Patents

Literature

254 results about "Refined grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refined grains, in contrast to whole grains, refers to grain products consisting of grains or grain flours that have been significantly modified from their natural composition. The modification process generally involves the mechanical removal of bran and germ, either through grinding or selective sifting. Further refining includes mixing, bleaching, and brominating; additionally, thiamin, riboflavin, niacin, and iron are often added back in to nutritionally enrich the product. Because the added nutrients represent a fraction of the nutrients removed, refined grains are considered nutritionally inferior to whole grains. However, for some grains the removal of fiber coupled with fine grinding results in a slightly higher availability of grain energy for use by the body. Furthermore, in the special case of maize, the process of nixtamalization (a chemical form of refinement) yields a considerable improvement in the bioavailability of niacin, thereby preventing pellagra in diets consisting largely of maize products.

Laser cladding nickel-based alloy powder and preparation method thereof

InactiveCN102912188AHigh hardnessNo crackMetallic material coating processesChemical compositionCrack free

The invention relates to laser cladding nickel-based alloy powder and a preparation method thereof. The laser cladding nickel-based alloy powder is characterized by comprising the following components by weight percent: 0.2-0.7% of C, 2-3.5% of Si, 1.5-3% of B, 1.0-1.5% of Mn, 3-10% of Cr, 2-5% of W, 3-5% of Mo, 0.5-1% of Nb, 0.5-2% of Co, less than 15% of Fe, 0.2-0.4% of Y, 0.2-0.5% of Ce and Ni and the balance of unavoidable impurity elements. A manufacturing process flow of the laser cladding nickel-based alloy powder is as follows: burdening, smelting, atomizing, drying and sieving. The alloy powder used for laser cladding provided by the invention is corrosion-resistant and also has higher hardness, and a treated laser cladding layer has the advantages of no crack, no pore, no impurity, compact structure and refined grain. A large-area thick crack-free laser cladding alloy layer can be obtained without preheating or follow-up heat treatment, and the cladding layer has the advantages of high strength, hardness and abrasion performance, good plasticity and toughness and low cost.

