Hot extrusion steel tube blank tail pad warming and transporting unit

A transmission device and hot extrusion technology, applied in the direction of metal extrusion, metal extrusion control equipment, pressure head/punch rod, etc., can solve the problems of waste of expensive raw materials, etc., achieve high production efficiency, compact device structure, and connection smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

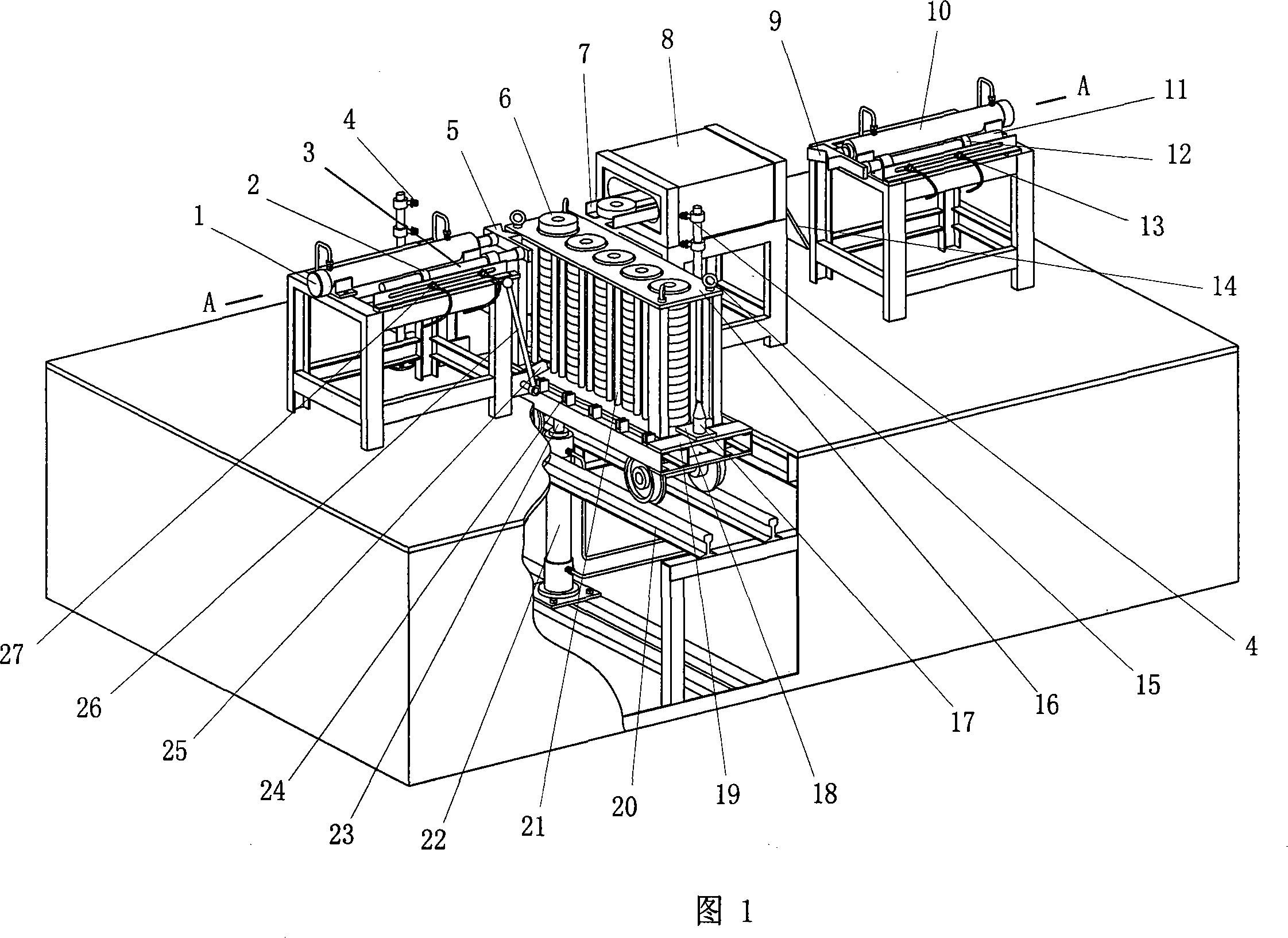

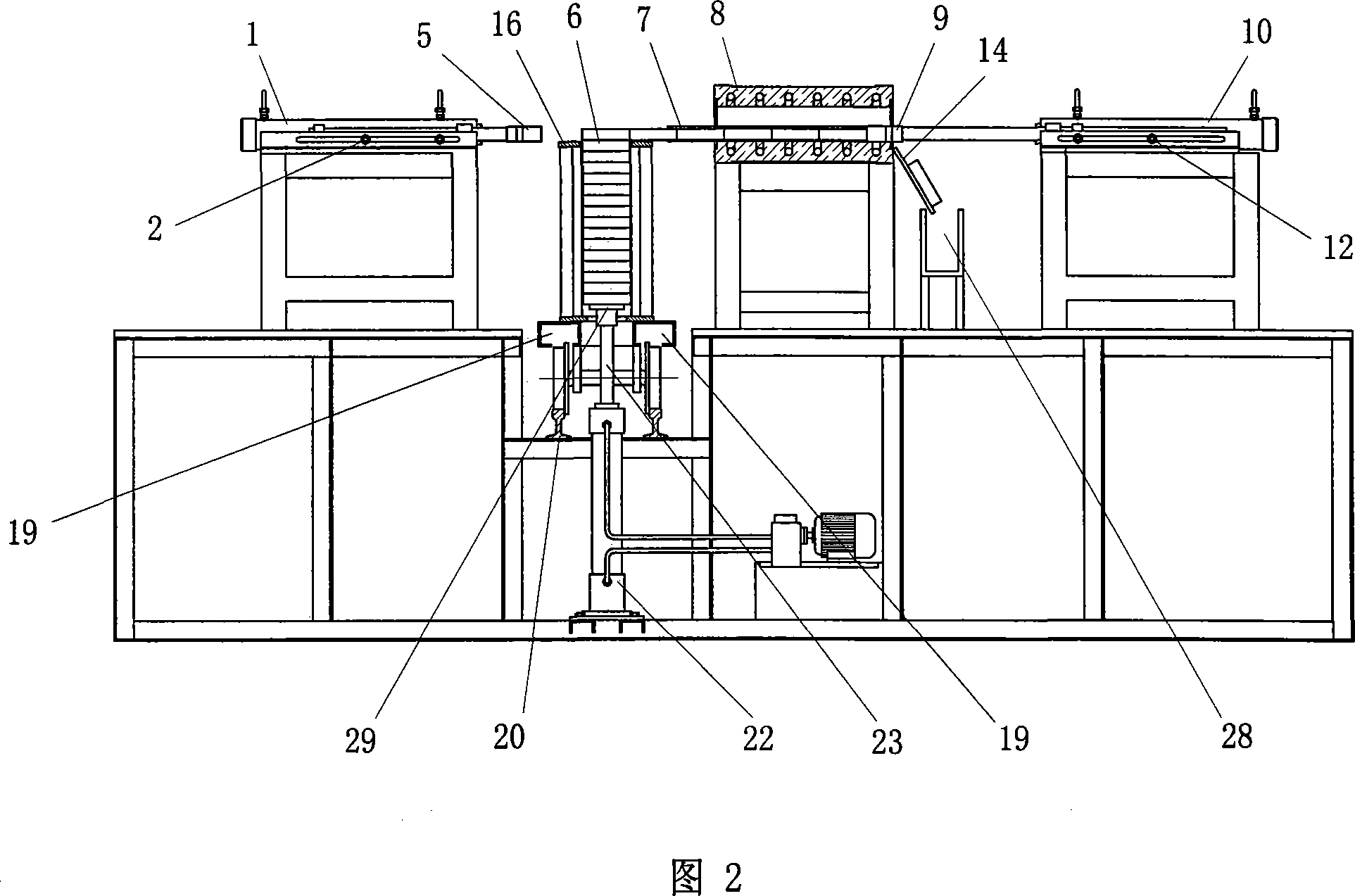

