Patents

Literature

165 results about "Starch powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh fried shrimp cake and production method

The invention relates to a fresh fried shrimp cake with fine color and flavor and rich nutrition, and a production method. The fresh fried shrimp cake adopts the technical scheme that: the fresh fried shrimp cake is characterized in that the fresh fried shrimp cake is prepared from the following raw materials in part by weight: 80 to 100 parts of fresh shrimp, 1 to 5 parts of soybean protein isolate, 2 to 20 parts of starch powder, 1 to 5 parts of composite phosphate, 2 to 8 parts of table salt, 2 to 5 parts of gourmet powder, 5 to 15 parts of white sugar, 1 to 8 parts of ginger, 1 to 8 parts of shallot, and 1 to 5 parts of spice. The invention also discloses the production method for the fresh fried shrimp cake.

Owner:吕文良

Superabsorbent Polymers and Starch Powders For Use in Skin Care Compositions

A skin care composition is provided that has an oil phase mixture and a water phase. The oil phase mixture has from about 5% to about 30% by weight of the composition, of a wax material and optionally from about 1% to about 20% by weight of the composition, of an oil that is liquid at room temperature. The oil phase mixture has a melting point of about 25° C. to about 50° C. The water phase has from about 0.1% to about 5%, by weight of the composition, of a superabsorbent polymer and from about 20% to about 85% by weight of the composition of water. The composition also has from about 6% to about 30%, by weight of the composition, of particulate material selected from the group consisting of starch particles, silicone elastomer particles and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

