Patents

Literature

286results about "Rams/plungers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

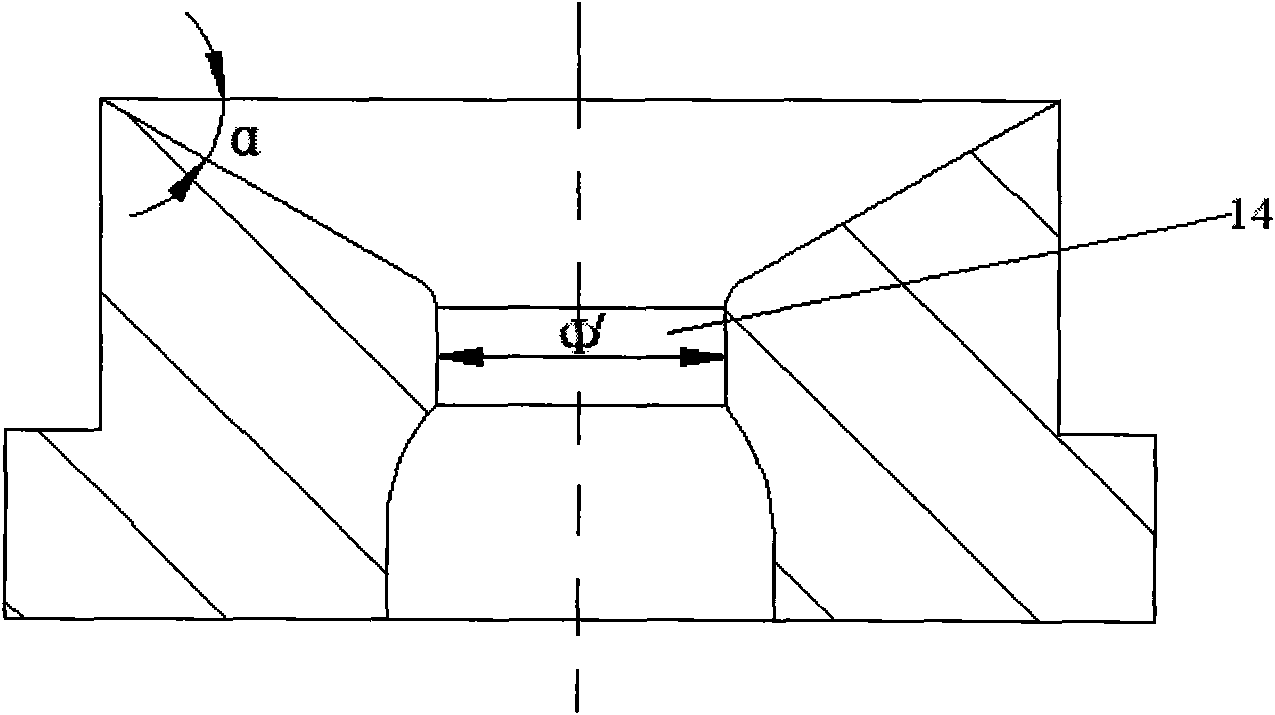

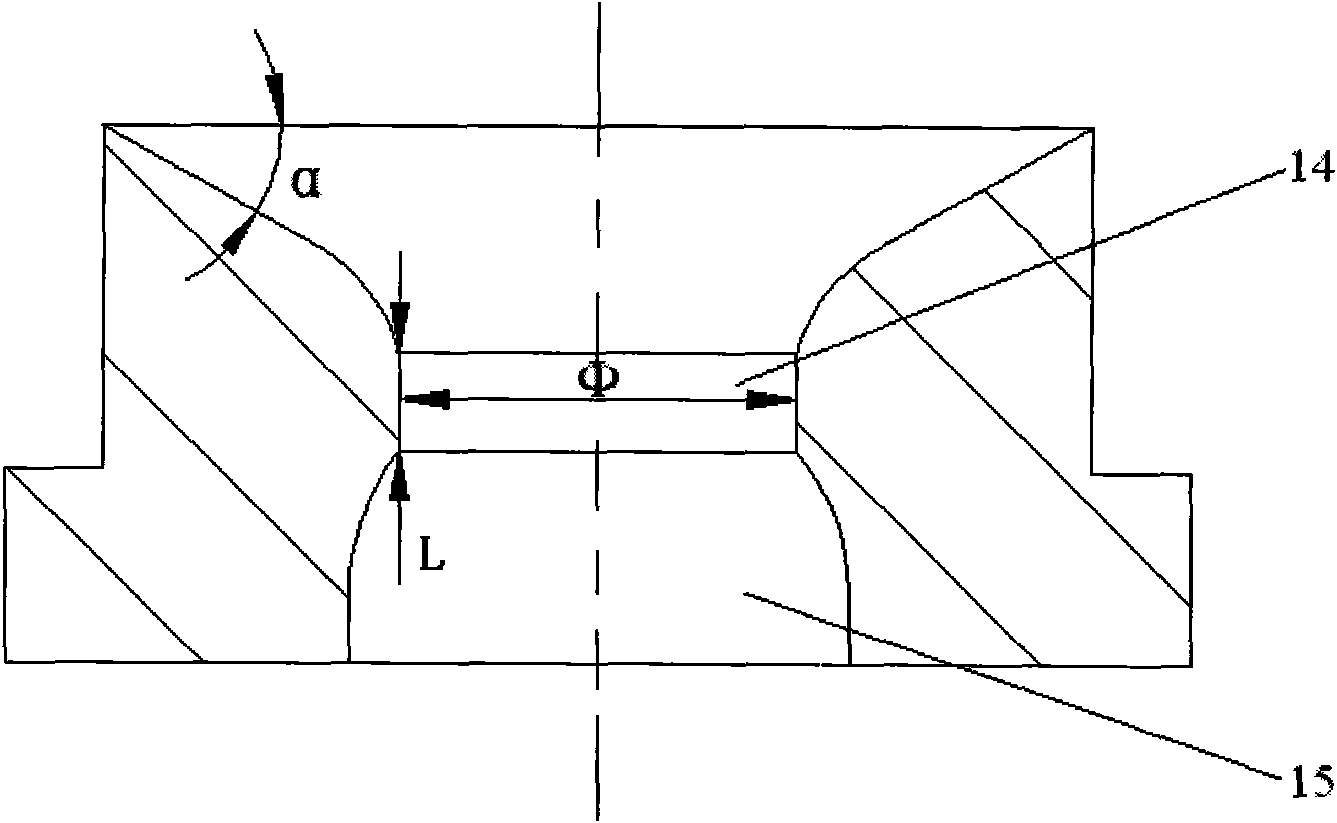

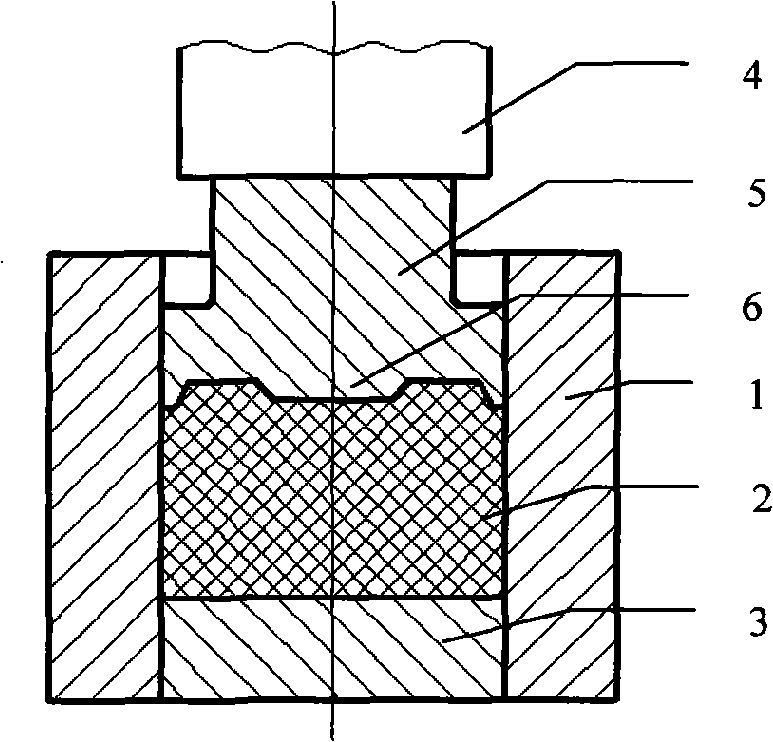

Rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold

InactiveCN101549361AIncrease profitReduce extrusion pressureExtrusion diesExtrusion containersThermal insulationRare earth

The invention relates to a rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold. The method includes: machine-tooling after casting ingot homogenization treatment into a hollow blank, performing pre-extrusion in the mold, extrusion molding after die change, and performing solid dissolving aging treatment for further improving the tube dynamics performance. The invention relates to a special mold, including an upper and a lower die holders, a thermal insulation sleeve, a squeezing barrel, a male die and a concave die, wherein, the concave die is composed of a pre-extrusion concave die and a shaping concave die, one of the pre-extrusion concave die and the shaping concave die is selected and interchangeable with the other, and is fixed on the lower die holder through a squeezing barrel. The invention can extrude a rare-earth magnesium alloy seamless thin wall tubule with the external diameter of 5-10mm and internal diameter of 4-8mm, which has features of high material utilization, small extruding force, high products dimensional precision, good surface accuracy, good dynamics performance and the like features. The inventive mold simultaneously has advantages of simple structure, easy operation, low cost, long life and so on.

Owner:CHONGQING UNIV

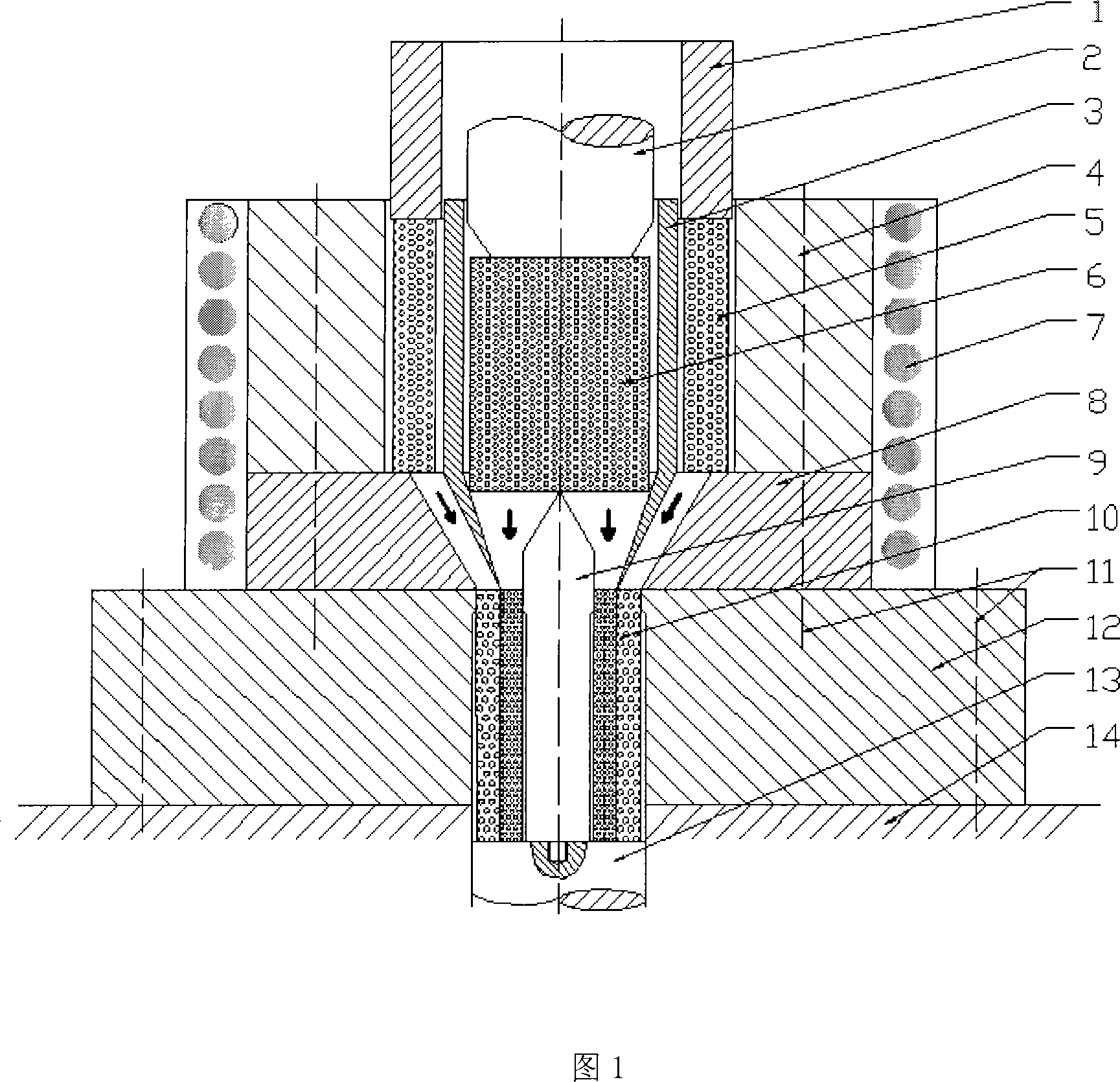

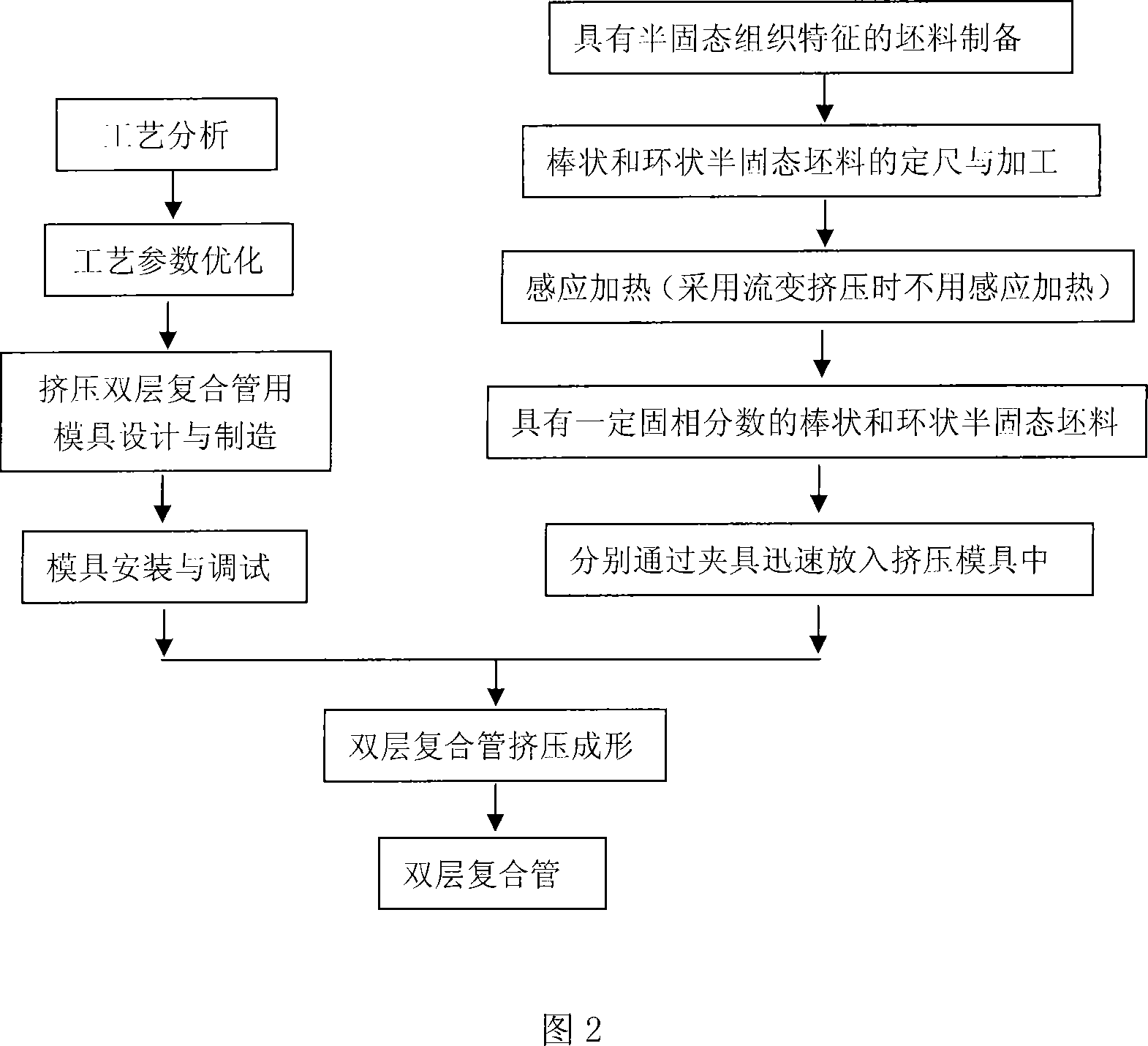

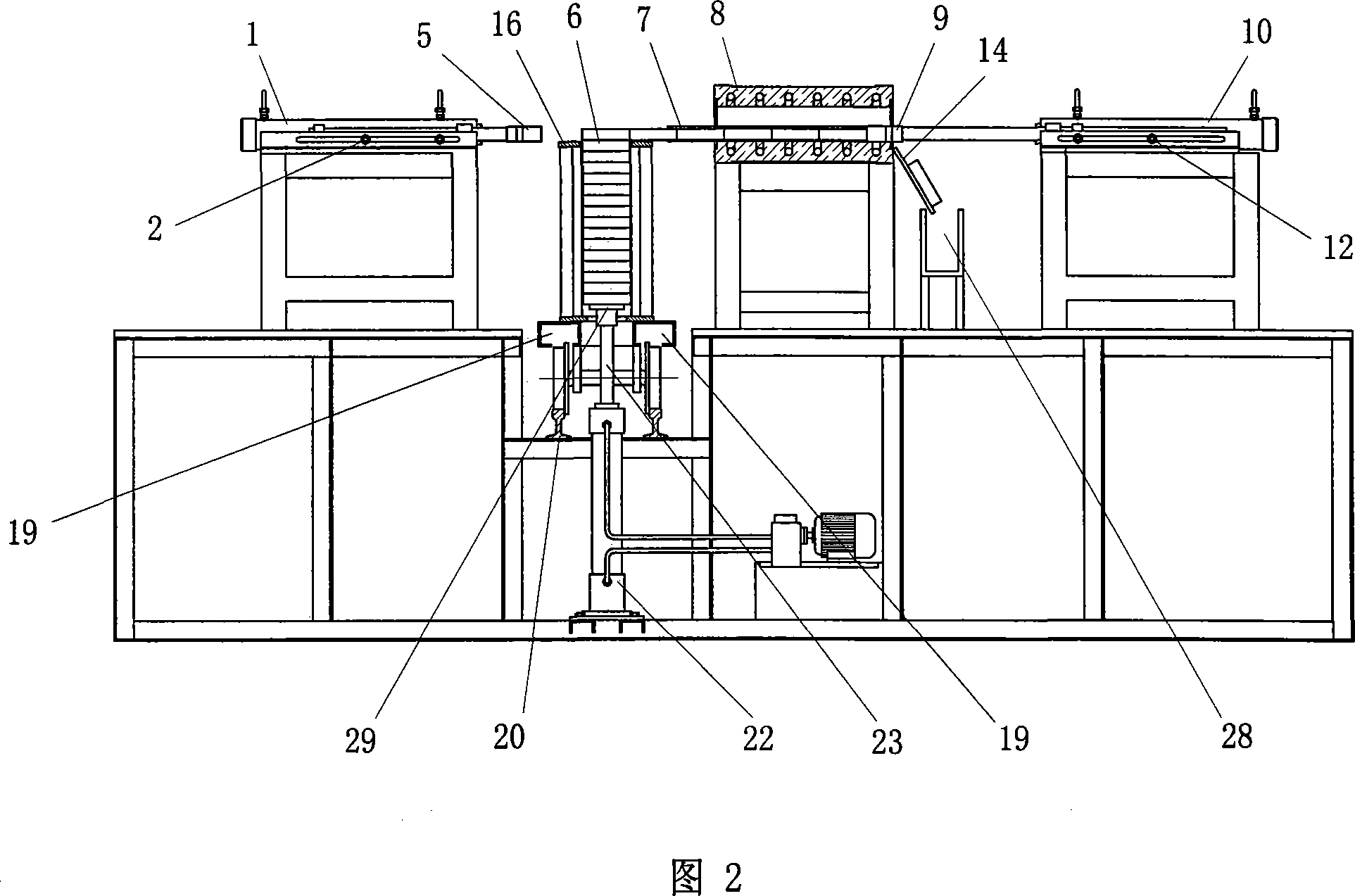

Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

InactiveCN101020201AReduce consumptionImprove product qualityExtrusion diesExtrusion control devicesTemperature controlControl system

The present invention relates to semi-solid forming technology, and is especially semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe. The technological process includes the following steps: pre-heating the mold to 200-300 deg.c and establishing temperature control system, setting the induction heated blank into the extruding mold, and extruding at regulated speed and stroke to obtain the required composite pipe. The new extruding process for making composite pipe has short procedure, low power consumption and high product quality.