Owner:江苏新亚特钢锻造有限公司

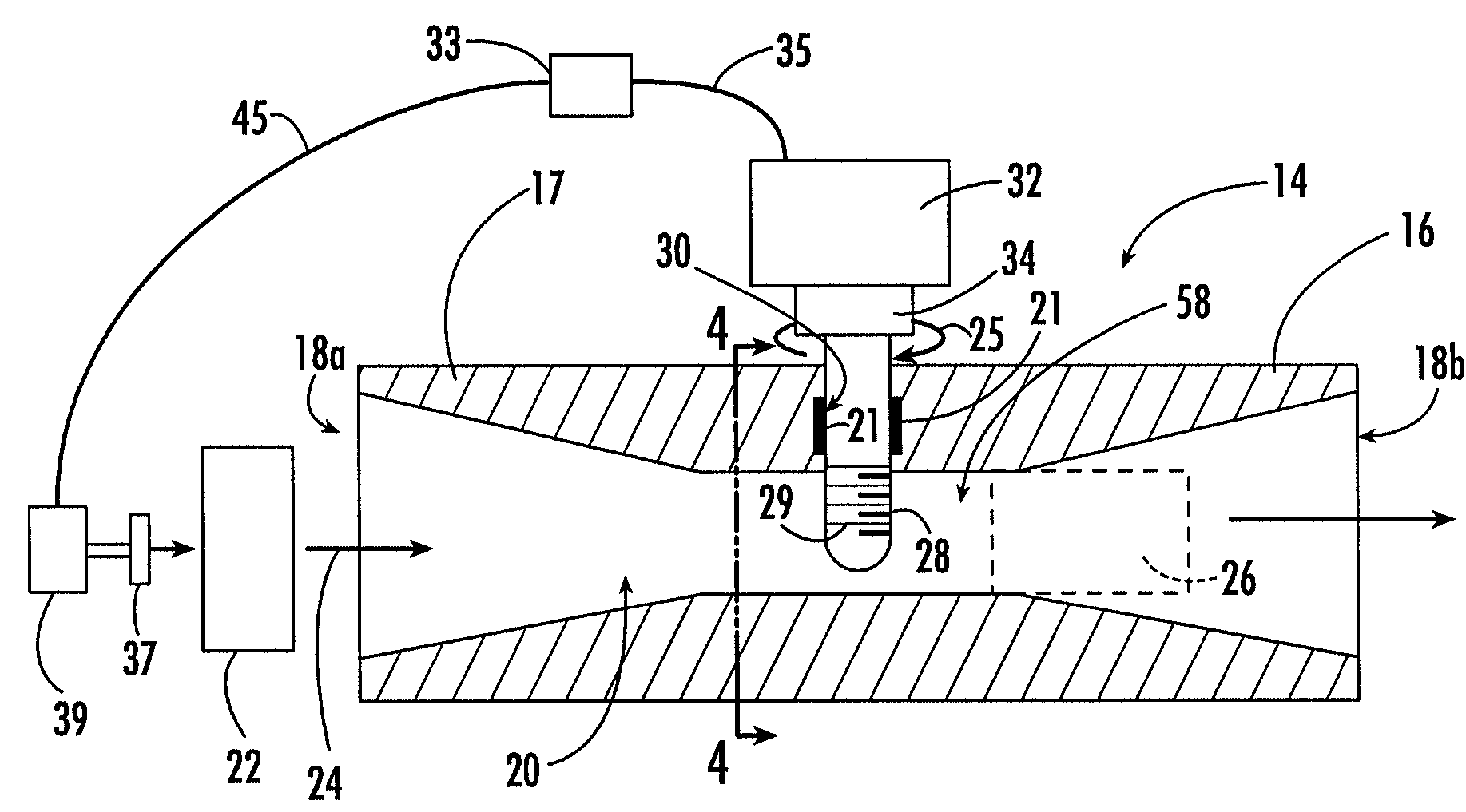

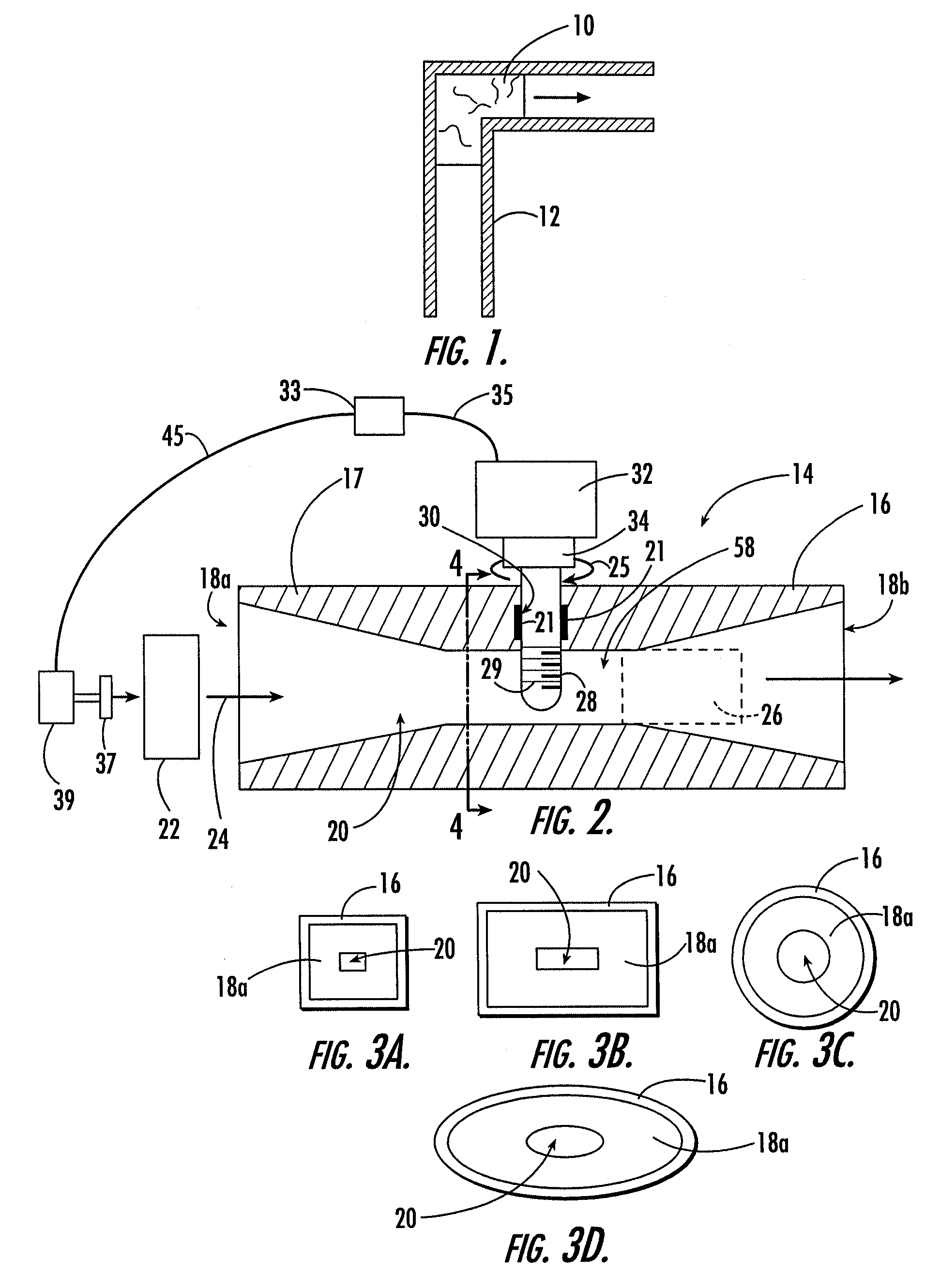

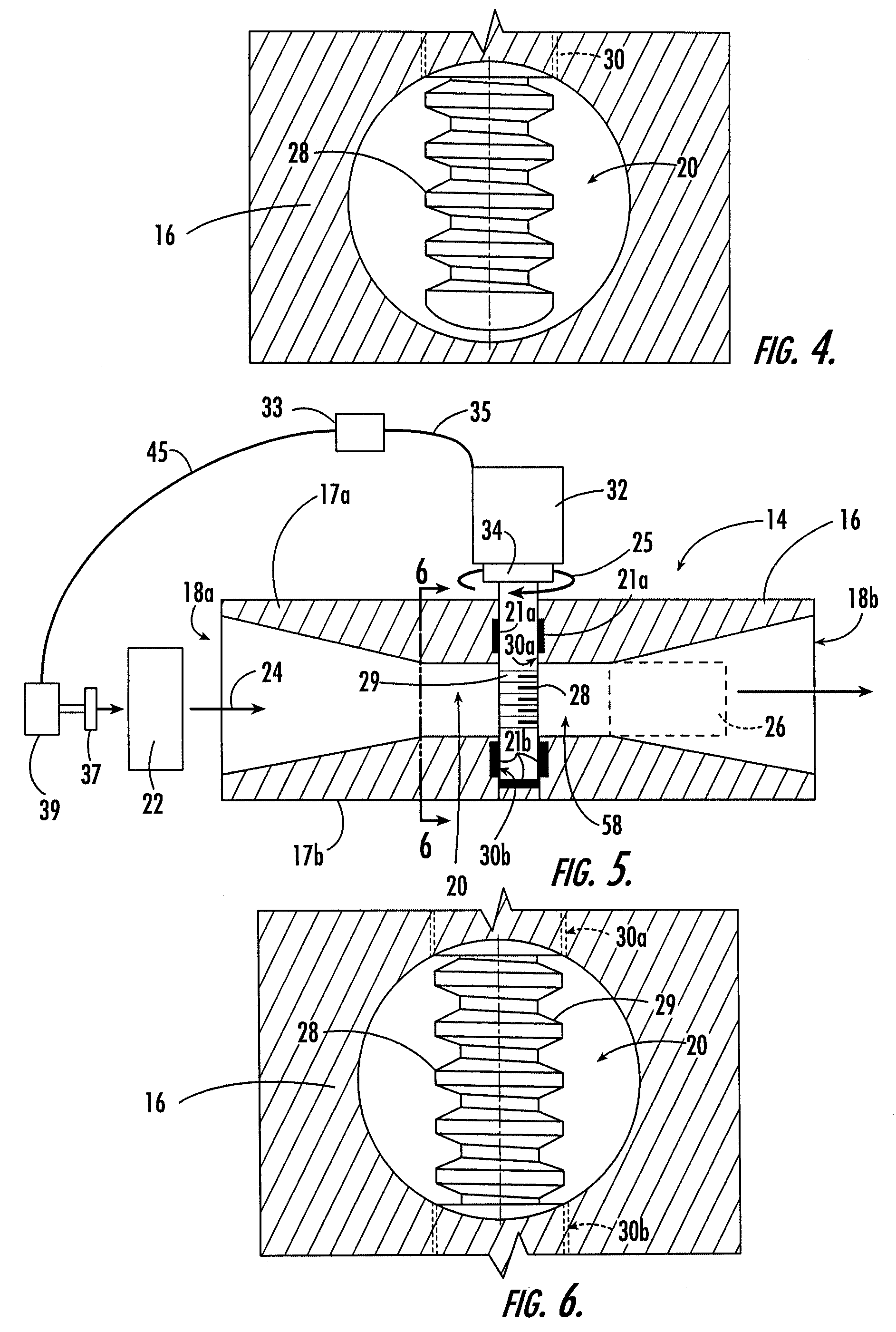

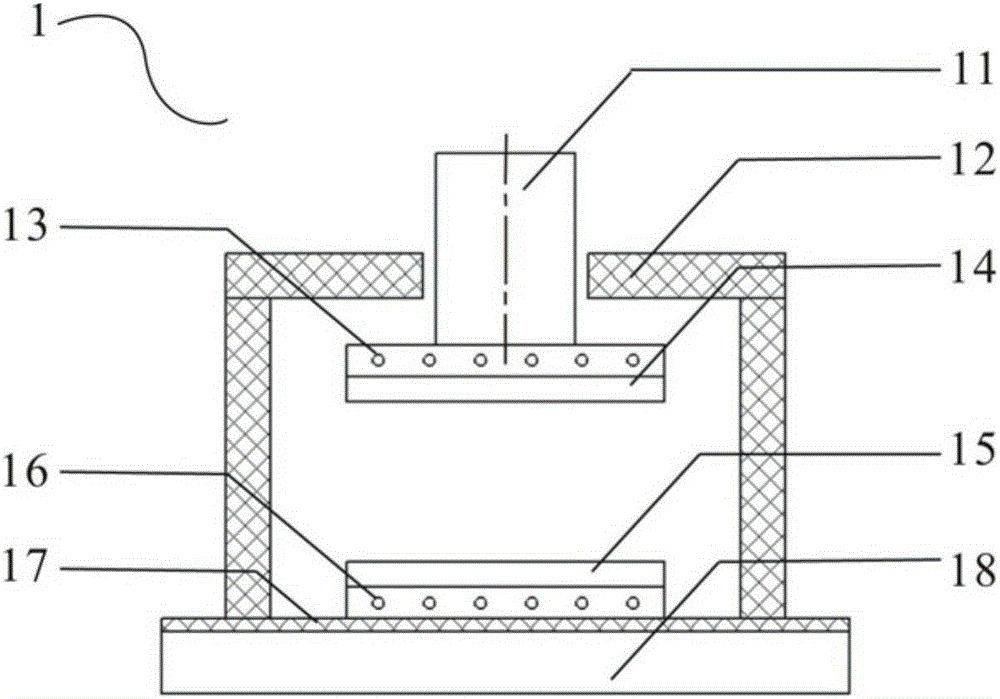

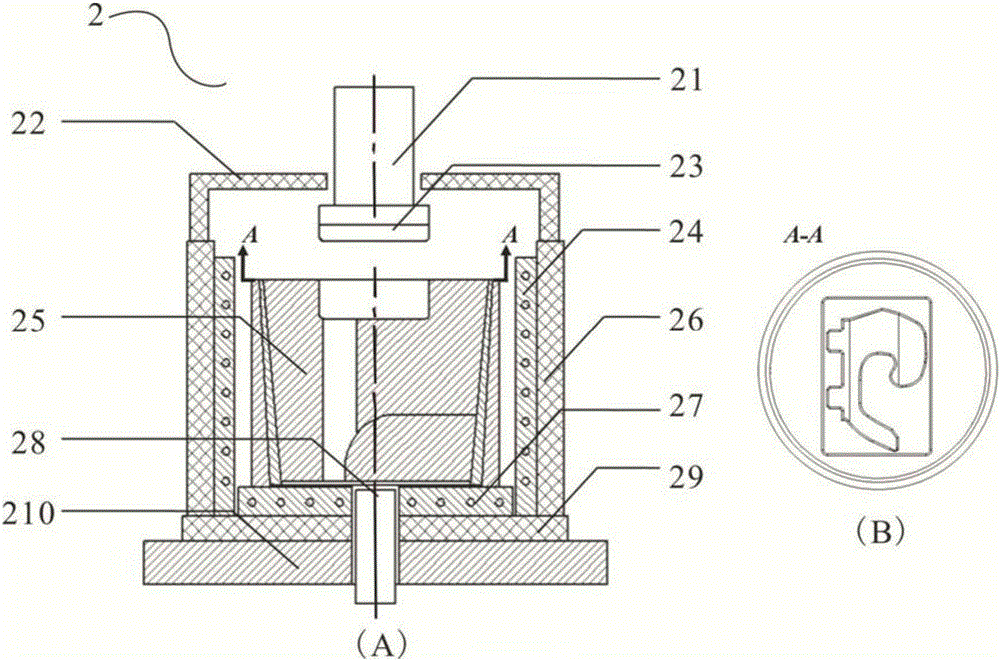

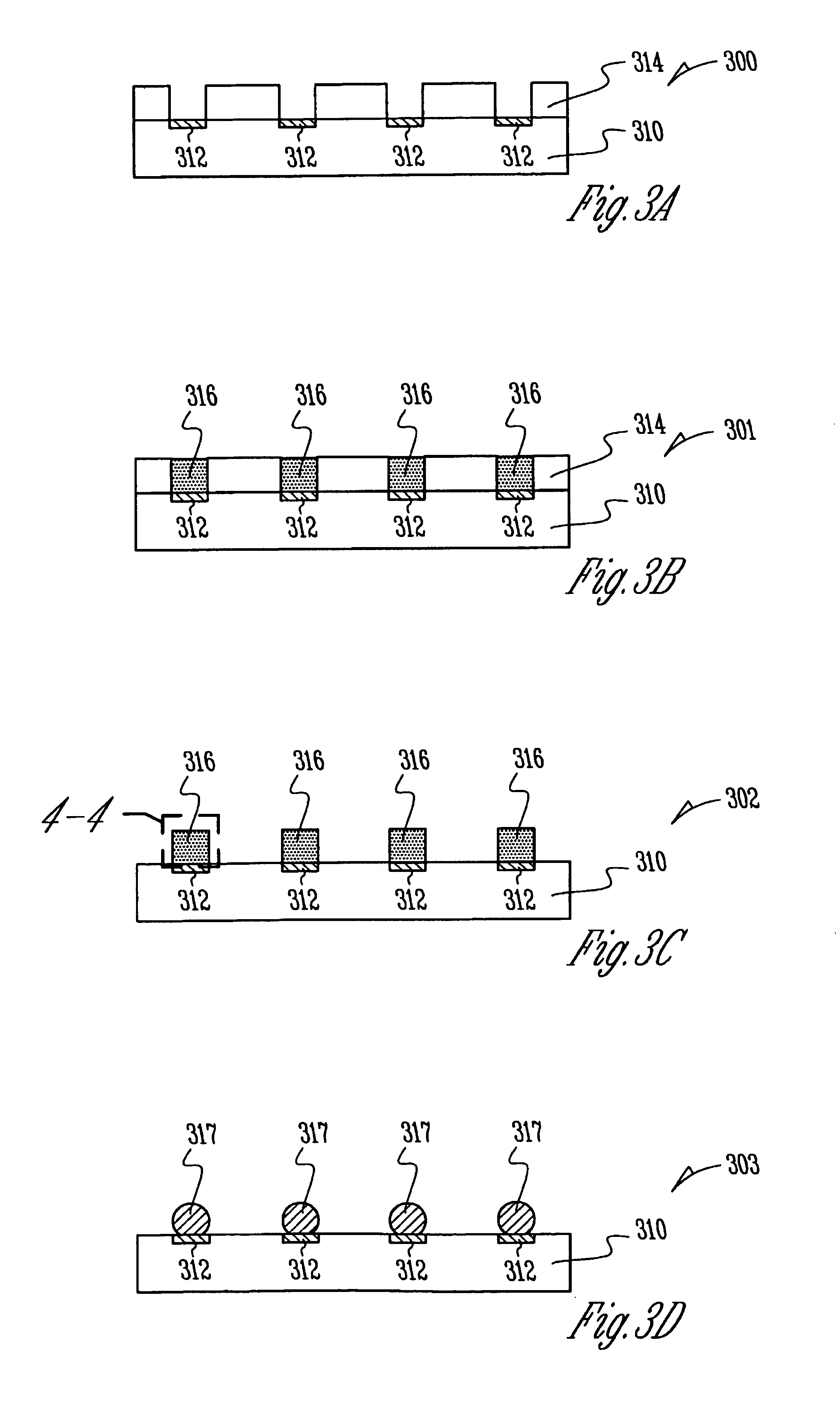

Method and apparatus for producing a refined grain structure

InactiveUS20030218052A2Improve material performanceLow costWelding/cutting media/materialsSoldering mediaGrain structureMechanical engineering

