Patents

Literature

196 results about "Liquid diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vater-absorbent resin composition and its production process

ActiveUS20060073969A1Little gel-blockingGood liquid permeabilityNon-fibrous pulp additionOther chemical processesLiquid diffusionCompound (substance)

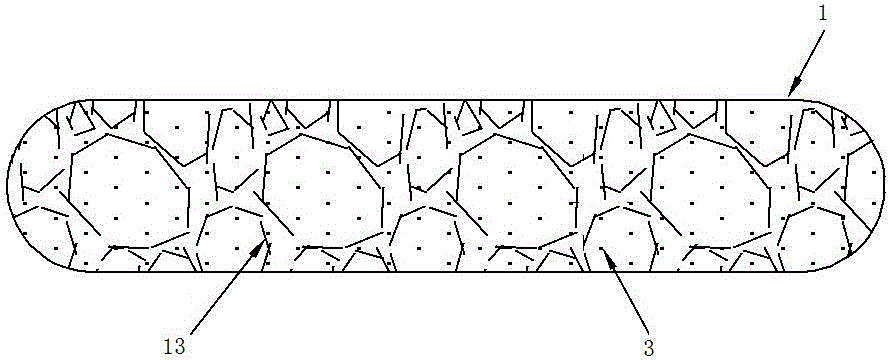

There are disclosed a water-absorbent resin composition and its production process, wherein the water-absorbent resin composition causes little gel-blocking and is excellent in the liquid permeability and liquid diffusibility and is high also in the absorption performances and further is strong also against the physical damage; and there are further disclosed a water-absorbent resin composition and its production process, wherein the water-absorbent resin composition has the following further advantages, in addition to the above, of involving little segregation of the metal compound and further having a dust prevention effect. One of water-absorbent resin compositions according to the present invention is a water-absorbent resin composition comprising water-absorbent resin particles obtained by polymerizing a monomer including acrylic acid and / or its salt, with the composition having a mass-average particle diameter of 100 to 600 μm and comprising water-soluble polyvalent metal salt particles and the water-absorbent resin particles that have been surface-crosslinked.

Owner:NIPPON SHOKUBAI CO LTD

Water absorbent resin composition and production method thereof

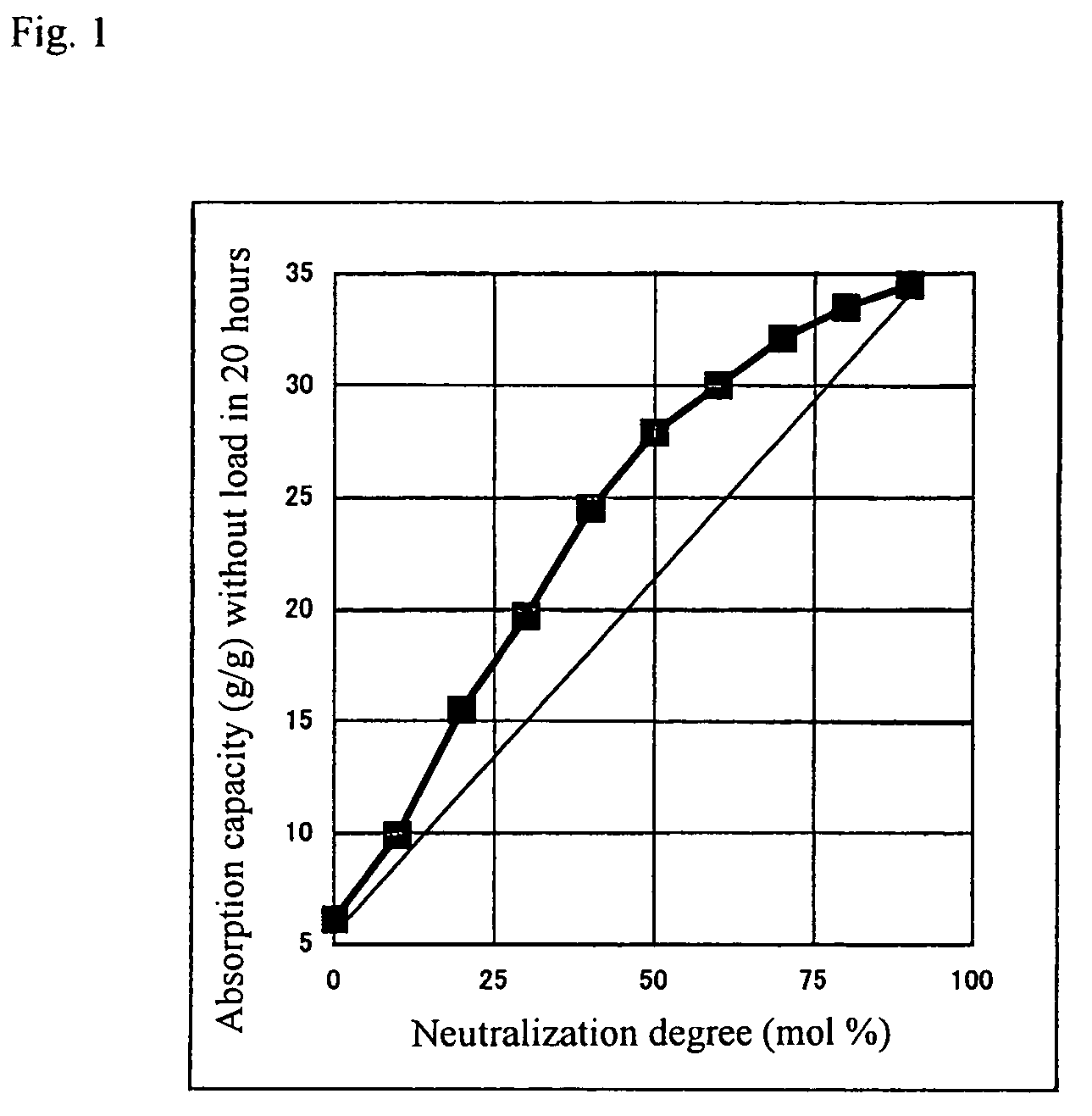

InactiveUS20050288182A1Promote absorptionInhibitionOther chemical processesBaby linensCross-linkAbsorption capacity

The water absorbent resin composition and the production method thereof according to the present invention are characterized by including: water absorbent resin particles having an internal cross-linked structure obtained by polymerizing a water-soluble unsaturated monomer; a nitrogenous ketone compound (A) (containing no carboxyl group) having a structure represented by formula (1); and a bivalent and / or trivalent and / or tetravalent water-soluble metal salt, wherein a total amount of the nitrogenous ketone compound (A) and the bivalent and / or trivalent and / or tetravalent water-soluble metal salt ranges from 0.01 to 100 parts by mass with respect to 100 parts by mass of the water absorbent resin particles, thereby providing a water absorbent resin composition, having an excellent absorption capacity represented by a centrifuge retention capacity (CRC), an absorbency against pressure of 4.83 kPa (AAP) etc., having excellent liquid permeability and liquid diffusion properties, having excellent fluidity at the time of moisture absorption, having an excellent damage resistance property, effectively suppressing occurrence of dusts, hardly bringing about permeation of added metal compounds into water absorbent resin particles, hardly bringing about segregation of added metal compounds.