Owner:TSINGHUA UNIV

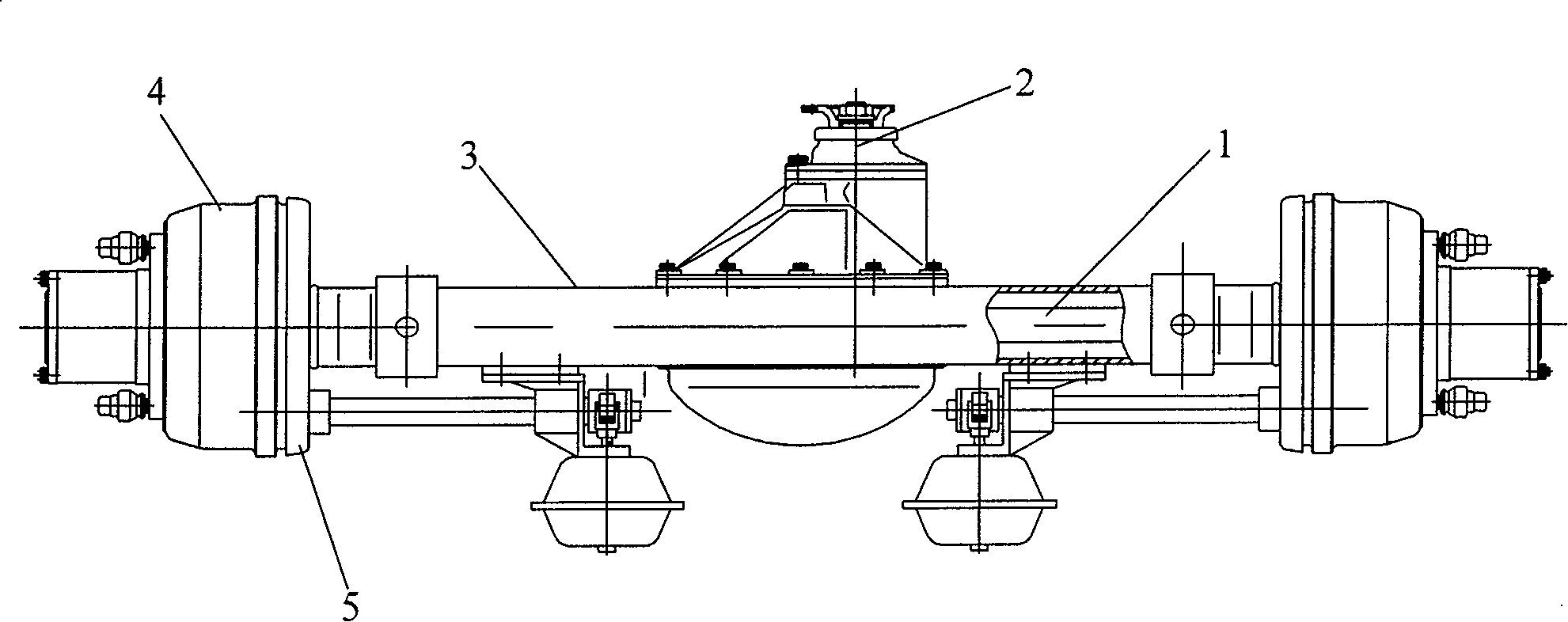

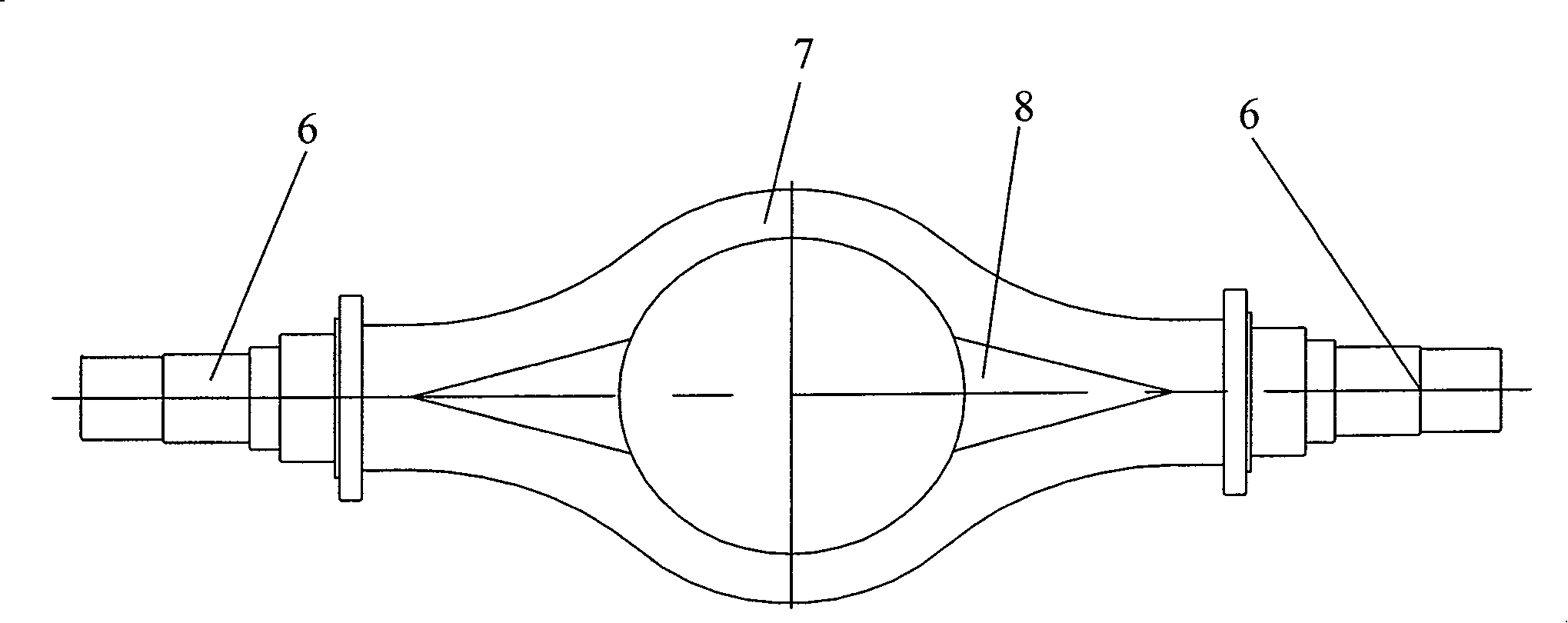

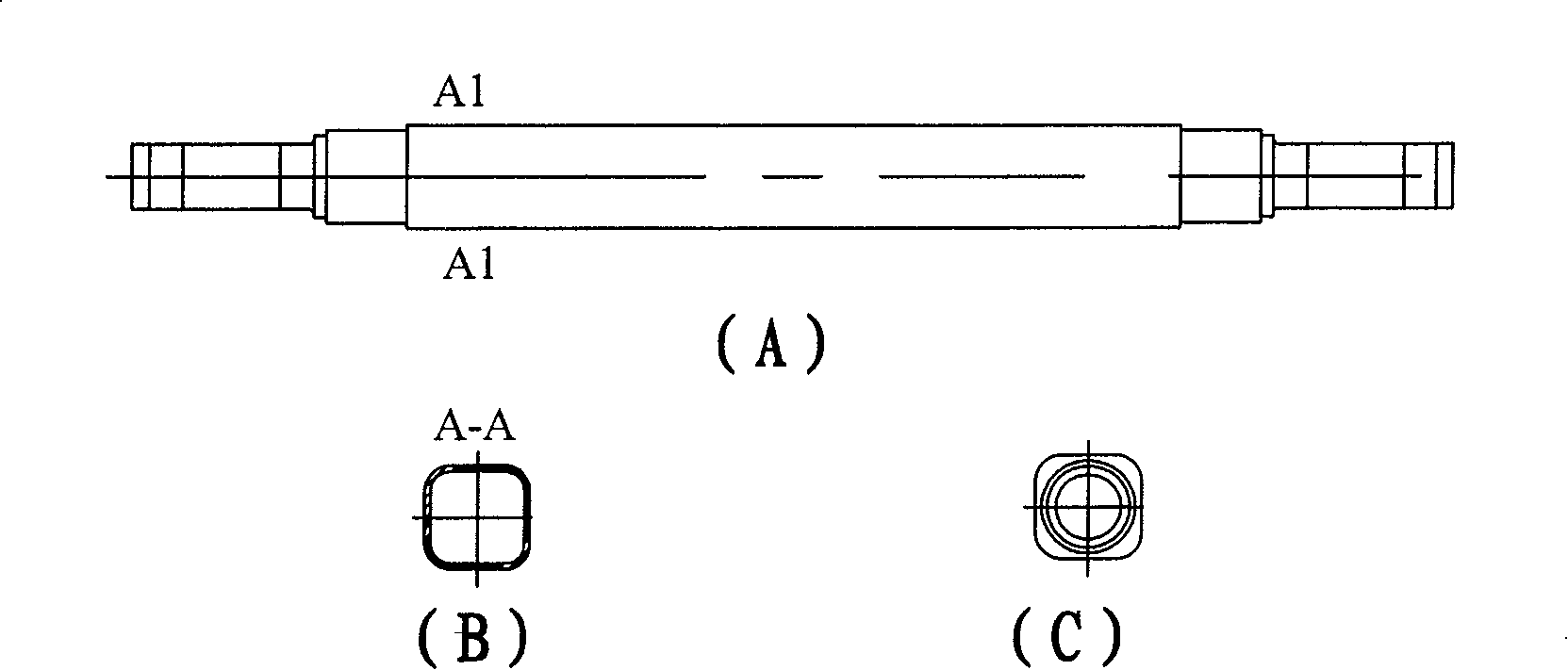

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

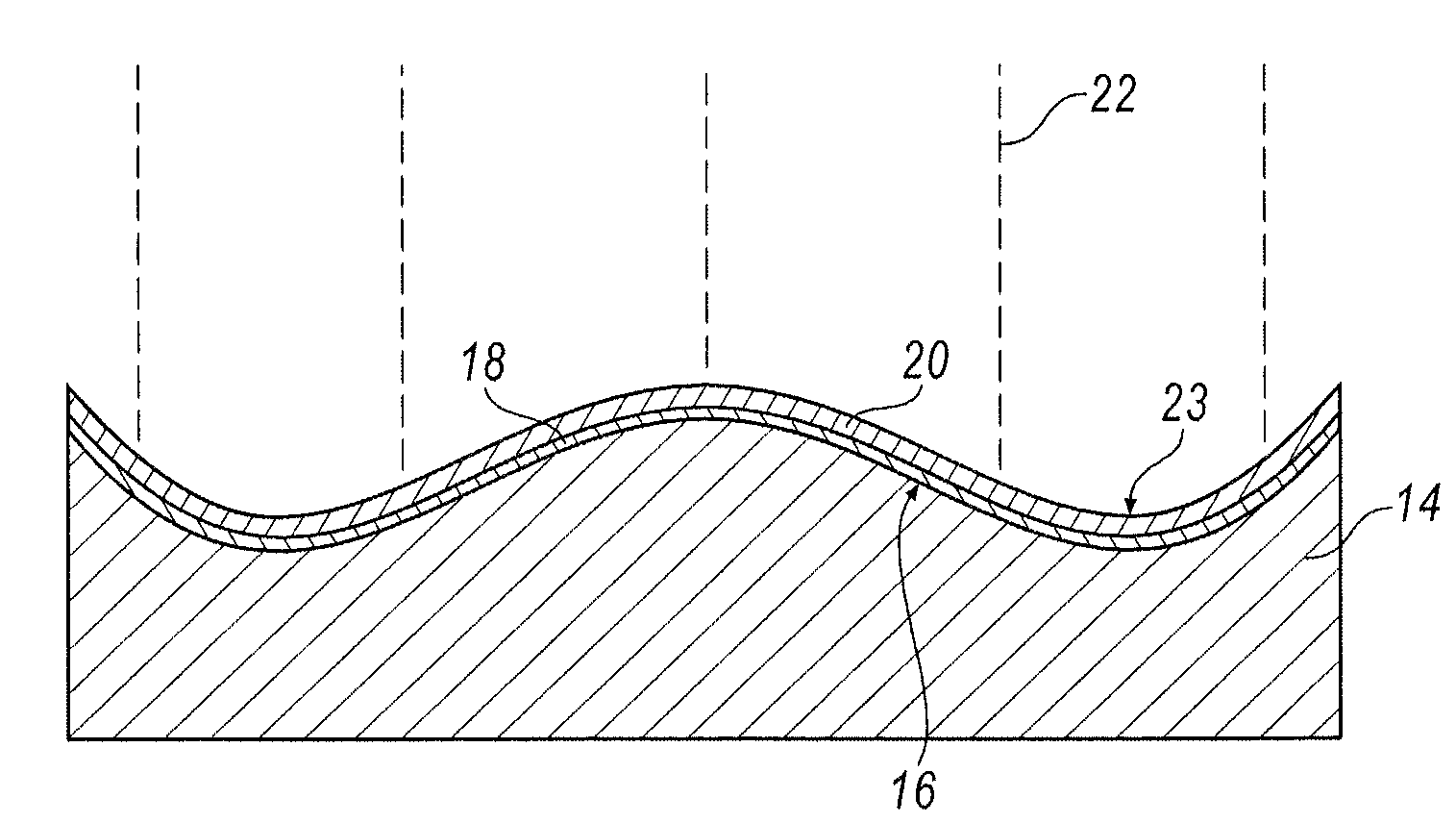

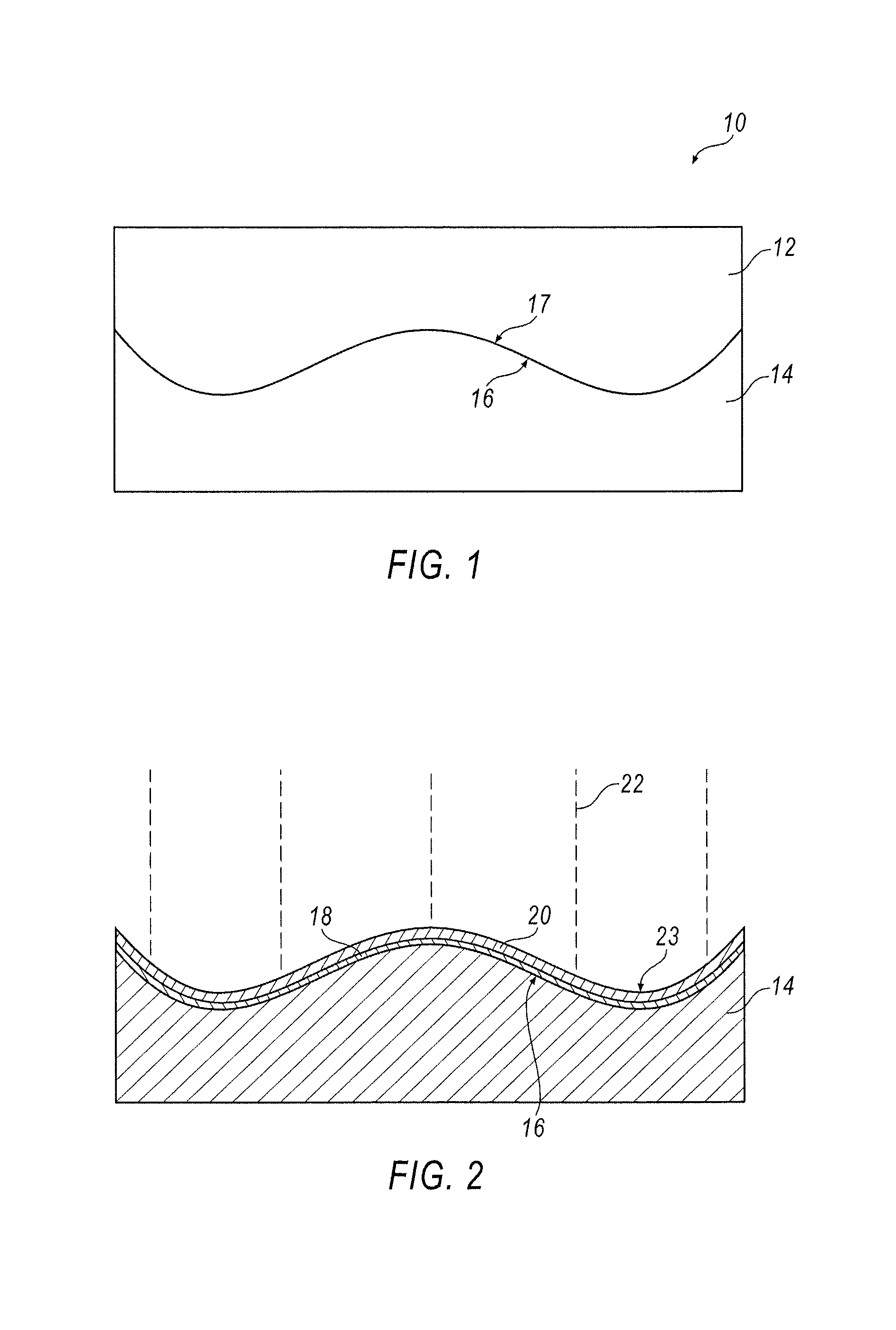

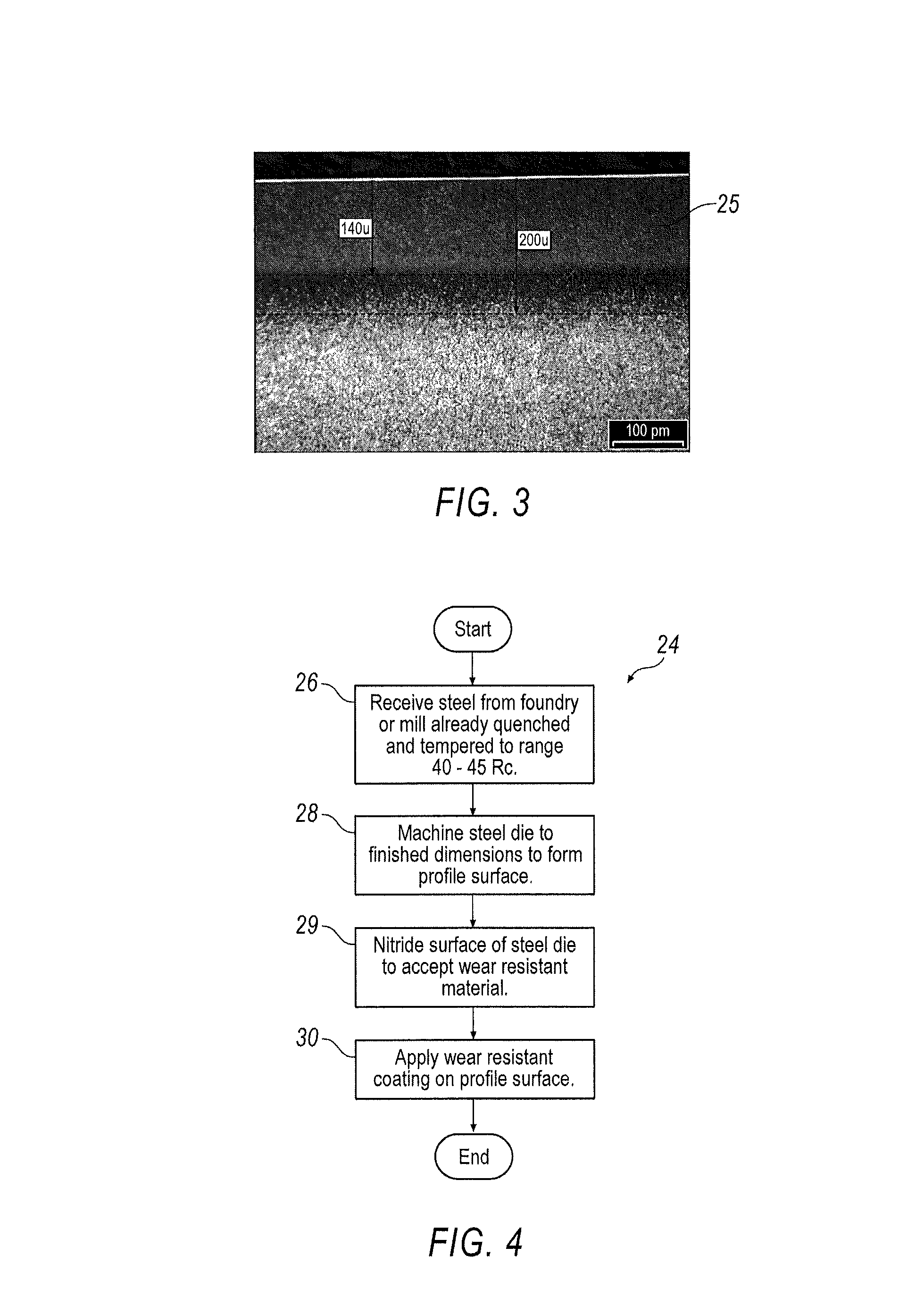

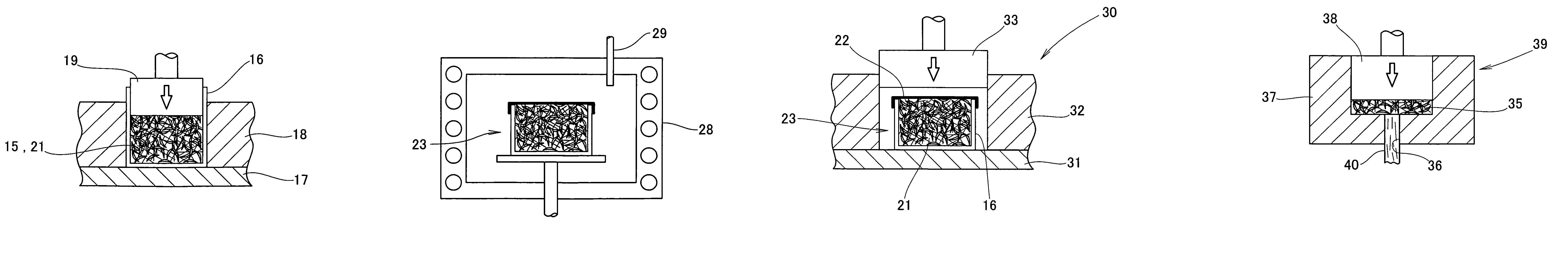

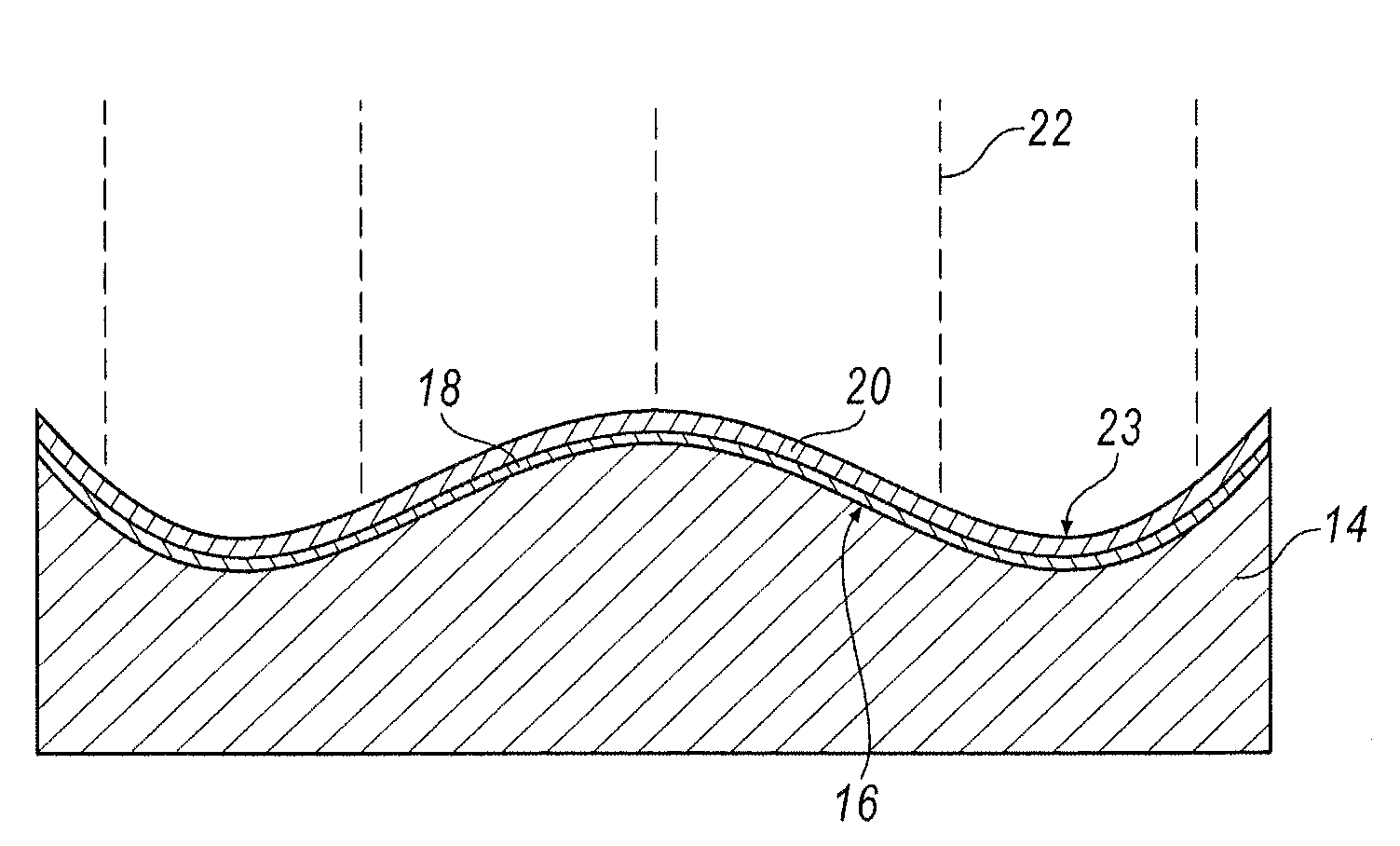

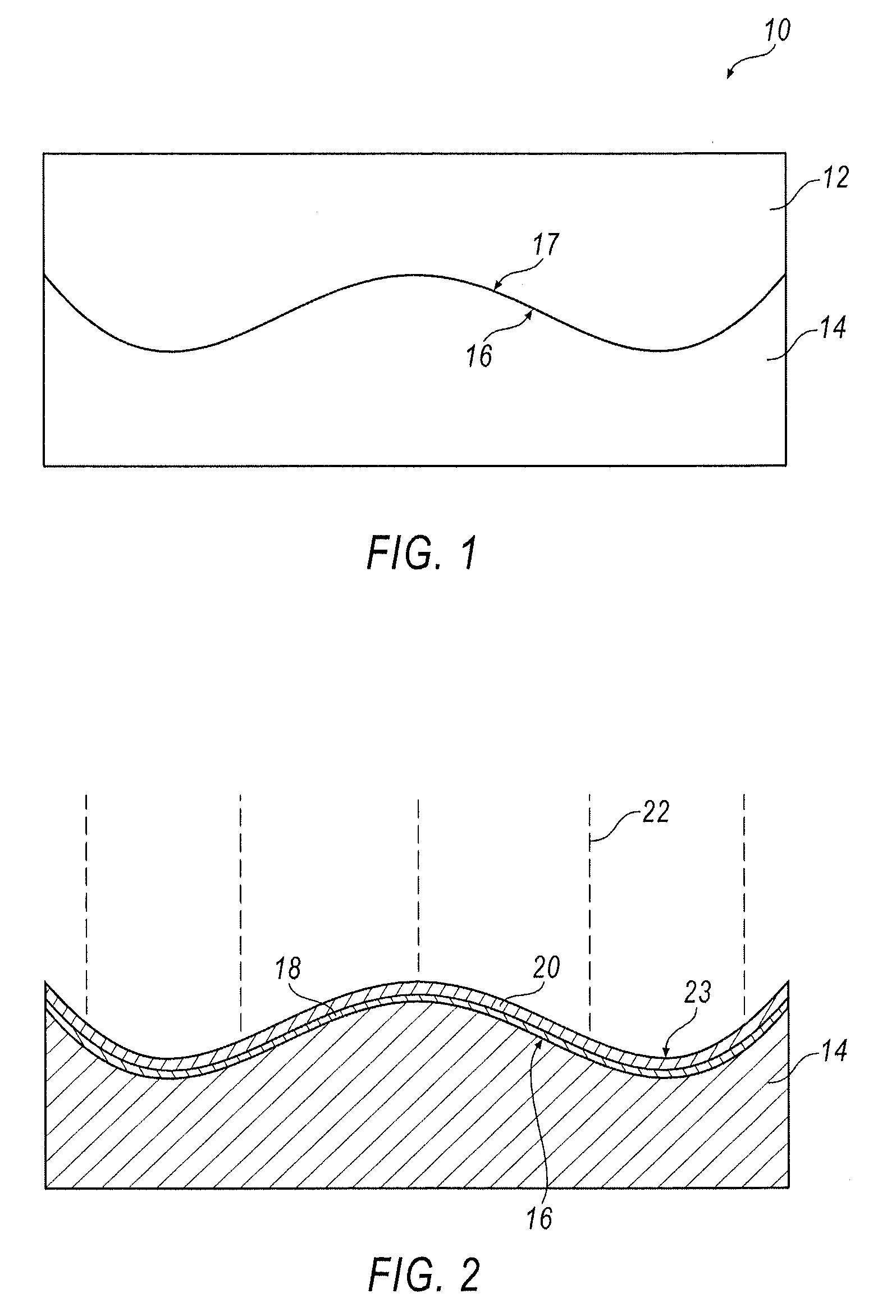

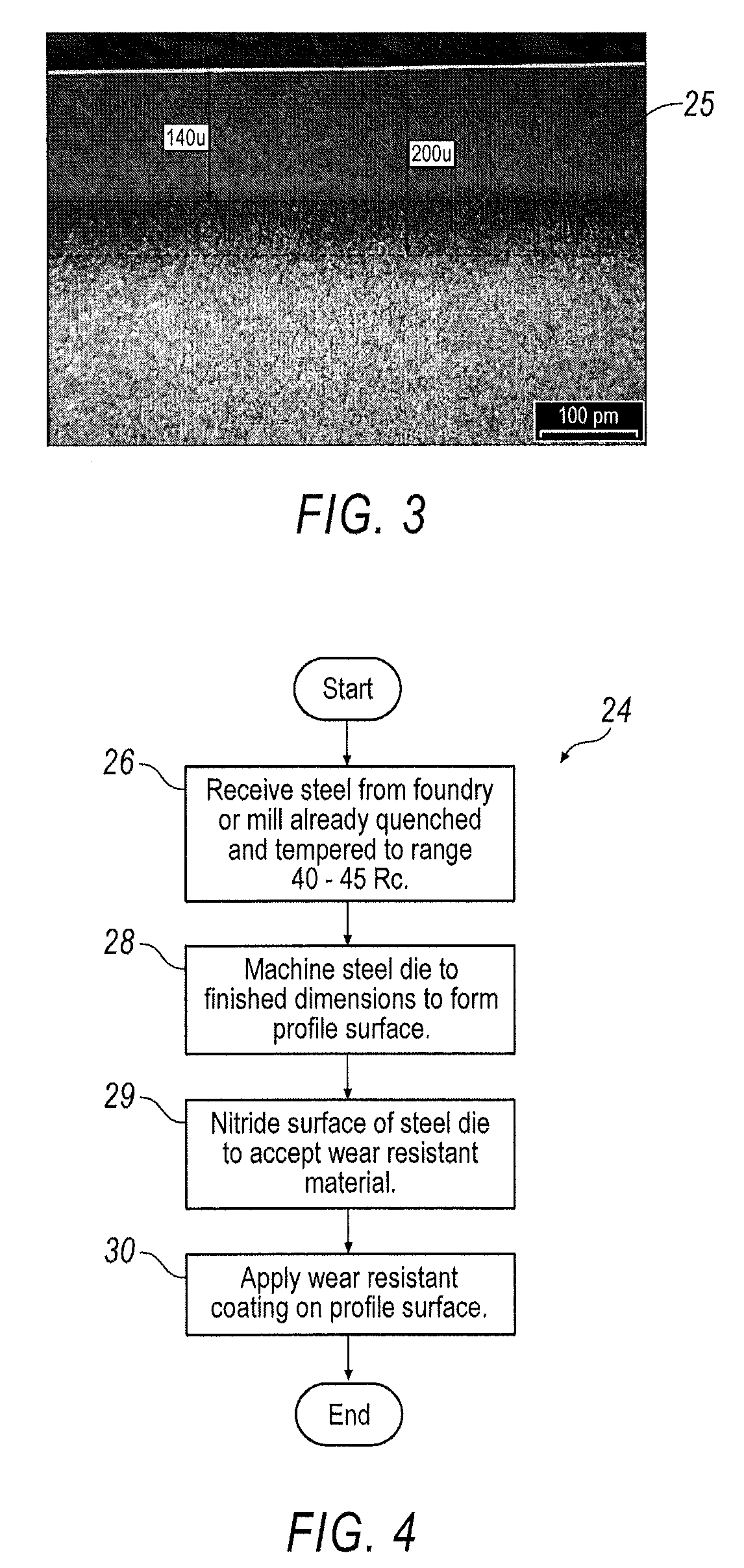

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS7587919B1Impart wear resistanceAvoid insufficient thicknessShaping toolsCutting toolsMetal formingGas phase