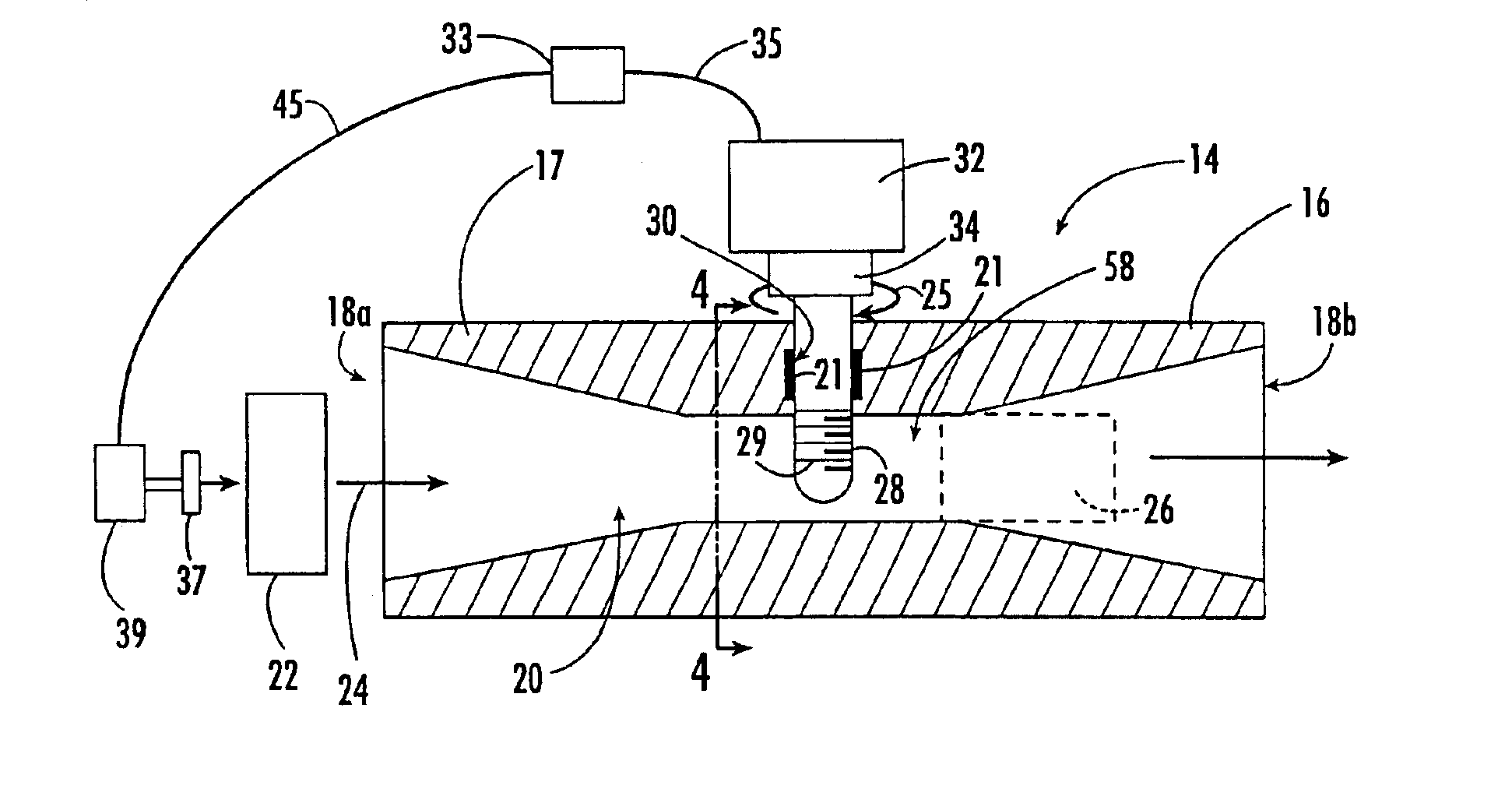

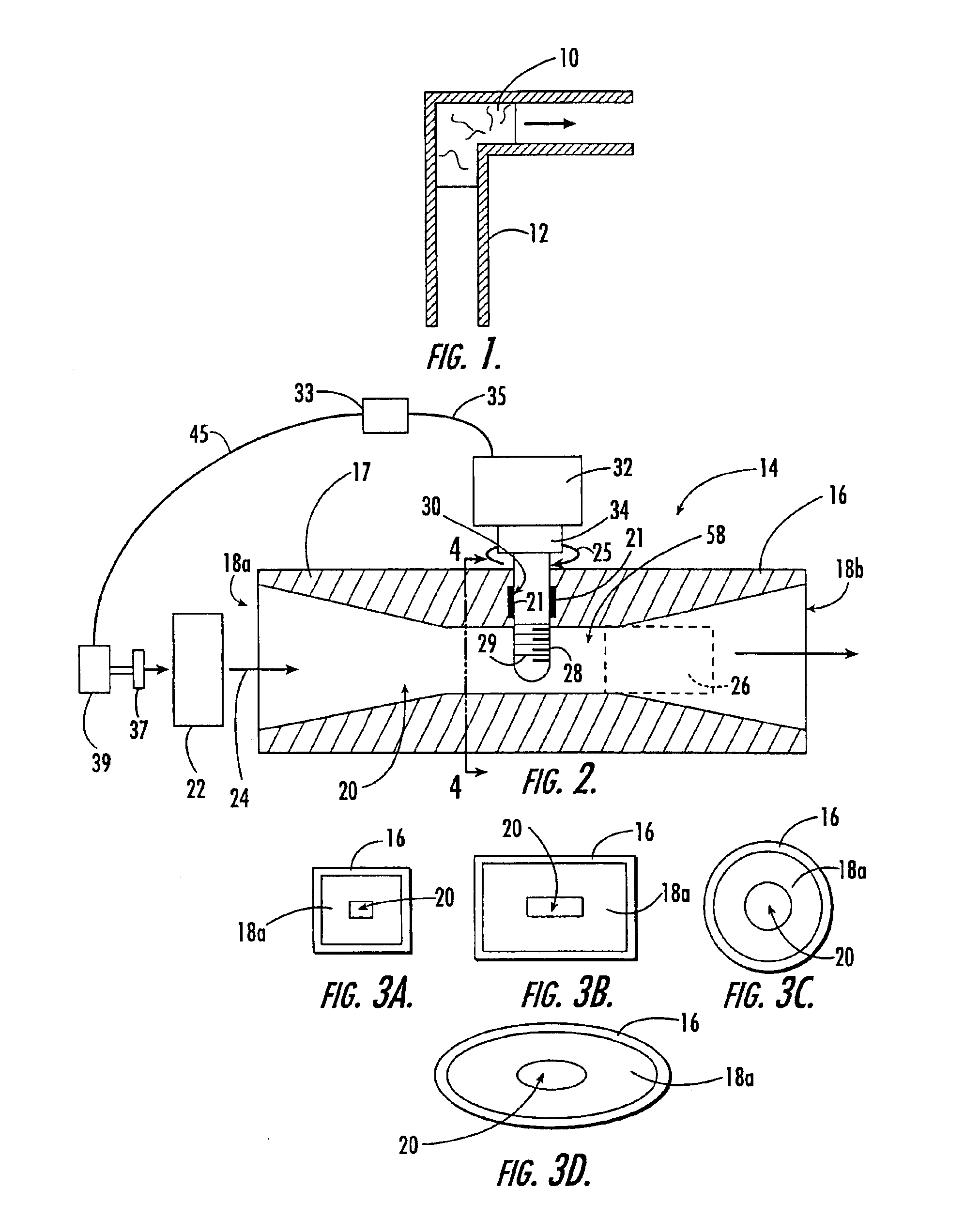

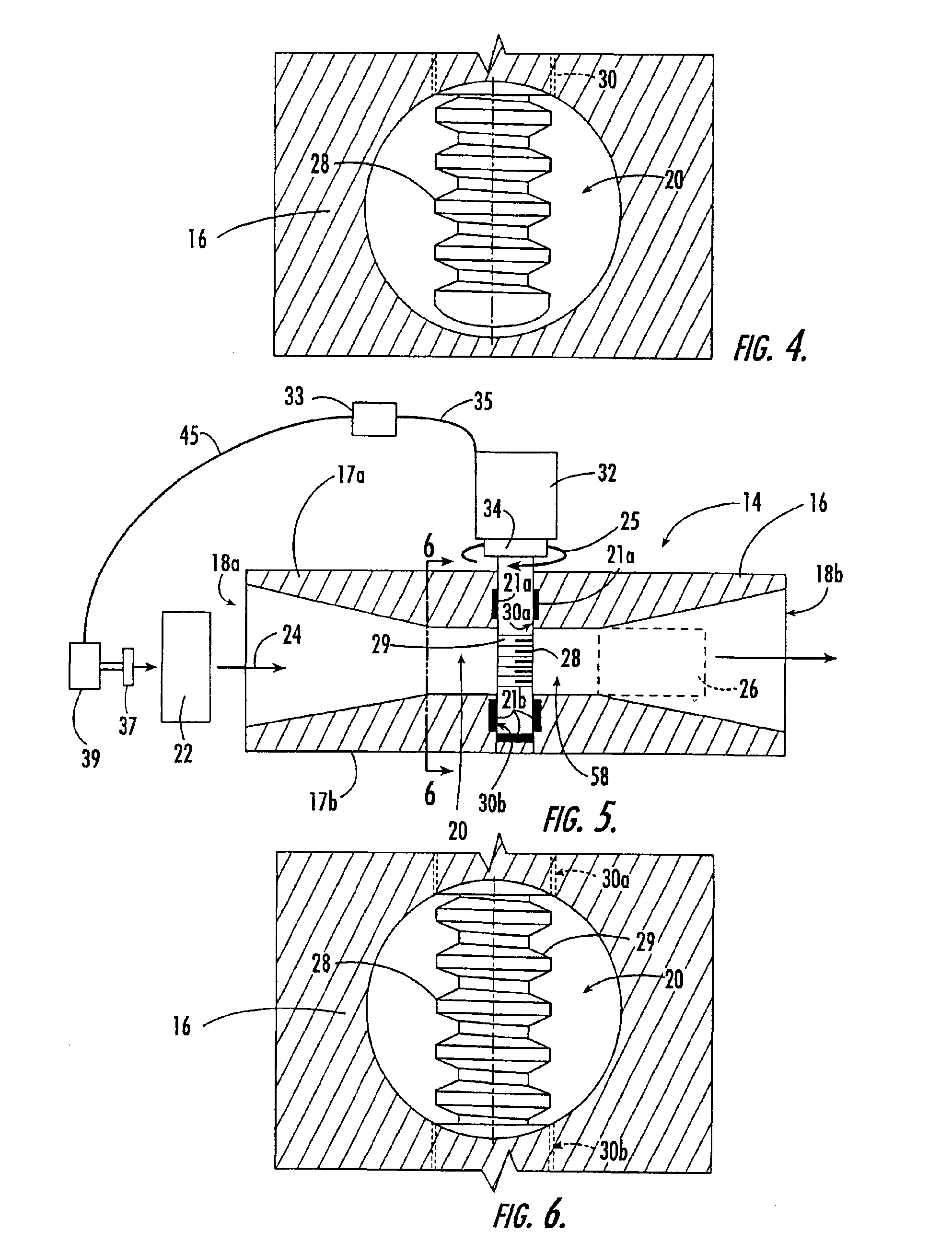

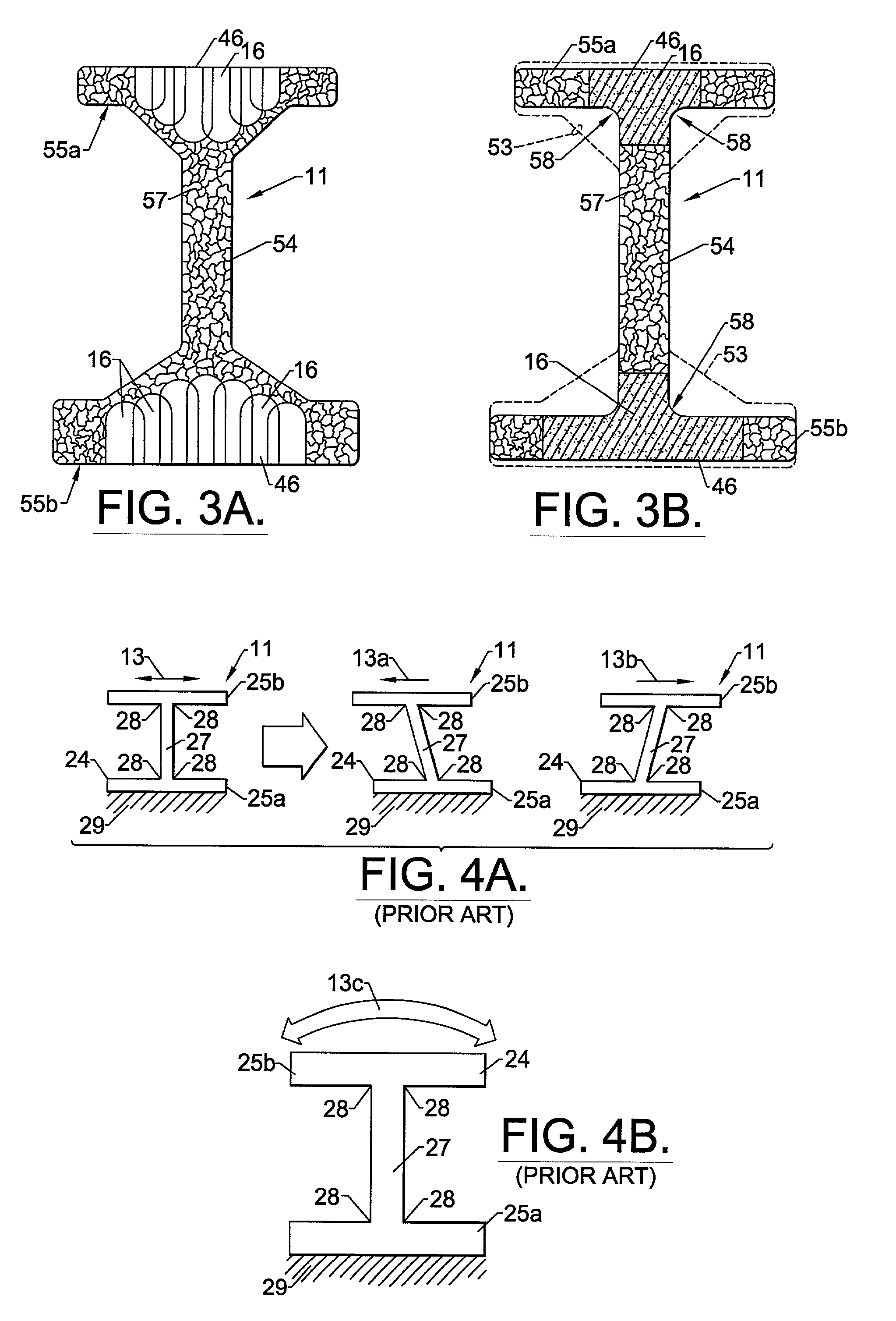

Abstract of the Disclosure The apparatus for operating on a workpiece includes a die defining first and second apertures and an interior therebetween. The first aperture and the interior of the die are structured to receive the workpiece. The interior of the die can be structured to shape the workpiece into a predetermined configuration. The apparatus includes at least one rotatable pin extending at least partially into the interior of the die. The pin is structured to at least partially stir the workpiece as the workpiece moves through the interior of the die to thereby refine the grain structure of the workpiece.

Owner:THE BOEING CO +1

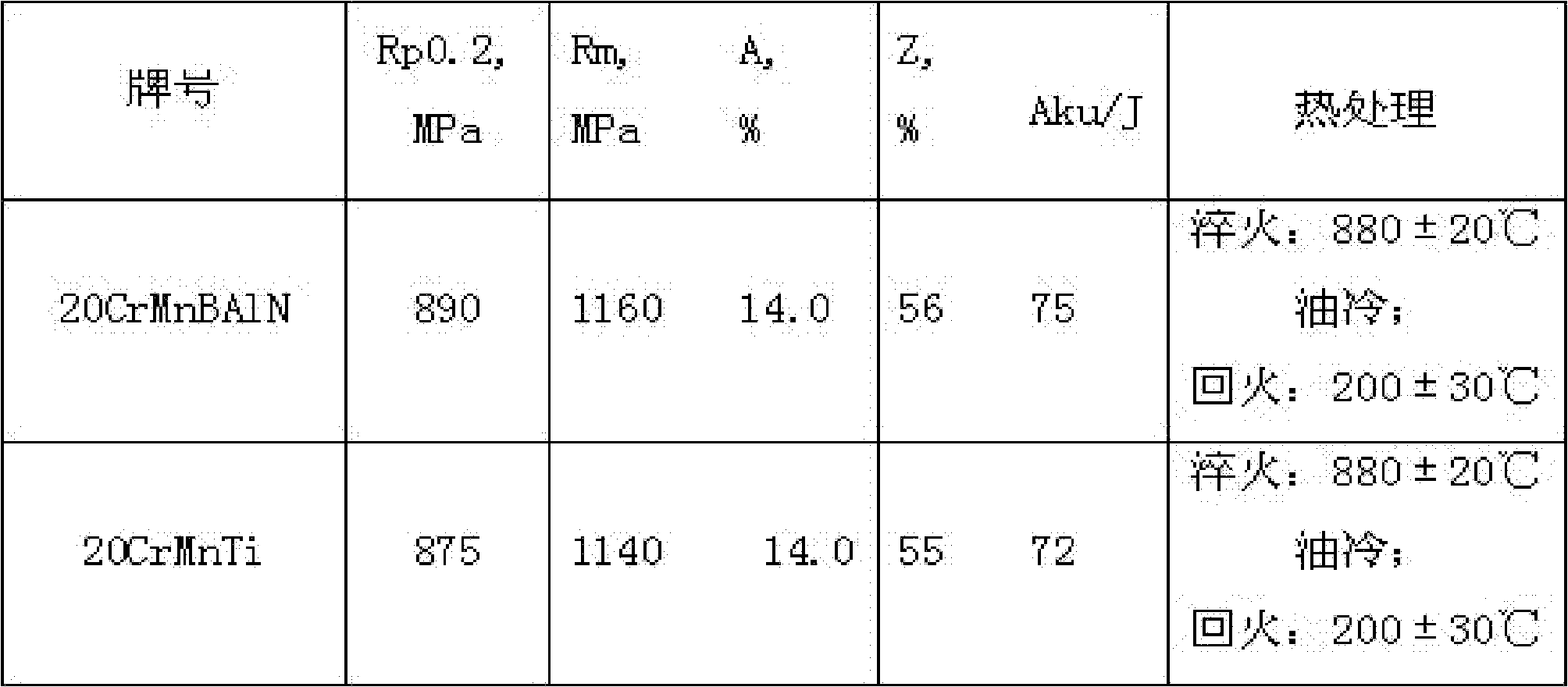

Grain-refined gear steel and production process thereof

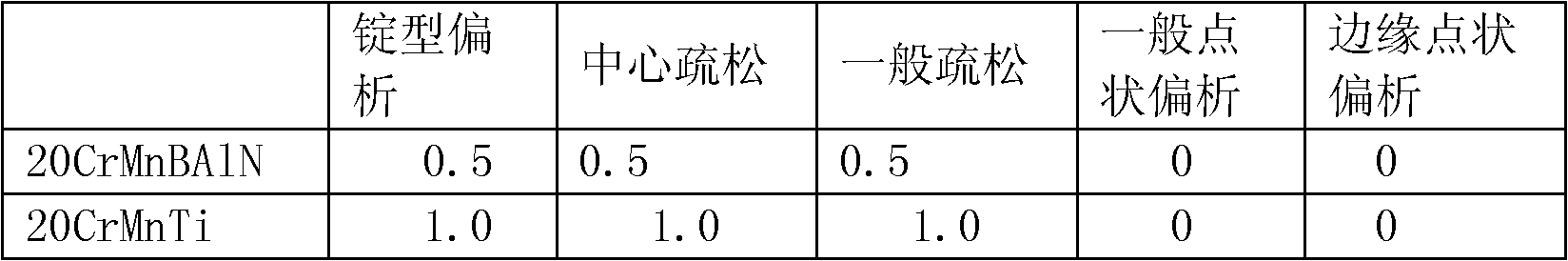

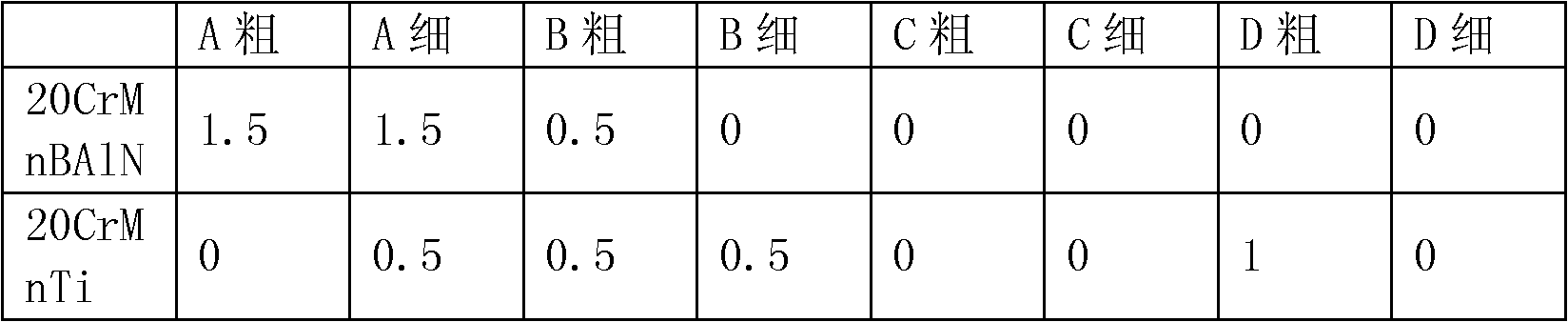

The invention discloses grain-refined gear steel and a production process of the grain-refined gear steel. The gear steel comprises the following compositions in percentage by weight: 0.14-0.22% of C, 0.20-0.35% of Si, 0.80-1.15% of Mn, 0.80-1.25% of Cr, 0.030-0.060% of Al, less than or equal to 0.035% of P, 0.015-0.030% of S, 0.0005-0.030% of B, less than or equal to 0.080% and more than or equal to 0.0140% of N, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Mo, less than or equal to 0.20% of Cu, and the balance of Fe and inevitable impurities. The production process comprises the procedures of smelting, continuous casting and rolling. According to the invention, the refined grains of intracrystalline ferrite are fully used, so that the impact strength is improved, and the fatigue characteristic is improved.

Owner:ZENITH STEEL GROUP CORP +1

Instant coarse grain rice partner and processing method thereof

ActiveCN104000124ANutritional balanceIncrease amino acidFood processesFood preparationPolygonum fagopyrumMicrowave

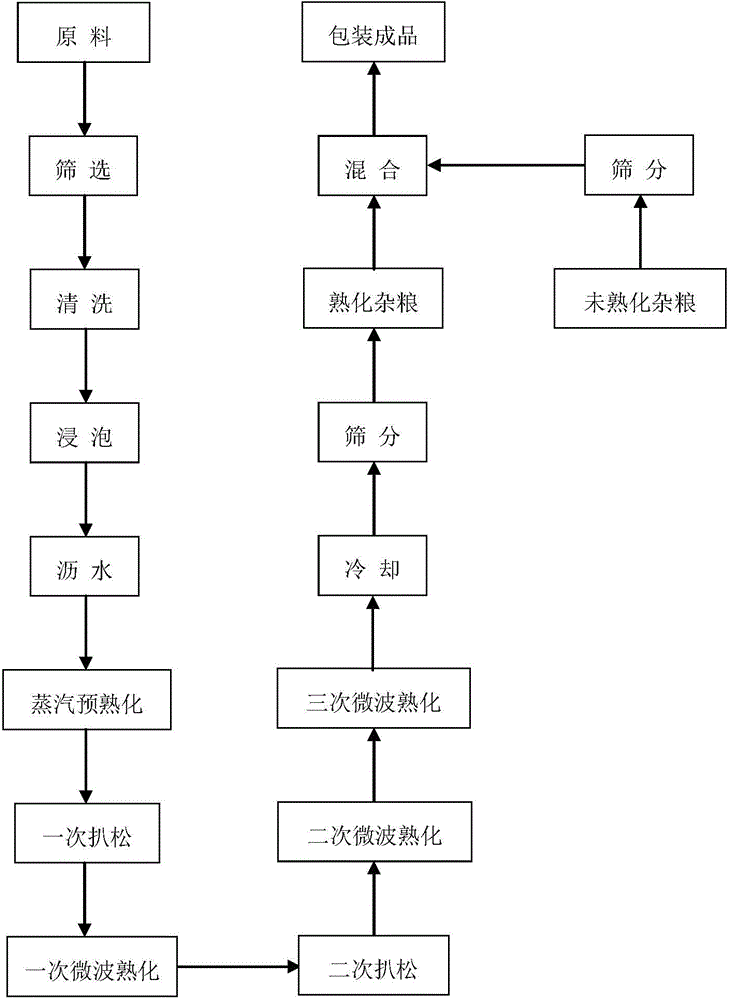

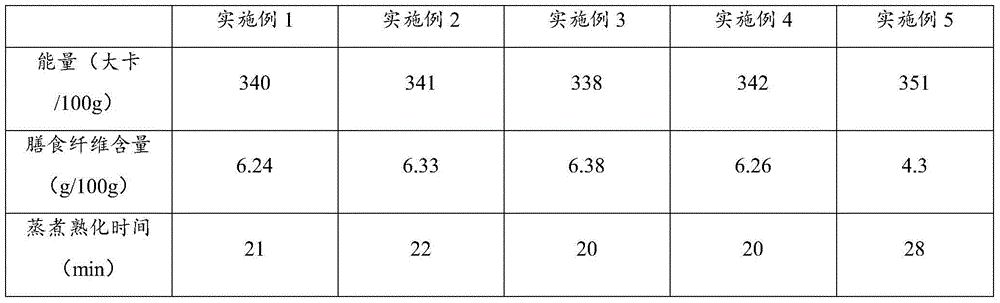

The invention discloses an instant coarse grain rice partner and a processing method thereof, and belongs to the technical field of deep processing of agricultural products. The instant coarse grain rice partner comprises 3-7 parts of black bean, 5-13 parts of Semen Phaseoli, 1-5 parts of kidney bean, 1-5 parts of green bean, 4-14 parts of black rice, 5-9 parts of brown rice, 4-10 parts of red polished round-grained rice, 5-9 parts of naked barley, 3-7 parts of coix seed, 3-11 parts of sorghum, 5-9 parts of corn grit, 2-6 parts of oat grain, 4-12 parts of buckwheat, 3-11 parts of Panicum miliaceum, 2-10 parts of millet and 9-13 parts of glutinous rice. The invention also provides a processing method combining preliminary steam slaking with microwave slaking. The rice partner produced by using the method has the characteristics of coarse and refined grain matching, balanced nutrition, simultaneous cooking with rice, fastness and convenience, and can meet the nutritional needs of different groups of people.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Manufacturing method of high strength bluing strapping steel

InactiveCN102719730AReduce harmful effectsHigh strengthSolid state diffusion coatingHardnessHigh intensity

The invention relates to a manufacturing method of high strength bluing strapping steel. The method includes the steps of smelting, hot rolling, cold rolling, uncoiling, striping, burring, bluing, cooling, waxing and drying. Steels free of alloying element of Nb are utilized to reduce the cost; the content of C is controlled to guarantee mechanical properties of products; the content of Mn is appropriately increased to improve the strength and hardness of raw materials and eliminate harmful effects of the S element to a greater extent; the content of Si is controlled to guarantee surface properties of the products; the contents of P and S are controlled to improve the purity of steels and reduce the possibility of brittle failures of products; and the content of Als is controlled to achieve the effects of refined grains and de-oxidation. The manufacturing method of the high strength bluing strapping steel has the advantages of being simple in process, low in cost and small in energy consumption and environmental pollution.

