Patents

Literature

5603 results about "Copper tubing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper tubing is most often used for the supply of hot and cold tap water, and as a refrigerant line in HVAC systems. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly.

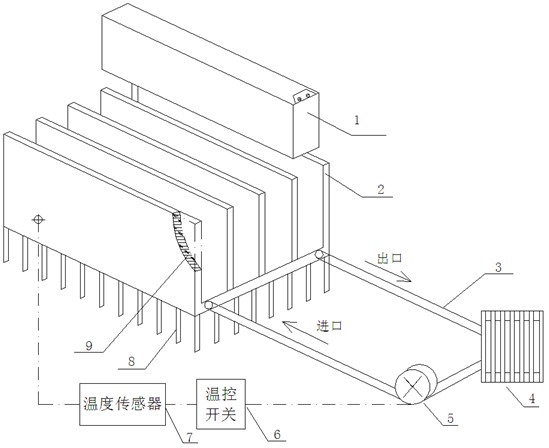

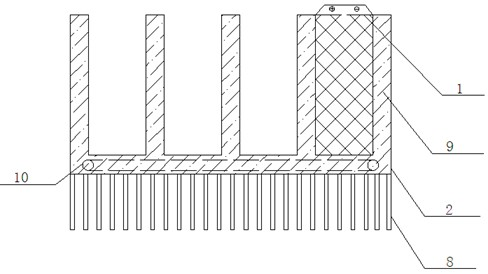

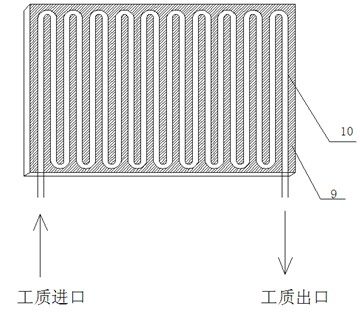

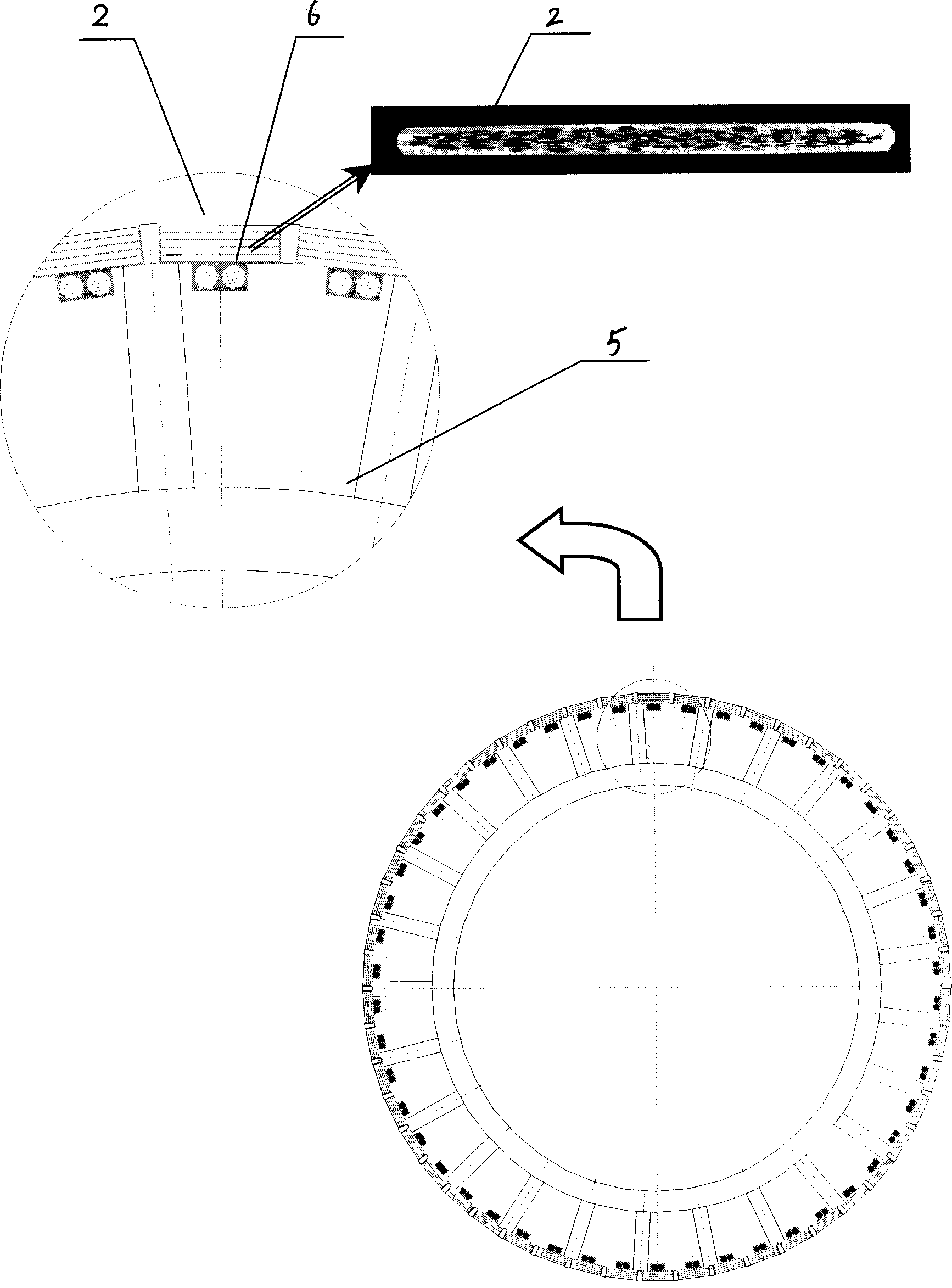

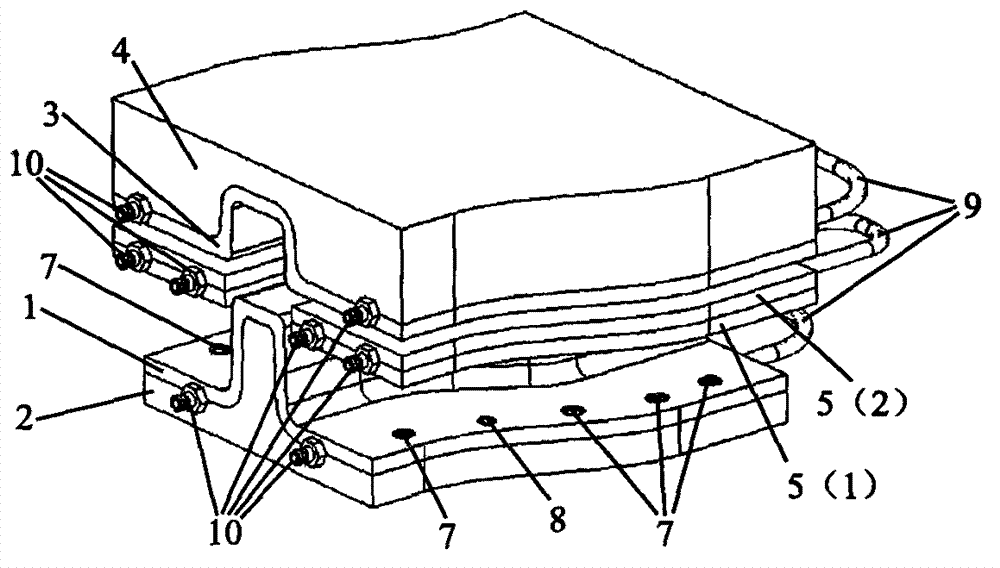

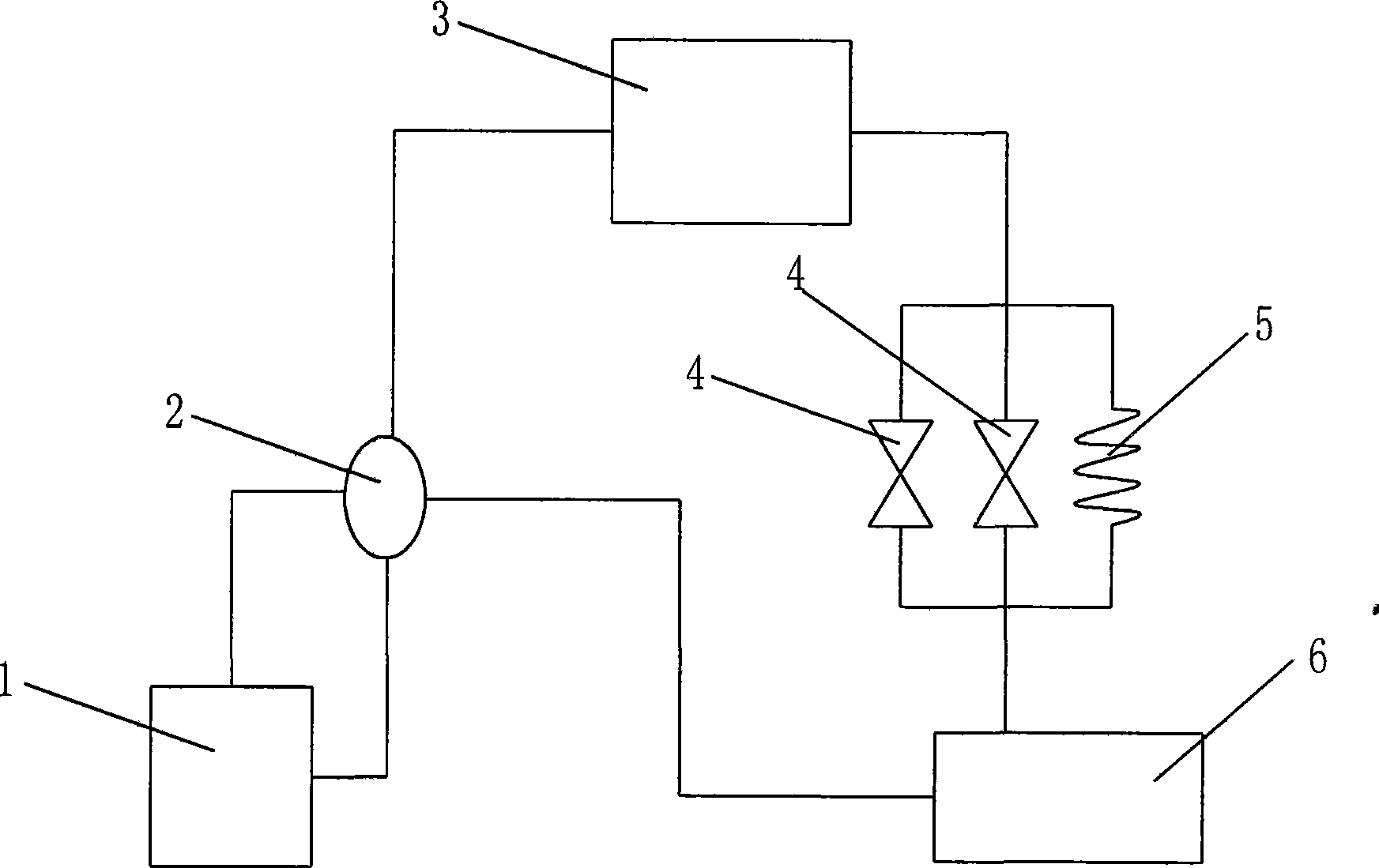

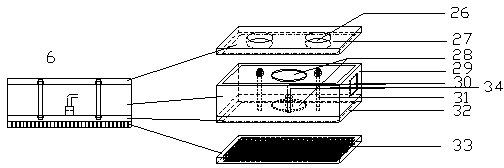

Radiating and cooling device for power battery

InactiveCN102664292ATemperature controlImprove energy efficiencySecondary cellsTemperature controlPower battery

The invention relates to a radiating and cooling device for a power battery. An aluminum hollow cold plate shell is in the form of a radiating fin; the inside of the shell is hollow; a plurality of groove spaces are formed on the aluminum shell; power batteries can be embedded into grooves; the aluminum hollow cold plate shell is filled with a phase change material; radiating fins are arranged on an aluminum hollow cold plate shell bottom plate; a snakelike copper tube is arranged at the bottom of an aluminum shell cavity, and is contacted with the phase change material; a liquid cooling working medium is introduced into the snakelike copper tube; the snakelike copper tube, a pump and an external heat exchanger are connected in series, so that an active liquid cooling system is formed; a temperature sensor is arranged on the surface of the power battery; and a temperature switch is connected in series with a pump body power supply. The flow of the cooling working medium can be adjusted according to different requirements of battery temperature control; the using amount of a metal is reduced by adding the phase change material on the premise of ensuring the battery radiating effect, so that the cost of a battery radiating device is reduced effectively; and the requirements of different power batteries are met.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

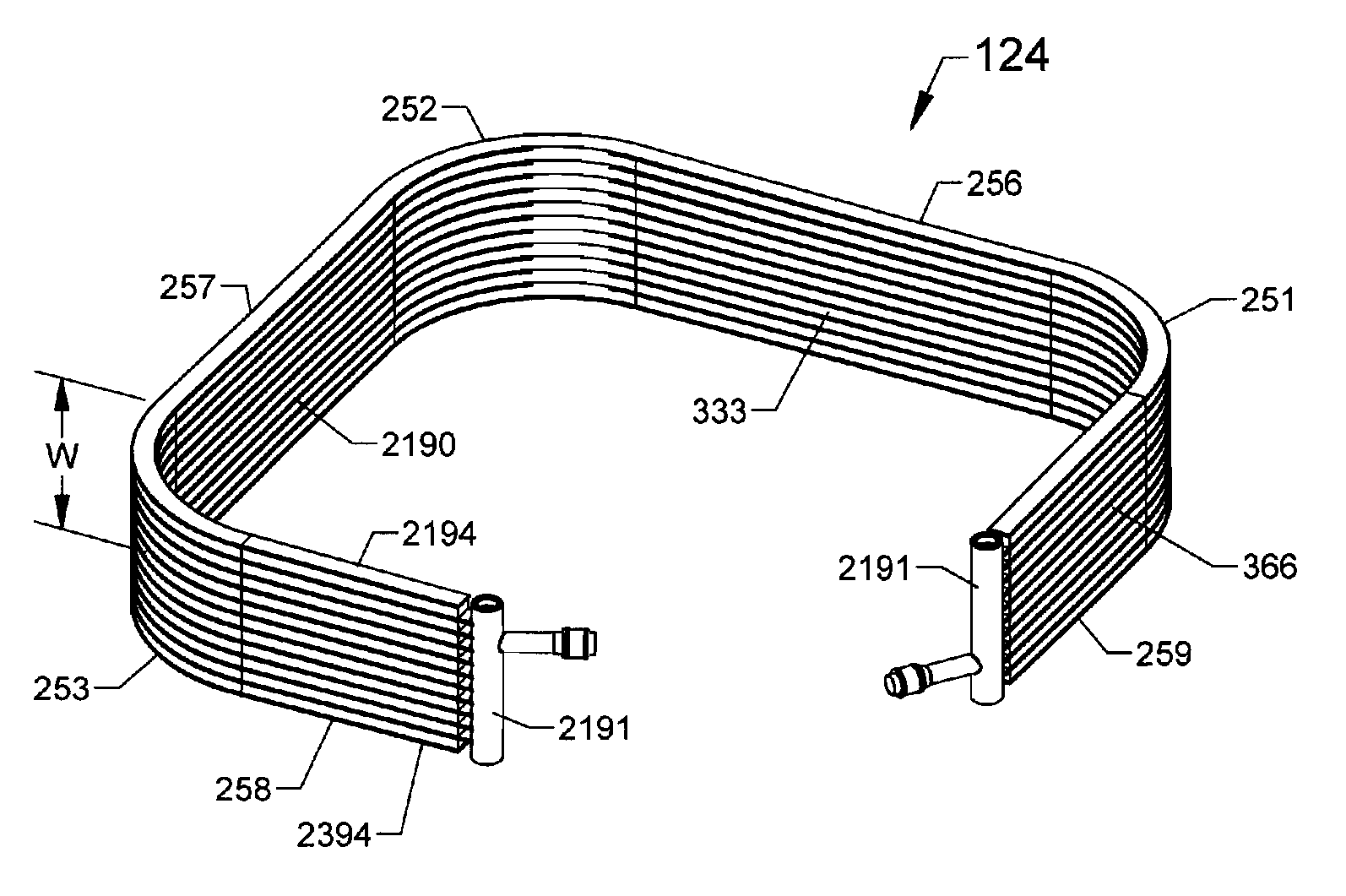

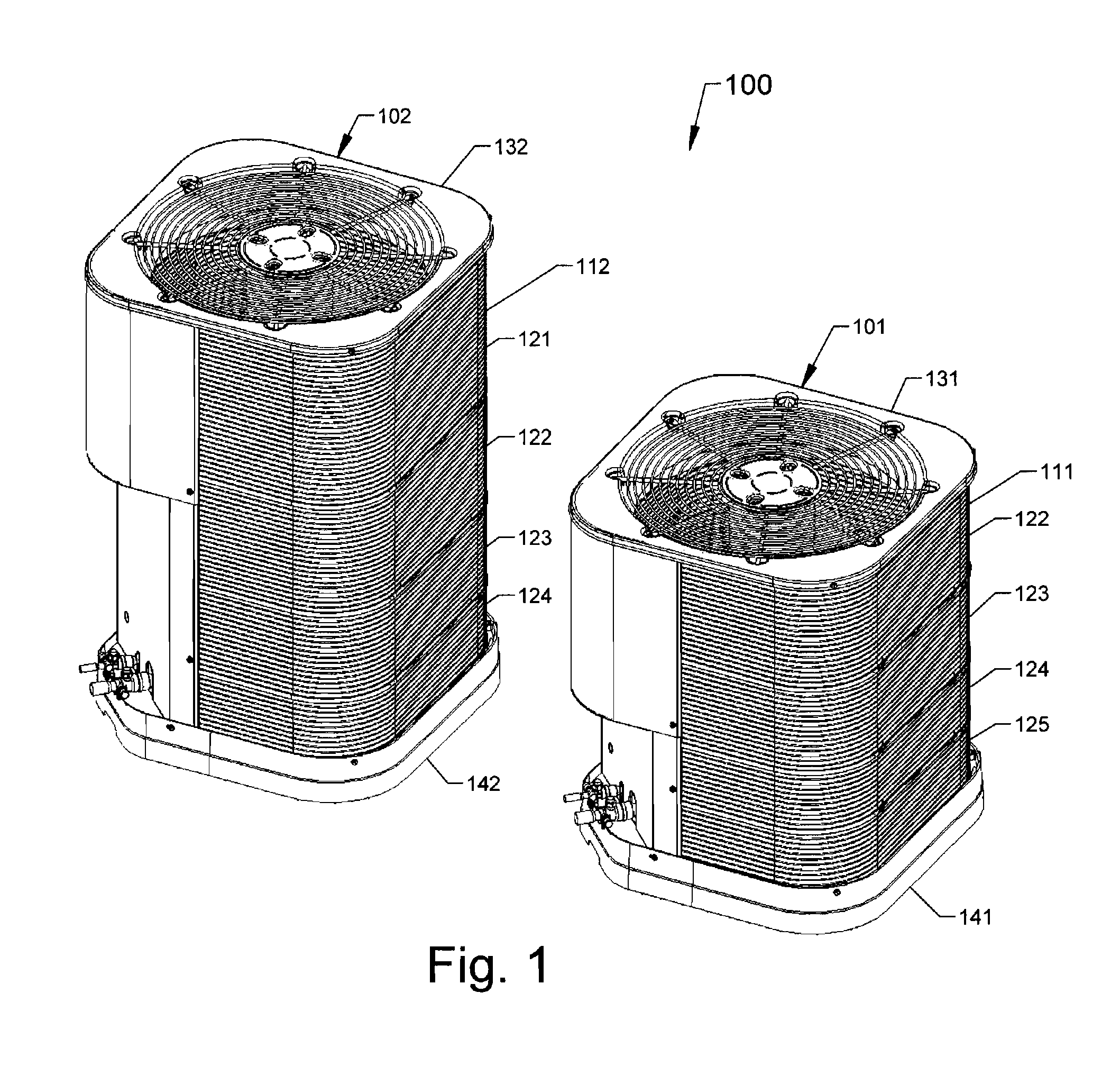

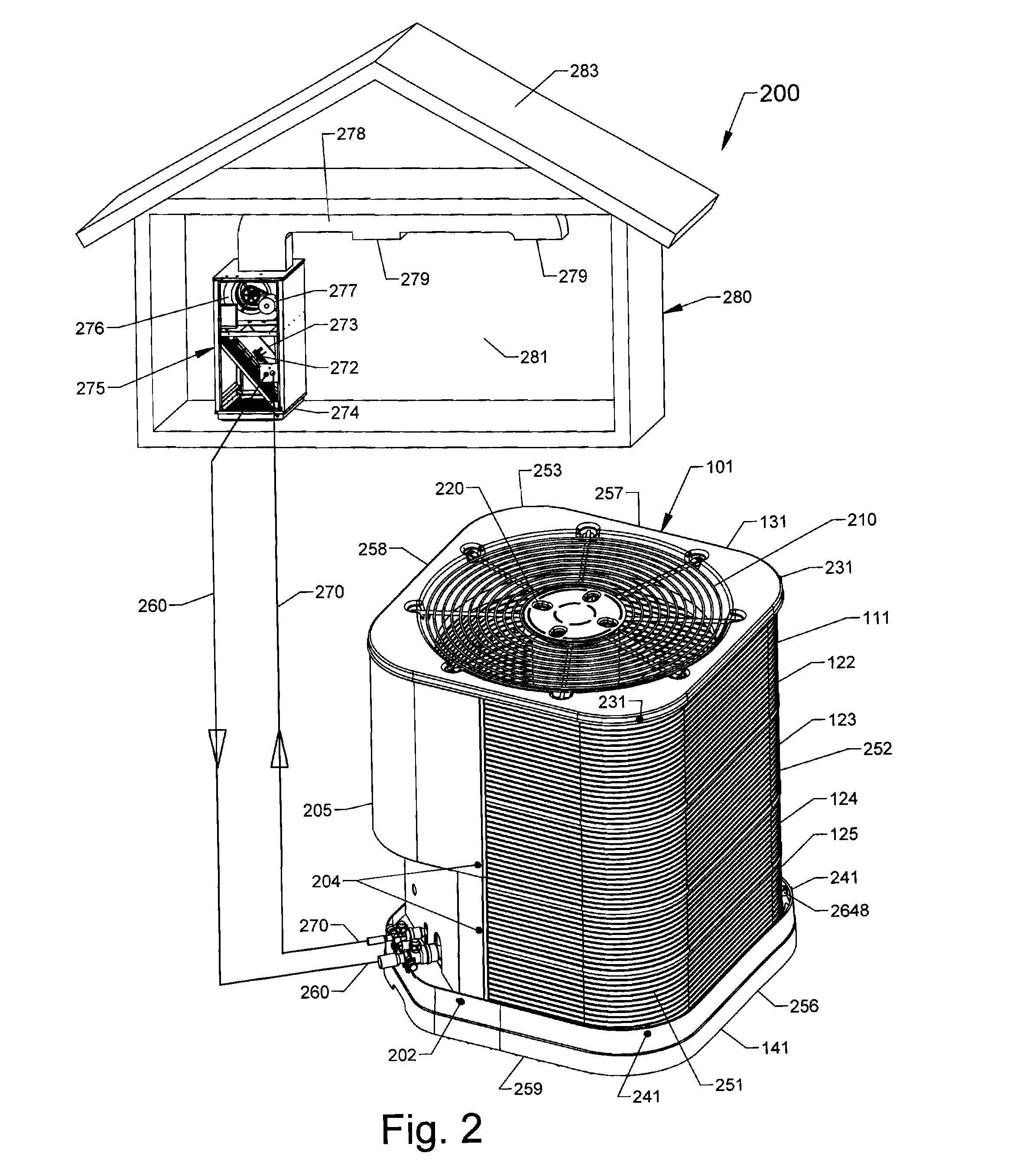

Air Conditioning Units with Modular Heat Exchangers, Inventories, Buildings, and Methods

InactiveUS20090084131A1Reduce the amount requiredEasy field replacementSpacing meansDomestic refrigeratorsComputer moduleEngineering

Air conditioning units, methods of manufacturing, inventories, and buildings wherein certain heat exchanger modules are combined to make air conditioning units. In some embodiments, different combinations of different size modules are used to produce air conditioning units having different capacities wherein some identical modules are used in different size units. Various heat exchanger assemblies include spacers between modules, bends formed after modules are assembled into heat exchanger assemblies, attachment rails at the ends of the modules, inactive multi-tubes at the top and bottom of the modules, copper tubing between aluminum modules to facilitate field replacement of individual modules, name plates that attach between modules, attachment clips or spacers that snap attach to the modules, or a combination thereof, as examples.