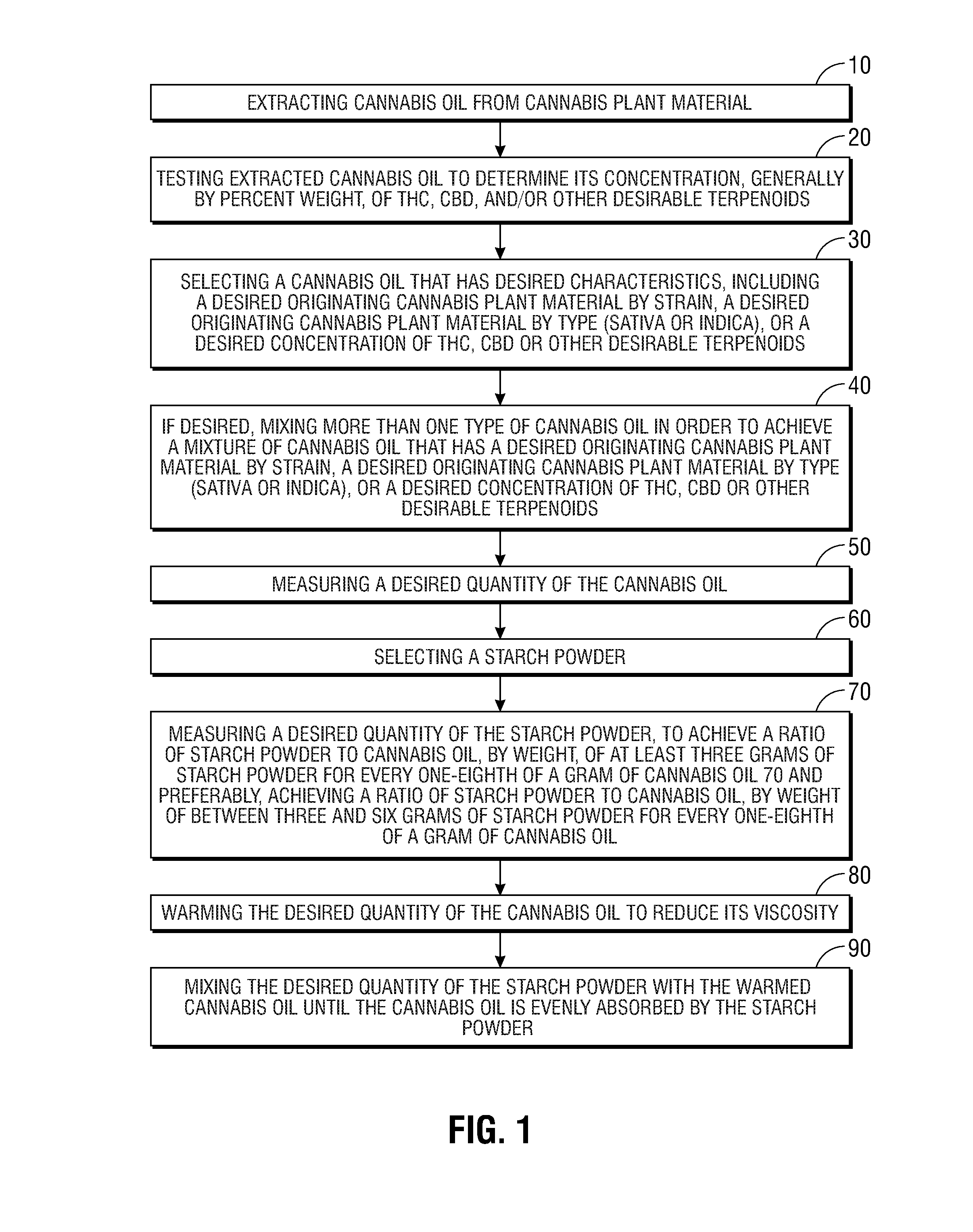

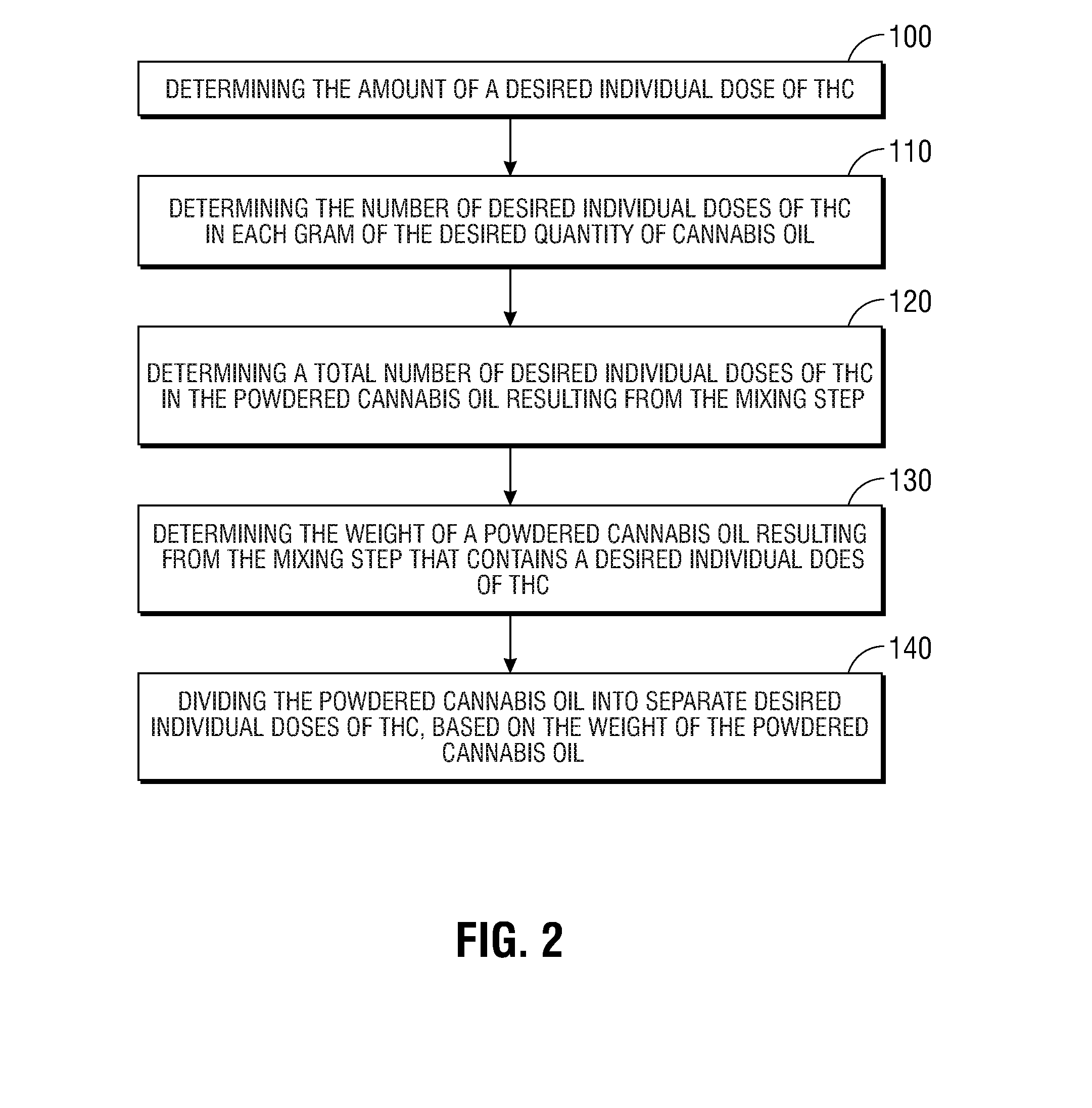

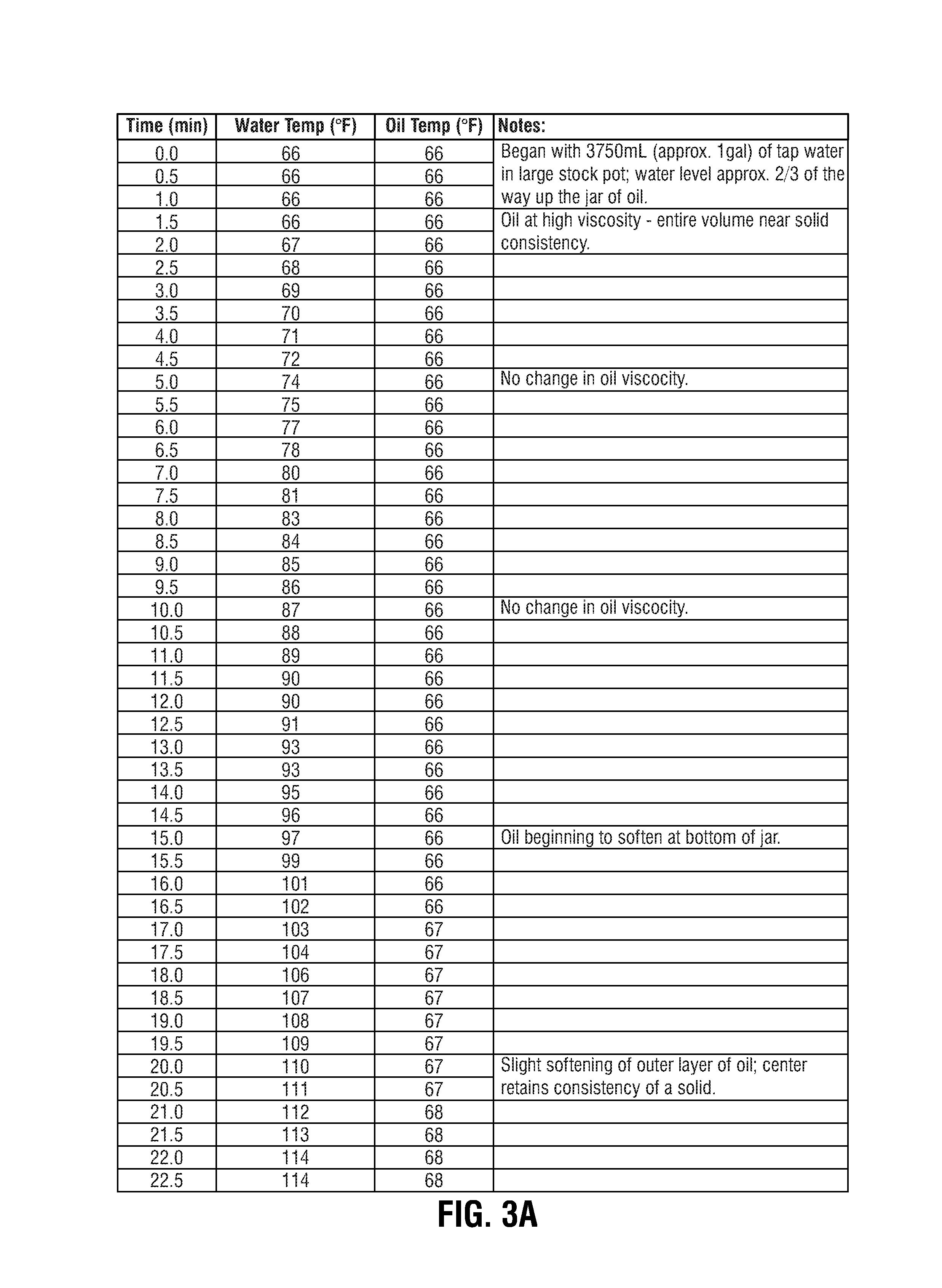

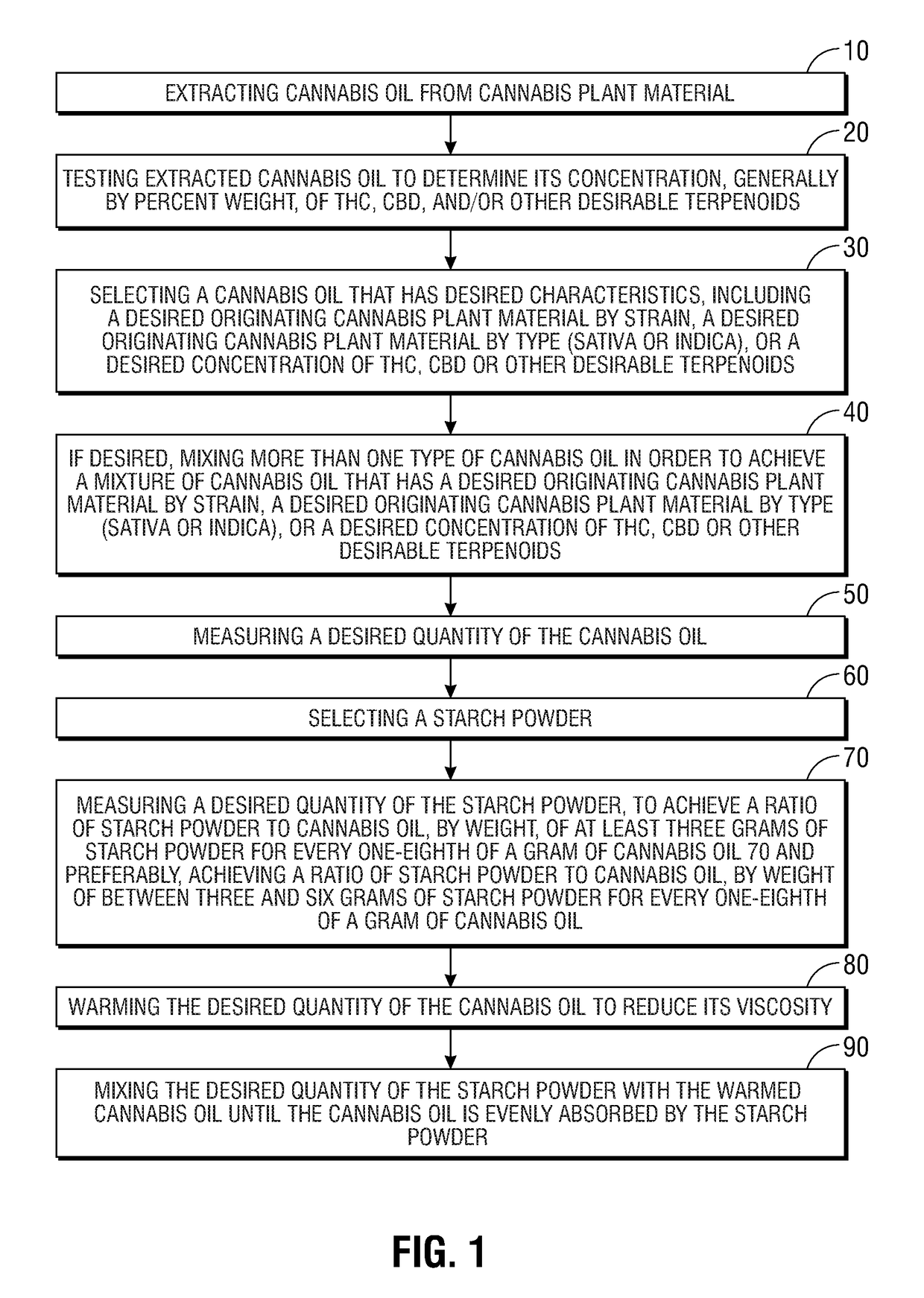

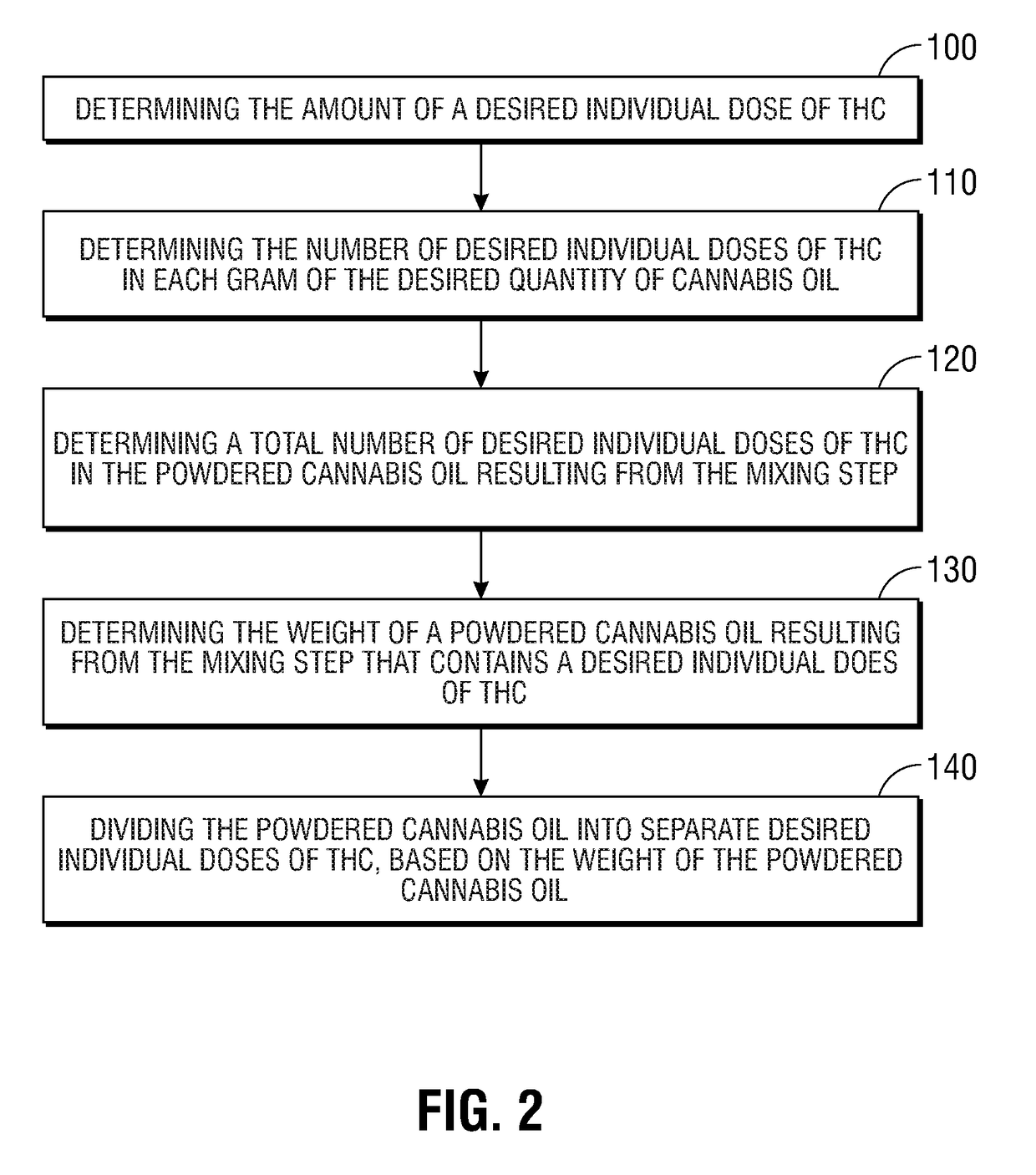

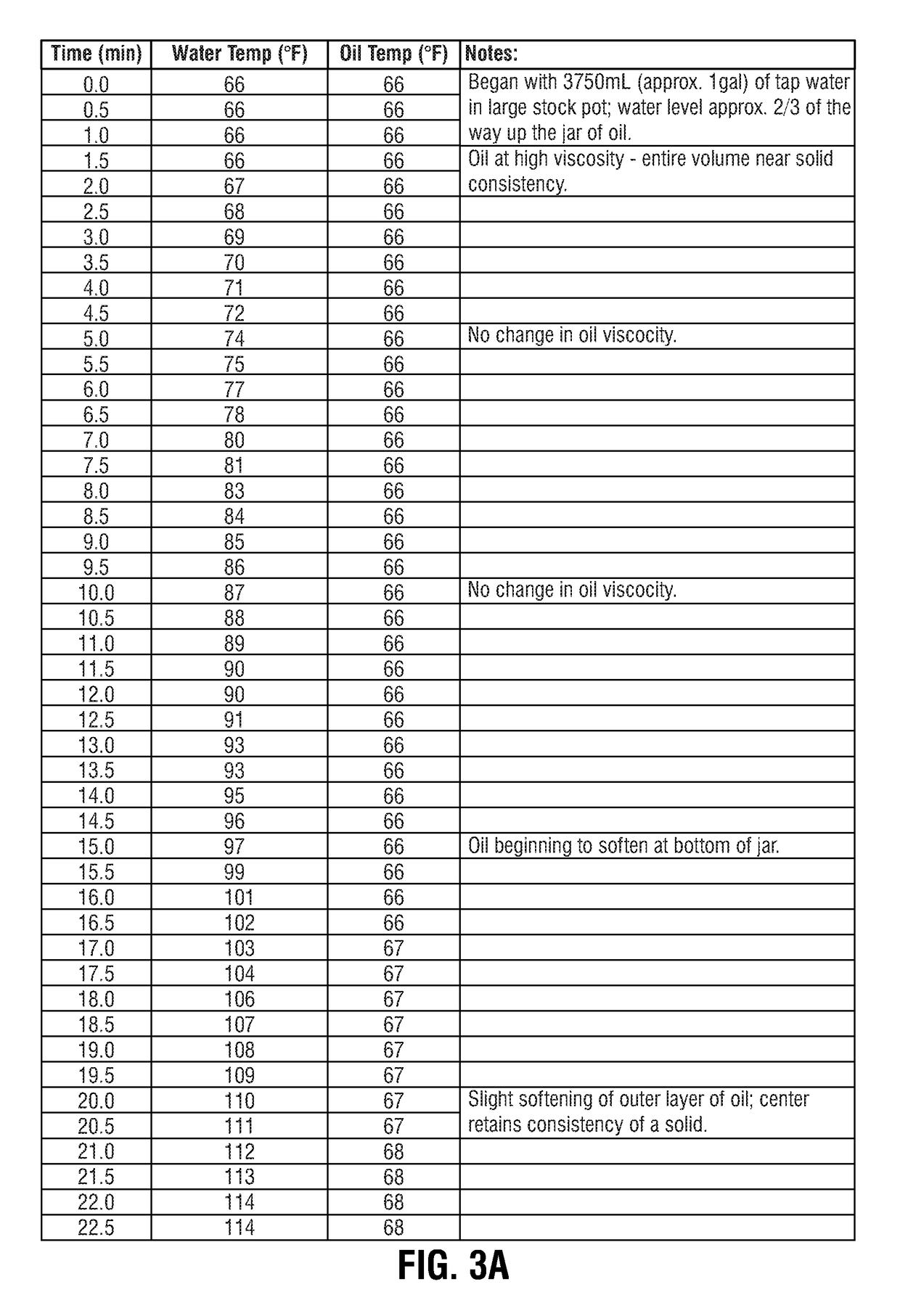

Method For Conducing Concentrated Cannabis Oil To Be Stable, Emulsifiable And Flavorless For Use In Hot Beverages and Resulting Powderized Cannabis Oil

ActiveUS20160243177A1Accurately repeatably deliverSocially acceptableOrganic active ingredientsPowder deliveryCannabisGram

A method for producing powderized cannabis oil, and the resulting powderized cannabis oil, in which concentrated cannabis oil is mixed with and absorbed by a modified starch powder, preferably maltodextrin, in a ratio of at least three grams of starch powder for every one-eighth of a gram of cannabis oil is disclosed. Further disclosed are beverages, baked goods and single-serve beverage brewing cartridges utilizing or incorporating the powderized cannabis oil to create human-consumable products that contain an emulsified, tasteless, and odorless dose of cannabis oil.

Owner:BETTERLIFE PHARMA US INC

Compound microporous starch powder hemostat and preparation method thereof

InactiveCN101559235AControl bleedingGood hemostasisSurgeryAbsorbent padsEnzymatic hydrolysisFreeze-drying

The invention belongs to the technical field of medical preparations, and in particular discloses a compound microporous starch powder hemostat and a preparation method thereof. The compound microporous starch powder hemostat uses potato starch and sweet potato starch as raw materials. The preparation method comprises the following steps: performing pregelatinization and ultrasonic pretreatment on the potato starch and the sweet potato starch, and then performing enzymatic hydrolysis on the potato starch and the sweet potato starch respectively to make pores so as to prepare microporous starches of the potato starch and the sweet potato starch respectively; in the process of enzymatic hydrolysis to prepare the microporous starches, adopting a vacuum freeze-drying method for drying the starches; using sodium trimetaphosphate to crosslink starch molecules so as to strengthen the structure; and mixing the potato crosslinking microporous starch and the sweet potato crosslinking microporous starch according to certain proportion to obtain the compound microporous starch powder hemostat. The microporous starch prepared by the method has strong hydroscopic property and obviously improved water-absorbing speed; besides, compared with the prior single-starch polysaccharide hemostatic material, the ingredients of the compound have improved performance and good hemostatic effect.

Owner:官培龙 +1

Preparing method of high content full cis-beta-carotene preparation

ActiveCN101016259ALess quantityInhibition of isomerizationOrganic active ingredientsOrganic chemistryBeta-CaroteneAlcohol

The invention discloses a making method of high-full trans-beta-carotene agent, which comprises the following steps: setting the weight rate of beta-carontene, combined antioxidant and solvent with emulsifier at 1:0.01-0.1:50-500; dissolving the mass into water to form solution under 30-60 deg.c; adding into high-speed stirring alcohol or isopropanol at spraying pattern; making beta-carontene to evolve at amorphous starch powder with size less than 2um; filtering; adding filtering pie into auxiliary water protected by gel in advance; emulsifying; removing residual solvent; spraying; drying; obtaining the product with antioxidant A and B.

Owner:ZHEJIANG UNIV +4

Method for conducing concentrated cannabis oil to be stable, emulsifiable and flavorless for use in hot beverages and resulting powderized cannabis oil

ActiveUS9629886B2Socially acceptableEliminating and minimizing effectOrganic active ingredientsBiocideCannabisGram

A method for producing powderized cannabis oil, and the resulting powderized cannabis oil, in which concentrated cannabis oil is mixed with and absorbed by a modified starch powder, preferably maltodextrin, in a ratio of at least three grams of starch powder for every one-eighth of a gram of cannabis oil is disclosed. Further disclosed are beverages, baked goods and single-serve beverage brewing cartridges utilizing or incorporating the powderized cannabis oil to create human-consumable products that contain an emulsified, tasteless, and odorless dose of cannabis oil.

Owner:BETTERLIFE PHARMA US INC

Surface-treated powder and cosmetics containing same

ActiveUS20090263660A1Easily dispersed uniformlyGood dispersionCosmetic preparationsToilet preparationsPolyesterDispersion stability

By coating the surface of a powder comprising a silicone resin and / or an organic powder with a specific hydrophilizing agent, such powder is hydrophilized. The hydrophilizing agent includes water-soluble polyoxyalkylene glycol derivatives. The organic powder is at least one selected from PMMA, nylon, polyester, polystyrene, cellulose, silicone elastomer powder, silicone rubber powder, benzoguanamine, styrenedivinylbenzene pinhole polymer, ethylene tetrafluoride, polyethylene powder, polypropylene powder, polyurethane powder, silk powder, metal soap powder, starch powder, N-acylated lysine, an organic pigment, and a composite of at least one of these organic powders described above with a metal oxide and / or a metal hydroxide. Such coated (treated) powder has extremely great dispersibility (ease of dispersion) and very good dispersion stability (long-term dispersion stability with lapse of time) in aqueous dispersion media, particularly under acidic and alkaline conditions, specifically at pH 3 through 13. Using the surface-treated powder, additionally, a dispersion with good dispersibility (ease of dispersion) and great dispersion stability, preferably for cosmetics can be provided. The use of the surface-treated powder, or the use of the dispersion can provide further a cosmetic excellent in dispersibility and dispersion stability and further in re-dispersibility and dispersion stability with lapse of time and smooth feeling as compared to the related art when selecting aqueous cosmetic as an agent form.