Owner:武汉钢铁有限公司

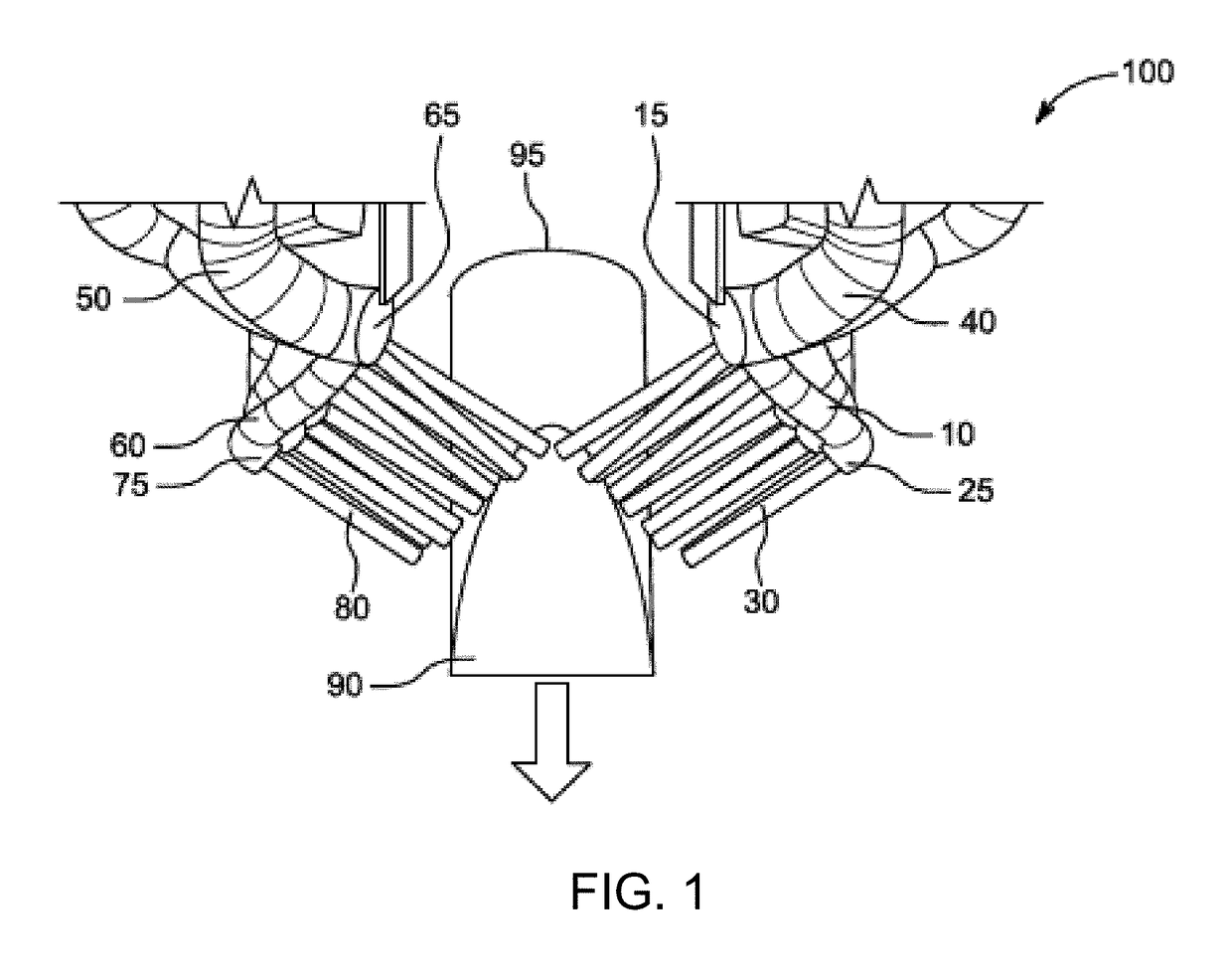

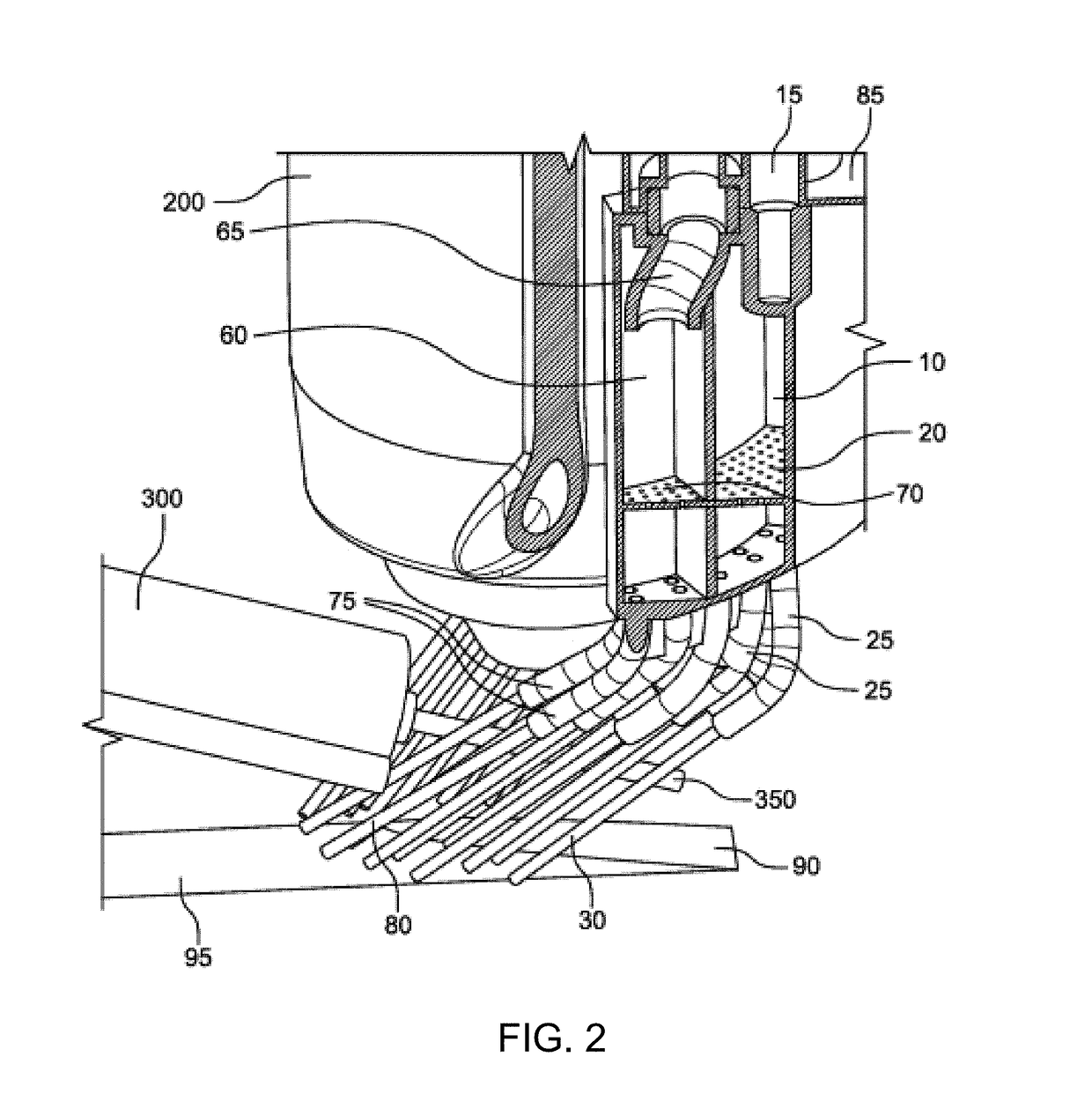

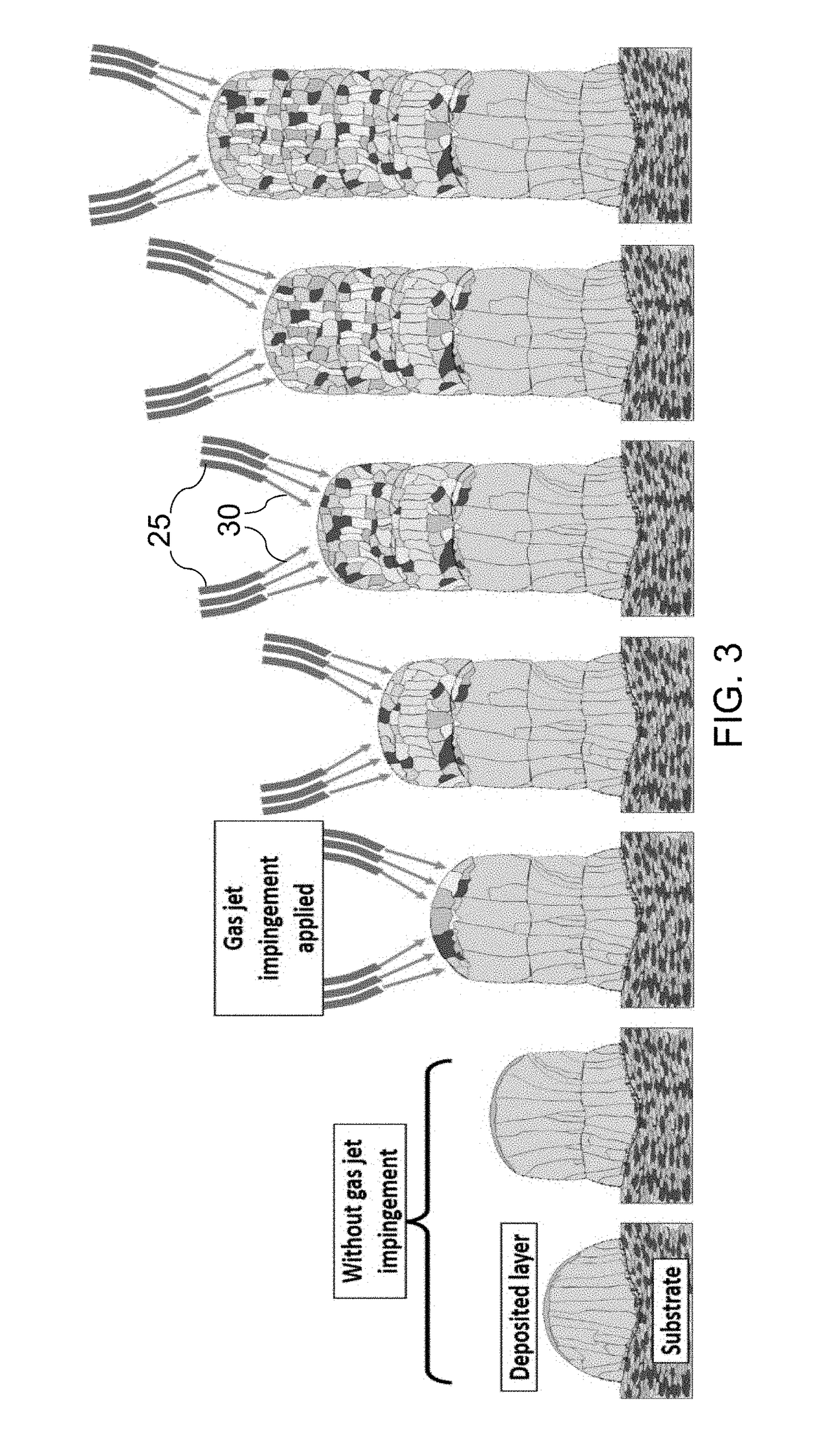

Solidification refinement and general phase transformation control through application of in situ gas jet impingement in metal additive manufacturing

PendingUS20190001437A1Reduce grain sizeIncrease deposition productivityAdditive manufacturing apparatusWelding/cutting auxillary devicesTitaniumTitanium alloy

Owner:NORSK TITANIUM

Minor cereal confected rice jointly cooked with rice and processing method of minor cereal confected rice

InactiveCN104642936AImprove water absorptionImprove gelatinizationFood preparationPolygonum fagopyrumAdditive ingredient

The invention relates to minor cereal confected rice which is jointly cooked with rice and a processing method of the minor cereal confected rice. The minor cereal confected rice meets nutritional requirements on 'Chinese dietary guide' and is prepared based on a formula obtained by linearly planning demand on cereal energy caused by a human body. Raw materials in the formula are several of sorghum, foxtail millet, buckwheat, oat, barley, black rice, broom corn millet, glutinous broom corn and coix seed and are pretreated. The processing method of the minor cereal confected rice comprises the following steps: firstly screening minor cereals, removing impurities, soaking or atomizing and modifying the minor cereals, draining off, carrying out microwave puffing, carrying out hot-air drying, cooling, and carrying out mixed loading. The minor cereal confected rice has the advantages that the nutrients of refined grains and minor cereals are supplemented each other, and daily energy demand of a consumer is met; meanwhile, the minor cereals are processed by utilizing a microwave puffing technology, the original nutritional ingredients of food are maintained to the utmost extent, the processing time is short, and puffing, drying and sterilizing techniques can be completed at the same time; besides, rice and the minor cereals can be jointly cooked, and a complex operation that the minor cereals need to be cooked firstly and then rice is added and cooked with the minor cereals when people want to eat minor cereal rice at present is eliminated, so that the minor cereal confected rice is convenient and practical.

Owner:JILIN AGRICULTURAL UNIV

Instant vegetable porridge and method for processing same

ActiveCN103005284AFull of nutritionGuaranteed to completeFood preparationBiotechnologyVegetable servings

The invention relates to instant vegetable porridge, comprising the raw materials in parts by weight: 30-80 parts of refined grain, 10-50 parts of coarse cereals and 5-40 parts of vegetables, wherein the refined grain comprises rice; and the coarse cereals are one or more of mung bean, corn, oat, millet and soybean. The invention also relates to a method for processing the instant vegetable porridge. The instant vegetable porridge provided by the invention is rich in nutrition, convenient and fast for eating, and capable of meeting the requirements of people having fast pace of life. The method for processing the instant vegetable porridge provided by the invention is simple to operate.

Owner:ANHUI YANZHIFANG FOOD

Die-cast aluminum alloy material and method for preparing same

The invention discloses novel high strength die-cast aluminum alloy material and a method for preparing the same. The novel die-cast aluminum alloy material takes the aluminum (Al) as the substrate and comprises the following elements by weight percent: 10-12 percent of silicon (Si), 0.5-1.0 percent of manganese (Mn), 0.5-3.0 percent of copper (Cu), 0-0.5 percent of titanium (Ti), 0.5 percent of ferrum (Fe) or less, 0-0.8 percent of other elements and the balance of aluminum (Al). The method for preparing the novel die-cast aluminum alloy material comprises the following steps: melting an pure aluminum ingot; keeping the heat of the melted pure aluminum ingot at 700-750 DEG C; adding the industrial Si, the industrial Cu, the Mn and the Ti to the melted pure aluminum ingot according to the formula, and stirring the industrial Si, the industrial Cu, the Mn, the Ti and the melted pure aluminum ingot with a mechanical stirrer; keeping the heat of the mixture for 30-60min; removing the slag and the gas with hexachloroethane for 10min; and modifying the mixture with the universal ternary modifier. Through improving the components of the die-cast aluminum alloy, the microstructure and the refined grain of the die-cast aluminum alloy in the crystallizing and the solidifying process are controlled, the morphology of the Si-Fe compound in the die-cast aluminum alloy is changed, the mechanical property of the die-cast part is improved, the elements in the die-cast aluminum alloy are dissolved in the substrate to form the solid solution, and the mechanical property of the die-cast aluminum alloy is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Composite nutritional healthcare rice and preparation method thereof

InactiveCN103494088AIncrease contentBalanced nutritionFood ingredient functionsFood preparationTrace elementBitter gourd

The invention discloses composite nutritional healthcare rice and a preparation method of the composite nutritional healthcare rice. The composite nutritional healthcare rice comprises the following raw materials: milled rice with embryo, sticky rice, black rice, oat powder, konjak refined powder, bitter duckwheat powder, bitter gourd powder, agaric, chestnuts, almonds, pine nuts, tricholoma matsutake and hawthorn. The composite nutritional healthcare rice has the beneficial effects that coarse grains are mixed with refined grains, a nutritional structure is balanced, the contents of vitamins, minerals, trace elements and the like are all higher than the contents of those in general rice, the immunity can be improved, and a better healthcare effect is achieved.