Owner:NIPPON SHOKUBAI CO LTD

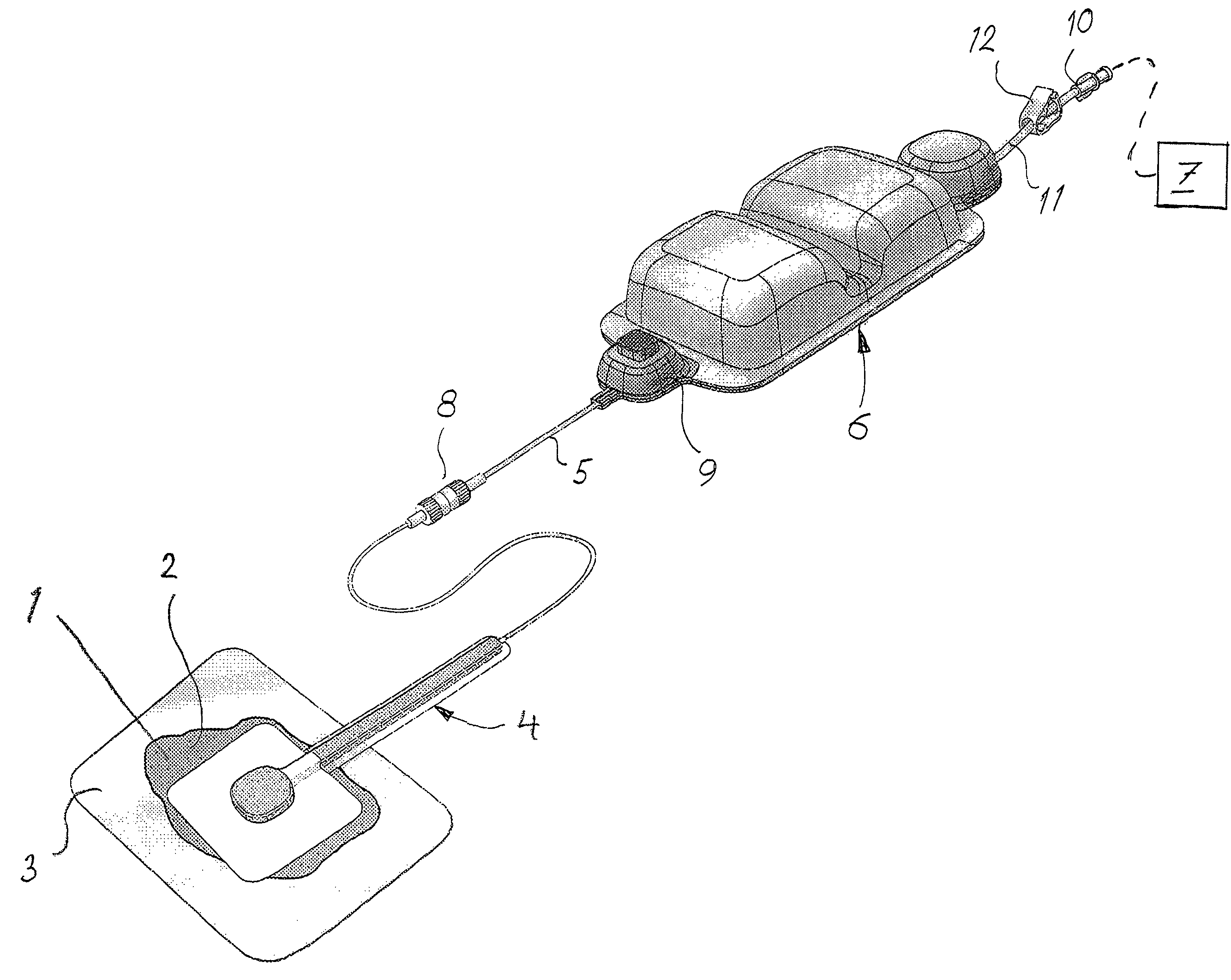

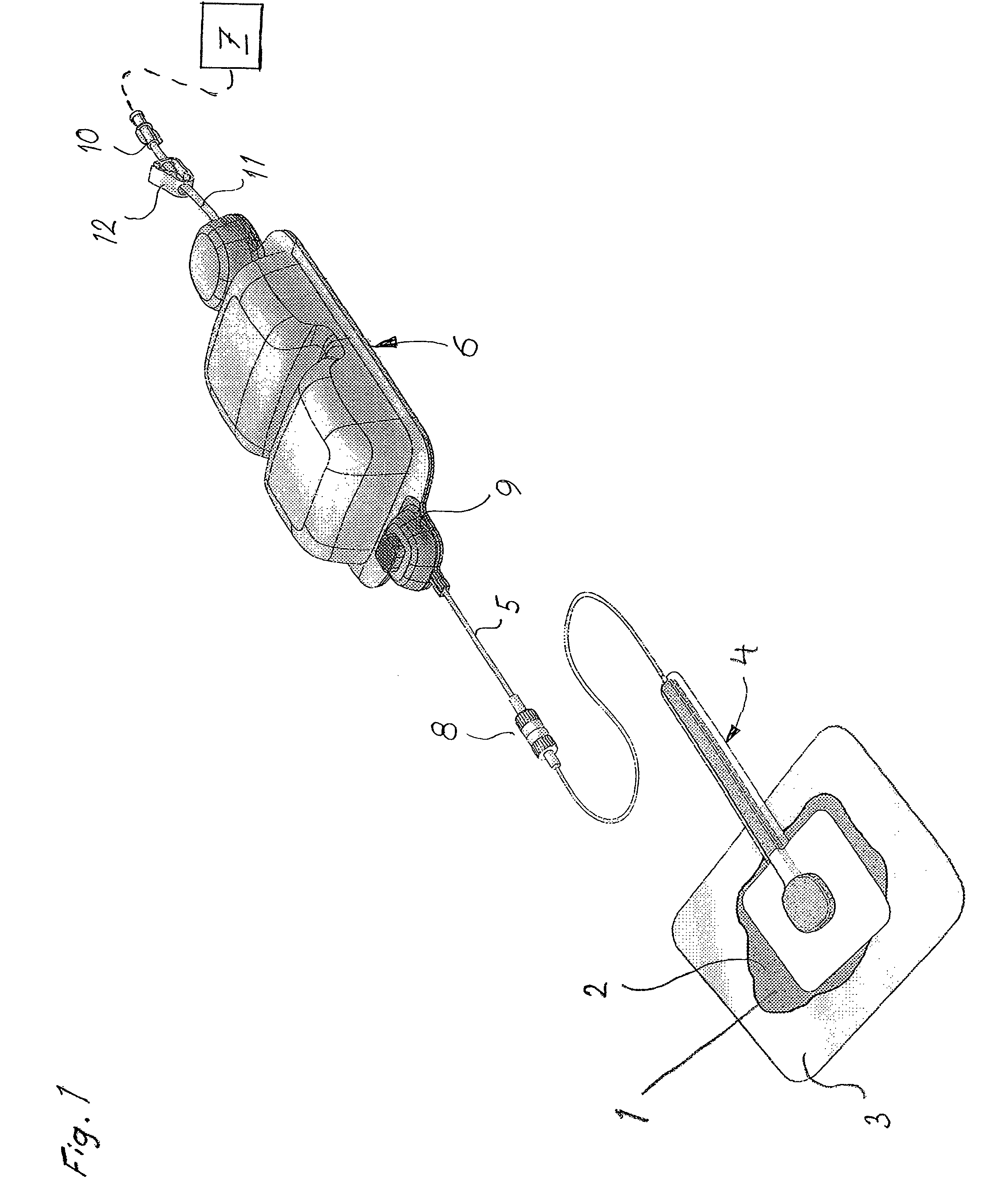

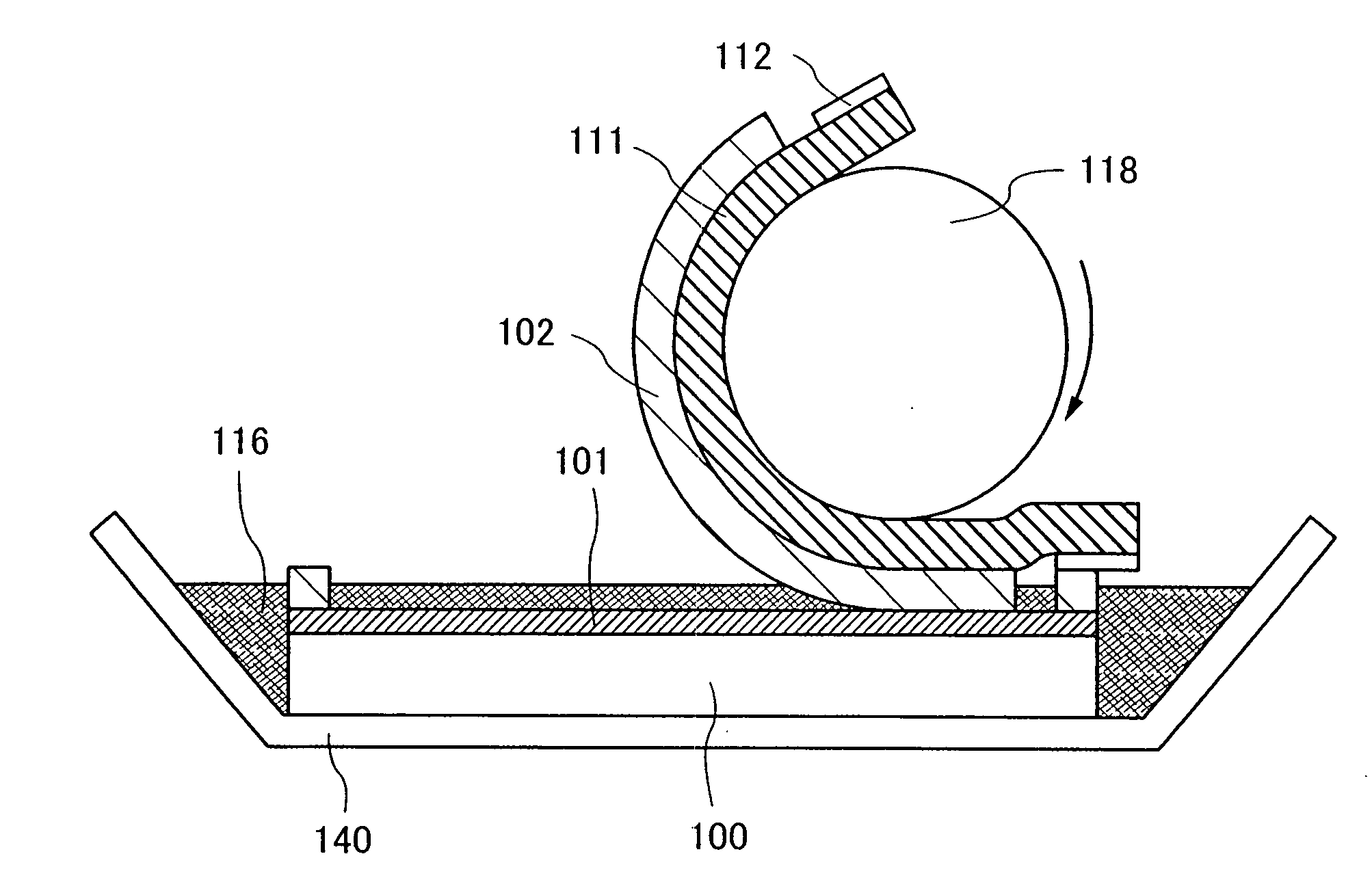

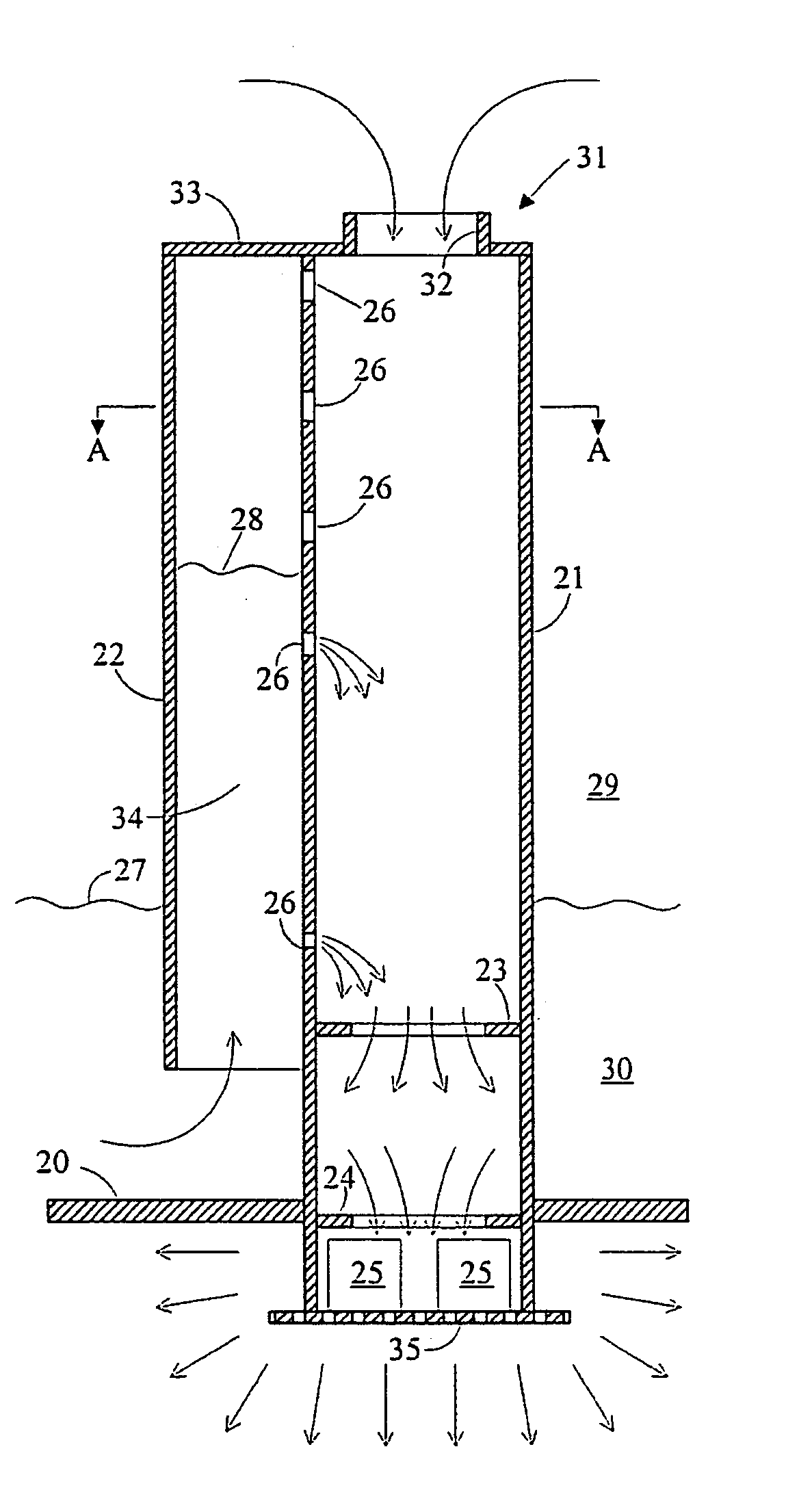

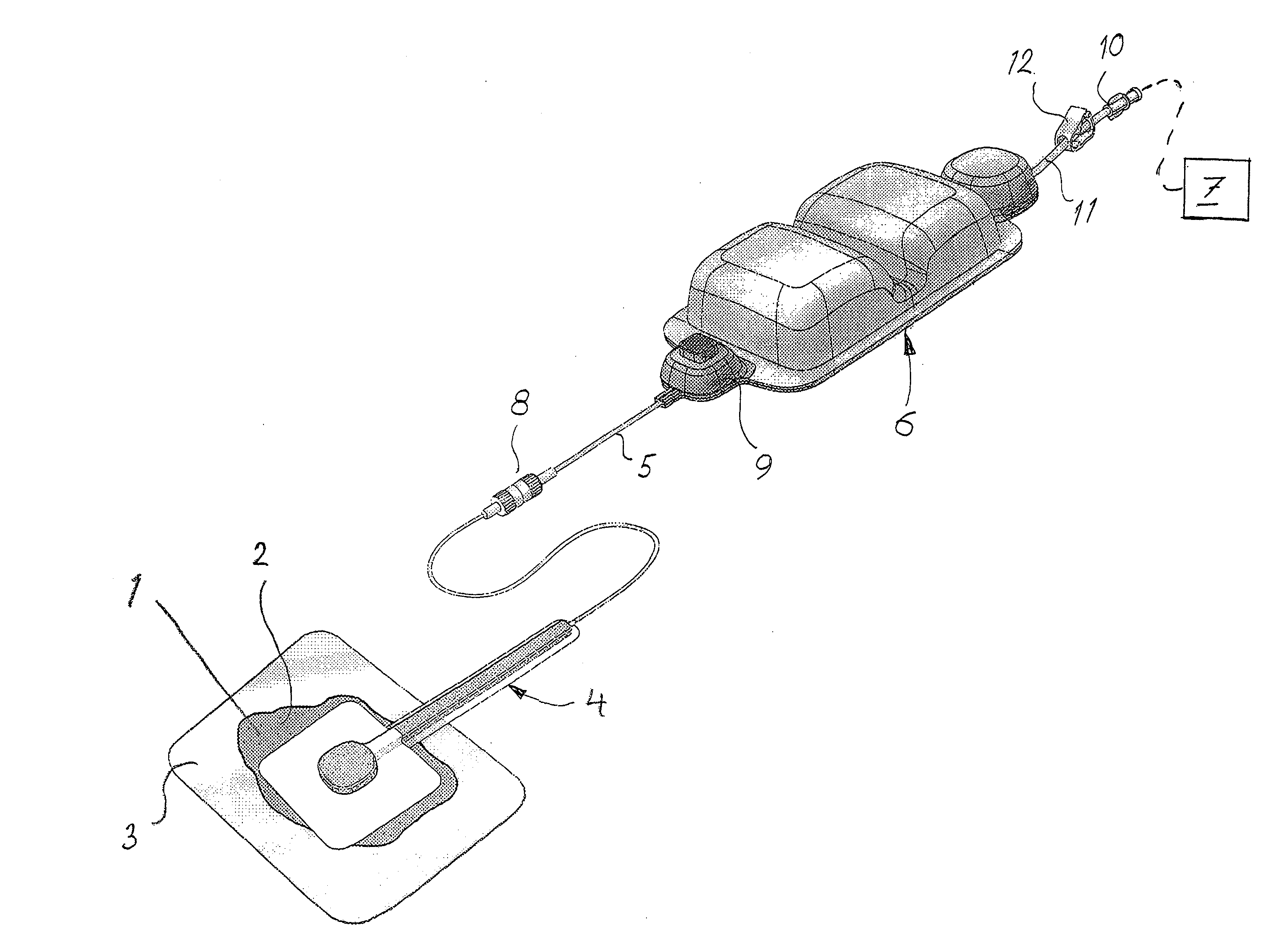

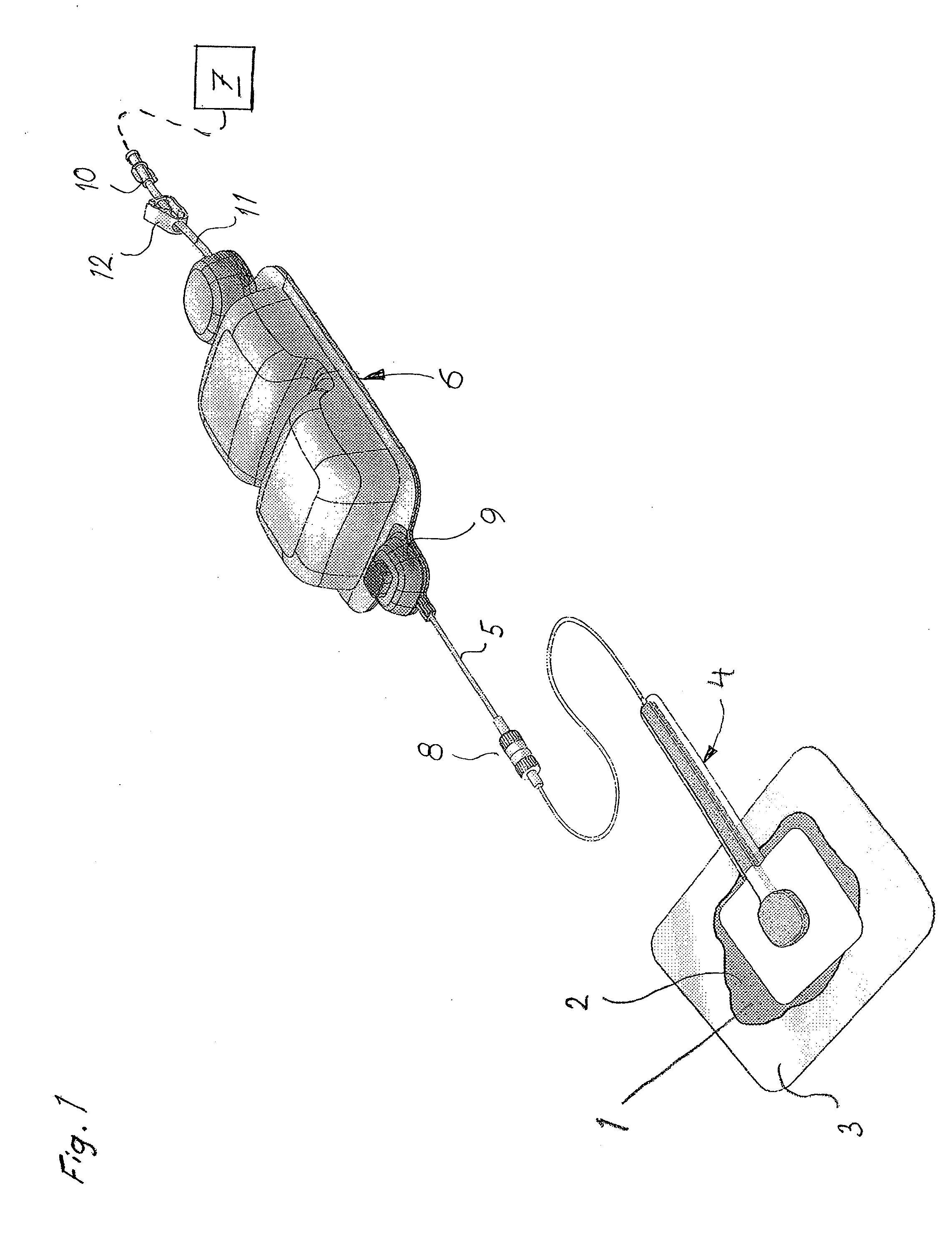

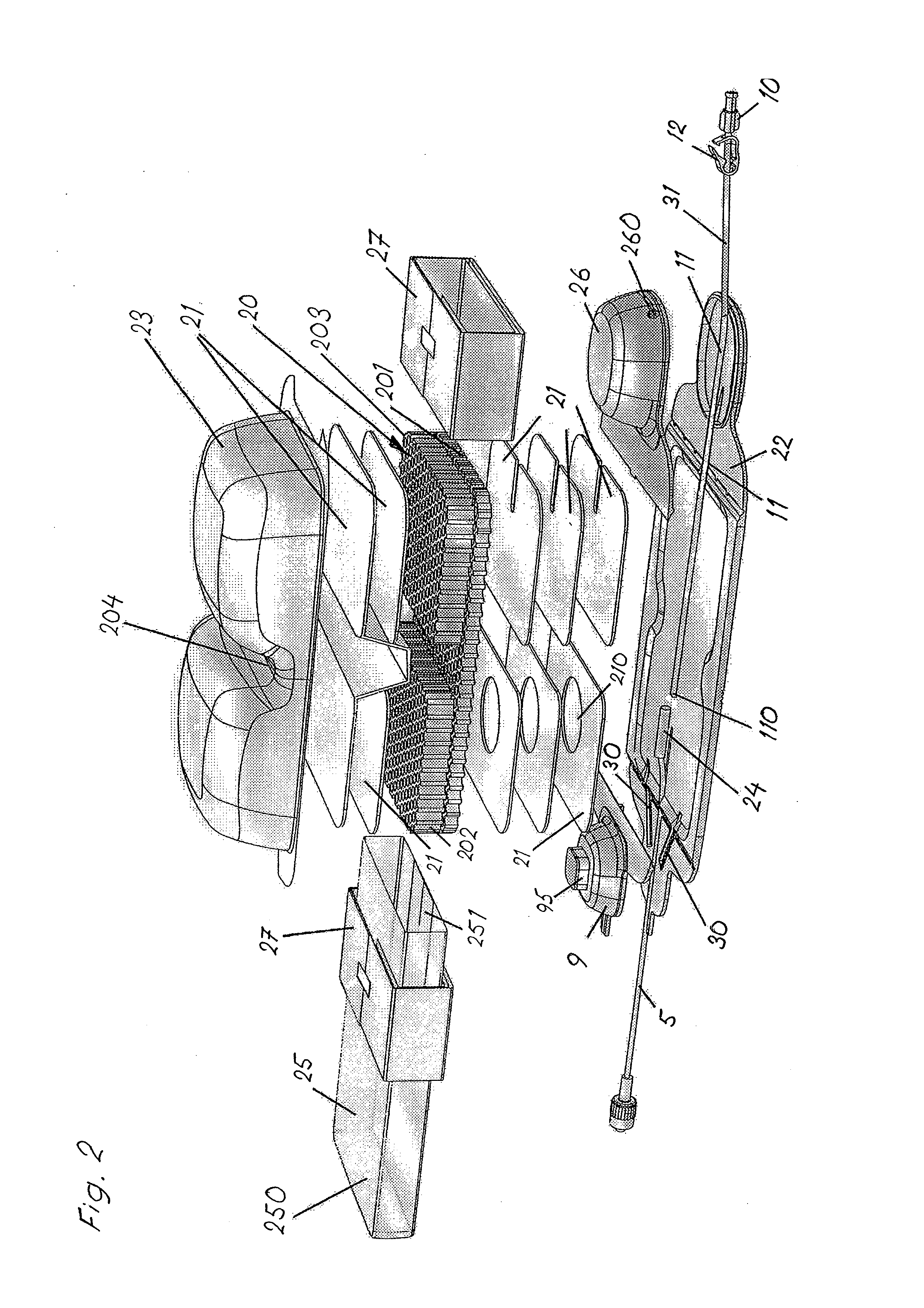

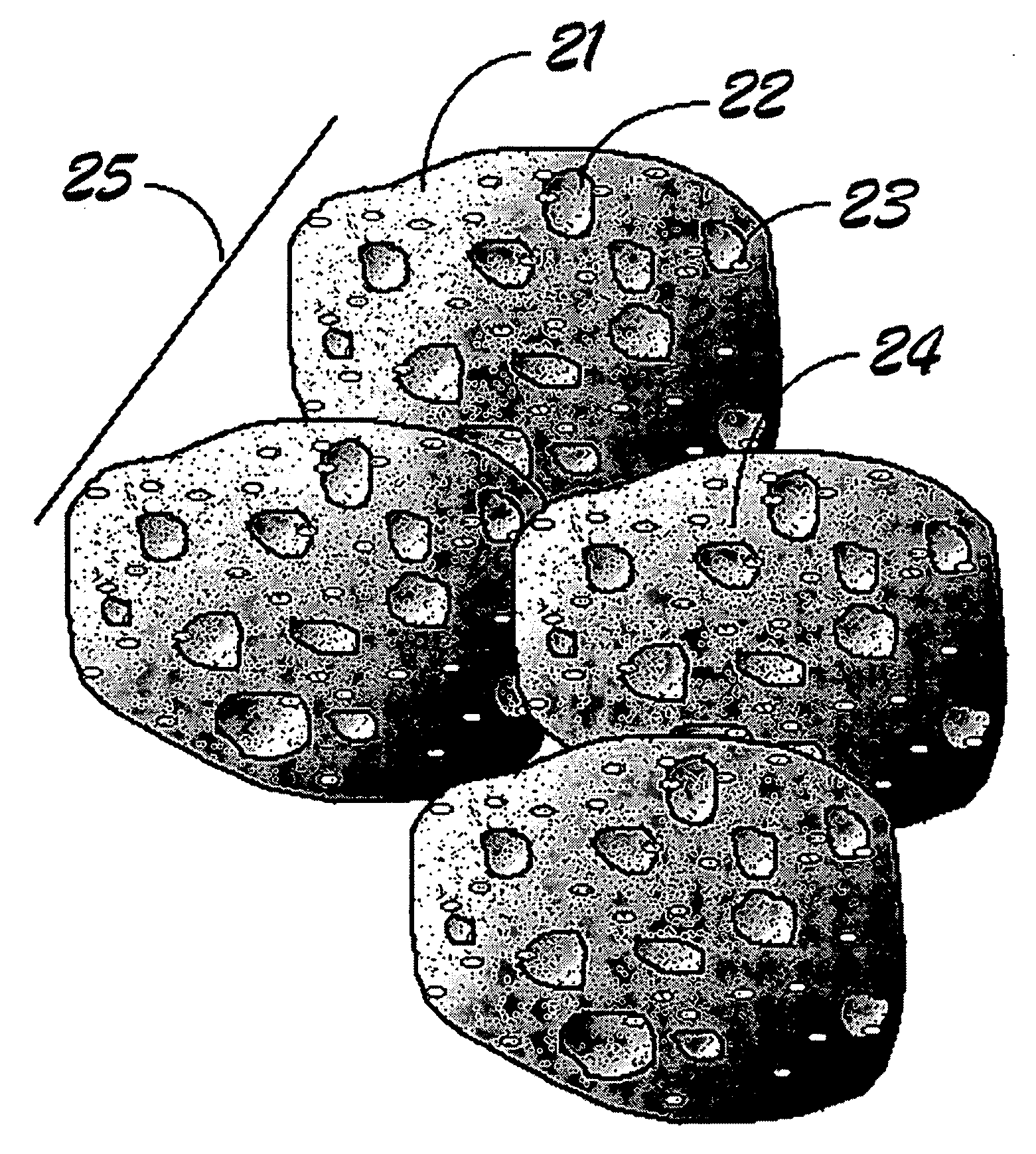

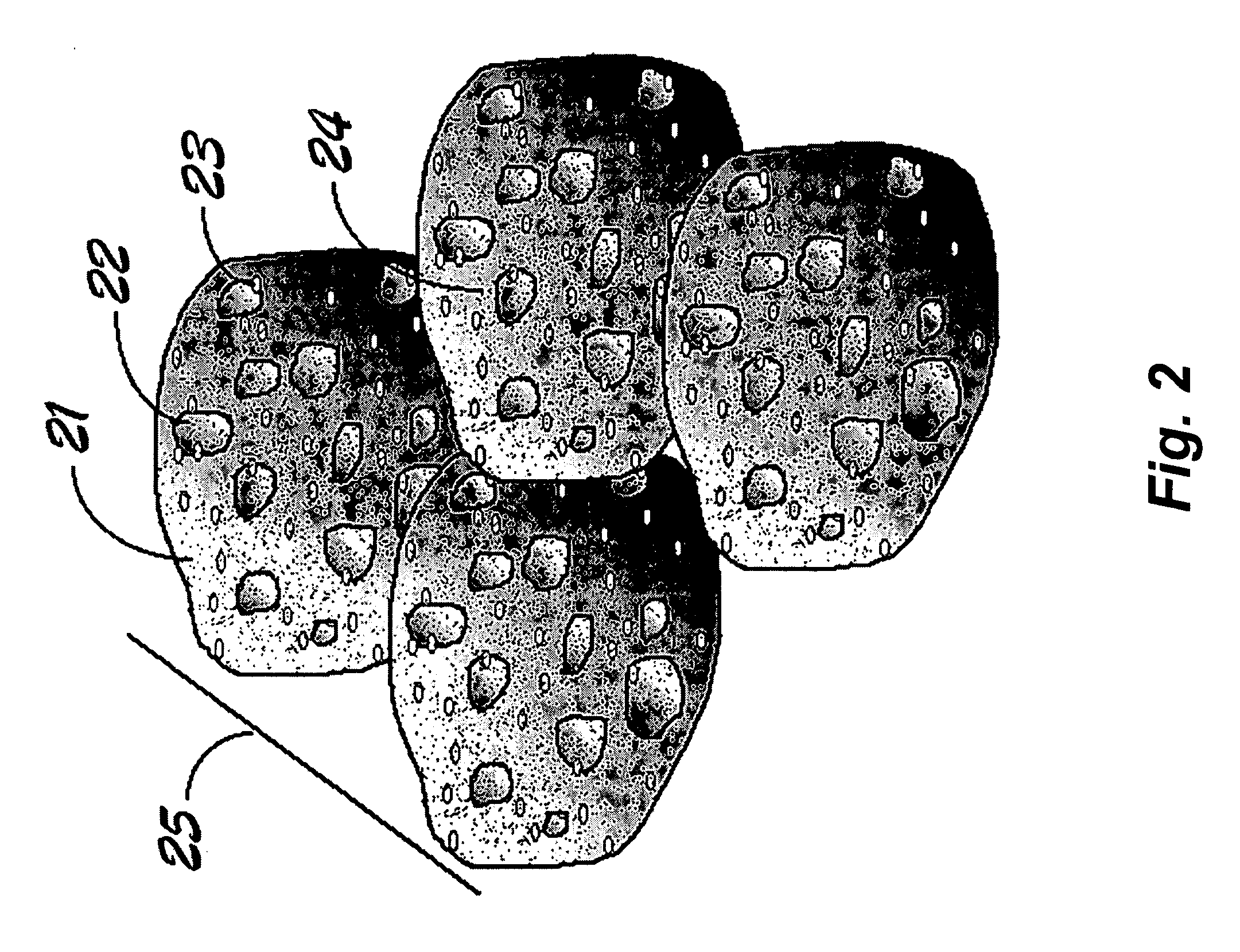

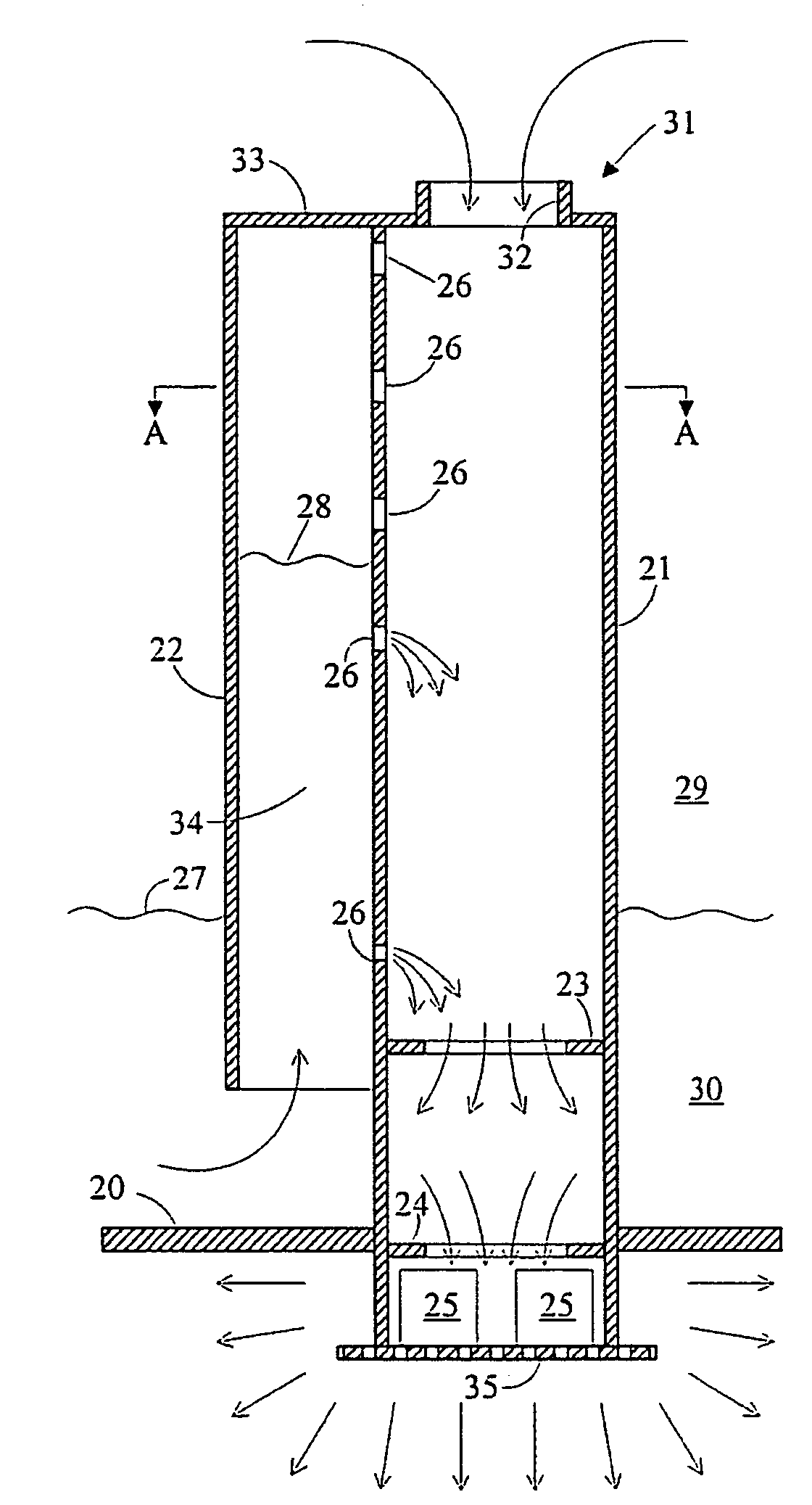

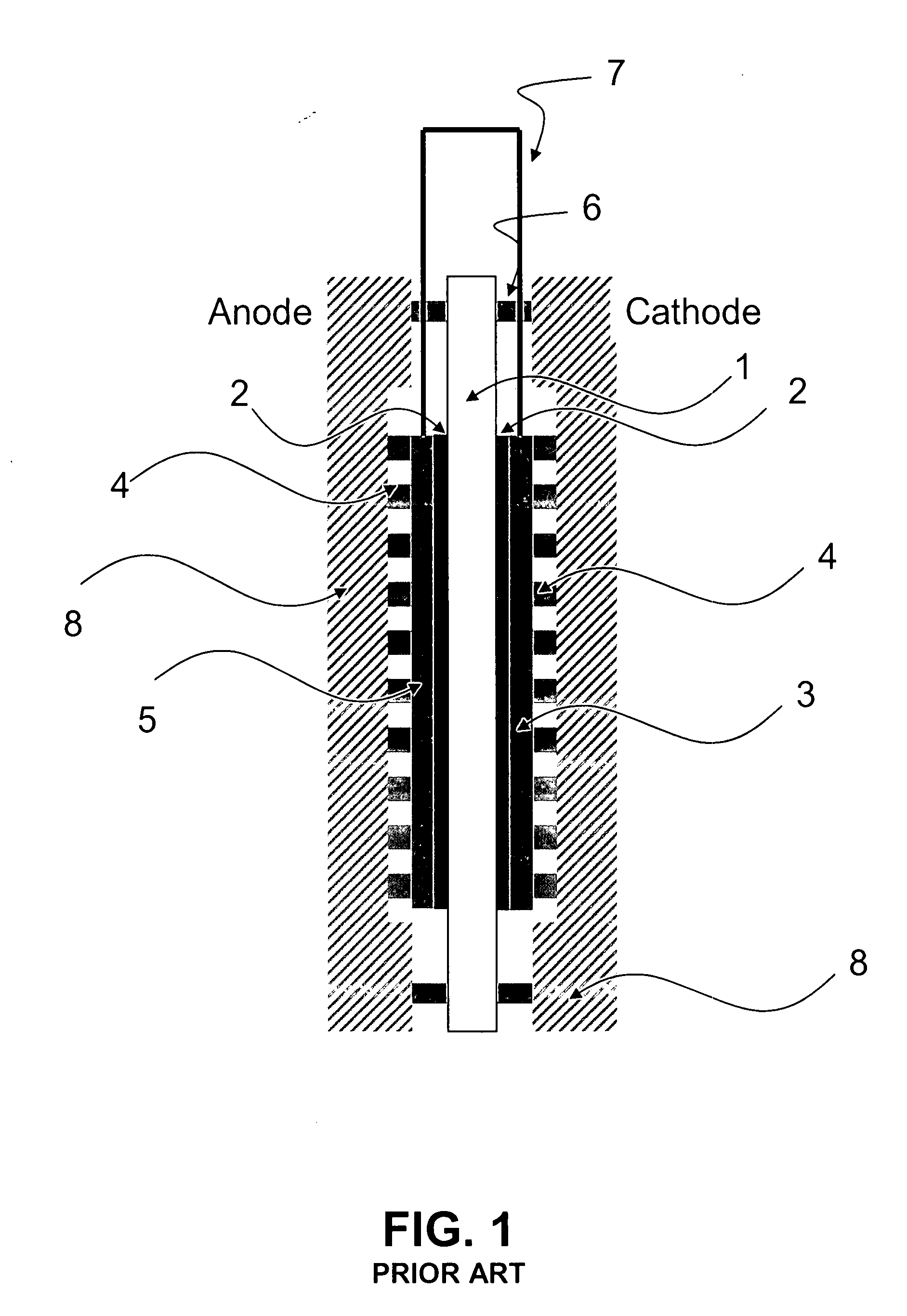

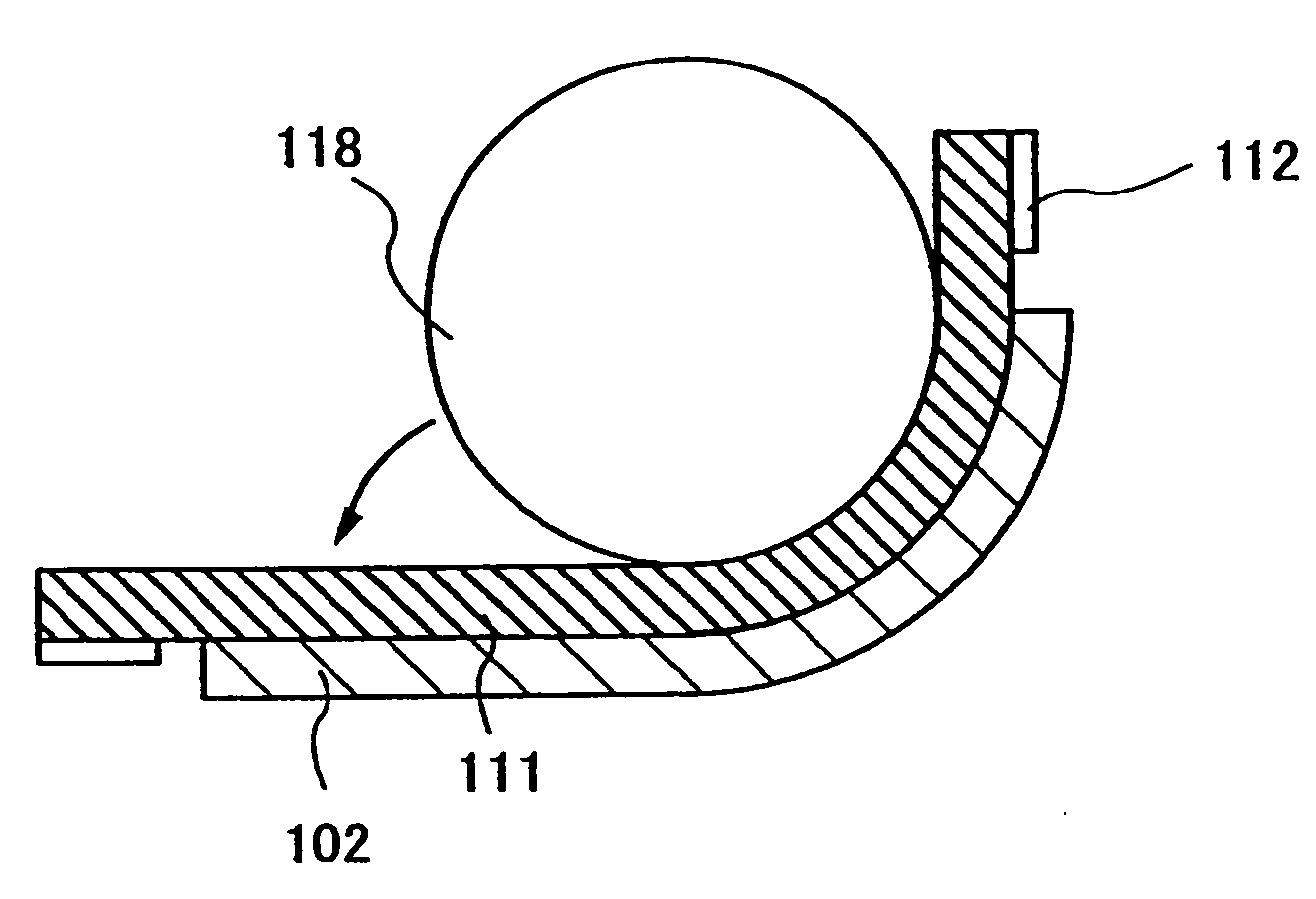

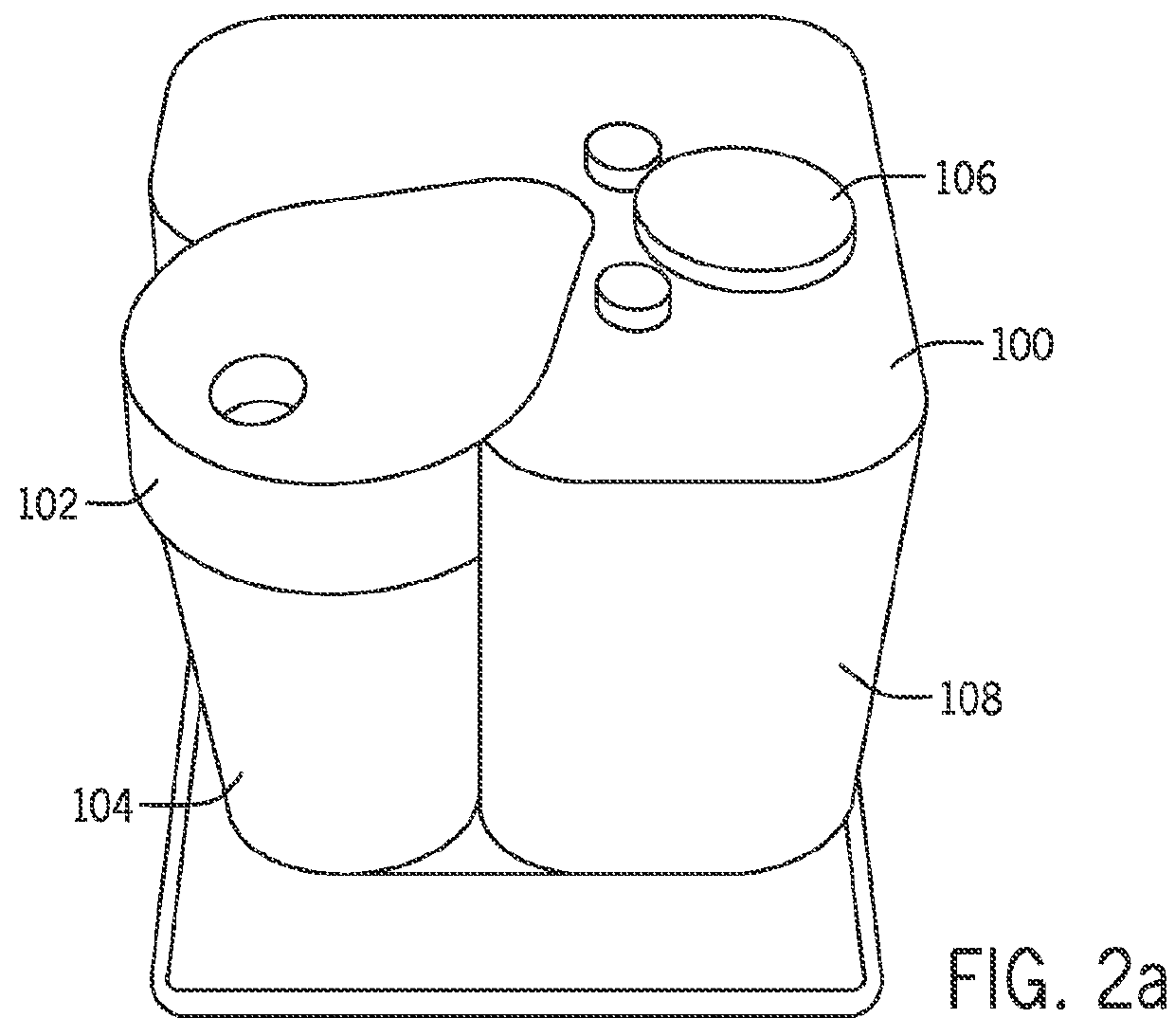

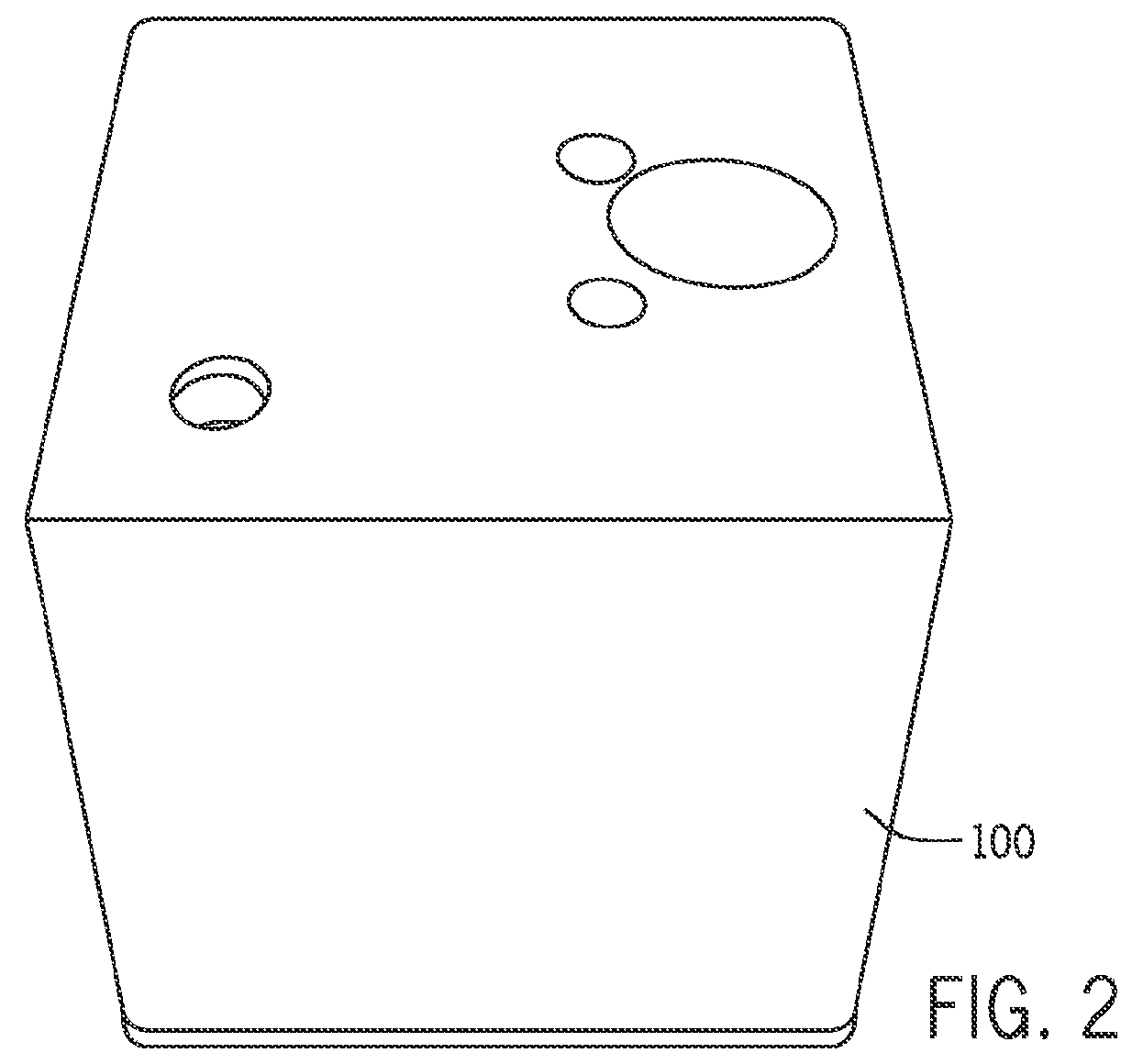

Device for treatment of wound using reduced pressure

ActiveUS8382731B2Reduce pressureKeep the pressureSurgeryMedical devicesLiquid diffusionCompressible material

Provided is a device for treatment of wounds using reduced pressure, which includes a pump, a gas barrier cover, a first compressible material which expands after compression, and a second material capable of absorbing wound fluids several times its own weight. The first and second materials are arranged inside the cover and form a reservoir connected to the pump. The device also includes an inlet for connecting the reservoir with a wound, a wound pad to be arranged in the wound cavity, and a sealing covering the wound and the wound pad. A third material with high liquid spreading capability is arranged around at least a major part of the first material, and the second material is in the form of at least one layer arranged outside the third material and separated from the first material by the third material.

