Evaporator self-cleaning method capable of improving frost layer thickness and air conditioner

An evaporator and self-cleaning technology, which is applied in air-conditioning systems, control input related to air characteristics, heating methods, etc., can solve problems such as unsatisfactory self-cleaning effect, thicker evaporator formation, and no air circulation, etc., to achieve self-improvement Cleansing effect, increase the thickness of frost layer, increase the effect of water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

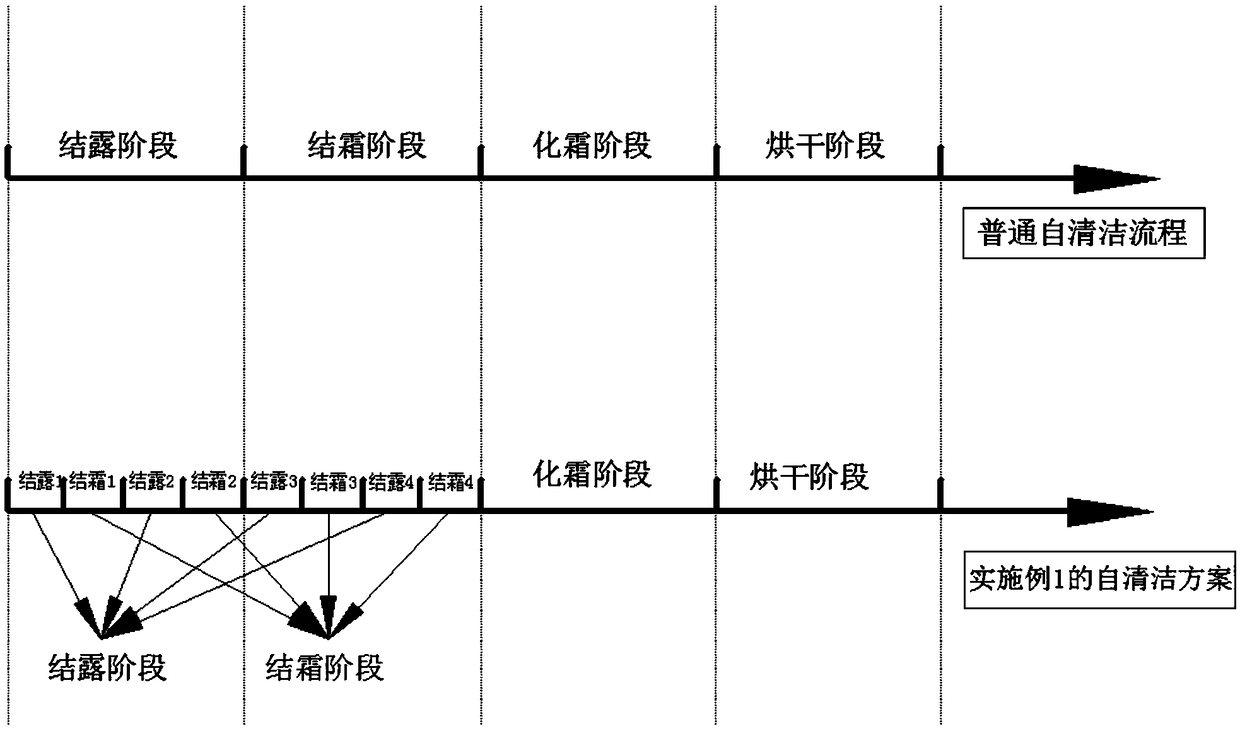

Embodiment 1

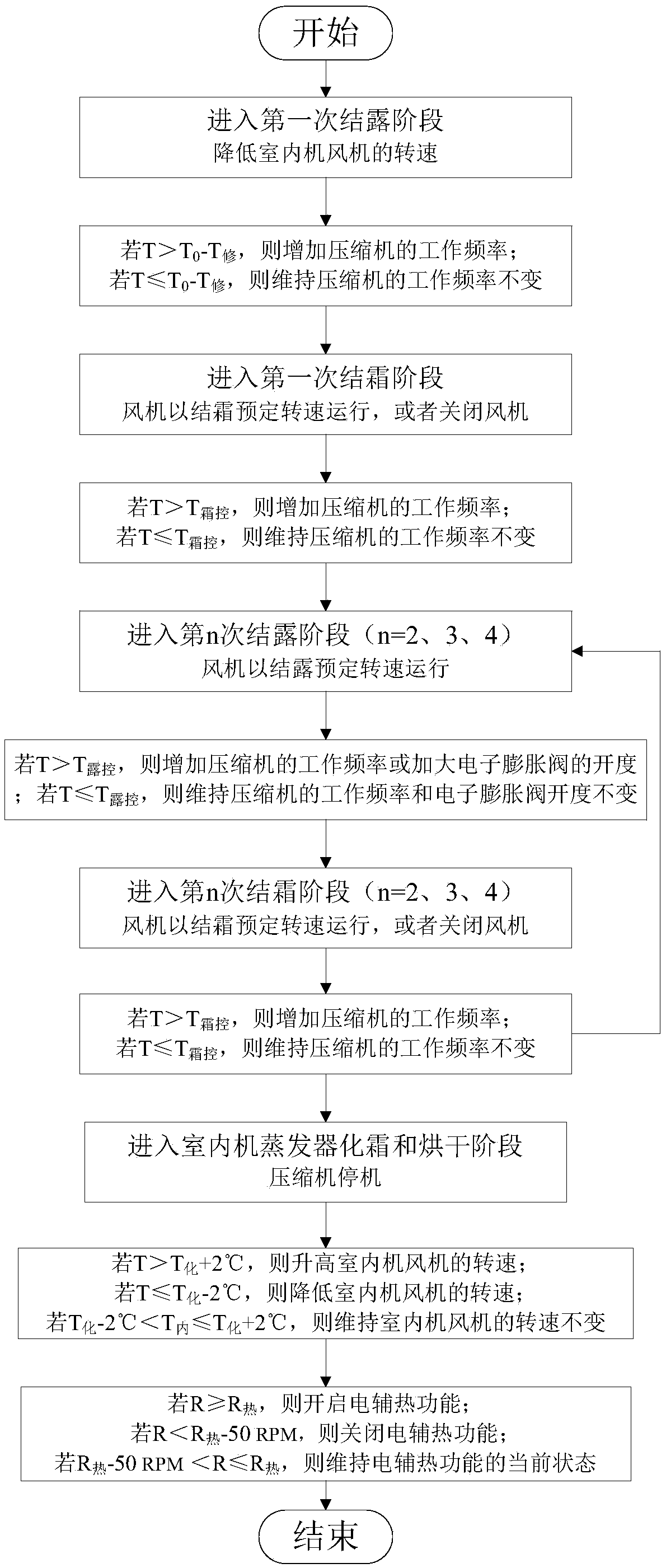

[0055] This embodiment relates to an air conditioner that can perform self-cleaning of an indoor unit according to the following process, such as figure 1 As shown, it specifically includes (pre-set in the air conditioning control program to experience 4 condensation-frosting processes):

[0056] (1) Enter the first condensation phase of the indoor unit of the air conditioner, adjust the speed of the fan of the indoor unit and / or the working frequency of the compressor to make the surface of the indoor unit evaporator the first condensation.

[0057] First, obtain the current indoor environmental temperature and current indoor environmental humidity in the room where the indoor unit is located, and determine the indoor dew point temperature T in the current environment according to the current indoor environmental temperature and current indoor environmental humidity. 0 =18℃; set the correction temperature T of the indoor unit evaporator condensation stage repair It is 8°C.

[0058]...