Owner:李玲

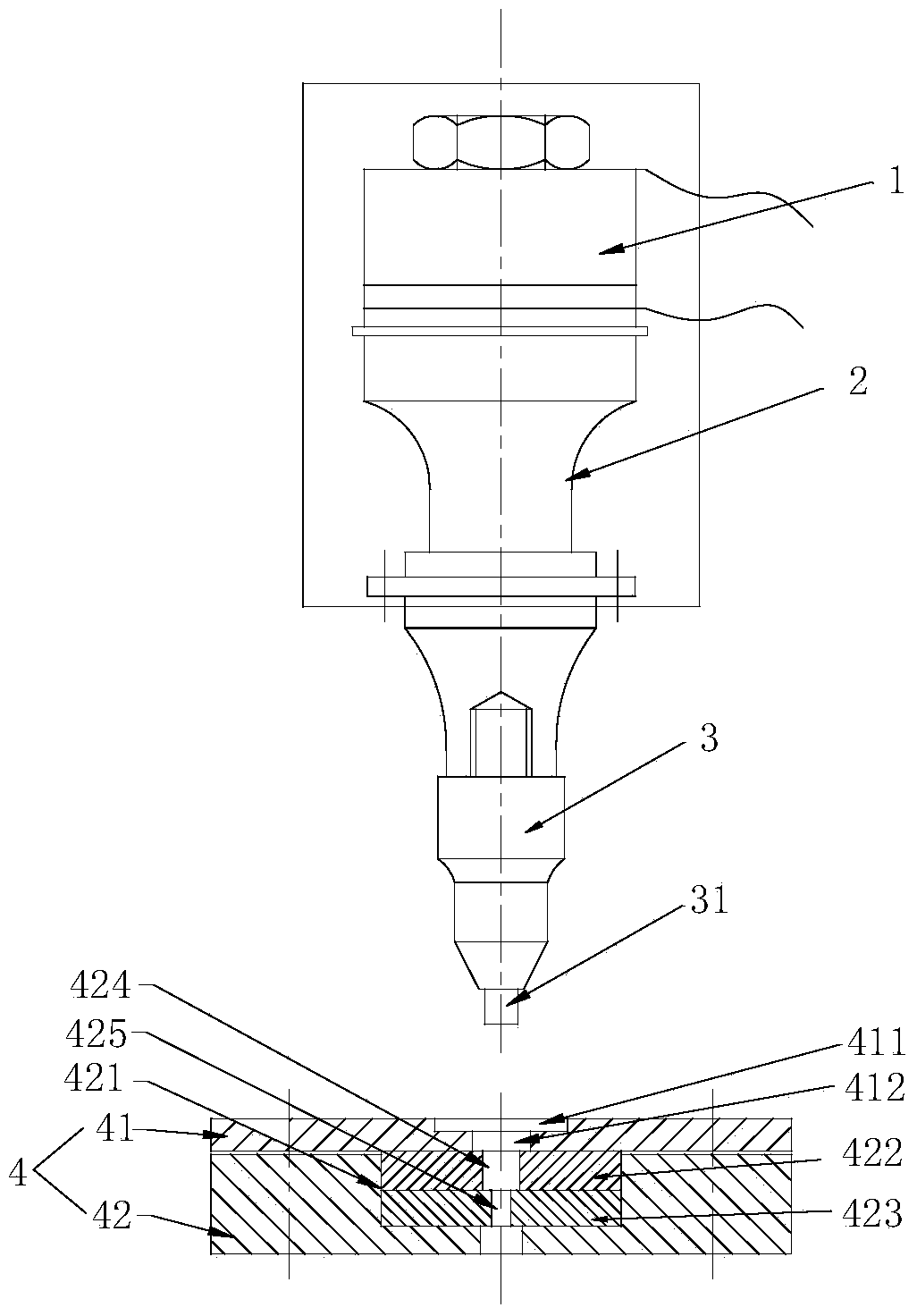

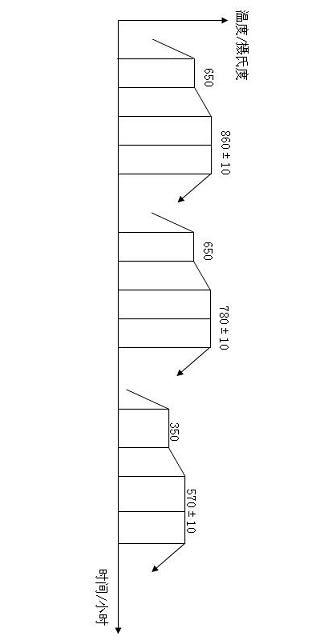

Magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature

ActiveCN104174677AImprove surface qualityIncrease productivityExtrusion diesRams/plungersRefined grainsUltrasonic generator

The invention provides a magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature. The technology comprises the following steps of manufacturing a male die and a female die, placing magnesium alloy parts into a cavity of the female die, performing die assembly extrusion on the magnesium alloy parts, performing separating die sinking, and taking out a formed part. According to the first step, an amplitude-change pole and an amplitude-change pole are sequentially connected to the tail end of the male die and can be touched by an ultrasonic generator. The magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at the normal temperature can reduce forming force of metal, reduces friction between materials and the dies, expands the machining range of metal material plastic forming, and improves plastic forming capability of the metal materials, and the good product surface quality and the higher size precision can be further obtained.

Owner:SHENZHEN UNIV +1

Steel plate for high toughness 15CrMoR pressure container

The invention relates to the manufacturing field of steel for a chrome-molybdenum heat resistant pressure container, in particular to a steel plate for a high toughness 15CrMoR pressure container. The steel plate is prepared by the following components in percentage by mass: 0.14-0.18% of C (Carbon), 0.15-0.40% of Si (Silicon), 0.45-0.70% of Mn (Manganese), no more than 0.020% of P (Phosphorus), no more than 0.005% of S (Sulfur), 0.90-1.10% of Cr (Chromium), 0.45-0.60% of Mo (Molybdenum) and the balance of Fe (Ferrum) and inevitable impurities. The steel plate for the high toughness 15CrMoR pressure container, provided by the invention, has the advantages as follows: (1) as impact toughness of 15CrMoR is high, low temperature impact performance is that transverse impact is not less than 80 J at -40 DEG C and far higher than the nationally specified transverse impact; (2) pure steel quality and low content of harmful elements such as S and the like; (3) as refined grain elements, such as Nb, V, Ti and the like, are not added, cost is greatly saved; and (4) when a requirement on low temperature toughness is satisfied, good conventional properties and good high-temperature tensile properties are obtained.

Owner:JIGANG GRP

3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy

The invention discloses a 3D super-plasticizing treatment method and superplasticity precision shaping method for magnesium alloy. Within the superplastic deformation temperature range of the magnesium alloy, a non-hollow magnesium alloy casting obtained after forging pretreatment passes through at least two cycles to obtain a forging stock of the set size, and 3D super-plasticizing treatment is finished, wherein the non-hollow magnesium alloy casting passes through the axis Z, the axis X and the axis Y in sequence to press down the stock to achieve a cycle. By means of 3D super-plasticizing forging treatment, through large plastic deformation in all directions, homogenizing, grain refining and structure densifying of materials are fully achieved, refined grains are averagely smaller than 20 microns, the equiaxial grain refining effect is remarkable, and the strength performance of the casting can be greatly improved. Through the superplasticity precision shaping method for the magnesium alloy based on 3D super-plasticizing treatment, a light magnesium alloy transition car coupler with high strength is prepared out; and compared with an existing transition car coupler, the weight is reduced by about 75%, the strength is above 350 MPa, and the requirement for the service life of the transition car coupler of this type can be met.

Owner:崇州天智轻量化制造有限公司

Degradable nano calcium phosphorous compound reinforced magnesium-zinc alloy bone fracture internal fixation material

InactiveCN101411891AControl degradation rateHigh strengthProsthesisBiocompatibility TestingZinc alloys

The invention discloses a degradable nano calcium-phosphor compound reinforced magnesium-zinc alloy fracture inner fixing material. The inner fixing material comprises the following components in weight percentage: 1 to 10 percent of nano calcium-phosphor compound, 1 to 6 percent of Zn, and the balance being Mg. Nano hydroxyapatite rod-like granule or beta-calcium phosphate is used as a reinforcement to prepare a nano calcium-phosphor compound reinforced Mg-Zn composite material. Magnesium matrix is reinforced by an alloy element Zn, and refined grains of trace nano calcium-phosphor compound are added, so as to further reinforce alloy, improve alloy plasticity, and improve erosion resistance; and at the same time, the nano grains can effectively adsorb the matrix eroding product, namely hydrogen, and is induced to form a protection layer. The degrading rate of the composite material is controlled by the adding amount of the nano calcium-phosphor compound; the degraded products Mg<2+>, Zn<2+>, Ca<2+> and the like are necessary trace elements for human body. The material does not contain toxic elements, has favorable mechanical property, degrading rate and biocompatibility, can become a degradable fracture inner fixing material of new generation, avoids secondary operations, and meets clinical use requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for preparing gold noodles

The invention provides a method for preparing gold noodles. With the adoption of the method, high lysine superfine corn starch, degreased soybean meal, high gluten wheatmeal, fresh hen eggs, grain milk powder, soy protein, lactalbumin, konjak powder, potato starch, vital gluten, edible salt, a thickening agent (407 carrageenan) and a thickening agent (415 xanthan gum) are taken as raw materials. The method comprises the following steps: directly grinding high lysine corns, wheat and degreased soybean; uniformly mixing the obtained high lysine superfine corn starch, degreased soybean meal and wheatmeal with other raw materials according to a certain ratio; adding water to make dough; and then carrying out the processes of combining, rolling, cutting into strips and drying and the like. The gold noodles have the characteristics of natural raw materials, comprehensive and balanced nutrition, and matched coarse grain and refined grain, thereby being beneficial for health; and the noodles are thin and smooth, golden in color, and golden silk type in shape, and the noodles are chewy and no thick soup is produced after the noodles are cooked thoroughly.

Owner:张世锋

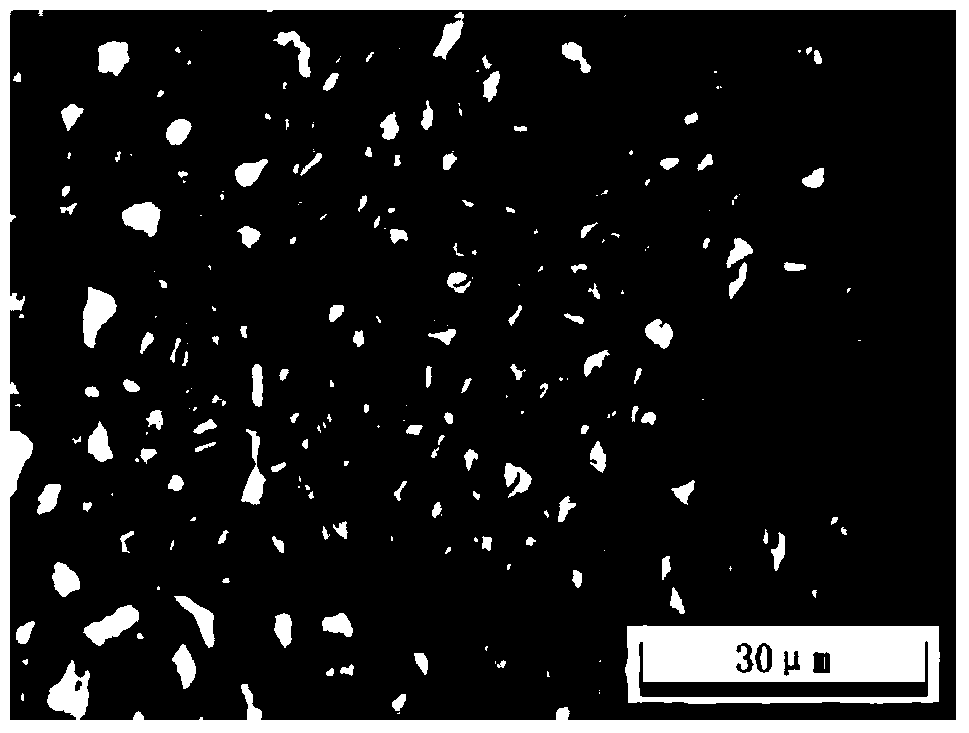

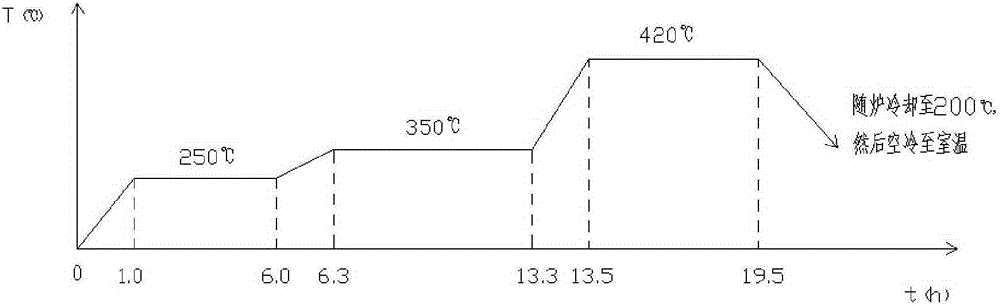

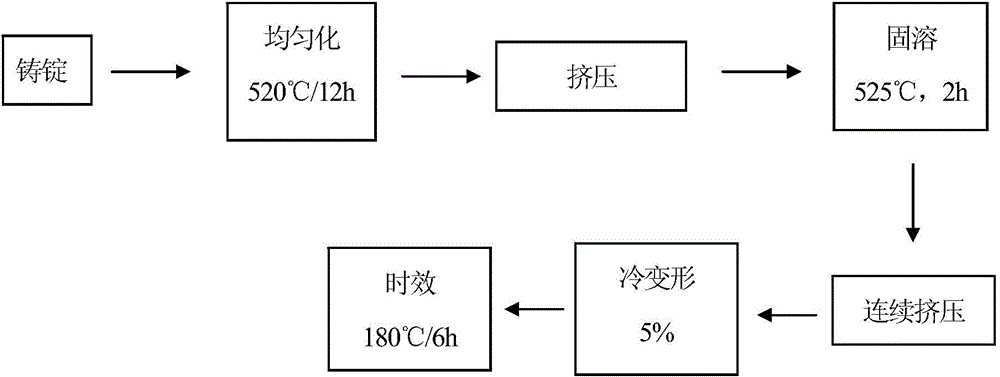

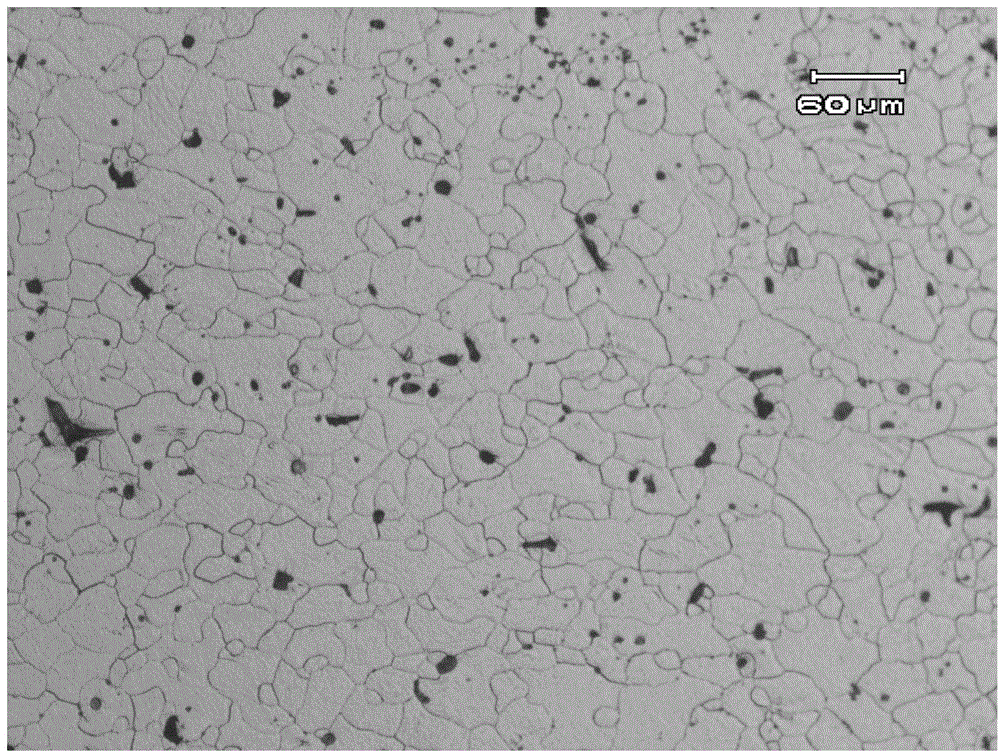

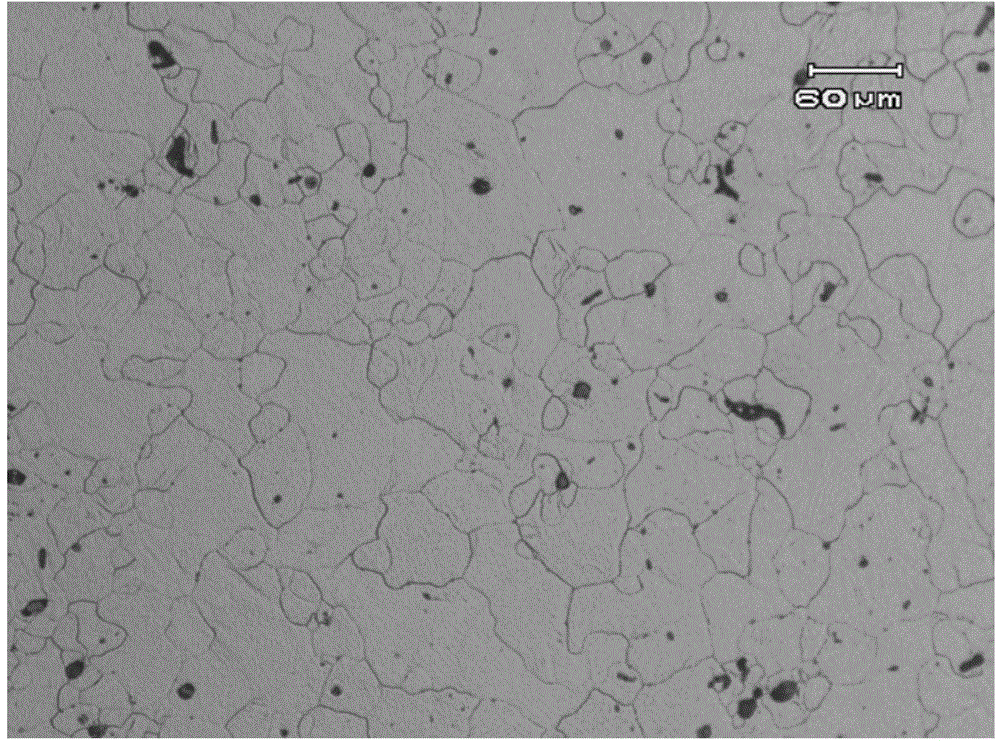

Preparation process of high-performance refined grain aluminum alloy wires and bars applied to aluminum bolts

The invention relates to the field f manufacture of aluminum alloy fasteners and in particular relates to a preparation process of high-performance refined grain aluminum alloy wires and bars applied to aluminum bolts. The preparation process is characterized by introducing a continuous extrusion process based on component optimization design to refine grains, carrying out solution treatment and aging treatment to prepare high-performance refined grain aluminum alloy wires and bars. The grain size of the aluminum alloy wires and bars produced by the process can reach about 30 microns; the corresponding yield strength can reach over 350MPa; the tensile strength can reach over 400MPa; the extension rate can reach over 10%. The material can be mainly used for manufacturing high-performance aluminum alloy bolts on the basis of the performance; meanwhile, the material can also be used for manufacturing other aluminum alloy connection part products such as high-strength rivets, high-strength connection belts and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method and apparatus for producing a refined grain structure

InactiveUS6865919B2Cost effectivelySimple structureWelding/cutting media/materialsSoldering mediaEngineeringGrain structure

The apparatus for operating on a workpiece includes a die defining first and second apertures and an interior therebetween. The first aperture and the interior of the die are structured to receive the workpiece. The interior of the die can be structured to shape the workpiece into a predetermined configuration. The apparatus includes at least one rotatable pin extending at least partially into the interior of the die. The pin is structured to at least partially stir the workpiece as the workpiece moves through the interior of the die to thereby refine the grain structure of the workpiece.