Owner:MOLNLYCKE HEALTH CARE AB

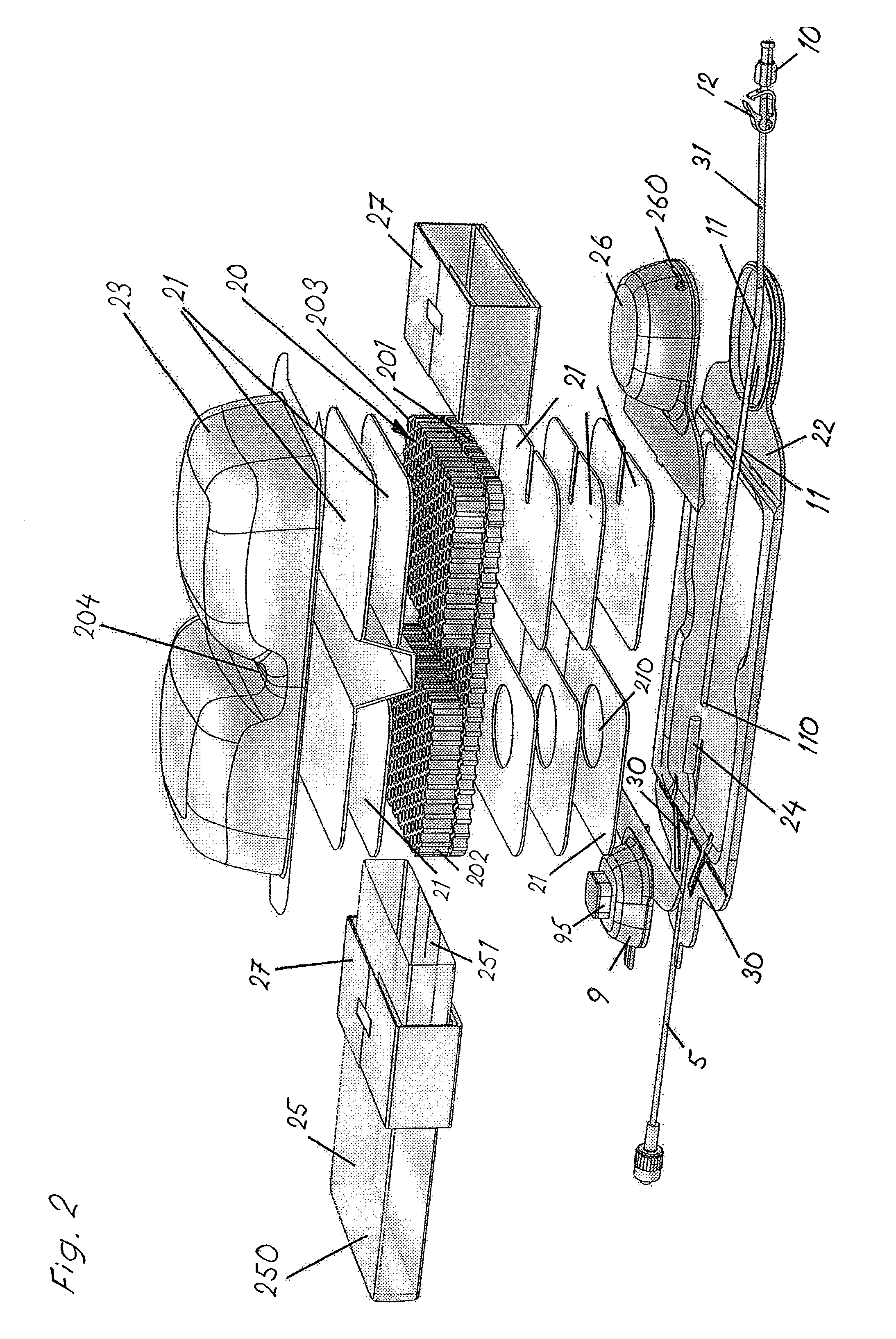

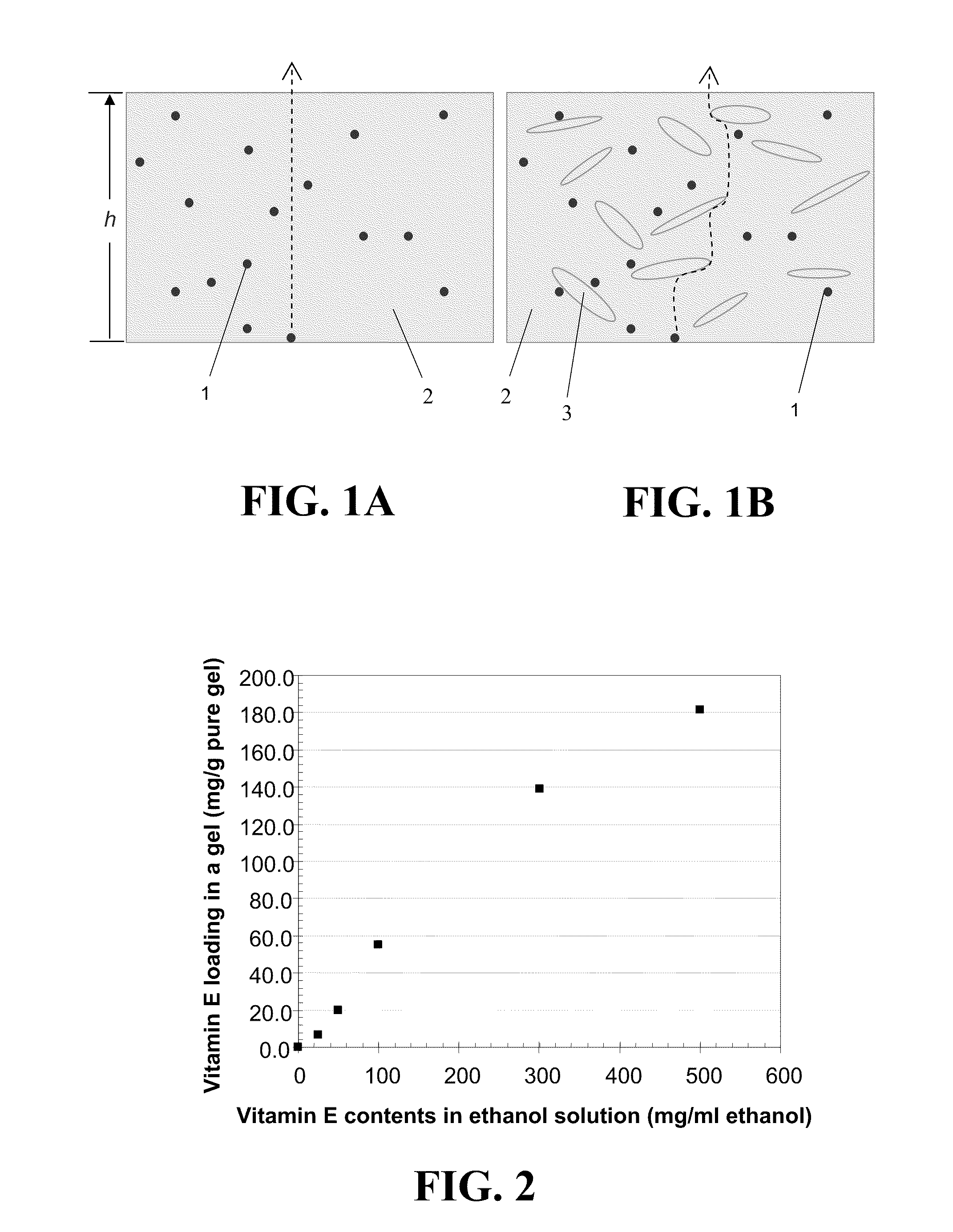

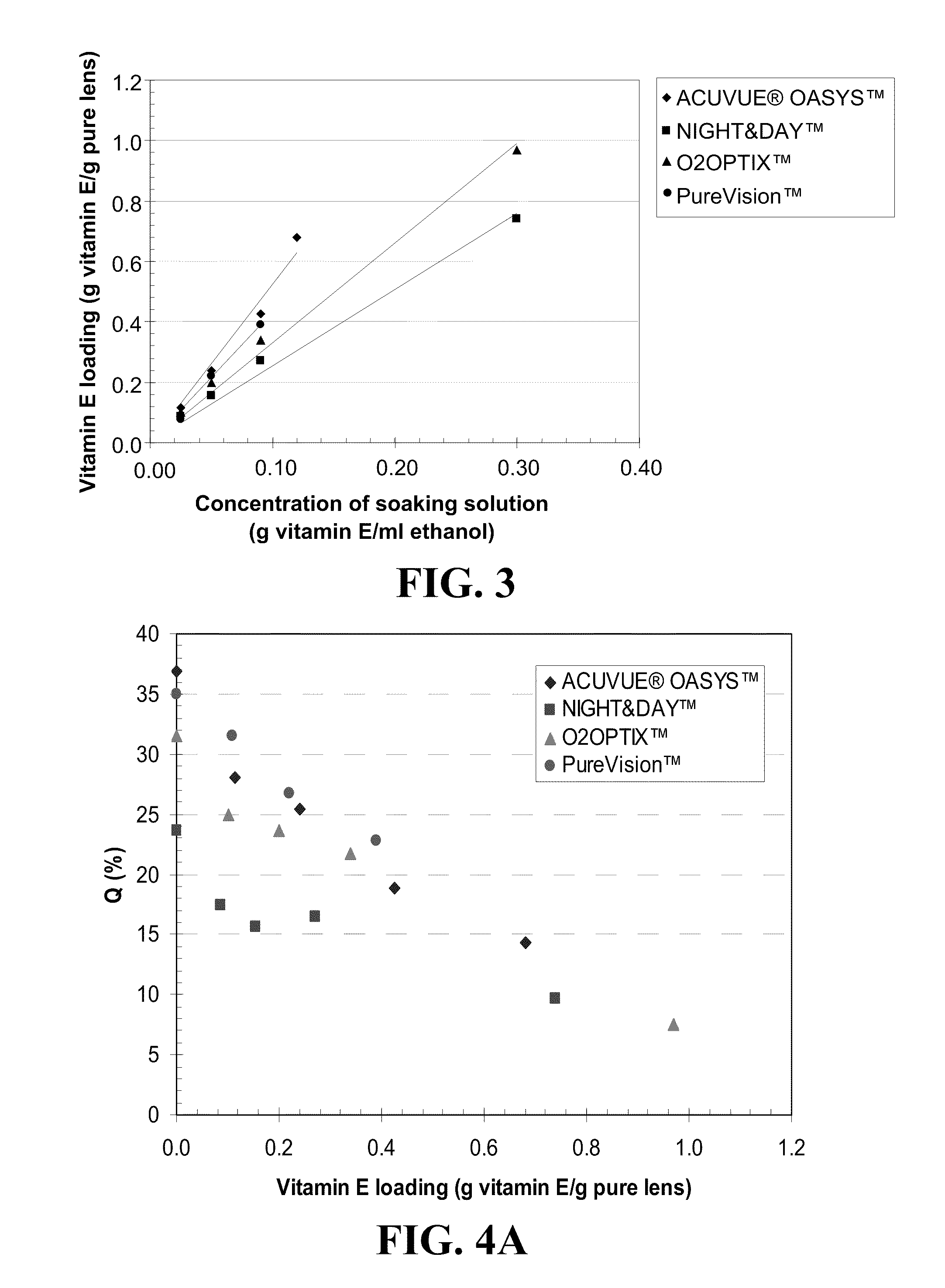

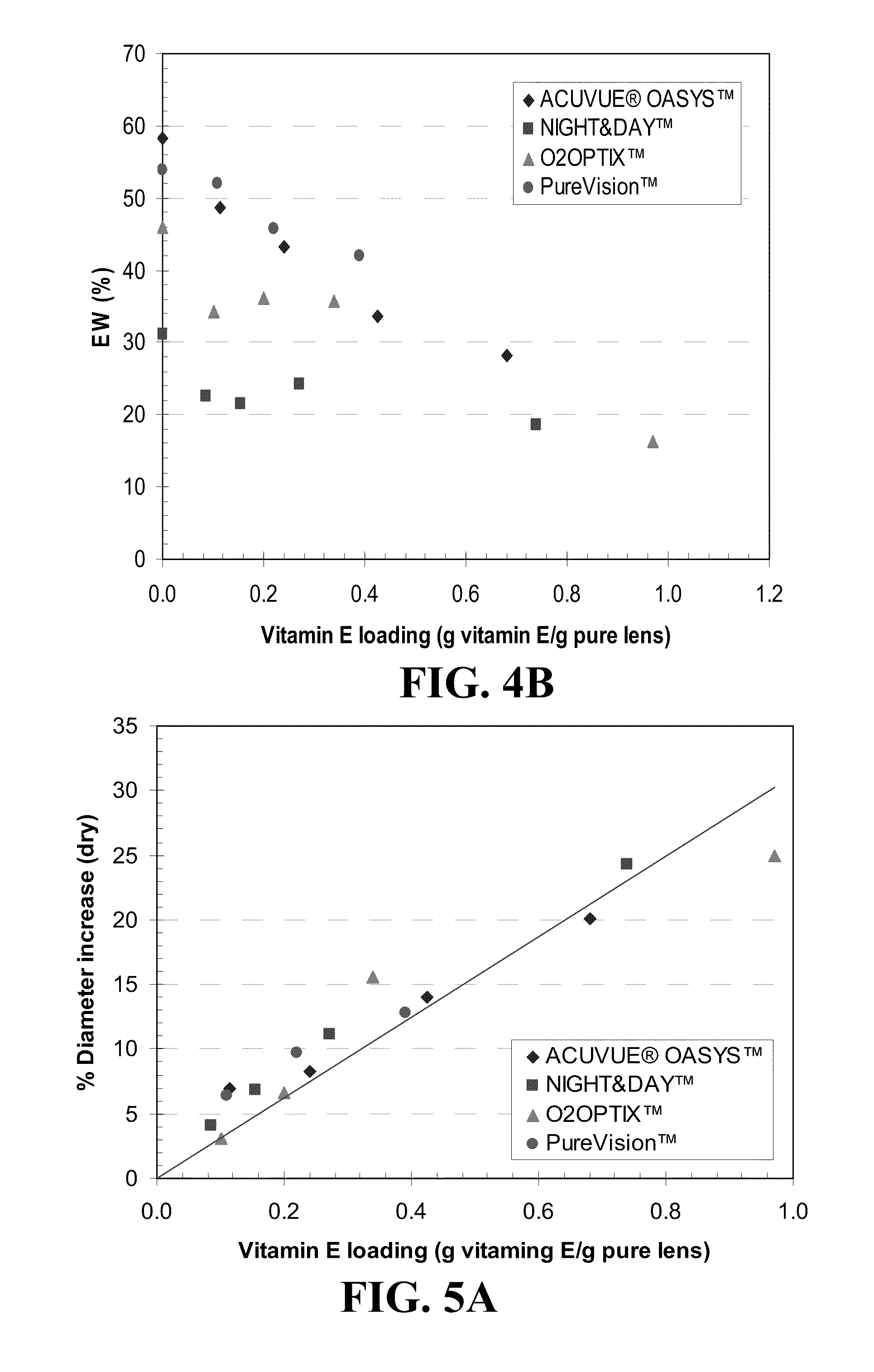

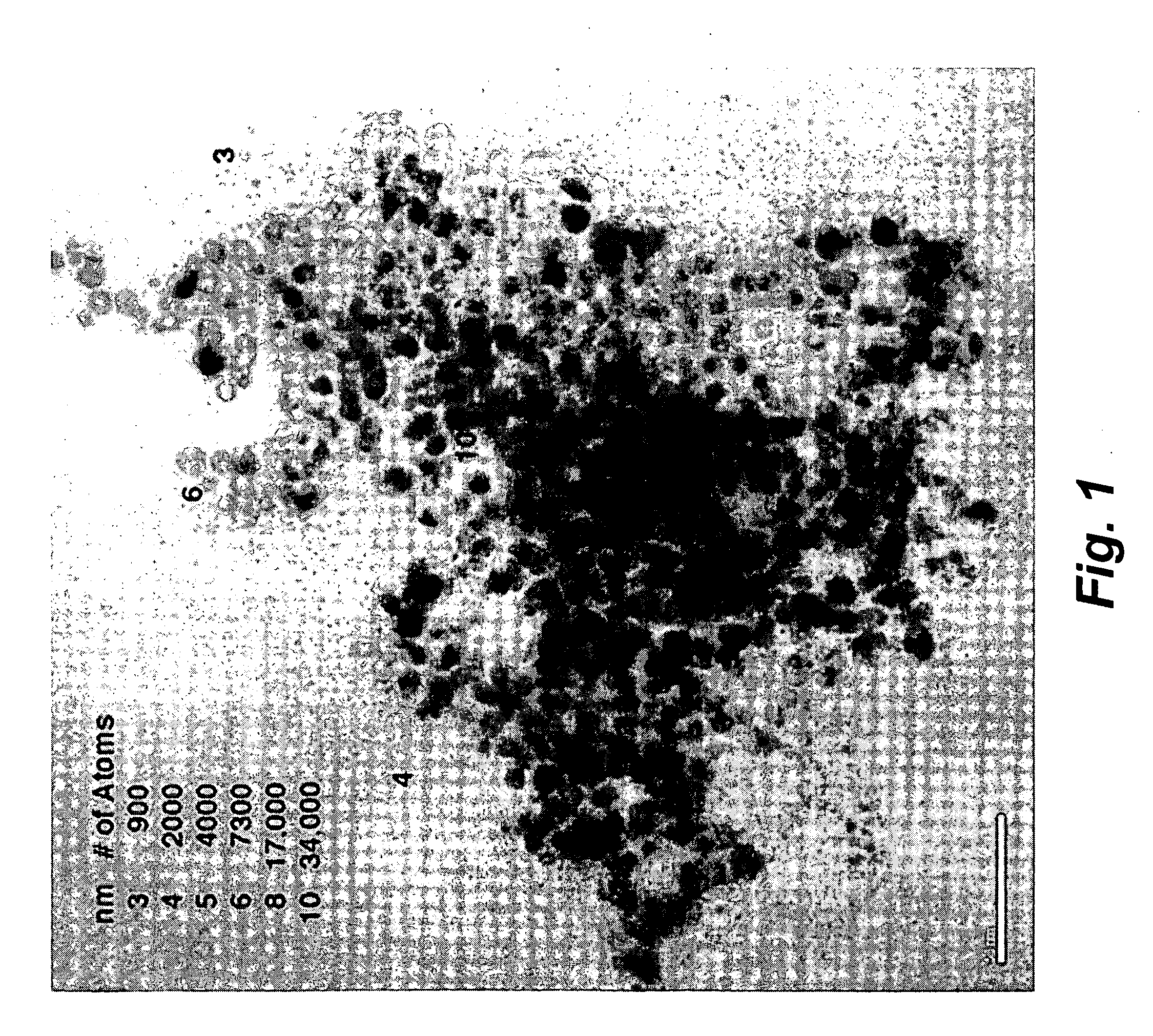

Contact lenses for extended release of bioactive agents containing diffusion attenuators

An appliance for the delivery of at least one bioactive agent to the eye has at least one diffusion attenuator within a hydrophilic or silicone-hydrogel contact lens. The bioactive agent can be a drug or a nutraceutical. The diffusion attenuator can be a plurality of solid particles or phase separated liquid aggregates within at least one continuous phase of the lens where the diffusion attenuators promote a tortuous path for the diffusion of the bioactive agent to mediate the rate by which the bioactive agent diffuses from the contact lens. The diffusion attenuator can be homogeneously dispersed throughout at least one continuous phase of the lens to modify the diffusivity of the bioactive agent through that phase. The diffusion attenuator can have little or no affinity for the bioactive agent or can be miscible with the bioactive agent. The diffusion attenuator can be incorporated while forming the contact lens by polymerization of a monomer mixture containing the diffusion attenuator. For liquid diffusion attenuators, the liquid can be co-absorbed with a solvent into the lens followed by removal of the solvent, where the bioactive agent can be co-absorbed or subsequently absorbed after the loading of the diffusion attenuator. The diffusion attenuator can be Vitamin E.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