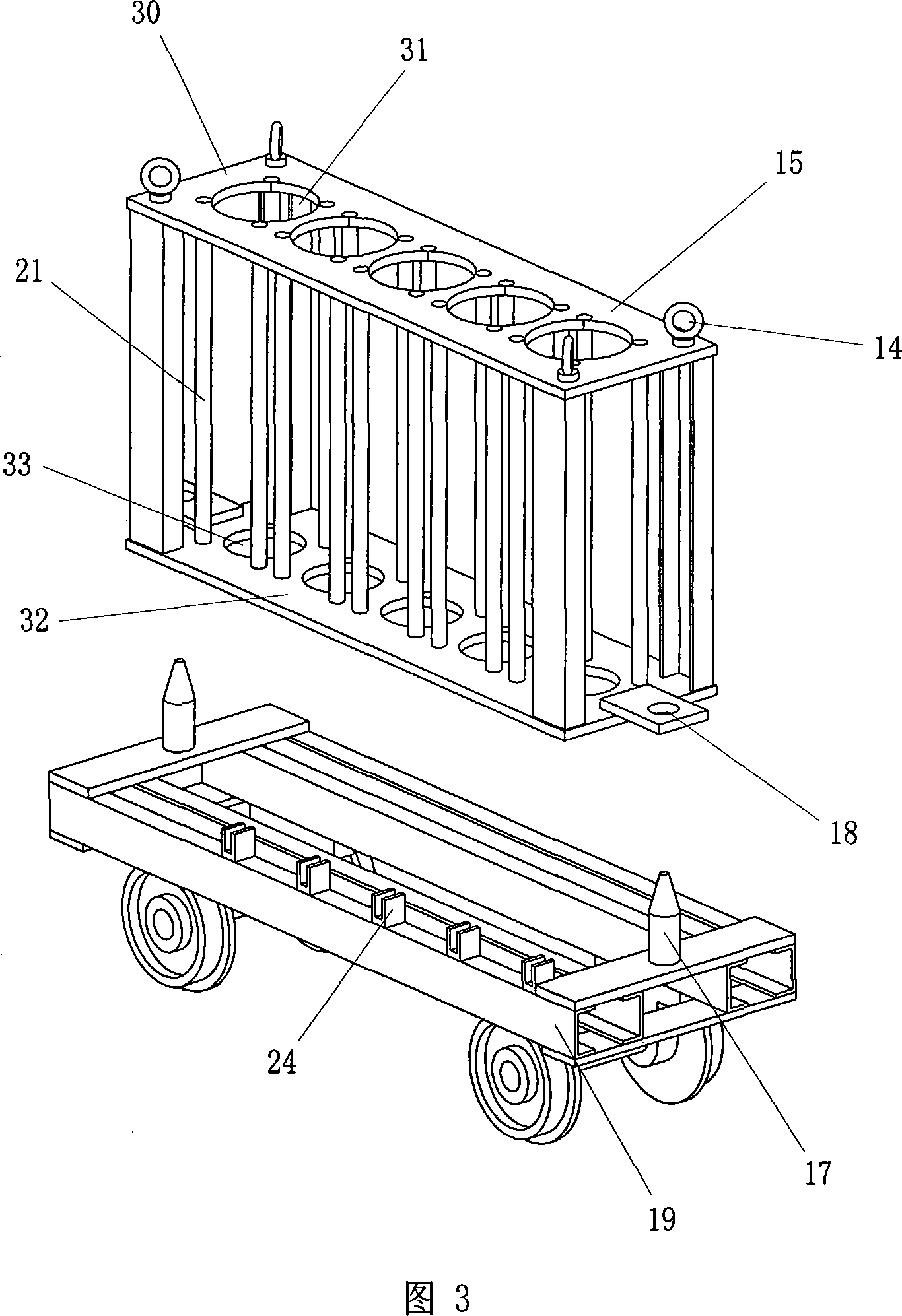

[0009] The present invention will be further described below with reference to the accompanying drawings.

[0010] The heating furnace 8 adopts an electric induction heating furnace, the front and rear furnace doors and the furnace are straight through, and the horizontal loading track 7 is installed in the furnace; the stacked material storage frame 16 of this embodiment is multi-unit parallel and single-row stacked Type material storage frame, it is provided with the upper frame plate 30 of some tail pad loading and unloading holes 31 in a row, the lower frame plate 32 with some oil cylinder piston rod jacking holes 33 corresponding to the upper frame plate tail pad loading and unloading holes and It is composed of tail pad surrounding rods 21 connected to the periphery of each pair of holes on the upper and lower frame plates, and the upper frame plate 30 is also provided with a hoisting ring 15; On the roller trolley 19 on the track 20 between, the two ends of the roller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com