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

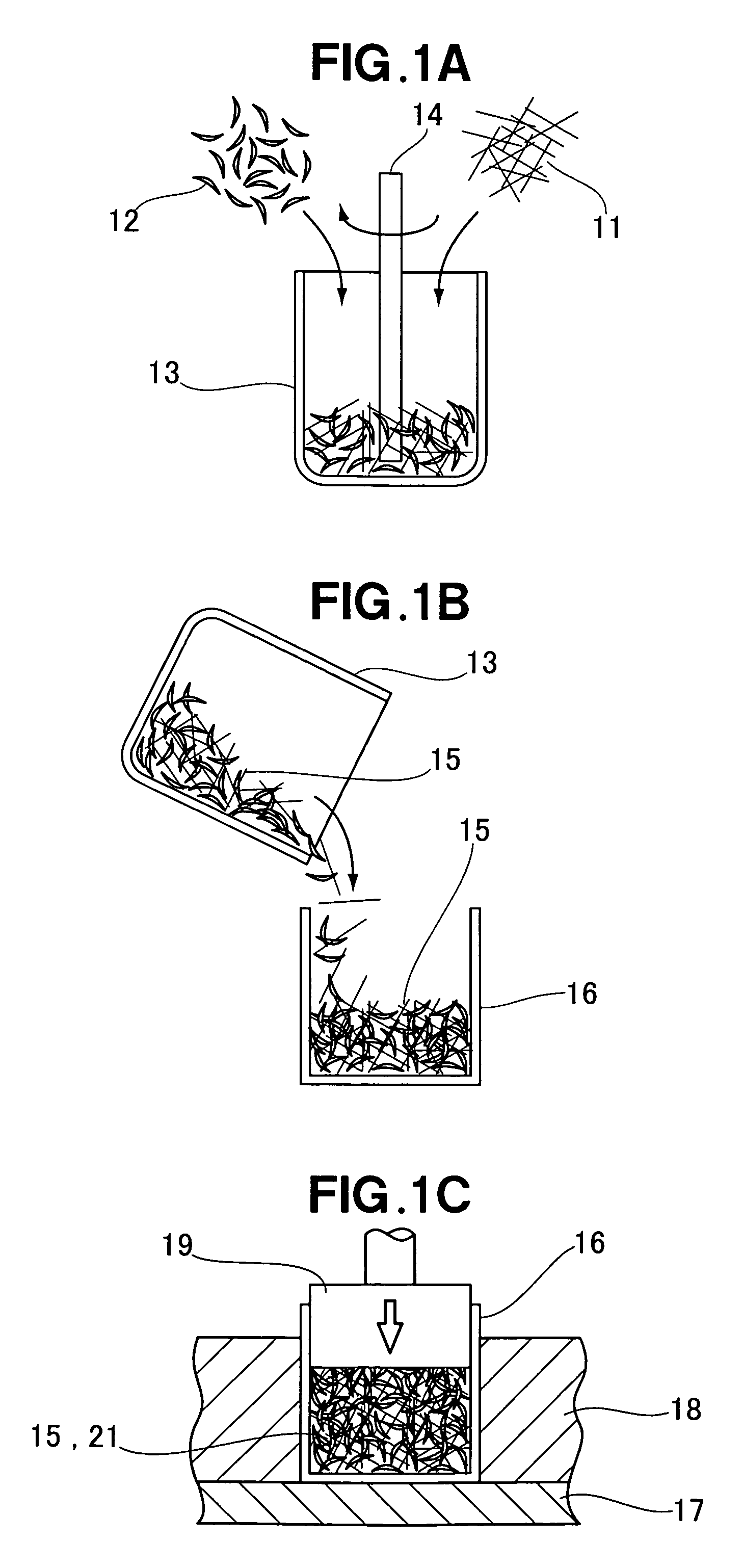

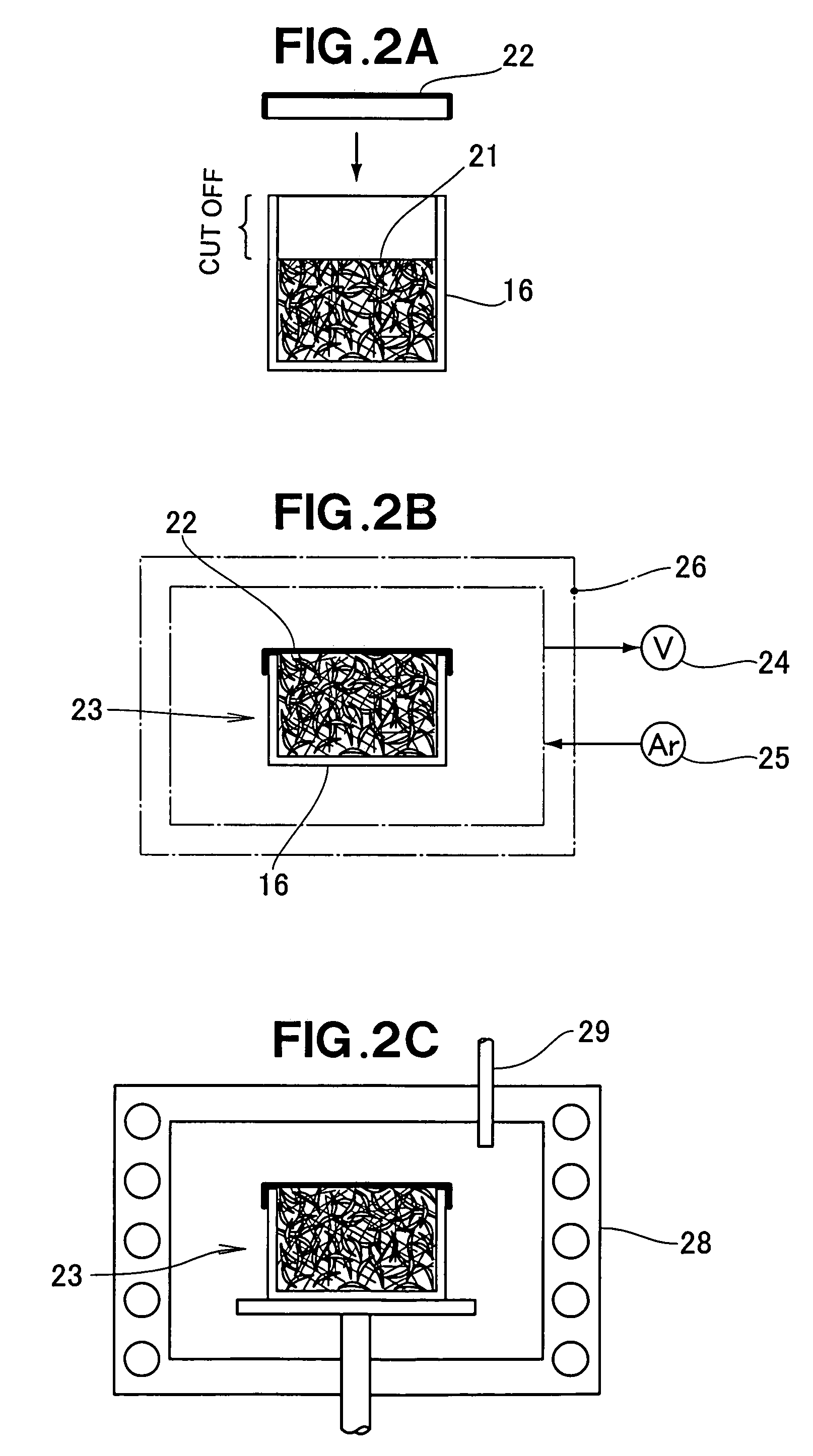

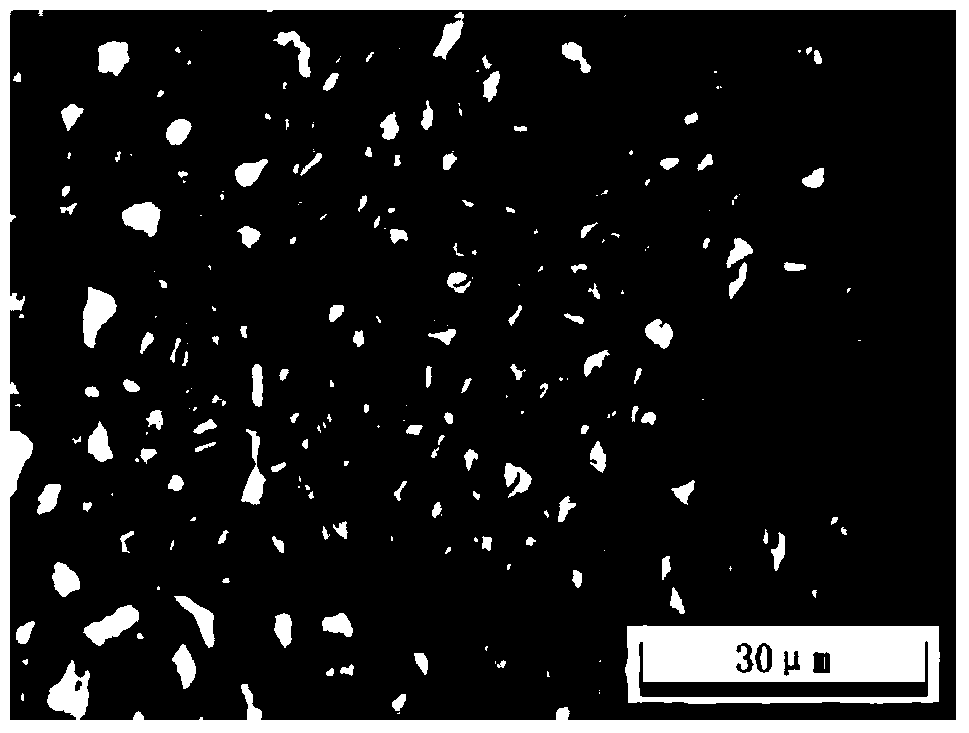

Process for manufacturing a nanocarbon-metal composite material

InactiveUS7311135B1Improve wear resistanceRestrict movementNanostructure manufactureExtrusion diesNanometreMetal

A composite material composed of nanocarbon materials and metallic materials for a matrix is extrusion molded to have the nanocarbon materials oriented in one direction.

Owner:NISSEI PLASTIC IND CO LTD +1

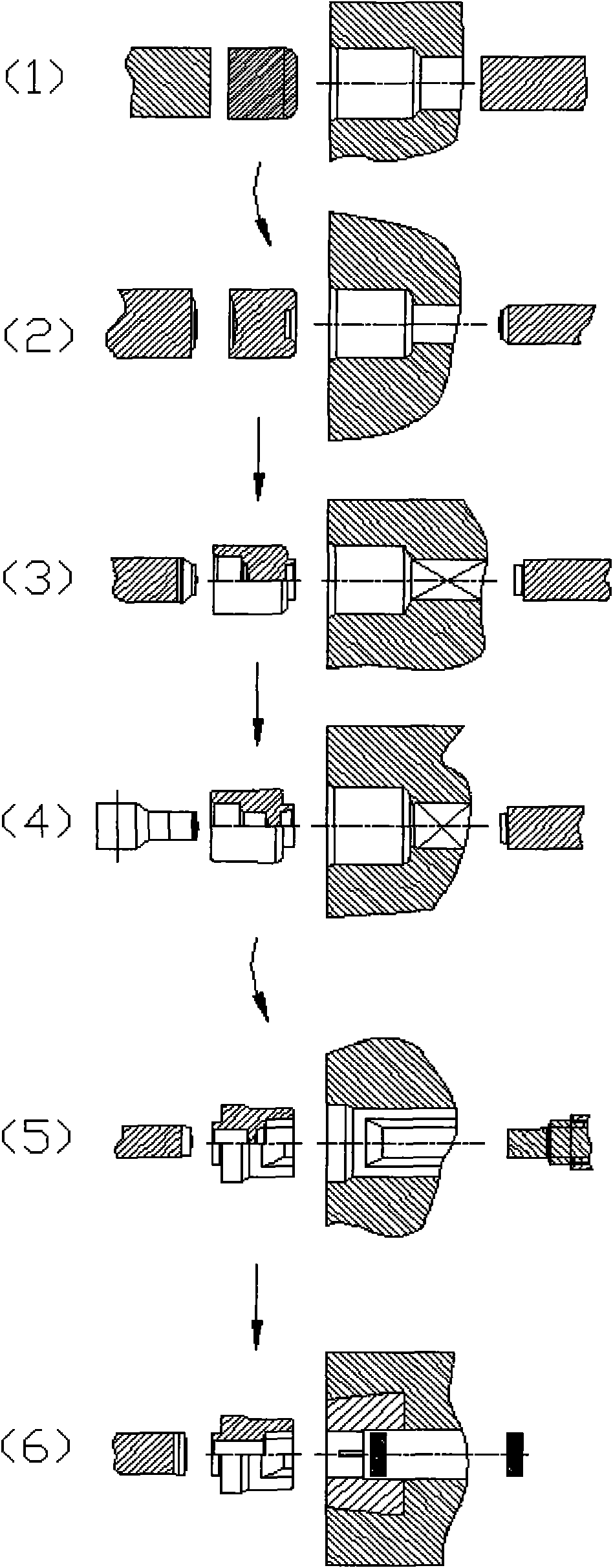

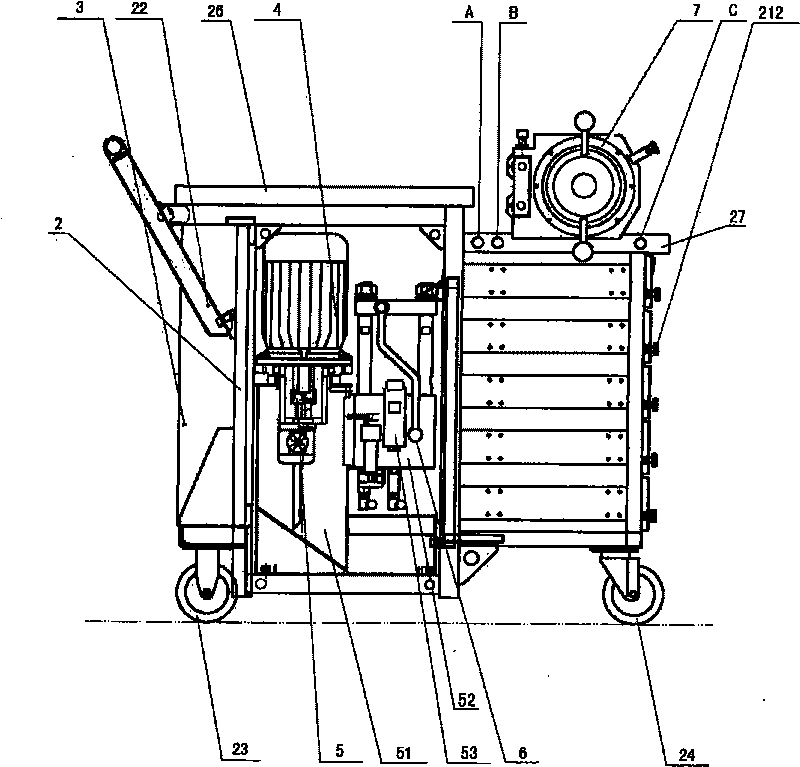

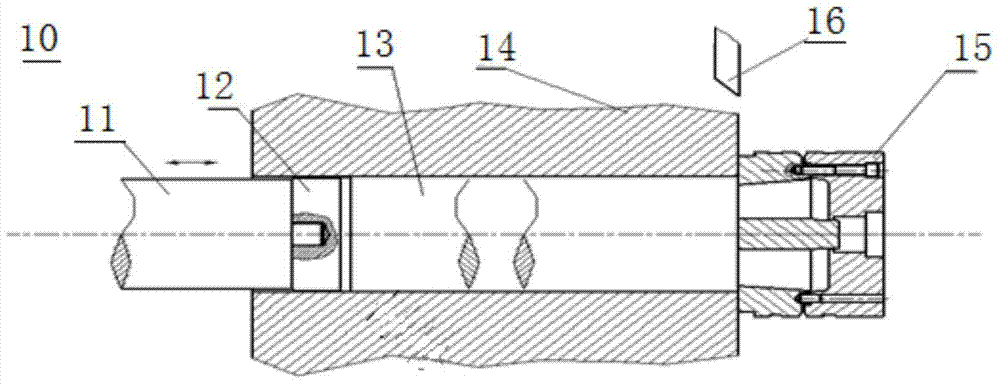

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

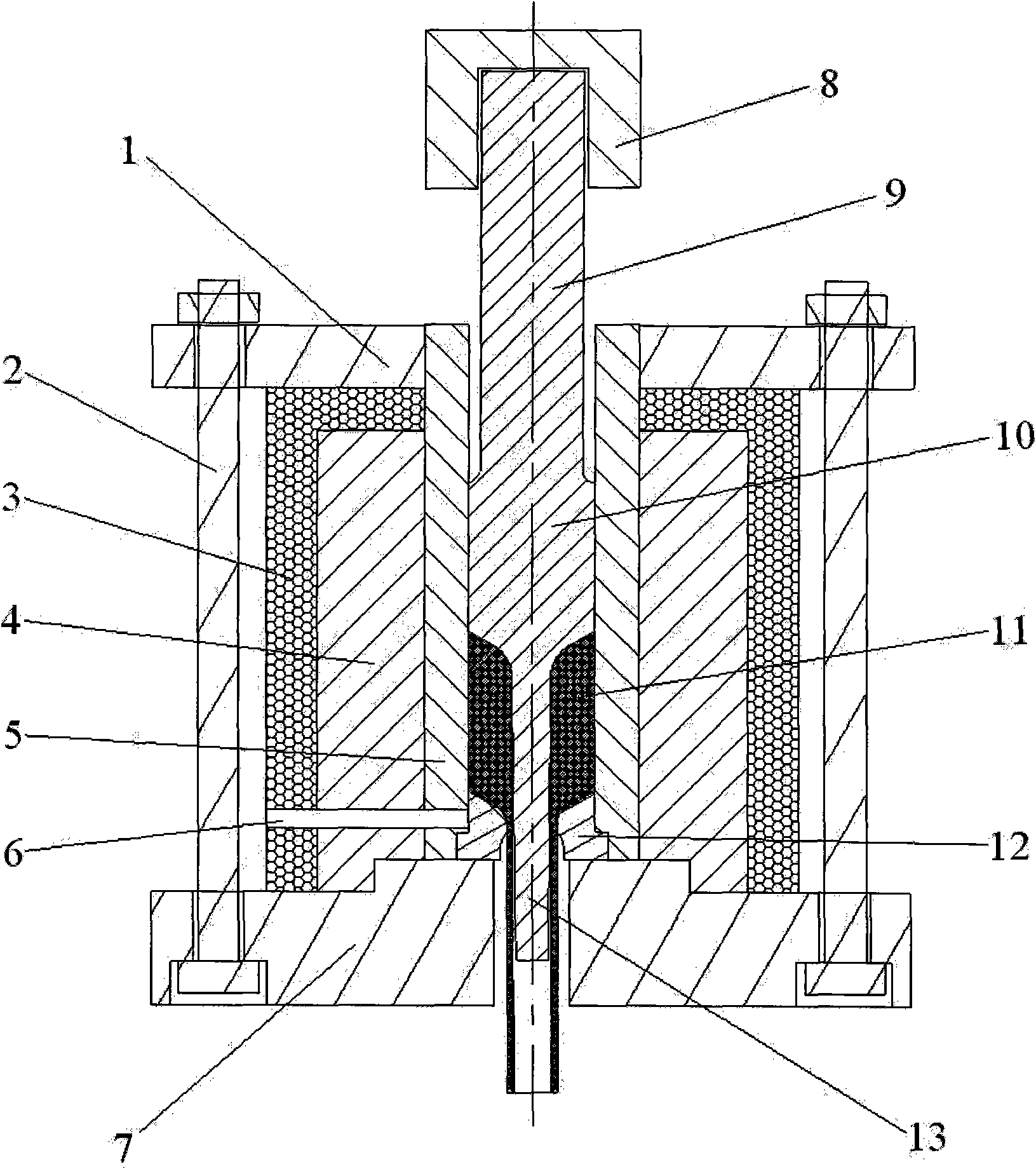

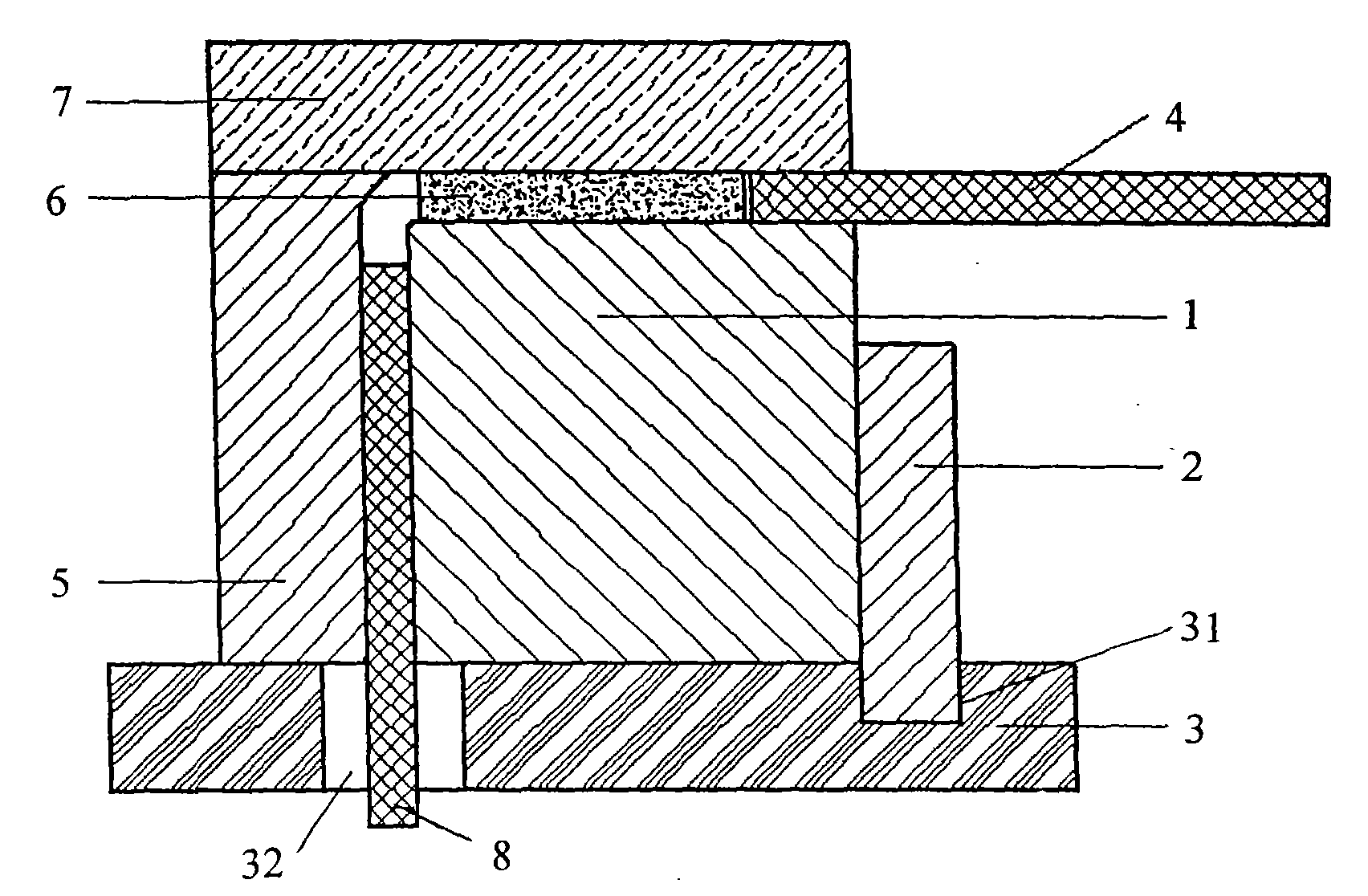

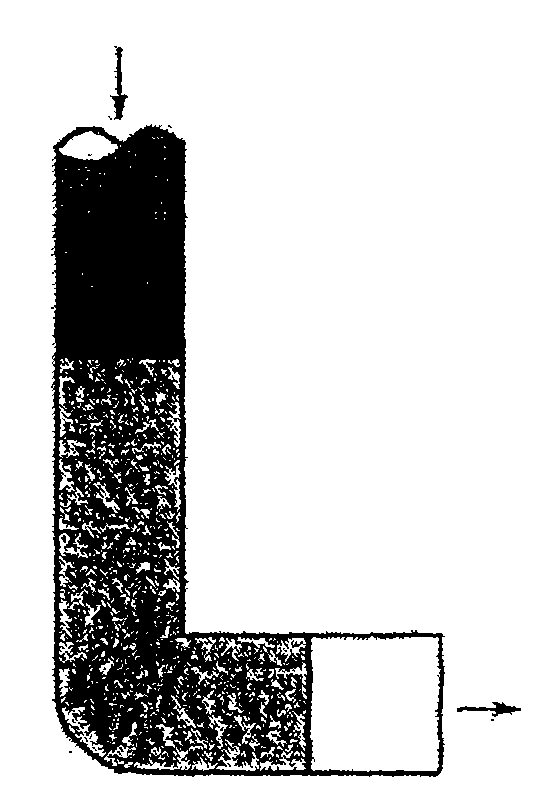

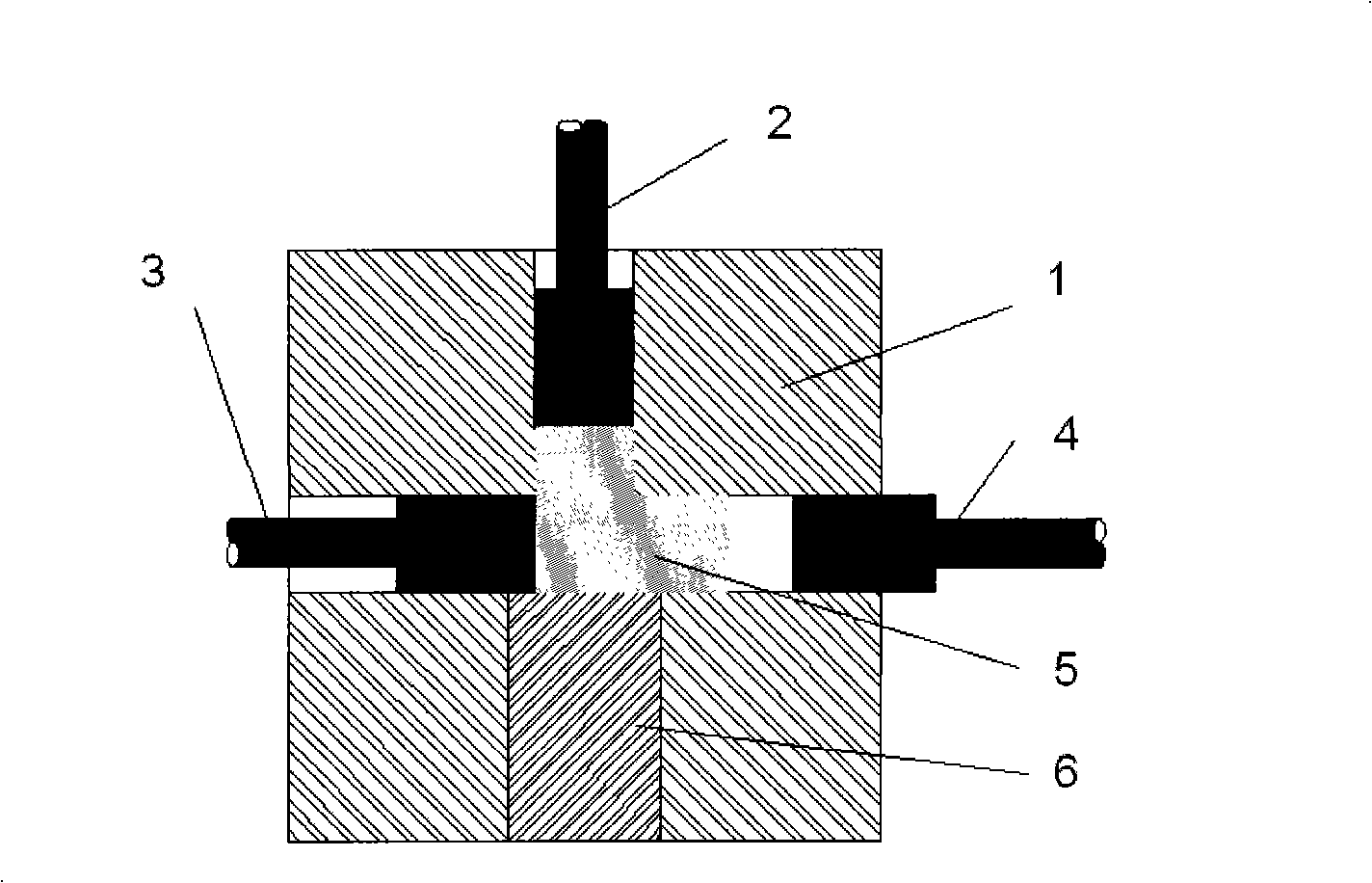

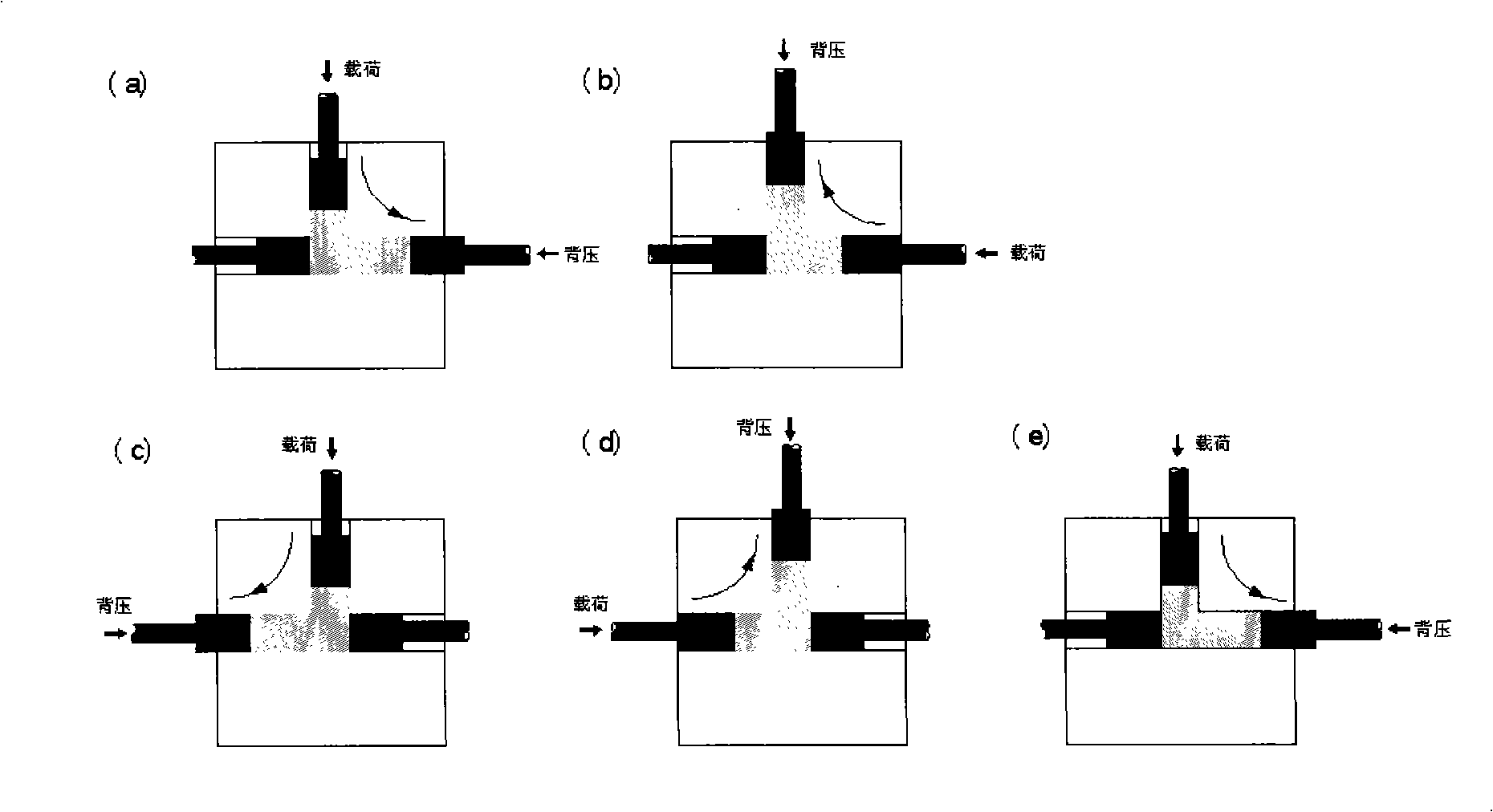

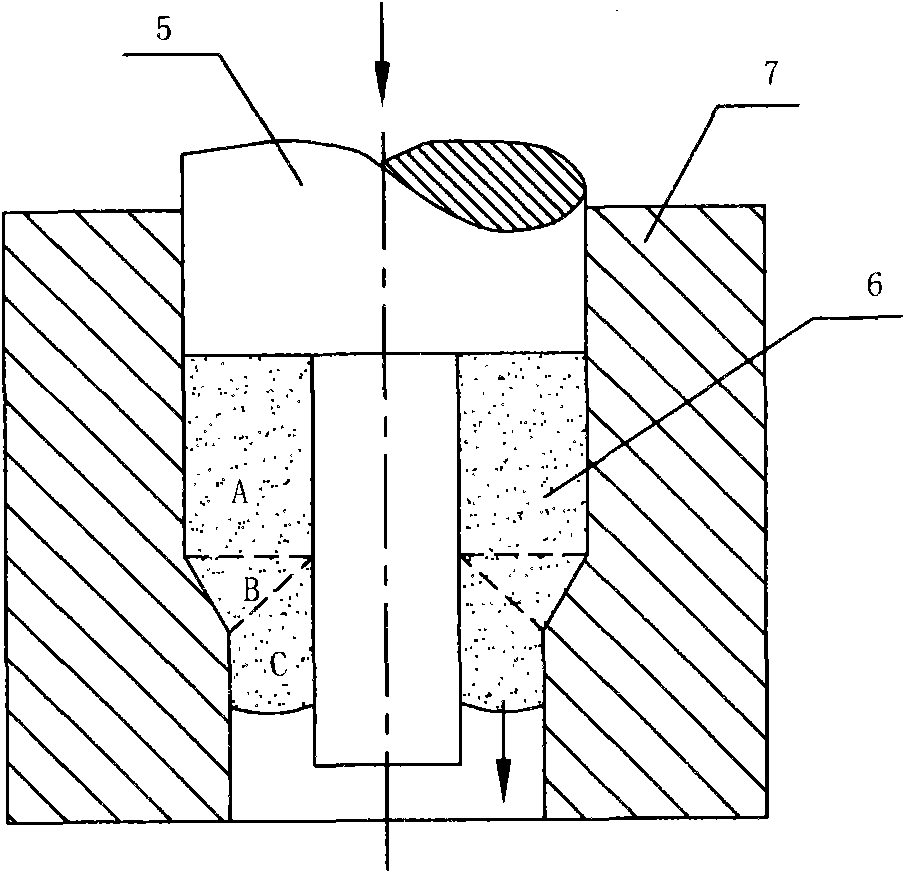

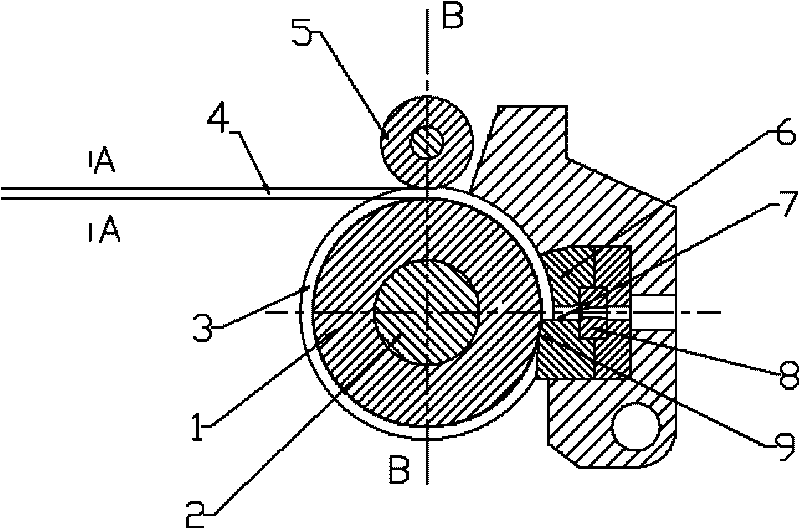

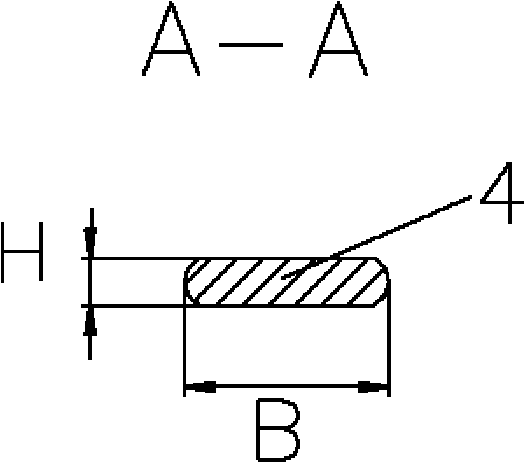

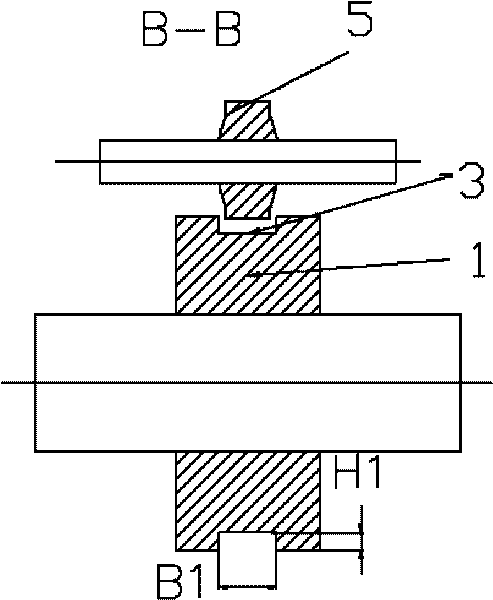

Method for preparing equal-channel reciprocating extrusion magnesium alloy with back pressure and extrusion die thereof