Embodiment 2

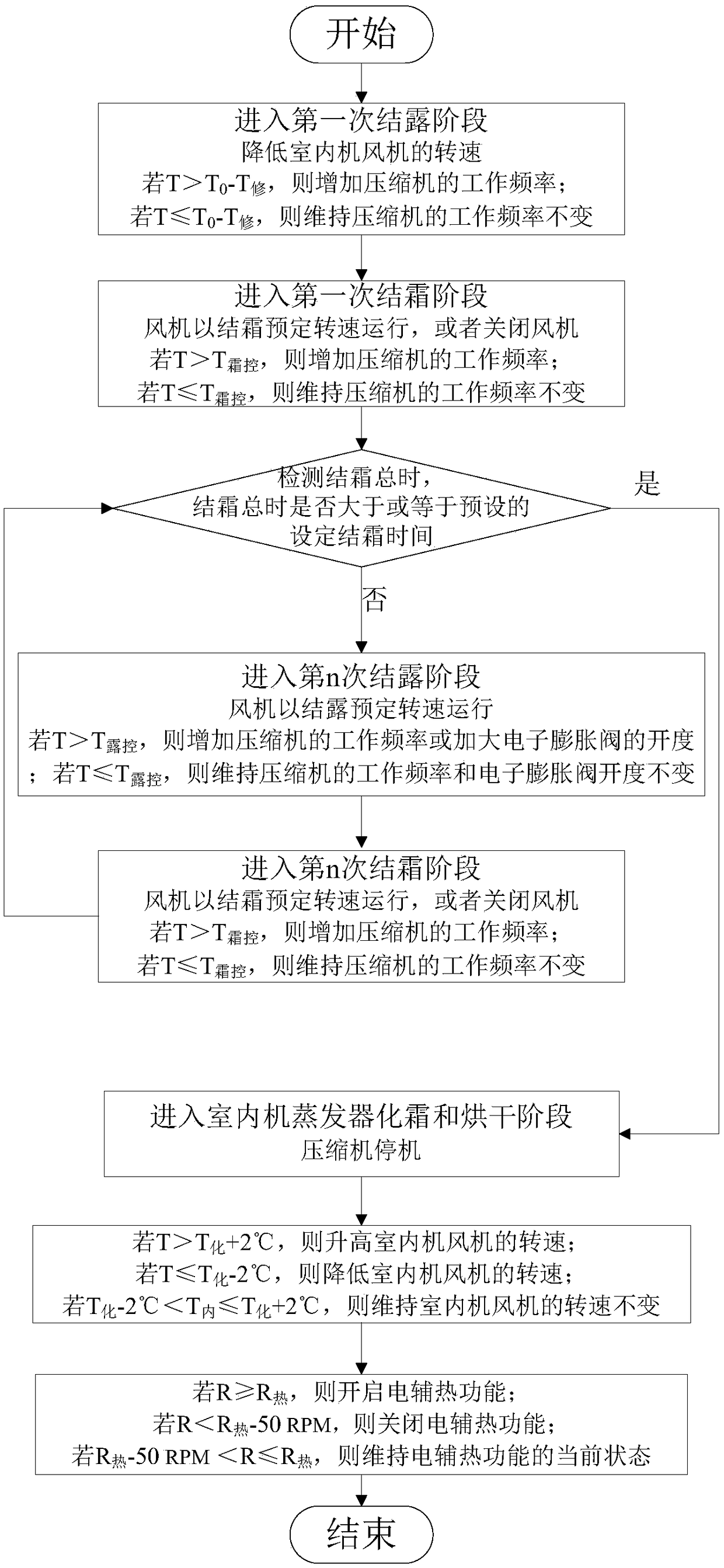

[0101] This embodiment relates to an air conditioner that can perform self-cleaning of an indoor unit according to the following process, such as image 3 As shown, specifically including:

[0102] (1) Enter the first condensation phase of the indoor unit of the air conditioner, adjust the speed of the fan of the indoor unit and / or the working frequency of the compressor to make the surface of the indoor unit evaporator the first condensation.

[0103] First, obtain the current indoor environmental temperature and current indoor environmental humidity in the room where the indoor unit is located, and determine the indoor dew point temperature T in the current environment according to the current indoor environmental temperature and current indoor environmental humidity. 0 =18℃; set the correction temperature T of the indoor unit evaporator condensation stage repair It is 8°C.

[0104] The indoor condensation temperature range is T 1 ≤T 0 -T repair = 10°C.

[0105] Then, reduce the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com