Owner:NORDYNE

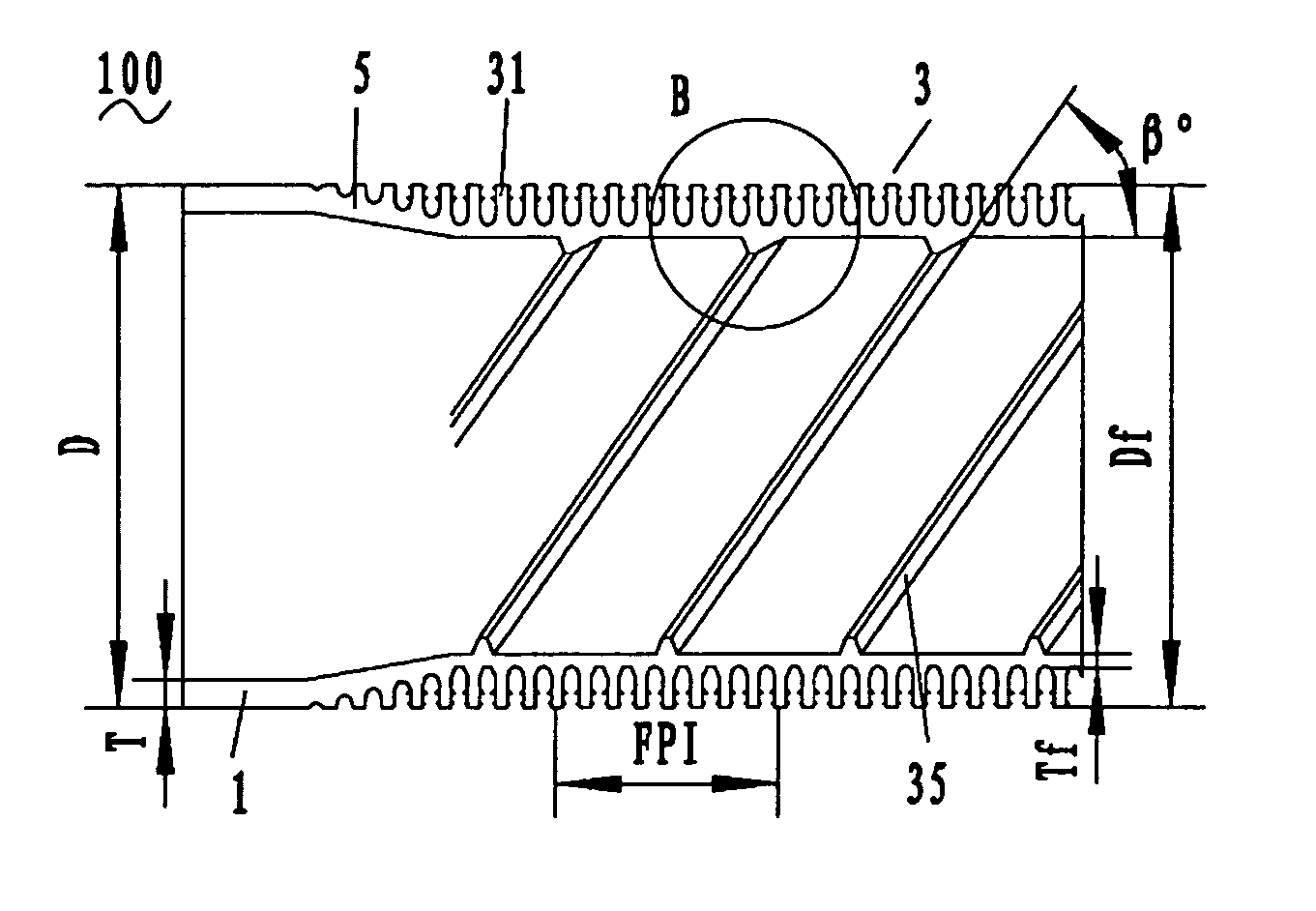

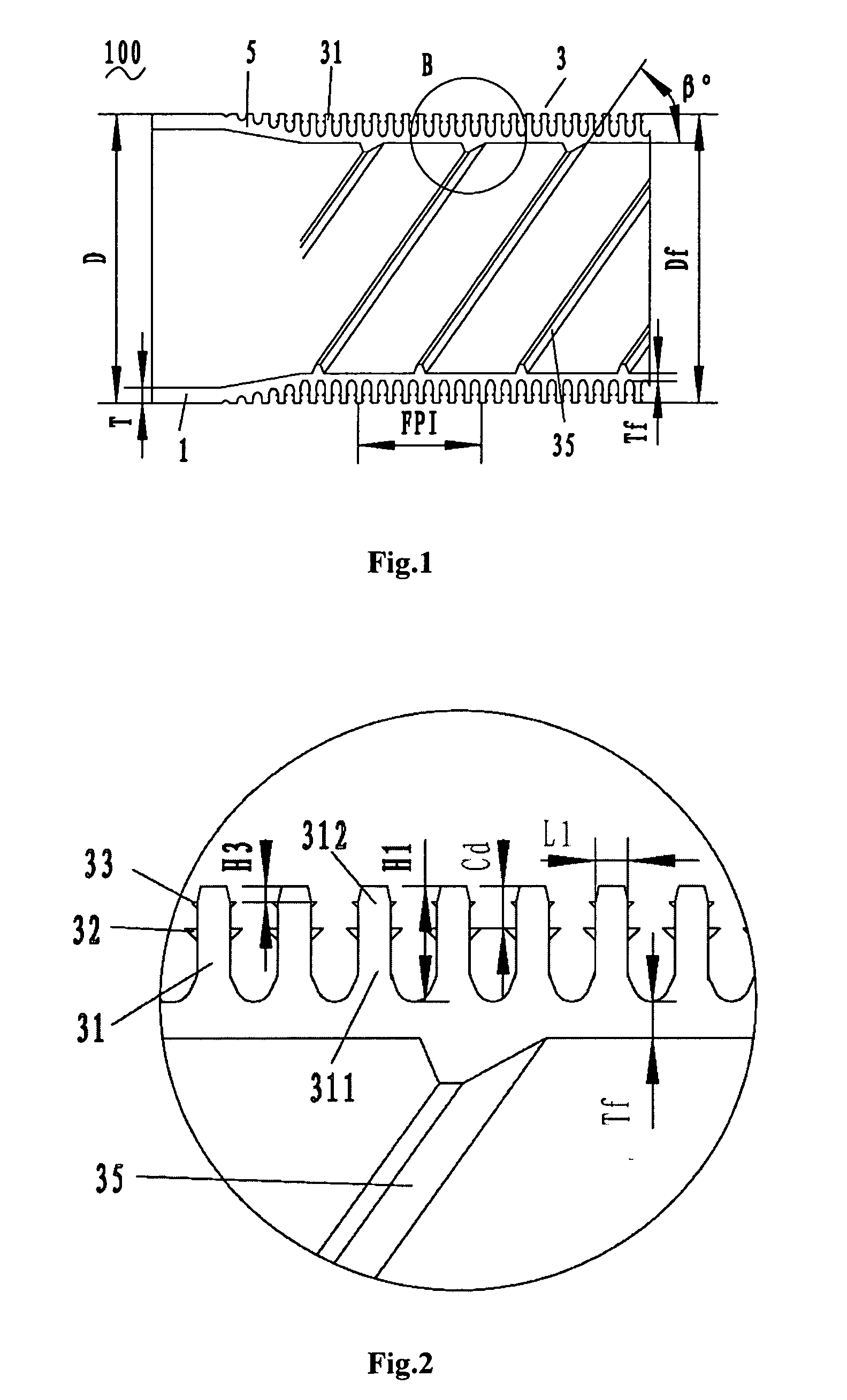

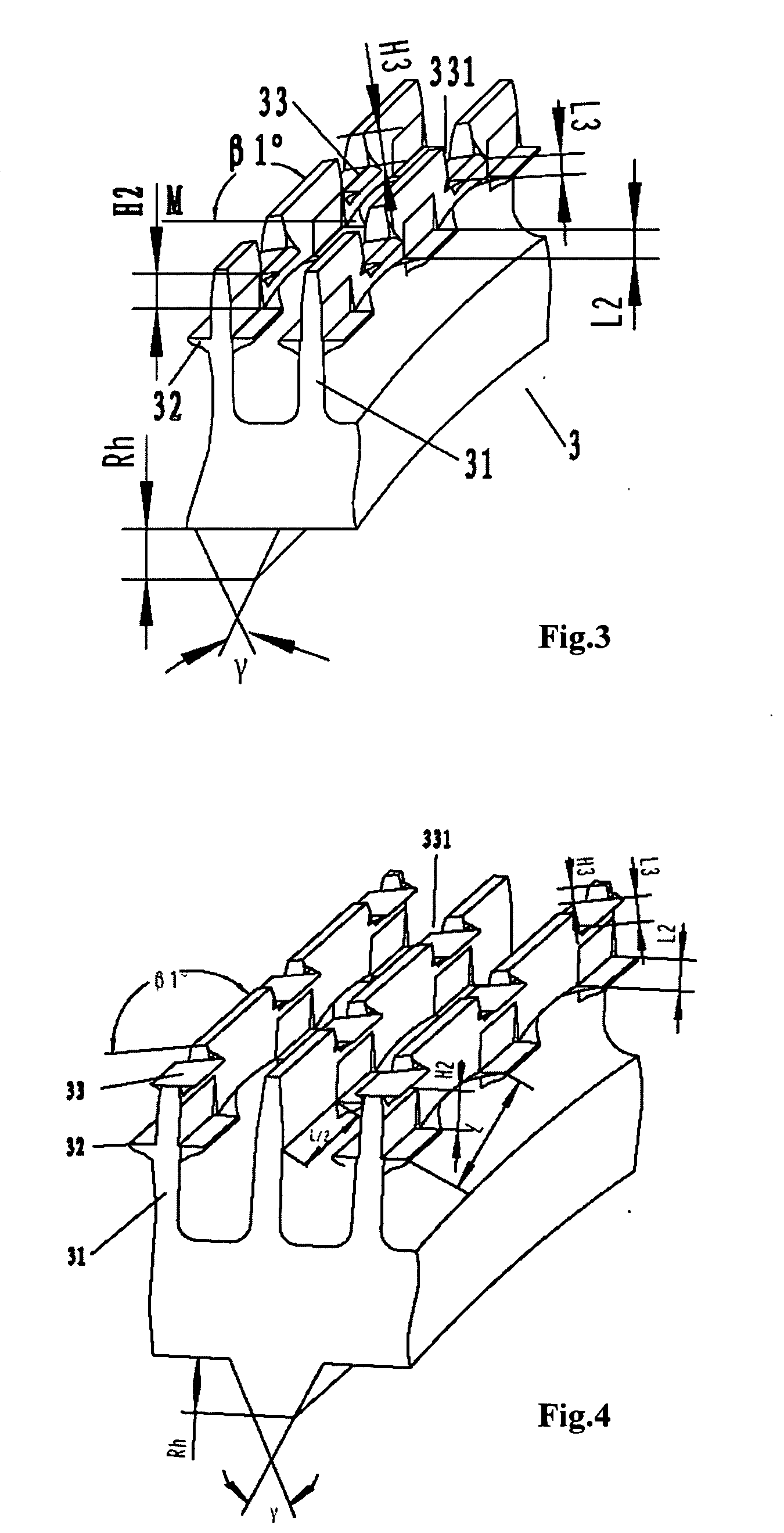

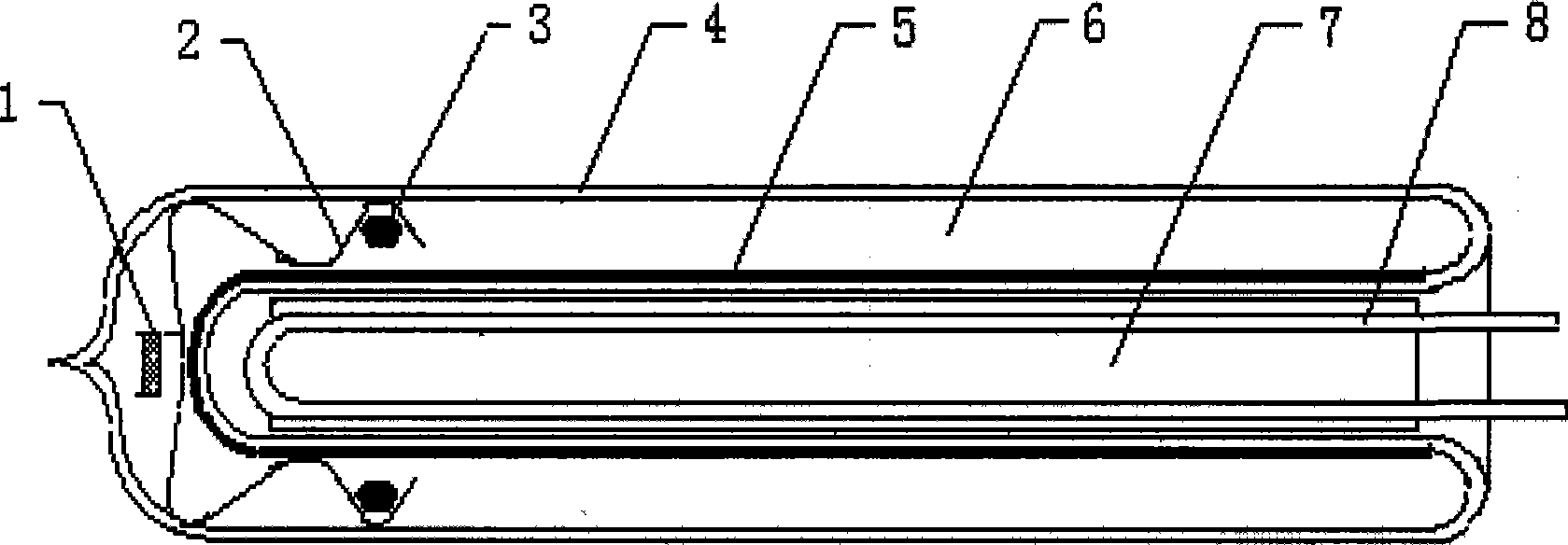

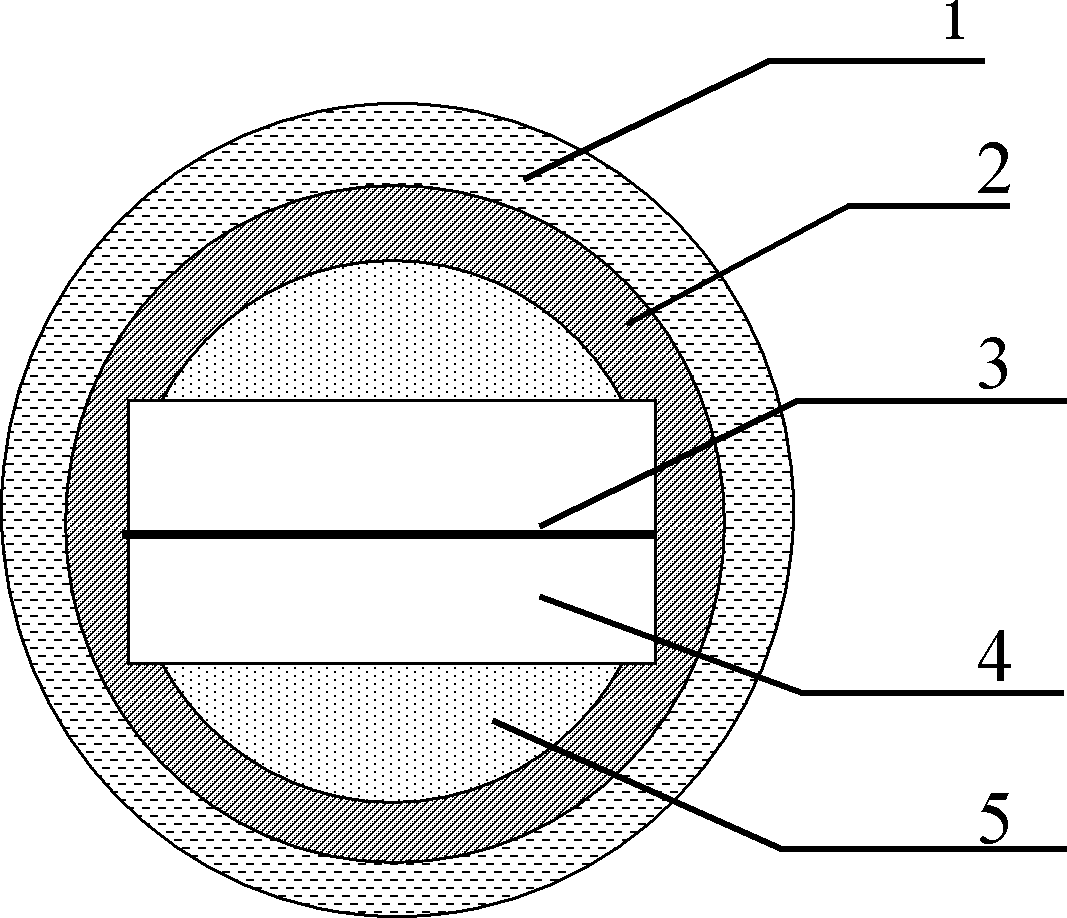

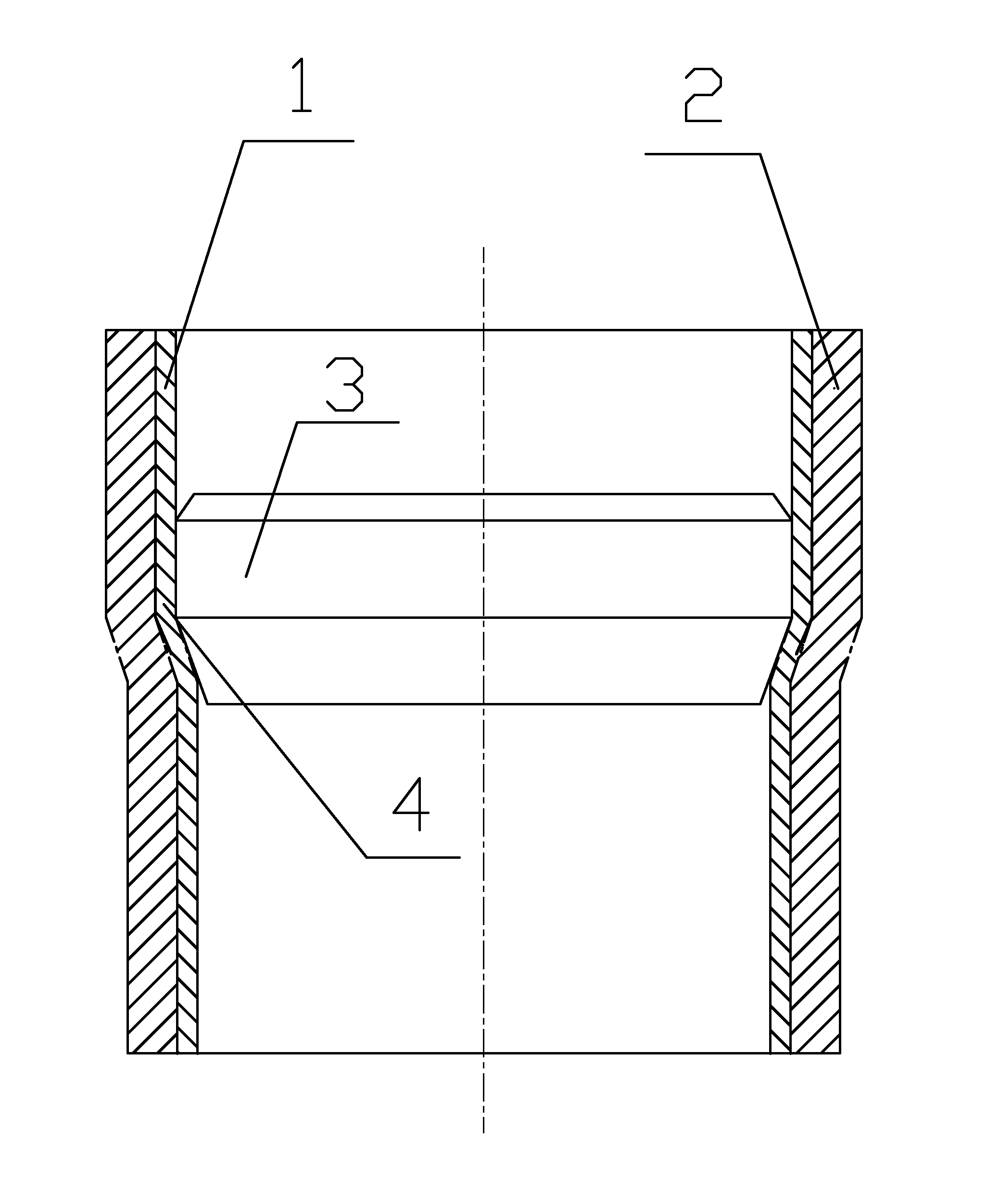

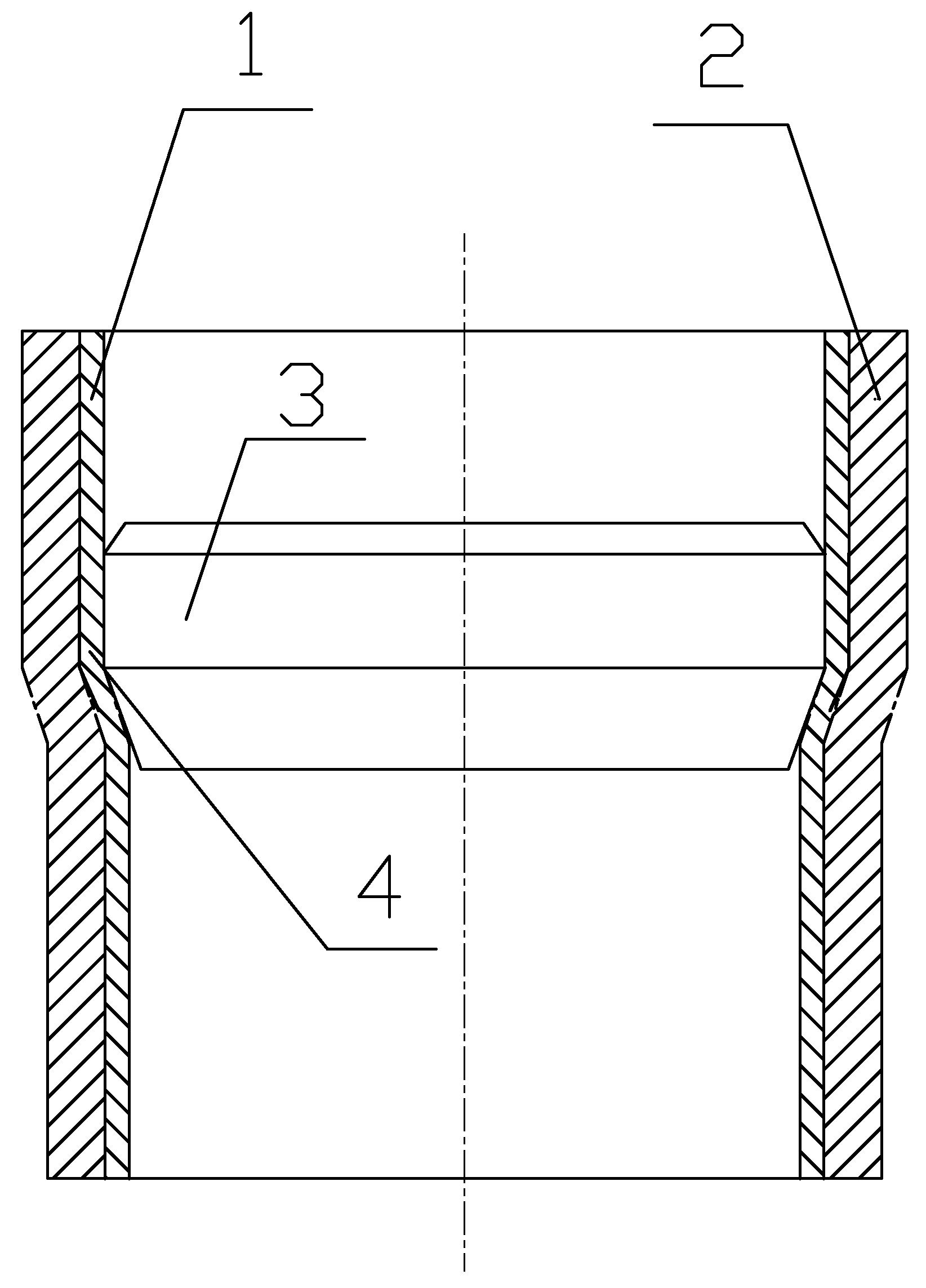

Condensing heat-exchange copper tube for an flooded type electrical refrigeration unit

ActiveUS20070131396A1Large heat transfer coefficientImprove heat transfer efficiencyEvaporators/condensersCorrosion preventionElectricityHeat resistance

The present invention discloses a condensing heat-exchange copper tube for a flooded type electrical refrigeration unit, which comprises a smooth surface portion, a finned portion provided with plurality of fins and a transitional portion connecting the smooth surface portion to the finned portion. Said fin includes a fin base close to the outer surface of the heat-exchange tube and a fin top away from the outer surface. Said fin is further provided with a secondary fin at the central portion of the fin and a third fin at the top portion of the fin, wherein a certain distance is provided between two axially adjacent secondary fins or two axially adjacent third fins. Secondary fins as well as third fins according to the invention further increase the heat transfer area for the heat-exchange tube. Meanwhile, secondary fins and third fins help to attenuate the condensate film such that the condensate film is substantially eliminated, and vapor condensation and heat transfer may be carried out in a better way. At the same time, secondary fins and third fins help to guide the condensate film away from the surface of the heat-exchange tube such that heat resistance may be reduced. Thus, the overall efficiency of heat transfer through condensation is enhanced, and the property of the condenser is improved.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

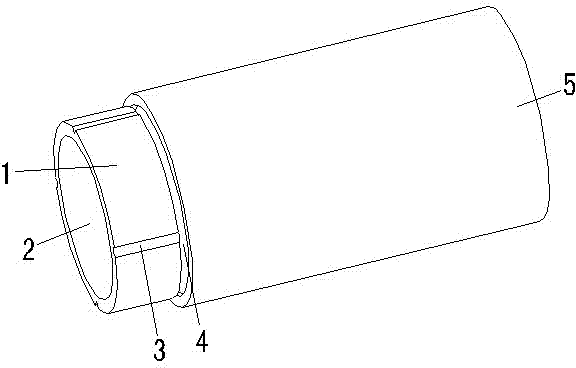

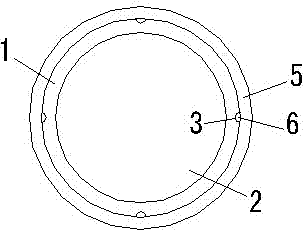

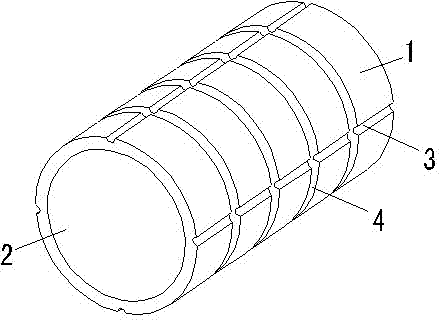

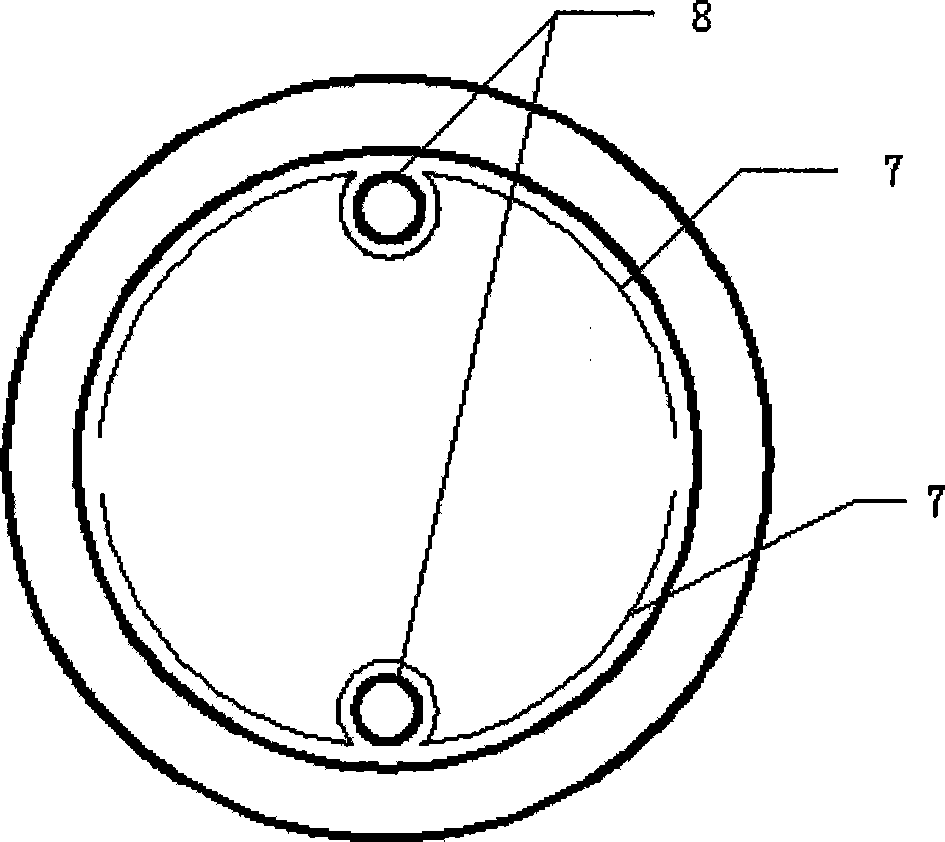

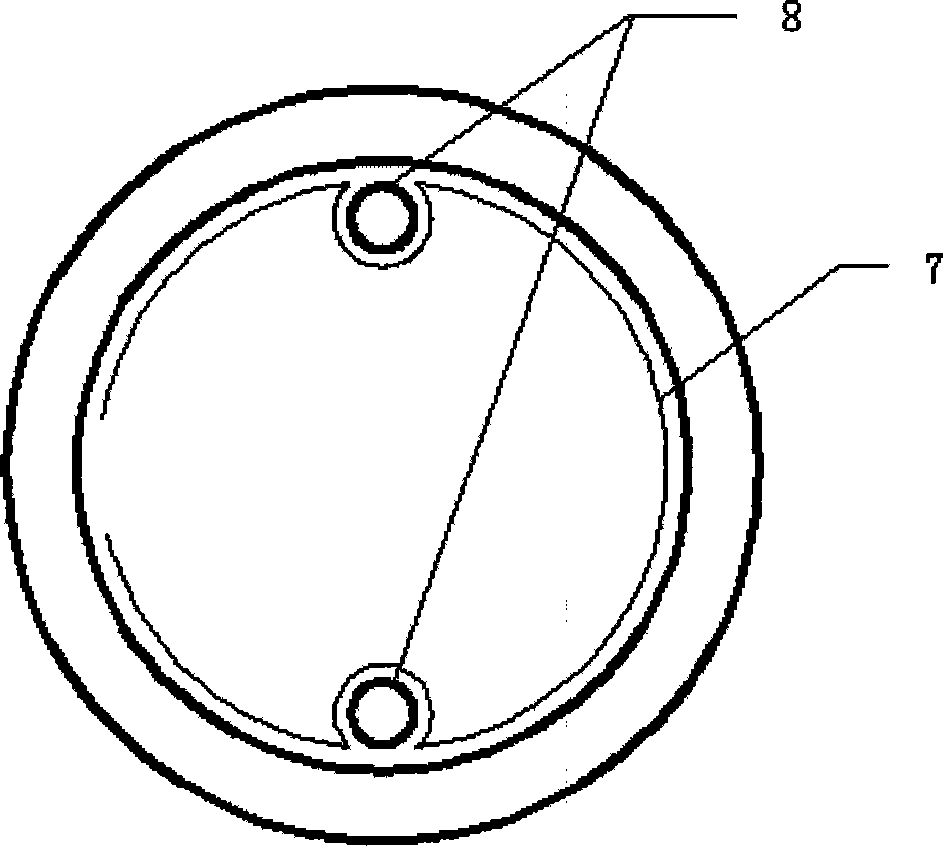

Telescopic copper pipe component

InactiveCN103591096AAchieve lockingSimple structureRod connectionsStructural engineeringOuter Cannula

The invention discloses a telescopic copper pipe component which comprises an inner pipe and an outer sleeve. The outer sleeve is sleeved on the inner pipe. A inner pipe through hole is formed in the center of the inner pipe. A plurality of linear grooves parallel with the central line of the inner tube are evenly distributed on the outer periphery of the inner pipe. Protrusions are disposed on the inner wall of the inner hole of the outer sleeve. The protrusions are disposed in the grooves. By the structure, when the outer sleeve is sleeved on the inner pipe, the protrusions can move linearly along the grooves, and the outer sleeve can move along the inner pipe. In addition, annular grooves are evenly formed in the outer periphery of the inner pipe, and the central line of each annular groove coincides with that of the inner pipe. When the protrusions enter the annular grooves, the outer sleeve can be relatively locked with the inner pipe by rotating the outer sleeve. The telescopic copper pipe is simple in structure and practical.

