Laterally-arranged heat pump clothes drying cabinet of deep dehumidification device

A technology of equipment side and dry closet, which is applied in household dryers, washing devices, textiles and papermaking, etc., which can solve the problem of decreased evaporating heat absorption capacity and dehumidification capacity of evaporators, high power consumption of compressors, condensing pressure and evaporating pressure. The problems such as large difference can be solved, and the effect of improving the working condition of the compressor, increasing the dehumidification energy efficiency ratio, and expanding the cooling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

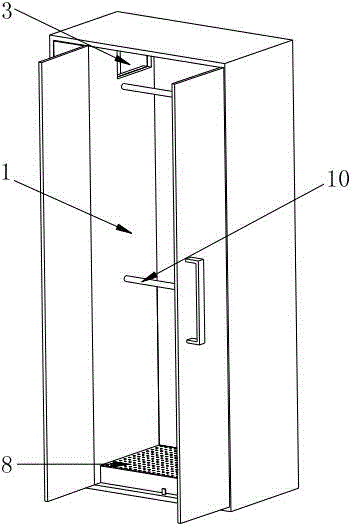

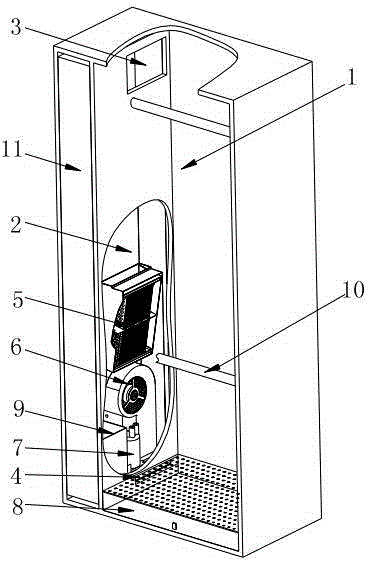

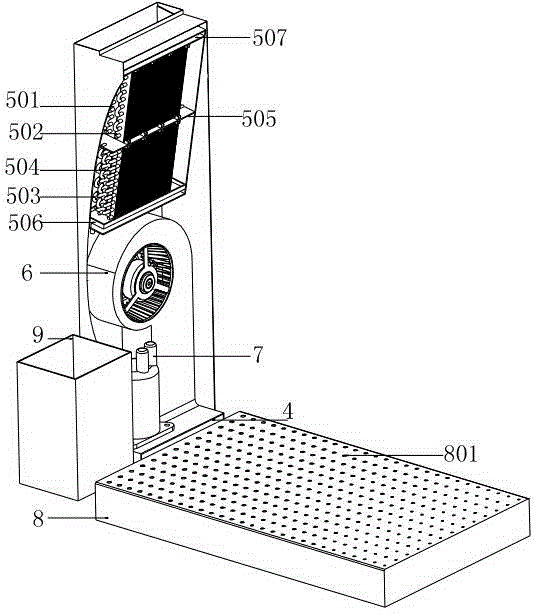

[0072] refer to Figure 1-8 , the present invention provides a heat pump dry closet with deep dehumidification equipment installed sideways, which is composed of a drying room 1 and an equipment room 2. A refrigeration and dehumidification device is installed in the equipment room 2, and the clothes to be dried are hung on the clothes rail of the drying room 1. 10 above; a closed-circuit air circulation is formed between the drying room 1 and the equipment room 2. The humid air in the drying room 1 is cooled and dehumidified by the refrigeration dehumidification device and heated to obtain dry air, and then transported to the drying room 1 to dry the clothes. dry.

[0073] Specifically, the shell of the dry closet can be made of wooden wall panels, steel-wood wall panels, or polyurethane foam and other thermal insulation materials to form thermal insulation wall panels, which are not limited here. like figure 2 As shown in , the entire drying cabinet is divided into a dryin...

Embodiment 2

[0098] The present invention also provides a heat pump dry closet installed on the side of the dehumidification system, including a drying room 1 and an equipment room 2 arranged on the side of the drying room 1. A refrigeration and dehumidification device is installed in the equipment room 2, and the specific structural form of the refrigeration and dehumidification device The refrigeration and dehumidification device described in Embodiment 1 can be used, and can also be designed according to specific conditions, which is not limited here. Between the upper and lower ends of the drying room 1 and the equipment room 2, there are an air inlet 3 and an air outlet 4 in the equipment room, wherein the air inlet 3 can be located at the upper end, and the air outlet 4 can be located at the lower end, or the air outlet 4 can be located at the upper end, and the air inlet can be located at the upper end. 3 is located at the end, which is not limited here. The air inlet 3 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com