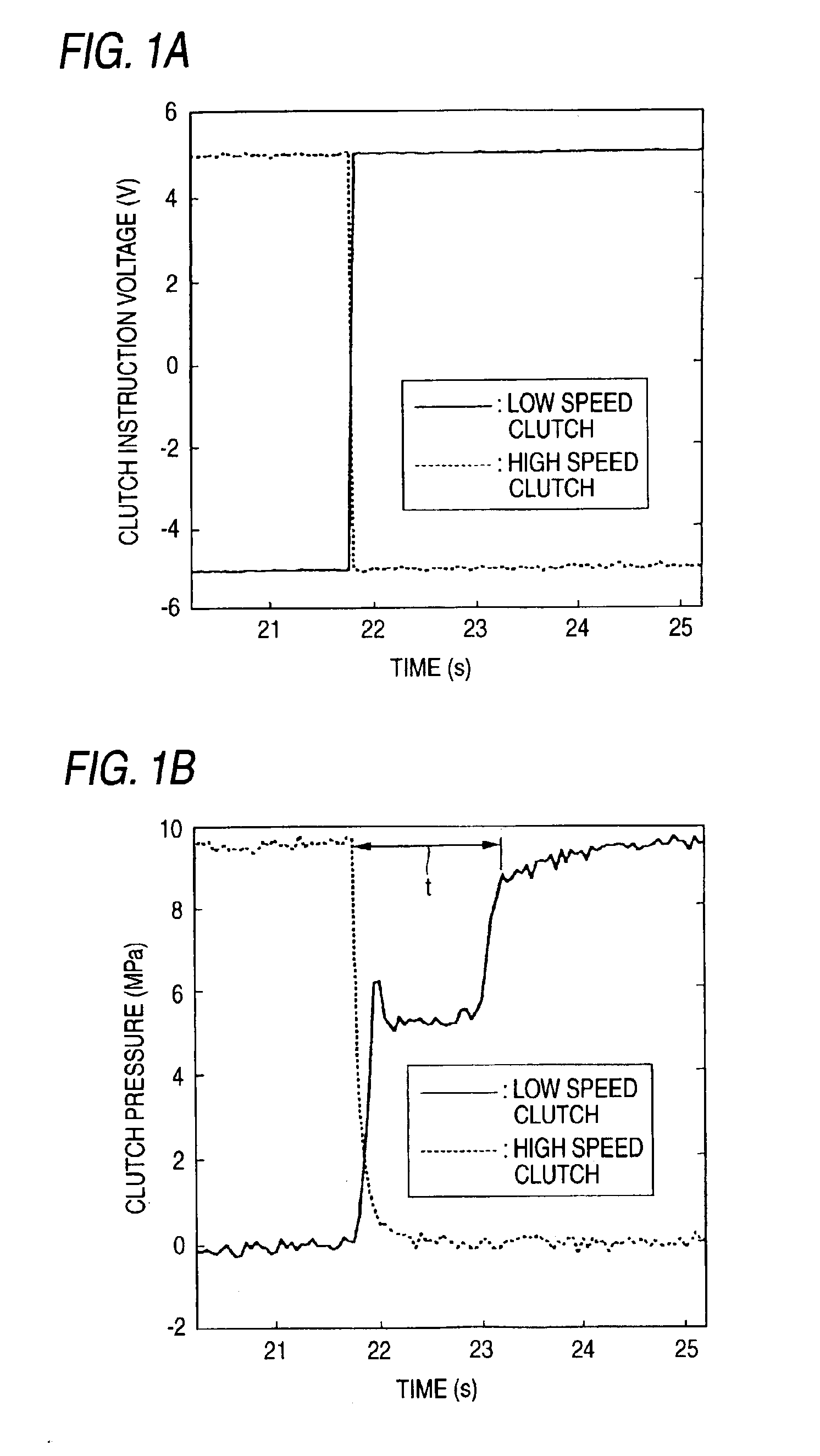

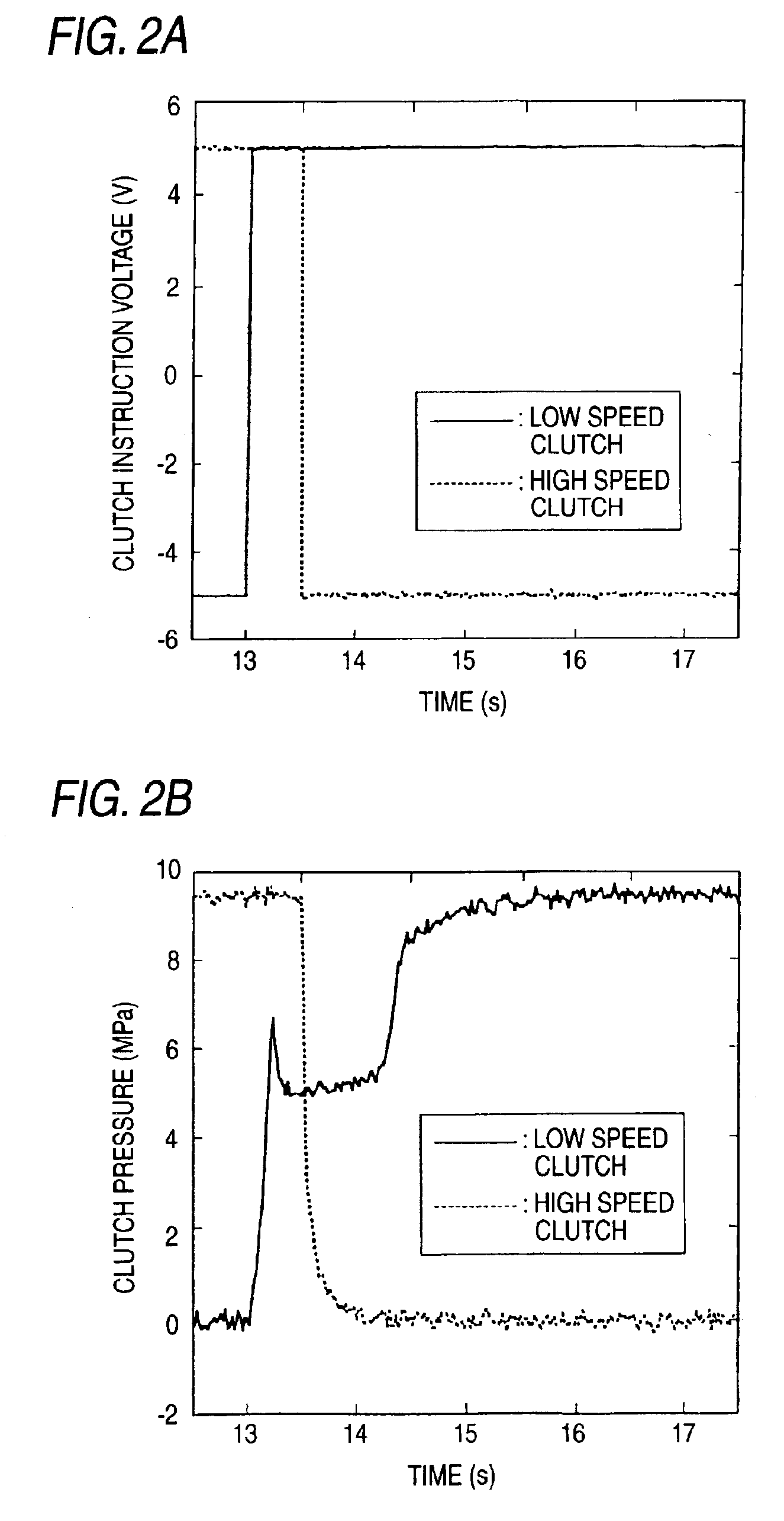

Continuously variable transmission apparatus

A continuously variable transmission apparatus has clutch device having a low speed clutch; a high speed clutch; and, a controller switching the transmission state into any one of a low speed mode and a high speed mode by connecting any one of the clutches, wherein timings for signaling by the controller for switching the connected and disconnected states of the clutches vary according to the switching directions of the low speed and high speed modes; and, a timing for signaling for connecting the low speed clutch with respect to the moment for signaling for cutting off the connection of the high speed clutch in order to switch the high speed mode over to the low speed mode is set earlier than a timing for signaling for connecting the high speed clutch with respect to the moment for signaling for cutting off the connection of the low speed clutch.

Owner:NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com