Owner:苏州市吴中区曙光铜管厂

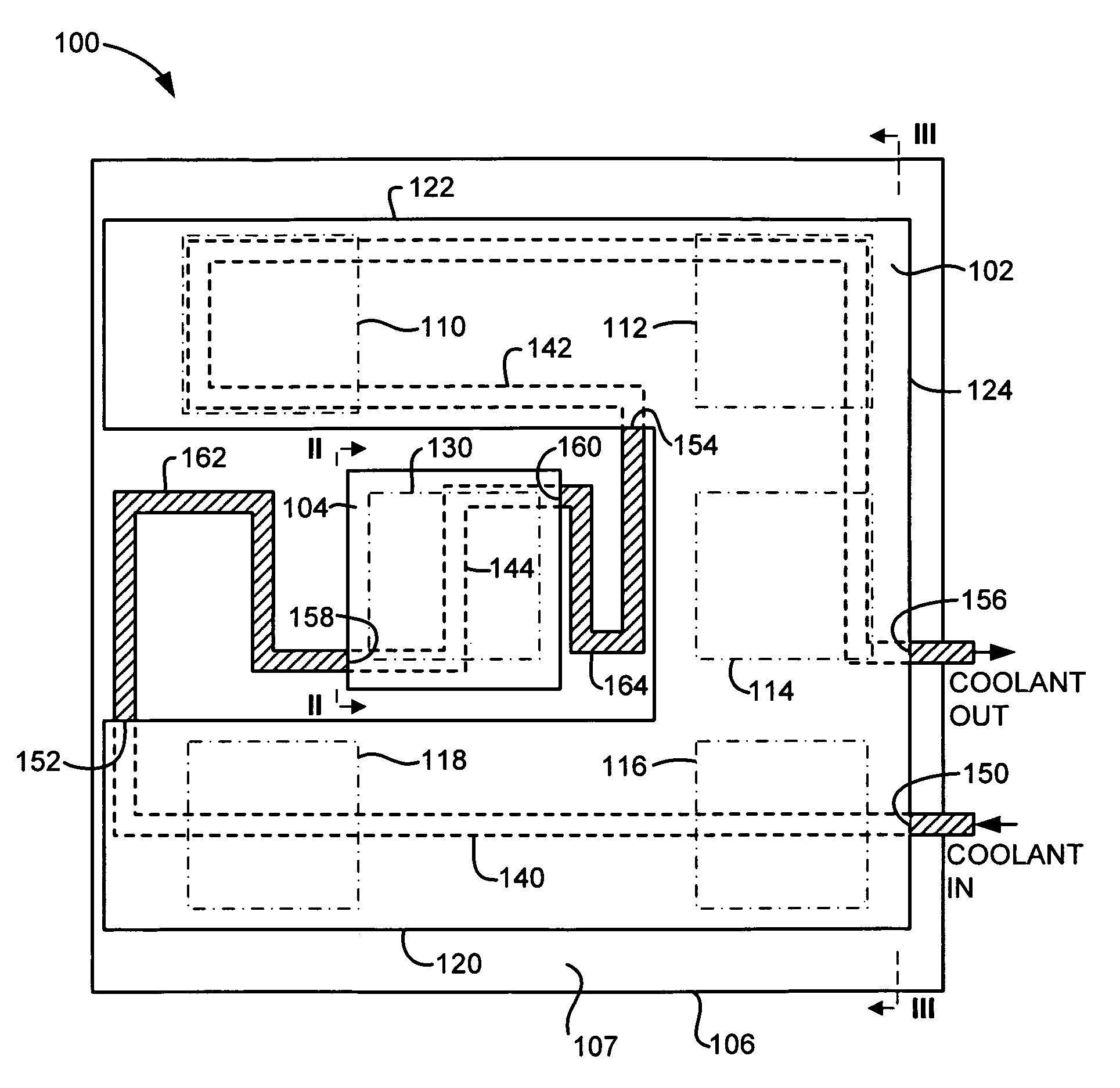

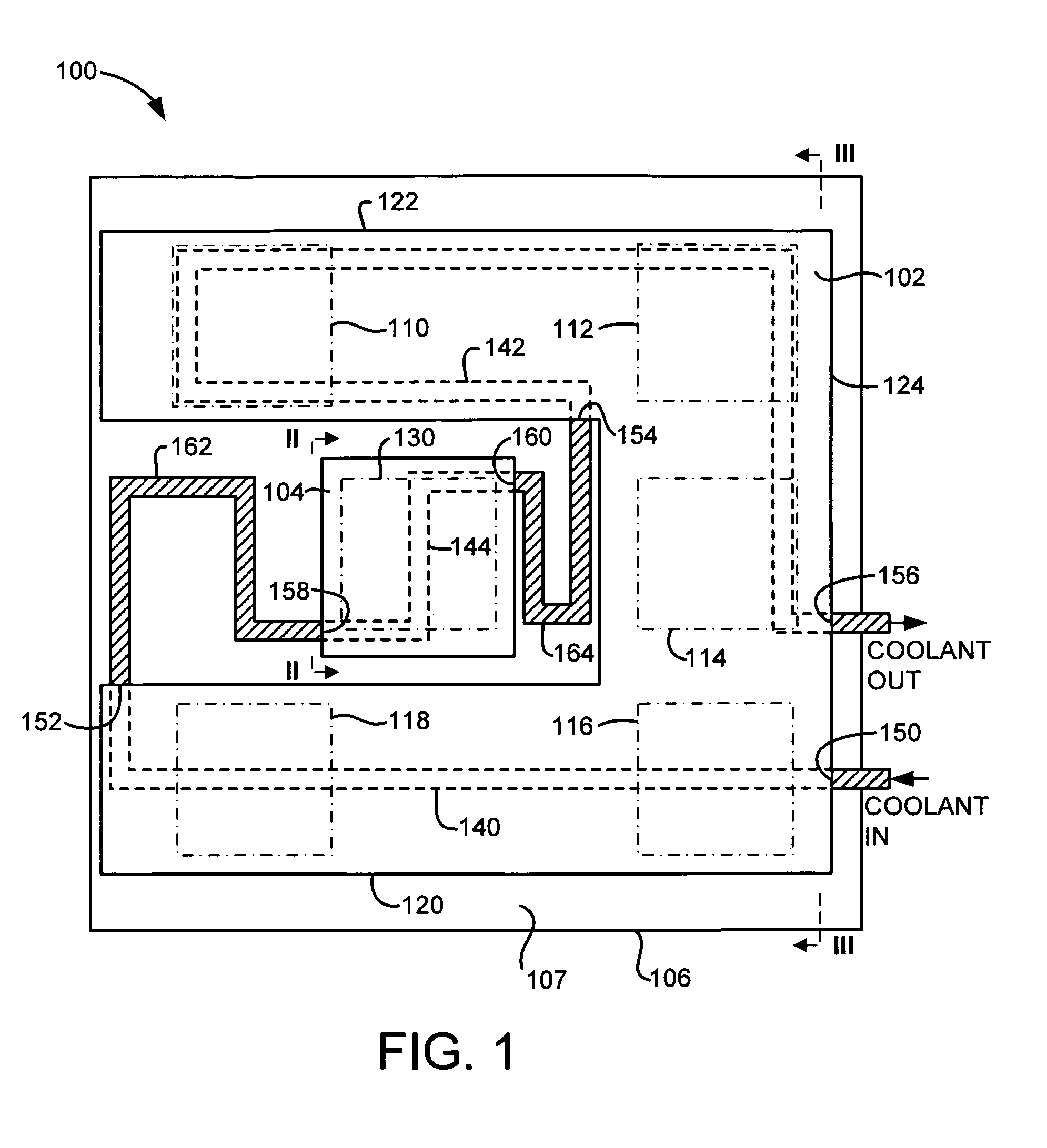

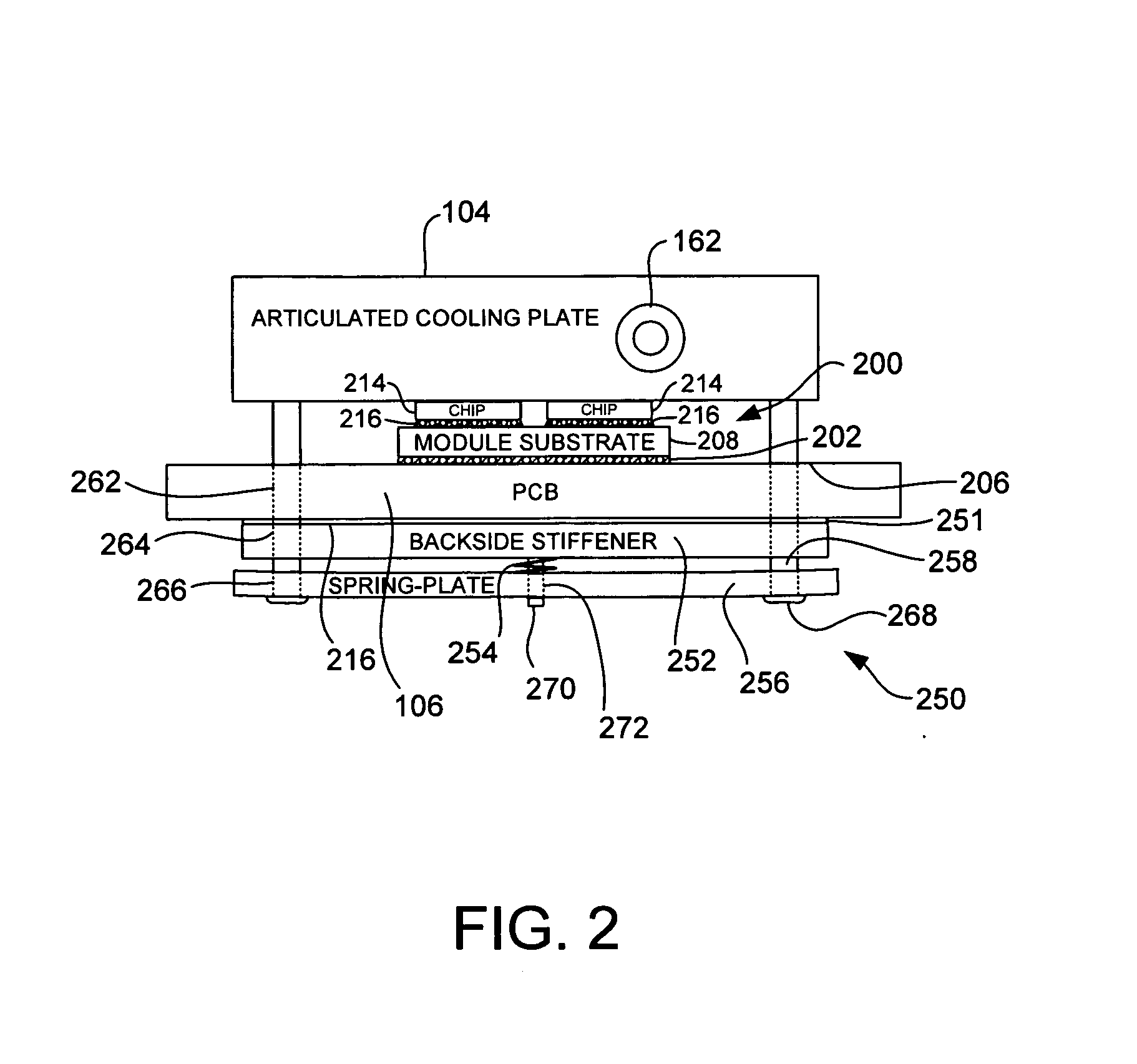

Cooling Plate Assembly with Fixed and Articulated Interfaces, and Method for Producing Same

InactiveUS20090213541A1Semiconductor/solid-state device detailsSolid-state devicesElastic compressionFree expansion

A cooling plate assembly for transferring heat from electronic components mounted on a circuit board includes both fixed and articulated interfaces. A fixed-gap coldplate is positioned over and in thermal contact with (e.g., through an elastomerically compressive pad thermal interface material) electronic components mounted on the circuit board's top surface. An articulated coldplate is positioned over and in thermal contact with at least one electronic component mounted on the circuit board's top surface. In the preferred embodiments, the articulated coldplate is spring-loaded against one or more high power processor components having power dissipation greater than that of the electronic components under the fixed-gap cooling plate. Thermal dissipation channels in the coldplates are interconnected by flexible tubing, such as copper tubing with a free-expansion loop. In the preferred embodiments, the coldplates and the flexible tubing are connected to define a portion of a single flow loop used to circulate cooling fluid through the coldplates.

Owner:IBM CORP

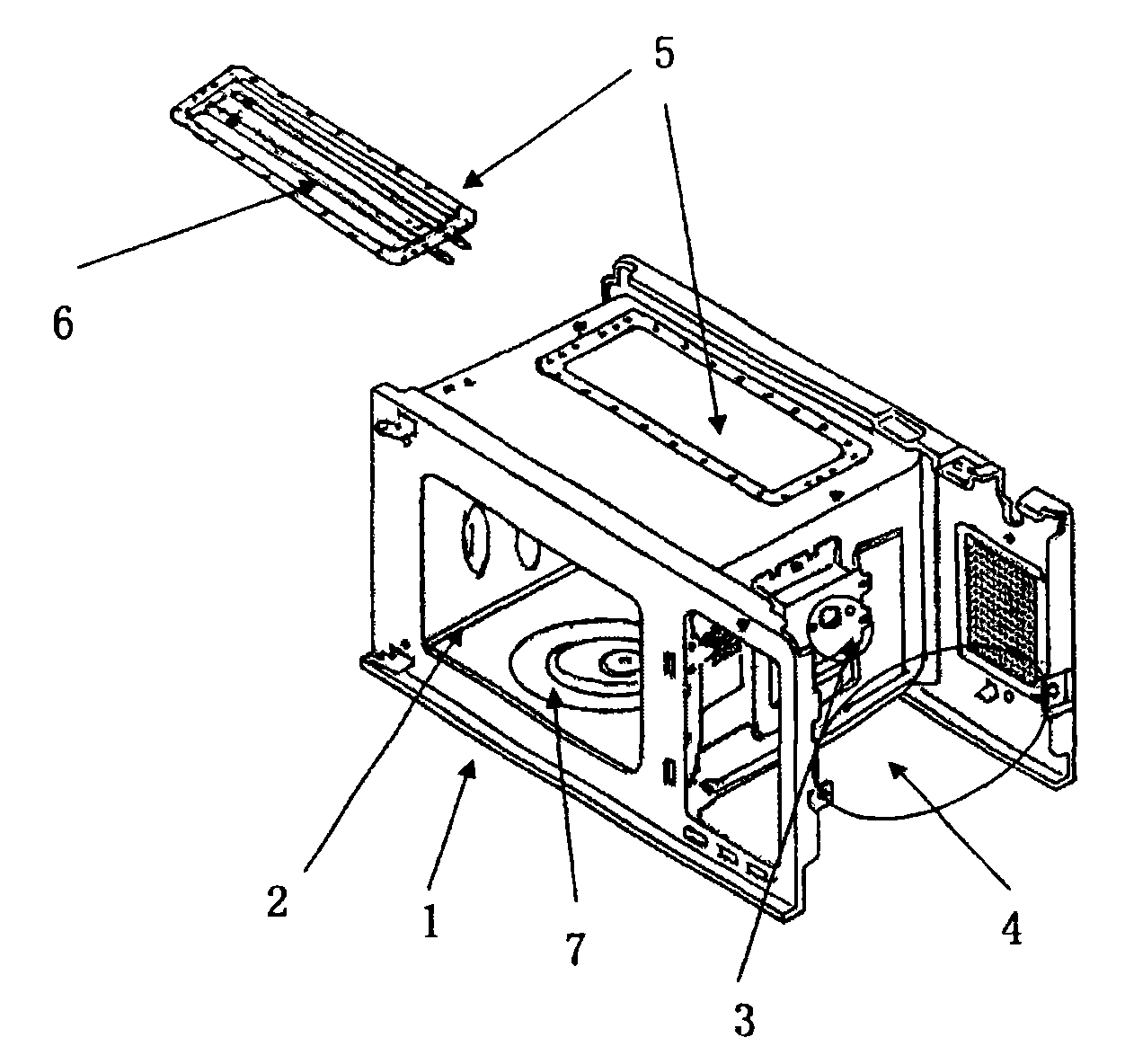

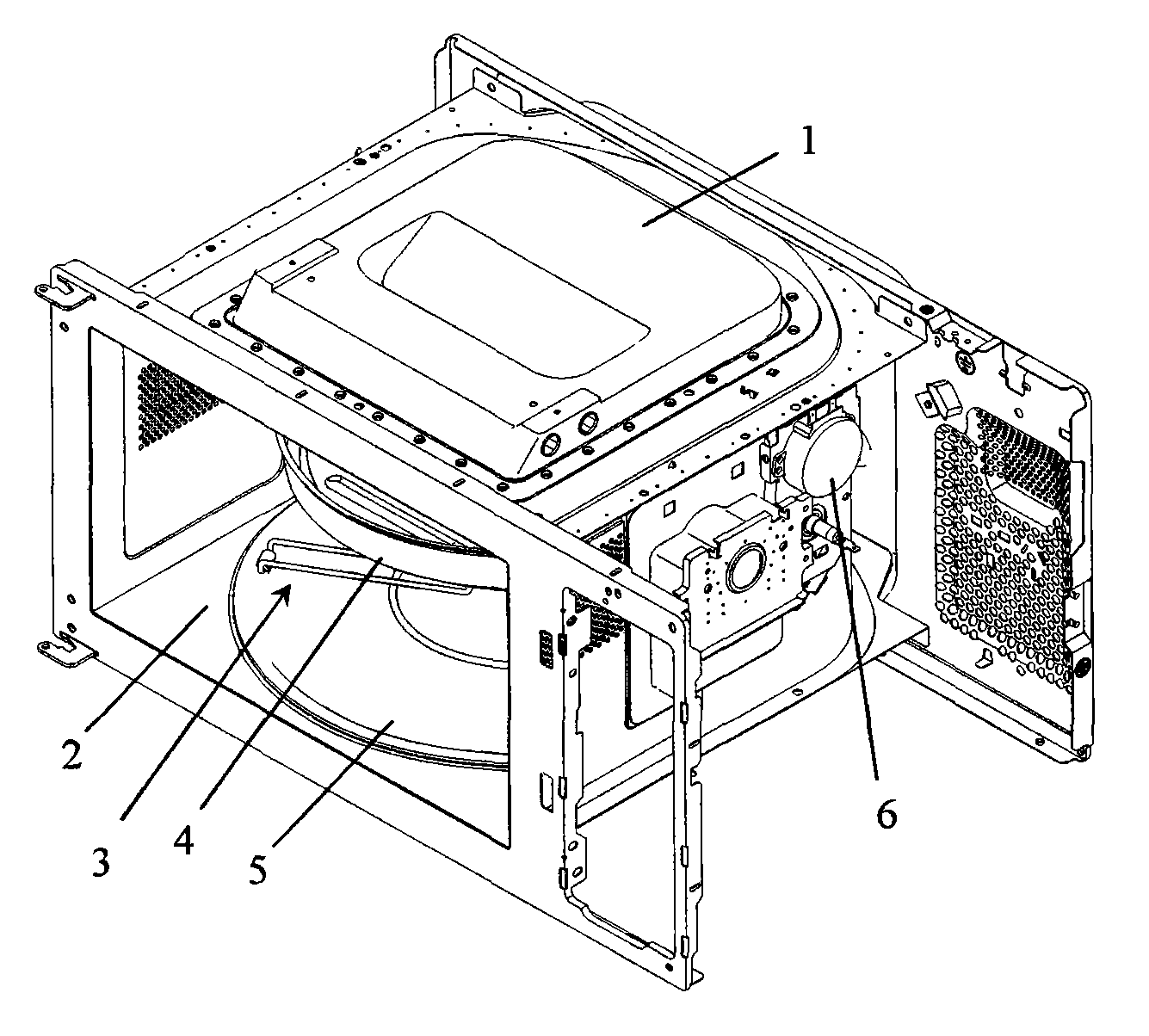

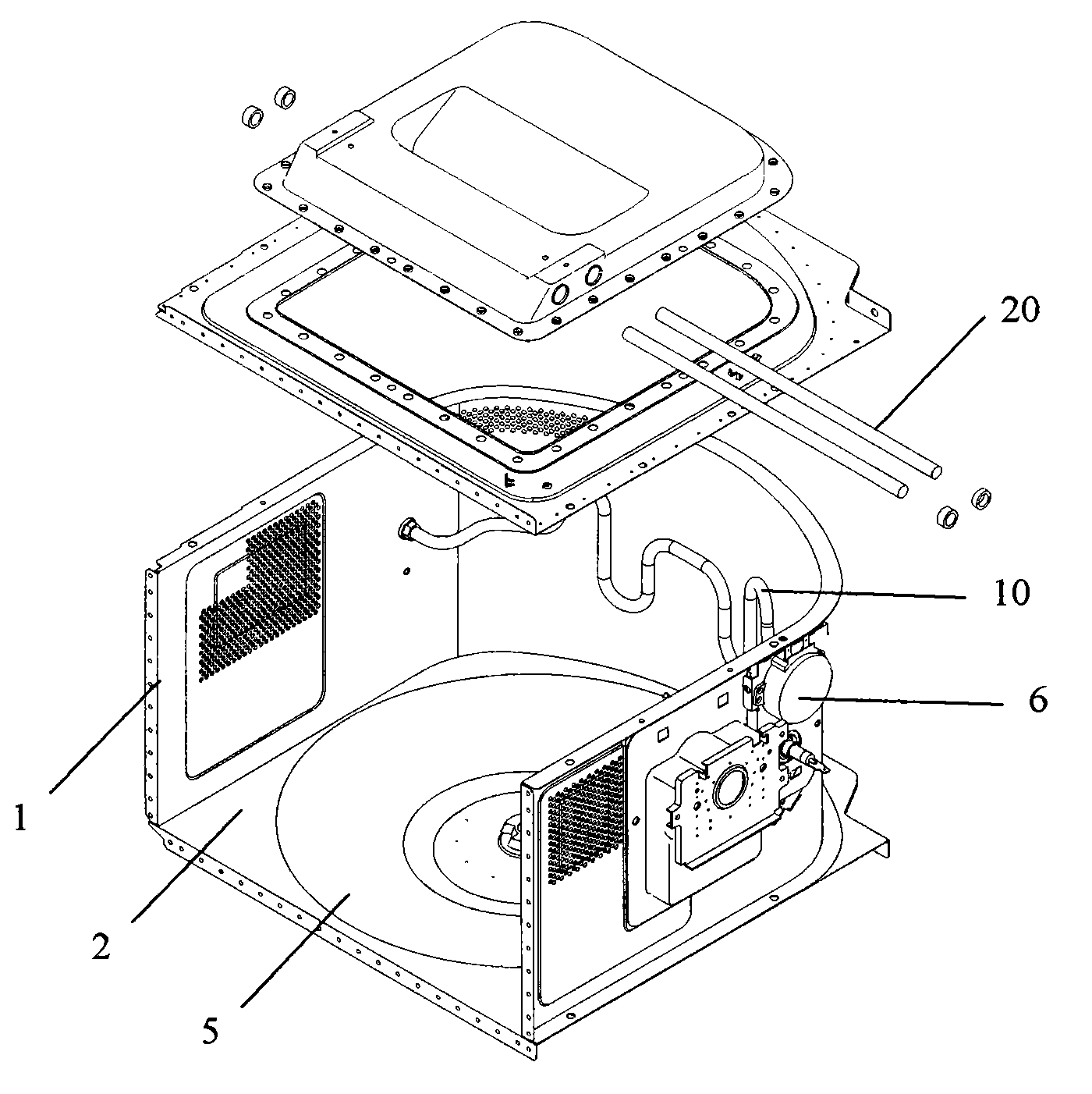

Novel barbecue type microwave oven

InactiveCN101936550AUniform tasteKeep the color and fragranceDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

The invention discloses a novel barbecue type microwave oven. The microwave oven comprises a cooking control module (100), which is connected with a barbecue copper tube (10), a straight barbecue tube and a magnetron (30) respectively for selectively combining at least one of the barbecue copper tube (10), the straight barbecue tube and the magnetron (30) for heating a food. The novel barbecue type microwave oven disclosed by the invention can cook the food in the microwave oven by using multiple cooking modes, so that the cooked food has uniform mouthfeel, elements of measurable cooking quality such as color, aroma, taste and the like of the food and the like are ensured, the product using experience of the microwave oven user is greatly enhanced, and the microwave oven has great production practice significance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

