Starch-based biodegradable PBAT modified material and preparation method thereof

A modified material, starch-based technology, used in biological packaging, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as feeding difficulties, sticky materials, etc., to improve processing efficiency and quality stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

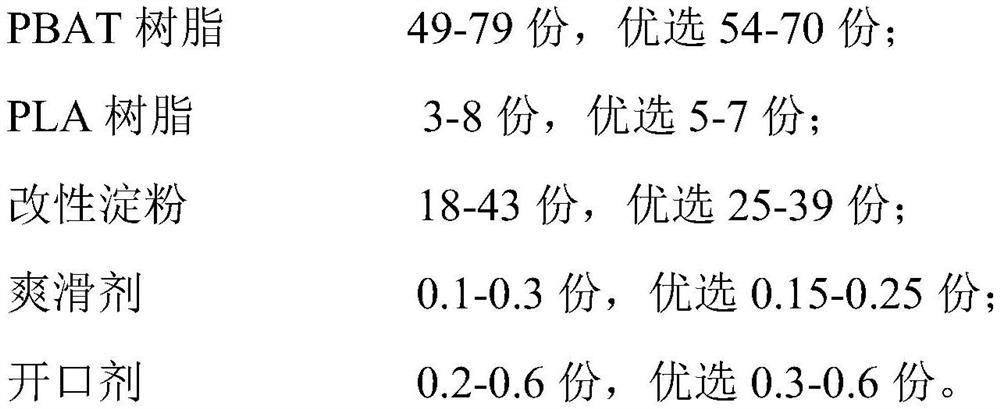

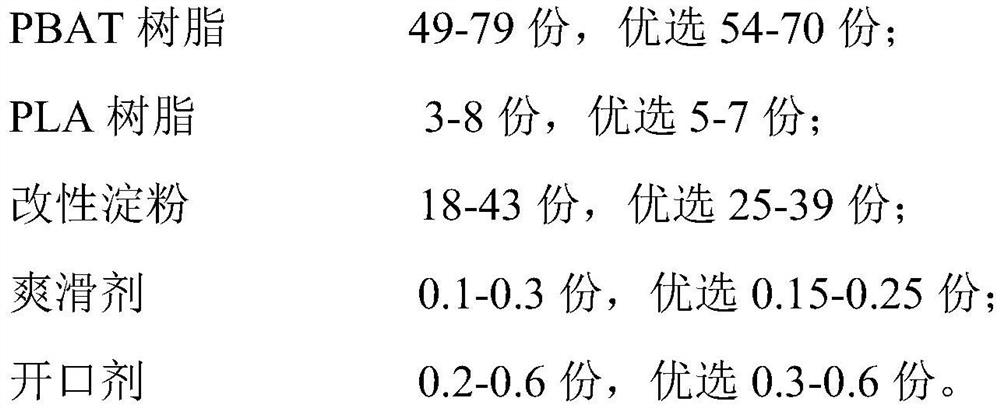

Method used

Image

Examples

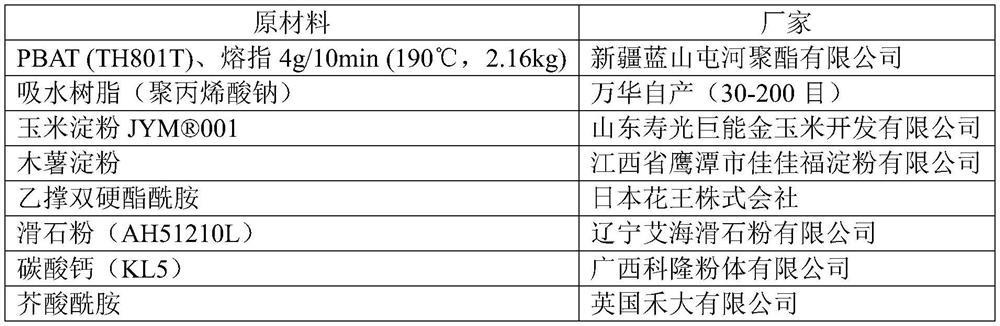

Embodiment 1

[0047](1) First weigh 50g of water-absorbent resin (30 mesh), add 4L of pure water, stir evenly and let it stand for 5 minutes, filter the above solution through a filter to remove excess water, and obtain 3kg of saturated water-absorbent resin particles with a water absorption rate of 60; Add 3kg of water-absorbing resin granules and 15kg of native starch powder (corn starch) into a MIXER mixer, stir at a stirring speed of 600rpm / min for 4min and mix evenly to obtain a modified starch mixture;

[0048] (2) Add the above-mentioned modified starch mixture into the twin-screw extruder through the main feeding method, use the front-end screw of the twin-screw to shear, mix and plasticize, and the water squeezed from the water-absorbing resin can plasticize the starch well, and then Add 79kg of PBAT resin and 3kg of PLA resin and 0.1kg of slippery agent (erucamide), 0.2kg of anti-blocking agent (talcum powder) and plasticized starch to shear and mix evenly, and vacuumize at the end...

Embodiment 2

[0050] (1) First weigh 62.5g of water-absorbent resin (60 mesh), add 6L of pure water, stir evenly and let it stand for 5 minutes, filter the above solution through a filter device to remove excess water, and obtain 5kg of saturated water-absorbent resin particles with a water absorption rate of 80; Add 5kg of water-absorbing resin particles and 20kg of native starch powder (corn starch) into a MIXER mixer, stir at a stirring speed of 600rpm / min for 4min and mix evenly to obtain a modified starch mixture;

[0051] (2) Add the above-mentioned modified starch mixture into the twin-screw extruder through the main feeding method, use the front-end screw of the twin-screw to shear, mix and plasticize, and the water squeezed from the water-absorbing resin can plasticize the starch well, and then Add 70kg PBAT resin and 5kg PLA resin and 0.15kg smooth agent (erucamide), 0.3kg opening agent (talcum powder) and plasticized starch by side feeding and mix evenly, and vacuumize at the end ...

Embodiment 3

[0053] (1) First weigh 58.3g of water-absorbent resin (120 mesh), add 8L of pure water, stir evenly and let it stand for 5 minutes, filter the above solution through a filter device to remove excess water, and obtain 7kg of saturated water-absorbent resin particles with a water absorption rate of 120; Add 7kg of water-absorbing resin granules and 25kg of native starch powder (tapioca starch) into a MIXER mixer, stir at a stirring speed of 600rpm / min for 4min and mix evenly to obtain a modified starch mixture;

[0054] (2) Add the above-mentioned modified starch mixture into the twin-screw extruder through the main feeding method, use the front-end screw of the twin-screw to shear, mix and plasticize, and the water squeezed from the water-absorbing resin can plasticize the starch well, and then Add 62kg PBAT resin and 6kg PLA resin and 0.2kg smooth agent (erucamide), 0.4kg opening agent (calcium carbonate) and plasticized starch to shear and mix evenly, and vacuumize at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com