InactiveCN101590493AAvoid deformationAvoid crackingExtrusion diesExtrusion control devicesMagnesium alloyHydraulic press

The invention relates to a method for preparing an equal-channel reciprocating extrusion magnesium alloy with back pressure and an extrusion die thereof. The preparation method uses a three-way extrusion hydraulic press; and a pressurizing mode comprises that a side extrusion rod and a lower extrusion rod are used as a main pressure and a back pressure by adopting a right cylinder and a bottom cylinder to extrude a sample according to the set pressure and speed; after the side extrusion rod reaches a left limit or the lower extrusion rod reaches an upper limit, the pressure of the right cylinder and the bottom cylinder is changed, the main pressure is changed into the back pressure, the back pressure is changed into the main pressure, and the sample is taken out after repeated reciprocating extrusion. The extrusion die consists of a die main body, a right baffle plate, a bottom plate, a left baffle plate, an upper cover plate, the side extrusion rod, the lower extrusion rod, and the like; and the extrusion die is characterized in that the die main body is provided with a right-angled extrusion groove which is bent with equal section. Because the extrusion direction of the sample adopts the back pressure and the extrusion deformation temperature is reduced at the same time, the performance and quality of the magnesium alloy sample are effectively improved. The preparation method and the extrusion die also can be used for mixing aluminum alloy and magnesium alloy powder into block materials at low temperature.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

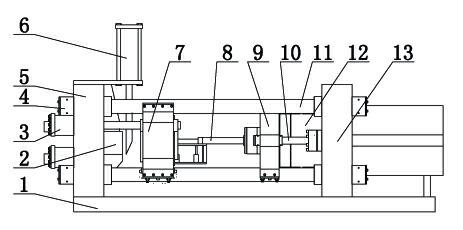

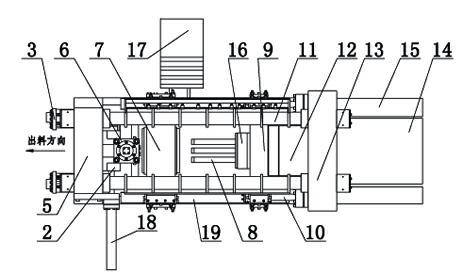

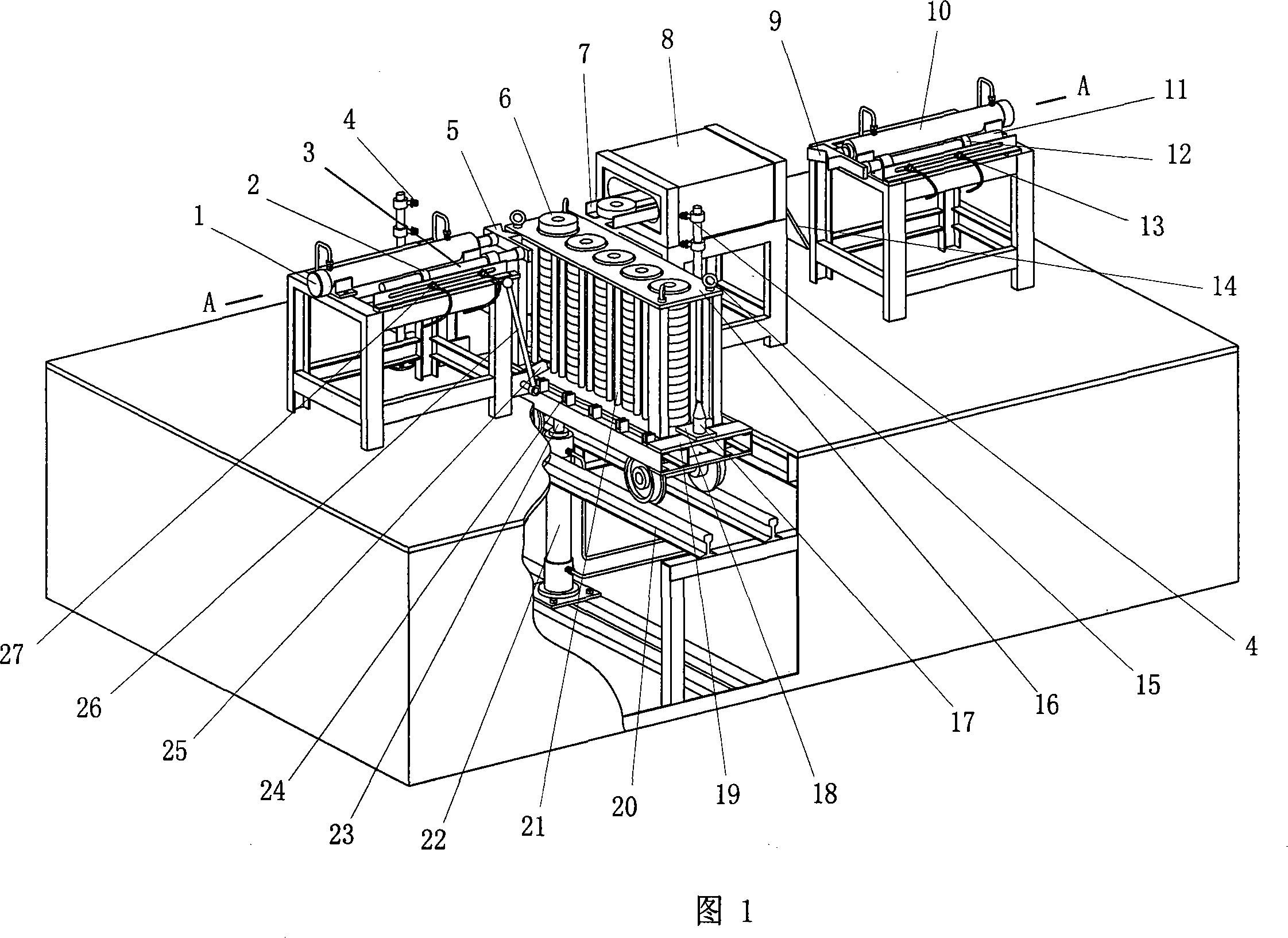

Automatized continuous processing equipment for T shaped corner extrusion press and its processing method

InactiveCN101342547AUniform tissueContinuous extrusionExtrusion diesRams/plungersControl systemEngineering

The invention discloses a tee corner extruding automatic continuous processing equipment and a processing method thereof, relating to the field of material processing, particularly relating to a tee corner extruding equipment which can automatically and continuously process and produce superfine crystals or nanocrystalline metal-base materials and a method thereof. The invention includes a mould, a first punch, a second punch, a third punch and a feeding and discharging opening. Tee corner extruding cavities are arranged in three neighboring directions in the mould, the first punch, the second bunch and the third punch are arranged in the three cavities respectively; the feeding and discharging opening is arranged in the direction of the other side; the cross-section size of the feeding and discharging opening is larger than the first punch, the second punch and the third punch; the first punch, the second punch and the third punch are connected with a hydraulic control system respectively. The invention is simple in structure, easy to be operated and has an extensive application scope.

Owner:HOHAI UNIV

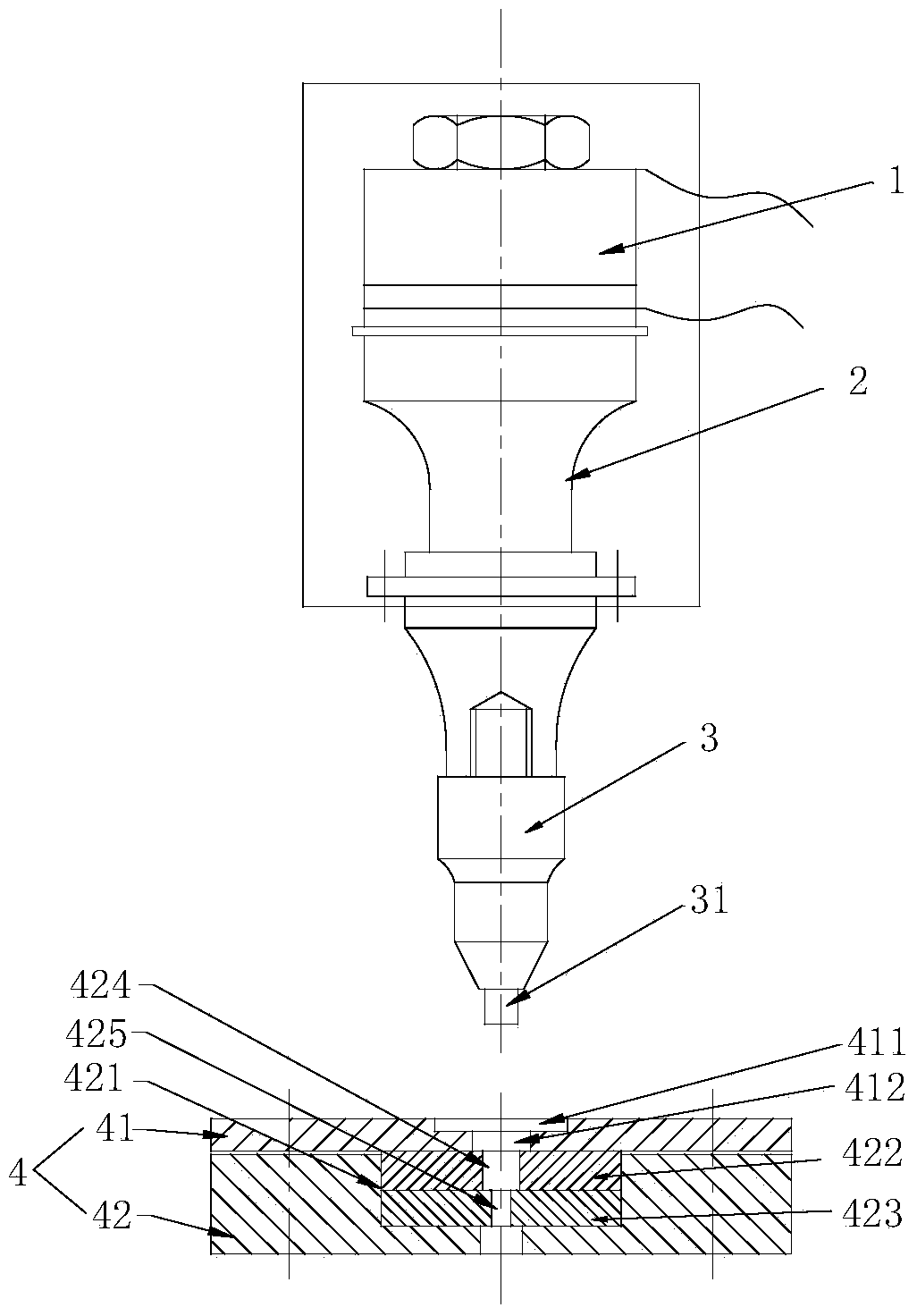

Magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature

ActiveCN104174677AImprove surface qualityIncrease productivityExtrusion diesRams/plungersRefined grainsUltrasonic generator

The invention provides a magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature. The technology comprises the following steps of manufacturing a male die and a female die, placing magnesium alloy parts into a cavity of the female die, performing die assembly extrusion on the magnesium alloy parts, performing separating die sinking, and taking out a formed part. According to the first step, an amplitude-change pole and an amplitude-change pole are sequentially connected to the tail end of the male die and can be touched by an ultrasonic generator. The magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at the normal temperature can reduce forming force of metal, reduces friction between materials and the dies, expands the machining range of metal material plastic forming, and improves plastic forming capability of the metal materials, and the good product surface quality and the higher size precision can be further obtained.

Owner:SHENZHEN UNIV +1

Continuous deformation magnesium alloy extruding method

InactiveCN1974045AReduce the temperatureWill not oxidizeExtrusion control devicesRams/plungersAviationNonferrous metal

The present invention is continuous deformation magnesium alloy extruding method, and belongs to the field of non-ferrous metal plastic forming technology. The technological scheme includes extruding deformation magnesium alloy wire blank in a continuous rotary extruder and regulating the contact surface length and running interval between the extruding wheel and the block so as to produce extrusion force between the deformation magnesium alloy blank and the rotary extruding wheel and friction heat for extruding the blank in the mold into product in continuous great shearing deformation mode. The product of the present invention may be used widely in aerospace, aviation, communication, computer, traffic and other fields.