Owner:MIYOSHI KASEI

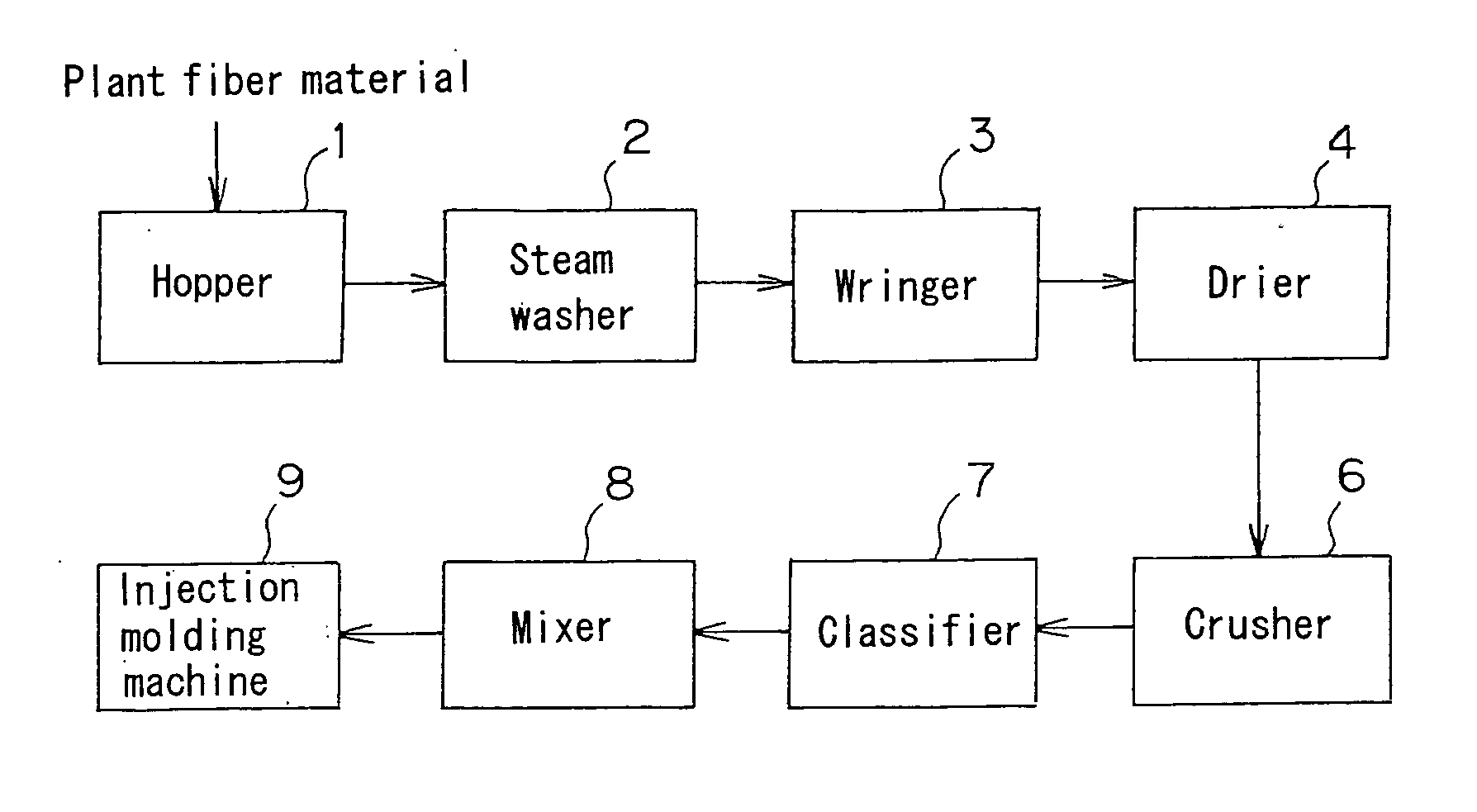

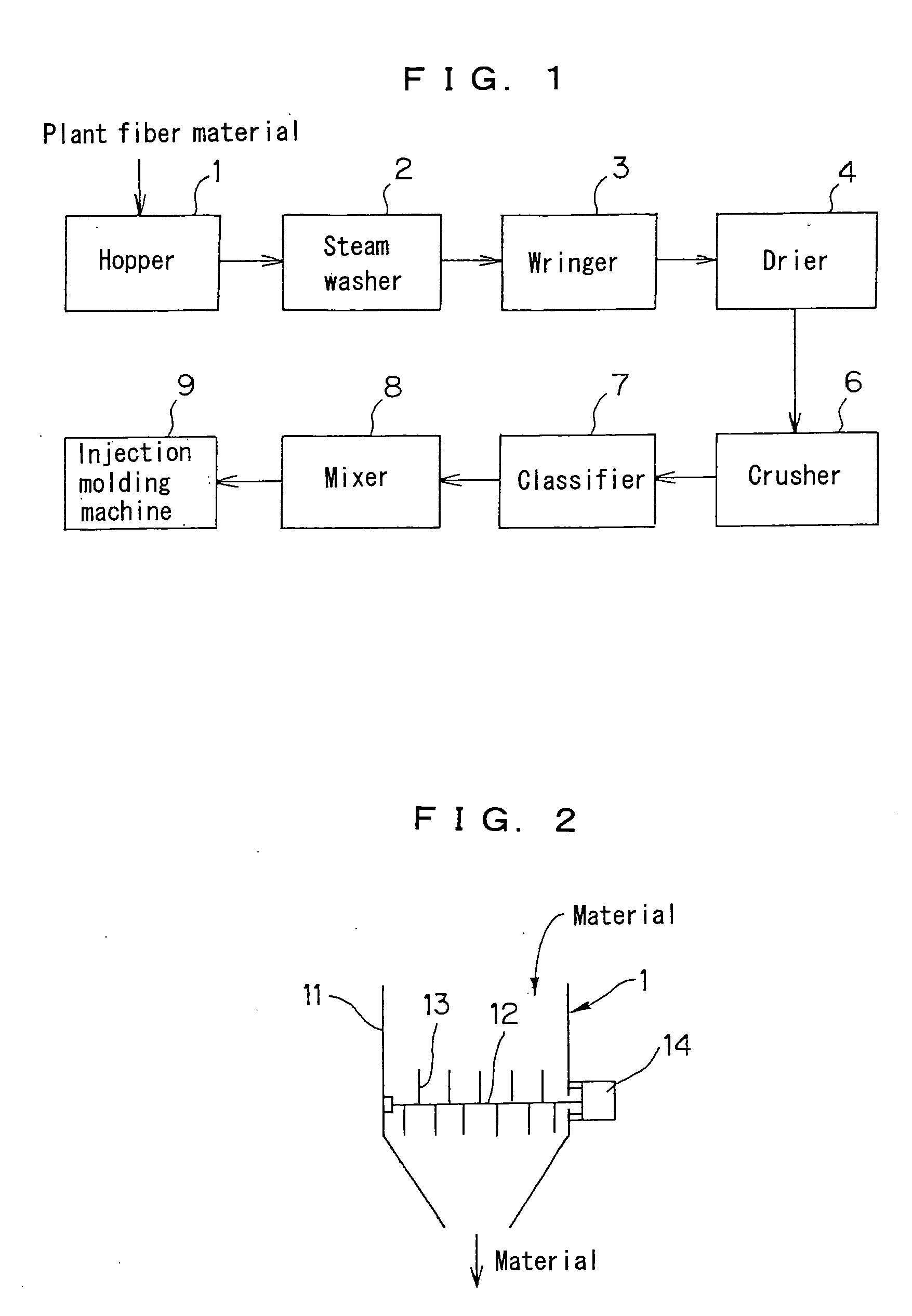

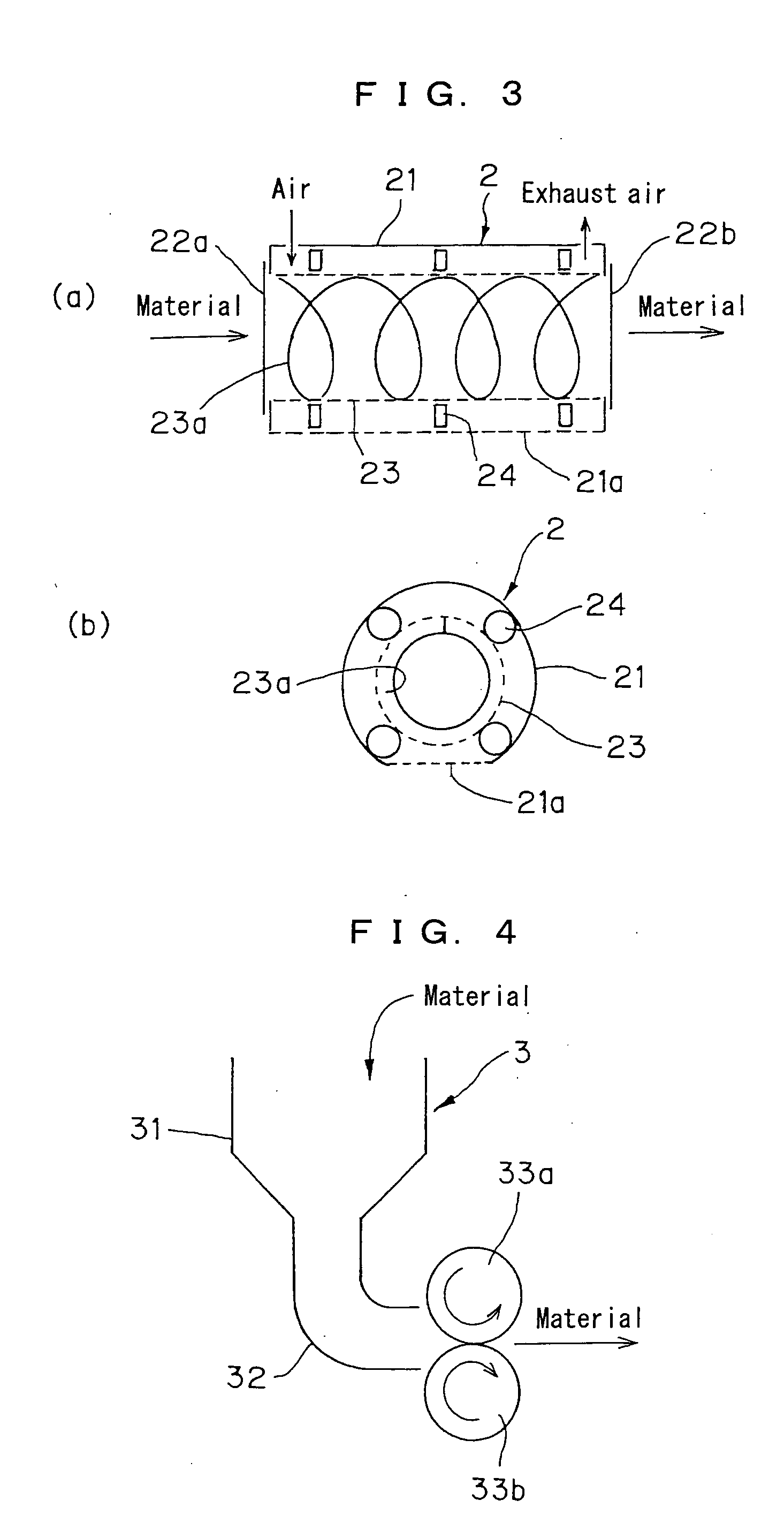

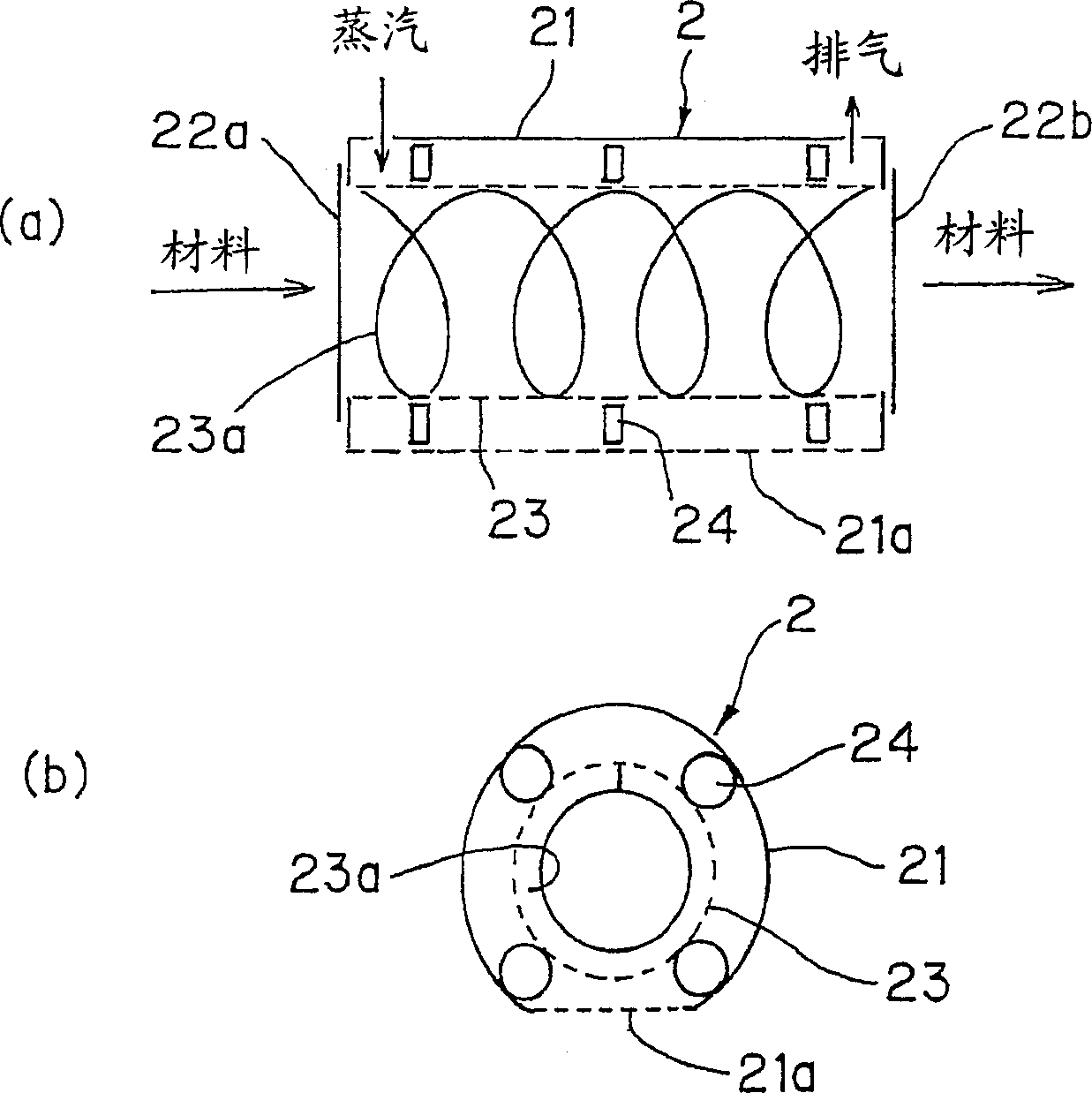

Process for producing biodegradable fiber molding

InactiveUS20050158541A1Little waterInexpensively mass-producedWood working apparatusCeramic shaping apparatusVegetable fibersMaterials science

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

Method for making seasoned fried fish skin food

The invention relates to a method for making a seasoned fried fish skin food, which comprises the following steps: removing fish scales, mucus, blood stains and other impurities on the surface of fish skin, cleaning, draining, soaking in tea water for removing fishy smell, shaping, starching, seasoning, frying, packaging and obtaining a finished product; and starchy seasoning liquid adopted for starching and seasoning comprises the following components by weight percent: 8-12% of sugar, 2-3% of aromatic vinegar, 2-4% of salt, 0.5-1% of ginger juice, 1.8-4% of sesame oil, 2-3% of monosodium glutamate, 1-3% of pepper powder, 3-5% of chili oil, 1.5-3% of yellow rice wine, 20-30% of mixed flour (flour: starch powder is equal to 2:1), 3-5% of yeast powder and the balance of water. The made seasoned fried fish skin food has the advantages of abundant nutrition, beautiful color and luster, crisp, delicious and special taste, and convenient eating, and the preparation method has the advantages of reasonable process, simple operation and stable product quality, thereby having good commercial value.

Owner:TAIXIANG GRP TECH DEV

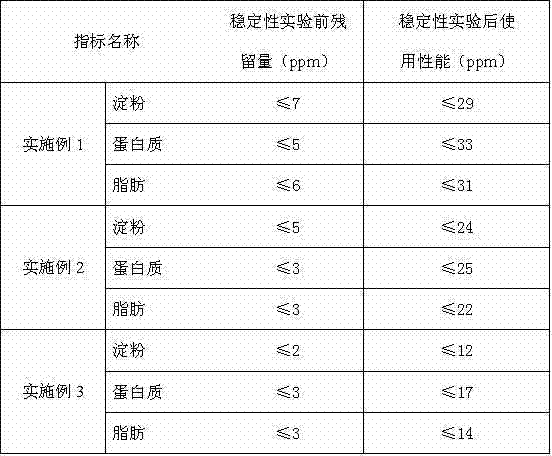

Pre-cleaning and moisturizing composition of medical apparatuses and method of preparing disinfectant by using same

InactiveCN103087834AReduce scratchesExtended service lifeBiocideSurface-active detergent compositionsFlexible endoscopyDisinfectant

The invention relates to a pre-cleaning and moisturizing agent suitable for medical apparatuses, and preparation method thereof. The invention is characterized in that the pre-cleaning and moisturizing agent for the medical apparatuses is composed of a surfactant, a corrosion inhibitor, a humectant, protease, lipase, starch powder, cellulase, an osmotic agent and an enzyme stabilizer. The pre-cleaning and moisturizing agent has no irritating odor, is safe, low in toxicity and corrosion, free of chemical residuals, stable in performance and convenient to use, can be used for pre-cleaning and moisturizing surgical instruments, microsurgical instruments, flexible endoscopes, dental instruments, minimally invasive surgical instruments, rigid endoscopes and high frequency instruments and the like which are prepared from stainless steel, alloy of the stainless steel, copper, rubber and other materials.

Owner:SHANGHAI LIKANG DISINFECTION HIGH TECH

Method for preparing superparamagnetic micron starch

ActiveCN102010525AImprove bioavailabilityLittle side effectsOrganic/organic-metallic materials magnetismPharmaceutical non-active ingredientsFreeze-dryingMagnetite Nanoparticles

The invention discloses a method for preparing superparamagnetic micron starch, comprising the following steps: 1) dissolving the weighed FeCl3.6H2O solid and FeCl2.4H2O solid, adding stronger ammonia water, dropwise adding oleic acid, stirring and reacting to obtain a black sol substance, and separating the obtained precipitation from a reaction system by adopting an externally applied magnetic field to obtain a magnetic fluid; 2) mixing the magnetic fluid and an enzyme preparation, and performing magnetic separation to obtain magnetic nano particles absorbed with the enzyme preparation; 3) adding deionized water into insoluble raw starch, and stirring to obtain a raw starch dispersion solution; 4) adding the magnetic nanoparticles absorbed with the enzyme preparation into the raw starch dispersion solution, and performing magnetic separation after reaction to obtain magnetic starch precipitation; and 5) drying or freeze drying the magnetic starch precipitation obtained in step 4) to obtain the superparamagnetic micron starch powder. The preparation process in the invention is simple, green and environment-friendly and no toxic reagent is utilized, thus the superparamagnetic micron starch can be utilized as a medical carrier.