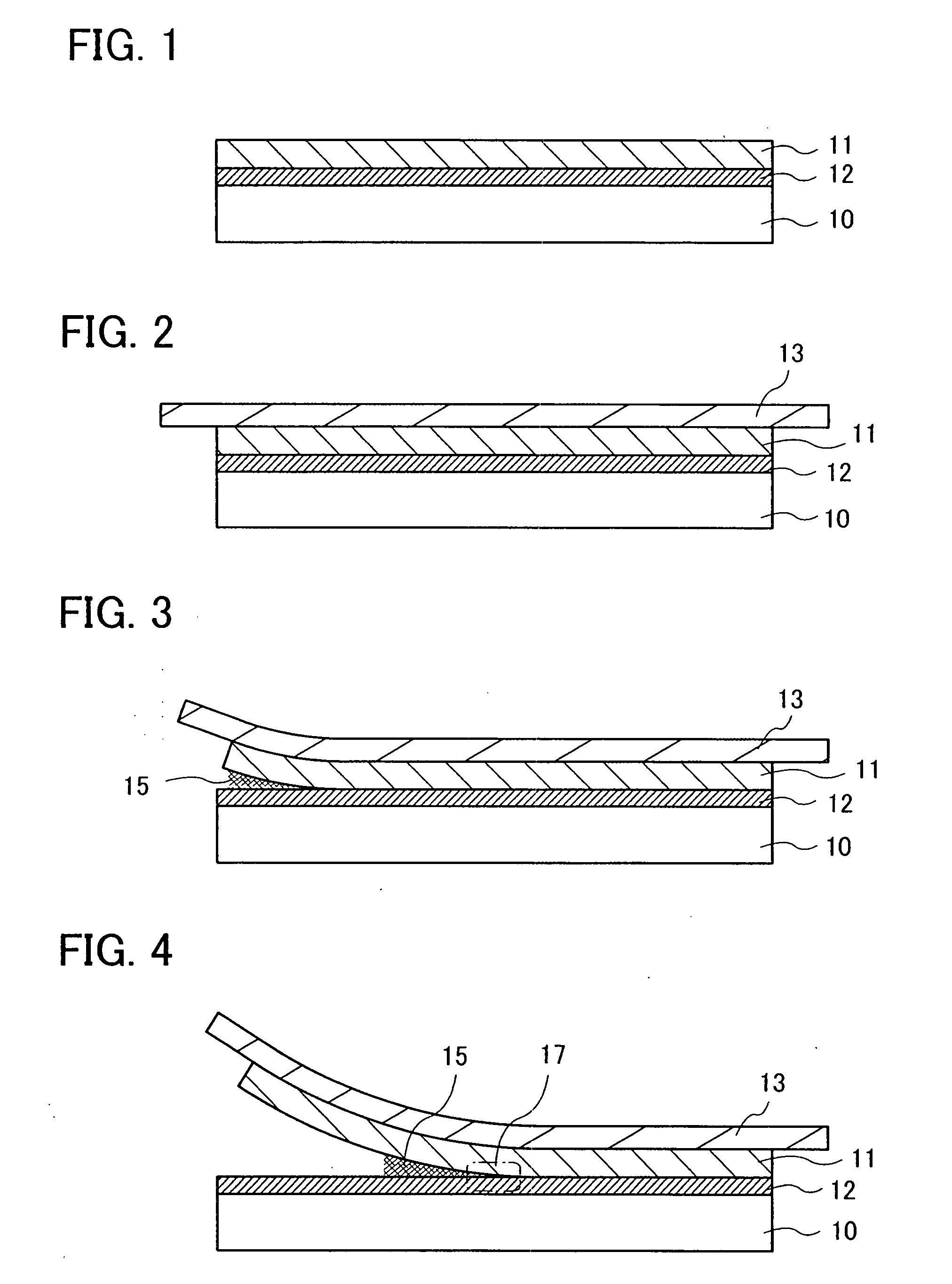

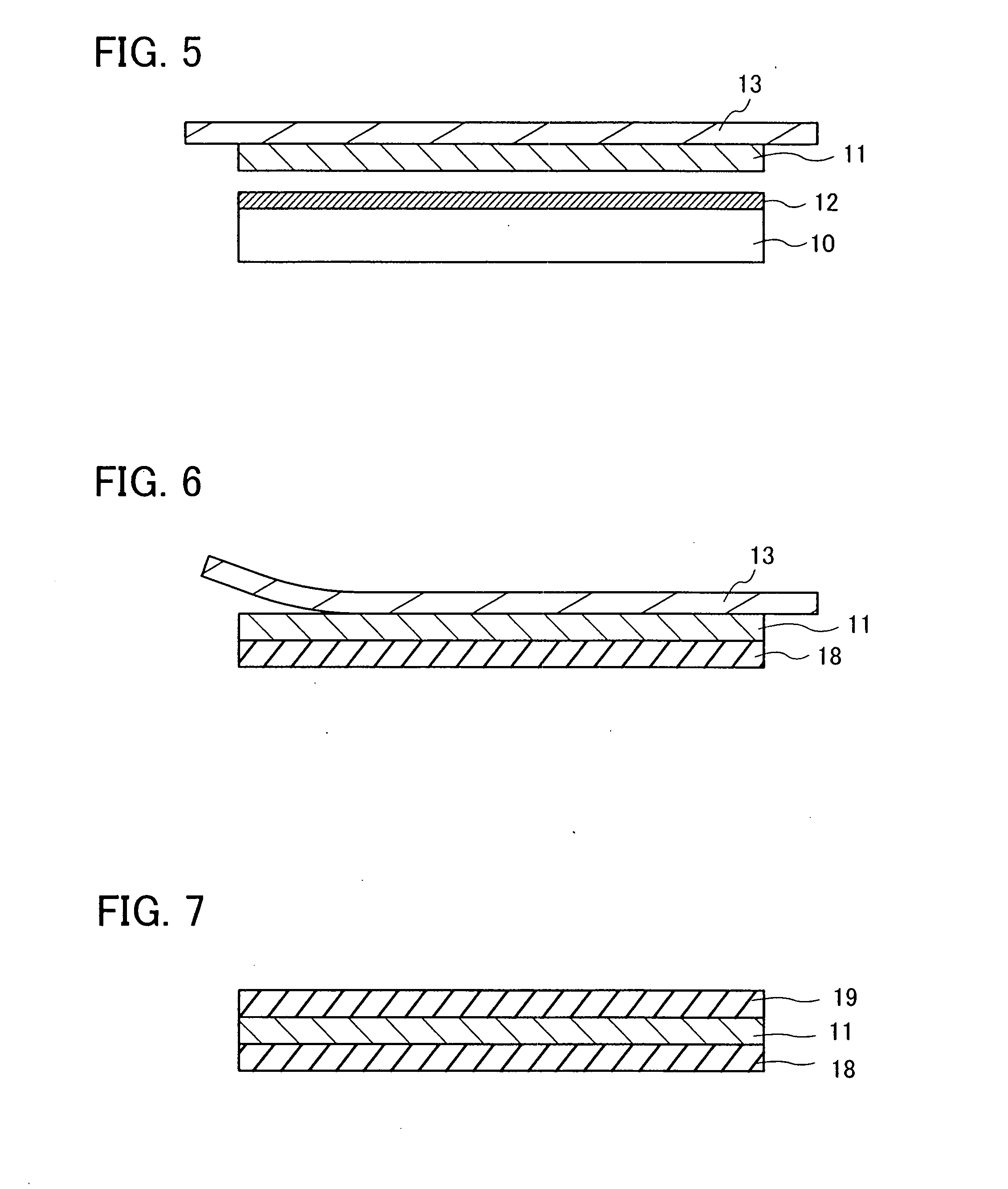

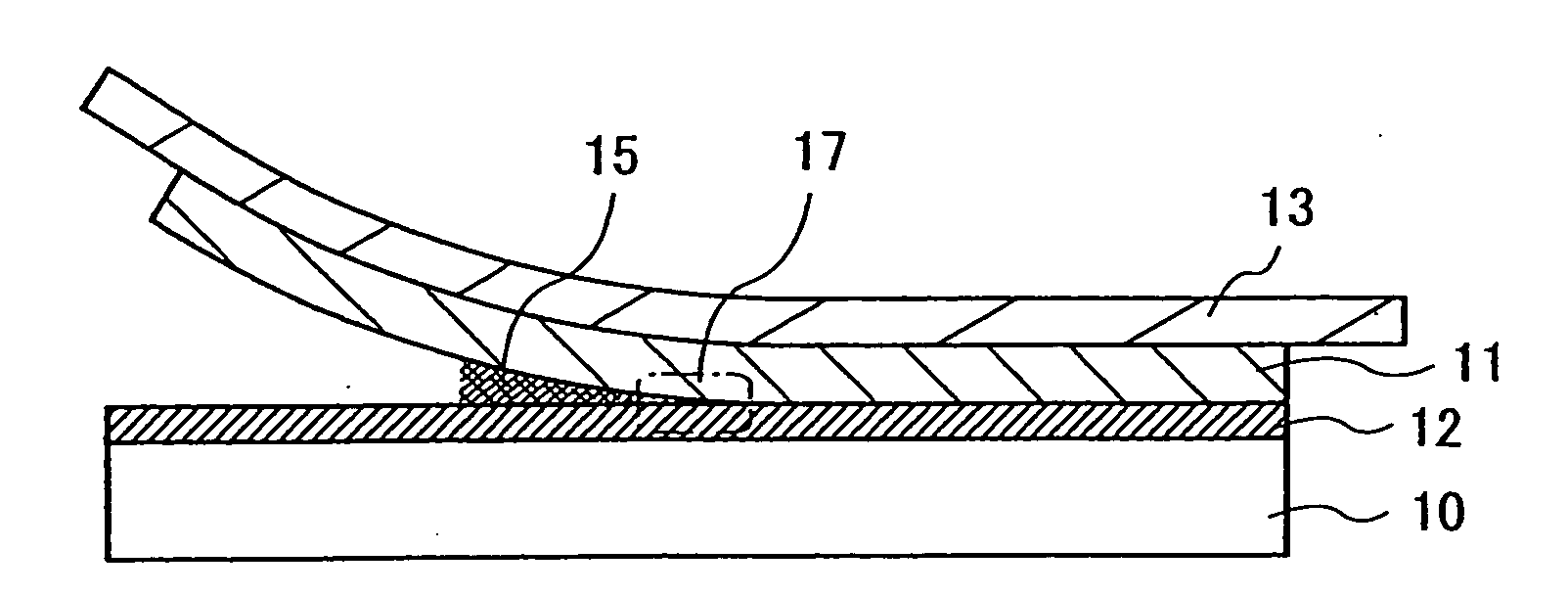

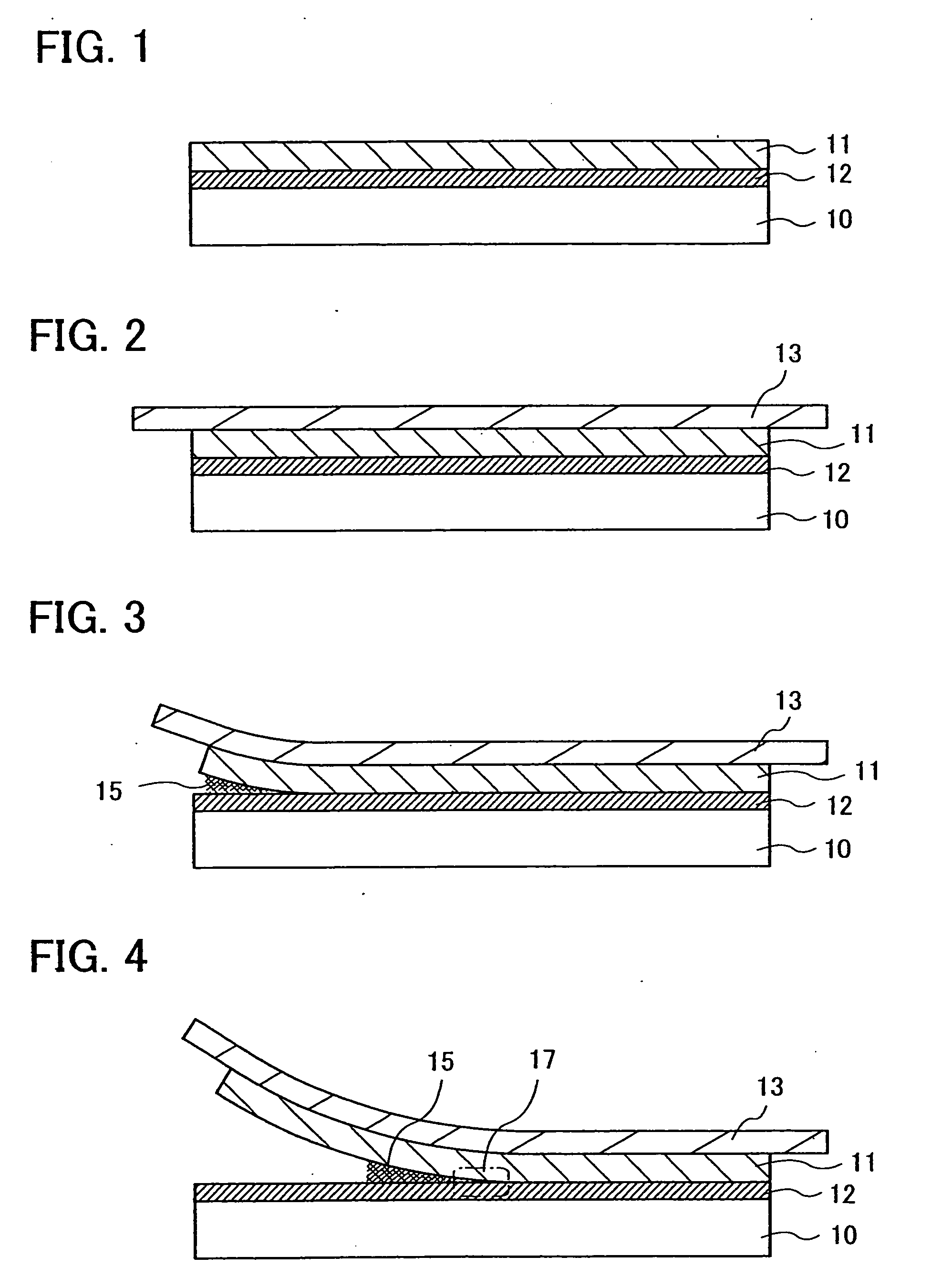

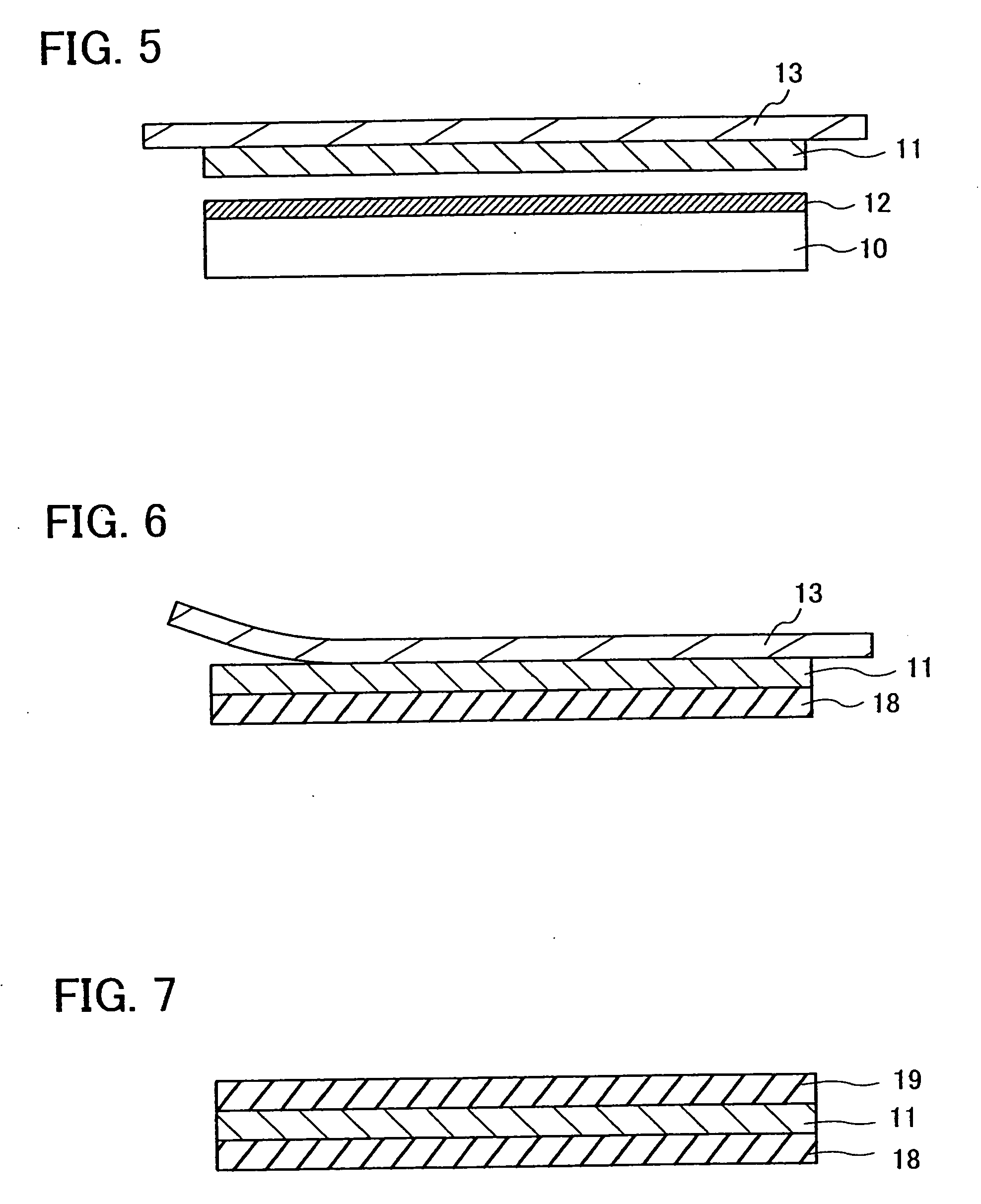

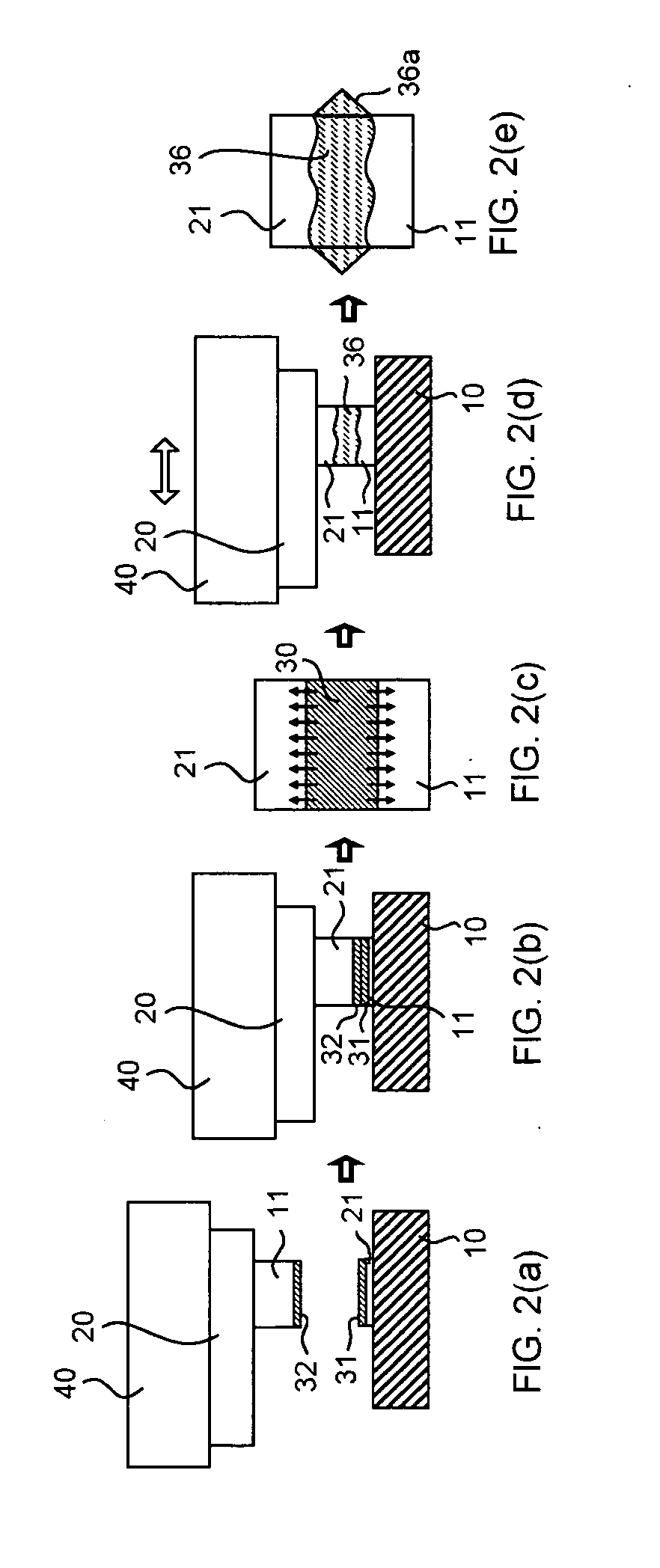

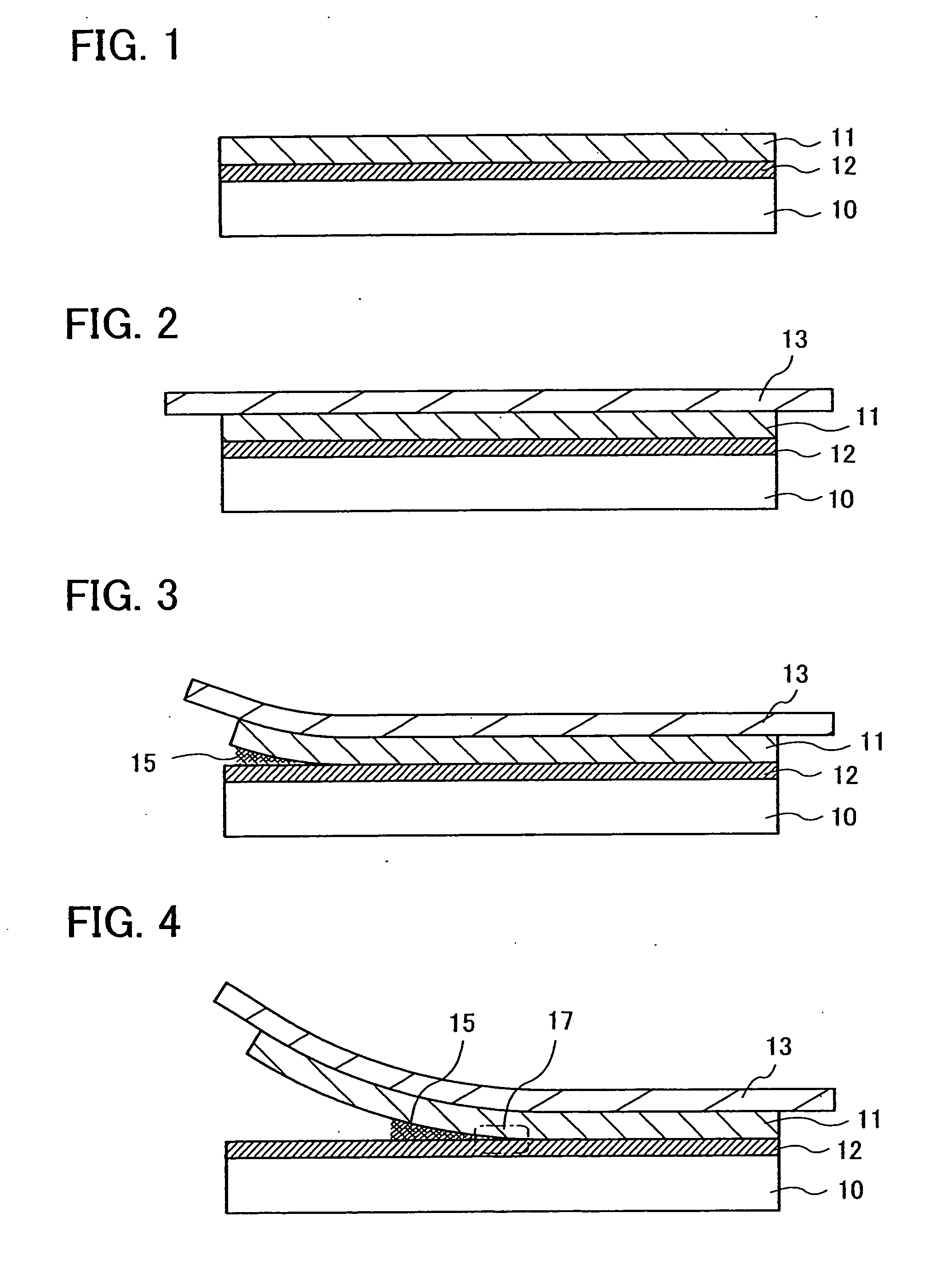

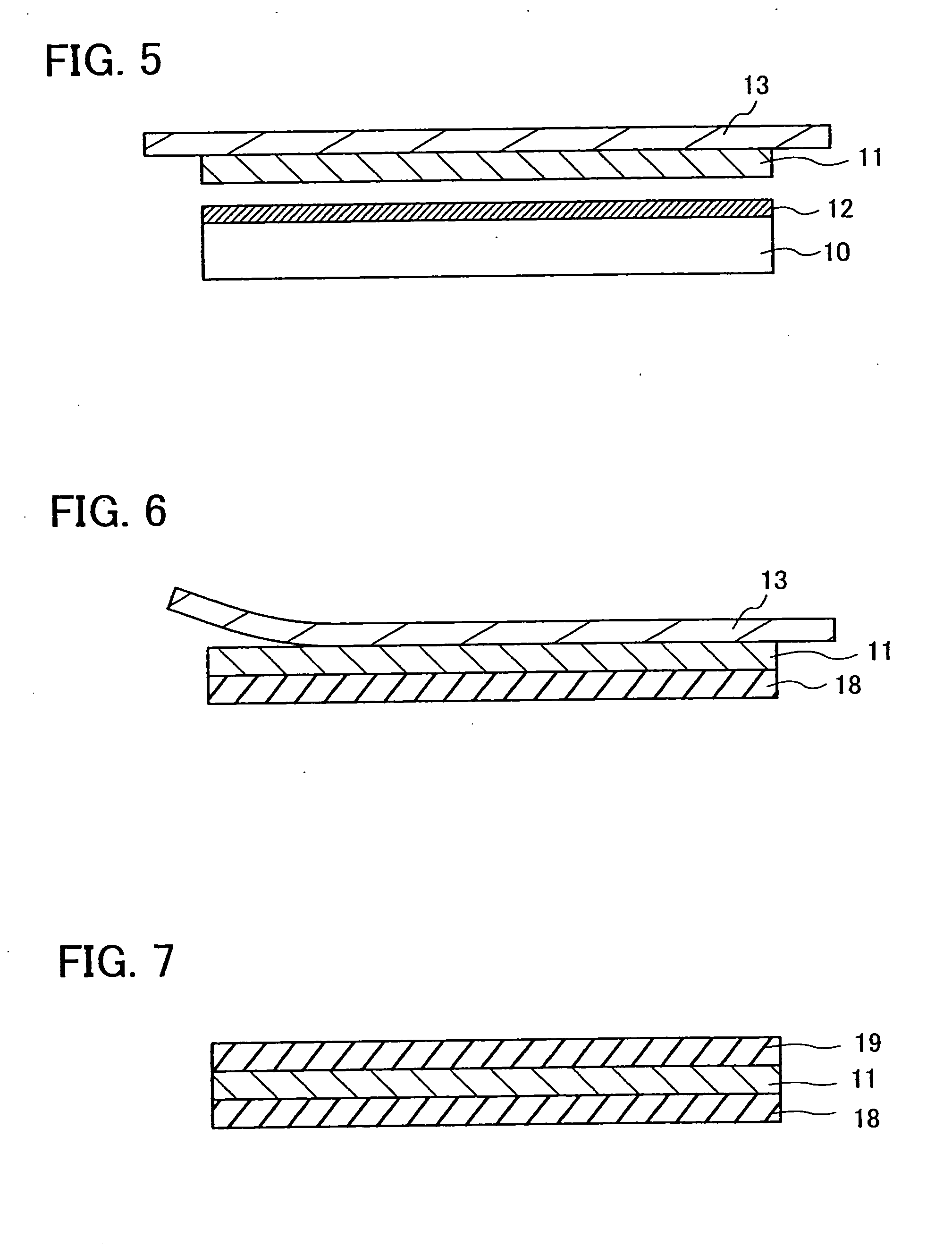

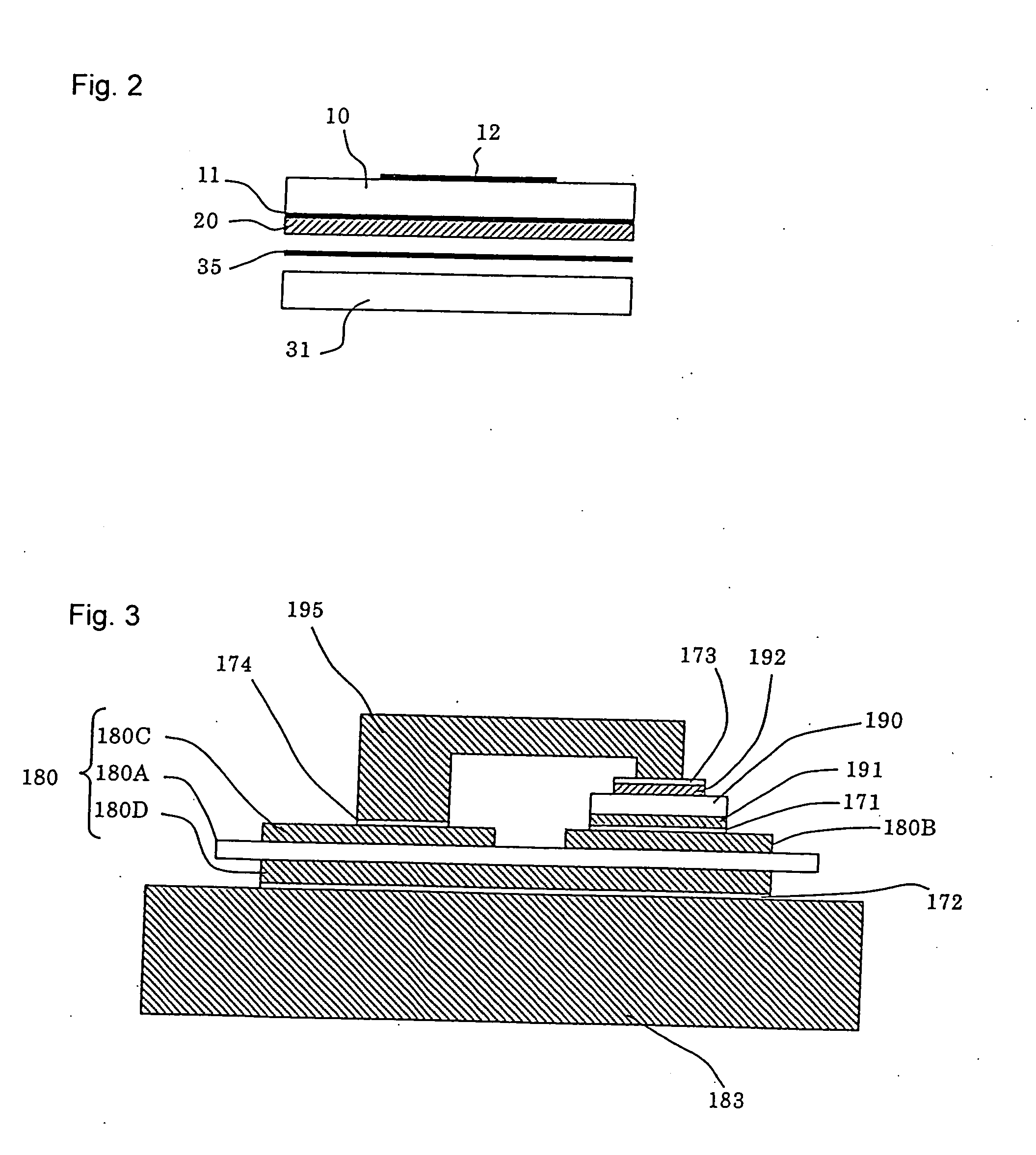

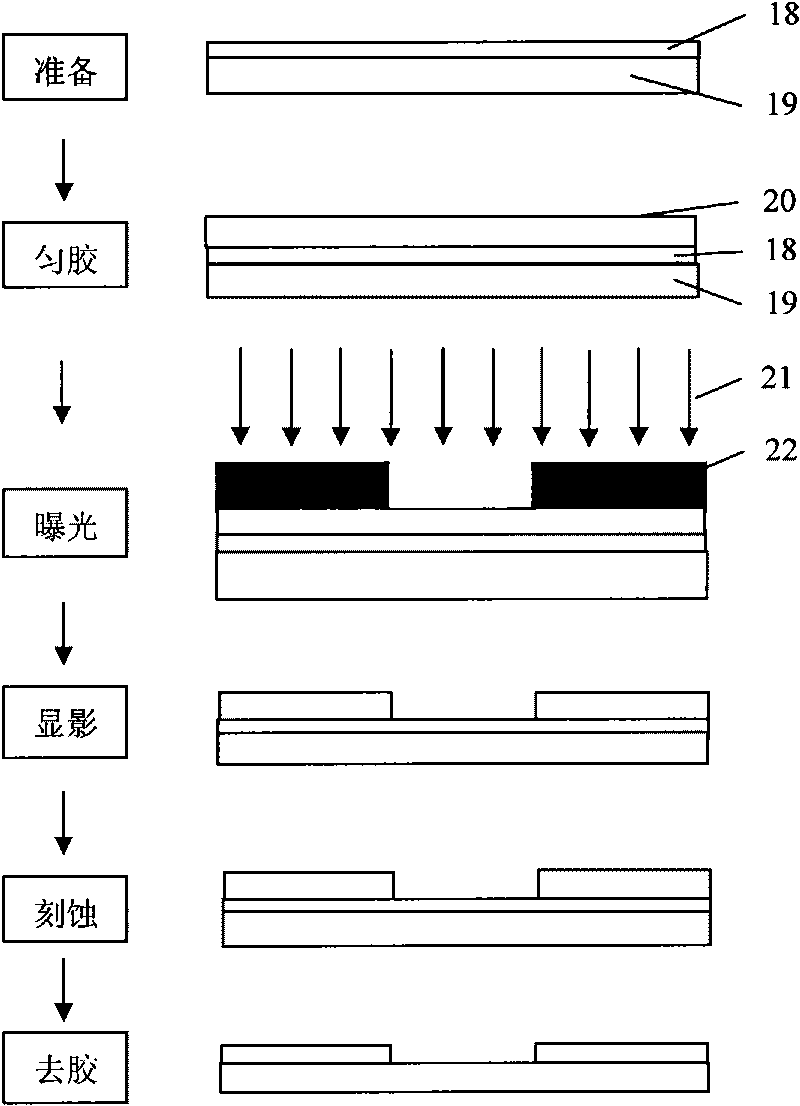

Method for manufacturing semiconductor device

ActiveUS20080132033A1Avoid destruction and characteristic deteriorationReduce surface resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid diffusionDevice material

An object is to suppress discharge due to static electricity generated by peeling, when an element formation layer including a semiconductor element is peeled from a substrate. Over the substrate, the release layer and the element formation layer are formed. The support base material which can be peeled later is fixed to the upper surface of the element formation layer. The element formation layer is transformed through the support base material, and peeling is generated at an interface between the element formation layer and the release layer. Peeling is performed while the liquid is being supplied so that the element formation layer and the release layer which appear sequentially by peeling are wetted with the liquid such as pure water. Electric charge generated on the surfaces of the element formation layer and the release layer can be diffused by the liquid, and discharge by peeling electrification can be eliminated.

Owner:SEMICON ENERGY LAB CO LTD

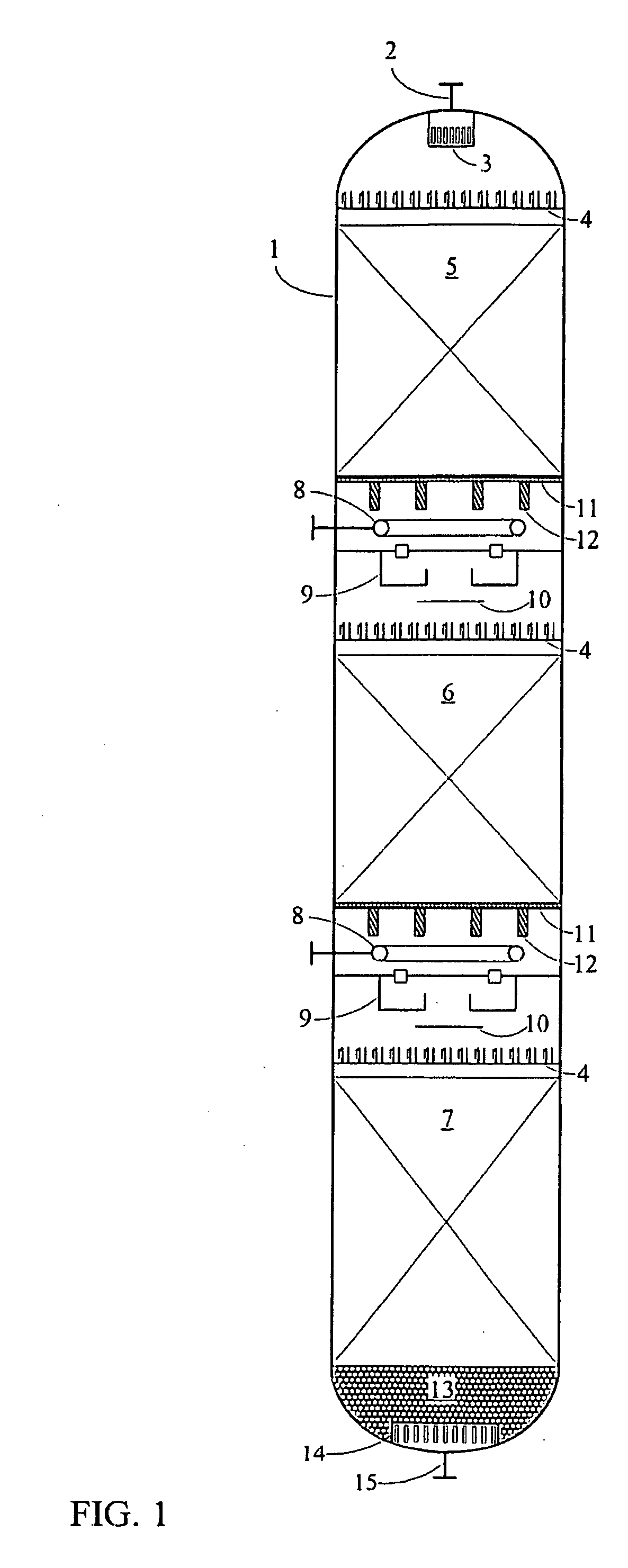

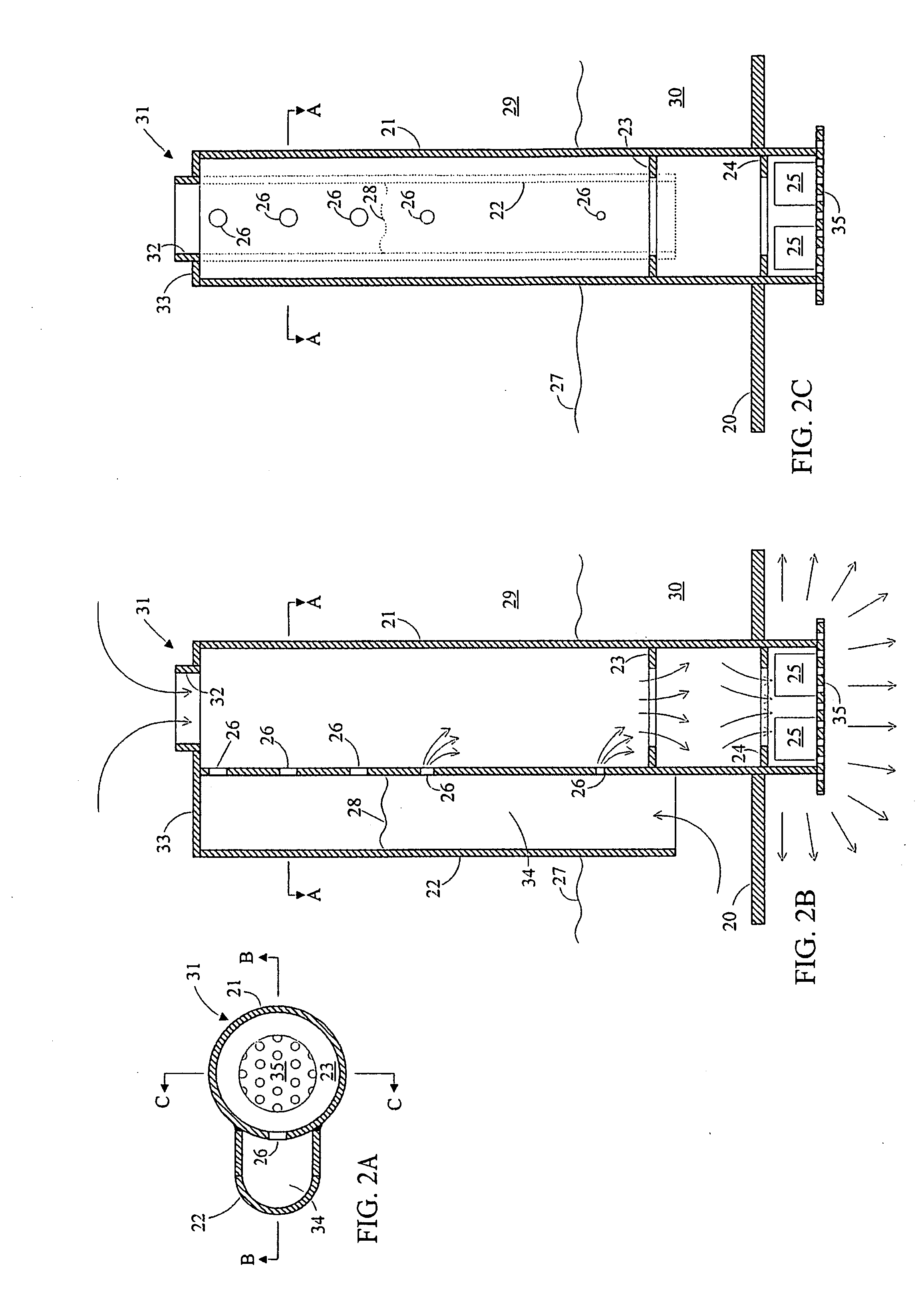

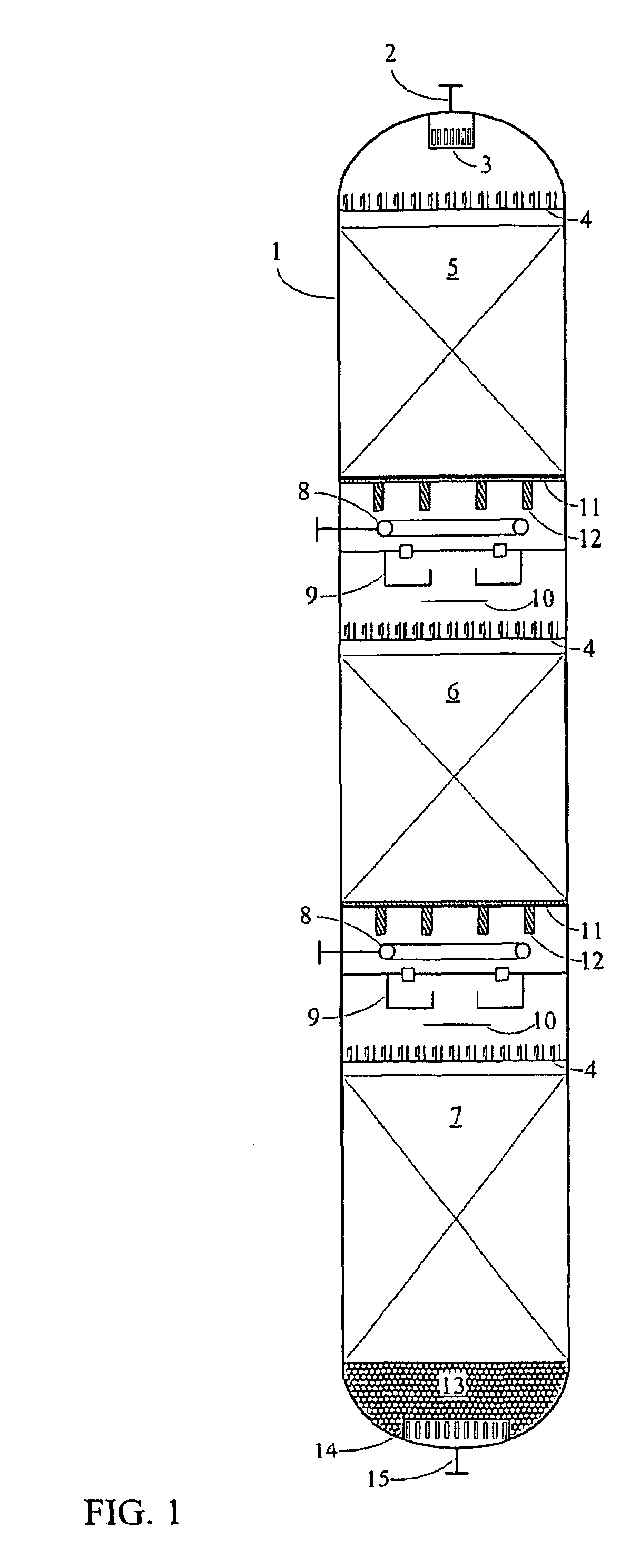

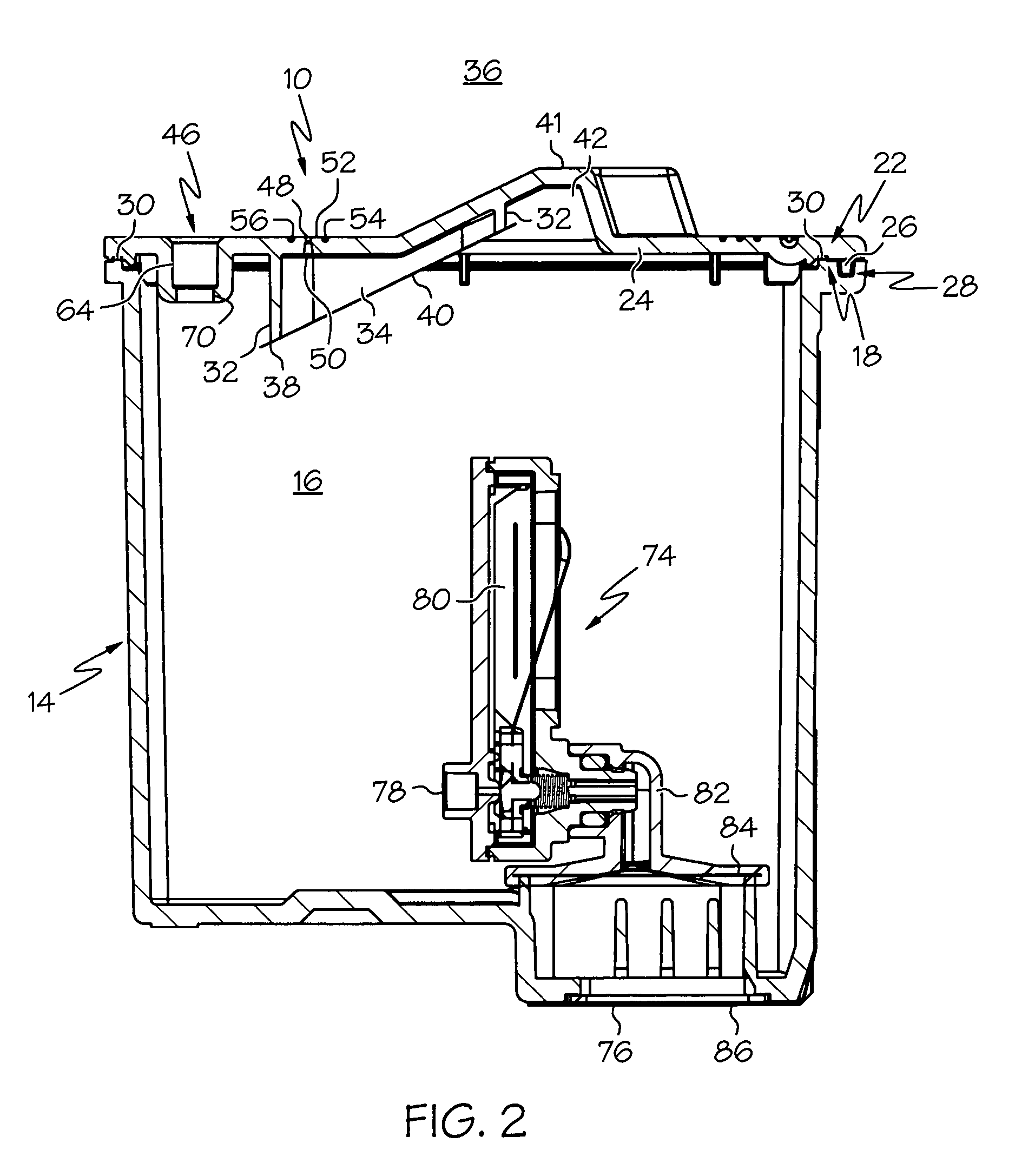

Distribution device for two-phase concurrent downflow vessels

ActiveUS20060163758A1Easy to spreadImprove distribution performanceCarburetting airMixing methodsLiquid diffusionStream flow

A distribution tray for distribution of vapor and liquid across a vessel has a plurality of downcomers extending above the tray and having open upper and lower ends. A liquid conduit for each downcomer has an inlet, a section for upward liquid flow, and openings in fluid communication with the downcomer. A reduced flow area section and a device for improved liquid spread may be used at the outlet of the downcomer. During operation, vapor enters the upper downcomer end. Liquid collected on the tray flows through the inlet, upward through the conduit, and through the openings into the downcomer, where the liquid is mixed with downwardly-flowing vapor. The two-phase stream passes the reduced flow area section with increased velocity for improved dispersion of the liquid before the stream flows through the device for improved liquid spread, and then exits through the lower end of the downcomer.

Owner:MORTEN MULLER LTD APS

Device for tratment of wound using reduced pressure

ActiveUS20110028920A1Reduce pressureKeep the pressureSurgeryMedical devicesLiquid diffusionCompressible material

A device for treatment of wounds using reduced pressure, comprisinga pump,a gas barrier cover,a first compressible material which expand after compression,a second material capable of absorbing wound fluids several times its own weight.The first and second material are arranged inside the cover and form a reservoir connected to said pump, The device further comprisingan inlet for connecting the reservoir with a wounda wound pad to be arranged in the wound cavity anda sealing covering the wound and said wound pad.A third material with high liquid spreading capability is arranged around at least a major part of the first material, and said second material is in the form of at least one layer arranged outside the third material and separated from the first material by said third material.

Owner:MOLNLYCKE HEALTH CARE AB

Electrochemical catalysts

InactiveUS20080280190A1Improve performanceReduce the amount of solutionMaterial nanotechnologyFuel and primary cellsElectrochemical responseHydrogen fuel cell

A composition useful in electrodes provides higher power capability through the use of nanoparticle catalysts present in the composition. Nanoparticles of transition metals are preferred such as manganese, nickel, cobalt, iron, palladium, ruthenium, gold, silver, and lead, as well as alloys thereof, and respective oxides. These nanoparticle catalysts can substantially replace or eliminate platinum as a catalyst for certain electrochemical reactions. Electrodes, used as anodes, cathodes, or both, using such catalysts have applications relating to metal-air batteries, hydrogen fuel cells (PEMFCs), direct methanol fuel cells (DMFCs), direct oxidation fuel cells (DOFCs), and other air or oxygen breathing electrochemical systems as well as some liquid diffusion electrodes.

Owner:BRICOLEUR PARTNERS LP

Distribution device for two-phase concurrent downflow vessels

ActiveUS7506861B2Improve distribution performanceLess susceptible to fouling and pluggingCarburetting airMixing methodsLiquid diffusionStream flow

A distribution tray for distribution of vapor and liquid across a vessel has a plurality of downcomers extending above the tray and having open upper and lower ends. A liquid conduit for each downcomer has an inlet, a section for upward liquid flow, and openings in fluid communication with the downcomer. A reduced flow area section and a device for improved liquid spread may be used at the outlet of the downcomer. During operation, vapor enters the upper downcomer end. Liquid collected on the tray flows through the inlet, upward through the conduit, and through the openings into the downcomer, where the liquid is mixed with downwardly-flowing vapor. The two-phase stream passes the reduced flow area section with increased velocity for improved dispersion of the liquid before the stream flows through the device for improved liquid spread, and then exits through the lower end of the downcomer.