Owner:HUNAN HUAKANG NEW MATERIAL

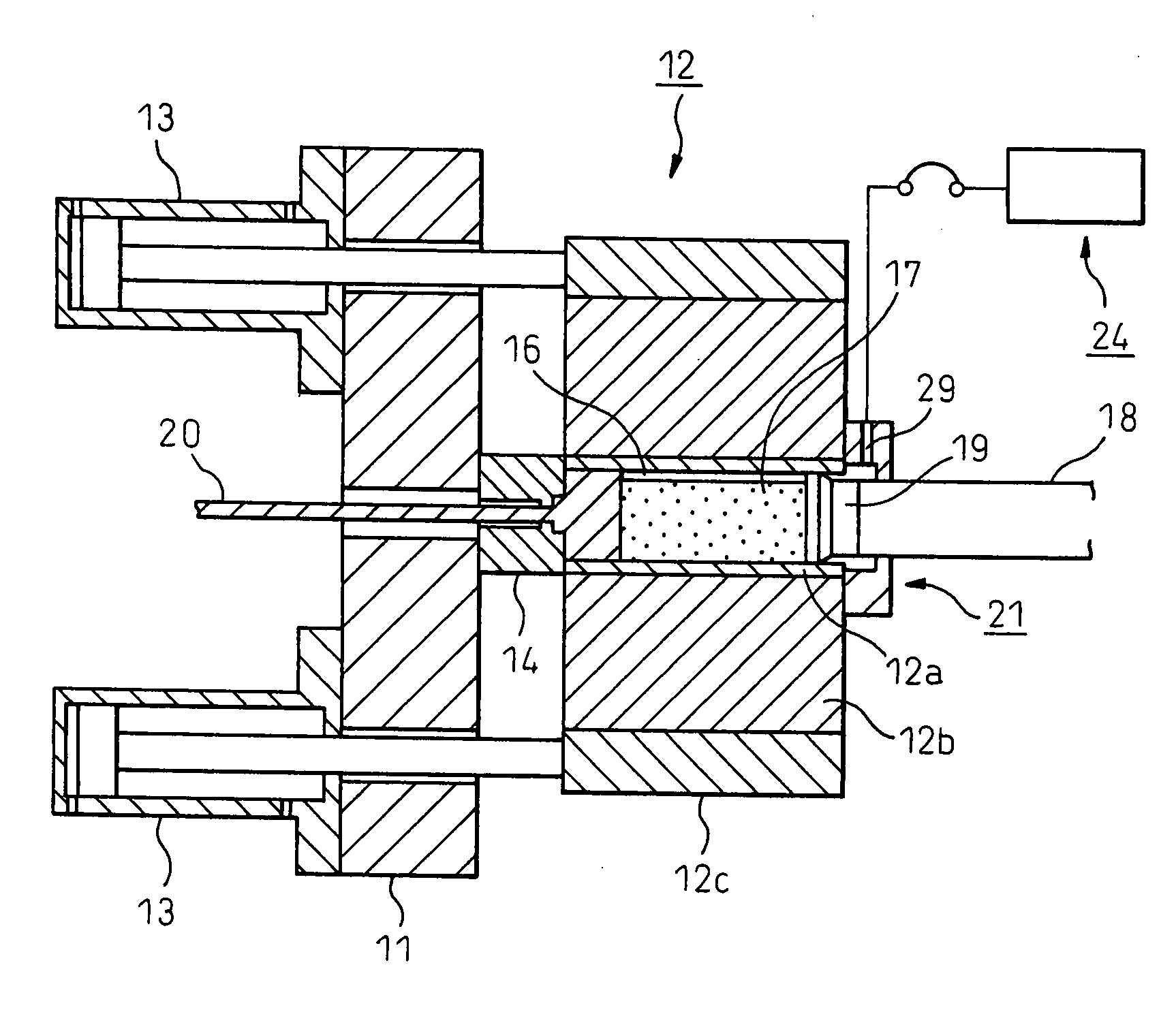

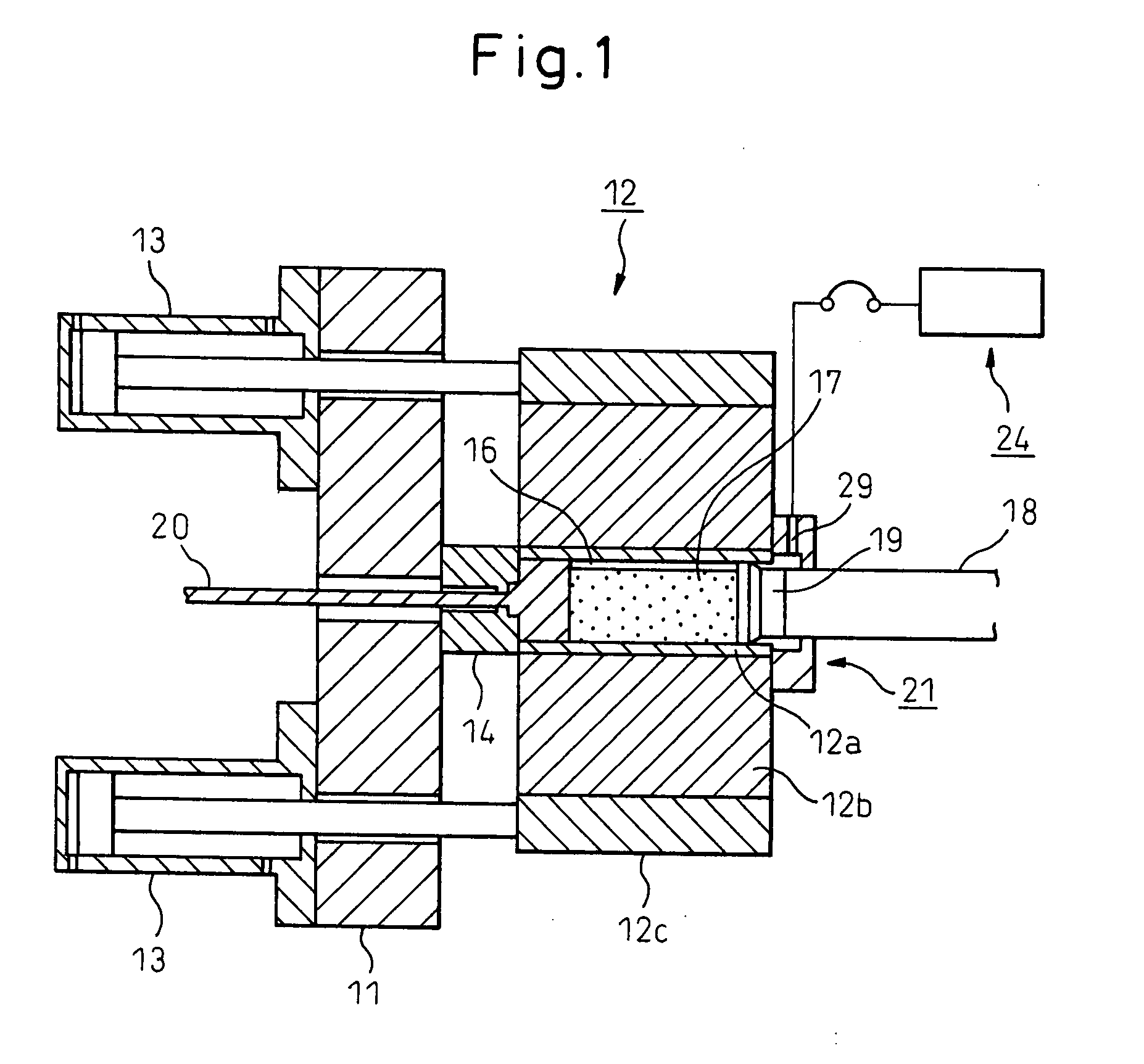

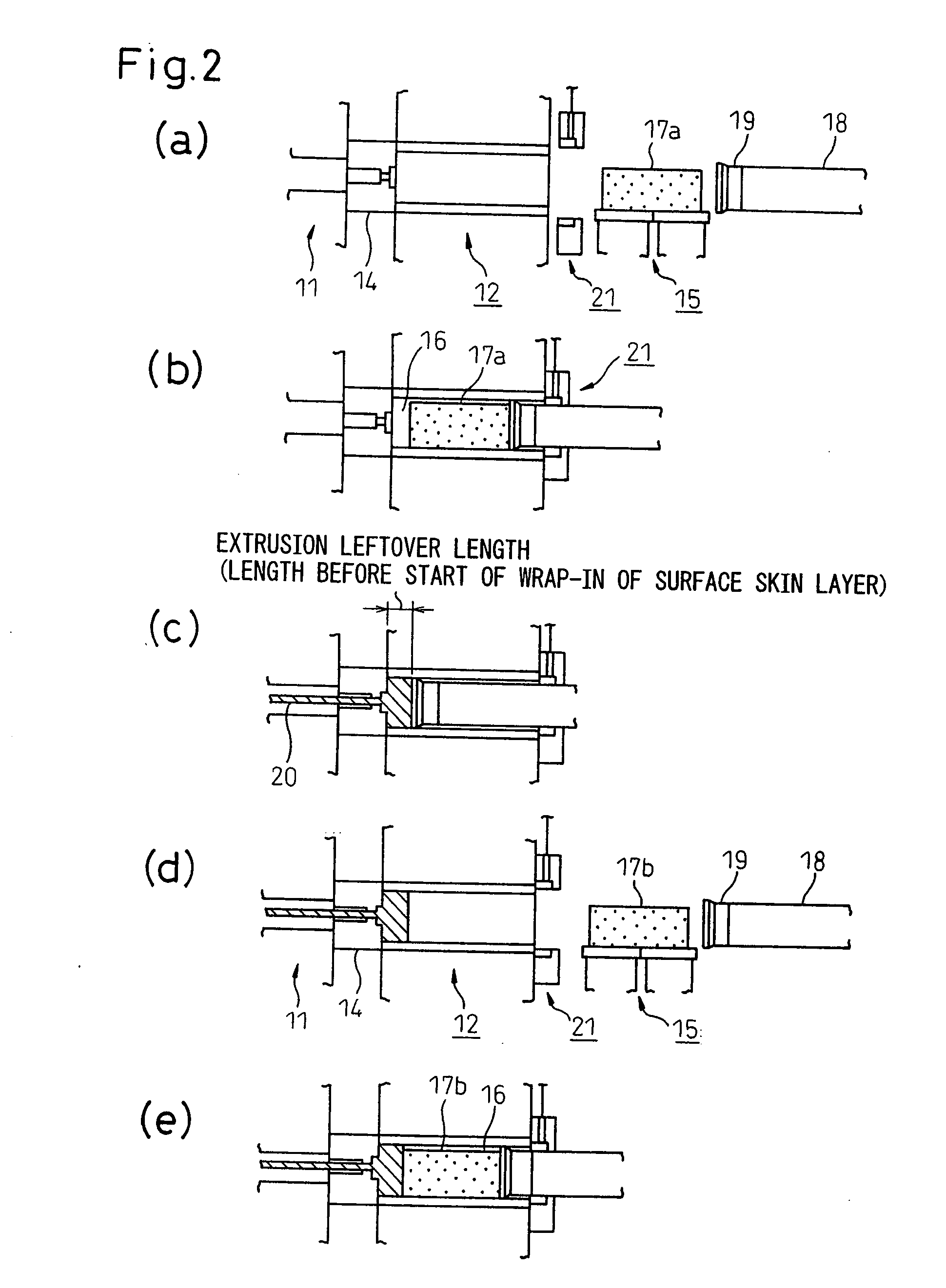

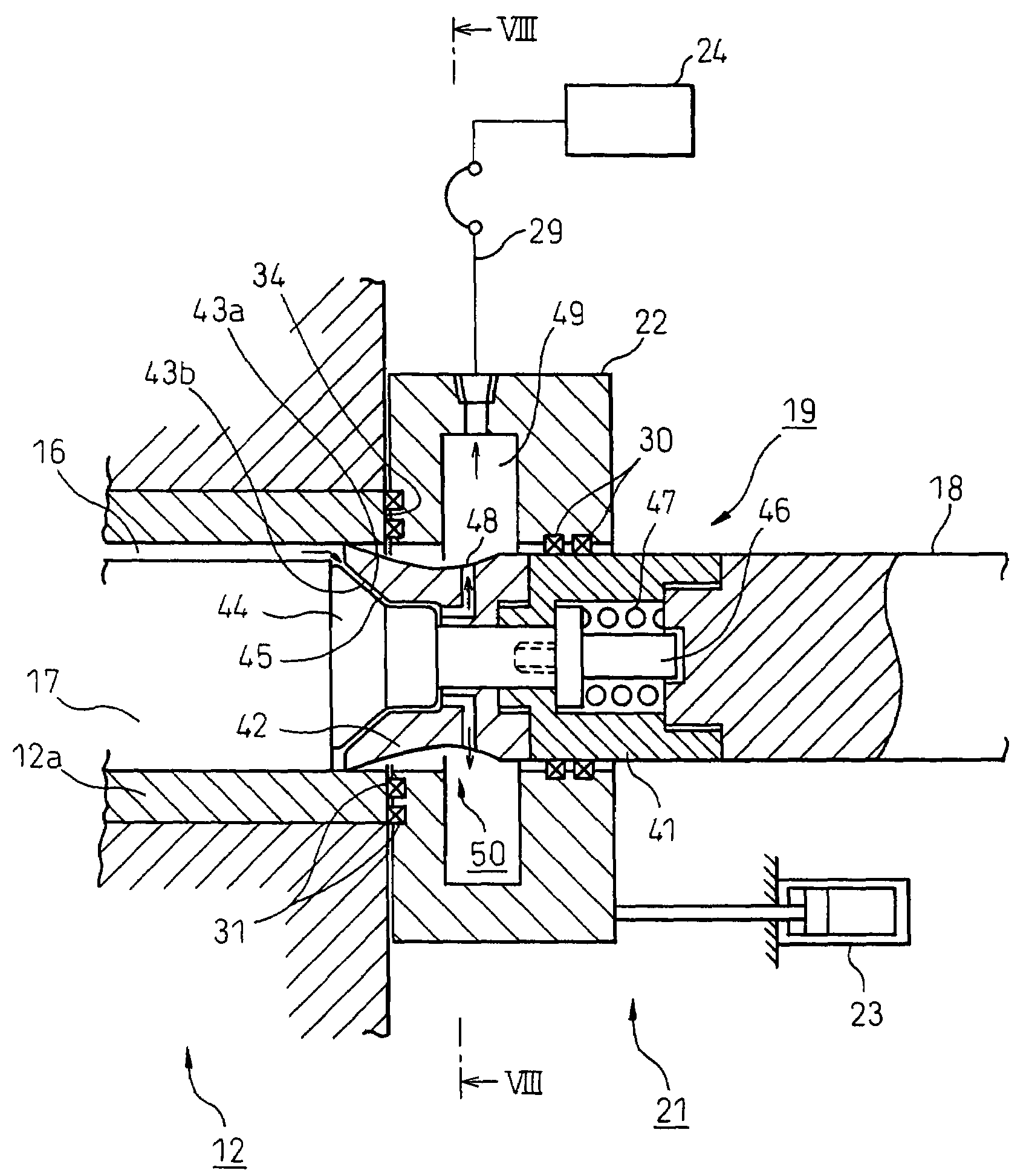

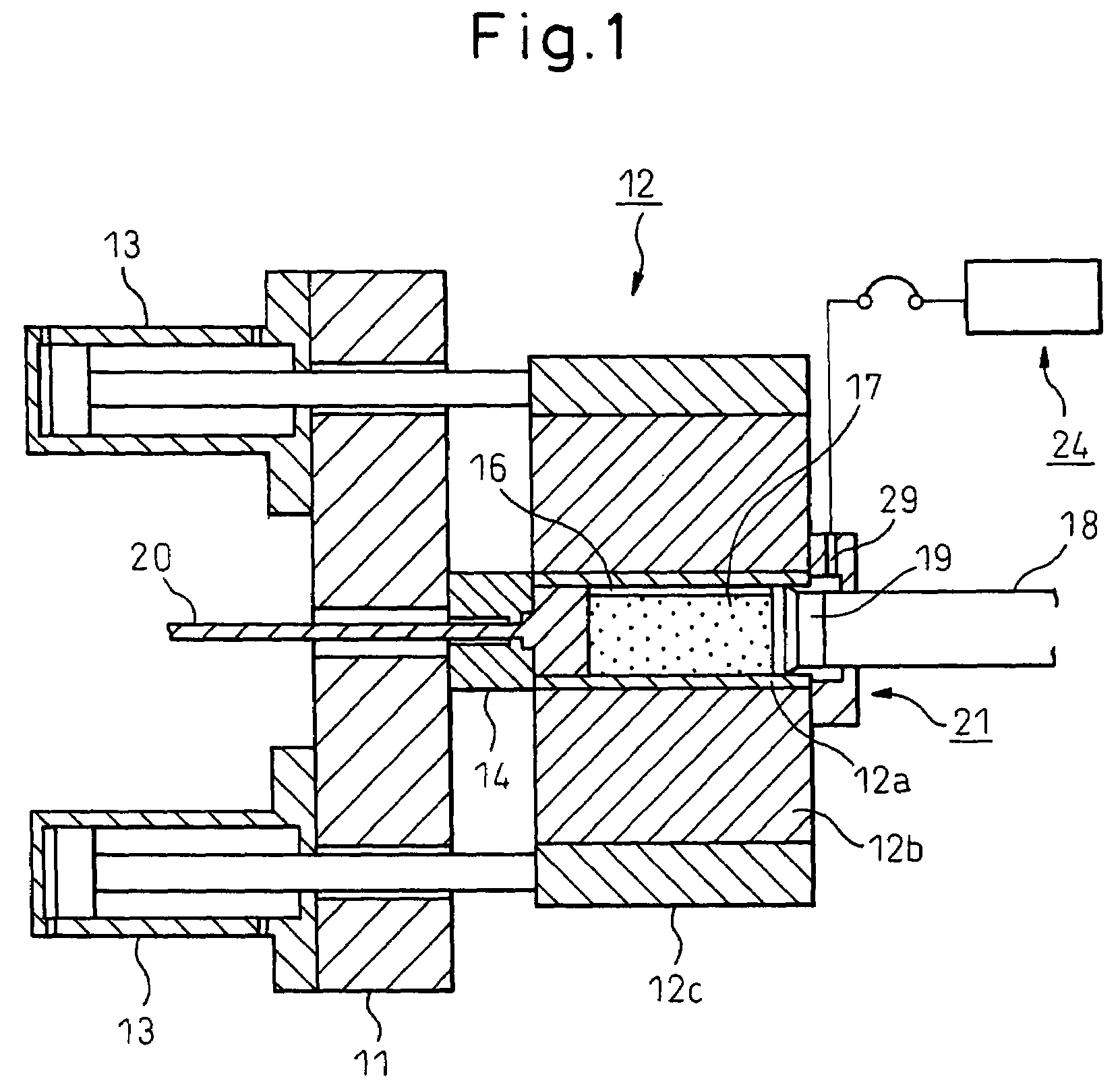

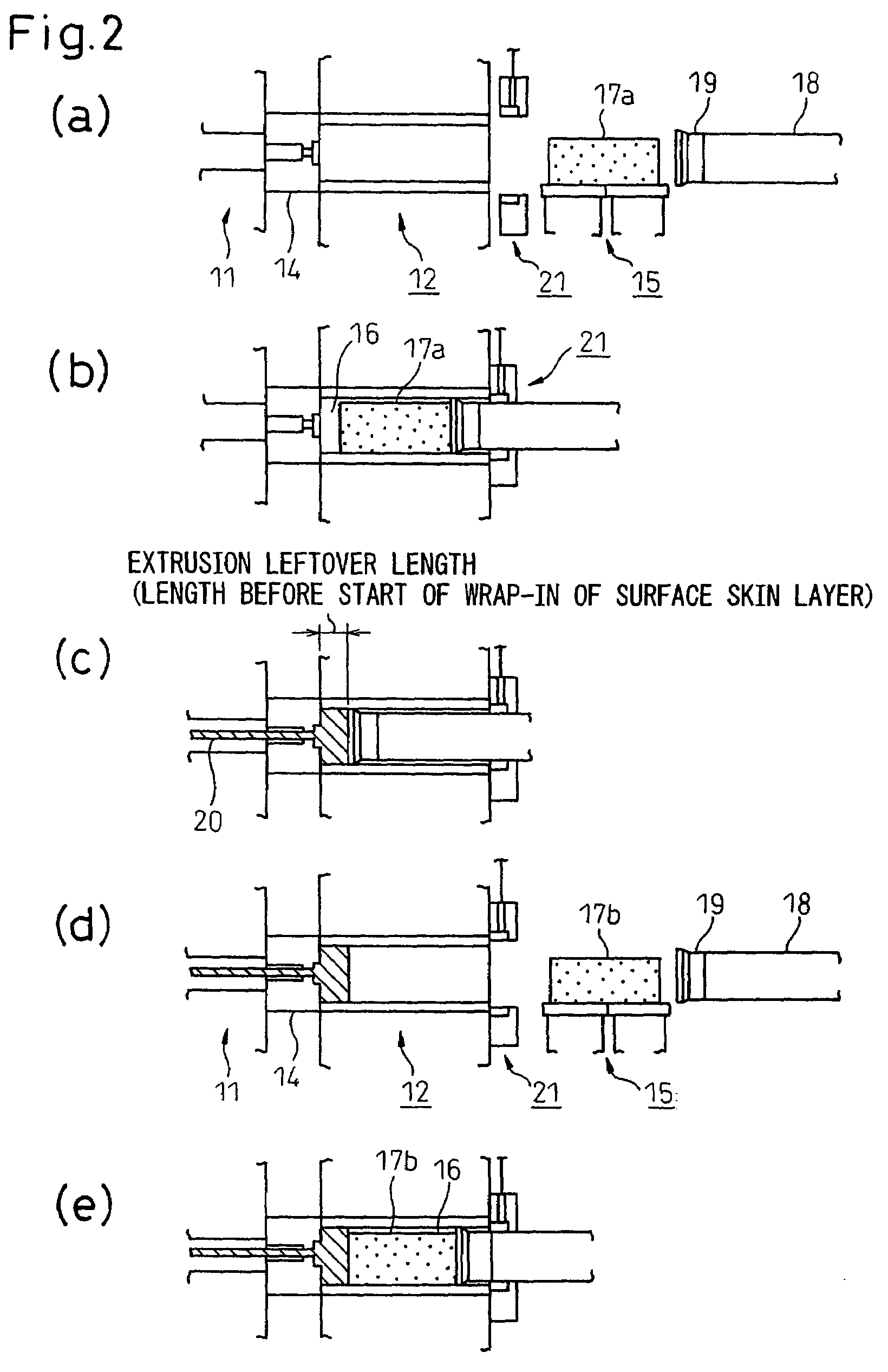

Extrusion molding method and apparatus of extrusion press

InactiveUS20070227221A1Stable container accuracyImprove accuracyExtrusion profiling toolsExtrusion containersEngineeringMechanical engineering

An extrusion molding method of an extrusion press includes a first step of loading a billet, the outer surface of which is subjected to a barking treatment, into a container, and extruding the billet in such a manner as to leave a predetermined length, a second step of loading a next billet into the container, additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined length of the succeeding billet; and a third step of loading a next billet into the container and additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined discard length of the succeeding billet and stopping extrusion. By way of these steps, the container does not move while maintaining contact with a die, and the billet is continuously extruded by leftover and additional extrusion.

Owner:UBE MASCH CORP LTD

Extrusion equipment with multiple extrusion rods

InactiveCN102172659AIncrease widthLess investmentExtrusion diesExtrusion containersEngineeringThin walled

The invention relates to extrusion equipment with multiple extrusion rods. In the extrusion equipment, an extrusion rod holder is arranged on a movable cross beam, at least two extrusion rods are arranged on the extrusion rod holder, and extrusion holes in the same number as the extrusion rods are formed at positions corresponding to positions of the extrusion rods; an extrusion die corresponds to an extrusion cylinder, the extrusion die comprises a deflector, an upper die and a lower die, which are connected in turn, deflecting grooves in the same number as the extrusion holes are formed in the deflector, the outlets of the deflecting grooves are communicated with each other, the inlets of the deflecting grooves correspond to the extrusion holes, and the deflecting grooves are communicated with the upper and lower dies. The plurality of extrusion holes are formed in the extrusion cylinder, the extrusion rods correspond to the extrusion holes are arranged, the deflector is arranged on the extrusion die, the extrusion rods extrude a metal extrusion blank material out from the plurality of extrusion holes, the extruded blank material is deflected by the deflector into the die, and thus, an extruder can produce metal sections, which are wider than those made by the conventional extrusion equipment of the same tonnage, particularly wide aluminum and magnesium alloy thin-wall hollow sections.

Owner:尚守亮 +1

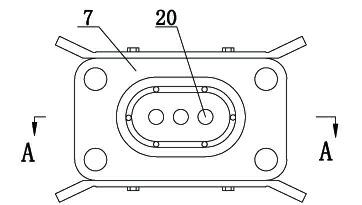

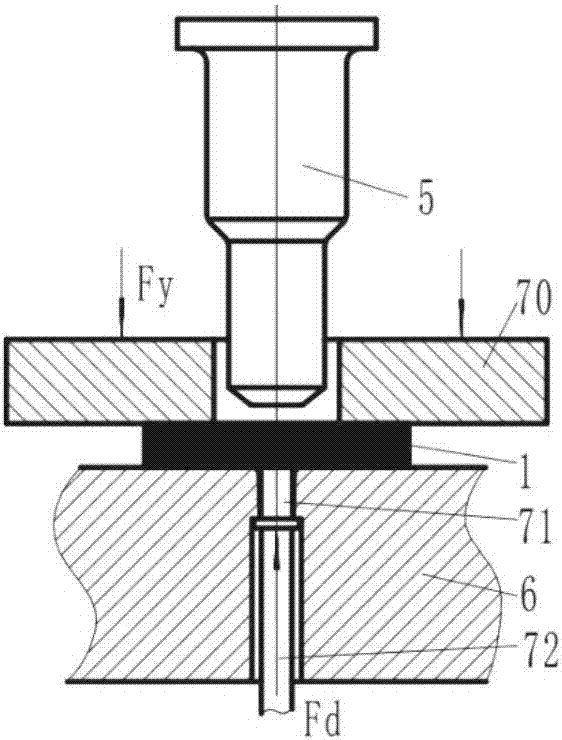

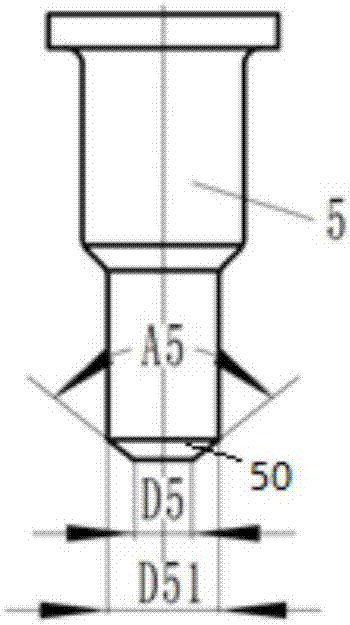

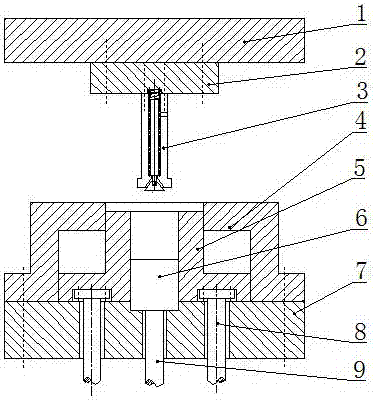

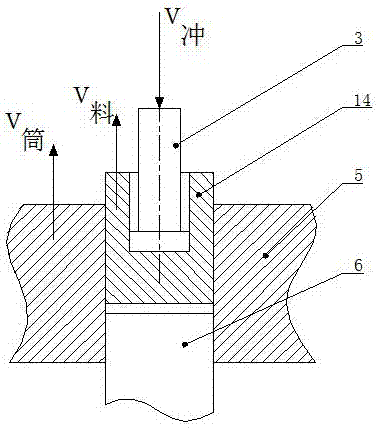

Counterbore stamping forming mould and process

ActiveCN106862374ASmall shape deformationAvoid problems such as swelling and crackingShaping toolsPerforating toolsPunchingCounterbore

The invention discloses a counterbore stamping forming mould and process. The counterbore stamping forming mould comprises an extrusion mould and a punching and sizing mould, wherein the extrusion mould is used for extruding a blank to form a workpiece, and the punching and sizing mould is used for punching and sizing the workpiece to obtain a finished product; the extrusion mould comprises an extrusion punch and an extrusion concave die, and the end part of the extrusion punch is an extrusion circular platform; an extrusion cutting edge is arranged at the top of the extrusion concave die, and a push rod hole is formed in the lower part of the extrusion cutting edge; the punching and sizing mould comprises a punching and sizing punch and a punching concave die; the bottommost part of the punching and sizing punch is a cylinder, and the upper part of the cylinder is connected with a sizing circular platform; a punching cutting edge is arranged at the top of the punching concave die. The taper angle of a workpiece counterbore is A2, the diameter at the large end is D21, and the diameter at the small end is D2. The taper angle of a finished product counterbore is A3, the diameter at the large end is D31, and the diameter at the small end is D3. The counterbore stamping forming mould and process realize the precise forming of counterbores under small deformation and low loading, avoid hole bursting, etc., improve the processing efficiency of the counterbores, and reduce the reject rate and the manufacture cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

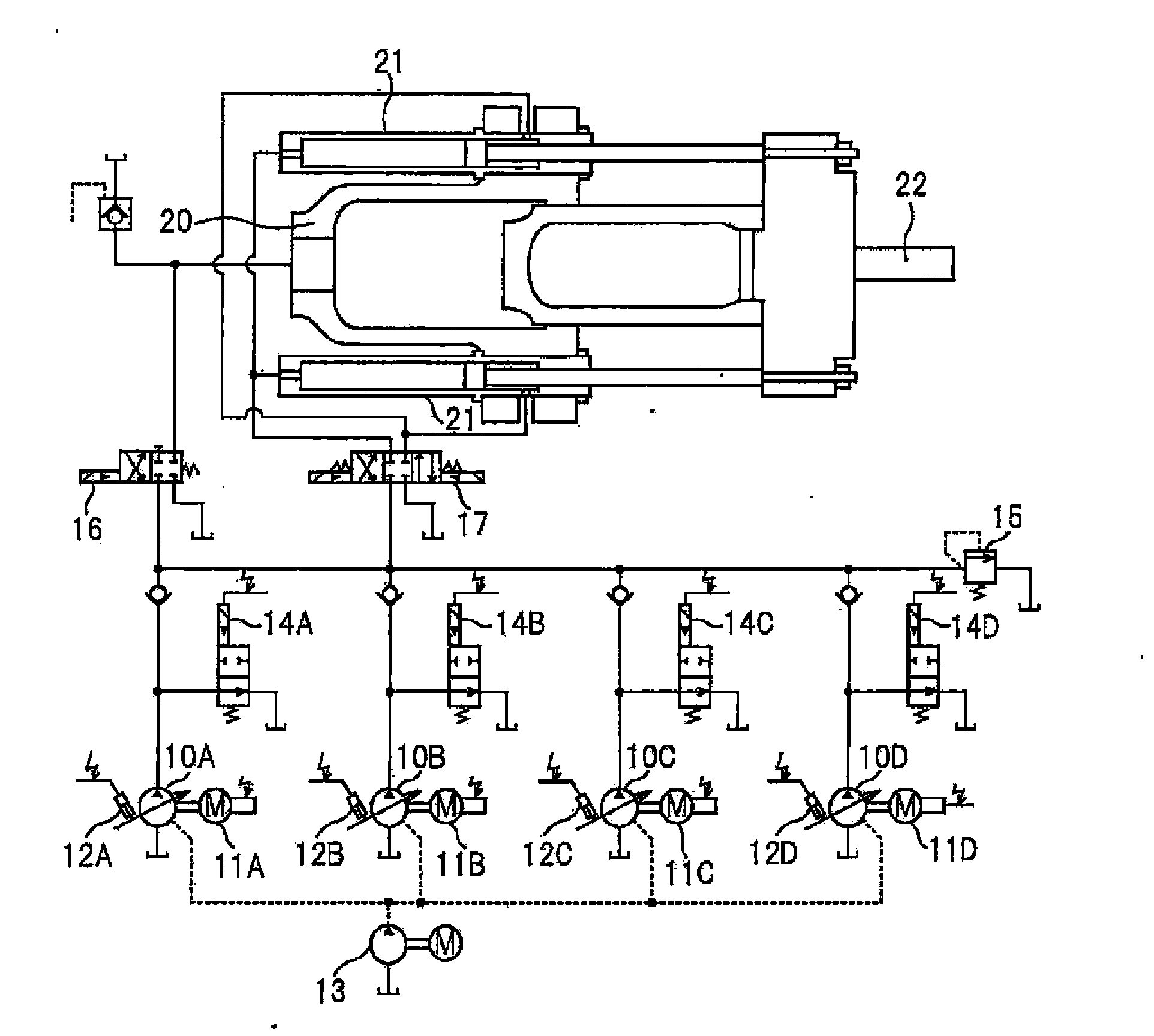

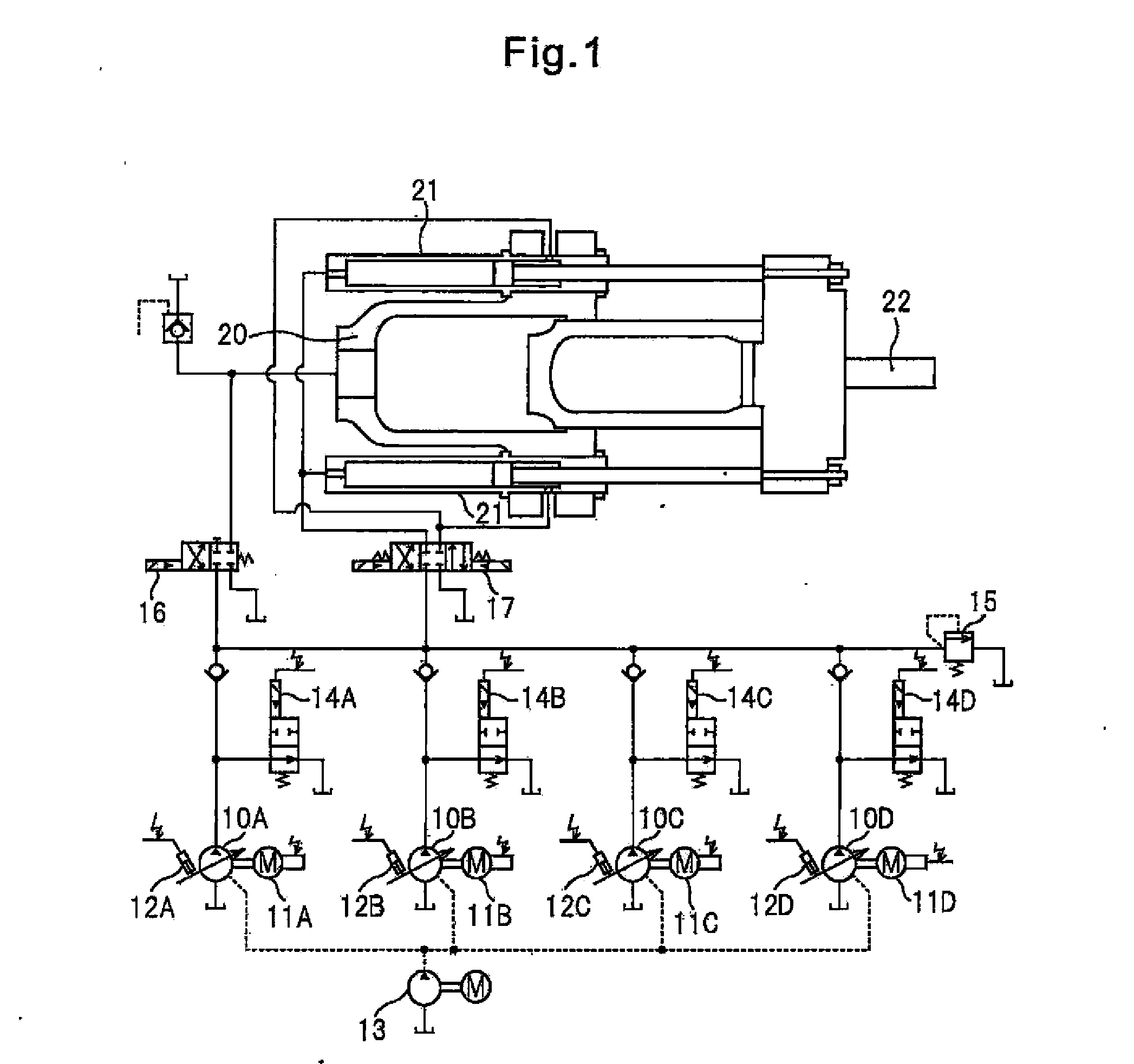

Extrusion press

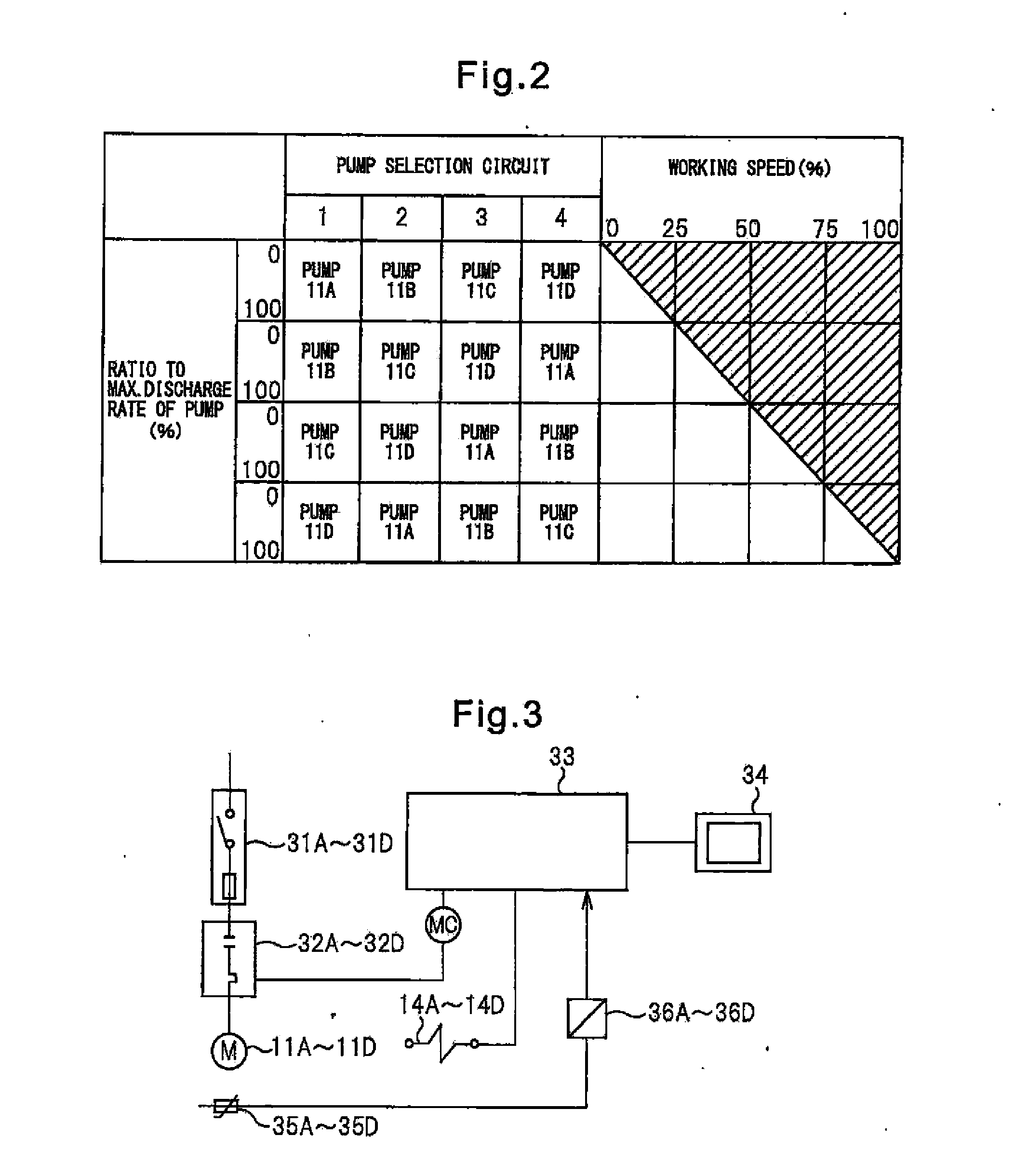

InactiveUS20140096581A1Suitable operational managementReduce power wasteExtrusion profiling toolsElectric motor controlHydraulic cylinderThermal fatigue

The present invention provides an extrusion press which eliminates unevenness of dynamic and thermal fatigue degrees of the hydraulic devices which form the hydraulic circuit in the extrusion press, the electric Motors which drive the hydraulic pump, the control devices, etc., which makes the dynamic and thermal fatigue degrees and remaining service lives of the component devices even, and which is excellent in energy saving effect.An extrusion press which has a plurality of variable capacity type hydraulic pumps connected to it in parallel for supplying working oil to hydraulic cylinders of the extrusion press, uses a preset working speed as the basis to find the required discharge rate of the hydraulic pumps, and selectively controls the drive operations of the hydraulic pumps, wherein the order of selection of the hydraulic pumps which are selectively controlled in drive operation is controlled by a program which progressively advances when a predetermined number of molding cycles are completed.