Owner:HUAQIAO UNIVERSITY

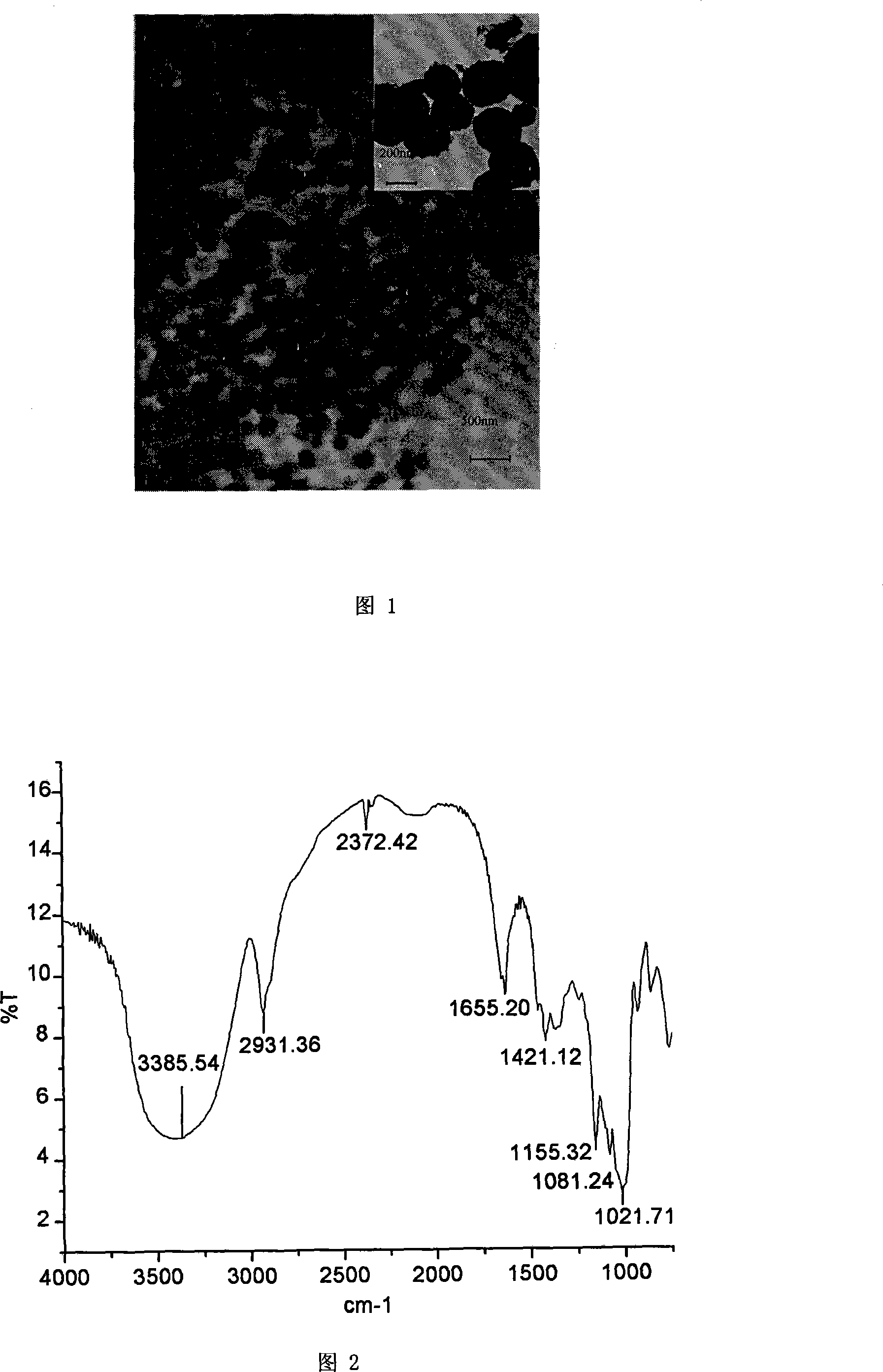

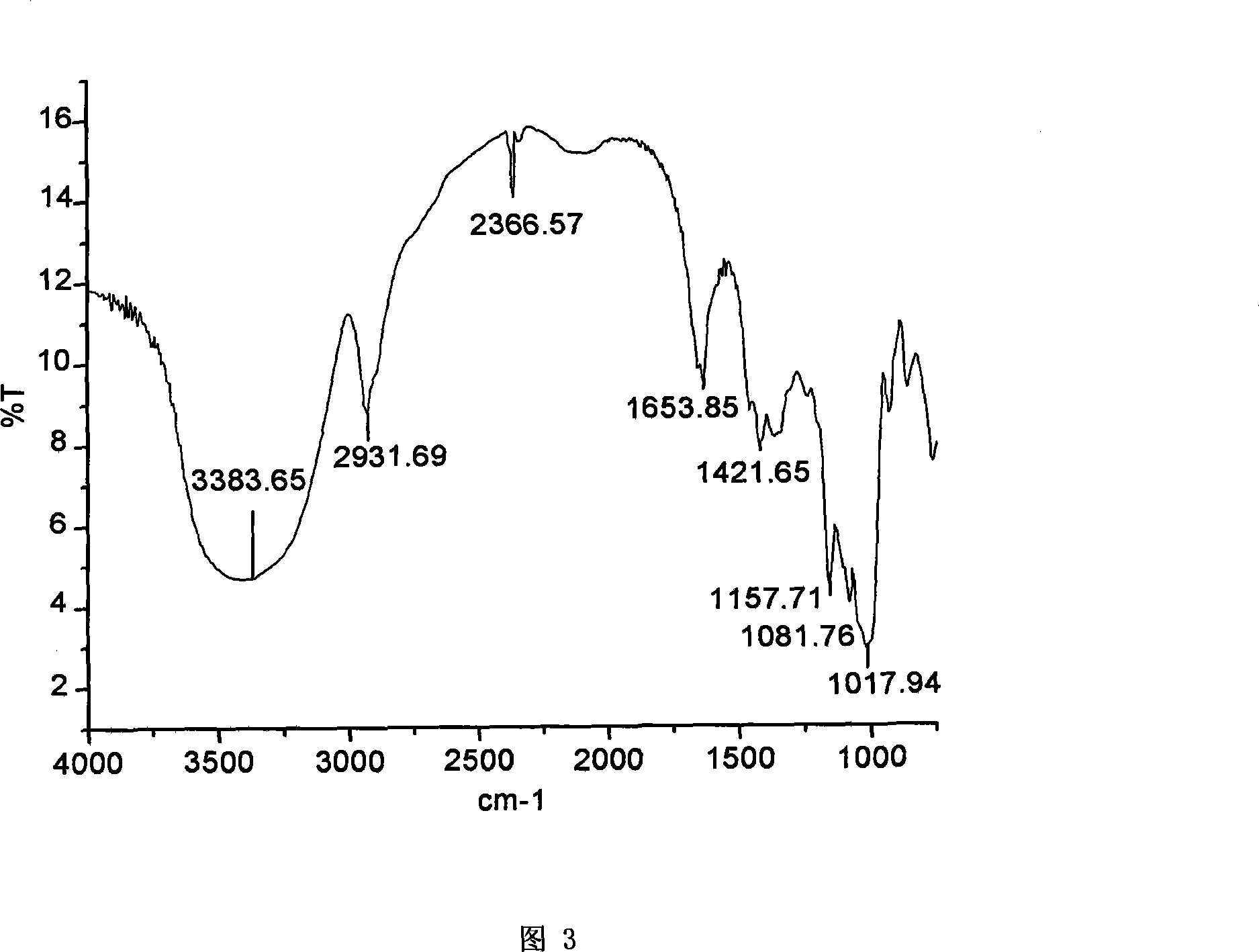

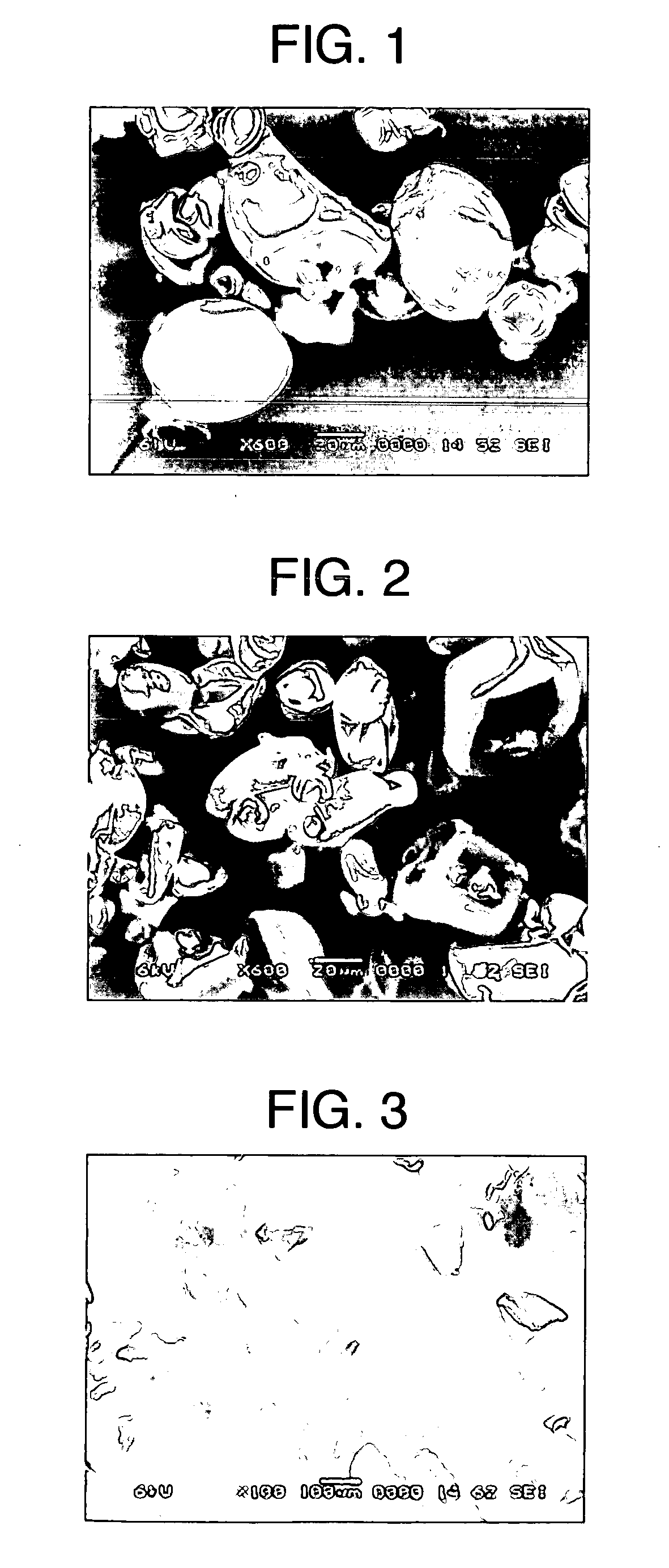

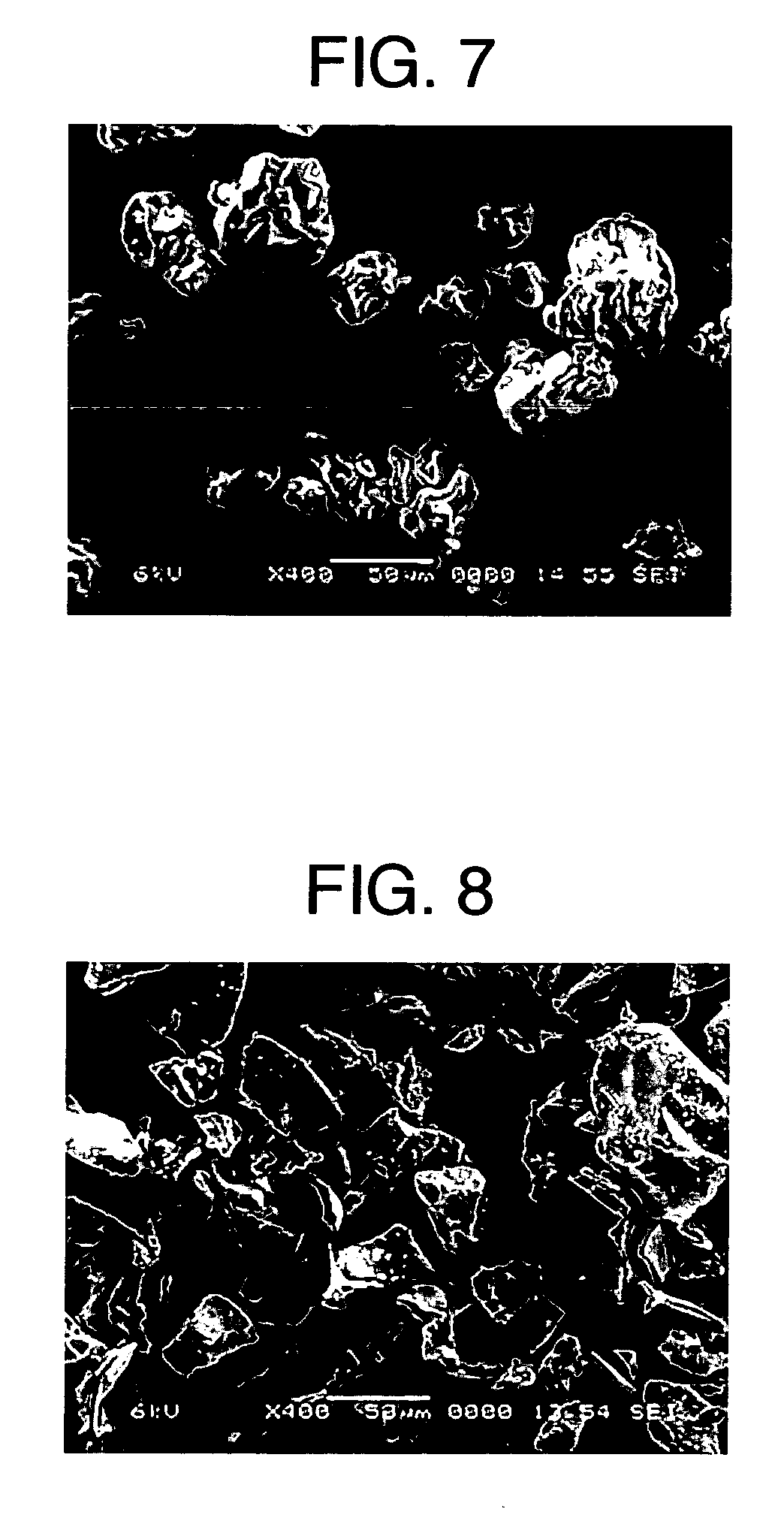

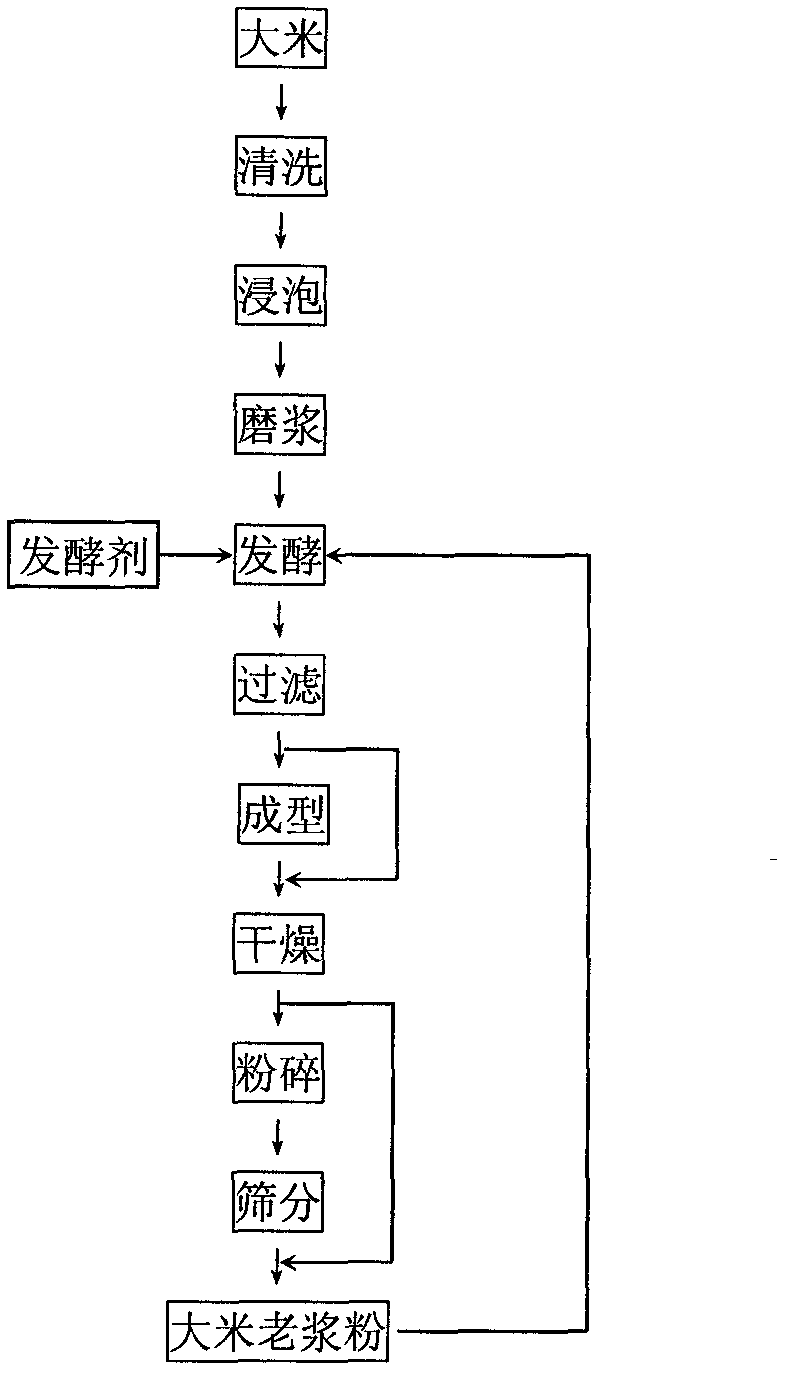

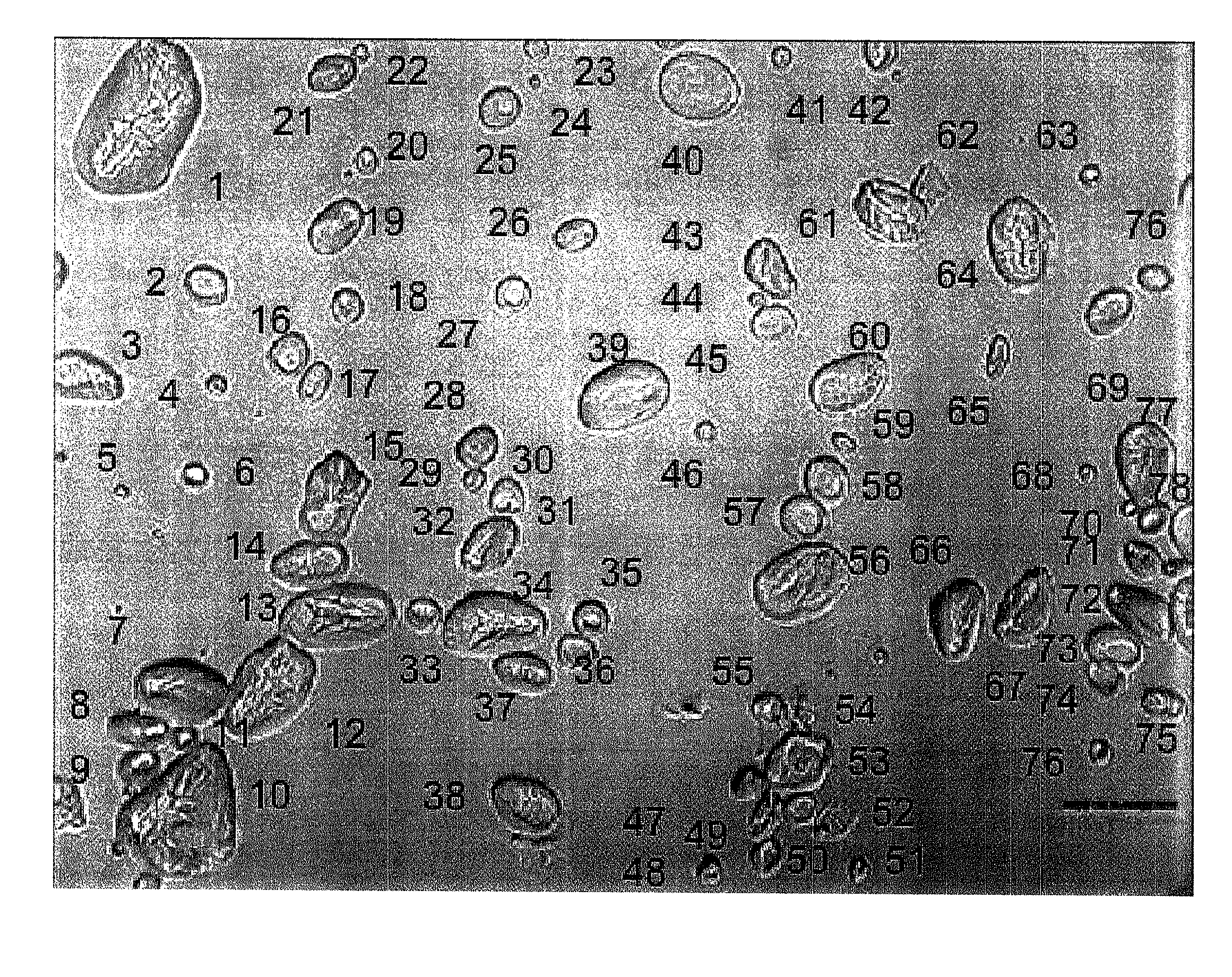

Process for preparing nano-starch powder

InactiveCN101215385AThe production technology cycle is shortReduce energy consumptionFood additiveWater baths

The invention provides a process for preparing nanometer fecula powder body material, the process comprises first, adding technical-grade cornstarch in deionized water which contains a certain amount of dispersing agent to prepare homogeneous dispersion solution whose density is 5% to 15% (starch quality percentage), second, adopting high-energy ultrasonic wave to intermittently deal the solution for 3-5 hours under the condition of guaranteeing the system temperature which is not lower than 50 DEG C, third, placing the solution in a 40 DEG C to 50 DEG C water bath vessel to stir with a stirrer, and slowly adding acid into the solution till the density in the acid is 5% to 10% to react in constant temperature for one hour, fourth, pumping and filtering the solution which is reacted, and washing products with NaOH dilute solution to neutral, respectively washing with deionized water and absolute ethyl alcohol for several times, finally, abrading the samples in 60DEG C to 80 DEG C for 2-4 hours to get nanometer starch products. All the raw material of the process is sold in markets, raw material is wide, the reaction process can be controlled, reproduction quality is excellent, and production cost is low. The nanometer starch starches which are prepared by the invention takes ball shape, the size of the starch diameter is evenly distributed, and the major function group of original starch is not changed, and the starch is not polluted and can be used as carriers of biological medicine or food additives, thereby the invention has wide application prospect.

