Extrusion press

A technology of extrusion machine and extrusion rod, which is applied in the direction of metal extrusion, pressure head/punch rod, metal processing equipment, etc., can solve the problems of difficult to achieve mechanical speed, position, increased operating cost, high noise, etc., and achieve control Excellent performance and operability, improved working environment, and the effect of avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred Mode for Carrying Out the Invention

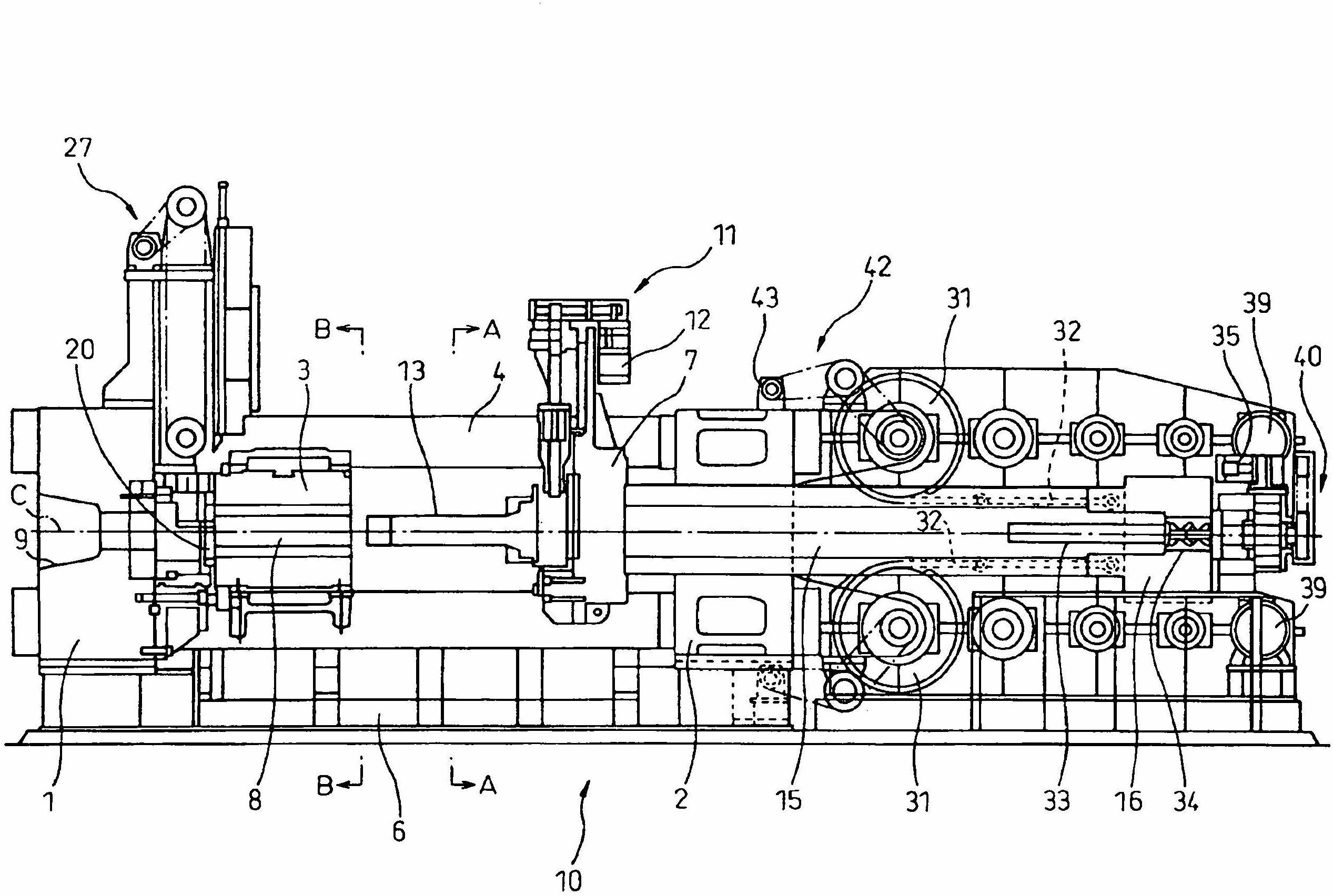