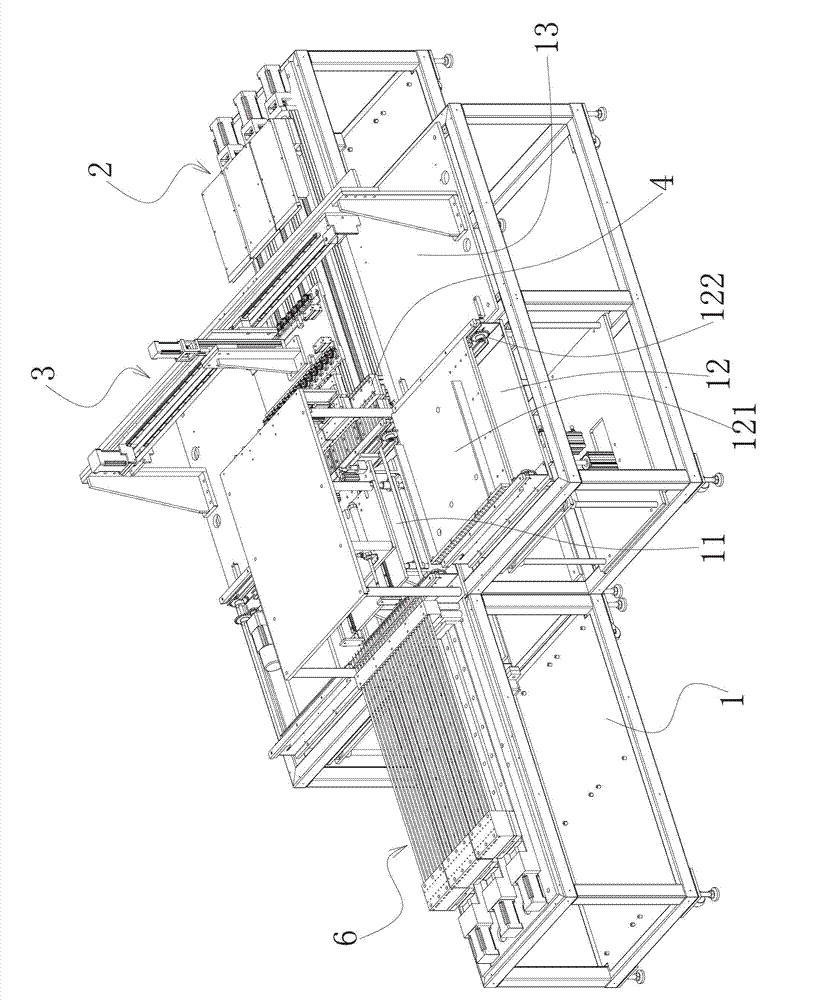

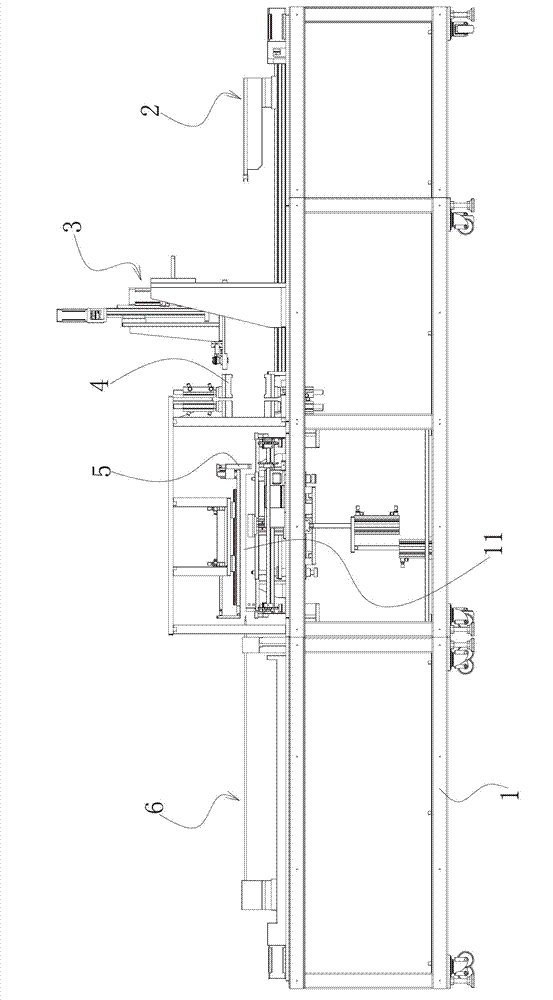

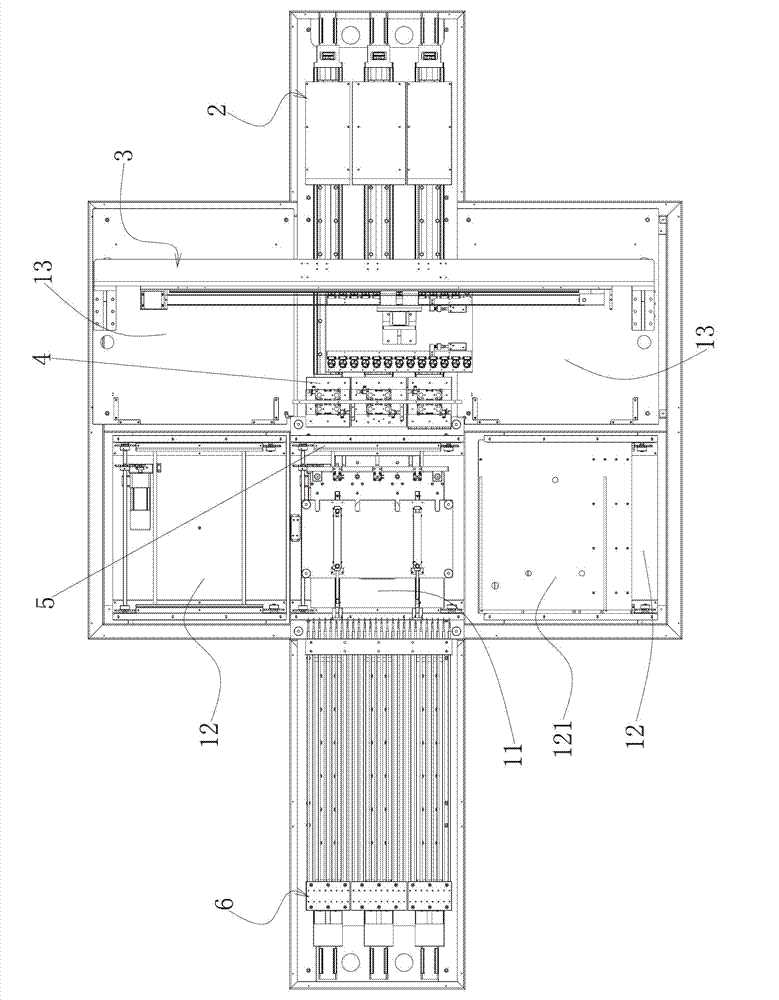

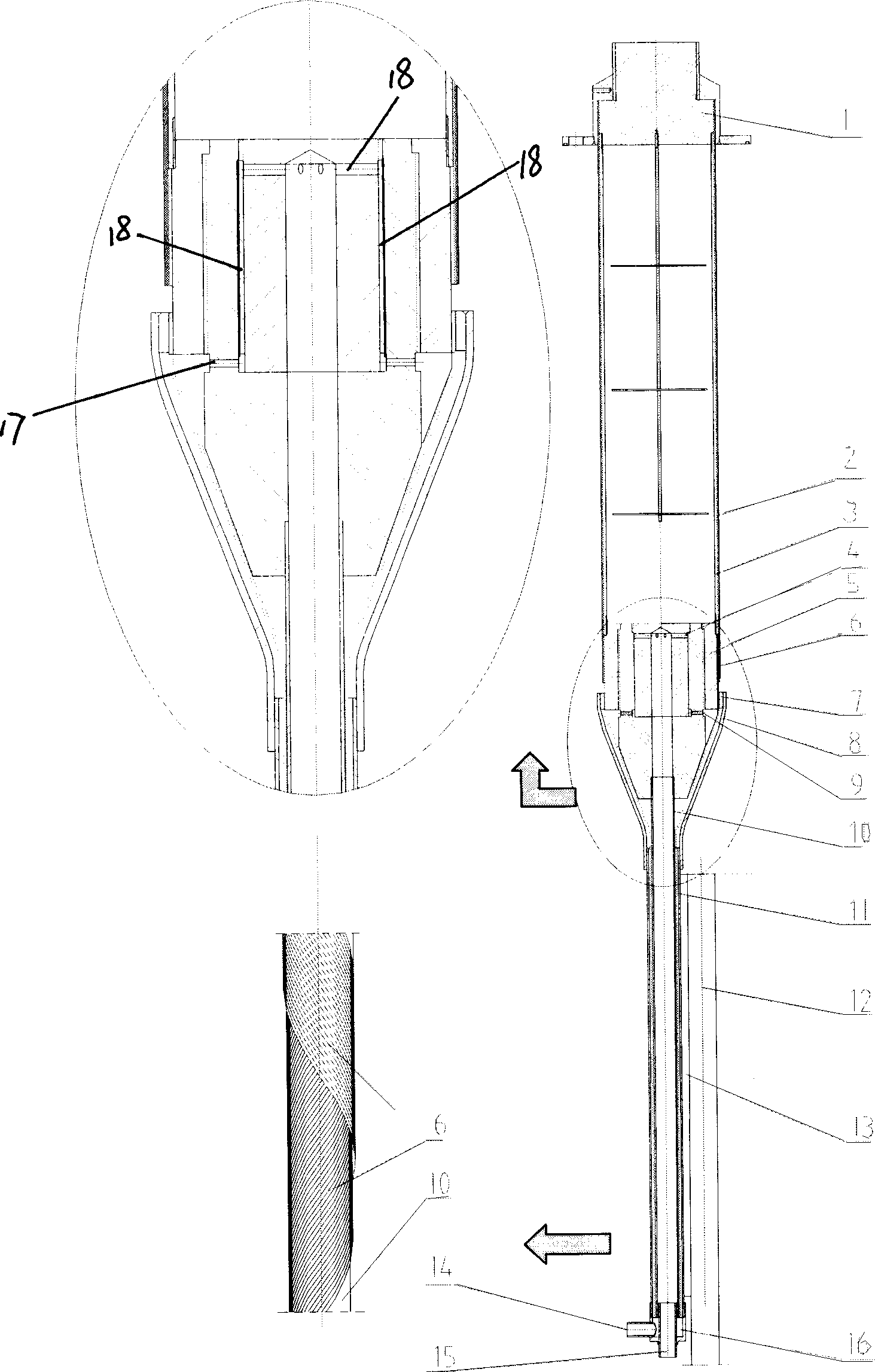

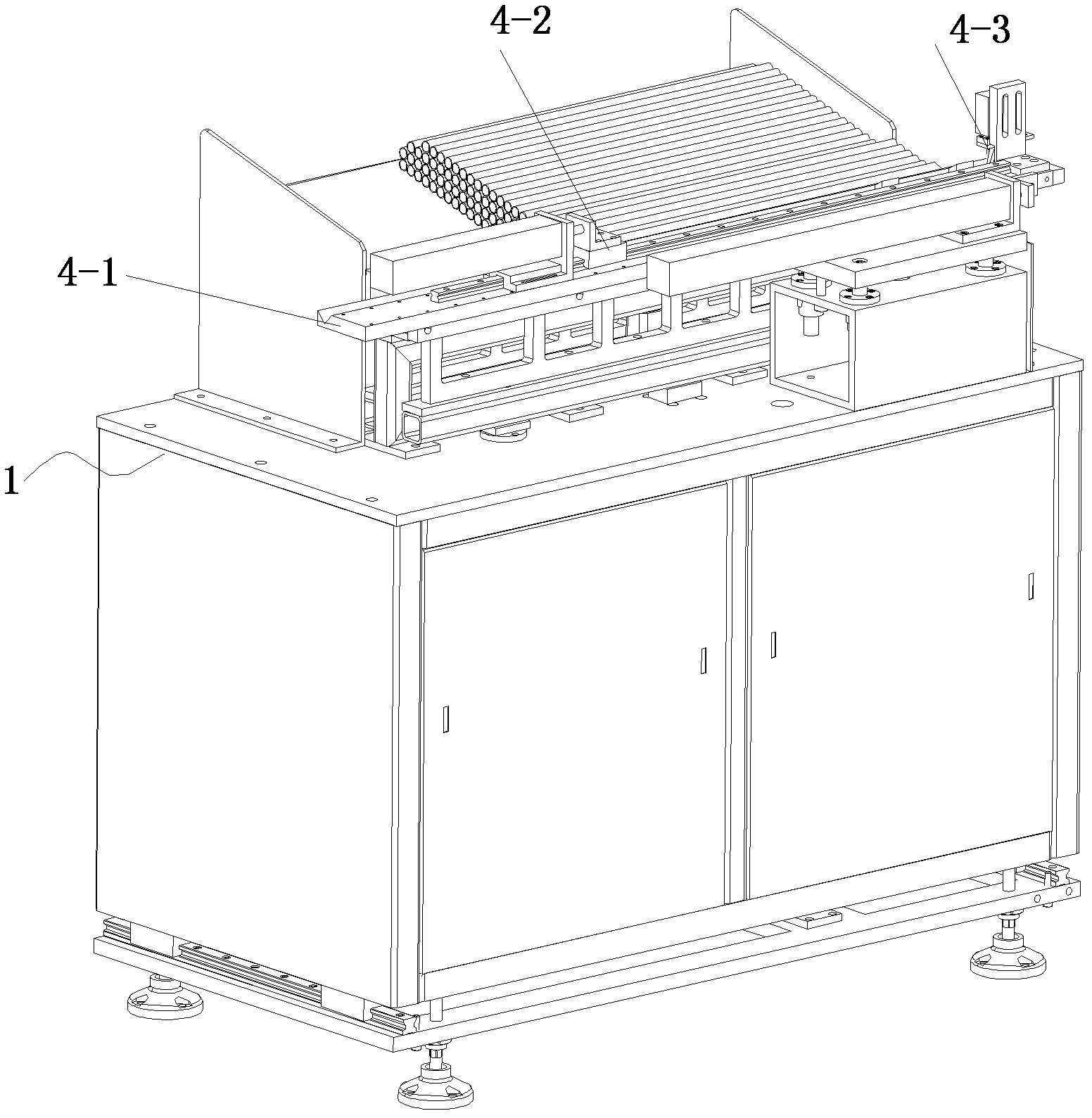

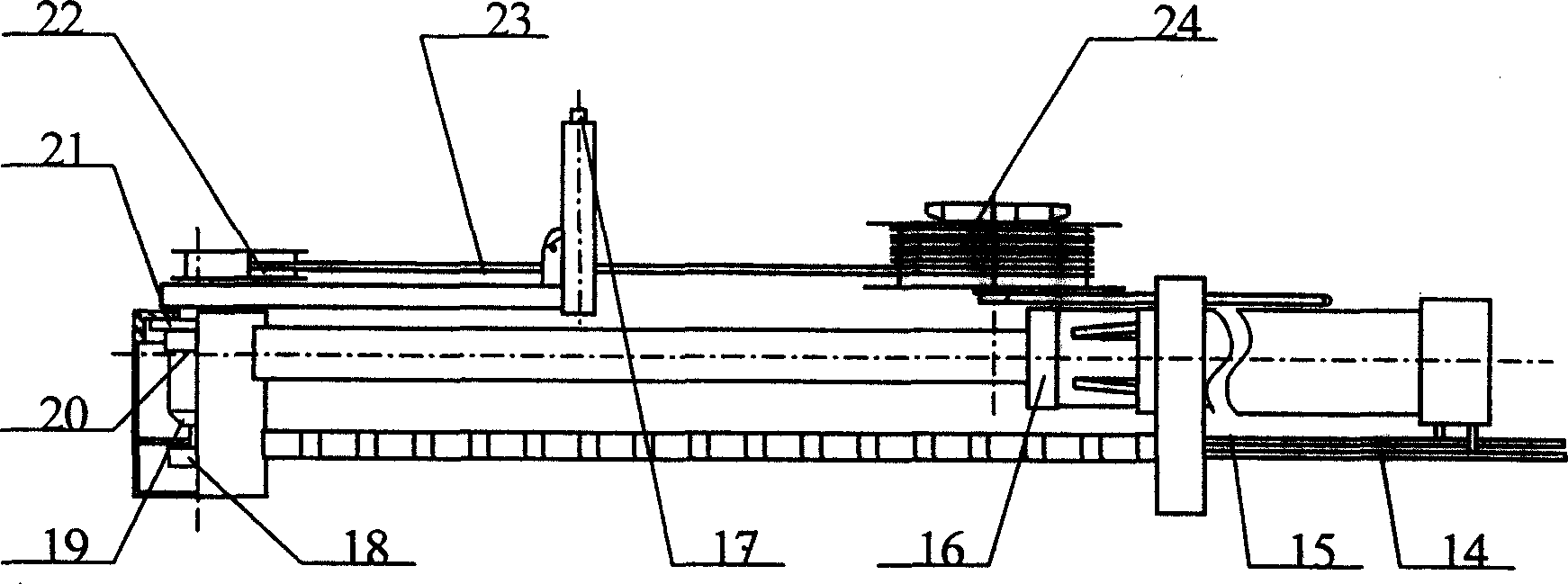

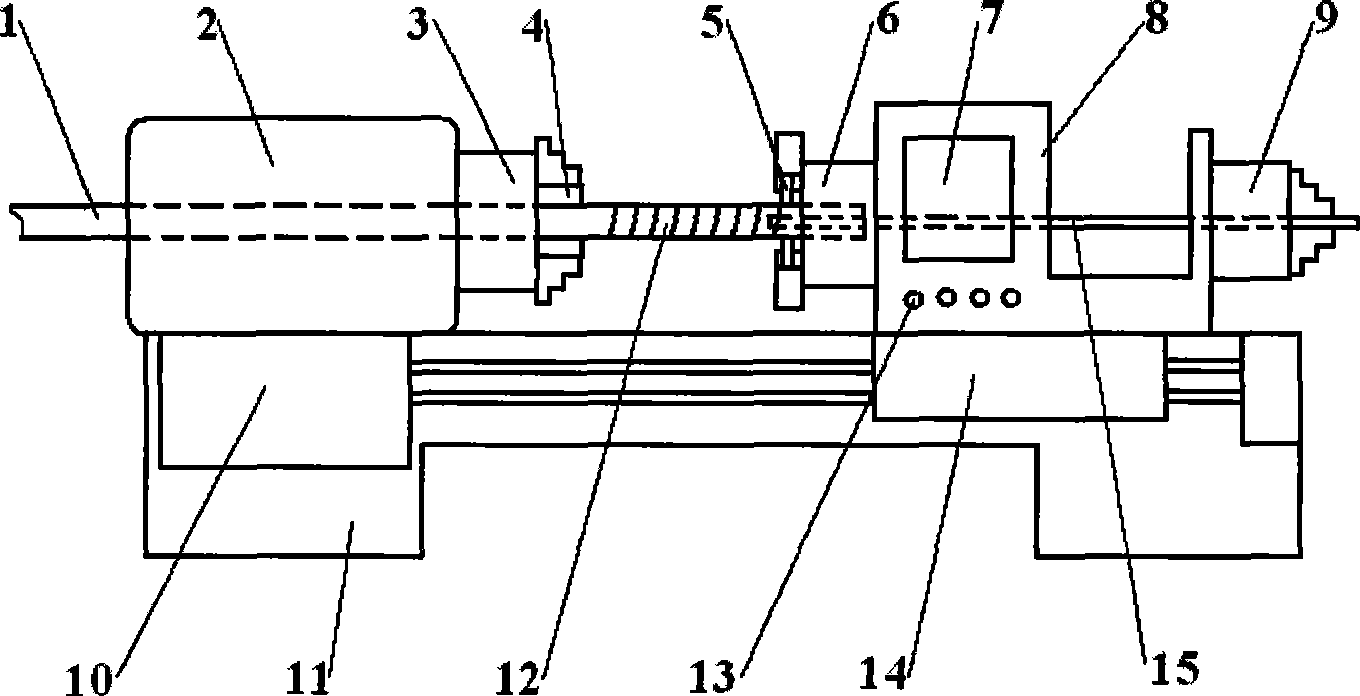

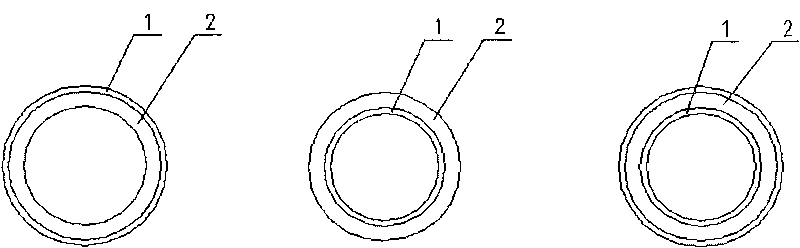

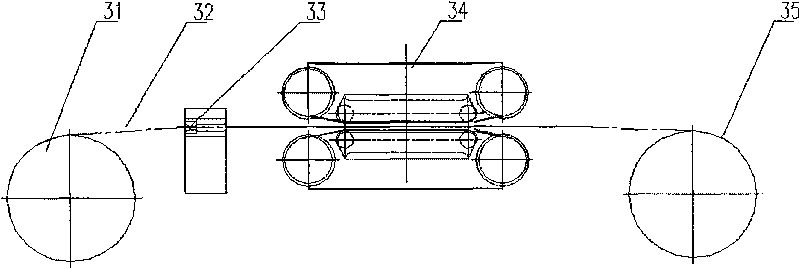

Full-automatic pipe penetrating equipment for inserting copper pipes into condenser fins and pipe penetrating technology

Full-automatic pipe penetrating equipment for inserting copper pipes into condenser fins is characterized by comprising a machine frame, a copper pipe pushing and inserting mechanism and a traction mechanism. A pipe penetrating working area is arranged between the copper pipe pushing and inserting mechanism and the traction mechanism, the traction mechanism comprises a traction rod and a driving device of the traction rod, and the traction can freely enter or exit assembling holes on the condenser fins and guide copper pipes to be inserted to the assembling holes of the fins when the traction rod exists the assembling holes. The copper pipe pushing and inserting mechanism comprises a pushing block and a driving device of the pushing block, the pushing block can enable copper pipes to be inserted into the end part of the traction rod and gradually inserted into the assembling holes of the fins under the guiding of the exiting of the traction rod. A pipe penetrating technology inserting cooper pipes into condenser fins is characterized by comprising the following steps of: entering the condenser fins into the pipe penetrating working area; inserting the traction rod into the assembling holes of the fins; and the pushing block pushes the copper pipes forward to enable the copper pipes to be inserted into the end part of the traction rod till the copper pipes are completely inserted into the fins under the guide of the traction rod. The full-automatic pipe penetrating equipment for the inserting copper pipes into the condenser fins and the pipe penetrating technology can lower cost and improve production efficiency.

Owner:CHENZHOU ZHIZAO TECH CO LTD

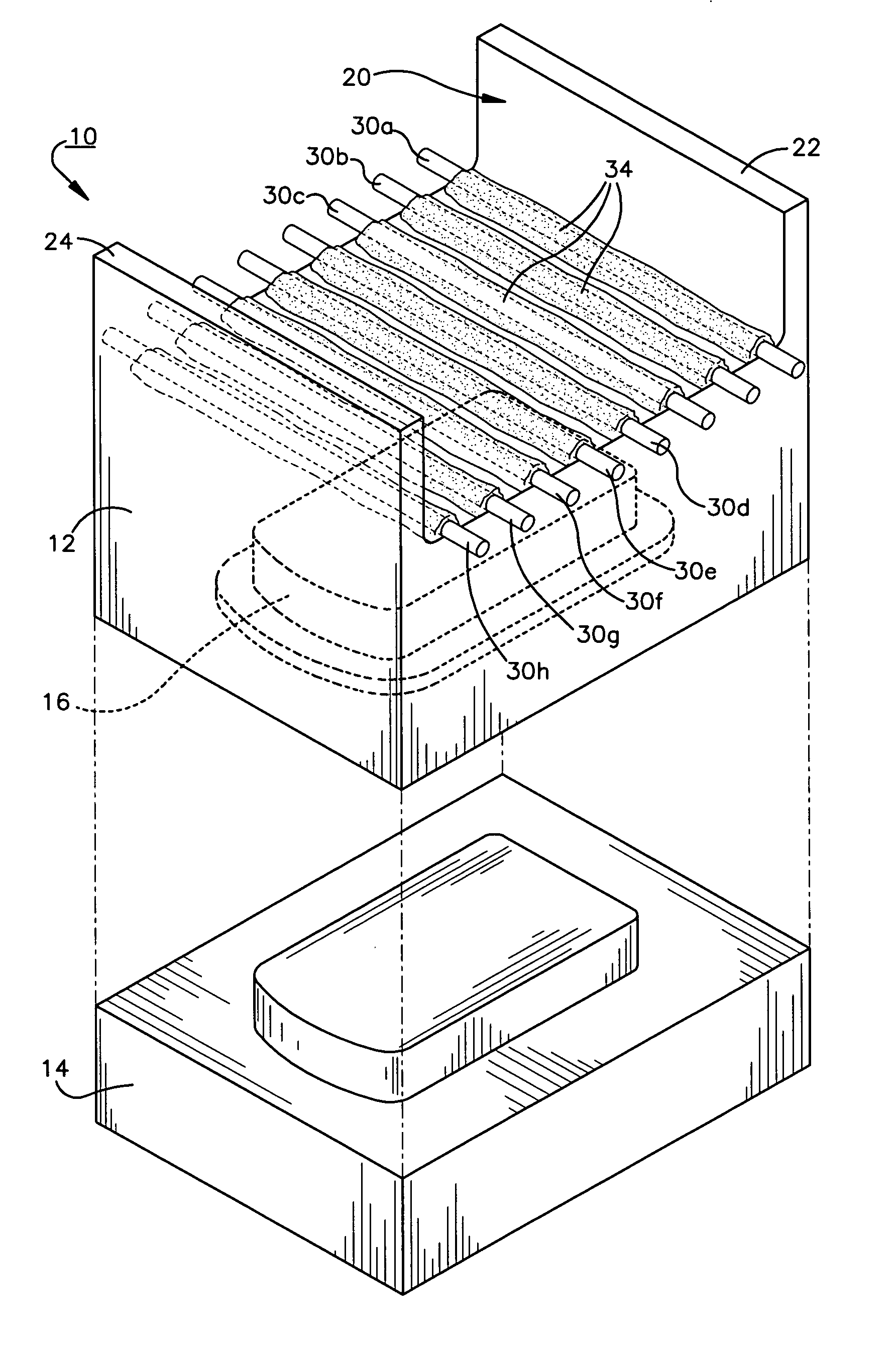

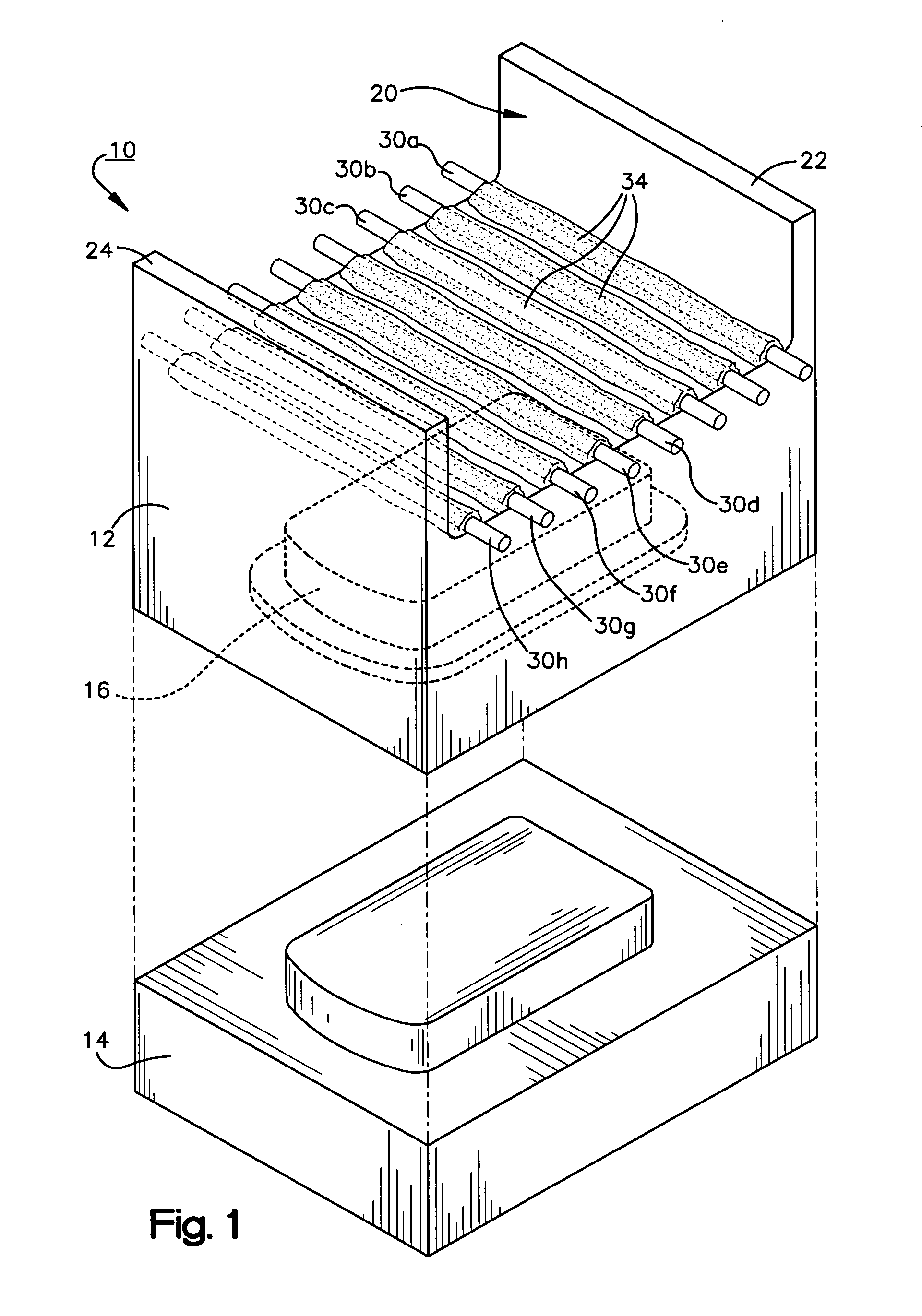

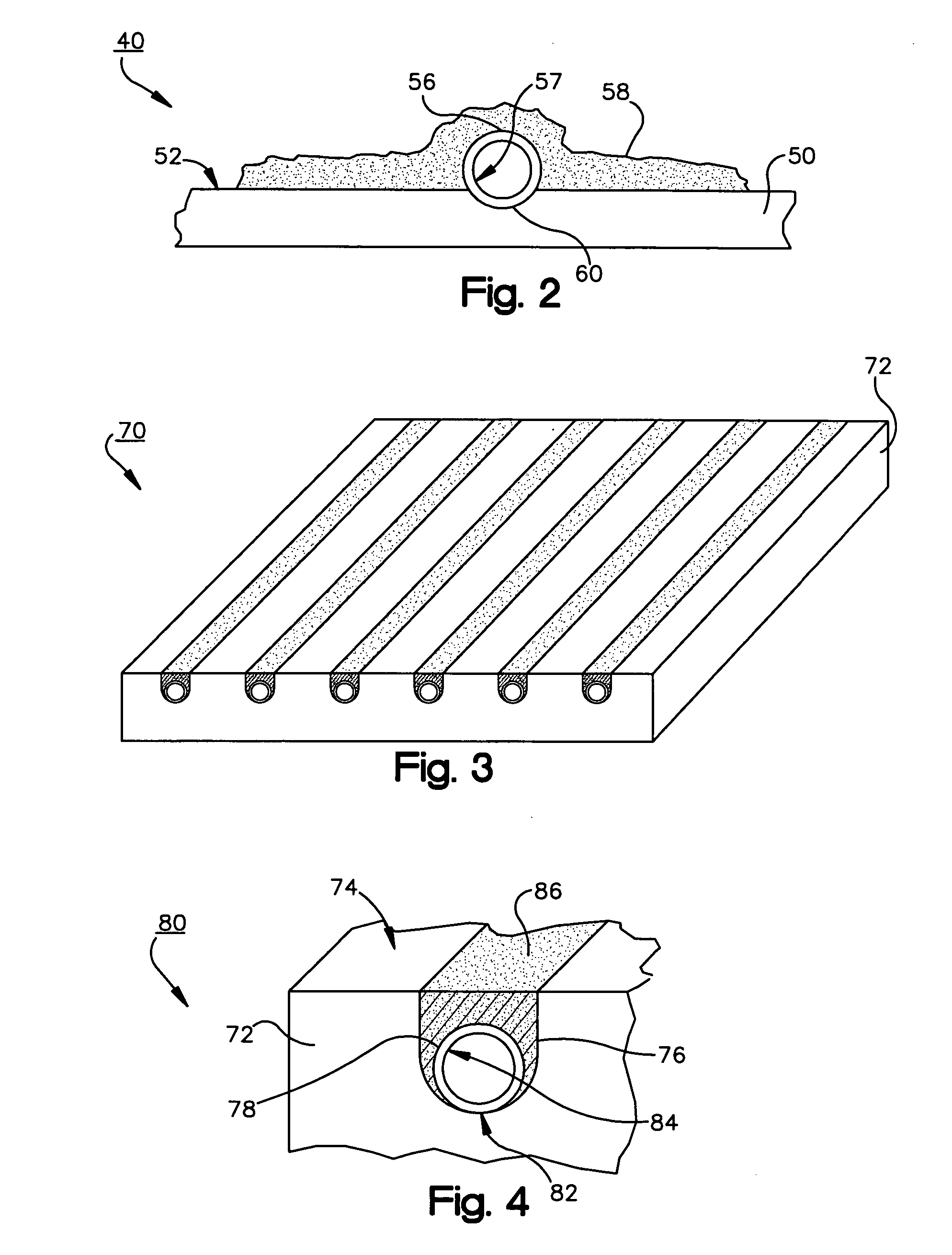

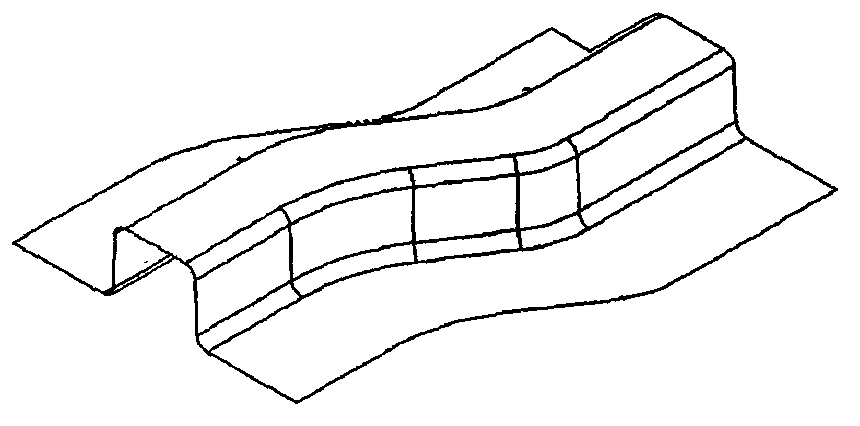

Heat transfer system for a mold

An apparatus for facilitating heat transfer in a mold is disclosed. The apparatus includes a mold section having an external surface defining a concave-shaped channel, a hollow elongated member positioned within the channel, and a binding material attaching the hollow elongated member to the mold section. Heat transfers from the mold section to relatively cooler heat transfer fluid when the fluid is directed through the hollow elongated member. Heat may also transfer from the molded piece to the mold section when the fluid is transported through the hollow elongated member. The apparatus may have any number of channels and members. The hollow elongated member may be a copper tube and be completely or partially positioned within the channel. The mold section and binding material may be made of aluminum. A method of manufacture of the apparatus is also disclosed.