Owner:UBE MASCH CORP LTD

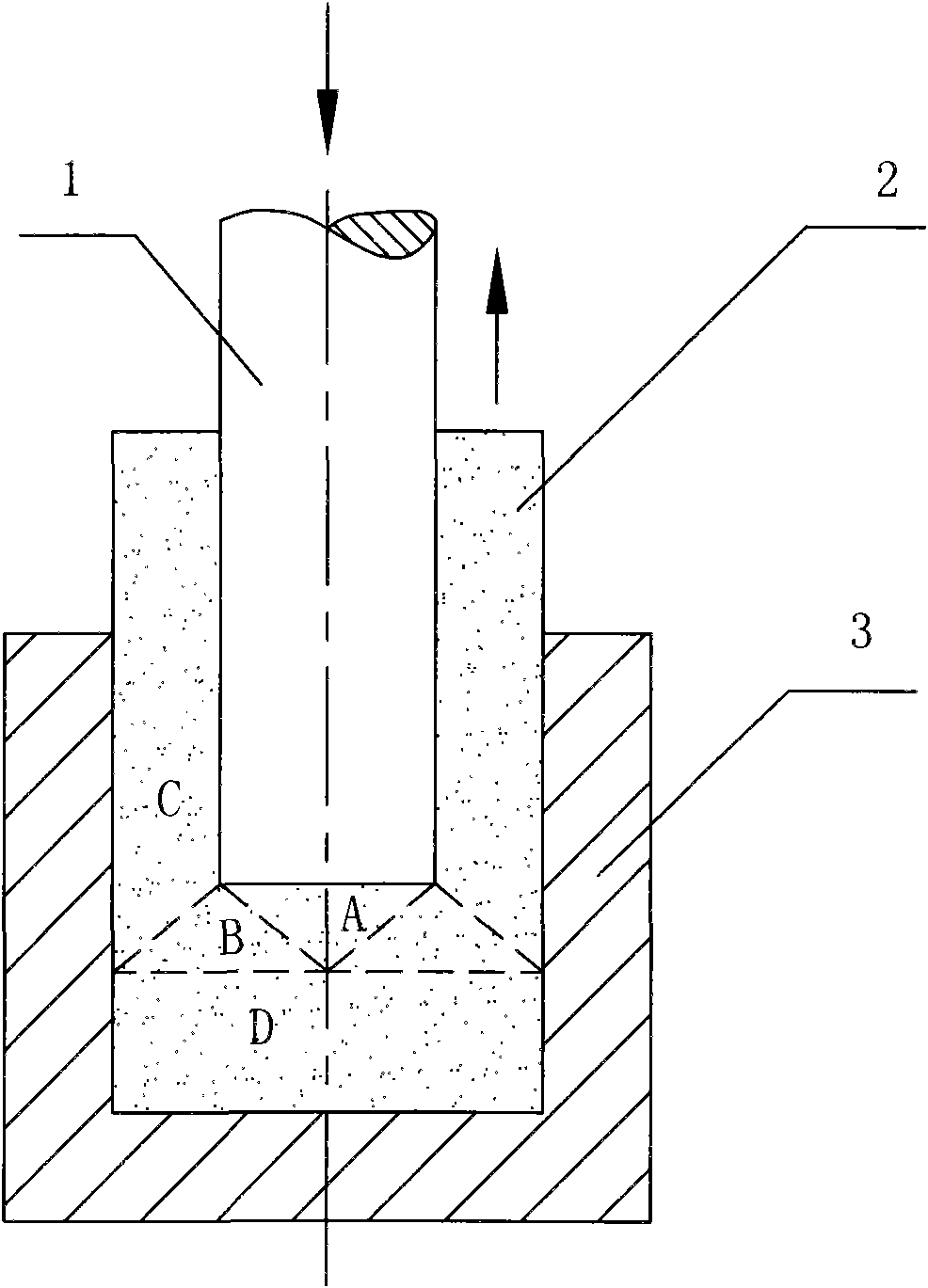

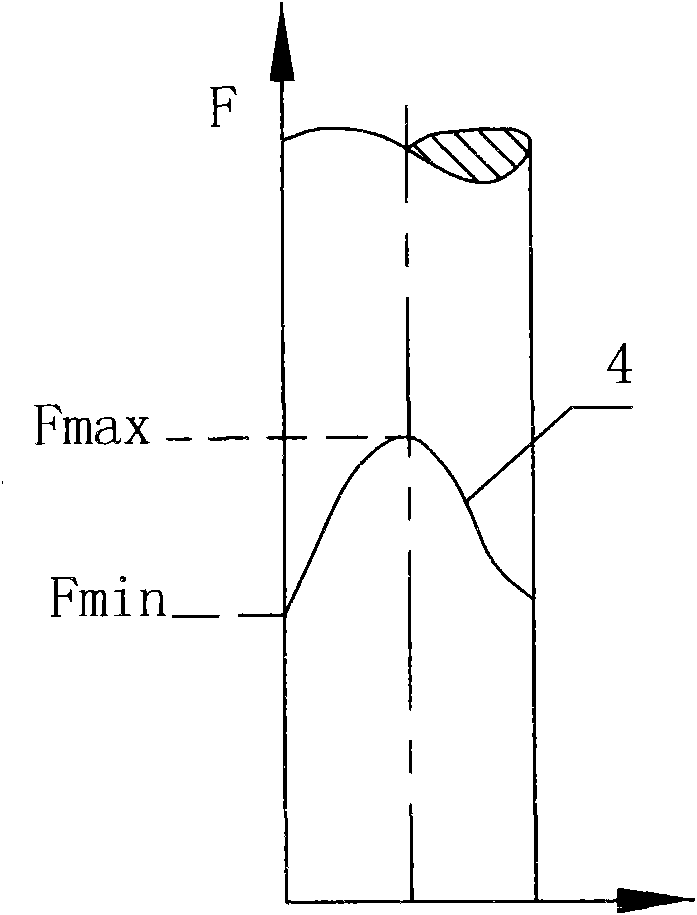

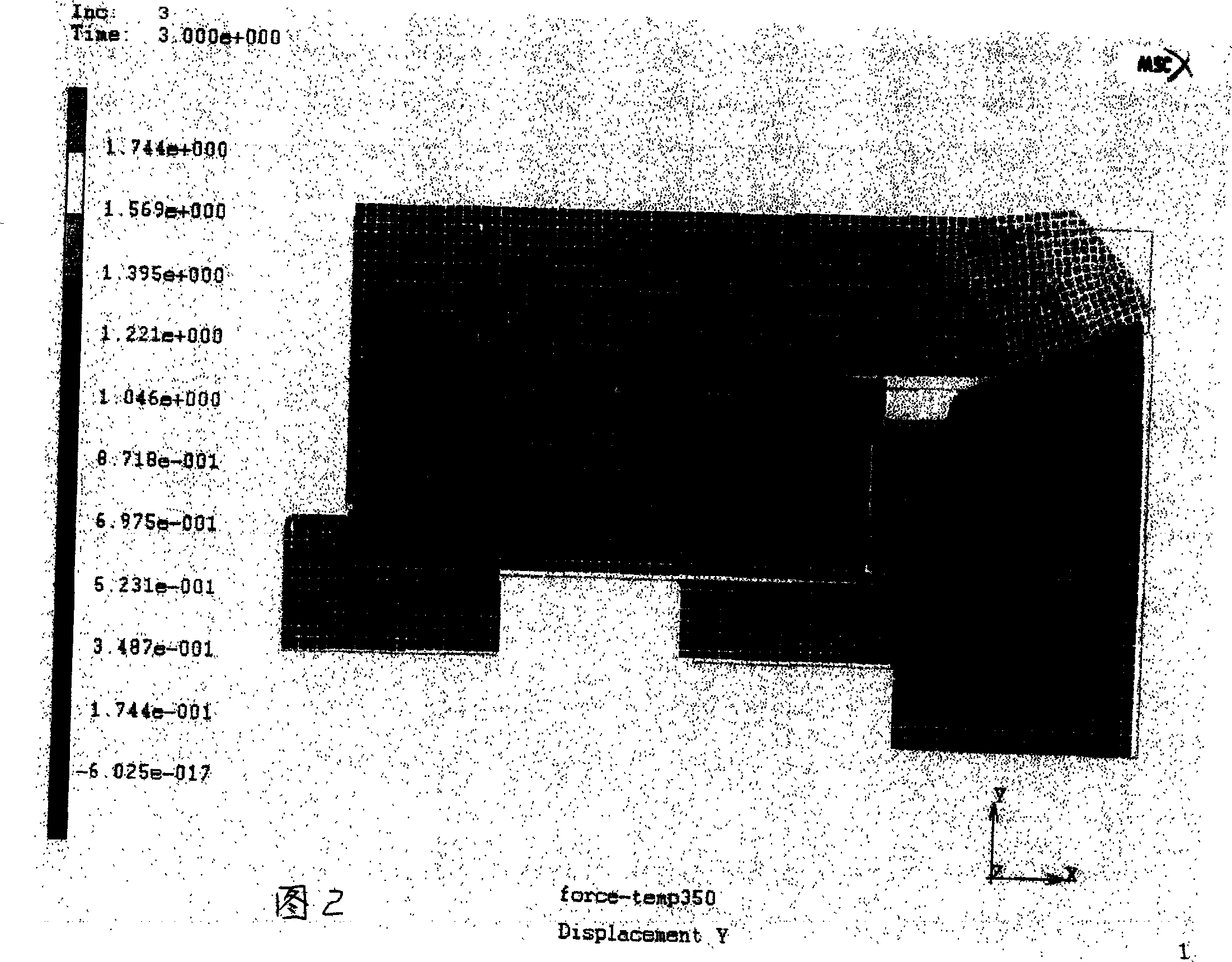

Deep hole extrusion forming process of medium-carbon low-alloy structural steel

ActiveCN101829696AHigh strengthImprove toughnessExtrusion diesRams/plungersMetallic materialsEngineering

The invention belongs to the formation field of metal materials and relates to a deep hole extrusion forming process of medium-carbon low-alloy structural steel. When a punch head extrudes downwards, the upper end of a blank keeps still, the lower end of the blank is extruded downwards along the barrel wall of a die, one or more punch heads are adopted to extrude according to the forming requirement of a deep hole, and the sizes of the punch head, the die and the initial blank and the relation among the punch head, the die and the initial blank meet the following forming conditions: the diameter of the punch head is d, and the initial length L1 of the blank is (1.5-6) d; the initial diameter of the blank is same as the inner diameter of the upper part of the die, and the size range of the initial diameter of the blank is greater than d+10 millimeters and less than 2d; a single-side gap between the punch head and the inner diameter of the upper part of the die is greater than 5 millimeters; an annular gap is arranged between the caliber D2 of a next-stage stair on the inner wall of the die and the punch head, and the single-side width of the annular gap is greater than 1 millimeter and less than 0.4d; the annular area of the next-stage stair on the inner wall of the die is 39% greater than the sectional area of the punch head; and the head of the punch head is in a 15-degree conical surface shape, the most front end of the head of the punch head is a circular-arc surface, and the length of the head of the punch head is (0.8-1) d. The invention can obtain better strength than tempering heat treatment and flexible comprehensive mechanical properties.

Owner:邓晓光

Continuous extrusion method and equipment for producing large-width copper strip base from noncircular rod material

InactiveCN101733298ASolve the technical problem of being unable to continuously extrude products with a width-to-thickness ratio greater than 20Simple production processExtrusion diesRams/plungersEngineeringCopper

The invention relates to the technical field of continuous extrusion. A noncircular blank continuous extrusion method is adopted, the noncircular blanks enter the groove of a rotary extrusion wheel through a compaction wheel, and are driven by the friction of the groove of a rotary extrusion wheel through a compaction wheel to reach the end surface of a baffle block of a cavity body and enter the cavity body from a cavity body material inlet, and finally are extruded into finished products by a mould. The invention adopts the noncircular blanks to be extruded continuously, thereby effectively solving the technical problem that products with the flakiness ratio above 20 can not be extruded continuously. The invention has simple production process and easy operation is easy and can improve processing efficiency and reduce production cost. The invention also discloses continuous extrusion equipment with simple structure. On the basis of using traditional standard structures and components as much as possible, the invention improves part of structures of the rotary extrusion wheel and the cavity body to match the noncircular blank continuous extrusion, thereby reducing the load of the extrusion wheel and the cavity body during extruding and successfully extruding out a cooper strip product with the flakiness ratio above 20.

Owner:大连康丰科技有限公司

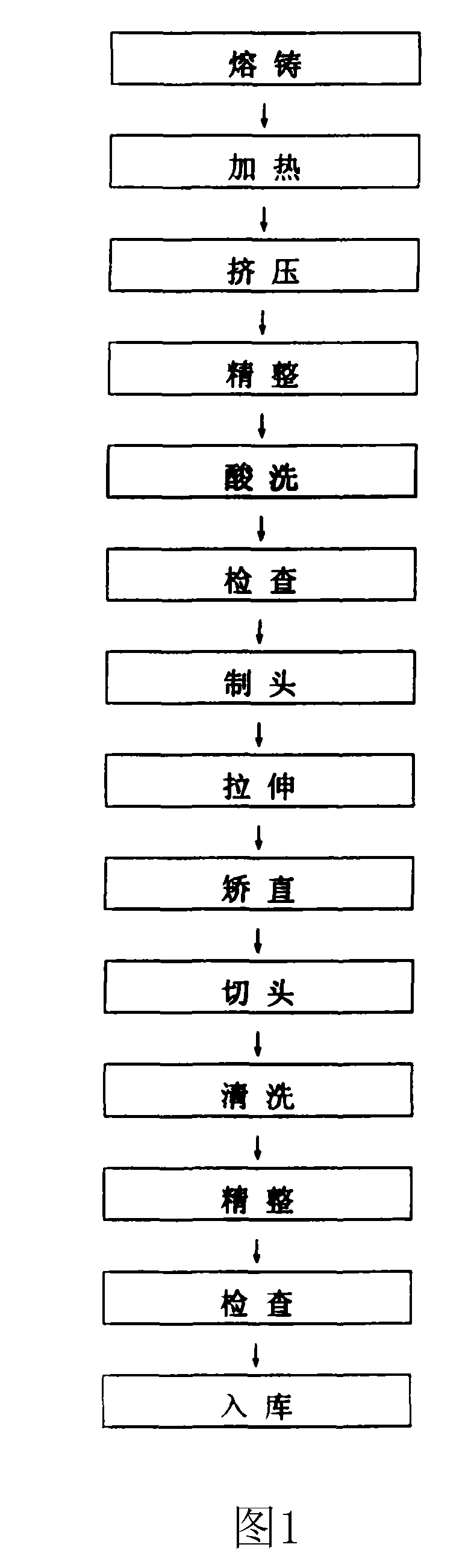

Manufacturing and processing method of D-type copper pipe

The invention discloses a producing method for a D-shaped copper tube, comprising: fusion casting, heating, extrusion pressing, final finishing, acid washing, examining, head making, drafting, straightening, cropping, washing, final finishing, examining, and storing; wherein the extrusion pressing process and drafting process are: replacing extrusion pressing and drafting process in the processing of circular copper tubes in prior art with extrusion pressing and drafting of D-shaped tubes with analogical transitivity and termination product drafting. D-shaped tubes are not-exclusively symmetrical tubes with strict technical index, and the production thereof is difficult. The invented method solves the technique problem in prior art and the D-shaped tubes are not dependent on importation.

Owner:中铝洛阳铜加工有限公司

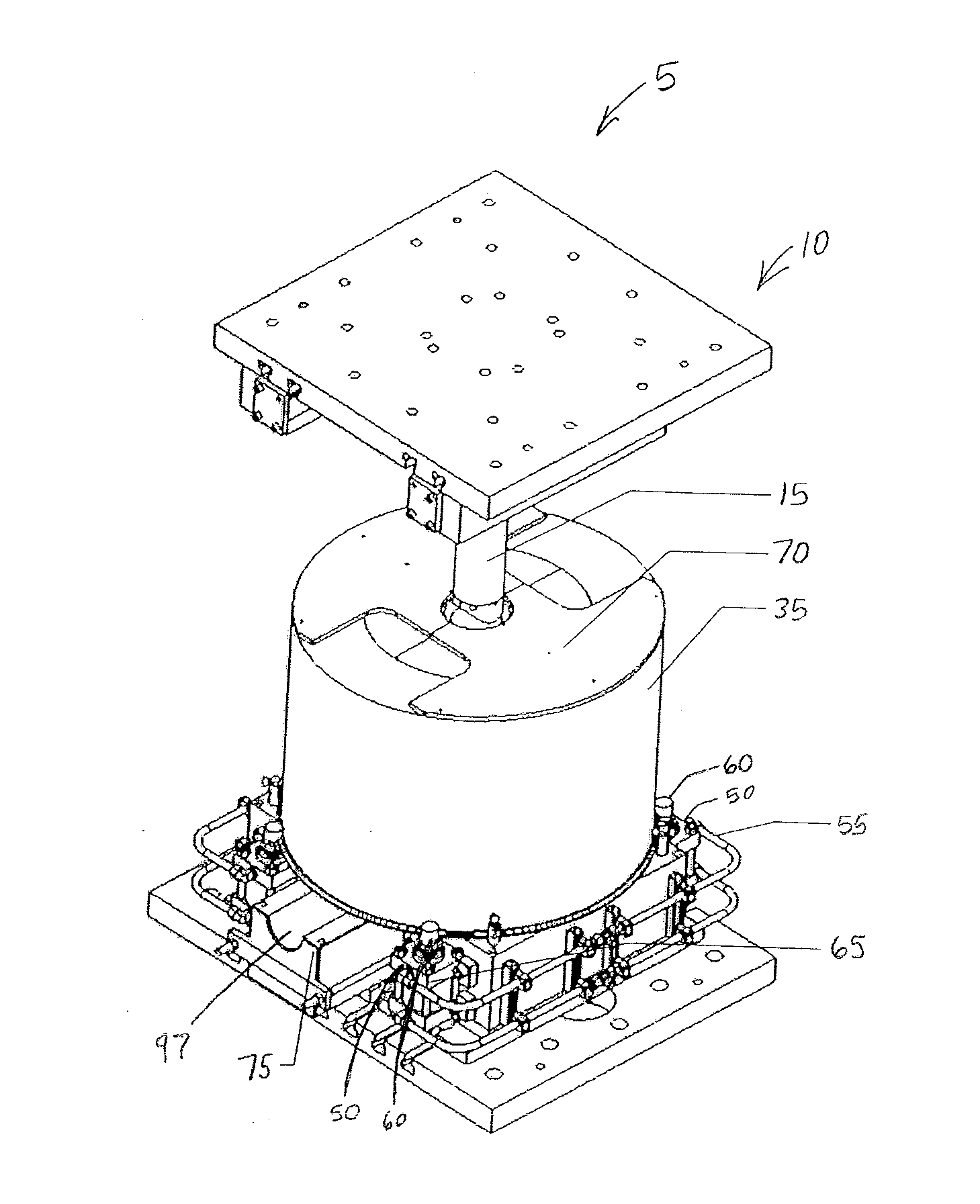

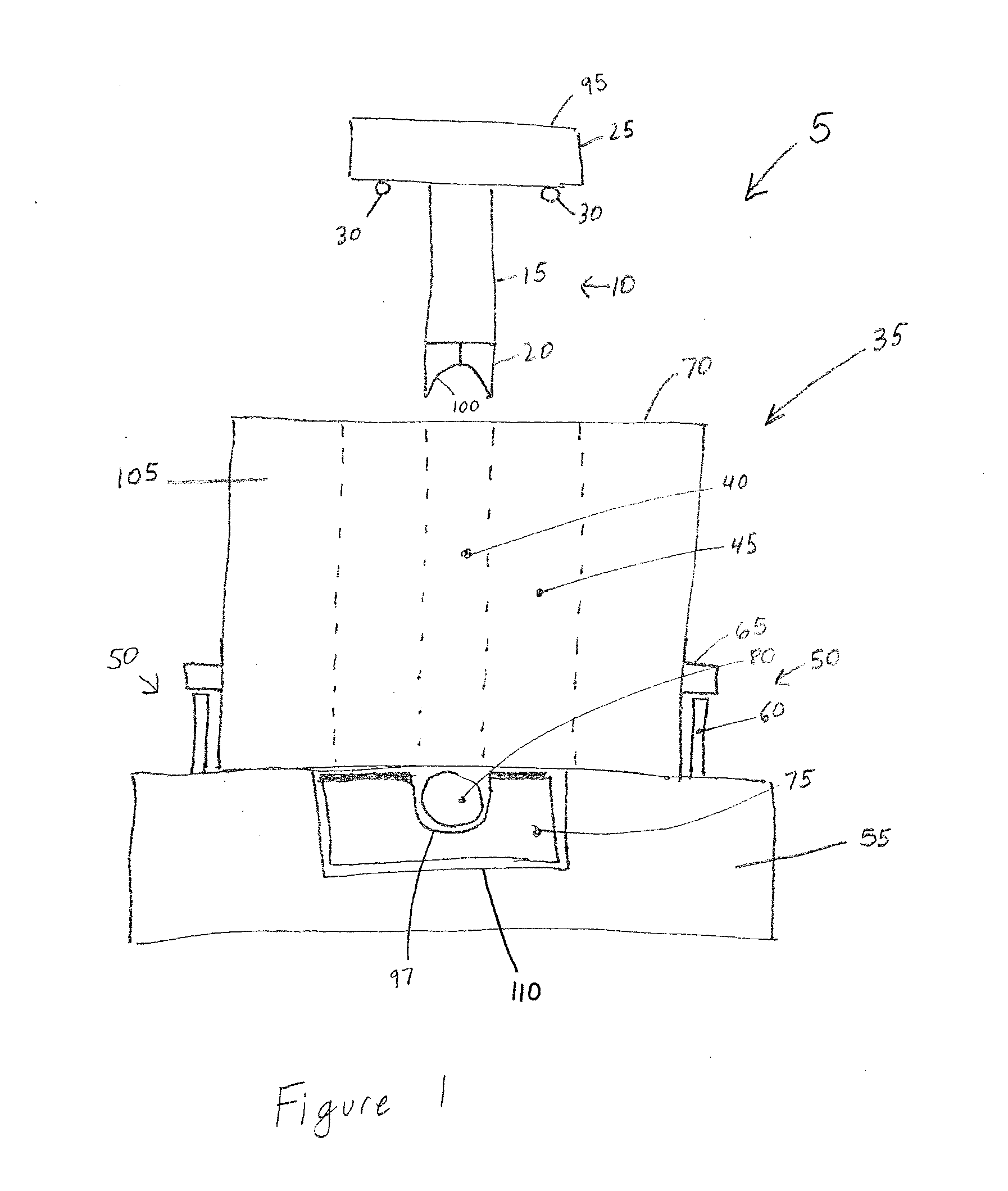

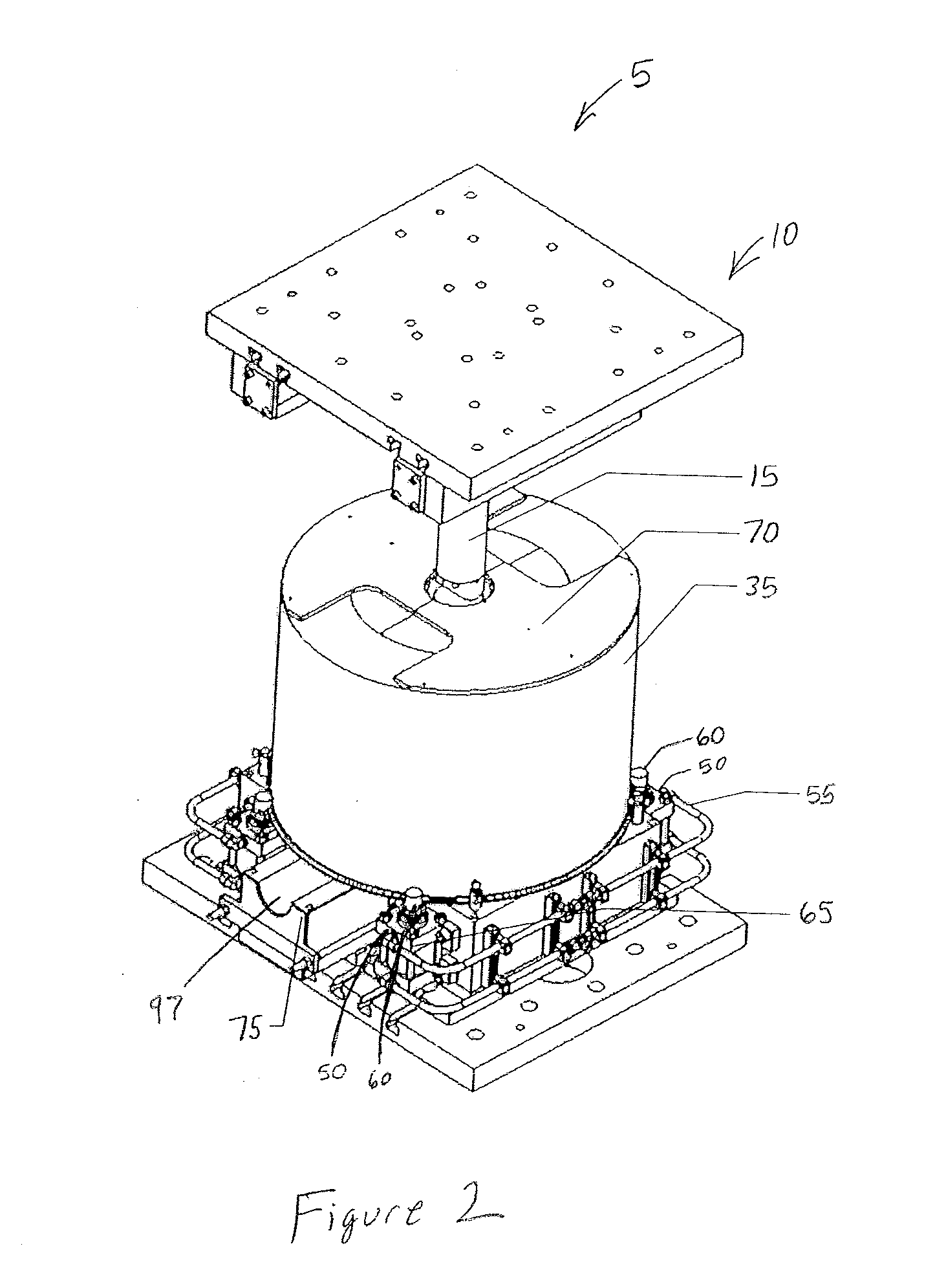

Apparatus for Deformation of Solid Sections

ActiveUS20130276501A1Extrusion profiling toolsAuxillary shaping apparatusInlet channelEqual channel angular extrusion

An equal channel angular extrusion tool comprising a punch assembly, a die set assembly, a base assembly, and a bottom slider assembly. The punch assembly comprises a punch, a punch nose, and a punch trolley. The die set assembly comprises an inlet channel and a removable core. The base assembly comprises a lifting mechanism which further comprises a die lift cylinder and a hold down ram. The bottom slider assembly comprises an ejection ram. The tool also includes a billet. The billet may be disposed in the bottom slider assembly. Severe plastic deformation is applied to the billet in the bottom slider assembly.

Owner:SHEAR FORM

Extrusion molding method and apparatus of extrusion press

InactiveUS7591163B2Improve productivitySufficiently madeExtrusion containersExtrusion mandrelsEngineeringMechanical engineering

An extrusion molding method of an extrusion press includes a first step of loading a billet, the outer surface of which is subjected to a barking treatment, into a container, and extruding the billet in such a manner as to leave a predetermined length, a second step of loading a next billet into the container, additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined length of the succeeding billet; and a third step of loading a next billet into the container and additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined discard length of the succeeding billet and stopping extrusion. By way of these steps, the container does not move while maintaining contact with a die, and the billet is continuously extruded by leftover and additional extrusion.