Owner:MORTEN MULLER LTD APS

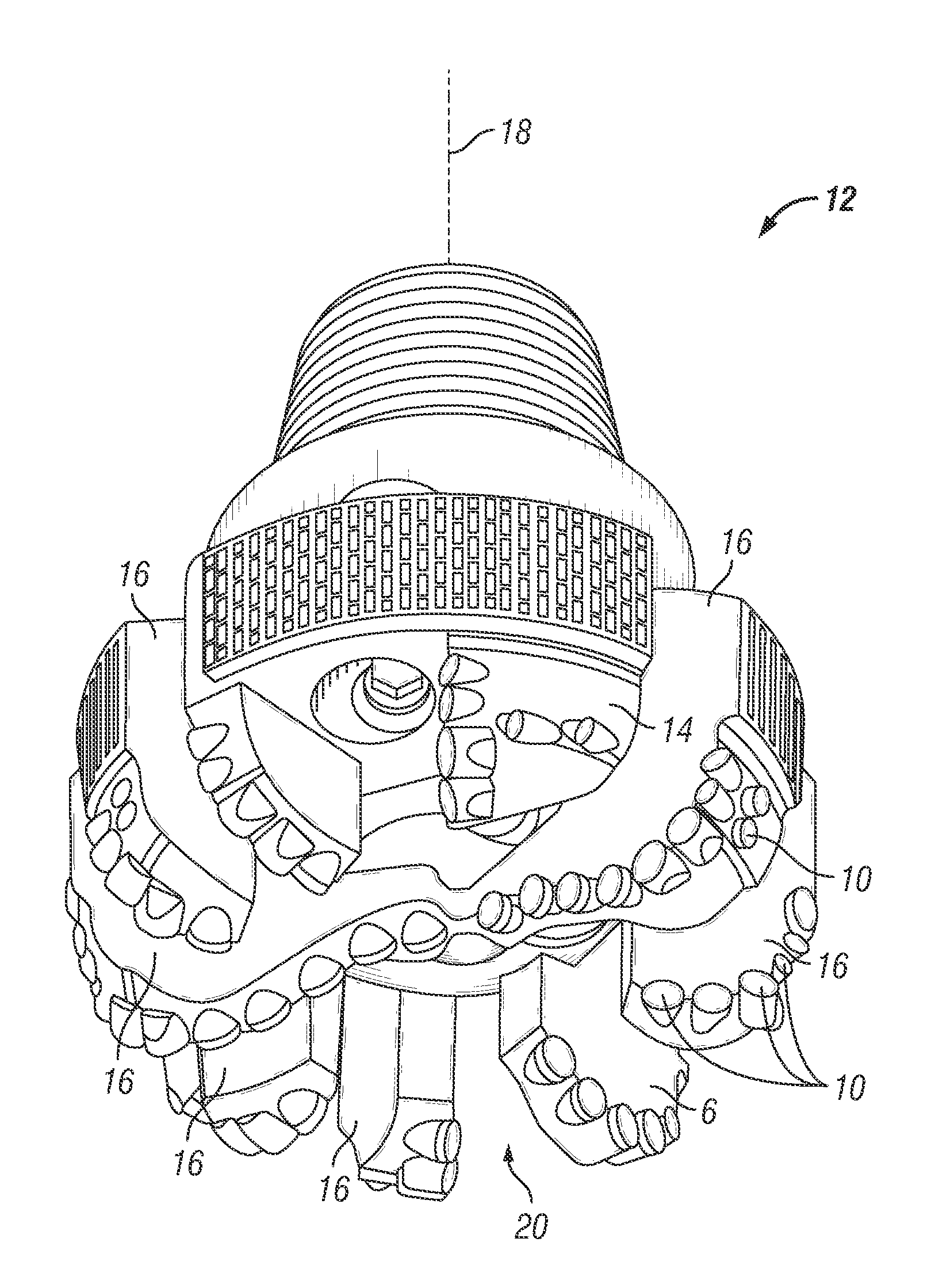

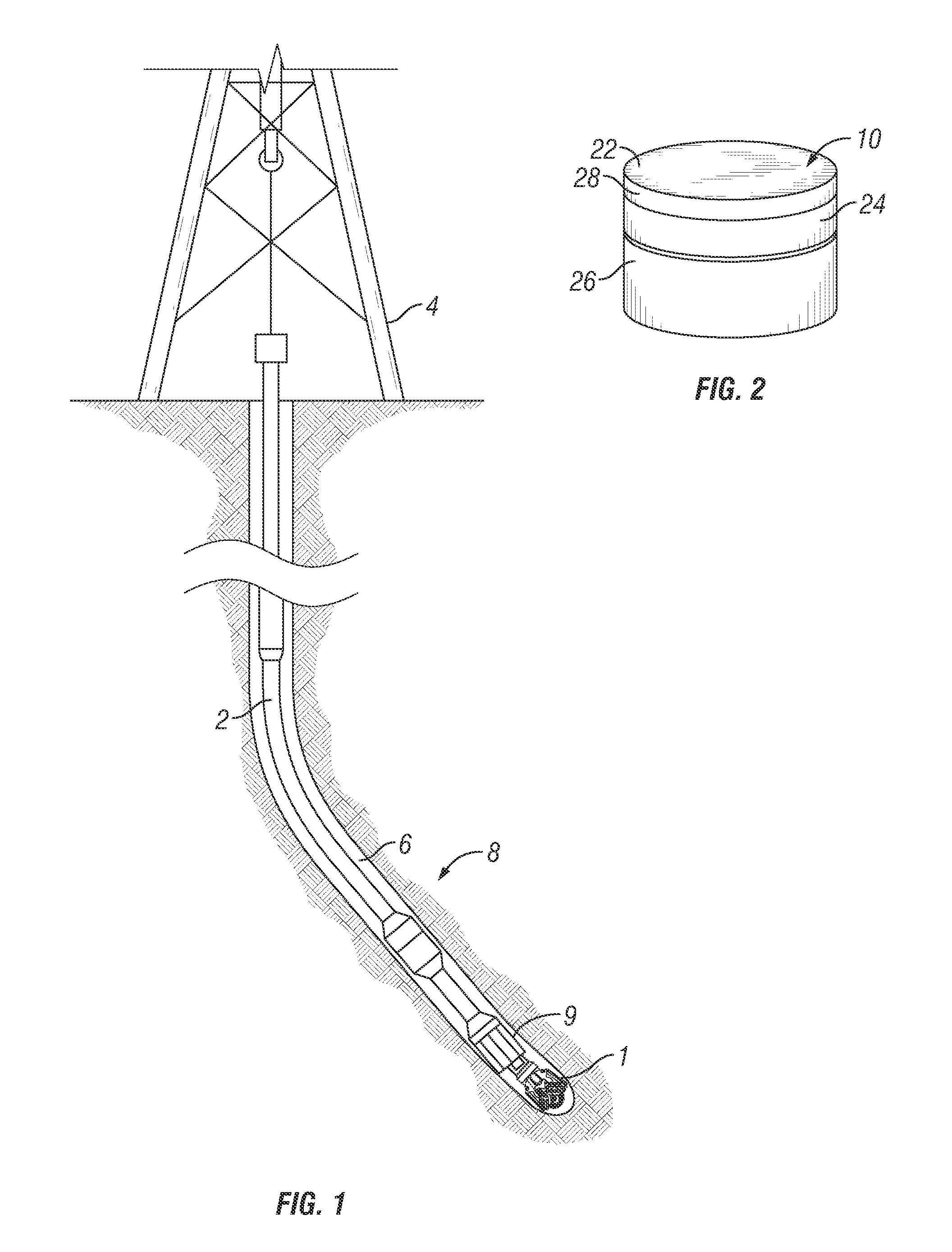

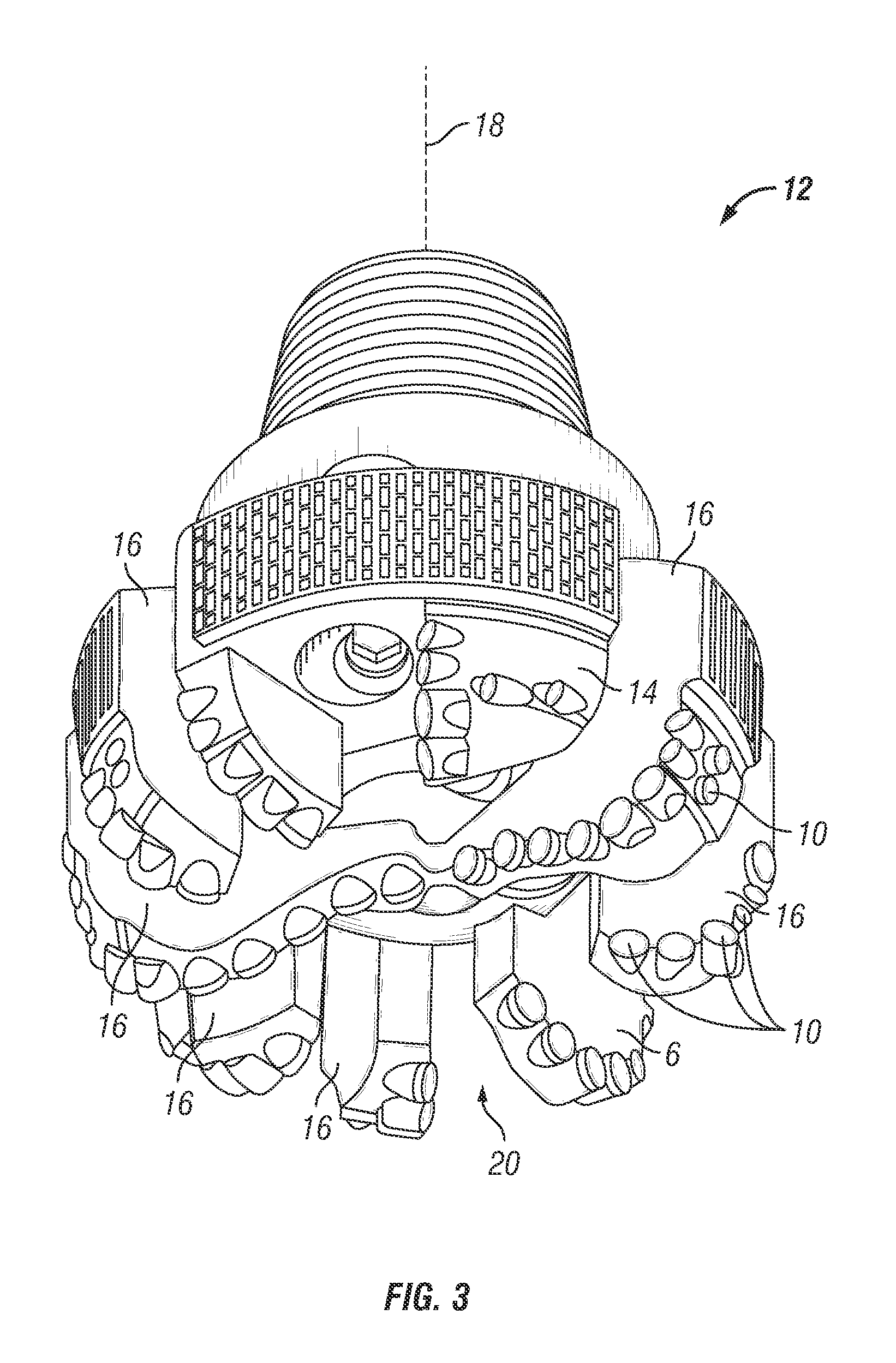

In-Situ Boron Doped PDC Element

A polycrystalline diamond compact formed in an in-situ boron-doped process. The in-situ boron-doped process includes consolidating a mixture of diamond crystals and boron-containing alloy via liquid diffusion of boron into diamond crystals at a pressure greater than 5 Gpa and at a temperature greater than the melting temperature of the boron-containing alloy, typically less than about 1450° C.