Owner:FREMONT PLASTIC MOLDS

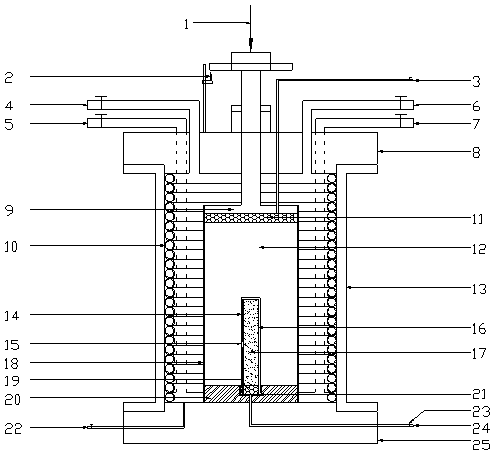

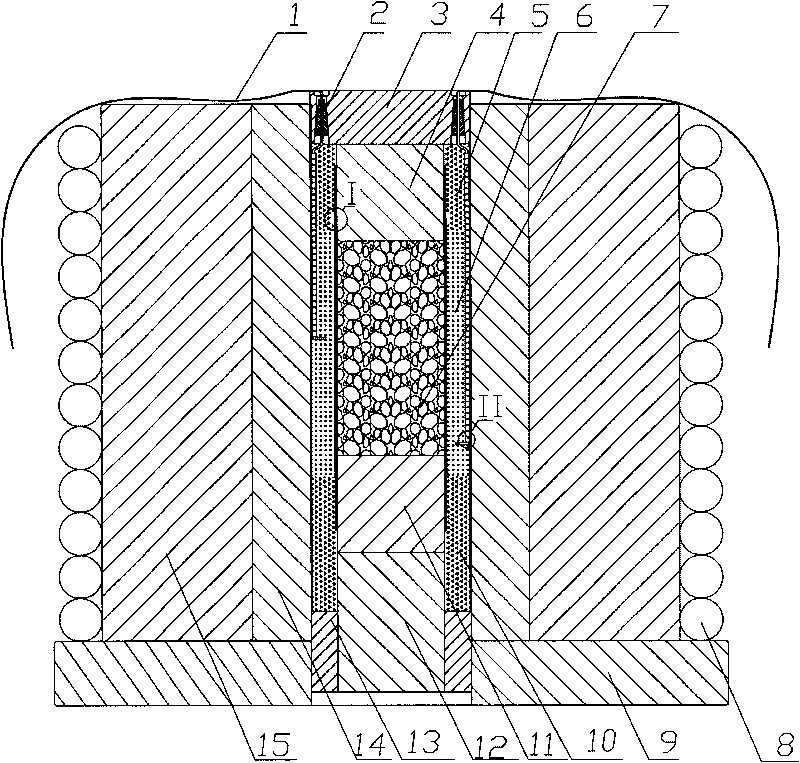

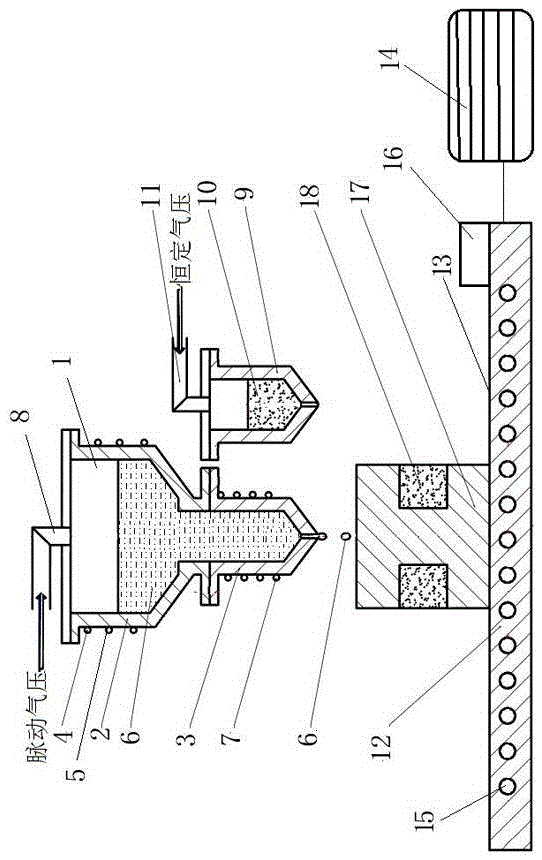

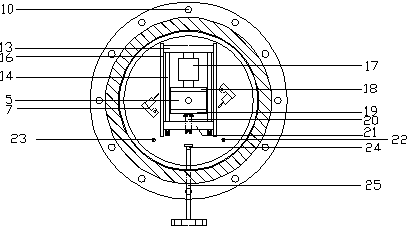

Device and method for clay core wall hydraulic fracturing experiments

ActiveCN103389249AReduce distortionReduce intensityPreparing sample for investigationMaterial strength using tensile/compressive forcesWater volumeAxial pressure

The invention relates to a device and a method for clay core wall hydraulic fracturing experiments under simulated coupling conditions. The method is characterized in that two semi-cylindrical molds are specially made and assembled into a sample mold which is easy to assemble and disassemble; the internal temperature of a pressure chamber is controlled through changing the temperature and amount of water in a copper water pipe; internal water pressure is applied to a sample by a water flow passing through a base of the pressure chamber, a permeable plate, coarse sand and finally a blowhole; and hydraulic fracturing features of the clay sample under different conditions are studied through changing the water temperature and loading schemes of the fracturing water pressure, the axial pressure and the confining pressure, etc. The method overcomes the defects of hydraulic fracturing experiments in the prior art on core walls of earth and rock-fill dams, simulates features, force conditions, influencing factors and the like of clay core walls more accurately, and thus can be widely applied in hydraulic engineering and geotechnical engineering.

Owner:HOHAI UNIV

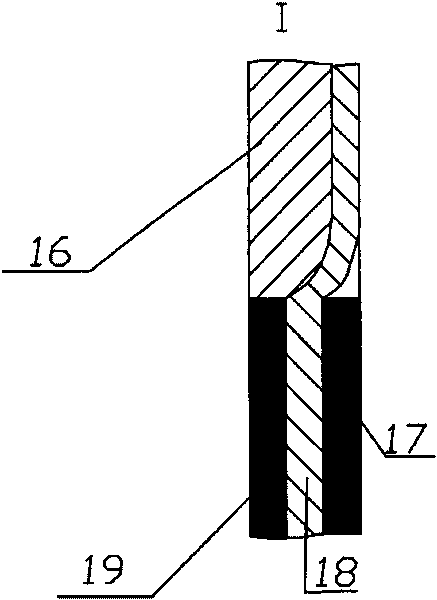

Cold end of heavy current lead out wire made from high-temperature superconductor, and low resistance connector of superconducting transmission line

InactiveCN1873847ASave cooling capacityLess investmentSuperconducting magnets/coilsEngineeringSuperconducting transmission lines

The disclosed adaptor between cold junction of leading wire in heavy current of high-temperature superconductor and low resistance of superconducting transmission line includes structure: welding piles of high-temperature superconductor arranged in spaces to outer wall of support tube made from stainless steel in low thermal conductance; welding warm end in piles of high-temperature superconductor to transition piece of copper; through braze welding, cold end in piles is joined to NbTi / Cu superconducting line; cross winding NbTi / Cu line on inner copper tube sheathed inside outer copper tube; cooling superconducting line and copper connector by using liquid helium between inner and outer copper tubes. Features are: simple structure, suitable to connection under 20kA. In the invention, resistance of adaptor is lowered as 1.4-4.6n ohm. In supercritical quantity of helium flow 4g / s, all loss of 6 pieces of adaptor and 12 pieces of butt end of transmission line is less than 0.1Mpa.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

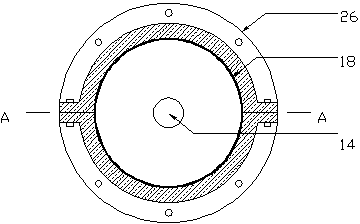

Device and method for heating rock specimen under triaxial pressure

InactiveCN101710048AMaterial strength using tensile/compressive forcesTemperature controlAxial pressure

The invention relates to a device and a method for heating a rock specimen under a triaxial pressure. The device consists of a triaxial pressure chamber furnace body, an axial pressure head, a confining pressure head, an upper pressure head, a lower pressure head, pressure-transmitting, heat-generating, insulating and heat insulation materials, a thermocouple, a traction trolley base, a triaxial pressure machine and a temperature control cabinet, wherein the triaxial pressure chamber furnace body is arranged on the traction trolley base; solid-particle pressure-transmitting materials, the thermocouple and heat-generating, insulating and heat insulation materials are arranged in a space encircled by the axial pressure head, the confining pressure head, the upper and lower pressure heads, the rock specimen and the inner wall of the triaxial pressure chamber furnace body; and water cooling copper pipes are distributed at the periphery of the triaxial pressure chamber furnace body. The triaxial pressure machine is used for pressurizing the axial pressure head and a confining pressure sleeve, adjusting the output current of the temperature control cabinet and changing the heat productivity of an electric heating alloy sheet; the heat passes through a piece of mica paper and is transmitted to the rock specimen; the thermocouple measures the ambient temperature of the electric heating alloy sheet in real time; and the temperature control cabinet displays and records the ambient temperature, compares the displayed temperature with the experimental fitted temperature, and adjusts the current to realize the controllable temperature of the rock specimen.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing copper and nickel alloy seamless copper tube

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

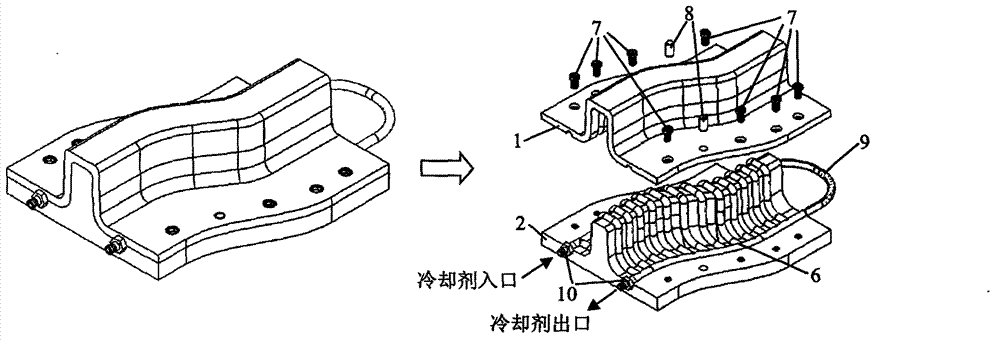

High strength steel plate hot stamping die for automobile parts

The invention discloses a high strength steel plate hot stamping die for automobile parts. The high strength steel plate hot stamping die for the automobile parts mainly consists of a male die body (a male die and a male die connecting fixing plate), a female die body (a female die and a female die connecting fixing plate), blank holders, cooling pipelines, connecting devices, positioning devices, U-shaped connecting hoses and pipe joints. The male die, the male die connecting fixing plate, the female die, the female die connecting fixing plate and the blank holders are respectively manufactured, and grooves used for fixing the cooling pipes are respectively processed. The cooling pipelines are manufactured into shape-following cooling pipelines which are consistent with the shape trends of the parts by adopting copper pipes, are respectively arranged in the grooves respectively arranged in the male die body, the female die body and the blank holders, and are externally connected with a master cooling pipeline through the U-shaped connecting hoses and the pipe joints to form a cooling closed loop. The hot stamping die disclosed by the invention is simple and compact in structure and convenient in maintenance, is reliable and practical, can be used for evenly and rapidly cooling the parts during a stamping process and is in favor of enhancing the working stability per se and prolonging the service life per se.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Medium temperature glass-metal structure solar vacuum thermal-collecting tube

InactiveCN101392965AMeet solar air conditioningFulfil requirementsSolar heating energySolar heat devicesMaterials scienceMetallic Nickel

The invention discloses an intermediate temperature glass-metallic structure solar vacuum thermal-collecting tube, which belongs to the technical field of solar utilization, wherein a layer of temperature-resistant anti-oxidation film is plated on the outer surface of a heat-transfer pipe provided with a heat-conductive wing in the intermediate temperature glass-metallic solar vacuum thermal-collecting tube, and the film layer is aluminum or zinc or nickel or chromium or stainless steel; the heat-conductive wing is a thin aluminum plate which is coiled into the shape of an opening cylinder or a semicircular cylinder, and is tightly connected or welded with a U-shaped copper tube or a copper heat pipe of the temperature-resistant anti-oxidation film; and a heat-conductive wing tube is arranged inside the all-glass solar vacuum thermal-collecting tube, and closely contacts the inner wall of the all-glass solar vacuum thermal-collecting tube. A non-evaporable getter can be arranged inside a vacuum interlayer of the all-glass solar vacuum thermal-collecting tube, thereby improving the vacuum service life of the all-glass solar vacuum thermal-collecting tube after the long-term operating temperature is extended to more than 140 DEG C. The invention is a novel intermediate temperature glass-metallic solar vacuum thermal-collecting tube with high cost performance, and can meet the requirements of solar air-conditioners and industrial heat.

Owner:TSINGHUA UNIV

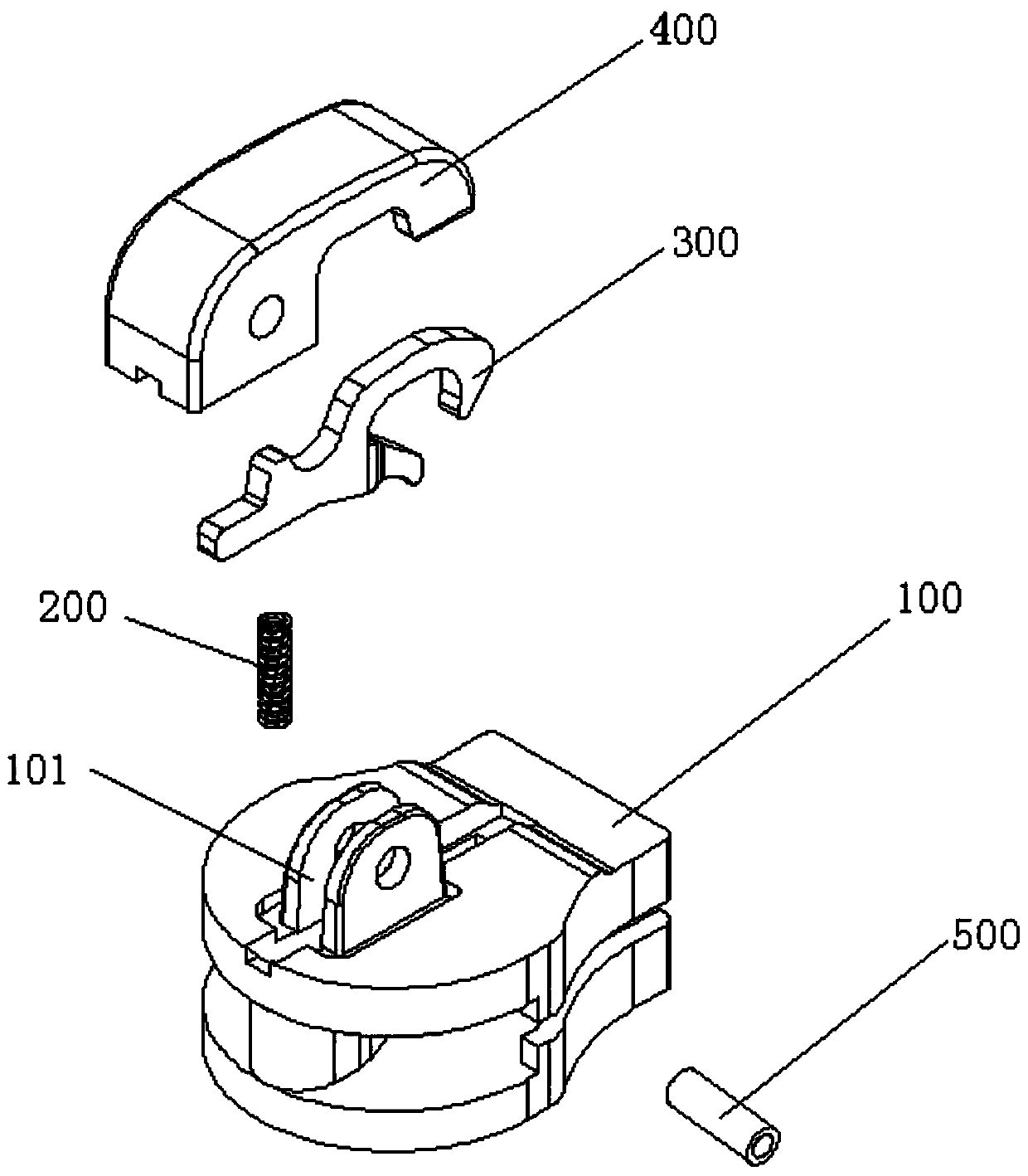

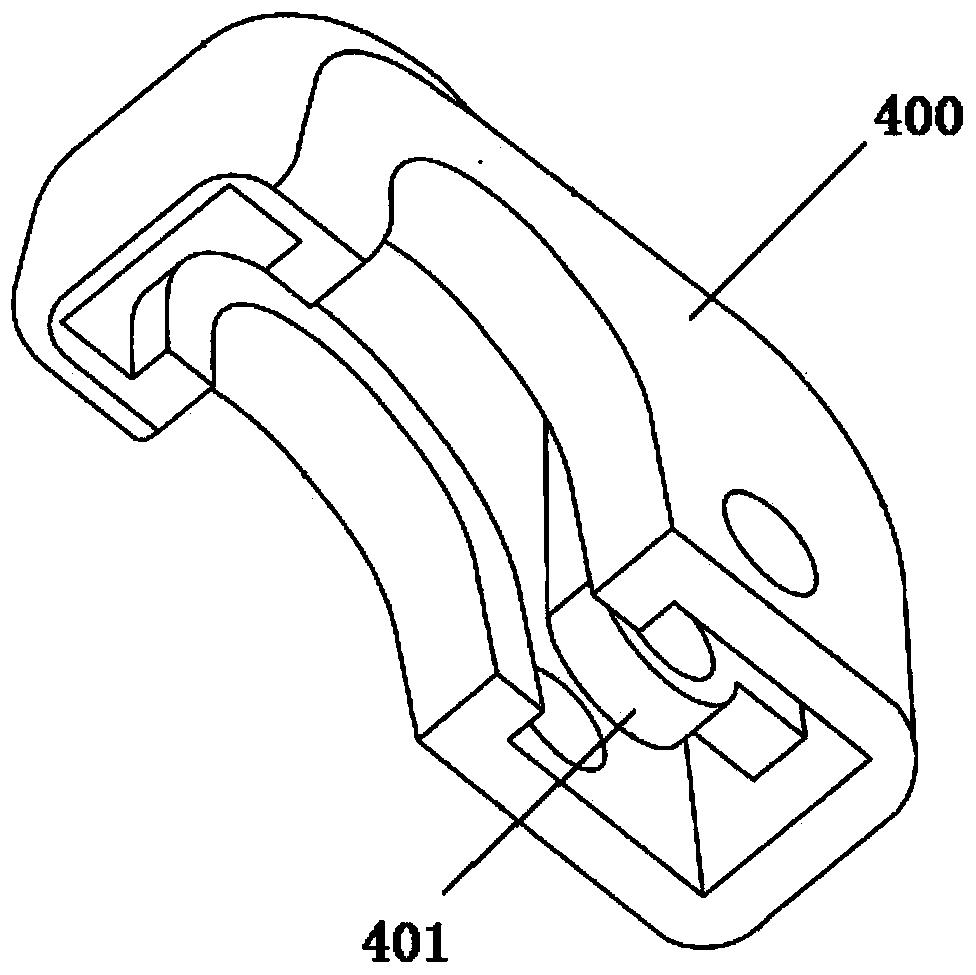

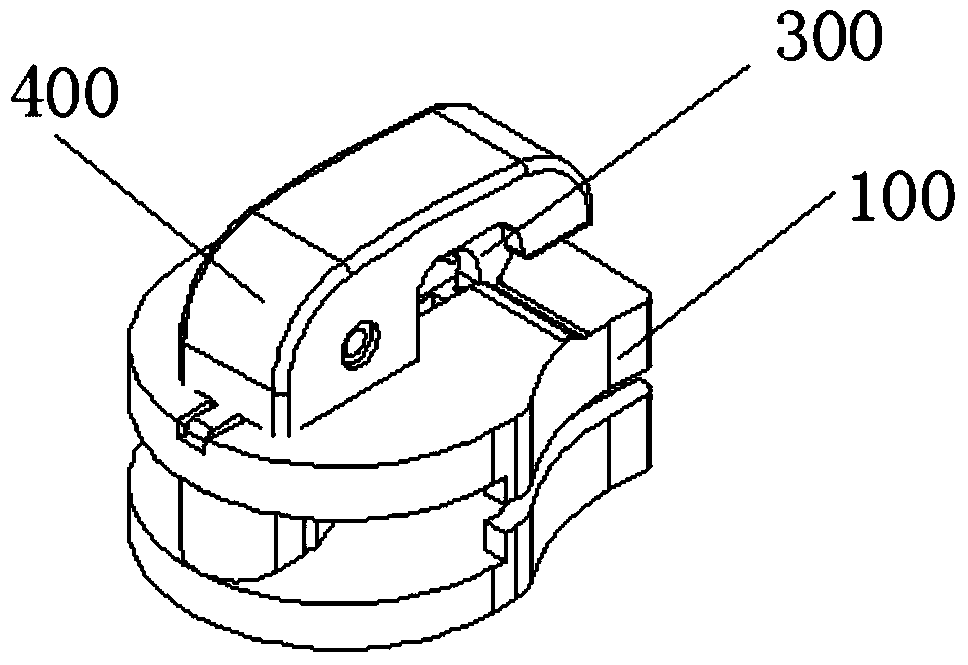

Automatic all-purpose zipper head assembly machine

ActiveCN103445407AGuaranteed smooth assemblyGuaranteed smooth productionSlide fastenersPunchingEngineering

The invention provides an automatic all-purpose zipper head assembly machine. The automatic all-purpose zipper head assembly machine comprises a machine base, wherein a power transmission device is arranged in the machine base; a rotary disc and a pressure disc are mounted above the machine base; the power transmission device not only enables the rotary disc to perform graduation intermittent rotation, but also enables the pressure disc to perform lifting movement; molds for placing a pull head are uniformly distributed on the periphery of the rotary disc; work station devices corresponding to the stop positions of the molds are fixed on the pressure disc or the table surface of the machine base; the work station devices include a feeding device, a detection device, a riveting device and a material returning device. The automatic all-purpose zipper head assembly machine is characterized by further comprising a burr removing device in front of the copper tube feeding device, and the burr removing device is formed by a cap cover pressing and fixing device mounted on the pressure disc and a punching device mounted on the table surface of the machine base. The automatic all-purpose zipper head assembly machine can automatically complete multi-wall pin penetrating all-purpose zipper head assembly, and is reliable in movement and high in production efficiency; in addition, the automatic all-purpose zipper head assembly machine is simple in structure and easy to debug and maintain, and lowers equipment cost.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

