A waste heat-driven double evaporator injection refrigeration system for refrigerated vehicles

A dual evaporator and refrigeration system technology, which is applied in the field of refrigerated vehicle waste heat-driven dual evaporator jet refrigeration system, can solve the problem that it is difficult to realize the deep cooling of refrigerated vehicle cab in summer at 0°C and below.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

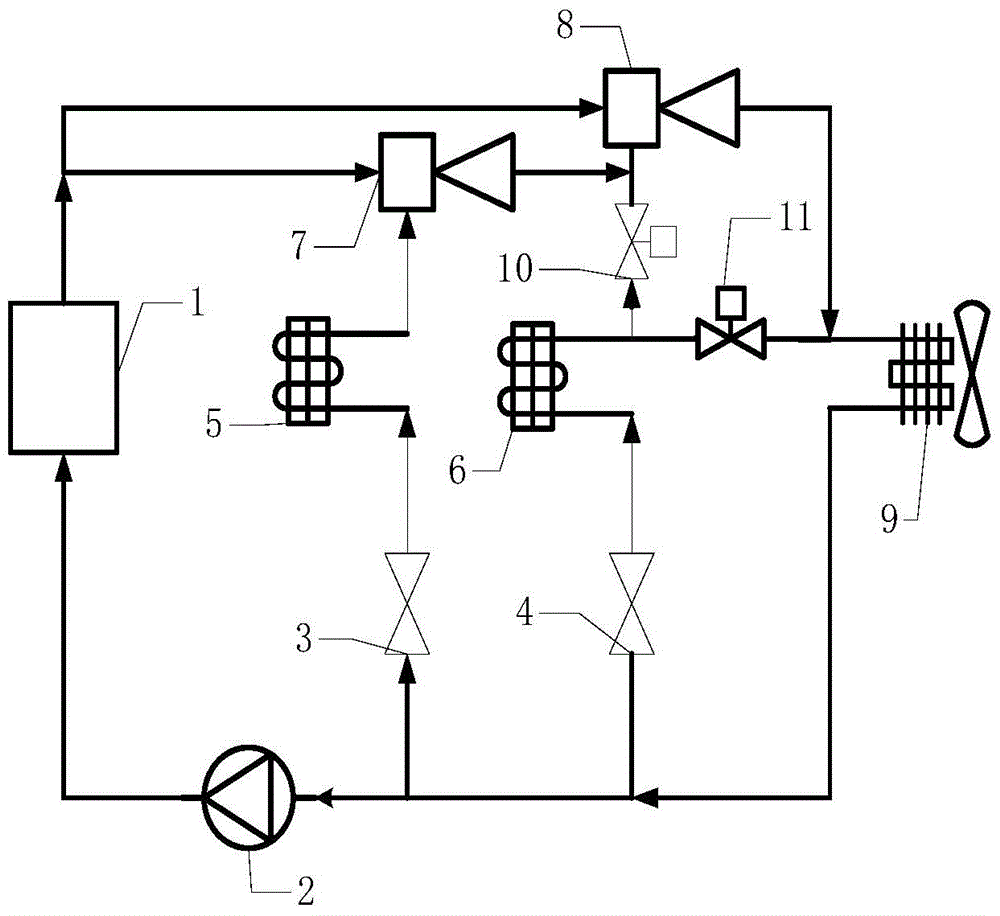

[0030] like figure 1 As shown, a waste heat-driven double evaporator jet refrigeration system for a refrigerated vehicle includes a waste heat recovery device 1, a circulation pump 2, a first throttling device 3, a second throttling device 4, a first evaporator 5, a second evaporator 6, the first ejector 7, the second ejector 8, the condenser 9, the first control valve 10 and the second control valve 11, the outlet end of the waste heat recovery device 1 is connected with the inlet end of the first ejector 7 and the second ejector respectively. The inlet end of the second ejector 8 is connected, the inlet end of the waste heat recovery device 1 is connected with the outlet end of the circulation pump 2, the outlet end of the first evaporator 5 is connected with the inlet end of the injection fluid of the first ejector 7, and the first evaporator The inlet port of the device 5 is connected with the outlet port of the first throttling device 3, the outlet port of the second evap...