Owner:SOUTHWEST UNIVERSITY

Compound microbial preparation capable promoting root development of crops

InactiveCN107129358AGood technical effectImprove adaptabilityBacteriaMicroorganism based processesBiotechnologySodium sulfate

The invention relates to a compound microbial preparation capable promoting the root development of crops and particularly relates to compound microbial preparation capable of promoting the root development of wheat. The compound microbial preparation contains the following components in parts by weight: 1-3 parts of bacillus subtilis, 1-5 parts of rhodopseudomonas palustris, 1-3 parts of rhizobium, 1-2 parts of paenibacillus kribbensis, 3-5 parts of bacillus amyloliquefaciens, 1-3 parts of klebsiella pneumonia, 3-10 parts of ammonium sulfate, 1-8 parts of potassium sulfate, 1.5-2.8 parts of fulvic acid, 0.1-3 parts of saccharose, 5-12 parts of diammonium phosphate, 0.1-0.6 part of boric acid, 0.01-0.8 part of sodium chloride, 1.5-3.8 parts of chitosan, 5-20 parts of plant ash, 0.1-3 parts of starch powder, 0.1-3 parts of calcium carbonate, 0.01-0.6 part of lauryl sodium sulfate and 5-20 parts of vermiculite. According to the compound microbial preparation, the normal development of roots is promoted, the lodging resistance of the wheat is enhanced, the yield increase of the wheat is promoted, and the yield is increased by 8%-15%.

Owner:BEIJING ZNFY GRP CO LTD

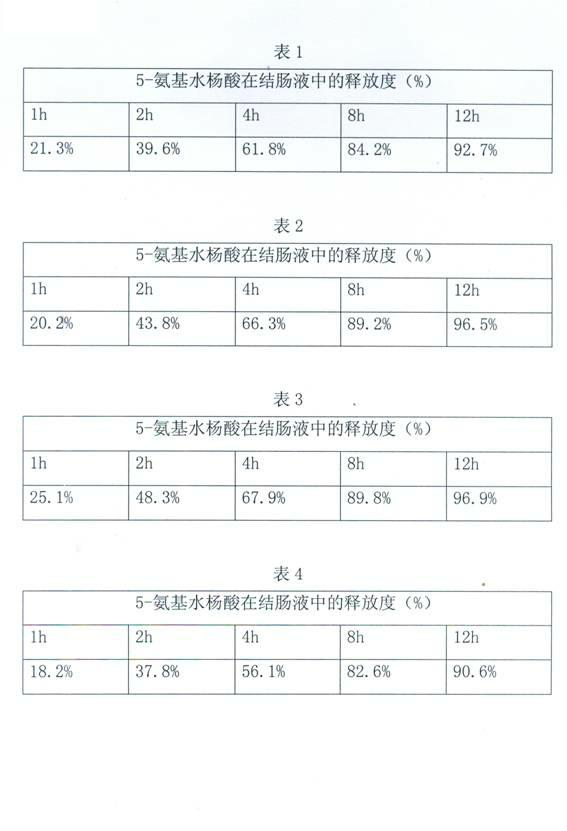

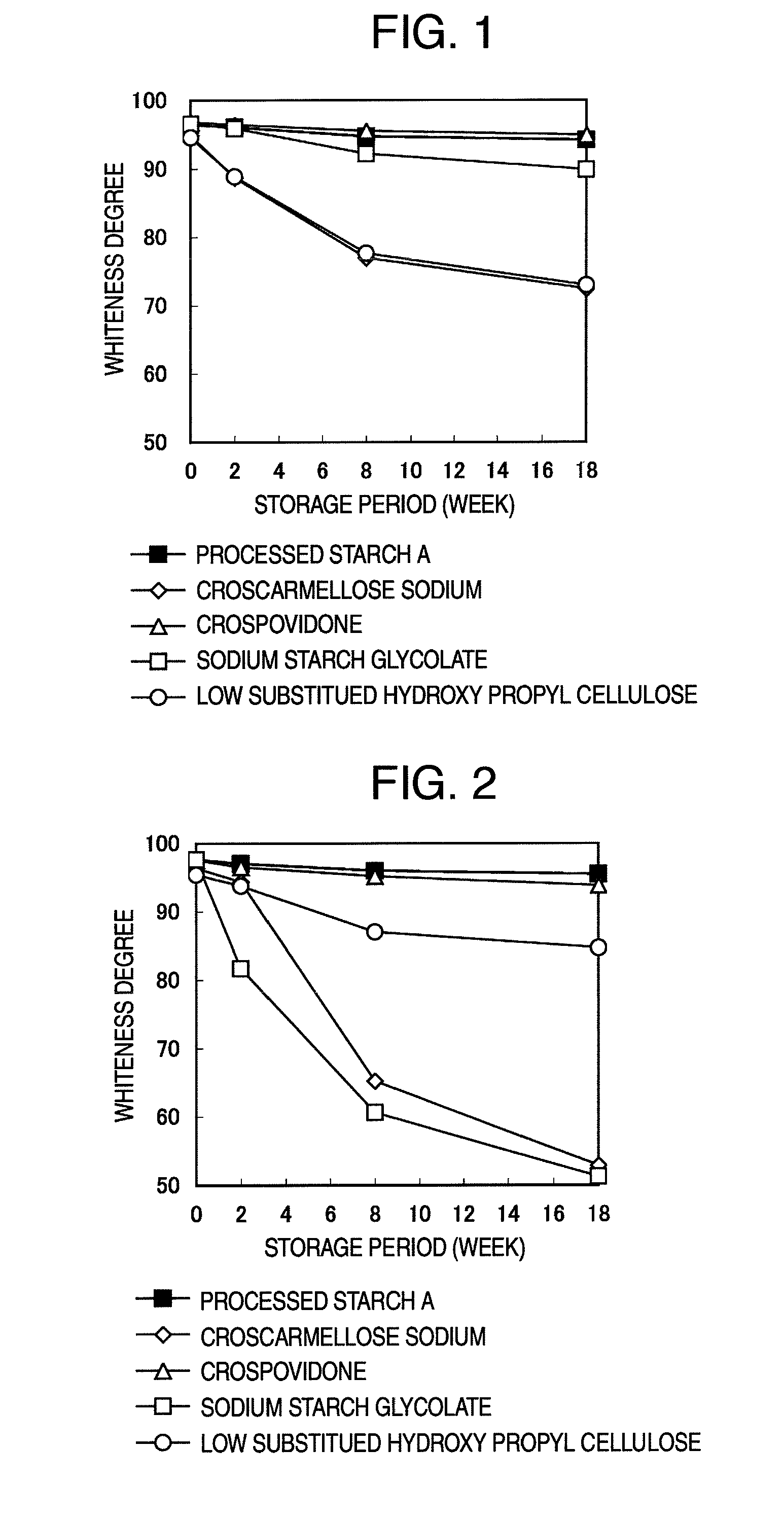

Functional starch powder

ActiveUS20060204569A1Satisfactory release-sustaining propertyIncrease resistanceOrganic active ingredientsBiocidePowder mixtureStarch granule

Functional starch powder of 400% or more water retention capacity, 5 hr or more collapse time and 200 g or more gel indentation load. This functional starch powder is produced through the step of heating a starch raw material in the presence of water at 60 to 150° C. so as to swell starch particles of the starch raw material and the subsequent step of drying the thus swollen starch particles so as to obtain a powder mixture comprising starch particles and, lying in the exterior thereof, amylose and amylopectin.

Owner:SANWA CORNSTARCH +1

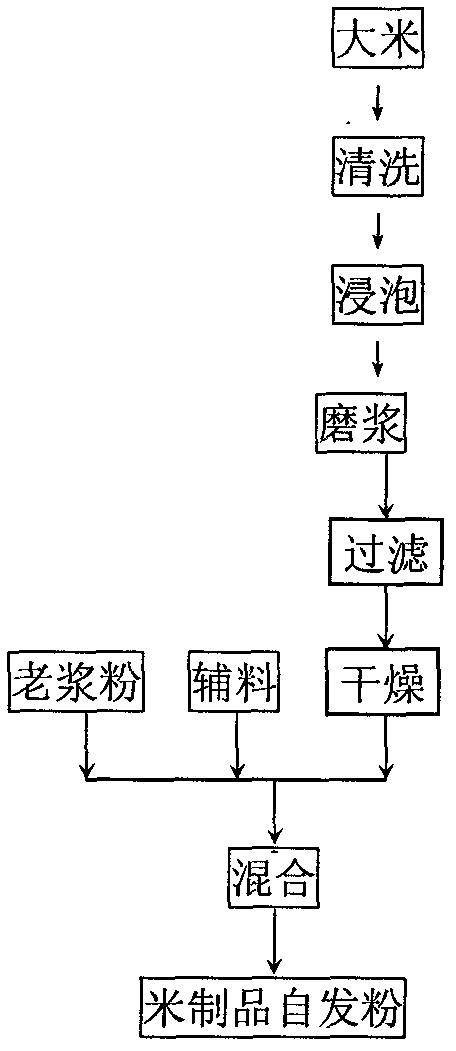

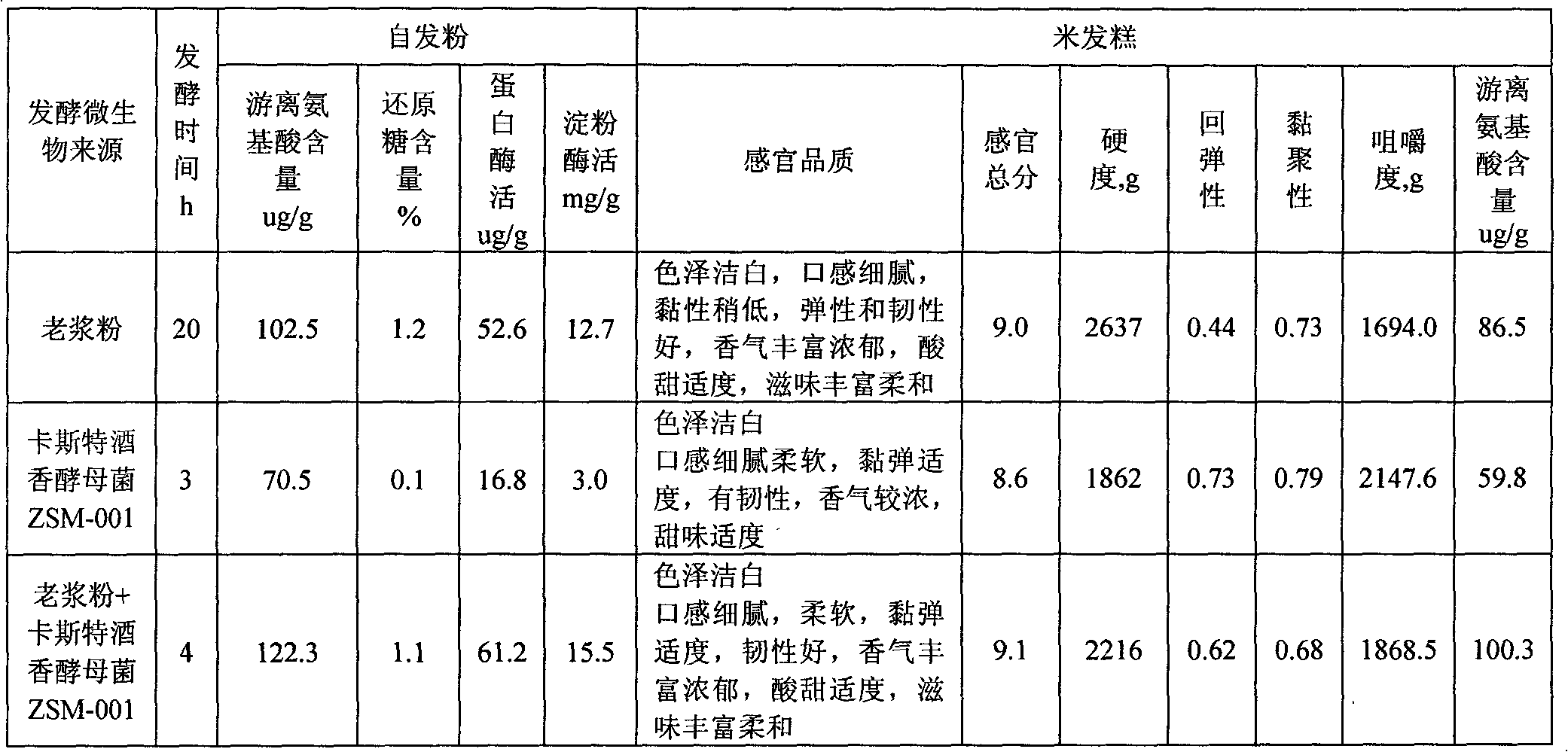

Rice product self-rising flour, producing method thereof and application thereof

The invention belongs to the technical field of foodstuff processing, and concretely relates to rice old slurry powder, rice product self-rising flour, a producing method thereof and an application thereof. The rice product self-rising flour provided by the invention comprises main material powder, the old slurry powder, fermenting bacteria agents and accessories, wherein the old slurry powder is produced by using a traditional fermentation process; the fermenting bacteria agents comprise Custer wine yeast, active dry yeast or plant Lactobacillus; the accessories comprise a sweetener, a sour agent, an enzyme preparation, flour, red bean powder, mung bean powder, calcium carbonate and starch powder; raw materials of the main material powder are selected from one of rice, broken rice, corn, millet, black rice and red rice, or combinations thereof; and the starch powder is selected from potato powder, sweet potato powder or yam powder. The invention further discloses a producing technology of the self-rising flour. Rice steamed sponge cakes, glutinous rice cakes and other products produced by the self-rising flour of the invention have advantages of soft flavor and high quality.

Owner:黄冈东坡粮油集团有限公司

Health-maintenance steamed meat powder

InactiveCN103141848ARetain natural nutrientsReduce depositionFood preparationBiotechnologyAdditive ingredient

The invention discloses a health-maintenance steamed meat powder. The steamed meat powder is prepared from the following raw materials in parts by weight: 28-32 parts of rice flour, 18-22 parts of steamed pteridium aquilinum starch powder, 4-6 parts of pit-removed red data powder, 4-6 parts of tuchahoe powder, 4-6 parts of Chinese yam powder, 4-6 parts of lycium chinense powder, 18-22 parts of corn flour, and 8-12 parts of soybean meal. The health-promotion steamed meat powder disclosed by the invention is prepared by uniformly mixing the raw materials and crushing the mixture to 40-60 meshes, and not only is nutritious, but also contains healthcare ingredients of a plurality of traditional Chinese medicinal materials and is good in taste after the coarse food grains and the refined grains are subjected to scientific combination.

Owner:周新福

Method for preparing starch powdered oil and fat by ultrahigh pressure micro-jet method

InactiveCN102388989AReduce surface oil contentHigh embedding rateEdible oils/fats production/working-upFood additiveOil and grease

The invention provides a method for preparing starch powdered oil and fat by an ultrahigh pressure micro-jet method to solve the problems that the conventional process for producing microencapsulated powdered oil and fat is complex, production cost is high, and a large amount of food additives are needed to be added during production. The method comprises the following specific steps of: preparing emulsified liquid by using oil and deionized water, adding starch into the emulsified liquid, stirring and mixing to prepare suspension, performing pregelatinization on starch, cooling, performing ultrahigh pressure micro-jet homogenizing, and spray-drying. The content of the prepared powdered oil and fat and product granularity can be adjusted, the production process is simple and production cost is low, food additives are not used during preparation, and the product has high safety.