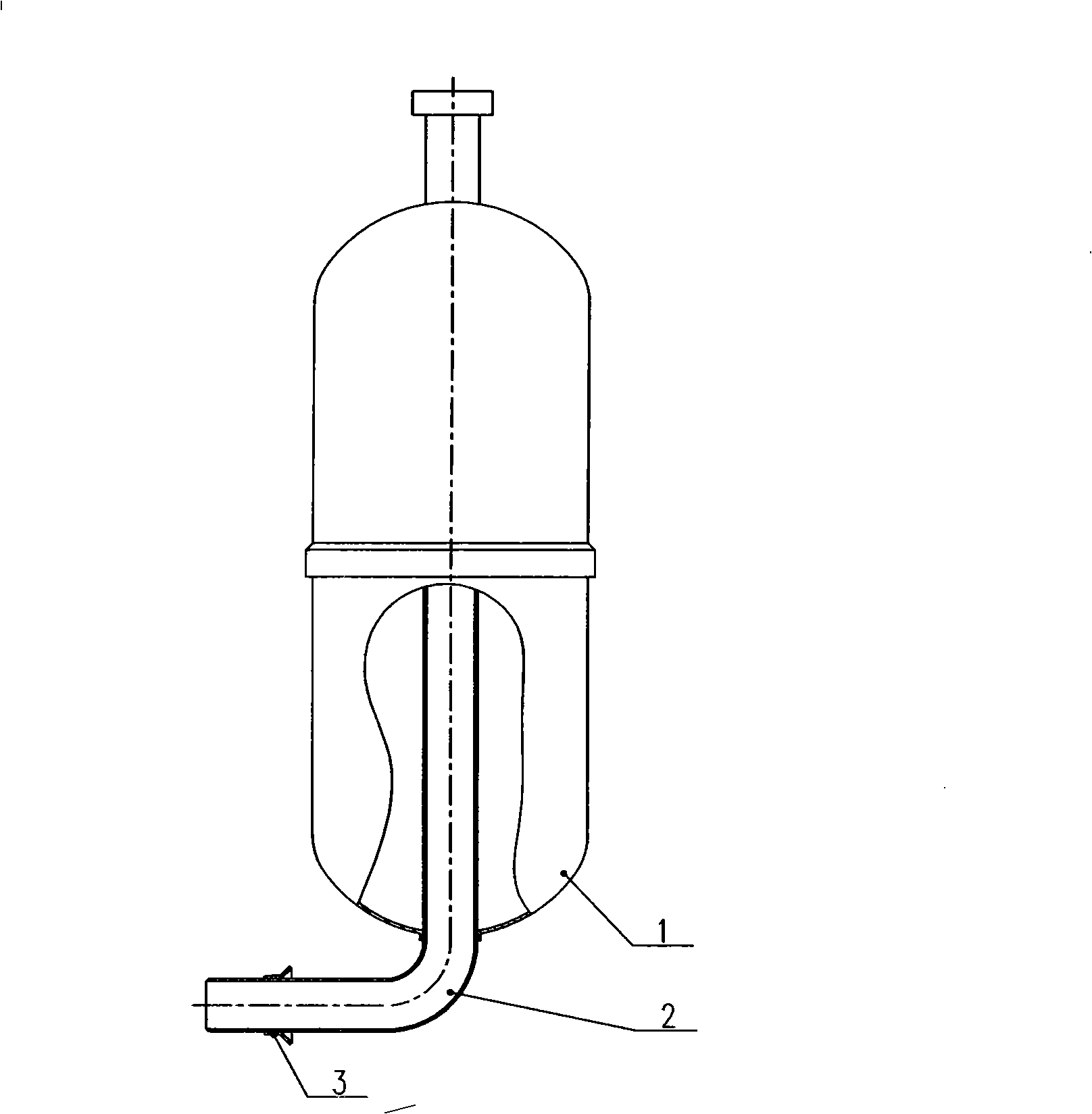

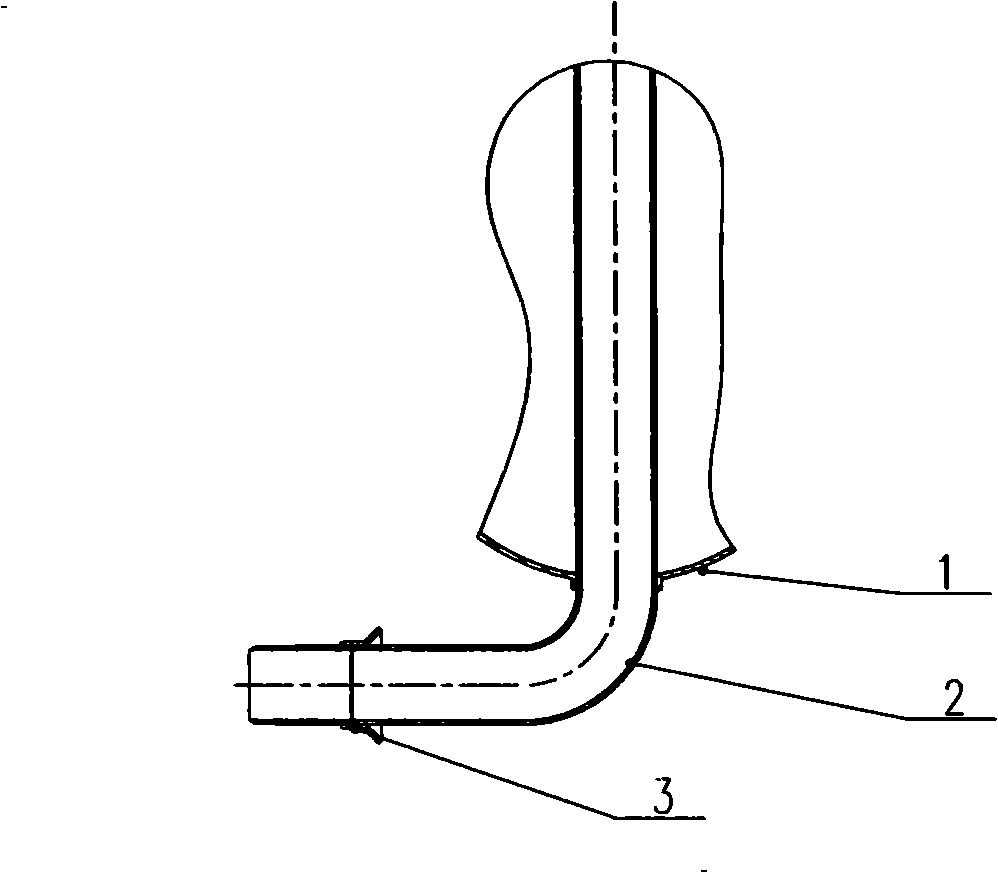

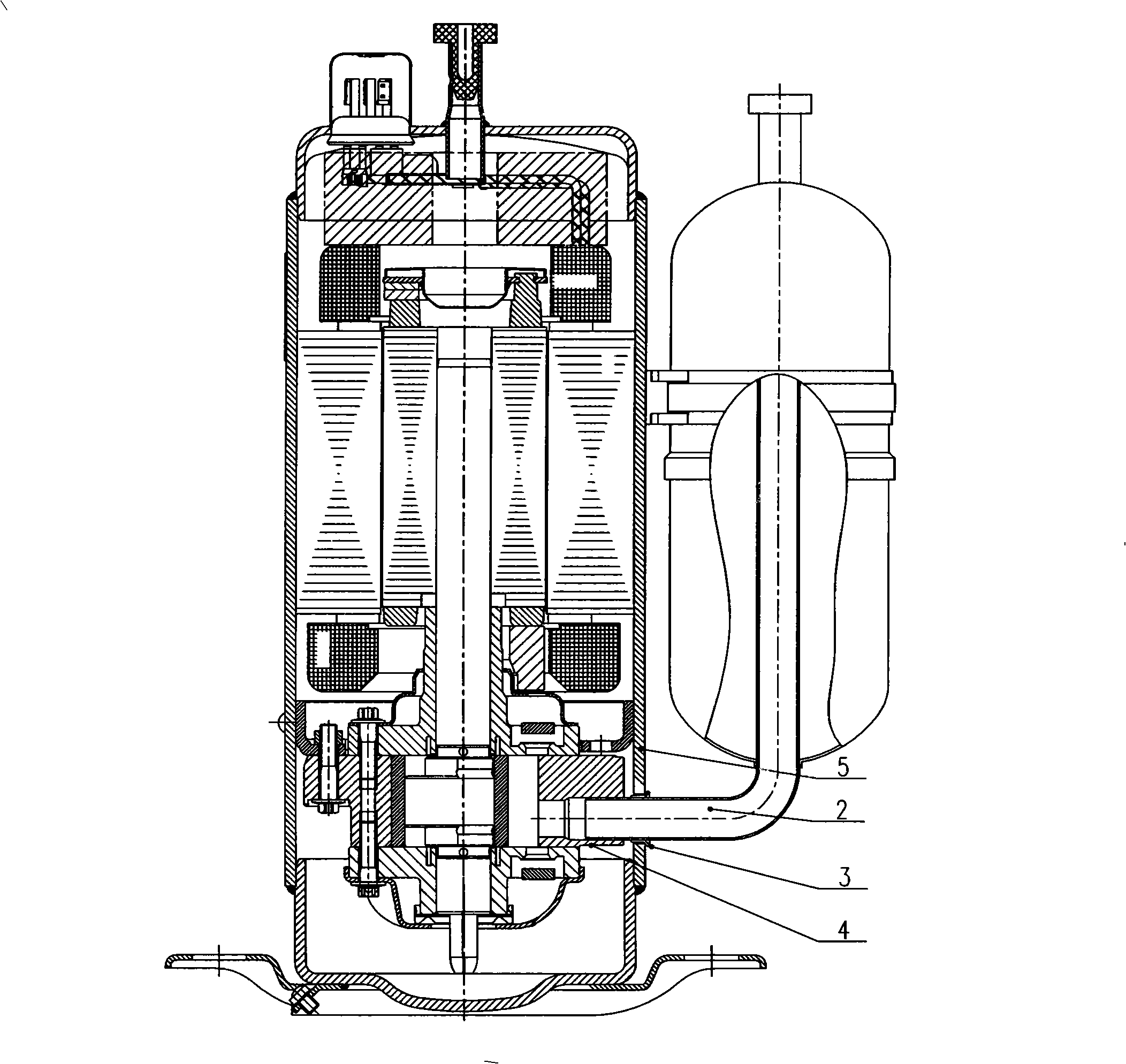

Suction duct of air conditioner compressor and fabricating and connecting method thereof

InactiveCN101328878ALow costReduce usagePositive displacement pump componentsSoldering apparatusInterference fitElectrical resistance and conductance

The invention provides a suction pipe for an air conditioner compressor and methods for manufacturing and connecting the same. The suction pipe is an all-steel bent pipe, a horizontal section is provided with an iron ring, an end port of a pipe column of the iron ring is pressed into the horizontal section of the bent pipe by a pressure machine based on requirements, a copper-based solder is placed at an annular seam which is arranged between the bent pipe and the iron ring and between a vertical section of the bent pipe and a main body of a liquid reservoir, which is welded in a furnace by means of braze welding so as to realize synchronous welding between the bent pipe and the iron ring and between the bent pipe and the liquid reservoir. The horizontal section of the bent pipe and a suction hole of an air cylinder of the compressor are connected directly, the sealing way has sealing of conical surface or sealing of interference fit of a cylindrical surface or filling sealing of high plastic metal deformation, and the iron ring on the bent pipe is welded by resistance welding on the shell of the compressor. The suction pipe omits a technical part of a conduit and performs all-steel pipe of the suction pipe, thereby greatly reducing use amount of the copper pipe material. In addition, twice welding are turned into once welding and applications on the prior high silver solder and the solder containing silver, phosphorus and copper are omitted, thereby reducing greatly cost of the air conditioner and improving product quality.

Owner:GUANGDONG MEIZHI COMPRESSOR

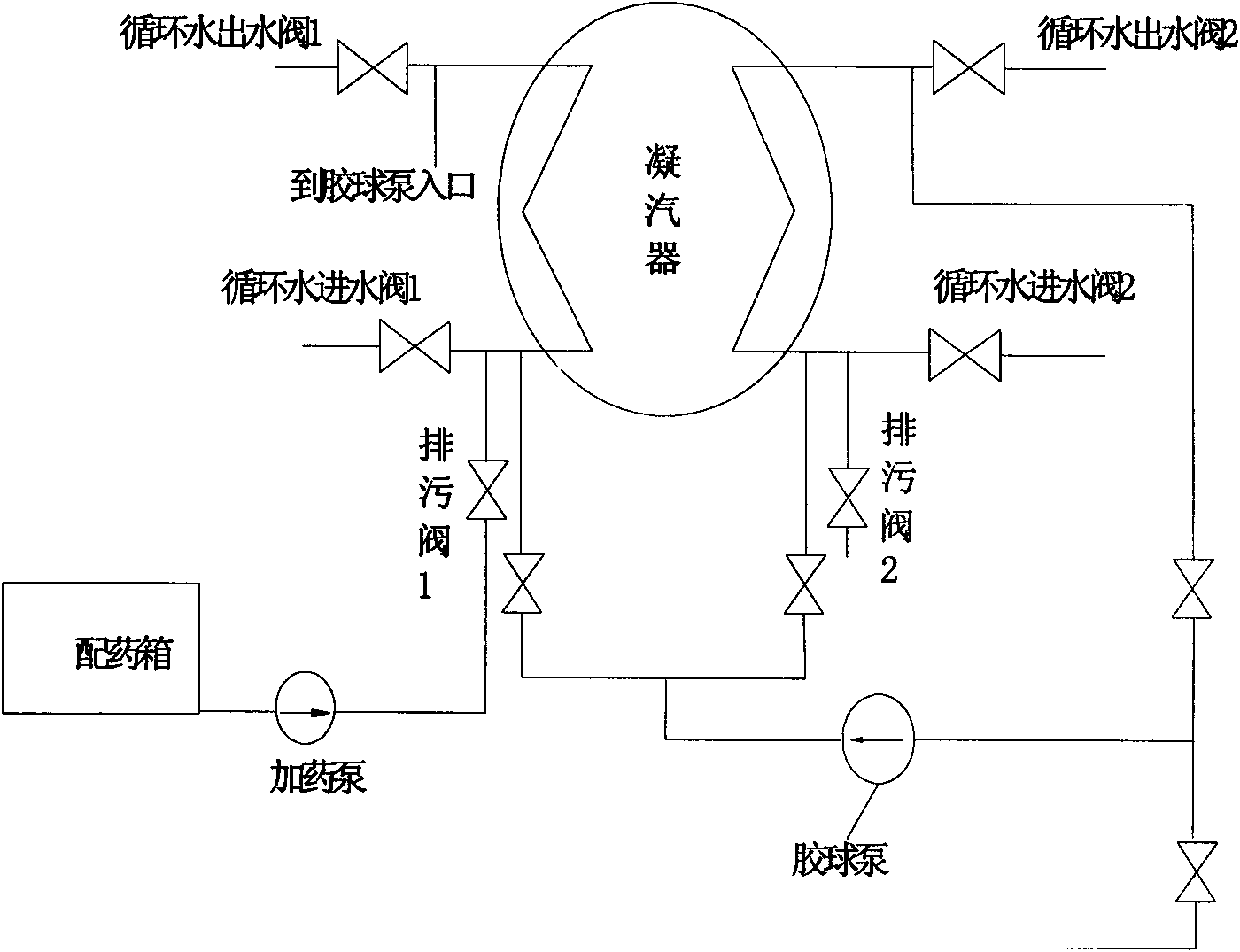

Method for cleaning copper tubes of condenser

A method for cleaning copper tubes of a condenser relates to the cleaning of heat transfer pipelines. The method comprises the following steps: the first step, closing an inlet valve and an outlet valve of circulating water after a turbine condenser is shut down; the second step, flushing the copper tubes of the condenser with clean water; the third step, injecting acid chemical cleaning liquor at water side of the condenser for soak cleaning; the fourth step, neutralizing soak solution with sodium hydroxide; the fifth step, flushing the copper tubes of the condenser with clean water; the sixth step, rinsing the copper tubes of the condenser with clean water; and the seventh step, replacing membrane, and commissioning after cleaning. Compared with the original method of cleaning with chemical agents to be added to a circulating water tank, the method is characterized in that chemical cleaning liquor is added to a single turbine condenser, which can help clean fouling off the copper tubes and improve vacuum degree of the turbine while ensuring no corrosion of the copper tubes, and has the advantages of low agent consumption, low cost, low corrosion rate, good cleaning effect and saving cleaning time. The method can be widely applied to cleaning and maintenance of the copper tubes of the condensers in power plants.

Owner:WENGFU (GRP) CO LTD

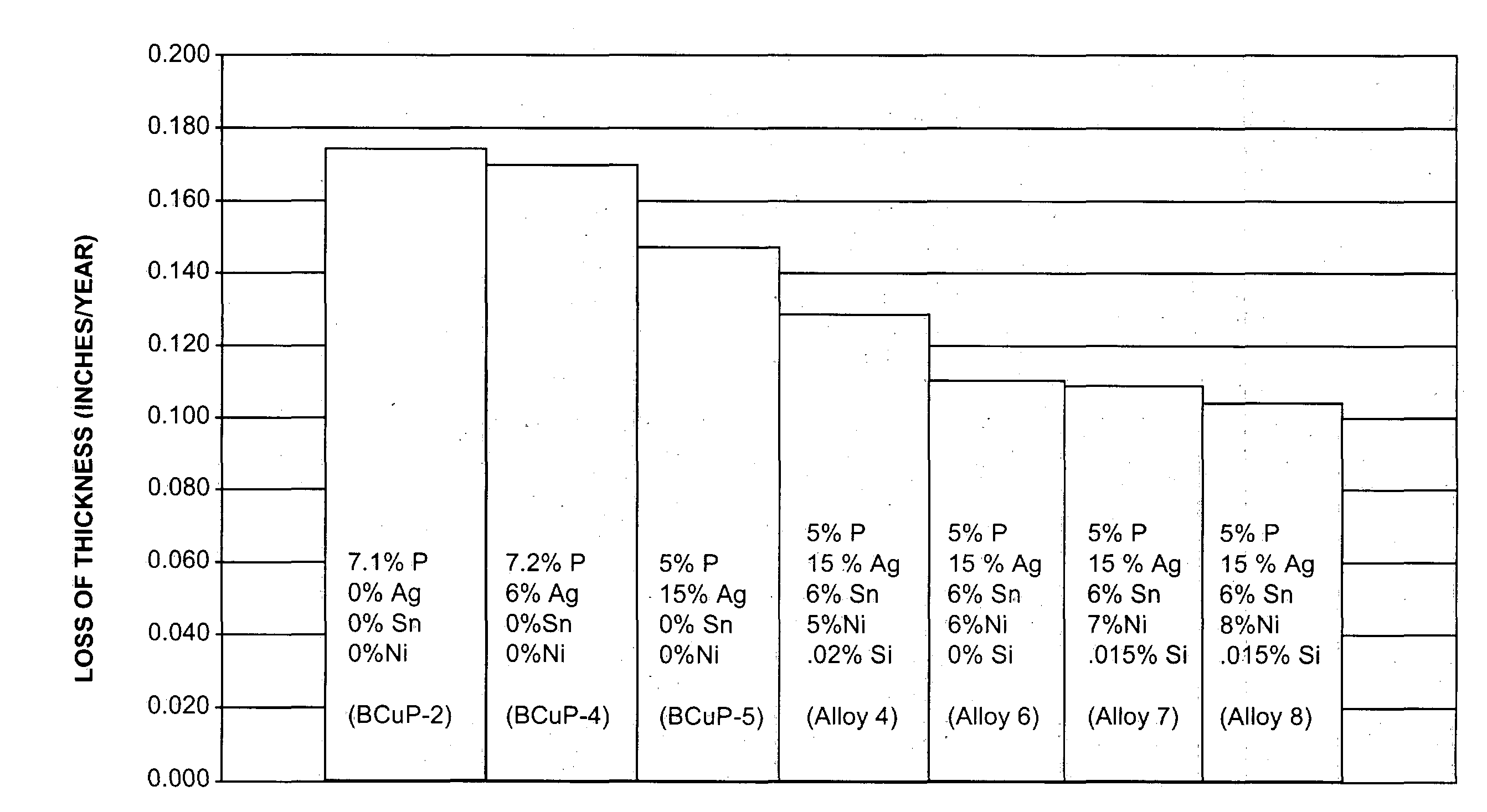

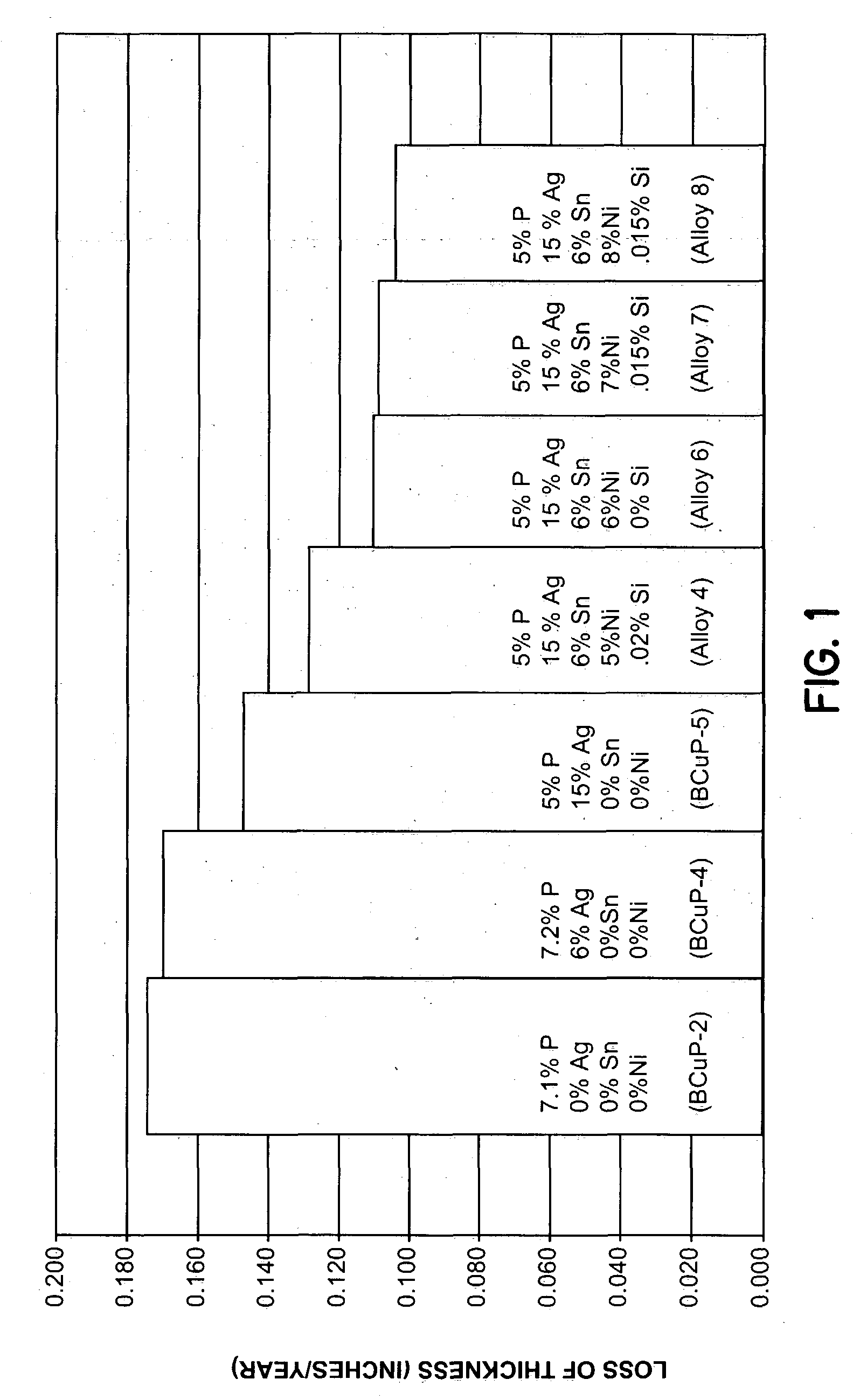

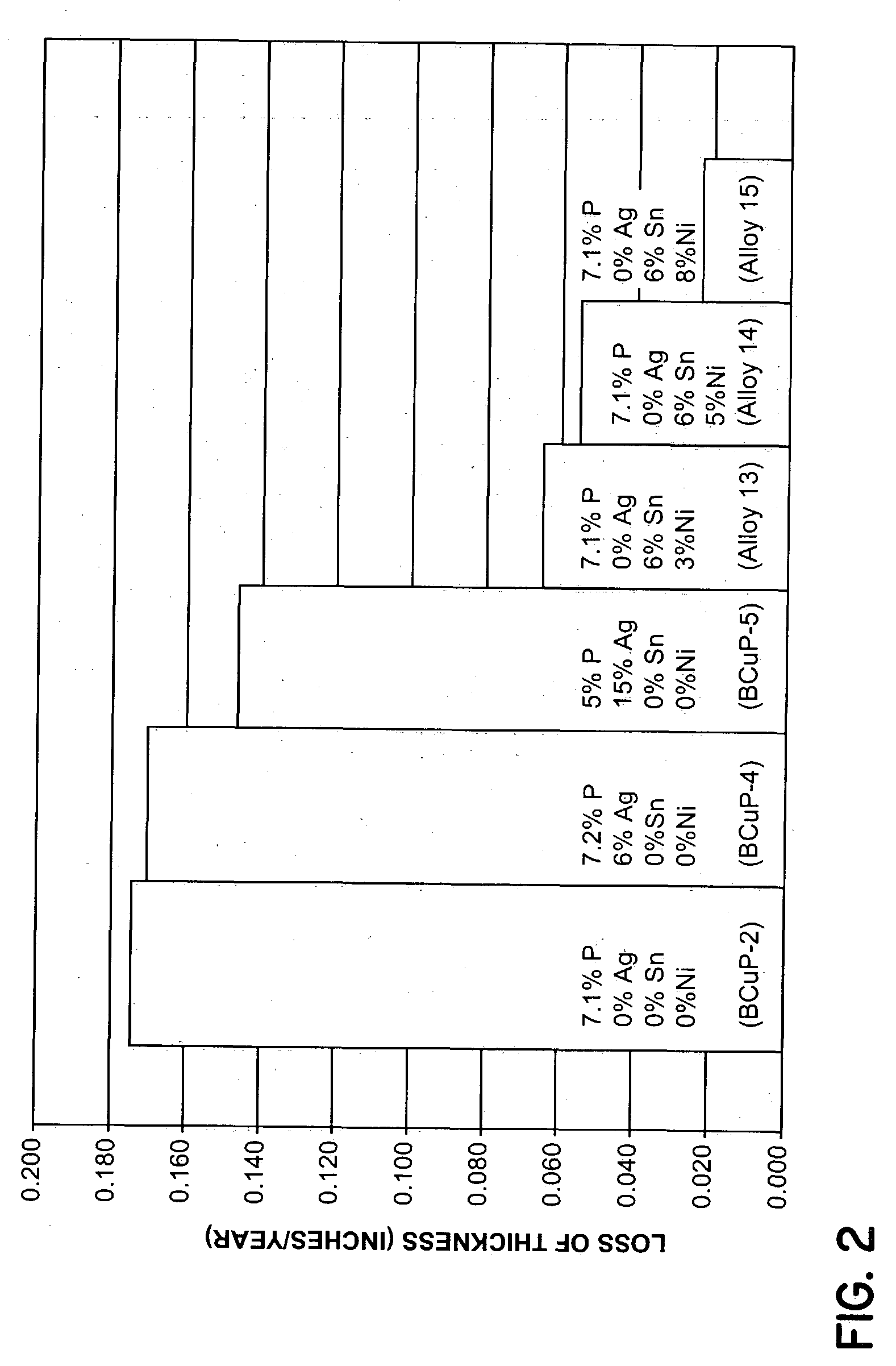

Phosphorous-copper base brazing alloy

InactiveUS20050249629A1Reduces melting rangeHigh hardnessWelding/cutting media/materialsSoldering mediaManganeseBraze alloy

A solid phos-copper base or silver-phos-copper base brazing alloy component for forming a brazed joint with a raised shoulder, little to no black oxide, and improved corrosion resistance. The brazing alloys of the present invention are visually distinguishable from copper and copper alloy parts. The solid brazing components of the present invention may be used in forming brazed joints at low brazing temperatures and result in a joint that is strong, ductile, smooth and corrosion resistant. The solid brazing components are provided in the form of wire, strip, foil or preform, and thus are advantageously used in a wide variety of brazing applications including copper tubing. The brazing components of the present invention are made of an alloy having a liquidus temperature above 840° F. and consist essentially of about 4-9% phosphorus, about 0.1-10% tin, up to about 4% antimony, about 0.1-15% nickel, up to about 3% silicon, up to about 18% silver, up to about 3% manganese, with the balance being copper. Exemplary embodiments include about 6-15% silver and / or 5-8% nickel.