Owner:NAT OILWELL DHT

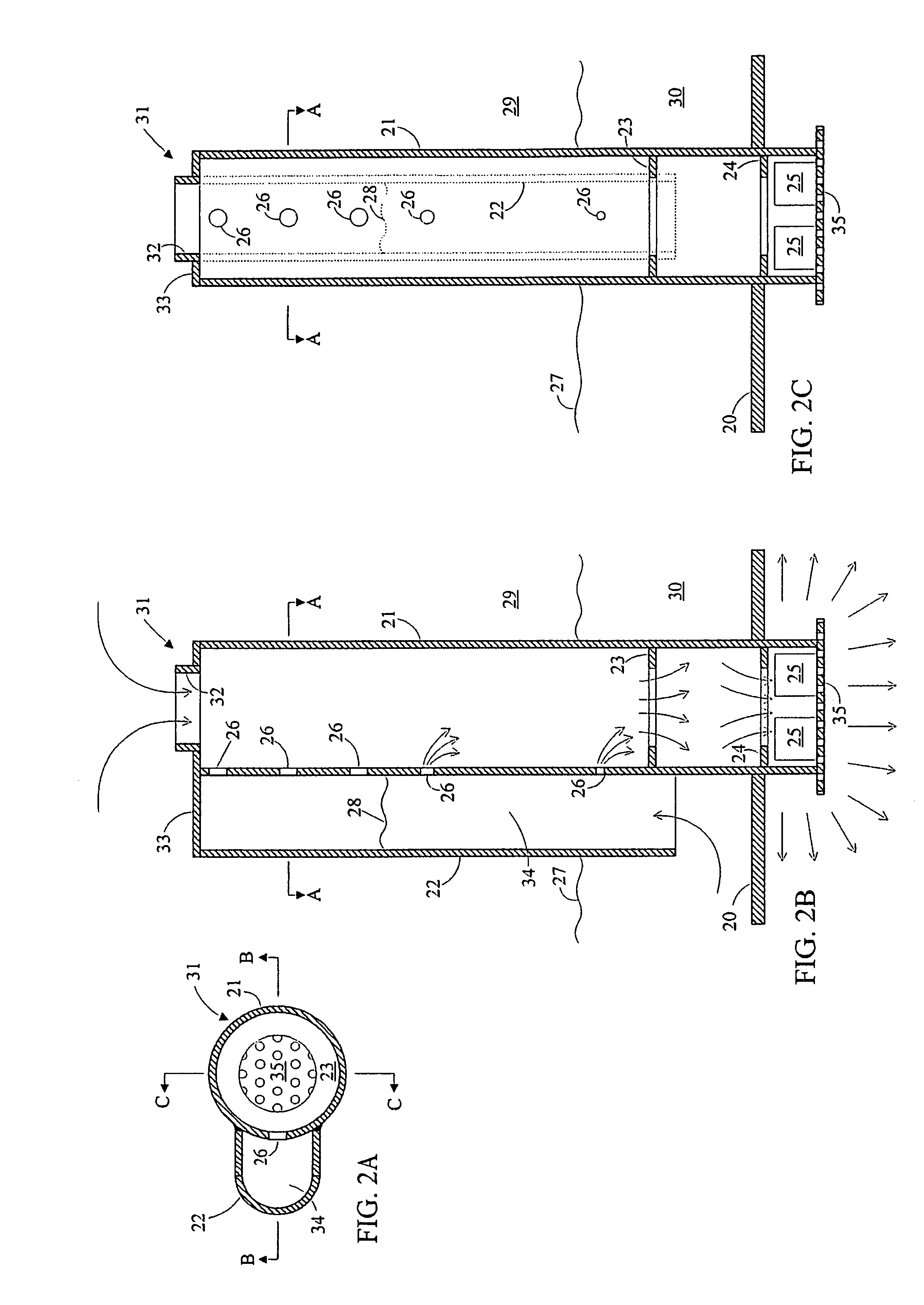

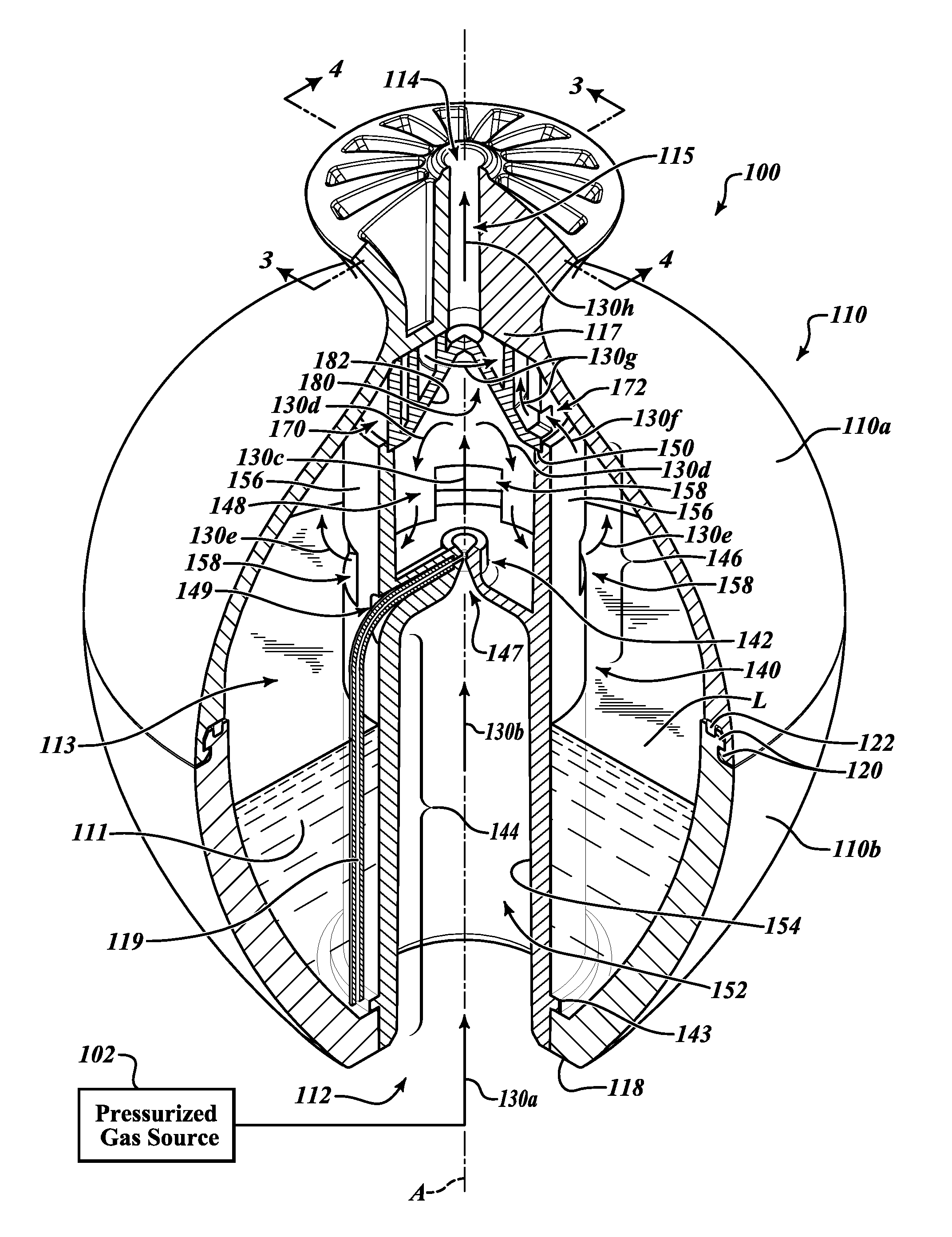

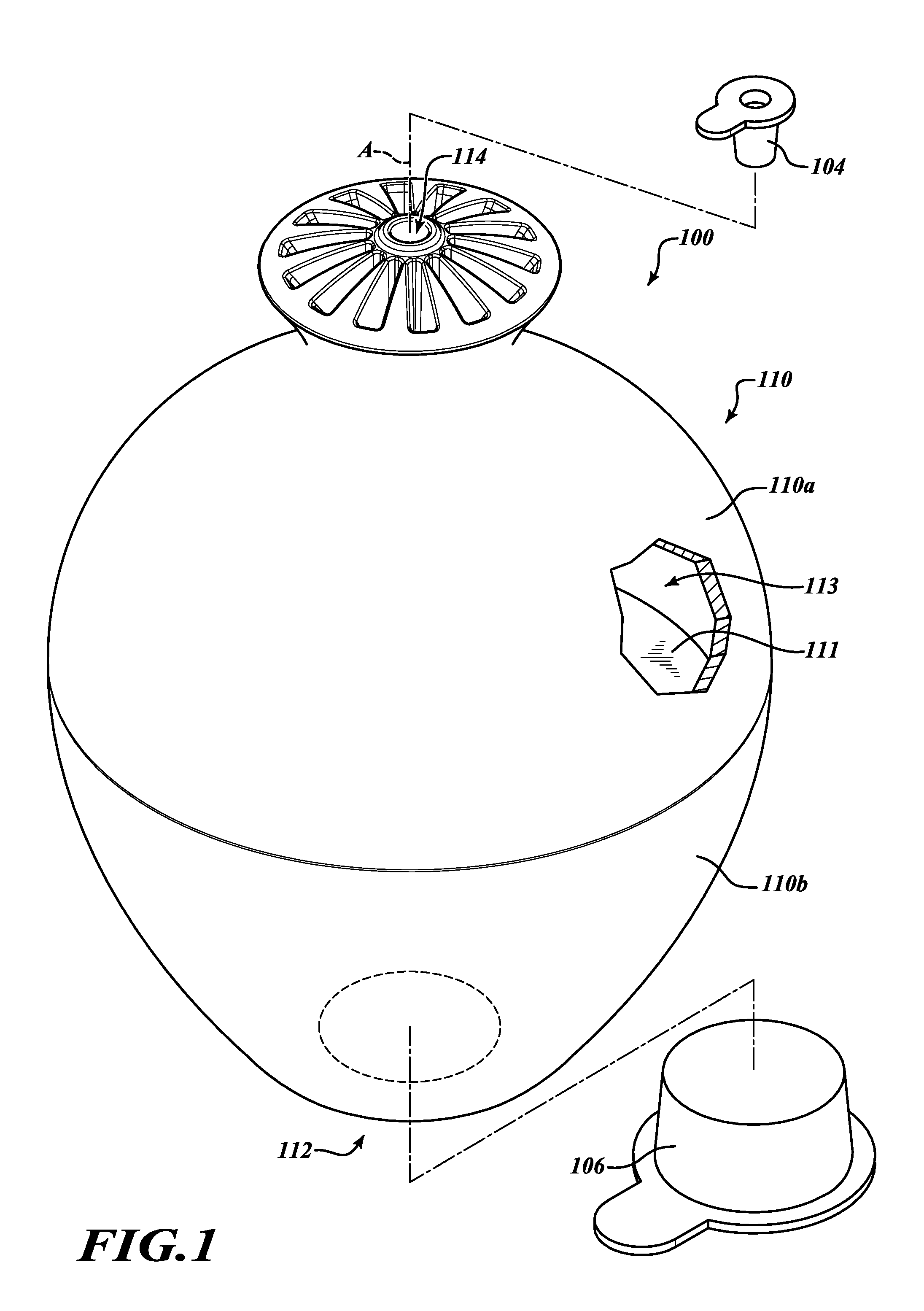

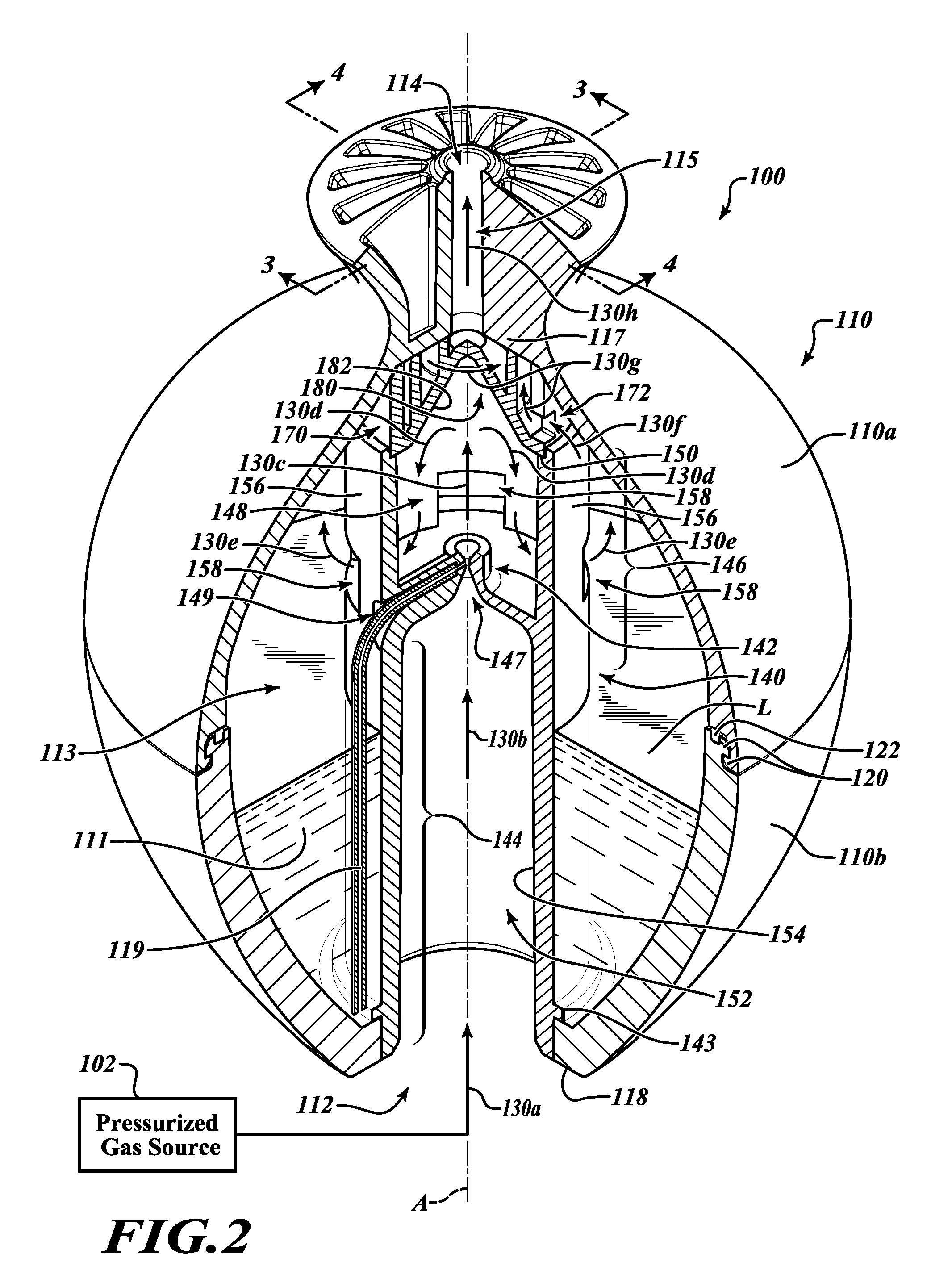

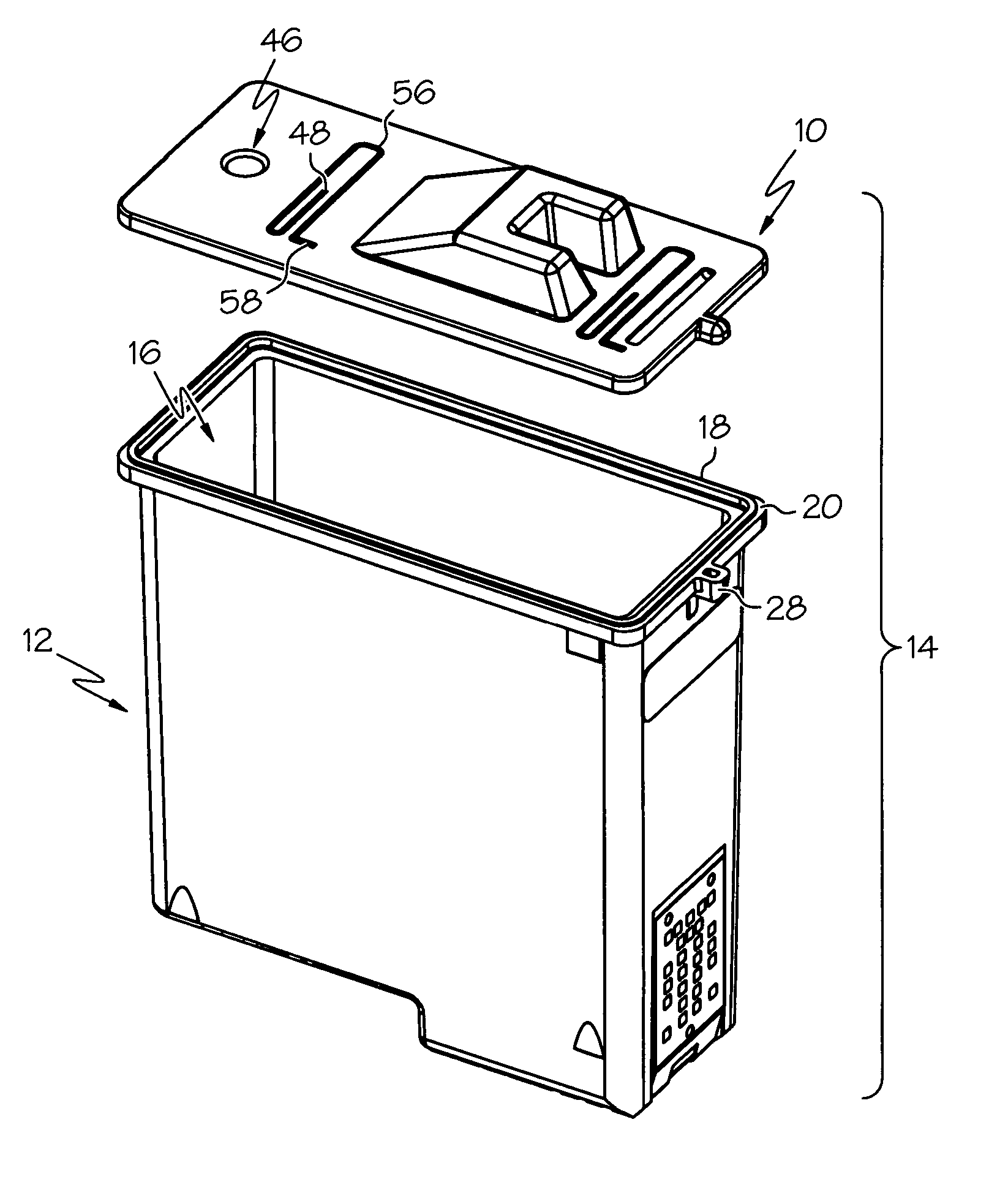

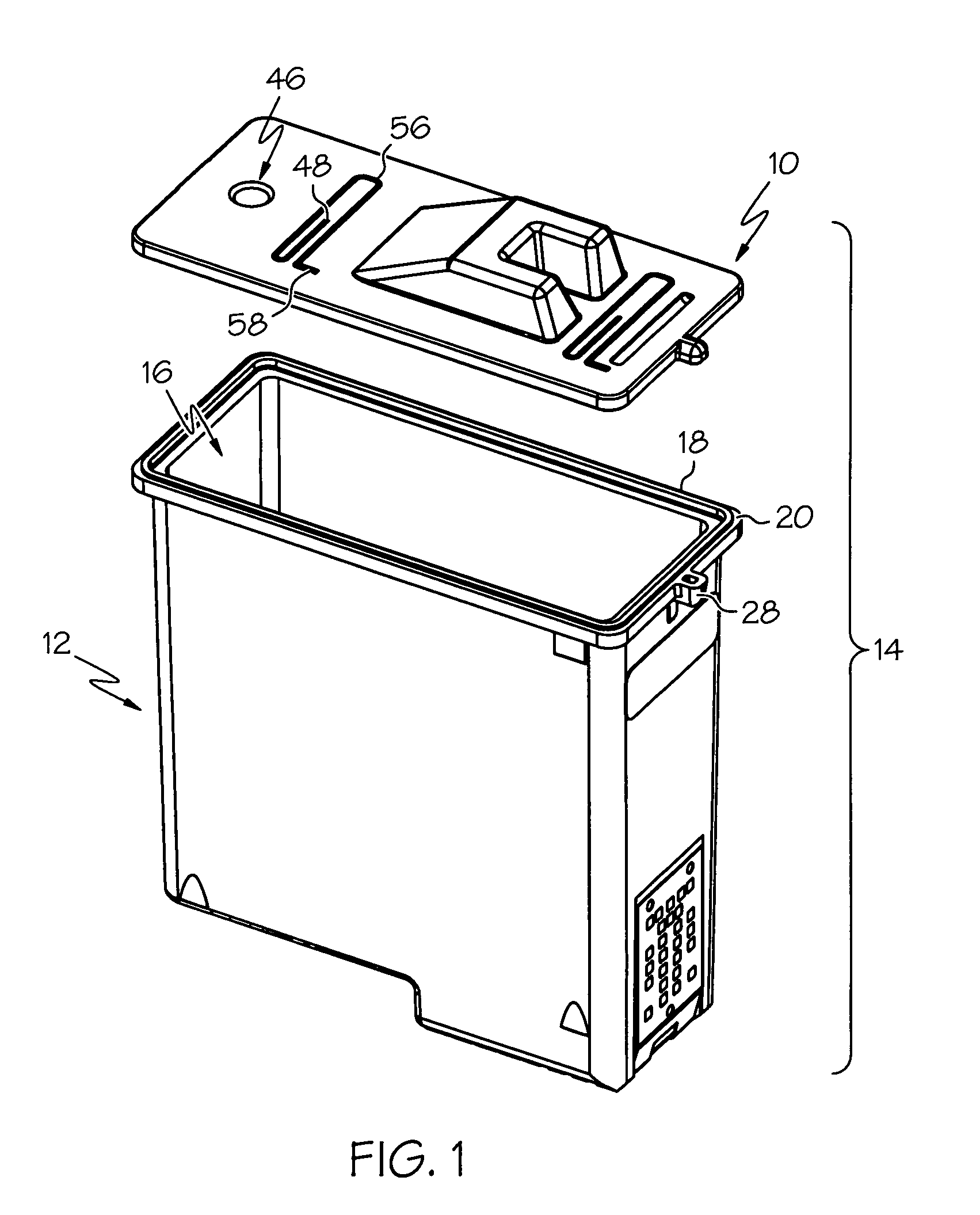

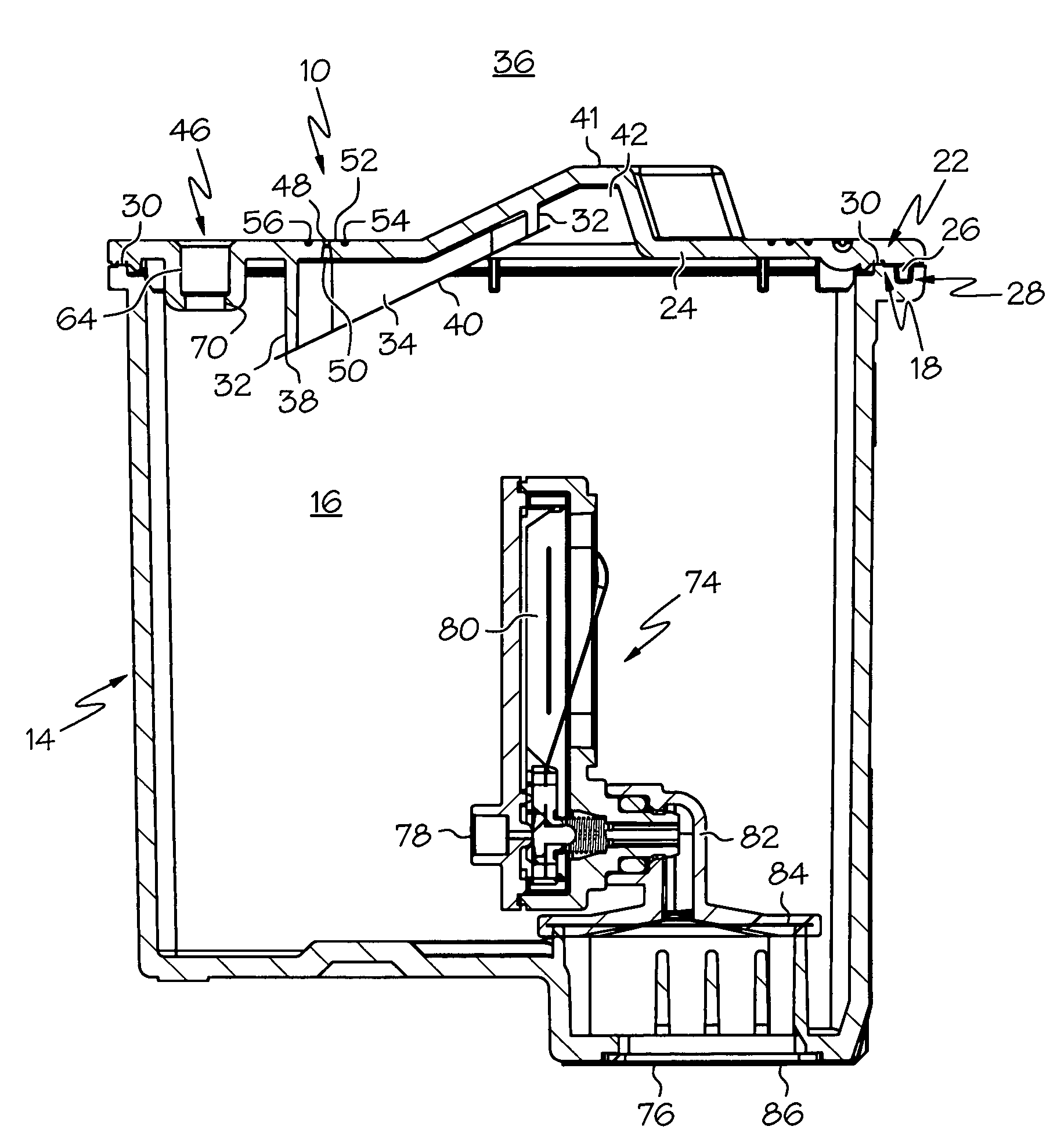

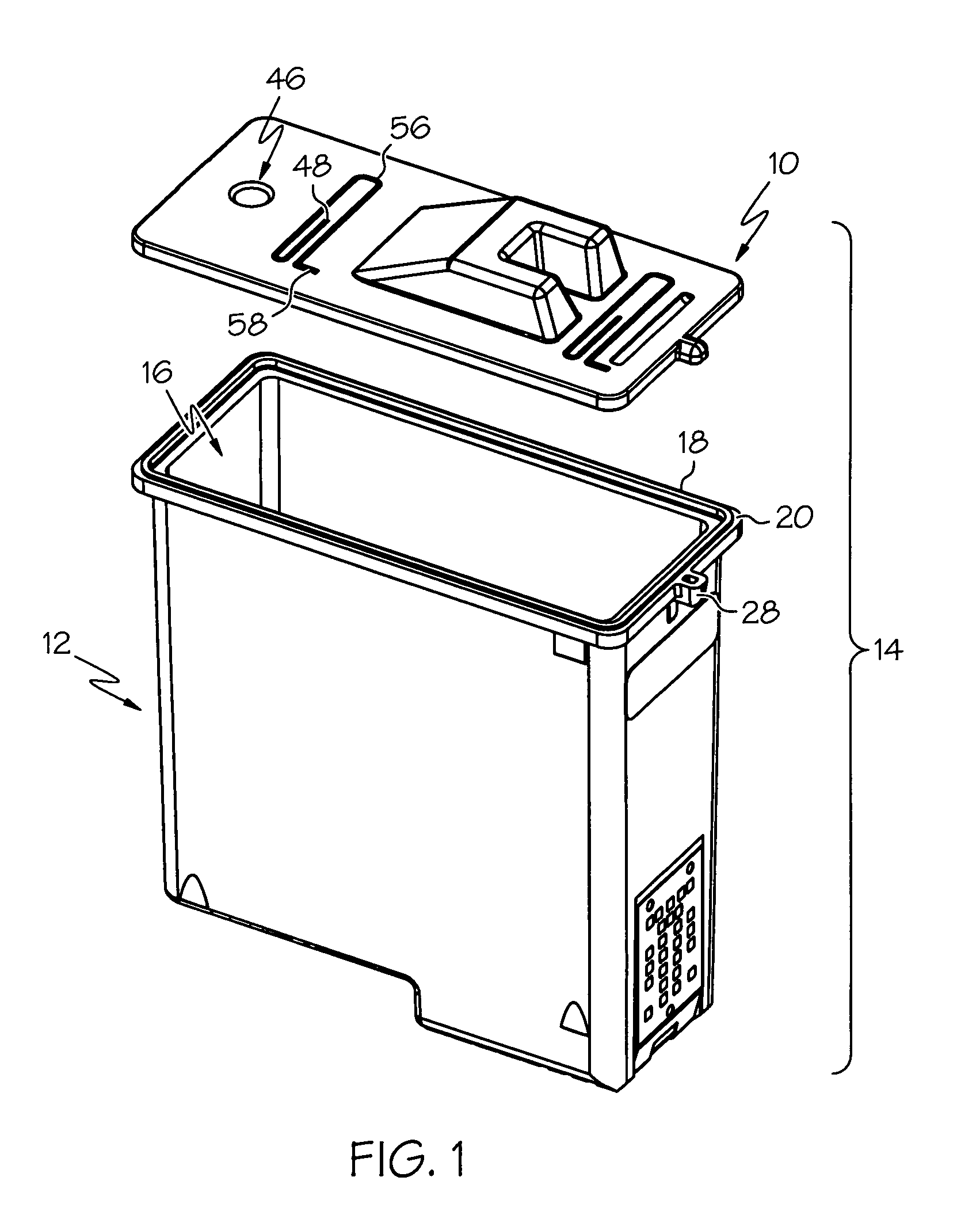

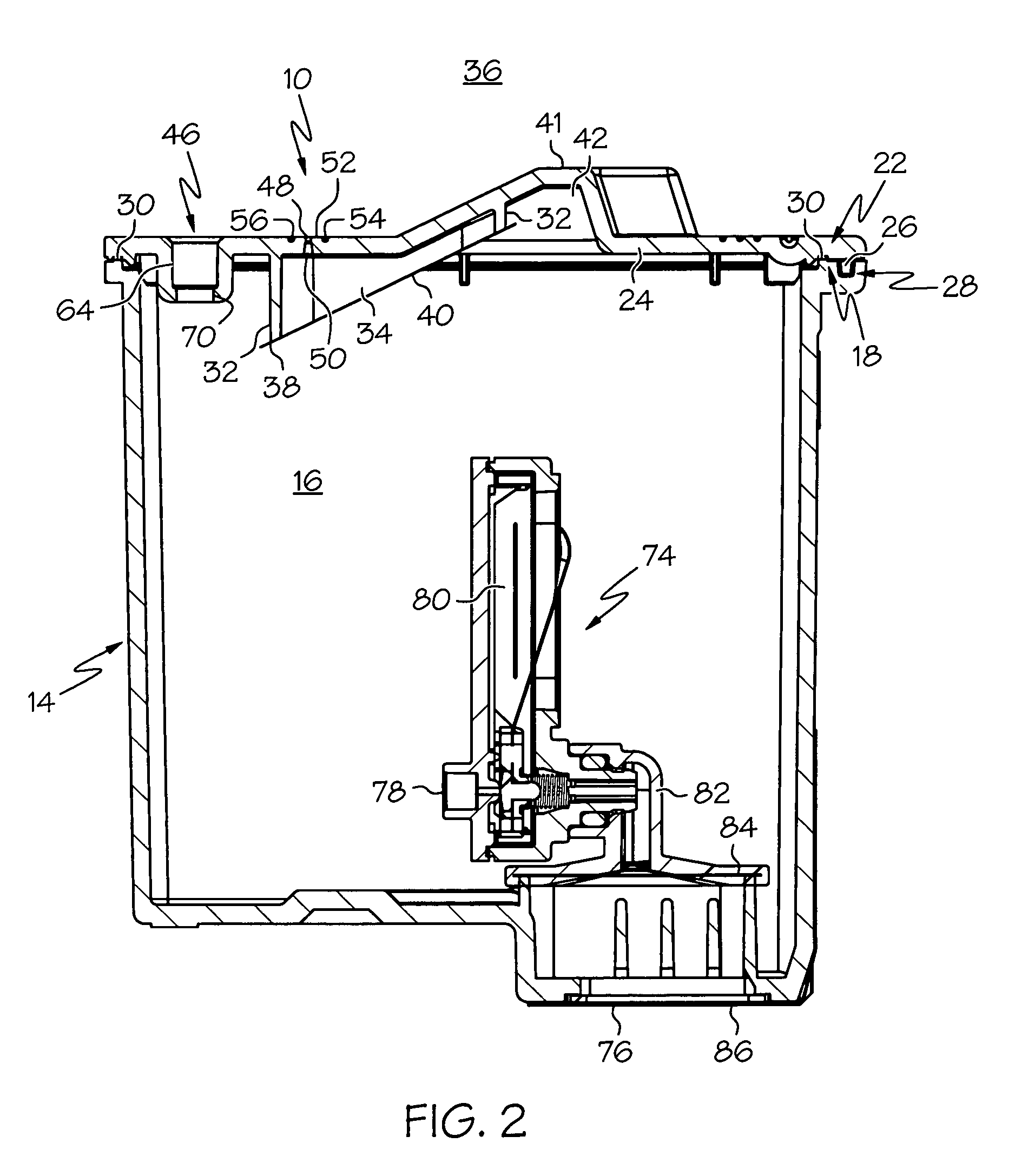

Removable cartridge for liquid diffusion device

ActiveUS9248461B2Effective treatmentPrevent non-destructive disassemblyFlow mixersLighting and heating apparatusLiquid diffusionEngineering

A removable cartridge for use with a liquid diffusion device is provided. The removable cartridge includes a cartridge housing defining an internal housing cavity, partially filled with a liquid to be diffused, and a diffusion head positioned within the internal housing cavity with a venturi device for generating diffused liquid from the liquid contained in the internal housing cavity. The diffusion head defines at least a portion of a gas supply conduit that extends from a bottom end of the removable cartridge to the venturi device through the liquid to be diffused to enable the venturi device to be supplied with pressurized gas from an external source via the bottom end of the removable cartridge.

Owner:PROLITEC INC

Removable cartridge for liquid diffusion device and cartridge insert thereof

ActiveUS9162004B1Small particle sizePrevent leakageFlow mixersLighting and heating apparatusLiquid diffusionEngineering

An insert of a cartridge for use with a liquid diffusing device is provided. The insert includes a body, an inlet provided in the body to receive diffused liquid generated within the cartridge during operation of the liquid diffusing device, an outlet zone defined at least in part by the body through which to discharge the diffused liquid toward an external environment, and a tortuous passage extending between the inlet and the outlet zone to aid in further reducing an average particle size of the diffused liquid as the diffused liquid moves through the tortuous passage. Removable cartridges for use with a diffusion device are also provided which include such an insert.

Owner:PROLITEC INC

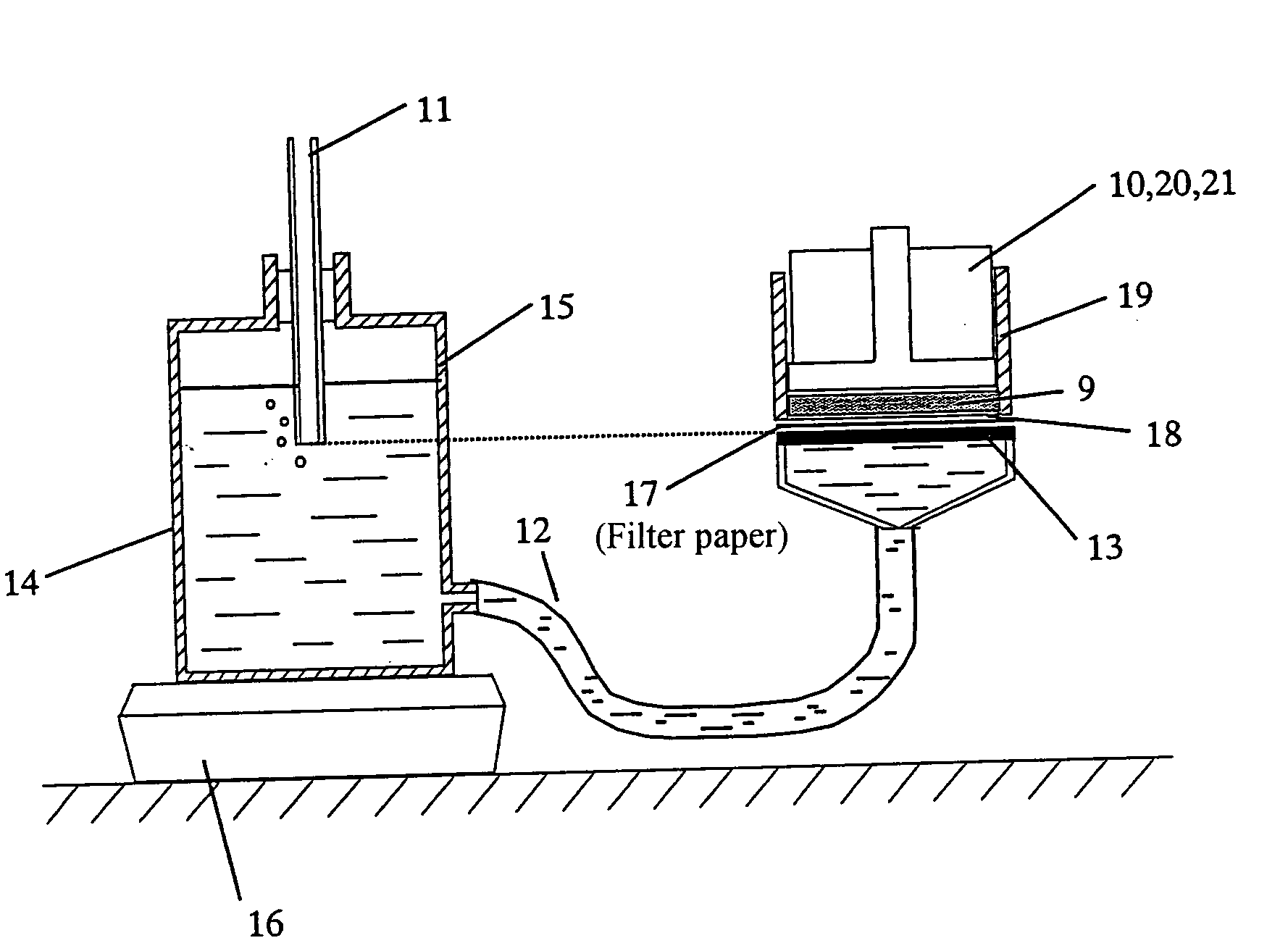

Integrity Test Method for Porous Filters

ActiveUS20110067485A1Semi-permeable membranesPermeability/surface area analysisLiquid diffusionEngineering

An improved method of testing the integrity of a porous filter is provided. The test method is an improvement over a gas-liquid diffusion test wherein the improvement comprises providing a conduit downstream of the filter and filling the conduit with a liquid, the conduit having a length to cross sectional area ratio selected to substantially resist diffusive flow of the gas through the liquid downstream of the filter material.

Owner:WL GORE & ASSOC INC

Semipermeable membrane for an ink reservoir and method of attaching the same

An inkjet assembly comprising a vented ink reservoir for containing a liquid ink therein, the vented ink reservoir defining an internal volume occupied at least in part by a semipermeable membrane in fluid communication with a vent that automatically adjusts for pressure differentials by enabling gaseous diffusion between an environment external to the vented ink reservoir and the internal volume of the vented ink reservoir, while inhibiting liquid diffusion therethrough. A method is also disclosed for mounting the semipermeable membrane to at least one of an ink reservoir cap and an ink tank.

Owner:SLINGSHOT PRINTING LLC

Method for manufacturing semiconductor device

ActiveUS20090017599A1Avoid destruction and characteristic deteriorationReduce surface resistanceLight-sensitive devicesSolid-state devicesLiquid diffusionEngineering

An object is to suppress discharge due to static electricity generated by peeling, when an element formation layer including a semiconductor element is peeled from a substrate. Over the substrate, the release layer and the element formation layer are formed. The support base material which can be peeled later is fixed to the upper surface of the element formation layer. The element formation layer is transformed through the support base material, and peeling is generated at an interface between the element formation layer and the release layer. Peeling is performed while the liquid is being supplied so that the element formation layer and the release layer which appear sequentially by peeling are wetted with the liquid such as pure water. Electric charge generated on the surfaces of the element formation layer and the release layer can be diffused by the liquid, and discharge by peeling electrification can be eliminated.

Owner:SEMICON ENERGY LAB CO LTD

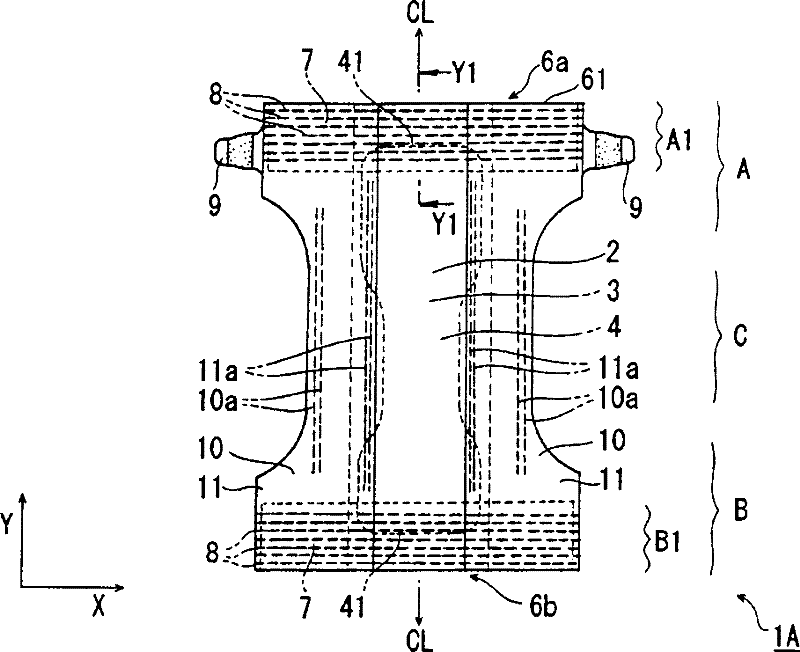

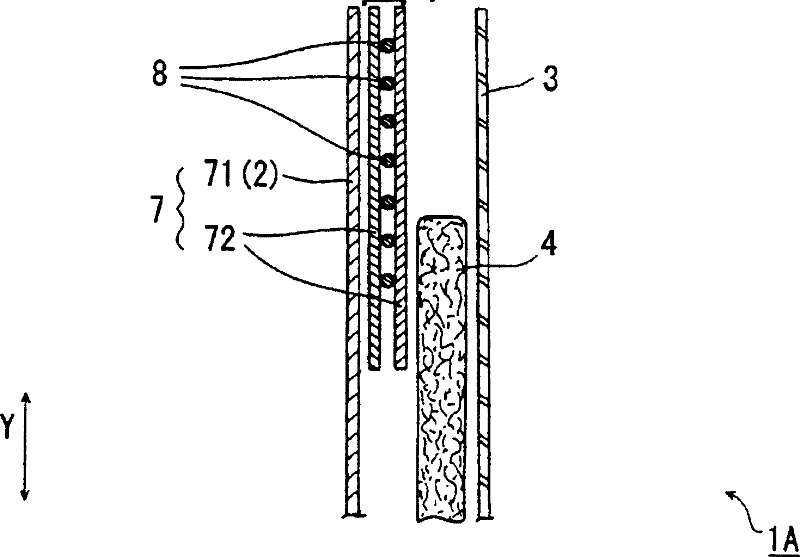

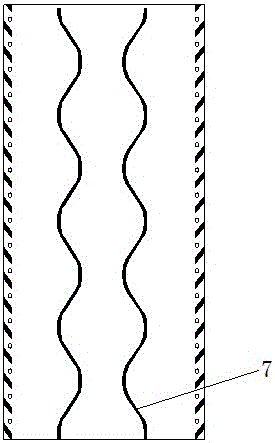

Absorbent article

A disposable diaper (1A) is equipped with a central absorbent body (4) spanning from a back-side section (A) to an abdomen-side section (B), and with waist flaps (6a, 6b) having a hydrophilic sheet (7) disposed therein. The hydrophilic sheet (7) has an inner hydrophilic sheet (71) and an outer hydrophilic sheet (72) disposed on the side of a surface not in contact with the skin. The outer hydrophilic sheet (72) uses elements having greater liquid diffusion properties that the inner hydrophilic sheet (71). The inner hydrophilic sheet (71) and outer hydrophilic sheet (72) are disposed in a waist region (A1) that includes the region between the edge (61) of the wast flap (6a) on the back-side section (A) and the edge (41) of the absorbent body (4). On the waist flap (6a), gathers that extend in the width direction (X direction) of the diaper (1A) are formed in an elastic waist member (8) disposed within the waist flap (6a).

Owner:KAO CORP

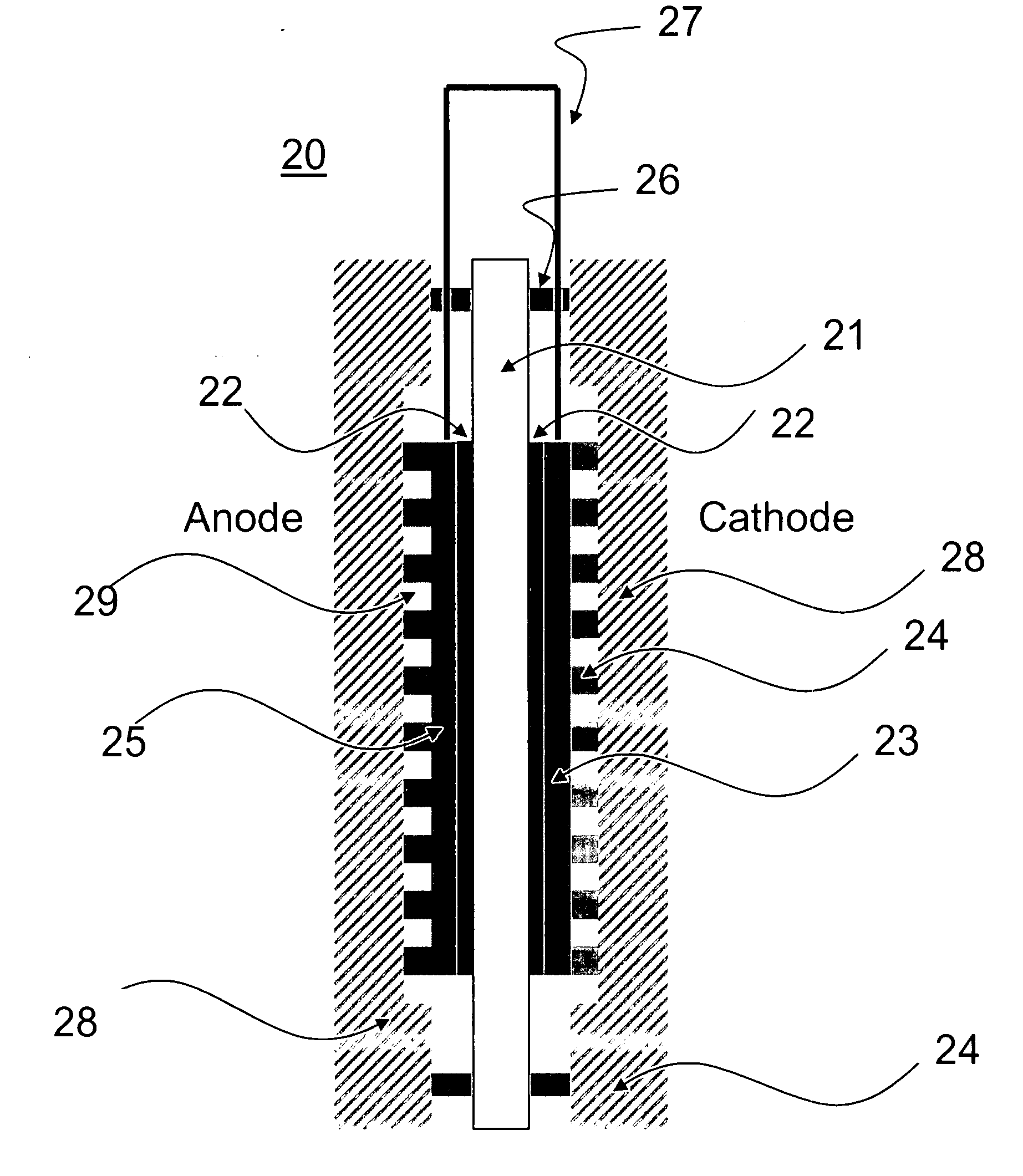

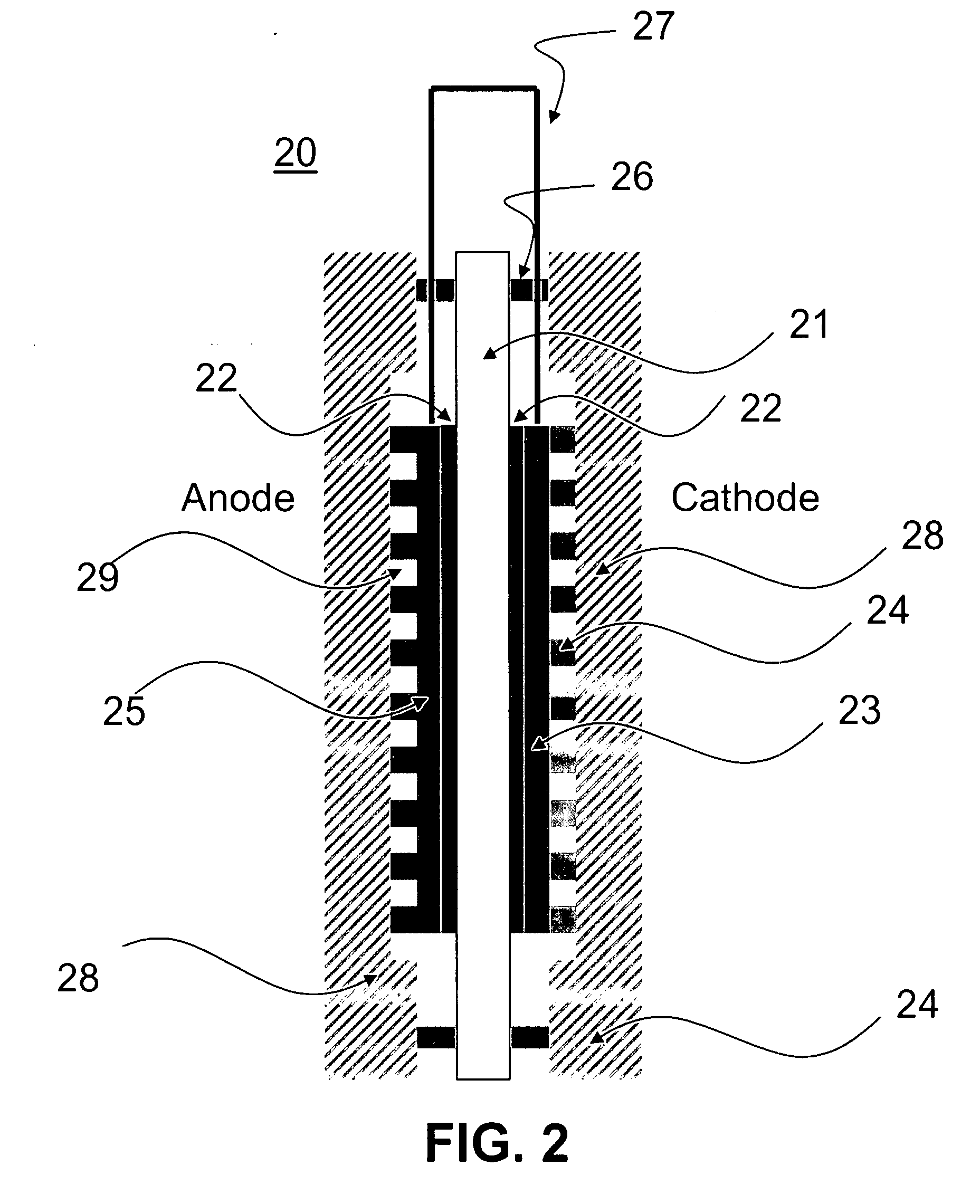

Integrated flow field plate and diffusion electrode in a fuel cell

InactiveUS20090169962A1Easy to assembleLow costCell electrodesFuel cellsEngineeringMethanol crossover

A fuel cell has at least one electrode having channels for delivering reactants, products, or both. The electrode is an anode or cathode of the fuel cell, or both. The electrode can serve as both a liquid diffusion layer and a flow field plate, thus replacing the traditional elements of carbon paper, cloth diffusion layer, and anode current collector. In some aspects, the fuel cell uses methanol, and the electrode is formed from flexible graphite. The electrode can have a structure sufficient to permit methanol diffusion while preventing methanol crossover. The electrode can also improve volumetric power density and eliminate contact resistance typically present between a conventional flow field plate and conventional diffusion electrode layer.