Owner:HARBIN INST OF TECH

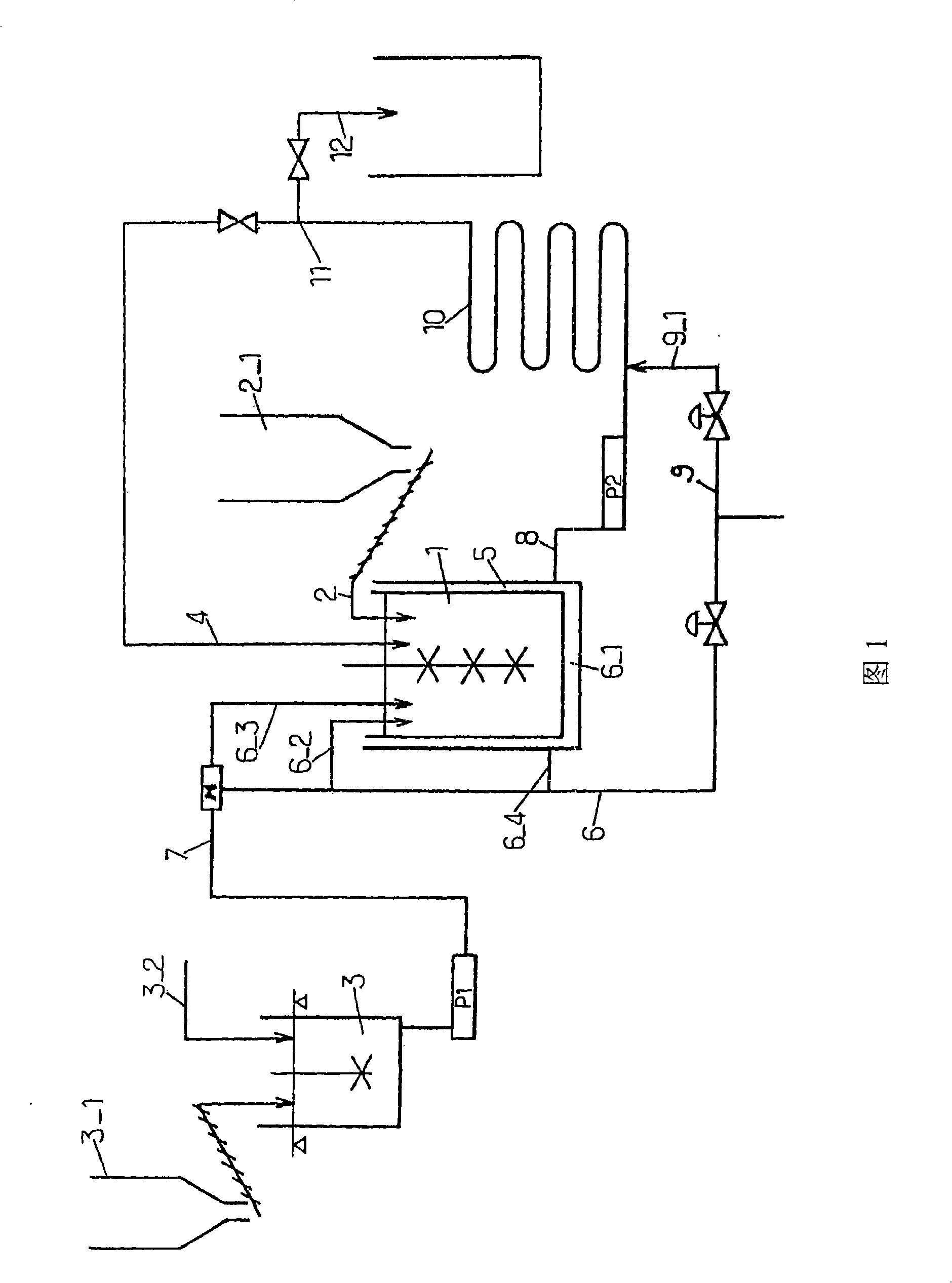

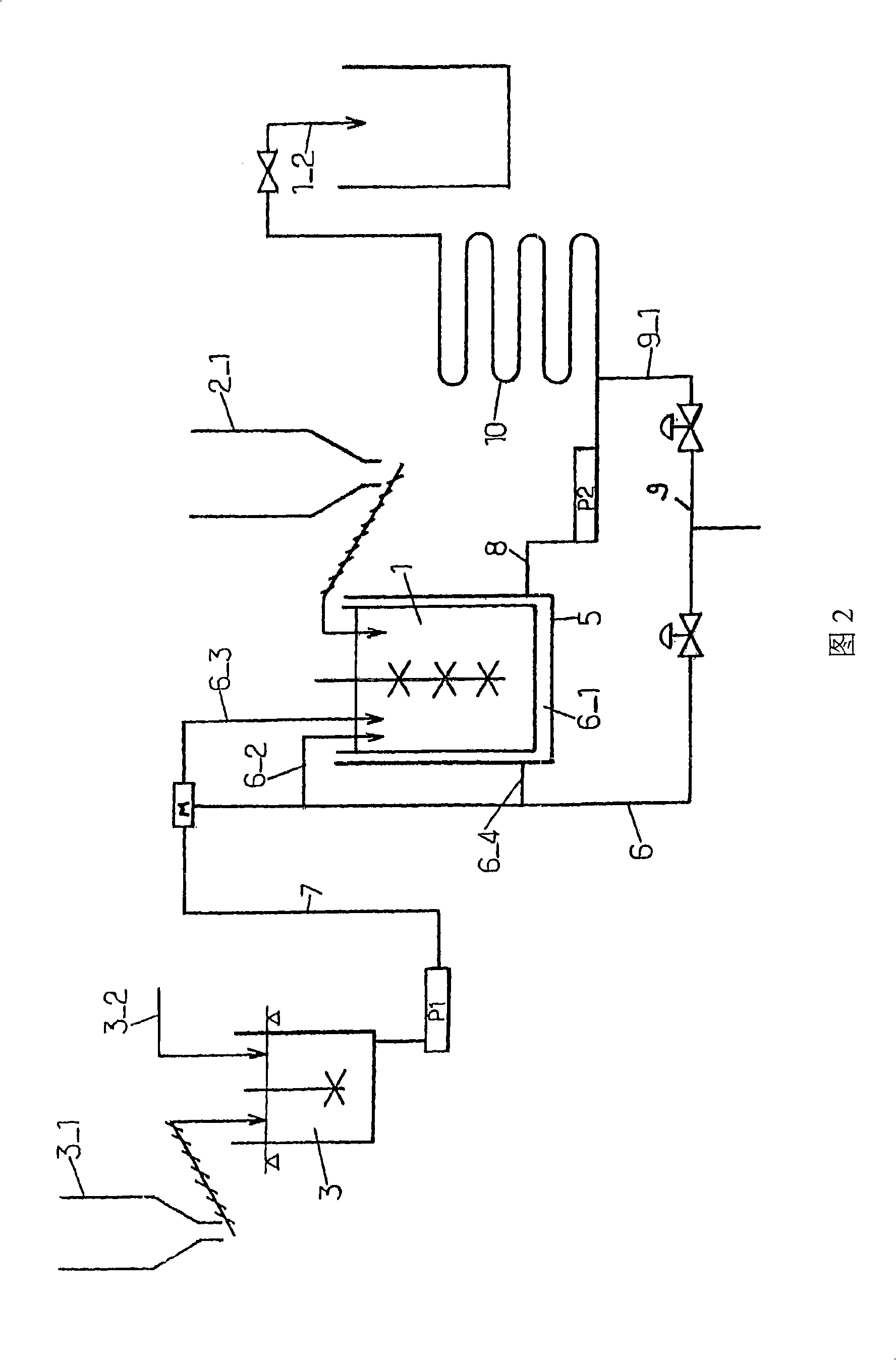

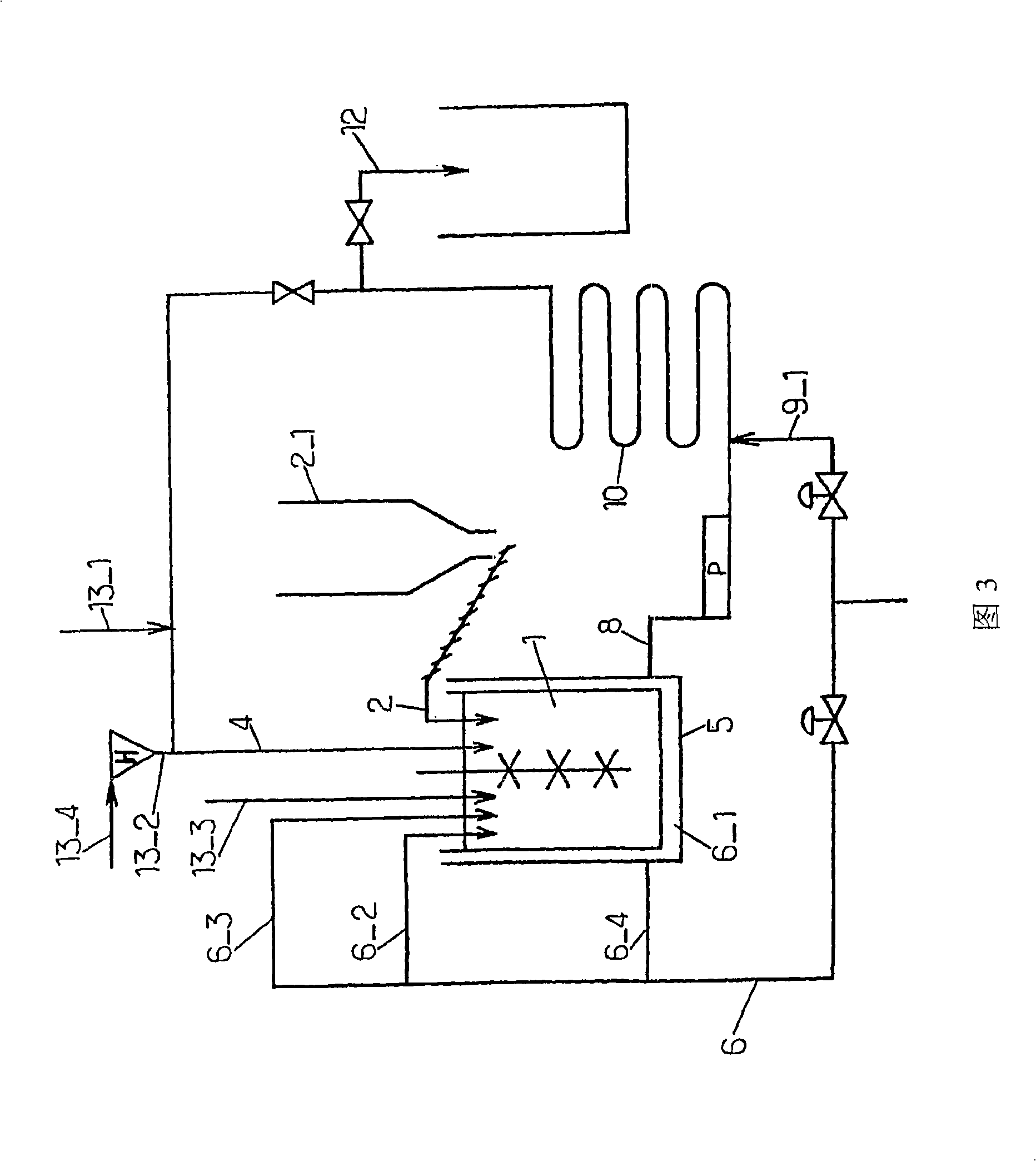

Method for cooking a starchy material with a high solids content for the preparation of an adhesive composition

InactiveCN101405302AKeep drySave raw materialsNon-fibrous pulp additionStarch adhesivesAtmospheric pressureSolid content

The invention relates to a method for cooking a starchy composition, comprising: (a) a first step comprising mixing at least one starch powder with an aqueous starch fluid, wherein the ratio of the mixture of the starch powder to the aqueous starch fluid is such that the total starch content of the mixture obtained is greater than 45% by weight, and wherein said first step is carried out in a cooking chamber maintained at a temperature at least equal to the highest gelatinization temperature (GT) of all the starches present in the mixture, for a period of time sufficient to obtain a colloidal solution of starch, and (b) a second step comprising heating the colloidal solution of starch obtained in step (a), at a pressure greater than atmospheric pressure and at a temperature of between 120 DEG C and 180 DEG C.

Owner:ROQUETTE FRERES SA

Slurry curing agent

The invention relates to a slurry curing agent, which is characterized in that the curing agent is formed by mixing the raw materials in percentage by weight: 10 percent to 50 percent of sulphoaluminate compounds, 5 percent to 40 percent of modified starch, 13 percent to 60 percent of fly ash, 1 percent to 10 percent of plaster and 1 percent to 3 percent of exciting agents, wherein 5 percent to 35 percent of curing agents are added according to the water content and the ingredients of slurry, the mixed materials are stirred for 3 to 10 minutes, and the slurry can be cured through being placed for 24 hours to seven days after the flowability loss. The pH value of condensate leaching liquid is 6 to 9, the condensate is similar to the soil, the soil hardening is overcome, the plant root breathing and the moisture evaporation and infiltration can be conveniently realized, the compression strength can meet the second ploughing and oilfield vehicle passing requirements, heavy metal ions in the slurry are encapsulated and fixed in the slurry and can not be free through ion exchange, macromolecular package and adhesion, and the harmless effect is realized.