Owner:UNITED TECH CORP +1

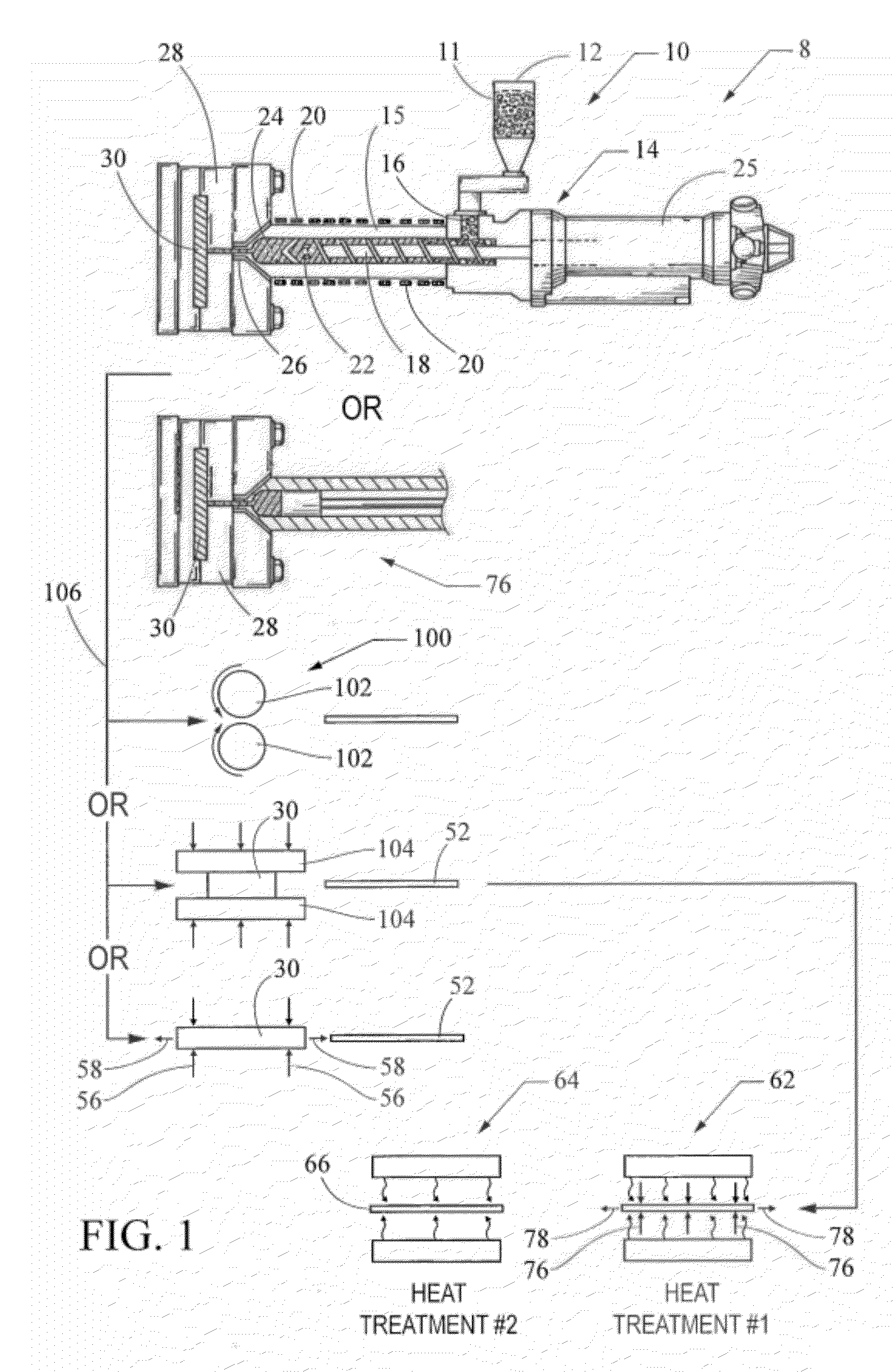

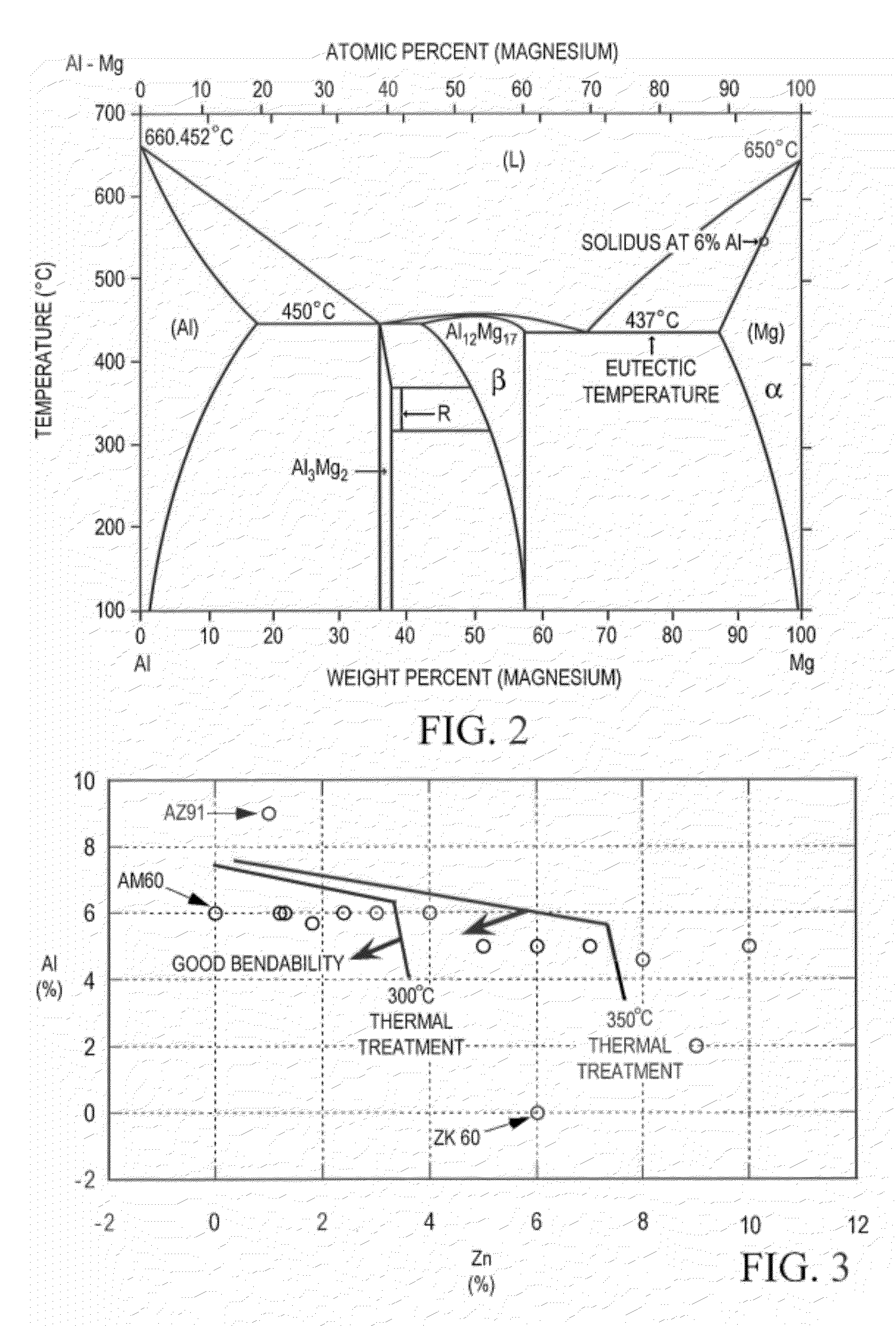

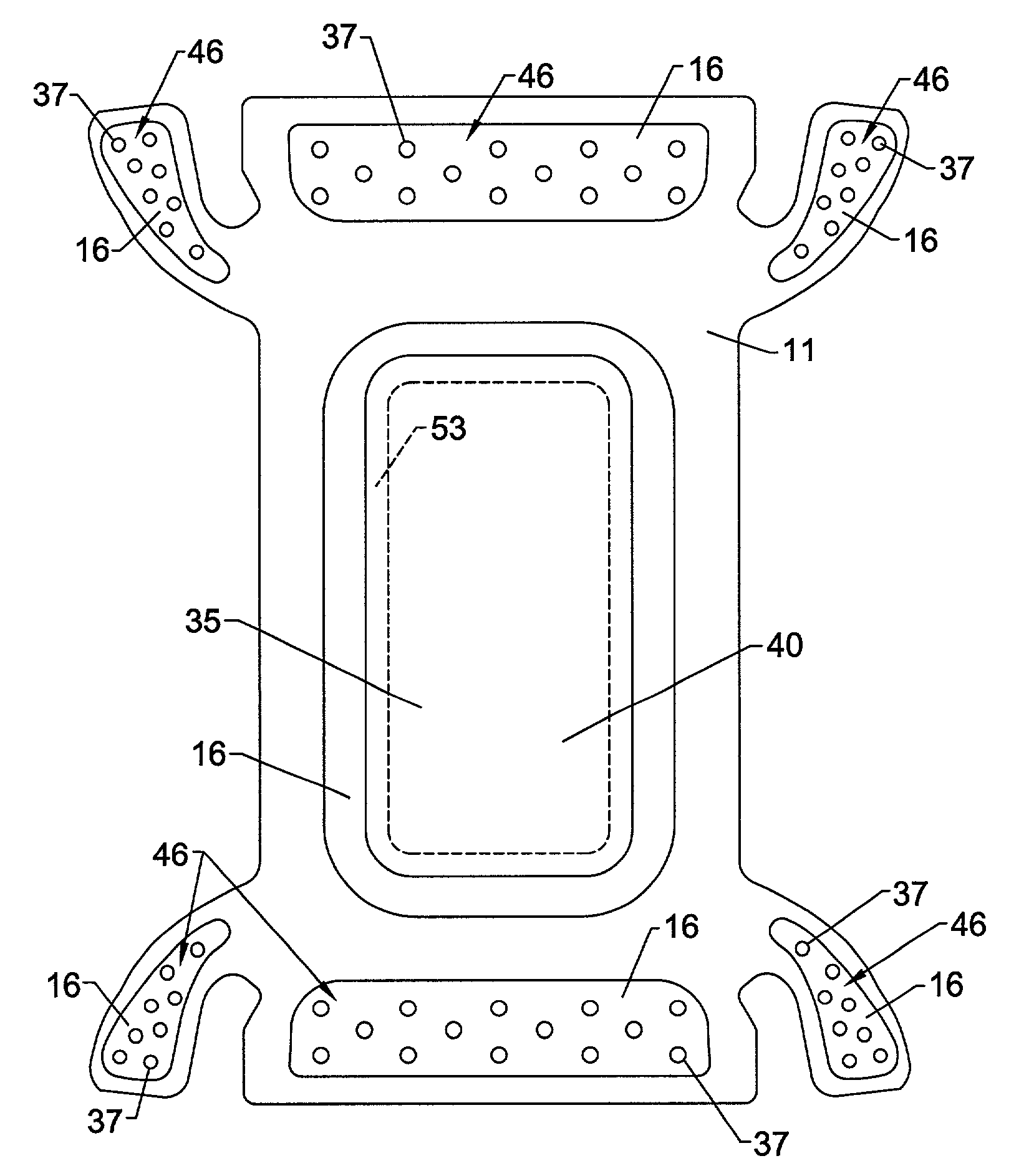

Method and apparatus of forming a wrought material having a refined grain structure

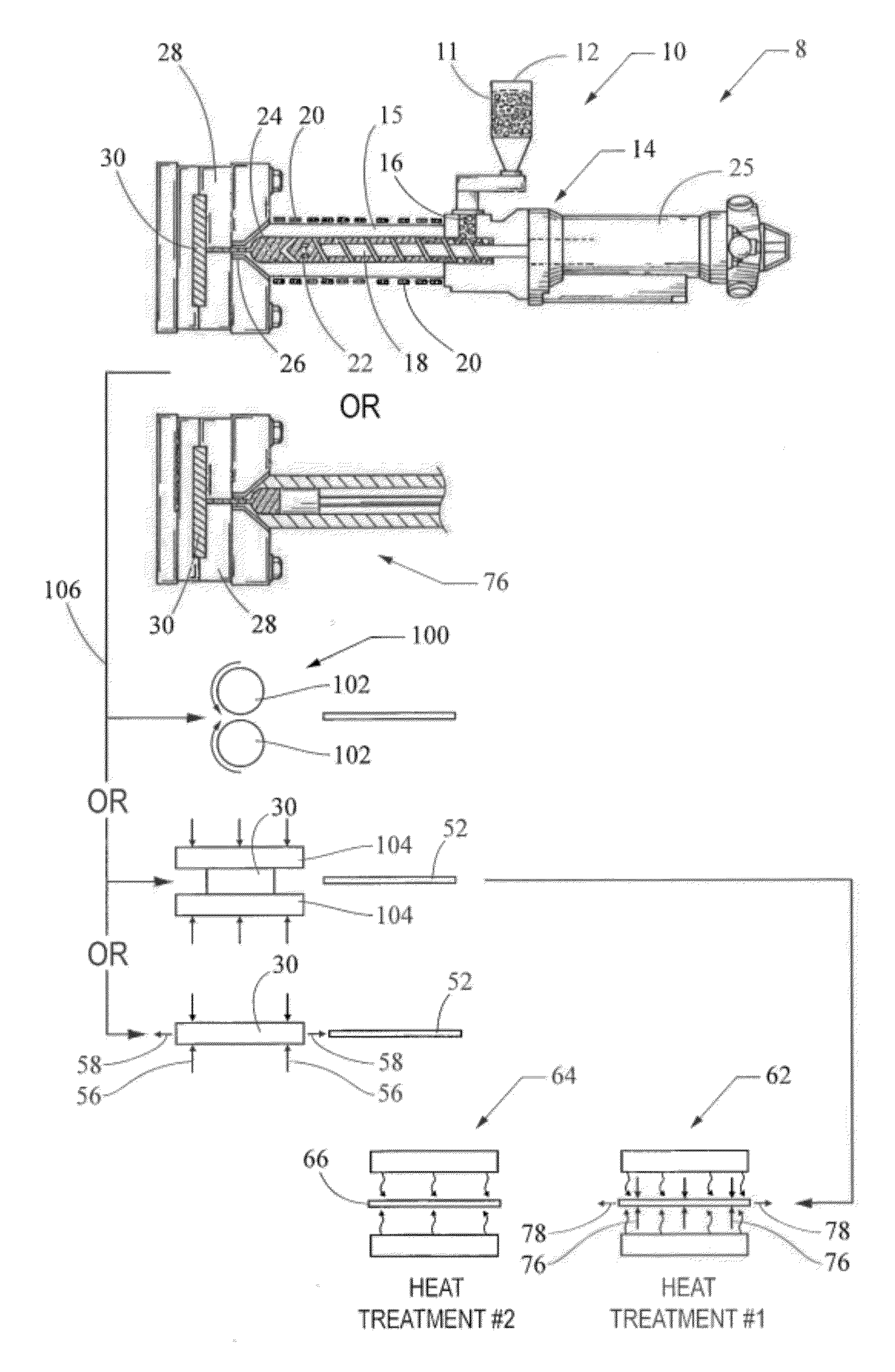

ActiveUS20120305145A1Provide formabilityProvide impact resistanceMould handling/dressing devicesMetal alloyShell molding

A method of forming a wrought material having a refined grain structure is provided. The method comprises providing a metal alloy material having a depressed solidus temperature and a low temperature eutectic phase transformation. The metal alloy material is molded and rapidly solidified to form a fine grain precursor that has fine grains surrounded by a eutectic phase with fine dendritic arm spacing. The fine grain precursor is plastic deformed at a high strain rate to cause recrystallization without substantial shear banding to form a fine grain structural wrought form. The wrought form is then thermally treated to precipitate the eutectic phase into nanometer sized dispersoids within the fine grains and grain boundaries and to define a thermally treated fine grain structure wrought form having grains finer than the fine grains and the fine dendritic arm spacing of the fine grain precursor.