Owner:LINCOLN GLOBAL INC

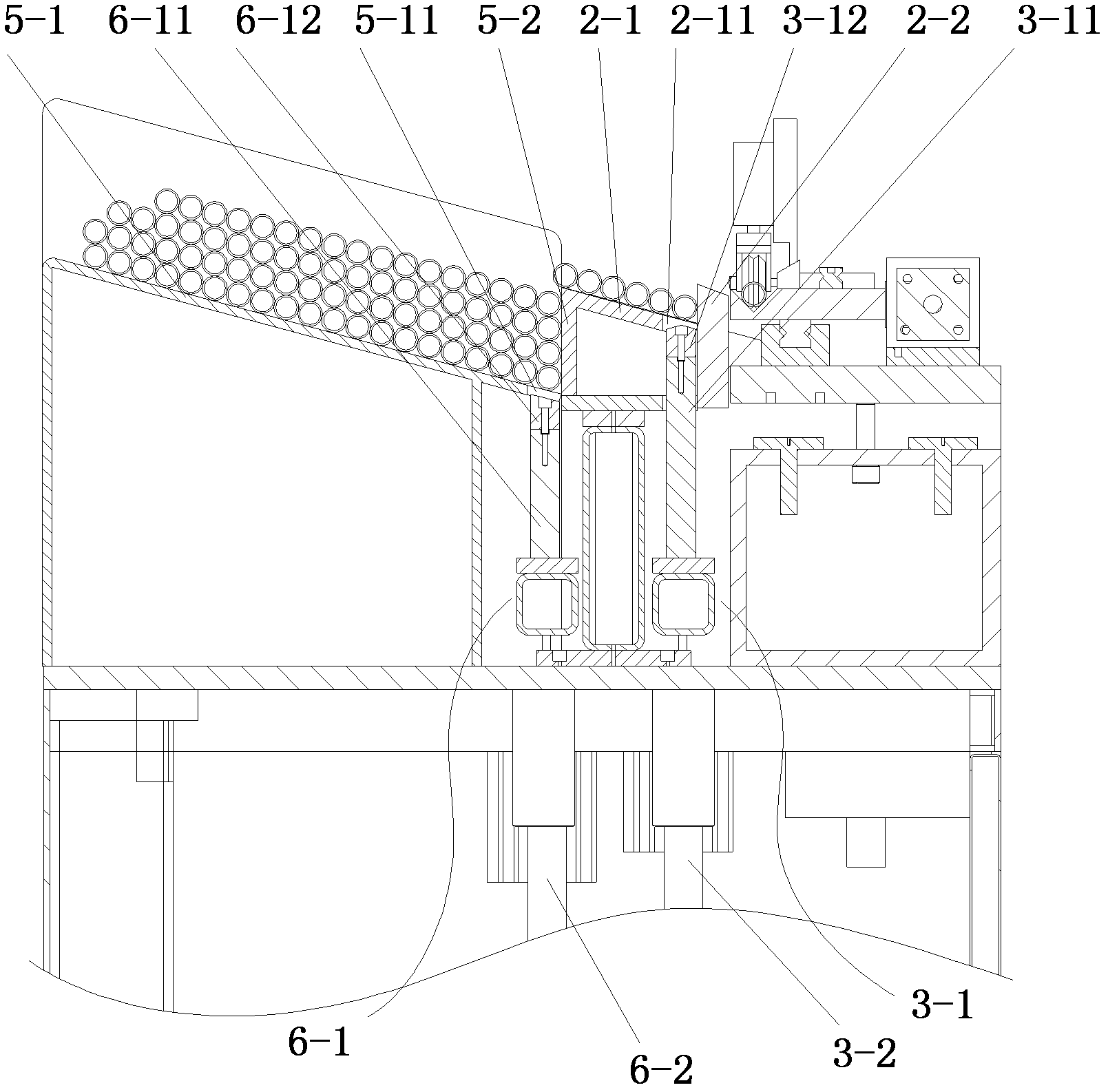

Device for realizing 3D metal printing by virtue of supporting structure

ActiveCN105618756AReasonable structureSimple structureAdditive manufacturing apparatusAutomatic controlShielding gas

The invention relates to a device for realizing 3D metal printing by virtue of a supporting structure. The device comprises a translation stage capable of moving along the X-axis, the Y-axis and the Z-axis. Heating resistance wires and a thermocouple are arranged on a base plate of the translation stage. The heating resistance wires are used for preheating the base plate, so as to enable metal droplet layers to be tightly overlapped. The thermocouple is used for realizing the measurement and the feedback control of a temperature. An electromagnetic induction heating copper pipe and a cooling water pipe are arranged outside a graphite crucible, metallic raw materials are enabled to be molten to form molten metal, the bottom of the graphite crucible is connected with a metal printing spray nozzle, a protective gas is inputted from a gas inlet pipe at the top of the graphite crucible, and under the pulse pressure, molten metal forms regular metal droplets to drip to the base plate of the translation stage. The 3D metal droplet printing is realized through the cooperation with the movement of the translation stage. A supporting material spray nozzle is adjacent to the metal printing spray nozzle. A uniform mixture of gypsum and photosensitive resin is extruded stably under the constant pressure inputted by the gas inlet pipe so as to print the supporting part of a part. The switching between metal and the supporting material is automatically recognized and controlled by a control system. The 3D metal printing device is reasonable, high in operability, high in degree of automation, high in production efficiency, and suitable for being widely popularized, and ensures the molding quality.

Owner:STATE GRID CORP OF CHINA +5

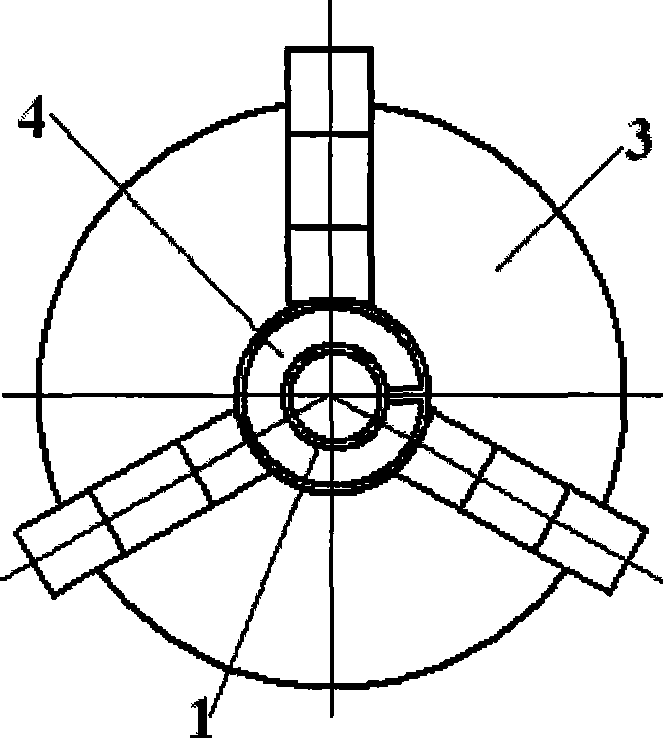

Automatic loading machine

ActiveCN102909283ARealize automated productionMetal-working feeding devicesPositioning devicesNumerical controlFixed length

The invention relates to an automatic loading machine which comprises a base, a copper pipe lining-up device, a copper pipe separation device and a feeding device. The copper pipe lining-up device is provided with a bottom plate of which the front part is inclined downward; a head baffle is arranged at the front end of the copper pipe lining-up device; a plurality of bottom plate openings are formed at the positions on the bottom plate, which are close to the head baffle; the copper pipe separation device comprises a material supporting ejector rod and a material supporting cylinder arranged on the base; the material supporting ejector rod is arranged on a push shaft of the material supporting cylinder; the material supporting ejector rod is provided with a plurality of ejector rods corresponding to the openings of the bottom plate; the upper end parts of the ejector rods are provided with material supporting modules; the material supporting ejector rod is pushed by the material supporting cylinder to ensure the ejector rods to pass through the openings of the bottom plate; the feeding device comprises a V-shaped groove; the lateral surface of the V-shaped groove is abutted on the head baffle; and one end of the V-shaped groove is provided with a push block pushed by a driving mechanism. The automatic loading machine has the advantage that a single copper pipe with a fixed length is fed into a chuck of a numerical control pipe bending machine, is automatically reset and is automatically taken out after being bent, so that the automation production of the numerical control pipe bending machine is implemented.

Owner:CHENZHOU ZHIZAO TECH CO LTD

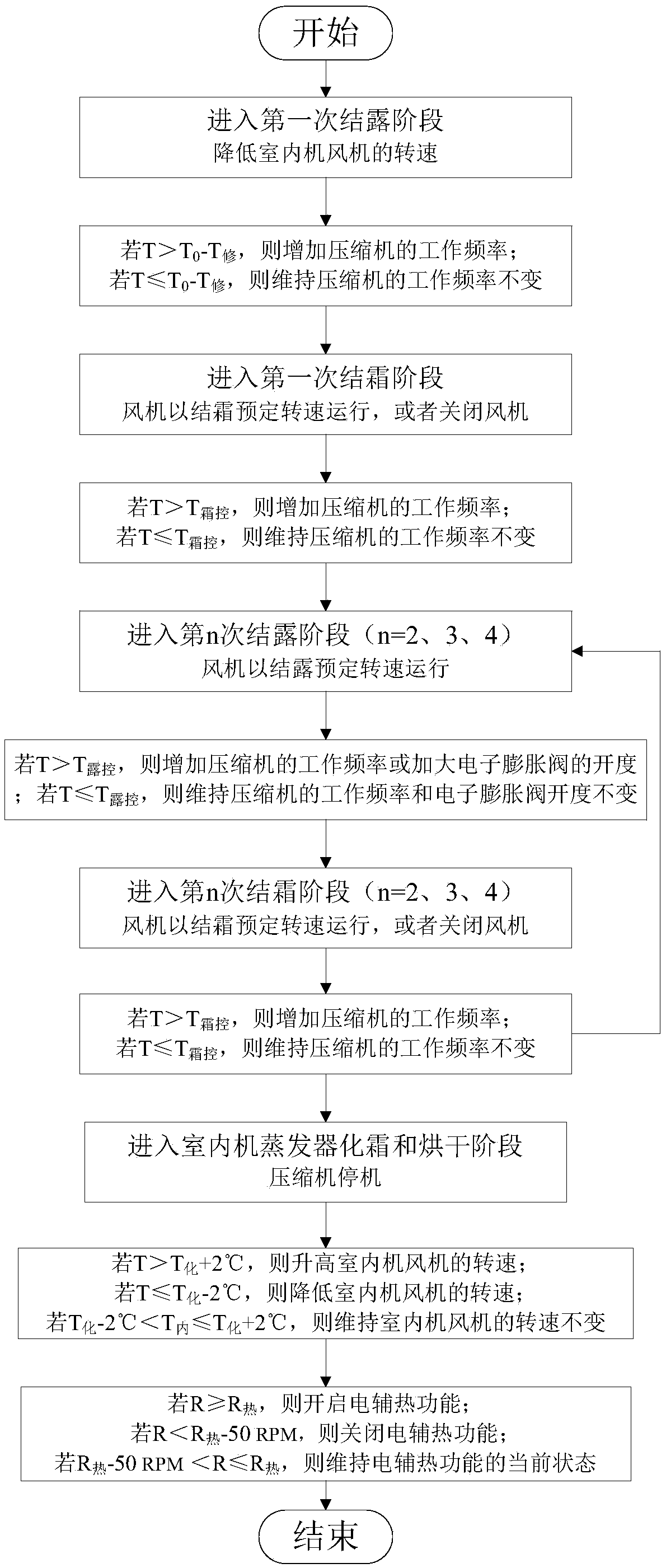

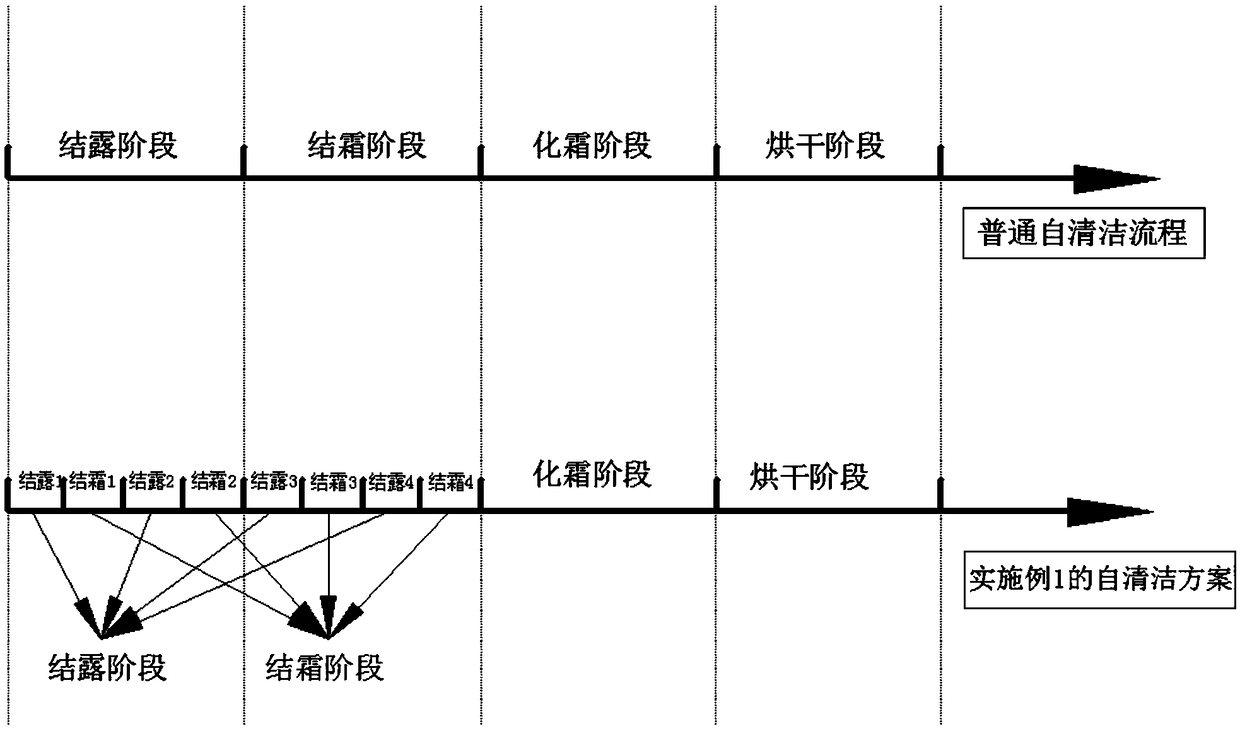

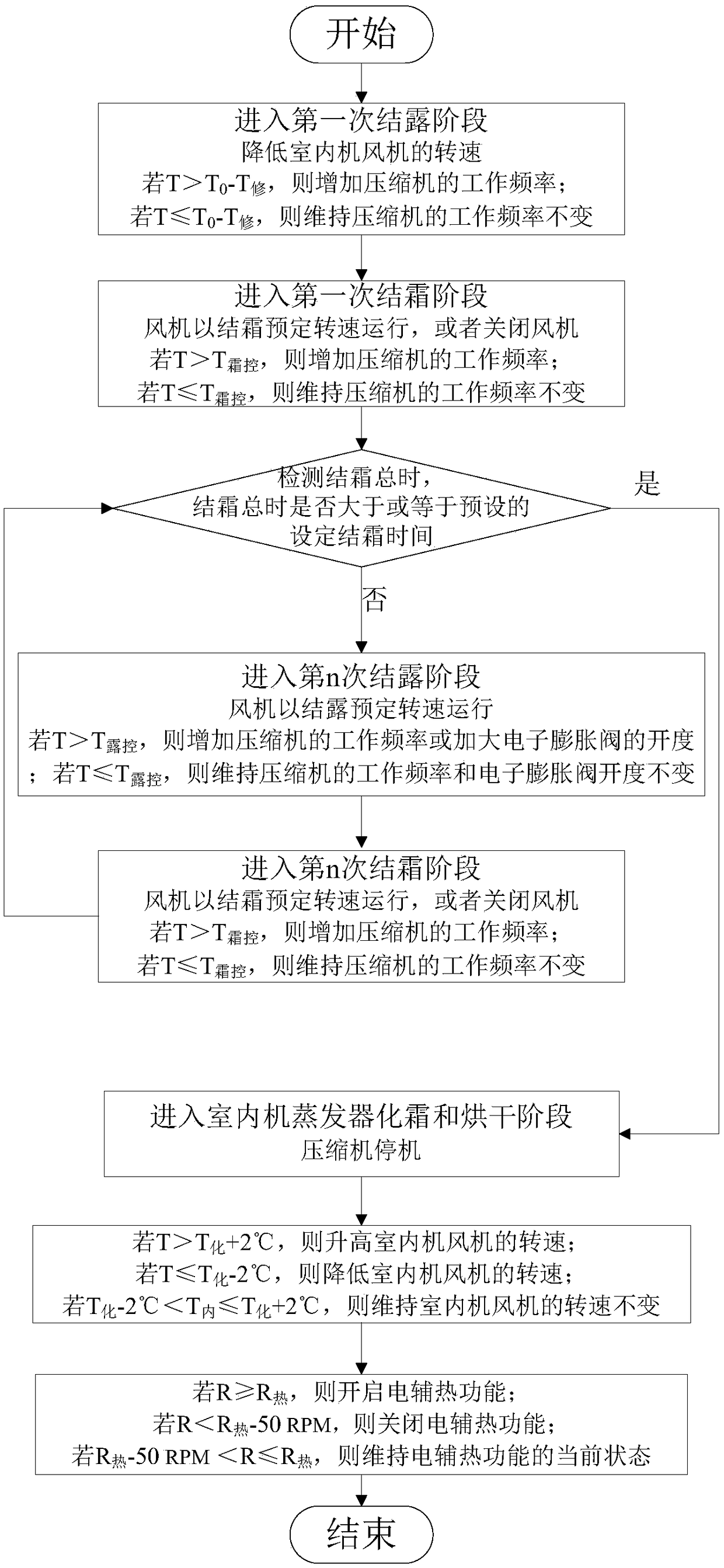

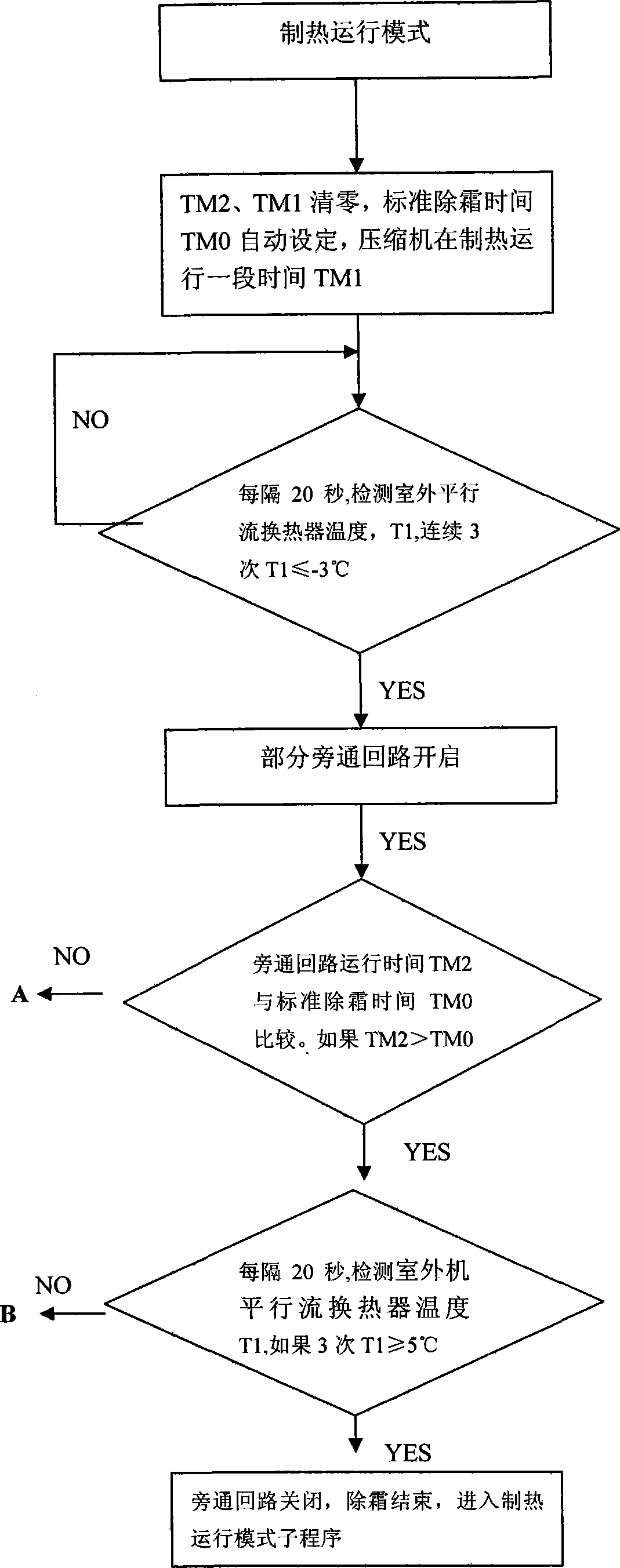

Evaporator self-cleaning method capable of improving frost layer thickness and air conditioner

ActiveCN109373504ALarge amount of waterIncreasing the thicknessMechanical apparatusLighting and heating apparatusFrostWater flow

Owner:GREE ELECTRIC APPLIANCES INC

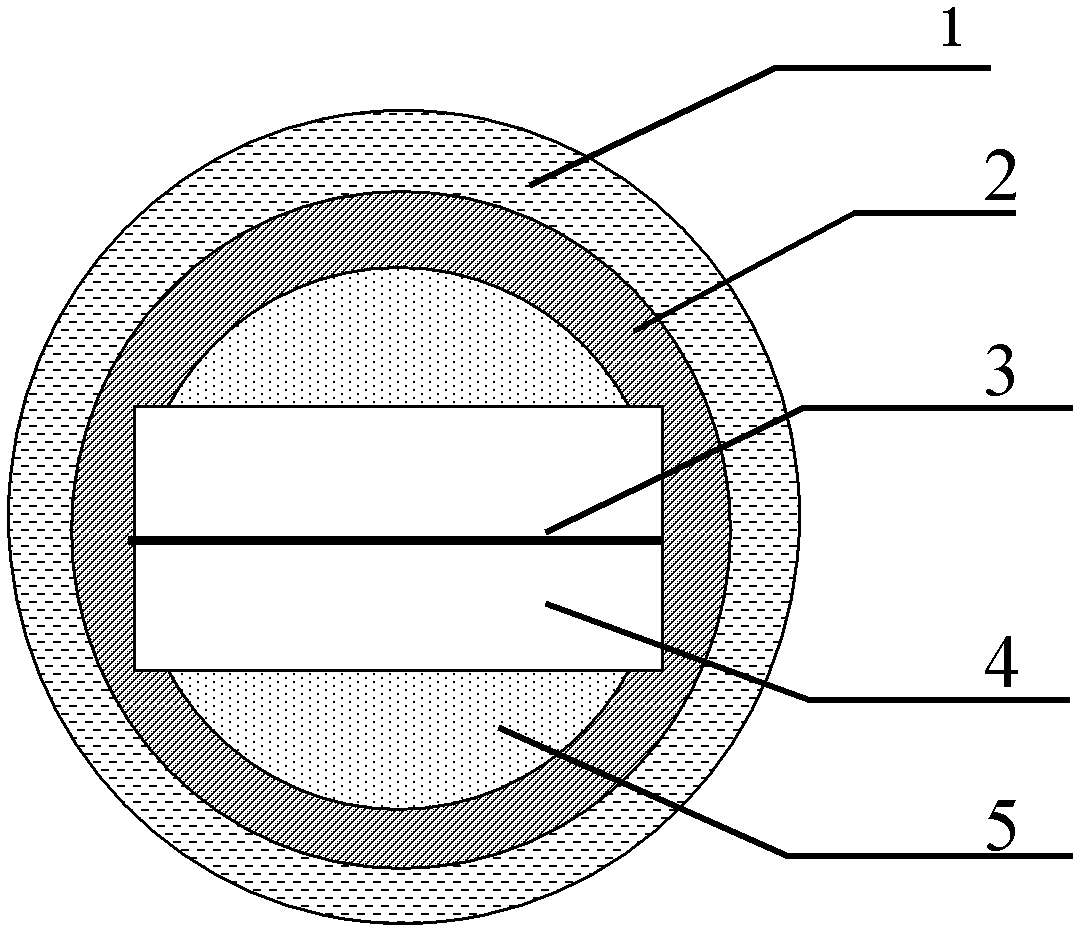

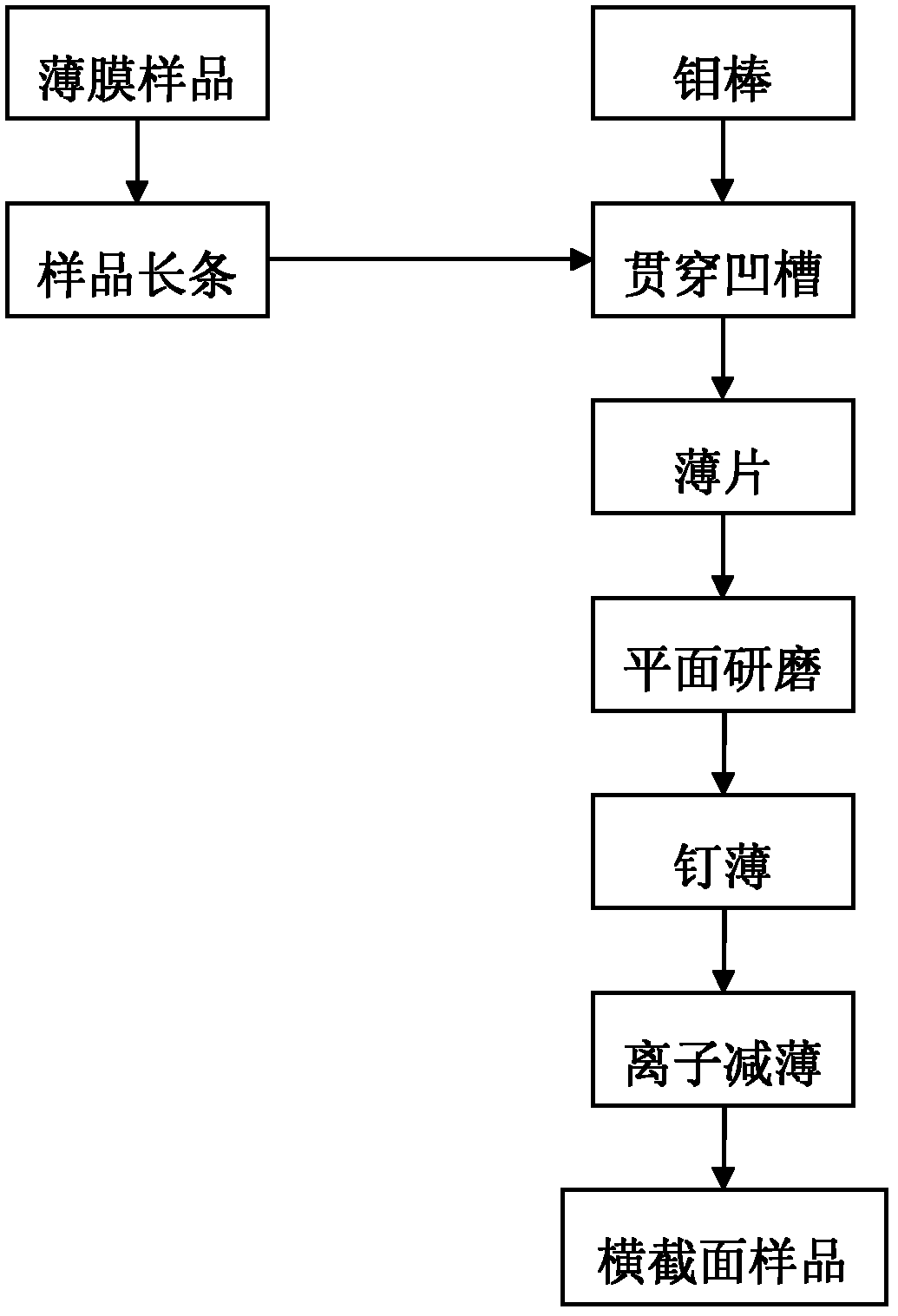

Method for preparing cross section transmission electron microscope sample

ActiveCN102519771AReduce the impactNo pollution in the processPreparing sample for investigationAdhesiveTest sample

The invention belongs to the technical field of testing, and relates to a method for preparing a cross section transmission electron microscope sample. The method includes the steps as follows: firstly cutting a sample into long strips, cleaning the surfaces of the long strip samples with acetone to remove impurities, then airing the long strip samples naturally, coating the surface of each long strip sample provided with a film with a layer of curable adhesive, correspondingly bonding the adhesive surfaces of two long strip samples, heating and solidifying the long strip samples after mutualbonding at the temperature of 130 DEG, and then cooling the heated and solidified samples to the room temperature; and secondly cutting a through groove at one end of a molybdenum rod along the center, coating the outer surface of a to-be-tested sample and the inner surface of the groove with a layer of curable adhesive respectively, heating and solidifying the to-be-tested sample after putting and fixing the to-be-tested sample into the groove, coating the inner surface of a copper pipe with a layer of curable adhesive uniformly, plugging the molybdenum rod groove embedded with the to-be-tested sample and provided with one end coated with curable adhesive in the copper pipe, and performing cutting, grinding, dimpling and ion milling to the cross section sample, so as to obtain the electron microscope cross section sample. The method has a simple process, safe and reliable operating procedures, has no pollution and deformation in the sample, and is highly practical.