Owner:任丘市华北石油天华环保节能有限公司

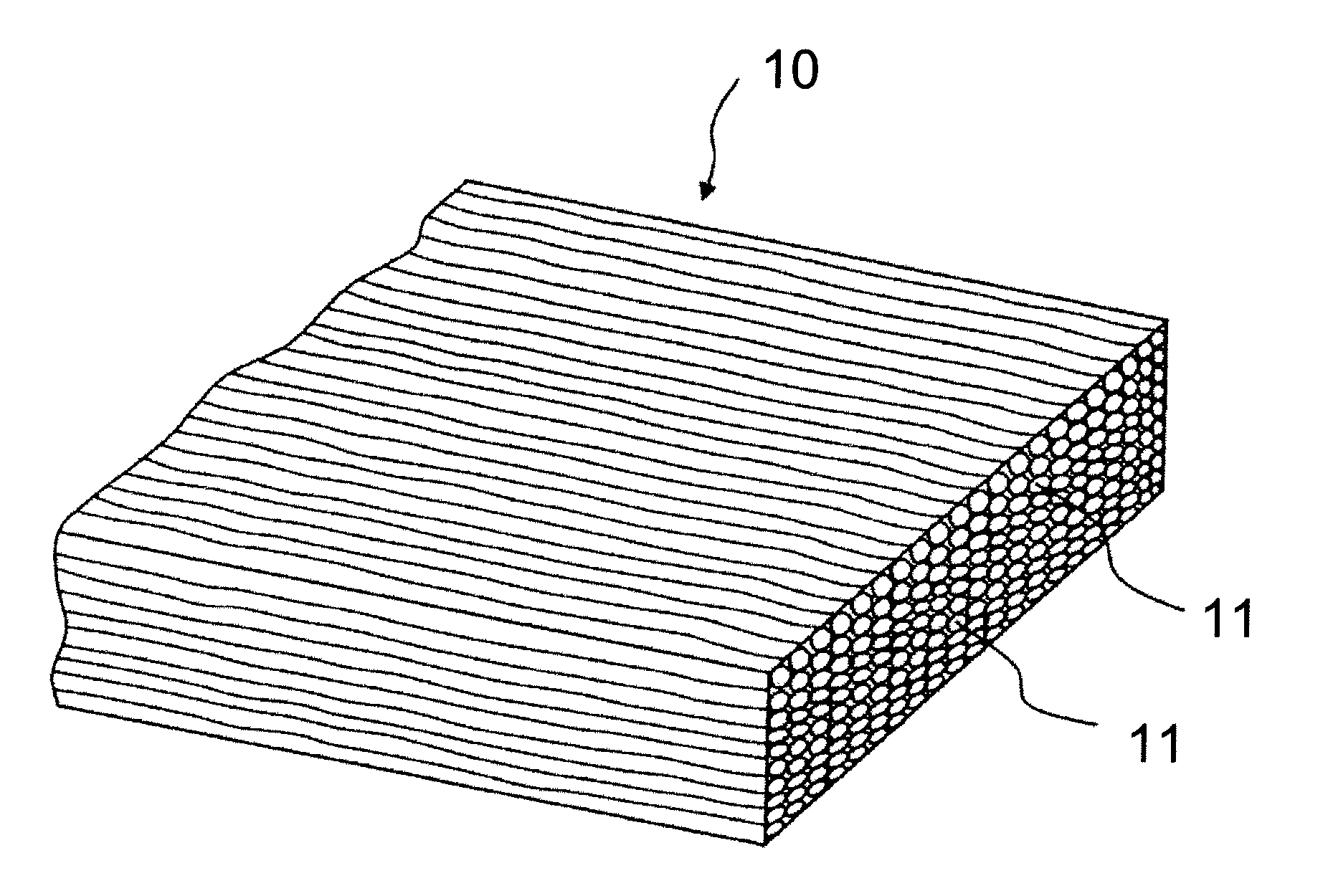

Microfoam and its manufacturing method

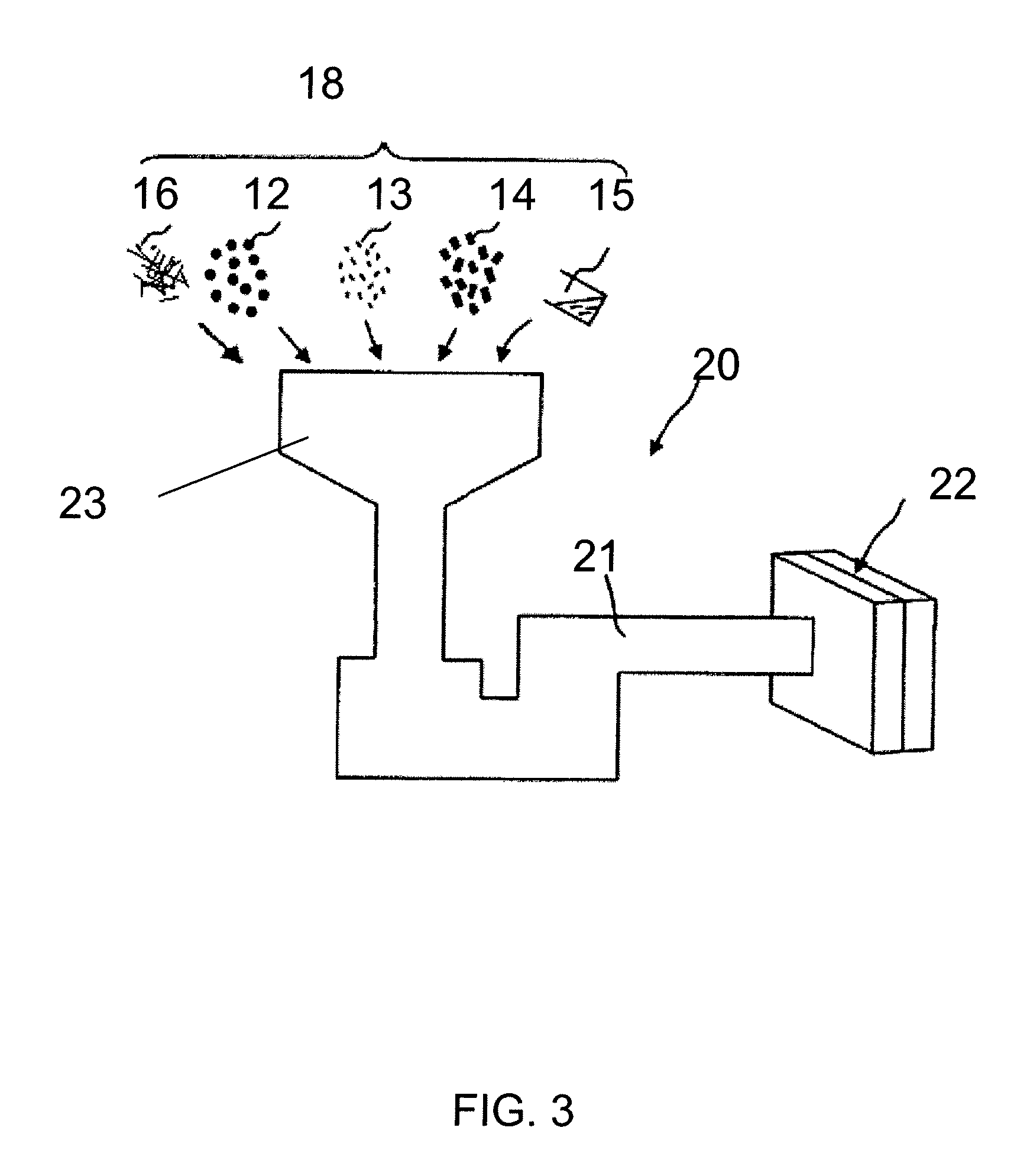

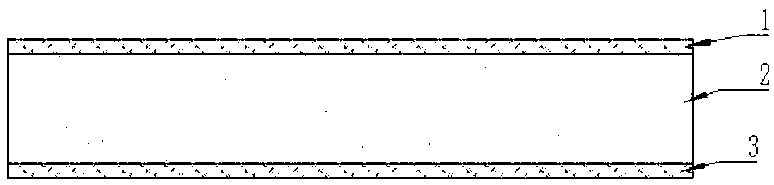

InactiveUS20100227149A1Improve performanceImprove buffering effectLayered productsConfectioneryPolypropylenePolymer chemistry

Foamed materials, and methods and systems of producing the same. At least one of the methods includes forming a composite material including paper powder having a maximum particle size between about 30 to about 100 μm 30 and being between about 20 and 40 weight percent (%) of the composite material, starch powder having a maximum particle size between about 5 to about 30 μm and being between about 20 and about 40 weight % of the composite material, a polypropylene resin being between about 30.0 and 49.5 weight % of the composite material, and a vapor solution being between about 10 and about 20 weight % of the composite material; and forming the foamed material from the composite material by producing an abrupt expansion of vapor in the composite material.

Owner:KOO KI NAM +1

Waterproof, fireproof, mildew-proof and high-strength glass fiber felt gypsum board and preparation method thereof

The invention discloses a glass fiber felt gypsum board, which comprises a gypsum board core and a glass fiber felt protective surface, and is characterized in that the gypsum board core comprises gypsum, a waterproof agent, a mildew preventive, chopped glass fibers, a reinforcing agent, a water reducing agent, modified starch, a powder additive, a foaming agent and water. The glass fiber felt gypsum board has good water resistance, fire resistance, mildew resistance, breaking load and weather resistance, and can be applied to an outer wall or a temporary outer wall. The invention further discloses a preparation method of the glass fiber felt gypsum board. The preparation method comprises the following steps: uniformly stirring the chopped glass fibers, gypsum, the reinforcing agent, the powder additive, the water reducing agent and the modified starch to obtain solid powder; adding the waterproof agent, the mildew preventive and the foaming agent into water, and stirring until foamingto obtain an aqueous solution; adding the solid powder into the aqueous solution, uniformly stirring to obtain gypsum slurry, and forming, solidifying, conveying, cutting and drying the gypsum slurryon a glass fiber felt to obtain the glass fiber felt gypsum board.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

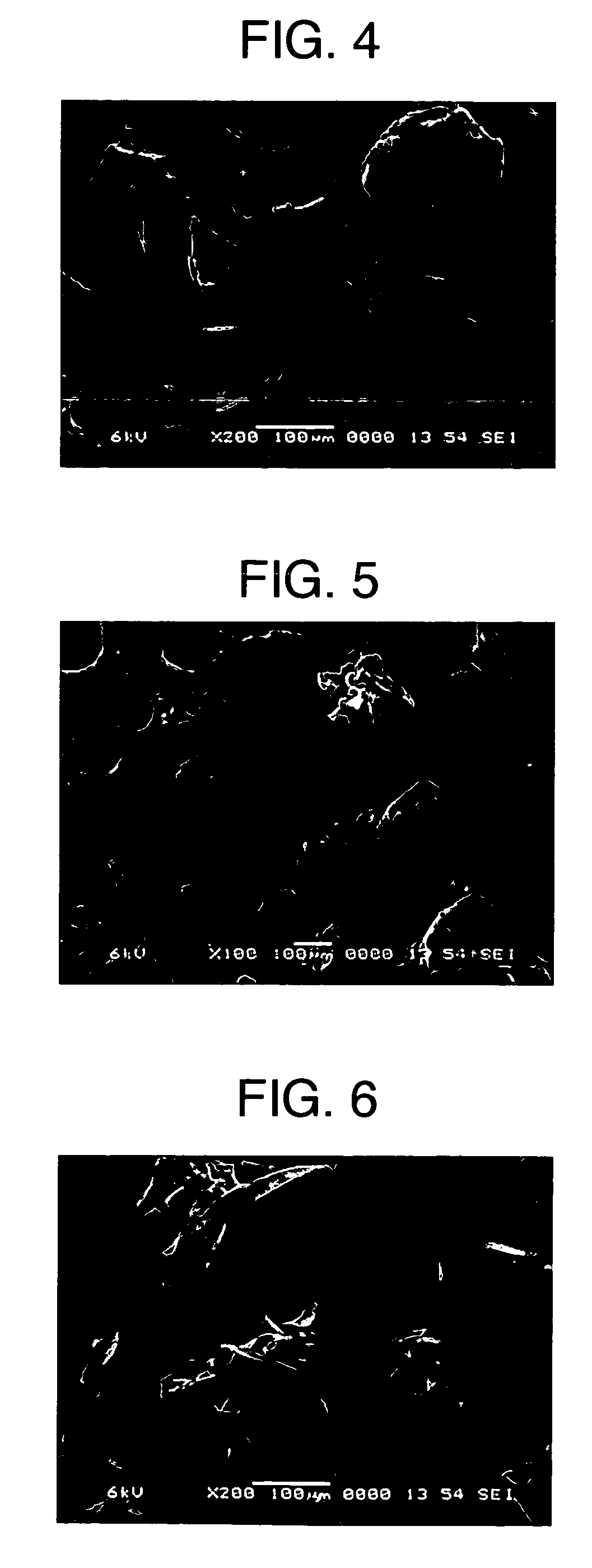

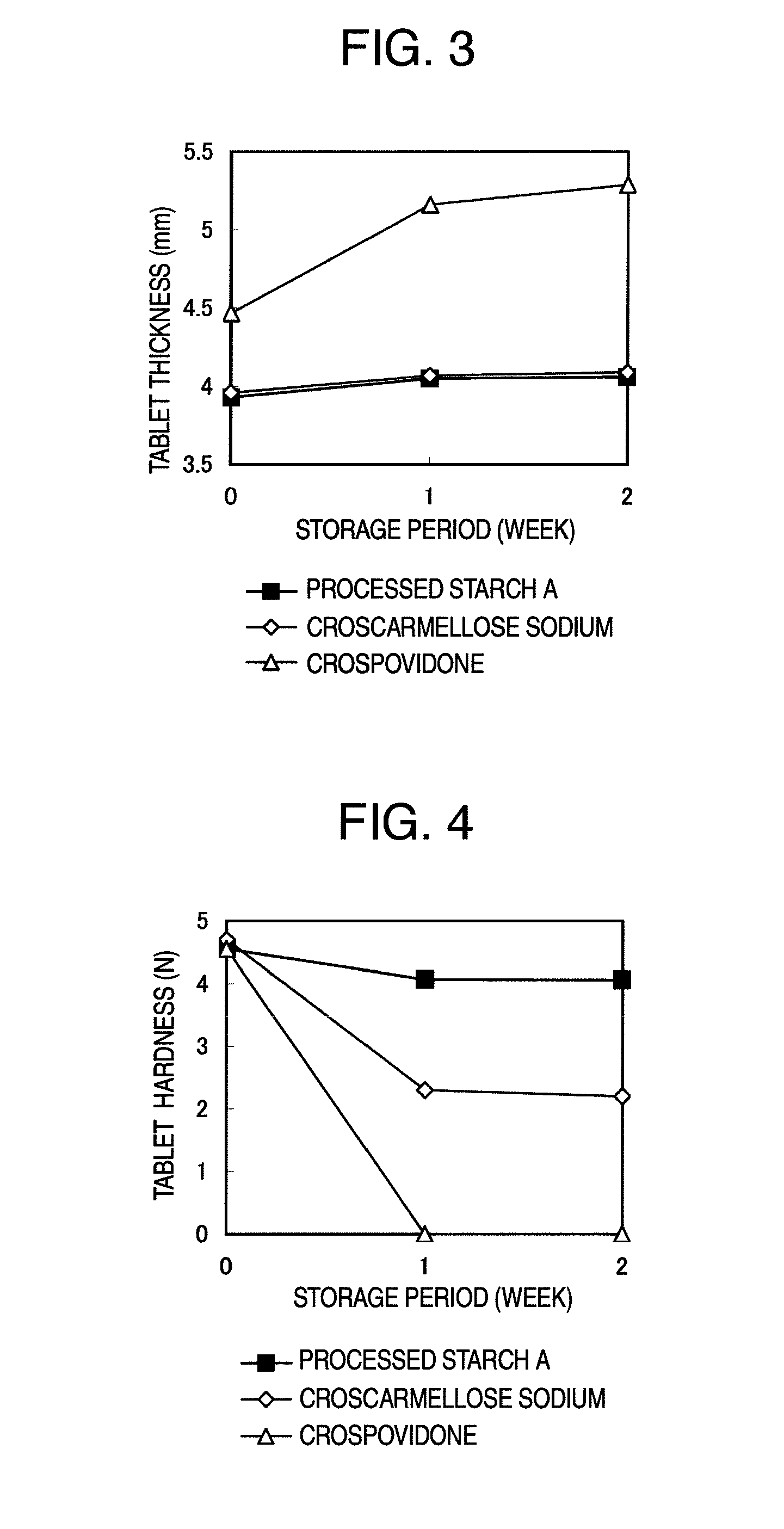

Processed starch powder with excellent disintegration properties and manufacturing method thereof

ActiveUS20110021643A1Reduced responseHigh strengthBiocideOrganic active ingredientsWater solubleStarch powder

Disclosed are a processed starch powder in which the amount of water soluble component is greater than 2 wt % but less than 10 wt %, the water retention amount is greater than 600% and 1500% or less, and which comprises nonbirefringent particles, and a manufacturing method thereof.

Owner:ASAHI KASEI KK +1

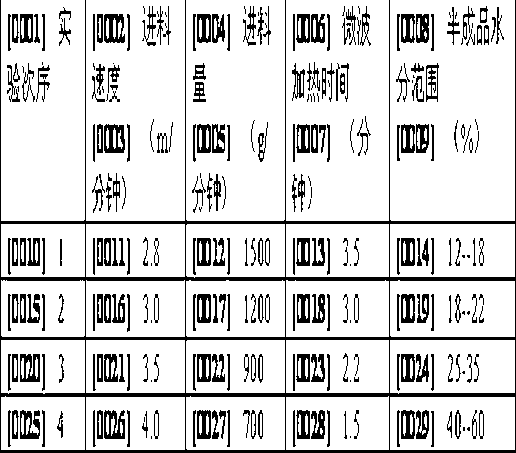

Microwave processed egg product and preparation method thereof

InactiveCN102987446AImprove aestheticsIncrease nutritionFood preparationBiotechnologyMonosodium glutamate

The invention relates to a microwave processed egg product which uses egg powder, starch, white granulated sugar, vegetable oil, sorbitol, phosphate, xanthan gum, edible salt, monosodium glutamate, soy powder, 5-flavor nucleotide, vitamin E and baking powder as main materials and prepared by microwave processing and drying and a preparation method of the microwave processed egg product. The preparation method comprises the steps of: mixing uniformly the egg powder and starch powder; adding liquid charging stock of the vegetable oil; mixing; adding tap water; mixing as paste; preparing wet particles / or extruding and forming; heating by a microwave production line; palletizing secondarily; drying by hot air; packaging; and continuously heating by the microwave production line. The egg product is convenient to produce, high in work efficiency, and environment-friendly and sanitary. Uniform microporous channels from inside to outside are formed in the prepared product after microwave processing. After hot water or soup base is added into the product, the product absorbs water quickly and expands and floats on the hot water or soup base, so that the inherent color, flavor and taste of fried egg are well represented, the attractiveness and nutrition of a main foot are improved, and the microwave processed egg product is suitable for an ingredient of a convenient food.

Owner:ZHENGZHOU GUANGHEYUAN AGRI TECH

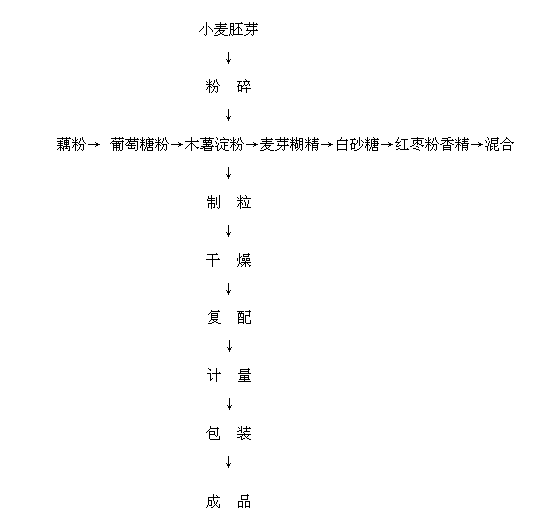

Wheat germ and lotus root starch powder, and its preparation method

A wheat germ and lotus root starch powder comprises 10-18 parts by weight of wheat germ powder, 30-40 parts by weight of lotus root starch, 8-15 parts by weight of glucose powder, 20-26 parts by weight of cassava starch, 10-15 parts by weight of maltodextrin, 10-18 parts by weight of white granulated sugar, and 0.3-0.5 parts by weight of a red date powder essence. A preparation method of the wheat germ and lotus root starch powder comprises the following steps: processing wheat germ to prepare the wheat germ powder, mixing the wheat germ powder with the above other raw materials, drying, and compounding to prepare the wheat germ and lotus root starch powder. The method maintains biological activities through low temperature drying, maintains biological cells in good condition through airflow crushing, and solves the problems comprising difficult keeping and bad mouthfeel of wheat germ in the prior art. The wheat germ and lotus root starch powder is an augmented product of the fine and further processing of agricultural products. The wheat germ and lotus root starch powder is convenient to eat, has extremely high nutritional values, can be easily accepted by people, and realizes the intake of a large amount of nutrients through eating a small amount of the wheat germ and lotus root starch powder, so people can obtain a plurality of nutritional components comprising natural vitamin E, vitamin B, proteins and the like from foods.