Owner:THIXOMAT

Instant fruit porridge and method for processing same

ActiveCN103005283AFull of nutritionGuaranteed to completeFood preparationFruit servingsRefined grains

The invention relates to instant fruit porridge, comprising the raw materials in parts by weight: 30-80 parts of refined grain, 10-50 parts of coarse cereals and 5-40 parts of fruits, wherein the refined grain comprises rice; and the coarse cereals are one or more of mung bean, corn, oat, millet and soybean. The invention also relates to a method for processing the instant fruit porridge. The instant fruit porridge provided by the invention is rich in nutrition, suitable for people having different constitutions to eat in different seasons, convenient and fast for eating and capable of meeting the requirements of people having fast pace of life. The method for processing the instant fruit porridge provided by the invention is simple to operate.

Owner:ANHUI YANZHIFANG FOOD

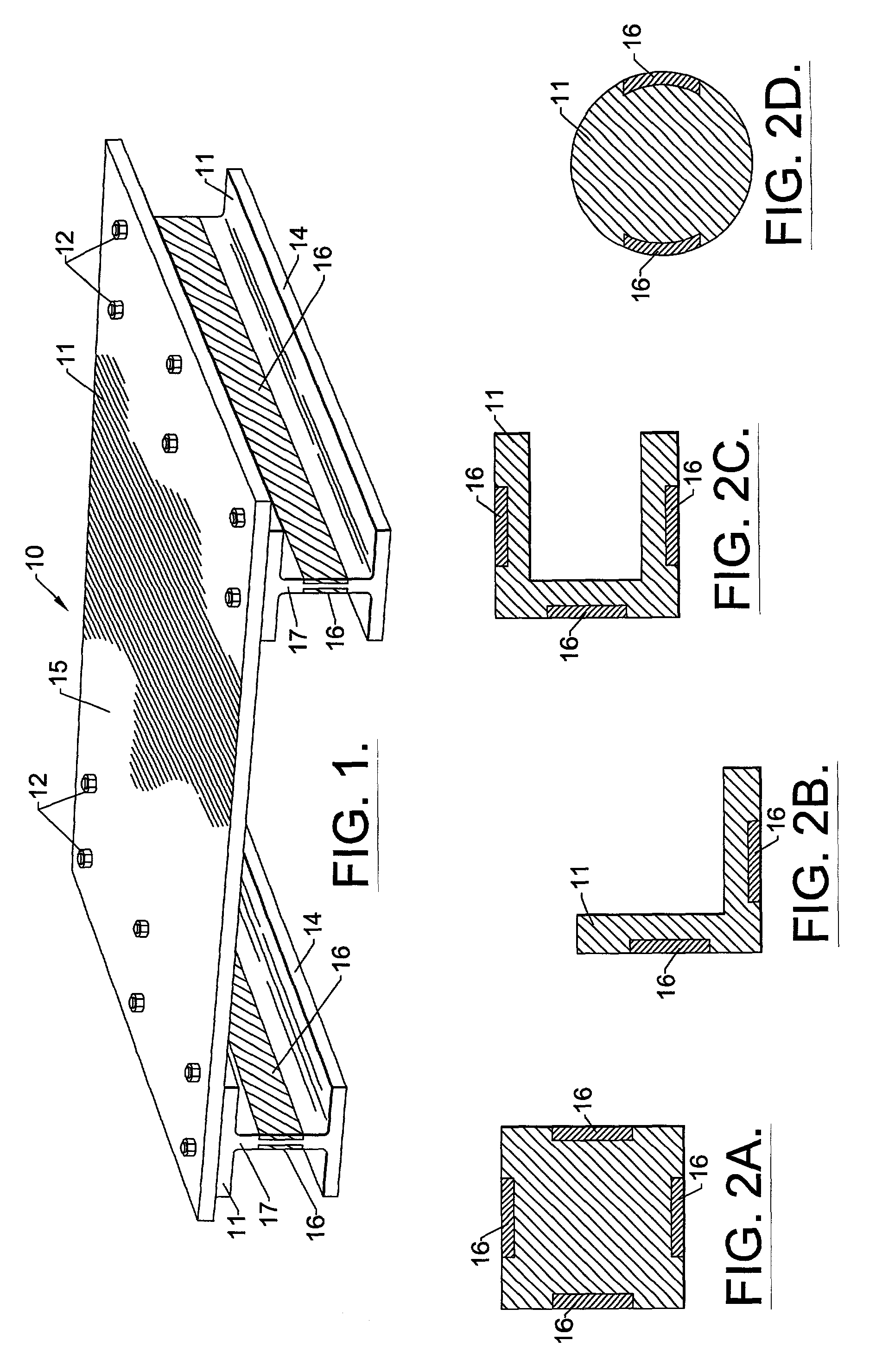

Friction stir grain refinement of structural members

InactiveUS6994916B2Improve fatigue resistanceHigh strengthFuselage framesElongated constructional elementsEngineeringGrain structure

The present invention provides an improved structural assembly constructed of a plurality of structural members secured together. At least one of the plurality of structural members defines a first region characterized by comparatively high operational stress and a second region having a locally refined grain structure positioned such that the second region at least partially encompasses the first region to thereby enhance the strength, toughness and fatigue resistance of the at least one structural member in the first region. The present invention also provides a method for selectively improving the strength, toughness and fatigue resistance of a structural member in a region of high operational stress including the steps of casting the structural member in a pre-selected configuration. Regions of the structural member having comparatively high operational stress are identified. The structural member is secured to prevent movement. The region of the structural member having comparatively high operational stress is then mixed with a rotating friction stir welding probe to locally refine the grain structure of the structural member within the region of high operational stress to thereby improve the strength, toughness and fatigue resistance of the structural member in the region. The structural member can be secured to other structural members to form the frame of an aircraft. The improved structural assembly will have an increased operational life, as well as require less stock material with a corresponding decrease in the overall weight of the assembly.

Owner:THE BOEING CO

Coarse grain and brown rice wine

InactiveCN102220204AIncrease productionHigh nutritional valueAlcoholic beverage preparationDietary fiberTrace element

The invention relates to raw materials for coarse grain and brown rice wine. The raw materials comprise unground coarse grain and brown rice. As compared with the traditional refined grain and milled rice wine, the coarse grain and brown rice wine provided by the invention has the beneficial effects of higher yield, more fragrance and more amino acids, proteins and trace elements essential to human body, and thus can balance human nutrition. During the grinding of the refined grain and milled rice, the cereal germ and the rice outer layer parts rich in dietary fiber are removed, thus the contents of vitamins and minerals are greatly reduced. Therefore the wine made by fermentation of refined grain and milled rice is less nutritive and less fragrant than the wine made by coarse grain and brown rice. The coarse grain and brown rice wine provided by the invention meets the healthy consumer demand of modern persons and meets the growing life demands of persons.

Owner:黄俊柳

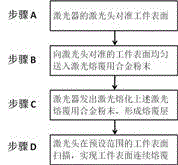

Alloy powder for laser cladding and method for laser cladding alloy powder

InactiveCN104878382AHigh hardnessImprove corrosion resistanceMetallic material coating processesAlloyHardness

The invention relates to the technical field of laser surface treatment and particularly discloses alloy powder for laser cladding and a method for laser cladding the alloy powder. The alloy powder for laser cladding comprises the following components in percentage by weight: 23-30% of TiC, 1-2% of free C and the balance of Ni 60. The alloy powder for laser cladding contains higher contents of C, Si, B and the like, so that a cladding layer has high temperature resistance, high abrasion resistance, high hardness, compact texture, refined grain and fewer pores and cracks; with adoption of the method for laser cladding the alloy powder, the working stability of a workpiece can be greatly improved, and the production cost can be effectively reduced.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

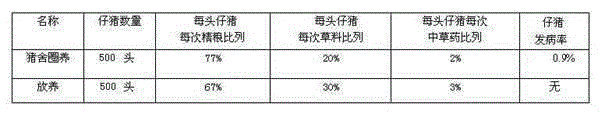

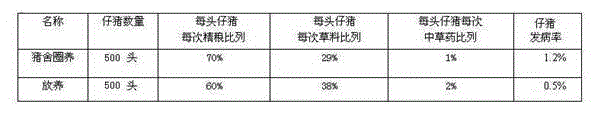

Breeding method of black pigs

InactiveCN104365555AImprove qualityIncrease proteinAnimal feeding stuffAnimal scienceAnimal Foraging

The invention discloses a breeding method of black pigs. Pigsty breeding and breeding outside pigsties are involved in the breeding method. Pigsty breeding is adopted for piglets not older than 3 mouths and not heavier than 25 kg, 5-10 piglets are put in each pigsty, the piglets are fed three times a day, and 70%-80% of refined grain, 20%-30% of forage and a small amount of Chinese herbal medicine are selected as pig feed; breeding outside the pigsties is adopted for piglets older than 3 mouths and heavier than 25 kg, pig feed is put in three times a day, and 60%-70% of refined grain, 30%-40% of forage and a small amount of Chinese herbal medicine are selected as the pig feed; according to the formula, the Chinese herbal medicine comprises 15-20 parts of negundo chastetree fruits, 15-20 parts of rhizoma atractylodis, 10-15 parts of purslane, 10-15 parts of dandelion, 5-10 parts of wild chrysanthemum, 5-10 parts of plantain herb and 5-10 parts of folium artemisiae argyi. By means of the breeding method of the black pigs, refined grain is saved, the breeding cost is saved, the morbidity of the piglets is decreased, and the quality of pork products is improved.

Owner:SHANDONG CHUNTENG FOOD

Health-maintenance steamed meat powder

InactiveCN103141848ARetain natural nutrientsReduce depositionFood preparationBiotechnologyAdditive ingredient

The invention discloses a health-maintenance steamed meat powder. The steamed meat powder is prepared from the following raw materials in parts by weight: 28-32 parts of rice flour, 18-22 parts of steamed pteridium aquilinum starch powder, 4-6 parts of pit-removed red data powder, 4-6 parts of tuchahoe powder, 4-6 parts of Chinese yam powder, 4-6 parts of lycium chinense powder, 18-22 parts of corn flour, and 8-12 parts of soybean meal. The health-promotion steamed meat powder disclosed by the invention is prepared by uniformly mixing the raw materials and crushing the mixture to 40-60 meshes, and not only is nutritious, but also contains healthcare ingredients of a plurality of traditional Chinese medicinal materials and is good in taste after the coarse food grains and the refined grains are subjected to scientific combination.

Owner:周新福

Super-conventional performance heat treatment process for large axial forgings of carbon steel

InactiveCN102021305AGuaranteed StrengthReduce intergranular precipitatesFurnace typesHeat treatment furnacesCarbon steelQuenching

The invention discloses a super-conventional heat treatment process for axial forgings of carbon steel in large forgings, comprising the steps of conventional quenching treatment, sub-temperature quenching and tempering. Incomplete austenitizing is adopted in the step of sub-temperature quenching, aiming to reduce intercrystalline precipitates and refined grains. The practical effect shows the aim is achieved. A detail must be paid attention to: the upper limit sub-temperature can not exceed Ac3. The process has the following advantages: obtaining the needed structure preparation through conventional quenching treatment, reducing the intercrystalline precipitates and refined grains through the incomplete austenitizing characteristic of sub-temperature quenching treatment under the premise of ensuring the strength, and improving the structure and the mechanical performance. The process ensures the common carbon steel to break through the bottleneck and obtain higher impact toughness.

Owner:WUXI HONGDA HEAVY IND

High-denier high-density double-weft cloth and manufacturing technique thereof

The invention relates to a high count high density weft backed fabric and a manufacturing technique thereof, wherein, the fabric adopts weft backed weave structure; end spacing of the fabric is 240 ends per inch and weft density of the fabric is 240 picks per inch; warp threads adopt JC100 purified cotton folded yarns and weft yarns adopt JC80 purified cotton yarns. The manufacturing technique for the fabric is to adopt special technological methods in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. By adoption of weft backed structure for weaving the high count high density fabric, the invention has the advantages of double-faced satin displayed on fabrics, bright luster of cloth covers, smooth hand feeling, refined grain and unique style; by adoption of 100 percent long stapled cotton, the invention has the characteristics of high count high density, flat and refined textile surface and good style of fabric covers.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Preparing method of molybdenum tantalum alloy sputtering target material for plane displayer

ActiveCN107916405AHigh purityUniform sizeVacuum evaporation coatingSputtering coatingHigh densityRefined grains

The invention discloses a preparing method of a molybdenum tantalum alloy sputtering target material for a plane displayer, and belongs to the technical field of sputtering target materials for planedisplayers. The method comprises following steps of 1, powder selecting; 2, powder mixing; 3, pressing forming; 4, sintering; 5, vacuum heat treatment; 6, rolling; 7, machining and 8 binding packaging. In the preparing process, pollutions are avoided, little resource waste is caused, the cost input is little, and the cost is reduced; in the molybdenum tantalum alloy preparing process, hydrogen absorption embrittlement is prevented, the target material machining performance is improved, the high-density molybdenum tantalum alloy sputtering target material is prepared, the purity of a molybdenumtantalum alloy is ensured, and the high-density molybdenum tantalum alloy target material with the uniform and refined grains can be prepared finally.