Owner:UBE MASCH CORP LTD

Manufacturing technology of braking cone

InactiveCN101579803ALess consumablesCompact structureExtrusion diesRams/plungersManufacturing technologyPunching

The invention discloses a manufacturing technology of a braking cone, billet steel raw material is made into disk raw material and then subjected to spheroidizing annealing, acid washing, thread-drawing sizing treatment and cutting respectively to form a single braking cone blank, and the molding procedure of the braking cone is conducted in a cold extruding mould. The molding procedure of the braking cone comprises the following steps of: material cutting, material shaping and leveling by upsetting, and forming of an inner bevel positioning hole by upsetting at an upper end; material overturning, shaping, and forming of the inner bevel positioning hole at the other end; punching of a large hole at the inner bevel part of the front end and bunching of an abnormal part at the tail end simultaneously; secondary punching and enlarging of the belly part by upsetting, and leveling of the abnormal part at the tail end simultaneously; material overturning, molding of an excircle by extrusion of an upper die and a lower die, and bunching of the abnormal part at the tail end; and leading-out of residual scrap iron at the middle hole part, thus manufacturing the product with a through hole. The technology promotes the production efficiency and product quality of the braking cone, saves raw material, and reduces the production cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

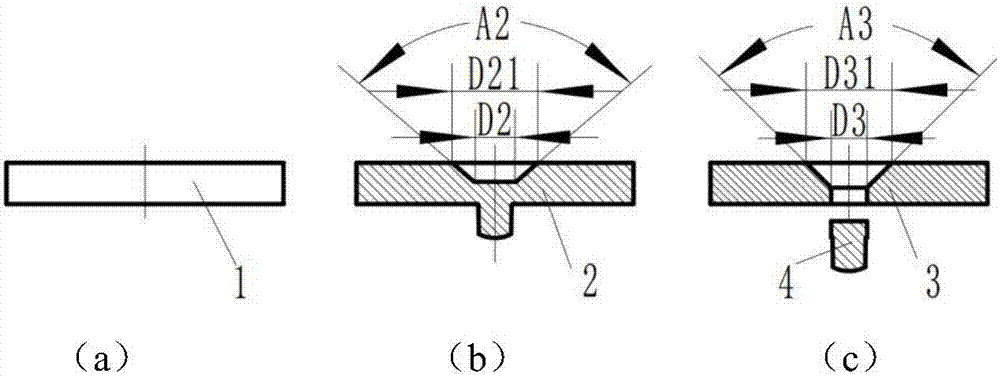

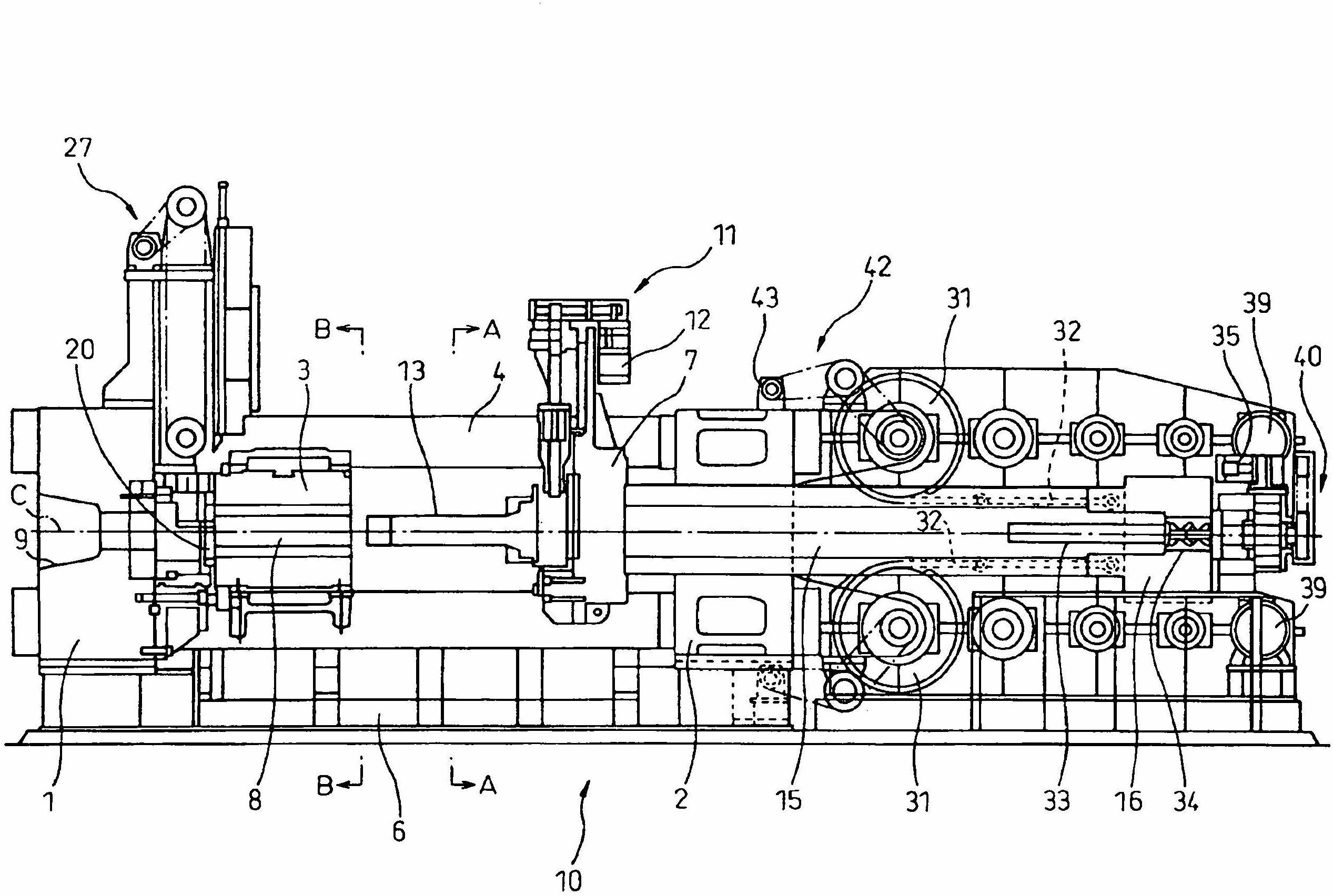

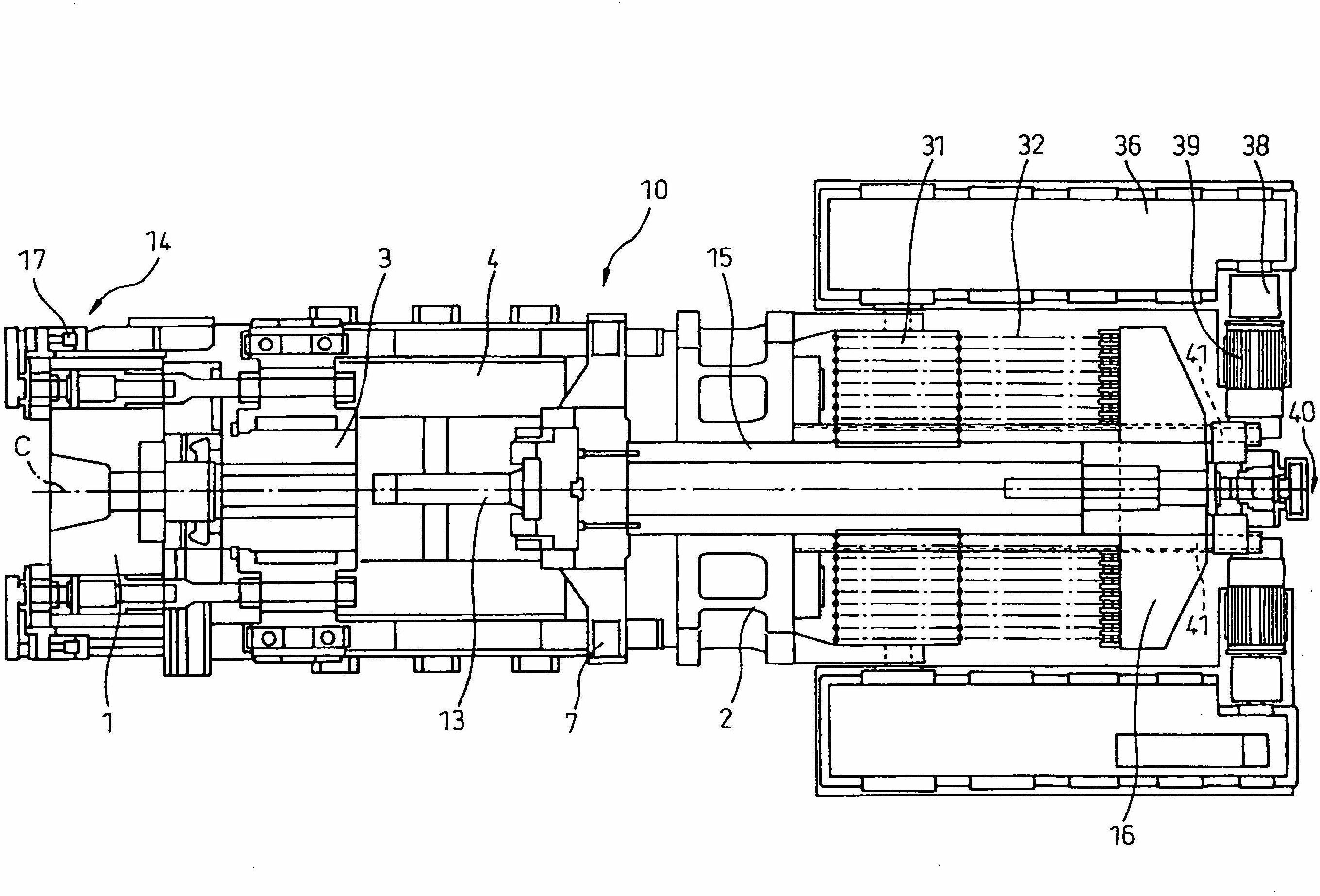

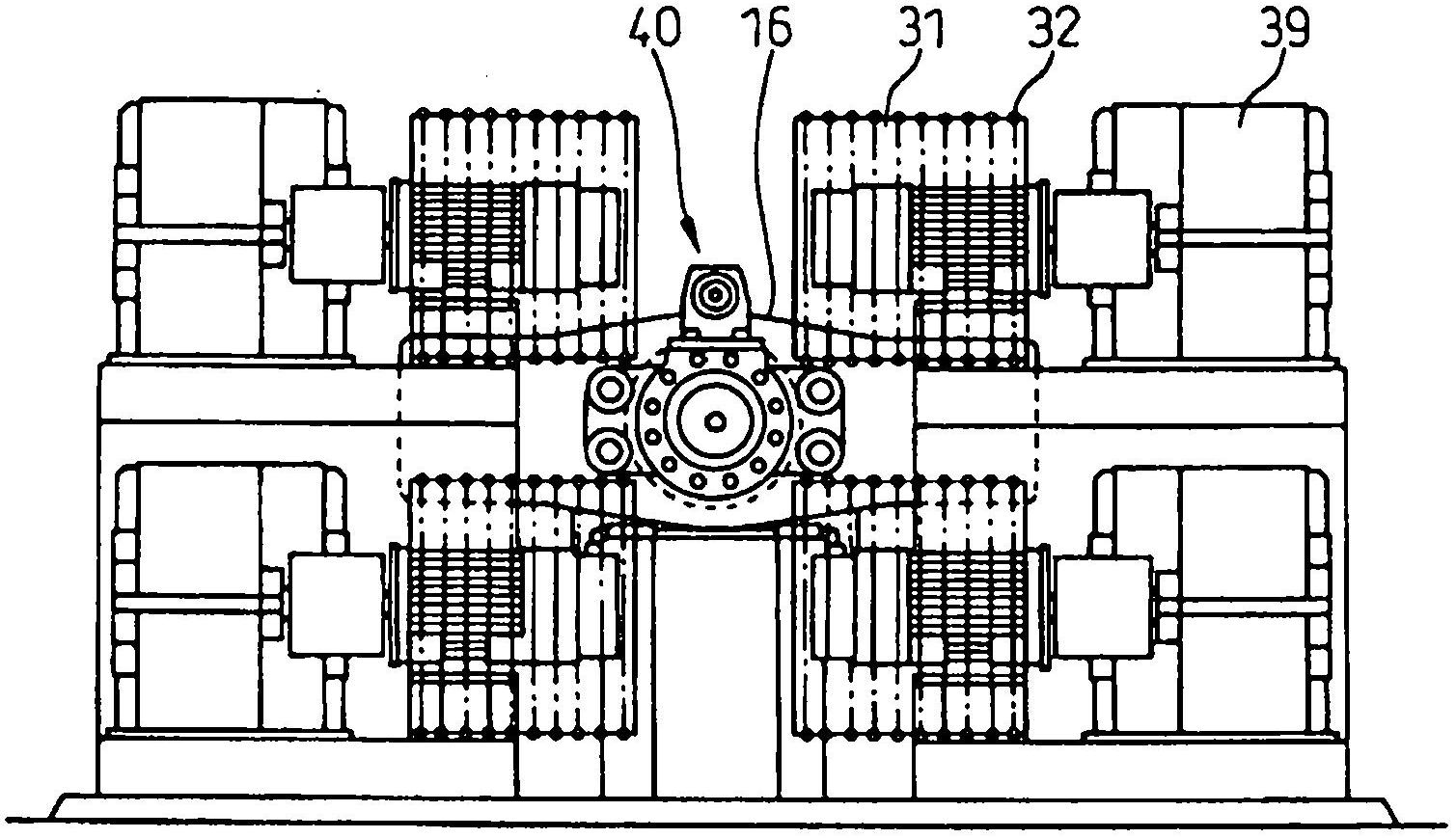

Extrusion press

InactiveCN102652040AExpected power reduction effectShorten the timeRams/plungersReciprocating motionElectric power

Disclosed is a fully electric extrusion press with reduced power consumption, improved maintainability and usability, and a reduced negative impact on the environment. Said extrusion press (10) is provided with an end platen (1), a fixed platen (2) disposed behind the end platen, a tie rod (4) that couples the end platen to the fixed platen (2), a die (20), a container (3) filled with billet (8), an extrusion stem (13) that presses on the billet (8), a cross head (7) to which the extrusion stem (13) is attached, and an extrusion drive device that drives the extrusion stem (13) back and forth. The extrusion drive device is provided with a rotatable wire drum (31) driven by an electric main extrusion motor (39). Extrusion molding is performed by rotating the wire drum (31) and taking up wire (32), thereby driving the extrusion stem (13).

Owner:UBE MASCH CORP LTD

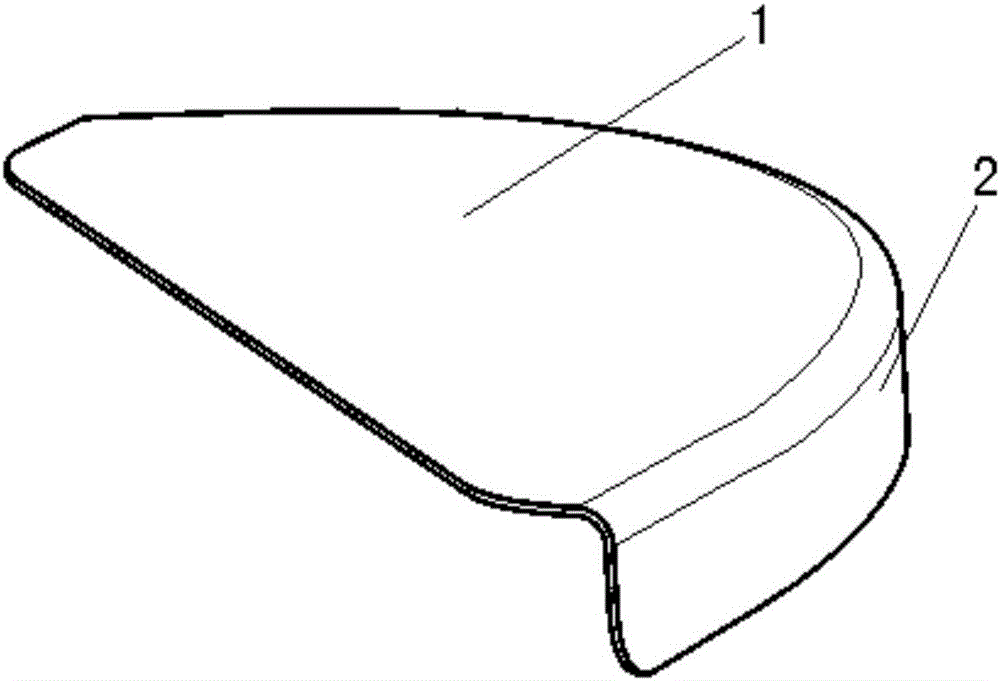

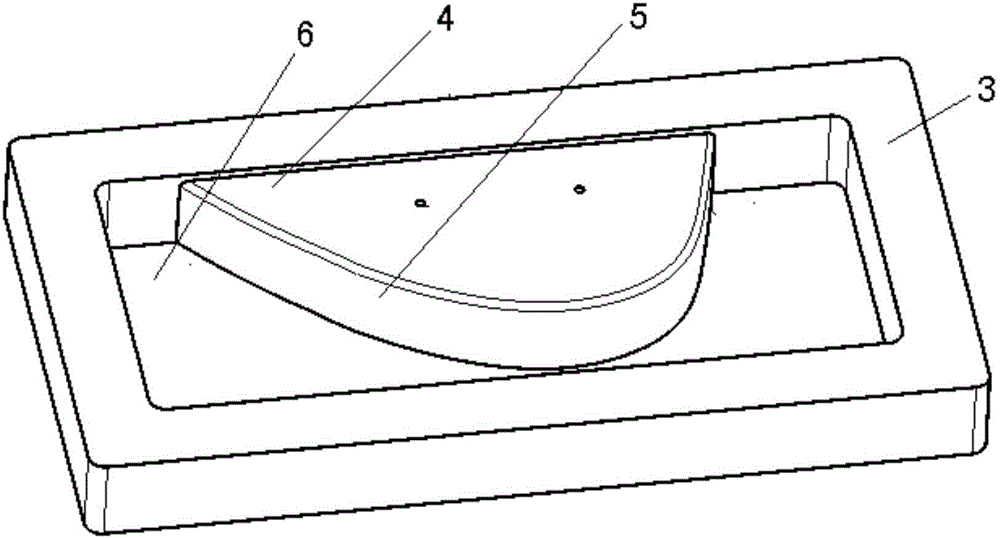

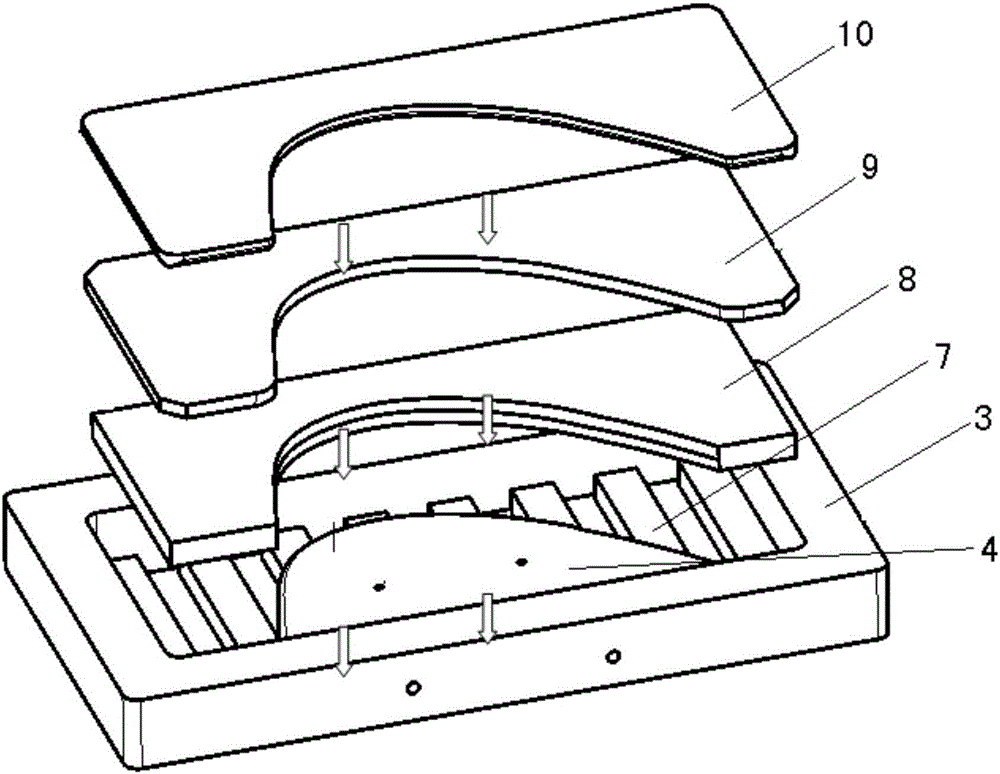

Rubber forming method and rubber forming mould of high-curvature high-flanging sheet metal part

ActiveCN106825096AThe operation method is simple and convenientStrong structural versatilityExtrusion diesRams/plungersEngineeringHydroforming

The invention discloses a rubber forming method and a rubber forming mould of a high-curvature high-flanging sheet metal part. The rubber forming mould comprises an accommodating box, a forming die, a pressing plate, a supporting plate and rubber pads, wherein the non-working surface on the inner side of the forming die is connected to the inner wall of one side of the accommodating box; a moulding cavity is formed between the working surface on the outer side of the forming die and the inner wall of the accommodating box; the outlines of the pressing plate and the supporting plate are smaller than the outline of the moulding cavity; the inner sides of the pressing plate and the supporting plate are matched with the working surface on the outer side of the forming die. The rubber forming method comprises the following steps: placing the accommodating box on a workbench of a hydraulic machine, placing a plurality of rubber pads with equal height inside the moulding cavity, and placing the supporting plate on the upper surfaces of the rubber pads so as to make the surface height of the supporting plate consistent with the height of the forming die; overlapping the pressing plate and the supporting plate, and clamping a flanging area of an unfolded blank; downwardly pressing the pressing plate by using hydraulic forming equipment, fitting the flanging area of the unfolded blank with the working mould surface of the forming die, and forming.

Owner:XIAN AIRCRAFT IND GROUP

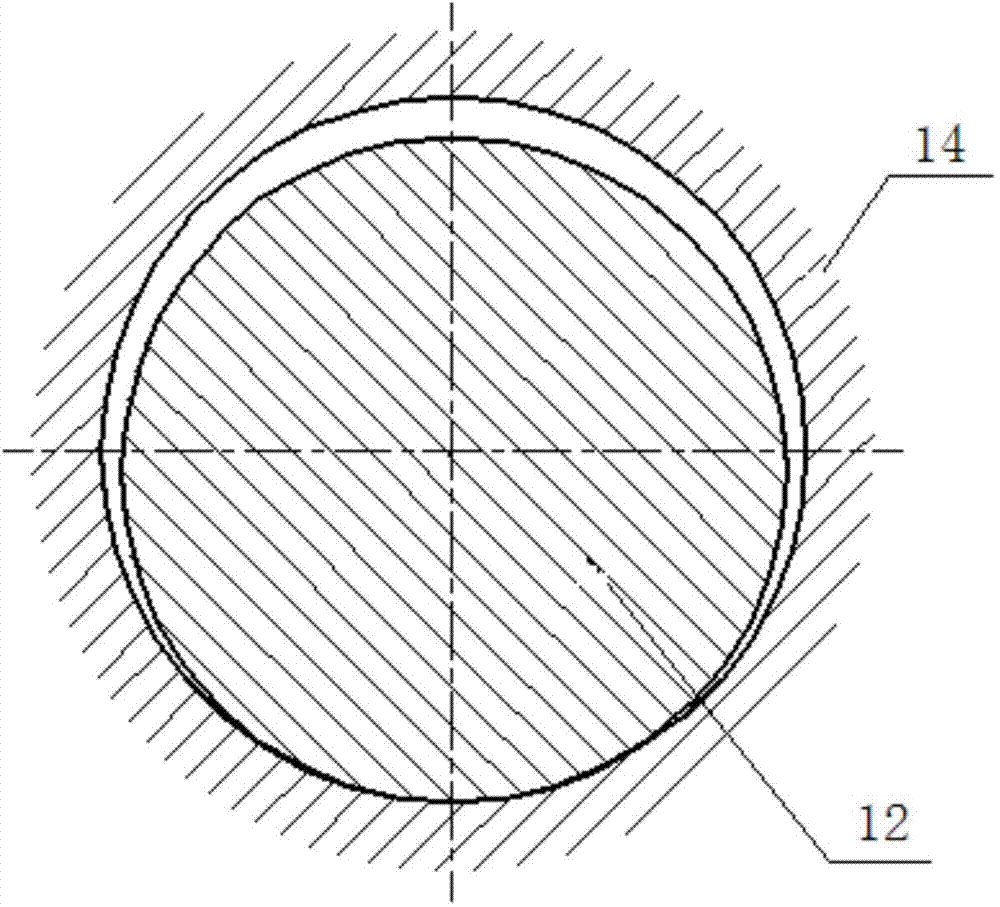

Fixed dummy block for aluminum section extruder

The invention relates to a fixed dummy block for an aluminum section extruder. The fixed dummy block comprises a fixed pad on an extrusion stem, a screw, an expanding ring and a conical gasket. The fixed pad is connected with the conical gasket through the screw; the expanding ring is arranged outside the fixed pad; and an inner conical surface of the expanding ring is matched with a conical surface of the conical gasket. The fixed dummy block is characterized in that: a conical angle between the inner conical surface of the expanding ring and the conical gasket is 48 to 51 degrees. The fixed dummy block has the advantages that: an angle of the fixed dummy block is reduced so as to make the expansion component force generated by the same extrusion force increased; the expansion deformation of the fixed dummy block can be controlled by adjusting a gap between the gasket and the fixed pad; a deformation working tape of the expanding ring is lengthened; a deformation part of the expanding ring is deepened and thinned and is easy to deform; a proper gap between the expanding ring and an extruding container can be guaranteed; and the service life of the expanding ring is prolonged.