Owner:HUBEI SANJIE AGRI INDZATION

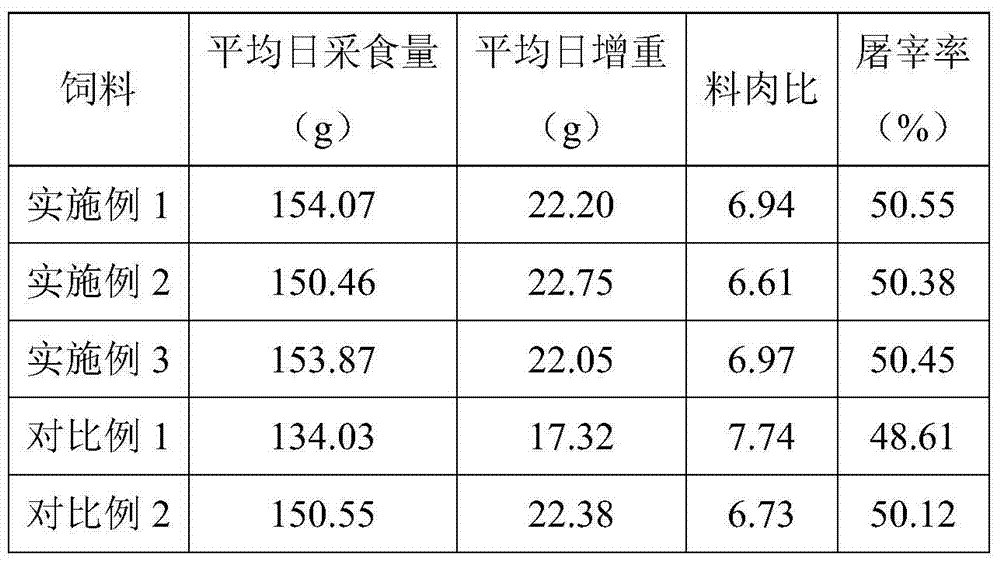

Vacuum after-spraying liquid feed additive for meat rabbits, straw pellet feed and preparation method thereof

InactiveCN103750031AMeet all needsIncrease production capacityAnimal feeding stuffAccessory food factorsWeight gainingButylated hydroxytoluene

The invention discloses a vacuum after-spraying liquid feed additive for meat rabbits, a straw pellet feed and a preparation method of the vacuum after-spraying liquid feed additive. The liquid feed additive is prepared from the following components: soybean oil, xanthan gum, water, calcium hydrogen phosphate, butylated hydroxytoluene, composite vitamins, calcium carbonate, composite enzyme, zinc sulfate and beer yeast. Nutritional substances of the vacuum after-spraying liquid feed additive for the meat rabbits are reasonably matched and are added into the pellet feed so as to be matched with corn powder, starch powder and the like, so that the nutritional value and the breeding rate of the straw pellet feed are increased; the comprehensive demand on the nutrition of the meat rabbit is met; the average daily weight gain and the slaughtering rate are effectively improved; the productivity of the meat rabbit is greatly improved; the utilization rate of straws is increased, the straw recycling progress is promoted, the cost of the feed is reduced, and the vacuum after-spraying liquid feed additive has a good economical benefit.

Owner:HENAN UNIV OF SCI & TECH

Stainless steel/silicon carbide ceramic-based composite material and preparation method thereof

InactiveCN104651699ASignificant rise in temperatureImprove corrosion resistanceStearic acidCorrosion

The invention discloses a stainless steel / silicon carbide ceramic-based composite material and a preparation method thereof. The stainless steel / silicon carbide ceramic-based composite material is characterized by being prepared from the following raw materials in parts by weight: 60-70 parts of silicon carbide, 9-12 parts of stainless steel powder, 7-9 parts of titanium powder, 2-4 parts of starch, 3-5 parts of coal ash, 1-2 parts of titanate coupling agent; 10-15 parts of absolute ethyl alcohol, 3-4 parts of highly wearable carbon black, 1-2 parts of calcium stearate, 1-3 parts of liquid paraffin, 2-4 parts of sintering aid and 80-100 parts of deionized water; according to the stainless steel / silicon carbide ceramic-based composite material, the added stainless steel powder and the titanium powder are capable of improving the high temperature resistance, the corrosion resistance, the strength and the toughness of the silicon carbide ceramics, increasing the relative density of the material, improving the sintering performance and expanding the application range of the ceramics; and the method has the advantages of easily available raw materials, short period, reduction of the sintering temperatures, reduction of the cost, and conservation of resources.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Expanded starch solid powder glue and preparation method thereof

InactiveCN103468161AEfficient killingLess effective dosageNon-macromolecular adhesive additivesStarch adhesivesPolymer scienceAdhesive

The invention relates to expanded starch solid powder glue, comprising the following components in parts by weight: 70-90 parts of expanded starch, 5-30 parts of tackifier, 0.05-1 part of complexing agent, 0.01-0.5 part of dispersing agent, 0.1-2 parts of quick dry agent, 0.01-1 part of thickener, 0.01-0.4 parts of bactericide and 0.01-0.4 parts of preservative. The expanded starch powder glue is non-toxic tasteless white powder; solid glue powder and water are stirred and mixed according to the ratio of 1:10 in use, and then the glue powder is dissolved into water and gelatinized to form a thick mucilage; the mucilage has strong cohesive force and good application property, and is anti-mildew and antibacterial, and suitable for bonding of kinds of wallpapers and matrixes; the performance of the mucilage accords with the requirements of the standard of JC / T548-1994 'wallpaper adhesive'. Therefore, the expanded starch solid powder glue has environmental protection and energy conservation effects relatively to liquid glue, and is the development direction of an environment-friendly starch adhesive for the wallpaper.

Owner:HANGZHOU MIKABO NEW MATERIAL TECH CO LTD

Preparation method of highly-conductive and antibacterial waterproof conductive paper

InactiveCN108018742AImprove antibacterial propertiesComplete structureSpecial paperPaper/cardboardFiberCarbon fibers

The invention relates to the technical field of preparation of conductive paper materials, in particular to a preparation method of highly-conductive and antibacterial waterproof conductive paper. Thehighly-conductive and antibacterial waterproof conductive paper is prepared from birch wood pulp fiber as a substrate, self-made silver-supported carbon nanotubes, a carbon fiber dispersion liquid and self-made cationic starch powder as reinforcing agents, as well as polyvinyl alcohol, tributyl phosphate and the like as auxiliary materials. Firstly, modified short carbon fibers are uniformly dispersed in water for obtaining the carbon fiber dispersion liquid, and then the carbon nanotubes are modified with a silver nitrate solution, so that the antibacterial property of the conductive paper is improved; the carbon nano tubes are attached to the carbon fibers and the substrate, a complete conductive network structure is formed, and conductivity of the conductive paper is improved; sweet potato starch is doubly modified with epoxy chloropropane and succinic anhydride, absorption of water can be limited by crosslinking treatment, the waterproof property of the conductive paper is improved, and wide application prospect is achieved.

Owner:李巧珍

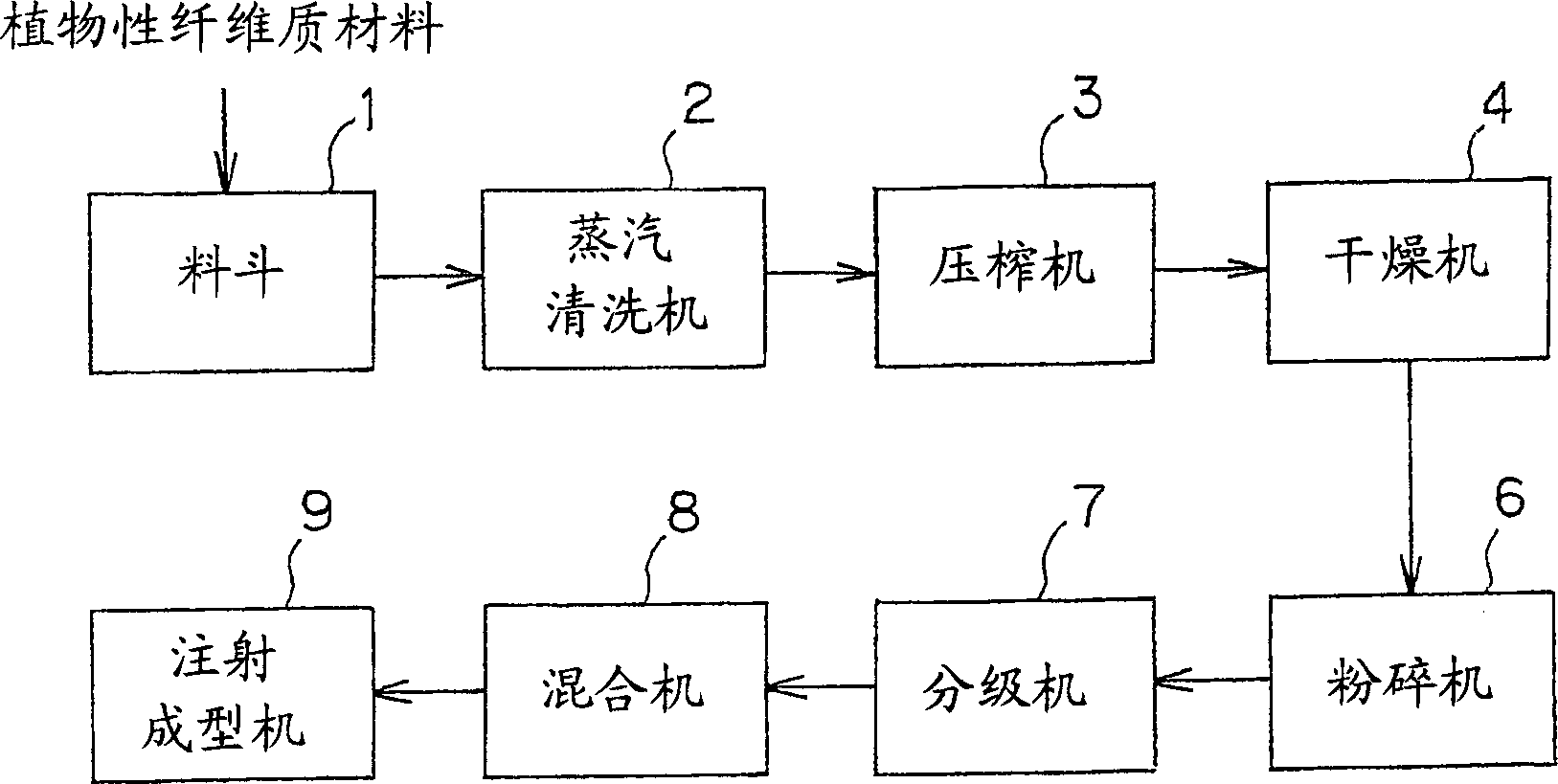

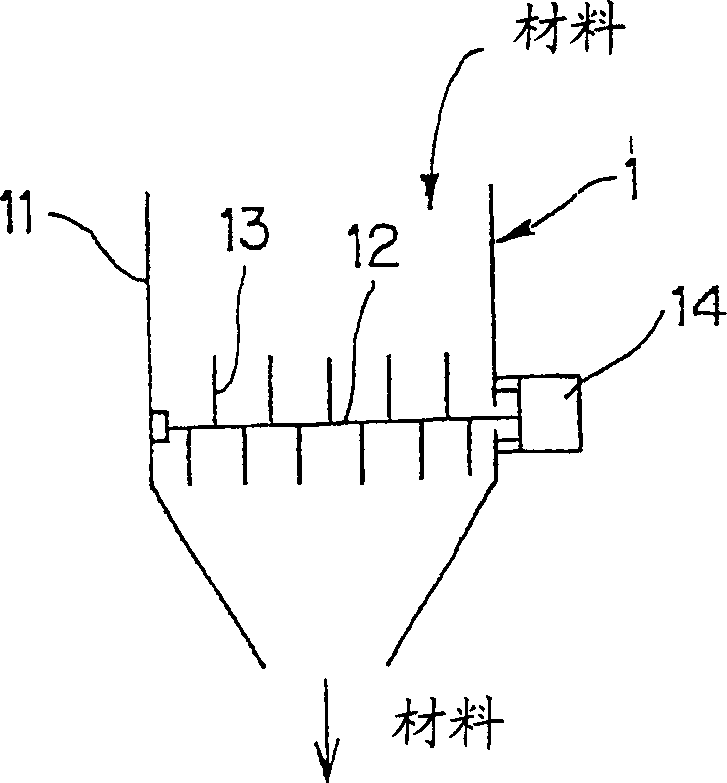

Process for producing biodegradable fiber molding

The invention relates to the vegetal fibre molding material and the molding method. The vegetal fibre powder is mixed with the vegetal binding agent powder which is formed by mixing the starch powder and the pectin powder. Then the mixture is mixed with water and then the vegetal fibre molding material is generated.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

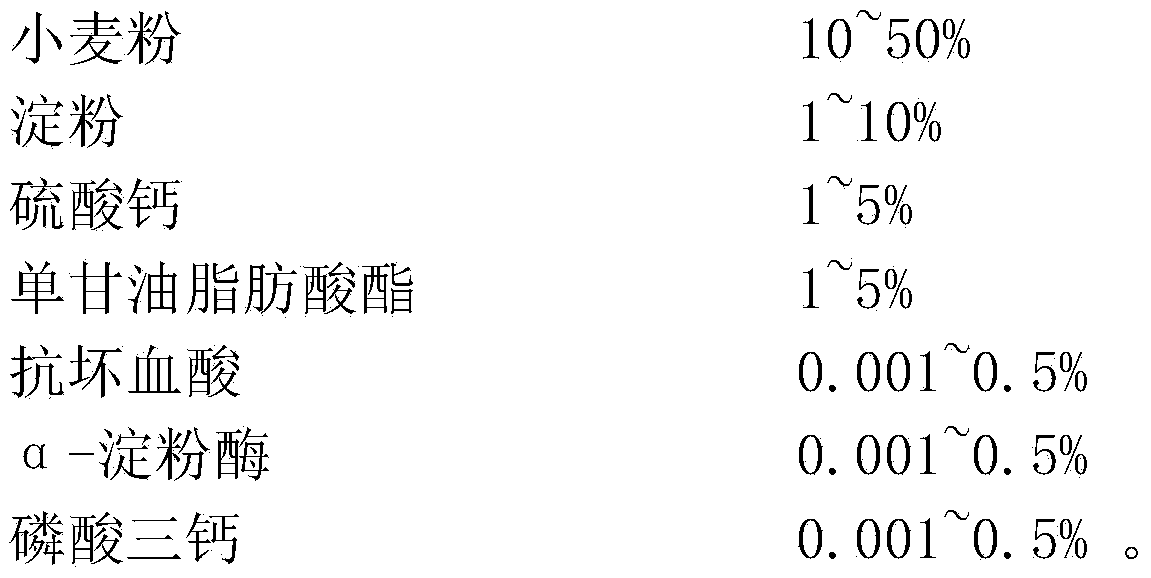

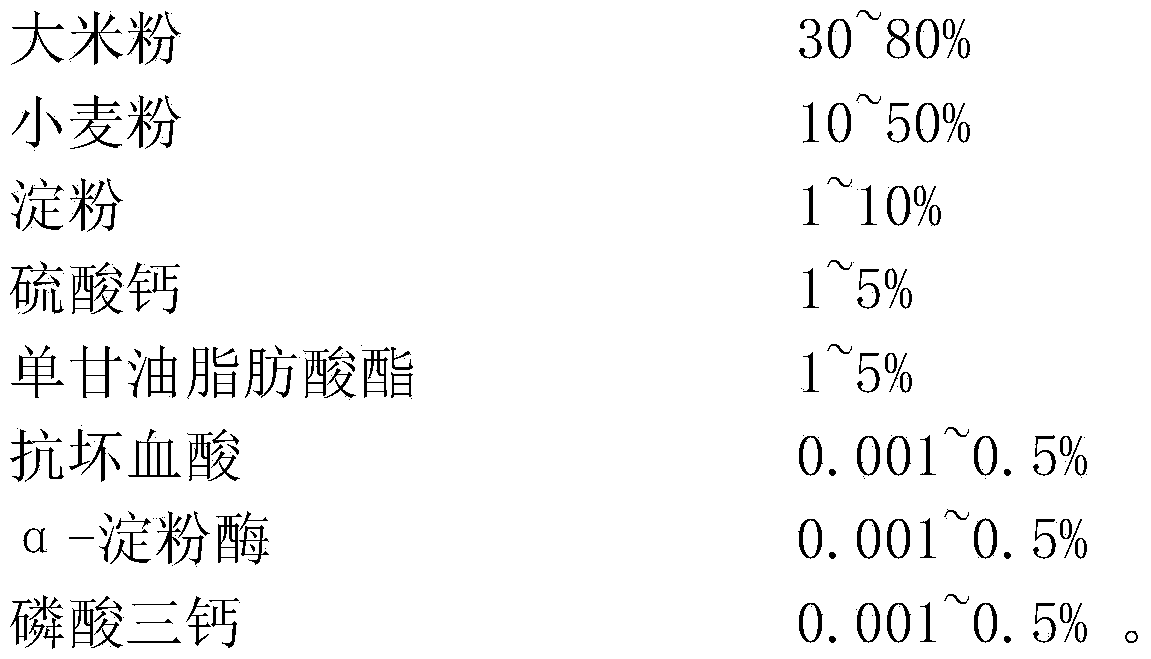

Aging-resistant starch gelatinizing type bread mix, starch gelatinizing type bread and manufacturing method thereof

InactiveCN103766432AImprove water retention and moisturizing abilityImprove water holding capacityDough treatmentPre-baking dough treatmentPhosphateResistant starch

The invention relates to an aging-resistant starch gelatinizing type bread mix. The mix consists of the following components in percentage by weight: 30% to 80% of rice powder, 10% to 50% of wheat powder, 1% to 10% of starch powder, 1% to 5% of calcium sulphate, 1% to 5% of glycerin fatty acid ester, 0.001% to 0.5% of ascorbic acid, 0.001% to 0.5% of alpha-amylase, and 0.001% to 0.5% of tricalcium phosphate. The mix has the advantages that the rice powder, the starch and the auxiliary wheat powder are scientifically used, so the anti-aging performance of the starch gelatinizing type bread is greatly improved, the manufactured bread has wet and soft mouth feel and elasticity, the freshness and softness can be maintained for 15 to 20 days at the room temperature, and the aging-retarding effect is very obvious.

Owner:TIANJIN YIBEIKE FOOD TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com