Owner:丰联科光电(洛阳)股份有限公司

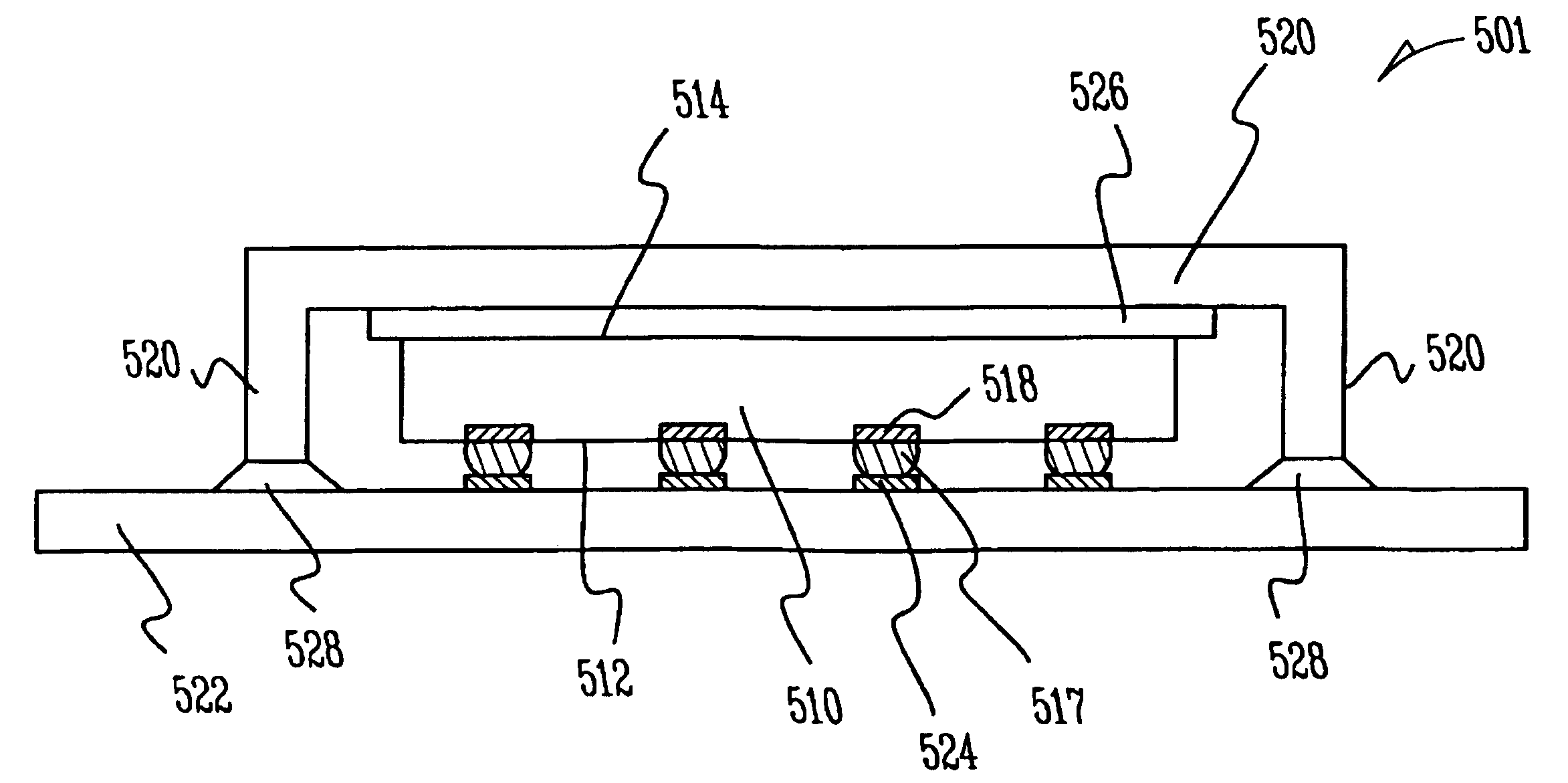

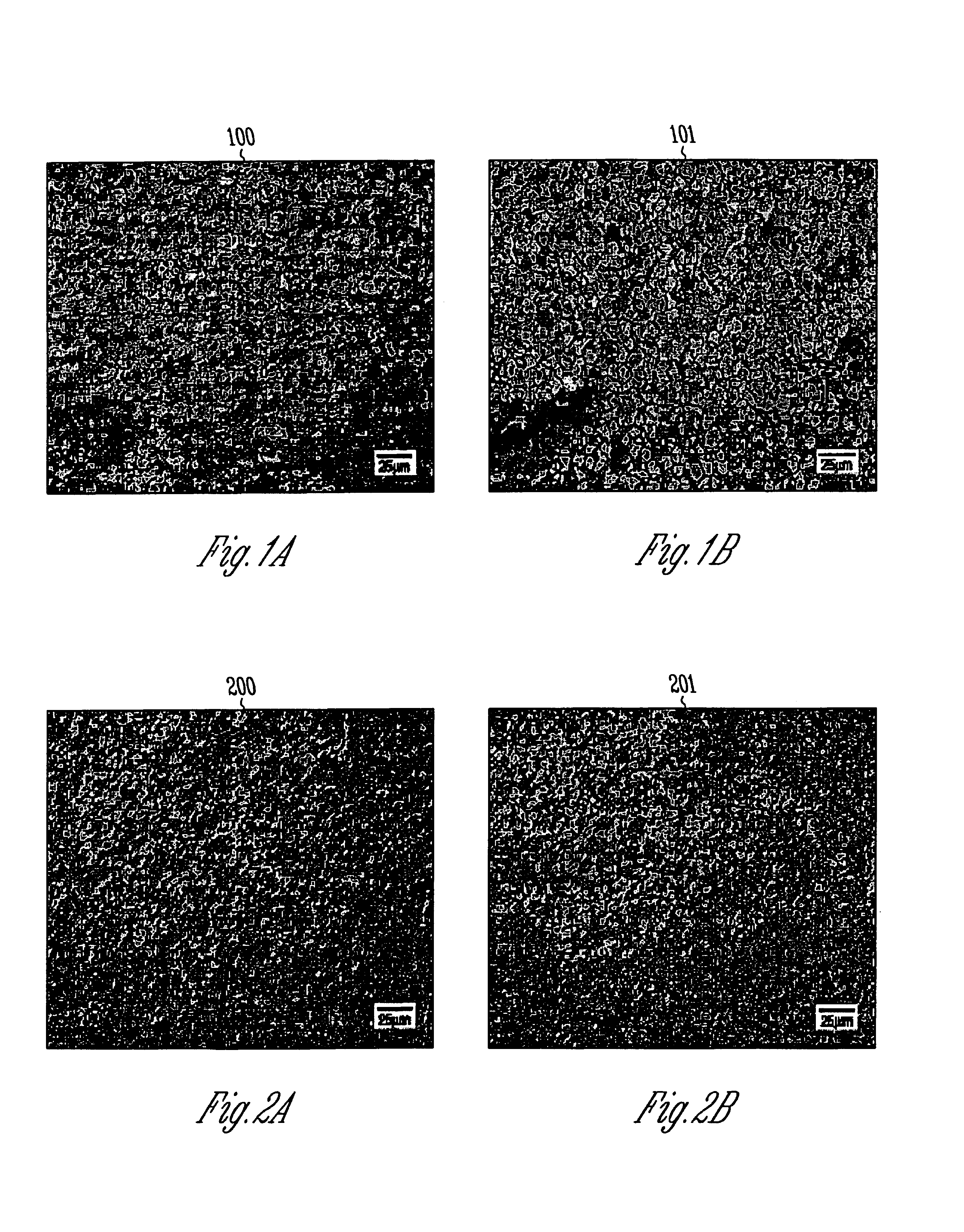

Solders with surfactant-refined grain sizes, solder bumps made thereof, and methods of making same

InactiveUS7111771B2Printed circuit assemblingSemiconductor/solid-state device detailsIndiumRefined grains

A doped tin-indium solder composition is disclosed. The doped tin-indium solder exhibits a retained fine-grain structure and superplasticity after significant thermal cycling and thermal and mechanical stresses experienced in a microelectronic package. A process of forming the doped tin-indium solder is also disclosed. A microelectronic package is also disclosed that uses the doped tin-indium solder composition. A method of assembling a microelectronic package is also disclosed. A computing system is also disclosed that includes the doped tin-indium solder.

Owner:INTEL CORP

Production process of Nb-containing mill coil for automobile

InactiveCN101792843AImprove performanceGood cold bending performanceTemperature control deviceProcess efficiency improvementUltimate tensile strengthMechanical property

The invention discloses a production process of a Nb-containing mill coil for automobile; the production process comprises the following working procedures: raw material preparation, EAF eccentric bottom tapping arc furnace smelting, LF external refining, VD vacuum arc degassing processing, CCM continuous casting, continuous-casting shot blasting, fault detection, heating, 3 / 4 continuous system rolling and curling steel belt; in the invention, Nb is used as microalloying element and has obvious refined grain action; the toughness is improved while improving intensity, the cold bending property is good and the integrated mechanical property is high; continuous casting production process is adopted, rolling in one heat is used, the energy consumption is low, the production period is short and the comprehensive rolling yield is high.

Owner:NANJING IRON & STEEL CO LTD

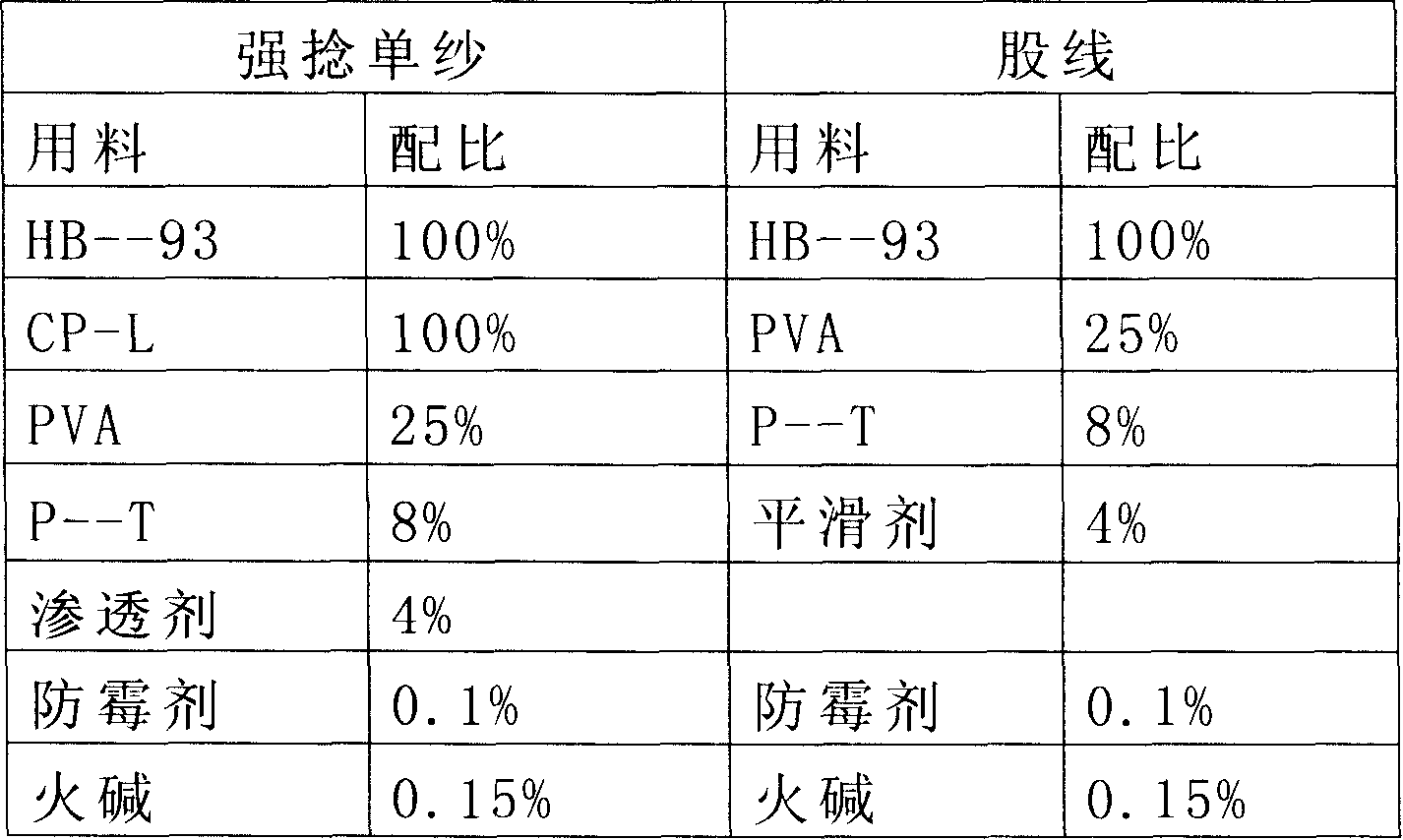

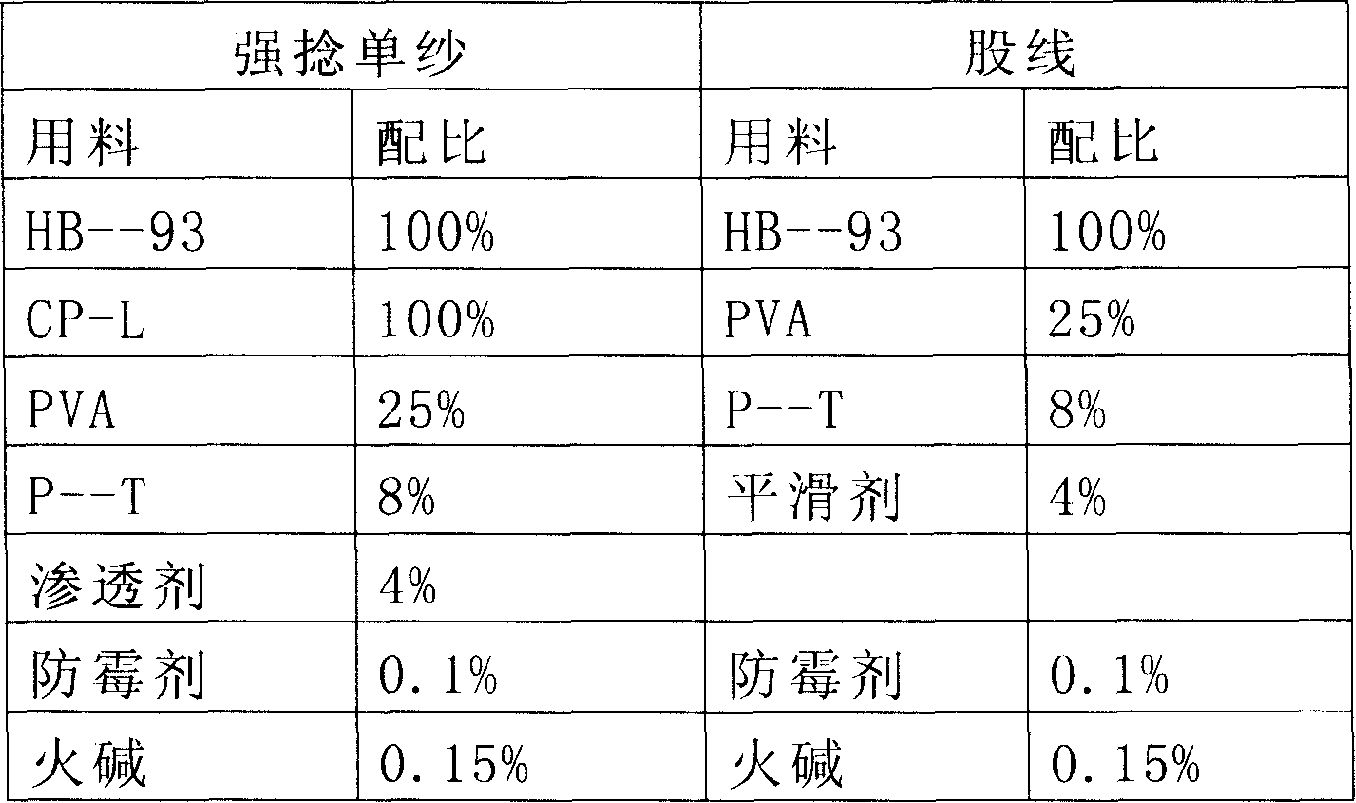

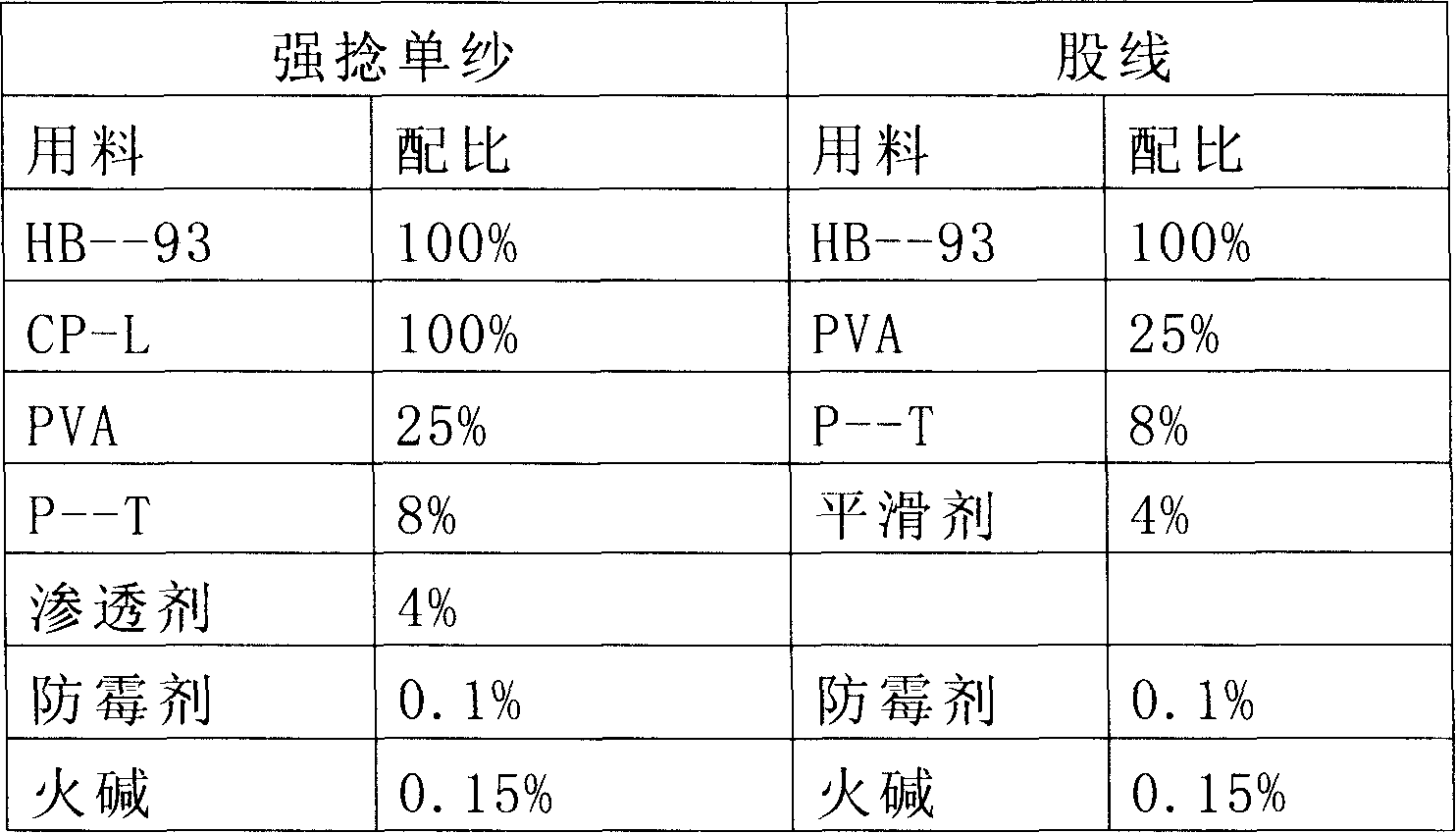

Pure cotton heavy twist striated fabric and preparation technique thereof

The invention relates to a purified cotton hard twisted stripe and a manufacturing technique thereof, wherein, the stripe adopts combined weave of 5 / 2 kettsatin and 1 / 1 plain weave; end spacing of the stripe is 450.5 ends per ten centimeters and weft density of the stripe is 301 picks per ten centimeters; warp threads adopt JC7.3Tex single yarns with a twist number of 210 twists per ten centimeters and JC7.3Tex x 2 folded yarns; compound yarns are used for closely weaving satin weaves, and hard twisted single yarns are used for weaving plain weaves; fabrics are of thick and thin variable stripe effect; weft yarns adopt JC9.7Tex single yarns with a twist number of 240 twists per ten centimeters. In the aspect of the manufacturing technique, special technological methods are adopted in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. Because the stripe adopts the combined weave of the 5 / 2 kettsatin and the 1 / 1 plain weave, the invention has the advantages of bright luster of cloth covers, smooth hand feeling and refined grain; because the compound yarns are used for closely weaving satin weaves and the hard twisted single yarns are used for weaving plain weaves, the fabrics are of thick and thin variable stripe effect and the style is unique.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com