Owner:QINGDAO UNIV

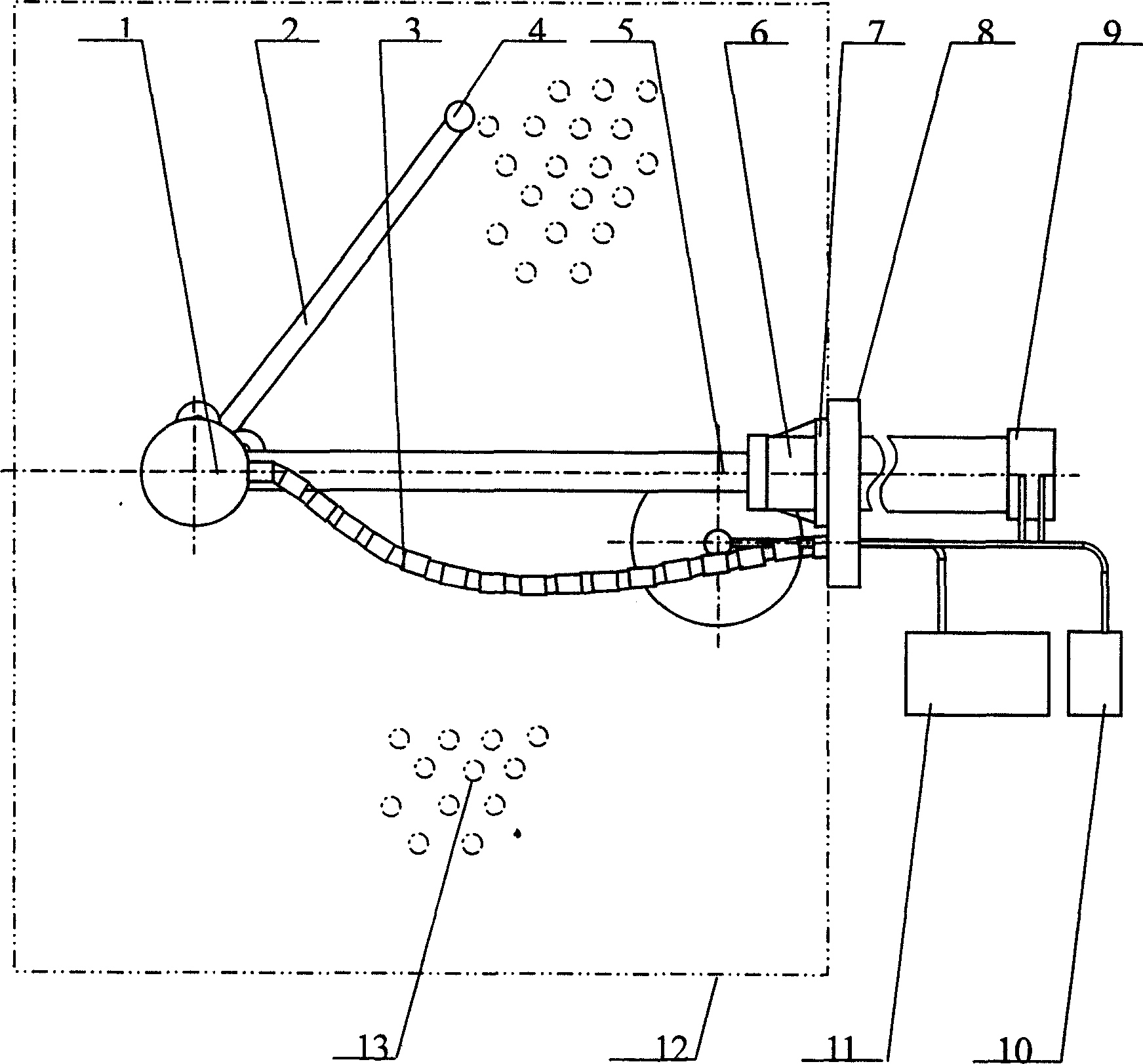

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

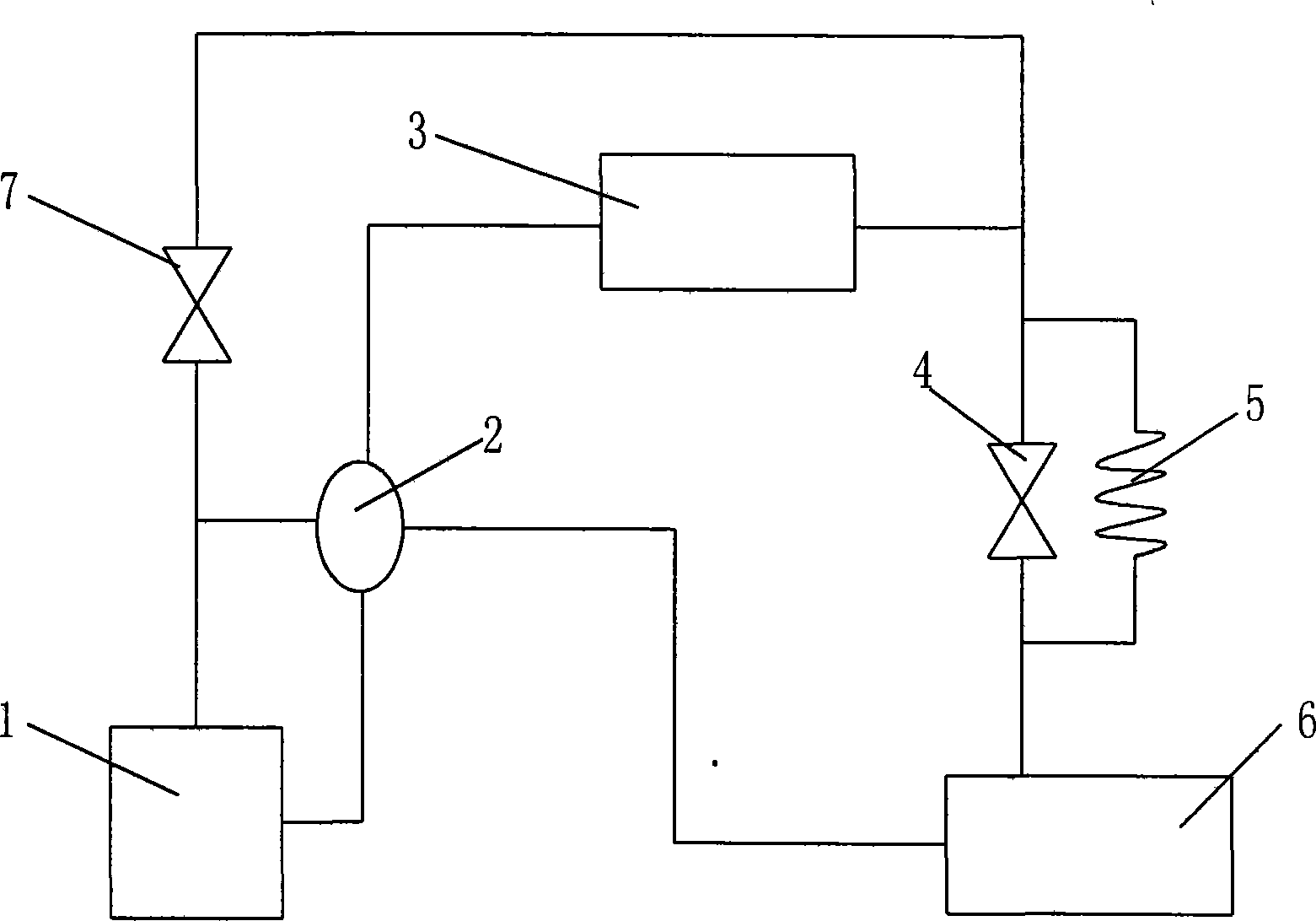

Parallel flow air conditioner and defrosting control method thereof

InactiveCN101387455AImprove comfortUninterrupted heatingHeat pumpsCorrosion preventionEngineeringHeat exchanger

Owner:TCL CORPORATION

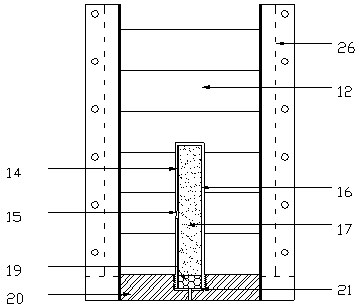

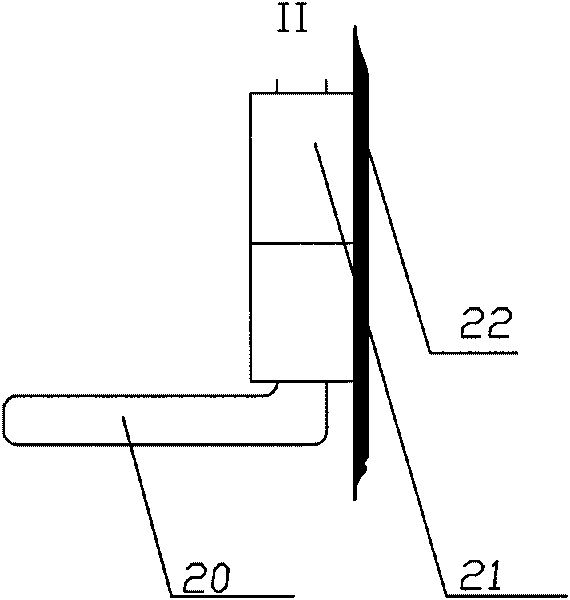

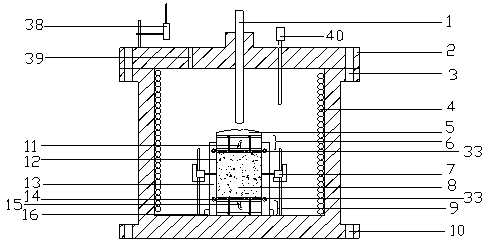

Testing device for simulating concrete test piece hydraulic fracture under multi-field coupling condition

ActiveCN103383325AStudy hydraulic fracturing propertiesMaterial strength using tensile/compressive forcesSteel framePipe

The invention relates to a testing device for simulating concrete test piece hydraulic fracture under a multi-field coupling condition. The testing device is characterized in that a large cylindrical pressure chamber is manufactured specifically, copper pipes are arranged on the inner wall of the pressure chamber, and the copper pipes are connected with an external refrigerating and heating system to control the temperature in the pressure chamber. A set of steel frame clamp manufactured specifically is fixed on a base plate of the pressure chamber, and a test piece is placed in the steel frame clamp. Water pressure is exerted on the test piece through a steel external member at the bottom of the test piece and a water permeable copper plate, and water is guided out from a steel external member on the upper portion of the test piece and the water permeable copper plate through a water pipe. Fracture water pressure and environment temperature simulation is added on the basis of a conventional three-shaft test. The device overcomes the defect that a traditional hydraulic fracture test can not simulate temperature environment change, can reflect a testing theory of the hydraulic fracture truly and is suitable for test research on concrete test piece hydraulic fracture under the water solid thermal coupling condition. The testing device has good market transformation prospects and is suitable for popularization.

Owner:HOHAI UNIV

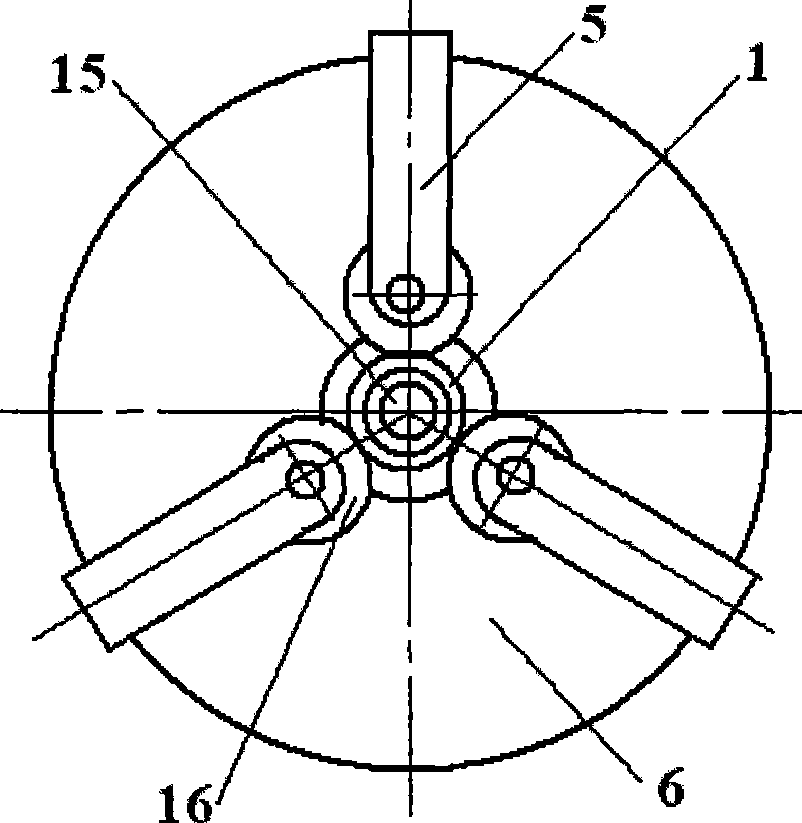

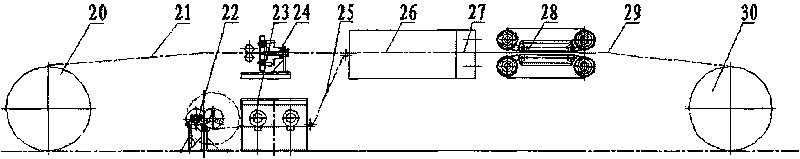

Copper corrugated pipe helical corrugation forming apparatus and forming process

InactiveCN101367100ASolve the problem of direct machining spiral corrugationLow input costEngineeringIdler-wheel

The invention discloses equipment for forming spiral corrugation on a corrugated copper tube and a forming process thereof. A copper tube (1) is a hard copper tube; an idler wheel device (5) is arranged on the forming equipment; three idler wheels (16) evenly distributed on the circumferential direction of the copper tube (1) are arranged on the idler wheel device (5) and carry out rolling machining to the copper tube (1); three idler wheels respectively deflect the same angle in the vertical direction of the axis of the copper tube (1); and the angle is a spiral lift angle of the spiral corrugation (12) of the copper tube. The technical proposal solves the difficult problem of directly machining the spiral corrugation on the hard copper tube; the prior idle machine tool, such as a common minitype horizontal type lathe, can be slightly reconstructed for use; the equipment has low input cost and high production efficiency, can fully ensure the quality of products, has simple operation, convenient use and low labor intensity and is worthy of popularizing and applying in the industry.

Owner:芜湖浩达金属制品有限公司

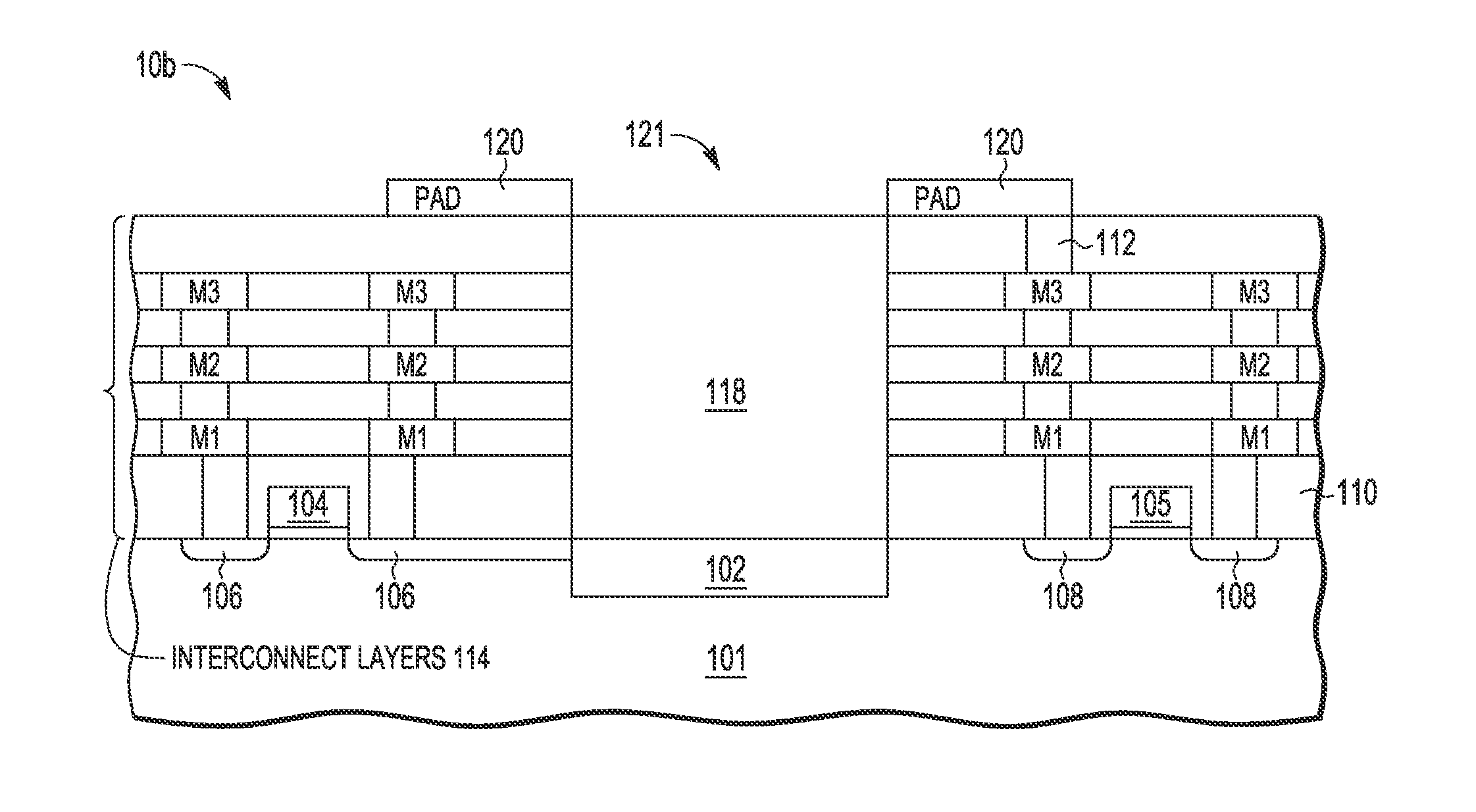

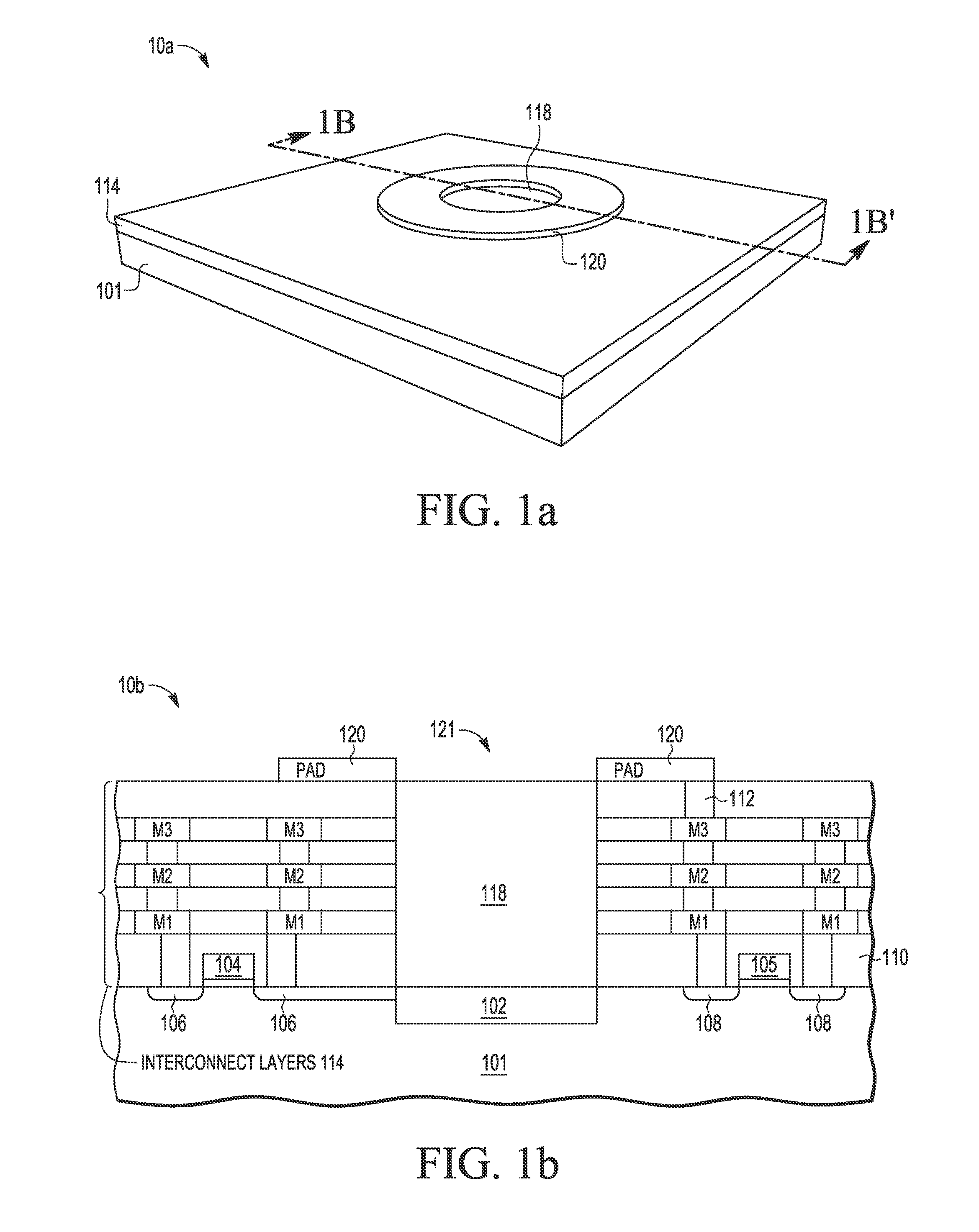

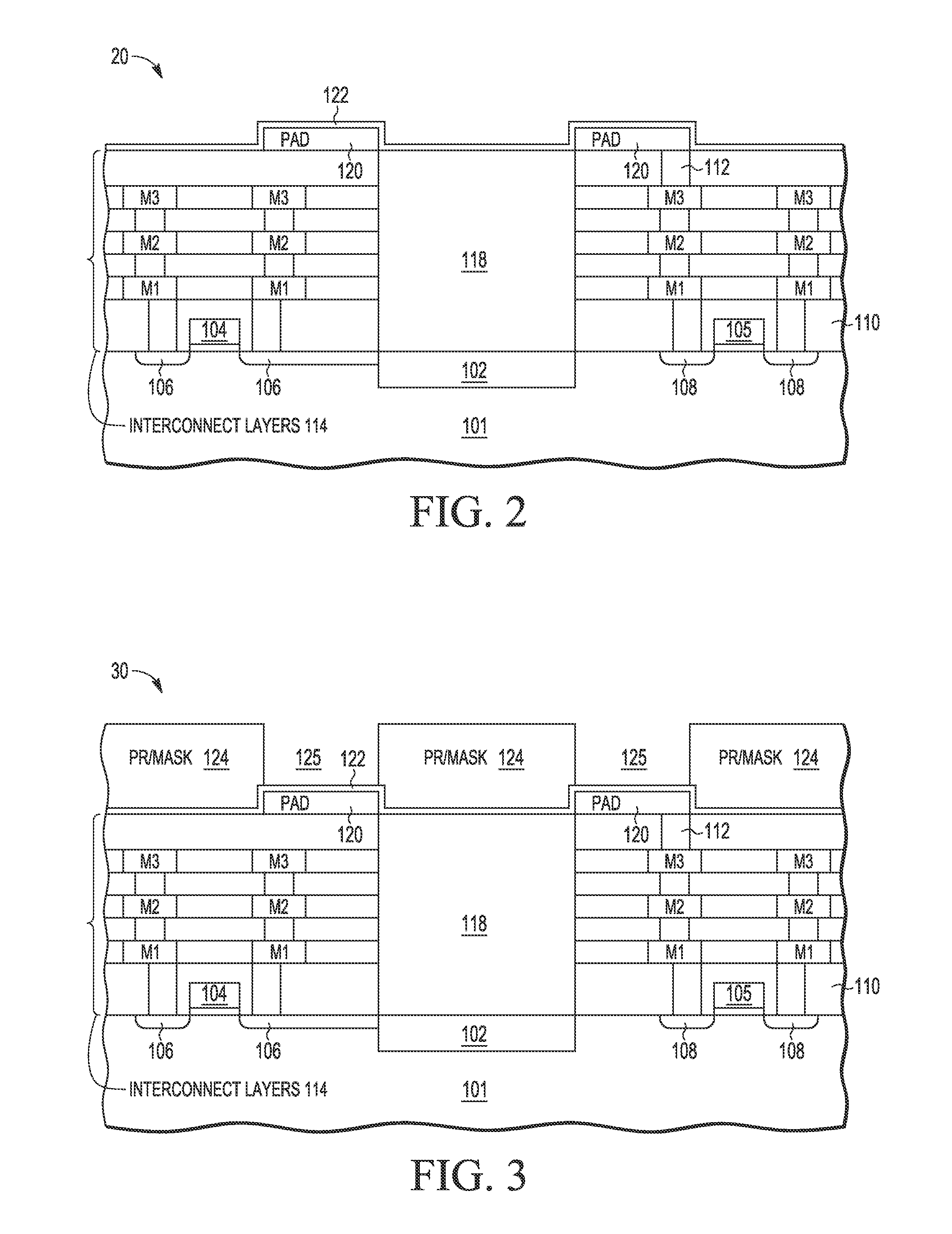

Copper Tube Interconnect

ActiveUS20150205041A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringOptical interconnect

A method and apparatus are provided for fabricating an electro-optical interconnect on an integrated circuit (101, 114) in which an optical circuit element (102) is formed by forming a cylinder-shaped conductive interconnect structure (120, 122, 126, 128) with one or more conductive layers formed around a central opening (129) which is located over an optically transparent layer (118) located over the optical circuit element (102).

Owner:NXP USA INC

Preparation method for oxygen-free copper tube for magnetron

ActiveCN102605192AReduce oxygen contentOxygen isolationMagnetronsTransit-tube cathodesGranularityLanthanum

The invention relates to a preparation method for an oxygen-free copper tube for a magnetron. The preparation method is characterized in that the contents of copper and silver in a material of the oxygen-free copper tube is larger than or equal to 99.97%, and oxygen content is smaller than or equal to 0.001%. The preparation method includes following process steps: 1, smelting: placing number 1 high-purity cathode copper in a power frequency induction furnace with a core, raising the temperature of the furnace to smelt the cathode copper into copper liquid, adding lanthanum with the mass fraction ranging from 0.01% to 0.016% into the copper liquid, keeping the copper liquid at the temperature of 1170 + / -10 DEG , and covering a charcoal layer with the thickness ranging from 100mm to 120mm and the charcoal granularity ranging from 40mm to 60mm on the surface of the copper liquid; 2, upward continuous casting; 3, precise cold rolling; 4, recrystallization; 5, cold drawing forming; and 6,finishing. The oxygen content is low, electric conduction is excellent, yield is high, and metal loss is low.

Owner:江阴和宏特种材料有限公司

End socket structure of copper and steel bimetallic pipe and seal welding method thereof

InactiveCN102155592ASimple processLow costNon-disconnectible pipe-jointsNon-electric welding apparatusThermal insulationShielding gas

The invention discloses an end socket structure of a copper and steel bimetallic pipe and a seal welding method thereof; and the end socket structure comprises a copper pipe and a steel pipe which are connected at the combining place of end sockets by a diffusion welding combining layer. The seal welding method comprises the following steps of: cleanly washing surfaces of the copper pipe end socket and the steel pipe end socket to be combined, and gluing the combining surfaces in advance; pressing an expanding plug into an inner hole of the copper pipe end socket; putting the copper pipe end socket and the steel pipe end socket into a diffusion annealing furnace filled with protective gas for heating and thermal insulation so that atoms of the copper and the steel mutually diffuse under the combined action of interference deformation force and temperature, discharging and air cooling, and dropping out the expansion plug. As the invention does not use an expensive silver-bearing welding material and a complex welding technology and only uses simple plastic deformation and the expansion plug, compared with the prior art, the end socket structure and the seal welding method have simple process and low cost and realize reliable welding seal between the cooper and the steel, and no crack is generated in end seams.

Owner:DALIAN MARITIME UNIVERSITY

Method for manufacturing copper-aluminum composite tube

InactiveCN101737565AEffective combinationCombined with effective maintenanceRigid pipesSurface cleaningAluminum composites

The invention relates to a method for manufacturing a copper-aluminum composite tube, and belongs to the technical field of manufacturing a metal composite tube. The method is characterized by comprising the following steps: A, preparing an inner tube and a covering belt, B. performing surface cleaning on the inner tube and the covering belt, C. covering the covering belt after surface cleaning on the surface of the inner tube after surface cleaning, performing vertical covering welding to manufacture a copper-aluminum composite tube blank, D. performing linear drawing on the copper-aluminum composite tube blank without strain furling, E. final annealing, and F. winding and furling to manufacture a finished product and other processing steps. The method can be used for manufacturing a copper-clad aluminum tube, an aluminum-clad copper tube and the copper-aluminum composite tube of which an inner layer and an outer layer are copper and the middle part is aluminum; and firm metallurgical bonding can be achieved between the copper and the aluminum.

Owner:JIANGSU XINGRONG HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com