Absorption core with efficient flow guide property and breathability and method for manufacturing absorption core

A technology for absorbing cores and manufacturing methods, which is applied in the field of sanitary products, can solve problems such as increasing the amount of hot melt adhesive used, uneven distribution, and easy movement of SAP, so as to improve the overall utilization rate, increase softness and comfort, and eliminate SAP The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

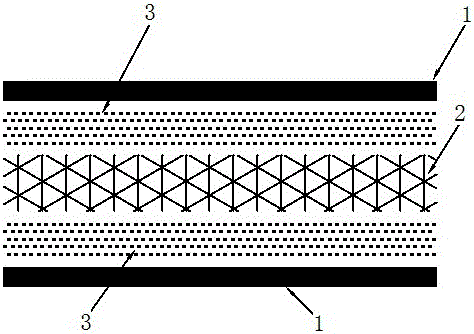

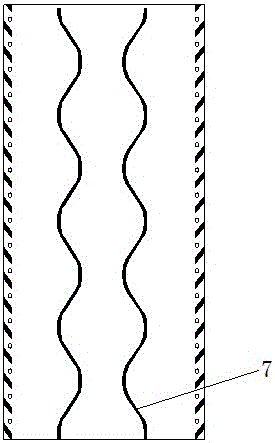

[0065] Such as Figure 3-5 As shown, an absorbent core with high-efficiency fluid conductivity and air permeability includes a surface layer 4, a bottom layer 5 and an absorbent layer between the surface layer 4 and the bottom layer 5. The absorption layer includes a non-woven fabric layer 6 bonded to the lower surface of the surface layer 4 , and superabsorbent resin is evenly spread in the non-woven fabric layer 6 .

[0066] The surface layer 4 is laminated with the non-woven fabric layer 6 to form a composite layer, and the composite layer is provided with an S-shaped diversion groove 7, and the diversion groove 7 divides the core body into a plurality of absorption regions.

[0067] The composite layer with diversion grooves 7 is connected to the upper surface of the bottom layer 5 .

[0068] Between the lower surface of the non-woven fabric layer 6 and the upper surface of the bottom layer 5, superabsorbent resin is uniformly spread.

[0069] The bonding method of the s...

Embodiment 2

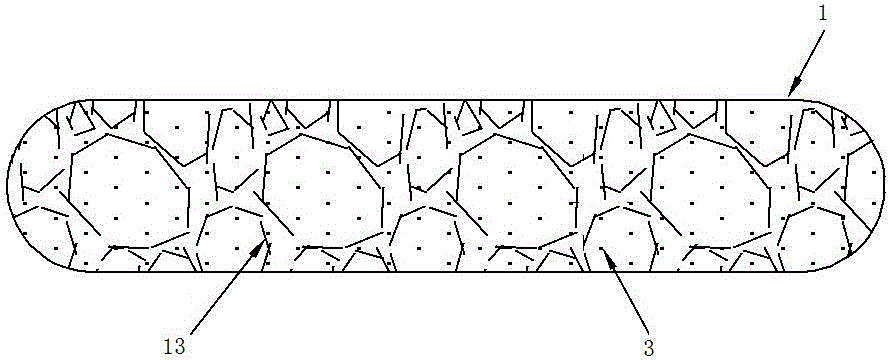

[0086] Such as Figure 6~7 As shown, Example 1 is repeated, except that: the non-woven fabric layer 6 includes a first non-woven fabric layer 61 and a second non-woven fabric layer 62 located below the first non-woven fabric layer 61 . The first superabsorbent resin 9 is evenly spread in the first non-woven fabric layer 61 . The second superabsorbent resin 10 is evenly spread in the second non-woven fabric layer 62 . Between the lower surface of the second non-woven fabric layer 62 and the bottom layer 5 , the third superabsorbent resin 11 is evenly spread.

[0087] Correspondingly, in step (a), the step of laminating the non-woven fabric layer 6 and the surface layer 4 to form a composite layer can be specifically decomposed into:

[0088] (a1) Evenly spread the first superabsorbent resin 9 in the gaps of the first non-woven fabric layer 61, and attach the first non-woven fabric layer 61 to the surface layer 4;

[0089] (a2) Evenly spreading the second superabsorbent resin...

Embodiment 3

[0094] Such as Figure 8 As shown, embodiment 1 or 2 is repeated, the difference is that the guide groove 7 is straight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com