Owner:THE HONG KONG UNIV OF SCI & TECH

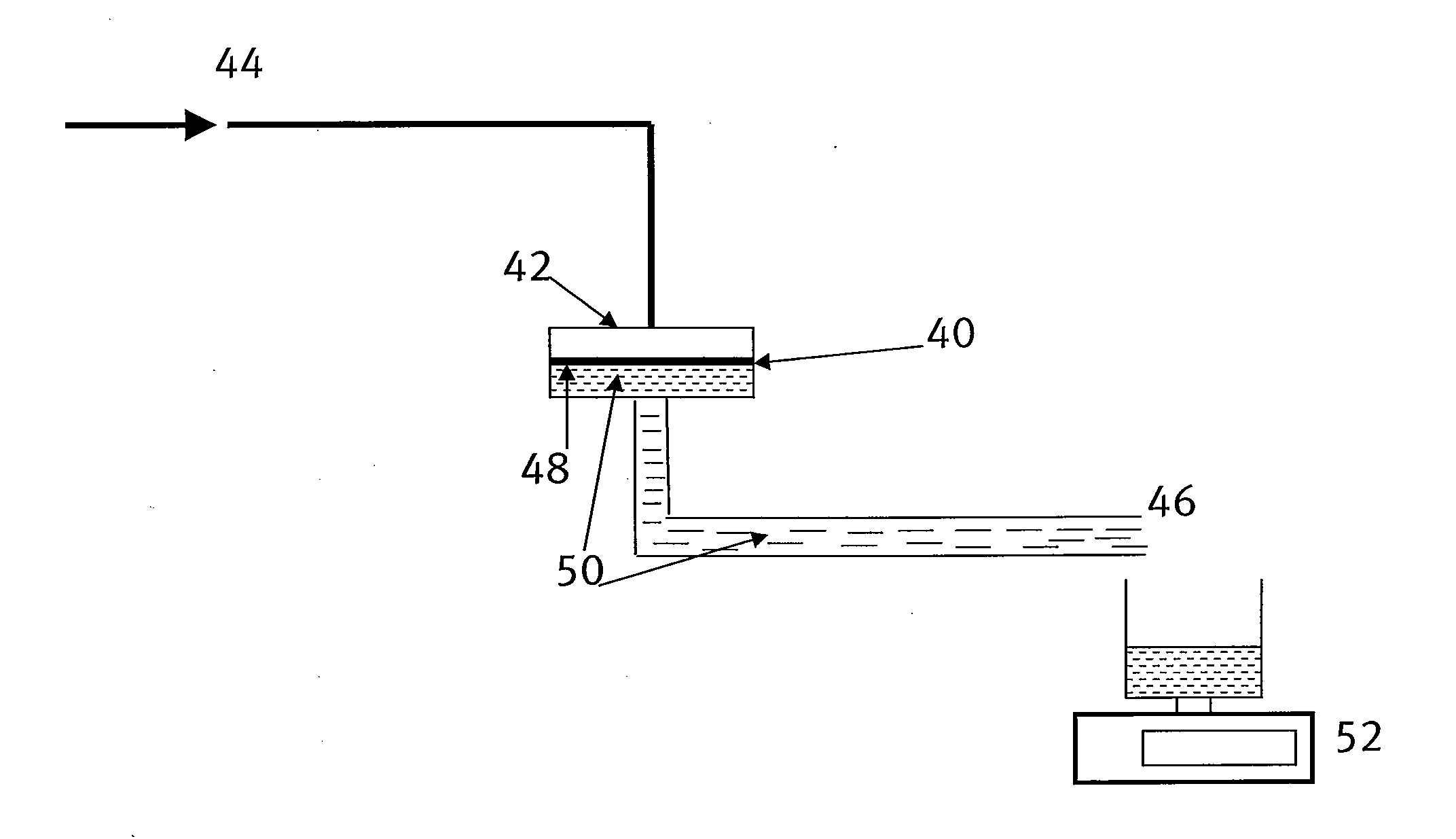

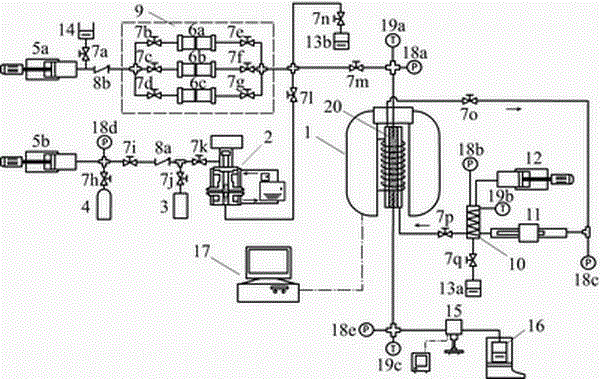

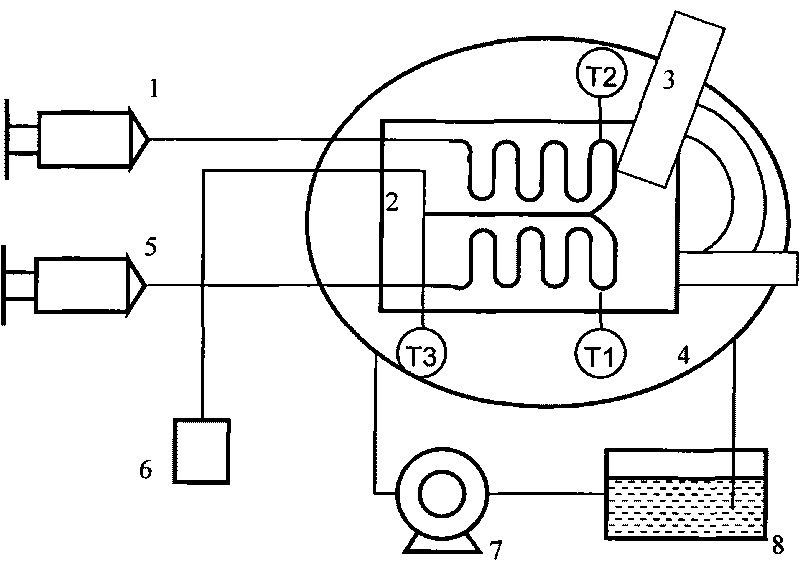

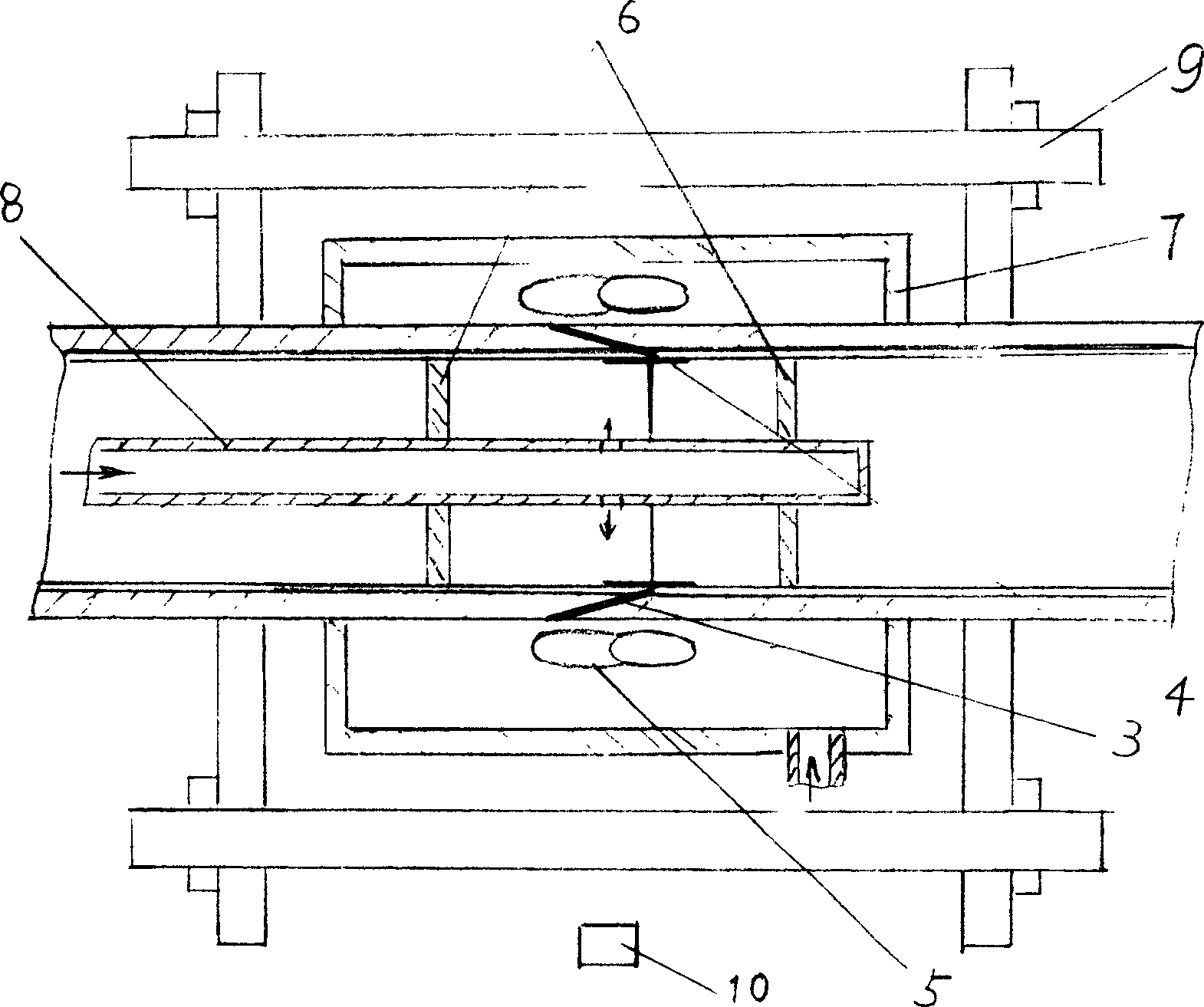

Device and method for detecting gas-liquid diffusion processes by using magnetic resonance imaging (MRI) technique

ActiveCN102879306ADensity determinationReal-time monitoring of density changesSurface/boundary effectLiquid diffusionTransverse relaxation

The invention relates to a device and a method for detecting gas-liquid diffusion processes by using an MRI technique, and belongs to the technical field of chemical engineering and petroleum engineering. The device comprises a magnetic resonance imaging system and a dual chamber pressure attenuation system. The magnetic resonance imaging system is provided with a rock core clamper in a magnetic resonance imaging instrument which is electrically connected with a data acquisition and processing system. According to the device and the method for detecting gas-liquid diffusion processes by using the MRI technique, proton density images, longitudinal and transverse relaxation and diffusion tensor distribution images of fluids in porous media can be measured in real time, visually and with no damage through the MRI technique. Quantitative analysis can be performed on porous medium porosity, permeability, saturation level and the like; an improved dual chamber pressure attenuation method can reduce the leakage rate, and confirm the initial gas density conveniently and accurately; and a magnetic suspension balance can monitor gas density changes in real time, and accordingly, deficiencies of traditional dual chamber pressure attenuation methods are compensated.

Owner:DALIAN UNIV OF TECH

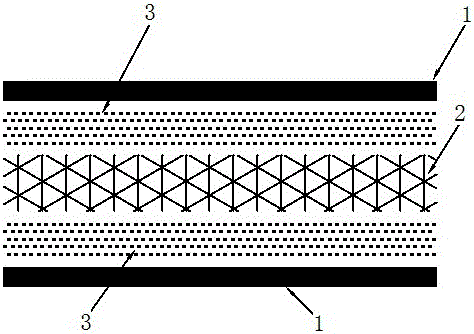

Absorption core with efficient flow guide property and breathability and method for manufacturing absorption core

ActiveCN105919733AReduce the degree of plasticizationIncreased softness and comfortPersonal careSynthetic resin layered productsLiquid diffusionSurface layer

Owner:湖南倍健卫生用品有限公司

Particulate water-absorbent resin composition

ActiveUS7285615B2Improve performanceAvoid problemsSynthetic resin layered productsCellulosic plastic layered productsParticulatesLiquid diffusion

Owner:NIPPON SHOKUBAI CO LTD

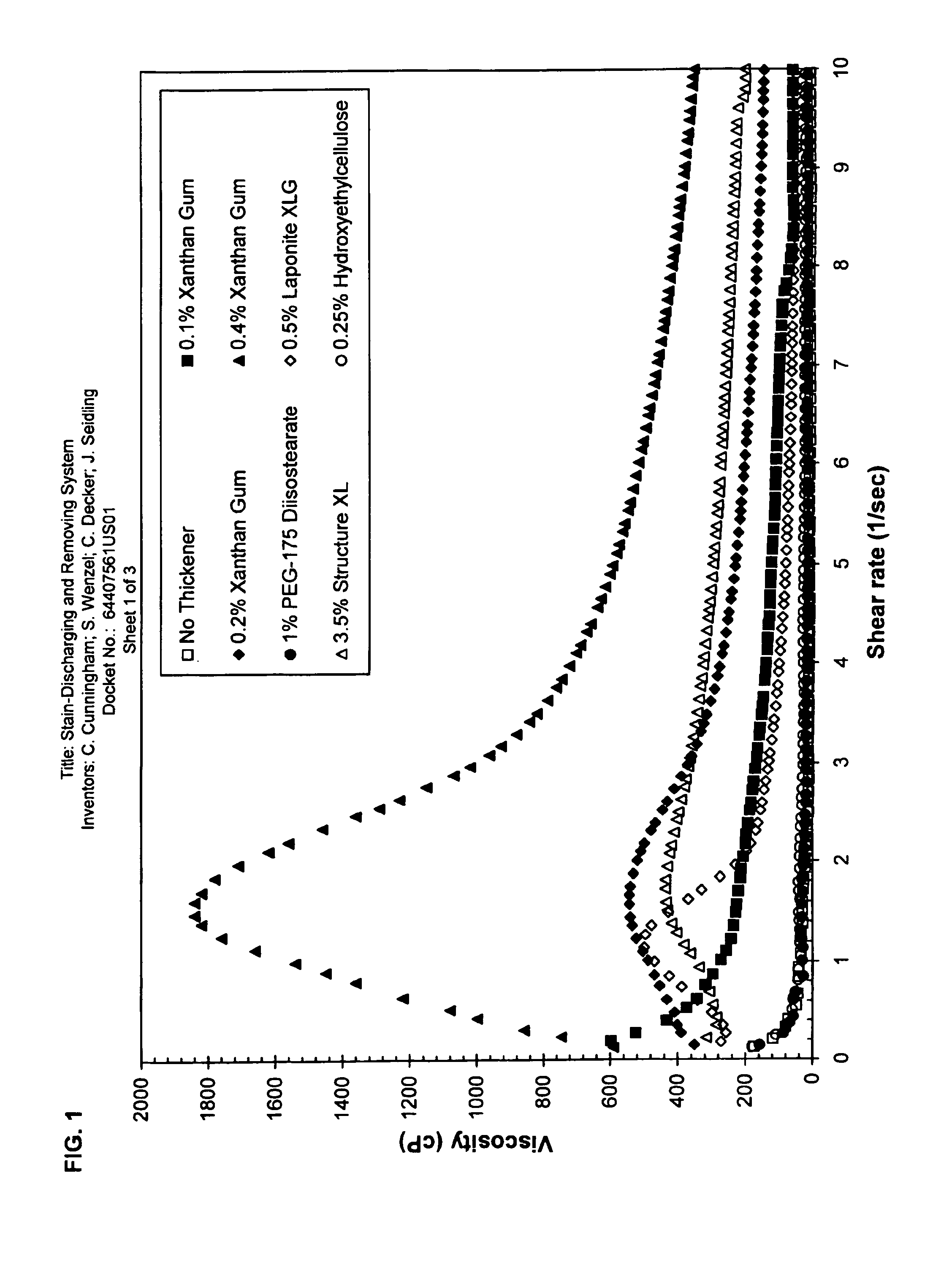

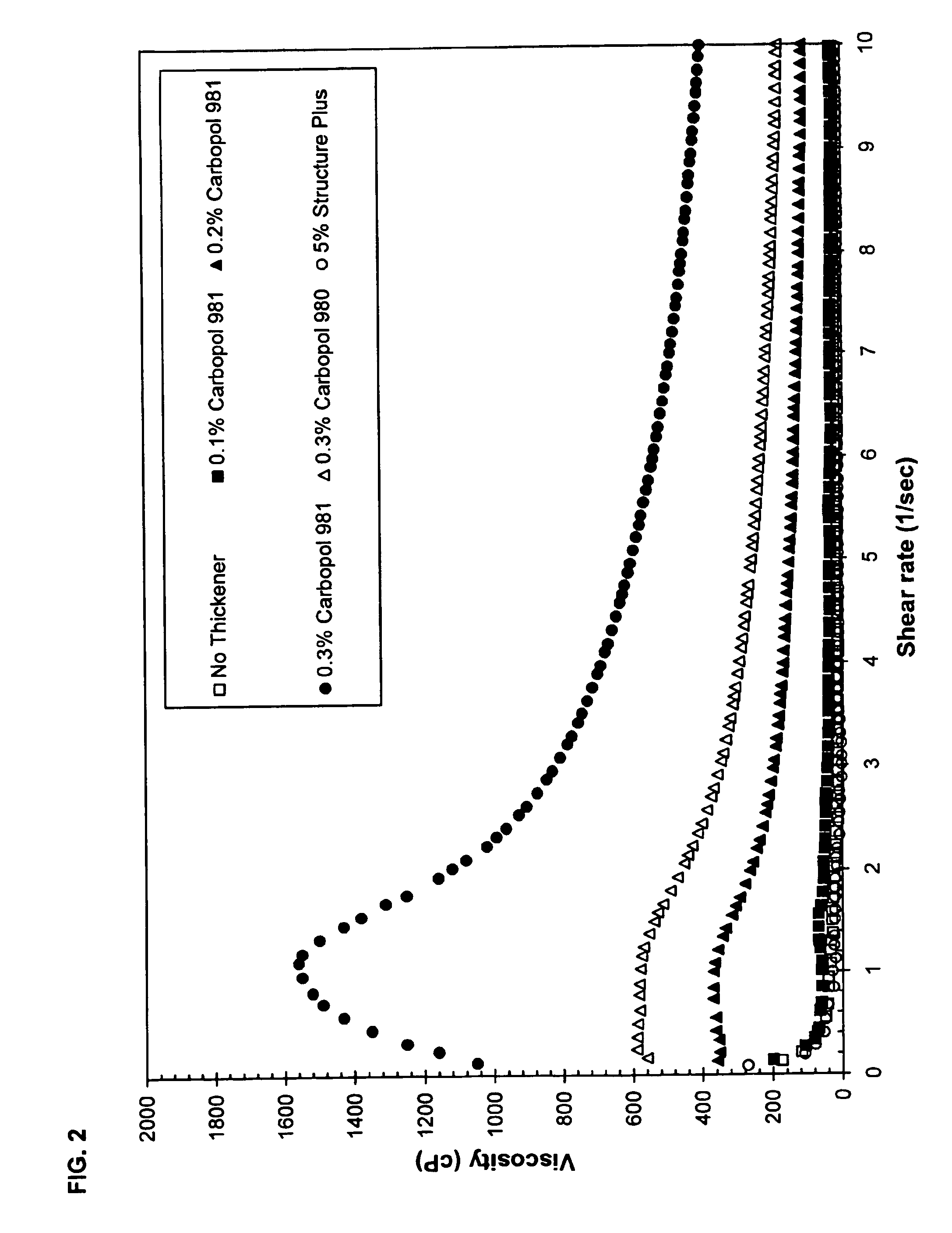

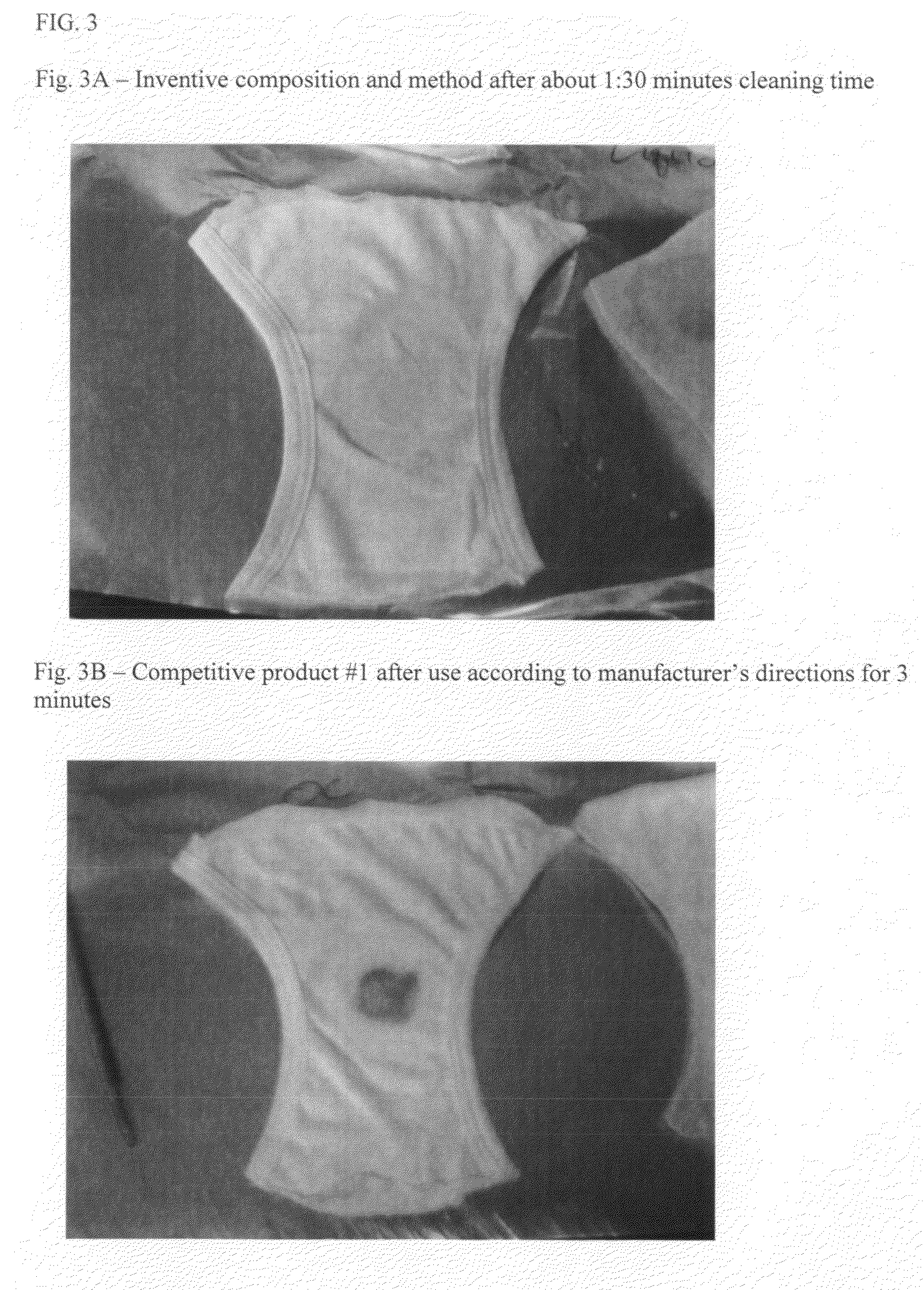

Stain-discharging and removing system

ActiveUS20090062172A1Improve distributionOrganic detergent compounding agentsAqueous liquid non-soap compositionsCelluloseAntioxidant

A cleaning composition that can discharge the color of blood, menstrual fluids, or other organic stains is provided. In particular, the present invention achieves a balance between control of unwanted liquid spreading by lateral wicking on a stained textile fabric to lessen the size of wet spots and maintaining the cleaning efficacy of the composition by means of specific kinds of thickening agents. The composition includes an oxidizing agent such as peroxides, a cell-lysing agent, a chelating agent, an antioxidant, a thickener, and other optional ingredients that are selectively employed to achieve an aqueous based composition that exhibits good shelf stability and stain removal properties. The thickening agent may include a cellulosic or clay material, starch, gum, fatty acid, fatty alcohol, hydrophilic colloidal particles, polyoxyethylene glycol or polyoxyethylene glycol derivatives including fatty acid esters and ethers, or a combination thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

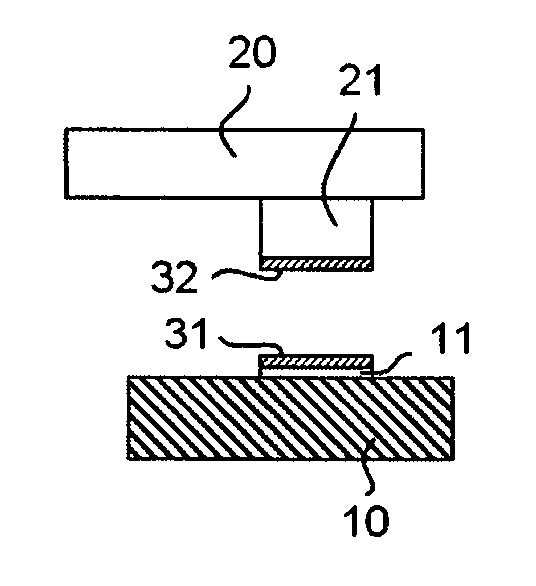

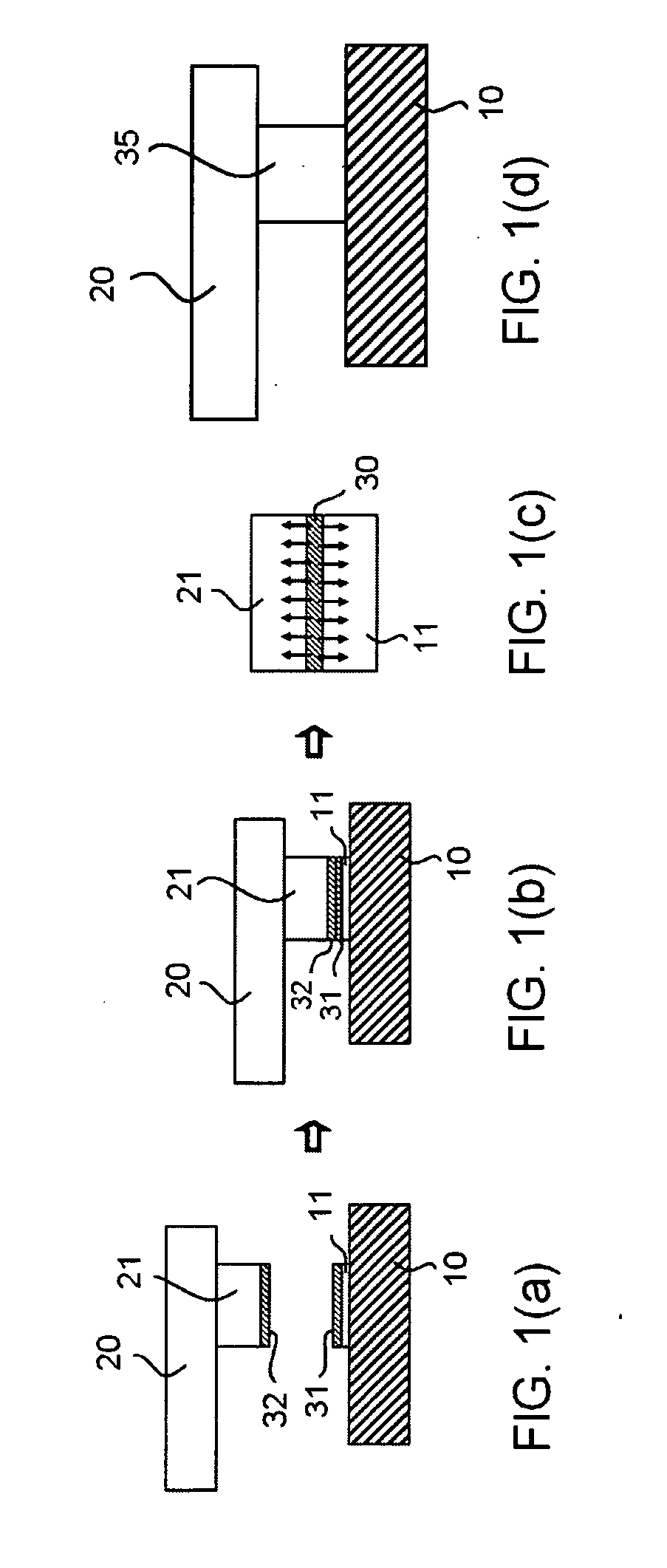

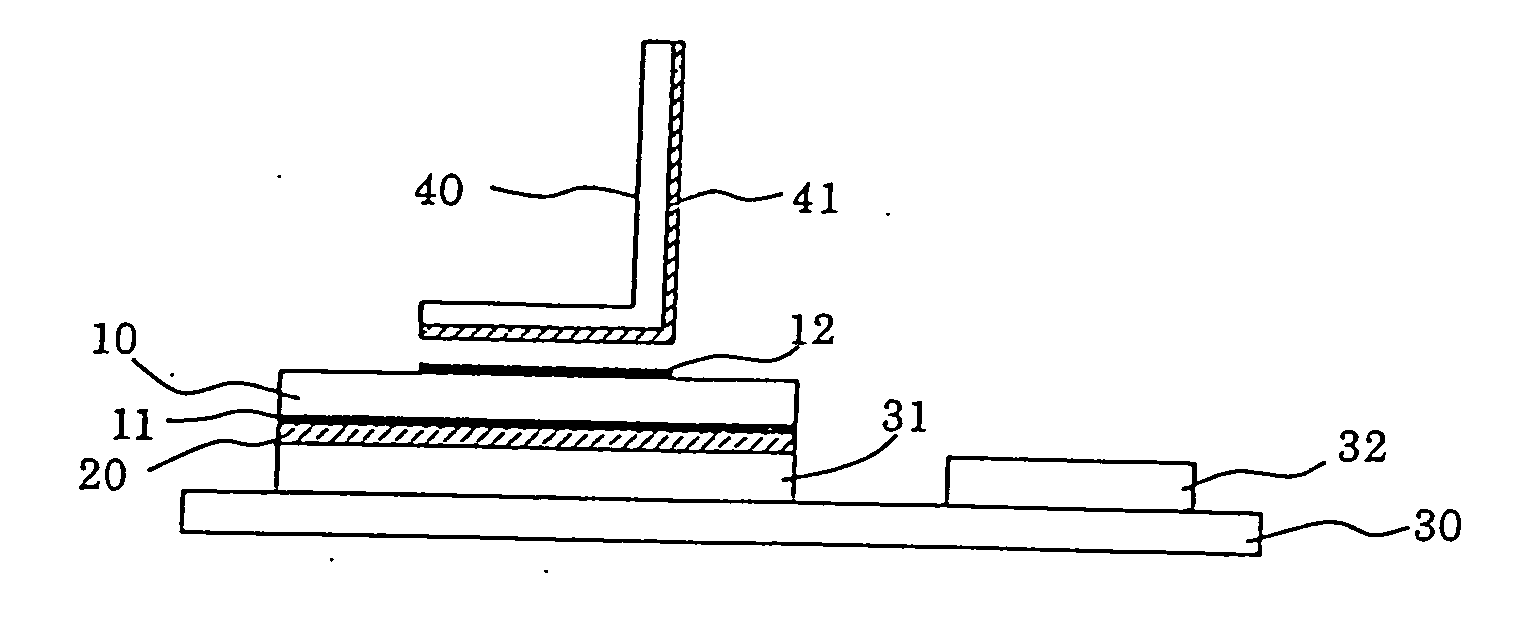

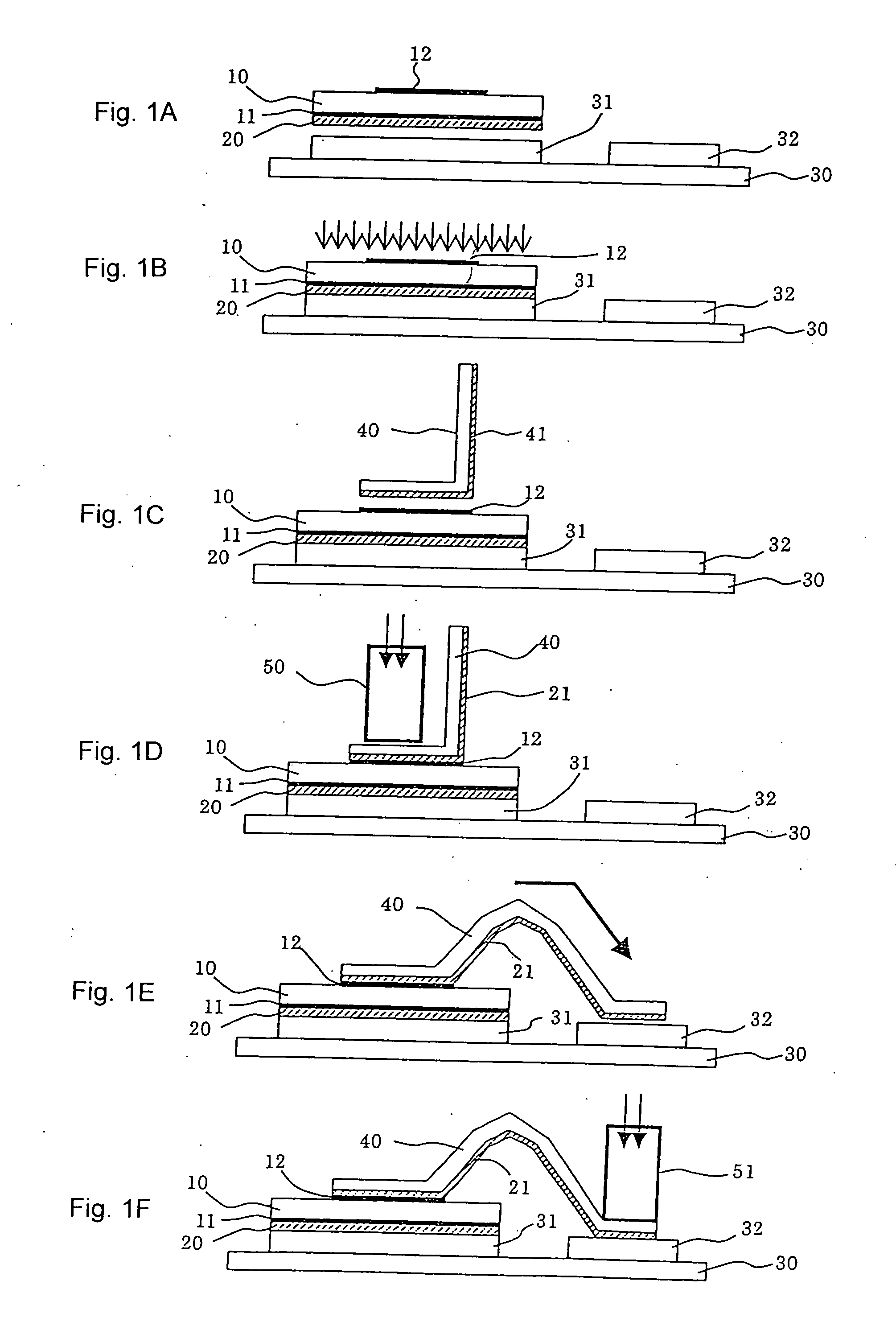

Electronic part mounting method

InactiveUS20070152025A1Good jointImprove reliabilityPrinted circuit assemblingSolid-state devicesLiquid diffusionEngineering

The present invention provides an electronic part mounting method which enables joining of electrodes at a low temperature and within a short time, can obtain the high reliability and, further, enables joining at a fine pitch. In an electronic part mounting method which joins circuit electrodes which are formed over a circuit board and die electrodes which are formed over the electronic parts thus mounting the electronic parts on the circuit board, a low-melting-point metal layer is preliminarily formed over the circuit electrode and / or the die electrode and, thereafter, the circuit electrode and the die electrode are arranged to face each other and are heated and pressurized for melting low-melting-point metal thus diffusing the low-melting-point metal into the circuit electrode and the die electrode by solid-liquid diffusion.