Embodiment 2

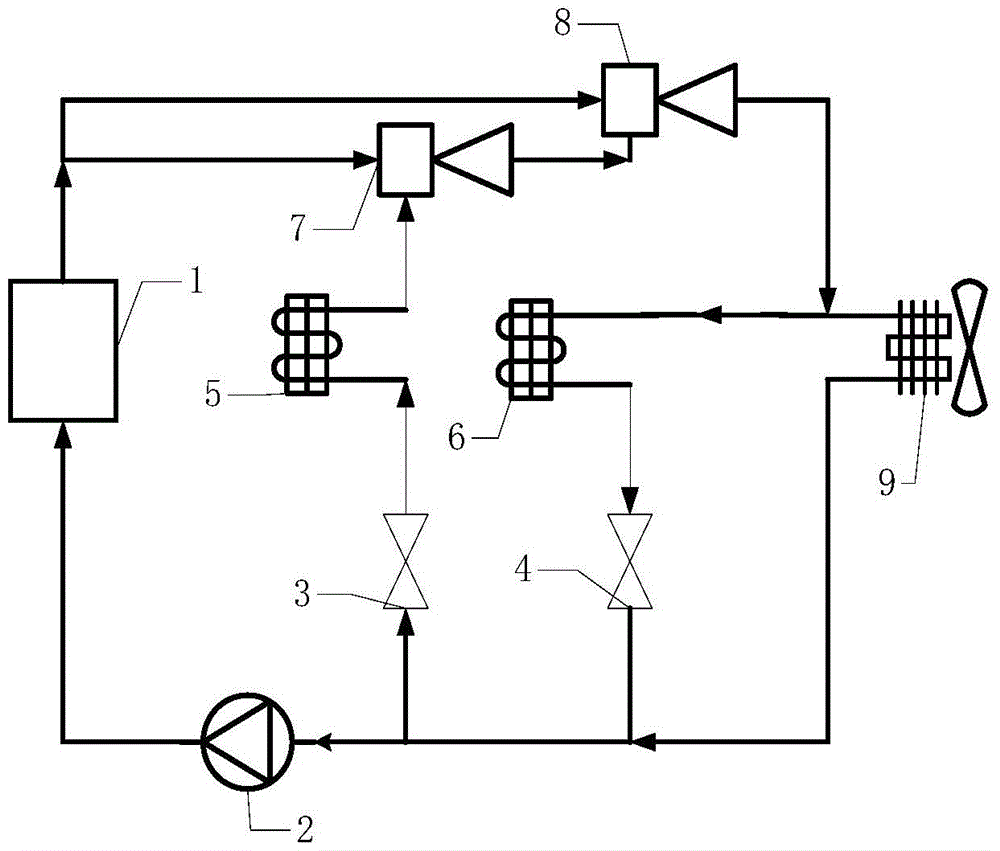

[0036] like Figure 4 As shown, a refrigerated vehicle waste heat-driven double evaporator jet refrigeration system includes a vehicle waste heat recovery device 1, a circulation pump 2, a first throttling device 3, a second throttling device 4, a first evaporator 5, a second The evaporator 6, the first ejector 7, the second ejector 8, the condenser 9, the four-way reversing valve 12, the outlet port of the automobile waste heat recovery device 1 are respectively connected with the working fluid inlet port of the first ejector 7 and the second ejector The working fluid inlet port of the injector 8 is connected, the inlet port of the automobile waste heat recovery device 1 is connected with the outlet port of the circulation pump 2, the outlet port of the first evaporator 5 is connected with the injection fluid inlet port of the first ejector 7, and the second The inlet end of the first evaporator 5 is connected with the outlet end of the first throttling device 3, the outlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com