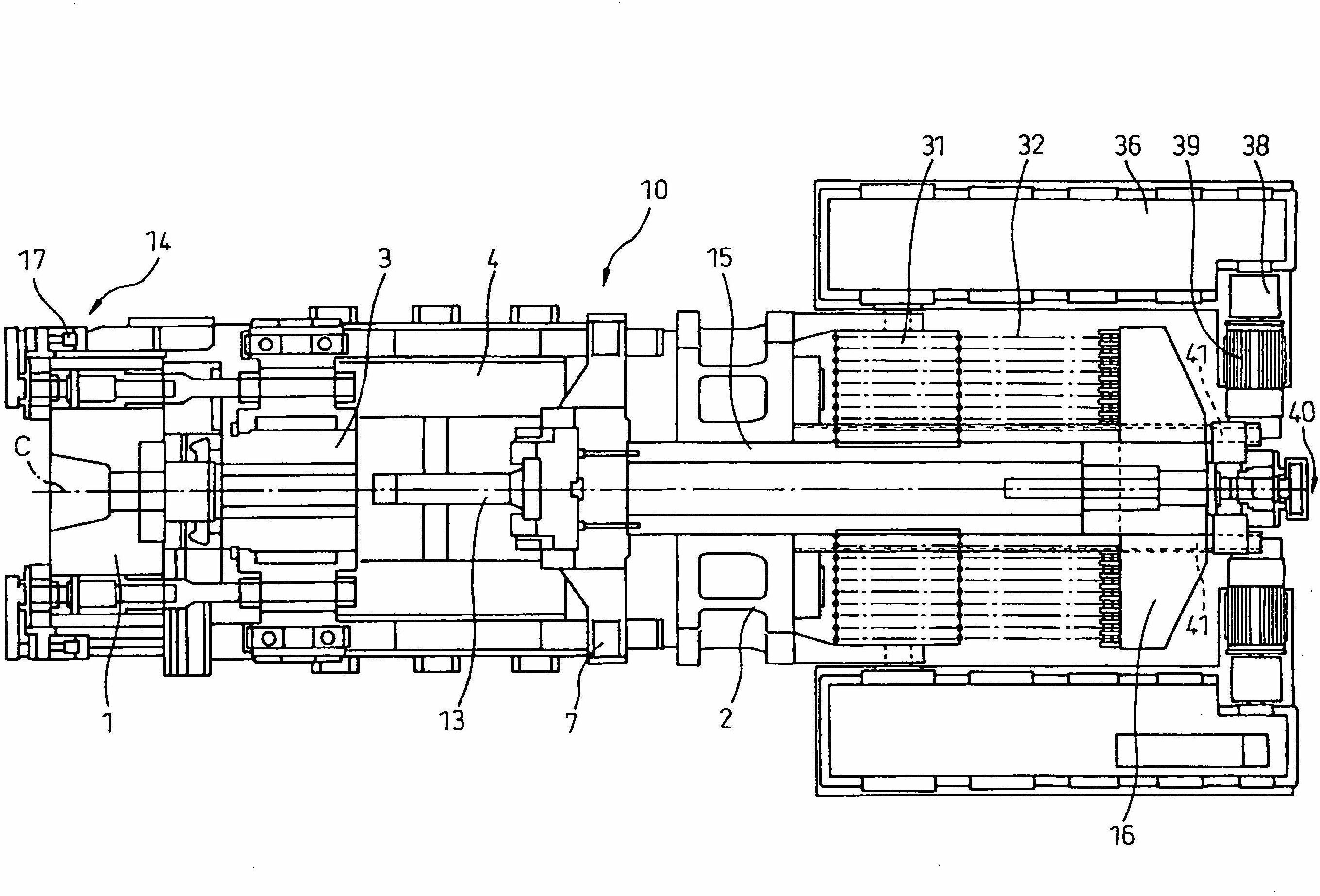

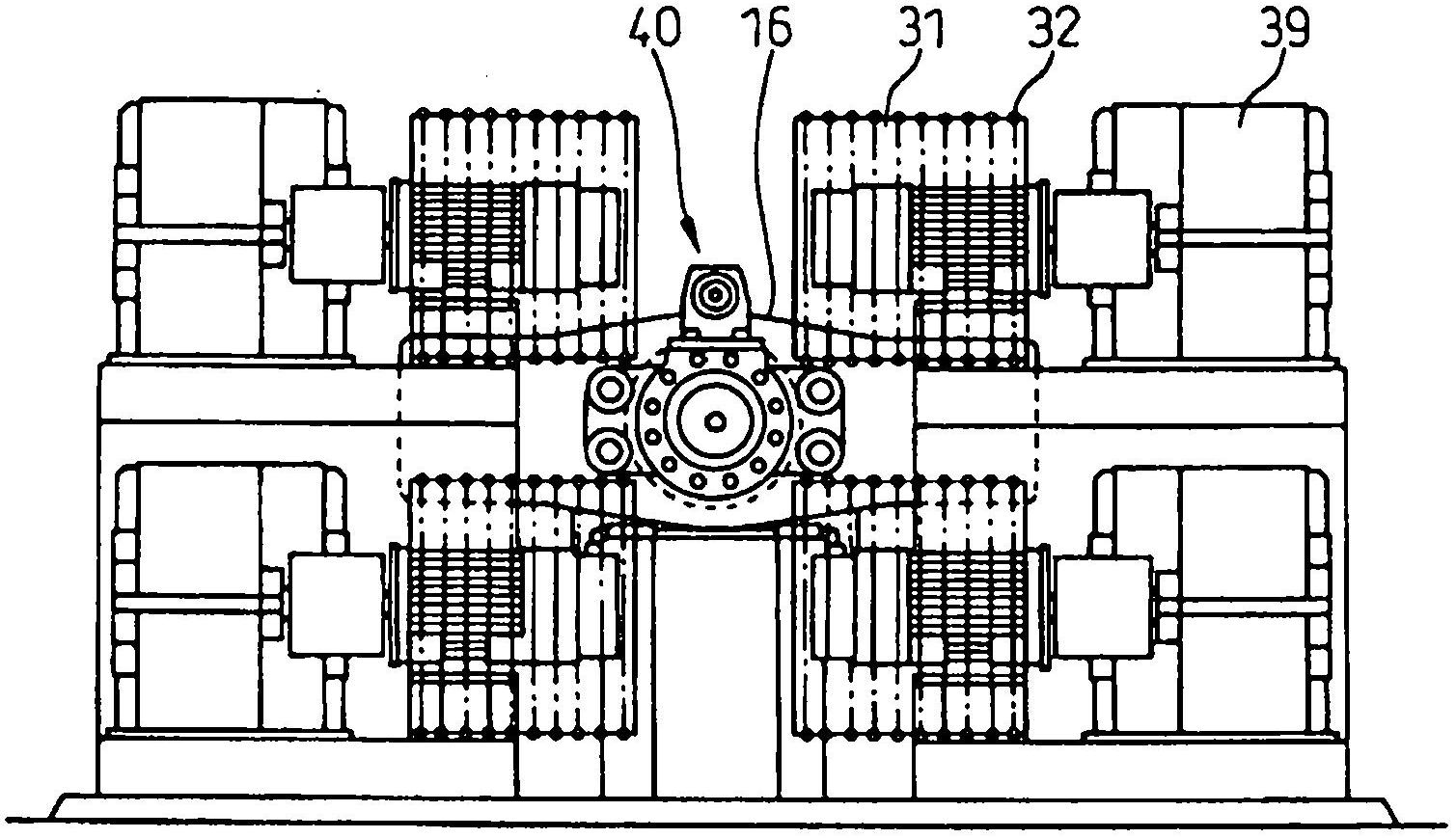

[0045] Next, an extruder according to a first embodiment of the present invention will be described in detail based on the drawings. figure 1 , figure 2 , image 3 and Figure 4 , which diagrammatically represents the first embodiment of the extrusion machine of the present invention (extrusion rod slide type extrusion machine), figure 1 It is a side view showing the outline structure of the extrusion machine of the first embodiment, figure 2 is viewed from above figure 1 A top view of the device, image 3 is viewed from behind figure 1 rear view of the device, Figure 4 and 5 Indicates viewing from the front figure 1 A-A sectional view of the device and B-B sectional view viewed from the rear. The extrusion machine of the present invention pushes the extrusion rod (or shaft) by the extrusion force generated by the electric extrusion drive device (mechanism) that converts the rotary motion into a linear mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com