Owner:FUJI ELECTRIC HLDG CO LTD

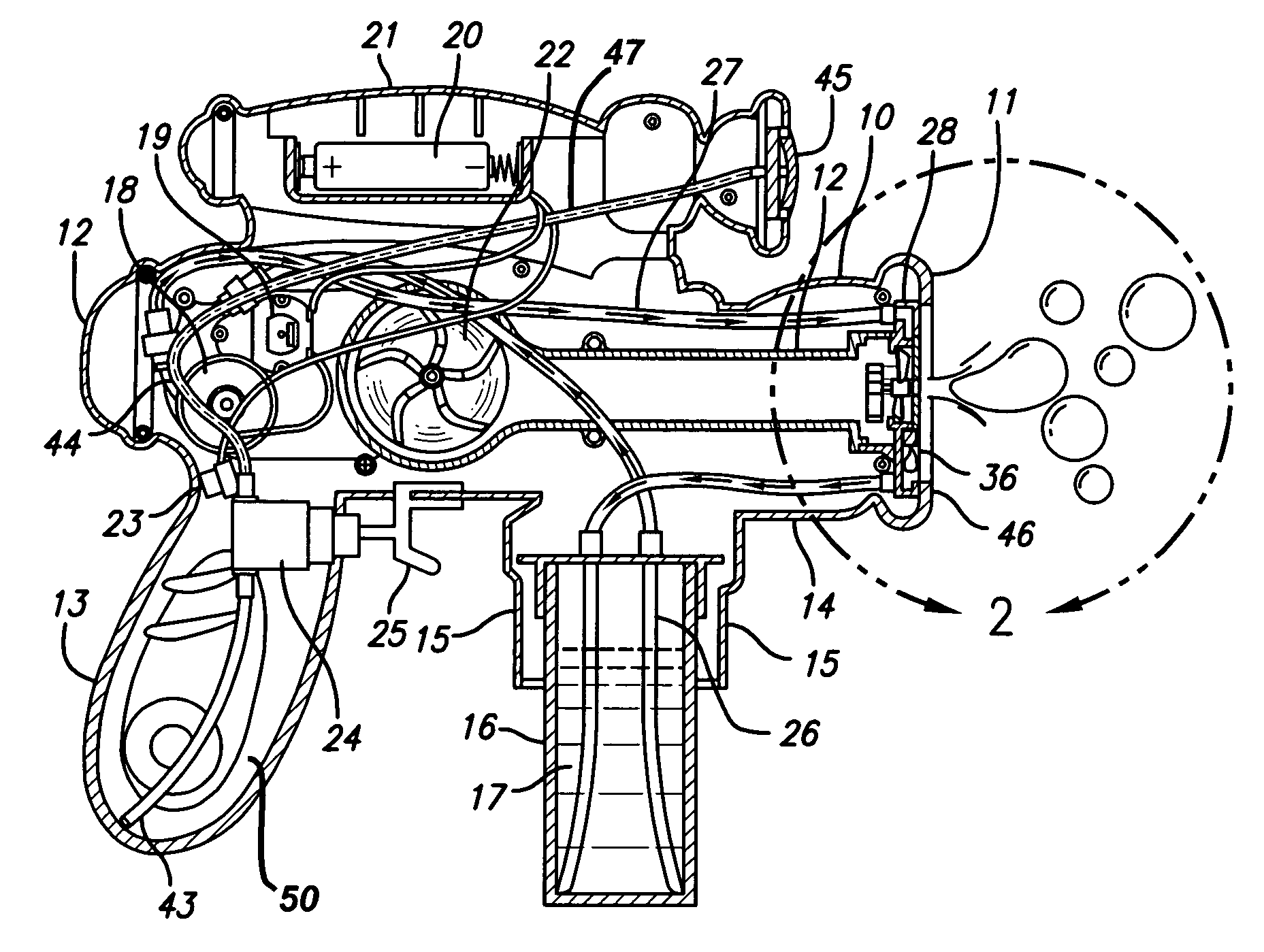

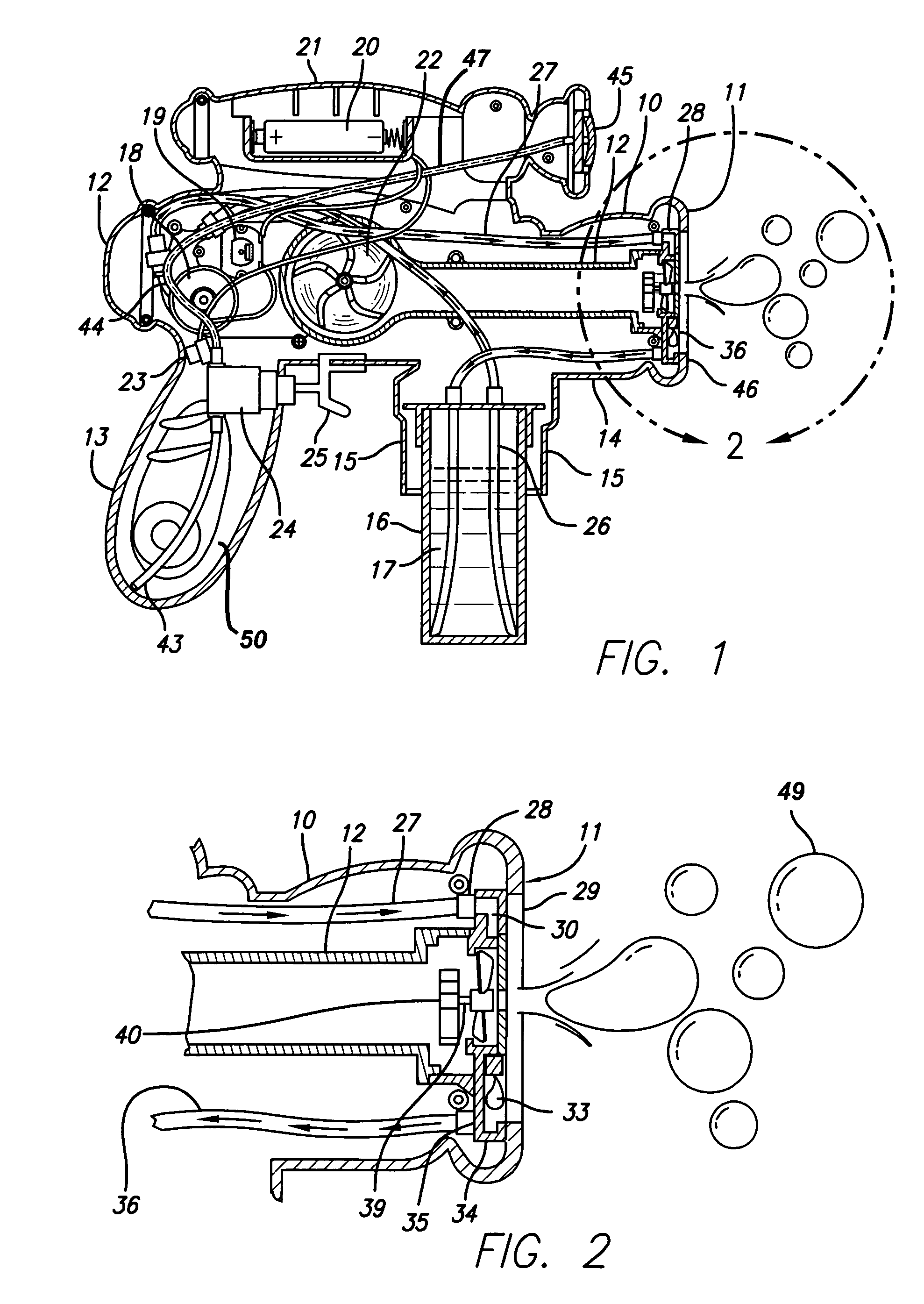

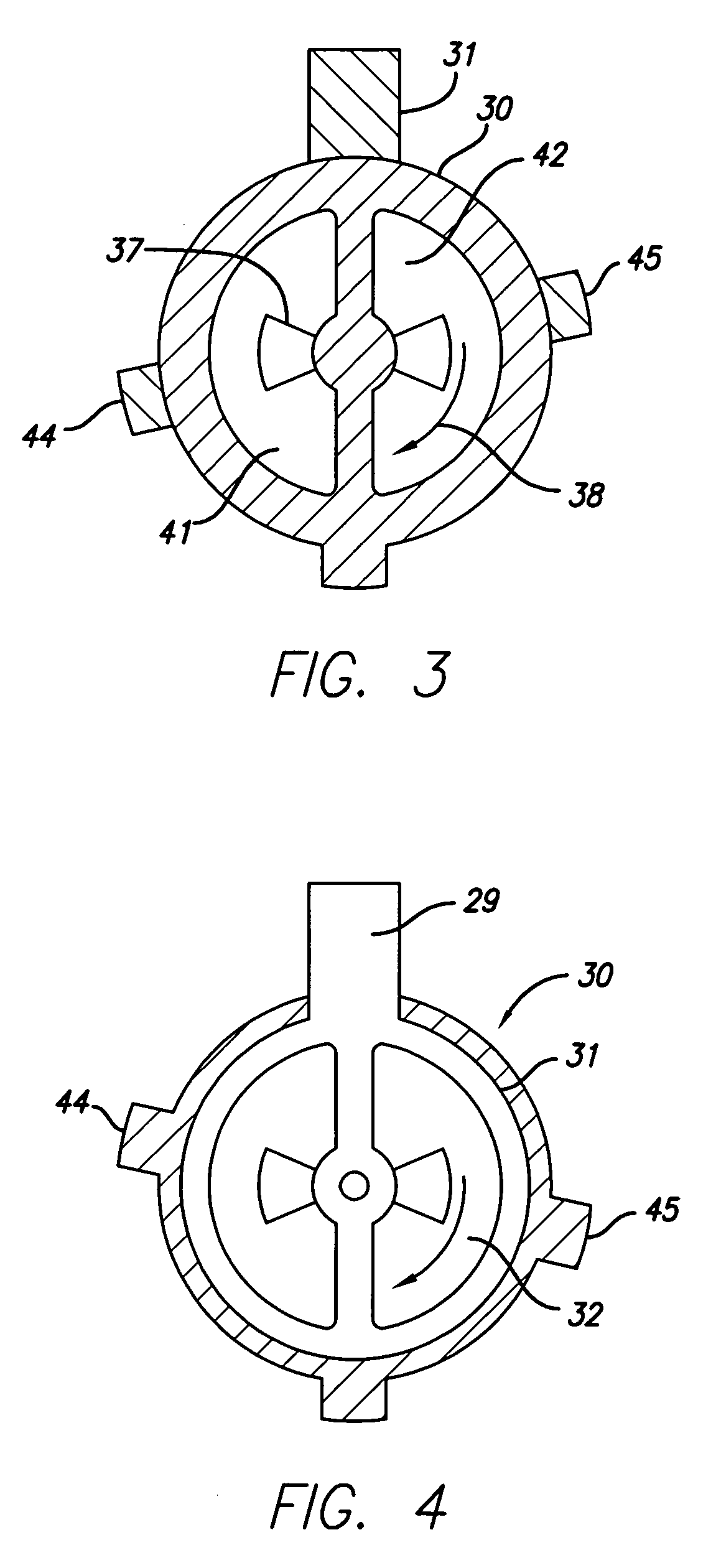

Toy for producing bubbles

A bubble making toy includes a propeller to cause liquid from an outlet port to spread across the space formed in a ring downstream of the propeller. The air generated by the propeller rotates under the action of a fan upstream of the propeller, and causes the ejection of air bubbles from the toy. The bubbles are formed by liquid which is pumped from a reservoir to a dispensing port above the circumferential ring. There is a second reservoir connected to an outlet and operable by finger action to effect the ejection of fluid such as water from a second orifice from the toy. The freely rotating propeller is mounted in the air path from the housing to the outlet for the bubbles and assists in spreading liquid across the space defined by the circumferential ring onto which liquid flows from the outlet port.

Owner:SILVERLIT TOYS MANUFACTORY

Method for manufacturing semiconductor device

InactiveUS20090017567A1Avoid destruction and characteristic deteriorationReduce surface resistanceLight-sensitive devicesSolid-state devicesLiquid diffusionSemiconductor device

An object is to suppress discharge due to static electricity generated by peeling, when an element formation layer including a semiconductor element is peeled from a substrate. Over the substrate, the release layer and the element formation layer are formed. The support base material which can be peeled later is fixed to the upper surface of the element formation layer. The element formation layer is transformed through the support base material, and peeling is generated at an interface between the element formation layer and the release layer. Peeling is performed while the liquid is being supplied so that the element formation layer and the release layer which appear sequentially by peeling are wetted with the liquid such as pure water. Electric charge generated on the surfaces of the element formation layer and the release layer can be diffused by the liquid, and discharge by peeling electrification can be eliminated.

Owner:SEMICON ENERGY LAB CO LTD

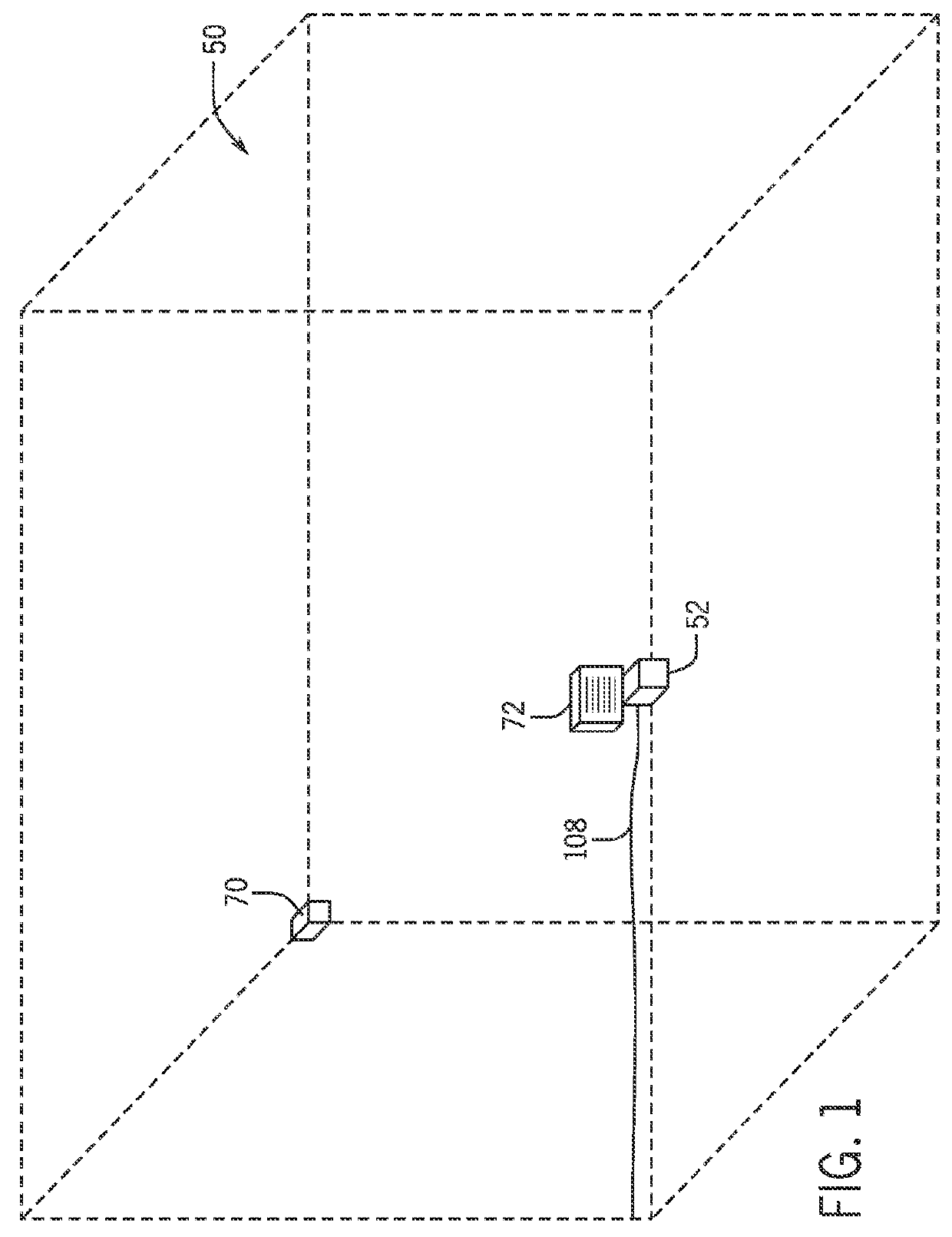

System and method of controlling operation of a liquid diffusion appliance

InactiveUS20160030621A1Mechanical apparatusLighting and heating apparatusLiquid diffusionReady to use

A method and system of controlling operation of a diffusion appliance to treat the atmosphere within an enclosed space. The appliance may be programmed to operate according to a control scheme specifying a flow rate of liquid to a diffusion means and a periodic operation of the diffusion means. Control schemes may be associated with different volumes of spaces to be treated by the appliance. Anti-fatigue schemes may provide variation of the flow rate or periodic operation of the appliance. Initiation controls schemes may be used to start treatment of the space before the appliance is programmed to operate according to one of the control schemes.

Owner:PROLITEC INC

Manufacturing method of semiconductor module

InactiveUS20070197017A1Reduce heat resistance requirementsImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesLiquid diffusionSemiconductor chip

The present invention provides a manufacturing method of a semiconductor module which enables the joining at a low temperature within a short time and can obtain more reliable joining portions by performing the joining without using a solder joining medium. The manufacturing method of a semiconductor module includes a first joining step for joining first circuit electrodes which are formed on a circuit board and back-surface-side die electrodes of a semiconductor die, a second joining step for joining the front-surface-side electrodes of the semiconductor die and one ends of lead frames, and a third joining step for joining another ends of the lead frame and second circuit electrodes which are formed on the circuit board, wherein a low-melting-temperature metal layer is formed on one conductive portion of a pair of conductive portions to be joined and, thereafter, the low-melting-temperature metal layer is heated and pressurized thus diffusing the low-melting-temperature metal layer into the pair of conductive portions by solid-liquid diffusion whereby the conductive portions are joined to each other.

Owner:FUJI ELECTRIC CO LTD

Method for enhancing coercive force of neodymium-iron-boron magnet through evaporation grain boundary diffusion

ActiveCN109360728AImprove coercive forceUniform penetrationInductances/transformers/magnets manufactureLiquid diffusionHydrogen

The invention discloses a method for enhancing the coercive force of a neodymium-iron-boron magnet through evaporation grain boundary diffusion, and belongs to the technical field of magnetic materials. The method comprises the specific technical steps that a neodymium-iron-boron orientated compact is subjected to vacuum pre-sintering, and a pre-sintered compact is obtained; rare earth and alloy elements are subjected to evaporation deposition to be in a form of ionized atoms / molecules and are diffused into the neodymium-iron-boron pre-sintered compact through pores of the pre-sintered compact, subsequently, the rare earth and alloy elements are densified through microwave sintering, and grain boundary diffusion is generated, so that the grain boundary structure of the magnet is improved,and the coercive force of sintered neodymium-iron-boron is improved. The method has the advantages that the rare earth and alloy elements as a diffusion source are in the form of gas-phase atoms / molecules, compared with a liquid diffusion source, the elements can more uniformly, effectively and deeply permeate into the magnet, and the periphery of the neodymium-iron-boron main phase is coated withthe elements; through testing, the coercive force of the neodymium-iron-boron magnet product obtained through gas-phase grain boundary diffusion can be increased by 30% or above, the diffusion depthcan reach 6 mm, and the neodymium-iron-boron magnet product has no hydrogen or fluorine generated through liquid-phase diffusion.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

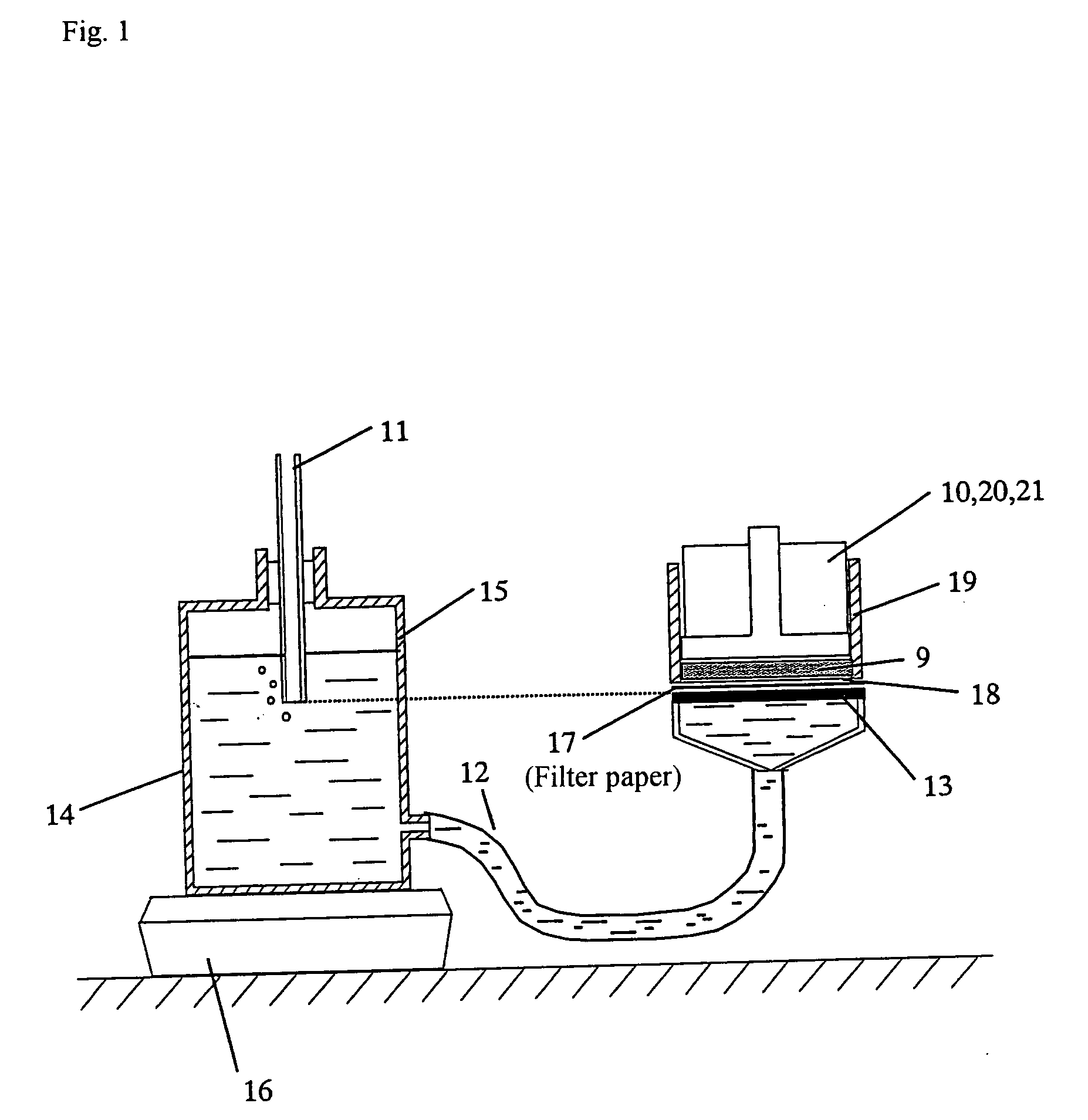

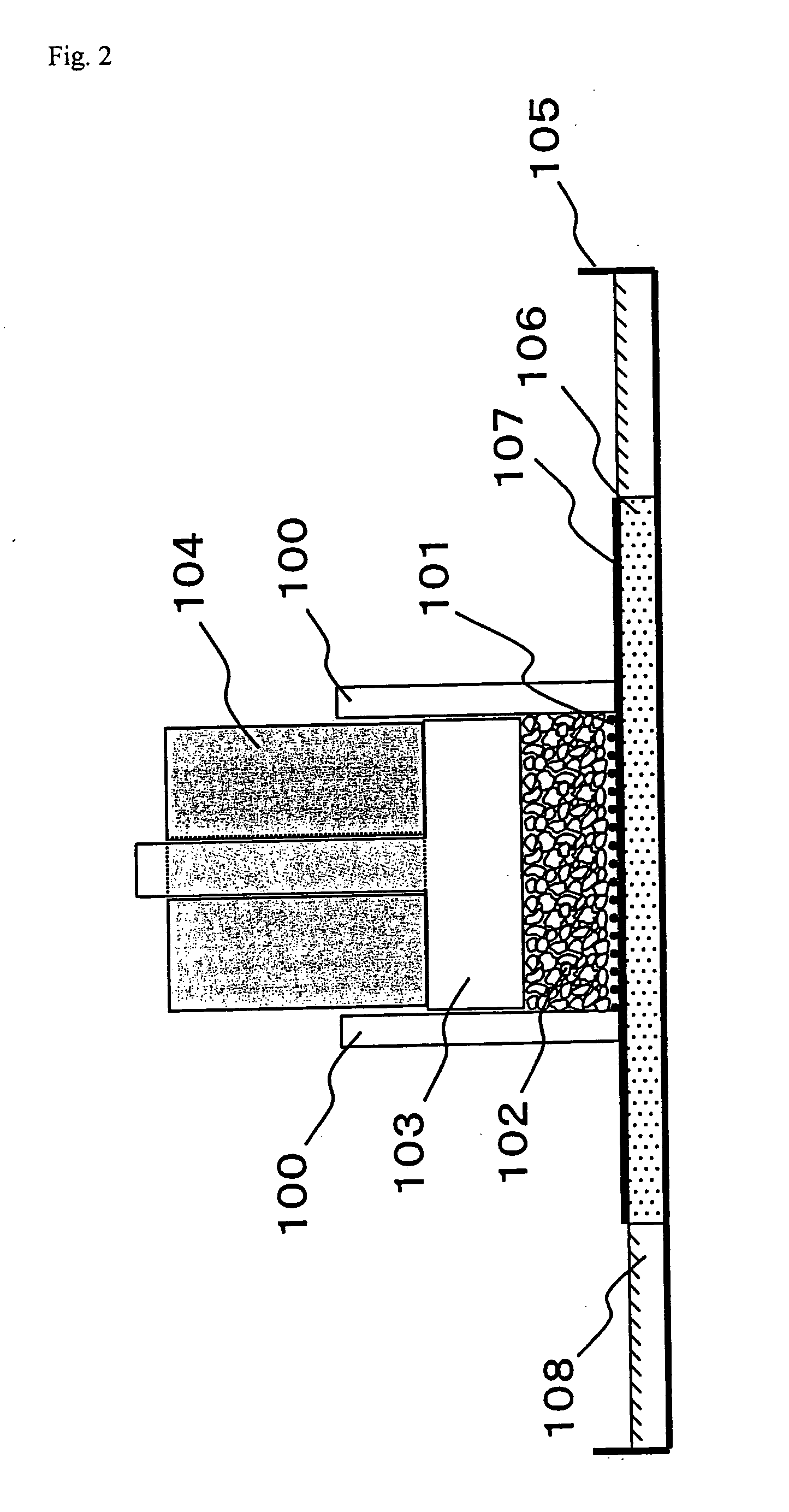

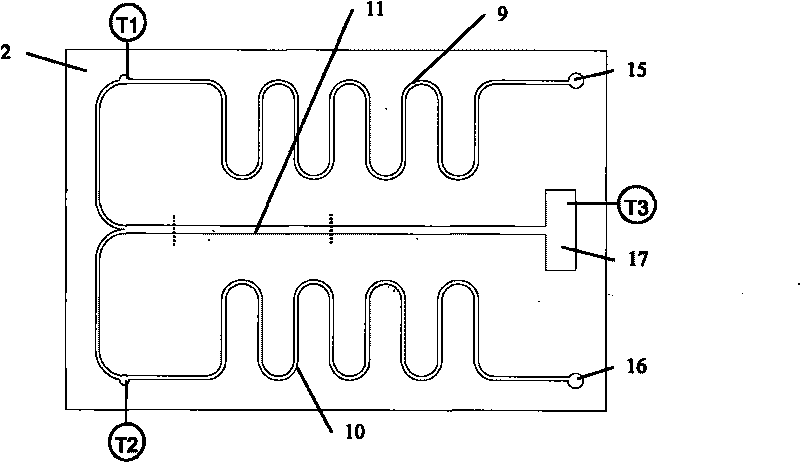

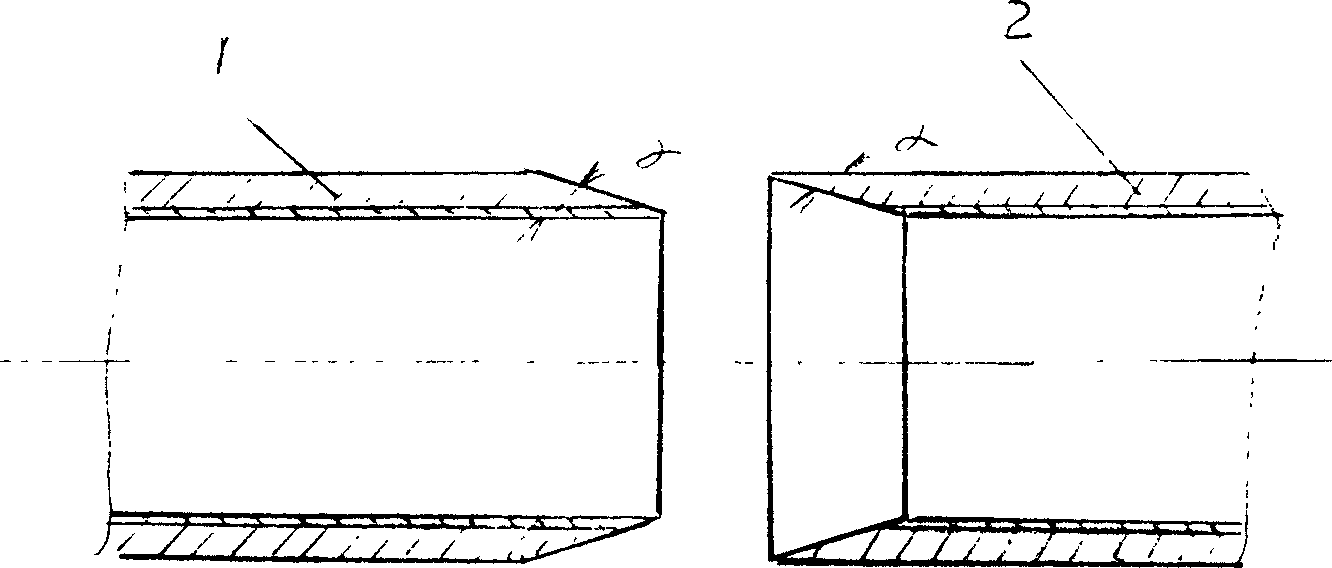

Device and method capable of measuring liquid-liquid diffusion coefficient at different temperatures

ActiveCN101701895AAchieve uniformityUniform surface temperatureSurface/boundary effectLiquid diffusionContinuous measurement

The invention relates to a device and method capable of measuring liquid-liquid diffusion coefficient at different temperatures. In the invention, solution in different concentrations is injected into a micro fluid control chip 2 by inject pumps 1 and 5, concentration distribution of mixing runner in the micro fluid control chip 2 is measured by a Raman spectroscopy, and further liquid-liquid diffusion coefficient is inverted. The micro fluid control chip is placed on a soaking block 4, and the soaking block is connected with a metering pump 7 and a thermostatic waterbath 8, so as to realize measurement at different temperatures. The micro fluid control chip 2 realizes high-accuracy measurement by design of winding micro runner structure before mixing, mixing runner section designed as a rectangle with high crown proportion and aluminizing at the bottom of runner. The device and method of the invention can realize continuous measurement of liquid-liquid diffusion coefficient at different temperatures and has the advantages of less sample usage, low cost, non contact, high sensibility, high repeatability, high efficiency, small error, safety and reliability and easy operation.

Owner:EAST CHINA UNIV OF SCI & TECH

Semipermeable membrane for an ink reservoir and method of attaching the same

An inkjet assembly comprising a vented ink reservoir for containing a liquid ink therein, the vented ink reservoir defining an internal volume occupied at least in part by a semipermeable membrane in fluid communication with a vent that automatically adjusts for pressure differentials by enabling gaseous diffusion between an environment external to the vented ink reservoir and the internal volume of the vented ink reservoir, while inhibiting liquid diffusion therethrough. A method is also disclosed for mounting the semipermeable membrane to at least one of an ink reservoir cap and an ink tank.

Owner:SLINGSHOT PRINTING LLC

Stainless steel composite steel pipe welding method

InactiveCN1669714AOvercome crackingEnhanced binding mechanical propertiesSoldering apparatusWorkpiece edge portionsLiquid diffusionJoint surface

This invention relates to pipe-welding method, especially for stainless steel compound pipe, mainly used to solve the defect that when welding compound pipe, it easily comes to gas hole and crackle, and improving the weld efficiency and lowering cost. The invention includes the following steps: washing the joint surface, coating intermediate material, assembling and clamping, induction heating to melt the intermediate material and actualize liquid diffusion weld. The method also can be used in welding other metal pipes.

Owner:凌星中

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com