Owner:天津锐新昌科技股份有限公司

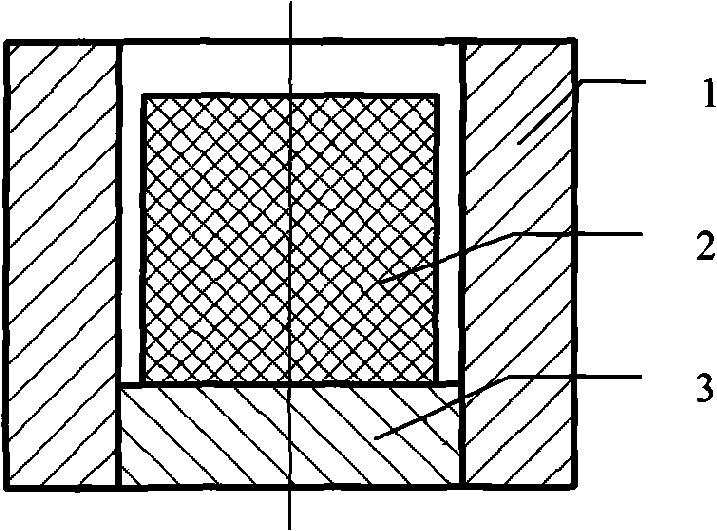

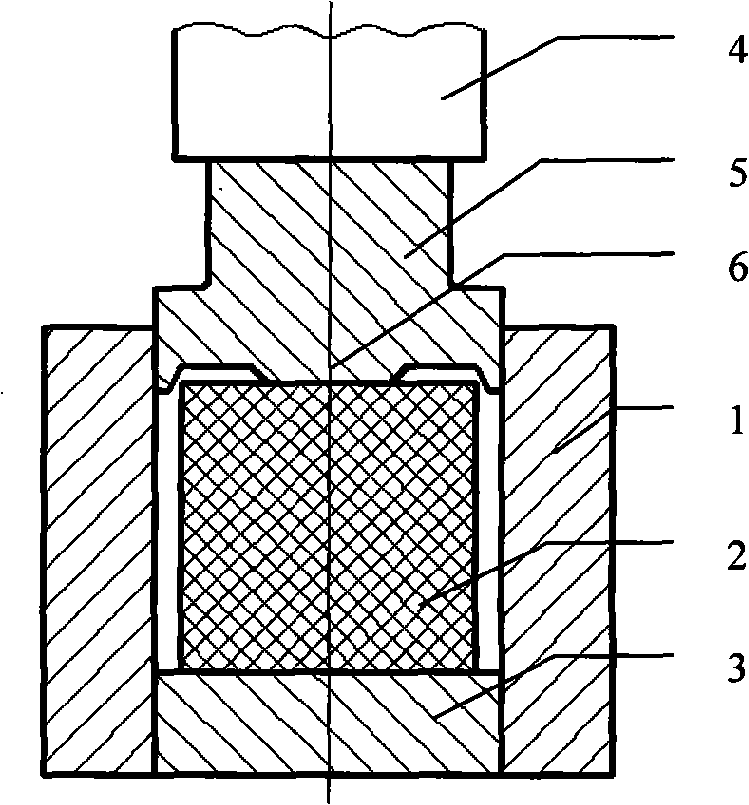

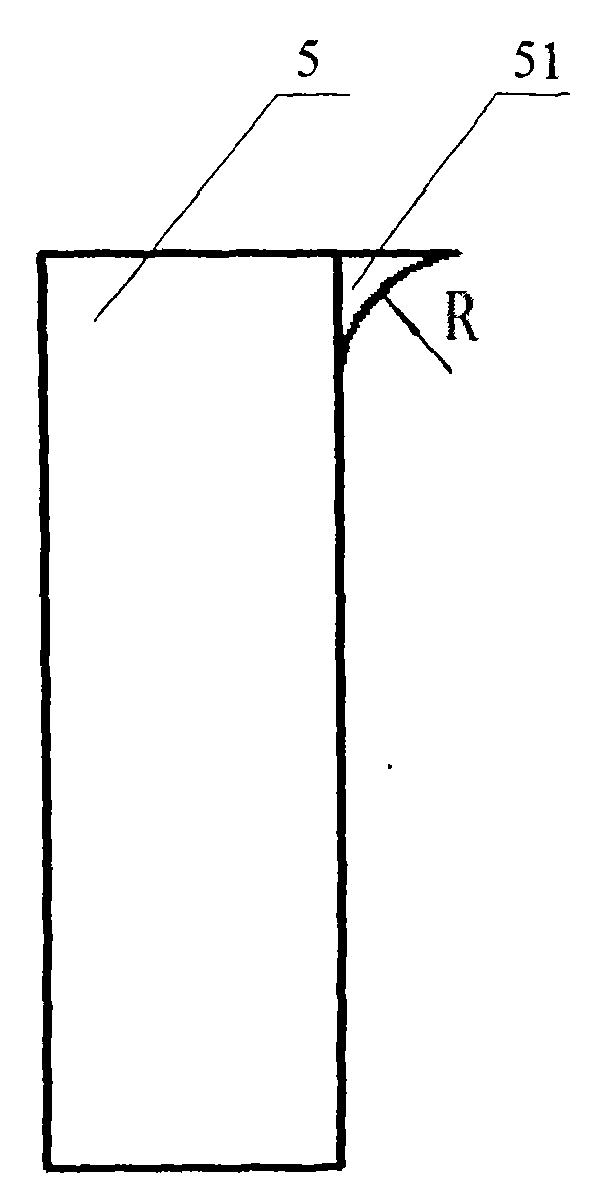

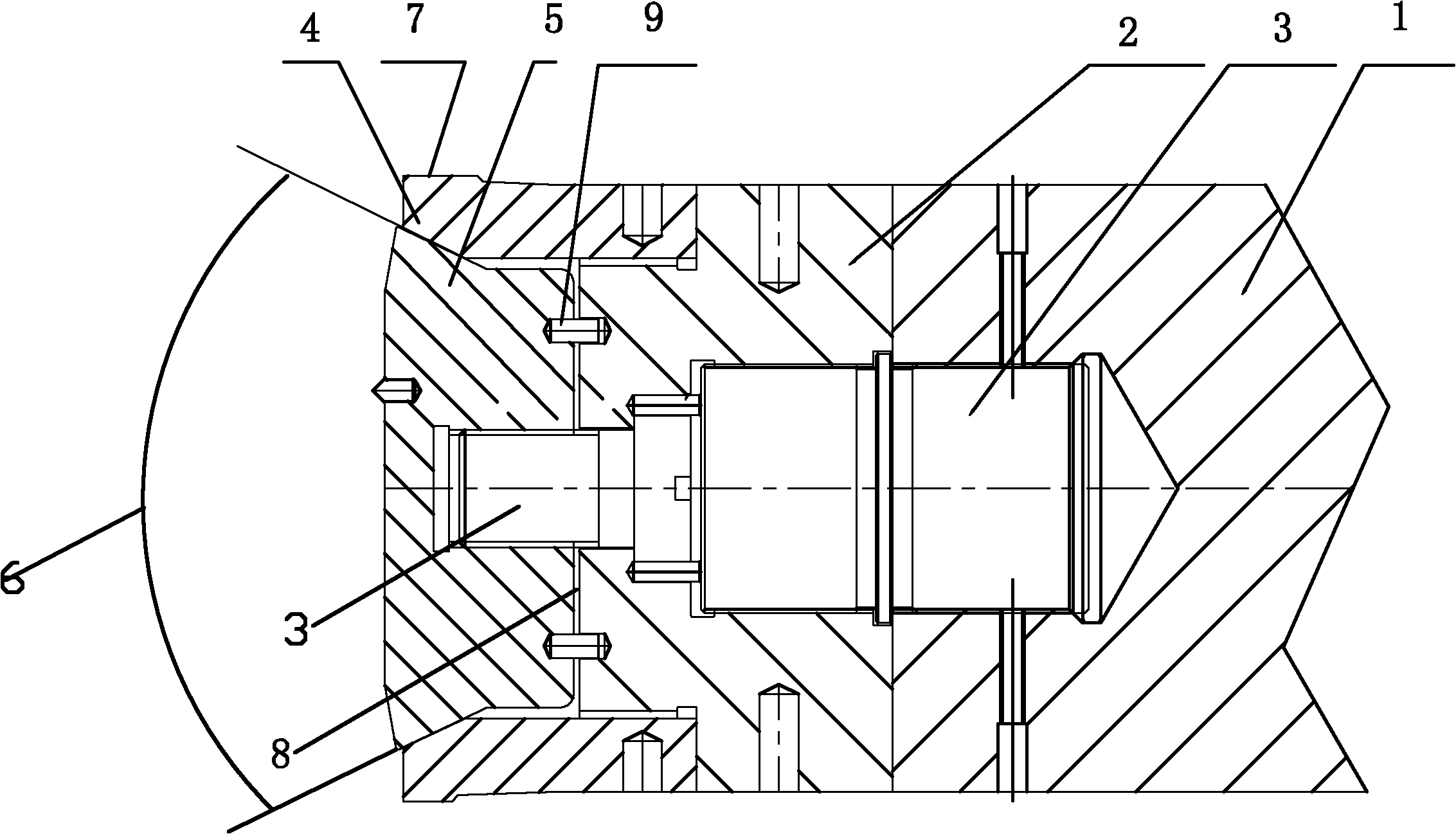

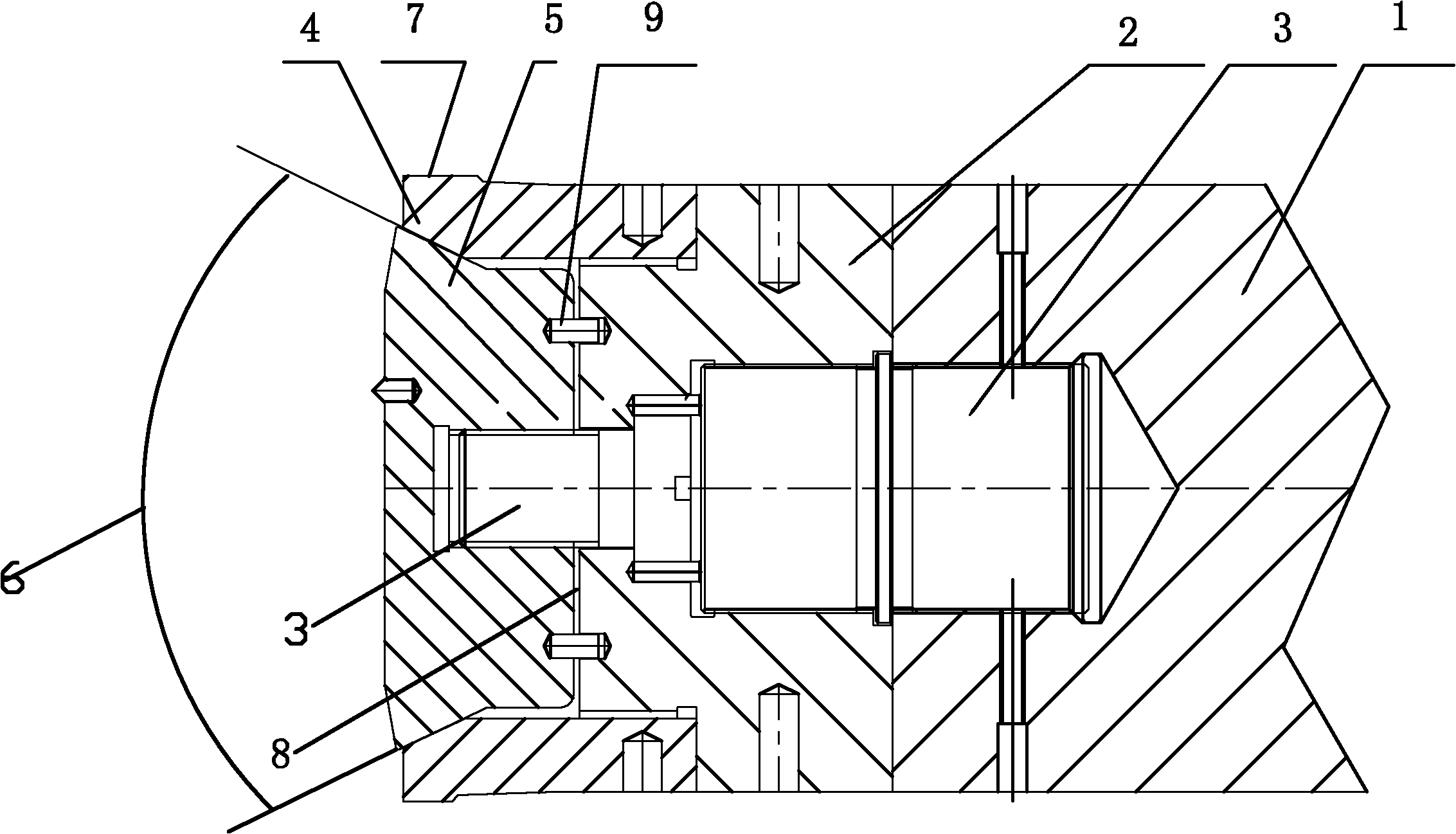

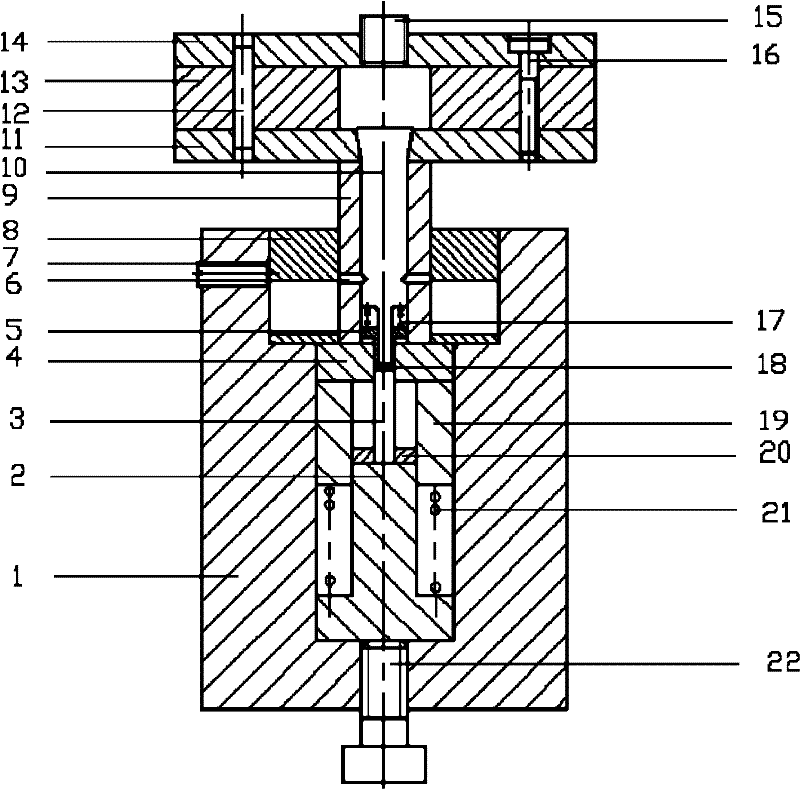

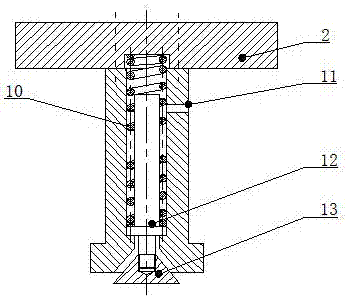

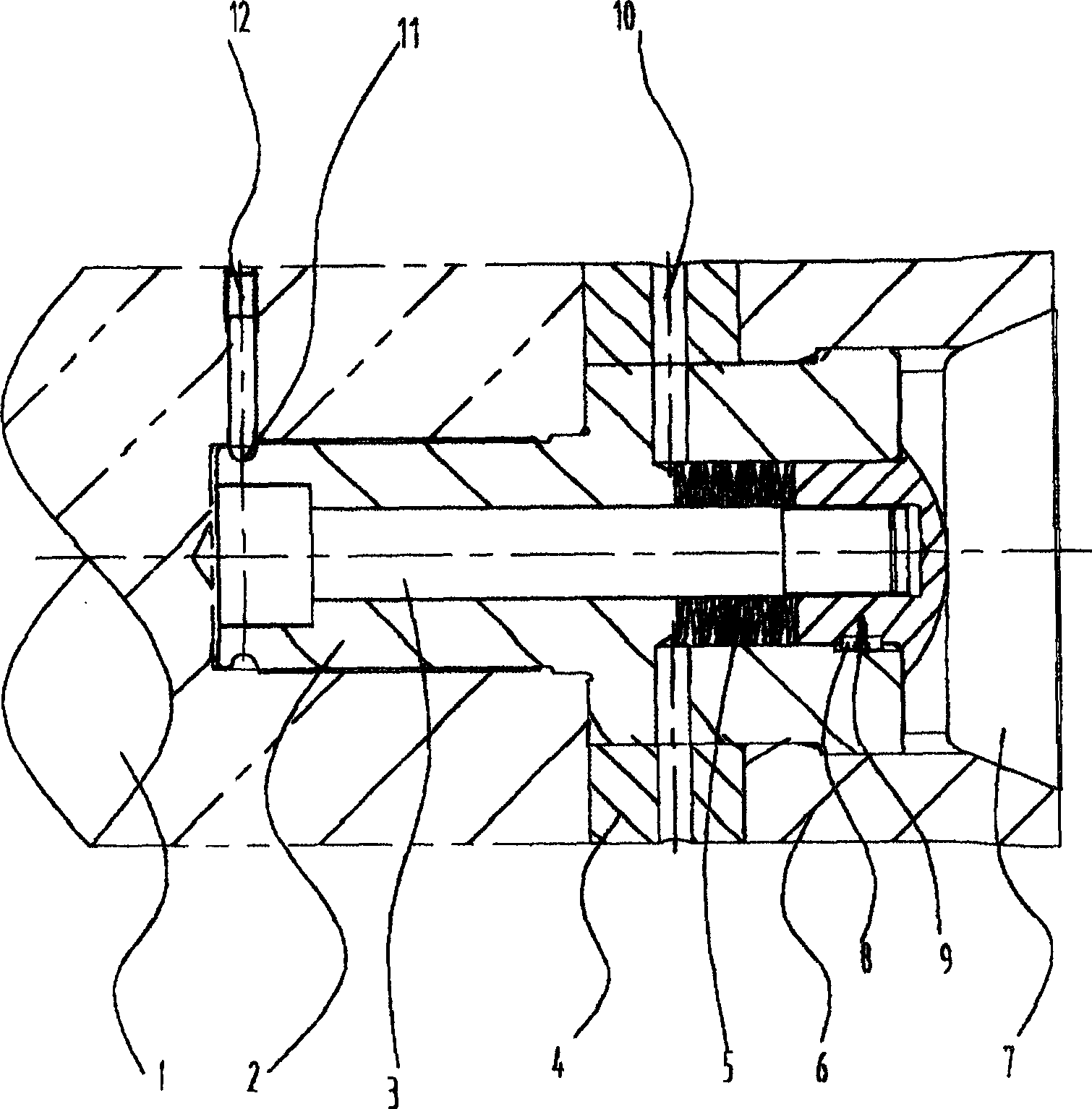

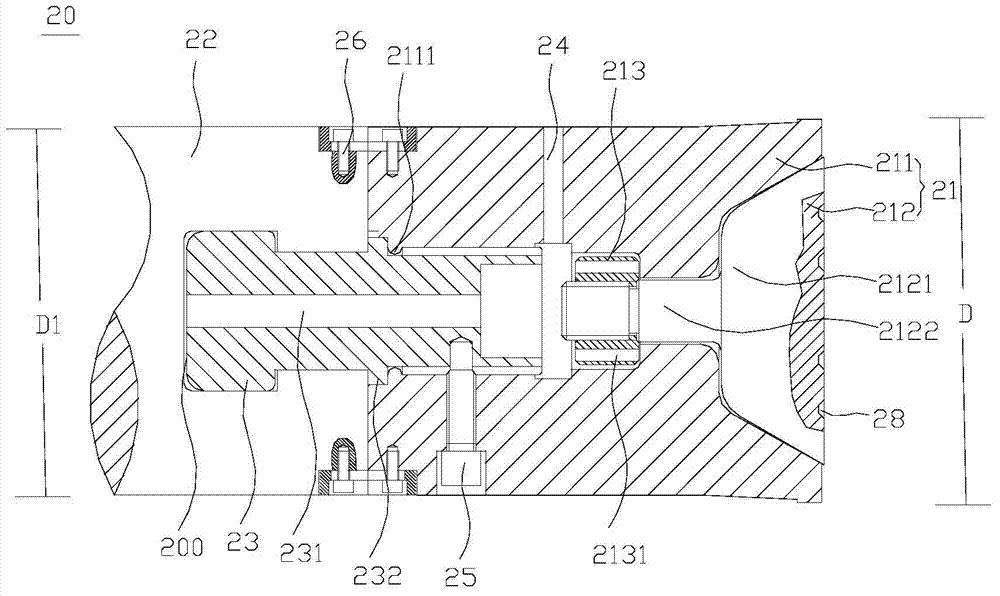

Backward extrusion forming device for miniature precision part

InactiveCN101745559AMeet the dimensional accuracyMeet size requirementsRams/plungersEngineeringMachining

The invention discloses a backward extrusion forming device for a miniature precision part in the technical field of machining work, which comprises a die holder, a combined pressure head, a floating device, a compressing mechanism, a fixed mechanism and a demolding bolt, wherein the die holder is positioned on a worktable of equipment; the floating device and the combined pressure head are positioned in the die holder; the lower end of the fixed mechanism is movably connected with the combined pressure head; the upper end of the fixed mechanism is fixedly connected with pressure equipment; and the demolding bolt is movably arranged in the die holder and contacted with the floating device. The invention realizes high-precision guidance of a terrace die and a cavity die in the forming process and controls the forming precision of final parts.

Owner:SHANGHAI JIAO TONG UNIV

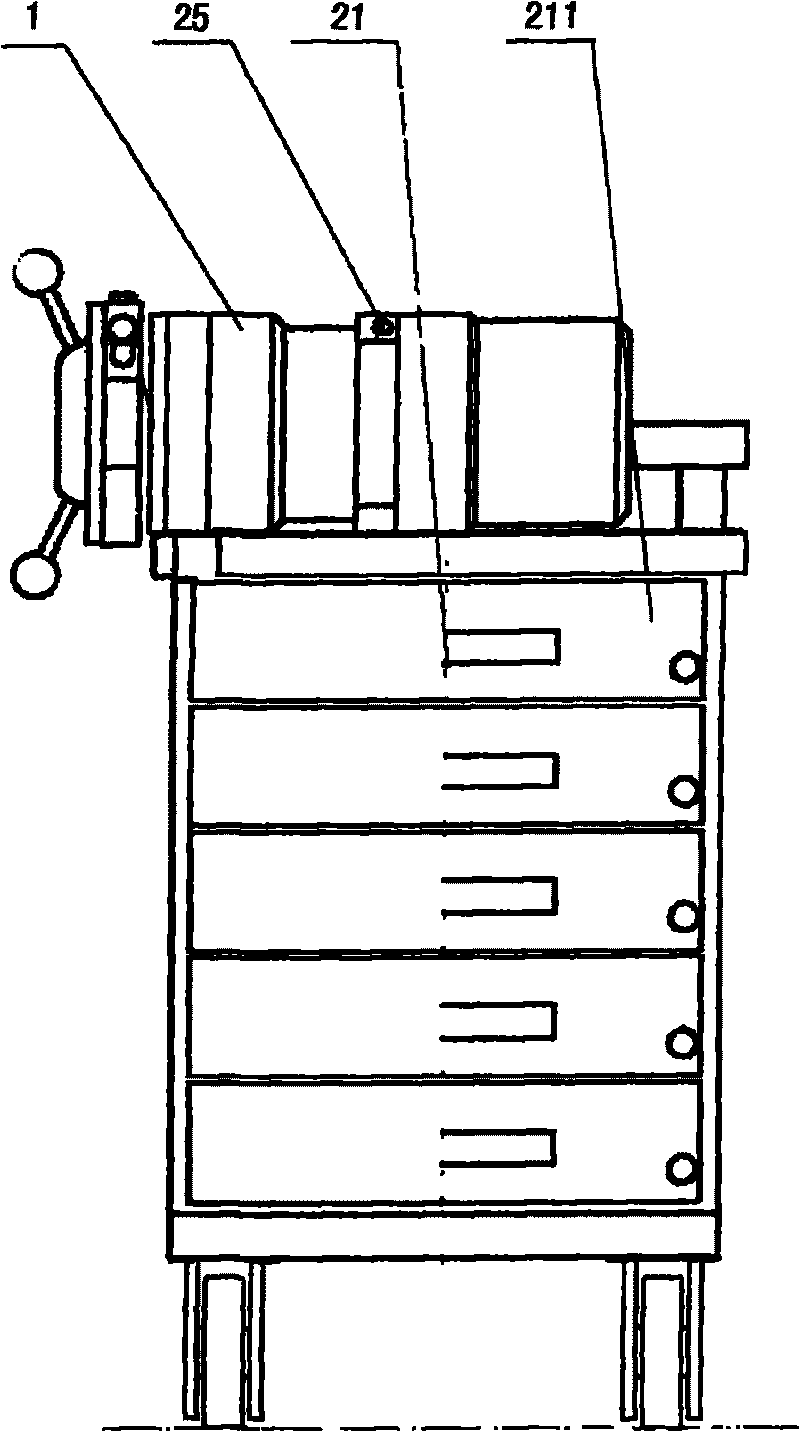

Pipe end extrusion molding machine

InactiveCN101745556AReasonable structural designUniform pressureExtrusion diesExtrusion control devicesLine tubingMolding machine

The invention provides a pipe end extrusion molding machine, comprising a frame, a hydraulic mechanism, an electric control mechanism, a compound hydro-cylinder, a pressurized cylinder, a mould and a nose. The hydraulic mechanism, the electric control mechanism and the pressurized cylinder are arranged in the frame; the compound cylinder, the mould and the nose are arranged on the panel of the frame; the mould is positioned in the nose and is connected with the compound cylinder; the electric control mechanism is connected with the hydraulic mechanism and the pressurized cylinder respectively; the hydraulic mechanism is connected with the pressurized cylinder through a hydraulic oil pipe, and is connected with the compound cylinder through an oil return pipe; the compound cylinder and the pressurized cylinder are connected through the hydraulic oil pipe; and a required specific shape can be extruded at the pipe end by a cold extruding method so as to realize pipeline extrusion molding connection. The machine has reasonable structure design, can be applied to pipeline pipe end extrusion molding in various sizes, has evenly pressurized pipe ends, good quality of molding manufacture, safe and reliable performance, stable operation, small noise and high working efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +3

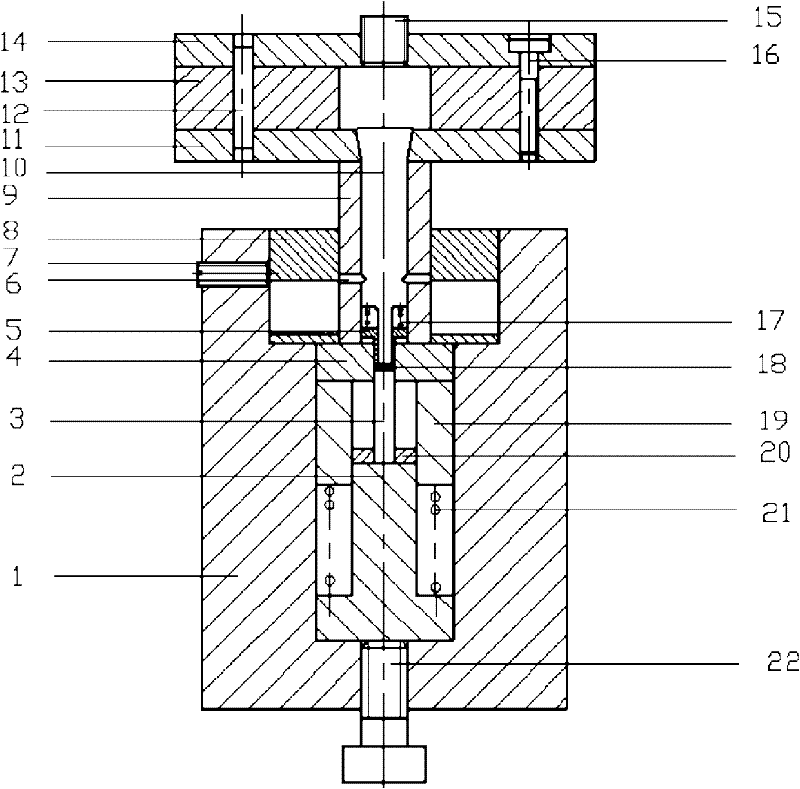

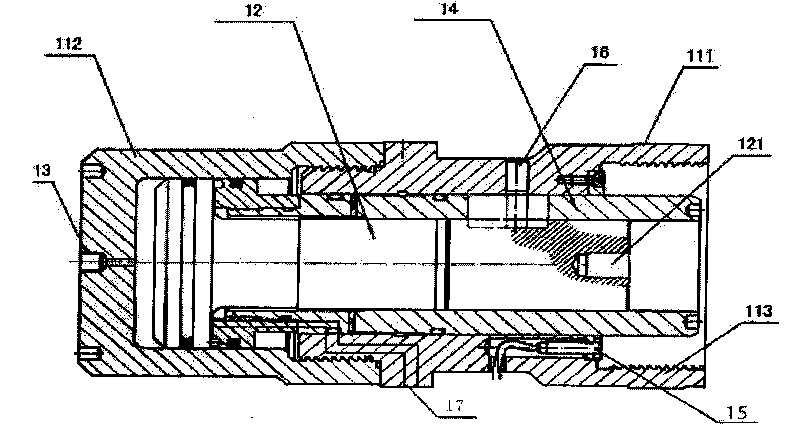

Cup-shaped part reverse extrusion molding device and method

InactiveCN106862290AReduce frictionSmall forming forceExtrusion diesExtrusion containersHydraulic cylinderBarrel Shaped

The invention discloses a cup-shaped part reverse extrusion molding device and method. The molding device comprise an upper mold plate, a base plate, a reverse extrusion punch, a compression spring, a limiting sleeve, a reverse extrusion barrel, an ejector block, an ejector rod, hydraulic cylinder pull rods and a lower mold plate. The base plate is arranged below the upper mold plate, the bottom of the base plate is connected with the reverse extrusion punch, the reverse extrusion barrel is arranged inside the limiting sleeve, the ejector block is arranged inside the reverse extrusion barrel, the ejector rod is arranged at the bottom of the ejector block, the hydraulic cylinder pull rods are fixed between the reverse extrusion barrel and the lower mold plate, the reverse extrusion punch is of a two-section stepped cylindrical structure, and a three-section through hole is formed in the punch. The reverse extrusion barrel is a barrel-shaped part with an inner cavity being a through hole. The upper portion of the through hole inner cavity is a containing cavity, and the lower portion of the through hole inner cavity is in clearance fit with the ejector block. The lower end of the reverse extrusion barrel is connected with the four hydraulic cylinder pull rods. Each hydraulic cylinder pull rod is of a T-shaped structure, and the reverse extrusion barrel is controlled to move up and down. The friction force between the punch and a blank and the friction force between the blank and the wall of the reverse extrusion barrel are reduced, the equipment service life is prolonged, and the cost is saved.

Owner:ZHONGBEI UNIV

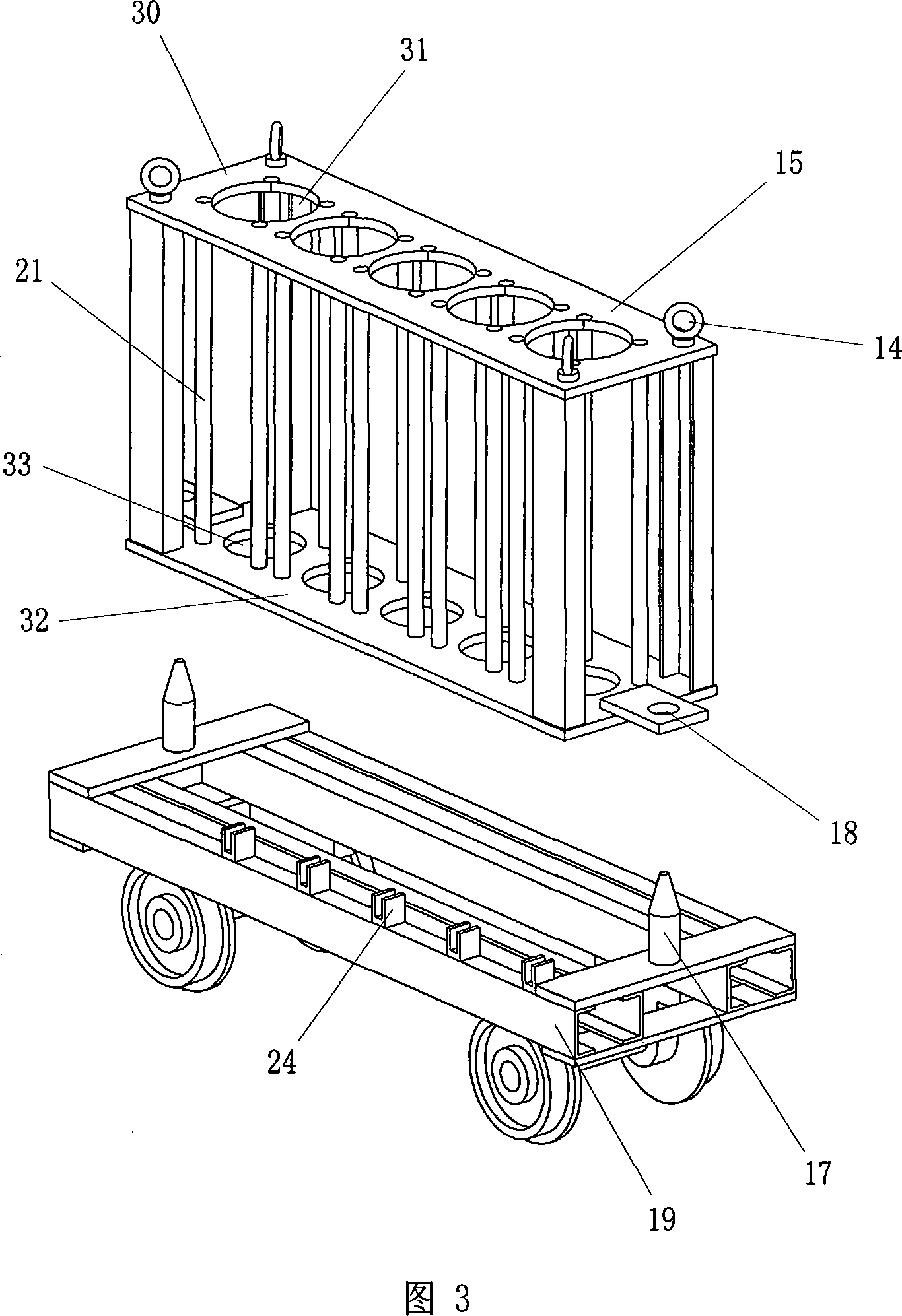

Hot extrusion steel tube blank tail pad warming and transporting unit

InactiveCN101134215ACompact structureSequential deliveryExtrusion control devicesRams/plungersHeating furnacePiston rod

The hot extruded steel pipe blank tail mat heating and conveying apparatus includes one heating furnace with horizontal tracks inside the hearth and penetrating doors, one superposing material frame before the feeding door of the heating furnace, and one vertical material pushing oil cylinder and one horizontal material pushing oil cylinder. The superposing material frame consists of one upper plate with tail mat loading and unloading hole, one lower plate with oil cylinder piston rod lifted hole, and tail mat surrounding bars between the upper plate and the lower plate. The hot extruded steel pipe blank tail mat heating and conveying apparatus can convey tail mats into the heating furnace safely accurately in order and heat the tail mats, and has compact structure, high production efficiency and other advantages.

Owner:ZHEJIANG JIULI HI TECH METALS

Expanding ring type fixed extrusion pad for aluminium extrusion machine

InactiveCN1597164AImprove reliabilityReduced no-extrusion cycle timeRams/plungersAluminium extrusionAluminium alloy

A fixed expanding-ring pressing block for the squeezer of aluminium part is composed of main body with spring in its central hole, conic pad, screw bolt for connecting said conic pad with main body, expanding ring with front and back conic surface for maching with said conic pad, pressing rod, ring pad between pressing rod and expanding ring, etc.

Owner:TAIYUAN HEAVY IND

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS20090241632A1Increased longevityHigh hardnessShaping toolsCutting toolsMetal formingWear resistant

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

Extrusion device and extruding machine with same

The invention relates to an extrusion device which comprises an extrusion pad, an extrusion rod and a connecting part, wherein the extrusion pad comprises an outer bush and a lining, the outer bush is axially provided with an accommodating hole, the lining is accommodated in the accommodating hole, and the outer bush is connected with the lining; the extrusion rod is axially provided with an inner hole; and one end of the connecting part is cooperated with the inner hole of the extrusion rod, and the other end of the connecting part is connected with the extrusion pad, so that the extrusion pad is fastened with the extrusion rod, and the connecting part and the extrusion rod can move relative to each other along the axial direction. In the extrusion device, the extrusion pad is fixedly connected with the extrusion rod, and therefore, in the process of extrusion, the extrusion rod is always attached to the end face of the extrusion pad; because the connecting part and the extrusion rod can move relative to each other along the axial direction, a situation that the extrusion rod directly transfers a force to the extrusion pad is ensured, and a situation that a force is transferred by the connecting part is avoided, thereby ensuring the service life of the extrusion device; and the extrusion rod drives the extrusion pad to withdraw, so that an aluminium ingot blank is completely separated from the extrusion pad, thereby solving the problem that remnant extruding materials are attached to the extrusion pad and the extrusion pad and an extruding cylinder are non-concentric.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com